Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

935results about How to "Inhibitory response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biosensor

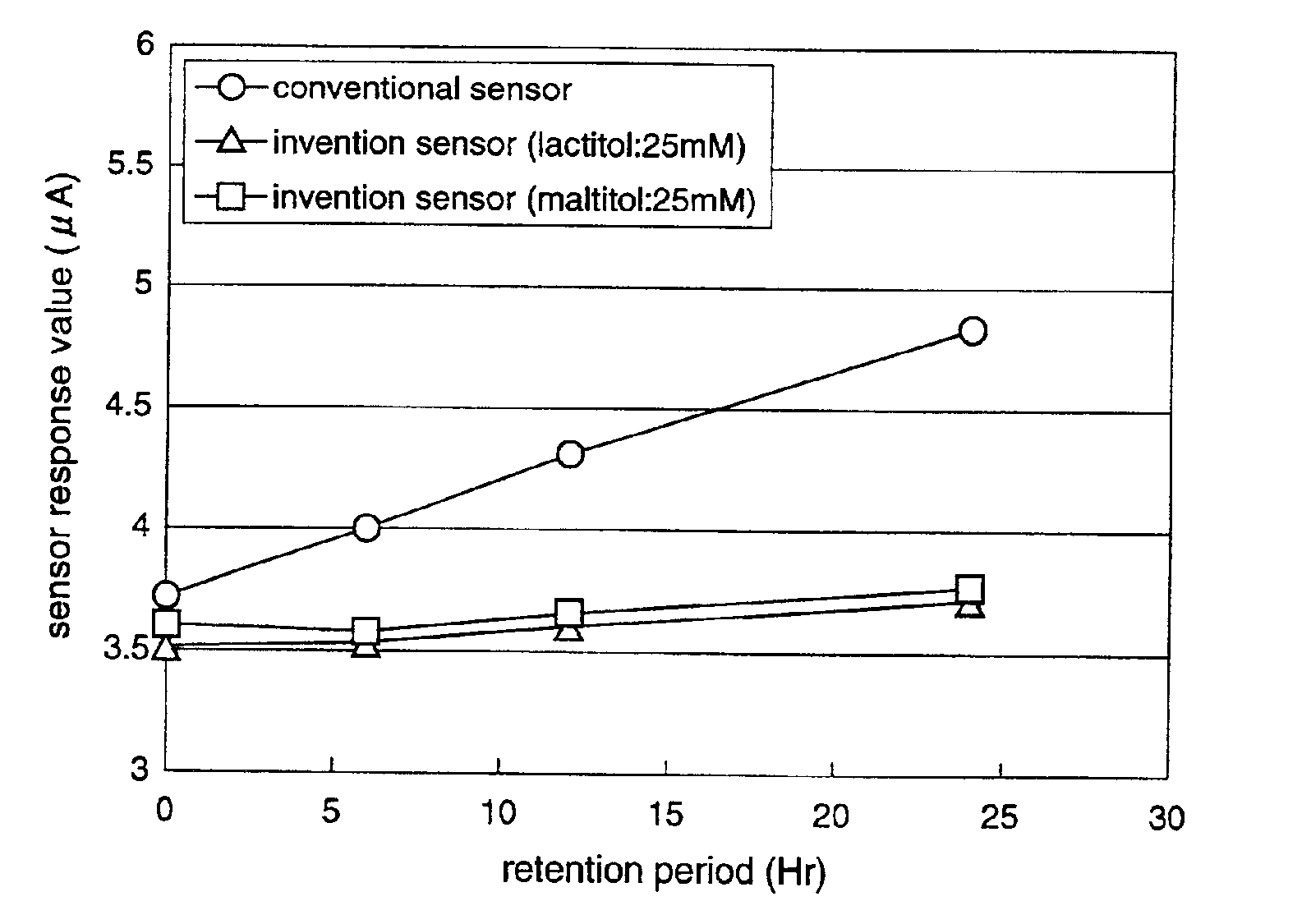

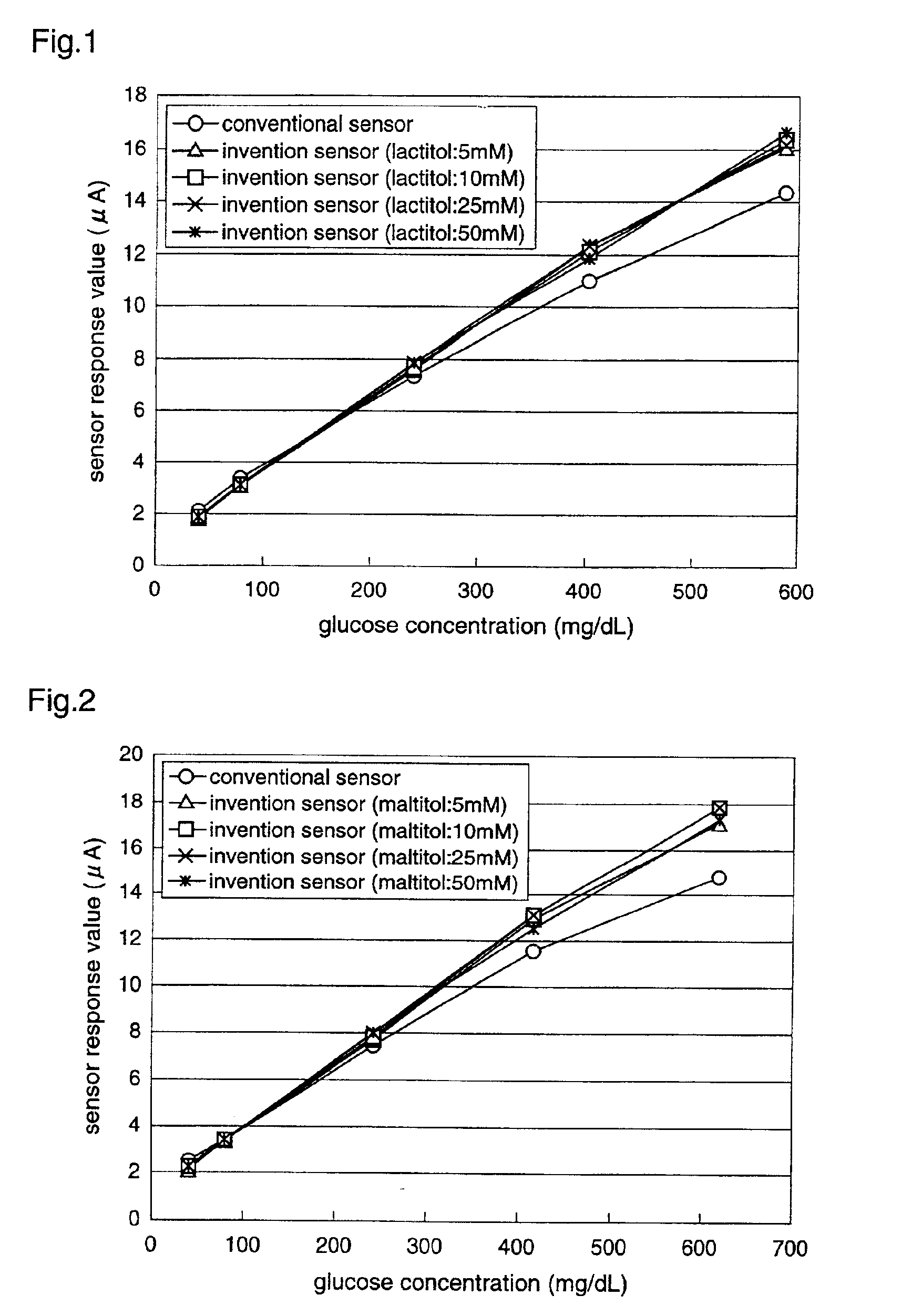

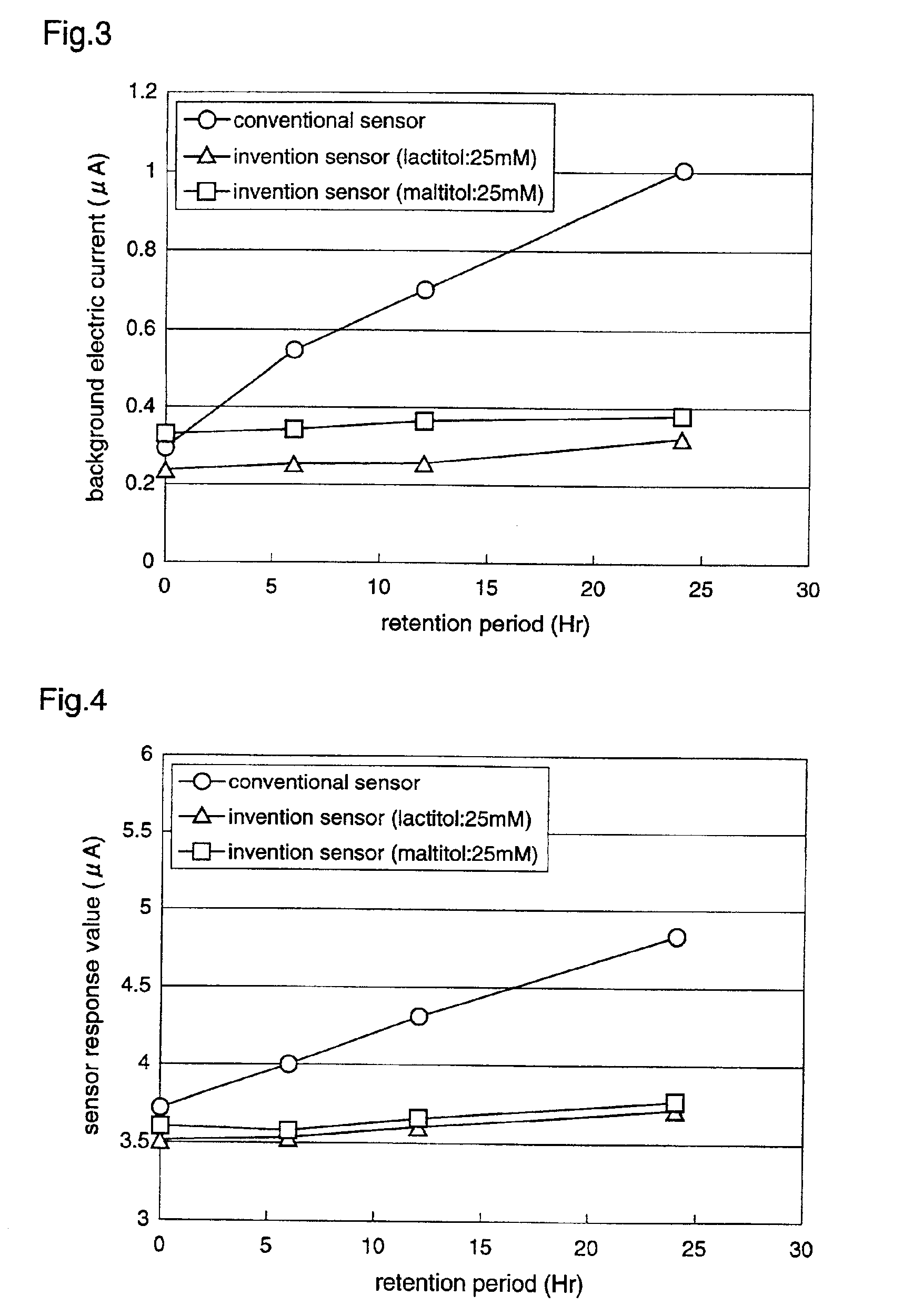

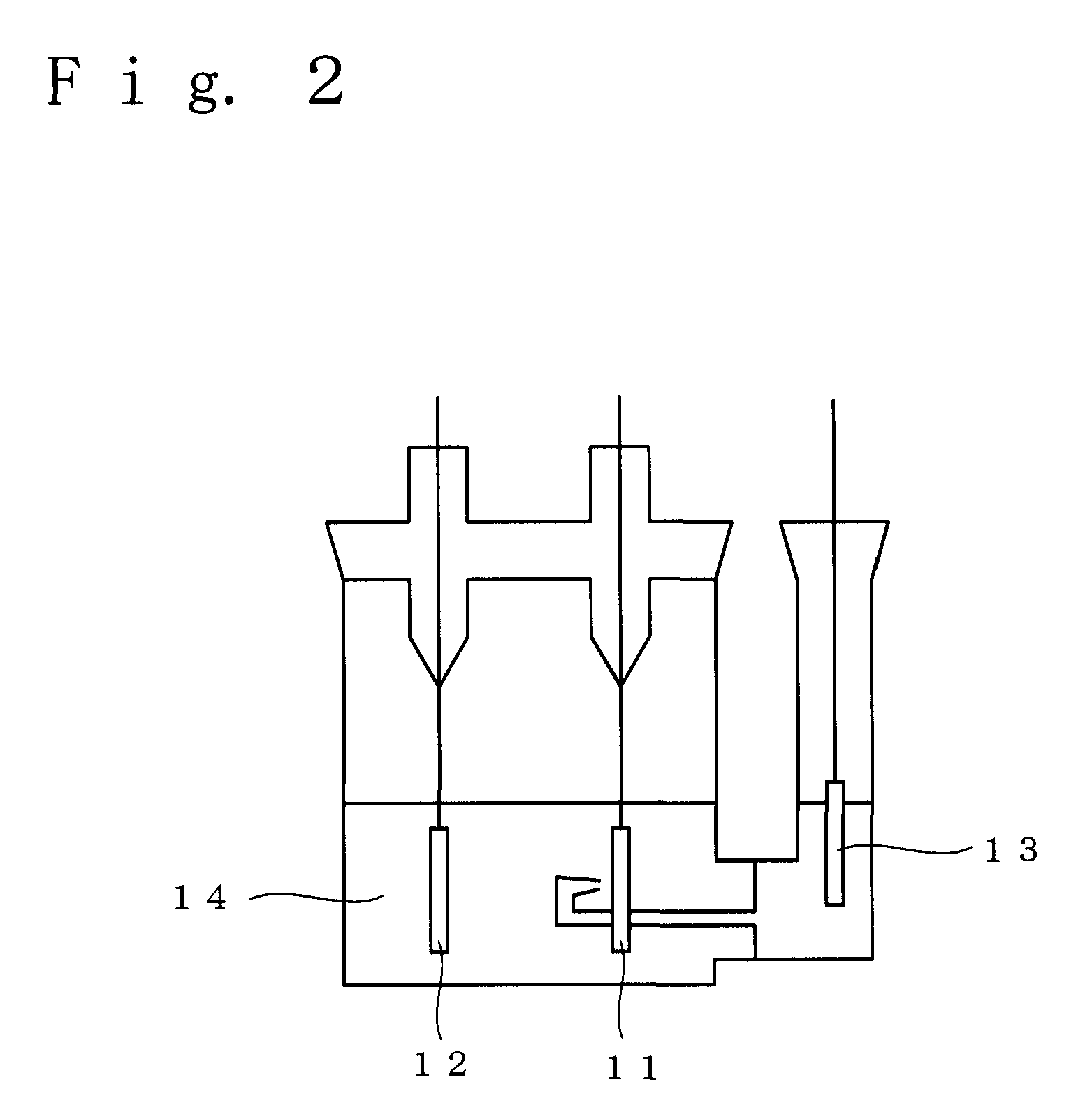

InactiveUS6911131B2Achieve effectImprove stabilityImmobilised enzymesBioreactor/fermenter combinationsOrganic acidAlcohol sugars

In a biosensor for measuring a specific substance in a liquid sample, one or a combination of sugar alcohol, metallic salt, organic acid or organic acid salt which has at least one carboxyl group in a molecule, and organic acid or organic acid salt which has at least one carboxyl group and one amino group in a molecule, is included in a reagent layer provided on electrodes, thereby providing a highly-accurate biosensor which is excellent in stability and has high response (sensitivity, linearity) of the sensor to the substrate concentration.

Owner:PHC HLDG CORP

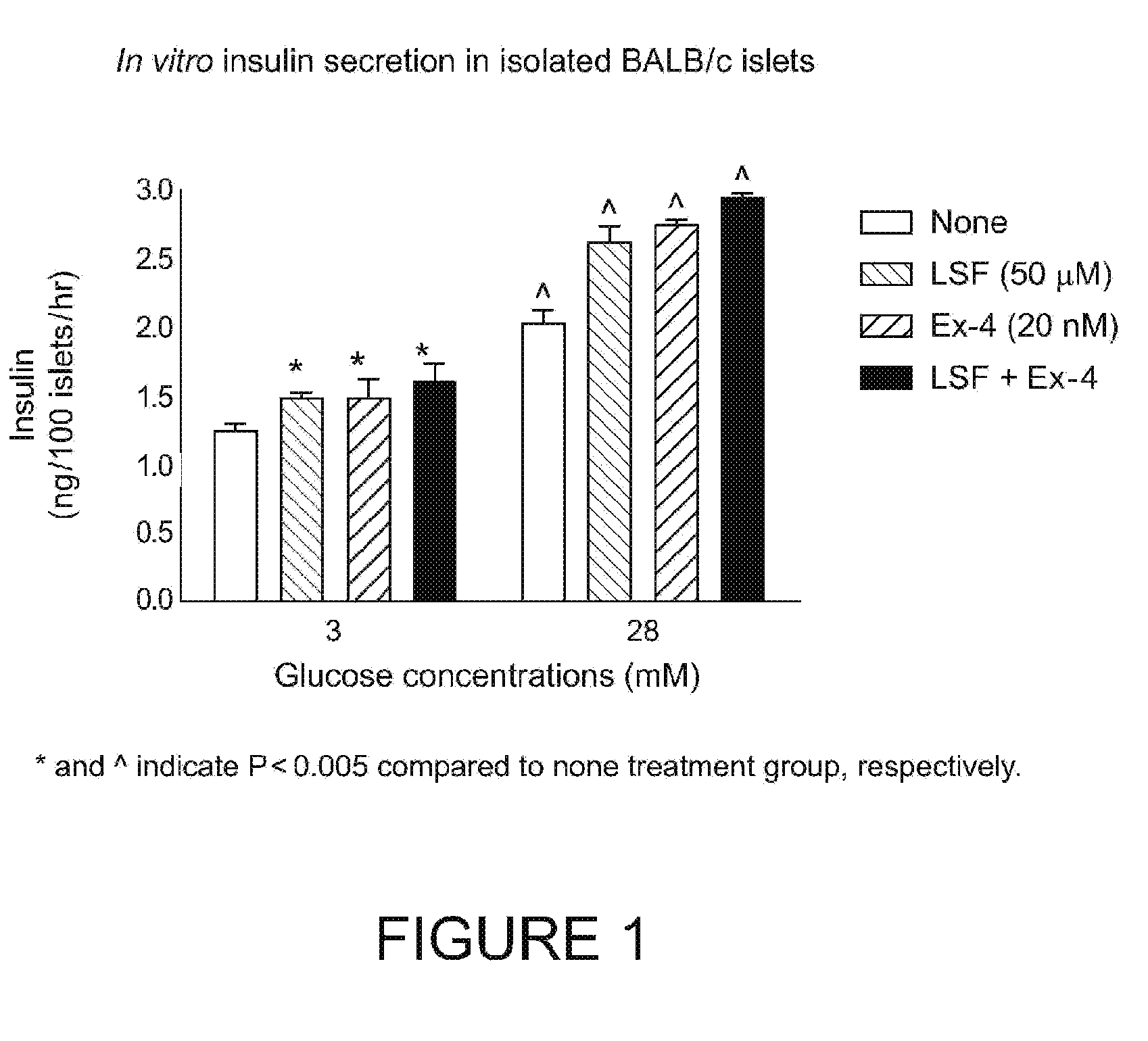

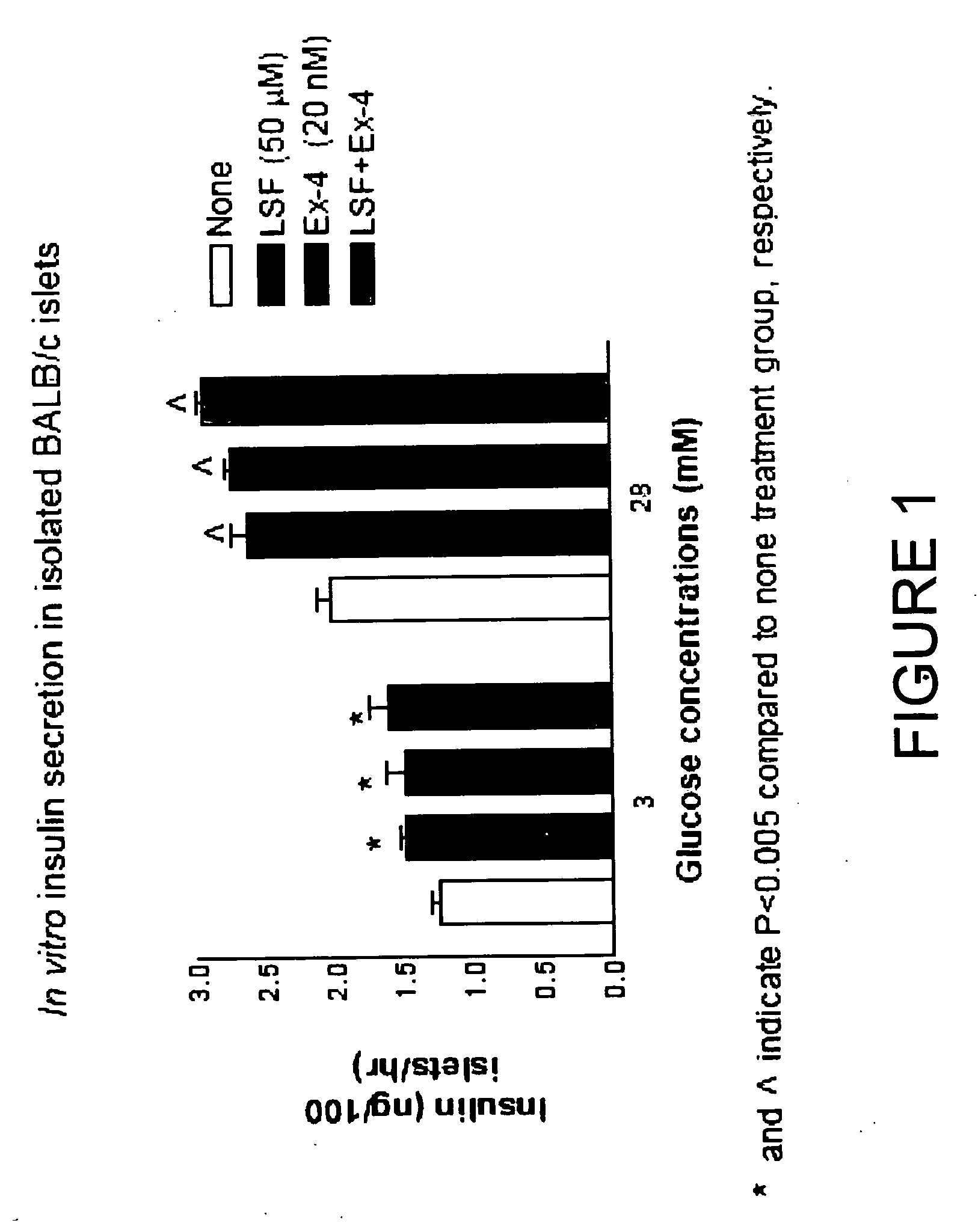

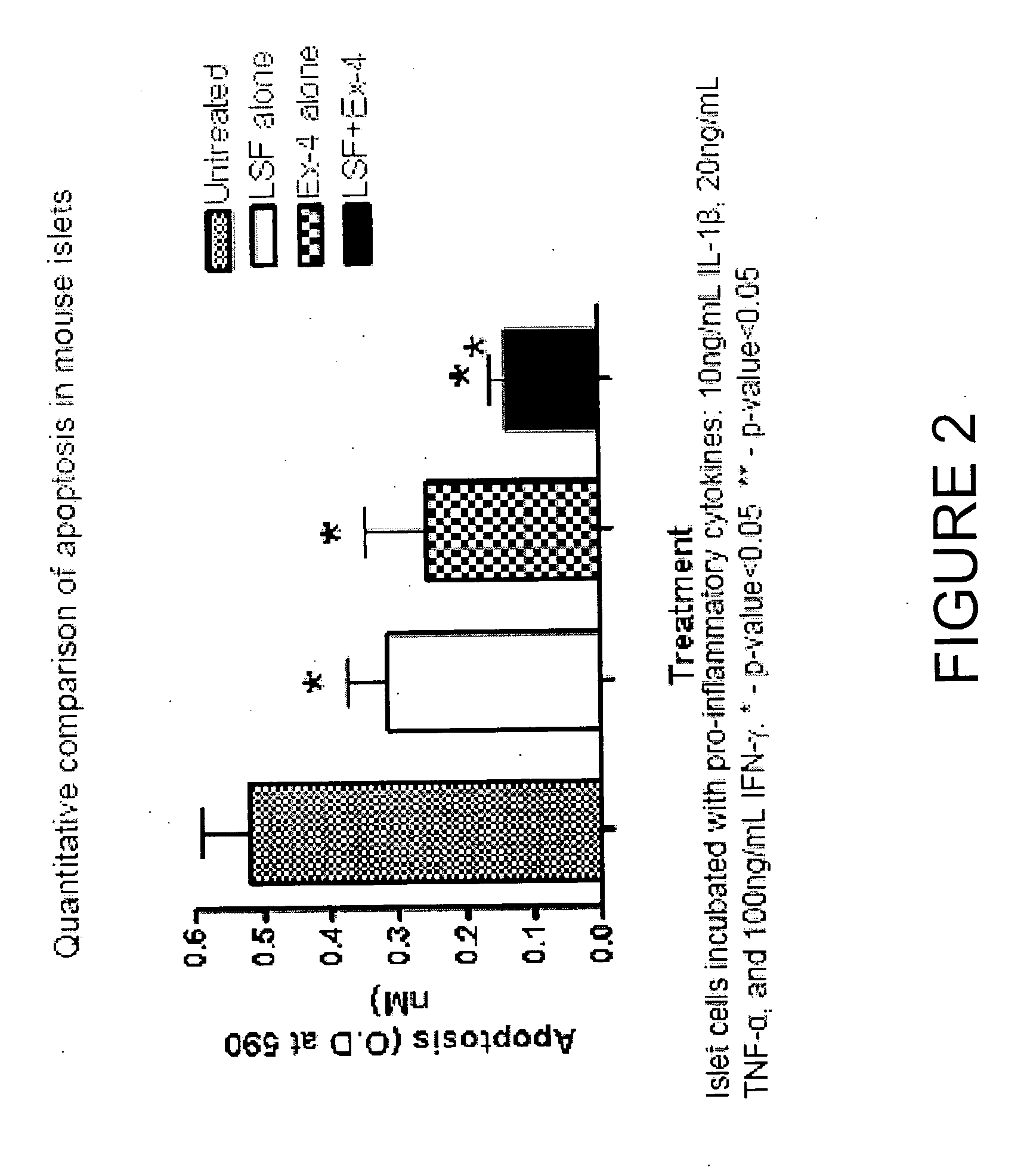

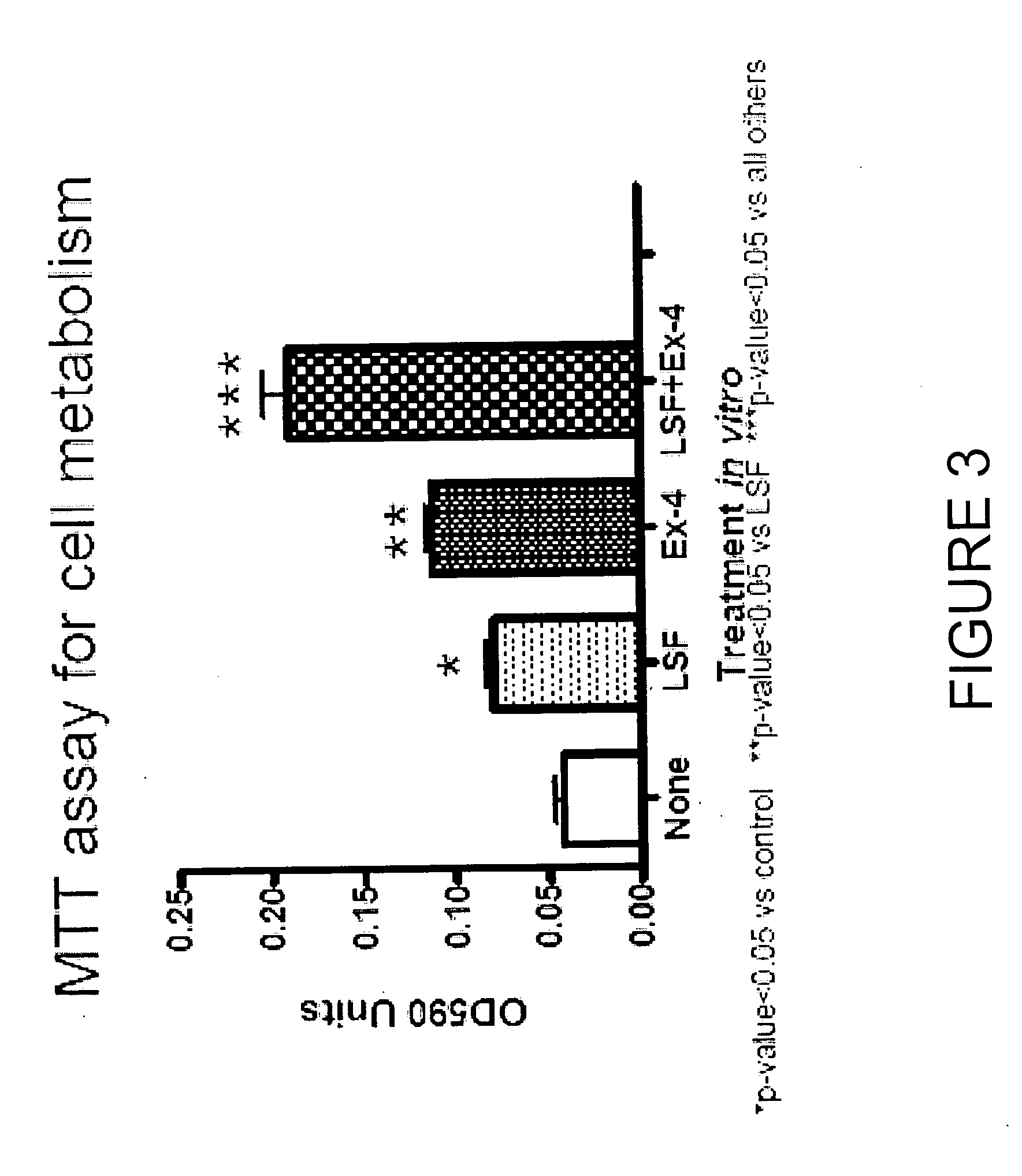

Pharmaceutical compositions and methods for restoring β-cell mass and function

ActiveUS7393827B2Increase the number ofInhibition formationOrganic active ingredientsPeptide/protein ingredientsAdjuvantCell mass

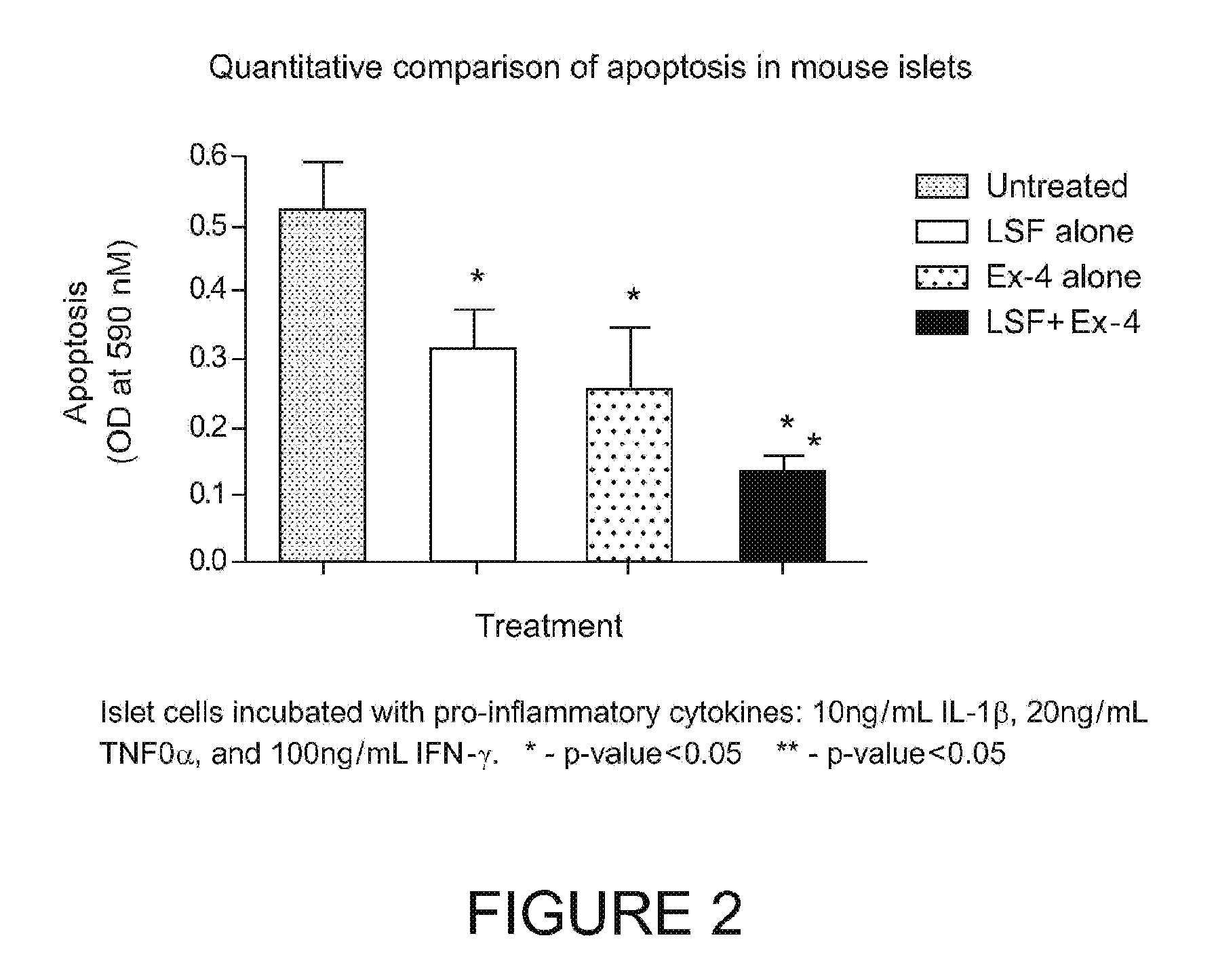

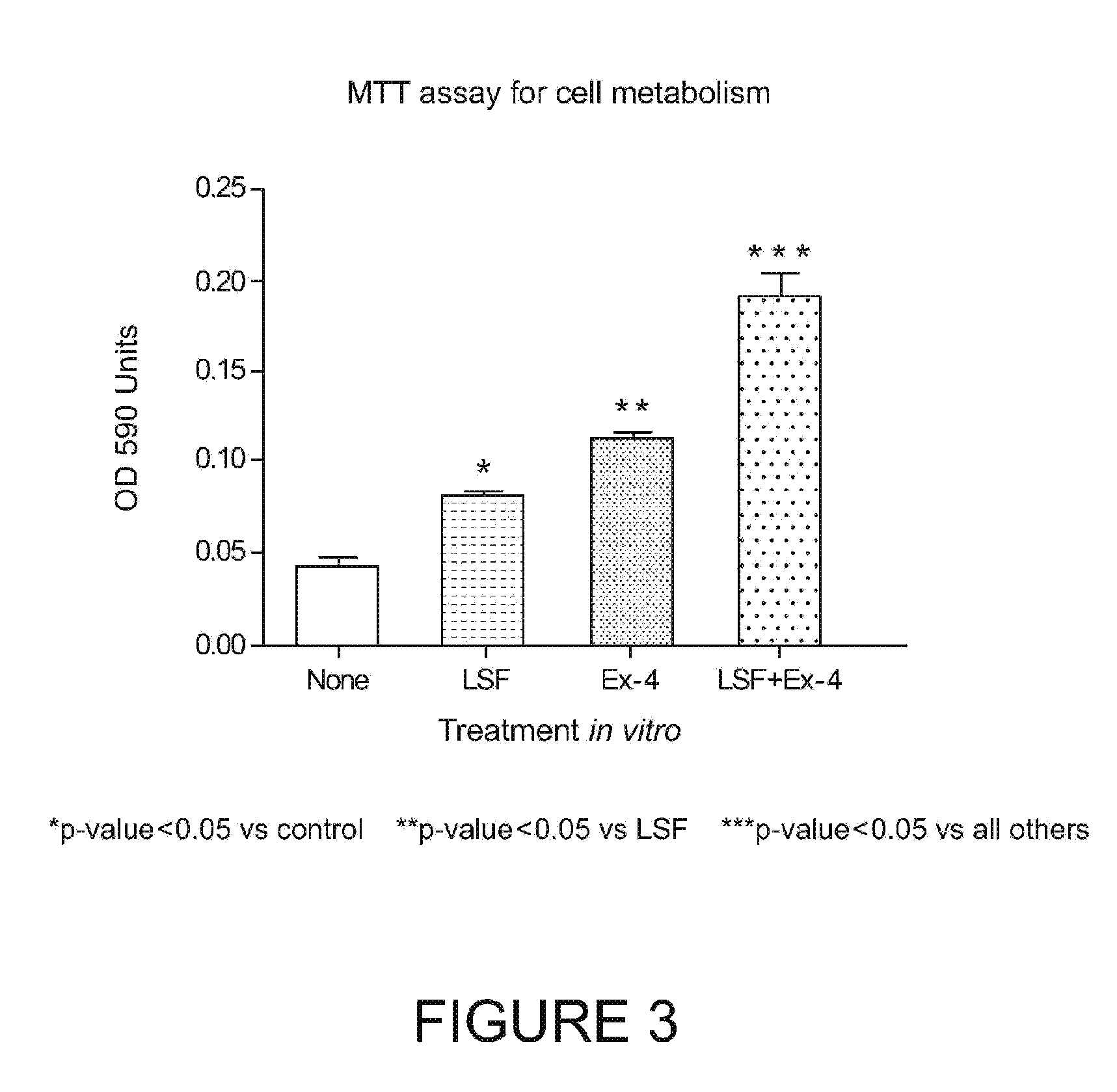

Pharmaceutical compositions and methods for using are provided for restoring β-cell mass and function in a mammal in need thereof. The pharmaceutical compositions have a biological response modifier and a β-cell growth factor in admixture with a pharmaceutically acceptable carrier, adjuvant or vehicle.

Owner:DIAKINE THERAPEUTICS

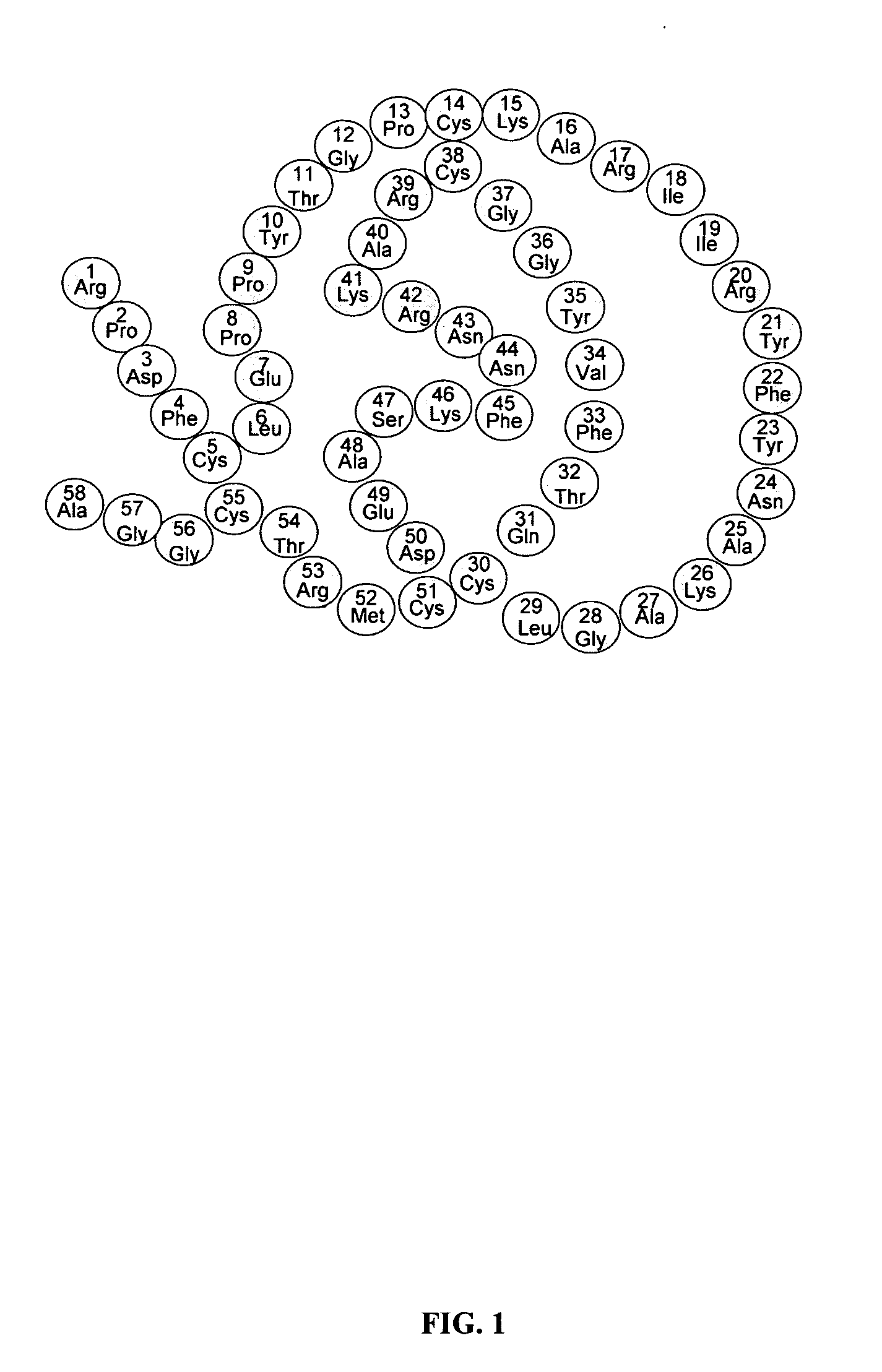

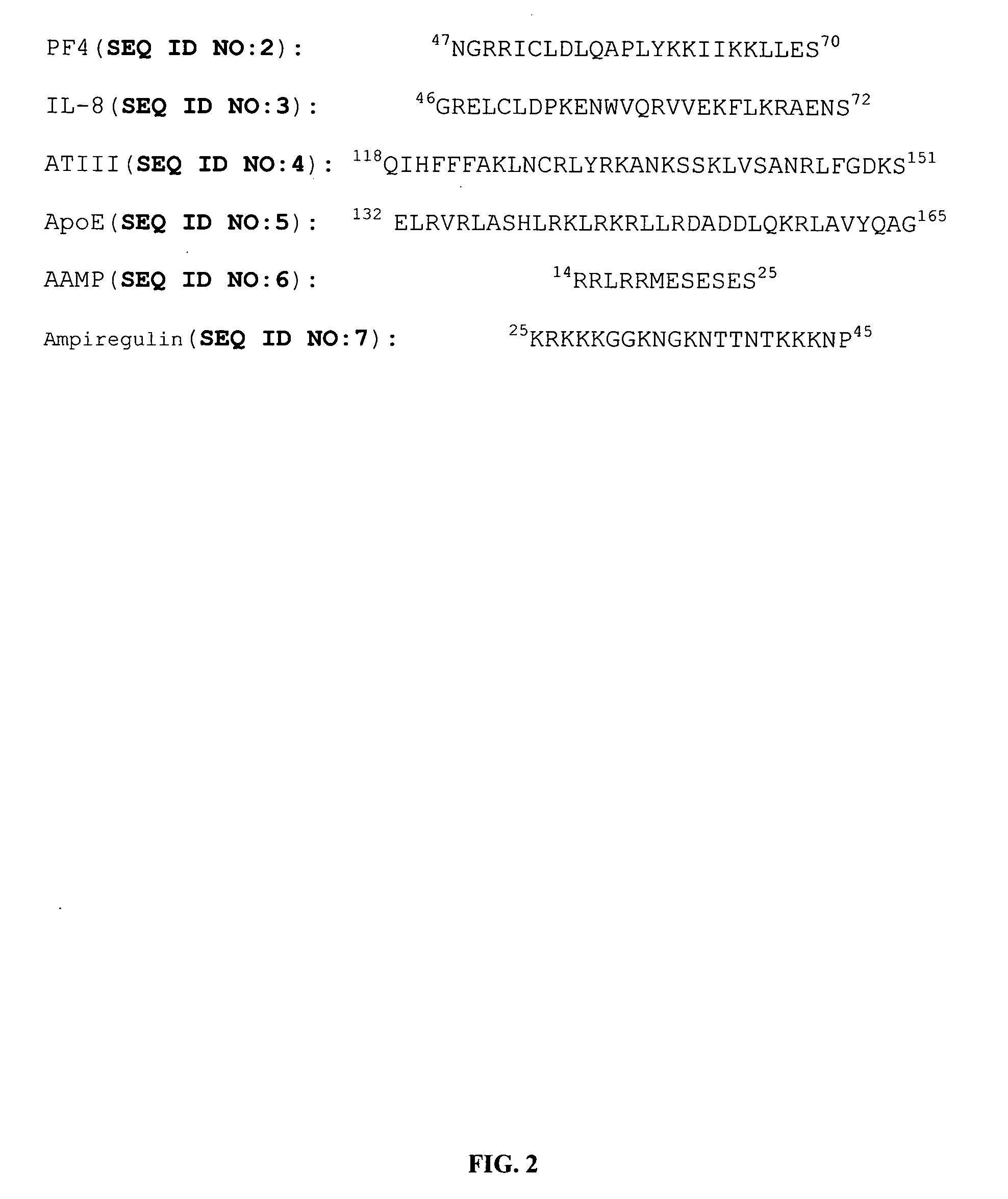

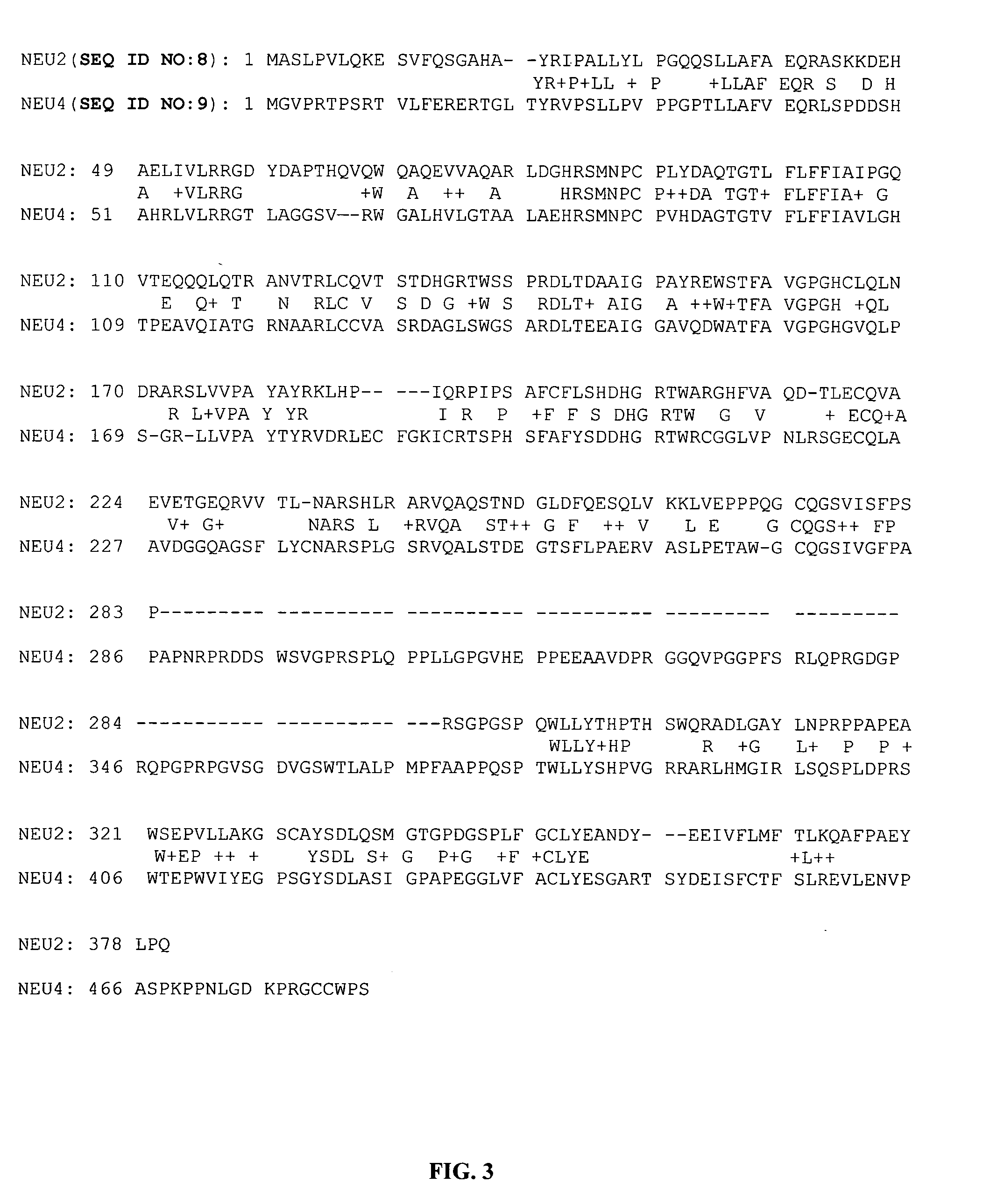

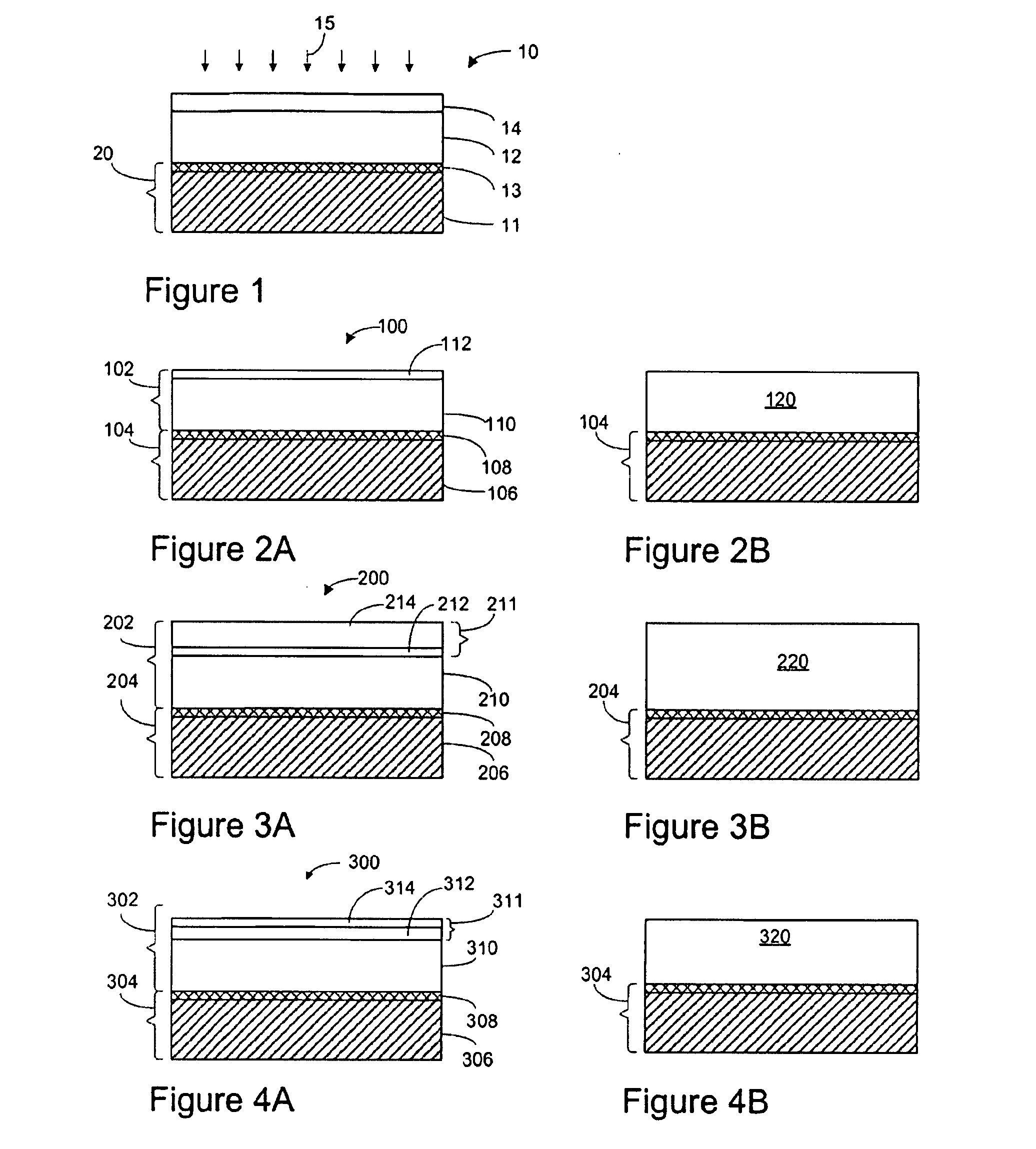

Novel class of therapeutic protein based molecules

ActiveUS20050112751A1Prevent and inhibit adhesion and functionInhibitory responseAntibacterial agentsSenses disorderTherapeutic proteinViral infection

The present invention provides new compositions and methods for preventing and treating pathogen infection. In particular, the present invention provides compounds having an anchoring domain that anchors the compound to the surface of a target cell, and a therapeutic domain that can act extracellularly to prevent infection of a target cell by a pathogen, such as a virus. The present invention also comprises therapeutic compositions having sialidase activity, including protein-based compounds having sialidase catalytic domains. Compounds of the invention can be used for treating or preventing pathogen infection, and for treating and reducing allergic and inflammatory responses. The invention also provides compositions and methods for enhancing transduction of target cells by recombinant viruses. Such compositions and methods can be used in gene therapy.

Owner:ANSUN BIOPHARMA

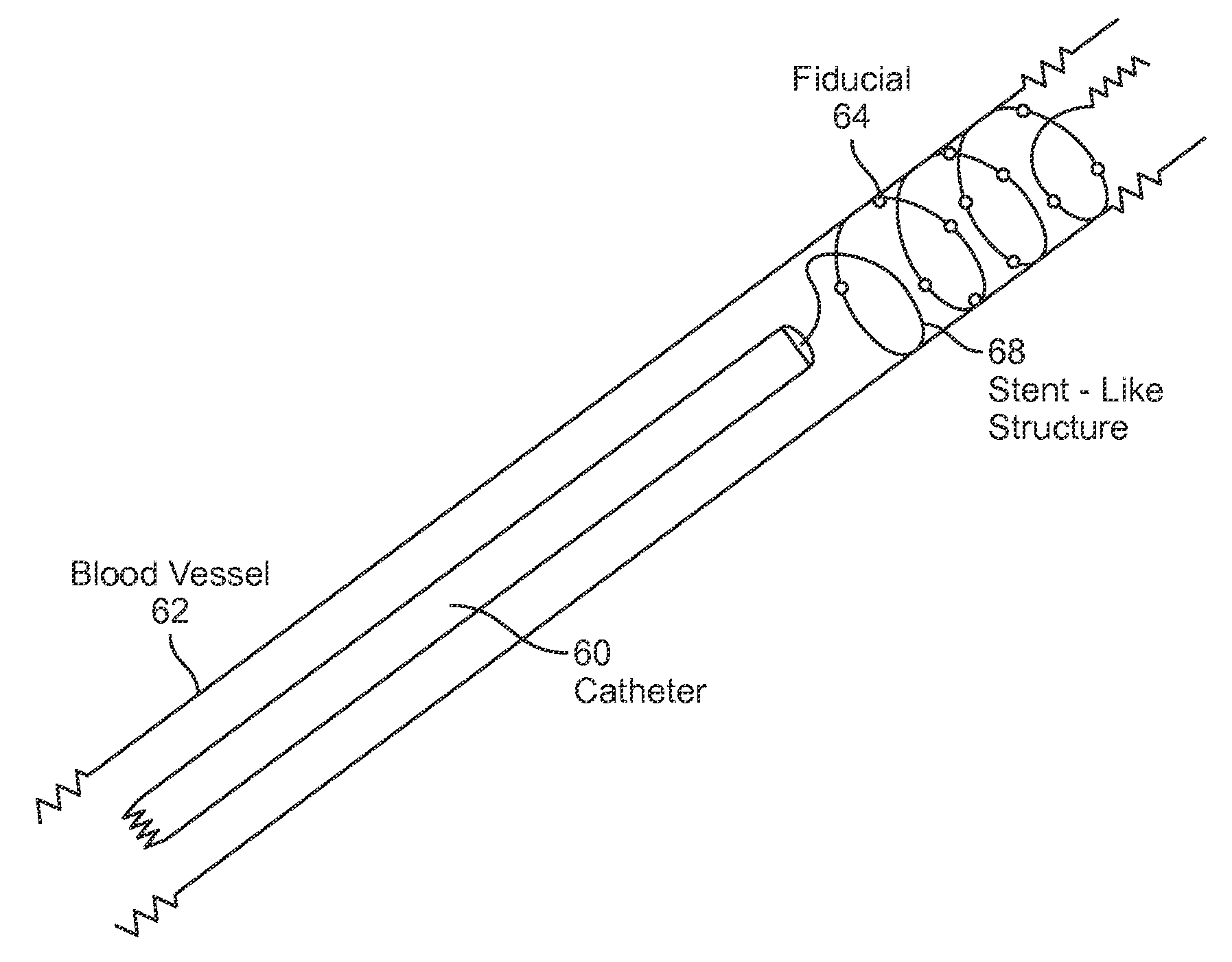

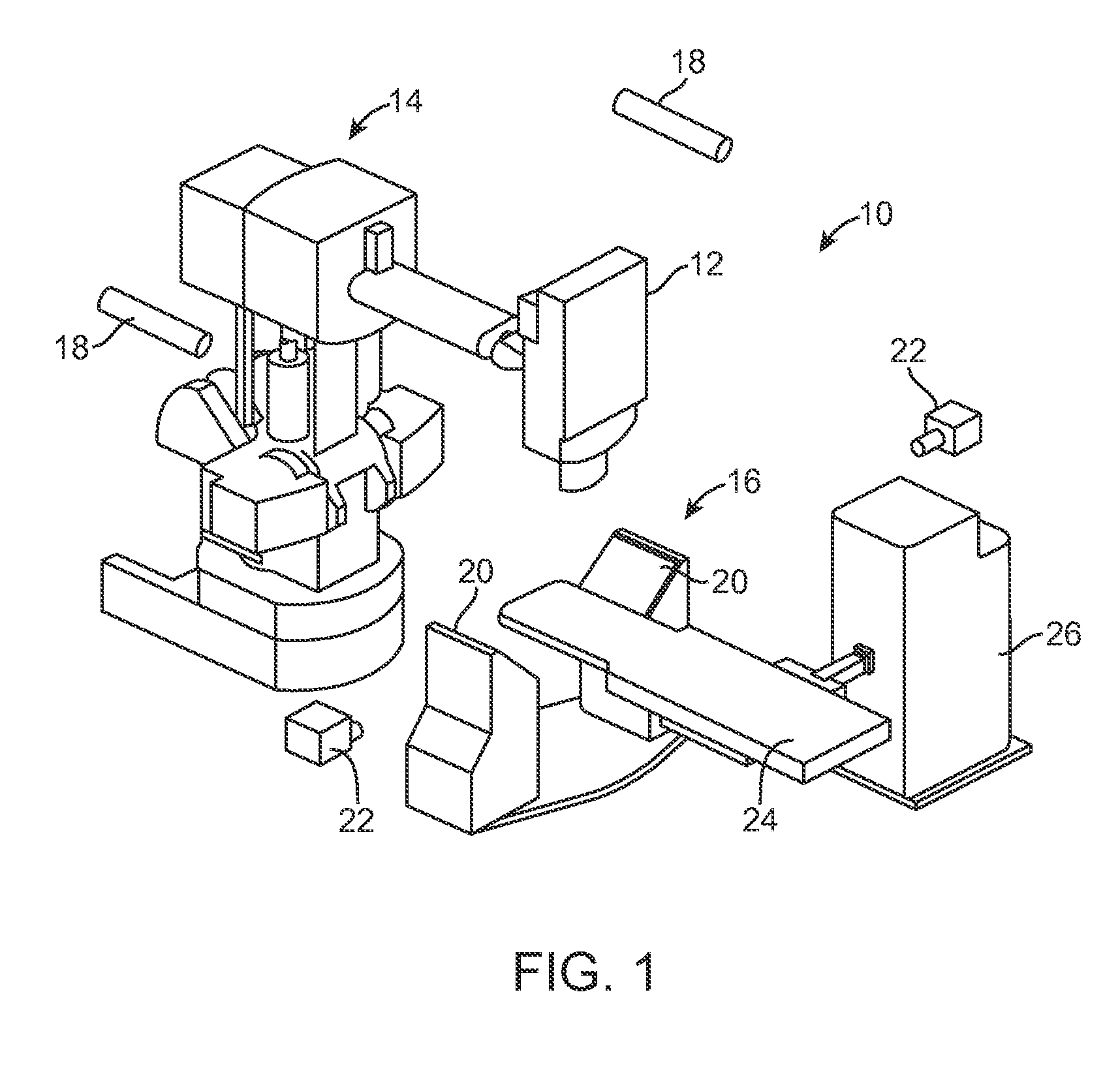

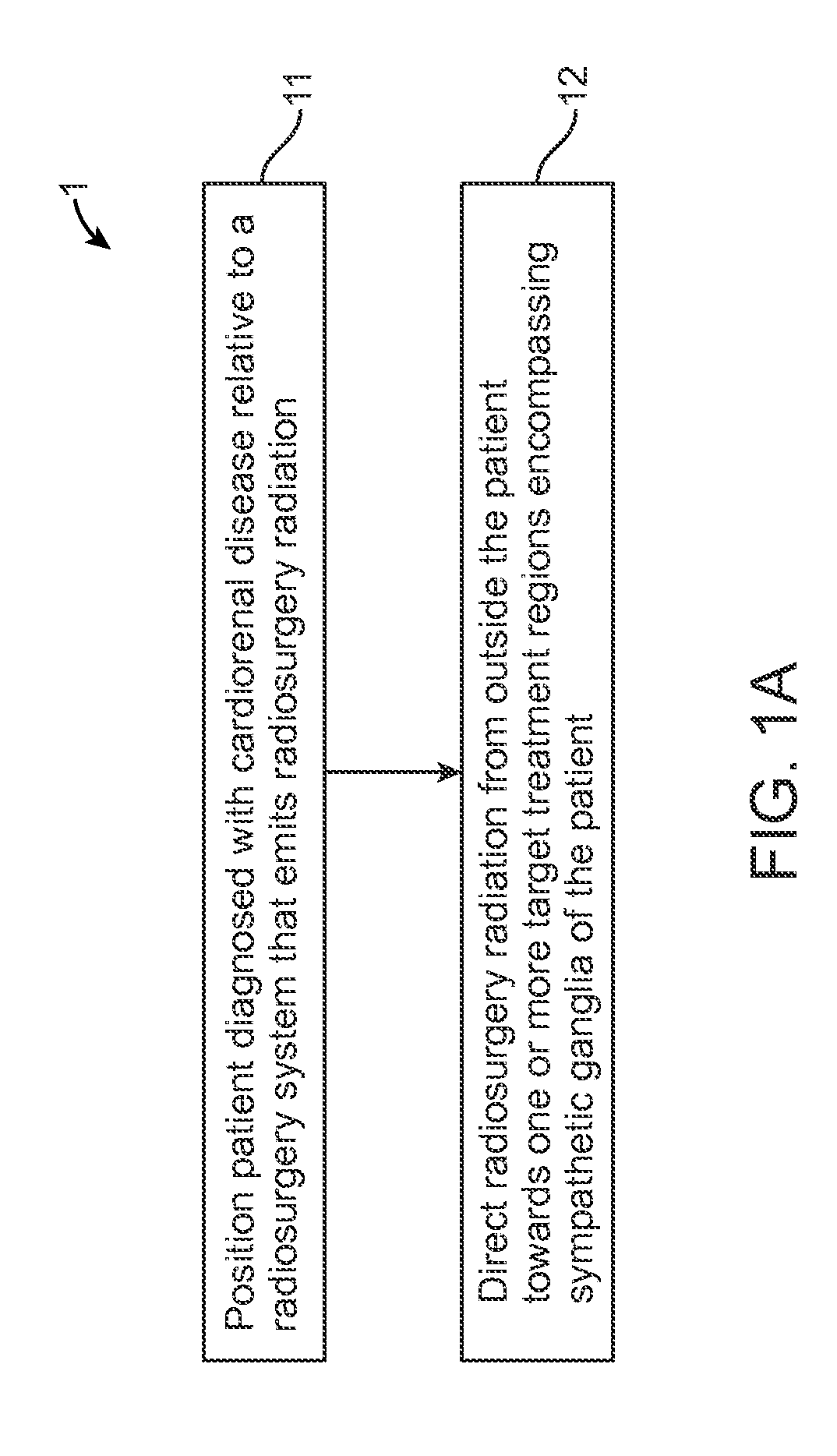

Renovascular treatment device, system, and method for radiosurgically alleviating hypertension

InactiveUS20120323233A1Reduce high blood pressureImprove securitySurgical instruments for heatingX-ray/gamma-ray/particle-irradiation therapyRadiosurgeryCardiorenal disease

A radiosurgical method for treating cardiorenal disease of a patient, the method including directing radiosurgery radiation from outside the patient towards one or more target treatment regions encompassing sympathetic ganglia of the patient so as to inhibit the cardiorenal disease. In an exemplary embodiment, the method further includes acquiring three dimensional planning image data encompassing the first and second renal arteries, planning an ionizing radiation treatment of first and second target regions using the three dimensional planning image data so as to mitigate the hypertension, the first and second target regions encompassing neural tissue of or proximate to the first and second renal arteries, respectively, and remodeling the target regions by directing the planned radiation from outside the body toward the target regions.

Owner:CYBERHEART

Recording medium, reproduction apparatus, recording method, program, and reproduction method

ActiveUS20060045481A1Prevents response debasementInhibitory responseTelevision system detailsRecord information storageInteractive graphicsMultiplexing

A BD-ROM has recorded therein an AV Clip generated by multiplexing a video stream and an interactive graphics stream. The video stream representing a motion picture made of a plurality of pictures, and the interactive graphics stream representing an interactive display to be overlayed on the motion picture, where the interactive graphics stream includes state control information (ICS) stored in a packet and a graphics data sequence (ODS), and the packet includes a time stamp that indicates a time at which the initial display is performed, the time being obtained by adding a predetermined duration to a decode ending time (PTS) of graphics data positioned midway through the graphics data sequence (S-ODSsfirst, S-ODSslast).

Owner:PANASONIC CORP

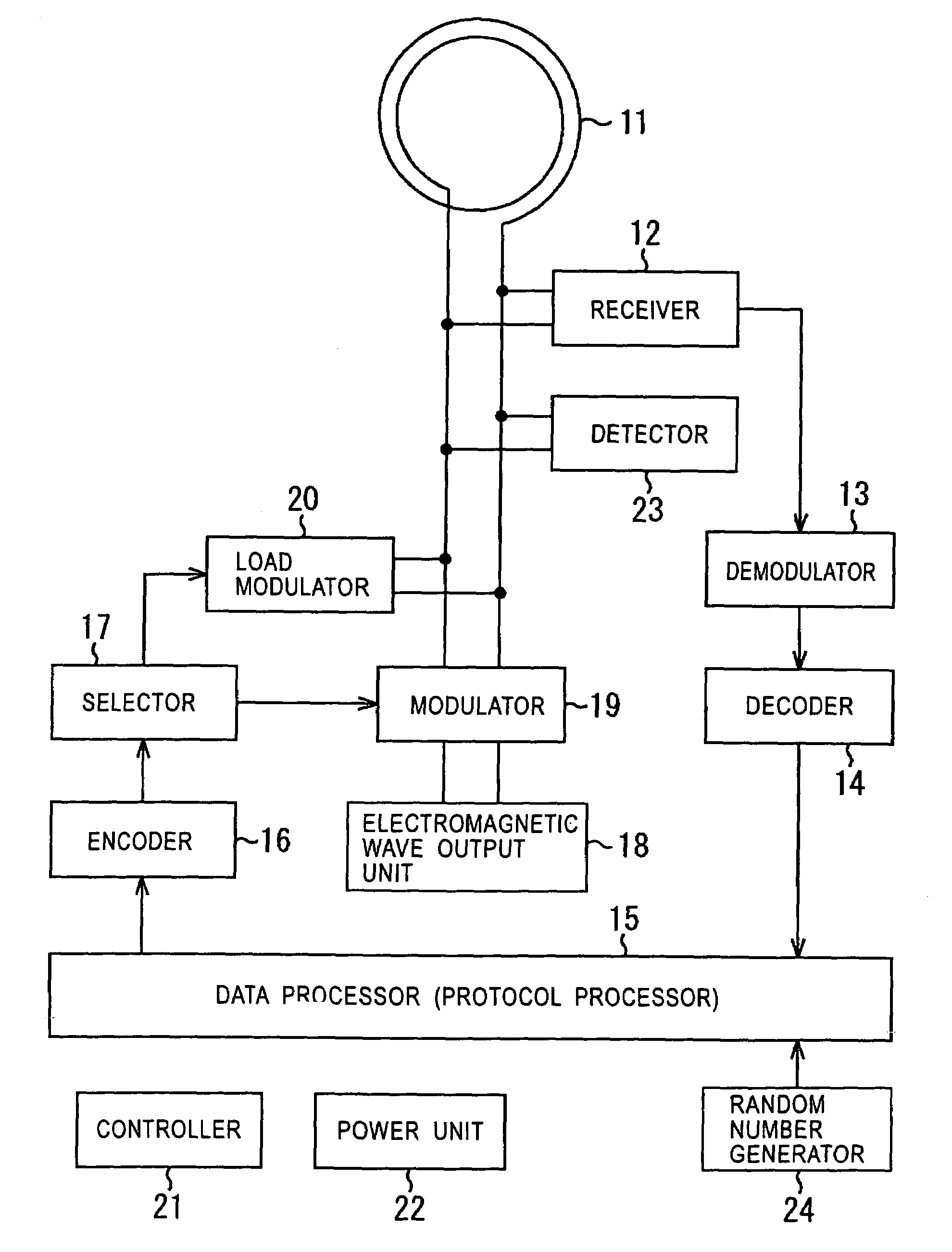

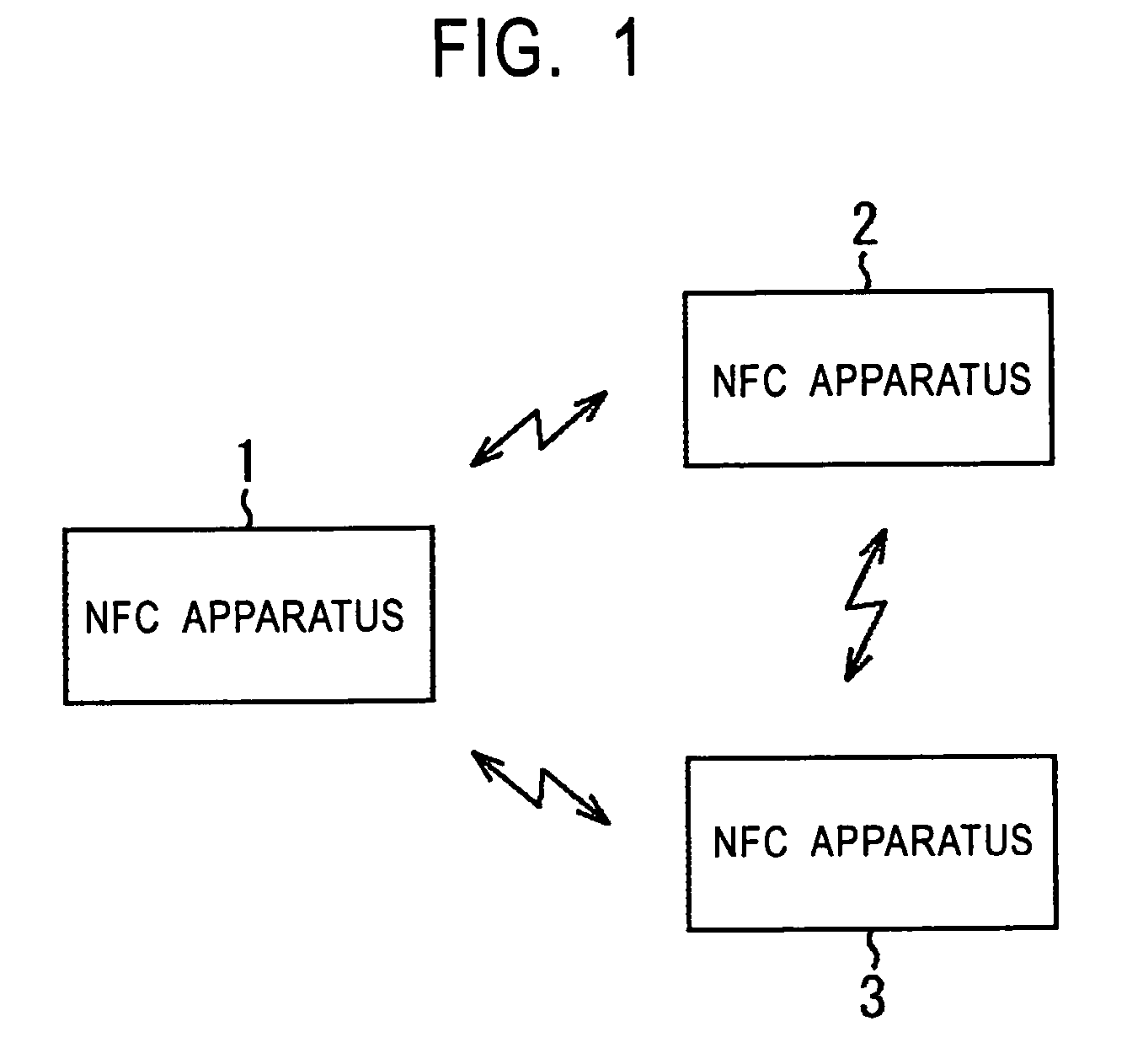

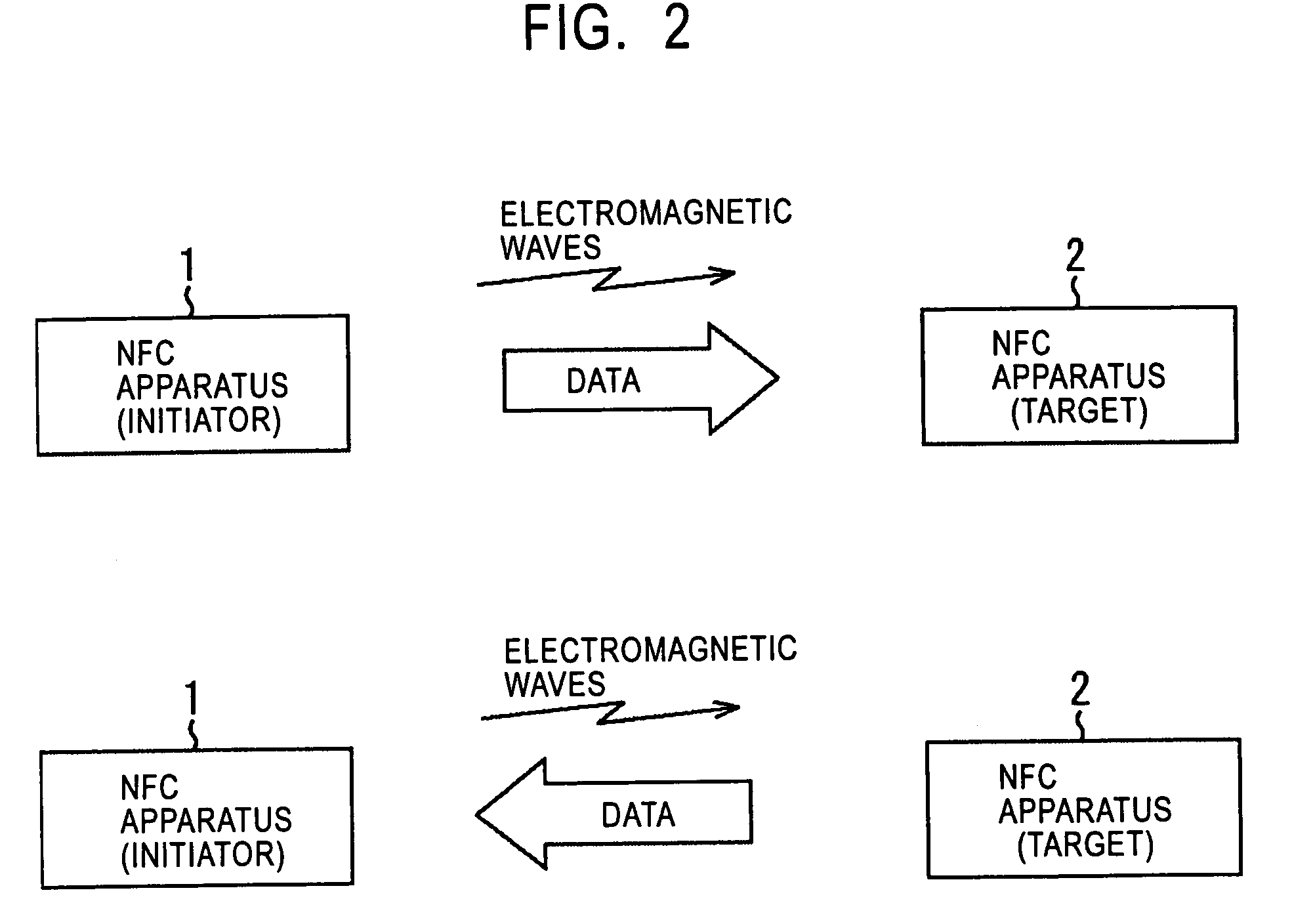

Communication apparatus and communication method

ActiveUS7209706B2Inhibitory responseSecurely identifyingUser identity/authority verificationMemory record carrier reading problemsCommunication deviceRandom number generation

A communication apparatus and a communication method prevent responses from being simultaneously received from two or more communicating parties. A first NFC apparatus transmits data for requesting IDs, and acquires IDs sent from second and third NFC apparatuses in reply to the request. After acquiring the IDs of the second and third NFC apparatuses, the first NFC apparatus transmits data that includes their IDs as the data for the second and third NFC apparatuses. If the first NFC apparatus cannot properly acquire the IDs of the second and third NFC apparatuses, then it sends the data for requesting their IDs again. Upon receipt of the request for the IDs, the second and third NFC apparatuses generate their own IDs by using random numbers and send the generated IDs. If the second and third NFC apparatuses receive the request for their IDs again, then they re-generate their own IDs by using random numbers, and send the re-generated IDs again. The present invention can be applied to, for example, an IC card system.

Owner:SONY CORP

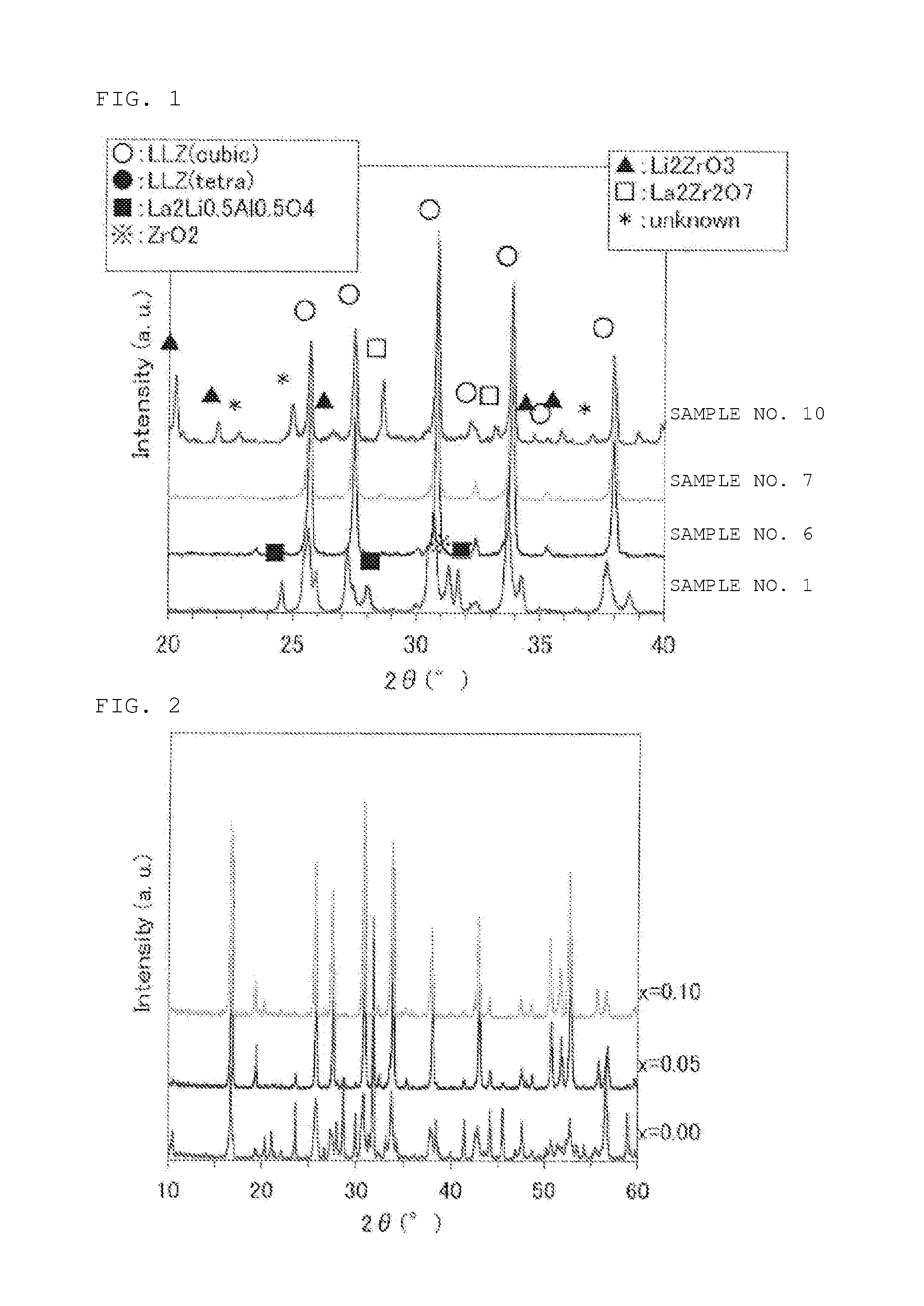

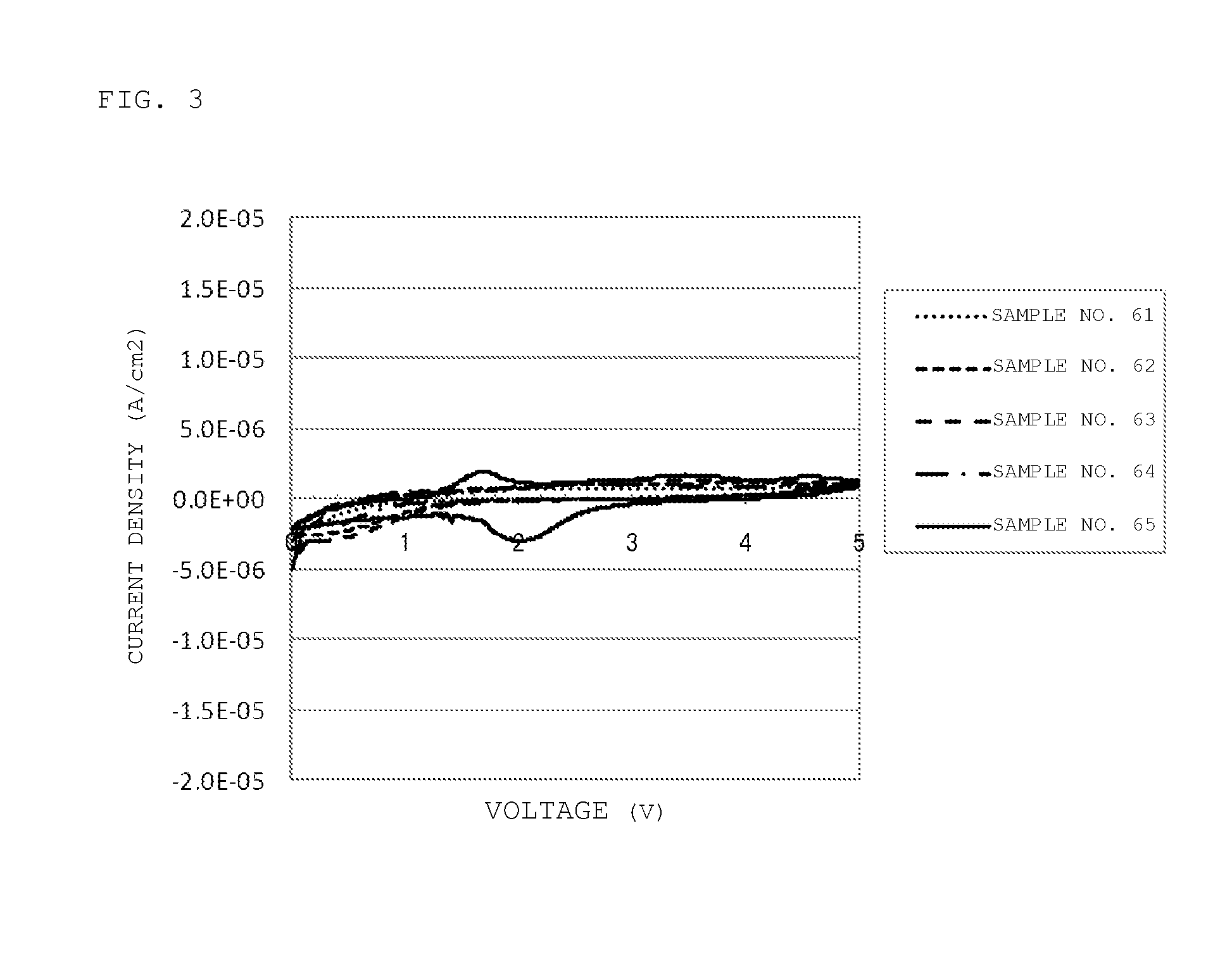

Material for solid electrolyte

ActiveUS20140186720A1Suppress and prevent reactionShort timeFinal product manufactureZirconium compoundsSolid state electrolyteCrystal structure

A material capable of producing a sintered body of cubic system garnet type Li7La3Zr2O12 as a solid electrolyte having specified ion conductivity by firing at relatively low temperature in short time. The material for the solid electrolyte is an oxide containing Li, La, Zr and Bi, and the oxide has a cubic system garnet crystal structure where La sites are partly or entirely substituted by Bi.

Owner:MURATA MFG CO LTD

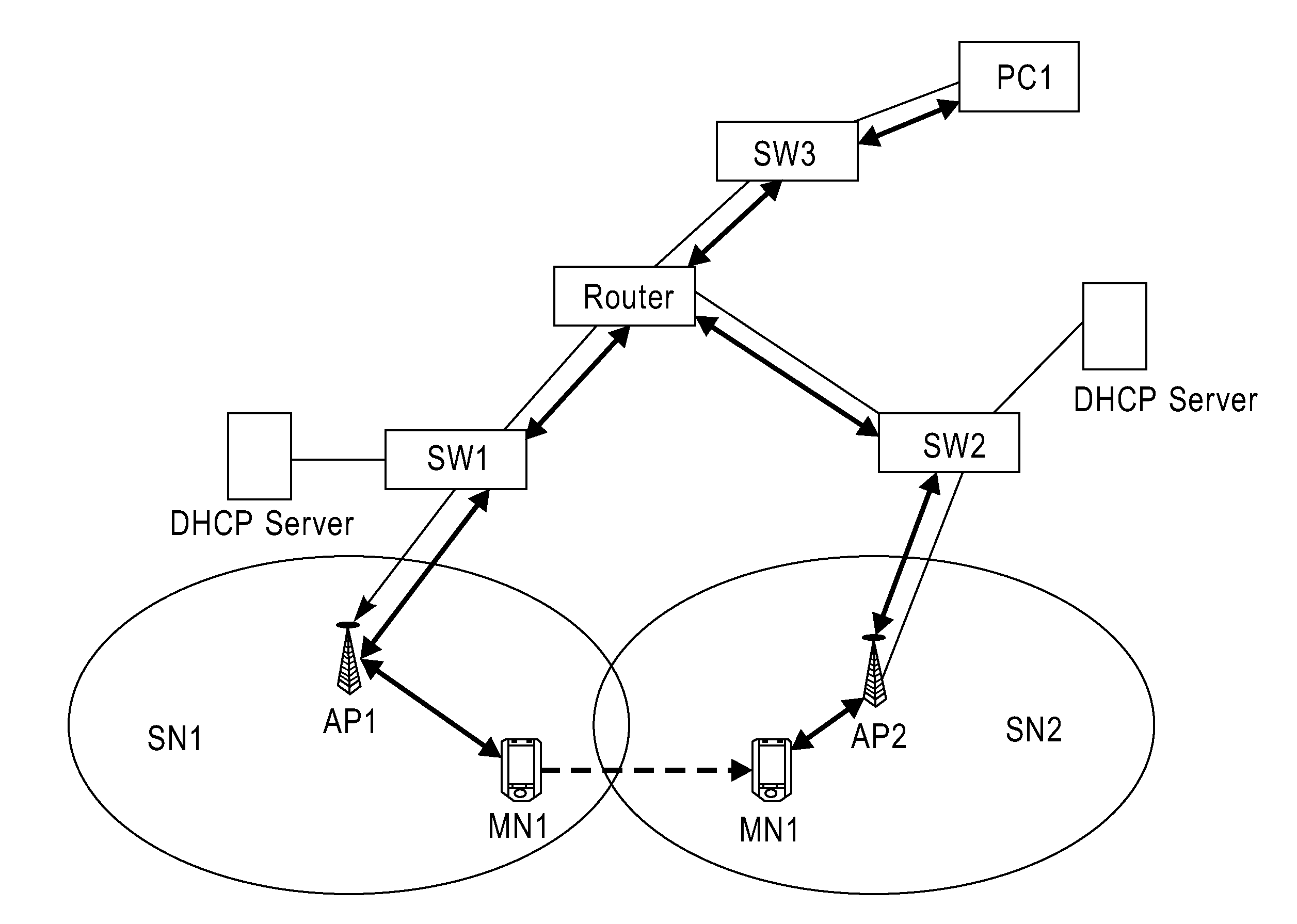

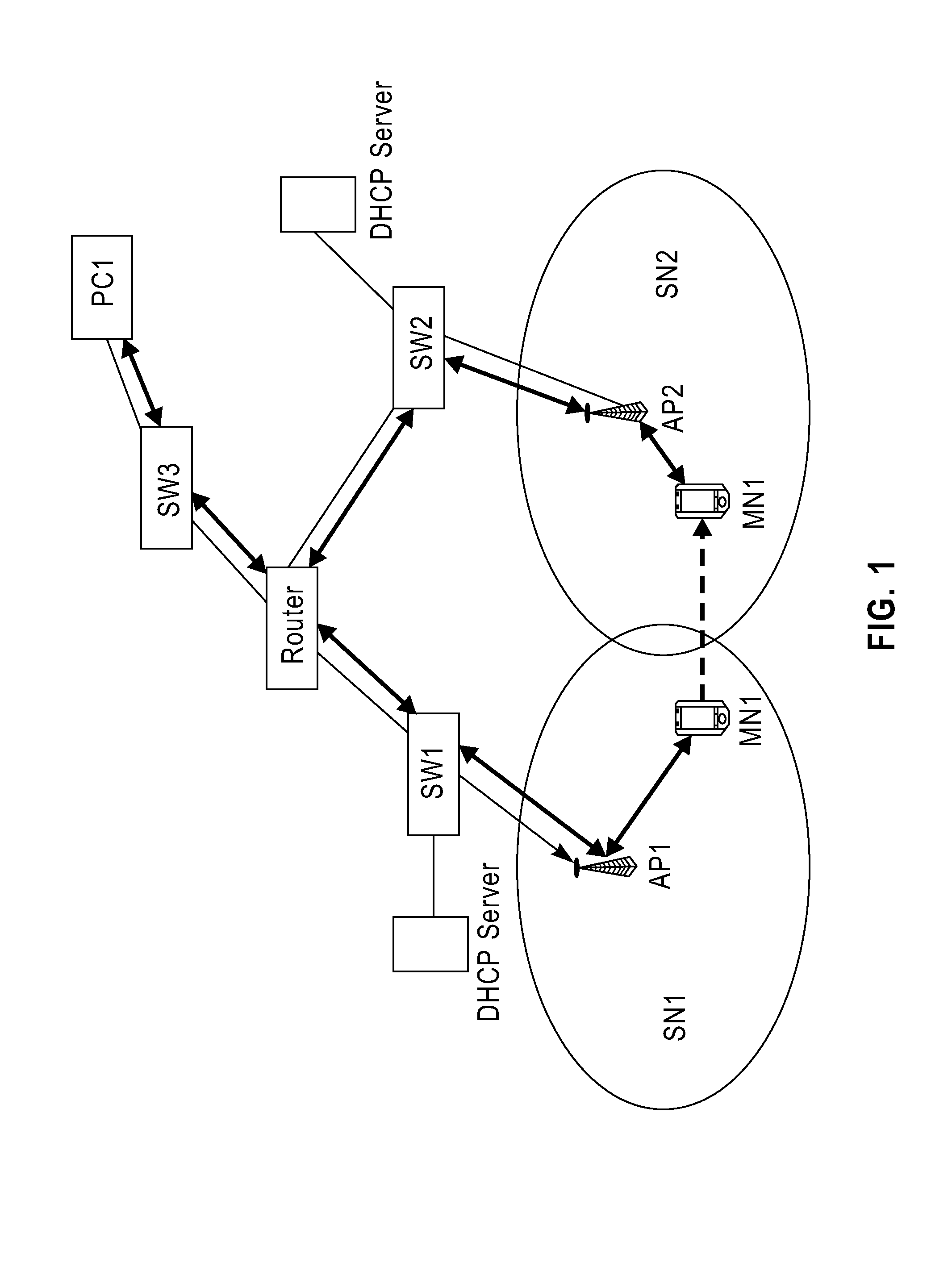

Method For Network Layer Handoff Over a Wireless LAN and an Associated Access Point Device

ActiveUS20100118831A1Extended handoff latencyExtended waiting timeData switching by path configurationMultiple digital computer combinationsIp addressWireless lan

A method and a wireless access point device for a network layer handoff of a wireless mobile node over a wireless local area network. The method includes detecting a wireless mobile node that has moved into the coverage area of the wireless access point device; maintaining an available IP address pool; selecting a temporary IP address from the IP access pool in response to the detection of the mobile node moving into the coverage area; and assigning a temporary IP address to the mobile node for use by the node during an interim period. The method produces a network layer handoff of a wireless mobile node over a local area network. Also provided is a computer readable article of manufacture tangibly embodying computer readable instructions for executing the steps of the method.

Owner:IBM CORP

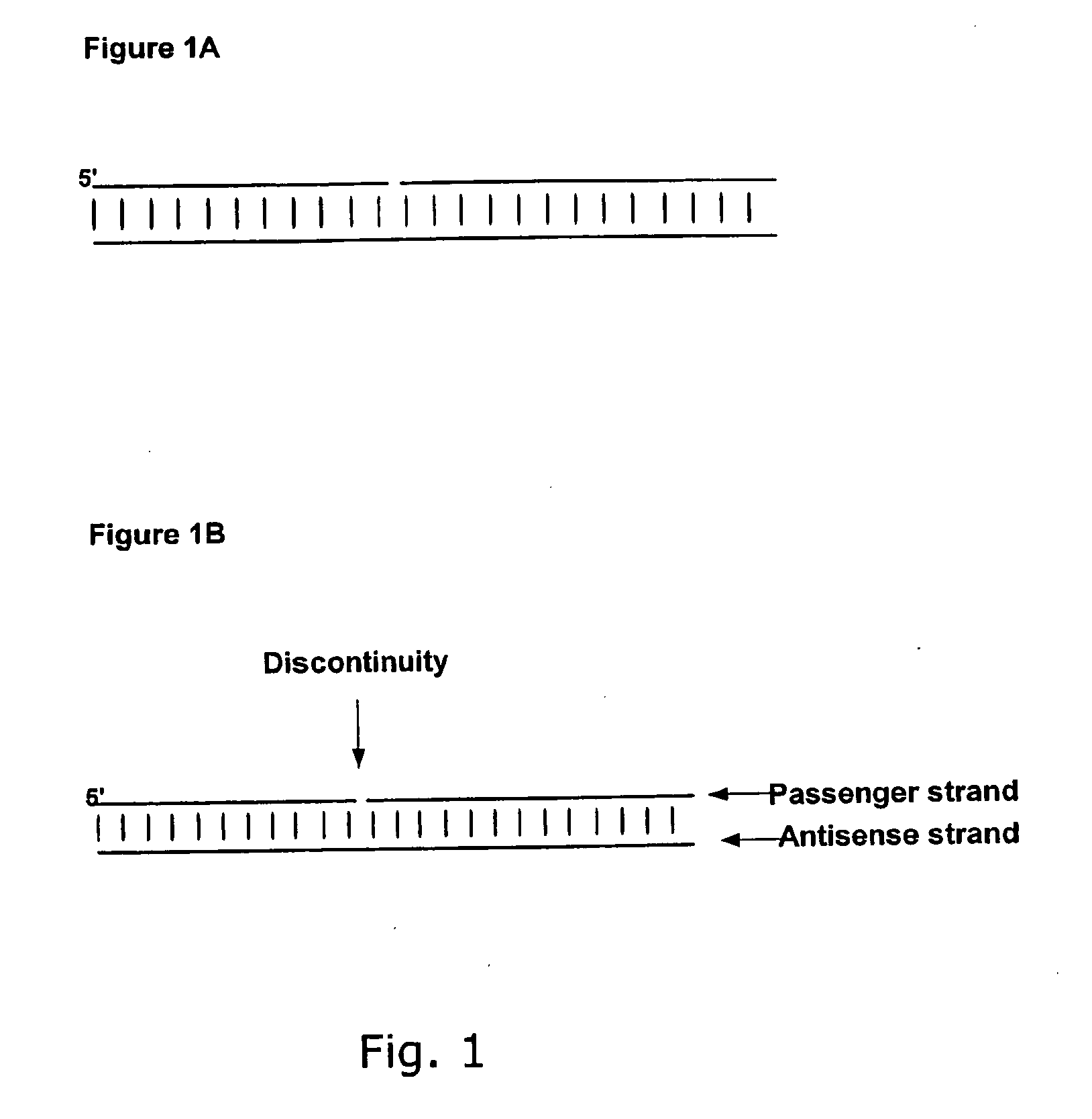

Small Internally Segmented Interfering RNA

ActiveUS20090182136A1Increase serum stabilityProlongs target knock downSugar derivativesActivity regulationPharmaceutical drugRegulator gene

The present invention is directed to pharmaceutical and therapeutic compositions which comprise RNA complexes comprising an antisense strand and a discontinued passenger strand capable of regulating gene expression. The use of a discontinued passenger strand reduces off target effects of the RNA complexes and also has other advantages.

Owner:ROCHE INNOVATION CENT COPENHAGEN

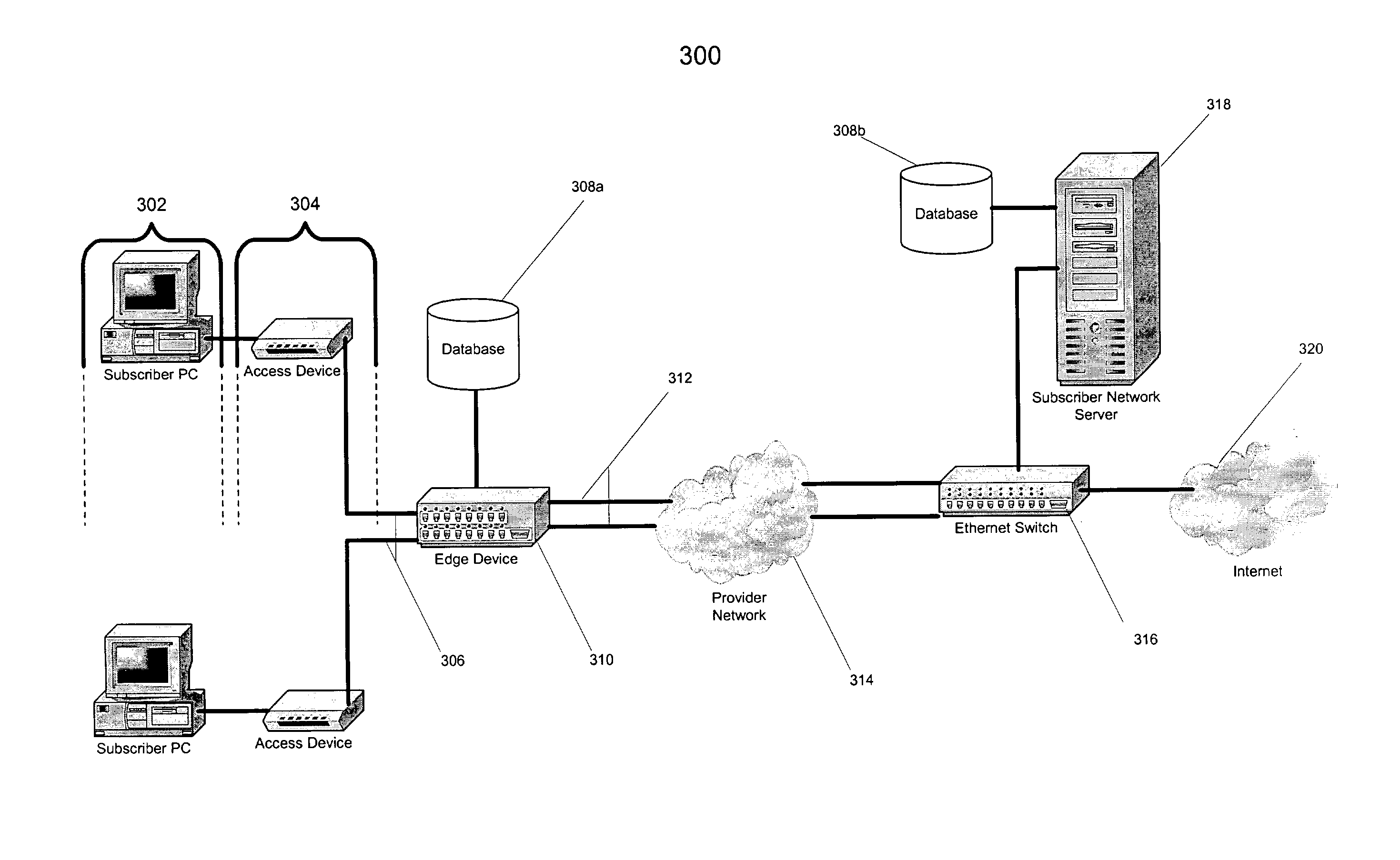

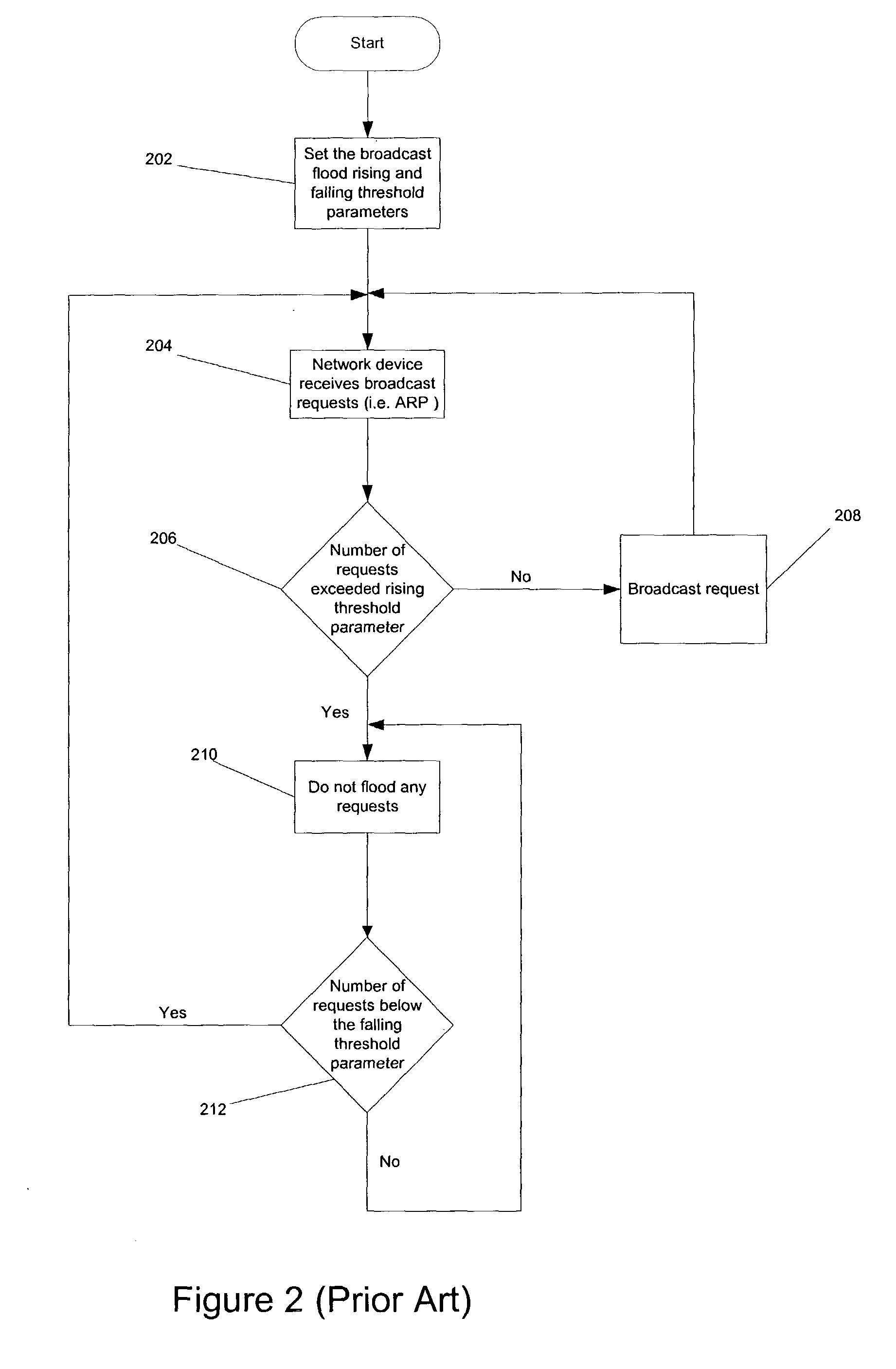

Controlling ARP traffic to enhance network security and scalability in TCP/IP networks

ActiveUS7490351B1Limit scopeInhibitory responseMemory loss protectionError detection/correctionExtensibilityTraffic capacity

A method of preventing ARP broadcast flooding of subscriber access links where an ARP packet is received at a subscriber network edge device and the source and destination information contained within the ARP packet is compared to address lease information for subscribers of a subscriber network. If the destination information obtained from the ARP packet is not associated with an address lease assigned to one of the subscribers, the network device only broadcasts the ARP packet to network uplinks. The method further includes preventing subscribers of a subscriber network from spoofing ARP responses by responding to an ARP request packet with an ARP response packet containing false information. The ARP response packet information is compared to address lease information for the transmitting subscriber. If the source information obtained from the ARP response packet corresponds to address lease information of the transmitting subscriber the ARP response packet is accordingly forwarded.

Owner:CALIX

Pharmaceutical compositions and methods for restoring beta-cell mass and function

ActiveUS20060160736A1Increase the number ofBlock autoimmune responseBiocidePeptide/protein ingredientsAdjuvantCell mass

Pharmaceutical compositions and methods for using are provided for restoring β-cell mass and function in a mammal in need thereof. The pharmaceutical compositions have a biological response modifier and a β-cell growth factor in admixture with a pharmaceutically acceptable carrier, adjuvant or vehicle.

Owner:DIAKINE THERAPEUTICS

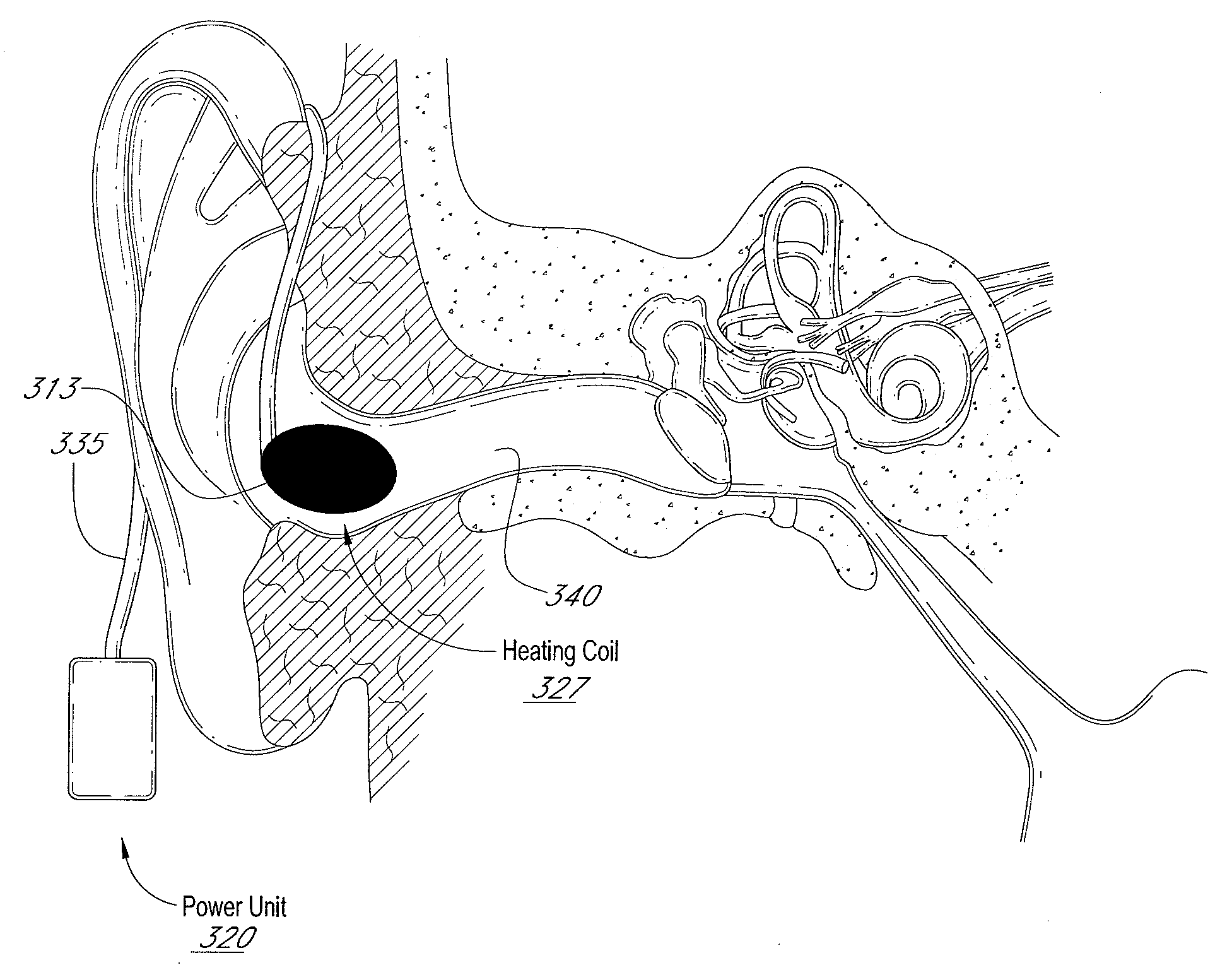

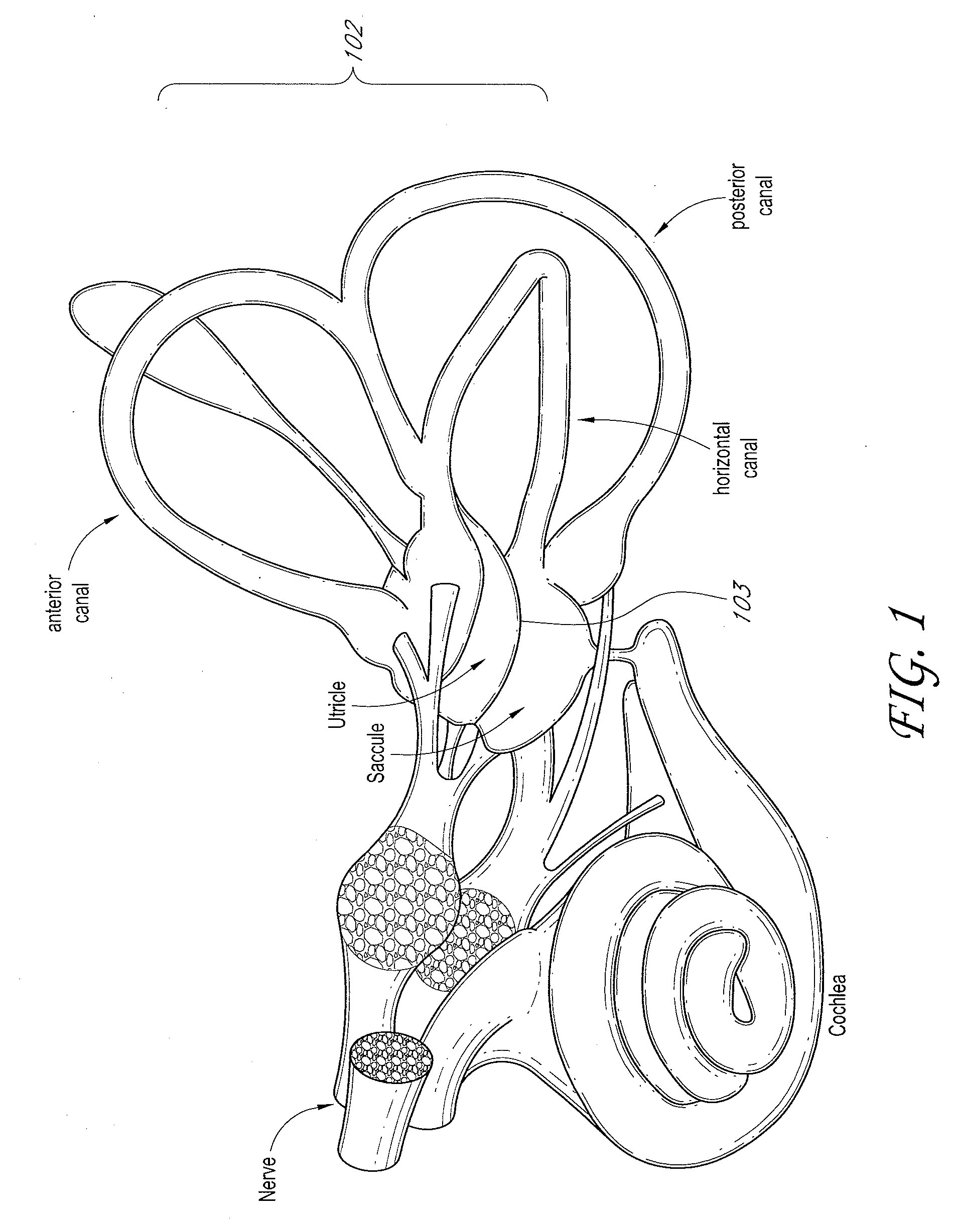

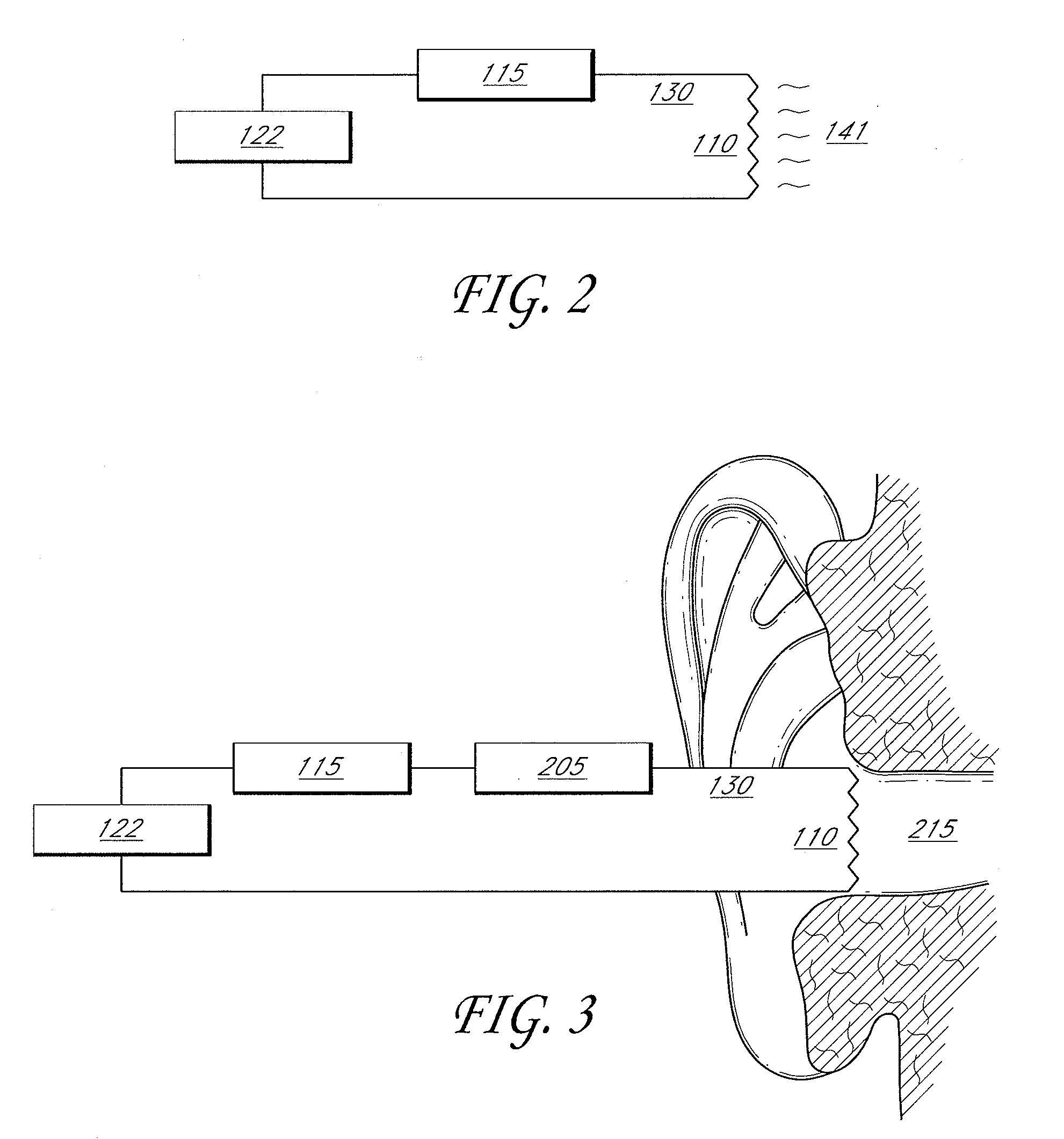

Auricular thermoregulation system for appetite suppression

InactiveUS20090182399A1Few calorieWeight controlTherapeutic coolingTherapeutic heatingSide effectVestibular system

Disclosed herein is a system to stimulate at least a part of the vestibular system of a patient to induce a sensation of anorexia to promote weight loss. The system can include a thermal element, a power source, a conduit, and a control unit configured to regulate the temperature of the thermal element, the duration in which the thermal element is applied, the duration in between thermal stimuli, and / or the number of stimulus cycles to promote a sensation of anorexia in a patient while avoiding or minimizing undesirable side effects such as nausea, vomiting, nystagmus, or vertigo. Methods of using the system are also disclosed.

Owner:SYLVESTRE DIANA

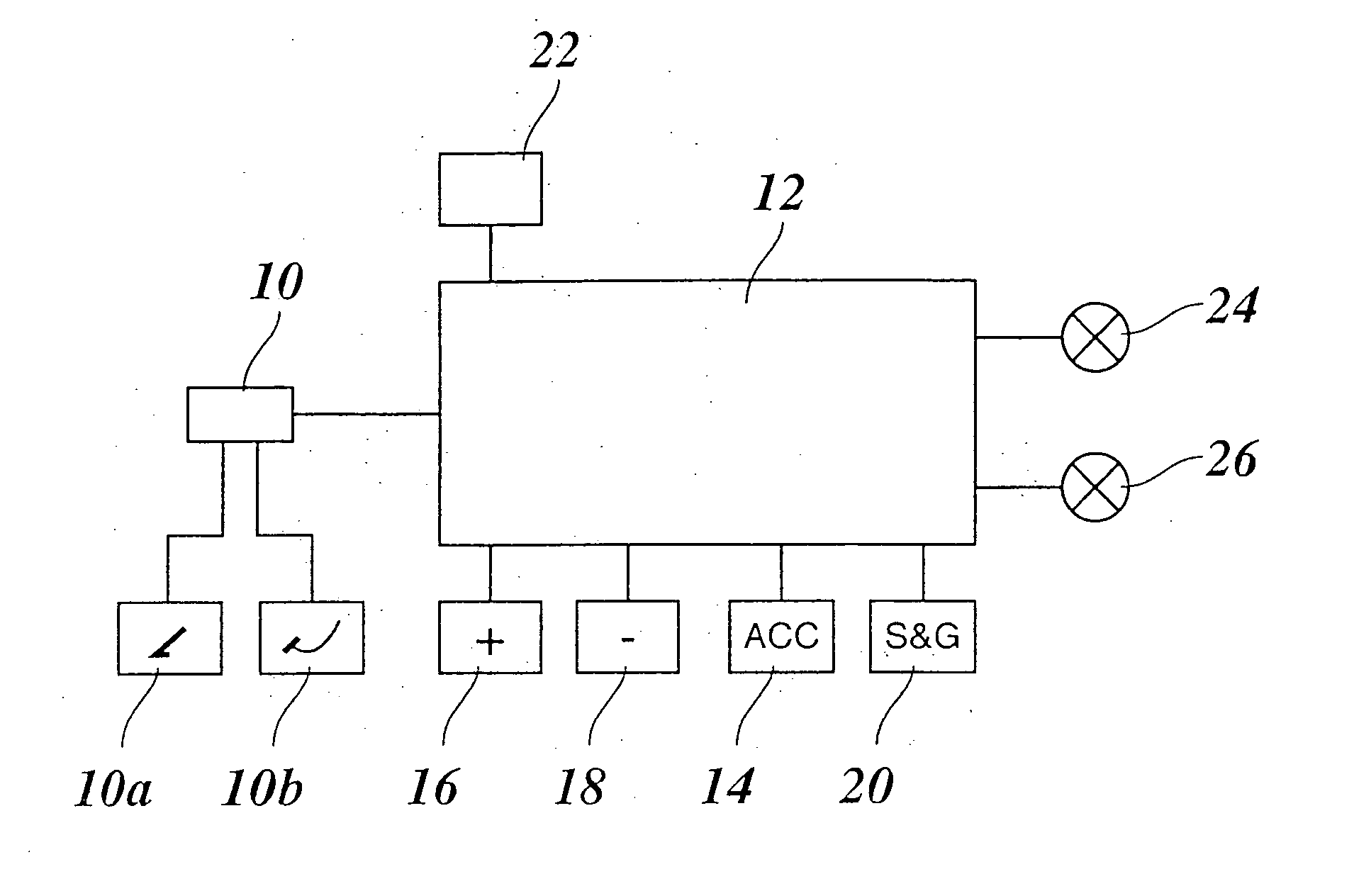

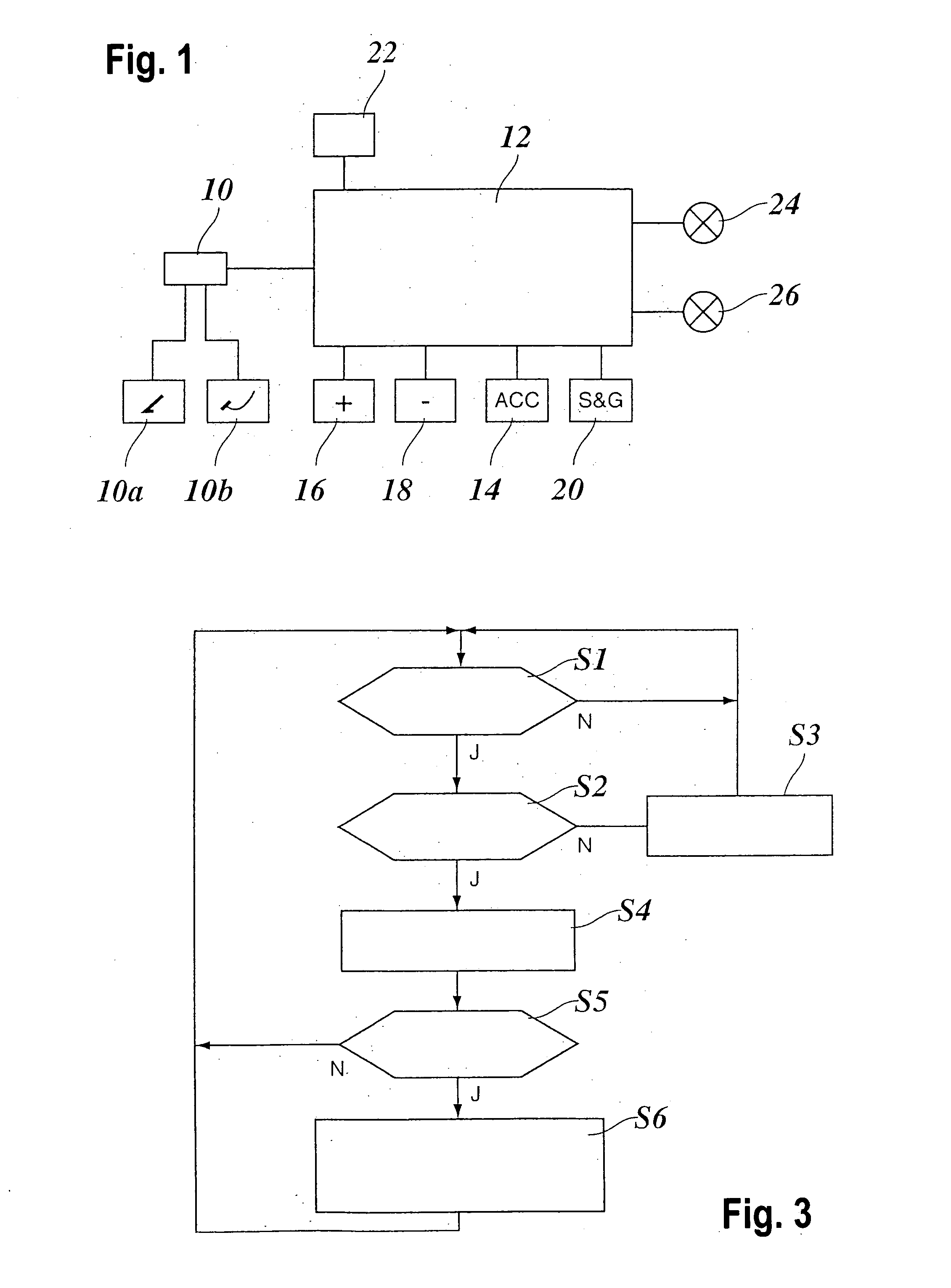

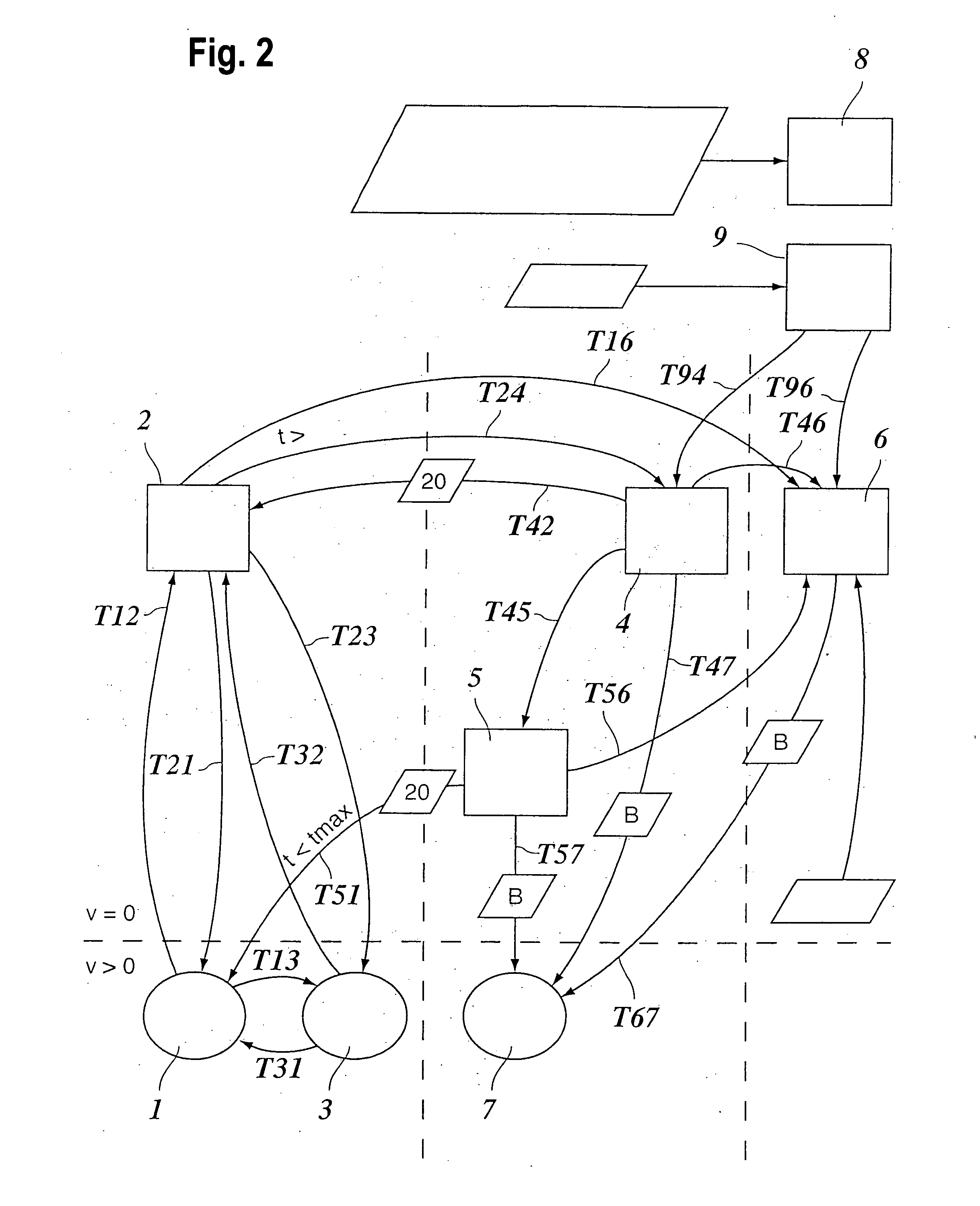

Cruise control system having a stop function

ActiveUS20050010352A1Reduce usagePrevent rollingVehicle fittingsDigital data processing detailsControl systemCruise control

A cruise control system for motor vehicles is described, having a sensor device for measuring the vehicle's performance characteristics and for measuring the distance to a target object ahead of the vehicle, and a controller which is used to control the vehicle's speed or acceleration as a function of the measured performance characteristics and distance data and has a stop function for automatically braking the vehicle to a standstill as well as at least one standstill state in which the vehicle is held in a stationary position by automatic brake activation, and from which it may only drive off again via an operational command by the driver, the operational command becoming effective only when a confirmation signal is present in addition to the operational command.

Owner:ROBERT BOSCH GMBH

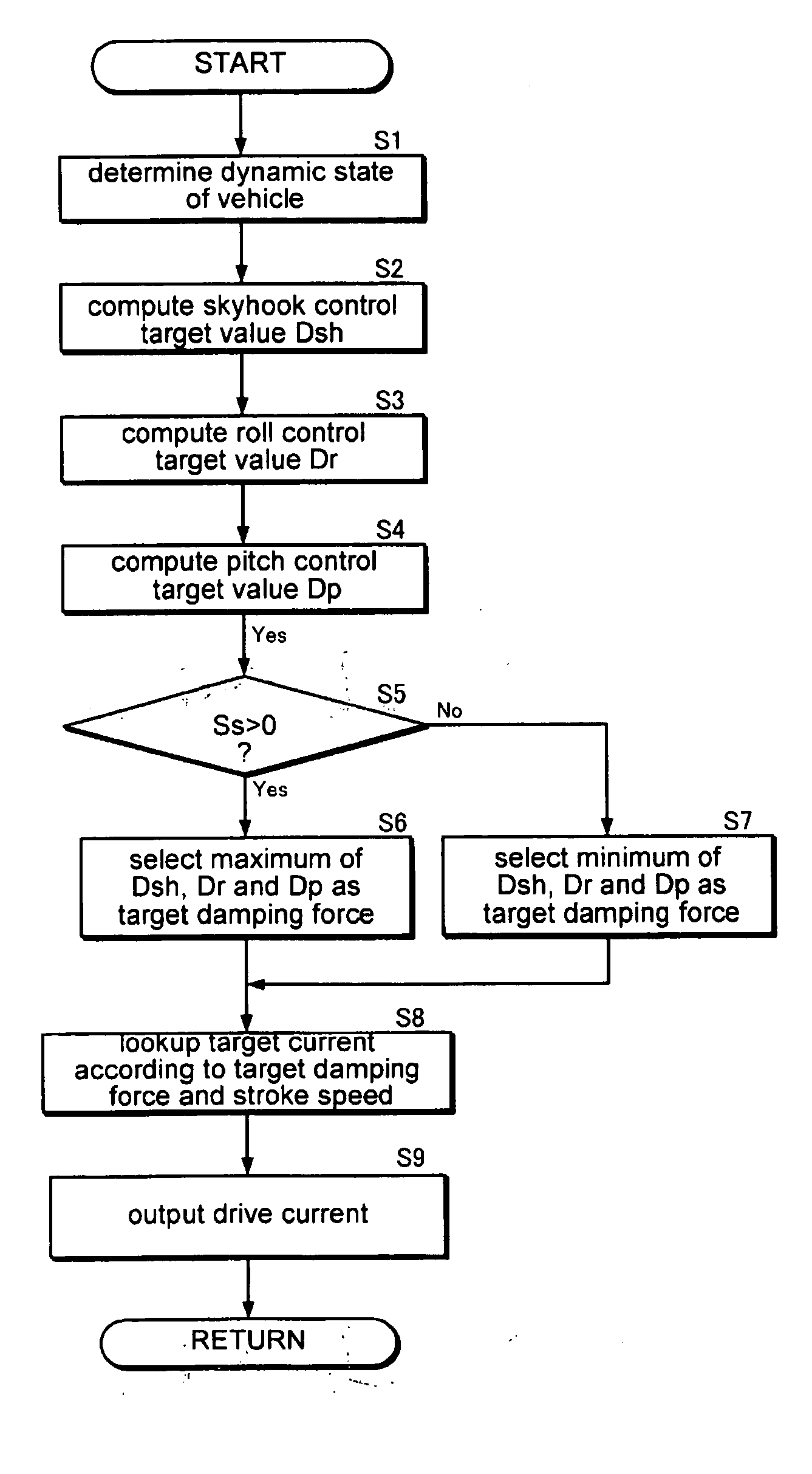

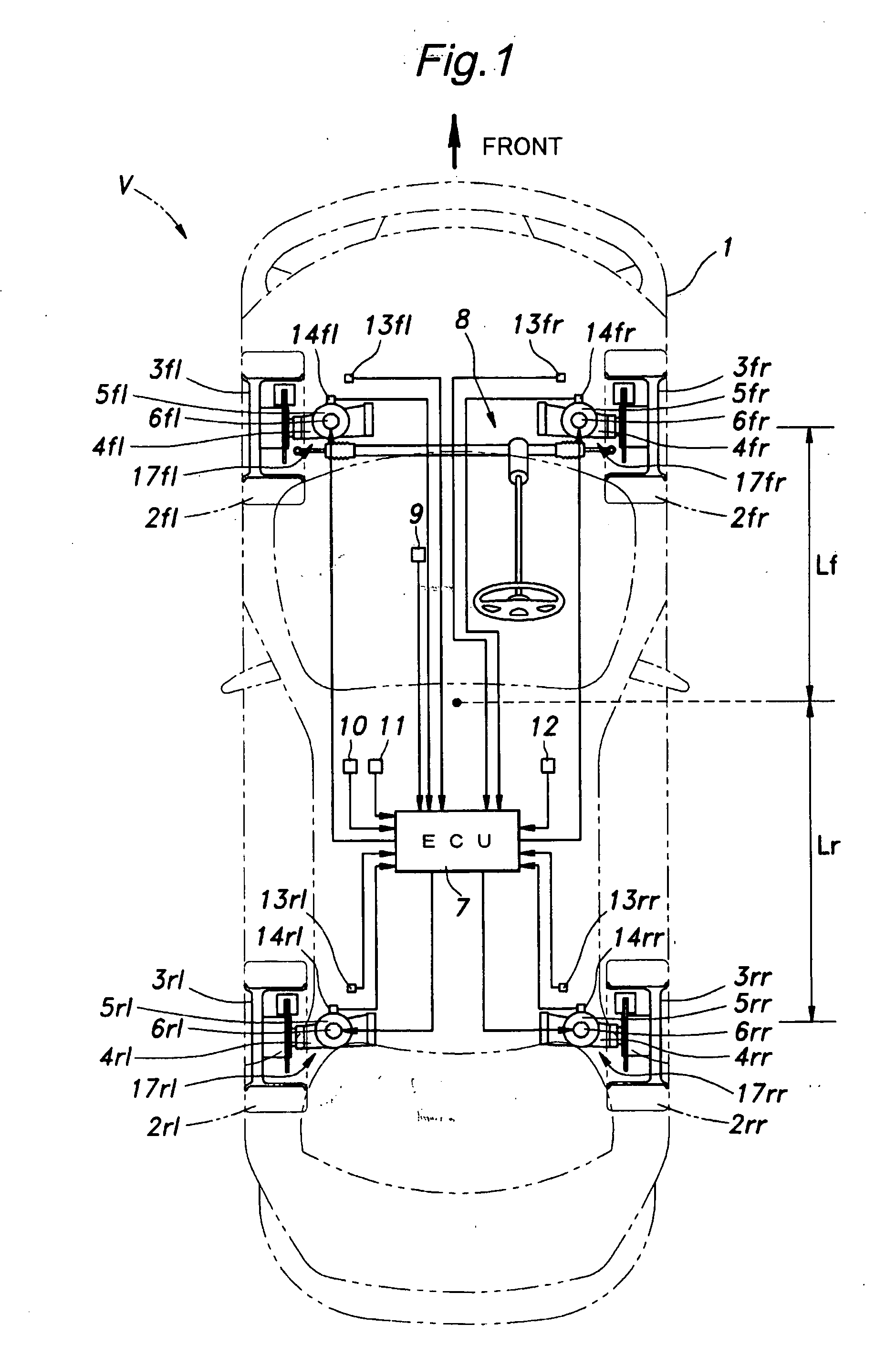

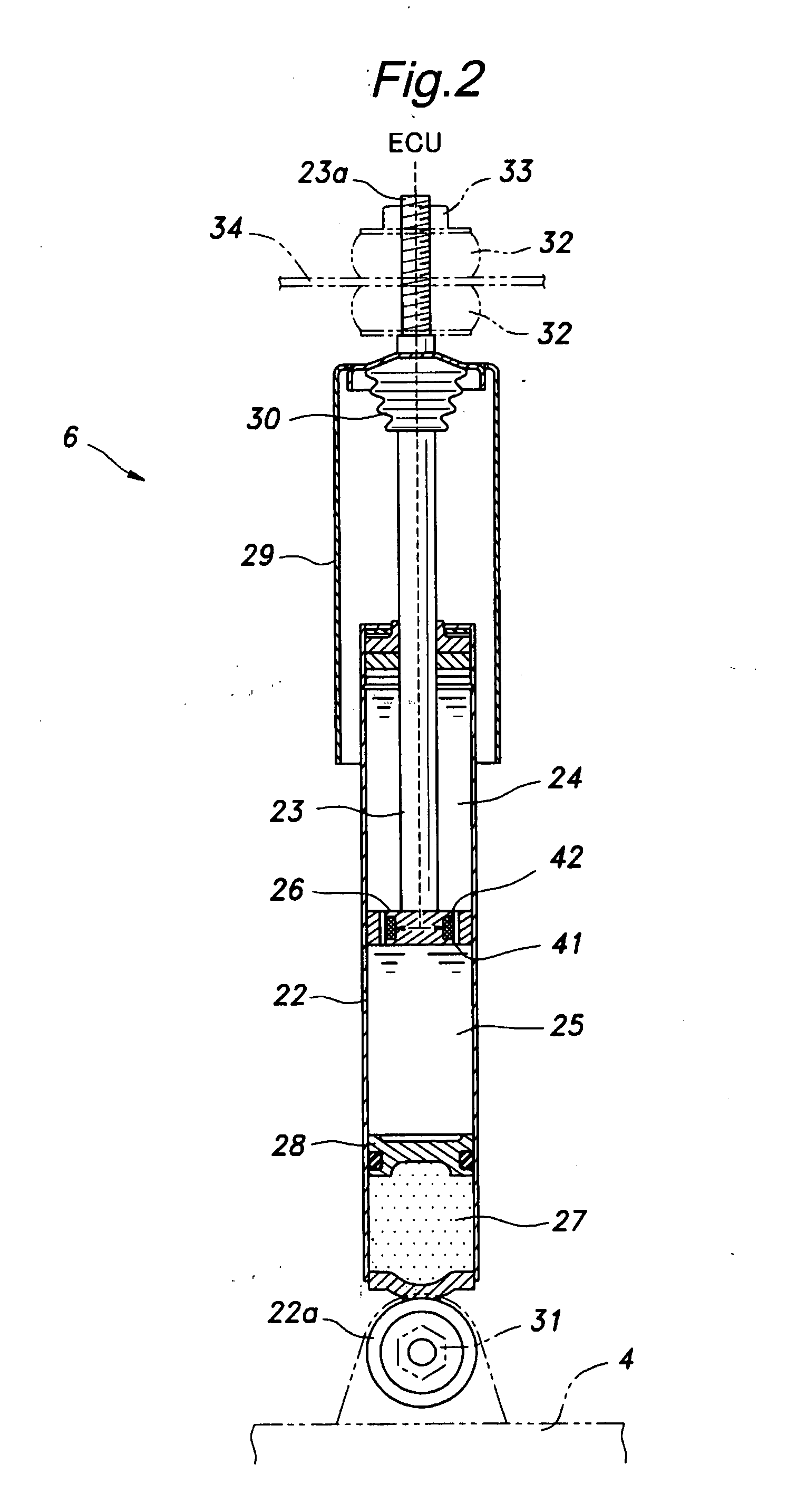

Control device for a wheel suspension system

ActiveUS20090248247A1Prevent undesired responseInhibitory responseDigital data processing detailsAnimal undercarriagesRoad surfaceSprung mass

In a control device for controlling a variable element of a wheel suspension system, the variable suspension element associated with one of the wheels is controlled at least according to an output of a sensor associated with a different one of the wheels. The output of the sensor may include a sprung mass speed of a vehicle part associated with each wheel. The variable suspension element may include a variable damping force damper or a variable spring constant spring. Thereby, an undesired response of a vehicle body can be avoided even when a vehicle is subjected to an uneven distribution of wheel loads such as when the vehicle is traveling over a slanted road surface or making a turn.

Owner:HONDA MOTOR CO LTD

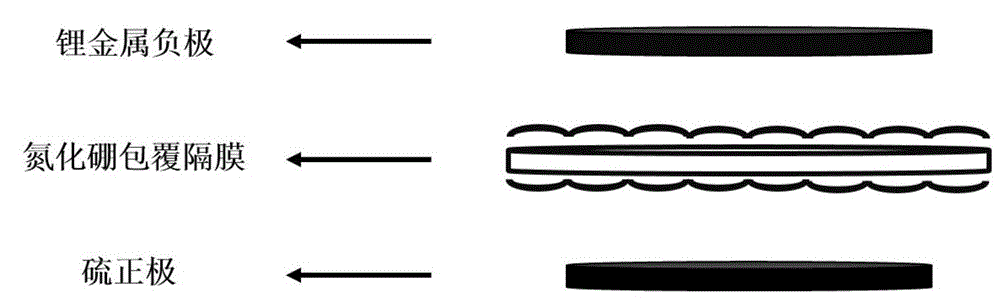

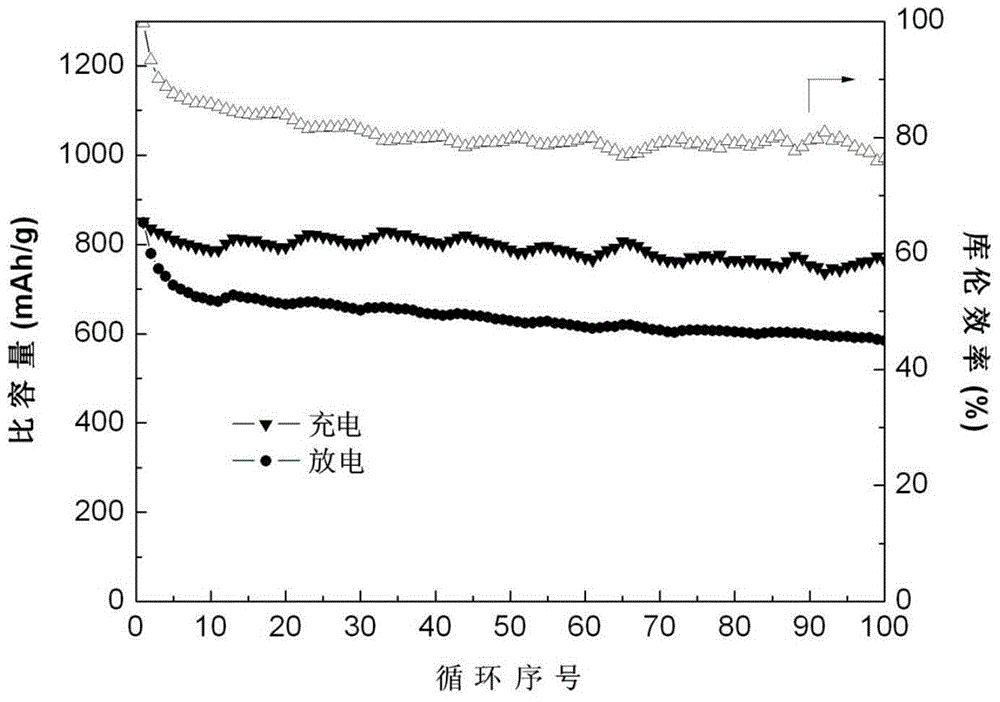

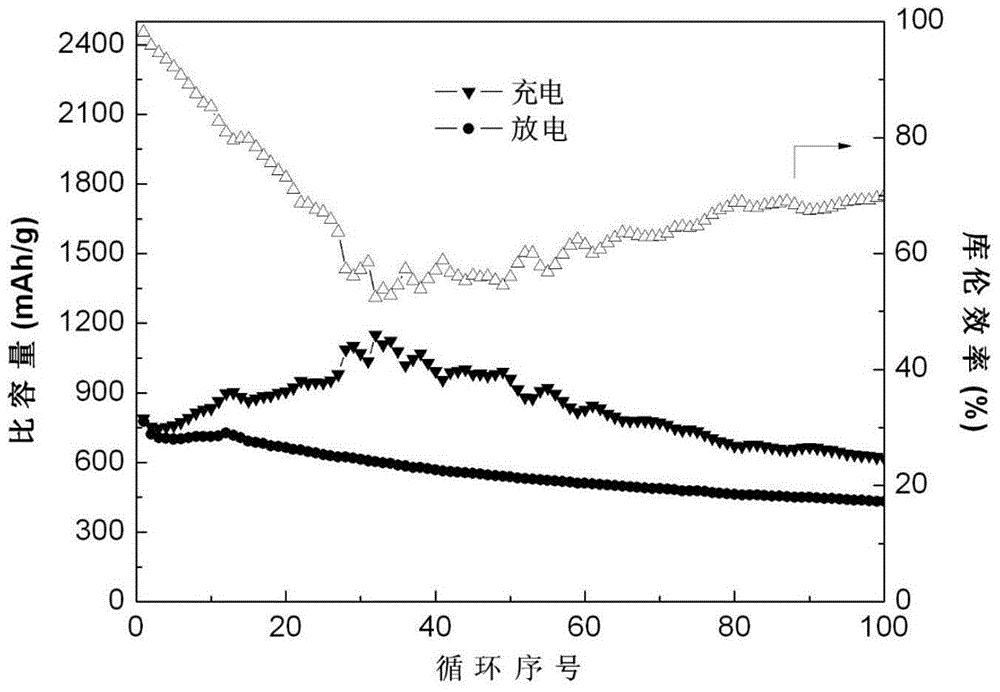

Production method of boron nitride coated diaphragm of lithium-sulfur battery

ActiveCN104993083AIncrease capacityImprove Coulombic efficiencyLi-accumulatorsCell component detailsHexagonal boron nitrideBoron nitride

The invention relates to a production method of a boron nitride coated diaphragm of a lithium-sulfur battery. The diaphragm is produced from a commercial polypropylene diaphragm, two sides of the diaphragm are uniformly covered with hexagonal boron nitride, and the characteristics of hexagonal boron nitride 'white graphite' are used, so lithium ions are allowed to pass, shuttle of polysulfide anions is obstructed, a reaction of a lithium negative electrode with the polysulfide anions is inhibited, formation of lithium dendrites, lithium sulfide precipitate and fixed lithium is prevented, the capacity, the coulombic efficiency and the cycle stability of the lithium-sulfur battery are improved, the growth of the negative electrode metal dendrite in the cycle process is effectively inhibited, and the safety of the battery is improved. The method has the advantages of simple process route and clear purpose, and the produced diaphragm has multiple functions, and can greatly overcome disadvantages of present technologies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

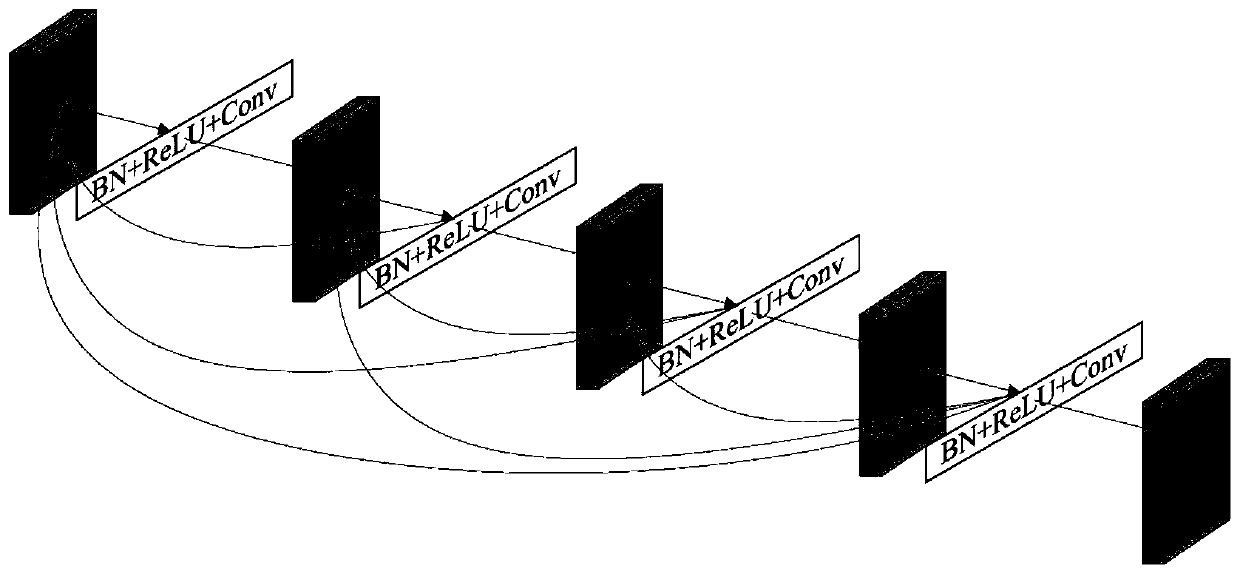

Medical image segmentation method based on deep learning

ActiveCN111145170AImprove performanceInhibitory responseImage enhancementImage analysisPattern recognitionVisual technology

The invention belongs to the technical field of medical image processing and computer vision, and particularly relates to a medical image segmentation method based on deep learning. According to the method, on the basis of U-Net Baseline, multiple technologies such as a multi-scale framework, a dense convolutional network, an attention mechanism, a pyramid model and small sample enhancement are fused, the method is helpful for realizing feature reuse, recovering lost context information, inhibiting response of an unrelated region and improving the performance of a small ROI, solves the problems of few ultrasonic image samples, low pixel, fuzzy boundary, large difference and other pain points, and obtains an optimal segmentation effect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

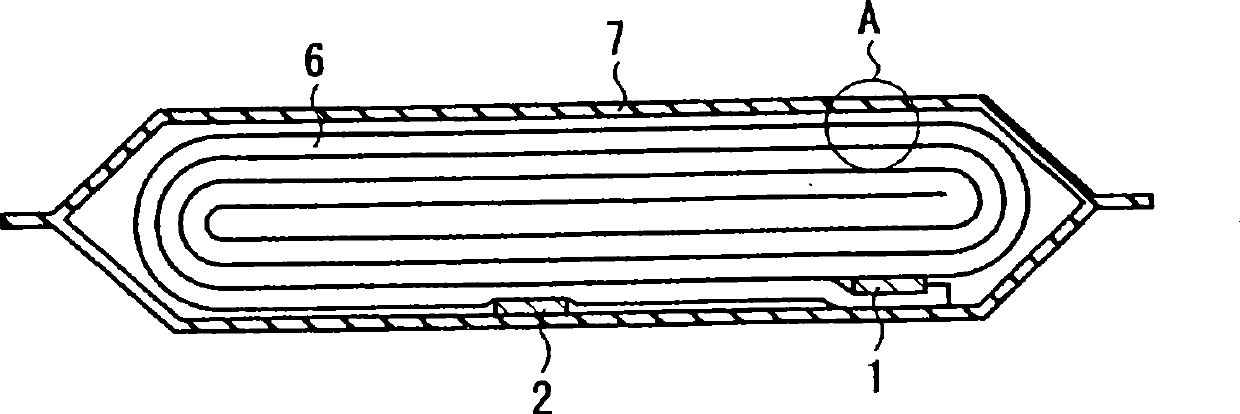

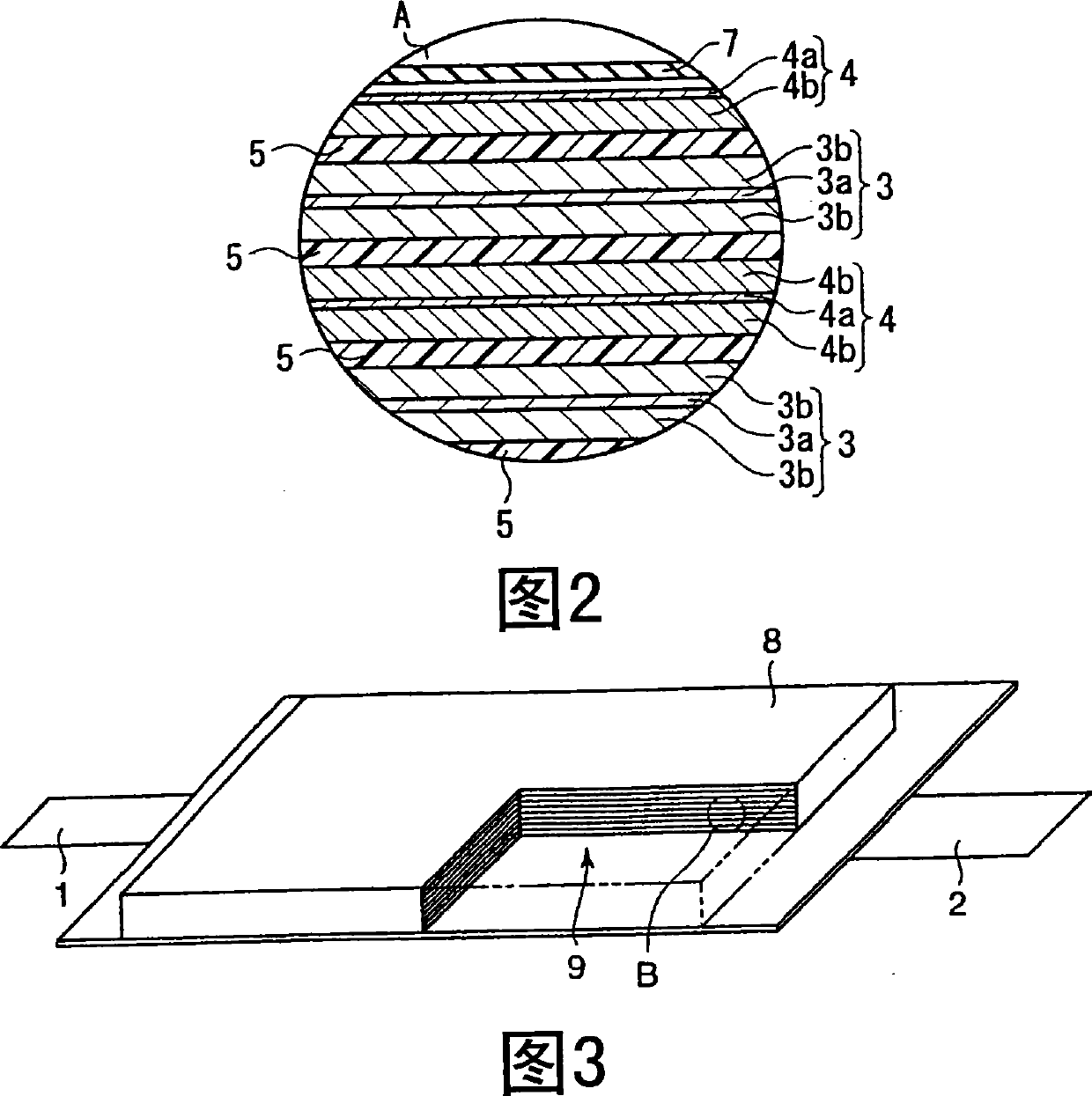

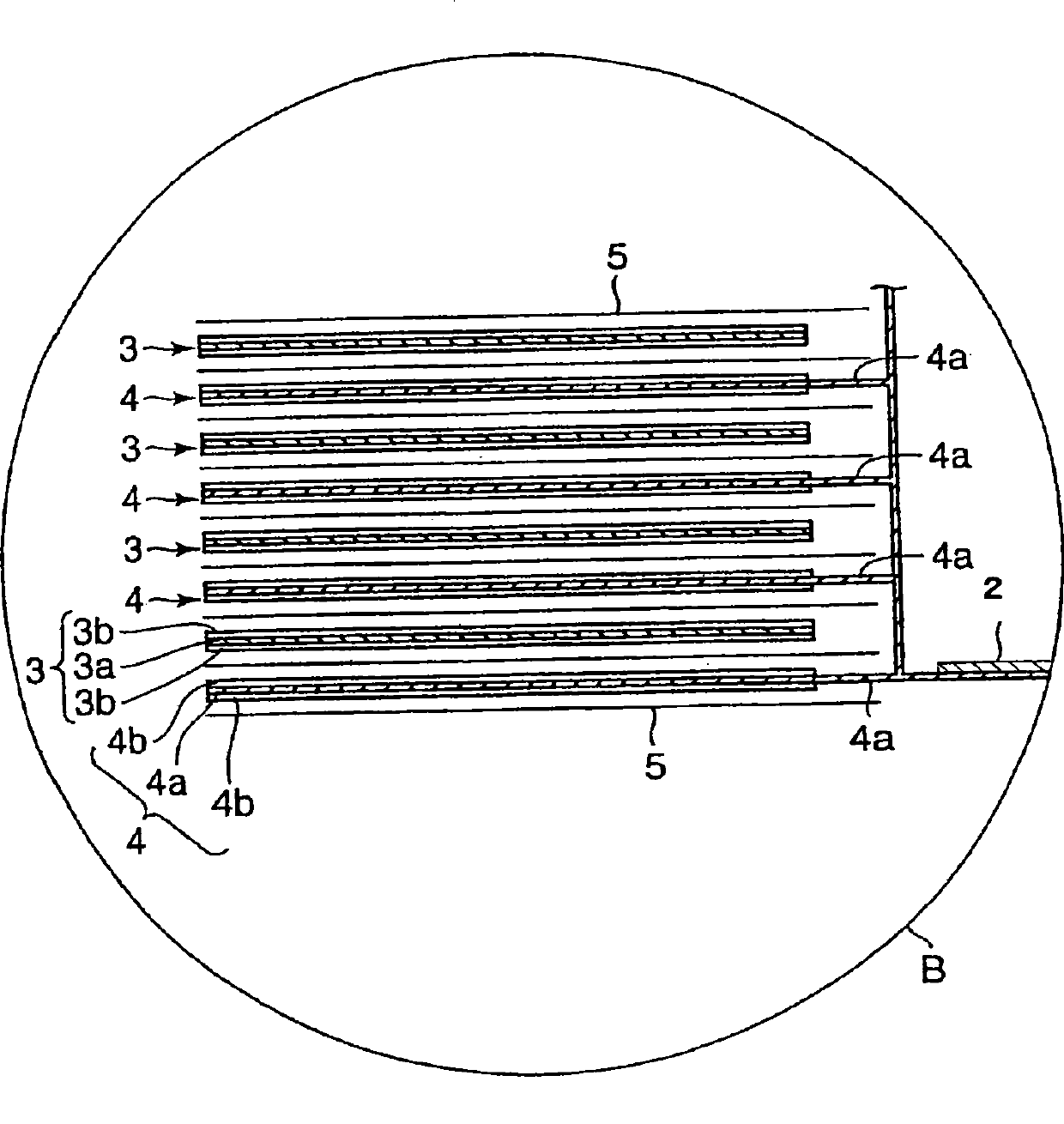

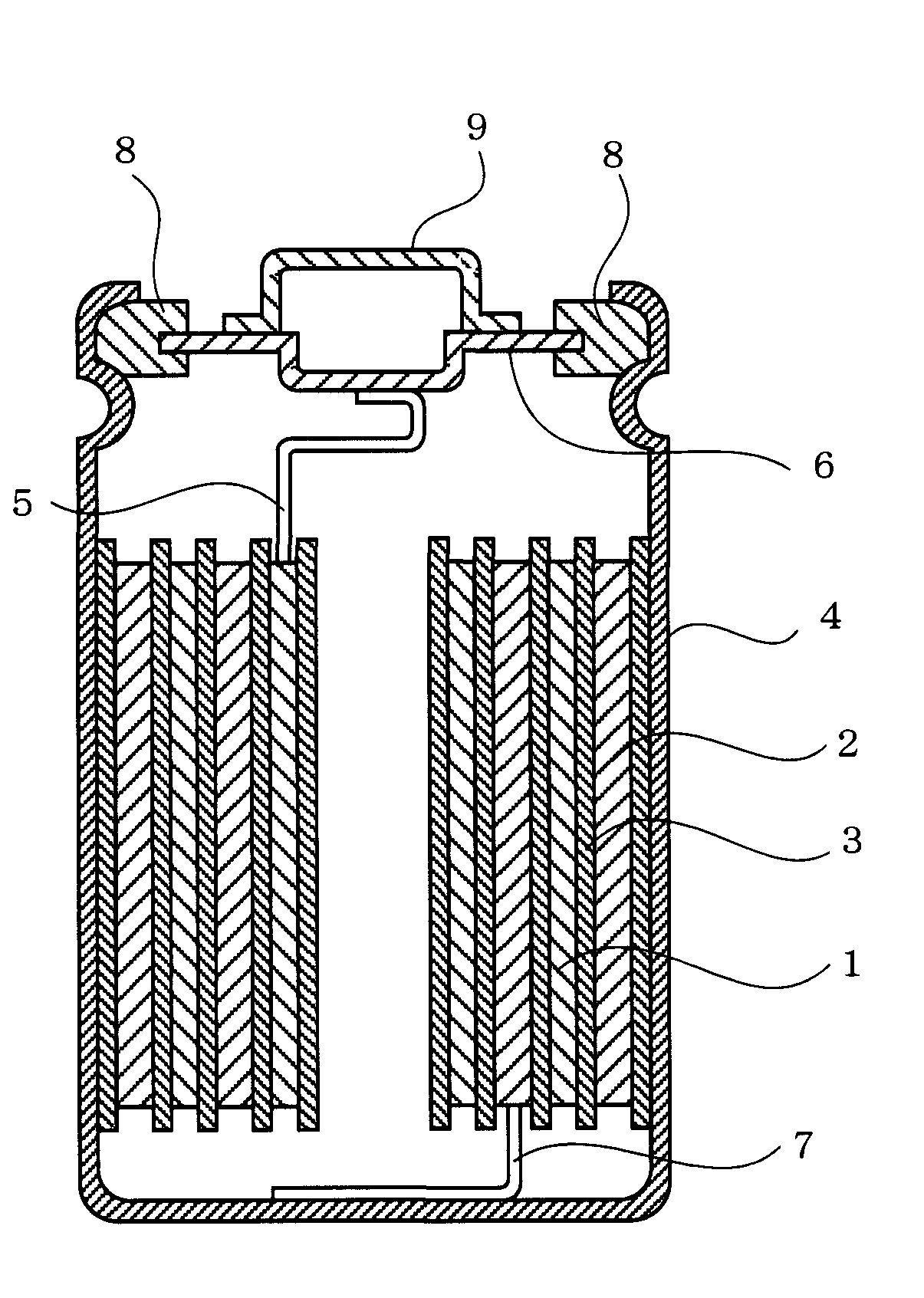

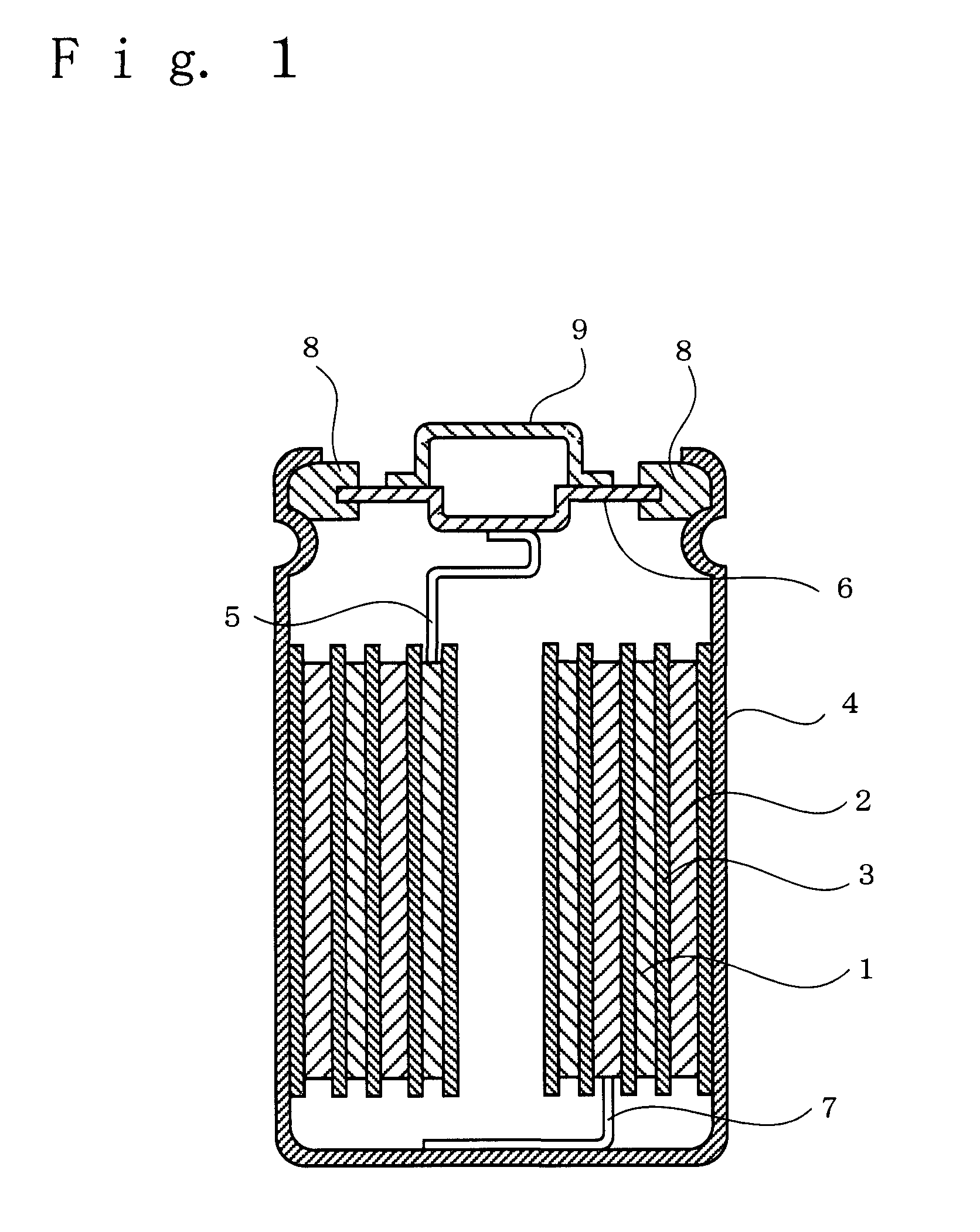

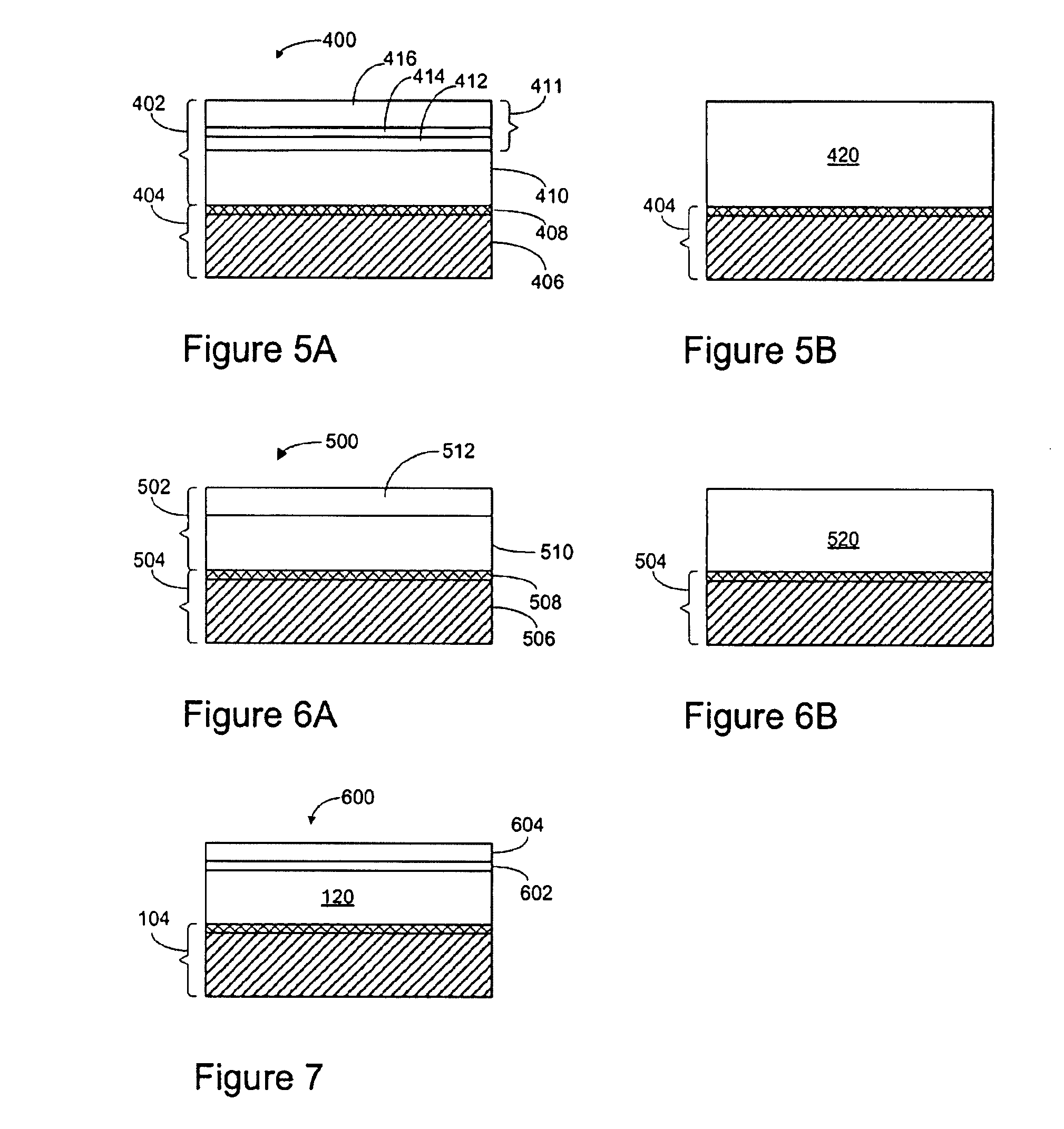

Nonaqueous-electrolyte battery

InactiveCN101373848AInhibitory responseImprove securityActive material electrodesSecondary cellsSimple Organic CompoundsLithium

The invention provides a nonaqueous-electrolyte battery which produces few gas and has good battery characteristic. The nonaqueous-electrolyte battery has a positive electrode 3 including a positive active material, a negative electrode 4 including a negative active material having a lithium insertion / release potential higher than 1.0 V (vs. Li / Li+), and a nonaqueous electrolyte, wherein an organic compound having one or more isocyanato groups has been added to the nonaqueous electrolyte.

Owner:KK TOSHIBA

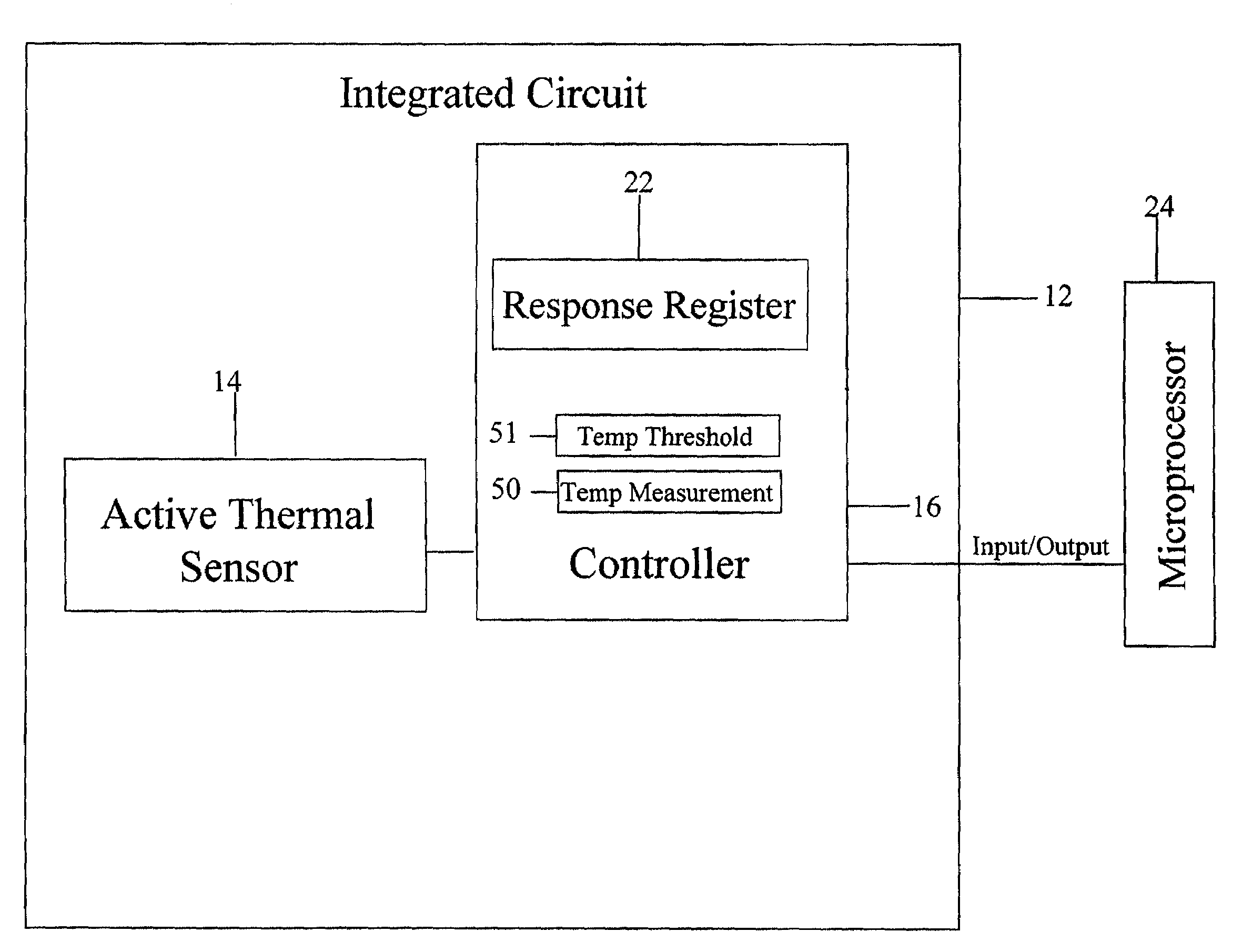

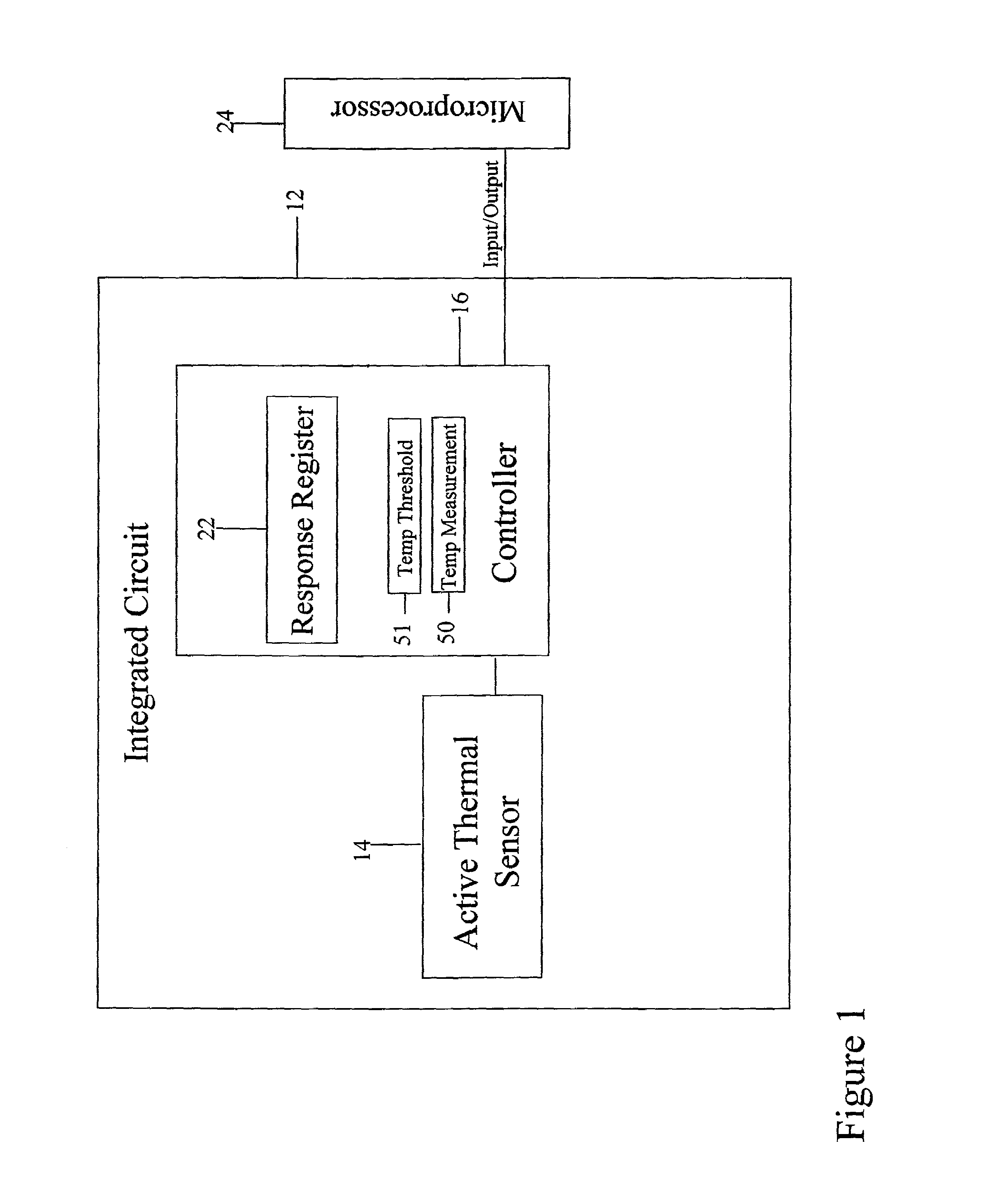

Method and system for monitoring and profiling an integrated circuit die temperature

InactiveUS6996491B2Avoid unnecessary responseAccurate temperature profileThermometer detailsDigital data processing detailsIntegrated circuitThermal sensors

A system and method are provided for sensing a physical stimulus of an integrated circuit. The system and method operate with one or more active thermal sensors embedded in the die of an integrated circuit to provide highly accurate die temperature measurements. The system and method are able to monitor and control the die temperature of the integrated circuit to avoid an integrated circuit malfunction due to an undesirable temperature condition.

Owner:ORACLE INT CORP

Preparation method and application of diethyl phosphinates

InactiveCN101891762AShort reaction timeTrigger fastGroup 5/15 element organic compoundsReaction rateUltraviolet lights

The invention discloses a preparation method and application of diethyl phosphinates, belonging to the field of green flame retardants. The preparation method of the diethyl phosphinates comprises the following steps of: making hypophosphorous acid and / or an alkali metal salt thereof react with ethylene under the irradiation of ultraviolet light in the presence of a photoinitiator in a solvent system to obtain diethyl phosphinic acid and / or an alkali metal salt thereof; and making the obtained diethyl phosphinic acid and / or the alkali metal salt thereof react with metallic compounds of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn and / or Fe to obtain corresponding diethyl phosphinates. In the invention, the photoinitiator is decomposed into free radicals under the irradiation of the ultraviolet light to initiate an additive reaction so that the reaction rate can be improved, the energy consumption required in the reaction can be reduced and the production cost of products can be lowered.

Owner:NANKAI UNIV

Methods of treating tendonitis in a subject by using an anti-cytokine agent

InactiveUS20080064626A1Inhibits rapid pro-inflammatory responseReduce inflammationBiocidePeptide/protein ingredientsIfn gammaAntibiotics

A method for treating tendonitis and bursitis in a subject involves providing an effective amount of an anti-cytokine agent to a musculo-tendinious structure. Anti-cytokine agents, such as, TNF-α inhibitors, NF-κB inhibitors, IL-1 inhibitors, IL-6 inhibitors, IL-8 inhibitors, IL-12 inhibitors, IL-15 inhibitors, IL-10, Interferon-gamma (IFN-gamma) act to prevent further inflammation initiated by cytokine factors. One embodiment includes, adding with the anti-cytokine agent one or more of an antibiotic or analgesic. Delivery of the anti-cytokine agent may be provided to the affected musculo-tendinious structure by injection, implantation, or a transdermal patch. These agents, individually or in combination directly address the underlying causes of tendonitis, bursitis and associated tendinopathies that result in inflammation and pain.

Owner:WARSAW ORTHOPEDIC INC

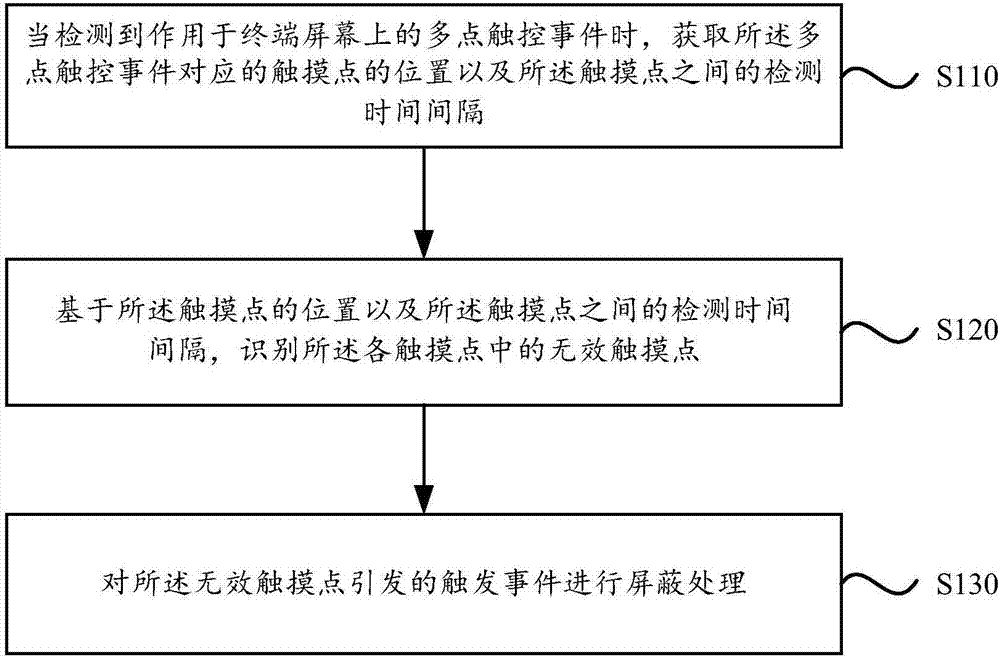

Method and device for preventing touch by mistake and terminal

ActiveCN106855782AInhibitory responseSolve misuseInput/output processes for data processingEvent triggerMulti point

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

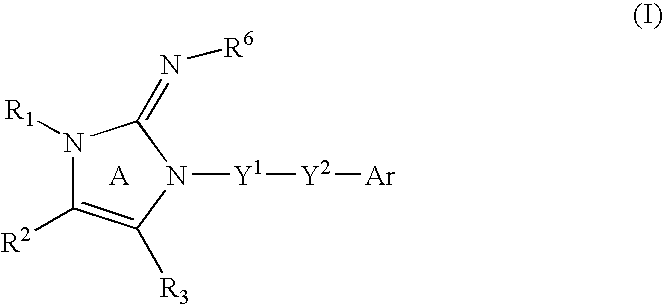

2-iminoimidazole derivatives (2)

InactiveUS20050004197A1Excellent thrombin receptor antagonismInhibitory responseOrganic active ingredientsBiocideMedicinal chemistryHydroxy compound

A 2-iminoimidazole derivative represented by the formula: {wherein R1, R2 and R3 represent hydrogen, optionally substituted C1-6 alkyl, etc.; R6 represents hydrogen, C1-6 alkyl, C1-6 alkyloxycarbonyl, etc.; Y1 represents a single bond, —CH2—, etc.; Y2 represents a single bond, —CO—, etc.; and Ar represents hydrogen, a group represented by the formula: [wherein R10-R14 represent hydrogen, C1-6 alkyl, hydroxyl, C1-6 alkoxy, etc., and R11 and R12 or R12 and R13 may bond together to form a 5- to 8-membered heterocycle], etc.}or salt thereof.

Owner:EISIA R&D MANAGEMENT CO LTD

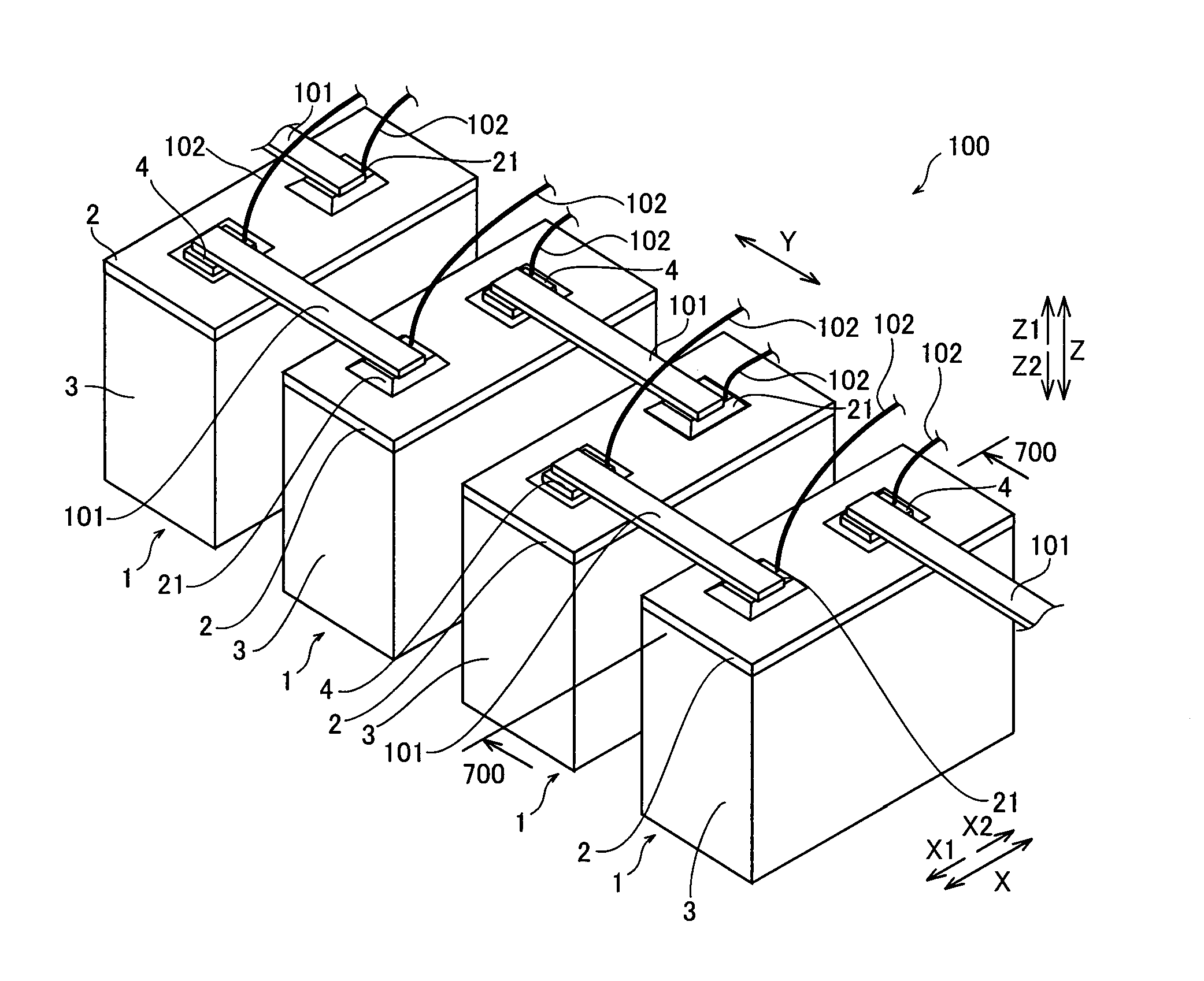

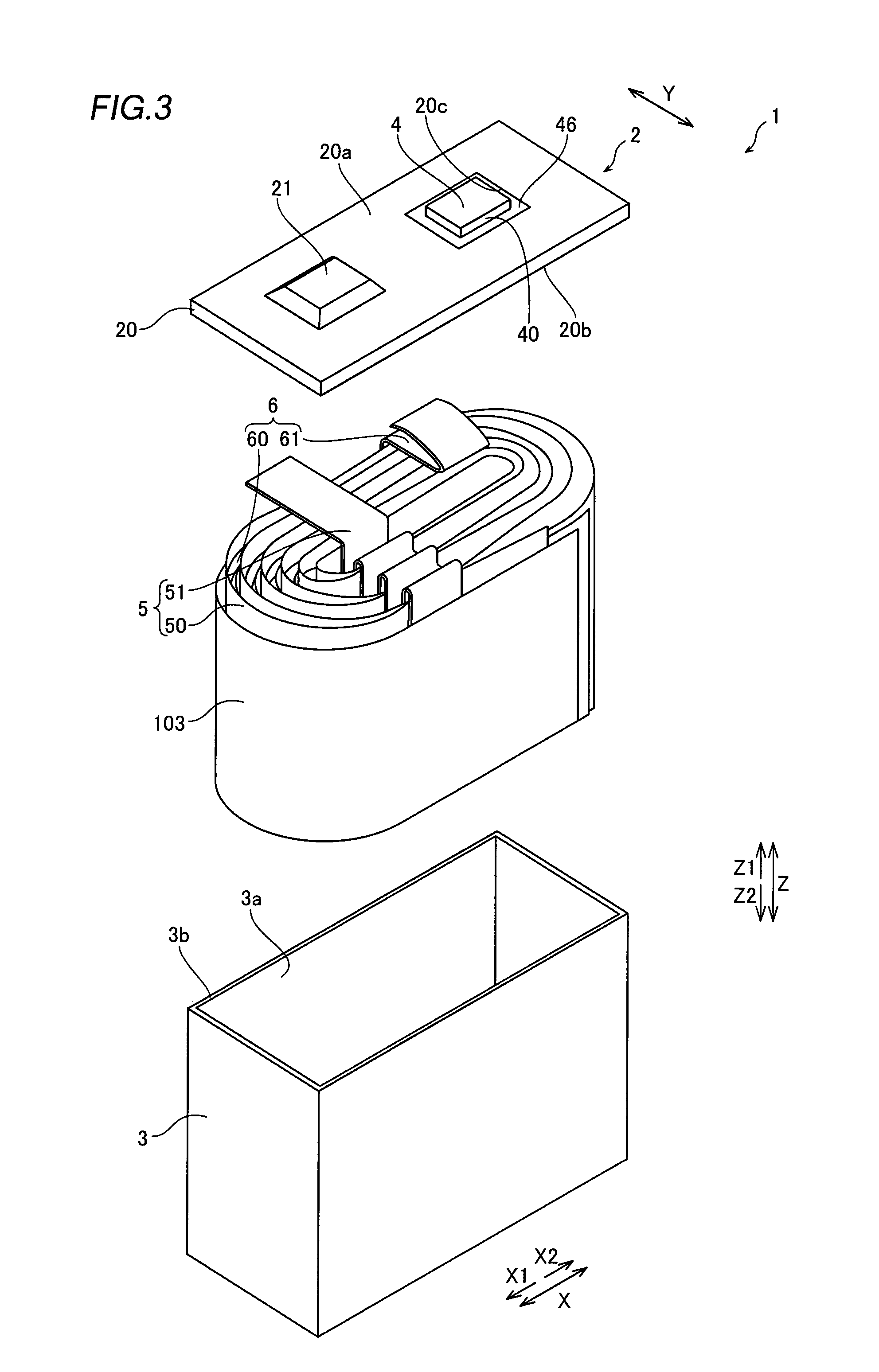

Negative electrode terminal and cover member for lithium ion battery, and lithium ion battery

ActiveUS20140011074A1High bonding strengthReduce in quantityPrimary cell to battery groupingCurrent conducting connectionsElectrical batteryAlloy

The present invention relates to a lithium ion battery employed by connecting the positive electrode side to a negative electrode portion made of Cu or a Cu alloy by a bus bar made of Al or an Al alloy and provides a negative electrode terminal for a lithium ion battery capable of providing sufficient bonding strength between the negative electrode portion and the bus bar when the negative electrode portion and the bus bar are metallurgically bonded to each other by resistance welding or the like, for example. This negative electrode terminal for a lithium ion battery is made of a clad material having a first metal layer made of Al or an Al alloy and a second metal layer made of Cu or a Cu alloy bonded to each other through a reaction-suppressing layer suppressing a reaction therebetween.

Owner:HITACHI METALS LTD

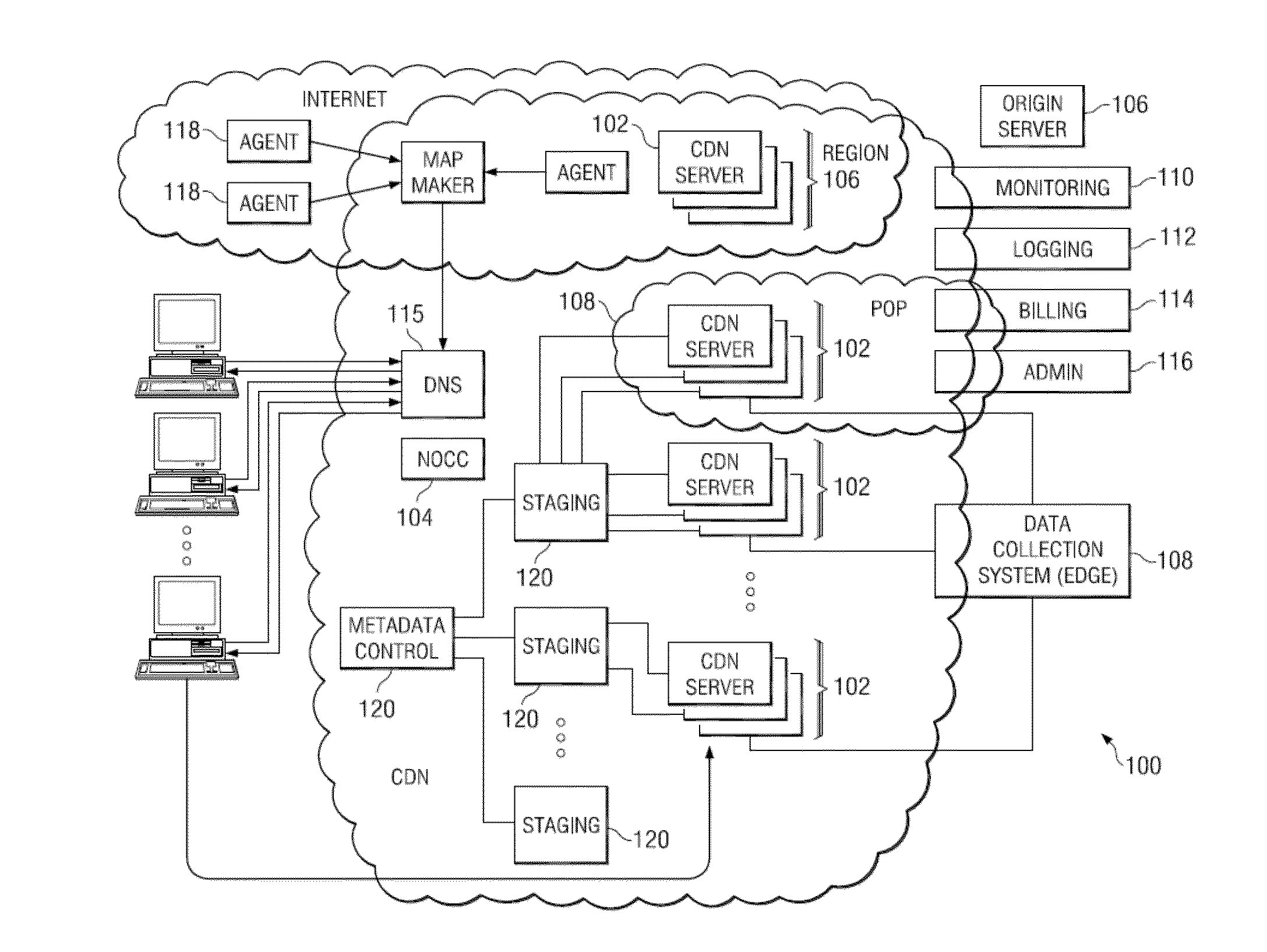

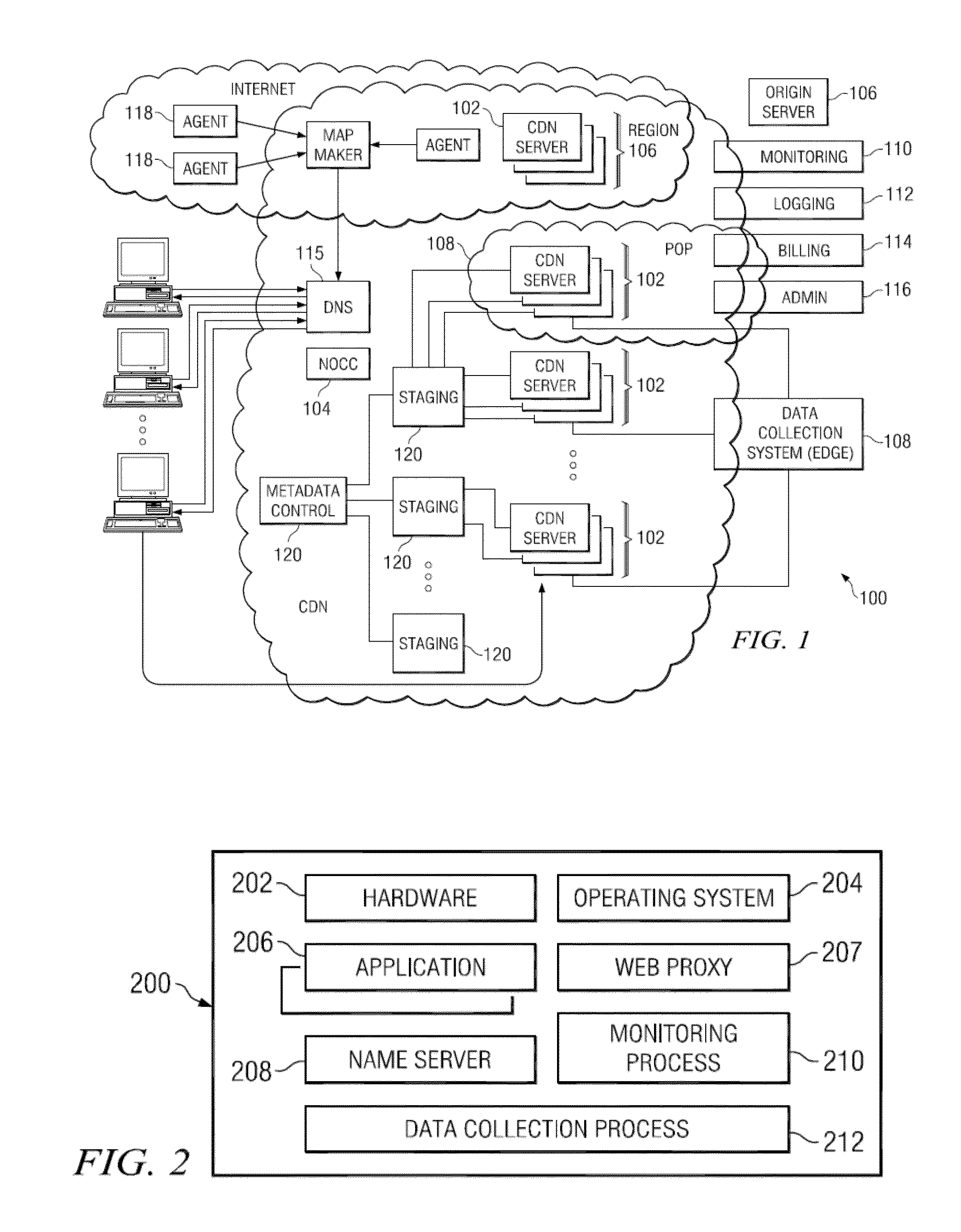

Hybrid HTTP and UDP content delivery

ActiveUS20140059168A1Reduce deliveryEasy to reuseMultiple digital computer combinationsTransmissionClient-sideBit rate

A hybrid HTTP / UDP delivery protocol provides significant improvements for delivery of video and other content over a network, such as an overlay. The approach is especially useful to address problems (e.g., slow startup times, rebuffering, and low bitrates) for HTTP-based streaming. In general, the protocol has two phases: an HTTP phase, and a UDP phase. In the HTTP phase, the client sends an HTTP GET request to a server. The GET request contains a transport header informing the server that the client would like to use UDP-based transfer over the protocol. The server may refuse this mode and continue in ordinary HTTP mode, or the server may respond by sending an empty response with header information informing the client how to make the connection to enter the UDP phase. In the UDP phase, the client initiates a connection and receives the originally-requested content over UDP.

Owner:AKAMAI TECH INC

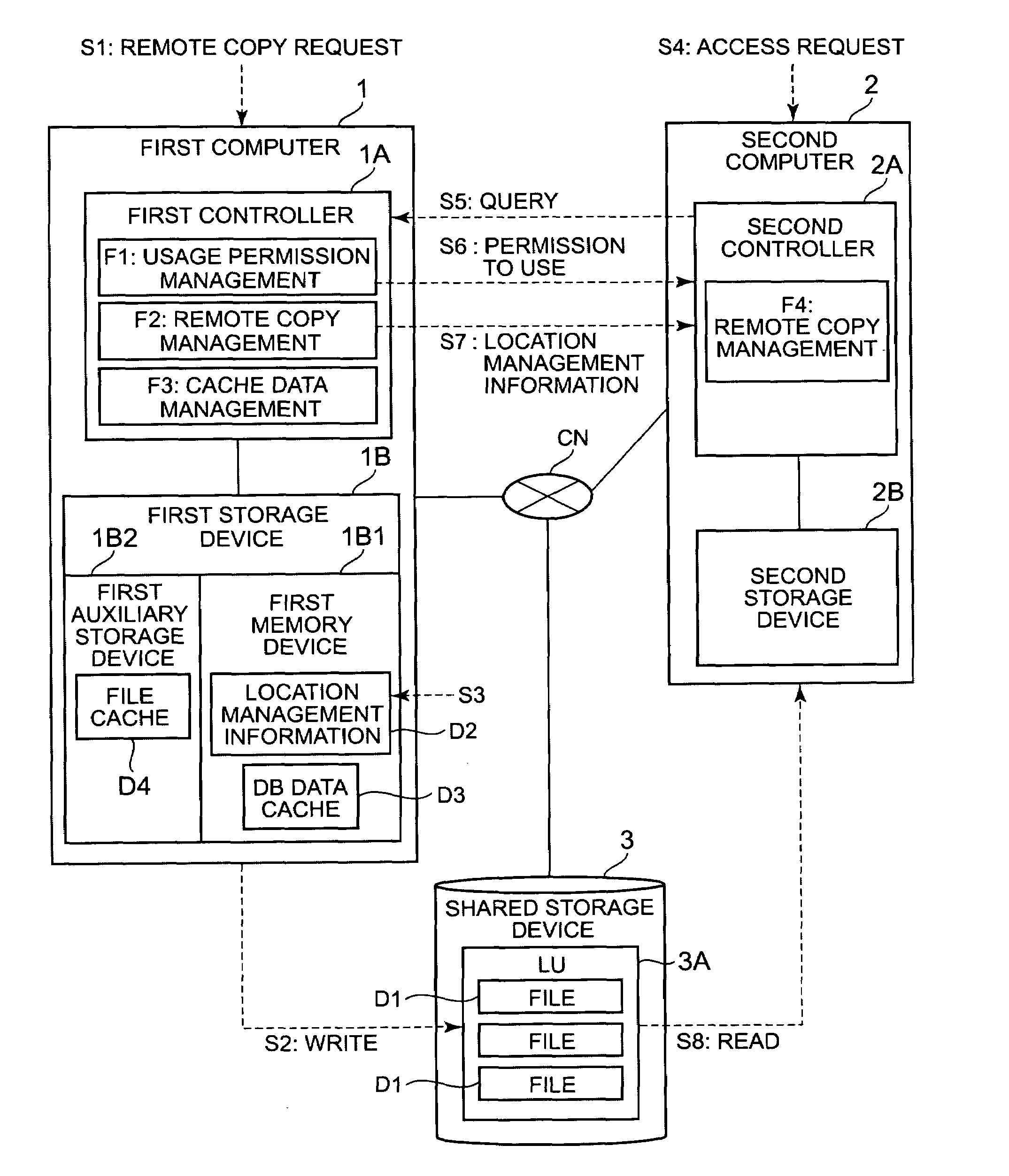

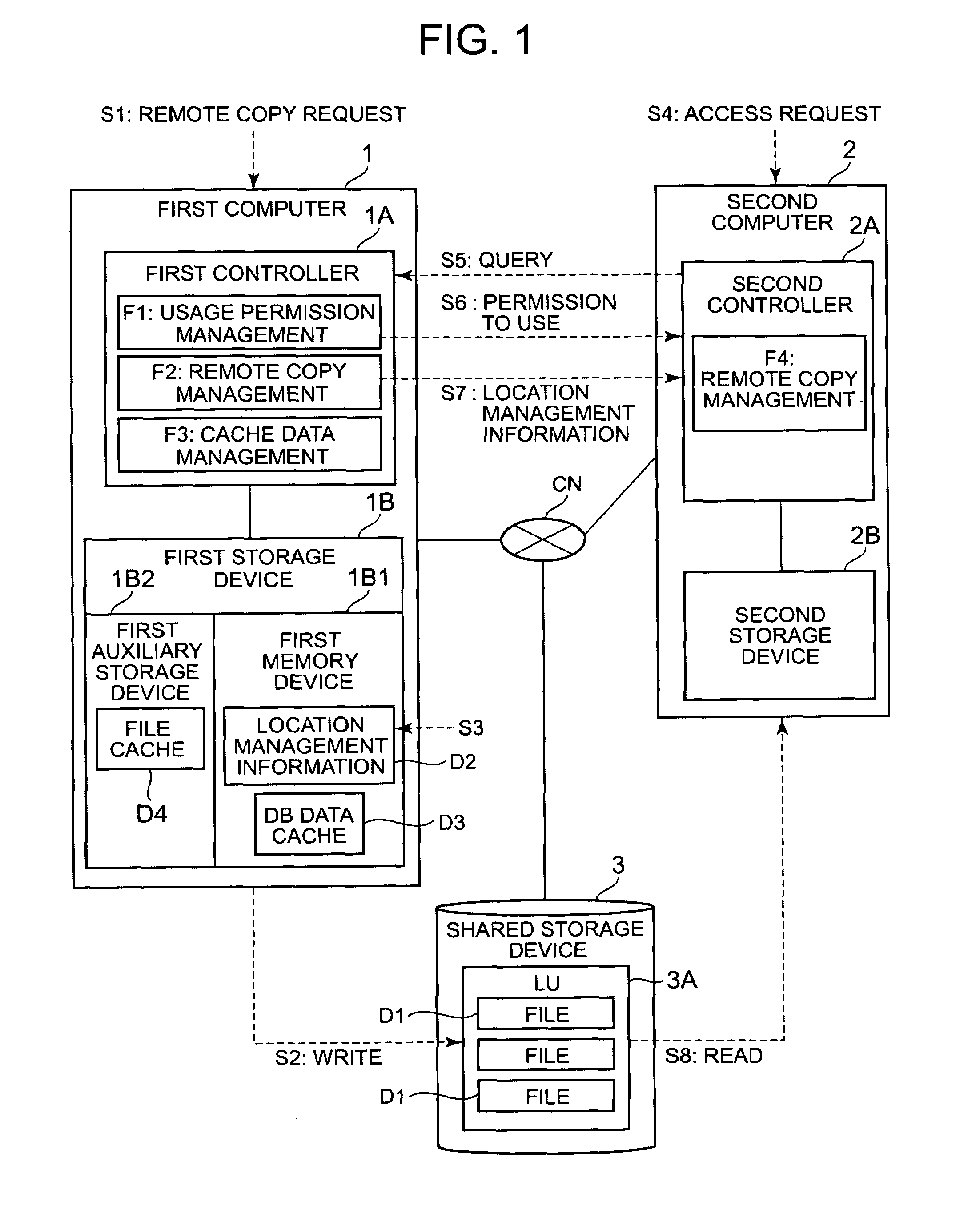

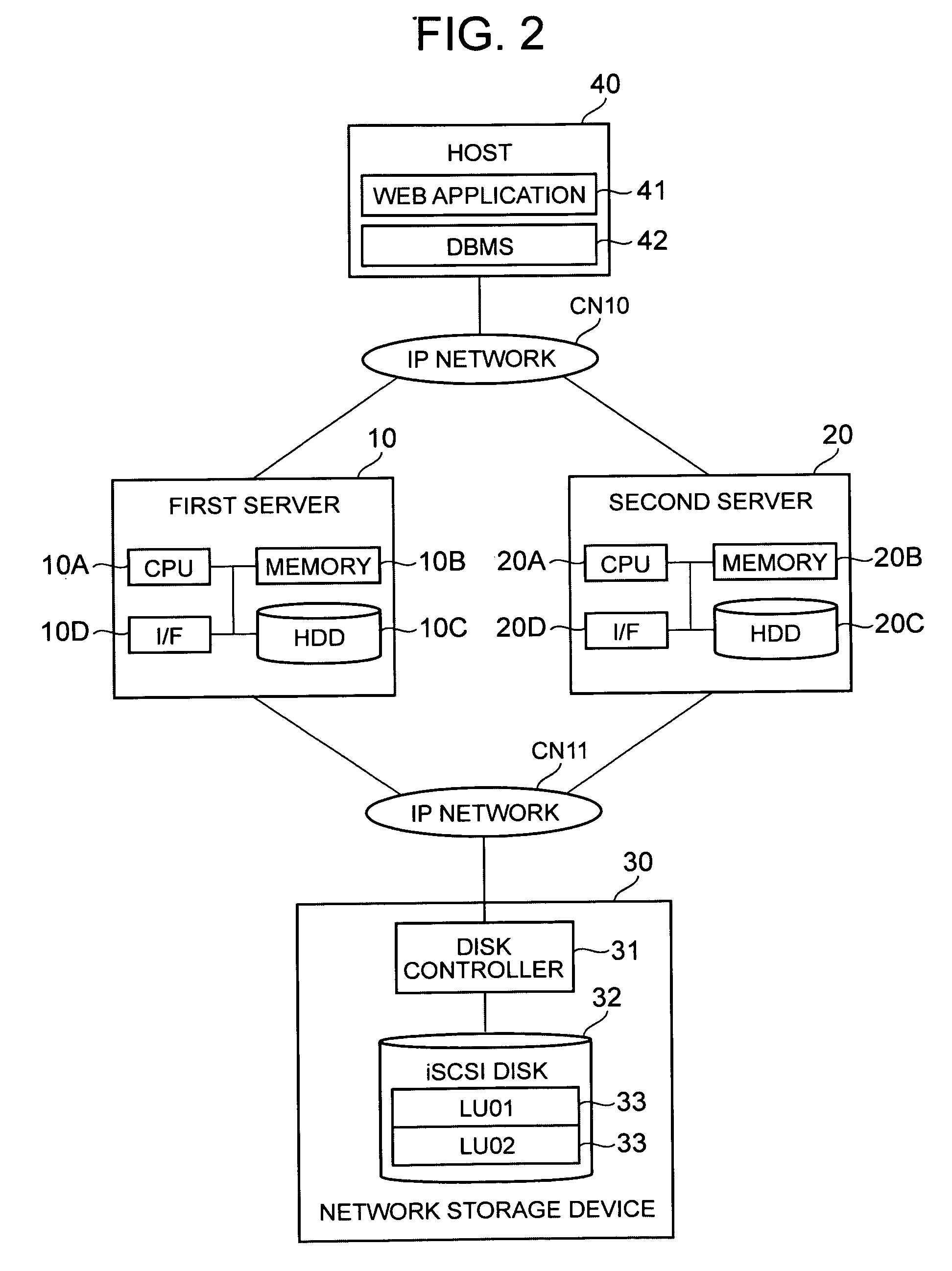

Computer system, remote copy method and first computer

InactiveUS20090193207A1Preventing response performanceImprove responsivenessMemory loss protectionDigital computer detailsReplication methodComputerized system

In a computer system of the present invention, the logical volume of a network storage device can be exclusively shared by a plurality of computers. A first computer, upon receiving a remote copy request, writes a remote copy target file to a logical volume inside a shared storage device, and stores location management information showing the write-destination or the like of the file in a memory device. A second computer, upon receiving an access request, acquires the logical volume lock from the first computer. The second computer mounts the logical volume, and executes the desired processing. Furthermore, the second computer reads out the file from the logical volume based on the location management information.

Owner:HITACHI LTD

Non-aqueous electrolyte for secondary battery and non-aqueous electrolyte secondary battery

ActiveUS8097368B2Decrease is limitedInhibitory responseOrganic electrolyte cellsLi-accumulatorsEquilibrium potentialCarboxylic acid

The present invention provides a non-aqueous electrolyte secondary battery comprising a positive electrode, a negative electrode, a separator, and a non-aqueous electrolyte, wherein the non-aqueous electrolyte comprises a non-aqueous solvent and lithium salt as an electrolyte, and wherein the non-aqueous solvent contains chain fluorinated carboxylic acid ester represented by the formula CH3COOCH2CH3-xFx (wherein x is 2 or 3) and a film forming chemical decomposed in the range of +1.0 to 3.0 V based on an equilibrium potential between metal lithium and lithium ion.

Owner:KANTO DENKA IND CO LTD +1

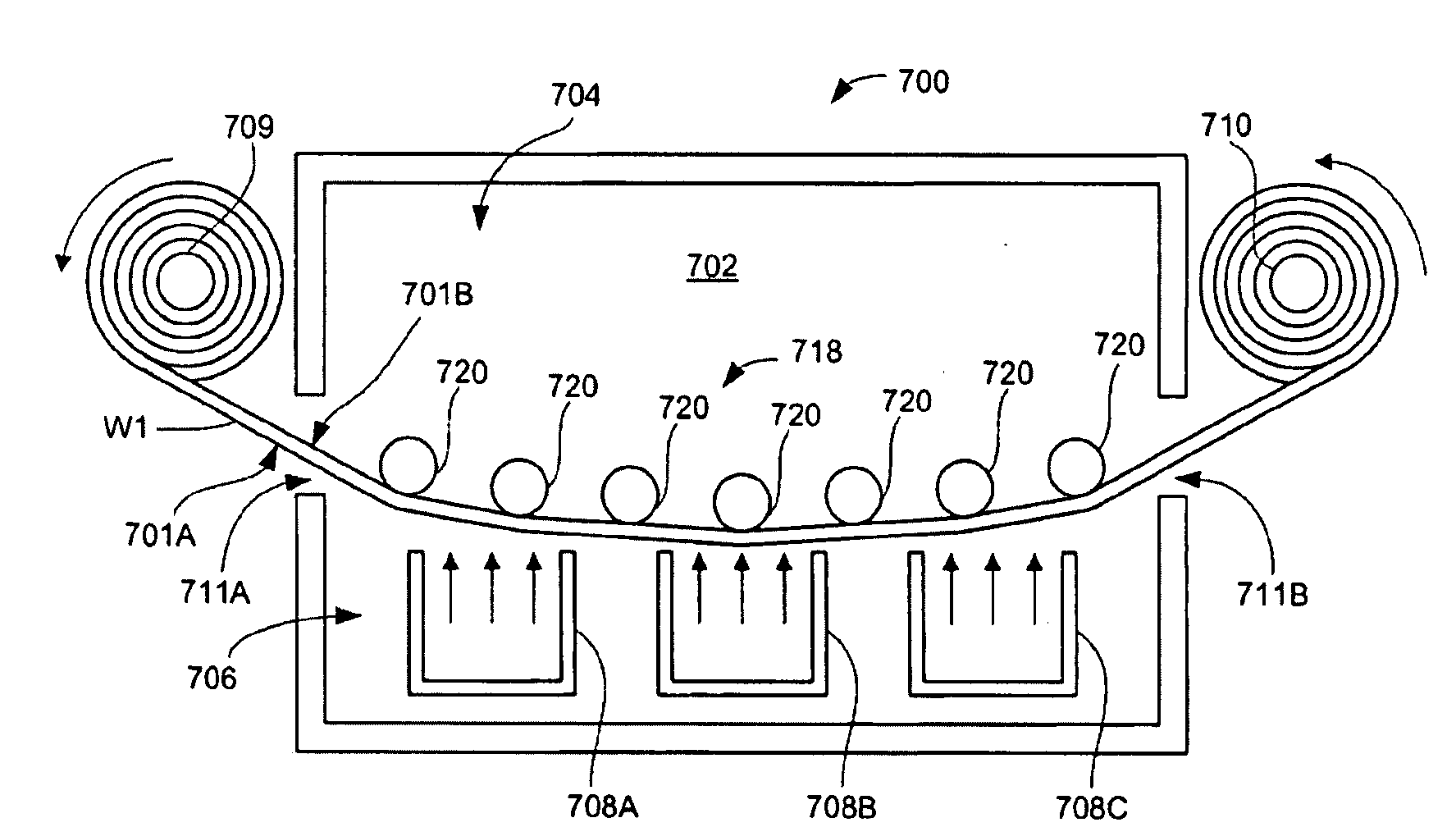

Roll to Roll Evaporation Tool for Solar Absorber Precursor Formation

InactiveUS20090092744A1Inhibitory responseFinal product manufactureVacuum evaporation coatingDopantElectrical battery

An evaporation tool for forming a dopant structure on a front surface of a continuous workpiece, wherein the front surface includes a precursor layer to form Group IBIIIAVIA absorbers for solar cells and the dopant structure is used to introduce dopants into the precursor layer. The tool includes at least a first vapor source station to deposit a Group VIA material, such as Se, and a second vapor station to deposit a dopant material, such as Na, onto the continuous workpiece. A moving assembly of the tool holds and moves the continuous workpiece within the tool by feeding the continuous workpiece from a first end and taking up from a second end of the tool. A support assembly of the tool contacts a back surface of the continuous workpiece to remove the heat from and apply tension to the continuous workpiece during the process.

Owner:SOLOPOWER

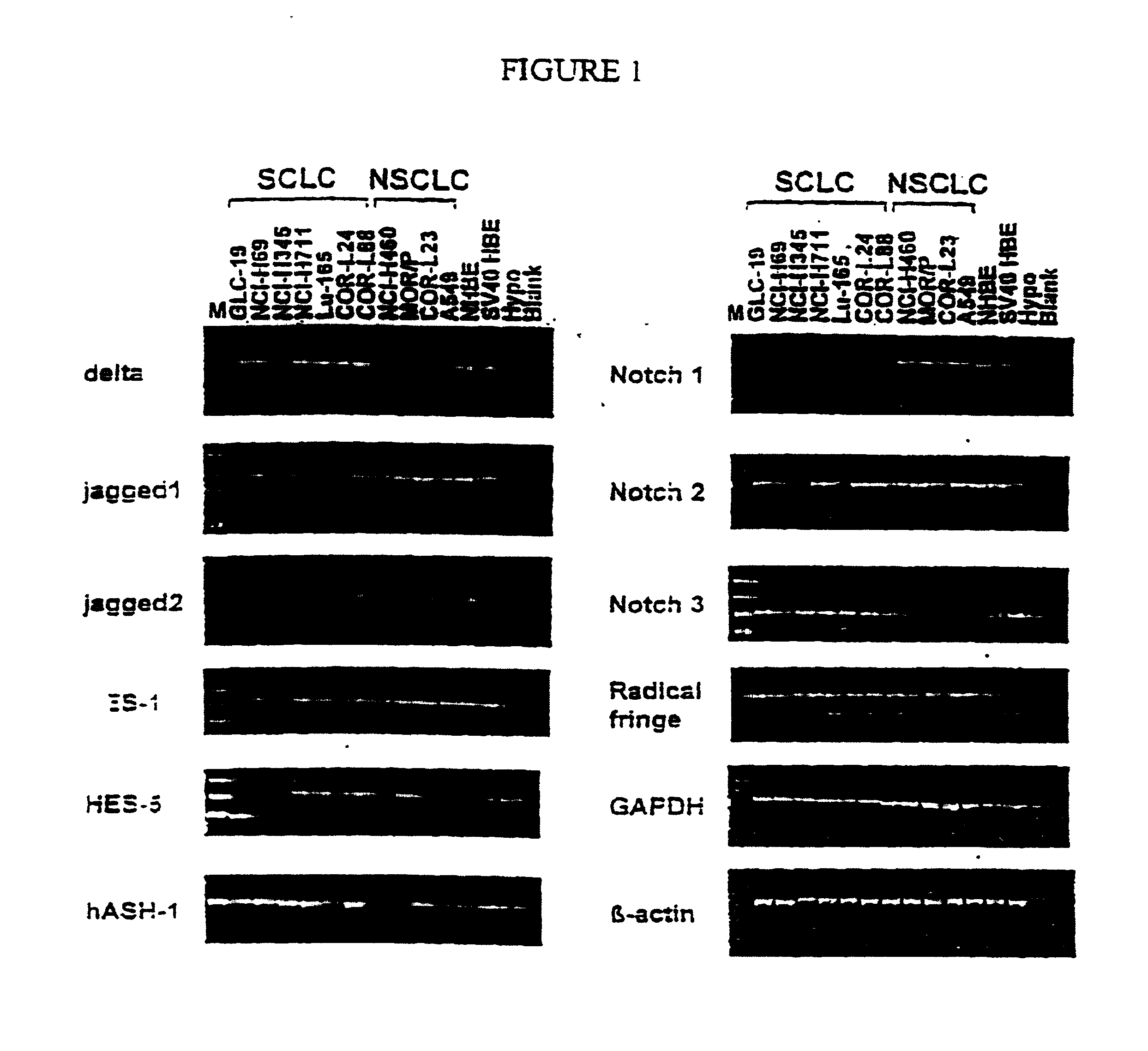

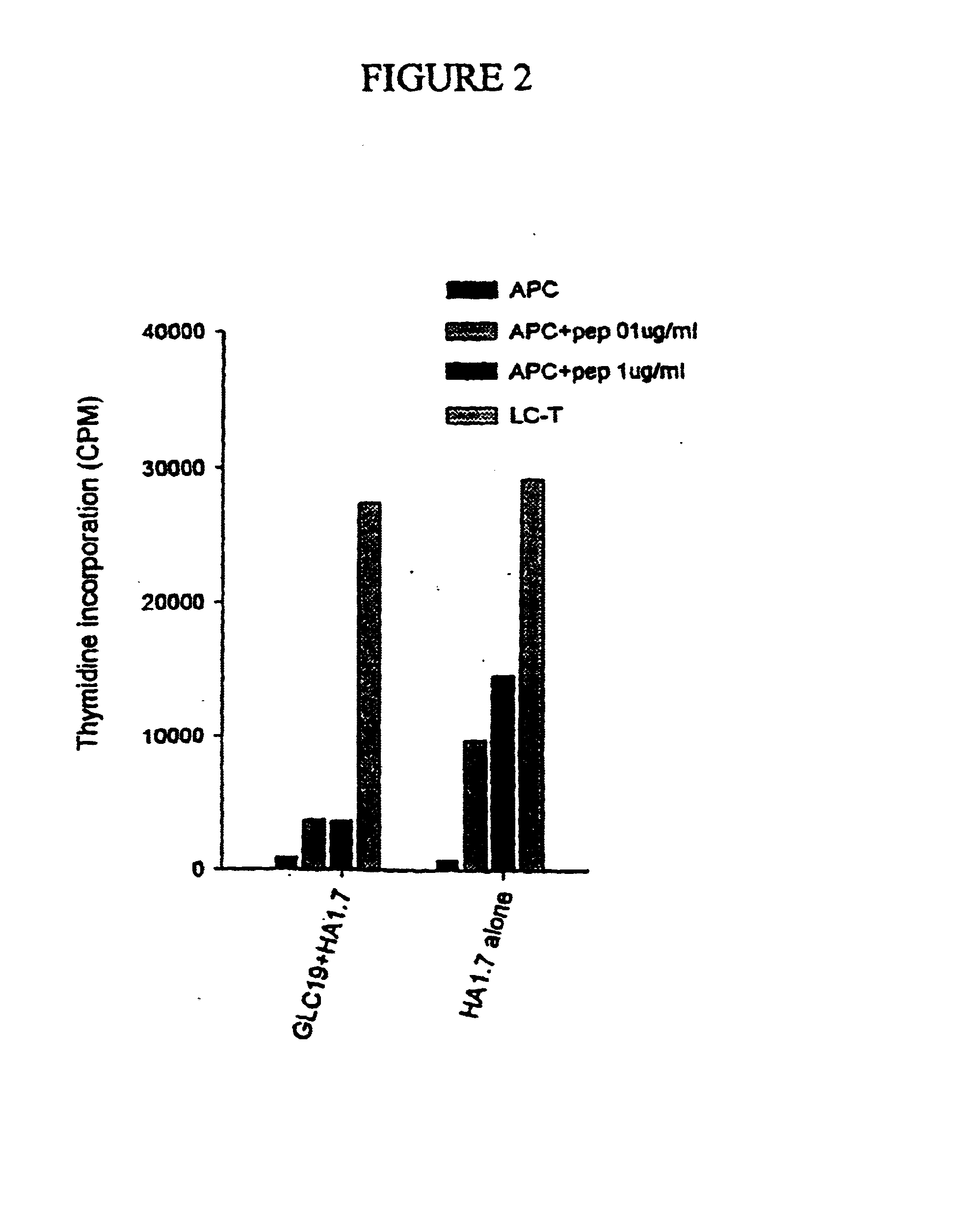

Immunotherapy

InactiveUS20030194804A1Inhibit T cell responseInhibitory responseBiocidePeptide/protein ingredientsNucleic acid sequencingWilms' tumor

A method is provided for enhancing the reactivity of a T cell toward a tumour cell which method comprises: (a) isolating a T cell which is a tumour infiltrating lymphocyte (TIL) from a patient having said tumour cell present in their body; (b) introducing a nucleic acid sequence into the TIL, which sequence is capable of inhibiting or preventing expression of an endogenous Notch ligand in the TIL; and (c) re-introducing the transfected TIL into the patient; wherein the T cell comprises a T cell receptor specific for a tumour antigen expressed by the tumour cell.

Owner:CELLDEX THERAPEUTICS LIMITED

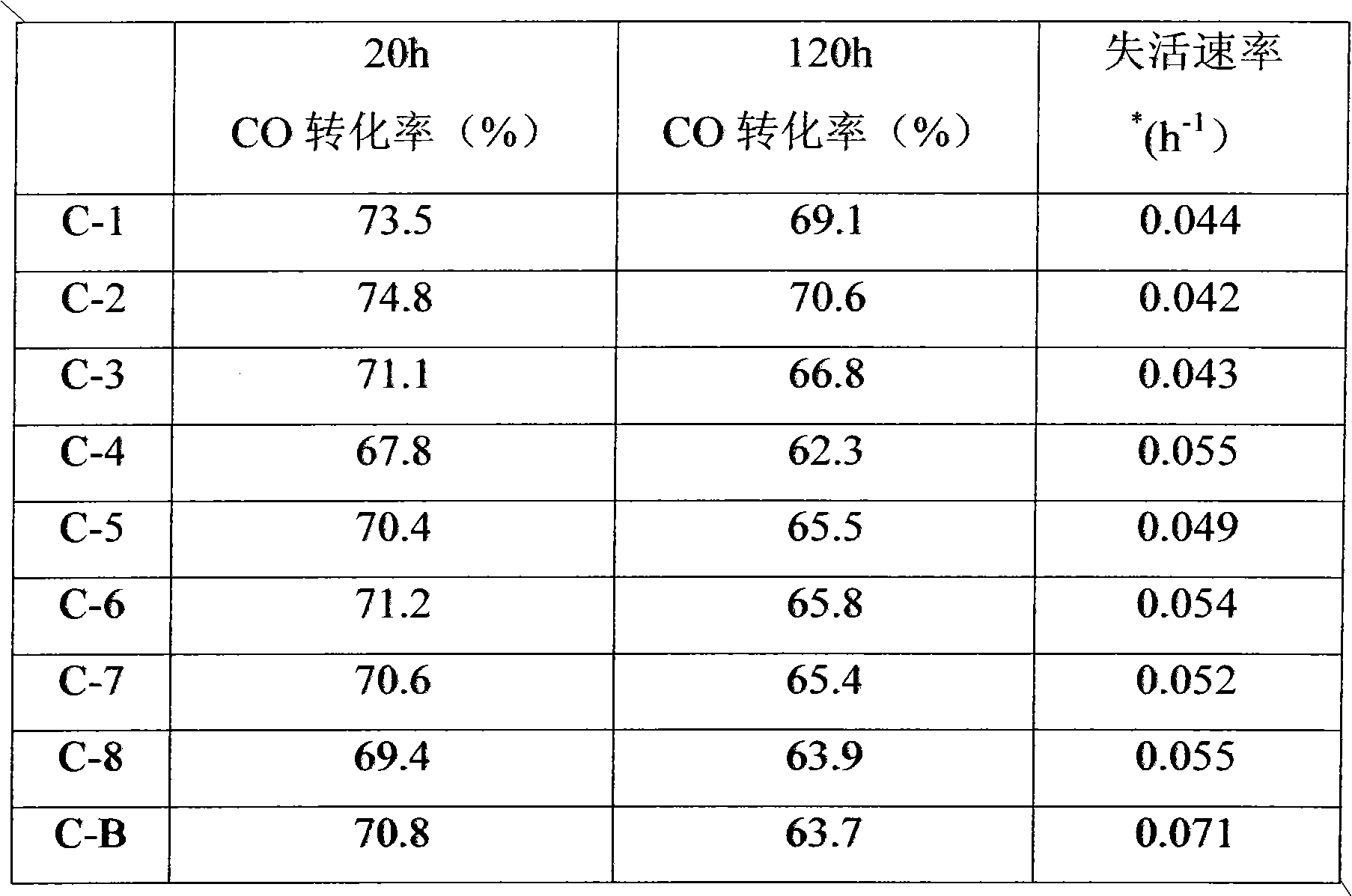

Method for preparing long-life cobalt-based catalyst for Fischer-Tropsch synthesis

ActiveCN101920200AInhibitory responseSuppress generationCatalyst activation/preparationLiquid hydrocarbon mixture productionSurface modificationFischer–Tropsch process

The invention discloses a method for preparing a long-life cobalt-based catalyst for Fischer-Tropsch synthesis. The method comprises the following steps of: performing surface modification on a silica gel carrier; and loading a metal aid and an active ingredient Co by adopting an immersion method, wherein the surface modification method for the silica gel carrier is to perform immersion treatmentby using acid solution of sugar. Compared with similar catalysts, the catalyst for Fischer-Tropsch synthesis prepared by the method has the advantages of reducing the reaction between the carrier andthe active ingredient in the processes of preparing and using the catalyst, and showing better stability in the reaction process, along with long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molten steel smelting technology for preventing nozzle clogging during sulfur-containing aluminium-containing steel pouring process

The invention relates to a molten steel smelting technology for preventing nozzle clogging during sulfur-containing aluminium-containing steel pouring process. The molten steel smelting technology comprises the steps of converter or electric furnace steelmaking, LF steel ladle refining, VD or RH vacuum refining, and continuous steel casting. According to the molten steel smelting technology, molten iron without desulfuration is directly supplied to a converter or an electric furnace for steelmaking, and iron sulfide powder is added into slag in the later period of LF steel ladle refining, so that the content of sulfur elements in the slag is increased, the reaction between the molten steel and the slag is inhibited during the vacuum treatment process, the loss amount of S elements in the molten steel is decreased, Al2O3 inclusions and CaS inclusions which are liable to cause nozzle clogging are reduced, the problem of nozzle clogging can be eliminated, the production is guaranteed to be smoothly carried out, and the production cost is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com