Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

529 results about "Hypophosphorous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hypophosphorous acid (HPA), or phosphinic acid, is a phosphorus oxyacid and a powerful reducing agent with molecular formula H₃PO₂. It is a colorless low-melting compound, which is soluble in water, dioxane, and alcohols. The formula for this acid is generally written H₃PO₂, but a more descriptive presentation is HOP(O)H₂, which highlights its monoprotic character. Salts derived from this acid are called hypophosphites.

Halogen-free flame retardant polycarbonate compositions

The present invention relates to a thermoplastic halogen-free flame retardant composition comprising at least an hypophosphorous acid metal salts as halogen-free flame retardant agent, and at least an aromatic polycarbonate s resin and / or its blends. The flame retardant composition may in addition comprise additives and fillers. The invention also refers to moulded thermoplastic articles made by using the flame retardant composition.

Owner:ITALMATCH KEMIKALS SPA

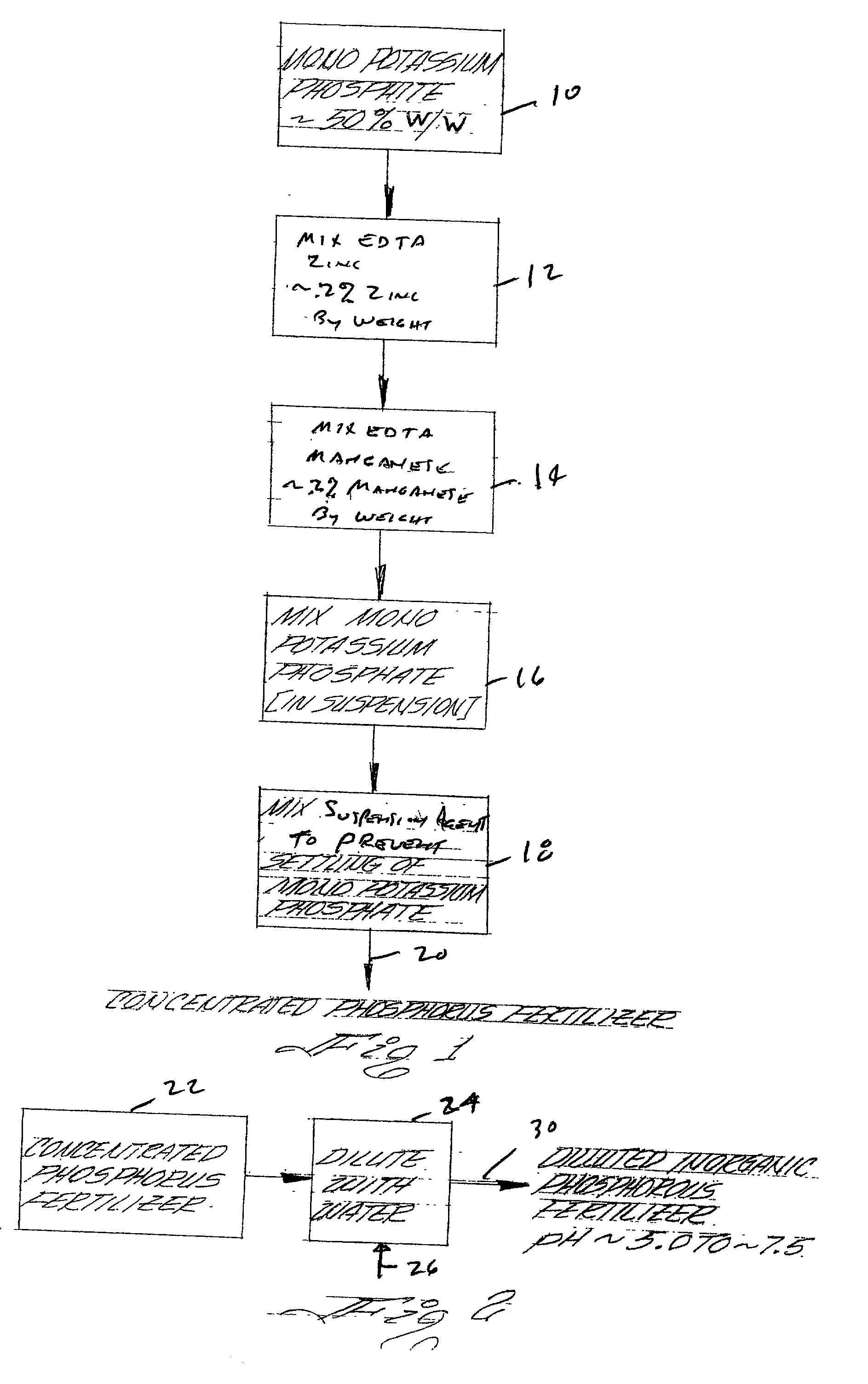

Concentrated phosphorus fertilizer

InactiveUS20020129632A1Easy to diluteImproving phosphorus uptakeAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorous acidSalt content

A concentrated fluid phosphorus fertilizer is shown. In the preferred embodiment, the concentrated fluid phosphorus fertilizer is an aqueous suspension fertilizer composition. The composition comprises one or more phosphorus-containing acids or salts thereof selected from the group consisting of phosphoric acid, polyphosphoric acid, phosphorous acid, polyphosphorous acid, hypophosphorous acid and polyhypophosphorous acid, and salts thereof. A suspension agent maintains undissolved solids in substantially homogeneous suspension wherein the suspension has a total acid and salt content of about 50% w / w to about 80% w / w. The concentrated fluid phosphorus fertilizer is a stable suspension and when diluted with water a substantially fully soluble fertilizer having acceptable pH for phosphorus uptake is formed. Methods for improving the phosphorus uptake and improving the growth rate of plants is also shown.

Owner:INTERFARM

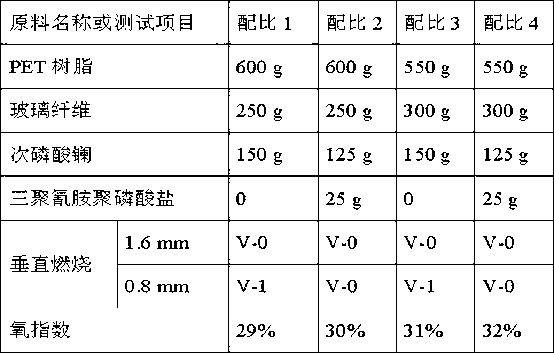

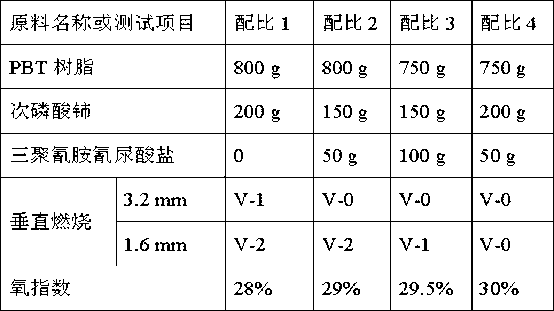

Polyester compositions flame retarded with halogen-free additives

Owner:ITALMATCH KEMIKALS SPA

Preparation method and application of diethyl phosphinates

InactiveCN101891762AShort reaction timeTrigger fastGroup 5/15 element organic compoundsReaction rateUltraviolet lights

The invention discloses a preparation method and application of diethyl phosphinates, belonging to the field of green flame retardants. The preparation method of the diethyl phosphinates comprises the following steps of: making hypophosphorous acid and / or an alkali metal salt thereof react with ethylene under the irradiation of ultraviolet light in the presence of a photoinitiator in a solvent system to obtain diethyl phosphinic acid and / or an alkali metal salt thereof; and making the obtained diethyl phosphinic acid and / or the alkali metal salt thereof react with metallic compounds of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Ce, Sn and / or Fe to obtain corresponding diethyl phosphinates. In the invention, the photoinitiator is decomposed into free radicals under the irradiation of the ultraviolet light to initiate an additive reaction so that the reaction rate can be improved, the energy consumption required in the reaction can be reduced and the production cost of products can be lowered.

Owner:NANKAI UNIV

Flame retardant polymeric compositions

The present invention provides flame retardant thermoplastic moulding compositions comprising: A) from 65% to 99,5% by weight (with respect of the total weight of the final 5 composition) of a polyolefinic polymer particularly selected among polypropylene polymers; B) from 0,1% to 30% by weight (with respect of the total weight of the final composition) of a synergic mixture of an hypophosphorous acid metal salt and halogenated organic compounds ; io C) from 0,5% to 10 % by weight (with respect of the total weight of the final composition) of a plurality of selected additives consisting of processing aids, heat and process stabilisers, UV stabilisers, antidripping agents (PTFE -Polytetrafluoroethylene), pigments, mould releasing agents, nucleating agents is D) from 0% to 50% by weight (with respect of the total weight of the final composition) of an inorganic filler.; The total of the percentages by weight of components A to D is 100 %.

Owner:伊塔尔麦奇化学股份公司

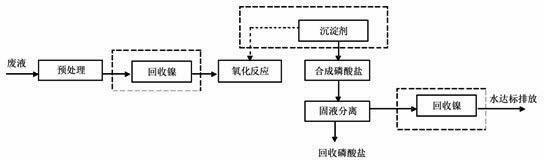

Method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid

InactiveCN102616961AReduce phosphorus contentRemove completelyPhosphatesWaste water treatment from metallurgical processPhosphorous acidLiquid waste

The invention discloses a method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid, which belongs to the technical field of environment-friendly waste water treatment and resource recycle. The method conducts oxidation degradation of organic pollutant in waste water through the oxidation technology, simultaneously oxidizes hypophosphorous acid radical and phosphorous acid radical in waste water into orthophosphate radical and recycles phosphate and nickel by enabling the orthophosphate radical and nonmetal or metal ions to be precipitated. The method achieves resource recycle while treating waste water and has good environment benefits and economical benefits and wide application prospect.

Owner:李朝林

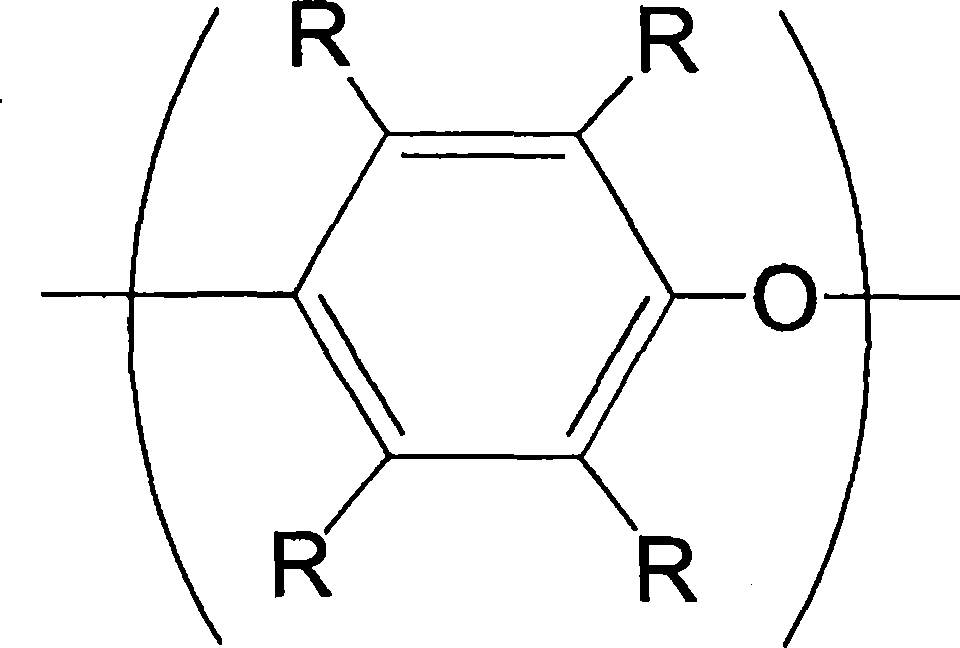

Polyamide-polyphenylene ether resin composition

ActiveCN101163746AExcellent retention stabilitySimplify moisture managementElastomerPhosphoric Acid Esters

A resin composition characterized by containing polyamide (A), polyphenylene ether (B), elastomer (C) and phosphorus compound (D) selected from among phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites and phosphoric esters wherein per 100 mass% of the sum of components (A) to (D), phosphorus element is contained in an amount of 1 to 35 ppm. Further, there is provided a molding of the resin composition. Application can be found in a wide spectrum of fields, such as electrical / electronic parts, OA parts, vehicle parts and mechanical parts. In particular, suitable application can be found in exterior parts of automobile, etc. wherein large moldings are required.

Owner:ASAHI KASEI KK

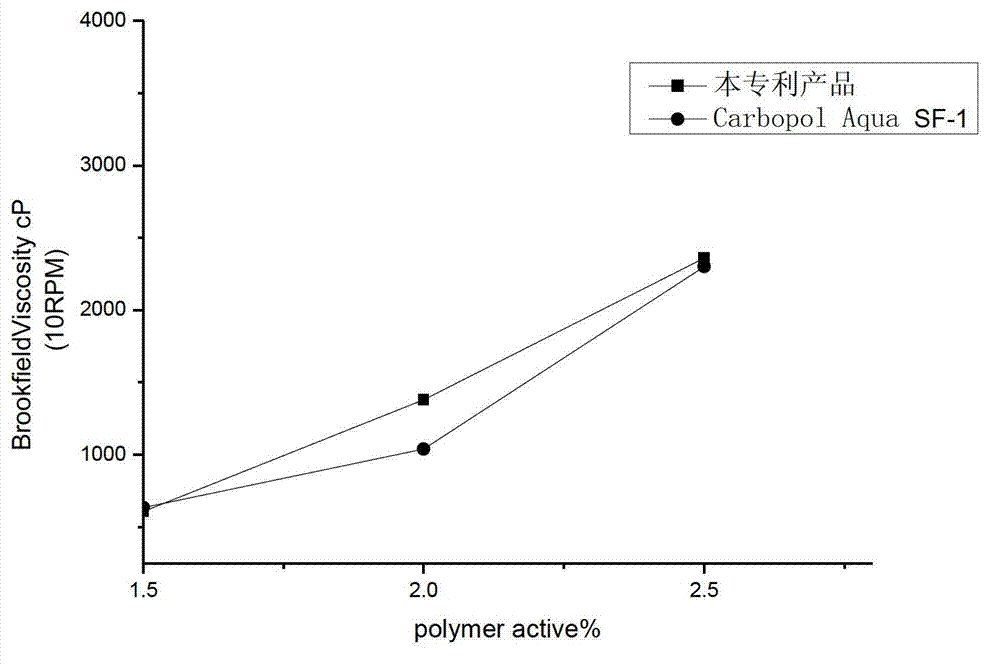

Polymer latex and application thereof

InactiveCN102863594AOmit demulsificationEasy to pumpTransportation and packagingSurface-active non-soap compounds and soap mixture detergentsPolymer sciencePhosphoric acid

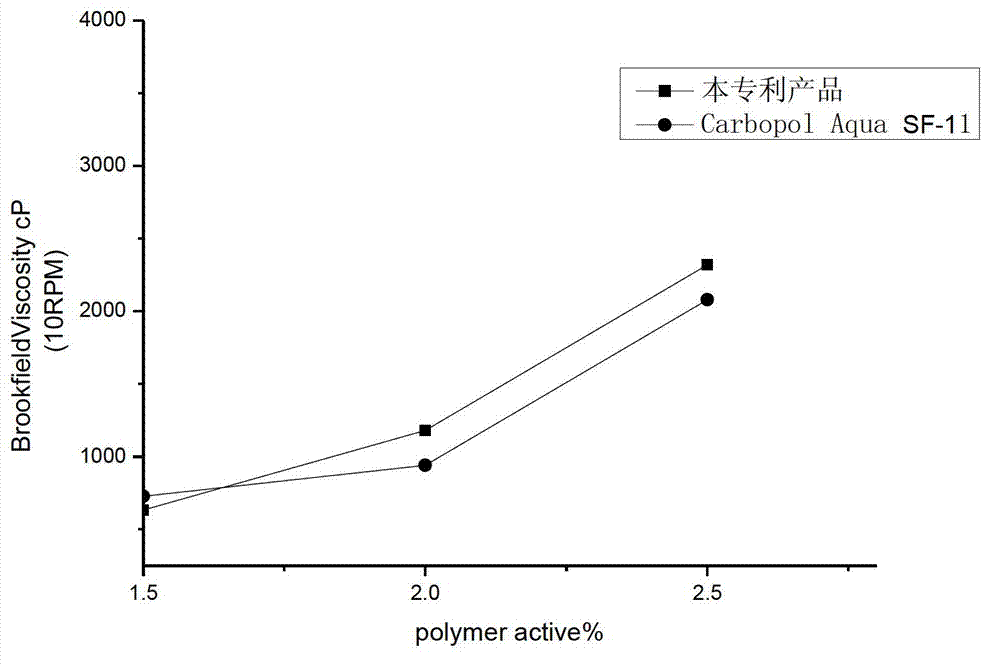

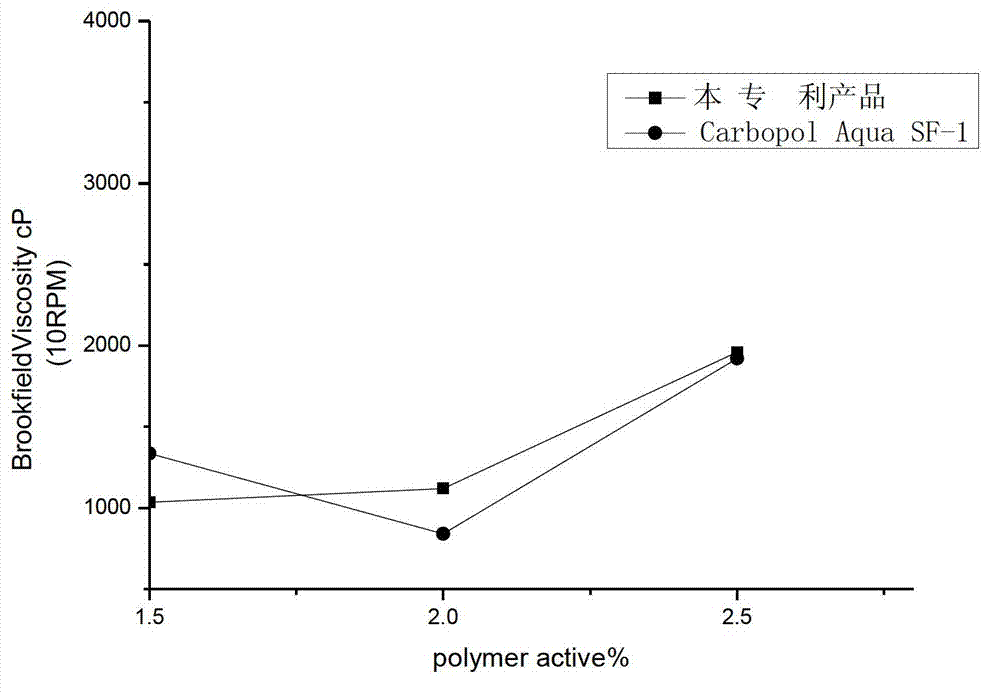

The invention discloses a polymer latex which can be obtained by the reaction among alpha, beta-vinyl unsaturated carboxylic acid monomer (I) and or acid monomer with sulfonic acid, phosphoric acid or hypophosphorous acid, alpha, beta-vinyl unsaturated monomer (II), hydrophilic unsaturated crosslinking monomer or bifunctional and multifunctional vinyl unsaturated crosslinking monomer (III-VI), nonionic vinyl or acryl surface active agent (VII), anionic emulsifier, initiator, and chain transfer agent, wherein the polymer latex can be used for forming into a binary system in a surface active agent composition. Due to the unique crosslinking nodes in the polymer latex, the polymer latex can be used in various fields even under the low-pH and high-salt content severe environment such as the cosmetics, the medicines, the emulsion paint, and the effective and high-efficiency thickening agent and suspending agent in cleaning composition.

Owner:JIANGSU FEIXIANG CHEM

Polyamide composition

ActiveUS20060142443A1Aluminium compoundsPlastic/resin/waxes insulatorsPhosphorous acidPhosphoric Acid Esters

A polyamide composition has (a) a polyamide, (b) at least one phosphorus compound selected from the group consisting of phosphoric acids, phosphorous acids, hypophosphorous acids, metal phosphates, metal phosphites, metal hypophosphites, phosphoric esters, and phosphorous esters, and (c) a soluble metal aluminate compound represented by the general formula (M2O)x(Al2O3)y (wherein X+Y=1 and M is a Group 1 metal of the Periodic Table), wherein the molar ratio of polyvalent metal to monovalent metal in the composition (polyvalent metal / monovalent metal) is from 0.25 to 1.0.

Owner:ASAHI KASEI CHEM CORP

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172668AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsOrganic solventPhosphate

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: organic solvent-water is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, organic solvent-water is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, the reaction period is short, obtained monoalkyl / dialkyl phosphinate can be precisely controlled, a total yield is high, and product purity is high. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:GUANGZHOU KINGSKY MATERIAL

Flame Retardant Polymeric Compositions

The present invention provides flame retardant thermoplastic moulding compositions comprising:A) from 65% to 99.5% by weight (with respect of the total weight of the final composition) of a polyolefinic polymer particularly selected among polypropylene polymers;B) from 0.1% to 30% by weight (with respect of the total weight of the final composition) of a synergic mixture of an hypophosphorous acid metal salt and halogenated organic compounds;C) from 0.5% to 10% by weight (with respect of the total weight of the final composition) of a plurality of selected additives consisting of processing aids, heat and process stabilisers, UV stabilisers, antidripping agents (PTFE—Polytetrafluoroethylene), pigments, mould releasing agents, nucleating agents;D) from 0% to 50% by weight (with respect of the total weight of the final composition) of an inorganic filler.The total of the percentages by weight of components A to D is 100%.

Owner:ITALMATCH KEMIKALS SPA

Process for the preparation of highly purified, dialkyl phosphinic acids

In a process for the production of dialkylphosphinic acids, especially branched, dialkylphosphinic acids in high purity via the reaction of an alpha olefin with a hypophosphorous acid or a salt thereof, the improvement comprising conducting the reaction in the presence of a stoichiometric excess of the olefin and isolating and purifying the desired dialkylphosphinic acid product by neutralizing the monoalkylphosphinic acid by-product with an aqueous base; removing the aqueous phase in which the neutralized monoalkylphosphinic acid is preferentially solubilized; acidifying the dialkyl product in the organic phase; and isolating the purified product.

Owner:ITALMATCH KEMIKALS SPA

Finish for nylon FDY and preparation method

The invention relates to the technical field of auxiliary manufacturing in the fiber processing technology, in particular to finish for nylon FDY and a preparation method. The finish for nylon FDY comprises the following components: 55-60% of isooctyl stearate, 5-7% of scouring agents, 5-7% of oleic acid, 8-10% of coconut oil diethanolamine, 5-7% of hydrogenated castor oil polyoxyethylene ether, 5-7% of fatty alcohol polyoxyethylene ether 4, 1-2% of oleic acid sarcosine, 0.5-1% of hypophosphorous acid, 1-1.5% of potassium hydroxide and 5-7% of wetting agent. The preparation method comprises the process steps of mixing, stirring and testing. The finish for nylon FDY has good thermal stability, is less in volatilization and free of coking and has low coefficient of dynamic friction in the drawing stage and good cohesion.

Owner:JIAXING NEW & HIGH TECH FIBER

Metal salt-converting method for treating high concentration phosphor-containing wastewater

InactiveCN101439901AGood removal effectReduce processing operating costsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationHigh concentrationSludge

The invention relates to a treatment method for chemical gold high concentration P-contained wastewater. The method is characterized in that the method comprises the following steps: lifting the wastewater from a collecting tank to an oxidation precipitation tank, opening the oxidation precipitation tank for aeration, adding steam, calcium hydroxide, ferrous sulfate and hydrogen peroxide solution into the wastewater for reaction, leading the supernatant into a subsequent physiochemical system for treatment, and pumping the precipitant into a sludge concentration tank for treatment through a sludge pump; after the catalytic oxidation reaction is completed, leading the supernatant into a physiochemical treatment neutralization tank, adding calcium hydroxide into the neutralization tank, leading the supernatant into a flocculating tank after a polyaluminium chloride reaction, adding polyacrylamide into the flocculating tank for intensive agitation, mixing and reaction, then leading the supernatant into a precipitation tank for solid-liquid separation, discharging the supernatant into the next flow, and pumping the sludge to the sludge concentration tank for treatment. A catalytic oxidation method is used to oxidize the stable hypophosphorous acid radical into the phosphate radical capable of easily reacting with metallic salts and producing precipitant; and then a physiochemical method is used to precipitate and remove the phosphate radical, thereby enabling the P content in the outputted water to reach the state emission standard.

Owner:TRIPOD WUXI ELECTRONICS

Composite catalyst and its application in preparing light-colored rosin esters

ActiveCN101264454APrevent oxidationPlay a bleaching roleOrganic-compounds/hydrides/coordination-complexes catalystsNatural resin chemical modificationPhosphinic AcidsRosin

The invention provides a compound catalysis used for preparing pale rosin ester, reducing the production cost and simplifying production technique as well as an application thereof. The compound catalysis comprises components of the following mass ratios: 1 to 200 portions of hypophosphorous acid and / or hypophosphite, 1 to 100 portions of sulfur-containing metal salt and 2 to 100 portions of organic disproportionation catalyst. The compound catalysis of the invention can prepare the pale rosin ester using common resin as the raw material to produce the pale rosin ester with solid garner color no larger than 2.

Owner:江西科茂林化科技有限公司

Method for removing phosphorus and nickel in electroless nickel-plating wastewater and treatment system

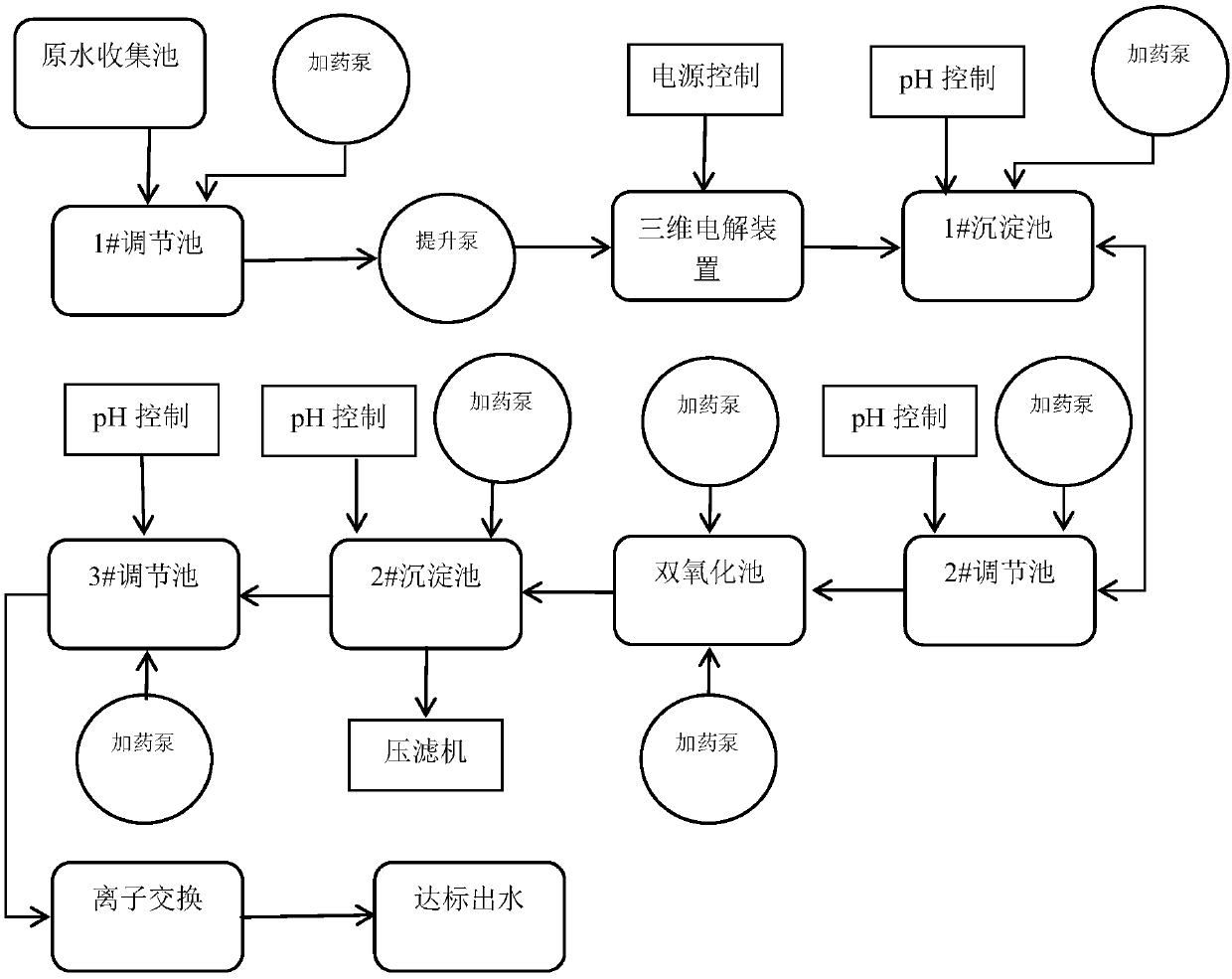

PendingCN106698764AEfficient recyclingSolve the problem of unsustainable complianceWater treatment compoundsWaste water treatment from metallurgical processPhosphorous acidElectrolysis

The invention discloses a method for completely removing phosphorus and nickel in electroless nickel-plating wastewater with advantages of low energy consumption and capacity of avoiding secondary pollution and an adopted treatment system. The nickel-plating wastewater with total phosphorus concentration of 3000mg / L and nickel concentration of 700mg / L is treated into effluent of reaching the standard with the total phosphorus concentration of less than 0.5ppm and nickel concentration of less than 0.1ppm. According to a three-dimensional electrolytic technology, hypophosphorous acid and phosphorous acid in the electroless nickel-plating wastewater can be oxidized into orthophosphoric acid, and nickel ions in a complex state are released. Due to dual oxidation and multiple mixed sludge precipitation reactions, the hypophosphorous acid and phosphorous acid can be further oxidized, the nickel ions in a free state are precipitated, finally the residual nickel ions in the wastewater are completely removed by an ion exchange column, and the effluent reaches the emission standard. Therefore, the pollutants in the electroless nickel-plating wastewater can be totally controlled, the national emission standard is continuously and stably reached, the treated sludge containing nickel and phosphorus is subjected to after-treatment, and the nickel and phosphorus can be effectively recovered.

Owner:深圳市世清环保科技有限公司

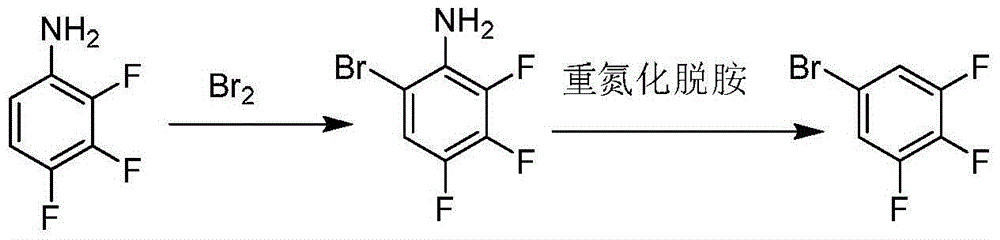

Preparation method of 3, 4, 5-trifluoro bromobenzene

ActiveCN103601613AHigh selectivityBromination reactionHalogenated hydrocarbon preparationBromineAniline

The invention discloses a preparation method of 3, 4, 5-trifluoro bromobenzene. The method comprises the following steps: (1) dispersing 2, 3, 4-trifluoro aniline in a solvent, dropwise adding bromine to carry out a bromination reaction, thus obtaining 2, 3, 4-trifluoro-6-bromaniline through aftertreatment after the reaction is completed; (2) dissolving sodium nitrite in sulfuric acid, dropwise adding the 2, 3, 4-trifluoro-6-bromaniline obtained in the step (1) while stirring to carry out a diazotization reaction, thus obtaining a diazonium salt intermediate; and (3) under the action of hypophosphorous acid and a copper catalyst, carrying out a desamination reaction on the diazonium salt intermediate obtained in the step (2), thus obtaining the 3, 4, 5-trifluoro bromobenzene through aftertreatment after the reaction is completed. The preparation method has the advantages that the 2, 3, 4-trifluoro aniline is adopted as a starting material; the bromination reaction is realized with high selectivity; by-products are reduced; the purity and the yield of the brominated product are increased; the final yield and purity of the 3, 4, 5-trifluoro bromobenzene are high.

Owner:ZHEJIANG LINJIANG CHEM

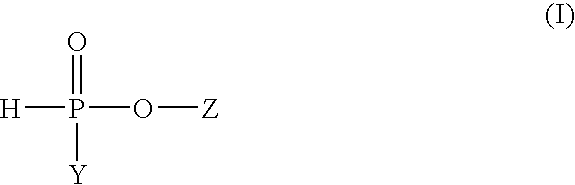

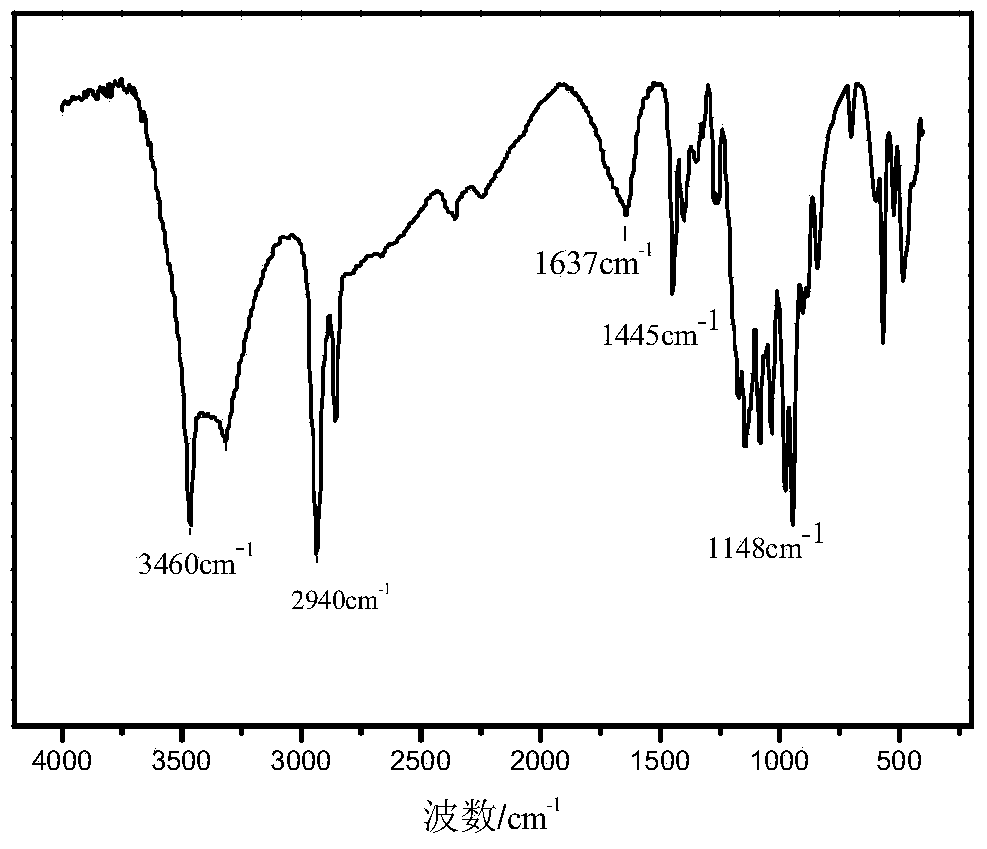

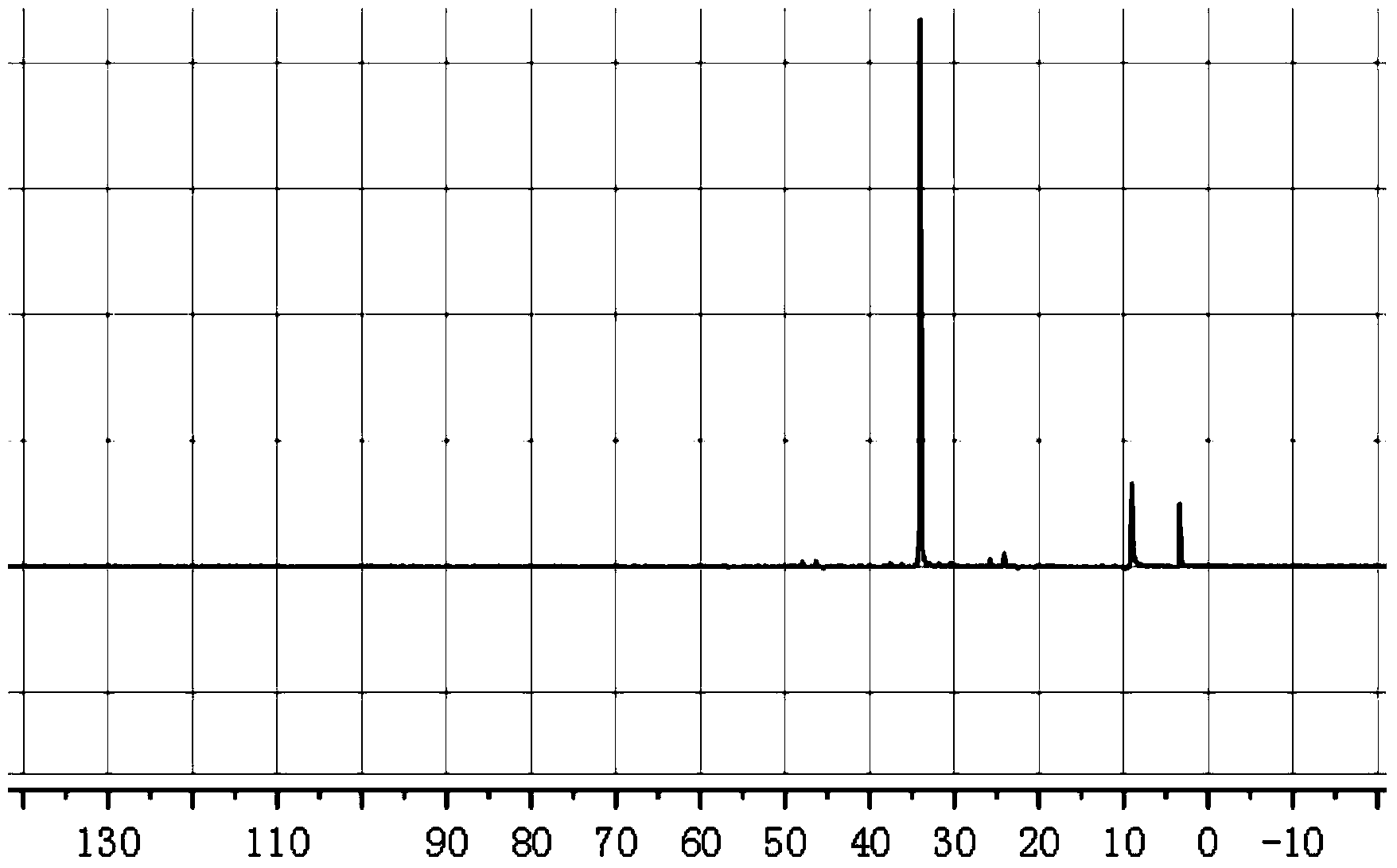

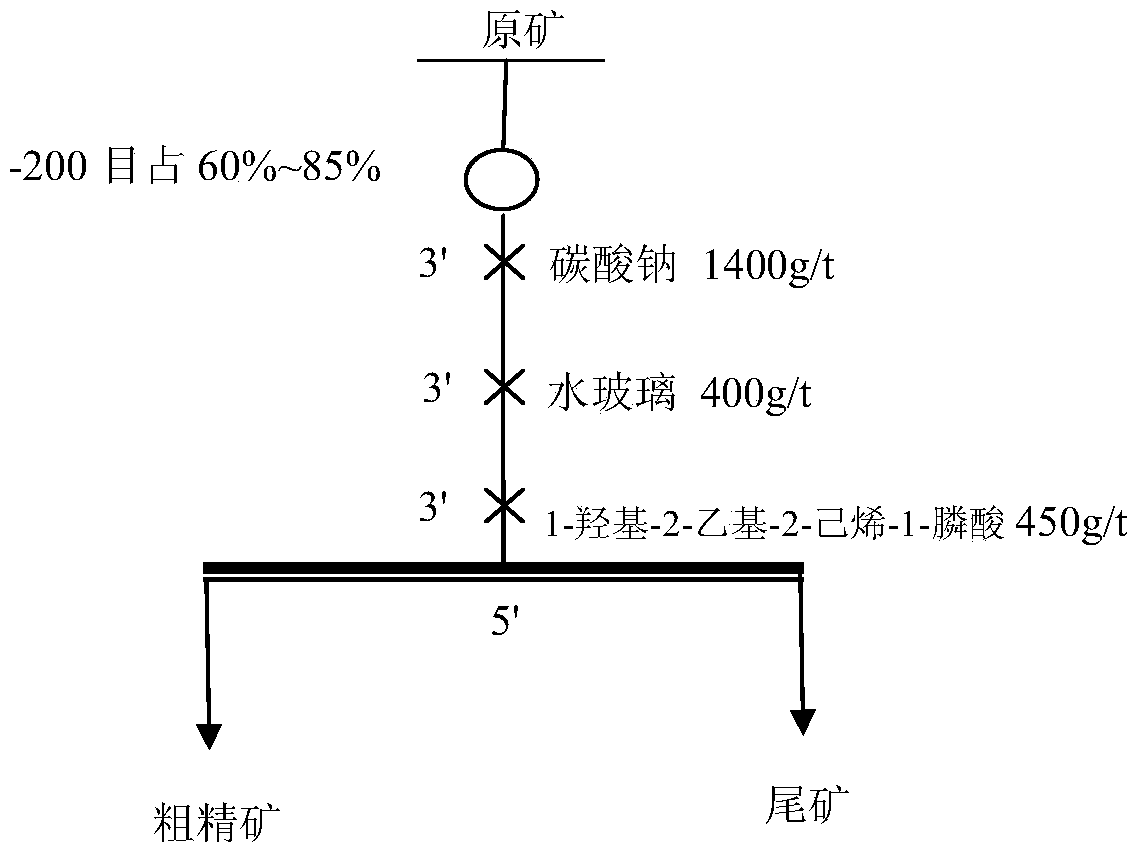

Alpha-hydroxy unsaturated alkylphosphonic acid compound as well as preparation method and application of alpha-hydroxy unsaturated alkylphosphonic acid compound

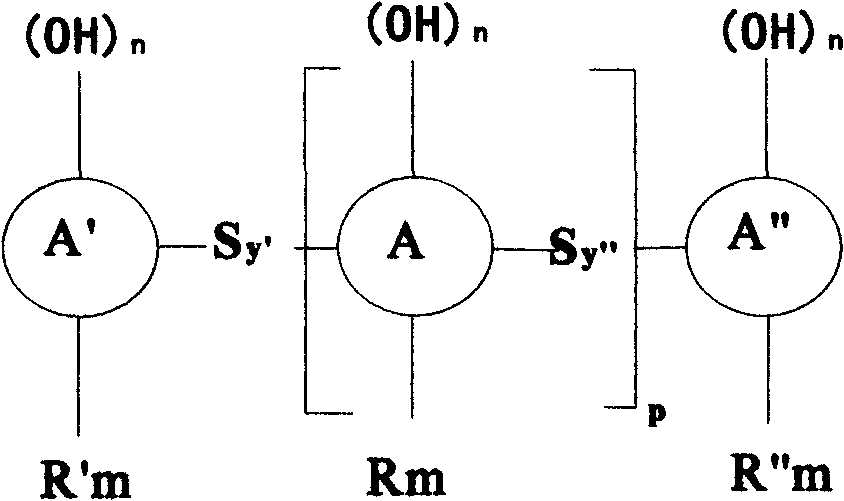

ActiveCN103613614AConducive to hydrophobizationStrong harvesting abilityGroup 5/15 element organic compoundsFlotationPhosphorous acidRare earth

The invention discloses an alpha-hydroxy unsaturated alkylphosphonic acid compound as well as a preparation method and application of the alpha-hydroxy unsaturated alkylphosphonic acid compound. The alpha-hydroxy unsaturated alkylphosphonic acid compound has the structural formula I as shown in the specification. The preparation method comprises the steps: subjecting 2-ethyl-2-hexenal and hypophosphorous acid or hypophosphite to addition reaction in the existence of an acid catalyst to generate 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphorous acid; subjecting 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphorous acid and an oxidizing agent to reaction to generate 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphonic acid. 30-600g / t of 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphonic acid is used as a flotation collector for bauxite, ilmenite, rutile, scheelite, wolframite, rare earth ores, tin ores, fluorite ores or lithium ores, and the pH value of a flotation solution is controlled at 4-12, so that a target ore and a gangue mineral can be effectively separated.

Owner:CENT SOUTH UNIV

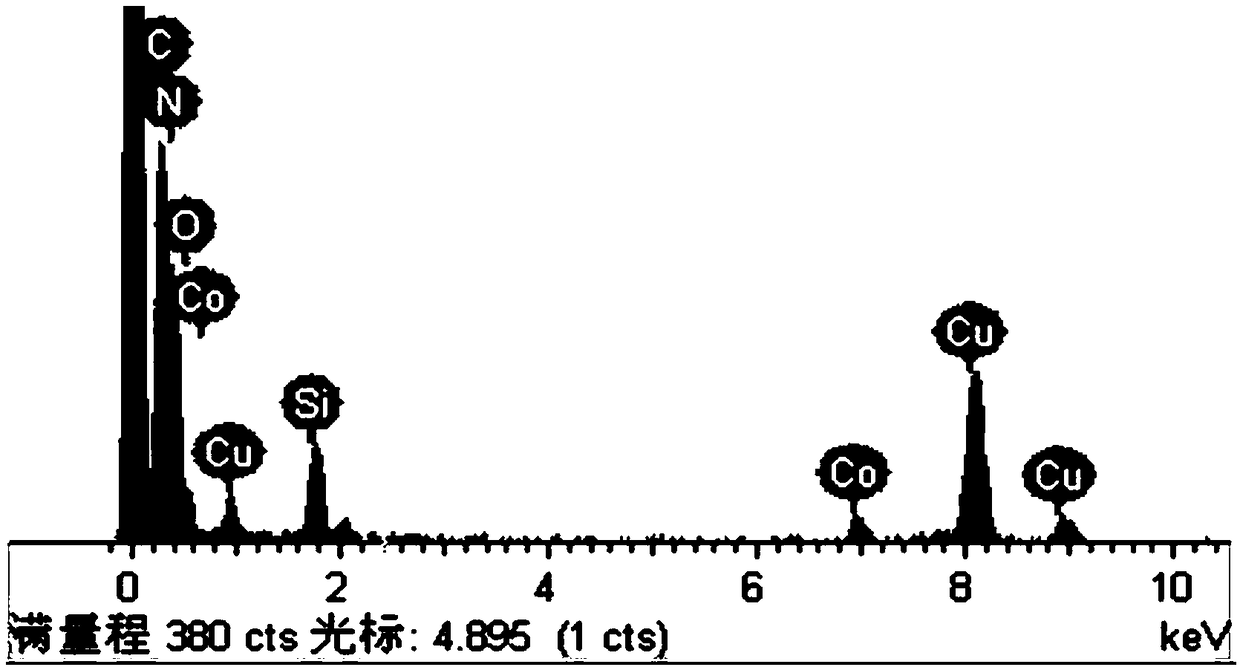

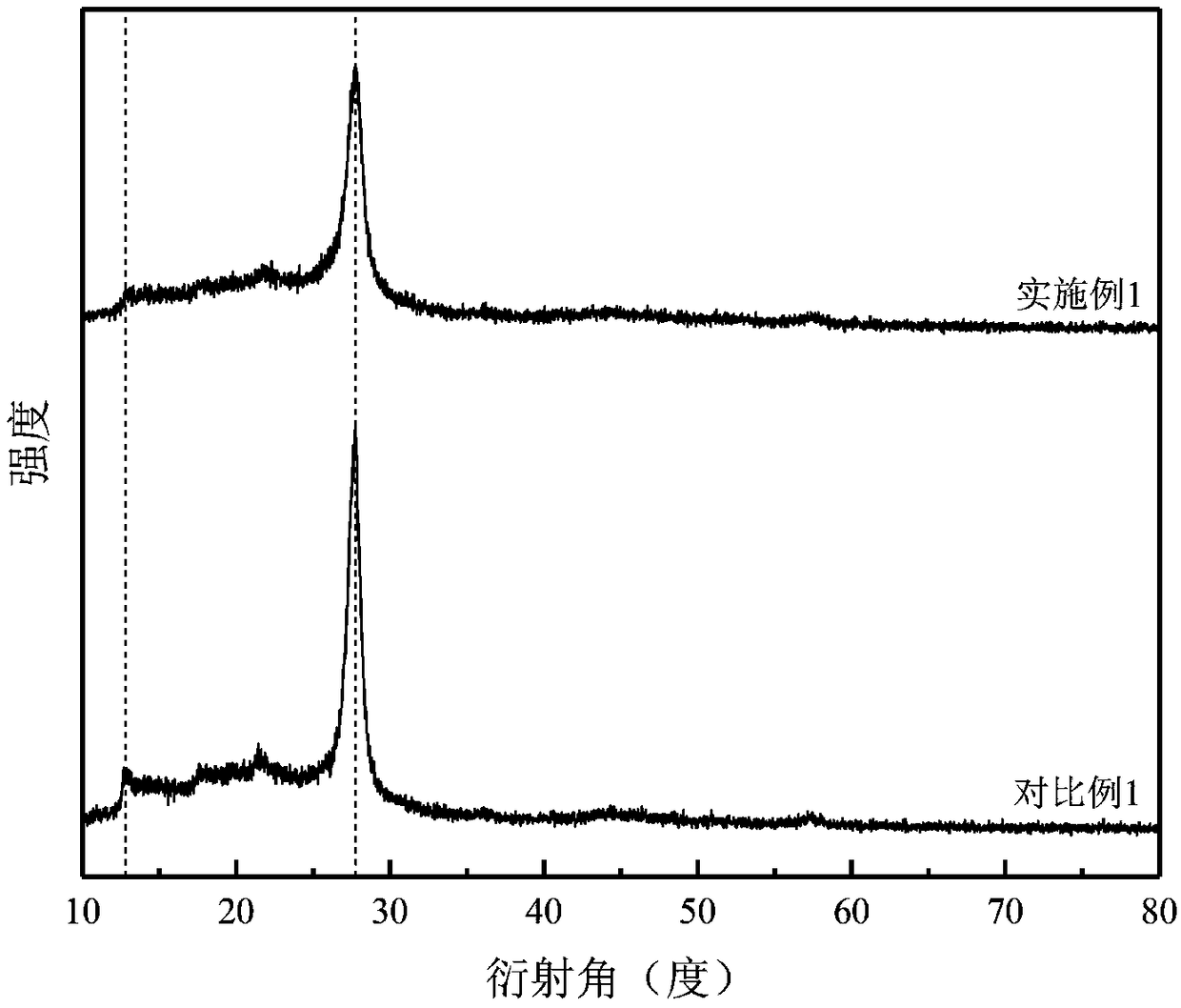

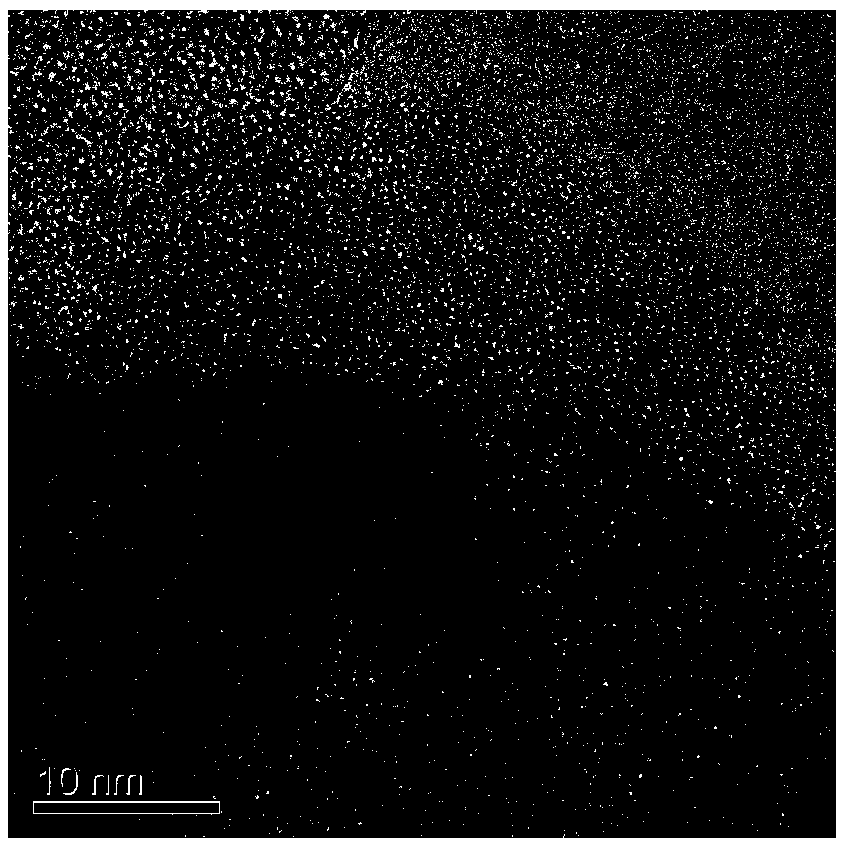

Preparation method for metal single atom/phosphor doping carbon nitride photocatalyst

InactiveCN108906105AImprove the utilization of visible light absorptionImprove the hydrogen production activity of photolysis waterPhysical/chemical process catalystsHydrogen productionSolventHeat treated

The invention discloses a preparation method for metal single atom / phosphor doping carbon nitride photocatalyst. The preparation process of the preparation method comprises the following steps: a) preparing urea metal complex: enabling metal salt and urea to react in a solvent to obtain urea metal complex; b: carrying out heat polycondensation: under the protection of inert atmosphere, evenly mixing the urea metal complex and carbon nitride precursor, and carrying out the heat polycondensation to obtain a heat polycondensation product; c) carrying out phosphorization: after the heat polycondensation product and hypophosphorous acid salt are evenly mixed, carrying out heat treatment under the inert atmosphere to obtain the metal single atom / phosphor doping carbon nitride photocatalyst. By use of the method disclosed by the invention, the carbon nitride photocatalyst of which the metal single atom capacity is 20wt% is prepared, and the hydrogen evolution rate is 2 times of that of phosphor doping carbon nitride which takes noble metal platinum as a hydrogen evolution cocatalyst. The preparation method has the advantages of rich raw material, low price, simple preparation method, lowpreparation cost and the like.

Owner:XIANGTAN UNIV

Chemical copper plating solution and technique thereof

InactiveCN101078111AAvoid pollutionLow costLiquid/solution decomposition chemical coatingChemical solutionCopper plating

A kind of chemical solution used to copperize, the following are the weight percent of the major components of it: blue vitriod0.8-3, Fe vitriol 0-0.5, complex agent 3-6, sodium hypophosphorous acid 4-6, ammonia sulfate 0.5-1, sulfourea 0-0.01. The following is the procedure of the copper coating method with the above copper coating solution: to widen and activate the plastic board->to clean->to make it electric->to clean->to coat nickel-copper alloy on it by chemical method. The following are the content of the chemical method: the plastic pretreated according the above description will be immersed in the above chemical solution used to copperize, the pH of which has been adjusted to 10-13 by vitriol and stranger ammonia water, the working temperature of it is 20-70deg.C, the time to copperize is 5-20 minutes. The chemical solution used to copperize in this patent does not contain formaldehyde, it improve the working circumstance, and is easy to control, the cost of it is lower, and it own high economical benefit and society benefit.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Microencapsulated aluminium hypophosphite and preparation method therefor and application thereof

ActiveCN105037808AGood compatibilityImprove flame retardant performanceMicroballoon preparationMicrocapsule preparationPolymer scienceIn situ polymerization

The invention discloses microencapsulated aluminium hypophosphite and a preparation method therefor and application thereof and belongs to the field of materials. The microencapsulated aluminium hypophosphite is synthesized through in situ polymerization by taking aluminium hypophosphite as a capsule core and melamino-formaldehyde resin and a derivative of the melamino-formaldehyde resin as a capsule material. The microencapsulated aluminium hypophosphite prepared by the preparation method disclosed by the invention is good in compatibility with polyurethane rigid foam, and the damage on the mechanical property is less while the flame retardance is improved. The preparation method disclosed by the invention is continuous in process, short in reaction time, low in production cost, high in production efficiency and easy to realize industrial production. By adding the microencapsulated aluminium hypophosphite through a one-step foaming method, the prepared high performance polyurethane rigid foam has high flame retardance and mechanical properties.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Electroless palladium plating liquid

ActiveUS7704307B2Improve stabilityExcellent corrosion resistance and solder bondability and wire bondabilitySolid-state devicesPretreated surfacesPhosphorous acidHydrazine compound

Owner:JX NIPPON MINING & METALS CORP

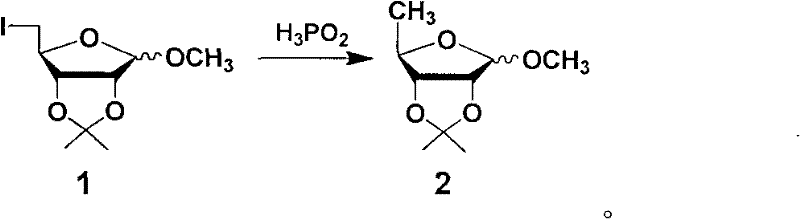

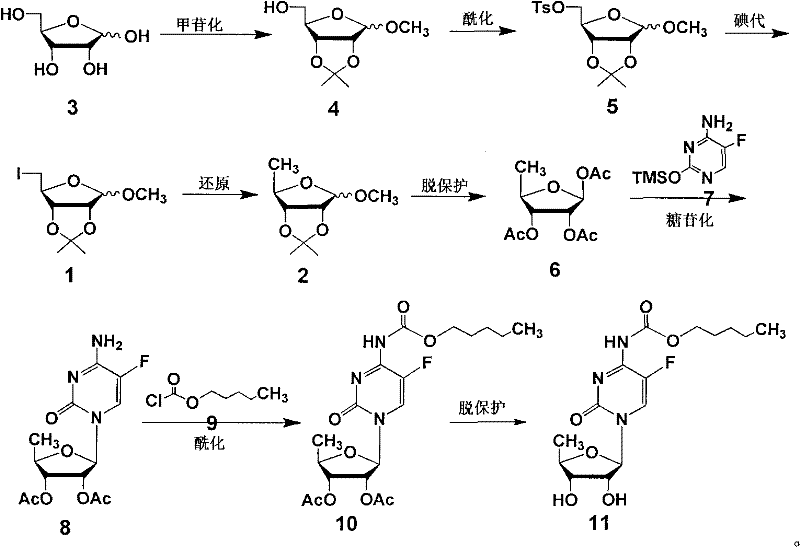

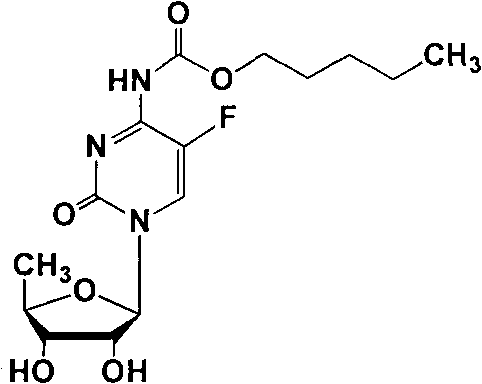

Preparation methods of capecitabine and intermediate thereof

ActiveCN102212095AAvoid it happening againReduce usageSugar derivativesSugar derivatives preparationPhosphoric acidTosylhydrazone

The invention discloses a preparation method of capecitabine. The method comprises the following steps: based on D-ribose serving as a starting raw material, carrying out hydroxyl protection, 5-site tosylation, iodine substitution, hypophosphorous acid deiodination and acetylation so as to obtain the key intermediate 12,3-tri-O-acetyl-5-deoxy-beta-D-ribofuranose; carrying out glycosylation on the key intermediate and 5-fluorocytosine; and finally, carrying out N-4 site acylation and deprotection so as to obtain the capecitabine. In the method, a metal catalyst dose not need to be used for participating in reaction, the reaction condition is mild, and the yield is high, thus the method is economical and effective as well as suitable for industrial production on a large scale.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD +2

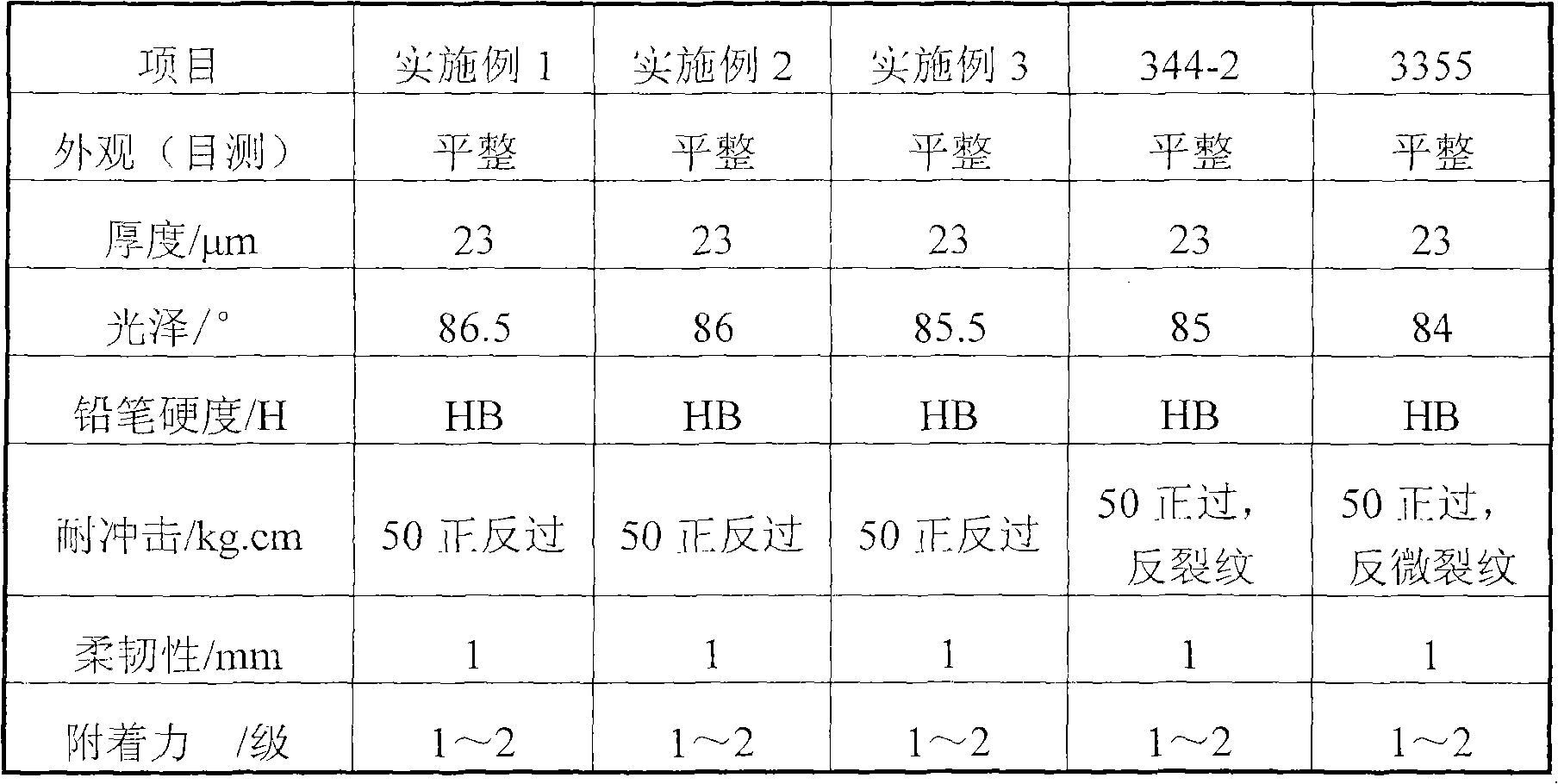

Alkyd and preparation method

ActiveCN101875719AReduce manufacturing costHigh impact strengthPolyester coatingsState of artPhthalic anhydride

The invention relates to alkyd which as low cost and good performance and especially can be used as baked enamel and PU (Polyurethane) paint and a preparation method thereof. The invention is characterized in that cheap castor oil fatty acid and water pool material (crude terephthalic acid) are adopted for carrying out catalytic esterification in the presence of hypophosphorous acid used as a catalyst. Compared with traditional soya oil fatty acid and phthalic anhydride type alkyd, the alkyd has the greatly reduced preparation cost of the resin with about 100yuan reduced per ton; in addition, the prepared resin has high impact strength, good glossiness, high adhesion and good color of final paint films; moreover, the obtained resin is short oil-length castor oil alkyd and especially can be used as the alkyd for making the baked enamel, which overcomes the defect that the traditional alkyd prepared by the prior art can not be used as the baked enamel as the low-cost water pool material is used; the one-step process also solves the technical problems that resin prepared by the traditional water pool material one-step process is not clear and has deeper color and the like; and furthermore, the esterification temperature is lower than that of the prior art for preparing the alkyd.

Owner:JIANGMEN SANMU CHEM

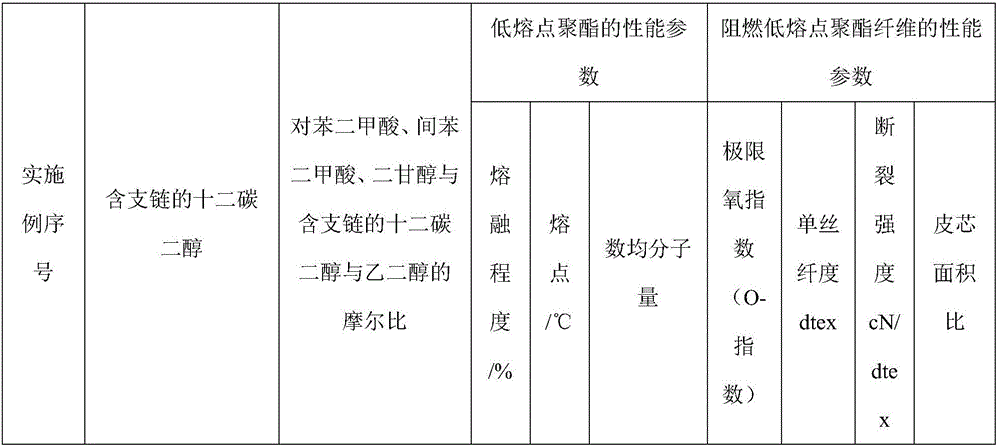

Flame-retarding low-melting-point polyester fiber and preparation method thereof

ActiveCN106811830ALow melting point temperatureFast meltingFilament/thread formingConjugated synthetic polymer artificial filamentsFiberDiethylene glycol

The invention discloses a flame-retarding low-melting-point polyester fiber and preparation method thereof, wherein the flame-retarding low-melting-point polyester fiber is a belt core structure, wherein the belt layer is low-melting-point polyester, and the core layer is flame-retarding polyester; the low-melting-point polyester is formed by terephthalic acid chain section, isophthalic acid chain section, glycol chain section, diglycol chain section and branch-chain-contained dodecynoic glycol chain section; the flame-retarding polyester consists of terephthalic acid chain section, glycol chain section, and flame retardant 2- ethoxy phenyl hypophosphorous acid chain section. The preparation method includes low-melting-point polyether polymerization and belt core composite spinning; the post spinning adopts drafting technique; the flame-retarding low-melting-point polyester fiber is acquired through rolling, cutting and drying. The flame-retarding low-melting-point polyester fiber is low in melting point and good in flame retarding effect.

Owner:扬州富威尔复合材料有限公司

Monoalkyl/dialkyl phosphinate and preparation method thereof

InactiveCN103172670AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsOrganic solventPhosphate

The invention discloses monoalkyl / dialkyl phosphinate and a preparation method thereof. The method comprises the steps that: water is adopted as a reaction medium; under the effect of an initiator I, hypophosphite is subjected to a reaction with alkene I under a temperature of 70-90 DEG C, such that monoalkyl phosphinate is obtained; the temperature is increased to 90-110 DEG C by heating; the obtained monoalkyl phosphinate is subjected to a reaction with alkene II under the effect of an initiator II, such that dialkyl phosphinate is obtained; Or, water is adopted as a reaction medium; under the effect of an initiator III, hypophosphite is subjected to a reaction with alkene III under a temperature of 70-120 DEG C, such that dialkyl phosphinate is obtained. The hypophosphite is hypophosphorous acid salt of Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, or Sr. According to the invention, hypophosphite is directly adopted as a raw material, and the monoalkyl / dialkyl phosphinate is obtained with a one-step method. The reaction period is short, a total yield is high, product purity is high, process flow is simple, no organic solvent or other solvent is adopted, and no subsequent processing is needed. When the product is salified, the contents of other salts are low. The product is easy to wash.

Owner:ZHUHAI WANTONG CHEM

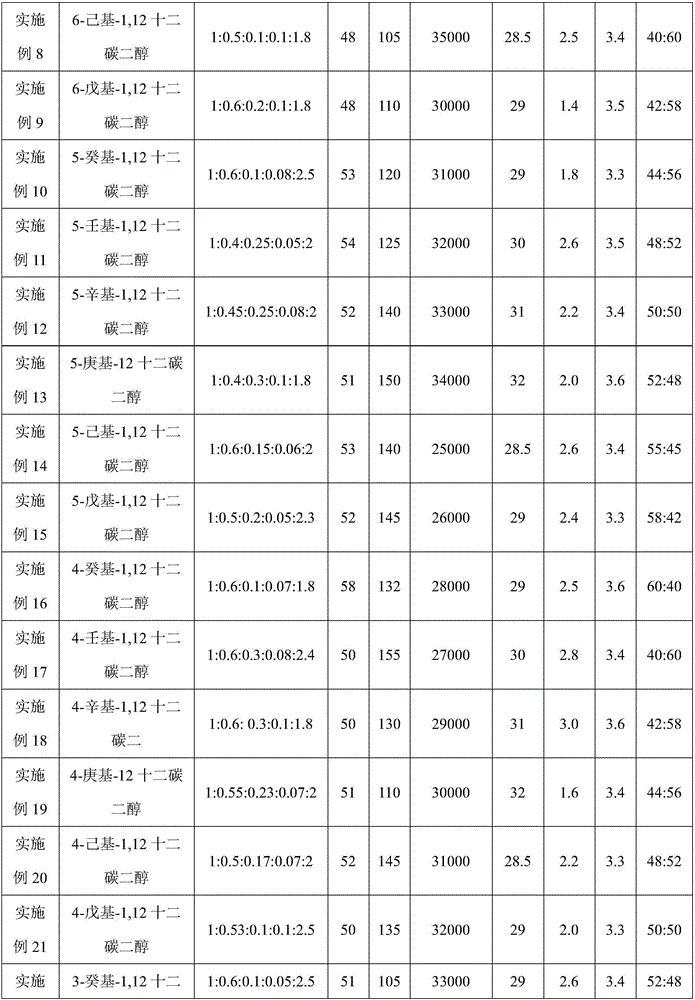

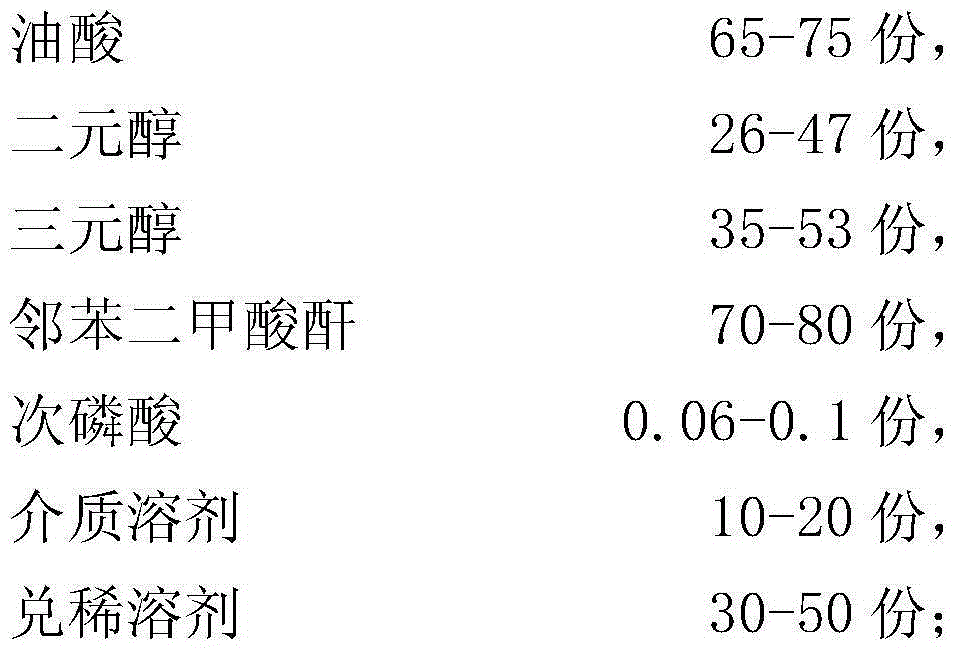

High-solid and low-viscosity short oil alkyd resin and preparation method therefor

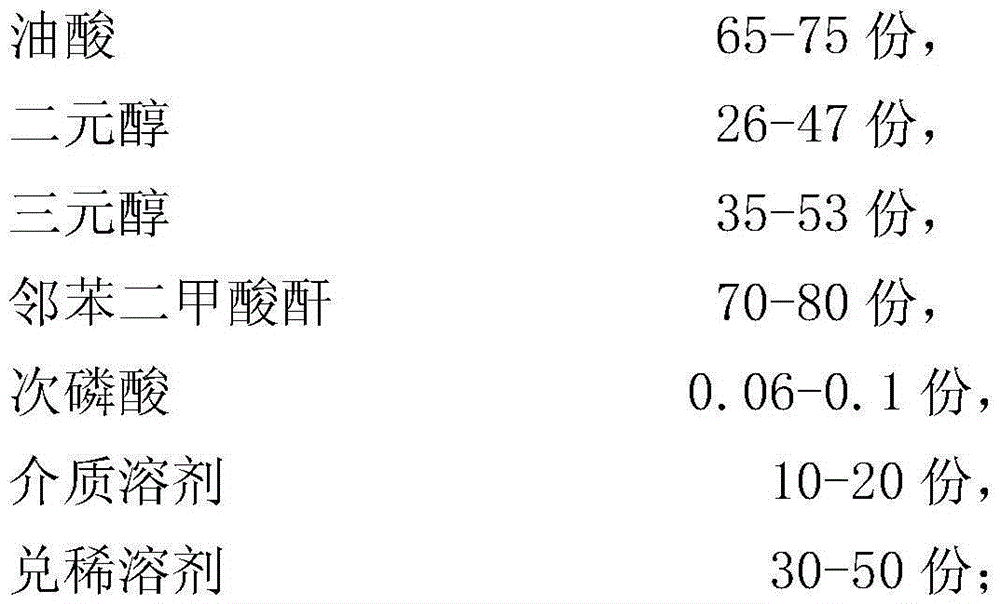

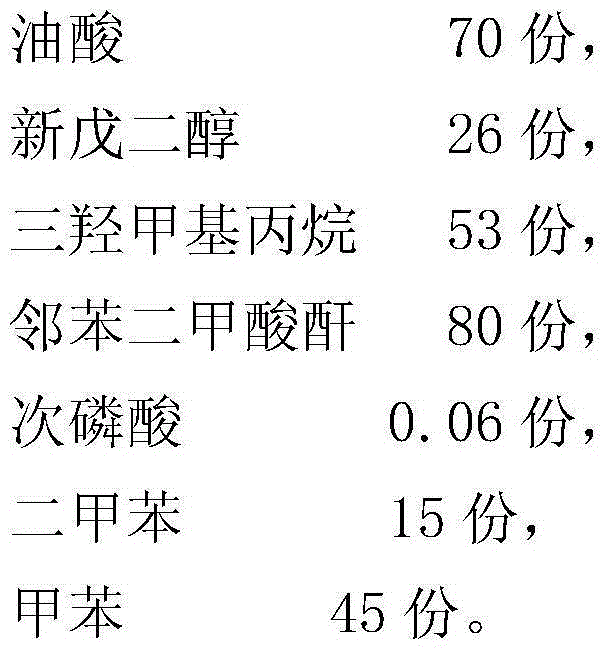

The invention relates to alkyd resin, particularly high-solid and low-viscosity short oil alkyd resin and a preparation method therefor. The high-solid and low-viscosity short oil alkyd resin provided by the invention is prepared from the following components in parts by weight: 65-75 parts of oleic acid, 26-47 parts of dihydric alcohol, 35-53 parts of trihydric alcohol, 70-80 parts of phthalic anhydride, 0.06-0.1 part of hypophosphorous acid, 10-20 parts of a medium solvent, and 30-50 parts of a diluting solvent. The short oil alkyd resin prepared by the invention is high in solid content and low in viscosity, can be used in light or matte polyurethane wood lacquer at the same time, remarkably reduces the content of VOC in paint, and has a good film effect.

Owner:SKSHU PAINT

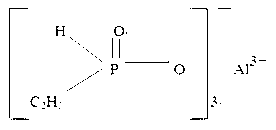

Rare earth metal hypophosphite and preparation method and application of rare earth metal hypophosphite

InactiveCN102838098AHigh densityImprove thermal stabilityHypophosphorous acidMetal chlorideMetal nitrate

The invention discloses rare earth metal hypophosphite higher in density and high in thermal stability, and a preparation method and an application of the rare earth metal hypophosphite as a flame retardant in a polymer material. The formula of the rare earth metal phosphate is Ln(H 2PO2)3(H2O).The preparation method of the rare earth metal hypophosphite comprises the steps of dissolving hypophosphite in water, adding sodium hydroxide to the solution to allow the pH of the solution to be 3.0-4.0, adding rare earth metal nitrate or an aqueous solution of rare earth metal chloride salt to be solution, stirring for 3-4 hours at 40-60 DEG C, cooling, filtering and washing to a reaction product, and obtaining the rare earth metal hypophosphite after drying. A halogen-free flame retardant polymer composite taking the rare earth metal hypophosphite as the flame retardant comprises the following components by mass percent: 40-90% of polymer and 10-25% of rare earth metal hypophosphite.

Owner:SUZHOU INST FOR ADVANCED STUDY USTC

Method for chemical plating nickel phosphor alloy

InactiveCN1546726AQuality improvementExtend your lifeLiquid/solution decomposition chemical coatingChemical platingAlloy

The invention discloses a method for chemical plating nickel phosphor alloy, wherein the chemical plating bath comprises the main constituents of the mixed solution of nickel hypophosphite and hypophosphorous acid, sodium citrate, ethyl acetate, sodium glucoheptonate and trace amount of lead, wherein the nickel hypophosphite and hypophosphorous acid mixed solution is prepared through electrolytic method. The invention realizes substantially improved coating property.

Owner:NANKAI UNIV +1

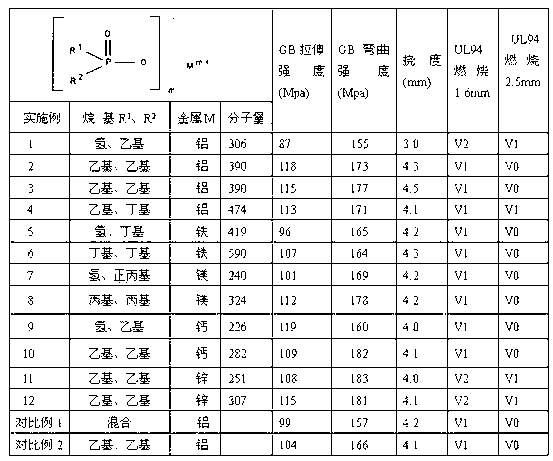

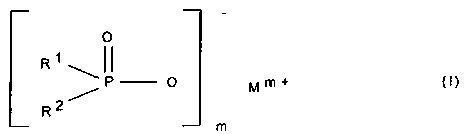

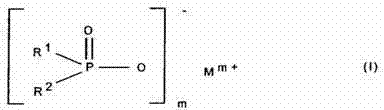

Dialkyl phosphinic acid salt and preparation method thereof

InactiveCN103073575AShort reaction cycleHigh yieldGroup 5/15 element organic compoundsBenzenePhosphoric acid

The invention discloses a dialkyl phosphinic acid salt with the following structural formula (I). R1 and R2 are the same or different, and represent C2-C6 alkyls; secondary M represents Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr or Sr; m equals to 1-4; and mole percent of a telomer is 0.1-10mol%. The preparation method comprises steps of: a) reacting hypophosphorous acid with high concentration with olefin under the effect of an initiator by using benzene as a solvent to obtain a dialkyl phosphinic acid-organic phase solution; b) removing the organic solvent by water extraction or vacuum distillation, and diluting with water to obtain a dialkyl phosphinic acid aqueous solution; c) neutralizing with an aqueous solution of an alkaline compound to obtain a dialkyl phosphinic acid alkali metal salt aqueous solution; and d) reacting the dialkyl phosphinic acid alkali metal salt aqueous solution with a metal compound aqueous solution to obtain dialkyl phosphinic acid salt. The method provided by the invention employs hypophosphorous acid with high concentration as a raw material and benzene as the solvent to obtain a product containing part of telomer, has a short reaction period only requiring 4-6 h to complete the process, and has a high total yield; the process is simple; and the organic solvent can be recycled.

Owner:GUANGZHOU KINGSKY MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com