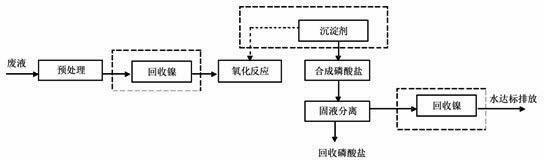

Method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid

A technology of organic pollutants and electroless nickel plating, applied in chemical instruments and methods, phosphate, phosphorus oxyacids, etc., can solve the problems of serious pollution of electroless nickel plating wastewater and difficulty in resource recovery, and achieve thorough removal of organic matter and phosphorus , Process recovery of resources, high practical value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Get 4 liters of electroless nickel plating waste liquid that nickel ion has been removed, containing COD 20800mg / L, total phosphorus is 18g / L, after it is filtered, add concentration and be 30% hydrogen peroxide (make H 2 o 2 Concentration is 55g / L), stirred by mechanical stirring, turn on the 80W UV lamp to irradiate the solution, start the oxidation reaction, turn off the UV lamp after 2.5 hours of reaction. Add 200g Al to the reacted solution 2 (SO 4 ) 3 Stirring was continued for 30 minutes, and finally the ferric phosphate and water were separated by filtration, and the separated ferric phosphate was dried at 105° C. for 3 hours to obtain dry ferric phosphate. The final effluent COD is 356mg / L, and dry AlPO is obtained 4 A total of 71g.

example 2

[0044] Get 4 liters of electroless nickel plating waste liquid that nickel ion has been removed, containing COD 26000mg / L, total phosphorus is 12g / L, after it is filtered, add concentration and be 30% hydrogen peroxide (make H 2 o 2 Concentration is 50g / L), stirred by mechanical stirring, turn on 80W ultraviolet light to irradiate the solution, start the oxidation reaction, turn off the ultraviolet light after 3 hours of reaction. Add 320g Fe in the reacted solution 2 (SO 4 ) 3 Stirring was continued for 30 minutes, and finally the ferric phosphate and water were separated by filtration, and the separated ferric phosphate was dried at 95° C. for 5 hours to obtain dry ferric phosphate. The final effluent COD is 451mg / L, and dry FePO is obtained 4 2H 2 O total 260g.

example 3

[0046] Get 4 liters of electroless nickel plating waste liquid, containing nickel ion 6.125g / L, COD 26000mg / L, total phosphorus is 12g / L, after it is filtered, add concentration and be 30% hydrogen peroxide (make H 2 o 2 Concentration is 50g / L), while adding 445g FeSO 4 ·7H 2 O, stirring by mechanical stirring, and reacting for 3 hours. After the reaction, the ferric phosphate and water were separated by filtration, and the separated ferric phosphate was dried at 95° C. for 5 hours to obtain dry ferric phosphate. The mother liquor after filtration uses ion-exchange resin to recover nickel sulfate, and the COD of the final effluent is 451mg / L to obtain dry FePO 4 2H 2 O total 260g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com