Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

482 results about "Electroless nickel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroless nickel is a broad term that incorporates a diverse mix of technology ranging from nickel boron and ternary alloys to highly functional composites. Nickel phosphorus deposits find the most use in the markets the plating industry serves.

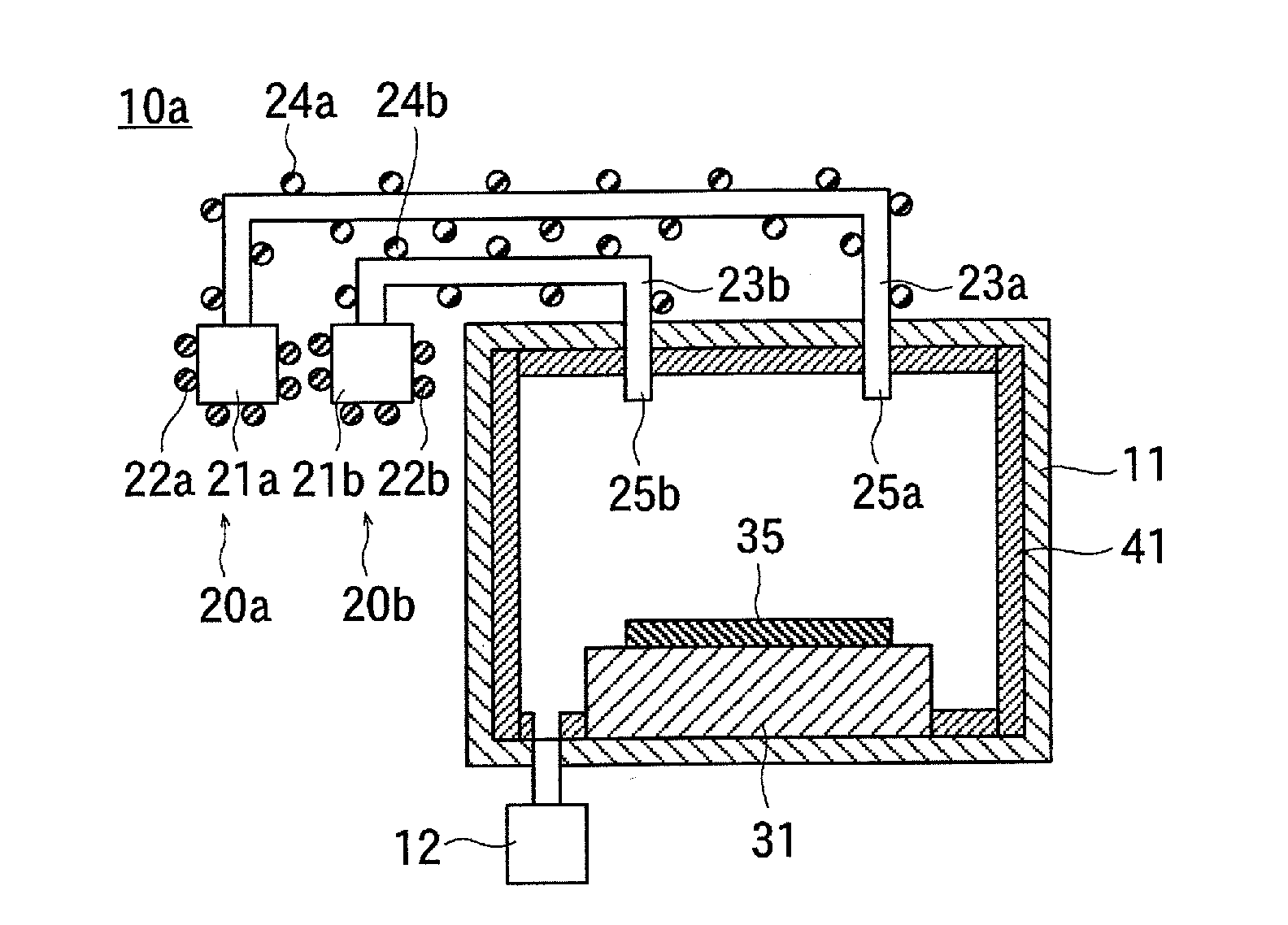

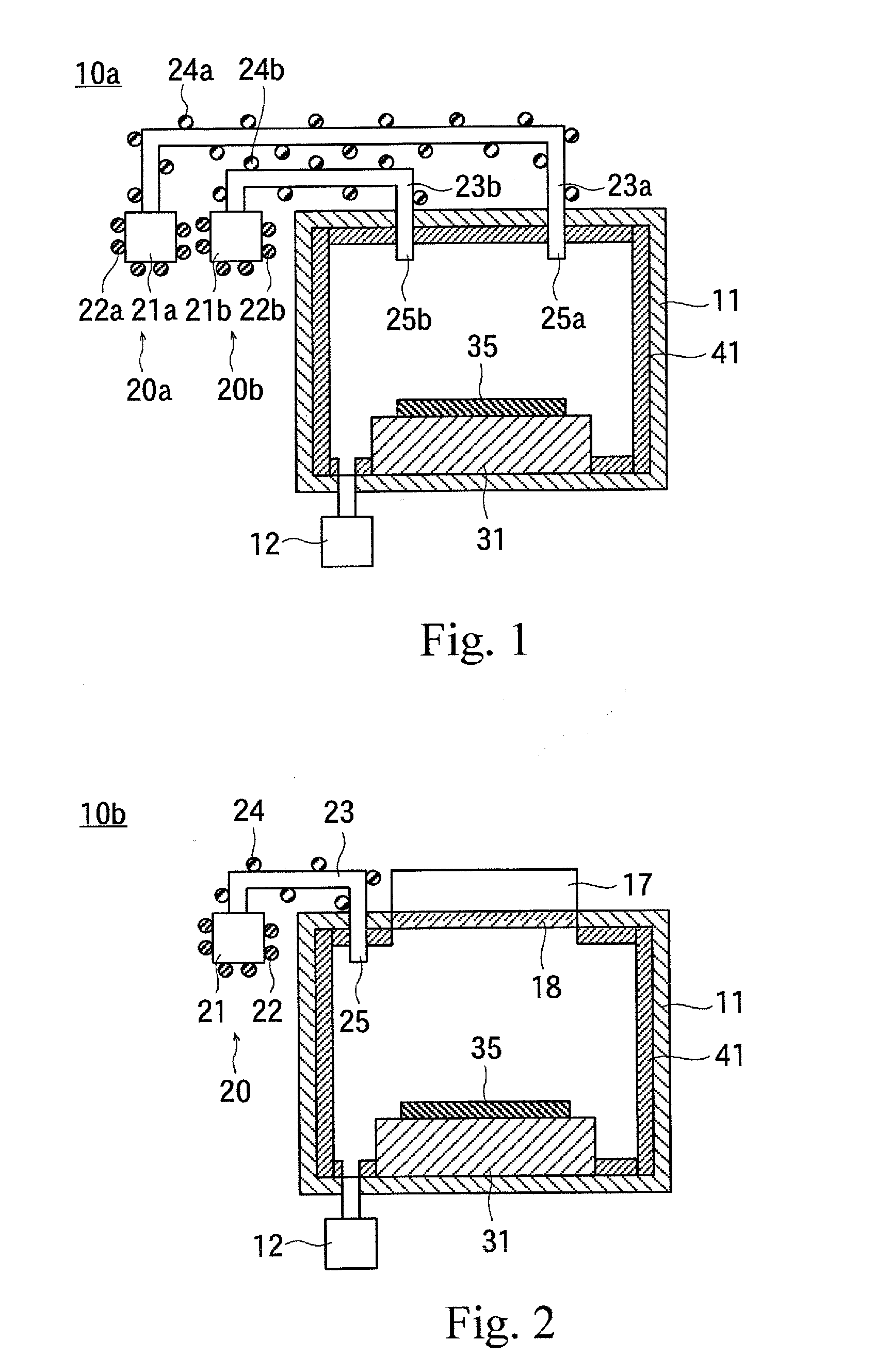

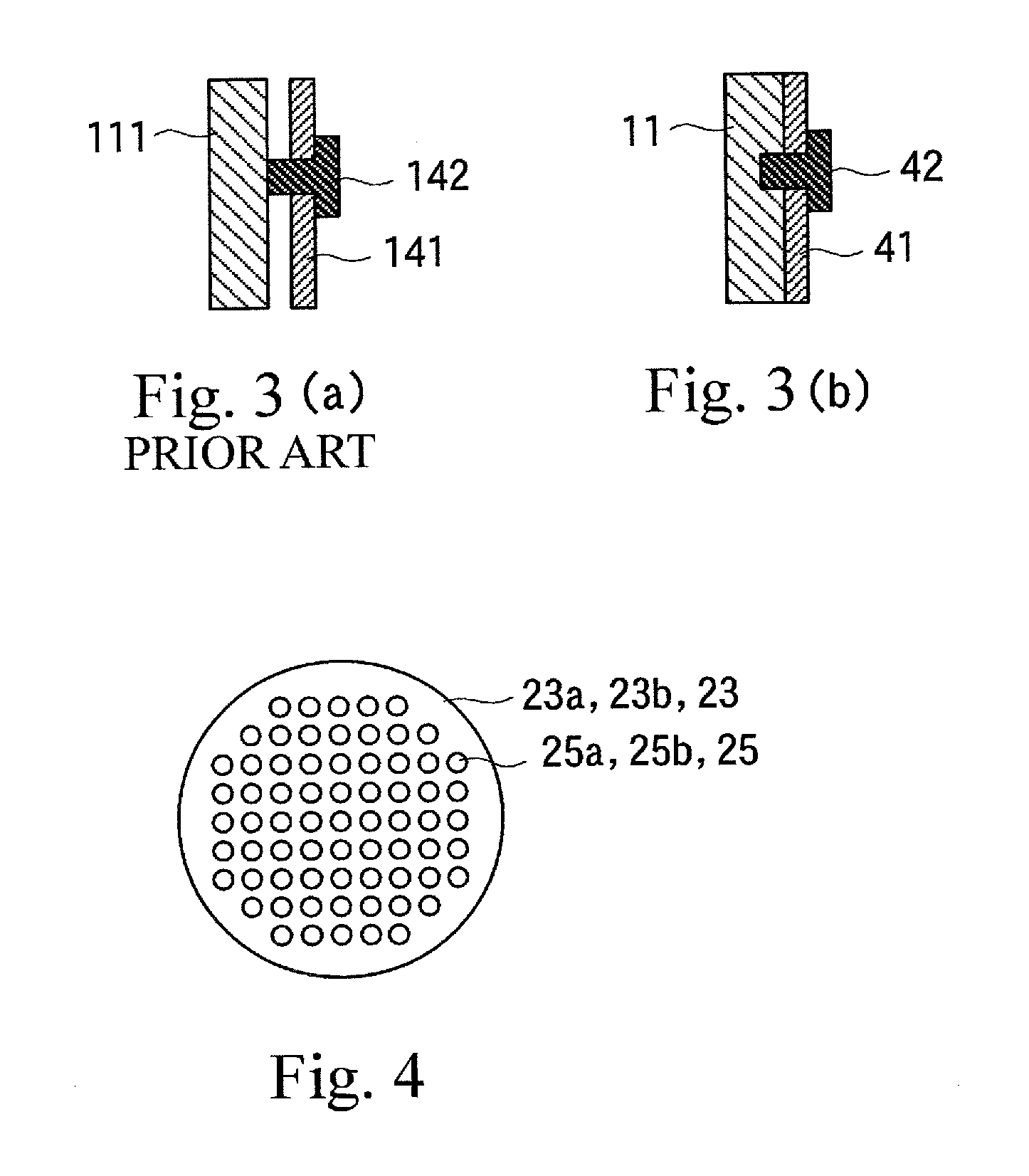

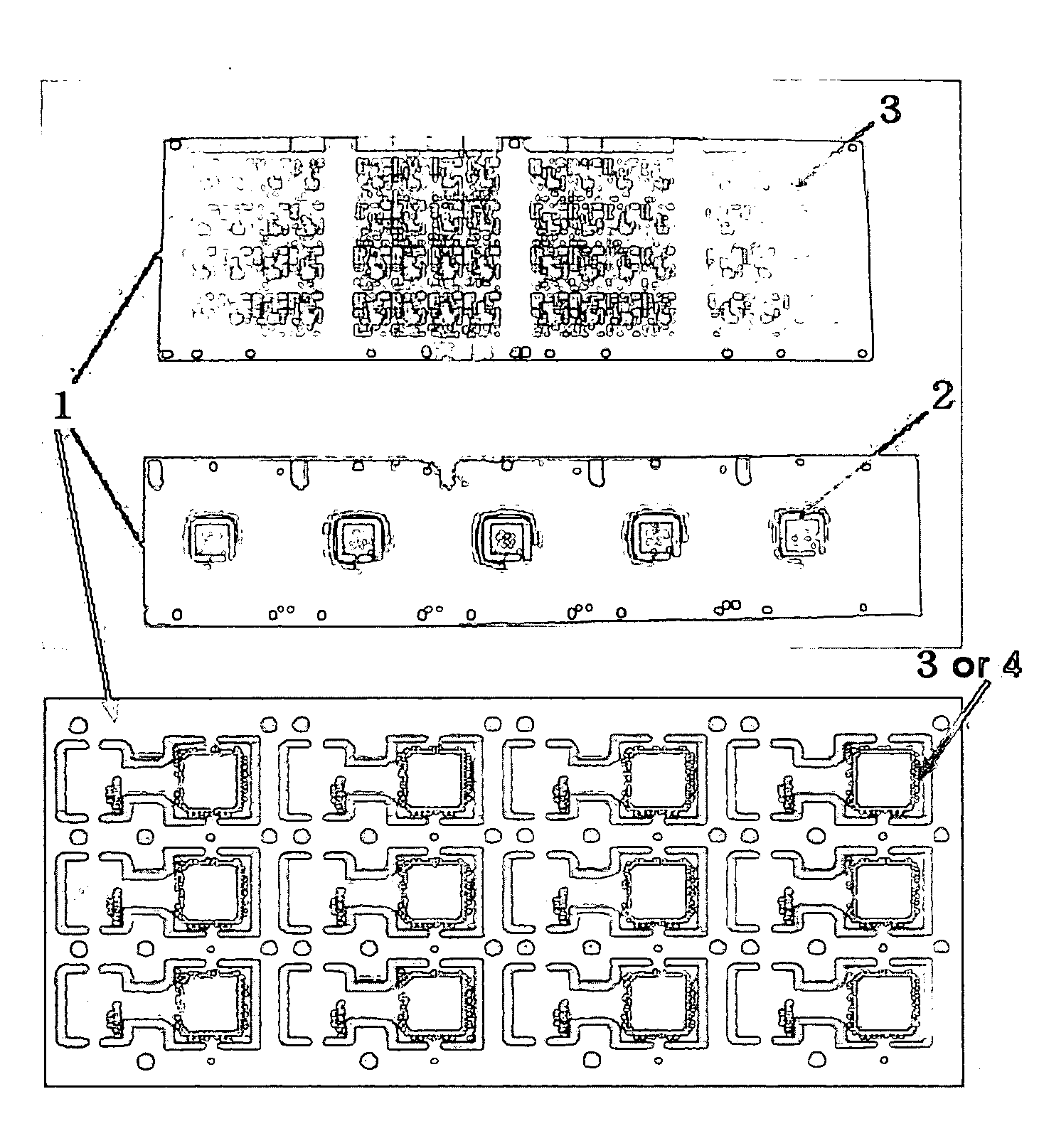

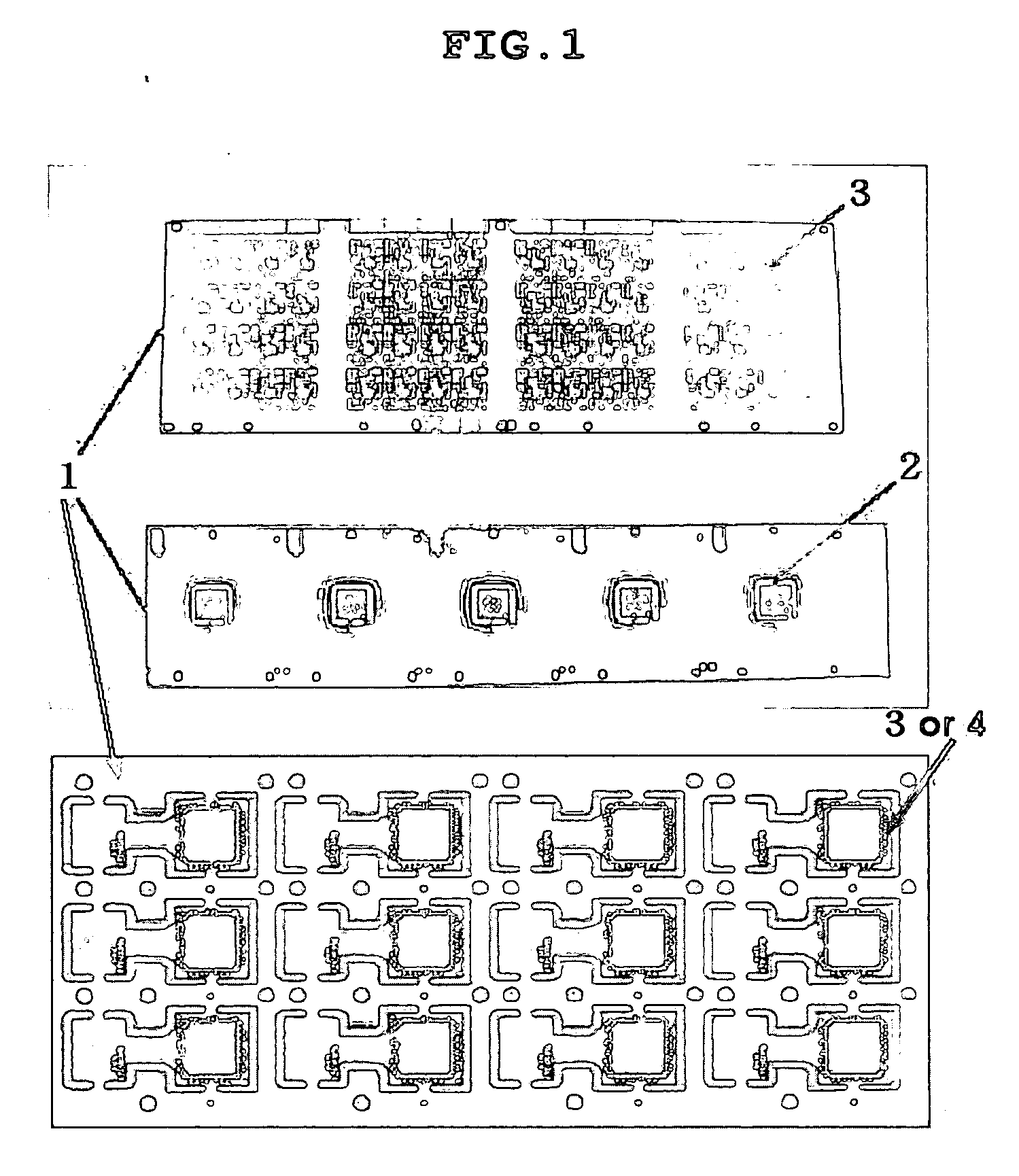

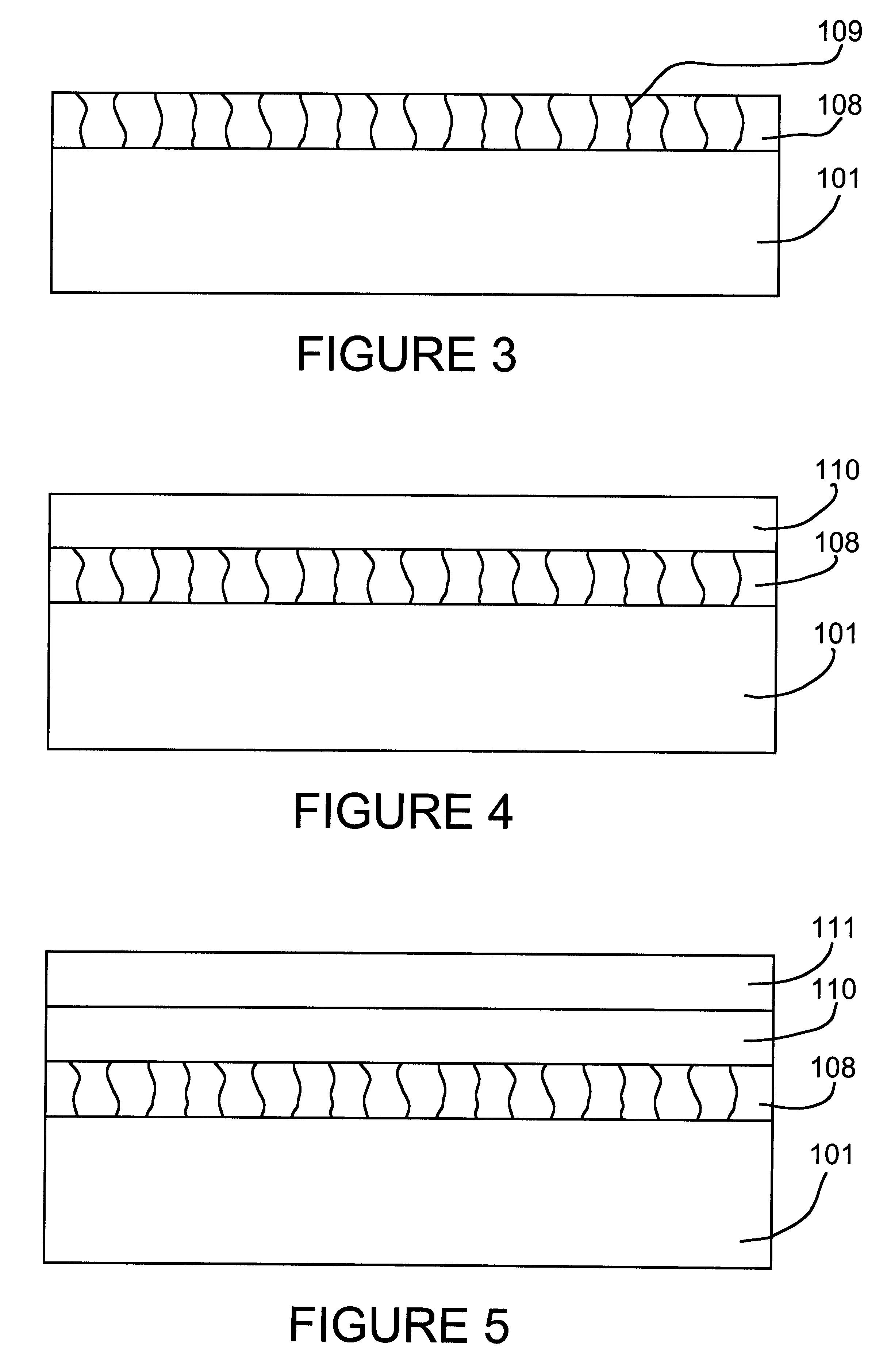

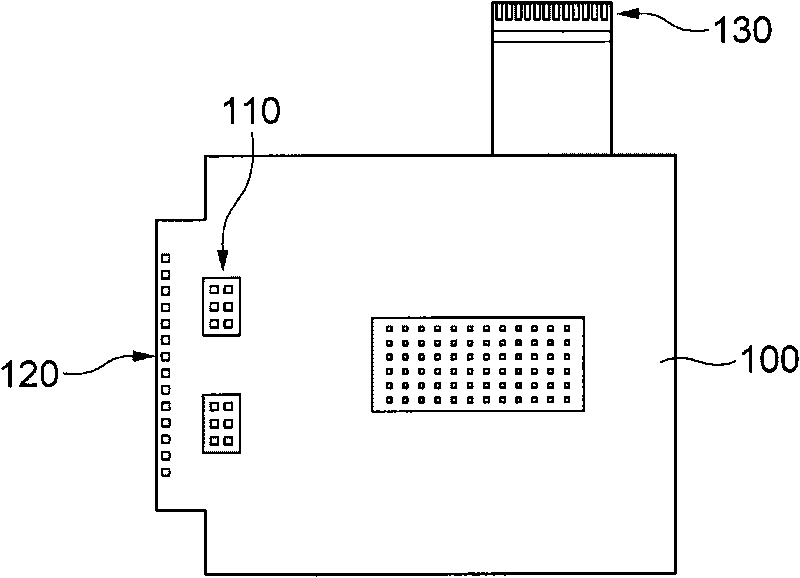

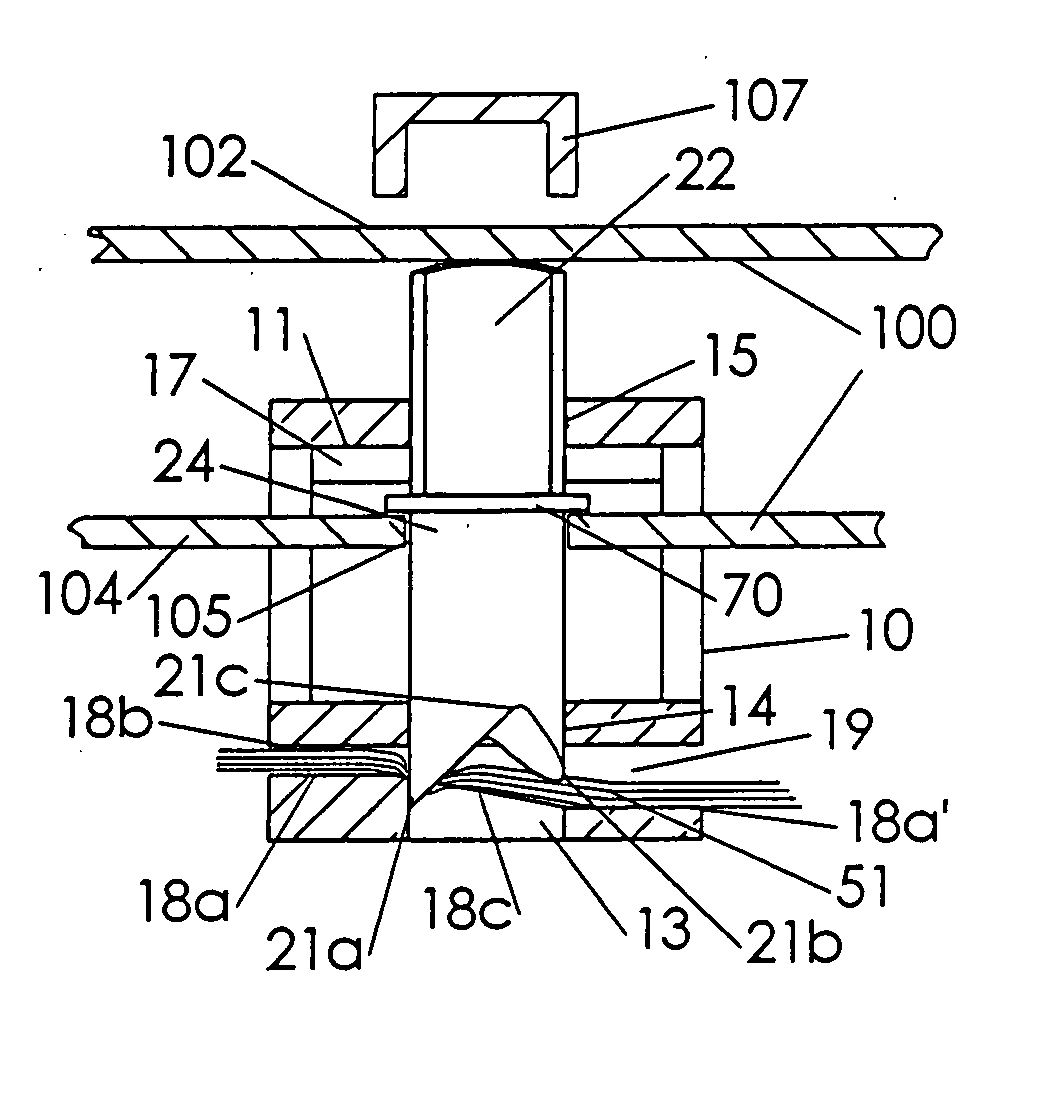

Organic thin film forming apparatus

InactiveUS20130333619A1Low costEasy to disassembleLiquid surface applicatorsVacuum evaporation coatingElectroless nickelOptoelectronics

An organic thin film forming apparatus that can easily remove an organic thin film adhered to a surface of a deposition preventive plate. The apparatus forms an organic thin film on a substrate disposed on a surface of a substrate stage from an organic gas. An electroless nickel film containing fluorine resin is formed on the surface of a deposition preventive plate. The electroless nickel film containing fluorine resin has mold release characteristics for an organic thin film. Even if the organic thin film adheres, the organic thin film can be easily removed by a method (such as, high pressure cleaning).

Owner:ULVAC INC

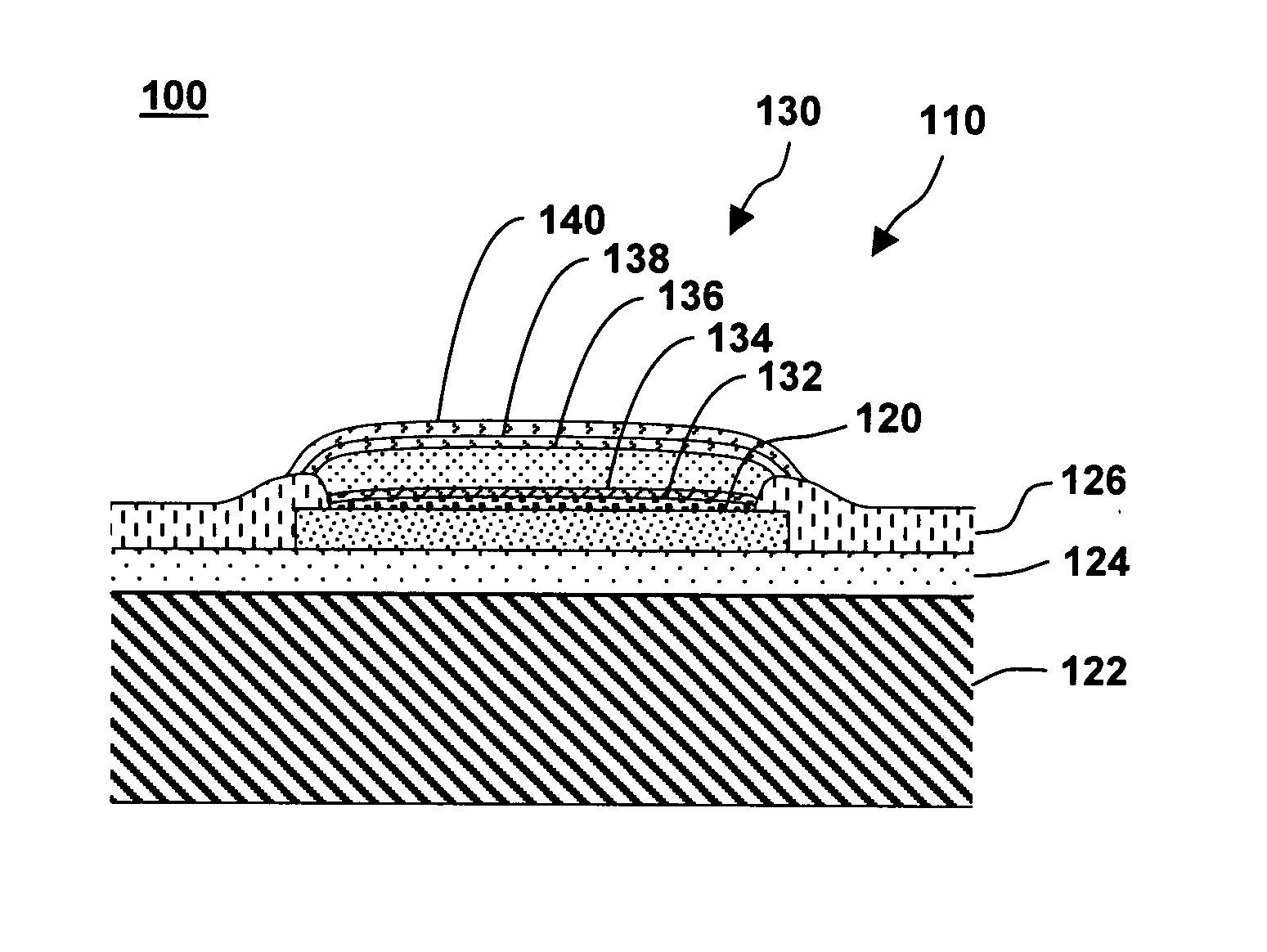

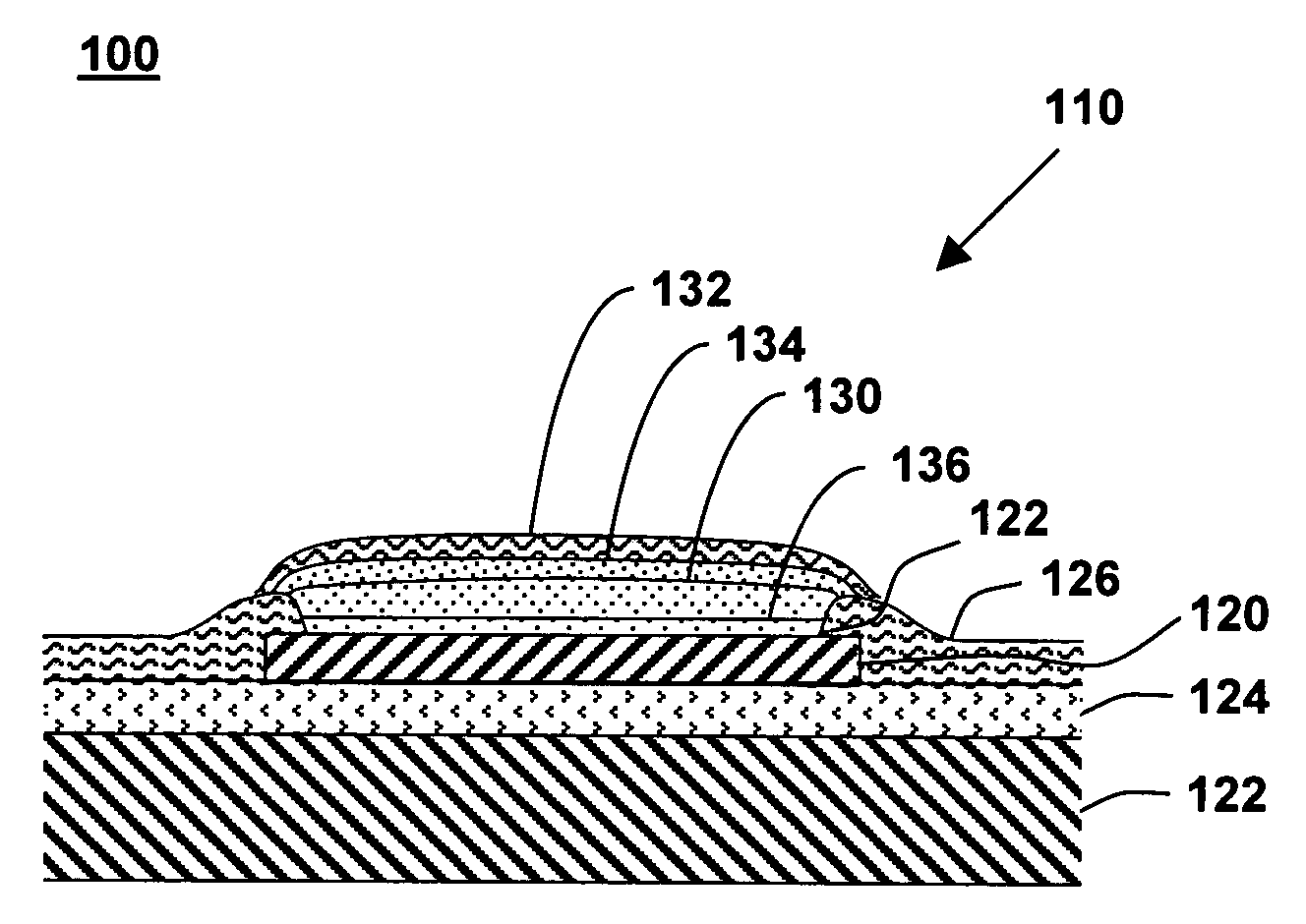

Corrosion-resistant copper bond pad and integrated device

InactiveUS20050001324A1Semiconductor/solid-state device detailsFluid pressure measurement by electric/magnetic elementsElectroless nickelAlloy

The invention provides an integrated device with corrosion-resistant capped copper bond pads. The capped copper bond pads include at least one copper bond pad on a semiconductor substrate. An activation layer comprising one of immersion palladium, electroless cobalt, or immersion ruthernium is disposed on the copper bond pad. A first intermediate layer of electroless nickel-boron alloy is disposed on the activation layer. A second intermediate layer comprising one of electroless nickel or electroless palladium is disposed on the first intermediate layer, and an immersion gold layer is disposed on the second intermediate layer. A capped copper bond pad and a method of forming the capped copper bond pads are also disclosed.

Owner:NORTH STAR INNOVATIONS

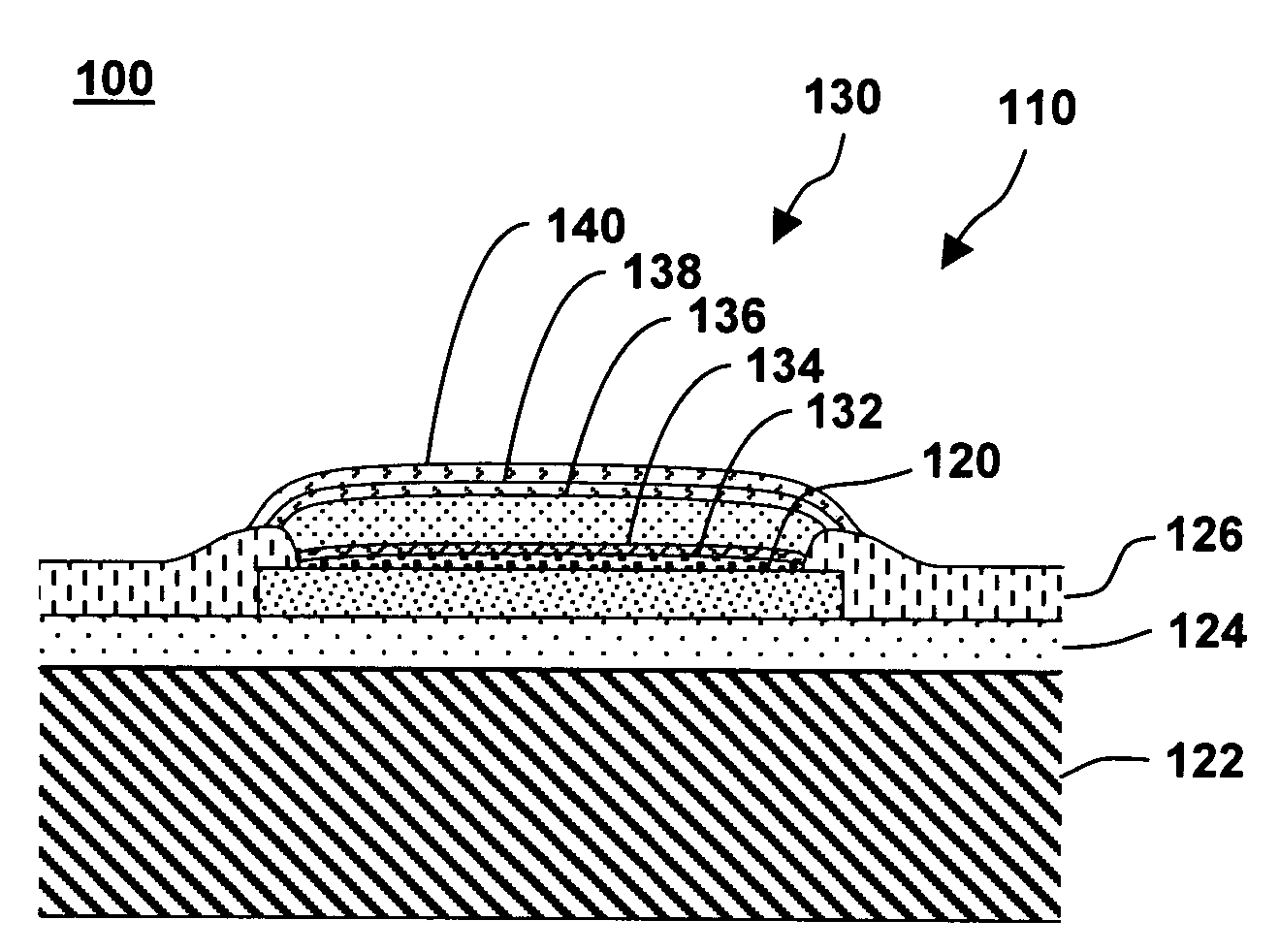

Corrosion-resistant bond pad and integrated device

InactiveUS20050104207A1Semiconductor/solid-state device detailsSolid-state devicesElectroless nickelSemiconductor

The invention provides an integrated device with corrosion-resistant capped bond pads. The capped bond pads include at least one aluminum bond pad on a semiconductor substrate. A layer of electroless nickel is disposed on the aluminum bond pad. A layer of electroless palladium is disposed on the electroless nickel, and a layer of immersion gold is disposed on the electroless palladium. A capped bond pad and a method of forming the capped bond pads are also disclosed.

Owner:FREESCALE SEMICON INC

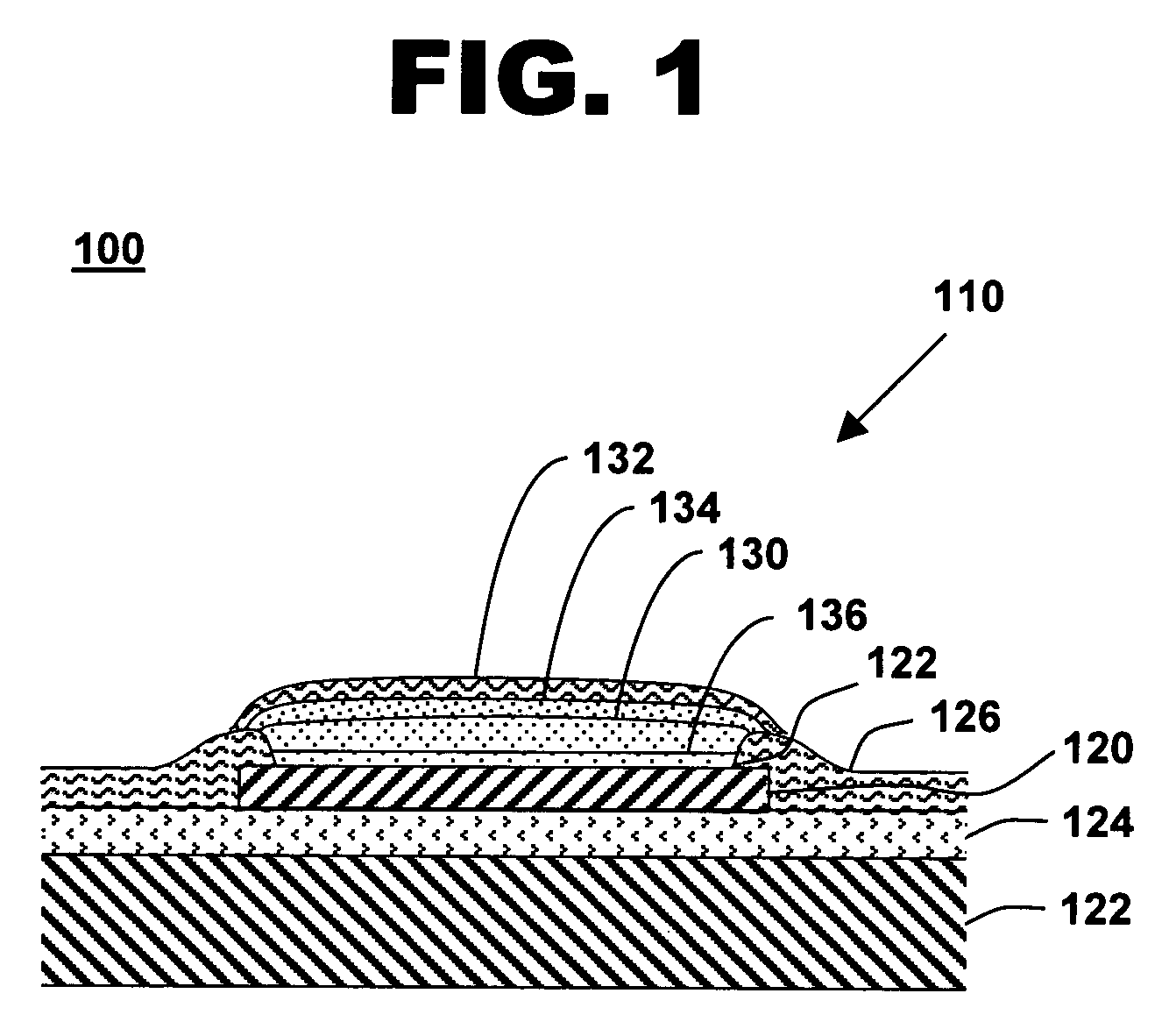

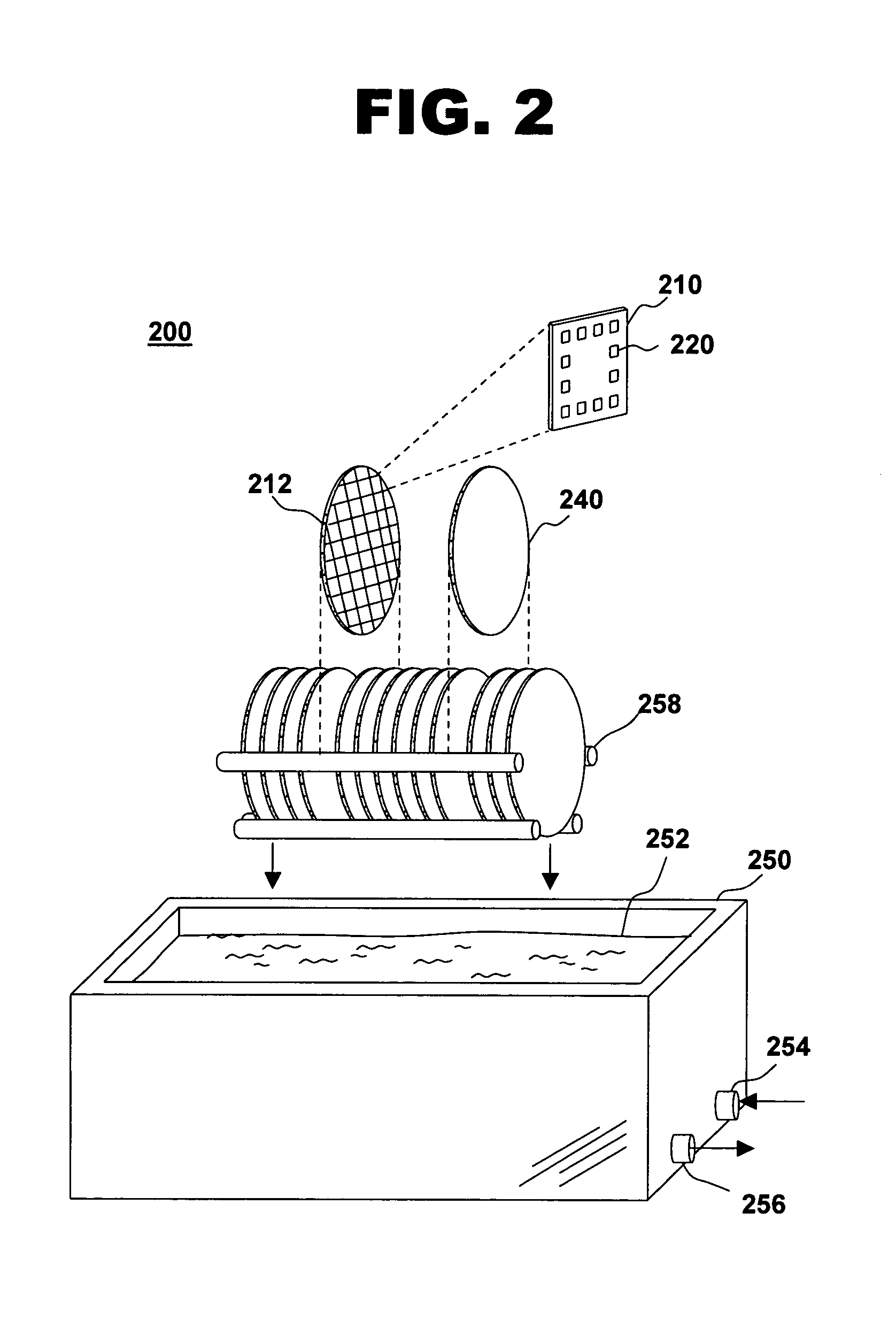

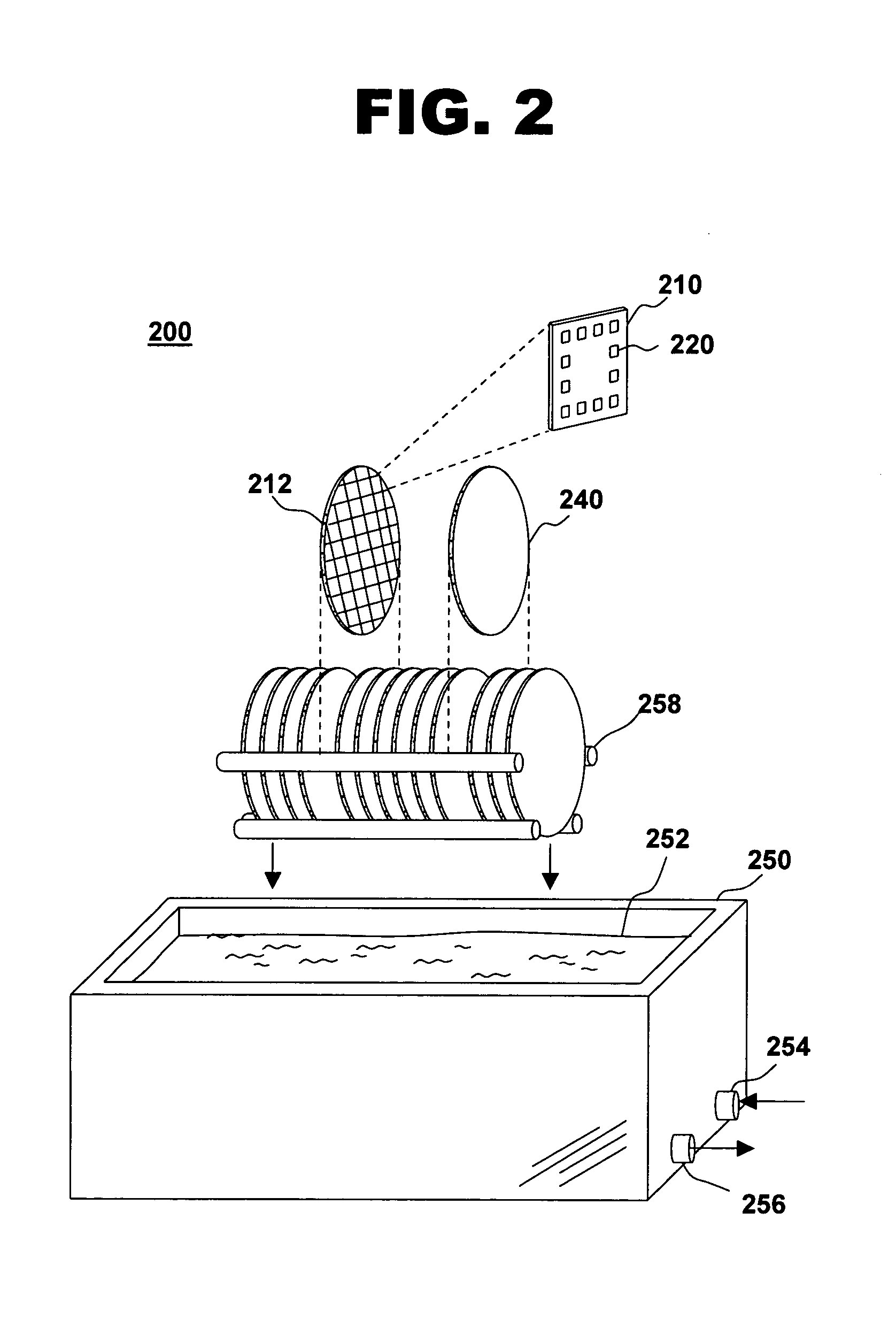

Activation plate for electroless and immersion plating of integrated circuits

The invention provides a method of plating an integrated circuit. An activation plate is positioned adjacent to at least one integrated circuit. The integrated circuit includes a plurality of bond pads comprising a bond-pad metal, and the activation plate also comprises the bond-pad metal. A layer of electroless nickel is plated on the bond pads and the activation plate, and a layer of gold is plated over the layer of electroless nickel on the bond pads and the activation plate. An integrated circuit with bond pads plated using the activation plate, and a system for plating an integrated circuit is also disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

Corrosion-resistant copper bond pad and integrated device

InactiveUS7078796B2Semiconductor/solid-state device detailsFluid pressure measurement by electric/magnetic elementsElectroless nickelAlloy

The invention provides an integrated device with corrosion-resistant capped copper bond pads. The capped copper bond pads include at least one copper bond pad on a semiconductor substrate. An activation layer comprising one of immersion palladium, electroless cobalt, or immersion ruthernium is disposed on the copper bond pad. A first intermediate layer of electroless nickel-boron alloy is disposed on the activation layer. A second intermediate layer comprising one of electroless nickel or electroless palladium is disposed on the first intermediate layer, and an immersion gold layer is disposed on the second intermediate layer. A capped copper bond pad and a method of forming the capped copper bond pads are also disclosed.

Owner:NORTH STAR INNOVATIONS

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveUS20070104929A1Reduce thicknessDecreasing solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Disclosed herein are a method for plating a printed circuit board and the printed circuit board manufactured therefrom. In the method, a bare soldering or wire bonding portion of a copper (Cu)- or copper alloy layer, is plated with palladium (Pd) or a palladium alloy, and then gold (Au) or a gold alloy is deposited over the palladium or palladium alloy plated layer by an electroless substitution plating process based on ionization tendency. Having superior hardness, ductility and corrosion resistance, palladium is suitable for use between a connector and a substrate and meets requirements for the printed circuit board even when applied to a low thickness, greatly reducing the process time. Accordingly, the problem of black pad, which frequently occur on electroless nickel and electroless gold finish upon surface mount technology, can be perfectly solved. Particularly, fatal bending cracks can be prevented from occurring in the rigid-flexible or flexible printed circuit boards.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

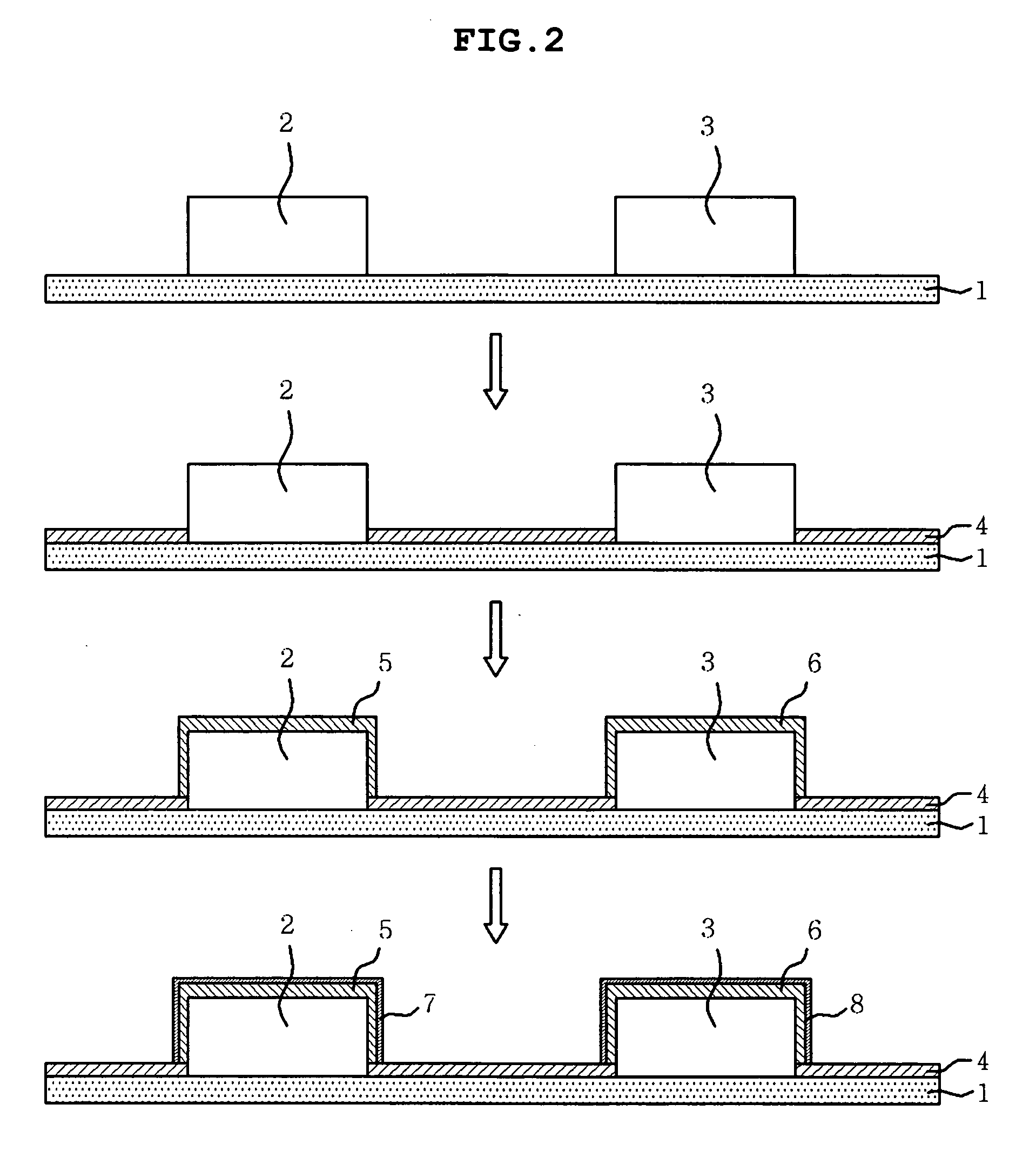

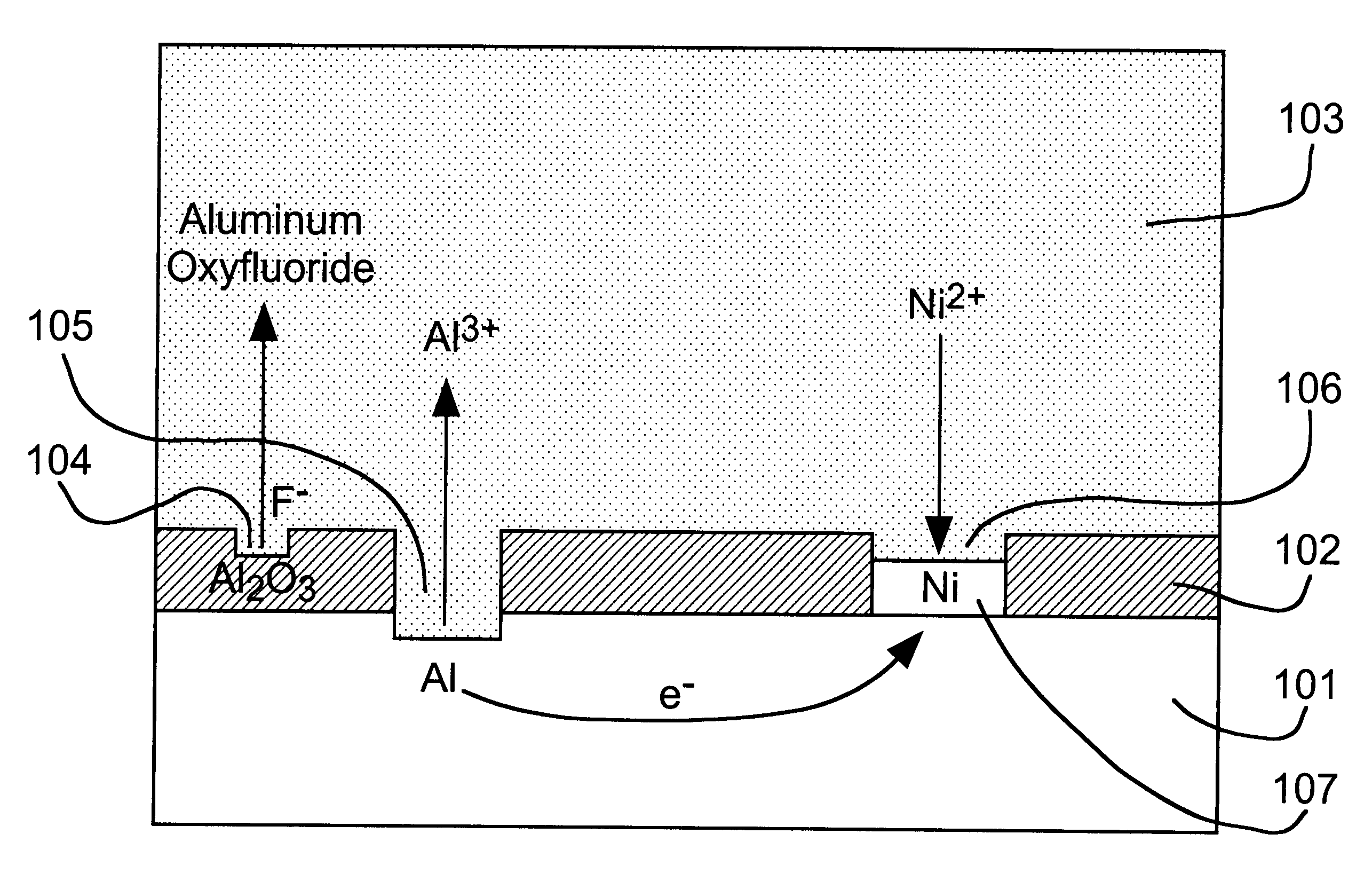

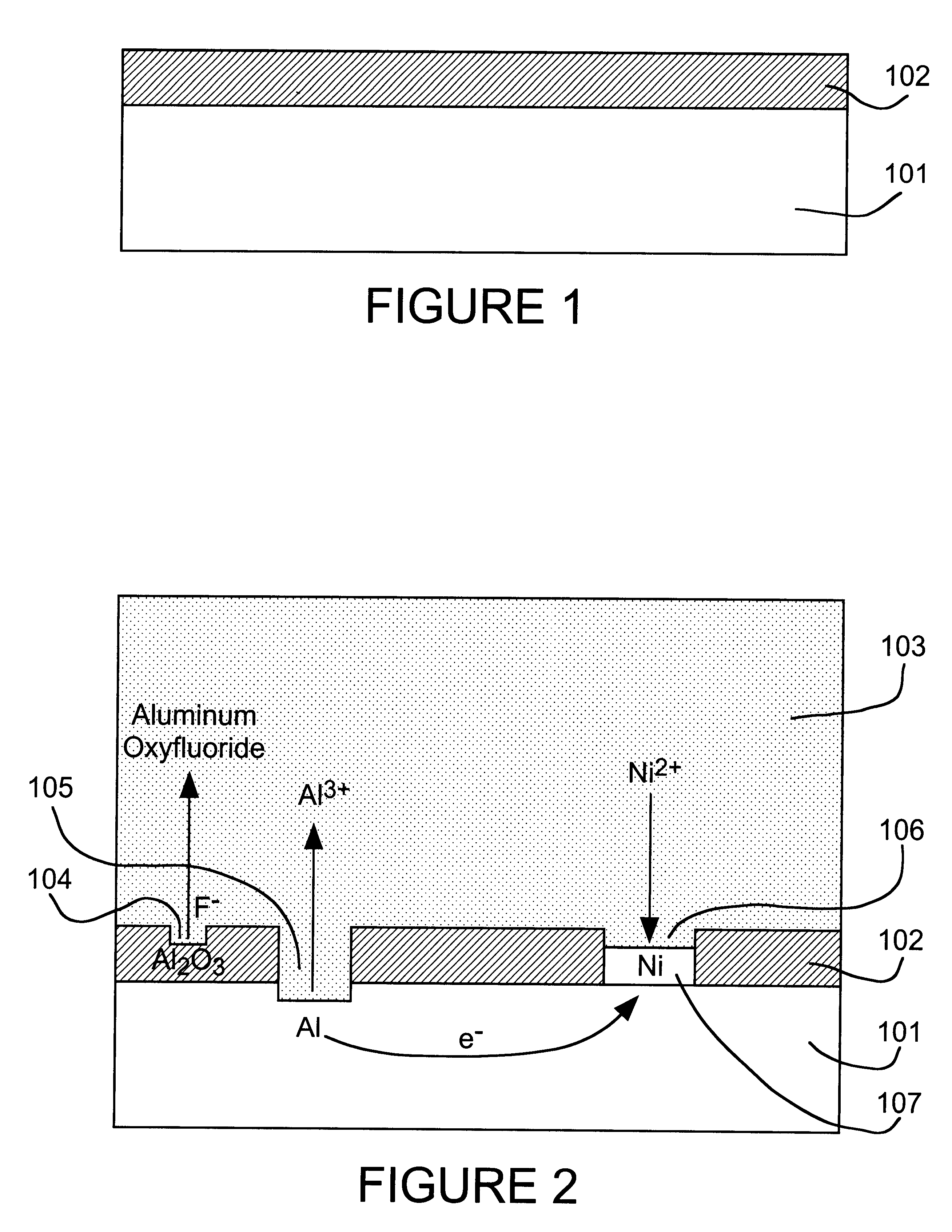

Controlled plating on reactive metals

InactiveUS6503343B1Avoid consumptionInhibited porositySolid-state devicesSemiconductor/solid-state device manufacturingElectroless nickelSolubility

A direct displacement plating process provides a uniform, adherent coating of a relatively stable metal (e.g., nickel) on a highly reactive metal (e.g., aluminum) that is normally covered with a recalcitrant oxide layer. The displacement reaction proceeds, preferably in a nonaqueous solvent, as the oxide layer is dissolved by a fluoride activator. Halide anions are used to provide high solubility, to serve as an anhydrous source of stable metal ions, and to control the rate of the displacement reaction. A low concentration of activator species and little or no solution agitation are used to cause depletion of the activator species within pores in the surface oxide so that attack of the reactive metal substrate is minimized. Used in conjunction with electroless nickel deposition to thicken the displacement coating, this process can be used to render aluminum pads on IC chips solderable without the need for expensive masks and vacuum deposition operations. Such coatings can also be used to preserve or restore wire bondability, or for corrosion protection of aluminum and other reactive structural metals and alloys. A thin layer of immersion gold can be used to protect the thickened coating from oxidation. The solderable aluminum IC chip pads provide the basis for a maskless bumping process for flip chip attachment.

Owner:CALLAHAN CELLULAR L L C

Activation plate for electroless and immersion plating of integrated circuits

InactiveUS20050003677A1Printed circuit aspectsSurface reaction electrolytic coatingElectroless nickelBiological activation

The invention provides a method of plating an integrated circuit. An activation plate is positioned adjacent to at least one integrated circuit. The integrated circuit includes a plurality of bond pads comprising a bond-pad metal, and the activation plate also comprises the bond-pad metal. A layer of electroless nickel is plated on the bond pads and the activation plate, and a layer of gold is plated over the layer of electroless nickel on the bond pads and the activation plate. An integrated circuit with bond pads plated using the activation plate, and a system for plating an integrated circuit is also disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

Method for performing electroless nickel plating on surface of aluminum nitride ceramic

ActiveCN101962760AHigh bonding strengthImprove high temperature resistanceLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention provides a method for performing electroless nickel plating on the surface of aluminum nitride ceramic, belonging to the ceramic thin-film metallization field. The method comprises the following specific steps: 1) polishing the surface of aluminum nitride with a machinery; coarsening the aluminum nitride substrate with mixed acid or alkali, completely cleaning away the residual acid or alkali; 3) sensitizing the coarsened substrate in stannous chloride solution, activating in palladium chloride solution or performing activation without palladium; 4) weighting a certain amount of nickel sulphate, sodium hypophosphite, sodium citrate, sodium acetate, lactic acid, thiourea and sodium dodecyl sulfate in sequence to prepare a chemical plating solution; and 5) adjusting the pH value of the solution to 4.0-6.0 with acid or alkali, heating the solution to 70-95 DEG C, and placing the prepared substrate in the solution to perform electroless nickel plating. The invention is characterized in that the electroless nickel plating can be performed on the surface of the aluminum nitride ceramic substrate which is difficult to plate; and a certain amount of surfactant is added so that the plating becomes denser and smoother, the binding force between the plating and the substrate is increased, and the solderability of the plating is better.

Owner:UNIV OF SCI & TECH BEIJING

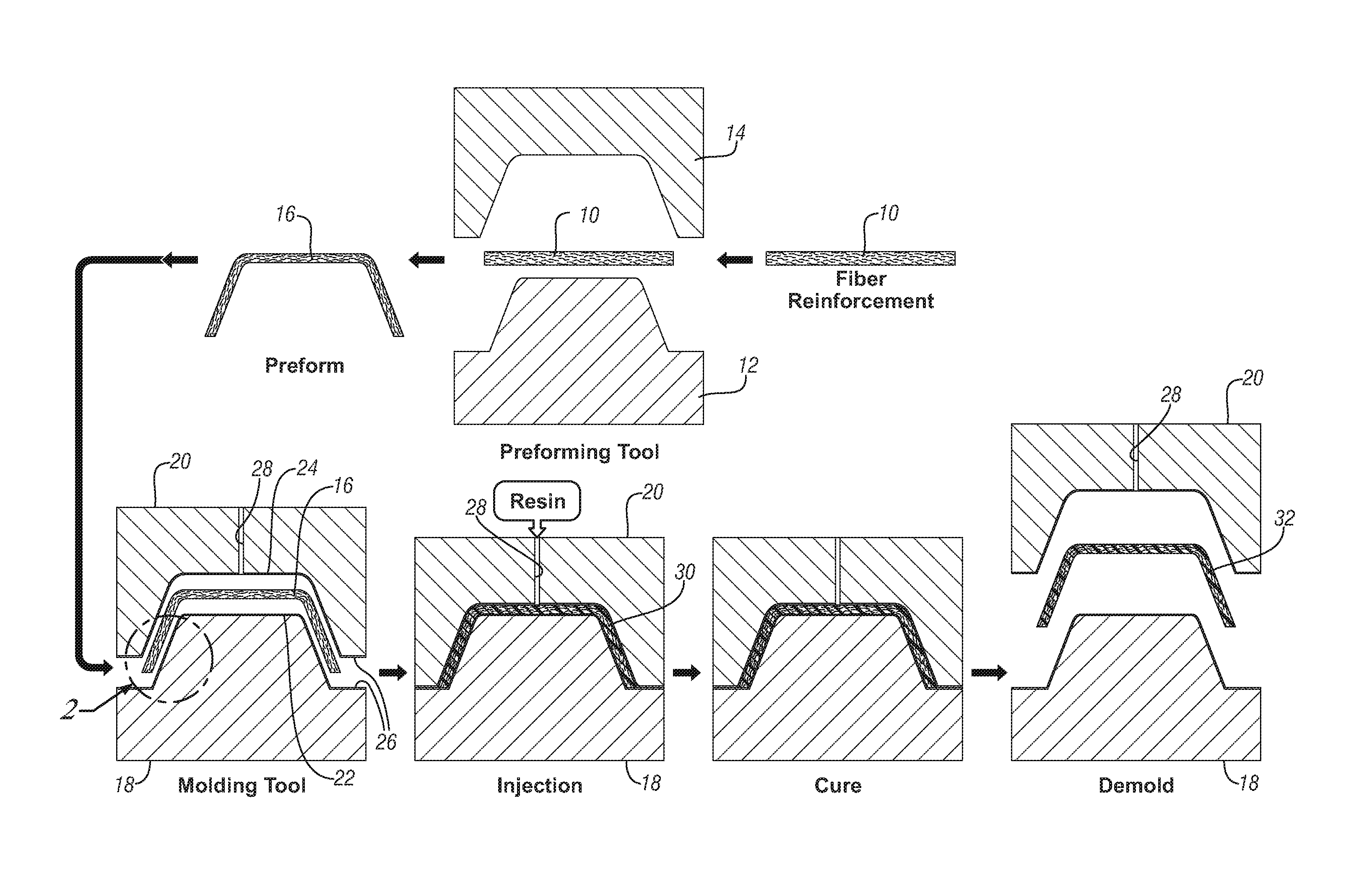

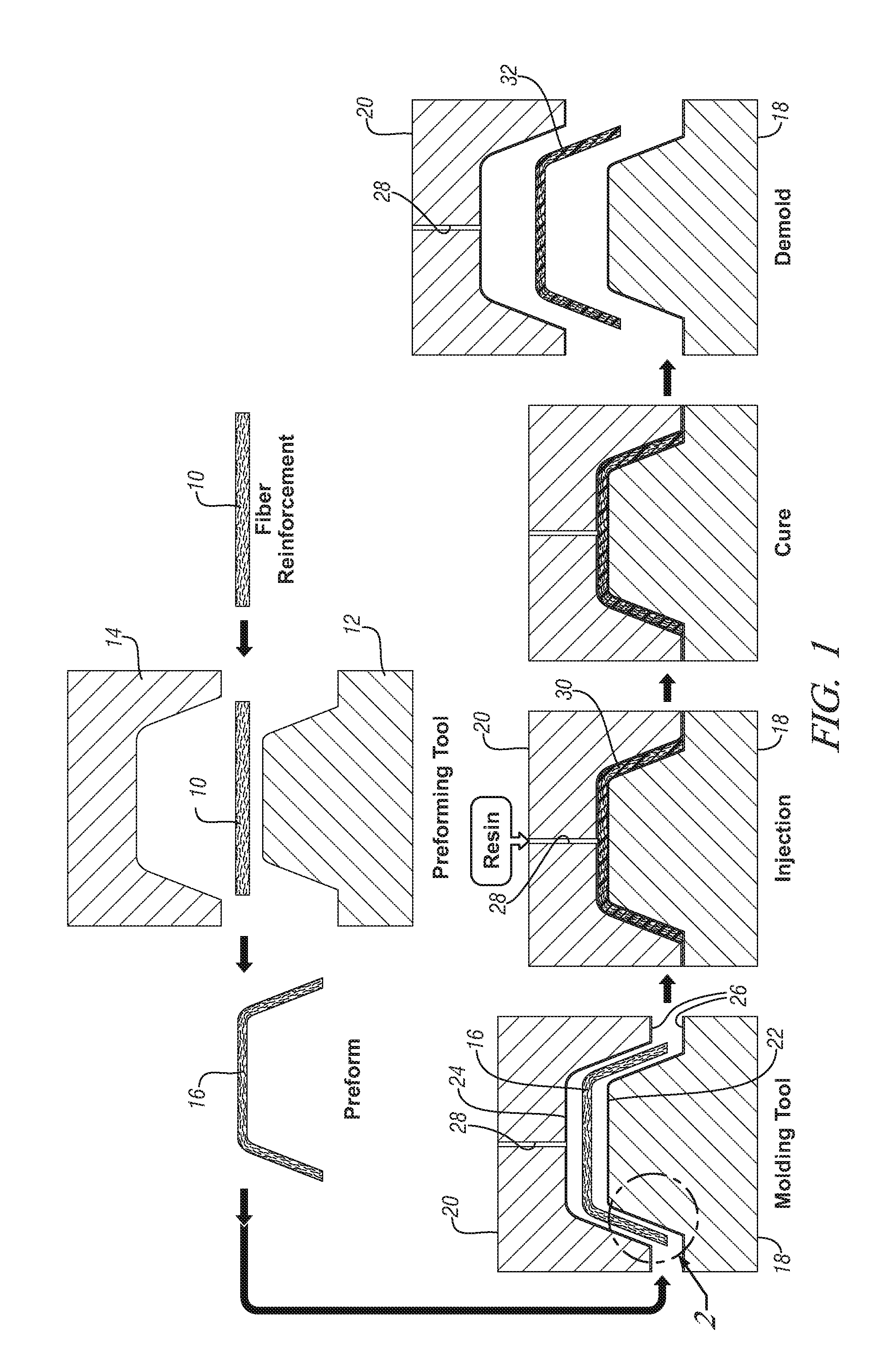

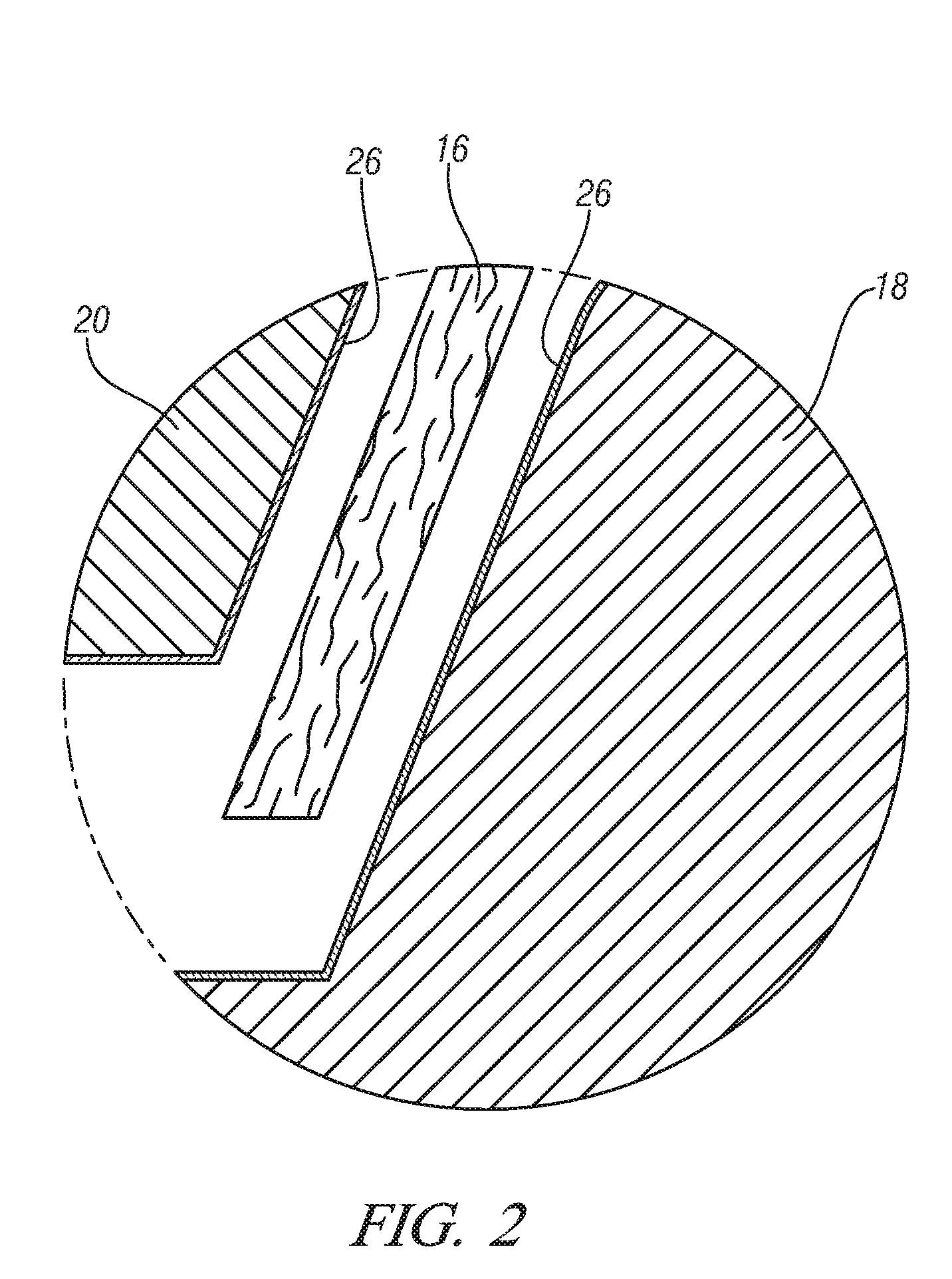

Durable tool for molding of polymer composites

ActiveUS20080241296A1High dimensional accuracyMore durableConfectioneryLaminationCarbon compositesFiber

Mold tooling formed of suitable iron-nickel alloys and provided with a hard electroless nickel coating on the mold cavity surface are useful for high volume production of carbon fiber reinforced, polymer matrix, composites. The iron and nickel alloy provides thermal expansion properties for the molding of dimensionally accurate parts. The nickel alloy coating provides a durable surface, without adversely affecting the expansion properties of the mold, and remains adherent to the base metal during the repeated thermal cycling encountered in high volume production of substantially identical molded carbon composite parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

Corrosion-resistant bond pad and integrated device

InactiveUS20050001316A1Semiconductor/solid-state device detailsSolid-state devicesElectroless nickelSemiconductor

The invention provides an integrated device with corrosion-resistant capped bond pads. The capped bond pads include at least one aluminum bond pad on a semiconductor substrate. A layer of electroless nickel is disposed on the aluminum bond pad. A layer of electroless palladium is disposed on the electroless nickel, and a layer of immersion gold is disposed on the electroless palladium. A capped bond pad and a method of forming the capped bond pads are also disclosed.

Owner:FREESCALE SEMICON INC

Electroless nickel-phosphorus plating process for Nd-Fe-Bo permanent magnet material

InactiveCN1807682AAvoid bulgingPrevent peelingLiquid/solution decomposition chemical coatingCleaning using liquidsElectroless nickelPhosphor

The invention discloses a chemical plating nickel plating method of neodymium-iron- boron permanent magnet material, which is characterized by the following: adopting plugging chemical plating to plug neodymium-iron-boron and thick and block-up neutral chemical plating; carrying on chemical plating nickel phosphor method of acidic high-phosphorus chemical plating, wherein the method comprises the following steps: tumbling; chamfering; degreasing; derusting; activating; plugging chemical plating; neutering chemical plating; acidifying high-phosphorus chemical plating; inactivating. The invention simplifies the application of industry, which reduces cost of production.

Owner:鲁国强

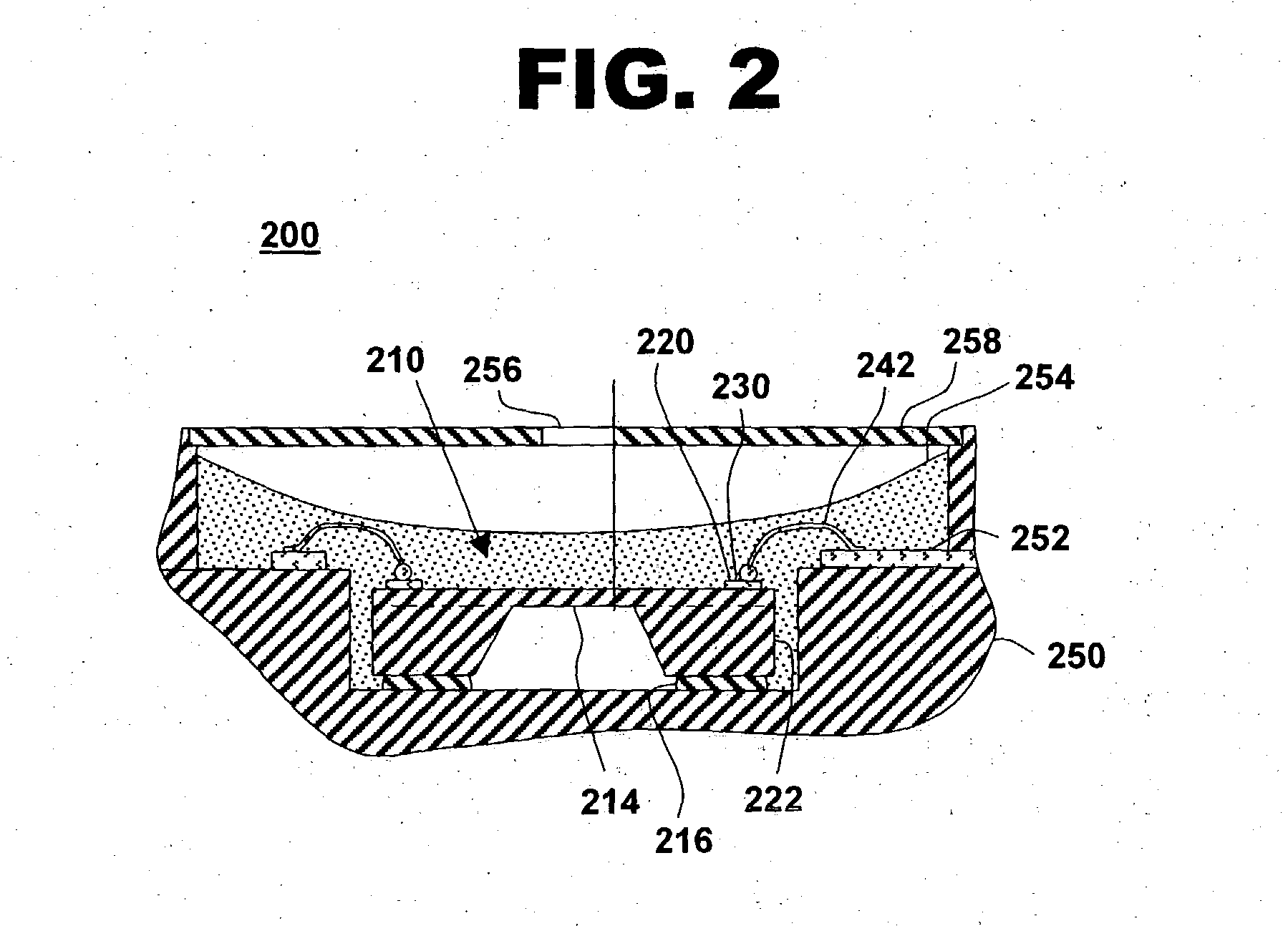

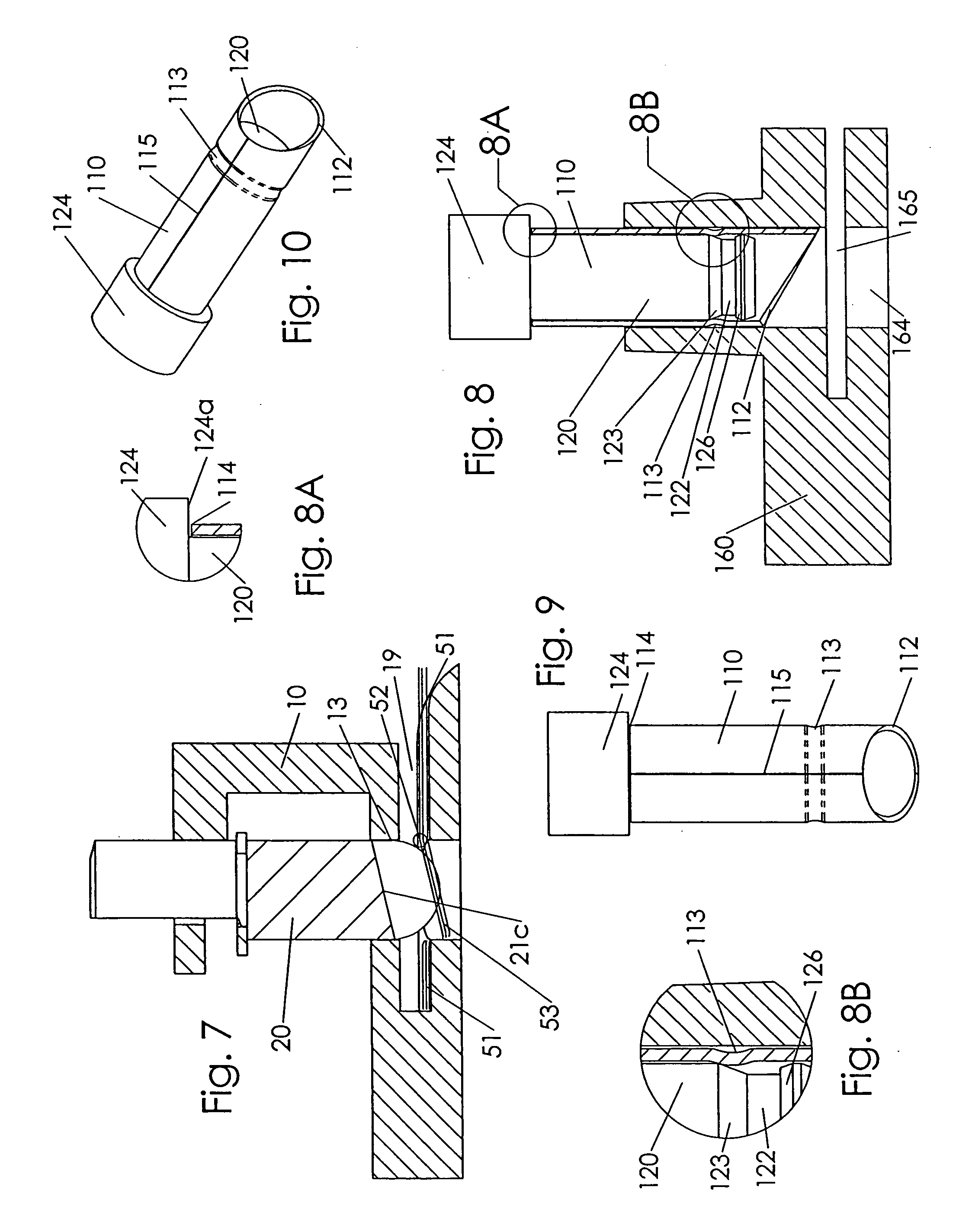

Optical component package with a hermetic seal

InactiveUS6020628ASemiconductor/solid-state device detailsSolid-state devicesElectroless nickelHermetic seal

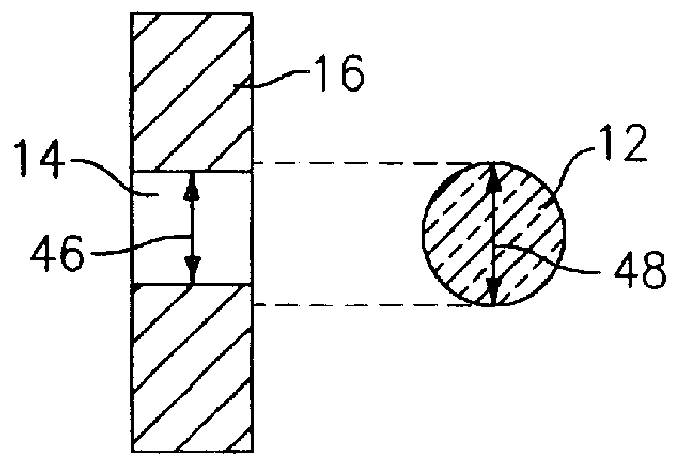

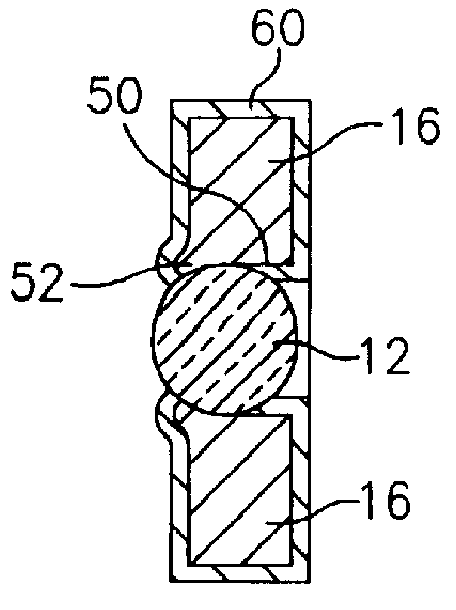

To hermetically seal an optically transparent ceramic or glass member to a metallic housing, an aperture with a diameter less than the diameter of the member is formed through the metallic housing. The member is then press-fit into the aperture, partially displacing metal from the walls of the aperture, forming an inner burr circumscribing the aperture. The walls of the aperture and the circumscribing burr are then coated with a second metal, preferably electroless nickel. The resultant seal maintains hermeticity following thermal cycling and is particularly suited for the manufacture of a hybrid electronic package having an optical or opto-electronic coupling.

Owner:OLIN AEGIS +1

Electroless Plated Fluid Flow Conditioner and Pipe Assembly

InactiveUS20120247223A1Avoid material accumulationImprove accuracyPretreated surfacesCorrosion preventionElectroless nickelHardness

A method and system for electroless nickel plating of fluid flow measurement components used in oil and gas pipelines provides uniformly and consistently plating of all surfaces of the fluid flow components, including flow conditioners, with an electroless nickel plating that imparts the component with desirable characteristics related to hardness, smoothness, wear and abrasion resistance, and corrosion and oxidation resistance, such that the build up of contaminant deposits on the component is reduced and repeatable and accurately fluid flow measurements can be made.

Owner:CANADA PIPELINE ACCESSORIES

Sheave for Use in an Elevator System

An elevator system (20) includes idler sheaves (32, 34, 36). A coating on a load bearing member contacting surface (40) of an idler sheave reduces friction between a load bearing member (26) and the contacting surface (40). A disclosed example includes an at least partially metallic coating comprising a fluoropolymer. One disclosed example includes an electroless nickel-polytetrafluoroethylene coating.

Owner:OTIS ELEVATOR CO

Treatment process for chemical nickel plating waste liquid in circuit board industry

InactiveCN104176852ASolve in-plant processing issuesReduce the risk of excessive emissionsSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentElectroless nickelSodium hydroxide

The invention provides a treatment process for a chemical nickel plating waste liquid in the circuit board industry. The treatment process comprises the following steps: pumping the chemical nickel plating waste liquid in the circuit board industry into a reaction tank; sequentially adding sulfuric acid for acidifying; adding ferrous sulfate and hydrogen peroxide for Fenton oxidation complexation; adjusting the pH by sodium hydroxide; adding sodium sulfide for a coagu-flocculation reaction; finally, adding PAM until suspended solids are just flocculently separated; after acidification, advanced oxidation complexation, and flocculation, filter-pressing all the waste liquid by a plate-frame; collecting the filtrate and regulating the pH; and sequentially carrying out sand filtering and resin adsorption and discharging after reaching standard level. The treatment process provided by the invention can be used for effectively treating the chemical nickel plating waste liquid in the circuit board industry, so that the treatment cost and the standard-reaching difficulty of the waste liquid in an enterprise are reduced.

Owner:江西红板科技股份有限公司

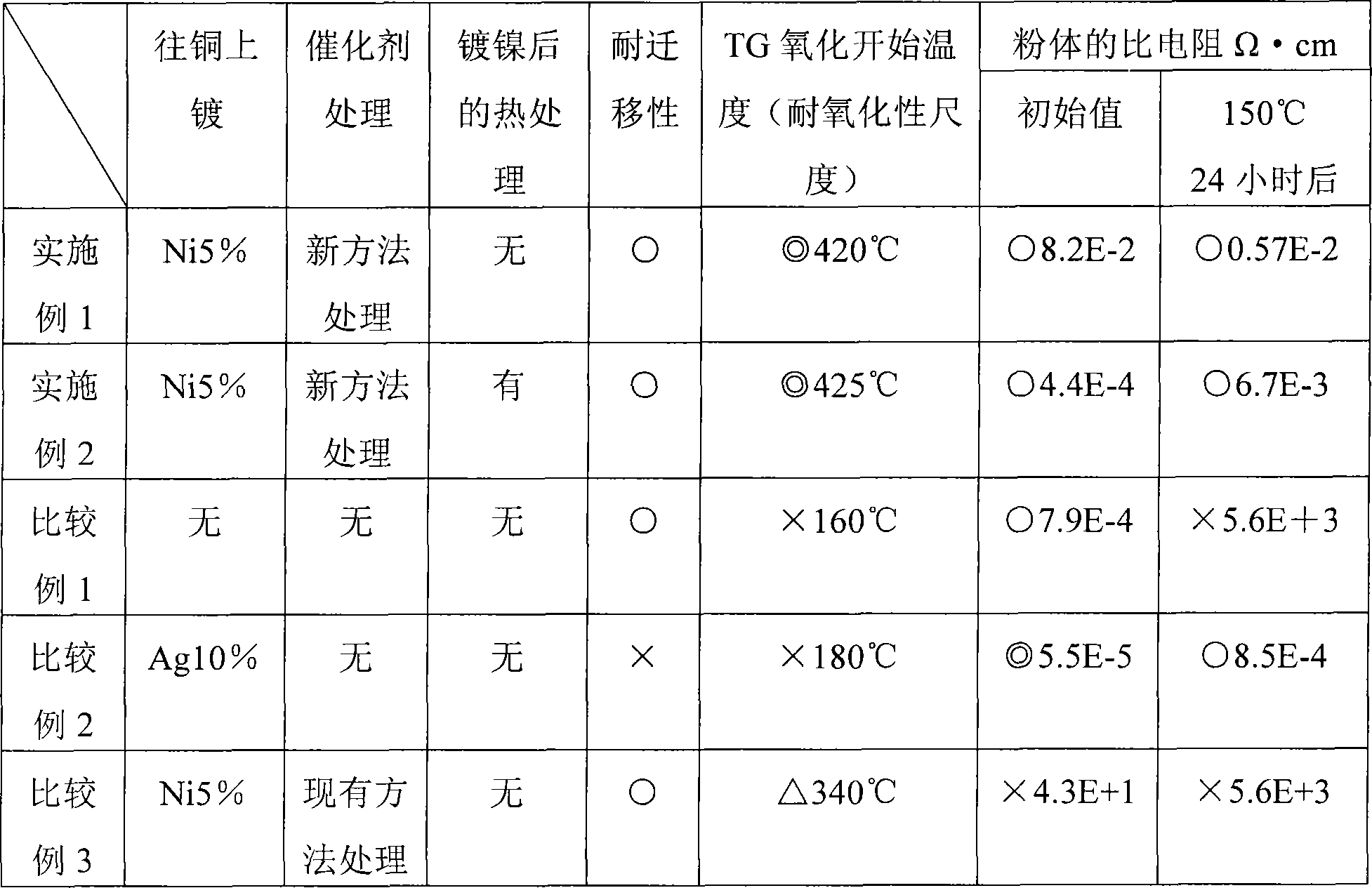

Nickel coated copper powder and process for producing the same

InactiveCN1988973AImprove adhesionImprove uniformityNon-insulated conductorsConductive materialConductive pasteElectroless nickel

An antioxidant nickel coated copper powder for conductive paste capable of forming conductive wiring parts for electronic circuits; and a process for producing the same. In particular, use is made of a nickel coated copper powder characterized by comprising a nickel coated copper powder produced by providing a copper powder as a core material, fixing a plating catalyst on the surface of copper powder through reduction reaction and applying electroless nickel plating to the outermost surface thereof. The reduction reaction is characterized in that hydrazine is used as a reducing agent.

Owner:MITSUI MINING & SMELTING CO LTD

Method for Treating Metal Surfaces

InactiveUS20120061698A1Reduce corrosionPrevent surfaceSoldering apparatusSemiconductor/solid-state device manufacturingElectroless nickelSilver plate

A method for treating a metal surface to reduce corrosion thereon and / or to increase the reflectance of the treated surface, the method comprising a) plating a metal surface with an electroless nickel plating solution; and thereafter b) immersion plating silver on the electroless nickel plated surface, whereby corrosion of the metal surface is substantially prevented and / or the reflectance of the silver plated surface is substantially improved. The treating method is useful for increasing the solderability of the metal surface, for example, in electronic packaging applications and in manufacturing light emitting diodes (LEDs).

Owner:MACDERMID ACUMEN INC

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveCN1956632AReduce thicknessImprove solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

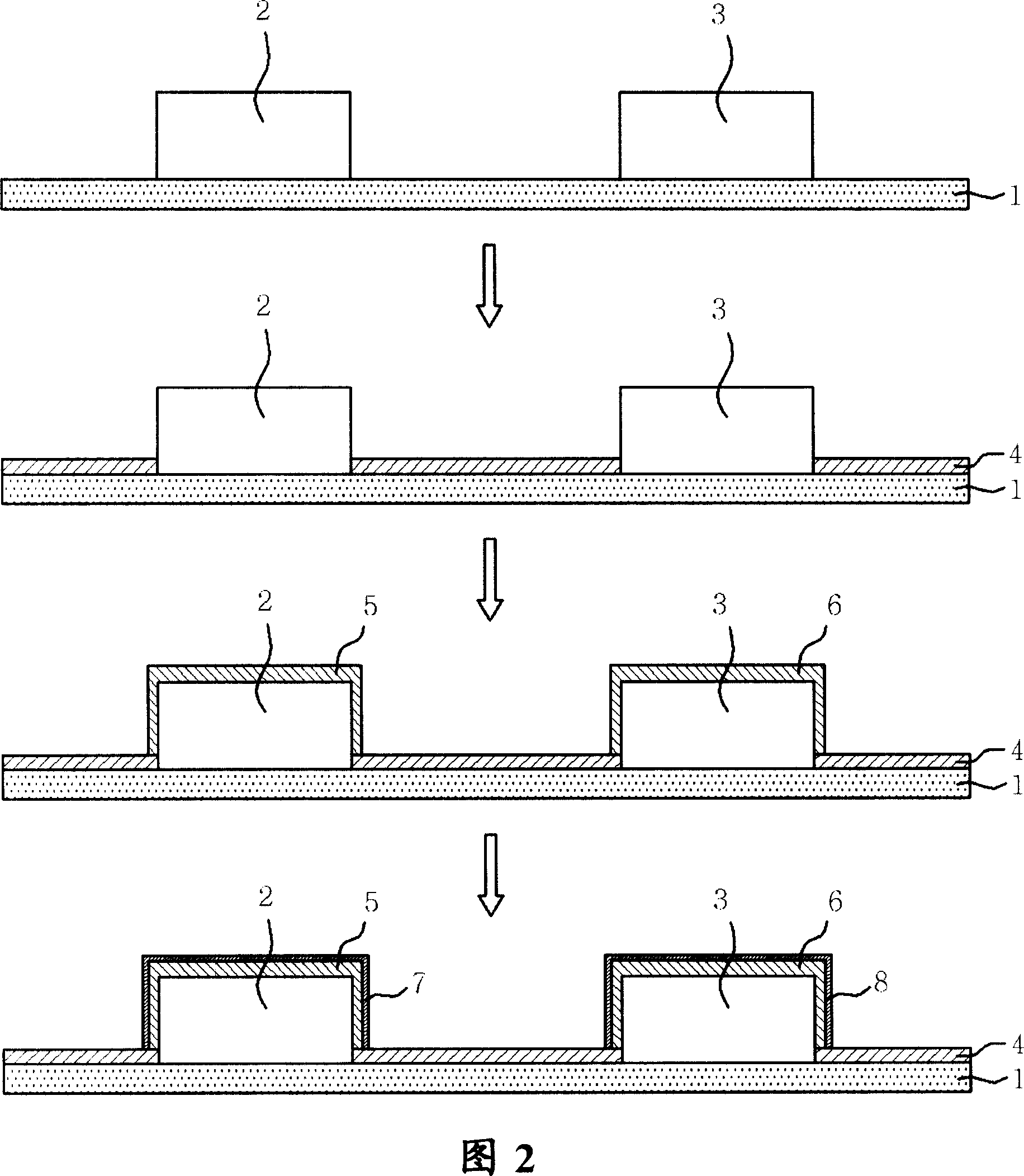

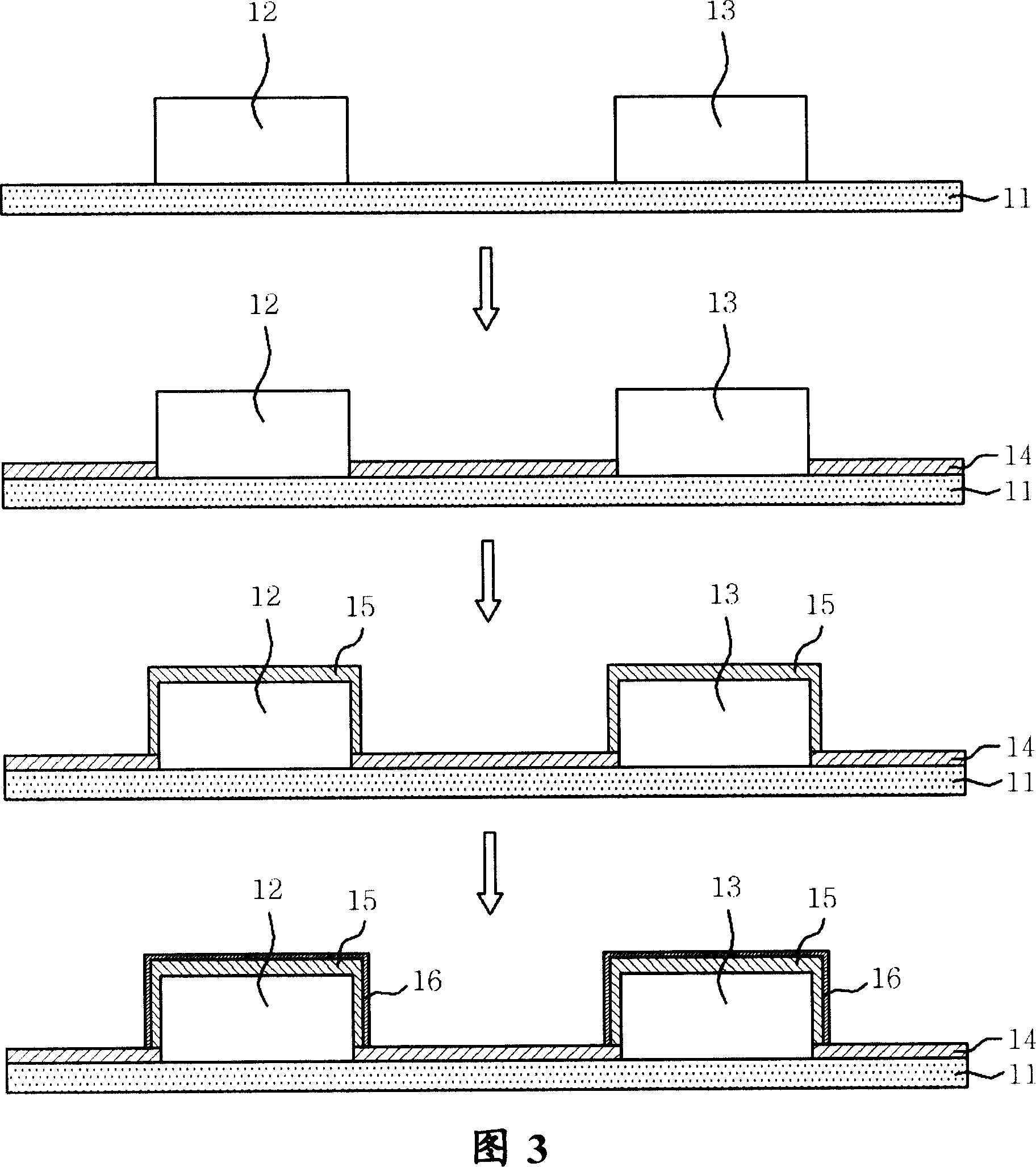

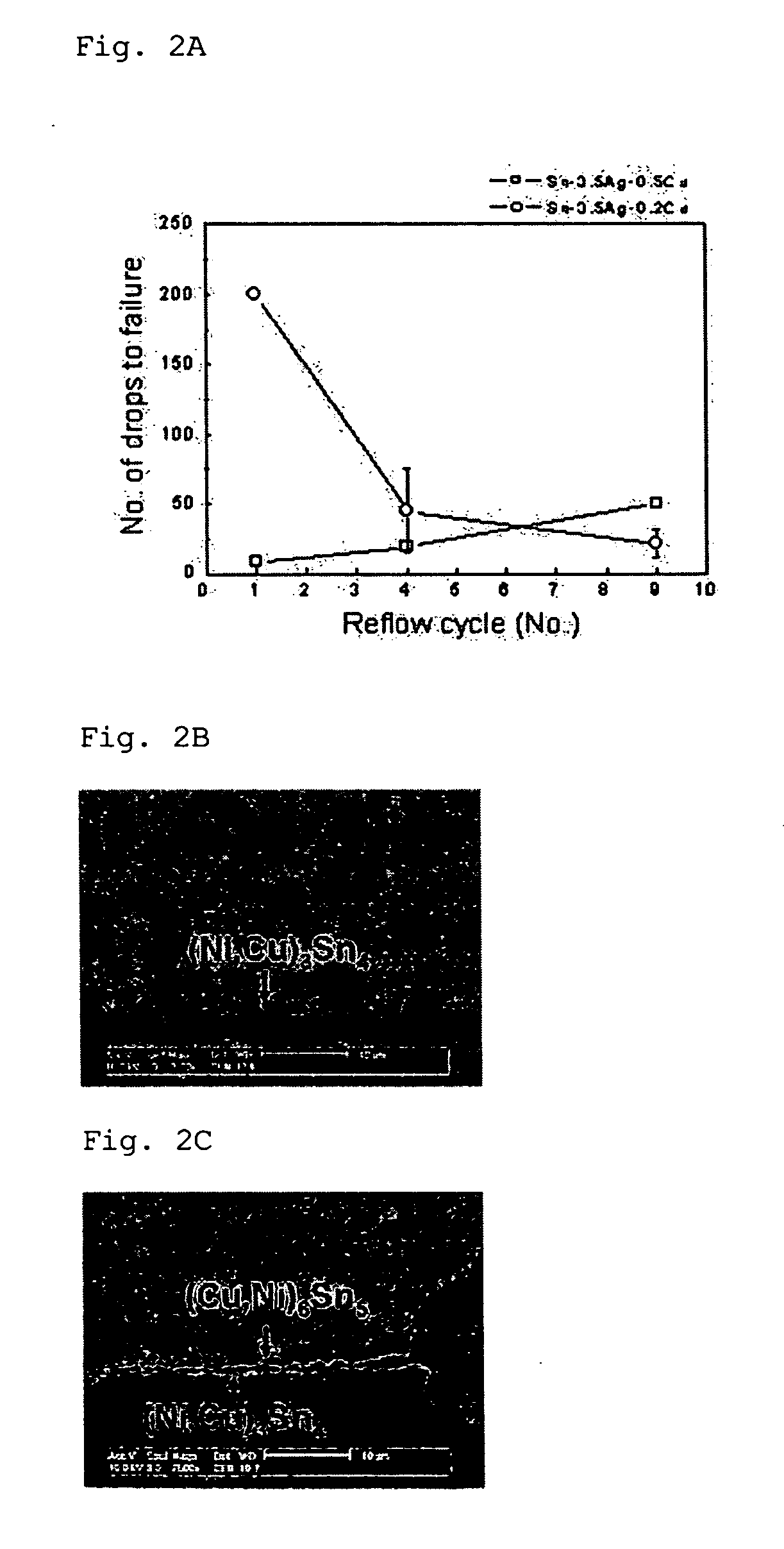

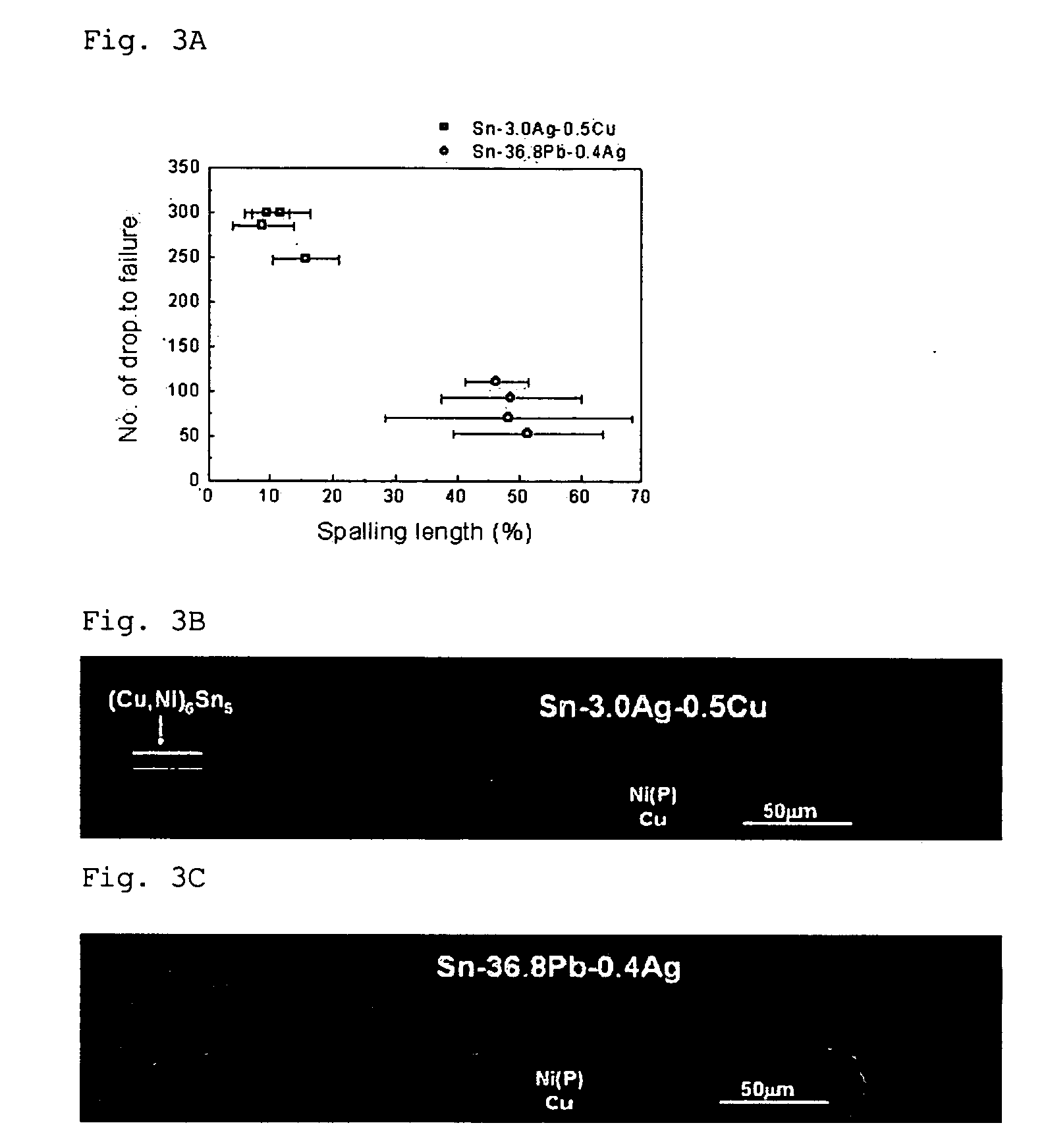

Method for joining electronic parts finished with nickel and electronic parts finished with electroless nickel

InactiveUS20070158391A1Preventing brittle fractureBrittle fractureCooking-vessel materialsSolid-state devicesElectroless nickelBrittle fracture

The present invention relates, generally, to methods for joining an electronic part finished with nickel and an electronic part finished with electroless nickel, which can prevent a brittle fracture, more particularly, to a method for joining an electronic part finished with nickel and an electronic part finished with electroless nickel with a solder by controlling the composition of the solder to prevent a brittle fracture occurring at the solder joining portion.A method for joining an electronic part finished with nickel and an electronic part finished with electroless nickel, comprising: (1) reflowing solder to a nickel portion of an electronic part finished with nickel to obtain an electronic part where an intermetallic compound and a solder are formed; (2) obtaining an electronic part finished with an eletroless nickel, of which the nickel portion is connected with the solder; and (3) solder-joining an electronic part finished with nickel obtained in the step (1) and the electronic part finished with electroless nickel obtained in the step (2).

Owner:KOREA ADVANCED INST OF SCI & TECH

A Process for Electroless Nickel-Phosphorus Alloy Plating on the Surface of Aluminum-Silicon Carbide Composite Material

ActiveCN102277564ANo pollution in the processPollution realizedLiquid/solution decomposition chemical coatingElectroless nickelNickel salt

The invention discloses a process for chemical nickel-phosphorus alloy plating on the surface of an aluminum and silicon carbide composite material, which comprises the following steps: pretreating the surface of a workpiece, removing oil, roughening, activating, plating and performing heat treatment, wherein chemical plating solution consists of a nickel salt, a reducer, a complexing agent, a stabilizer, a brightener and deionized water. The process disclosed by the invention is simple, convenient for operation, low in cost, high in efficiency, widely applicable, environment-friendly and capable of realizing industrial production; and the obtaining plating is bright, flat, uniform and compact.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

Middle-temperature acidic electroless nickel plating-phosphor alloy formula

InactiveCN101348905AImprove stabilityImprove performanceLiquid/solution decomposition chemical coatingSodium acetateElectroless nickel

The invention provides a formulation of medium-temperature acidic electroless nickel-phosphorus alloy, which is characterized in that the formulation is as follows: 25 to 30 grams of nickel sulfate per liter, 25 to 35 grams of sodium hypophosphite per liter, 12 to 18 grams of sodium acetate per liter, 0.5-1.3 milligrams of thiourea per liter, 7 to 13 milliliters of lactic acid per liter, 7 to 13 milliliters of acetic acid per liter, 4-10 grams of organic acid per liter, 5-16 milligrams of potassium iodide or potassium iodate per liter, and the loadage is between 0.5 and 1.5 dm<2> / L. The invention has the advantages that: the formulation improves the stability of a plating solution, obviously improves plating rate, has good corrosion resistance and the comprehensive properties of plating; the stability of the plating solution can reach over 1800 s; the stability of periodic experiments is more than ten periods; the corrosion resistance of the plating reaches over 130 s; and the hardness of the plating reaches 480 HV.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for chemical plating nickel-phosphorus alloy on surface of magnesium alloy

InactiveCN101275221AReduce pollutionHarm reductionLiquid/solution decomposition chemical coatingElectroless nickelChemical plating

The invention relates to a method of electroless Ni-P alloy on surface of magnesium alloy, comprising following steps: (1) degreasing: the magnesium alloy is degreased in non-phosphate alkaline degreasing solution with a temperature of 55 deg C to 65 deg C; (2) acid cleaning: a mixture of organic acid and anionic surfactant is used as magnesium alloy acid cleaning solution instead of traditional chromic acid solution to remove oxide film of the surface of the magnesium alloy; (3) surface conditioning: the acid cleaned magnesium alloy is processed surface conditioning in alkaline surface conditioning solution with a temperature of 80 deg C to 100 deg C; (4) activating: the surface conditioned magnesium alloy is processed activation in HF solution; (5) acid dipping zinc; (6) nickel plating: in a condition that the temperature is 80 deg C to 90 deg C and ph value is in the range of 5 to 6, a brightener is added into electroless nickel solution to process nickel plating reaction Ni-P alloy coating. The invention has following beneficial effects: (1) reducing pollution for environment and damage for bodies of operators, and at the same time, easily controlling the operation and uneasily losing control for process parameters; (2) improving appearance of the Ni-P alloy coating, and being provided with better decorative.

Owner:周学华

Electroless nickel plating solution composition, flexible printed circuit board and manufacturing method thereof

InactiveCN101760731ALiquid/solution decomposition chemical coatingPrinted circuit manufactureElectroless nickelNickel compounds

The present invention relates to an electroless nickel plating solution composition, a flexible printed circuit board and a manufacturing method thereof, and more particularly, to an electroless nickel plating solution composition, a flexible printed circuit board and a manufacturing method thereof capable of simultaneously satisfying plating characteristics respectively required for a pad unit and external connection units of the flexible printed circuit board by forming a nickel plating layer having a vertical growth structure with the electroless nickel plating solution composition including a water-soluble nickel compound, a reducing agent, a complexing agent and a vertical growth inducer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

Pretreatment solution used for electroless nickel-phosphorus alloy plating layer on surface of aluminum alloy

InactiveCN101619448ASimplify operating proceduresGood metallic lusterLiquid/solution decomposition chemical coatingElectroless nickelSodium hydroxide

The invention discloses a pretreatment solution used for an electroless nickel-phosphorus alloy plating layer on the surface of an aluminum alloy, which comprises the following components: 5-40g / L of sodium molybdate, 5-30g / L of sodium hydroxide or 10-40ml / L of ammonia and the balance of deionized water. The pretreatment solution has the following advantages that: the pretreatment solution simplifies the operation steps of nickel-phosphorus deposition to 9 steps from 15 steps, thereby being easy to realize industrialization and improving production efficiency; the pretreatment solution only consists of two substances, thereby reducing cost and improving economic benefits; the pretreatment solution does not need to adopt nitric acid for carrying out zinc withdrawal treatment, thereby avoiding the pollution and the toxication to chemical nickel plating solution, prolonging the service life of the plating solution, avoiding environmental pollution and reducing influences on the health of operation staffs; and the prepared nickel-phosphorus electroless plating layer has uniform densification, good corrosion resistance, high microhardness, firm combination with an aluminum alloy base body, good metal luster and good appearance, thereby providing a good protection effect for the aluminium alloy.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

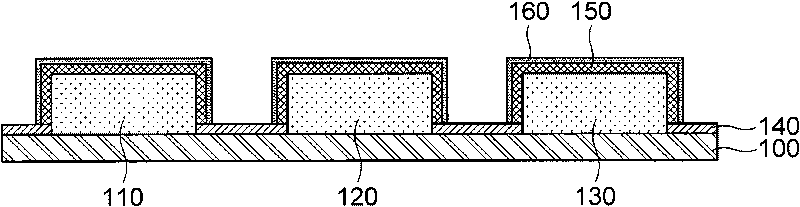

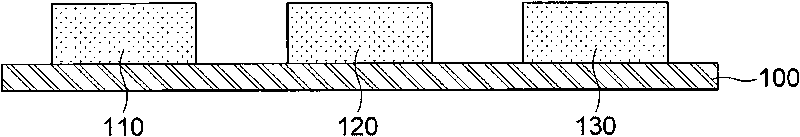

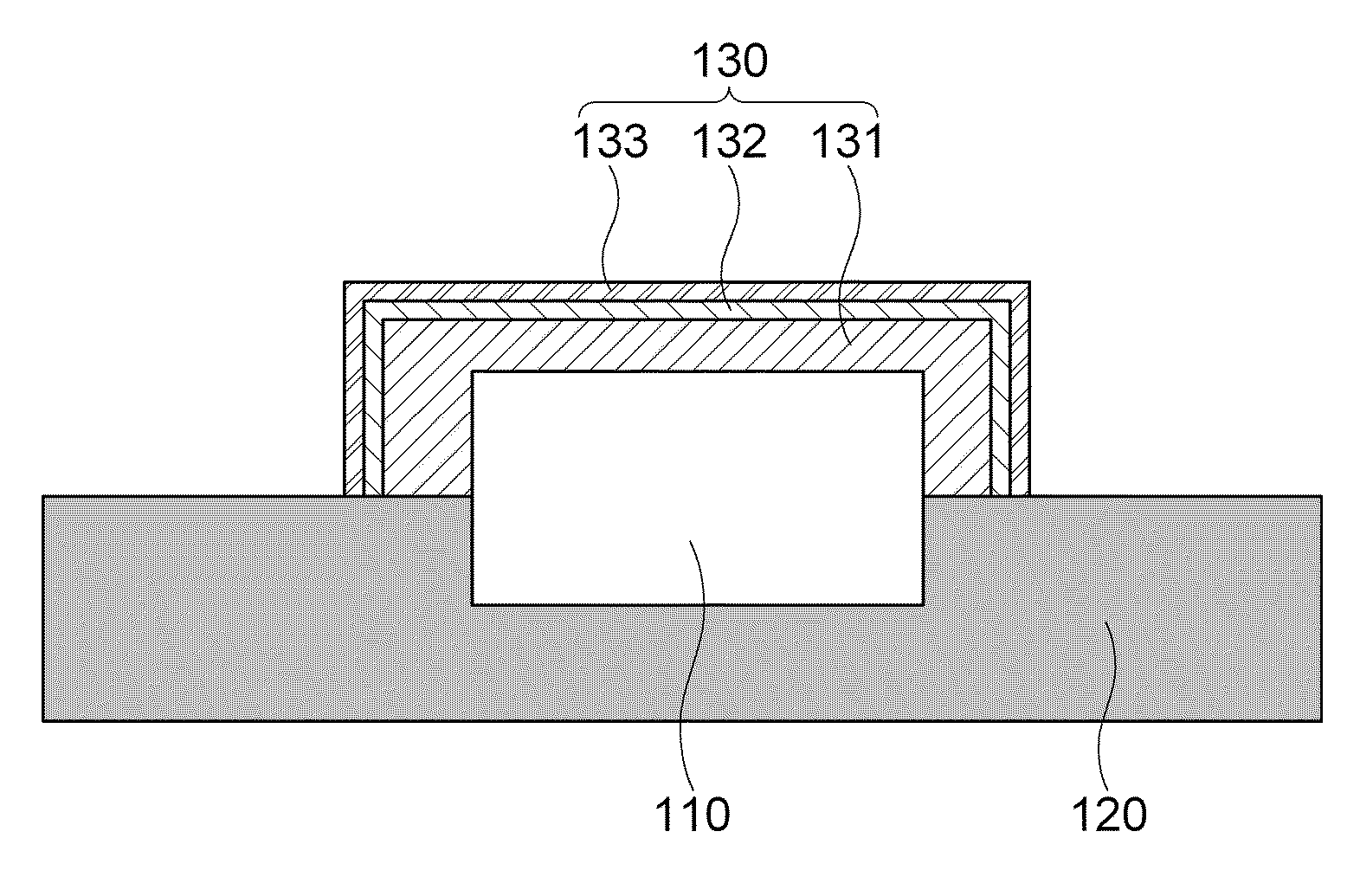

Electroless surface treatment plated layers of printed circuit board and method for preparing the same

ActiveUS20130003332A1Non-uniformity problemPrevent oxidationSolid-state devicesElectrical apparatus contructional detailsElectroless nickelPalladium

Disclosed herein are an electroless surface treatment plated layer of a printed circuit board, a method for preparing the same, and printed circuit board including the same. The electroless surface treatment plated layer includes: electroless nickel (Ni) plated coating / palladium (Pd) plated coating / gold (Au) plated coating, wherein each of the electroless nickel, palladium, and gold plated coatings has a thickness of 0.02 to 1 μm, 0.01 to 0.3 μm, and 0.01 to 0.5 μm. In the electroless surface treatment plated layer of the printed circuit board, a thickness of the nickel plated coating is specially minimized to 0.02 to 1 μm, thereby making it possible to form an optimized electroless Ni / Pd / Au surface treatment plated layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Electrolytic method of and compositions for stripping electroless nickel

InactiveUS6332970B1Polycrystalline material growthElectrolysis componentsElectroless nickelElectrolysis

Electrolytic stripping solutions, which incorporate the novel use of oxoacids and / or oxoacid salts, and hydrogen peroxide, have been formulated for the rapid removal of electroless nickel from iron, steel, aluminum, and titanium alloys as well as other selected electrically conductive substrates. The formulations provide improved resistance to etching of the substrate and can be formulated to be free of chelates, chromates, nitrates, or concentrated acid solutions thereby increasing worker safety and reducing the cost of waste disposal of spent stripping solutions.

Owner:COFFEY BARRY W

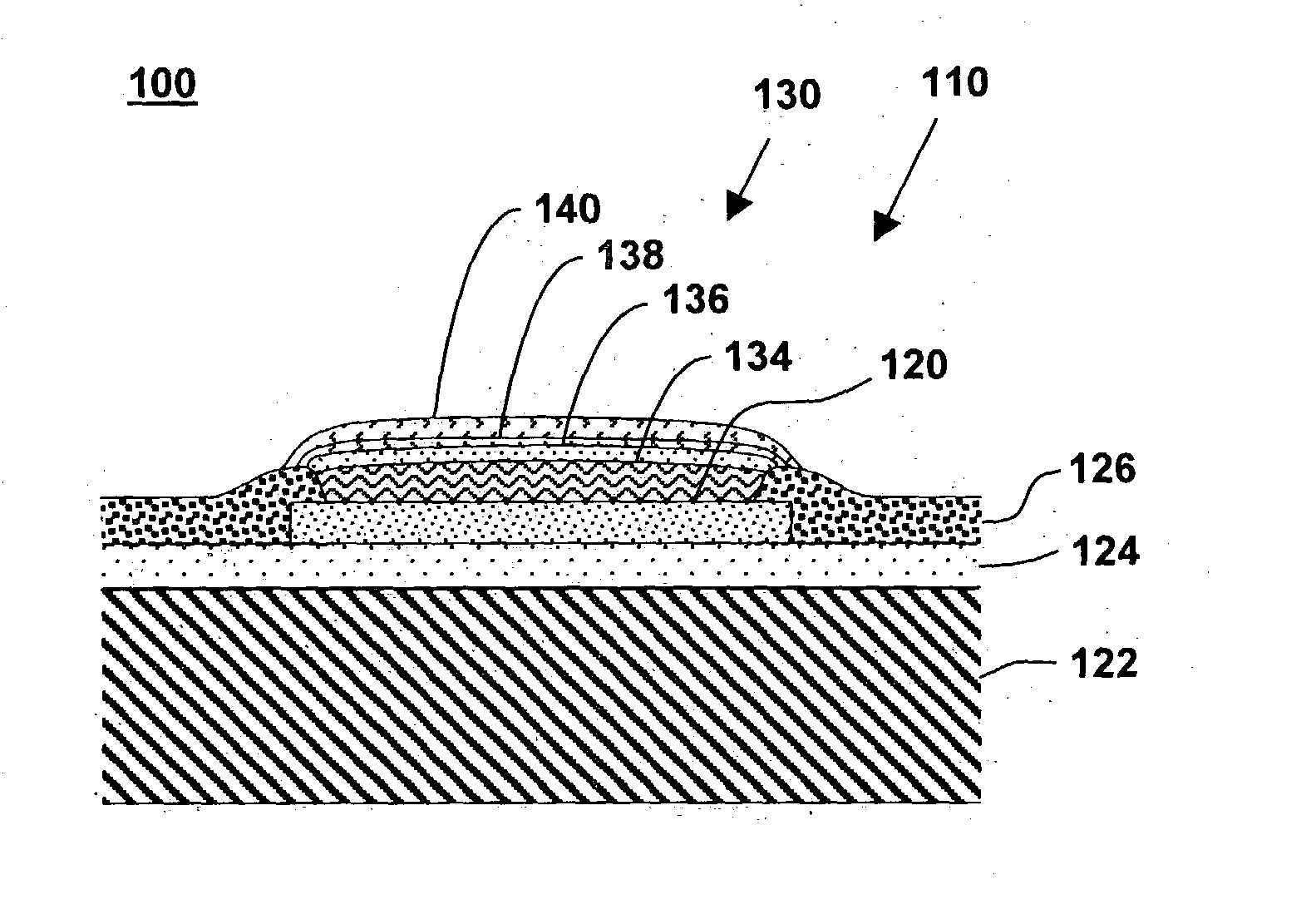

Process for improving the adhesion of polymeric materials to metal surfaces

ActiveUS20080038476A1Improve adhesionLiquid surface applicatorsLiquid/solution decomposition chemical coatingElectroless nickelLead frame

A process is disclosed for the purpose of increasing the adhesion of a polymeric material to a metal surface. The process comprises plating the metal surface with a layer of electroless nickel, electroless cobalt or electroless (or immersion) tin followed by phosphating the plated layer prior to bonding the polymeric material thereto. The process is particularly suited to treating printed circuit board inner-layers and lead frames.

Owner:MACDERMID ACUMEN INC

Low friction hole punch element

InactiveUS20070044623A1Reduce punching effortMinimize return spring forceMetal working apparatusElectroless nickelCutting force

A hole punch device that reduces the force required to create a hole in papers or other sheet media. A punch element of the hole punch device includes a locally sloped or indented floor to create a bend in the sheet media as it is punched to create an enlarged, oval hole. The punch pin may include an expanding sleeve surround the pin that forms a larger diameter during the cutting stroke and springs back to a smaller diameter during a pull out stroke. A coiled torsion return spring is positioned remotely from and non-coaxially with the punch pin. A keyed pin and support frame arrangement ensures a predetermined rotational orientation of the pin for sequential cutting for reduced cutting force. The pin and / or other components optionally include electroless nickel plating to reduce friction and wear at the component or pin sliding and cutting surfaces.

Owner:WORKTOOLS

A kind of chemical nickel plating solution and chemical nickel plating process

InactiveCN102268658AReduce stressImprove toughnessLiquid/solution decomposition chemical coatingElectroless nickelNickel salt

The invention relates to an electroless nickel plating solution and an electroless nickel plating process for a flexible printed circuit board. The electroless nickel plating solution of the present invention comprises the following components: nickel salt, calculated as Ni2+ content, is 4.5-5.5g / L; reducing agent, 15-40g / L; complexing agent, 20-100g / L Stabilizer, 0.01~10mg / L; Accelerator, 0.001~1g / L; Low stress additive, 0.01~10g / L; The low stress additive is sodium naphthalene disulfonate, sodium benzenesulfonate, saccharin, gelatin, One or more of butynediol, acetic acid, coumarin, formaldehyde, and acetaldehyde. In the chemical nickel plating process of the present invention, the temperature of the chemical nickel plating liquid is 75-90 DEG C, the pH value of the chemical nickel plating liquid is 4.5-5.4, and the chemical nickel plating time is 15-30 minutes. The electroless nickel plating solution and the electroless nickel plating process of the present invention can effectively reduce the stress of the nickel layer, improve the toughness of the nickel layer, make the nickel layer have good bending performance, and meet the production and assembly requirements of flexible printed circuit boards , to further improve the yield rate.

Owner:SHENZHEN JINGCHENGDA CIRCUIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com