Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

961 results about "Fenton oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

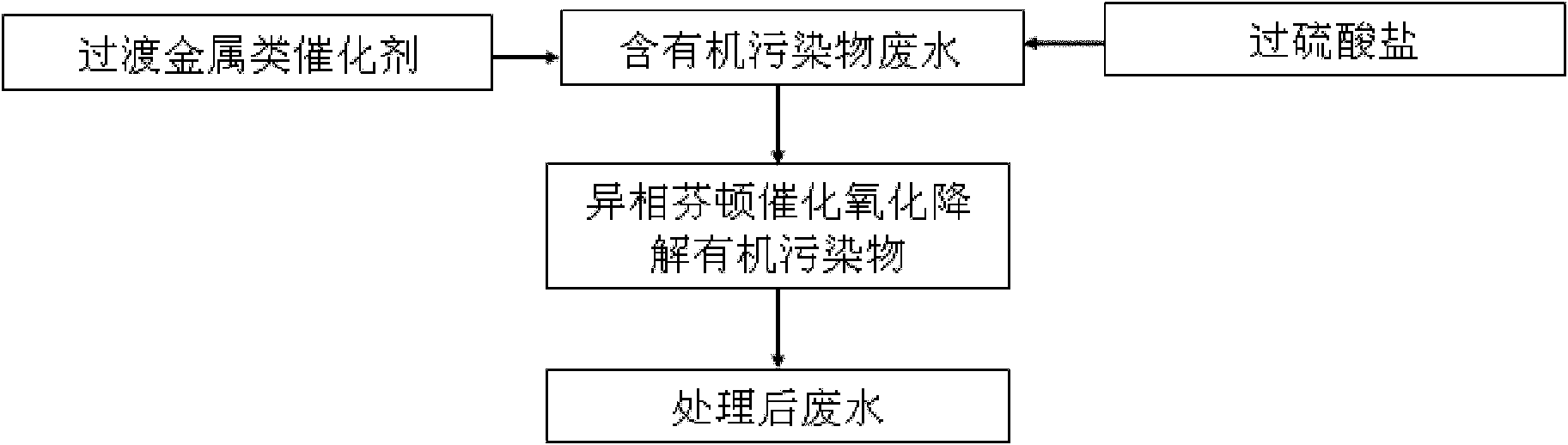

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

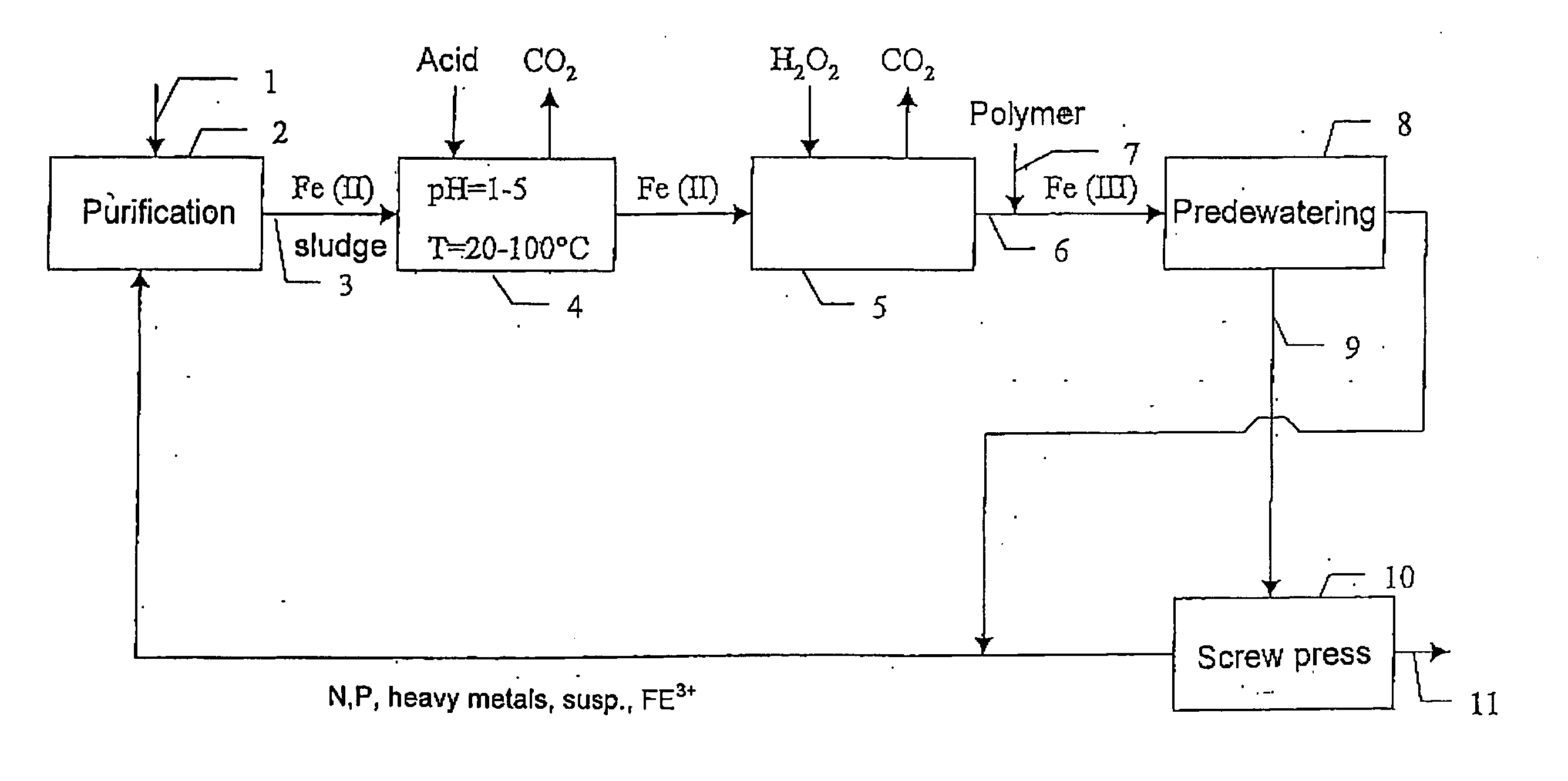

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

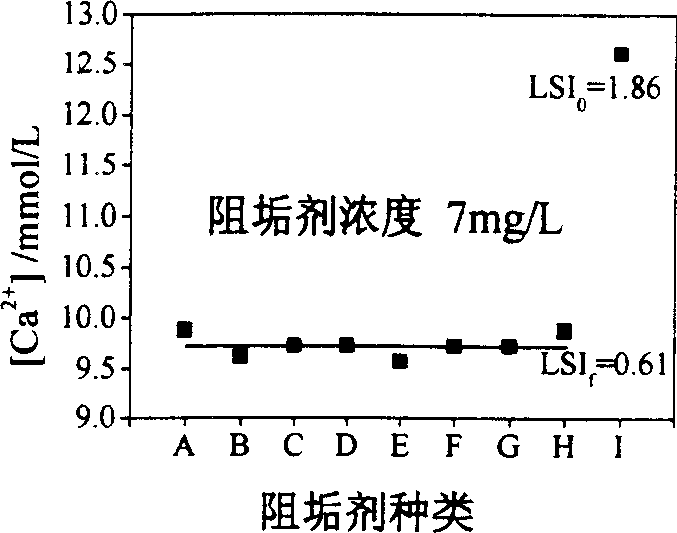

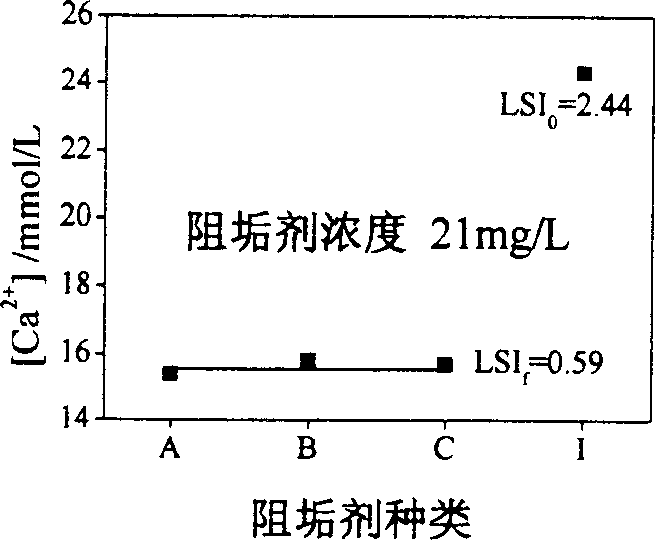

E-Fenton oxidation technique of dirty blocking agent in reverse osmosis concentrating liquid

InactiveCN1541757AHigh salt concentrationImprove conductivityWater/sewage treatment bu osmosis/dialysisReverse osmosisElectrolysisProcess scaling

The electric Fenton oxidation process for processing scale inhibitor in reverse osmosis concentrated liquid adopts anode of iron plate and cathode of porous graphite and ventilated with air pump and processes reverse osmosis concentrated liquid through electrolyzing in stirring, stirring coagulation via adding aluminum sulfate and filtering the coagulated solution. Bivalent iron ion produced intelligent the electric Fenton process is made to react with hydrogen peroxide to produce strong oxidizing free hydroxy radical oxidizing and destructing the scale inhibitor; and the subsequent coagulation separates out scaling salt to lower the scaling trend, so that the concentrated liquid may be utilized as influent water to raise the water recovering rate of reverse osmosis system.

Owner:SHANGHAI JIAO TONG UNIV

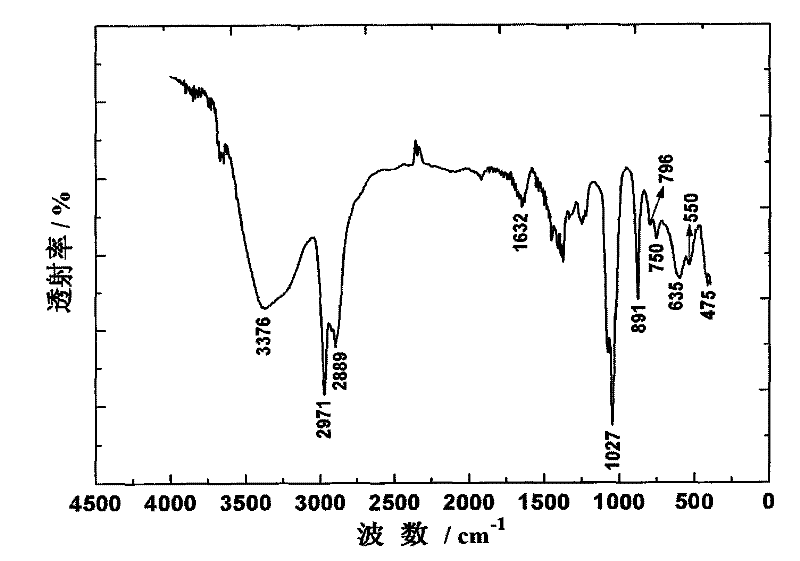

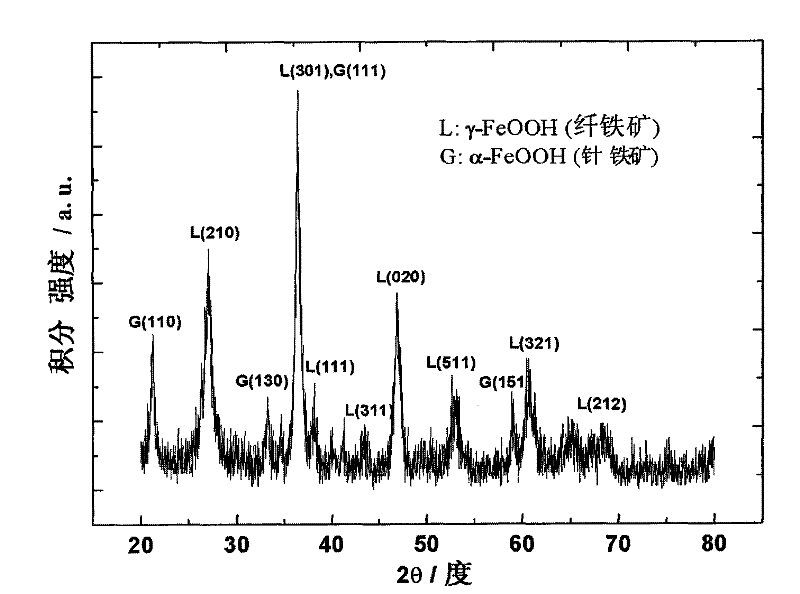

Preparation method of supported FeOOH catalyst, and electro-Fenton waste water treatment system

ActiveCN102218319AEasy to separateNothing producedMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationSludgeWater processing

The invention discloses a preparation method of a supported FeOOH catalyst, and an electro-Fenton waste water treatment system. The invention belongs to the technical field of waste water processing. The invention is characterized in that active carbon is utilized as a carrier and ferrous sulphate is utilized as a precursor; through dipping, ethylene diamine tetraacetic acid and ammoniacal undergo an oxidation reduction reaction with active carbon and ferrous sulphate in the presence of oxygen to produce active carbon supported objects and then the active carbon supported objects are washed by deionized water and then are placed in a vacuum oven to be dried at a temperature of 40 to 50 DEG C for 10 to 12 hours to form a supported FeOOH catalyst; active components of the supported FeOOH catalyst comprise alpha-FeOOH and gamma-FeOOH; and under an applied electric field, an out-phase electro-Fenton oxidation system is composed of the supported FeOOH catalyst and hydrogen peroxide and canremove efficiently organic pollutants in waste water. The invention has effects and advantages that an out-phase catalyst can be separated from waste water easily and recycled, and an out-phase electro-Fenton oxidation system can operate in a neutral medium without need of PH adjustment and generation of chemical sludge.

Owner:DALIAN UNIV OF TECH

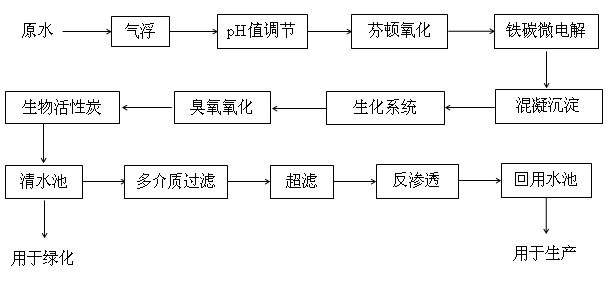

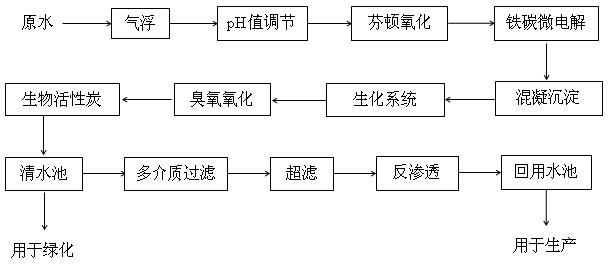

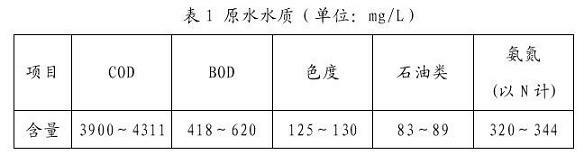

Treatment method for recycling complex waste water in coal chemical industry

InactiveCN102515442AImprove biodegradabilityRealize resourcesMultistage water/sewage treatmentWater useBiological activated carbon

The invention provides a treatment method for recycling complex waste water in the coal chemical industry and relates to recycling technologies for enhanced pretreatment, biochemical treatment, deep purification and regeneration process of waste water. The invention provides the process scheme as follows: first enhanced pretreatment for the complex waste water in the coal chemical industry is carried out by using the combined process of air floatation, Fenton oxidation and ferric-carbon micro-electrolysis, so as to improve the biodegradability of the waste water; then the waste water is poured into a biochemical system comprising a hydrolyze acidification zone pool, an anoxic pool and an aerobic pool; the biodegraded water is discharged into a deep purification system with the function ofozone-biological activated carbon filtration, so that materials which are difficult to degrade are further removed, and the discharged water can be used for green spaces and other landscapes; after that, most of salt ions are removed by using a regeneration recycling system with the functions of multi-media filtration, ultrafiltration and reverse osmosis, so as to obtain water can be reused for production.

Owner:蓝星环境工程有限公司

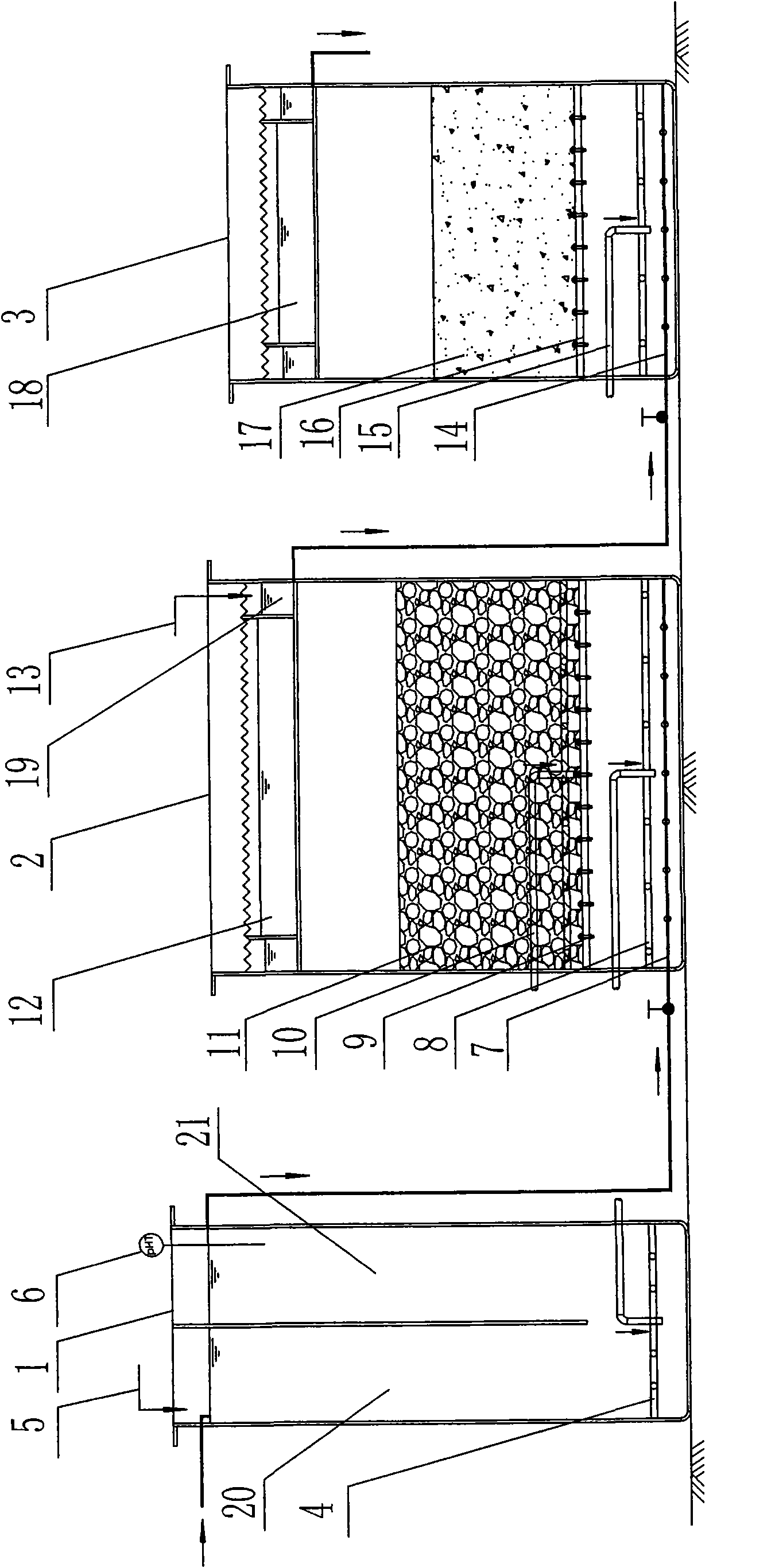

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082AImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentPretreatment methodElectrolysis

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while the bottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

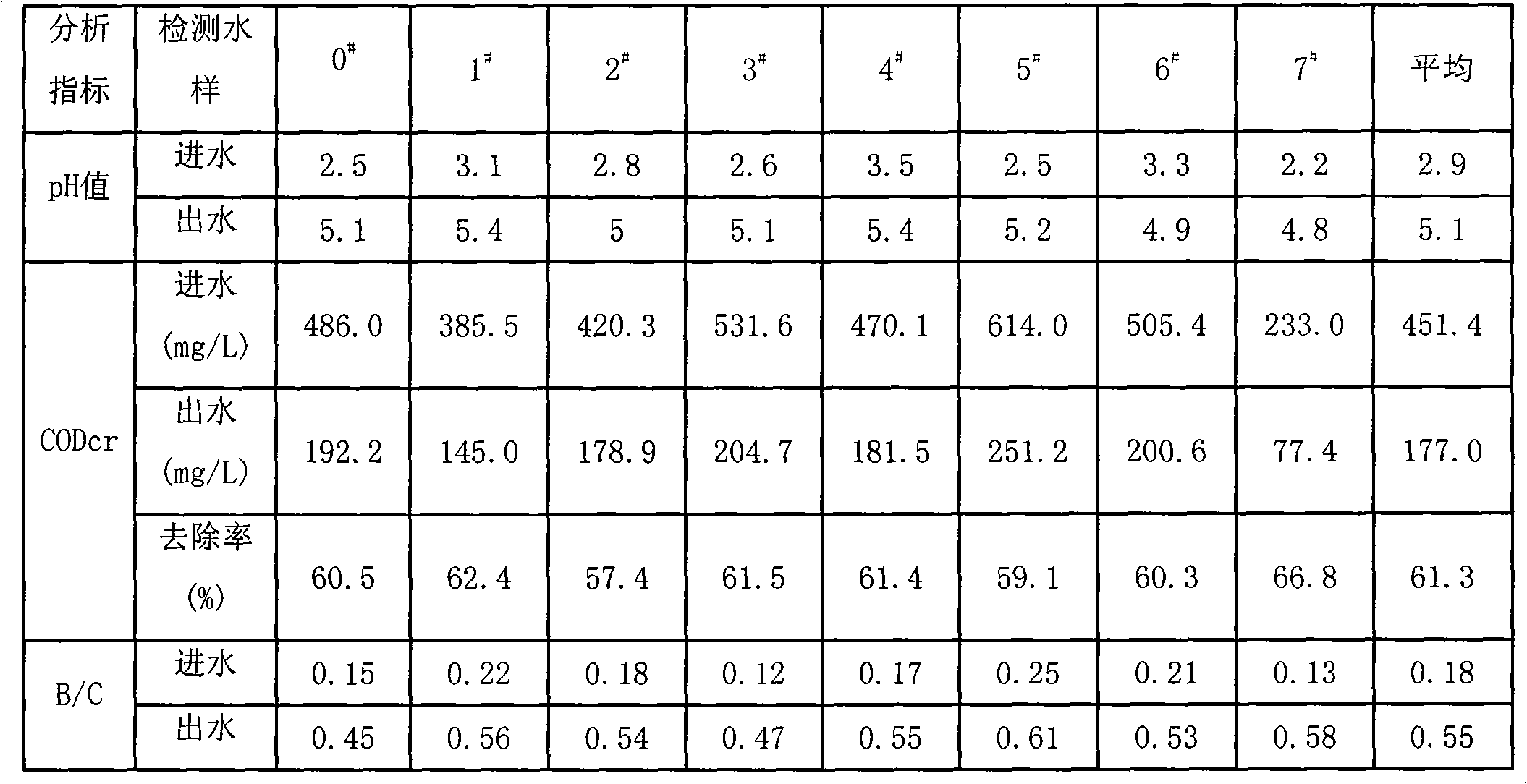

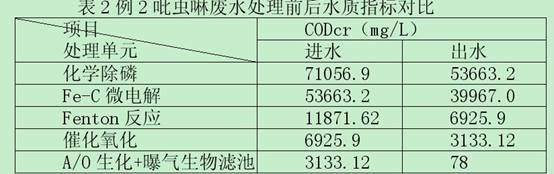

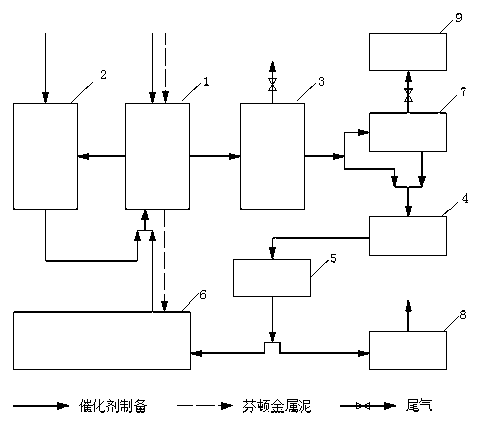

Imidacloprid pesticide wastewater treatment method

ActiveCN102040318AImprove biodegradabilityImprove the overall physical and chemical treatment effectMultistage water/sewage treatmentChemical treatmentPretreatment method

The invention relates to improvement on an imidacloprid pesticide wastewater treatment method. The imidacloprid pesticide wastewater treatment method is characterized by comprising the following steps of: performing physical and chemical pretreatment, namely performing chemical phosphorus removal and ferrum-carbon (Fe-C) micro-electrolysis sequentially and then performing Fenton oxidation and catalytic oxidation respectively; and performing biochemical treatment, namely performing aerobic biochemical treatment in the presence of salt-tolerant aerobic bacteria. By the imidacloprid pesticide wastewater treatment method, the total physical and chemical treatment effect is greatly improved; physical and chemical pretreatment can be performed at normal temperature and normal pressure; organic matters difficult to biochemically degrade is degraded and the biochemical property of the wastewater is improved under the condition of low cost; the dilution factor of the wastewater is greatly reduced; and the using amount of diluting water is reduced by 50 to 80 percent, so that the treatment is more economic. The imidacloprid pesticide wastewater treatment method is simple in pretreatment method, mild and stable in process reaction condition, simple in operation (for example, the catalytic oxidation can be performed at normal temperature and normal pressure and a catalyst can be recycled), low in operating cost, good in treatment effect, low in the using amount of the diluting water during the subsequent biochemical treatment and low in total treatment cost, and the water from the biochemical treatment can reach a national level 1 of discharge standard.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

Catalytical ozonization catalyst utilizing multi-source sludge to prepare and application thereof

ActiveCN103007937ANo pollution in the processReduce manufacturing costOther chemical processesCarbon compoundsActivated carbonIndustrial waste water

The invention discloses a catalytical ozonization catalyst prepared by utilizing multi-source sludge and an application thereof, and establishes a method for preparing a sludge group active carbon catalyst for catalytical ozone oxidation organic industrial waste water. The method comprises the following steps of: utilizing multi-source sludge such as surplus sludge generated by urban sewage factory biochemical treatment and a metal sludge generated by a Fenton oxidation method, preparing a skeleton which is a sludge group active carbon through steps such as organic substance adding, actification, dehydration, drying, mixing, roasting and screening, wherein a surface layer contains a solid catalyst of metallic oxide, and the ratio of the sludge group active carbon and the metallic oxide in parts by weight is 1:(0.3-0.5). The catalyst is used for catalyzing ozone oxidation treatment organic industrial waste water and has higher catalytic activity and stability, the processing range is wide, the realization and popularization and application are easy, and the economic benefits are improved in an organic industrial waste water processing procedure.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

Chlopyrifos pesticides waste water treatment process

InactiveCN101172728APromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCatalytic oxidationPendimethalin

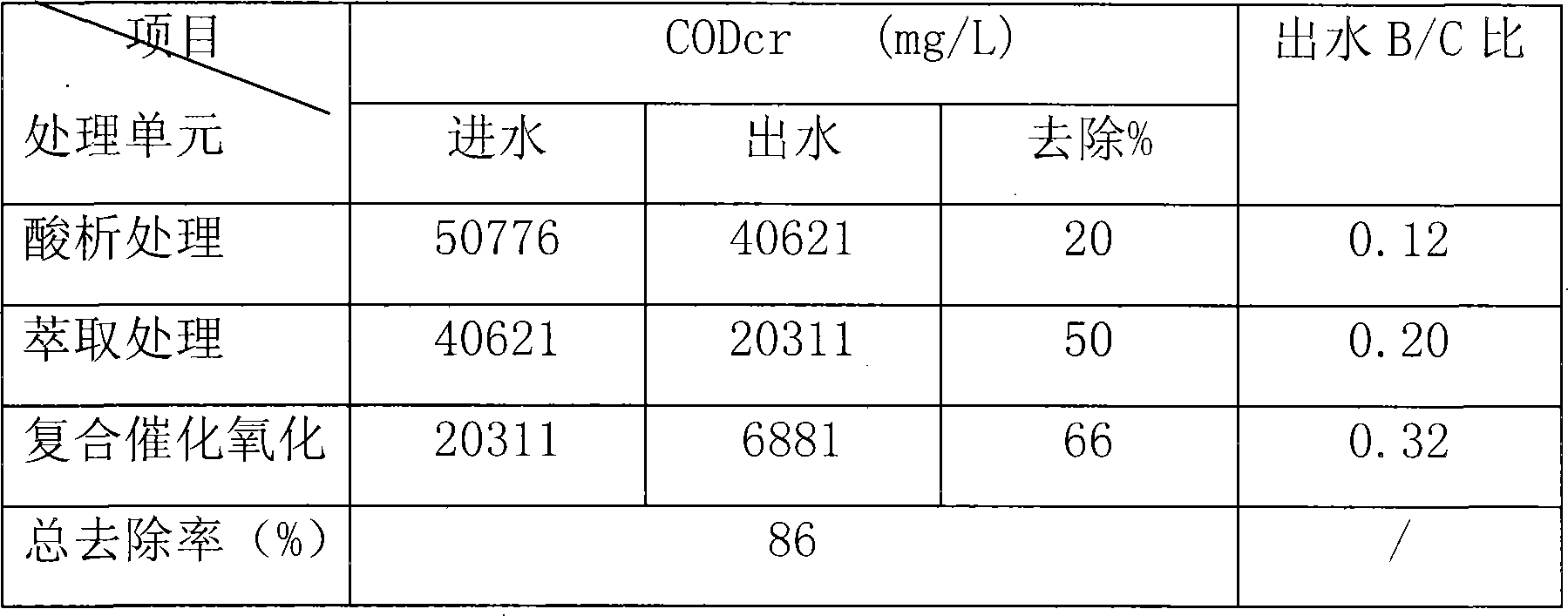

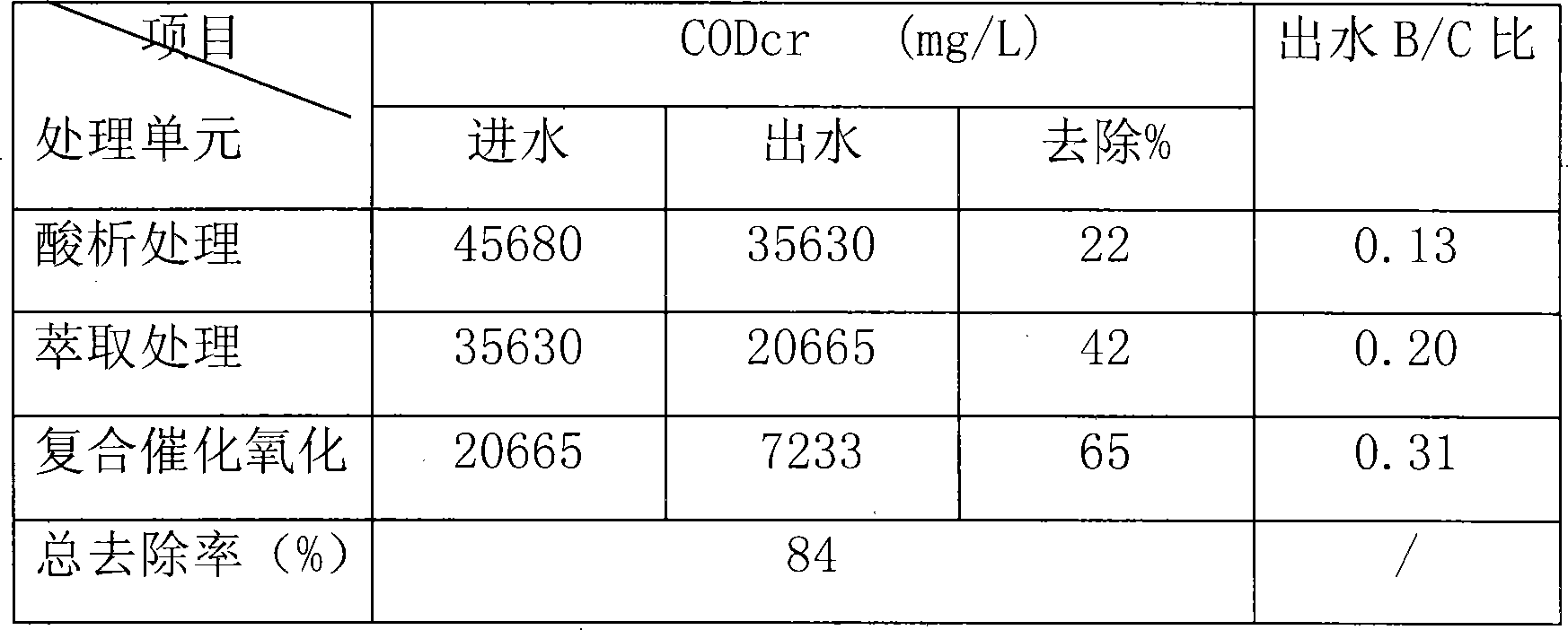

The invention discloses a treatment process of waste water polluted by the pesticide of Dursban, and the process includes the procedures of acid eduction, complexation and extraction, Fenton oxidation and catalytic oxidation. The invention is characterized in that Dursban waste water and herbicide Pendimethalin waste water are comprehensively treated, thereby achieving the proposal of waste controlled by the waste, decreasing the load of organic pollutant being hard to be graded in the waste water, improving the biological degradability of the waste water, removing the pollutant from the waste water, and increasing the biochemical performance of the waste water. Besides, the invention has the advantages of safe and advanced technique, clean operation and low waste water treatment cost.

Owner:山东华阳农药化工集团有限公司

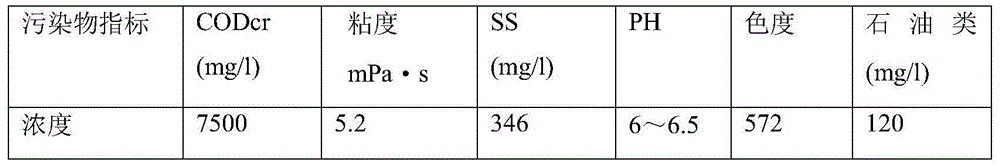

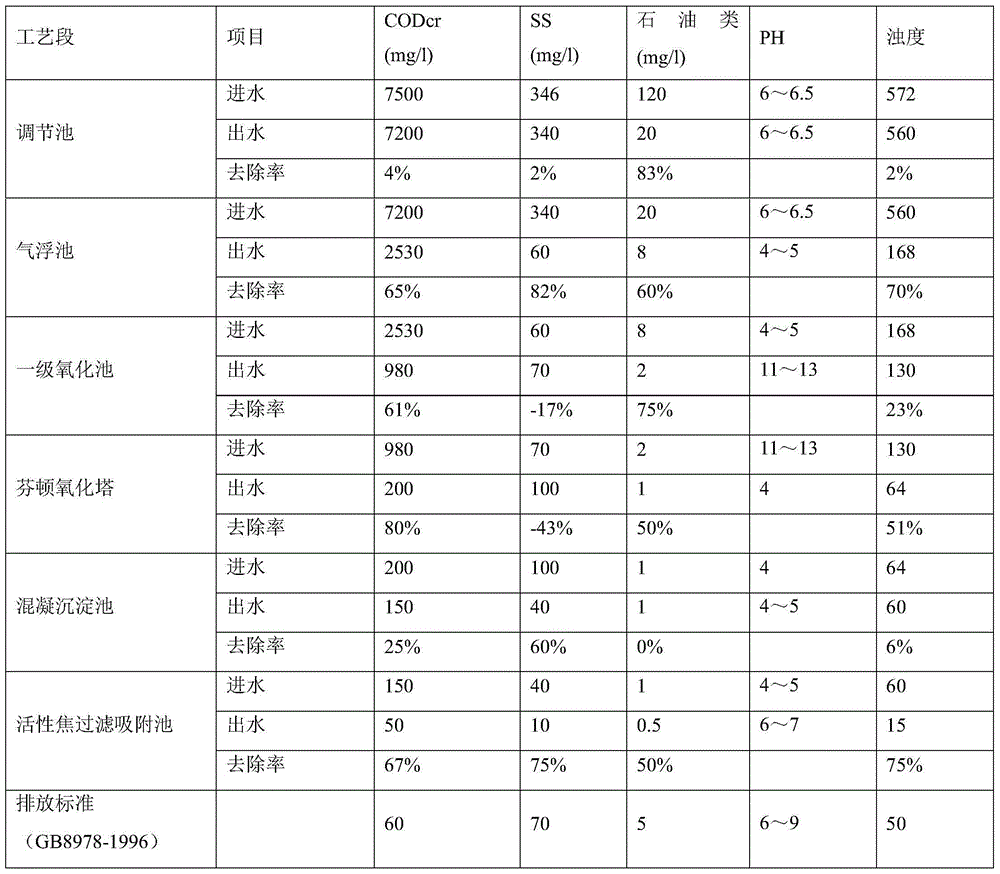

Oil and gas field fracturing flow-back fluid treatment process

InactiveCN104628185AReduce cloggingReduce blockWaste water treatment from quariesMultistage water/sewage treatmentFiltrationUnconventional oil

The invention belongs to the technical field of wastewater treatment and in particular relates to an oil and gas field fracturing flow-back fluid centralized treatment process. The oil and gas field fracturing flow-back fluid centralized treatment process comprises the following steps: 1, collecting fracturing flow-back fluid into an adjusting tank, carrying out homogenizing and quantity equalizing treatment on the fracturing flow-back fluid, and enabling the fracturing flow-back fluid to enter a sand settling and oil removal tank to be subjected to sand settling and oil removal; 2, lifting effluent of the adjusting tank into a coagulation / air floatation tank, adding a flocculating agent, and removing floating oil and suspended matters through flocculation and air floatation; 3, enabling effluent of the air floatation tank to enter a primary oxidation unit, adding sodium hypochlorite, and primarily oxidizing and decomposing macromolecular organic compounds; 4, enabling effluent of a primary oxidation tank to enter a Fenton oxidation tower, and deeply oxidizing and decomposing by adopting a Fenton oxidizing agent; 5, enabling effluent of the Fenton oxidation tower to enter a sedimentation tank; and 6, enabling effluent of the sedimentation tank to enter an activated coke filtration and adsorption tank to be subjected to filtration and adsorption treatment, various indexes of effluent of the activated coke filtration and adsorption tank can reach the standard, and the effluent of the activated coke filtration and adsorption tank can be discharged or recycled. The oil and gas field fracturing flow-back fluid centralized treatment process is applicable to treatment of fracturing flow-back fluid in unconventional oil and gas field fracturing mining of petroleum, natural gas, shale gas and coal bed gas.

Owner:乌鲁木齐奥森碳环生物能源有限公司

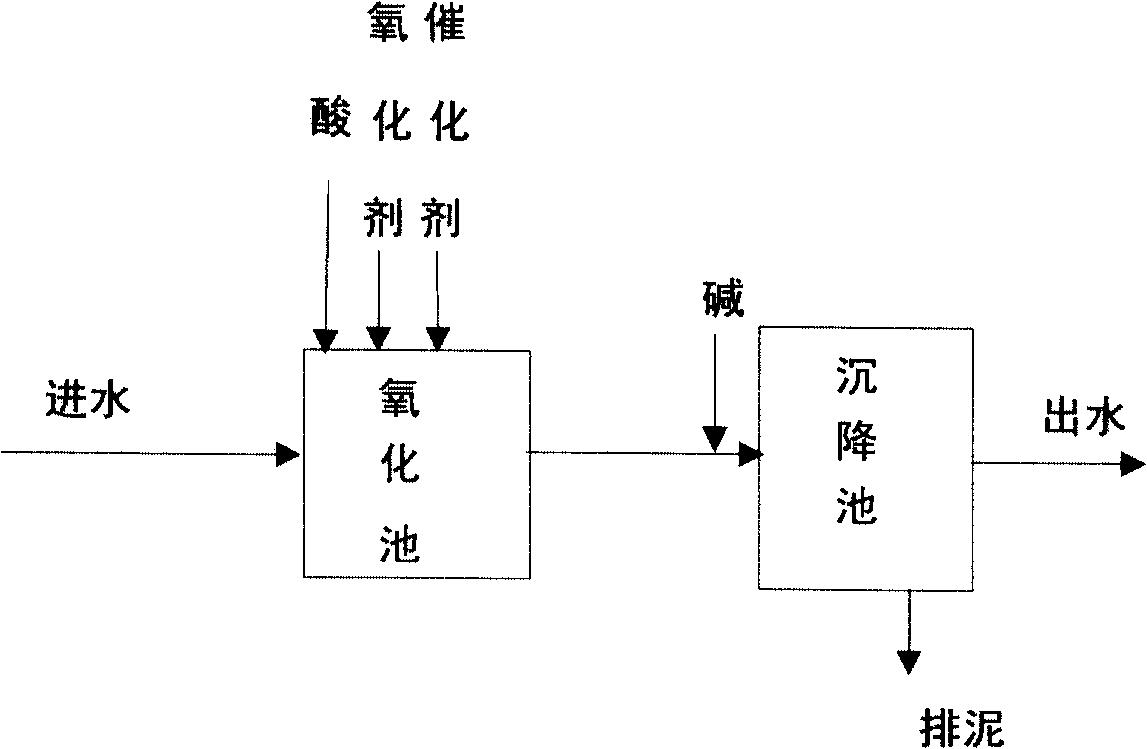

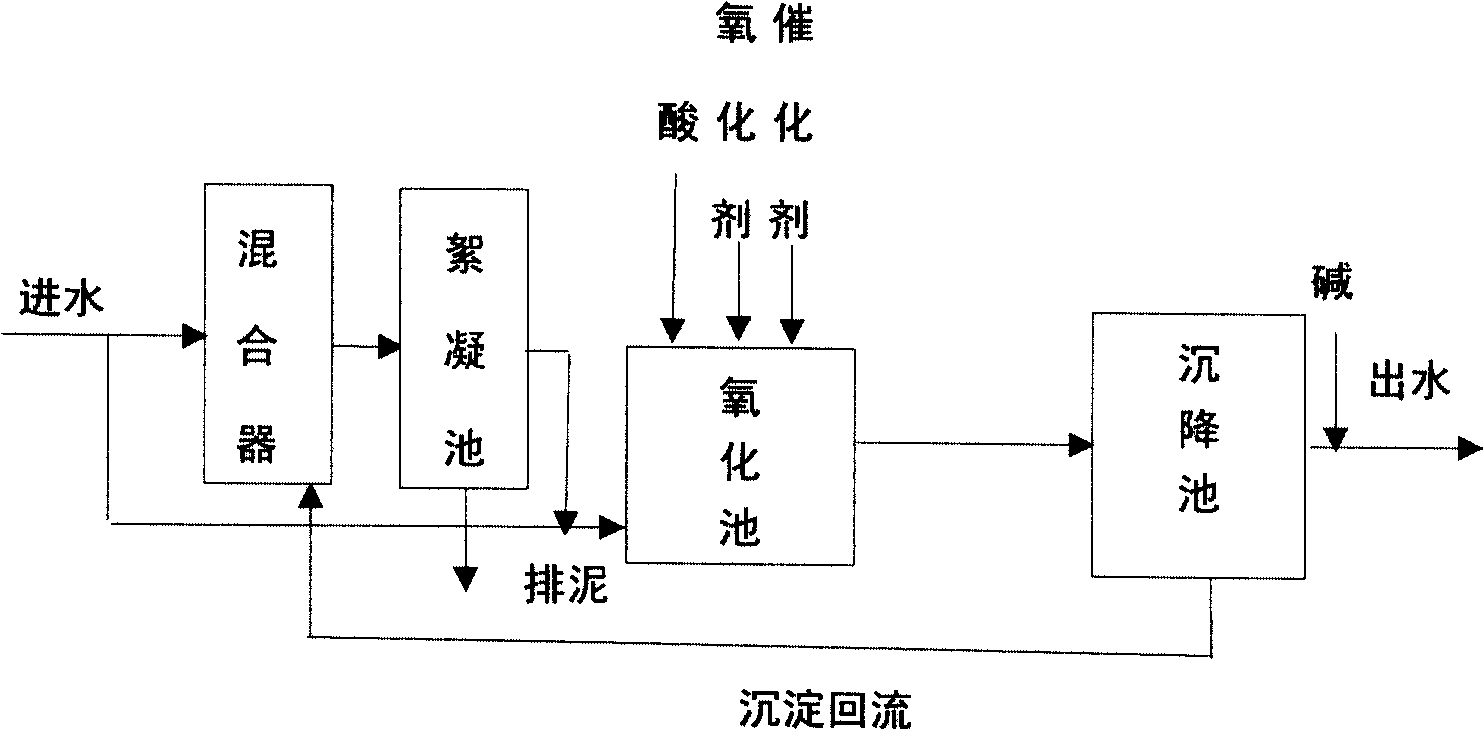

Method for processing waste water by fenton oxidation

InactiveCN101570368AReduce the amount addedReduce consumptionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationWater processing

The invention relates to a method for processing waster water by fenton oxidation, comprising the following steps: (1) enabling alkaline waste water to be processed to enter a flocculation pond so as to be flocculated and precipitated; (2) enabling the flocculated waste water to enter an oxidation pond so as to be oxidized for fenton oxidation reaction; (3) enabling oxidized waste water to enter a precipitation pond so as to be precipitated; (4) adding alkali to supernatant discharged from precipitated waste water to adjust the pH value of the waste water till the waste waster is neutralized, and directly discharging the waste waster or processing the waste water by the next step; and (5) enabling acid precipitate obtained in the step (4) to return to a mixer in a refluxing way to be mixed with total or part of waste water to be processed. With the method for processing waster water through fenton oxidation, the consumption of acid and the alkali can be greatly reduced and content of salt in the waste water can be reduced so that the waste water processing effect is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

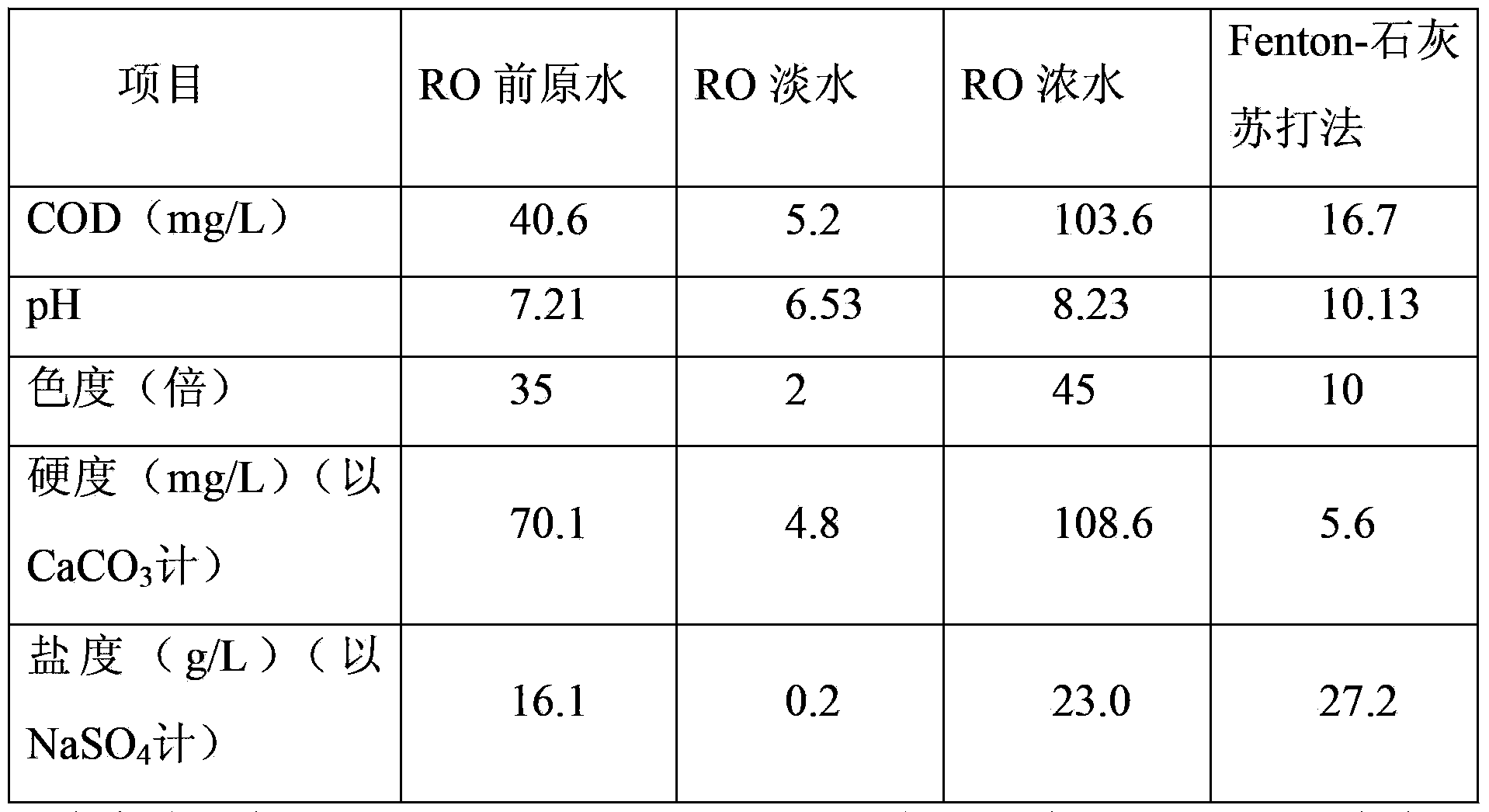

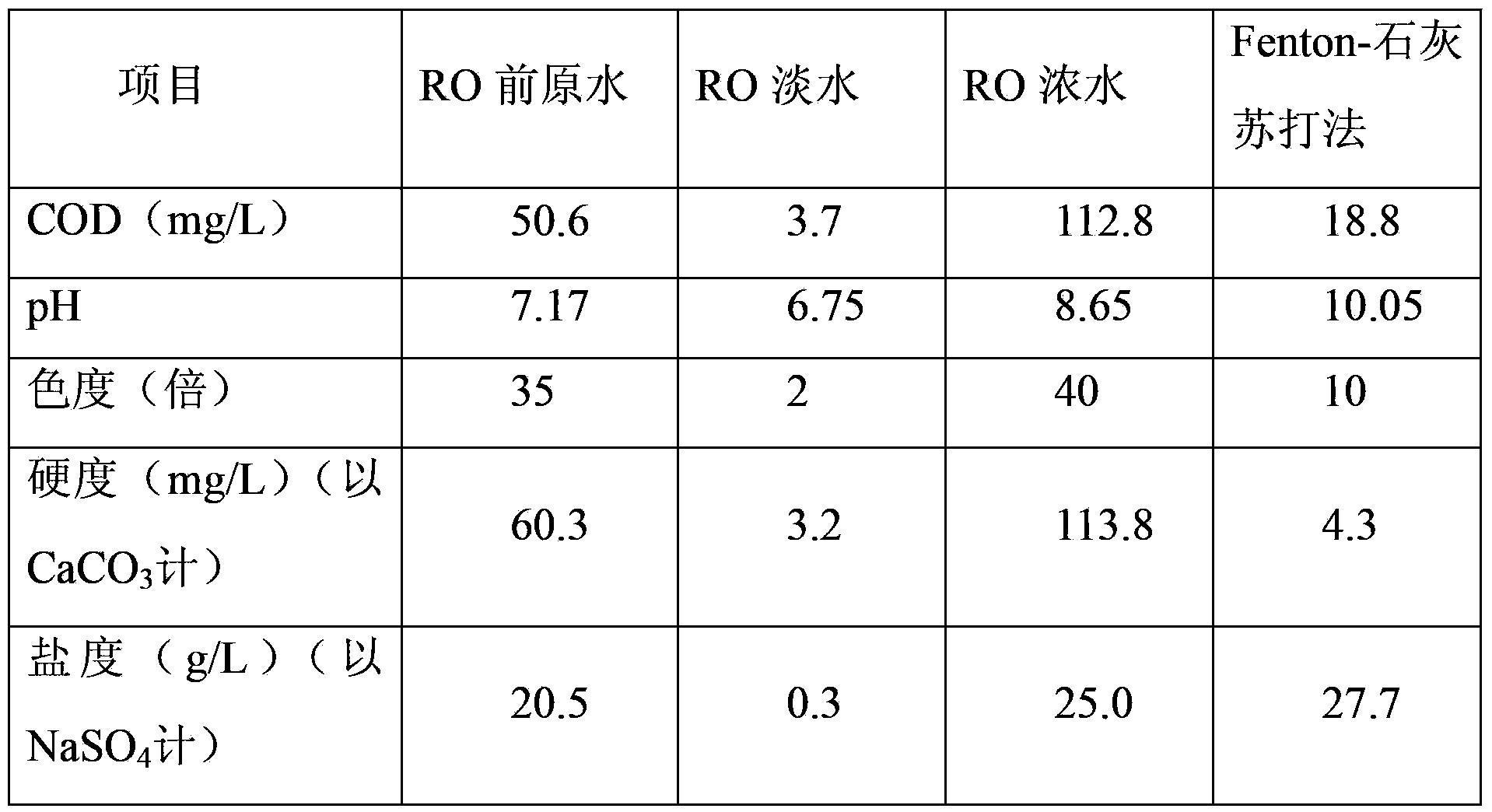

Treatment method for realizing zero emission of printing and dyeing wastewater

ActiveCN103359878AReduce energy consumptionNo secondary pollutionMultistage water/sewage treatmentWaste water treatment from textile industryEcological environmentUltrafiltration

The invention discloses a treatment method for realizing zero emission of printing and dyeing wastewater. The treatment method comprises the following steps: performing physicochemical and biochemical treatments on printing and dyeing wastewater stoste; performing such advanced treatments on the discharged water as sand filtration, ultrafiltration and security filtration, and then, conveying the discharged water into a nanofiltration or reverse osmosis membrane treatment system to perform membrane treatment, thus obtaining fresh water and concentrated water through the membrane treatment, wherein the fresh water is low-COD and low-hardness ionized water and is used as process water to be directly recycled in dyeing procedure, boiler water addition, general washing or circulating cooling water. The concentrated water is high-salinity and high-hardness wastewater containing organic pollutants, the concentrated water is treated by a Fenton oxidation coupling lime soda method, the concentrated water becomes low-COD and low-hardness water with high salinity, and salt is directly added in the concentrated water according to dyeing process requirements so as to recycle the concentrated water in the dyeing procedure. The treatment method provided by the invention can be used for completely recycling the treated wastewater to realize zero emission of printing and dyeing enterprises and save the cost, and the treatment method is free of secondary pollution, thereby protecting the ecological environment and recycling the printing and dyeing wastewater.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous ink waste water disposal process

InactiveCN1765762ASatisfy the requirement of complete decolorizationAchieve emission standardsWater/sewage treatment by irradiationWater/sewage treatment by neutralisationSludgeUltraviolet lights

The invention discloses a treatment for ink sewage, which comprises: adding proper PAC as flocculant in sewage, mixing round quickly, and adding proper ferrous sulfate as coagulant aid; mixing, depositing; using the supernatant for UV / Fenton oxidation under ultraviolet light; before oxidation, using hydrochloric acid to regulate solution pH value to optimal, adding given superoxol and ferrous sulfate; after reaction, adjusting solution to neutrality with superoxol and get rid of iron ion; depositing, and separating out water. The treated water has 97-100% transmittance with total removal rate to COD more than 93% that are between highest limit of second and third class discharge standard (GB 8978-1996).

Owner:ZHEJIANG GONGSHANG UNIVERSITY

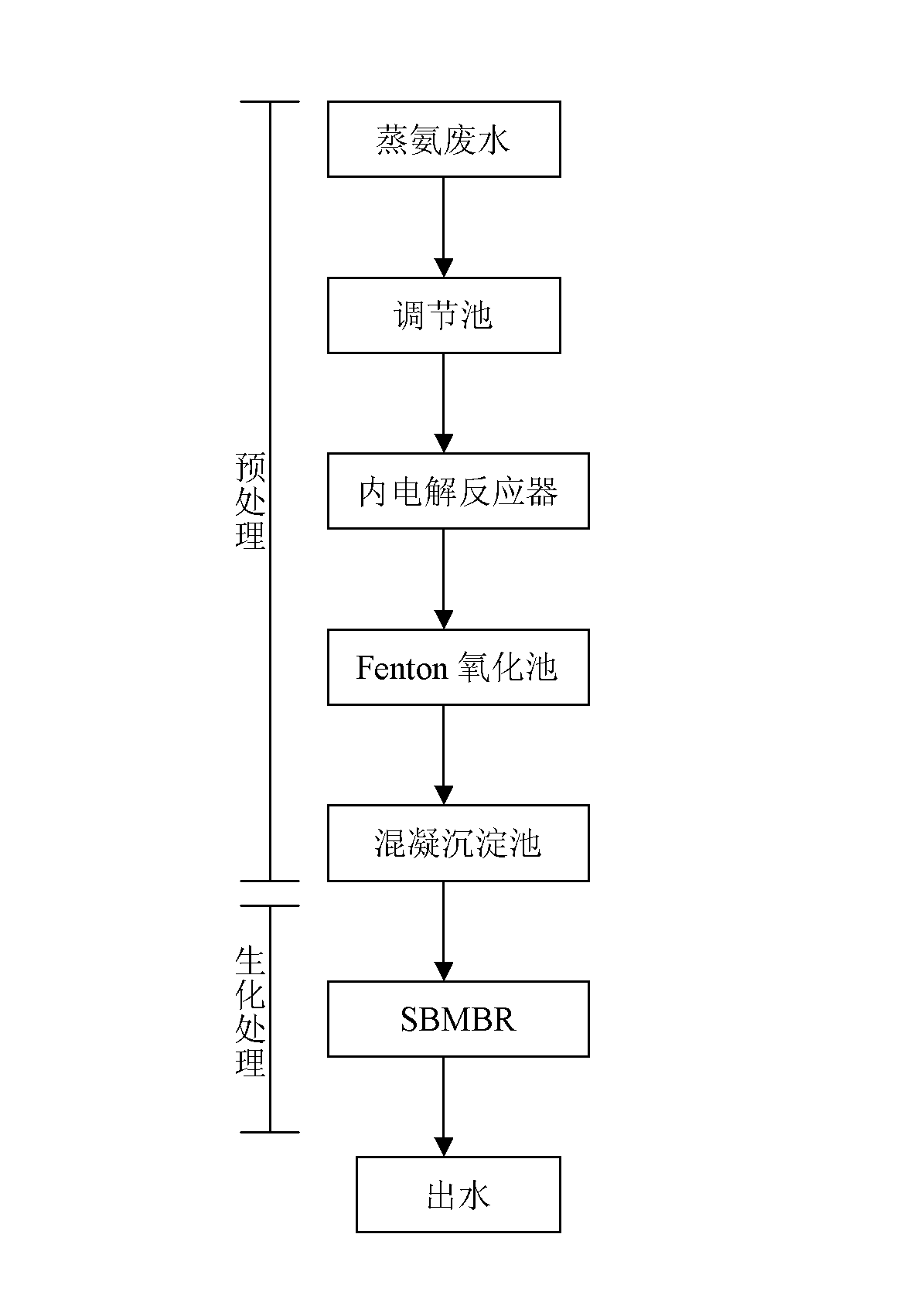

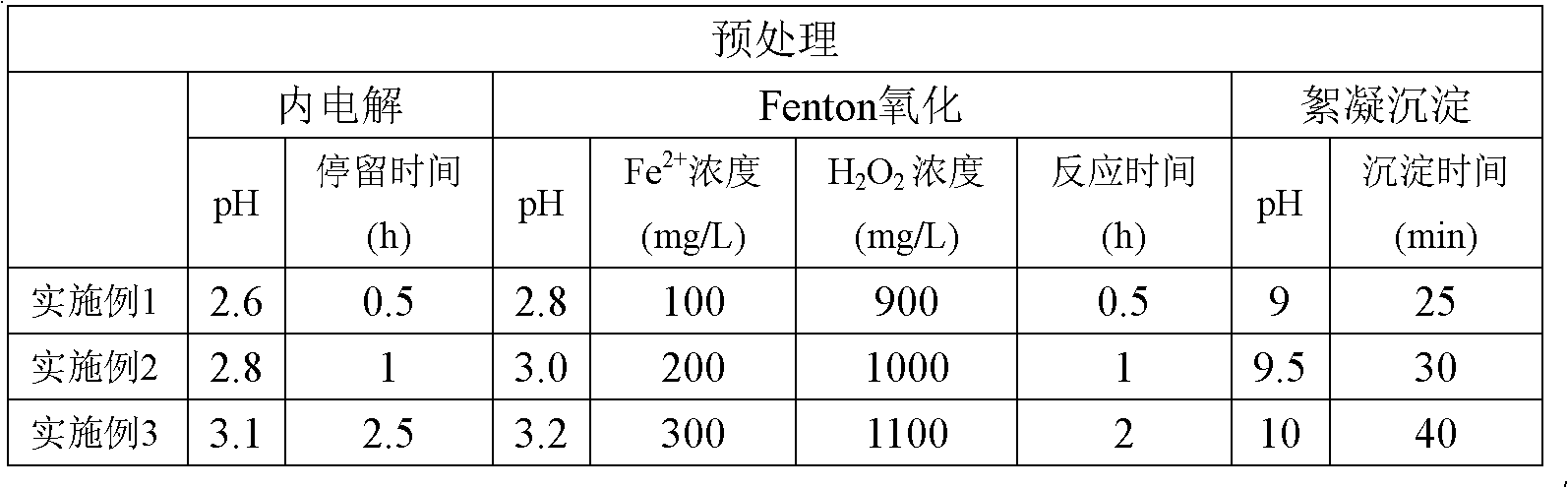

Processing method of coking steaming ammonia wastewater

ActiveCN103130379AEasy to useEasy to recycleMultistage water/sewage treatmentElectrolysisPersistent organic pollutant

The invention discloses a processing method of coking steaming ammonia wastewater. The processing method of the coking steaming ammonia wastewater comprises pretreatment of coking steaming ammonia wastewater and biochemical treatment of the coking ammonia wastewater. The pretreatment of the coking steaming ammonia wastewater uses an adjusting pool, an internal electrolysis reactor, a Fenton oxidation pond and a coagulative precipitation tank. A sequencing batch membrane bioreactor technology is adopted by the biochemical treatment, and working procedures of inflow, unused-leaving, reacting and discharging are sequentially performed according to a time period. The processing method of the coking steaming ammonia wastewater can effectively remove persistent organic pollutants and ammonia nitrogen, strengthen effluent quality, and reduce operational and investing costs of equipment.

Owner:ANGANG STEEL CO LTD

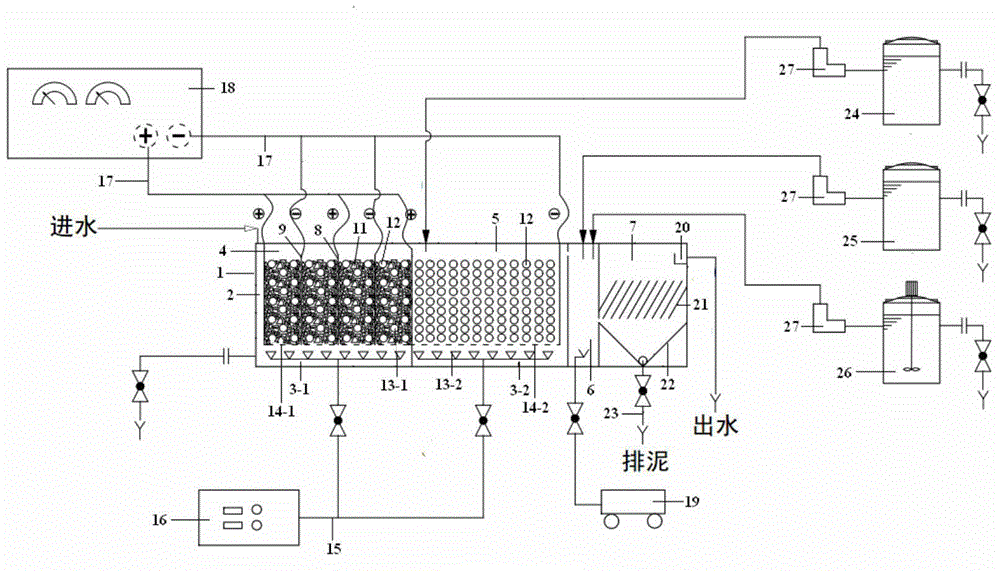

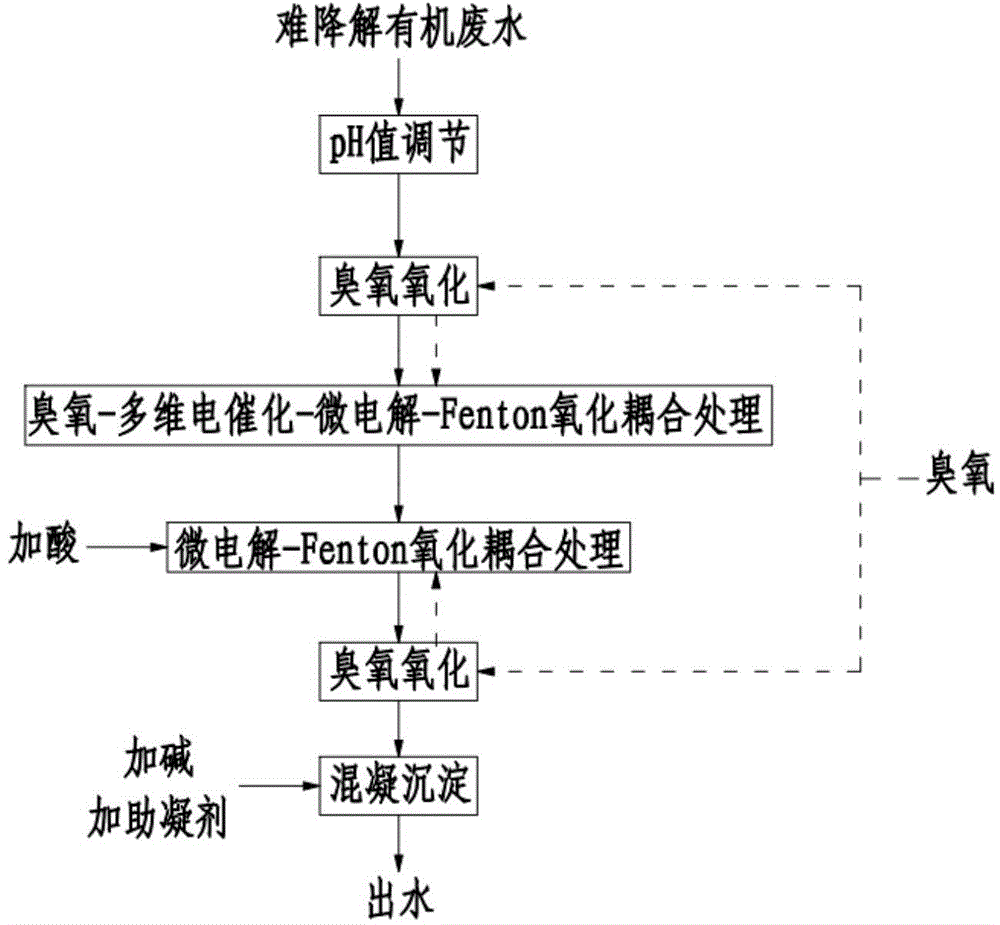

Advanced oxidative coupling device and process for treating organic wastewater difficult to degrade

ActiveCN104787941AImprove removal efficiencyLow running costWater contaminantsWater/sewage treatment by electrochemical methodsElectrolysisMulti dimensional

The invention discloses an advanced oxidative coupling device and process for treating organic wastewater difficult to degrade. A main device body comprises an ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area, an ozone oxidation-microelectrolysis / Fenton area, a coagulation area and an inclined plate sedimentation area, wherein the ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area comprises a multi-dimensional electrolysis / microelectrolysis area at the upper part and an ozone oxidation area at the lower part; the ozone oxidation-microelectrolysis / Fenton area comprises a microelectrolysis / Fenton area at the upper part and an ozone oxidation area at the lower part. The device combines four levels of advanced oxidation systems, and electrocatalytic oxidation, ozone oxidation, Fenton oxidation and a microelectrolysis reaction are mutually coupled in function, so that an organic matter difficult to degrade is subjected to multi-level oxidation to realize complete oxidative cracking; when the device is used for treating the organic wastewater difficult to degrade, the yield and the production rate of *OH are increased, the liquid phase transfer process is accelerated, the overall current efficiency of the device is increased, operation expenses are saved, flexible regulation and control of a process unit are realized, and the device can be used for treating various kinds of organic wastewater difficult to degrade.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

Pharmaceutical wastewater treatment process

ActiveCN106007221AHigh activityHigh removal rateSludge treatment by de-watering/drying/thickeningWater treatment parameter controlCatalytic oxidationHydrolysis

The invention relates to the technical field of wastewater treatment, and discloses a pharmaceutical wastewater treatment process which comprises steps: preforming wastewater pre-treatment and comprehensive treatment, pumping wastewater into a coagulation gas floatation clarifier, adding polyaluminum chloride and polyacrylamide in a water input pipeline through a coagulation medicine adding system, then enabling mixed wastewater to enter a three-phase catalytic oxidation tower, a coagulative precipitation tank, a pre-acidification pool, a thermoregulation pool, a UASB reaction pool and a combined type hydrolysis acidification pool sequentially, subjecting the mixed wastewater to hydrolysis acidification, enabling the wastewater to enter a primary A / O pool, a primary precipitation pool, a secondary A / O pool, a secondary precipitation pool, a Fenton oxidation pool and a tertiary precipitation pool sequentially, and discharging standard outlet water from a standard discharging opening. The process has the advantages of stable running effect, high ammonium-nitrogen removal rate, and low running cost, thereby being suitable for treatment of wastewater, which is refractory to degrade, in the pharmaceutical industry.

Owner:ZHEJIANG HUANYAO ENVIRONMENTAL CONSTR

Coking wastewater treatment system and treatment method

ActiveCN103880248AEfficient processing performanceLow running costMultistage water/sewage treatmentNitrationSmall footprint

The invention discloses a coking wastewater treatment system, including an upflow anaerobic sludge blanket reactor, an anoxic denitrification biofilter, an aerobic nitration biofilter, a multistage iron carbon micro-electrolysis coupling Fenton oxidation bed reactor, an aerobic nitration biofilter and an anoxic denitrification biofilter. A coking wastewater treatment method comprises the following steps of coking wastewater enters the upflow anaerobic sludge blanket reactor, the anoxic denitrification biofilter, the aerobic nitration biofilter, the multistage iron carbon micro-electrolysis coupling Fenton oxidation bed reactor, the aerobic nitration biofilter and the anoxic denitrification biofilter from a raw coking wastewater inlet pipe from bottom up, and is discharged. The coking wastewater treatment system disclosed by the invention has the advantages of being small in occupation area and low in energy consumption, having efficient wastewater treatment efficiency, reducing the operation cost of wastewater treatment, and being high in treatment load, low in energy consumption and small in sludge production yield.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Treatment process for chemical nickel plating waste liquid in circuit board industry

InactiveCN104176852ASolve in-plant processing issuesReduce the risk of excessive emissionsSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentElectroless nickelSodium hydroxide

The invention provides a treatment process for a chemical nickel plating waste liquid in the circuit board industry. The treatment process comprises the following steps: pumping the chemical nickel plating waste liquid in the circuit board industry into a reaction tank; sequentially adding sulfuric acid for acidifying; adding ferrous sulfate and hydrogen peroxide for Fenton oxidation complexation; adjusting the pH by sodium hydroxide; adding sodium sulfide for a coagu-flocculation reaction; finally, adding PAM until suspended solids are just flocculently separated; after acidification, advanced oxidation complexation, and flocculation, filter-pressing all the waste liquid by a plate-frame; collecting the filtrate and regulating the pH; and sequentially carrying out sand filtering and resin adsorption and discharging after reaching standard level. The treatment process provided by the invention can be used for effectively treating the chemical nickel plating waste liquid in the circuit board industry, so that the treatment cost and the standard-reaching difficulty of the waste liquid in an enterprise are reduced.

Owner:江西红板科技股份有限公司

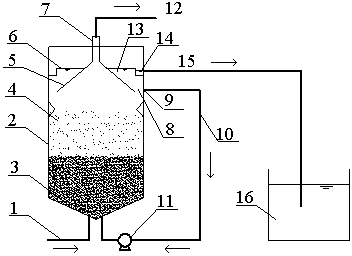

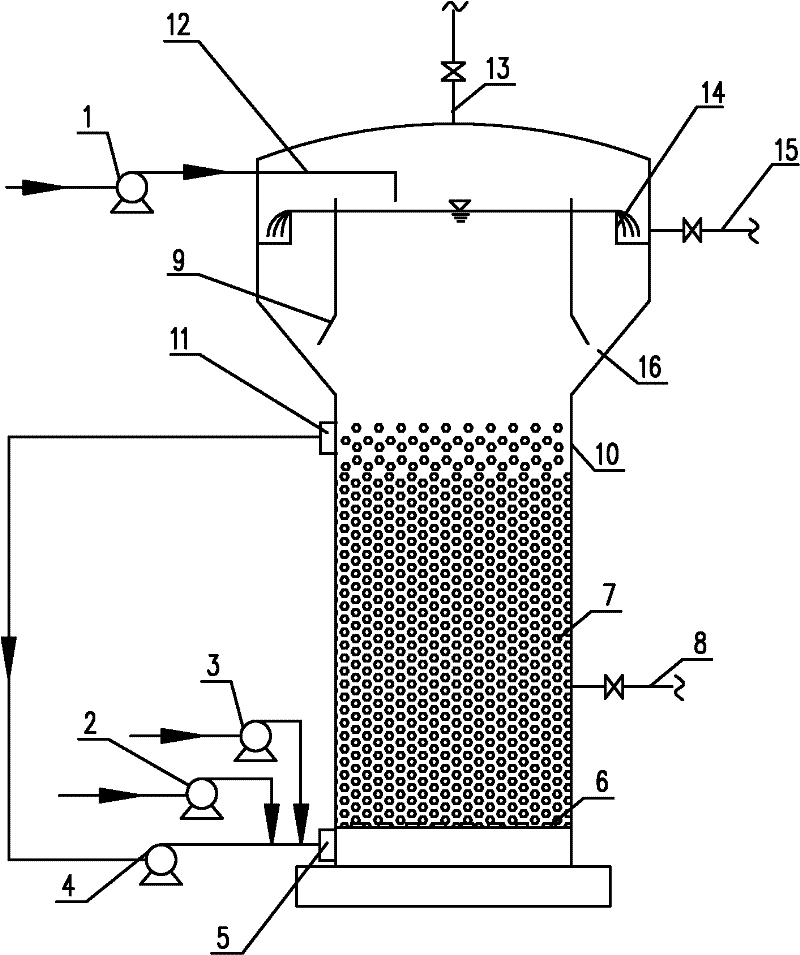

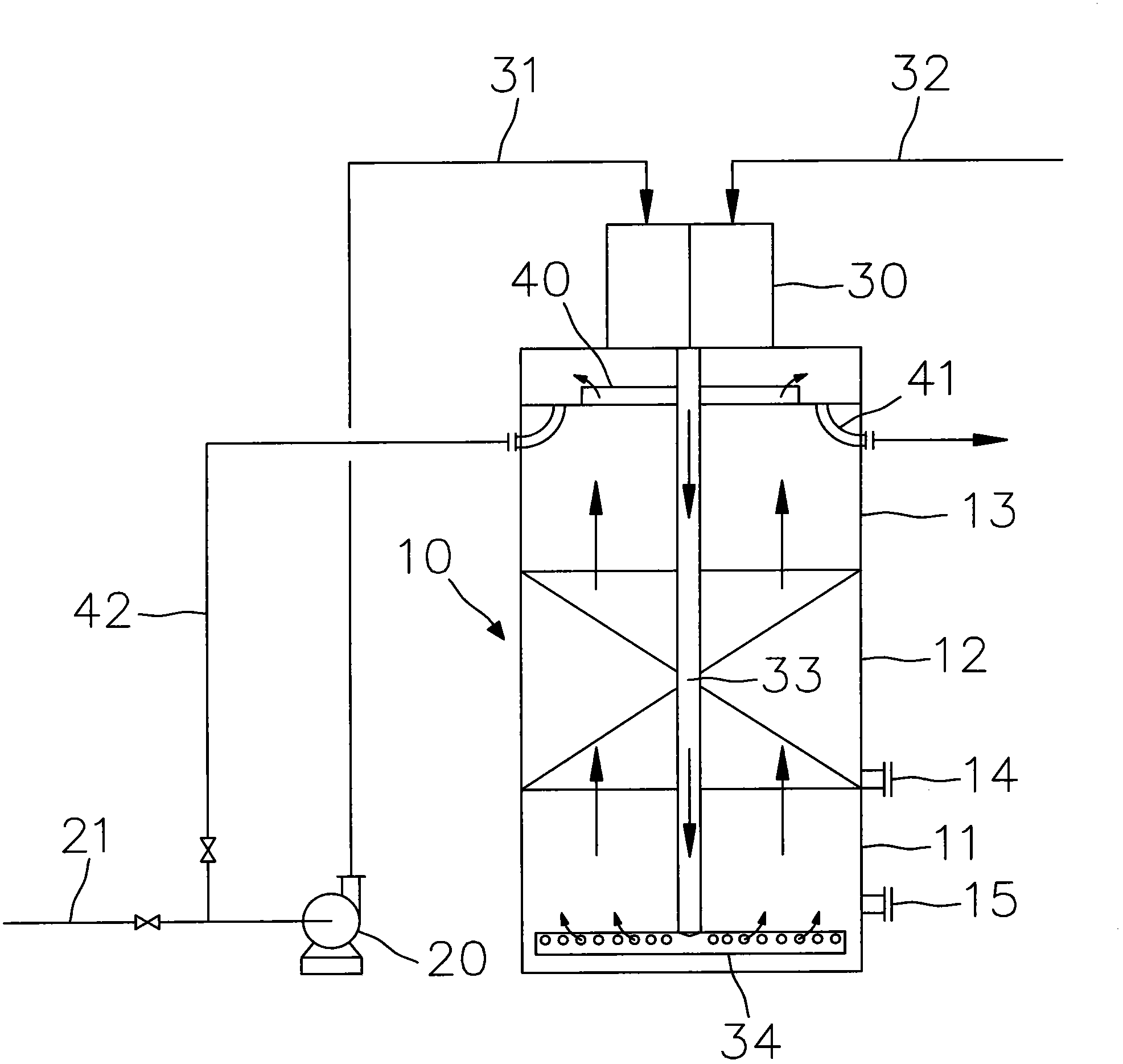

Circulating fluidized bed advanced treatment equipment for industrial wastewater

ActiveCN102249393ASmooth layoutIncrease profitWater/sewage treatment by oxidationIndustrial effluentSludge

The invention discloses circulating fluidized bed advanced treatment equipment for industrial wastewater. The equipment comprises a tank body for the Fenton oxidation reaction of wastewater, wherein the tank body is divided into a circulating water distribution zone, a FeOOH crystallization zone and a gas-water separation zone from bottom to top in turn; the circulating water distribution zone is provided with a water distributor and a circulating water inlet; the circulating water inlet is connected with the output ends of a FeSO4 dosing pump, a H2O2 dosing pump and a circulating pump simultaneously; the FeOOH crystallization zone is provided with a crystal bed layer, a solid discharge pipe and a circulating water outlet; the circulating water outlet is connected with the input end of the circulating pump; the gas-water separation zone is provided with a gas-water separation barrel, a wastewater input pipe extending to the gas-water separation barrel, a gas discharge pipe, an annular effluent weir and a purified water discharge pipe; and the wastewater input pipe is connected with the output end of an influent pump. The equipment has the characteristics of low operating cost, low sludge yield and good treatment effect, is flexibly and conveniently operated, and is particularly suitable for the industrial wastewater containing non-degradable organic matters.

Owner:上实环境控股(武汉)有限公司

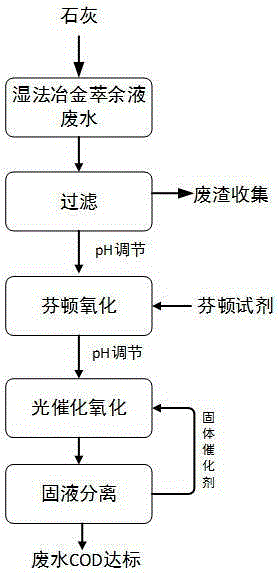

Hydrometallurgy industry raffinate waste water COD removal method

InactiveCN105198139AEfficient Adsorption RemovalReduce CODWaste water treatment from metallurgical processMultistage water/sewage treatmentPhoto catalyticSulfate radicals

The invention discloses a hydrometallurgy industry raffinate waste water COD removal method. According to the method, lime is added into waste water, and is combined with sulfate radical, phosphate radical, carbonate radical, fluorinions, metal ions and the like to generate defecation mud, the defecation mud is taken as an adsorber to remove dispersed oil in the waste water, filter liquor generated after filtering is subjected to pH regulation, then fenton oxidation is performed to degrade macromolecular organic compounds, further pH regulation is performed, then low molecular weight organic matters are deeply degraded by photo-catalytic oxidation, finally solid-liquid separation is performed to obtain a solid catalyst and waste water with the COD content smaller than 100mg / L, and the solid catalyst is returned to photo-catalytic oxidation reaction for cyclic utilization. The method is good in COD removal effect, free of adsorber regeneration and low in operation cost, and has industry application prospect.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

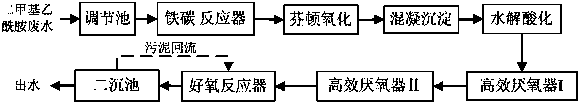

Harmless dimethylacetamide wastewater treatment method

InactiveCN103359876ALow biological toxicityImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentElectrolysisTreatment effect

The invention relates to a harmless dimethylacetamide wastewater treatment method which comprises the following steps of: (1) regulating the pH of wastewater in a regulating reservoir; (2) performing pretreatment in an iron carbon-Fenton oxidation pond; (3) performing flocculating sedimentation treatment; (4) adding a carbon source to perform hydrolytic acidification treatment; (5) performing anaerobic biochemical treatment in a primary upflow anaerobic sludge blanket (UASB) reactor; (6) performing anaerobic treatment in a secondary UASB (Upflow Anaerobic Sludge) reactor; (7) treating in an aerobic pond; (8) performing mud-water treatment in a secondary sedimentation tank to drain water. An aerated micro electrolysis method, a Fenton oxidation method and a biological method are combined; moreover, a good wastewater treatment effect is kept, the treatment cost is reduced, and the harmless dimethylacetamide wastewater treatment method has the obvious characteristics of high organic matter removal efficiency, stable effluent quality, low engineering investment, low energy consumption and the like, and is easy to popularize and apply.

Owner:苏州有色金属研究院有限公司

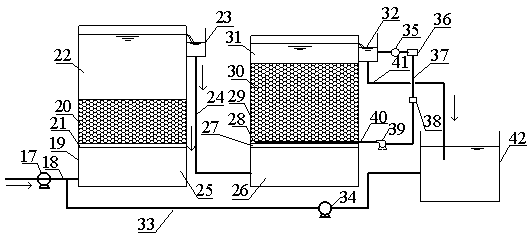

Microelectrolysis-fenton oxidizing reaction device

ActiveCN103663802AReduce the additional amountPlay a catalytic roleMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrochemical responseElectrolysis

The invention belongs to the technical field of sewage treatment, and in particular relates to a microelectrolysis-fenton oxidizing reaction device. The oxidizing reaction device comprises a wastewater supply device, and a hollow-out reactor made of anti-corrosive materials; a barrel body of the reactor is internally divided into a fenton oxidizing reaction area, a microelectrolysis reaction area and a flocculoreaction area from bottom to top; the microelectrolysis reaction area is full of iron-carbon fillers. The device also comprises a draining device arranged at the upper side of the reactor. The draining device is convenient for draining the treated wastewater to the outside of the oxidizing reaction device. The microelectrolysis-fenton oxidizing reaction device has the advantages that the microelectrolysis technology and the fenton oxidizing technology are integrated, so that the effective space of the reactor can be furthest utilized, i.e.,, the electrochemical reaction and the oxidization-reduction reaction can be carried out synchronously within the effective space of every independent unit device, therefore, the wastewater treatment process can be greatly simplified, the impact of various factors on wastewater treatment operation can be reduced, the purification performance of unit equipment in wastewater treatment can be improved, and as a result, an ideal treatment effect can be obtained.

Owner:安徽南风环境工程技术有限公司

Printed circuit board high-concentration organic wastewater and acidic wastewater treating process

ActiveCN103496828AEfficient and thorough removalGuaranteed emission standardsMultistage water/sewage treatmentHigh concentrationWater treatment system

Disclosed are printed circuit board high-concentration organic wastewater and an acidic wastewater treating process. The acidic wastewater treating process mainly includes a plurality of steps, namely, acidifying and filter-pressing, iron-carbon micro-electrolysis, Fenton oxidation and flocculent settling, SBR bio-treatment and the like. By the process, organic matters in water can be removed efficiently and thoroughly, and the water is ensured to be capable of reaching the standard and discharged after being mixed with other wastewater through a comprehensive wastewater treating system.

Owner:江西红板科技股份有限公司

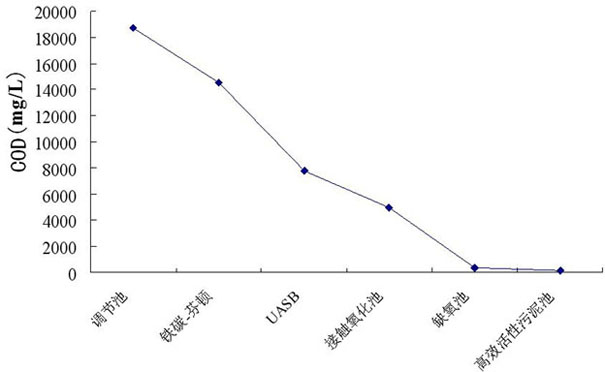

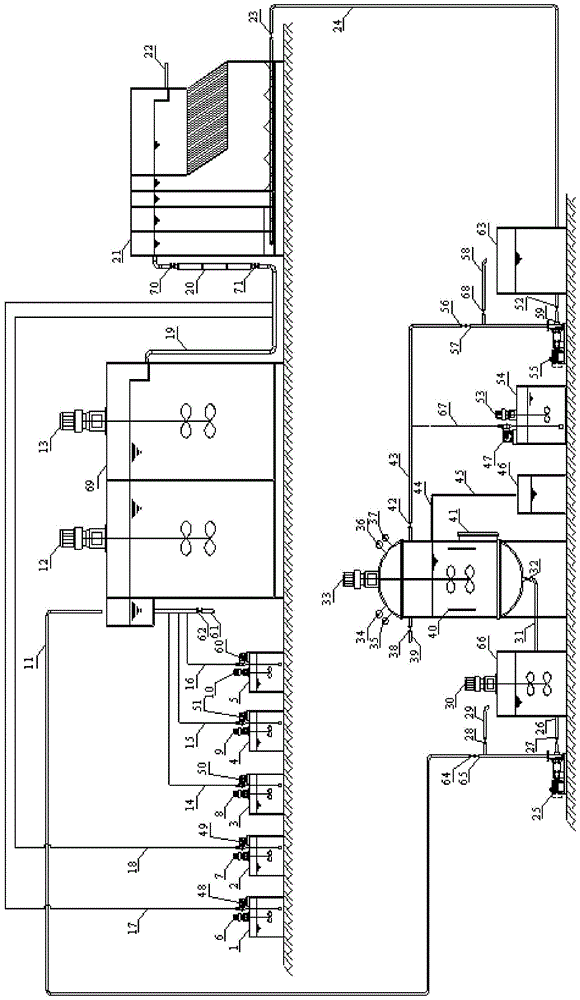

Caffeine production wastewater treatment method

InactiveCN101781066ACODReduce CODTreatment using aerobic processesTreatment with anaerobic digestion processesActivated sludgeHydrolysis

The invention discloses a caffeine production wastewater treatment method, and relates to a wastewater treatment method. The method solves the problem that the content of organic and inorganic substances in effluent produced by the traditional caffeine production wastewater treatment method is high and cannot reach the second-level discharge standards of GB8978-96 'Integrated Wastewater Discharge Standard', and comprises the following steps: 1, adjusting pH of wastewater in a regulating pond; 2, pre-treating the wastewater in an iron-carbon-Fenton oxidation pond; 3, treating the wastewater in a floatation tank; 4, performing anaerobic hydrolysis-acidification treatment on the wastewater in a UASB reactor; 5, treating the wastewater in a biological contact oxidation pond; 6, treating the wastewater in a hydrolyzing multifunctional pond; 7, treating the wastewater in a high-efficiency activated sludge pond; and 8, treating the wastewater in a secondary sedimentation tank to obtain drain water. The whole removing rate of the method is 90 to 98 percent (mass); the pH of the drain water is 7 to 8; COD is 100 to 200 mg / L; ammonia nitrogen is 5 to 25 mg / L; and the color removal rate reaches the national second-level discharge standards.

Owner:HARBIN INST OF TECH

Fe-recycling Fenton oxidation method with zero sludge discharge and device thereof

ActiveCN105621740AAchieving zero emissionsLow running costSludge treatmentWater treatment compoundsActivated carbonFenton reaction

The invention relates to a Fe-recycling Fenton oxidation method with zero sludge discharge and a device thereof. The Fenton oxidation method provided by the invention comprises the following steps: treating industrial wastewater by virtue of a Fenton oxidation reactor, adding Fe<2+>, H2O2 and acid during initial operation of the reactor, adding produced iron-containing sludge into a thermocatalytic reduction reaction kettle, adding activated carbon powder, sealing the reaction kettle, heating to 180-200 DEG C, stirring and reacting for 3.0-4.0 h, so as to obtain a solid-liquid two-phase mixture, discharging, adding into a water inlet of the Fenton oxidation reactor, mixing with the industrial water, acid and H2O2, and then entering the reactor and carrying out Fenton reaction, wherein initially and exogenously added Fe<2+> is replaced, and sludge produced during reaction is recycled. The method provided by the invention can realize zero sludge discharge of a Fenton oxidation technology, Fe in the Fenton oxidation reactor is recycled, and great advantage in the aspect of saving reagent expense of the Fenton oxidation technology and sludge treatment cost is shown.

Owner:DONGHUA UNIV

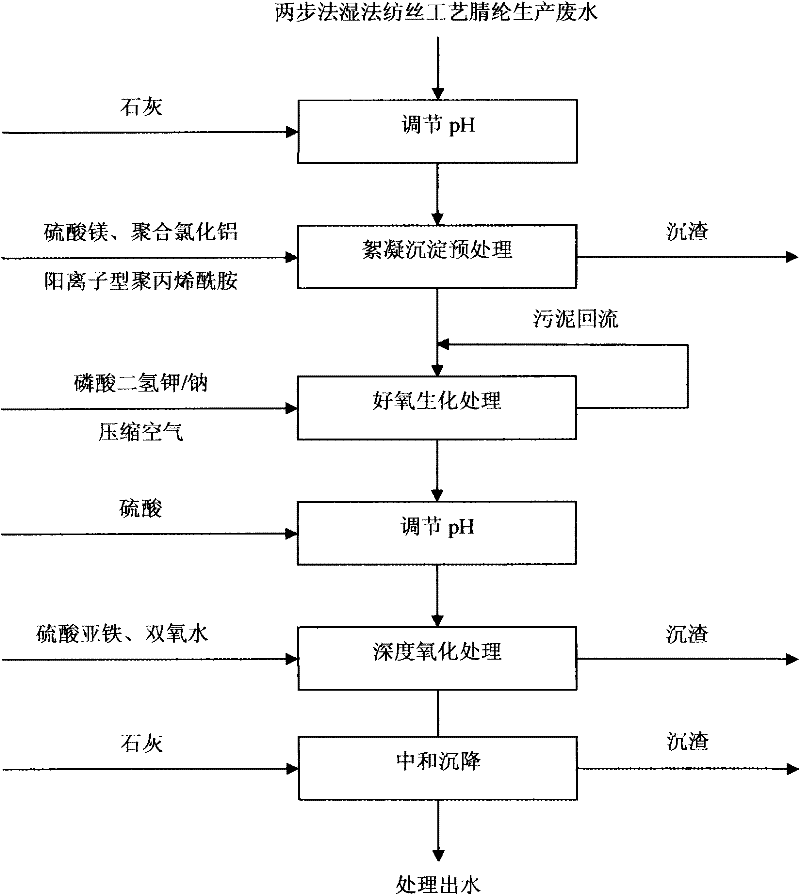

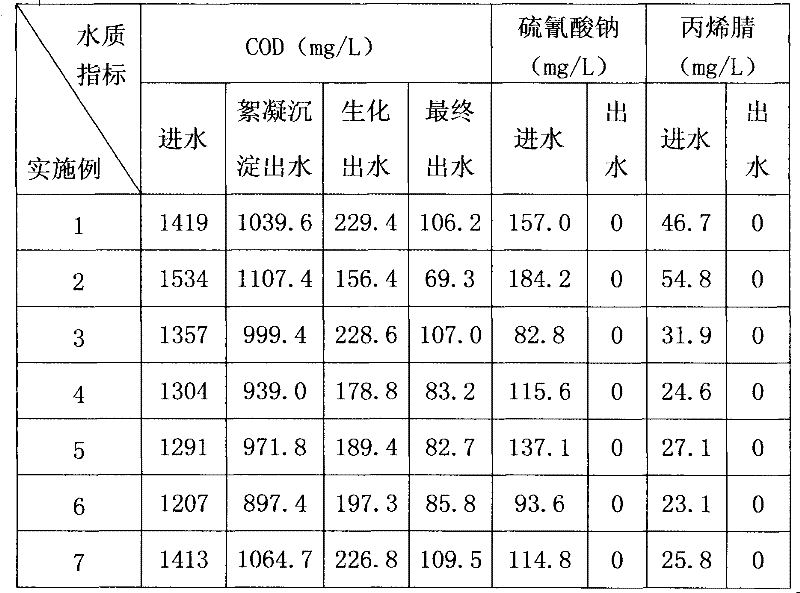

A kind of treatment method of waste water produced by wet process acrylic fiber in a kind of two-step method

ActiveCN102295382AHigh removal rateMultistage water/sewage treatmentSustainable biological treatmentChemical oxygen demandSodium thiocyanate

The invention relates to a treatment method of industrial wastewater, in particular to a treatment method of two-step wet acrylic fiber production wastewater. The method comprises the following steps of: a, flocculent settling treatment with a composite flocculating agent for removing compounds of nitrile, amine, cyanogen and the like harmful to organisms, preventing the compounds from adhering and poisoning microbes, removing suspension and colloidal chemical oxygen demand (COD) and lightening the load of a biochemical system; b, aerobic biochemical treatment for degrading organic substancesin the wastewater and removing COD; c, Fenton oxidation deep treatment for oxidizing and decomposing residual organic substances and further removing COD; and d, neutralizing treatment, wherein the produced water after the neutralizing treatment reaches the standards and is discharged or is recycled to the production process. After being treated by the treatment method of the two-step wet acrylicfiber production wastewater, the appearance of the two-step wet acrylic fiber production wastewater is colorless and transparent, the COD removal rate is improved by about 10 to 20 percent compared with a method in the prior art, the COD of the produced water is less than 160mg / L, the treated two-step wet acrylic fiber production wastewater reaches the national grade 1 discharge standard of the acrylic fiber industry, and acrylonitrile and sodium thiocyanate in the produced water are lower than the detection limit.

Owner:CHINA PETROLEUM & CHEM CORP +1

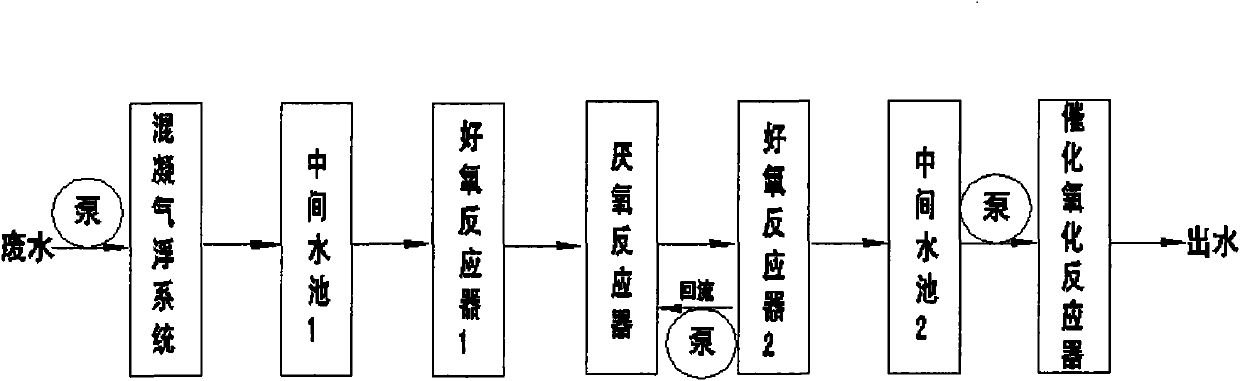

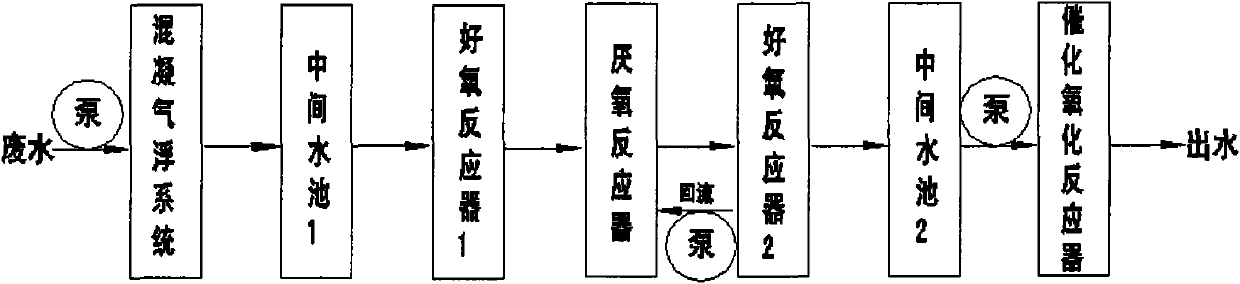

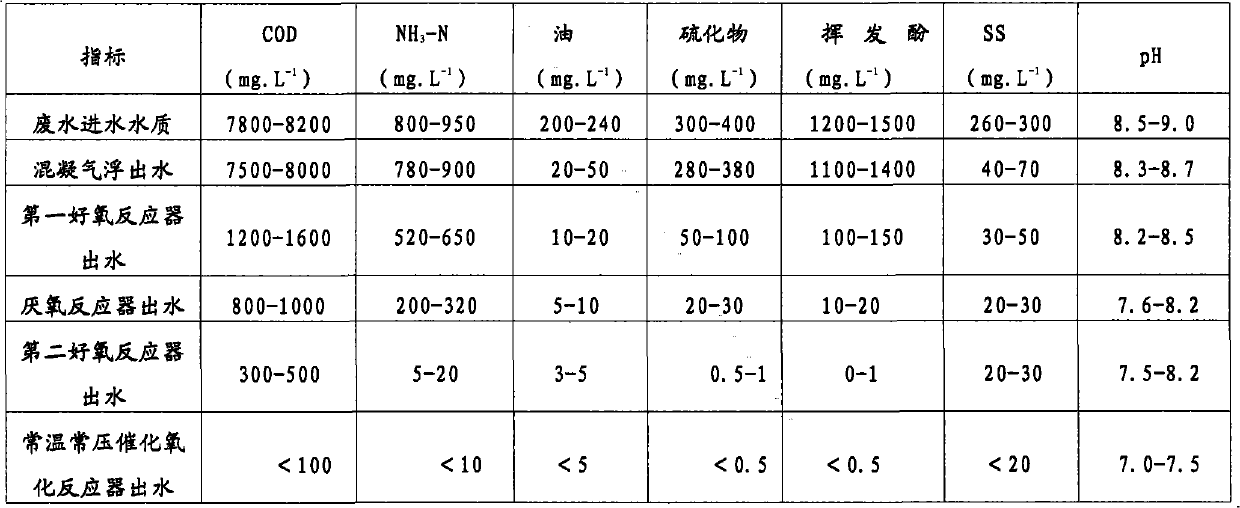

Coal gasification wastewater processing method

ActiveCN102557328ATreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

The invention relates to a coal gasification wastewater processing method. The method comprises the following steps: carrying out coagulation processing and air floatation processing on coal gasification wastewater, sequentially carrying out aerobic biological processing, anaerobic biological processing and the aerobic biological processing by allowing the wastewater to flow through a first aerobic reactor, an anaerobic reactor and a second aerobic reactor, allowing parts of water discharged from the second aerobic reactor to return to the anaerobic reactor, and carrying out normal-temperature normal-pressure catalytic oxidation or carrying out Fenton oxidation and normal-temperature normal-pressure catalytic oxidation on the residual water.

Owner:ENN ENVIROTECH CO LTD

Purifying method of waste brine in glyphosate production

ActiveCN104163519ASolve problems such as difficulty in utilization as by-productsMultistage water/sewage treatmentNature of treatment waterChemical treatmentChlorine dioxide

The invention discloses a chemical treatment method, and concretely relates to a purifying method of waste brine in a glyphosate production process. The method comprises the following steps: adjusting the total phosphorus content and TOC and total nitrogen L in the waste brine, adjusting the pH value of the waste brine to 6-10, and carrying out nanofiltration membrane separation to obtain a penetrating fluid; processing the penetrating fluid by adopting a catalytic oxidation technology to obtain a first stage salt solution, wherein the catalytic oxidation is one or a combination of more of a Fenton oxidation processes, a hydrogen peroxide active carbon oxidation process, a sodium hypochlorite active carbon oxidation process, an ozone active carbon oxidation process and a chlorine dioxide oxidation process; and adsorbing by adopting an adsorbent to obtain a second stage salt solution, wherein the adsorbent can be one or a combination of more of macro-porous adsorption resin, chelating resin, molecular sieve, silica gel and activated alumina. The method can effectively solve the problems of difficult treatment, difficult us of waste salt as a byproduct and the like, and has very high economic and social benefits.

Owner:浙江海禹环保科技有限公司

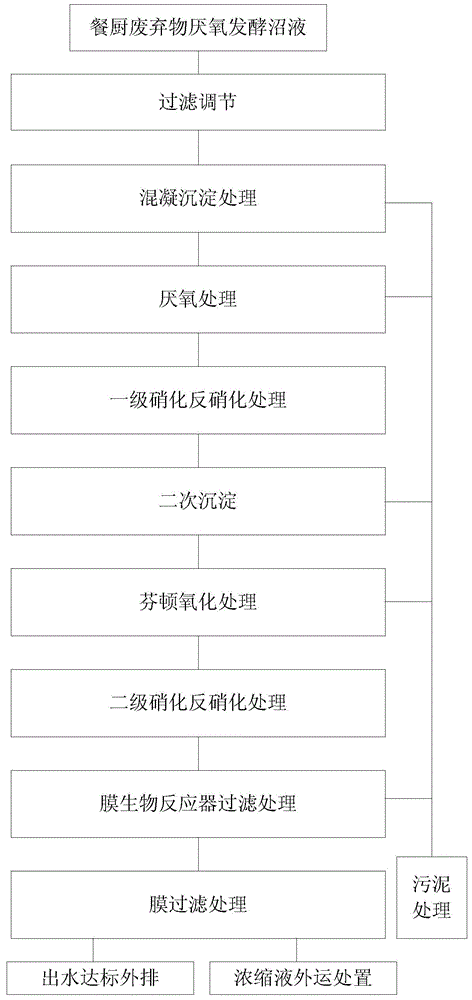

Treatment system and method for biogas slurry produced from anaerobic fermentation of kitchen waste

InactiveCN104478175AGuarantee water qualityGuaranteed uptimeTreatment by combined electrochemical biological processesWaste based fuelFiltrationWater quality

The invention discloses a treatment system and method for biogas slurry produced from anaerobic fermentation of kitchen waste. The system comprises a filtering and adjusting treatment unit, a coagulating sedimentation treatment unit, an anaerobic treatment unit, a primary nitrification and denitrification treatment unit, a secondary sedimentation tank, a Fenton oxidation treatment unit, a secondarynitrification and denitrification treatment unit, a membrane bioreactor filtration treatment unit, a membrane filtration treatment unit and a sludge treatment unit. The method comprises the main following steps: (1), hydraulic screen sieving and water quality and quantity adjustment; (2), coagulating sedimentation treatment; (3), anaerobic treatment; (4), primary nitrification and denitrification treatment; (5), Fenton oxidation treatment; (6), secondarynitrification and denitrification treatment; (7), membrane bioreactor filtration treatment and (8), membrane filtration treatment. The treatment method is resistant to impact load, the system operates stably, the treatment effect is good, pollutant discharge is greatly reduced, and the method has broad applicationprospect.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

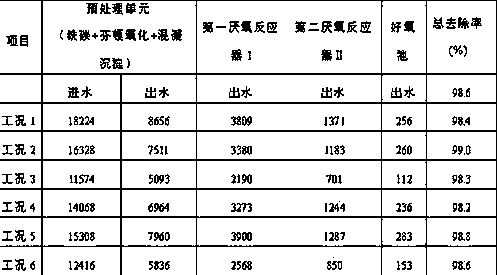

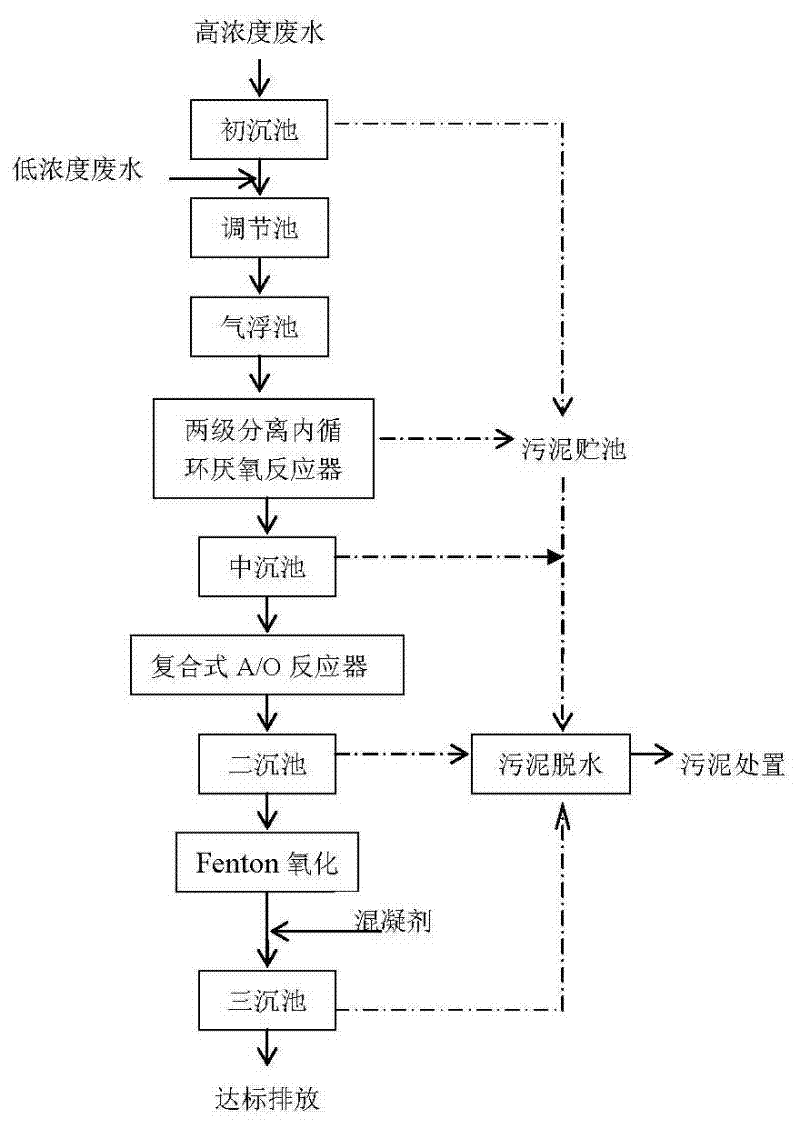

Integrated treatment method for fermentation pharmaceutical wastewater

InactiveCN102351377APollution minimizationLow running costMultistage water/sewage treatmentAmmoniacal nitrogenAnaerobic reactor

An integrated treatment method for fermentation pharmaceutical wastewater belongs to the technical field of waste water treatment and comprises steps that the waste water is pretreated with precipitation and air floatation, then flows through a two stage separation internal circulation anaerobic reactor and a compound A / O reactor for biological treatments, and outlet water is treated with Fenton oxidation. The treatment method reasonably integrates advantages of the internal circulation anaerobic reactor, the compound A / O reactor and the Fenton oxidation technology, has a waste water COD clearance reaching 99% and an ammonia nitrogen clearance reaching 90%, can produce biogas products with economical values and has multiple advantages of low treatment costs, easily controlled operating process, high load of the matching reactors and small land occupation, etc.

Owner:ZHENGZHOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com