Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

494results about How to "Guaranteed Emission Standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

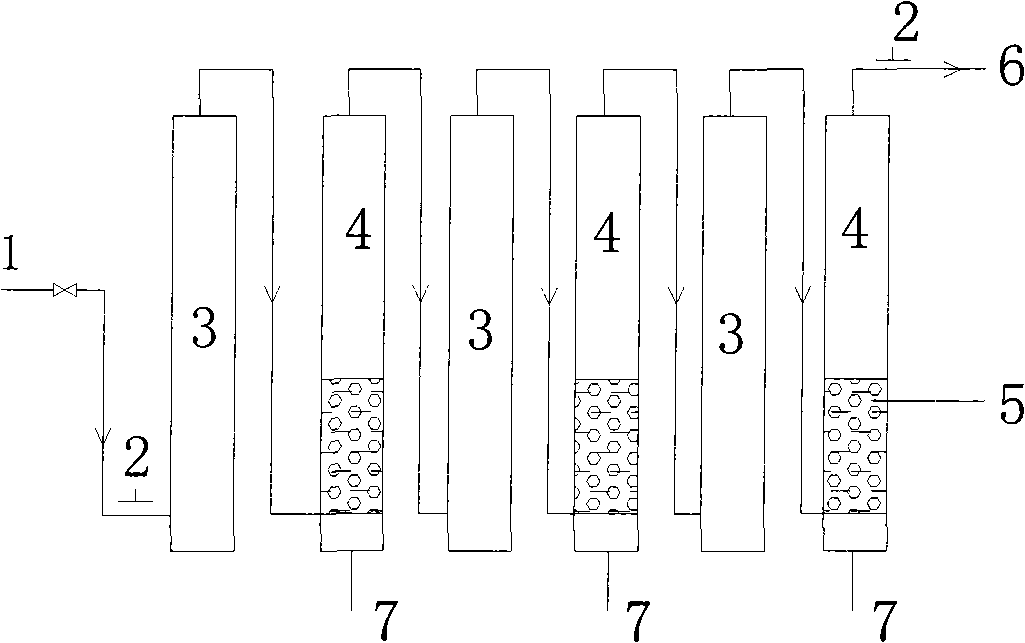

Catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater

InactiveCN101665311AReduce processing loadEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationElectrolysis

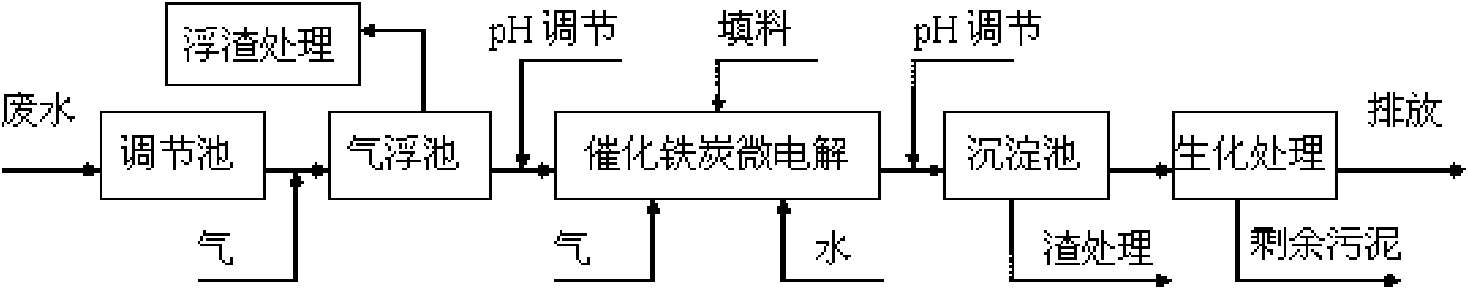

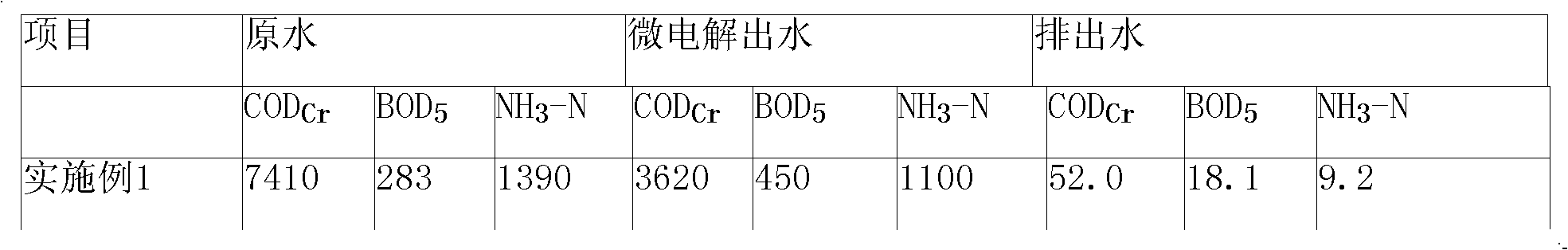

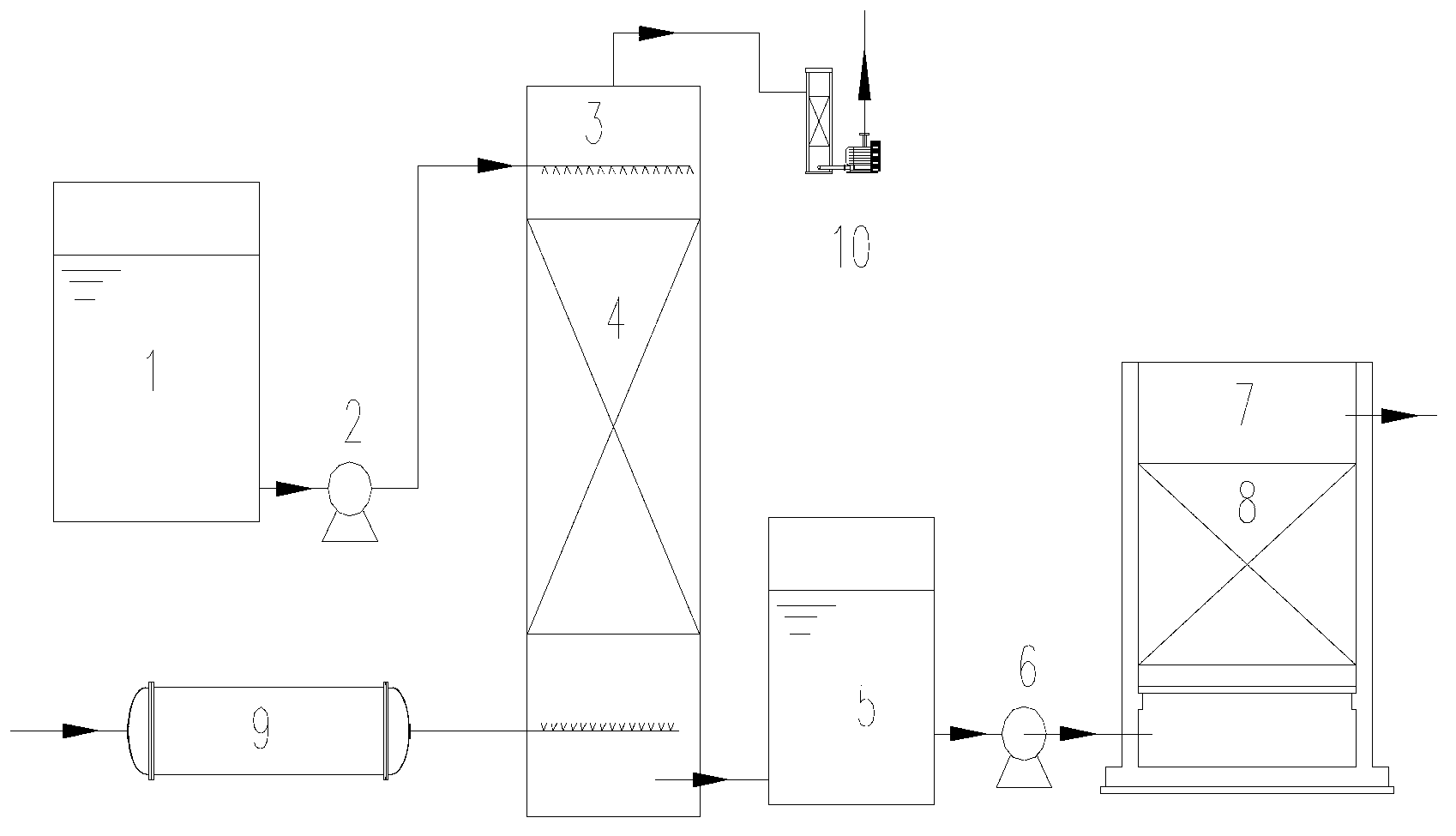

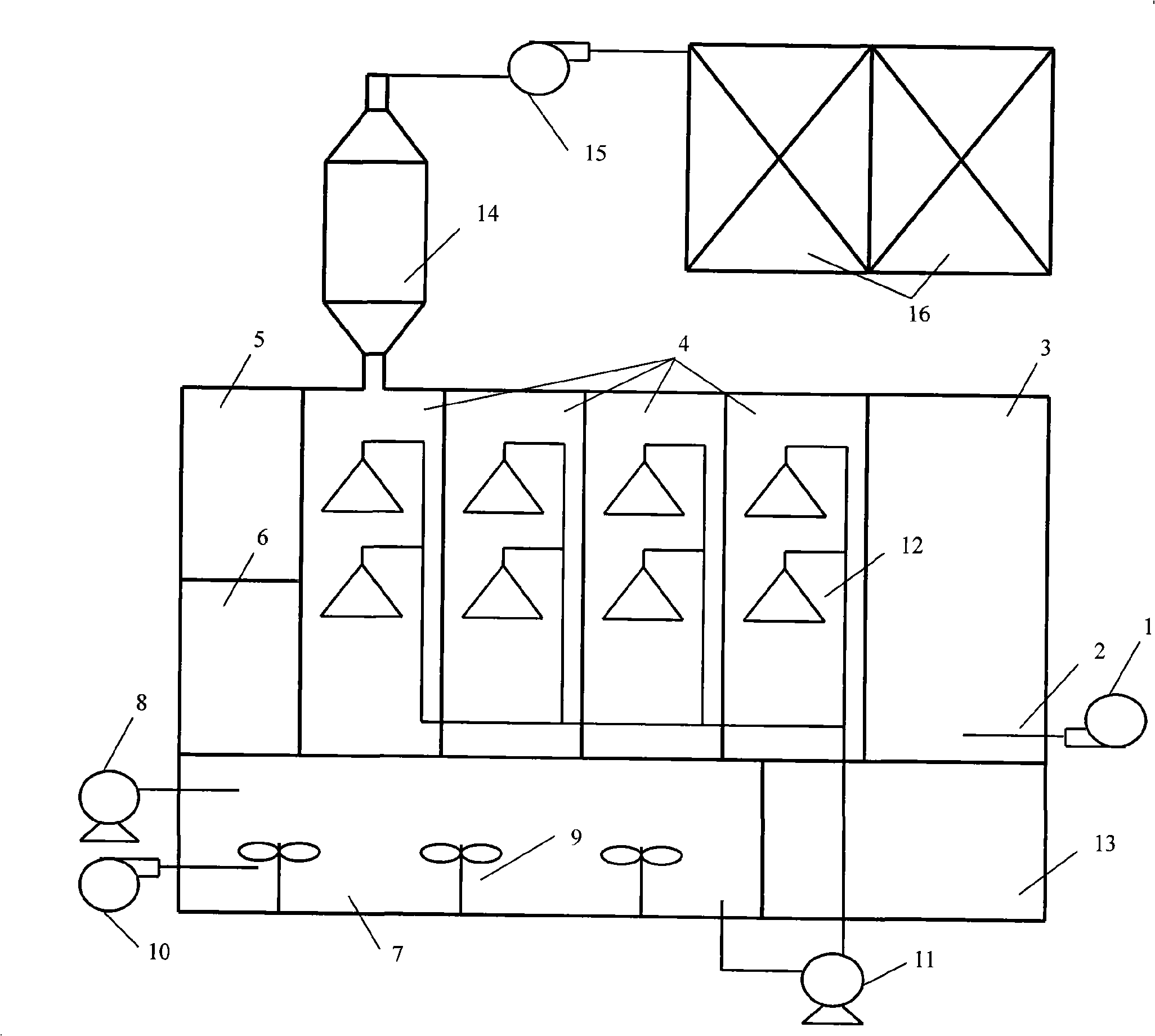

The invention relates to a catalysis and micro-electrolysis combined technology for high-concentration refractory organic wastewater; the organic wastewater is collected to an adjusting tank and enters an air floatation tank for air floatation treatment to remove part of the organic matters after the adjustment of water volume and water quality; the scruff is collected or recovered; the wastewatergoes through Ph adjustment and then enters a catalytic iron-carbon and micro-electrolysis unit to improve the biochemical quality; the effluent goes through Ph adjustment and then enters a sedimentation tank; the effluent of the sedimentation tank adopts anoxic-aerobic biochemistry treatment to remove the organic matters and ammonia nitrogen and then is emitted after reaching the standard; and the filler of the catalytic iron-carbon and micro-electrolysis unit comprises iron, carbon and a catalyst, wherein the mass ratio of the iron, carbon and catalyst is 1: (0.3-1.5): (0.01-0.5). The invention can effectively improve the micro-electrolysis electrochemical reaction efficiency and the degrading capability to the organic matters, and reduce the wastewater treatment cost with convenient technological operation.

Owner:CENT SOUTH UNIV

Deepness denitrogenation method for treating organic wastewater in high concentration

ActiveCN101050026AGuaranteed emission standardsThe process route is compactWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationTotal nitrogen

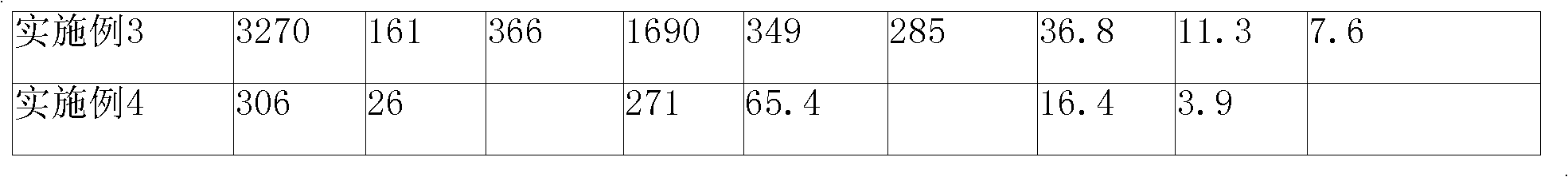

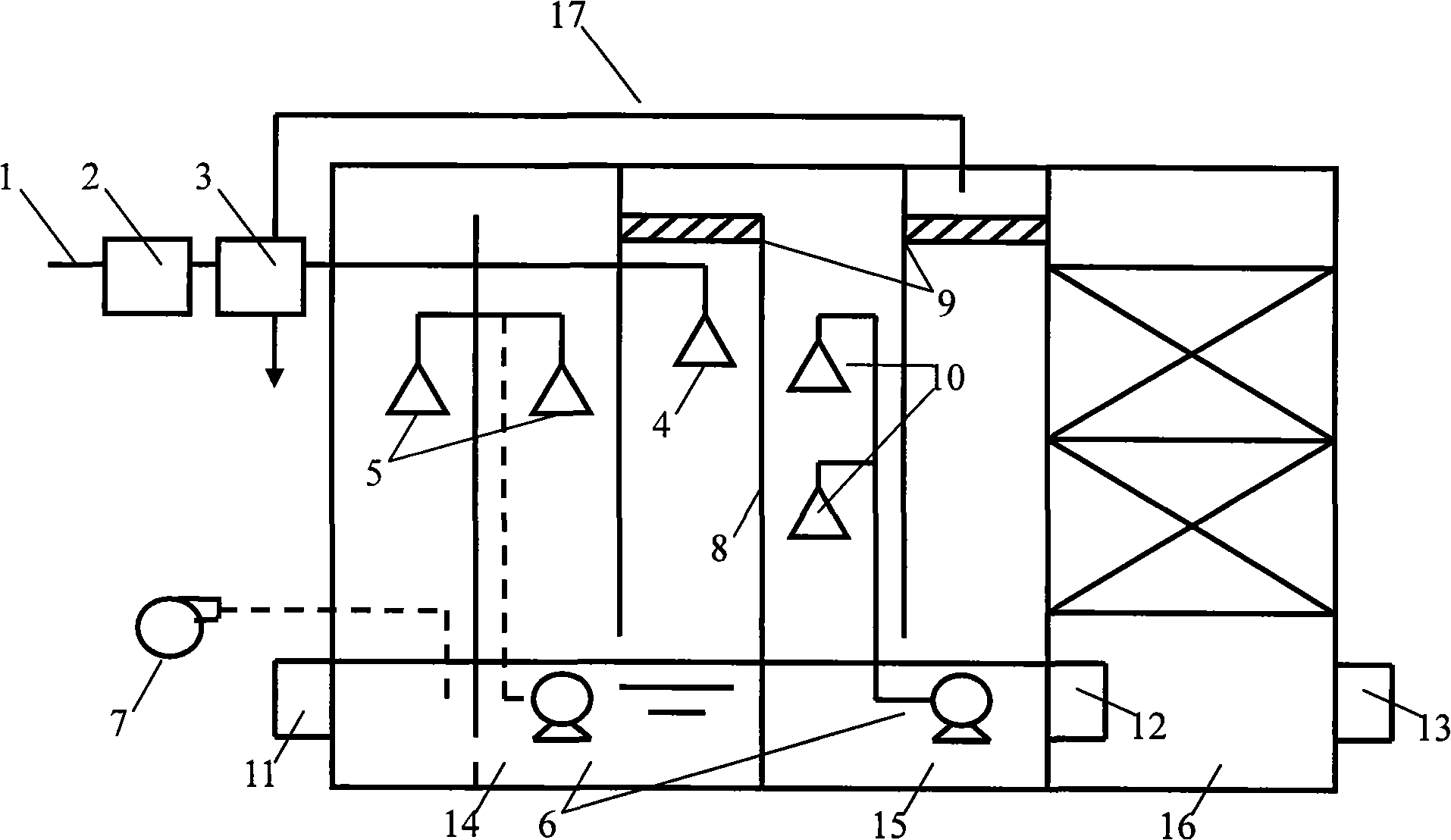

This invention discloses a method for deep denitrification treatment of high-concentration organic wastewater. The apparatus comprises an anaerobic decarbonization zone, an aerobic nitrosation / anaerobic ammoxidation denitrification zone, and a traditional nitrification / denitrification zone. In the anaerobic decarbonization zone, an anaerobic bioreactor is utilized to perform anaerobic biotreatment on the organic pollutants in raw water to remove the majority of organic matters. In the aerobic nitrosation / anaerobic ammoxidation denitrification zone, ammonia nitrogen and nitrite nitrogen are removed in the form of nitrogen gas. In the traditional nitrification / denitrification zone, nitrate in the water discharged from the aerobic nitrosation / anaerobic ammoxidation denitrification zone is subjected to denitrification and removed in the form of nitrogen gas. Excess organic matters are subjected to aerobic bioreaction and removed. The method can ensure COD; total nitrogen and ammonia nitrogen contents in the treated water are qualified for discharge. The method has such advantages as high decarbonization and denitrification efficiency, low energy consumption, and high running stability.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

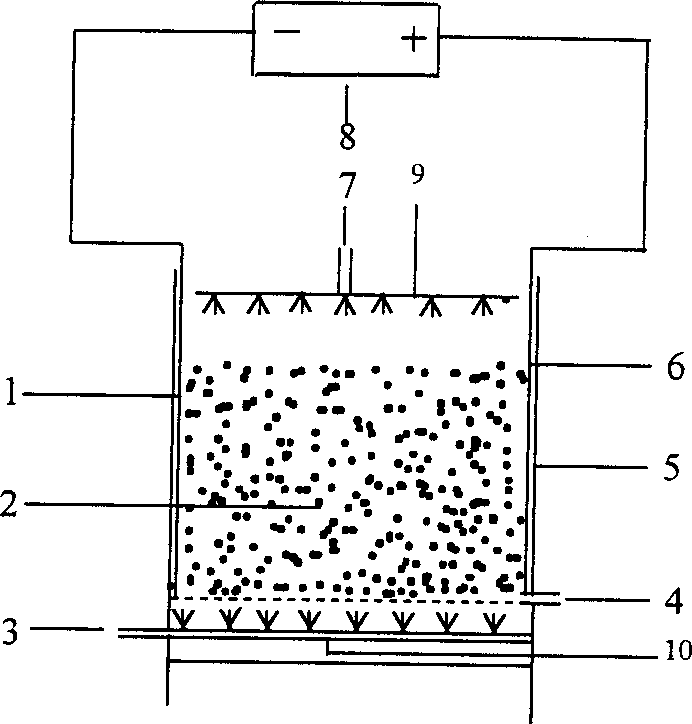

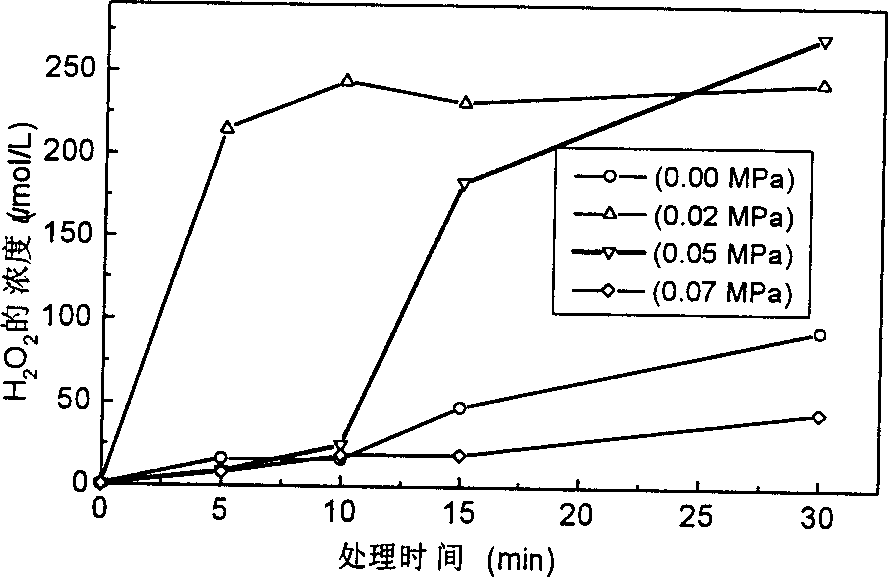

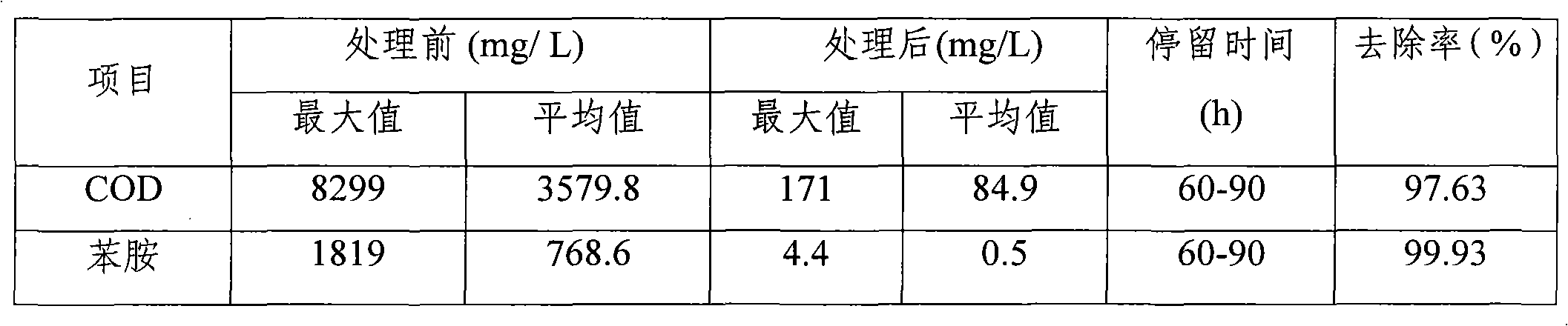

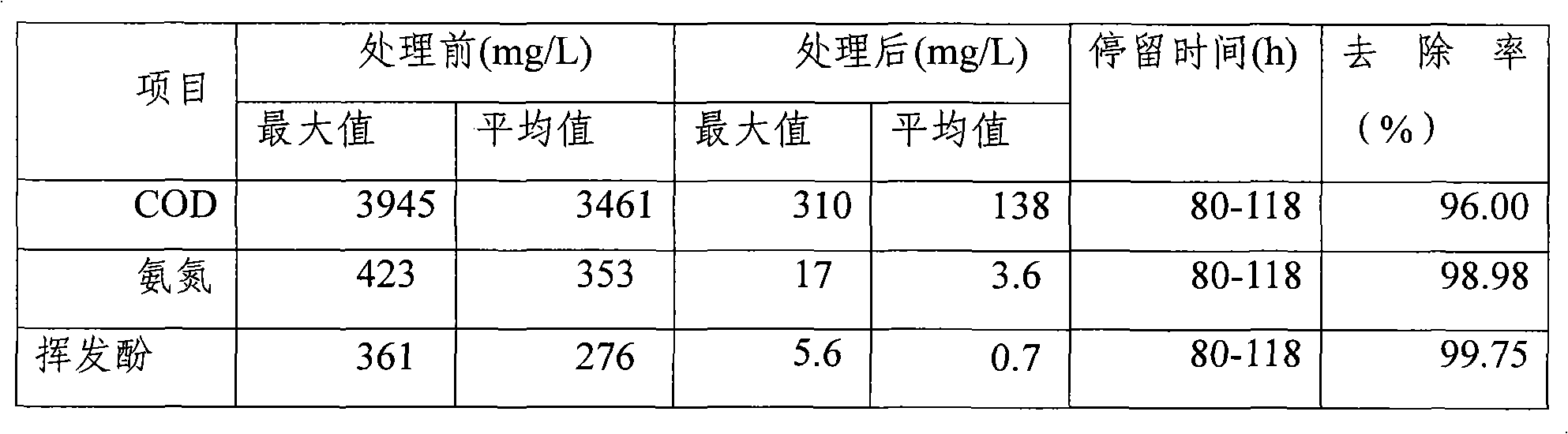

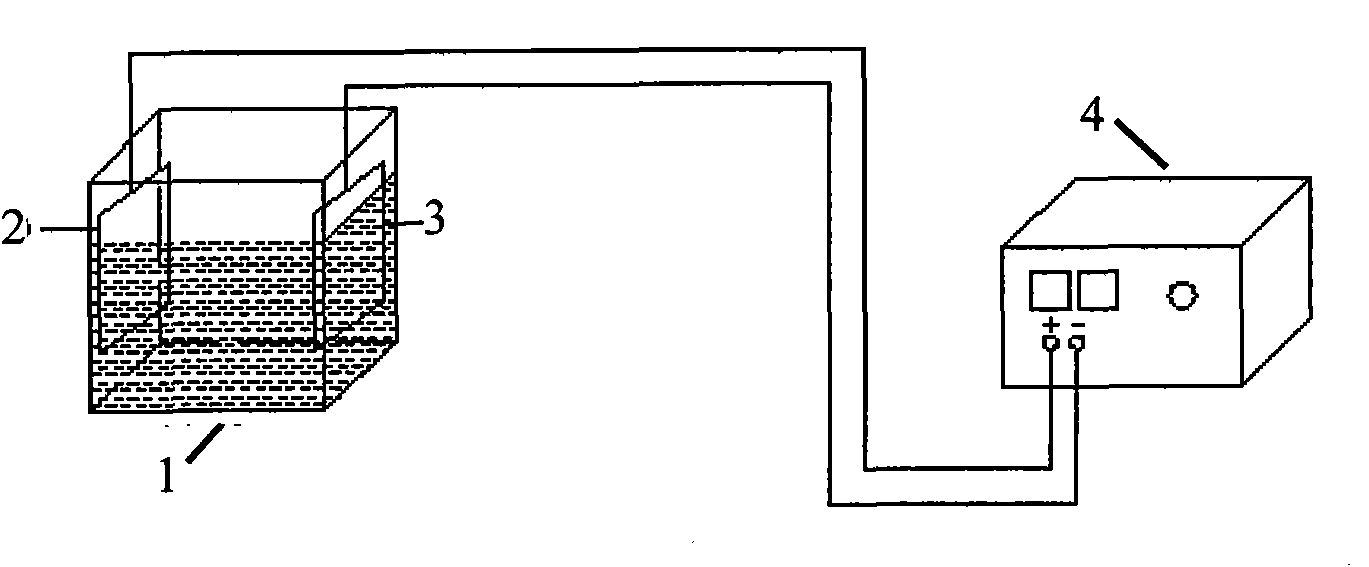

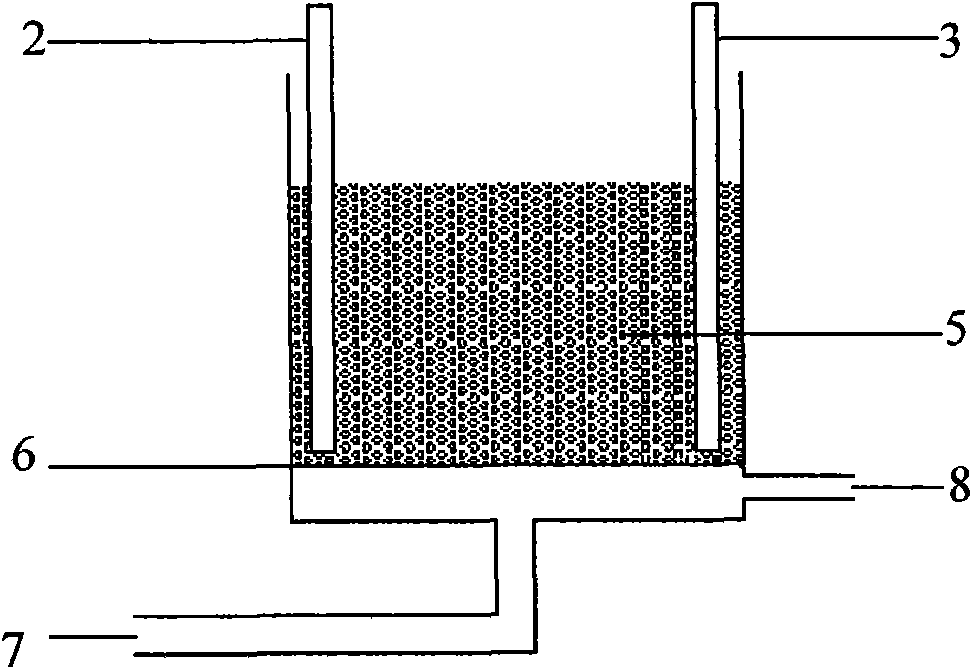

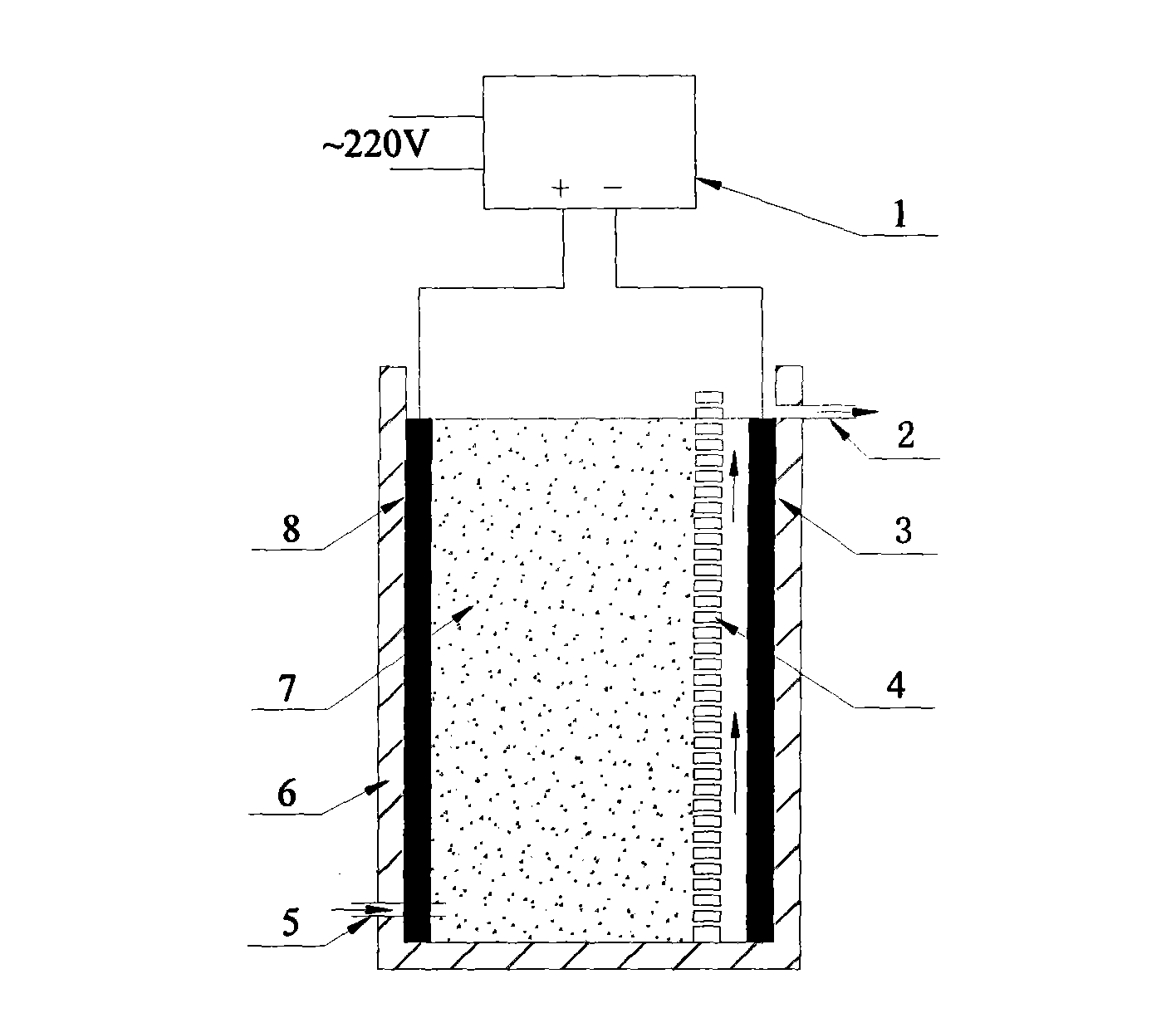

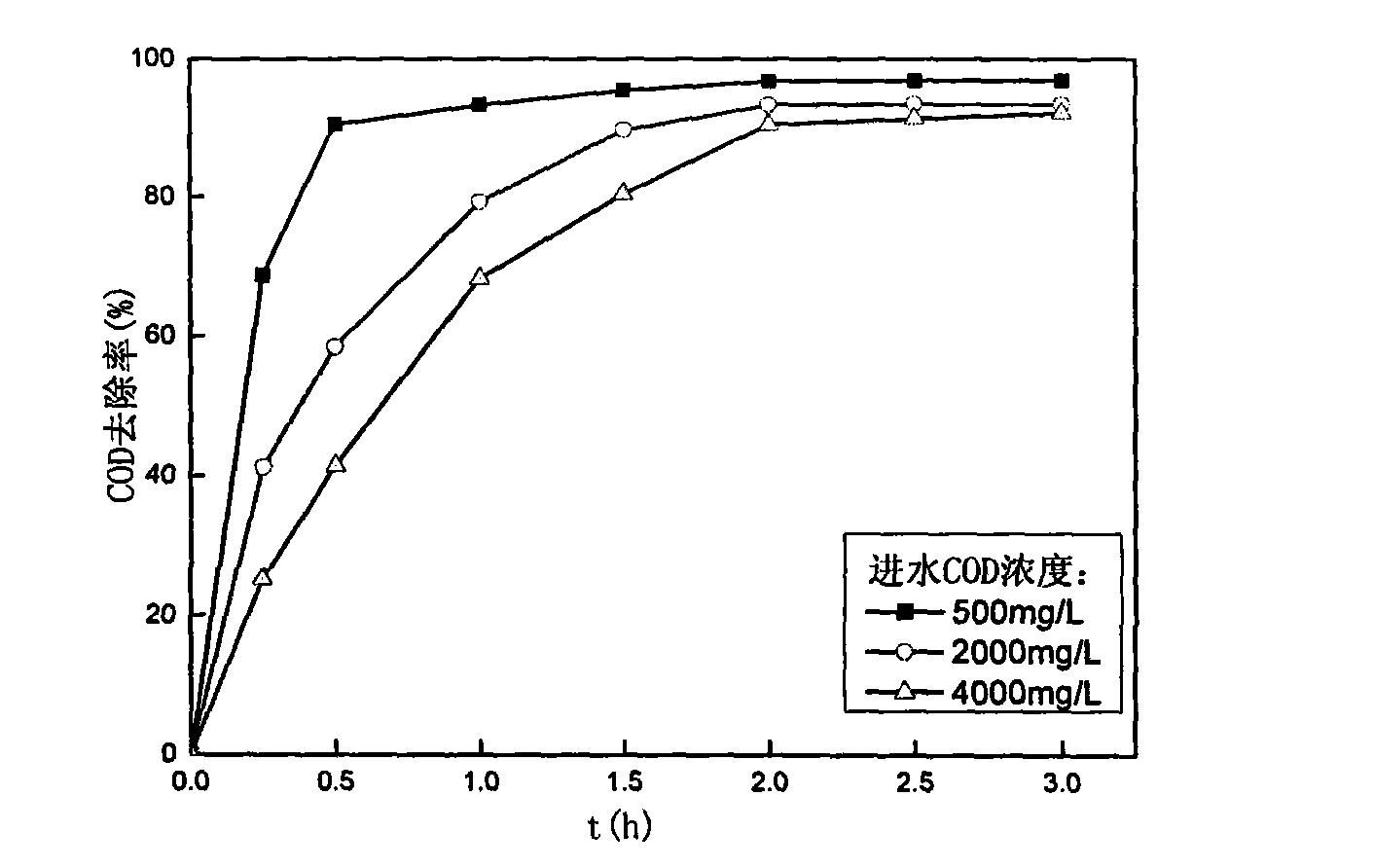

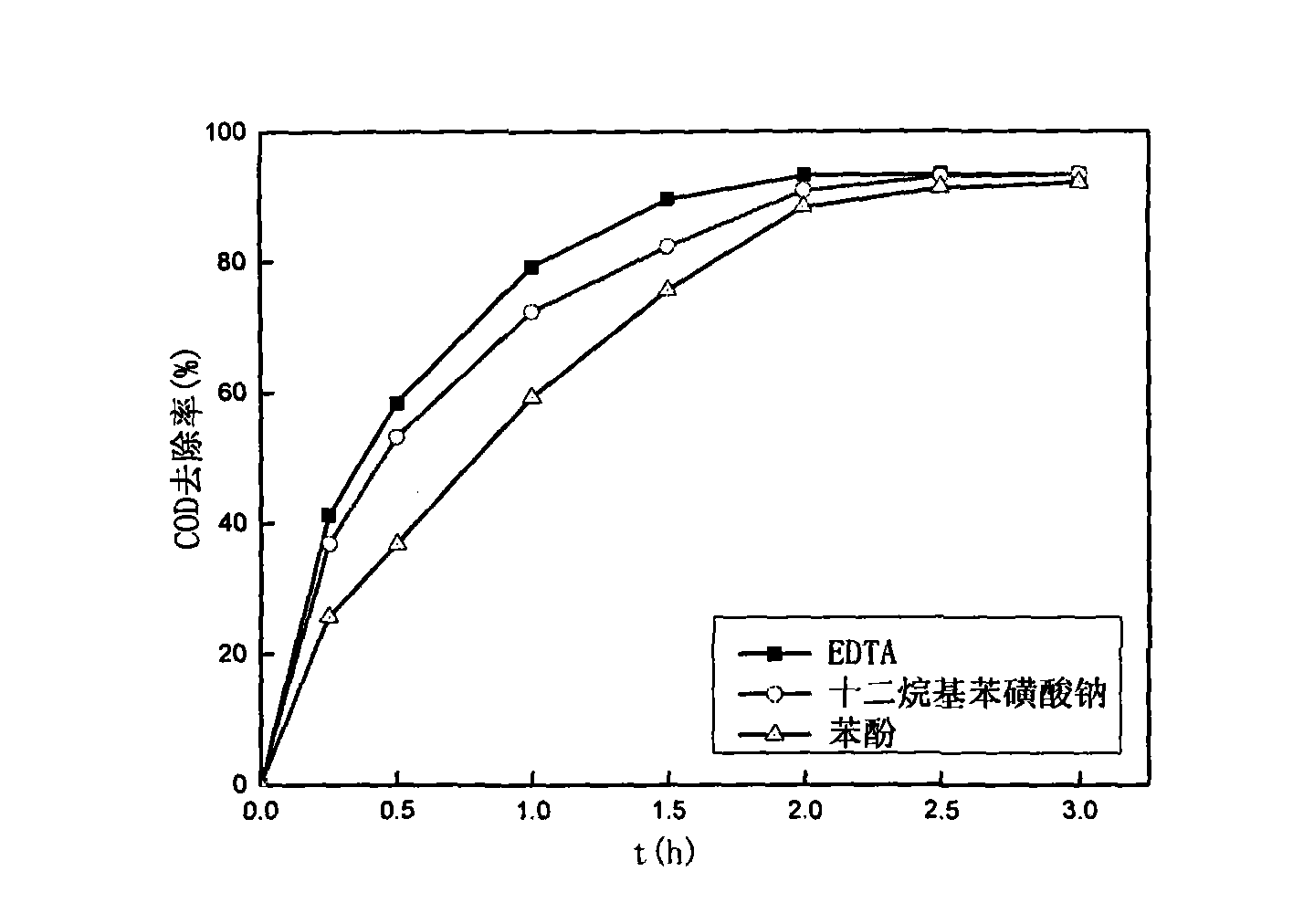

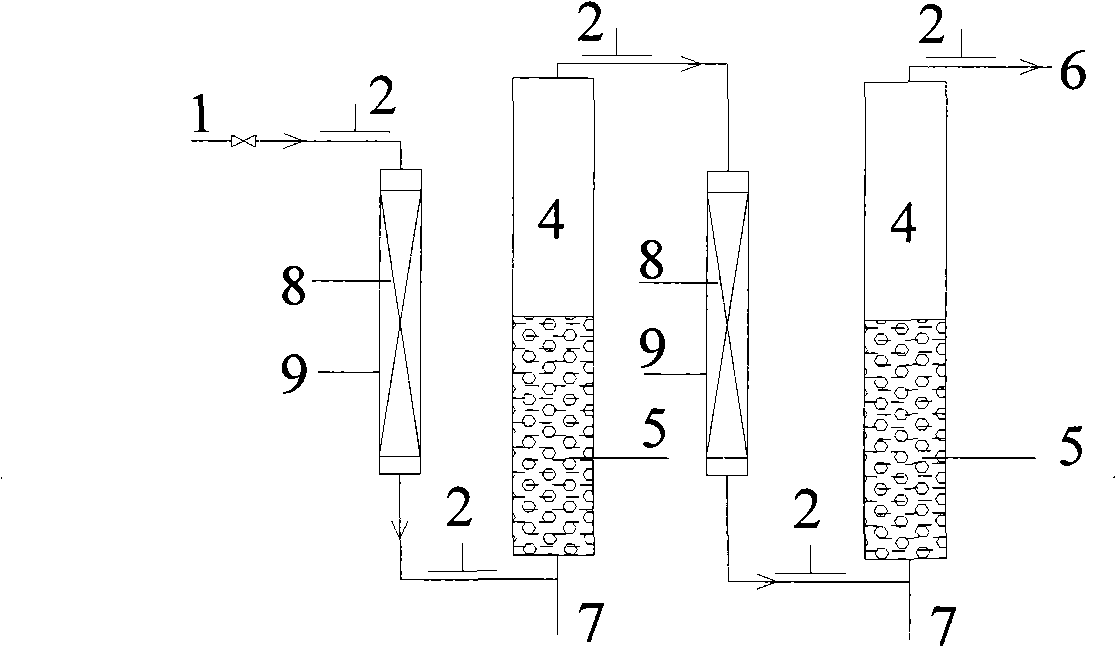

Three-dimension electrode reactor and use for treating organic waste water

InactiveCN1358672AImprove biodegradabilityGuaranteed emission standardsWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationDecompositionPollutant

The present invention relates to a three-D electrode reactor and its application for treating organic waste water. Said reactor is formed from bed body, feeder negative electrode, feeder positive electrode, particle electrode, water-distributing plate, aeration plate and D.C. power supply. It is a three-D electrode reactor using electric energy as excitation energy, air as raw material and particles electrode containing initiating agent as working electrode. Said reactor can produce strong oxidizing agents of H2O2 and OH, and can effectively make oxidation-decomposition, and can compltely mineralize organic pollutant into the inorganic materials of CO2 and water. It can be used for pretreating organic waste water, and can be used for making after treatment of waste water passed through biological chemical treatment so as to ensure standard discharge of waste water.

Owner:SUN YAT SEN UNIV

Composite efficient microbial preparation for treating difficultly-degradable waste water and preparation and application

The invention discloses a composite efficient microbial preparation for treating difficultly-degradable waste water. The composite efficient microbial preparation comprises the following active ingredients of: bacillus, pseudomonas, alcaligenes eutrophus, aspergillus and yeast. The composite efficient microbial preparation has a unique treating effect on high-concentration organic sewage and highammonia and nitrogen sewage which are difficult to treat by the conventional activated sludge process and contain macromolecules and difficultly-degradable harmful constituents.

Owner:北京三泰正方生物环境科技发展有限公司

Particle electrode catalyst filling for three-dimensional electrode and preparation method thereof

InactiveCN1669942ALess investmentLower energy costsWater/sewage treatment by oxidationWastewaterCopper oxide

The invention discloses a particle electrode catalyst filling for three-dimensional electrode and preparation method, calculated by weight percent, the material comprises activated charcoal 50-54%, adhesive 14-19%, the initiating agent comprises 13-16% ferrum oxide, 12-15% copper oxide, 4-7% manganese oxide, 1-1.5% zinc oxide, 0.5-1% zirconium oxide, 0.5-1% cerium oxide.

Owner:SUN YAT SEN UNIV

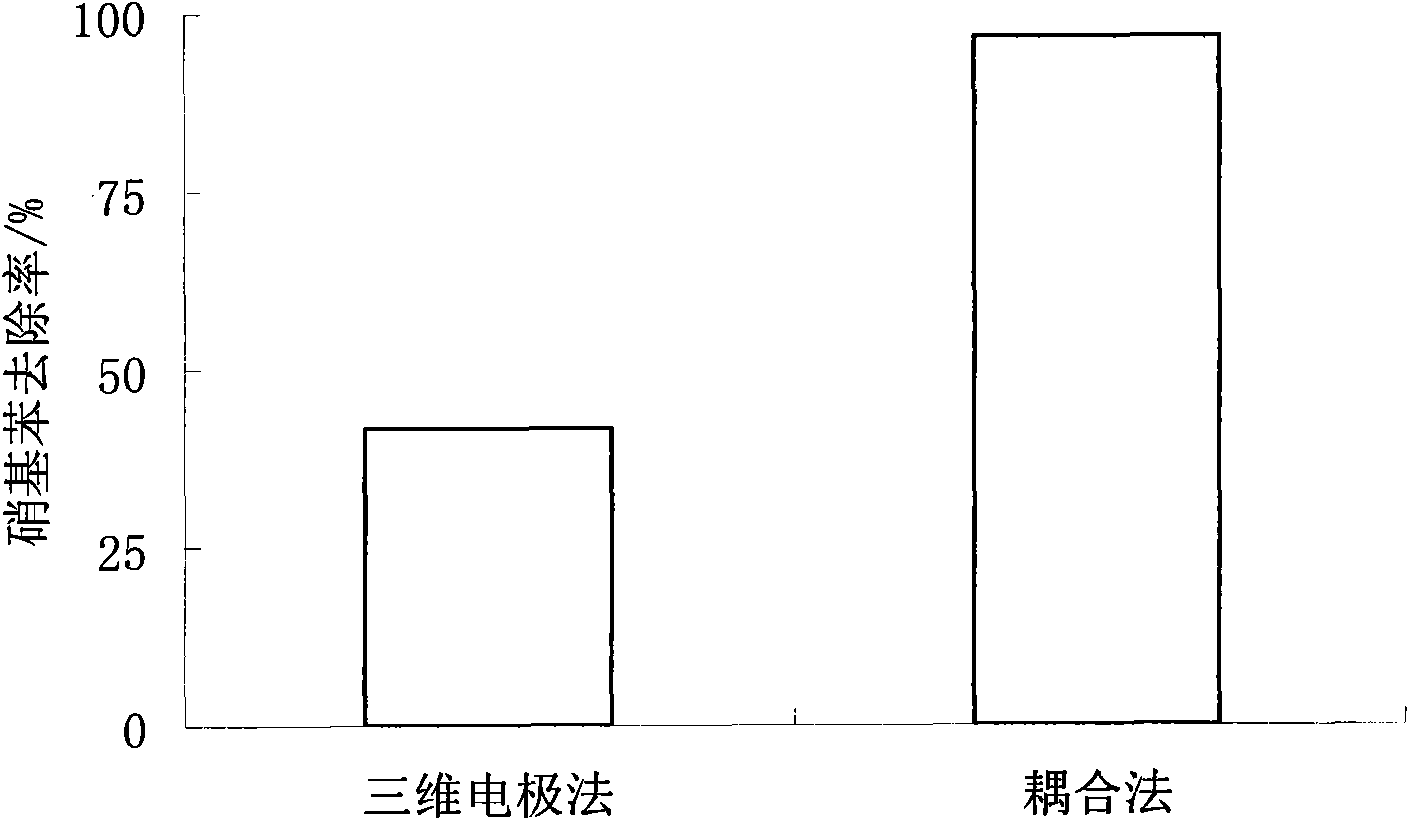

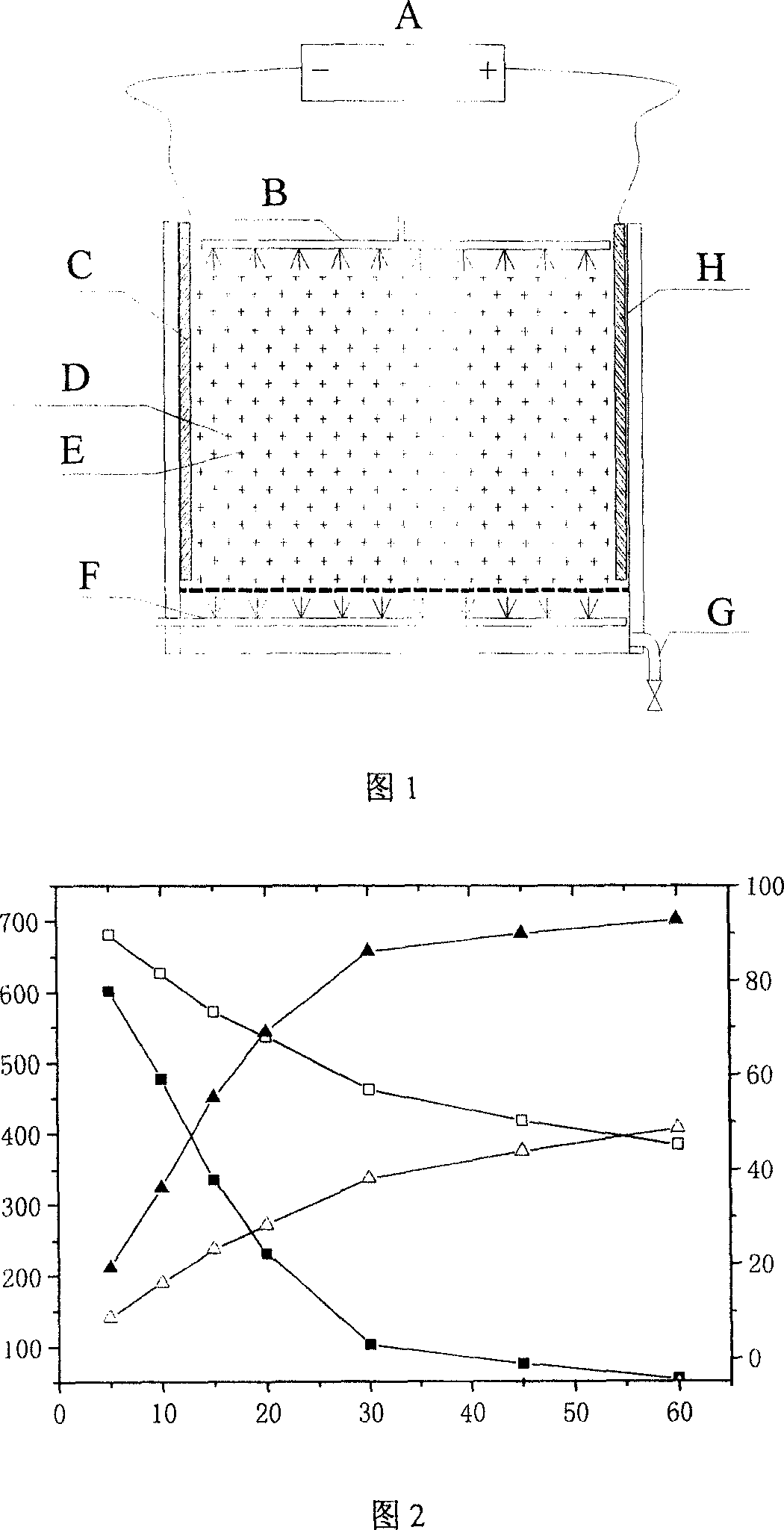

Method for degrading nitrobenzene waste water by polyphase electrocatalytic oxidation-Fenton coupling process and reactor thereof

ActiveCN101838074AGuaranteed emission standardsPromote generationMultistage water/sewage treatmentWater/sewage treatment by oxidationCarbon dioxideHigh concentration

The invention belongs to the technical field of treatment of high concentration organic waste water, and particularly relates to a method for degrading nitrobenzene waste water by a polyphase electrocatalytic oxidation process. The invention solves the problems of high cost and long time consumption in the traditional nitrobenzene waste water methods, low efficiency and high energy consumption in the electrolytic process, high oxidant consumption, high cost and the like in the Fenton process in the prior art for treating high concentration nitrobenzene water waste. The invention mainly adopts the catalytic oxidation action of transition metal catalysts in the electric field, and combines the Fenton process, thereby effectively degrading the high concentration nitrobenzene waste water. The method comprises the following steps that: (1) heterocatalytic reagents (solid catalysts) and particle electrodes, mainly including active carbon, and transition metal oxides and salts, are used for avoiding economic loss and secondary pollution to the environment, which are caused by catalyst loss in heterocatalytic oxidation; (2) under the condition of low pH value of the waste water in cooperation with Fe2+ with strong reducibility, a coupling reactor composed of an electrolysis field and oxidation reaction is used for generating chain reaction for generating an OH hydroxyl free radical, and the OH hydroxyl free radical can carrying out nonselective oxidization on organic substances, thereby finally oxidizing organic pollutants into carbon dioxide and water; (3) by using electric energy as an excitation energy and using cheap air as raw material, nitrobenzene substances in waste water are efficiently degraded under the coupling action of the polyphase electrocatalytic oxidation process and the Fenton process; (4) and the reactor is composed of a direct current regulated power supply, a feed electrode and an electrolytic bath.

Owner:广东华凯明信科技有限公司

Granular electrode catalyst stuffing for 3D electrode reactor and its preparing method

InactiveCN1986434ALow ashLarge specific surface areaOther chemical processesWater/sewage treatment by electrochemical methodsFilm-coated tabletWater quality

The present invention is granular electrode catalyst stuffing for 3D electrode reactor and its preparation process. The electrode catalyst stuffing consists of modified active carbon 60-70 wt% and film coating active carbon 40-30 wt%. The modified active carbon is prepared with active carbon through acid or alkali modification, oxidizing modification and metal supporting modification; and the film coating active carbon is prepared with active carbon through acid or alkali modification and soaking in cellulose acetate solution. The 3D granular electrode stuffing is used in waste water treatment, and has the advantages of great adsorption capacity, fast reaction speed, stable treating effect, etc.

Owner:NANJING UNIV OF TECH

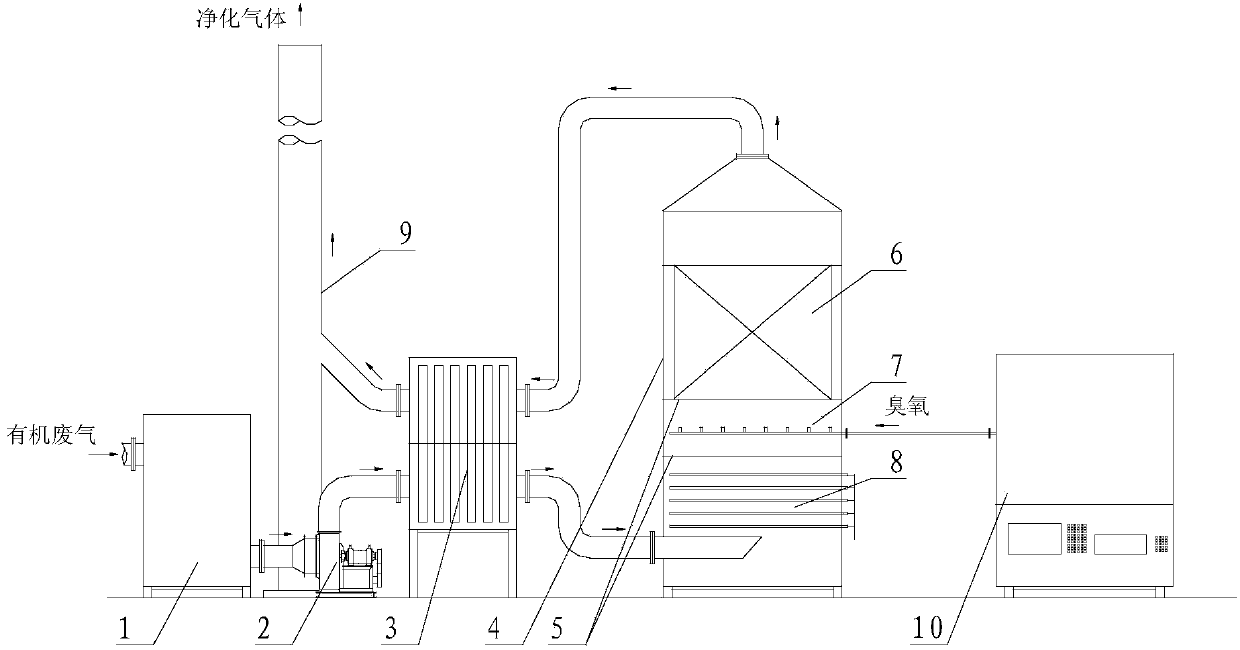

Device and method for treating organic waste gas by catalysis and ozonation

ActiveCN103721563AReduce energy consumptionWith processing efficiencyDispersed particle separationCatalytic oxidationPre treatment

The invention discloses a device and a method for treating organic waste gas by catalysis and ozonation. The method comprises the following steps: (1) the organic waste gas is collected and enters a pretreater, the waste gas is pretreated and oil drops, particulate matter, acid etchant gas and fog drops in the waste gas are intercepted; (2) after the pretreated organic waste gas is pressurized by an induced draft fan, the organic waste gas enters the cold end of a heat exchanger to be preheated; (3) the preheated organic waste gas enters a catalytic oxidation device, the organic waste gas entering the catalytic oxidation device is warmed up and then is mixed with ozone fed into the catalytic oxidation device, and the mixed gas enters a catalytic oxidation reaction region of the catalytic oxidation device to be subjected to the catalytic oxidation reaction so as to remove organic pollutants; (4) the purified gas serving as a heat source enters the hot end of the heat exchanger in the step (2) to be subjected to heat exchange and the gas subjected to heat exchange is discharged by an exhaust pipeline. When being combined with the treatment device disclosed by the invention, the treatment method disclosed by the invention has a better purifying effect on the waste gas and not only ensures purifying efficiency of the waste gas, but also is energy-saving and environment-friendly.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

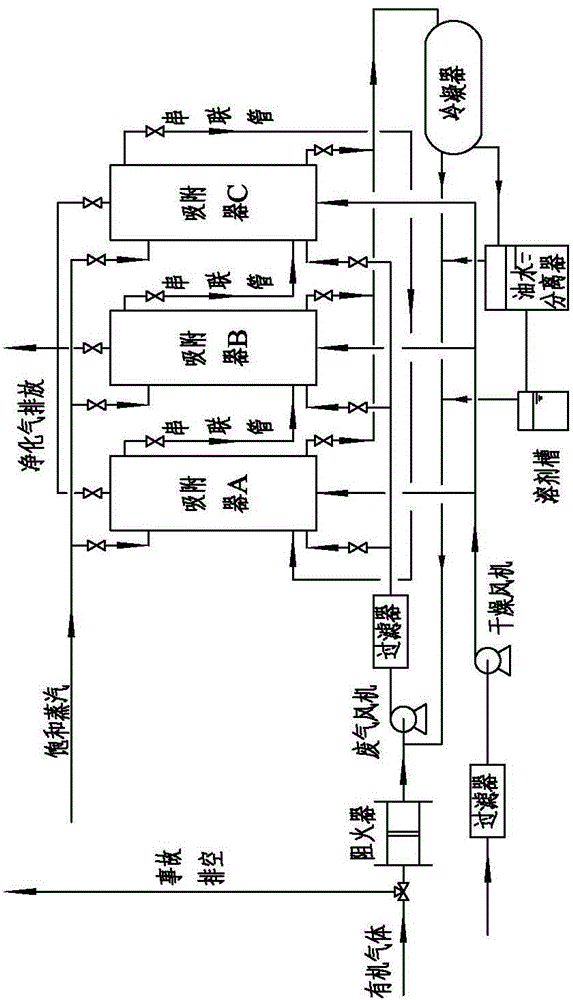

Method for multistage adsorption and recovery of organic gases through active carbon fiber

InactiveCN104906917AGuaranteed emission standardsFlexible operationDispersed particle separationFiberOrganic solvent

The invention provides a method for multistage adsorption and recovery of organic gases through active carbon fiber. All adsorbers can operate the organic gases in a series-parallel manner through series tubes arranged between every adjacent adsorbers to realize multistage adsorption of the organic gases, the highest adsorption grade can reach (N-1) grade (N is the quantity of the adsorbers contained in a system), and the opening or closure of the series tubes can be controlled to switch the adsorption grade between 1 and (N-1). After the adsorbers are saturated, saturated steam is used to desorb the adsorbers, desorbed steam is processed through a condenser and an oil-water separator, and an organic solvent is recovered. The desorbed adsorbers are dried and regenerated by air or an inert gas, then enter an adsorption process, and respectively work according to the above flow in a circulating manner, and the last stage adsorption in the adsorption process is desorption of the regenerated adsorbers. Compared with present multistage adsorption technologies, the method has the advantages of agile operation, low running cost, small device investment, high adsorption grade and obvious investment saving.

Owner:北京日新达能技术有限公司

3D electrode reactor and application to non-degradable organic wastewater treatment

InactiveCN101514040AImprove biodegradabilityGuaranteed emission standardsWaste water treatment from textile industryWater/sewage treatment by oxidationHigh concentrationBiochemical Process

The invention relates to a wastewater treatment device, in particular to a 3D electrode reactor applicable to non-degradable organic wastewater treatment. The reactor consists of a tank, an electrode cathode, an electrode anode, a particle electrode, a diaphragm plate and a DC power supply; the 3D electrode reactor takes electric energy as excitation energy, and takes the particle electrode with catalytic activity as a work electrode. The reactor can be used for ordinary organic wastewater treatment and the non-degradable organic wastewater treatment to reach standard stably; the reactor can be used for pretreatment of non-biodegradable organic wastewater with high concentration to decompose the wastewater into easily biodegradable organic matters with smaller molecular weight to greatly enhance biodegradability of the wastewater; and the reactor can also be used for post-treatment of wastewater biochemical process to ensure that wastewater discharge reaches the standard.

Owner:CENT SOUTH UNIV

Gas phase oxidation-liquid phase reduction method for absorbing and removing nitrous oxides in exhaust air

InactiveCN101279185AAchieve emission standardsSimple processDispersed particle separationGas phaseEmission standard

The invention provides a gas-phase oxidation / liquid-phase reduction method for absorbing and removing NOx. The method utilizes O2 in waste gases as an oxidizer; after be processed by non-catalyst oxidization or catalyzed oxidation by modified active carbon materials, NOx waste gas with low oxidization degree reacts with an alkaline reducing solution fully to remove NOx. After going through multi-grade oxidization, reduction and absorption, the NOx in waste gases can fully meet the emission standard. The method of the invention has the advantages of being able to realize up-to-standard emission of NOx waste gas with low oxidization degree, simple technique, small cost and high removing efficiency.

Owner:ZHEJIANG UNIV OF TECH

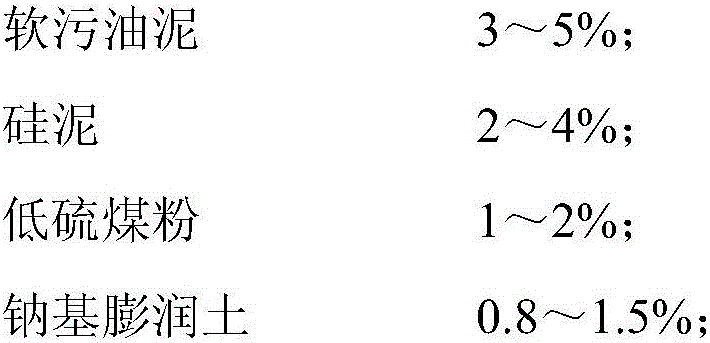

Sulfur-fixing combustion-supporting high-temperature profile control agent, and preparation method and application thereof

ActiveCN106833588AImprove temperature resistanceImprove seal strengthDrilling compositionFiberCellulose

The invention provides a sulfur-fixing combustion-supporting high-temperature profile control agent, and a preparation method and application thereof. By taking the total weight of the sulfur-fixing combustion-supporting high-temperature profile control agent as 100%, the profile control agent is prepared from the following raw materials in percentage by weight: 3-5% of soft oil sludge, 2-4% of silicon sludge, 1-2% of low sulfur coal powder, 0.8-1.5% of sodium bentonite, 0.5-1.2% of plant fiber particle, 0.2-0.3% of saltpetre powder, 0.1-0.2% of coal gangue powder, 0.2-0.4% of limestone powder, 0.1-0.2% of polyanionic cellulose, 0.08-0.15% of alpha-sodium olefinsulfonate, 0.1-0.2% of sodium tripolyphosphate and the balance of water. The profile control agent has favorable stratum compatibility, causes no damage to the oil reservoir, does not pollute the stratum, and has favorable temperature tolerance; and meanwhile, the profile control agent has sulfur-fixing and combustion-supporting functions, thereby being completely applicable to a profile control technology for a thick oil fireflood chemical profile control gas injection well.

Owner:PETROCHINA CO LTD

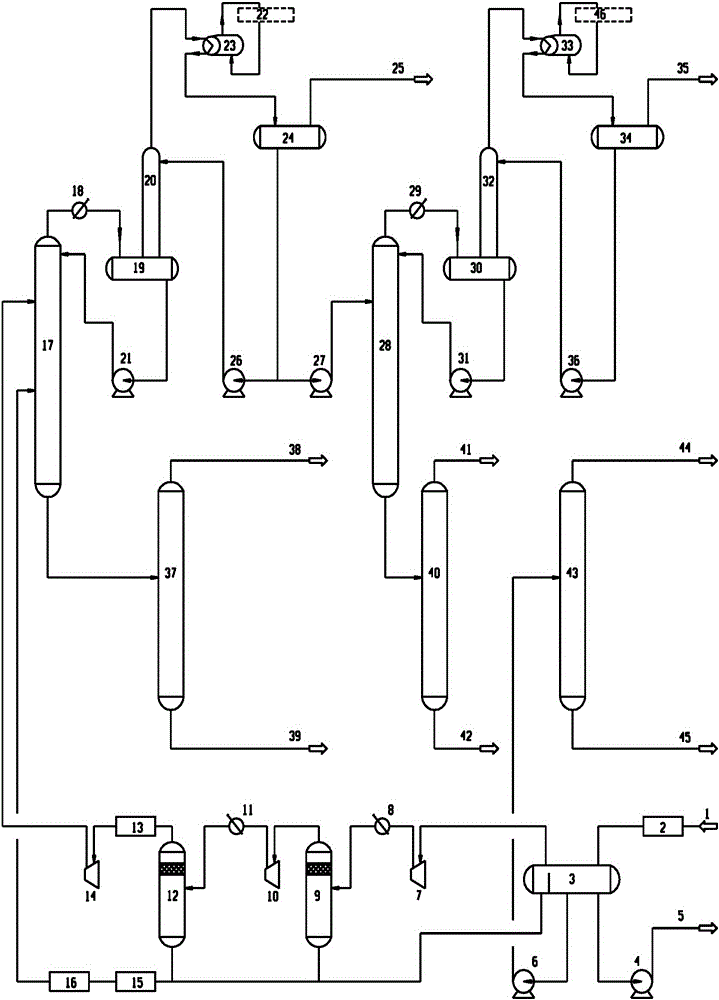

Separation method for methanol-to-propylene (MTP) reaction product

ActiveCN106316752AGuaranteed emission standardsReduce the temperatureDistillation purification/separationHydrocarbonsFractionating columnLiquid phase

The invention discloses a separation method for a methanol-to-propylene (MTP) reaction product. According to the method, gas-phase feedstock and liquid-phase feedstock, which are obtained through subjecting the MTP reaction product to pretreatment and reaction product separator separation, sequentially enter a debutanizer and a deethanizer for treatment, treatment is carried out by a debutanizer refluxing tank top fractionating column debutanization and deethanizer refluxing tank top fractionating column deethanization combined process, and then, polymerization-grade propylene is obtained. According to the method, the product quality and recovery rate of the propylene can be effectively guaranteed, meanwhile, the debutanizer and the deethanizer have no need of being operated at low temperatures, and a fractionating system is energy-saving remarkably.

Owner:SINOPEC GUANGZHOU ENG +1

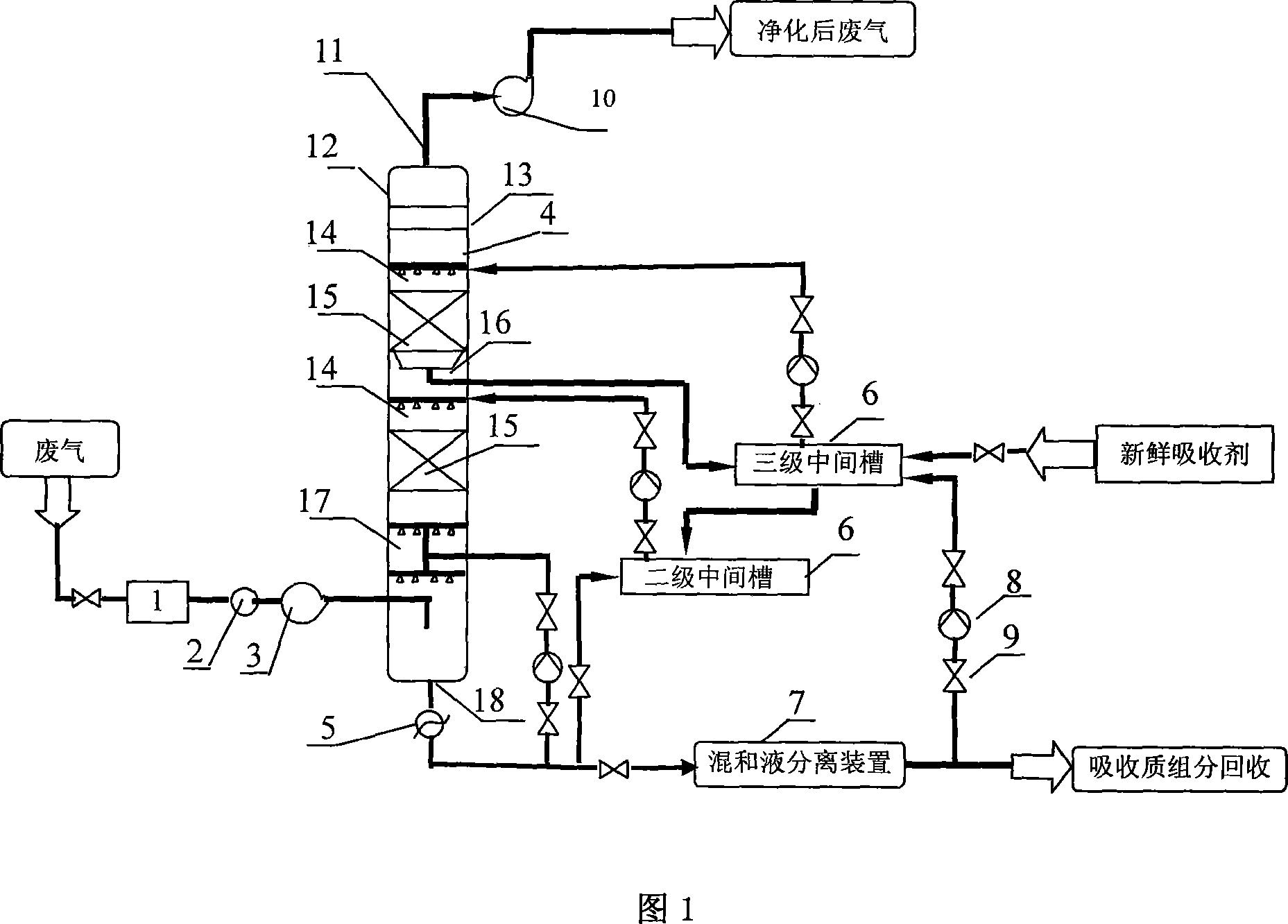

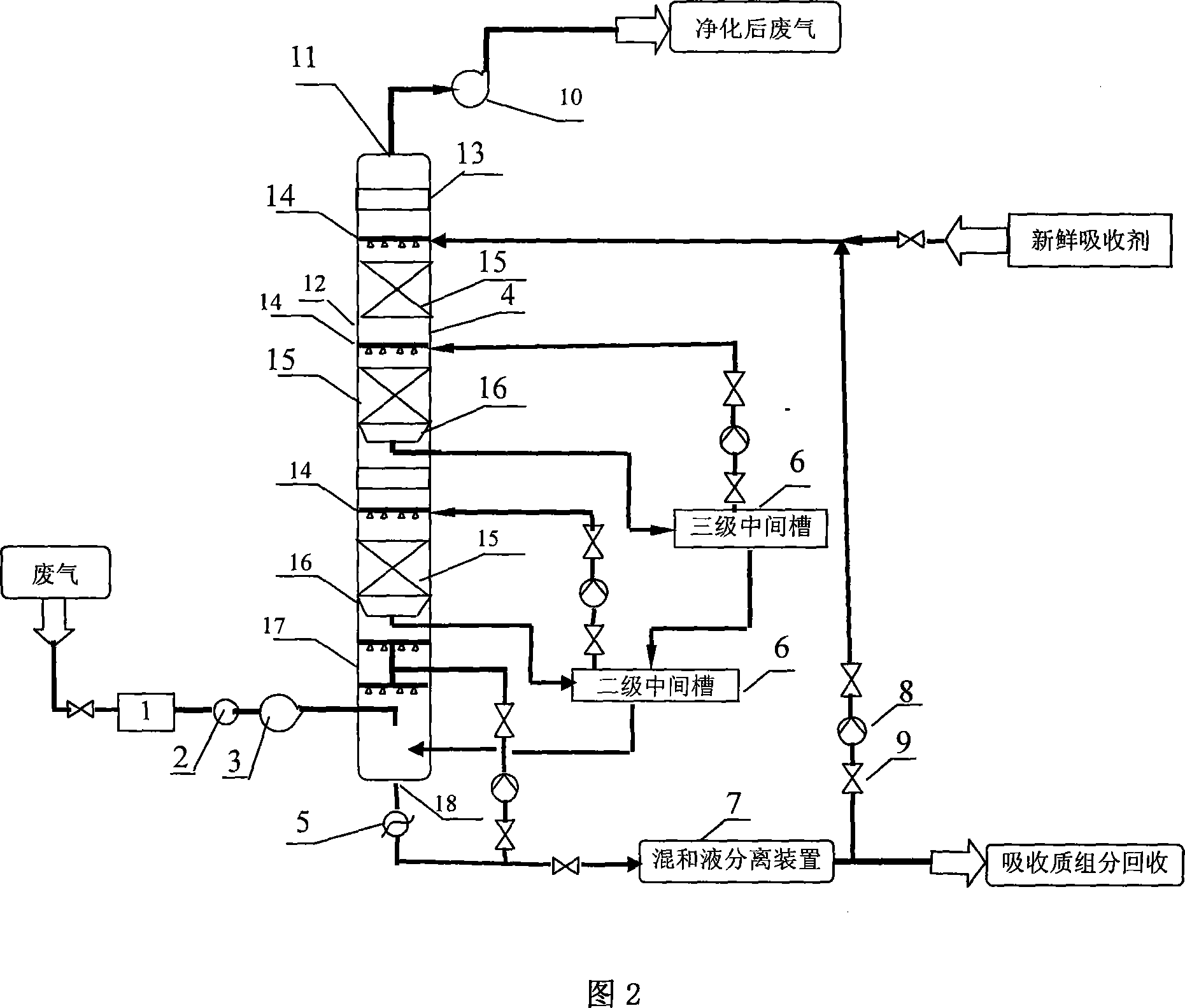

Process method of purifying and recycling mixed organic waste gas

InactiveCN101108296APromote absorptionHigh flash pointDispersed particle separationChemical industryOrganic solvent

The invention belongs to chemical industry and waste gas process field, in particular providing a process method which mixes organic waste gas purifying and resource recovery. The specific procedure is that: make the mixed waste gas pass through a filter to be filtered, and then enters into a single-seat multilevel absorption tower and contacts with a packing layer and a liquid distribution device; when the series of the single-seat tower is 3, the second-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising the mixing liquid which is pumped in after cooled by a heat interchanger at the bottom of the adsorption tower and the mixing liquid which generates in the middle groove of the third-grade; the third-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising fresh absorbent, the regenerating liquid recycled by a mixing liquid separation device and the collecting liquid collected by a collecting hopper of third-grade; when the series of the single-seat tower is N and is larger than 3, all grades of absorbent from the second grade to the N minus 2 is a mixing liquid comprising a mixing liquid generated in the middle groove of the next grade and a collecting liquid collected by the collecting hopper on the same grade, the absorbent of the N minus grade is the colleting liquid collected by the collecting hopper of the N minus 1 grade, the absorbent of the N grade is a mixing liquid comprising of pumped fresh absorbent and the regenerating liquid recycled by the mixing liquid separation device. The fresh absorbent is an environment-protected organic solvent with high boiling point, strong lipophilicity and low volatility. The invention can recycle a plurality of organic infectant in waste gas, the technics procedure is simple, practical, and the operation cost is low.

Owner:上海同济华康环境科技有限公司

Treatment method for slaughter wastewater

InactiveCN105110565AImprove biodegradabilityFunctionalWaste water treatment from animal husbandryMultistage water/sewage treatmentAutomatic controlSludge

The invention discloses a treatment method for slaughter wastewater. The treatment method includes the steps of pretreatment, biochemical treatment, precipitation separation, oxidative decolorization, activated carbon adsorption, disinfection treatment and sludge concentration. Through adopting the advanced, practical, mature and reliable treatment technology, the inflow requirements for water large in water quality fluctuation and amount are met, and it is ensured that the treated wastewater can not be discharged until reaching standards. By the adoption of the reasonable technology and reasonable arrangement, the construction cost is lowered as far as possible, and on the premise of guaranteeing safe, economical and stable operation of a system, the good treatment effect is achieved with the minimum investment. Based on the rule of the advanced and mature technology and reliable quality, the relation between manual operation and automatic control is reasonably handled, an automation technology is adopted for the step where manual operation is inconvenient, and the labor cost is high, and therefore the operation management level of the system is increased.

Owner:济南兄弟环保科技有限公司

Treatment process of antibiotic wastewater

ActiveCN104671597ASimple facilitiesSimple and fast operationMultistage water/sewage treatmentEmission standardOxygen

The invention discloses a treatment process of antibiotic wastewater. The treatment process comprises the following steps: firstly carrying out coagulating sedimentation pretreatment on wastewater, and adding acidized supernate into a hydrolysis acidification pool; mixing returned sludge, anaerobic effluent and hydrolysis acidification effluent in proportion in a water distribution pool, and simultaneously regulating the pH value; feeding the regulated wastewater into a anaerobic treatment stage, converting most pollutants into water and carbon dioxide, simultaneously producing marsh gas, carrying out gas-solid-liquid separation by virtue of a three-phase separator, collecting marsh gas in a gas chamber, returning the sludge to a reaction region, returning partial supernate to the water distribution pool, and sequentially feeding rest supernate into an aerobic treatment stage and an advanced treatment stage. The antibiotic wastewater treated by virtue of the treatment process can thoroughly reach the emission standard, and the removal rate of various pollutants reaches above 99%; furthermore, facilities are simple and are easy and convenient to operate.

Owner:PUCHENG CHIA TAI BIOCHEM

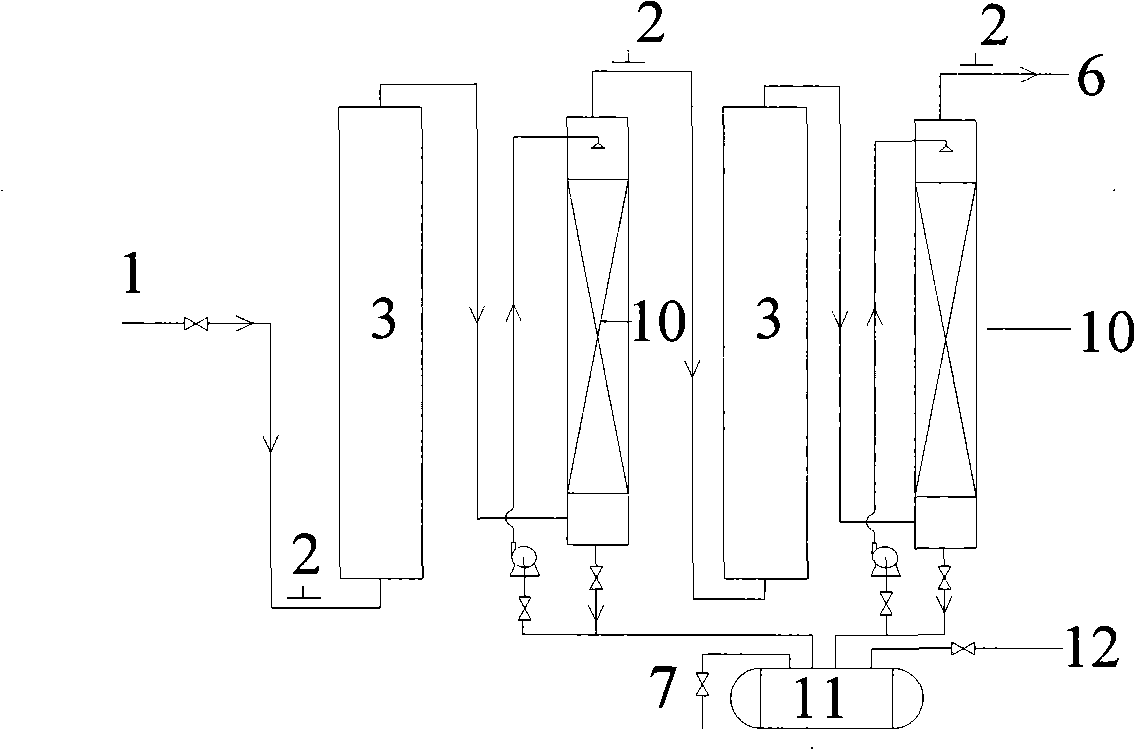

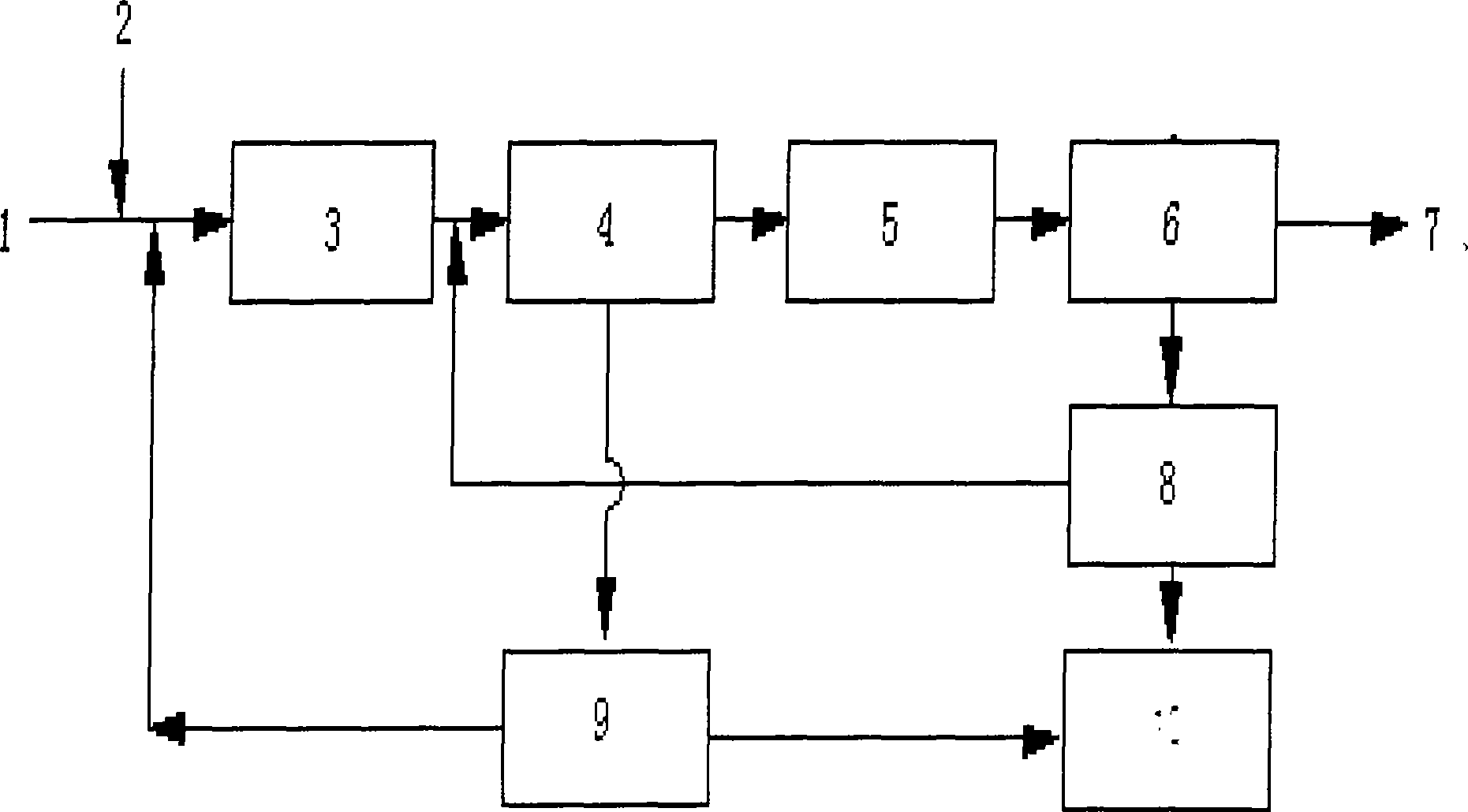

Device and method for removing refractory organics and total nitrogen in waste water simultaneously

ActiveCN102936083AImprove biodegradabilityEfficient removalTreatment with anaerobic digestion processesMultistage water/sewage treatmentCatalytic oxidationBiological filter

The invention relates to a device and a method for removing refractory organics and total nitrogen in waste water simultaneously. The device comprises an ozone catalytic oxidation tower (3) and a rear-mounted anoxic biological filtering tank (7). The waste water is subjected to catalytic oxidation firstly in the ozone catalytic oxidation tower (3) and is discharged after entering the anoxic biological filtering tank (7) for the denitrification reaction. According to the device and the method, ozone serves as an oxidizing agent, refractory organic pollutants are oxidized into micro-molecule easily-degradable organics under the effect of a catalyst, and the biodegradability of the waste water is improved; and by the aid of the denitrification reaction of the anoxic biological filtering tank, micro-molecule easily-degradable organics produced by the catalytic oxidation serve as a carbon source, and the nitrate nitrogen in the waste water is eliminated. By the aid of the device and the method, the total nitrogen can be eliminated effectively, the emission of the effluent total nitrogen after treatment can meet the standard, and the special catalyst is used in the method for oxidizing refractory organics, so that pollutants are eliminated, simultaneously, the problem of carbon sources during total nitrogen removal reaction can be solved, external carbon sources are not required, and the operation cost is low.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

Treatment method and apparatus for recycling ammonia nitrogen wastewater

InactiveCN101318752AReduce dosageGuaranteed preprocessing effectMultistage water/sewage treatmentWater/sewage treatment by heatingResource utilizationSewage

The invention relates to a method and a device for recycling treatment of ammonia nitrogen wastewater. The use method combining the device comprises the following steps that: a PH value of ammonia nitrogen wastewater is adjusted in an automatic medicine addition device; the ammonia nitrogen wastewater is preheated in a preheater, evenly distributed by a spraying device in a removal working section and collected in a bottom liquid storage zone; after ammonia is blown off by adopting forced-air blast, the ammonia in the wastewater is repeatedly removed by a circulating spraying system, purified and discharged from an effluent weir; ammonia-containing waste gas is filtered by a demisting device and subject to multilevel spraying and absorption so as to reclaim an ammonia crude product; and the purified gas is exhausted from the top part. The method and the device for recycling treatment of the ammonia nitrogen wastewater are suitable for ammonia nitrogen wastewater produced in the process of various industrial and agricultural productions, the treatment of domestic sewage and the resource utilization of materials, reclaim useful substances as possible while treating wastewater, reduce the cost for pollutant treatment and the emission of the pollutants and improve economical benefit while protecting environment.

Owner:ZHEJIANG UNIV

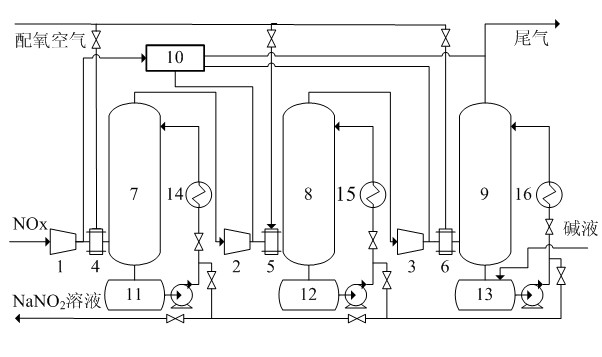

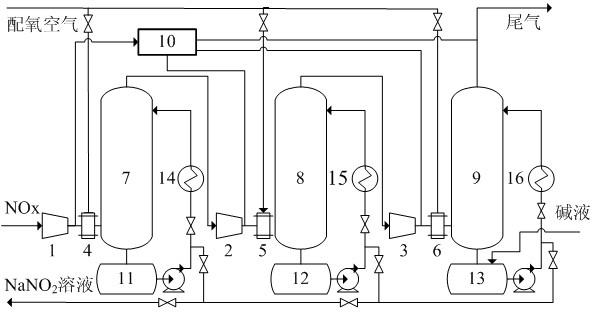

Method for preparing sodium nitrite from nitric oxide waste gas through multistage oxidation absorption

InactiveCN102078752ARealized benefitsEmission reductionDispersed particle separationExhaust fumesNitric oxide gas

The invention relates to a method for preparing sodium nitrite from nitric oxide waste gas with low oxidation degree in the industrial process, which comprises the following steps of: after water is removed from the nitric oxide waste gas, mixing the nitric oxide waste gas with oxygen supplying air according to a certain ratio, and introducing the mixture into multistage serial alkaline liquor absorption towers from the bottom of the first stage of absorption tower, wherein the temperature of the absorption liquor is below 50 DEG C, and the pressure inside the tower is 0.03-0.08 MPa; discharging the purified gas up to the standard from the top of the tail tower; and extracting a sodium nitrite solution from the bottom of the first stage of absorption tower. During the serial absorption process, after water is removed from the nitric oxide gas discharged by the last stage of tower, the concentrations of NO2 and NO are measured according to an online nitric oxide analyzer, and the oxygen supplying air is input through PRC control. During the absorption process, the circular absorption liquor of each absorption tower is first conveyed to a cooling device to cool, and thus, the temperature in the absorption tower is controlled. In the invention, common tower equipment with low cost is adopted to obtain sodium nitrate / sodium nitrite (0.02 sodium nitrite solution), the emission of nitric oxide is reduced, and the purposes of energy saving, emission reducing and recycling are achieved.

Owner:NANJING UNIV

Composite permeable reactive barrier and in-situ treatment method thereof

InactiveCN102070262AGood decolorizationReduce pollutionMultistage water/sewage treatmentChemical reactionLoad resistance

The invention discloses an irregular landfill site leachate composite permeable reactive barrier and an in-situ treatment method thereof in the technical field of domestic garbage treatment of environmental protection. Active iron powder material, zeolite and active carbon are added into a barrier body; and when the leachate flows through the barrier body under the action of personal hydraulic gradient, the leachate and the barrier body fully undergo physical and chemical reaction, then most organic pollutants, ammonia nitrogen, heavy metals and colored substances in the leachate are removed, and the treated leachate is discharged after reaching the standards. The method is simple in construction, flexible in arrangement, low in running and maintenance expense and strong in impact load resistance, is economic and energy-saving, and has high practical value.

Owner:TSINGHUA UNIV

Method for disposing high-salt high-polymer wastewater through Fenton oxidation and biology combined technology

ActiveCN103449685AImprove biodegradabilityReduce dosageMultistage water/sewage treatmentFiltrationOxygen

The invention provides a method for disposing high-salt high-polymer wastewater through the Fenton oxidation and biology combined technology. The disposed high-salt high-polymer wastewater is drilling wastewater. The method is characterized in that the technology comprises primary chemical oxidization, filtration, phosphorous removal, sedimentation, filtration, hydrolyzation, anaerobic processing, secondary chemical oxidization, primary aerobiotic processing and secondary aerobiotic processing. Firstly, due to the fact that the B / C ratio of the wastewater is low, primary chemical oxidization method processing is conducted on the wastewater the B / C ratio can be improved; after oxidized discharged water is filtrated, the water enters a phosphorous removal reaction pool and is deposited and filtrated again; the water with phosphorus removed enters a hydrolysis acidification pool and then enters a middle adjusting pool, and after a pH value is adjusted, the water enters an anaerobic reaction pool; secondary chemical oxidization method processing is conducted on anaerobic discharged water, the B / C ratio is improved, the water enters an aerobiotic biochemical system, and primary contact aerobiotic processing and secondary contact aerobiotic processing are conducted.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

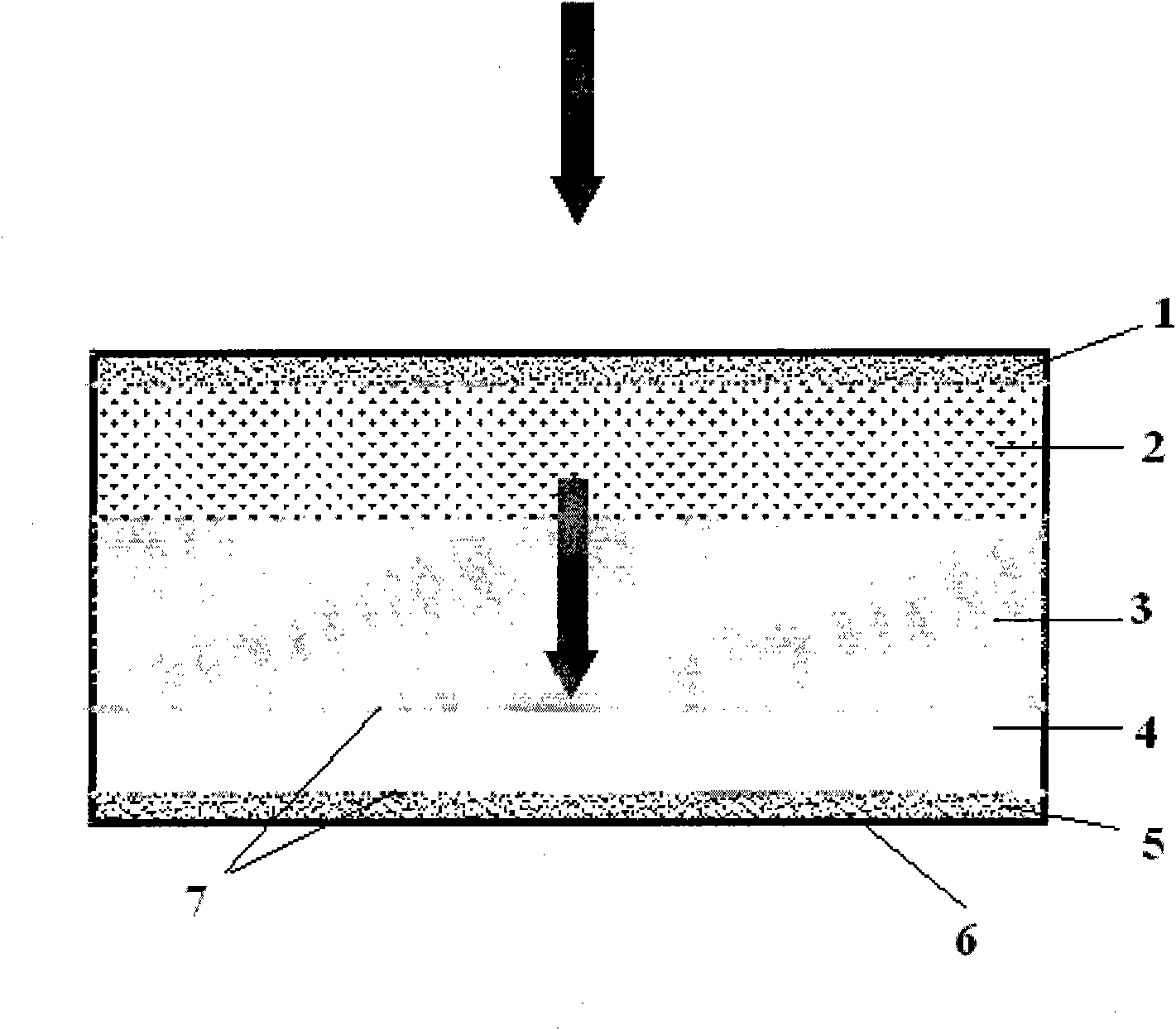

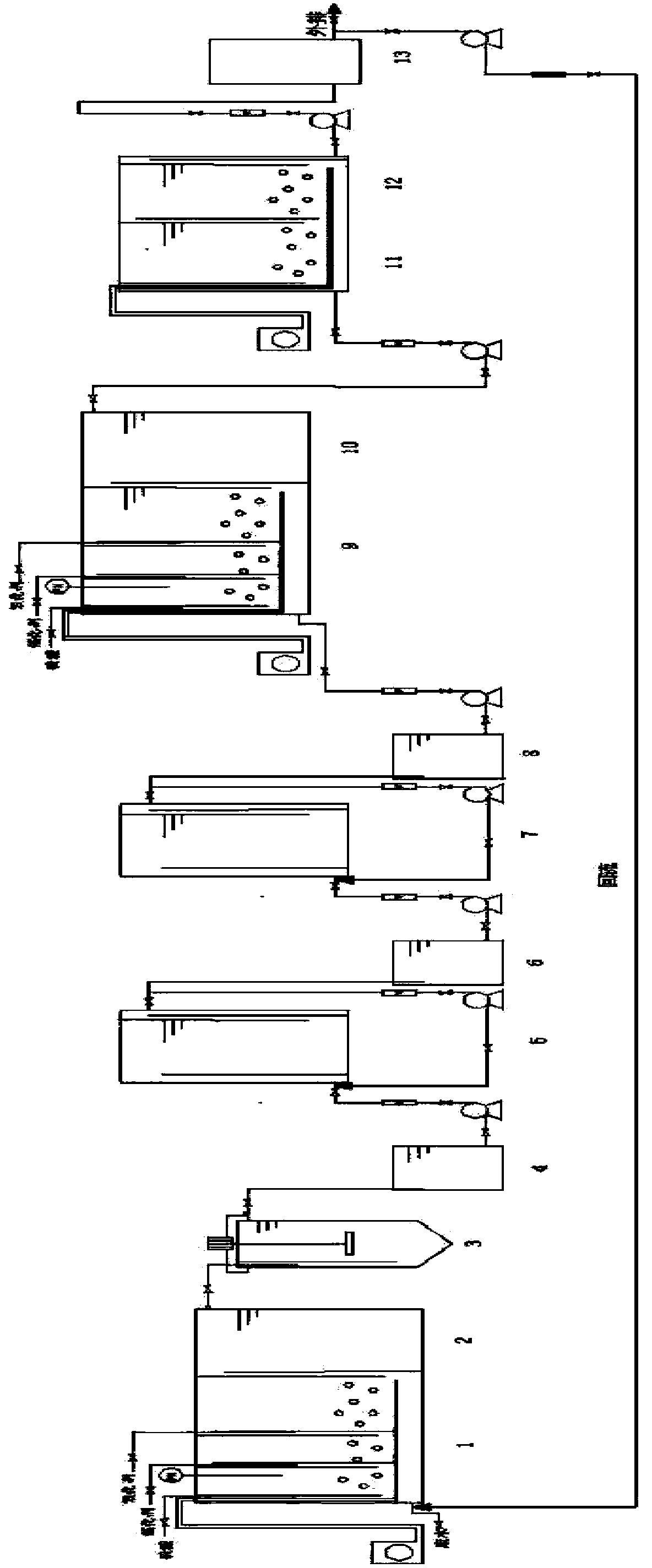

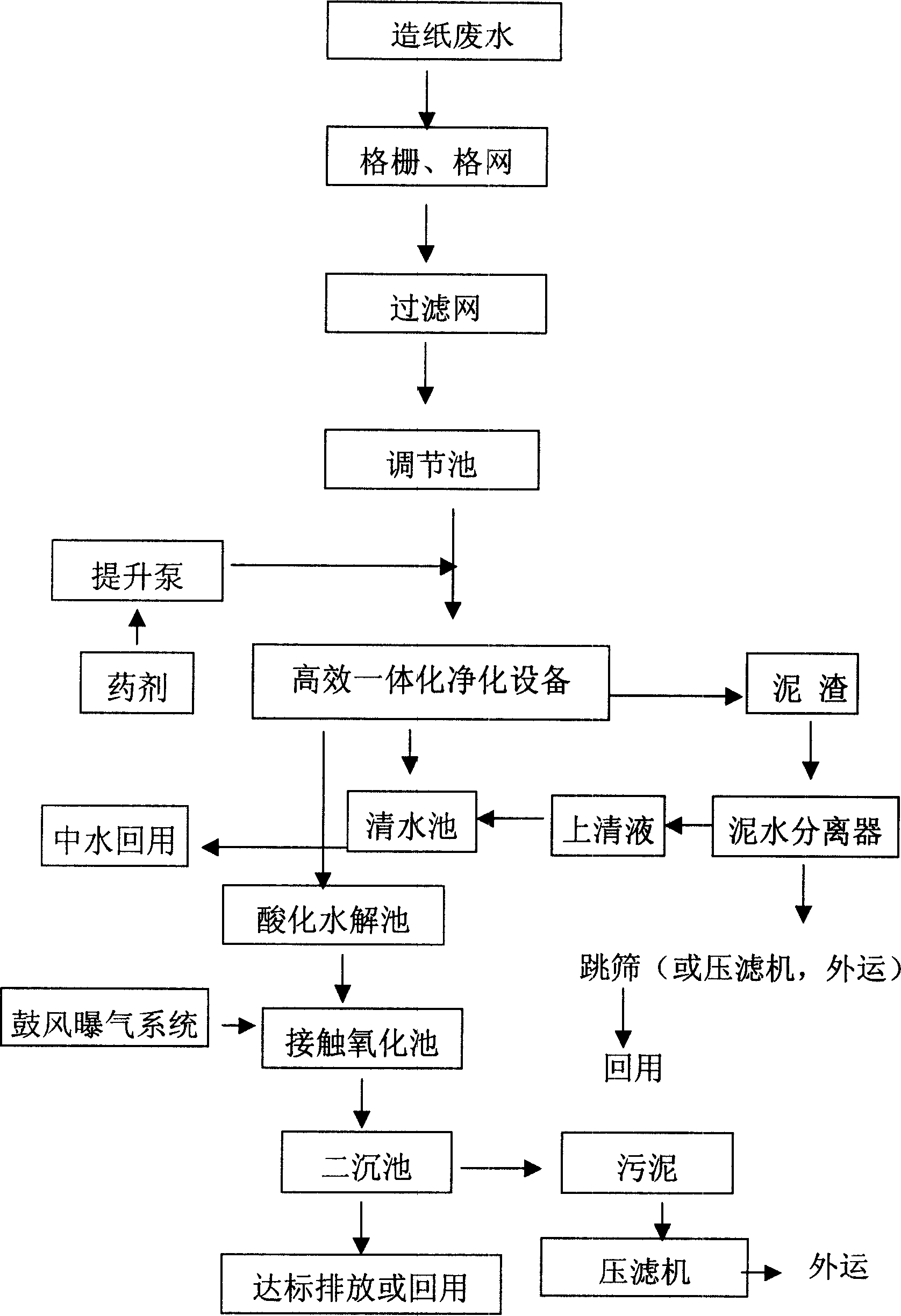

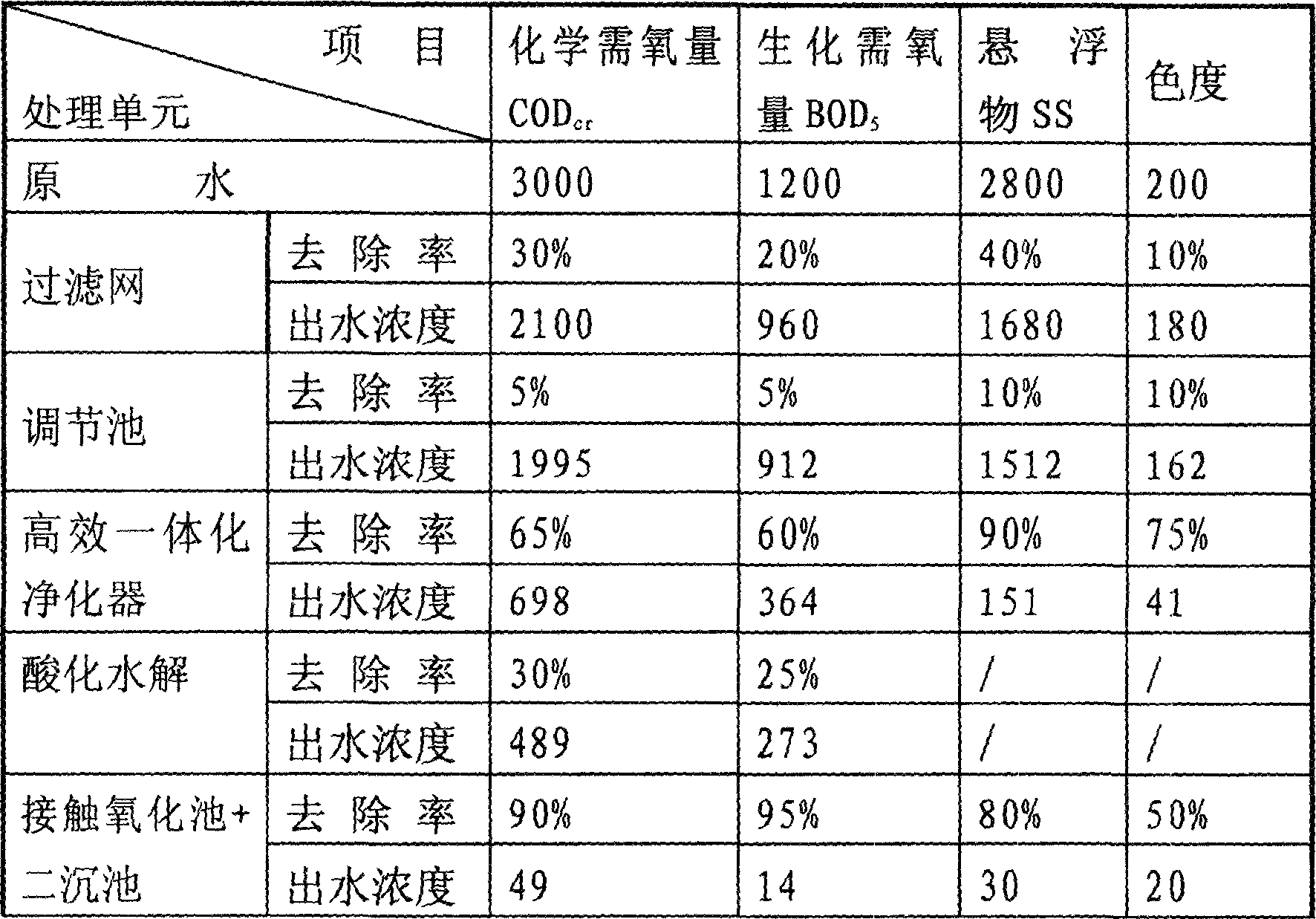

Process for treatnig paper-making waste water of waste paper

InactiveCN1587089ALow running costLow soluble CODSustainable biological treatmentWater/sewage treatment by flocculation/precipitationChemical treatmentAluminium sulfate

The treating process of waste water produced in making paper with waste paper includes the first stage of physical and chemical treatment with the apparatus of patent ZL 97114281.5 with aluminum sulfate added to the inlet as coagulant and acrylamide as coagulant aid; and the second stage of biochemical treatment in hydrolysis acidification-contact oxidation technique and perforation and flow dispersing aeration mode, with the waste water from biochemical treatment flowing into the secondary deposition pond. Of water after the first stage of treatment, 60-80 % is used as intermediate water returned to work shop, while other flows into the second stage of treatment for reuse in production or exhaust. The sludge from the first stage of treatment is treated in jigging sieve before reuse in production. The present invention may realize the closed circular use of paper-making waste water to reduce waste water exhaust.

Owner:SOUTH CHINA UNIV OF TECH

Radioactive liquid waste treatment device

The invention relates to a radioactive liquid waste treatment device comprising a feeding device, a volume reducer of radioactive wastes, a tail gas and residual liquid treatment device and a conveyer. The feeding device, the tail gas and residual liquid treatment device and the conveyer are respectively connected with the volume reducer; the feeding device, the tail gas and residual liquid treatment device, the conveyer and the volume reducer are integrally arranged under a vacuum environment; the volume reducer comprises a macroscopic dehydration volume-reduction unit for macroscopically dehydrating and reducing volume of the radioactive liquid wastes and a heating-drying volume-reduction unit, and the heating-drying volume-reduction unit and the macroscopic dehydration volume-reductionunit for breaking the organization structure of the radioactive wastes are connected by a pipeline to form a seal system. A movable radioactive liquid waste treatment device disclosed by the invention has the advantages of little environment pollution, safe and reliable treatment process and reduced storage space, and reaches the state standard of effluent discharge.

Owner:HUANCHUANG XIAMEN TECH

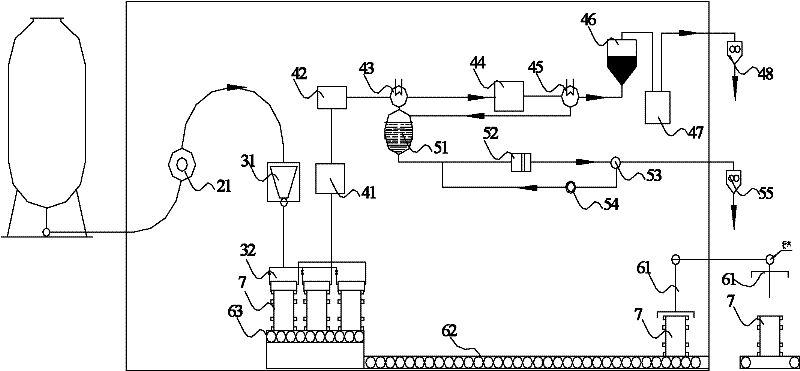

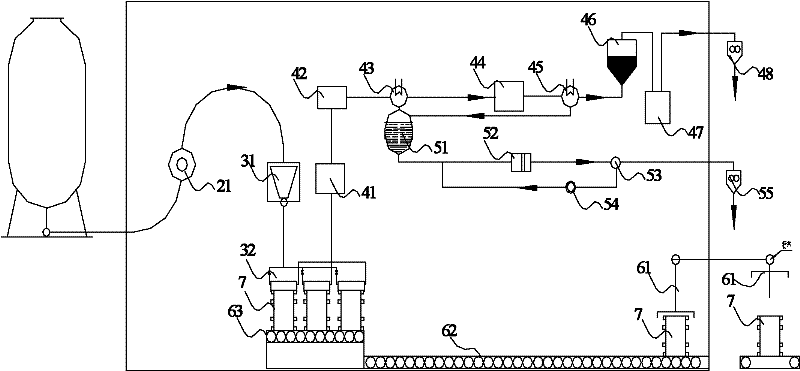

Processing system and operation method for phosphor-containing organic wastewater

InactiveCN101434445AGuaranteed uptimeGuaranteed Emission StandardsMultistage water/sewage treatmentSustainable biological treatmentPhosphateSulfide

The invention relates to a treatment system and an operation method of phosphorus-containing organic wastewater. A chemical phosphorus removal system is combined with an aerobic biochemical system, thus forming a system that removes phosphate and organic matters in the effluent of an aerobic removal system. The chemical phosphorus removal system consists of a chemicals feeding system, a mixed reaction pool, a sedimentation pool, a residual sludge refluxing system and a chemical sludge refluxing system. The aerobic biochemical system consists of an aerobic contact oxidation system and an aerobic activated sludge system. During the process of chemical phosphorus removal, sulfide and part of the organic matters can be removed simultaneously, thus causing the subsequent aerobic process to run stably and reducing running cost thereof. The residual sludge of the aerobic biochemical system is subjected to aeration and then refluxes to the chemical phosphorus removal system, and flocculation is absorbed and chemical sludge flocculating constituents are settled by utilizing residual activated sludge, thus improving chemical phosphorus removal efficiency. Part of the chemical phosphorus removal sludge refluxes after aeration, thus reducing the feeding amount of chemicals and reducing running cost. The treatment system and the operation method can cause organic wastewater with high phosphorus concentration to reach strict discharge standard after being treated.

Owner:TIANJIN UNIV

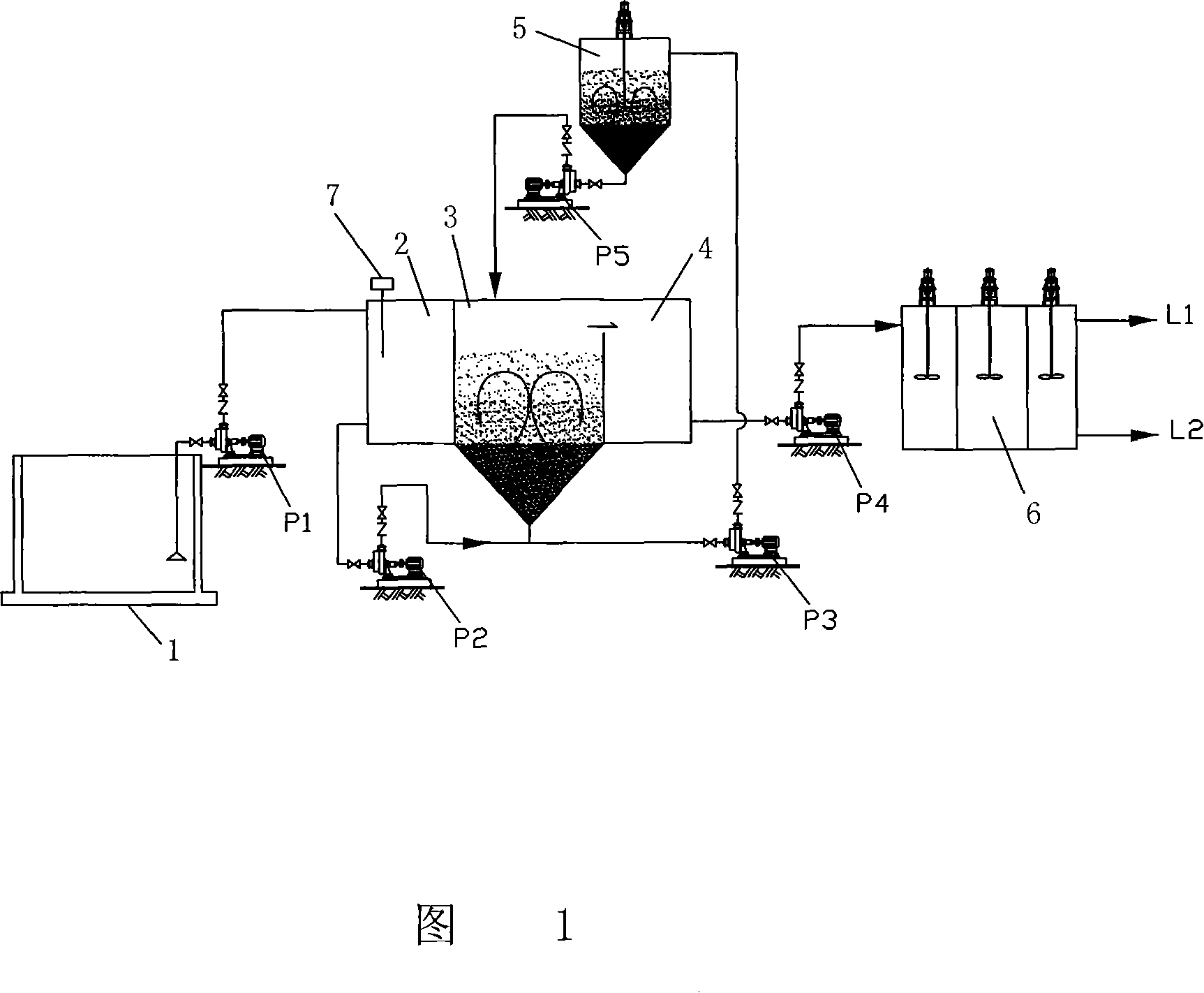

Process and apparatus for treating waste water containing metal complex

InactiveCN101088936AEasy to handleLow costWaste water treatment from metallurgical processMultistage water/sewage treatmentIron powderFluidized bed

The process of treating waste water containing metal complex includes: regulating pH value to 2-4 and adding H2O2, contacting with iron powder in a fluidized bed reactor to produce displacement reaction and complex eliminating reaction, adding alkali in a deposition tank one deposit metal ion, and separating supernatant and the lower precipitate. The process can prevent the aggregation and deactivation of iron powder in the reaction, and has greatly raised reaction efficiency, low cost and high waste water treating effect.

Owner:ZHEJIANG UNIV

Twin tower type recovering sulfur resource ammonia desulfuration equipment and method

ActiveCN101708412AHigh purityGuaranteed purityUsing liquid separation agentAmmonium sulfitesPollutionBy-product

The invention discloses twin tower type recovering sulfur resource ammonia desulfuration equipment and a method. The equipment comprises a dynamic wave washing tower, a primary absorption tower, a secondary absorption tower and the like; the exhaust gas passes through the dynamic wave washing tower to remove ash and passes through a dynamic wave washer to lower the temperature, and then enters the primary absorption tower and the secondary absorption tower in sequence; the primary absorption tower and the secondary absorption tower are both provided with five spraying layers; the lower three spraying layers spraying and absorbing the exhaust gas; the upper two spraying layers are used for preventing ammonia escape; and the exhaust gas is discharged after being sprayed and absorbed by the primary absorption tower and the second absorption tower. The invention has the following advantages: 1) the purity of the by-product is high; 2) the twin tower design can not only obtain higher desulfurization efficiency, but also produce by-product with high purity; 3) the technology takes ammonium acid sulfite as the ultimate by-product, not only saving the technologies of crystallization and drying in the traditional technology, but also improving the additional value of the by-product; and 4) the technology in the invention can be recycled and has no secondary pollution.

Owner:ZHEJIANG UNIV

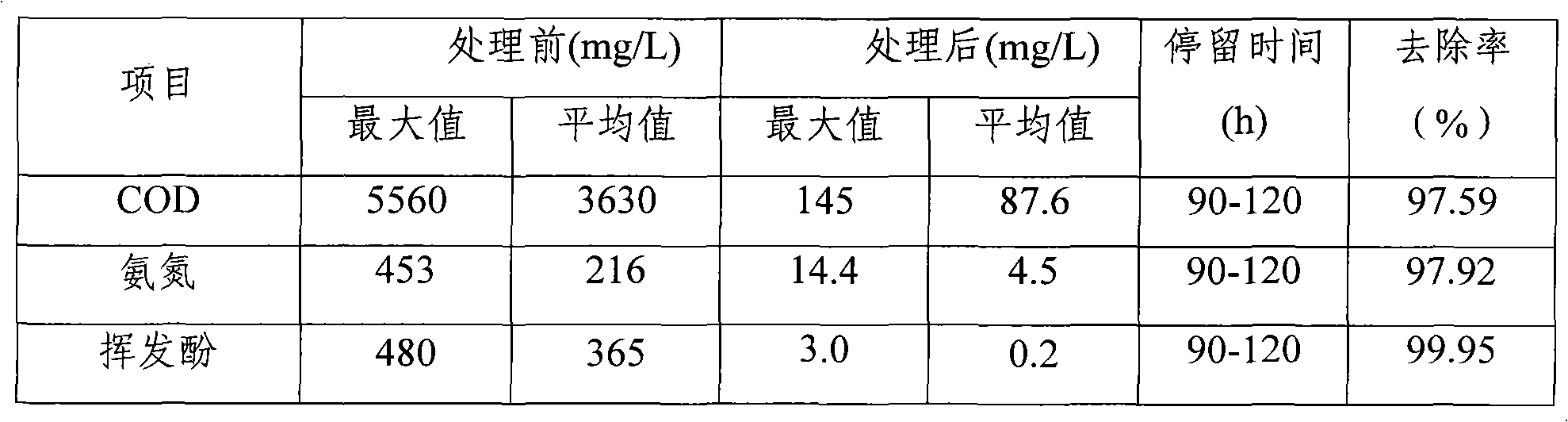

Technology of treating coking wastewater by biomembrance process

ActiveCN101597125AWater quality fluctuates greatlyGuaranteed emission standardsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAnaerobic bacteriaFiltration

The invention relates to a technology of treating coking wastewater by biomembrance process, belongs to the field of environmental protection and difficult degradable industrial wastewater treatment, is mainly used to treat coking wastewater, can also be used to treat high COD and high ammonia nitrogen industrial wastewater and can realize that COD can be removed effectively and denitrification can be carried out effectively. The reactors used by the invention comprise an anaerobic bacteria filter, an aerobic biological fluidized bed, an anoxic biofilter and a settling pond. The technology is that the pretreated coking wastewater flows through the anaerobic bacteria filter for hydrolysis acidification, the aerobic biological fluidized bed for oxidation, then the anoxic biofilter for filtration, the settling pond for removing suspended matter and the treated water generated in the settling pond is directly discharged and part of the treated water flows back to the anaerobic bacteria filter. The COD removal rate of effluent can be above 95%, and the other indexes can all reach the primary standard of the national standard (GB8978-1996) for effluent discharge. The treatment technology has higher hydraulic loading and resistance shocking and lower floor area.

Owner:UNIV OF SCI & TECH BEIJING

Oil refinery sewage treatment and reusing process system and operation method thereof

ActiveCN101117259ALow investment costLow running costFatty/oily/floating substances removal devicesTreatment using aerobic processesHigh concentrationProcess systems

The invention provides a process system for disposal and recycling of sewage in oil plants and the corresponding operation method, wherein the process system comprises a disposal unit for sewage of superhigh concentration, a disposal unit for sewage of high concentration, a disposal unit for sewage of low concentration and a sewage recycling unit. The invention is characterized in that: after treated by an oxidation tower and a sequencing bioreactor, the sewage of superhigh concentration is effluent and incorporated in the sewage of high concentration; after treated by a separation tank, a floatation tank and a biological aerated filter, one part of the sewage of the high concentration which comes up to the standards is released, another part is used for dilution water of the sequencing bioreactor, and last part is incorporated in the sewage of low concentration; after treated by a separation tank, a floatation tank and a biological aerated filter, one part of the sewage of low concentration is effluent and used for recycling in a reclaimed water system, one part is incorporated in the sewage of high concentration, another part is used for dilution water of the sequencing bioreactor, and last part which comes up to the standards is released. The process system of the invention realizes respective treatment and water recycling of sewage of high and low concentration in oil plants, can ensure that the effluent water quality is stable and qualified and the cost of disposal and recycling of sewage is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

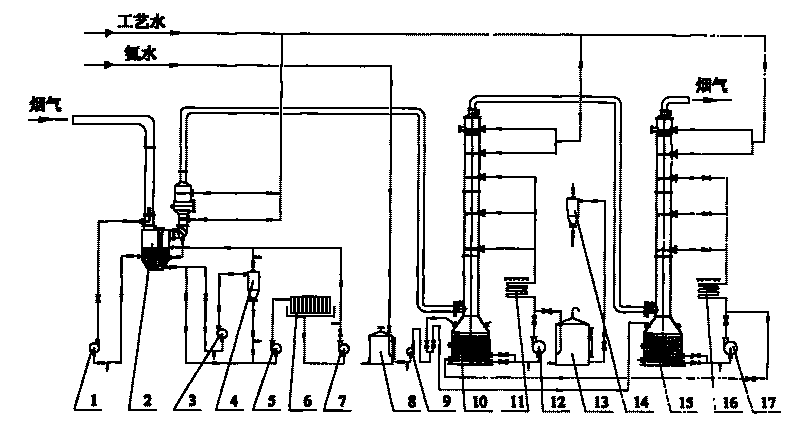

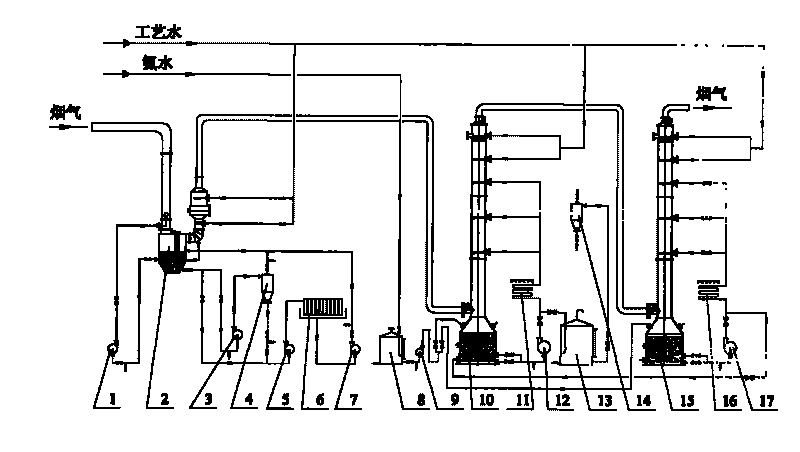

Exhuast gas desulfurization, recycle and treatment method and apparatus

InactiveCN101342459AReduce manual operationStable processing capacityCalcium/strontium/barium sulfatesDispersed particle separationGypsumExhaust gas

The invention relates to a smoke gas desulfurization and recycling method; the smoke gas is processed in an smoke desulfurization and recycling integrated device; the smoke gas desulfurization and recycling technology has three stages: a first stage is an exhaust gas dedusting technology, by which particulate matter in the smoke gas is removed; a second stage is an exhaust gas desulfuration technology, by which SO<2> / SO<3> is removed; a third stage is a post-processing technology, by which the exhaust gas is dried and purified and manufactured into a product; and waste seriflux is made into gypsum after being oxidized; the smoke gas desulfurization and recycling method and the device of the invention are suitable for processing the smoke gas containing the SO<2> / SO<3> produced in various industrial production processes and recycling a material, thereby taking full advantage of a resource, decreasing pollutant emission and having the advantages of high processing efficiency, high coefficient of recovery, wide adaptability and smaller investment.

Owner:ZHEJIANG UNIV

Method for treating waste water in coal chemical industry

InactiveCN102659204AReduction of recycling energy consumptionImprove recycling efficiencyWater/sewage treatment by extractionChemical oxygen demandKetone

The invention relates to a method for treating waste water in coal chemical industry. The method comprises the following steps of: extracting and dephenolizing the waste water which contains phenol, tars, petroleum hydrocarbons and chemical oxygen demand (COD) and is subjected to gasification, coking, destructive distillation, liquefaction and the like in the coal chemical industry and methyl amylene ketone serving as an extracting agent in an extraction tower or a mixed clarificator. By the method, most of pollutants of the tars and the petroleum hydrocarbons can be removed simultaneously, the pollution load of the waste water is reduced, the load of a subsequent biochemical section can be relieved, and the discharge of the waste water can reach the standard or the waste water can be recycled.

Owner:QINGDAO UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com