Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1181 results about "Organic gases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Although the number of organic gases in industrial use is vast, many of these gases arise from the petrochemical and chemical industries. Examples of products from ethylene synthesis include: ethylene oxide, vinyl acetate, ethylene dichloride, acrylonitrile, styrene, butadiene, olefins, and ethanol.

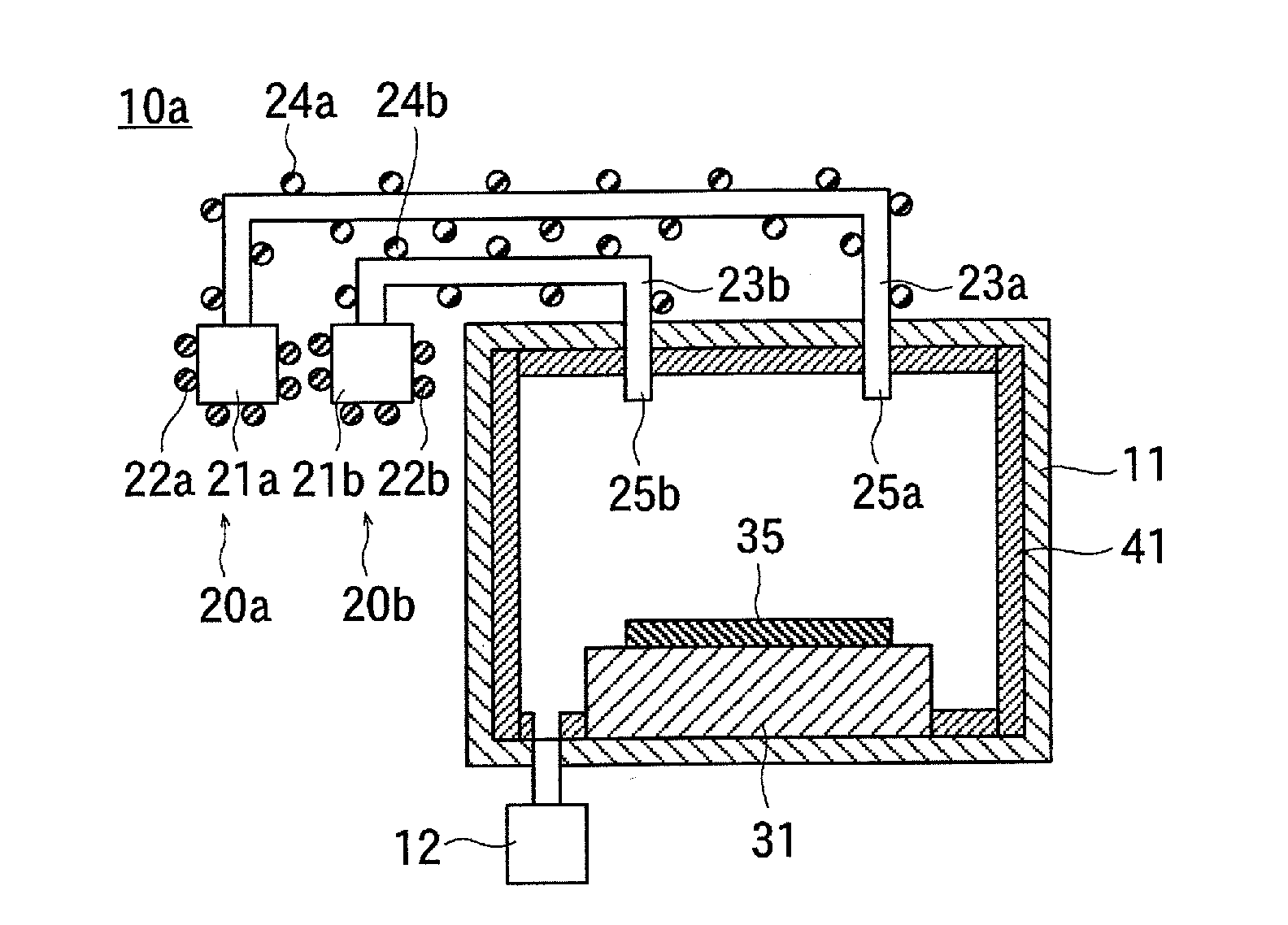

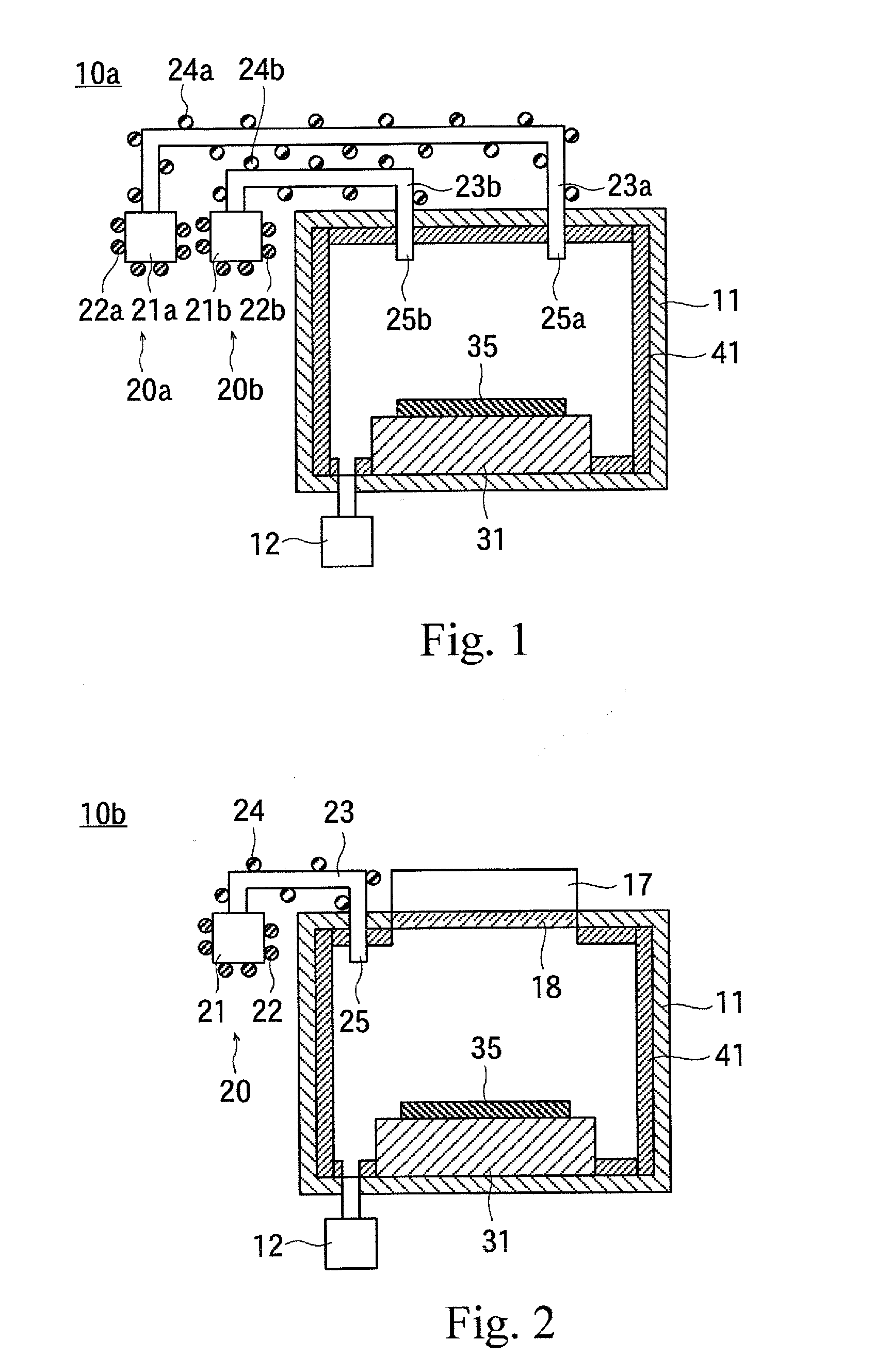

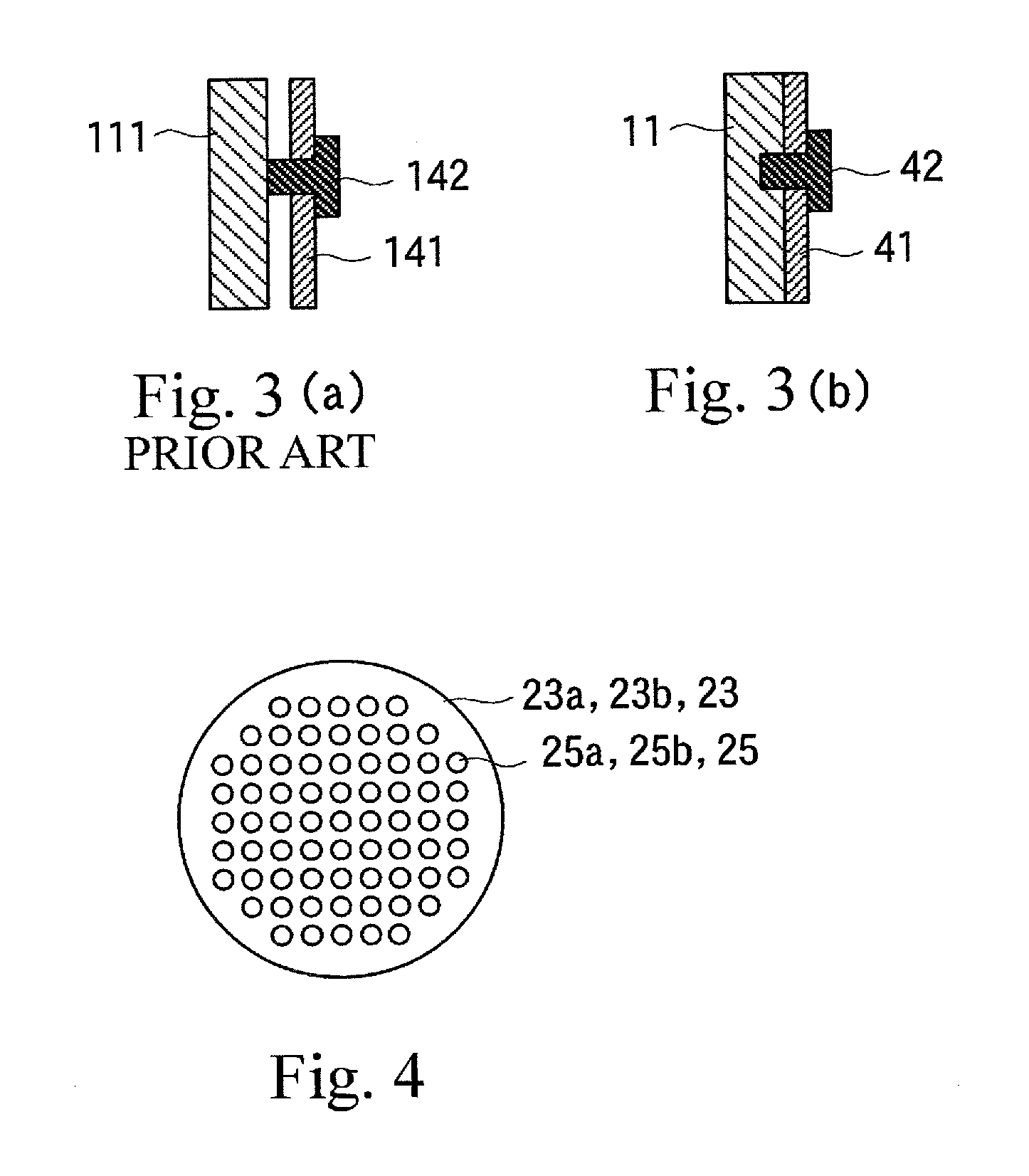

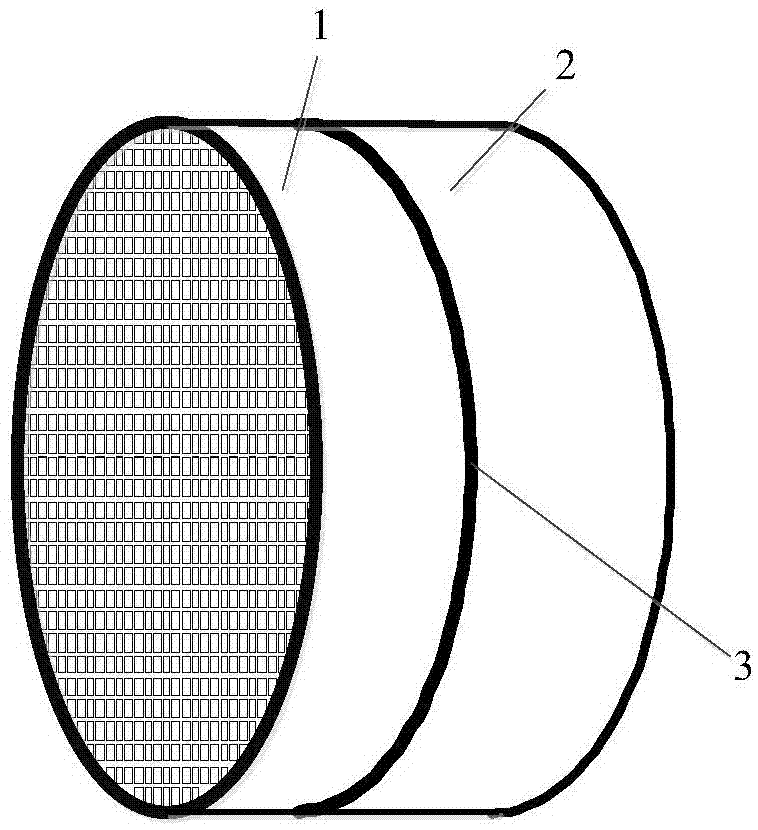

Organic thin film forming apparatus

InactiveUS20130333619A1Low costEasy to disassembleLiquid surface applicatorsVacuum evaporation coatingElectroless nickelOptoelectronics

An organic thin film forming apparatus that can easily remove an organic thin film adhered to a surface of a deposition preventive plate. The apparatus forms an organic thin film on a substrate disposed on a surface of a substrate stage from an organic gas. An electroless nickel film containing fluorine resin is formed on the surface of a deposition preventive plate. The electroless nickel film containing fluorine resin has mold release characteristics for an organic thin film. Even if the organic thin film adheres, the organic thin film can be easily removed by a method (such as, high pressure cleaning).

Owner:ULVAC INC

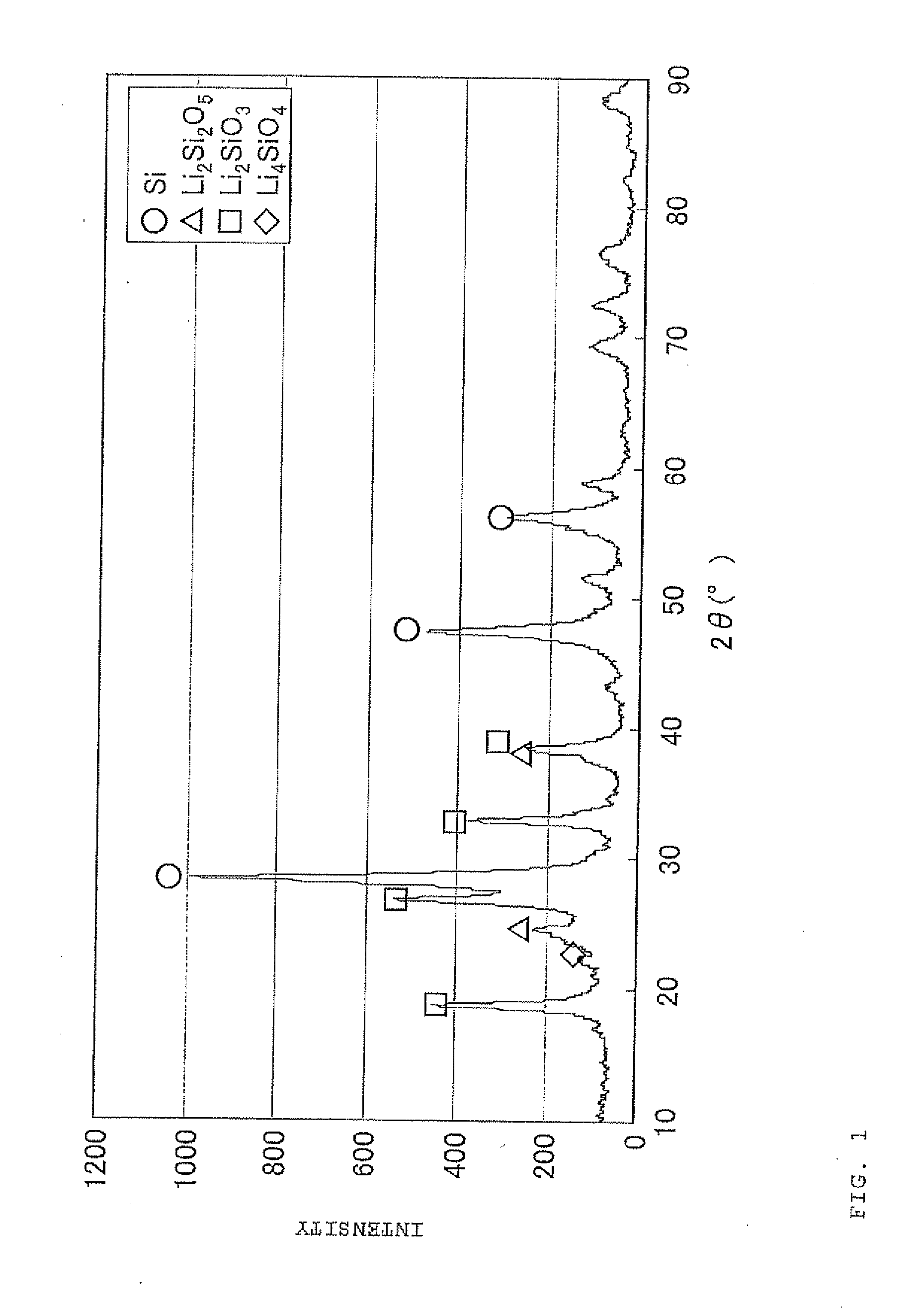

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

ActiveUS20110244333A1Cycle durability of negativeElectronic conductivity of negativeMaterial nanotechnologyElectrode thermal treatmentOxide compositeAtomic order

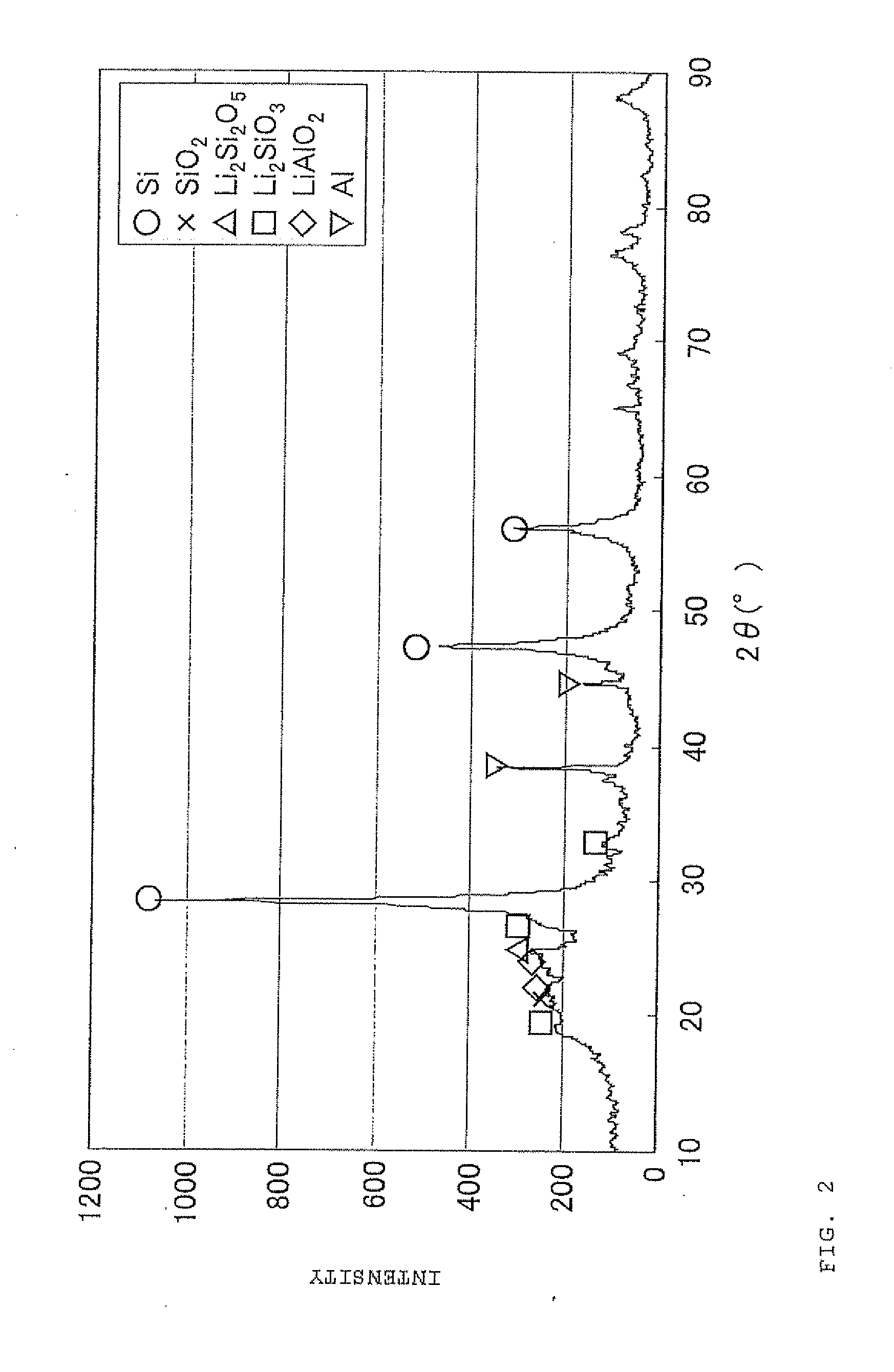

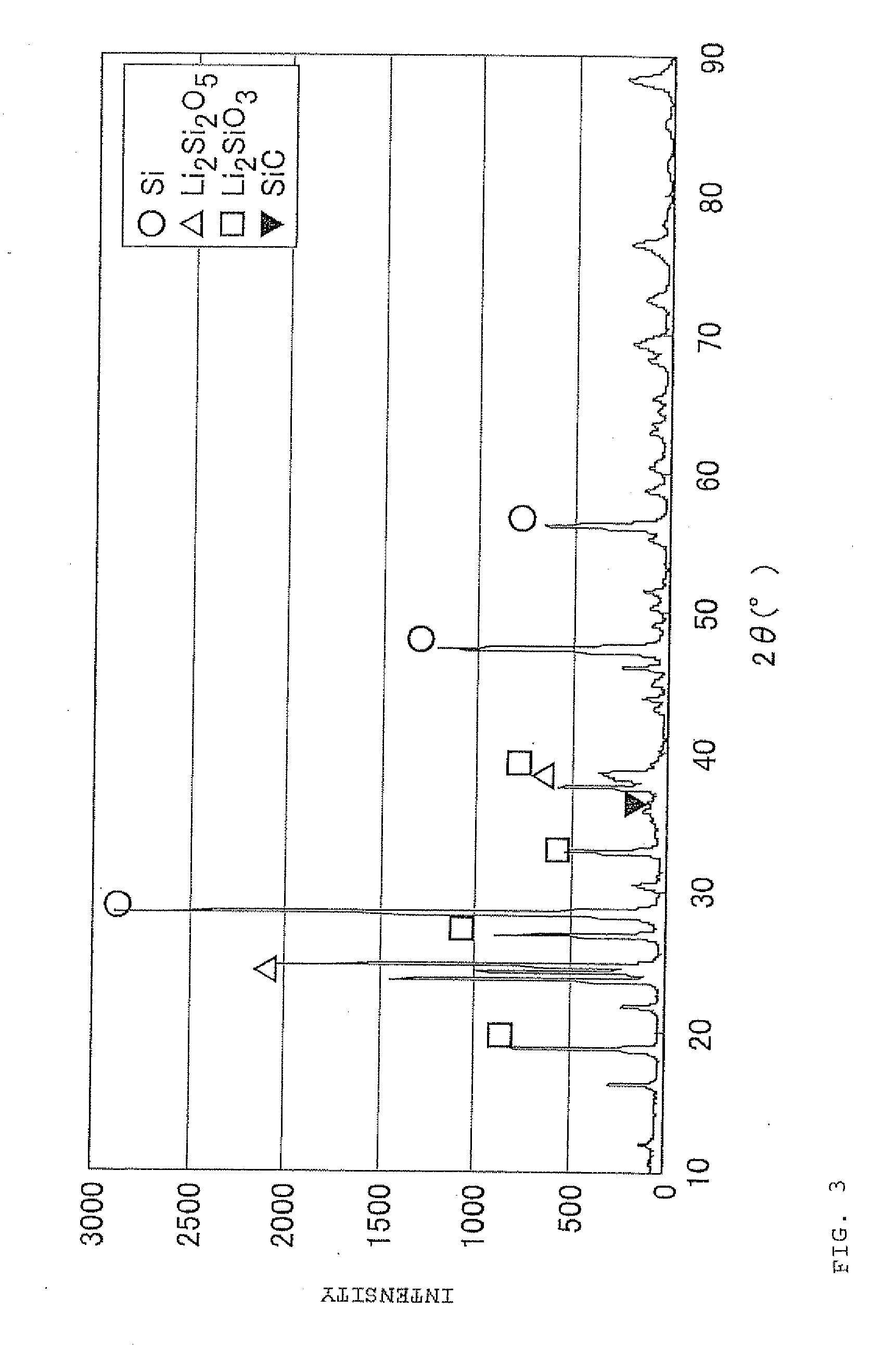

The present invention is a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least: coating a surface of powder with carbon at a coating amount of 1 to 40 mass % with respect to an amount of the powder by heat CVD treatment under an organic gas and / or vapor atmosphere at a temperature between 800° C. and 1300° C., the powder being composed of at least one of silicon oxide represented by a general formula of SiOx (x=0.5 to 1.6) and a silicon-silicon oxide composite having a structure that silicon particles having a size of 50 nm or less are dispersed to silicon oxide in an atomic order and / or a crystallite state, the silicon-silicon oxide composite having a Si / O molar ratio of 1 / 0.5 to 1 / 1.6; blending lithium hydride and / or lithium aluminum hydride with the powder coated with carbon; and thereafter heating the powder coated with carbon at a temperature between 200° C. and 800° C. to be doped with lithium at a doping amount of 0.1 to 20 mass % with respect to an amount of the powder. As a result, there is provided a method for manufacturing a negative electrode material for a secondary battery with a non-aqueous electrolyte that enables a silicon oxide negative electrode material superior in first efficiency and cycle durability to conventional ones to be mass-produced (manufactured) readily and safely even in an industrial scale.

Owner:SHIN ETSU CHEM IND CO LTD

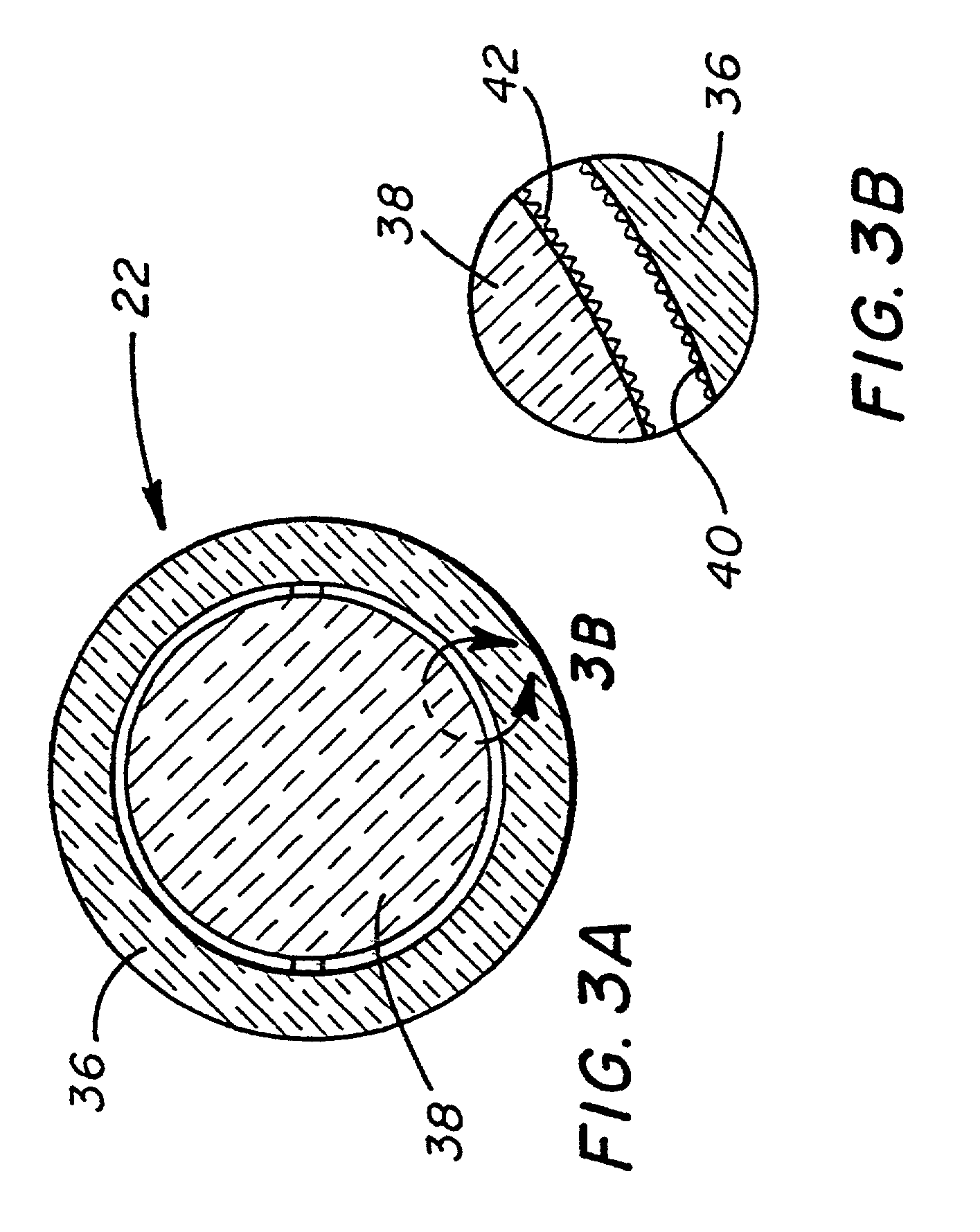

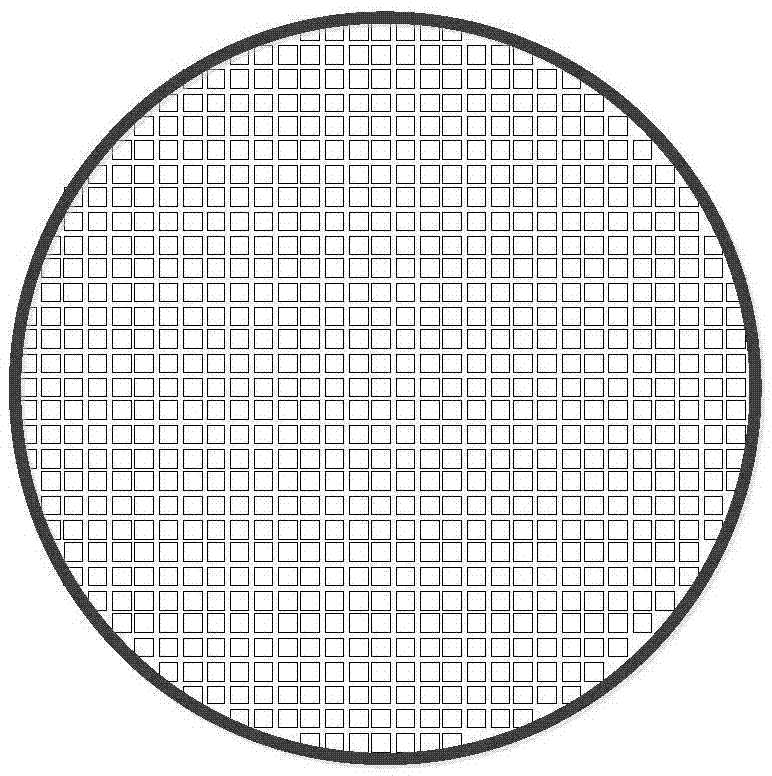

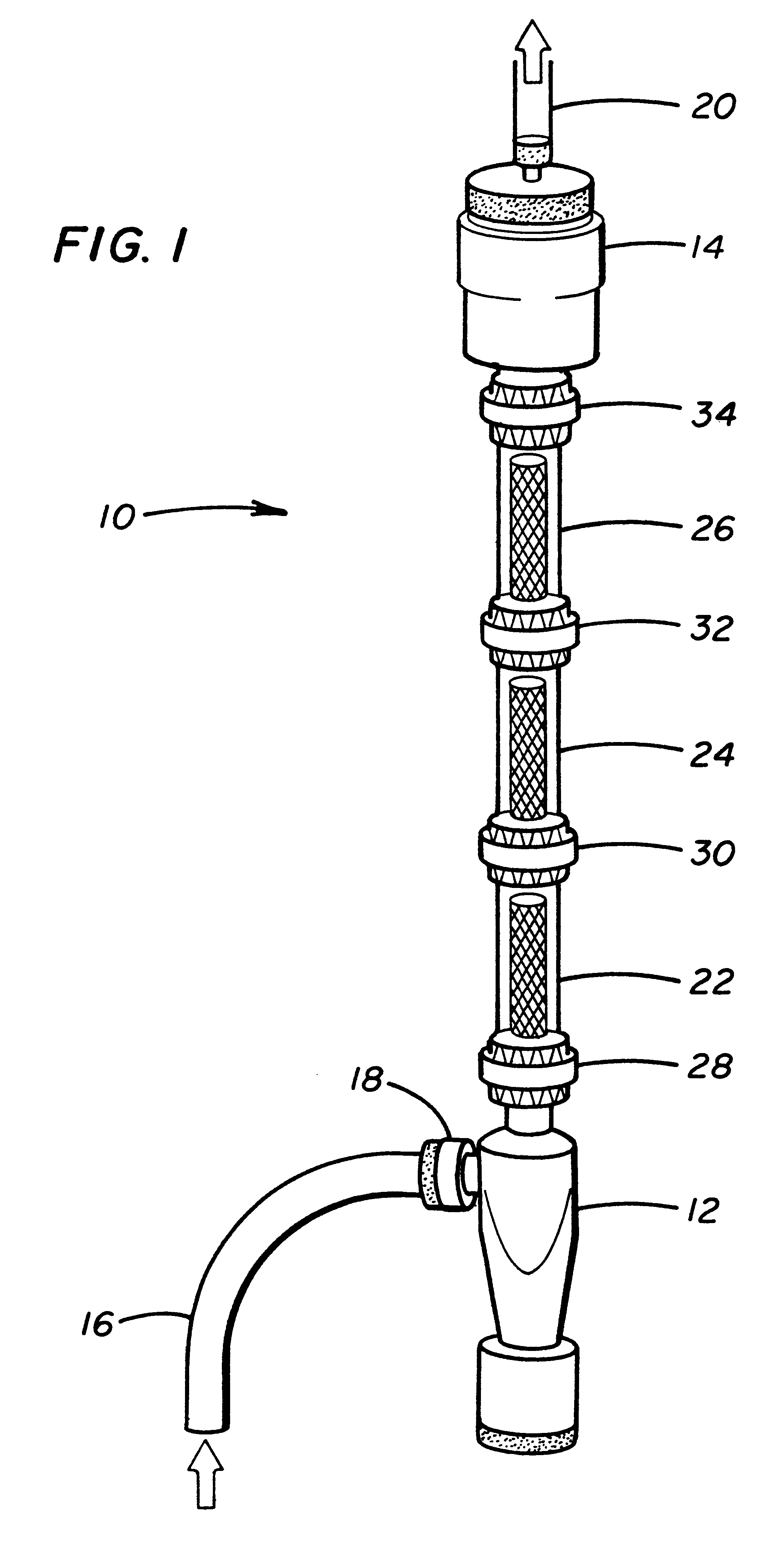

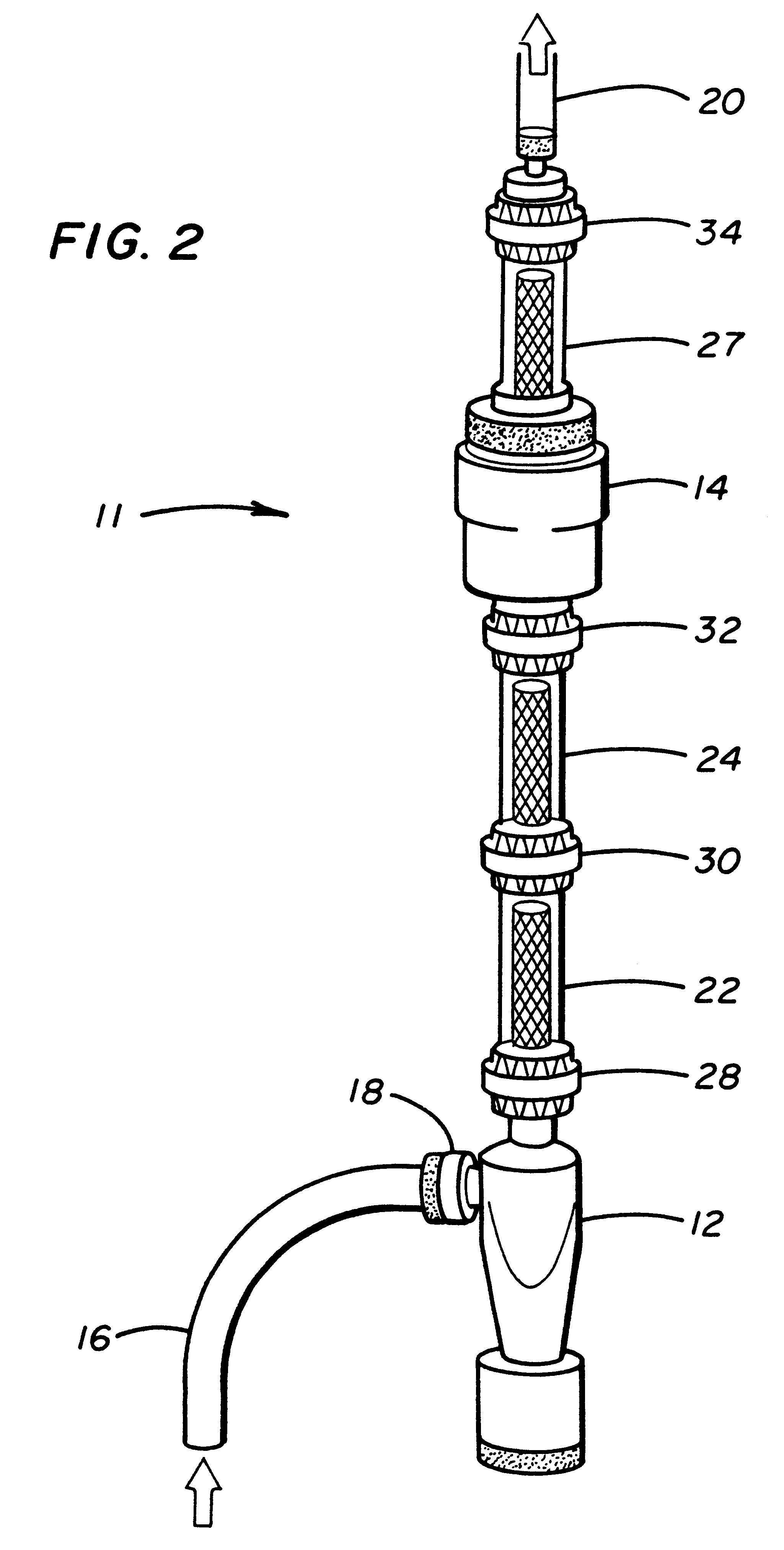

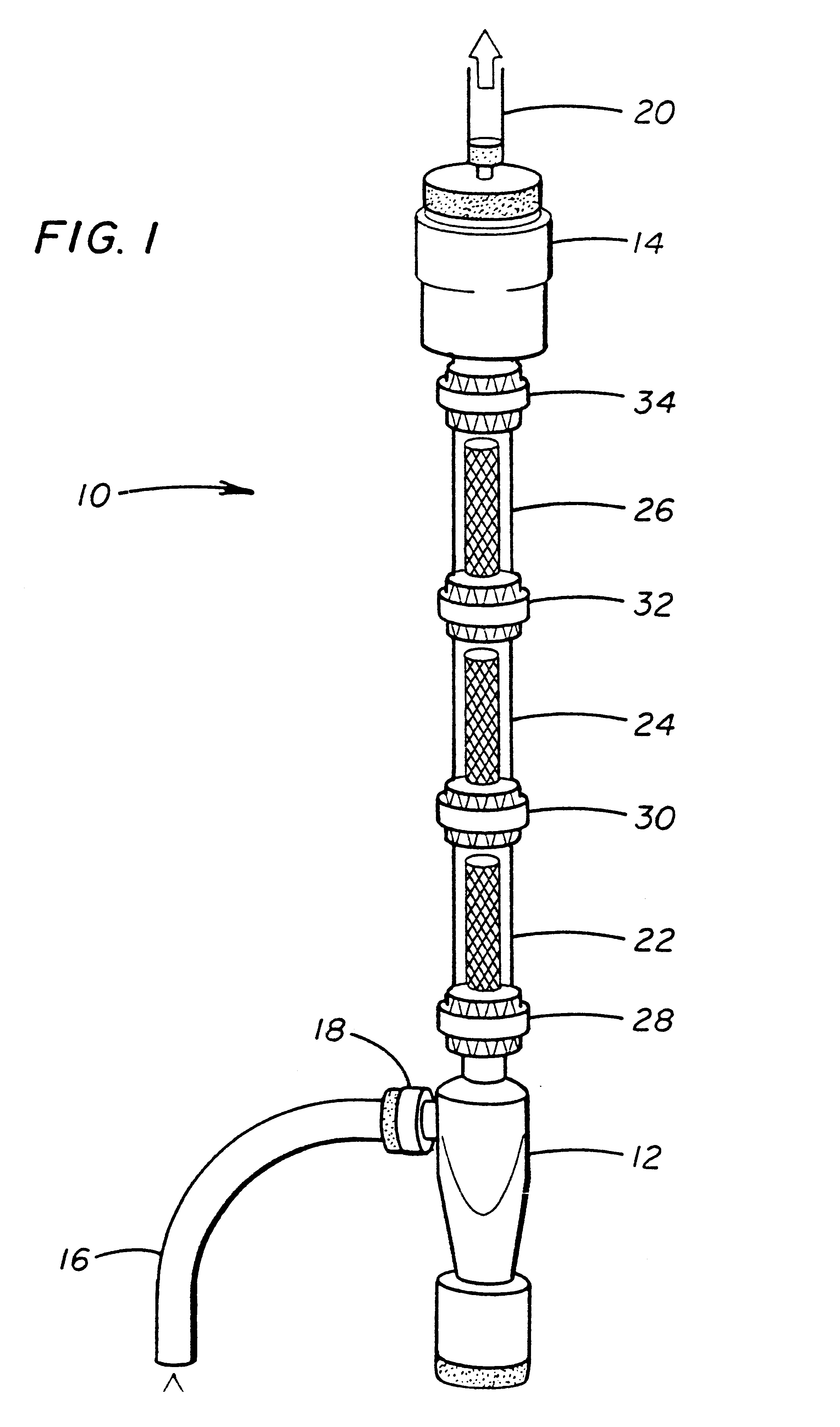

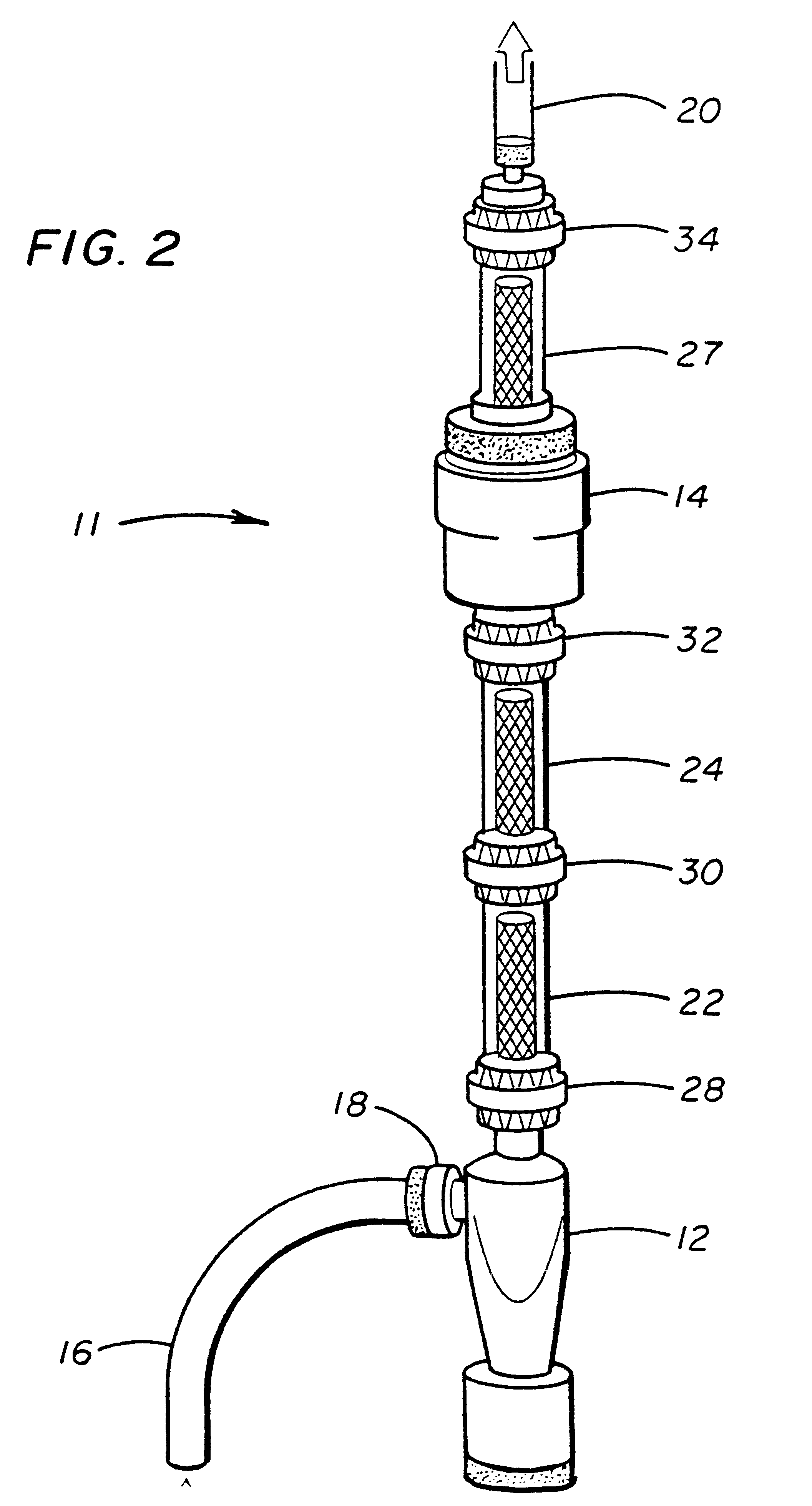

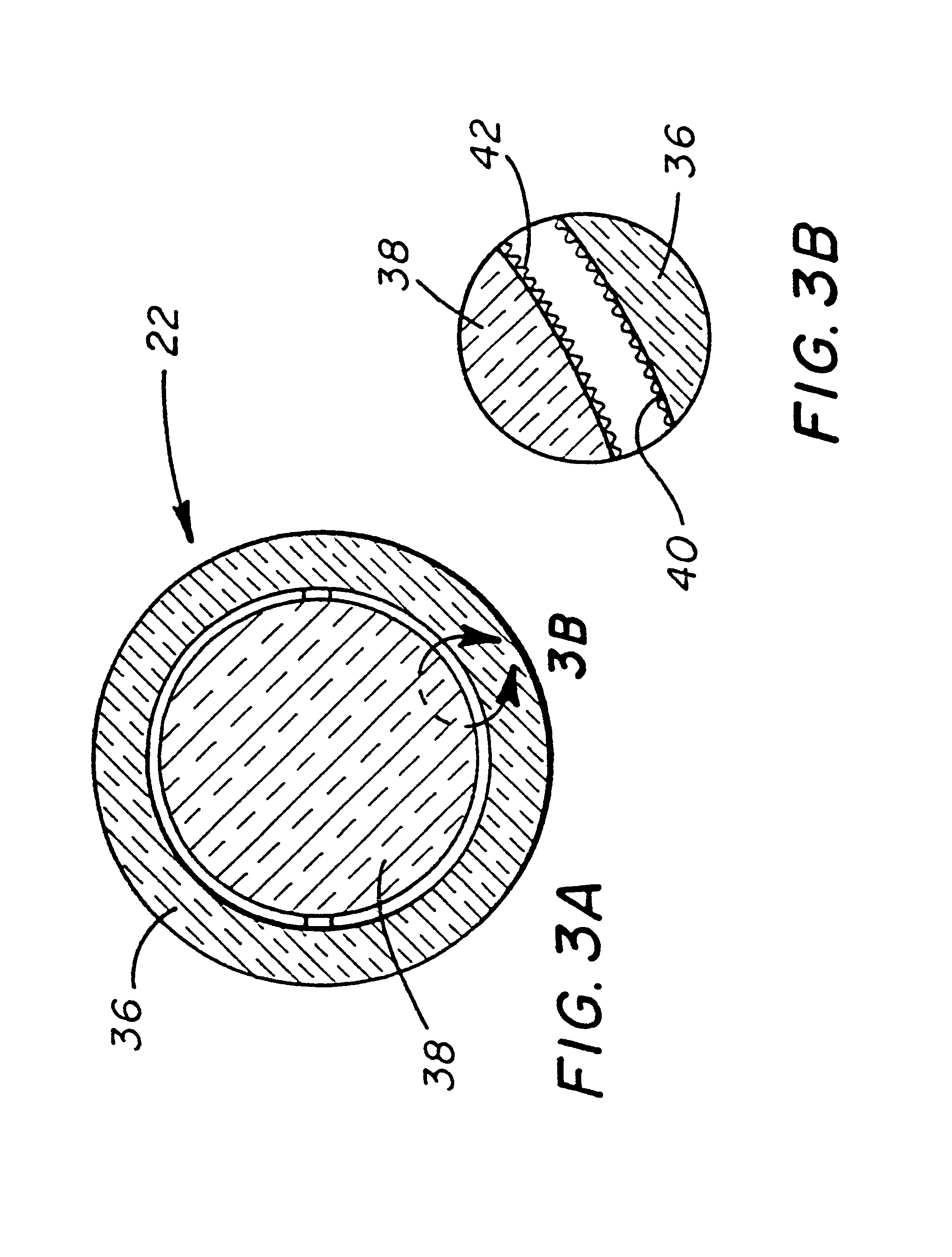

Quantitative organic vapor-particle sampler

InactiveUS20010045000A1Displacement minimizationEliminate artifactsOther chemical processesWithdrawing sample devicesDiffusionMicrosphere

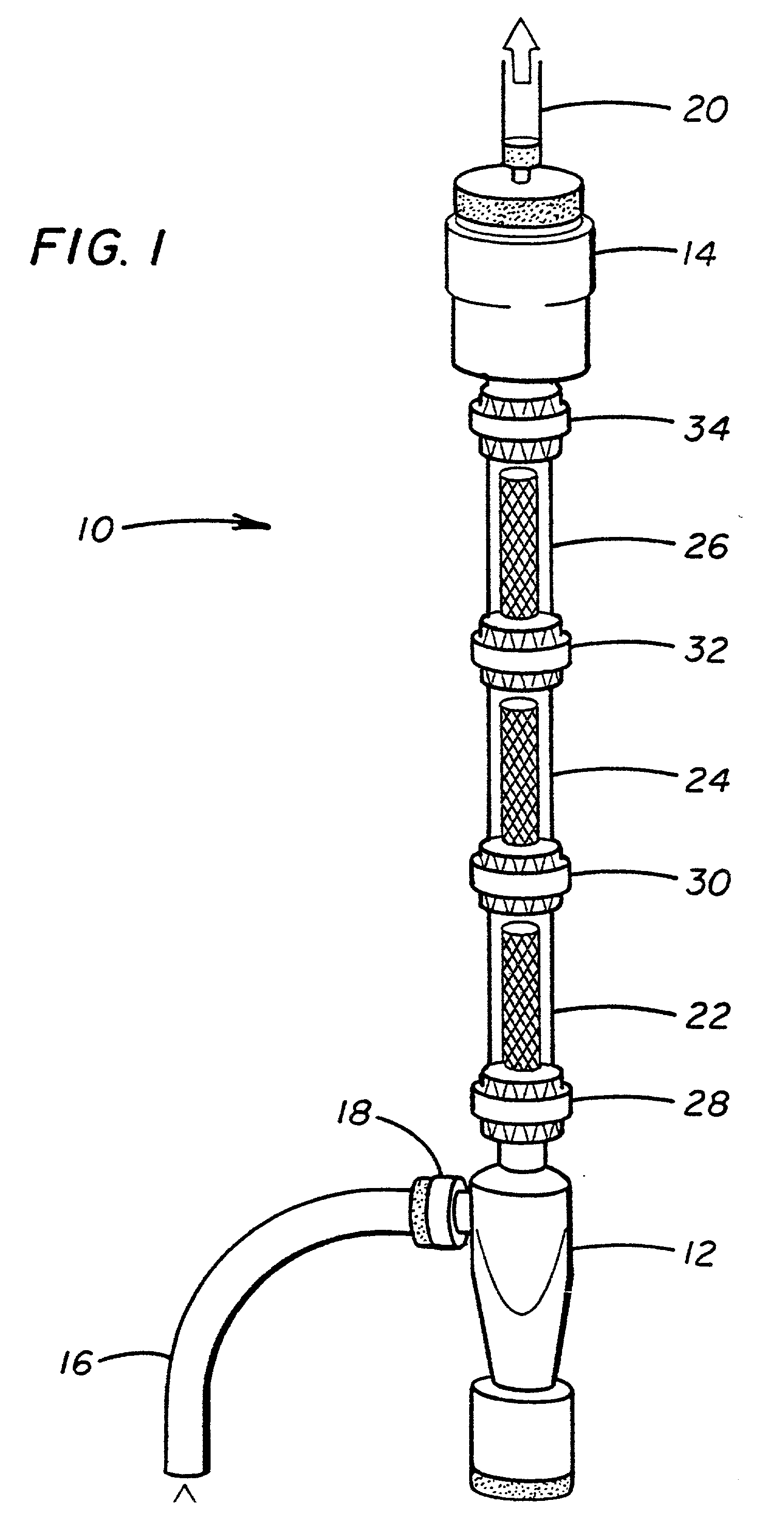

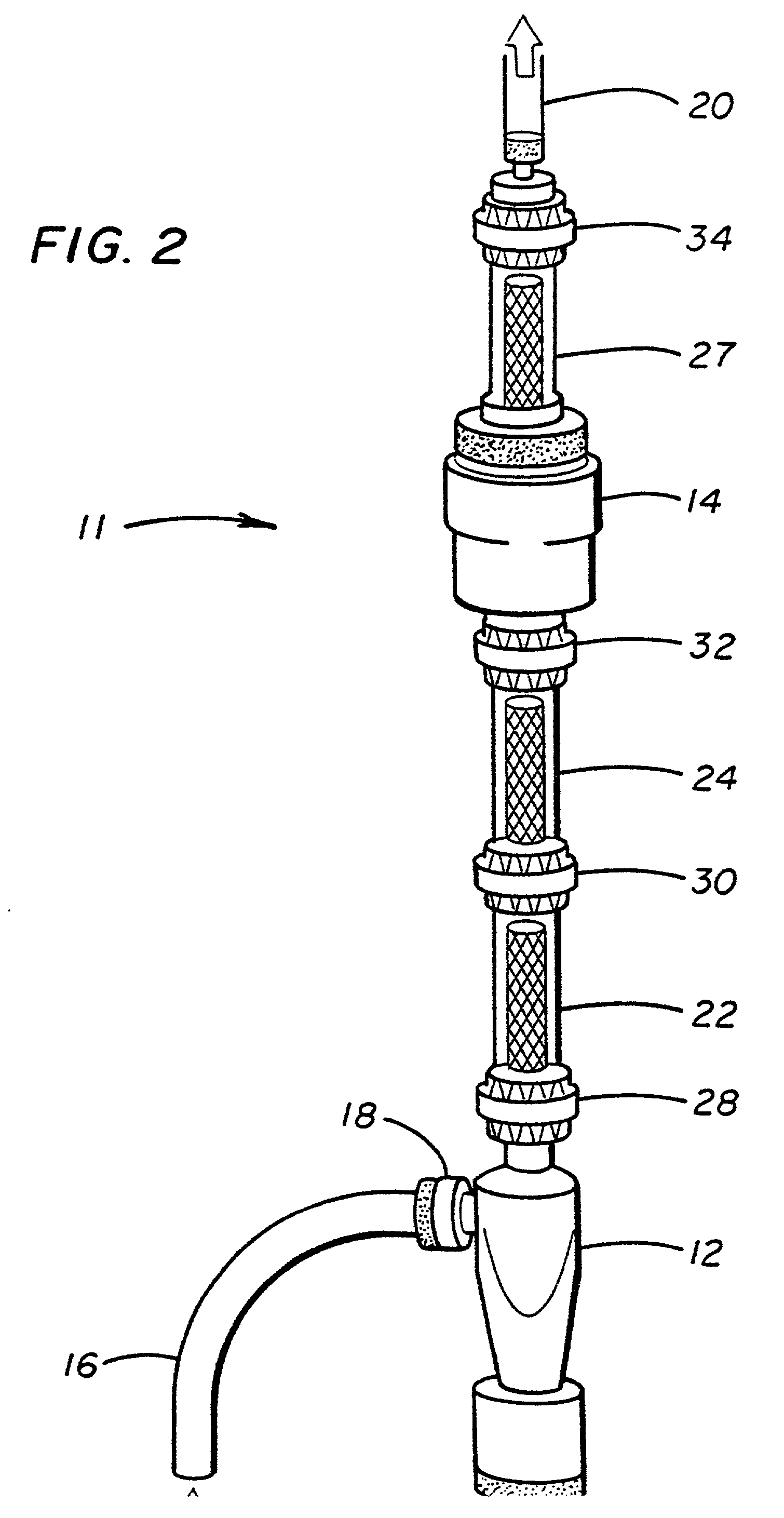

The present invention concerns a quantitative organic vapor-particle sampler which can efficiently sample both semi-volatile organic gases and particulate components through the use of a unique sorbent resin coating and process. The sampler of the present invention comprises in its broadest aspect a tubular device having an inlet at one end through which organic vapor / particles are introduced, an outlet at the other end through which gases exit, at least one annular denuder interposed there between which is coated on the inside surface of the annulus with a specially prepared resin absorbent, which selectively absorbs organic vapors contained in the gases introduced into the inlet, and a filter which traps and collects particles. The invention further concerns a semi-volatile organic reversible gas sorbent for use in an integrated diffusion vapor-particle sampler comprising macroreticular resin agglomerates of randomly packed microspheres with the continuous porous structure of particles ranging in size between 0.05-10 mum.

Owner:RGT UNIV OF CALIFORNIA

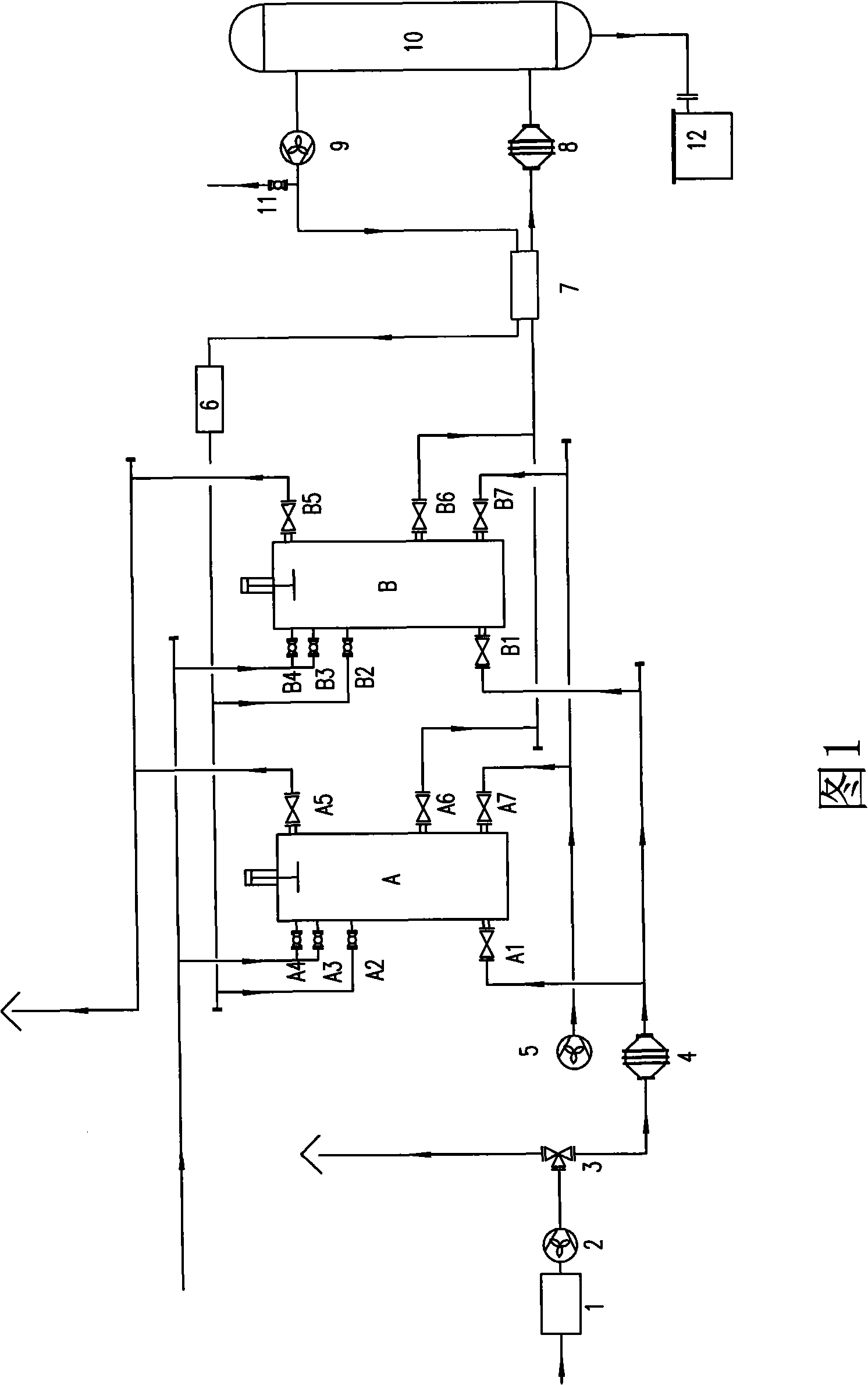

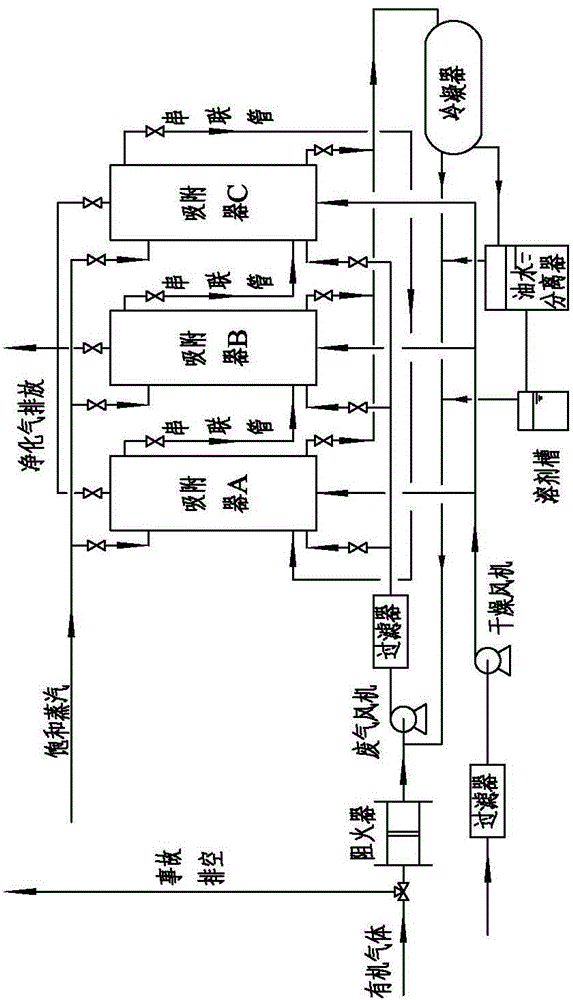

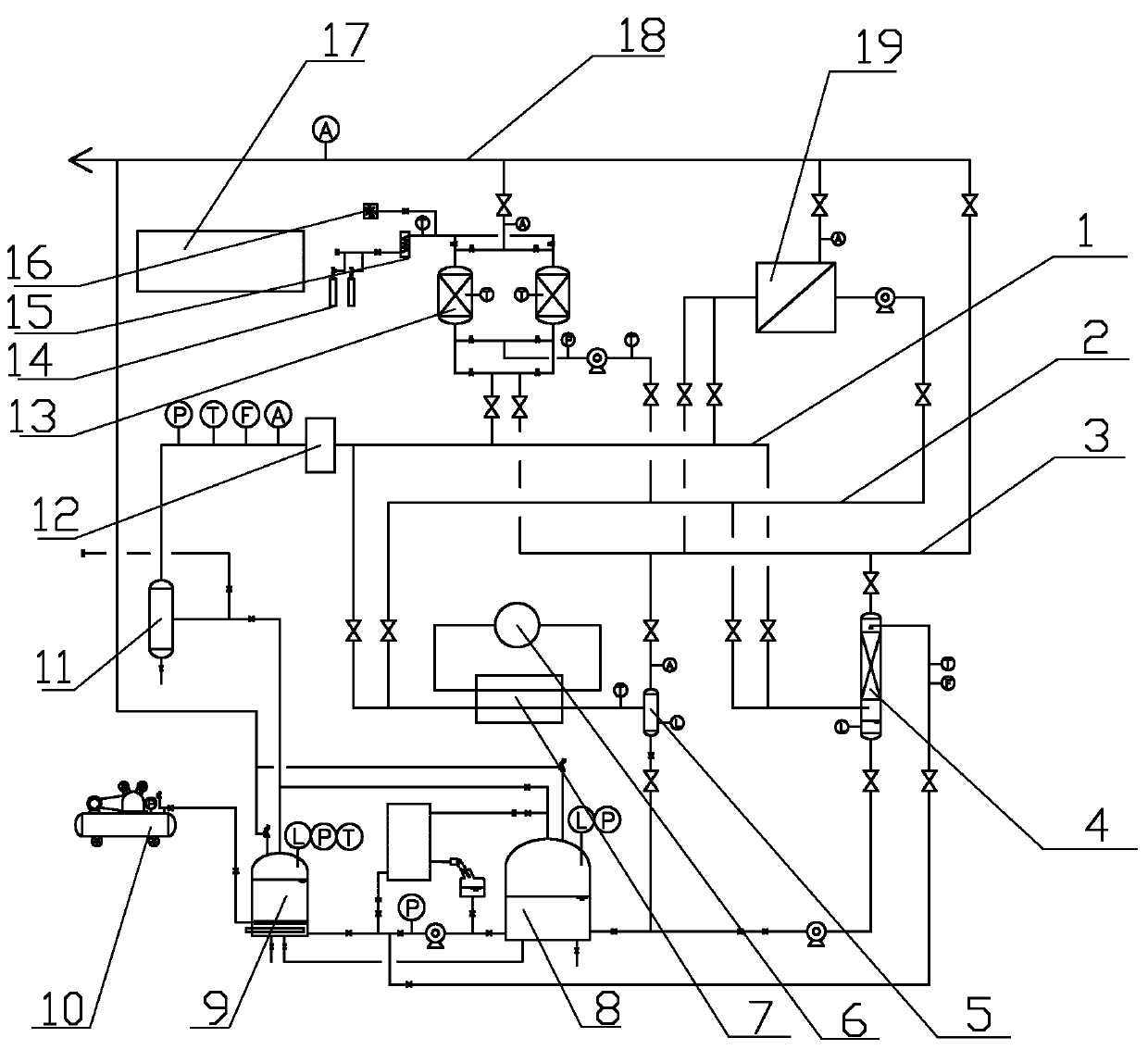

Active carbon fiber organic gas recovery method and system using nitrogen as desorption medium

InactiveCN101288820AReduce water contentAchieving zero emissionsDispersed particle separationCombustible gas purificationSolubilityFiber

The invention relates to a method for recovering active carbon fibre organic waste gas by taking nitrogen as desorption medium, belonging to the field of environmental protection. The method for recovering active carbon fibre organic waste gas by taking nitrogen as desorption medium takes the active carbon fibre as a fixed bed adsorber of the adsorbent, adopts thermal nitrogen desorption and can recover and reuse the organic waste gas and nitrogen at the same time. The method of the invention adopts the thermal nitrogen adsorption, generates no secondary contaminant, realizes that the exhaust reaches the standard of the environmental protection, leads the adsorption layer to keep dry at the same time, improves the utilization ratio of the active carbon fibre and prolongs the service life of the active carbon fibre. As vapour is not used for desorption, the equipment has no corrosion problem, thus greatly reducing the manufacture cost of the equipment. The method of the invention has extremely good recovery effects on solvent with large water solubility and easy hydrolysis performance and organic waste gas with high boiling point, has low water content in the recovered products, high quality of the solvent and reduces the running cost.

Owner:中节能天辰(北京)环保科技有限公司

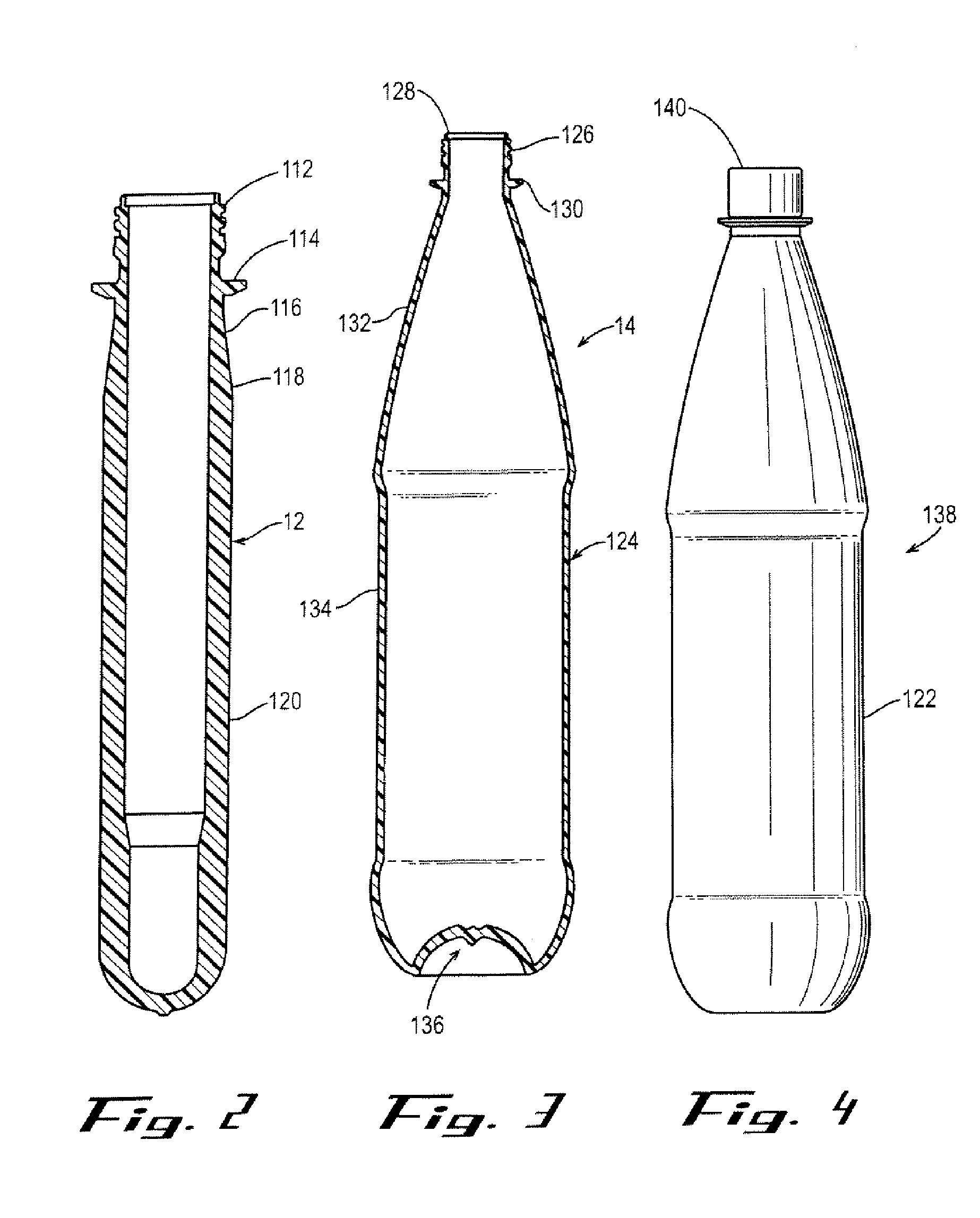

Polyester Container with Enhanced Gas Barrier and Method

ActiveUS20060275568A1Excellent gas barrier performanceHigh gas barrierBottlesSynthetic resin layered productsPolyesterOrganic gases

A polyester container with enhanced gas barrier properties comprises a polyester composition having an IV of 0.65 dL / g to 1.0 dL / g and comprising a polyester and a reactive organic gas barrier enhancing additive. The polyester is made using at least one first polycondensation catalyst selected from the group consisting of metals in Groups 3, 4, 13, and 14 of the Periodic Table and comprises a catalyst residue remaining in the polyester from formation of the polyester. The catalyst residue comprises at least a portion of the at least one first polycondensation catalyst.

Owner:THE COCA-COLA CO

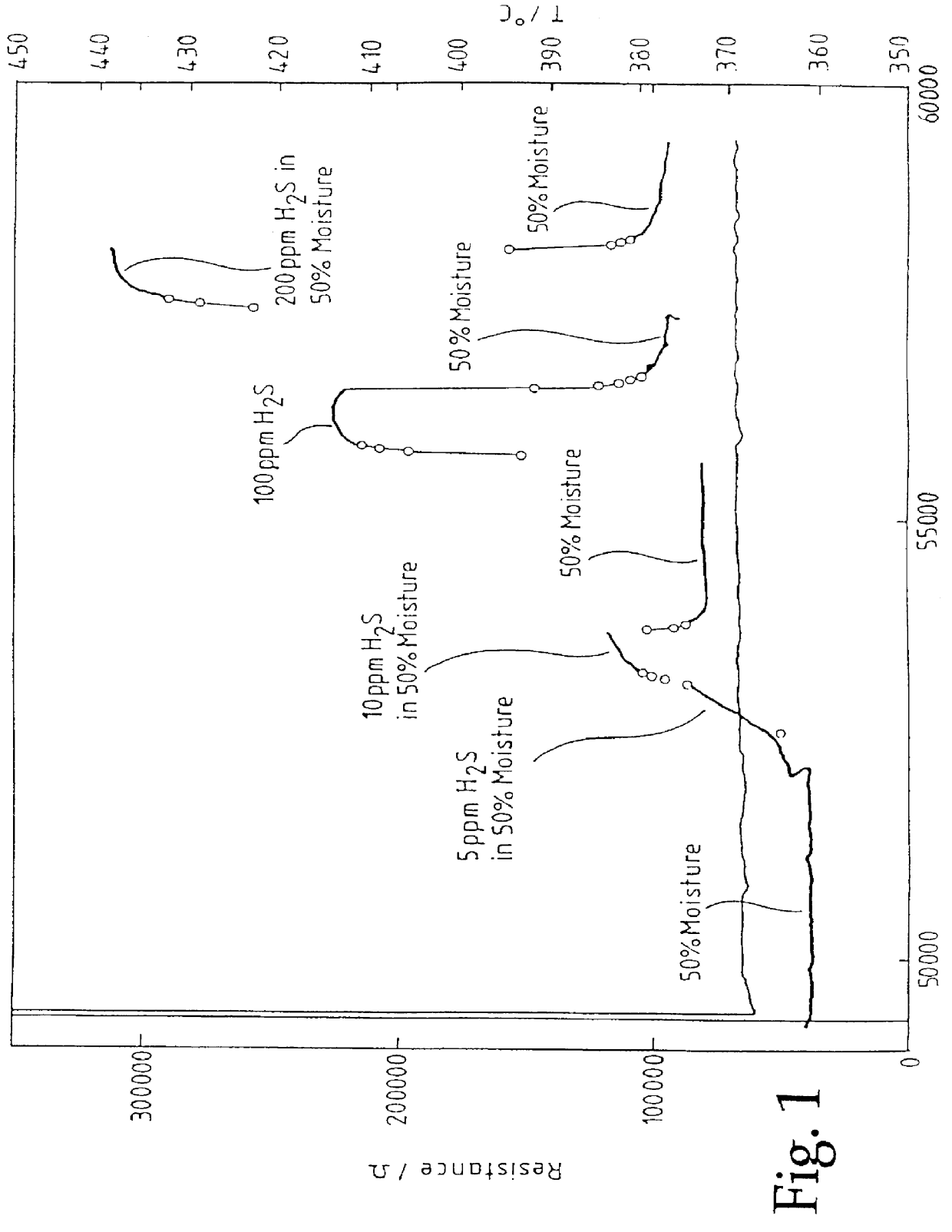

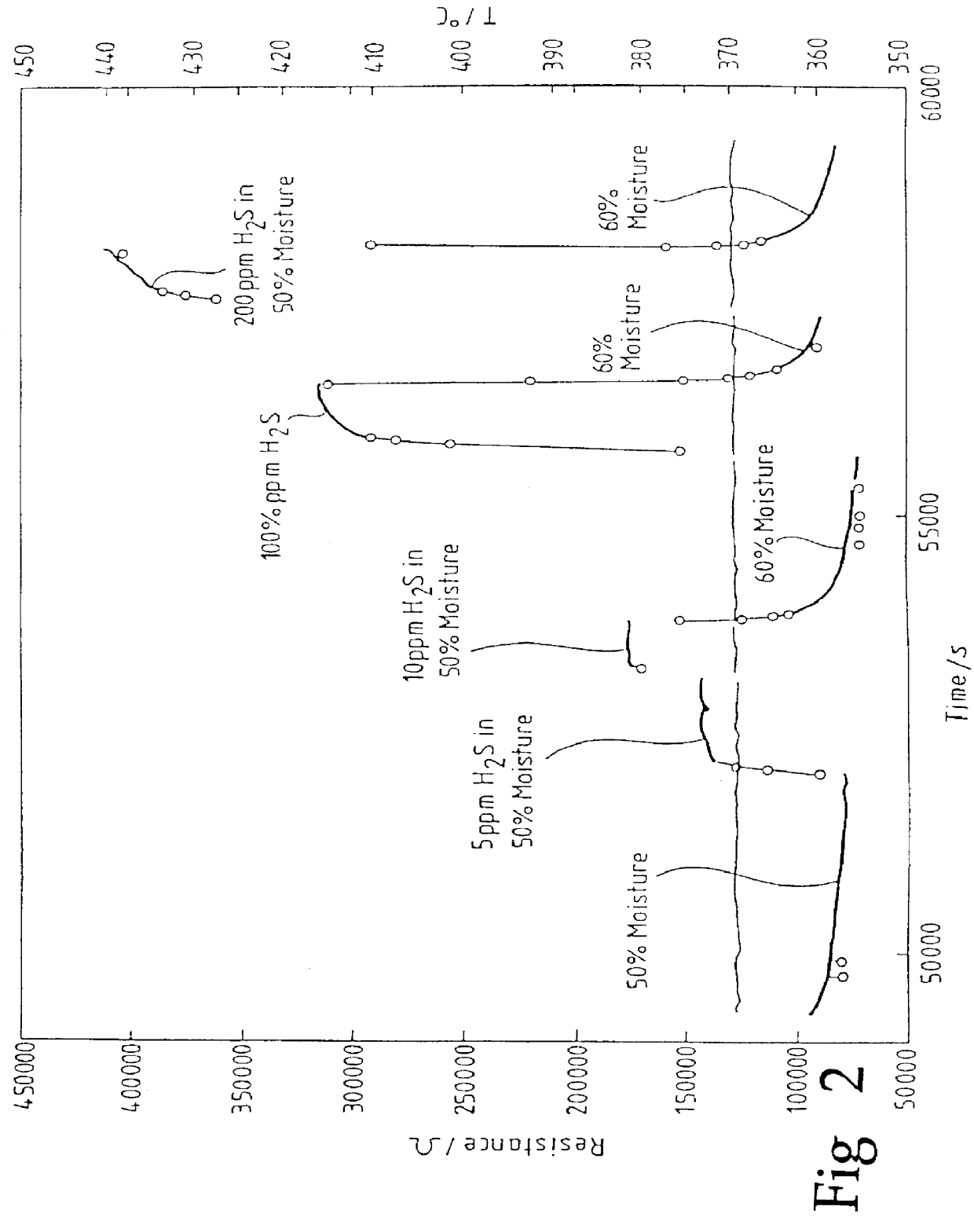

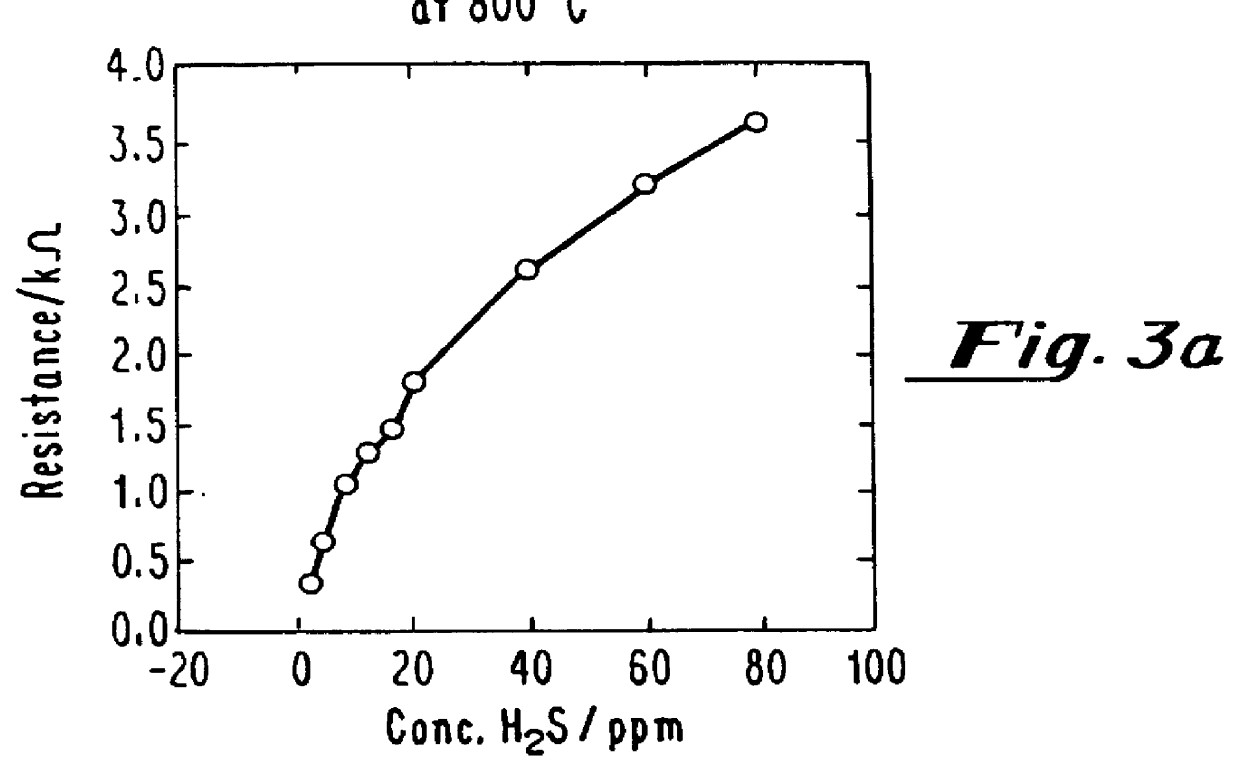

Semiconducting oxide gas sensors

InactiveUS6046054AShort stabilization timeGreatly reduced baseline driftFuel testingBiological testingAmmoniaPartial pressure

The selectivity of response of resistive gas sensors to specific gases or vapors is improved by the selection of specified gas-sensitive materials which are not previously known for the applications described, which include detection of hydrocarbons in the presence of CO, H2S, SO2, chlorine, NO2, CO2 (especially in low concentrations), CFC's, ammonia, free oxygen by determination of partial pressures, and numerous organic gases and vapors.

Owner:CAPTEUR SENSORS & ANALYZERS +1

Adsorbing material for effectively adsorbing formaldehyde and other harmful substances in air

The invention relates to an adsorbing material for effectively adsorbing formaldehyde and other harmful substances in the air, belonging to the field of the adsorbing material for improving the air quality. The adsorbing material has the technical scheme that the material is characterized by comprising the raw materials based on the parts by weight: 10-20 parts of zeolite, 20-30 parts of sepiolite, 15-25 parts of diatomite, 10-15 parts of bentonite, 15-25% of active carbon and 6-12 parts of silicasol, wherein the silicasol is nanoscale silicon dioxide colloid water solution. The technical scheme also comprises the raw materials based on the parts by weight: 10-15 parts of higher molecular weight organic amine polymer with the molecular weight of 1800-50000, 5-10 parts of active carbon fiber and 10-20 parts of non-woven fabrics. The invention selects the substances with very strong adsorbing function and designs a set of formulation according to the different adsorption capacity and selectivity of the substances, so as to lead the substances to be matched with each other for adsorbing common indoor pollution gases such as formaldehyde, benzenes, hydrocarbons, other organic gas molecules larger than oxygen and nitrogen molecules in the air as well as virus bacterium and fine dust, thus purifying the indoor air, preventing decoration disease and improving the health level of residents.

Owner:傅桂云 +1

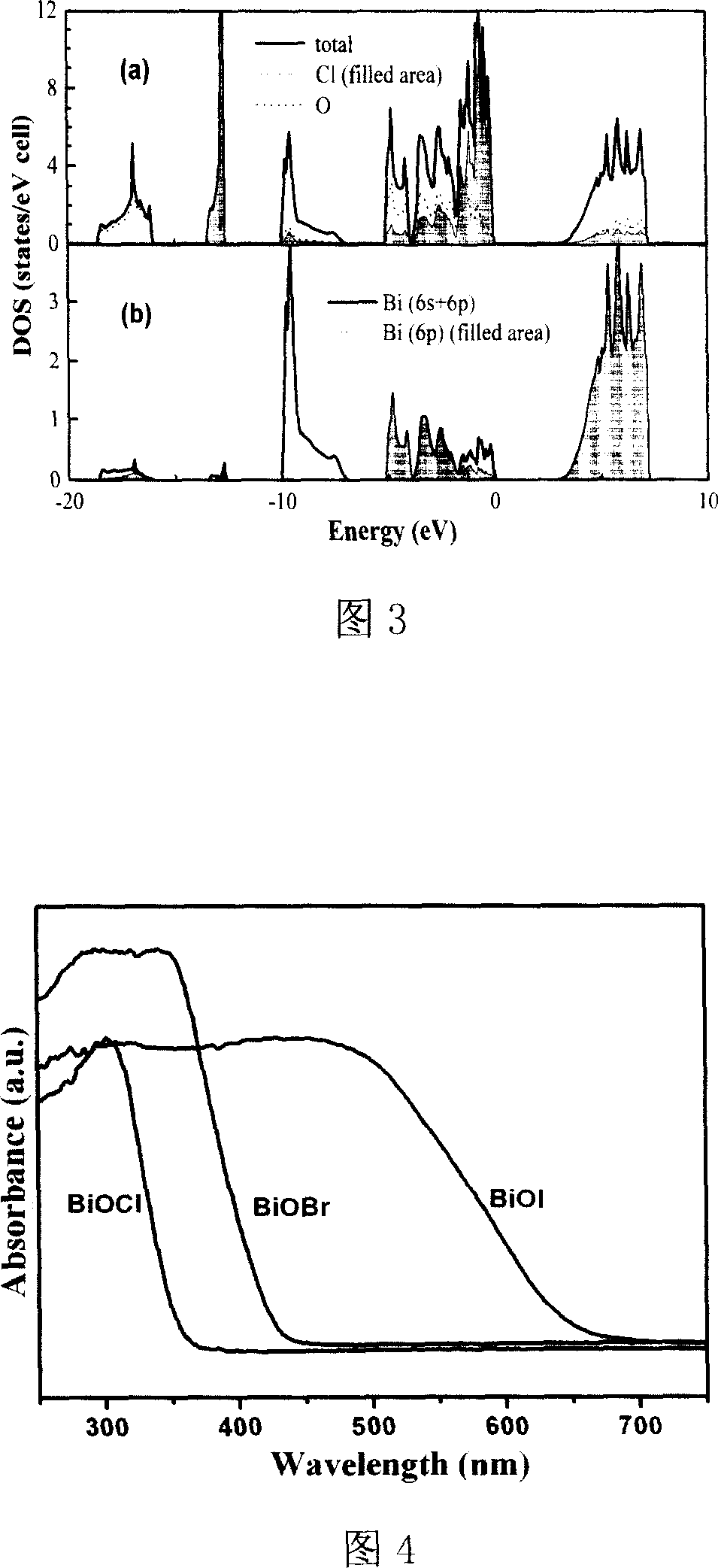

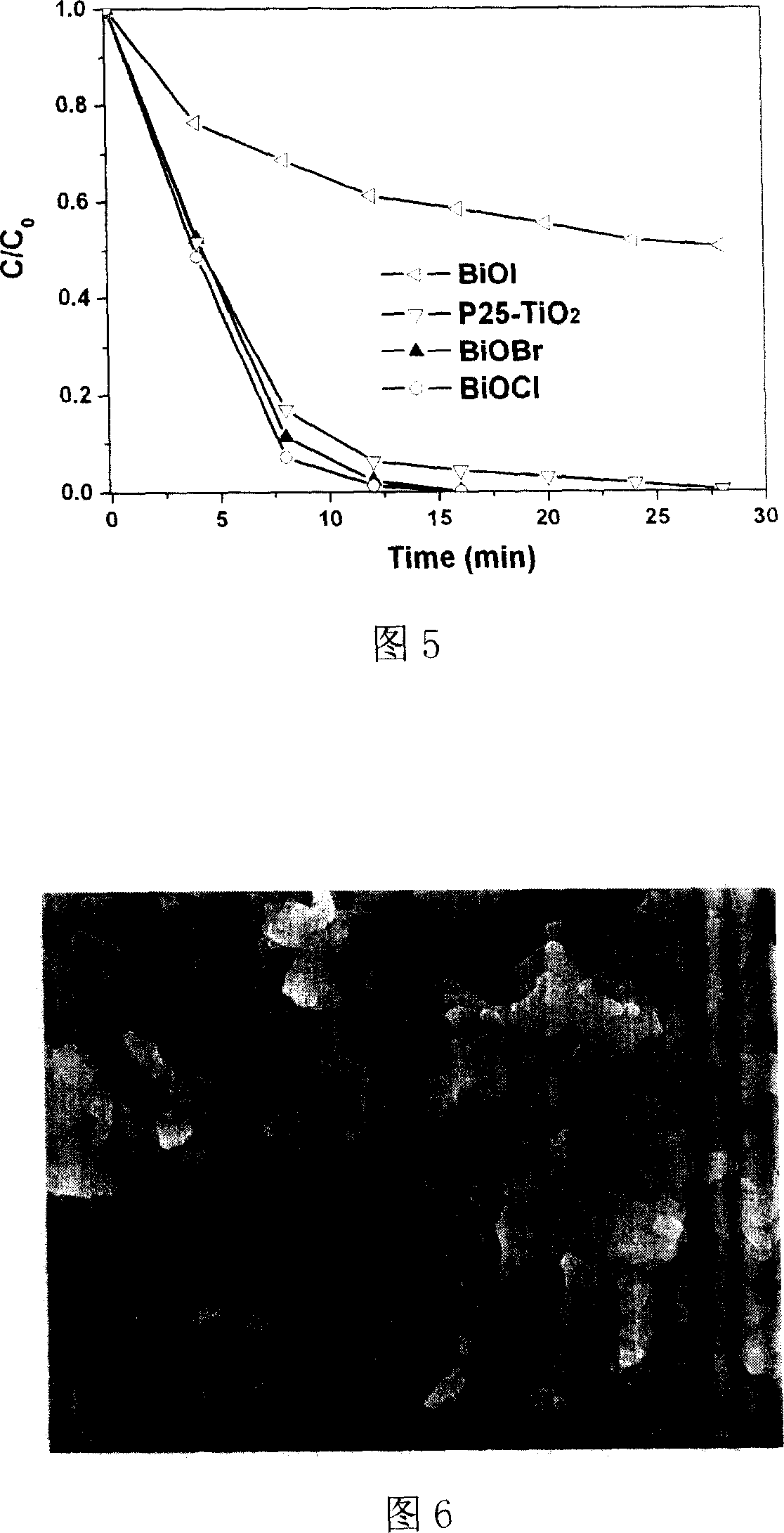

Use of bismuth oxyhalide

InactiveCN101020143AExcellent ability to degrade organic pollutantsPhysical/chemical process catalystsHydrogen productionChemical compositionHydrogen

The present invention belongs to the field of photocatalyst material technology, and is especially use of bismuth oxyhalide. Bismuth oxyhalide as photocatalyst material is prepared through one solid phase or liquid phase process. It has the chemical composition of BiOX, where, X=Cl, Br or I; and laminated crystal confuration formed with [Bi2O2] and [X] structural layers stacked alternately in the C axis direction. Bismuth oxyhalide has excellent photocatalytic performance. It is used in degrading organic dye and harmful organic gas, killing bacteria and photolyzing water to produce hydrogen. Supporting nanometer Ag, Pt or other metal particle with powerful electron affinity can raise the photocatalytic performance greatly.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ultraviolet-cured stripping protective material and preparation method and application thereof

ActiveCN103627313AHigh elongationEasy to dryPolyurea/polyurethane coatingsPolyethylene terephthalate glycolUltraviolet lights

The invention belongs to the technical field of surface protective materials, and discloses an ultraviolet-cured stripping protective material and a preparation method and application thereof. The stripping protective material comprises the following components in parts by weight: 50-90% of polyurethane modified acrylic ester, 5-35% of acrylics reactive diluent, 1-8% of photoinitiator, 1-15% of filler, and 0-10% of additive. According to the ultraviolet-cured stripping protective material, the ultraviolet light is used for triggering a chained polymerization, the time for curing is short, generally 1-5 seconds, and the production efficiency is high; not any organic gas is released, so that the preparation method is more environment-friendly; the use and operation process is simple and convenient, the surface of the material is not affected due to overheating curing, mist is generated after stripping; the integral protective material can be better stripped, is not sticky, has no mist, and is applicable to protecting surfaces of ITO (indium tin oxide) glass, ITO membranes and PET (polyethylene terephthalate) membranes.

Owner:GUANGZHOU MECHANICAL ENG RES INST

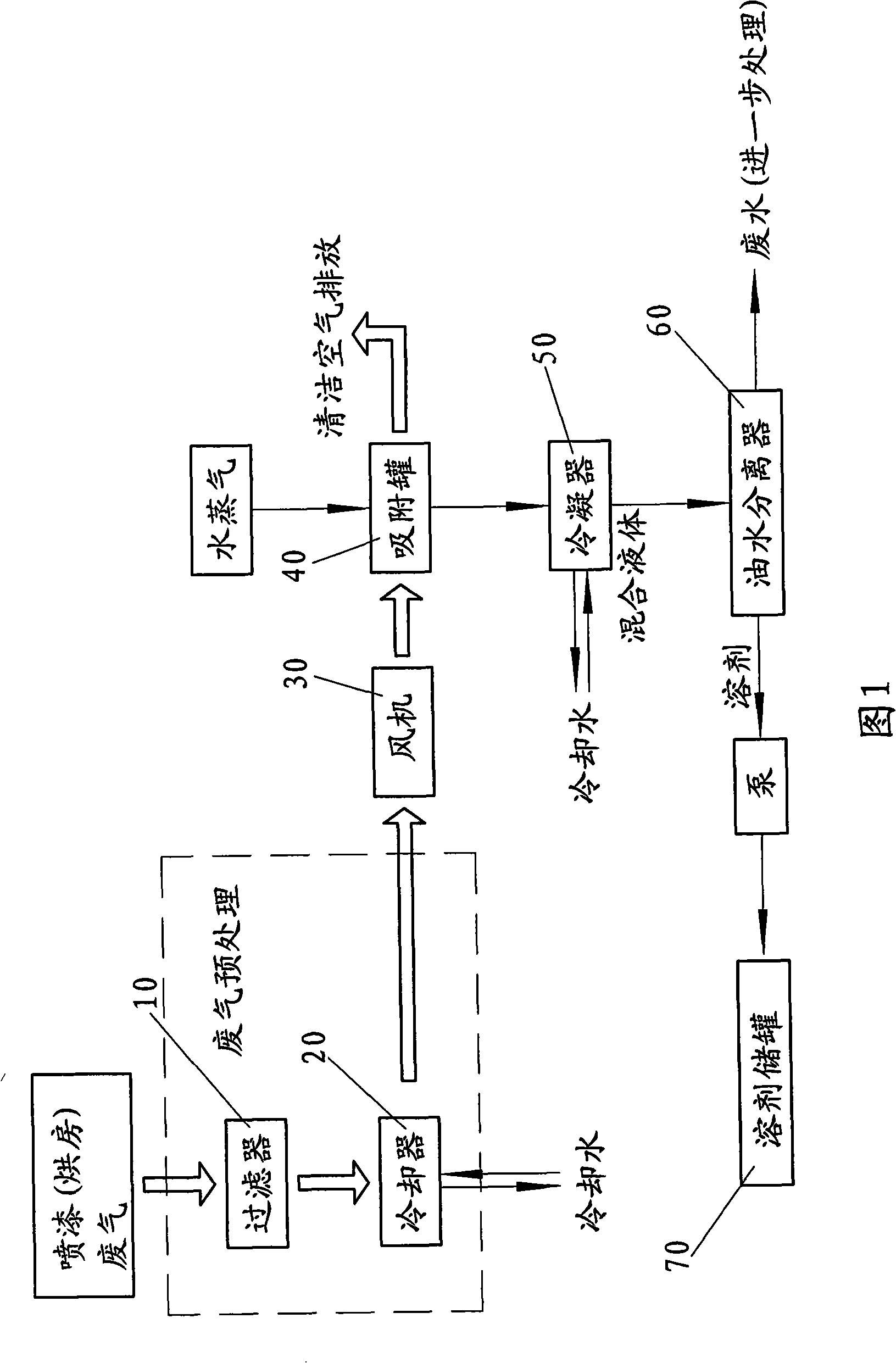

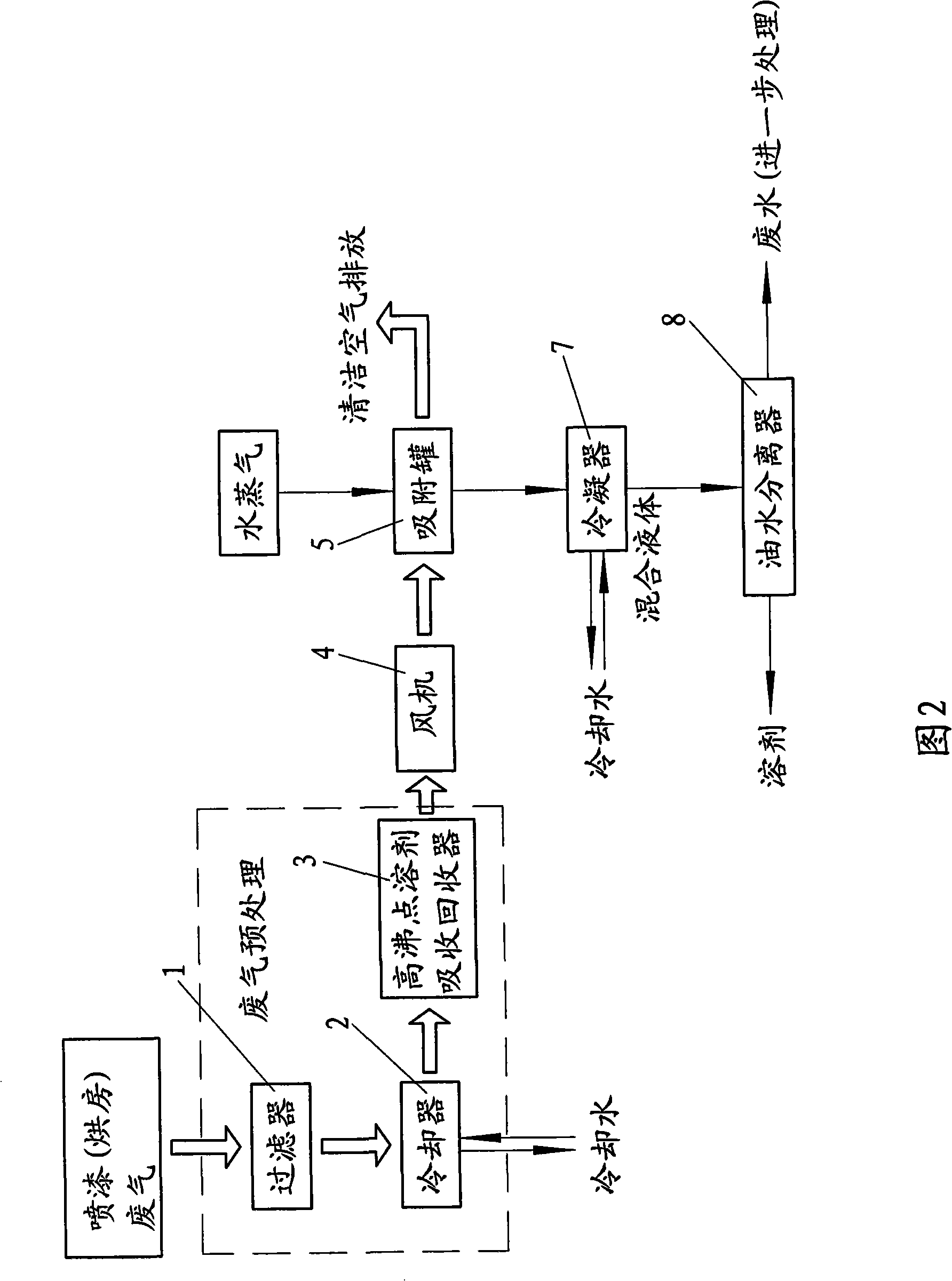

Method for cleaning, recovering and treating painted lacquer exhaust organic gas and device

ActiveCN101274150AGuaranteed uptimeDisplay and monitor working status in real timeDispersed particle separationVapor condensationFiltrationLacquer

The invention discloses a spraying paint organic exhaust gas purification recovery disposal method and a device. The method has the steps as follows: (1) the dust and paint mist of the spraying paint organic exhaust gas are removed by filtration, and high boiling point organic solvent component with the boiling point more than 110 DEG C is condensed; (2) a high boiling point solvent absorption recoverer is used for recovering the high boiling point organic solvent; (3) residual organic exhaust gas is sent into an adsorption tank, the organic solvent component in the exhaust gas is adsorbed, and the exhaust gas is exhausted after being adsorbed by the adsorption tank; (4) by adopting a vapour desorption method, the organic solvent adsorbed by the adsorption tank is desorbed; (5) the desorbed solvent steam and vapour are condensed as liquid; (6) the condensed mixed liquid is separated by the oil and water separator, the separated organic solvent can be used again, and the separated wastewater can be disposed separately. Therefore, precious resources can be recovered, secondary pollution can be reduced, the recovered solvent can be used again, and the consumption of energy source can be reduced.

Owner:蔡志煌

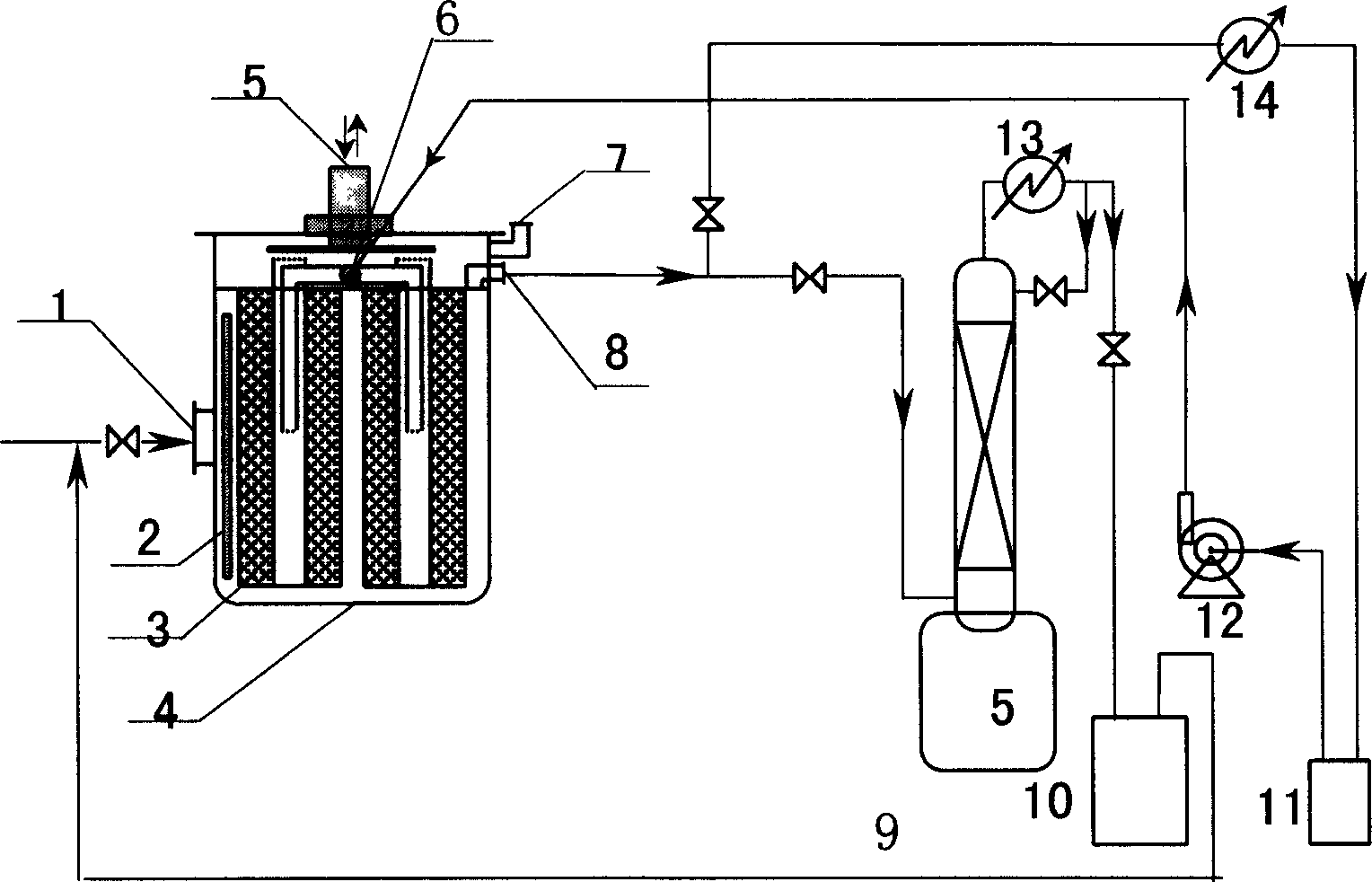

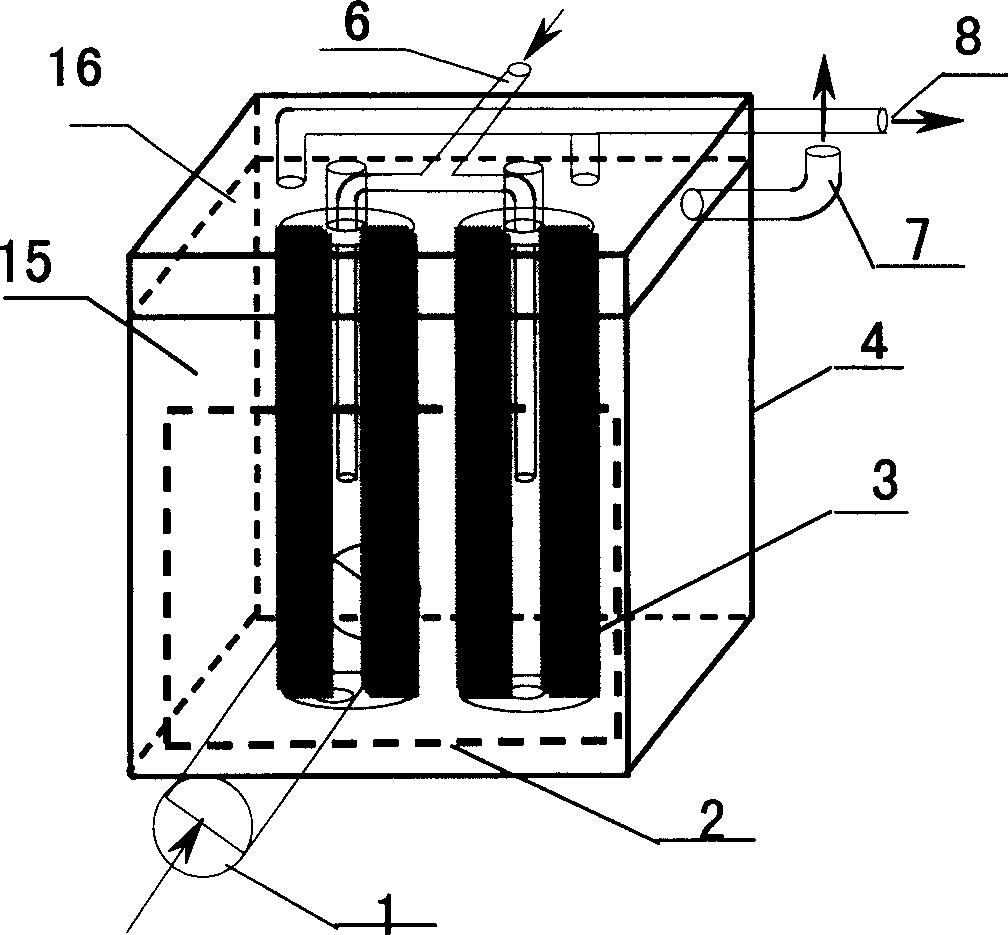

Active carbon fiber device and method for adsorbing, recovering and treating organic waste gas

ActiveCN1608710AEfficient use ofSeparation by using its own heat, effective analysis and recoveryDispersed particle separationFiberSingle stage

The present invention features that the waste organic gas recovering and treating apparatus includes also one rectifying and recovering system, which comprises rectifying tower between the outlet of analyzed gas and the condensator and solvent accepting trough between the rectifying tower and the condensator and is for recovering the organic solvent; and may includes also one analyzed gas by-pass cooling system and one gas distributing baffle. The method of recovering and treating waste organic gas may be alternate single stage adsorption-analysis-cooling and dehumidifying in two or three serially connected adsorbors, and through connection and arrangement of pipeline and valves, uninterrupted recovering and treating of waste organic gas is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

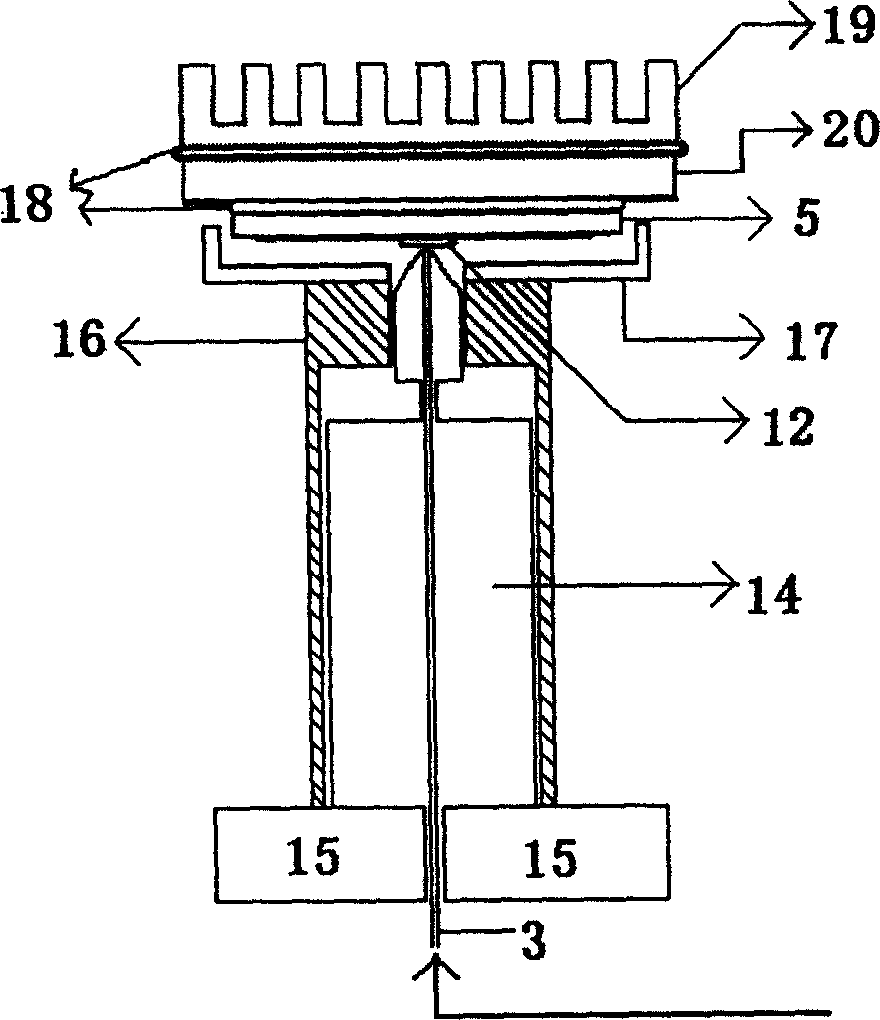

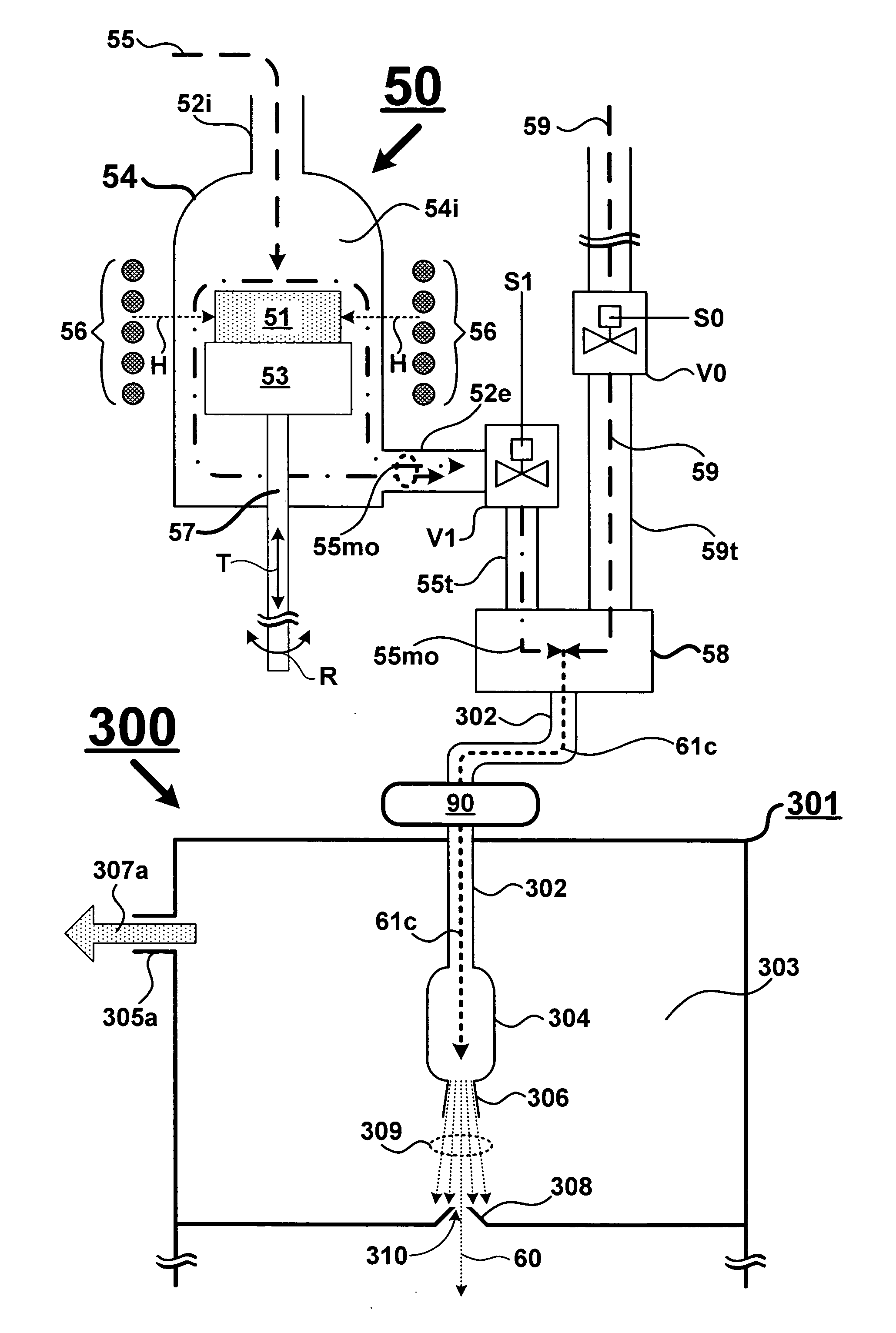

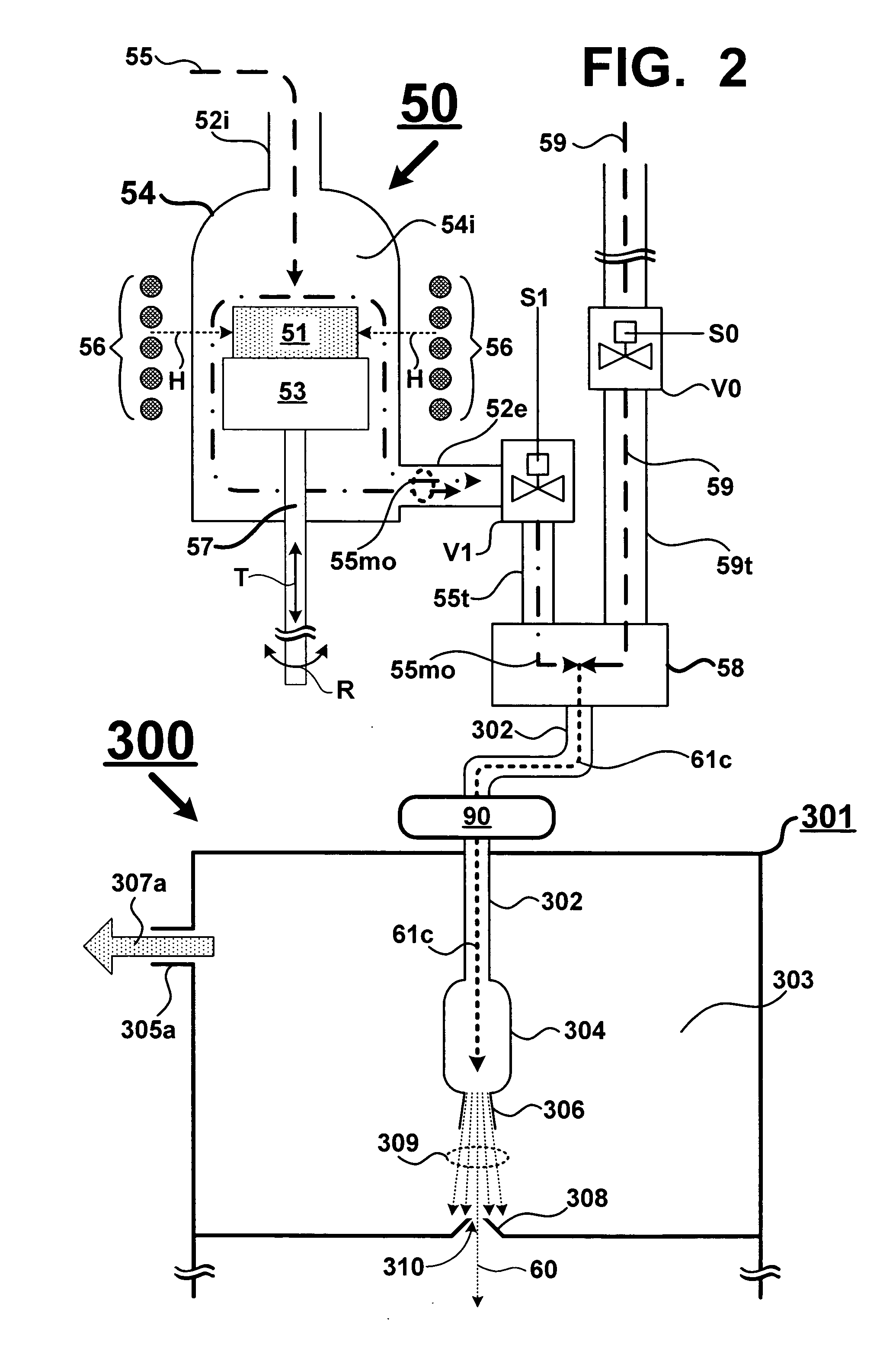

Respiration detecting method and its device for diagnosing early lung cancer

InactiveCN1647756AWide detection rangeHigh detection sensitivityRespiratory organ evaluationNerve networkSolid-phase microextraction

The present invention discloses a kind of respiration detecting method and apparatus for diagnosing lung cancer in early stage. The method includes solid phase micro extraction to pre-enrich the exhaled gas of the patient, inserting the solid phase micro extraction with adsorbed organic gas component into hot gas desorbing unit to desorb, separating the desorbed organic gas component with vapor capillary chromatographic column, adsorbing the organic gas component with the organic gas sensing film in the detecting head of one pair of HF delay line ASW sensors to detect the organic gas content, and performing image processing and nerve network mode distinction on 11 kinds of detected lung cancer labeling organic components to diagnose lung cancer patient. The technology of the present invention may be also used for detecting volatile organic matters in other various fields.

Owner:ZHEJIANG UNIV

Activated carbon fiber organic solvent recovery novel technique using nitrogen as desorption medium

InactiveCN101301558ARealize environmental protection standard emissionIncrease profitDispersed particle separationFiberCarbon fibers

The invention provides a novel organic gas processing technique, which expends the application area of activated carbon fiber adsorbent. The technique uses hot nitrogen as desorption medium, and recovers the enriched desorption gas in a cooling or absorption manner, thereby realizing zero-release of pollution. The nitrogen is replaced before heating-desorption, and the safe running of a recovery device can be guaranteed by using temperature and oxygen content on-line monitoring system to control the switch of a nitrogen safety valve. By using the hot nitrogen as the desorption medium, the problems of secondary pollution, corrosion and high running cost etc. generated during water vapor desorption in the traditional technique can be overcome, thereby improving the efficiency, prolonging the serving life and expanding using range, so that the technique has good application and popularization value.

Owner:中节能天辰(北京)环保科技有限公司

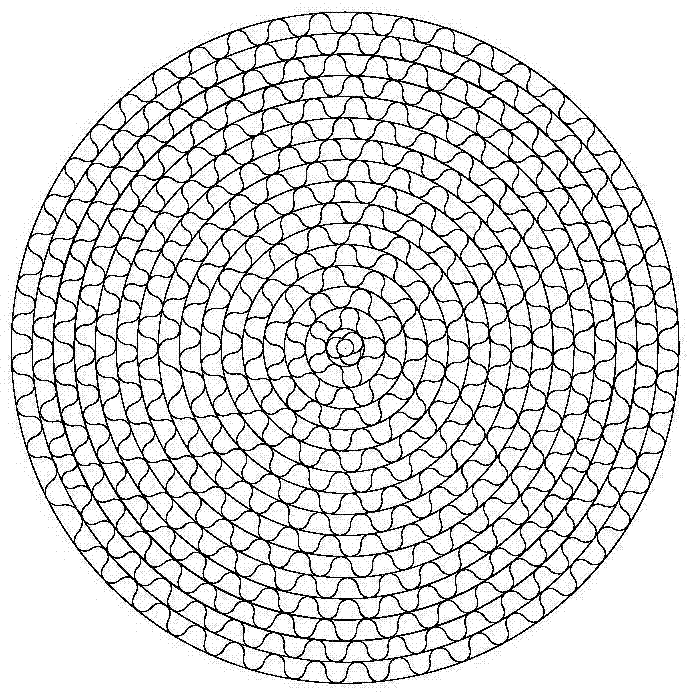

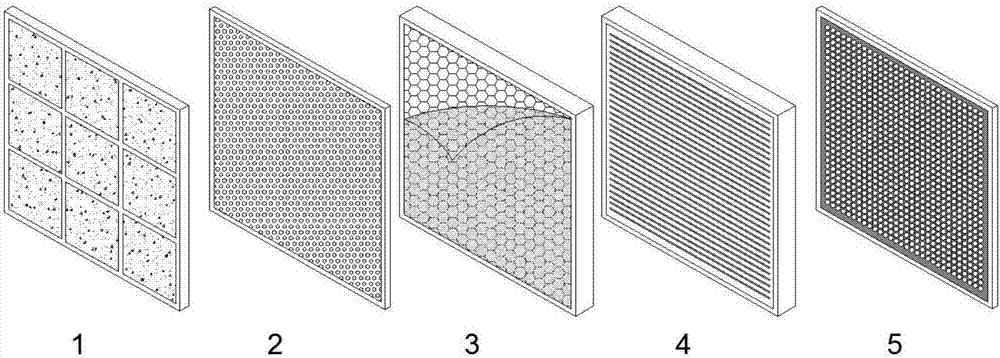

Compound VOCs absorbing concentration turning wheel and use method thereof

InactiveCN105435582AImprove adsorption capacityAvoid affecting the purification effectGas treatmentOther chemical processesActivated carbonMolecular sieve

The invention discloses a compound VOCs absorbing concentration turning wheel and a use method thereof and belongs to the technical field of absorption of organic gas. The compound VOCs absorbing concentration turning wheel is formed by coaxially equal-diameter butt-jointing a molecular sieve turning wheel and a honeycomb activated carbon turning wheel, wherein the honeycomb activated carbon turning wheel is located on a VOCs inlet side; an absorbing area, a desorption area and a cooling area are arranged on each turning wheel; an isolating ring is arranged at the butt-joint of the two turning wheels; the isolating ring is used for isolating the absorbing areas, the desorption areas and the cooling areas of the two running wheels, redistributing wind and reducing wind resistance; the molecular sieve turning wheel is acquired by attaching the VOCs adsorbent to the honeycomb turning wheel in the manner of spraying, leaching or impregnating. According to the invention, the molecular sieve turning wheel and the honeycomb activated carbon turning wheel are combined with each other, so that the absorbing scope is widened, the purifying efficiency is increased, the quality of purified gas is further ensured and the occupied space of equipment is saved.

Owner:青岛纳博科环保科技有限公司

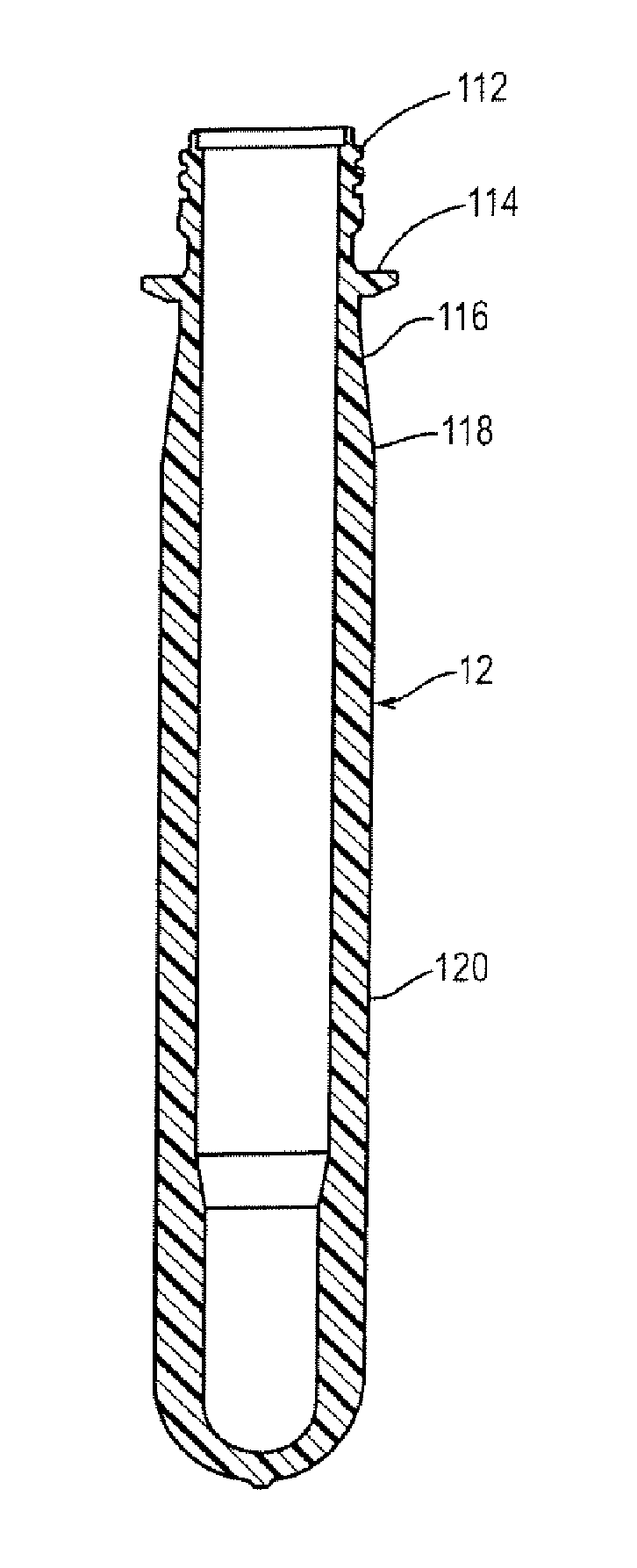

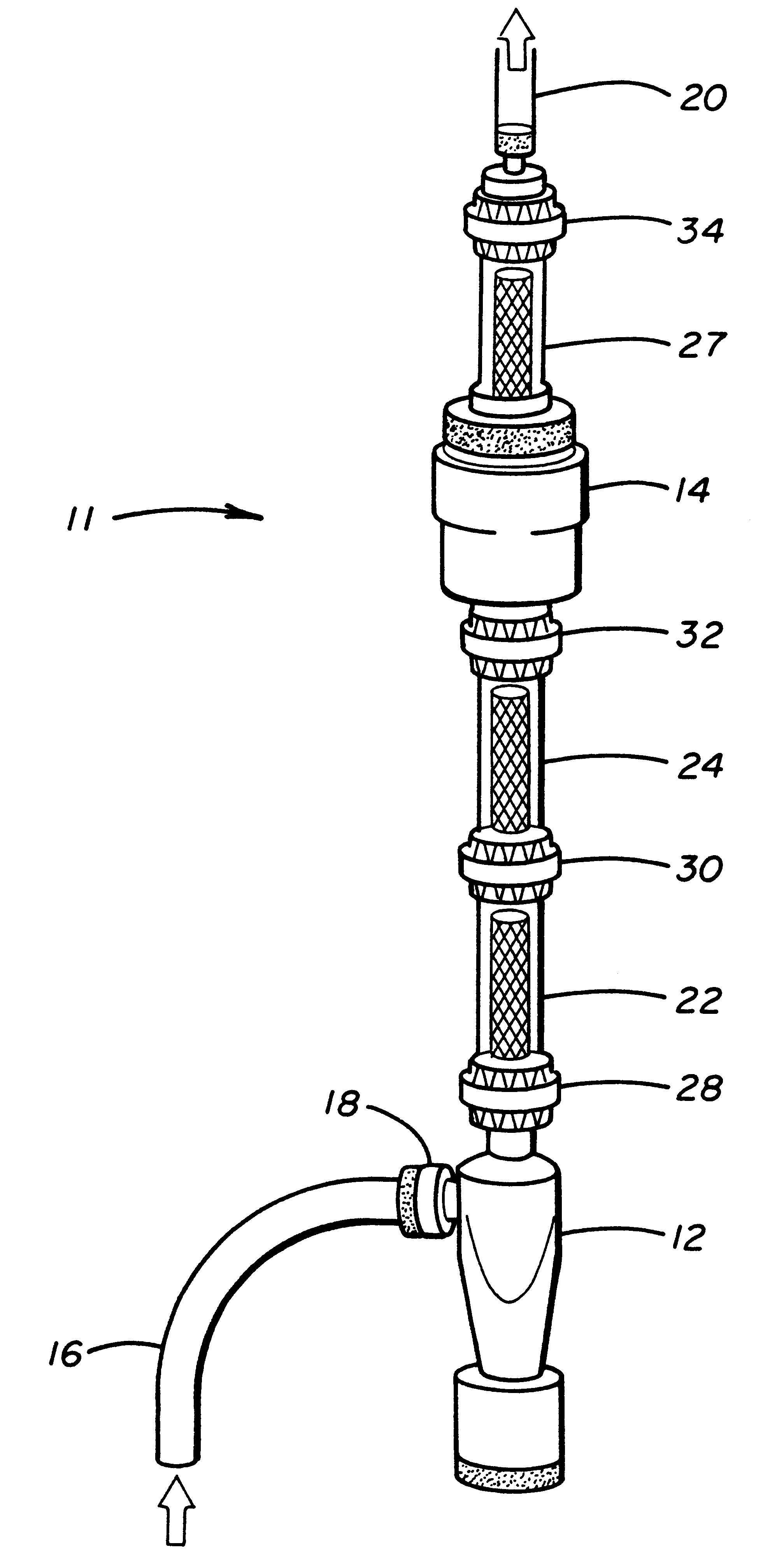

Method for fabricating a quantitative integrated diffusion vapor-particle sampler for sampling, detection and quantitation of semi-volatile organic gases, vapors and particulate components

InactiveUS6226852B1Displacement minimizationEliminate artifactsOther chemical processesWithdrawing sample devicesTest sampleOrganic vapor

A method for fabricating a quantitative organic vapor-particle sampler for efficient sampling, detection and quantitation of semi-volatile organic gases, vapors and particulate components. The sampler comprises a diffusion chamber and at least one annular denuder of which surface is coated with a macroreticular resin agglomerates which selectively absorbs organic gases, vapors or particulate matter present in tested samples.

Owner:RGT UNIV OF CALIFORNIA

Purification for stink and organic waste gas

ActiveCN1745883AImprove purification rateStable growth environmentDispersed particle separationAir quality improvementSorbentSewage

A process for treating the offensive smell in petrochemical sewage treating plant and cleaning the low-concentration waste organic gas features use of immobilized microbial membrane as filler and 1-3 stages of microbial treatment. It includes such steps as wet dusting for pre-treating, microbial treating and post-treating by absorbent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of engineering a property of an interface

InactiveUS20060093753A1Liquid surface applicatorsElectric discharge tubesSimple Organic CompoundsGas cluster ion beam

A method of engineering a property of an interface using a gas cluster ion beam (GCIB) apparatus is disclosed. The method includes introducing a metal-organic compound with a carrier gas to form a metal-organic gas and mixing the metal-organic gas with a cluster gas used in the GCIB. The GCIB forms a plurality of gas cluster ions that include the metal-organic compound, focuses the gas cluster ions into a beam, and then accelerates the beam towards an interface surface of a target material where the gas cluster ions impact on the interface surface and at least a portion of the metal-organic compound remain in contact with the interface surface and modifies a property of the interface surface. The metal-organic gas can include a plurality of metal-organic compounds.

Owner:HEWLETT PACKARD DEV CO LP

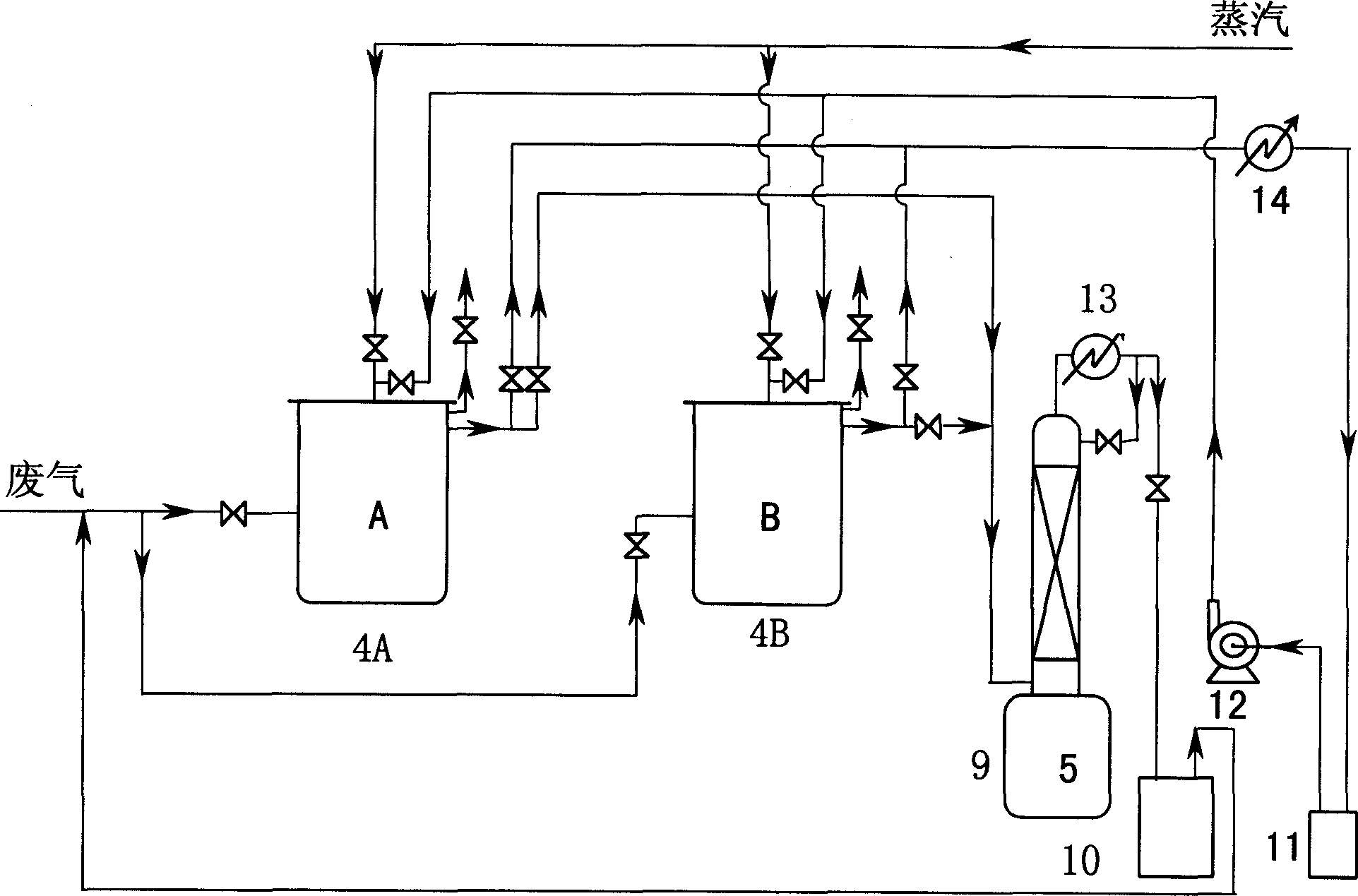

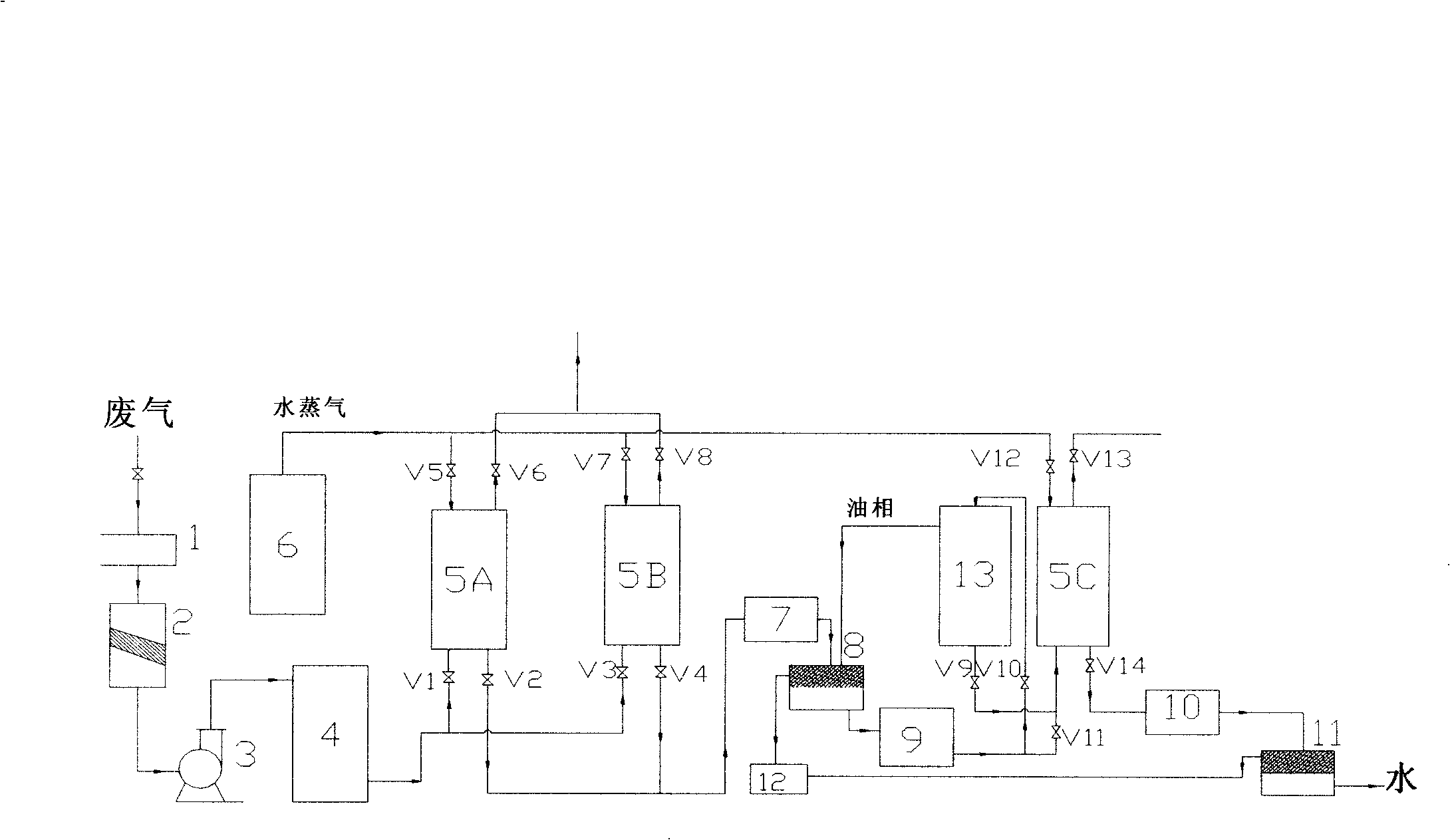

Method for multistage adsorption and recovery of organic gases through active carbon fiber

InactiveCN104906917AGuaranteed emission standardsFlexible operationDispersed particle separationFiberOrganic solvent

The invention provides a method for multistage adsorption and recovery of organic gases through active carbon fiber. All adsorbers can operate the organic gases in a series-parallel manner through series tubes arranged between every adjacent adsorbers to realize multistage adsorption of the organic gases, the highest adsorption grade can reach (N-1) grade (N is the quantity of the adsorbers contained in a system), and the opening or closure of the series tubes can be controlled to switch the adsorption grade between 1 and (N-1). After the adsorbers are saturated, saturated steam is used to desorb the adsorbers, desorbed steam is processed through a condenser and an oil-water separator, and an organic solvent is recovered. The desorbed adsorbers are dried and regenerated by air or an inert gas, then enter an adsorption process, and respectively work according to the above flow in a circulating manner, and the last stage adsorption in the adsorption process is desorption of the regenerated adsorbers. Compared with present multistage adsorption technologies, the method has the advantages of agile operation, low running cost, small device investment, high adsorption grade and obvious investment saving.

Owner:北京日新达能技术有限公司

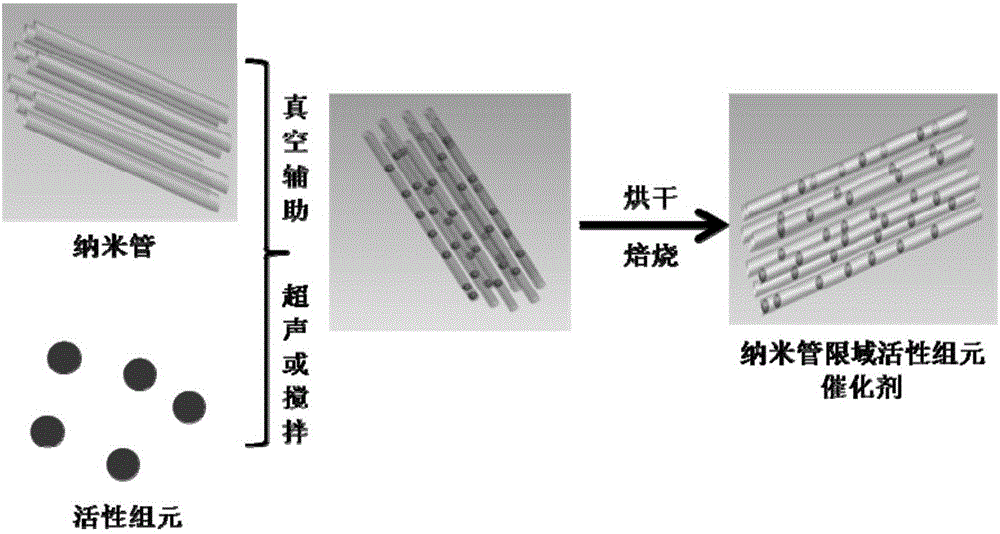

Method for low-temperature oxidative degradation of organic gas

InactiveCN106076113AImprove stabilityAvoid reunionGas treatmentHeterogenous catalyst chemical elementsReaction temperatureCatalytic oxidation

The invention discloses a method for low-temperature oxidative degradation of organic gas. The method comprises the steps that a nanotube limited-range active component catalyst is used as a catalyst, a reaction is carried out under the conditions that the temperature is 45-220 DEG C and the airspeed is 100-100000h<-1> for 0.5-1500h for a catalytic oxidation degradation reaction of organic gas, and the organic gas is oxidized into degradation reaction and water. According to the method, by means of the nanotube open-framework structure and micronanospace, the active component of the catalyst for treating organic gas is planted into the nanotube open-framework structure to prepare the nanotube limited-range active component catalyst with high activity and stability, the limited-range catalyst is used for oxidative degradation of organic gas and can rapidly oxidize the organic gas at a low temperature into carbon dioxide and water, the organic gas removal rate reaches up to 95% or more, the catalyst is high in activity and long in service life, and the problems that reaction temperature is high, catalyst activity and stability are low and the catalyst active component service life is short in the prior art are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Biological dripping and filtering system for purifying organic waste gases and method quick-speed preparing mvcoderm

InactiveCN101077472ASimplify the startup processFast startupDispersed particle separationAir quality improvementFiltrationFilter system

The organic waste gas purifying biological trickling filtration system and the fast pellicle preparing process are suitable for purifying low concentration waste gas with insoluble and non-degradable organic matter. The biological trickling filtration system consists of a biological trickling filtration reactor, a liquid circulating device, a waste gas input device, a purified gas circulating device, etc. The present invention adopts the ' inducer-target pollutant' double substrate specific degrading bacteria domesticating mode, and circulating gas-liquid sync domesticating and forced filming start mode to simplify the program of starting the biological trickling filtration system. The biological trickling filtration system has high organic pollutant eliminating capacity, stable technological performance and other advantages, and is suitable for industrial application.

Owner:CHINA UNIV OF MINING & TECH

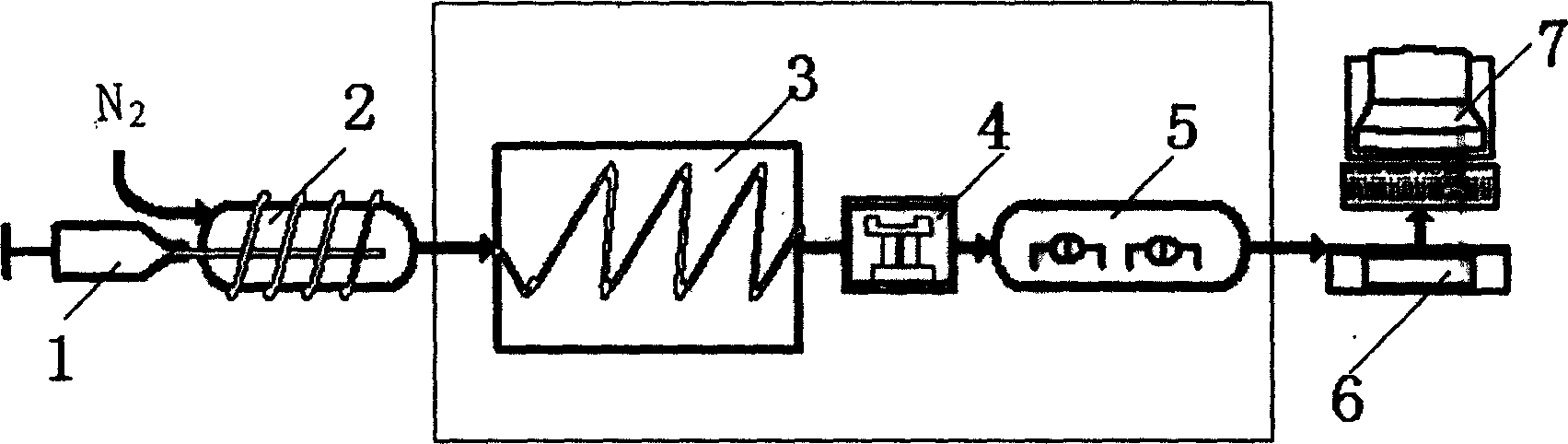

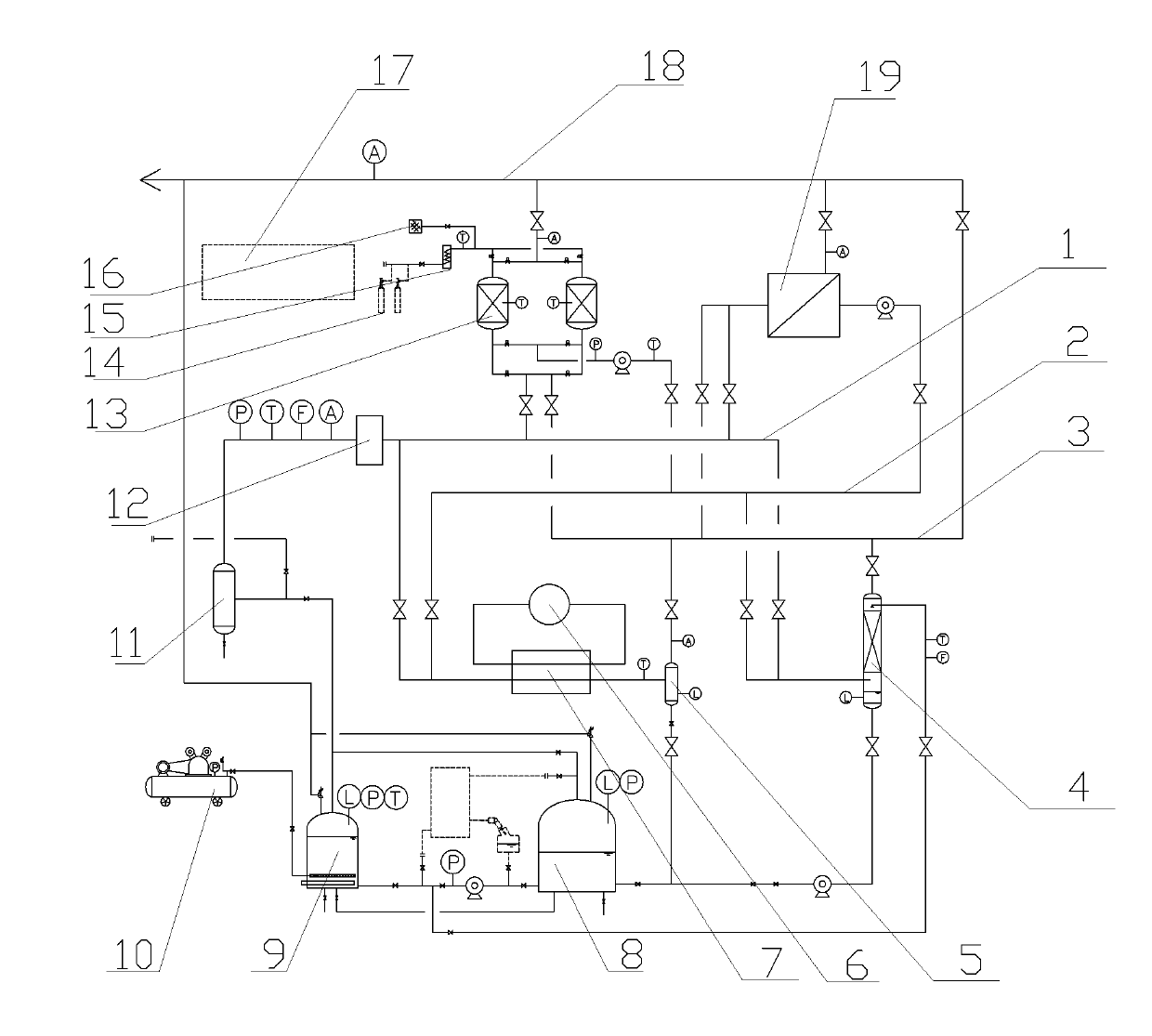

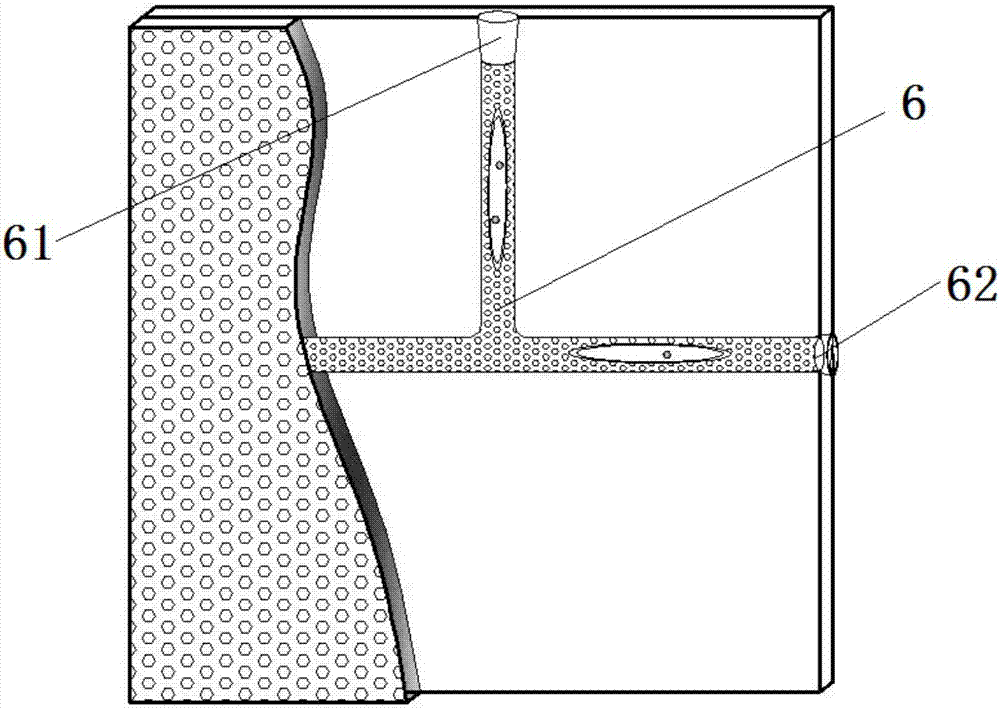

Simulation test device for recovering volatile organic gases

ActiveCN102166463ASimple structureCompact structureDispersed particle separationVapor condensationEngineeringOrganic gases

The invention provides a simulation test device for recovering volatile organic gases. The simulation test device is controlled by a valve, and can form different process programs such as 'adsorption and absorption', 'adsorption and condensation', 'absorption and membrane', 'condensation and membrane', 'membrane and absorption', 'membrane and condensation', 'condensation and adsorption', pure condensation, pure absorption and the like. The simulation test device can be used for various simulation tests for recovering the volatile organic gases.

Owner:BAY ENVIRONMENTAL TECH BEIJING

Reasonable catalytic combustion thermal energy distribution method and equipment of enameling machine

InactiveCN101482364ASave space on siteSimple installation and debuggingDrying solid materials with heatDrying gas arrangementsThermal energyDistribution method

The present invention provides a method for reasonably distributing catalytic combustion heat by an enamelling machine and a device thereof. A circulating fan is installed on a position which is at the upper part of main furnace body and is next to the middle part. An exhaust organic gas inlet is installed above a front furnace area. A primary catalyzing chamber is provided above the organic gas inlet. A hot air mixing chamber is positioned at the side surface of the primary catalyzing chamber. The circulating fan is communicated with the primary catalyzing chamber and the hot air mixing chamber, and drives the circulating hot air after catalytic combustion into the hot air mixing chamber. The hot gas mixing chamber is communicated with a front furnace area, a middle furnace area and a back furnace area of main furnace body through a front gas passage, a middle gas passage and a back gas passage. The invention quickens the baking process and increases the production efficiency by 20% due to the reasonable distribution of heat. As the exhaust gas is effectively collected and executed with the secondary catalytic combustion, and the circulating hot air is repeatedly executed with the primary catalytic combustion, the discharge standard is reduced to 500mg / m. The invention can save electrical energy by 50% as the catalytic combustion heat is used for baking.

Owner:DONGGUAN ZELONG WIRE & CABLE

Quantitative organic vapor-particle sampler

InactiveUS6780818B2Eliminate artifactsDisplacement minimizationOther chemical processesWithdrawing sample devicesDiffusionSorbent

The present invention concerns a quantitative organic vapor-particle sampler which can efficiently sample both semi-volatile organic gases and particulate components through the use of a unique sorbent resin coating and process.The sampler of the present invention comprises in its broadest aspect a tubular device having an inlet at one end through which organic vapor / particles are introduced, an outlet at the other end through which gases exit, at least one annular denuder interposed there between which is coated on the inside surface of the annulus with a specially prepared resin absorbent, which selectively absorbs organic vapors contained in the gases introduced into the inlet, and a filter which traps and collects particles.The invention further concerns a semi-volatile organic reversible gas sorbent for use in an integrated diffusion vapor-particle sampler comprising macroreticular resin agglomerates of randomly packed microspheres with the continuous porous structure of particles ranging in size between 0.05-10 mum.

Owner:RGT UNIV OF CALIFORNIA

Resourceful treatment method for inorganic salts in industrial waste water

ActiveCN103708572AHigh purityReduce wasteWater/sewage treatment by heatingAlkali metal chloridesInorganic saltsIndustrial waste water

The invention discloses a resourceful treatment method for inorganic salts in industrial waste water. The method comprises the following steps: evaporating and concentrating waste water to obtain solid salts; carrying out thermal cracking on organic substances in the solid salts into organic gas; introducing the organic gas obtained by thermal cracking into a burning device for full burning, quickly cooling produced tail gas, and exhausting the cooled tail gas; further purifying the thermally-cracked solid salts via high-temperature carbonization to obtain high-purity solid salts, and introducing gas produced by carbonization into the burning device for full burning. According to the method, the flow is simple, the process is mature, industrial utilization is facilitated, and the methd can be applied to treatment of pesticides and even other industrial high-salt waste water. By adopting the method, the purity of the inorganic salts is increased, so that the inorganic salts can be reused. Secondary wastes which are difficult to treat are not produced in a production process, so that waste of resources is reduced, environmental pollution caused by the waste water is lowered, and very good economical and social benefits are achieved.

Owner:SHANDONG WEIFANG RAINBOW CHEM

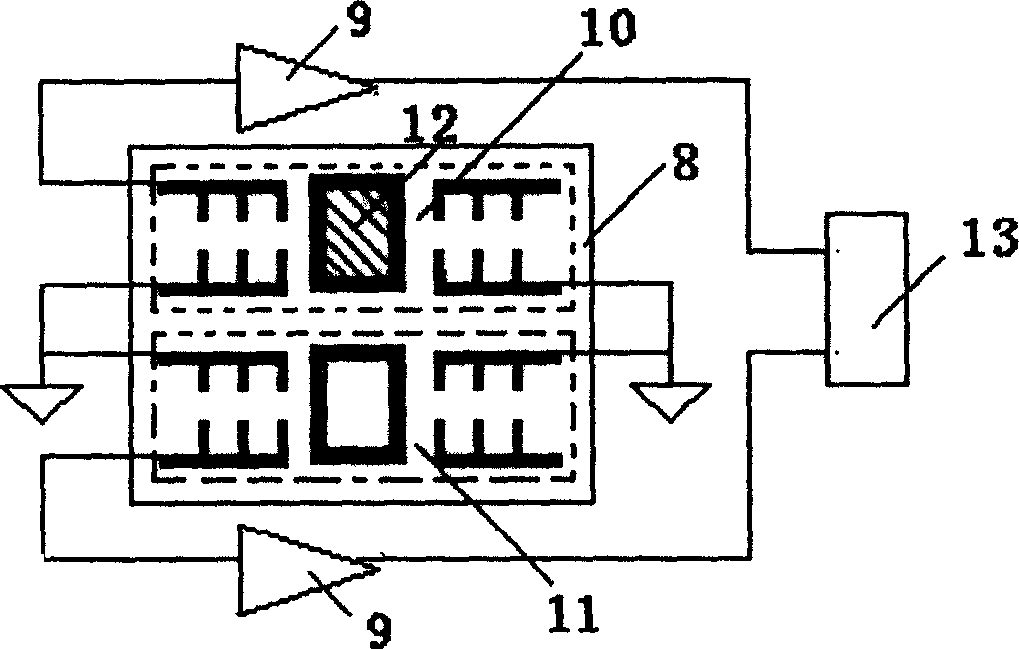

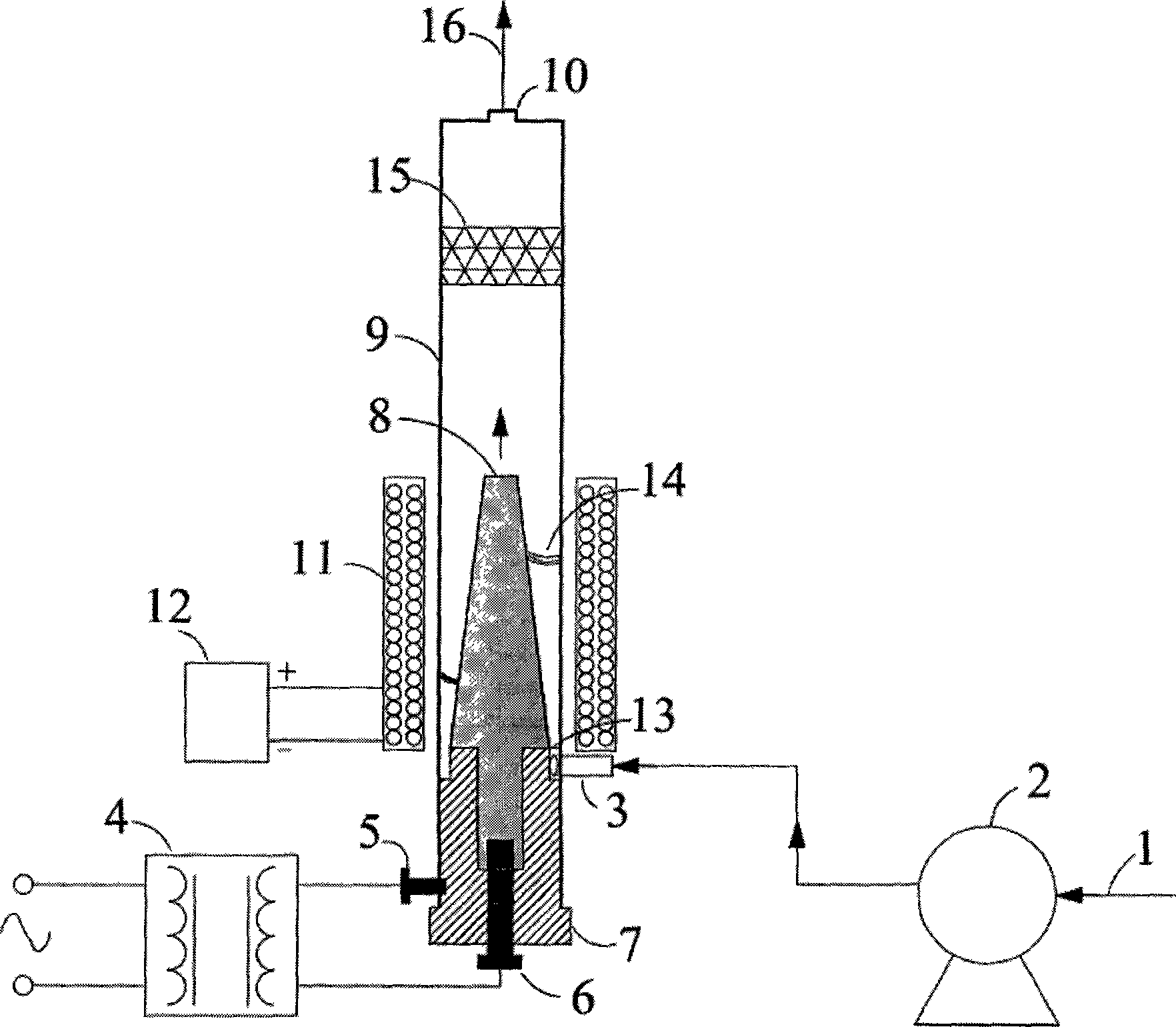

Rotating electric-discharging low temperature plasma organic waste gases purifying device

InactiveCN101239269AUniform discharge space distributionLarge discharge plasma areaDispersed particle separationEnergy based chemical/physical/physico-chemical processesElectric dischargeEngineering

The present invention provides a whirl discharging non-thermal plasma organic gas purifying device, the device is composed of a AC high voltage source 4, a radial deflection terminal 8, an outside electrode 9, a field coil 11, gas circuit. The field and the tangential organic gas flow make the electrical discharge arc rotate in the high speed around the radial deflection terminal 8, and quickly push down to extinguish at the same time, meanwhile, the electric arc is ignited in the minimum distance between electrodes, and repeating the procedures, pulse-type whirl arc discharging 14 is formed, to generate a large scale whirl discharging non-thermal plasma containing active particles such as O, O2, O3, H, OH2, NO etc, UV and other element, organic feculence in the organic gas is degraded to micromolecule organic matter under the oxygenizement of active particles, even directly converted to carbon dioxide and water etc. When the down stream of the radial deflection terminal is set with a carrier 15 attached with TiO2, whirling discharging plasma to excite TiO2, forming TiO2 light-catalyzed reaction, organic feculence of undegradation by plasma is continuously oxidized and decomposed.

Owner:SUN YAT SEN UNIV

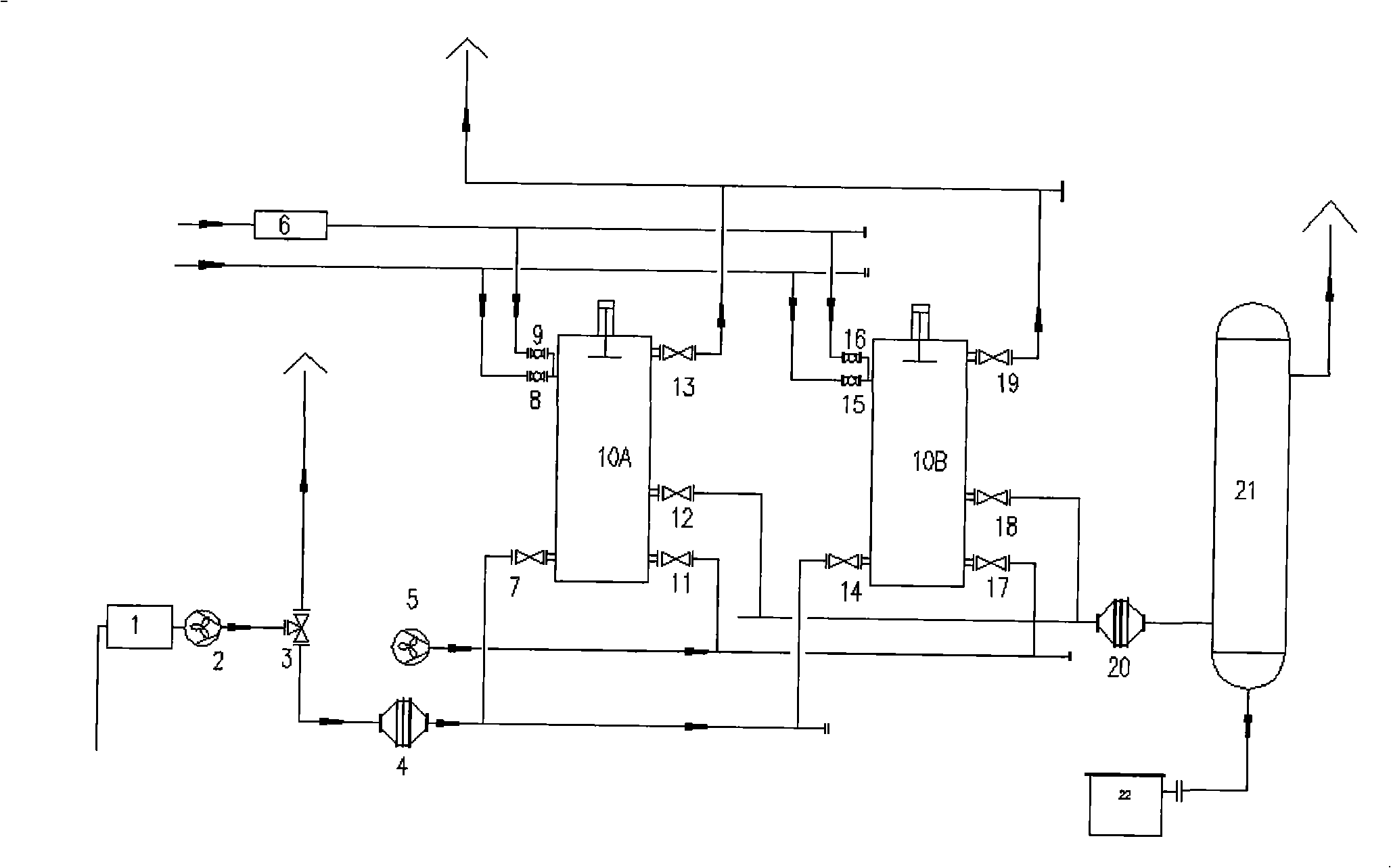

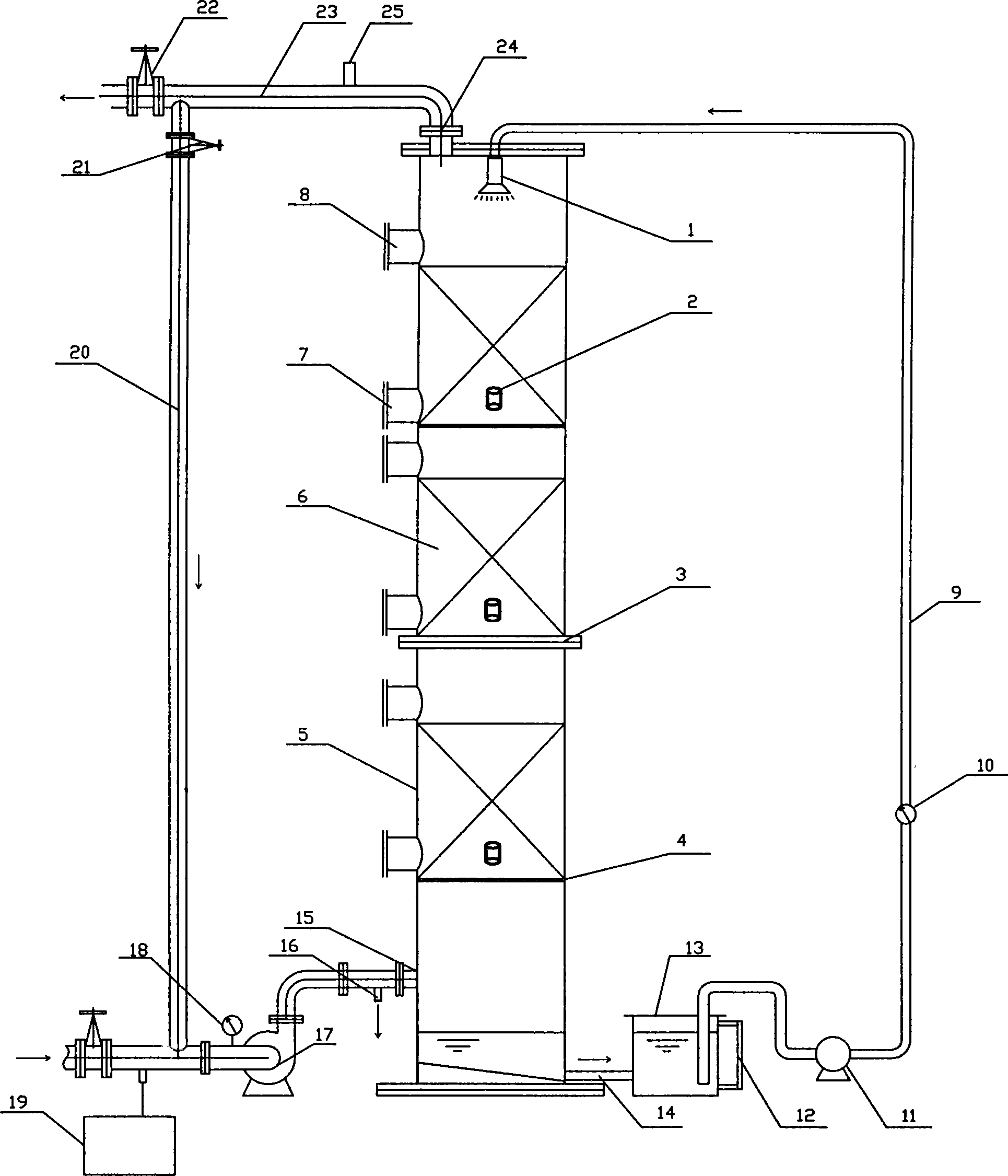

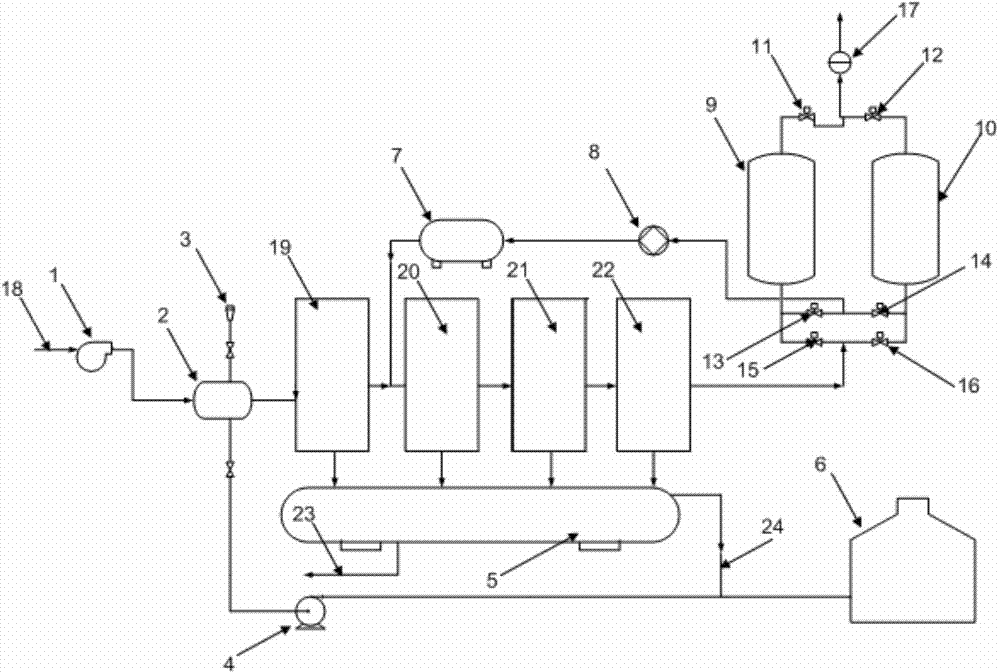

Method for recovering multi-component organic gas mixture

InactiveCN103566619AReduce and prevent frostingDispersed particle separationVapor condensationDesorptionGasoline

The invention relates to a method for recovering a multi-component organic gas mixture, and is mainly used for solving the problem in the prior art that volatile gases such as benzene, toluene, dimethylbenzene and gasoline produced in the large and small breathing of truck loading, shipping, storage tanks and the like of a chemical plant cannot be simultaneously recovered. The method for recovering the multi-component organic gas mixture comprises the following steps of (a) causing organic gases to sequentially enter a condensate tank (2) and a refrigerating unit, causing condensed liquid to enter an oil-water separator (5), and causing organic substances of the oil-water separator (5) to enter a storage tank (6); (b) adsorbing the gases in an adsorption tank (9); (c) after the adsorption tank (9) is saturated, switching to an adsorption tank (10), and starting the desorption of the adsorption tank (9); (d) returning substances desorbed from the adsorption tank (9) to the refrigerating unit. According to the technical scheme, the problem is well solved; the method can be used for recovering the volatile gases such as benzene, toluene, dimethylbenzene and gasoline produced in the large and small breathing of truck loading, shipping and storage tanks of the chemical plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for recovering organic solvent from waste gases of printing industry

InactiveCN101259357AImprove pollutionImprove recycling efficiencyDispersed particle separationActivated carbonOrganic solvent

The invention relates to a method for adsorbing and recycling organic solvent from exhaust gas in printing industry and a device. An adsorber 1 and an adsorber 2 of the device are respectively connected with a cooler by a valve and a pipeline, which lead the exhaust gas in printing industry to enter the adsorbers; the adsorber 1 and the adsorber 2 are also respectively connected with a condenser 1 by the valve and the pipeline; the condenser 1 is connected with a decanter 1 which is connected with a storage vat 1; the storage vat 1 is respectively connected with an adsorber 3 and an extraction column by the valve and the pipeline; the extraction column is also respectively connected with the adsorber 3 and the decanter 1. The method consists of an adsorption process, a desorption process, a separation process and a water treatment process. The exhaust organic gas containing toluene, acetone and isopropyl alcohol can be adsorbed by an activated carbon adsorber; after the activated carbon adsorption is saturated, steam is assisted to carry out the desorption process, while the mixed liquid desorbed is carried out to separate oil from water in the decanter. The method and device has the advantages of simple process, convenient operation, low price, high efficiency of purification and recovery and so on.

Owner:SOUTH CHINA UNIV OF TECH

Air purifying method and air purifying filter element

InactiveCN107096320AAvoid breedingQuality improvementGas treatmentDispersed particle filtrationChlorine dioxideIndoor air quality

The invention relates to an air purifying method and an air purifying filter element. The air purifying filter element manufactured by the air purifying method comprises a primary particle filtering layer, a catalytic oxidizing and sterilizing layer, an organic gas adsorbing layer, a high-efficiency filtering layer and an ozone degrading catalyzing layer, wherein the pore diameter of the primary particle filtering layer is greater than or equal to 2.5 micrometers; the catalytic oxidizing and sterilizing layer is loaded with a formaldehyde oxidizing catalyst and a T-shaped tube, a chloride dioxide slow-release tablet is arranged in the T-shaped tube, and the organic gas adsorbing layer comprises adsorbent particles for adsorbing organic gas; the filtering pore diameter of the high-efficiency filtering layer is smaller than 2.5 micrometers; the ozone degrading catalyzing layer comprises a nanometer oxide catalyst for decomposing the ozone into oxygen at normal temperature. The air purifying filter element has the advantages that the breeding of pathogenic bacteria in the air purifying device can be inhibited by the chloride dioxide, and the indoor air quality is further improved; after the chloride dioxide is combined with the formaldehyde oxidizing catalyst, the double functions of reducing the content of formaldehyde and sterilizing bacteria are realized, and the indoor ozone pollution is eliminated.

Owner:ZHEJIANG UNIV OF TECH +1

Preparation method and application of composite paper based material with organic matter adsorption and degradation function

InactiveCN101319478AIncrease the burdenSolve problems such as light radiation is blockedInorganic fibres/flakesSpecial paperFiberCardboard

The invention relates to a method for preparing a composite paper base material with functions of adsorbing and degrading organic matters, and an application of the composite paper base material. The material consists of 30 to 50 percent of metal oxide powder, 15 to 35 percent of absorbent powder, 0 to 25 percent of inorganic fiber, 10 to 30 percent of paper pulp and 0.5 to 5 percent of dual retention aid. When the material is prepared, the metal oxide powder, the absorbent powder, the inorganic fiber and the paper pulp are mixed into a suspension liquid with the concentration of between 2 to 8 percent, the suspension liquid is subjected to mediation for 5 to 30min, and added with the dual retention aid to dilute until the concentration is reduced down to 0.5 percent so as to prepare wet paper sheets; the paper sheets are subjected to pressing and drying to prepare the composite paper base material. The composite paper base material prepared is further processed into a paper component, and the paper component is placed in a low concentration volatile organic compound environment to realize continuous photocatalysis degradation. By utilizing the paper base material of the invention, the problems that the cost is high and the pulverization occurs due to the friction between granular materials when the zeolite is used as a carrier to prepare compound catalytic materials are resolved, and the paper base material can also adsorb low concentration volatile organic gases.

Owner:FUJIAN NORMAL UNIV

High activity deoxidant, and its preparing method

ActiveCN101003014ALarge capacityExtend the life cycleNitrogen purification/separationOther chemical processesOxygenHigh activity

A high-activity deoxidant for the deep deoxidization of N2, H2, CO, CH4, C2H4, C3H6, etc is composed of active component (the low-valence oxide of Mn and Fe) and the carrier chosen from cement, gypsum, kaolinite, alumina, diatomite, etc. Its preparing process is also disclosed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com