Method for cleaning, recovering and treating painted lacquer exhaust organic gas and device

A technology of organic waste gas and waste gas, applied in chemical instruments and methods, separation methods, vapor condensation, etc., can solve the problems of mixing, difficult desorption, and failure, and achieve the purpose of reducing energy consumption, protecting the environment, and realizing recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

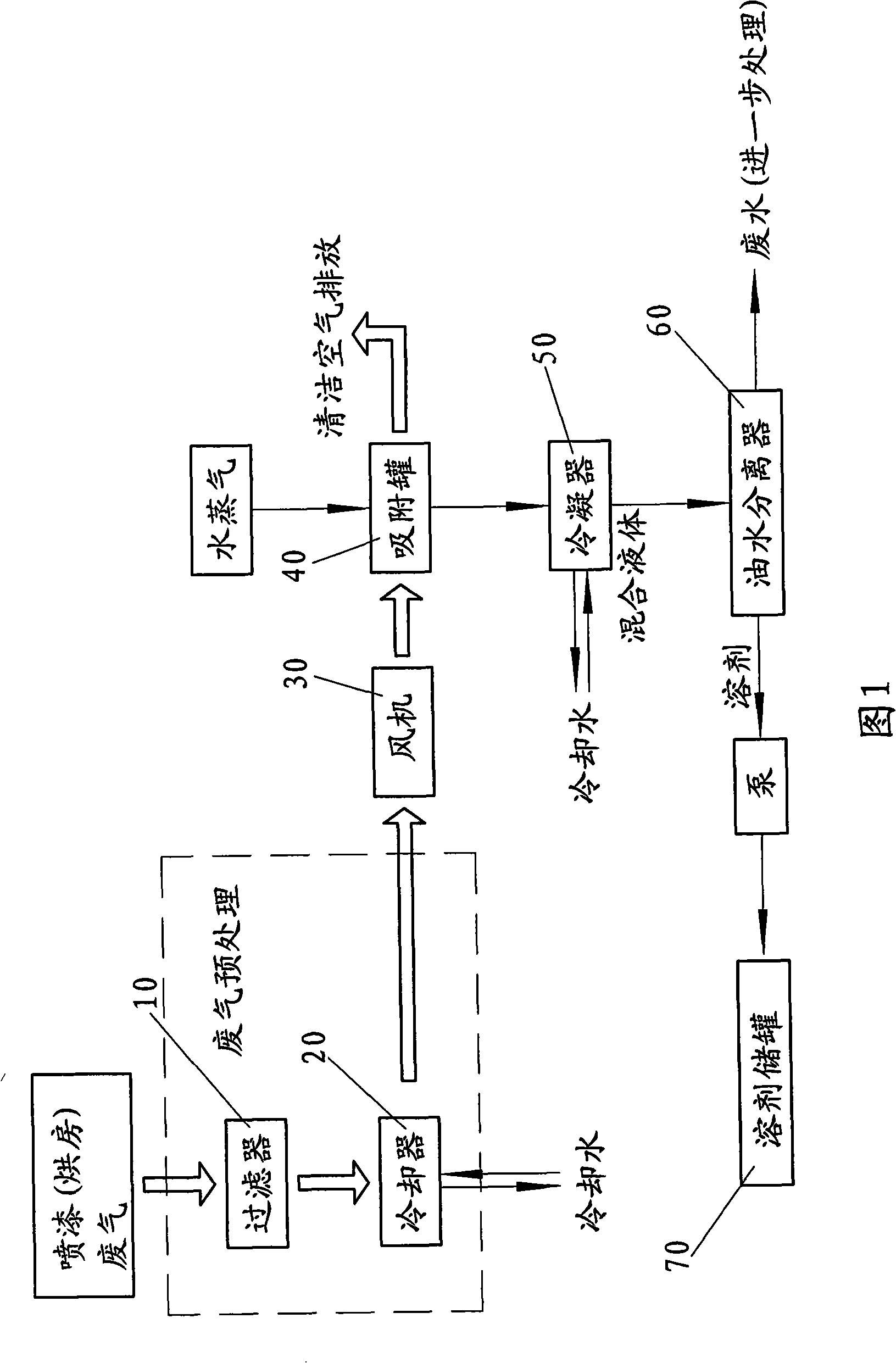

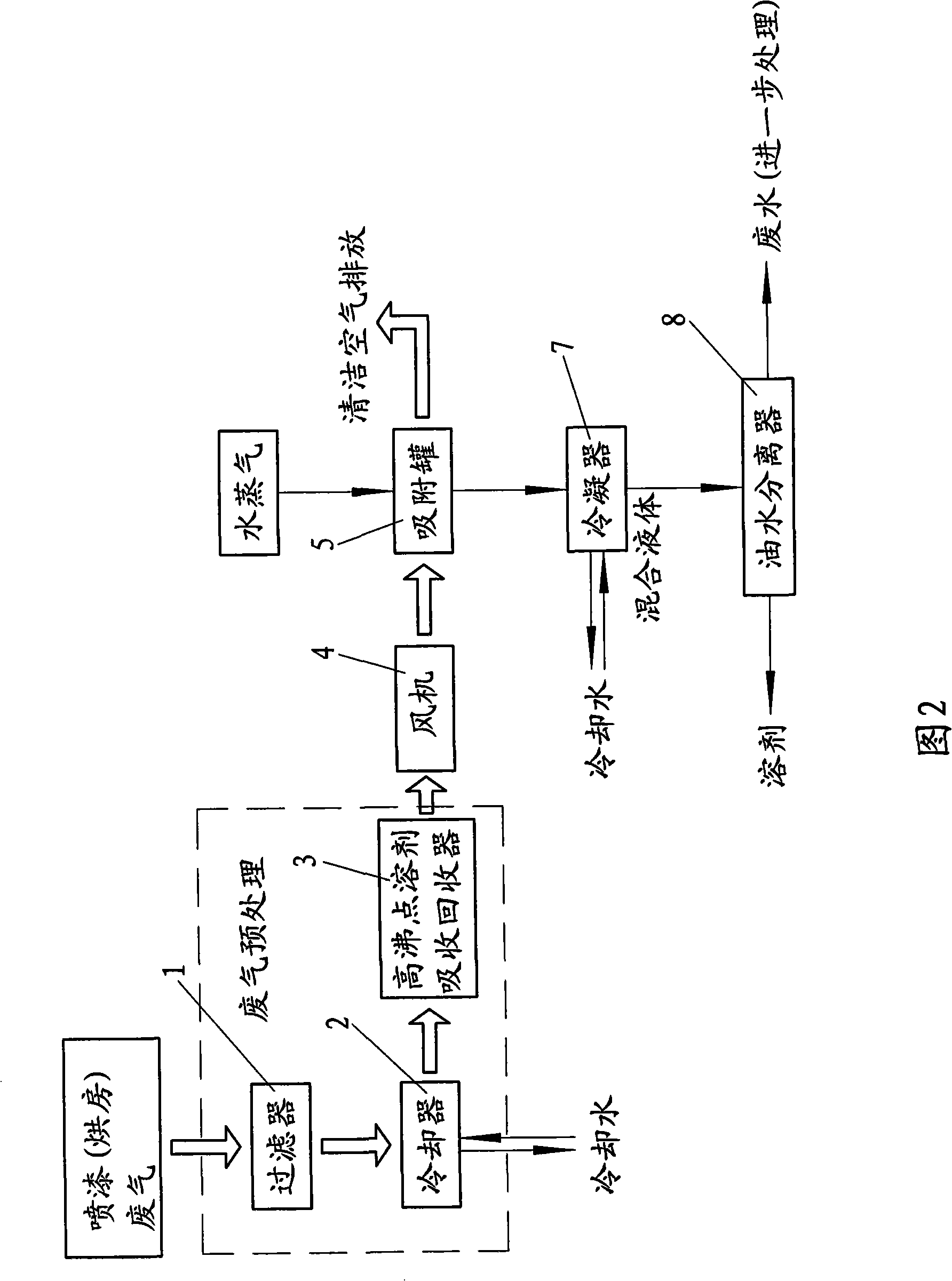

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] As shown in Figure 2, it is a flow chart of the spray paint organic waste gas purification and recovery treatment method of the present invention, and the specific steps are as follows:

[0033] (1) The organic waste gas from the painting production line is collected or comes out of the paint spraying room and paint drying room, and is filtered through filter 1 to remove most of the dust, paint mist and other harmful substances in the waste gas that are harmful to activated carbon. Then pass through the cooler 2 to condense some of the high-boiling organic solvent components in the organic waste gas, such as: xylene, trimethylbenzene, tetramethylbenzene, ethylene glycol monoethyl ether, ethylene glycol ether acetate, aromatic hydrocarbon solvents (such as SOLVESSO100# , 150#, 200# solvent oil) and other organic solvent components with a boiling point higher th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com