Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

901 results about "Methyl isobutyl ketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl isobutyl ketone (MIBK) is the organic compound with the formula (CH₃)₂CHCH₂C(O)CH₃. This colourless liquid, a ketone, is used as a solvent for gums, resins, paints, varnishes, lacquers, and nitrocellulose.

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

Preparation method for aviation kerosene

The invention relates to a new synthesis route of a liquid branched paraffin fuel, the method adopts a lignocellulose based platform compound as a raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as an aviation kerosene (or diesel) substitute or as an additive to increase the cetane number and cold resistance of fuel. The method provided by the invention includes two steps of: 1) under the promotion of a base catalyst, subjecting a lignocellulose based furfural compound (including furfural, methylfurfural or 5 hydroxymethylfurfural) and branched chain keto (including methyl isobutyl ketone, and mesityl oxide, etc.) to aldol condensation reaction so as to synthesize an oxygen-containing organic compound with a carbon chain length of 9-16; and 2) conducting hydrodeoxygenation on the aldol condensation product generated in step1 to obtain biomass aviation kerosene branched hydrocarbon with a carbon chain length of 9-16, higher energy density, stability and low freezing point.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

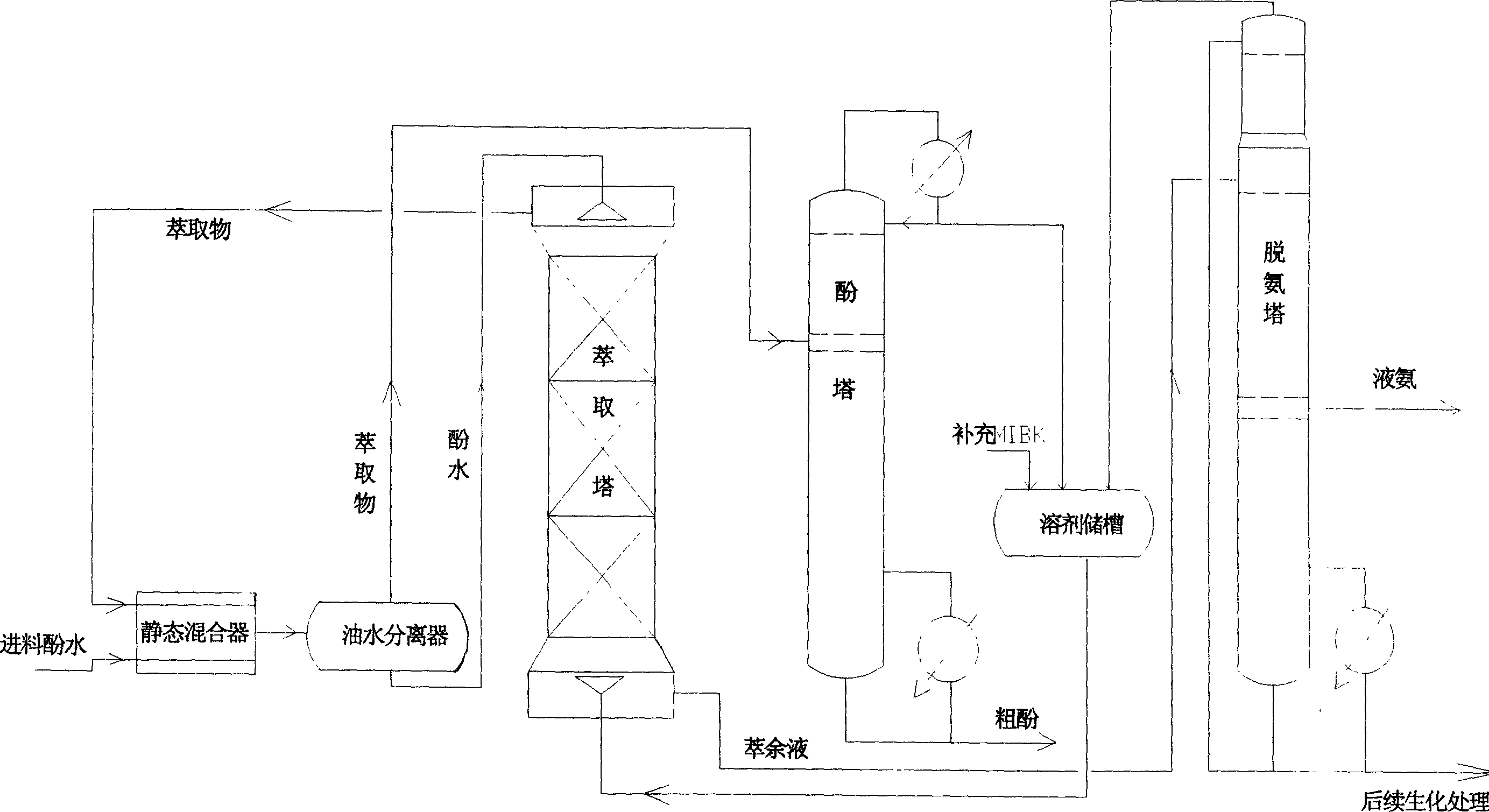

Treatment and reclaimation method of coal gasification wastewater contg. phenol

InactiveCN1834039AEfficient extractionHigh partition coefficientMultistage water/sewage treatmentWater/sewage treatment by extractionHigh concentrationCoal gasification wastewater

This invention relates to a method to dispose and recycle coal-gasification sewage containing high-concentration hydroxybenzenes, which includes following steps: a) acid removal; b) hydroxybenzene removal by extraction; c) regeneration of extraction solvent; d) ammonia recycling and rudimental extraction solvent recycling. The extraction solvent is isobutyl methyl ketone. After disposal with this method, more than 92% hydroxybenzenes and 99.5% ammonia can be recycled from the sewage. The extractant can be regenerated by distillation separation. The regenerated extractant is high purified and can meet the requirement of circulative extraction. Besides, while hydroxybenzenes, especially polyphenols are effectively recycled, CODCr of the sewage is also greatly lowered, which is benefic to sewage biochemical standardization.

Owner:SOUTH CHINA UNIV OF TECH

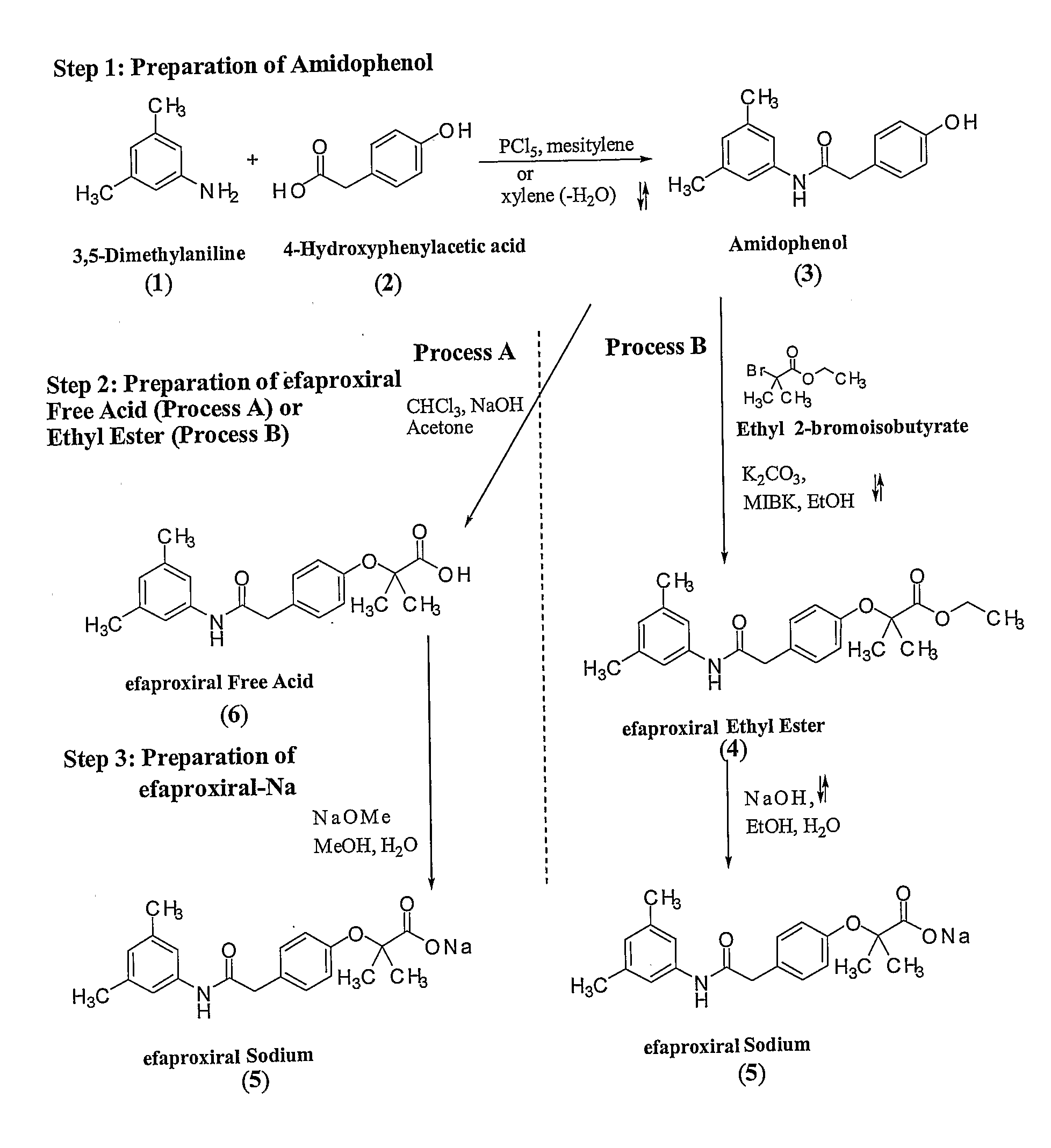

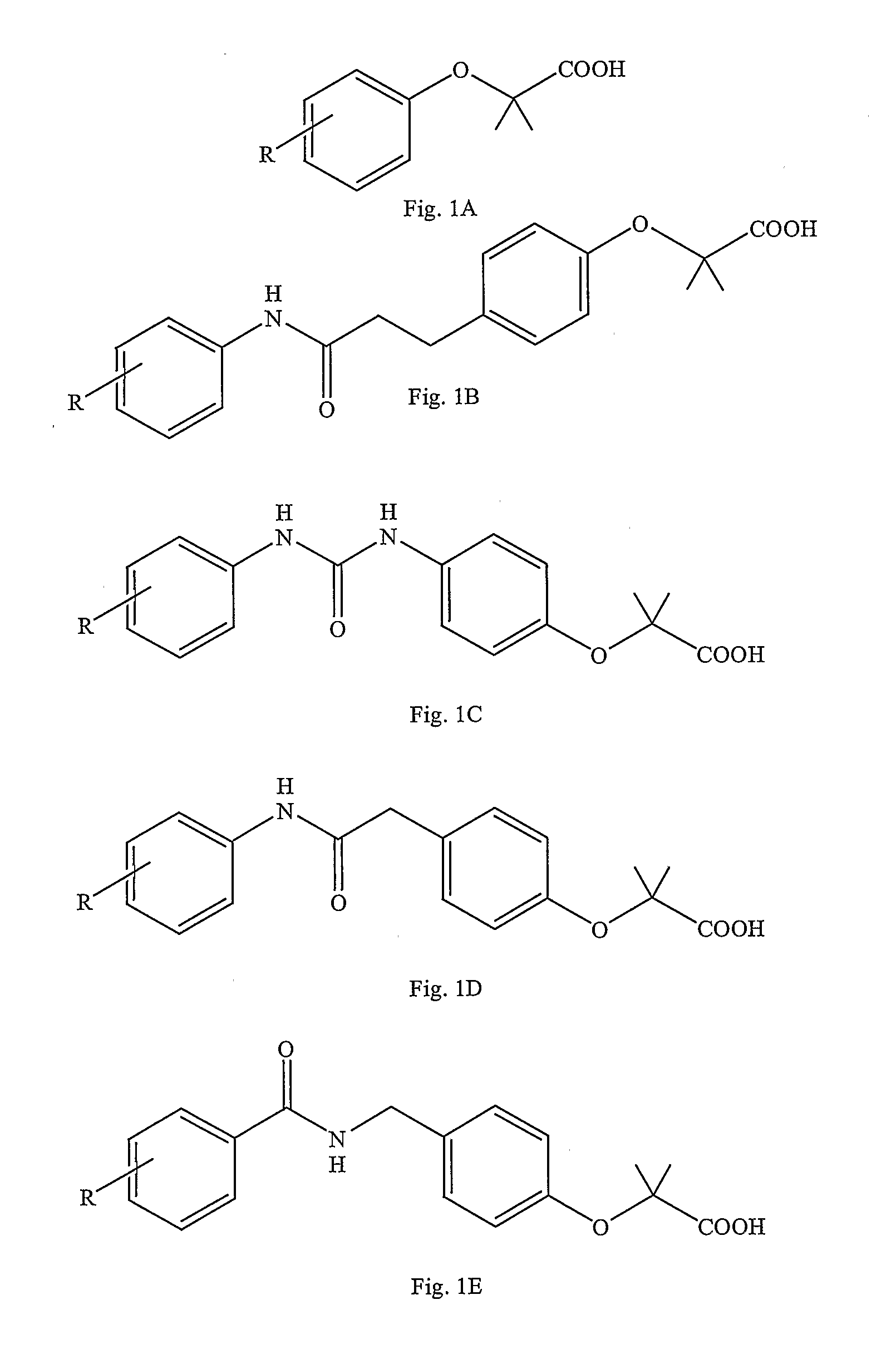

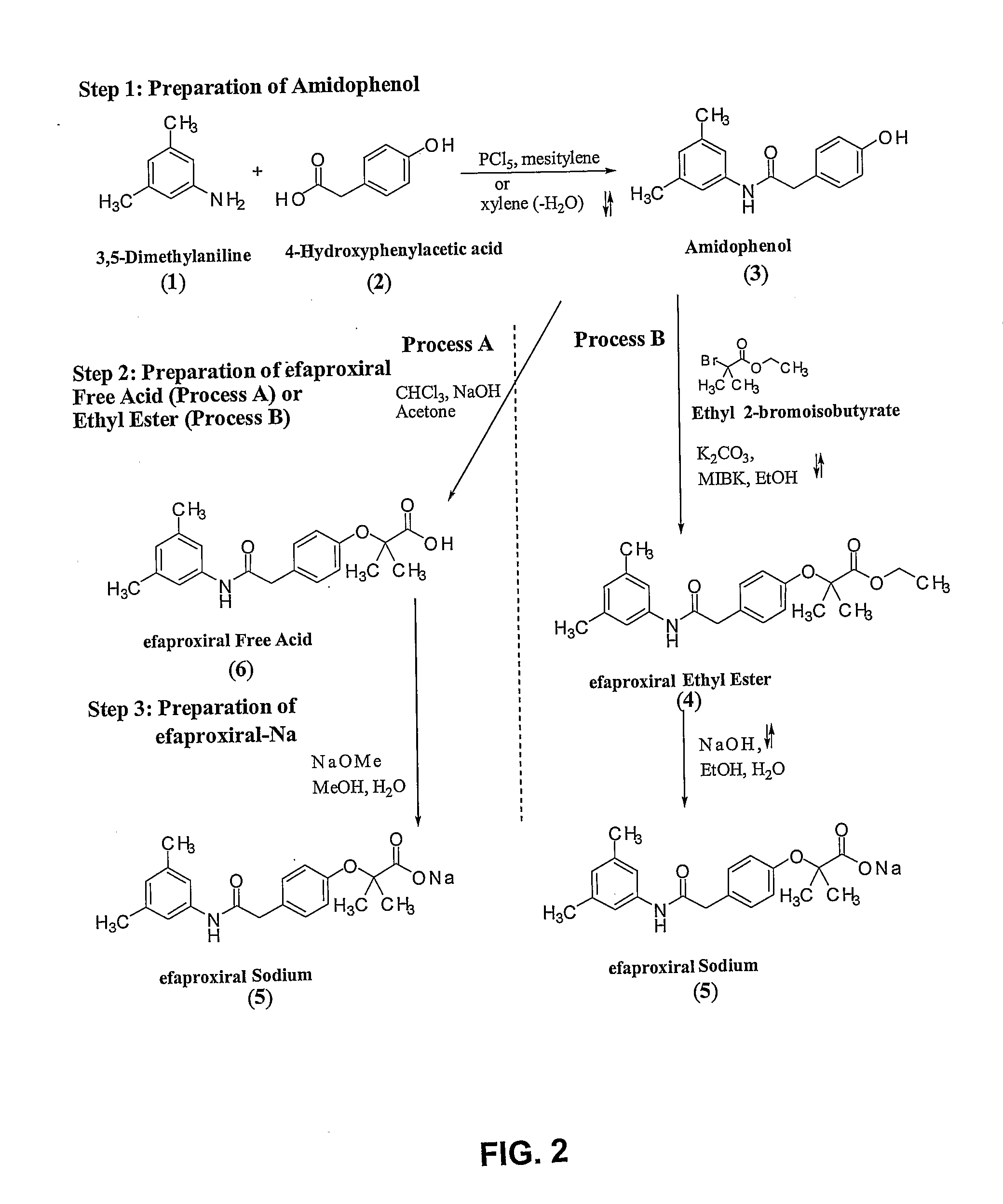

Compositions of Allosteric Hemoglobin Modifiers and Methods of Making the Same

InactiveUS20070293698A1High sensitivityCorrection accuracyOrganic active ingredientsPeptide/protein ingredientsMethyl isobutyl ketoneFiltration

The present invention provides novel compositions of allosteric hemoglobin modifiers which are substantially free of impurities, specifically polymeric impurities. In one embodiment, the novel compositions contain an allosteric hemoglobin modifier compound and less than 100 ppm of the polymeric impurities generated during the preparation of this compound. Included in the present invention are novel methods for preparing allosteric hemoglobin modifiers that are substantially free of polymeric impurities. Also included in the present invention are improved methods for the purification of the product formed by the method of this invention. The novel methods of purification comprise extracting the crude composition with a water immiscible or partially immiscible solvent such as methylisobutyl ketone (MIBK) to lower amounts of impurities, specifically polymeric impurities. Also included are methods to reduce impurities by recrystallization of the crude synthesized product, followed by filtration of the recrystallized product. The present invention also includes the products made by the processes of the invention and methods for analyzing compositions comprised of these products.

Owner:ALLOS THERAPEUTICS

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

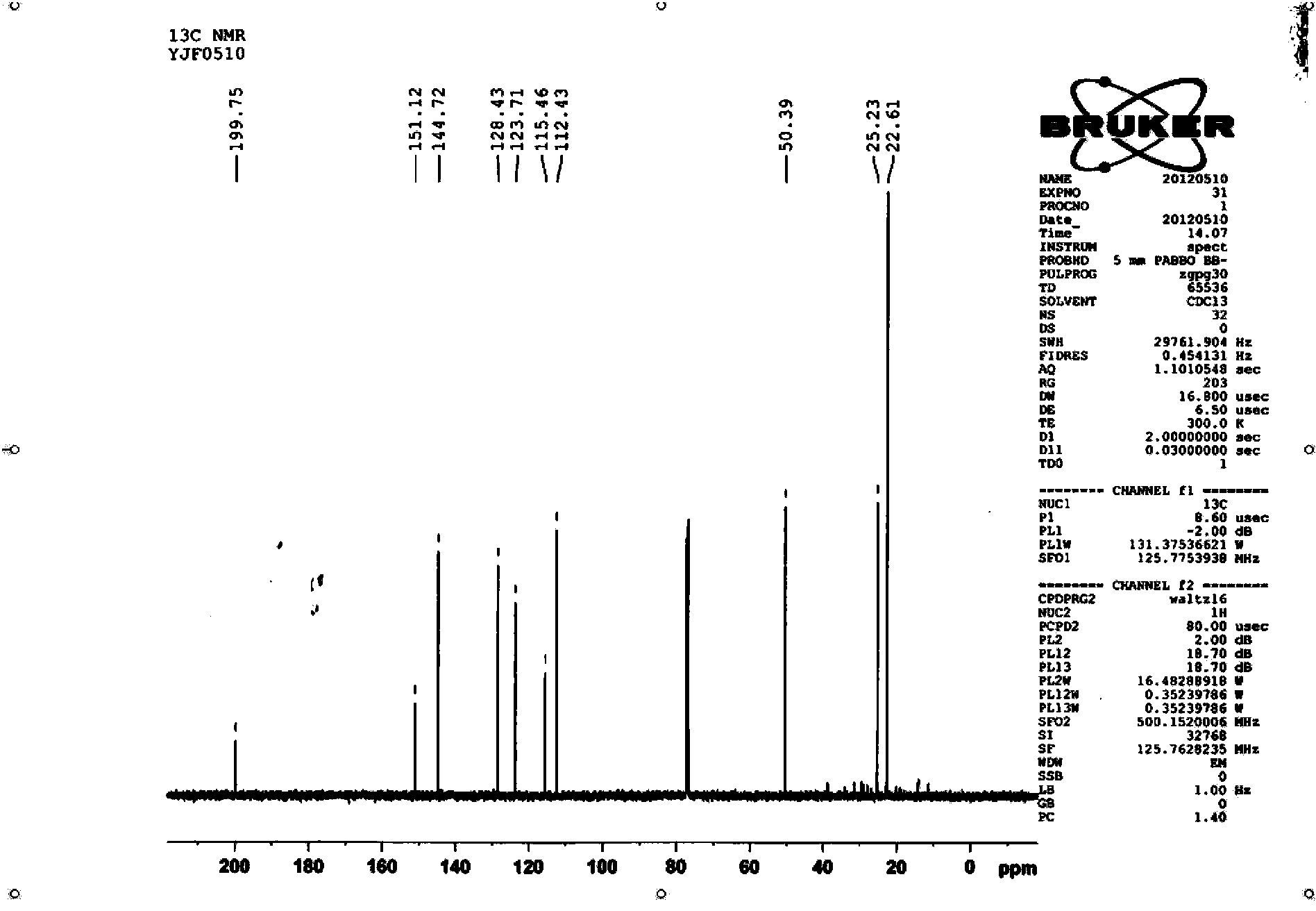

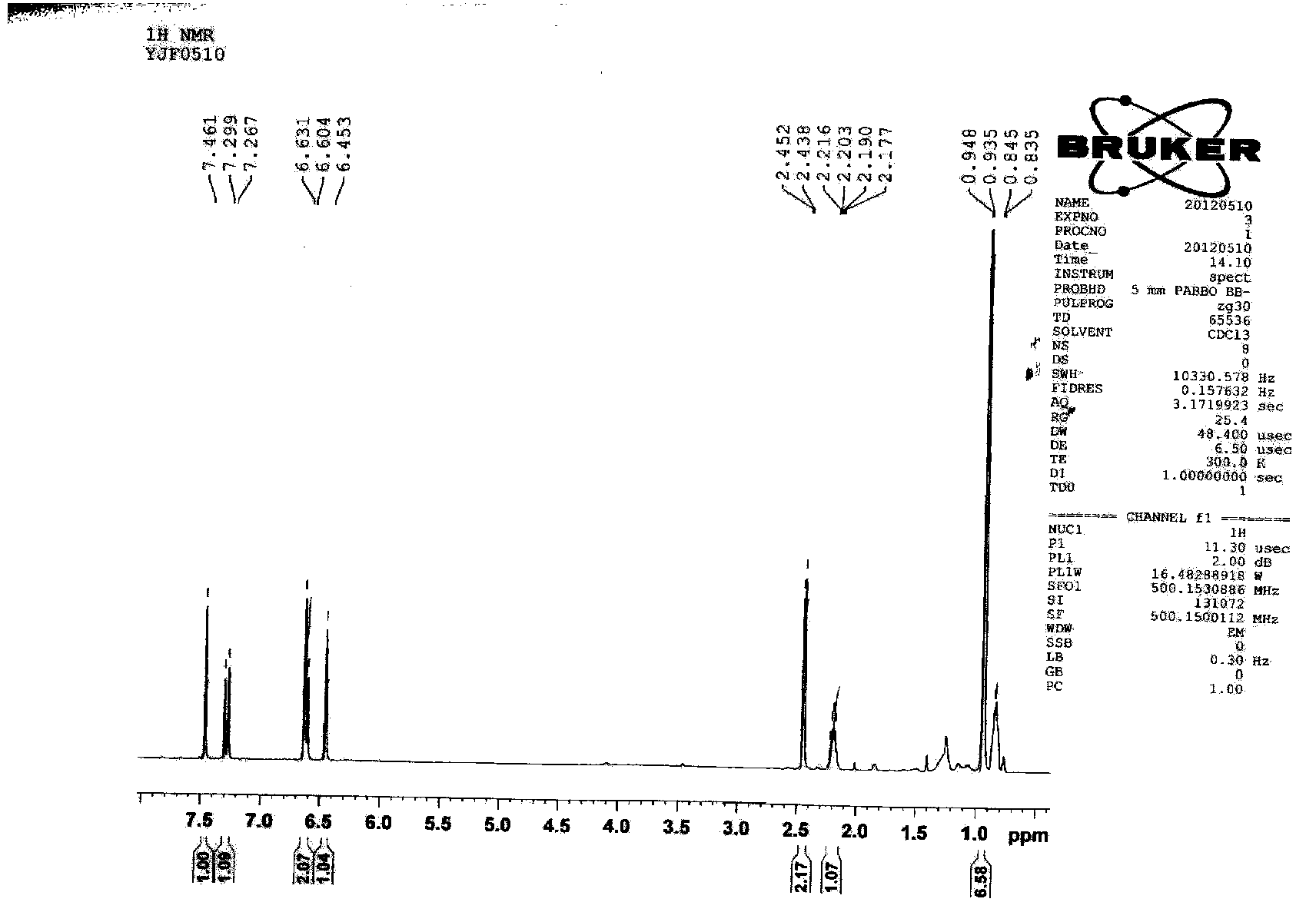

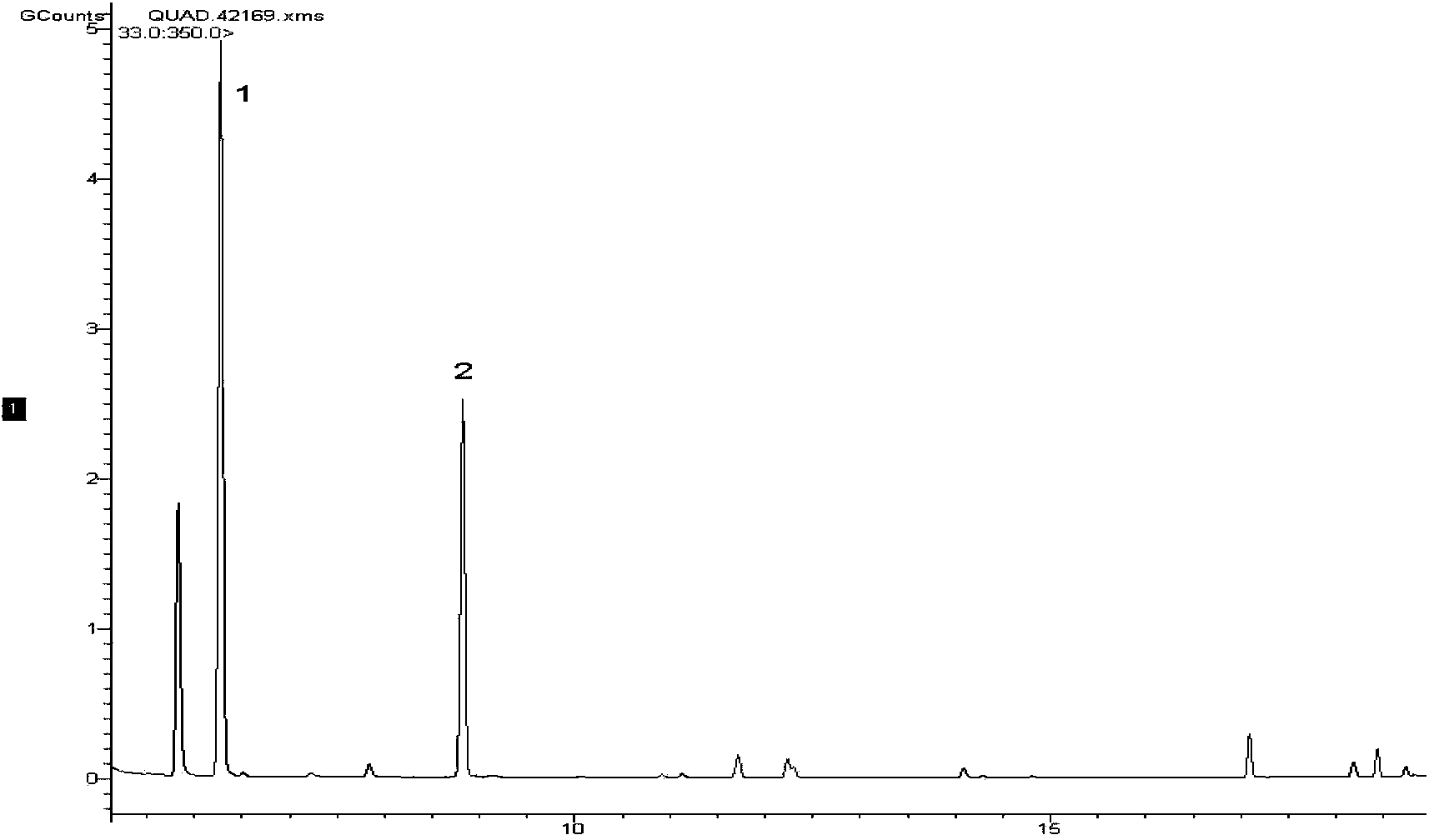

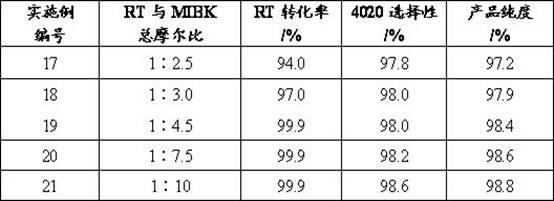

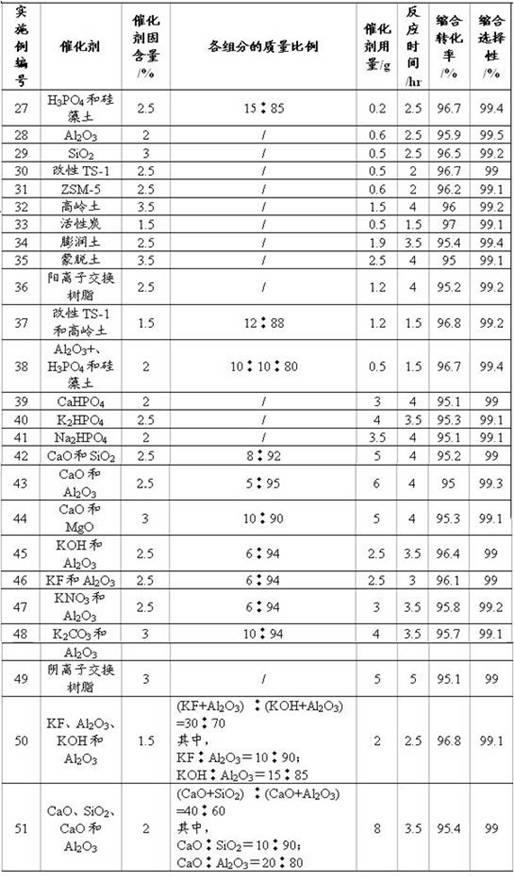

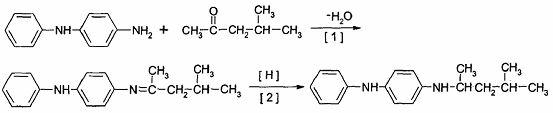

Method for preparing p-phenylenediamine rubber aging inhibitor

InactiveCN102146042ALow costReduce consumptionOrganic compound preparationAmino compound preparationChemical synthesisPtru catalyst

The invention discloses a method for preparing a p-phenylenediamine rubber aging inhibitor, and relates to the technical field of chemical synthesis. The method comprises the following steps of: adding 4-aminodiphenylamine and partial methyl isobutyl ketone into a condensation reaction kettle, performing condensation reaction at a certain temperature under certain pressure, removing water generated by the reaction, and obtaining a condensation solution; adding the condensation solution, a hydrogenation catalyst and replenished methyl isobutyl ketone into the reaction kettle, performing hydrogenation reaction at a certain temperature under certain pressure, and obtaining a hydrogenation solution; and performing post treatment on the hydrogenation solution to obtain the p-phenylenediamine rubber aging inhibitor 4020, wherein the hydrogenation catalyst is a nickel, palladium or platinum catalyst. From the practice of industrial production, the rubber aging inhibitor 4020 is synthesized by adopting two-step reaction of condensation and hydrogenation; the difficulty of the hydrogenation reaction is reduced; and the requirement on the catalyst is reduced. The method has mild reaction conditions, high product quality and simple flow and no pollution, and is easy to realize industrialization.

Owner:JIANGSU YANGNONG CHEM GROUP +2

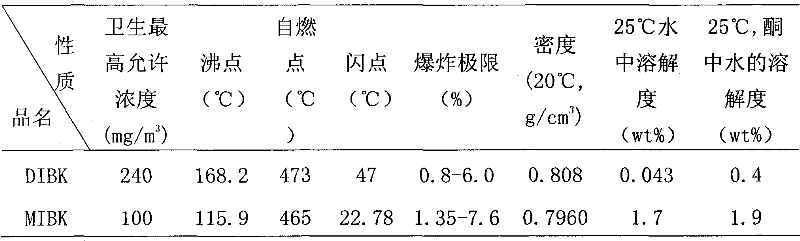

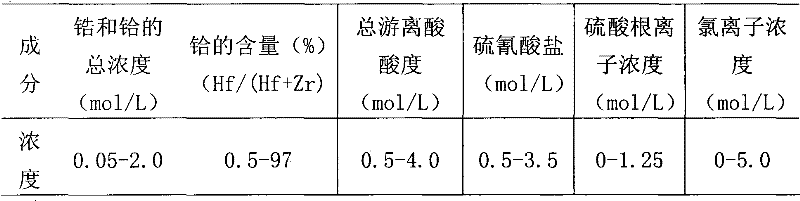

Method for separating zirconium and hafnium

ActiveCN102453801ALess mass transferLarge extraction capacityProcess efficiency improvementSolubilityHafnium

The invention relates to a method for separating zirconium and hafnium, which specifically comprises the following steps of: using the acidic water solution of a zirconium compound as a raw material, extracting hafnium in the material liquid into an organic phase by using diisobutyl ketone (DIBK) or the synergism of DIBK with a neutral phosphorous extracting agent or the synergism of DIBK with anacidic phosphorus-containing extracting agent, and washing and stripping the oganic phase to produce a hafnium-rich liquid such that the separation of zirconium and hafnium is realized; respectively precipitating the hafnium-rich liquid and the remaining organic phase by using ammonia water, and washing and roasting the precipitates to obtain atomic energy level zirconium oxide and hafnium oxide.In the technical method provided by the invention, low content of hafnium in zirconium hafnium is preferably extracted, and the method has simple process and high extraction efficiency. The extraction system used in the method reaches the same zirconium and hafnium separation performance to MIBK (Methyl Isobutyl Ketone) but has smaller water solubility, high boiling point and flashing point and smaller toxicity compared with MIBK, and the problems of great solvent loss, easy outbreak of fire, environmental pollution and the like in the MIBK extraction separation method are solved.

Owner:有研资源环境技术研究院(北京)有限公司

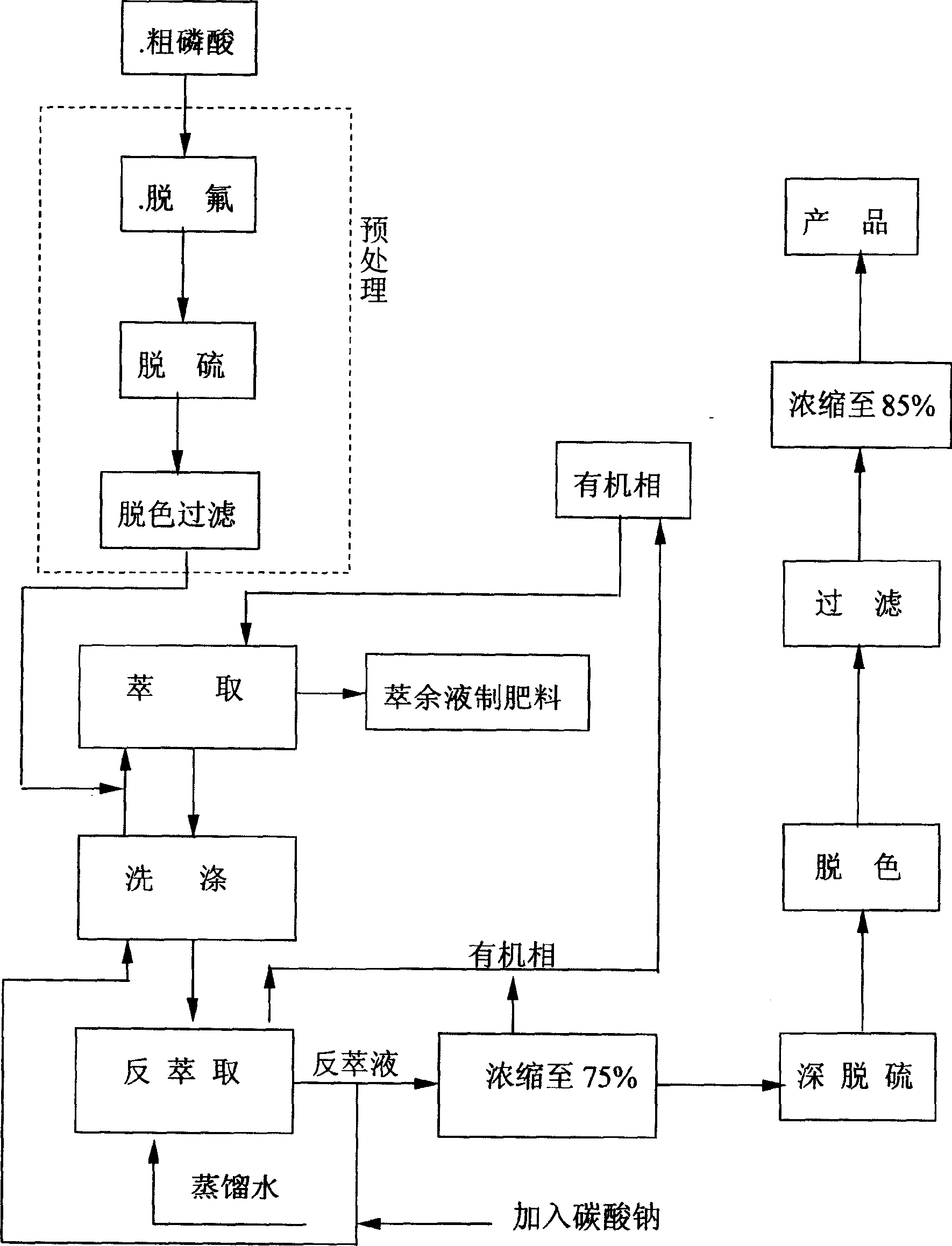

Method of solvent extraction purification of wet method phosphoric acid produced from medium and low grade phosphosus ore

ActiveCN1751987AReduce the concentration of ortho acidThe extraction and purification process is continuousPhosphorus compoundsPhosphoric acidN-Butanol

A process for preparing wet phosphoric acid from medium-or low-grade phosphorus are through solvent extracting and purifying includes such steps as concentrating the crude wet phosphoric acid, defluorinating, desulfurizing, decoloring, filtering, counter current extracting in the mixture of n-butanol, methylisobutyl ketone and synergist by 7-10 stages while adding sulfuric acid at the 3rd or the 7th stage, counter current washing with phosphoric acid solution containing Na salt by 4-5 stages, counter-current reverse extracting of organic phase with distilled water by 3-5 stages, concentrating, recovering solvent, decoloring, filtering, adding the phosphoric acid solution of BaCO3 for removing ''SO4'' radicals, decoloring, filtering and concentrating.

Owner:HUAZHONG NORMAL UNIV

Process for covering water transfer printing on wood plastic, plastic and metallic products

The invention discloses a water-coated transfer printing process for wood, plastic, and metal products, which comprises the following steps: according to the necessary background color, spraying oil paint on the surfaces of the wood, the plastic, and the metal products; spreading a water-coated transfer printing film on the water surface by putting the surface with printing ink patterns to face upwards; spraying an activator on the water-coated transfer printing film evenly through a spray gun when the water-coated transfer printing film is softened and spread levelly; and according to the positions of the patterns floating on the water surface, pressing an obtained product downwards into the water for 2 to 10 seconds and taking out the product, and transferring the patterns on the water-coated transfer printing film to the surface of the product under the action of water pressure. The process further comprises the following steps: washing the obtained product clean by water and then putting the product into a drying furnace to be dried at a temperature between 50 and 70 DEG C; or using a blowing gun to blow off the water, drying the product at room temperature, spraying a layer of transparent oil paint on the surface of the product, putting the product in the drying furnace and curing the product at a temperature between 50 and 160 DEG C. The compositions of the activator are as follows according to percentage by weight: 33 percent of xylene, 15 percent of butyl acetate, 15 percent of methyl acetate, 10 percent of methyl isobutyl ketone, 5 percent of isobutanol, 8 percent of isophorone, 5 percent of methyl methacrylate, 7 percent of cyclo ethyl ketone, and 2 percent of nitrocellulose resin.

Owner:张艳 +1

Preparation method of catalyst for coproducing isopropanol and methyl isobutyl ketone by acetone hydrogenation

ActiveCN102806086ALow content of active metal componentsExtended service lifeOxygen-containing compound preparationOrganic compound preparationNitrateMethyl isobutyl ketone

The invention relates to a preparation method of a catalyst for coproducing isopropanol and methyl isobutyl ketone by acetone hydrogenation. The catalyst comprises an alumina carrier and Ni and Mg loaded on the gamma-Al2O3 carrier, and particularly comprises, by total weight, 10-18% of the Ni, 3-8% of the Mg and the balance alumina; and the BET specific surface area of the catalyst ranges from 100m<2> / g to 180m<2> / g, and the pore volume of the catalyst ranges from 0.35mL / g to 0.55mL / g. The preparation method includes steps of (1), preparing the carrier by details of weighing pseudo-boehmite powder, adding binders and extrusion assistants into the pseudo-boehmite powder, forming by strip extrusion or granulating by rotation, drying and calcining, cooling to reduce temperature so as to obtain the stripped or spherical carrier; (2), impregnating the carrier into magnesium nitrate by details of loading a magnesium additive onto the carrier by means of saturated impregnation, drying and then calcining for 2-6 hours at the temperature ranging from 400 DEG C to 500 DEG C; (3), loading the actively metallic nickel by details of impregnating for 10-24 hours and calcining for 2-6 hours at the temperature ranging from 350 DEG C to 480 DEG C; and (4), loading the actively metallic nickel again by details of drying a semi-finished product, impregnating the dried semi-finished product into impregnation liquid of nickel nitrate again, repeating the step (3) once, and calcining the semi-finished product for 2-4 hours at the temperature ranging from 400 DEG C to 450 DEG C so as to obtain the finished catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Extraction and dephenolization process of coal gasification wastewater

InactiveCN1834040AHigh partition coefficientSolve the problem of ineffective extraction of polyphenolsMultistage water/sewage treatmentWater/sewage treatment by extractionCoal gasification wastewaterHigh concentration

This invention discloses a method to remove high-concentration hydroxybenzenes from coal-gasification sewage, that is, coal-gasification sewage containing hydroxybenzenes and isobutyl methyl ketone as extracting solvent are mixed and separated so as to obtain solvent phase and remnant aqueous phase liquid. Solvent and crude hydroxybenzene are extracted from the solvent phase by distillation. Multiple-class reflux extraction is carried out towards remnant aqueous phase liquid and rudimental solvent is further extracted from the extract. Facilities involved in this method include a static mixer, an oil-water separator, a hydroxybenzene distillation tower and an extraction tower. Extracting coal-gasification sewage containing high-concentration hydroxybenzenes with the method provided by this invention, total hydroxybenzene extraction ratio can be as high as 92%. Besides, it also has the advantages of simple technique, soft conditions and recyclable extraction solution.

Owner:SOUTH CHINA UNIV OF TECH

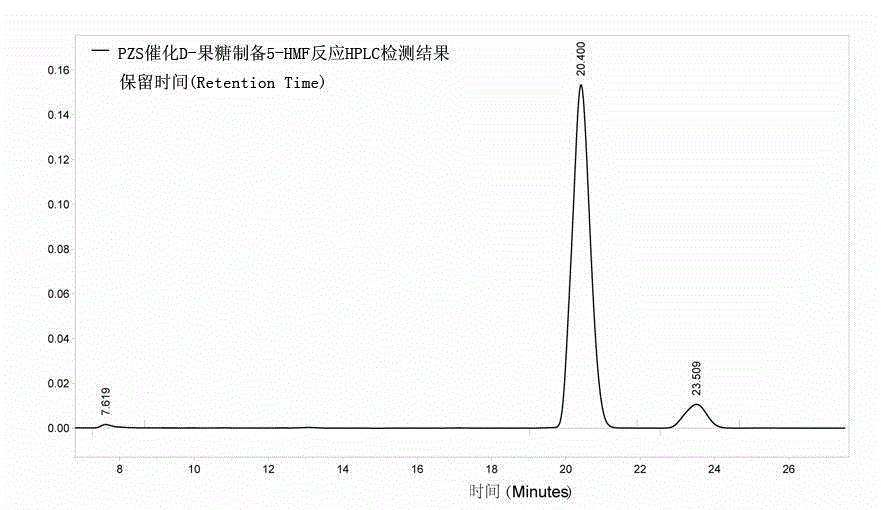

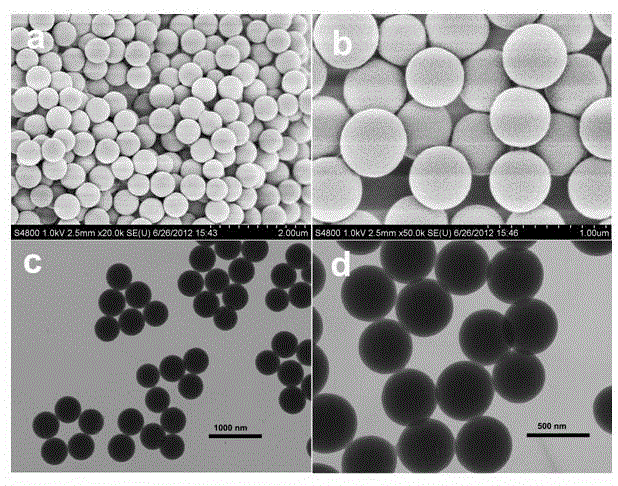

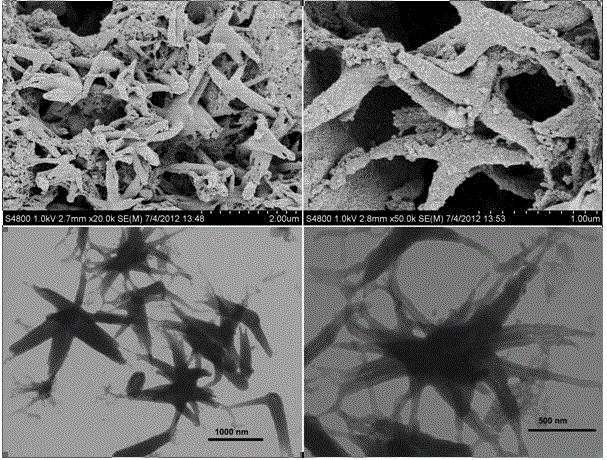

Method for preparing 5-hydroxymethylfurfural

InactiveCN102911142AImprove conversion rateHigh selectivityOrganic chemistryPtru catalystFuraldehyde

The invention belongs to the technical field of productions of chemical products, in particular to a method for preparing 5-hydroxymethylfurfural. The method includes steps of taking a macromolecular polyphosphazene polymer matrix as a solid acid type heterogeneous catalyst, taking monosaccharide, disaccharide or polysaccharide as raw materials, reacting for 5minutes to 24 hours in single-component solvent or double-component solvent such as dimethyl sulfoxide, acetonitrile, methyl isobutyl ketone, water and the like at the temperature of 25-120 DEG C under normal pressure, and finally producing the 5-hydroxymethylfurfural efficiently. The method has the advantages that conversion efficiency of raw material is high, HMF selectivity is good, operation conditions are mild, reaction speed is high, the processing is simple and environment-friendly, the catalyst is easy to prepare and the like, corrosion to equipment and environment pollution due to common liquid strong-acid homogenous catalysts are avoided, and a new way is developed for preparing commodity chemicals and substitute fuels according to regenerative biological resources.

Owner:FUDAN UNIV

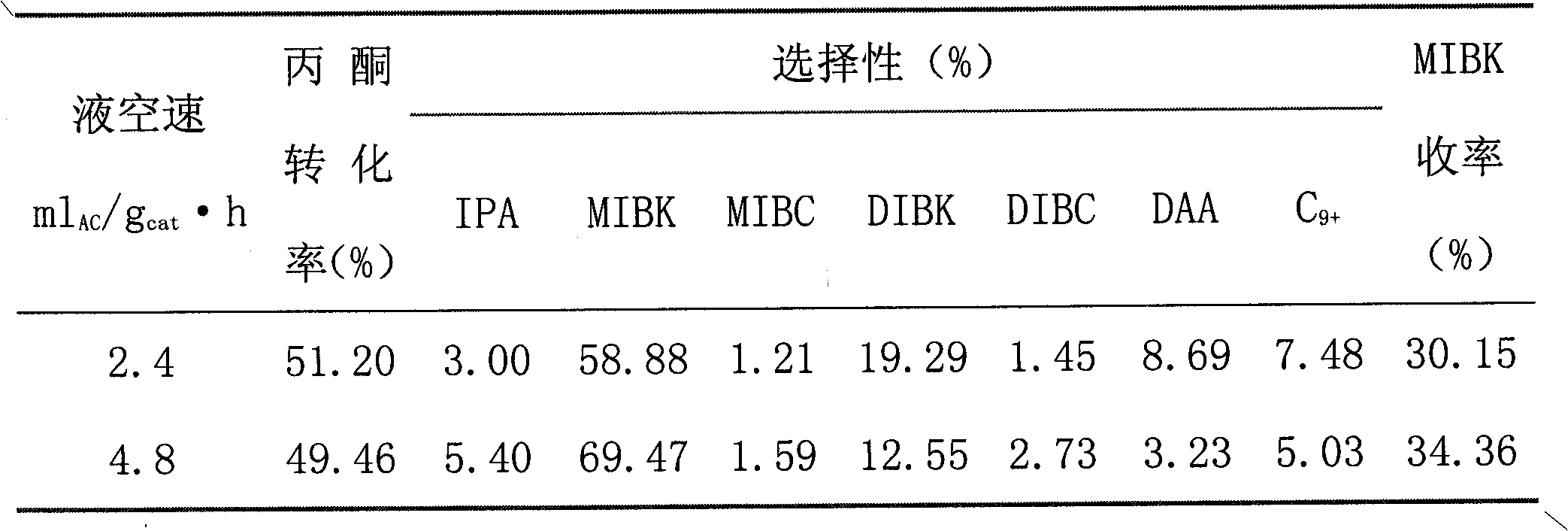

Method for preparing Ni/MgO-Al2O3 catalyst for coproduction of methylisobutylketone and diisobutylketone

InactiveCN101875012AImprove reducibilitySimple preparation processOrganic compound preparationCarbonyl compound preparationHydrogenMethyl isobutyl ketone

The invention discloses a method for preparing a Ni / MgO-Al2O3 catalyst for coproduction of methylisobutylketone and diisobutylketone, and relates to a chemical solvent. In the method, a Pd / MgO-Al2O3-ZrO2 catalyst is used, the catalyst consists of 4 weight percent of Ni, 53 weight percent of MgO and 43 weight percent of Al2O3, and the catalyst is prepared from a reconfigured NiMgAl hydrotalcite-like compound at the reaction temperature of between 150 and 240 DEG C at the liquid space velocity of 2.4 to 4.8 ml / gcat.h in a molar ratio of hydrogen to ketone of 0.5-2; and in a fixed bed reactor, the conversion rate of acetone is 30 to 56 percent, and the selectivity of the methylisobutylketone reaches 57 to 69 percent. Ni<2+> of the Ni / MgO-Al2O3 catalyst prepared by a reconfigured hydrotalcite-like method is mainly distributed on the surface of the catalyst, is easy to reduce, is used in the reaction of synthesizing MIBK by an acetone gas phase one-step method, and has high catalytic performance.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Weather-resistant epoxy polyurethane anticorrosive paint and preparation thereof

InactiveCN101298535AGood weather resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSiloxane

The invention relates to a weather resistant epoxy-polyurethane anti-corrosion coating and a manufacturing method thereof, which adds phenol-A epoxy resin, bisphenol-F epoxy resin, hydroxyl contained saturated polyester resin and fluorocarbon resin into the mixed solvent of dimethylbenzene, n-butyl acetate, methyl isobutyl ketone and butanone; then adds rutile type titanium pigment, saponite, sericite in powder, polyacrylate co-polymer, polymethyl alkyl siloxane, benzotriazole, gas phase silica and iso-caprylic acid znic to make the fluid A of the weather resistant epoxy-polyurethane anti-corrosion coating while adds fatty group polyisocyanate into the mixed liquor of anhydro-dimethylbenzene and the n-butyl acetate to make fluid B, and mix the two components during application. The invention can be applied to the preservation of the surfaces of outdoor steel structures, pipes and concrete requiring weather resistance, light aging resistance and acid, alkali and salt corrosion resistance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS20040192825A1Improve tire performanceEliminate emissionsSpecial tyresInflatable tyresElastomerSilicon dioxide

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

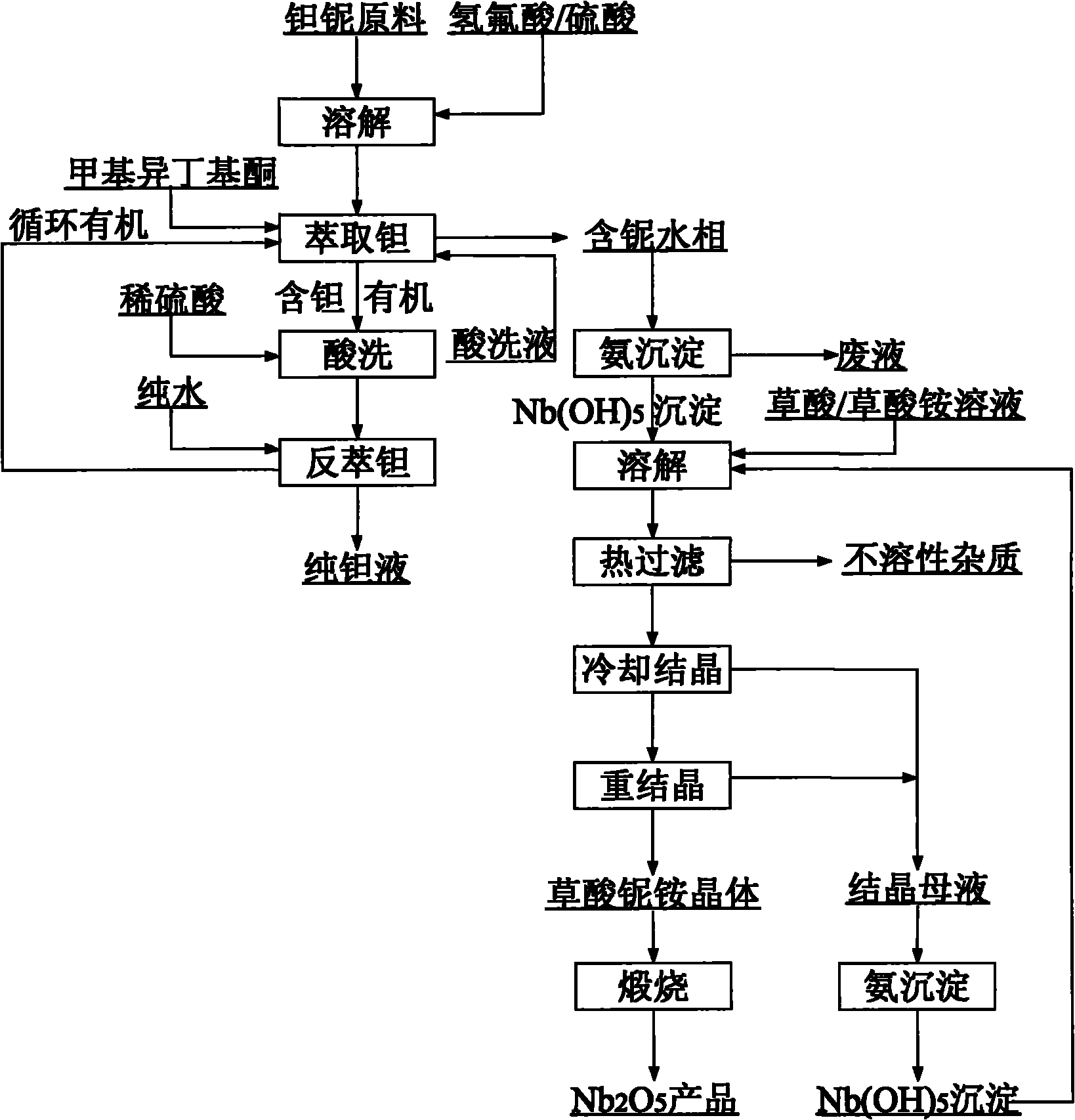

Method for separating tantalum and niobium

InactiveCN101955228AReduce concentrationReduce productionTantalum compoundsNiobium compoundsCoordination complexAmmonium oxalate

The invention relates to a method for separating tantalum and niobium from a raw material containing the tantalum and the niobium, comprising the following steps: dissolving the raw material containing the tantalum and the niobium by utilizing hydrofluoric acid or the mixing solution of the hydrofluoric acid and sulfuric acid to obtain the solution containing tantalum and niobium fluorine coordination compounds; extracting the tantalum by utilizing methyl isobutyl ketone to obtain a tantalum-containing organic phase and a niobium-containing aqueous phase; washing the tantalum-containing organic phase by dilute sulphuric acid, and performing back-extracting by pure water to obtain the pure tantalum liquid; precipitating the niobium-containing aqueous phase to obtain the Nb (OH)5 precipitation; dissolving the obtained Nb (OH)5 precipitation by utilizing an oxalic acid and ammonium oxalate mixing solution to obtain an oxalic acid niobium ammonium solution; carrying out hot filtering, crystallizing, and recrystallizing process to obtain the oxalic acid niobium ammonium crystal; and calcining the crystal to obtain the pure niobium pentaoxide. The method can realize extraction and separation of the tantalum and the niobium at low hydrofluoric acid concentration, and solves the problems that a large amount of fluorine-containing waste liquid and waste residue are generated in the extracting and separating process at the high hydrofluoric acid concentration, and F content in the final product is higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

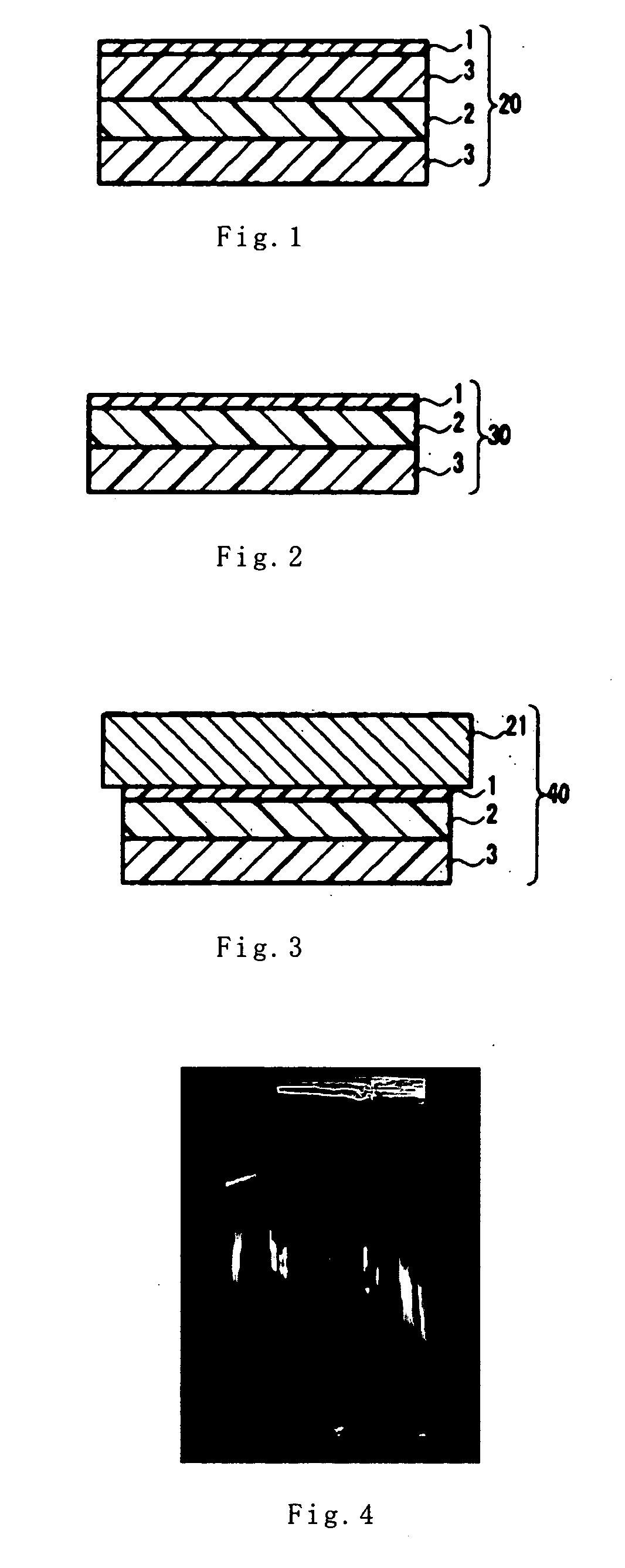

Optical film, liquid crystal panel including the same and liquid crystal display

InactiveUS20060204678A1Low solvencyHigh birefringenceLiquid crystal compositionsPolarising elementsMethyl isobutyl ketoneLiquid-crystal display

An optical film whose retardation distribution is uniform, whose rainbow-like irregularity is suppressed, whose color is transparent and whose optical characteristics are extremely good is provided. A birefringent material containing a non-liquid crystal polymer is dissolved in methyl isobutyl ketone so as to prepare a coating solution. This coating solution is applied onto a transparent film, thus forming a coating film. By drying the coating film, an optical film having a birefringent layer formed on the transparent film is obtained. As the non-liquid crystal polymer, it is possible to use polyimide that has a birefringence (Δnxyz) in a thickness direction when formed into a film of at least 0.03 and is soluble in methyl isobutyl ketone.

Owner:NITTO DENKO CORP

Low VOC (volatile organic compounds), dimethyl-2-piperidone solvent-based, PVC and CPVC pipe and component adhesives and primers containing minimal or no tetrahydrofuran

Novel low VOC solvent-based adhesives are provided, comprising a mixture of low vapor pressure, isomeric dimethyl-2-piperidones (DMPD) blended with (1) a non-solvent diluent, specifically, acetone (a VOC-exempt compound), or with mixtures of acetone and other known ketonic solvents such as methyl ethyl ketone (MEK), diethyl ketone (DEK), methyl propyl ketone (MPK), and methyl iso-butyl ketone (MIBK), cyclohexanone, and (2) thermoplastic PVC or CPVC resins. Omission of the resin provides a novel primer for pipes. The blended mixture yields PVC or CPVC pipe adhesives and primers that: (1) result in low VOC formulas (e.g., less than 510 g / l for PVC pipe and less than 490 g / l for CPVC pipe); (2) are very economical in the industry; (3) yield strong, quick setting, durable pipe joints that meet the required standards and performance criteria (e.g., ASTM D-2564 lap shear for PVC); (4) yield stable, low viscosity solutions that, in the case of adhesives, can be readily adjusted with thixotropes (e.g., Aerosil 200) to give desirable flow characteristics and body, as well as primers for solvent welding PVC and CPVC pipe and components; and (5) can be formulated with minimal (10 wt %) or no cyclic ethers such as THF.

Owner:IPS

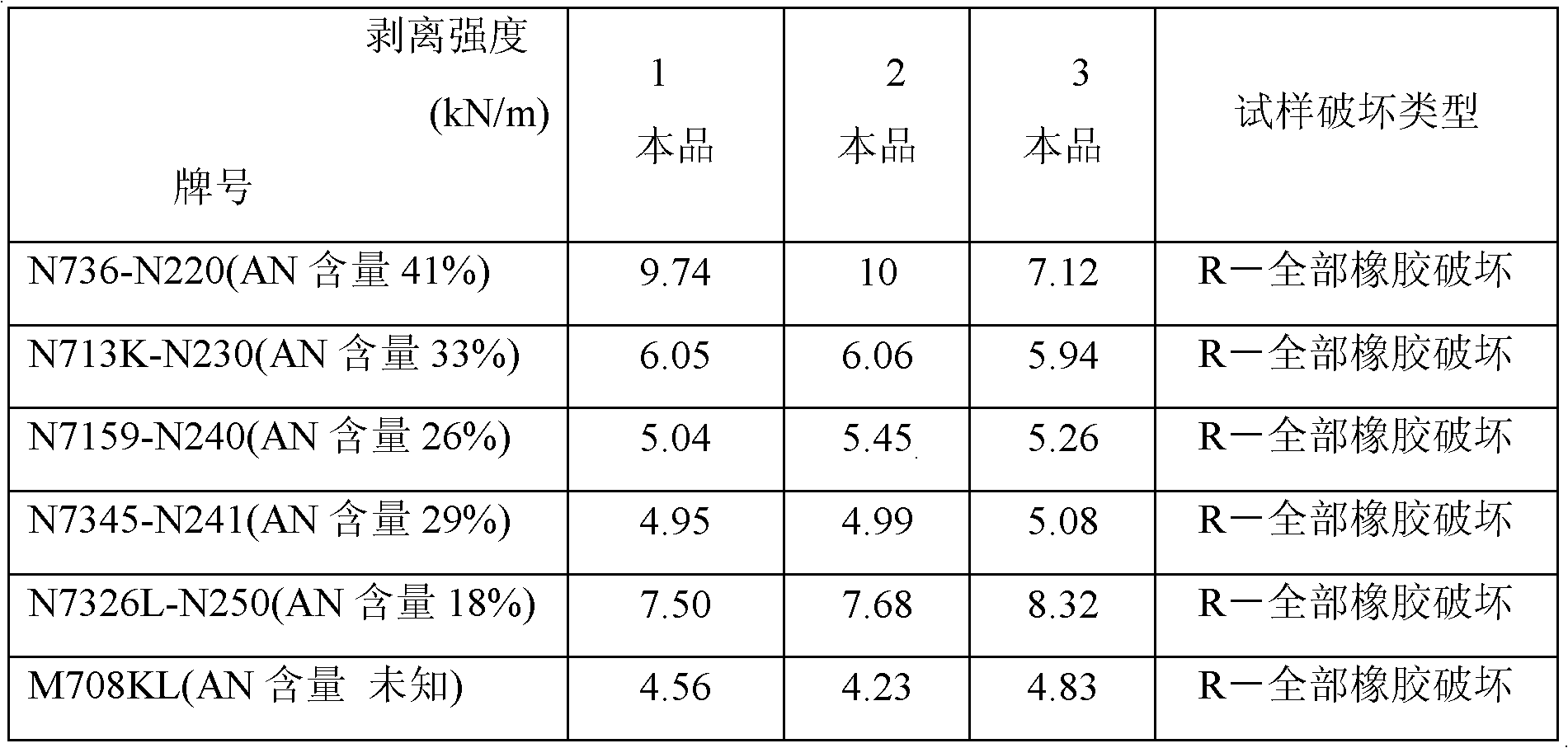

Phenolic-nitrile rubber hot vulcanized adhesive and preparation method thereof

ActiveCN102108274ALow costEasy to handleNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesNitrile rubberPolymer science

The invention discloses a phenolic-nitrile rubber hot vulcanized adhesive and a preparation method thereof. The adhesive consists of the following raw materials: crude nitrile rubber, phenolic resin, an inorganic filler, a vulcanizing agent, a tackifying resin, a coupling agent, an anti-aging agent and methyl isobutyl ketone. The preparation method comprises the following steps of: plasticating the crude nitrile rubber for 1 to 3 minutes on an open mill; sequentially adding the tackifying resin, the inorganic filler, the coupling agent, the anti-aging agent and the vulcanizing agent into the open mill for mixing; after plasticating the mixture, shearing the mixture; adding the sheared mixture into the methyl isobutyl ketone for swelling; after stirring and dissolving the mixture, obtaining a rubber slurry; and adding the phenolic resin into the rubber slurry to obtain the phenolic-nitrile rubber hot vulcanized adhesive after uniformly stirring the mixture.

Owner:安徽安大中鼎橡胶技术开发有限公司

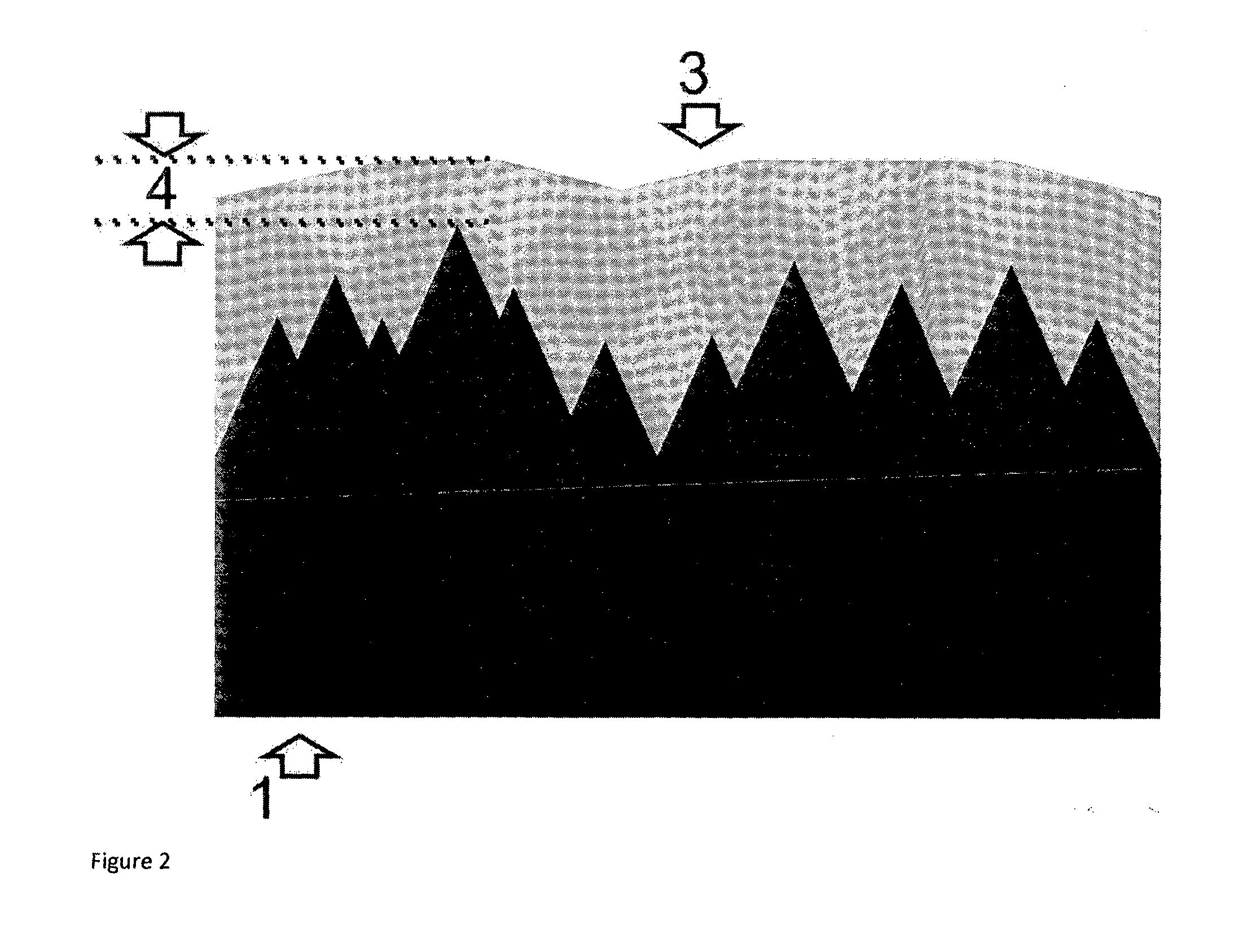

Spin-on-glass assisted polishing of rough substrates

InactiveUS20150197455A1Reduce polishing costsImprove the quality of anticorrosionDecorative surface effectsVacuum evaporation coatingOptical radiationPolymer science

A method produces a smooth surface on a rough substrate. The rough substrate is coated with a film or particles of spin-on-glass (SOG) dissolved in a solvent using spin coating, spray coating or dip coating. The SOG is made to reflow by using thermal melting and solvent thinning. The reflow is done in an atmosphere containing a partial pressure of the solvent. The reflow allows the SOG to partially melt and to decrease the surface roughnesss of the film. The SOG is cured by thermal curing or UV exposure radiation curing into a hard durable and chemical inert silicon dioxide film. The SOG can be hydrogen silsesquioxane or methyl silsesquioxane dissolved in either methyl isobutyl ketone or volatile methyl siloxanes. The method can include embossing, chemical mechanical polishing, etching and functionalizing the surface. The substrate can be a cast, mould or form for producing a polymer or a glass replica.

Owner:INMOLD BIOSYST

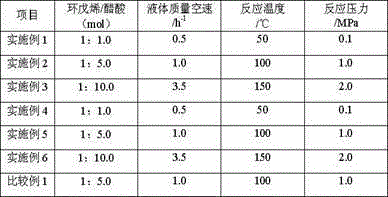

Method for preparing cyclopentanol by hydrating cyclopentene

ActiveCN106674003AImprove conversion rateHigh selectivityOrganic compound preparationCarboxylic acid esters preparationCyclopenteneAcetic acid

The invention discloses a method for preparing cyclopentanol by hydrating cyclopentene. The method comprises the following steps: (1) performing addition reaction on cyclopentene and acetic acid under the action of modified sulfonic acid group cation exchange resin to produce cyclopentyl acetate, wherein the modified sulfonic acid group cation exchange resin is prepared by soaking the conventional sulfonic acid group cation exchange resin with methylbenzene and methyl isobutyl ketone sequentially; (2) enabling the material obtained in the step (1) to enter a rectifying tower, forming azeotrope with water on the lower part of the rectifying tower, performing hydrolysis reaction on the material and water under the action of a sulfonic acid group cation exchange resin catalyst filling the upper part of the rectifying tower, withdrawing a product cyclopentanol from the top of the tower and withdrawing acetic acid from the bottom of the tower. The method has the advantages of simple technical process, low energy consumption, high conversion rate, high selectivity, high product yield and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

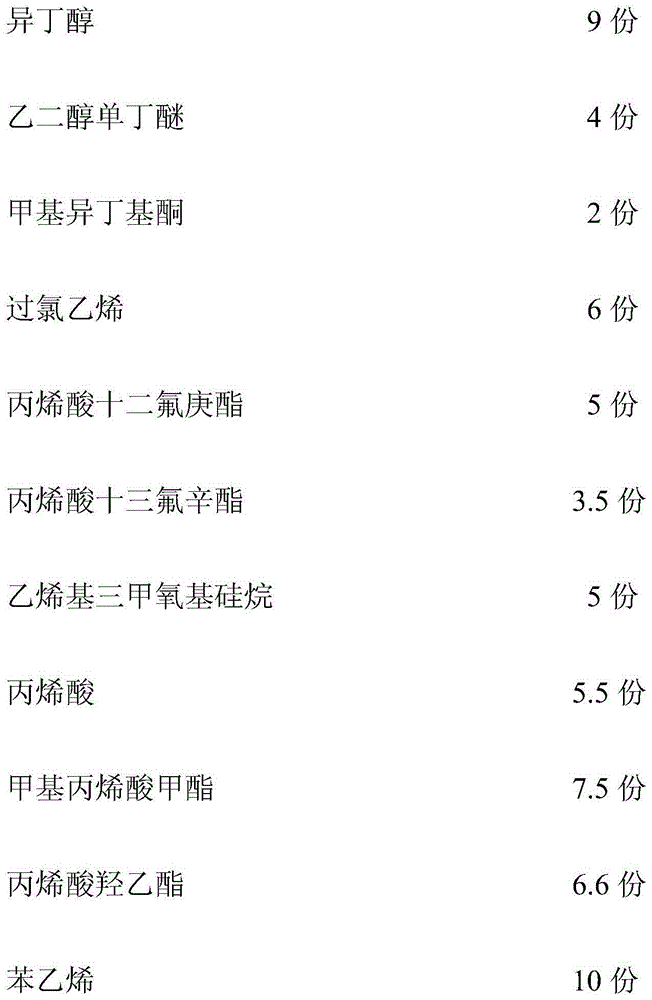

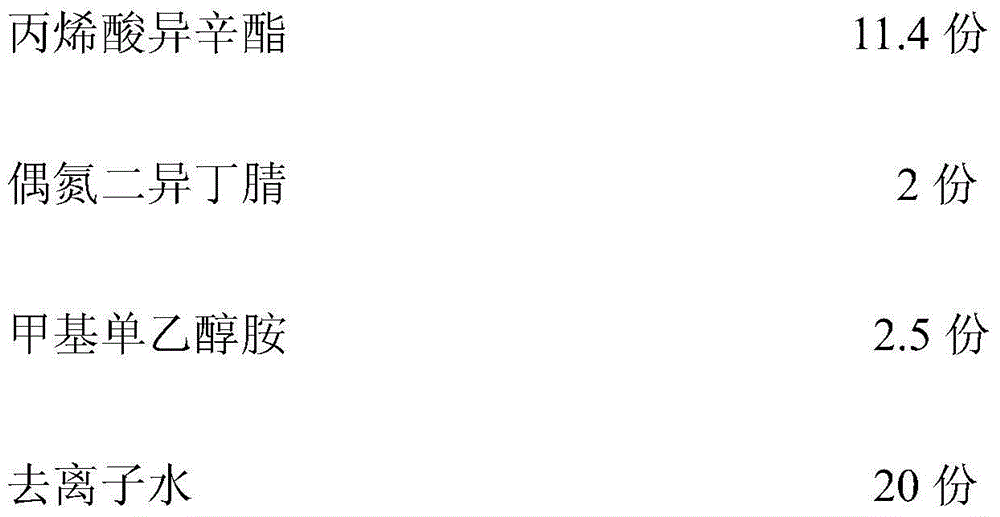

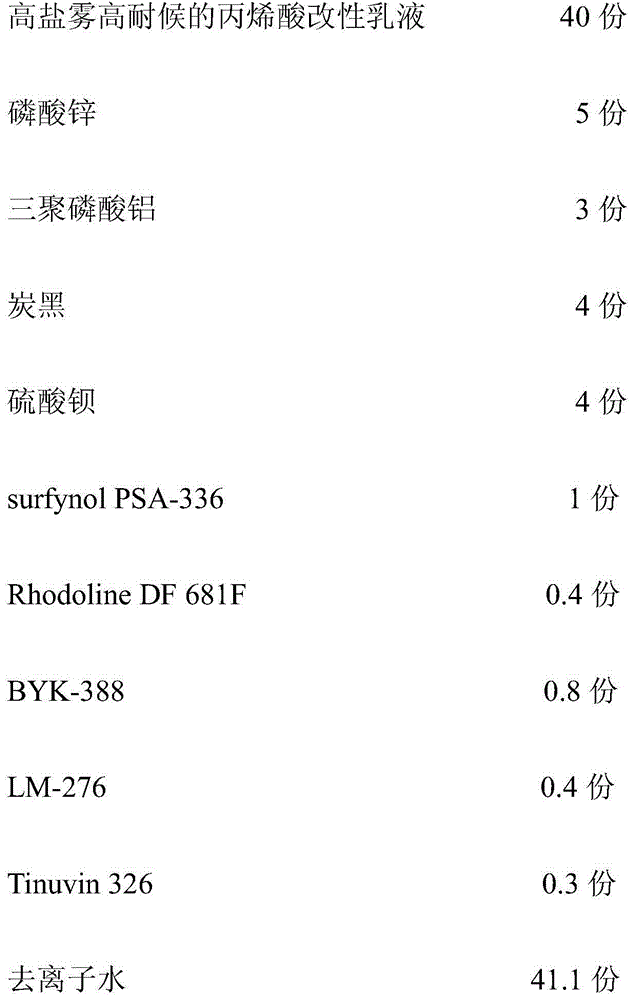

High-salt-mist high-weather-proof water paint and preparing method thereof

ActiveCN104140732AFlat and bright appearanceImprove the level ofAnti-corrosive paintsMethacrylateIsooctyl acrylate

The invention relates to high-salt-mist high-weather-proof water paint and a preparing method of the high-salt-mist high-weather-proof water paint. The high-salt-mist high-weather-proof water paint mainly comprises acrylic acid modified emulsion. The acrylic acid modified emulsion is composed of isobutyl alcohol, ethylene glycol monobutyl ether, methyl isobutyl ketone, vinylidene chloride, dodecafluoroheptyl methacrylate, perluorooctyl acrylate, vinyl trimethoxy silane, acrylic acid, methyl methacrylate, hydroxyethyl acrylate, phenylethylene, 2-ethylhexyl acrylate, azodiisobutyronitrile, N-methyl monoethanolamine and deionized water. The paint is quite excellent primer-topcoat coating and suitable for metal workpieces, the paint is dried at normal temperature after being sprayed, the appearance of a coating is smooth and bright, the leveling property is good, the mechanical property is good, the weather-proof property is excellent, after 2500 hours of QUV aging tests, the dulling rate is smaller than or equal to 15%, and delta E is smaller than or equal to 1.5, meanwhile, corrosion resistance is good, salt mist resistance reaches 1000 hours, and the one-way corrosion width is smaller than or equal to 2 mm.

Owner:HAOLISEN COATING SHANGHAI +1

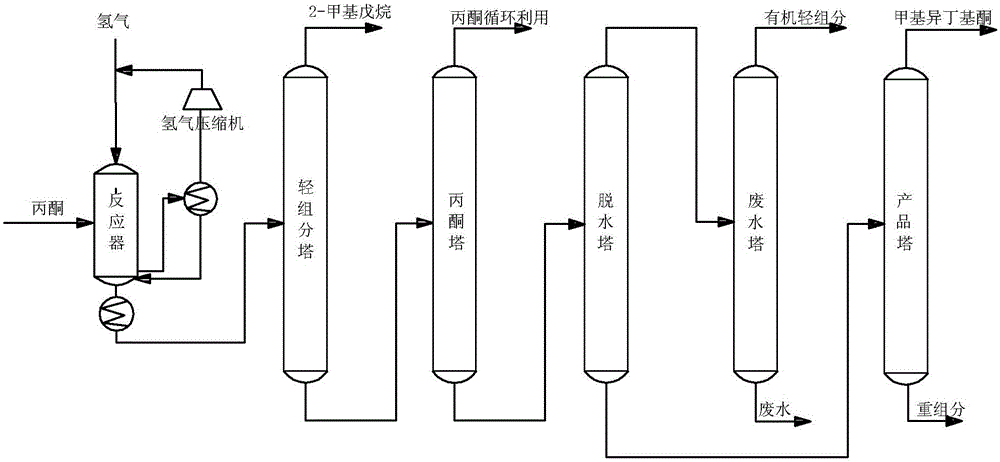

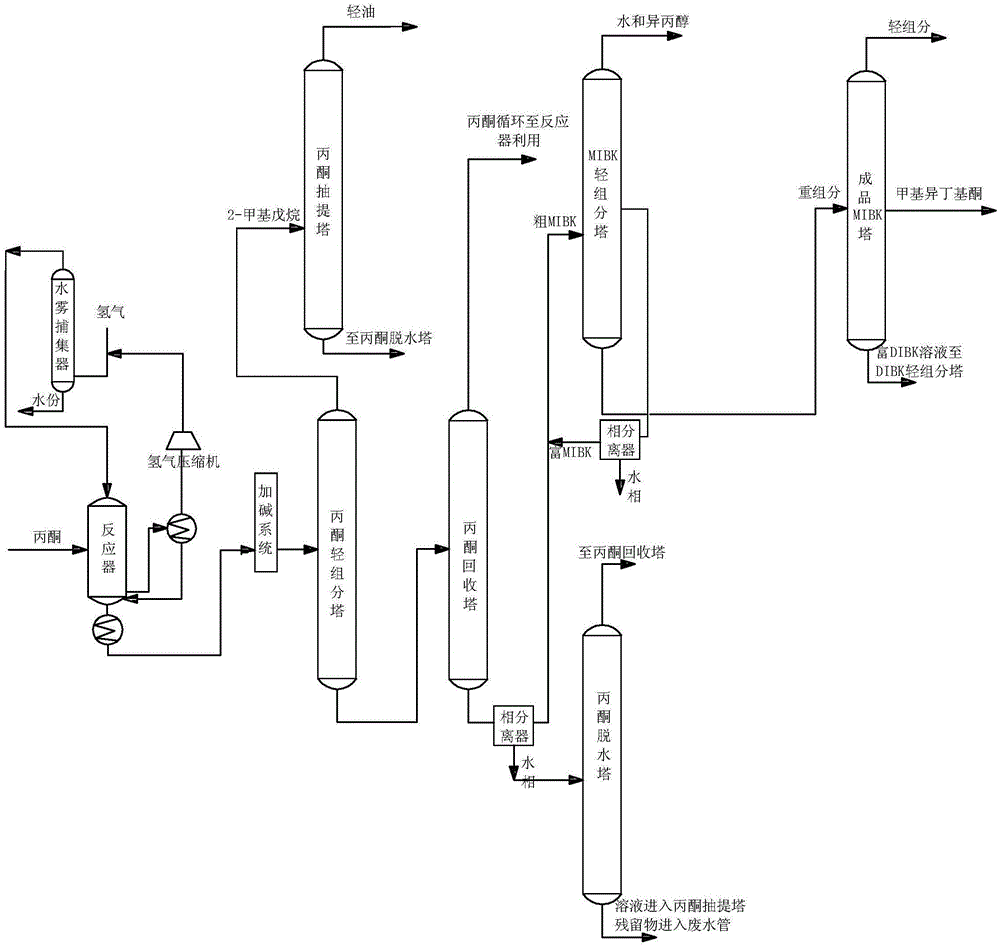

Production process of methyl isobutyl ketone

ActiveCN105130778AGuaranteed conversion rateGuaranteed selectivityOrganic compound preparationCarbonyl compound preparationPtru catalystMethyl isobutyl ketone

The invention provides a production process of methyl isobutyl ketone. The production process includes the following steps that a, hydrogen is conveyed into a water mist catcher for water removal; b, hydrogen and acetone are mixed and conveyed into a reactor to react, an adopted catalyst is strong acid positive ion exchange resin treated through palladium acetate, a reaction product is subjected to water removal again through hydrogen obtained after condensation separation and reused in the reactor for the reaction; c, alkali is added to a condensation product solution; d, the product solution to which alkali is added enters an acetone light-component tower to be separated, a solution produced from the bottom of the tower enters an acetone recovery tower for rectification, negative pressure operation is conducted in the acetone recovery tower, acetone produced from the top of the tower is reused in a fixed bed reactor, coarse MIBK produced from the bottom of the tower enters a phase separator; e, the coarse MIBK enters an MIBK light-component tower for rectification, heavy components produced from the bottom of the tower enter a finished MIBK tower for rectification, and finished MIBK is produced from the lateral line of the finished MIBK tower. Thus, energy utilization is greatly reduced, and meanwhile safe and efficient production can be facilitated while the utilization rate of original raw materials is guaranteed.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

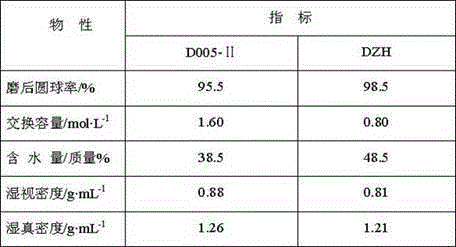

Process for preparing palladium-resin catalyst

InactiveCN1457927APromote exchangeIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsMethyl isobutyl ketoneIon exchange

The present invention discloses the preparation process of Pd / resin catalyst, and is especially the preparation process of Pd / resin catalyst for the one-step process to synthesize methyl isobutyl ketone. Pd-containing acid solution and resin are made to produce ion exchange to obtain the catalyst with high activity and high selectivity. The present invention has raised Pd utilization, and the catalyst may be used in hydroetherification of gasoline, synthesis of methyl isobutyl ketone with acetone and other reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of fluorin modified crylic acid resin for helicopter skining paint

the invention discloses a fluorine modified acrylic resin and preparing method for helicopter covering paint, which comprises the following steps: blending composite monomer methacrylic acid borneol ester, n-butyl methacrylate, hydroxyethyl methacrylate, butyl acrylate, methacrylic acid and fluorine monomer in the composite solvent with xylene, propylene glycol methyl ether acetic ester, methyl isobutyl ketone and 100# solvent oil; dripping carbonic glycide ester to polymerize acted by trigger pentaphen peroxide to obtain the product.

Owner:ZHEJIANG UNIV +1

A kind of anti-aging agent 4020 continuous production process

InactiveCN102260176ASmall sizeEven by forceAmino preparation from aminesChemical/physical processesChemistryMethyl isobutyl ketone

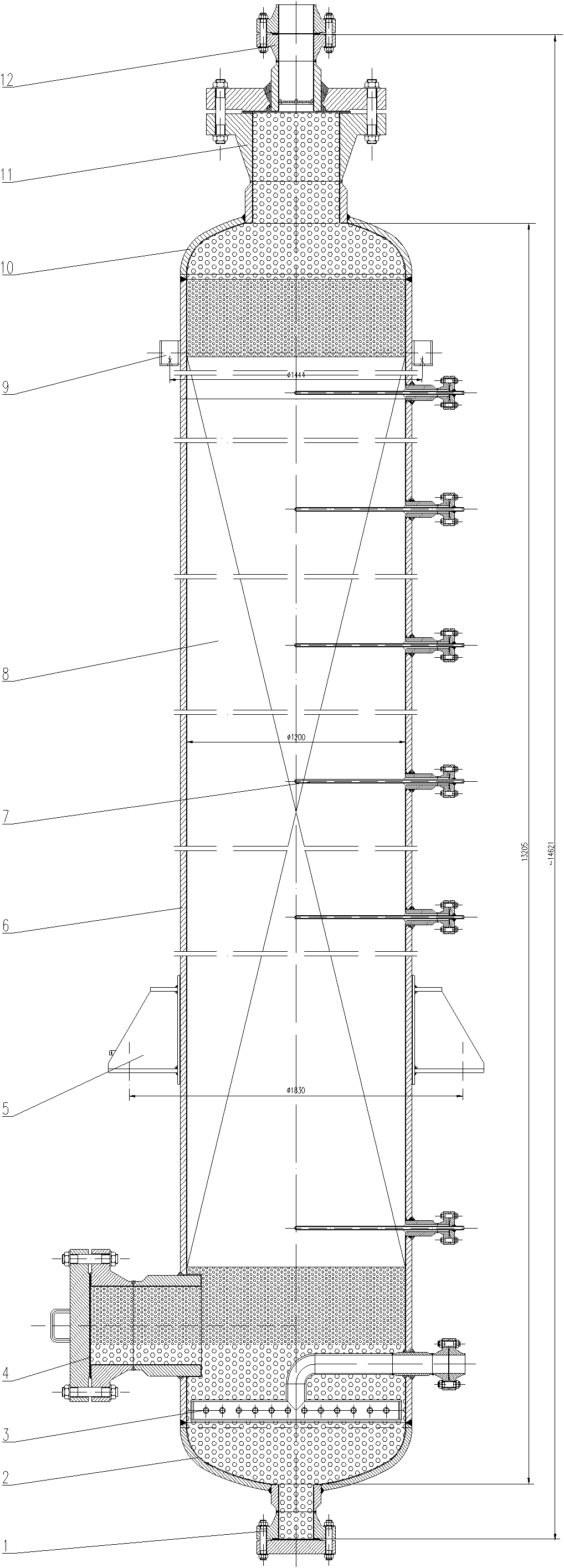

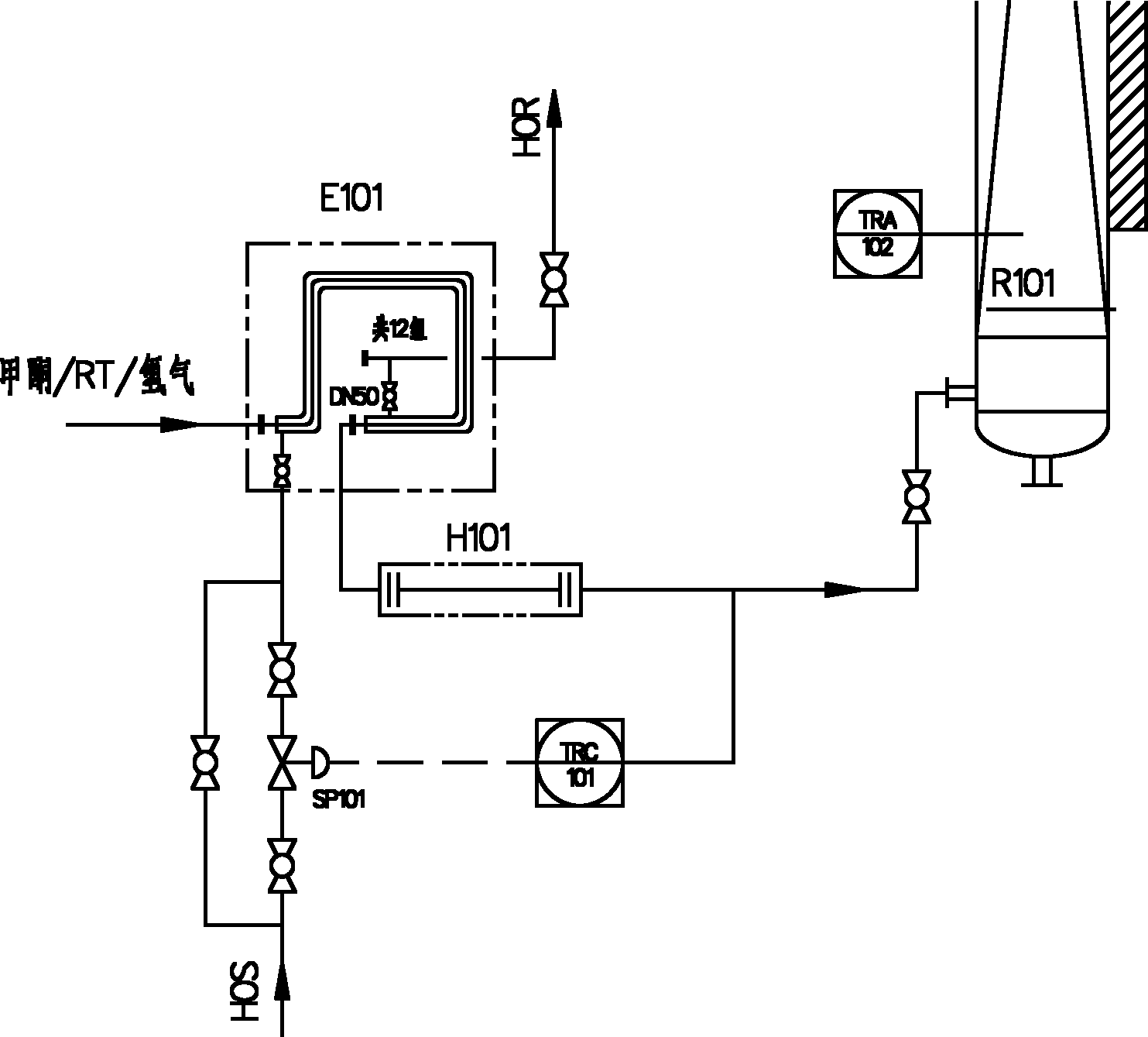

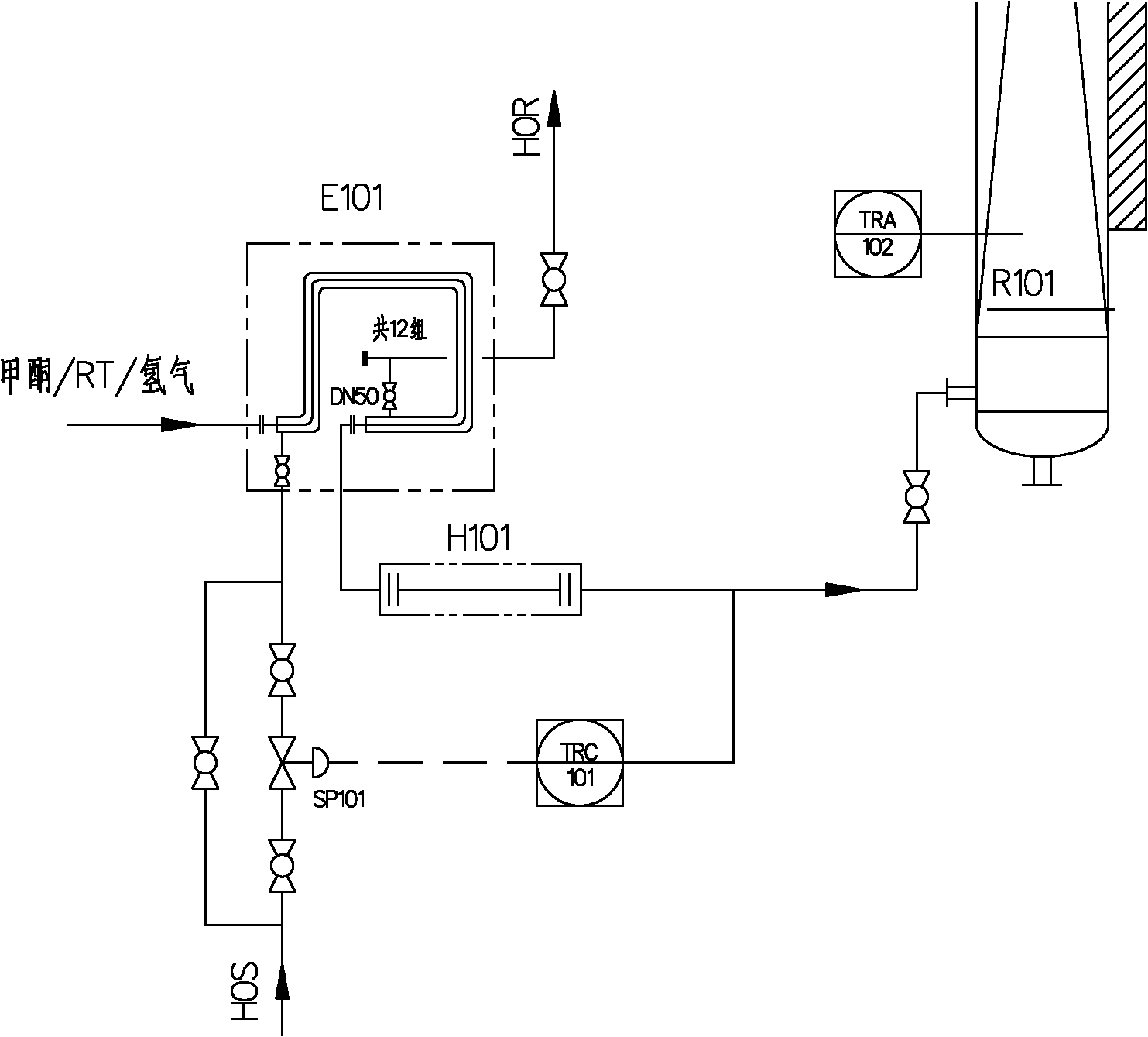

The invention discloses a continuous producing process of an anti-aging agent 4020, which has the advantages of stability and reliability in operation and high production efficiency. The process comprises the following steps of: adopting 4-aminodiphenylamine, methyl isobutyl ketone and hydrogen as raw materials; mutually preheating all raw materials by a preheater E101; enabling the preheated rawmaterials to enter a reactor; and carrying out catalytic hydrogenation reaction on the raw materials at a high pressure under the effect of a catalyst so as to obtain the anti-aging agent 4020, wherein the reactor is a gas-liquid-solid three-phase fixed bed hydrogenation reactor; the hydrogenation reaction is continuous operation carried out by using the gas-liquid-solid three-phase fixed bed hydrogenation reactor; the gas-liquid-solid three-phase fixed bed hydrogenation reactor comprises a main body container, a discharging opening, a completely discharging opening, a feed pre-distributor, an upper seal head, a lower seal head, an upper support, a lower support and a temperature measuring opening, wherein the feed pre-distributor is an exhaust pipe type pre-distributor which is mounted at the lower part of the main body container; the upper seal head is an elliptical seal head; and the lower seal head is also an elliptical seal head; and the temperature is 165-230 DEG C, the pressureis 5.5-6.0 MPa, the keto-amine ratio is 2-4:1 and the hydrogen-oil ratio is 2000-5000:1 during reaction.

Owner:NANJING ENVIRO CHEM ENG DESIGN

Transfer printing ink with release function

The invention relates to a transfer printing ink with a release function. The transfer printing ink comprises, by weight, 16 to 25% of a polymethacrylate resin, 1.5 to 2.5% of a cellulose acetate resin, 7 to 30% of a pigment, 50 to 62.5% of a mixed solvent, 0 to 2% of an auxiliary agent, 0 to 1% of matt powder and 0 to 2% of wax powder, wherein the mixed solvent is a mixture of two or more selected from the group consisting of ethyl acetate, n-propyl acetate, isopropyl acetate, n-butyl acetate, toluene, butanone, methyl isobutyl ketone, isopropanol, propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate mixed at any ratio, the auxiliary agent is one or a mixture of more selected from the group consisting of a dispersant, an antistatic agent and an organosilicon leveling agent, the matt powder is gas phase silica, and the wax powder is polymer micro wax powder. The transfer printing ink provided by the invention has all the properties of a traditional transfer printing ink, e.g., pigment concentration, brilliance and good printability and heat resistance, further has excellent release performance and can be used as a release agent in a transfer printing process.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

Cardanol epoxy resin

The invention relates to a cardanol epoxy resin, belonging to epoxy resin materials. The process comprises the following steps of: 1, adding bisphenol A, cardanol and epichlorohydrin in proportion into a reaction kettle; 2, heating and adding solid sodium hydroxide; 3, dropwise adding a sodium hydroxide solution, discharging water generated by reaction and the epichlorohydrin out of the reaction kettle by azeotropy, and returning the epichlorohydrin into the reaction kettle after condensing and decomposing for continuing the reaction; 4, after the reaction, distilling off water and most of the epichlorohydrin from the material in the reaction kettle, and removing the residual epichlorohydrin by a film evaporator to obtain crude resin; 5, adding an organic solvent and soft water into a refining kettle, dropwise adding the residual sodium hydroxide solution, wherein the organic solvent is toluene or methyl isobutyl ketone; and 6, removing the organic solvent from the refined resin solution by a film evaporator to obtain the product. The used cardanol is environment-friendly, energy-saving and pollution-free, and the cardanol epoxy resin obviously improves the brittleness, toughness and weatherability of the cured resin.

Owner:徐州中研科技工业有限公司

Method and composition for improving fuel combustion

InactiveUS20050081430A1Promote combustionLighting and heating apparatusGaseous fuelsCombustionMethyl isobutyl ketone

Owner:CARROLL & ASSOC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com