Transfer printing ink with release function

An ink and functional technology, applied in inks, household appliances, applications, etc., can solve the problems of unclear pattern printing, insufficient color density and vividness, and inability to peel off, and achieve excellent printability and heat resistance. Production printing process, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

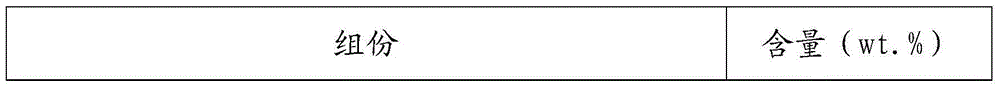

[0022] A kind of transfer printing ink with release function, its composition is as shown in table 1:

[0023] Table 1. Each component of the transfer printing ink of embodiment 1 and its weight percentage

[0024]

[0025]

[0026] The molecular weight of polymethyl methacrylate is 90,000, and the glass transition temperature is 80°C. The preparation method of the transfer printing ink with release function is as follows: first, the resin and a part of the solvent are dispersed and dissolved into a resin liquid, and then the pigment and auxiliary Put the agent into the resin liquid and disperse evenly, then grind it through a sand mill until the fineness is acceptable, then add the remaining solvent, matte powder and wax powder, stir and disperse at high speed for 20 minutes.

Embodiment 2

[0028] A kind of transfer printing ink with release function, its composition is as shown in table 2:

[0029] Table 2. Each component of the transfer printing ink of embodiment 2 and weight percent thereof

[0030]

[0031]

[0032] Among them, the molecular weight of polymethyl methacrylate is 70,000, and the glass transition temperature is 100°C; the molecular weight of polybutyl methacrylate is 50,000, and the glass transition temperature is 60°C. The transfer printing ink can be prepared in the following way: first, disperse and dissolve the resin and a part of the solvent to form a resin liquid, then put the pigment and additives into the resin liquid to disperse evenly, and then grind to a qualified fineness by a sand mill, and then Add the remaining solvent, matte powder and wax powder, stir at high speed and disperse for 20 minutes.

Embodiment 3

[0034] The composition of the transfer printing ink with release function according to this embodiment is shown in Table 3.

[0035] Table 3. Each component of the transfer printing ink of embodiment 3 and weight percent thereof

[0036]

[0037] Among them, the molecular weight of polymethyl methacrylate is 90,000, and the glass transition temperature is 120°C; the molecular weight of polybutyl methacrylate is 70,000, and the glass transition temperature is 75°C. The transfer printing ink can be prepared in the following way: first, disperse and dissolve the resin and a part of the solvent to form a resin liquid, then put the pigment and additives into the resin liquid to disperse evenly, and then grind to a qualified fineness by a sand mill, and then Add the remaining solvent, matte powder and wax powder, stir at high speed and disperse for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com