High-conductivity silver paste and preparation method thereof

A high-conductivity, silver paste technology, used in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of poor device sensitivity and low conductivity, and achieve good printing and printing. The effect of high conductivity, high conductivity and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of high conductivity silver paste of the present invention, comprises the steps:

[0031] Preparation of organic vehicle: put the polymer resin and solvent in proportion to the stirring tank, and stir for several hours to obtain the organic vehicle. For example, the polymer resin and the solvent are put into a stirred tank according to the mass ratio, and stirred at a high speed of 60-80° C. for 4-6 hours to obtain an organic vehicle.

[0032] Preparation of high-conductivity silver paste: Stir and mix the additives and additives with the organic vehicle in proportion, then add metal silver powder and stir and mix to obtain a mixture, grind and roll the mixture until the dynamic viscosity at room temperature is 15000-50000 centipoise , to obtain the highly conductive silver paste. For example, mix the additives and auxiliary agents with the organic carrier at a high speed for 1 hour according to the mass ratio, then add metal silver powder ...

Embodiment 1

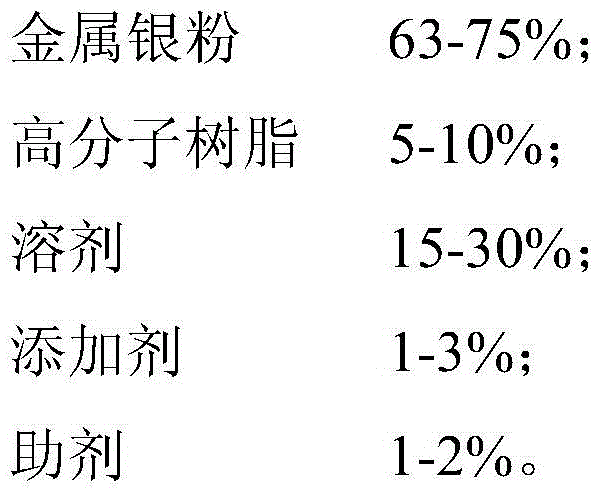

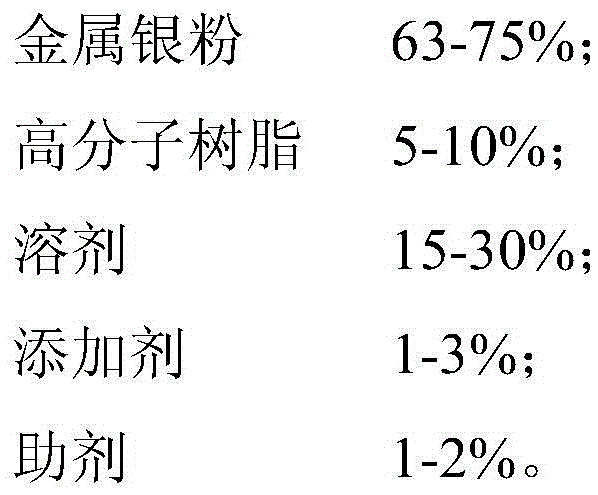

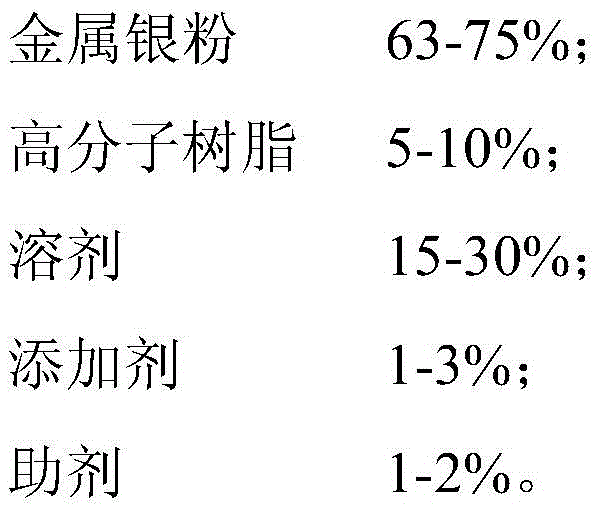

[0035] A low-temperature curing high-conductivity silver paste, its components and mass percentages are as follows:

[0036] Flake silver powder with an average particle size of 15 μm: 41.6%;

[0037] Spherical silver powder with an average particle size of 0.8 μm: 16.9%;

[0038] Nano-silver powder with an average particle size of 10nm: 6.5%;

[0039] Thermoplastic bisphenol A epoxy resin: 9%;

[0040] Isophorone: 15%;

[0041] DBE mixed esters: 7%

[0042] Conductive graphite: 2%

[0043] Hydrogenated castor oil: 0.7%;

[0044] Titanate coupling agent: 0.8%;

[0045] Silicone defoamer: 0.5%.

[0046] The preparation method of above-mentioned high conductivity silver paste is as follows:

[0047] Step 1: Add 15g of isophorone and 7g of DBE mixed ester into a mixing vessel, then add 9g of thermoplastic bisphenol A epoxy resin, stir in a constant temperature water bath at 60-80°C, and stir at 1000RPM for 4.5h to obtain an organic vehicle.

[0048] Step 2, put 2g of con...

Embodiment 2

[0050] A low-temperature curing high-conductivity silver paste, its components and mass percentages are as follows:

[0051] Flake silver powder with an average particle size of 10 μm: 44.8%;

[0052] Spherical silver powder with an average particle size of 0.5 μm: 18.2%

[0053] Nano silver powder with an average particle size of 15nm: 7%;

[0054] Thermoplastic bisphenol A epoxy resin: 5%;

[0055]Thermoplastic vinyl resin: 3%;

[0056] Isophorone: 10%;

[0057] Diethylene glycol ethyl ether butyrate: 8%;

[0058] Conductive graphite: 1.5%;

[0059] Ethyl cellulose: 1.2%;

[0060] Titanate coupling agent: 0.8%;

[0061] Silicone defoamer: 0.5%.

[0062] The preparation method of above-mentioned silver paste is as follows:

[0063] Step 1: Add 10g of isophorone and 8g of diethylene glycol ethyl ether butyrate into the mixing container, then add 5g of thermoplastic bisphenol A epoxy resin, 3g of thermoplastic vinyl acetate resin, and constant temperature water bath 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com