Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4441 results about "Silver paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

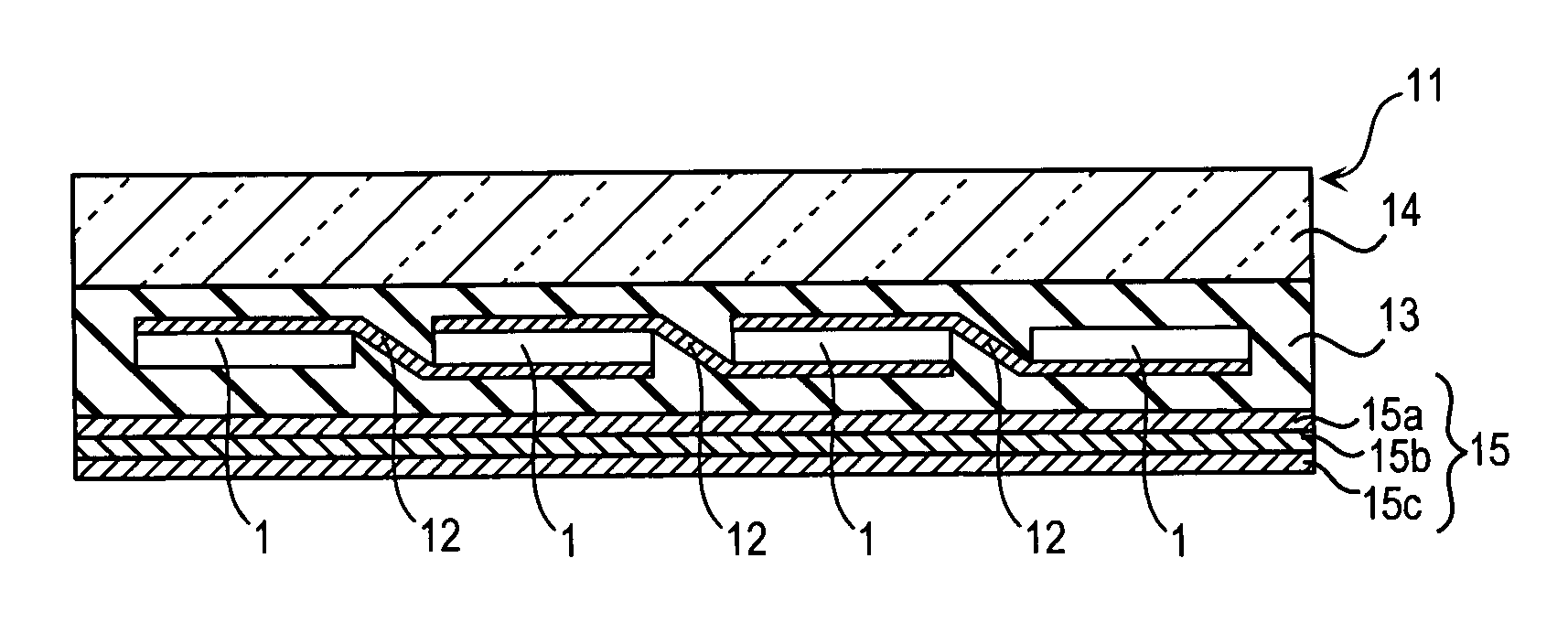

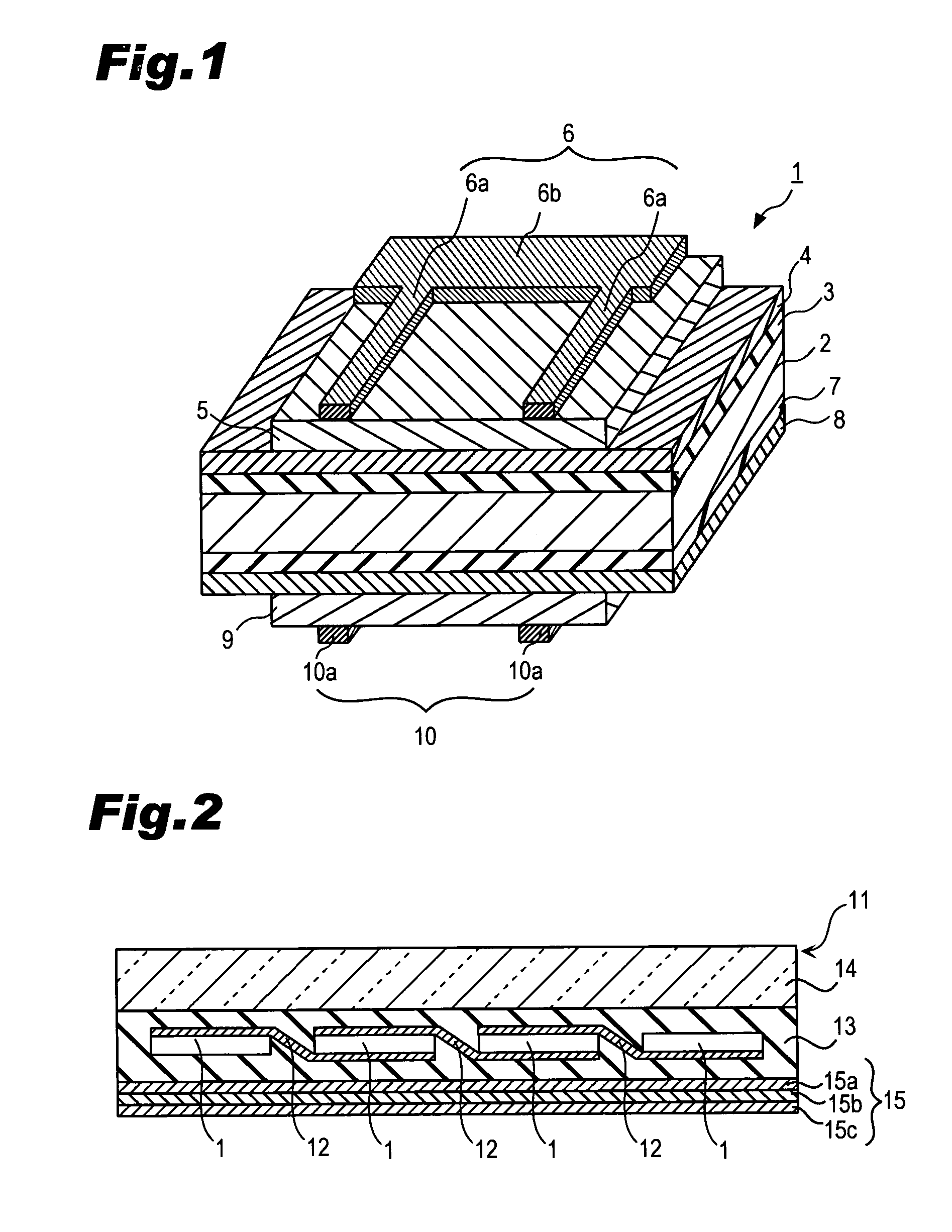

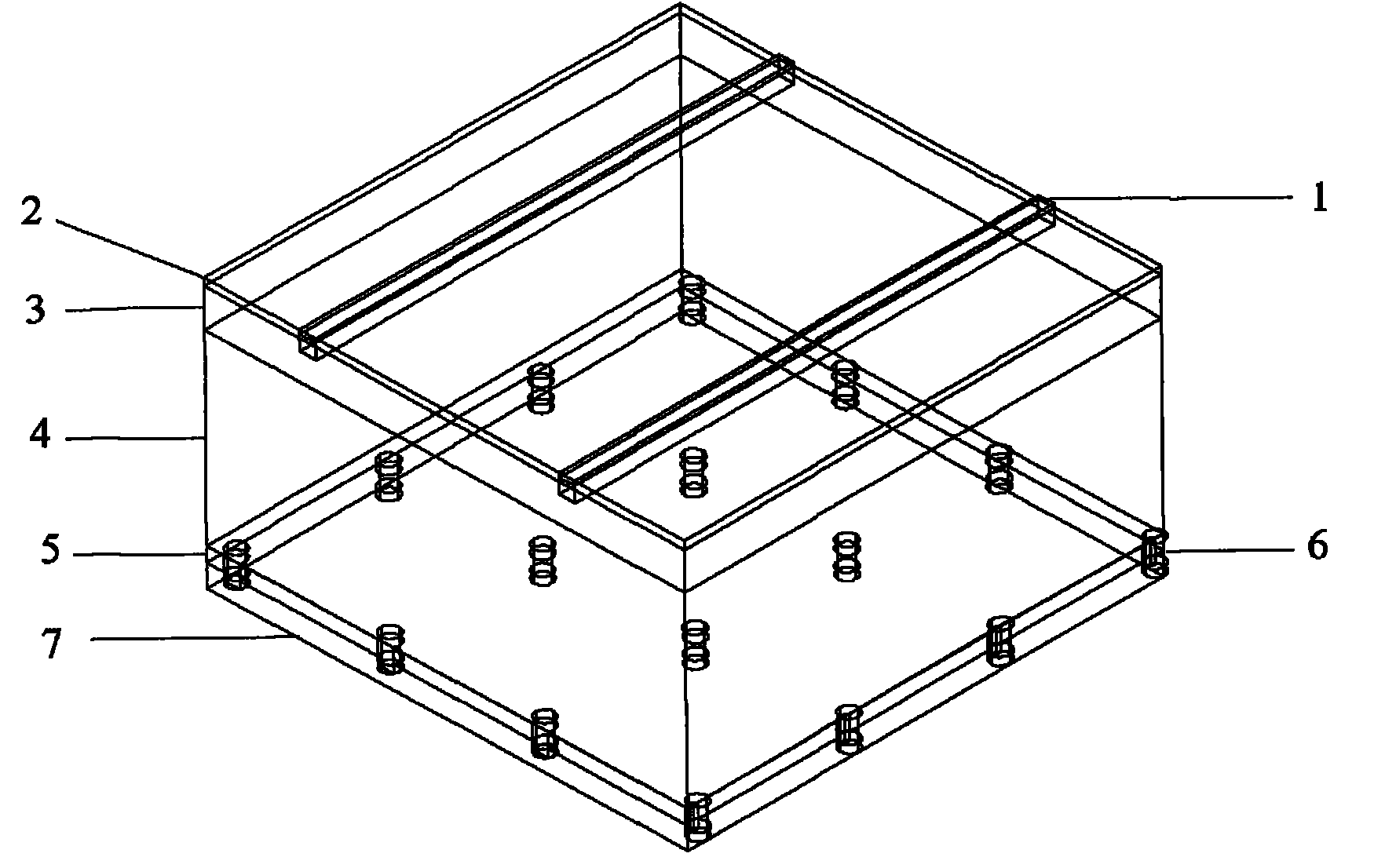

Solar cell module

InactiveUS20050199279A1Easy to solveImprove moisture resistancePV power plantsPhotovoltaic energy generationVitrificationSilver paste

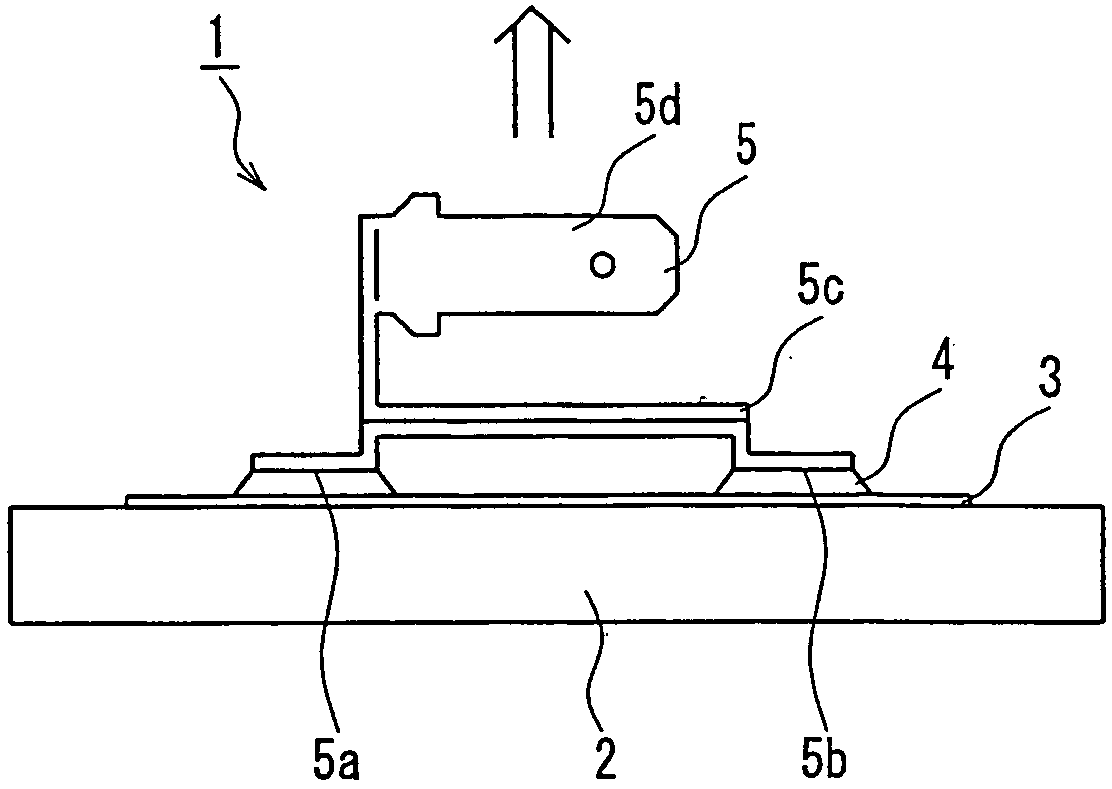

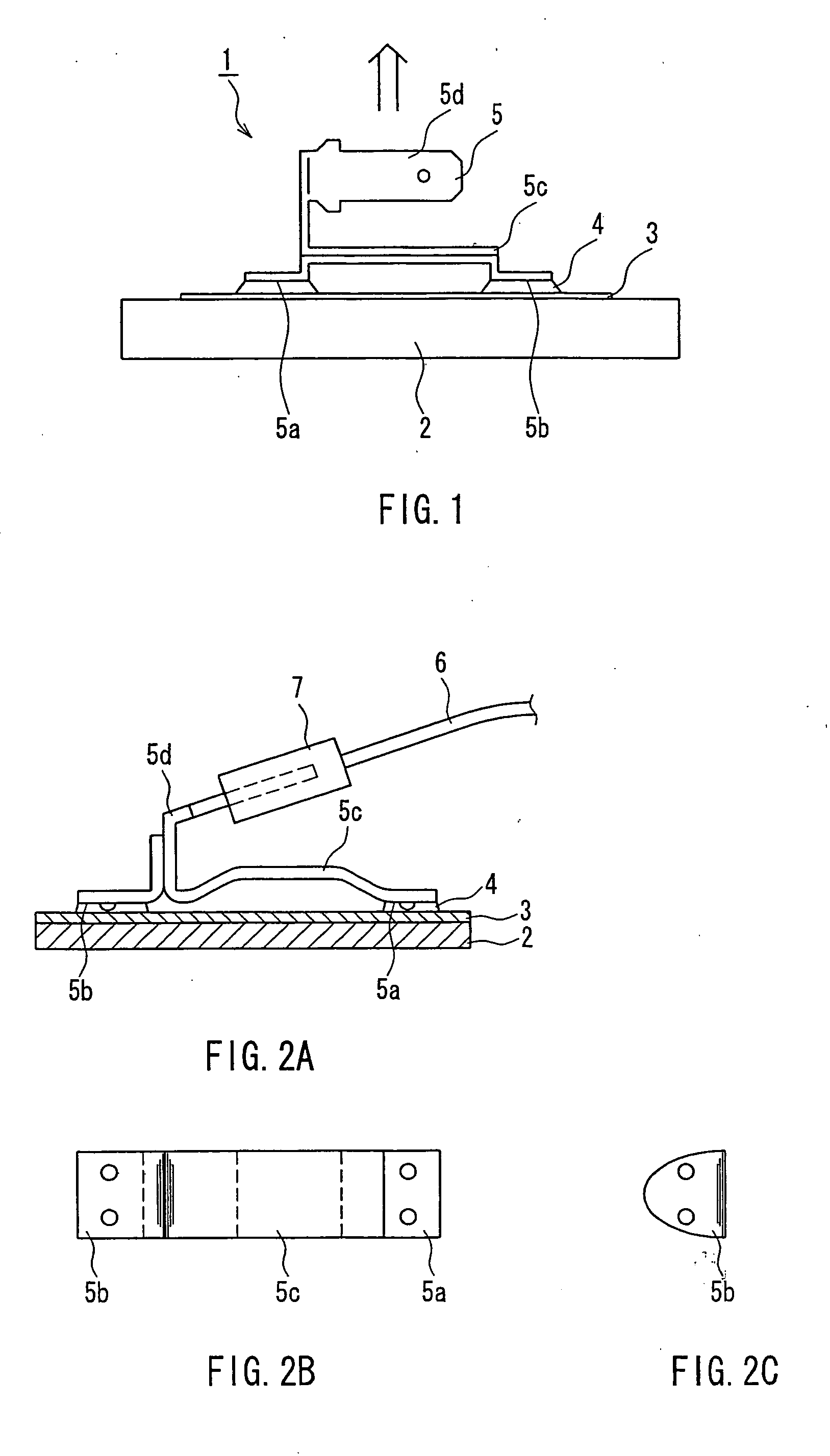

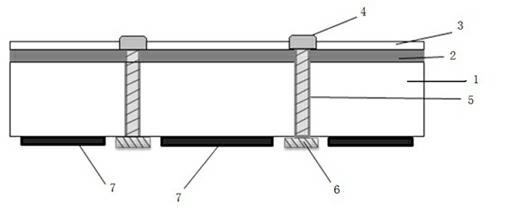

A solar cell module of the present invention was made to improve adhesion between electrodes, which is formed with thermosetting resin containing silver paste, of a solar cell element and connecting tabs coated with lead (Pb) free solder. To achieve this purpose, the solar cell module is comprised of a front surface member, a rear surface protective member, a plurality of solar cell elements provided between the front surface member and the rear surface protective member, and connecting tabs for electrically connecting the solar cell elements to each other through electrodes with the use of lead free solder. The electrodes of the solar cell elements are made of silver paste containing thermosetting resin and silver powder. The thermosetting resin contains epoxy resin at volume ratio of 70% or more having a glass transition rate of 80° C. to 200° C. measured by a TMA method. The connecting tabs coated with lead free solder are soldered to the electrodes.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

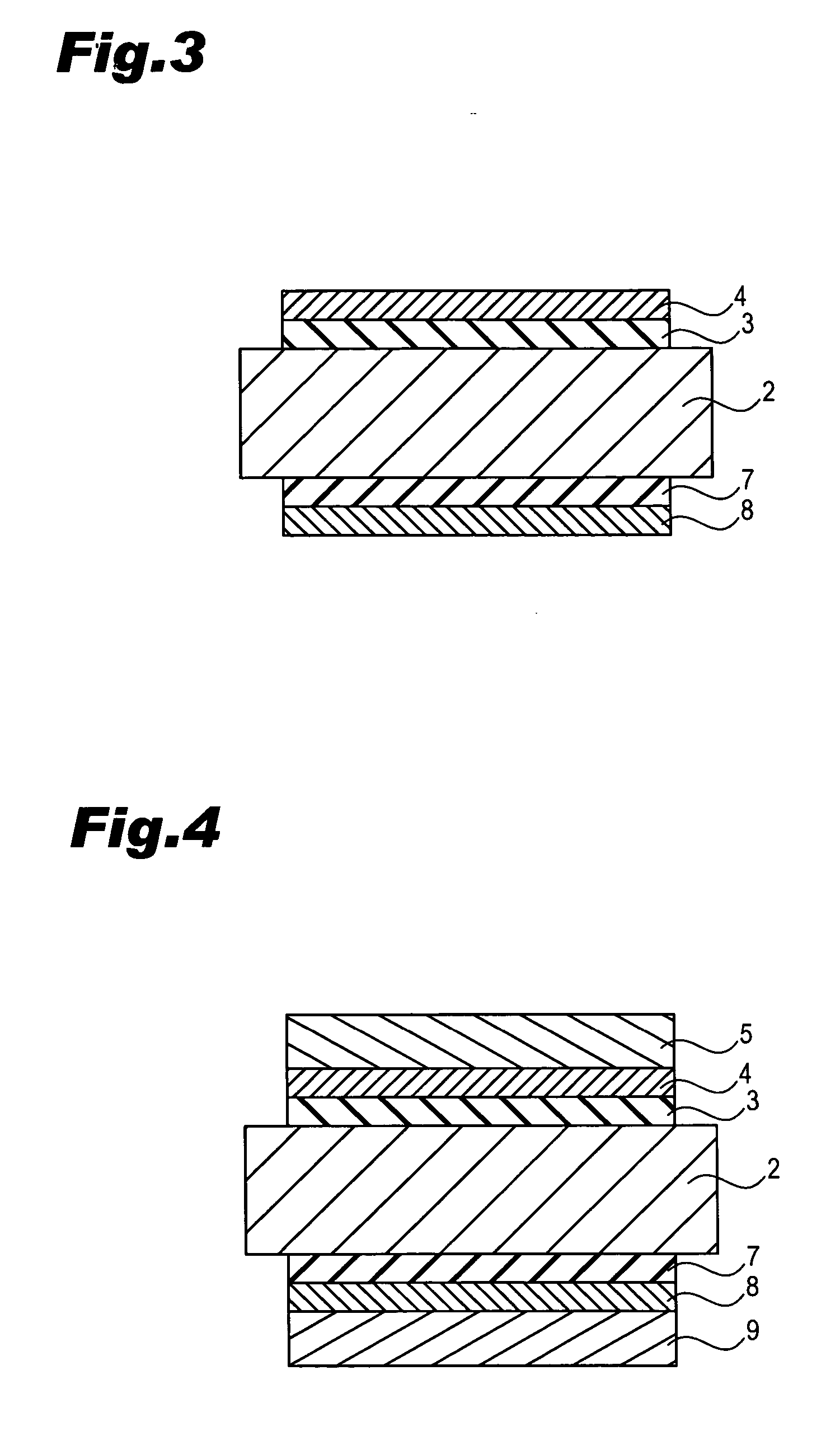

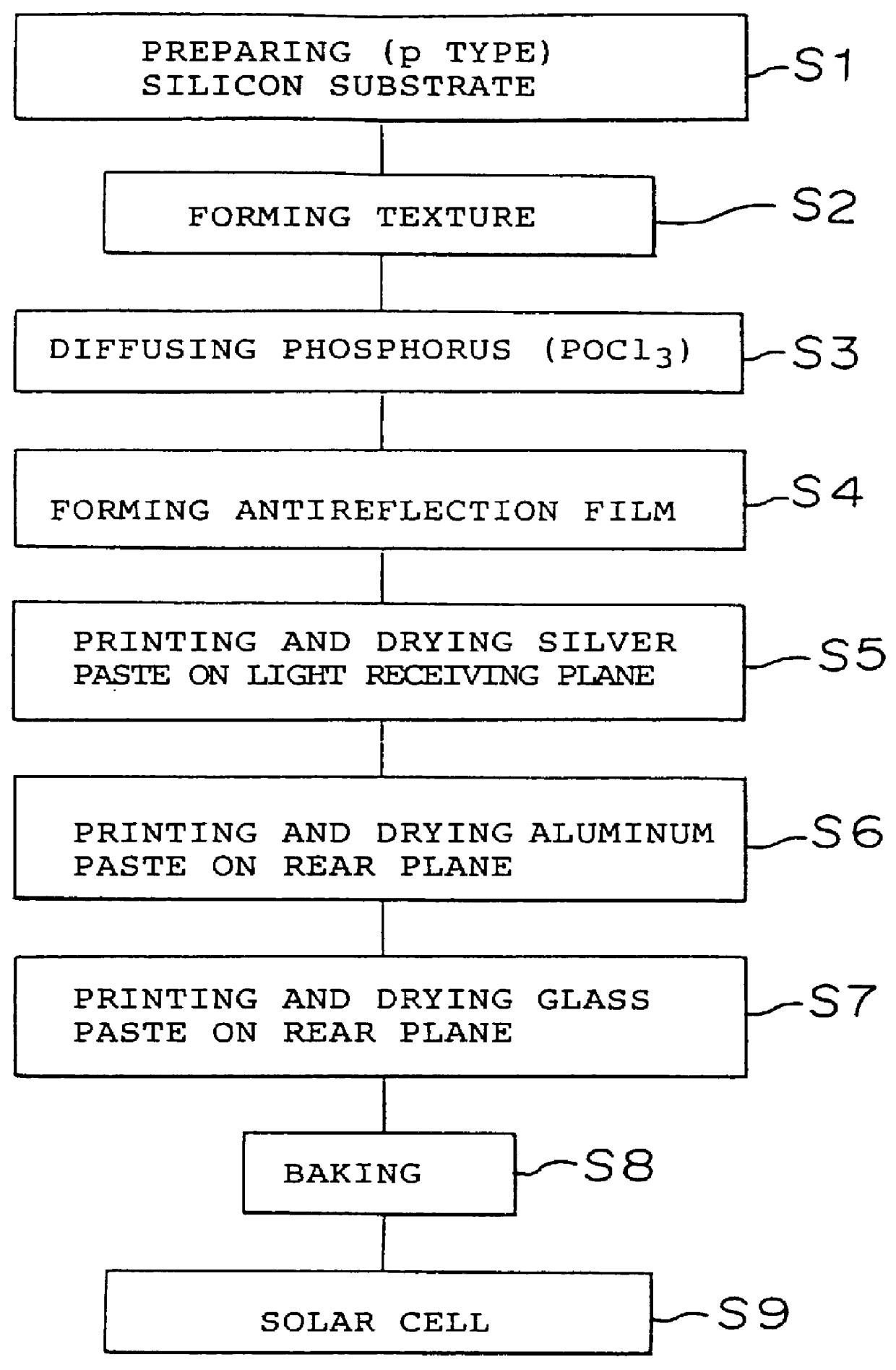

Method of producing a solar cell; a solar cell and a method of producing a semiconductor device

InactiveUS6093882ASemiconductor/solid-state device manufacturingPhotovoltaic energy generationSilver pasteSolar cell

Owner:MITSUBISHI ELECTRIC CORP

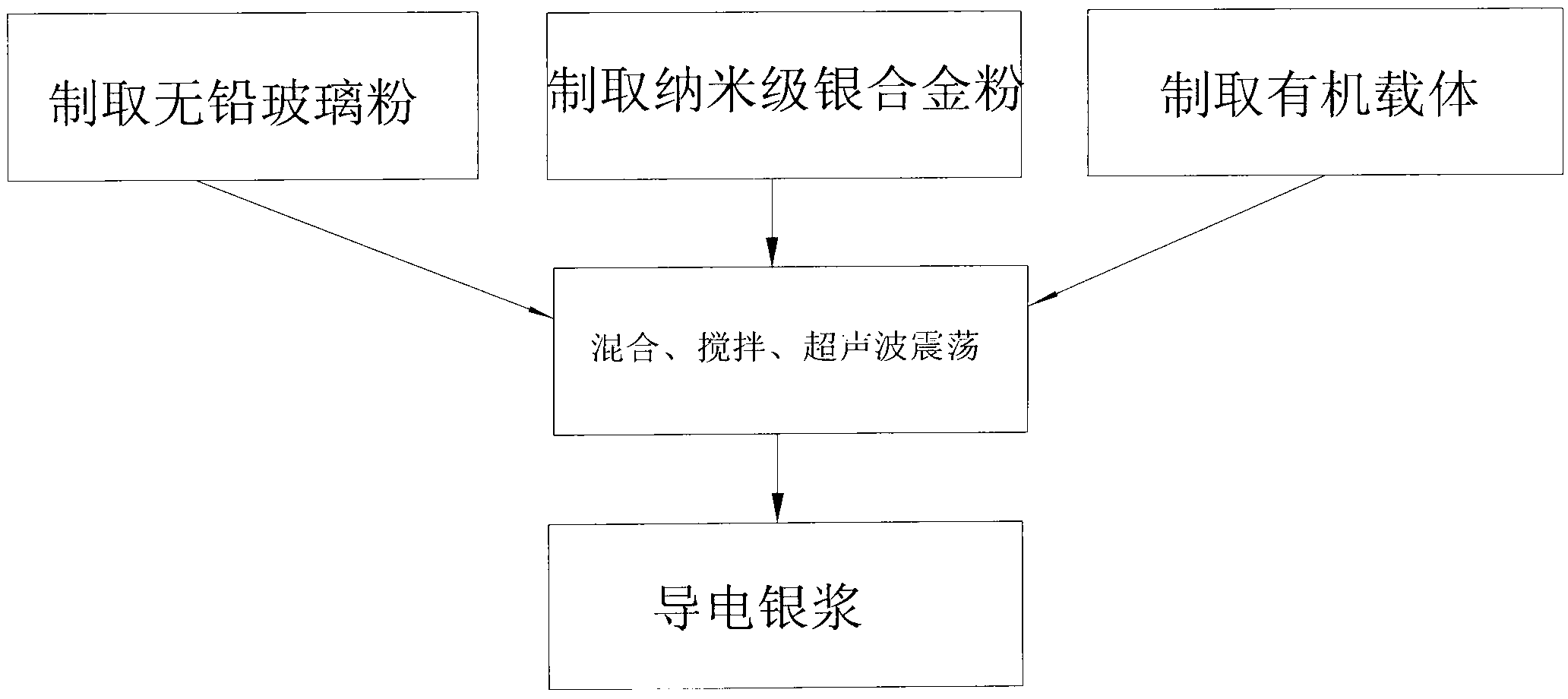

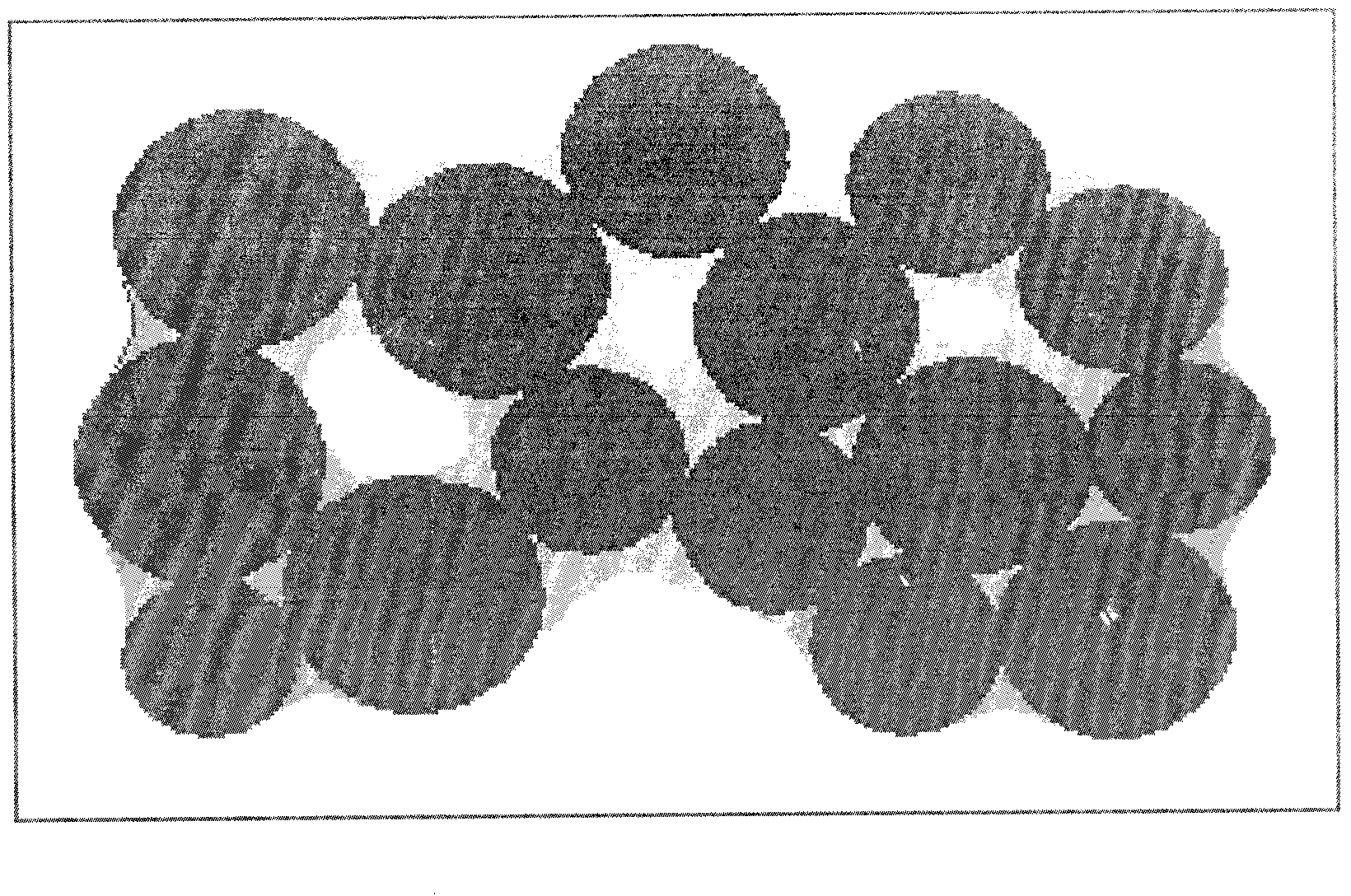

Electric conductive silver paste and manufacturing method thereof

ActiveCN103258584AEnhanced interconnectionIncrease contact areaNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetal alloy

The invention discloses electric conductive silver paste and a manufacturing method of the electric conductive silver paste. The electric conductive silver paste comprises, by mass percentage, 35 - 65 % of micron-sized silver powder, 1-10 % of nanometer-sized silver powder of or 1-20 % of nanometer-sized silver and other metal alloy powder, and 1-10 % of an organic carrier; for ceramics, solar cell silver paste comprises 2-15 % of unleaded glass powder, each component is manufactured in parts, weighed, mixed and stirred or mixed and rapidly scattered, and ultrasonic-vibrated or fine adjusted of viscosity of solvent, and therefore the electric conductive silver paste is obtained. Due to the fact that the nanometer-sized silver powder or the nanometer-sized silver alloy powder is mixed with the micron-sized silver powder, intensity of conductivity and a circuit is improved, adhesive force of crushing resistance and a base plate is improved, at the same time unleaded slurry good in thixotropy, low in contacting resistance and low in piece-needed slurry amount replaces lead slurry materials, the electric conductive silver paste is used for manufacturing crystalline silicon solar cells, improves photoelectric conversion efficiency, accords with environmental-protection ideas, and can be produced in large scales continuously.

Owner:SHENZHEN CHENGGONG CHEM

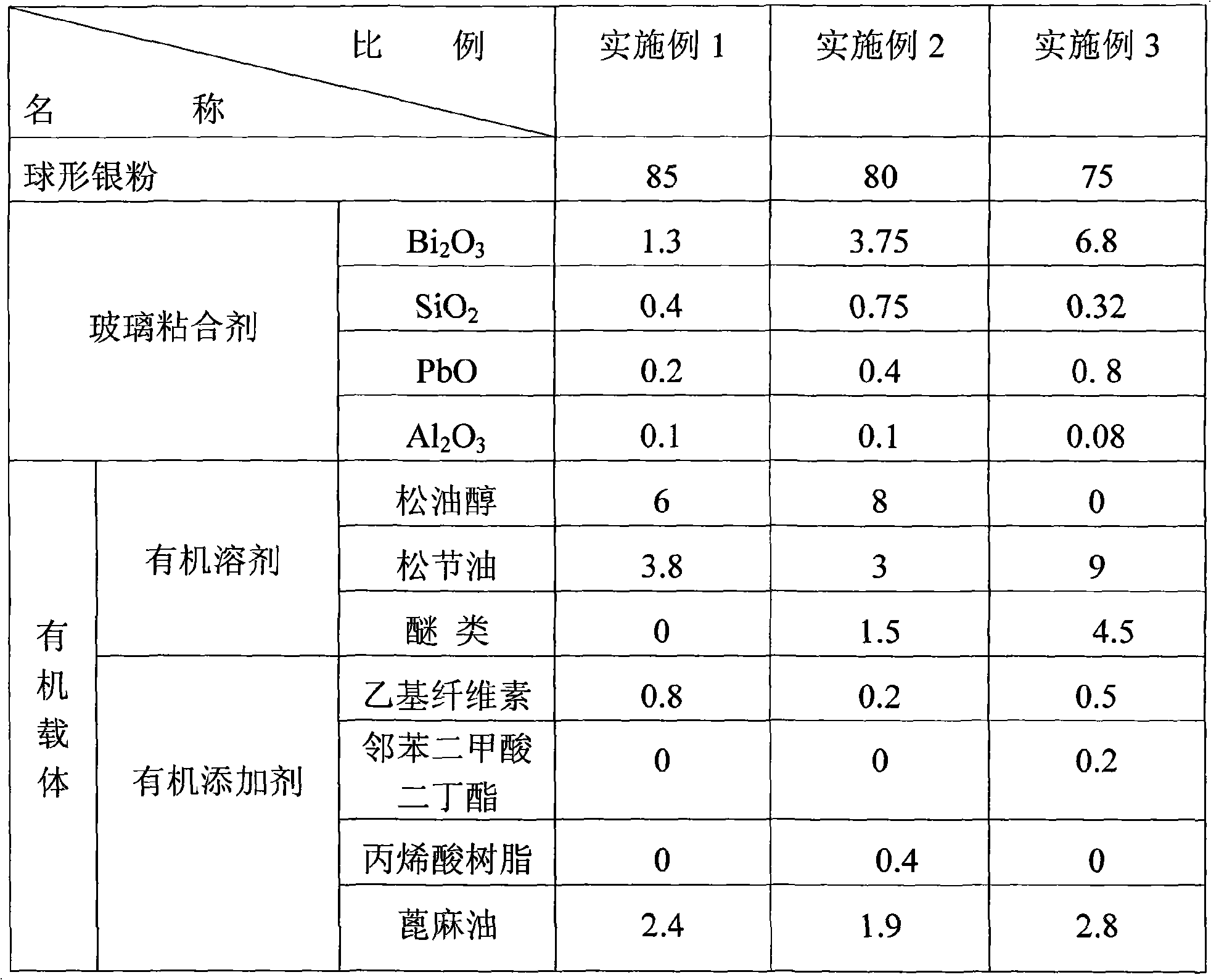

High-viscosity solar cell front side silver paste and method for producing the same

InactiveCN101271928AIncrease aspect ratioImprove photoelectric conversion efficiencyFinal product manufactureNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention relates to a high viscosity solar cell front silver serum and a preparation method thereof. The composition and the weight ratio of the high viscosity solar cell front silver serum are that conductive silver powder accounts for 75-85 percent, glass glue accounts for 2-10 percent, organic carrier accounts for 5.5-20 percent, the particle size of the conductive silver powder is 0.2-2mum; the composition and the weight ratio of the glass glue are that Bi2O3 accounts for 65-85 percent, SiO2 accounts for 5-20 percent, PbO accounts for 1-15 percent and Al2O3 accounts for 1-5 percent. After such processes are carried out by the serum as screen printing, low temperature drying and high temperature sintering, the aspect ratio of a conducting electrode formed on the surface of solar cell is high, the solar cell produced by using the method has small front shading area and high photoelectric conversion efficiency.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Method for preparing N-type crystalline silicon solar cell with aluminum-based local emitters on back side

InactiveCN101853897AAvoid damageAvoid Edge Leakage SituationsFinal product manufactureSemiconductor devicesP–n junctionMaterials science

The invention provides a method for preparing an N-type crystalline silicon solar cell with aluminum-based local emitters on the back side. The method comprises the following steps: firstly, selecting N-type silicon wafers to carry out the surface-textured etching process; further forming a front surface field through phosphorous diffusion; depositing a passivating film on the front surface after the phosphorosilicate glass is formed during the removal of diffused phosphorous; carrying out the back-side chemical polishing process on the silicon wafers to remove the N+ layer formed on the back side during the phosphorous diffusion; then, sequentially printing an aluminum layer or a silver-aluminum layer through the passivating film deposited on the back side, local holes or grooves on the back side and screens on the back side; then, printing silver paste on the front surface; and finally, carrying out the one-step sintering process to form a local P+ layer on the back side and allowing the P+ layer to coming into ohmic contact with the electrodes on the front and back surfaces. By using the N-type substrate, forming local aluminum-based P-N junctions on the back side and further using the back-side chemical polishing process to remove the edge junctions, the invention can substitute for the conventional stacking-type plasma etching process, simplify the technological procedures and further bring a series of performance improvement to cells.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

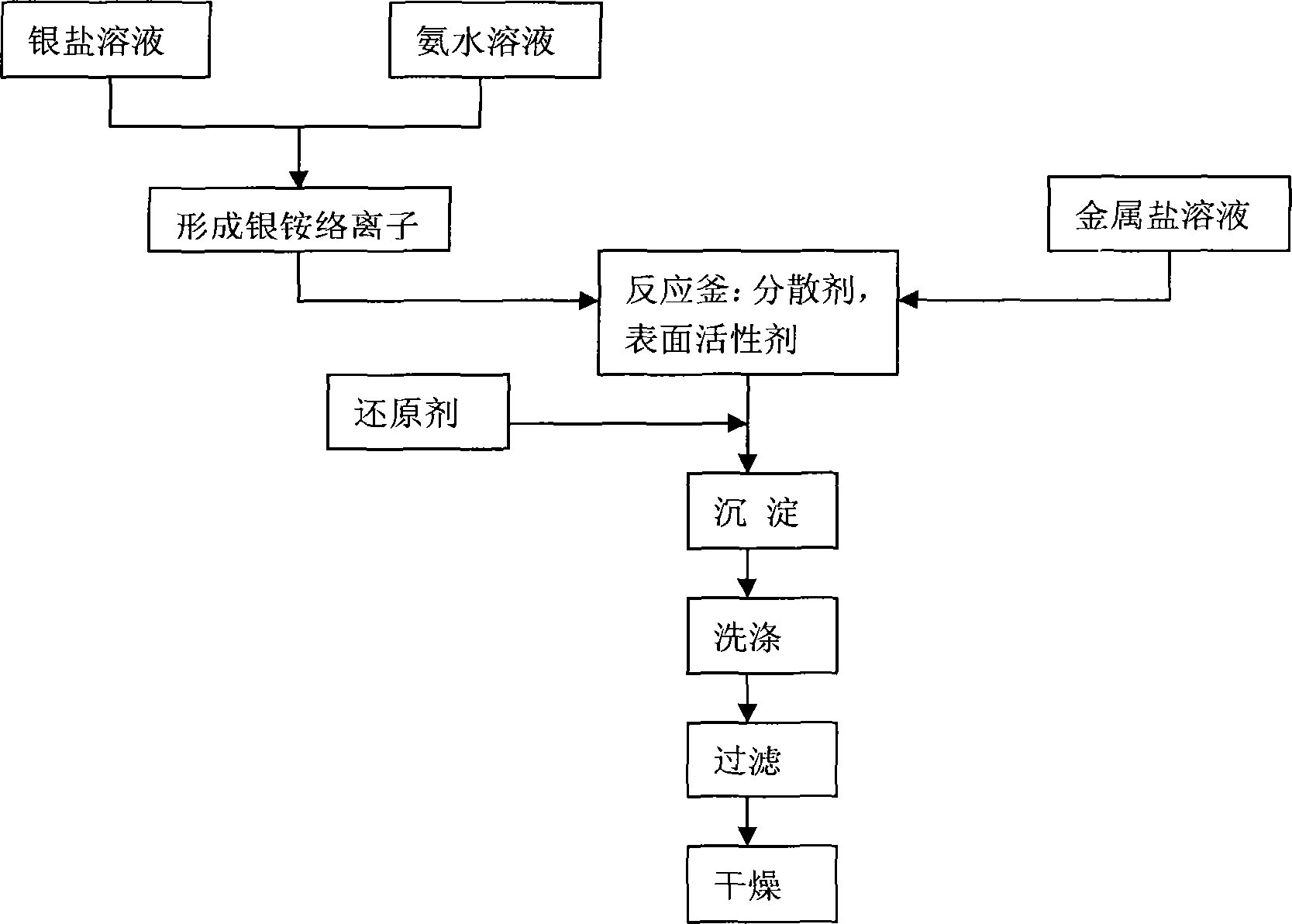

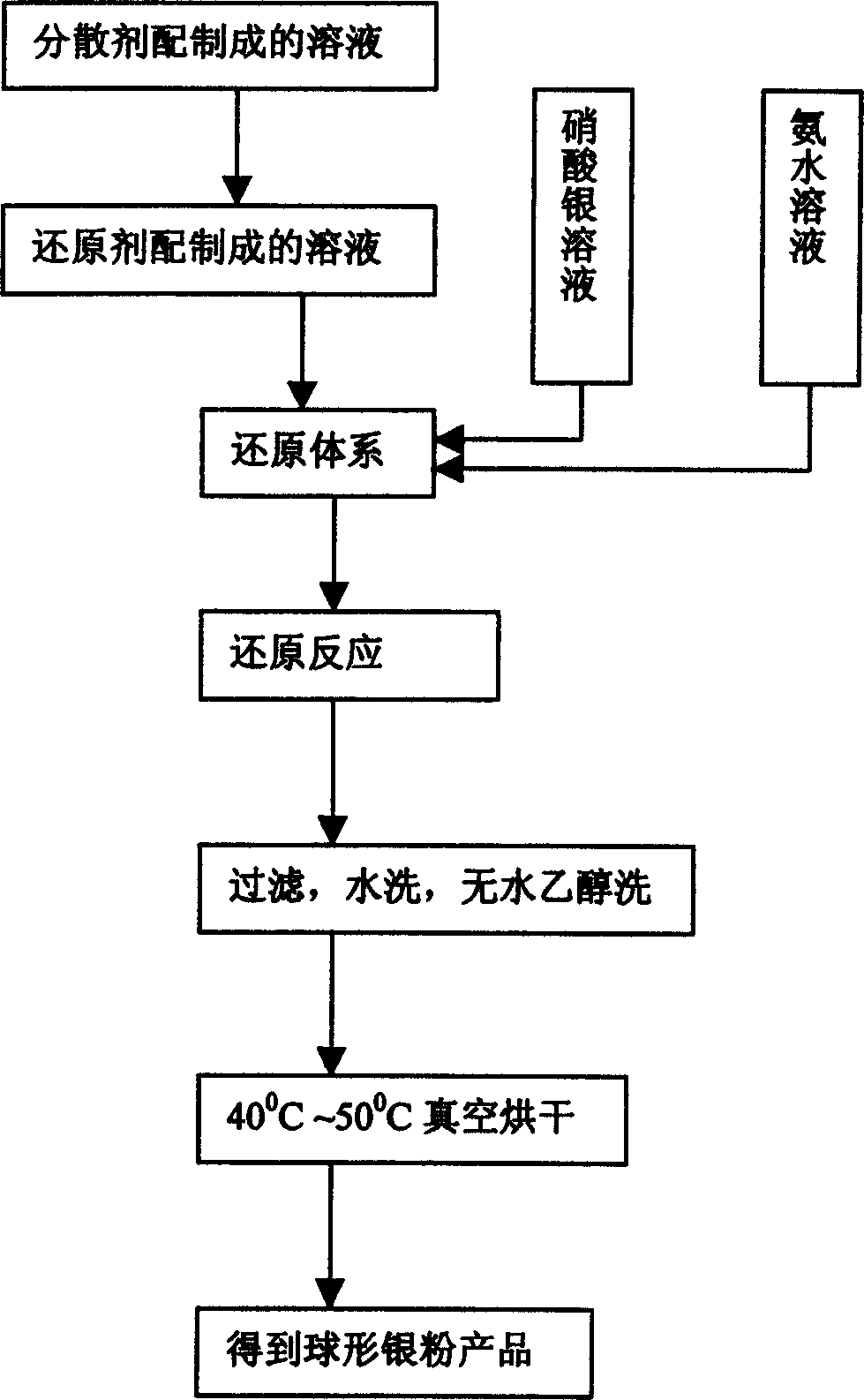

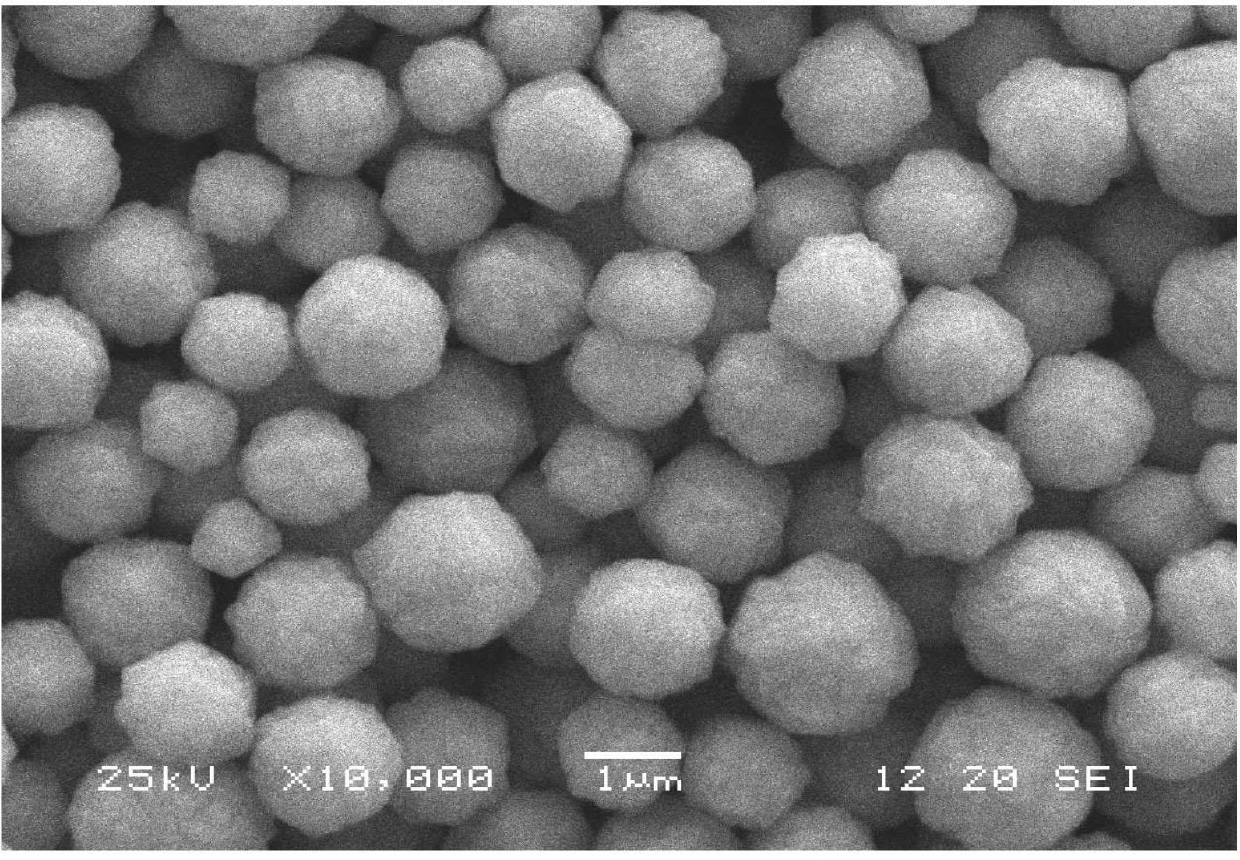

Preparation method of micron grade ball shape silver powder for conductive silver paste

A process for preparing the micron-class spherical silver powder used for electrically conductive Ag slurry features that in the redox procedure, the silver nitrate solution is dripped into reducer and disperser while the ammonia water is used to regulate the pH value of solution, and the kind of disperser, stirring speed, and reaction temp and time are regulated.

Owner:SOUTHEAST UNIV

PTC graphene heating printing ink, preparation method thereof and heating film prepared from PTC graphene heating printing ink

InactiveCN107446408AImprove securityAchieving self-limiting temperature characteristicsInksHeating element materialsSilver pasteAdhesive

The invention discloses PTC graphene heating printing ink and a preparation method thereof. The PTC graphene heating printing ink is prepared from the following components in percentages by mass: 50% to 70% of a binder, 9% to 21% of a solvent, 1% to 3% of an additive, 10% to 20% of a conductive filler and 5% to 20% of a PTC functional material. The preparation method comprises the following steps: (1) firstly stirring and dispersing the binder, the solvent and the additive for 20 to 30 min, then adding the PTC functional material into stirring equipment for stirring for 8 to 12 min, and finally adding the conductive filler for uniform stirring to obtain a coarse paste; and (2) carrying out four to six times of three-roller grinding on the coarse paste so as to obtain the PTC graphene heating printing ink. The invention also discloses a heating film. The heating film comprises an organic polymer base material film, the PTC graphene heating printing ink, a conductive silver paste, conductive copper foil and an organic polymer adhesive film. The PTC function of the graphene heating film is increased, the potential safety hazard problem of an existing graphene heating film is eliminated, and the practicability is improved.

Owner:DEYANG CARBONENE TECH

Silver paste for positive electrode of crystalline silicon solar cell and preparation method thereof

InactiveCN102157219AReduce contact resistanceImprove rheologyNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetallurgy

The invention discloses high-conductivity silver paste for a positive electrode of a crystalline silicon solar cell. The silver paste comprises the following components in percentage by weight: 75-90% of Ag powder, 2-10% of glass powder and 5-20% of organic carrier, wherein the glass powder comprises the following components in percentage by weight: 30-75% of PbO, 7-30% of SiO2, 2-30% of Bi2O3, 1-5% of Al2O3, 1-5% of V2O5, 1-10% of ZnO, 1-5% of Ag2O and 1-8% of MgO. The silver paste has the following beneficial effects: the micron-sized silver powder is adopted to prepare the silver paste, the prepared silver paste has good rheological behavior and thixotropy, a single wafer consumes less silver paste, and the compactness of the positive grid line is improved, thus improving the conductivity; and the glass powder with low-melting erosion property is adopted and can effectively and moderately erode the antireflective film, thus reducing the contact resistance of the crystalline silicon solar cell and improving the conversion efficiency.

Owner:XIAN INTAIN NEW ENERGY MATERIALS SCI & TECH +1

Glass fixture-joined glass article and joint structure using this

ActiveUS20050112291A1Reduced strengthReduce crackingLiquid surface applicatorsAntenna connectorsSilver pasteFrit

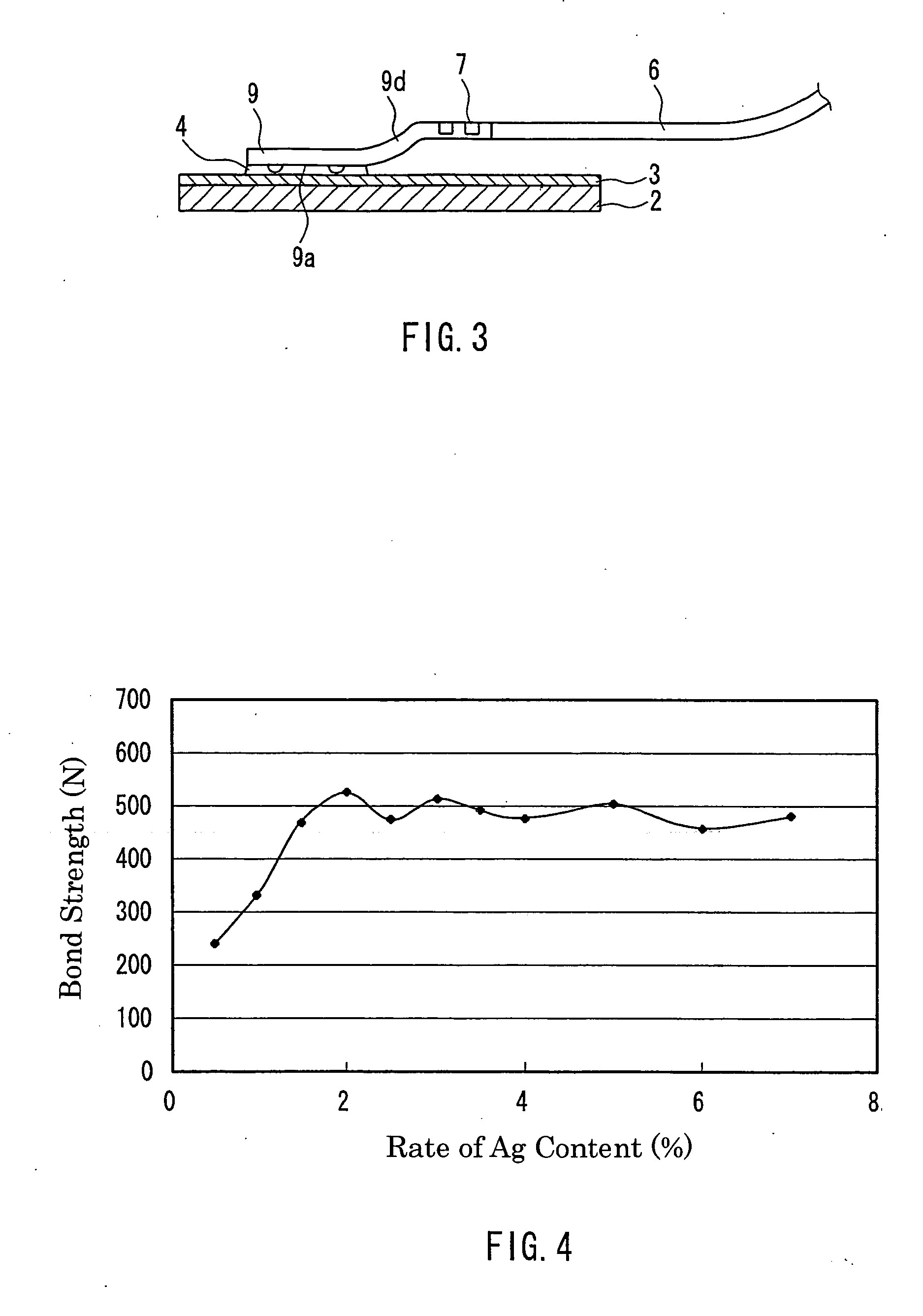

The present invention is intended to provide a glass article with a metal member joined thereto in which an electroconductive coating film is formed on at least a part of the surface of the glass article by baking a silver paste that includes Ag particles and a glass frit, a joining plane of the metal member is fixed onto the electroconductive coating film with a lead-free solder alloy containing Sn as a main component, and the lead-free solder alloy contains at least 1.5 mass % of Ag, which prevents the appearance of the electroconductive coating film and the bonding strength from degrading. Furthermore, in the present invention, when using a metal member having at least two joining planes, the total area of the joining planes is set within a range of 37 mm2 to 50 mm2, which allows high bonding strength between the glass article and metal member to be maintained while using the lead-free solder alloy. Moreover, in the present invention, the volume of the lead-free solder alloy to be provided on each joining plane is set to be 1.0 to 2.0 times the product of the area of the joining plane concerned and the thickness of the lead-free solder alloy, which prevents cracks from occurring in the glass article.

Owner:NIPPON SHEET GLASS CO LTD

Conductive silver paste and conductive film formed using the same

ActiveUS20050194577A1Good reproducibilityImprove conductivityConductive materialNon-conductive material with dispersed conductive materialEpoxySilver paste

A conductive silver paste according to the present invention comprises epoxy resin, flake-shaped silver powders having an average particle diameter of 0.5 to 50 μm, and spherical silver powders, each having its surface coated with organic matter, having an average particle diameter of not more than 1 μm, and a conductive film according to the present invention is formed by printing or applying the conductive silver paste on a surface of a base material, followed by drying, and then thermosetting the epoxy resin.

Owner:SUMITOMO ELECTRIC IND LTD

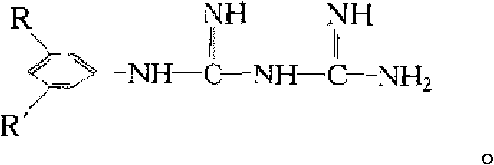

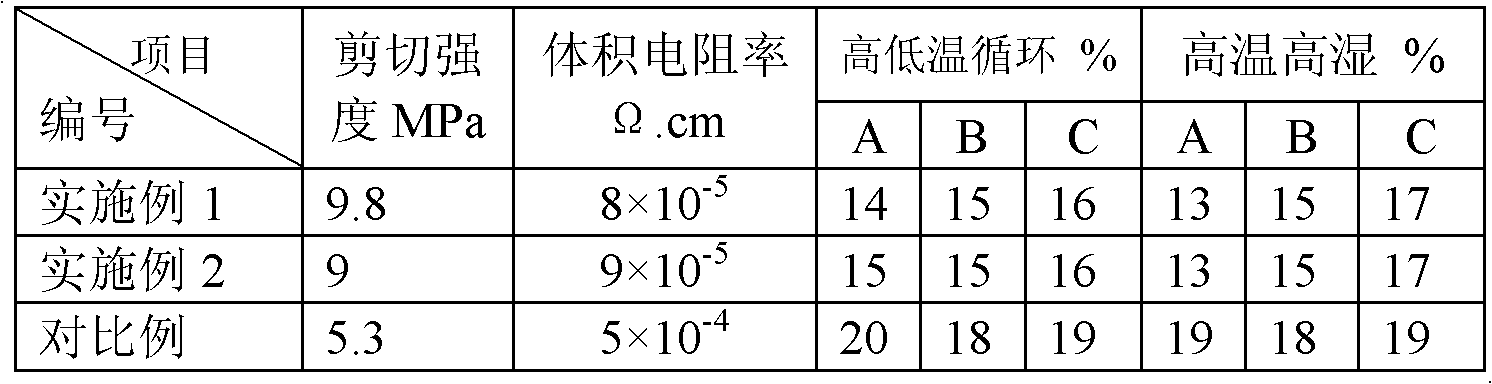

Conductive silver paste for microelectronic packaging and preparation method thereof

InactiveCN102086364AIncrease contactReduce bulk resistivityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxySilver paste

The invention discloses a conductive silver paste for microelectronic packaging, which contains the following components in parts by mass: 10-12 parts of liquid epoxy resins, 9-10 parts of diluents, 10-13 parts of spherical silver powder, 50-57 parts of platy silver powder, 0.5-1.5 parts of latent curing agents, 0.2-0.8 part of curing promoter, 1-2 parts of coupling agents, 0.5-1 part of conductive promoters, 0.5-1 part of aging resister and 1.5-2.3 parts of toughening agents. The body resistivity of the conductive silver paste prepared by the invention reaches 10-5 omega.cm, the shear strength is greater than 9MPa, and the conductive silver paste has stable contact resistance; and after low-temperature circulation, high-temperature humidity aging tests and other aging tests, the shear strength, the impact-resistant toughness and the contact resistance change are all less than 18%. The prepared conductive silver paste is suitable for microelectronic packaging and has the advantages of stable contact resistance and strong impact resistance.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

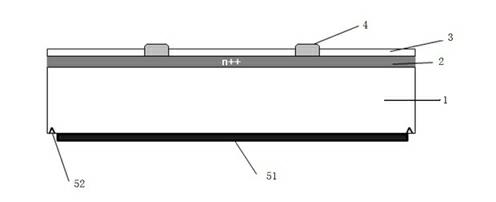

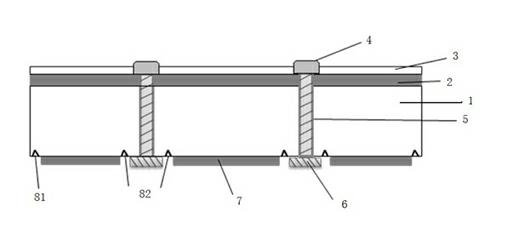

Preparation method of MWT (Metal Wrap Through) solar cell

ActiveCN102208486AImprove efficiencyBusbarPhotovoltaic energy generationSemiconductor devicesPhotovoltaic industryChemical solution

The invention discloses a preparation method of an MWT (Metal Wrap Through) solar cell, comprising the following steps of: (1) carrying out phosphorous diffusion by using a p-type crystal silicon substrate; (2) etching one surface of the crystal silicon substrate by using a chemical solution to remove a phosphorous diffused layer so as to form a polished surface; (3) depositing a passivated antireflective film on the other surface of the crystal silicon substrate to form a light receiving surface; (4) forming a conductive through hole on the crystal silicon substrate by using laser lights; (5) filling a conductive silver paste into the conductive through hole by using a wire mesh on the polished surface so as to form an emitter contact electrode; (6) printing an aluminum paste on the polished surface by using a wire mesh so as to form a base contact electrode; (7) printing a silver contact grid line on the light receiving surface and connecting the silver contact grid line with the conductive through hole; and (8) forming the ohmic contact between a metal and the silicon substrate through sintering so as to finish the solar cell making process. The preparation method of the MWT (Metal Wrap Through) solar cell, disclosed by the invention, has the advantages of simple process flow and easiness in operation, is completely compatible with a solar cell production line widely applied in the current photovoltaic industry and is suitable for mass production.

Owner:JA SOLAR TECH YANGZHOU

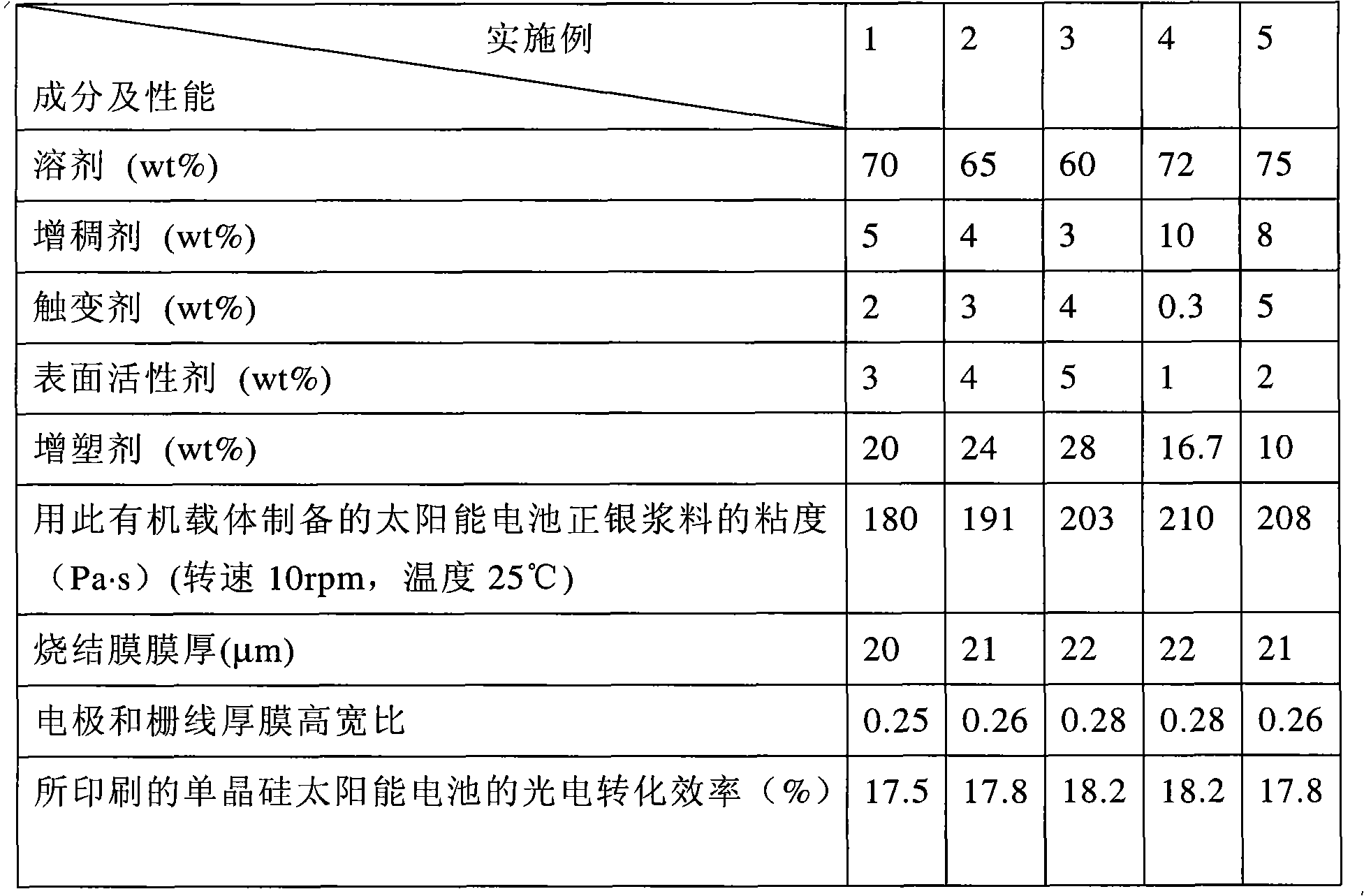

Organic carrier for silver paste and preparation method thereof as well as silver paste containing organic carrier and solar cell manufactured from silver paste

InactiveCN102136308AModerate viscositySuitable ThixotropyNon-conductive material with dispersed conductive materialSemiconductor devicesSolventChemical stability

The invention discloses an organic carrier for conductive silver paste applied to a front face electrode and a grid line of a solar cell, a preparation method of the organic carrier, silver paste containing the organic carrier and a solar cell manufactured from the silver paste. The organic carrier comprises the following components in percentage by weight: 60-75 percent of solvent, 1-10 percent of thickener, 0.3-5 percent of thixotropic agent, 1-5 percent of surfactant and 10-30 percent of plasticizer. The preparation method of the organic carrier comprises the following steps of: weighing various raw materials; adding various aids into a solvent respectively; and heating and stirring until the aids are dissolved completely. The organic carrier has proper viscosity and a simple preparation process. Paste prepared from the organic carrier has proper viscosity, fineness, leveling property, thixotropy and chemical stability. After the paste is subjected to screen printing and sintering on a cell substrate, the thicknesses of a front face electrode and a grid line thick film of a cell panel can be over 20 micros, and the prepared electrode and the grid line thick film can obtain a higher height-width ratio.

Owner:湖南威能新材料科技有限公司

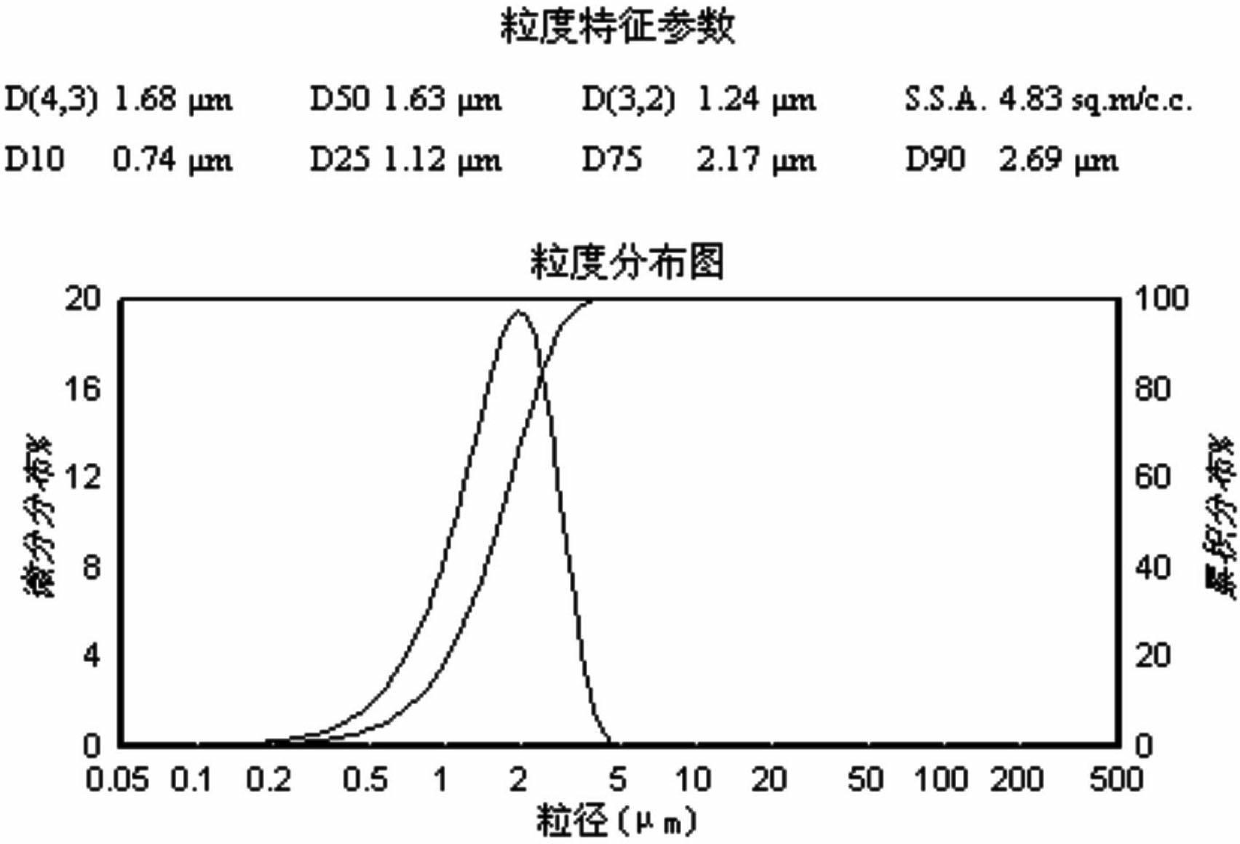

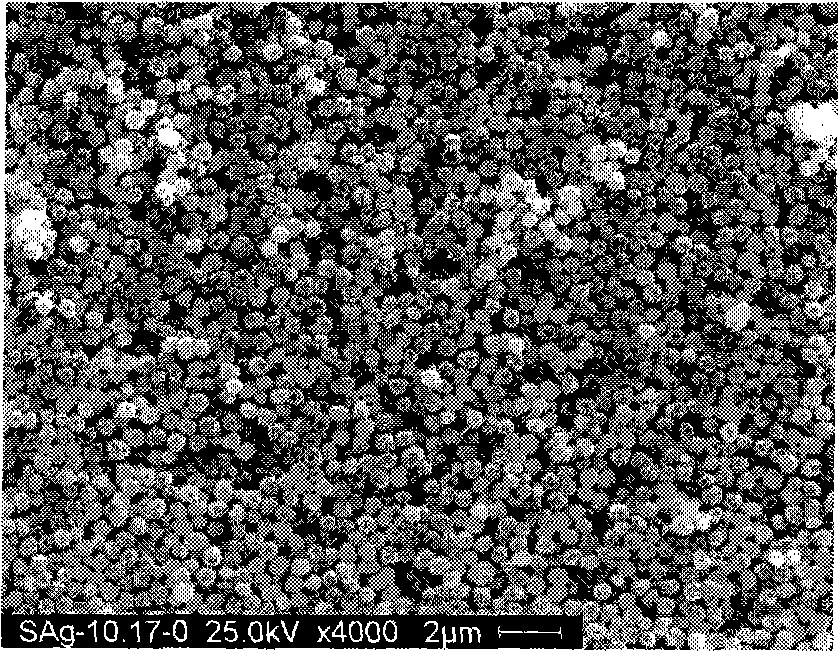

Spherical silver powder and preparation method thereof

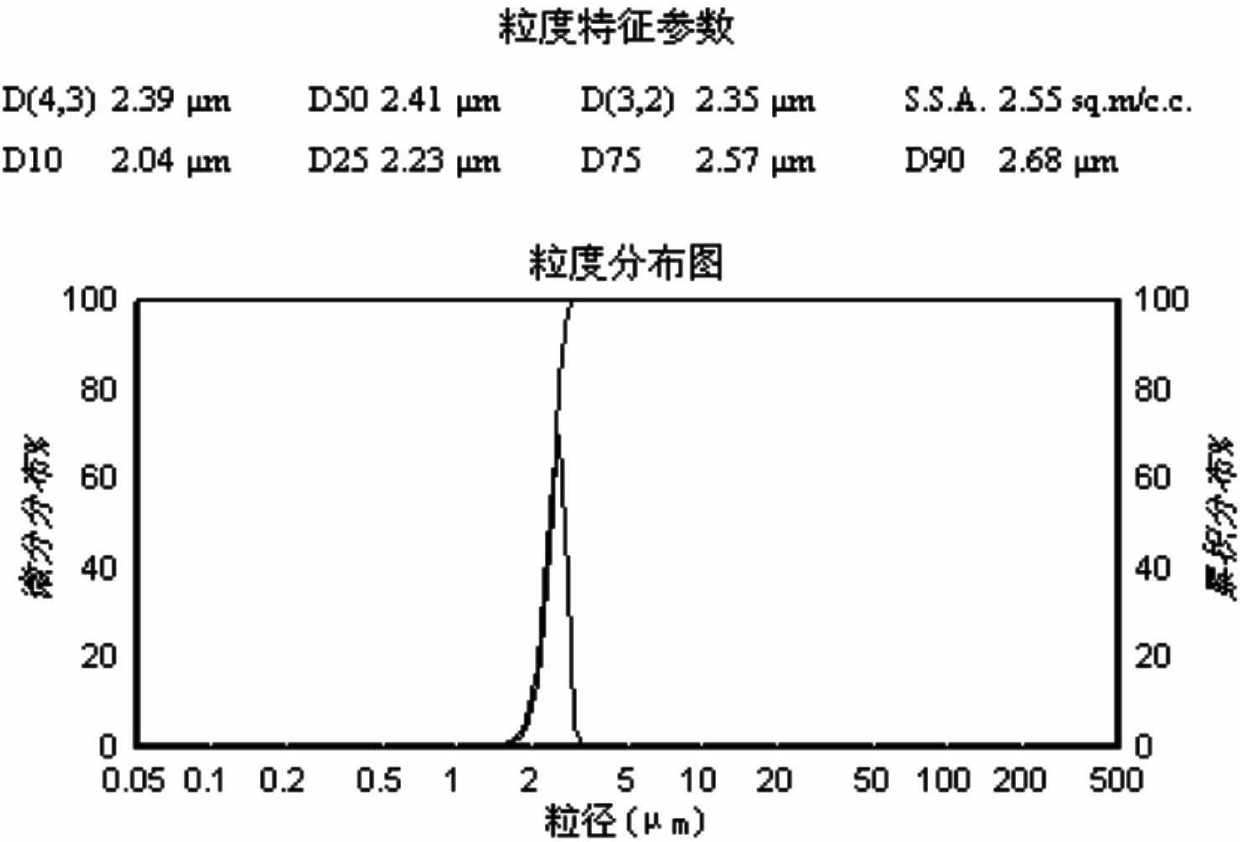

ActiveCN102632248ANarrow particle size distributionSimple preparation processPyrrolidinonesDisplay device

The invention discloses a spherical silver powder, wherein the particle size distribution range of the spherical silver powder is 0.1-5 mum, and the D50 particle size is 1.0-3.5 mum; the tap density of the spherical silver powder is greater than 3.6 g / cm<3>; and the specific surface area of the spherical silver powder is less than 1.0 m<2> / g. The preparation method for the spherical silver powder comprises the following step of: with L-ascorbic acid as a reductive agent and polyvinylpyrrolidone as a protective agent, reducing silver out of a reaction material, namely silver nitrate solution, by a chemical reduction method, wherein the pH value of the reaction system is controlled to be constant between 3 to 6 during the whole reaction process of the chemical reduction method, so as to keep the speed of the reduction reaction for silver nitrate stable. The spherical silver powder disclosed by the invention is narrow in particle size distribution range, excellent in dispersity, high in tap density, small in specific surface area, and especially suitable for preparing a silver paste for the electrode of a solar cell and the electrode of a plasma displayer.

Owner:NAT UNIV OF DEFENSE TECH +1

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

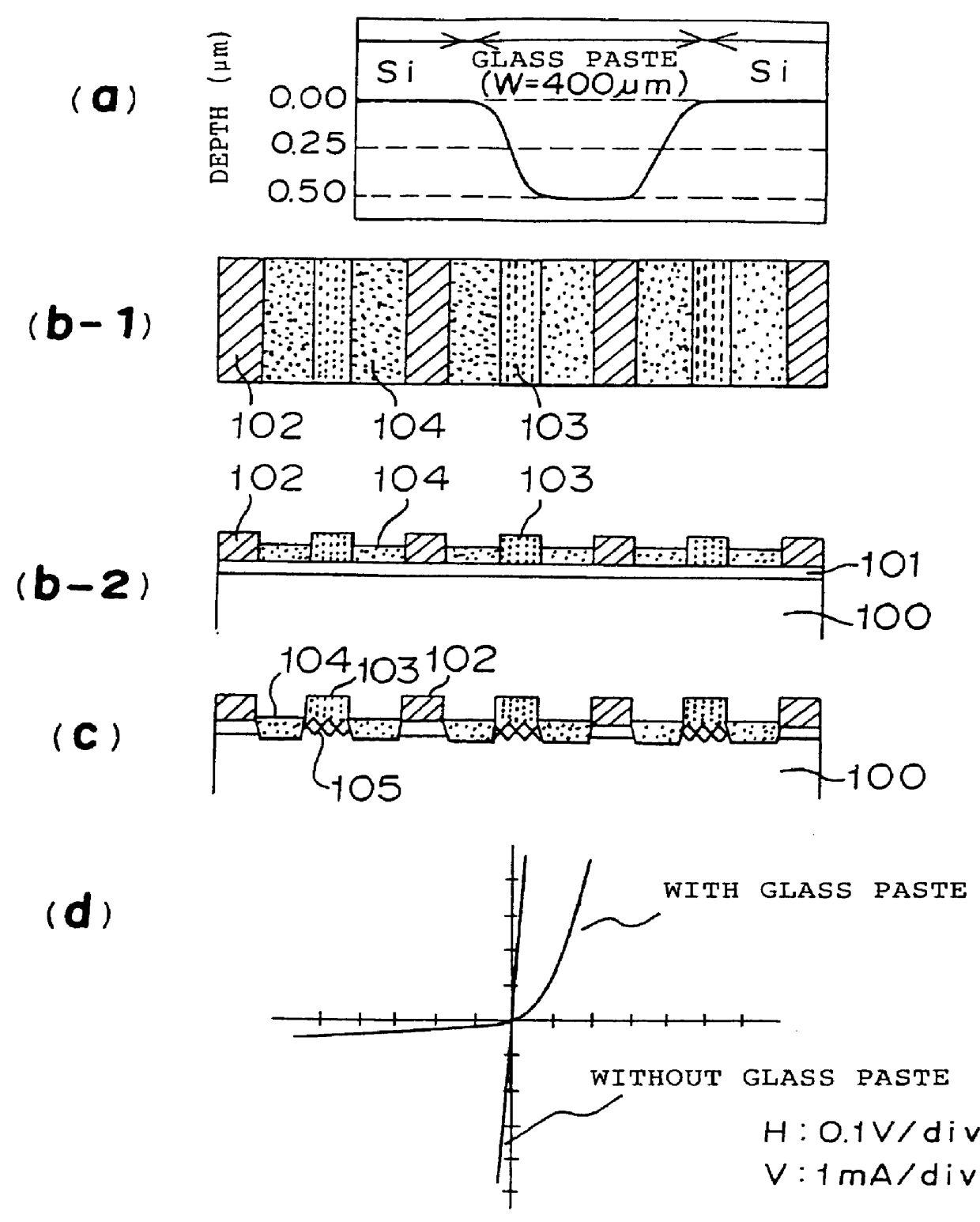

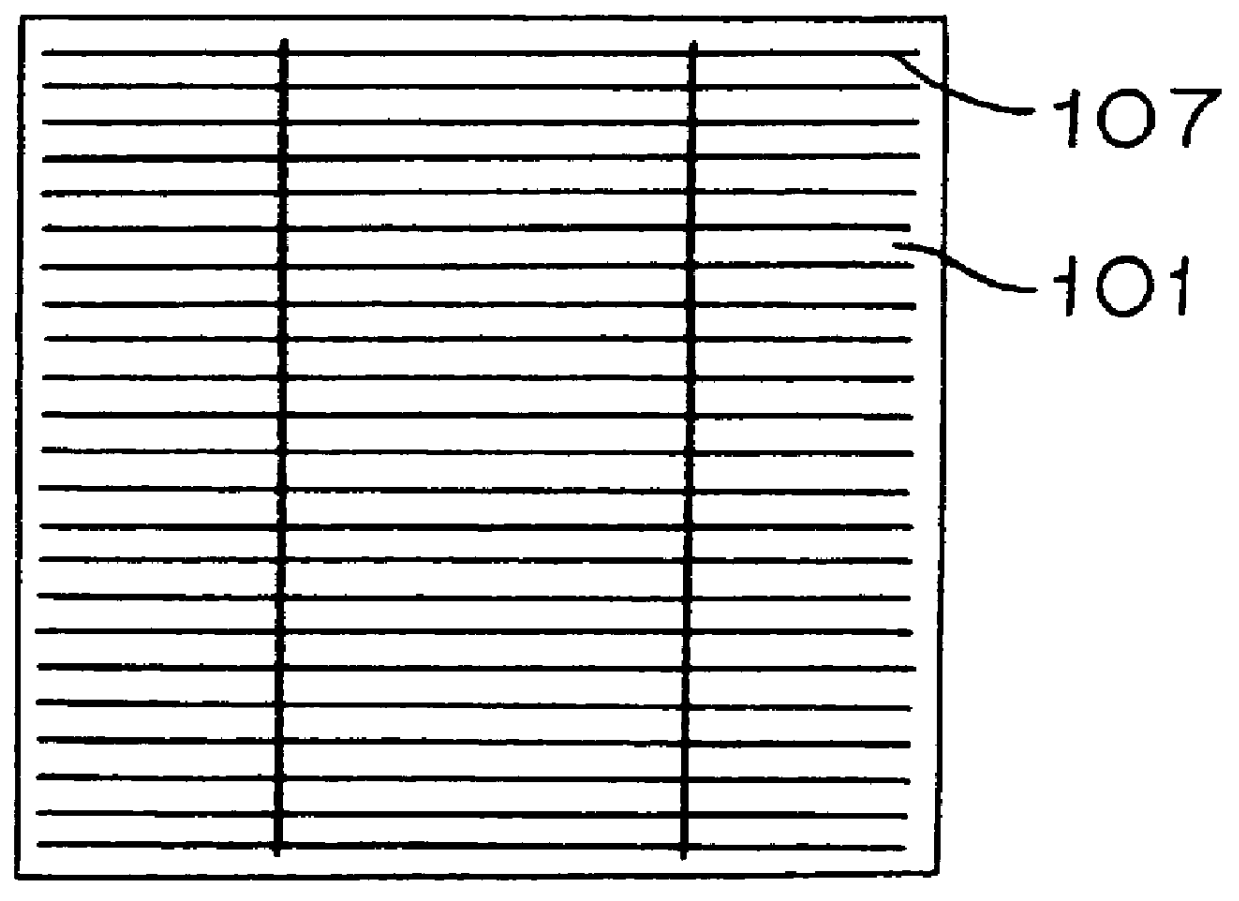

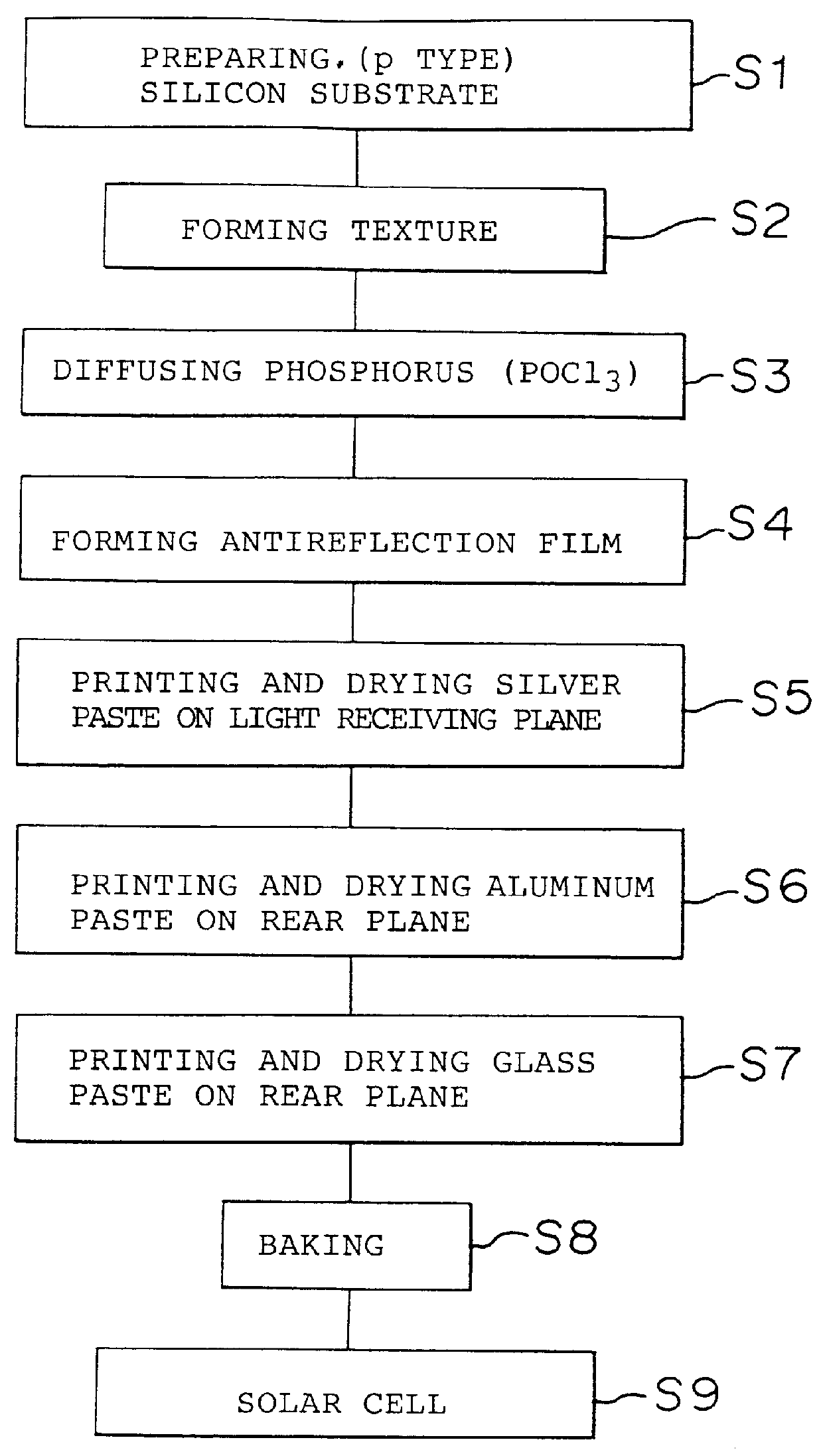

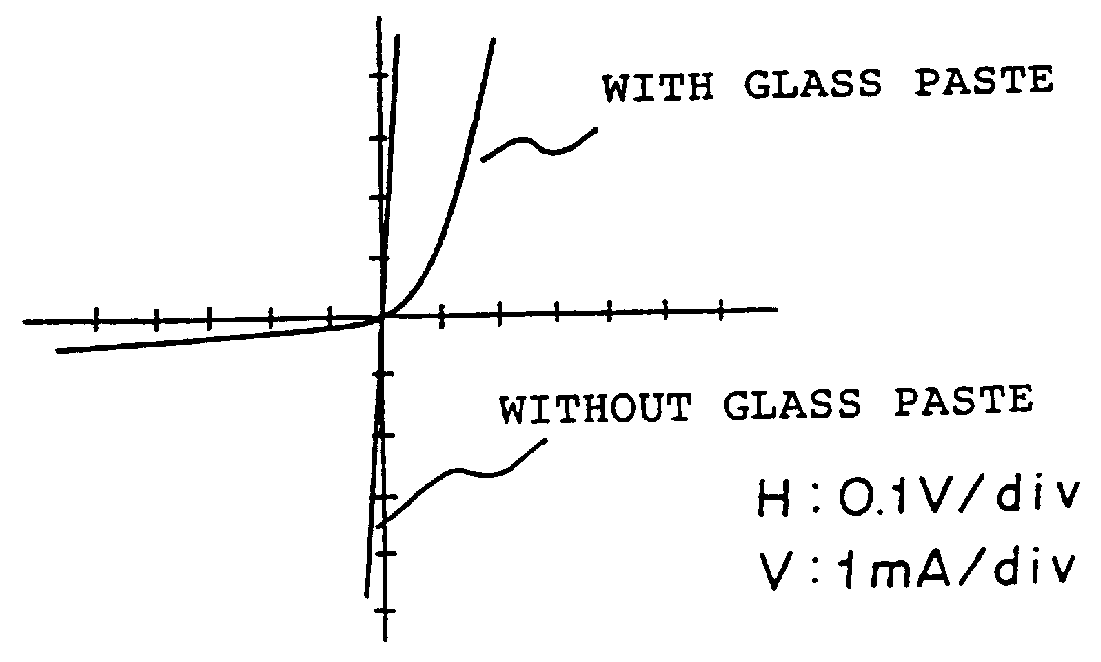

Method of producing a solar cell

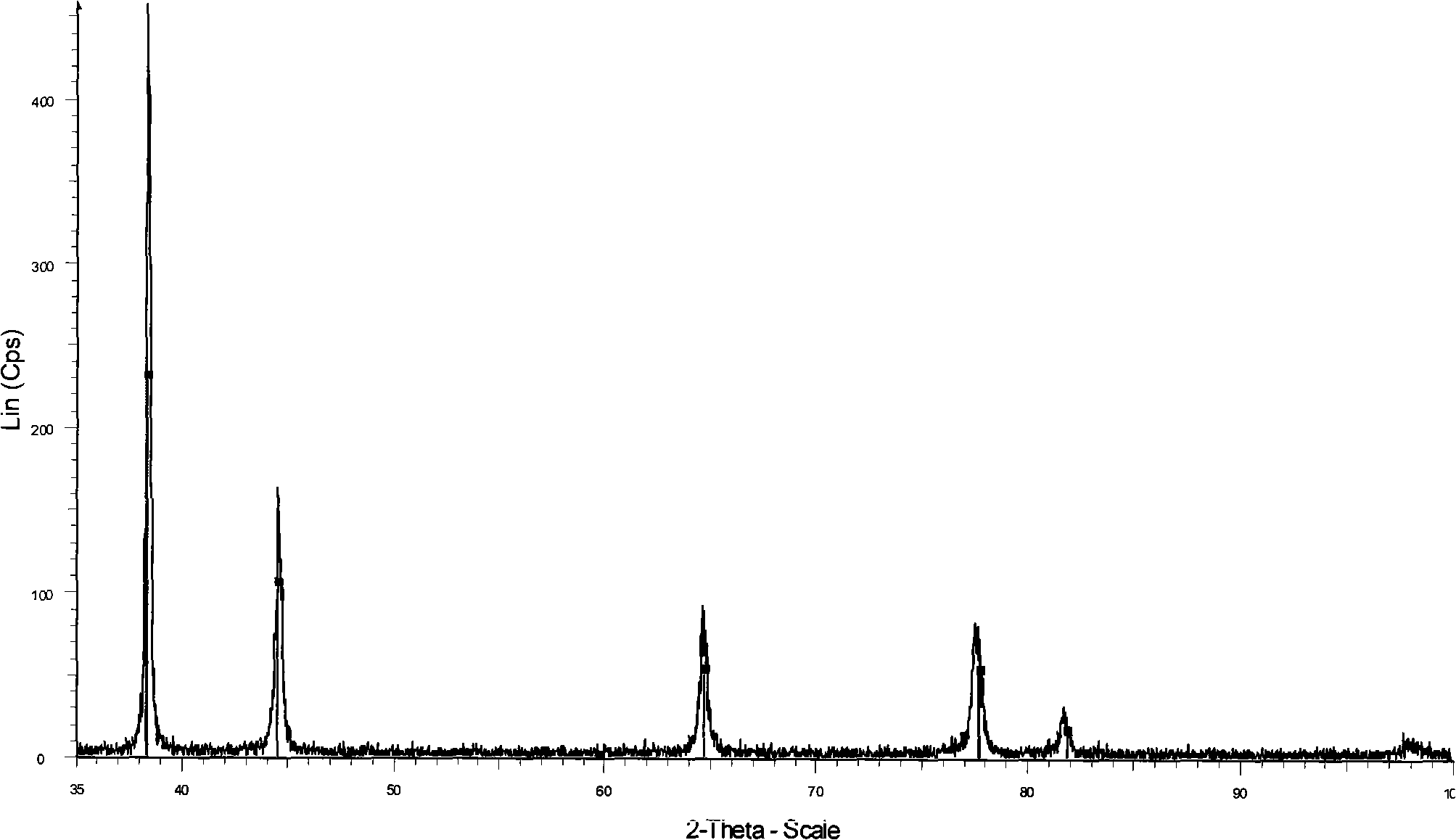

InactiveUS6071753ASemiconductor/solid-state device manufacturingPhotovoltaic energy generationSilver pasteP–n junction

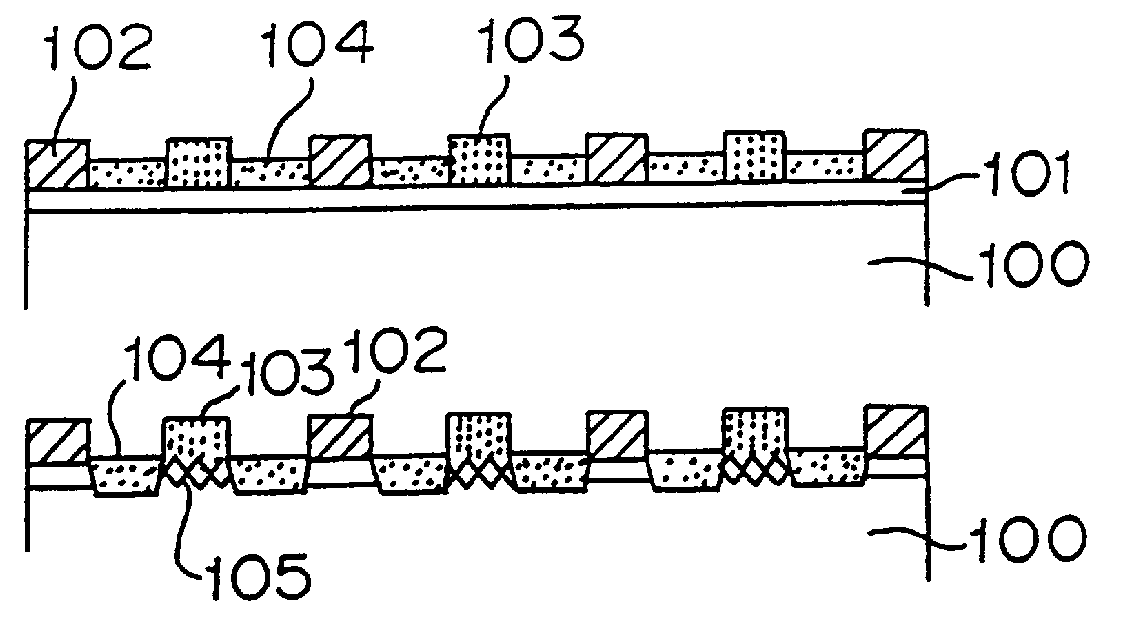

A solar cell and a method of producing the same which realizes electrical separation of the p n junction in a simple manner, and a method of producing a semiconductor device a method of producing a semiconductor device in which an electrode is formed by using a metallic paste material on a substrate covered with a silicon nitride film or a titanium oxide film, wherein a glass paste 104 composed mainly of glass which has a property of melting silicon is provided on an n type diffusion layer 101 in the p n junction; the substrate is baked so that penetration of the n type diffusion layer 101 is effected by the glass paste; aluminum is diffused in the n type diffusion layer 101 below a p electrode 103 formed of an aluminum silver paste to thereby form a p type inversion layer 105 inverted to a p type, whereby the electrical separation of the p n junction can be realized. Further, when a metallic paste material is provided on an insulating film and the metallic paste material is baked, the material penetrates the insulating film to electrically contact with the semiconductor substrate.

Owner:MITSUBISHI ELECTRIC CORP

Preparation method for high-dispersing silver powder used for conductive silver paste

Owner:CHINA LUCKY FILM CORP +1

Nanometer conductive silver paste and preparing method thereof

InactiveCN104240793AGood silver powder solubilityModerate boiling pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePlasticizer

The invention relates to a nanometer conductive silver paste and a preparing method thereof. The nanometer conductive silver paste is characterized in that mass percentage content of the components are as follows: 20-90% of a silver powder, 0.01-5% of a high-molecular resin, 0.01-5% of an organic silicone oil, 0.01-10% of a thickening agent 1, 0.01-5% of a thickening agent 2, 0.01-5% of a plasticizer, 0.5-1% of a dispersant, 0.5-1% of a leveling agent, 5-20% of a solvent 1, and 5-20% of a solvent 2. The nanometer conductive silver paste of the invention has a remarkable low-temperature sintering property and saves energy. A formed circuit has advantages of high conductivity, high adhesiveness and high hardness. A selected Teslin substrate is degradable and environment-friendly. The nanometer conductive silver paste has wide application prospect in paste application fields of RFID electronic label, LED circuit board, touch screen circuit, etc.

Owner:NANO TOP ELECTRONICS TECH

Lead-free glass powder, preparation method thereof, silver paste containing glass powder and crystal silicon solar cell manufactured by using silver paste

InactiveCN102126829AImprove adhesionStrong adhesionNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteScreen printing

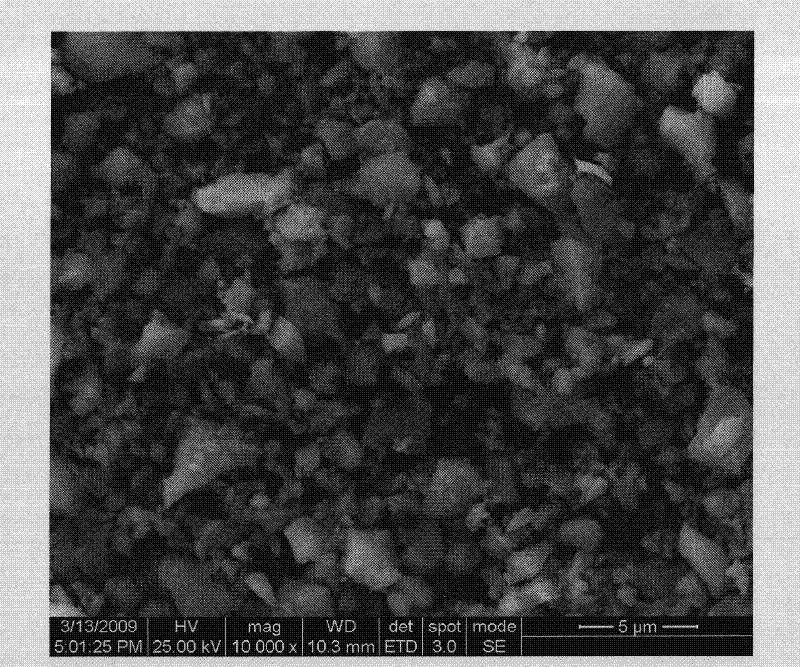

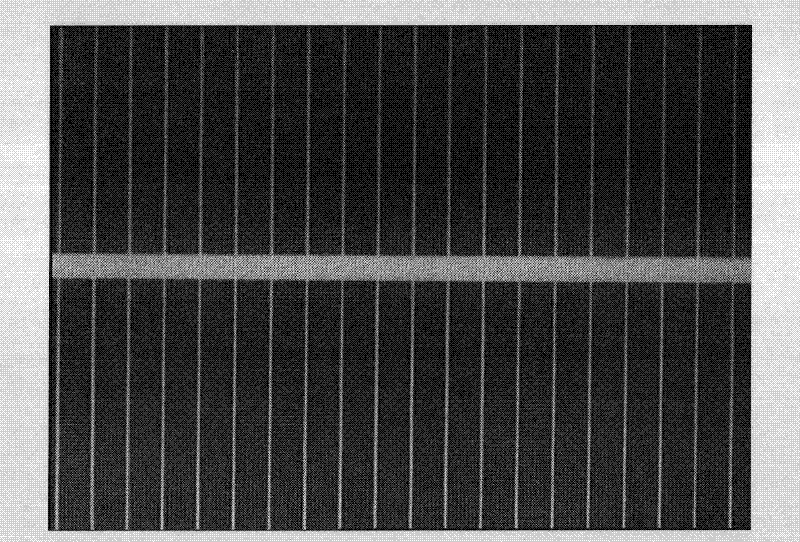

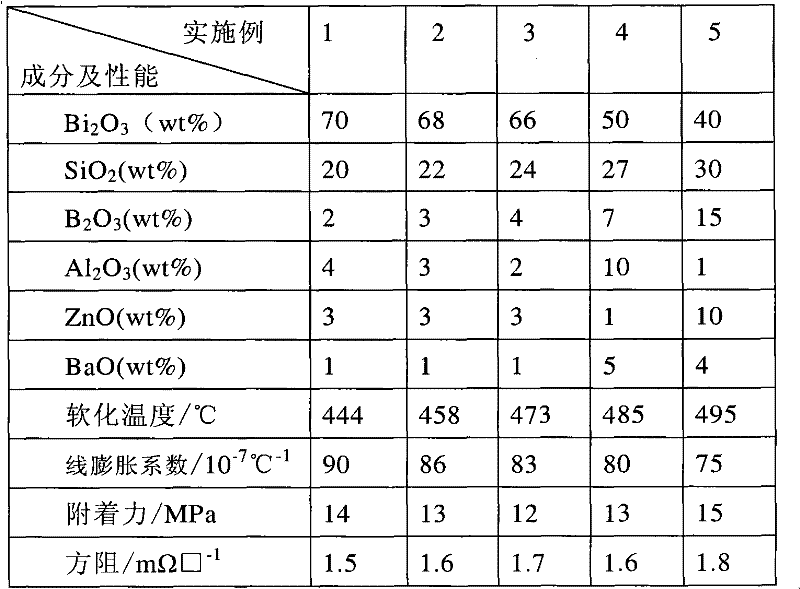

The invention discloses lead-free glass powder, a preparation method thereof, silver paste containing the glass powder and a crystal silicon solar cell manufactured by using the silver paste. The lead-free glass powder comprises the following components in percentage by weight: 20-30 percent of SiO2, 2-15 percent of B2O3, 40-70 percent of Bi2O3, 1-10 percent of ZnO, 1-10 percent of Al2O3 and 1-5 percent of BaO. The preparation method comprises the following steps of: (1) weighing the components for preparing a mixture; (2) putting the mixture into a crucible for melting; (3) performing water quenching on molten glass; (4) drying; (5) smashing the mixture into powder by planetary ball milling; and (6) screening. The needed silver paste is prepared from the lead-free glass powder, silver powder, an additive and an organic carrier. A solar panel front face electrode and a grid line are manufactured by performing screen printing and sintering on conductive silver paste on a cell substrate, so that the needed solar cell is obtained. The lead-free glass powder has low melting temperature, low softening temperature and low linear expansion factor.

Owner:湖南威能新材料科技有限公司

High-conductivity silver paste and preparation method thereof

ActiveCN105632588AImprove conductivityGood stacking densityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteLow temperature curing

The invention provides a high-conductivity silver paste and a preparation method thereof. The high-conductivity silver paste comprises metal silver powder, wherein the metal silver powder is a mixture of micro-order sheet-shaped silver powder, submicron-order spherical silver powder and nanometer silver powder. The high-conductivity silver paste has the advantages that silver powders with different grain sizes and morphological structures are fully utilized and mutually matched, so that the silver powder can form a more compact status on the structure, and the low-temperature sintered nanometer silver powder is added to be further connected with the conductive silver powder; after mixing the silver paste with macromolecule resin, a solvent, an additive and an assistant agent, the paste can acquire relatively high conductivity under a condition of low-temperature curing (less than or equal to 150 DEG C); and meanwhile, the paste has favorable printing adaptability and favorable attachment performance, and can be applied to the fields of a printed conductive circuit, a radio frequency identification (RFID) label antenna and the like.

Owner:KUSN HISENSE ELECTRONICS

Method for preparing silicon-based solar front silver paste

InactiveCN101887764AChange printing heightChange conversion efficiencyFinal product manufactureNon-conductive material with dispersed conductive materialSilver pastePlasticizer

The invention discloses a method for preparing silicon-based solar front silver paste. The paste consists of 0.5 to 5 percent of glass powder, 40 to 85 percent of laminar silver powder, 5 to 45 percent of nano silver powder, 5 to 10 percent of organic carrier, 2 to 6 percent of solvent and 0.2 to 2 percent of auxiliary agent. The method mainly comprises the following steps of: (1) preparing the glass powder, (2) preparing the organic carrier, and (3) preparing the paste. According to the main design scheme of the invention, the printing height of a grid line and the conversion efficiency of a contact resistor and a battery can be changed by changing the adding proportion of the glass powder, the laminar silver powder and the nano silver powder; the viscosity and the printability of a product can be adjusted by changing the adding proportion of the organic carrier and the solvent; and the plasticity, leveling property and printability of the product can be adjusted by changing the adding proportion of a plasticizer. The paste of the invention has excellent printability, the sintered paste and a silicon chip form good alloy, a grid line electrode has great height, the series resistance is low, and the battery has high conversion efficiency.

Owner:IRICO

Preparation of high dispersed superfine spherical silver powder for conductive silver slurry

A preparation method of high-dispersion ultra-fine spherical silver powder used for conductive silver paste relates to a preparation method of ultra-fine spherical silver powder, in particular to the preparation method of the high-dispersion ultra-fine spherical silver powder for the conductive silver paste in the electronic industry. The preparation method is characterized in that silver ammonia solution is dropped in a reduction system which consists of a reducing agent of formaldehyde, a dispersant of polyvinyl alcohol PVA and sodium hydroxide solution, thus obtaining high-dispersion ultra-fine silver powder slurry, and the high-dispersion ultra-fine spherical silver powder with the particle size range of 0.3 to 1.0Mum can be obtained by solid-liquid separation and drying. The method of the invention has simple and feasible process flow, low production cost, less equipment investment, stable and reliable process conditions, small particle size of the product silver powder, narrow distribution range, high yield and easy realization of industrial mass production.

Owner:JINCHUAN GROUP LIMITED

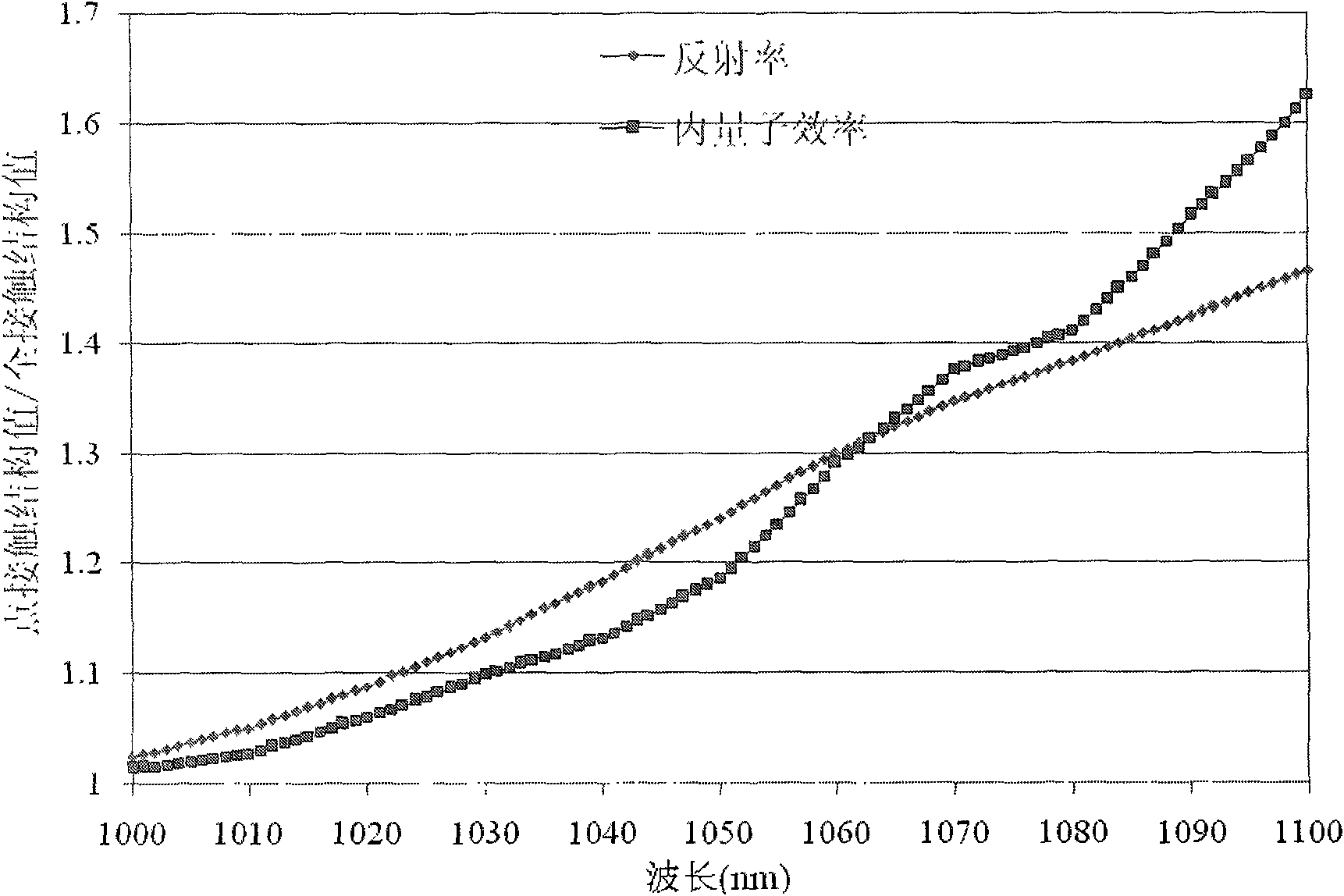

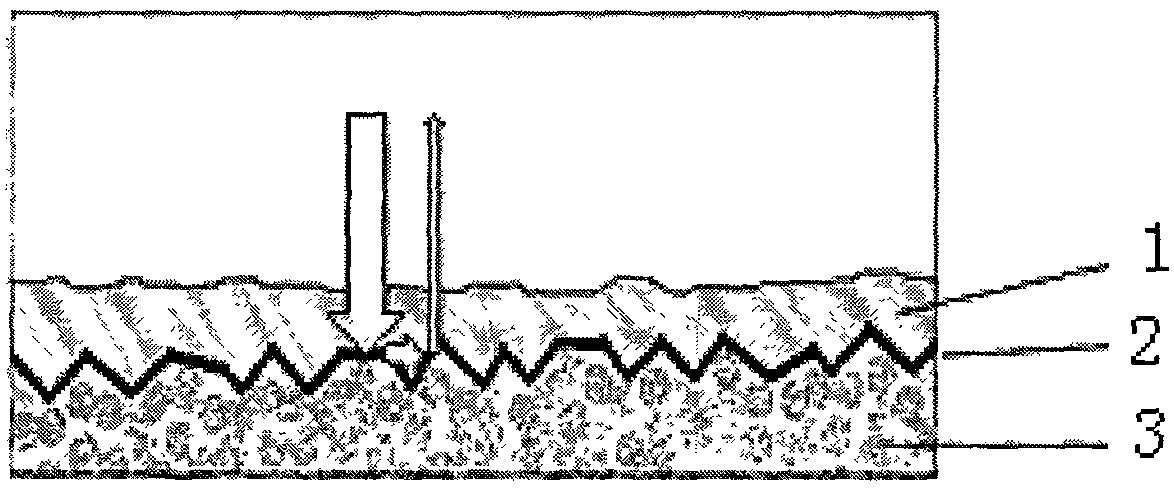

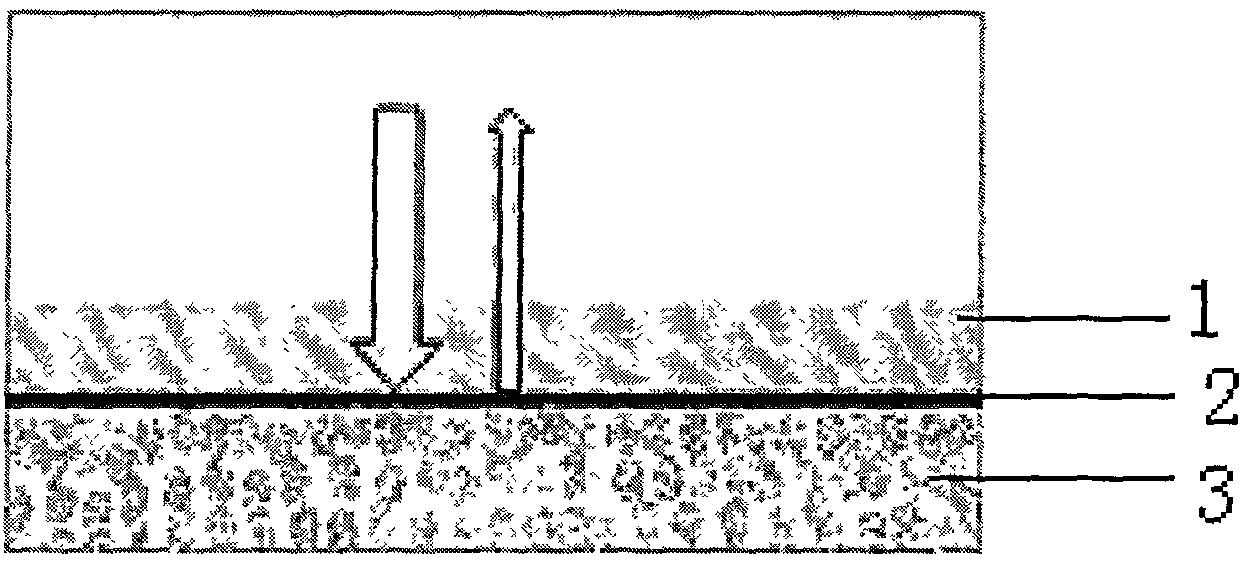

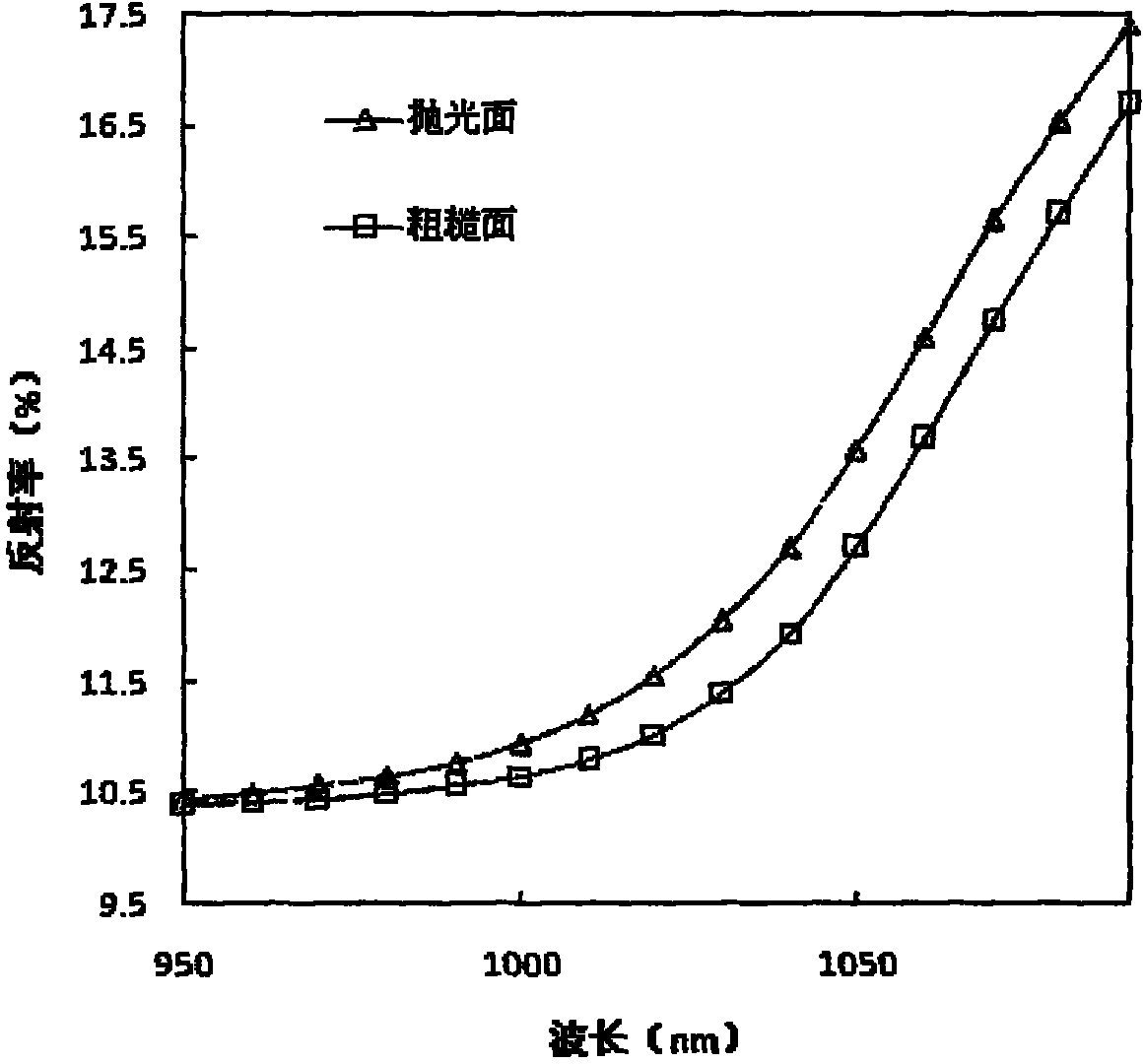

Industrialized production process of crystalline silicon solar battery

ActiveCN101840961AReduce the probability of electric leakageReduce process stepsFinal product manufactureSemiconductor devicesSpectral responseBack surface field

The invention discloses an industrialized production process of a crystalline silicon solar battery, which comprises the following steps of: selecting a silicon chip; performing front surface matte making, phosphorous diffusion, the removal of phosphorosilicate glass formed on the surface during the phosphorous diffusion, and the deposition of silicon nitride on the front surface through PECVD inturn, and then putting an anti-reflecting film protected silicon ship provided with the front surface silicon nitride into heated alkali liquor to perform back polishing so as to remove a diffusion layer on the back surface; and washing and drying the silicon chip, and printing and sintering the silicon chip by adopting a bending-resistant aluminum paste silk screen. The process adopts a chemicalmethod to replace a plasma etching process, realizes non-contact of a matte surface of the silicon chip in the whole production flow, avoids matte surface damages caused by silicon chip friction, so the probability of electric leakage after facade silver paste sintering is reduced; the flat and clean back surface is favorable for the reaction of aluminum and silicon during the sintering to form amore uniform aluminum back surface field; and a polished surface has a stronger reflex action compared with an irregular matte surface, and can increase the absorption of incident light, improve the spectral response of the long-wavelength of a battery chip, and significantly improve a short-circuit current and an open-circuit voltage.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

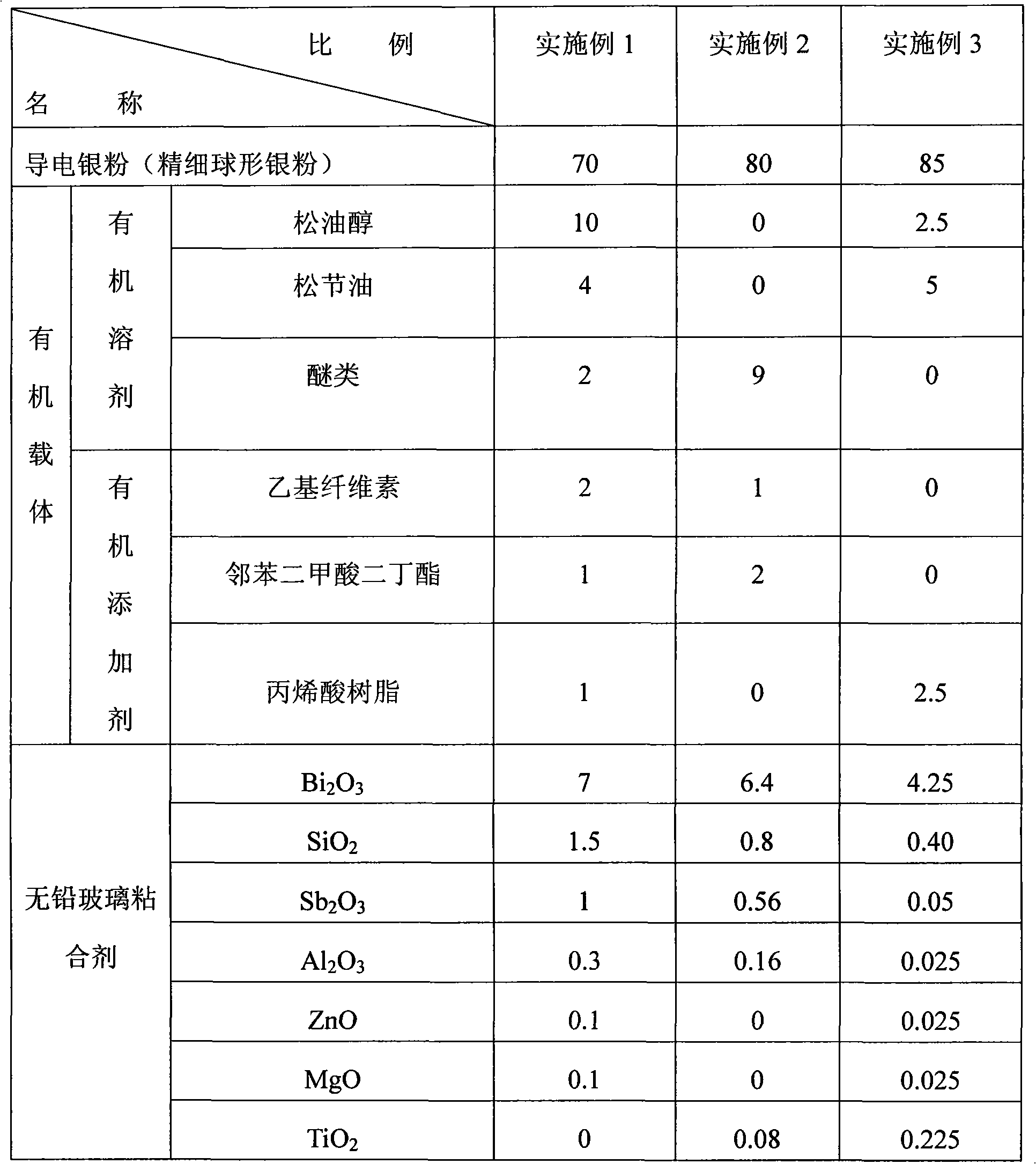

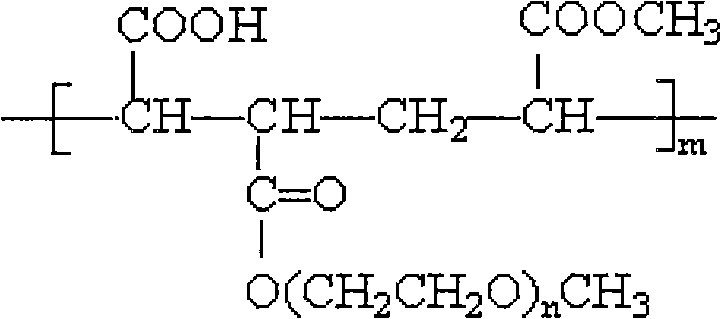

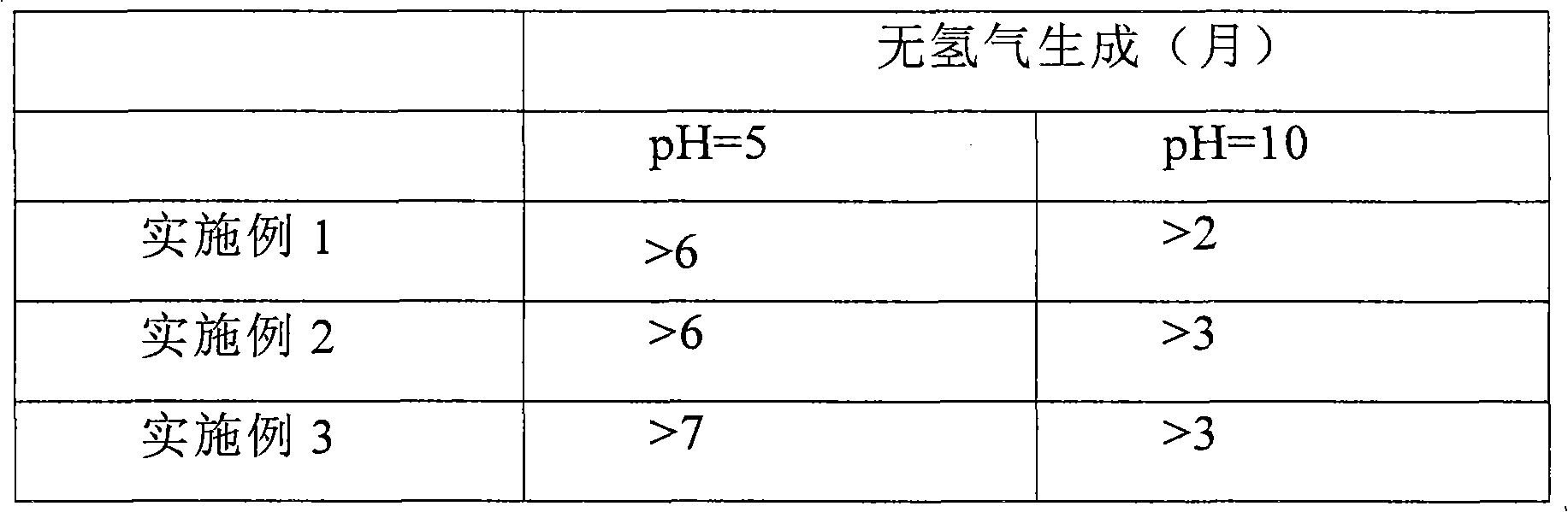

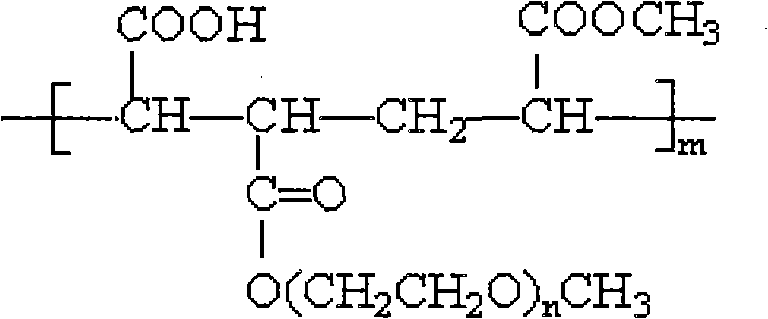

Leadless solar battery silver paste and method for producing the same

InactiveCN101271929AImprove photoelectric conversion efficiencyStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAcrylic resinContact resistance

The invention discloses lead-free solar cell silver serum and a preparation method thereof, which consists of 70-85 percent of conducting silver powder, 5-10 percent of lead-free glass glue and 5.5-25 percent of organic carrier, wherein, the organic carrier consists of organic solvent and organic additive, the organic solvent is any kind of terpineol, terebinth and ethers or their combination; the organic additive is any kind of ethyl cellulose, dibutyl phthalate and acrylic resin or their combination; the particle size of the conducting silver powder is 0.2-2mum; and the lead-free glass glue belongs to bismuth-silicon- antimony glass system. The solar cell silver serum obtained by the method in the invention is lead-free, which complies with requirements of environmental protection, and a conducting electrode with strong adhesive force and low ohm contact resistance can be formed on the surface of the solar cell. The cell has high photoelectric conversion efficiency and is an ideal substituent of the lead silver serum.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Preparation method of aqueous aluminum silver paste

InactiveCN102093761AEasy to useNo sheddingPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsDispersitySolvent

The invention provides a preparation method of aqueous aluminum silver paste. The preparation method comprises the following steps of: 1, adding an aluminum powder pigment and acetone into a vessel, stirring and filtering to obtain washed aluminum powder; 2, adding the washed aluminum powder obtained in the step 1 into an alcohol solvent, ultrasonically dispersing, adding into a reaction vessel, adding organic silicon, stepwise adding ammonia water, abnd stirring to make the mixture react 3, filtering the product obtained in the step 2 and drying in a vacuum drying box; 4, adding the product obtained in the step 3 into an acetone solution of a comb-like polymer comprising an anchor group and a hydrophilic group and stirring; and 5, removing the acetone from the product obtained in the step 4 by decompressing and distilling to obtain the aqueous aluminum silver paste. According to the preparation method of the aqueous aluminum silver paste, coating completeness is enhanced, falling, dusting and agglomeration of a coating are prevented, and the coating has high dispersity, so that the using performance of the prepared aqueous aluminum silver paste is integrally enhanced.

Owner:SHENZHEN POLYTECHNIC

Silver paste for back face of lead-free crystal silicon solar cell and preparation method thereof

InactiveCN102364583AToxicStrong pollutionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSilver electrode

The invention discloses silver paste for the back face of a lead-free crystal silicon solar cell. The paste is characterized by being prepared from the following components in percentage by weight: 55-84 percent of silver powder, 15-38 percent of modified organic bonding agent and 1-10 percent of inorganic bonding agent. The invention further discloses a preparation method of the silver paste forthe back face of the lead-free crystal silicon solar cell. The silver paste has the advantages of excluding of toxic substances such as lead and the like, small damage to human bodies and realizationof high adhesion between a silver electrode and a silicon substrate.

Owner:NINGBO GUANGBO NEW NANOMATERIALS STOCK

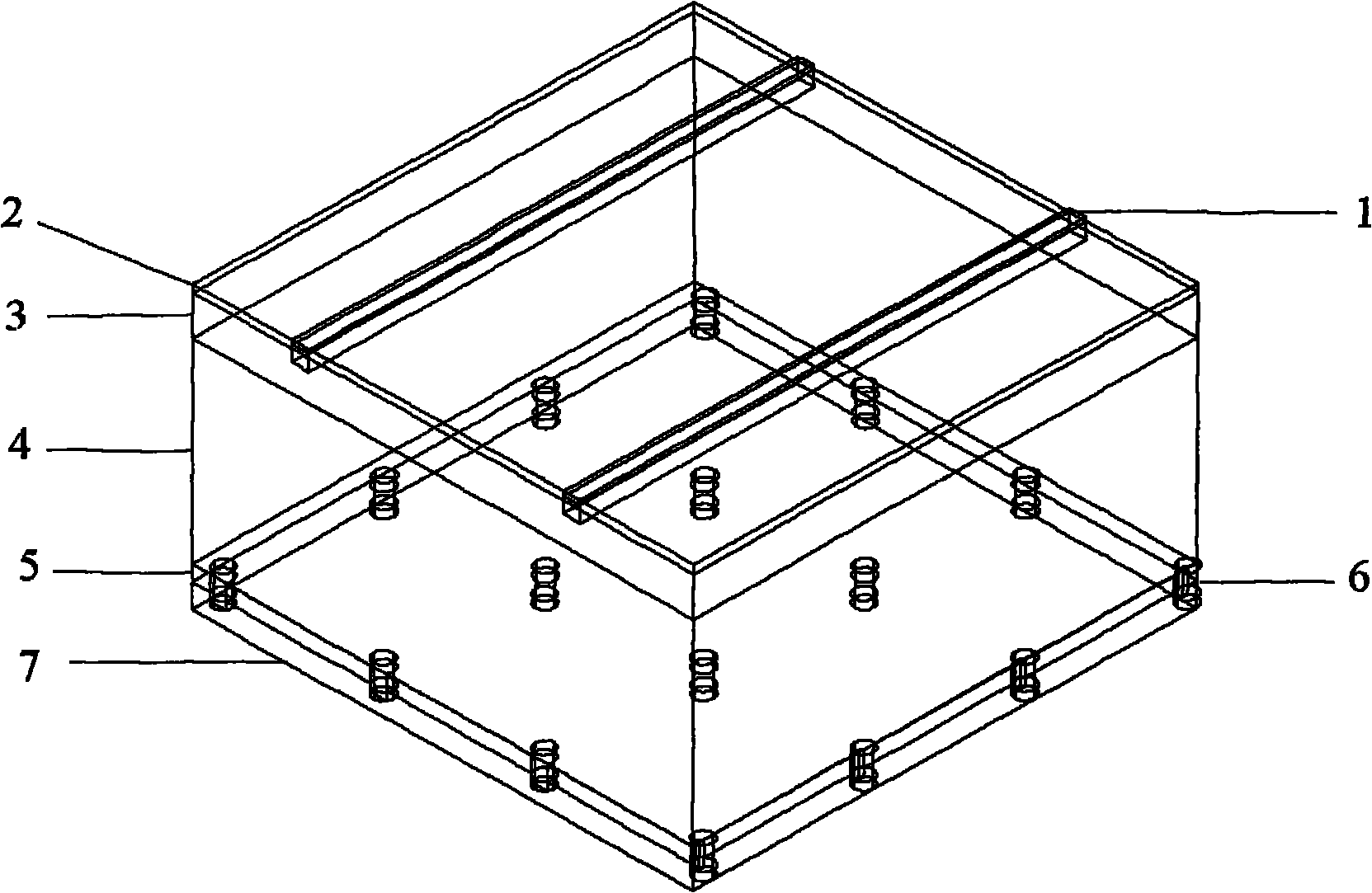

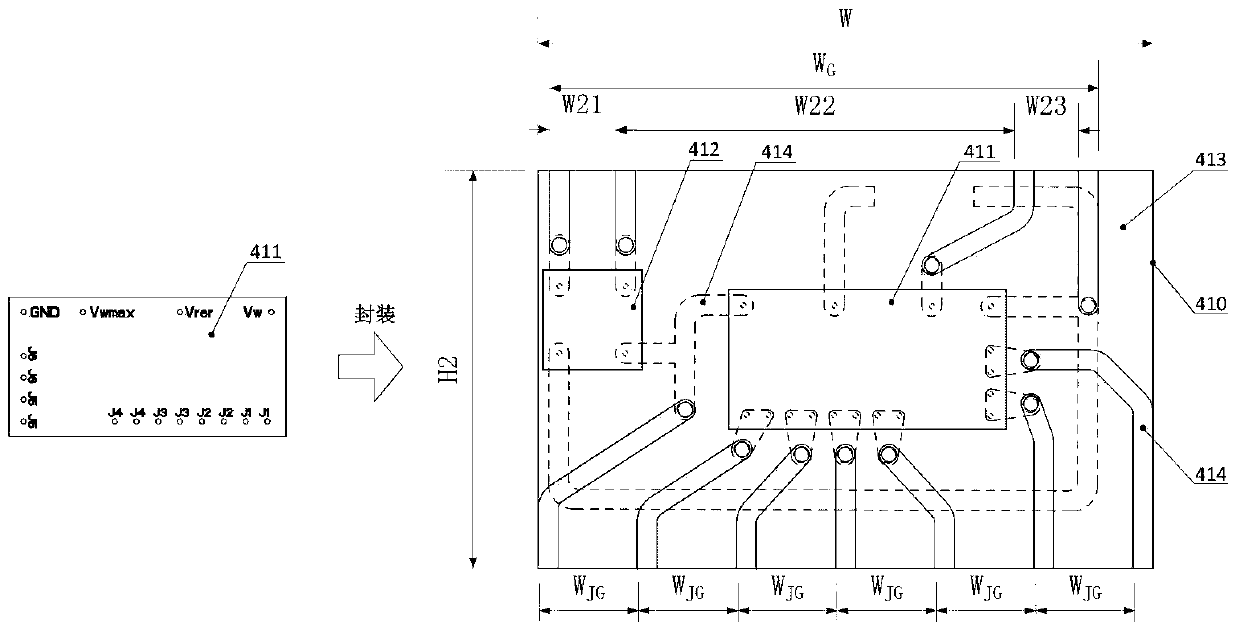

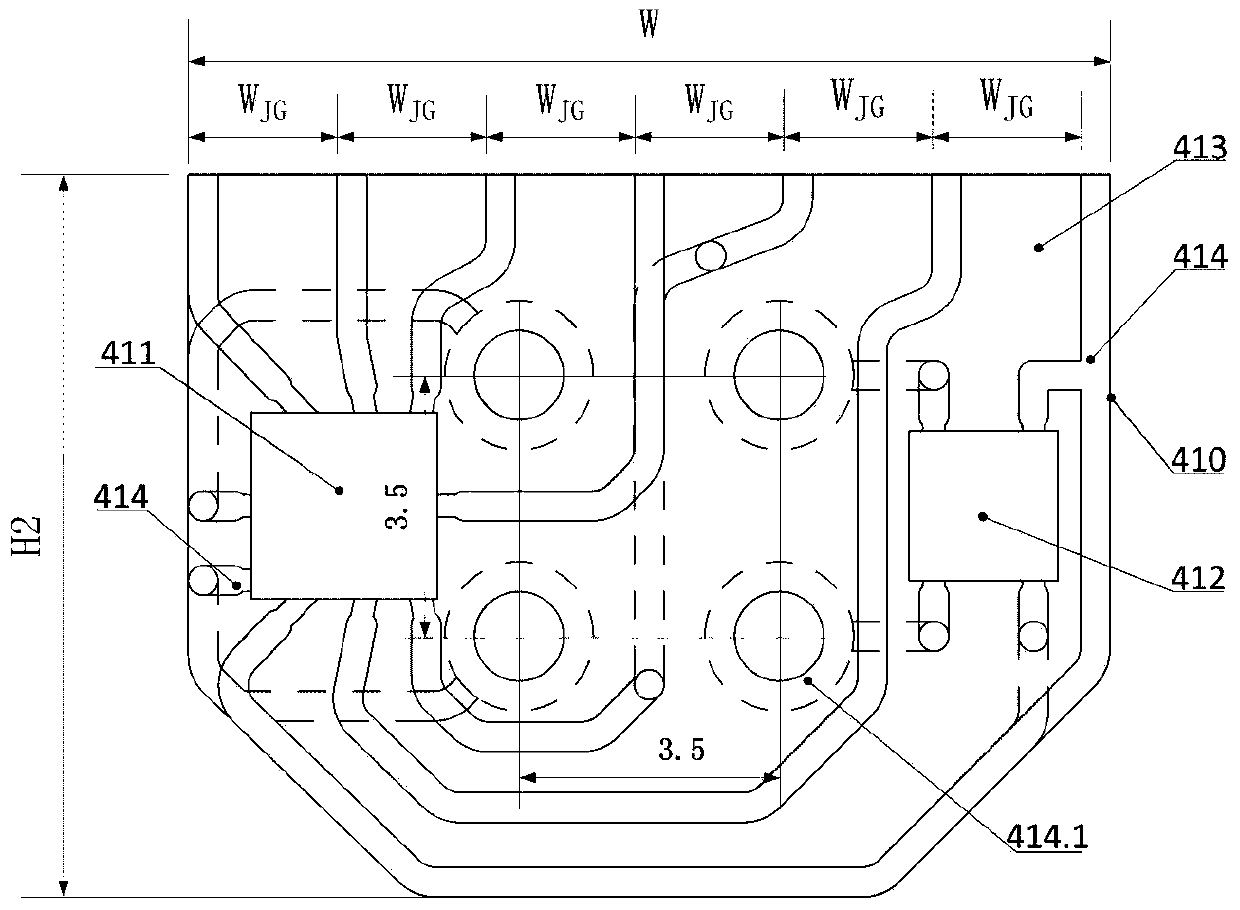

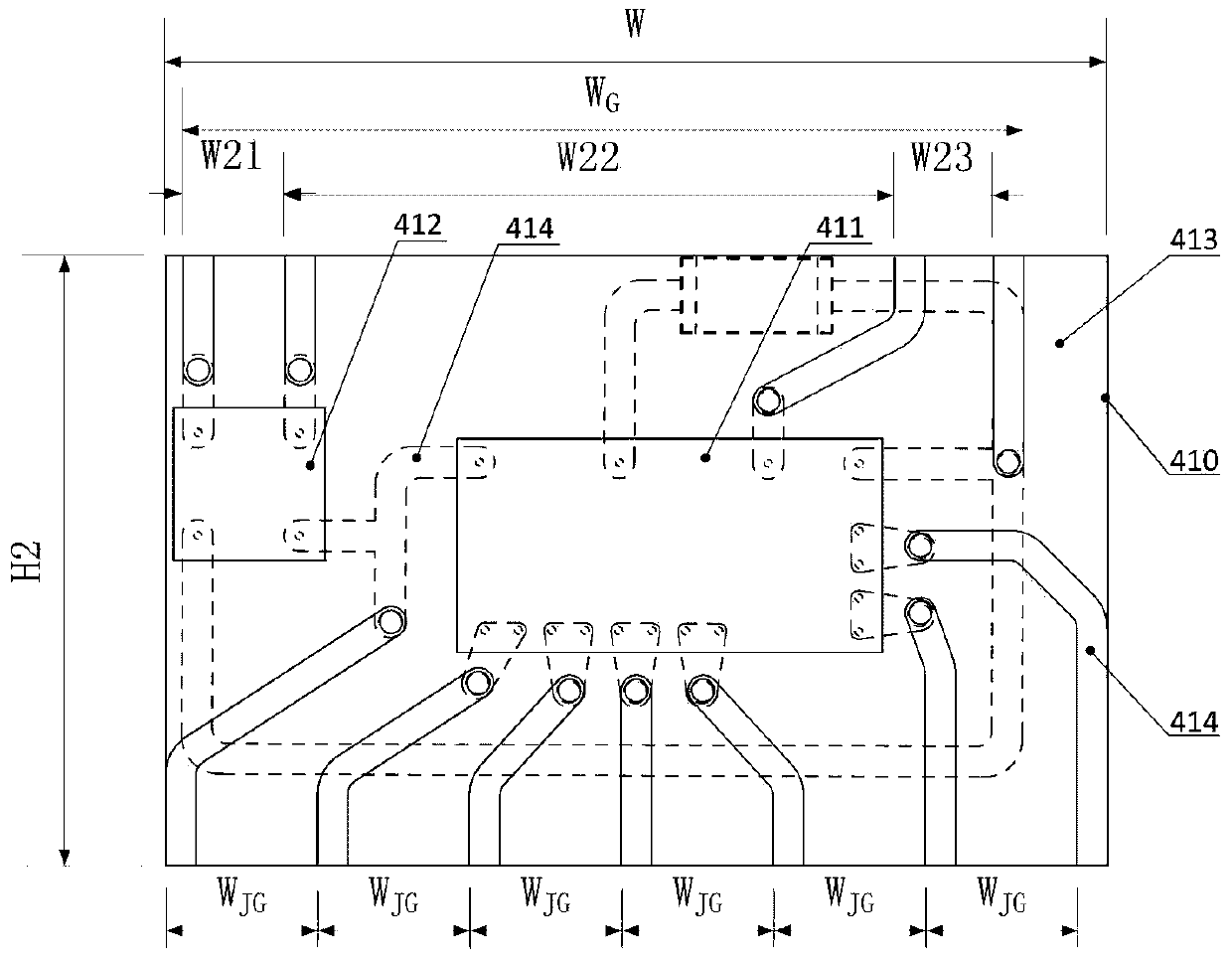

LED (light emitting diode) driving power supply large chip

ActiveCN103953902ALow costReduce volumePoint-like light sourceElectric circuit arrangementsWire widthSlurry

The invention discloses an LED (light emitting diode) driving power supply large chip, which comprises transparent base plates (413) with the width constantly being W, wherein a second transparent base plate (413) is printed with a silver slurry circuit, and an interface conducting wire is formed on the silver slurry circuit and is provided with an input end and an output end; the width of the input end is identical to the width WG of a conducting wire input end of a light machine template (43), or the input end is provided with a welding disc connected with an electric connector; N+1 parallel interface conducting wires are arranged on the silver slurry circuit arranged at the output end, and the space WJG of the two adjacent interface conducting wires can be obtained through dividing the difference value of W and the width of the interface conducting wire by N; an unencapsulated power supply driving wafer level chip (411) and a rectifier bridge wafer level chip (412) are firstly pasted on the second transparent base plate (413), and then, the unencapsulated power supply driving wafer level chip (411) and the rectifier bridge wafer level chip (412) are welded onto the second transparent base plate (413).

Owner:GUIZHOU GUANGPUSEN PHOTOELECTRIC

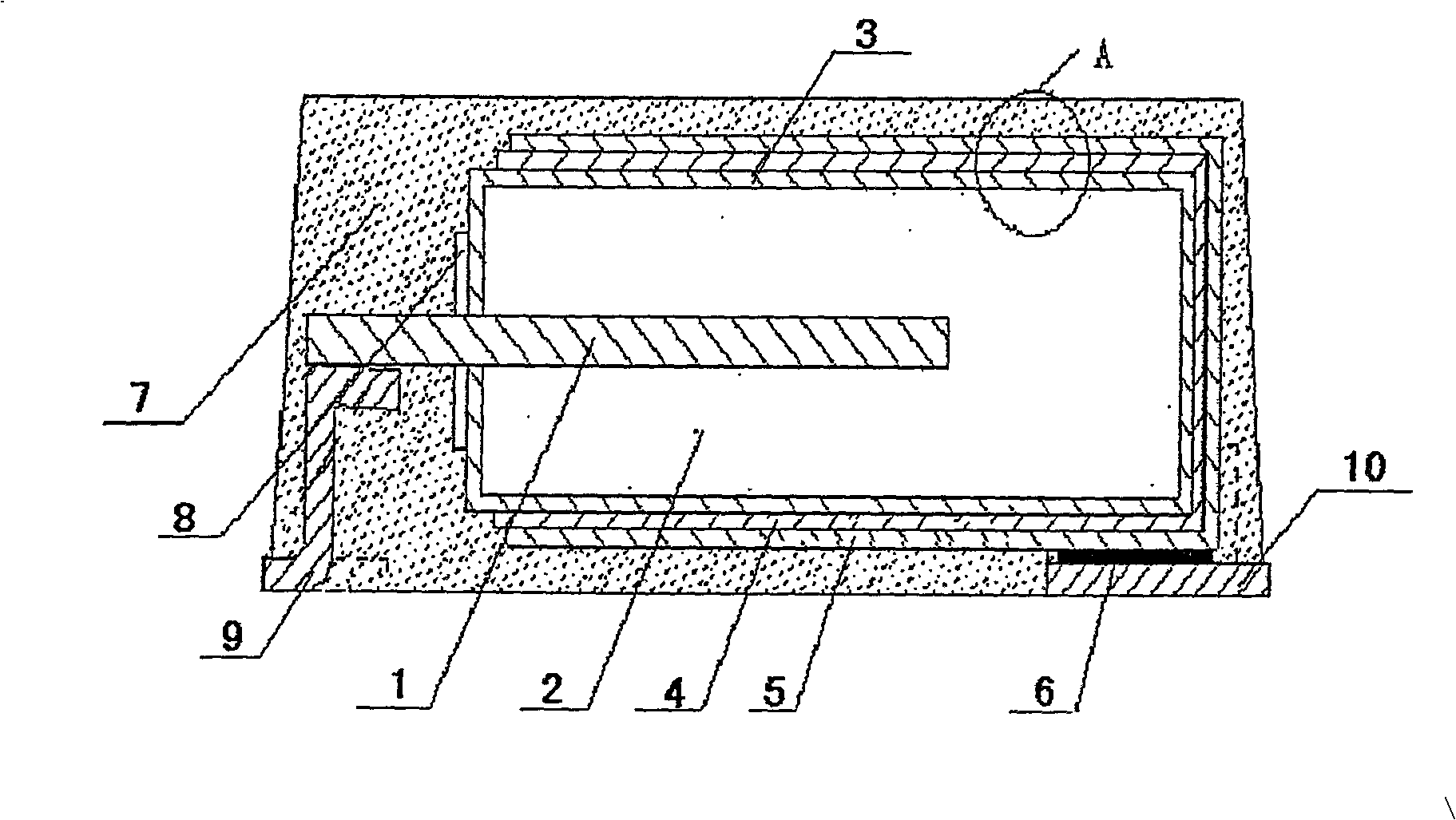

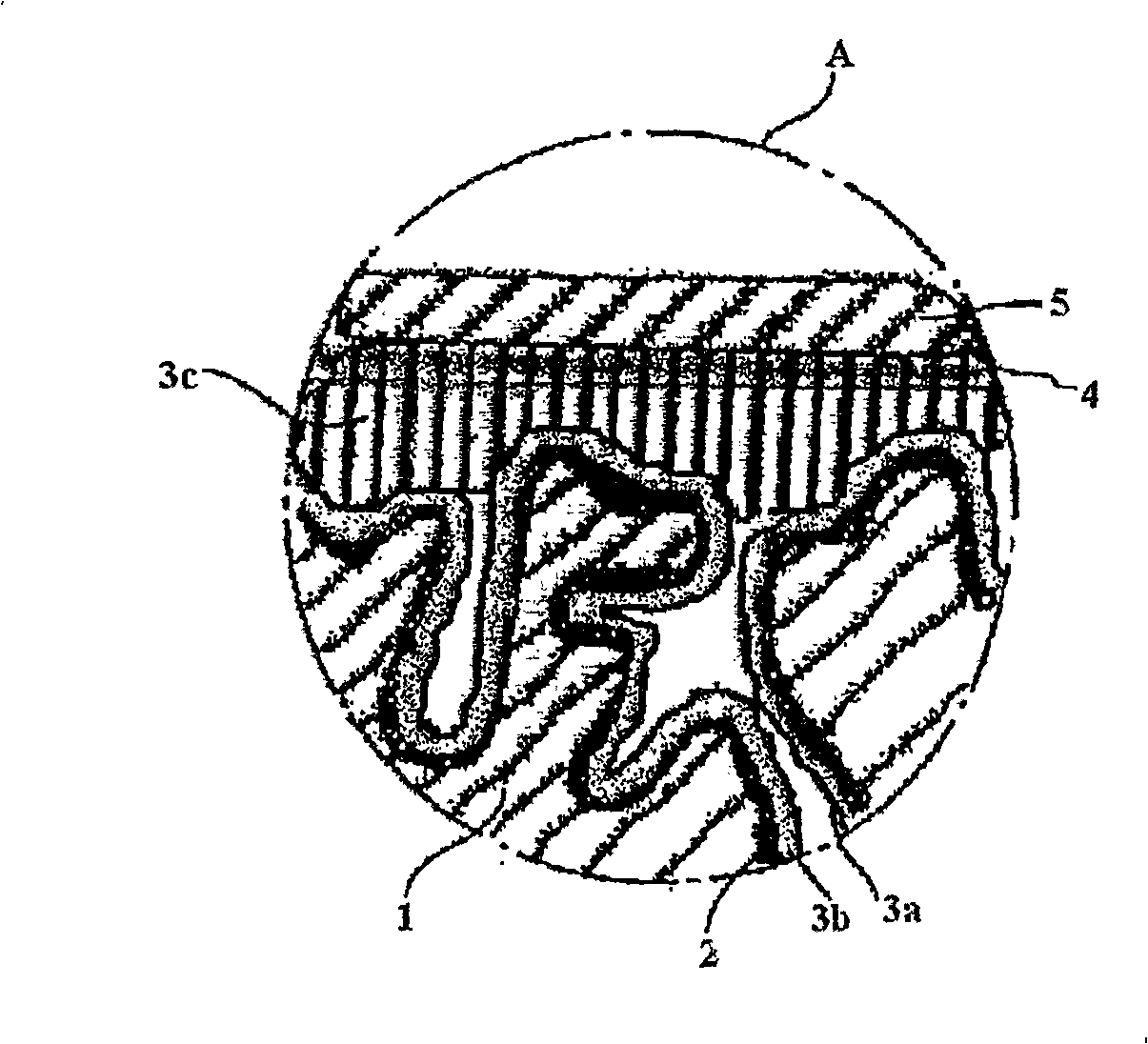

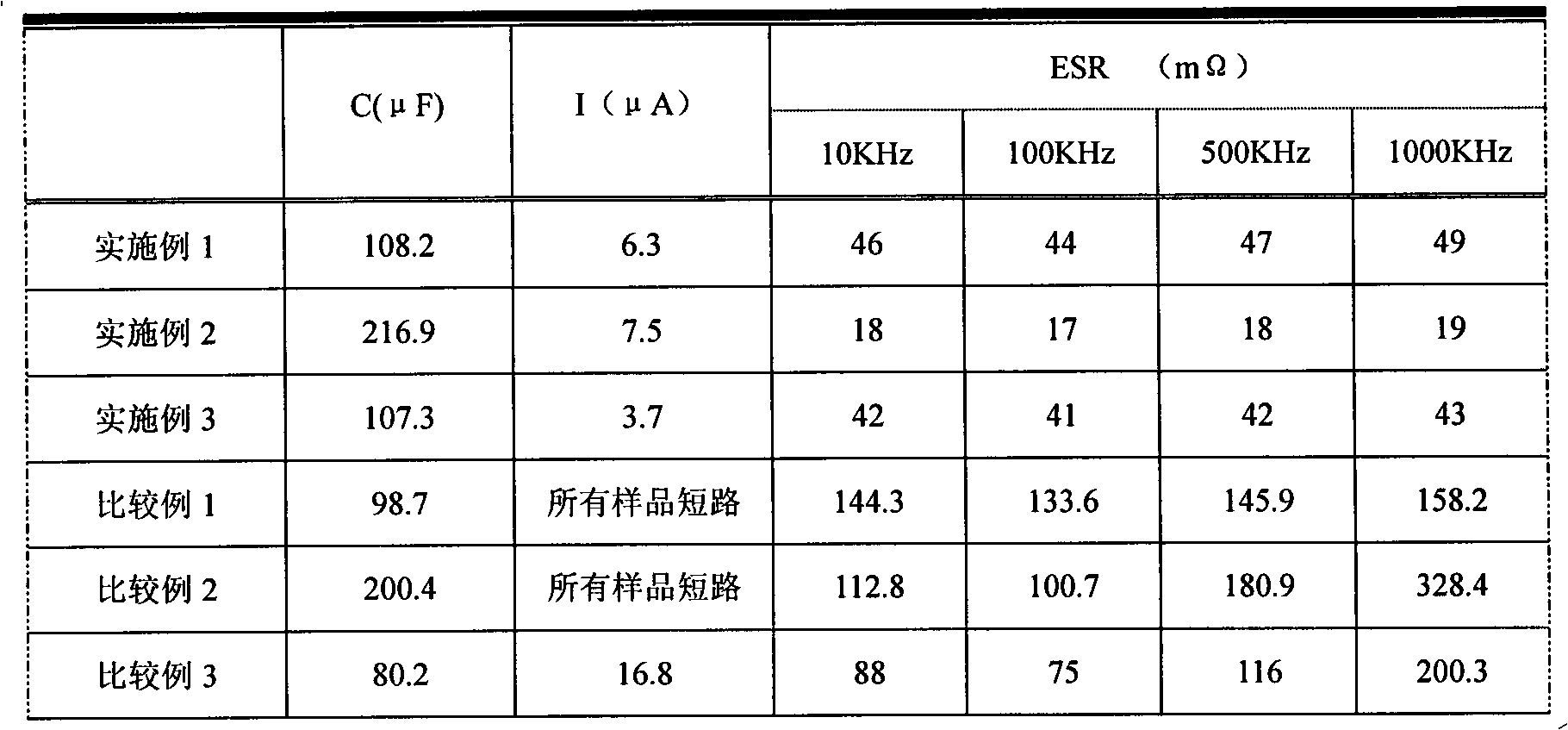

Solid electrolyte capacitor with ultra-low equivalent series resistance and manufacturing method thereof

ActiveCN101350253AImprove volumetric efficiencyTightly boundSolid electrolytic capacitorsCapacitor terminalsElectrolysisNiobium

The invention relates to a solid electrolytic capacitor and the method for preparing the solid electrolytic capacitor, wherein the solid electrolytic capacitor takes solid conducting high molecular polymer as electrolyte and takes valve metals, such as tantalum, niobium, titanium, aluminum and the like as an anode. The solid electrolytic capacitor is characterized by sufficiently explaining the techniques for the design of the anode, the function assignment, the chemical oxidative in-situ polymerization, the dip-coating graphite silver paste, the making of bottom extraction electrode and the like, with the technical proposal of the invention, a high polymer film, a graphite layer and a silver layer can be compactly combined, the manufactured electrolytic capacitor can be provided with very low equivalent series resistance (ESR), very high volumetric efficiency and good impedance frequency characteristic, the ESR value can be stable in the range of 10KHz-1000KHz, and the requirements of the frequency of a modern electronic equipment can be satisfied.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

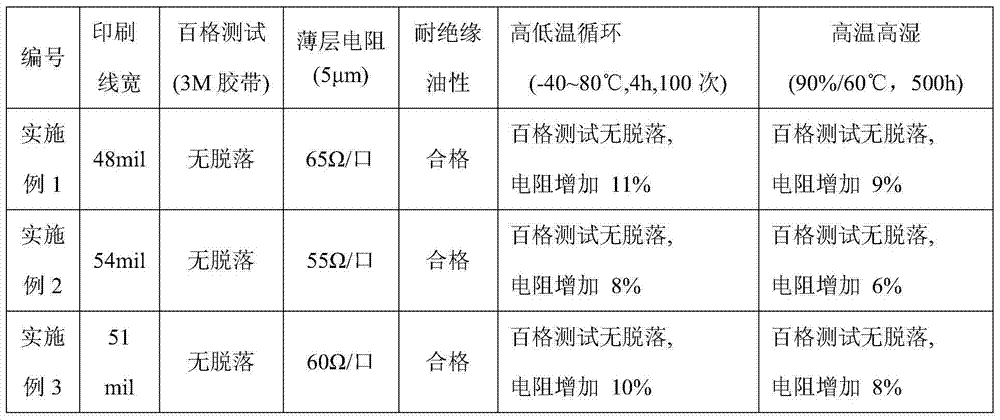

Silver paste used for grapheme touch screen, and preparation method thereof

ActiveCN103500596AHigh resolutionGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteWeather resistance

The invention discloses silver paste used for a grapheme touch screen, and a preparation method thereof. The silver paste is prepared from flake-like silver powder, spherical silver powder, inorganic electric conduction additive, organic carrier, accessory ingredient and diluent of residual percentage by weight. The preparation method comprises the following steps of: firstly, preparing the organic carrier; adding the flake-like silver powder, the spherical silver powder, the inorganic electric conduction additive, the accessory ingredient and the diluent into the organic carrier; fully and evenly mixing; finally, grinding by a three-roller machine, and carrying out vacuum defoaming. The silver paste disclosed by the invention has the advantages of good overall performance, convenience in printing, good adhesion property, good bending resistance, good weather resistance, good stability and good electrical conductivity and insulating oil performance and can pass a long-time high-temperature high-moisture aging test and thermal shock tests for more than hundred times, and the requirement on the conductive silver paste by the grapheme touch screen can be satisfied.

Owner:广州市尤特新材料有限公司

Conductive silver paste and conductive film formed using the same

ActiveUS7198736B2Good reproducibilityImprove conductivityConductive materialNon-conductive material with dispersed conductive materialSilver pasteEpoxy

A conductive silver paste according to the present invention comprises epoxy resin, flake-shaped silver powders having an average particle diameter of 0.5 to 50 μm, and spherical silver powders, each having its surface coated with organic matter, having an average particle diameter of not more than 1 μm, and a conductive film according to the present invention is formed by printing or applying the conductive silver paste on a surface of a base material, followed by drying, and then thermosetting the epoxy resin.

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com