Industrialized production process of crystalline silicon solar battery

A solar cell and production process technology, applied in the field of solar cells, to achieve strong reflection, increase absorption, and reduce the probability of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

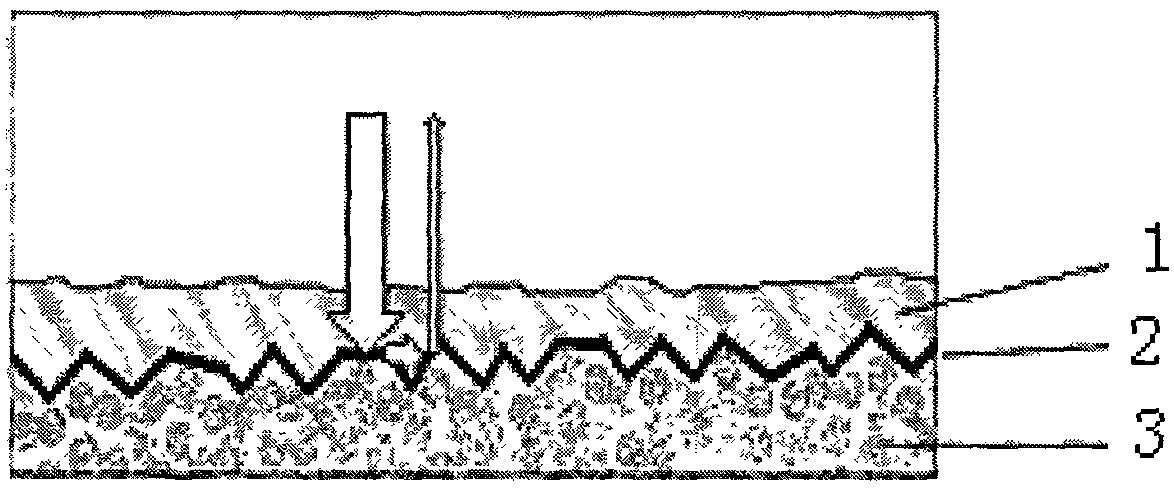

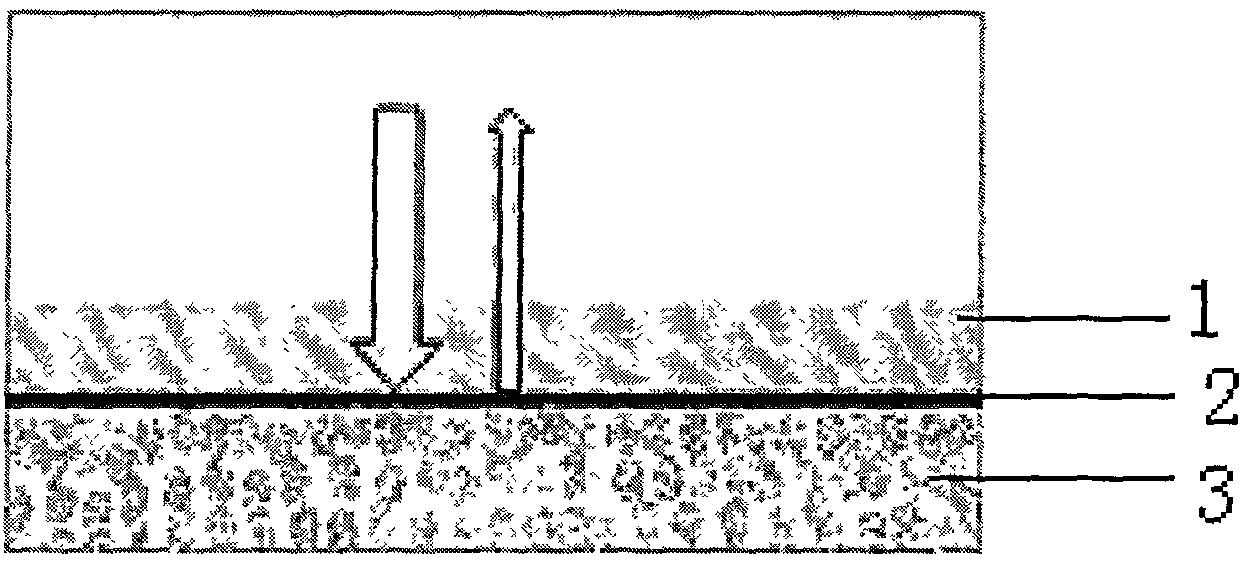

[0029] The industrial production process of crystalline silicon solar cells provided in this example is as follows: select silicon wafers, perform texturing on the front surface, phosphorus diffusion, removal of phosphosilicate glass formed on the surface during phosphorus diffusion, and silicon nitride deposition on the front surface by PECVD in sequence, The silicon wafer protected by the silicon nitride anti-reflection film on the front surface is placed in heated lye for back polishing to remove the diffusion layer on the back, and then cleaned and dried with anti-bending aluminum paste for screen printing and sintering.

[0030] The lye used during polishing is inorganic lye, which is an aqueous solution of sodium hydroxide or potassium hydroxide, with a weight percentage of 10-40% and a temperature of 50-90°C; organic lye can also be used for polishing. The lye, the organic lye is an aqueous solution of tetramethylammonium hydroxide or ethylenediamine, its weight percenta...

Embodiment 2

[0032] The industrial production process of crystalline silicon solar cells provided in this embodiment includes the following steps:

[0033] (1) Suede corrosion

[0034] Select a single-crystal silicon wafer with a resistivity of 1.0-5Ω·cm, put the two pieces together in a flower basket, and then place them in a hydrogen oxide with a temperature of 80-95°C and a volume percentage of 1-10% alcohol. Carry out one-sided etching of the front surface in sodium aqueous solution, the weight percentage of sodium hydroxide aqueous solution is 0.5-1.5%, soak the silicon wafer in 10% dilute hydrochloric acid for 2 minutes after making texture, then rinse it with deionized water, and set aside ;

[0035] (2) Phosphorus diffusion

[0036] Using phosphorus oxychloride liquid source, diffusion is carried out in an industrial tubular diffusion furnace, so that the temperature in the constant temperature zone is 800 ℃ ~ 900 ℃, the diffusion time is 30 ~ 50 minutes, and the diffusion square...

Embodiment 3

[0044] The industrial production process of crystalline silicon solar cells provided in this embodiment includes the following steps:

[0045] (1) Suede corrosion

[0046]Select a single-crystal silicon chip with a resistivity of 1.0-5Ω·cm, put the two pieces together in a flower basket, and then place them in a glass with a temperature of 80-95°C and a volume percentage of 1-10% isopropanol. The front surface is etched on one side in sodium hydroxide aqueous solution, the weight percentage of sodium hydroxide aqueous solution is 0.5-1.5%, the silicon chip after texturing is soaked in 10% dilute hydrochloric acid for 2 minutes, and then rinsed with deionized water ,spare;

[0047] (2) Phosphorus diffusion

[0048] Phosphorus oxychloride liquid source is used to diffuse in an industrial tubular diffusion furnace. The temperature in the constant temperature zone is 800℃~900℃, the diffusion time is 30~50min, and the diffusion resistance is controlled at 40~60Ω / □;

[0049] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com