Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3743 results about "Volume Percentage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volume percent is a common expression of a solution's concentration. It is the volume fraction expressed with a denominator of 100, and thus is defined as: Volume percent is usually used when the solution is made by mixing two fluids, such as liquids or gases.

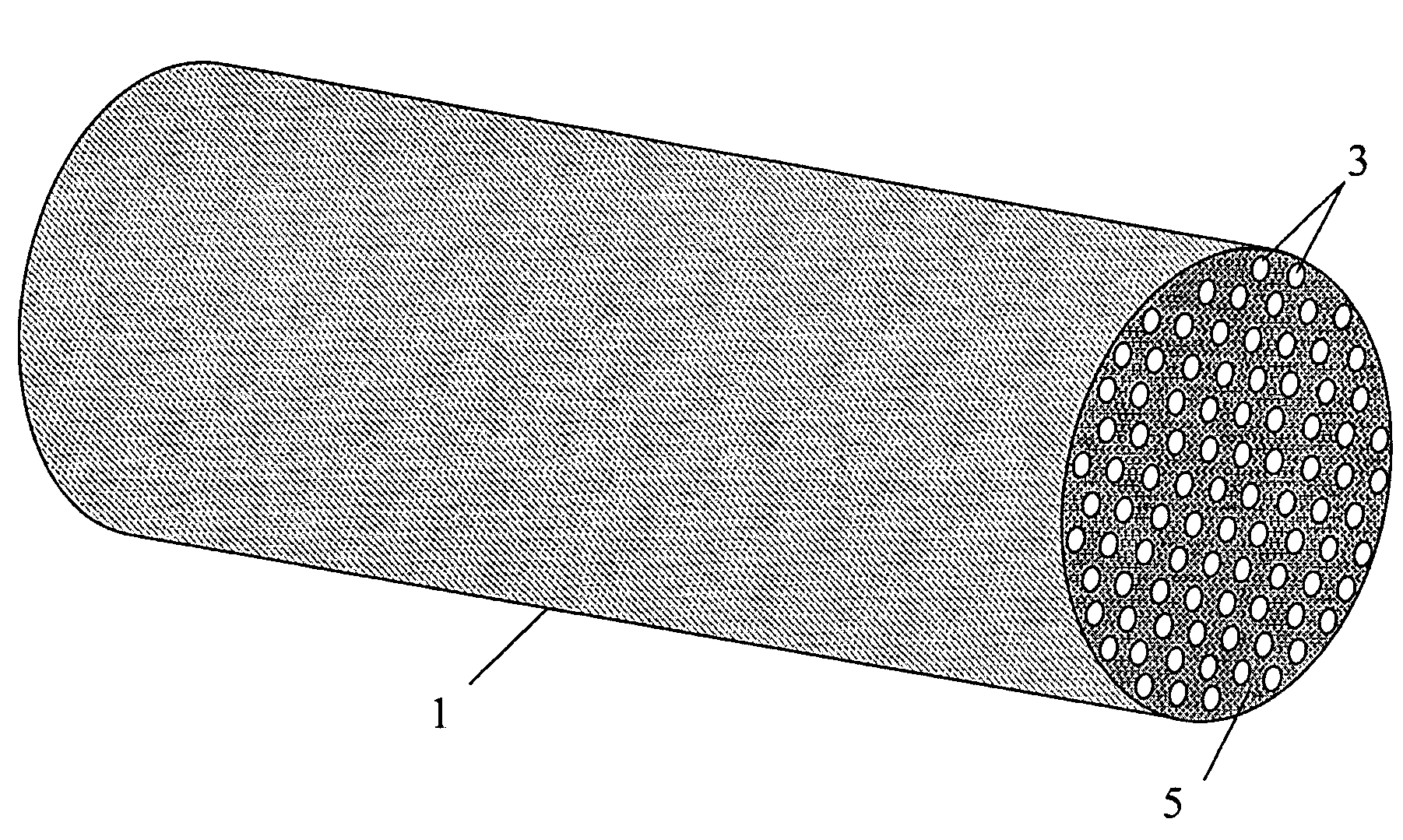

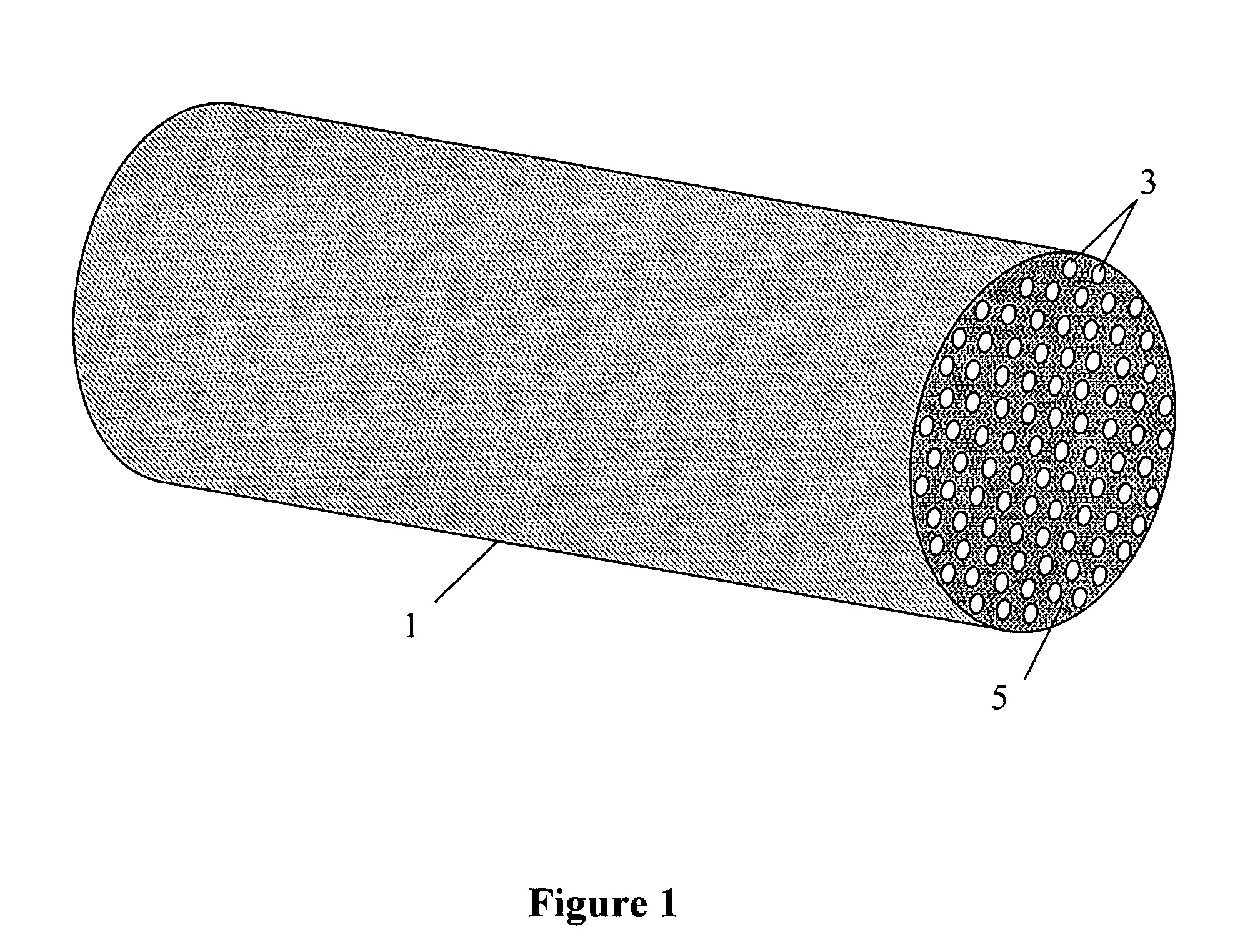

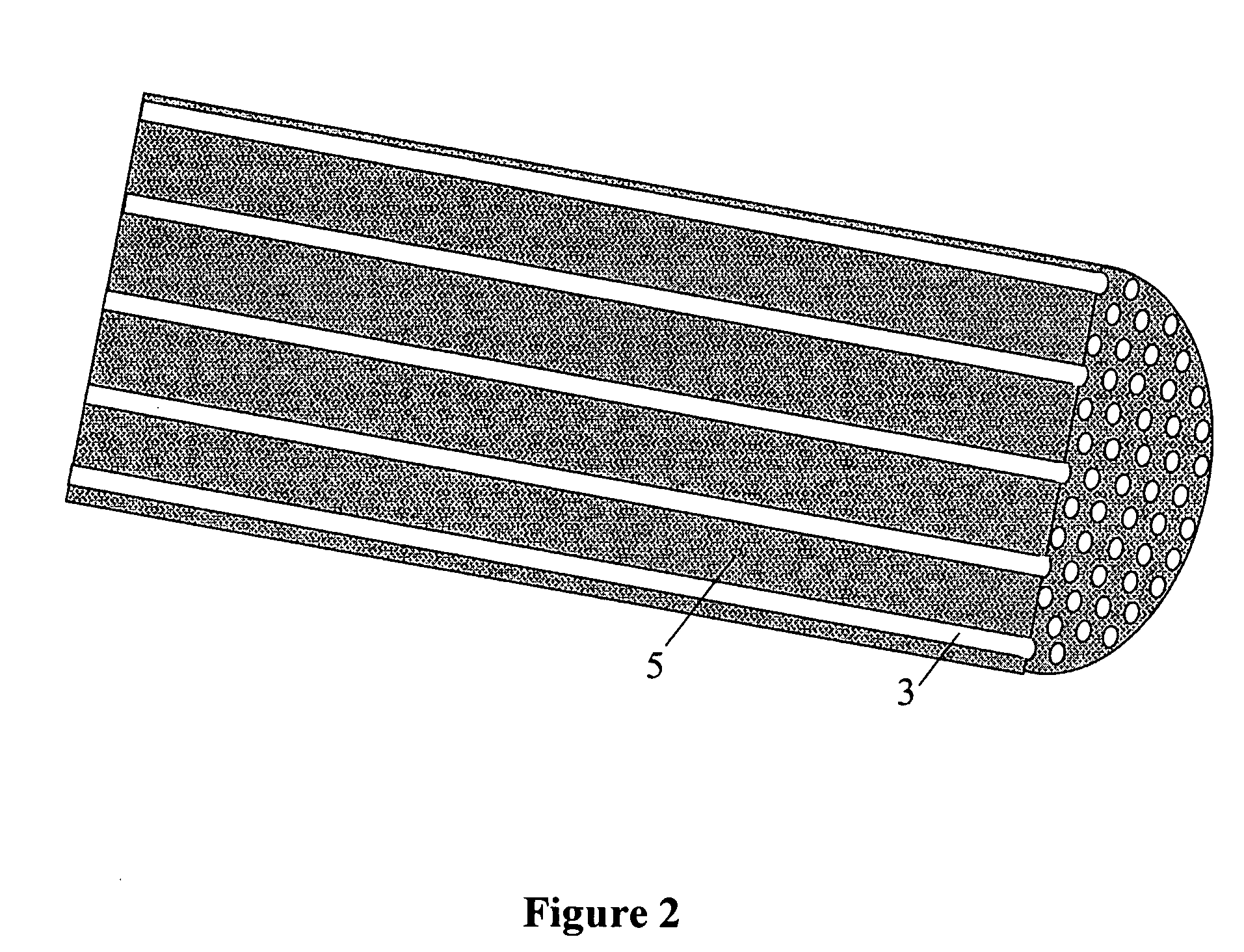

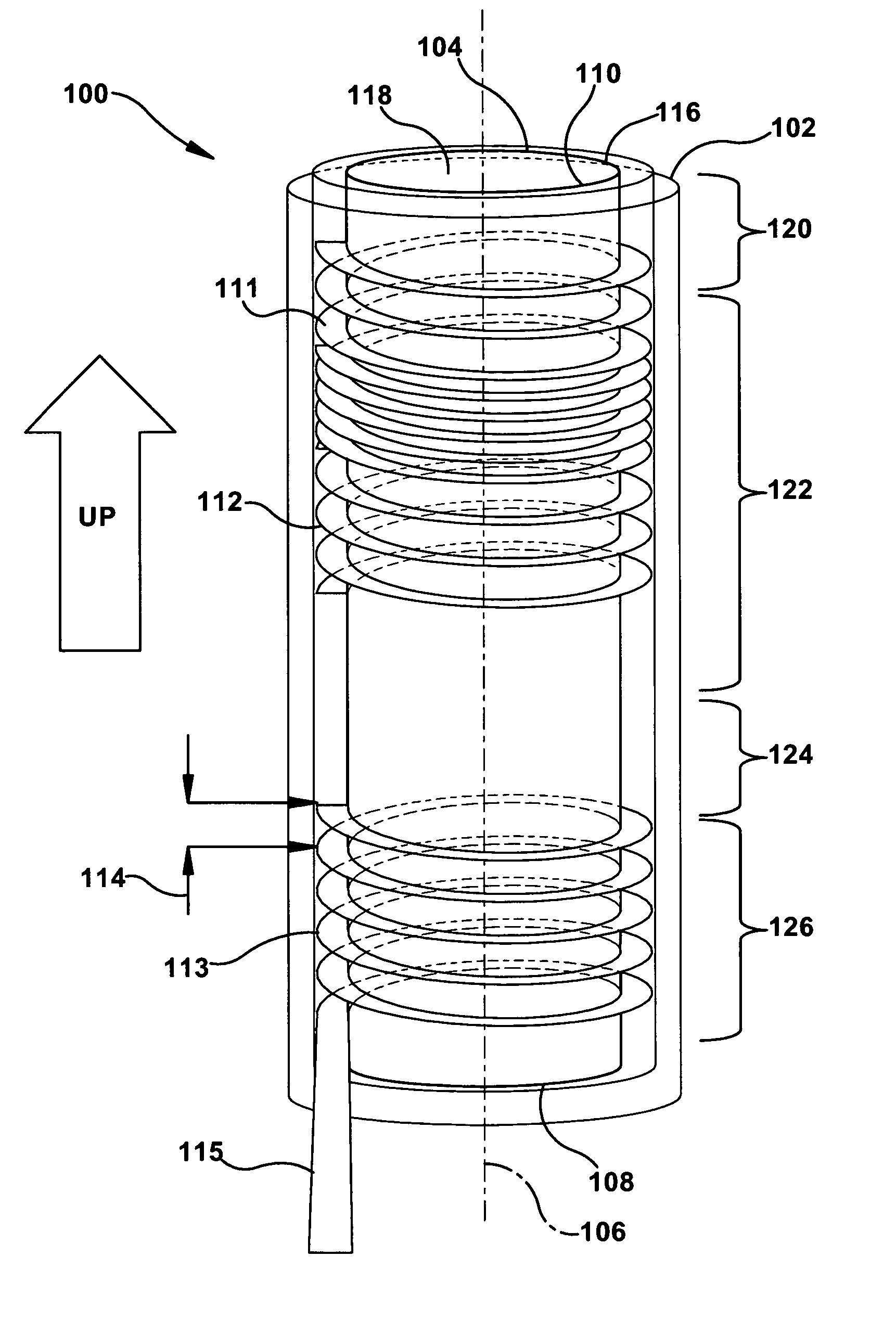

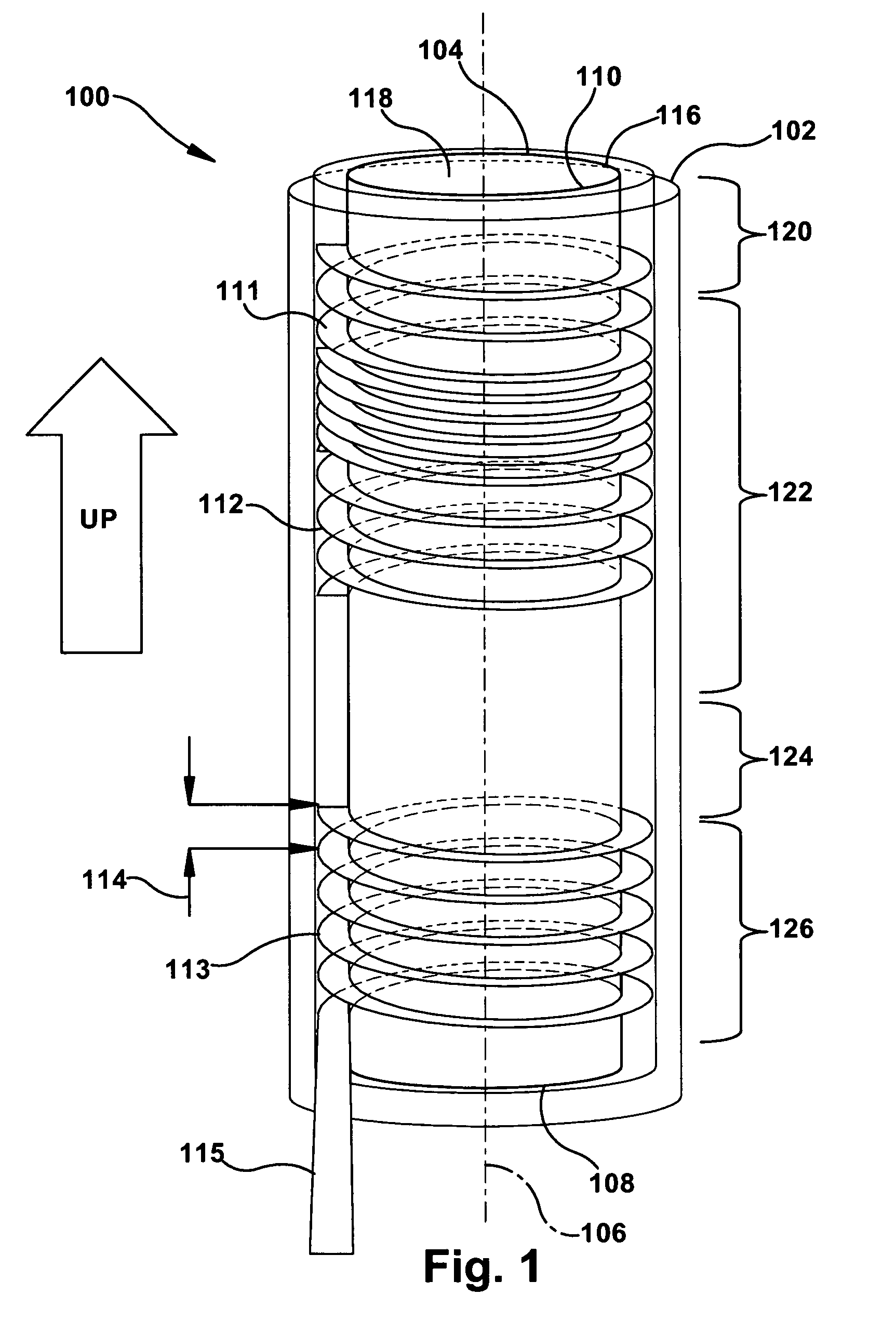

Low mesopore adsorbent contactors for use in swing adsorption processes

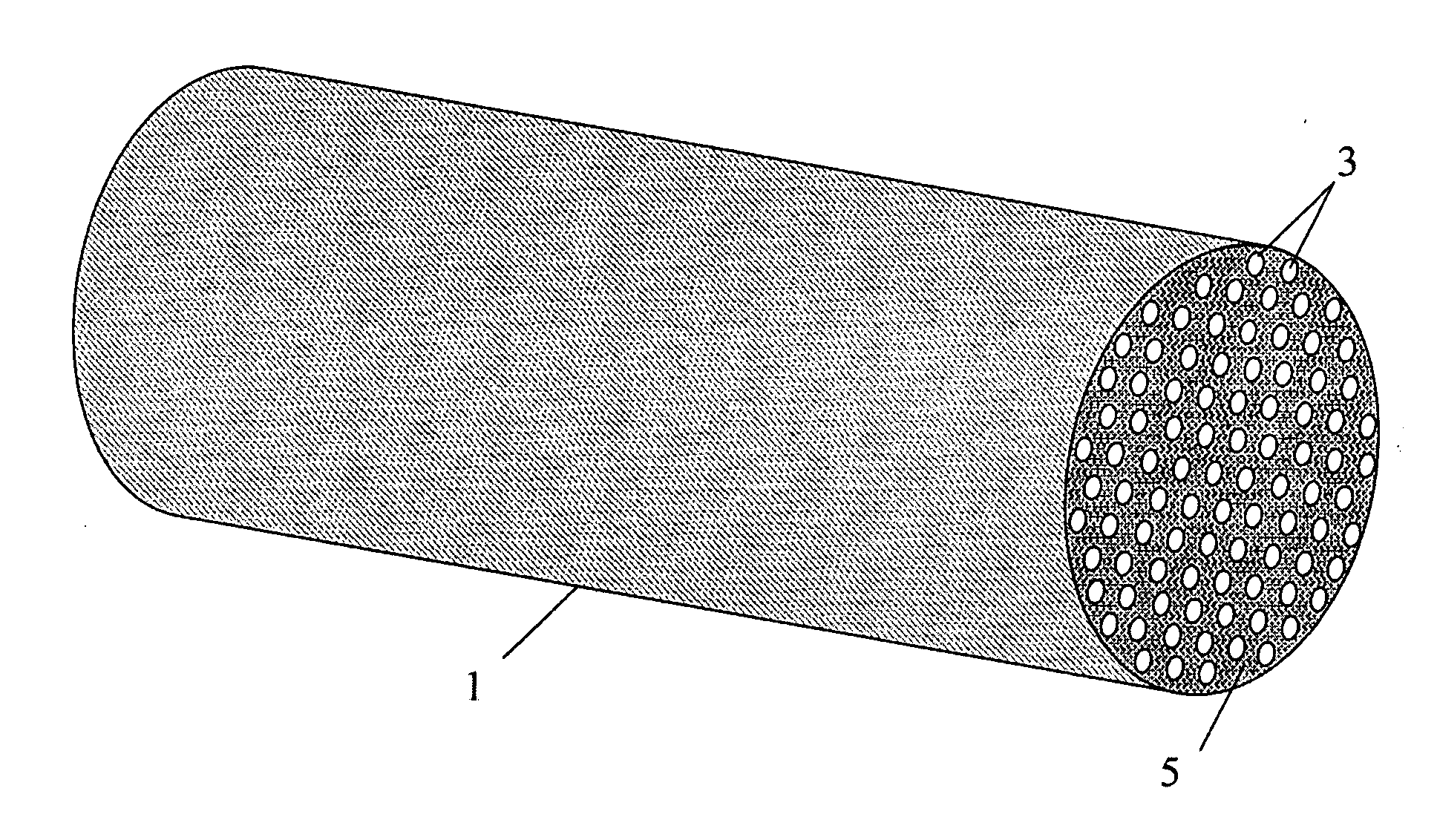

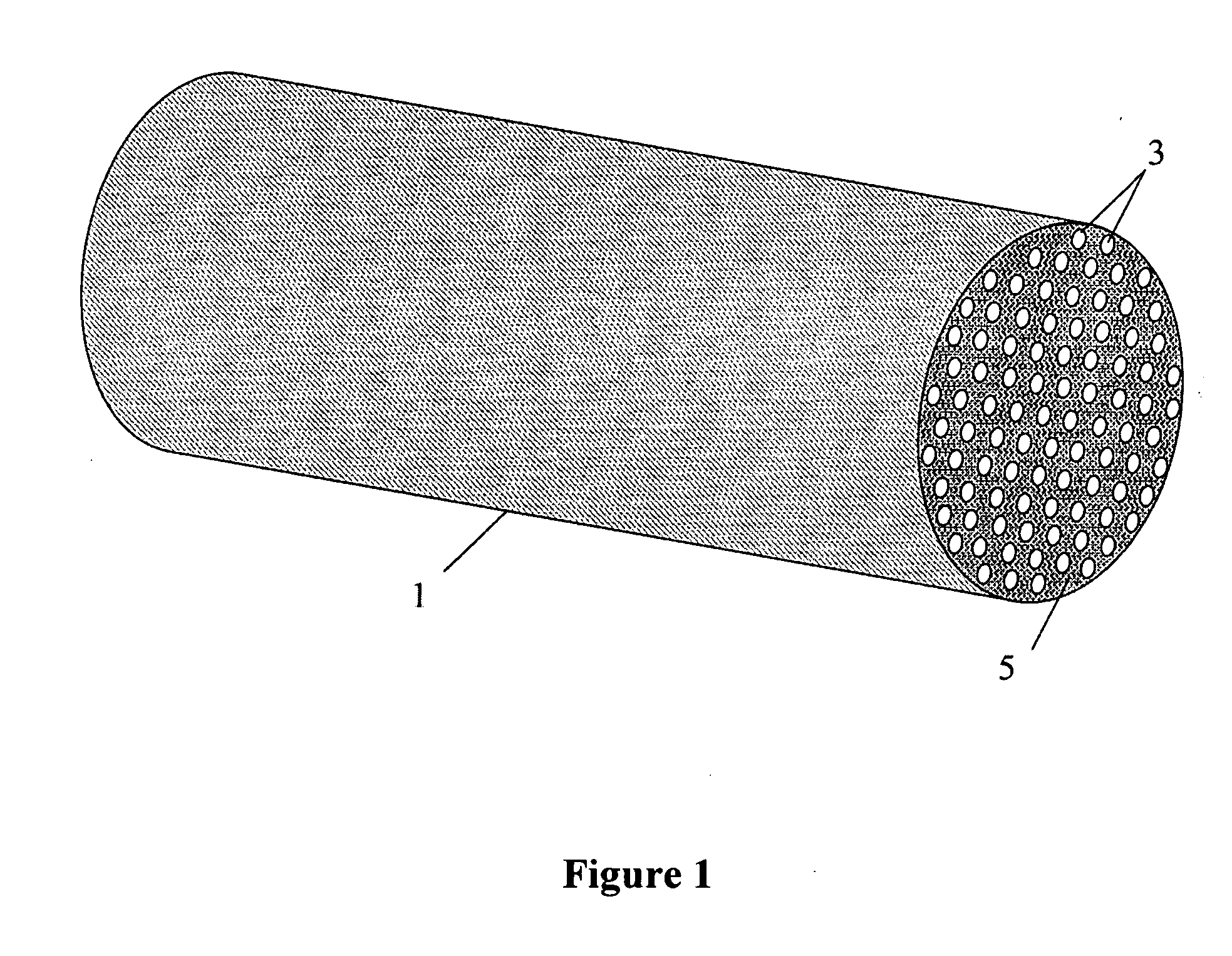

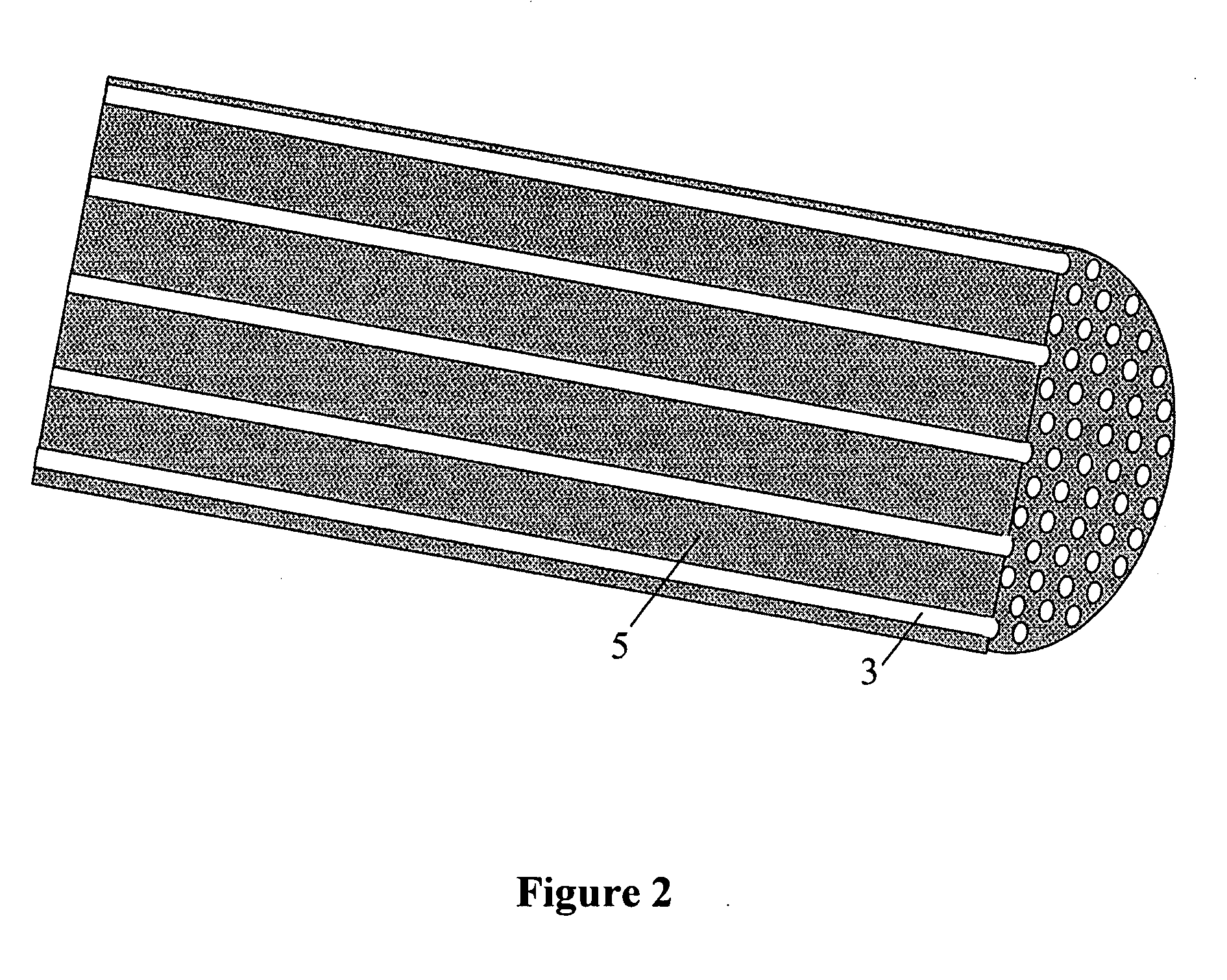

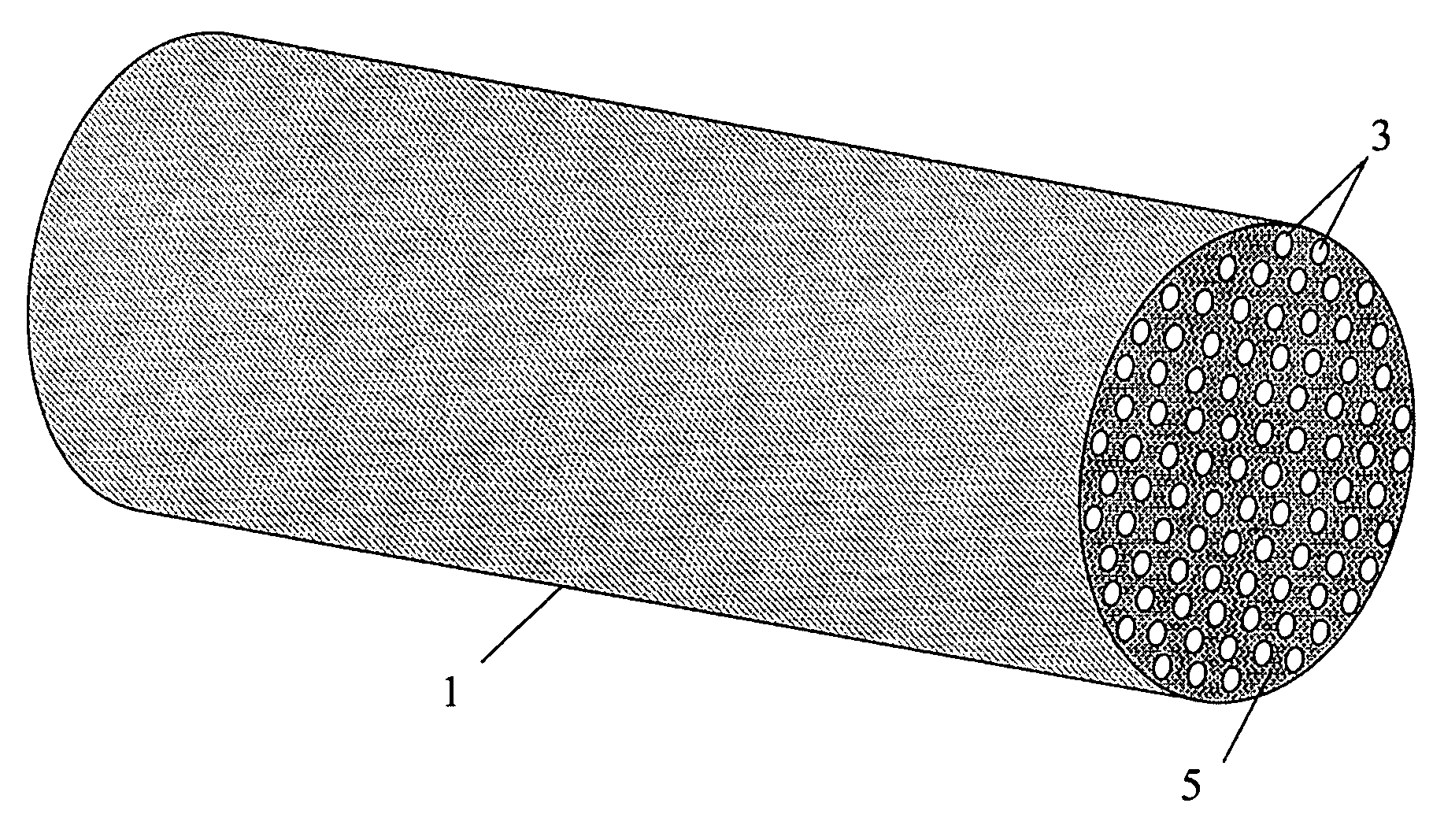

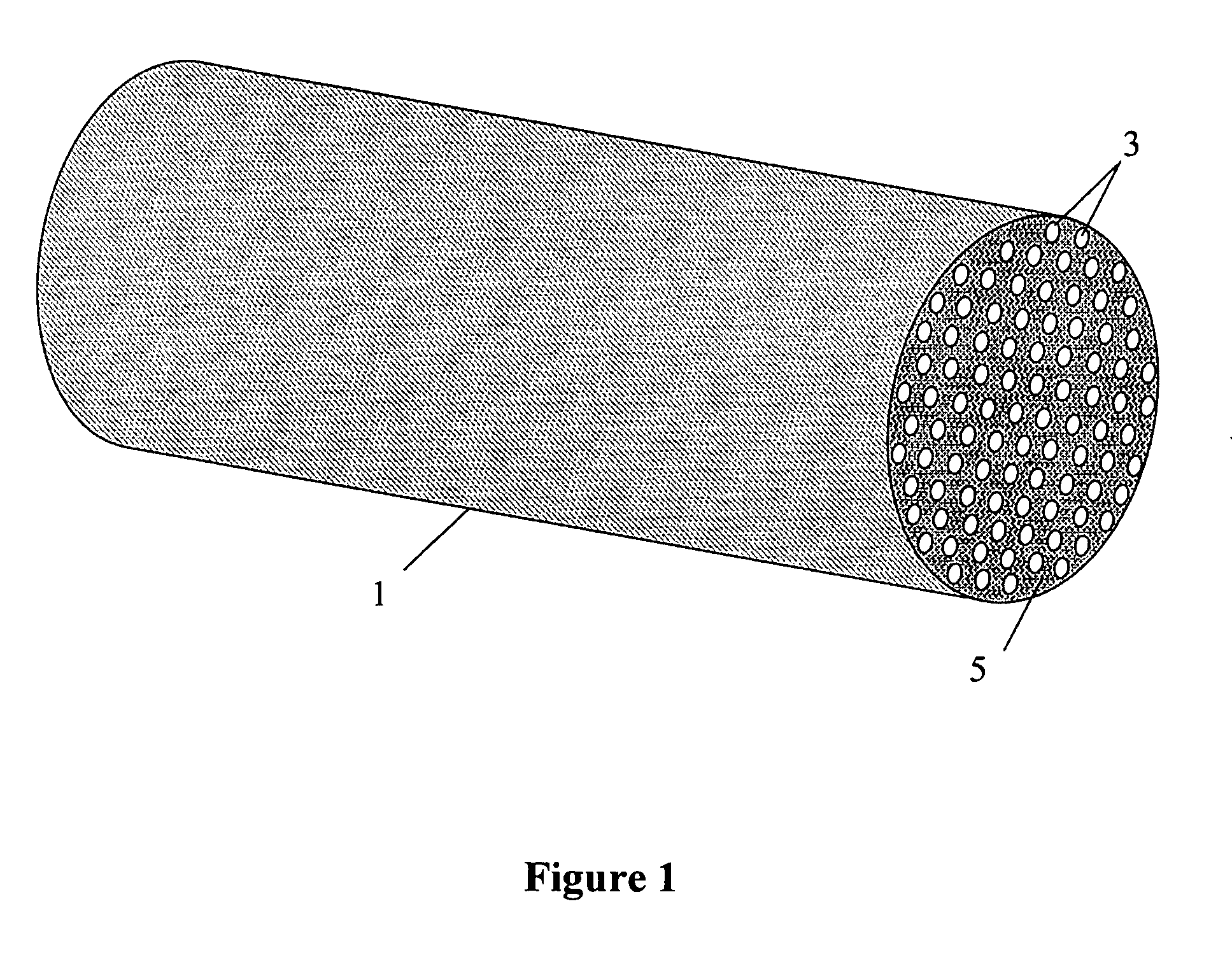

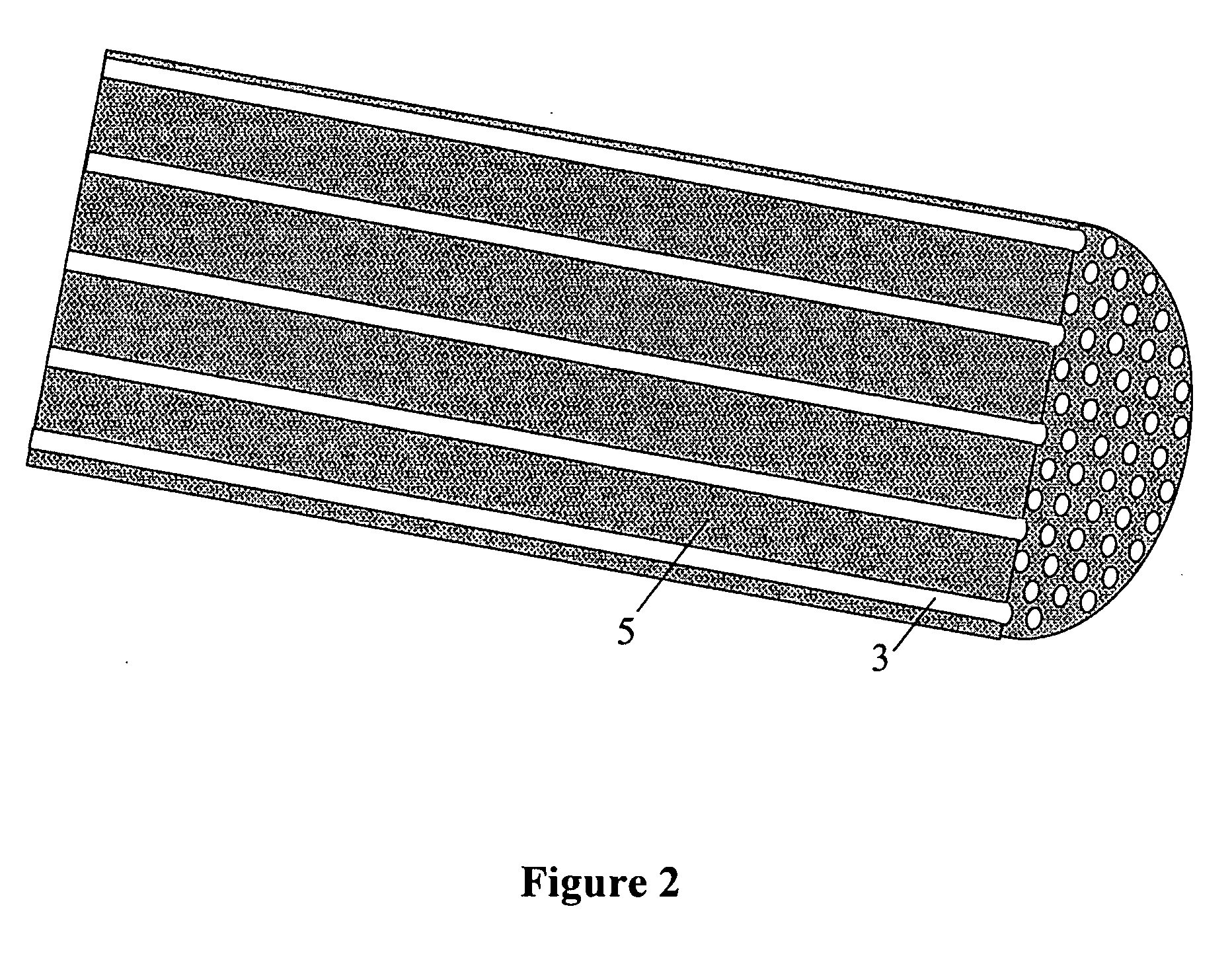

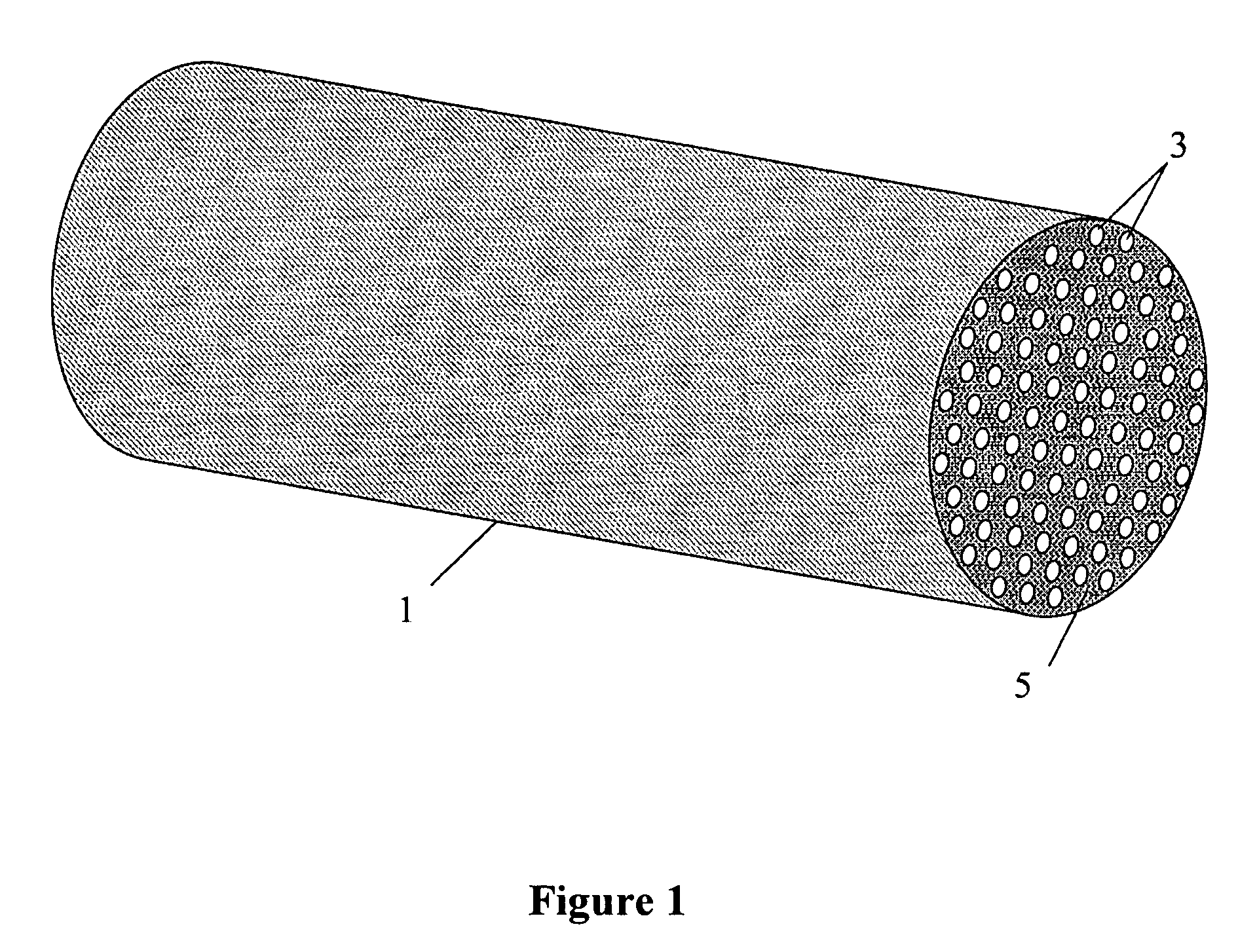

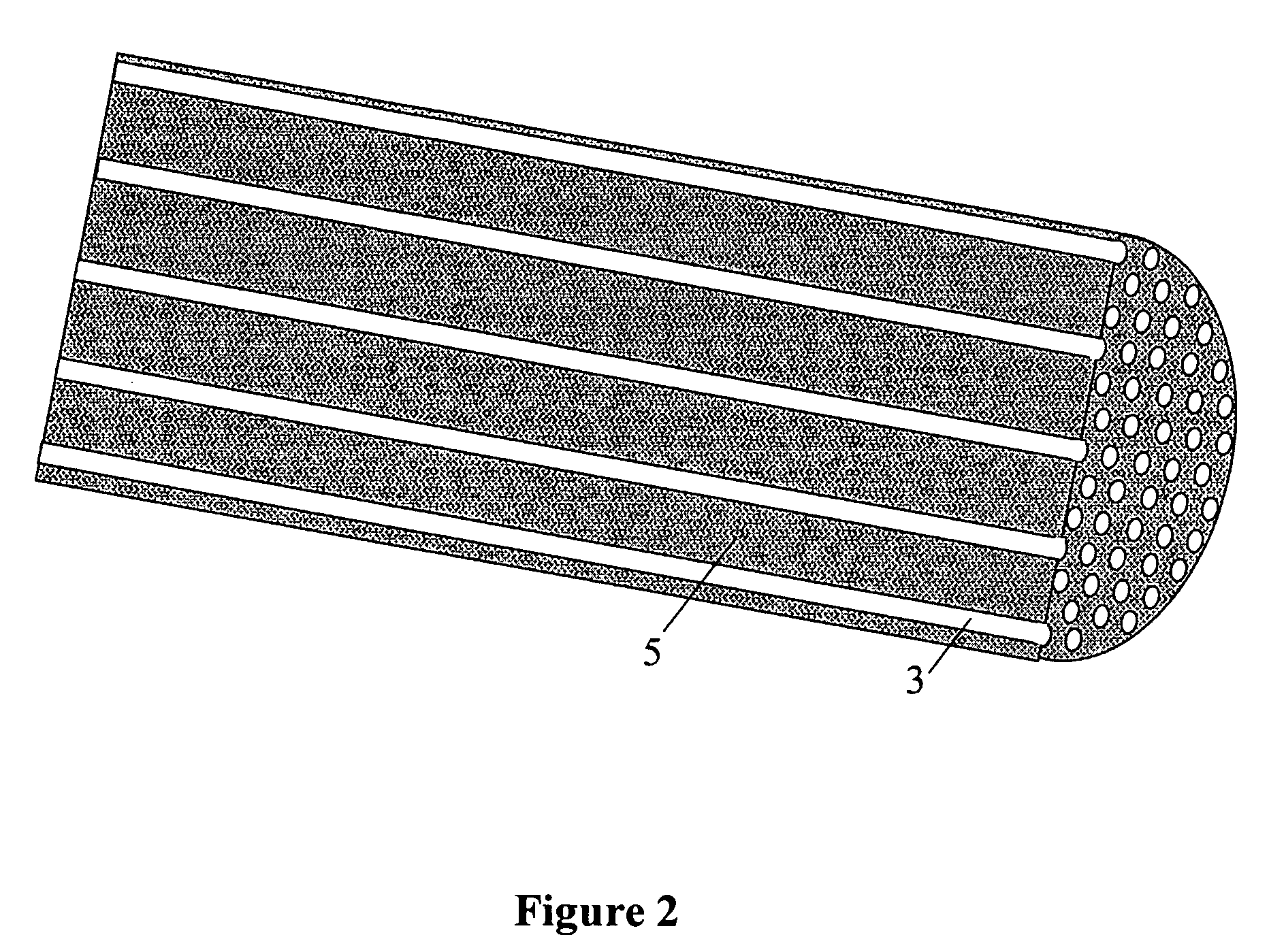

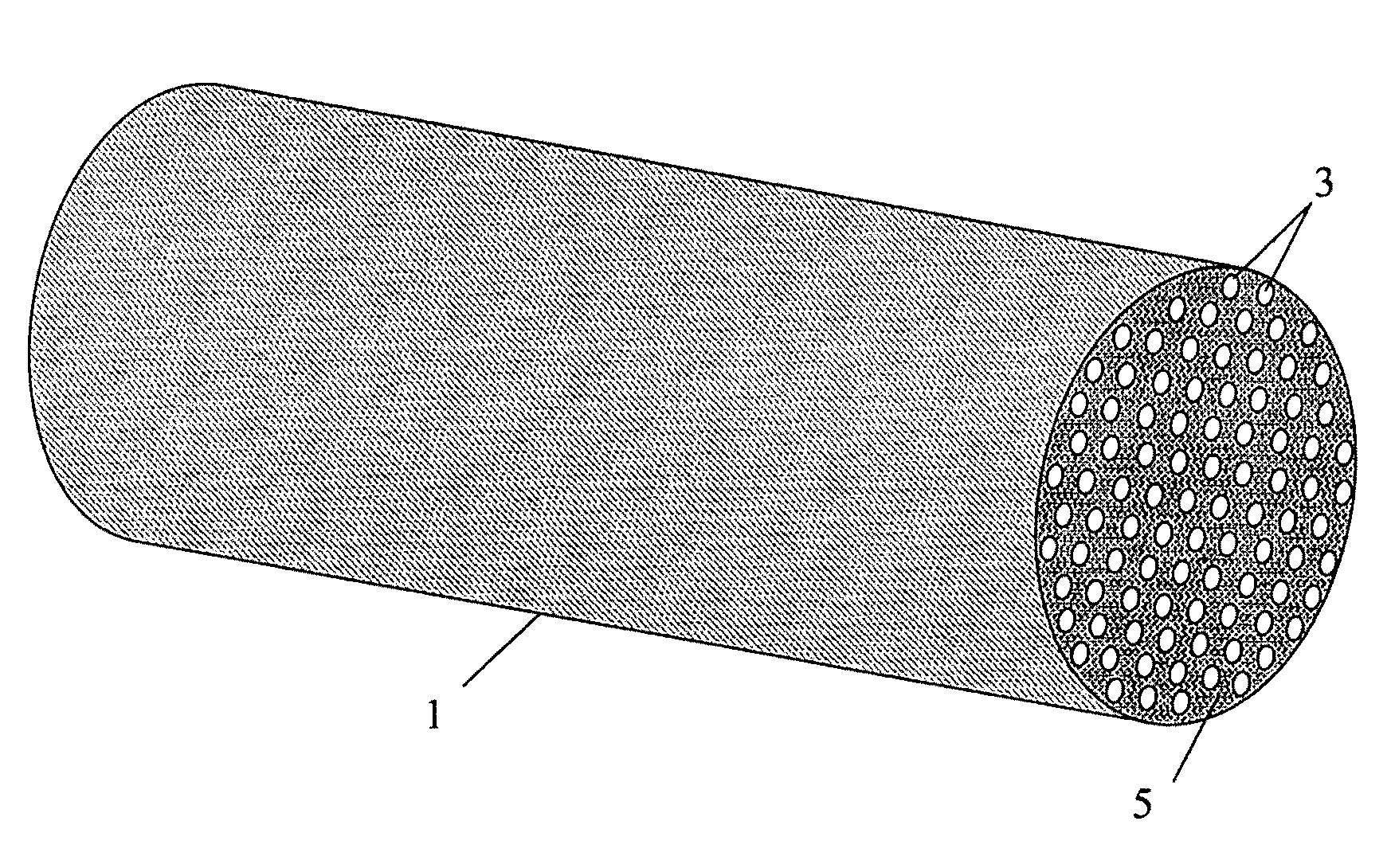

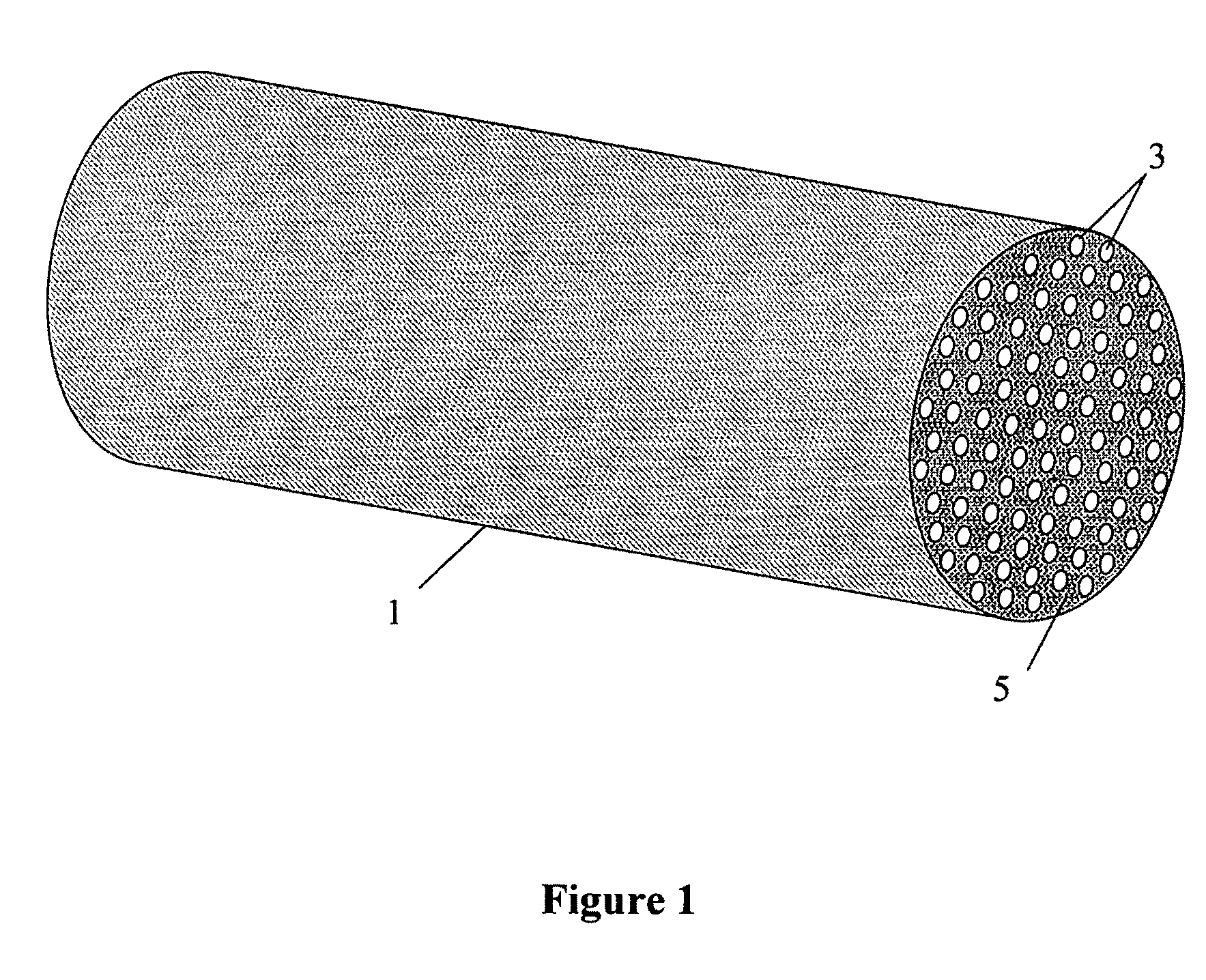

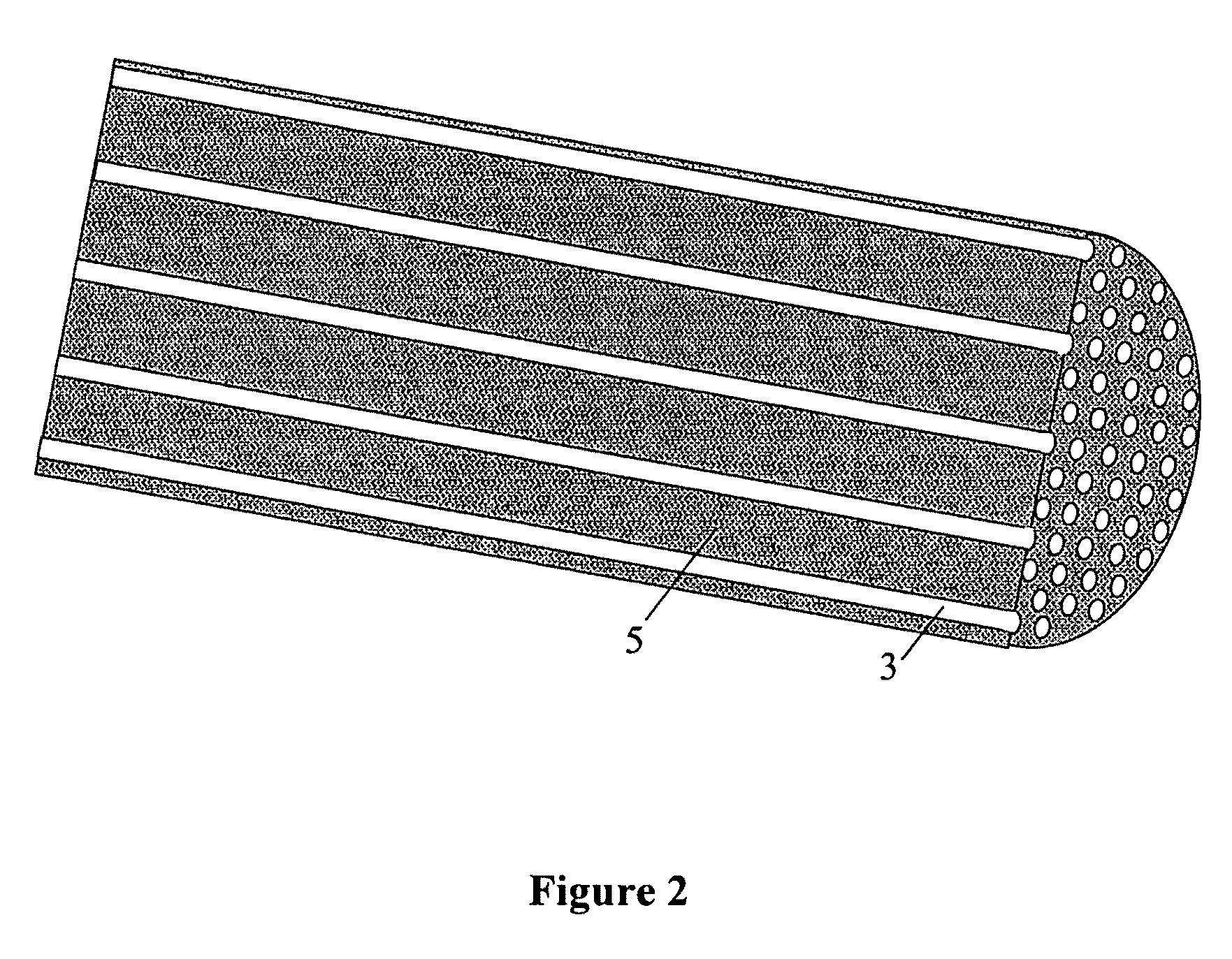

The present invention relates to engineered structured adsorbent contactors for use in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

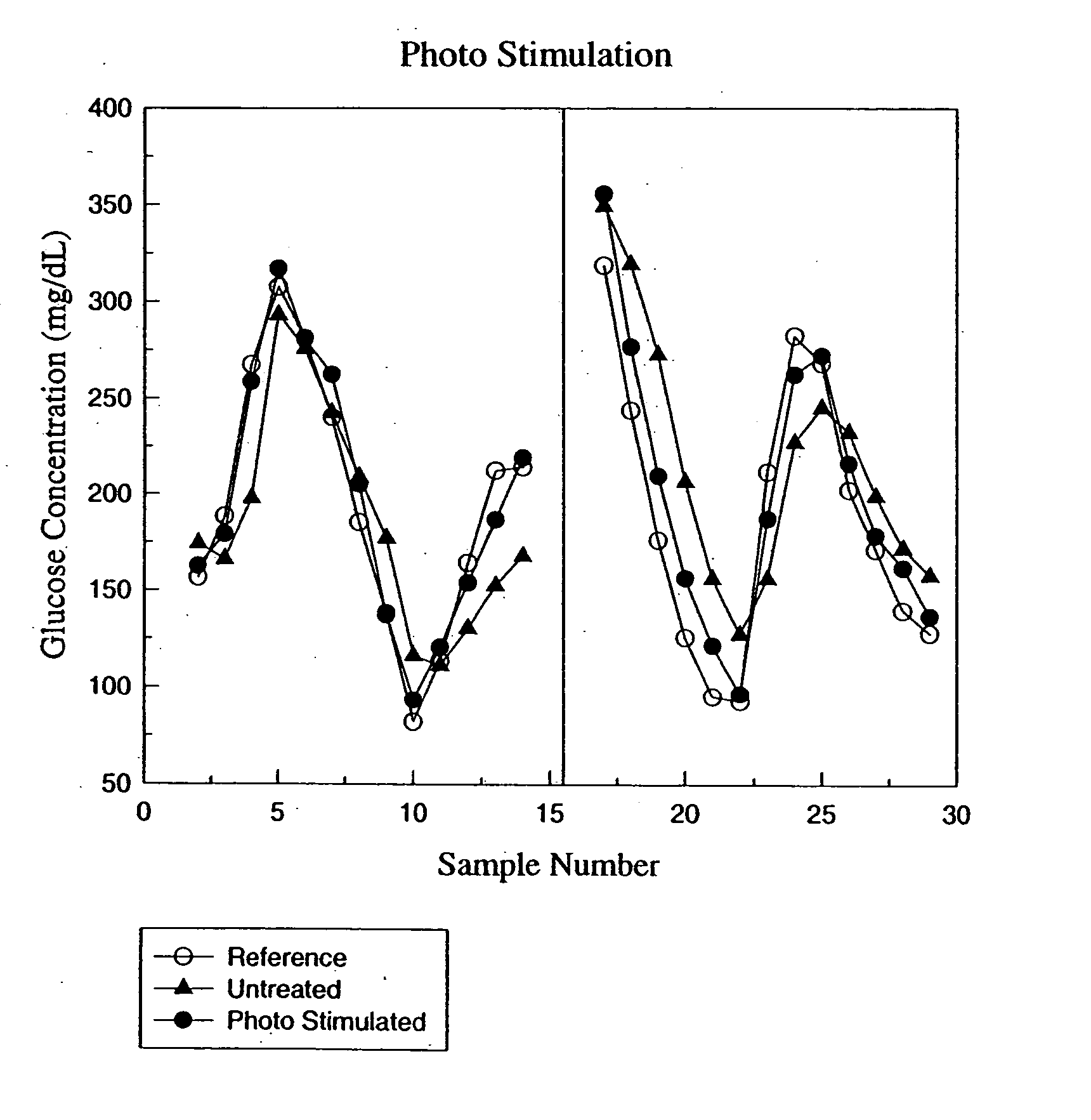

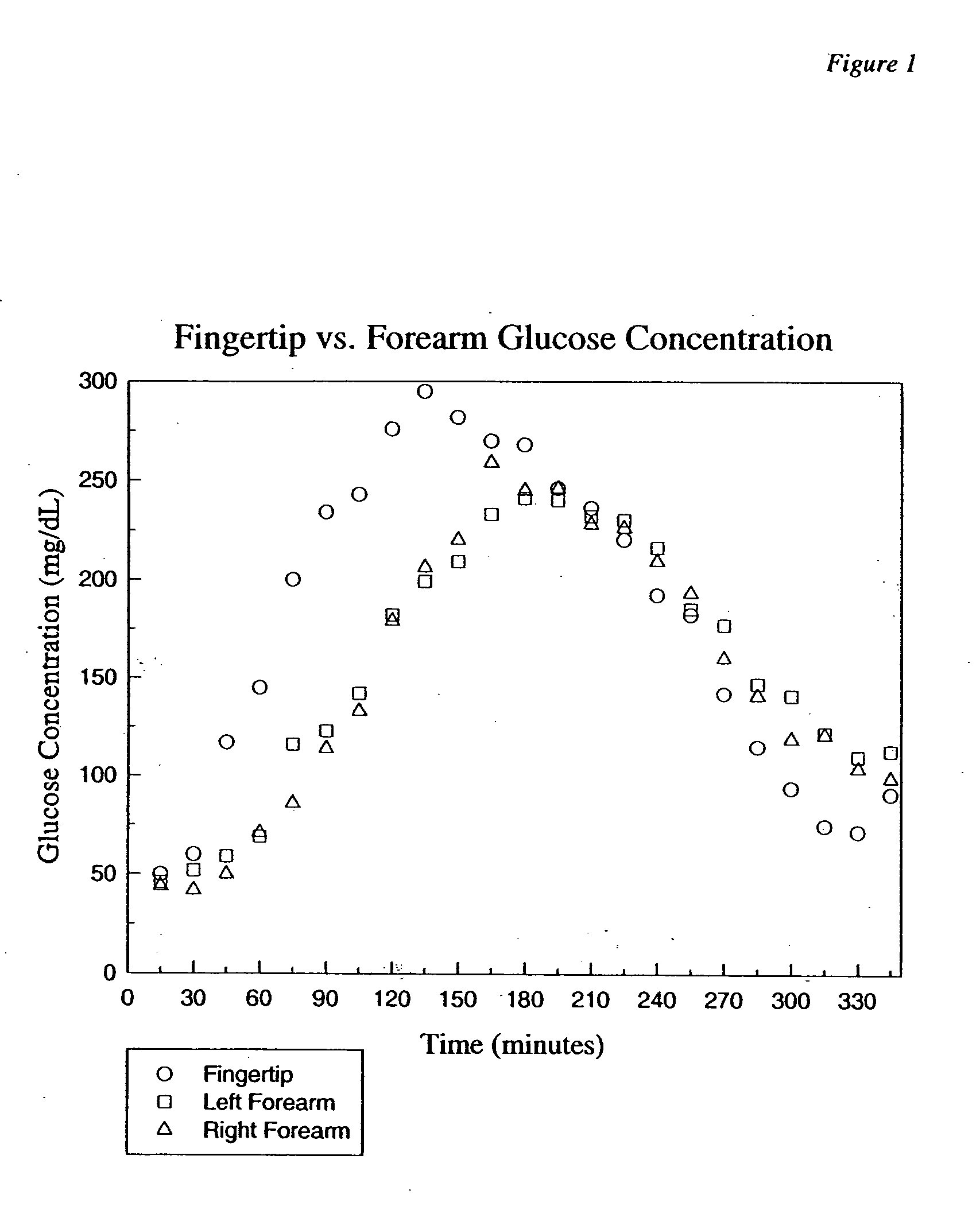

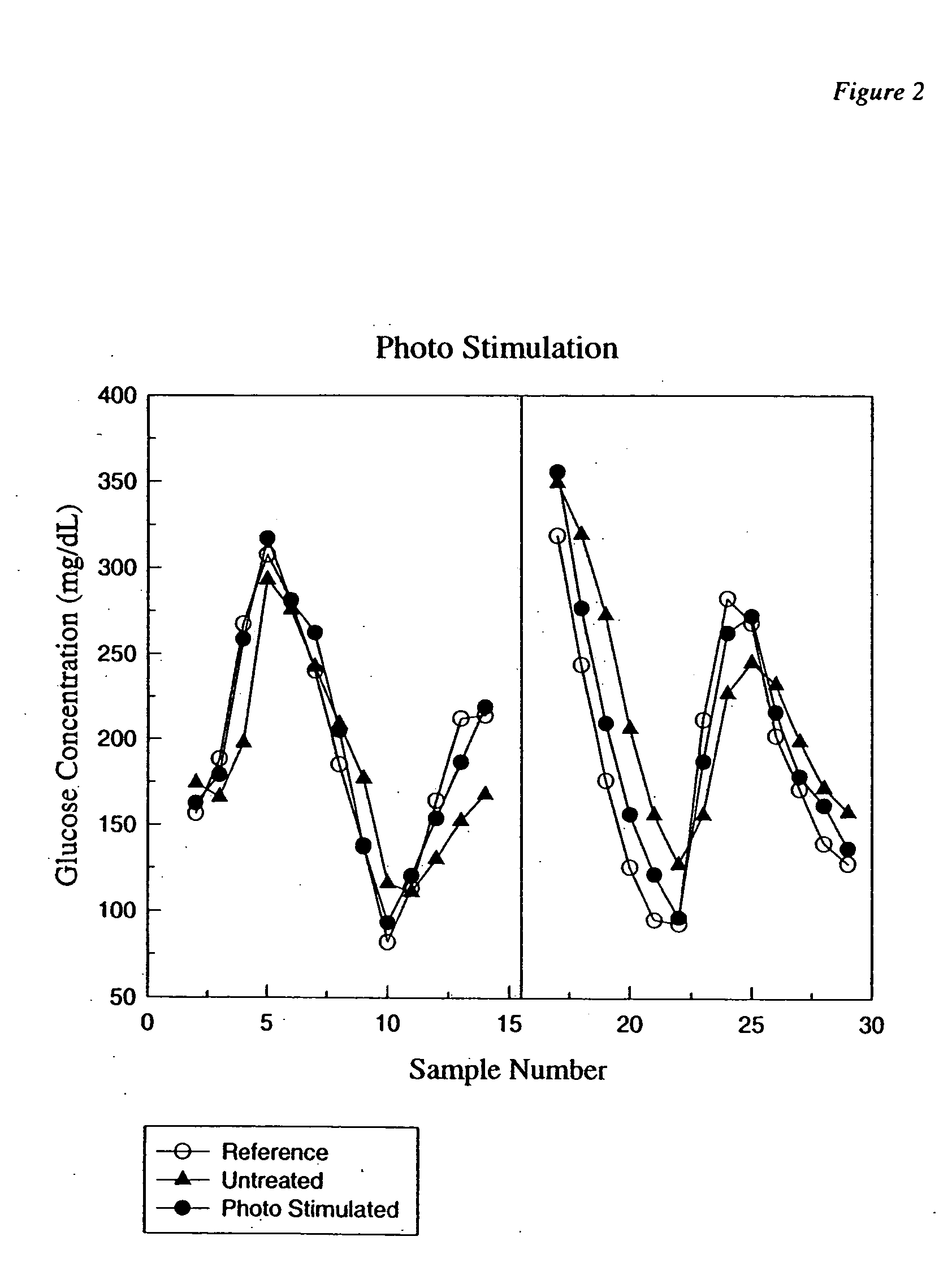

Photostimulation method and apparatus in combination with glucose determination

InactiveUS20050054908A1Increase perfusionReduce errorsDiagnostics using spectroscopyColor/spectral properties measurementsBody compartmentPerfusion

A method and apparatus using photo-stimulation to treat or pretreat a sample site prior to analyte concentration determination is presented. More particularly, photo-stimulation at or near at least one sample site is used to enhance perfusion of the sample site leading to reduced errors associated with sampling. Increased perfusion of the sample site leads to increased volume percentages of the target analyte and / or allows the blood or tissue constituent concentrations to more accurately and / or precisely track corresponding sample constituents in more well perfused body compartments or sites such as arteries, veins, or fingertips. In one embodiment, analysis of the photo-stimulated site is used in conjunction with glucose analyzers to determine the analyte concentration with greater ease, accuracy, or precision and may allow determination of the analyte concentration of another non-sampled body part or compartment.

Owner:GLENN PATENT GROUP

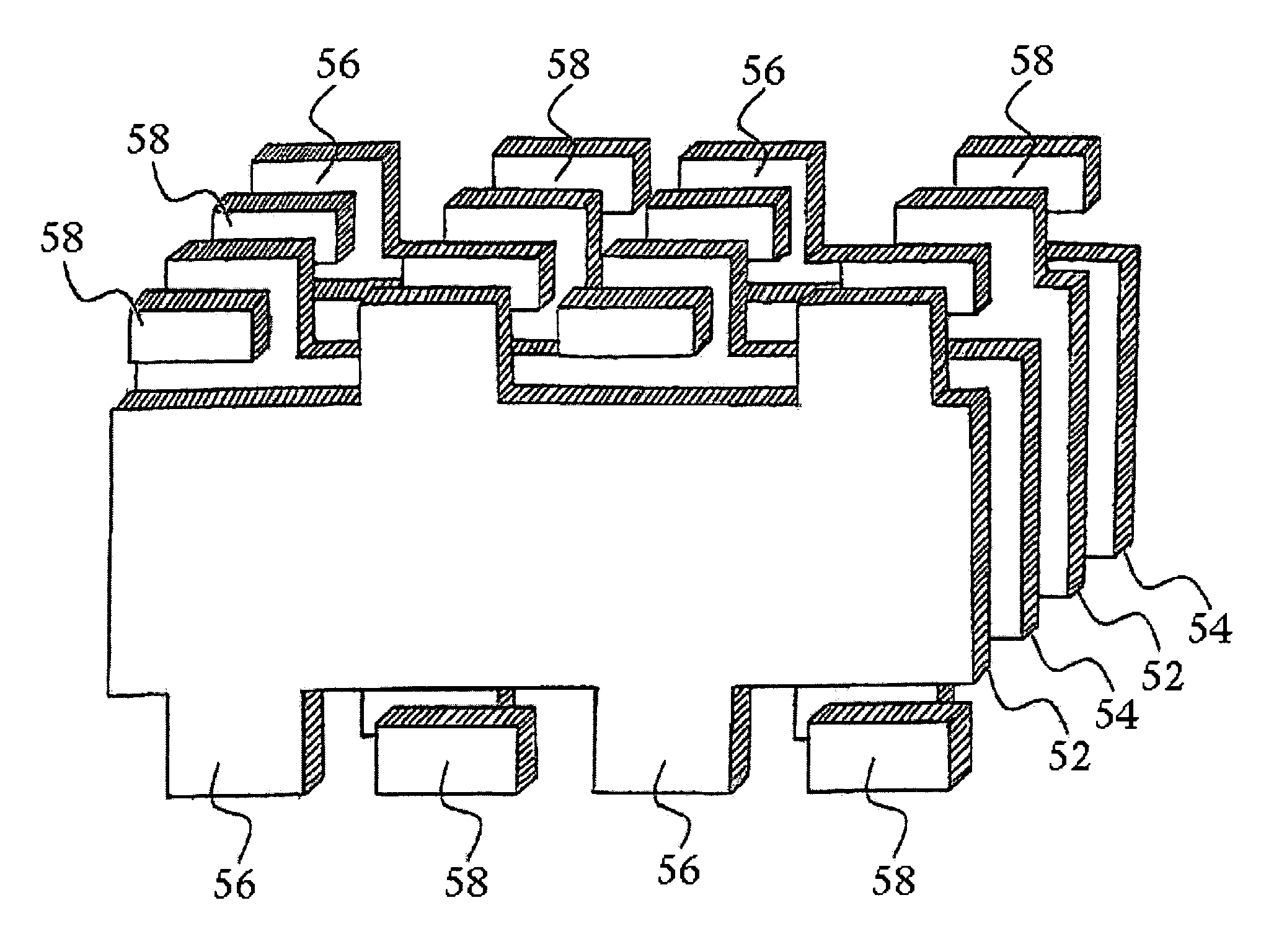

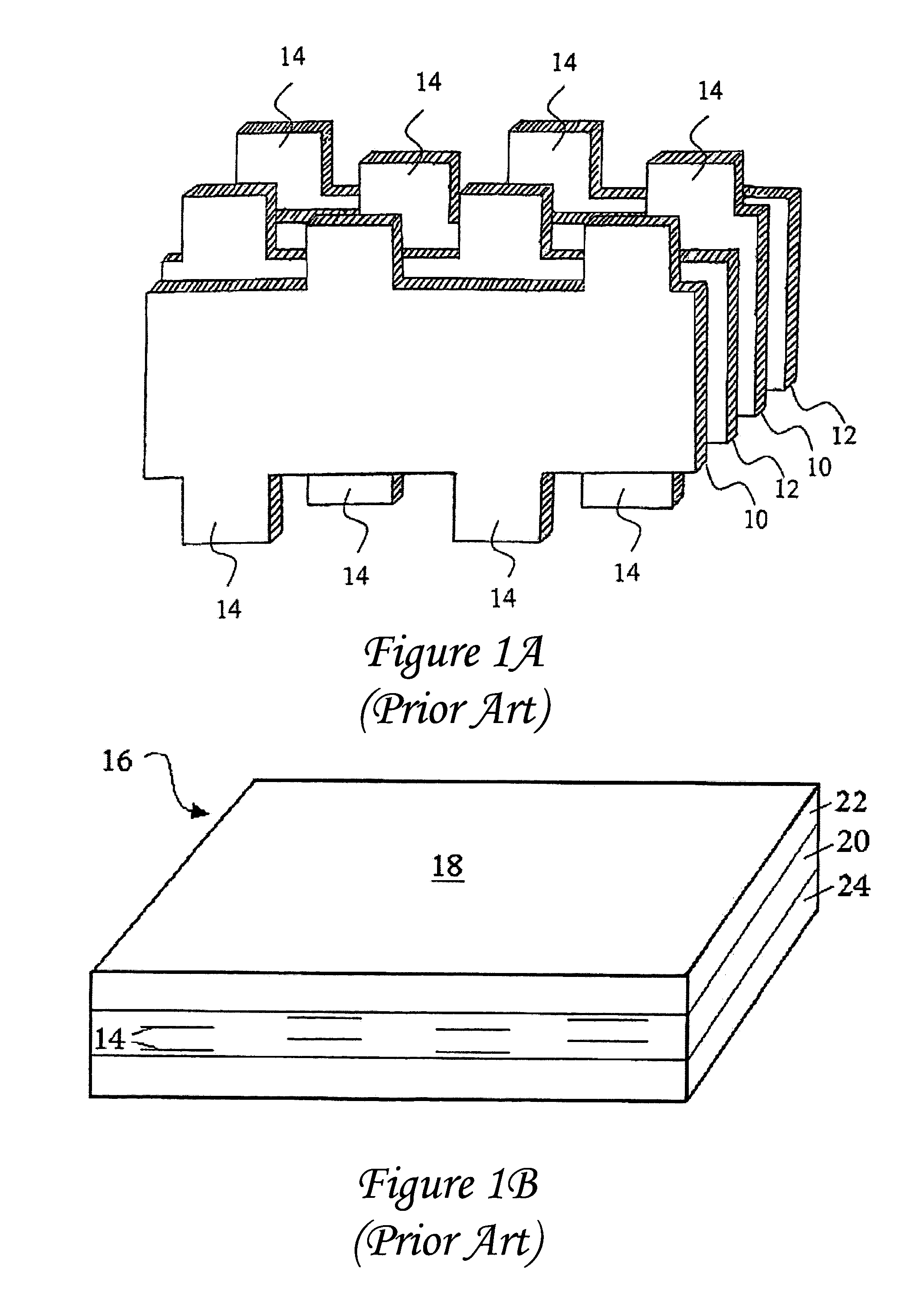

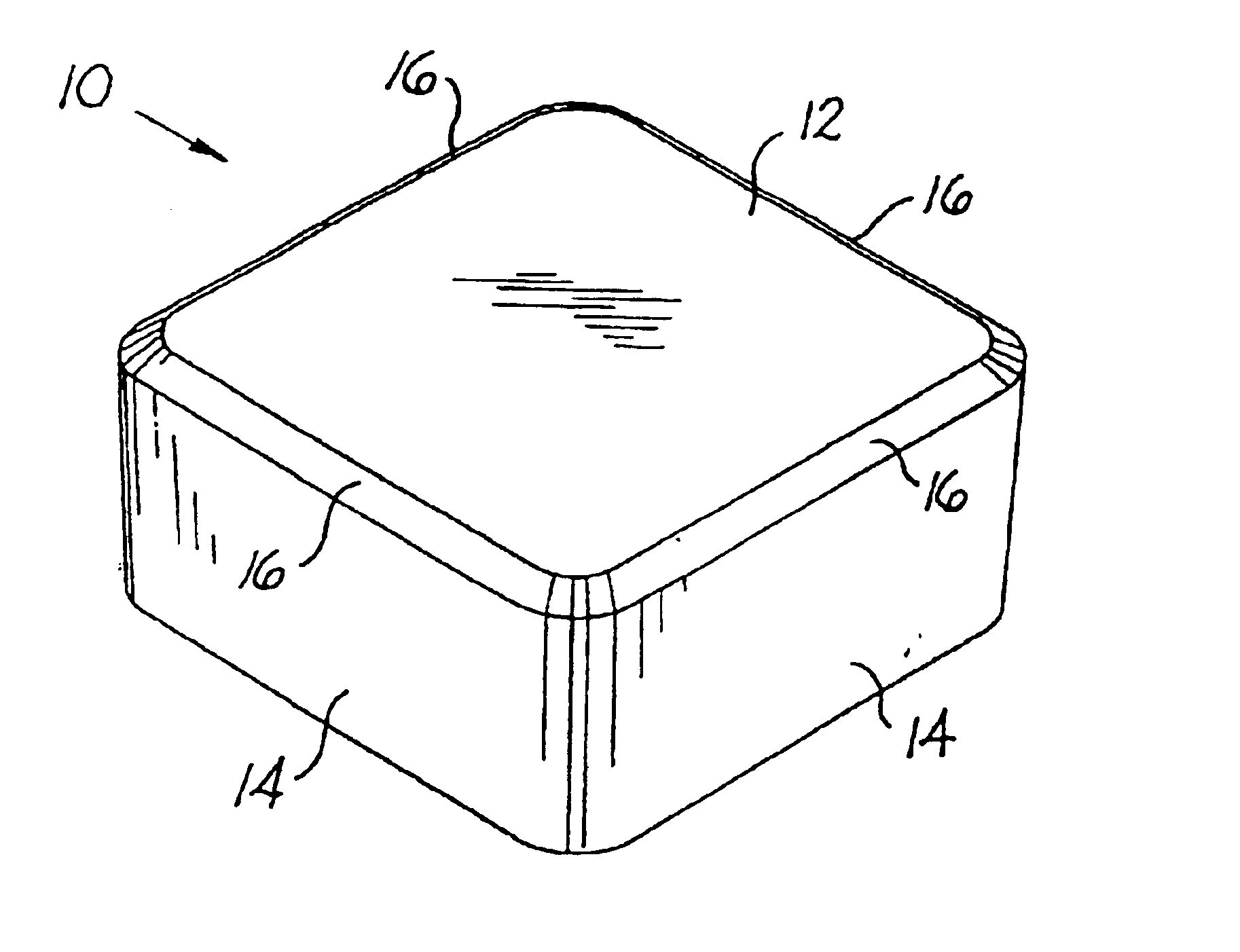

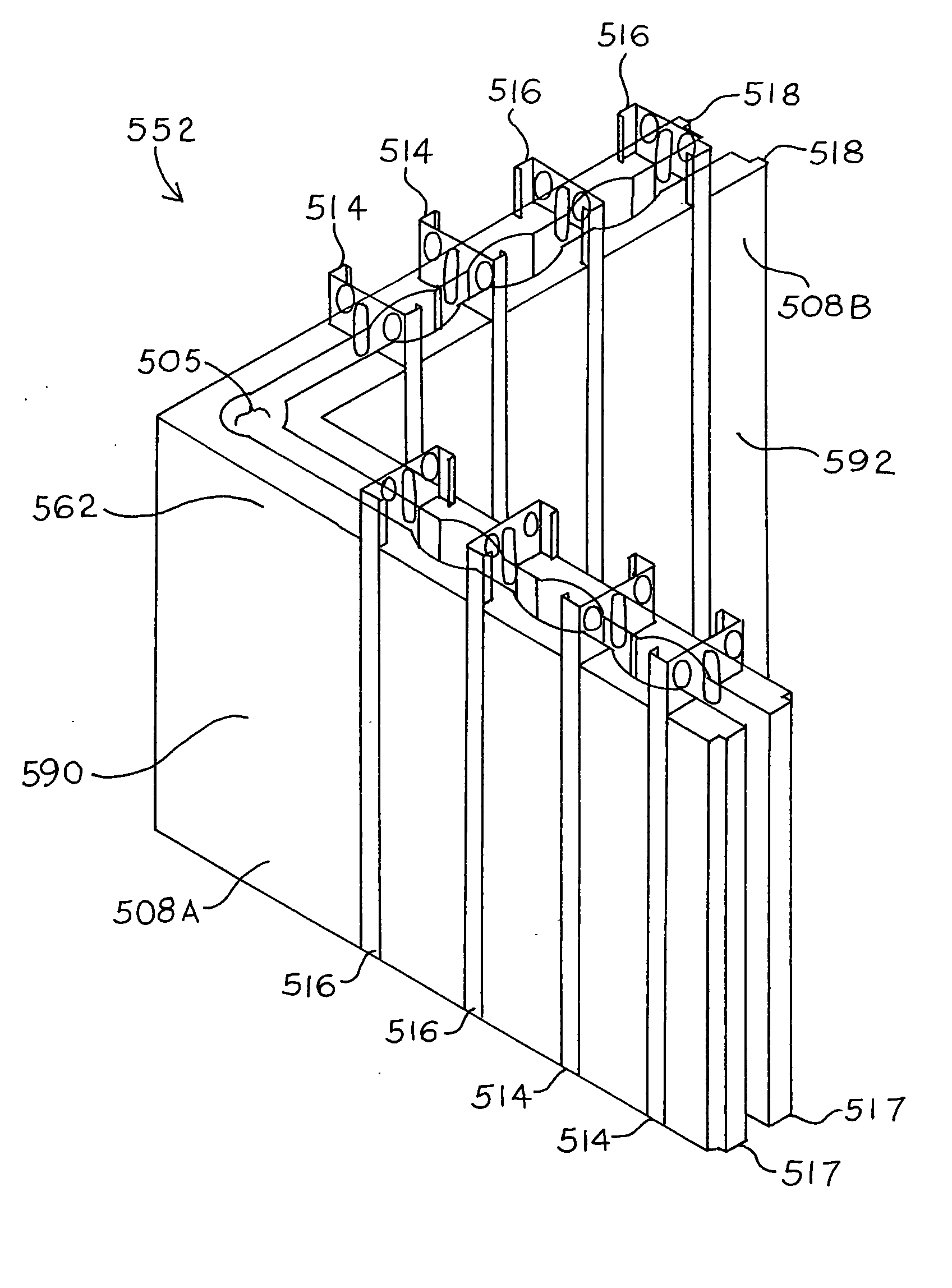

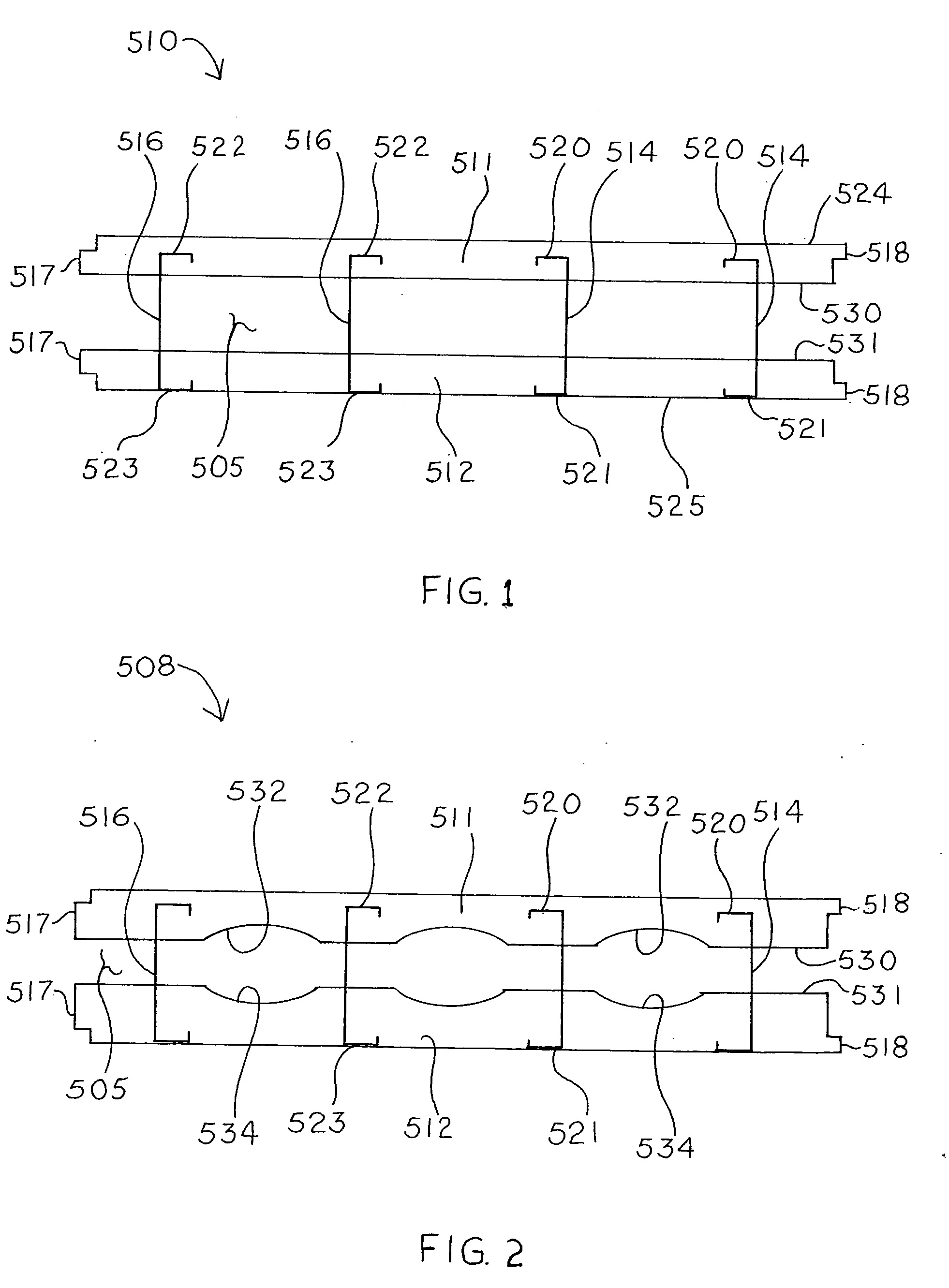

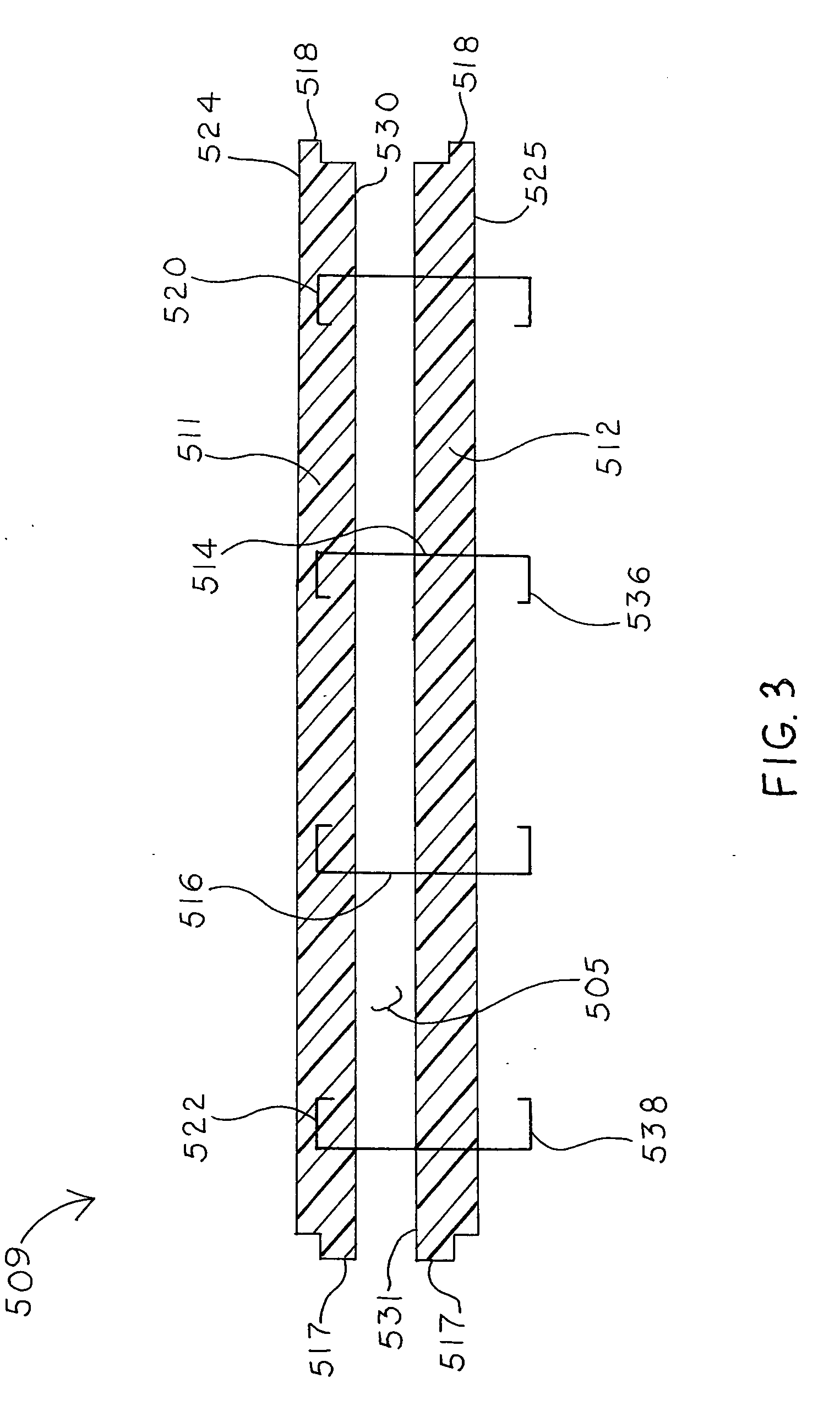

Plated terminations

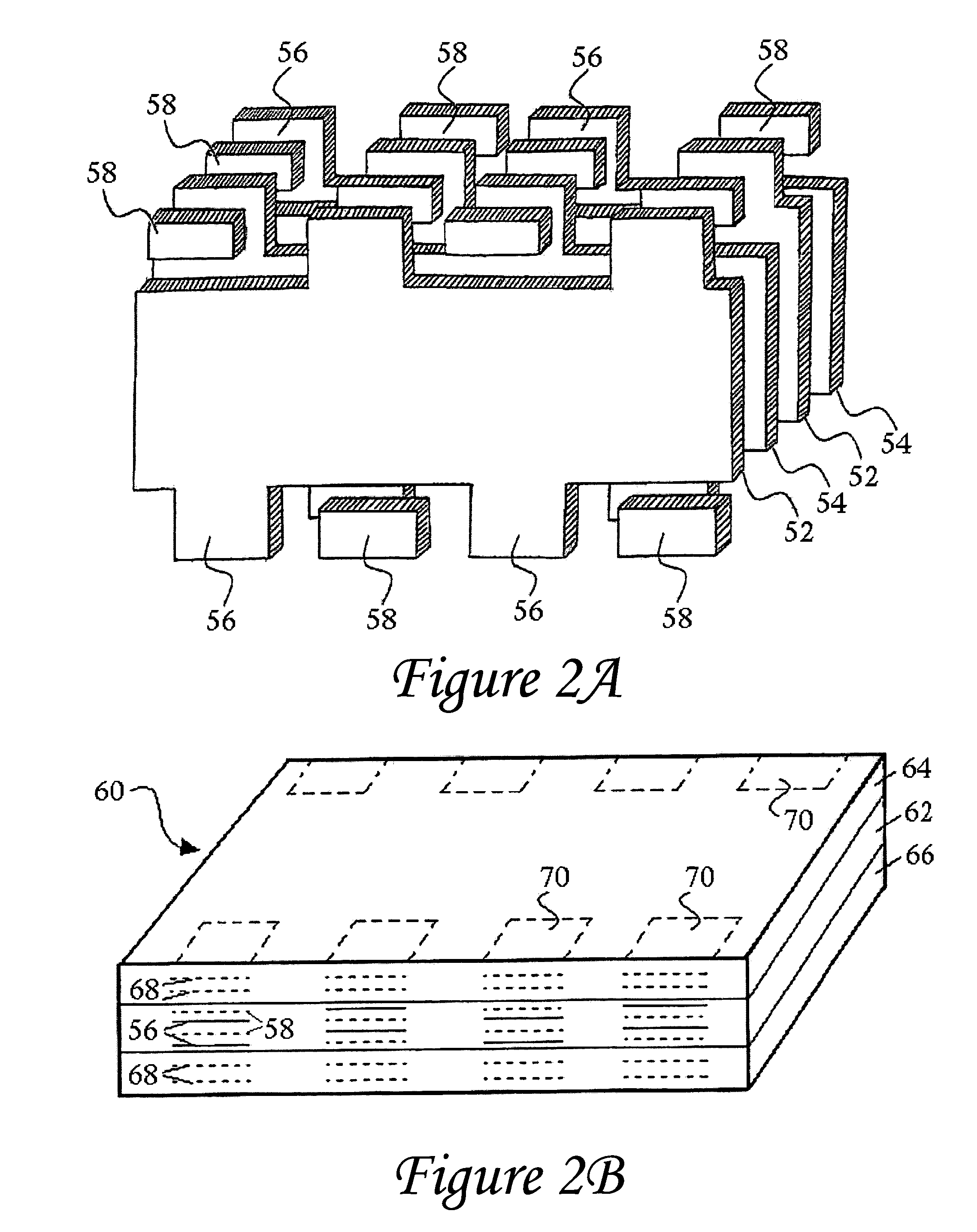

InactiveUS7177137B2Improved termination featureEliminate or greatly simplify thick-film stripesFixed capacitor electrodesFixed capacitor dielectricHigh densityEngineering

A multilayer electronic component includes a plurality of dielectric layers interleaved with a plurality of internal electrode elements and a plurality of internal anchor tabs. Portions of the internal electrode elements and anchor tabs are exposed along the periphery of the electronic component in one or more aligned columns. Each exposed portion is within a predetermined distance from other exposed portions in a given column such that bridged terminations may be formed by depositing one or more plated termination materials over selected of the respectively aligned columns. Internal anchor tabs may be provided and exposed in prearranged relationships with other exposed conductive portions to help nucleate metallized plating material along the periphery of a device. External anchor tabs or lands may be provided to form terminations that extend to top and / or bottom surfaces of the device. Selected of the conductive elements may be formed by a finite volume percentage of ceramic material for enhanced durability, and external lands may be thicker than internal conductive elements and / or may also be embedded in top and / or bottom component surfaces. A variety of potential internal electrode configurations are possible including ones configured for orientation-insensitive component mounting and for high density peripheral termination interdigitated capacitors.

Owner:KYOCERA AVX COMPONENTS CORP

Removal of CO2, N2, or H2S from gas mixtures by swing adsorption with low mesoporosity adsorbent contactors

The present invention relates to the separation of one or more of CO2, N2, and H2S gas components from a gas mixture containing at least a second gas using a swing adsorption process unit. The adsorbent contactors of the swing adsorption process unit are engineered structured adsorbent contactors having a plurality of flow channels wherein 20 volume percent or less of the open pore volume of the contactors is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

Removal of heavy hydrocarbons from gas mixtures containing heavy hydrocarbons and methane

A process for the separation of one or more heavy hydrocarbon gases from a gas mixture containing heavy hydrocarbon gas components and methane. The process is conducted in swing adsorption apparatus containing adsorbent contactor having a plurality of flow channels and wherein 20 volume percent or less of the open pore volume of the contactors, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

Process for removing a target gas from a mixture of gases by swing adsorption

The present invention relates the separation of a target gas from a mixture of gases through the use of engineered structured adsorbent contactors in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

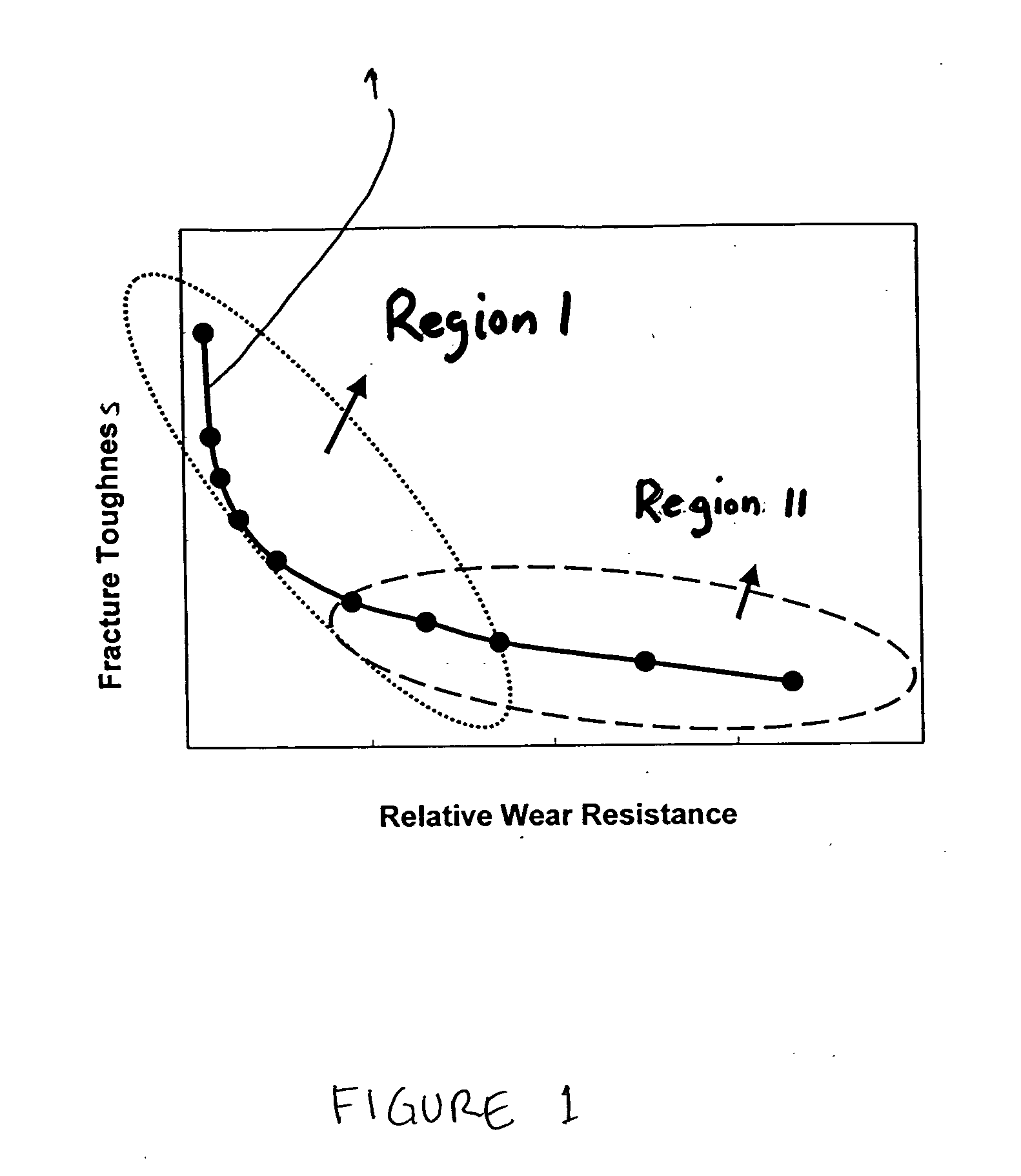

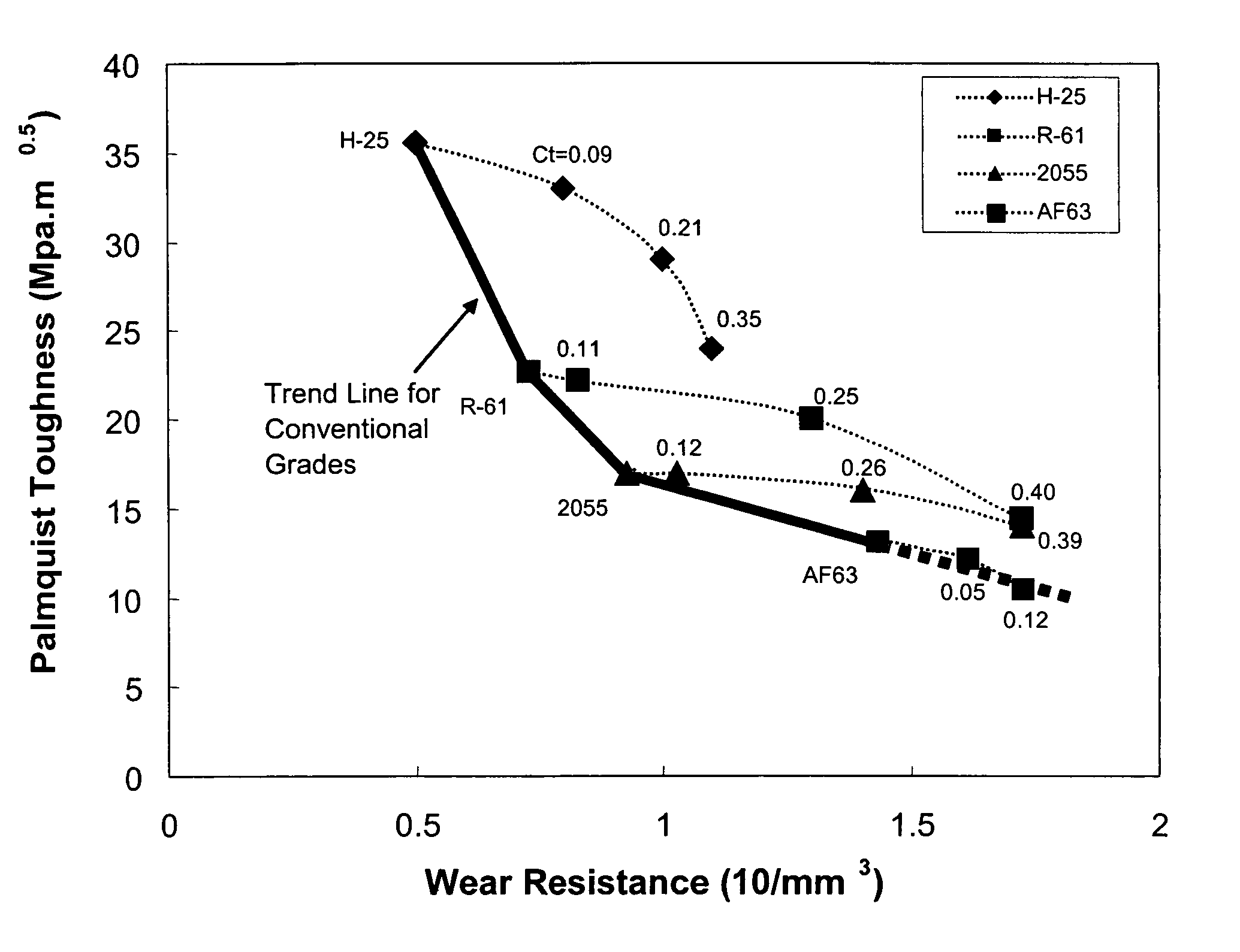

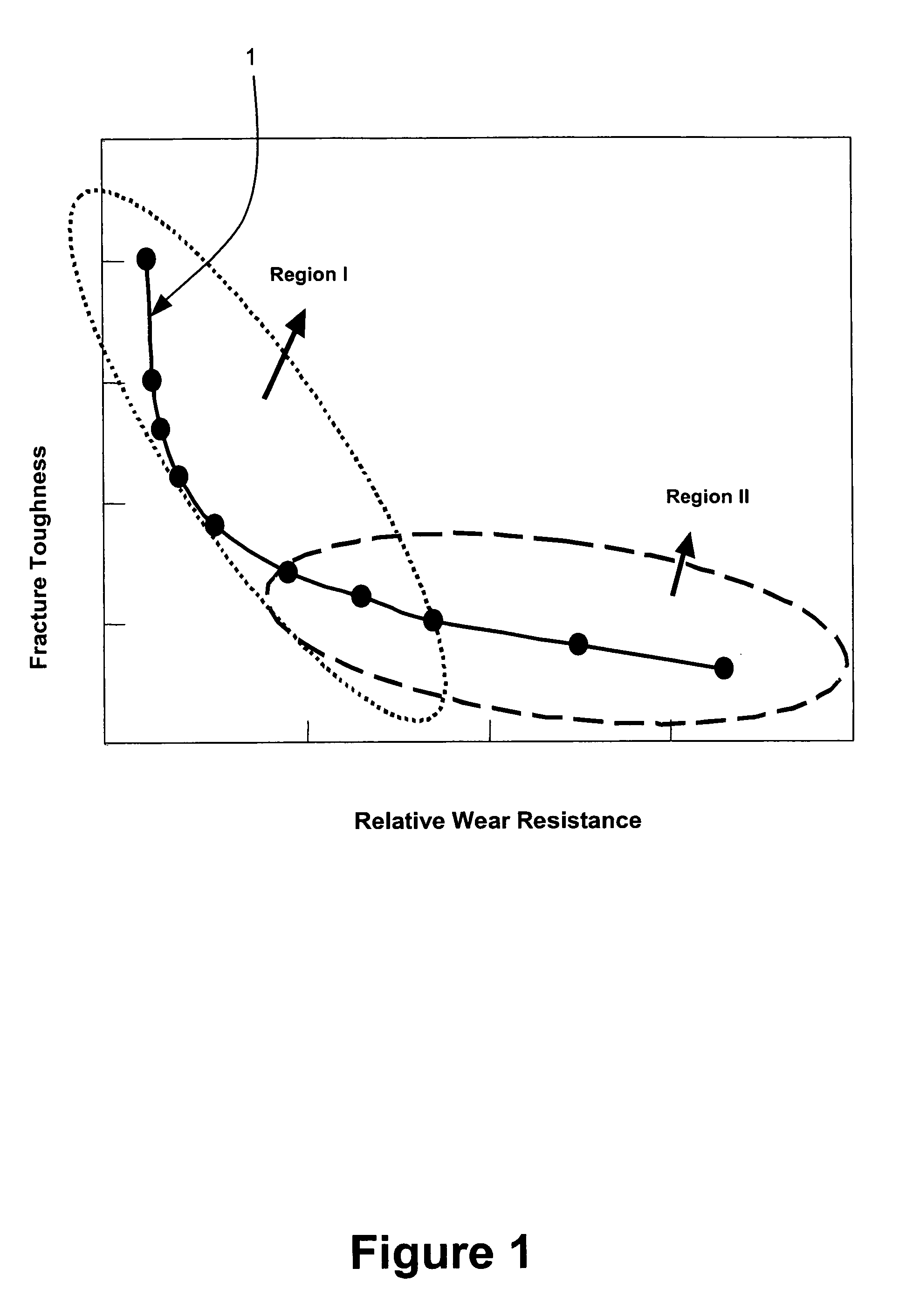

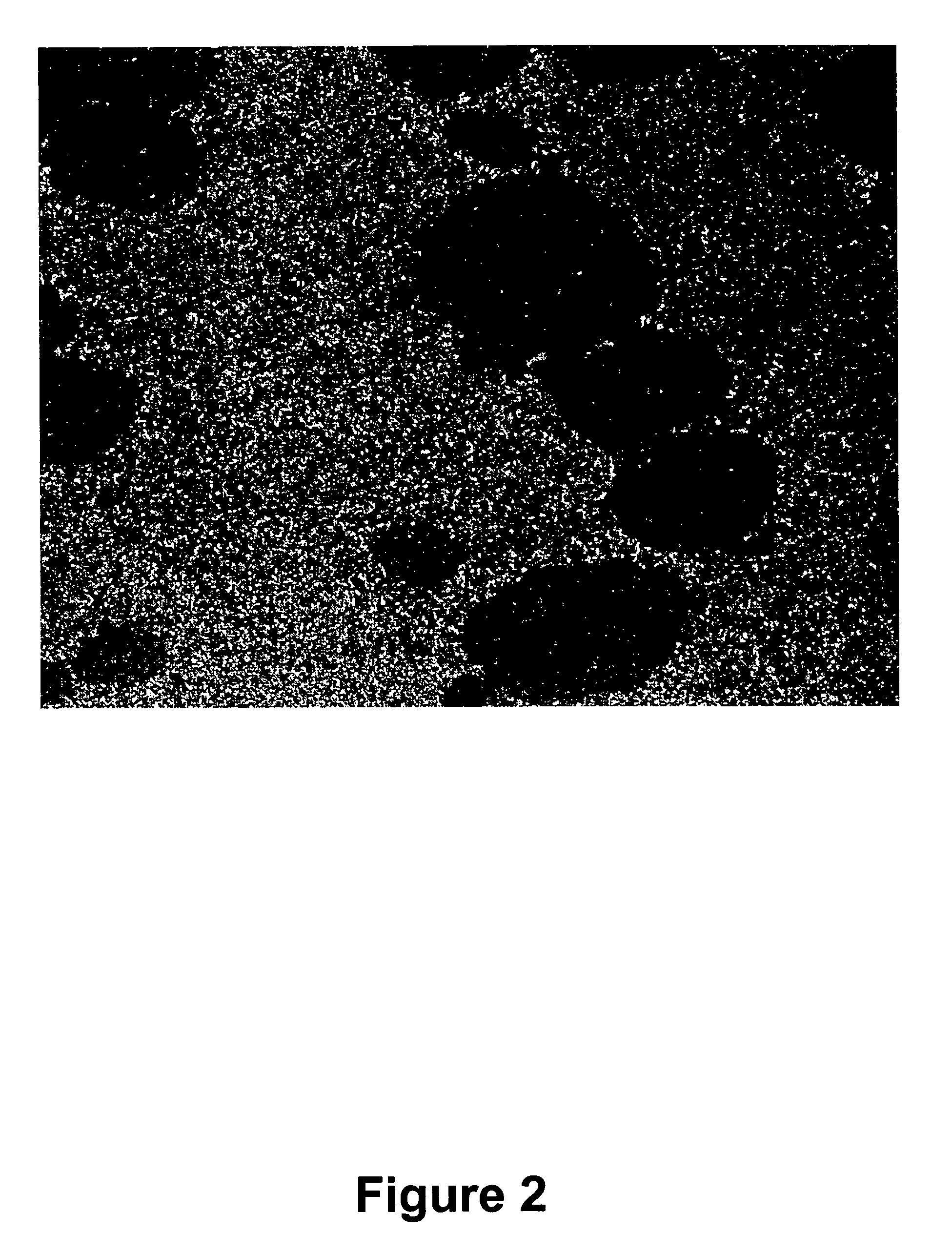

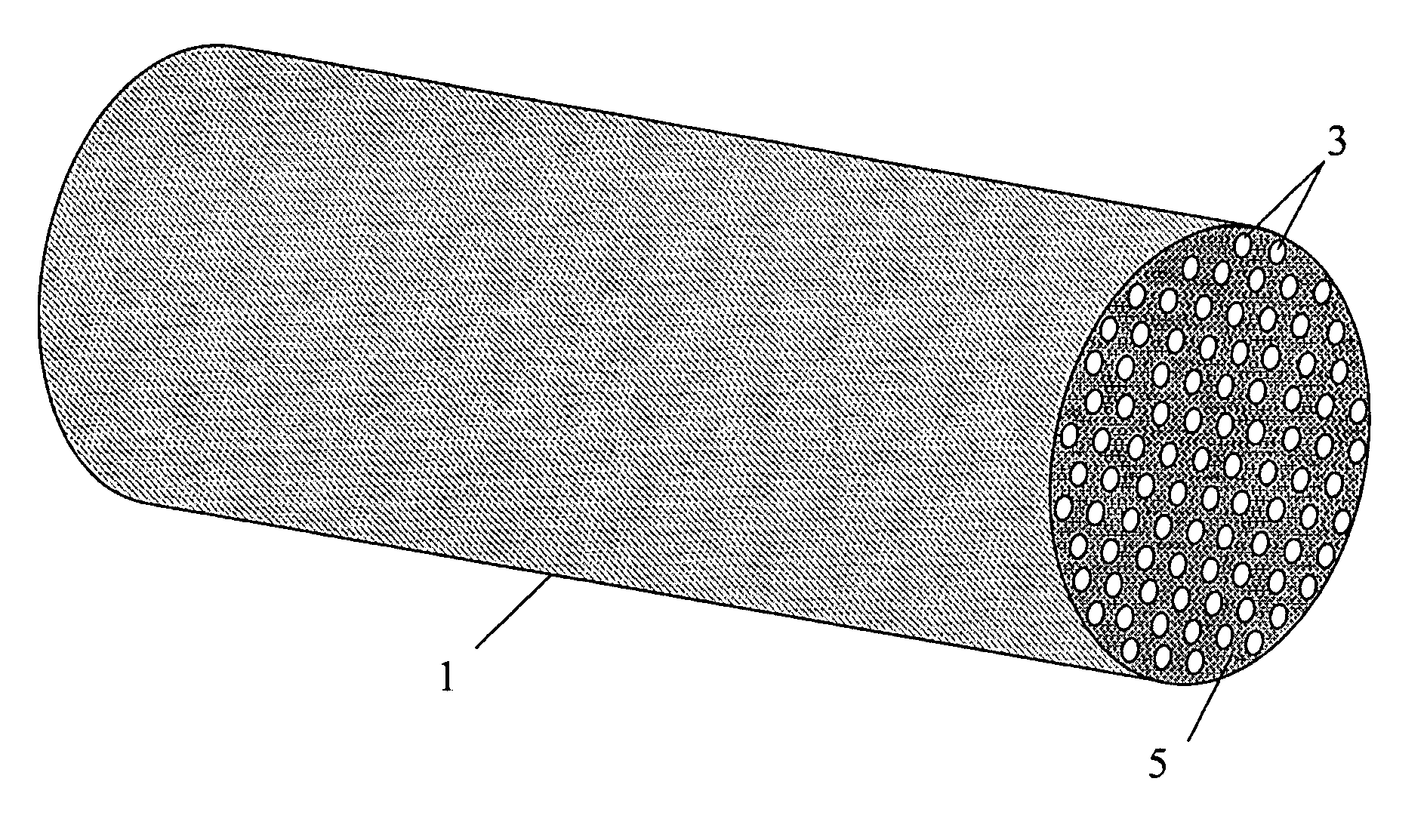

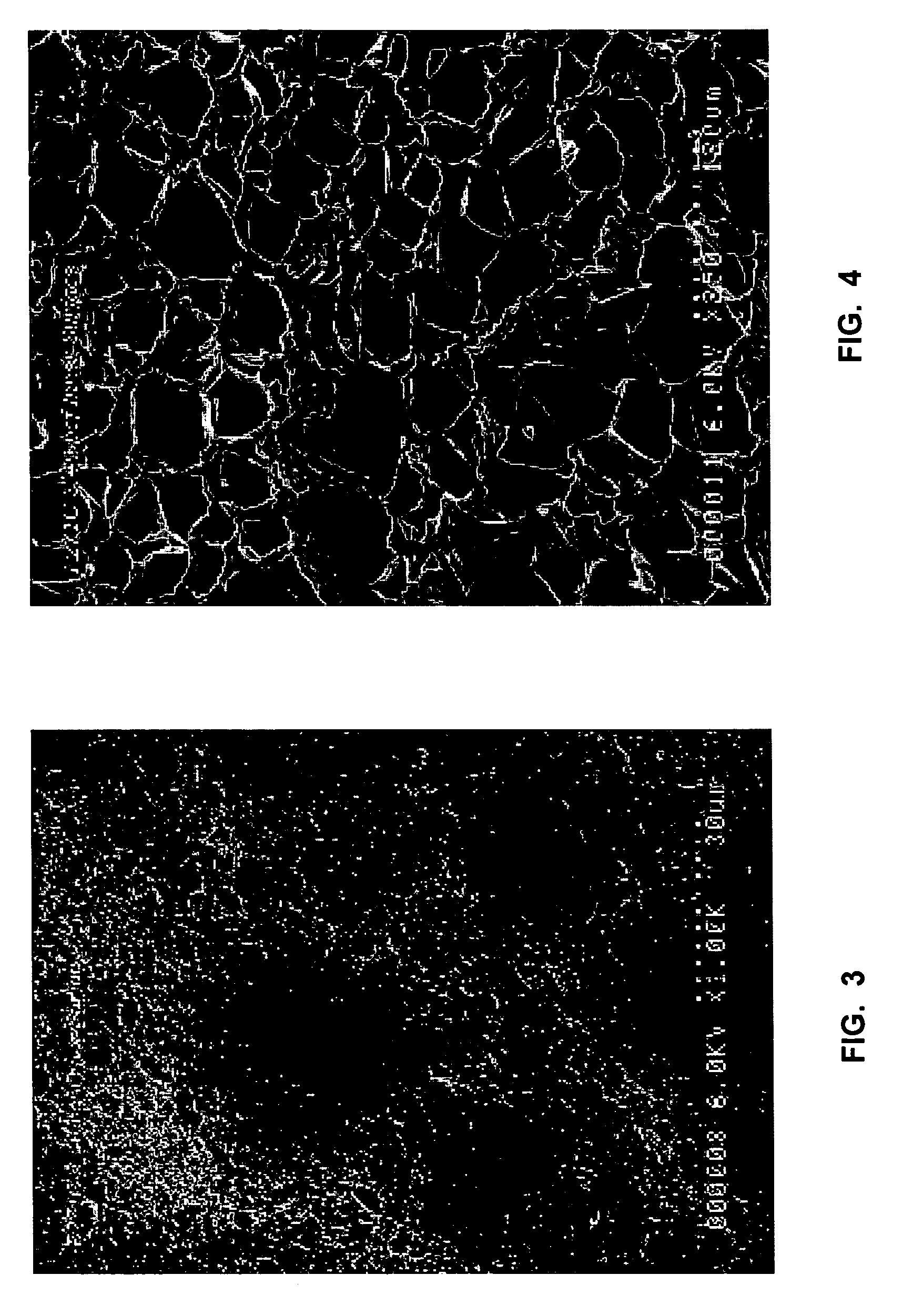

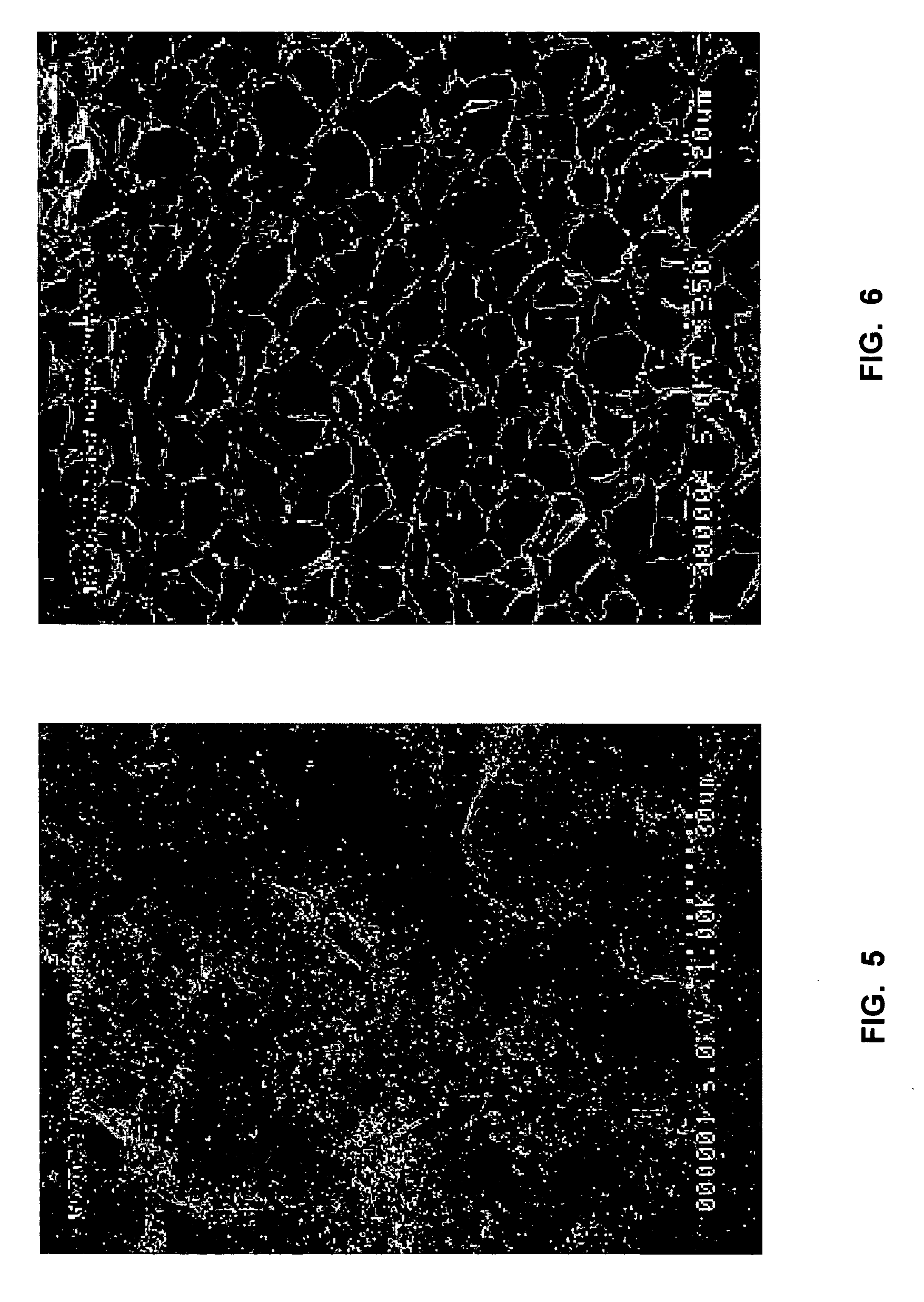

Hybrid cemented carbide composites

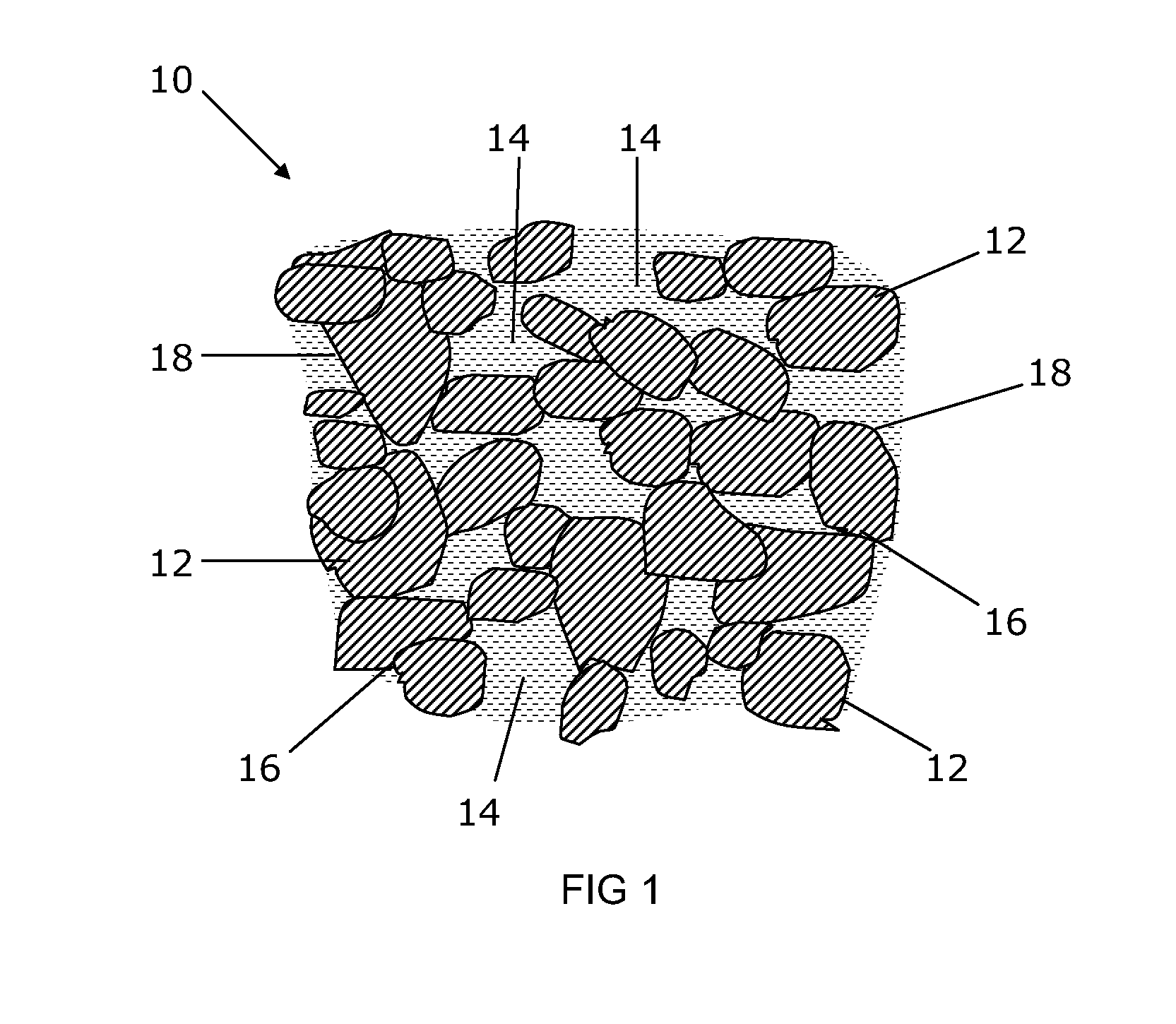

Embodiments of the present invention include hybrid composite materials comprising a cemented carbide dispersed phase and a cemented carbide continuous phase. The contiguity ratio of the dispersed phase of embodiments may be less than or equal to 0.48. The hybrid composite material may have a hardness of the dispersed phase that is greater than the hardness of the continuous phase. For example, in certain embodiments of the hybrid composite material, the hardness of the dispersed phase is greater than or equal to 88 HRA and less than or equal to 95 HRA and the hardness of the continuous phase is greater than or equal to 78 and less than or equal to 91 HRA. Additional embodiments may include hybrid composite materials comprising a first cemented carbide dispersed phase wherein the volume fraction of the dispersed phase is less than 50 volume percent and a second cemented carbide continuous phase, wherein the contiguity ratio of the dispersed phase is less than or equal to 1.5 times the volume fraction of the dispersed phase in the composite material. The present invention also includes a method of making a hybrid cemented carbide composite by blending partially and / or fully sintered granules of the dispersed cemented carbide grade with “green” and / or unsintered granules of the continuous cemented carbide grade to provide a blend. The blend may then be consolidated to form a compact. Finally, the compact may be sintered to form a hybrid cemented carbide.

Owner:KENNAMETAL INC

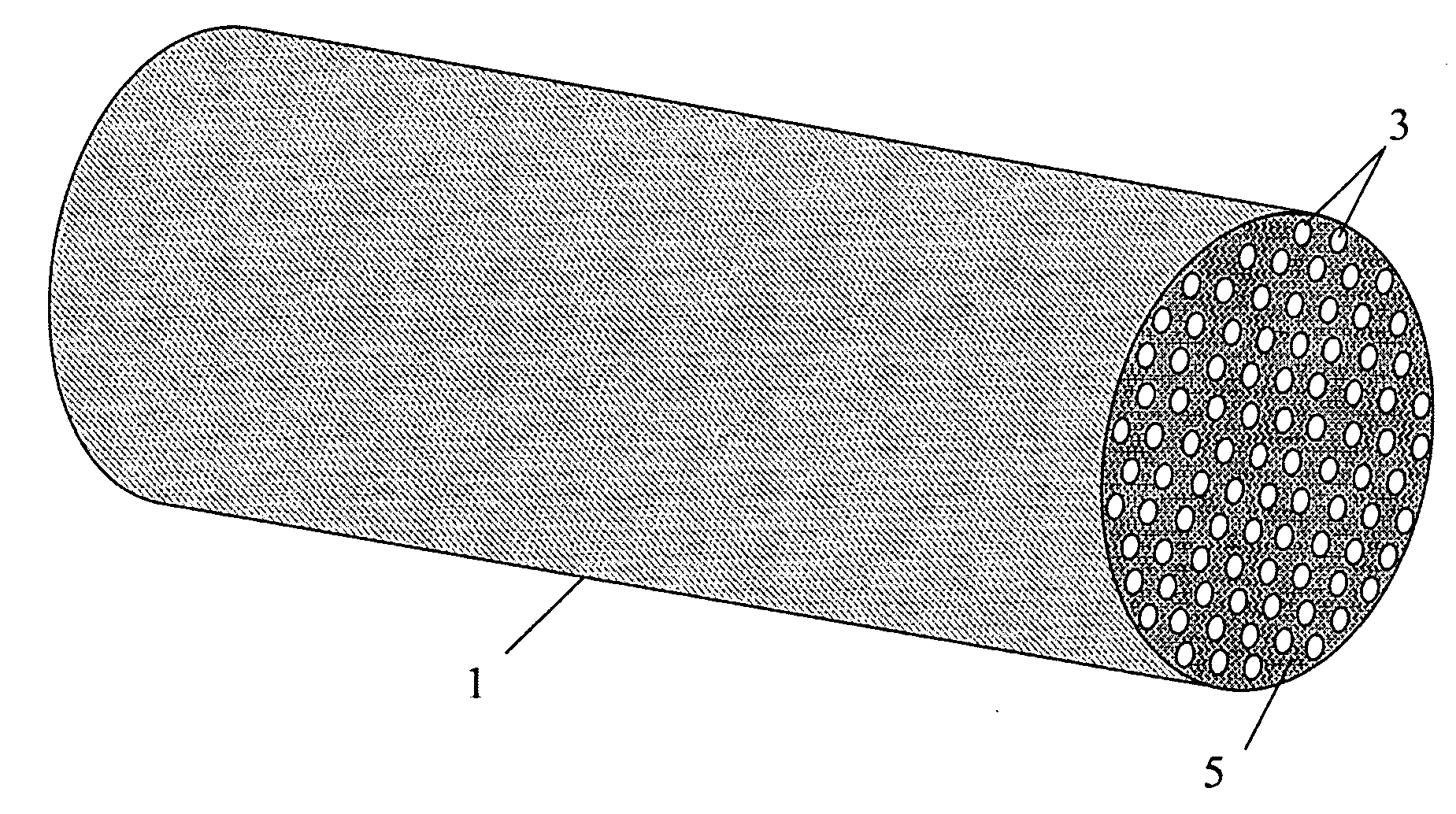

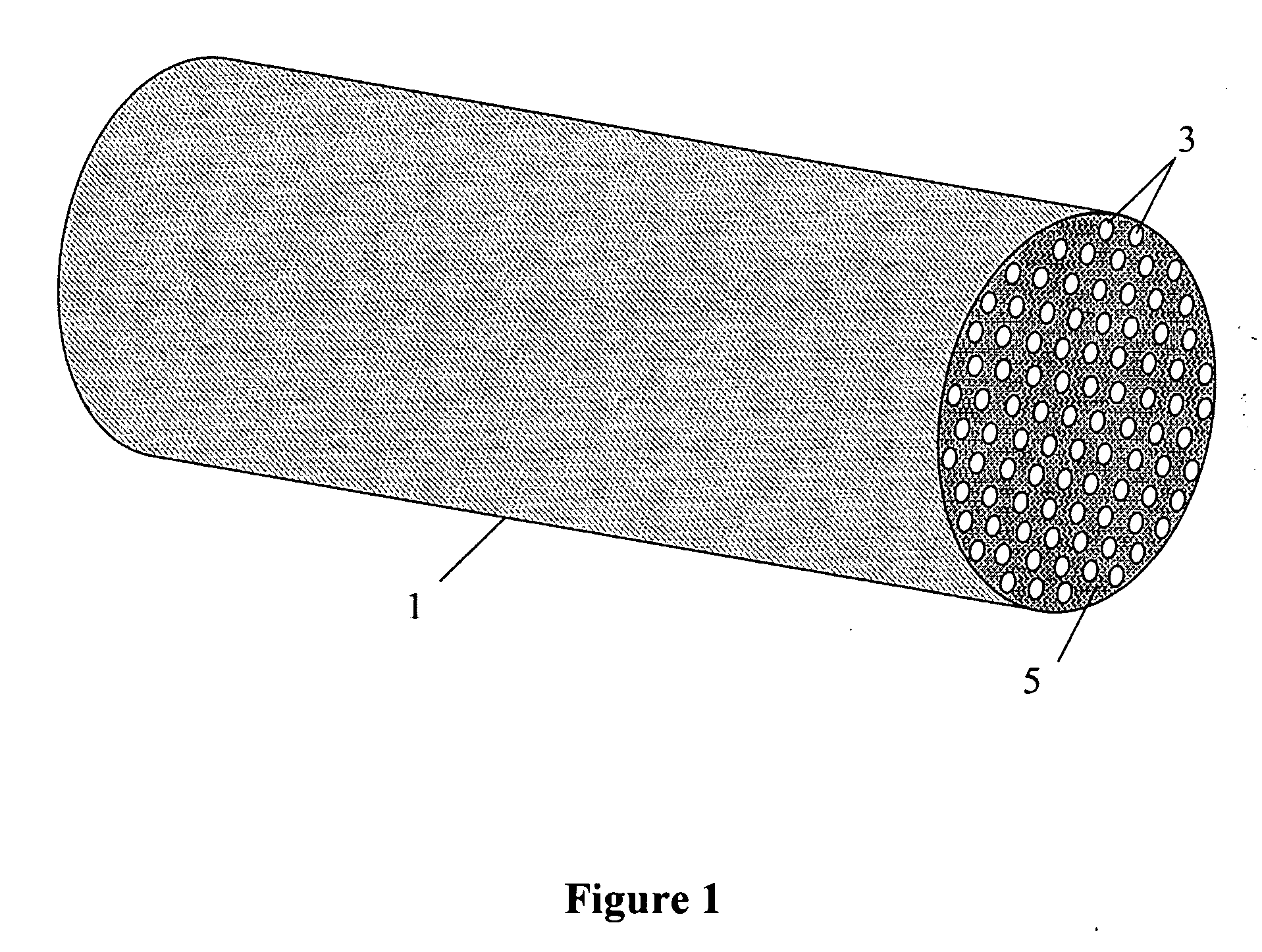

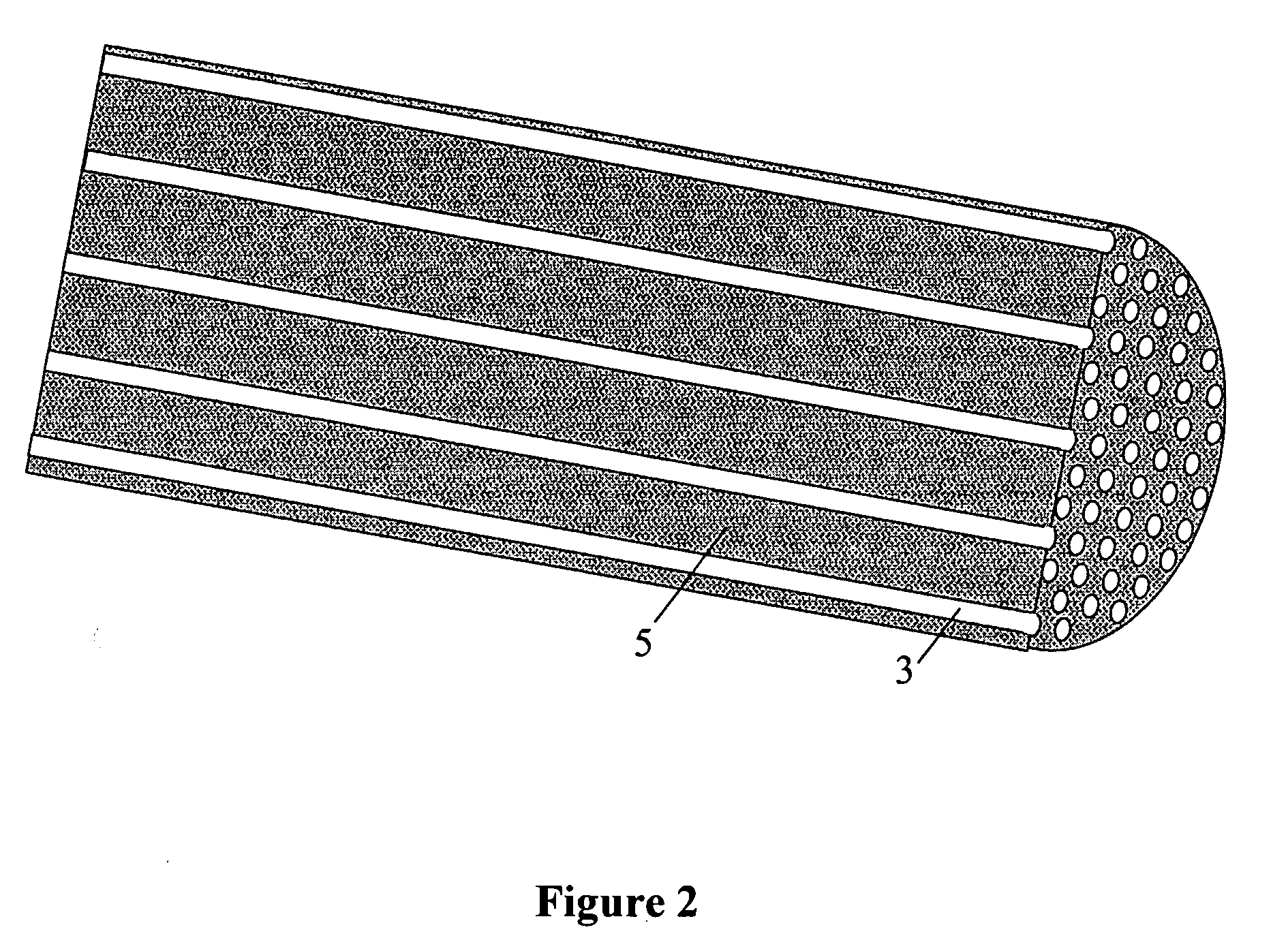

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

Hybrid cemented carbide composites

Embodiments of the present invention include hybrid composite materials comprising a cemented carbide dispersed phase and a cemented carbide continuous phase. The contiguity ratio of the dispersed phase of embodiments may be less than or equal to 0.48. The hybrid composite material may have a hardness of the dispersed phase that is greater than the hardness of the continuous phase. For example, in certain embodiments of the hybrid composite material, the hardness of the dispersed phase is greater than or equal to 88 HRA and less than or equal to 95 HRA and the hardness of the continuous phase is greater than or equal to 78 and less than or equal to 91 HRA.Additional embodiments may include hybrid composite materials comprising a first cemented carbide dispersed phase wherein the volume fraction of the dispersed phase is less than 50 volume percent and a second cemented carbide continuous phase, wherein the contiguity ratio of the dispersed phase is less than or equal to 1.5 times the volume fraction of the dispersed phase in the composite material.The present invention also includes a method of making a hybrid cemented carbide composite by blending partially and / or fully sintered granules of the dispersed cemented carbide grade with “green” and / or unsintered granules of the continuous cemented carbide grade to provide a blend. The blend may then be consolidated to form a compact. Finally, the compact may be sintered to form a hybrid cemented carbide.

Owner:KENNAMETAL INC

Low mesopore adsorbent contactors for use in swing adsorption processes

Owner:EXXON RES & ENG CO

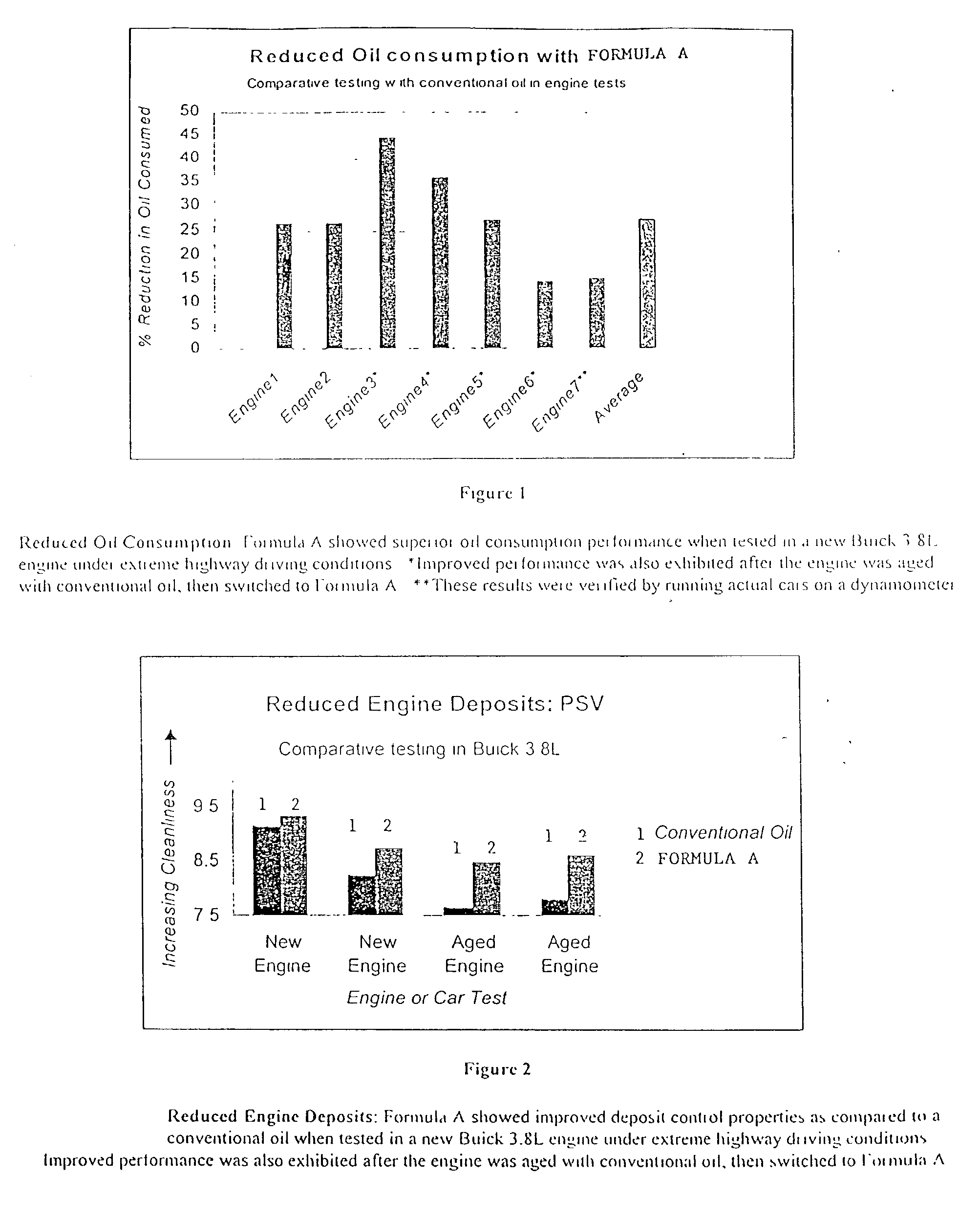

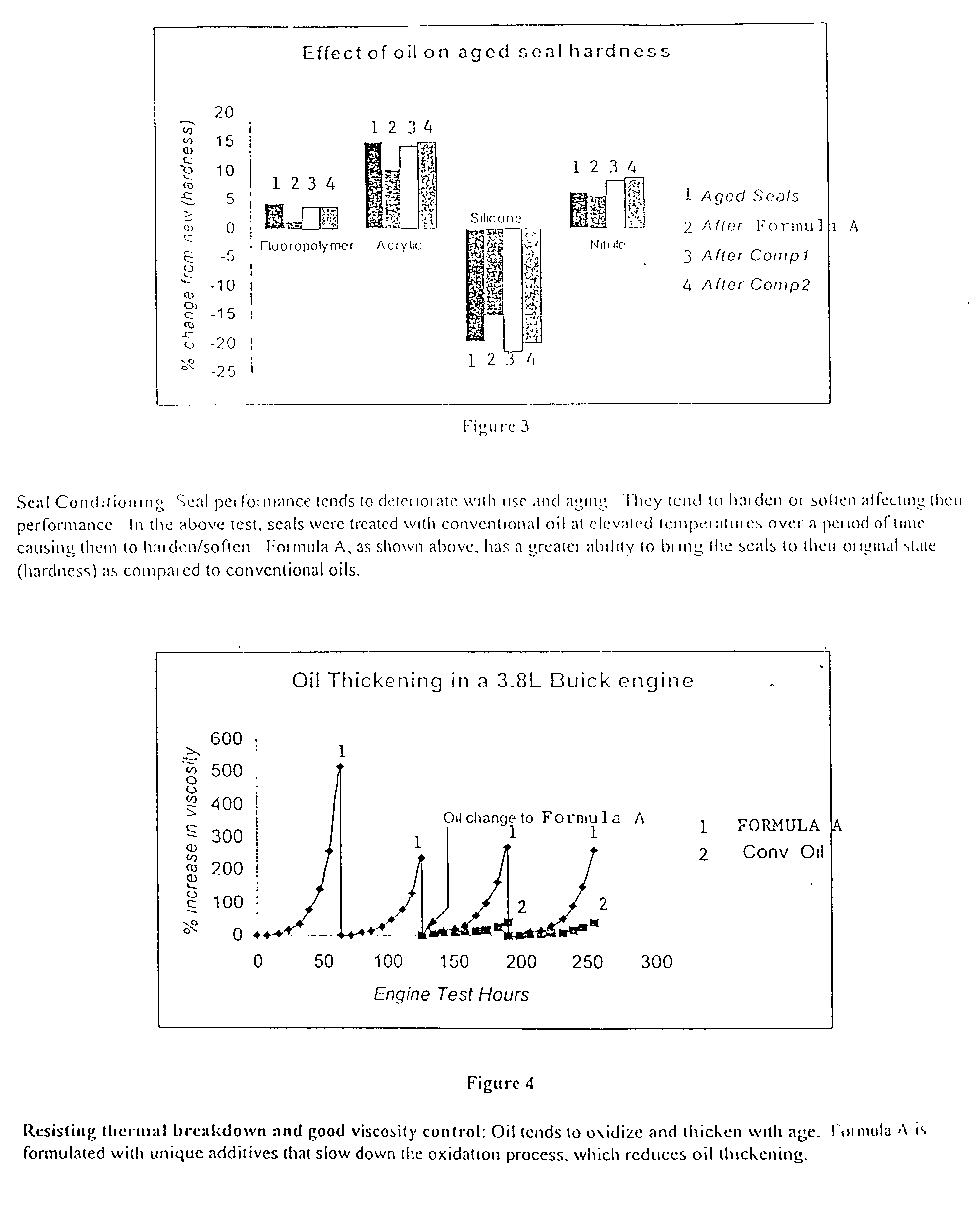

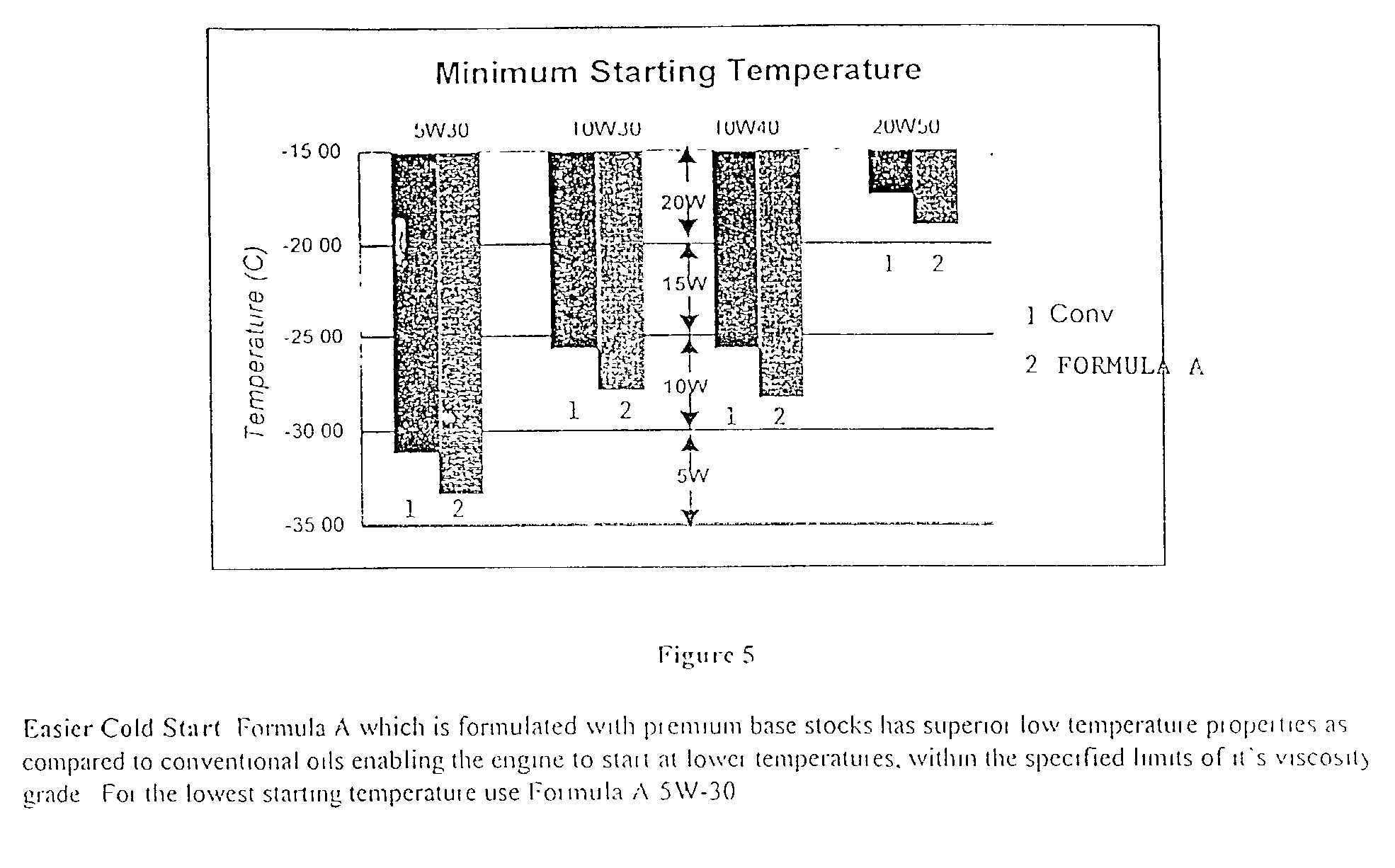

Lubricant and additive formulation

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

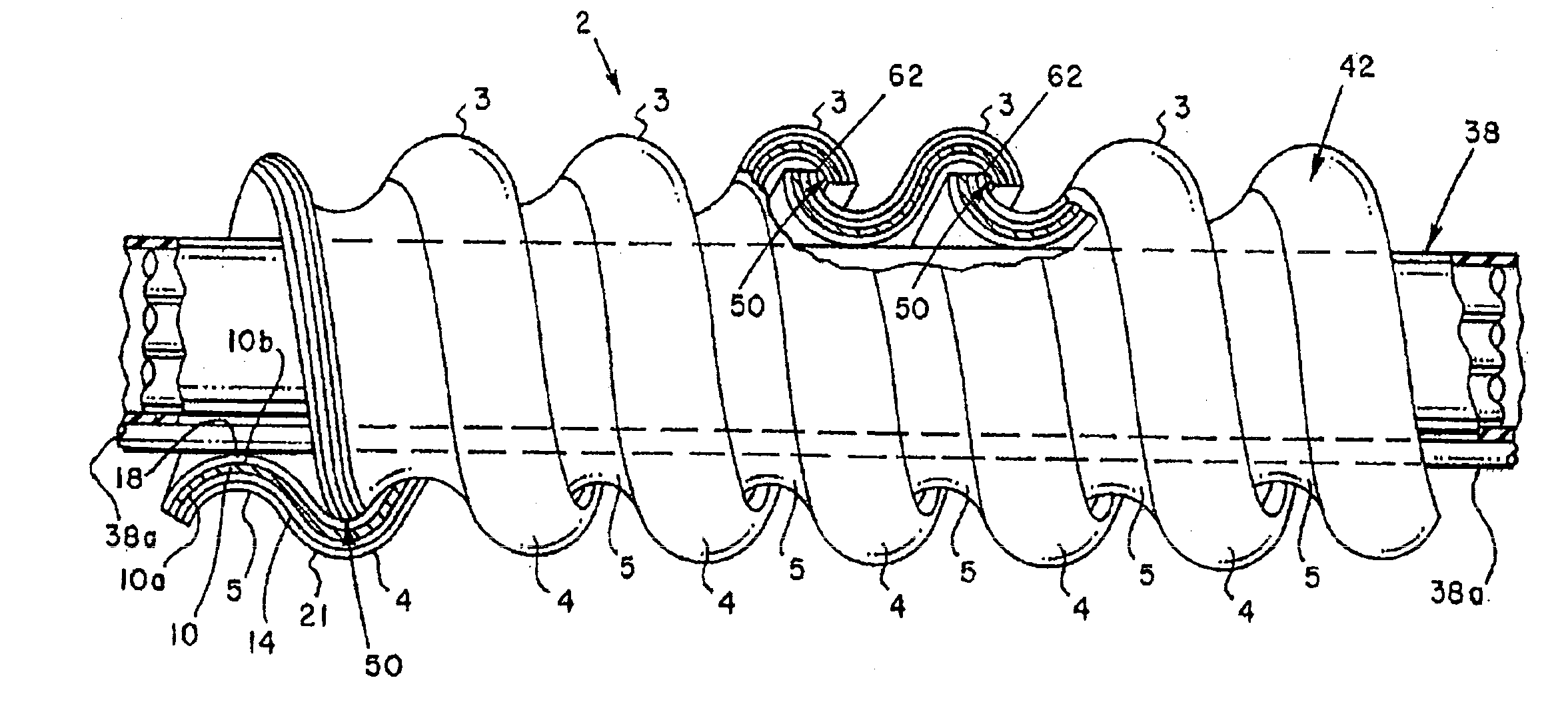

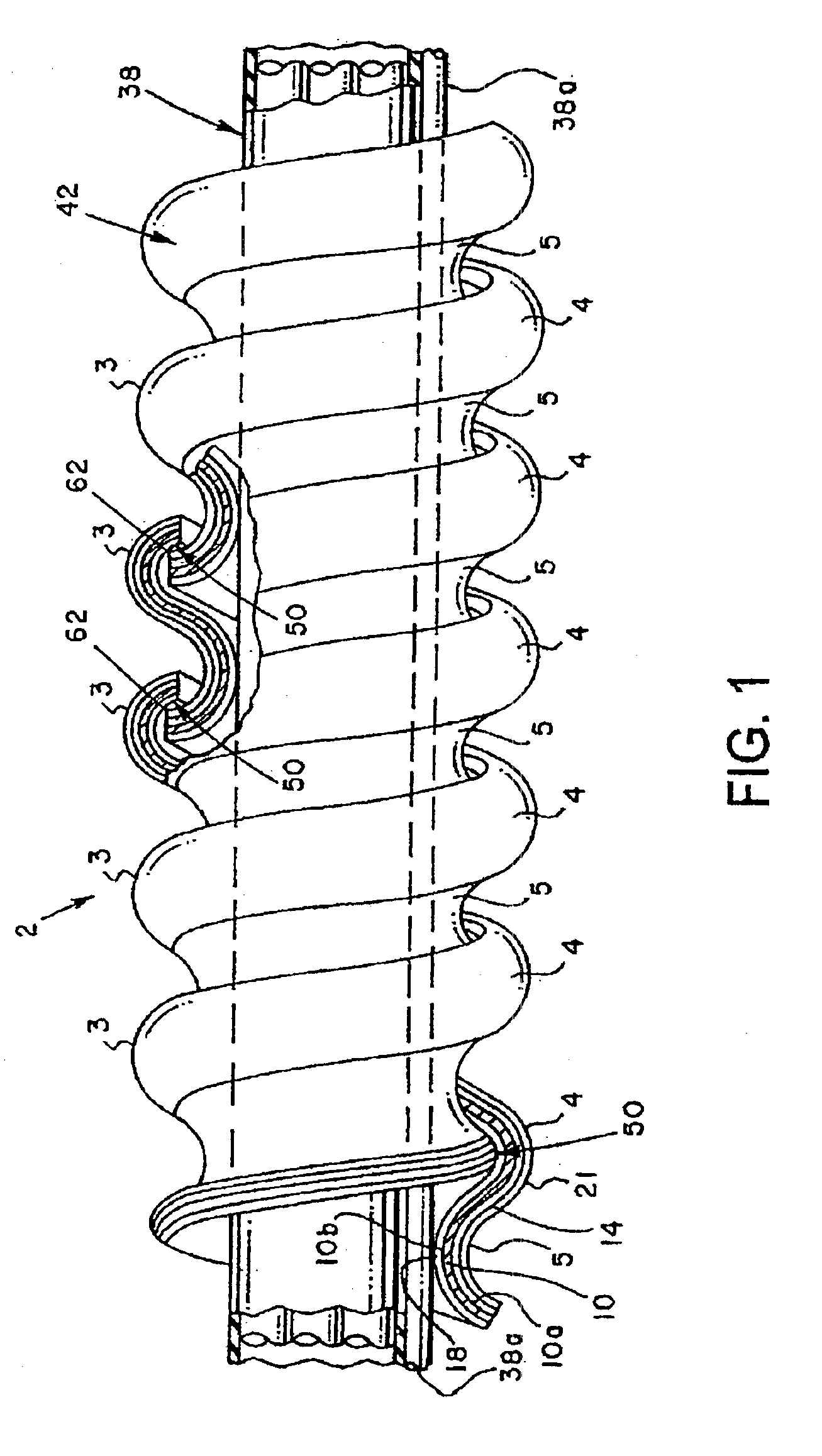

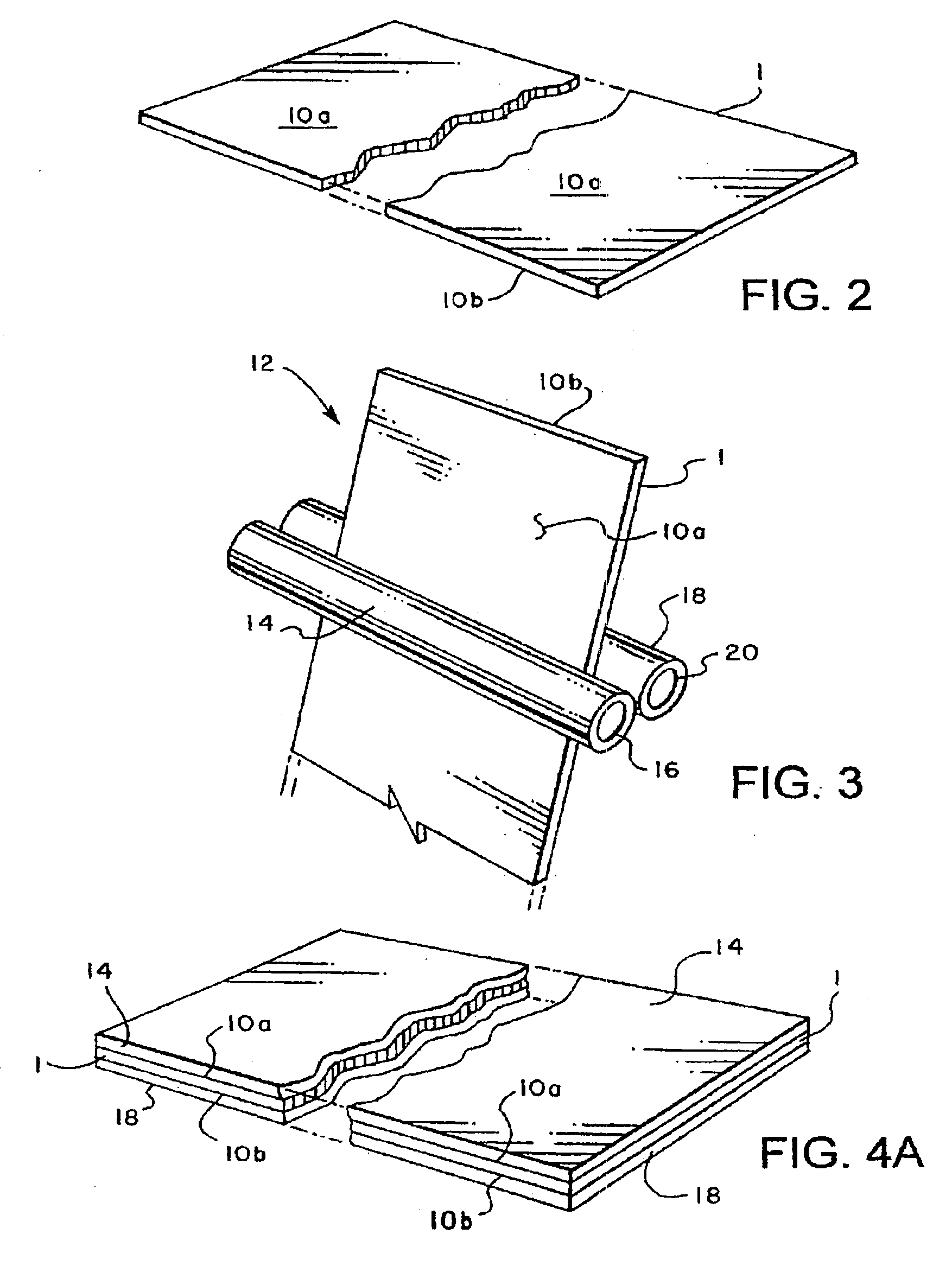

Color-coded armored cable

ActiveUS6906264B1Extend your lifeEasy to manufacturePower cables with screens/conductive layersInsulated cablesMetal stripsHelical line

A color coded flexible armored cable includes a tubular sheath formed from a metal strip having a continuous, non-patterned, non-conductive color coating applied to the entirety of an abraded outer surface of the strip. The color coating is of a predetermined precise thickness and includes a polyethylene based wax lubricant in a percent by volume of about 0.45 to 0.55. The strip is formed into helical convolutions having a cross-sectional shape which provides for overlap and interlocking of adjacent convolutions and contact between adjacent convolutions along a helical line such that, upon bending the sheath, the convolutions remain in contact at a trailing edge of one convolution and the inner surface of an adjacent convolution in a way such that the color coating is not scraped off of the outer surface of the sheath. The sheath is preferably formed such that the number of convolutions per unit length of sheath is maximum for sheath flexibility and retention of the coating on the outer surface of the sheath.

Owner:SOUTHWIRE CO LLC

Removal of heavy hydrocarbons from gas mixtures containing heavy hydrocarbons and methane

A process for the separation of one or more heavy hydrocarbon gases from a gas mixture containing heavy hydrocarbon gas components and methane. The process is conducted in swing adsorption apparatus containing adsorbent contactor having a plurality of flow channels and wherein 20 volume percent or less of the open pore volume of the contactors, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

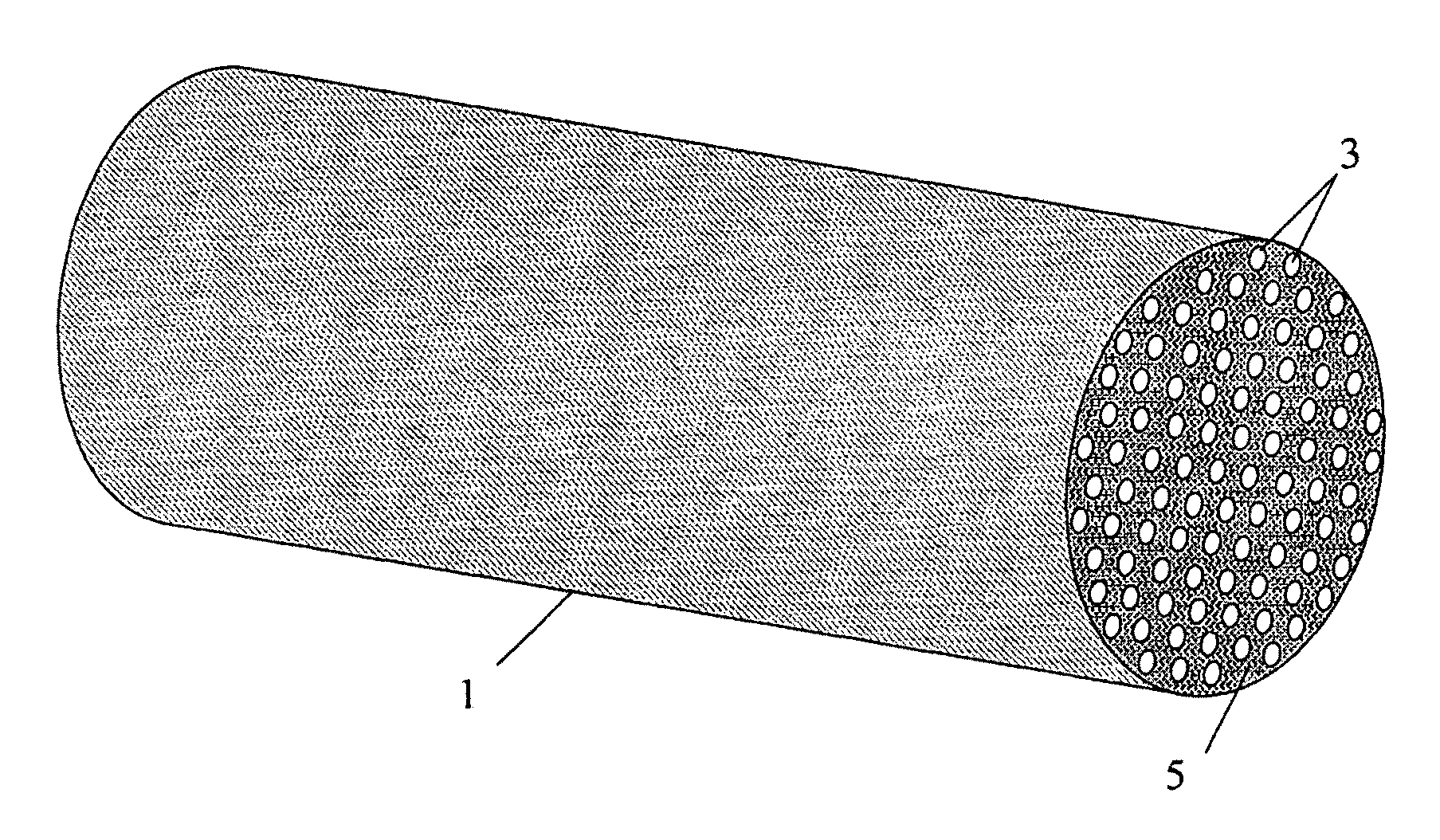

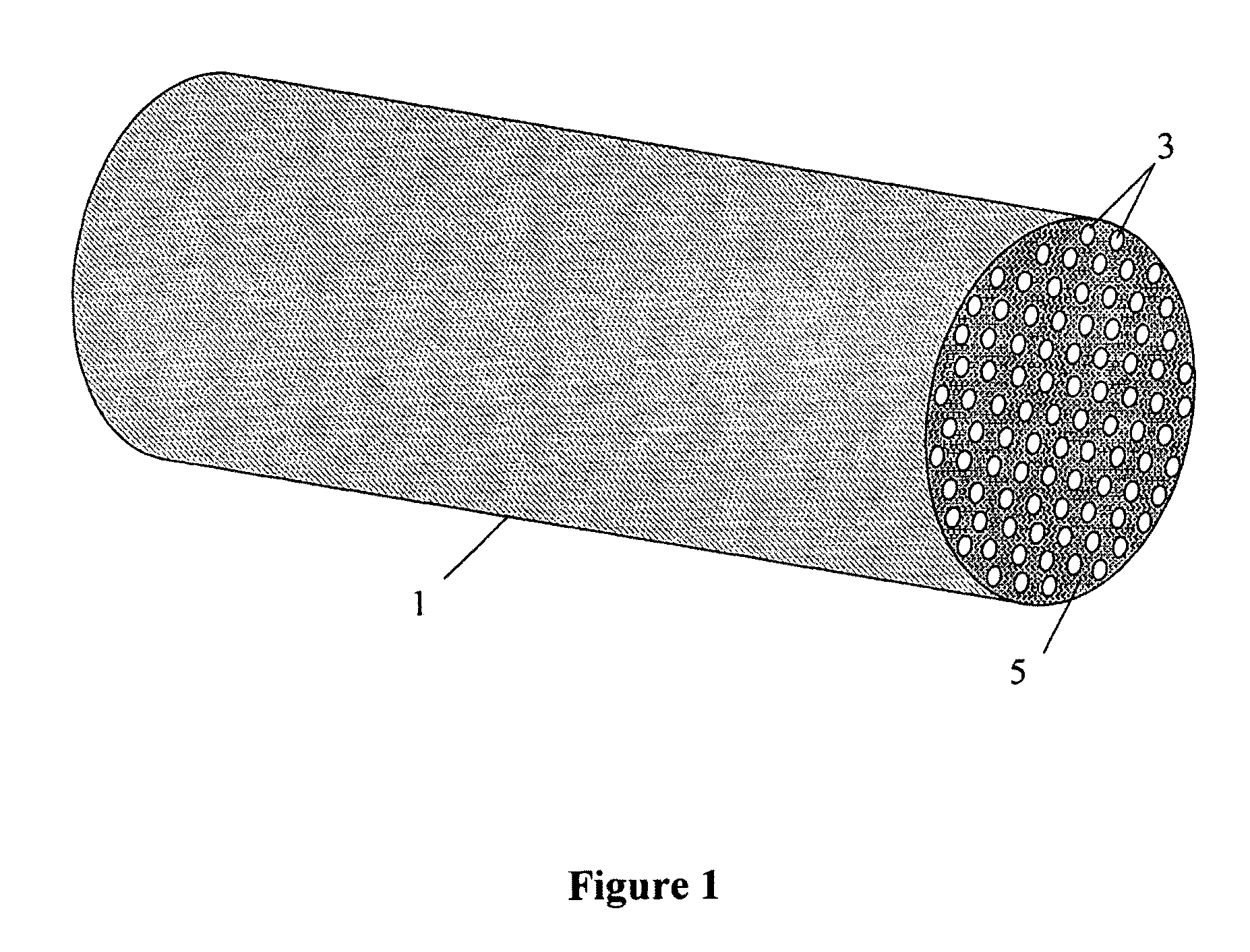

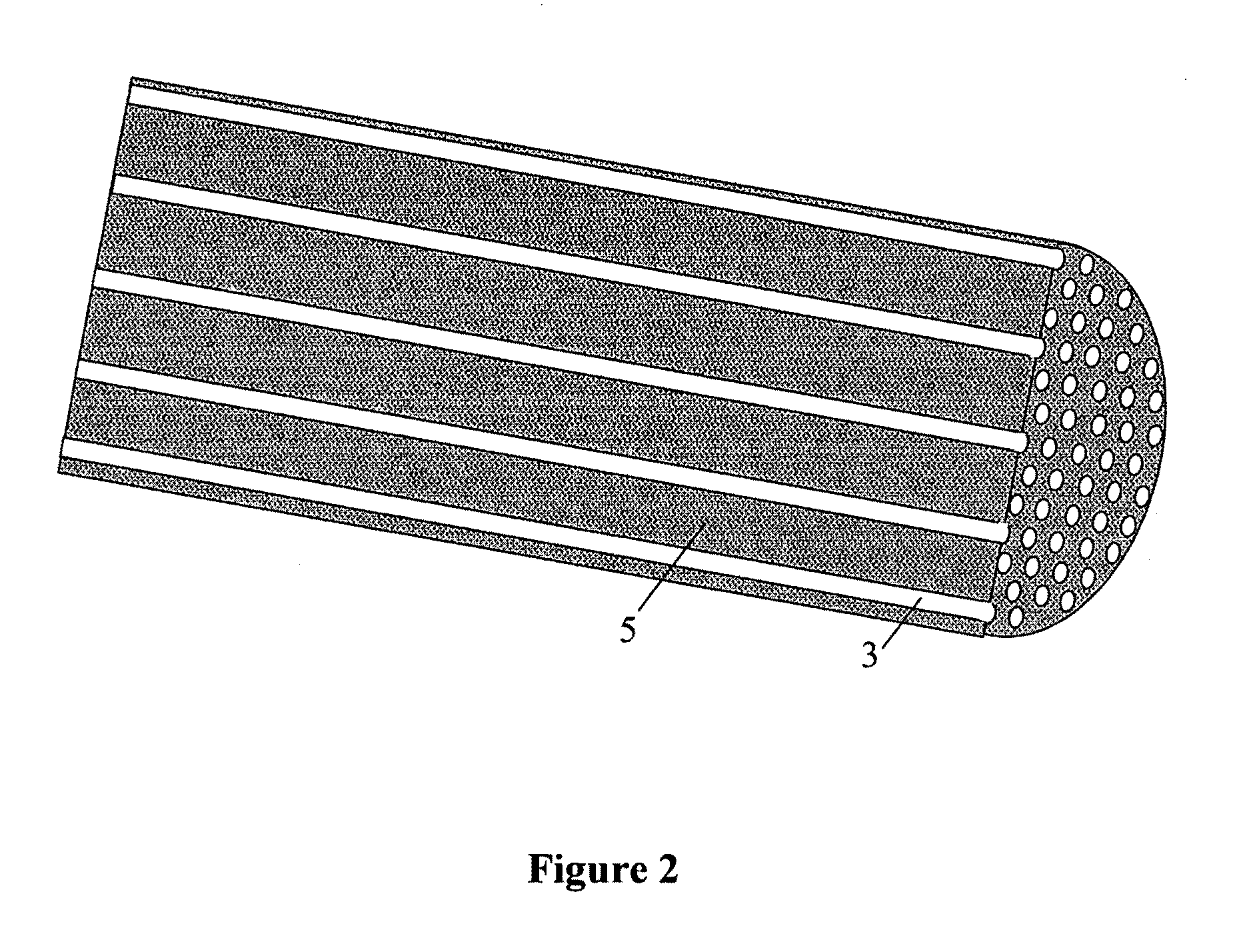

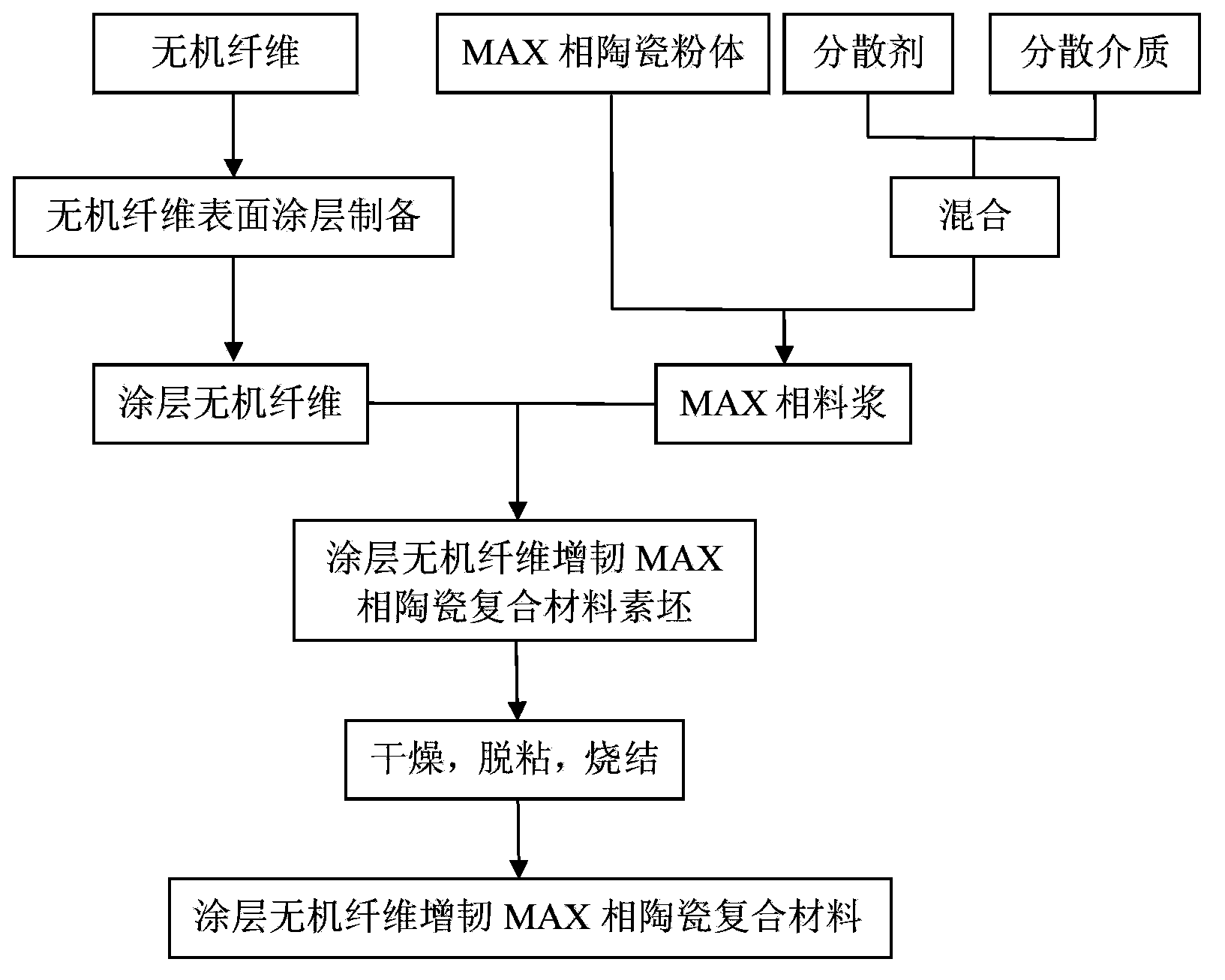

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

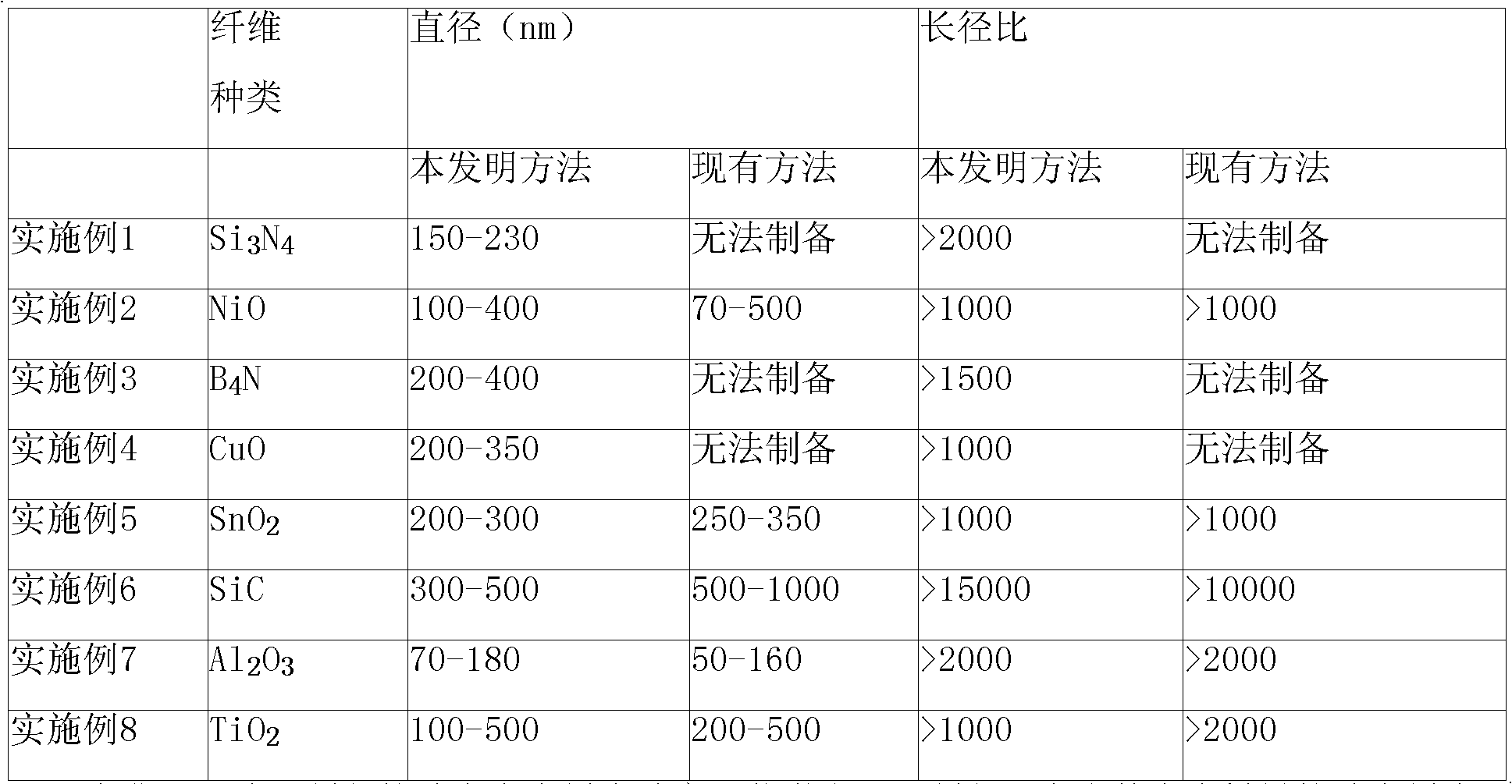

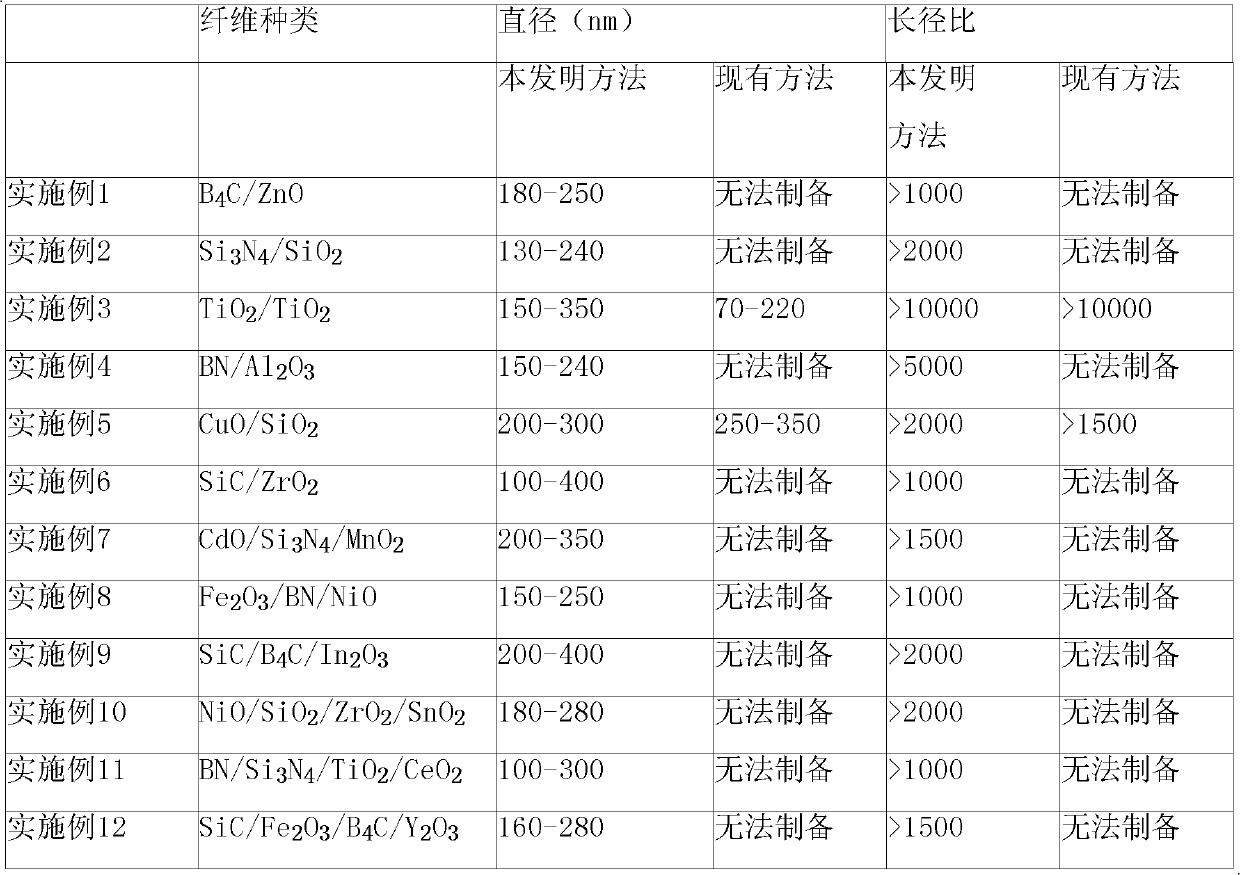

Method for preparing nano ceramic fibers

InactiveCN101880917AAverage diameter distributionHigh aspect ratioInorganic material artificial filamentsFilament/thread formingFiberWater baths

The invention discloses a method for preparing nano ceramic fibers, which is implemented by the following steps: 1, preparing 3 to 15 volume percent of 10 to 30 nanometer ceramic nanoparticles, 5 to 30 volume percent of spinnable high polymer, 0.5 to 5 volume percent of dispersant and the balance of solvent, wherein the total volume of the raw materials is 100 volume percent; 2, adding the spinnable high polymer into the solvent, heating the mixture in a water bath with magnetic stirring to obtain solution of spinnable high polymer; 3, adding the ceramic nanoparticles and the dispersant into the solution of spinnable high polymer obtained by the step 2, keeping the temperature of the mixture constant in a water bath, performing dispersion and ultrasonic dispersion, and performing swelling at a constant temperature to obtain ceramic nanoparticle / spinnable high polymer / solvent spinning solution; 4, controlling the electrostatic spinning process parameters of the spinning solution obtained by the step 3 to obtain nano fibers; and 5, sintering the nano fibers at 400 to 1,200 DEG C to obtain nano ceramic fibers.

Owner:XIAN UNIV OF TECH

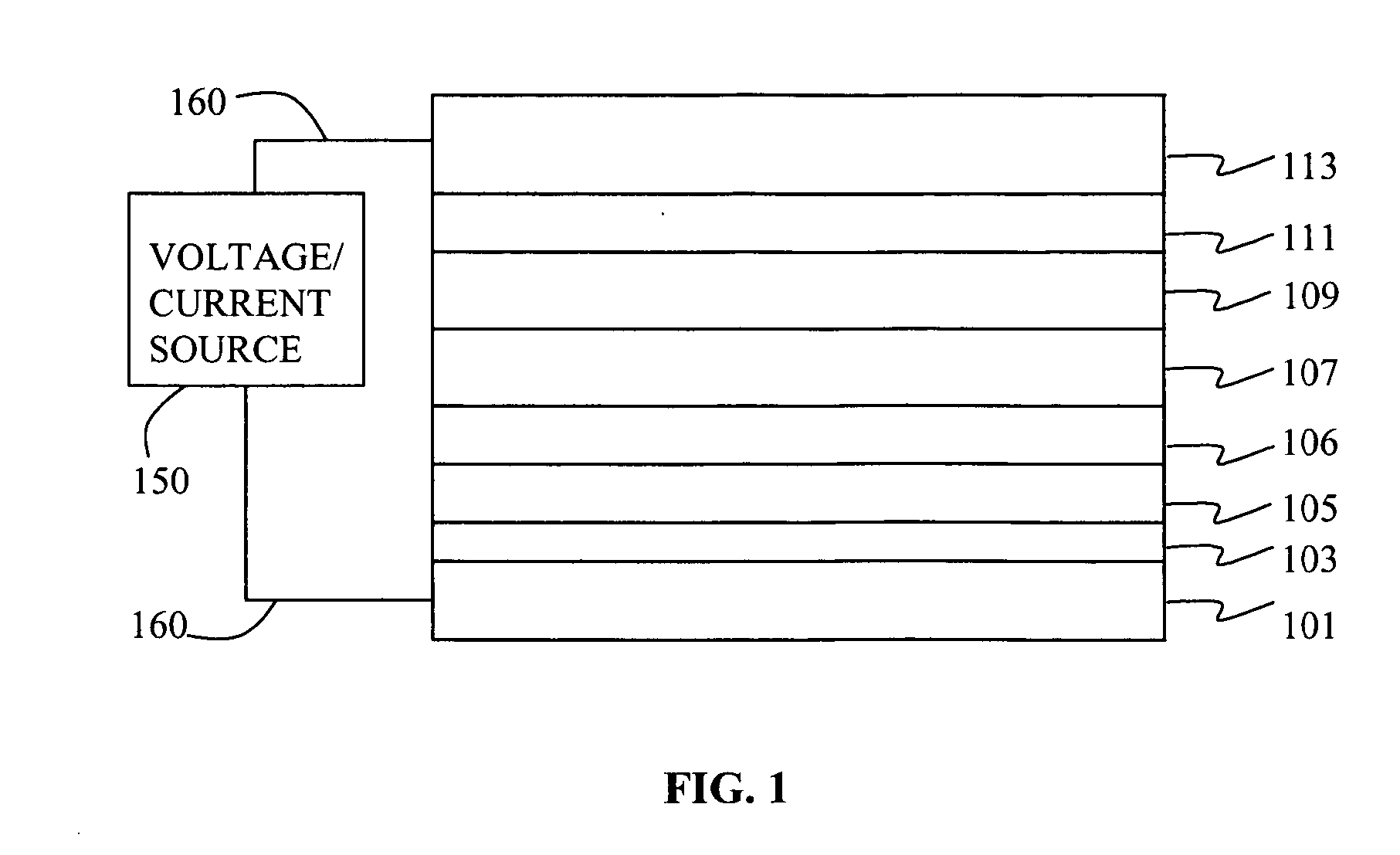

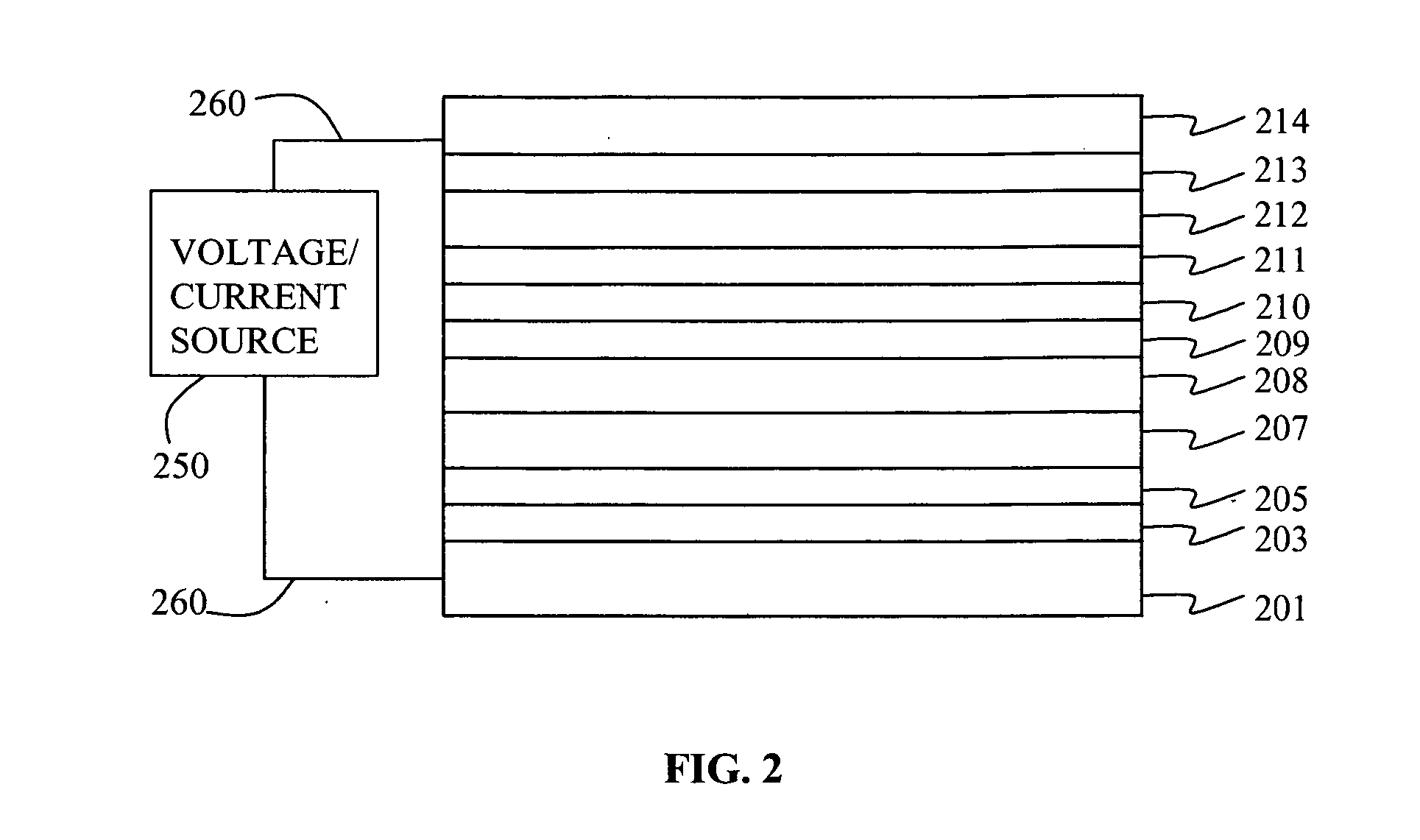

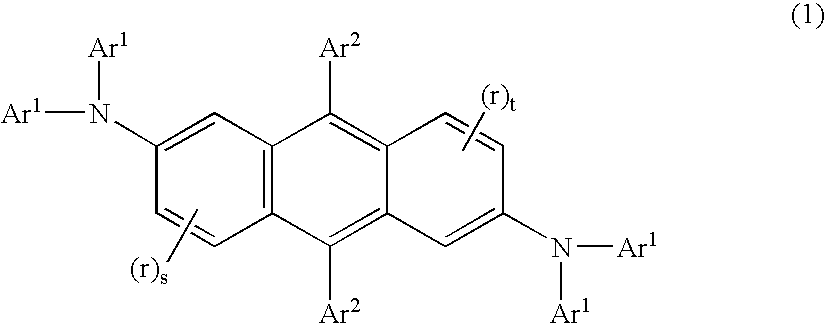

Electroluminescent device containing an anthracene derivative

InactiveUS20070134512A1Reduce voltageImprove stabilityDischarge tube luminescnet screensLamp detailsAnthraceneElectroluminescence

An OLED device comprises a cathode, an anode, and located therebetween a light emitting layer, the device comprising a further layer between the light-emitting layer and the anode but not contiguous to the light-emitting layer, the further layer containing a 2,6-diamino-substituted anthracene compound and containing a larger volume percentage of the 2,6-diamino-substituted anthracene compound than the layer contiguous to the light-emitting layer on the anode side.

Owner:EASTMAN KODAK CO

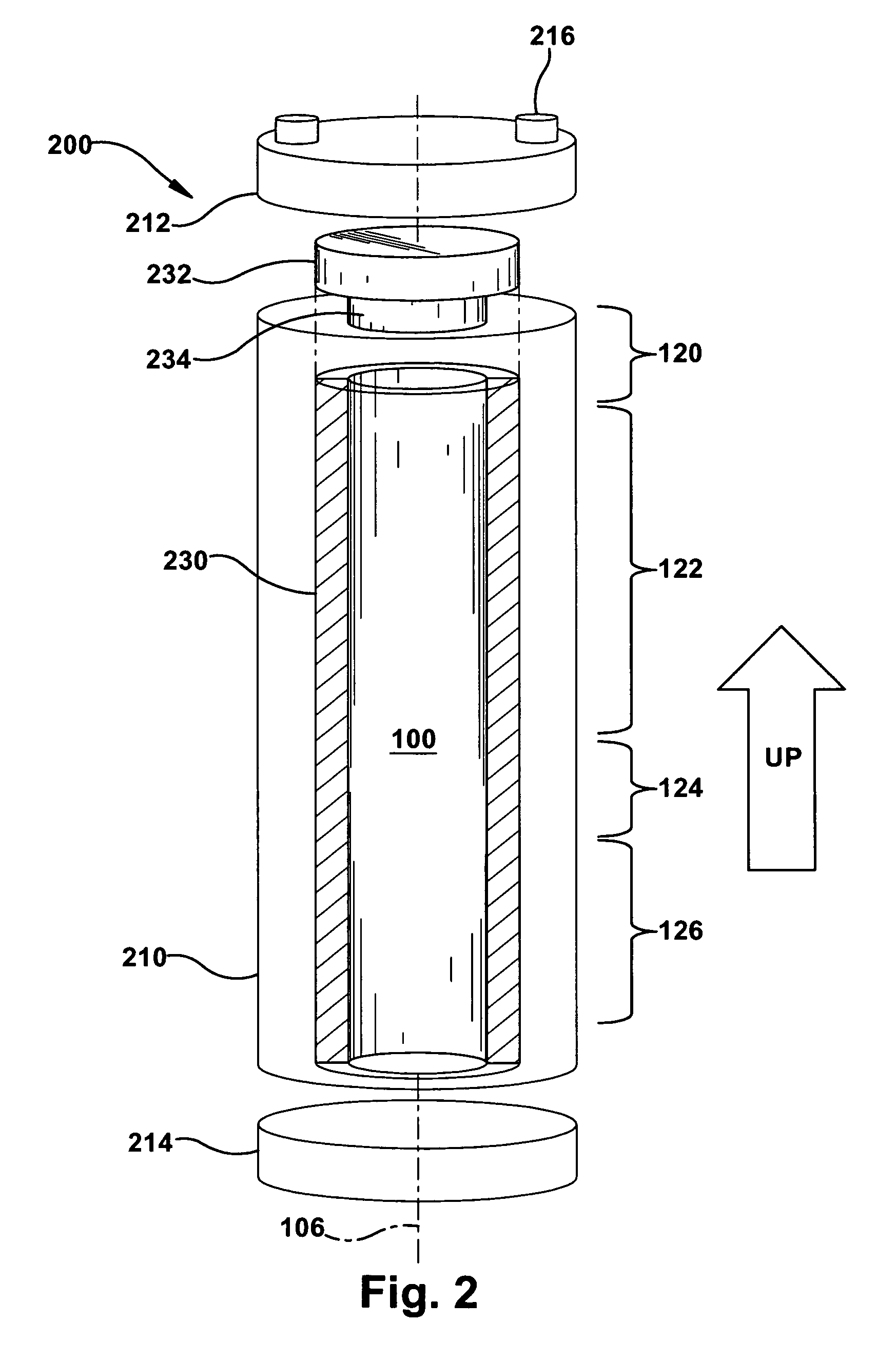

Heater, apparatus, and associated method

A heater that may include an outer housing and an inner tube is provided. The inner tube is in a coaxial relation to and within the outer housing. An inward facing surface of the inner tube defines a volume sufficient to receive a reaction capsule, and the outward facing surface is radially spaced from an inward facing surface of the outer housing sufficient to define a gap. A filler material is disposed within the gap. The filler material responds to pressure such that the filler volume is reduced by less than 5 volume percent at greater than 500 MPa pressure and at greater than 500° C. temperature. One or more heating elements are disposed in the gap. The heating elements are in thermal communication with the inner tube.

Owner:SLT TECH

Electrostatic spinning preparation method of ceramic nanometer composite fibers

The invention discloses an electrostatic spinning preparation method of ceramic nanometer composite fibers, comprising the following concrete steps of: firstly, according to volume percentage, weighing 3-10 percent of ceramic nanometer particles with the partilce size of 10-300 nm, 3-20 percent of ceramic precursor, 5-30 percent of spinnable polymer and 40-89 percent of solvent with the total volume of 100 percent; secondly, adding the spinnable polymer into the solvent, heating in water bath and magnetically stirring; thirdly, adding the ceramic precursor into the spinnable polymer solution obtained in the second step, heating in water bath, magnetically stirring and ageing; fourthly, adding the ceramic nanometer particles into the ceramic precursor spinnable solution obtained in the third step, heating at constant temperature in the water bath and forming a spinning solution by carrying out ultrasonic dispersion and constant temperature swelling; fifthly, preparing composite nanometer fibers by the spinning solution according to an electrostatic spinning technology; and sixthly, obtaining the ceramic nanometer composite fibers by sintering the composite nanometer fibers. In the method, raw materials have wide selection conditions and wide optional range.

Owner:XIAN UNIV OF TECH

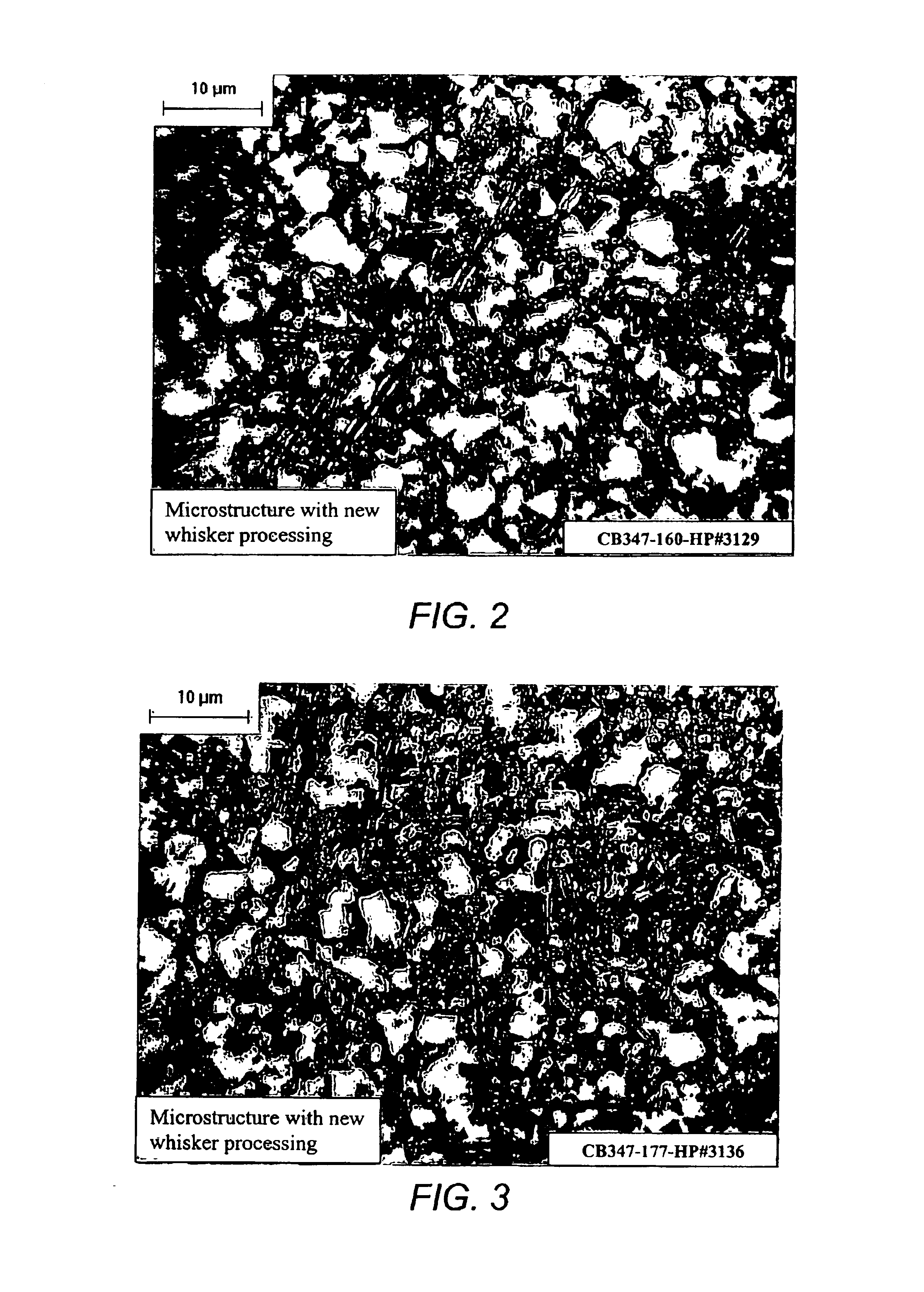

Ceramic body reinforced with coarse silicon carbide whiskers and method for making the same

InactiveUS6905992B2Solve the lack of densityThin material handlingMetal layered productsPowder mixtureSquare Millimeter

A ceramic composite made by compacting a starting powder blend. The composite includes between about 50 volume percent and about 99 volume percent of a ceramic matrix; and between about 1 volume percent and about 50 volume percent as-processed silicon carbide whiskers. The ceramic composite having a fracture toughness (KIC) of greater than about 4.0 MPam1 / 2. The ceramic has a silicon carbide whisker density as measured in whiskers per square millimeter equal to or less than about 1500 times the volume percent of silicon carbide whiskers, but in a density sufficient for the ceramic composite to have the fracture toughness.

Owner:KENNAMETAL INC

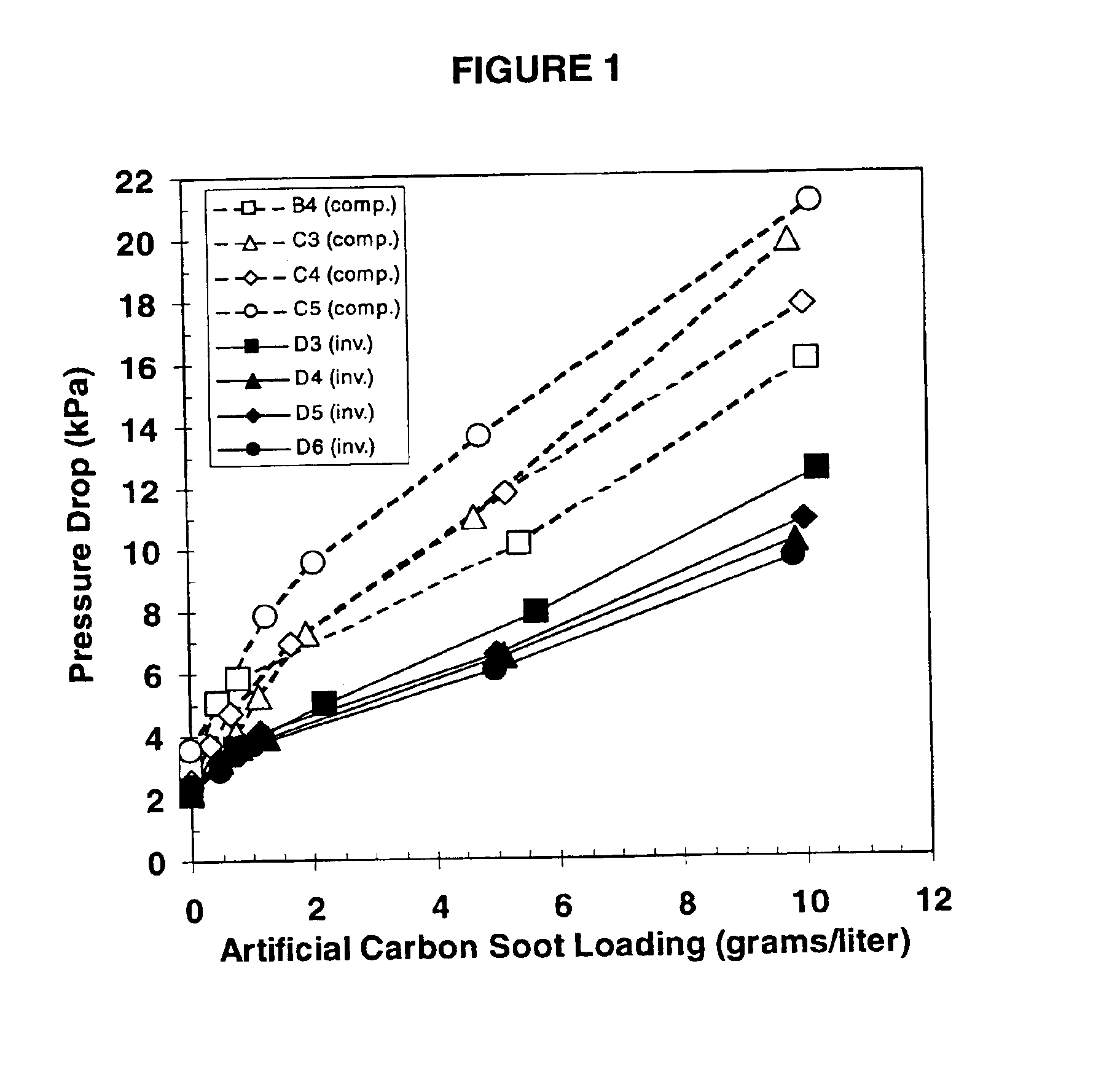

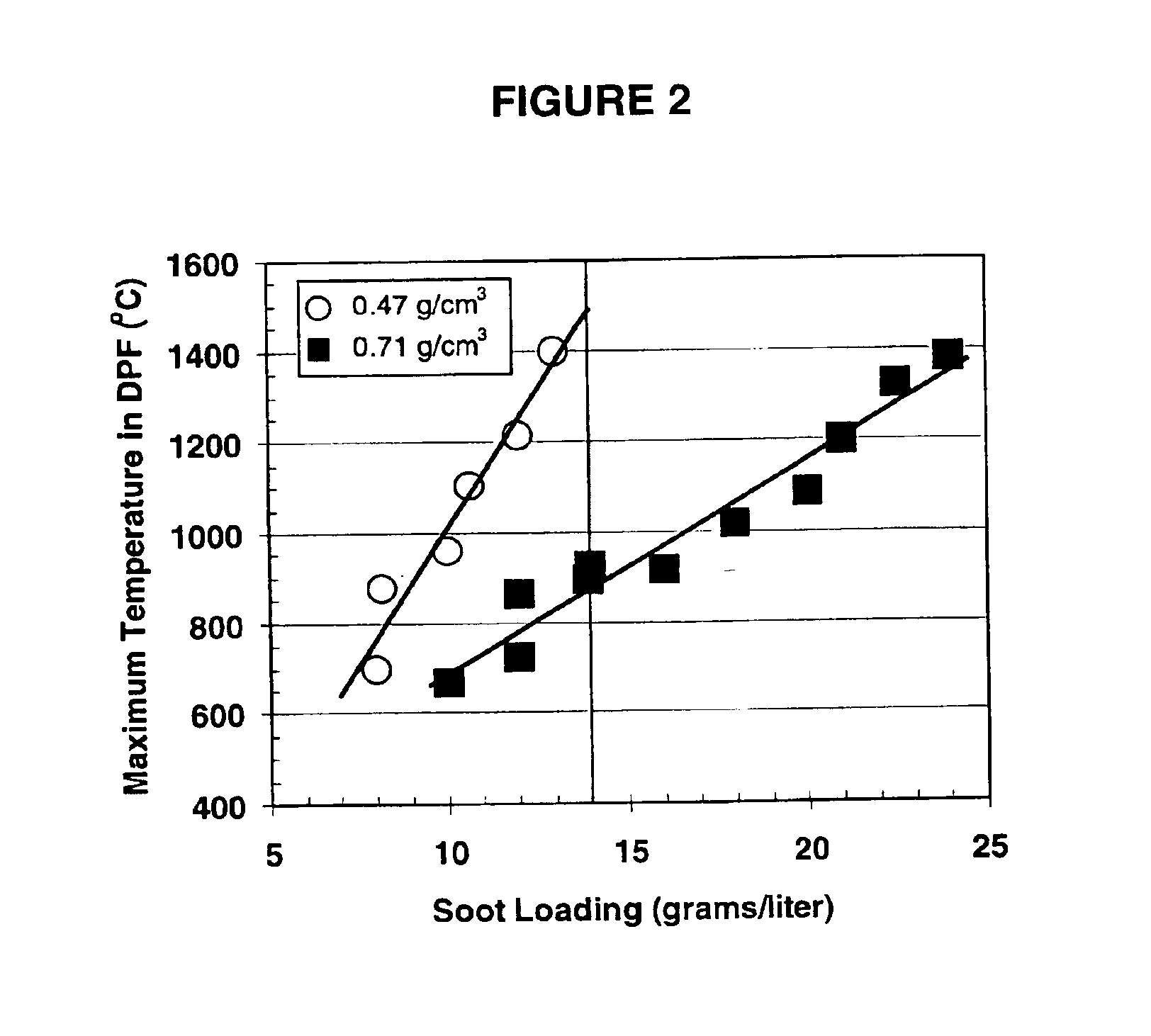

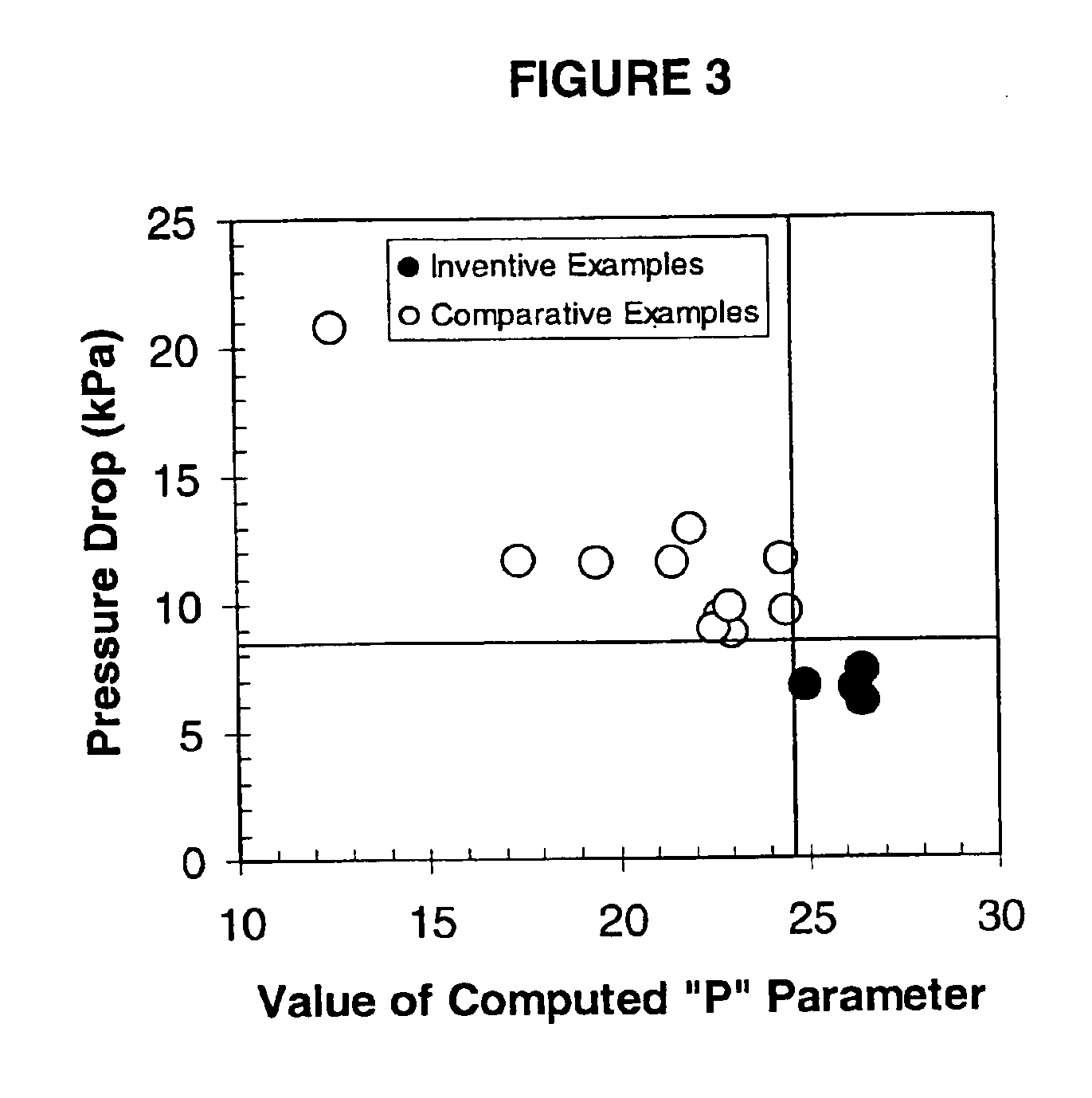

Cordierite body

InactiveUSRE38888E1Improve permeabilityReduce back pressureDispersed particle filtrationSilencing apparatusGramVolumetric Mass Density

A ceramic comprising predominately a cordierite-type phase approximating the stoichiometry Mg2Al4Si5O18 and having a coefficient of thermal expansion (25-800° C.) of greater than 4×10−7 / ° C. and less than 13×10−7 / ° C. and a permeability and a pore size distribution which satisfy the relation 2.108 (permeability)+18.511 (total pore volume)+0.1863 (percentage of total pore volume comprised of pores between 4 and 40 micrometers)>24.6. The ceramic is suitable in the fabrication of cellular, wall-flow, diesel particulate filters having a pressure drop in kPa that at an artificial carbon soot loading of 5 grams / liter and a flow rate of 26 scfm is less than 8.9-0.035 (number of cells per square inch)+300 (cell wall thickness in inches), a bulk filter density of at least 0.60 g / cm3 and a volumetric heat capacity of at least 0.67 J cm−3 K−1 as measured at 500° C.

Owner:CORNING INC

Lightweight compositions and articles containing such

A lightweight cementitious composition containing from 22 to 90 volume percent of a cement composition and from 10 to 78 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles and can be included as a layer on wall panels and floor panels and can be used in insulated concrete forms. Aspects of the lightweight cementitious composition can be used to make lightweight structural units.

Owner:SYNTHEON

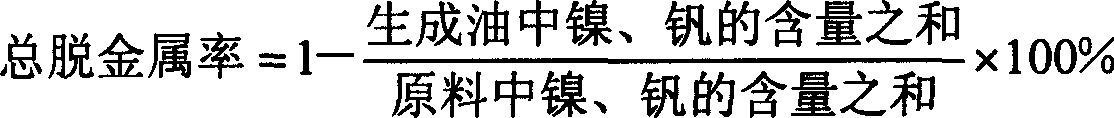

Alumina supporter possessing duplicate orifice, catalyst and preparation method

ActiveCN1796500AHigh activityEliminate the possibility of runawayCatalyst carriersRefining to eliminate hetero atomsNitrogenResidual oil

A catalyst for residual oil hydrodemetalling, which is composed of a carrier containing two types of pores and metal components such as Mo and / or W and Co and / or Ni, fixes on the carrier. The distribution of the pores in the said carrier is: the volume percentage of 10-20nm diameter pores in the total pore volume is 35-80%, the volume percentage of 500-1200nm diameter pores in the total pore volume is 15-60%, and the volume percentage of the pores with diameters ú“10nm, ú¥20-ú“500nm and ú¥1200nm in the total pore volume is 5-40%. The process for preparing the carrier comprises the steps of: mixing an alumina precursor with a nonacid nitrogenous compound, molding and sintering. The catalyst in this invention can be used as the catalyst for crude oil and normal atmosphere residual oil hydrodemetalling.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for removing a target gas from a mixture of gases by swing adsorption

The present invention relates the separation of a target gas from a mixture of gases through the use of engineered structured adsorbent contactors in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

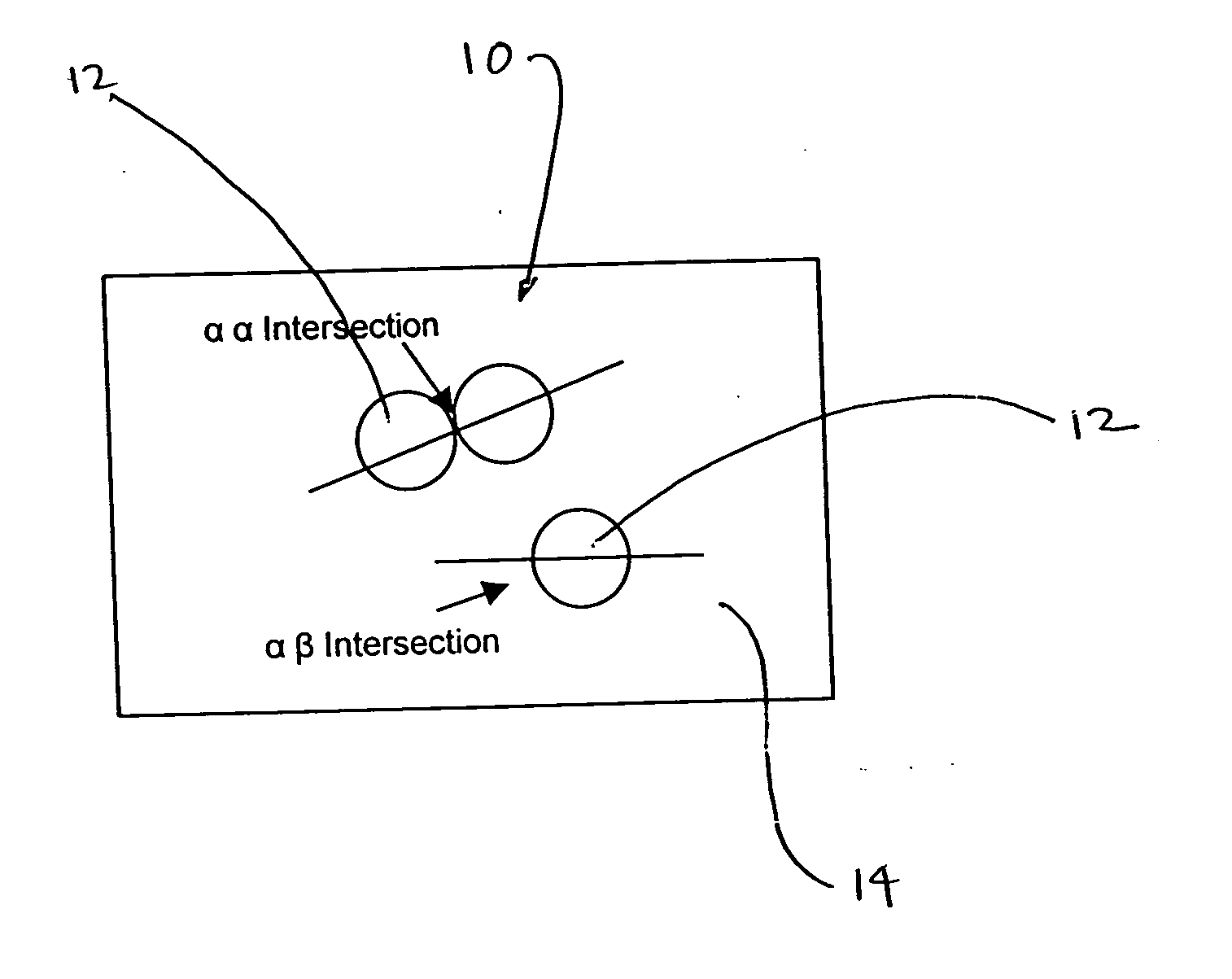

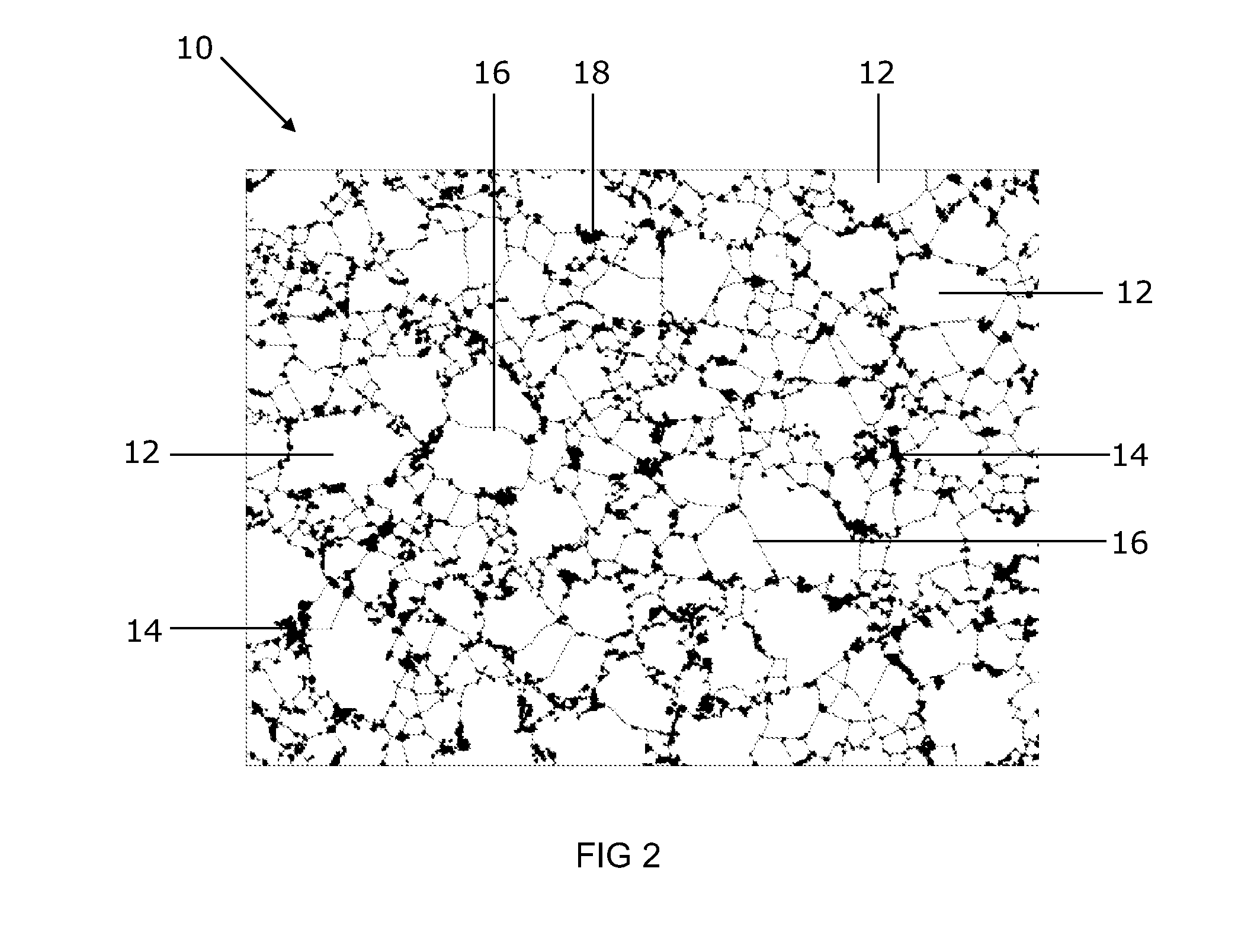

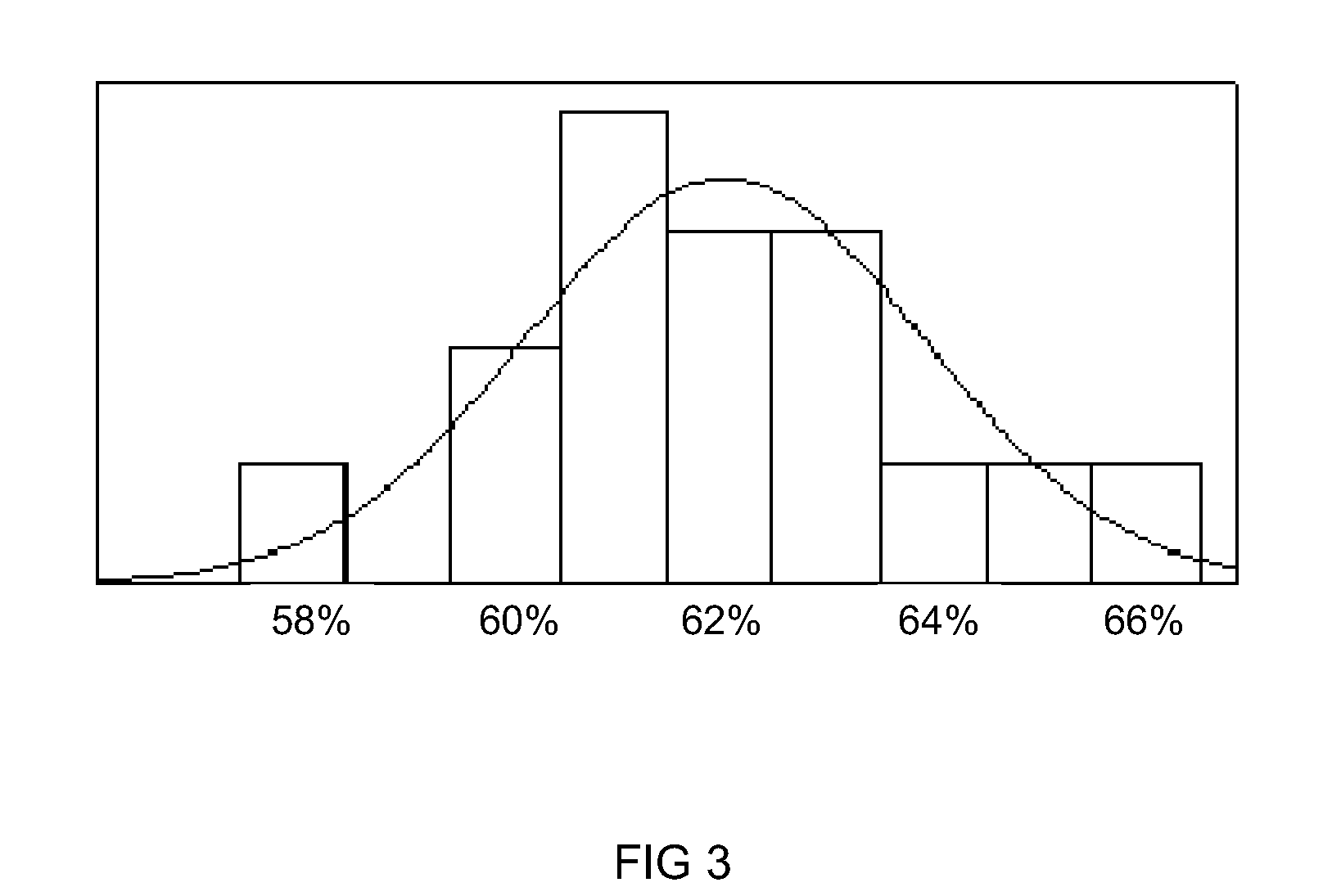

Polycrystalline diamond

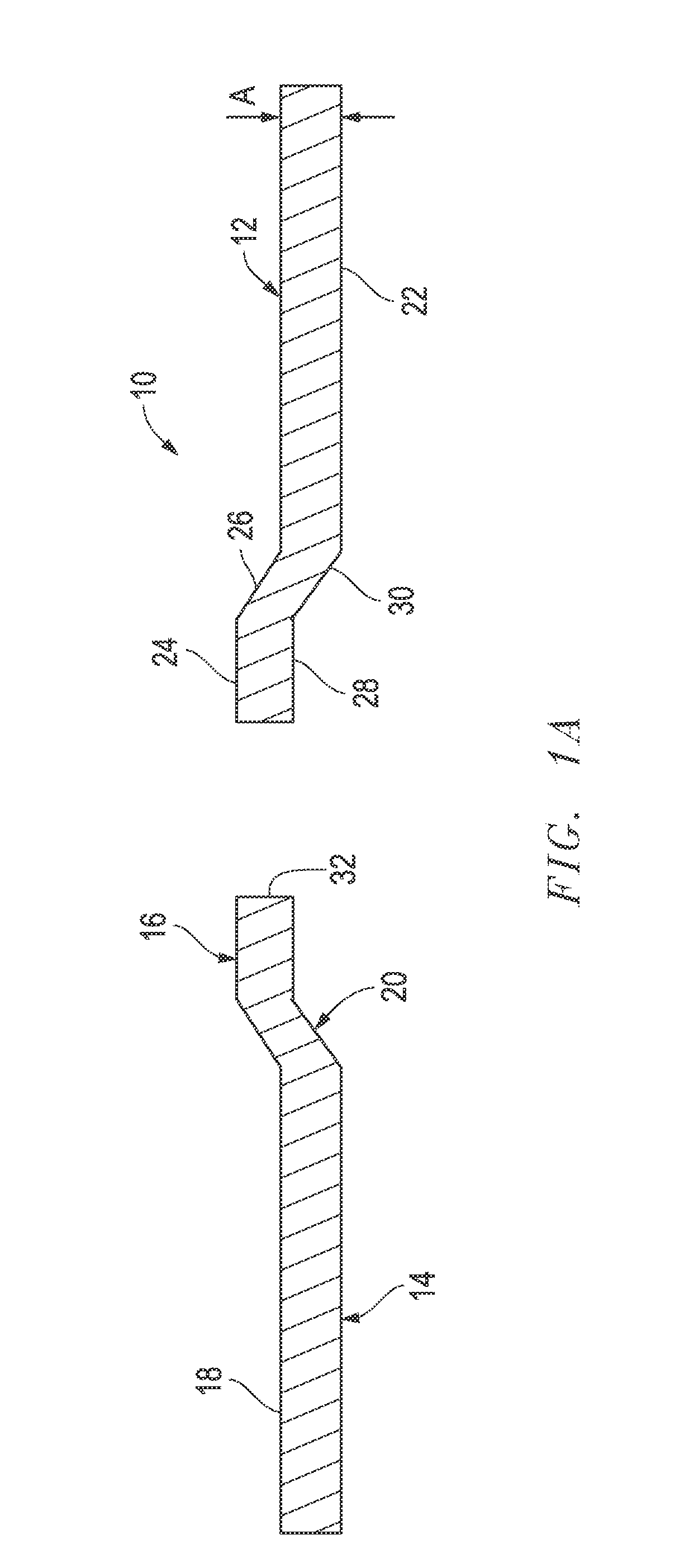

A polycrystalline diamond (PCD) material 10 comprising at least 88 volume percent and at most 99 volume percent diamond grains 12, the mean diamond grain contiguity being greater than 60.5 percent. The PCD material 10 is particularly but not exclusively for use in boring into the earth.

Owner:ELEMENT SIX ABRASIVES

Lightweight concrete compositions

A lightweight cementitious composition containing from 10 to 90 volume percent of a cement composition, from 10 to 90 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, and from 10 to 50 volume percent of sand and / or other fine aggregate, where at least a portion of the sand and / or fine aggregate has a fineness modulus of less than 2; where the sum of components used does not exceed 100 volume percent, and where after the lightweight cementitious composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39 after seven days. The cementitious composition can be used to make concrete masonry units, construction panels, road beds and other articles.

Owner:SYNTHEON HLDG SPA +1

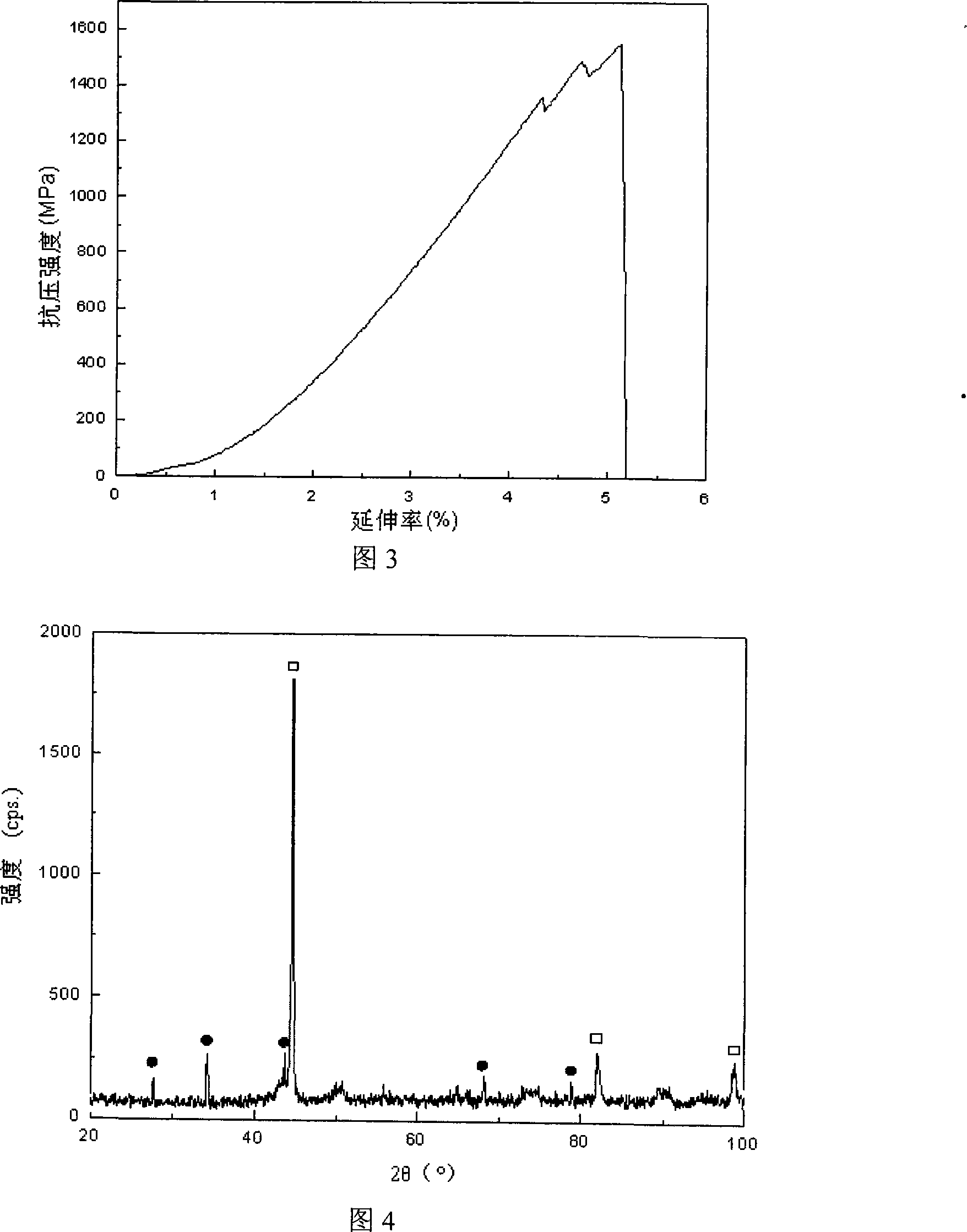

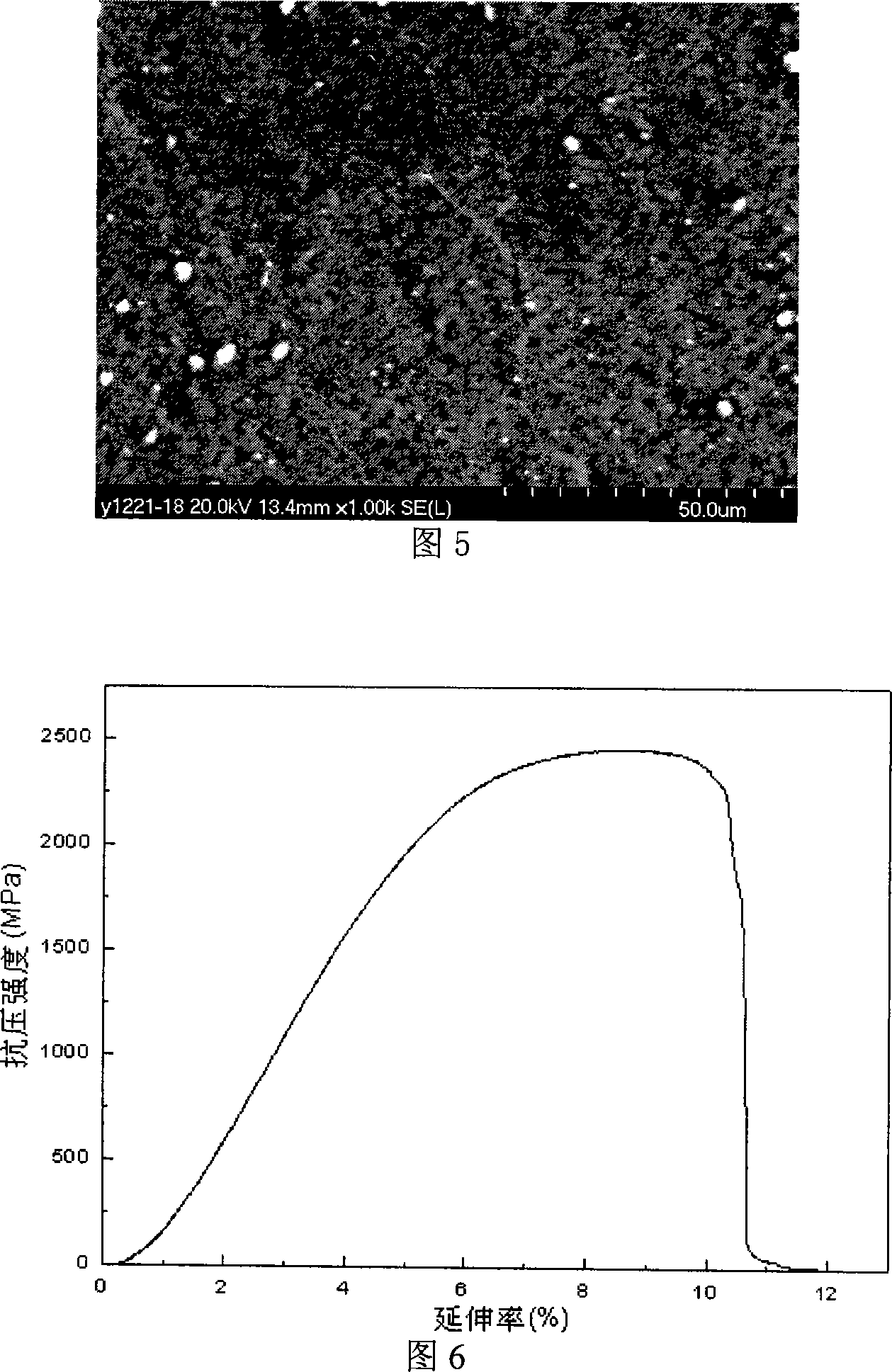

High-entropy alloy-base composite material and preparation method thereof

The invention provides a high-entropy alloy based composite material and a method for preparation, which relates to an alloy composite material and a method for preparation. The invention provides the high-entropy alloy based composite material and a method for preparation, and a composite material whose comprehensive performance is better than high-entropy alloy. The high-entropy alloy based composite material is made from 1-45 percent of reinforced phase and 55-99 percent of high-entropy alloy base according to the volume percentage. The high-entropy alloy based composite material is prepared by an in-situ spontaneity method or a non- in-situ spontaneity method, and the reinforced phase is prepared in an original position in the high-entropy alloy base or is added from the outer portion. The invention further improves the mechanical properties of materials basing on original high-entropy alloy, and is capable of playing the potentiality of the high-entropy alloy base in maximum limit. The high-entropy alloy based composite material of the invention is capable of being used by various preparation processes, the operation is easy and is easy to operate.

Owner:HARBIN INST OF TECH

Abrasive article and method of making same

An abrasive article may include an abrasive body having a grinding layer, where the grinding layer may include a bond and abrasive particles contained within the bond. The abrasive body also may include a volumetric ratio GLVb / GLVap of at least about 0.4, where GLVb is a volume percent of bond for a total volume of the grinding layer and GLVap is a volume percent of abrasive particles for a total volume of the grinding layer. The abrasive particles may include seeded sol-gel ceramic and may have an average particle size of at least about 600 microns. In addition, the abrasive particles may include a coupling agent that may include an organic material with a silane functional group. Prior to formation of the abrasive article, the abrasive particles may be coated by the coupling agent at a ratio ACOA / AAB of at least about 0.1, where CCOA is the amount of coupling agent in grams in a pre-formation mixture and AAB is the amount of abrasive particles in pounds (lbs) in the pre-formation mixture.

Owner:SAINT GOBAIN ABRASIVES INC +1

Lightweight concrete compositions

ActiveUS20070062415A1Other chemical processesSolid waste managementVolumetric Mass DensitySand granules

A lightweight ready-mix concrete composition that contains 8-20 volume percent cement, 11-50 volume percent sand, 10-31 volume percent prepuff particles, 9-40 volume percent coarse aggregate, and 10-22 volume percent water, where the sum of components used does not exceed 100 volume percent. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The slump value of the composition measured according to ASTM C 143 is from 2 to 8 inches. After the lightweight ready-mix concrete composition is set for 28 days, it has a compressive strength of at least 1400 psi as tested according to ASTM C39.

Owner:SYNTHEON HLDG SPA

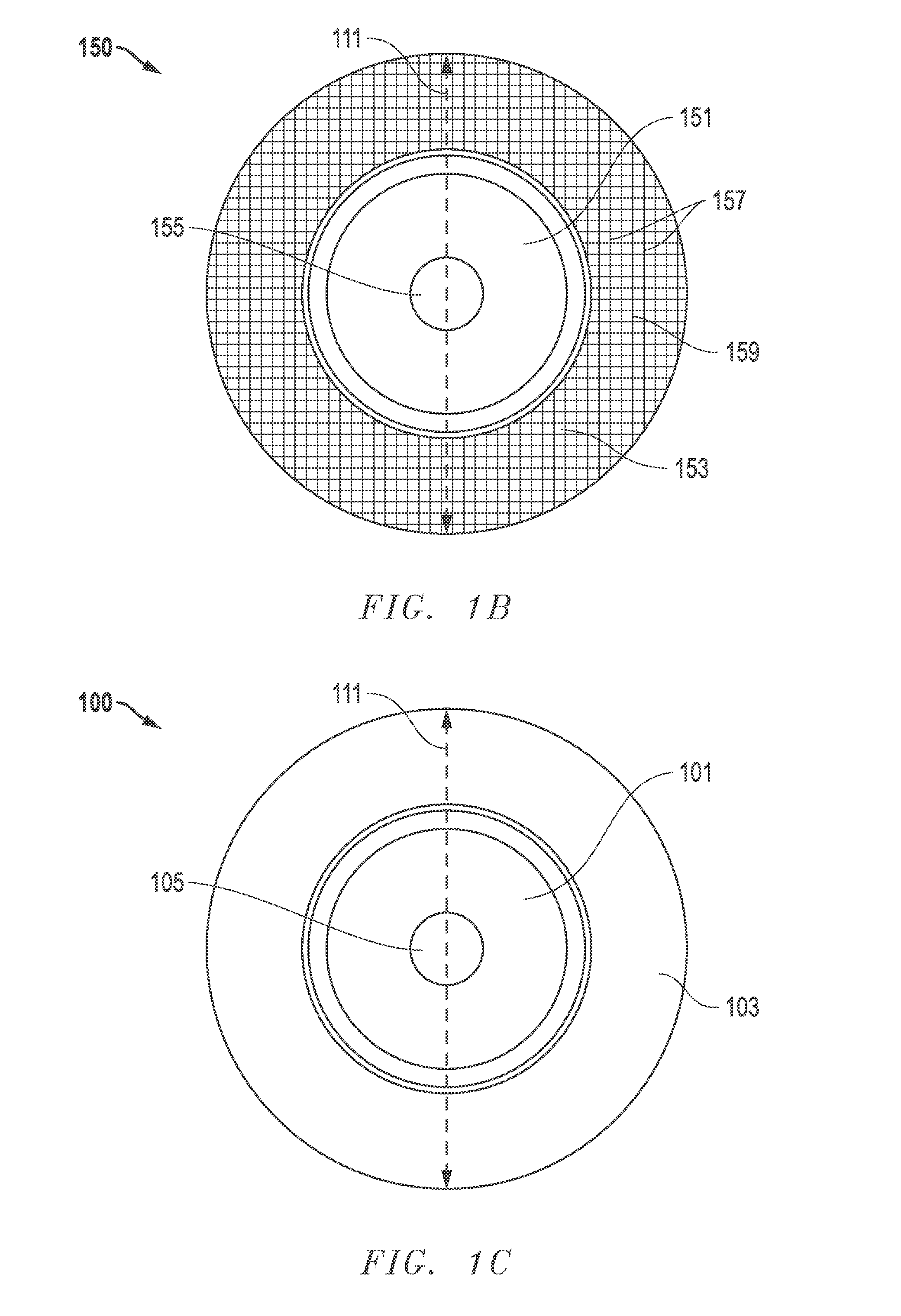

Polishing pad

A polishing pad is useful planarizing semiconductor substrates. The polishing pad comprises a polymeric material having a porosity of at least 0.1 volume percent, a KEL energy loss factor at 40° C. and 1 rad / sec of 385 to 750 1 / Pa and a modulus E′ at 40° C. and 1 rad / sec of 100 to 400 MPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

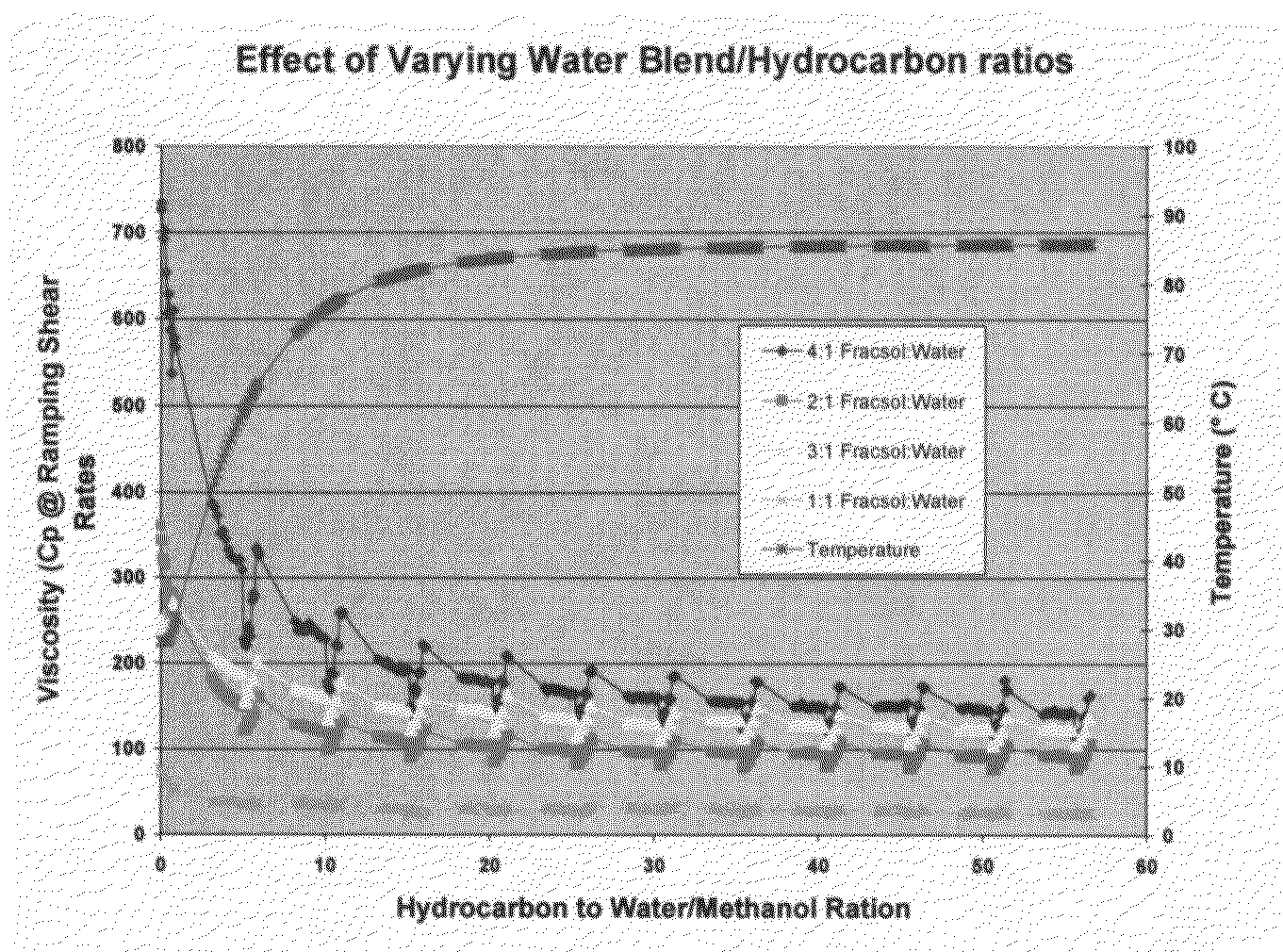

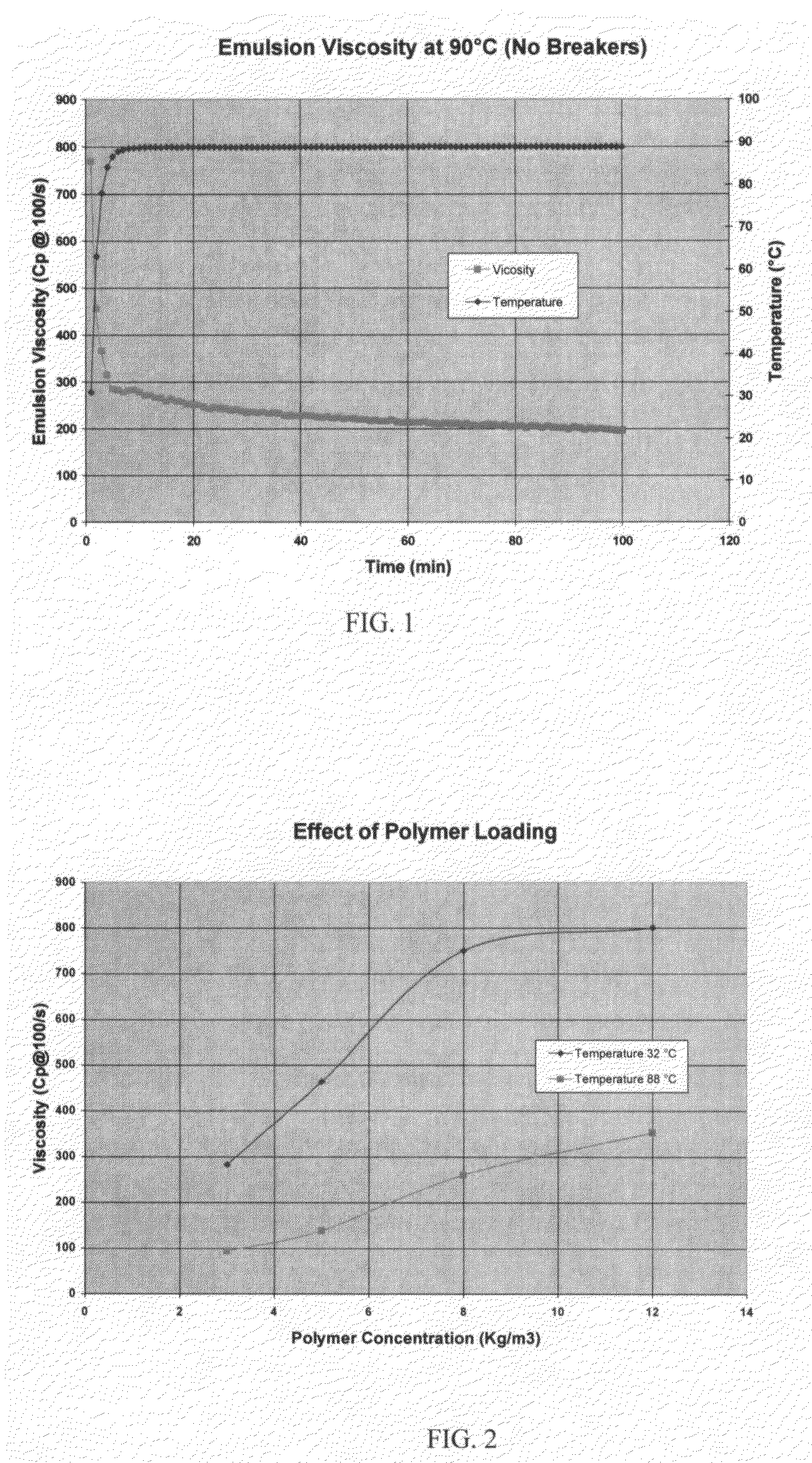

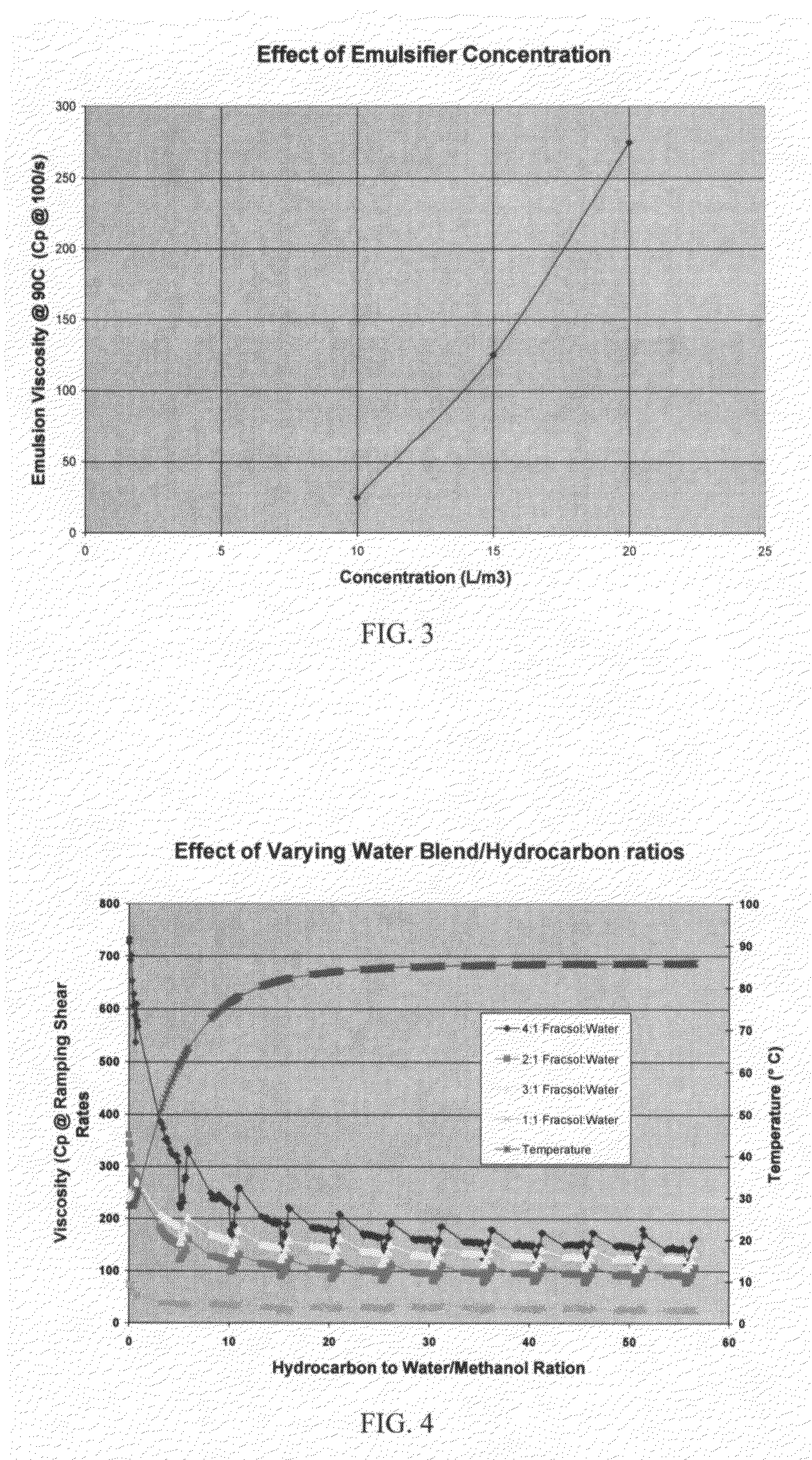

Gelled emulsions and methods of using the same

InactiveUS20080217012A1Reduce hydrationMinimizes pumping friction pressureTransportation and packagingFluid removalOrganic fluidWater soluble

Gelled emulsions contain (i.) an external phase of an aqueous water-soluble solvent solution, polymeric viscosifying agent and, optionally, an oxidative and / or acidic breaker; and (ii.) an internal phase of a dispersed organic fluid. The aqueous water-soluble solvent solution constitutes between from about 15 to about 50 volume percent of the gelled emulsion and the dispersed organic fluid is presented in the gelled emulsion in amounts ranging from about 50 to about 85 volume percent. The gelled emulsions are useful in a variety of applications including, but not limited to, oil field, pipeline and processing facility applications.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com