Gelled emulsions and methods of using the same

a gelled emulsion and gel technology, applied in the field of gelled emulsions, can solve the problems of reducing affecting the so as to reduce the initial viscosity of the gelled emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

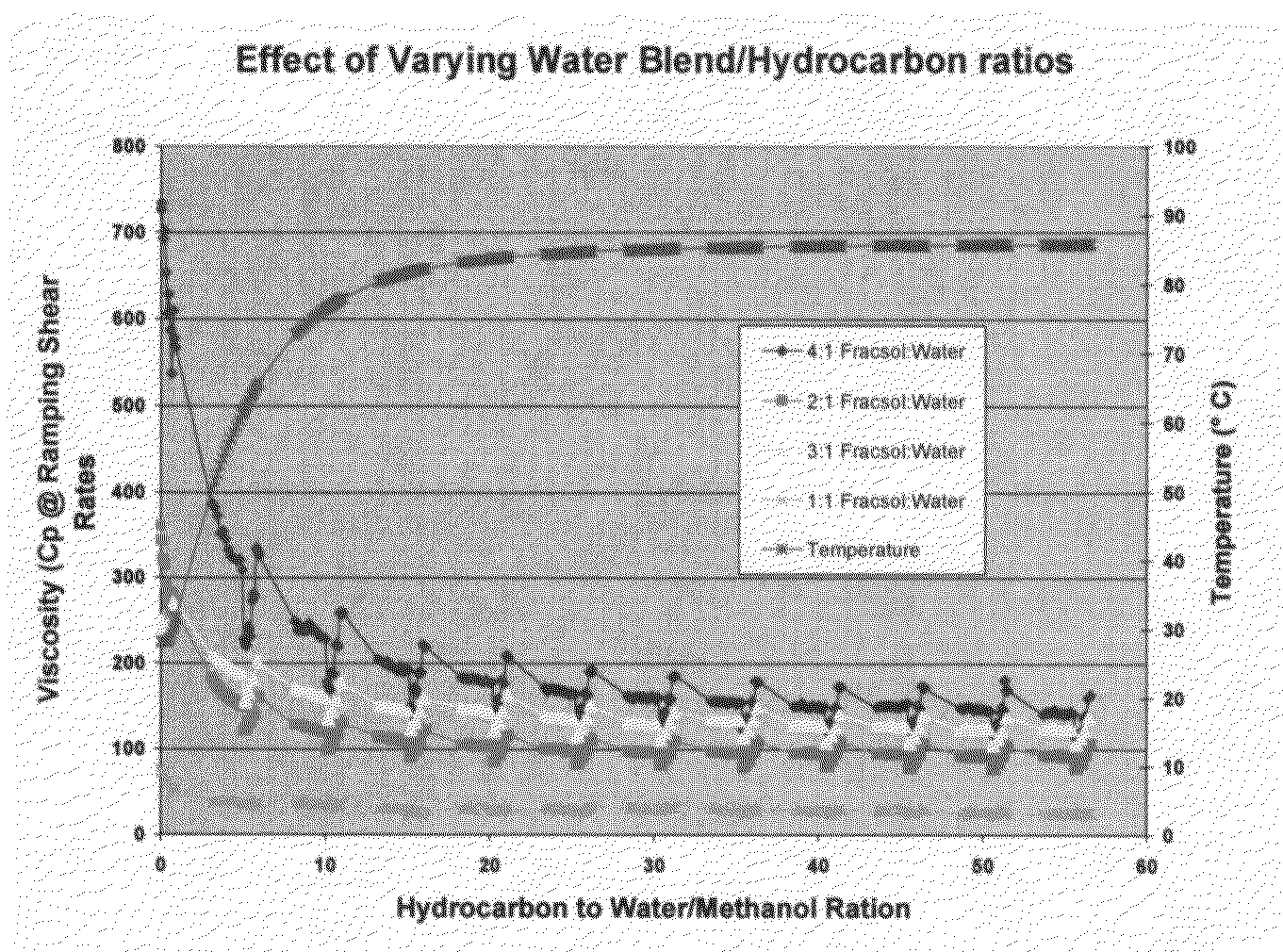

[0083]An emulsion, not containing a breaker, was prepared by making a base gel containing 60 vol % methanol in water to which was added 2 L / m3 acetic acid (60%), 2 L / m3 of a 60% choline chloride solution (a temporary clay stabilizer which avoids the swelling of the clay), 8 kg GM-55 methanol gellant and 20 l / m3 CSA-40 / 70. The acetic acid was used as a buffer to ensure hydration of the GM-55 gellant. One volume of this solvent blend was then emulsified with 3 volumes of Fracsol. The viscosity was then measured on a Brookfield Model PVS high pressure rheometer equipped with a B5 bob. The results are graphically displayed in FIG. 1.

example 2

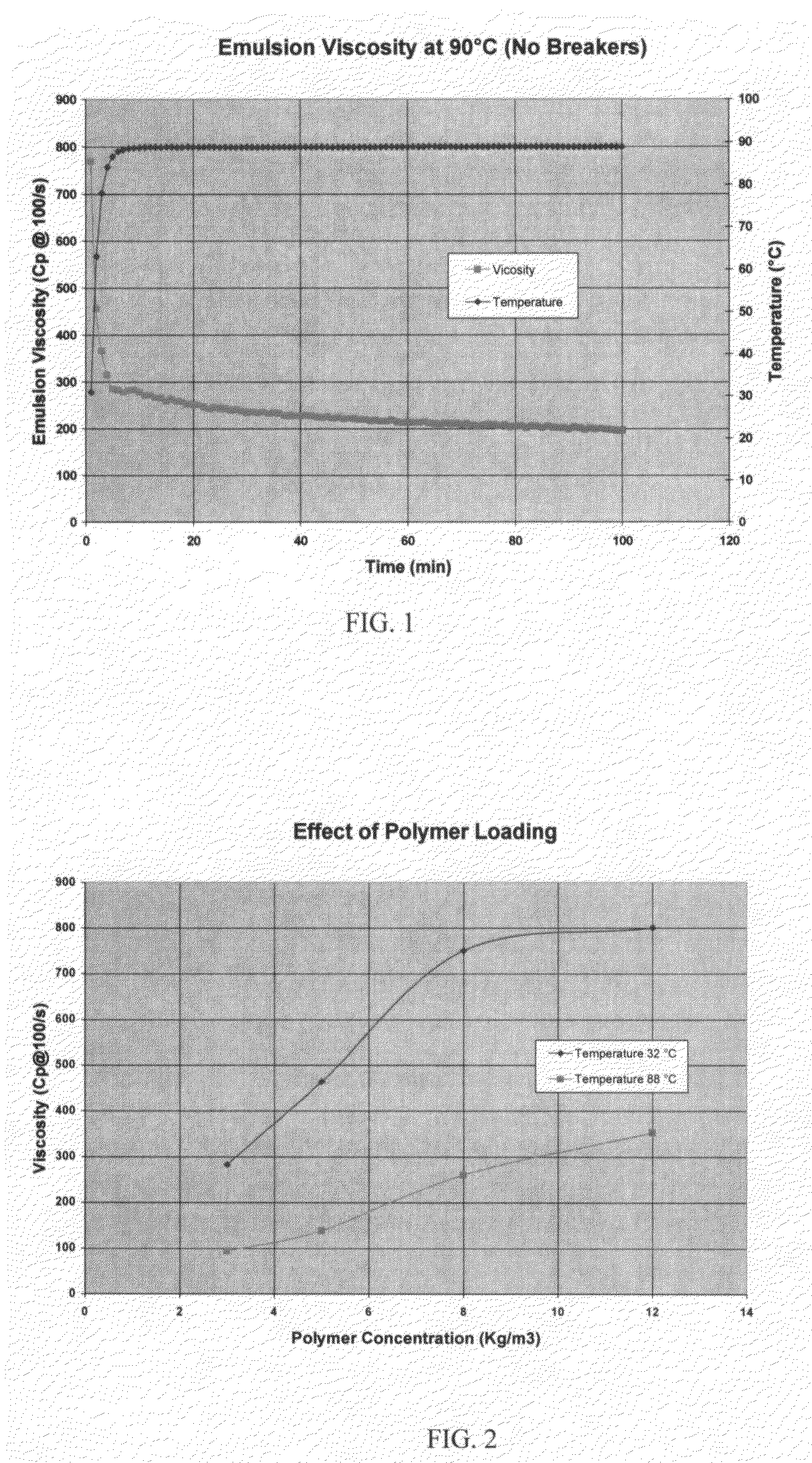

[0084]An emulsion was prepared as set forth in Example 1 except that the concentration of gellant was varied. The results are graphically displayed in FIG. 2.

example 3

[0085]An emulsion was prepared as set forth in Example 1 except that the concentration of gellant was 3 kg / m3 and the concentration of emulsifying agent was varied. FIG. 3 illustrates the effect of emulsifier concentration on viscosity of the gelled emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by volume | aaaaa | aaaaa |

| Substance count | aaaaa | aaaaa |

| Substance count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com