Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Change microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag-corrosion-resistant magnesite-spinel brick and preparation method thereof

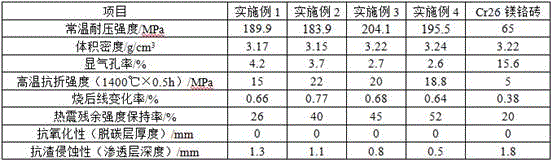

The invention provides a slag-corrosion-resistant magnesite-spinel brick and a preparation method thereof and relates to a slag-corrosion-resistant magnesite-spinel brick. The slag-corrosion-resistant magnesite-spinel brick is prepared from, by mass, 61-81% of fused magnesite particles and fine powder, 0-8% of magnesium aluminate spinel particles, 3-10% of magnesium aluminate spinel fine powder, 2-8% of aluminum powder, 0.5-3% of titanium dioxide, 0.5-10% of zirconium oxide fine powder and 0.1-0.5% of yttrium oxide powder. The slag-corrosion-resistant magnesite-spinel brick is obtained through the steps of material preparation, premixing of materials, mixing of the materials and forming. Slag corrosion resistance, high-temperature oxidation resistance and compactness of the magnesite-spinel brick are improved, and accordingly the aim of prolonging the service life of the magnesite-spinel brick is achieved.

Owner:LUOYANG LIER REFRACTORY MATERIAL

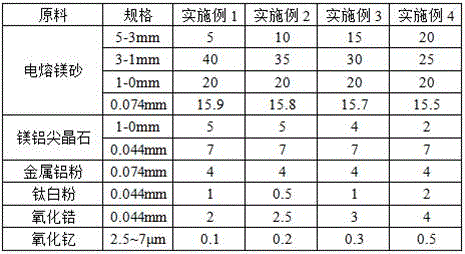

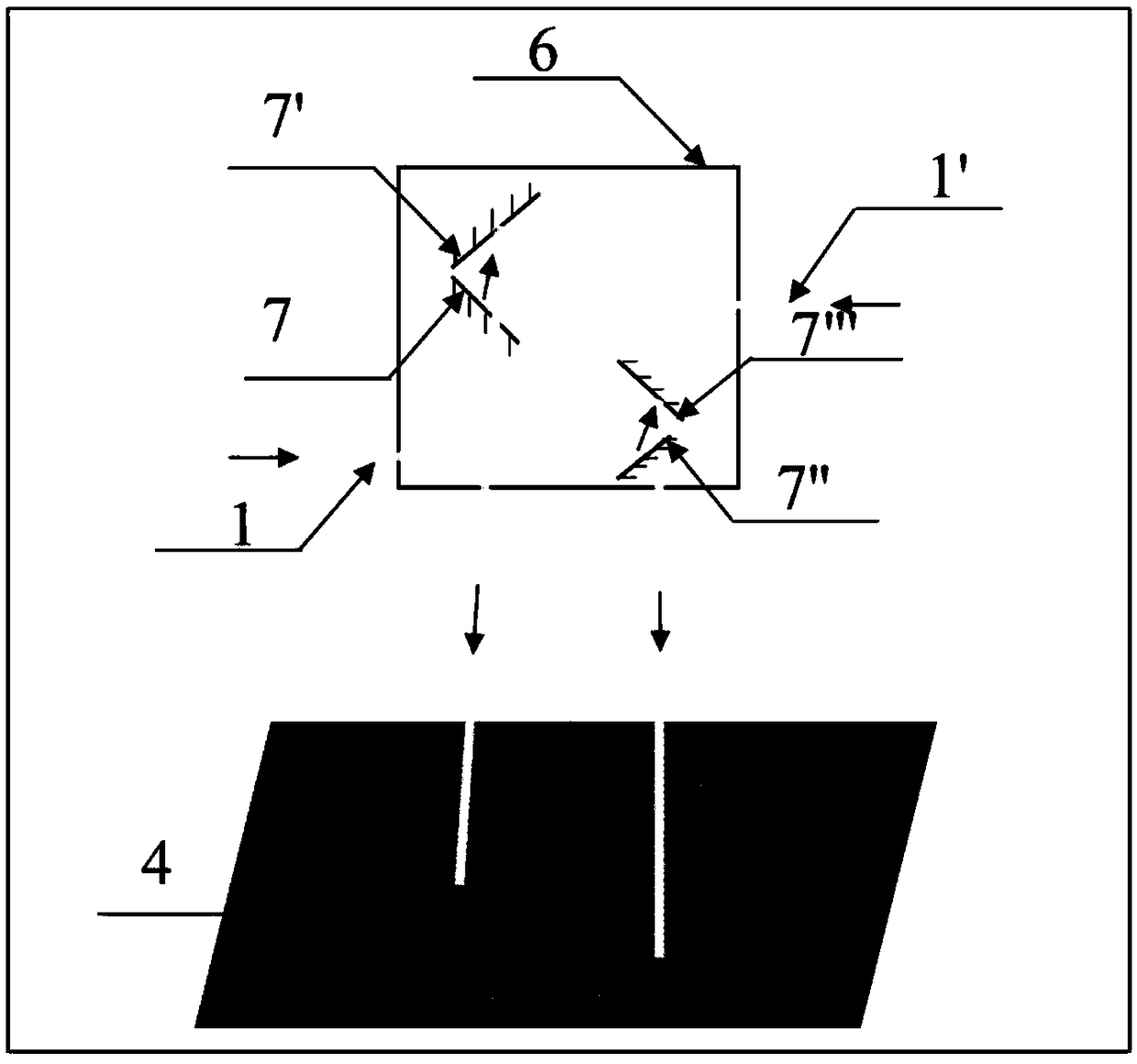

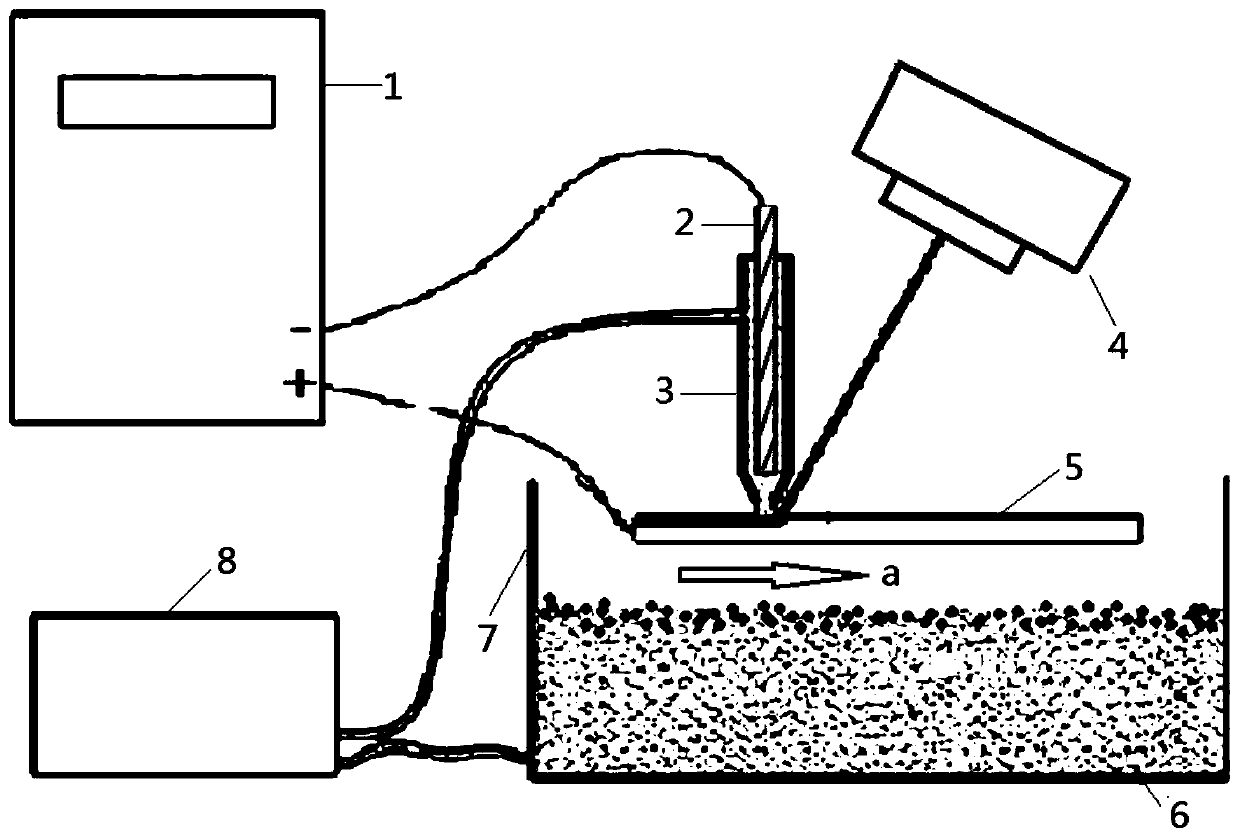

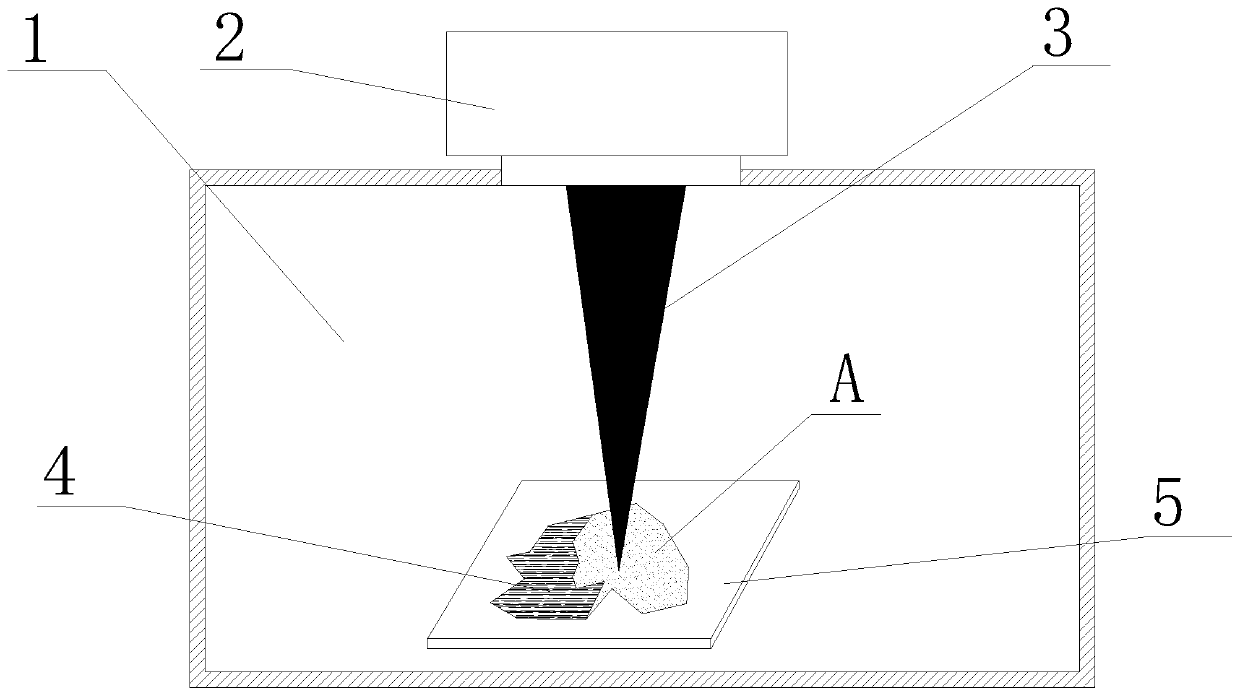

Multi-energy beam high-efficiency additive manufacturing method

ActiveCN109434107AOvercomes the limitation of not being able to cover the entire forming webImprove forming efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyInternal stressPhysics

The invention discloses a multi-energy beam high-efficiency additive manufacturing method. The multi-energy beam high-efficiency additive manufacturing method is characterized in that a plurality of energy beams exist in one surface, each energy beam can irradiate an entire forming region, the energy beams perform mutually independent scanning and / or mutually matched scanning on a to-be-formed region, and raw material powder is formed in the to-be-formed region. According to the multi-energy beam high-efficiency additive manufacturing method, scanning processing is carried out through the plurality of energy beams, scanning strategies of more varieties can be achieved, forming efficiency of equipment can be improved, microscopic structures of components can be regulated, forming internal stress is improved, and forming quality of the components is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

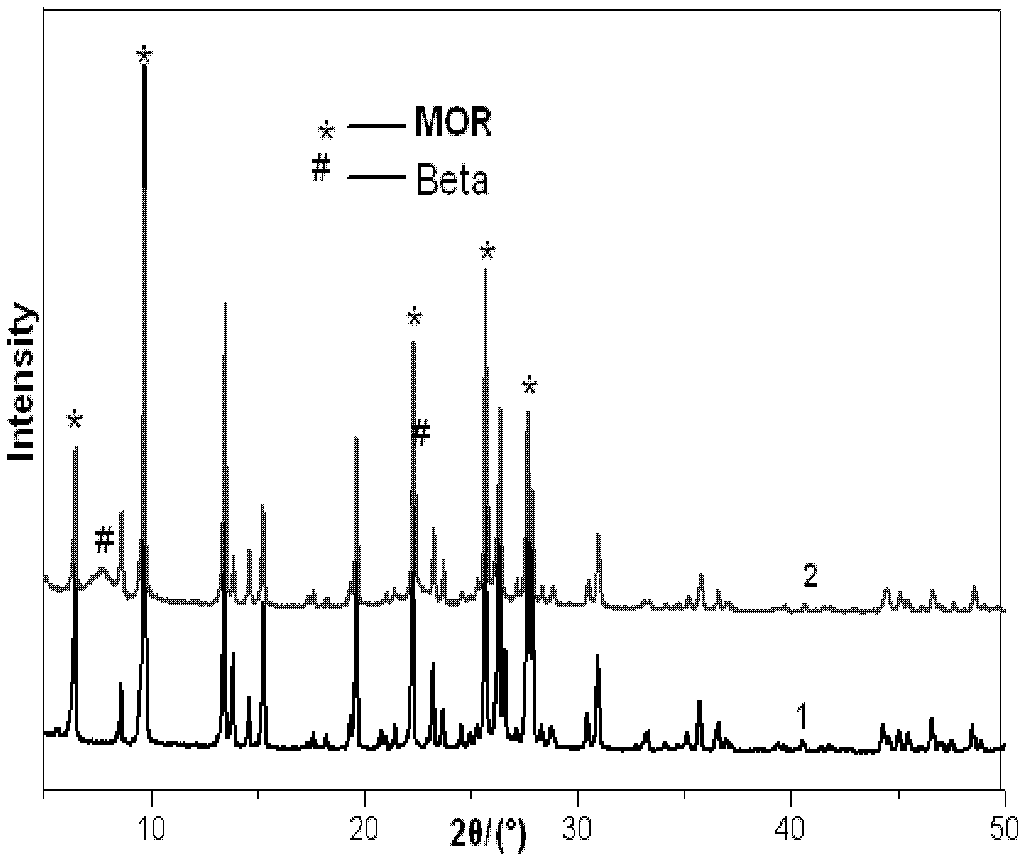

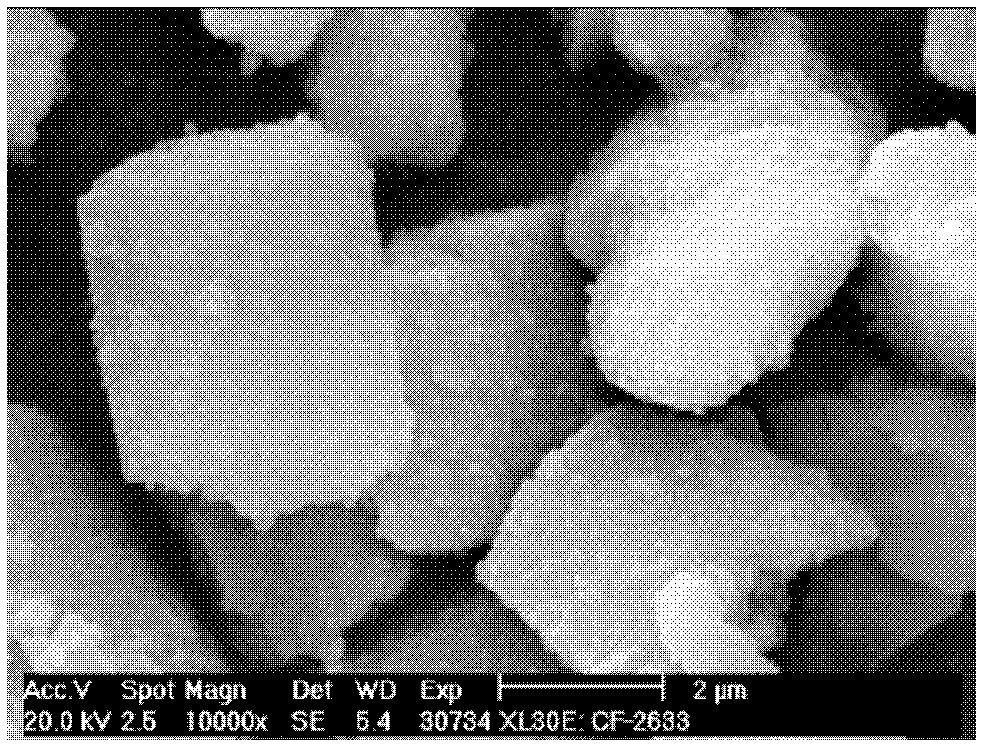

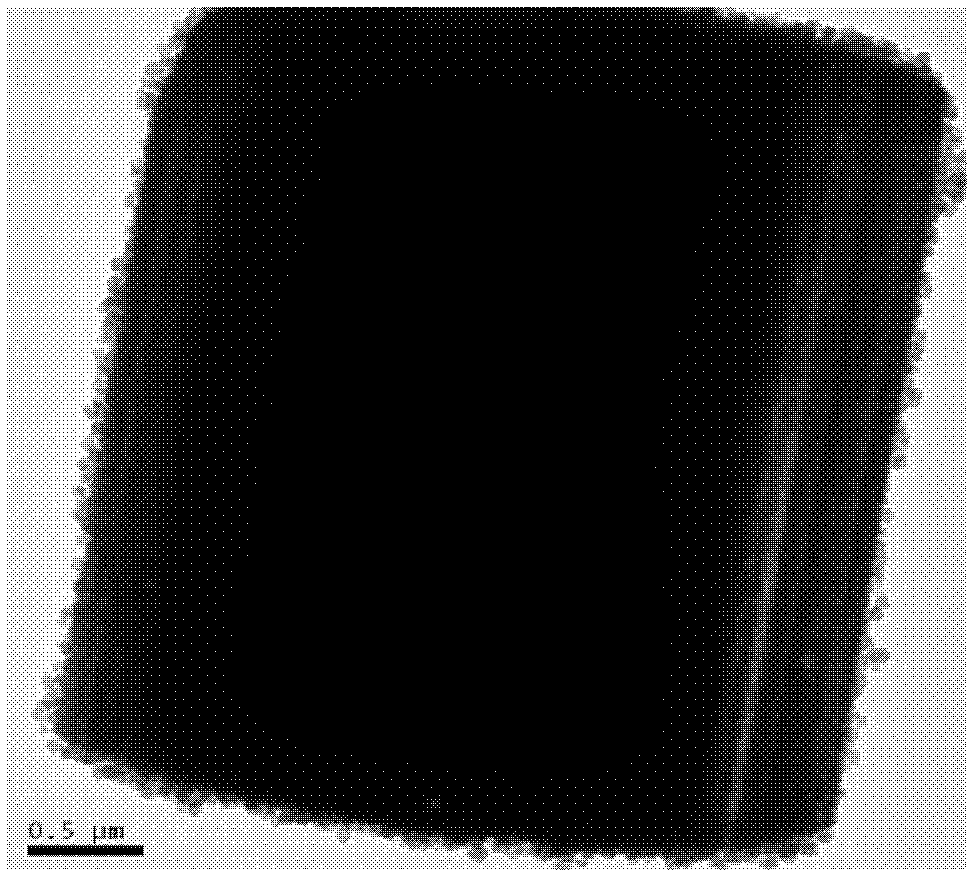

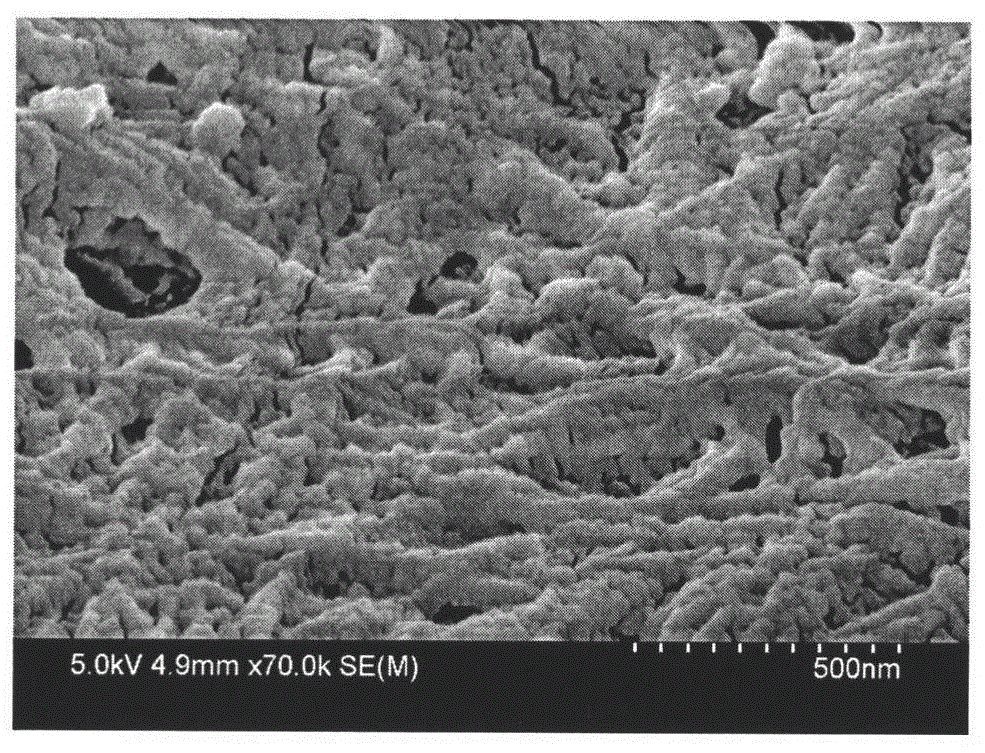

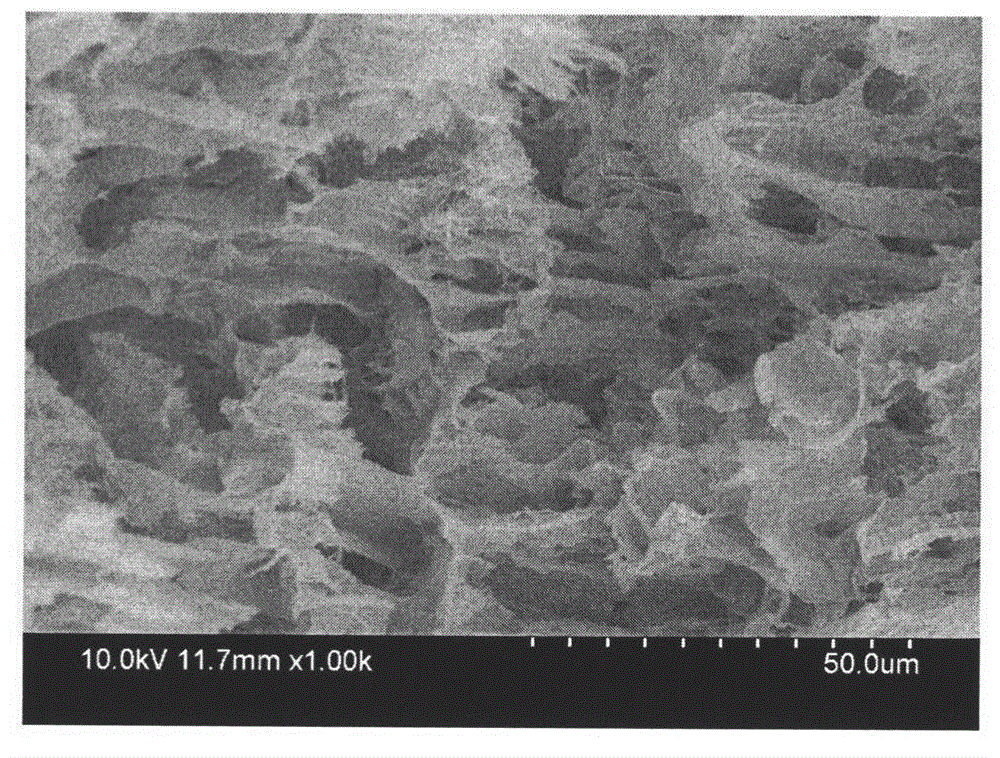

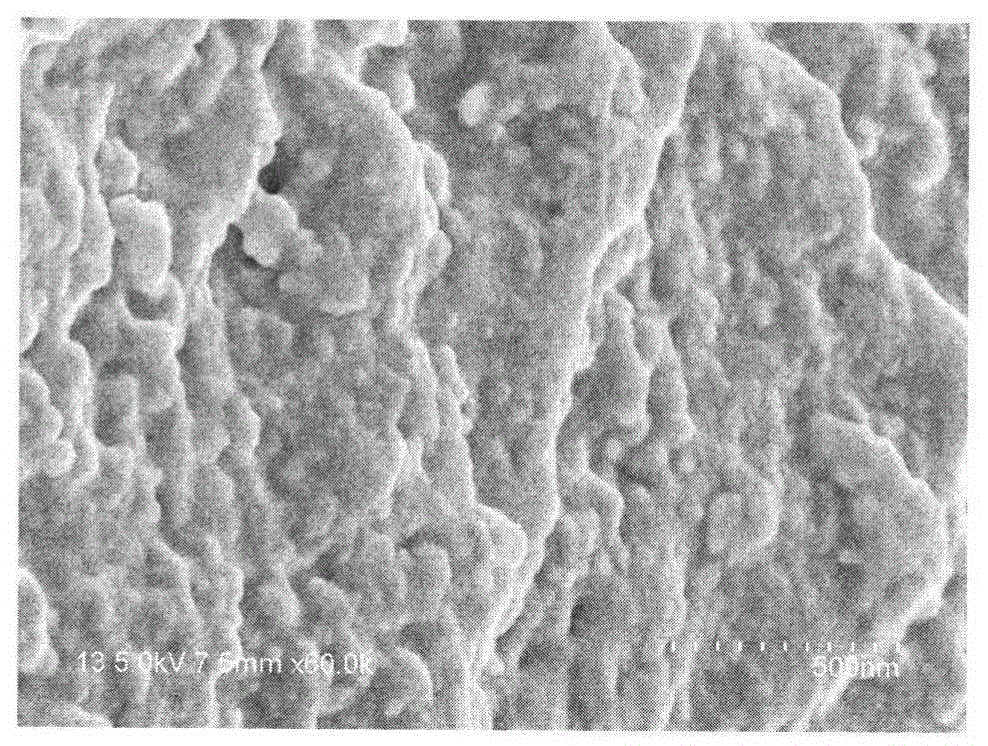

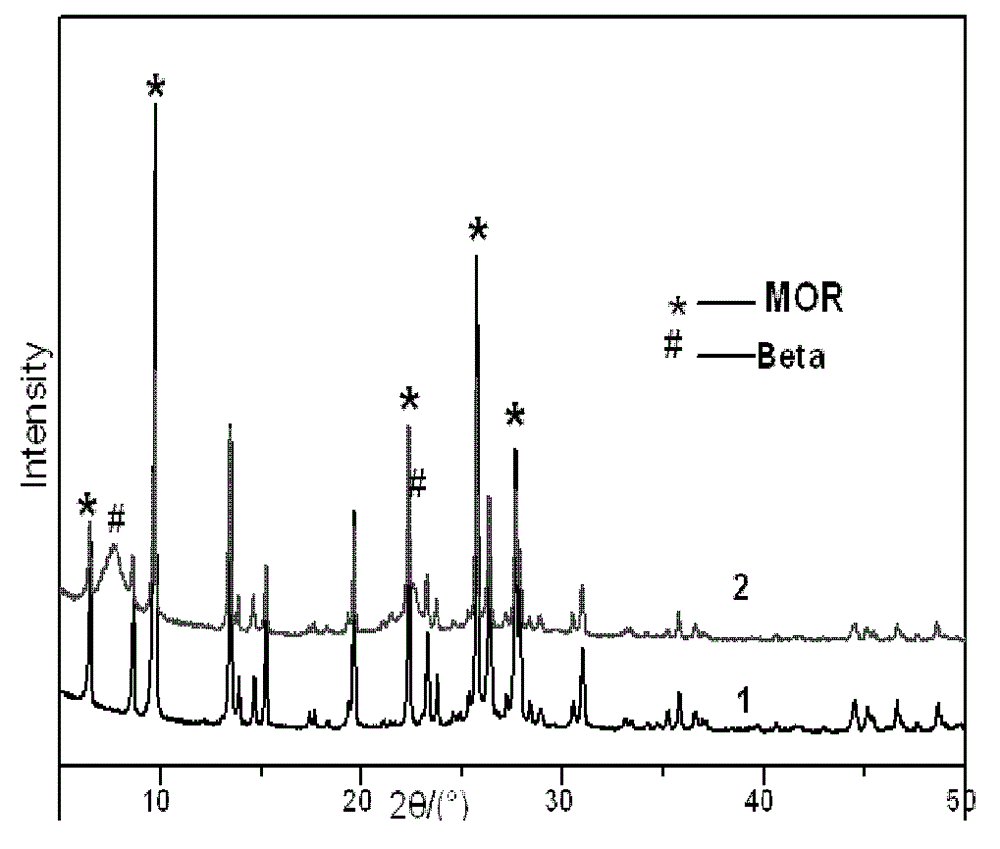

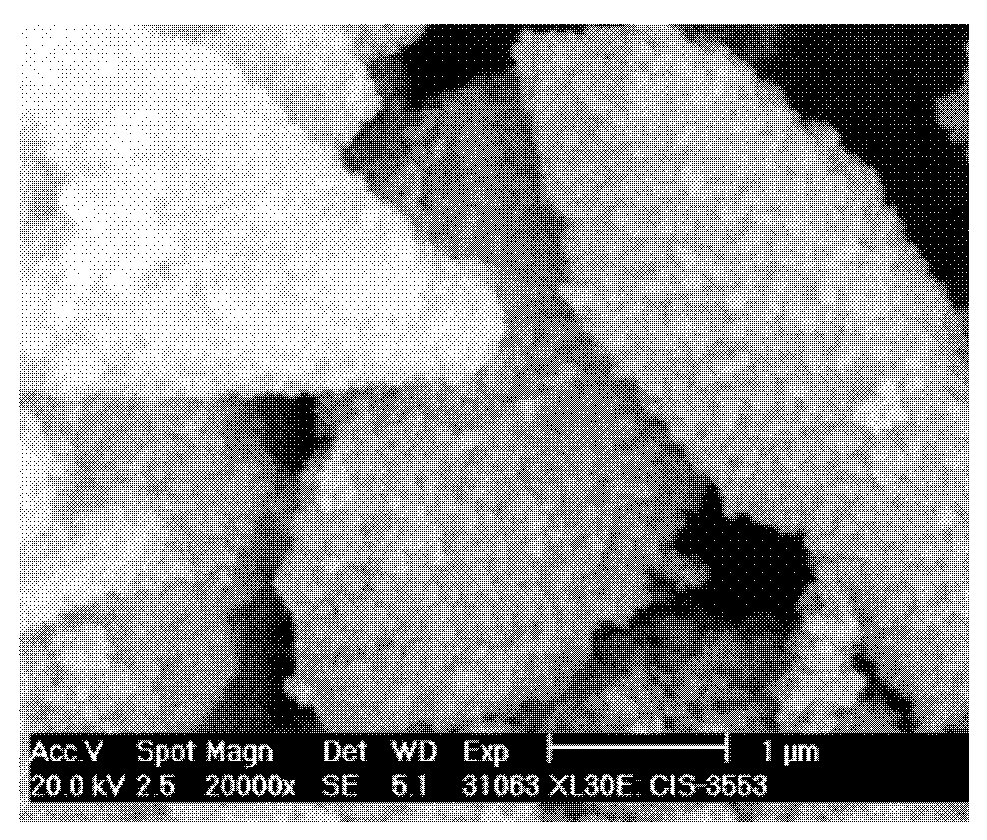

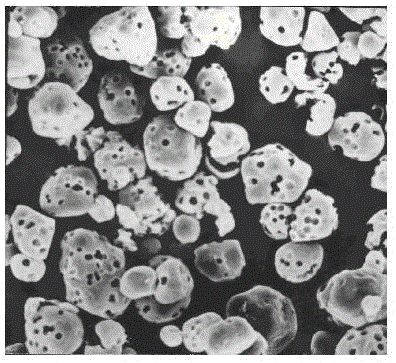

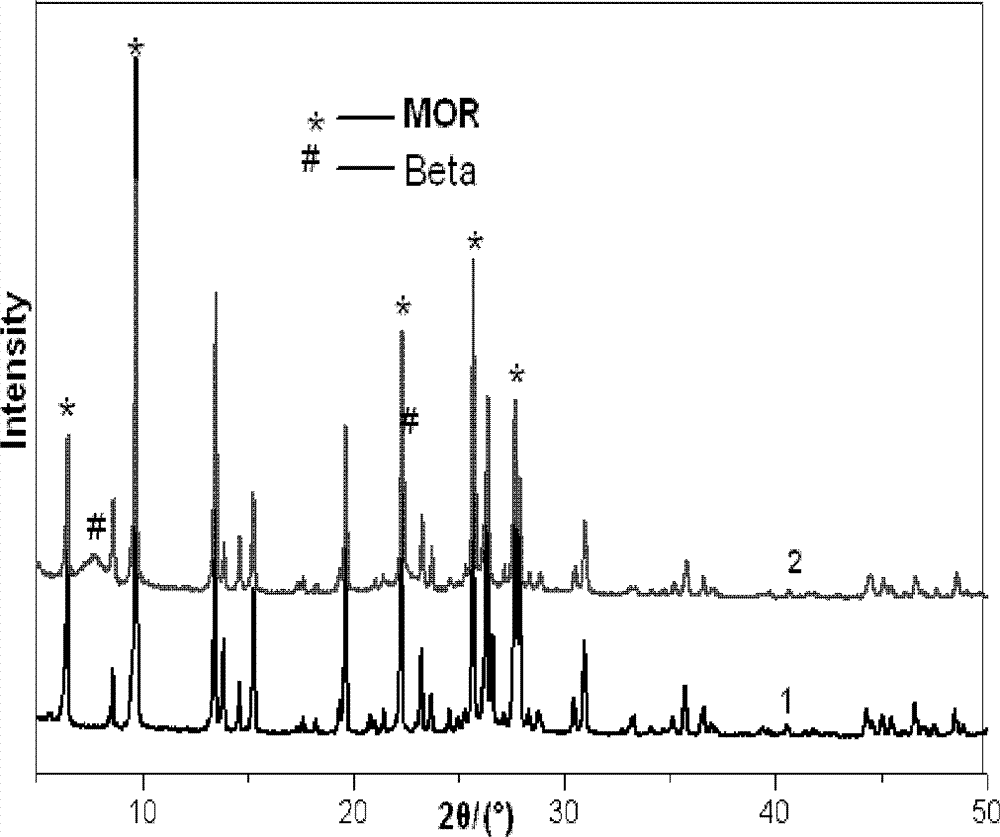

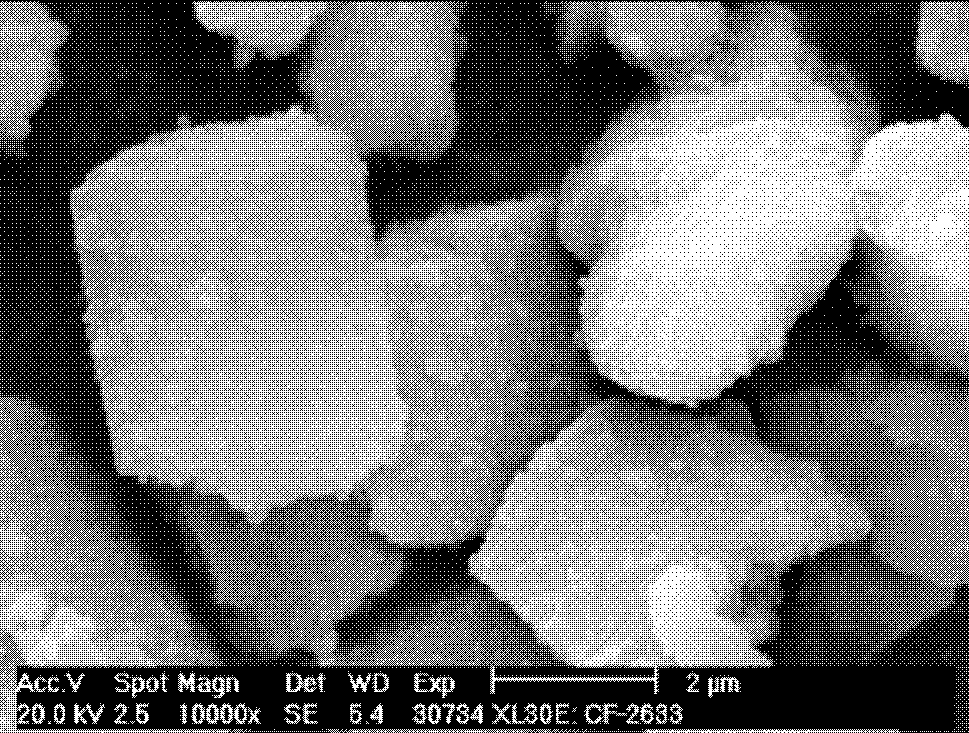

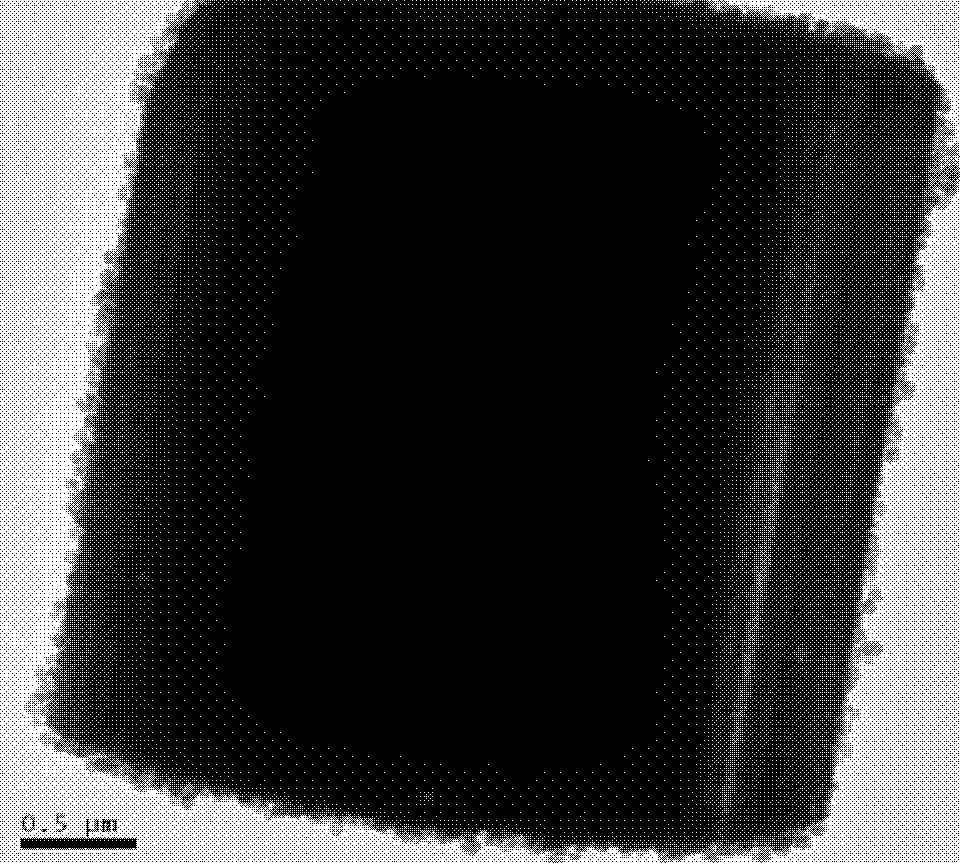

Preparation method of core-shell molecular sieve MOR/BEA (mordenite/bromoethylamine)

ActiveCN103121686AChange microstructureImprove adhesionCrystalline aluminosilicate zeolitesChemistryMolecular sieve

The invention relates to a preparation method of core-shell molecular sieve MOR / BEA (mordenite / bromoethylamine) and mainly solves the problem that a core-shell molecular sieve layer is low in coverage in the prior art. The preparation method includes: firstly, pre-processing mordenite to obtain mordenite I; secondly, adding the mordenite I into solution of nano beta-zeolite, and adhering nano beta-zeolite seed crystal to the surface of the mordenite I to obtain mordenite II; and thirdly, adding the mordenite II to solution containing silicon source, aluminum source and template R to allow for crystallization, and performing filtration, washing, ammonium exchange and drying after crystallization to obtain core-shell molecular sieve MOR / BEA. The problem is solved well by the application of the technical scheme. The preparation method is applicable to industrial production of core-shell molecular sieve MOR / BEA.

Owner:CHINA PETROLEUM & CHEM CORP +1

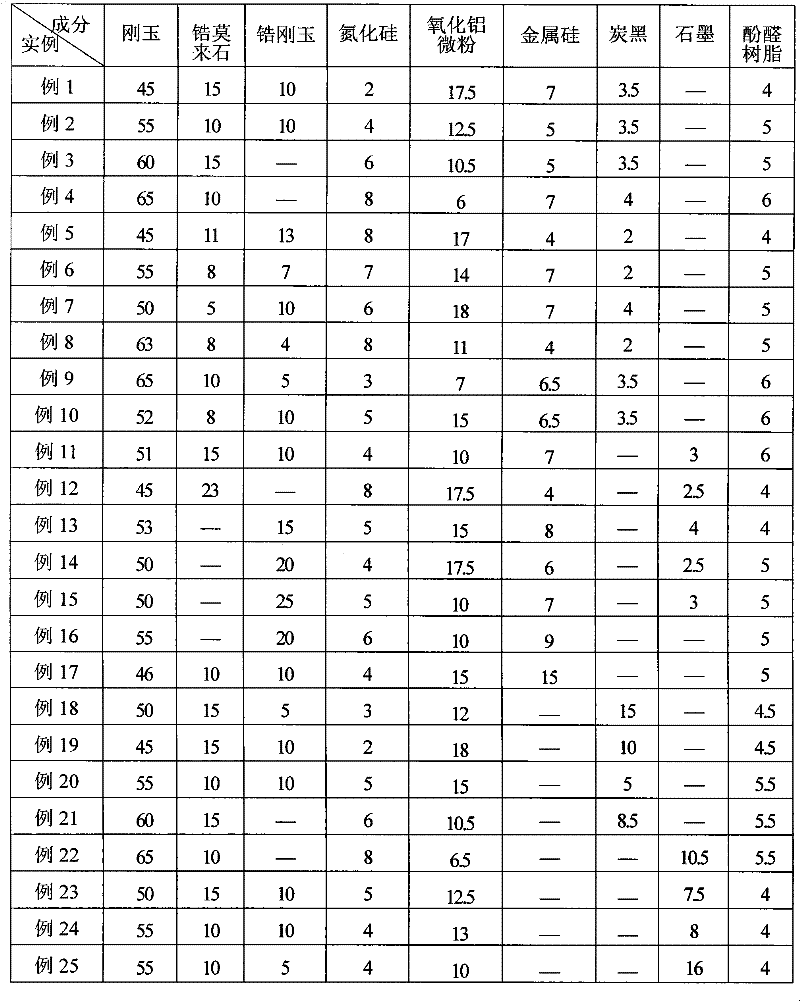

Slide plate refractory with silicon nitride added and production method thereof

The invention relates to a slide plate refractory with silicon nitride added and a production method thereof. The slide plate is prepared by the following raw materials in percentage by weight: 45-65% of corundum, 10-25% of zirconia-mullite and / or zirconia-corundum, 2-8% of silicon nitride, 6-18% of alumina fine powder and the balance one or more of silicon metal, carbon black and graphite powder and a phenolic resin binder accounting for 4-6% of the total above raw materials. The production method is characterized by proportionally weighing the raw materials, uniformly mixing the raw materials, obtaining the mixture through mixing, press-forming the mixture, drying the formed mixture at 190-210 DEG C for 6-10h and then carrying out nitridation firing on the dried mixture at1200-1400 DEG C. The invention has the following benefits: by adding silicon nitride and reasonably adding other components according to the amount and ratios, the slide plate composite material with structure of Al2O3-ZrO2-Si3N4-C is formed, and the oxidation resistance of the slide plate is improved; and the apparent porosity of the refractory is 1-4%, the cold compression strength is 150-220MPa, the high temperature rupture strength is 28-33MPa and such performance indexes as the oxidation resistance, the scouring resistance, the thermal shock resistance and the like are all excellent or good.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

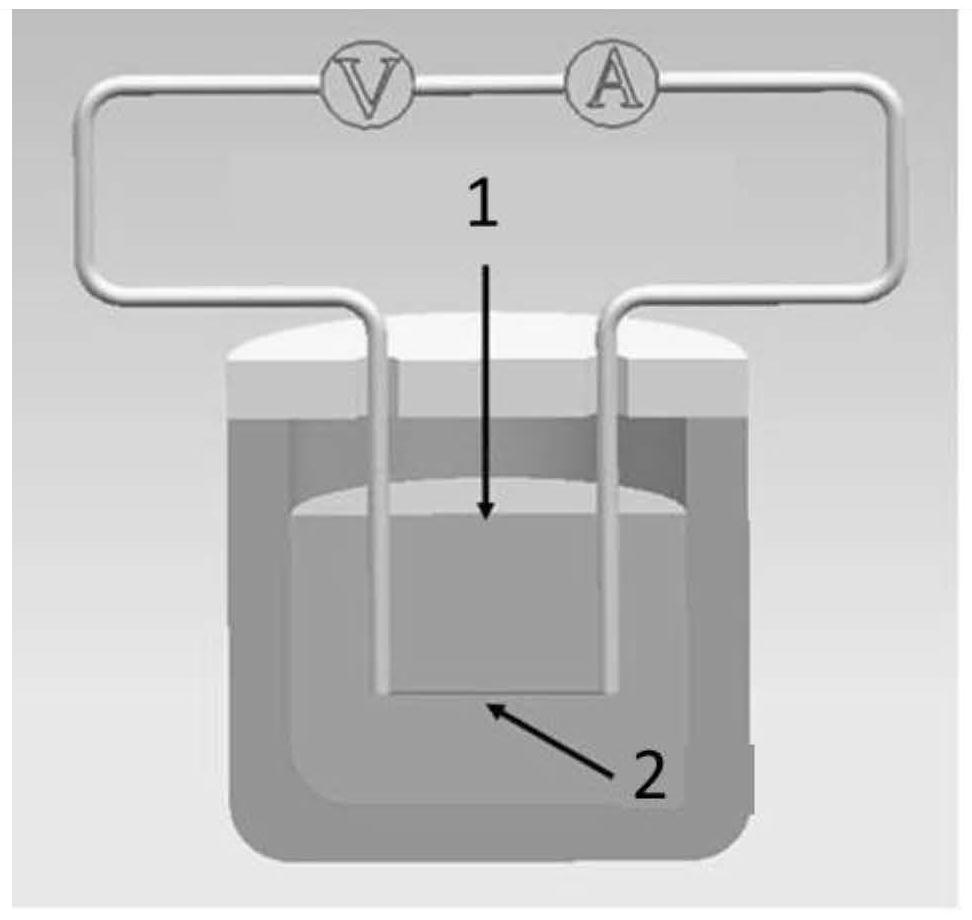

Scanning type laser-assisted micro-arc oxidation device and method

The invention provides a scanning type laser-assisted micro-arc oxidation device and method. The device is not limited by the size of the electrolytic cell and does not require power supply of ultra-high power and can perform local strengthening or repairing treatment so as to reduce the energy consumption, improve the film forming efficiency and the film layer quality, reduce micro-arc oxidationarcing voltage and energy consumption, perform micro-arc oxidation more easily and enter a film forming stage more quickly, realize machining of large-size workpieces or workpieces with complex moldedsurfaces, solve the problems of the area effect and point discharge in the traditional machining device, the reduce limitation of the workpiece size on the power output power and realize micro-arc oxidation of a specific area controlling an inter-electrode electric field.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of conductive hydrogel based on nanocellulose-graphene-polyvinyl alcohol-polyethylenediamine

PendingCN112175232AMaximize electrostatic attractionLow costElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsFiberSpinning

The invention relates to the field of intelligent materials, and discloses a preparation method of conductive hydrogel based on nanocellulose graphene polyvinyl alcohol polyethylenediamine. The methodcomprises the following steps: firstly, selecting polyvinyl alcohol and polyethylenediamine as matrixes of hydrogel; then uniformly dispersing the nano-crystalline cellulose graphene conductive compound serving as a nano-enhanced phase into a hydrogel matrix, so that the conductive hydrogel fiber is obtained by adopting a wet spinning method; and finally, carrying out post-treatment on the synthesized hydrogel by adopting a freezing and unfreezing circulation method. The invention discloses a conductive hydrogel based on nano-crystalline cellulose graphene polyvinyl alcohol polyethylenediamine. The hydrogel prepared by the method has huge application value in the fields of photoelectric devices, flexible wearable equipment, sensors and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Casting method of rare earth alloy copper strip

The invention discloses a casting method of a rare earth alloy copper strip; the specific of the casting method is as follows: charging-covering-smelting-blending and dregs catching-warming a converter and pouring copper water-adding rare earth-horizontally continuous casting; wherein the additive amount of the compound rare earth accounts for 0.03-0.05% of the weigh of copper material; the compound rare earth comprises lanthanum and chromium which account for 0.01-0.07% of the weigh of the rare earth; zinc accounts for 0.5-5.0% of the weigh of the rare earth; chromium accounts for 0.5-5.0% of the weigh of the rare earth; and zirconium accounts for 0.5-5.0% of the weigh of the rare earth. The casting method effectively removes various complex harmful impurities brought about by waste material and plating white material by adding compound rare earth into a heating preserving furnace. The casting method can effectively improve the form, size and distribution of sulfide, improves the machining operation performance, causes the copper strip to have good welding performance, the mechanical property of the copper strip to be increased, and the overall performance of the phosphor bronze strip to be better.

Owner:MAANSHAN TIANCHENG COPPER IND

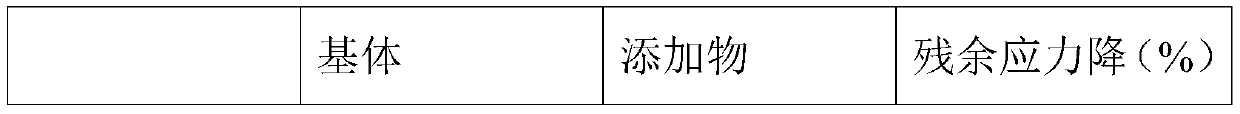

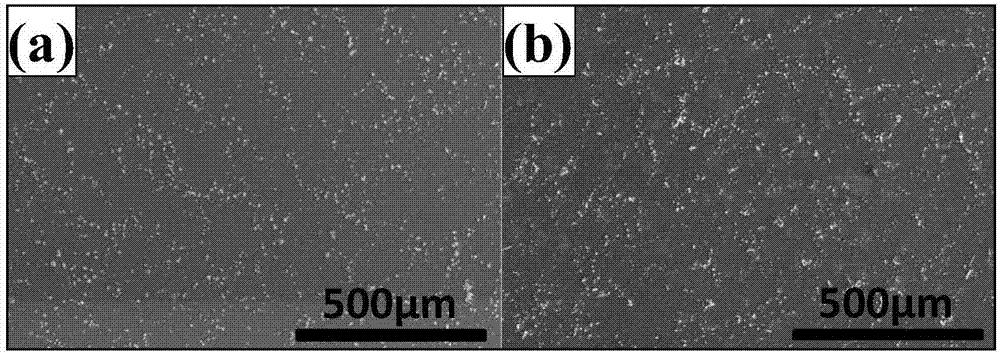

Method for lowering residual stress of titanium-based composite material prepared due to selective laser melting

InactiveCN110385429AReduce residual stressReduce microstructureAdditive manufacturingTransportation and packagingSelective laser meltingRare-earth element

The invention discloses a method for lowering the residual stress of a titanium-based composite material prepared due to selective laser melting. The method includes the steps that titanium-based composite material powder is prepared, and comprises base body powder and additive powder; the base body powder comprises a titanium element; the additive powder comprises one or more of a boron element,a carbon element and a rare earth element; the titanium-based composite material powder is placed into a selective laser melting device in a magnetic field to be subjected to selective laser melting till a titanium-based composite material component is made; and the residual stress in the made titanium-based composite material component is lowered by 20-80% than a component made without being subjected to the selective laser melting of the selective laser melting device in the magnetic field. According to the method, due to cooperation of the magnetic field and additives in the composite material, distribution of reinforcement bodies is more uniform, the microscopic structure of the titanium-based composite material is changed, the residual stress of the titanium-based composite material is remarkably lowered, and the precision and the yield of products are improved; and operation is easy, cost is low, efficiency is high, adaptability is high, and great application prospects are achieved.

Owner:SHANGHAI UNIV OF ENG SCI

Environment-friendly bentonite adsorbent and preparation method thereof

InactiveCN107321332AImprove adsorption capacityHigh grafting rateOther chemical processesMicro structureSodium Bentonite

The invention relates to the field of materials, in particular to an environment-friendly bentonite adsorbent and a preparation method thereof. The environment-friendly bentonite adsorbent is prepared from, by weight, 60-75 parts of bentonite, 7-13 parts of chitosan, 4-5 parts of starch, 4-5 parts of partially hydrolyzed polyacrylamide, 0.7-1.5 parts of cetyl trimethyl ammonium bromide and 11-15 parts of microbead particles with the particle size of 0.1-5 microns. Through the modification of the micro-bead particles and the bentonite by various organic substances, the adsorbent with a good adsorption property is finally prepared. The partially hydrolyzed polyacrylamide can be effectively grafted onto the starch to increase the grafting rate of nonionic groups on the starch. The microbead particles are filled among bentonite particles. Through the modification of the outer surfaces of the micro-bead particles and bentonite by the organic substances, the surface activity and micro-structures of interlayers are changed to improved the adsorption property of the adsorbent.

Owner:重庆卡美伦科技有限公司合川分公司

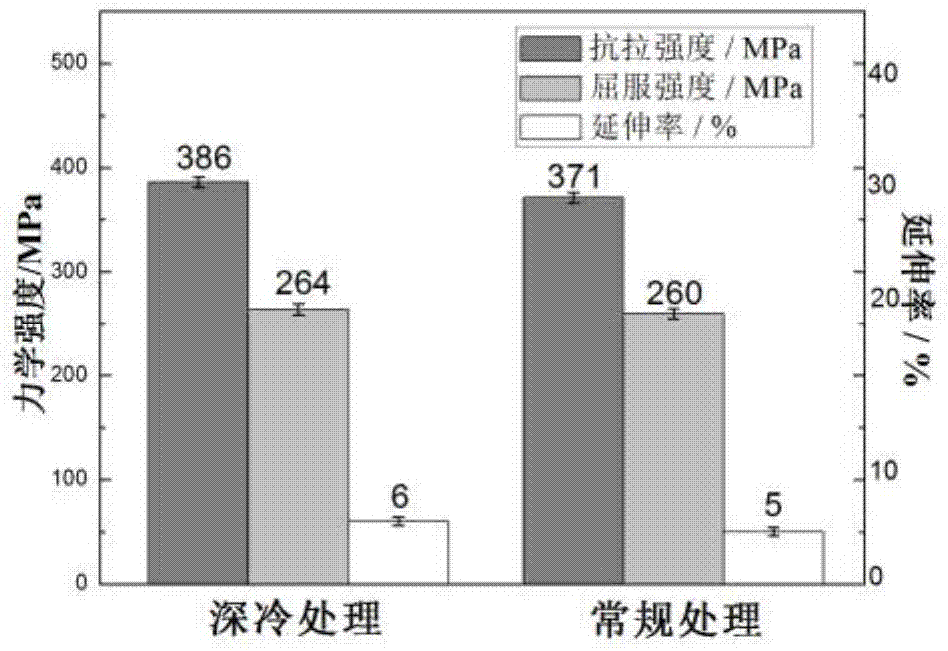

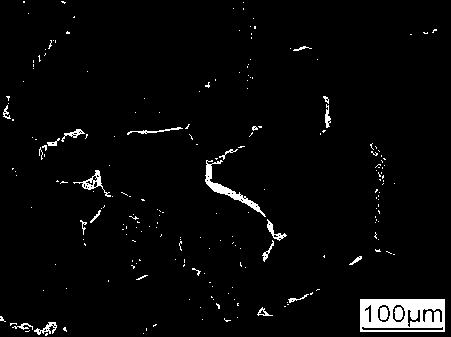

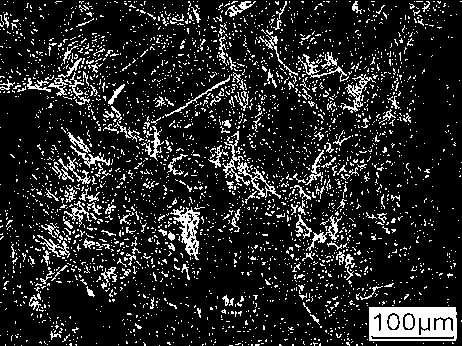

Processing method for improving corrosion resistance of Mg-Y-Nd based alloy

ActiveCN107574392AImprove mechanical propertiesImprove wear resistanceSolution treatmentSolid solution

The invention belongs to the technical field of metal material thermal treatment and particularly relates to a processing method for improving corrosion resistance of an Mg-Y-Nd based alloy. The method comprises the steps that the to-be-processed alloy is subjected to deep cooling and solid solution treatment, soaked in a liquid nitrogen environment for quenching after being treated, and placed inthe liquid nitrogen environment after being quenched; and then the alloy is subjected to deep cooling aging treatment again, soaked in the liquid nitrogen environment for quenching after being treated, and placed in the liquid nitrogen environment after being quenched, the sample is completely stabilized at the liquid nitrogen temperature of minus 196 DEG C, and thus the magnesium alloy with thecorrosion resistance improved is obtained. By adoption of the method, the corrosion resistance of the Mg-Y-Nd based alloy can be remarkably improved while the excellent mechanical performance is ensured. The application range of the Mg-Y-Nd based alloy treated by the deep cooling treatment process is broad.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Method for improving low-carbon aluminum killed steel blank hot cracks by adopting low-voltage pulse current

The invention discloses a method for improving low-carbon aluminum killed steel blank hot cracks by adopting low-voltage pulse current, belonging to the technical field of improving the steel blank hot cracks. According to the method disclosed by the invention, when a low-carbon aluminum killed steel blank is cut by a continuous casting machine, pulse current is applied to the low-carbon-aluminumkilled steel blank; the pulse current parameters are as follows: the pulse voltage is 21-35 V, the pulse current is 35-100 A and the pulse frequency is 20-50 Hz; and low-carbon aluminum killed steel is the aluminum killed steel with omega[C] which is less than 0.25%, wherein omega[Al] is more than or equal to 0.01% and less than or equal to 0.40%. According to the method disclosed by the invention, the low-voltage pulse current is adopted, microcosmic tissues of the low-carbon aluminum killed steel blank are changed, and the high-temperature mechanical property of a casting blank is improved,so that the hot cracks of the casting blank are effectively reduced; and the normal production is not influenced by the method, the existing production process does not need to be changed, alloy elements do not need to be added, temperature-reduction treatment does not need to be carried out on the casting blank, no pollution to the casting blank and equipment is generated, and no harms on workers are formed, so that the method is an environment-friendly, safe and new technology for reducing defects of the casting blank.

Owner:马鞍山市安工大智能装备技术研究院有限公司

Sm-doped modified quickly-quenched FeSiAl magnetic metal wave-absorbing material and preparation method thereof

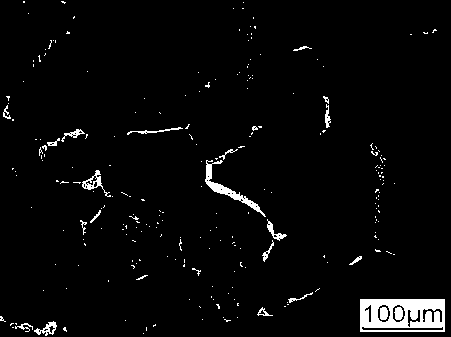

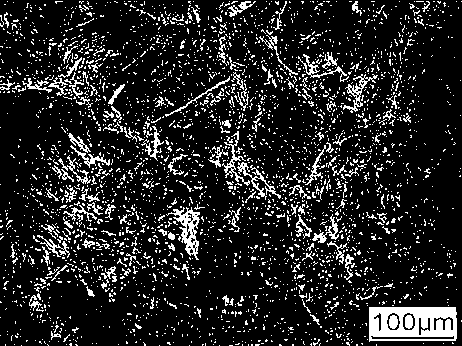

InactiveCN110740628AChange microstructureTuning Dielectric Matching PropertiesMagnetic/electric field screeningInorganic material magnetismRadarIngot

The invention relates to a preparation method of an Sm-doped modified quickly-quenched FeSiAl magnetic metal wave-absorbing material. The preparation method comprises the steps of smelting, quick quenching, and crushing and fine grinding. According to the smelting step, raw materials of rare earth Sm and FeSiAl are added into a vacuum smelting furnace so as to be smelt, so that an alloy master ingot can be obtained. According to the quick quenching step, the alloy master ingot is rapidly quenched in a vacuum rapid quenching furnace, so that an alloy quickly-quenched thin strip is obtained. According to the crushing and fine grinding step, the quickly-quenched thin strip is crushed on a high-speed crusher, and refined and crushed metal powder is subjected to high-energy ball milling on a high-energy ball mill, so that ball-milled powder can be obtained; and the powder which has been subjected to high-energy ball milling is subjected to vacuum drying, so to that the Sm-doped modified FeSiAl magnetic alloy wave-absorbing material can be obtained. The Sm-modified quickly-quenched FeAlSi magnetic metal wave-absorbing material prepared by the preparation method can be used for absorbingelectromagnetic waves in an S waveband and a C waveband of radar waves.

Owner:NANJING UNIV OF POSTS & TELECOMM

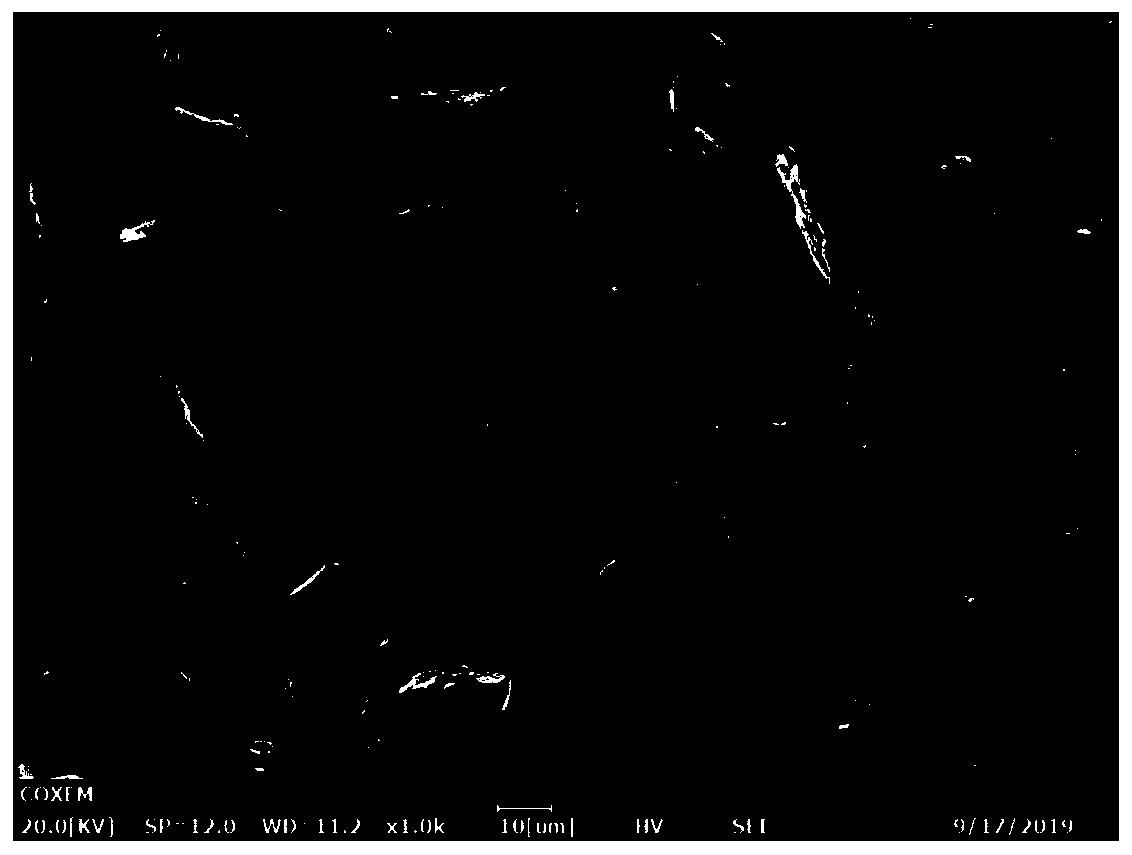

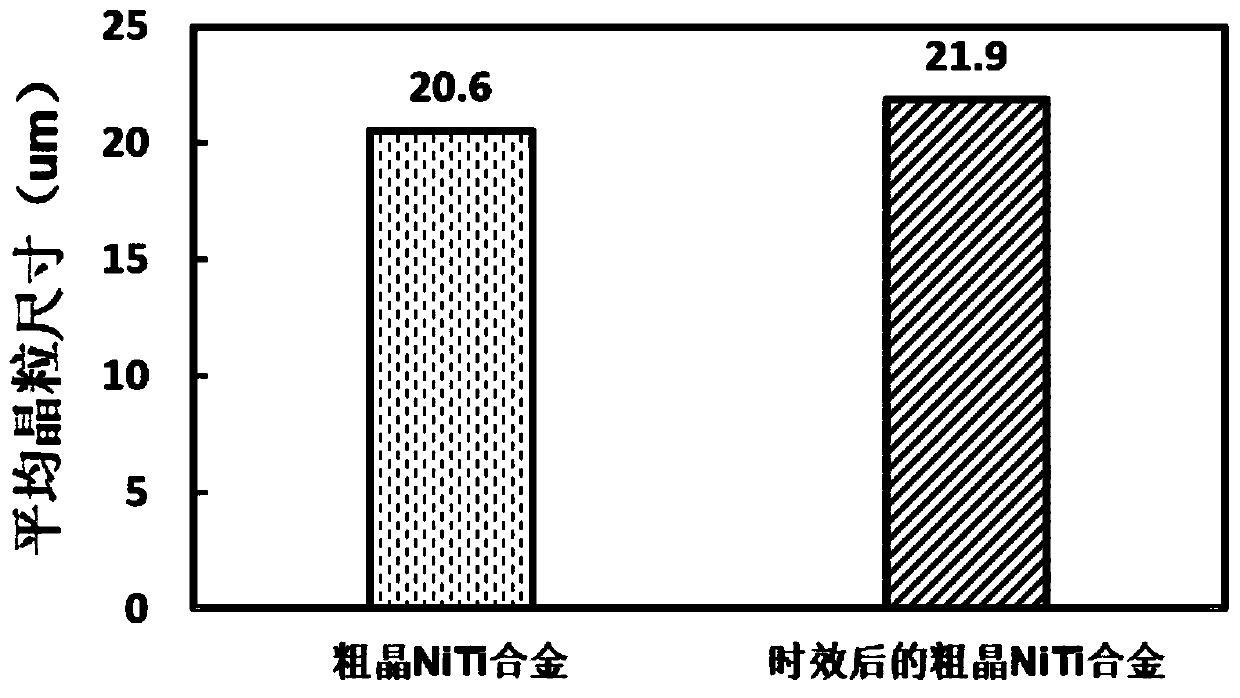

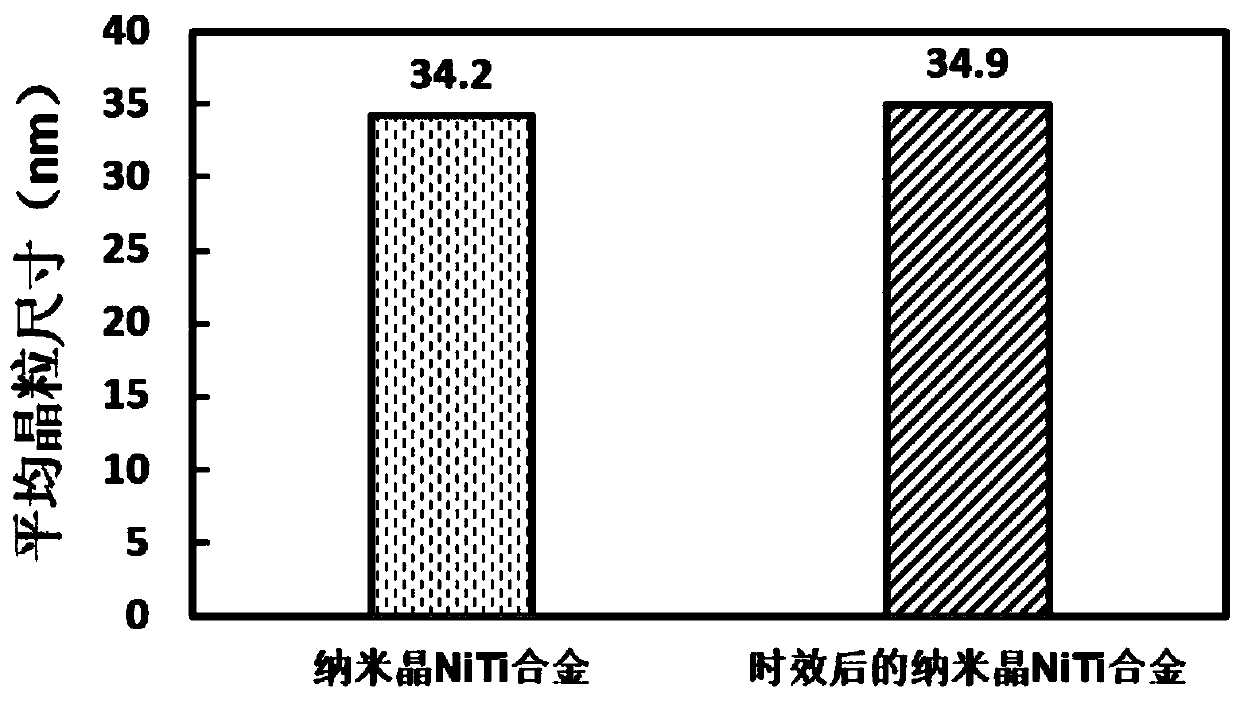

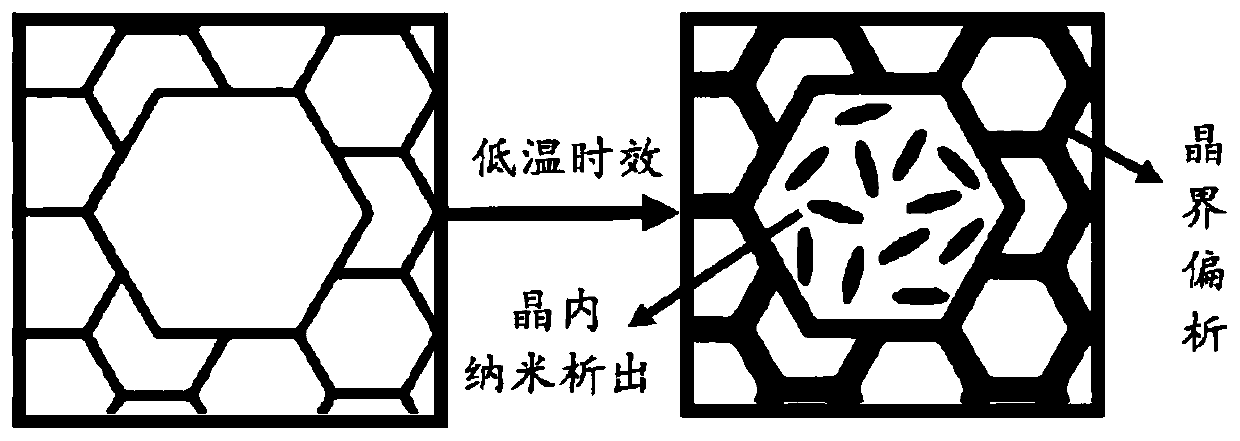

Functional regulation and control method for shape memory alloy

The invention provides a functional regulation and control method for a shape memory alloy. The method is characterized in that low-temperature aging is carried out on the shape memory alloy, after the low-temperature aging is carried out, the grain size of the shape memory alloy is unchanged, but the function characteristic of the shape memory alloy is changed; and the aging temperature during the low-temperature aging needs to be lower thanthe recrystallization temperature or grain growth temperature of the shape memory alloy or below. According to the functional regulation and control method, the functional characteristics of the shape memory alloy are regulated and controlled while the high strength, the high hardness, the high elasticity modulus, the high fatigue resistance, the highcorrosion resistance and the low biotoxicity of the nanocrystalline and ultrafine grain shape memory alloy are retained.

Owner:TONGJI UNIV

High-strength wear-resistant steel and production method thereof

InactiveCN107130187AHigh strengthImprove wear resistanceFireproof paintsPolyether coatingsTungstenHardness

The invention discloses high-strength wear-resistant steel and a production method of the high-strength wear-resistant steel and belongs to the technical field of steel production. The high-strength wear-resistant steel is mainly prepared by mixing the components of by weight, 5-10% of silicon, 3-6% of tungsten, 3-6% of manganese, 2-5% of phosphorus, 2-5% of sulfur, 0.2-3% of carbon, 0.1-3% of niobium, 0.1-2% of titanium, 3-10% of molybdenum, 2-6% of chromium, 1-4% of boron, 3-8% of a binder, 0.5-5% of a wear-resisting agent, 0.1-3% of a flame retardant, 1-5% of a molding agent, 0.2-6% of a reinforcing agent, 1-5% of an antioxidant and the balance iron. The production method of the steel is simple and effective, and the obtained steel has good hardness, wear resistance, yield strength and tensile strength.

Owner:广西浩昌敏再生资源利用有限公司

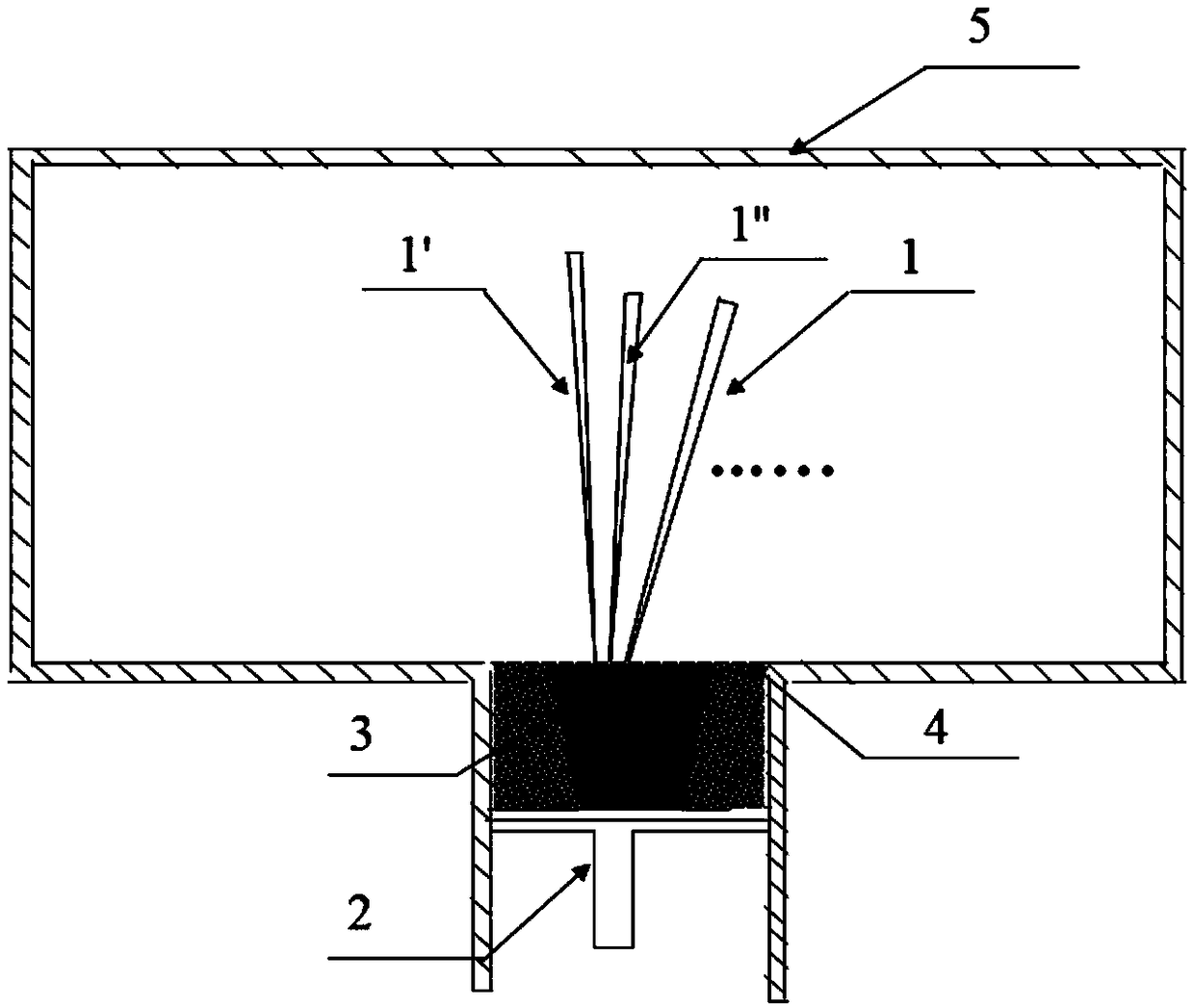

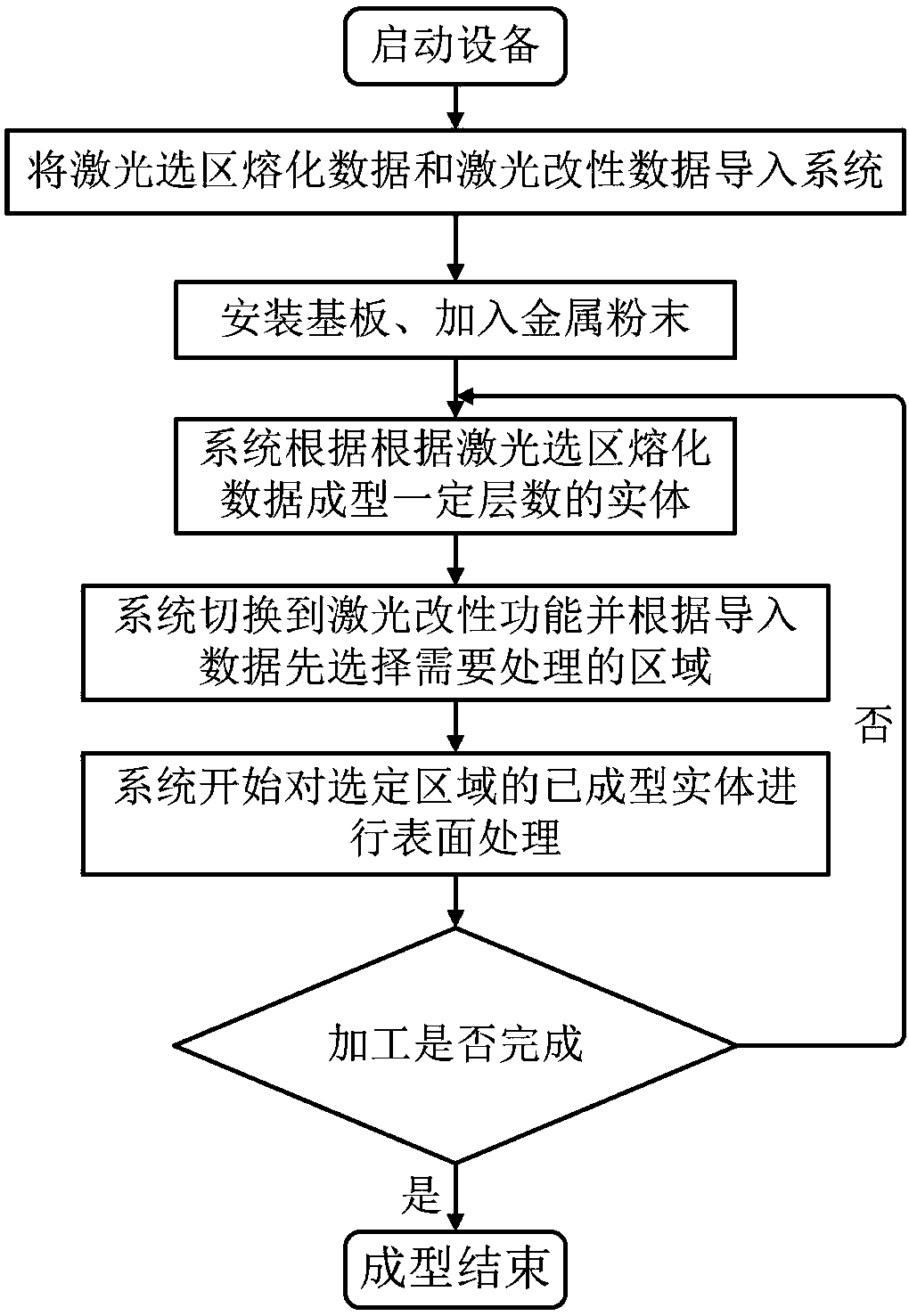

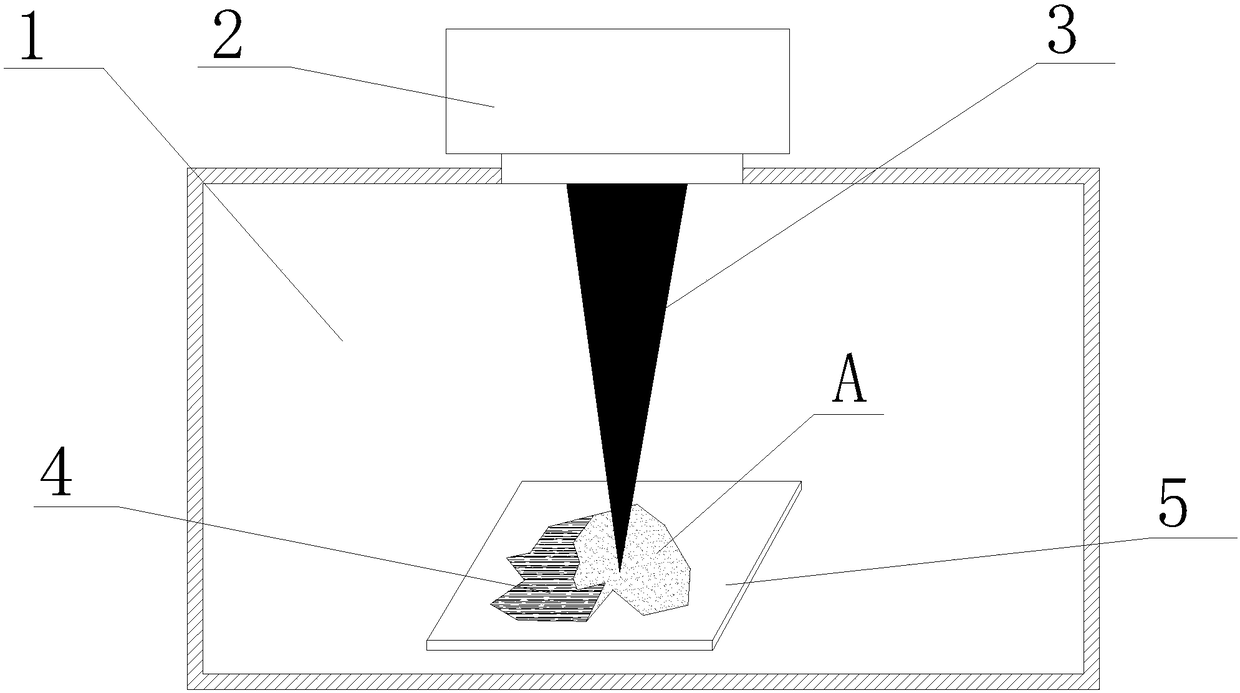

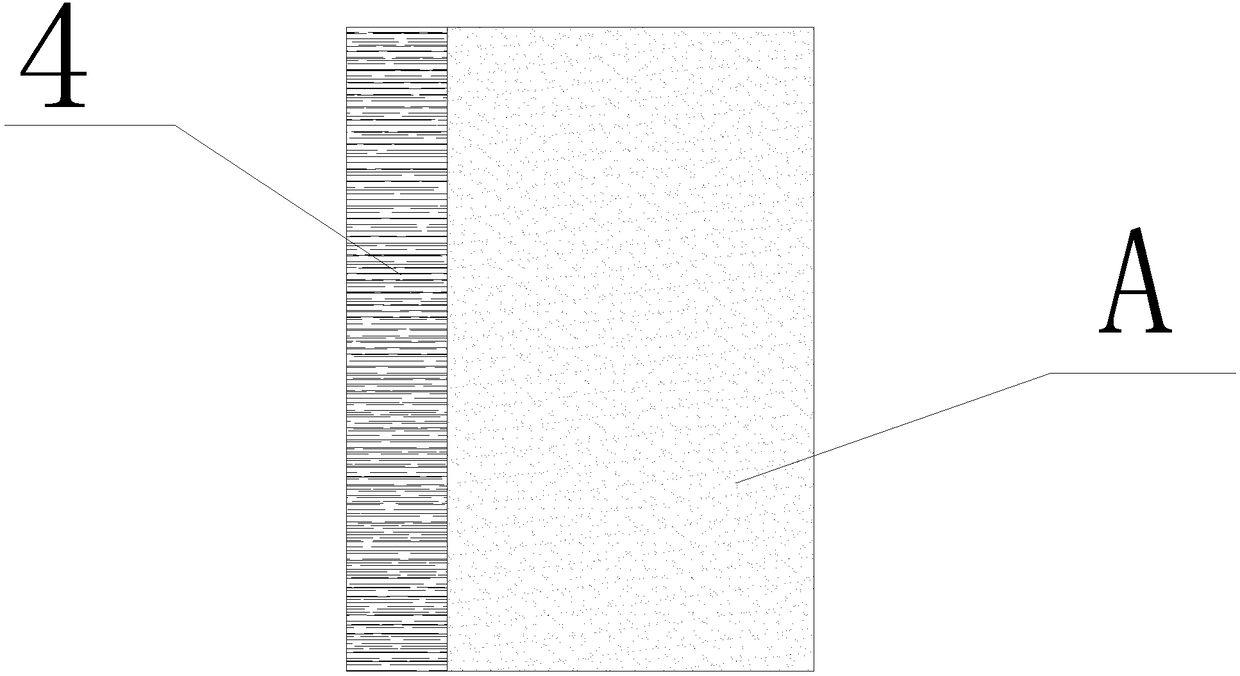

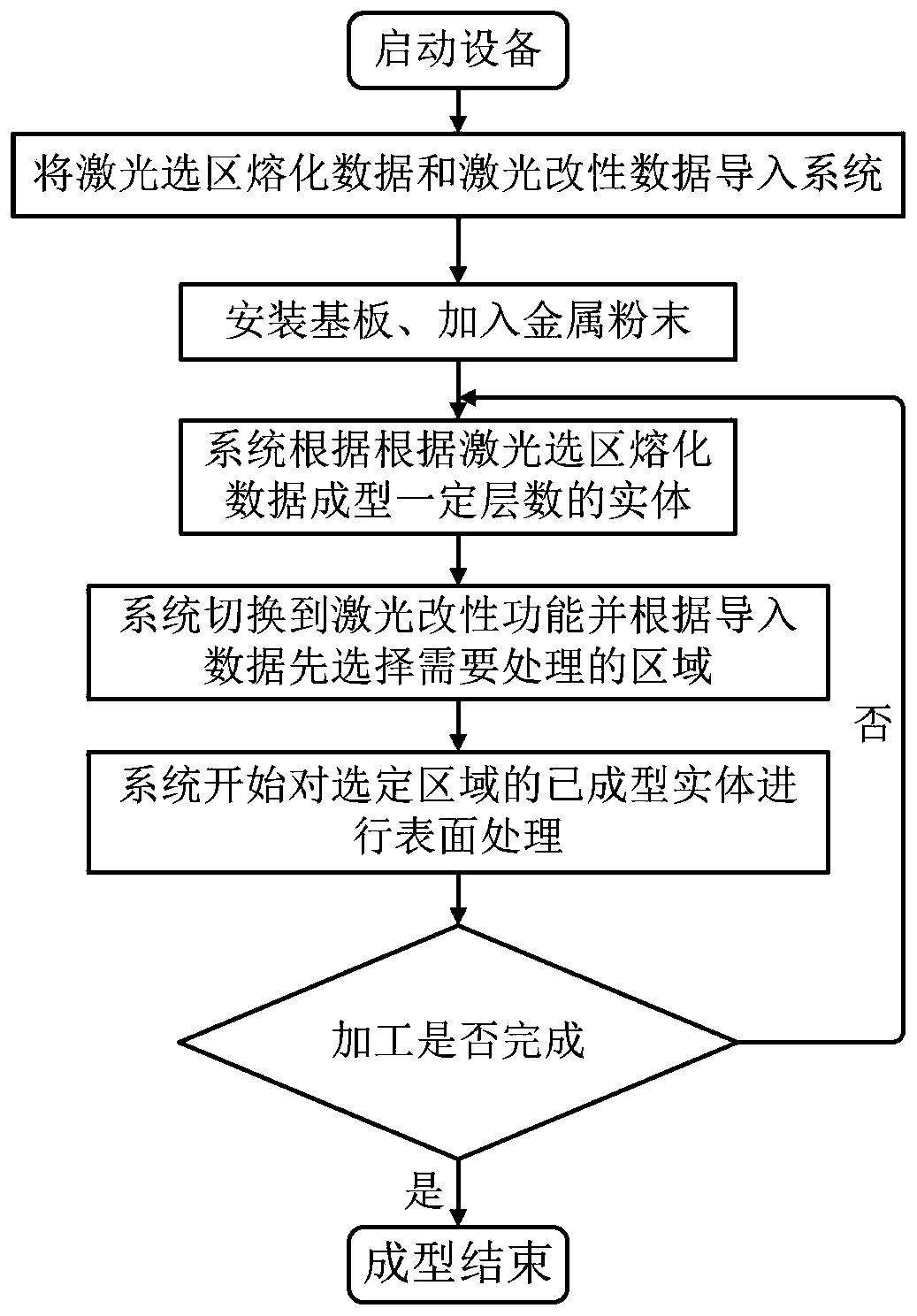

Method for molding gradient materials by interlayer laser improved selective laser melting

ActiveCN108080637AChange microstructureChange mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a method for molding gradient materials by interlayer laser improved selective laser melting. A laser surface modifying process is integrated with a selective laser melting process; and through a laser modifying mode for rescanning of molded parts by laser beams after molding of a certain number of lasers through selective laser melting at each time, microscopic structuresand performances of different areas of the parts are changed to obtain high-performance parts with different performances and gradients. Meanwhile, through rescanning by the laser beams, such defectsas holes in the layers, micro cracks and surface projections can be eliminated, so that the compactness and the surface quality of the molded parts are improved. The structure and performance change of the parts can be realized through modes of adjusting the set layer number, the laser rescanning power, the laser beam scanning speed and the laser beam scanning gap. When the compactness of the molded parts is improved, the direct molding of multi-performance gradient materials by the selective laser melting technology is realized, and a significant effect on promotion of the industrial technology development is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Building curtain wall

ActiveCN106906927AChange microstructureImprove machinabilityWallsAnti-corrosive paintsCorrosion preventionMetal

A building curtain wall comprises a cement-based heat insulation inner layer plate and a curtain wall metal outer layer plate attached outside the cement-based heat insulation inner layer plate, and the curtain wall metal outer layer plate is coated with an antirust agent. A copper alloy plate serves as the curtain wall outer layer and has high strength, high hardness and good heat conductivity, so that when the copper alloy plate serves as the curtain wall outer vertical face, the service life is prolonged, the plate is not prone to being damaged, and the maintenance expenses and maintenance workloads are reduced. The antirust agent on the copper alloy surface can rapidly form a nanoscale protection layer on the copper alloy surface, and after the nanoscale protection layer is formed on the metal surface, a matrix has the superior corrosion prevention performance, environmental pollution is small, skin is not burned during using, damage is avoided, and the building curtain wall is safe, reliable and easy to operate.

Owner:SHENZHEN GASU ADORN DESIGN ENG

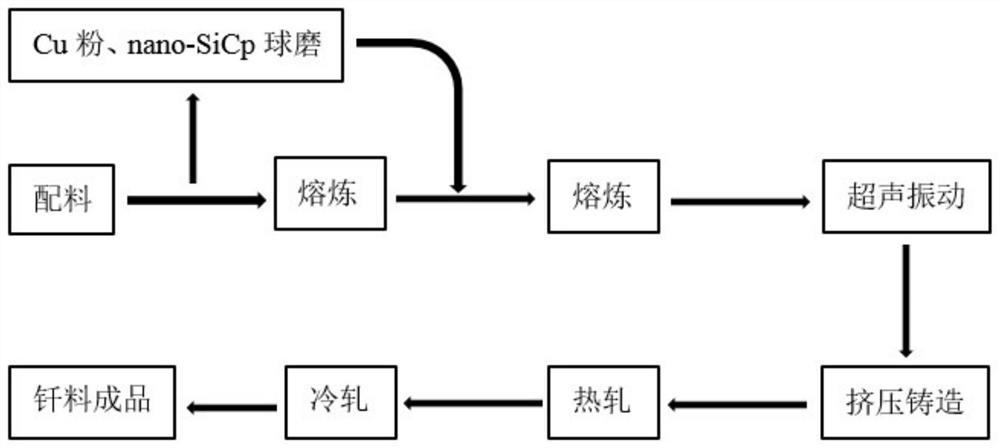

Compound brazing filler metal used for hard alloy tool brazing and preparation method thereof

ActiveCN111889917AEvenly dispersedGood dispersionWelding/cutting media/materialsSoldering mediaCrucibleIngot

The invention relates to compound brazing filler metal used for hard alloy tool brazing. The compound brazing filler metal is composed of 25%-27% of Ag, 37%-39% of Cu, 3.0%-5.0% of Mn, 2.0-4.0% of Ni,1.5%-2.5% of In, 0.5%-1.0% of nano-SiCp, 0.15%-0.3% of Si, 0.1%-0.2% of B, 0.05%-0.1% of Co, 0.01%-0.05% of Fe, 0.01%-0.1% of La, Ce and Y mixed rare earth and the balance Zn, wherein the mixed rareearth includes at least two of La, Ce and Y. A preparation method includes the steps that firstly, raw materials are weighed according to the ratio; secondly, segmented variable-speed high-energy ballmilling is conducted on Cu powder and nano-SiCp to obtain Cu / nano-SiCp particles; thirdly, the Ag, Cu ingots, the Zn, the Mn, the Ni, the Si, the Co and the Fe are placed in a medium-frequency induction smelting furnace to be heated and molten, and then the In, the B, the Cu foil wrapped mixed raw earth and the Cu / nano-SiCp particles are sequentially added in a crucible; fourthly, the mixture ismoved into a well type resistance furnace to be subjected to ultrasonic vibration and squeeze casting forming; and fifthly, hot rolling and cold rolling are conducted on cast ingots to form the foil sheet brazing filler metal. By means of segmented variable-speed ball milling and ultrasonic vibration, uniform dispersion of the nano-SiCp is ensured, the brazing filler metal is good in wettability and joint filling capacity, the brazing manufacturability is good, the preparation method is simple, and the finished product rate is high.

Owner:YUNNAN PRECIOUS METALS LAB CO LTD

Water-soluble phosphate rock powder and preparation method thereof

The invention discloses water-soluble phosphate rock powder and a preparation method thereof. The water-soluble phosphate rock powder is porous hydrophilic particles and can be quickly dispersed in water, phosphorus and microelements in the water-soluble phosphate rock powder can be well dissolved in the water, and the water-soluble phosphate rock powder can serve as a water-soluble phosphate fertilizer. After the water-soluble phosphate rock powder is applied to soil, the area of contact with microorganisms in the soil can be enlarged due to porous structures, the release time of phosphorus in the phosphorus rock powder in the soil is remarkably shortened, nutrients are provided for crops to promote growth of the crops, and the quality of the crops can be improved due to the microelements in the phosphorus rock powder. According to the preparation method, a laser drilling method is adopted, a production process is simple, and an environmental can not be polluted; the phosphorus rock powder is water-soluble and porous, so that the dissolving-out efficiency of phosphorus in the phosphorus rock powder is improved and the utilization rate of the phosphorus rock powder is increased; the preparation method has wide market prospects.

Owner:云南新正达磷化工有限公司

Method for preparing nano SiO2 composite starch/polyvinyl alcohol membrane

The invention discloses a method for preparing a nano SiO2 composite starch / polyvinyl alcohol membrane, belonging to the technical field of functional materials. The preparation method comprises the following steps: 1, adding corn starch, corn starch / polyvinyl alcohol, and starch / polyvinyl alcohol or starch to ultrasonically dispersed nano SiO2 to mix with deionized water, and preparing a certain concentration of solution; 2, putting the solution in the step 1 into a digital magnetic stirrer to heat up, stirring the solution at a certain speed, controlling the temperature of the solution to be constant when the temperature of the solution achieves certain temperature, paying attention to preventing the solution from boiling until the solution becomes clear, carrying out heat preservation for a certain period of time, and preparing the membrane; and 3, cooling the polymeric membrane sample prepared in the step 2 at room temperature for a certain period of time, pouring into liquid nitrogen, freezing the polymeric membrane sample for a certain period of time, and freezing and drying the polymeric membrane sample in vacuum for a certain period of time, so as to obtain micro-nano porous starch membranes which are even in aperture distribution. The method disclosed by the invention has the advantages of simple process, low energy consumption, high efficiency and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Anti-corrosion rolled steel and manufacturing method thereof

The invention discloses anti-corrosion rolled steel and a manufacturing method thereof, and belongs to the technical field of rolled steel. The anti-corrosion rolled steel is formed by mixing the following main components including, by weight, 5-10% of silicon, 3-6% of tungsten, 3-6% of manganese, 2-5% of phosphorus, 2-5% of sulfur, 0.2-3% of carbon, 0.1-3% of niobium, 0.1-2% of titanium, 3-10% of molybdenum, 2-6% of chromium, 1-4% of boron, 3-8% of a binder, 2-7% of an anti-corrosion agent, 0.1-3% of a fire retardant, 1-5% of a forming agent, 0.2-6% of a passivator, 1-5% of an antioxidant and the balance iron. The manufacturing method of the rolled steel is simple and effective, and the manufactured rolled steel has good hardness, corrosion resistance, yield strength and tensile strength.

Owner:广西浩昌敏再生资源利用有限公司

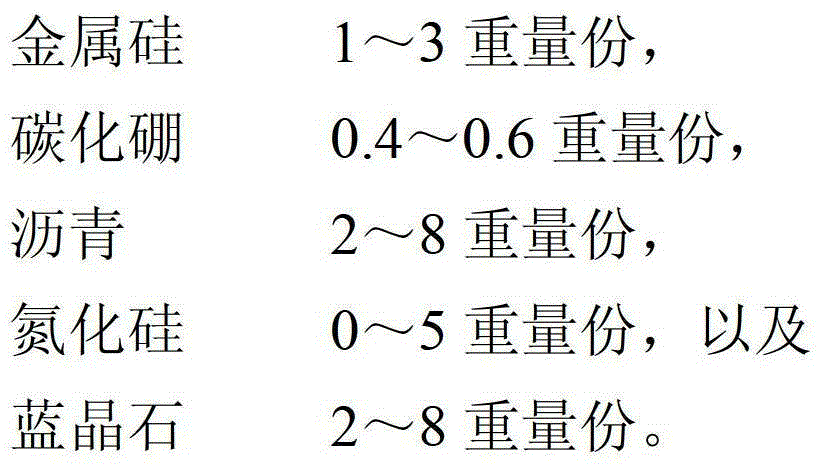

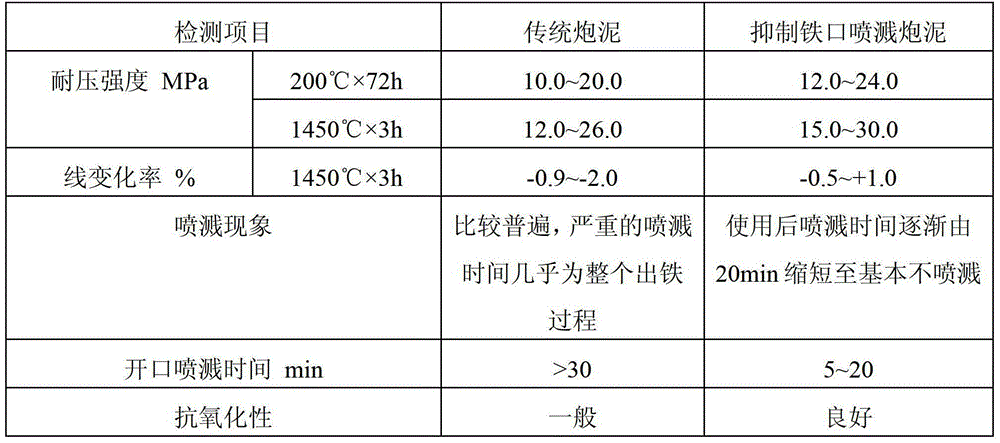

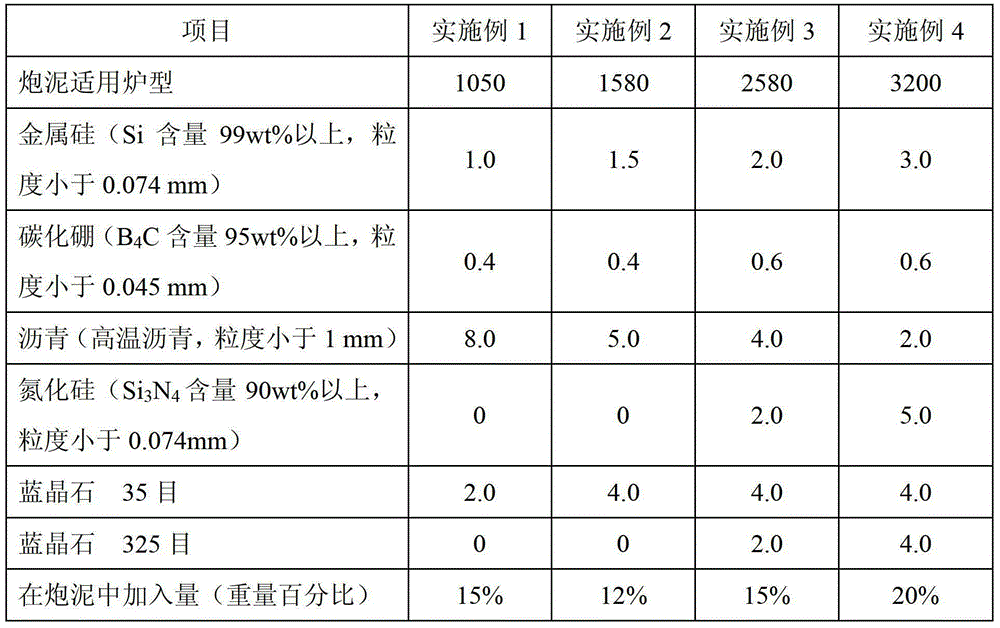

Additives for taphole clay to suppress spattering of iron holes

The invention belongs to the technical field of metallurgical refractory matters and relates to an additive for stemming for inhibiting iron notch splash. The additive comprises the following components in parts by weight: 1-3 parts of silicon metal, 0.4-0.6 part of boron carbide, 2-8 parts of asphalt, 0-5 parts of silicon nitride and 2-8 parts of kyanite. When the additive for stemming for inhibiting iron notch splash disclosed by the invention is added into the stemming, a proper amount of glass phase components can be generated at high temperature, and possible cracks generated in an iron notch channel can be plugged by the glass phase contacted with molten iron under the condition that the high-temperature performance is not influenced, so that splash caused by gas channeling is effectively prevented. Moreover, the additive has the advantages of proper micro expansion effect, medium and high temperature strength, slag iron erosion resistance and oxidation resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Synthesis method of MOR (Mordenite)-BEA (Beta Zeolite) core-shell zeolite

ActiveCN103121688BChange microstructureImprove adhesionCrystalline aluminosilicate zeolitesMolecular sievePhysical chemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

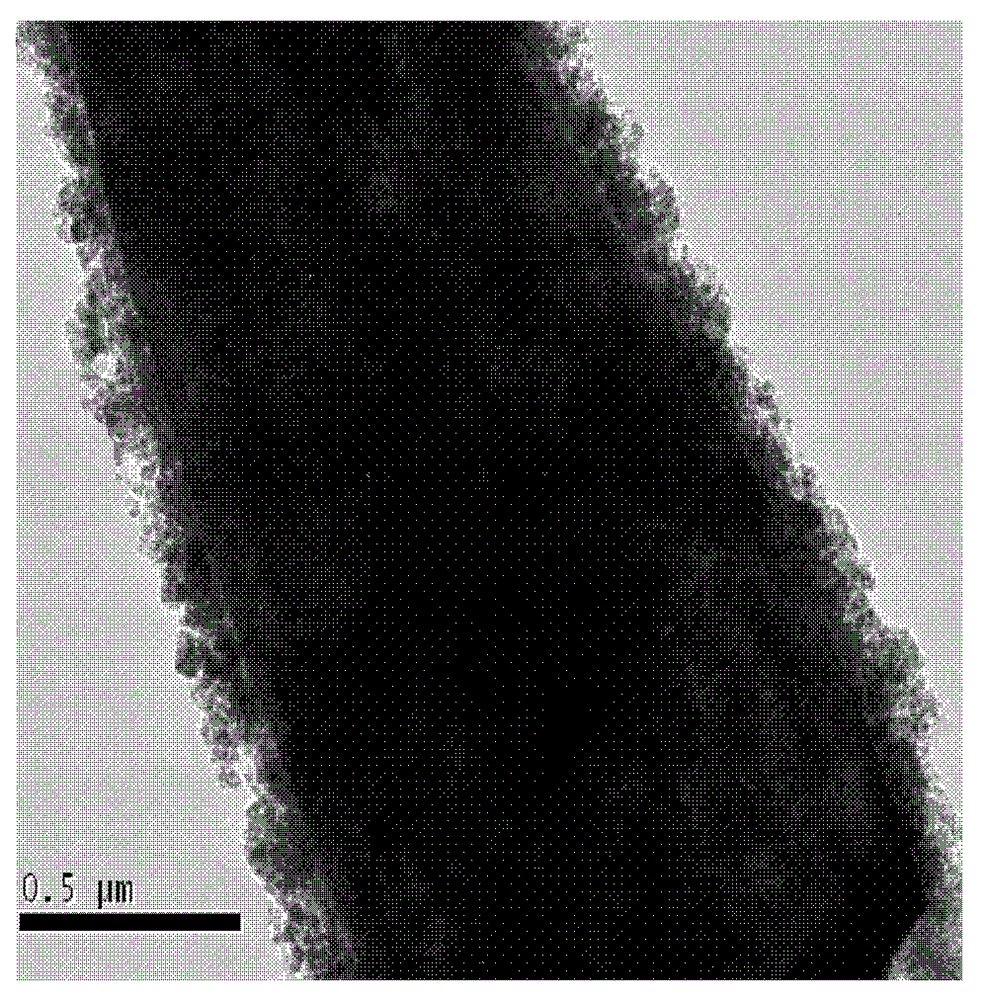

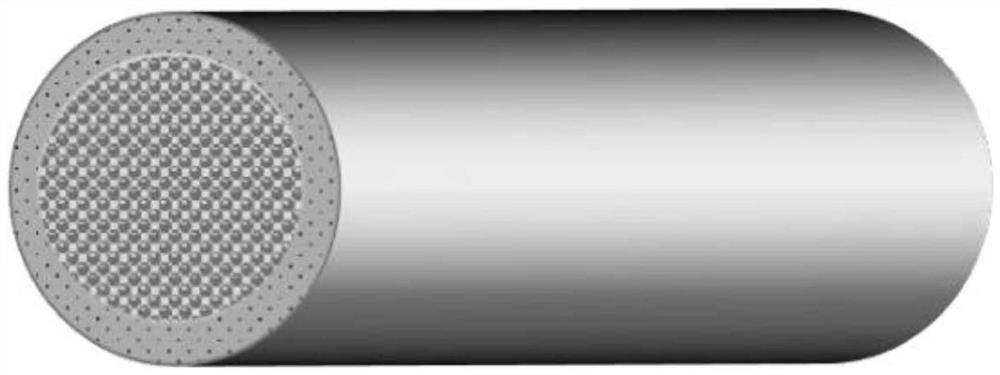

A method and application of controlling co-based amorphous fiber to form core-shell structure

A method and application for controlling Co-based amorphous fibers to form a core-shell structure, belonging to the technical field of functional materials. In order to obtain a Co-based amorphous fiber with a multiphase composite structure of nanocrystalline core-amorphous shell, so that it has better mechanical and giant magnetoresistance properties, the present invention provides a controlled Co-based amorphous fiber The method for forming the core-shell structure is to prepare raw materials according to the element content of each component in the Co-based amorphous fiber, and to prepare the Co-based amorphous fiber by using the melt drawing method, and to carry out a step-by-step DC current on the Co-based amorphous fiber. Annealed to obtain composite structure amorphous fibers with core-shell structure. The Co-based amorphous fiber with a core-shell structure prepared by the invention can be used to prepare a magnetic sensor.

Owner:HARBIN INST OF TECH

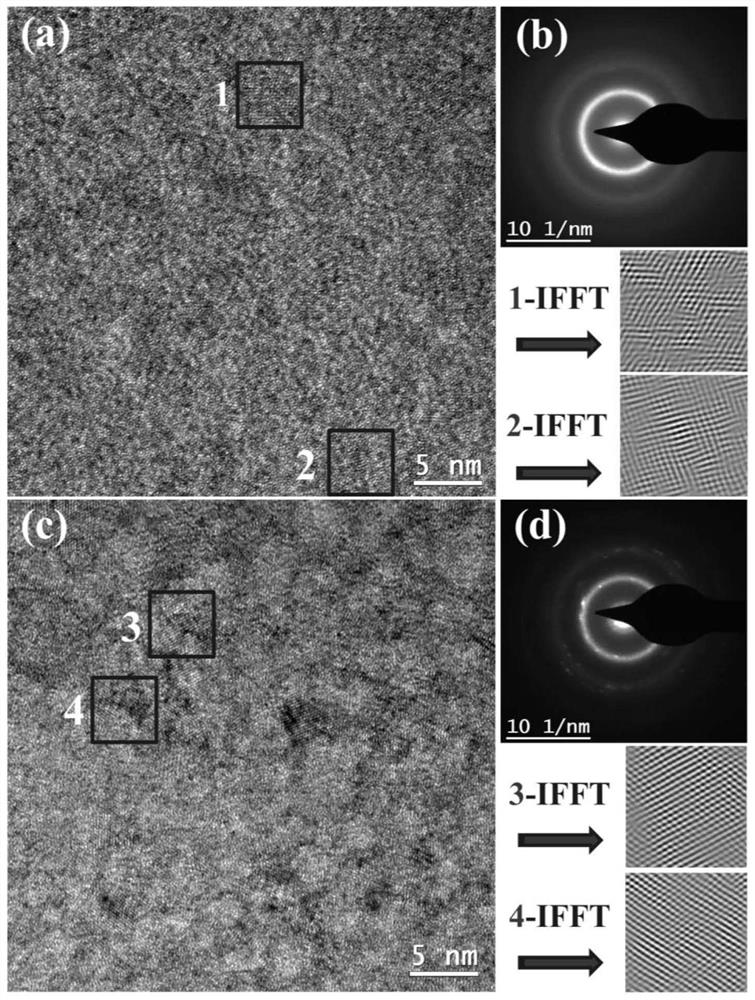

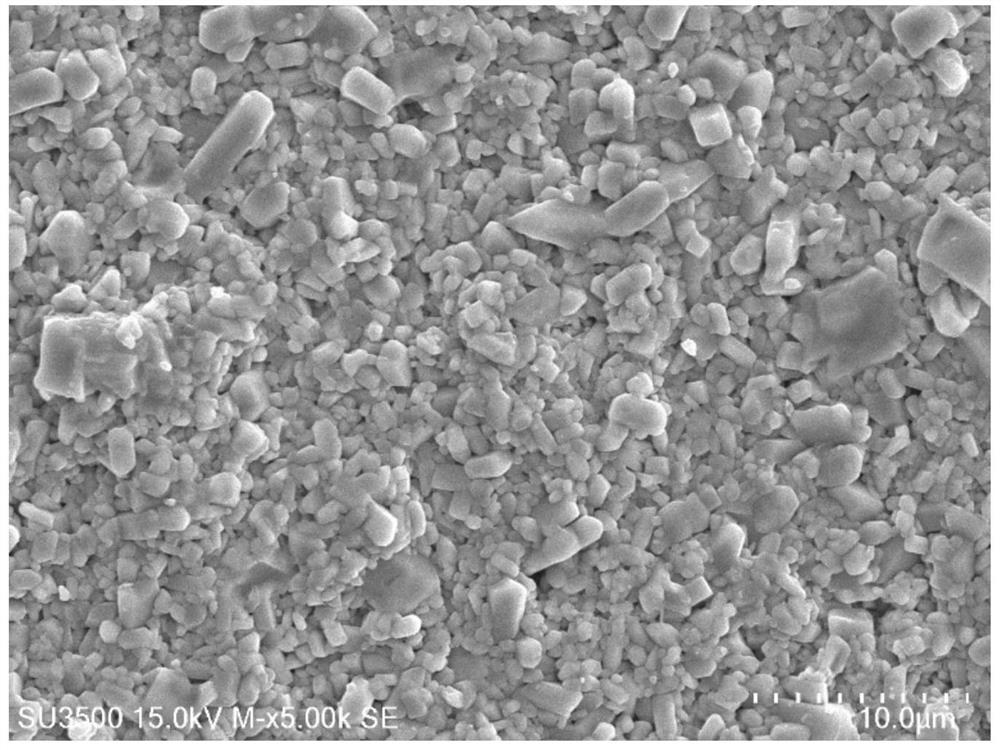

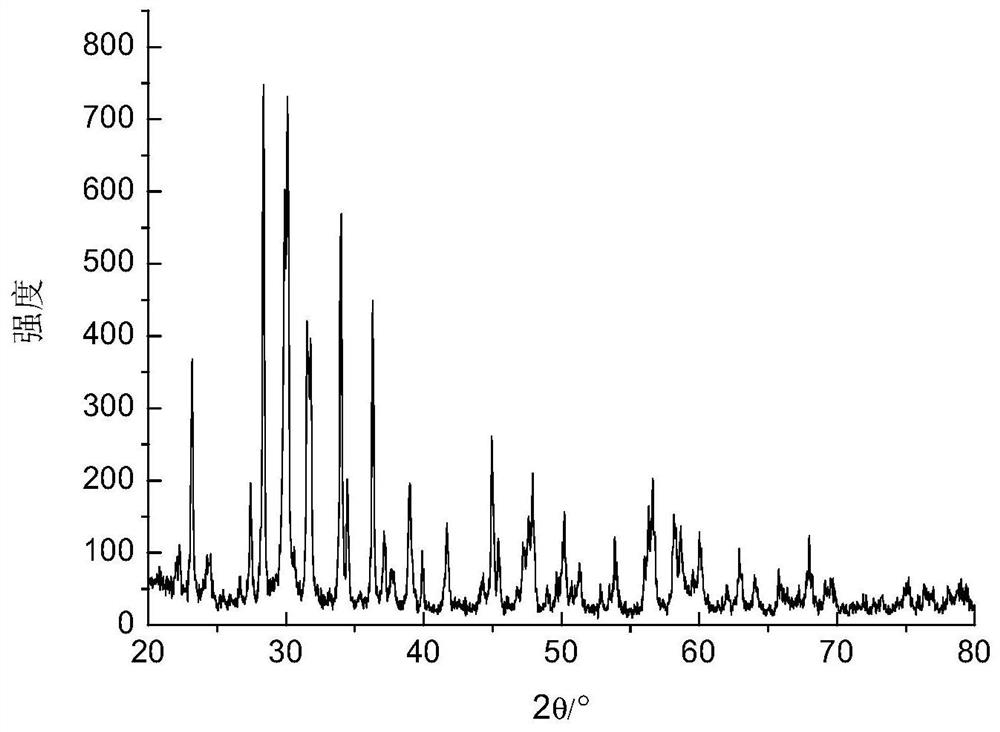

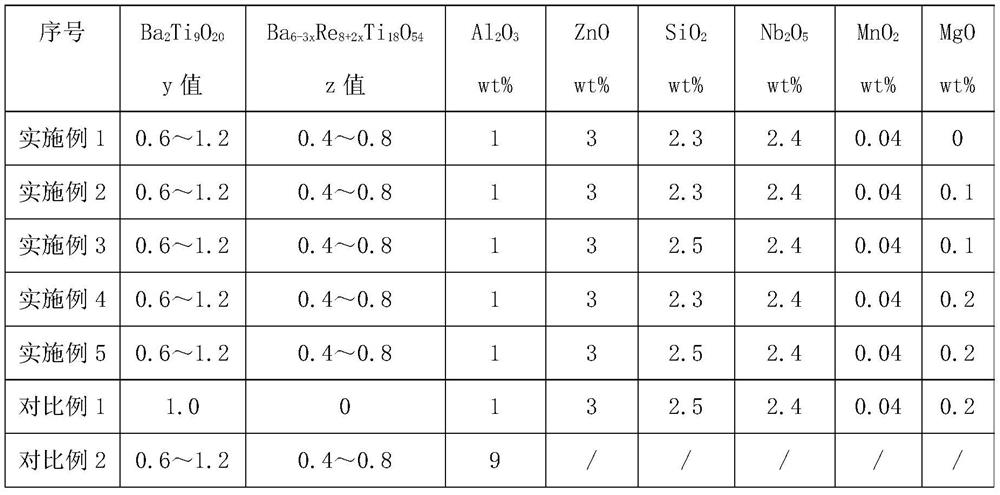

Dielectric ceramic material for BT-BRT composite ultralow-loss multilayer ceramic dielectric capacitor, preparation method and application thereof

ActiveCN111825446AConforms to COG characteristicsComply with ROHS directiveFixed capacitor dielectricStacked capacitorsDielectric lossDielectric permittivity

The invention belongs to the technical field of electronic ceramic materials, and provides a dielectric ceramic material for a BT-BRT composite ultralow-loss multilayer ceramic dielectric capacitor, apreparation method and application thereof. The dielectric ceramic material is prepared by mixing a BT-BRT compound and a modified additive. The dielectric constant of the dielectric ceramic materialis 40 at 1MHz, the dielectric loss value tg delta is less than 1.5*10<-4>, and the dielectric loss value is small; and in a temperature range of -55 to 125DEG C, the capacity temperature coefficientis closer to zero, and the COG characteristic of the American EIA standard is met. The preparation method of the dielectric ceramic material comprises the following steps of: (1) synthesizing Ba2Ti9O20; (2) synthesizing Ba6-3xRe8+2xTi18O54; and (3) preparing the dielectric ceramic material. The preparation method can effectively improve the dielectric loss of the dielectric ceramic and improve thereliability of the dielectric ceramic material.

Owner:CHENGDU HONGMING & UESTC NEW MATERIALS

Slide plate refractory with silicon nitride added and production method thereof

The invention relates to a slide plate refractory with silicon nitride added and a production method thereof. The slide plate is prepared by the following raw materials in percentage by weight: 45-65% of corundum, 10-25% of zirconia-mullite and / or zirconia-corundum, 2-8% of silicon nitride, 6-18% of alumina fine powder and the balance one or more of silicon metal, carbon black and graphite powderand a phenolic resin binder accounting for 4-6% of the total above raw materials. The production method is characterized by proportionally weighing the raw materials, uniformly mixing the raw materials, obtaining the mixture through mixing, press-forming the mixture, drying the formed mixture at 190-210 DEG C for 6-10h and then carrying out nitridation firing on the dried mixture at1200-1400 DEG C. The invention has the following benefits: by adding silicon nitride and reasonably adding other components according to the amount and ratios, the slide plate composite material with structure of Al2O3-ZrO2-Si3N4-C is formed, and the oxidation resistance of the slide plate is improved; and the apparent porosity of the refractory is 1-4%, the cold compression strength is 150-220MPa, the high temperature rupture strength is 28-33MPa and such performance indexes as the oxidation resistance, the scouring resistance, the thermal shock resistance and the like are all excellent or good.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

A method for interlayer laser-modified laser selective melting to form gradient materials

ActiveCN108080637BChange microstructureChange mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyLaser beamsMaterials science

The invention discloses a method for interlayer laser modification of laser selective melting to form gradient materials; the laser surface modification process is integrated with the laser selective melting process, and the laser beam is re-scanned after each laser selective melting to form a certain number of layers. Laser modification of molded parts is used to change the microstructure and performance of different regions of the part, so as to obtain high-performance parts with different performance gradients. At the same time, through the re-scanning of the laser beam, defects such as voids, micro-cracks, and surface protrusions in the layer can be eliminated, and the density and surface quality of the molded parts can be improved. Changes in part organization and performance can be achieved by adjusting the set number of layers, laser rescanning power, laser beam scanning speed, and laser beam scanning spacing. Therefore, while improving the density of the molded parts, the present invention realizes the direct molding of multi-performance graded materials by laser selective melting technology, which plays an important role in promoting the development of industrial technology.

Owner:SOUTH CHINA UNIV OF TECH

A kind of water-soluble phosphate rock powder and preparation method thereof

A water-soluble phosphate rock powder and a preparation method thereof. The water-soluble phosphate rock powder is a porous hydrophilic particle that can be quickly dispersed in water, and phosphorus and trace elements therein can be well dissolved in water, and can be used as A water-soluble phosphate fertilizer. After the water-soluble phosphate rock powder is applied to the soil, its porous structure can increase the contact area with the microorganisms in the soil, significantly shorten the release time of phosphorus in the phosphate rock powder in the soil, provide nutrients for crops, and promote crop growth. The trace elements in it can improve the quality of crops; the preparation method of the present invention adopts the laser drilling method, the production process is simple, and there is no pollution to the environment. The utilization rate of ore powder is improved, which has a broad market prospect.

Owner:云南新正达磷化工有限公司

Preparation method of core-shell molecular sieve MOR/BEA (mordenite/bromoethylamine)

ActiveCN103121686BChange microstructureImprove adhesionCrystalline aluminosilicate zeolitesMolecular sievePhysical chemistry

The invention relates to a preparation method of core-shell molecular sieve MOR / BEA (mordenite / bromoethylamine) and mainly solves the problem that a core-shell molecular sieve layer is low in coverage in the prior art. The preparation method includes: firstly, pre-processing mordenite to obtain mordenite I; secondly, adding the mordenite I into solution of nano beta-zeolite, and adhering nano beta-zeolite seed crystal to the surface of the mordenite I to obtain mordenite II; and thirdly, adding the mordenite II to solution containing silicon source, aluminum source and template R to allow for crystallization, and performing filtration, washing, ammonium exchange and drying after crystallization to obtain core-shell molecular sieve MOR / BEA. The problem is solved well by the application of the technical scheme. The preparation method is applicable to industrial production of core-shell molecular sieve MOR / BEA.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving low-carbon aluminum killed steel blank hot cracks by adopting low-voltage pulse current

The invention discloses a method for improving low-carbon aluminum killed steel blank hot cracks by adopting low-voltage pulse current, belonging to the technical field of improving the steel blank hot cracks. According to the method disclosed by the invention, when a low-carbon aluminum killed steel blank is cut by a continuous casting machine, pulse current is applied to the low-carbon-aluminum killed steel blank; the pulse current parameters are as follows: the pulse voltage is 21-35 V, the pulse current is 35-100 A and the pulse frequency is 20-50 Hz; and low-carbon aluminum killed steel is the aluminum killed steel with omega[C] which is less than 0.25%, wherein omega[Al] is more than or equal to 0.01% and less than or equal to 0.40%. According to the method disclosed by the invention, the low-voltage pulse current is adopted, microcosmic tissues of the low-carbon aluminum killed steel blank are changed, and the high-temperature mechanical property of a casting blank is improved, so that the hot cracks of the casting blank are effectively reduced; and the normal production is not influenced by the method, the existing production process does not need to be changed, alloy elements do not need to be added, temperature-reduction treatment does not need to be carried out on the casting blank, no pollution to the casting blank and equipment is generated, and no harms on workers are formed, so that the method is an environment-friendly, safe and new technology for reducing defects of the casting blank.

Owner:马鞍山市安工大智能装备技术研究院有限公司

curtain wall for building

ActiveCN106906927BHigh hardnessImprove thermal conductivityWallsAnti-corrosive paintsHardnessUltimate tensile strength

A curtain wall for construction, comprising a cement-based thermal insulation inner layer board and a curtain wall metal outer layer board attached to the cement-based thermal insulation inner layer board, the metal outer layer board of the curtain wall is coated with an antirust agent, and the copper alloy sheet of the present invention is used as a curtain wall The outer layer has high strength, high hardness and good thermal conductivity, which makes it prolong the service life when used as the facade of the curtain wall, is not easy to be damaged, and reduces the maintenance cost and maintenance workload. The copper alloy surface rust inhibitor of the present invention, copper The antirust agent on the surface of the alloy quickly forms a nano-protective layer on the surface of the copper alloy, and after the nano-protective layer is formed on the metal surface, the substrate has excellent anti-corrosion performance, and has little environmental pollution. It will not burn the skin and cause no damage when used. , Safe and reliable, easy to operate.

Owner:SHENZHEN GASU ADORN DESIGN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com