Compound brazing filler metal used for hard alloy tool brazing and preparation method thereof

A technology of composite solder and hard alloy, which is applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problem of restricting the use and production of clad materials, high requirements on the plasticity and bonding surface of ingots, and extrusion problems. The quality of laminated materials is difficult to achieve the effect of stable and reliable product quality, improved fluidity and filling ability, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of composite solder used for hard alloy tool brazing of the present invention, each component is by mass percent: 25% Ag, 37% Cu, 3.0% Mn, 2.0% Ni, 1.5% In, 0.5% nano-SiCp, 0.15% Si, 0.1% B, 0.05% Co, 0.01% Fe, 0.01% La, Ce, Y mixed rare earth, and the balance is Zn.

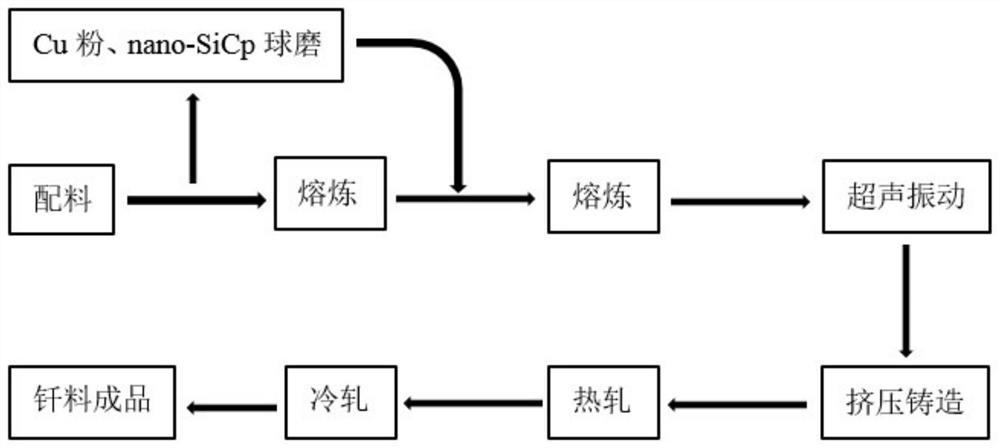

[0033] A kind of composite silver filler metal preparation method step that is used for cemented carbide tool brazing of the present invention is as follows:

[0034] (1) Pour nano-SiCp and Cu powder into the ball mill tank, and conduct segmented dry high-energy ball milling according to the ball-to-material ratio of 3:1 to obtain Cu / nano-SiCp particles: the first stage of 120rpm ball milling for 3h, the second stage of 200rpm ball milling 4h, the second stage of 300rpm ball milling for 5h, with an interval of 1h between each stage;

[0035](3) Rapidly heat and melt Cu ingots, Ag, Zn, Mn, Ni, Si, Co, and Fe in an intermediate frequency induction furnace under atmospheric atmosphere, and then rapid...

Embodiment 2

[0040] The components of the composite solder described in this implementation are: 25.5% Ag, 37.5% Cu, 3.0% Mn, 2.0% Ni, 1.5% In, 0.5% nano-SiCp, 0.15% Si, 0.1% of B, 0.05% of Co, 0.01% of Fe, 0.01% of La, Ce, Y mixed rare earth, and the balance is Zn. The preparation method of the composite solder described in this embodiment is the same as that in Embodiment 1.

[0041] In this embodiment, the melting temperature of the solder is 691-772° C., and the shear strength of the brazing joint is 361 MPa.

Embodiment 3

[0043] The components of the composite solder described in this implementation are by mass percentage: 25.5% Ag, 37.5% Cu, 3.5% Mn, 2.5% Ni, 1.5% In, 0.5% nano-SiCp, 0.15% Si, 0.1% of B, 0.05% of Co, 0.02% of Fe, 0.01% of La, Ce, Y mixed rare earth, and the balance is Zn. The preparation method of the composite solder described in this embodiment is the same as that in Embodiment 1.

[0044] In this embodiment, the melting temperature of the solder is 692-771° C., and the shear strength of the brazing joint is 364 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com