Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

975results about How to "Extend the production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

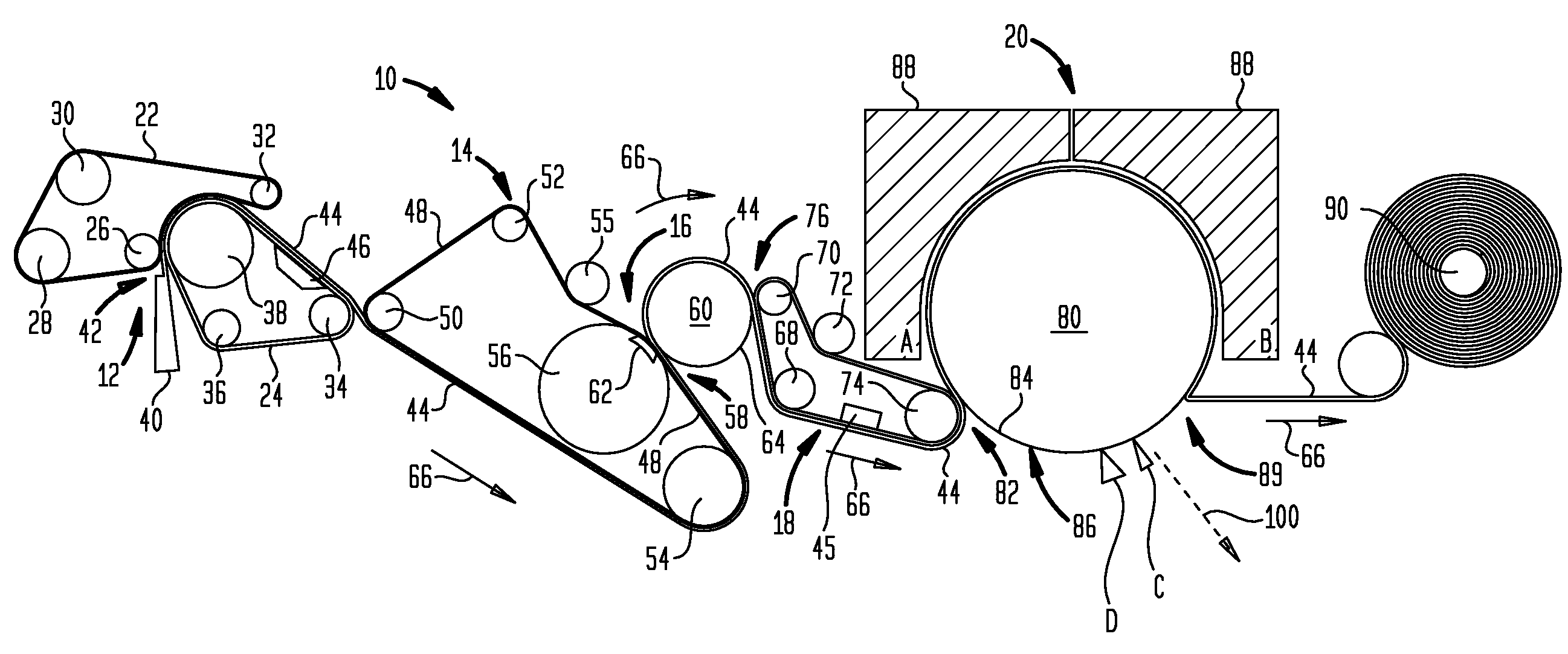

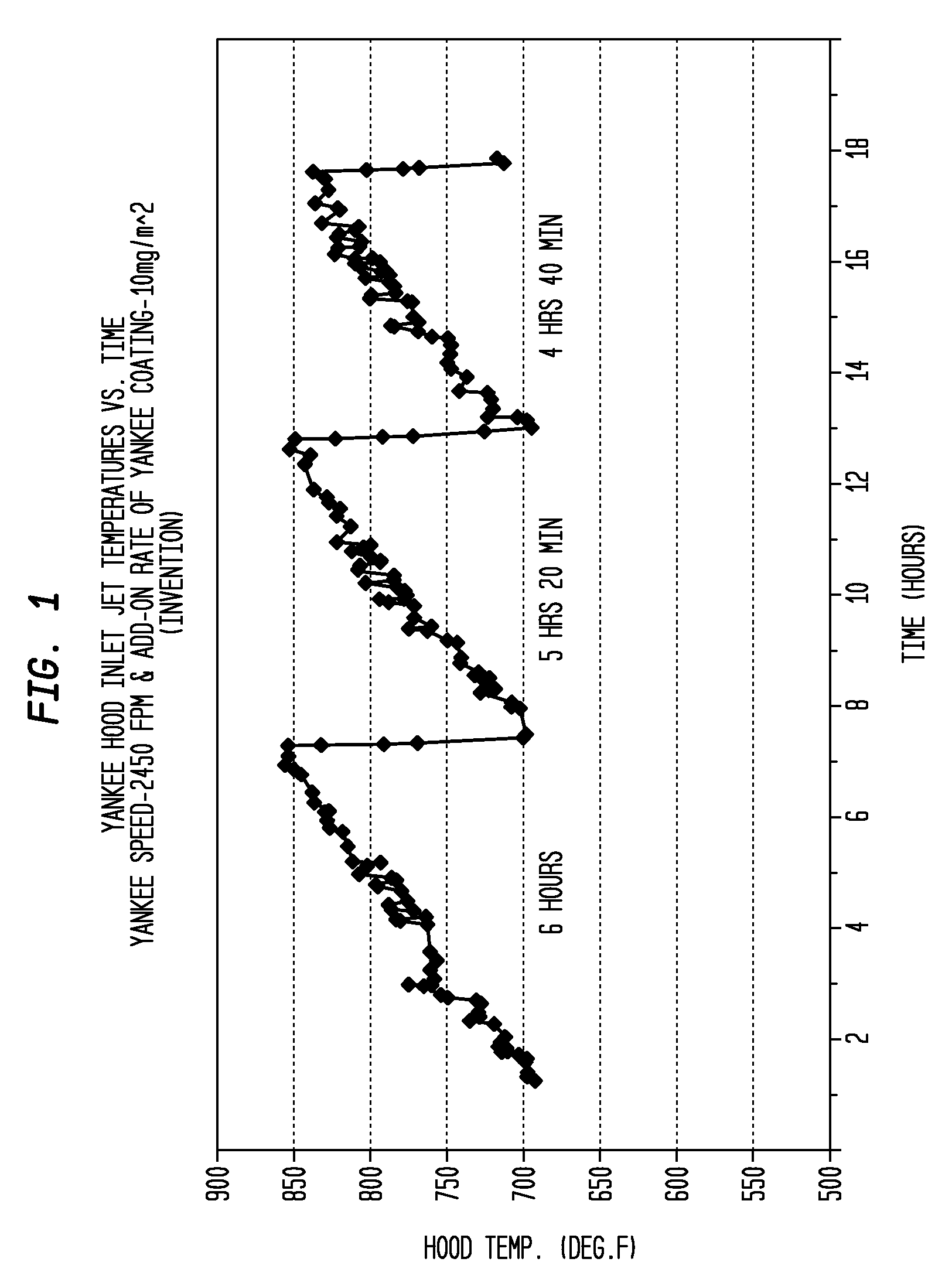

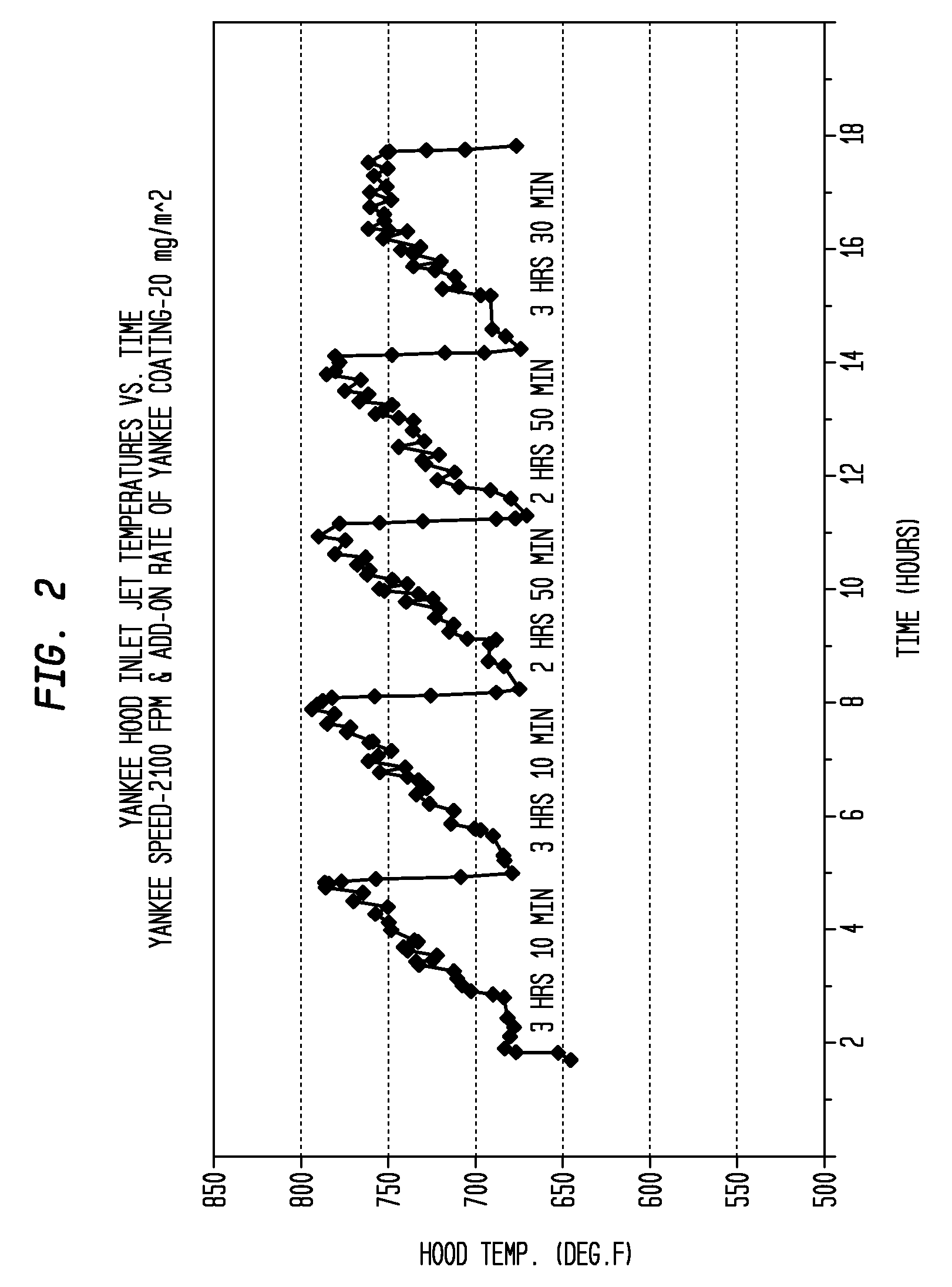

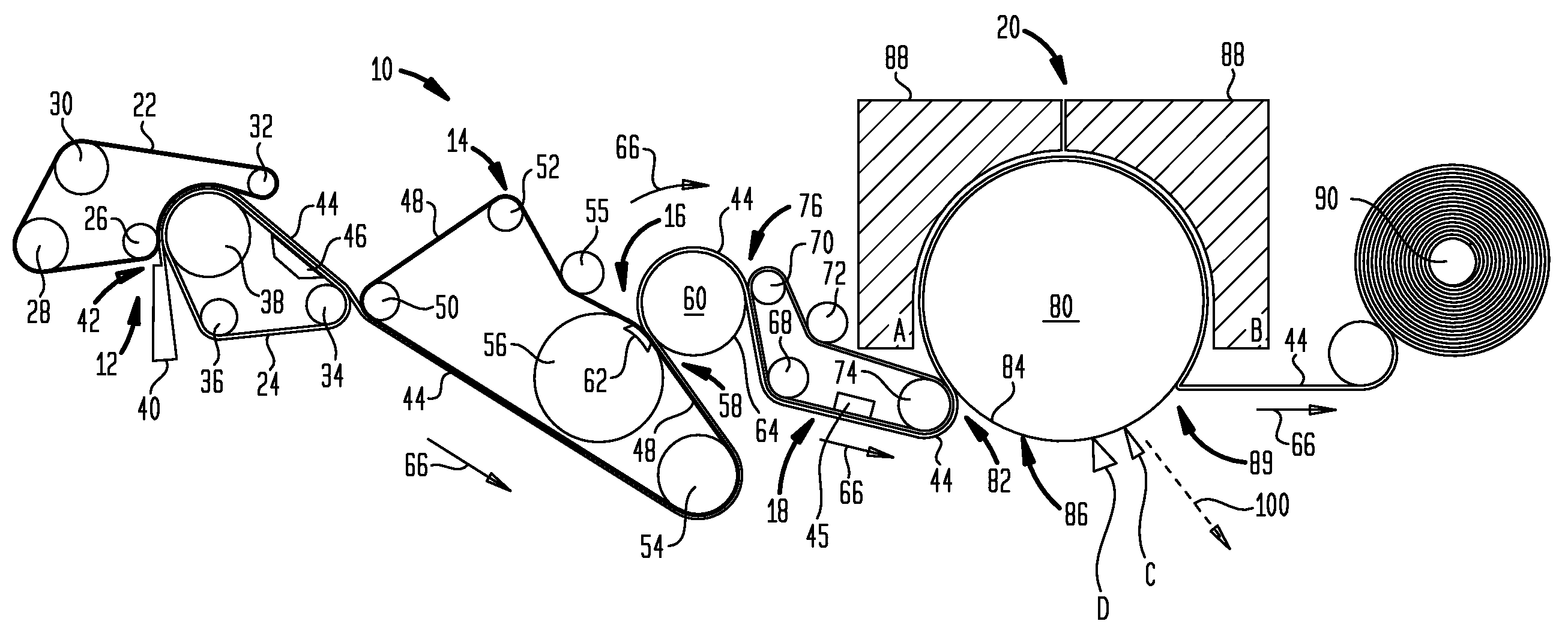

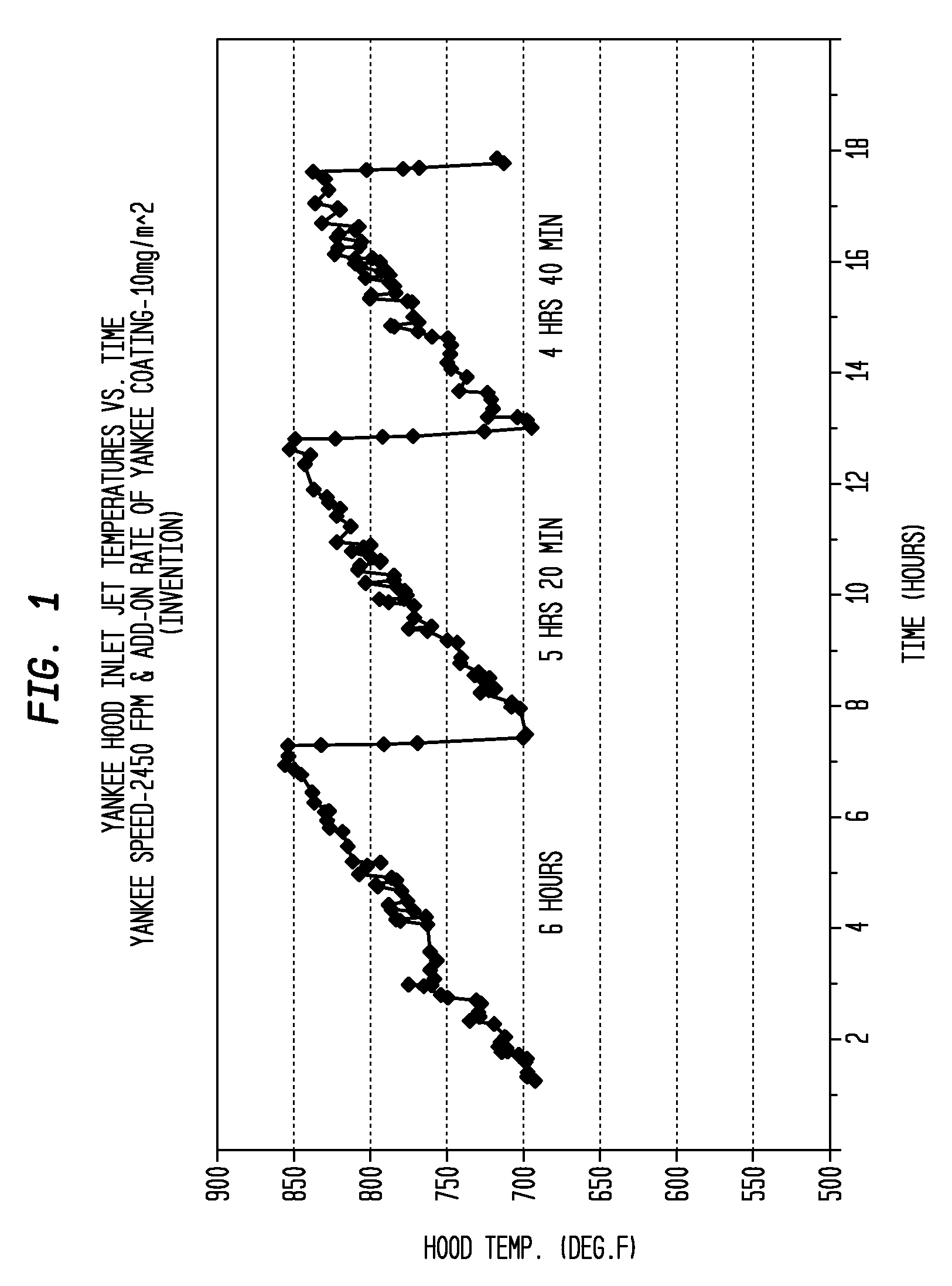

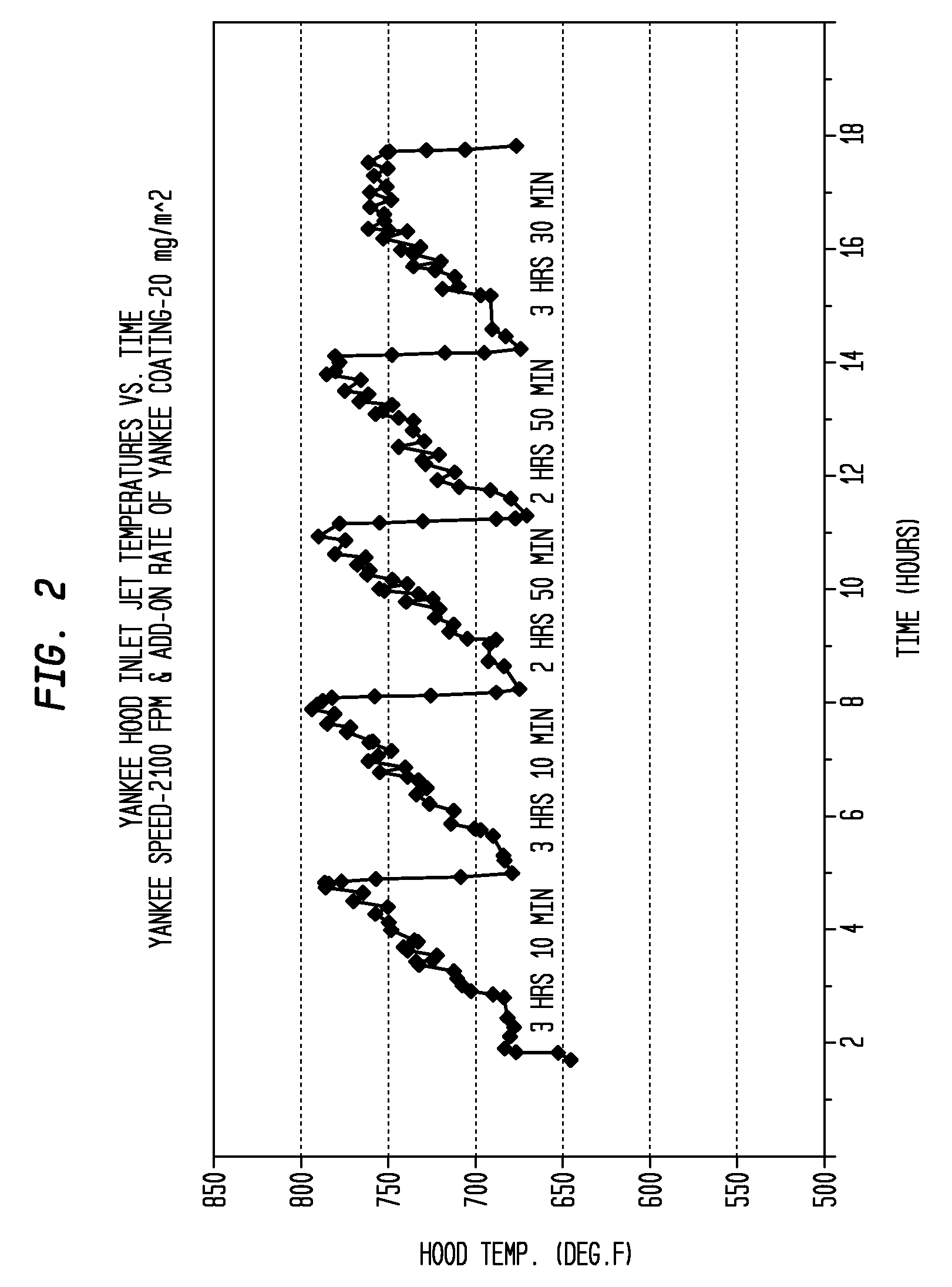

Fabric-crepe process with prolonged production cycle and improved drying

ActiveUS7608164B2Increases the amount of production available from a paper machineKeep dryNon-fibrous pulp additionDrying using combination processesAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

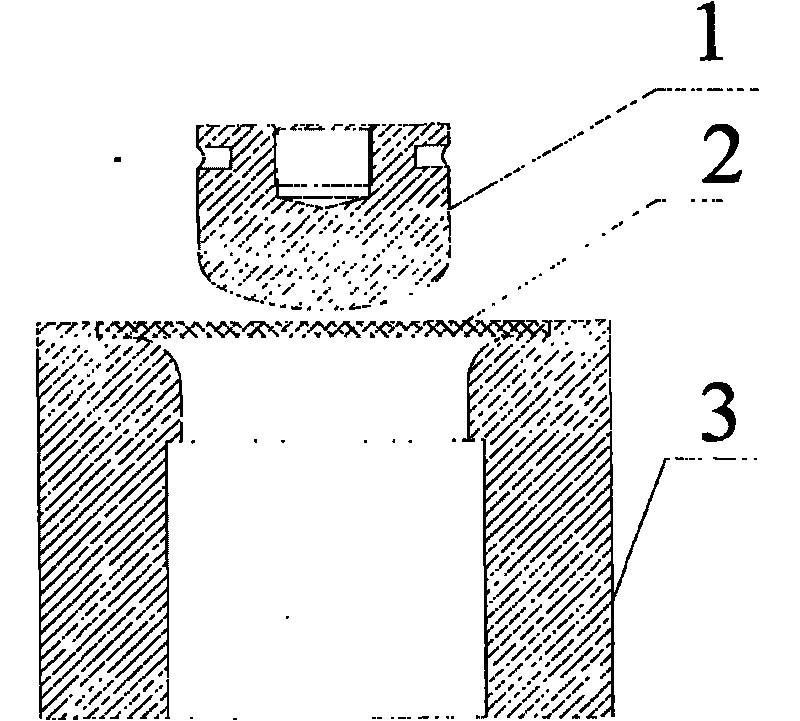

Channeling preventing and plugging agent and construction method for controlling plugging and sealing channeling by utilizing channeling preventing and plugging agent

ActiveCN105086967AExtend the production cycleEnhanced overall recoveryDrilling compositionSealing/packingEngineeringTemperature resistance

The invention provides a channeling preventing and plugging agent and a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The channeling preventing and plugging agent comprises a high-temperature-resistance pre-plugging agent serving as a pre-posed pre-plugging plug, an enhanced gel plugging agent serving as an intermediate enhanced plug and a high-strength resin plugging agent serving as a postposed sealing plug. The channeling preventing and plugging agent has the characteristics of high temperature resistance, long-term stability, good plugging performance and the like. The invention further provides a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The method has a simple constructing process, and can be used for constructing after the channeling preventing and plugging agent is directly prepared on the spot. The channeling preventing and plugging agent can be used for effectively solving the adverse impact of the steam / air channeling phenomenon of a heavy oil thermal production well on production, and has an important effect on prolonging the production cycle of a heavy oil well and improving the recovery efficiency.

Owner:PETROCHINA CO LTD

Exploitation method for wax precipitation oil reservoir

ActiveCN101839123AEfficient miningSolve the problem of wax analysisFluid removalDrilling compositionEconomic benefitsChemical agent

The invention discloses an exploitation method for a wax precipitation oil reservoir. The method comprises the step of adding a chemical agent and thermal fluid into an oil layer to make crude oil in the oil layer smoothly seep into an oil well and then rise to the ground surface. The method has the advantages of effectively solving the problem of wax precipitation of the crude oil in the oil layer and exploiting the wax precipitation oil reservoir, greatly reducing the exploitation cost of the wax precipitation oil reservoir, prolonging the production period and increasing the yield of the oil well and enhancing the final recovery efficiency of the oil reservoir, along with easy implementation, safety and reliability and obvious economic benefit.

Owner:盘锦河升大地石油科技有限公司

Exploitation method of thick oil type oil deposit

InactiveCN101839127AEfficient miningReduce mining costsFluid removalDrilling compositionEconomic benefitsOil type

The invention discloses an exploitation method of a thick oil type oil deposit, which comprises the following steps of: adding a chemical agent and hot fluid into an oil layer, enabling crude oil in the oil layer to be successfully seeped to an oil well and then enabling the crude oil to be raised to the ground from the inside of the oil well. The invention has the following advantages that: the invention can effectively solve the problem of phase precipitation of the asphaltene of the crude oil in the oil layer, can effectively exploit the thick oil type oil deposit, lowers the exploitation cost of the thick oil type oil deposit greatly, prolongs the production period of the oil well, increases the yield of the oil well, enhances the final recovery ratio of the oil deposit and has easy execution, high safety and reliability and obvious economic benefit.

Owner:盘锦河升大地石油科技有限公司

Fabric-Crepe Process With Prolonged Production Cycle and Improved Drying

ActiveUS20080264589A1Improve productivityLower levelDrying using combination processesNon-fibrous pulp additionAdhesiveCoating

A method of manufacturing absorbent sheet is directed to a wet-press / fabric-crepe process wherein add-on of adhesive to the Yankee surface is at relatively low levels, yet sheet transfer is maintained and production increased. Materials are selected and process parameters are controlled such that a paper machine can be operated for at least 4 hours before the Yankee coating needs to be stripped. Preferably, average increase in Yankee hood temperature is less than 1° F. / minute during a production interval.

Owner:GPCP IP HLDG LLC

Composite fruit and vegetable crisp chip and manufacturing method thereof

The invention relates to a composite fruit and vegetable crisp chip and a manufacturing method thereof, especially to a composite fruit and vegetable crisp chip manufactured by using combined microwave vacuum freeze drying technology and vacuum low temperature frying technology, belonging to the field of food processing technology. The manufacturing method for the composite fruit and vegetable crisp chip comprises the following steps: preparation of condensed fruit and vegetable pulp; batching; batch mixing; die molding; microwave vacuum freeze drying; vacuum low temperature frying; etc. With the manufacturing method, generation of harmful substances like acrylamide and trans-fatty acids is reduced in the process of manufacturing, and the manufactured composite fruit and vegetable crisp chip has the advantages of crisp taste, a bright color, small nutrient loss, etc.

Owner:宁夏虹桥有机食品有限公司

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

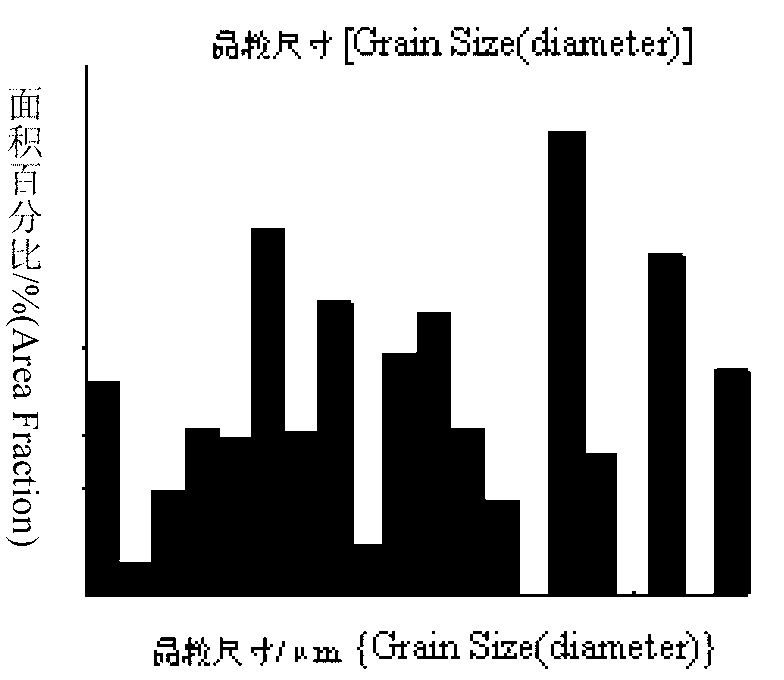

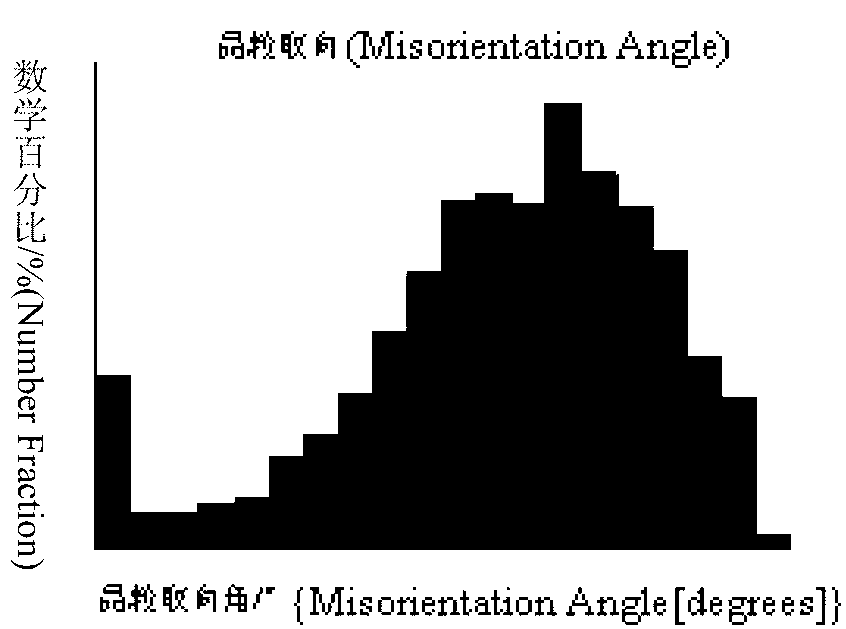

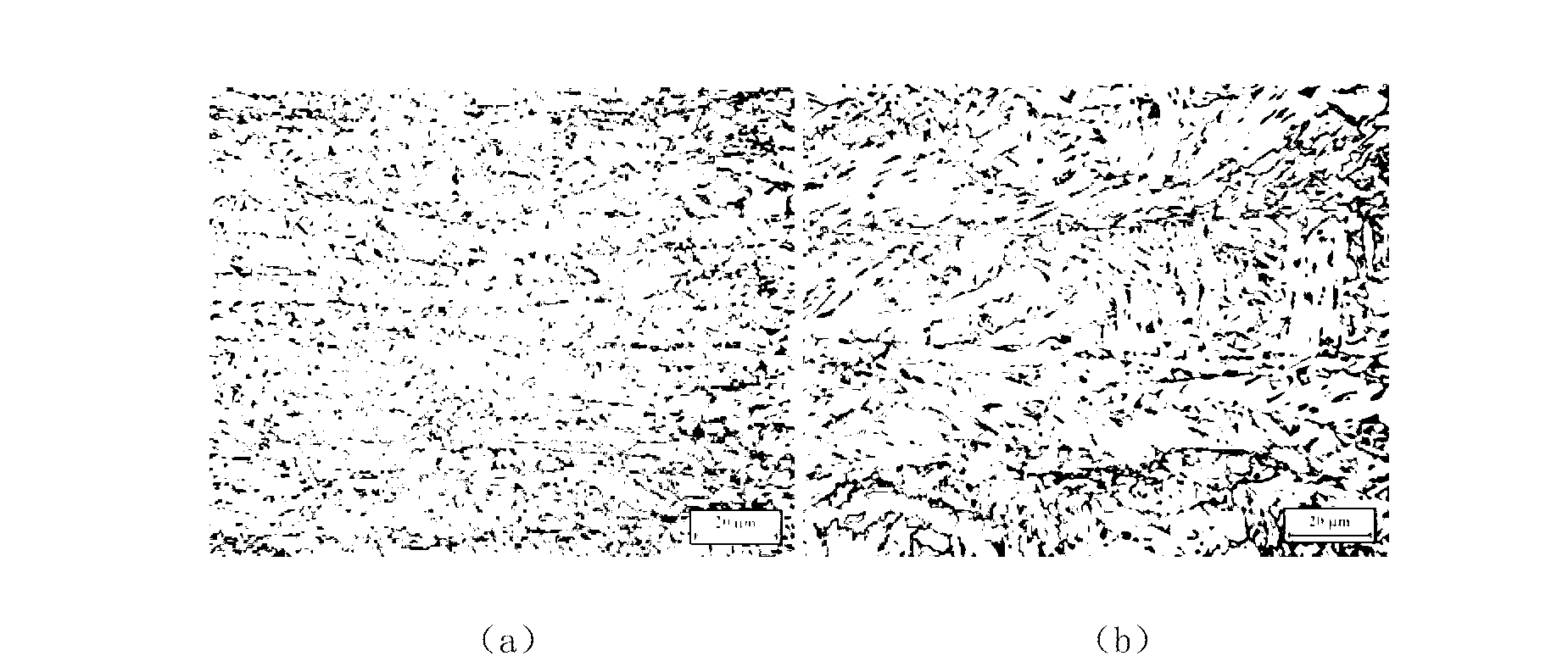

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

ActiveCN102994874APromote productionIncrease the lengthHeat treatment process controlReduction rateChemical composition

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

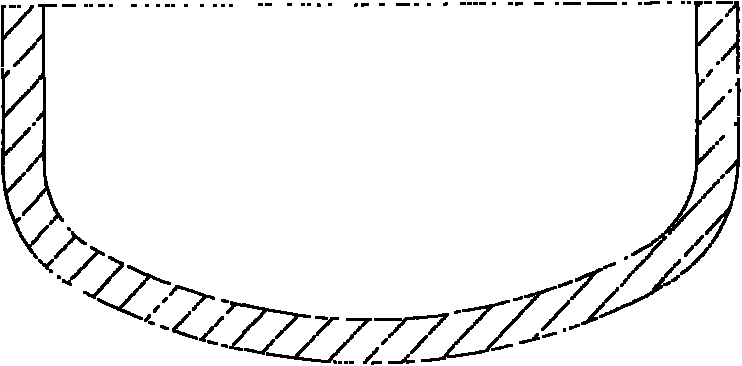

Simple forming process of seal head for titanium alloy cylinder

InactiveCN101745784AReduce productionReduce changeover processShaping toolsPlasma welding apparatusManufacturing technologyPunching

The invention relates to a machining process and a manufacture technique of metal materials, in particular to a simple forming process of a seal head for a titanium alloy cylinder. The process comprises the following steps: increasing the thickness of a blank during the design of a die, and correspondingly increasing the die clearance; blanking; preprocessing the blank, and heating to a temperature of 20-50 DEG C below a transformation point by using an electric furnace; preheating the die to 300 plus or minus 20 DEG C; ensuring the forming temperature to be within the alloy forging temperature range and avoiding overlarge temperature difference between the die and the blank; and punching by multiple heating numbers to finish the forming process. A product manufactured by adopting the process meets the technique data requirement. Compared with a common forming process with multiple heating numbers, the invention reduces the manufacture of at least one set of die, reduces a working procedure of changing tools during producing the dies, reduces the cost by more than 40 percent and shortens the production cycle by more than 50 percent.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

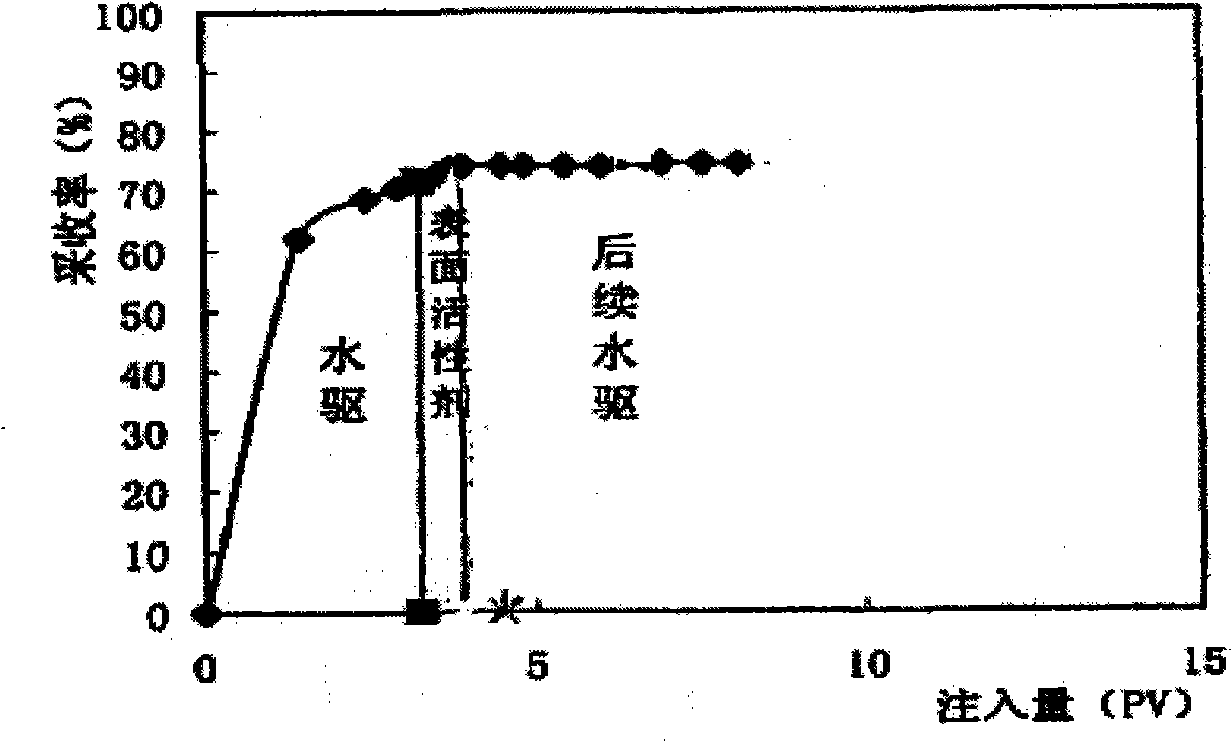

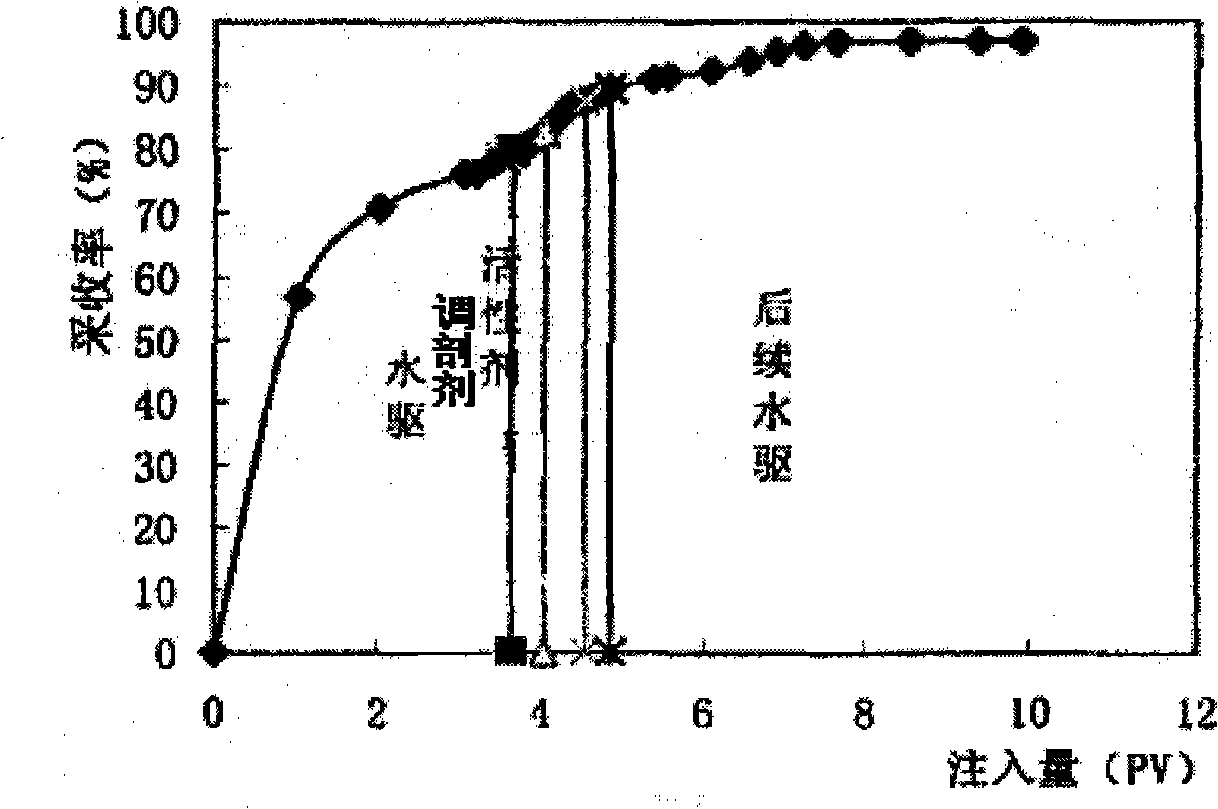

Oil well chemical gorge and disgorge yield increasing and inverse direction regulating block connection working process

InactiveCN101280678AImprove the spread factorEnhanced overall recoveryFluid removalDrilling compositionActive agentBlocked Connection

The invention relates to a technique combining the chemical huff and puff stimulation and the reversed plugging control. The technique adopts slug-type injection mode, including active agent slug, water plugging profile modification agent slug an displacement fluid slug, and includes the following steps: (1) firstly, injecting the active agent into the oil production layer, (2) injecting the water plugging profile modification agent 0-20 hours later, (3) then using excessive displacement fluid to lift all chemical agents to a place which is more than 3m away from well bore, and then using water to displace the excessive displacement fluid to the stratum and finally closing the well for 1 to 2 days for condensation. The purpose of the technique is to combine the huff and puff of the active agent with high oil-washing efficiency and low interfacial tension and the reversed profile control and flooding of the oil well, thus not only increasing the conformance factor of the injection of the water but also improving the oil displacement efficiency and extending the life circle.

Owner:DAQING HUILIAN TECH DEV

Highly effective pour depressant for thermodynamic oil extraction process

ActiveCN101210173AImprove applicabilityStrong pouring capacityDrilling compositionWater basedDepressant

A high-efficiency pour point depressant for thermal recovery process comprises (1) biphenyl, polycyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbon derivatives free of chlorine and sulfur elements; (2) liquid petroleum products containing arene larger than 5%, petroleum resin in liquid state at normal temperature or natural hydrocarbon aggregates in particle state at normal temperature; (3) surfactant; (4) fusel oil; (5) alcohol ethers having a closed cup flash point larger than 20 DEG C; and (6) oil-soluble or water-soluble polymers respectively having a nonpolar section eutectic with paraffin molecule and a polar section for twisting crystal form of wax crystal on a main chain and / or a branch chain. The high-efficiency pour point depressant of the invention performs all functions of both water-base pour point depressant and oil-base pour point depressant, and can efficiently assist the prior various thermal recovery processes in exploring high pour-point oil and heavy oil reservoirs, with the advantages of greatly reduced exploitation cost, prolonged production cycle of the oil well, increased output of the oil well, increased ultimate recovery of the oil reservoir,as well as significant economic benefit.

Owner:盘锦河升大地石油科技有限公司

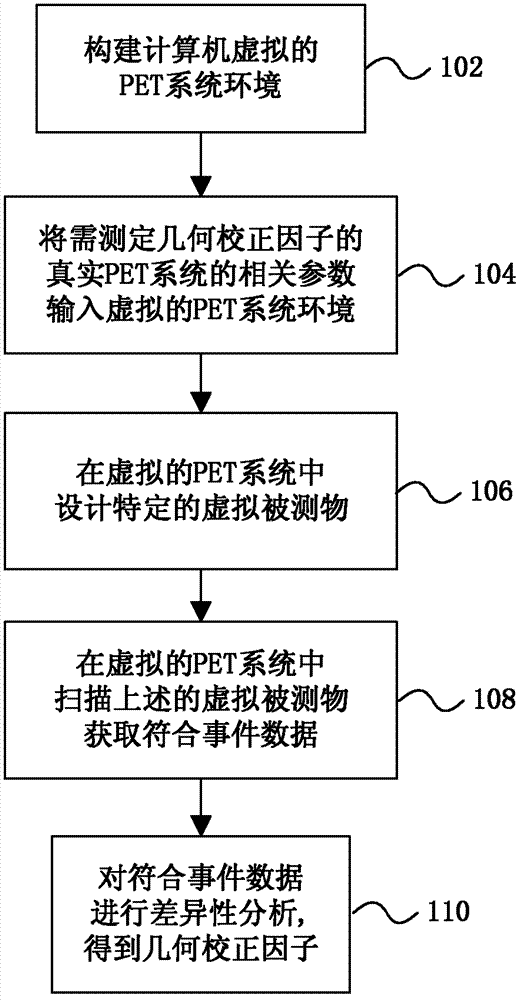

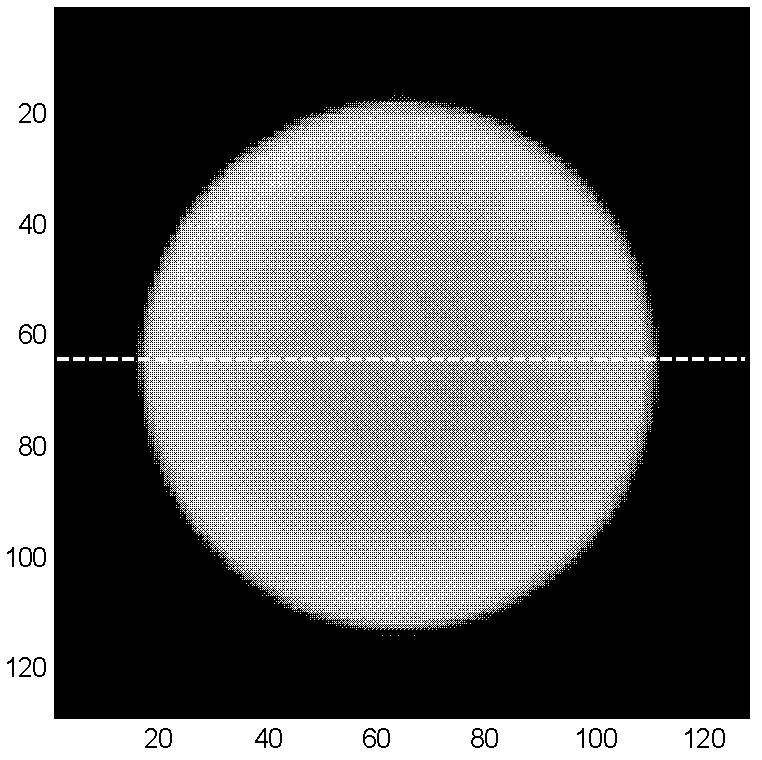

Method for acquiring geometric correction parameter of PET (positron emission tomography) system

ActiveCN102789510ASimple processGuaranteed accuracyComputerised tomographsTomographyObject modelCoincidence

The invention discloses a method for acquiring a geometric correction parameter of a PET (positron emission tomography) system. The method comprises the steps of 1) building a virtual PET system environment by using computer software; 2) inputting the related parameter of a real PET system of which the geometric correction parameter needs to be measured into the virtual PET system environment; 3) designing a specific virtual measured object in the virtual PET system environment; 4) scanning the specific virtual measured object in the virtual PET system environment to acquire coincidence data; and 5) performing difference analysis to the coincidence data to obtain the geometric correction parameter. According to the method, preparation for object PET equipment and a measured object model is eliminated, and the process of acquiring the geometric correction parameter is simple, economical, quick and free from the limit of environment factor, and therefore, the accuracy of the geometric correction parameter is ensured. In addition, the method can be executed before or after development and production of the PET system, so that the design, development and production period of the PET system is accelerated.

Owner:SHANGHAI RES CENT OF BIOMEDICAL ENG

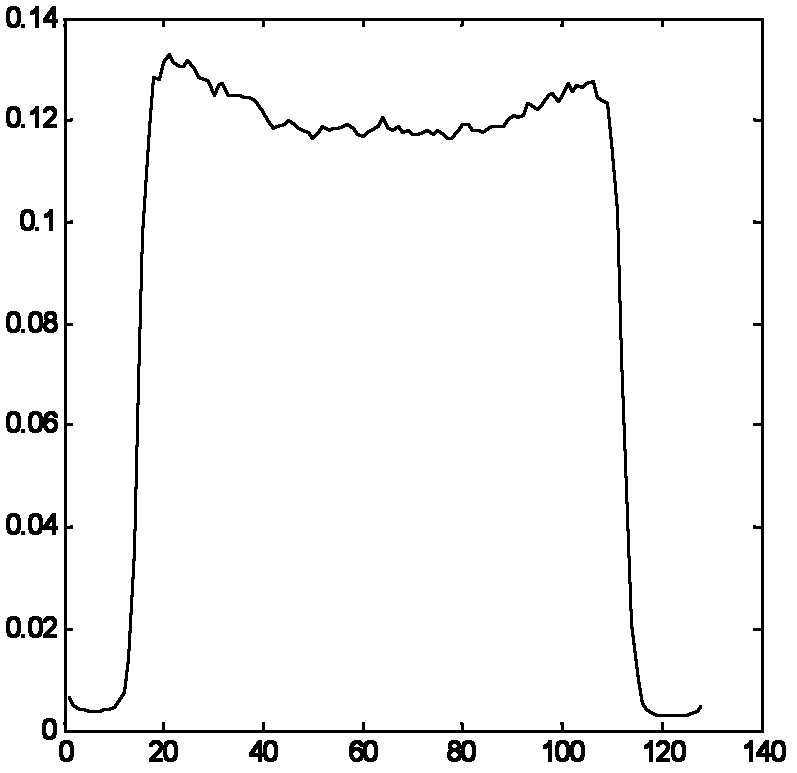

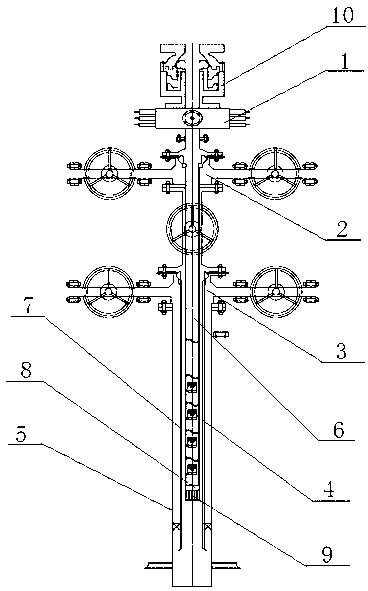

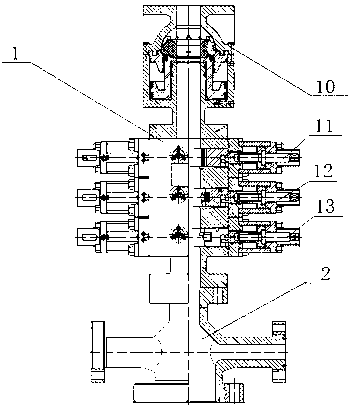

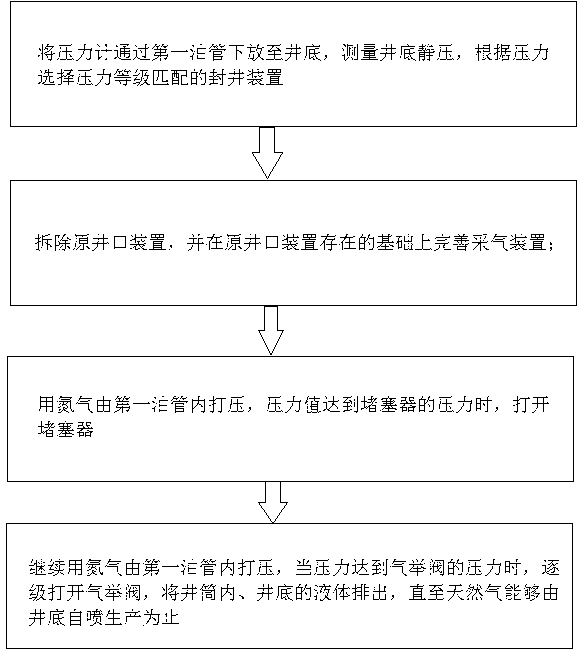

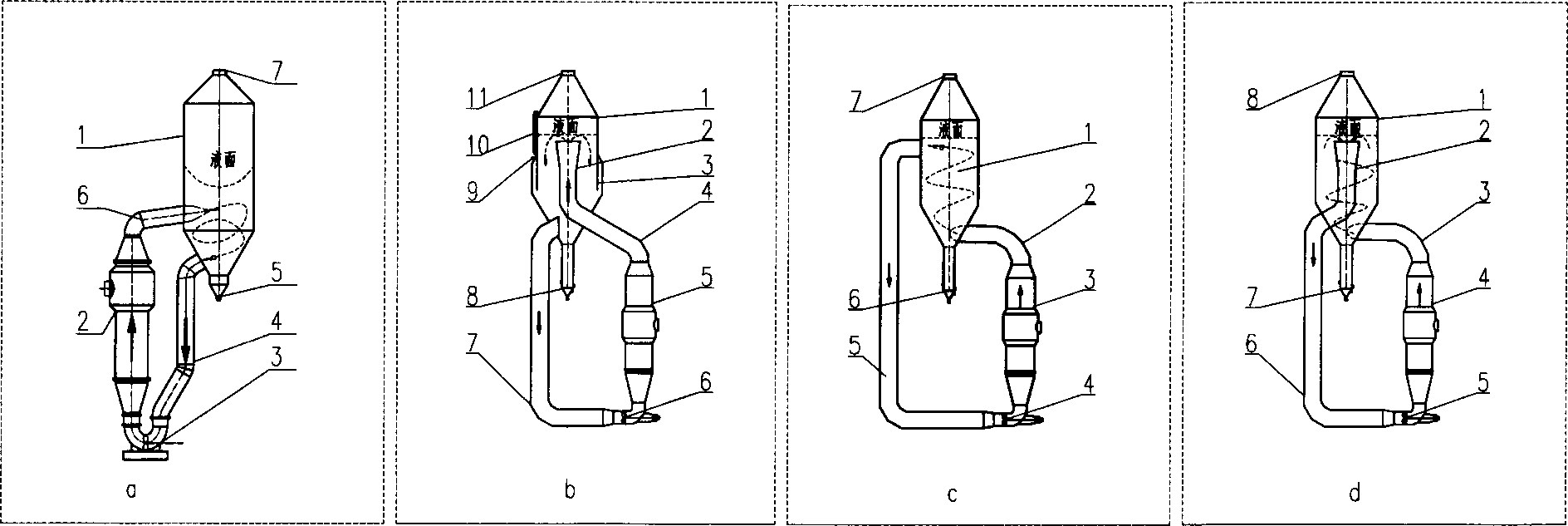

Drainage gas recovery device and method

ActiveCN103306643AReduce Waterlogging ProblemsExtend the production cycleFluid removalNitrogenEngineering

The invention relates to a drainage gas recovery device and method. The method comprises the following steps of laying a pressure gauge down to the bottom of a well through a first oil pipe to measure the static pressure and the liquid level at the bottom of the well, selecting a matched well shutting device according to the pressure and setting the pressure value of a plug and a gas lift valve; dismantling an original well head, perfecting the drainage gas recovery device on the basis of existence of the original well mouth device; pressurizing a second oil pipe with nitrogen and opening the plug when the pressure of the second oil pipe reaches an opening pressure of the plug; and continuing pressurizing the second oil pipe with nitrogen and opening the gas lift valve step by step when the pressure of the second oil pipe reaches an opening pressure of the gas lift valve to drain out liquid inside the shaft and at the bottom of the well until the flowing production of natural gas is achieved. The drainage gas recovery device and method has the advantage of being capable of draining out the fluid inside the oil pipes by opening the gas lift valve through multiple flowing inducing of nitrogen lift to reduce slippage loss greatly and water accumulation, thereby prolonging the production cycle of the gas well. Besides, the drainage gas recovery device and method is easy to operate, low in cost and safe and reliable in sealing.

Owner:崔斌

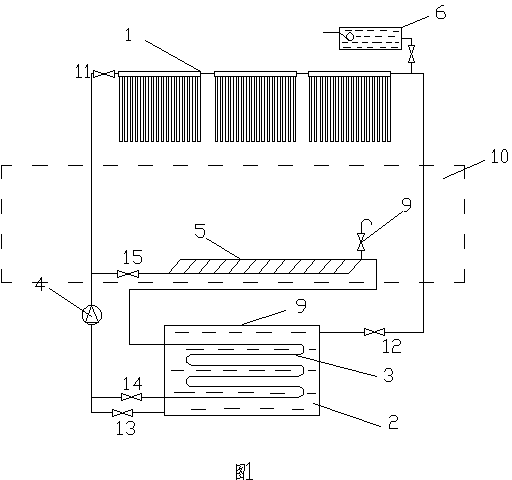

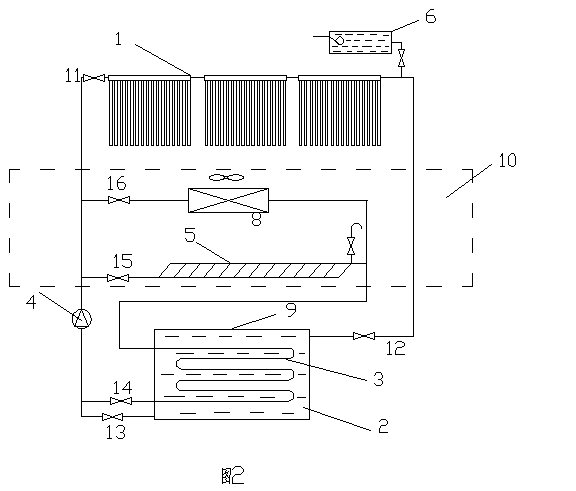

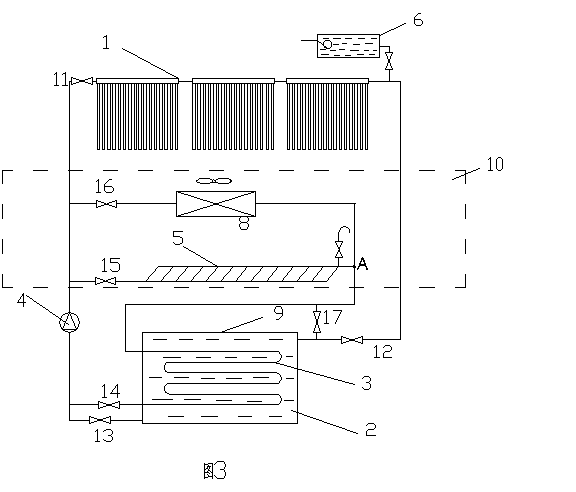

System for comprehensively utilizing energy sources in greenhouse

InactiveCN102986479ATo promote metabolismReduce consumptionClimate change adaptationRenewable energy machinesPlant rootsFluid infusion

The invention relates to a greenhouse energy source comprehensively utilizing system, in particular to a system for comprehensively utilizing energy sources in a greenhouse and belongs to the technical field of the greenhouse. The system is suitable for being used under the conditions of temperature difference between day and night, low temperature in winter and continuous overcast and rainy seasons and mainly improves various energy source utilizing efficiency of the greenhouse through various energy source utilizing technologies. The system for comprehensively utilizing energy sources in the greenhouse comprises a solar heat collecting system, an underground heat storage system, an efficient heat exchange system, a control system, an underground cooling system, a fluid infusion water tank, a circulating pump, a fan and a heat storage tank body. The system remarkably improves the greenhouse energy source utilizing rate by combining a solar energy utilizing technology, a heat exchange technology and a heat storage technology in greenhouse warming, has great technological and economic advantages, can maintain appropriate soil temperature required by plant root systems and ensure the requirement of greenhouse plants to the house temperature, can enable crops to rapidly grow and being high in yield, high in quality and benefit, improves the solar energy utilizing rate of an existing greenhouse, reduces existing energy consumption and production cost, prolongs a production period, and has high economic and social benefits.

Owner:SHAOXING INST OF TECH COLLEGE OF ENG PEKING UNIV BIOENG CENT

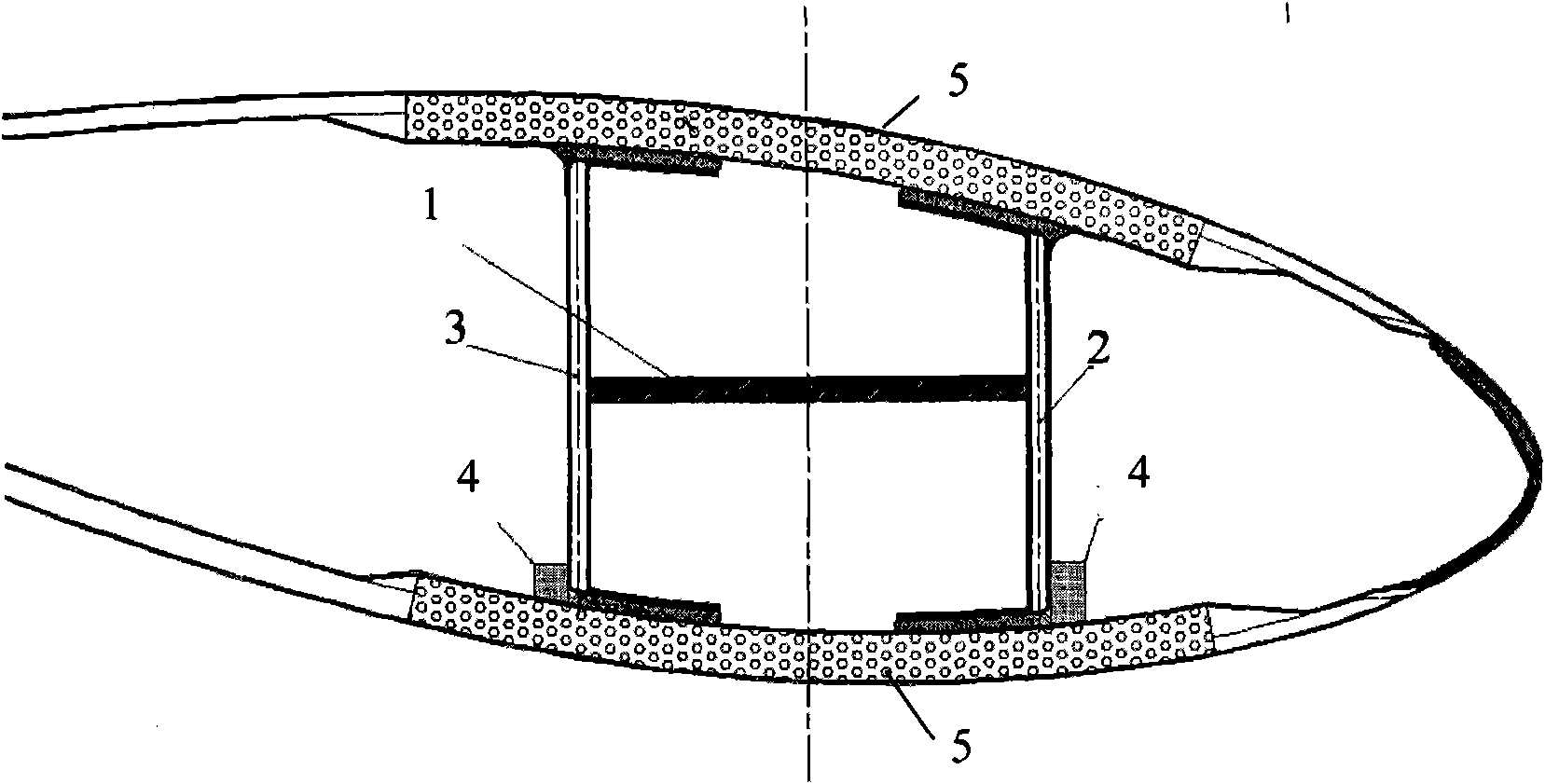

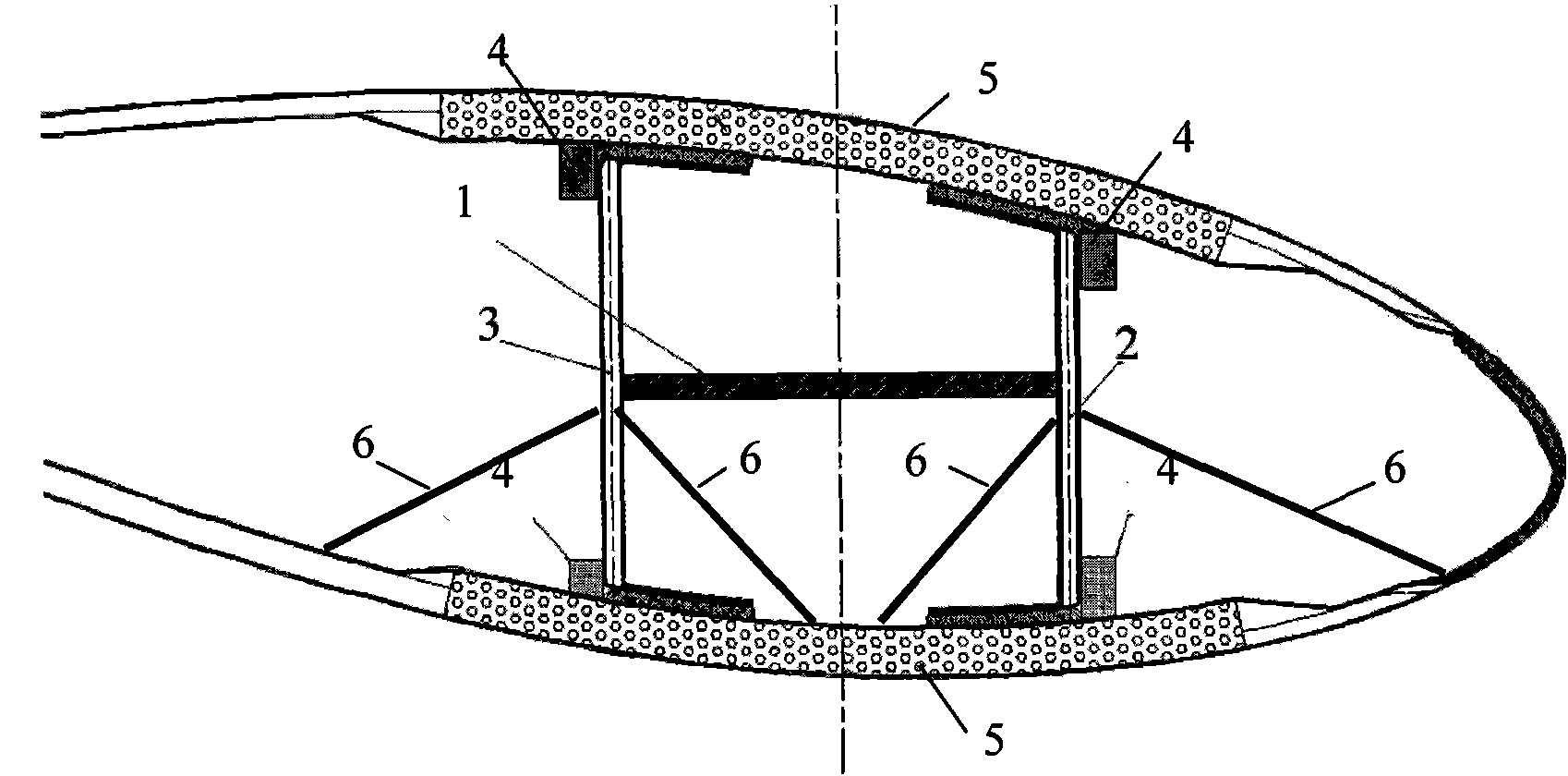

Manufacturing process of wind power vanes

InactiveCN101830074AExtend the production cycleReduced service lifeFinal product manufactureMachines/enginesElectricityWind power

The invention discloses a manufacturing process of wind power vanes. A one-step die assembly technology is adopted, i.e. when a main bracket is bonded with a shell, another shell is immediately bonded with the main bracket, and the die assembly of the vanes is continuously finished, therefore, the die assembly is carried out continuously instead of being carried out after the main bracket and the shell are bonded and solidified. By adopting the manufacturing process of the wind power vanes, the quality of the vanes can be improved, the use levels of tools and raw materials and auxiliary materials are both greatly reduced, glue is especially saved, the production cost of the vanes is reduced, the unnecessary time for weighting the solidification of the glue is reduced, and the production efficiency is improved.

Owner:SINOMATECH FUNING WIND POWER BLADE

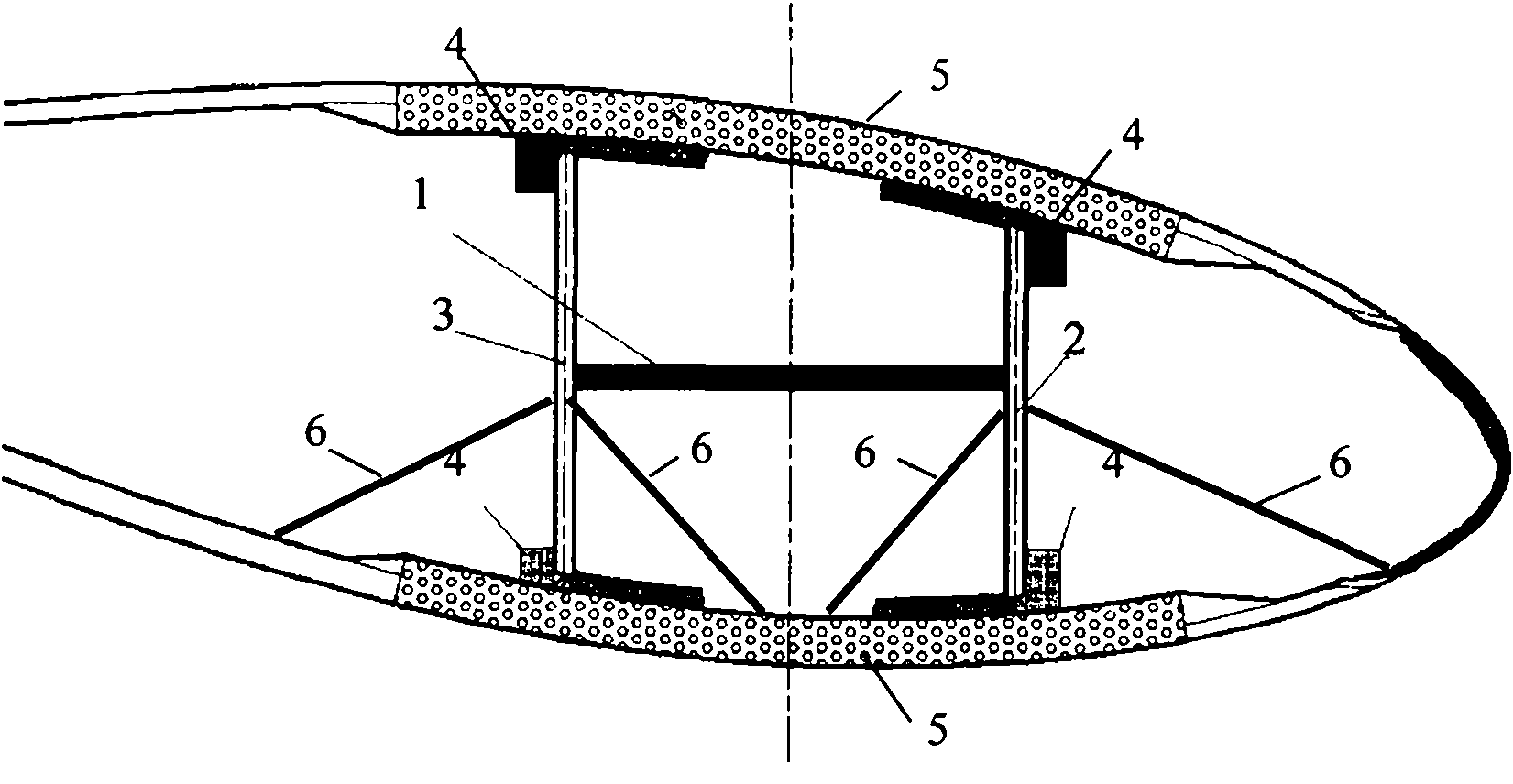

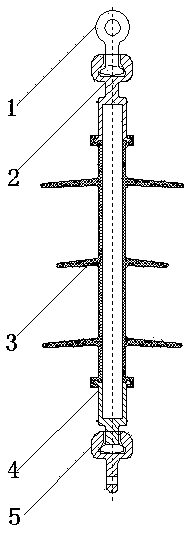

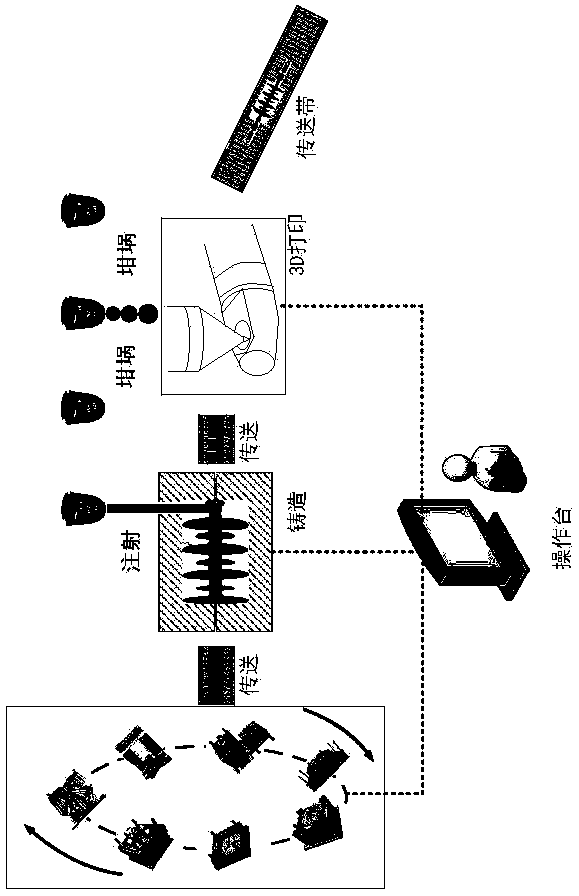

Overhung composite insulator string and method for printing same by using 3D

ActiveCN104103385AHigh degree of manufacturing flexibilitySave timeSuspension/strain insulatorsComputer Aided DesignComposite insulators

The invention discloses an integrated overhung composite insulator string and a method for printing a composite insulator string connecting metal tool by using 3D. The method comprises the following steps of: firstly, generating a three-dimensional CAD (Computer-Aided Design) model of a part in a computer, and printing the three-dimensional CAD model by utilizing a 3D molten-drop printing machine; then slicing up and layering the model according to a certain thickness, converting the three-dimensional information of the part into a series of two-dimensional profile information; melting down metal by using a crucible, and enabling the molten metal to flow out of a nozzle to form molten drops; then accumulating the molten drops layers by layer according to the two-dimensional profile information under the control of the computer so as to obtain a three-dimensional entity part or a part in similar shape. After the method is adopted, a ball-socket series of metal tools is shaped for once directly through the molten-drop 3D printing machine, the connecting cooperation is more reliable and more stable, secondary installation is unnecessary, and the production efficiency is improved; meanwhile, the efficiency of the site construction is provided, and a great influence to the construction of a high-voltage overhead power line is generated.

Owner:STATE GRID CORP OF CHINA +3

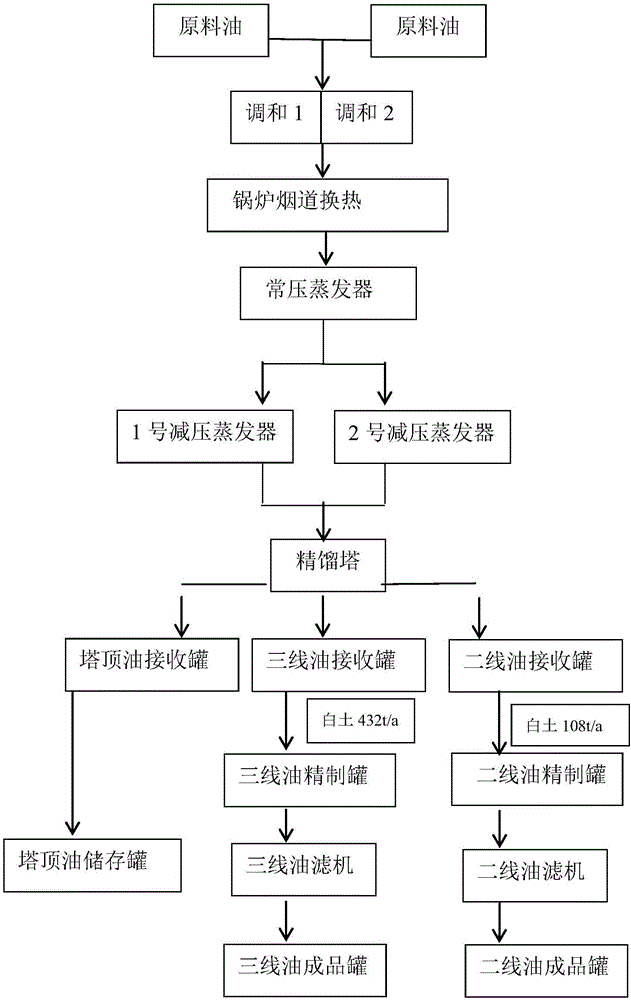

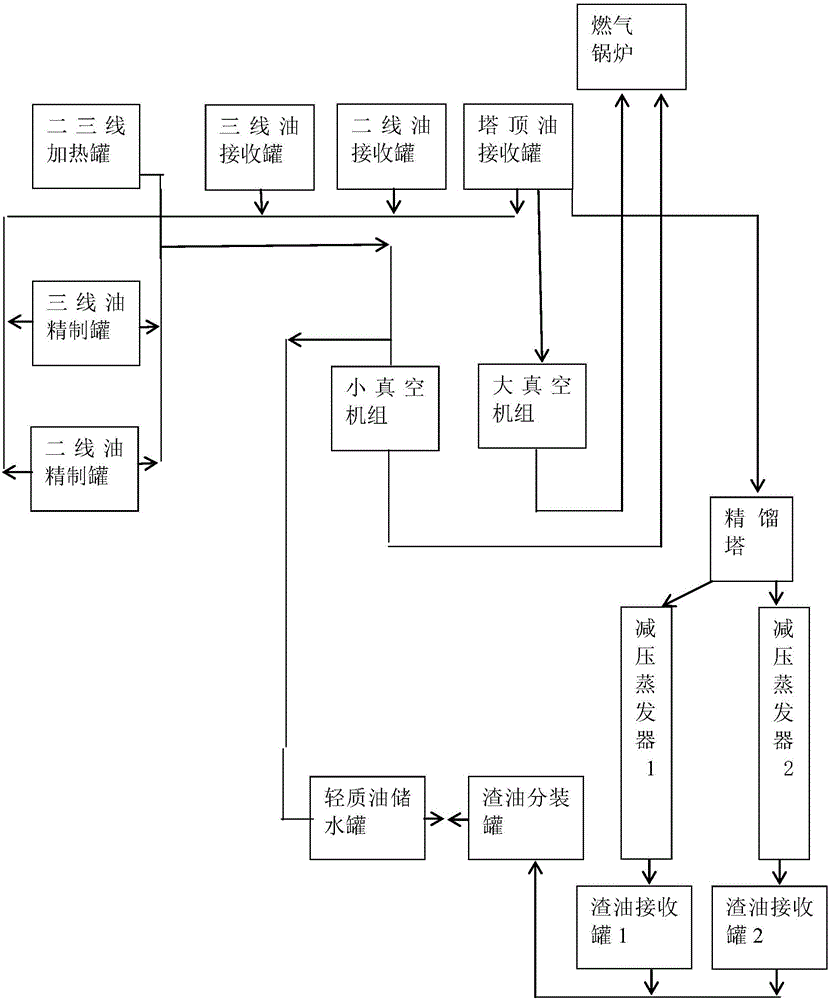

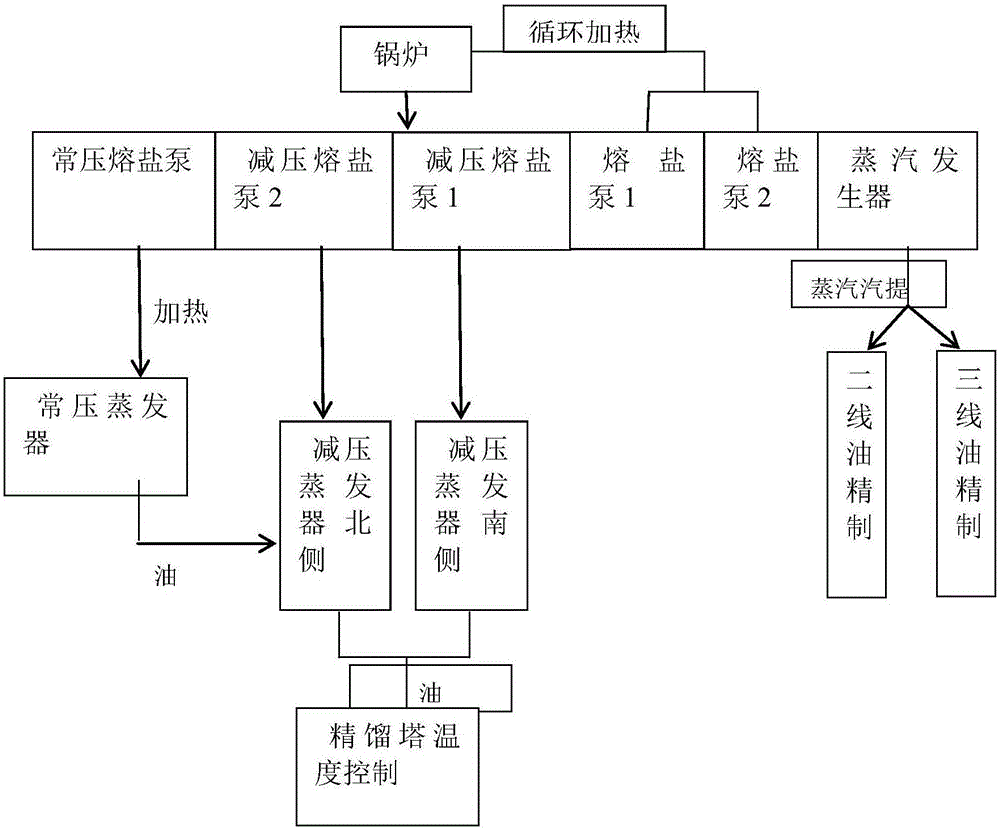

Refining technique of base oil regenerated from used lubrication oil

Disclosed is a refining technique of base oil regenerated from used lubrication oil, and the refining technique comprises the following steps of 1, removing solid waste, which includes removing solid waste from used lubrication oil by centrifugation; 2, solvent pretreatment, which includes extracting mixed impurities and moisture through a solvent and obtaining raw oil after removing upper oil; 3, flocculation treatment, which includes turning mixtures obtained from step 2 into a mixture of flocculation; 4, atomospheric distillation; 5, carrying out reduced pressure distillation; 6, carrying out rectification; 7, solvent refining: putting oil produced from a rectifying column into a treatment tank and when the height of the oil level in the treatment tank reaches 65%-75% of the height of the treatment tank, adding by mass 10%-40% of 1-Methyl-2-pyrrolidinone, and carrying out solvent refining. The refining technique of base oil regenerated from used lubrication oil has the advantages of low investment and high yield efficiency, meanwhile, the refining technique accords with the requirement of environmental protection, reduces vacuum residuum by 15%, improves product yield, facilitates the overhauling of equipment, prolongs the production period, largely improves production efficiency and appearance quality of minus line oil, and helps to obtain high quality regenerated base oil.

Owner:济南亿诺再生资源有限公司

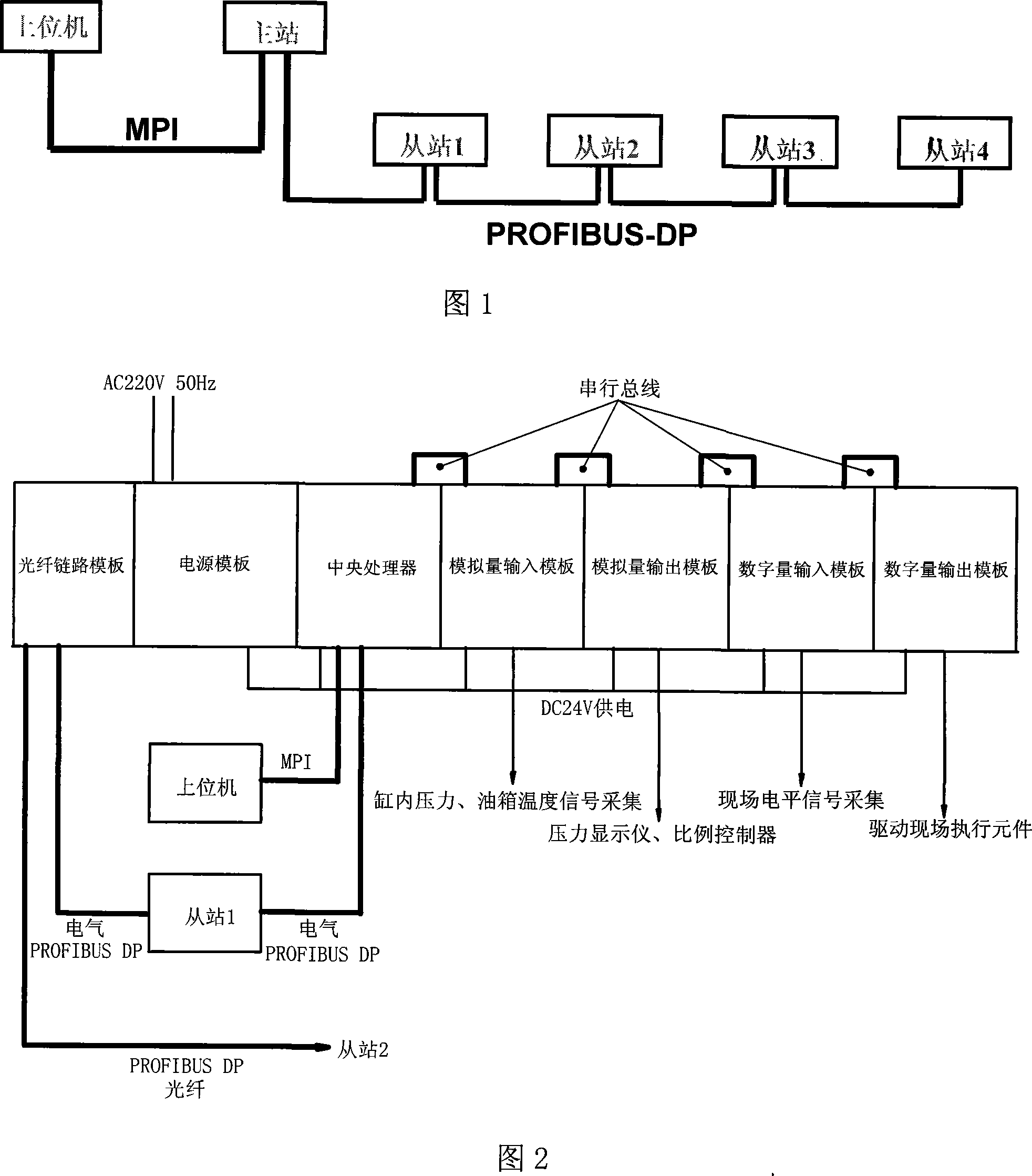

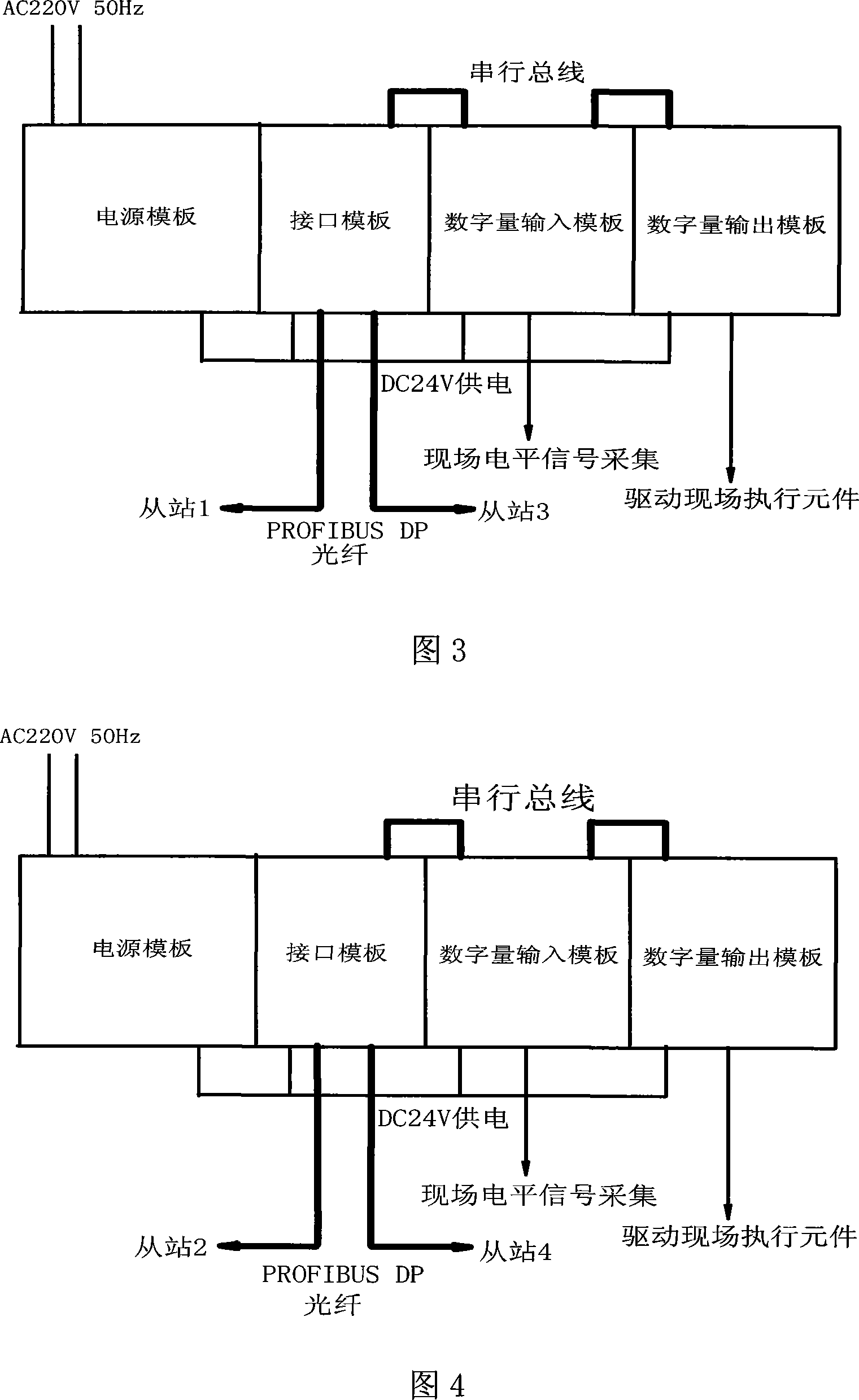

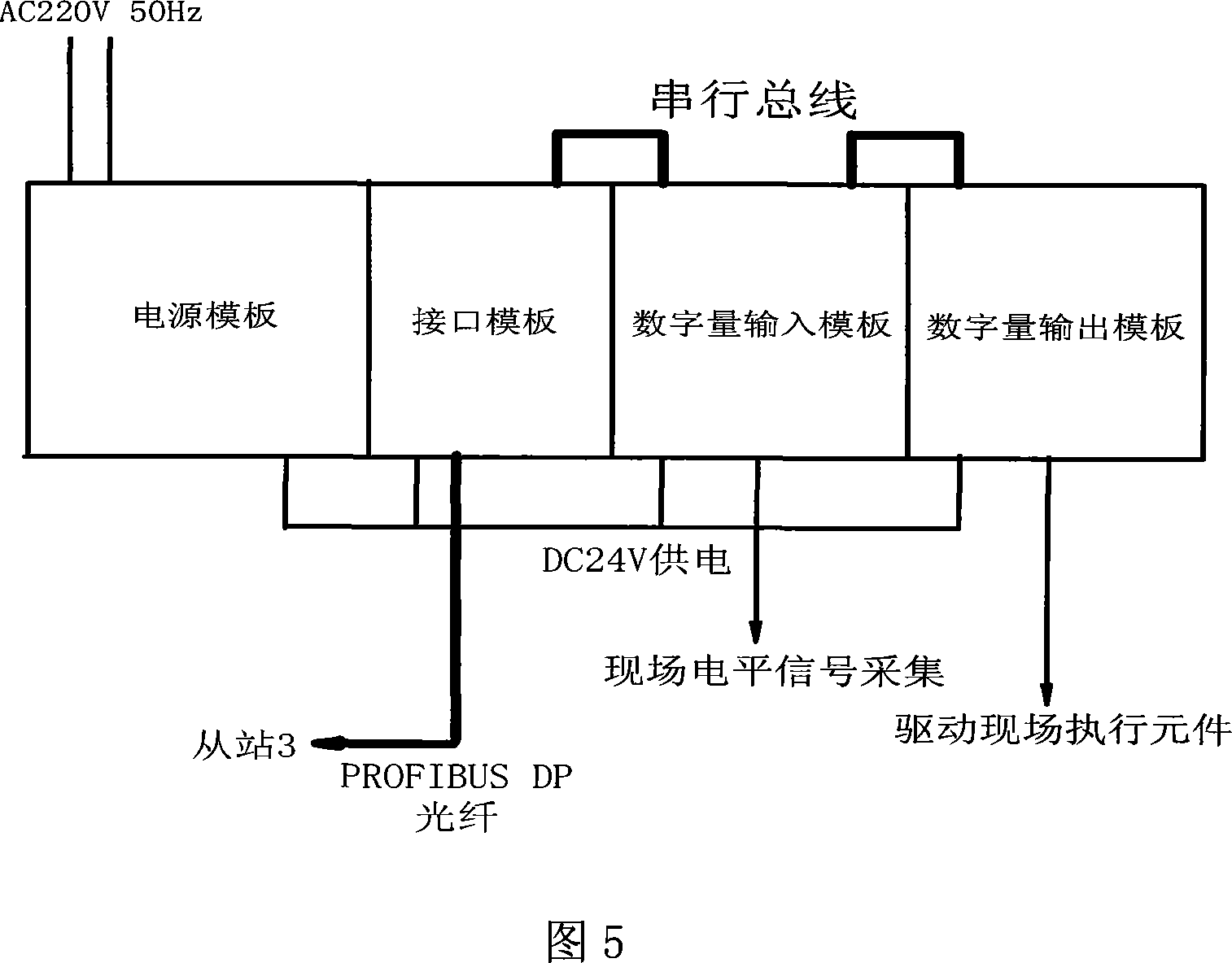

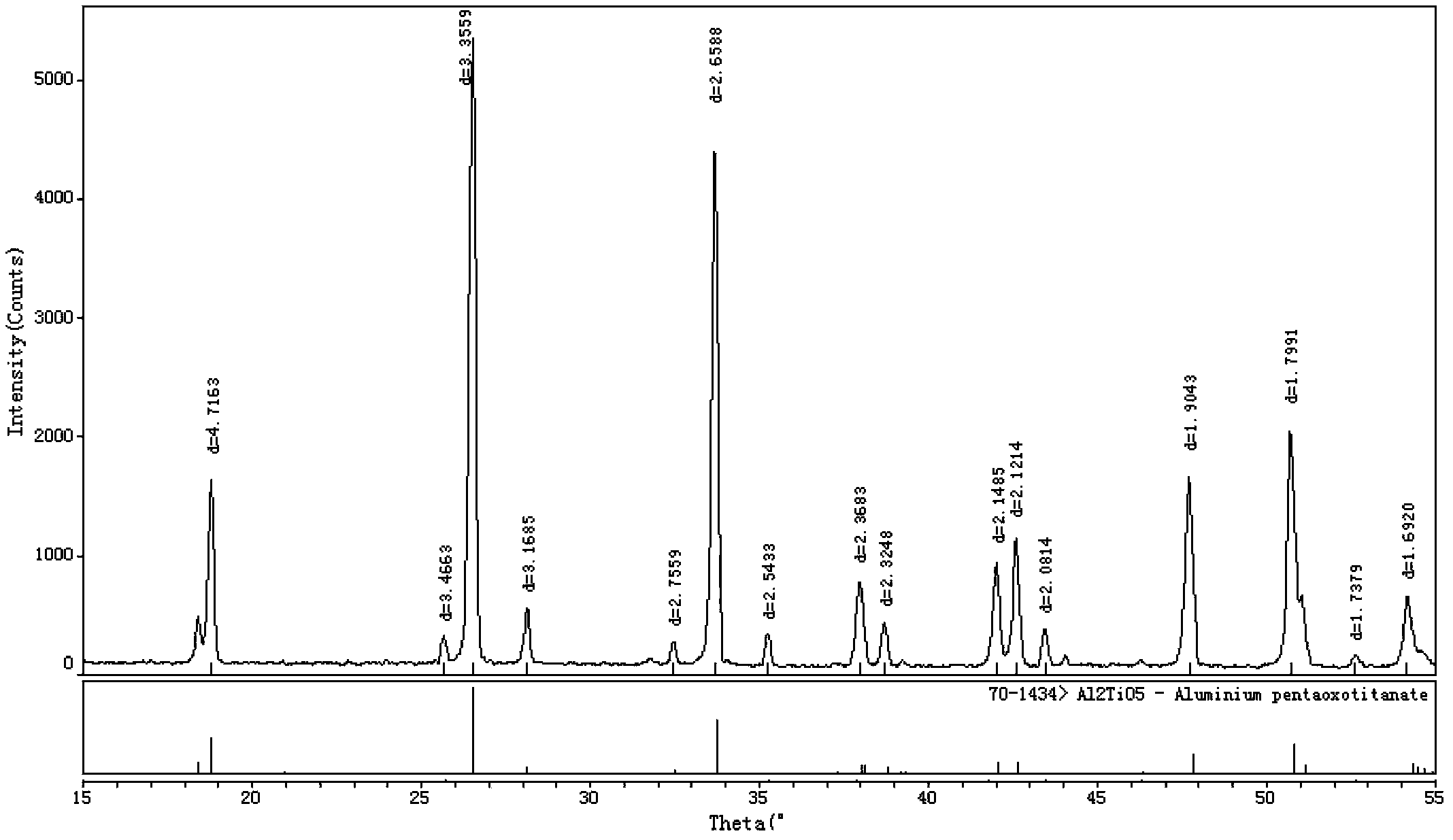

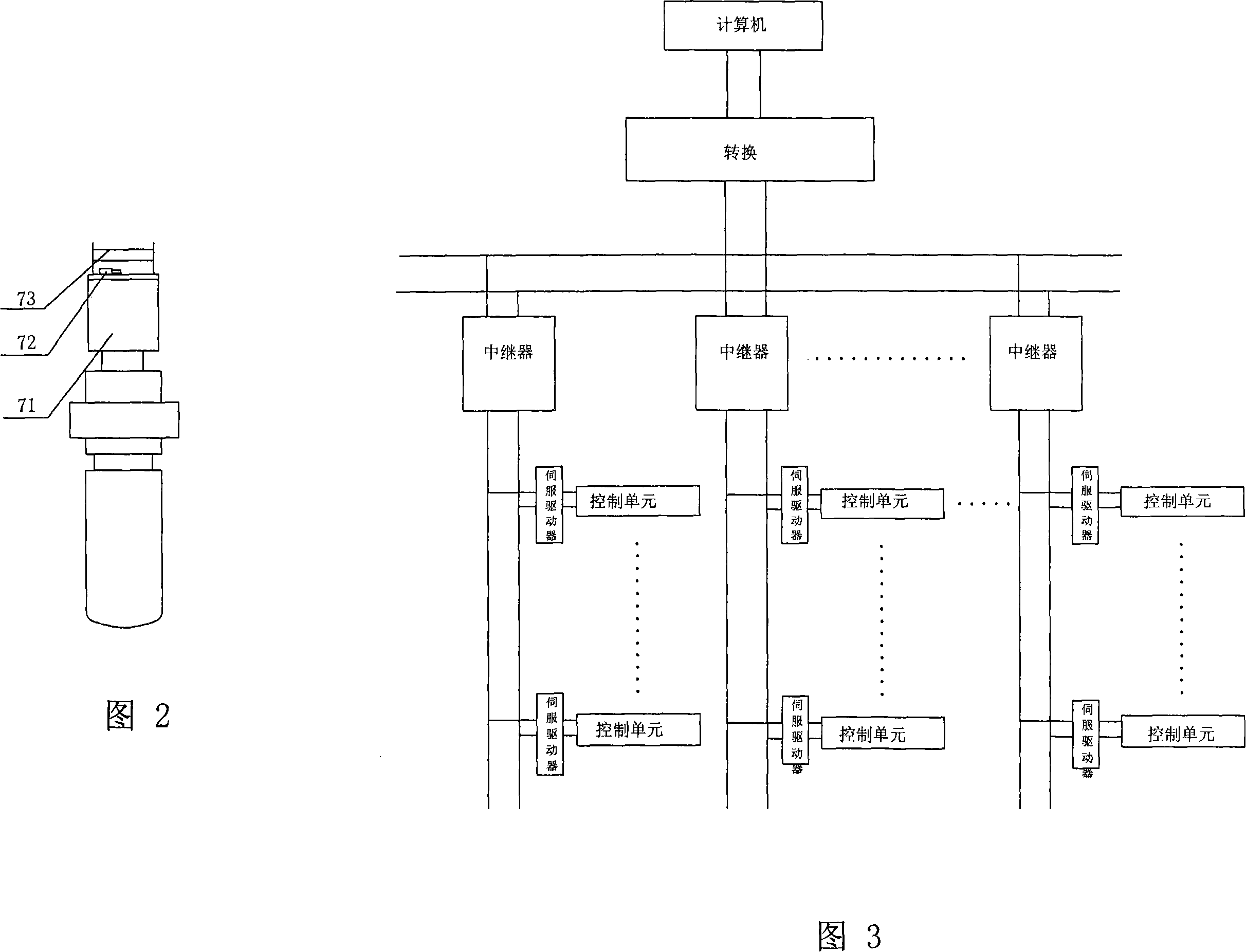

Electrical control workstation of macrotype isostatic pressing machine

InactiveCN101221438AReduce round tripsSimple designComputer controlSimulator controlData accessElectric control

The invention discloses an electric control work station of a large-scale isostatic press, comprising an upper computer provided with a programming software part and a monitoring software part, a master station with an on-the-spot and process communication PROFIBUS-DP interface and at least one slave station connected with a multi-branch communication network bus, wherein the master station through which a programmable controller (PLC) passes realizes bus communication control and management and completes periodic data access; a master station can control a plurality of slave stations on the bus; moreover, at least one logic link adopting round robin communication mode in information exchange is set up between the master station and each slave station. By means of the programmable controller, the invention sets up a high-performance industrial on-the-spot local area network through an on-the-spot and process communication field bus, thereby realizing network monitoring of process and reducing a great amount of wiring and cable investment; meanwhile, the communication network field bus with an all digital multi-branch structure improves system accuracy and reliability; moreover, the invention has low cost in installation, operation and maintenance, simpler operation and more visualized monitoring.

Owner:SICHUAN AVIATION IND CHUANXI MACHINE

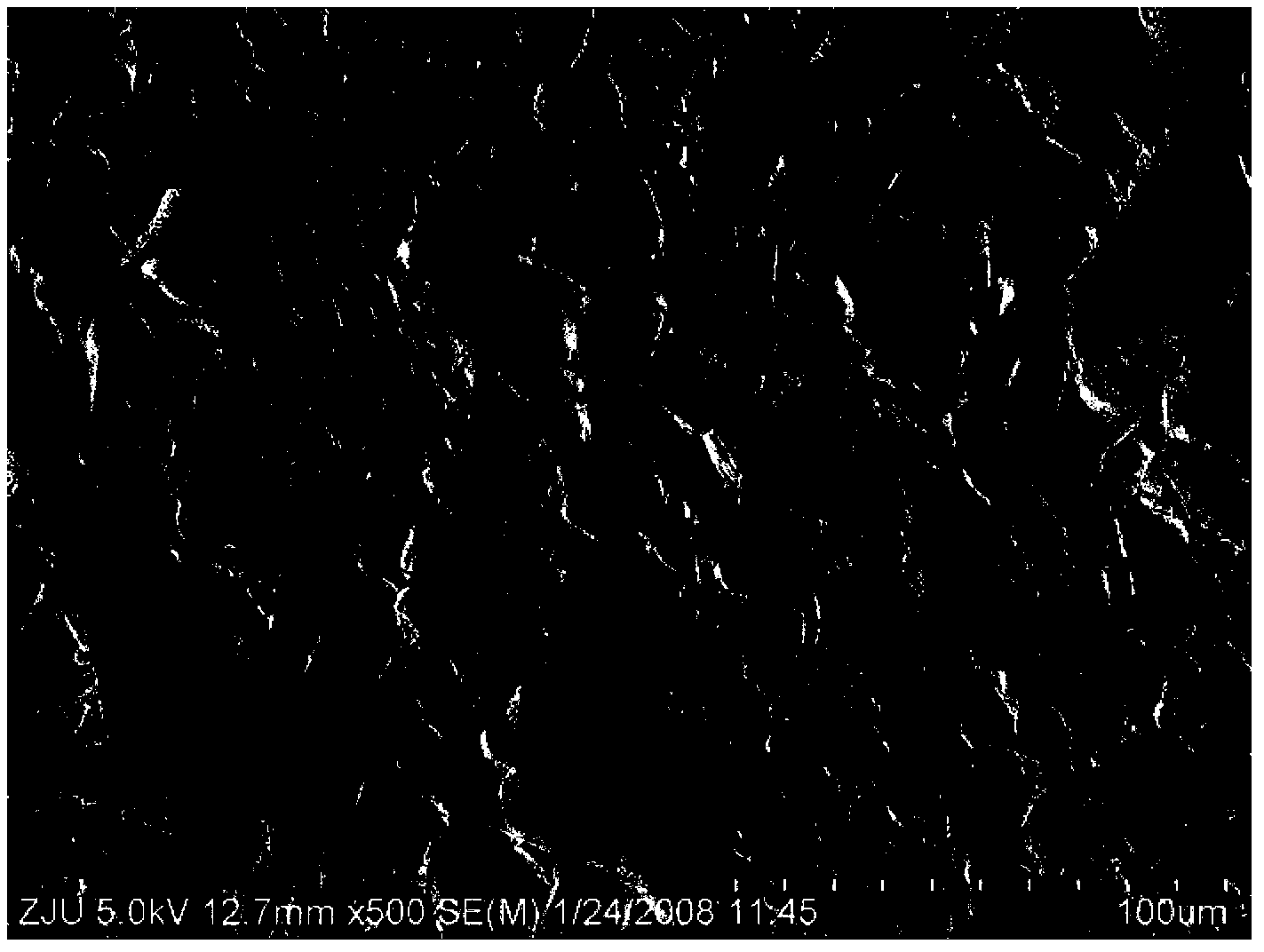

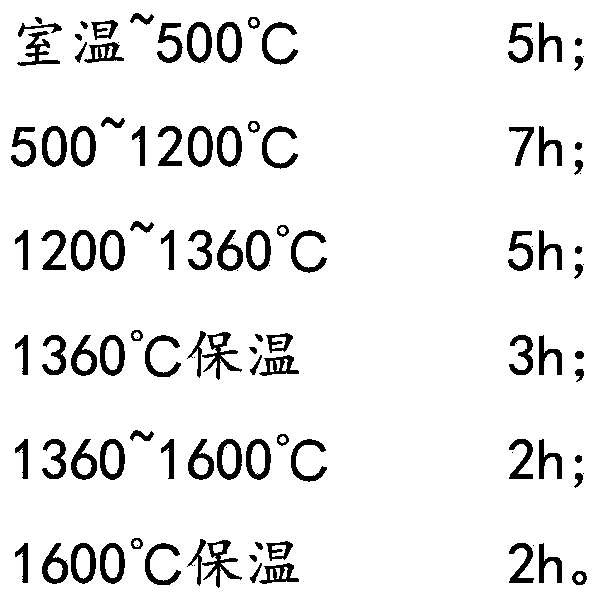

Preparation method for aluminum titanate ceramic

The invention discloses a preparation method for an aluminum titanate ceramic. According to the invention, industrial alumina and titanium oxide are used as basic raw materials, one or more raw materials selected from the group consisting of MgO, Fe2O3, SiO2, ZrSiO4, mullite and the like are used stabilizing agents, and an aqueous polyvinyl alcohol solution is used as a binder; a mixture of the above-mentioned ceramic raw materials is uniformly mixed through ball milling and is then dried to remove moisture, a desired ceramic body is compacted through isostatic pressing, and binder removal and high temperature sintering are successively carried out so as to obtain the ceramic. The preparation method provided by the invention omits the traditional procedure of preparation of aluminum titanate powder before preparation of an aluminum titanate product, overcomes the problems of a long cycle, high cost, instable quality and the like of traditional processes and has the advantages of conservation of processing cost, environmental protection, a short production period, good thermal shock resistance of the product and suitability for industrial mass low-cost production.

Owner:无锡特科精细陶瓷有限公司

Production method of paper RFID hot stamping label

ActiveCN105893890ALow costEasy to recycleDigital marking by photographic/thermographic registrationHot stampingAntenna substrate

The invention belongs to the technical field of information, and in particular relates to a production method of a paper RFID hot stamping label. A paper substrate is used as an antenna substrate, wherein variable or invariable barcode information or a LOGO pattern is printed on one side of the antenna substrate, the other side of the antenna substrate is subjected to alignment printing to form an electronic label antenna surface, and then the electronic label antenna surface is compounded and compacted with a PET film coated with an isolation layer to obtain an antenna; a chip is bound to the compounded antenna to be manufactured into an electronic label inlay layer; an adhesive film is coated on an inlay surface bound with the chip; then the hot stamping electronic label is cut into a single label or single-row labels by a positioning die, and the single label or the single-row labels are rolled up to obtain a product. The production method of the paper RFID hot stamping label disclosed by the invention realizes a dual-information safety guarantee of visual information and electronic label information, and is environment-friendly and pollution-free, and the prepared electronic label has non-transferability, high anti-counterfeiting strength, fast hot stamping speed and high efficiency.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

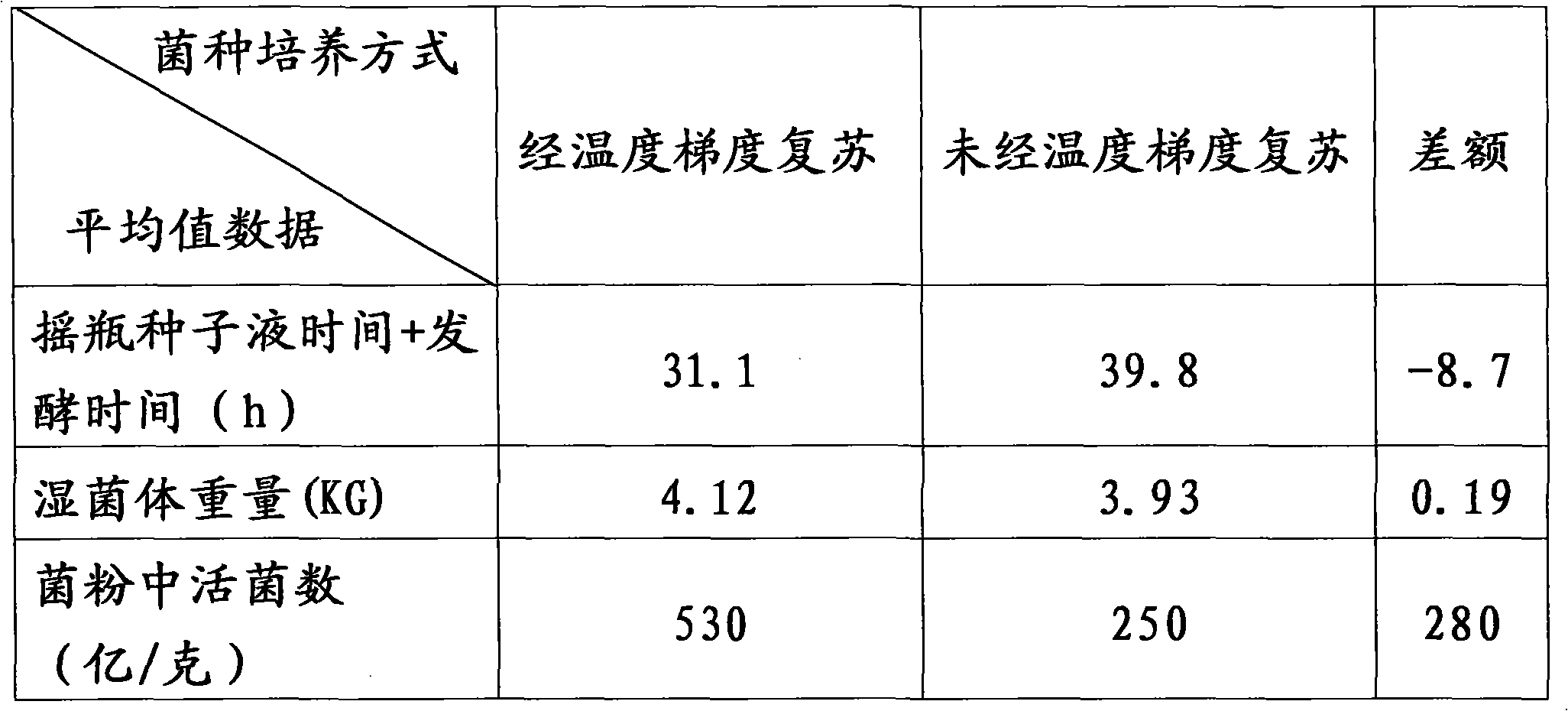

Preparation method of Bacillus licheniformis powder and microbial ecological agent

ActiveCN102120972AExtend the production cycleImprove energy consumptionBacteriaBacteria material medical ingredientsBacillus licheniformisFreeze-drying

The invention relates to preparation and application of Bacillus licheniformis. In order to solve the problems of small obtained viable count, long production period, high energy consumption, high production cost, low production efficiency and large workload for culturing the Bacillus licheniformis in the prior art, the invention provides a new preparation method of Bacillus licheniformis powder and microbial ecological agent, comprising the following steps: firstly, carrying out temperature gradient anabiosis culture on the freeze-dried strain of the Bacillus licheniformis; then, breeding strains, fermenting, and decentralizing and drying to obtain bacterial powder; and preparing the microbial ecological agent by taking the bacterial powder as a raw material. The freeze-dried strain of the Bacillus licheniformis can be subjected to the temperature gradient anabiosis culture, and the freeze-dried strain can gradually adapt to the final culture temperature; and meanwhile, the activity of enzyme in the bacteria is activated so as to improve the metabolism speed of the bacteria and quicken the bacteria breeding speed, thereby improving the obtained viable count, shortening the production period and improving the production efficiency.

Owner:ZHEJIANG JINGXIN PHARMA

Method for improving dried meat slice sensory quality

The present invention provides a method for improving dried meat slice sensory quality, and belongs to the technical field of food processing. According to the present invention, the method includes adding 1-5% by weight of trehalose in dried meat slice production, the trehalose wholy or partly replaces sucrose in the dried meat slice formula, and is added together with accessories or food additives in the process of salting, wherein the salting is at low temperature or room temperature, and then the dried meat slice is produced by a conventional dried meat slice production process or a meat paste production process. The method of the present invention can slow hardening of protein and decomposition and oxidation of unsaturated fatty acid, reduce non-enzymatic browning occurrence, improve drying speed of the meat slice, improve baking performance of the dried meat slice, improve rehydration performance of the dried meat slice, and achieve good sensory quality including good elasticity, bright color, delicate tissue, tender quality and good taste.

Owner:HANSHAN NORMAL UNIV

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

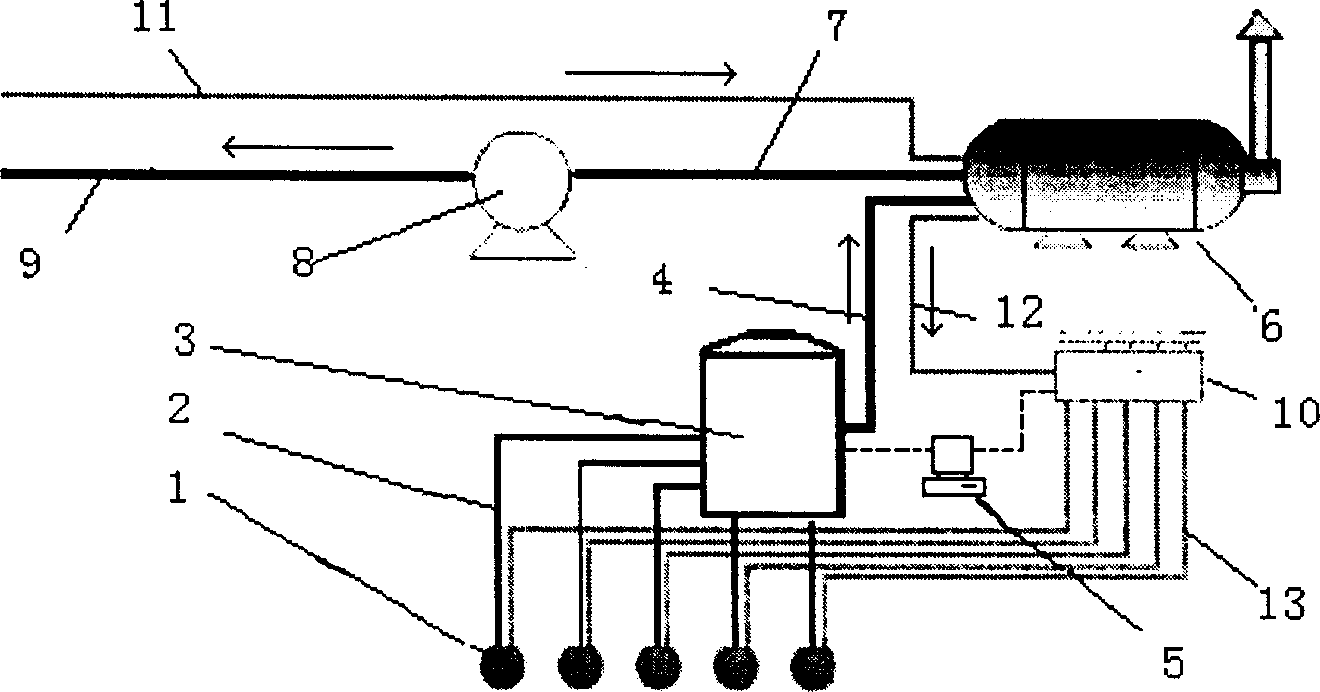

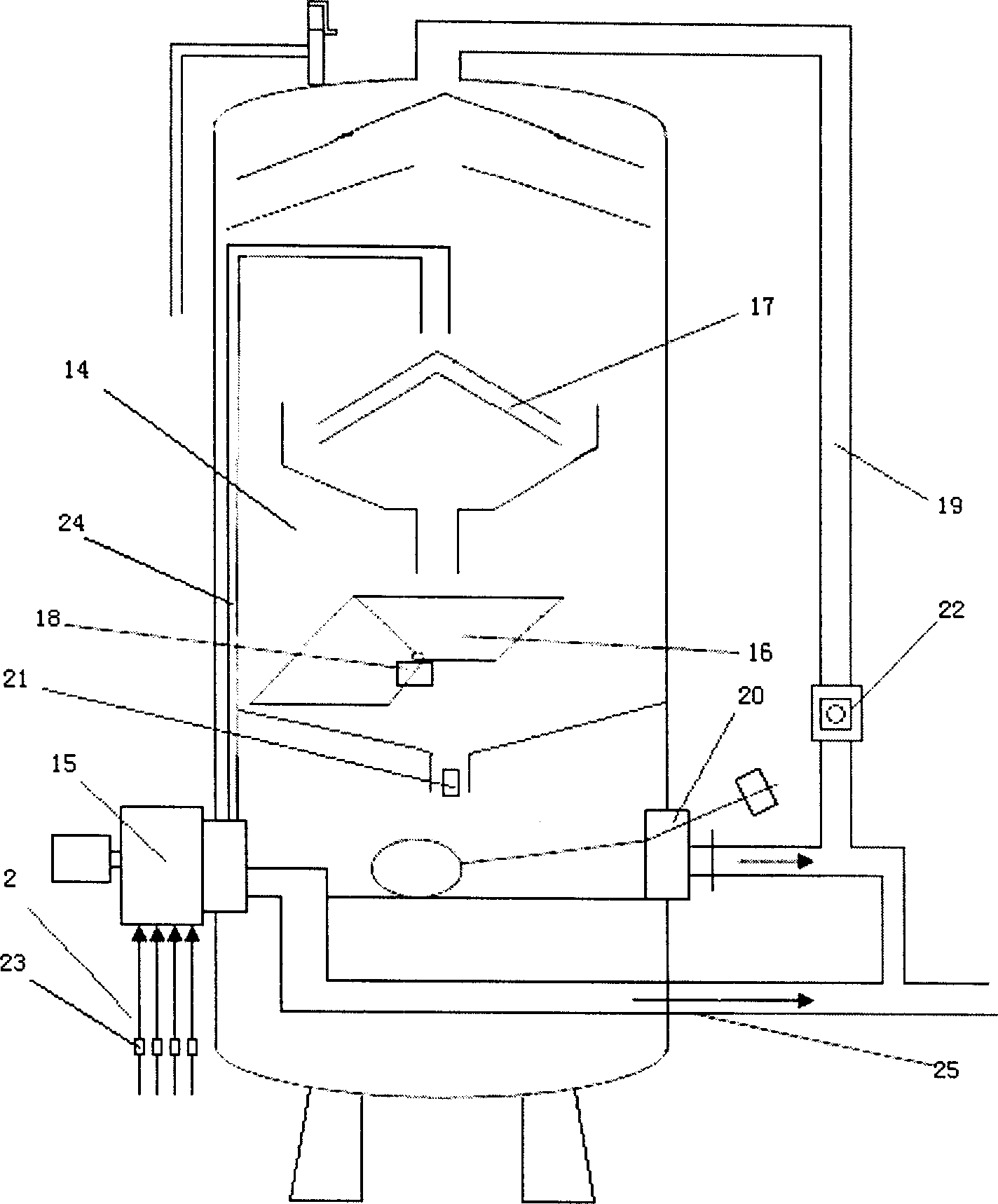

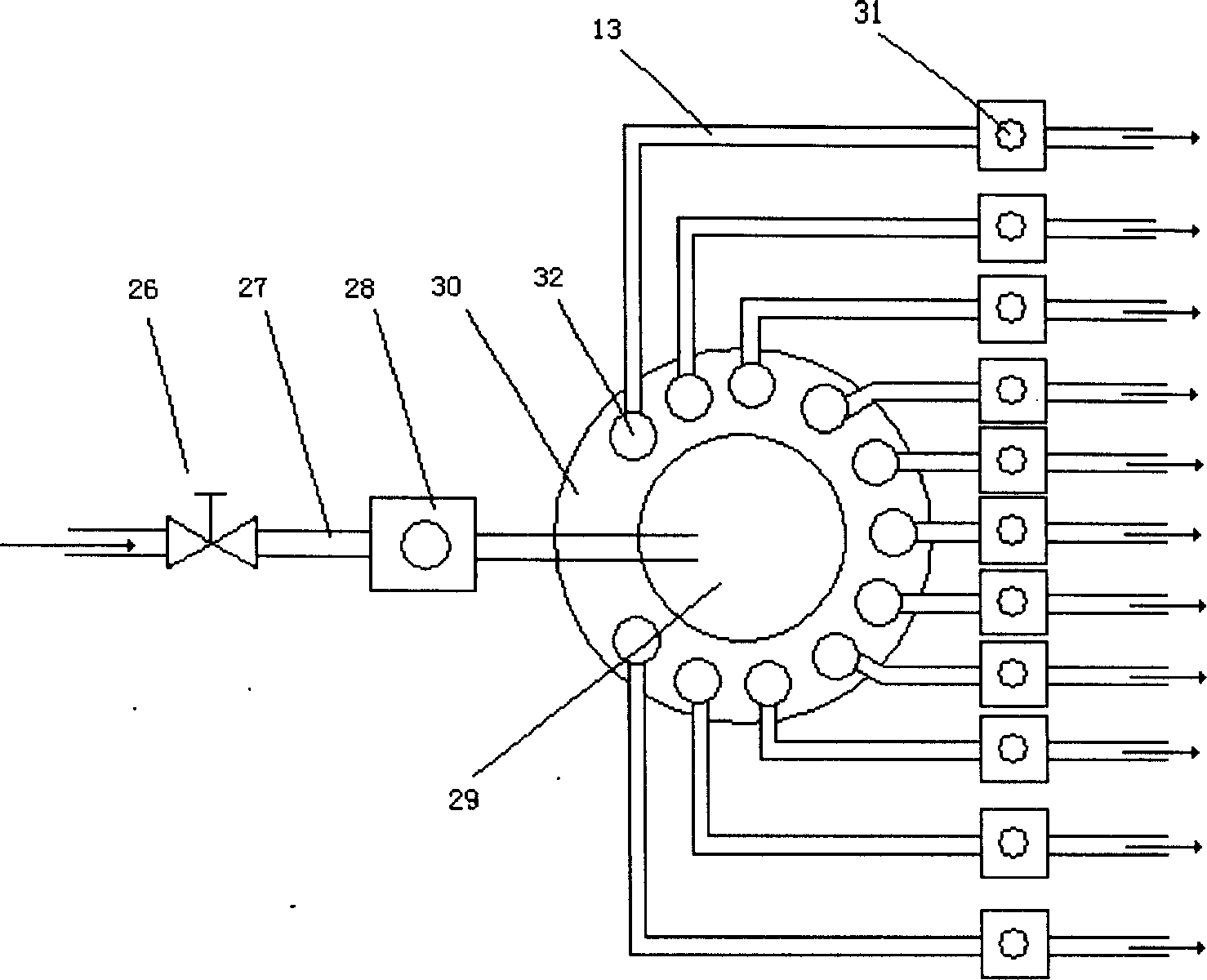

Overground gathering and transporting system for petroleum exploitation and method thereof

InactiveCN1828009ARealize automatic dosingImplement gas-liquid direct transmissionSurveyFluid removalPetroleumOil well

The invention relates to an oil exploitation ground transmission system and relative method, belonging to the oil exploitation technique. Said invention can measure the oil well, add liquid into oil well, heat the oil well and mixed transmit the oil gas. And said invention comprises four parts as aforementioned functions. Wherein, the oil well measuring part uses a liquid automatic measurer, which comprises a skip measurer, an automatic oil well switcher and a transmission tube. The invention uses industry computer to realize said functions, with high automatic degree, high practicability, and unmanned management.

Owner:岳玉全 +1

Oil layer wax-condensing type oil reservoir mining method

ActiveCN101265800AReduce the temperatureSignificant pour point and viscosity reductionFluid removalEconomic benefitsDepressant

The invention discloses an oil layer wax precipitation type oil resource exploitation method which is progressed cyclically by the following steps: 1. 0.1-500 tons of pour point and viscosity depressant are injected into oil layers through an oil well; 2. 1-10000 tons of thermal fluids mixed with 30-400 DEG C of pour point and viscosity depressant are injected into the oil layers through an oil well; in the thermal fluids mixed with pour point and viscosity depressant, the weight proportion of the thermal fluids and the pour point and viscosity depressant is 100:0.001-10; 3. the oil well is closed, reacting for 2-240 hours when the well is closed; 4. a mixture of oil and water is sprayed through the oil well; 5. the oil is produced normally by a pumping unit. The exploitation method can effectively exploit the oil layer wax precipitation type oil resource, which greatly reduces the production cost, prolongs the production cycle of the oil well, improves the oil well production and increases the final recovery rate of the oil resource. Moreover, the exploitation method has the advantages of easy operation, safety and reliability and significant economic benefits.

Owner:盘锦河升大地石油科技有限公司

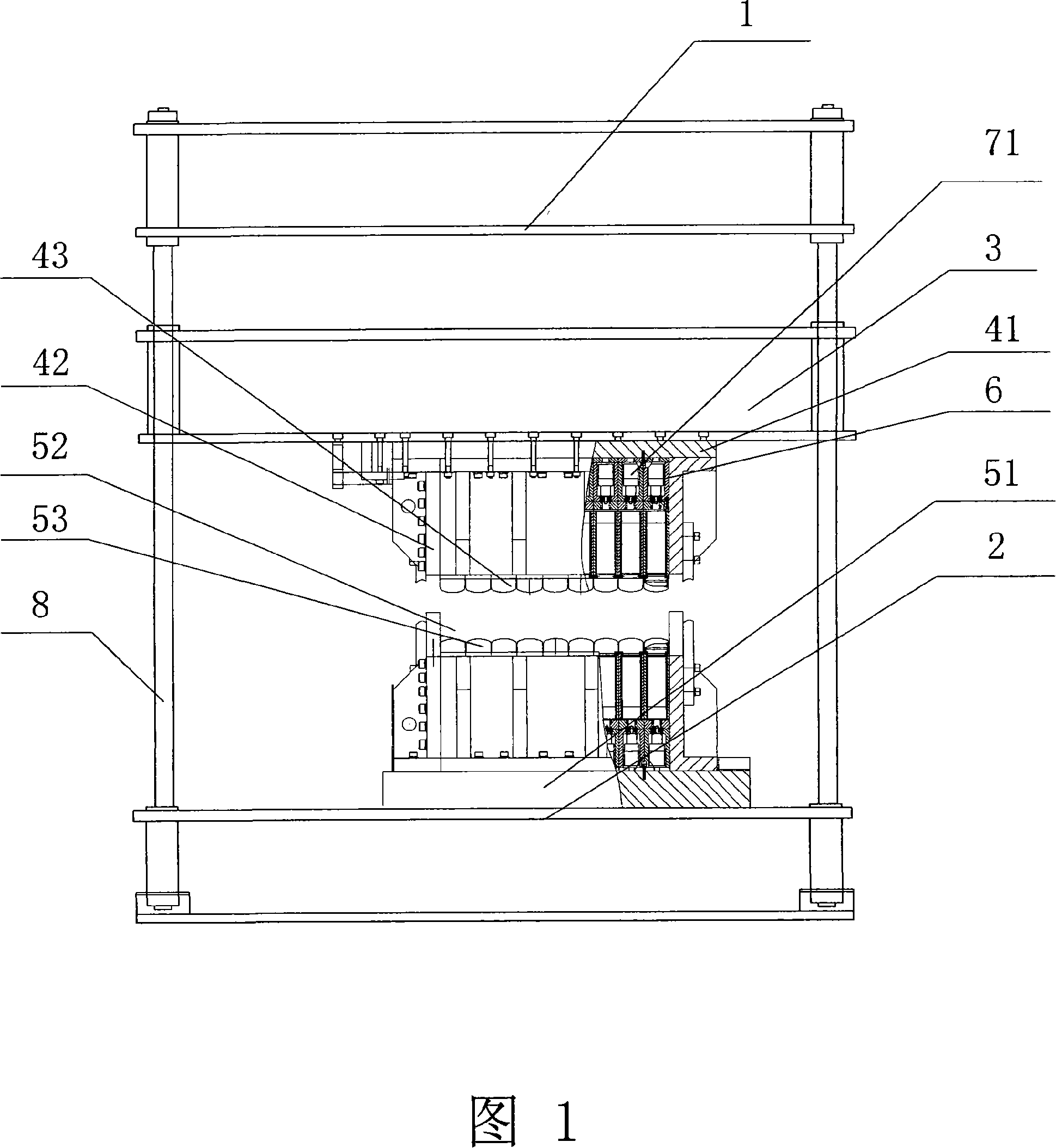

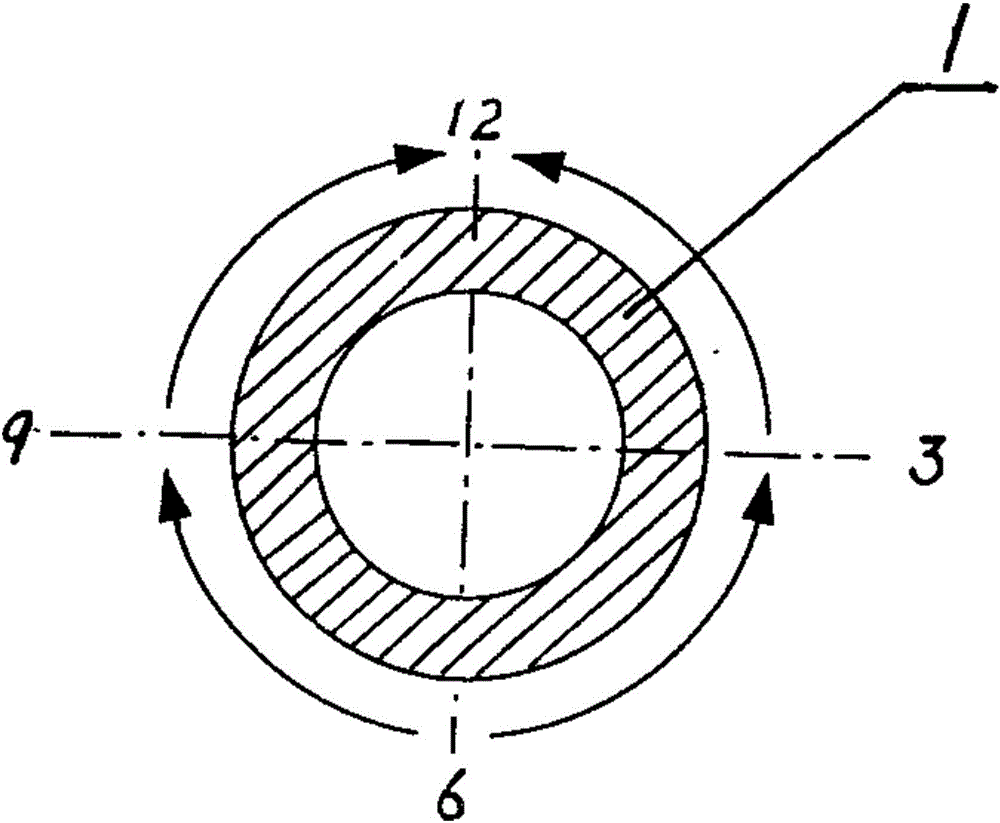

Non-mould multi-point forming system for plate

InactiveCN101104188AMeet the needs of shapingAchieve moldless formingShaping toolsNumerical controlAutomatic controlEngineering

The invention discloses a molding system that molds plates from plural points without a mould, comprising upper beam frames that are connected with each other and a lower beam frame with a lower fixing plate. An active beam frame with an upper fixing plate is arranged between the upper beam frame and the lower beam frame. The active beam frame is provided with an upper basic body controlling unit cluster with an automatic adjusting mechanism. The lower beam frame is provided with a lower basic body controlling unit cluster with an automatic adjusting mechanism. The upper basic body controlling unit cluster and the lower basic body controlling unit cluster correspond to each other up and down. With such a structure, the invention can realize automatic control, and can randomly change the shape of a molded surface by utilizing the upper basic body controlling unit cluster and the lower basic body controlling unit cluster, and thus the invention can replace the traditional mould to realize the molding effect from plural points of plates.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Small-caliber pipe butt-welding method

InactiveCN106077917ADock volume increasedReduce auxiliary workloadArc welding apparatusMetal working apparatusButt weldingButt joint

The invention relates to a small-caliber pipe butt-welding method. The method comprises a barrier-free small-caliber pipe whole-position welding method and a barrier small-caliber pipe welding method. The method is characterized in that the whole-position welding ground method is adopted, an overall welded junction is adopted as the lower side of a clock, namely, 6 o'clock, the left and right sides are 3 o'clock and 9 o'clock, at the moment, arc striking is performed at the position of 6 o'clock, arc application is performed from the two directions, and welding is performed at 12 o'clock. The method has the advantages that whole-position butt-welding is performed, auxiliary workloads are greatly reduced, the production circulation period is accelerated, and the welding junction butt-welding amount is remarkably increased; inner concave and incomplete penetration defects are effectively controlled and prevented; the first-passyield of butt-welding junctions of the barrier-free small-caliber pipe is increased from 93% to 97-98%, barrier pipes and pipe bundles are in butt welding, pipe bundles are in butt joint, the pipe junction first-passyield is increased from 85-90% to 96% or more, the welding junction first-passyield is obviously increased, and the production period is greatly shortened.

Owner:TIANJIN CITY BINHAI NEW AREA JURONG TECH

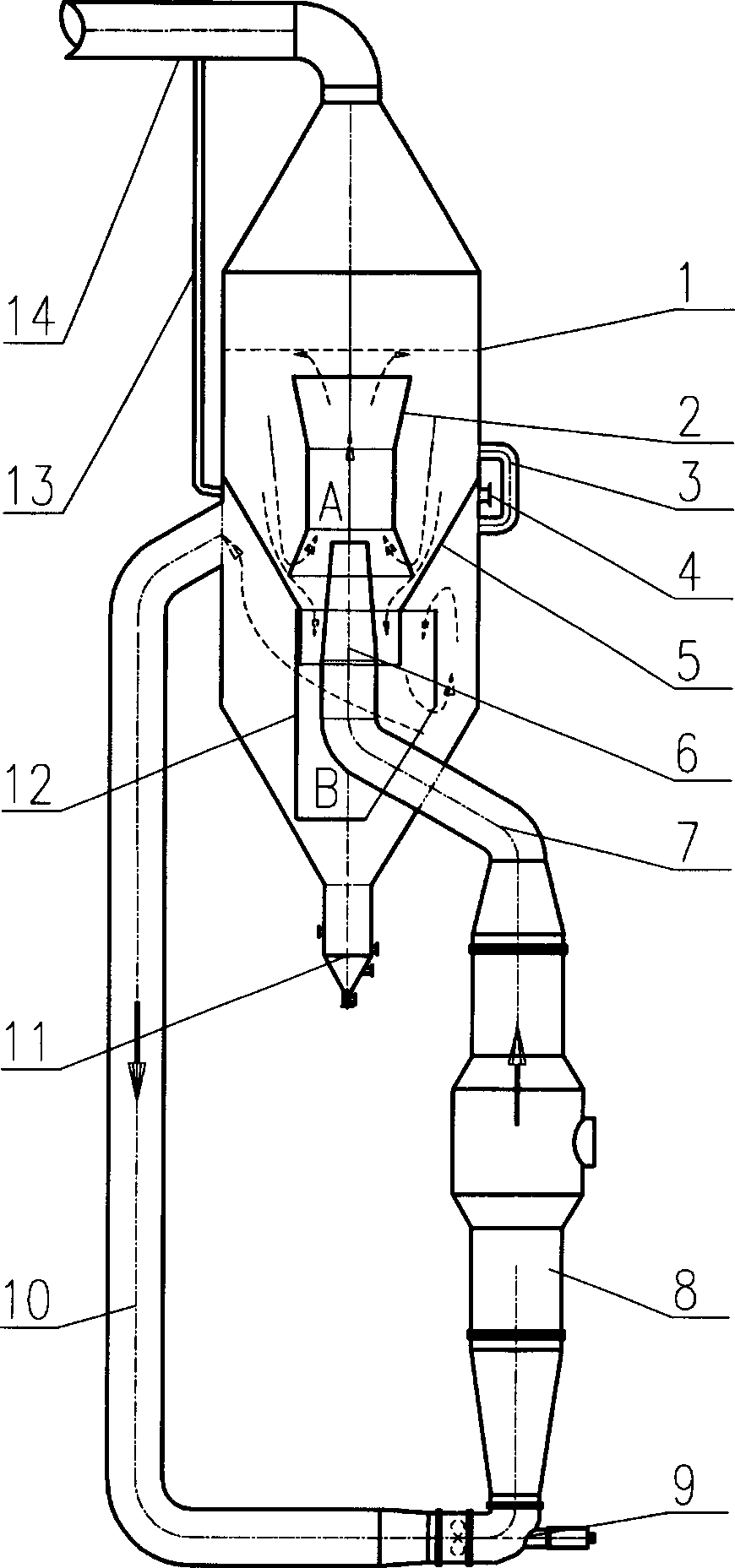

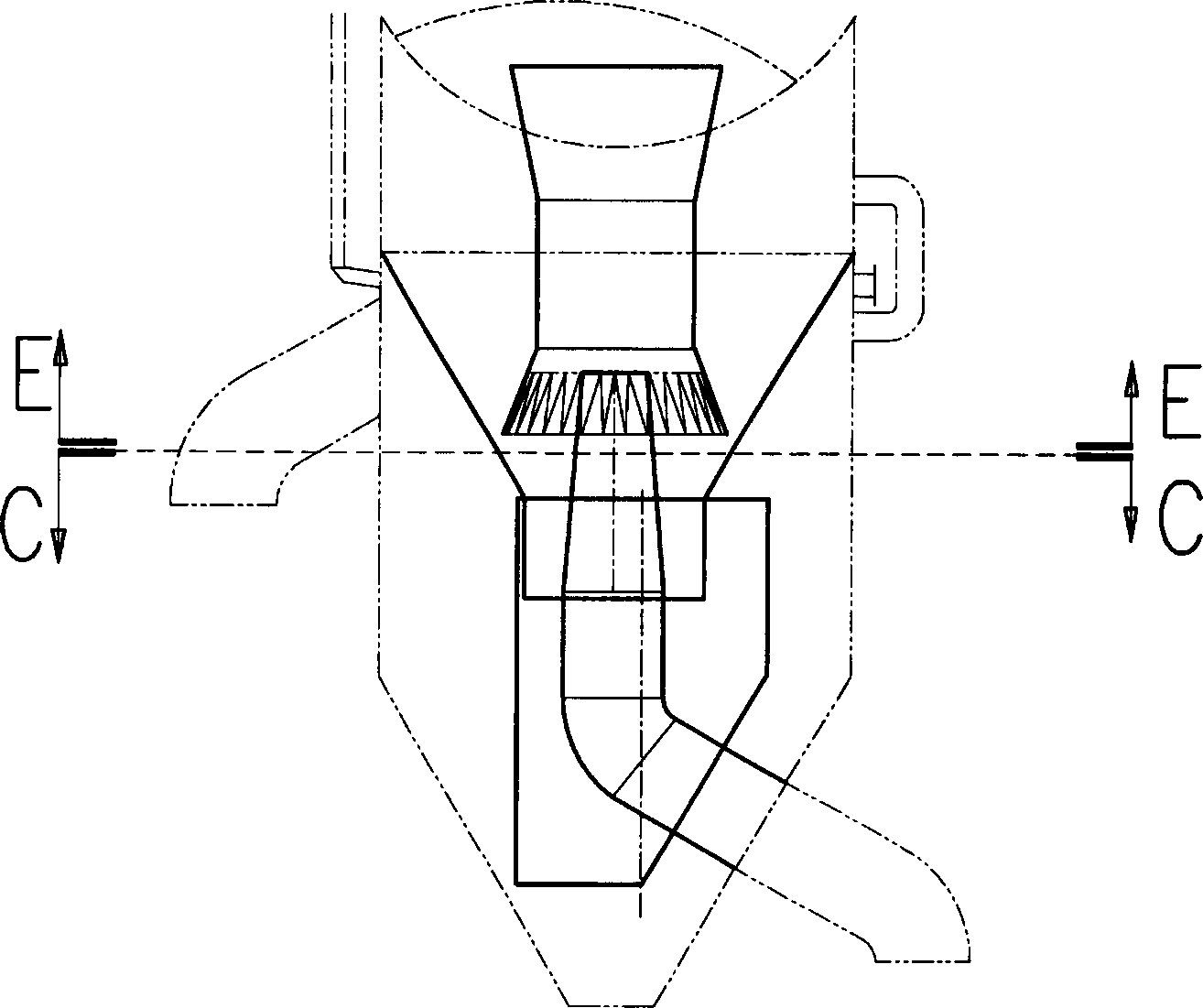

Evaporating crystallizer

ActiveCN103071310AExtended routeExtended stayEvaporationSolution crystallizationEconomic benefitsEngineering

The invention relates to an evaporating crystallizer which comprises an evaporating chamber, a center drainage cylinder, an evaporating chamber inner cone, a clear liquid transfer pipe, a crystal cultivation settling chamber baffling cylinder, an upper circulation pipe, an outer circulation feed nozzle, a heating chamber, a lower circulation pipe, a forced circulation pump, a salt foot, a secondary steam pipe and a steam discharge pipe. Outer circulation of the evaporating crystallizer are formed by the evaporating chamber, the upper circulation pipe, the heating chamber, the forced circulation pump and the lower circulation pipe; and inner circulation of the evaporating crystallizer is formed by the center drainage cylinder, the evaporating chamber inner cone and the crystal cultivation settling chamber baffling cylinder. With the adoption of the evaporating crystallizer, salt crystals with large particle sizes and high purity can be produced, energy consumption per unit product is further reduced, the normal production cycle is prolonged, and the comprehensive economic benefit is increased.

Owner:江苏苏盐井神股份有限公司

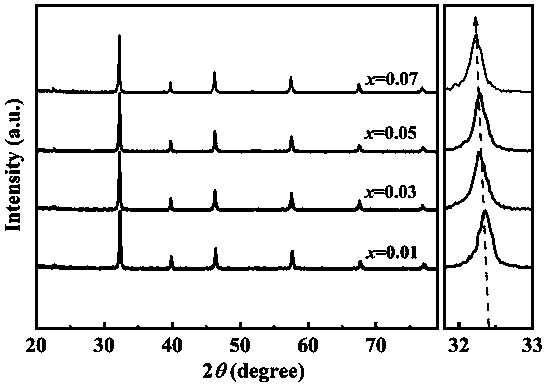

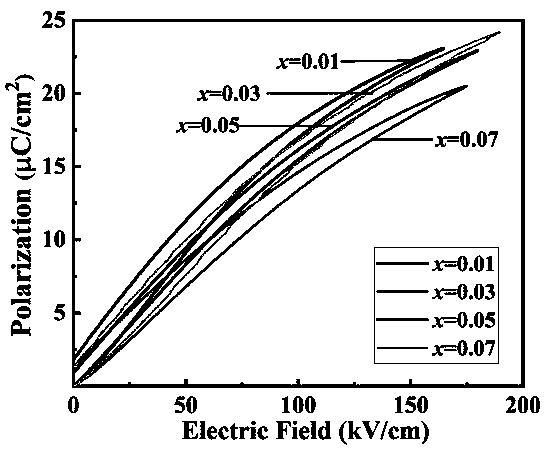

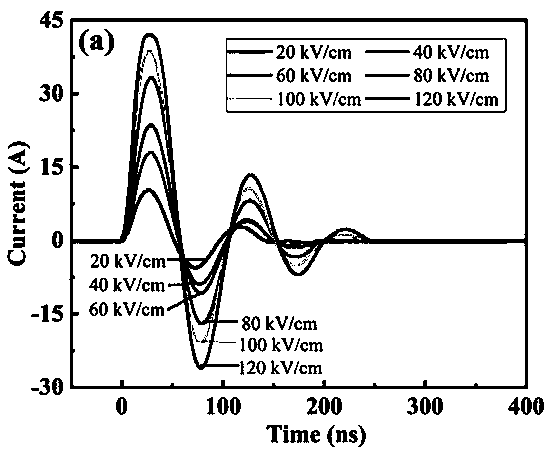

Sn-doped high-entropy perovskite oxide ceramic material with high power density, and preparation method thereof

ActiveCN111039672AHigh breakdown strengthGrowth inhibitionFixed capacitor dielectricOxide ceramicFree energies

The invention discloses a Sn-doped high-entropy perovskite oxide ceramic material with high power density. The preparation method of the material comprises the following steps: taking Na2CO3, Bi2O3, BaCO3, SrCO3, CaCO3, TiO2 and SnO2 as raw materials according to a chemical formula (Na0.2Bi0.2Ba0.2Sr0.2Ca0.2)Ti[1-x]Sn[x]O3, carrying out wet ball-milling mixing on the powder, pre-firing the dried powder at 900 DEG C for 2 hours, carrying out secondary ball-milling, sieving and molding, and finally sintering at 1250 DEG C for 2 hours to obtain the single-phase high-entropy perovskite oxide ceramic material. According to the invention, the high-entropy ceramic material prepared by the invention is simple in preparation process and low in manufacturing cost, the discharge energy storage density can reach 1.74 J / cm<3> and the power density can reach 51.4 MW / cm<3> by selecting a proper x value, and a new lead-free energy storage material matrix is provided.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of dispersion fuel pellet with high uranium loading capacity

ActiveCN108335760AHigh thermal conductivityHigh retention performanceNuclear energy generationReactor fuel susbtancesCore shellMaterials science

The invention discloses a preparation method of a dispersion fuel pellet with high uranium loading capacity, which comprises the steps of firstly adopting means such as pelleting, self-grinding balling and rolling coating to realize the balling of a uranium-based fuel and the coating with a reinforcing phase, then performing high temperature plasma sintering on a coated ball to obtain the uranium-based fuel pellet; forming a large amount of pores in a core pellet of the fuel by utilizing the volatilization of a pore-forming agent under high temperature, then promoting the low-temperature rapiddensification sintering of the reinforcing phase by combining the high temperature plasma sintering technology and a sintering aid, thus obtaining the dispersion fuel pellet with high uranium loadingcapacity, wherein the dispersion fuel pellet has a special core-shell structure in which the compact reinforcing phase coats the porous fuel core pellet, and the special core-shell structure is loosein the interior and compact in the exterior. The method has the advantages that the preparation is simple and the preparation cost is low, can be used for the scale production of the uranium-based fuel pellet; the uranium-based fuel pellet prepared by the method has the advantages of high thermal conductivity, high safety, high uranium loading capacity and high economy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com