Preparation method for aluminum titanate ceramic

A technology of ceramic products and aluminum titanate, which is applied in the field of preparation of aluminum titanate ceramic products, can solve the problems of short production cycle, unstable quality, high cost, etc., and achieve the effects of short production cycle, environmental protection and saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

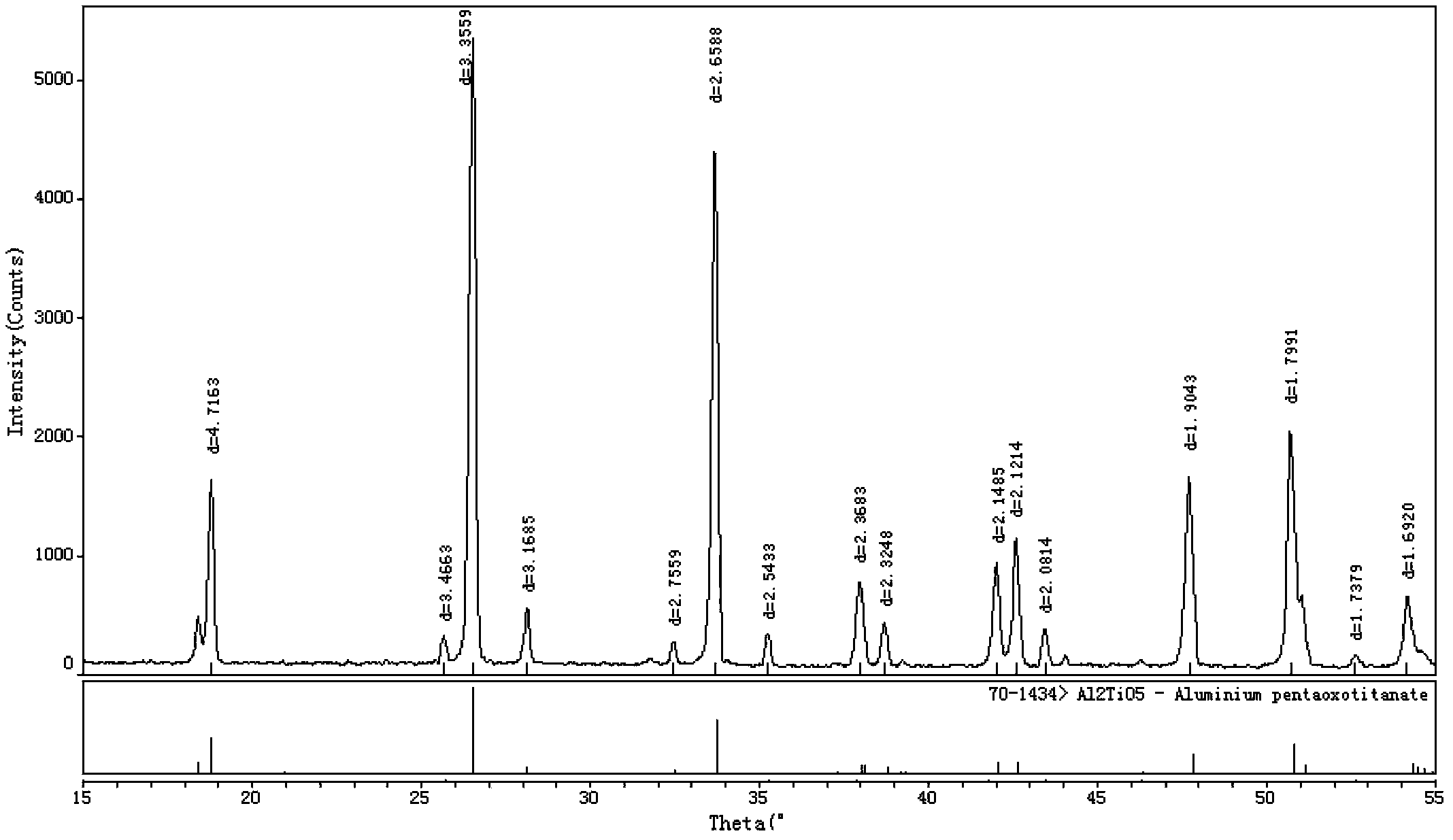

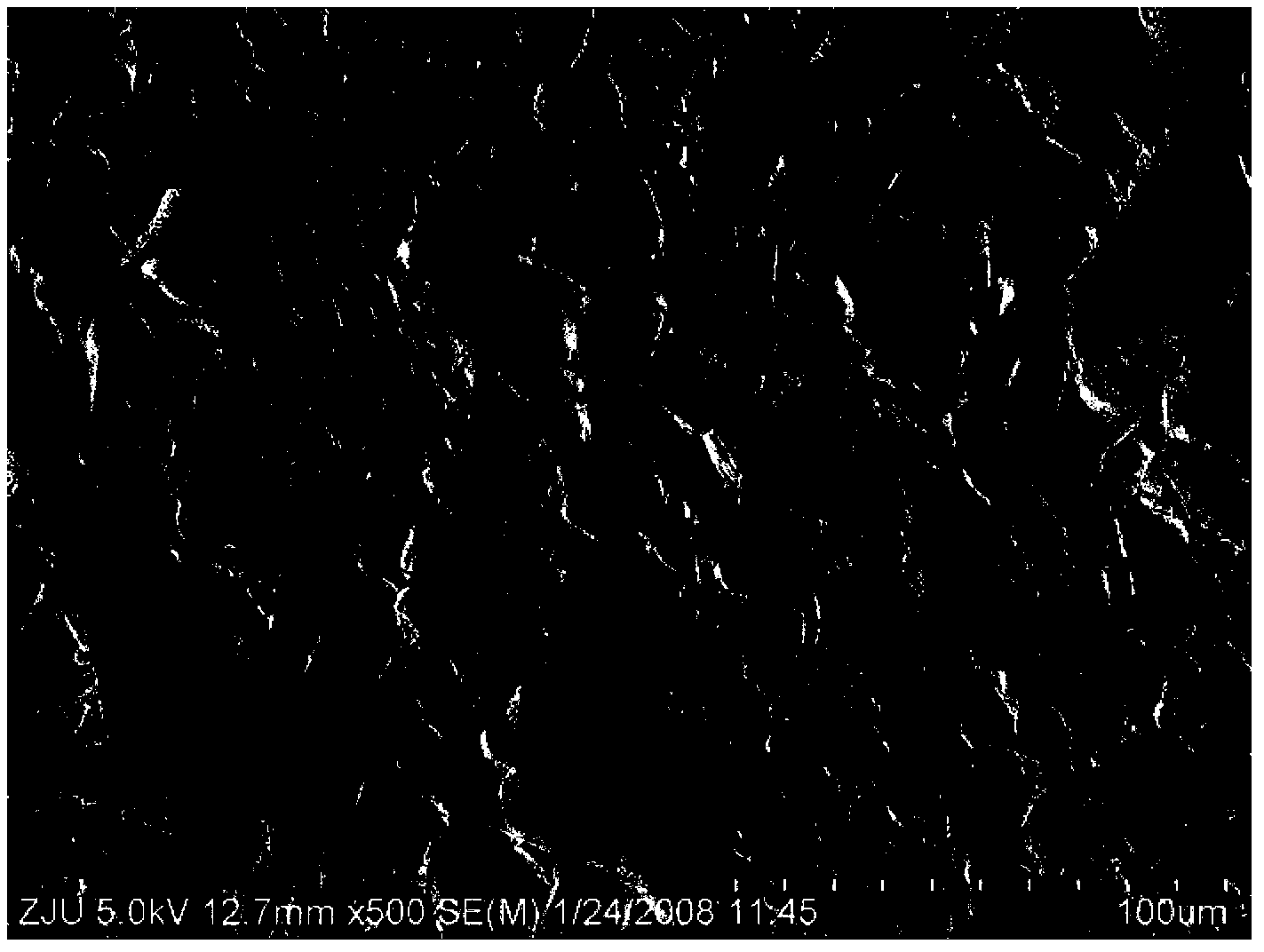

Image

Examples

preparation example Construction

[0025] The present invention proposes a method for preparing aluminum titanate ceramic products, which includes the following steps or operations.

[0026] Step 1: Pour the adhesive, aluminum oxide powder, titanium oxide powder, and stabilizer into a ball mill bottle and ball mill and mix evenly to obtain a suspension.

[0027] In one embodiment, this step can be specifically carried out as follows: polyvinyl alcohol aqueous solution, aluminum oxide powder and titanium oxide powder with a molar ratio of 1:1, and MgO, Fe 2 o 3 , SiO 2 ,ZrSiO 4 Or one or several nanoscale ultrafine powder stabilizers composed of mullite are poured into a ball mill bottle and mixed evenly to obtain a suspension, wherein the purity of the alumina powder and the titanium oxide powder is greater than Or equal to 99%.

[0028] In another embodiment, it also includes pouring a dispersant into a ball mill bottle, preferably, the dispersant is ammonium citrate.

[0029] Step 2, drying the suspensio...

Embodiment 1

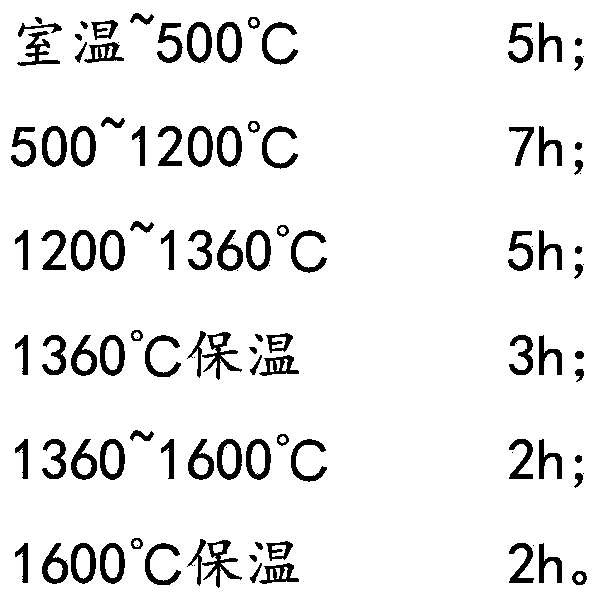

[0039] Weigh 40 grams of polyvinyl alcohol and dissolve it in 2000 grams of deionized water, pour it into a 5L ball mill bottle after fully dissolving, add 1020 grams of alumina powder (purity is 99%, average particle size is 1.5 μm) and 800 grams of titanium oxide powder (purity is 99%, average particle size is 1 μ m), weigh 180 grams of silicon oxide and 90 grams of magnesium oxide, and add in the ball mill bottle at the same time, described silicon oxide and magnesium oxide are analytical pure, with 20 grams of ammonium citrate As a dispersant, pour it into a ball mill bottle, pour out the suspension after 24 hours of ball milling, dry and remove the water, grind the ceramic powder and pass it through a 500-mesh screen, and prepare a crucible with a volume of 0.25 liters by isostatic pressing. The wall thickness is 10 mm. After slow debinding, it is put into a high-temperature sintering furnace and sintered into products.

[0040] Among them, the temperature rise curve dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com