Drainage gas recovery device and method

A drainage gas recovery and wellhead device technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high repair cost, loss of well killing fluid, great formation damage, etc., and reduce slippage loss , prolong the production cycle, and ensure the effect of formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

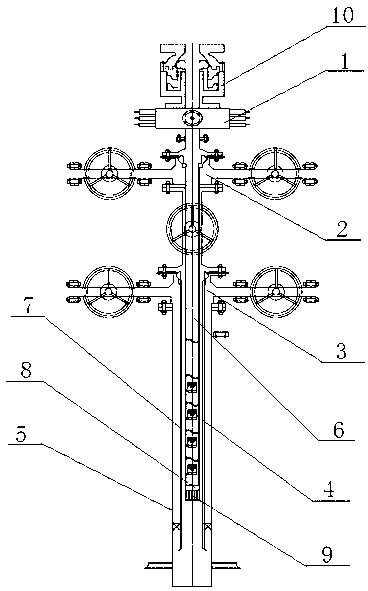

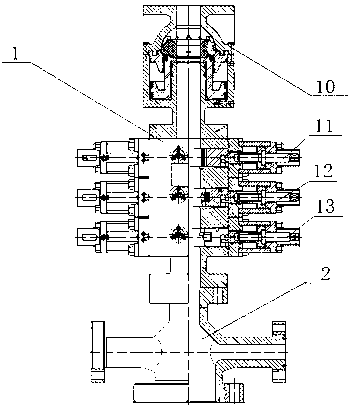

[0019] Example 1, such as figure 1 and 2 As shown, a drainage and gas production device includes a first four-way 3, a first oil pipe 6 and a casing 5, the first oil pipe 6 is embedded in the casing 5, and the bottom end of the first four-way is connected with the casing, The first oil pipe is connected with the first oil pipe hanger stuck in the first four-way, the top of the first four-way is connected with the second four-way 2, the second oil pipe hanger is stuck in the second four-way, the bottom of the second oil pipe hanger Connect the second oil pipe 7, the second oil pipe passes through the second four-way and the first four-way in sequence longitudinally, and is embedded in the first oil pipe, a closed annular cavity is formed between the first oil pipe and the second oil pipe; located in the downhole Several stages of gas-lift valves 4 are fixedly connected in the second oil pipe, the bottom end of the second oil pipe is connected with a plug 8, and a plug recovery...

Embodiment 2

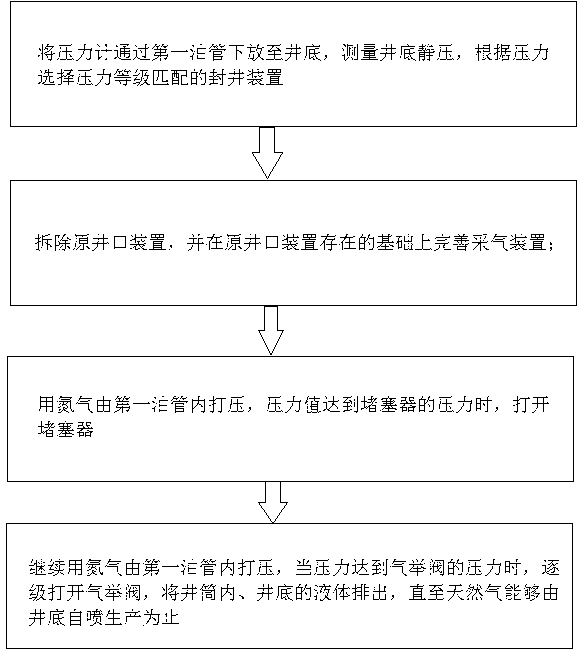

[0025] Example 2, such as image 3 Shown, a kind of drainage gas recovery method, this method comprises the following steps:

[0026] 1) Lower the pressure gauge to the bottom of the well through the first oil pipe, measure the static pressure and liquid level at the bottom of the well, select the sealing device with matching pressure level according to the pressure, and set the opening pressure value of the plug and the gas lift valve;

[0027] 2) Remove the original wellhead device, and improve the gas production device on the basis of the original wellhead device;

[0028] 3) After the gas extraction device is installed, pressurize the second oil pipe with nitrogen, and open the plug when the pressure reaches the opening pressure of the plug;

[0029] 4) Continue to use nitrogen to pressurize the second oil pipe. When the pressure reaches the opening pressure of the gas lift valve, open the gas lift valve step by step to discharge the liquid in the wellbore and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com