Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1349results about "Condensed water drain-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

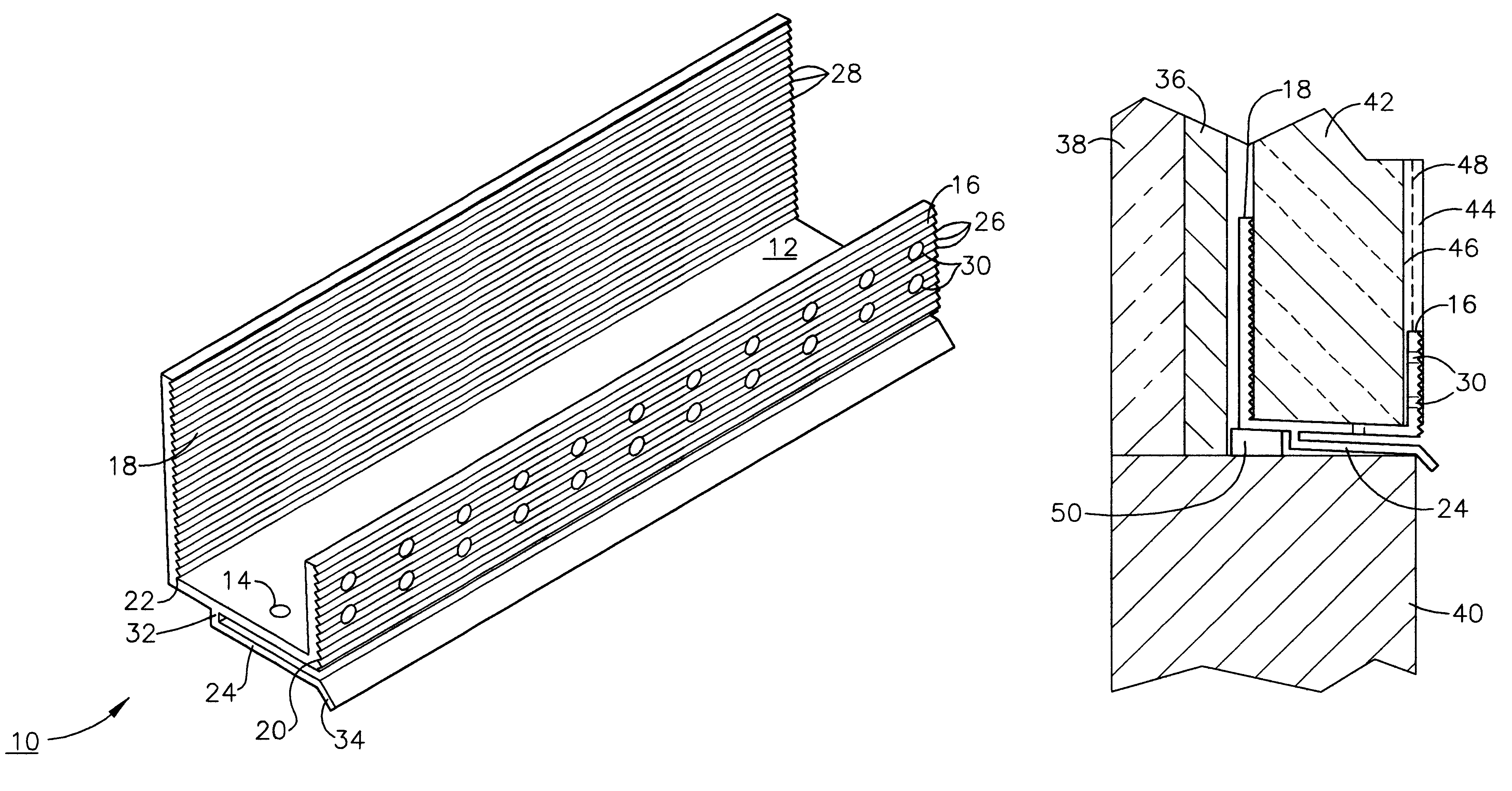

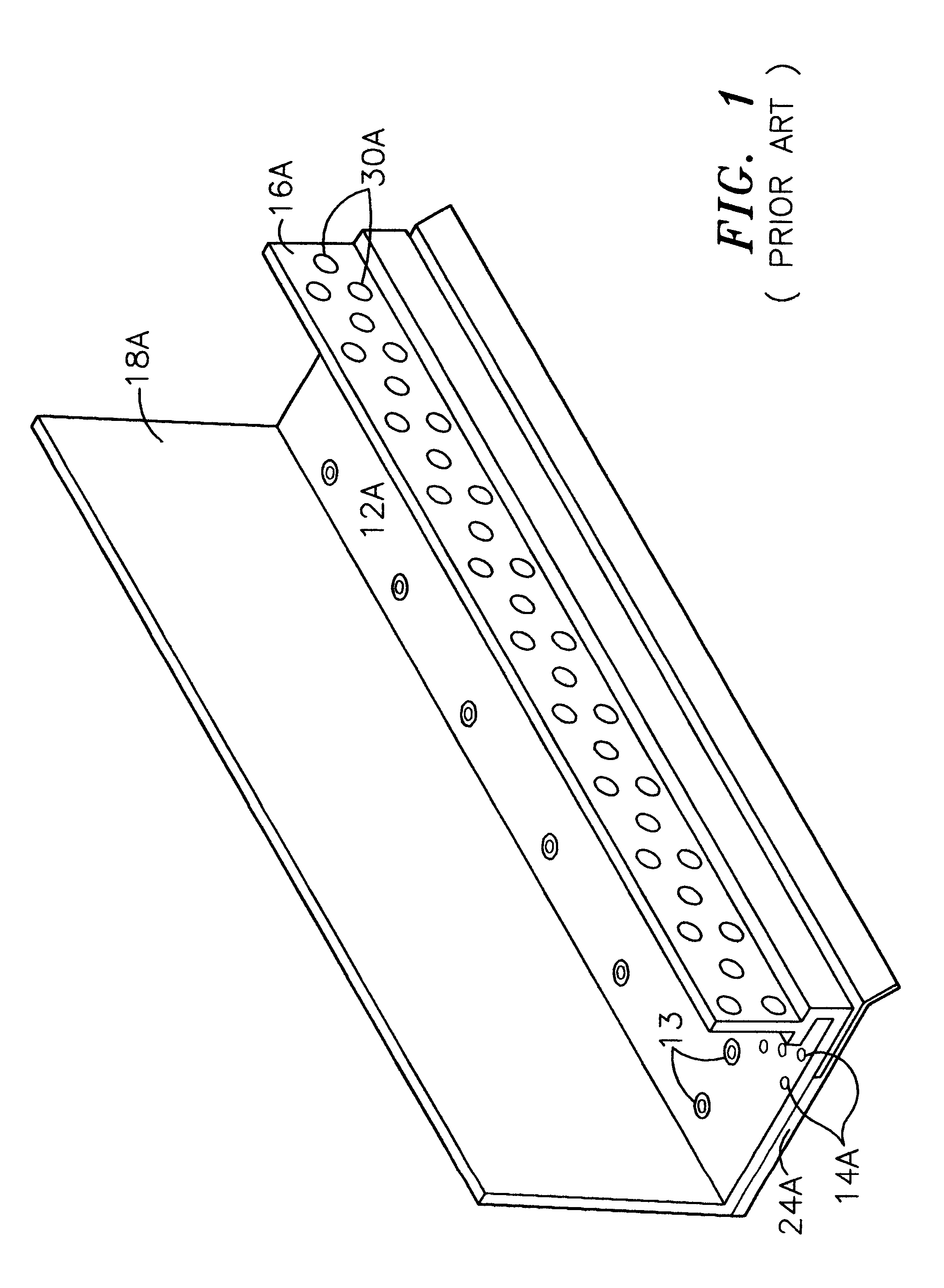

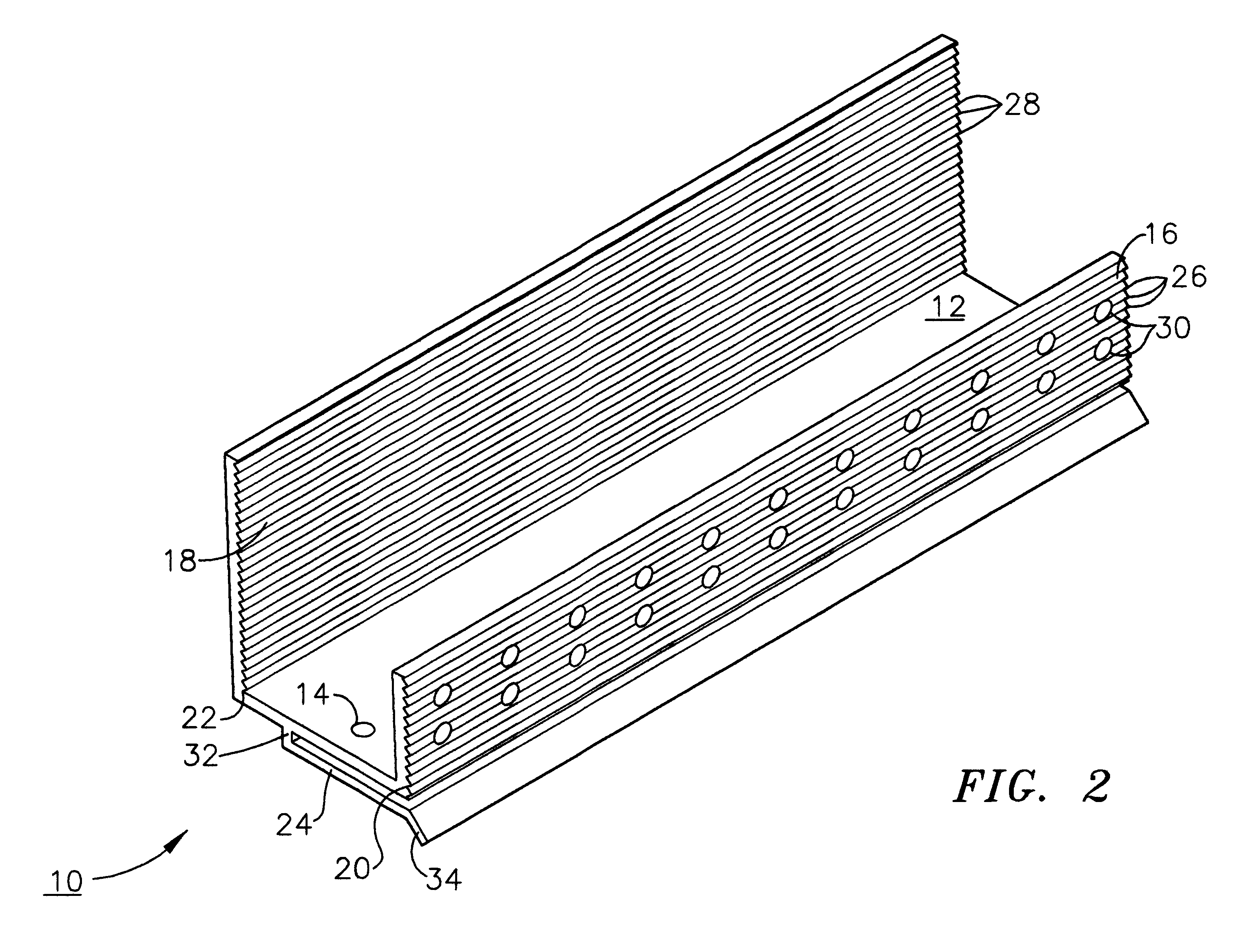

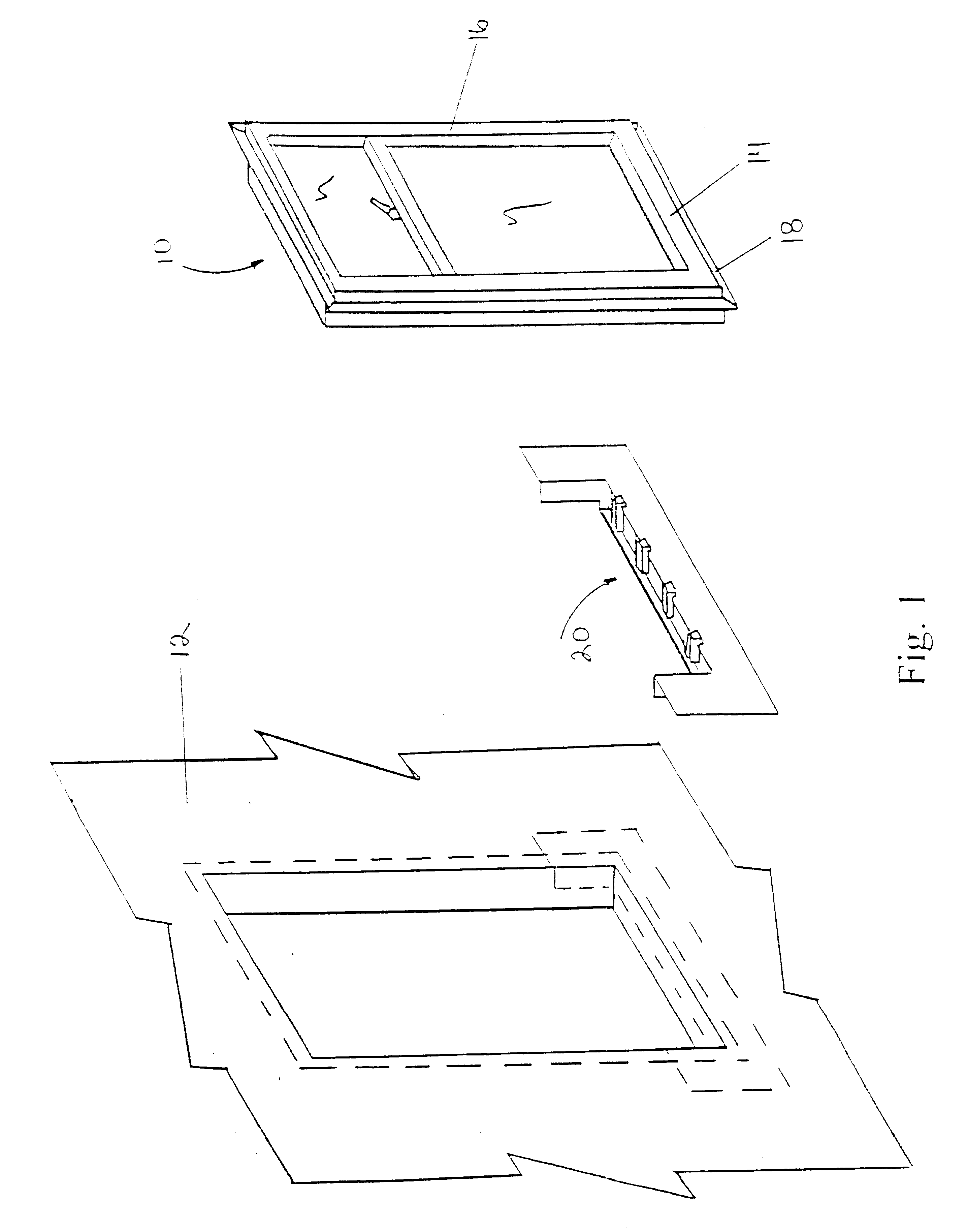

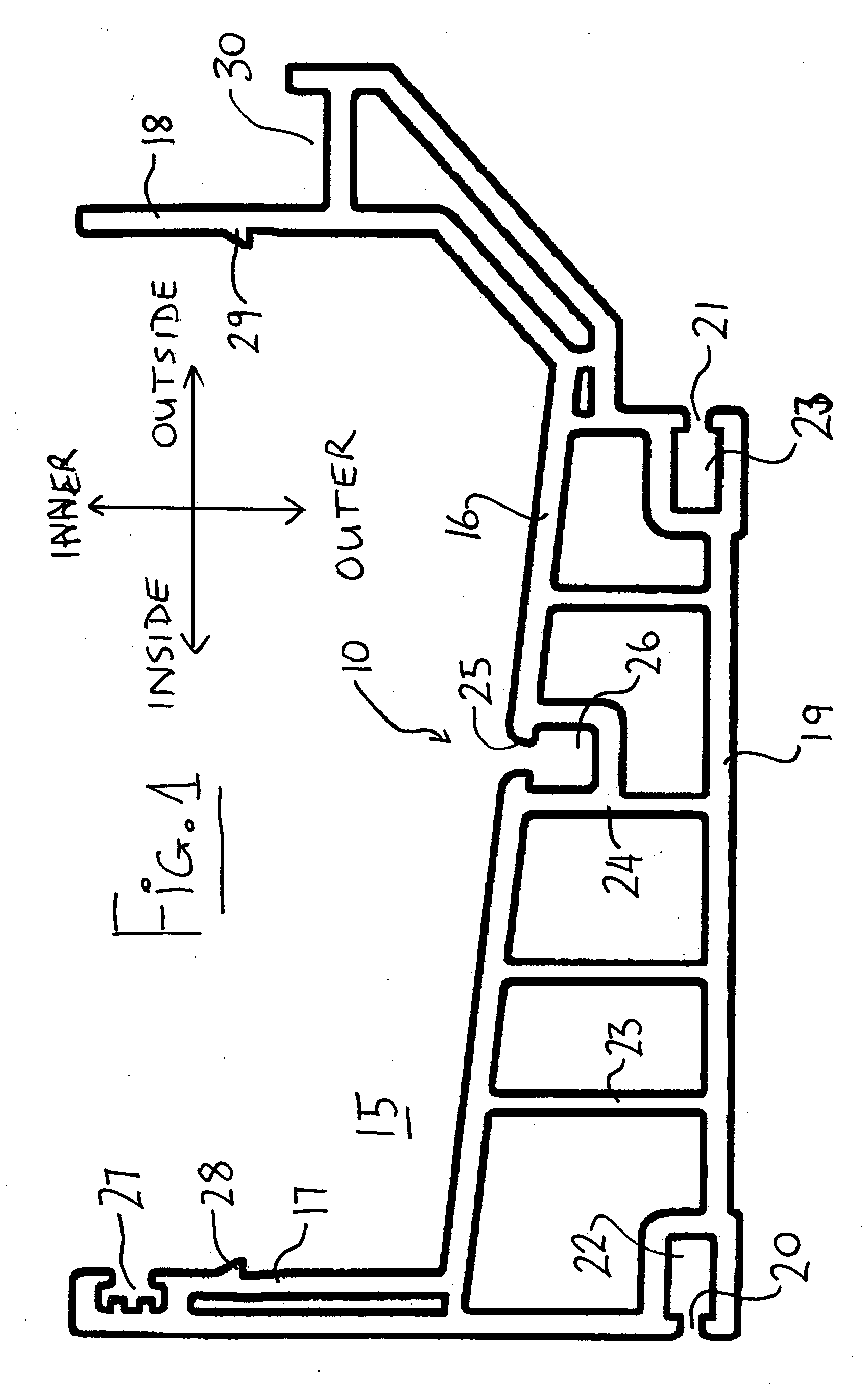

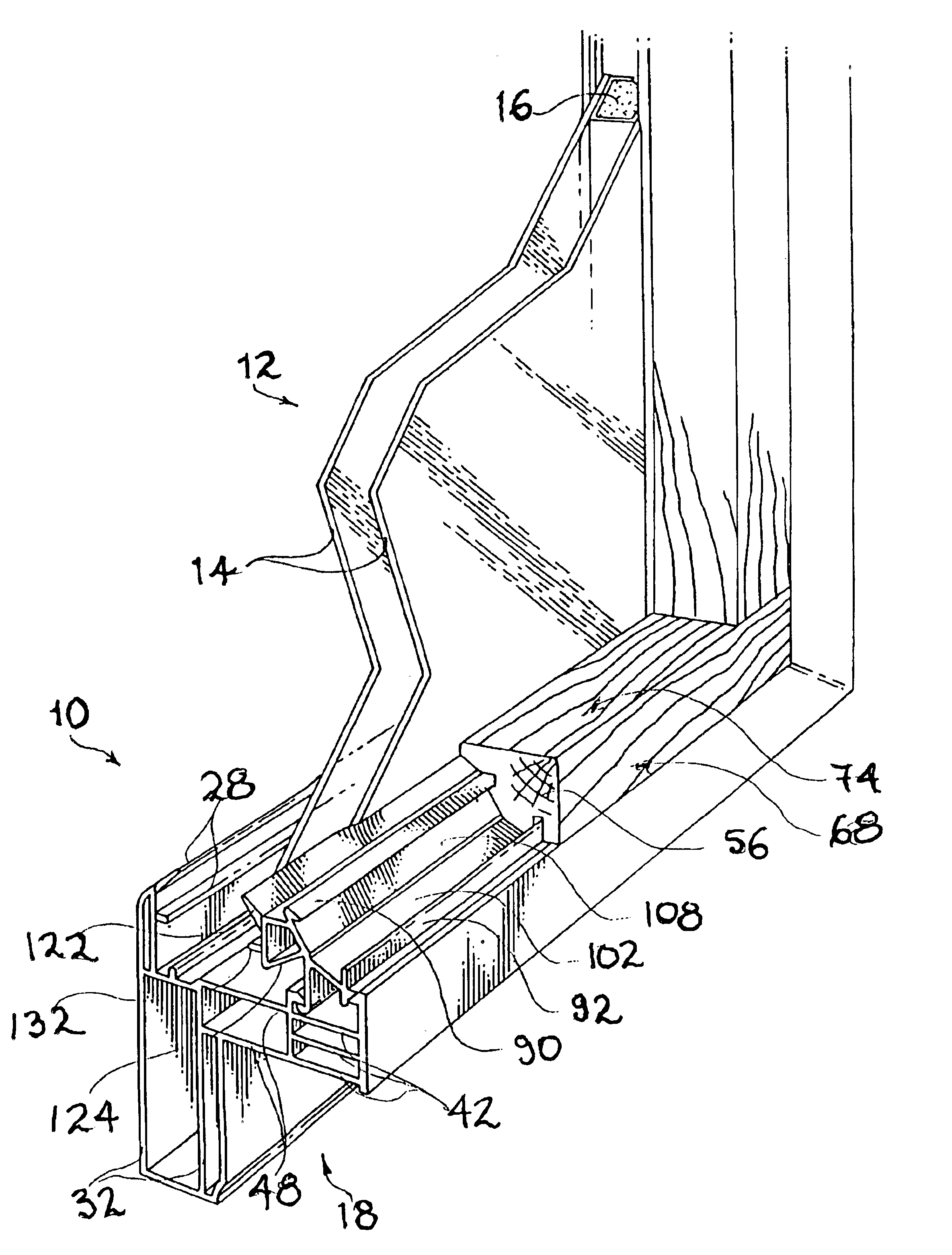

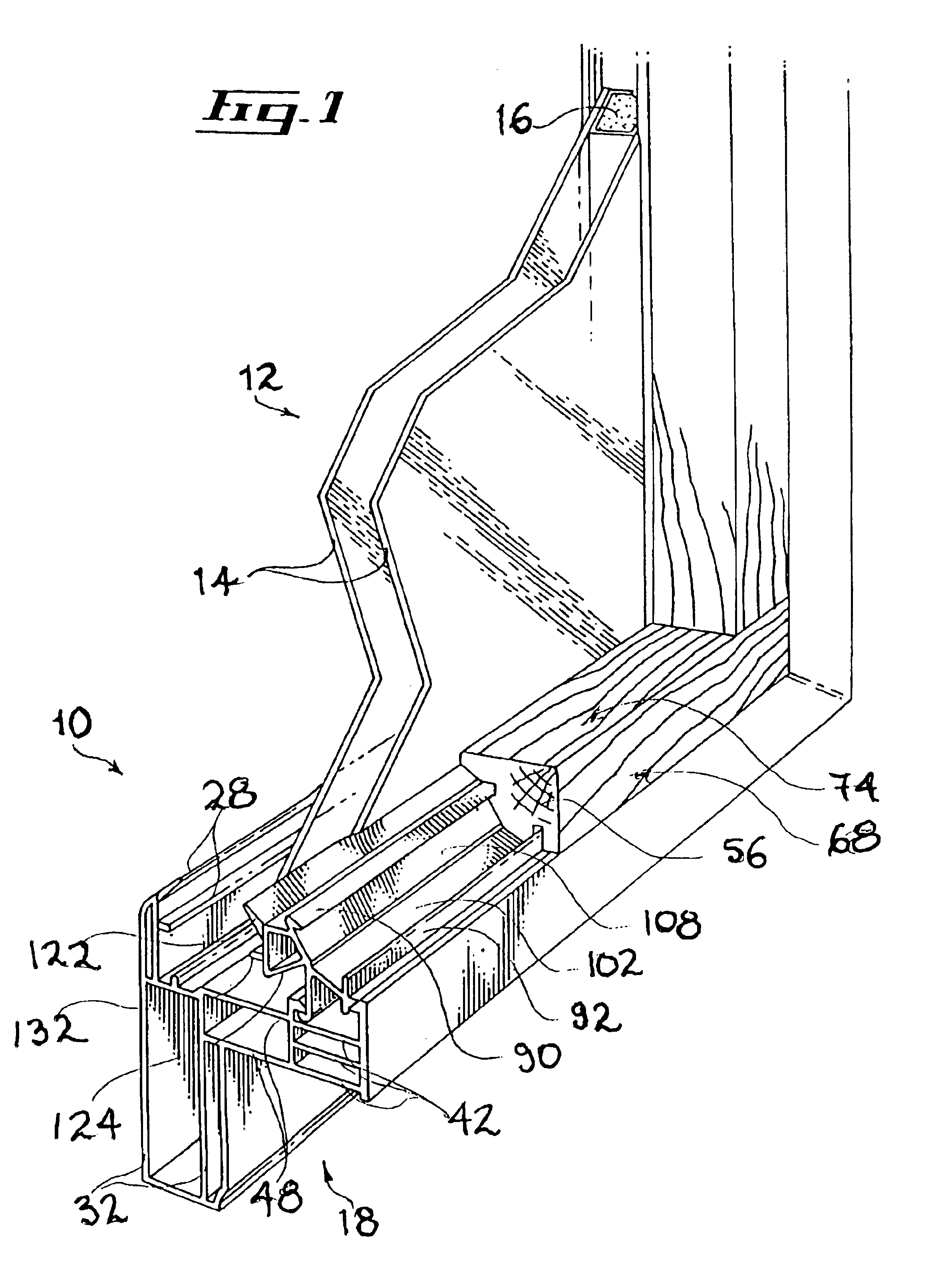

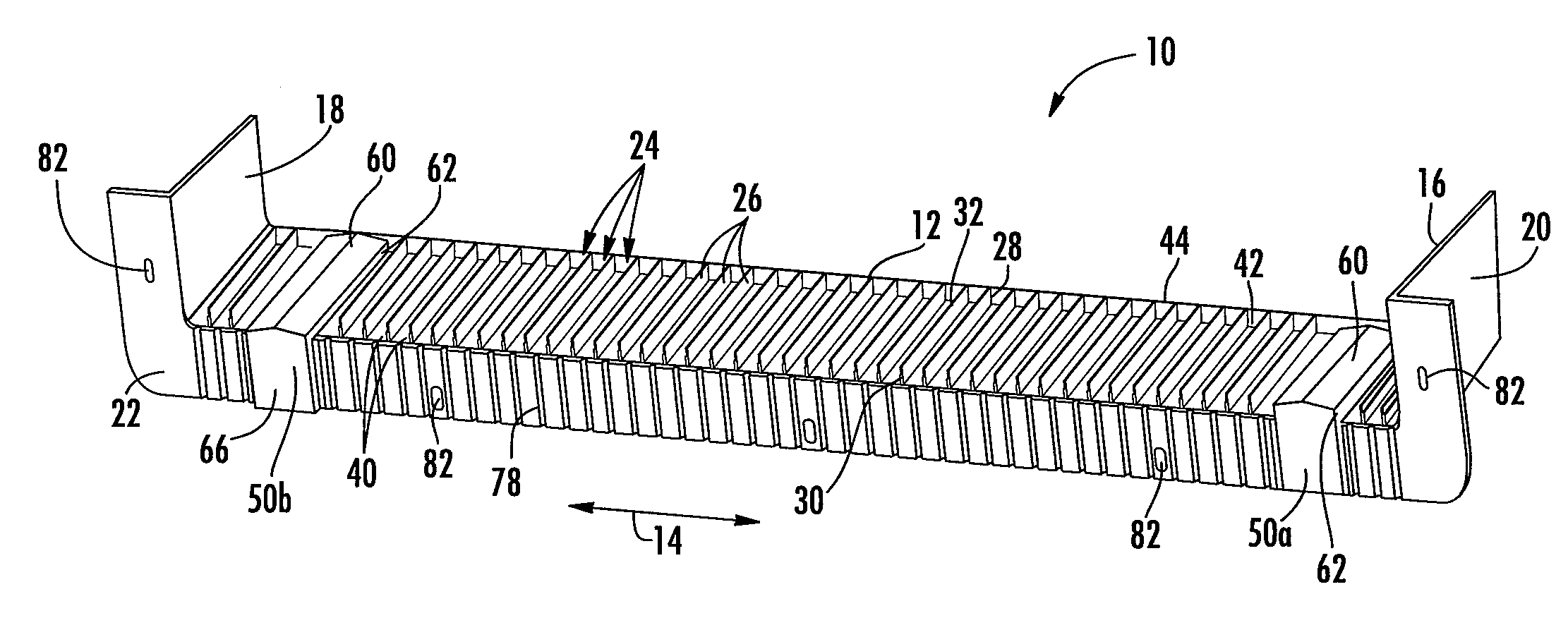

Moisture management system

InactiveUS6293064B1Improve water resistanceImprove featuresRoof covering using slabs/sheetsRoof covering using tiles/slatesAdhesiveEngineering

A moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base having weep holes therein, an upright front wall and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water entering the moisture management system through the weep holes in the base. Elongated striations in the front faces of both the front and rear upright walls as well as holes in the front upright wall provide adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

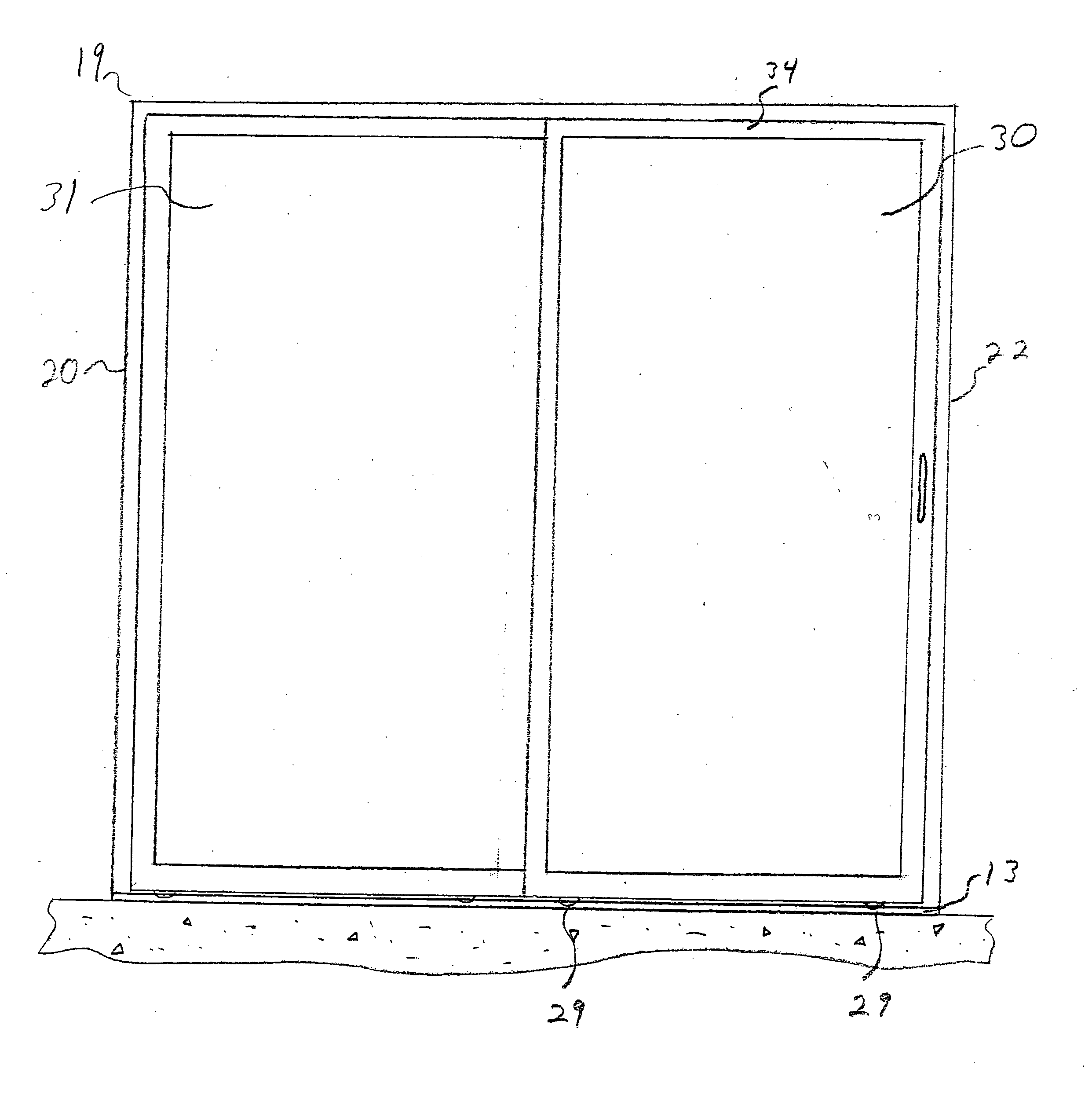

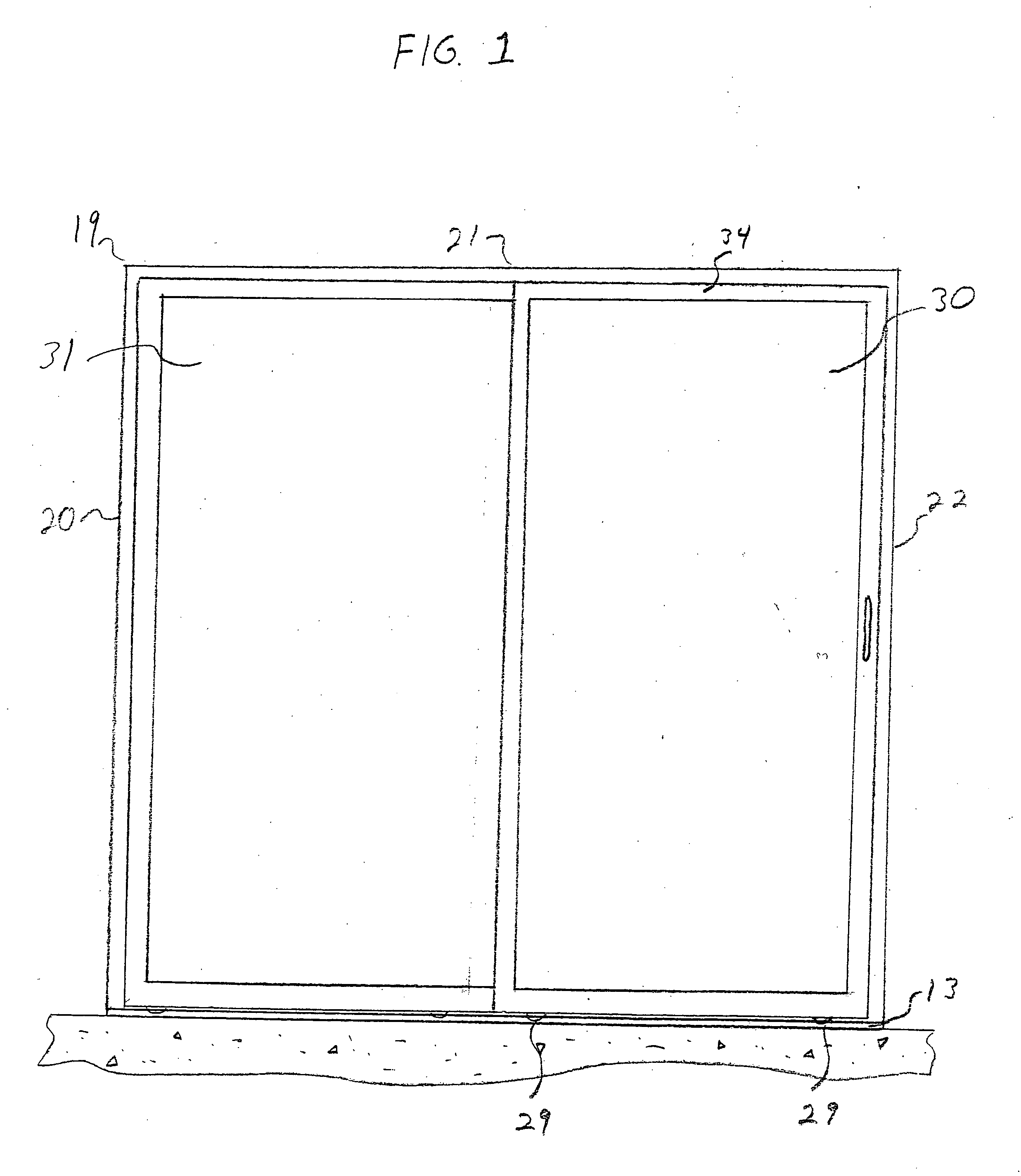

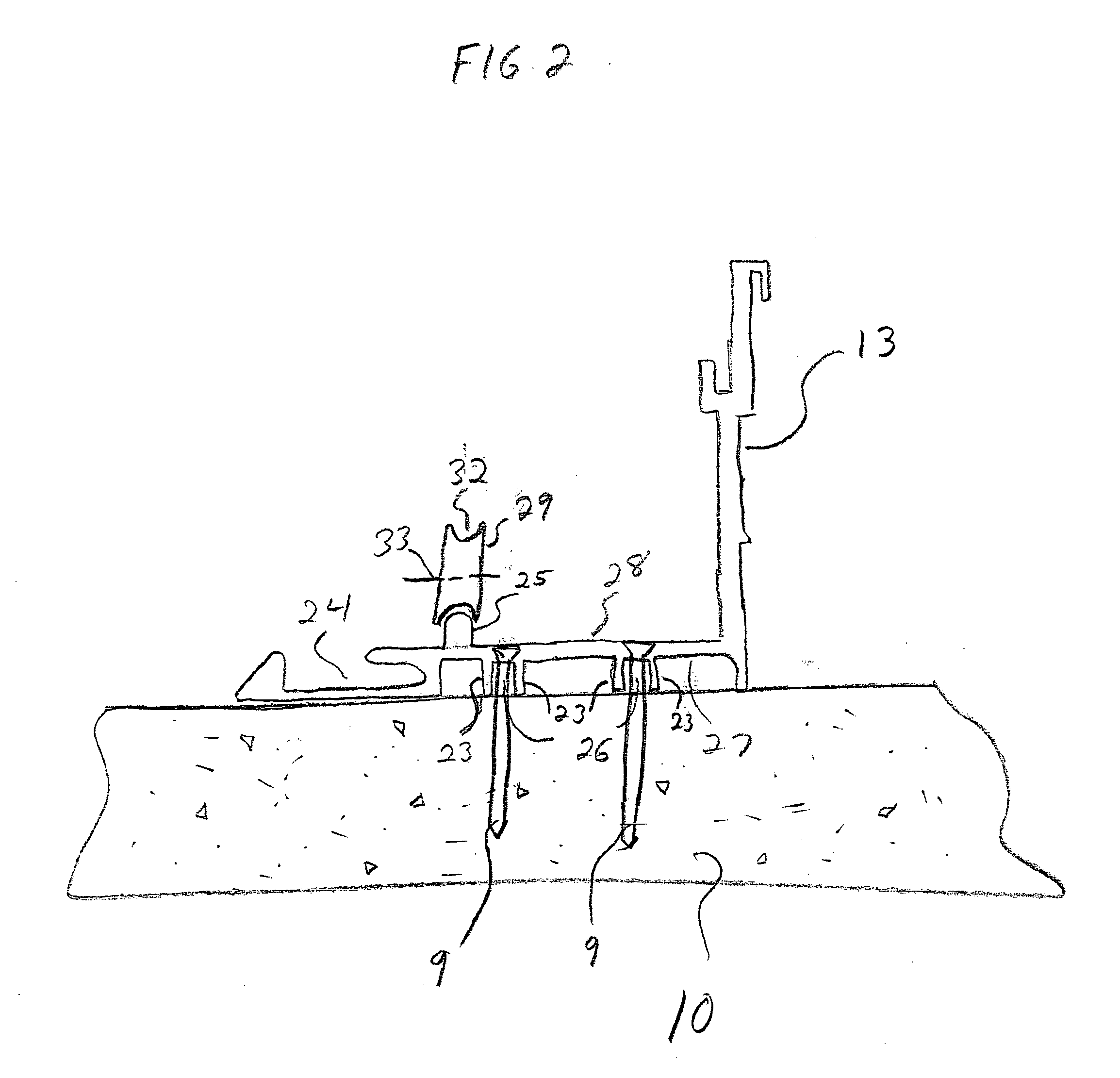

Window drain

Window drain comprises, in general, a base having a horizontally extending lower surface and a sloping downwardly and outwardly upper surface. To the base are connected: a front flange, an upstanding rear rib, an end flange at each end, window supports and spacers attached on the front flange. In one embodiment, the window drain is made for a window of a specific width. In another embodiment, the window drain, is versatile so it can be used for windows of different widths. In a third embodiment, the window drain can be made, in situ, for different window widths.

Owner:WARK SCOTT ARTHUR

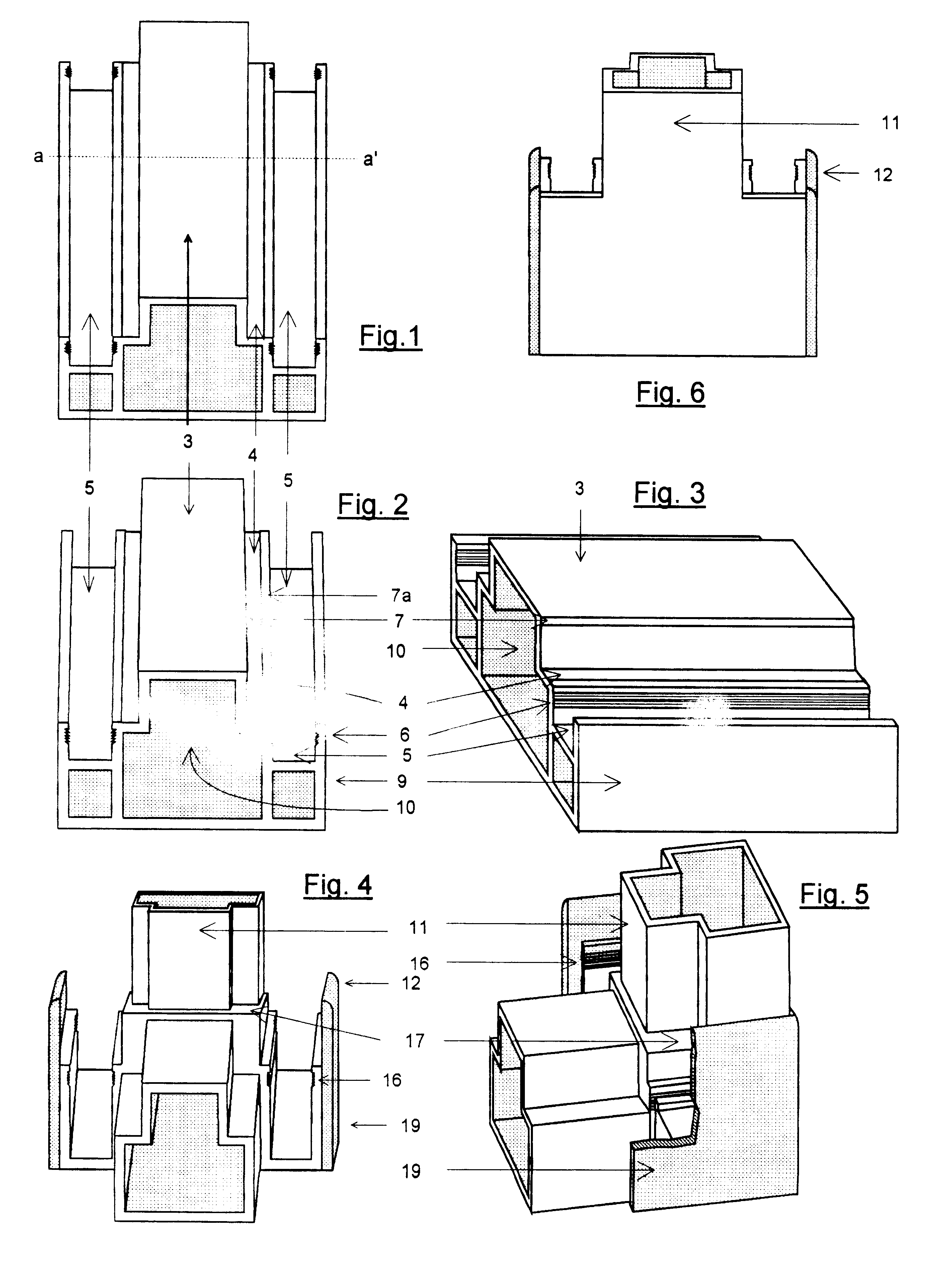

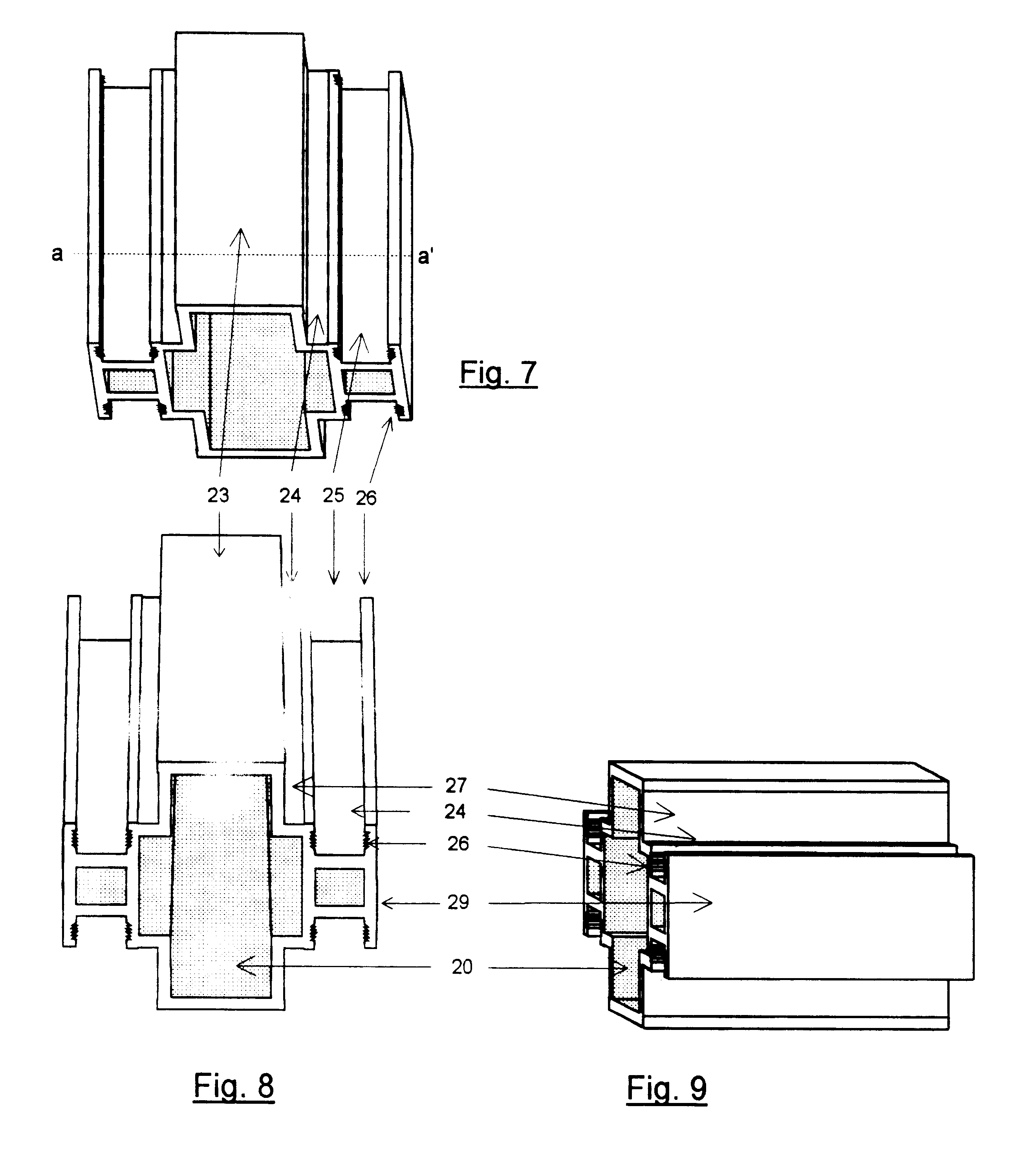

Assembly system for thermoacoustic windows

An assembly system used to build two pane thermoacoustic windows for houses and buildings is provided. The assembly system uses a set of profiles and joints and a permanently installed valve to assemble the window frame without a fusion welding machine. The system creates an airtight chamber directly on the frame. The valve allows the assembler to evacuate the air in the airtight chamber to make a vacuum, or to inflow a gas. The system improves the insulating thermal and acoustic capacity of the window, and allows a supplier to sell the components to build the window, which is then assembled by snapping together profiles and joints. The system can also be applied to assembly one pane window and for other purposes.

Owner:VALDERRAMA MARIO

Water resistant window frame

InactiveUS6334283B1Increase impactHigh strengthRoof coveringWindow/door framesDouble wallEngineering

A window frame incorporating a sliding sash, the frame providing increased water resistance by incorporating an integral J-rail return, the return portion of which has a double wall to provide a depending trough at the bottom of the frame with a wall forming a chamber including the trough, opening from the bottom of the frame into the chamber and from the bottom of the trough to the exterior to provide increased dam height against water backing up and spilling over the interior sill of the frame.

Owner:ROYAL GROUP

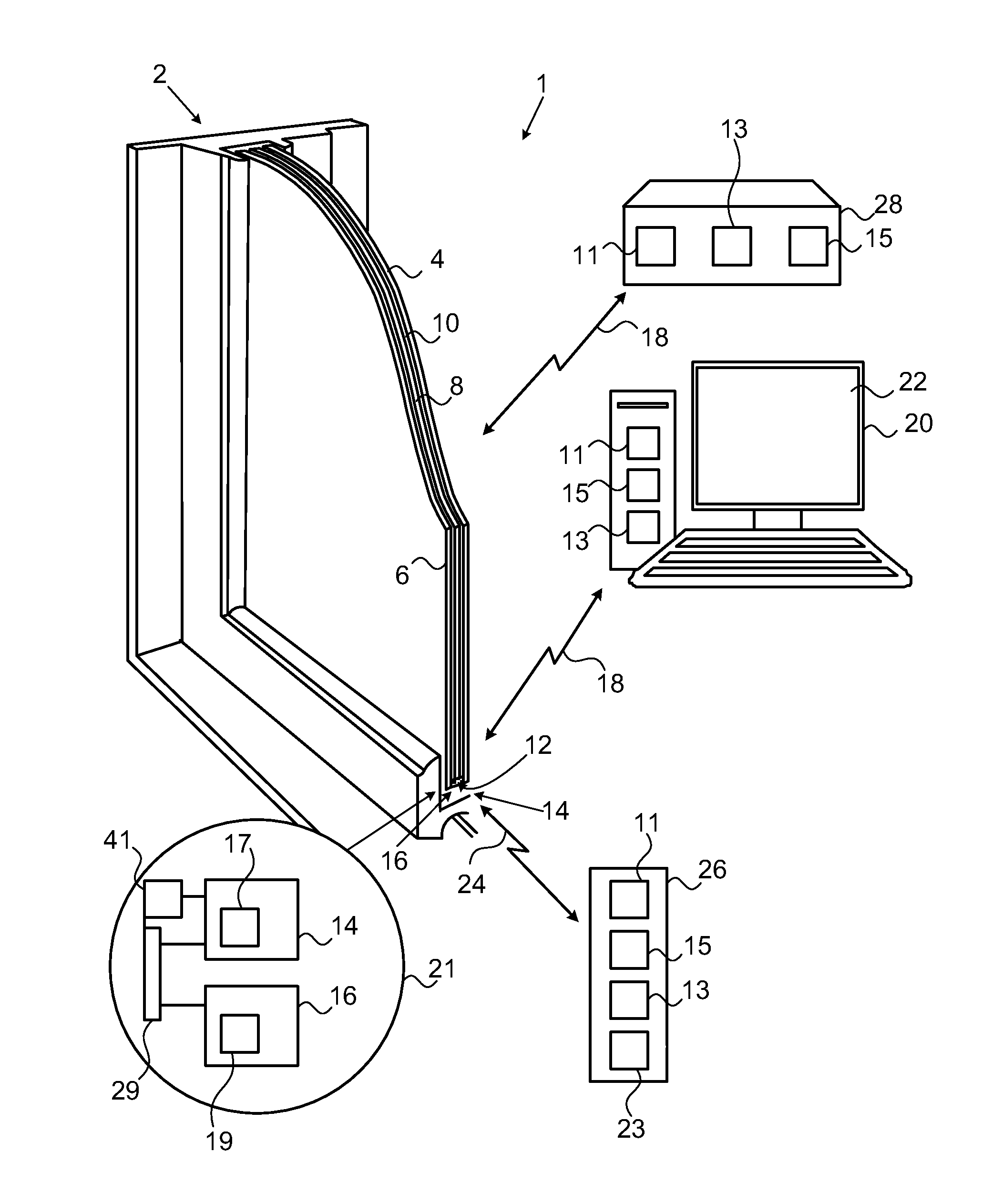

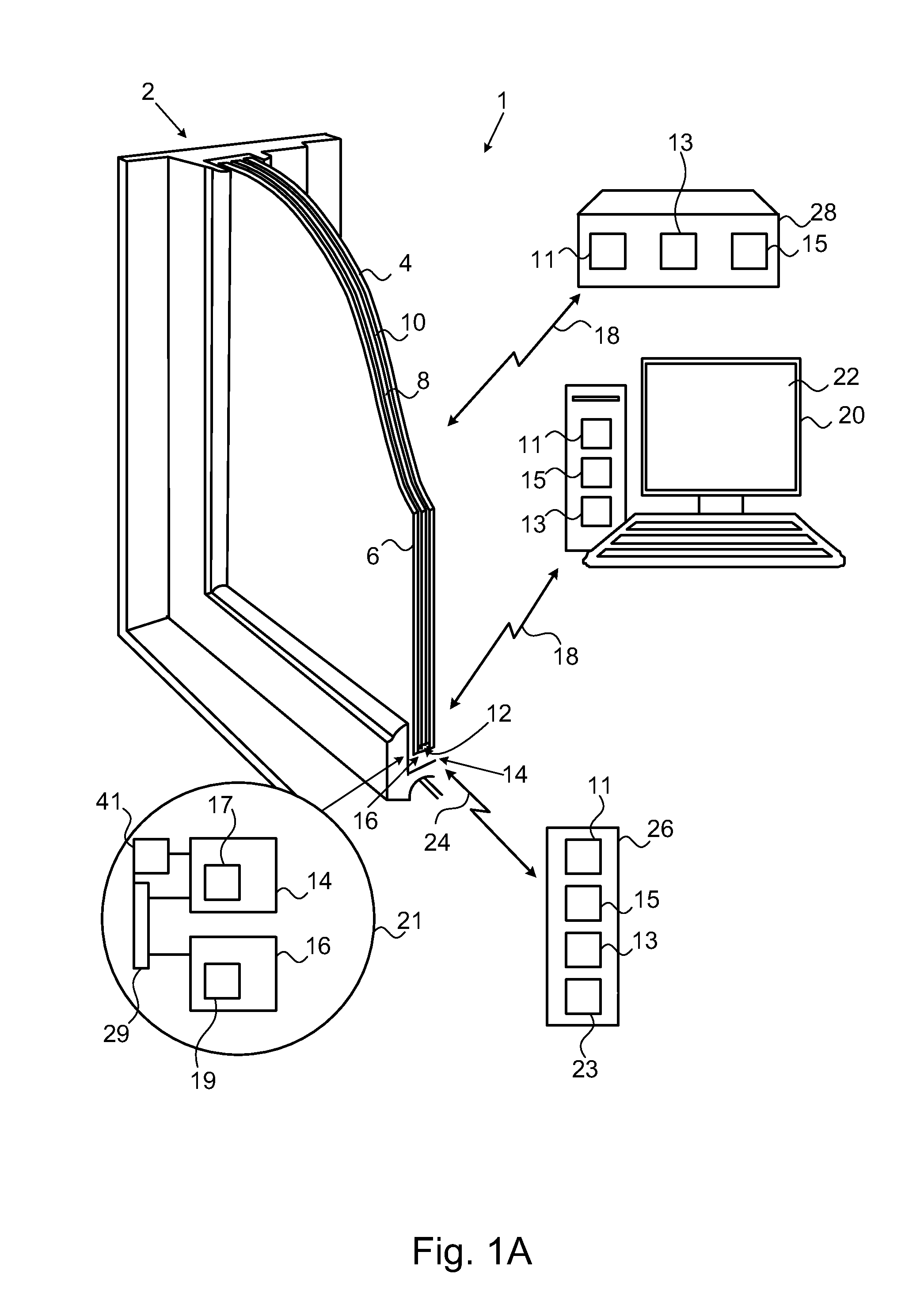

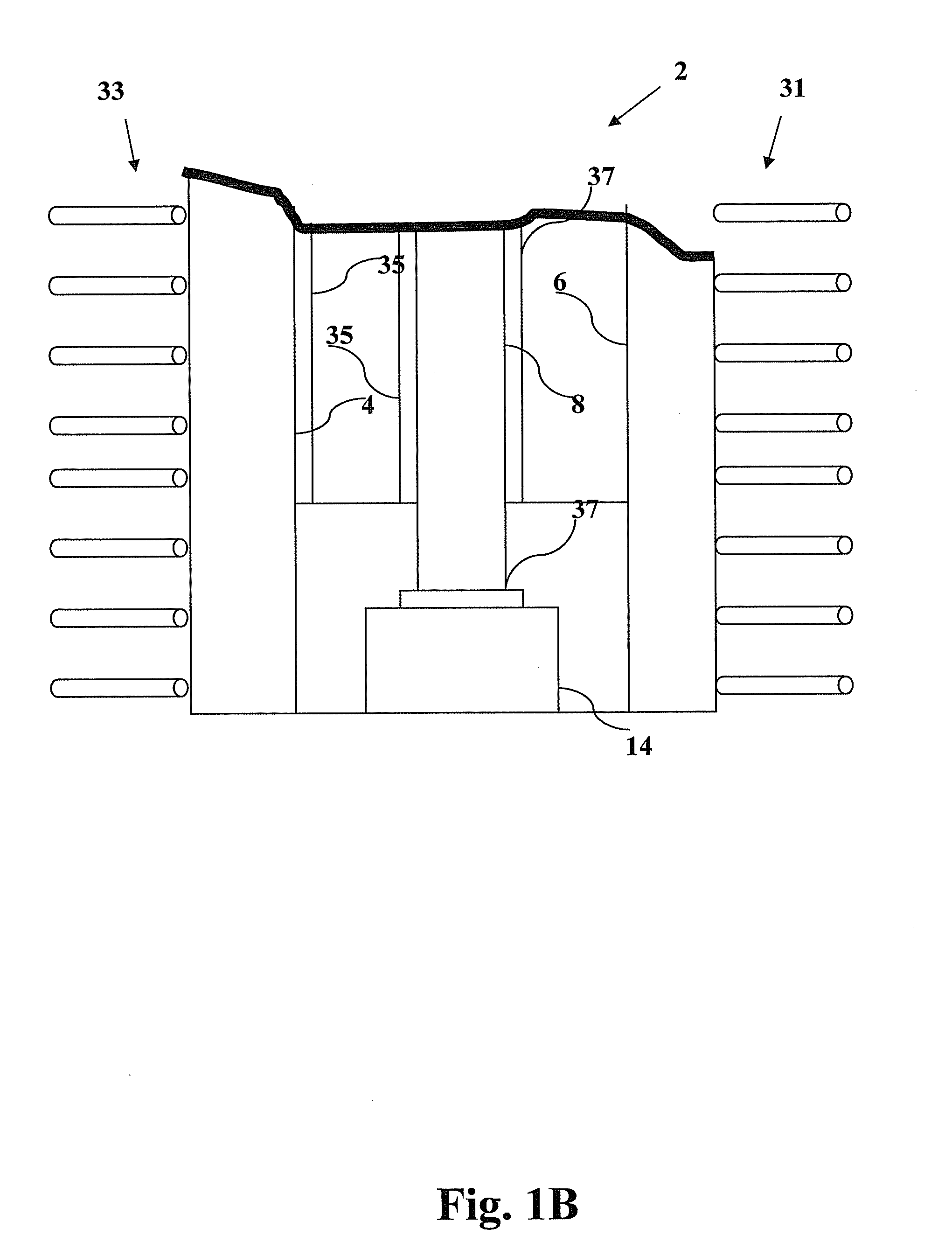

Multi-Sheet Glazing Unit With Internal Sensor

A system and method is provided for a multi-sheet glazing unit including two or more sheets oriented by a spacer in a substantially parallel and spaced apart relationship. The sheets may include a peripheral edge and an air space or gap therebetween. A sensing device may be inside or in air communication with the air space. The sensing device may be used to sense an environmental condition data in the air space or gap.

Owner:GLASSLOGIC

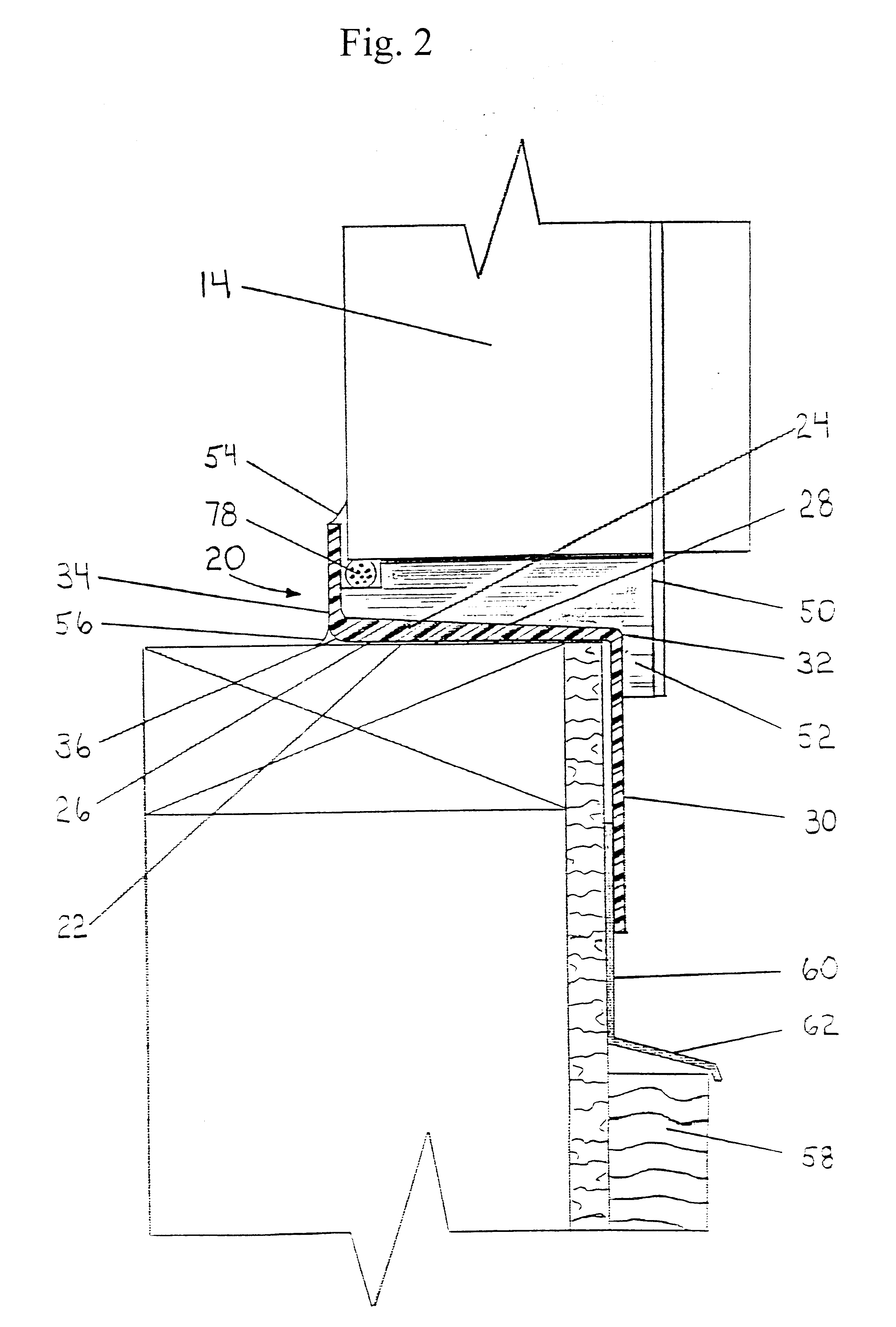

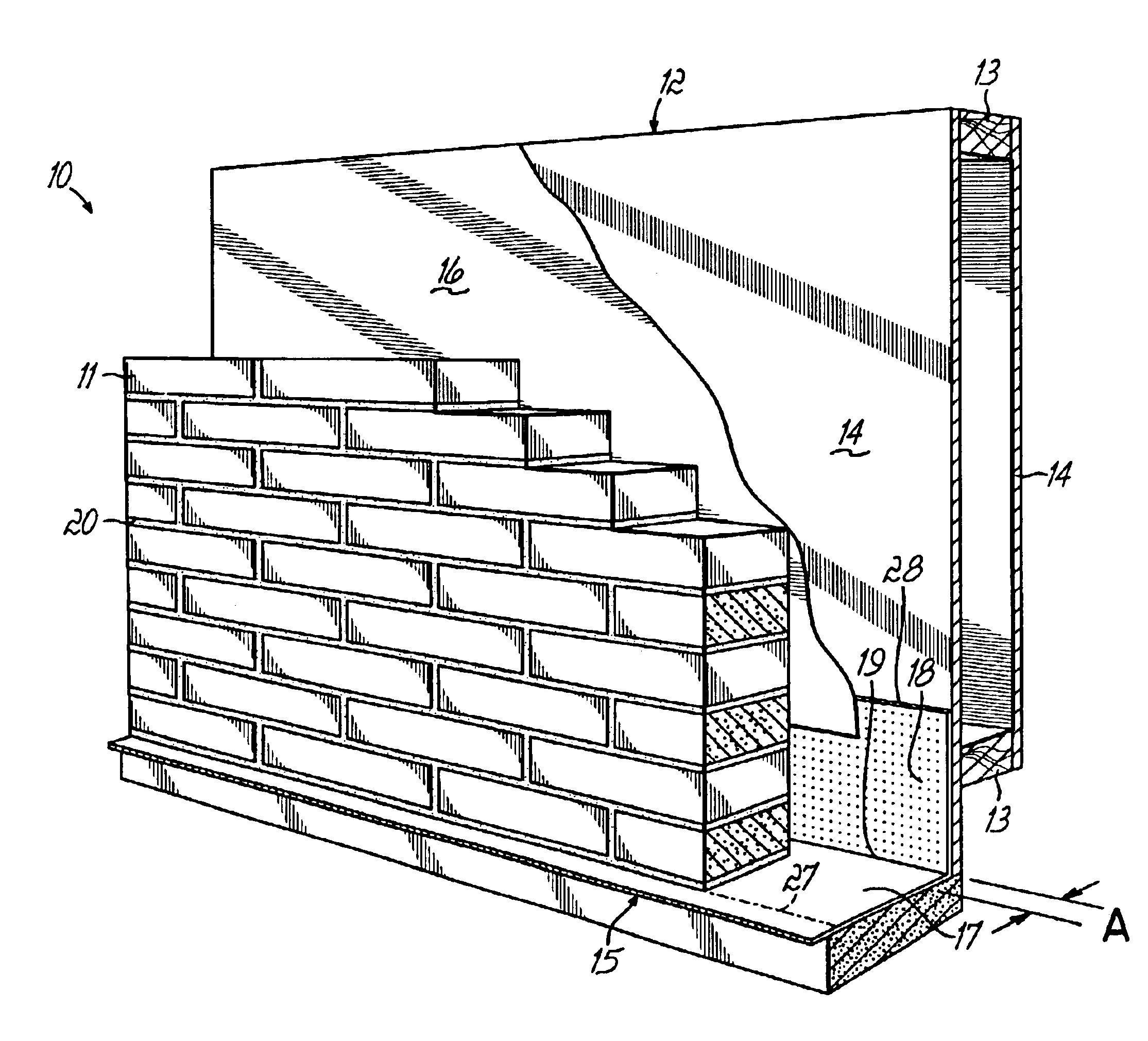

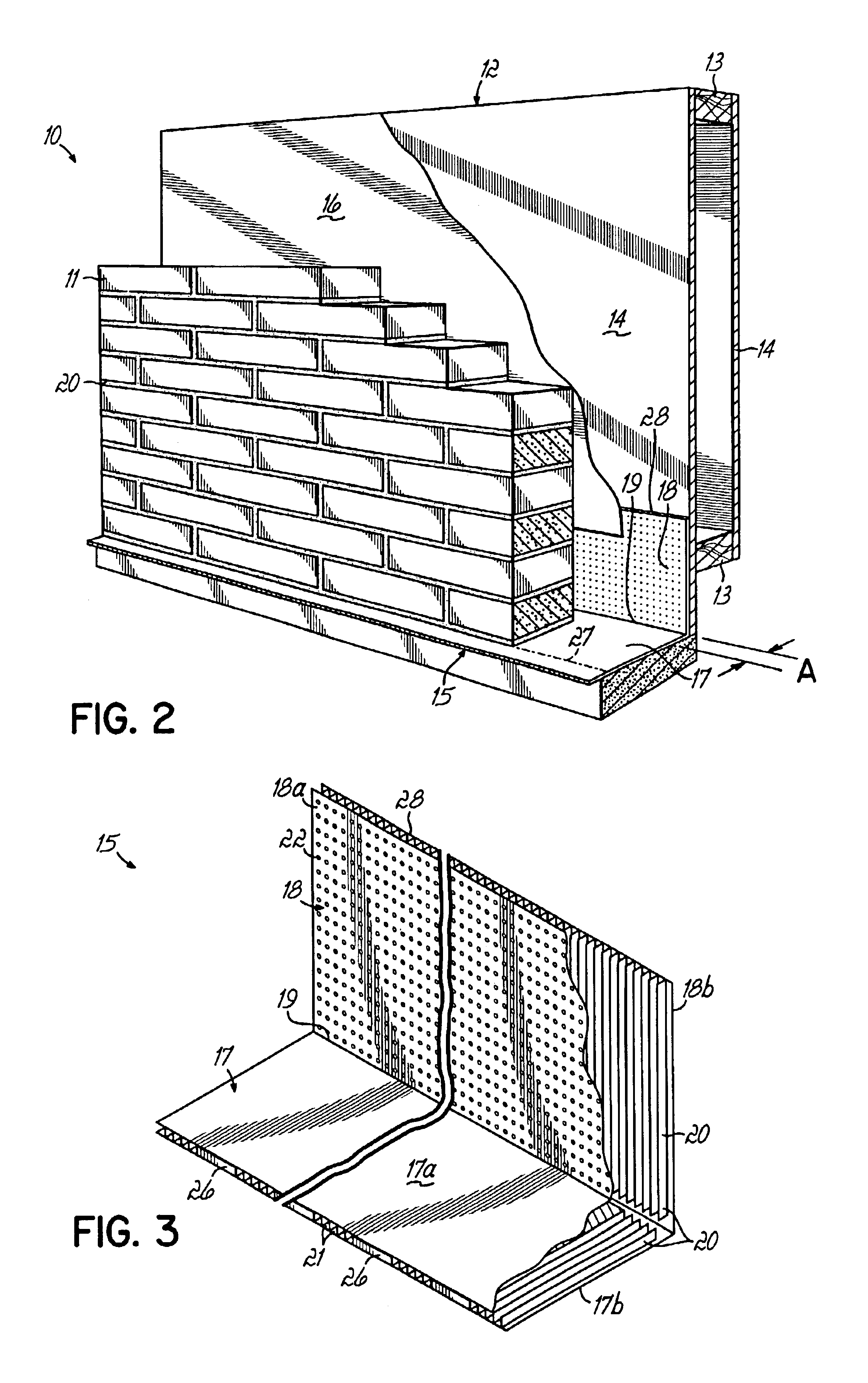

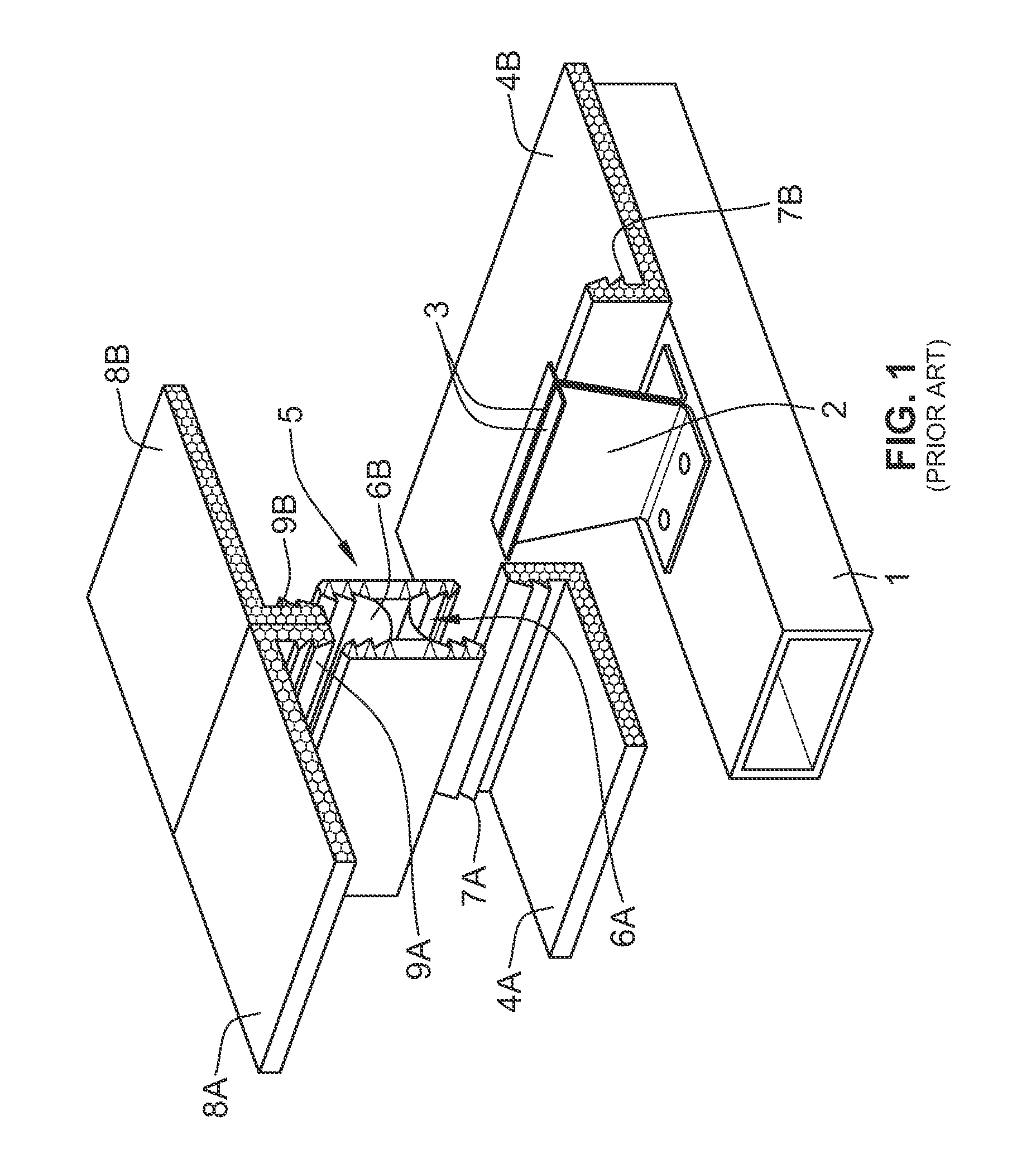

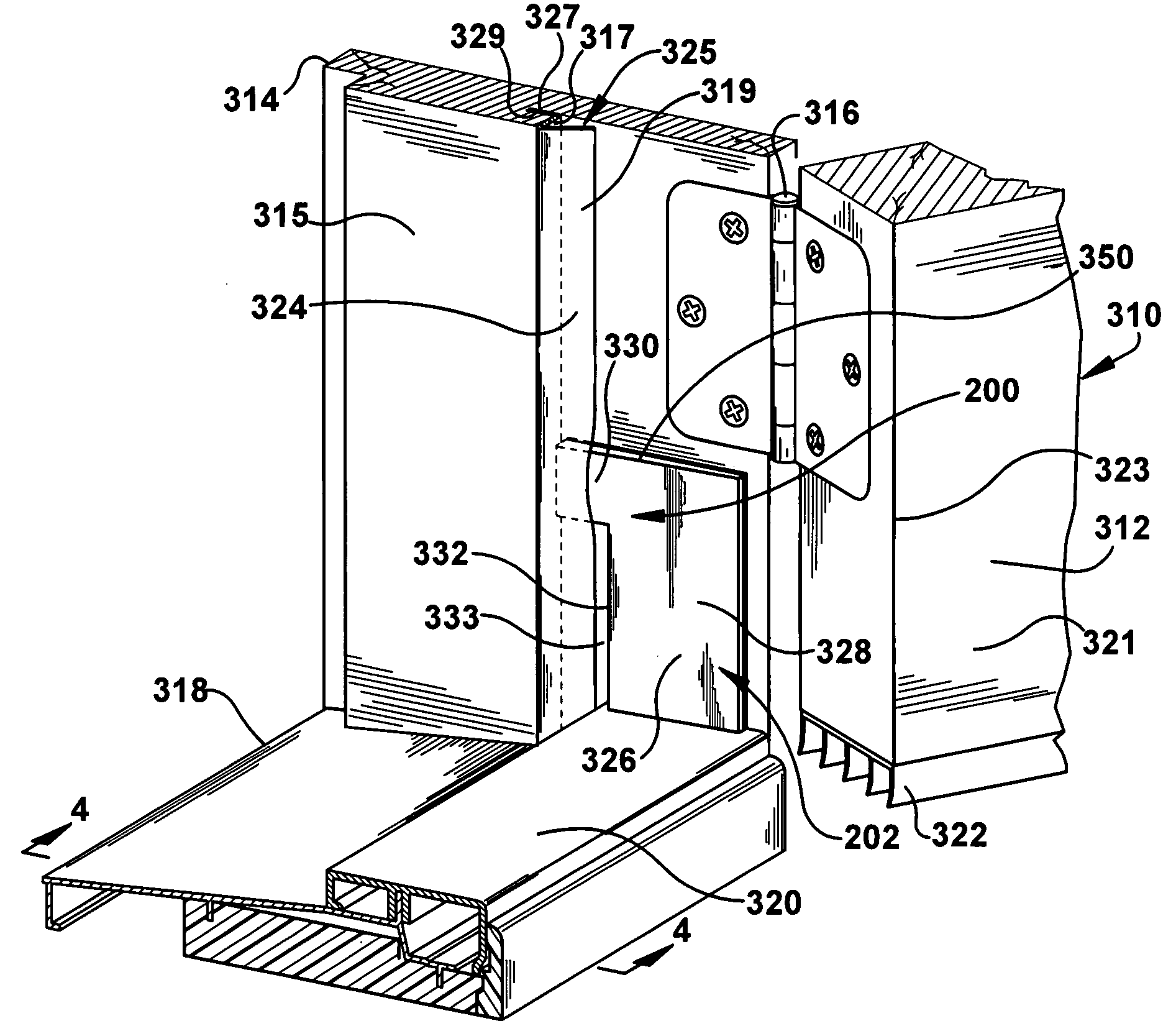

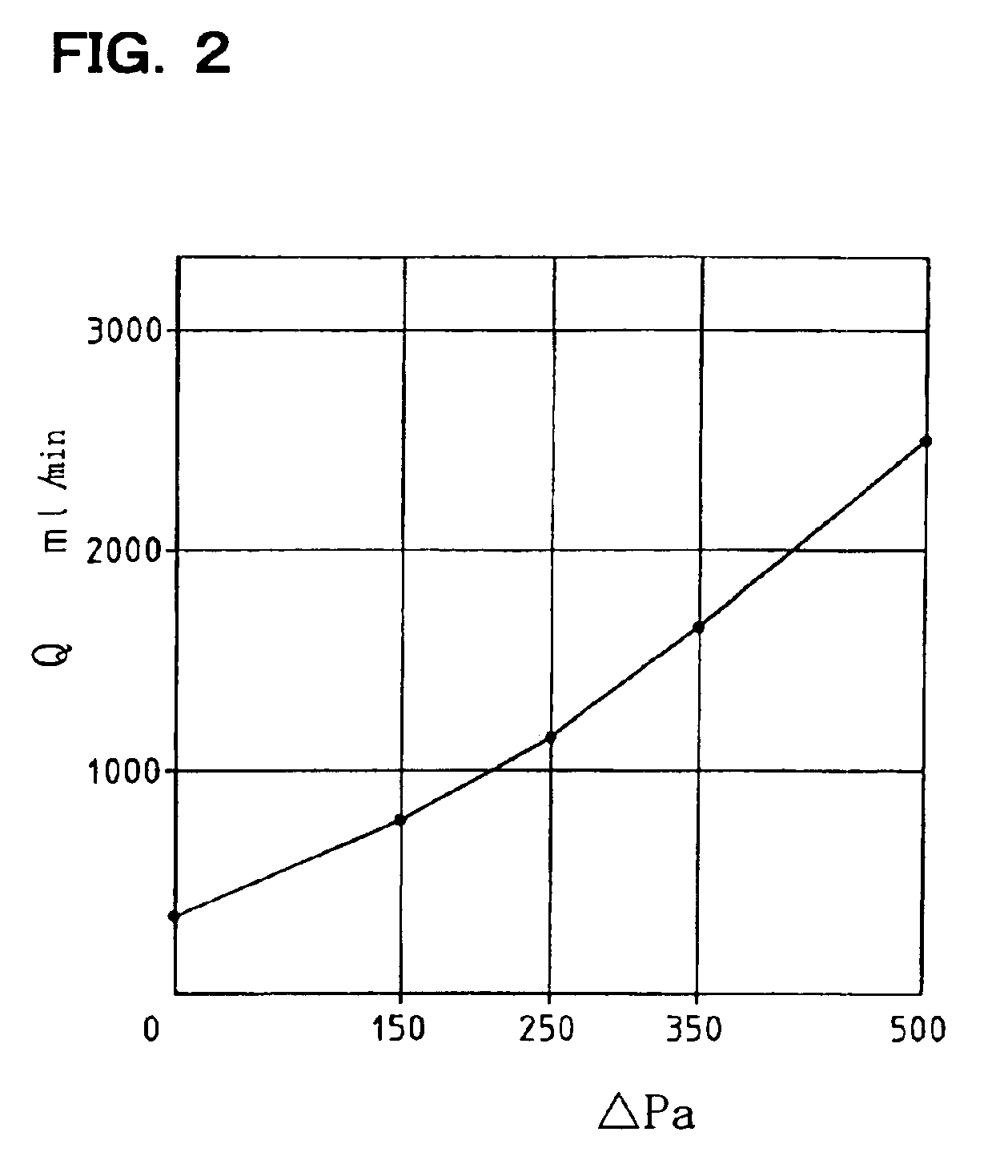

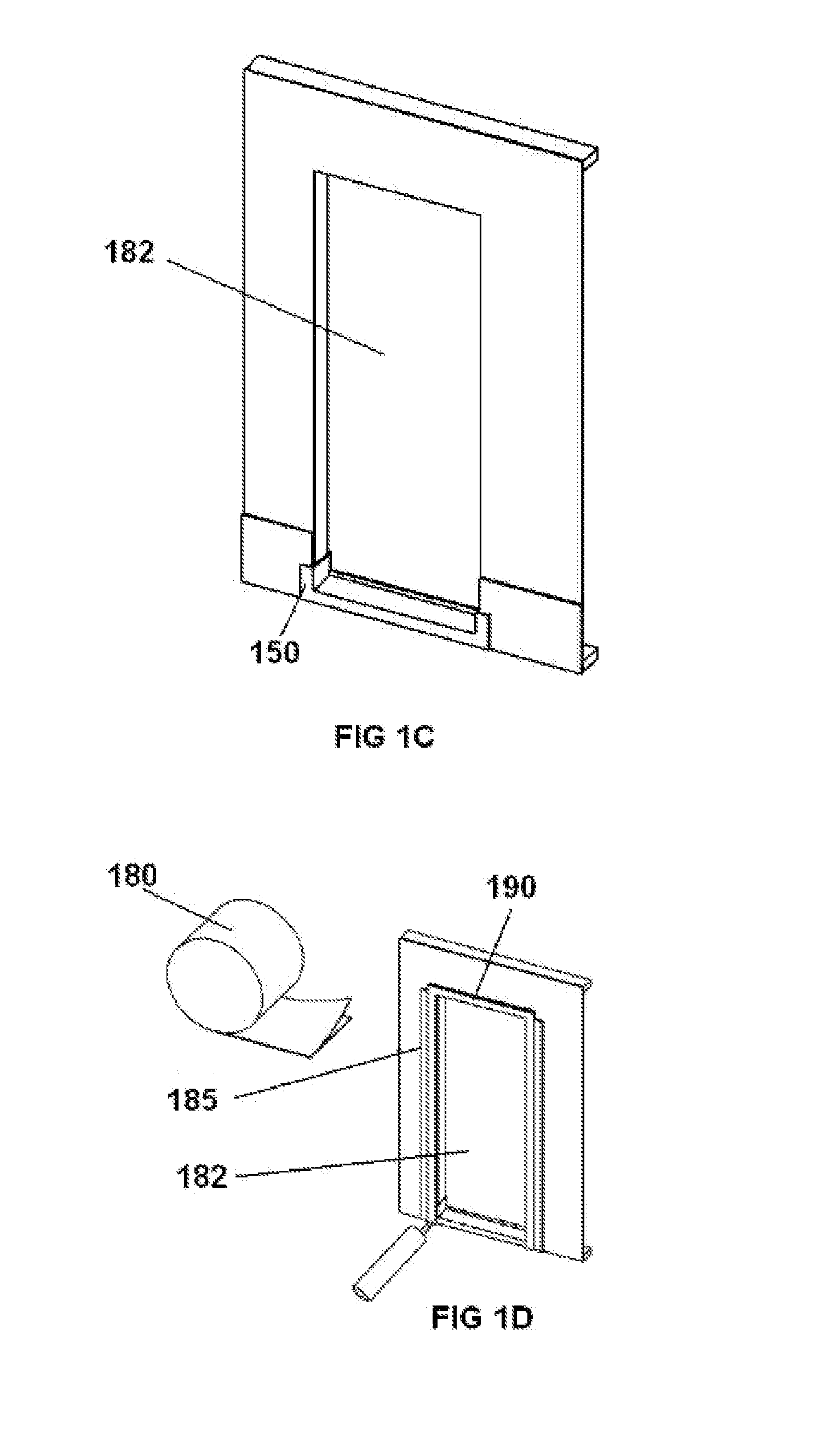

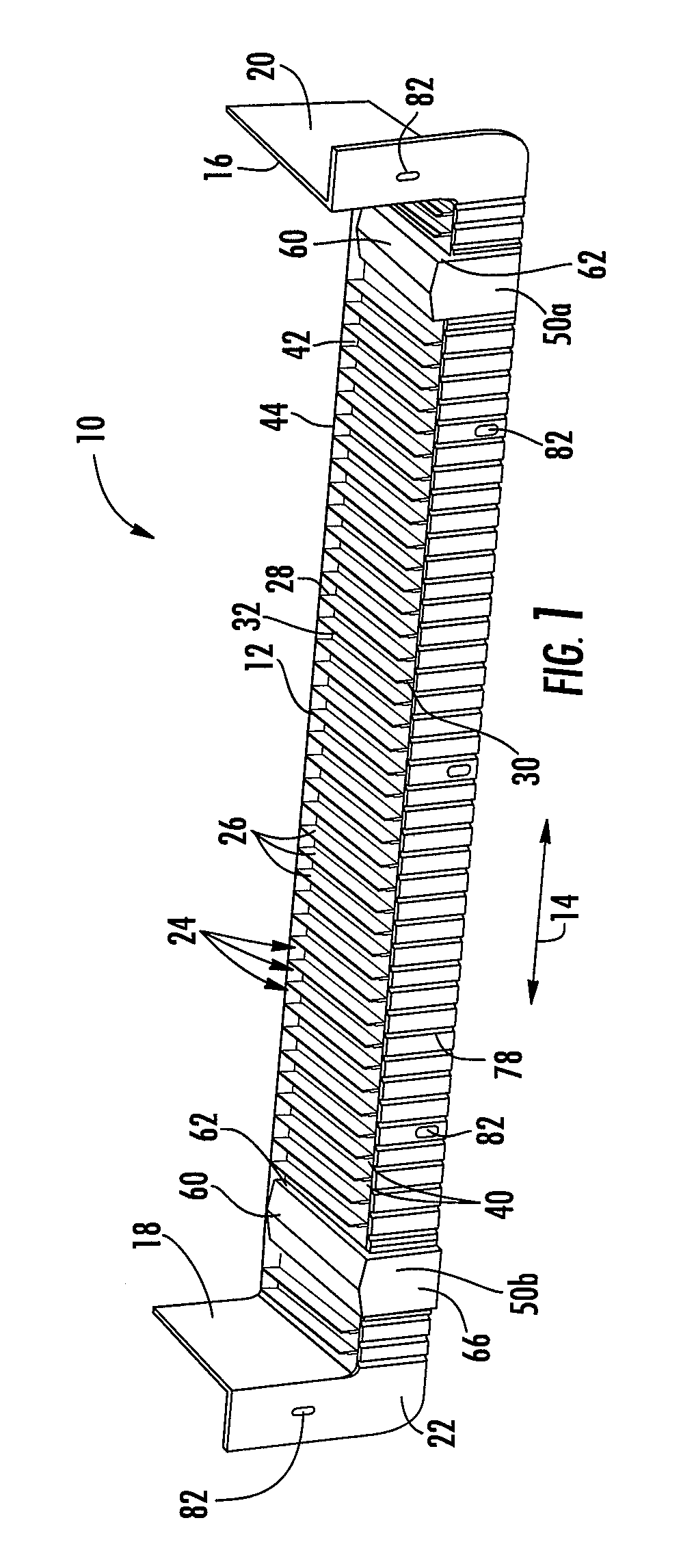

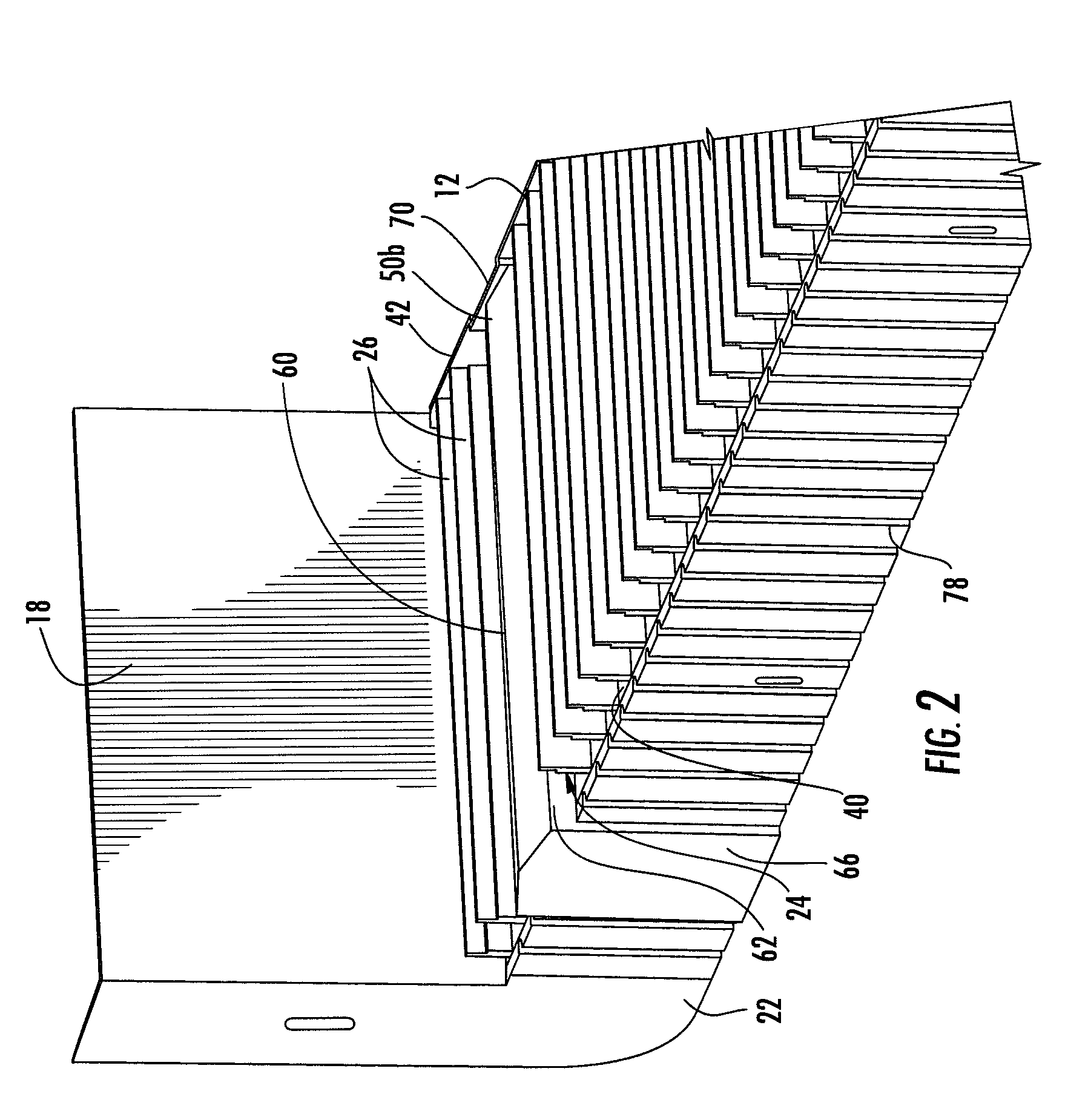

Flashing and weep apparatus for masonry wall window and door installations

ActiveUS6964136B2Easy to installEasy to implementRoof covering using slabs/sheetsRoof covering using tiles/slatesCavity wallMoisture

A flashing and weep apparatus allows for simple installation and accurate placement windows and doors in cavity wall construction. In a first embodiment, the flashing and weep apparatus is a two-panel extrusion that has a flashing panel that acts as a non-porous support for the masonry veneer. This embodiment also includes a second panel which is joined at a generally right angle to the first panel to be juxtaposed against the outer face of the inner wall in the cavity wall construction. Weep channels are formed between the two panels and allow for the drainage and dissipation of water and other moisture in the cavity wall system. In a second embodiment, membrane is initially attached to and draped along the lower portion of the inner wall immediately above the sill or lintel. The membrane extends across the cavity spacing between the walls to underlie the masonry components forming the outer veneer. Weep channels on the membrane communicate and transmit water and moisture from the cavity between the walls to the exterior of the veneer. The weep channels are positioned at the joint between adjacent bricks. The membrane extending beyond the mortar joint at the masonry veneer is trimmed during the installation process so as not to extend beyond the outer veneer wall while still providing an easily installed and implemented flash and weep system.

Owner:TY DAS BUILDING PROD LLC

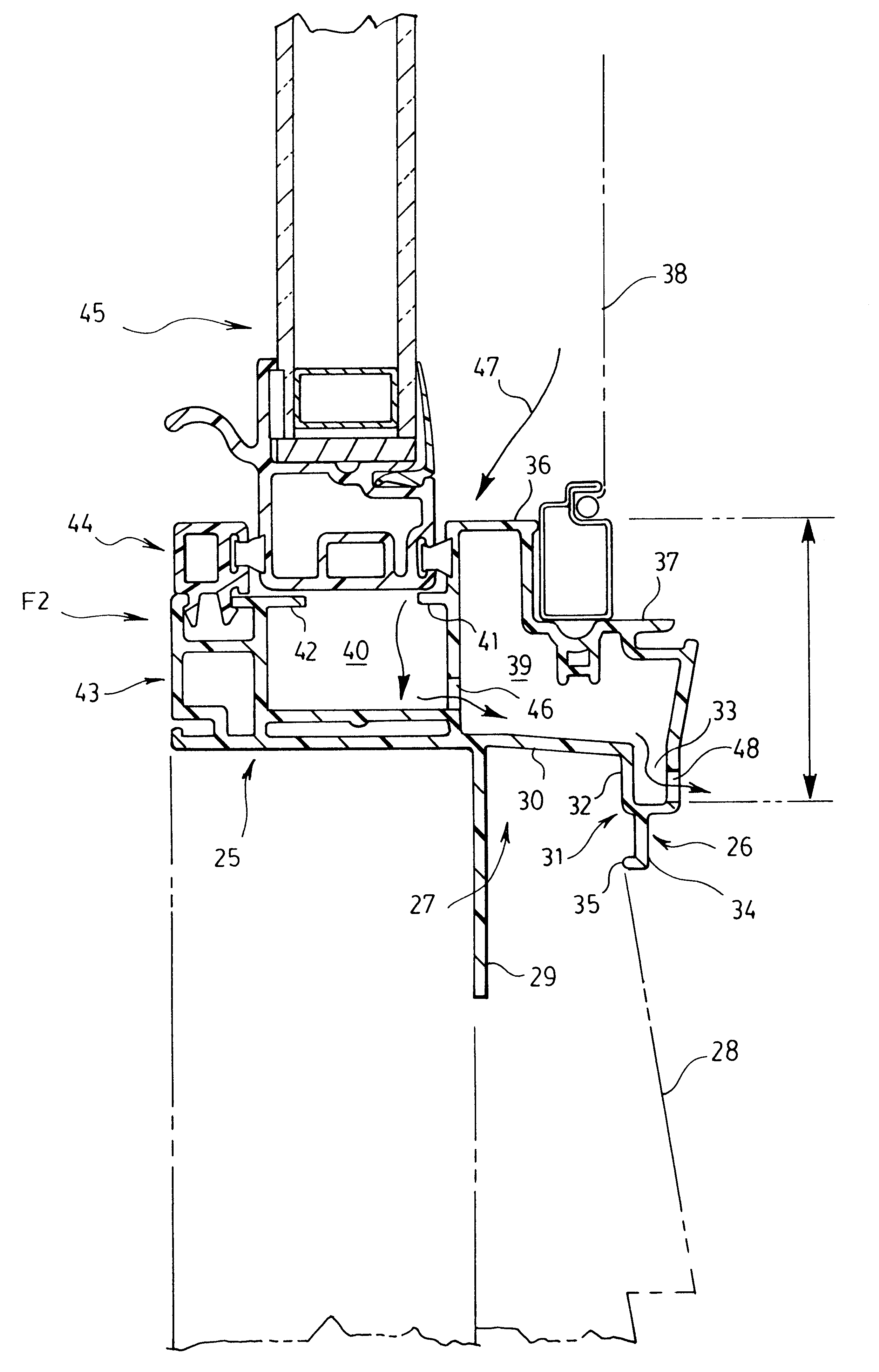

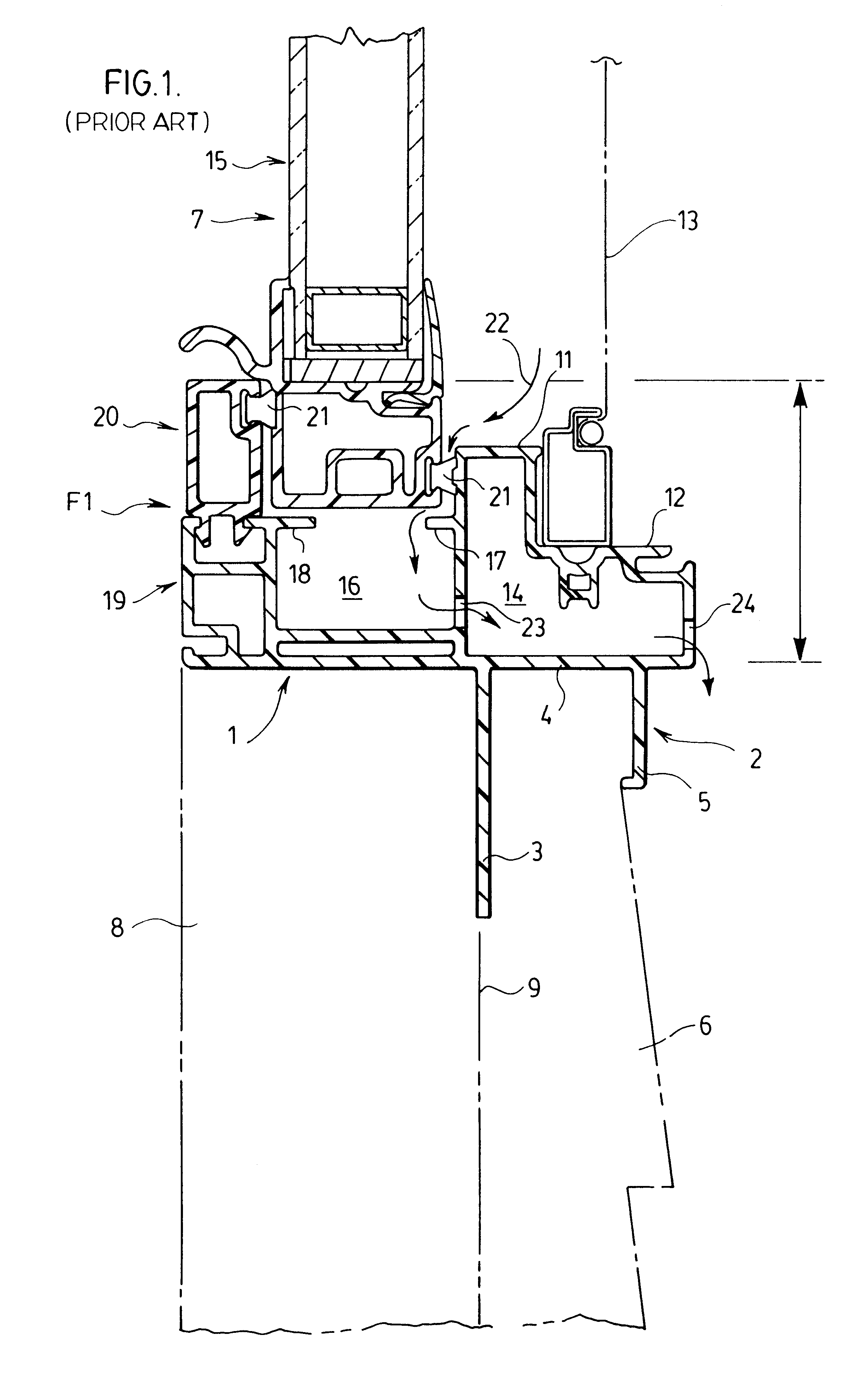

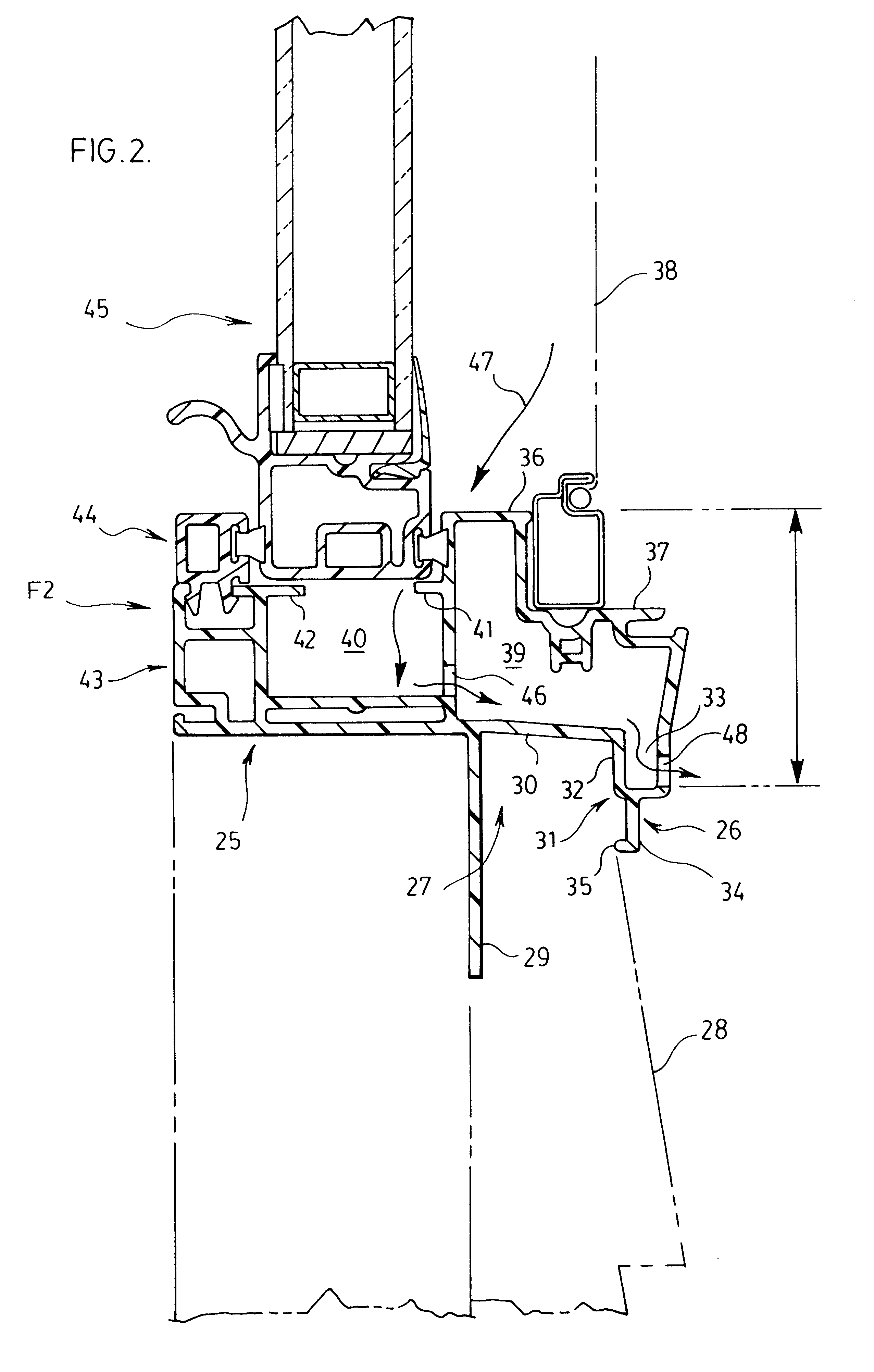

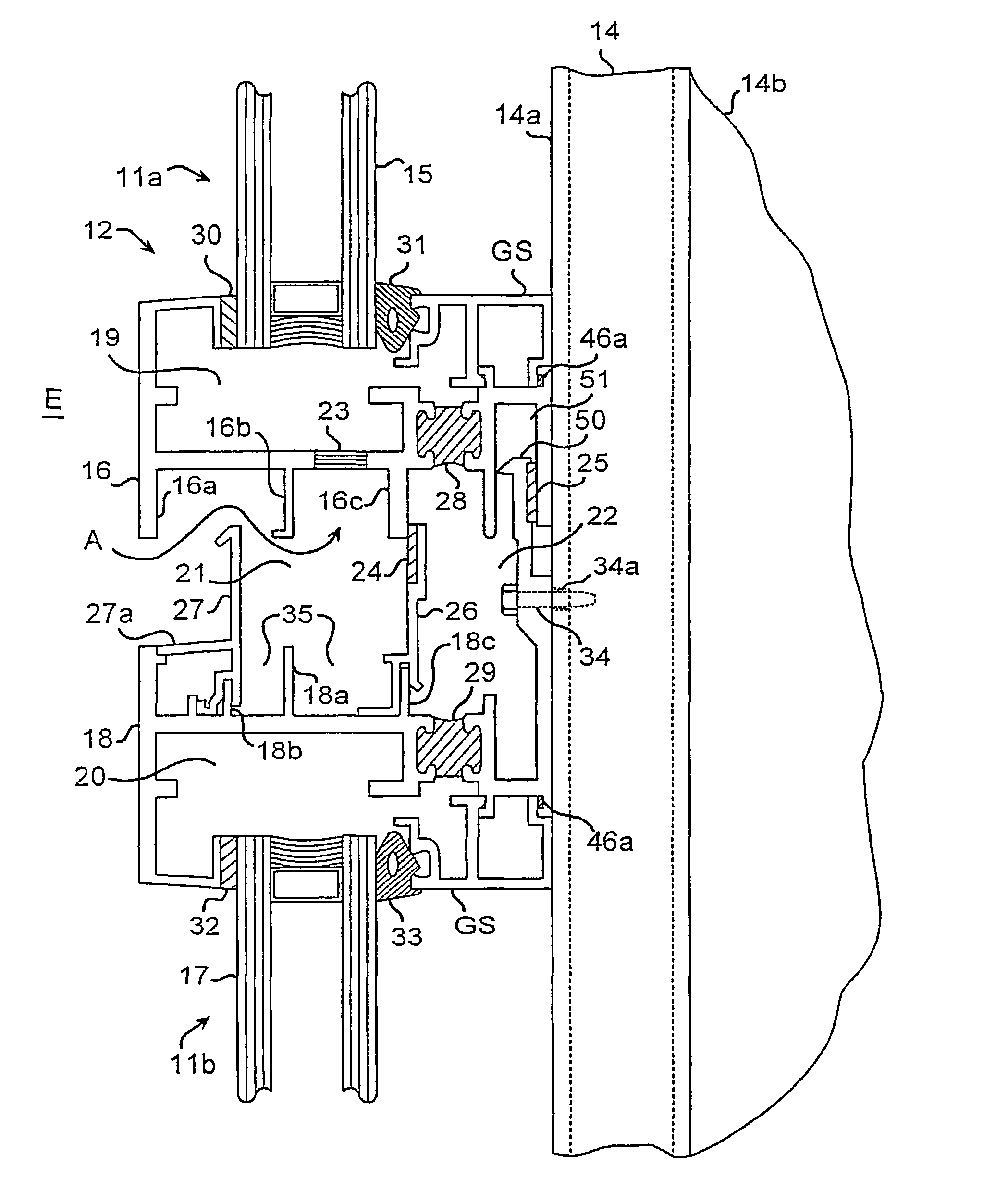

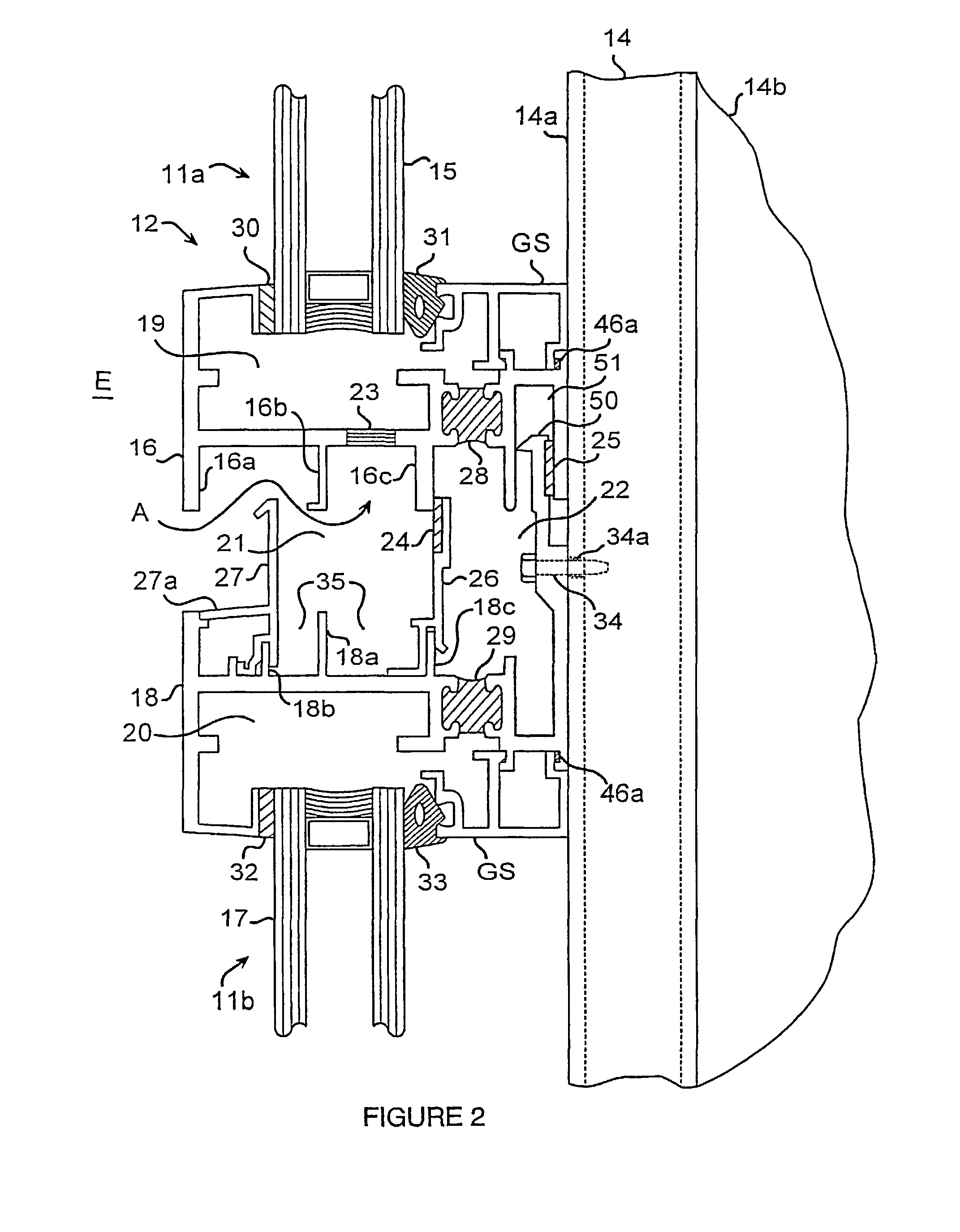

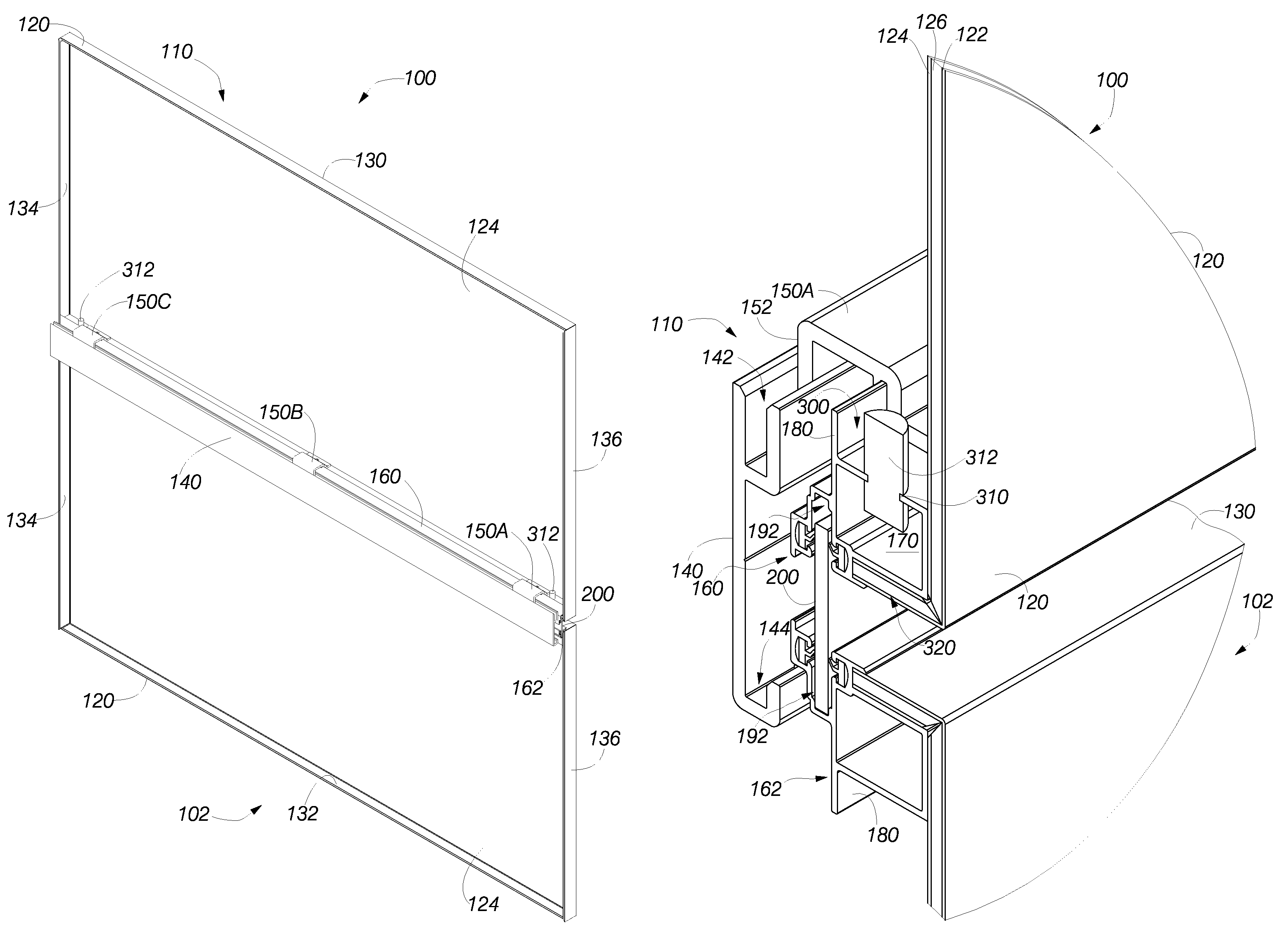

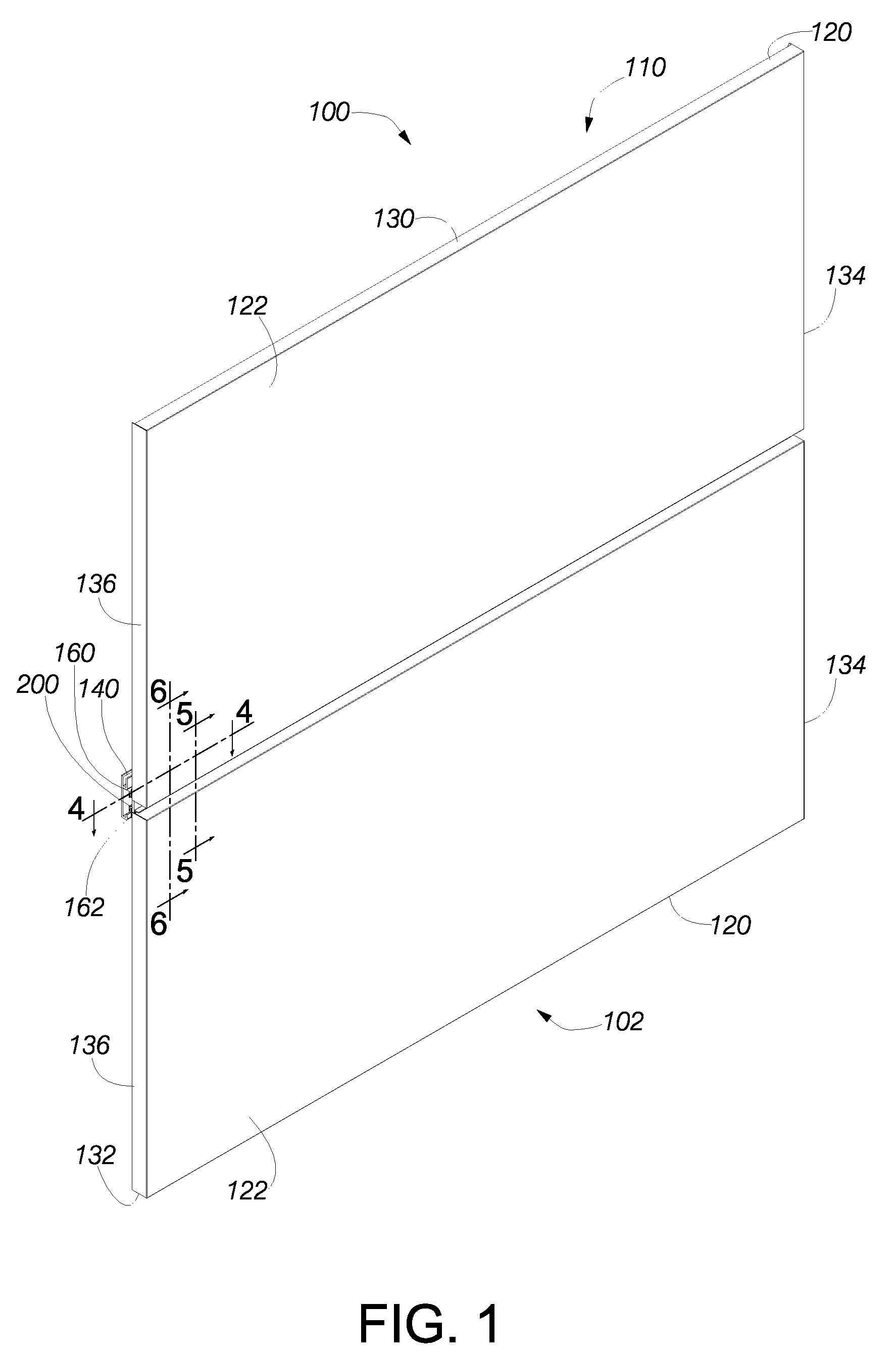

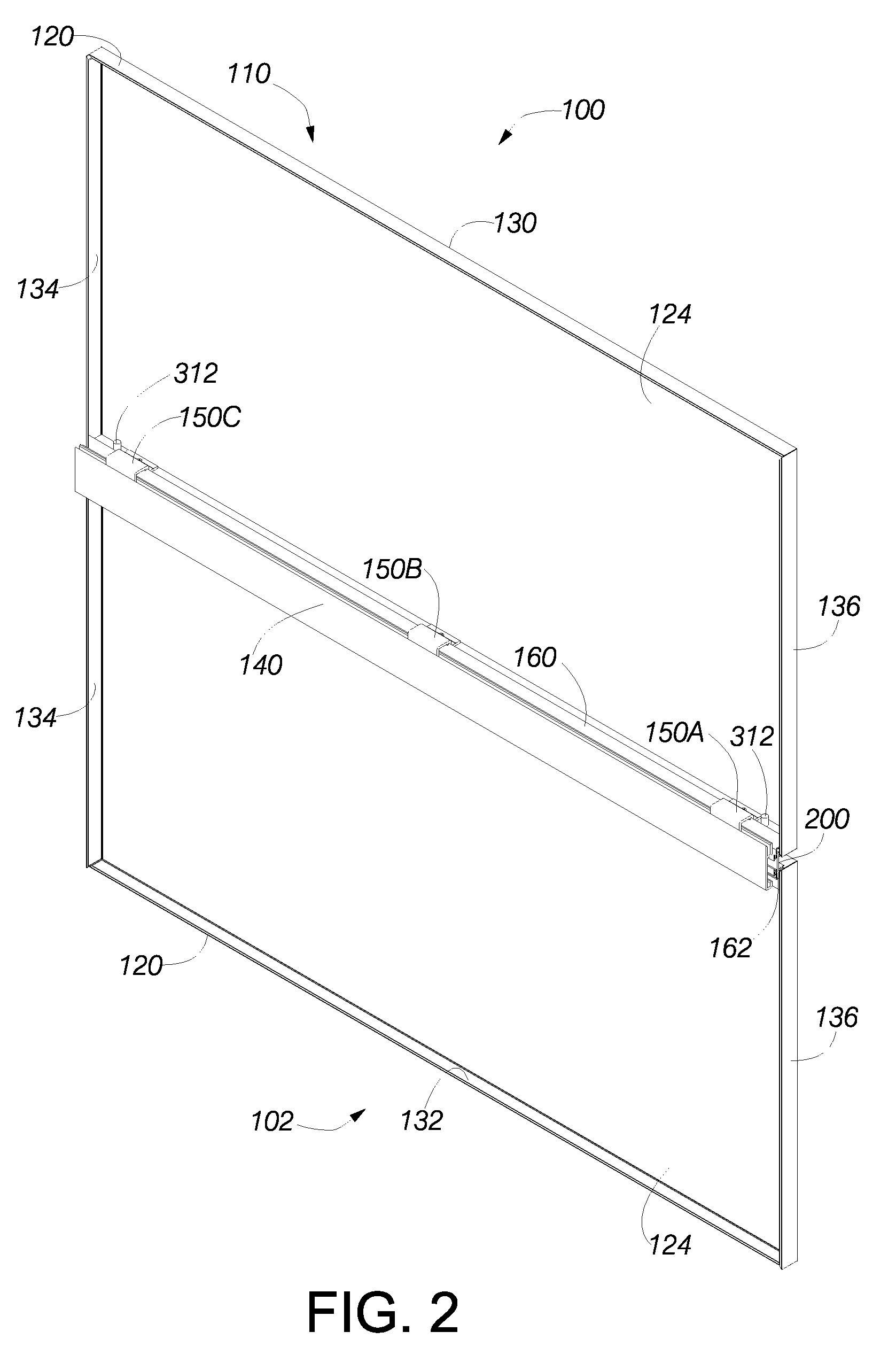

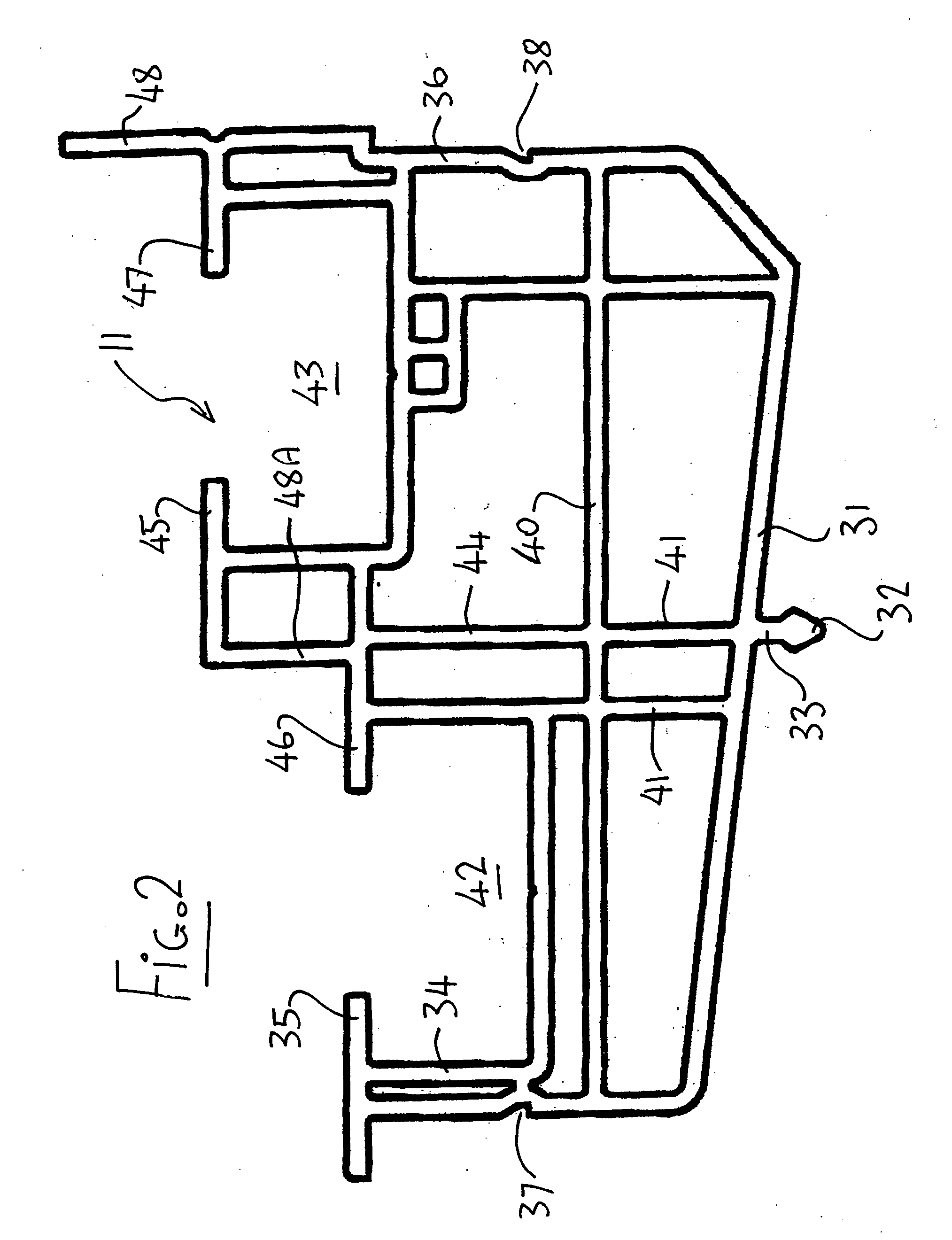

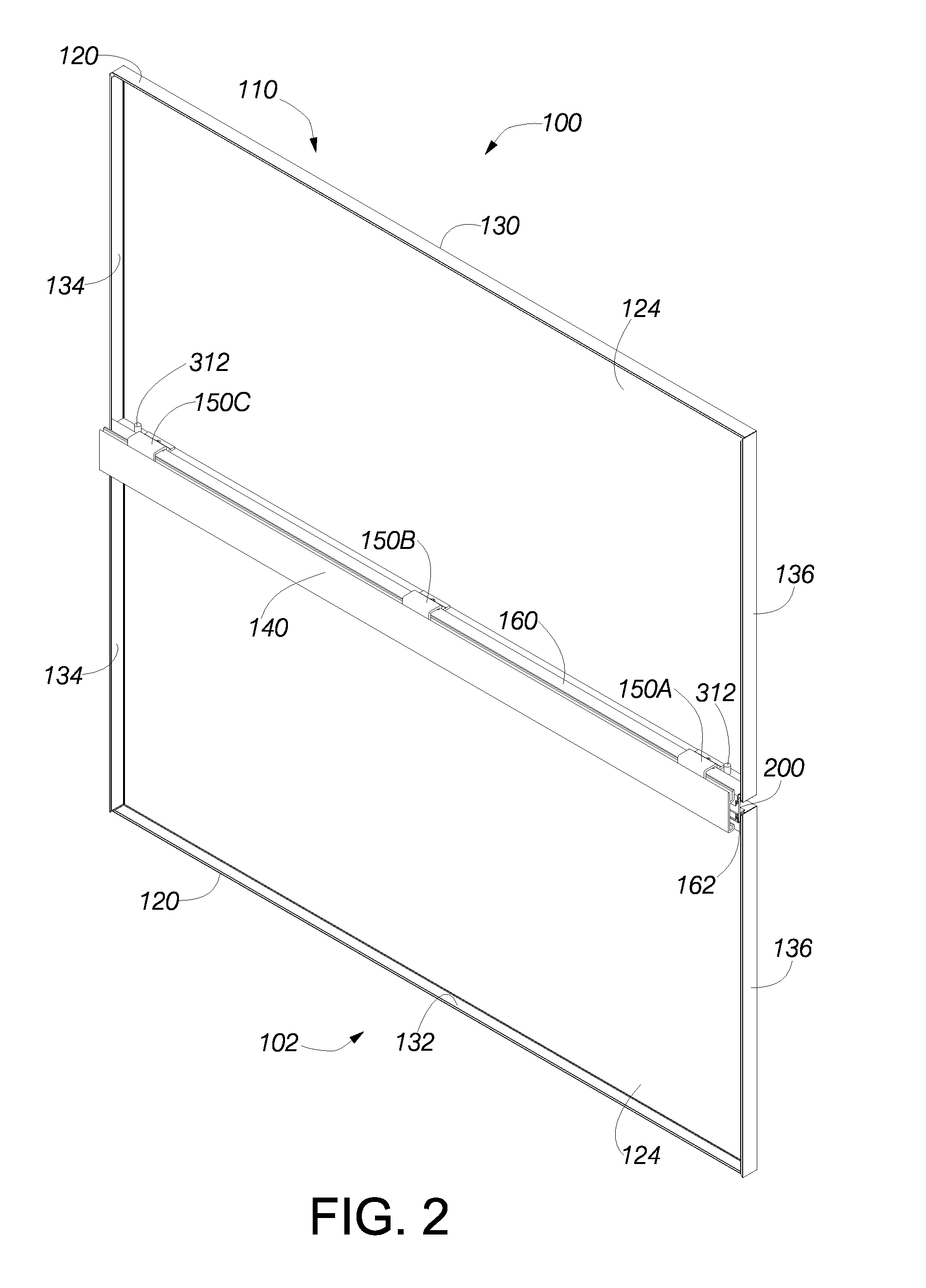

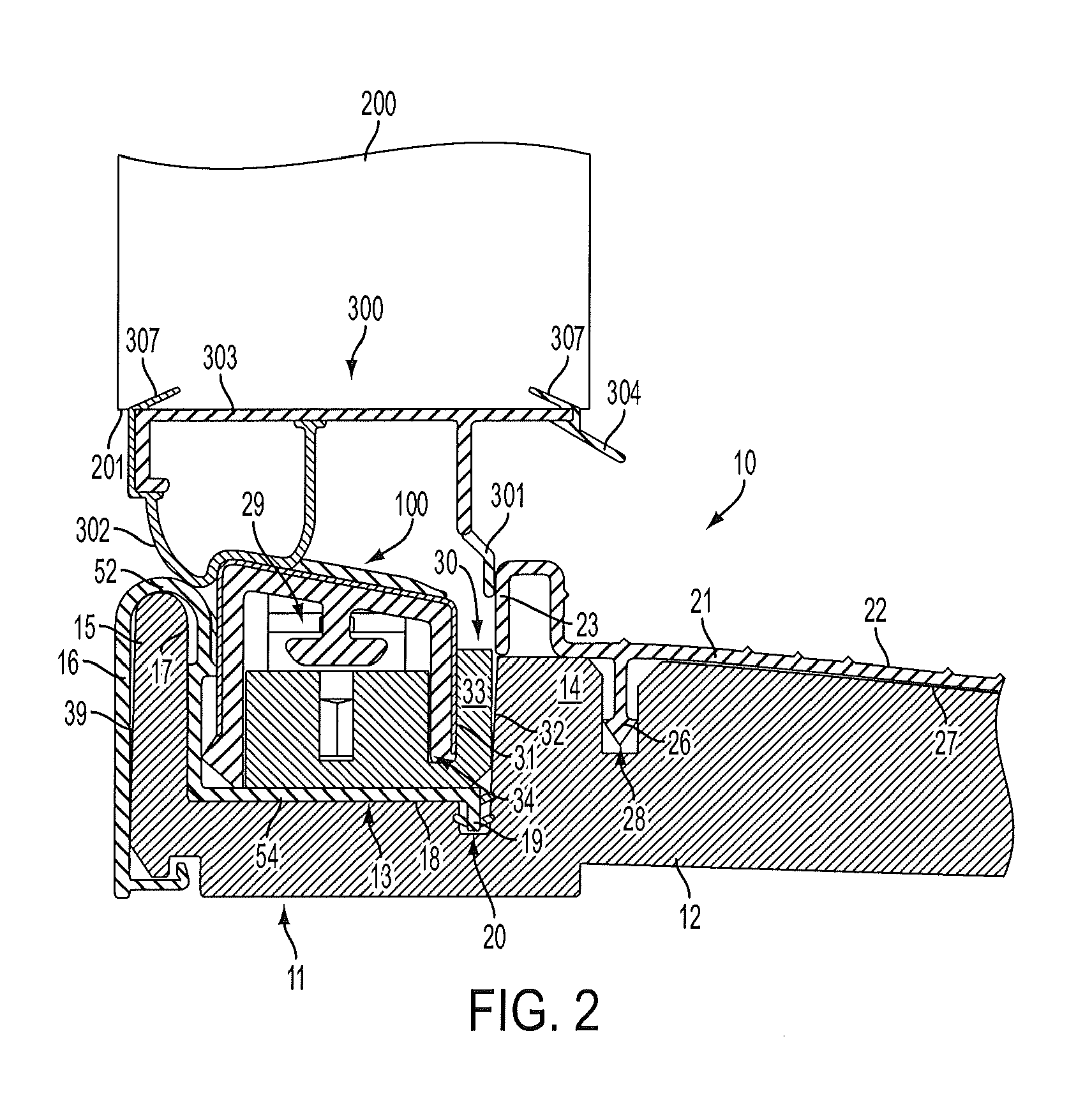

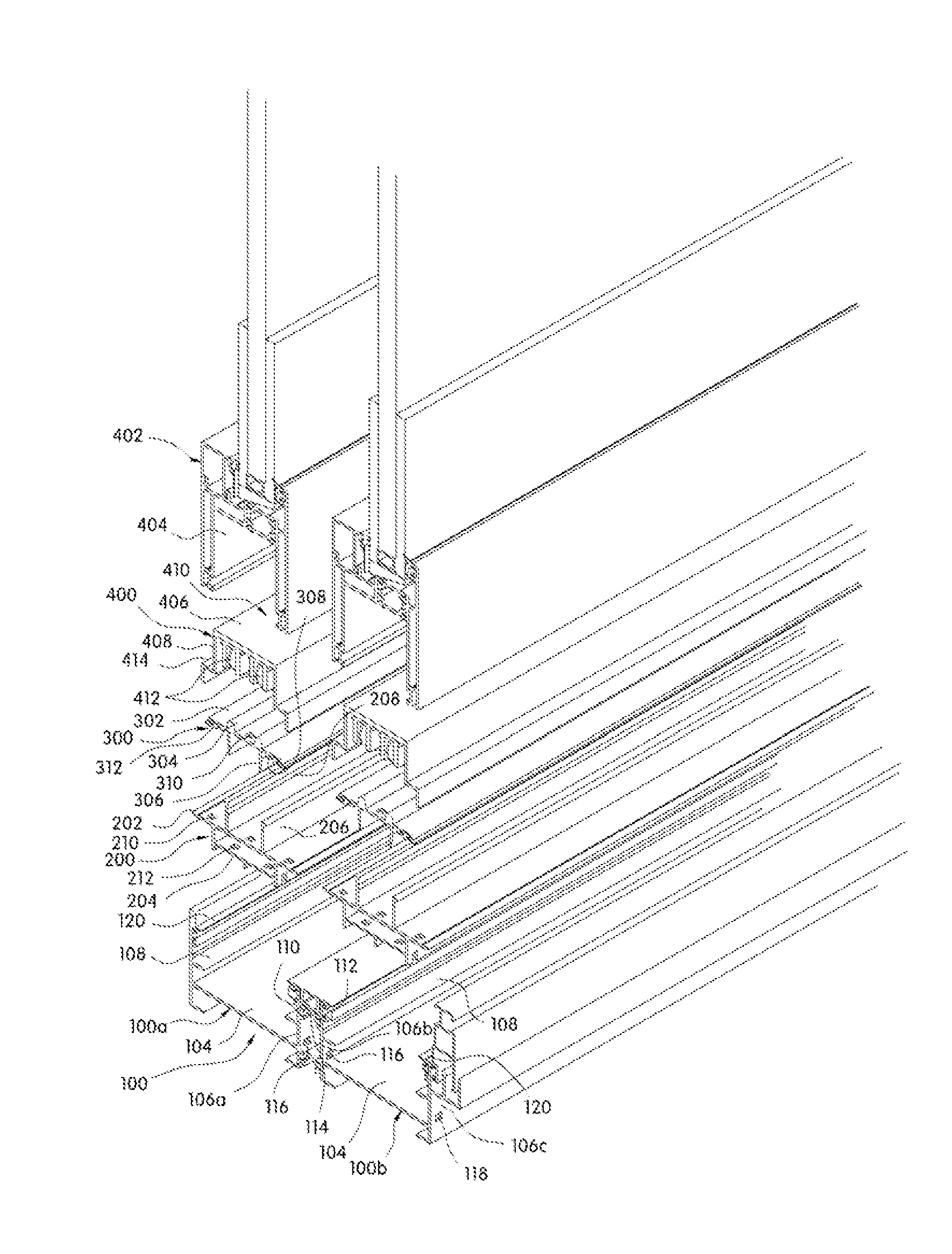

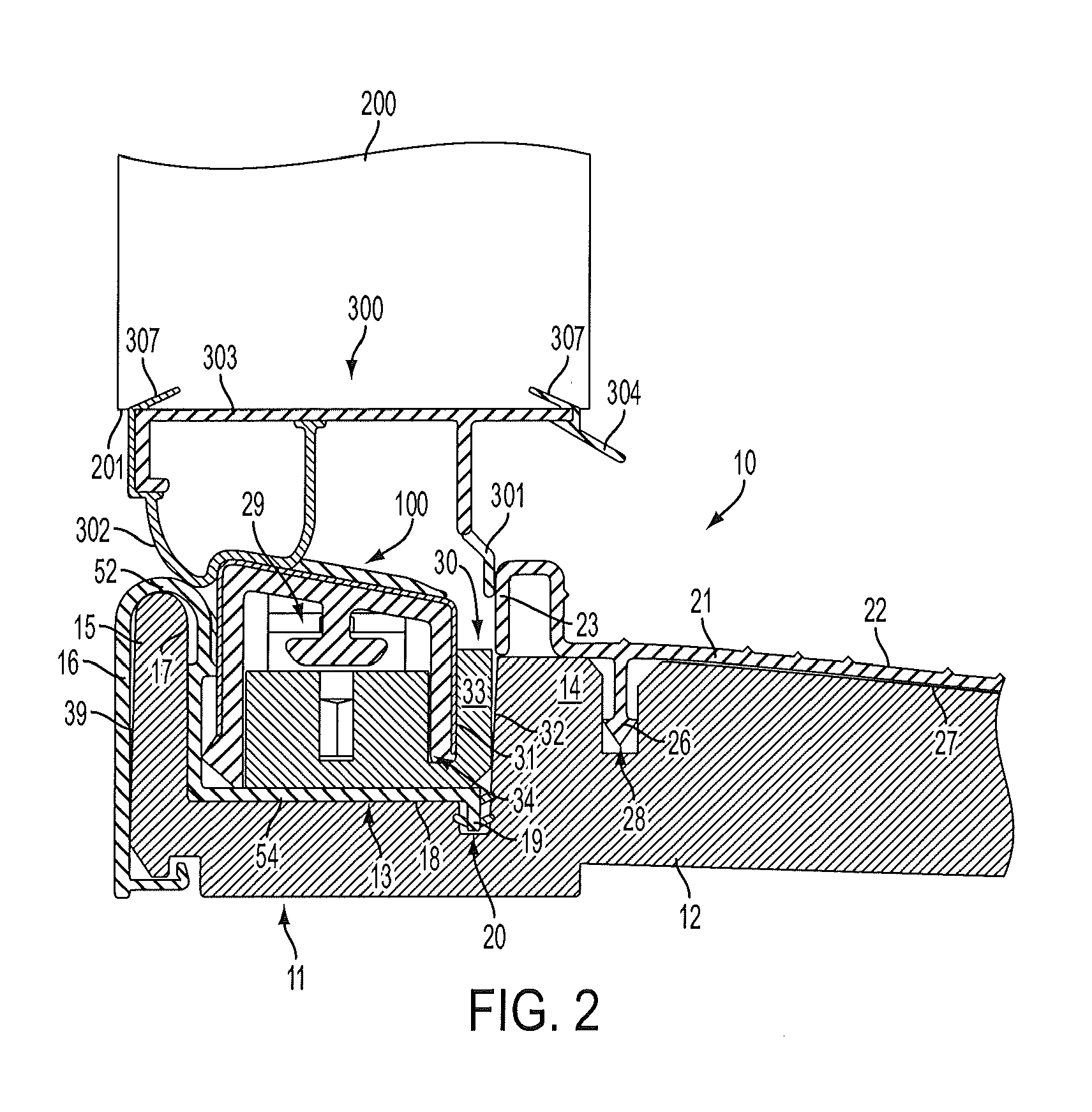

Enhanced curtain wall system

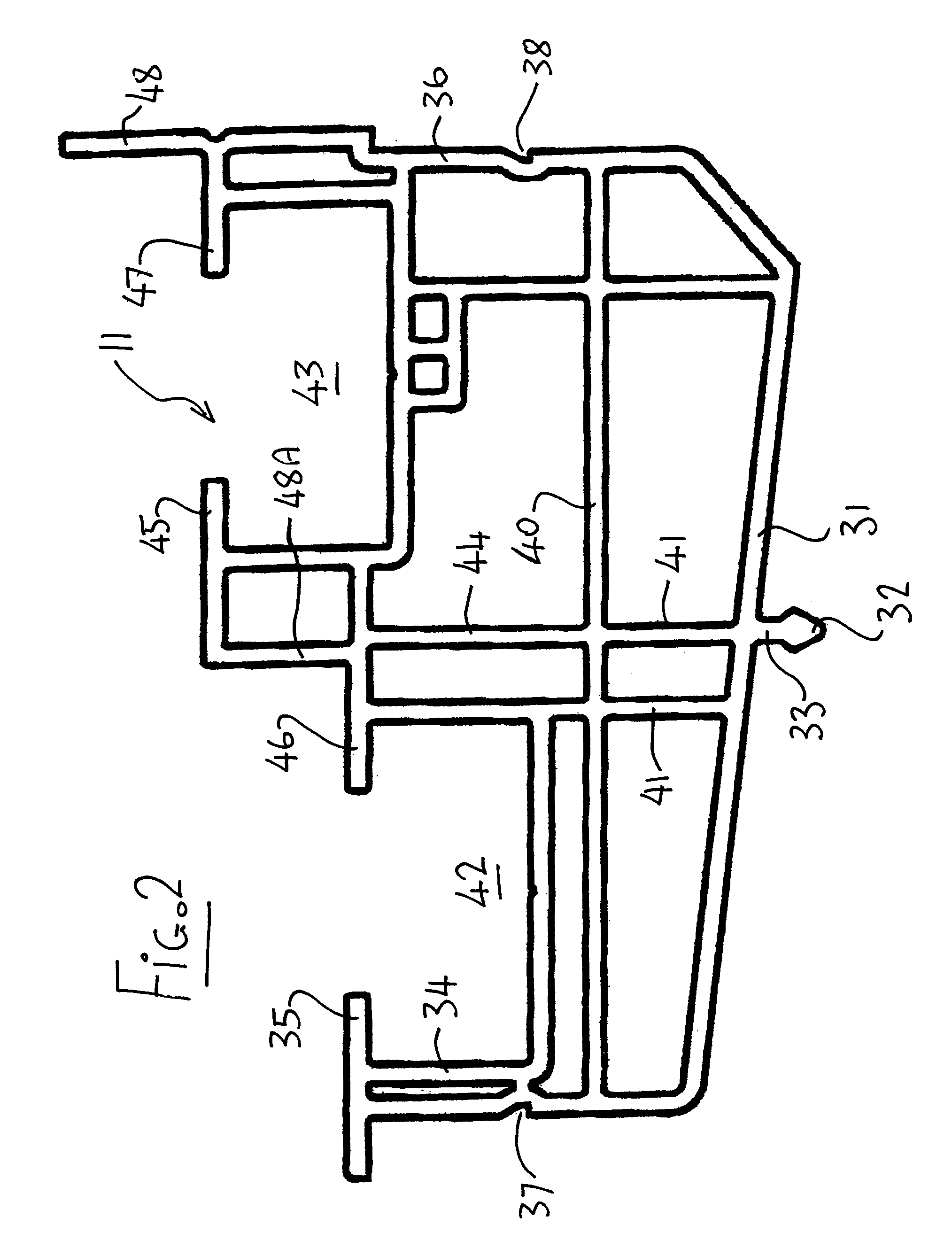

When assembled to a building support structure to form a curtain wall system of adjoining panels, a preferred embodiment of the enhanced airloop wall system as shown in FIG. 2 comprises panel frame segments that, when assembled, form interconnected inner and outer airloop segments that separate and improve water seal and air seal functions and improve sealing performance, a circuitous path (e.g., “A”) at an enlarged air opening into an airloop to pressure equalize and limit water entry into the airloop, a two point fastener support of each panel assembly to allow interfloor deflections under seismic or other loads without excessive loads on the panel assembly, a structural hook-like protrusion for resisting building outward loads on panels separate from fasteners, a splitter in a drainage cavity in the outer airloop that creates a dual drainage path and a surface upon which droplets can collect.

Owner:ADVANCED BUILDING SYST

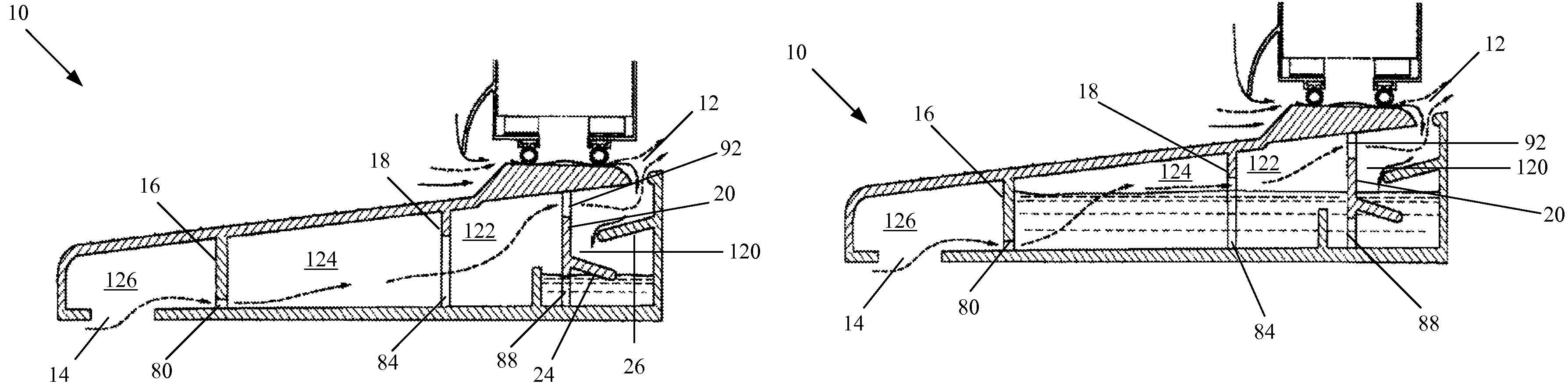

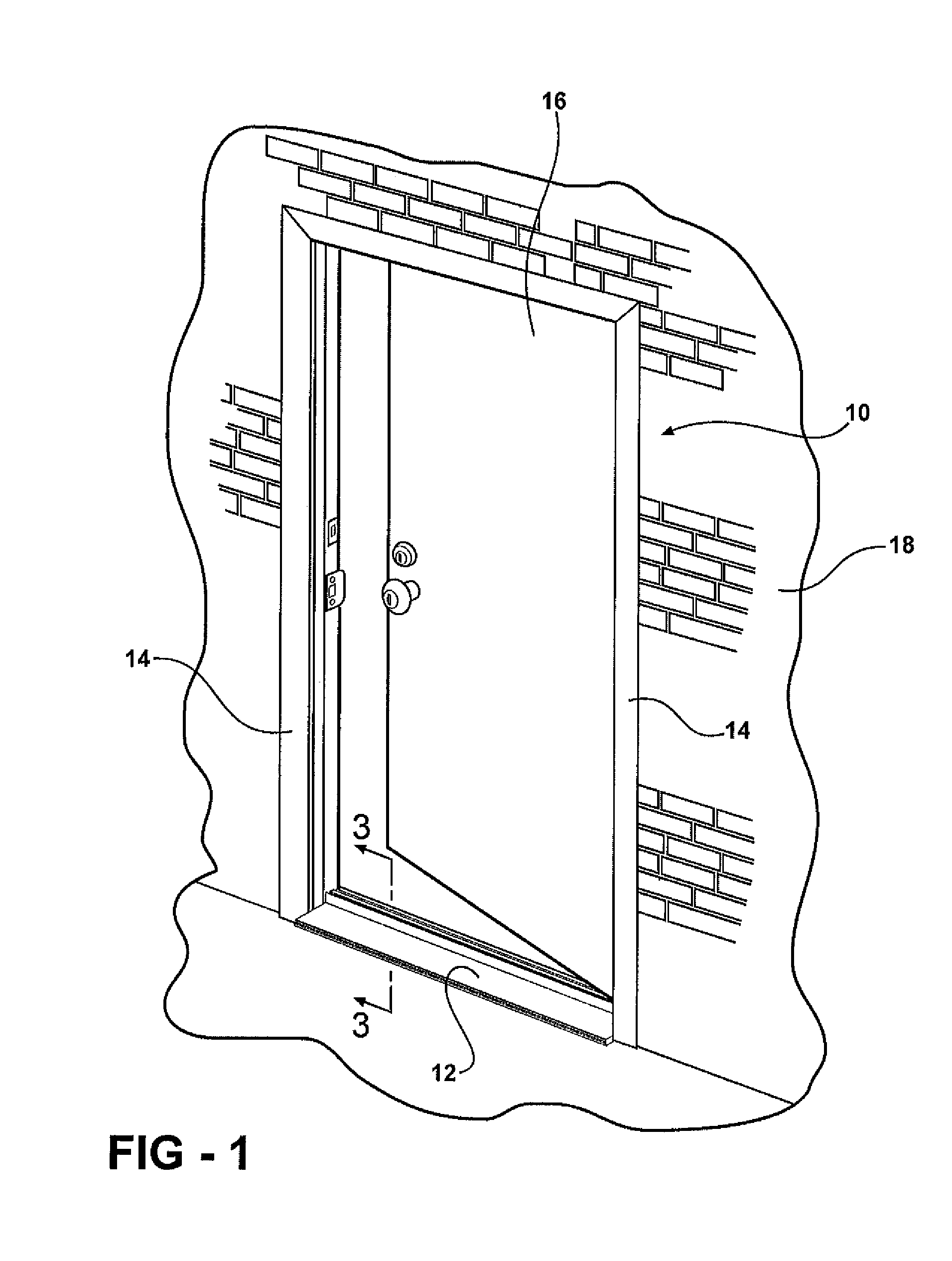

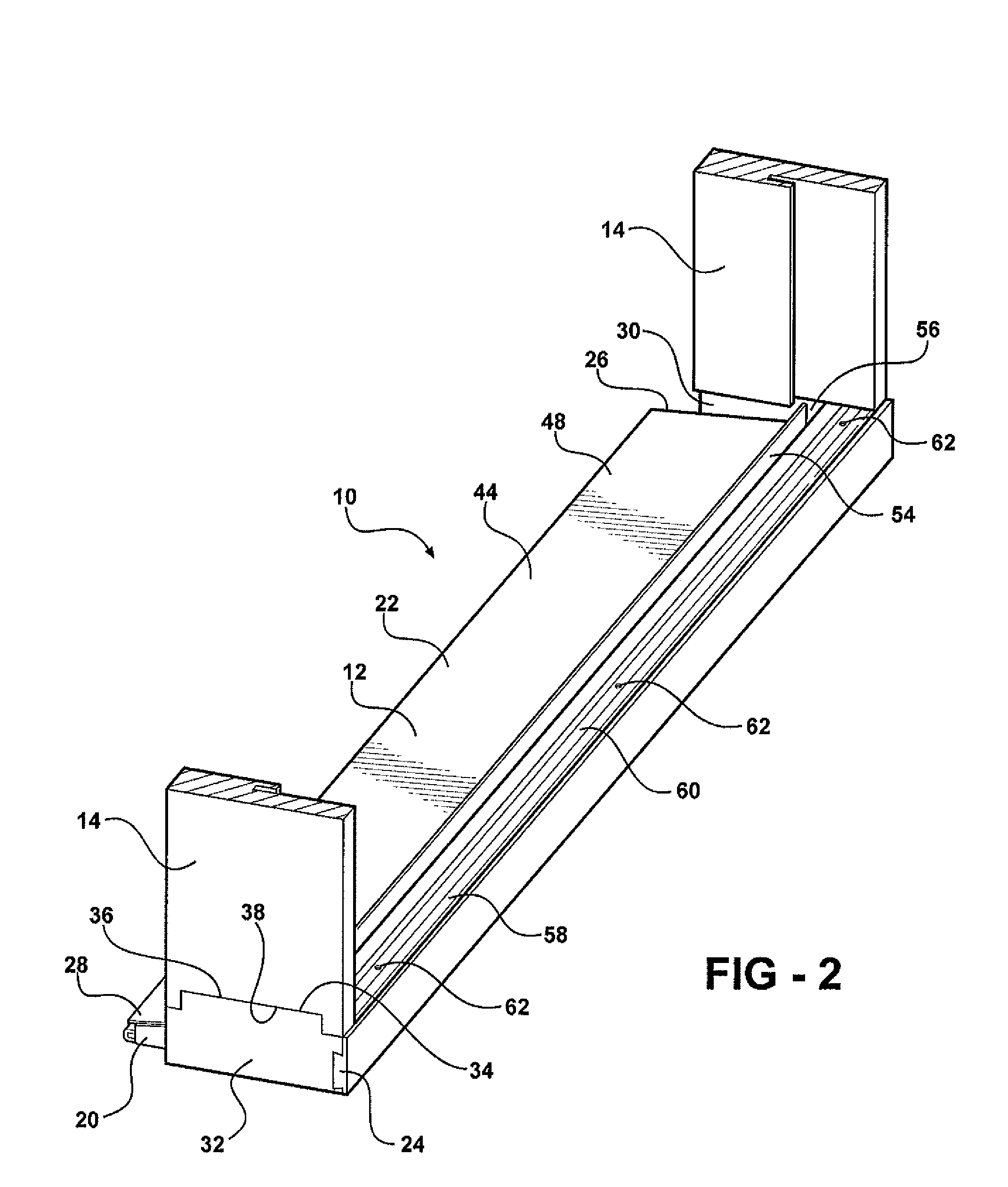

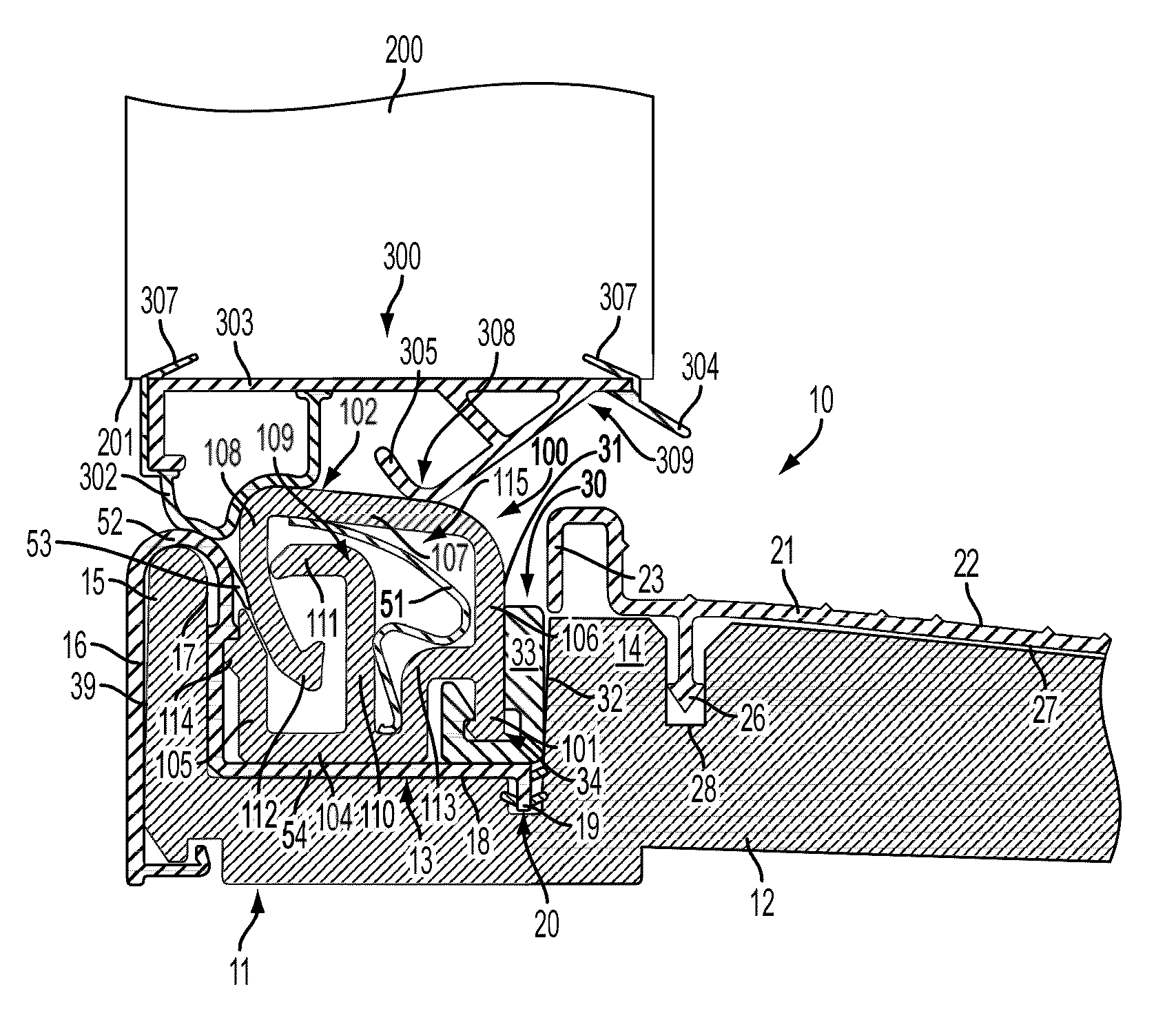

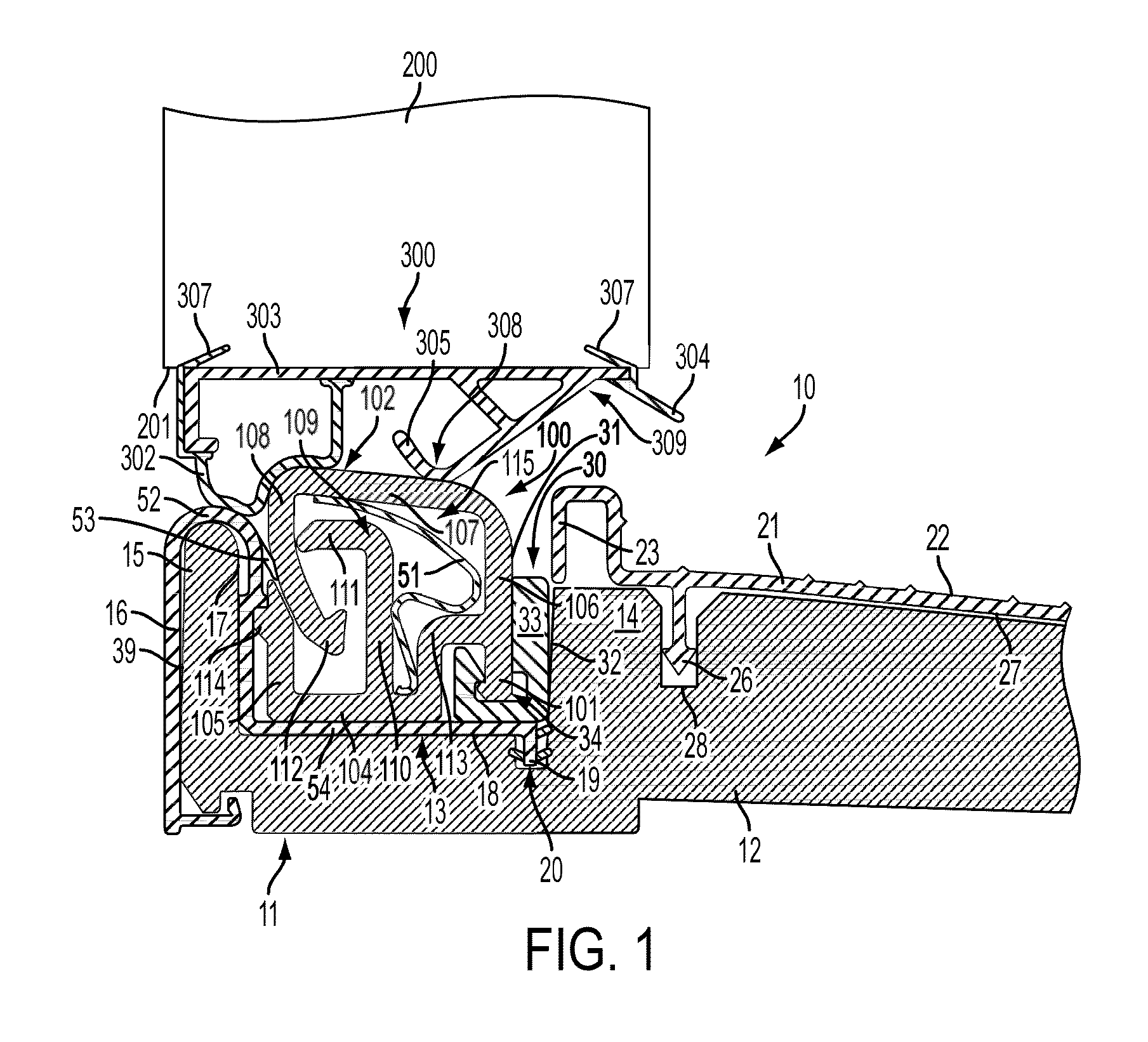

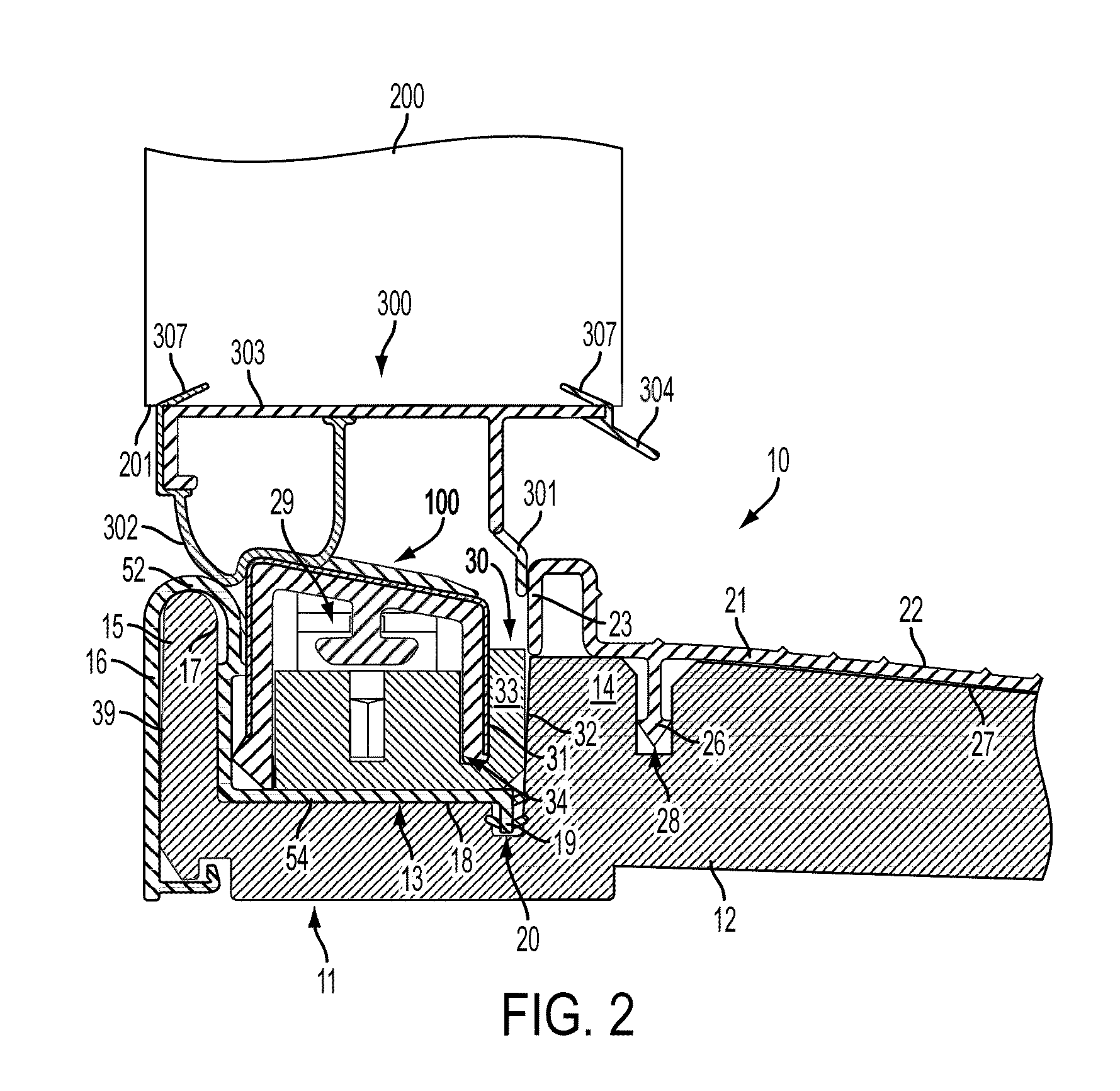

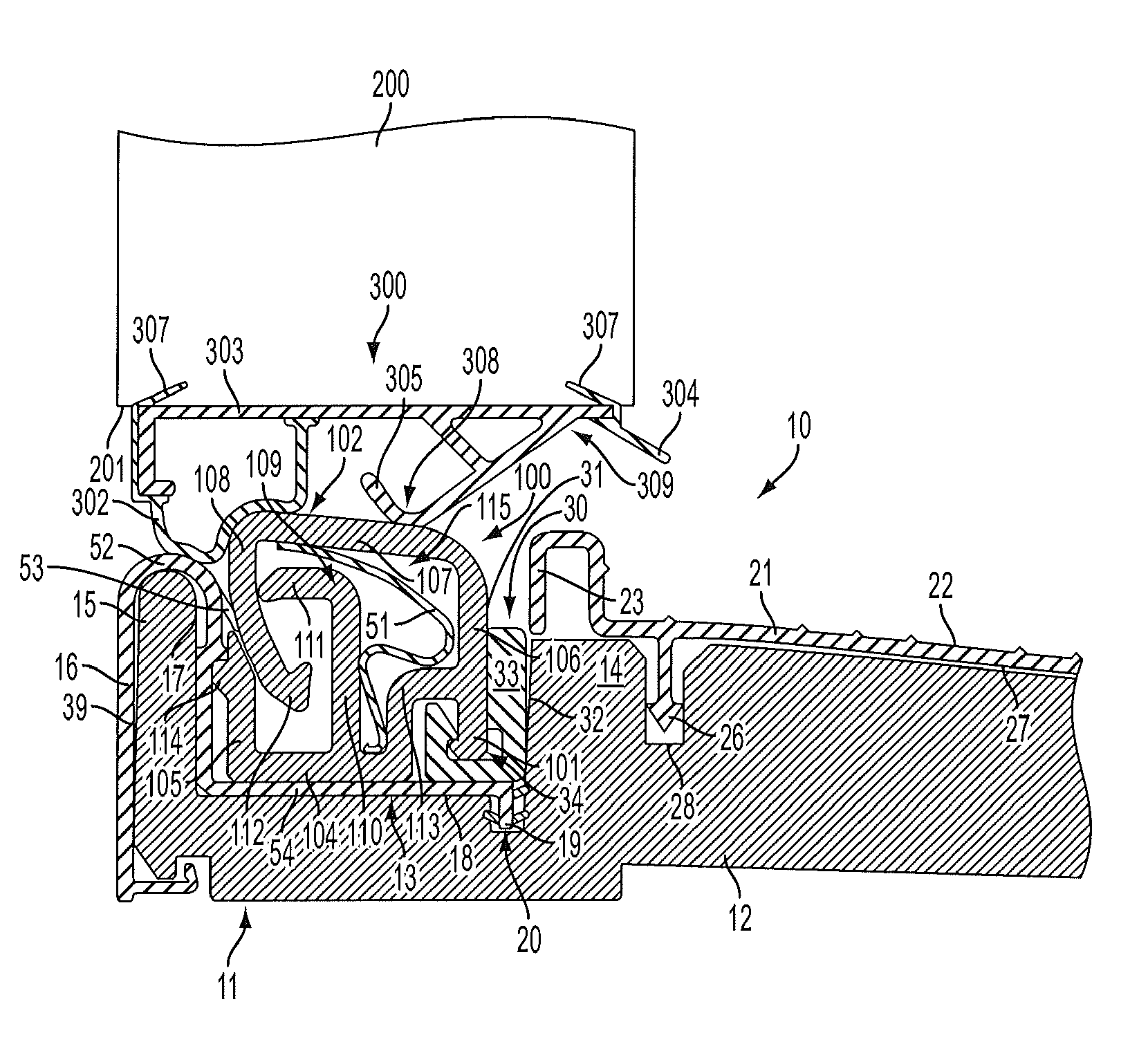

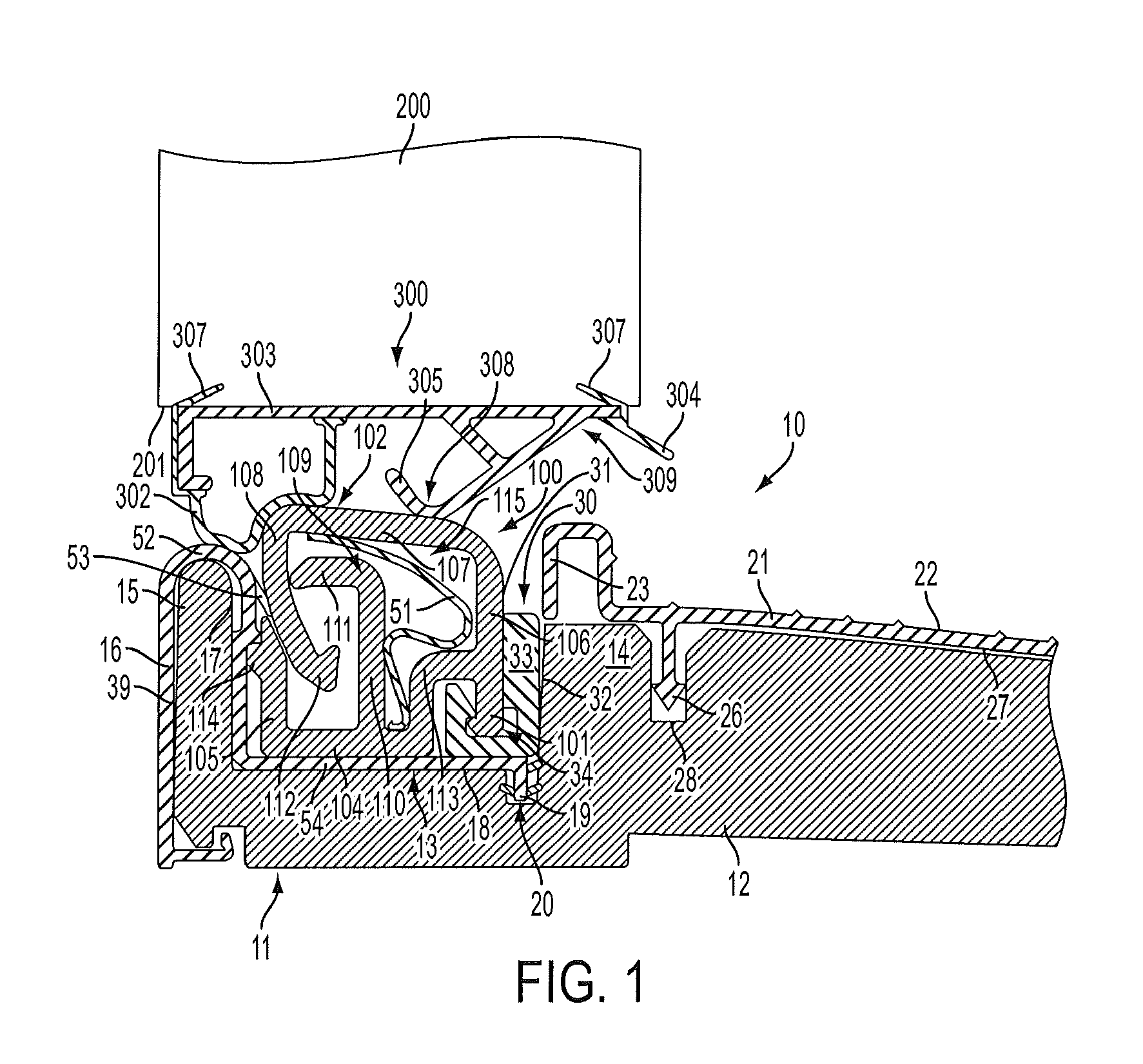

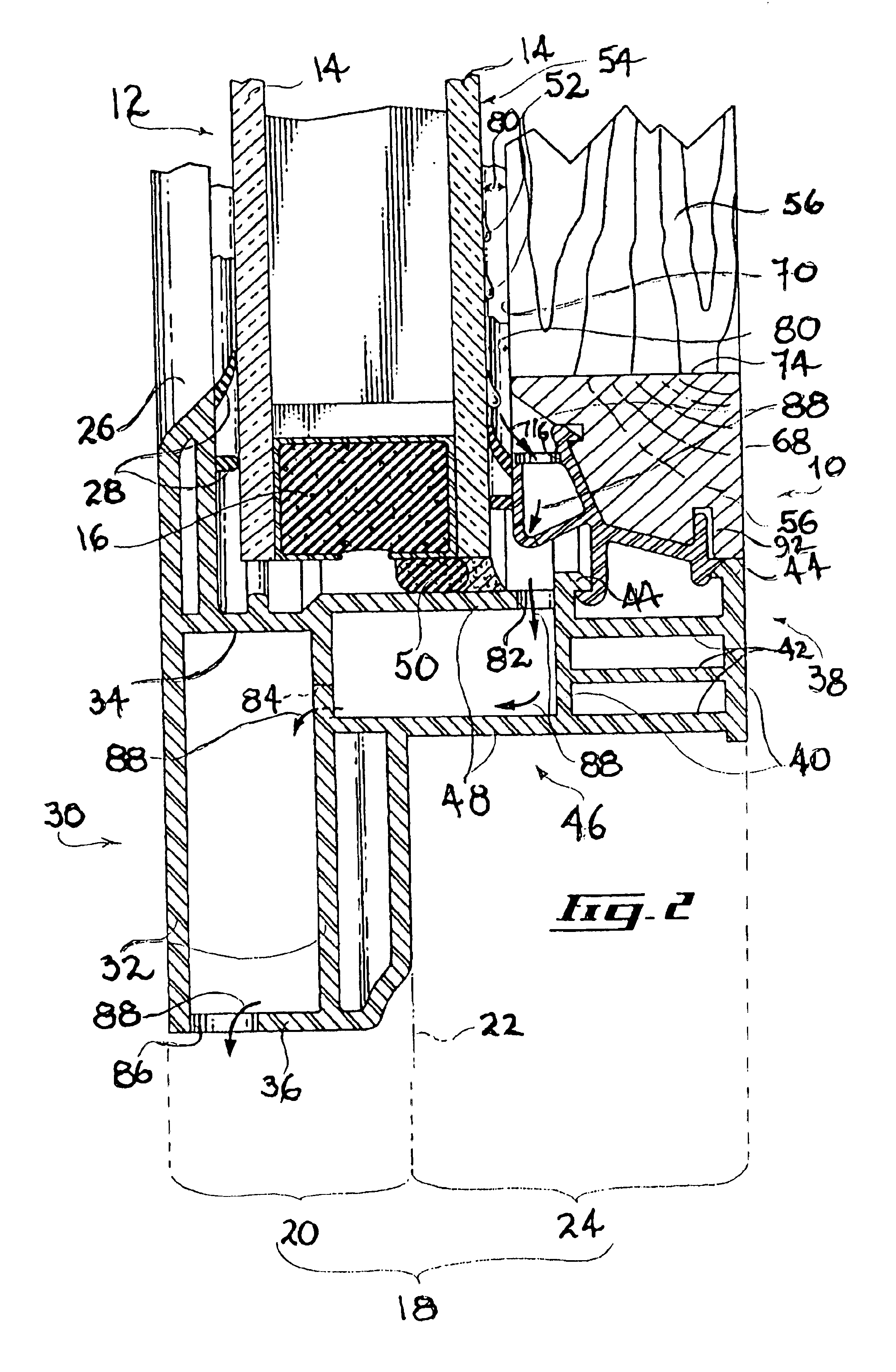

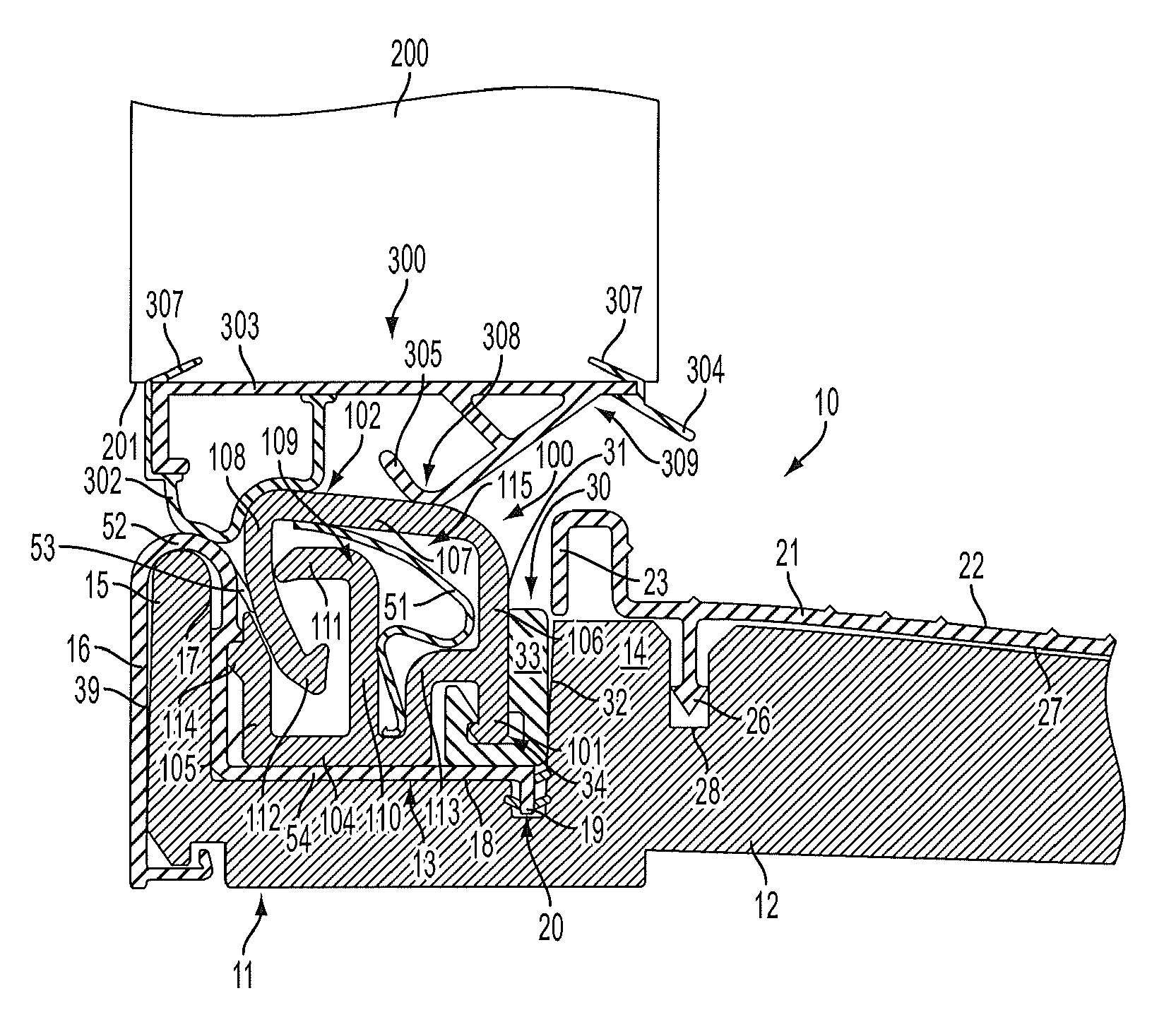

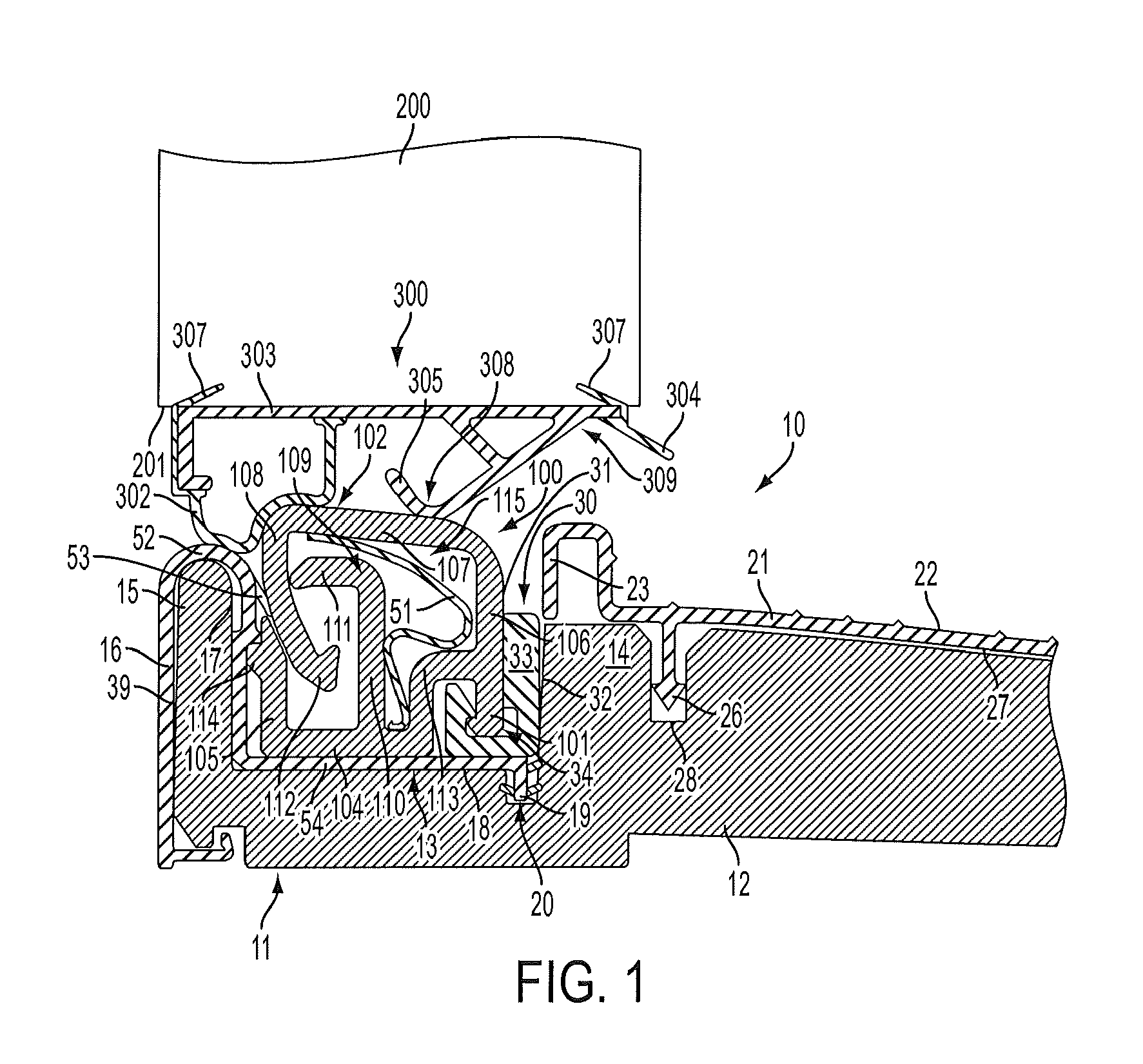

Door threshold water return systems

InactiveUS20060150521A1Prevent buildupAvoid enteringWindow/door framesSills/thresholdEngineeringMechanical engineering

A door threshold water return system, comprising: a lower sill; an upper sill; a rear wall; and a front wall forming a chamber, wherein at least one baffle is provided projecting into the chamber from the rear wall, a first gap is provided in proximity to the rear wall and between the upper sill and the rear wall, and a second gap is provided in proximity to the lower sill and between the lower sill and the front wall, whereby water introduced into the system through the first gap exits the system through the second gap.

Owner:HENRY MICHAEL PAUL

Door threshold water return systems

InactiveUS7669369B2Prevent buildupSimple and safe to useWindow/door framesSills/thresholdMechanical engineering

A door threshold water return system, comprising: a lower sill; an upper sill; a rear wall; and a front wall forming a chamber, wherein at least one baffle is provided projecting into the chamber from the rear wall, a first gap is provided in proximity to the rear wall and between the upper sill and the rear wall, and a second gap is provided in proximity to the lower sill and between the lower sill and the front wall, whereby water introduced into the system through the first gap exits the system through the second gap.

Owner:HENRY MICHAEL PAUL

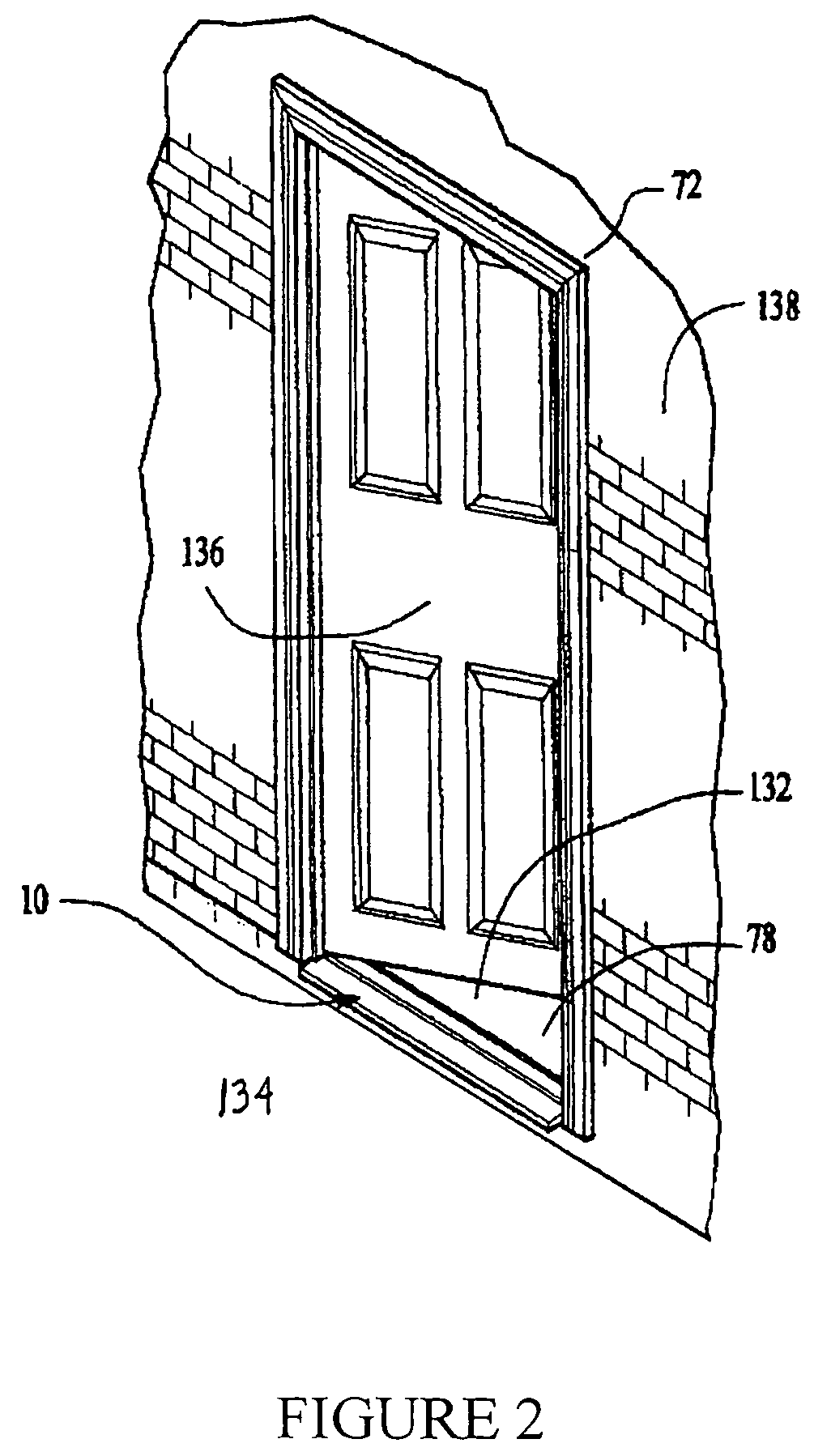

Entryway system including a threshold assembly

A threshold assembly is disposed below a closure. The threshold assembly includes a sill having a first end and a second end spaced from each other and having an entry portion sloping downwardly from a proximate end to a distal end between the first and second ends. A pair of jamb pedestals are disposed at the first and second ends of the sill, respectively. Each jamb pedestal supports a jamb spaced above the sill. A first wall extends upwardly from the proximate end of the entry portion and a second wall extends upwardly from the sill and along the first wall to define a channel extending longitudinally between the jamb pedestals. The first wall defines an opening which establishes fluid communication from the channel to the entry portion of the sill between the jamb pedestals for directing water from the channel away from the threshold assembly along the entry portion.

Owner:QUANEX HOMESHIELD LLC

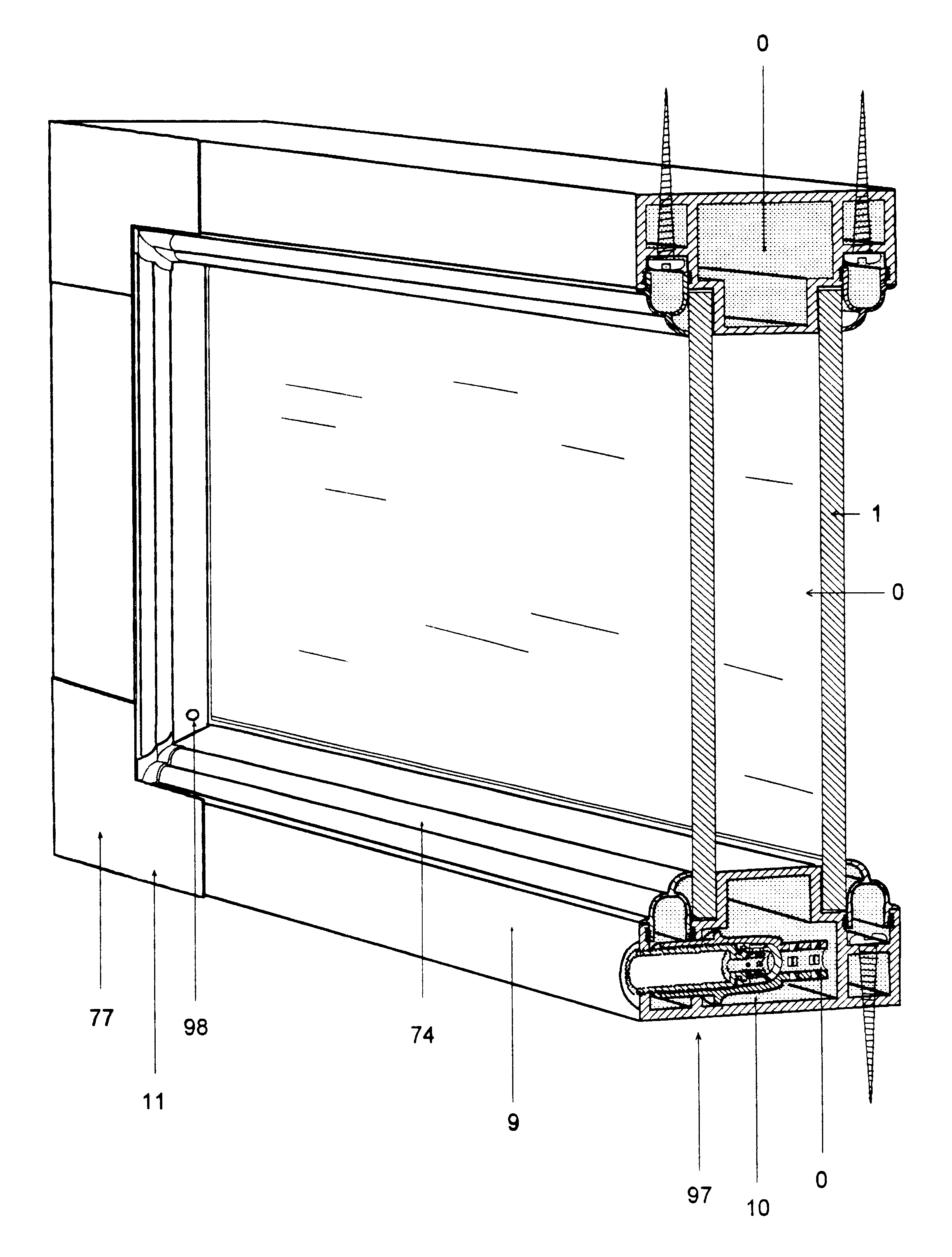

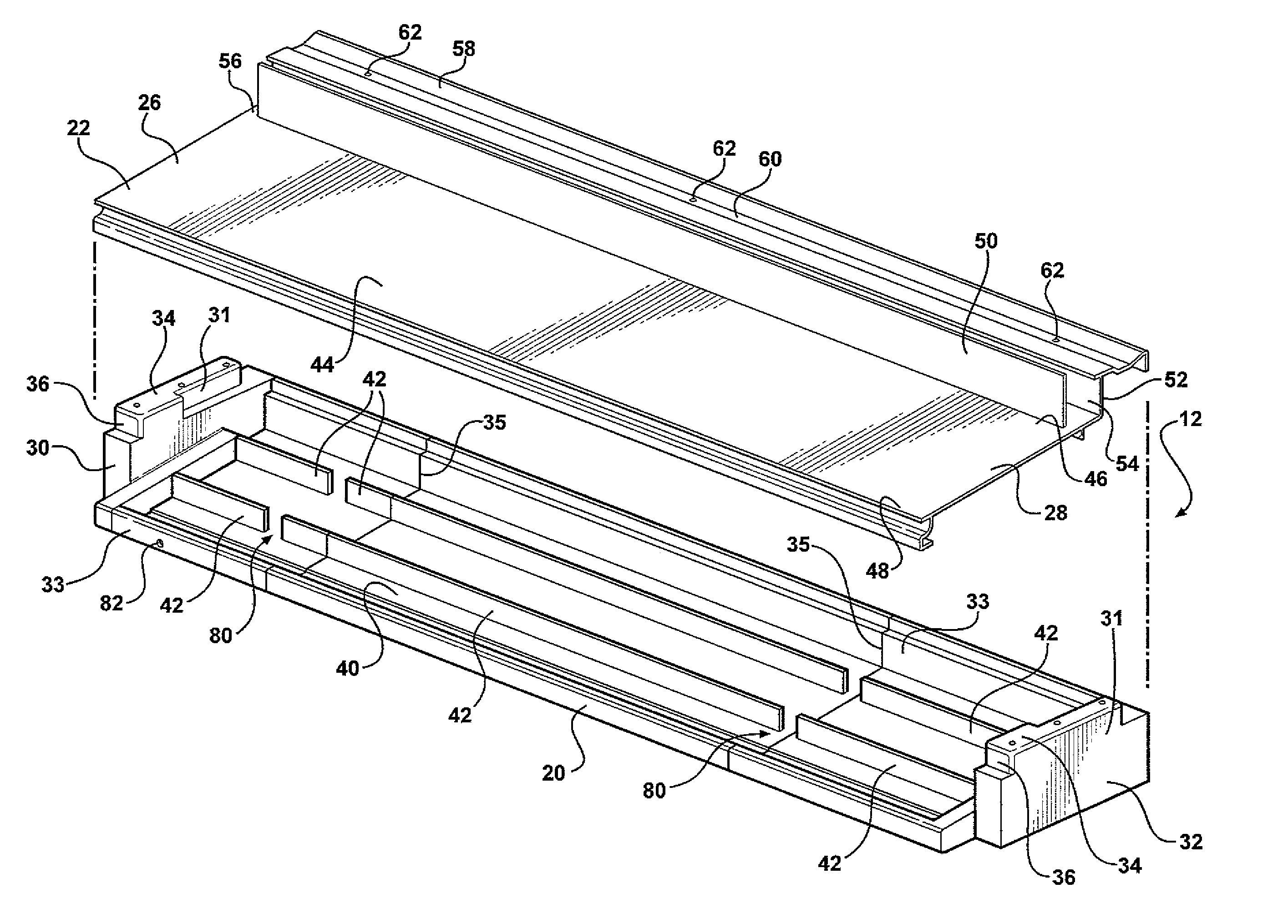

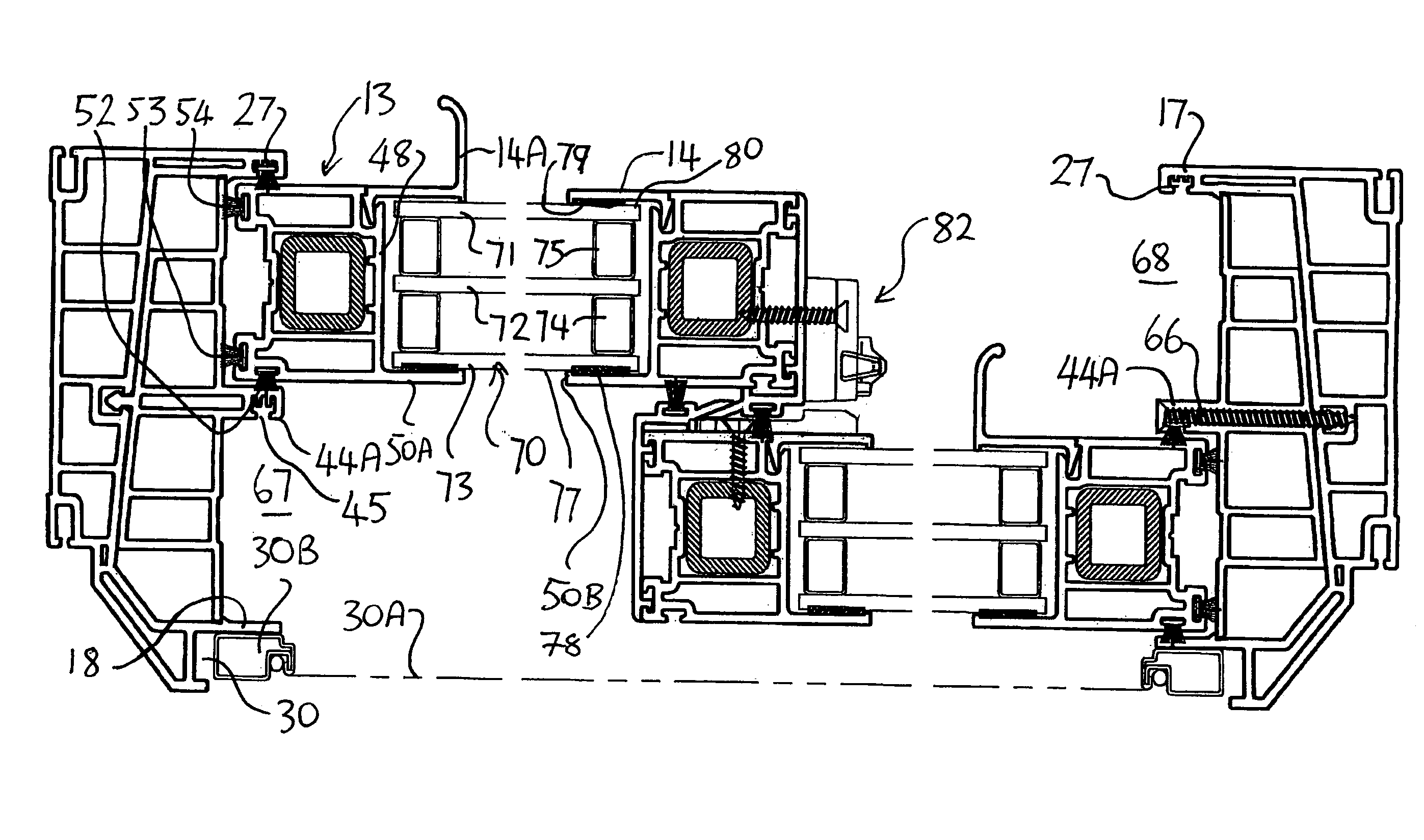

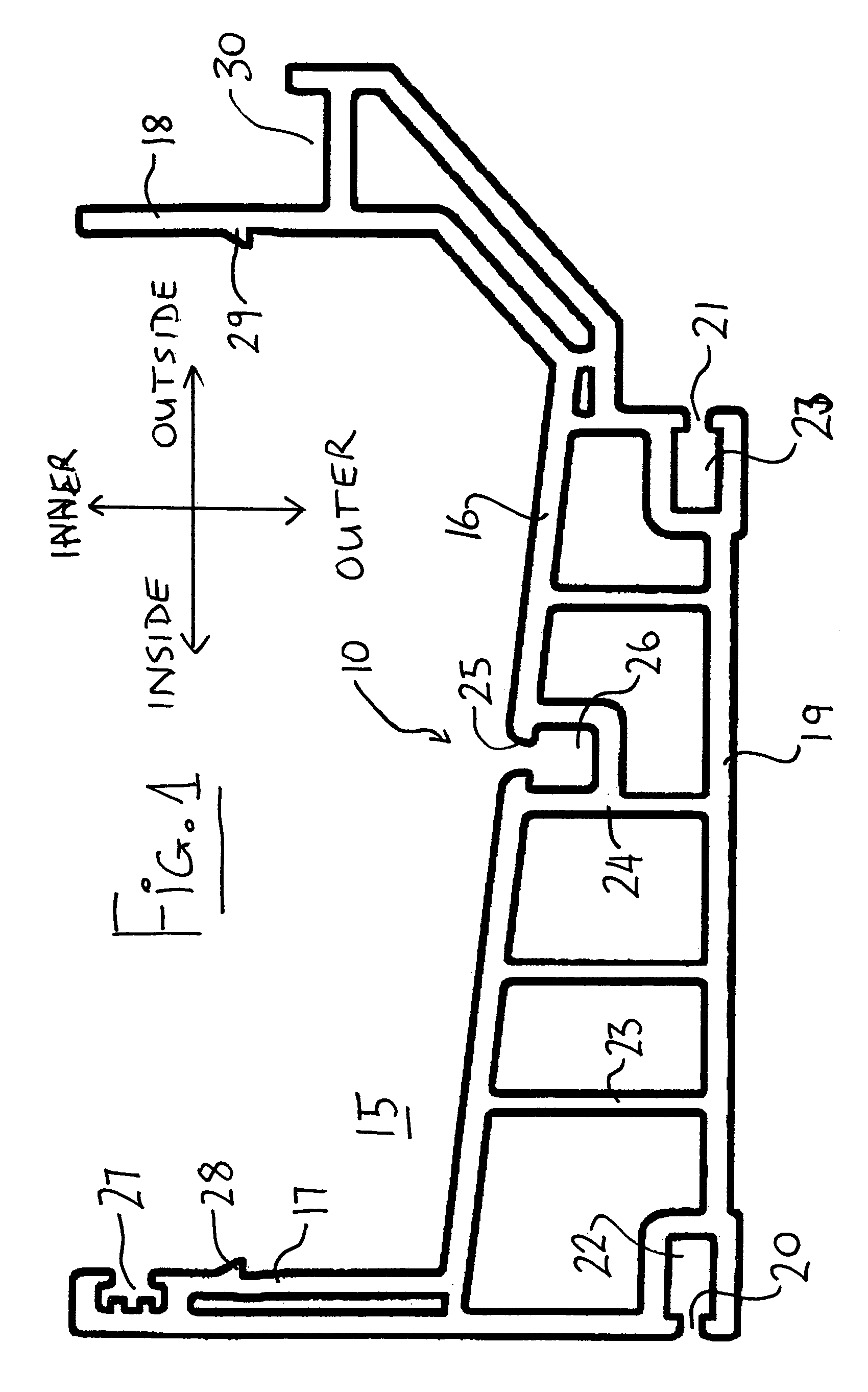

Extruded profile system for forming sliding fenestration products

A combination of profiles for forming slider and double hung sash windows or patio doors includes a common outer profile and two different inner profiles so that one inner profile can be used to form the double hung and the other to form the slider. This allows the slider top inner to be cut away to form a floating section resting on the top of the sash. This allows the drain holes to be formed separately in the inner and the outer to be longitudinally offset to prevent direct air penetration. The sash frame is formed with a removable glass stop on one side which snaps into engagement at right angles to the glass surface of the sealed unit to allow formation of a tri-pane with 0.5 inch spacing and to allow the use of two strips of adhesive one on each side of the sealed unit with no need for drainage.

Owner:HI TECH ENERGY WINDOWS

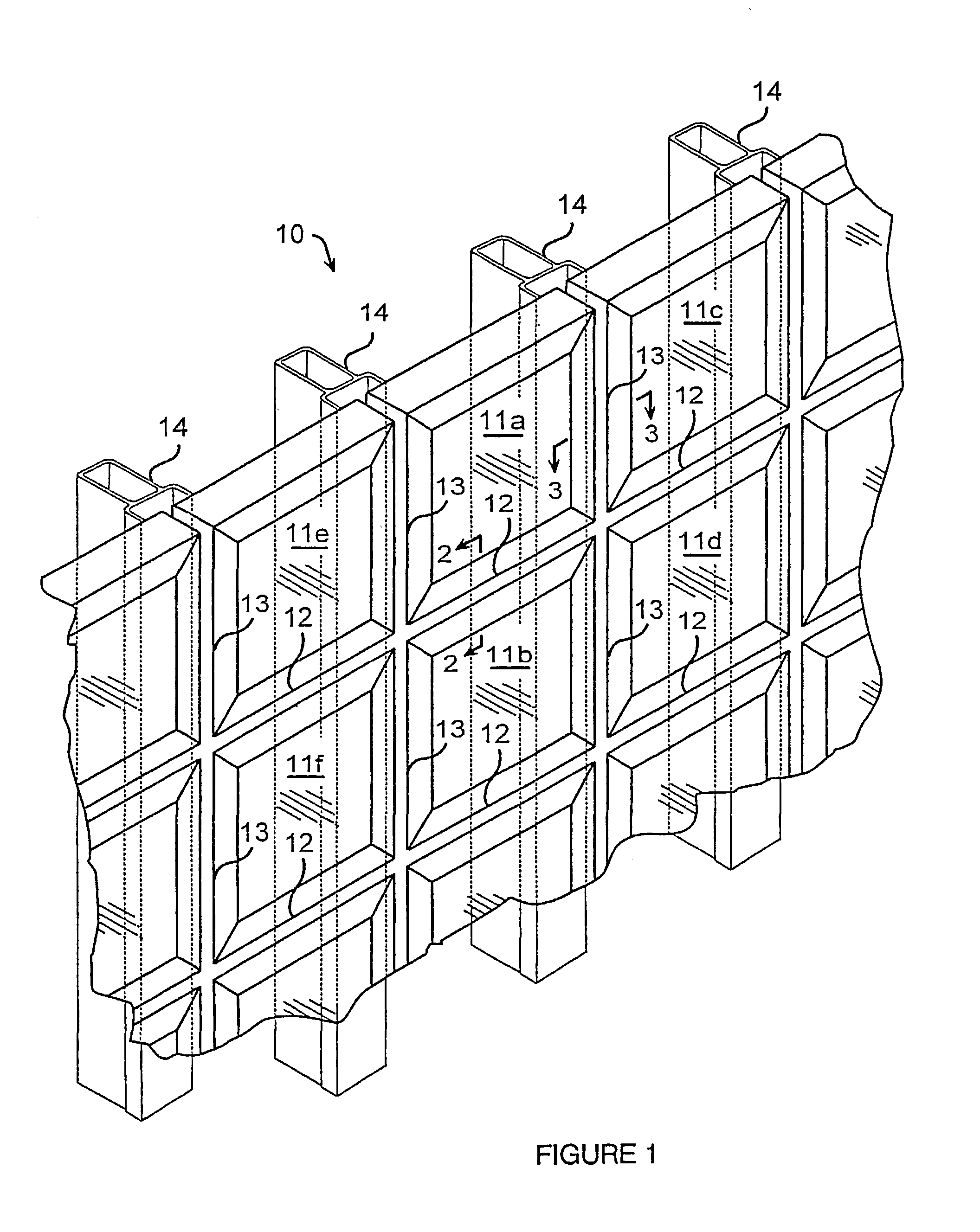

Dual glazing panel system

ActiveUS8056289B1Avoid buckling of the panelsRoof covering using slabs/sheetsBuilding repairsEngineeringLateral expansion

A transparent or translucent modular upstanding seam flange panel unit comprising opposed seam flange panels mounted in metal male and female locking engagement members designed to interlock and provide an internal gutter for collecting infiltrating water and for accommodating lateral expansion and contraction of the panels as well as a method for erecting an architectural structure for passing sunlight into an interior region of a building using such panel units.

Owner:CPI DAYLIGHTING

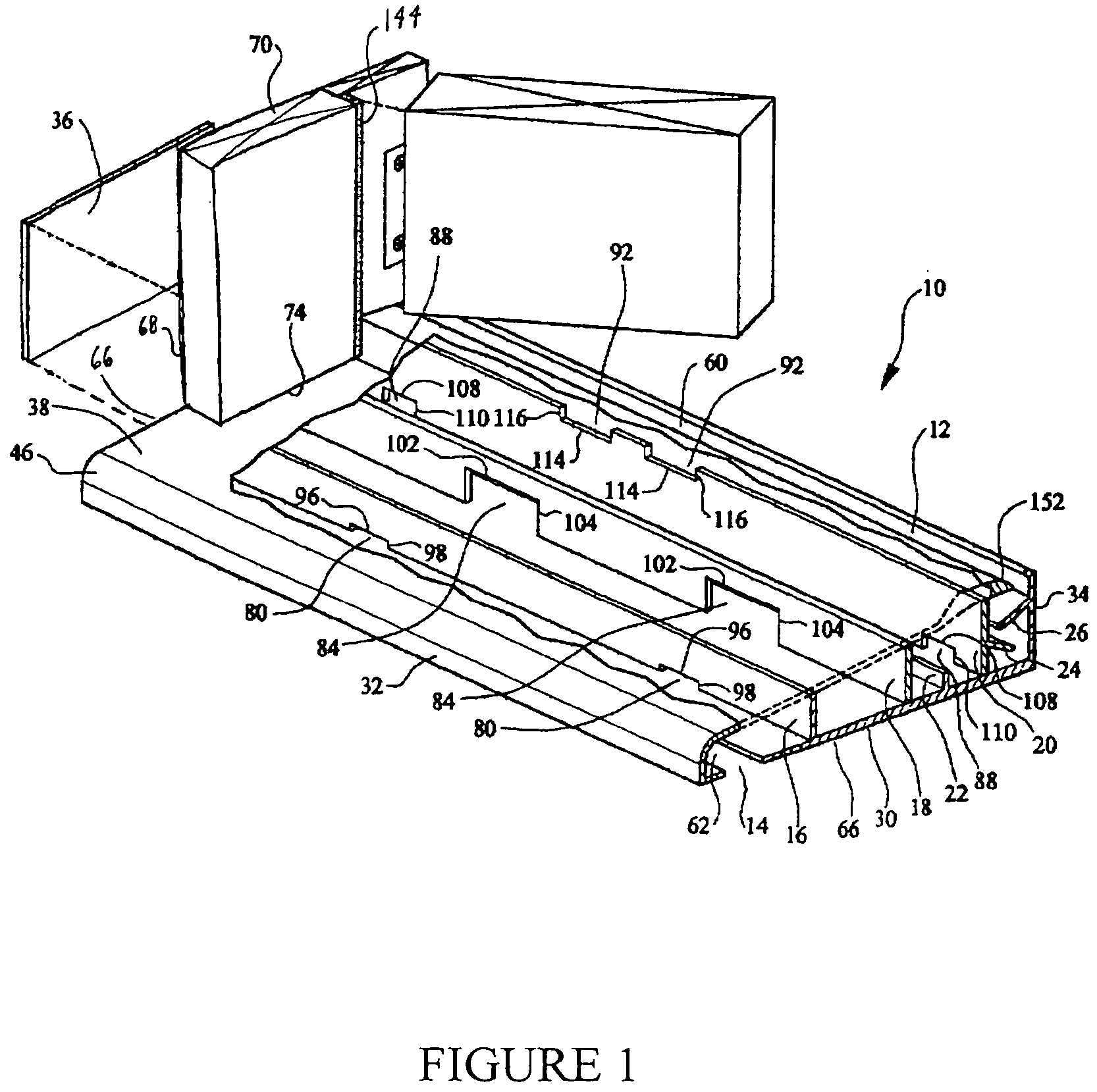

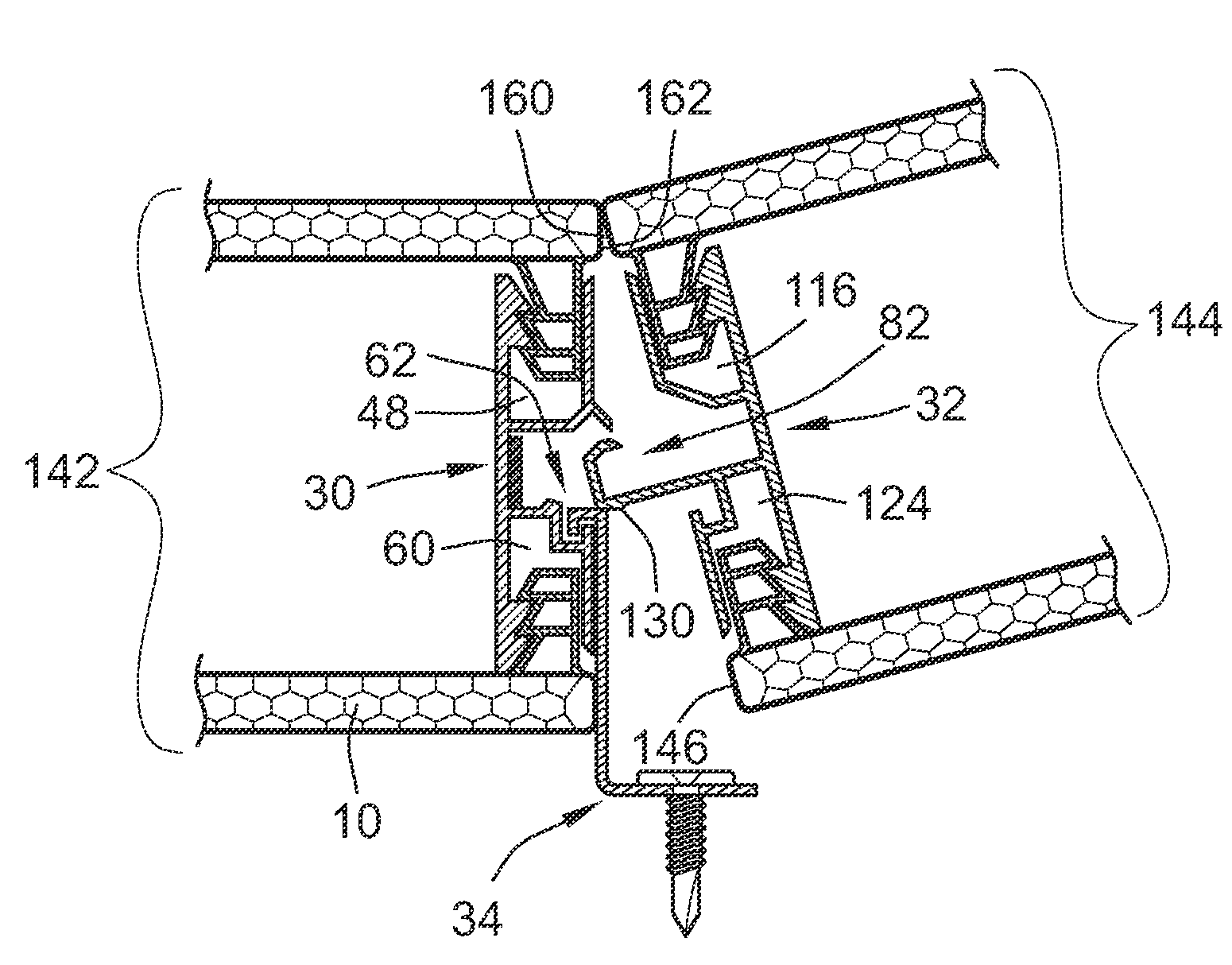

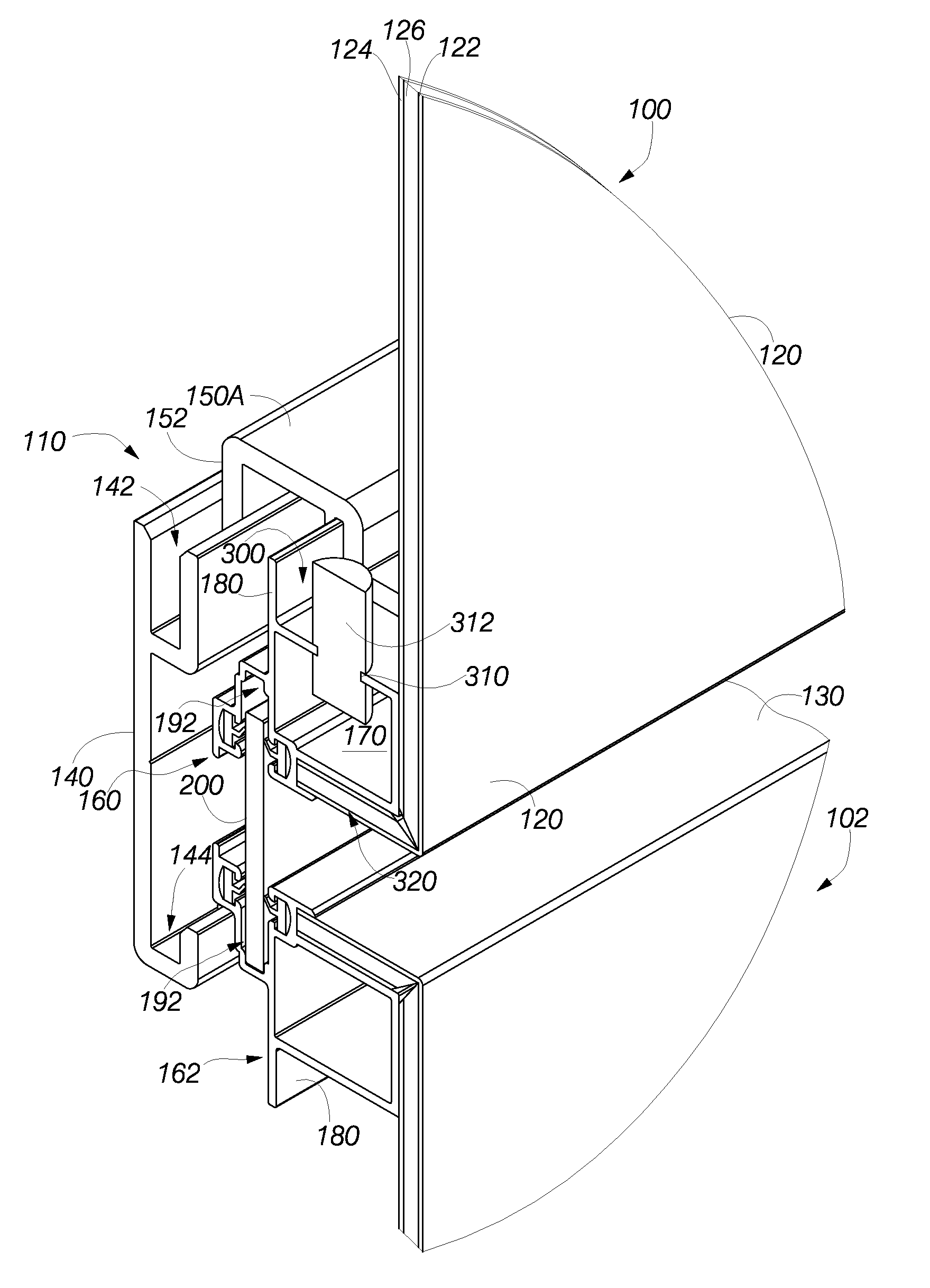

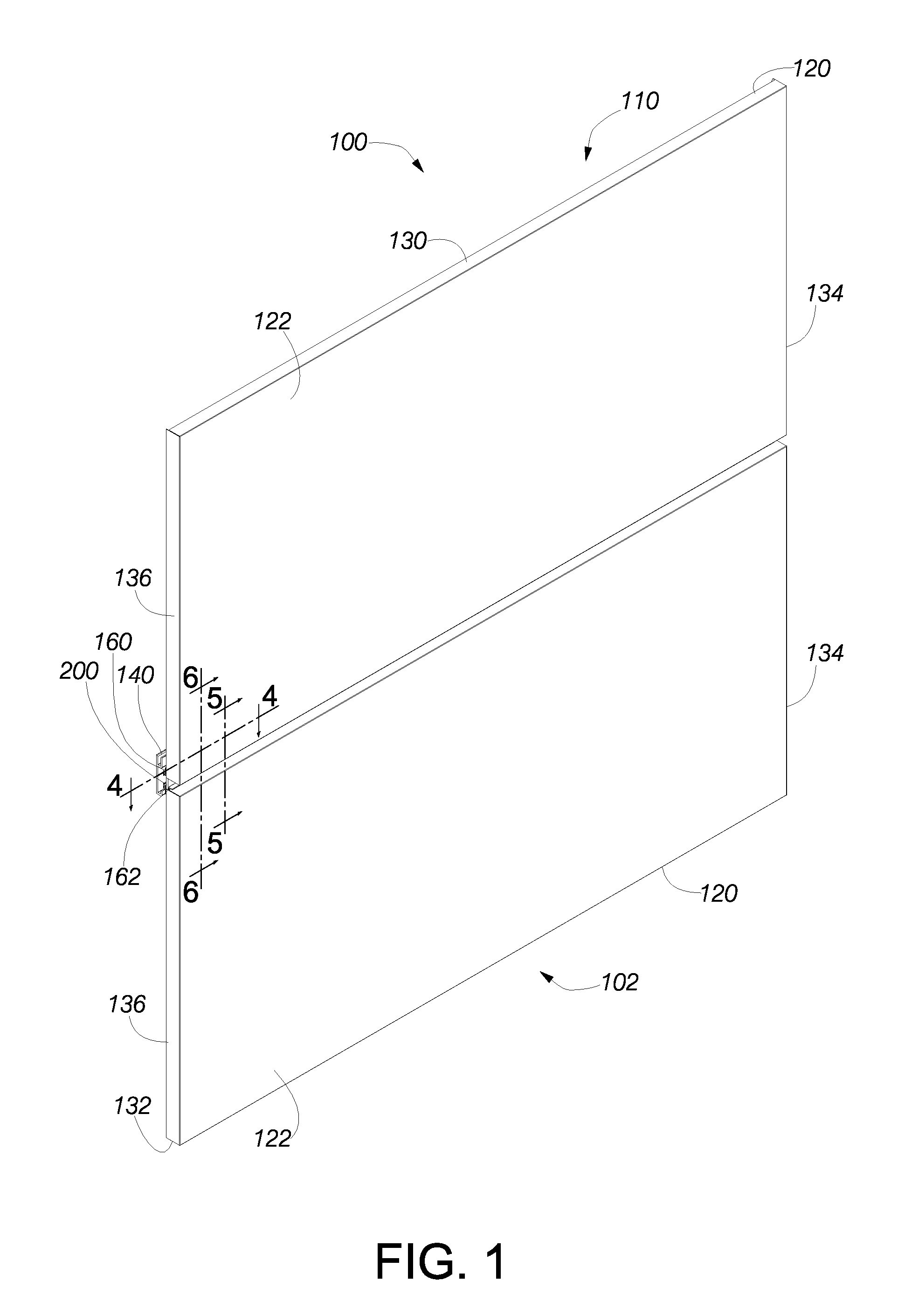

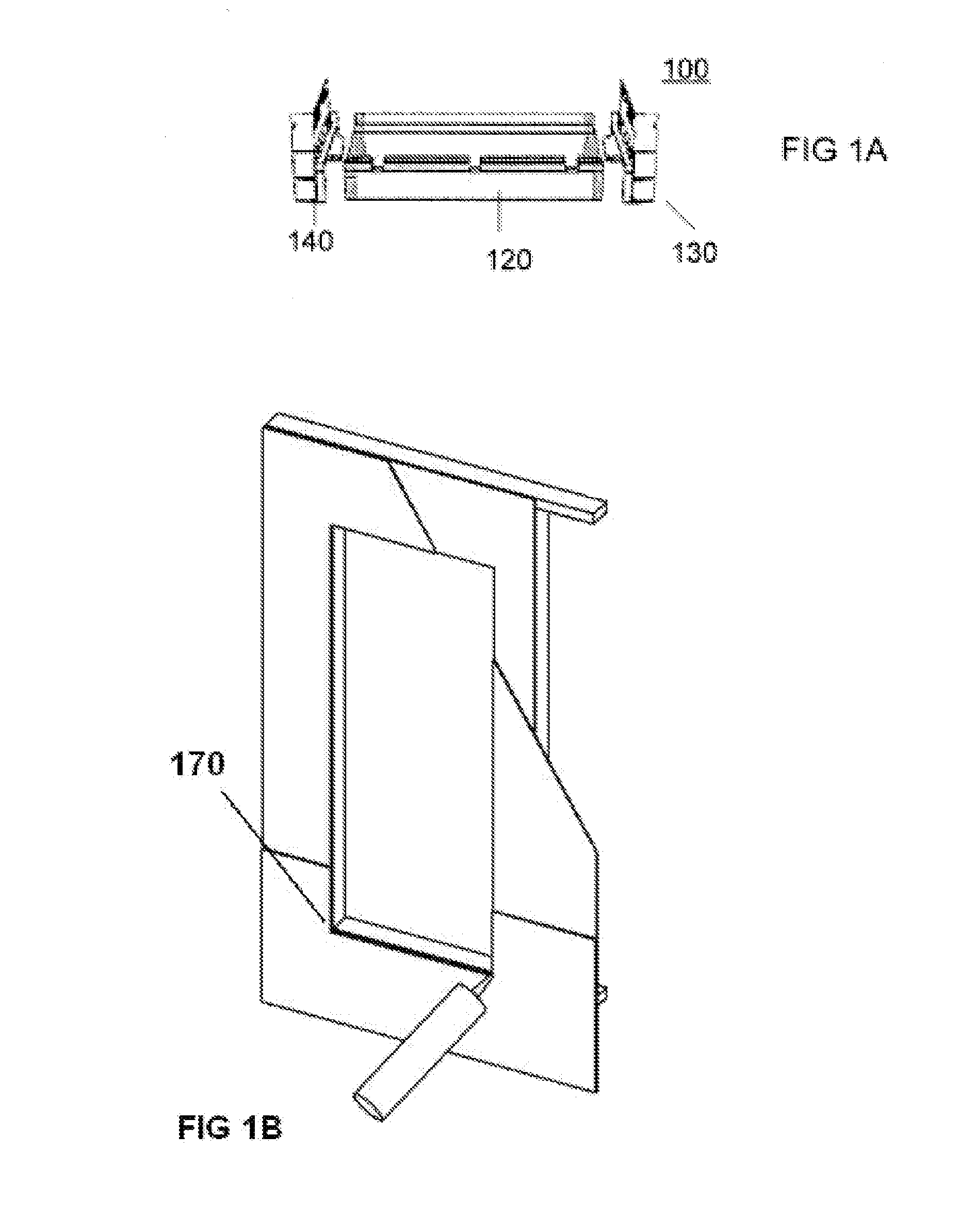

Exterior building panel with condensation draining system

A building panel subject to interior condensation of moisture and exterior wind-driven moisture includes a sheet having an inner surface onto which condensed moisture forms. An open upper reservoir is positioned proximate a bottom portion of the inner surface of the sheet to receive the condensed moisture. A lower chamber having at least one drain port is positioned below the upper reservoir. A wicking port connects the upper reservoir to the lower chamber. The wicking port weeps the condensed moisture from the upper reservoir to the lower chamber to drain the upper reservoir. The condensed moisture drains from the lower chamber via the drain port. The wicking port blocks the upward flow of wind-driven moisture that enters the lower chamber via the drain port.

Owner:THE CARVIST CORP

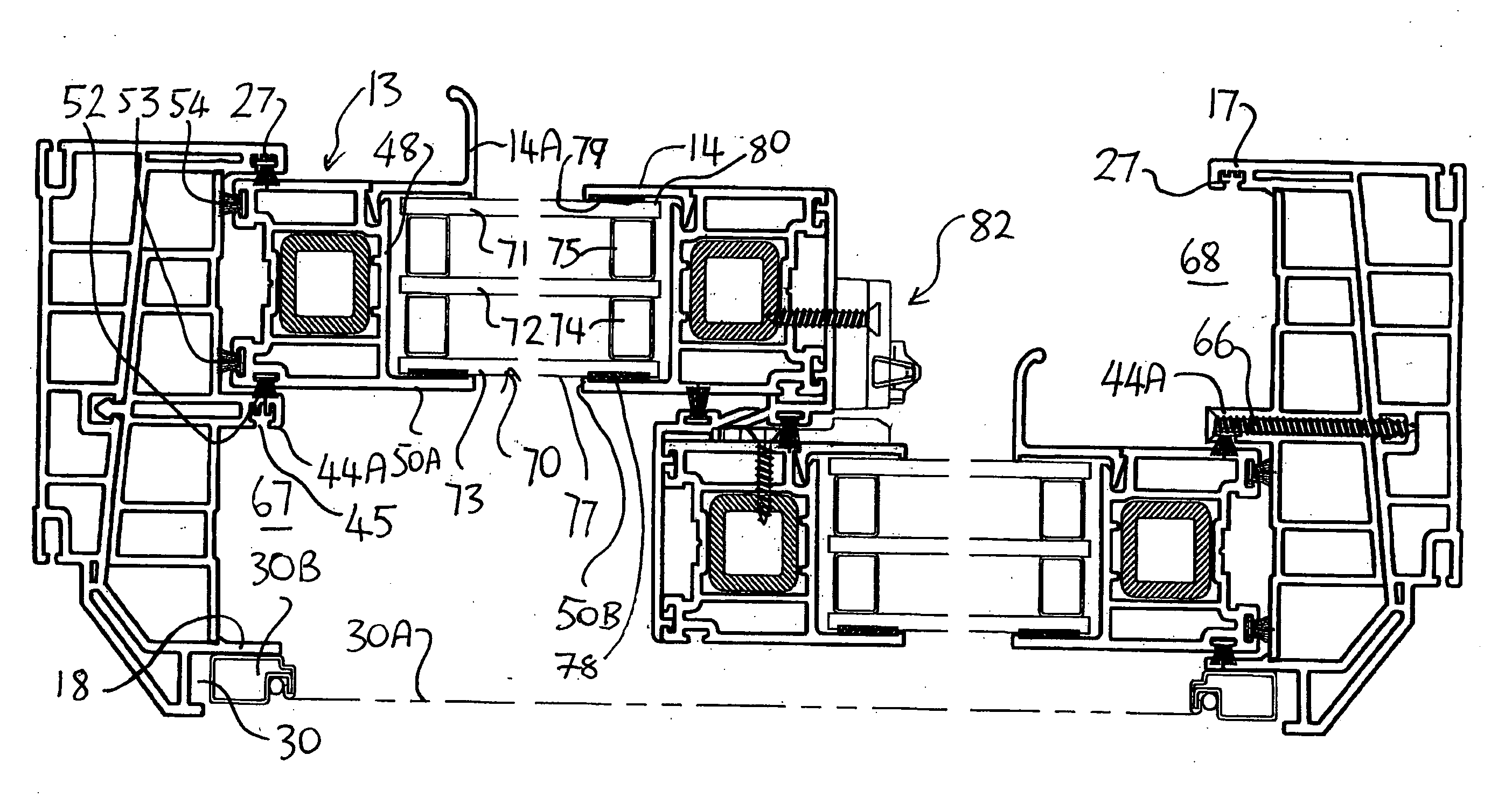

Extruded profile system for forming sliding fenestration products

A combination of profiles for forming slider and double hung sash windows or patio doors includes a common outer profile and two different inner profiles so that one inner profile can be used to form the double hung and the other to form the slider. This allows the slider top inner to be cut away to form a floating section resting on the top of the sash. This allows the drain holes to be formed separately in the inner and the outer to be longitudinally offset to prevent direct air penetration. The sash frame is formed with a removable glass stop on one side which snaps into engagement at right angles to the glass surface of the sealed unit to allow formation of a tri-pane with 0.5 inch spacing and to allow the use of two strips of adhesive one on each side of the sealed unit with no need for drainage.

Owner:HI TECH ENERGY WINDOWS

Exterior building panel

Owner:THE CARVIST CORP

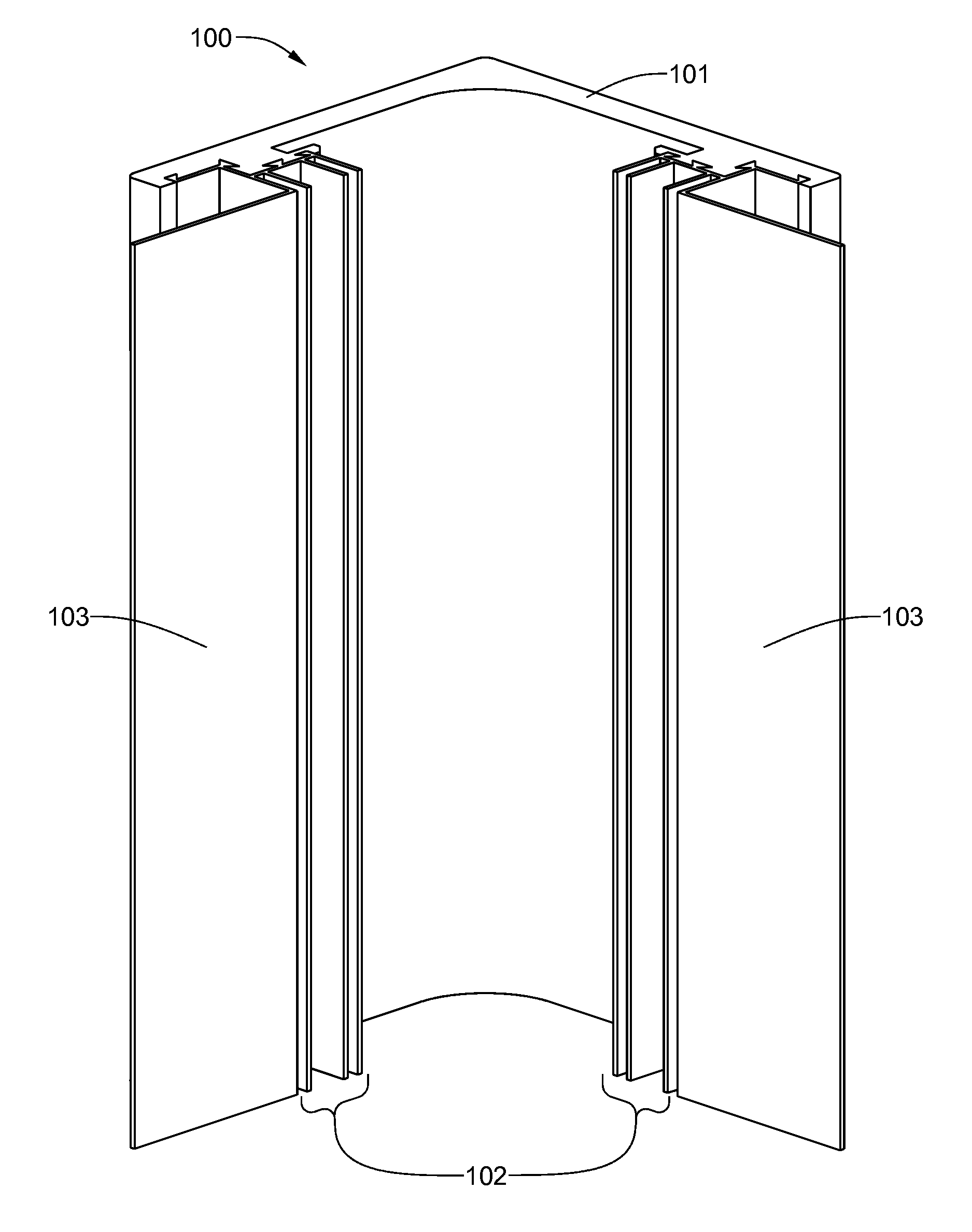

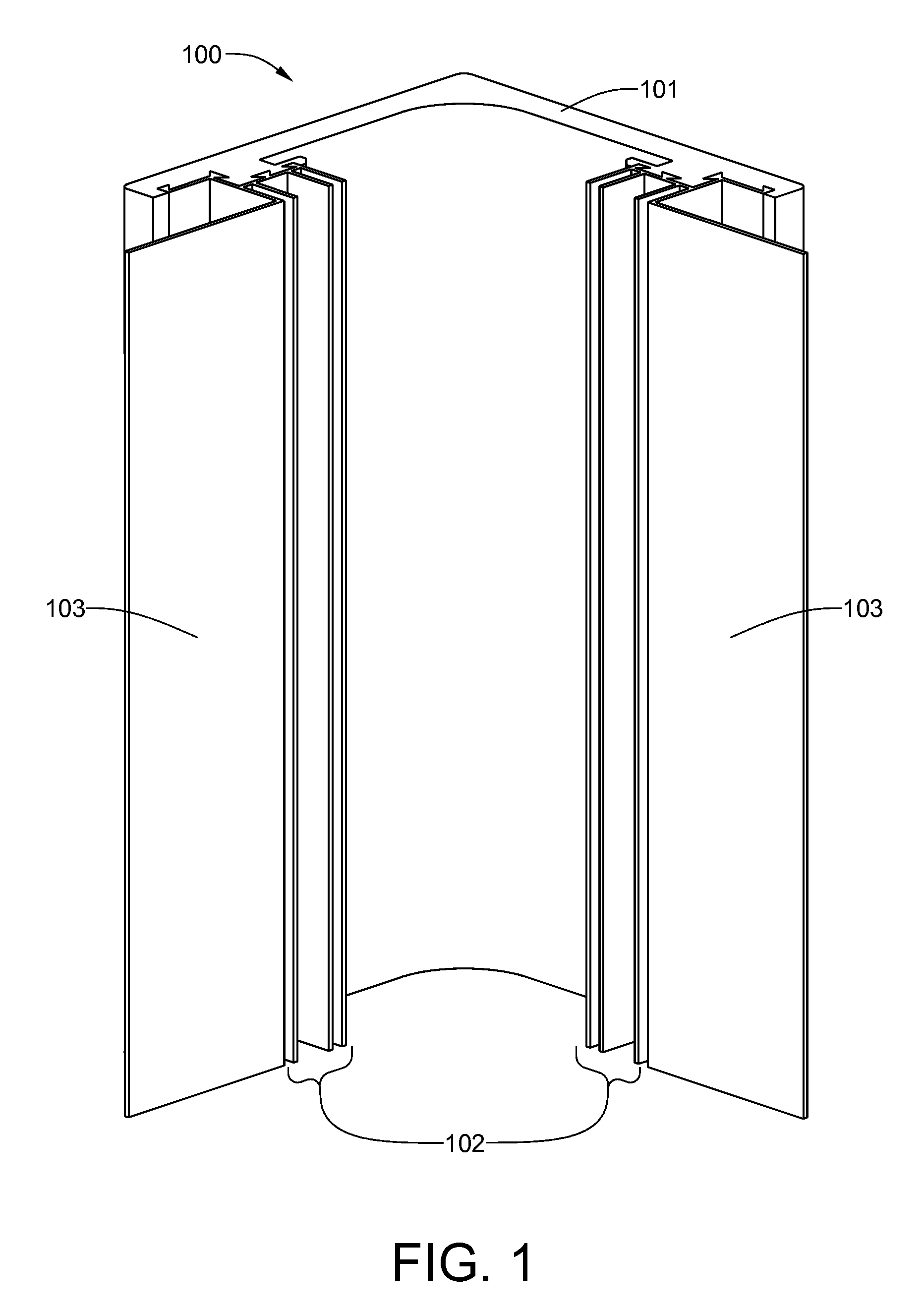

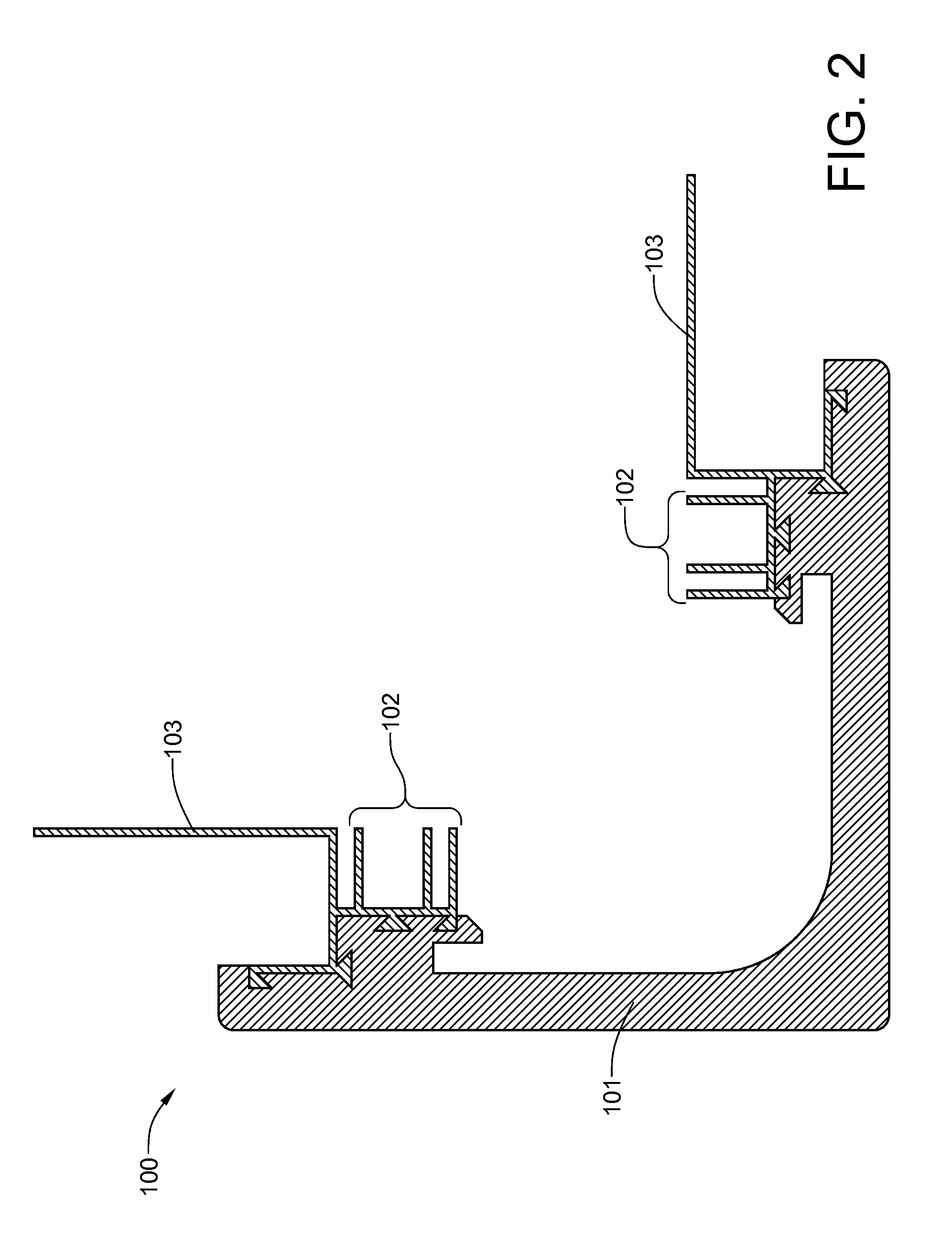

Entry system with water infiltration barrier

The present application discloses embodiments of entry systems that minimize water infiltration due to a wind driven rain. In one embodiment, the entry system includes a corner pad that includes an upper portion that seals against the weather strip when the door is closed and a lower portion that is spaced apart from the weather strip to form a gap between the lower portion and the weather strip. The lower portion seals against the door when the door is closed.

Owner:THERMA TRU

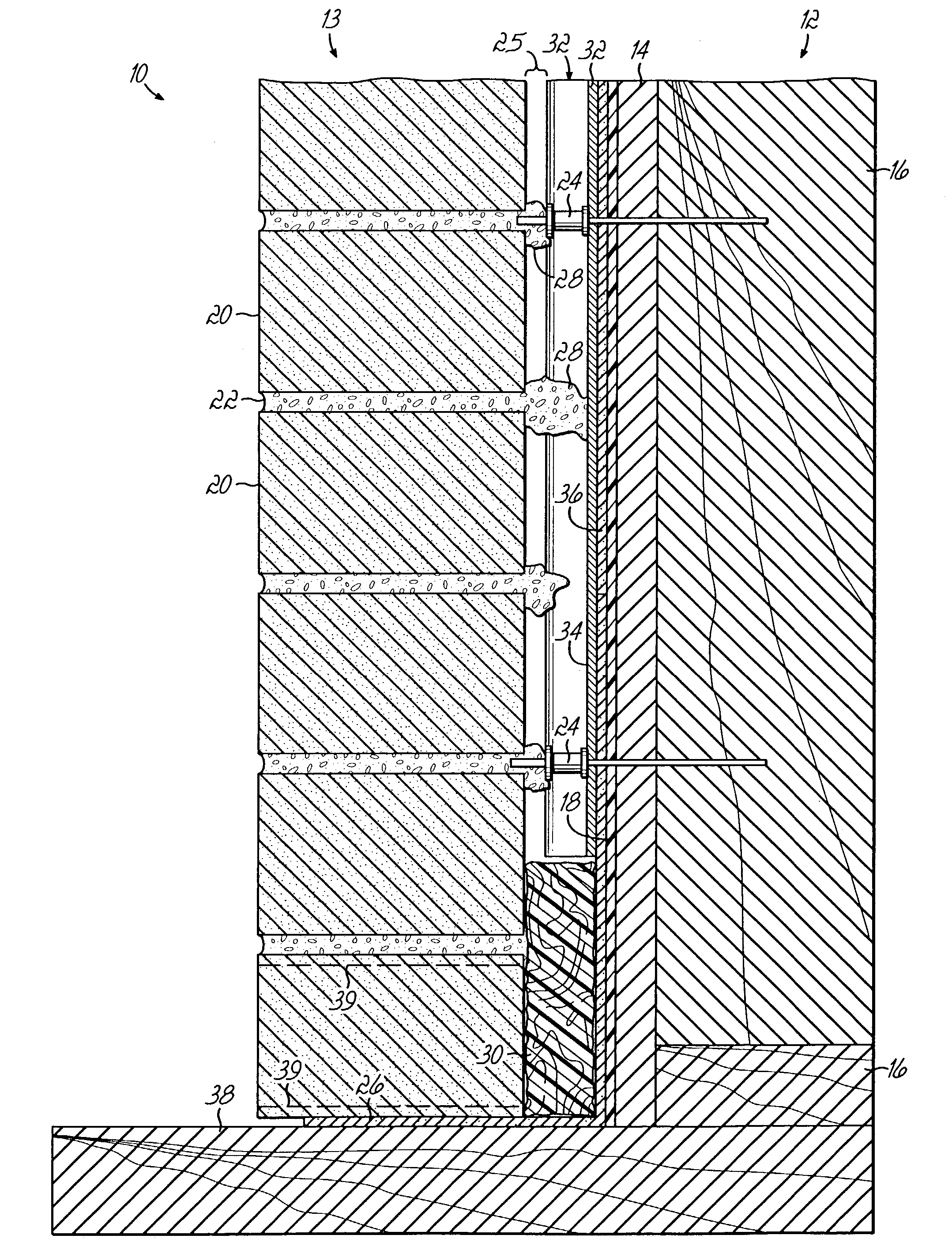

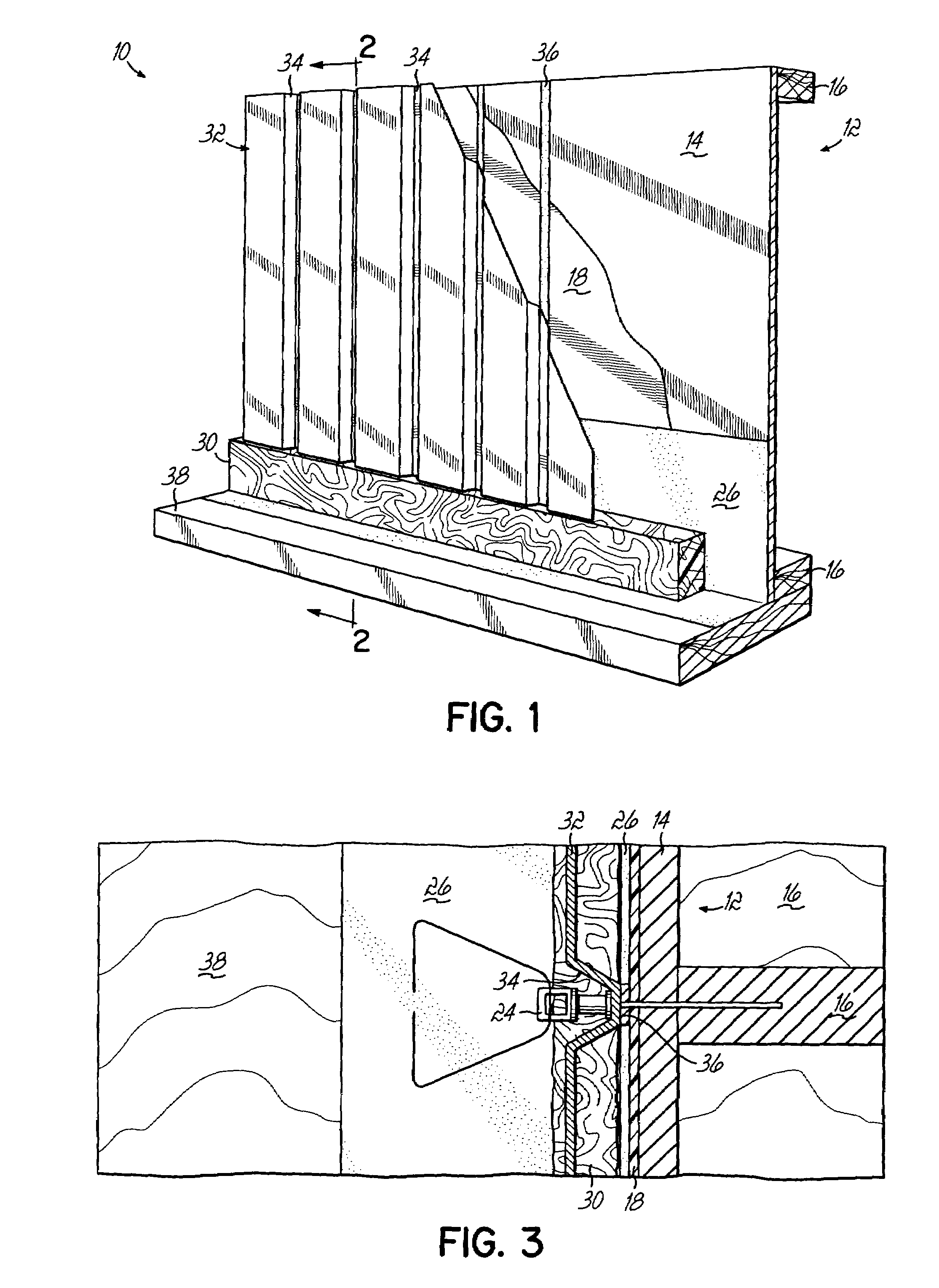

Air circulation board for cavity wall construction

A corrugated board is secured to the inner wall of a cavity wall construction to establish a defined spacing between the inner and outer walls and prevent excess mortar from bridging to the inner wall. The corrugated board has a series of spaced channels, furrows or grooves into which an anchor projects into the studs of the inner wall to secure the outer wall. The corrugated board is installed prior to the construction of the outer wall and establishes a minimum spacing or gap between the walls based upon the thickness of the board. The outer wall is constructed immediately adjacent to the outer face of the corrugated board. The grooves or channels of the corrugated board create a chamber for vapor and air circulation. The board eliminates bridging by the mortar and provides an air conduit to exhaust even the minimal amounts of vapor that will occur in the cavity.

Owner:TY DAS BUILDING PROD LLC

Door entryway system

A door entryway system can include a door sweep capable of attachment to a bottom of a door panel. The system also includes a threshold assembly having a self-articulating threshold cap configured to be biased toward the door sweep and interact therewith to form a sealing barrier when the door panel is in a closed position.

Owner:ENDURA PRODS

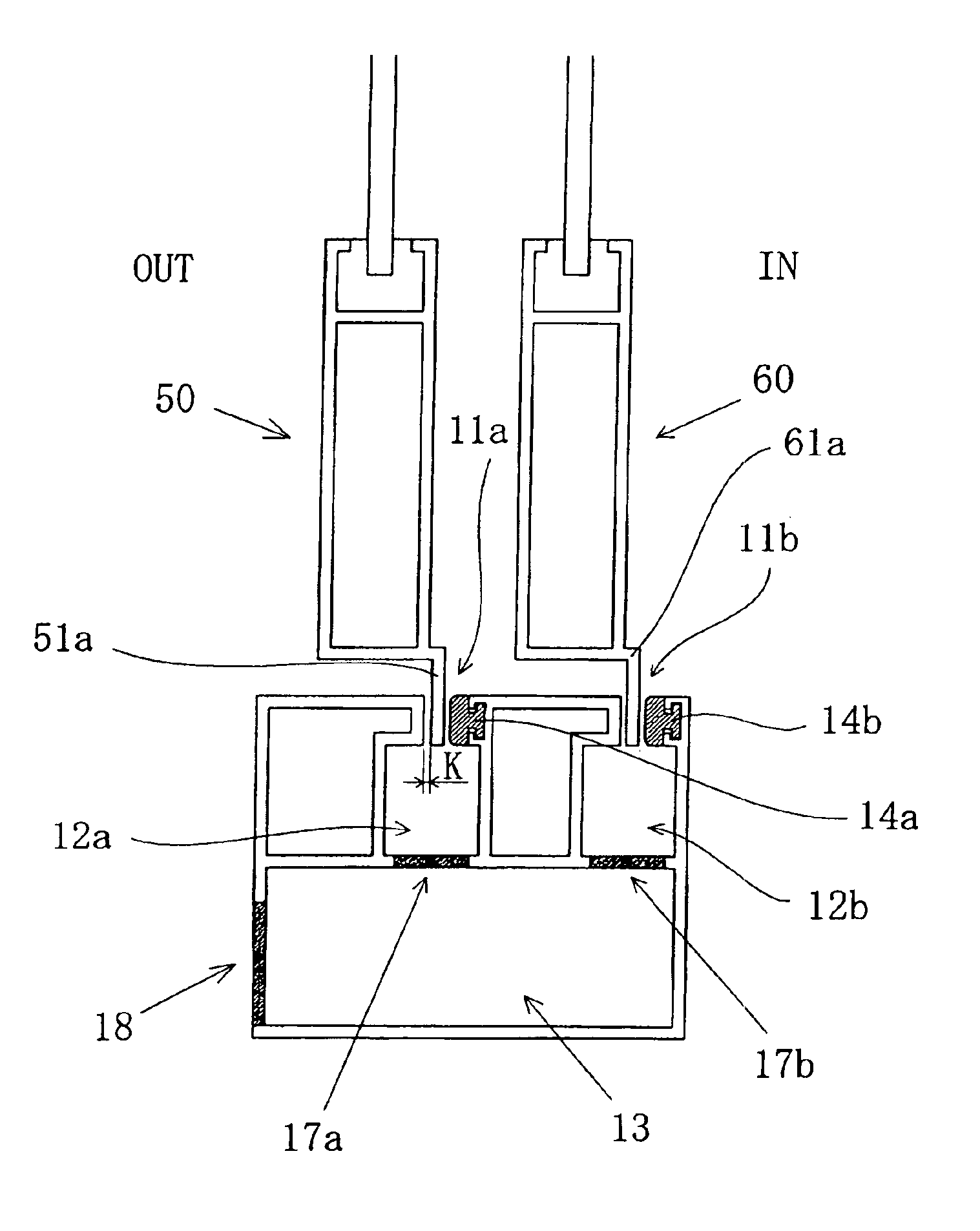

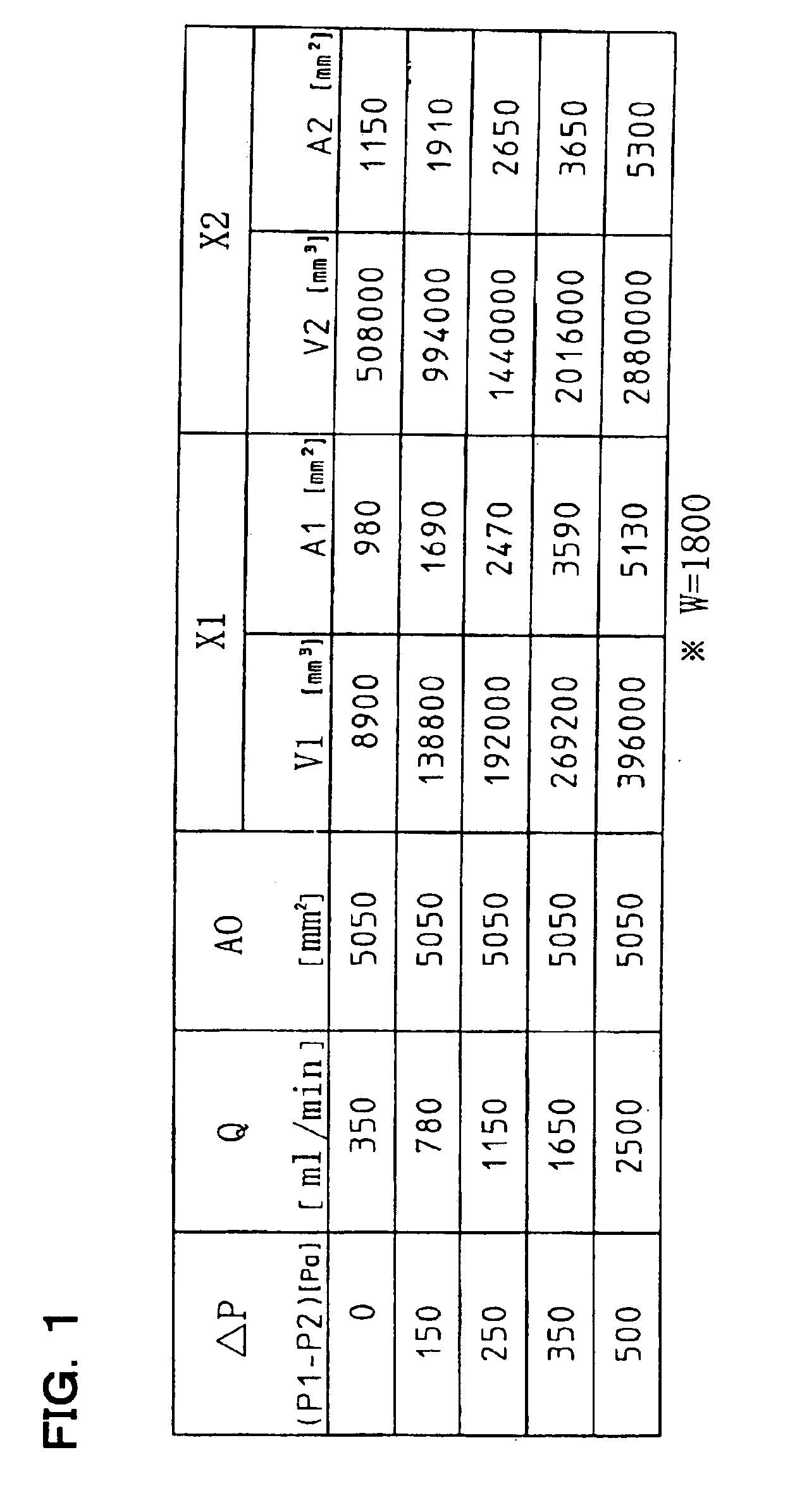

Outdoor window

InactiveUS6883279B2Superior in drainage of rainwaterHigh in watertightness against indoor water leakageCondensed water drain-offSealing arrangementsSash windowEngineering

Owner:TATEYAMA ALUMINUM IND

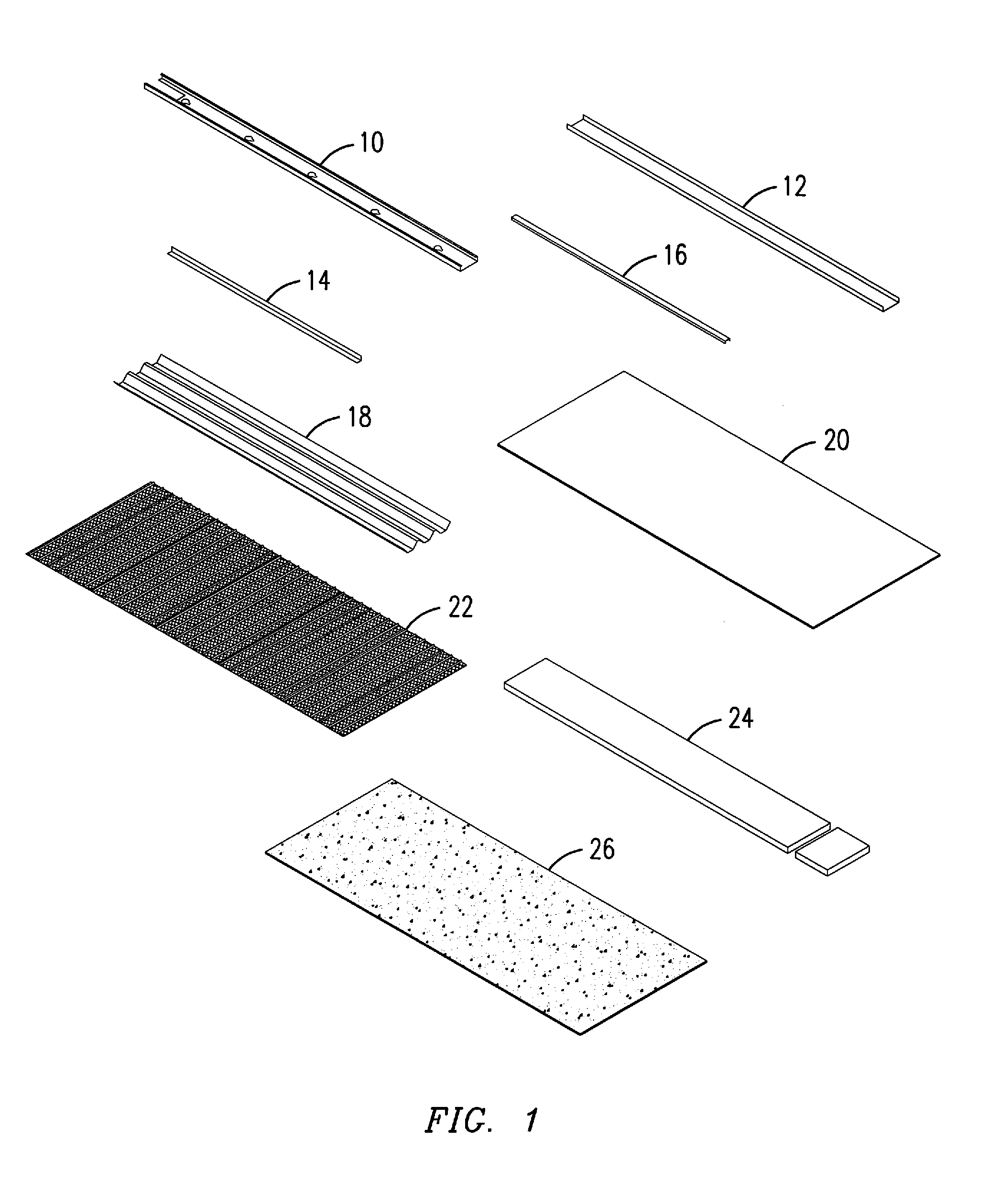

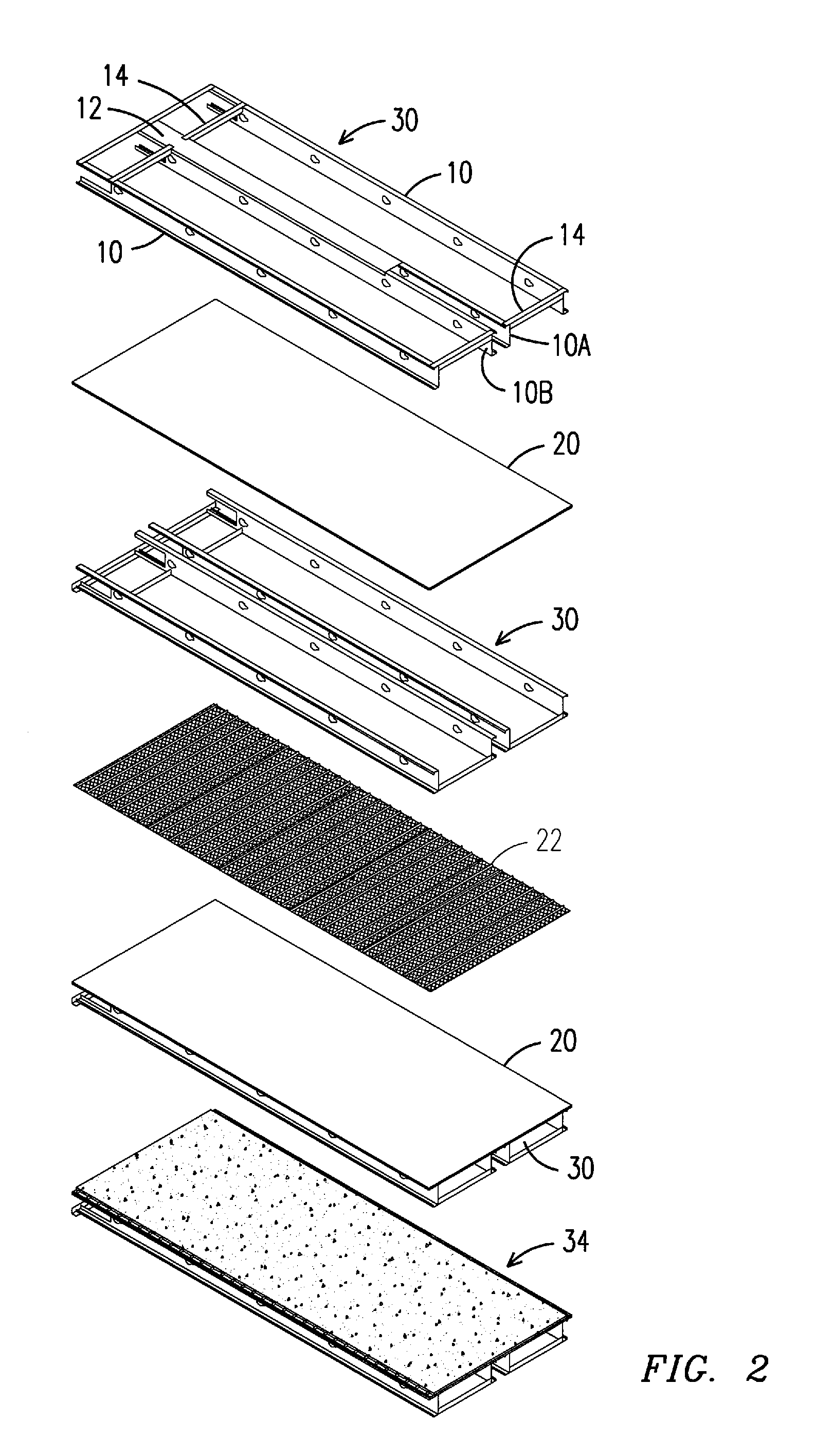

Prefabricated wall panel system

A prefabricated wall system used in constructing a structure, the system including a wall segment configured to be lightweight and easily handled manually while constructing the structure, and a securing system configured to secure the wall segment in place on the structure.

Owner:LITETECH

Door entryway system

A door entryway system can include a door sweep capable of attachment to a bottom of a door panel. The system also includes a threshold assembly having a self-articulating threshold cap configured to self-adjust toward the door sweep and interact therewith to form a sealing barrier when the door panel is in a closed position.

Owner:ENDURA PRODS

Condensation evacuating window sill

InactiveUS6848225B2Inhibit deteriorationImprove aestheticsFixed grillesCondensed water drain-offWindow sillEngineering

A condensation evacuating sill for evacuating condensate having formed on an inner surface of a window pane includes a molding strip and an attachment extrusion for attaching the molding strip to the window frame. The attachment extrusion includes an extrusion-to-molding attachment section for attaching the molding attachment surface to the attachment extrusion and an extrusion-to-frame attachment section for attaching the attachment extrusion to the window frame. The attachment extrusion is configured and sized for attaching the molding strip to the window frame so that the molding inner edge is spaced relative to the inner surface by a pane-to-molding spacing allowing the condensate to flow therethrough without contacting the molding strip. The attachment extrusion further includes flow guiding components for guiding the flow of condensate from the pane-to-molding spacing to a discharge location located away from the attachment extrusion.

Owner:LAPIERRE NORMAND

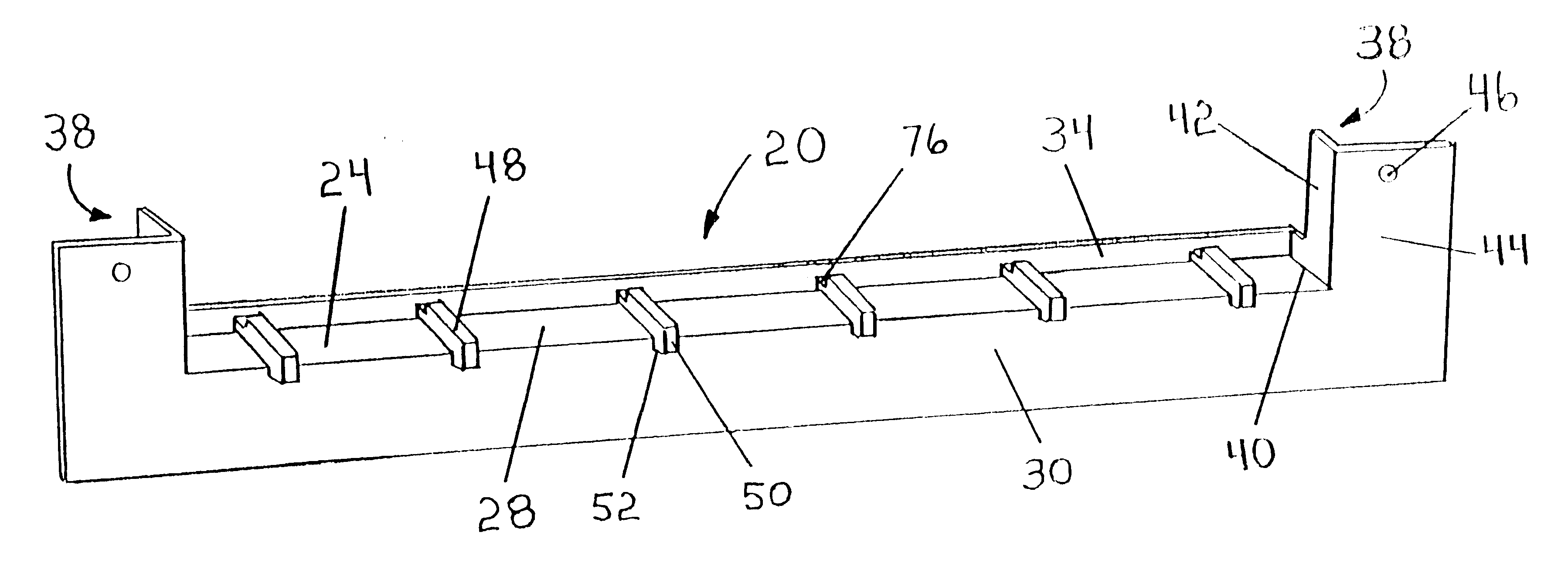

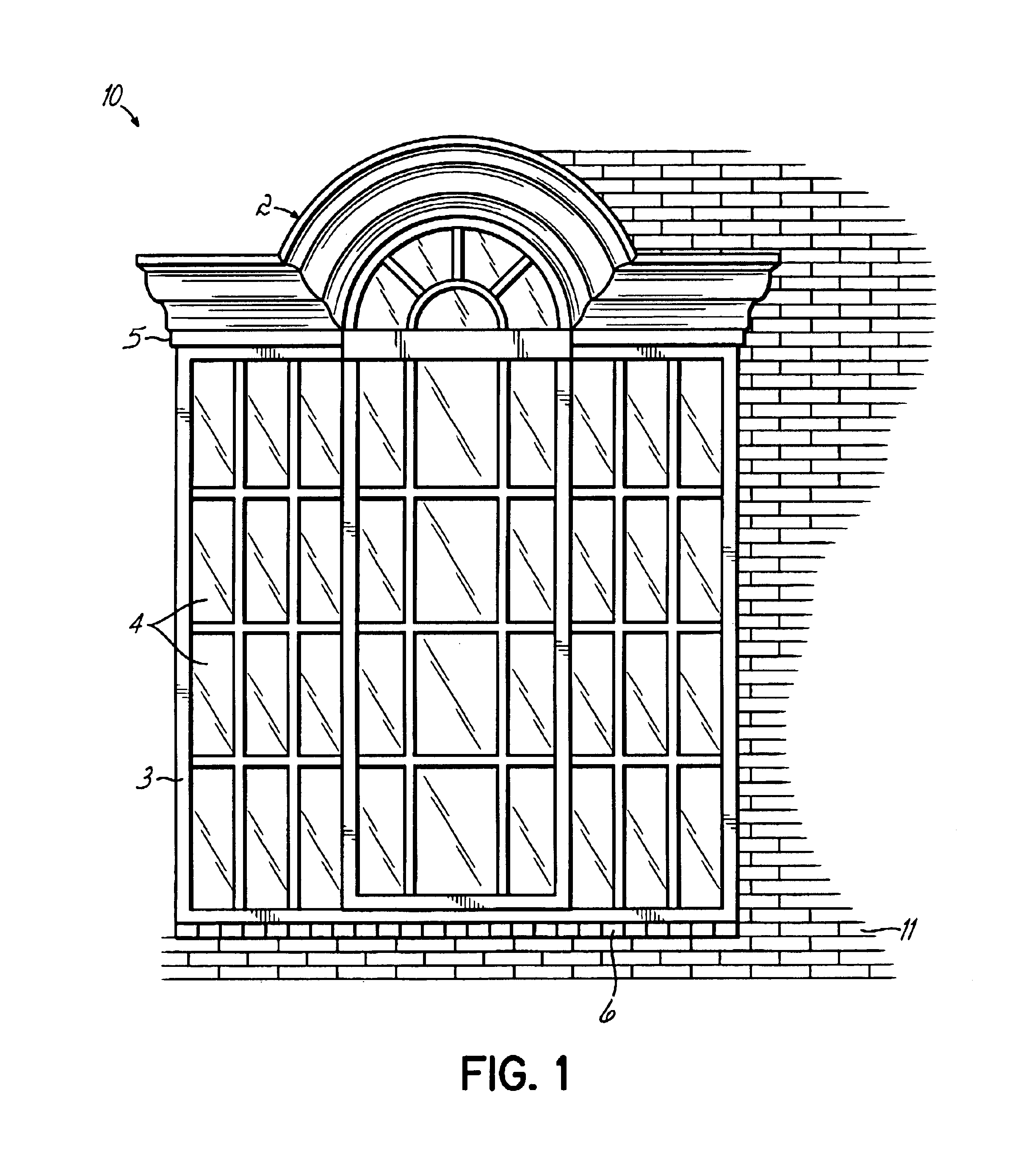

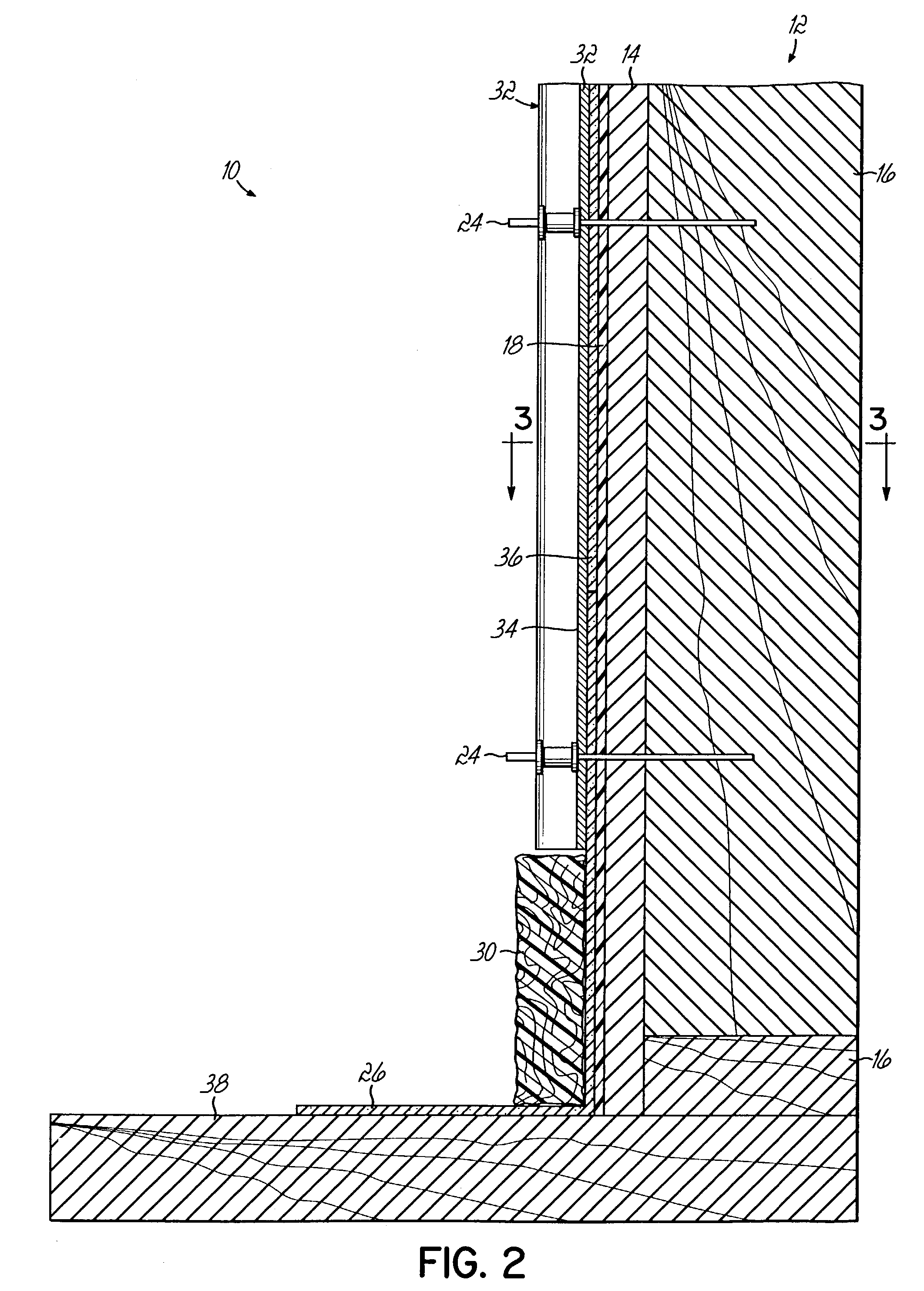

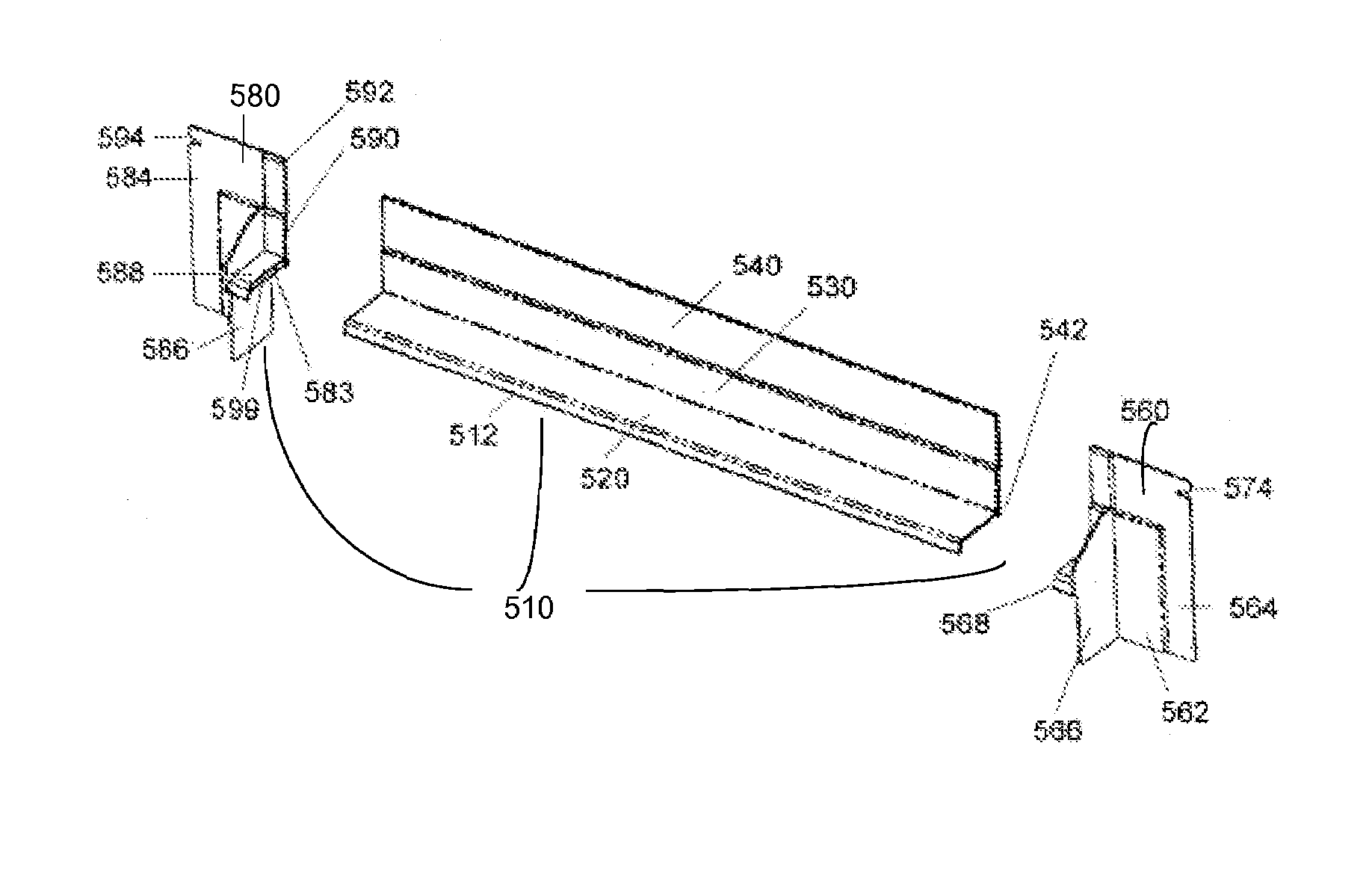

Apparatus and method for door and window head flashing

ActiveUS7676996B2BuildLow costRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringWindow Width

A window and door head flashing assembly is fabricated at a construction site to fit specific door or window widths. A center section which may be extruded with a sloped base, a rear flange, and a front lip. End caps may be provided to snap or glue on the center section. The end caps have a perpendicular fin which serves as an end dam to block the lateral movement of water. The assembly may be inverted for use as a sill pan. The center section may be cut to a desired length and installed over arched windows or doors by bending to shape as it is installed. For arched applications, a combination of rigid and flexible PVC may be coextruded to provide a desired cross sectional profile that is flexible enough to be bent around the arch, but stiff enough to retain its cross section for drainage.

Owner:TEODOROVICH MISHKO

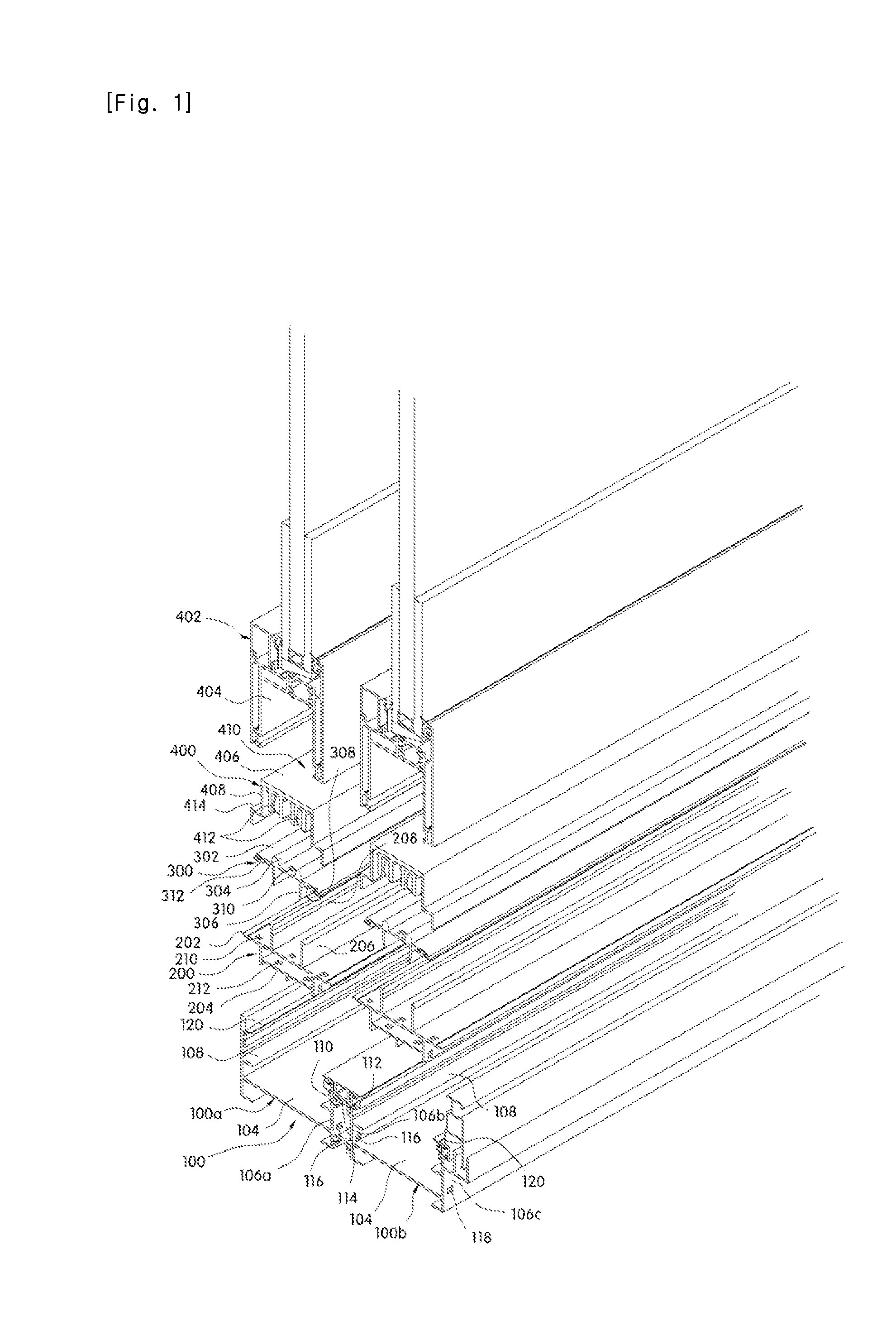

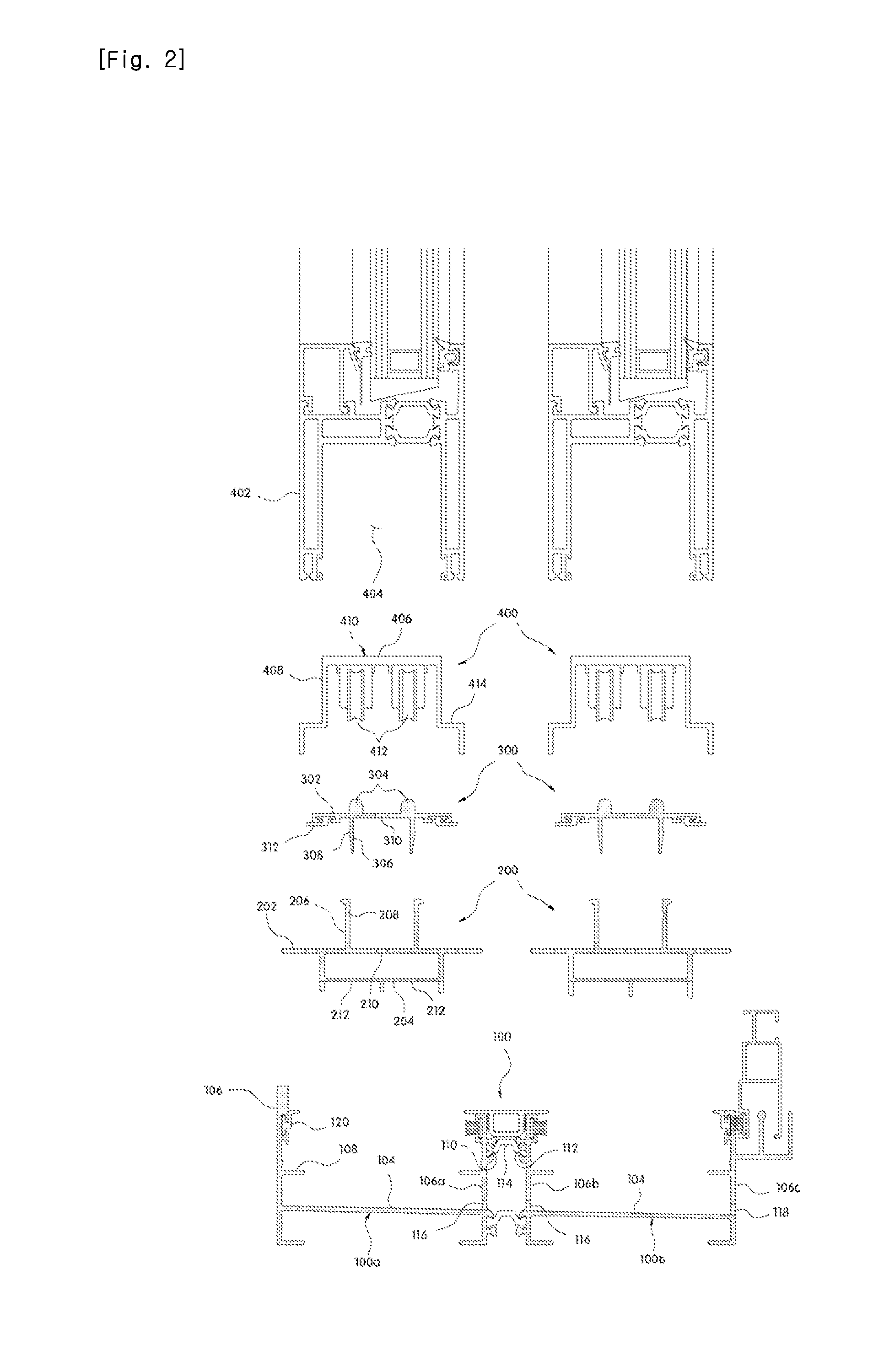

Easy-to-construct window apparatus

InactiveUS20120005975A1Easy to separateEasy to operateMan-operated mechanismWindow/door framesEngineeringFastener

Disclosed is an easy-to-construct window apparatus including to assure easy construction and superior drainage ability. The window apparatus includes a window frame fixing unit including a bottom plate, vertical plates formed at lateral ends of the bottom plate and a rack plate formed at each vertical plate, a window frame support unit including a seat plate on the rack plate, a support plate configured to be supported on the bottom plate, fastening pieces protruding from the seat plate, and a holding groove formed in each fastening piece, a rail unit including a horizontal plate provided with a rail and a coupling piece, and a holding ridge formed at the coupling piece so as to be coupled with the holding groove, a window drive unit including a press-fit structure to be press-fitted into a window, and water discharge holes perforated in the aforementioned units.

Owner:KIM SOON SEOK

Door Entryway System

A door entryway system can include a door sweep capable of attachment to a bottom of a door panel. The system also includes a threshold assembly having a self-articulating threshold cap configured to self-adjust toward the door sweep and interact therewith to form a sealing barrier when the door panel is in a closed position.

Owner:ENDURA PRODS

Window and door sub-sill and frame adapter and method of attaching a sill

InactiveUS20050262771A1High strengthSuperior in water prevention capabilityCondensed water drain-offWing suspension devicesArchitectural engineeringWindow sill

An apparatus and method for attaching a window or door sill to a building support structure is provided. The apparatus includes a rectangular frame that is attachable to a building support structure and provides an upper surface for a sill, to be securely attached to the apparatus. The apparatus thereby provides a raised surface with which to attach the sill. The apparatus includes a lip, which helps align the sill along the upper surface of the apparatus, and also helps prevent water intrusion. The apparatus further includes a support vein that runs through the center and along the length of the apparatus to provide added support strength.

Owner:CONSTR CONCEPTS UNLTD

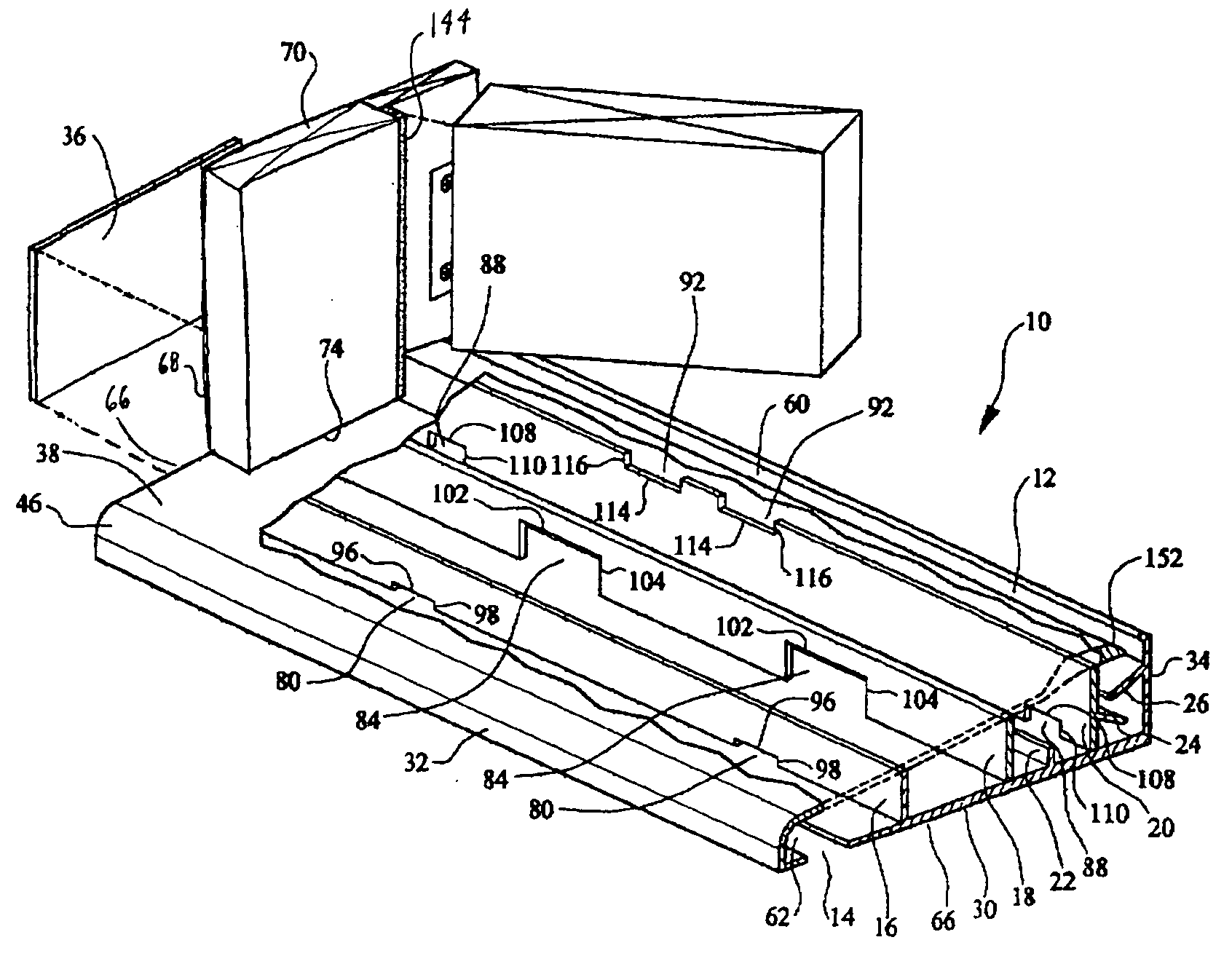

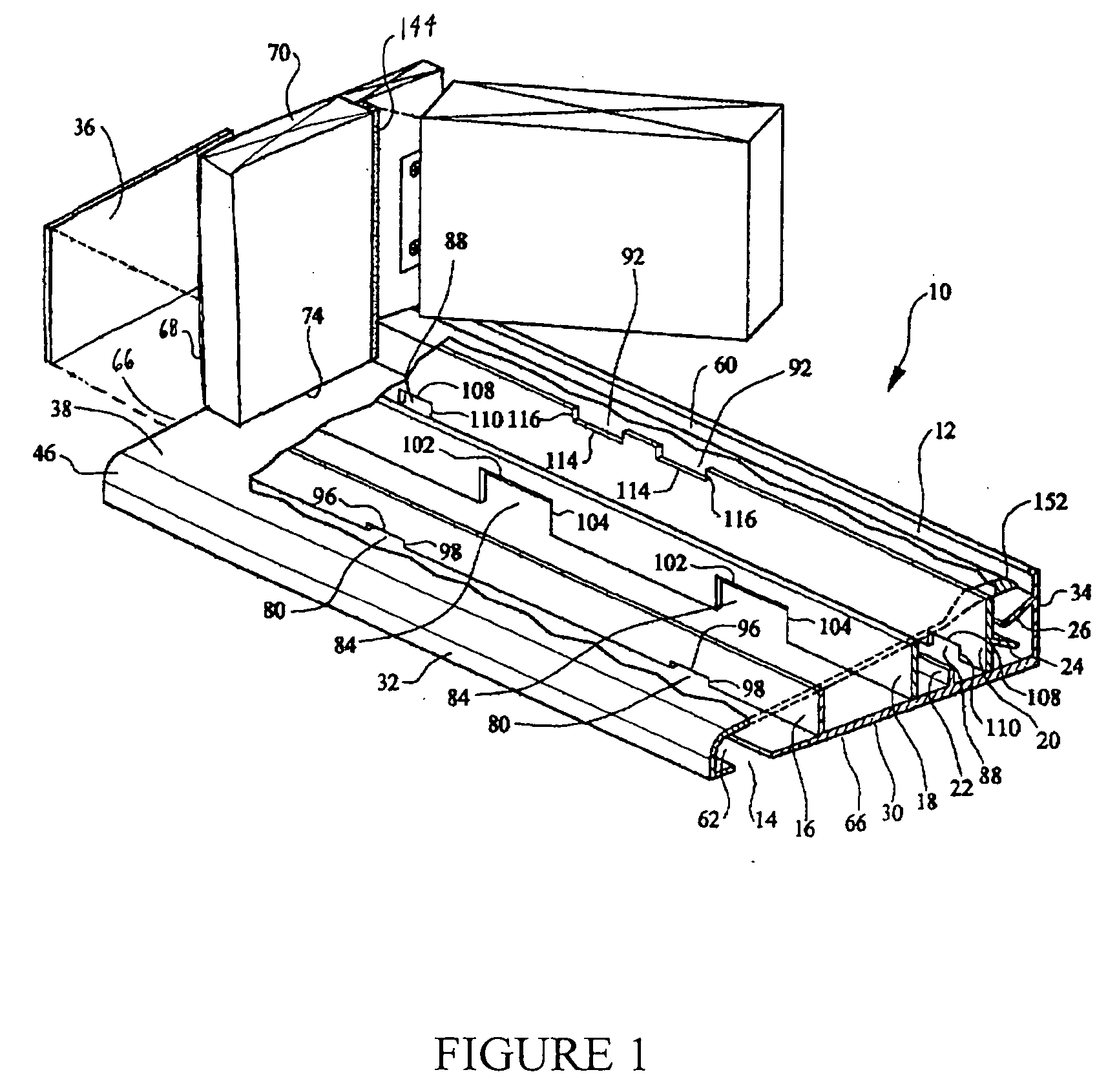

Trim components for lapboard siding that are co-extruded from wood-plastic composites and polyvinyl chloride

ActiveUS20120328823A1Reduce installation costsUse amountCovering/liningsSynthetic resin layered productsPolyvinyl chlorideEngineering

A lapboard siding and trim system is provided in which trim siding components for board-and-batten siding and associated trim components are manufactured using a co-extrusion process, whereby wood / thermoplastic resin composite material and polyvinyl chloride thermoplastic resins are co-extruded through a single die assembly, thereby producing a trim piece having a plastic composite component, that will be visible following installation, fused under heat and pressure to the polyvinyl chloride standoff and attachment fins, that will be hidden following installation. Also provided is a lapboard siding and trim system in which siding components for clapboard siding are manufactured by extruding wood / thermoplastic resin composite material through a die. Associated trim components are manufactured using the co-extrusion process described above. The siding and trim components are completely waterproof, and installation proceeds with almost no face nailing and almost no caulk.

Owner:MONTEER SHAUN ROBERT

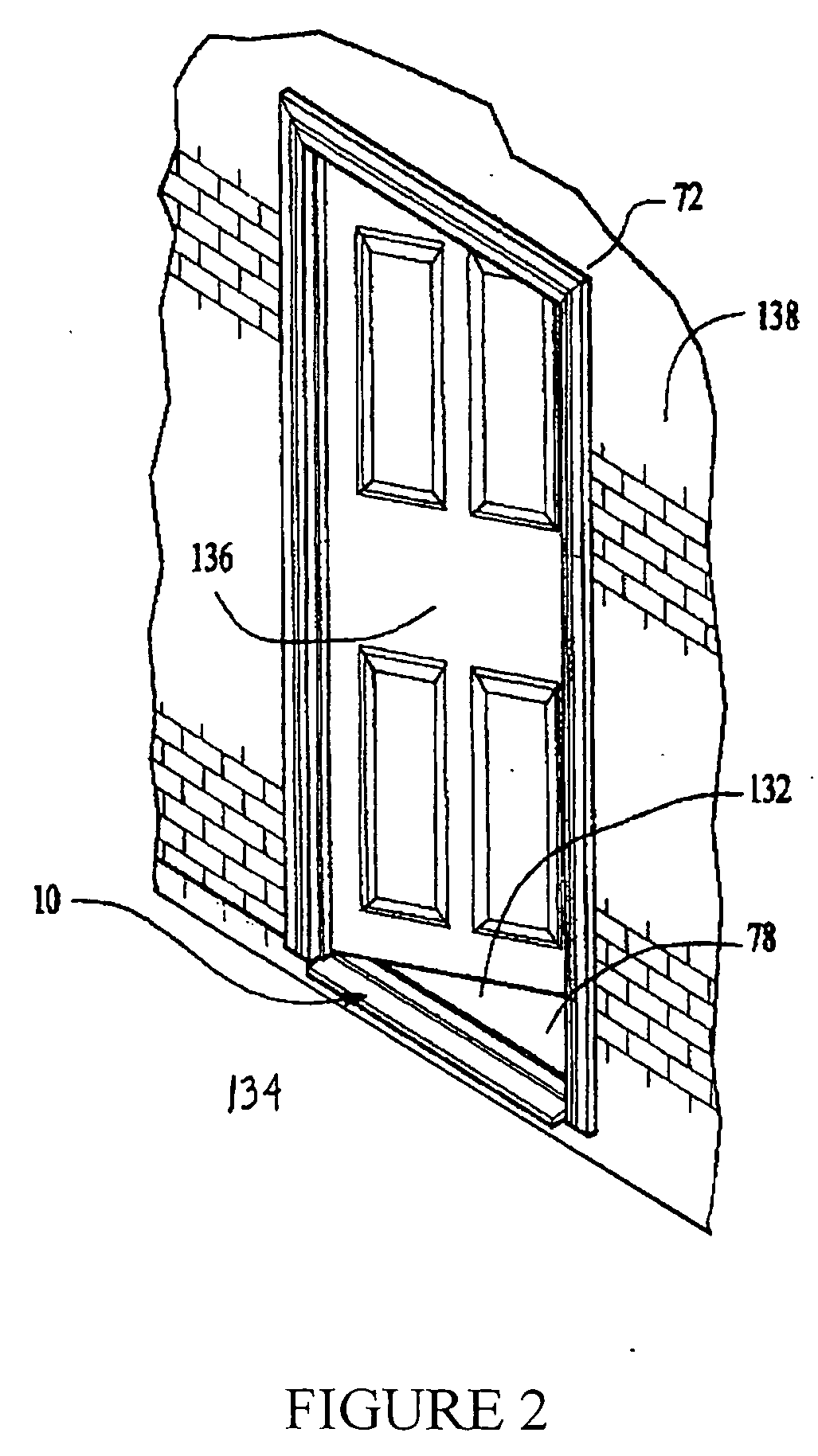

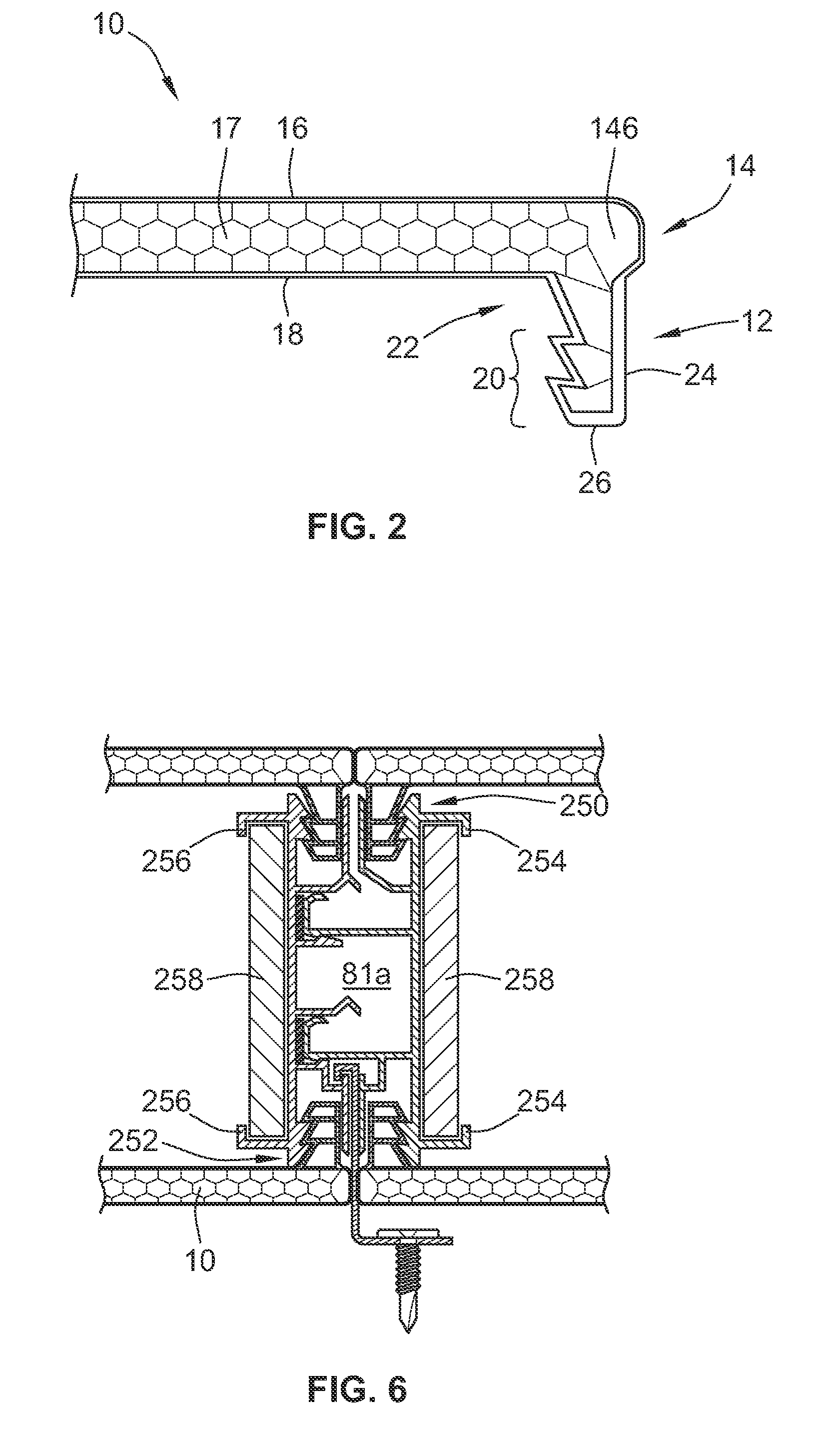

Sill flashing and associated method

ActiveUS7775004B2Easy to installRestricts passageRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringMechanical engineering

A sill flashing and method for installing a window or other portal in a wall opening are provided. The flashing includes a sill portion, at least one jamb portion at an angle relative to the sill portion, and a front face plate. The flashing is configured to be disposed in the opening with the sill portion disposed against a sill of the opening, an outer surface of the jamb portion disposed against one of the jambs of the opening, and a front face plate at an outer surface of the wall. The sill portion defines a plurality of support portions and a rear dam which can support the portal in the opening. The sill portion also includes one or more integral housing, configured to overlap an adjacent support portion when the flashing is cut and disposed multiple parts defining an interface therebetween.

Owner:ALLEN L ROSS

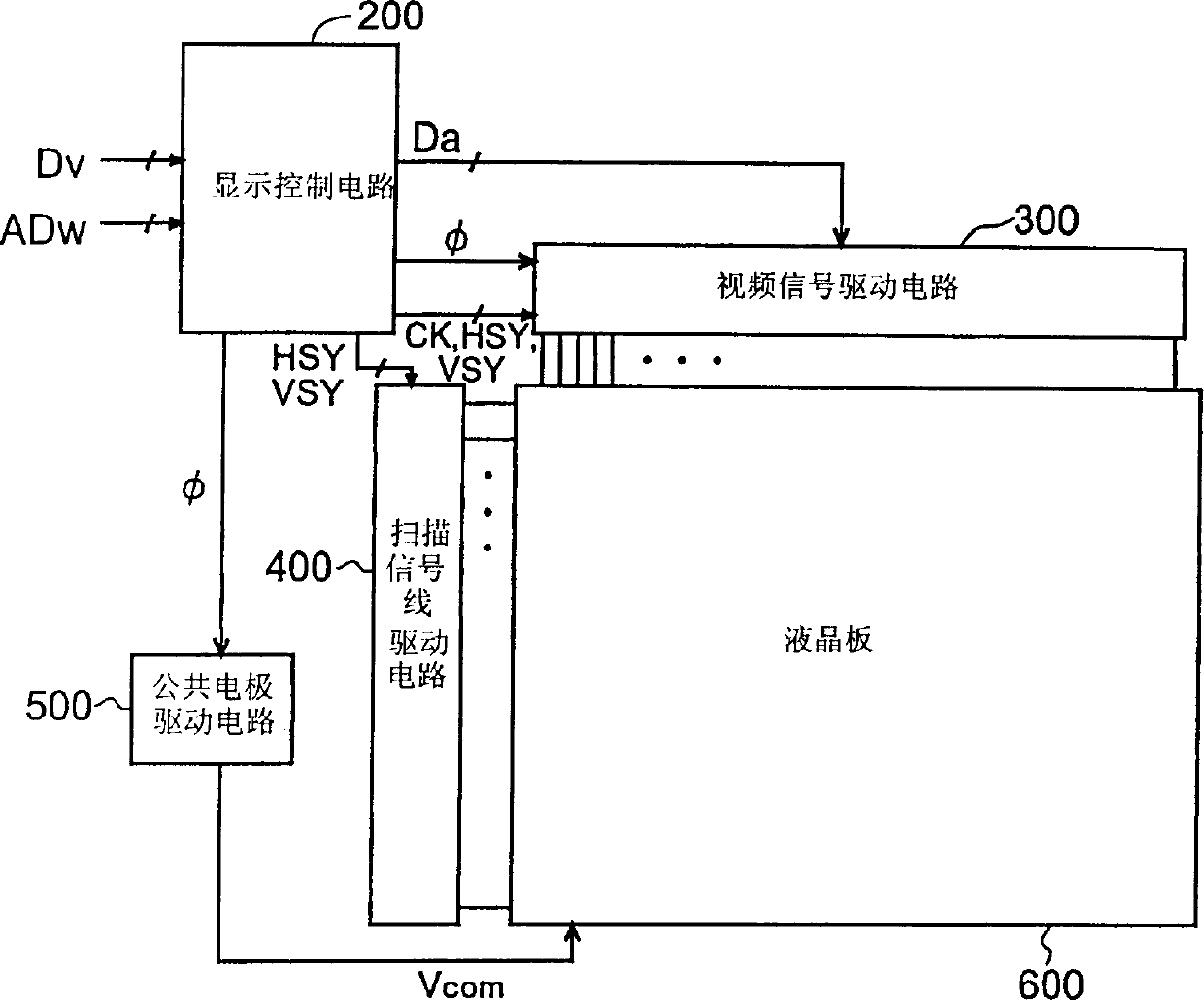

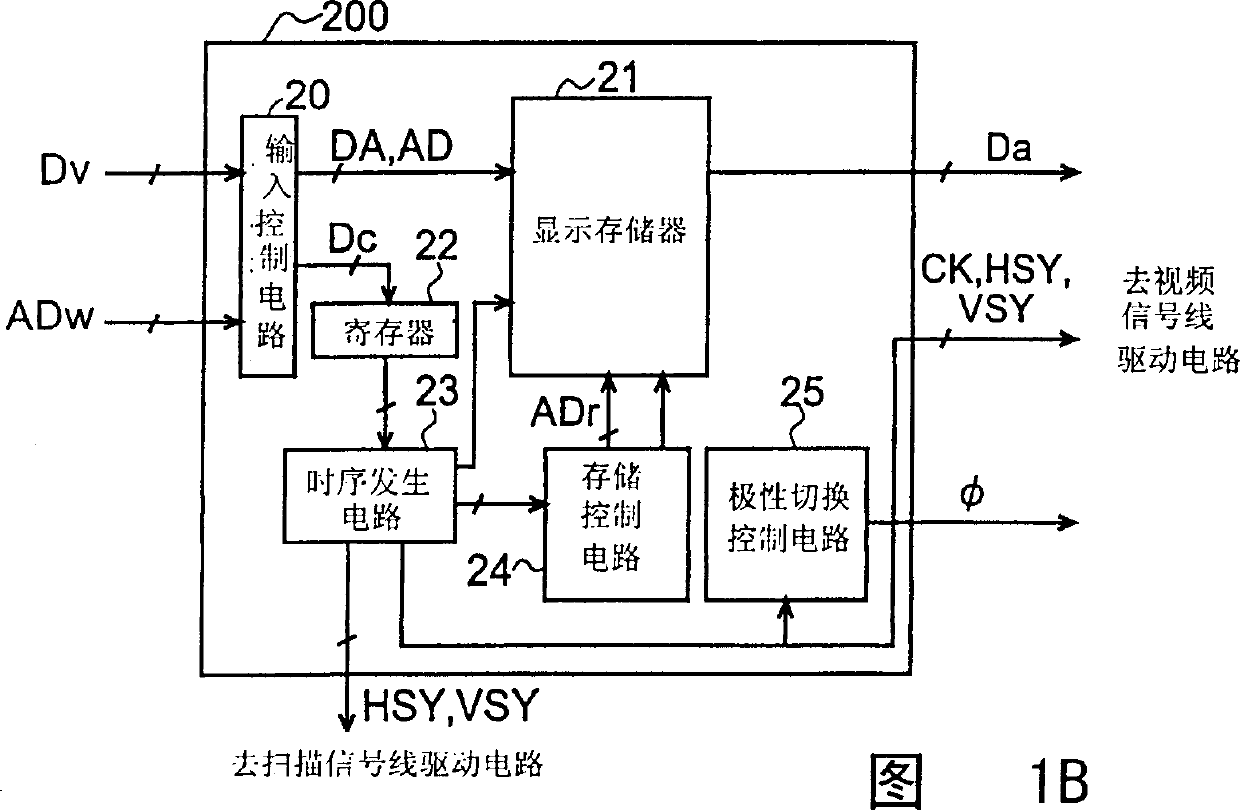

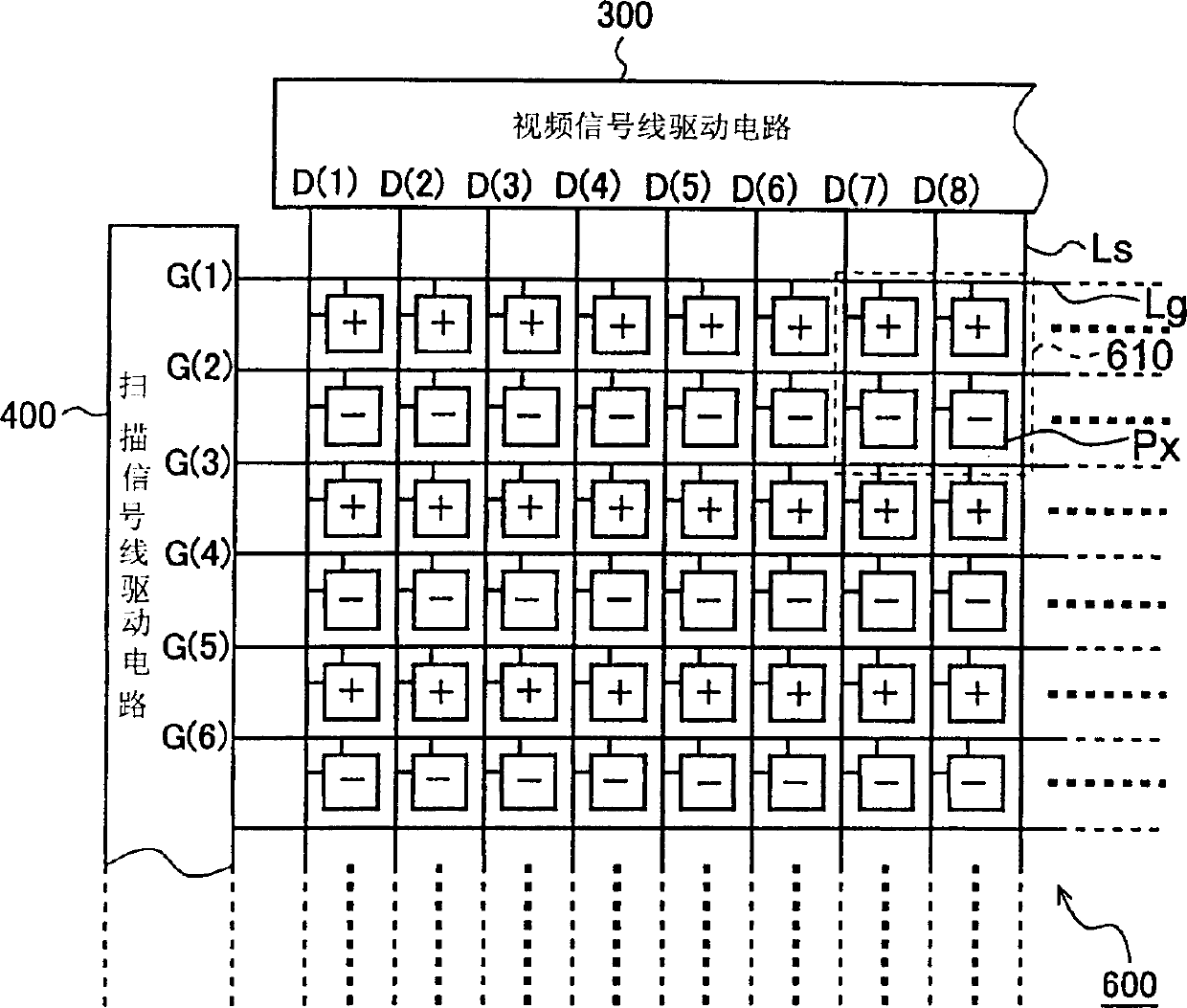

Liquid crystal display device and its driving method

In a liquid crystal display device, a first skipping scanning process is performed by activating the scanning signals G(1), G(3) and G(5) corresponding to the odd-numbered rows in a pixel matrix made of numerous pixel formation portions in that order in a first half-period of a given frame, and voltages corresponding to the pixel values to be written into the pixel formation portions of the odd-numbered rows of the pixel matrix are applied to the video signal lines as positive-polarity video signals. In a second half-period of that frame, a second skipping scanning process is performed by activating the scanning signals G(2), G(4) and G(6) corresponding to the even-numbered rows in the pixel matrix in that order, and voltages corresponding to the pixel values to be written into the pixel formation portions of the even-numbered rows of the pixel matrix are applied to the video signal lines as negative-polarity video signals. Thus, line inversion driving is accomplished.

Owner:SHARP KK

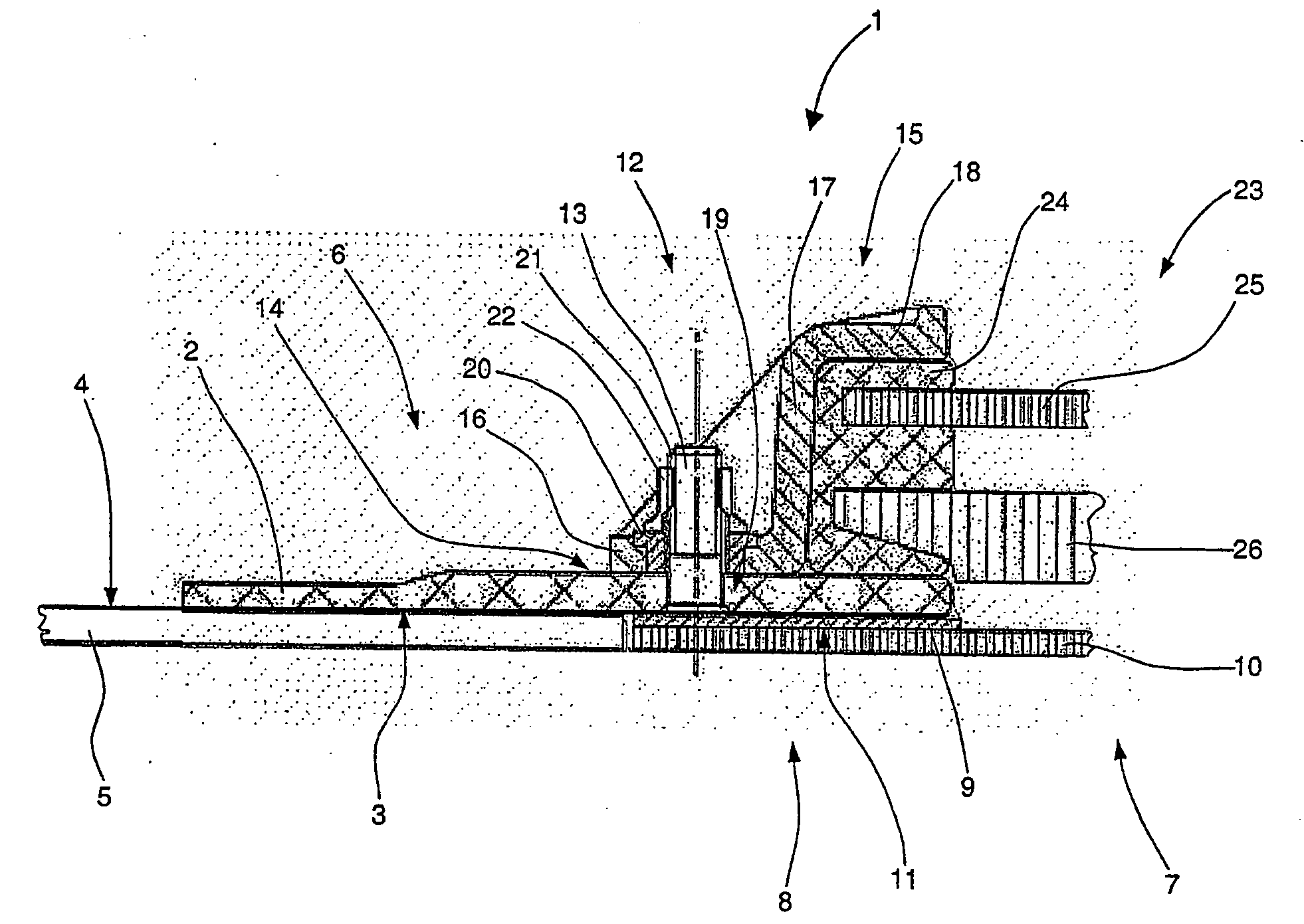

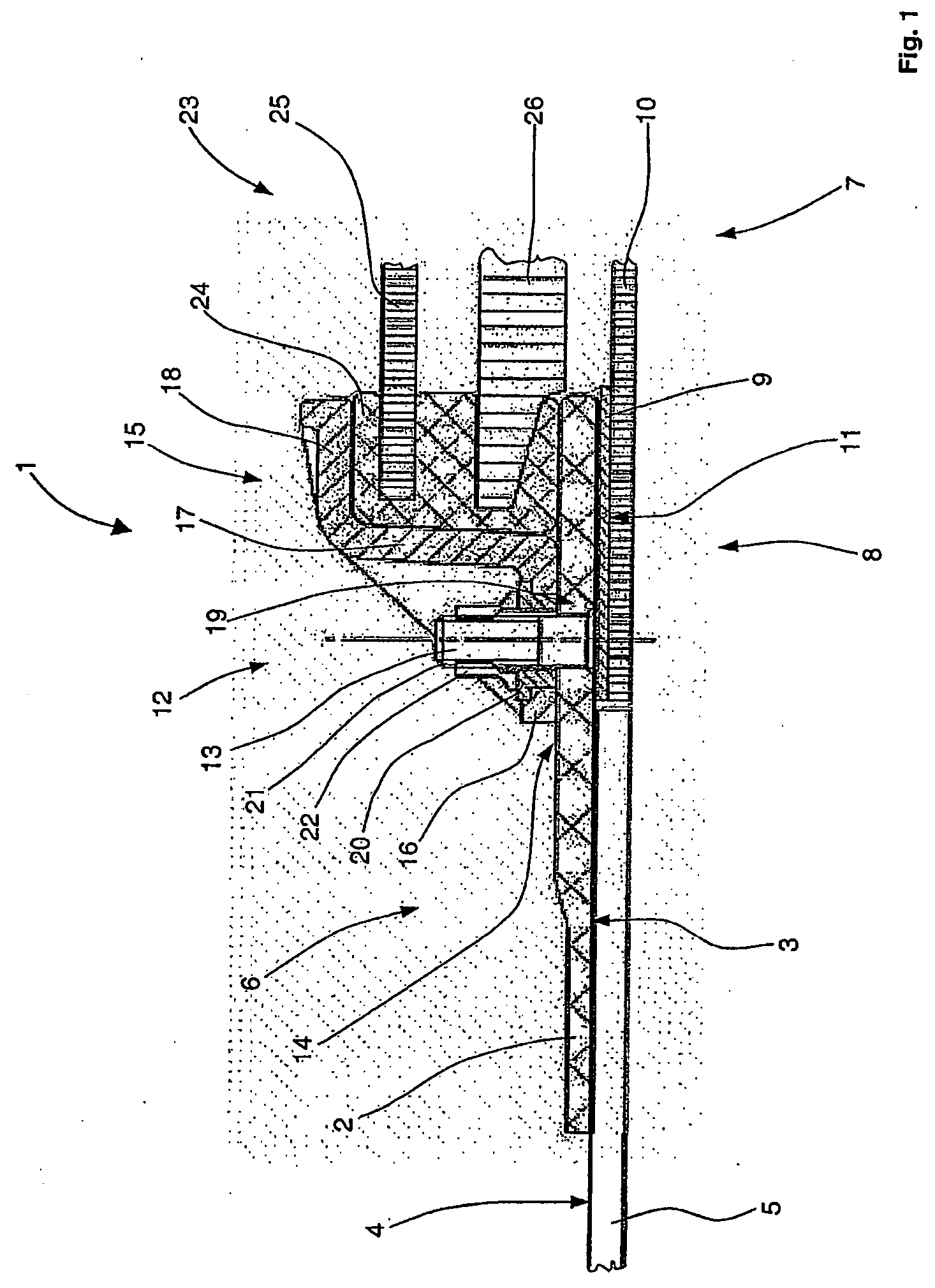

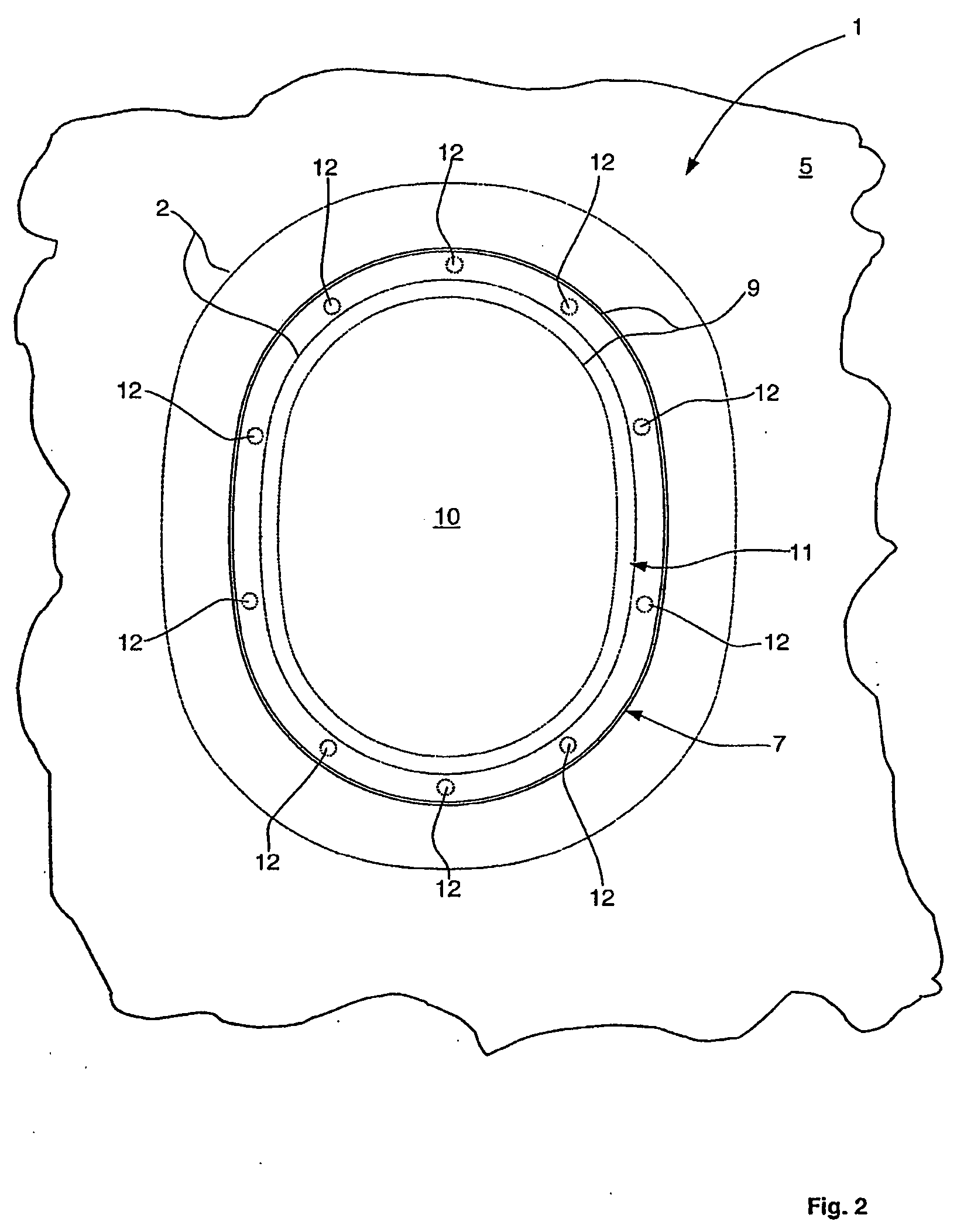

Window element for insertion in a window aperture in an outer skin of a transport

ActiveUS20060123718A1Easily and rapidlyEasy to produceLighting and heating apparatusVentilation arrangementEngineeringExterior space

A window element has a cover pane which is substantially flush with an outer skin of an aircraft or other transport, achieving a fluid-dynamically favourable, substantially unbulged exterior surface. As a result of the presence of an additional back-ventilated cover pane 10 arranged in front of the actual outer pane of the window element, a fluid-dynamically favourable integration of the window element into the outer skin of an aircraft fuselage airframe is achieved. Any deformation, such as any buckling or bulging of the outer pane of the window element, as a result of a difference in pressure between the interior of the aircraft fuselage airframe and the exterior space at cruising altitudes, has no fluid-dynamically disadvantageous effect. The outer pane is covered by the cover pane which remains substantially undeformed with respect to the outer skin of the aircraft fuselage airframe, for example. Any deformation of the cover pane is largely eliminated by this back-ventilation.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com