Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15946results about "Building repairs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

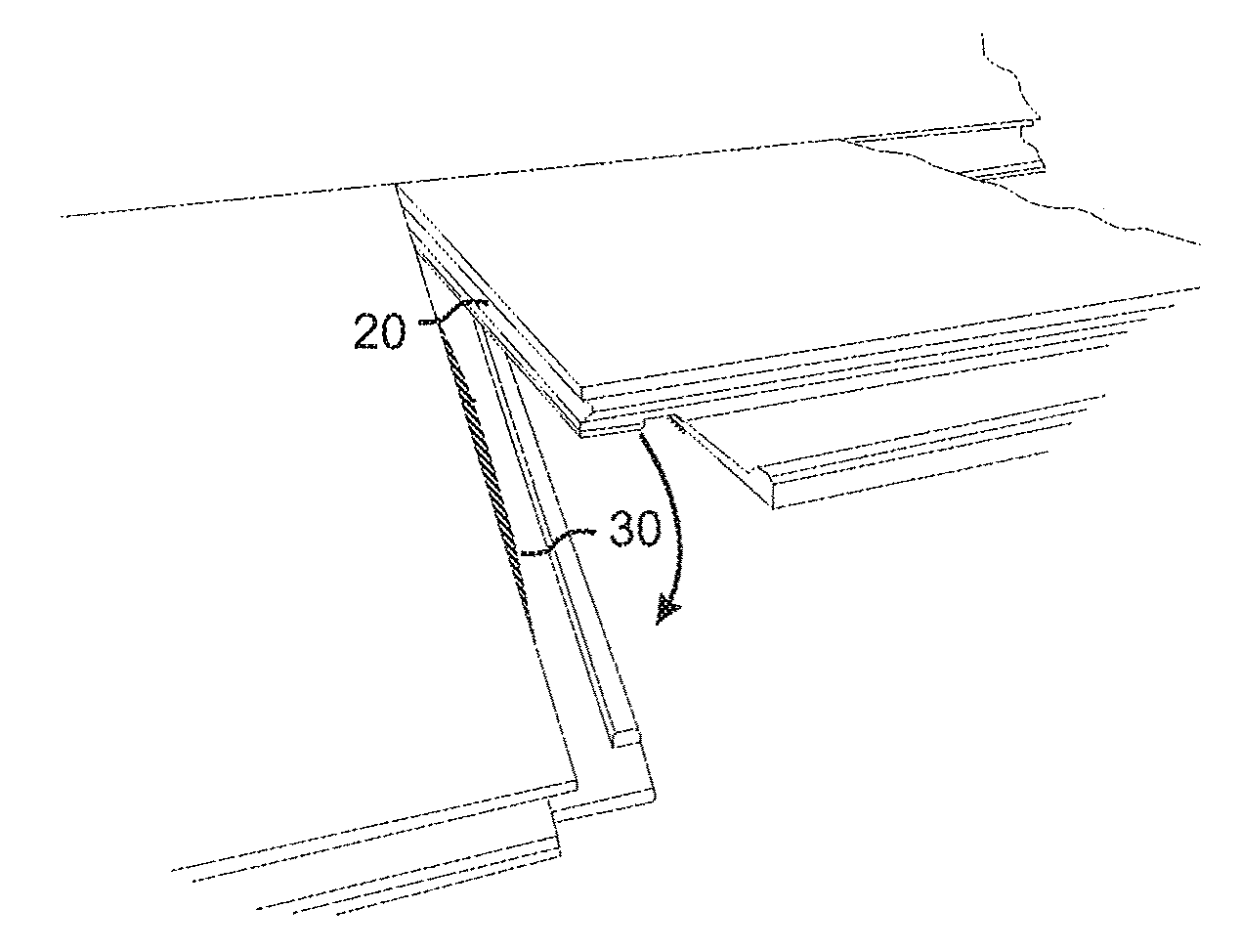

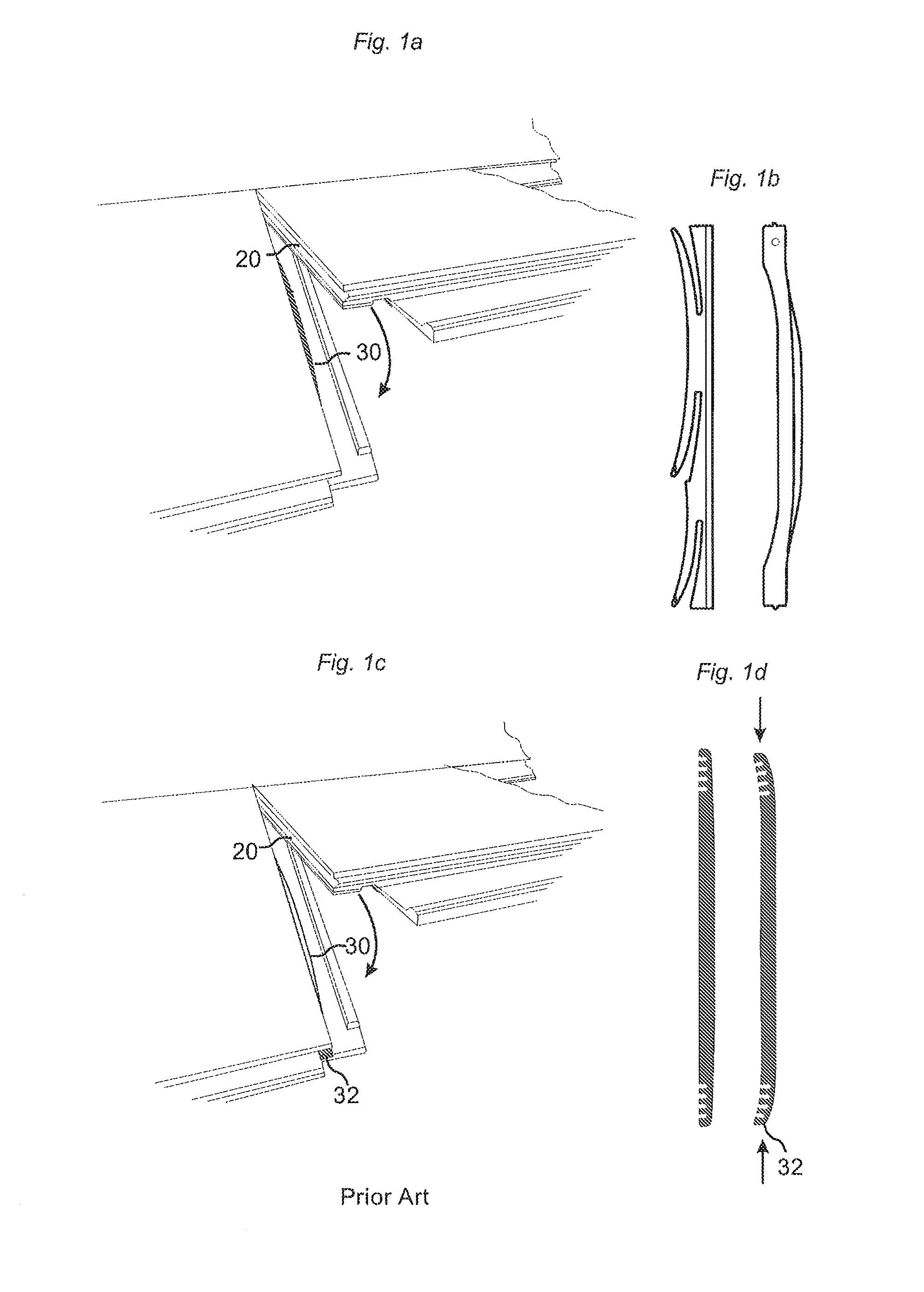

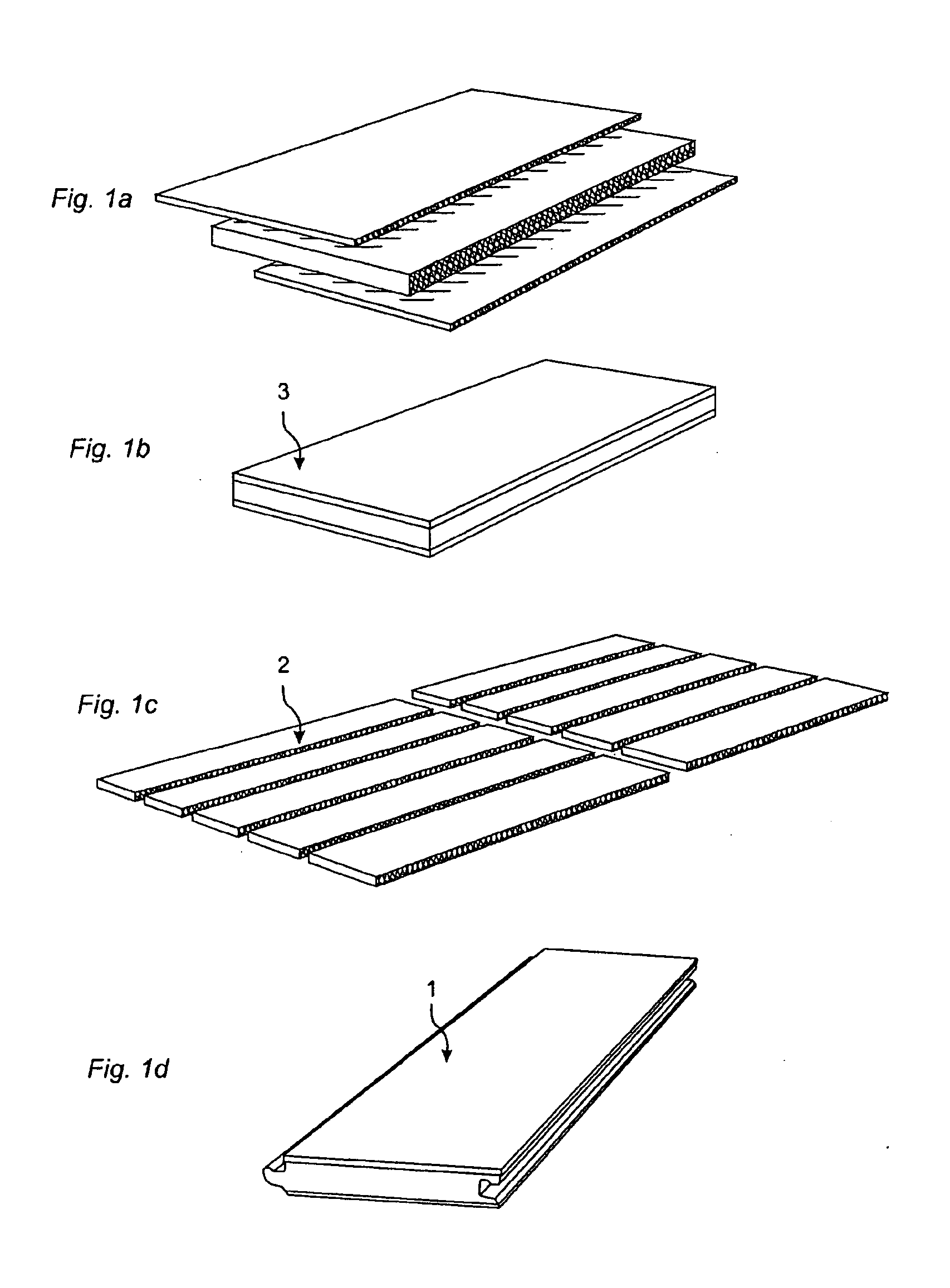

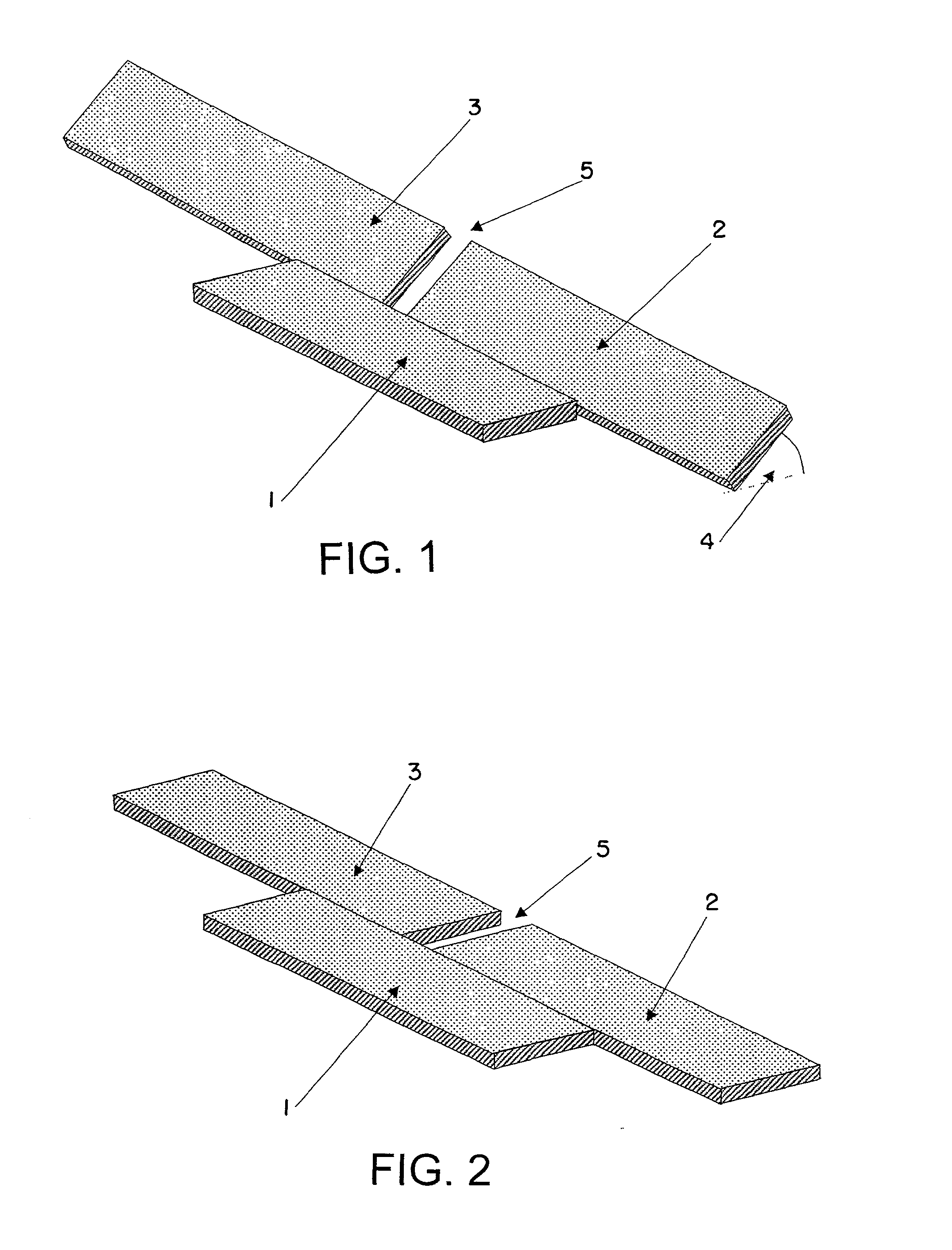

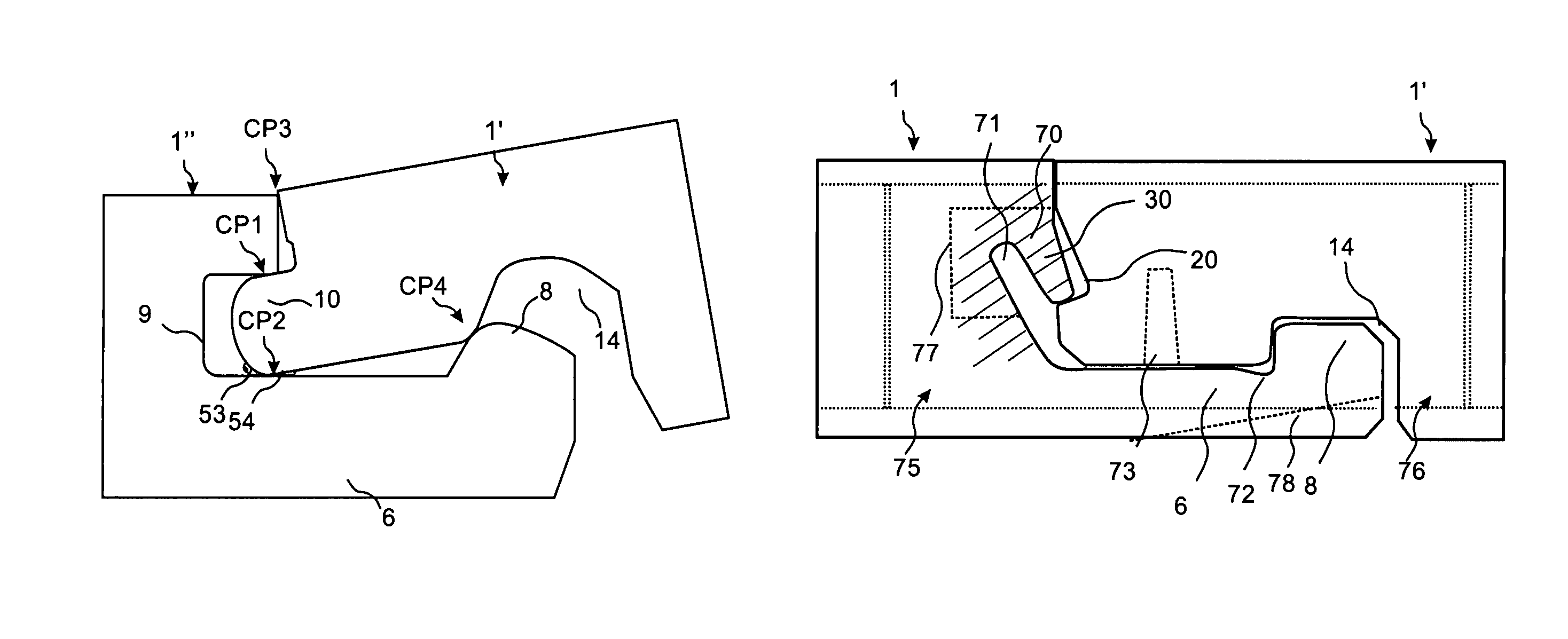

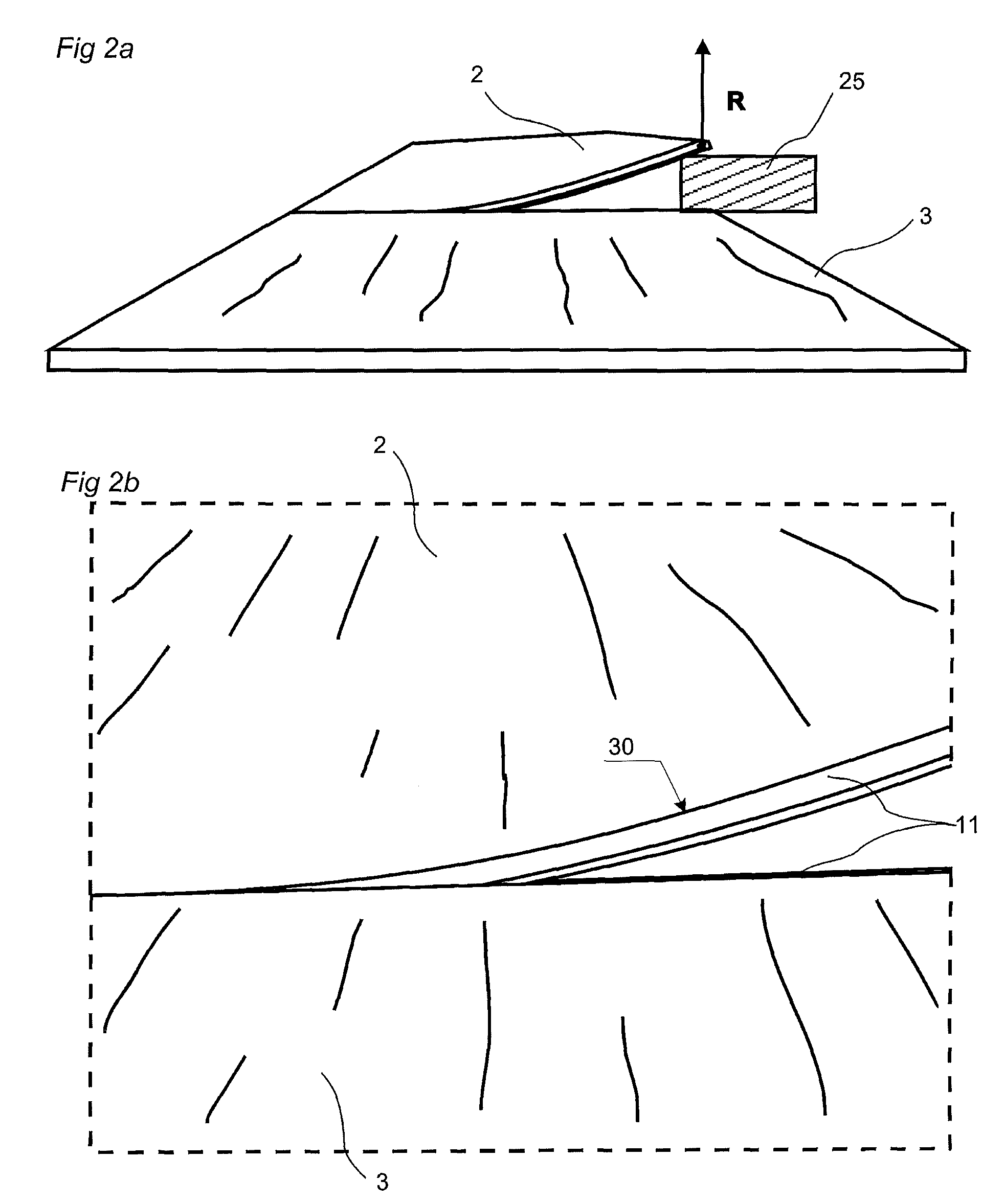

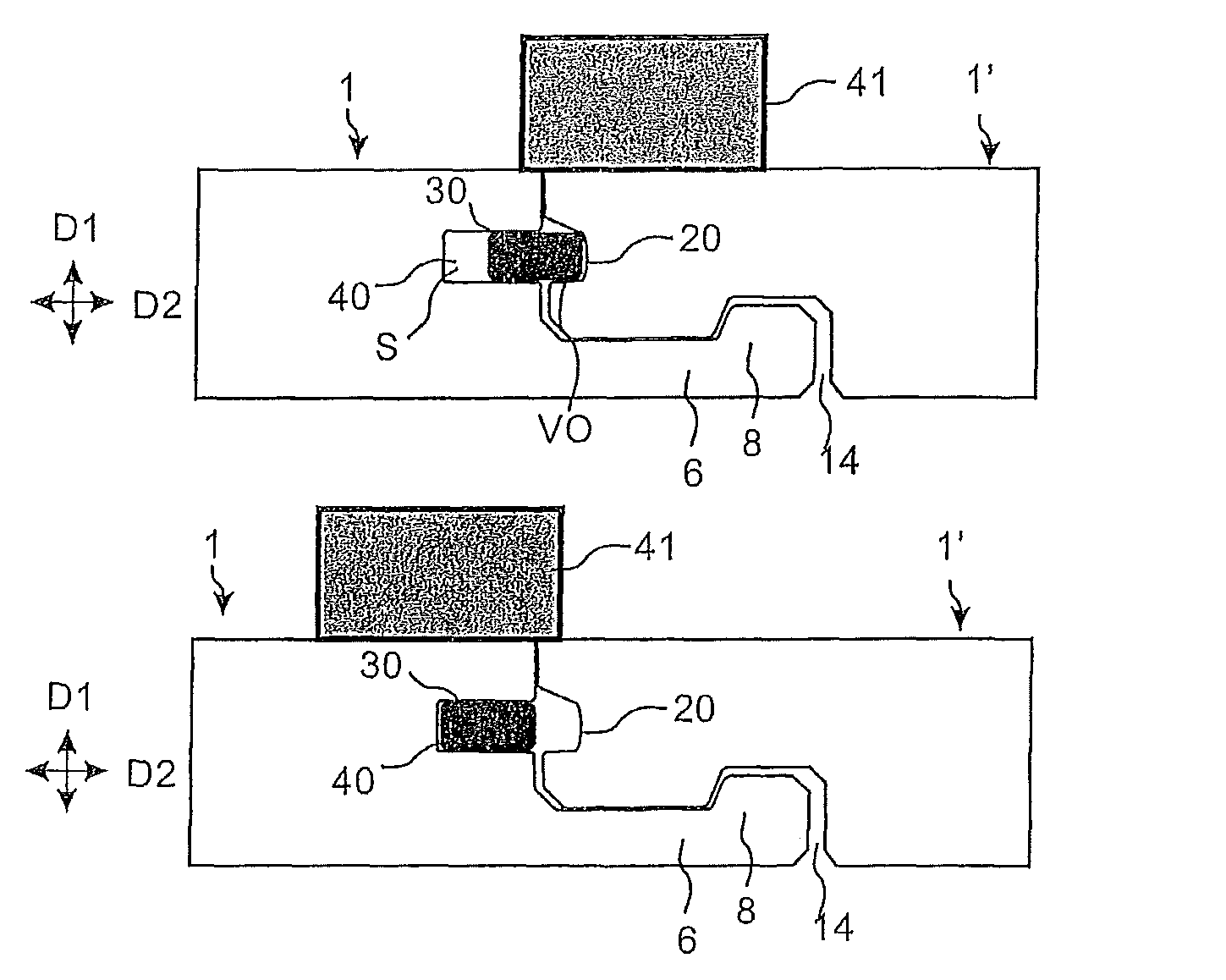

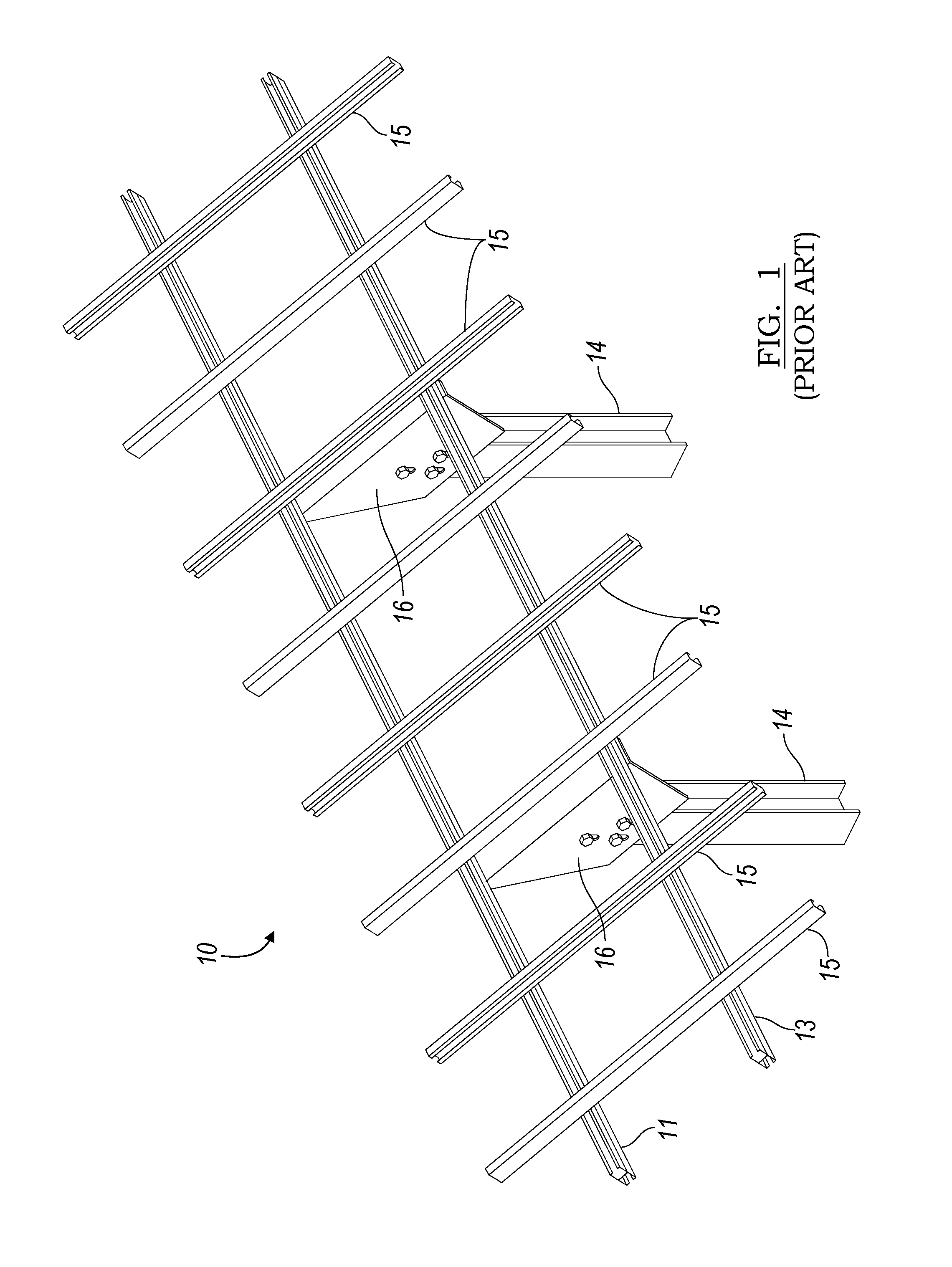

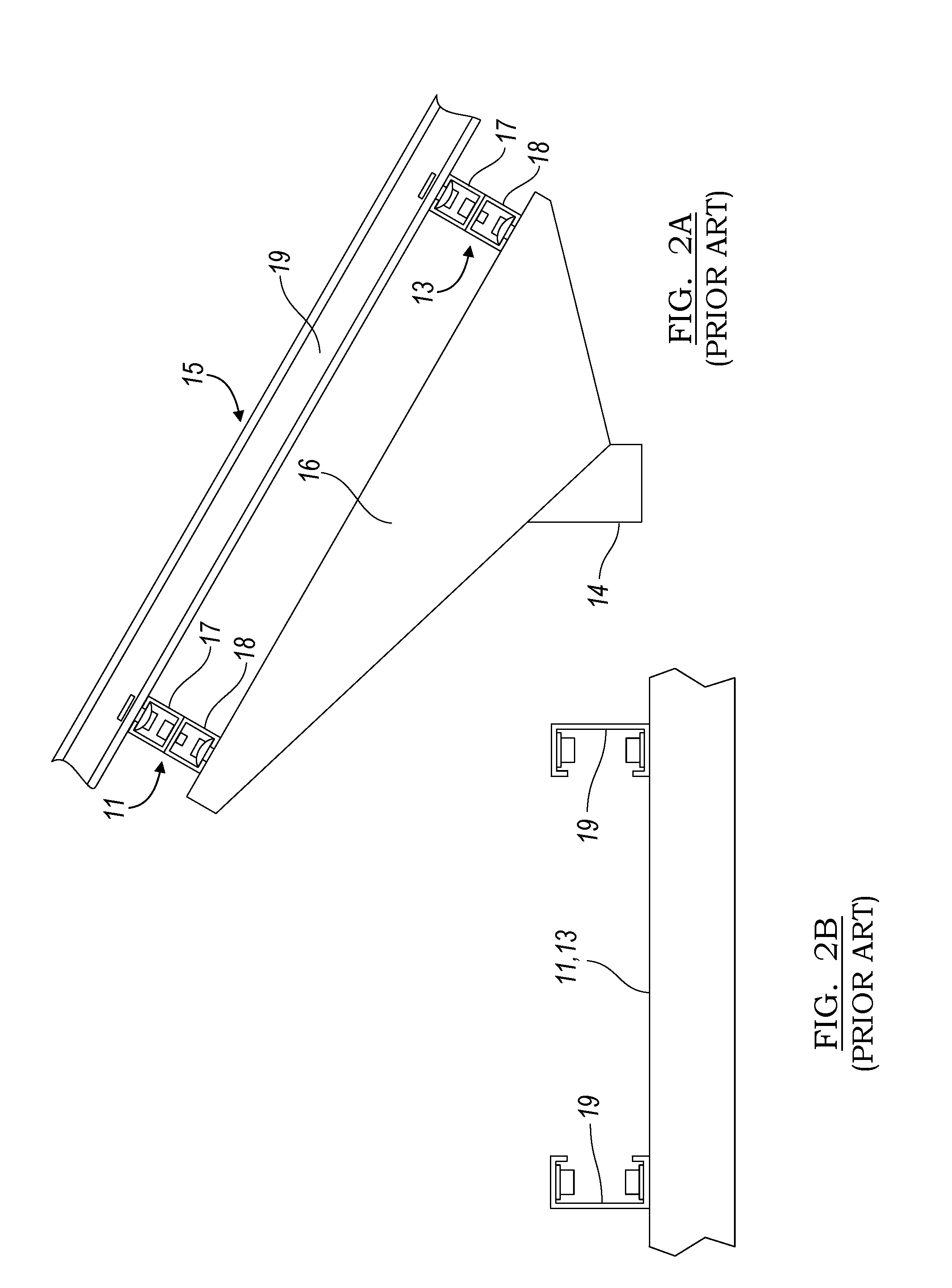

Mechanical Locking of Floor Panels With a Flexible Tongue

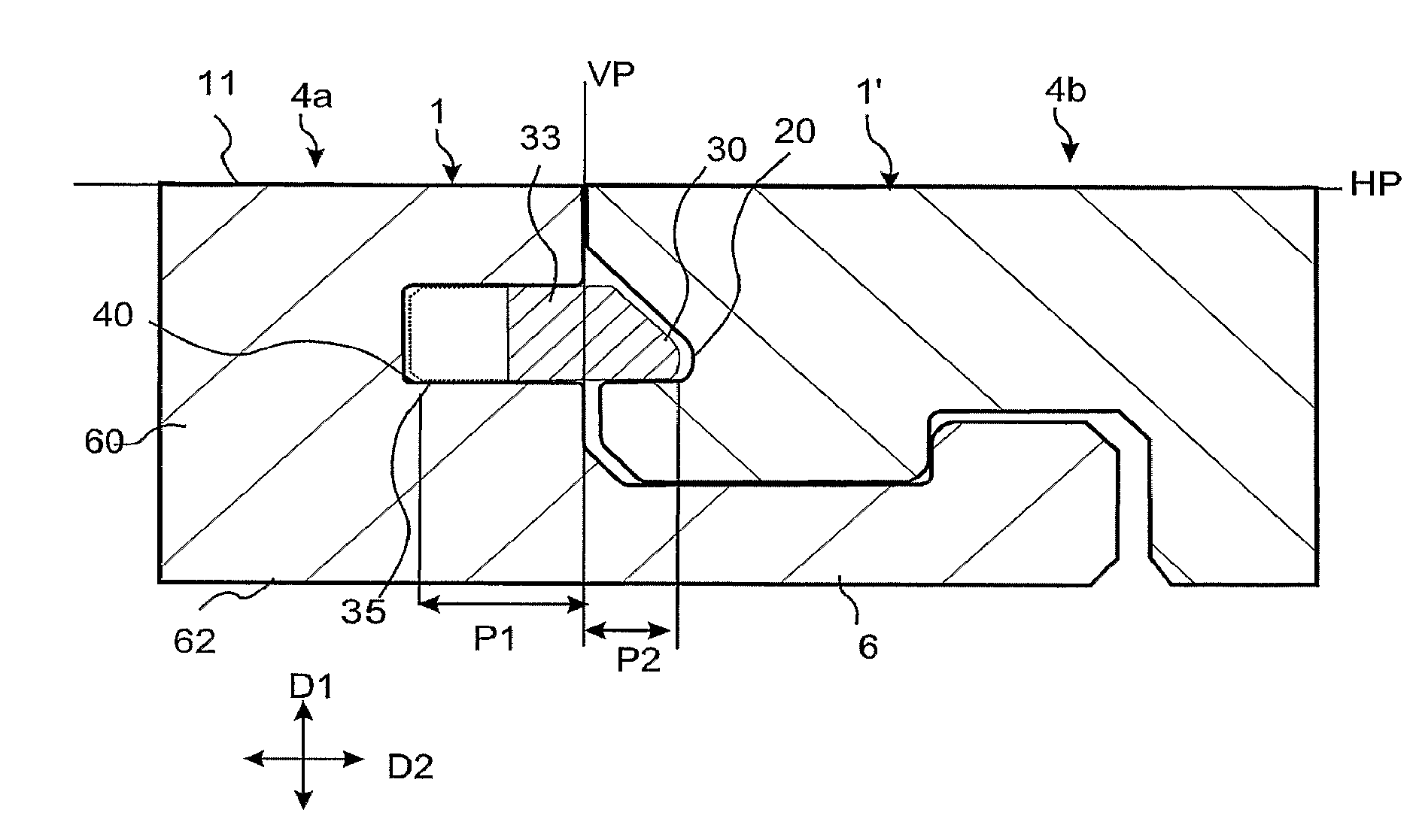

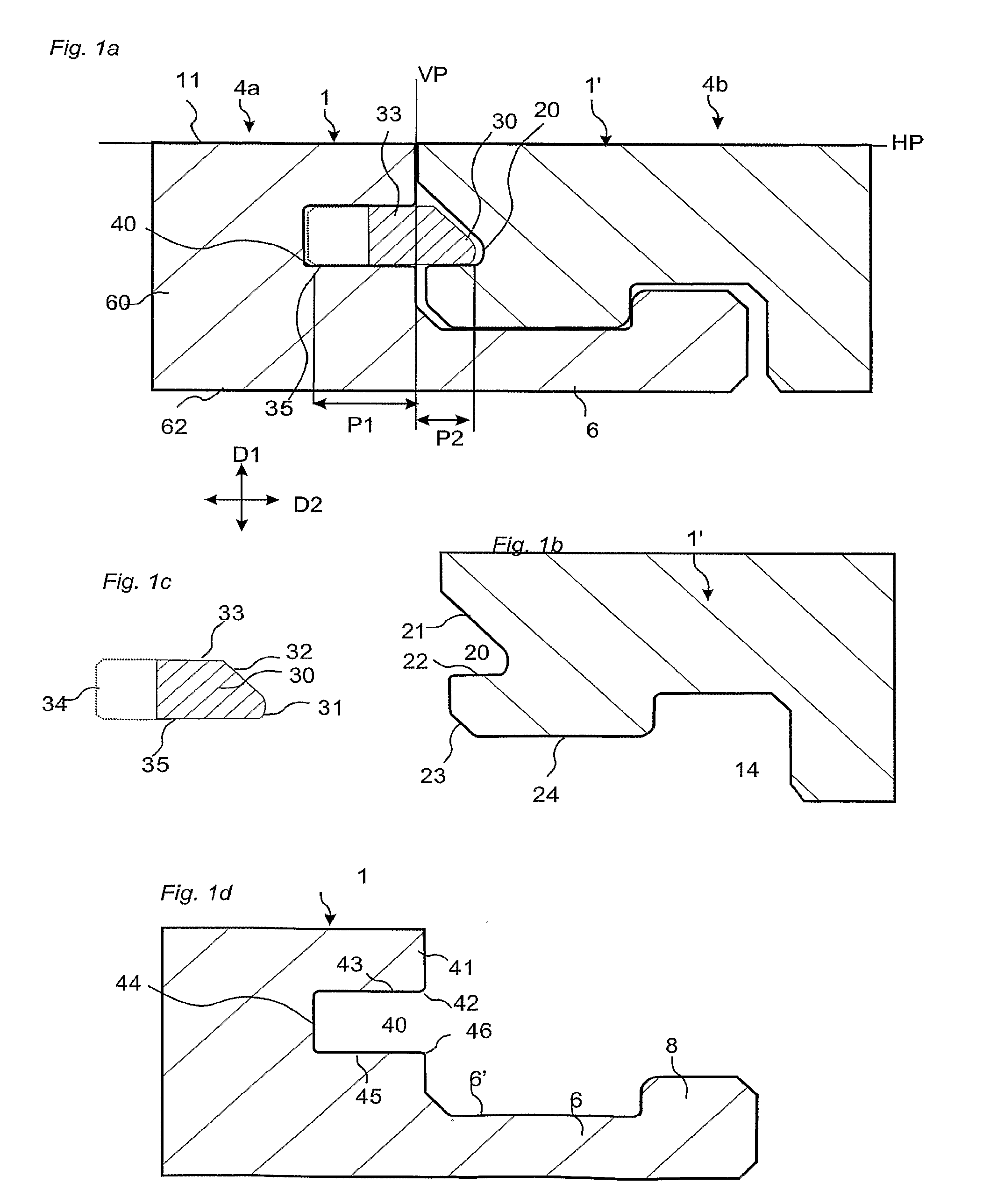

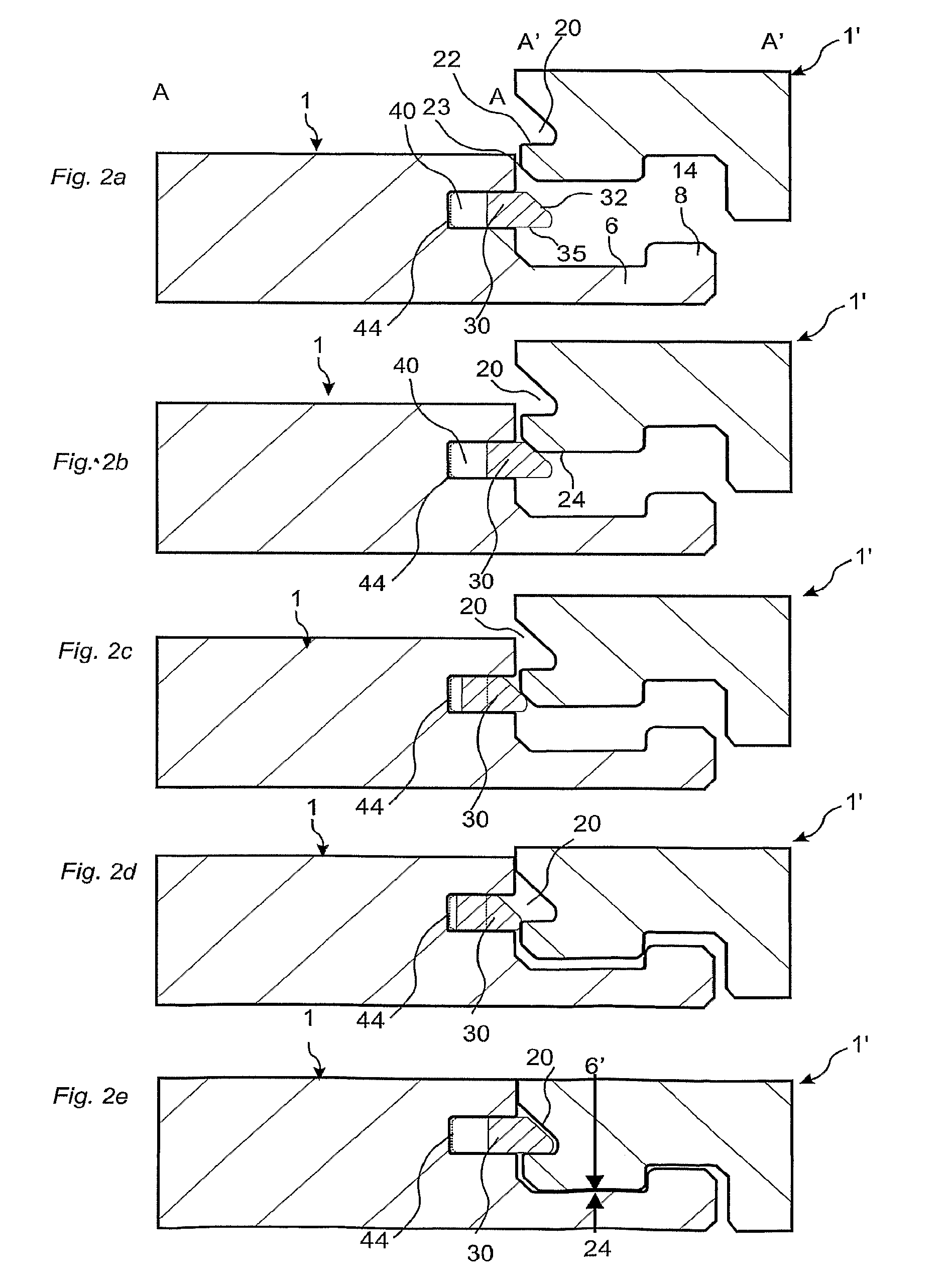

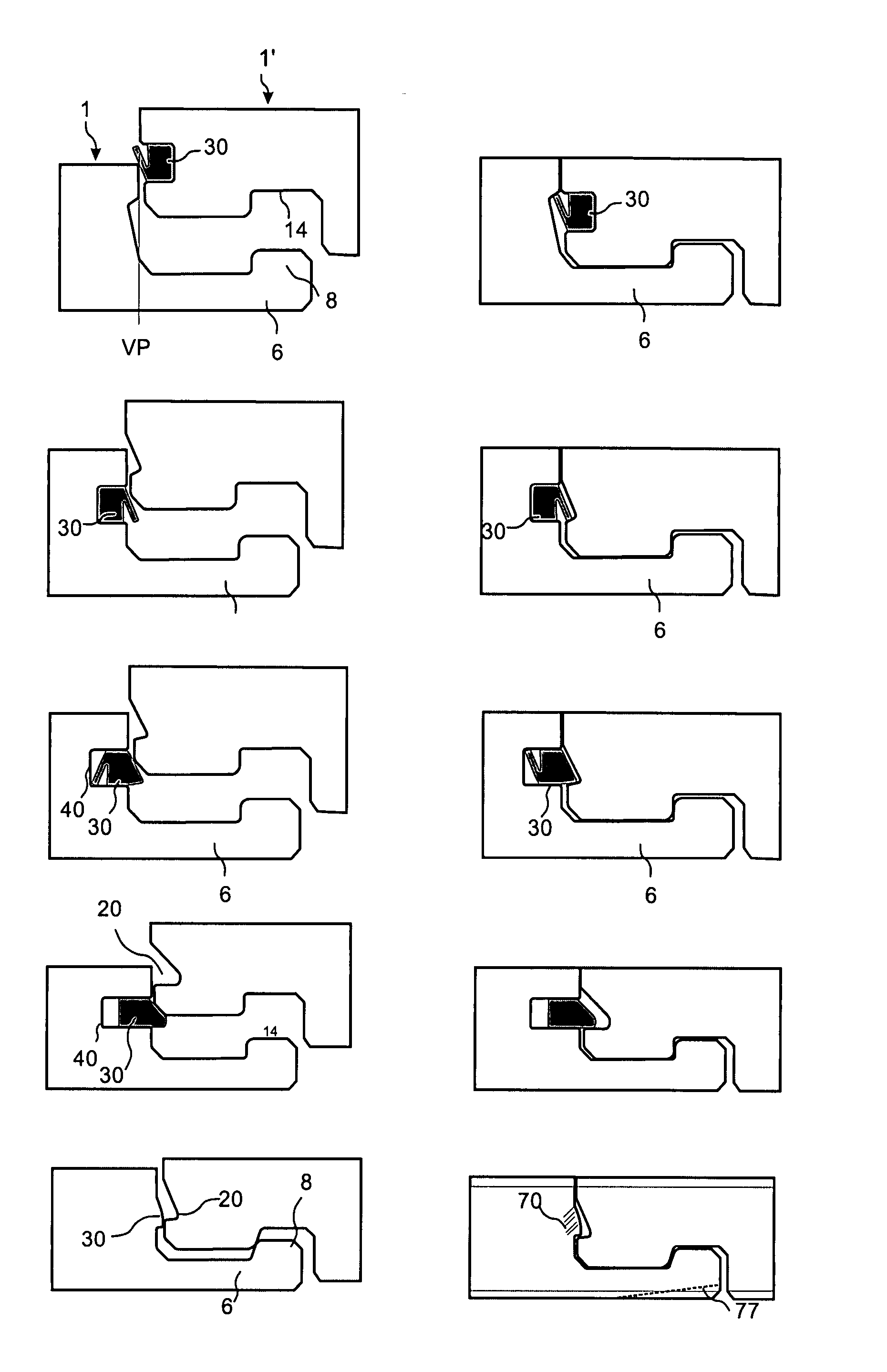

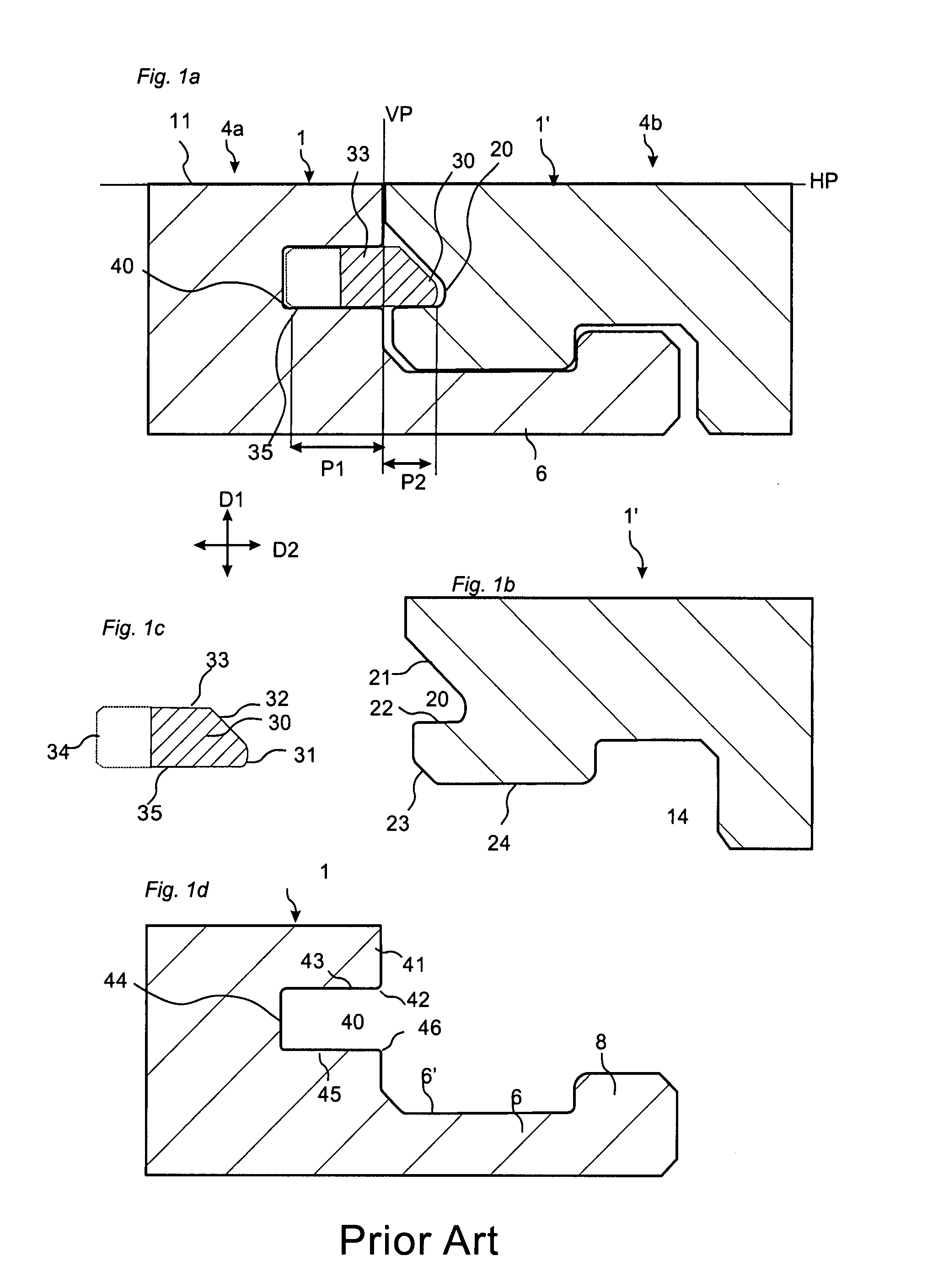

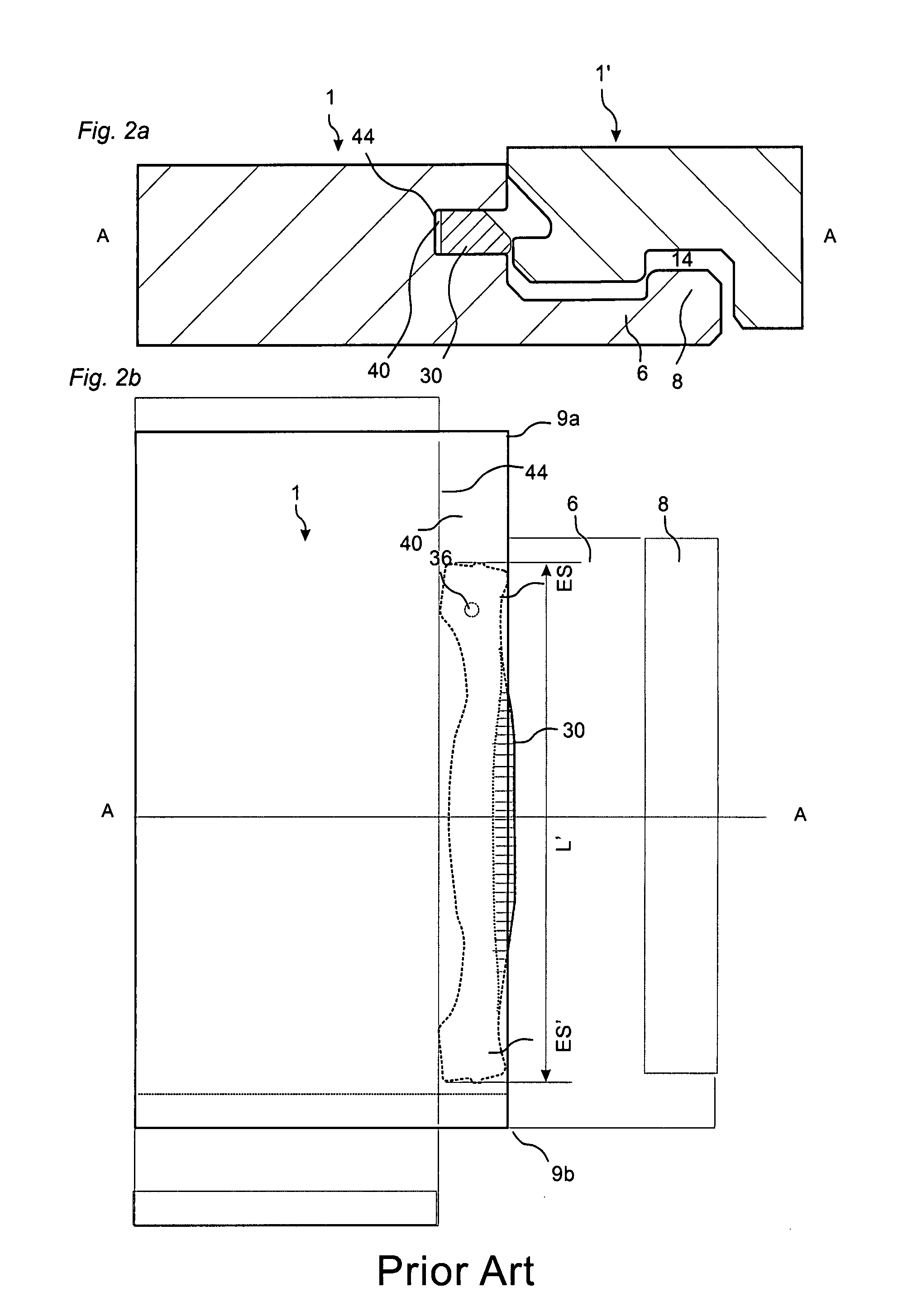

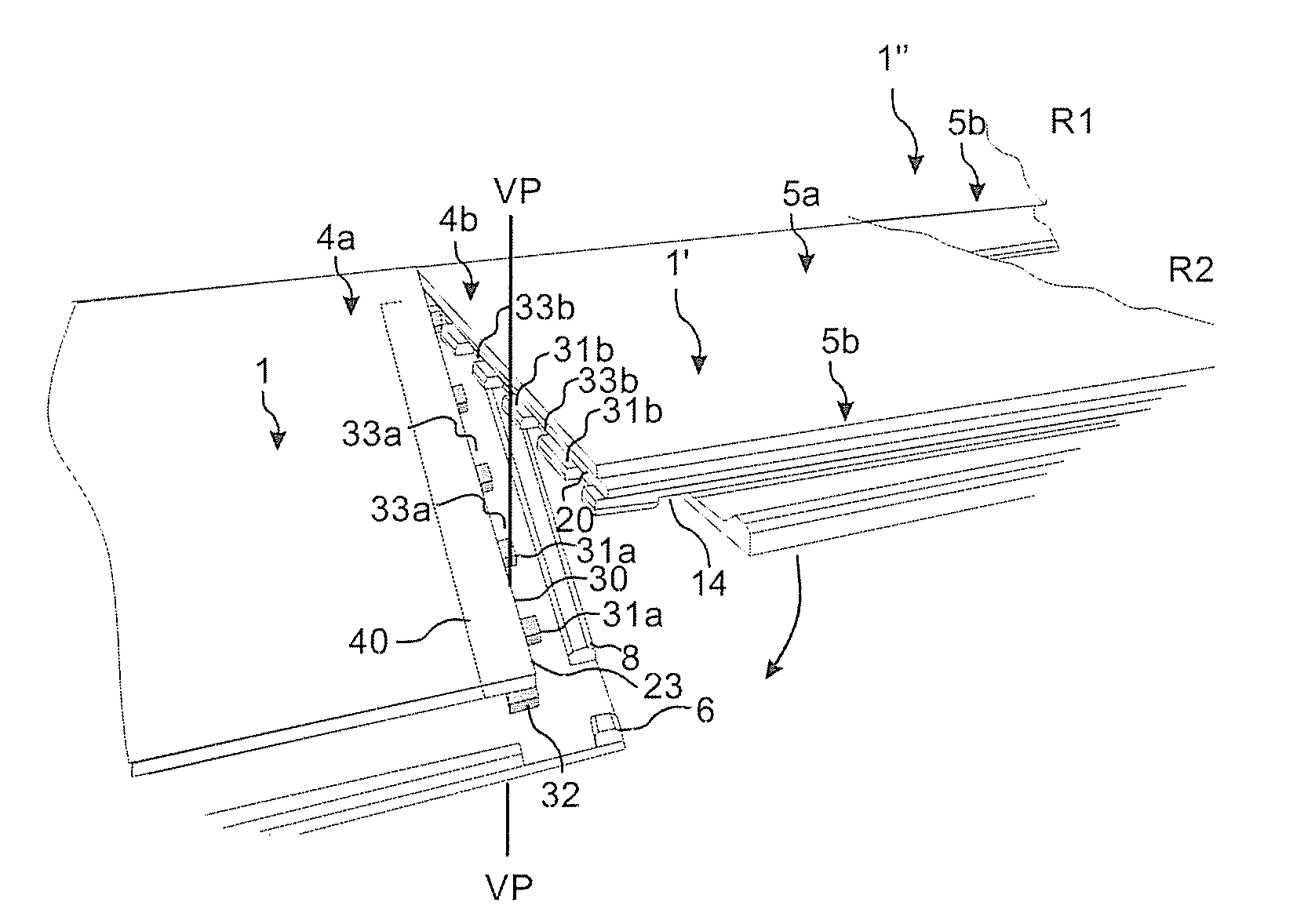

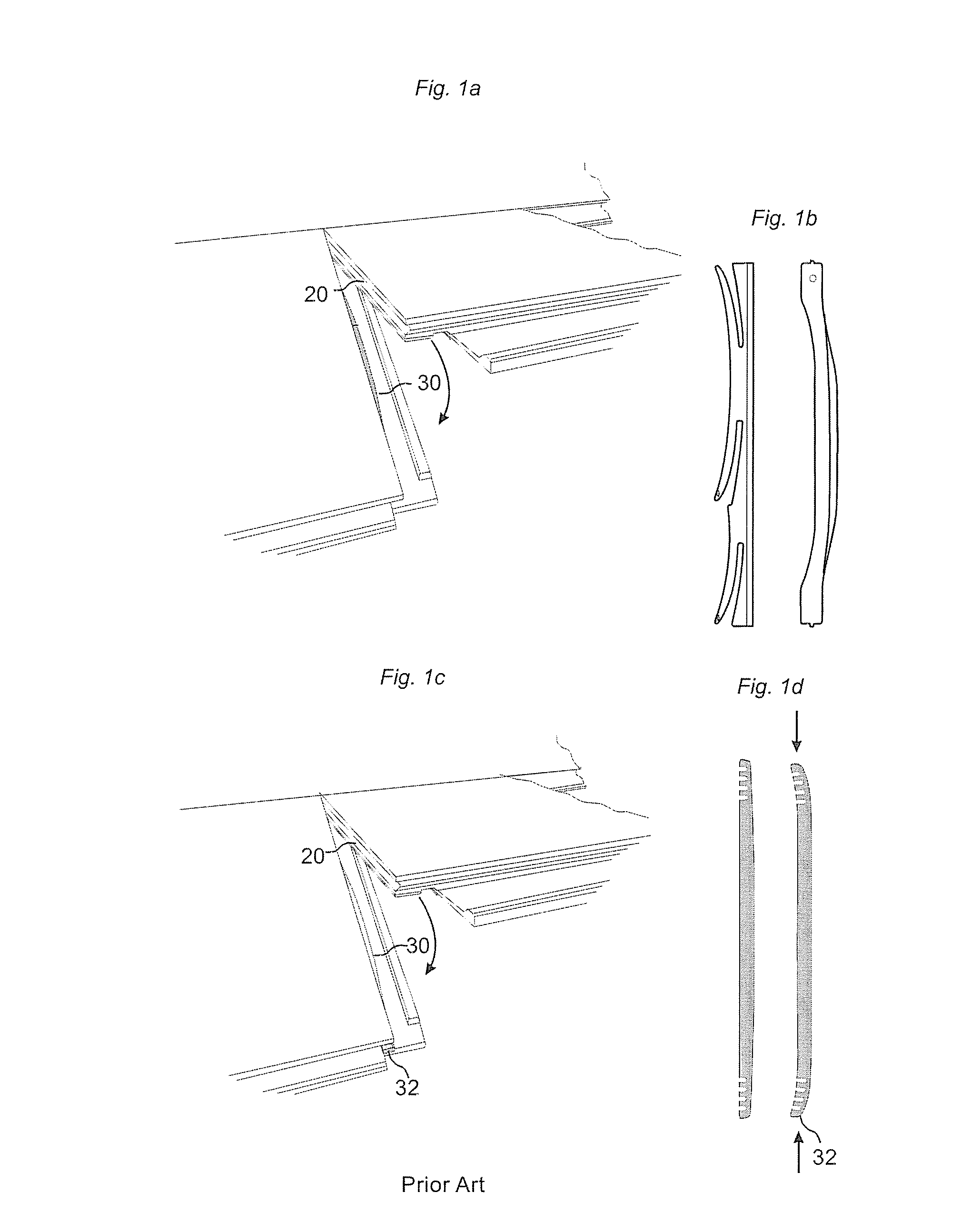

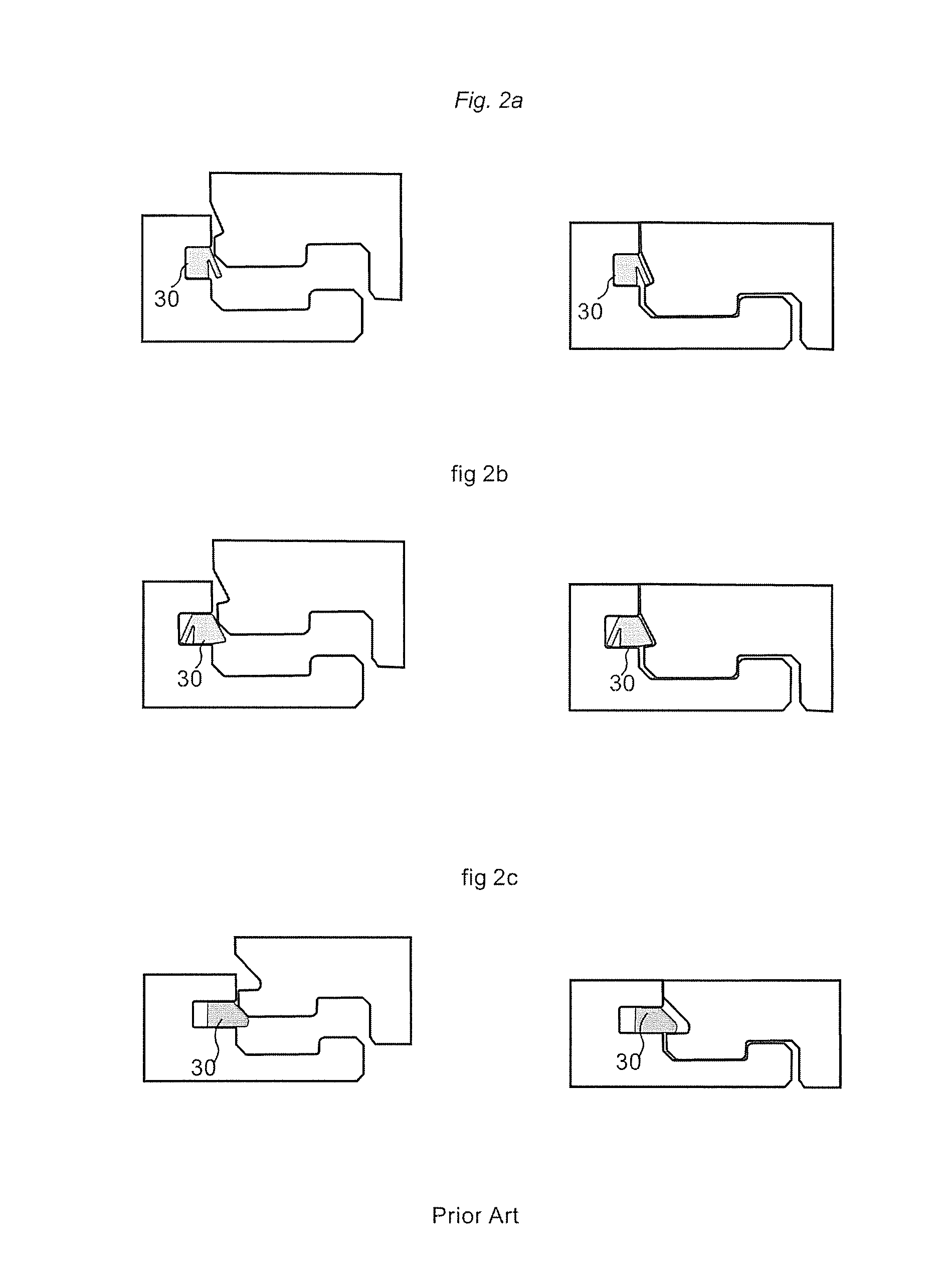

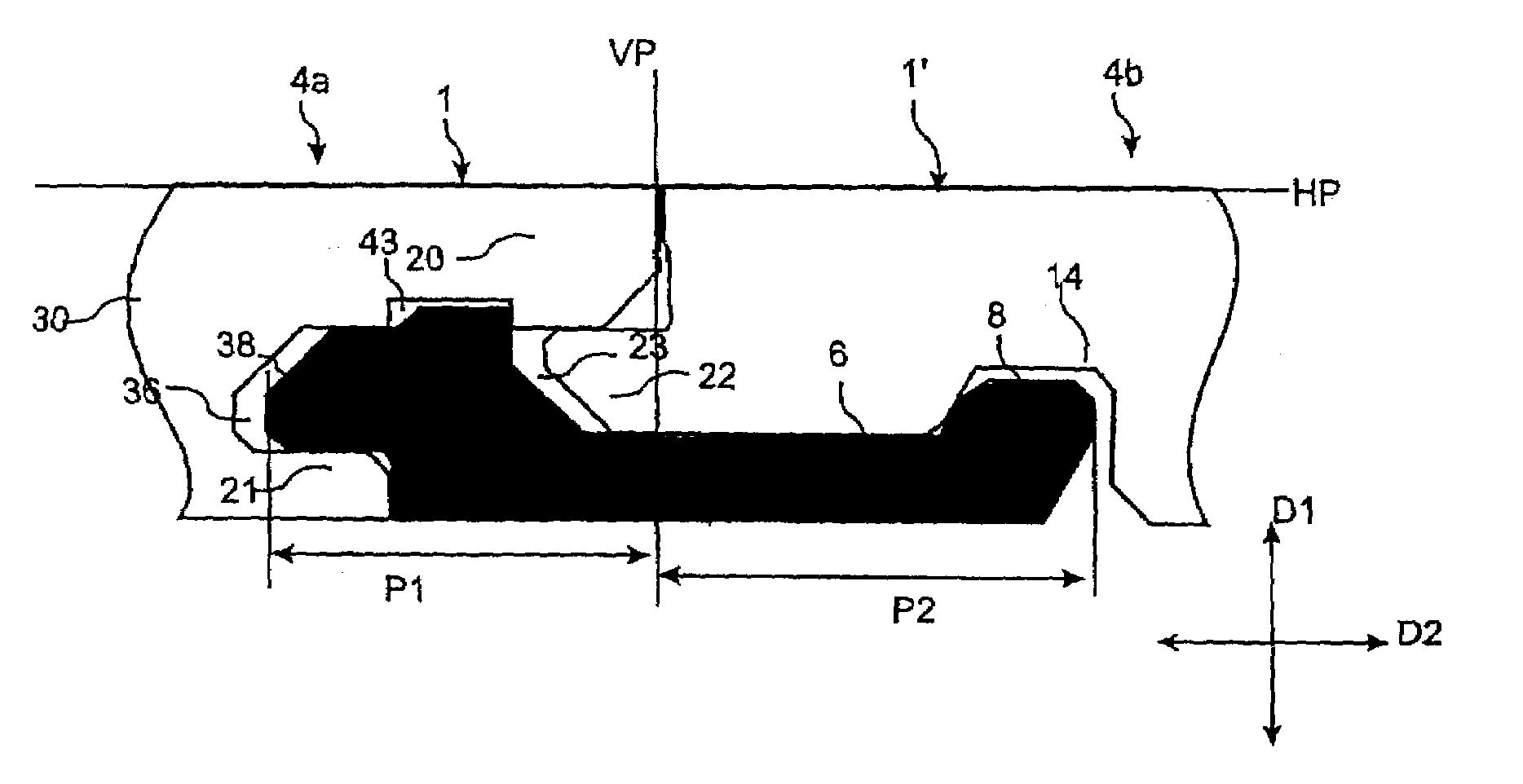

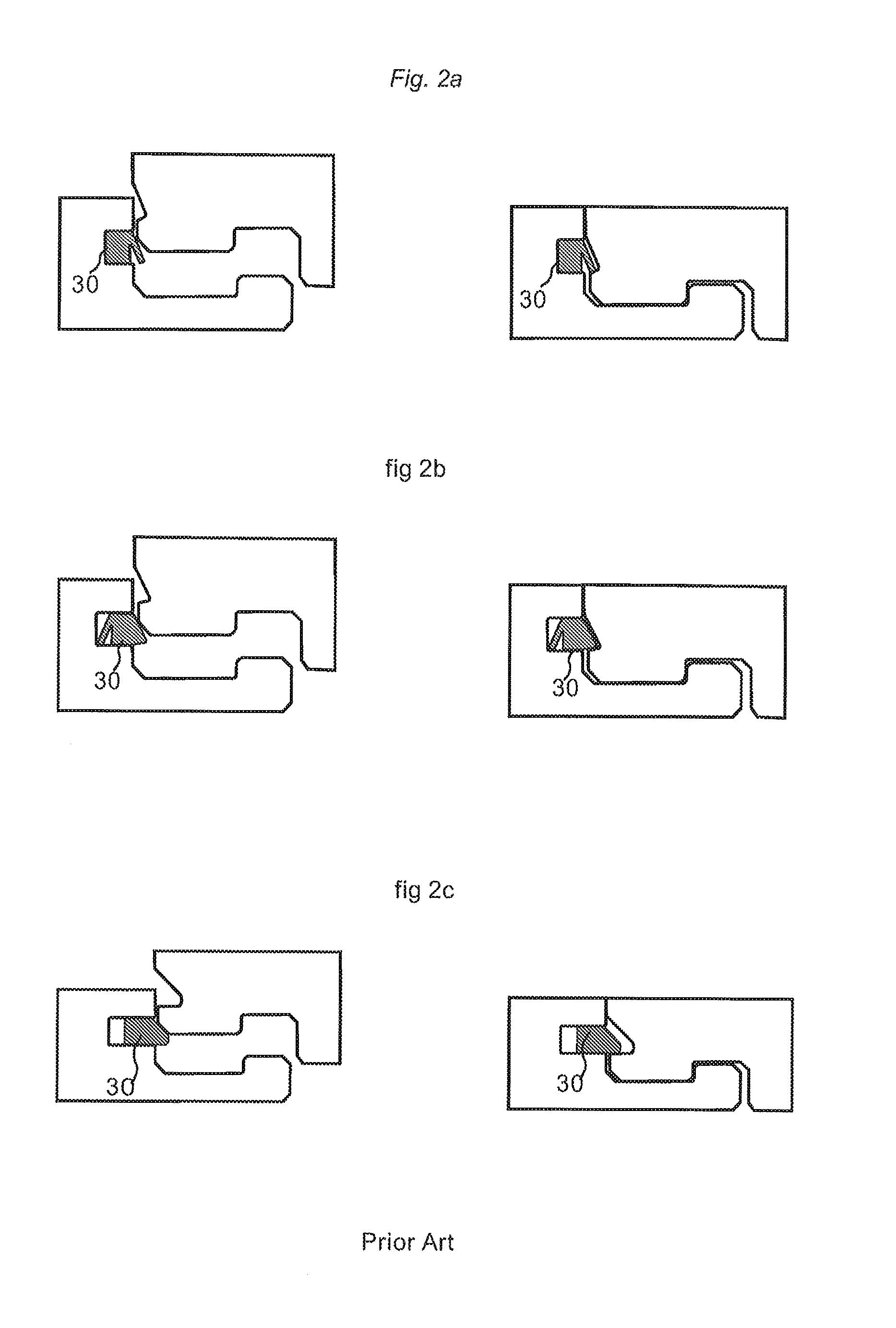

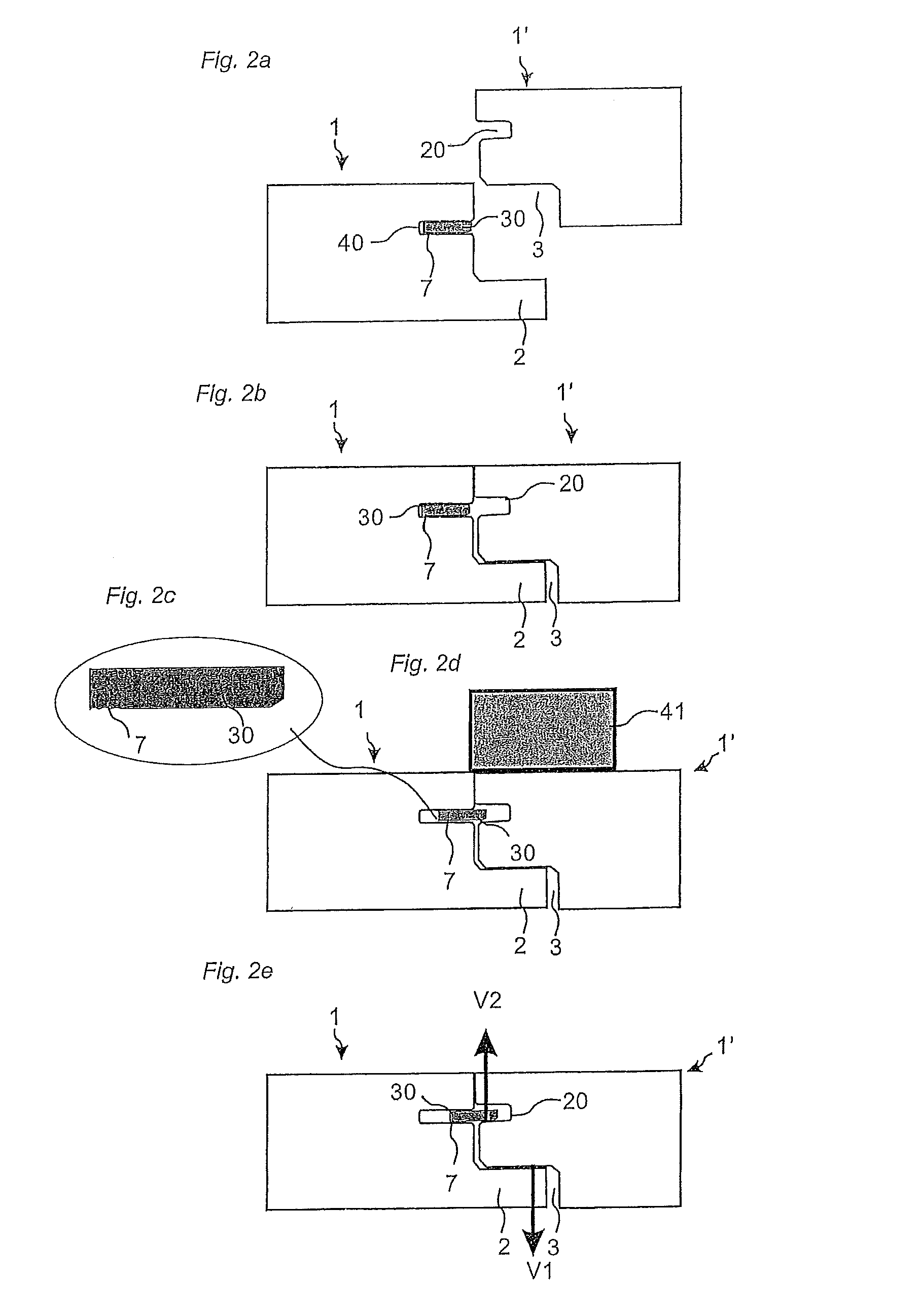

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system having a flexible tongue (30) in a displacement groove (40), which during a vertical folding motion is displaced. Moreover, a tongue blank (50), a production method and an installation method are shown.

Owner:VÄLINGE INNOVATION AB

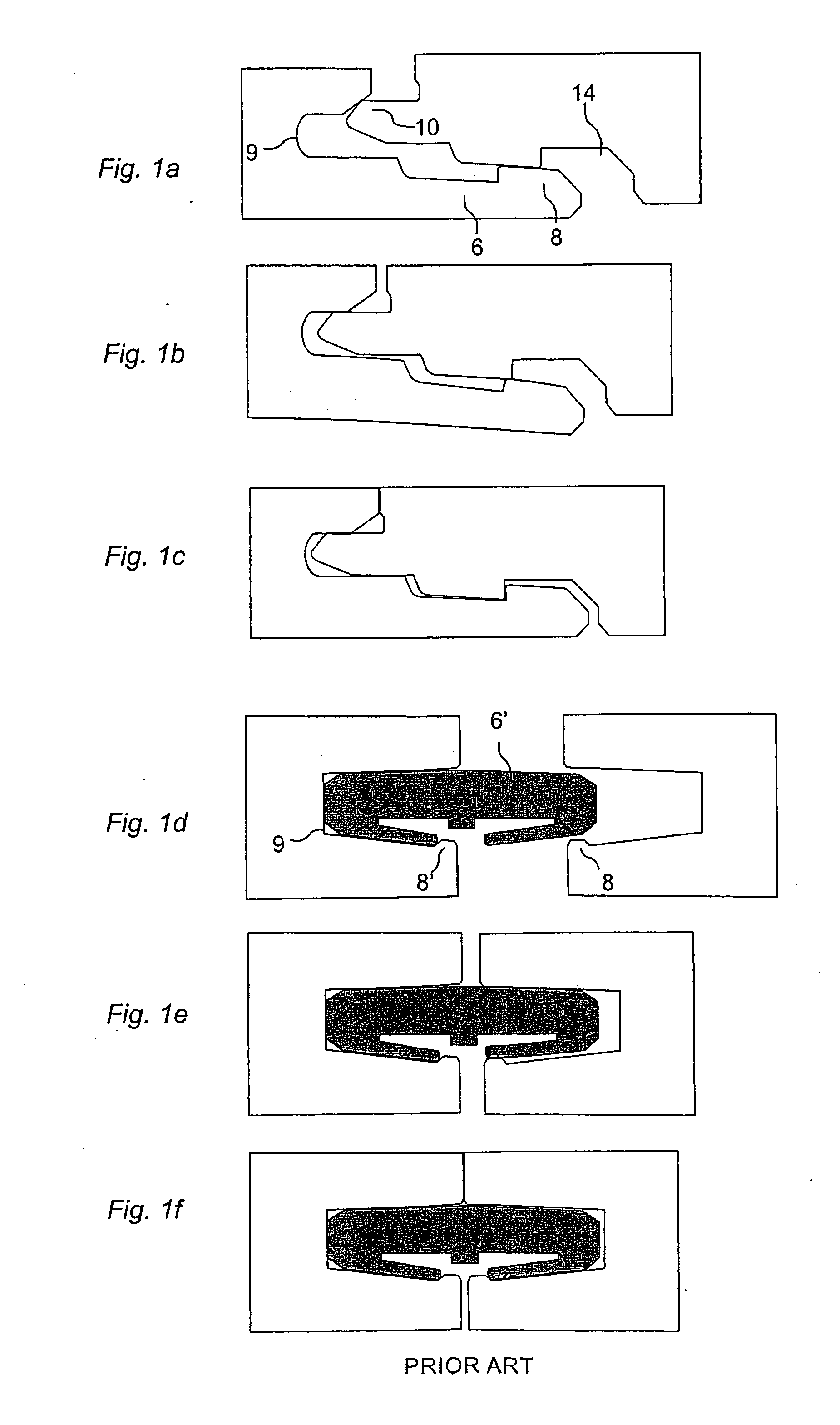

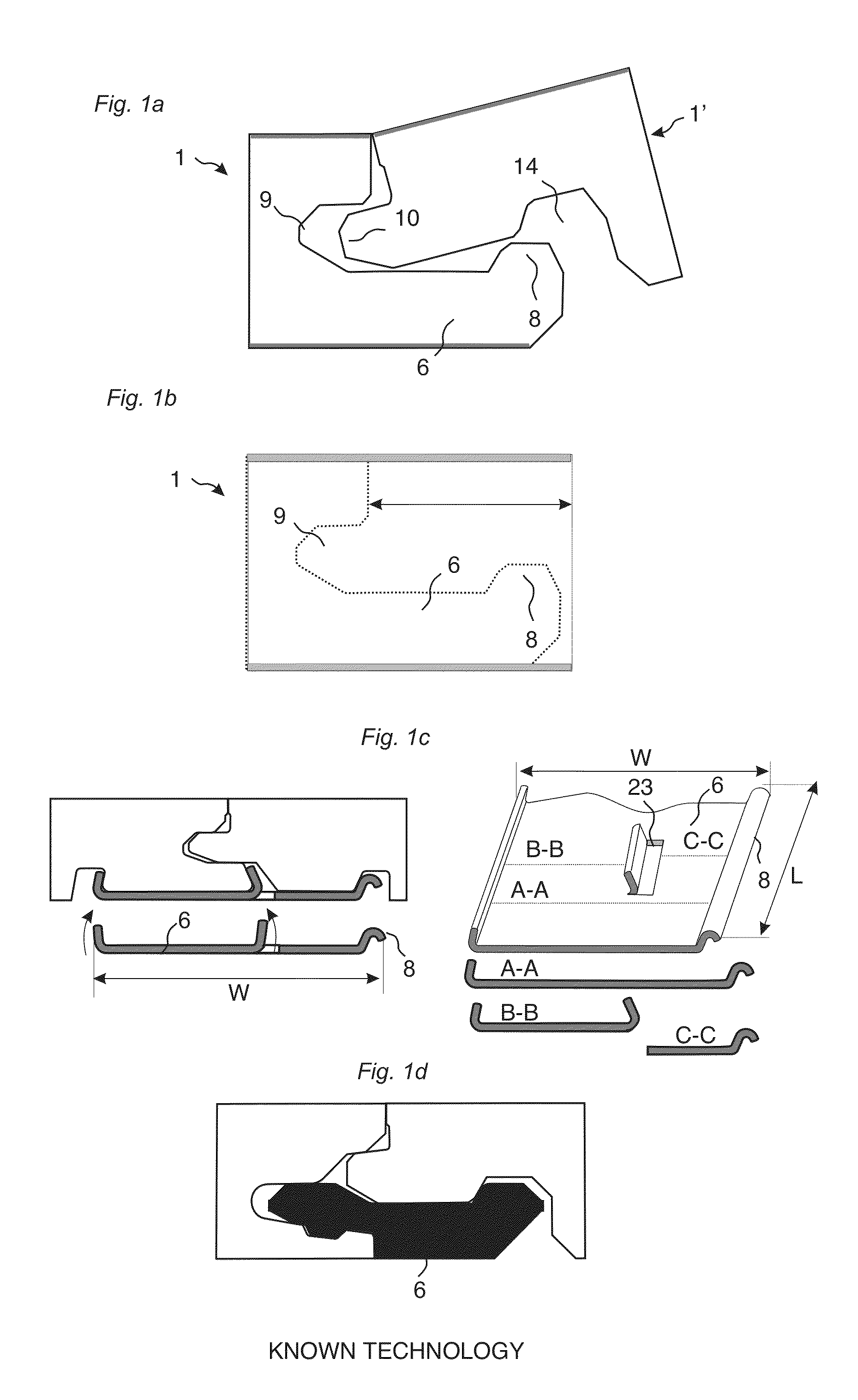

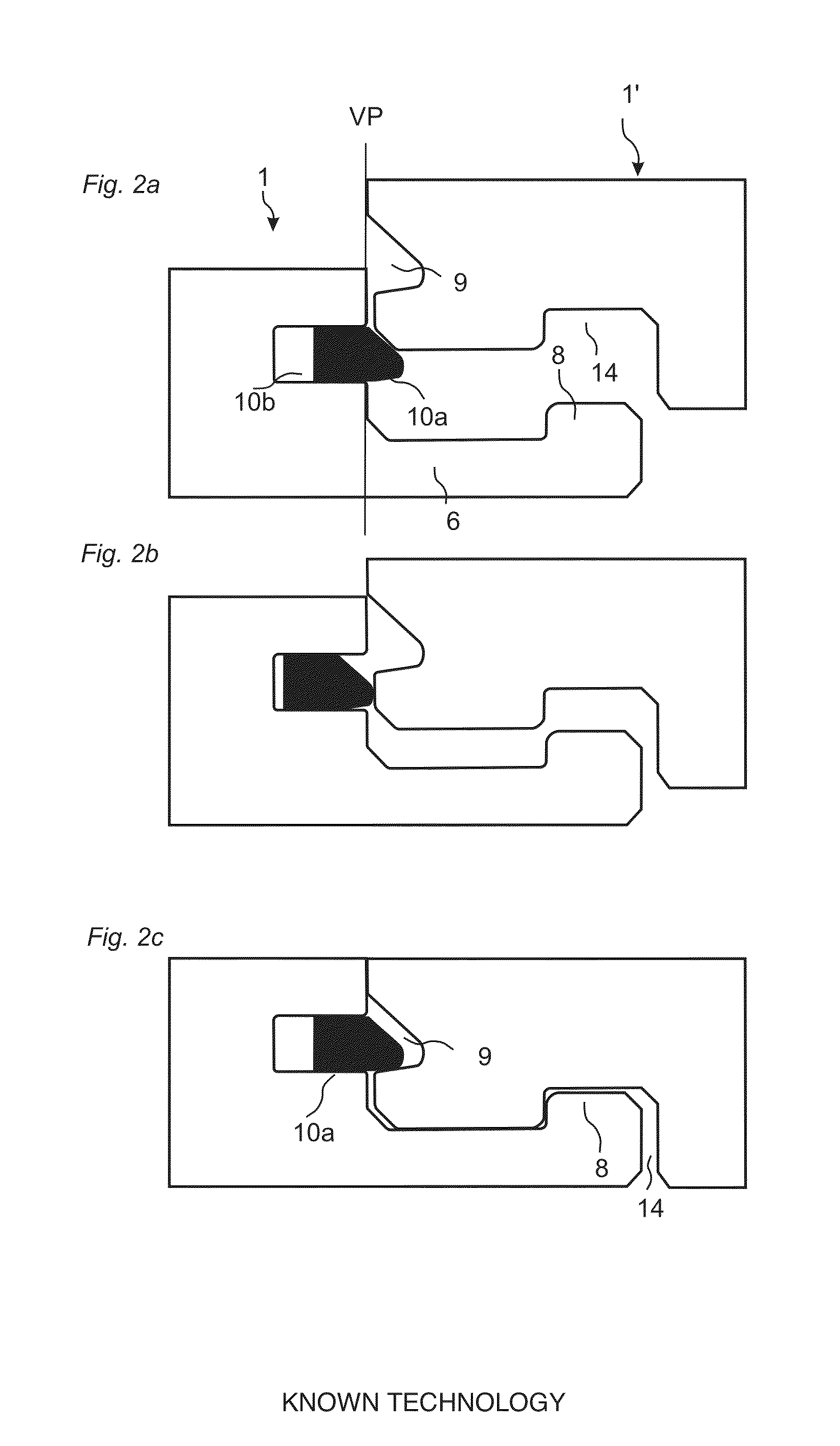

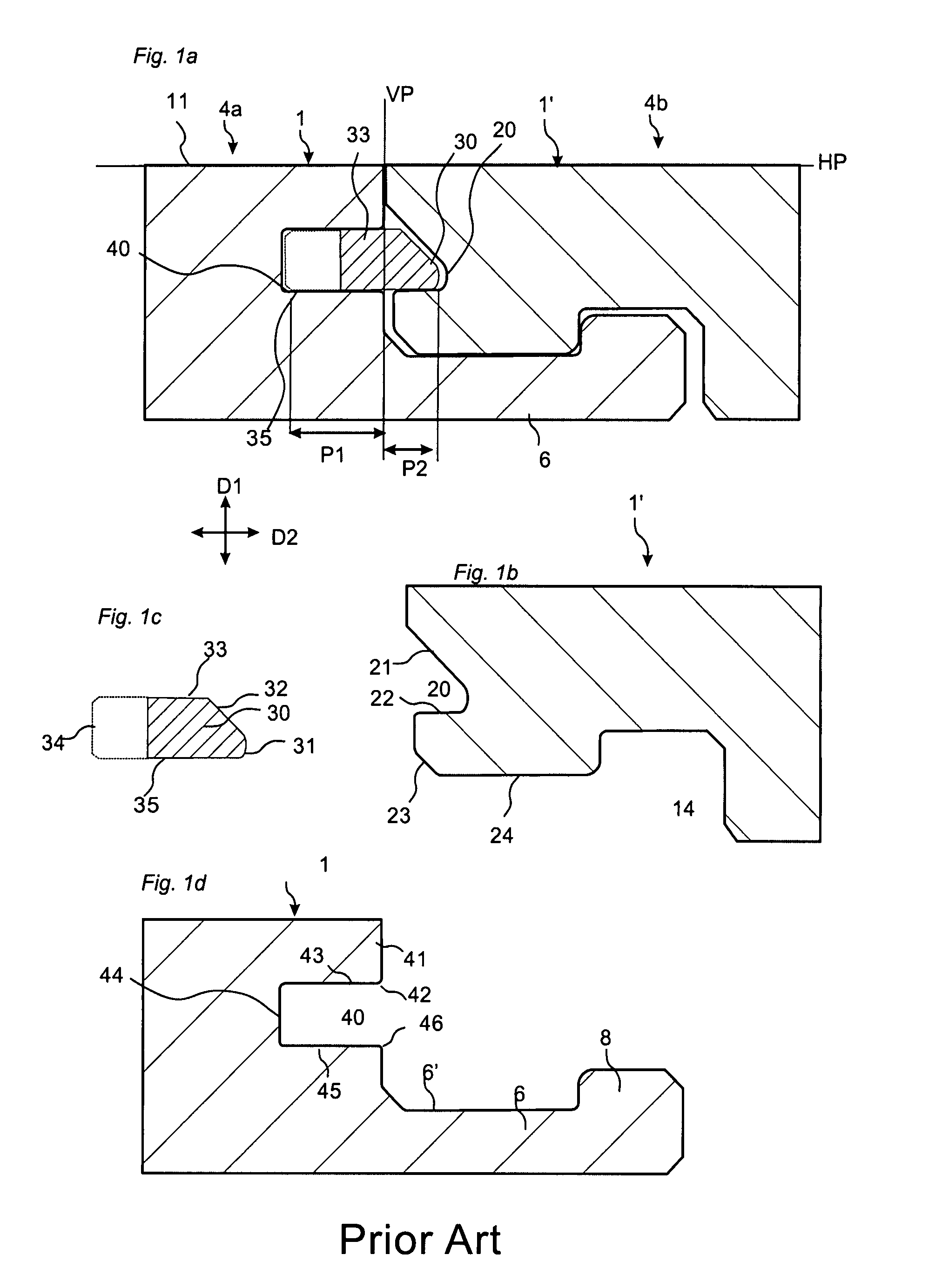

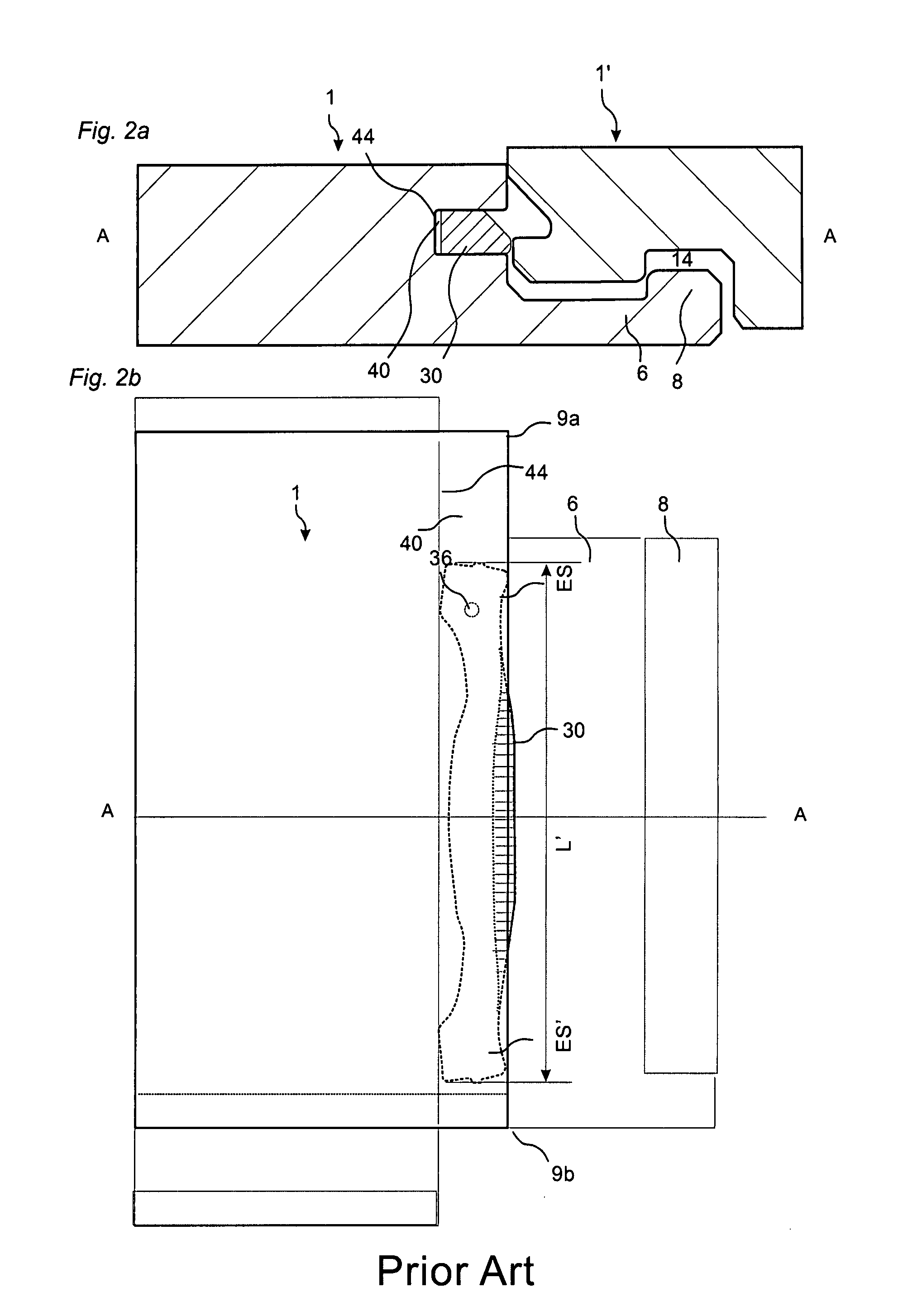

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

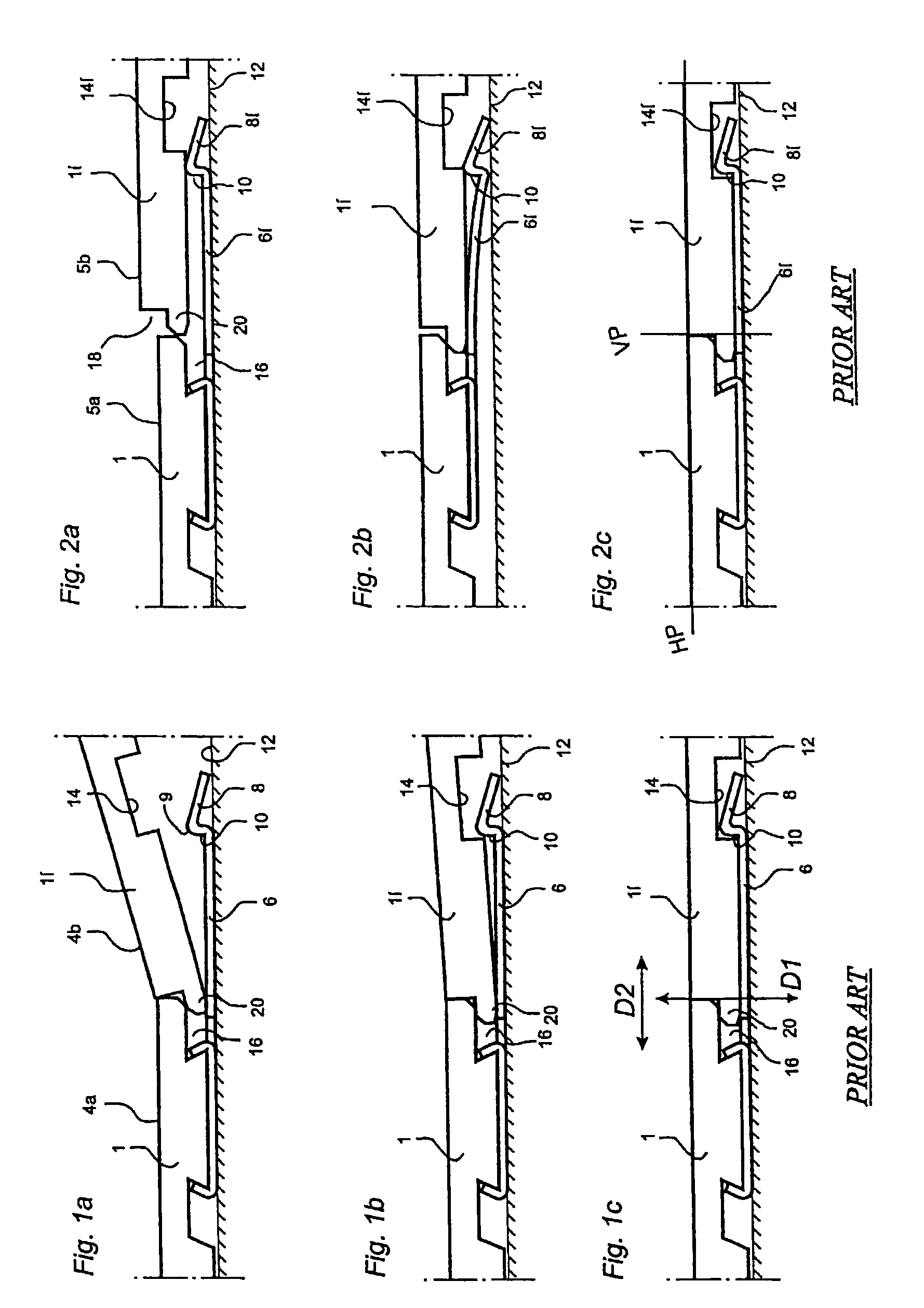

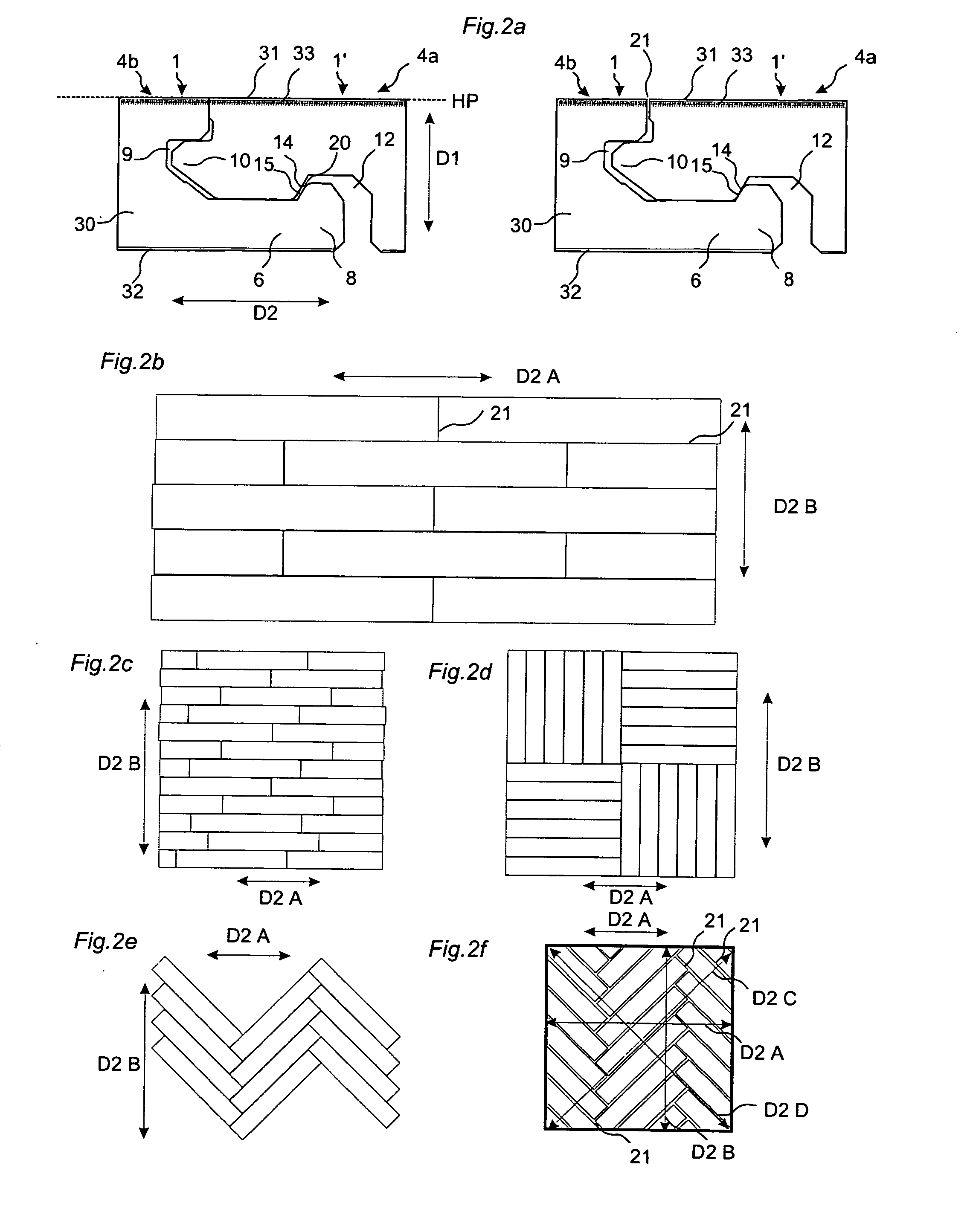

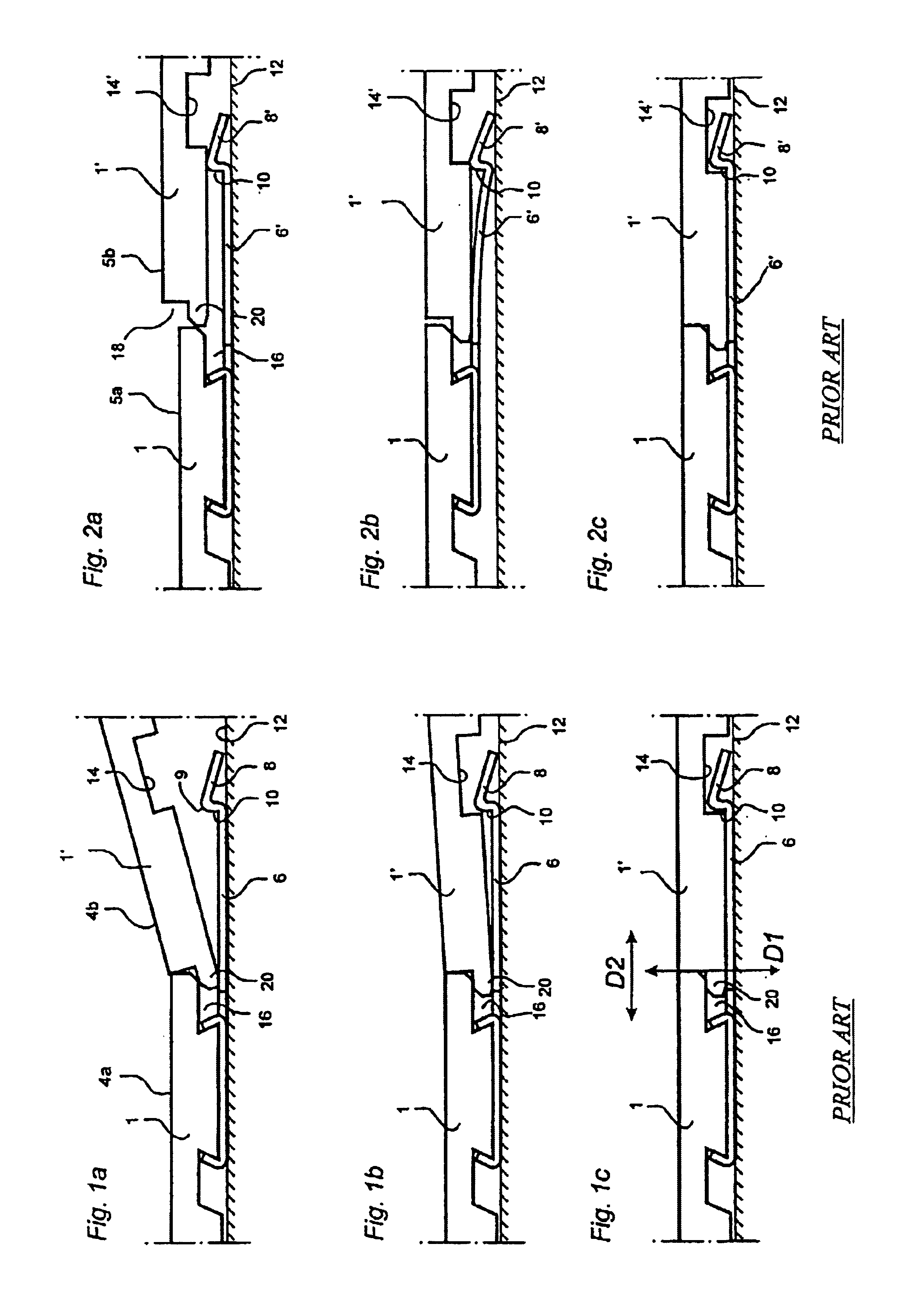

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Mechanical locking system for floating floor

InactiveUS7051486B2Rational and cost-efficientReduce the amount requiredStrutsTreadsEngineeringFloating floor

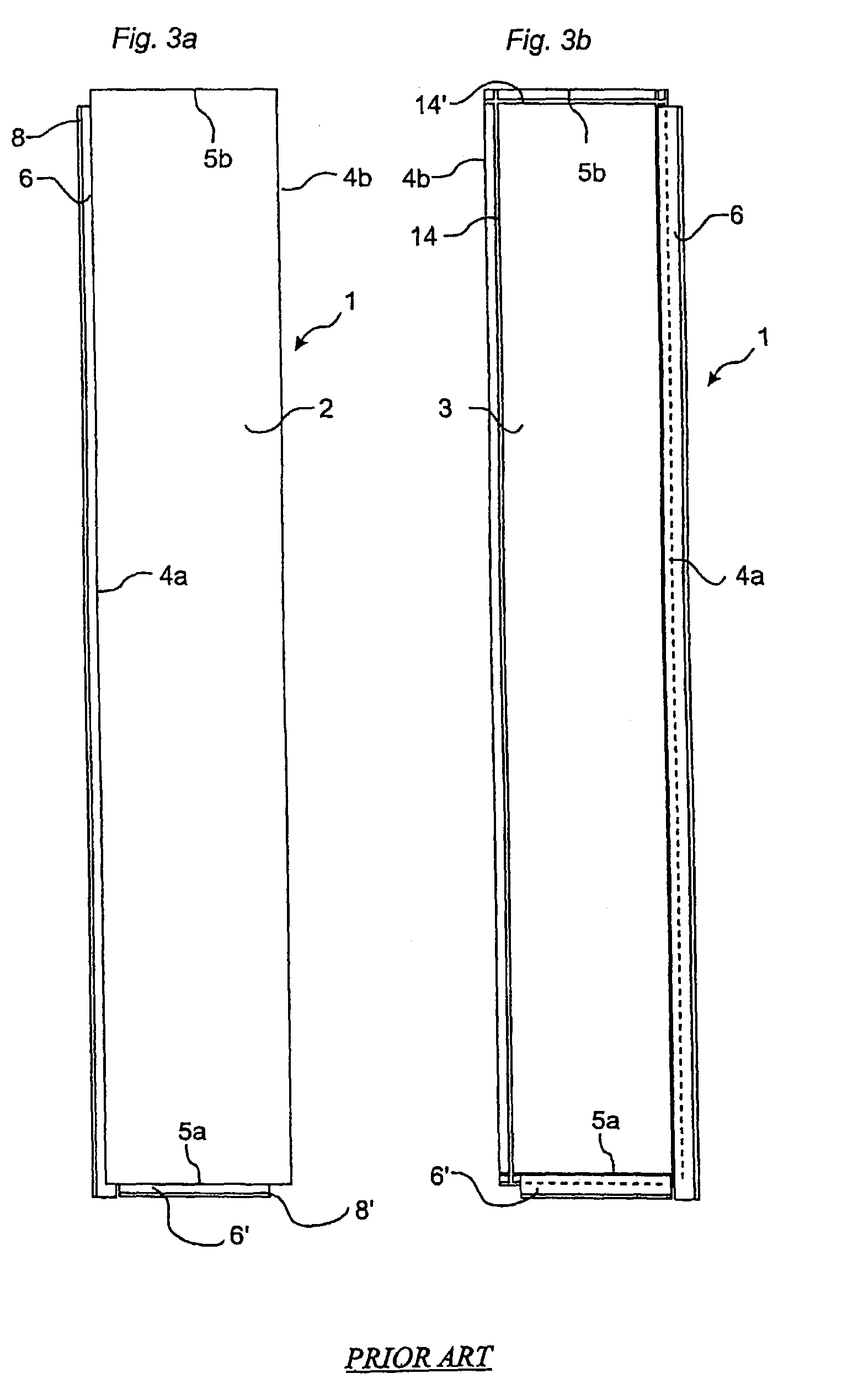

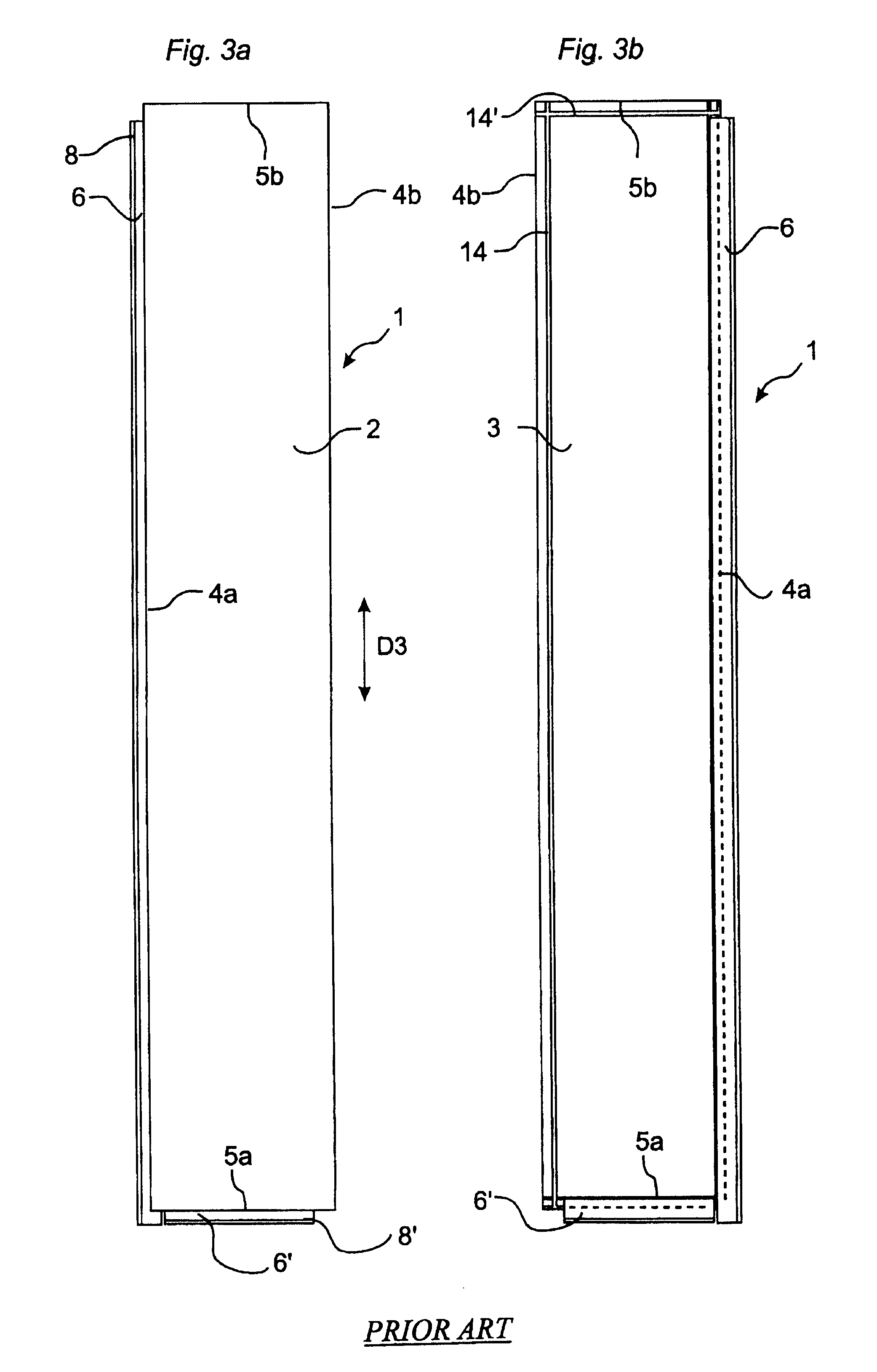

Floorboards with a mechanical locking system having a separately machined strip which is mechanically joined with the floorboard.

Owner:VÄLINGE INNOVATION AB

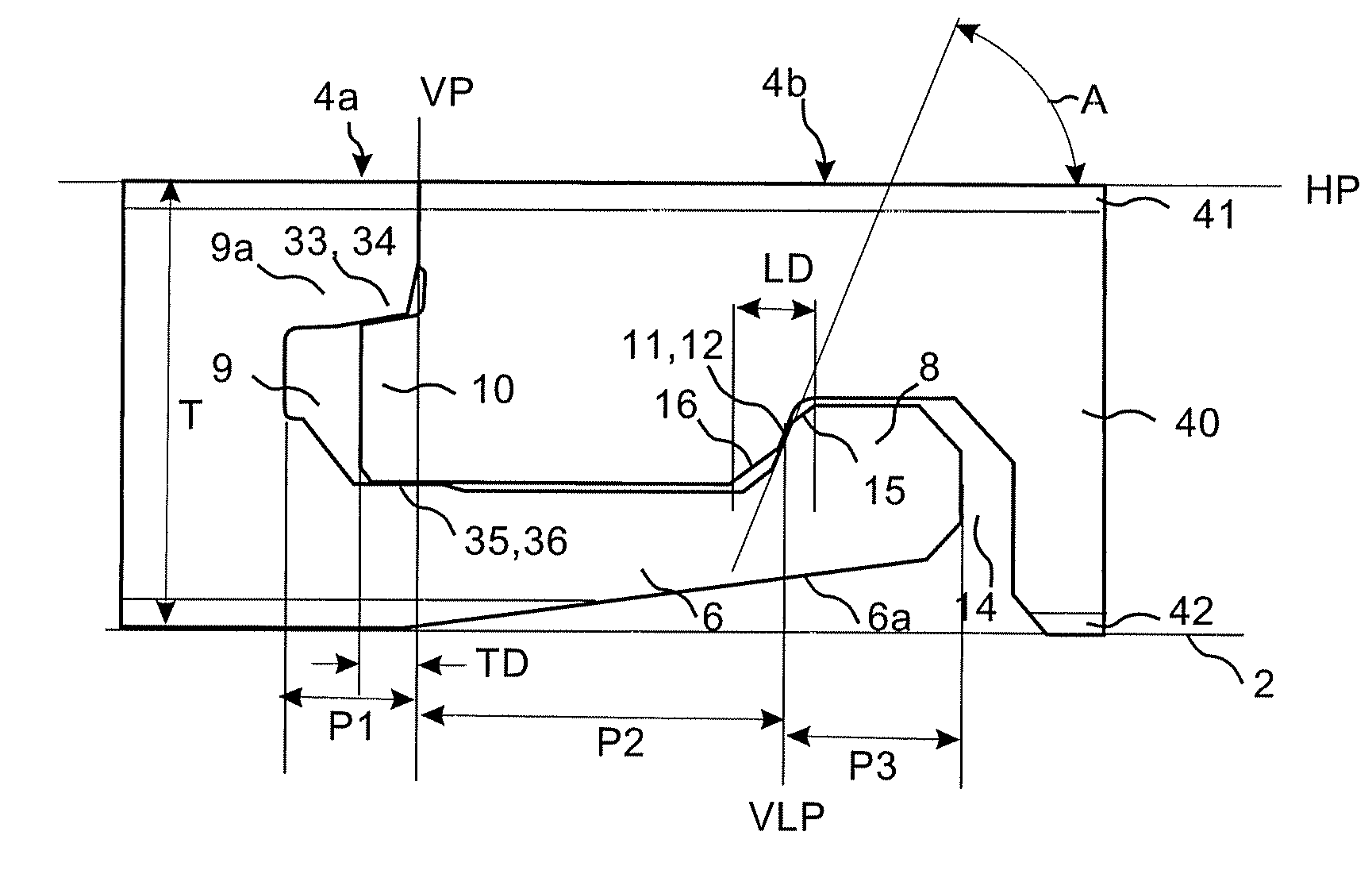

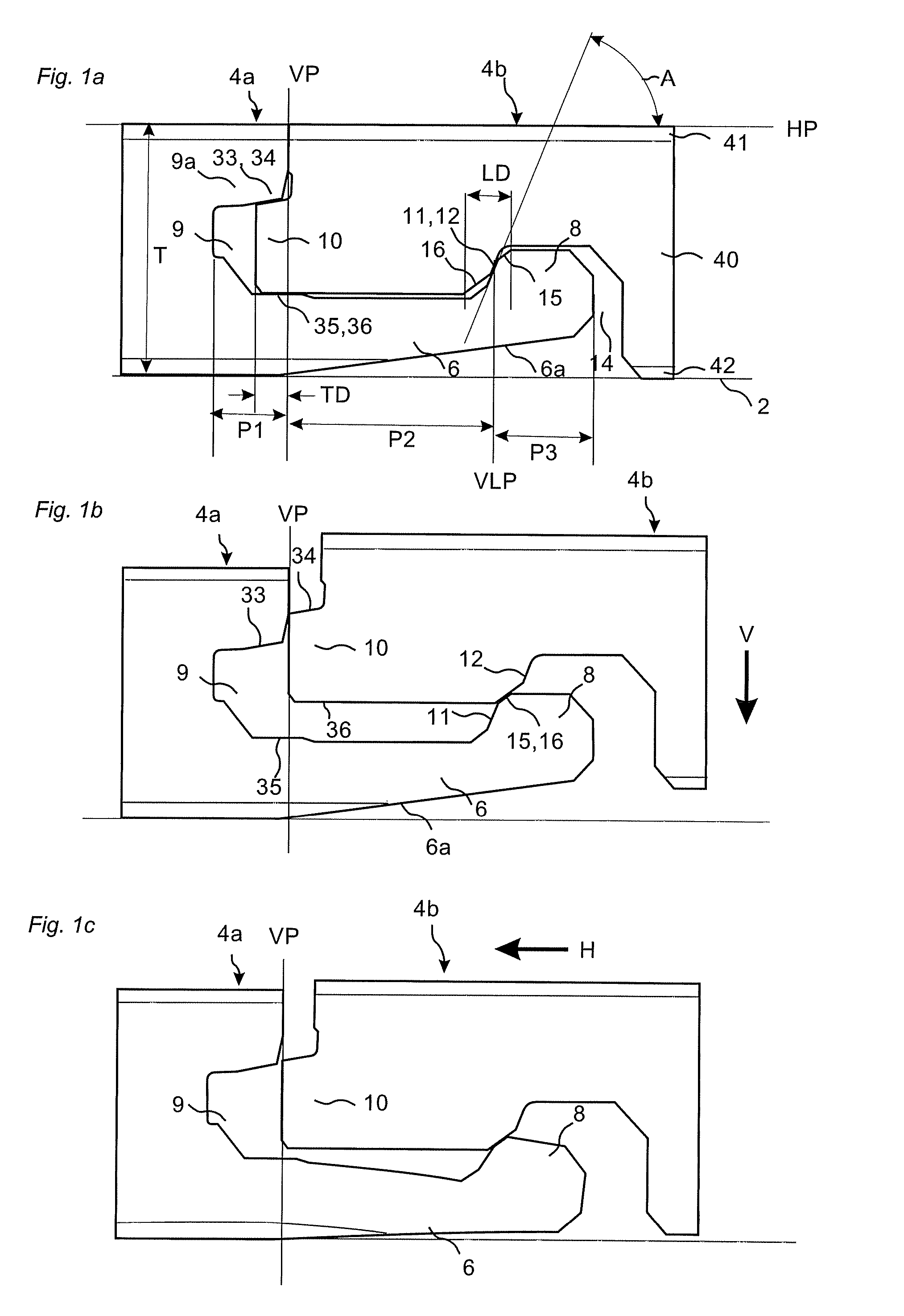

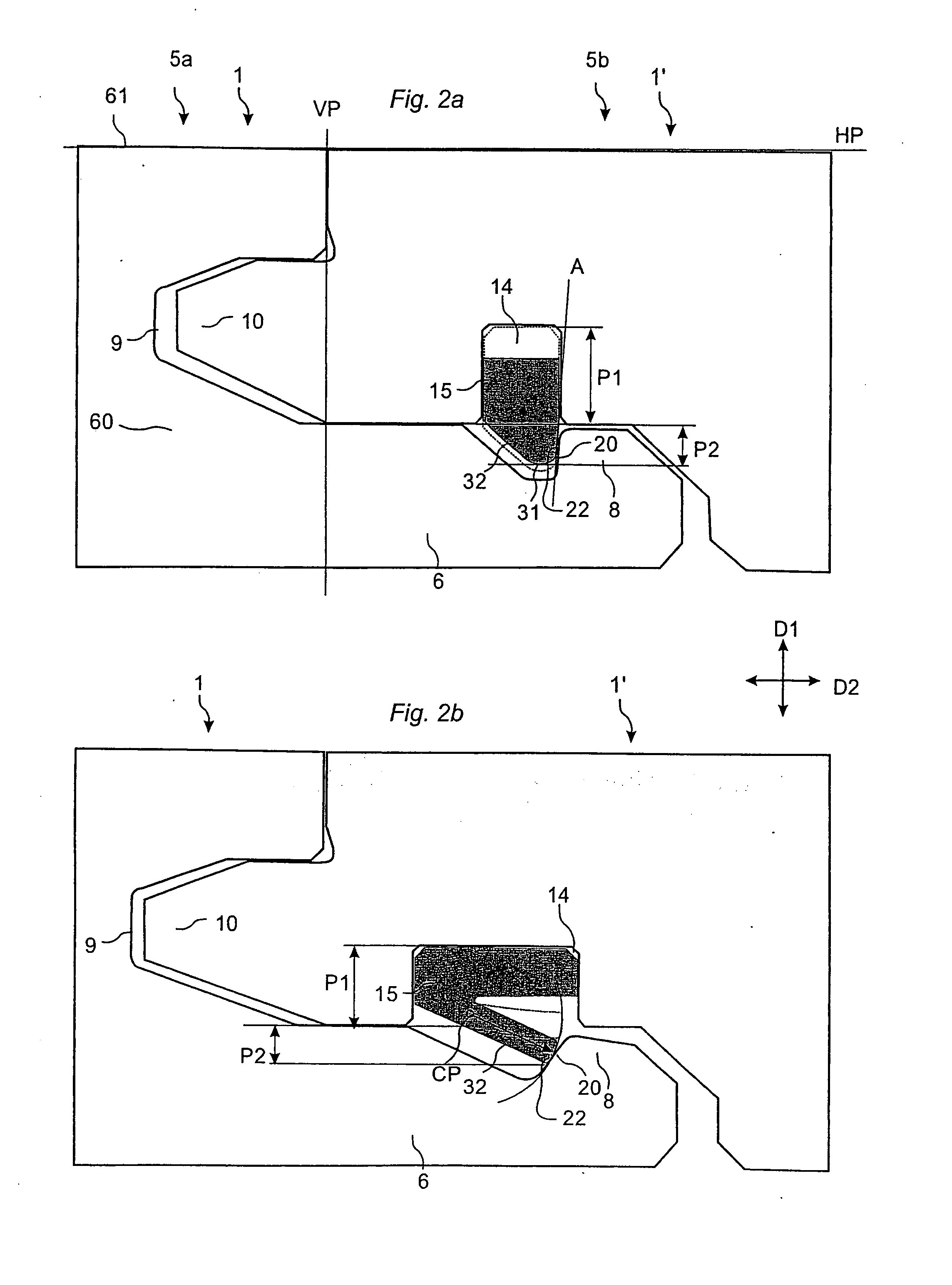

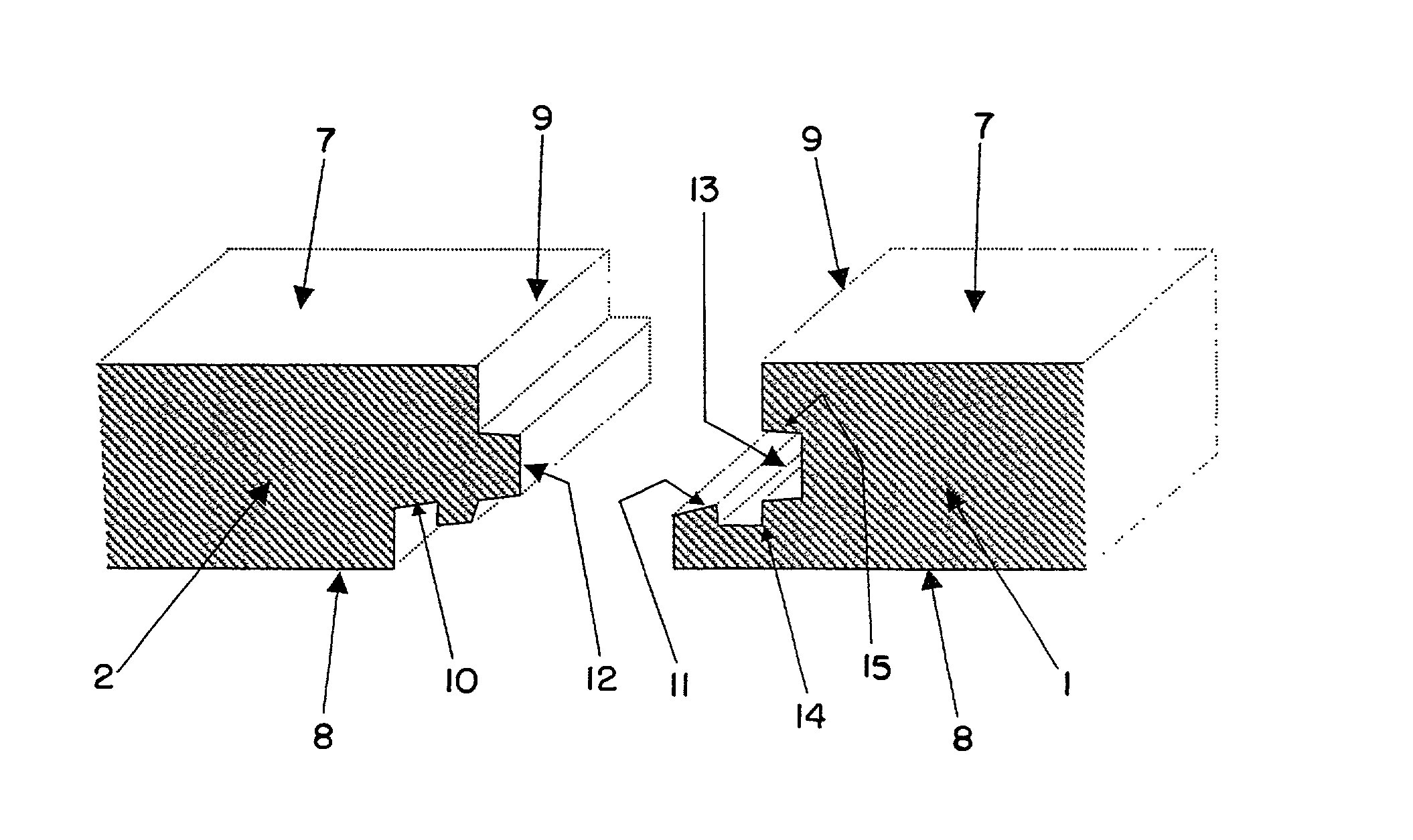

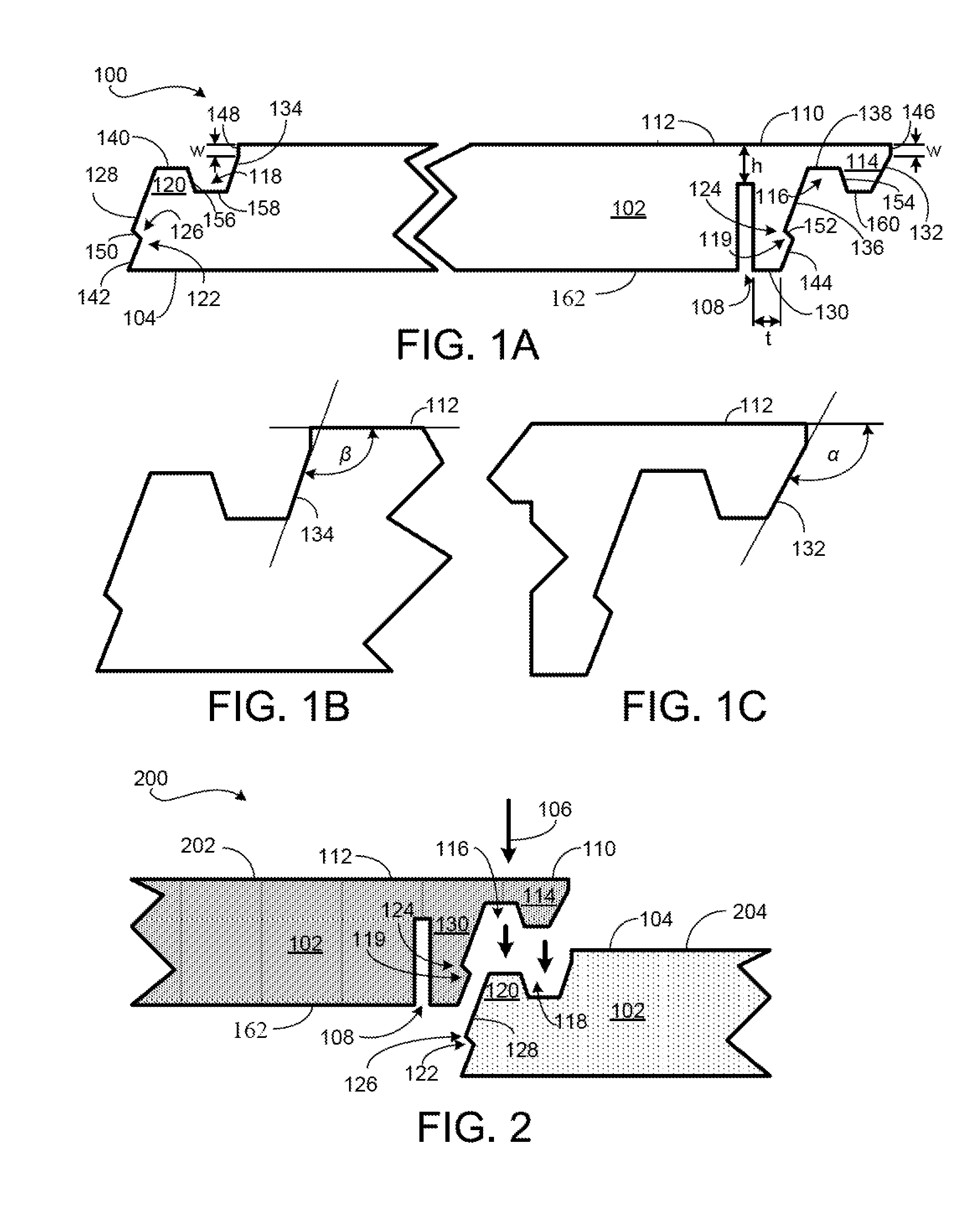

Mechanical locking system for panels and method of installing same

ActiveUS20080034708A1Simple horizontal displacementReduces snapping resistanceCovering/liningsWallsMechanical engineeringEngineering

Floor panels ( 1, 1 ') are provided with a mechanical locking system including a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

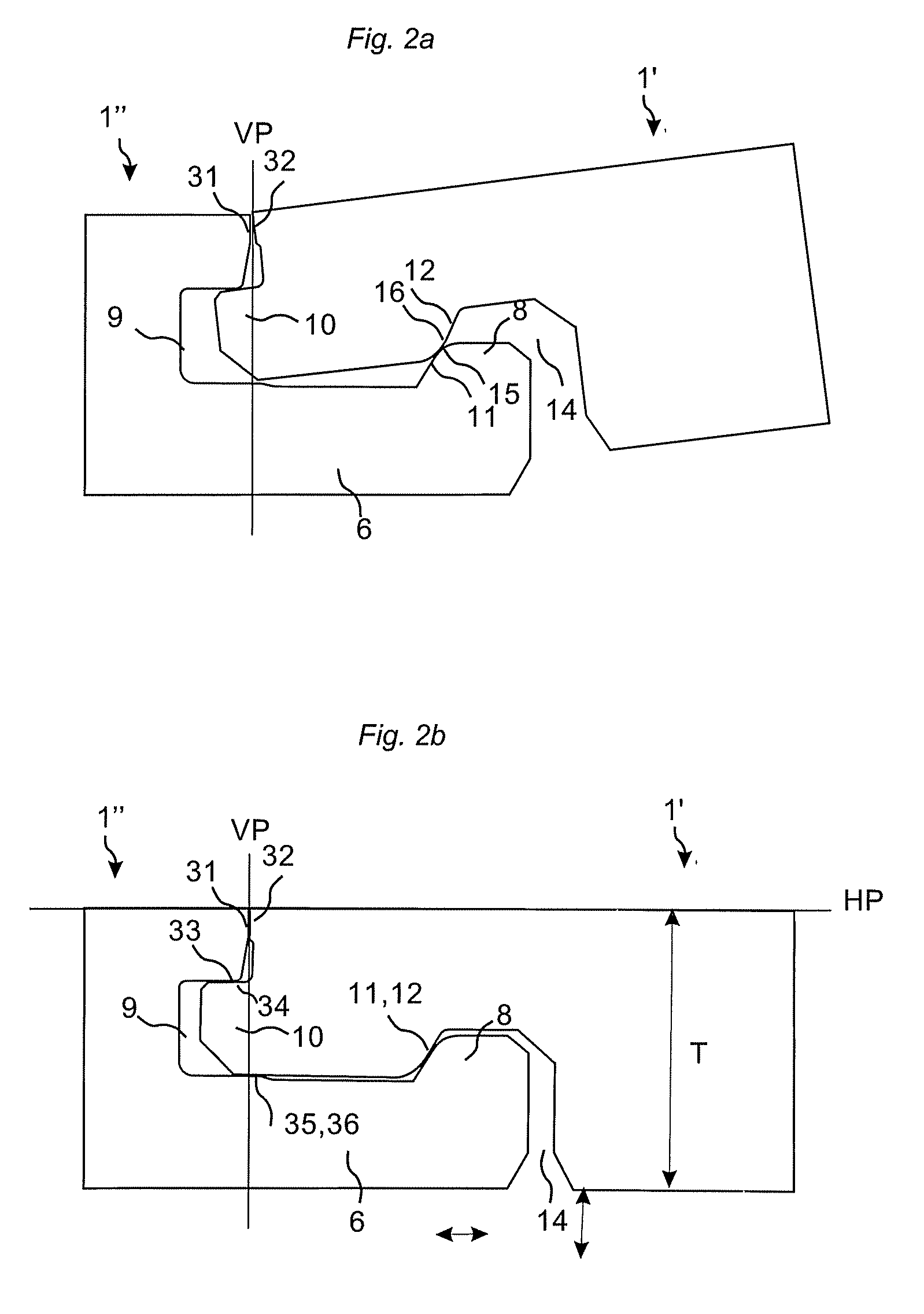

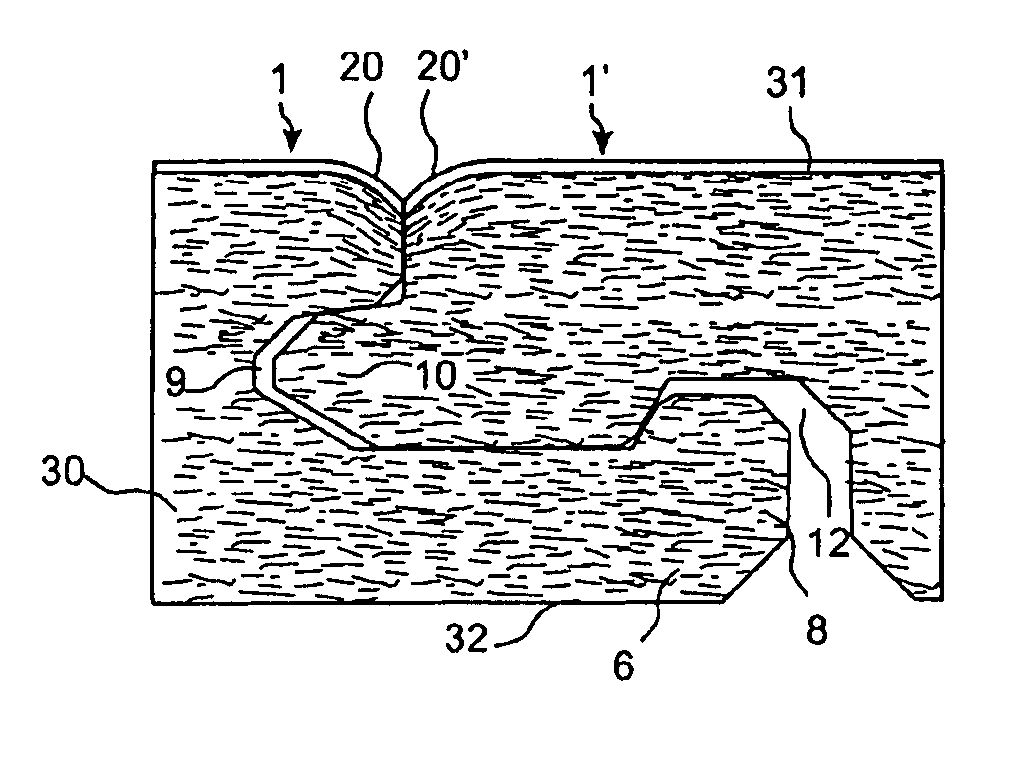

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Floor covering and locking systems

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

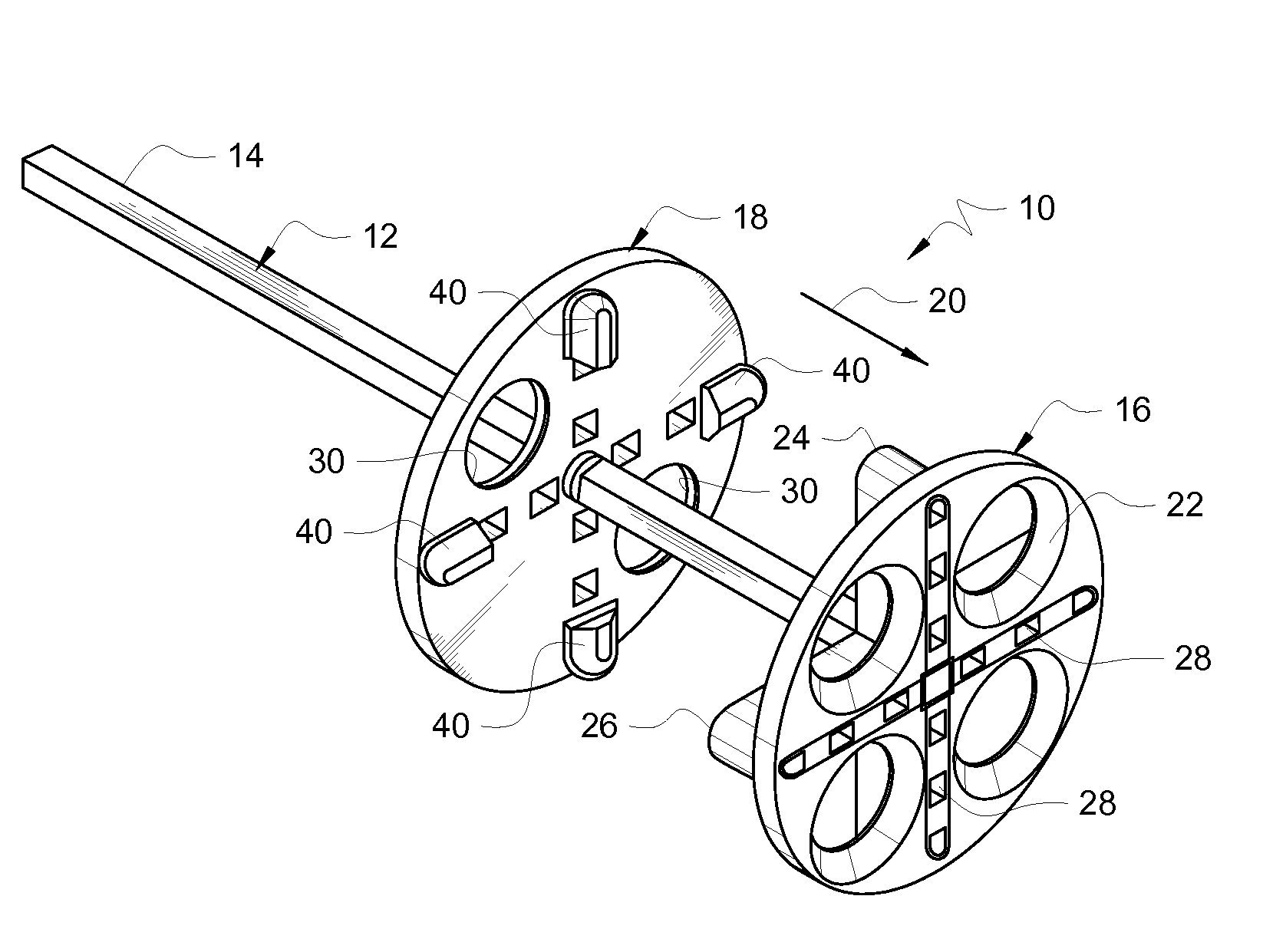

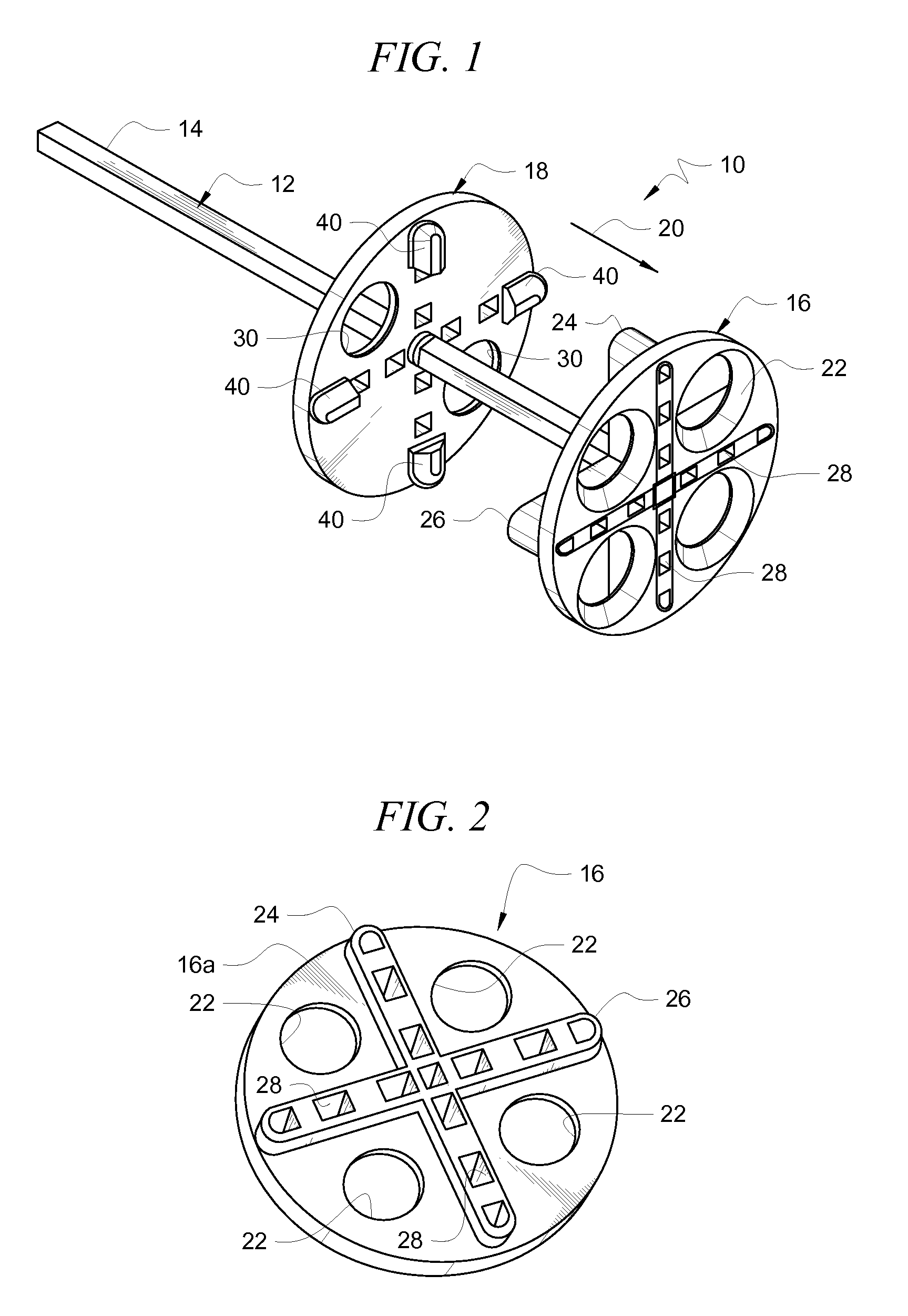

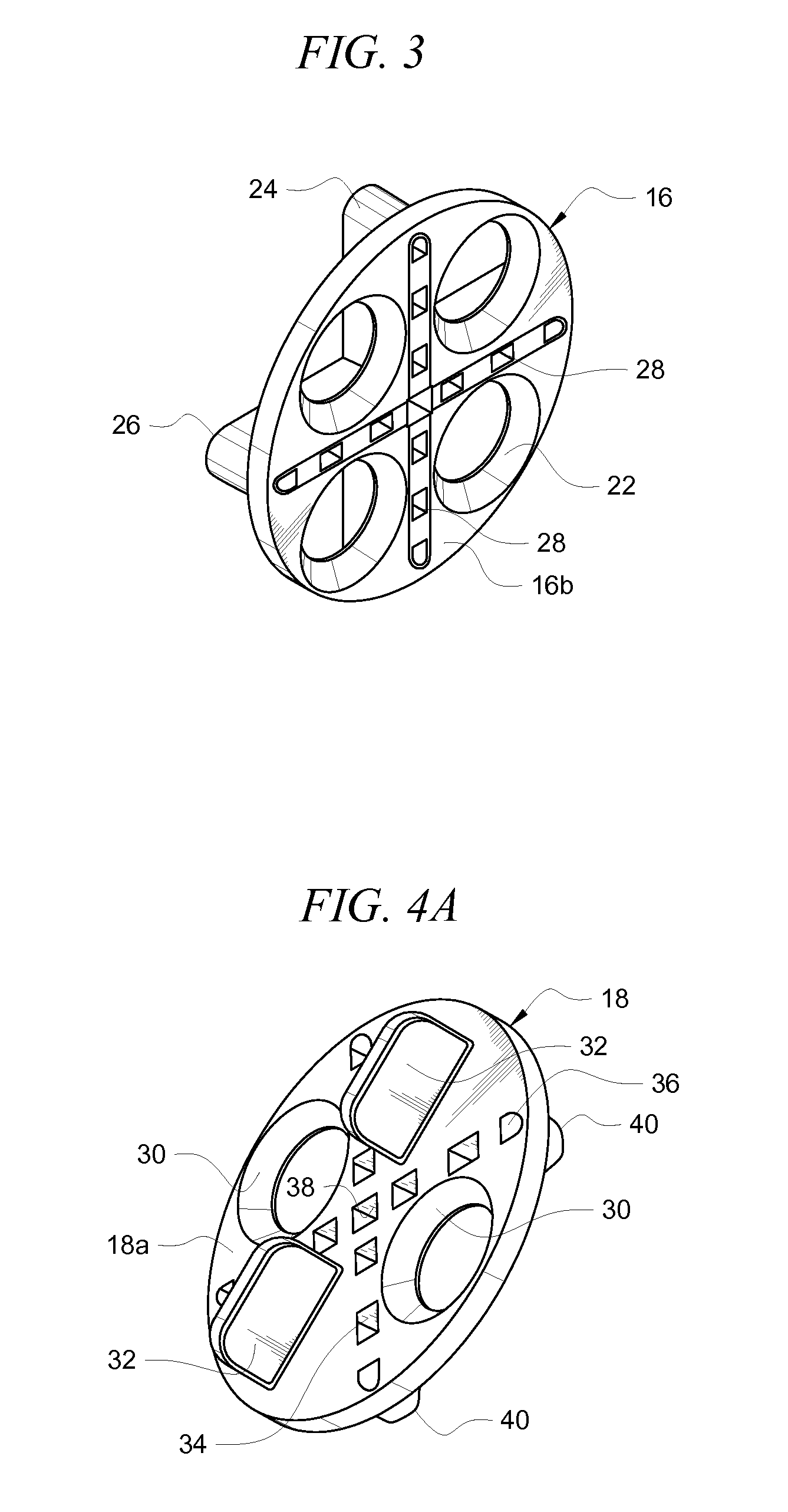

Tile spacer and leveler

A method for installing tiles includes the steps of positioning a base in overlying relation to cementitious material. First and second spacer arms are formed on the base in normal relation to one another. Preselected corners of four tiles are positioned in overlying relation to the base and are spaced apart from one another by the spacer arms. A post having ratchet teeth is formed integrally with the base at the center of the base. A disc receives the post and a pawl formed in the disc prevents displacement of the disc away from the base. The disc is positioned in overlying relation to the four corners of the tiles so that it overlies and holds the tiles level between the base and the disc. After curing of the cementitious material, an installer twists the disc in a plane parallel to the tiles until the post breaks off.

Owner:KIRBY MARK E

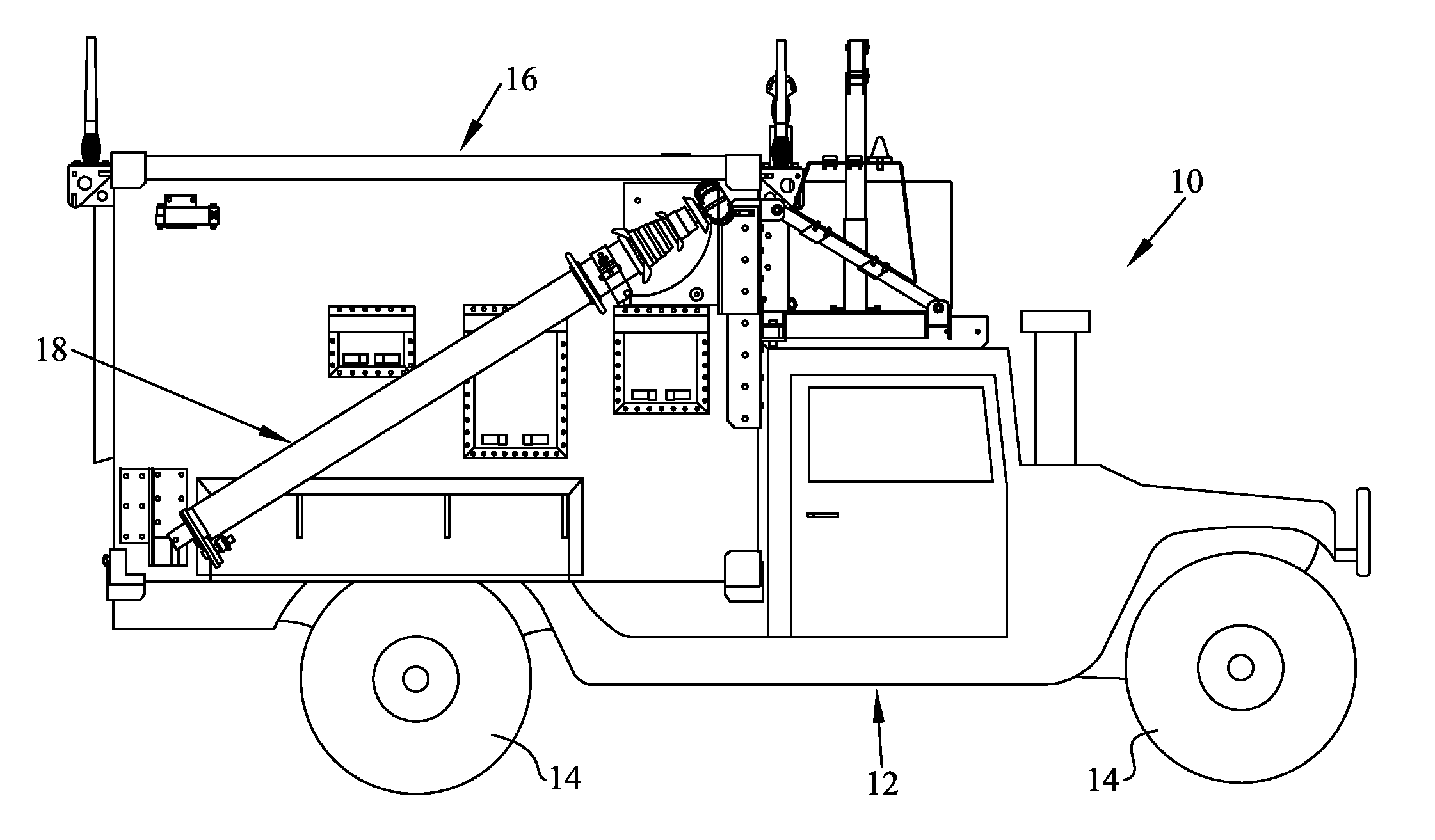

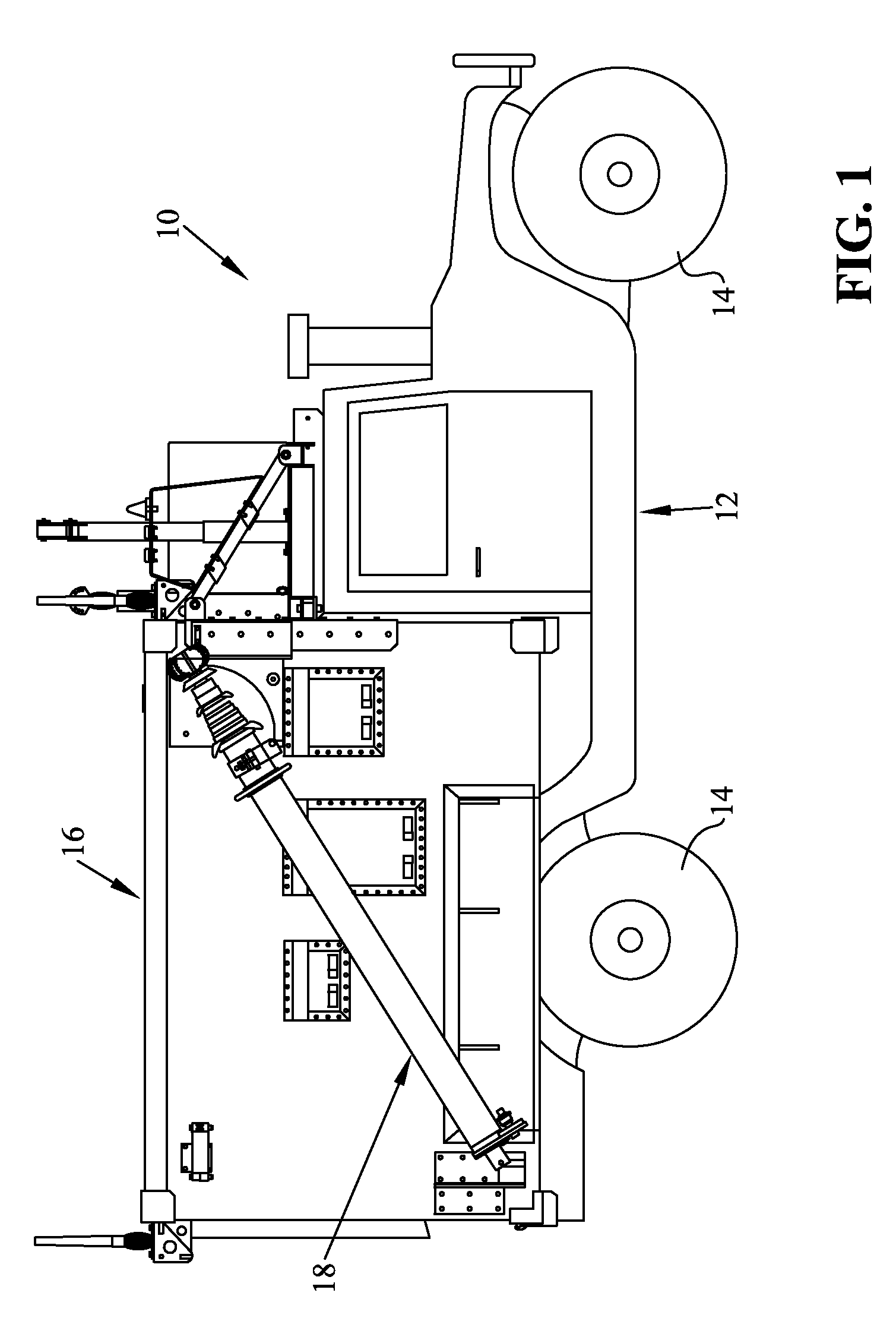

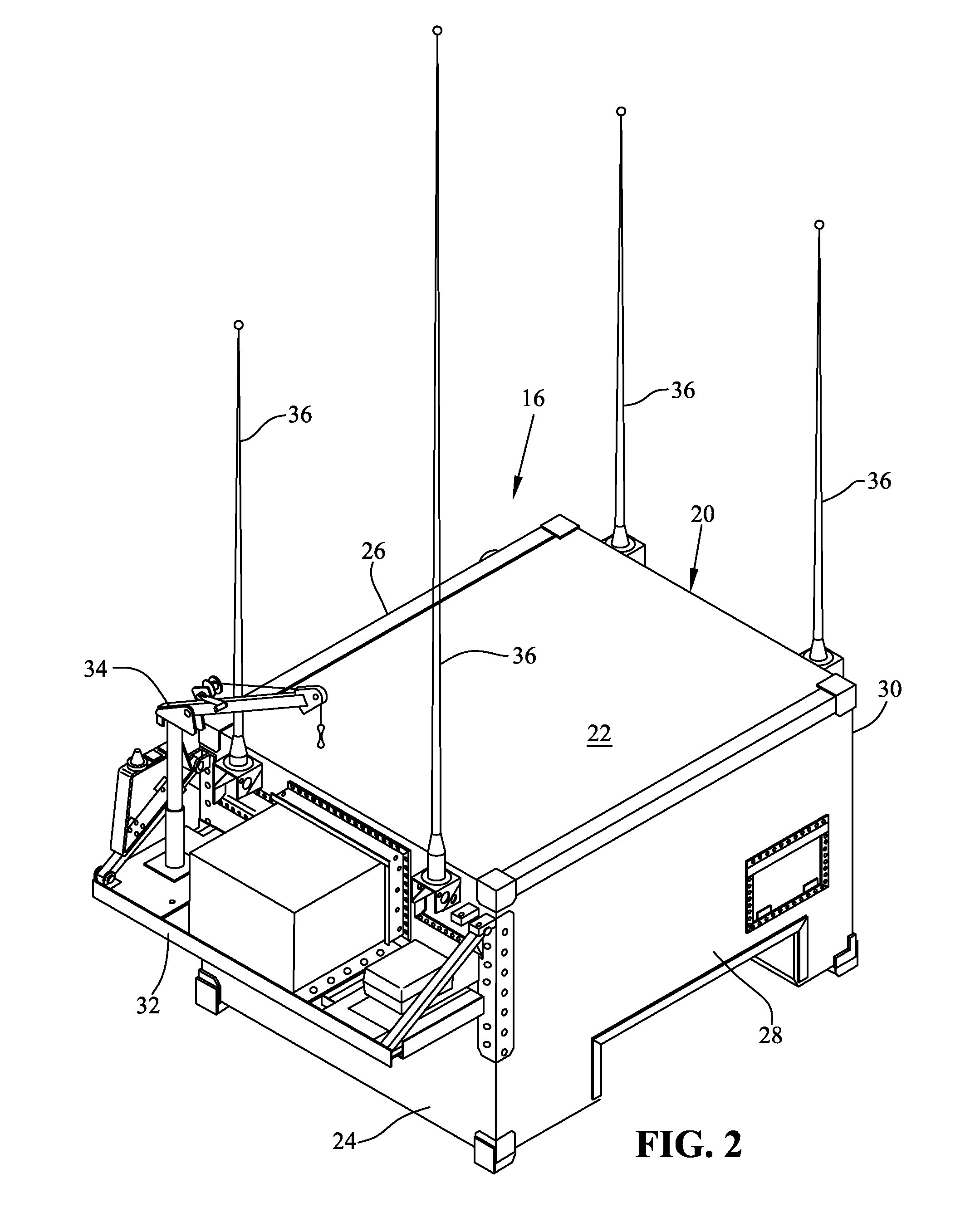

Vehicle and mast mounting assembly therefor

ActiveUS8276325B2Antenna supports/mountingsAntenna adaptation in movable bodiesEngineeringMechanical engineering

A vehicle is disclosed having a mast assembly mounted to a sidewall of the vehicle. The mast is pivotally mounted and can be held in a first stowed position by way of a first clamp member. The mast is pivotal relative to the sidewall, to an essentially vertical and erect position, and held in the second position by way of a second clamp.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

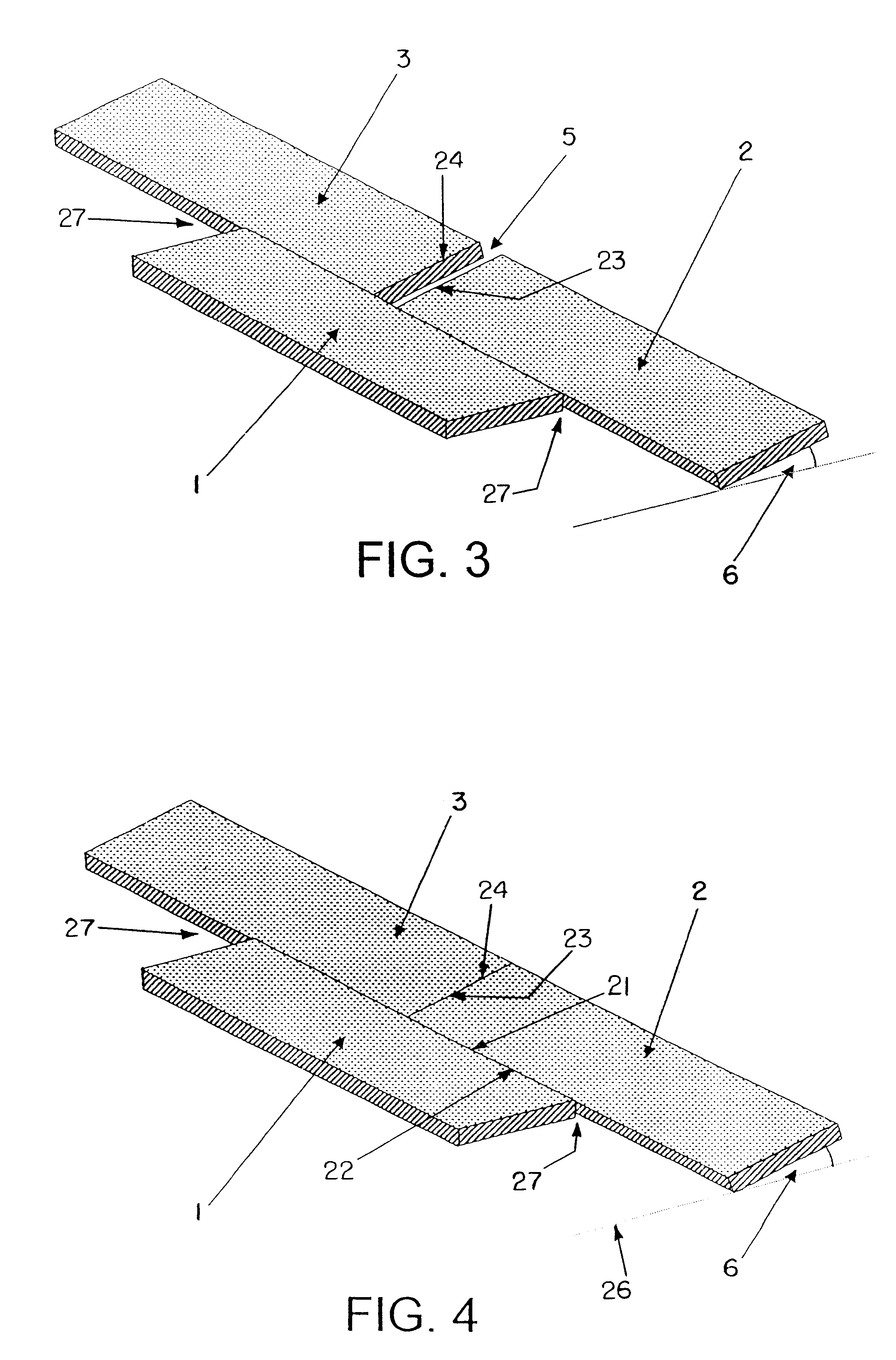

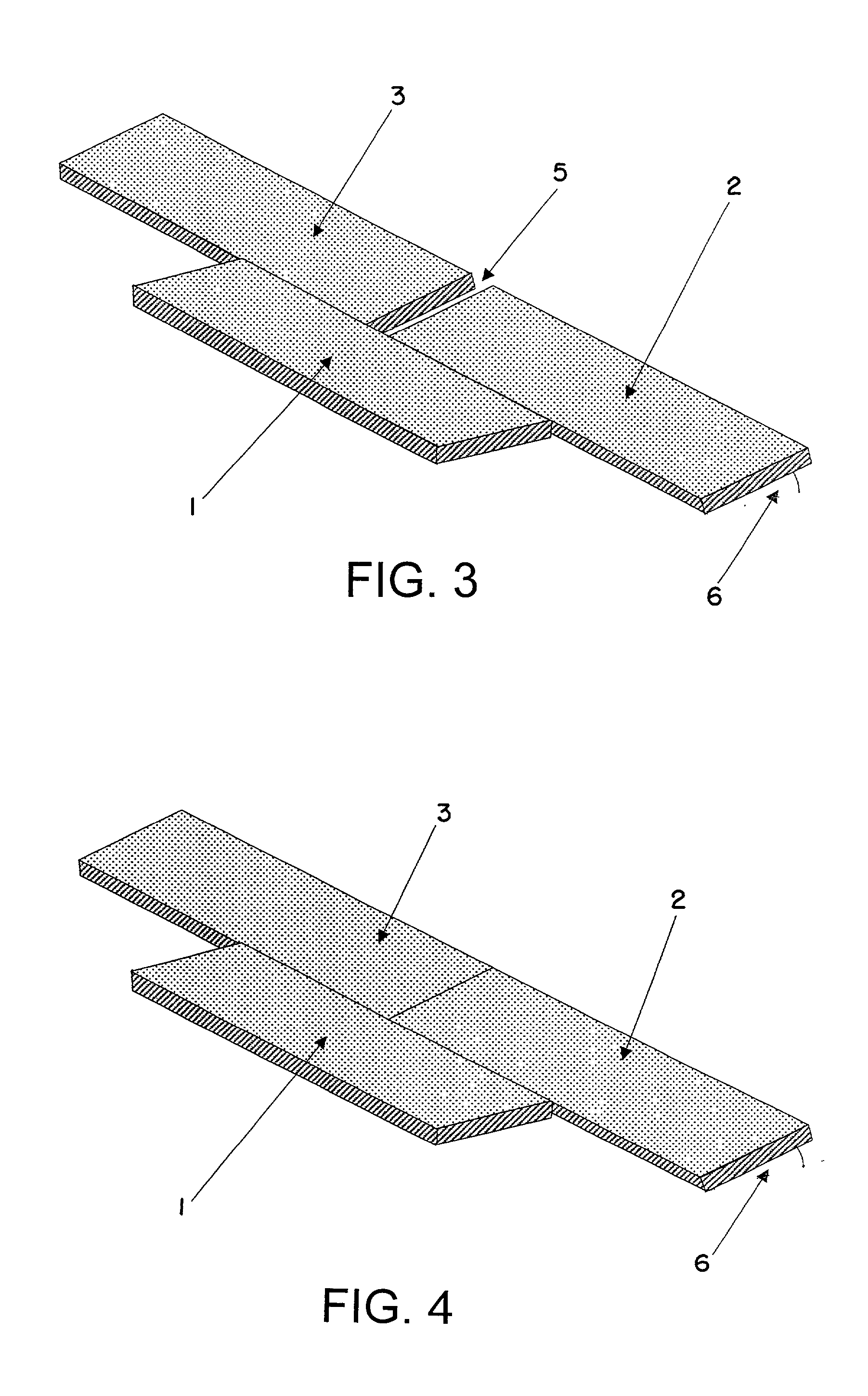

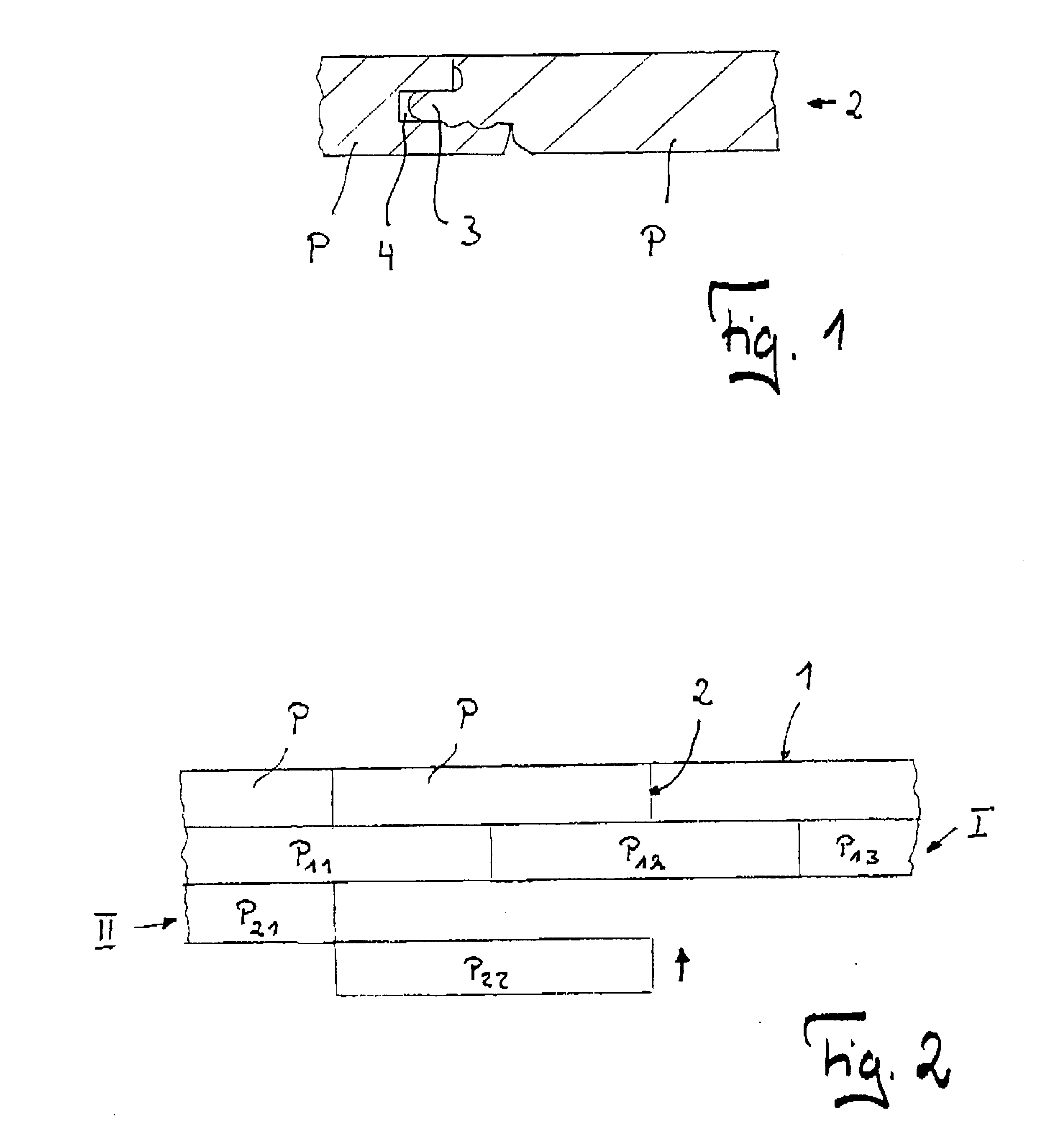

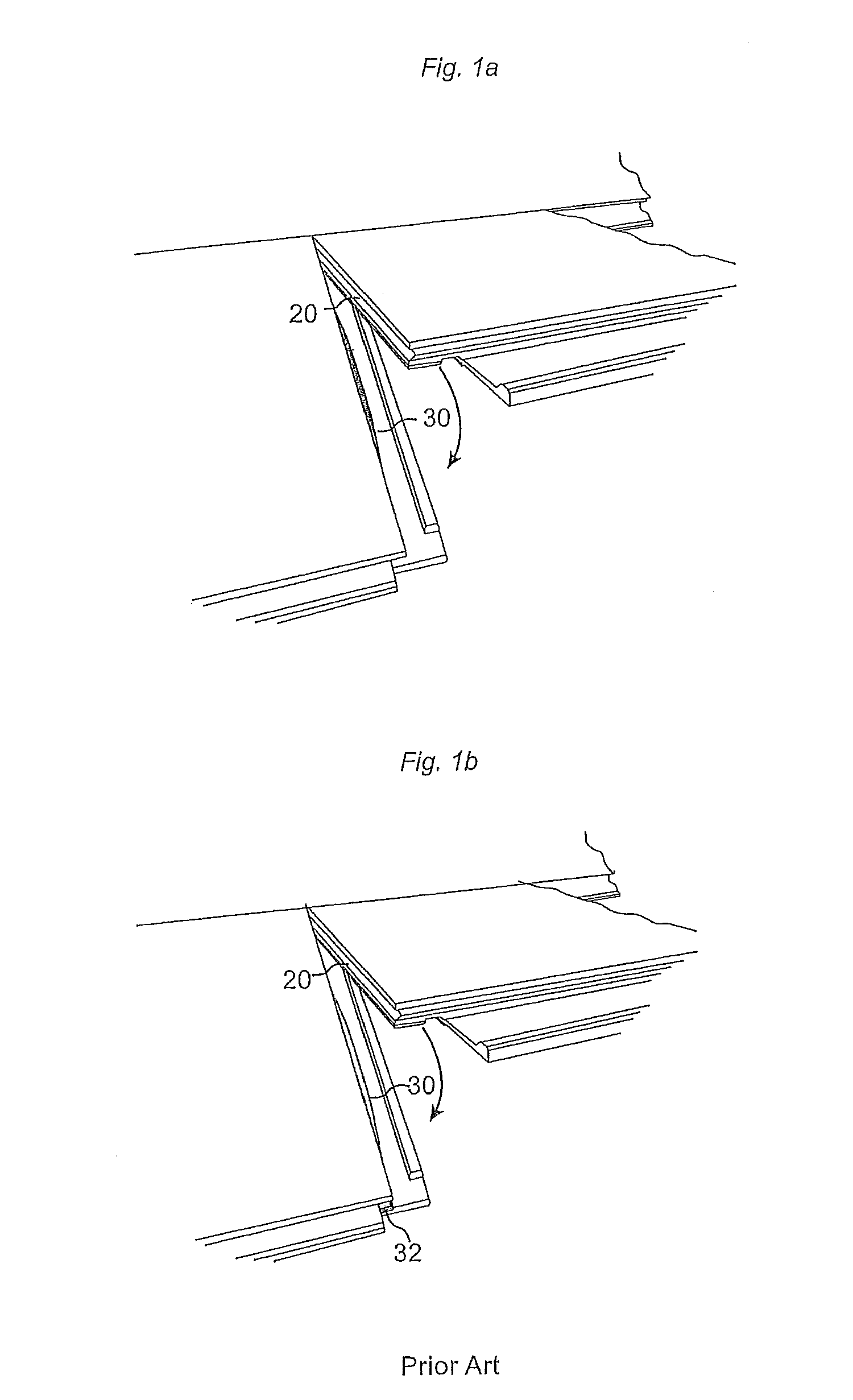

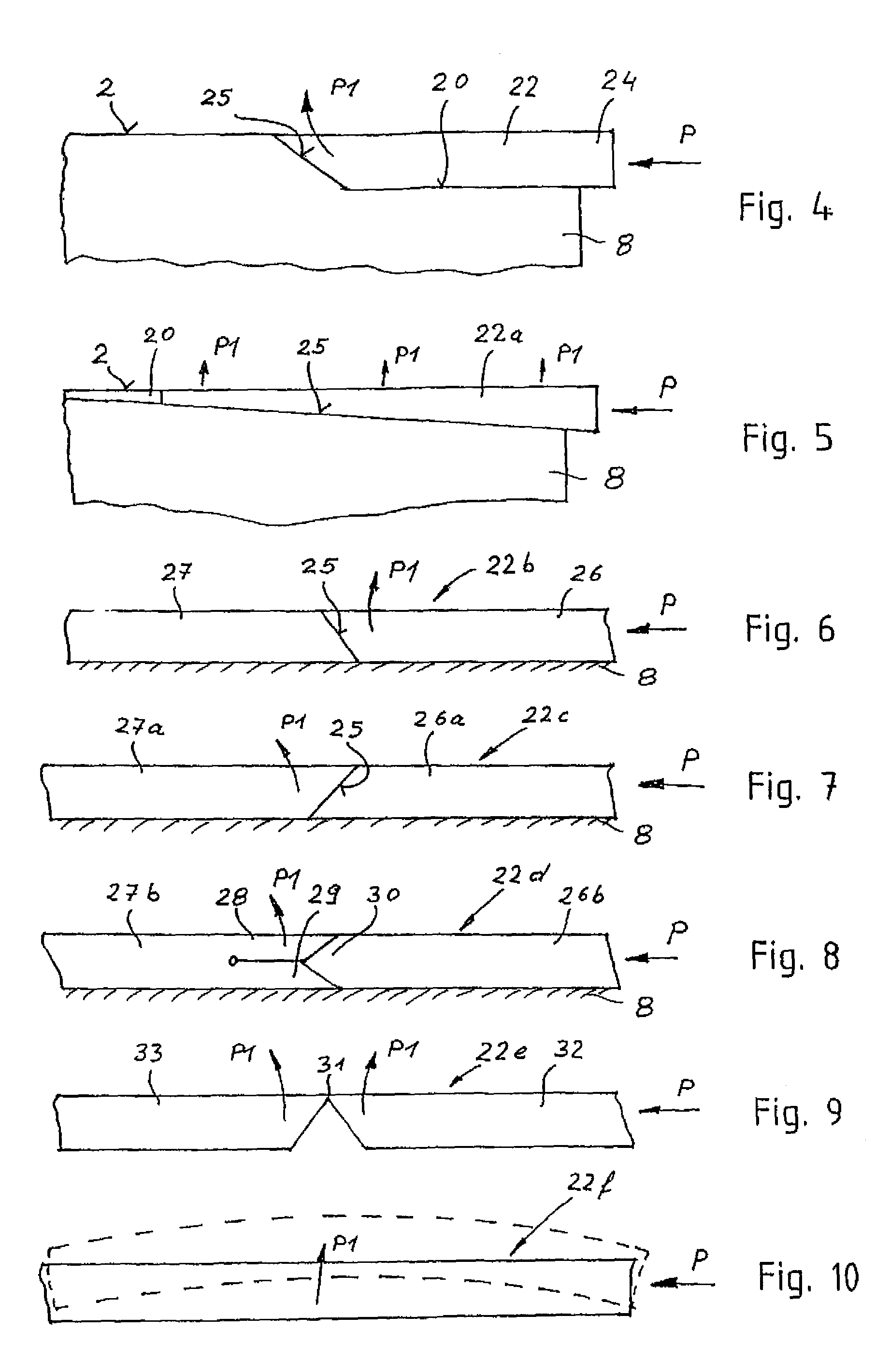

Method of laying panels

InactiveUS6546691B2Increase displacementAvoid the needRoof covering using tiles/slatesWallsEngineeringMutual position

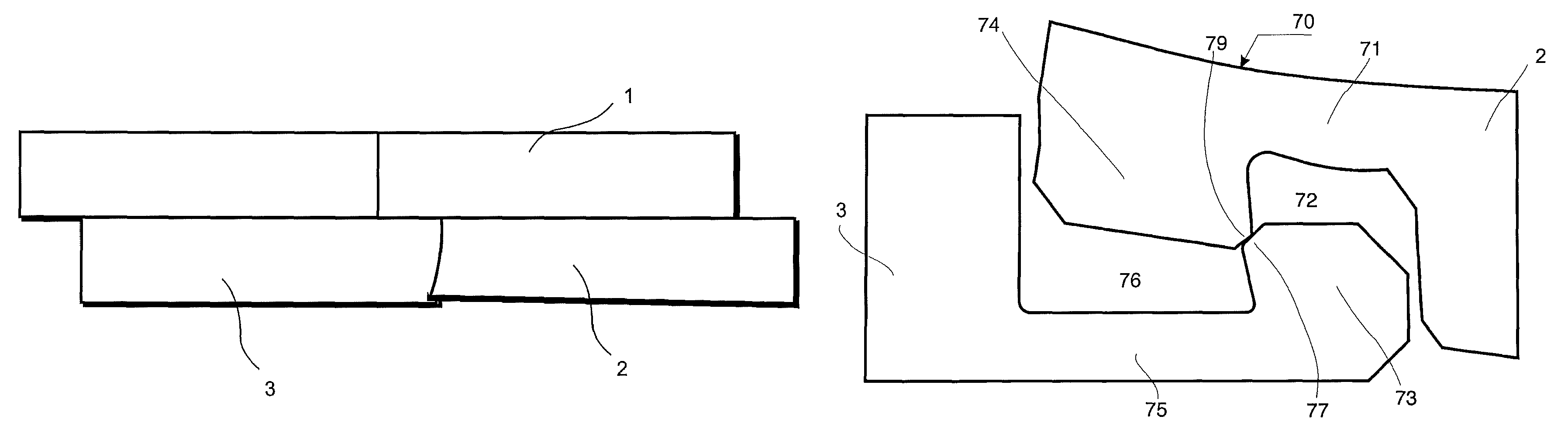

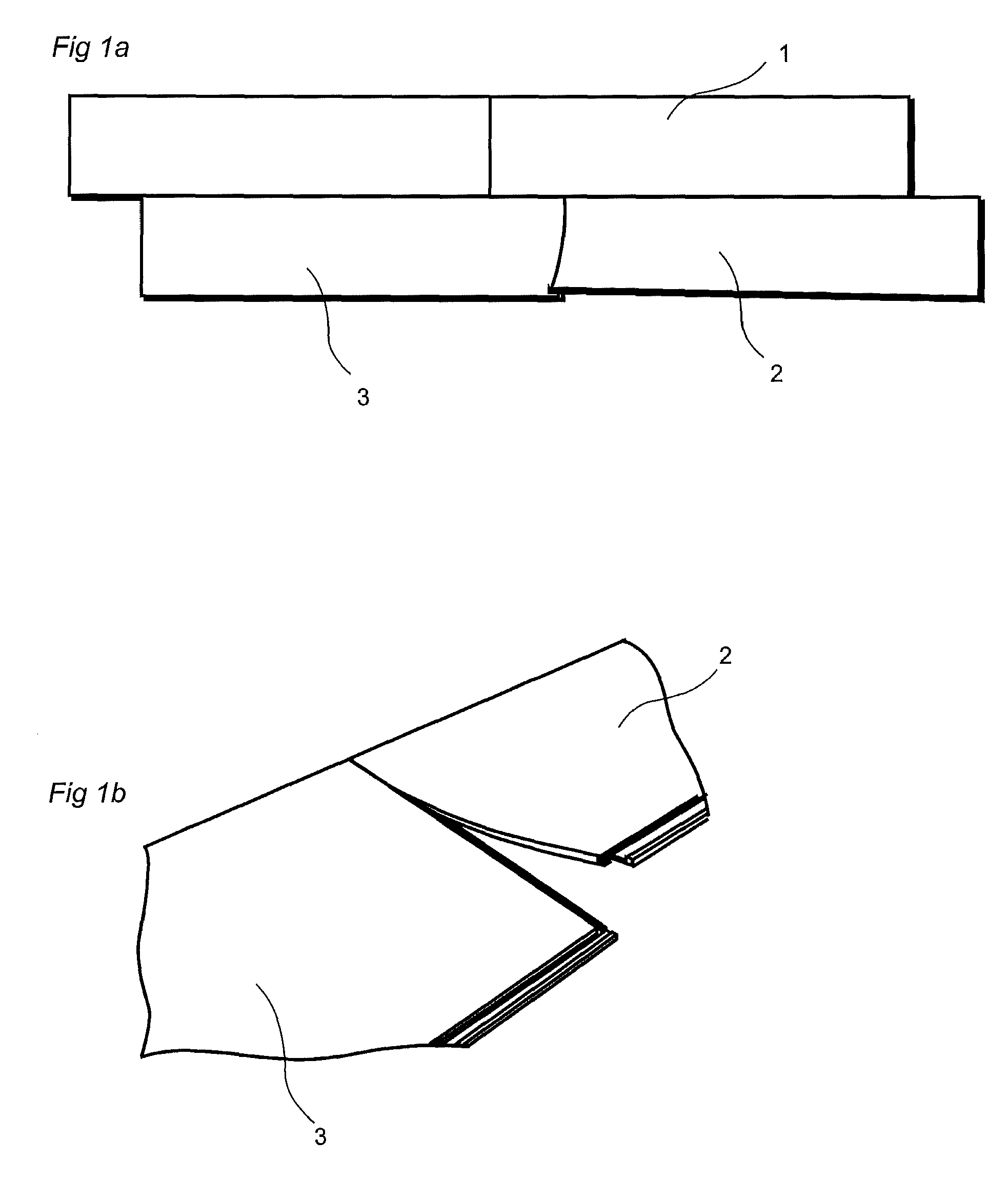

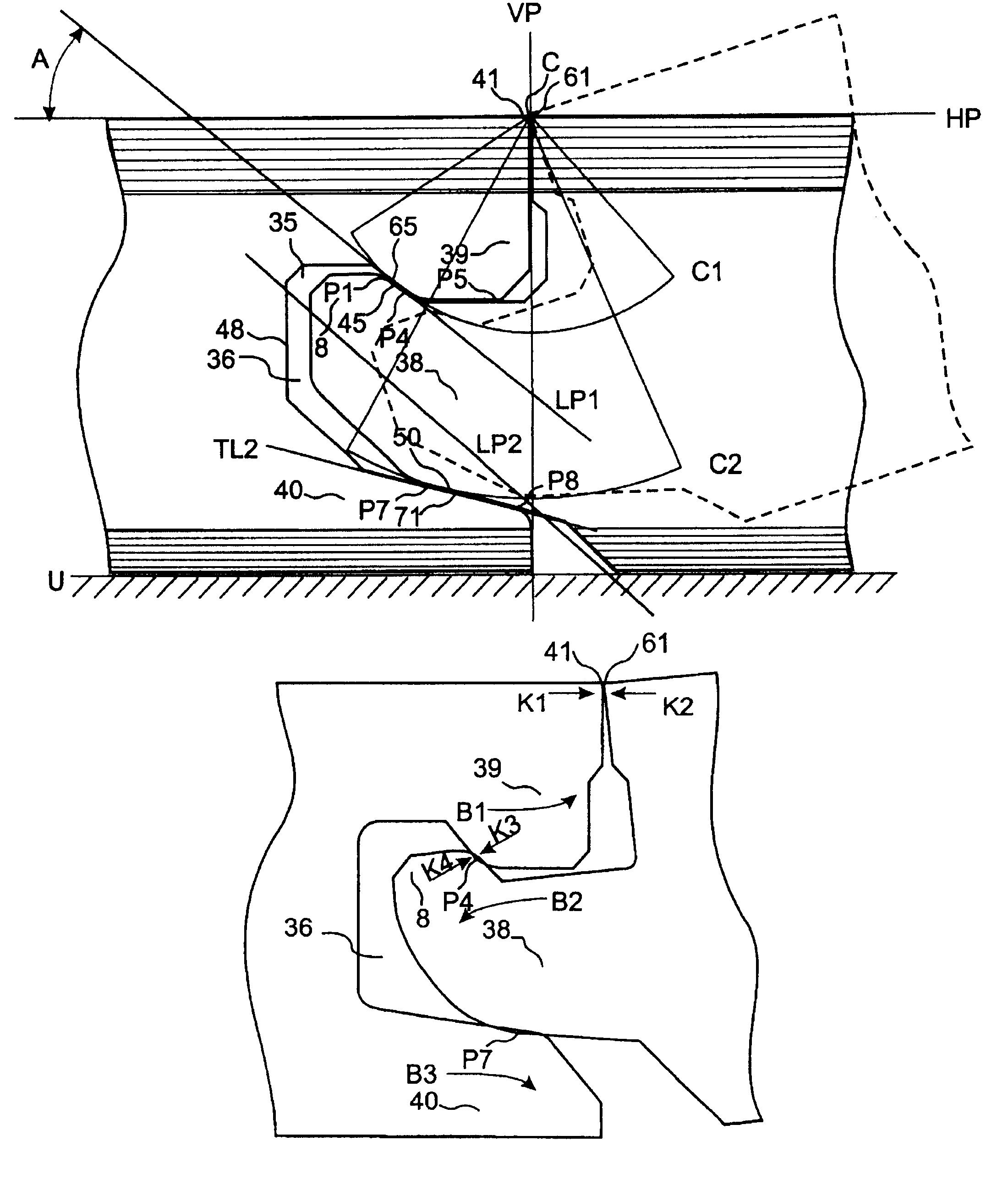

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

Mechanical locking system for floor panels

Building panels, especially floor panels are shown, which are provided with a locking system including several separate strip parts connected to the panel edge.

Owner:CERALOC INNOVATION AB

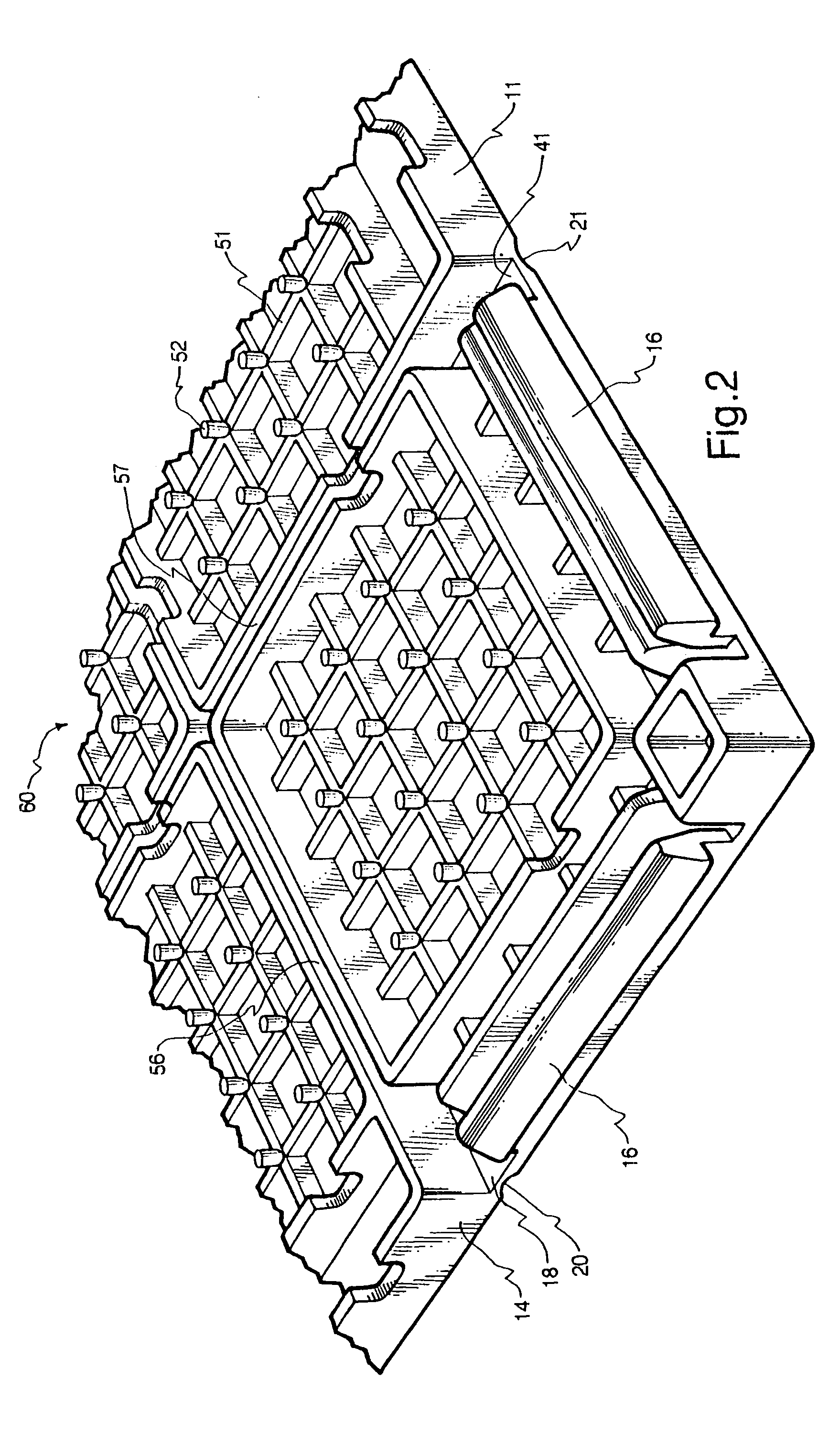

Composite roofing members having improved dimensional stability and related methods

InactiveUS6044604AGood baseRoof covering using slabs/sheetsConstruction materialGlass fiberPolymer science

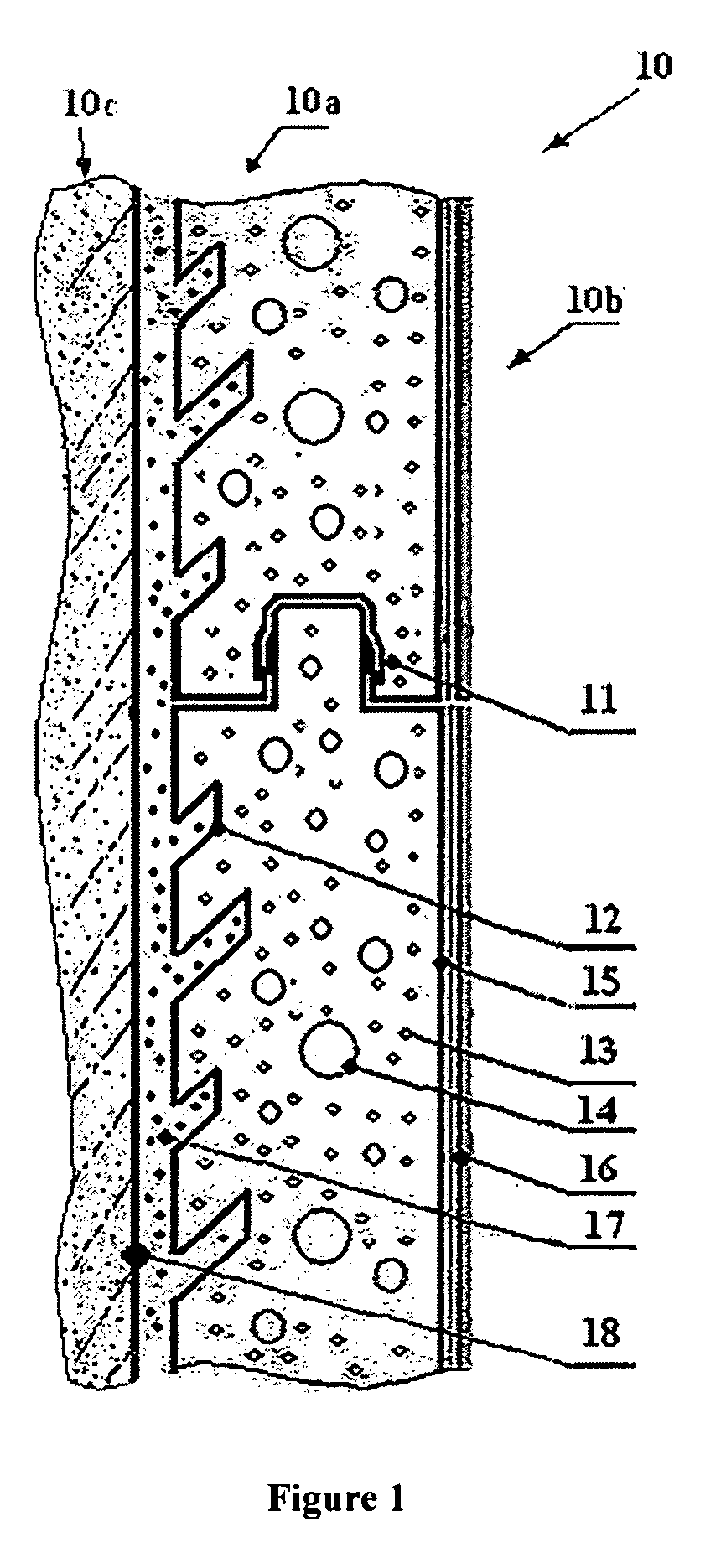

A composite recovery board (10) containing a foam core (11) of polyisocyanurate, polyurethane materials or mixtures thereof; a facer (15), applied to one major surface (13) of the foam core, where the facer includes polymer materials, reinforced polymer materials, cellulosic materials, paper, aluminum foil or trilaminates thereof, wherein the reinforced polymer material and the cellulosic material are reinforced with glass strands, glass fibers, or mixtures thereof; and, gypsum board (14), applied to the opposite major surface (12) of the foam core. A method of reroofing a roof by applying composite recovery boards of the present invention to a roof deck; and, applying a weather protective layer over the recovery boards. A continuous method of making a composite recovery board by feeding gypsum board (14) into a laminator assembly (21); depositing a foamable polymer liquid (36) onto the gypsum board; feeding a facer material (15) into the laminator assembly above the foamable polymer liquid; allowing the polymer liquid to rise between the gypsum board and facer material forming polymer foam of a pre-determined thickness; curing the polymer foam under heat (44) to create the composite board; and cutting the composite board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

Building panel with compressed edges and method of making same

ActiveUS20080034701A1Efficient productionImproved abrasionWallsSpecial ornamental structuresSurface layerEngineering

Floorboards comprising a core and a surface layer with curved edge portions, which are formed by a compression of the core.

Owner:VÄLINGE INNOVATION AB

Method of laying panels

InactiveUS20020069611A1Easy to provideIncrease displacementRoof covering using tiles/slatesWallsEngineeringMutual position

The present invention provides a method of laying and mechanically joining panels, especially floor panels. In a first step a first panel is already located in a first row. A second panel is positioned in a second row in a first position in relation to the first panel. A third panel is now brought into the second row and into the first position in relation to the first panel. In this position, there is a mutual distance between the adjacent edges of the second and third panel. In a second step the second and third panel are angled into the third mutual position in relation to the first panel. Thereby, the second and third panel each achieve the possibility of easy displacement in the third direction in relation to the first panel. In a third step one or both of the second and third panel are moved in relation to the first panel. By this displacement the second and third panel get in a second position in relation to each other. An additional intermediate step may be employed between the first and the second step. In this intermediate step the second and third panel are angled down into the second mutual position in relation to the first panel.

Owner:KRONOSPAN TECHN

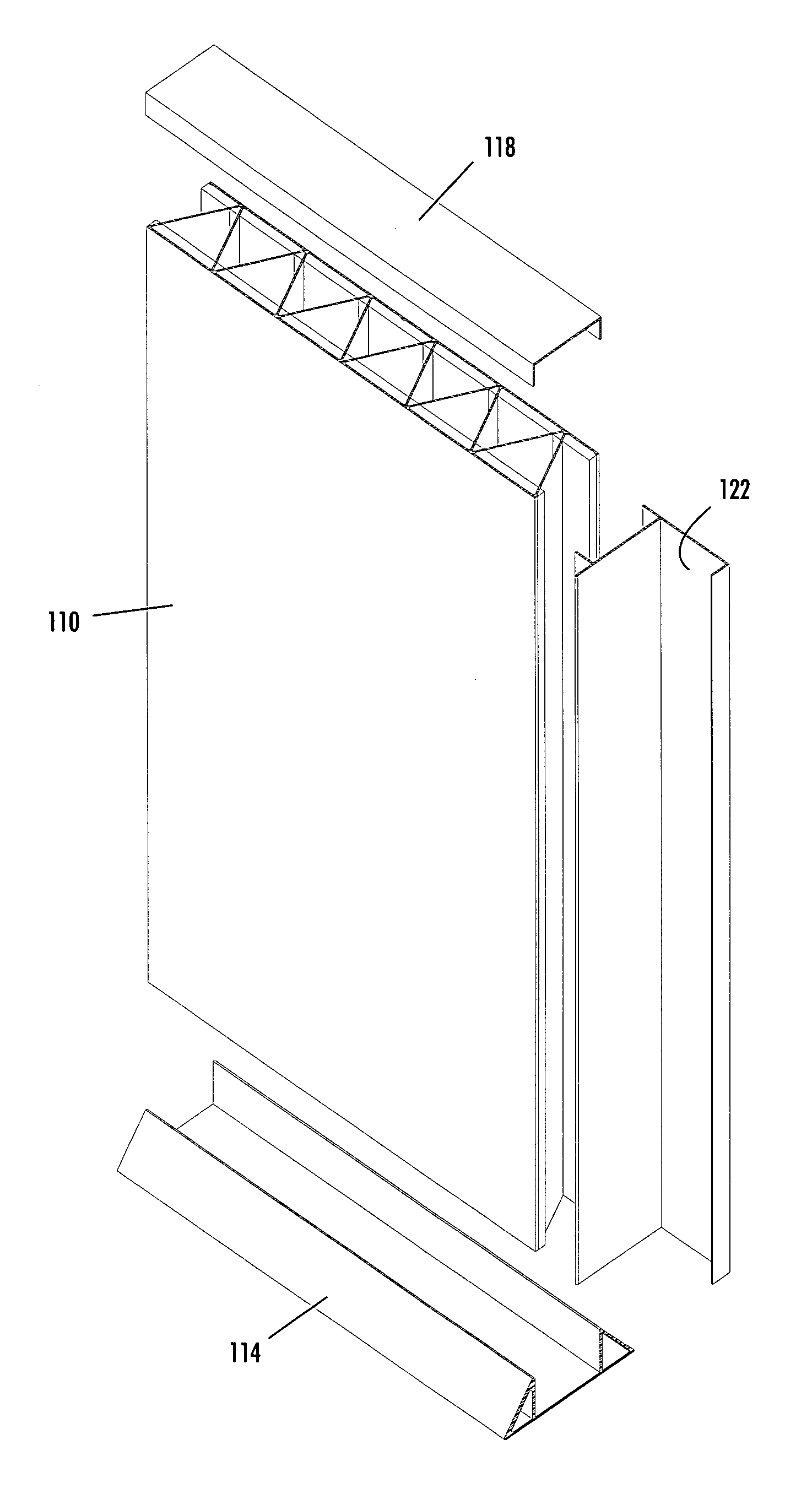

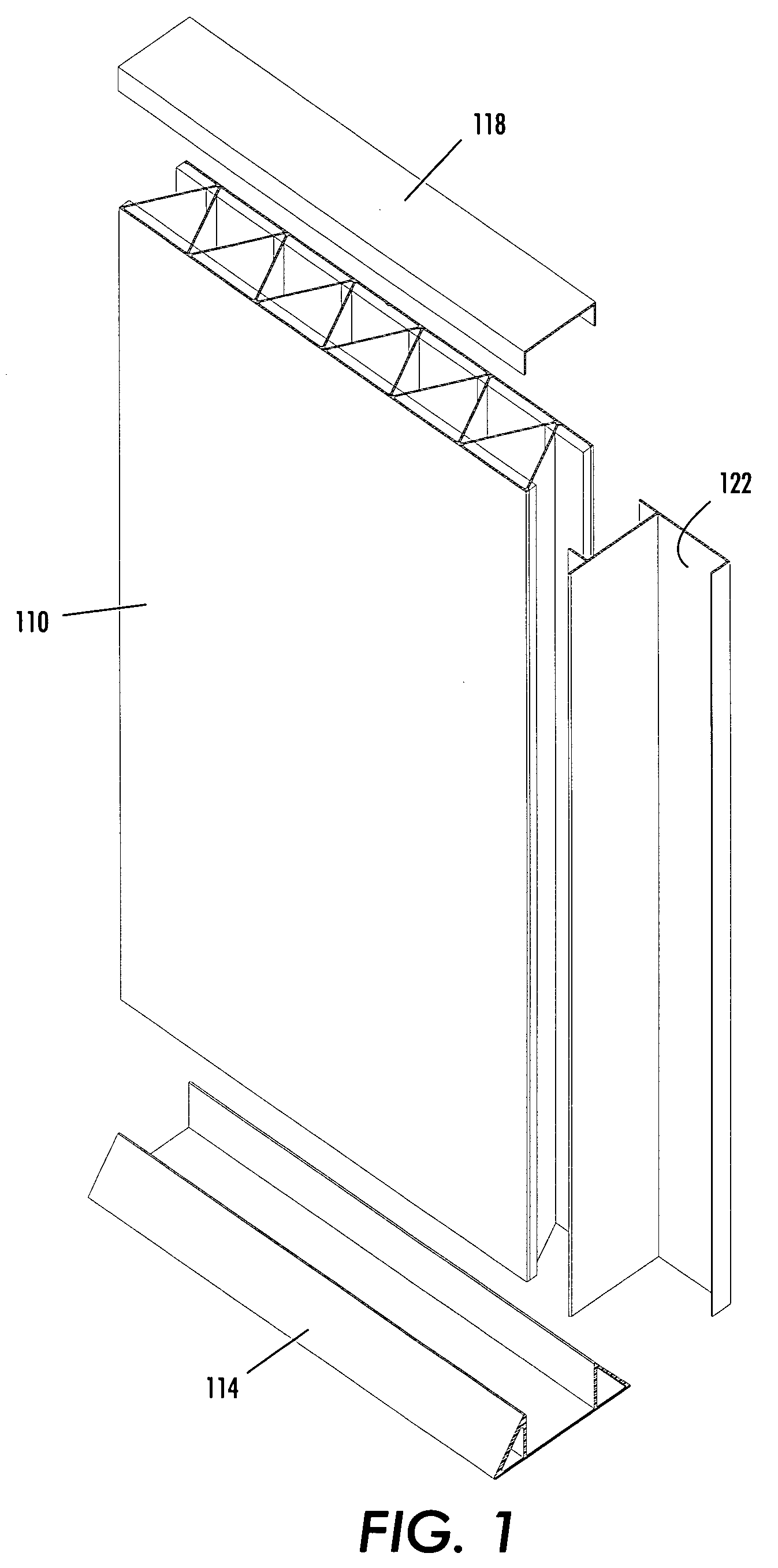

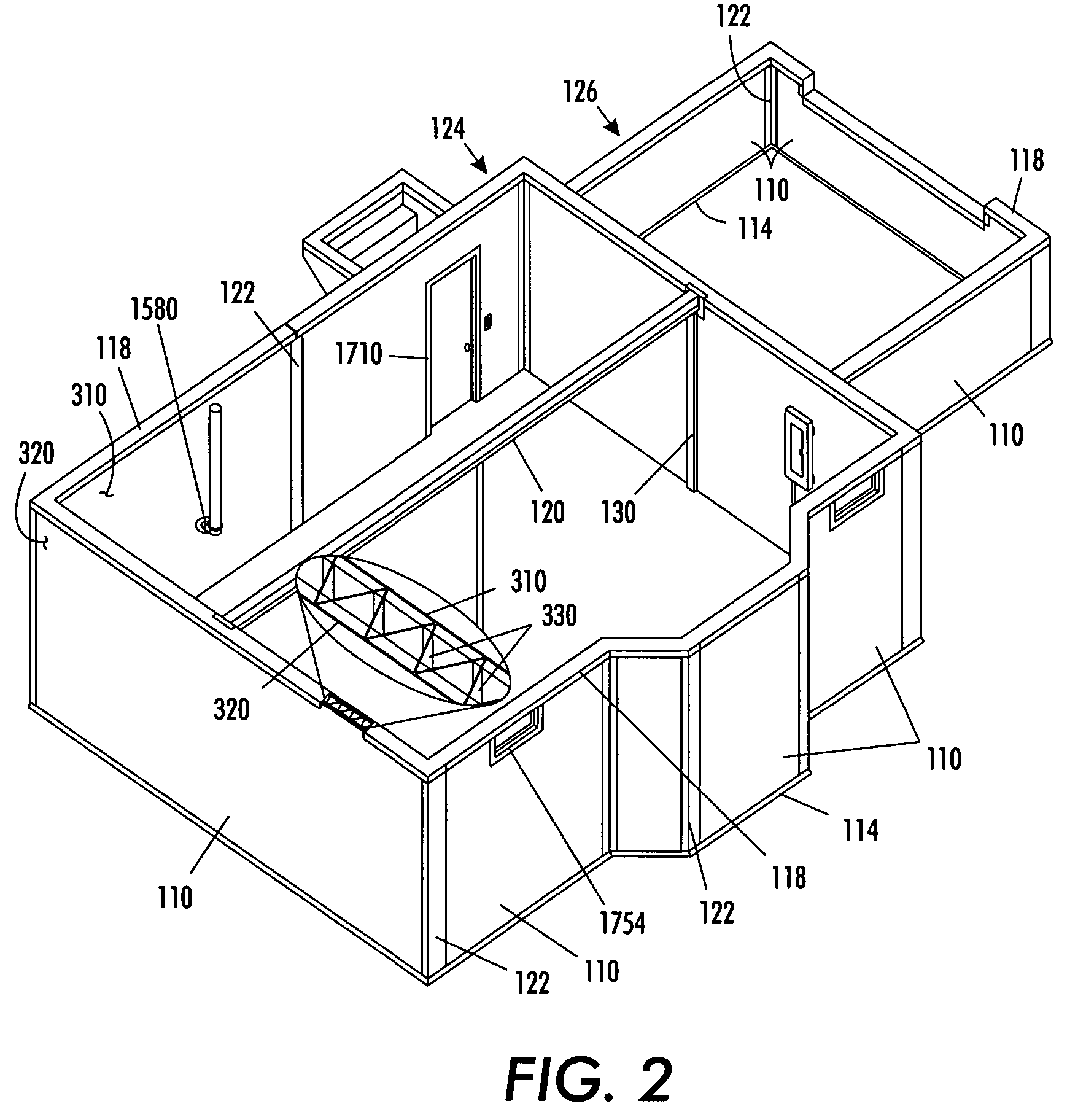

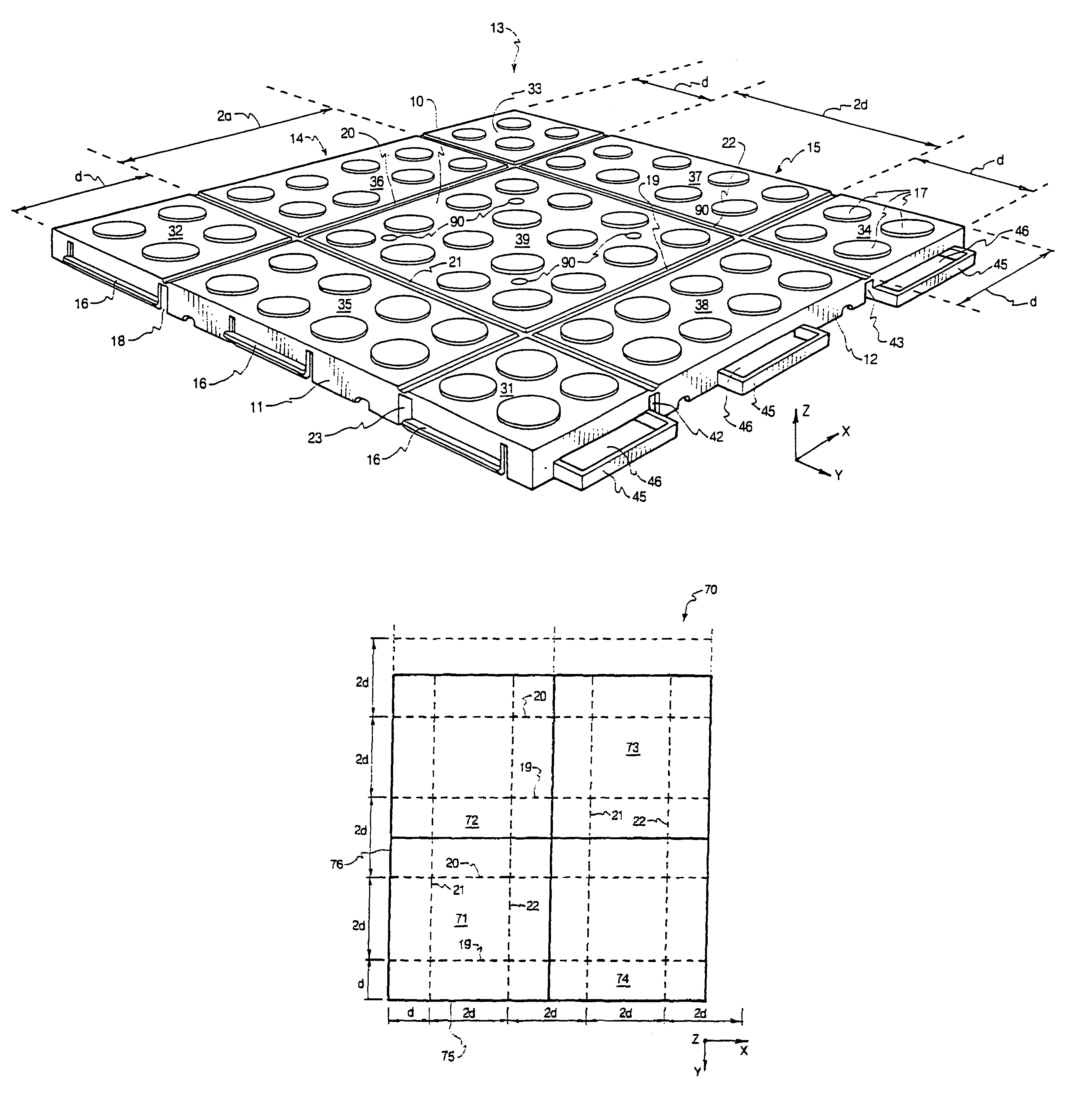

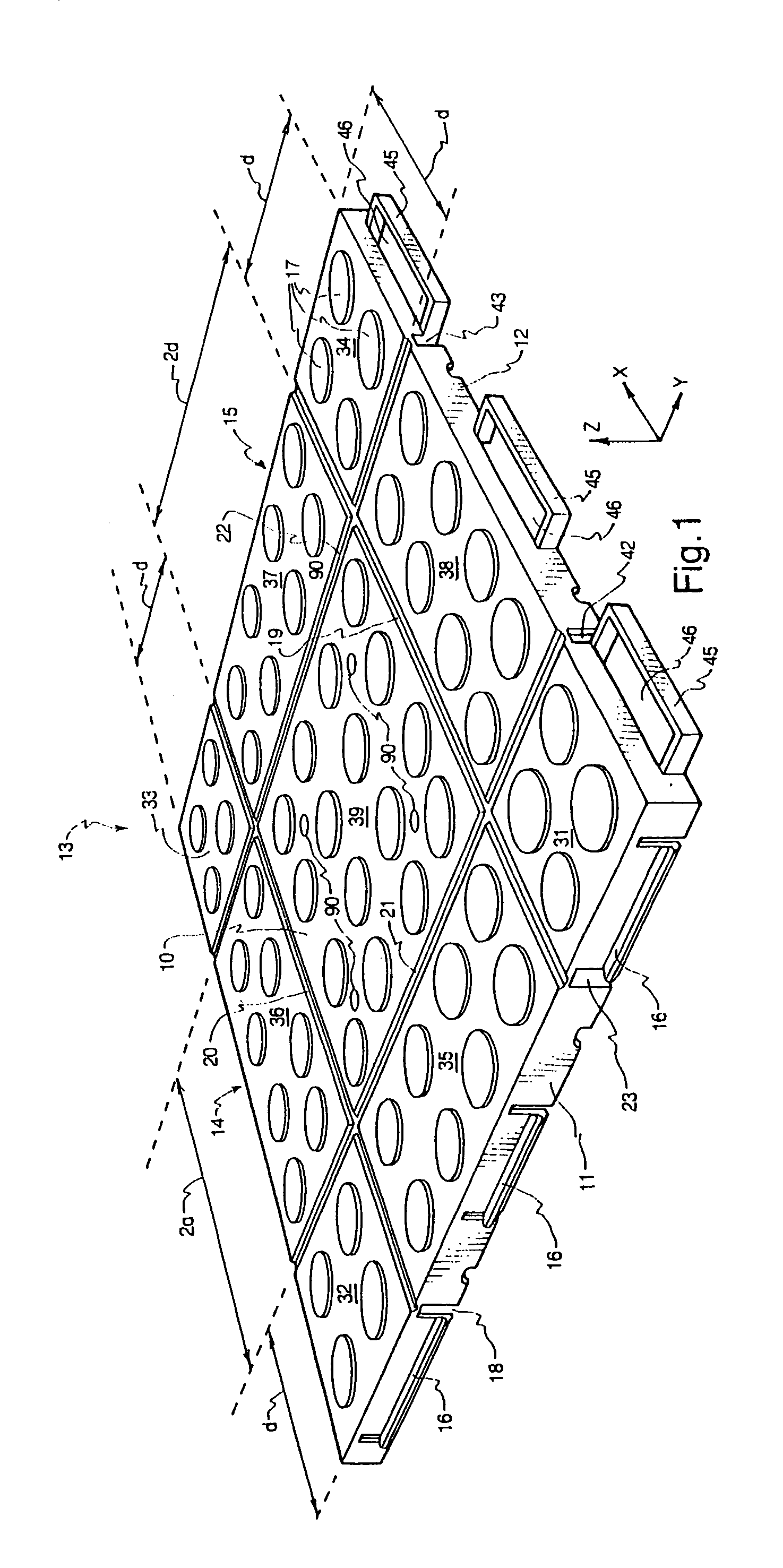

Modular structure for building panels and methods of making and using same

The present invention is a polymeric panel system and method for production and use thereof, enabling the rapid construction of a building foundation wall or other structure and in particular a below-grade foundation. The polymeric foundation system includes polymeric wall panels and other components suitable for withstanding lateral and end compression loads. The walls include two parallel faces separated by a series of webs or ribs, where the webs and faces of the wall panels may be formed of a similar polymer material such as polyvinylchloride (PVC). The wall panels and / or other components may be extruded so as to enable the rapid production of sections of wall panels, where the panels may be cut to length and then affixed to adjacent panels to form a foundation wall. The method of affixing adjacent panels may include welding, gluing or other techniques and may be performed on the job site or in a pre-fabrication facility. Furthermore, the wall panels may be co-extruded with an insulating material inserted in the voids between the parallel faces so as to provide improved thermal performance of the foundation as well.

Owner:DOUGLAS ROBERT B

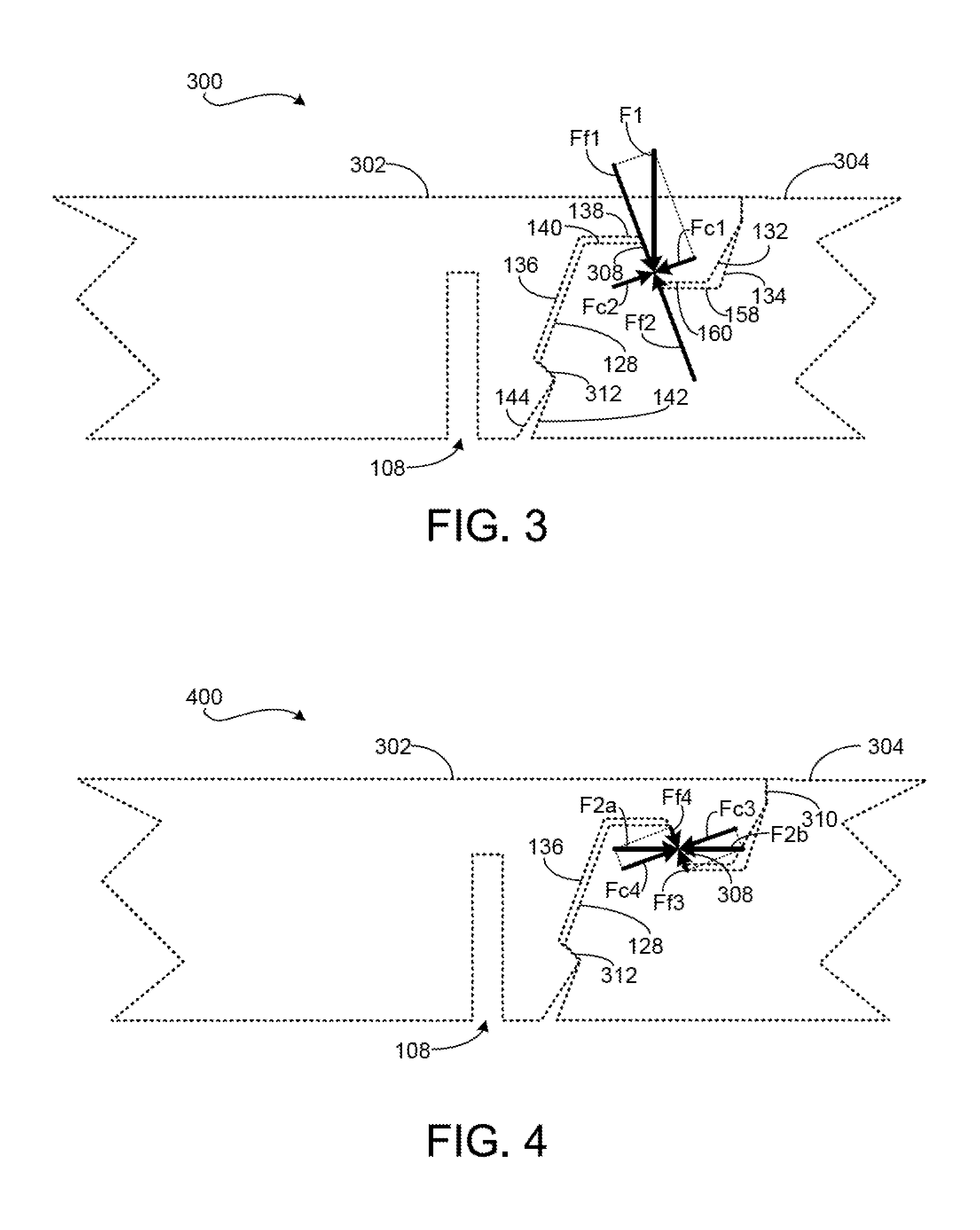

Mechanical locking of floor panels with vertical folding

ActiveUS8689512B2Easy to installCounteract and prevent separationSnap fastenersCovering/liningsMechanical engineering

Owner:VÄLINGE INNOVATION AB

Roll-up floor tile system and method

A plurality of interlocking tile pieces form a generally flat traffic-carrying surface. The tile are locked together in a manner to form a plurality of non-bendable tile joints. The tile includes a hinge or fold line along a first axis and a hinge or fold line along a second axis. The hinges allow the multi-tile traffic carrying surface to be rolled up into a hollow tube from any direction along one of the axes, beginning at any edge of the traffic carrying surface. The rolled-up floor covering is made up of a plurality of tile panels.

Owner:SNAP LOCK INDS

Substrate and the application

InactiveUS20090308001A1Reducing global warmingImprove energy efficiencyPhotovoltaic supportsSolar heating energyThermal energyThermal insulation

This invention relates to a substrate and the application. In particular, this invention discloses a substrate which has at least one contact structure at least on one side and at least one contact structure at least on one surface of the substrate. The substrate includes a thermal insulation material comprising at least two materials selecting from a thermal energy reflecting material, a homogeneous foam material, a heterogeneous foam material, a skin material, a skeleton structured material, an electromagnetic wave shielding material. The substrate may be used to construct various articles with different features of energy saving, decoration and protection as well as simple installation for various applications.

Owner:WU SHAOBING

Resilient floor

Owner:VÄLINGE INNOVATION AB

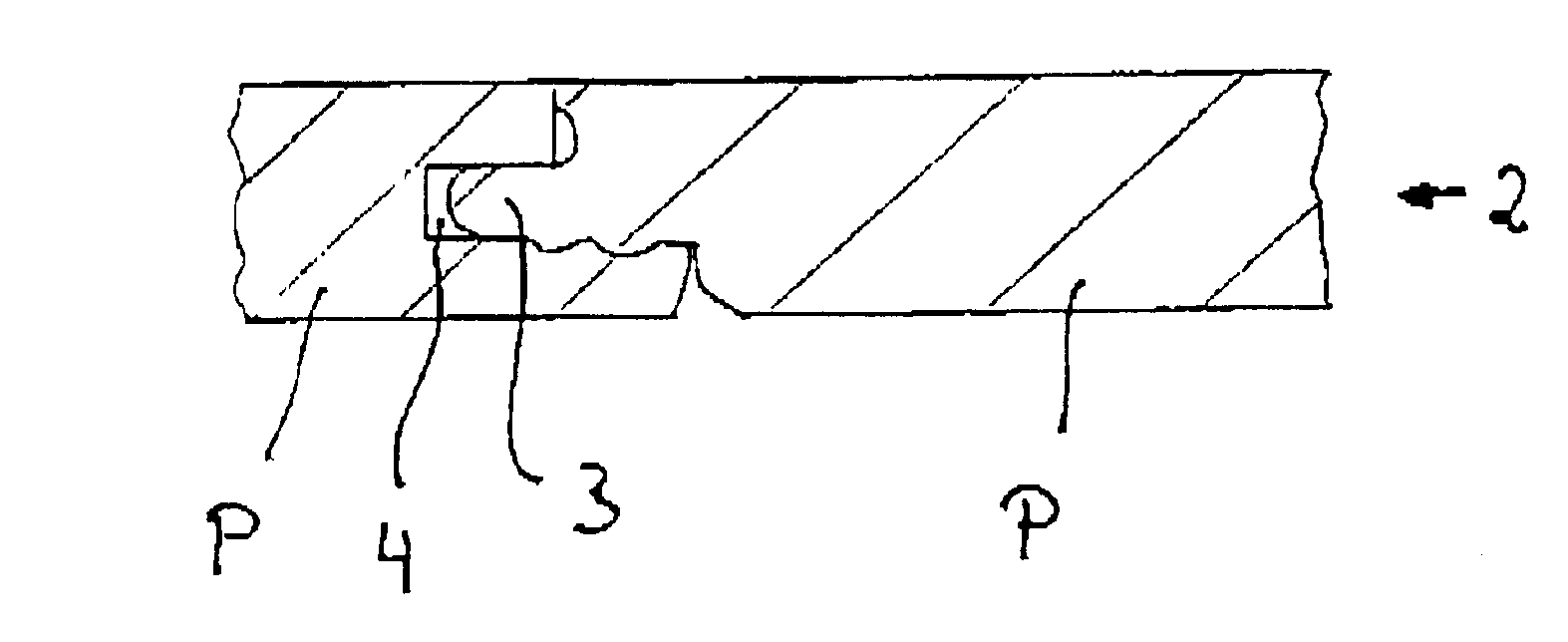

Process of laying floorboards

InactiveUS6711869B2Reduce frictionIncrease frictionCovering/liningsWallsTongue and grooveEngineering

A process is proposed for laying and mechanically jointing floorboards provided with tongue and groove engagements on all sides for horizontal attachment. The process involves a) jointing of a number of boards and making them engage on their transverse sides n order to lay a first row on the floor of a room, b) jointing of a first board for a second row and making it engage with one or two boards in the first row using the tongue and groove joint on the longitudinal side for the purpose of starting a second row, c) pushing the tongue (or groove) of a second board into the groove (or tongue) on the transverse side of the first board in the second row, with movement from the longitudinal side towards the boards in the first row, and d) making the second board engage with one or two boards in the first row.

Owner:KRONOTEX USA

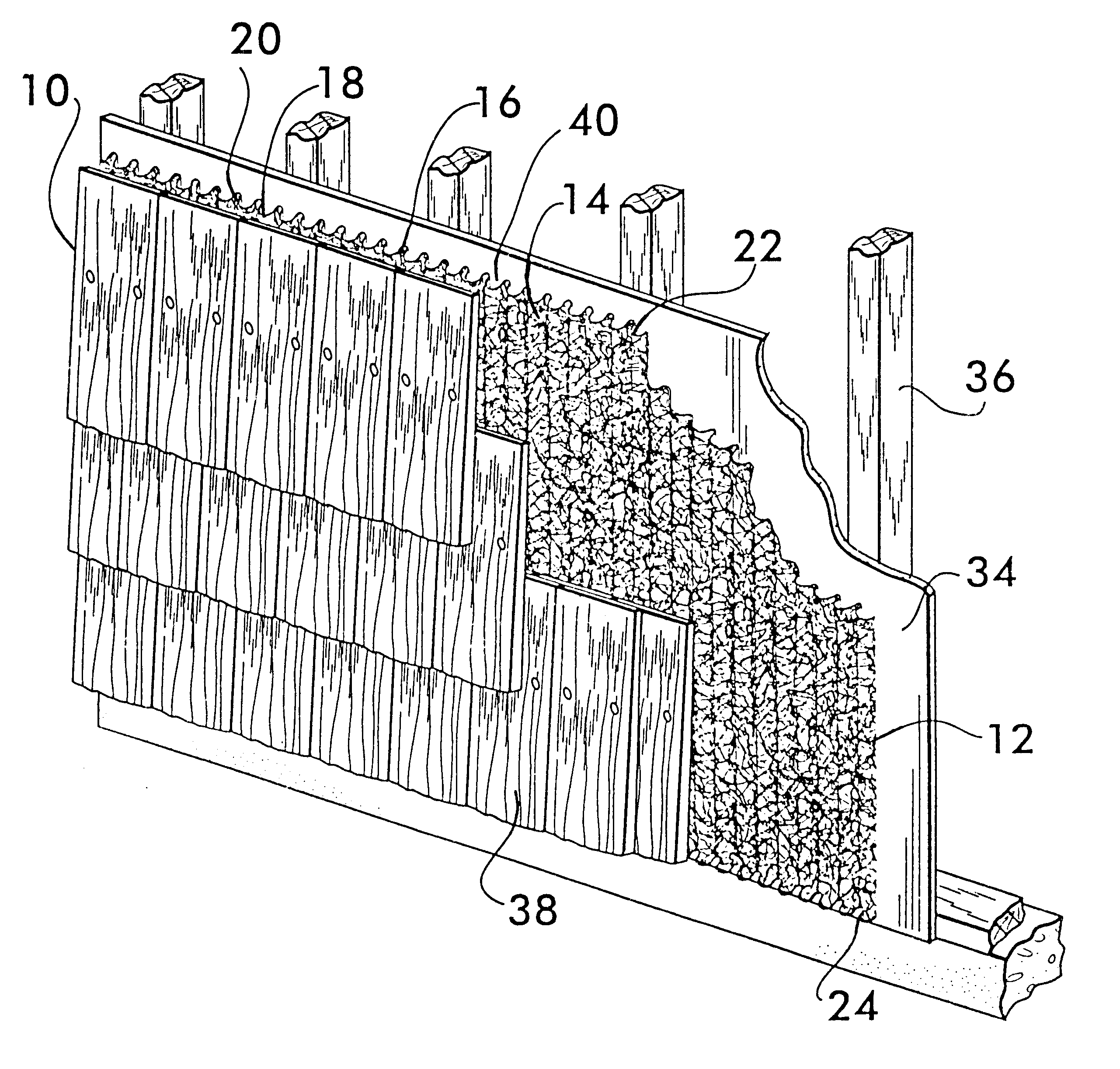

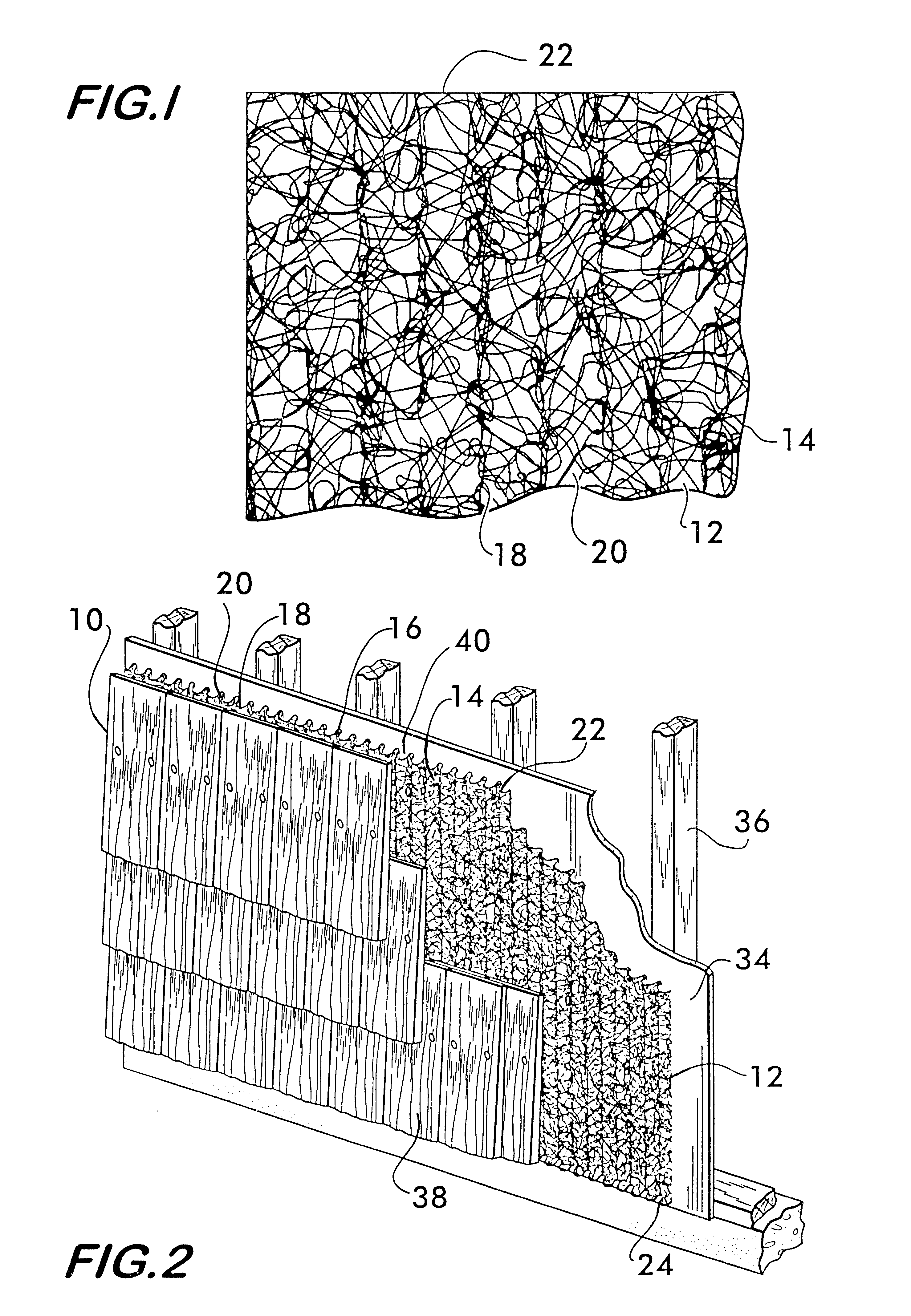

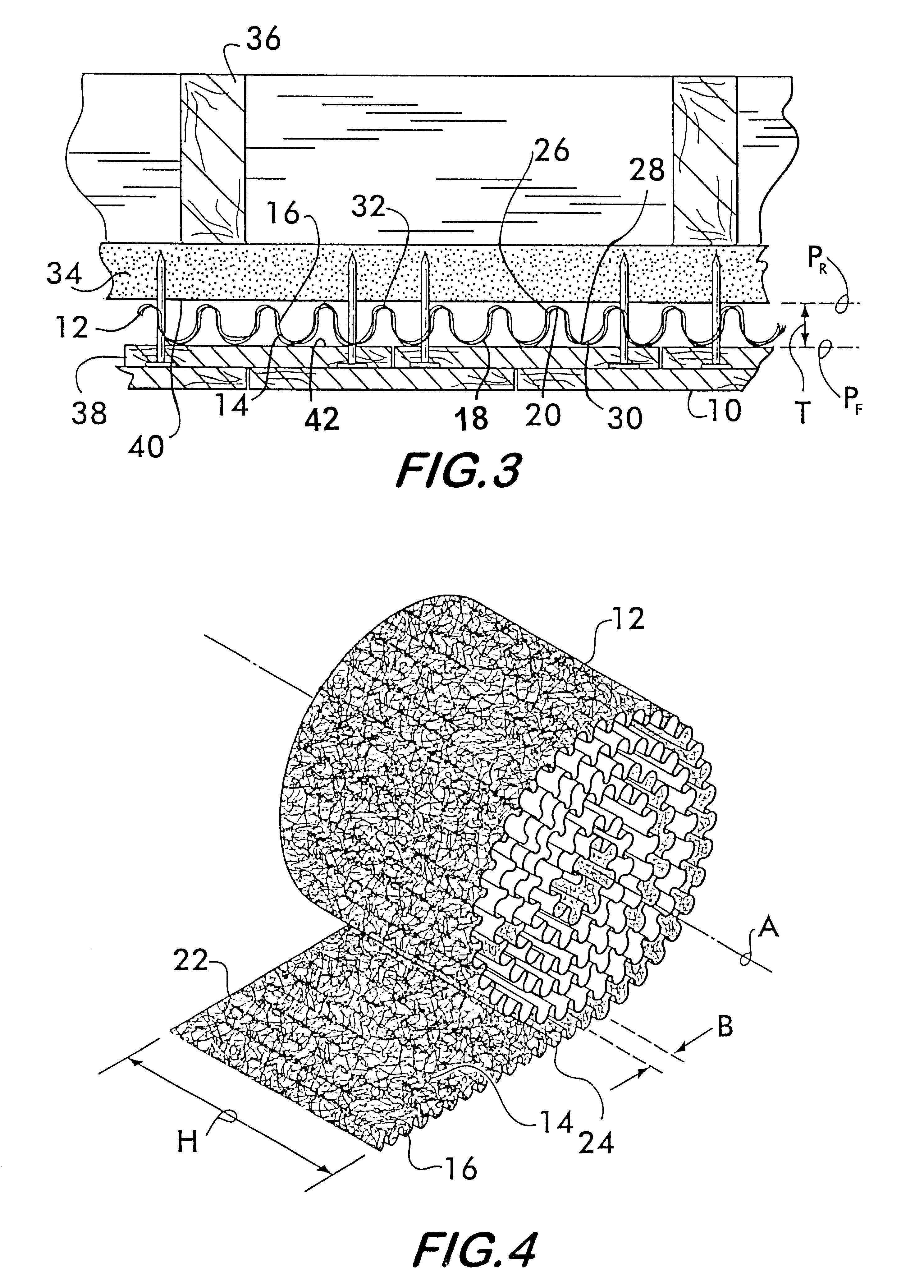

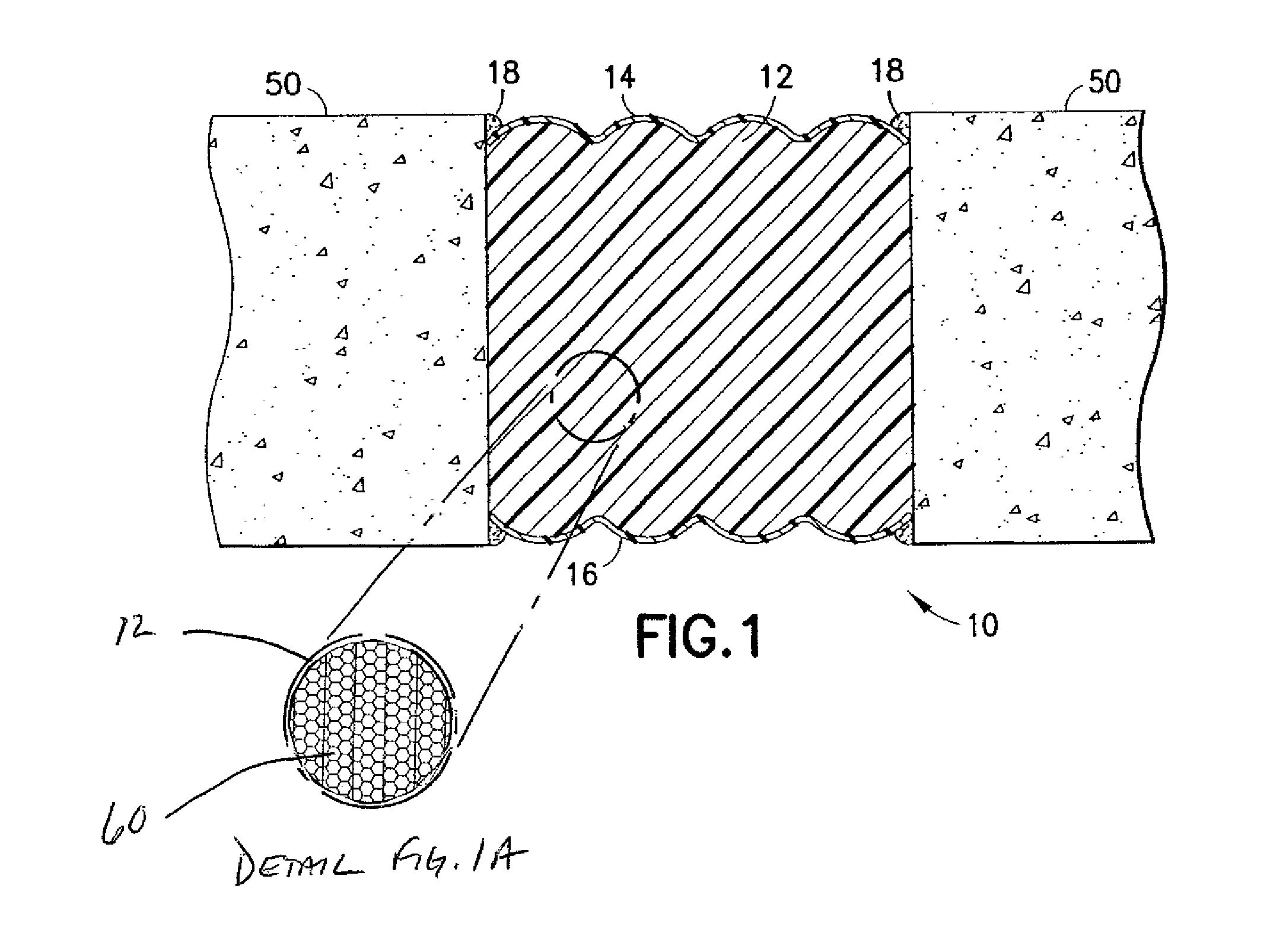

Spacer for providing drainage passageways within building structures

InactiveUS6594965B2Easy to installEfficient and economicalLighting and heating apparatusBuilding repairsEngineeringMoisture

A roll-form spacer product providing air space and drainage passageways within a building structure. Preferably, the spacer product is a corrugated web of material having undulating front and rear faces and serpentine-shaped longitudinally extending edges. The faces include alternating arrays of grooves and ridges which extend perpendicular to the side edges and parallel to an axis of a spiral roll of the spacer. Thus, when the spacer is unrolled and applied to a building structure in a plurality of horizontally extending rows, the ridges and grooves are substantially vertically-disposed to form a plurality of unobstructed passageways for the drainage of moisture. Preferably, the web is made of an openwork mat of randomly convoluted polymeric filaments, and thus, enables ready circulation of air.

Owner:BENJAMIN OBDIKE

Mechanical locking of floor panels

ActiveUS8112967B2Separation forces of the short edges during installation are reduced or completely eliminatedEasy to installCovering/liningsWallsEngineeringMagnetic field

Floor panels are shown, which are provided with a mechanical locking system having tongue of magnetic material that could be locked vertically by a magnetic field.

Owner:VÄLINGE INNOVATION AB

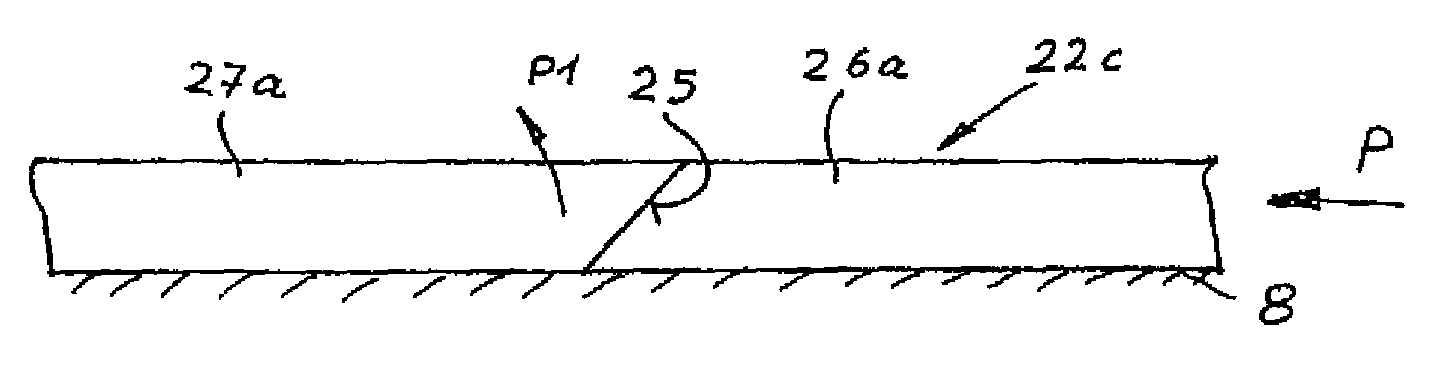

Floorboards and methods for production and installation thereof

InactiveUS6851241B2Improve material utilizationImprove overall utilizationWallsBuilding repairsEngineering

A floorboard and an openable locking system therefor comprise an undercut groove on one long side of the floorboard and a projecting tongue on the opposite long side of the floorboard. The undercut groove has a corresponding upwardly directed inner locking surface at a distance from its tip. The tongue and the undercut groove are formed to be brought together and pulled apart by a pivoting motion which has its center close to the intersection between the surface planes and the common joint plane of two adjoining floorboards.

Owner:VÄLINGE INNOVATION AB

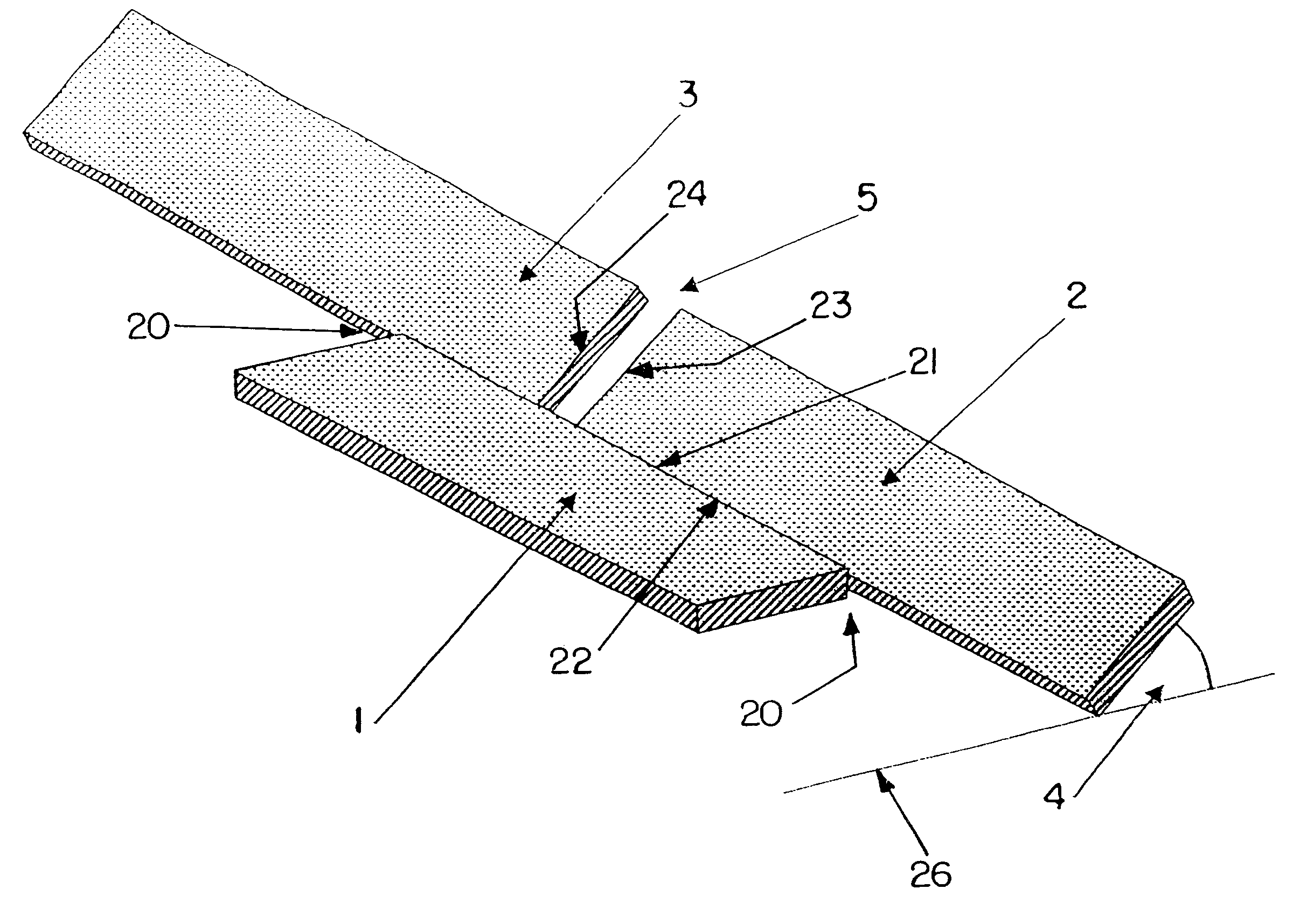

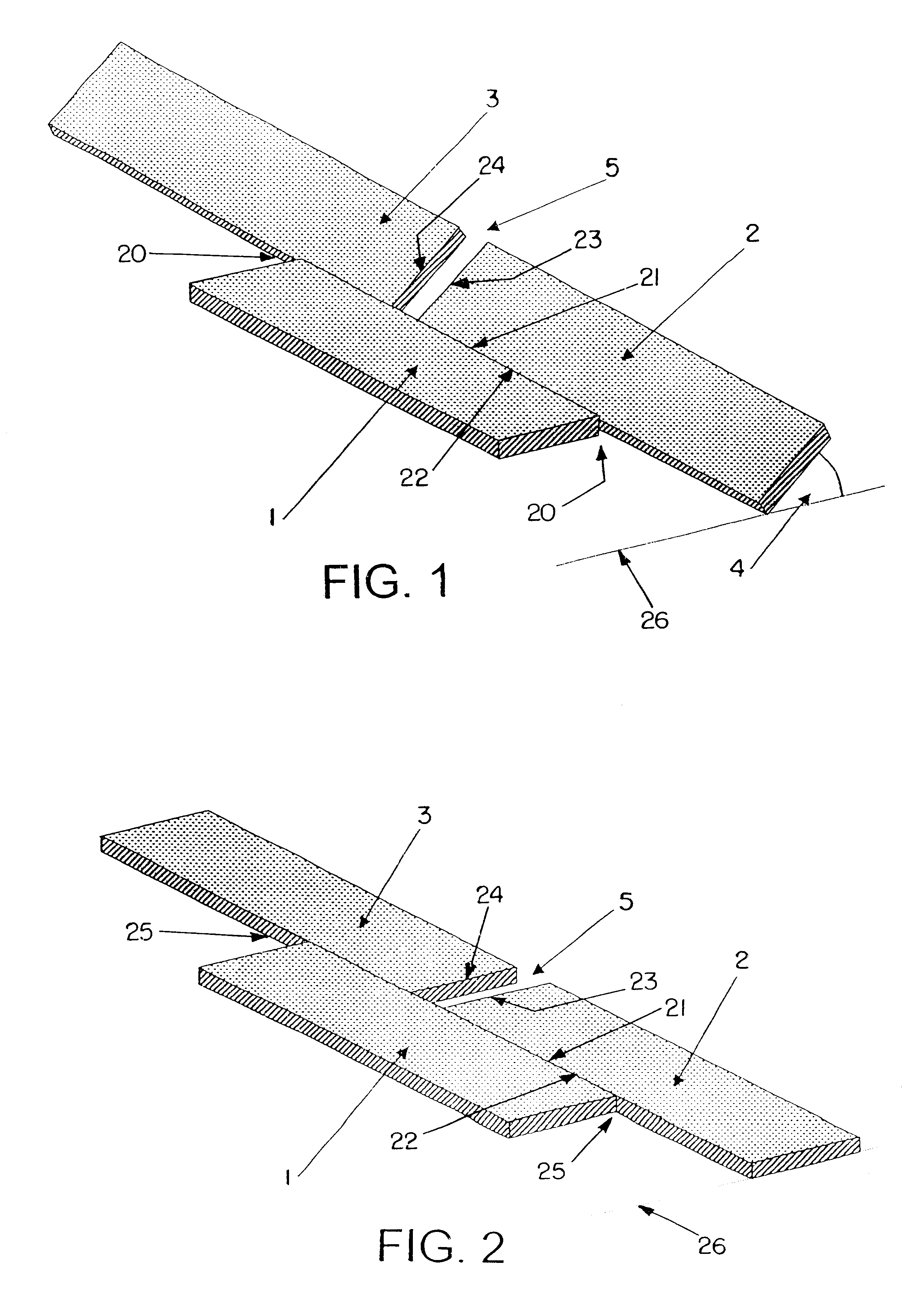

Laminated shingle

Laminated shingles are manufactured from roll stock roofing material that is wider than that used to make similar laminated shingles. The roll stock includes longitudinal edge strips having a reduced thickness. The roll stock is cut into strips of tabbed top sheets and backing sheets. The strips of material used for the backing sheets are at once wider than commonly used in the industry, and include the longitudinal edge strips of reduced-thickness material. Because the backing sheet is wider two rain seal strips are laid down on the backing sheet prior to being laminated to the tabbed top sheet. The backing sheets are laminated to the tabbed top sheets with the longitudinal edges aligned. The wider backing sheet provides a substantially wider nail zone. In addition, since it allows for a second rain seal strip, provides somewhat more protection against leakage. The portion of the backing sheet that comprises the added width is relatively thinner than the remaining portions of the sheet. Paired shingles may therefore be oriented adjacent one another in opposite directions and stacked and bundled. The total thickness of the stack will be the same throughout the stack, so the stack of shingles is flat.

Owner:HERBERT MALARKEY ROOFING

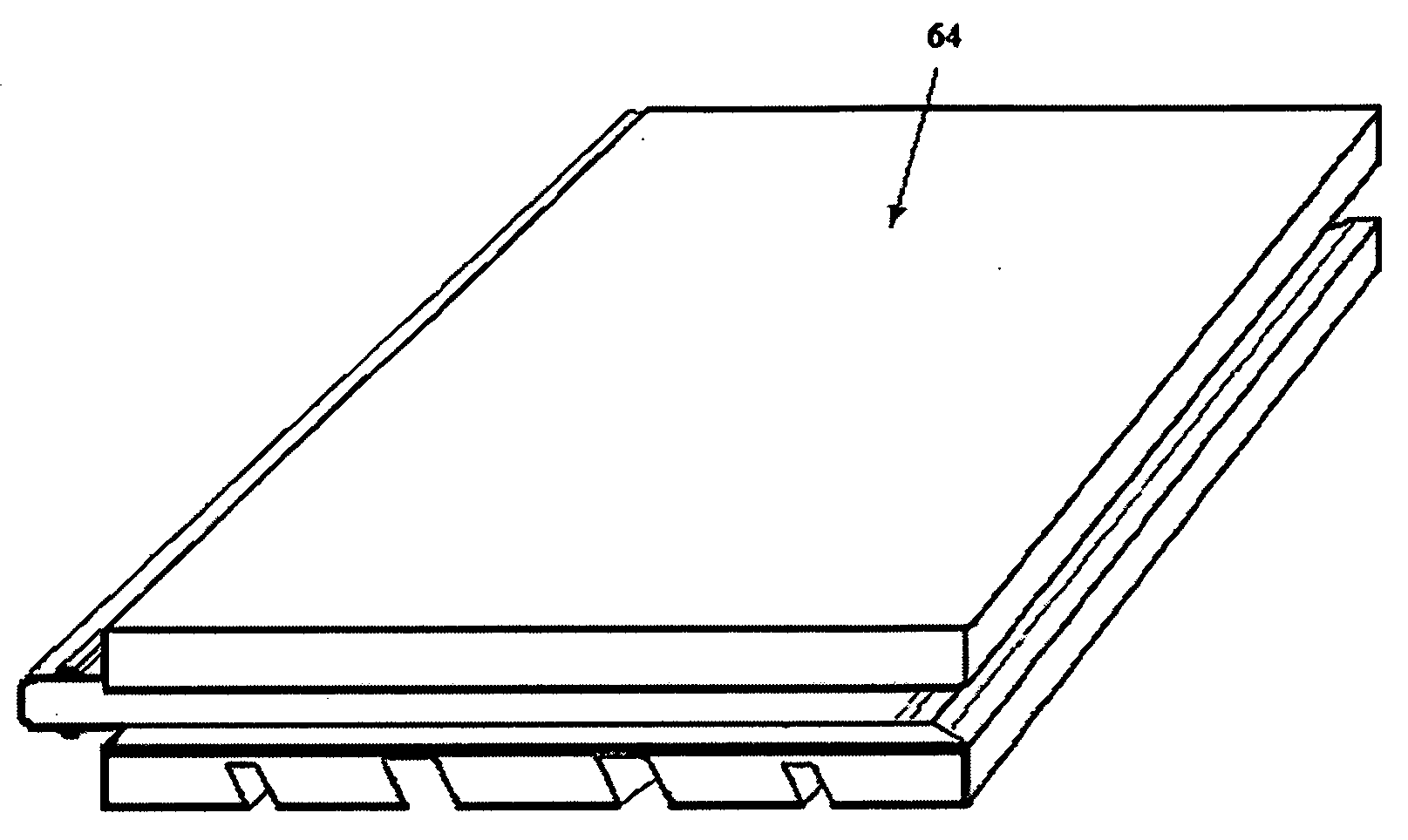

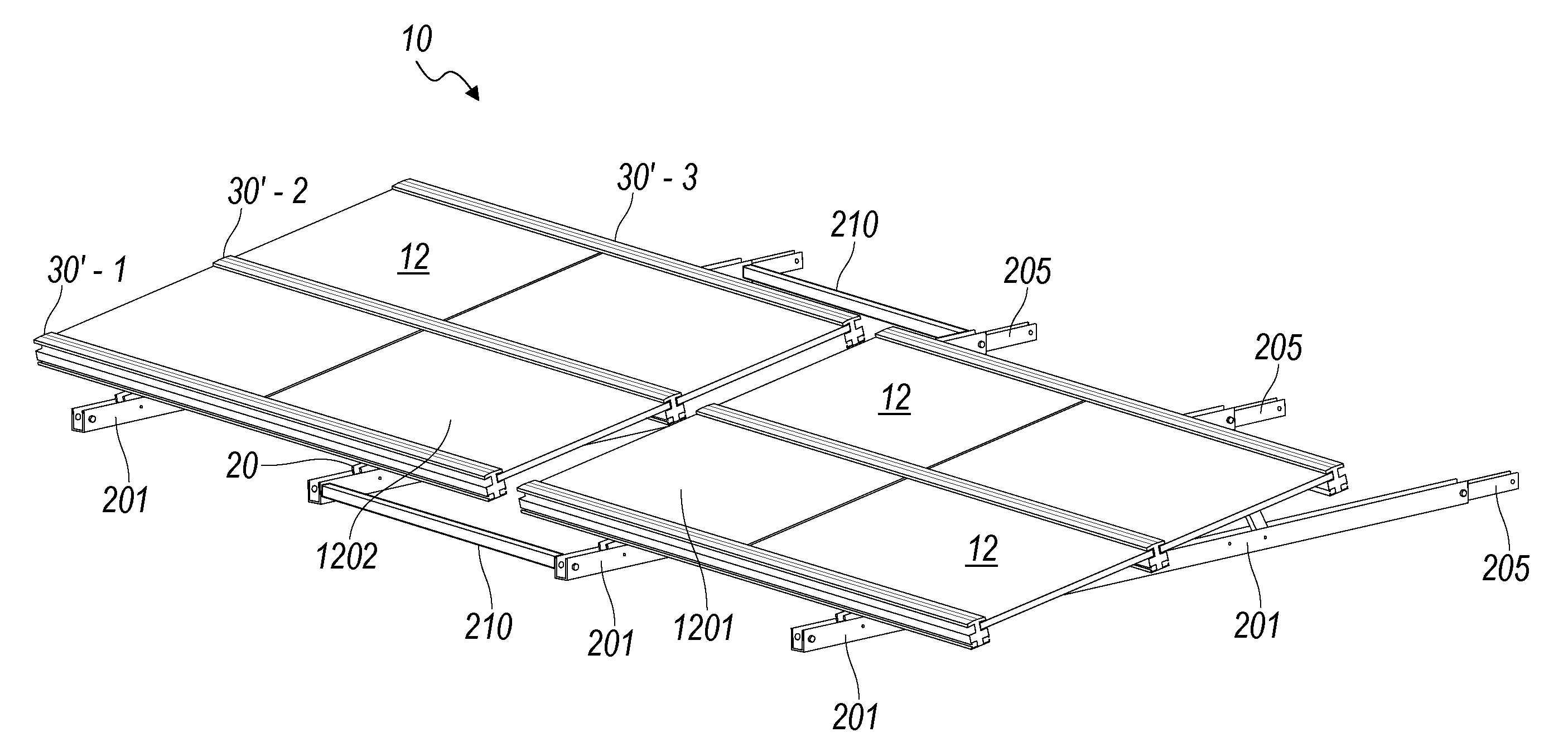

Support System for Solar Panels

ActiveUS20100236183A1Easy to deployEasy to removePhotovoltaic supportsSolar heating energySupporting systemBraced frame

Precise parameters are maintained in a support system for solar panels or other panel-like structures through use of a collapsible folding, support frame which is preassembled to precise tolerances at a convenient staging site before being collapsed for shipment. Installation on flat roofs is also facilitated through the use of a roof interface frame which rotatably supports the panel support frame of the support system and folds along with it at the assembly, staging site.

Owner:NORTHERN STATES METALS

Flooring Boards With Press Down Locking Mechanism

A hardwood floor system with press down locking mechanism. Each floor board is equipped with both male and female locking mechanisms. The male locking mechanism of a floor bard can be locked into the female locking mechanism of an adjacent floor board by simply exerting downward force on the floor board. The female locking mechanism is equipped with a spring slot that enables easy engagement of male and female locking mechanisms. The invention may be applied not only floor boards, but also to wall tiles and roof tiles.

Owner:LIU DAVID C +1

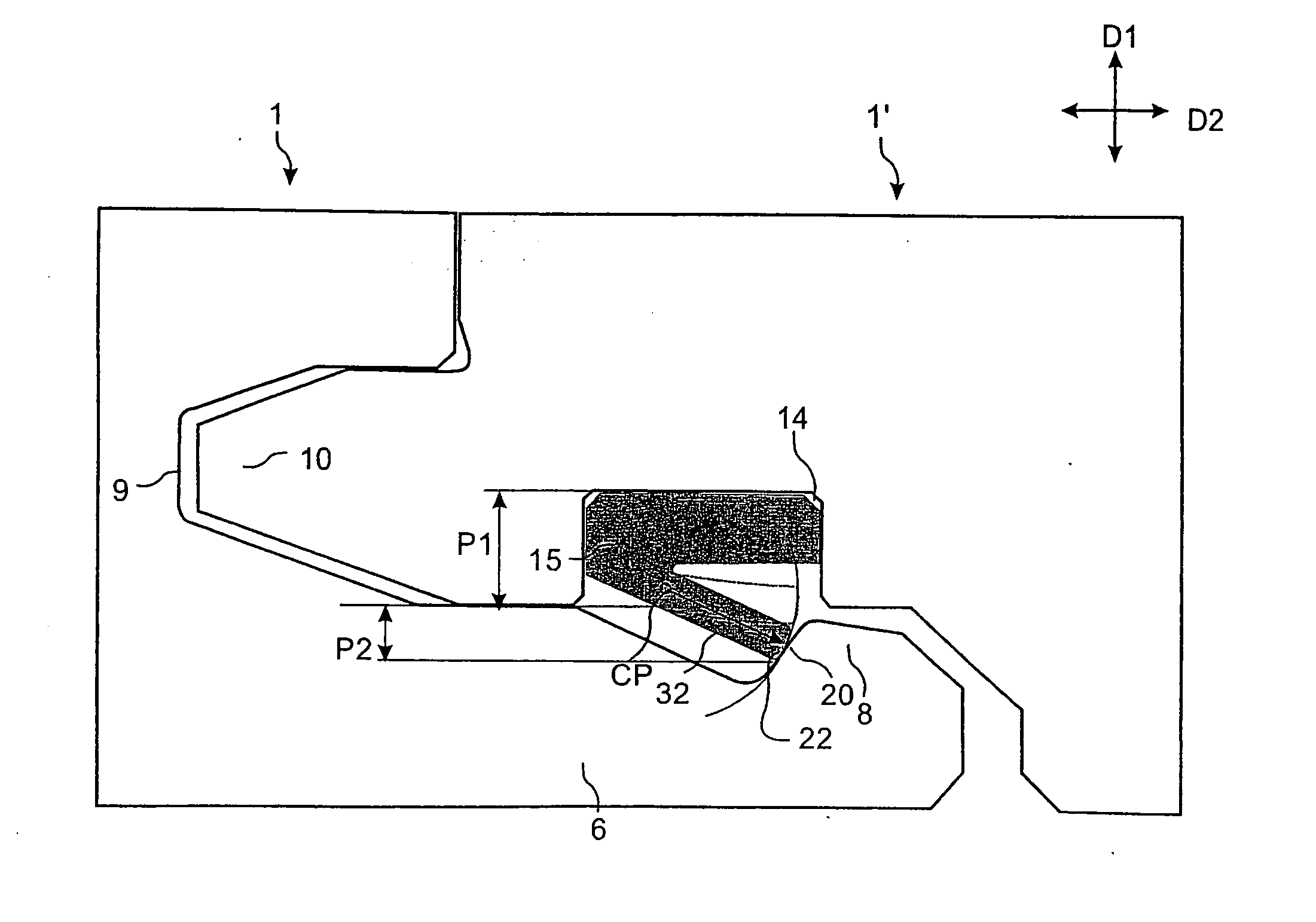

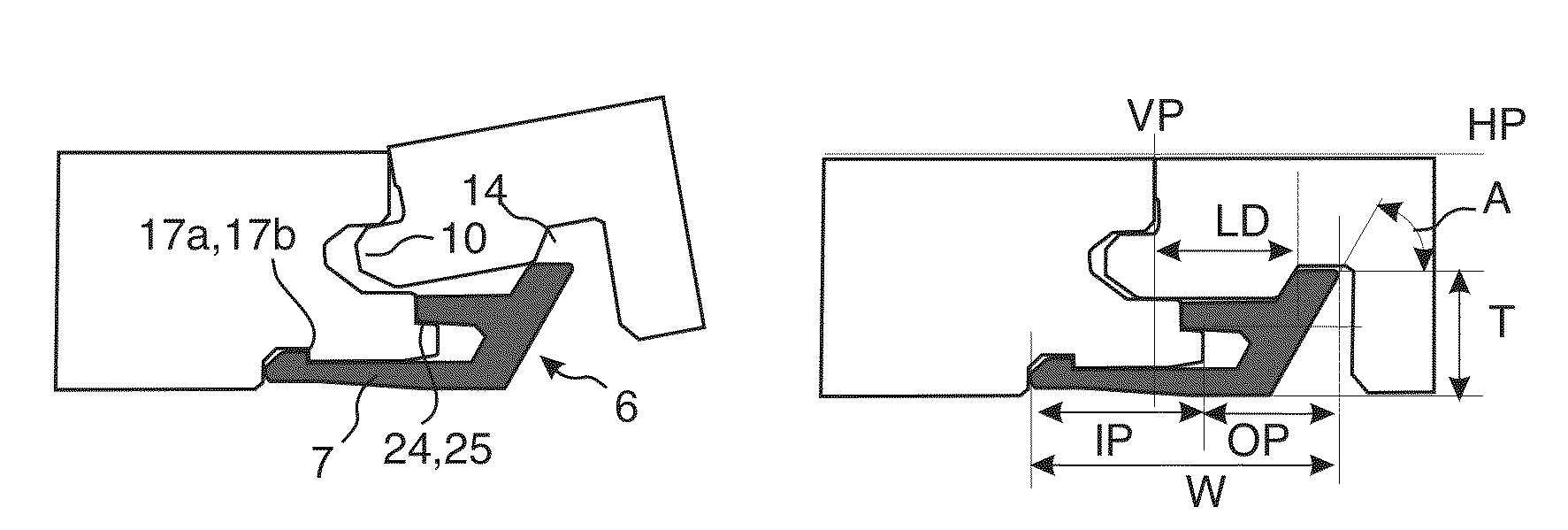

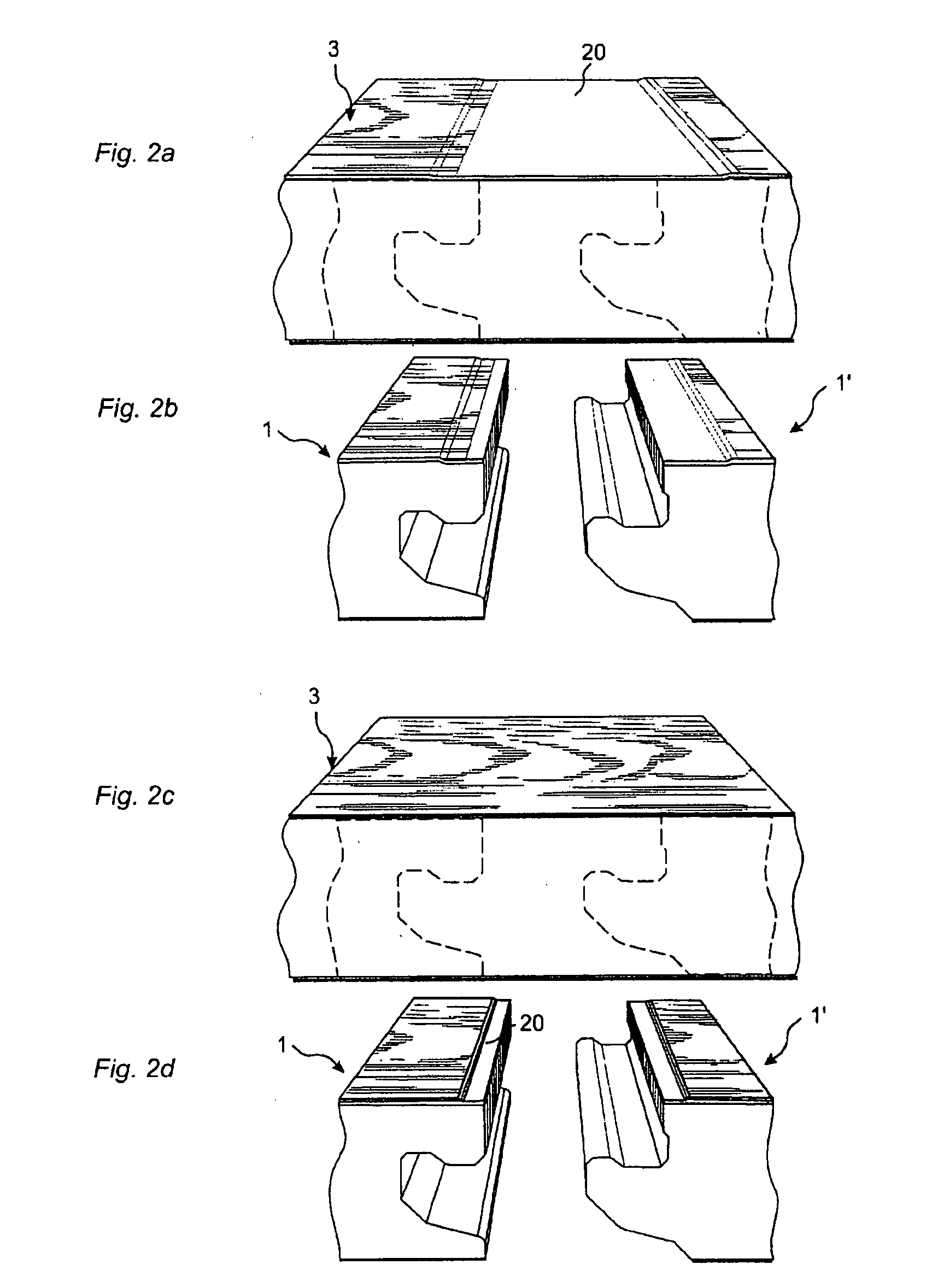

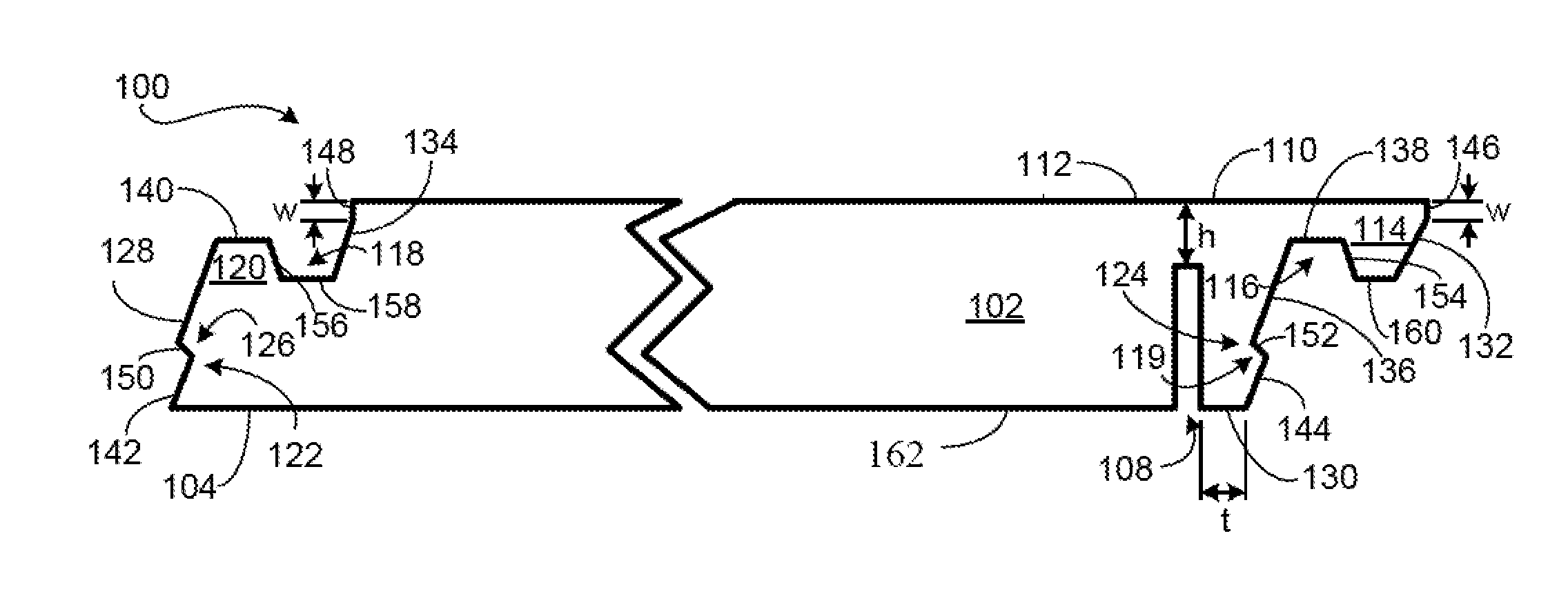

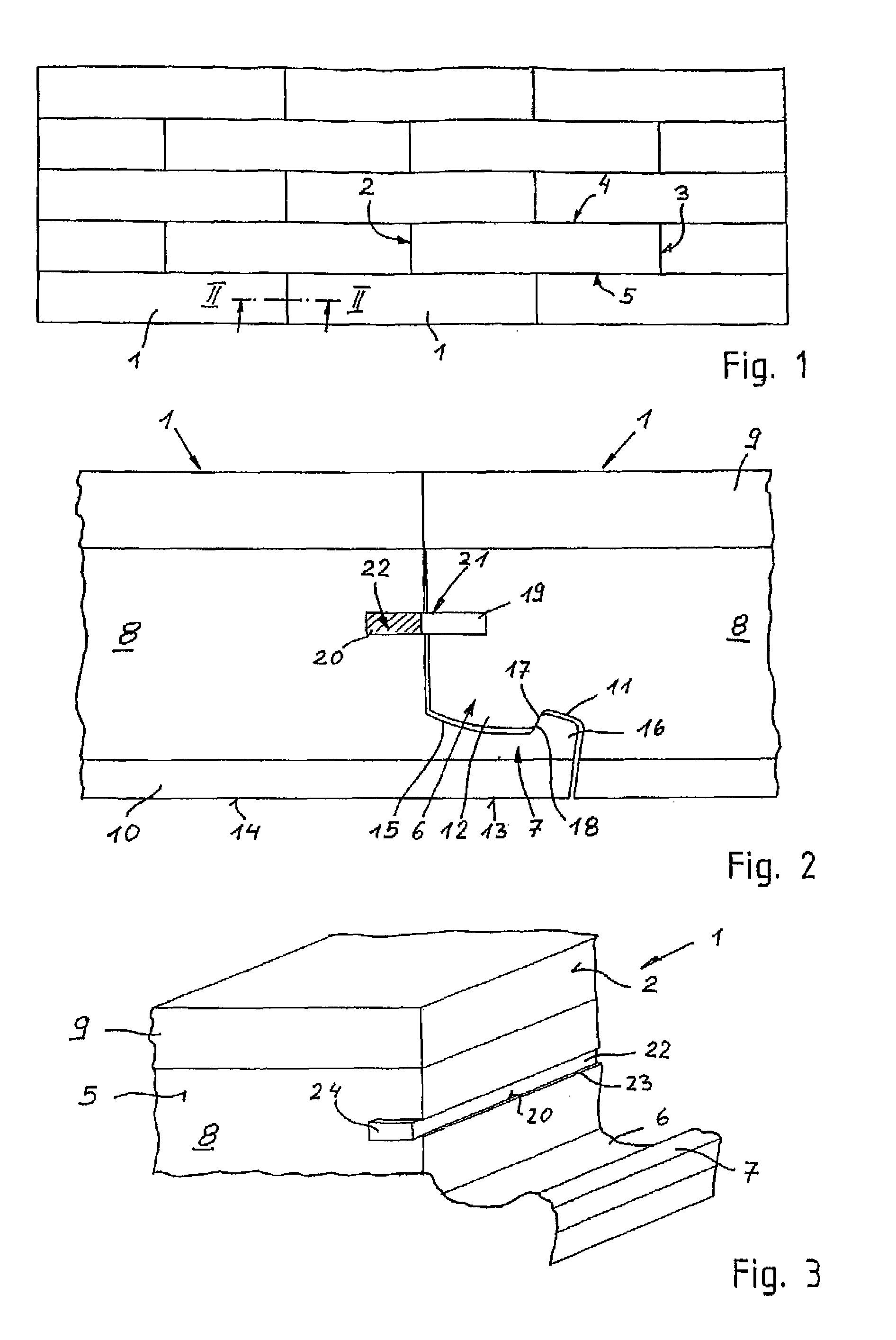

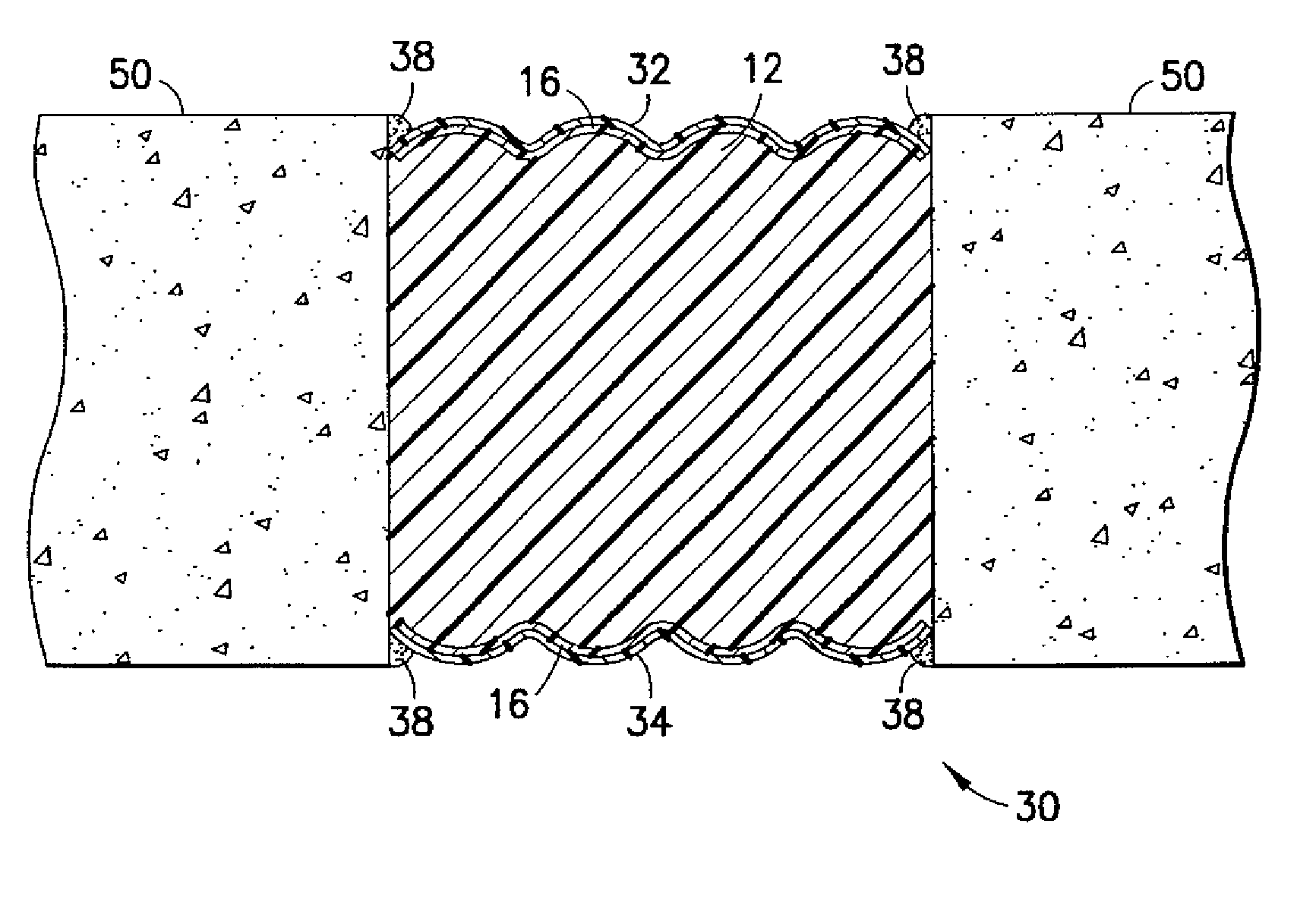

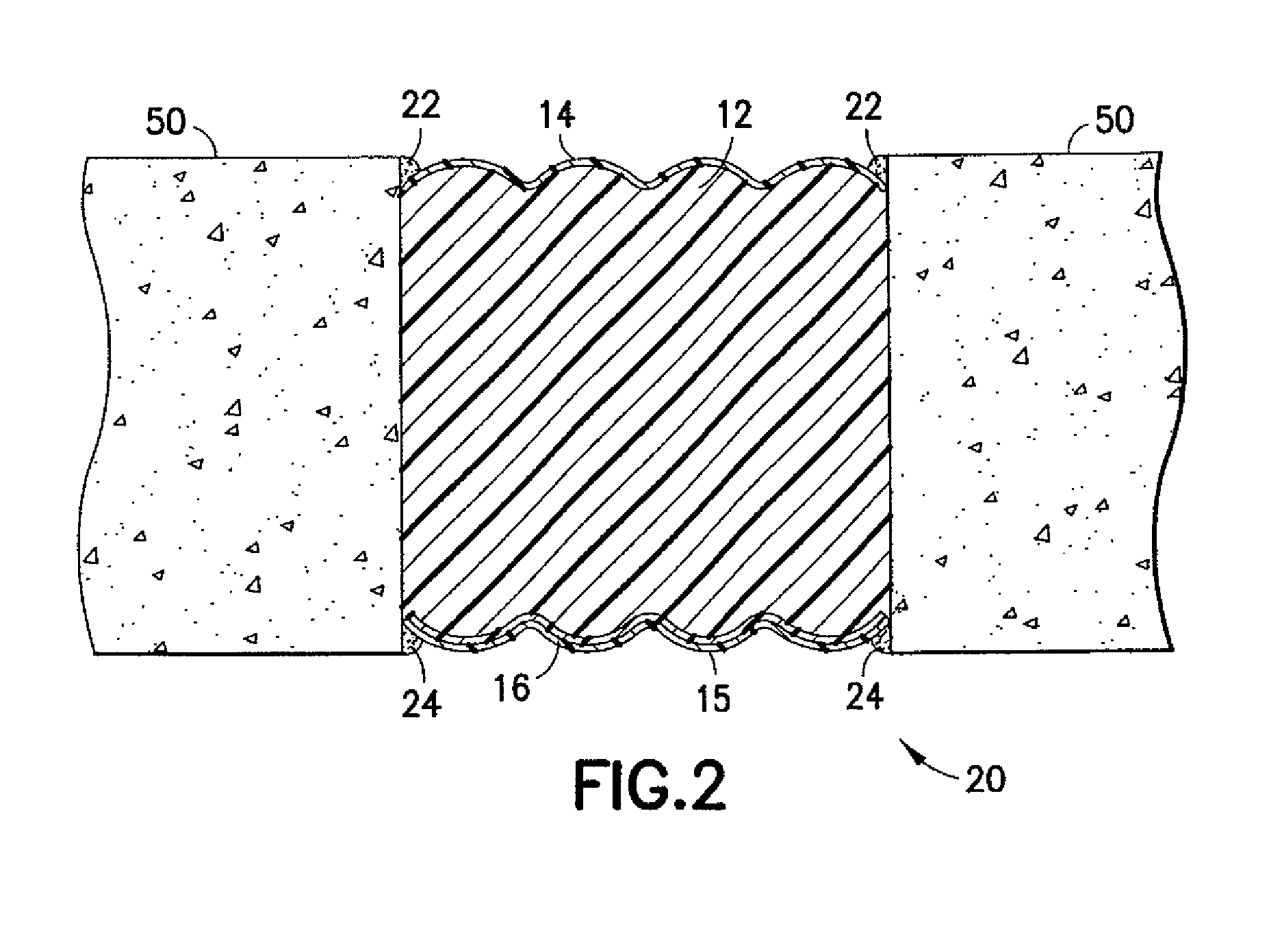

Floor covering and installation method

ActiveUS8302367B2Easy to operateSave a lot of timeCovering/liningsLayered productsBiomedical engineeringFloor covering

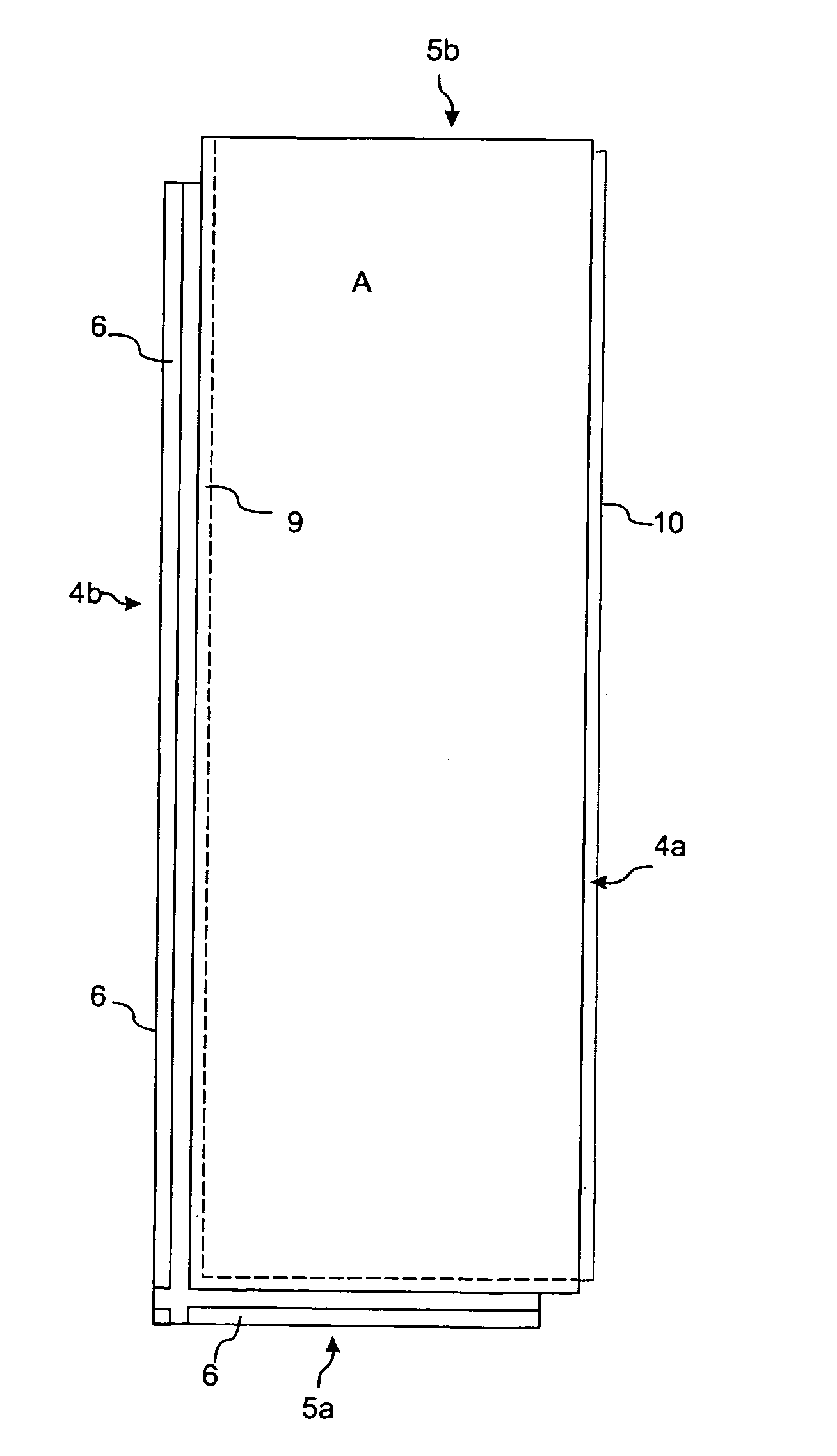

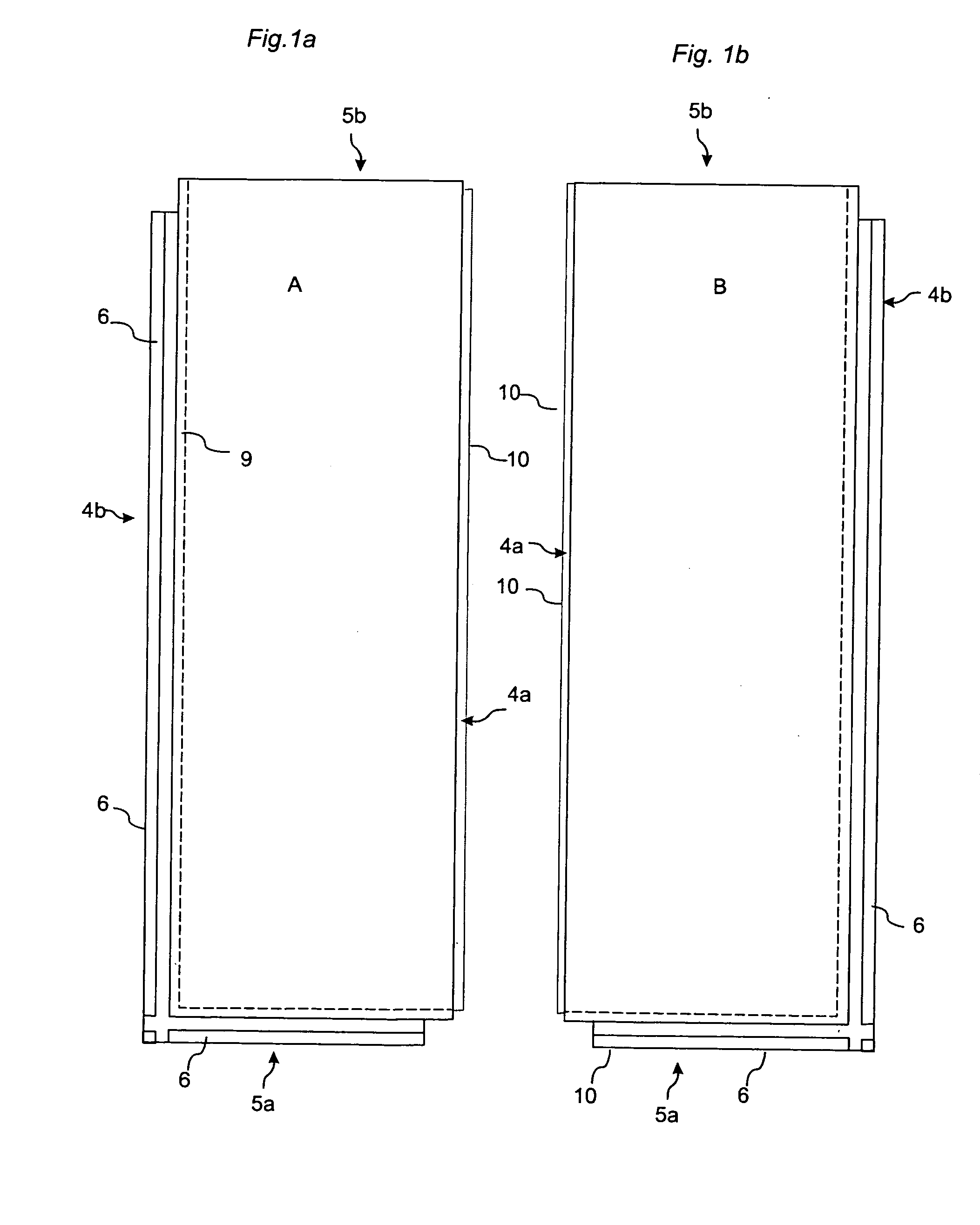

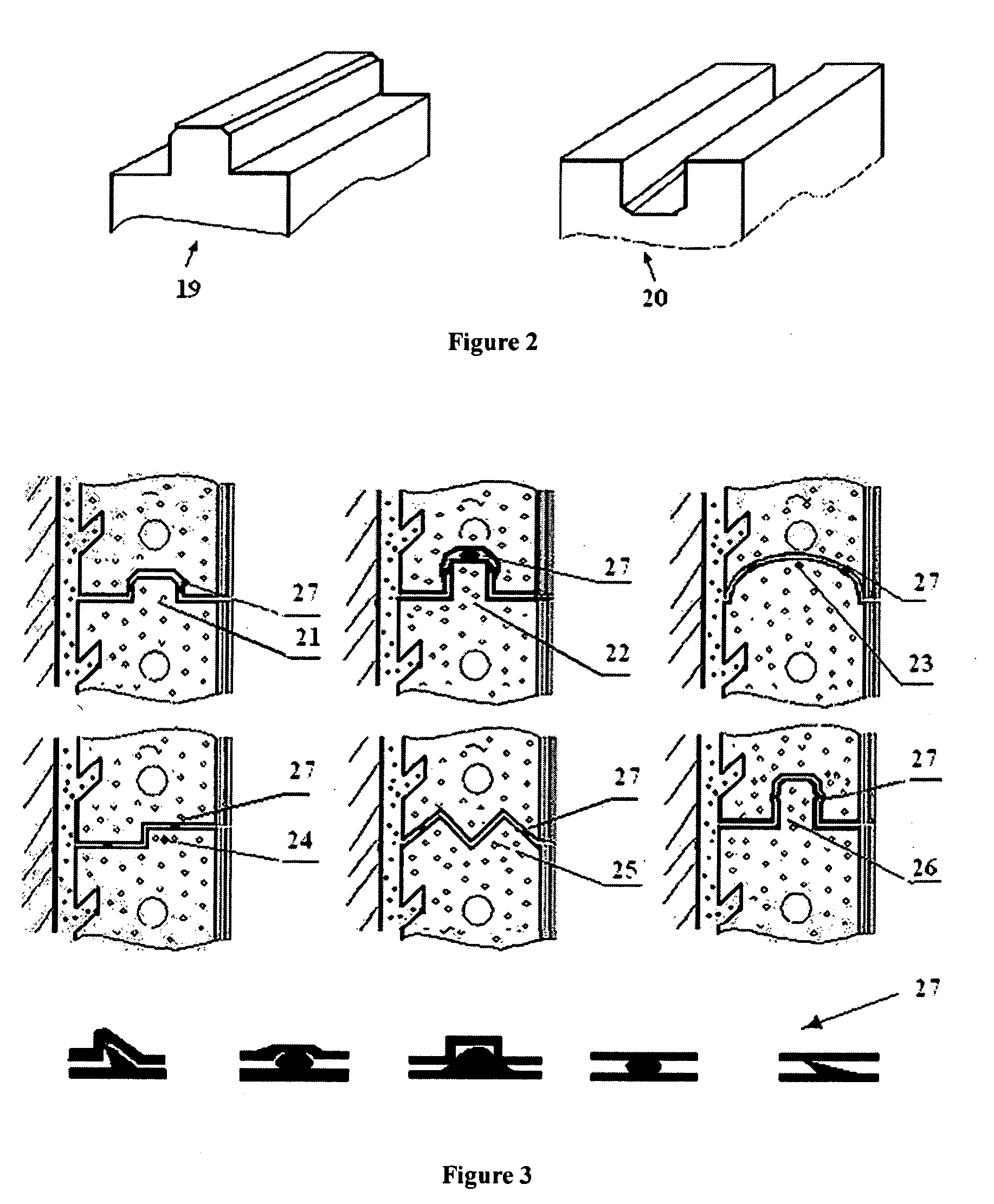

Floor covering comprising a plurality of unit panels (1) laid in a pattern, these panels being provided on their head sides (2, 3) and on their longitudinal sides (4, 5) with locking strips (6, 7) which engage with one another in the assembled position in which unit panels (1) are arranged adjacently within a covering, wherein grooves (19, 20) are provided in the head sides (2, 3) and wherein the grooves (19, 20) of two abutting head sides (2, 3) correspond and form a locking channel (21) intended to accommodate a head tongue (22, 22a-k). The head tongue (22) is preassembled in the groove (20) and projects beyond an end of the groove (20) that faces the longitudinal side (5) of the unit panel (1). At the same time, the head tongue (22) in the preassembled state is embedded completely within the groove (20) and can be displaced at least partially from one groove (20) into the corresponding groove (19) of the adjacent unit panel (1) by sliding the projecting end (24) of the head tongue (22) into the groove (20).

Owner:SCHULTE GUIDO

Fire and water resistant expansion joint system

A fire resistant and water resistant expansion joint system comprises a compressed lamination of fire retardant infused open celled foam, one coat of an elastomeric waterproofing or water resistant material on the lamination, and another coat of an intumescent material on an opposing surface of the lamination, thereby providing fire resistance in one direction and water resistance in the opposite direction. The intumescent material may be further coated with a similar elastomeric material, thereby providing fire resistance in one direction and water resistance in both directions. In the alternative, the compressed lamination may comprise first and second opposing layers of intumescent material thereon each having a respective layer of elastomeric material to provide both water resistance and fire resistance in both directions.

Owner:EMSEAL JOINT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com