Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

678results about "Reactor fuel susbtances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

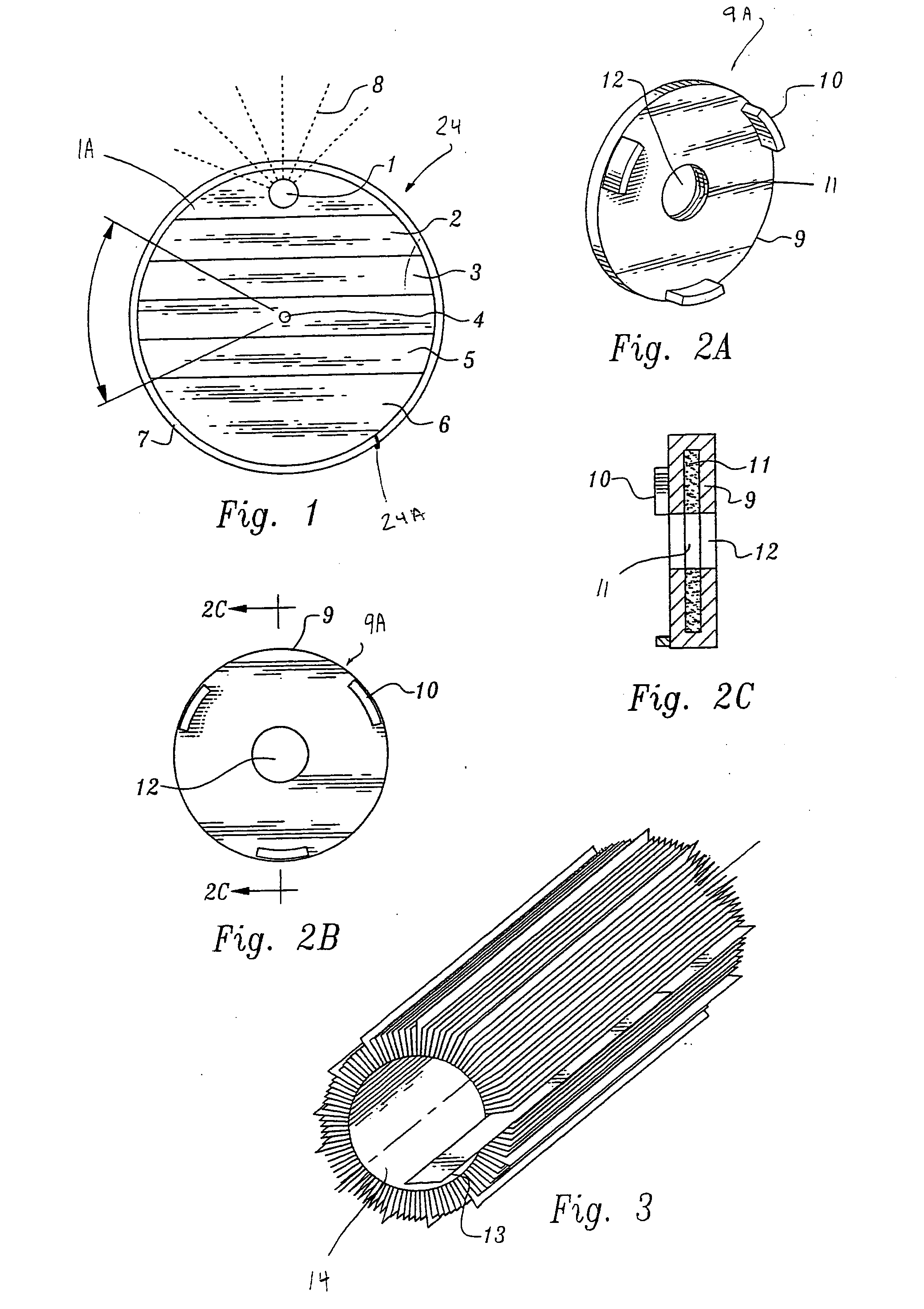

Non Proliferating Thorium Nuclear Fuel Inert Metal Matrix Alloys for Fast Spectrum and Thermal Spectrum Thorium Converter Reactors

InactiveUS20080144762A1Improve heat transfer performanceRobust assemblyOptical rangefindersNuclear energy generationHigh energyEpithermal neutron

A set of alloy formulations is disclosed to use with thorium based nuclear fuels in a fast spectrum reactor; with thorium based nuclear fuels in existing thermal spectrum power reactors; for medical isotope production in the epithermal, the fast, the fission spectrum and the thermal spectra; and to use as fuel in test and experimental reactors that are non proliferative. The alloys form inert metal matrixes to hold fine particles of dispersed thorium containing fuel. The formulations also are useful for the production of medical and commercial isotopes in the high energy, fast and epithermal neutron spectra.

Owner:RGT UNIV OF CALIFORNIA

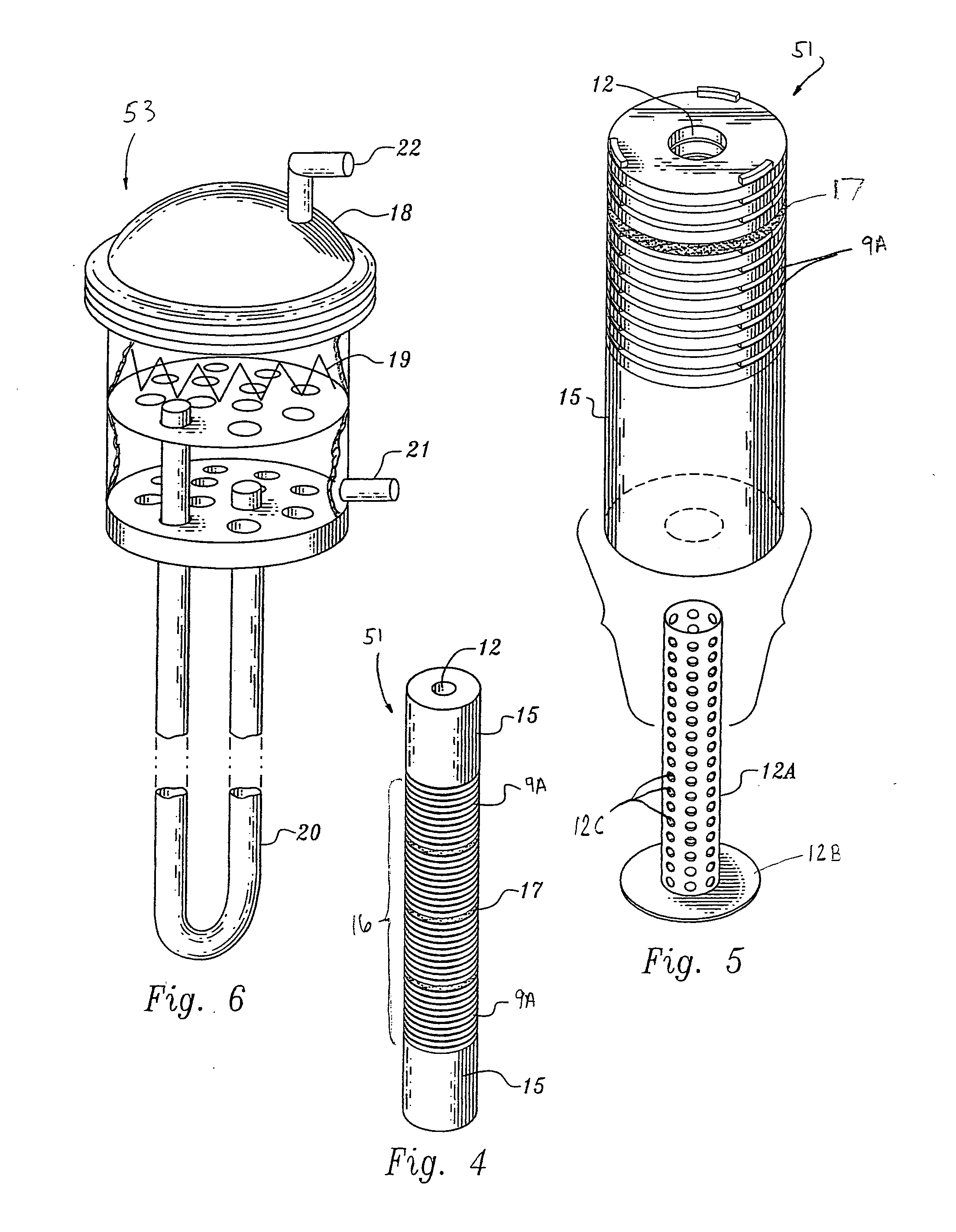

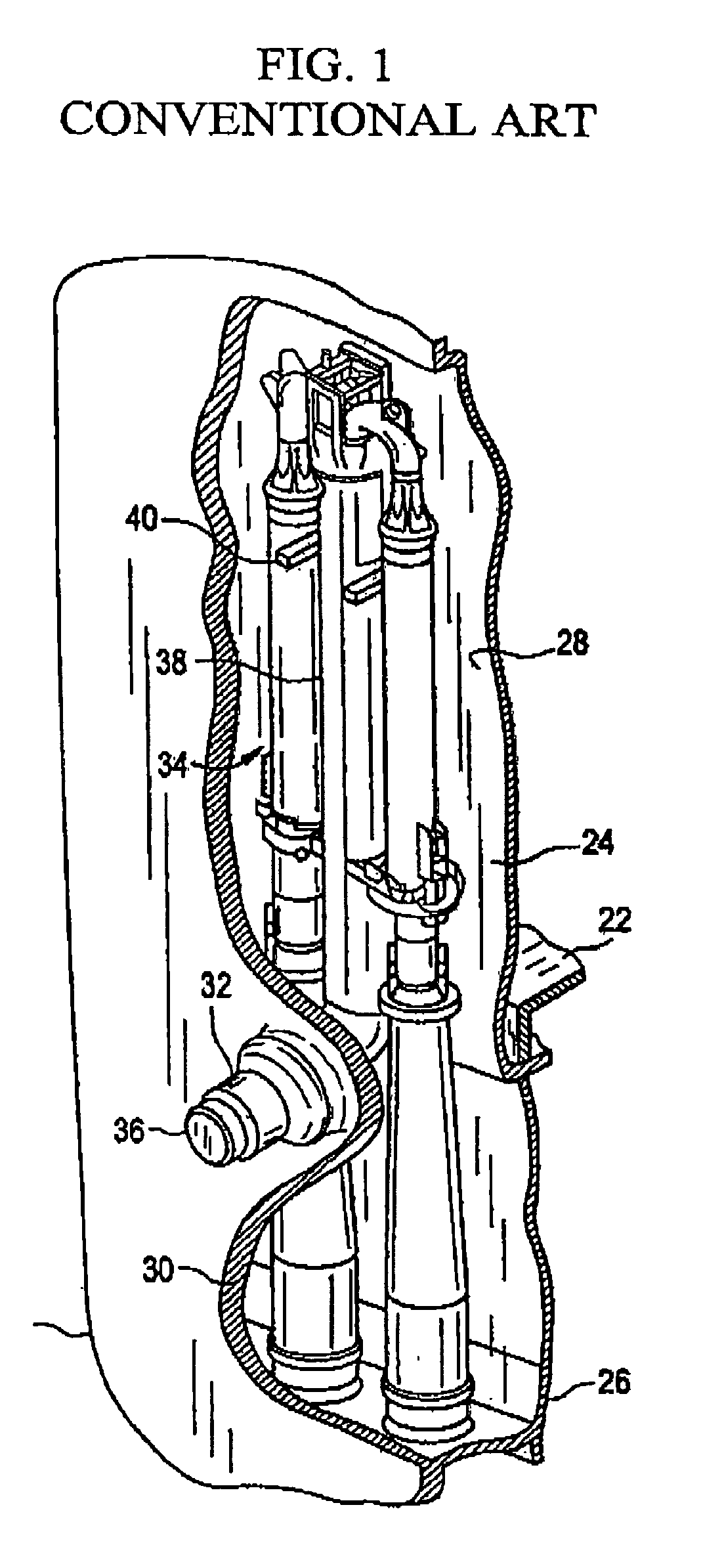

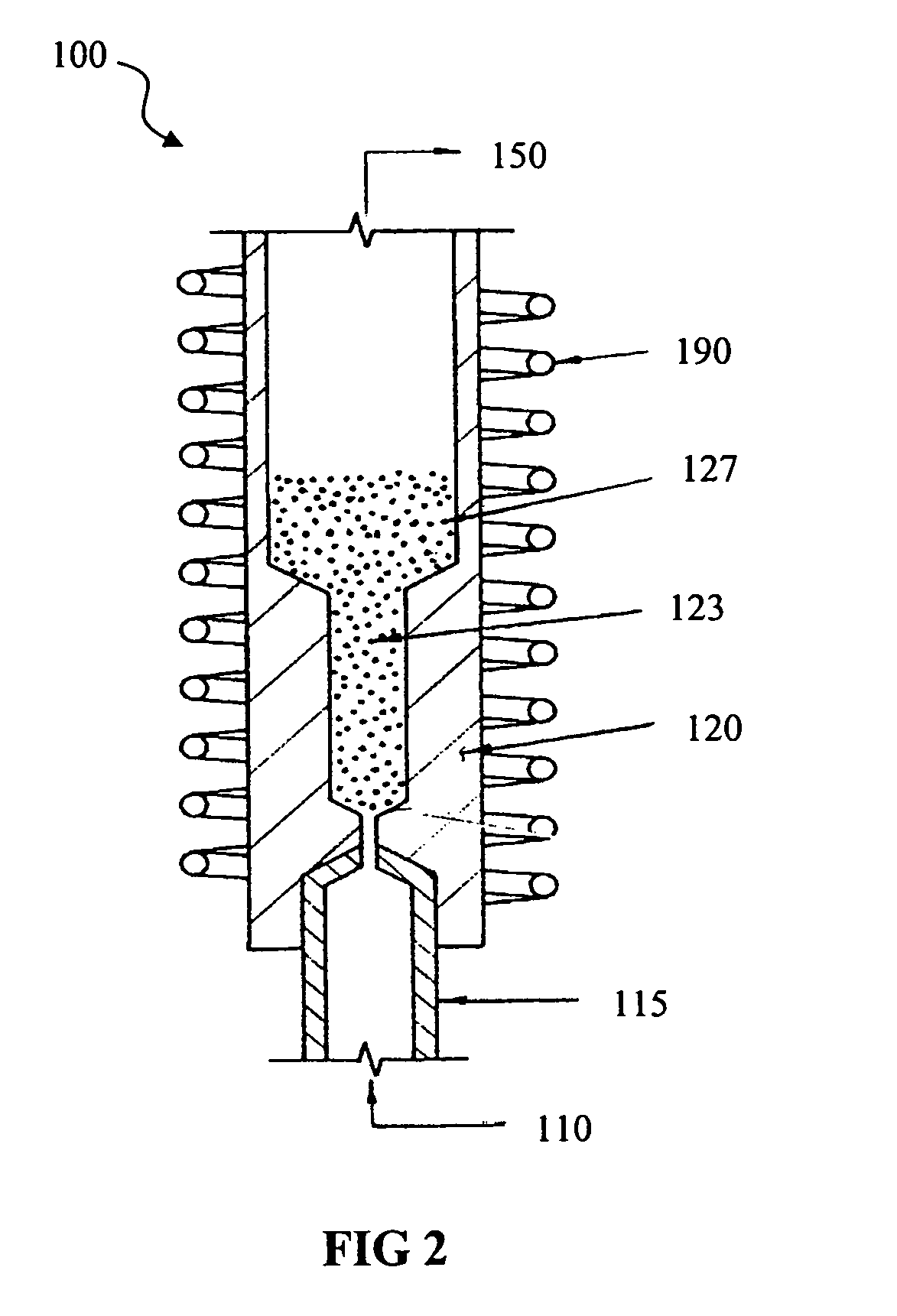

Reactor tray vertical geometry with vitrified waste control

InactiveUS20060171498A1Reduce the amount of wasteNegative environmental impactConversion outside reactor/acceleratorsNuclear energy generationThermal energyVitrification

A nuclear-powered plant for systems of up to about 100 MWs with a confinement section where the reaction takes place in a core having a reactive thorium / uranium-233 composition, and where an external neutron source is used as a modulated neutron multiplier for the reactor core output. The core is housed in a containment structure that radiates thermal energy captured in a multiple-paths heat exchanger. The exchanger heat energy output is put to use in a conventional gas-to-water heat exchanger to produce commercial quality steam.

Owner:D B I CENTURY FUELS & AEROSPACE SERVICES

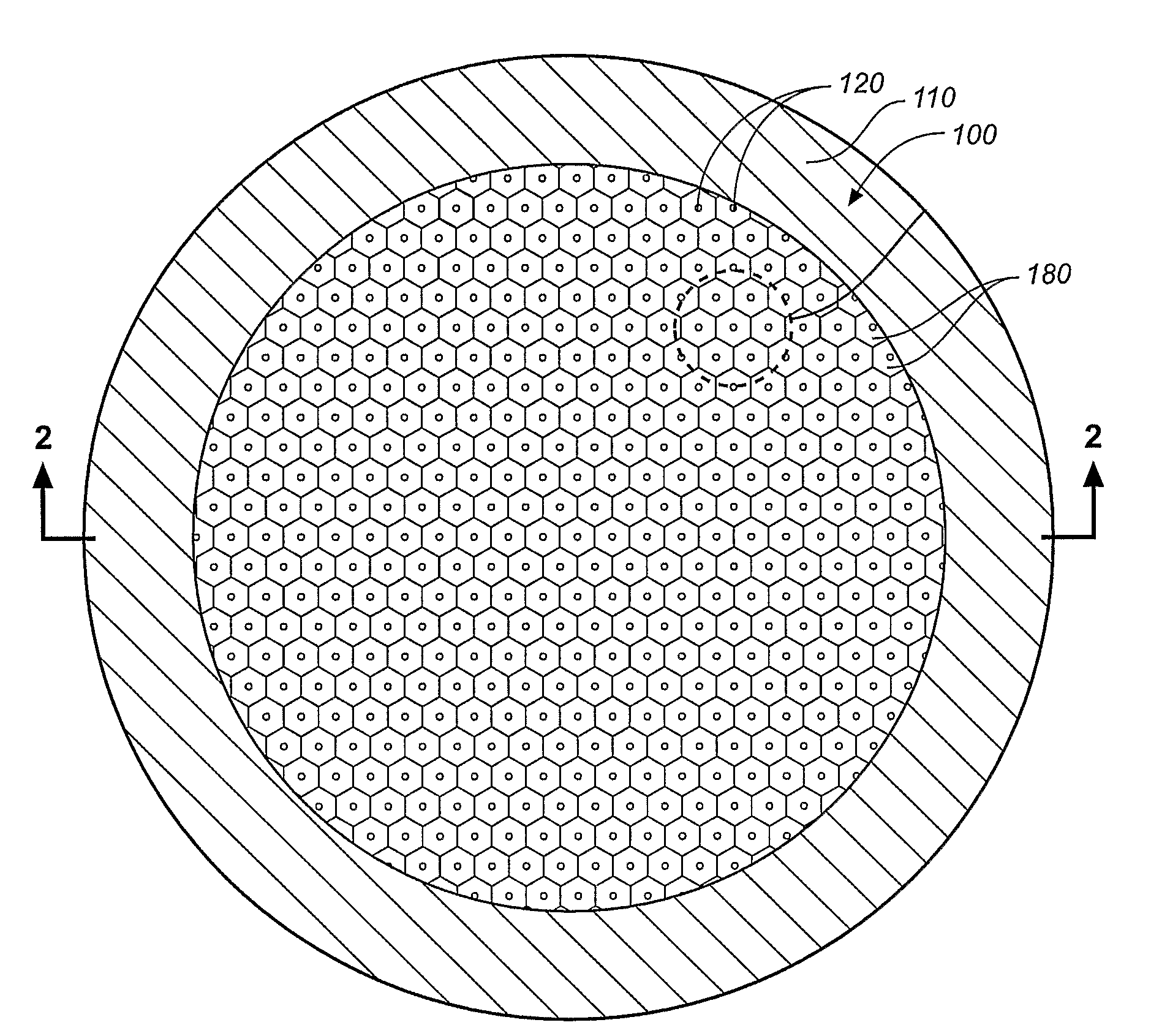

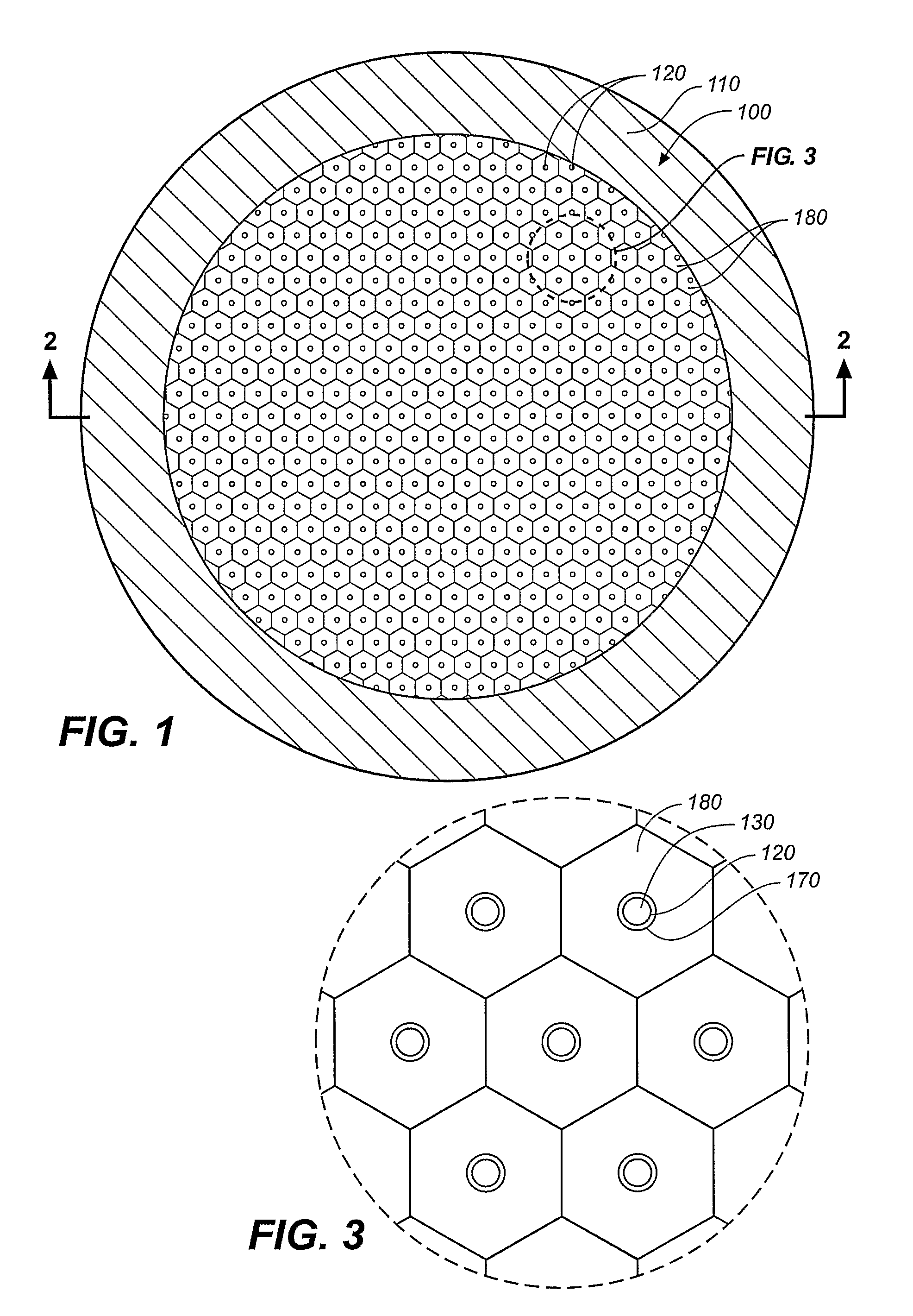

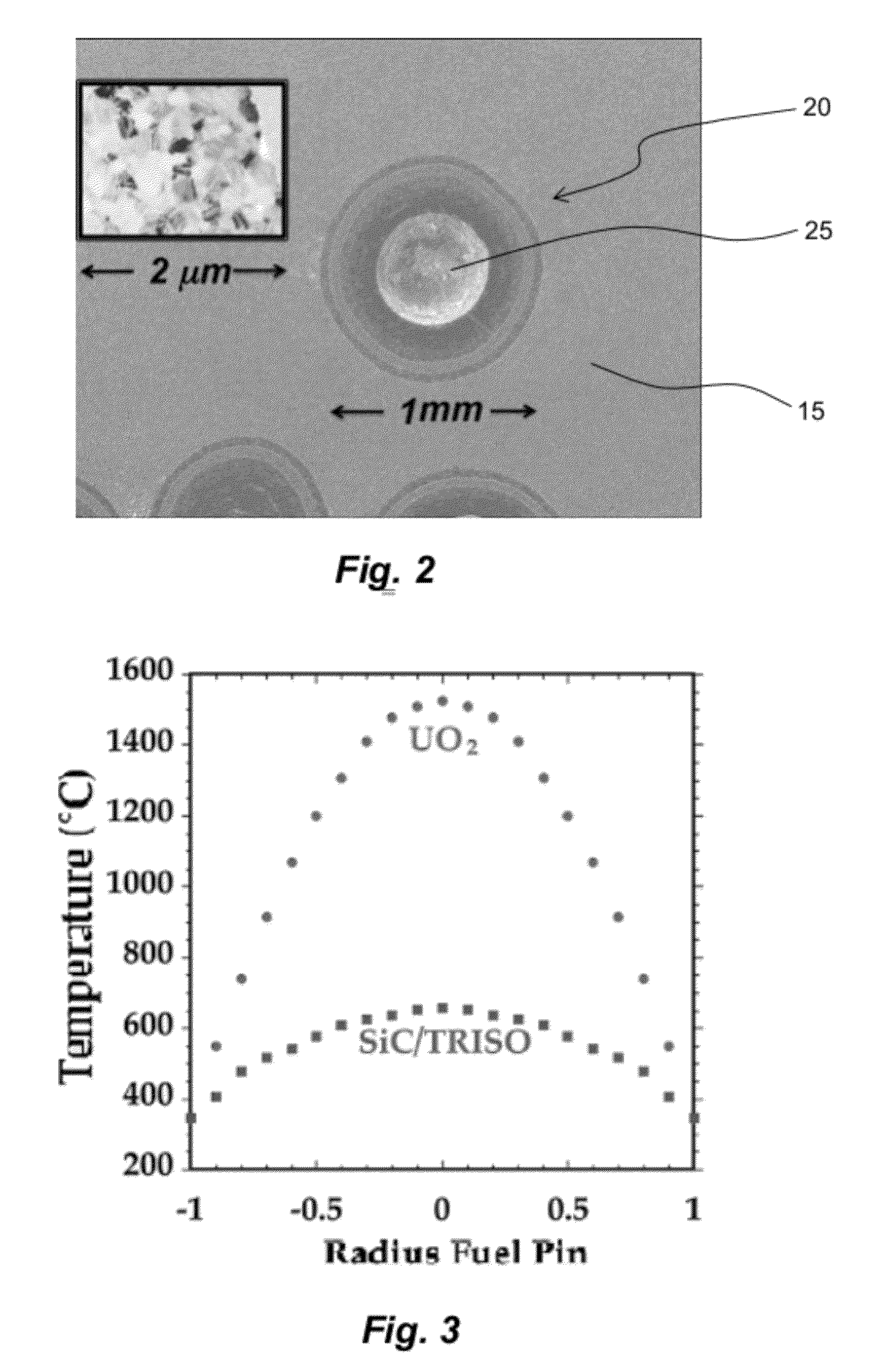

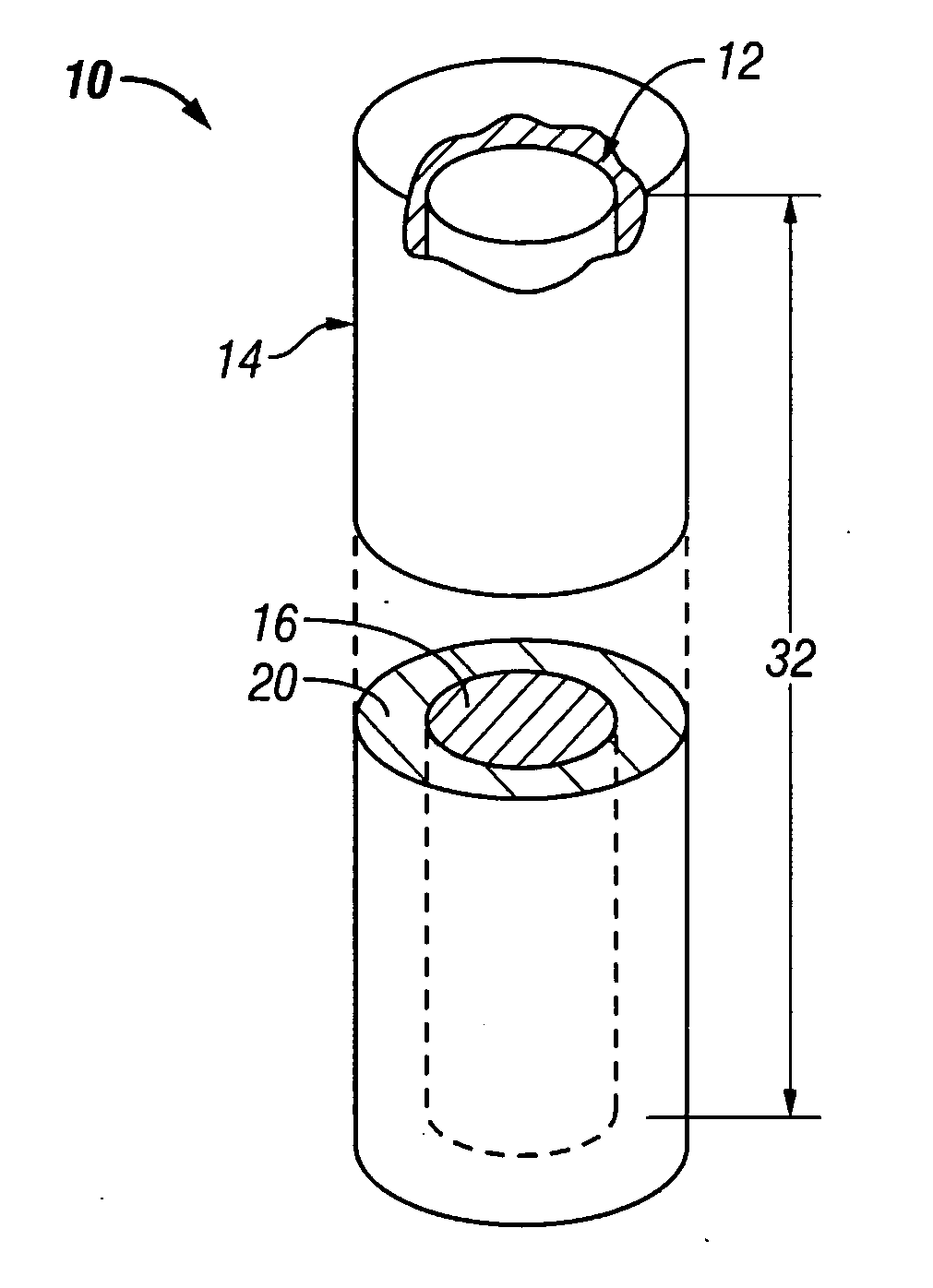

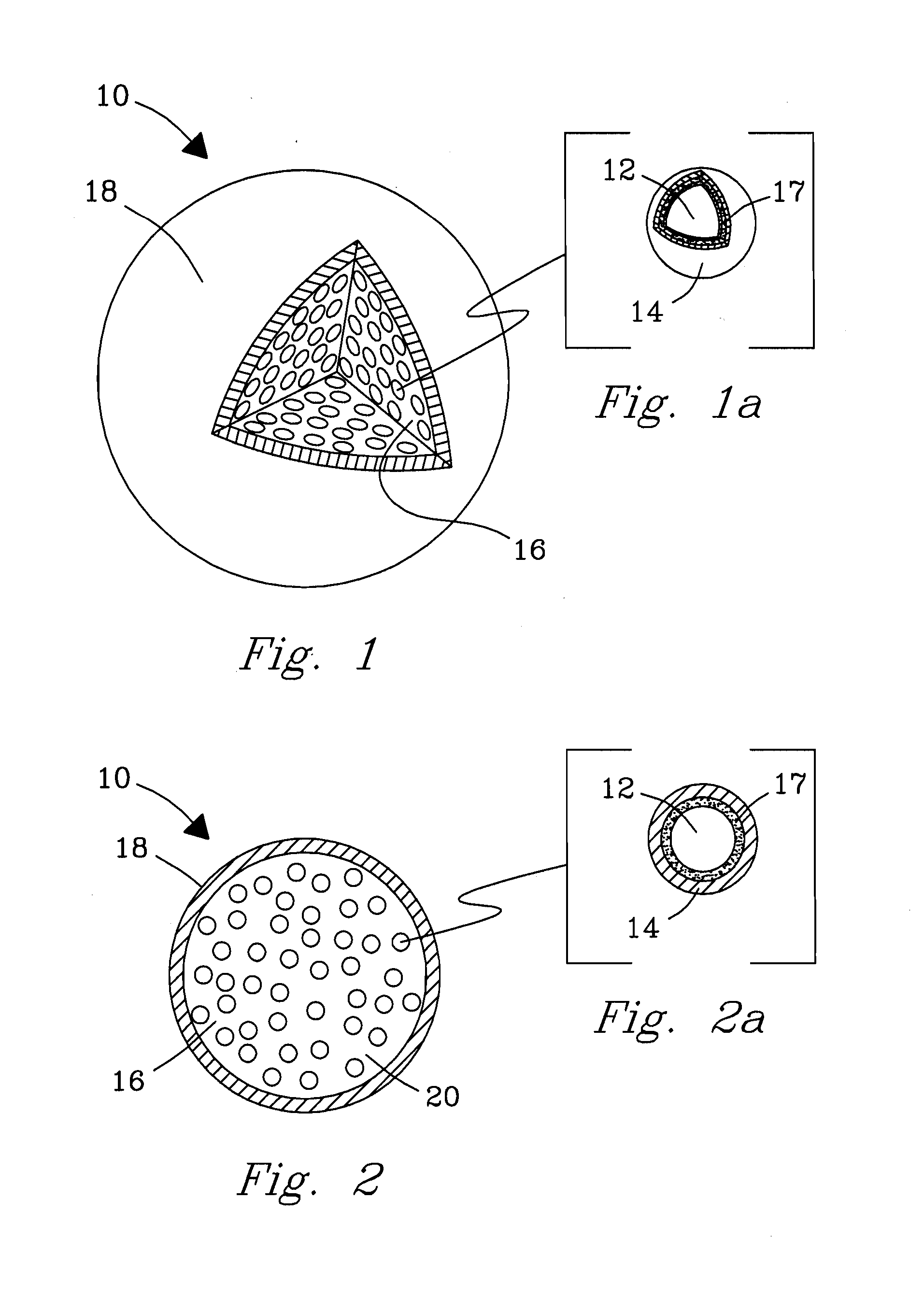

Fully ceramic nuclear fuel and related methods

Various embodiments of a nuclear fuel for use in various types of nuclear reactors and / or waste disposal systems are disclosed. One exemplary embodiment of a nuclear fuel may include a fuel element having a plurality of tristructural-isotropic fuel particles embedded in a silicon carbide matrix. An exemplary method of manufacturing a nuclear fuel is also disclosed. The method may include providing a plurality of tristructural-isotropic fuel particles, mixing the plurality of tristructural-isotropic fuel particles with silicon carbide powder to form a precursor mixture, and compacting the precursor mixture at a predetermined pressure and temperature.

Owner:UT BATTELLE LLC +1

High-density, solid solution nuclear fuel and fuel block utilizing same

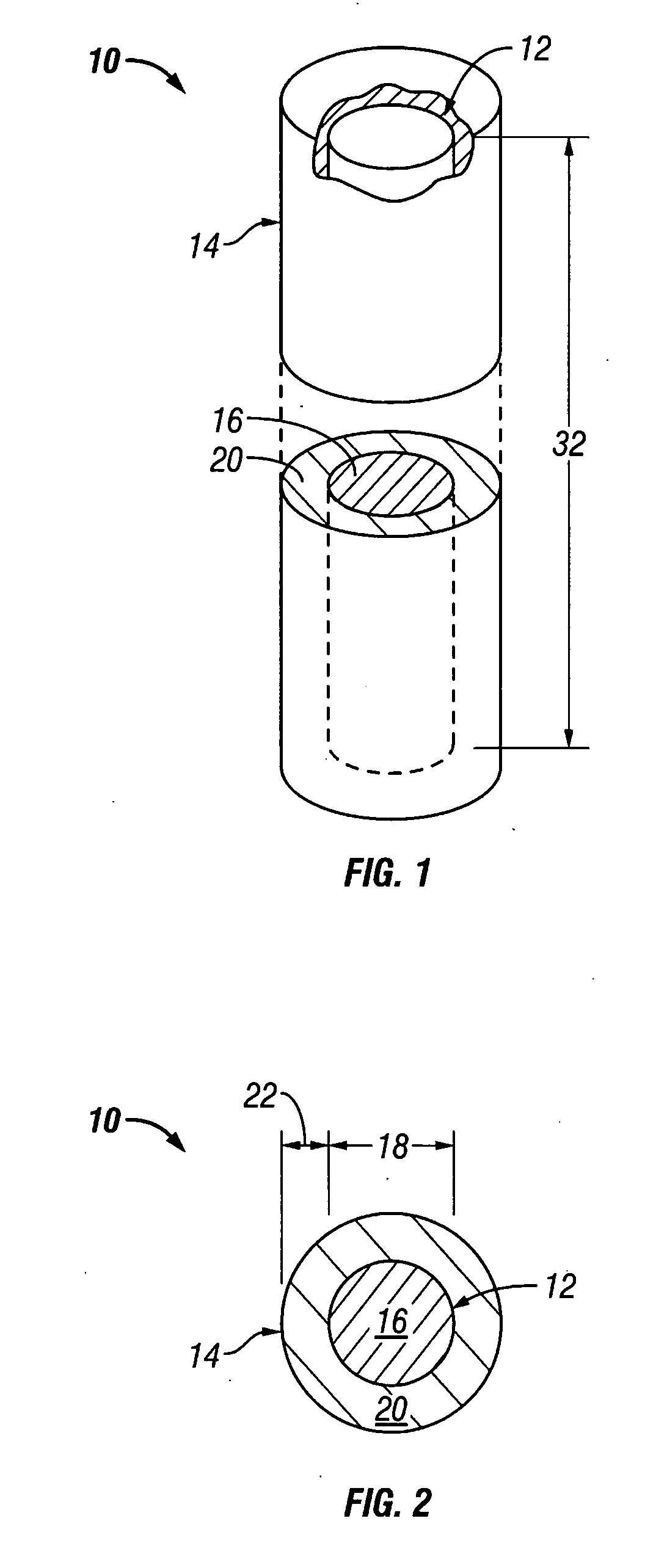

A nuclear fuel element includes a core formed from a high density solid solution fissile material that is substantially free of carbon and void space. A cladding substantially surrounds the core.

Owner:MICRON TECH INC +1

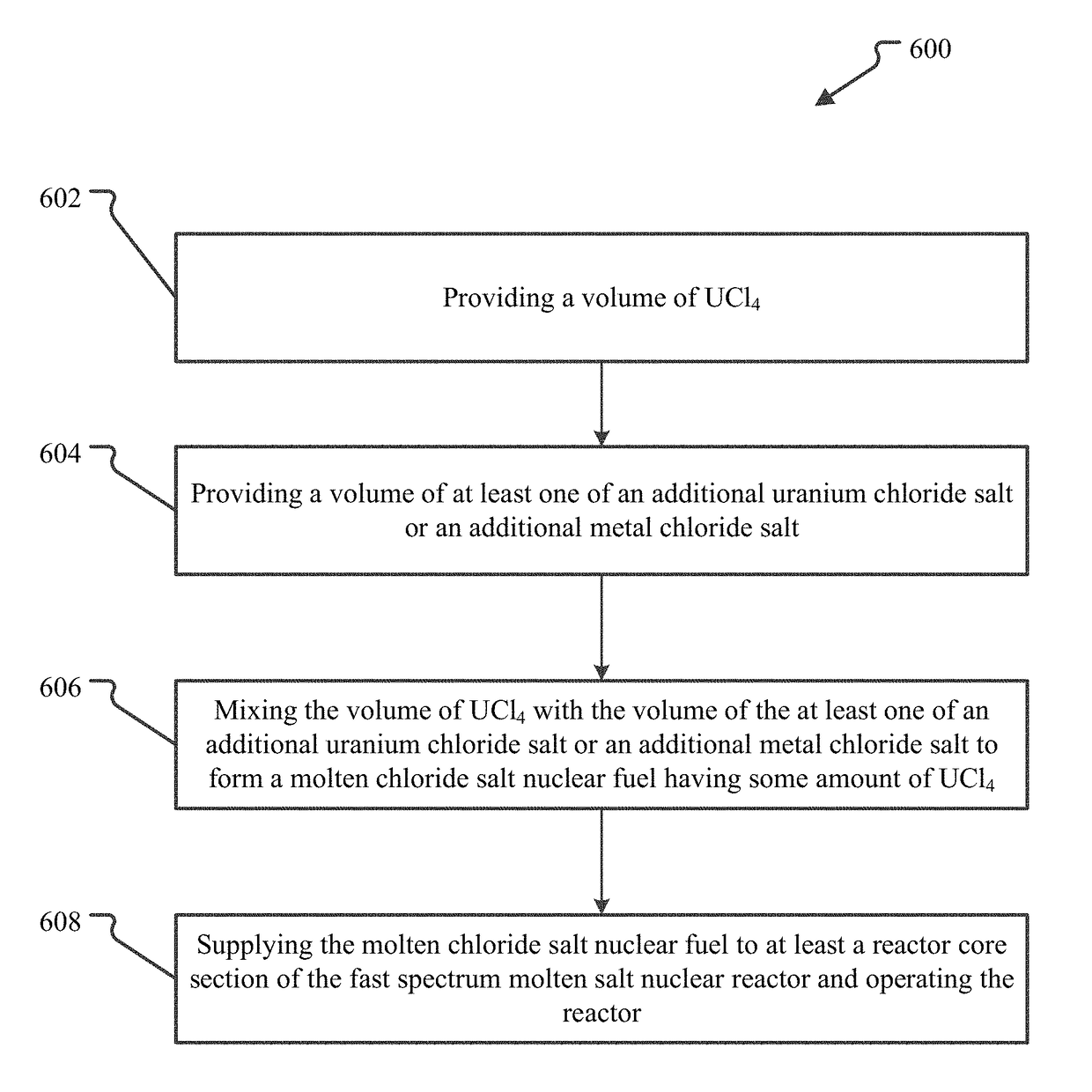

Molten nuclear fuel salts and related systems and methods

InactiveUS20160189813A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

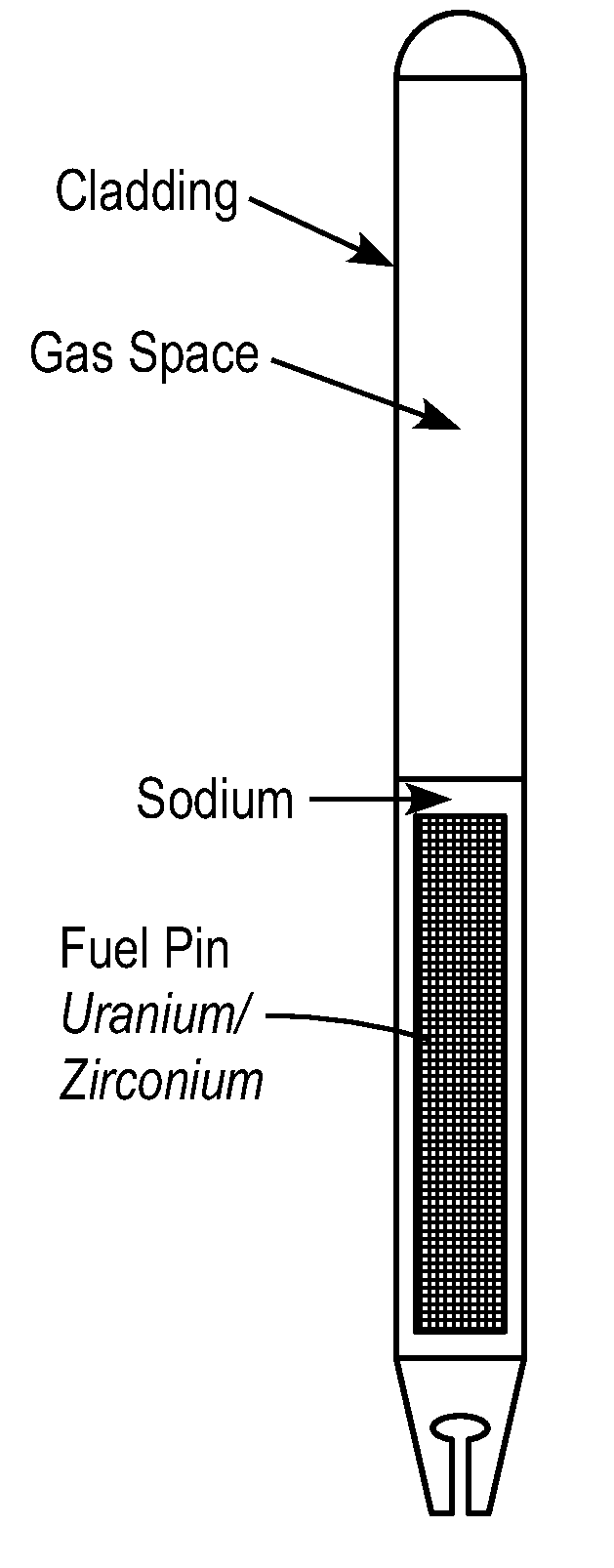

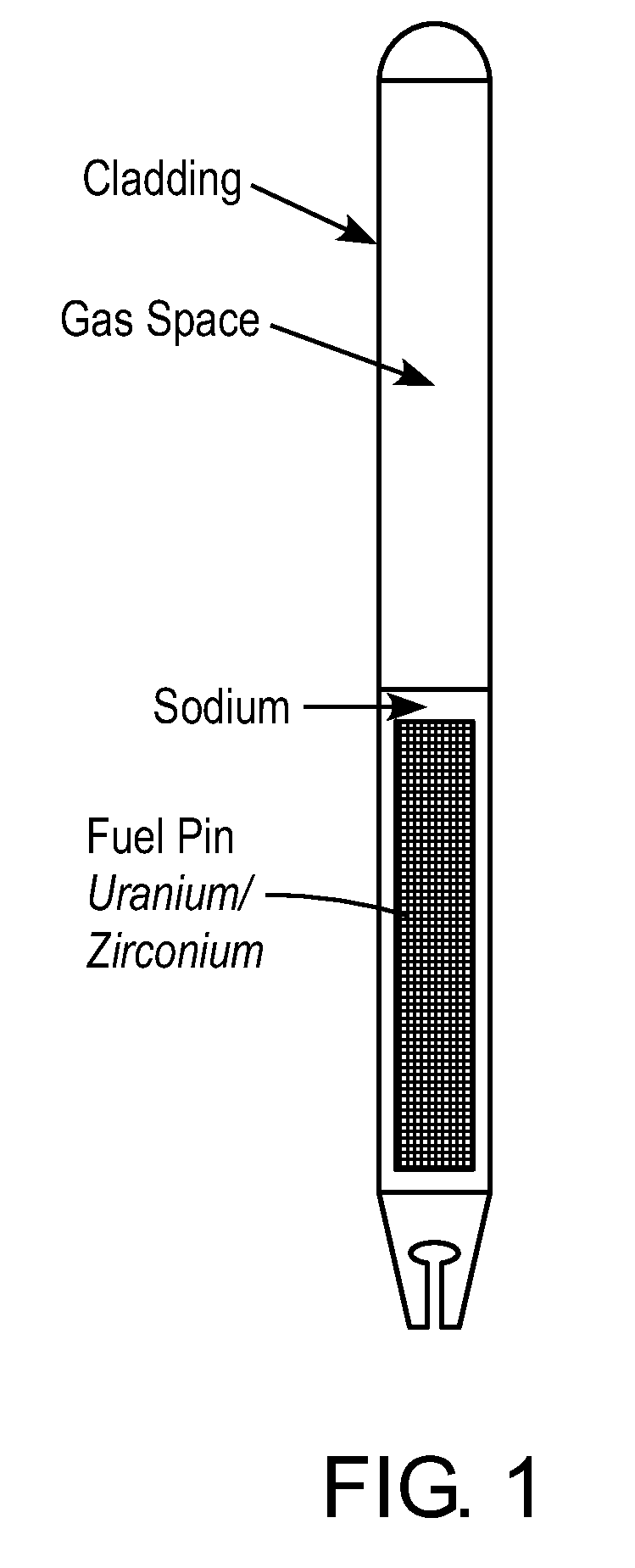

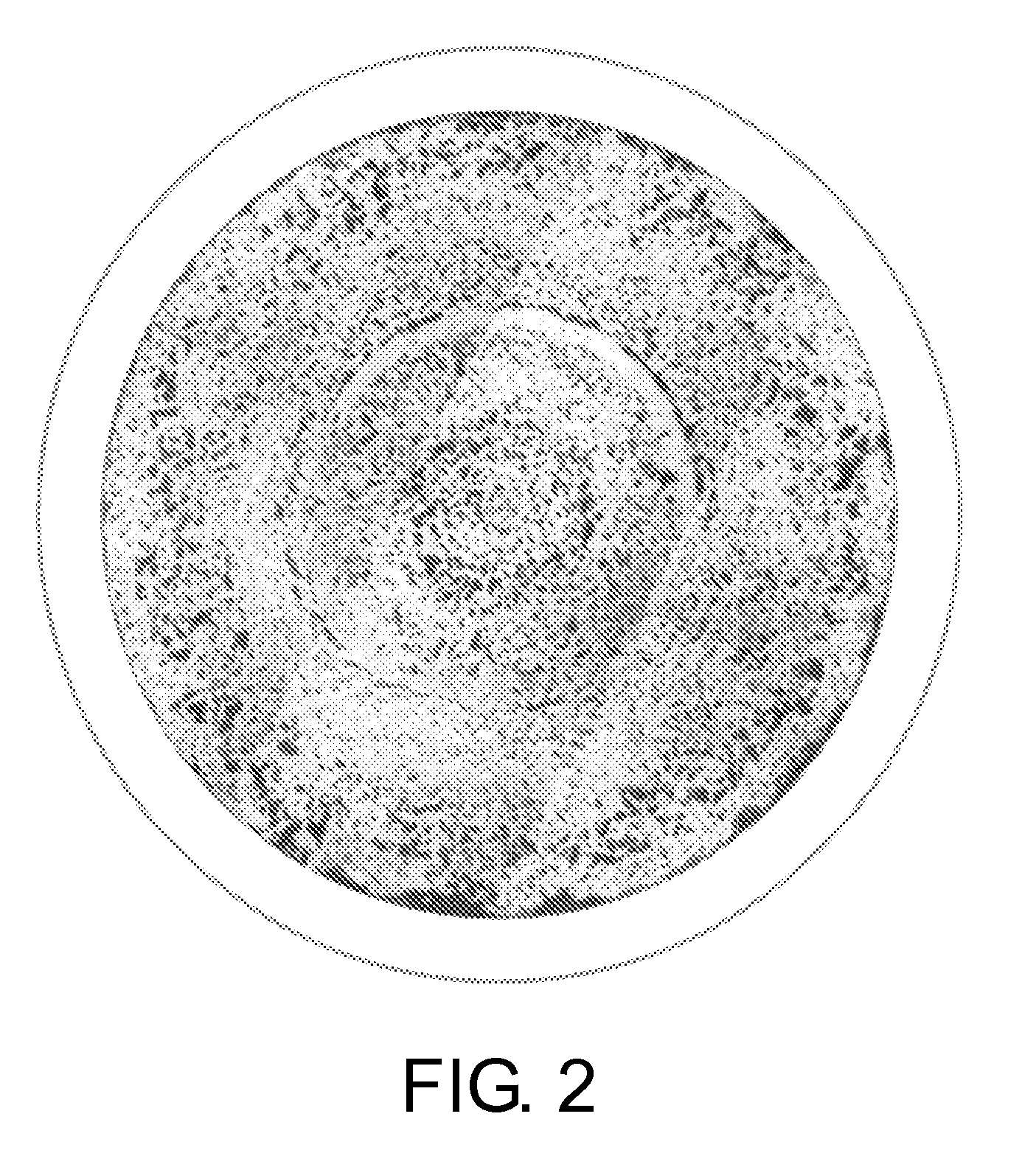

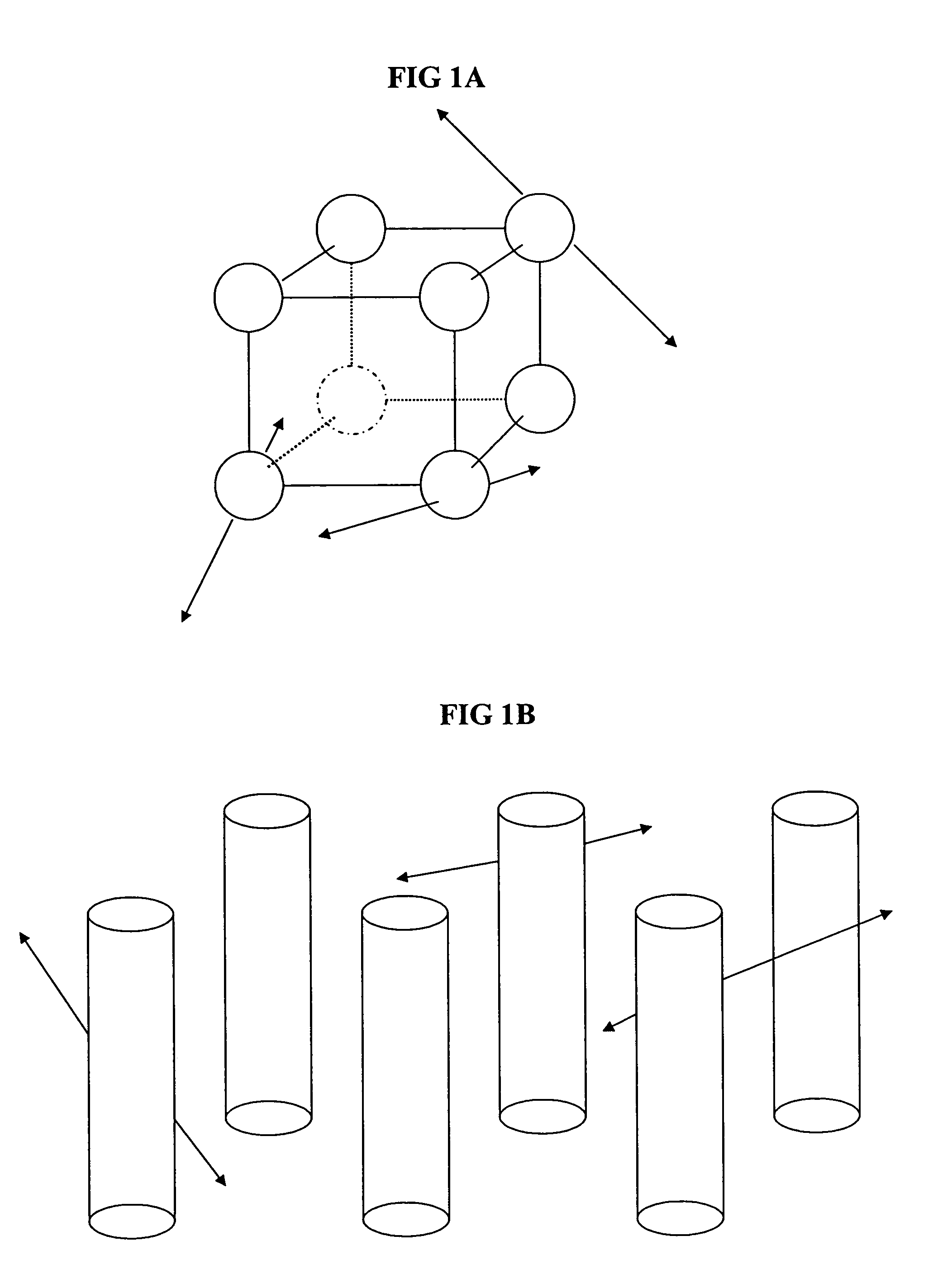

Particulate metal fuels used in power generation, recycling systems, and small modular reactors

ActiveUS20100303193A1Fix fuel costEliminate needNuclear fuel reprocessingFuel elementsNuclear reactor coreNuclear reactor

A metal particulate fuel system is described. The metal fuel system may include particulate metal fuel for use in nuclear reactors. The particulate metal fuel may include a plurality of particles of at least one enriched alloy where the particles are compacted into a fuel column. The metal particulate fuel system may also include a cladding and / or a gas-filled plenum.

Owner:ADVANCED REACTOR CONCEPTS

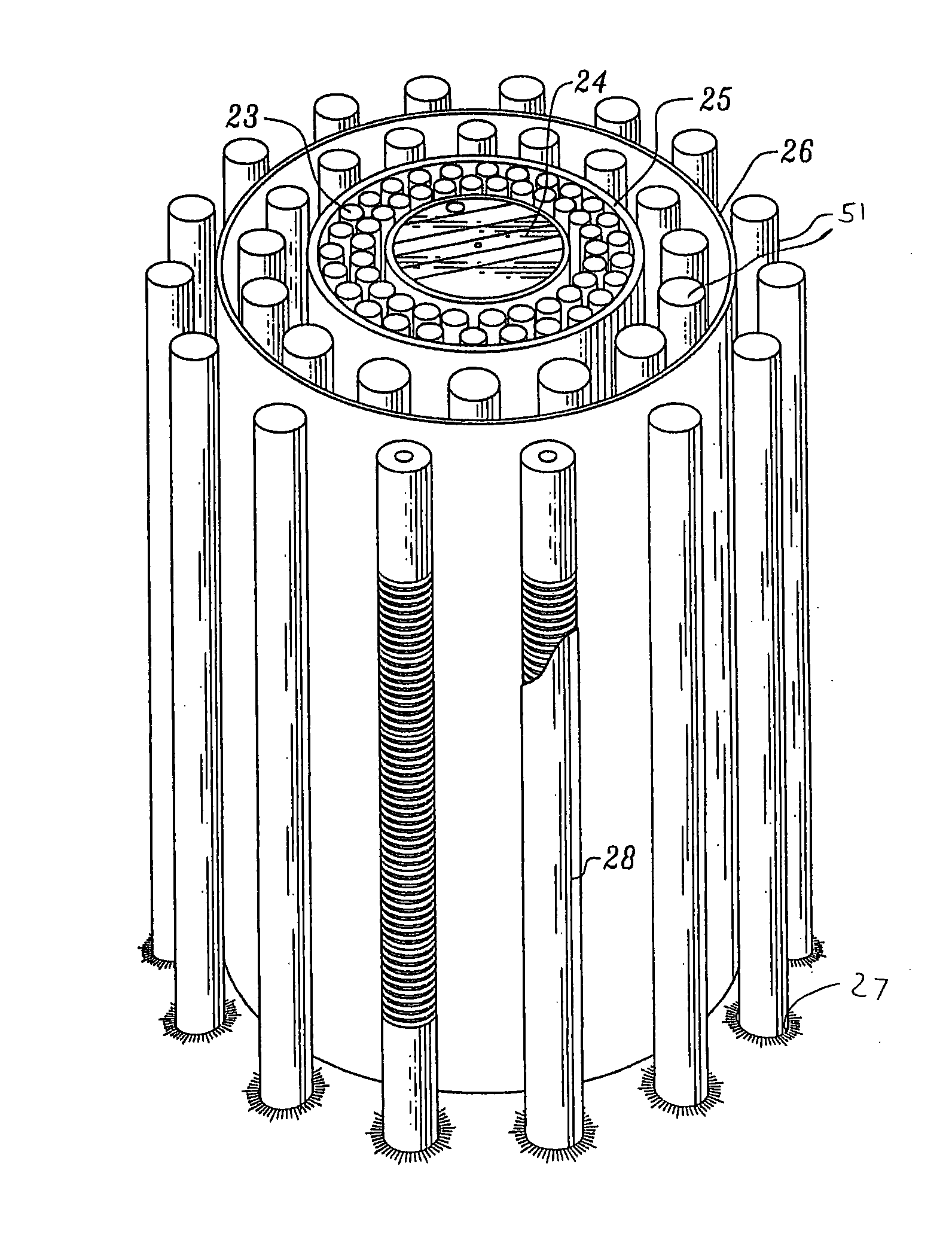

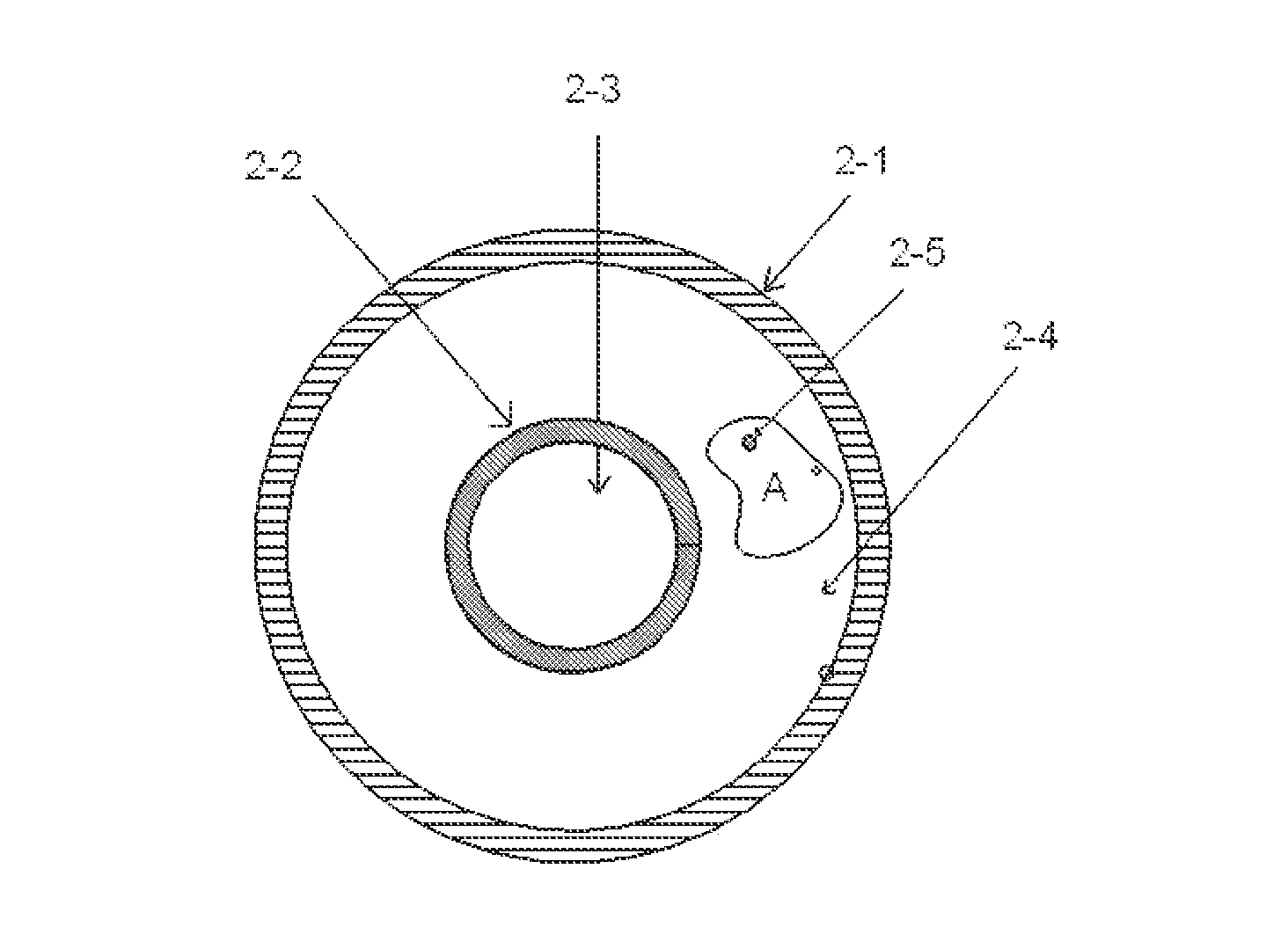

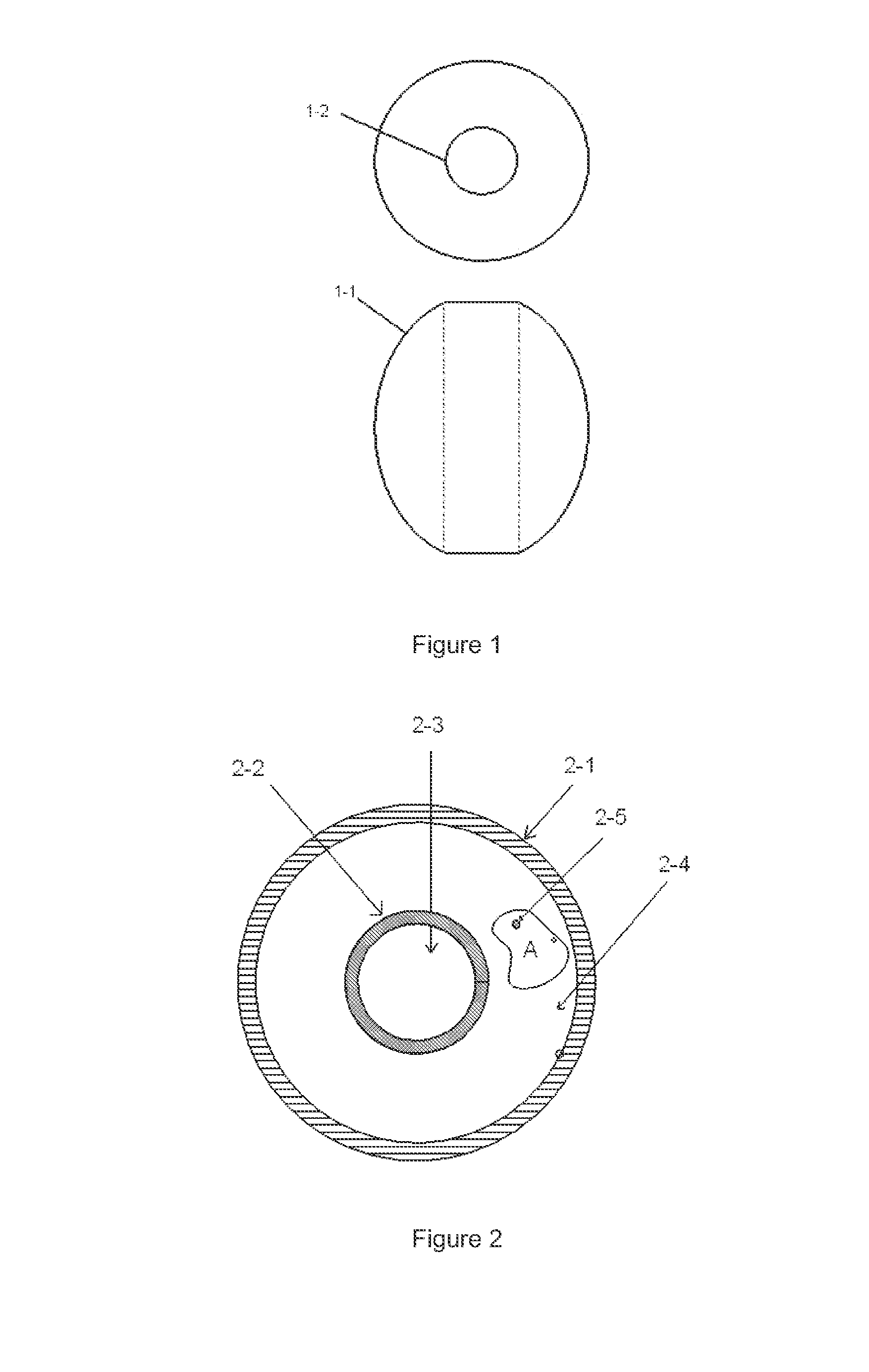

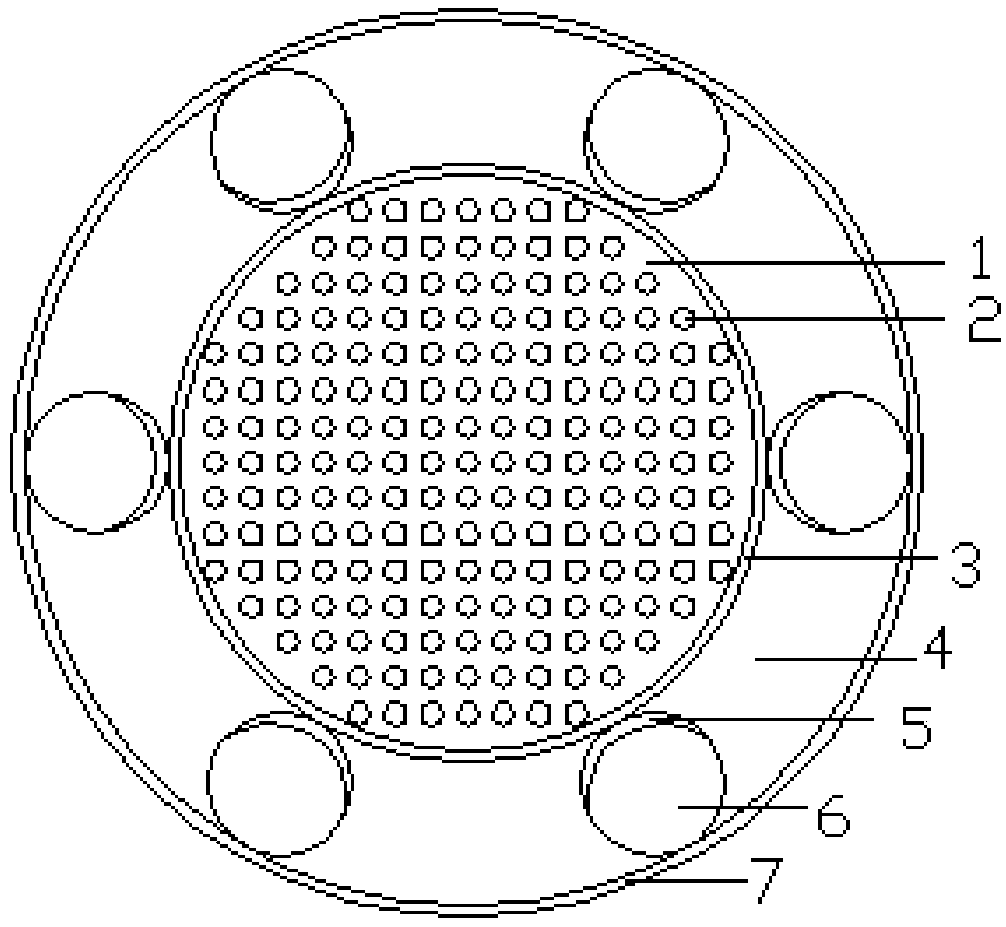

Fast reactor type coupling nuclear reaction implementation method and nuclear reactor for same

InactiveCN105023621AInherently safeReduce engineering difficultyFuel elementsNuclear energy generationNuclear reactor coreInherent safety

The present invention relates to a fast reactor type coupling nuclear reaction implementation method and a nuclear reactor for same. The main contents comprise: a fast reactor type coupling nuclear reaction implementation method, a reactor modular design approach, a fast reactor type coupling nuclear reactor, a reactor core, a fuel element, a nuclear control system, and a proliferation fuel system. The fast reactor type coupling nuclear reactor mainly combusts thorium and nuclear waste, and has inherent security. The reactor main container is composed of a fission pool and a moderating pool that are completely isolated from each other but coupling to each other. A primary coolant is separated from a moderator. A thermal insulation layer is disposed between the fission pool and the moderating pool so that both can perform neutron exchange but heat exchange is blocked. Fast neutrons produced by the fission pool and moderated neutrons reflected by the moderating pool may enable the reactor core to simultaneously perform coupling nuclear reaction of the two types of neutrons. The moderating pool may be provided with the nuclear control system, and ex-core coupling core control may be implemented. The moderating pool is provided with a thorium purification fuel system, and on-line extraction of the purification fuel can be performed, and separation of nuclide is safe and simple, thereby providing a solution to the technical bottleneck of "thorium reactor".

Owner:陈安海

Heat pipe molten salt fast reactor with stagnant liquid core

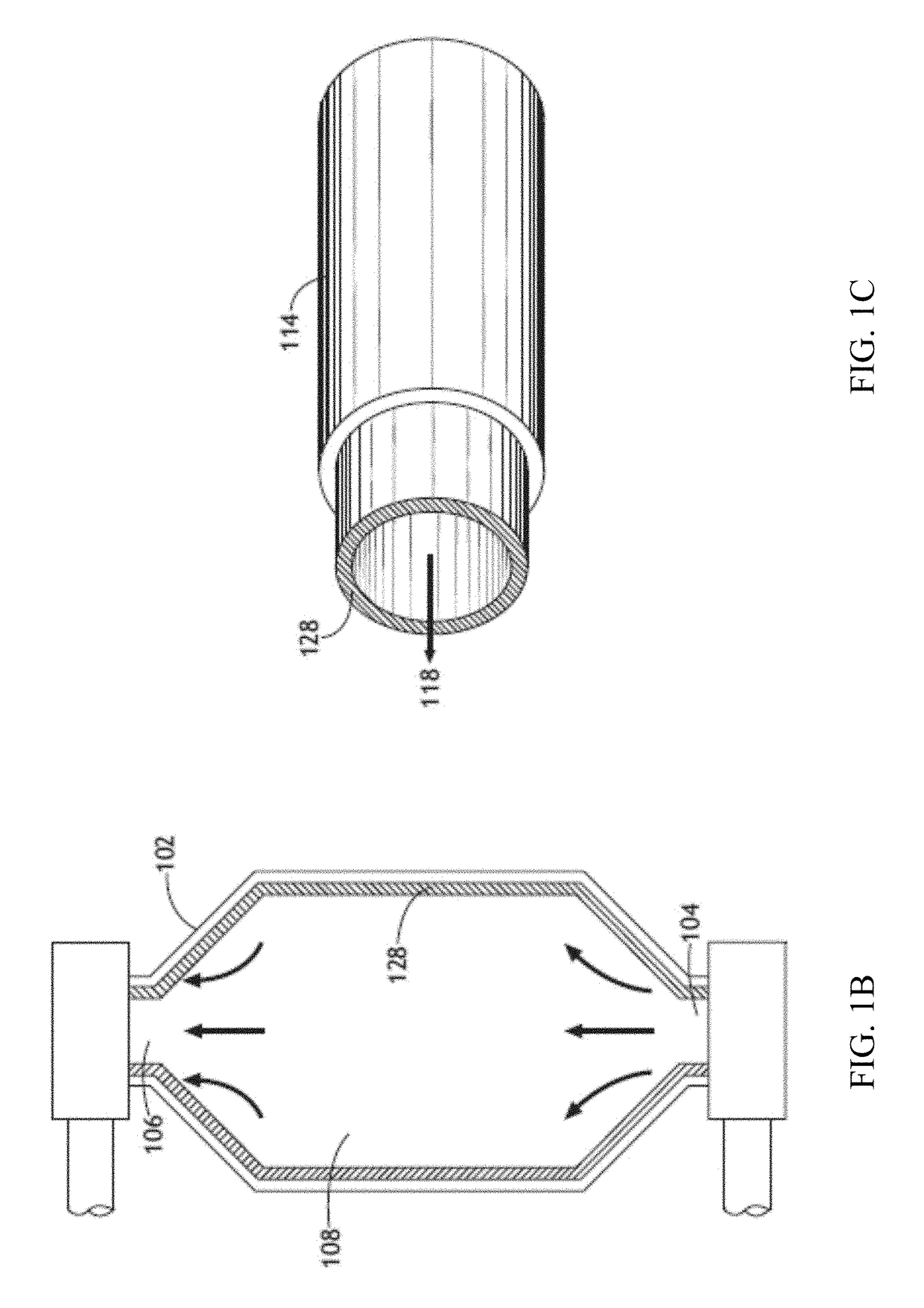

A molten salt reactor is described that includes a containment vessel, a reactor core housed within the containment vessel, a neutron reflector spaced from the containment vessel and positioned between the core and the containment vessel, a liquid fuel comprised of a nuclear fission material dissolved in a molten salt enclosed within the core, a plurality of heat transfer pipes, each pipe having a first and a second end, wherein the first end is positioned within the reactor core for absorbing heat from the fuel, a heat exchanger external to the containment vessel for receiving the second end of each heat transfer pipe for transferring heat from the core to the heat exchanger, and at least one and preferably two or more reactor shut down systems, where at least one may be a passive system and at least one or both may be an active or a manually operated system. The liquid fuel in the core is kept within the core and heat pipes are used to carry only the heat from the liquid core to the heat exchanger.

Owner:WESTINGHOUSE ELECTRIC CORP

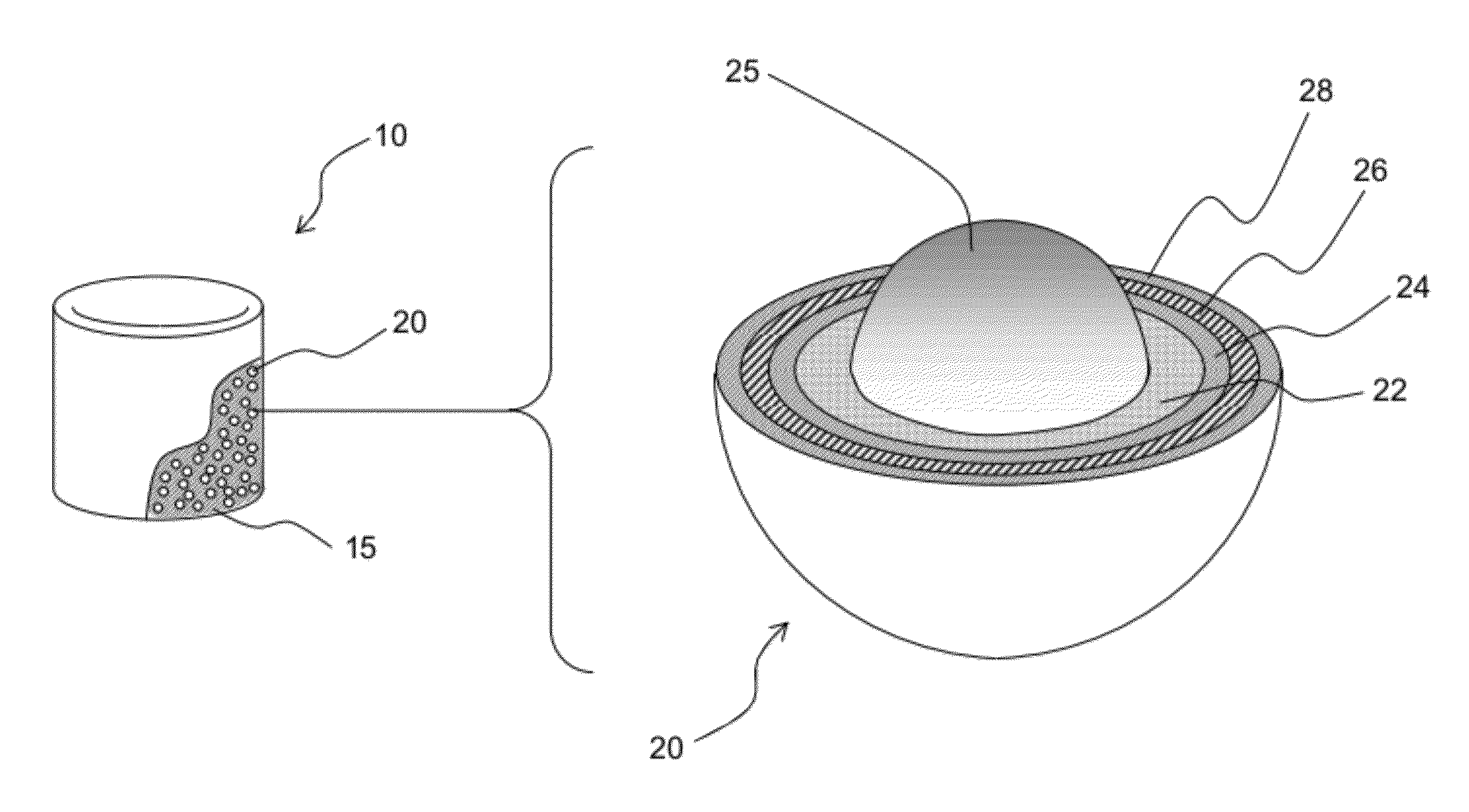

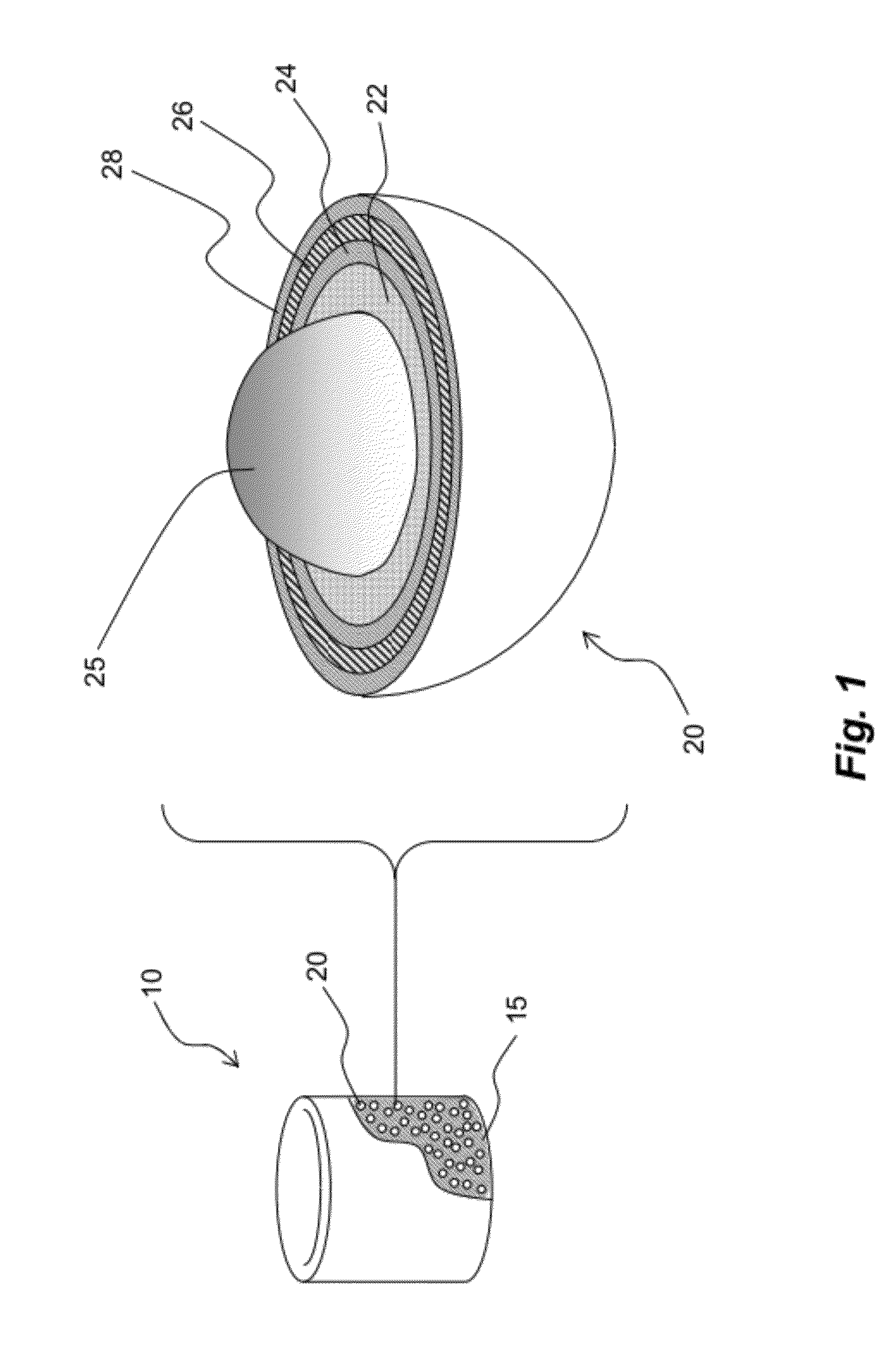

Ceramic encapsulations for nuclear materials and systems and methods of production and use

InactiveUS20130077731A1Improve heat transfer performanceFunctional safetyOptical rangefindersNuclear energy generationPorosityCeramic composite

A novel containment system for encapsulating nuclear fuel particles is disclosed. The containment system has a gas-impervious ceramic composite hollow shell having a spheroidal or ovoidal shape. The shell has a pair of longitudinally aligned round openings that are sealed with a gas-impervious ceramic composite tube to define a cavity between the shell inner surface and the tube outer surface. A ceramic composite matrix containing the nuclear fuel particles is enclosed within the cavity. The ceramic composite matrix has a controlled porosity, and can contain moderators or neutron absorbing material. The tube and shell are composed of a ceramic matrix composite material composed of ceramic reinforcement material that is bound together by a polymer-derived ceramic material.

Owner:TORXX GROUP

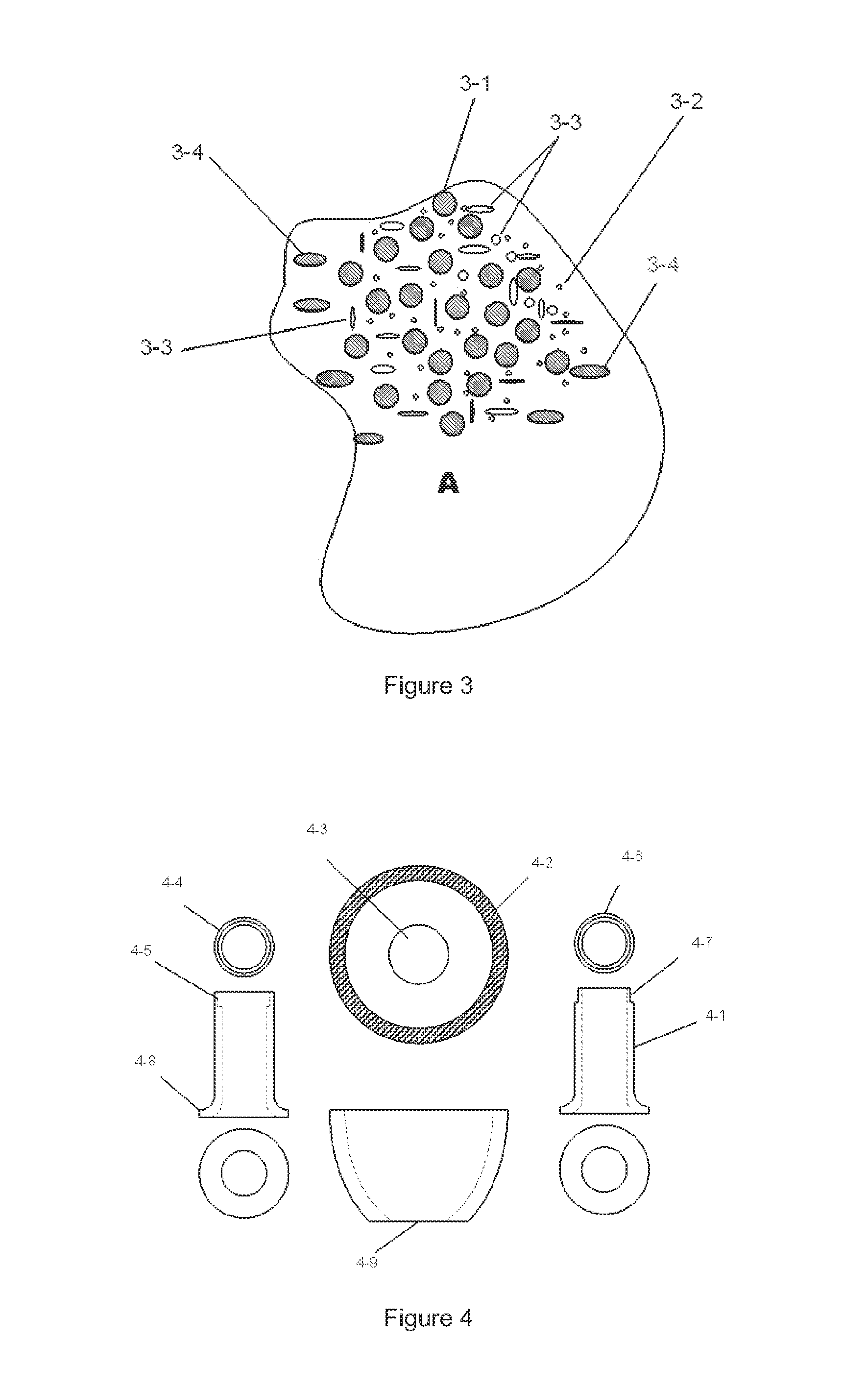

Method for preparing metal reinforced uranium dioxide nuclear fuel pellet

ActiveCN107256726ALow densityHigh strengthNuclear energy generationReactor fuel susbtancesMicro cellTwo step

The invention discloses a method for preparing metal reinforced uranium dioxide nuclear fuel pellets. The method mainly comprises two steps: firstly, preparing core-shell structure granules, namely performing low-temperature rapid pre-sintering on UO2 powder by using a Spark Plasma Sintering SPS technique, pelletizing, balling to obtain UO2 pellets, performing physical mixing on the UO2 pellets with metal (one of Mo, Cr, W and the like) micro powder to coat surfaces of the UO2 pellets by the metal micro powder, thereby obtaining metal coated uranium dioxide core-shell structure granules; secondly, preparing a nuclear fuel pellets, namely performing high-temperature liquidation on the metal powder on the surfaces of the UO2 pellets, thereby forming a micro cell structure continuous phase similar to a cytomembrane structure around the UO2 pellets, and obtaining the special metal reinforced UO2 nuclear fuel pellets with a UO2 substrate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

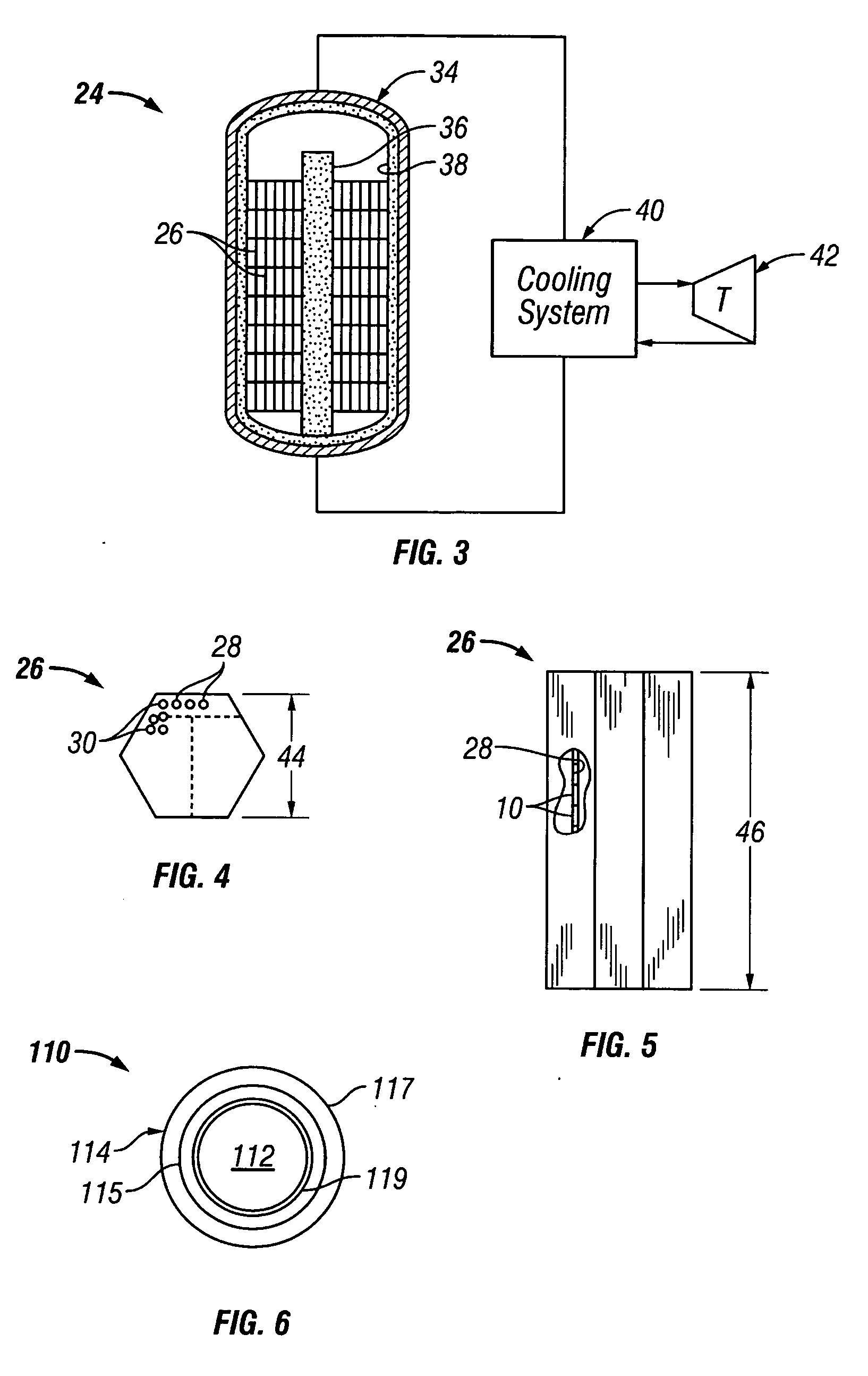

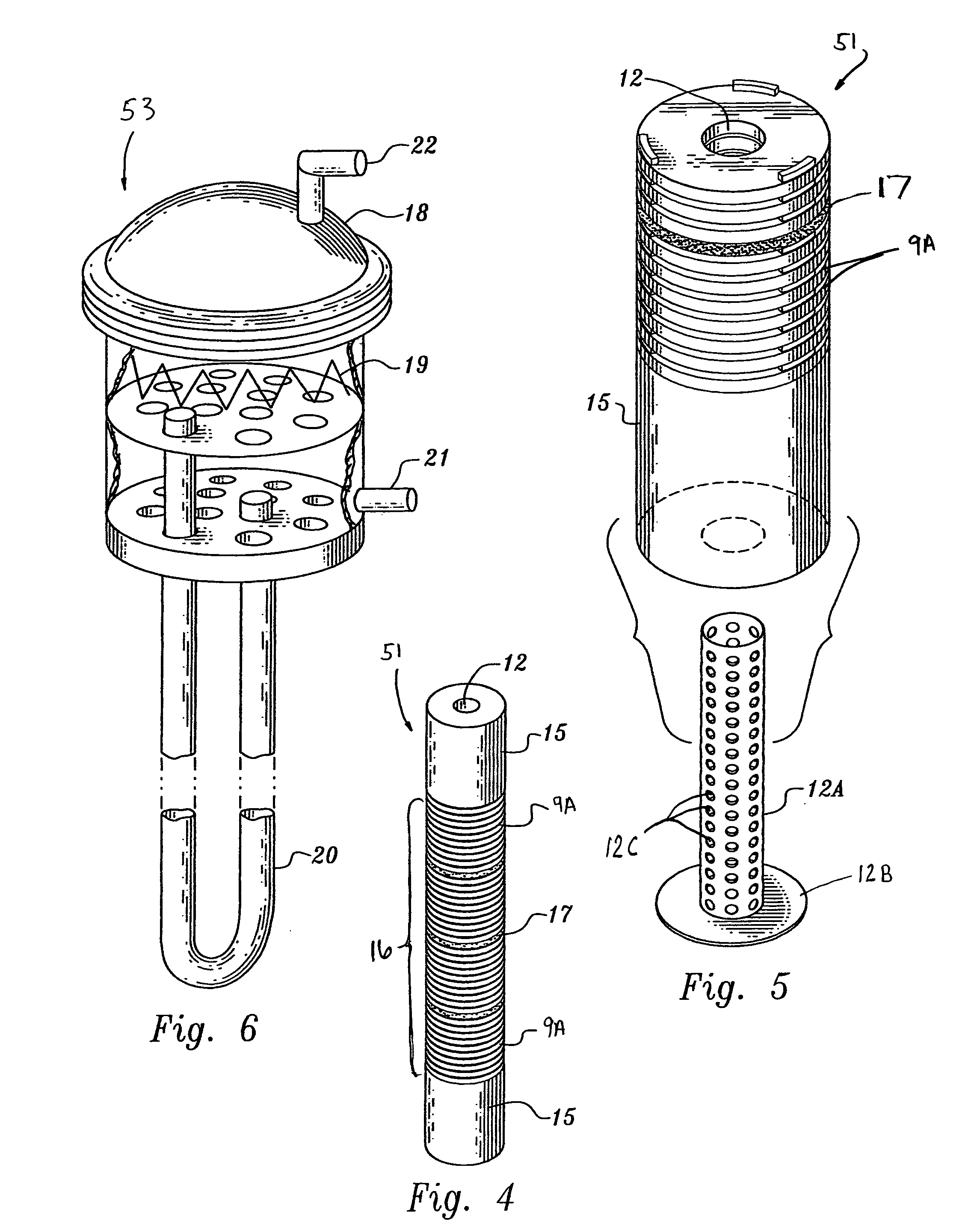

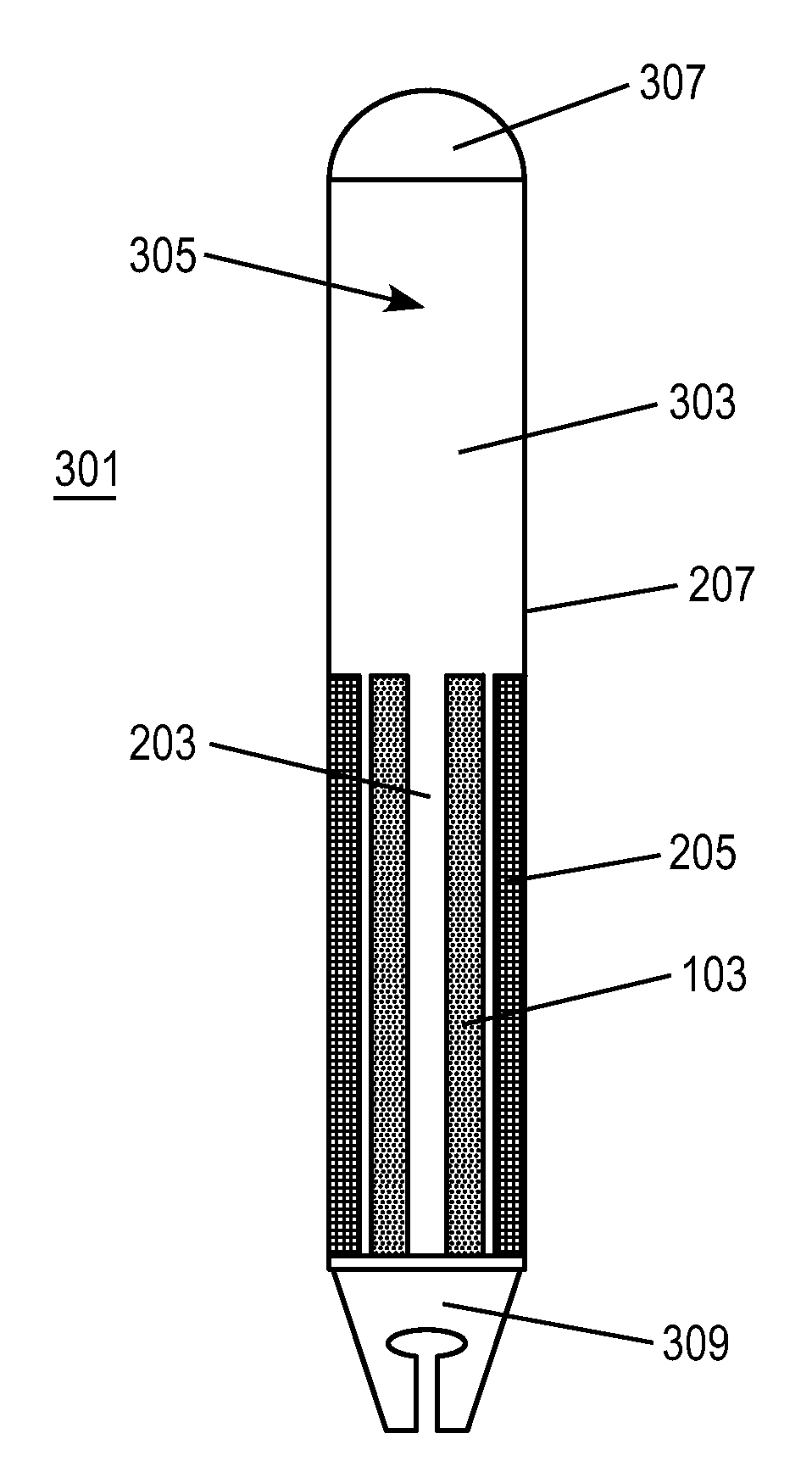

Fuel elements for nuclear reactor system

A fuel element for nuclear power generation made up of at least one coated UO2 fuel kernel embedded in a matrix containing Zr. The kernel and the element each having a coating that provides desired spacing and fission product barrier protection. The fuel enables the functioning and deployment of small scale nuclear reactors with a various features desired for deployment of such devices in developing nations, with limited electrical distribution infrastructure.

Owner:BATTELLE MEMORIAL INST

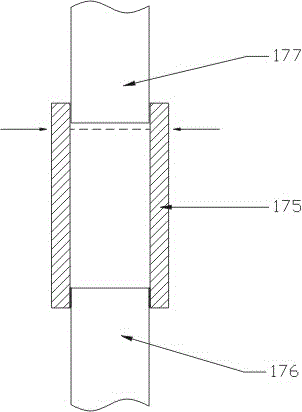

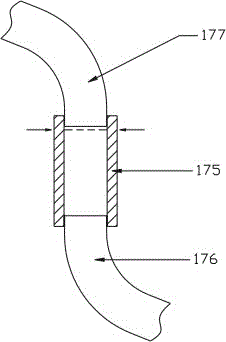

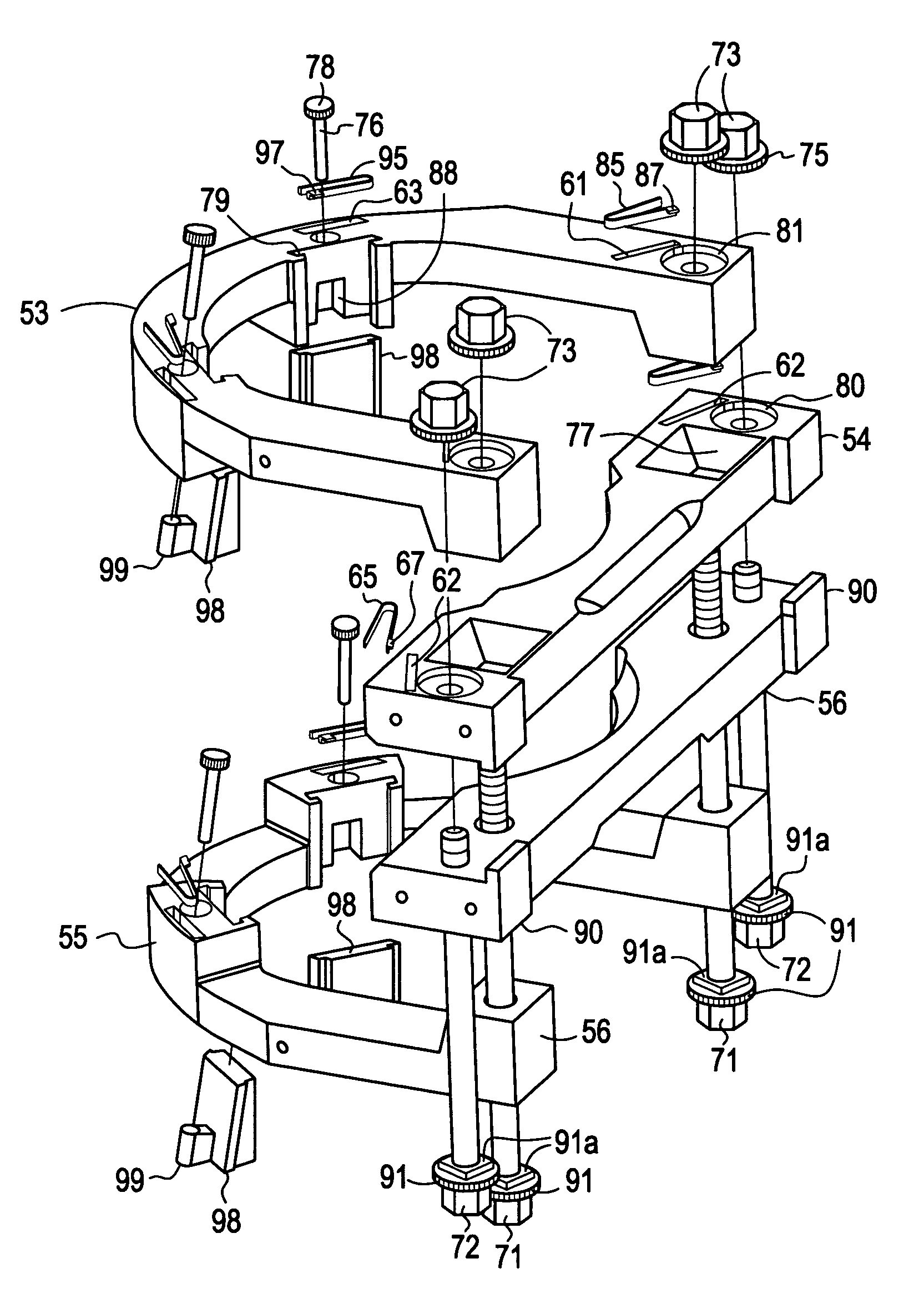

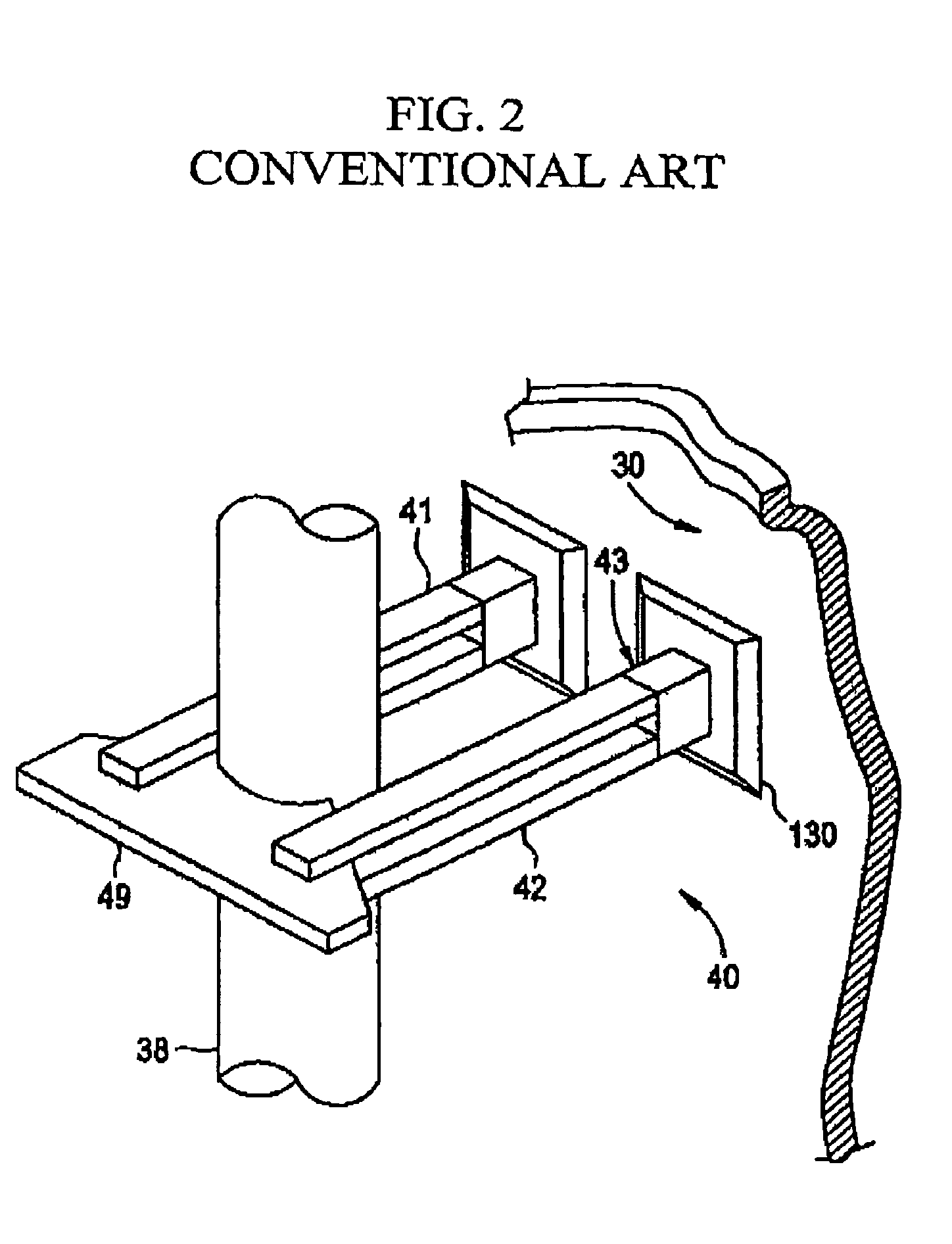

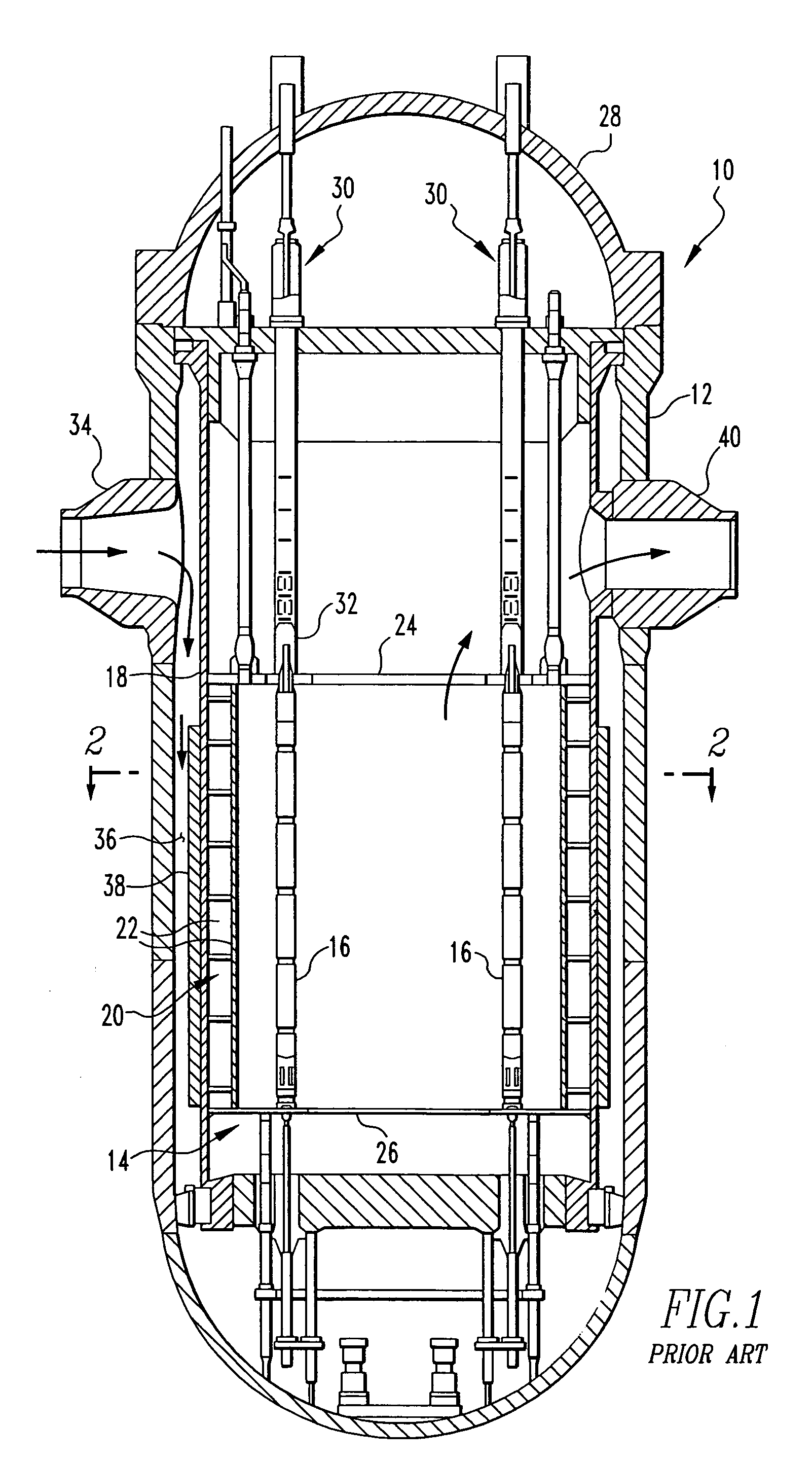

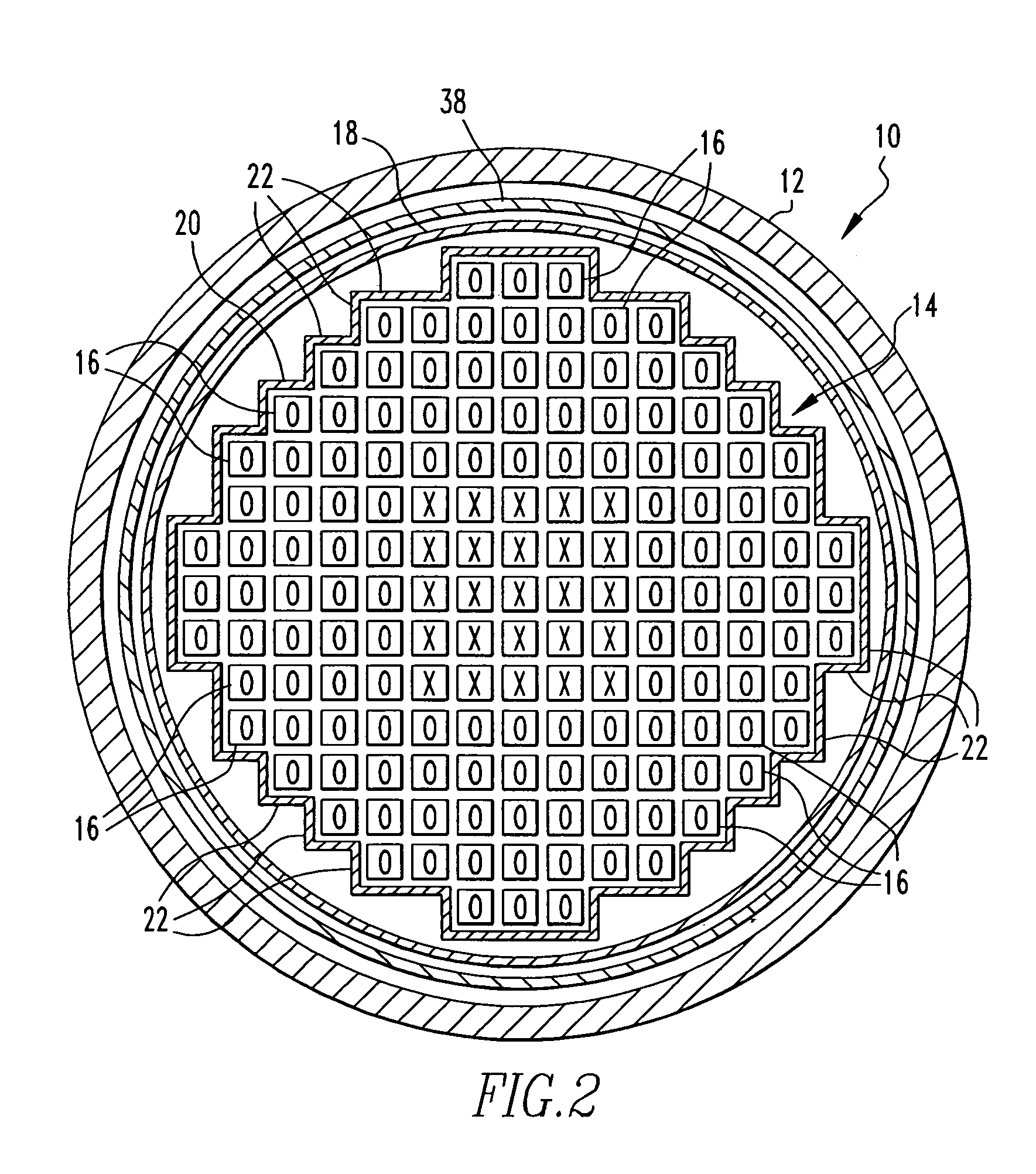

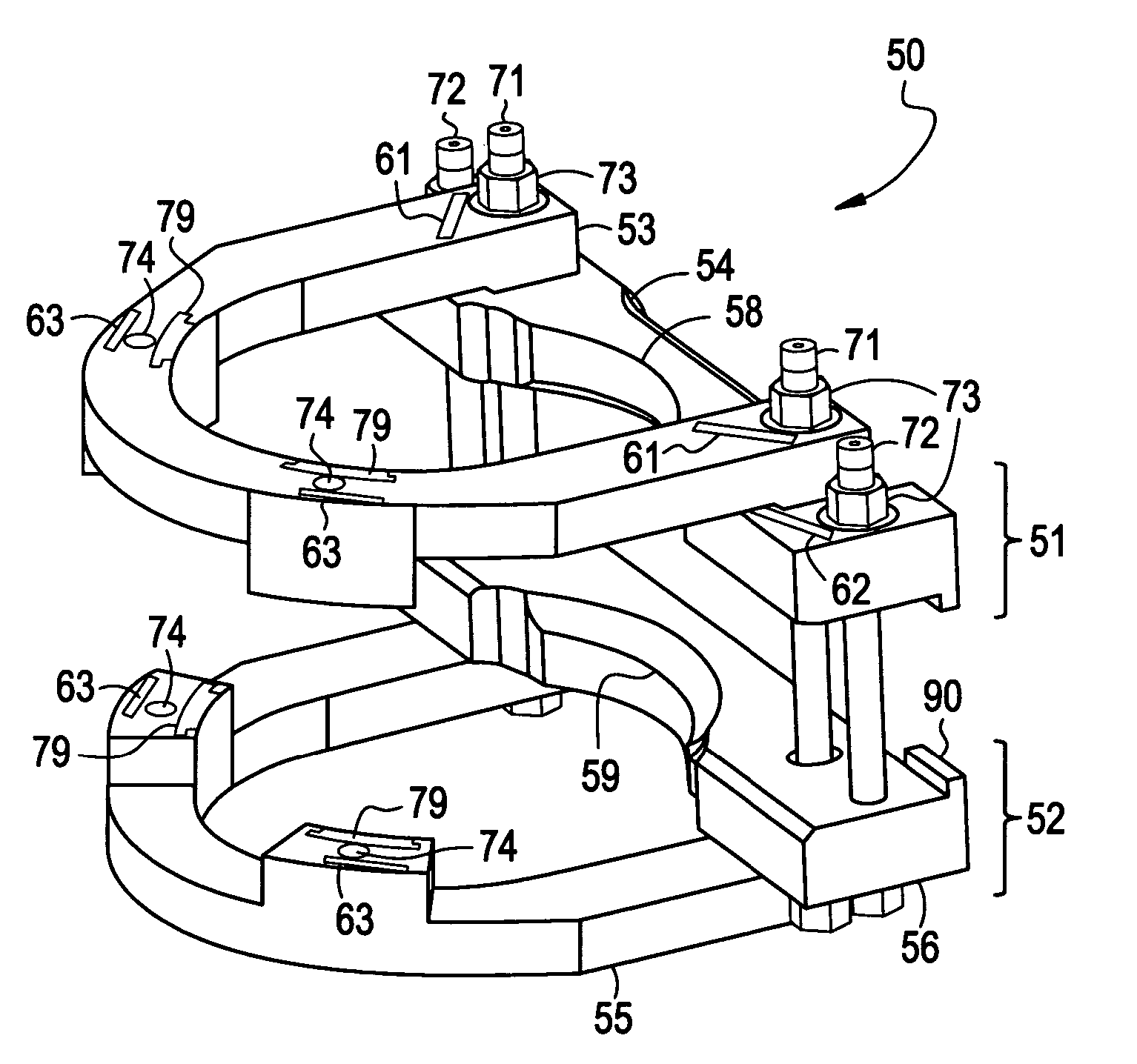

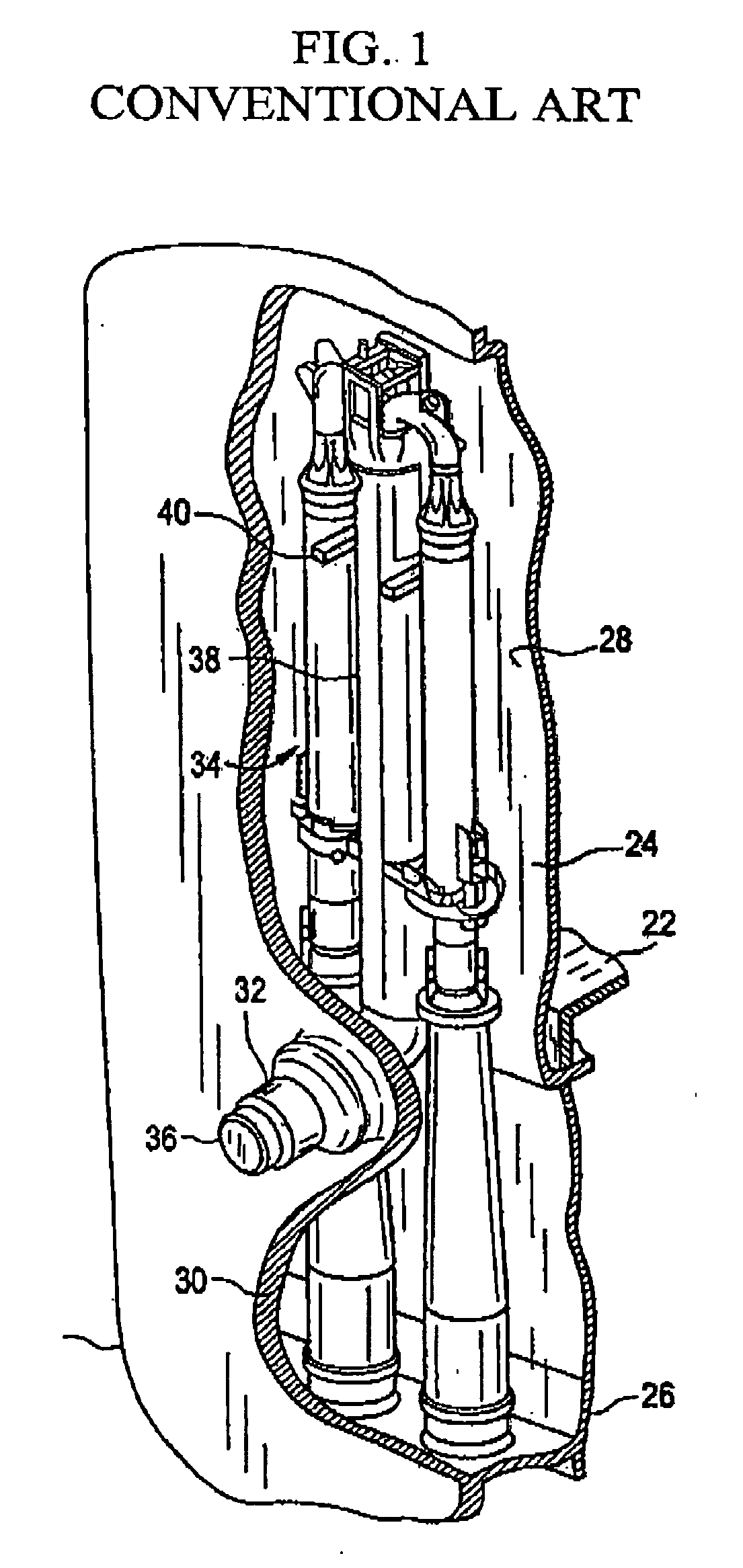

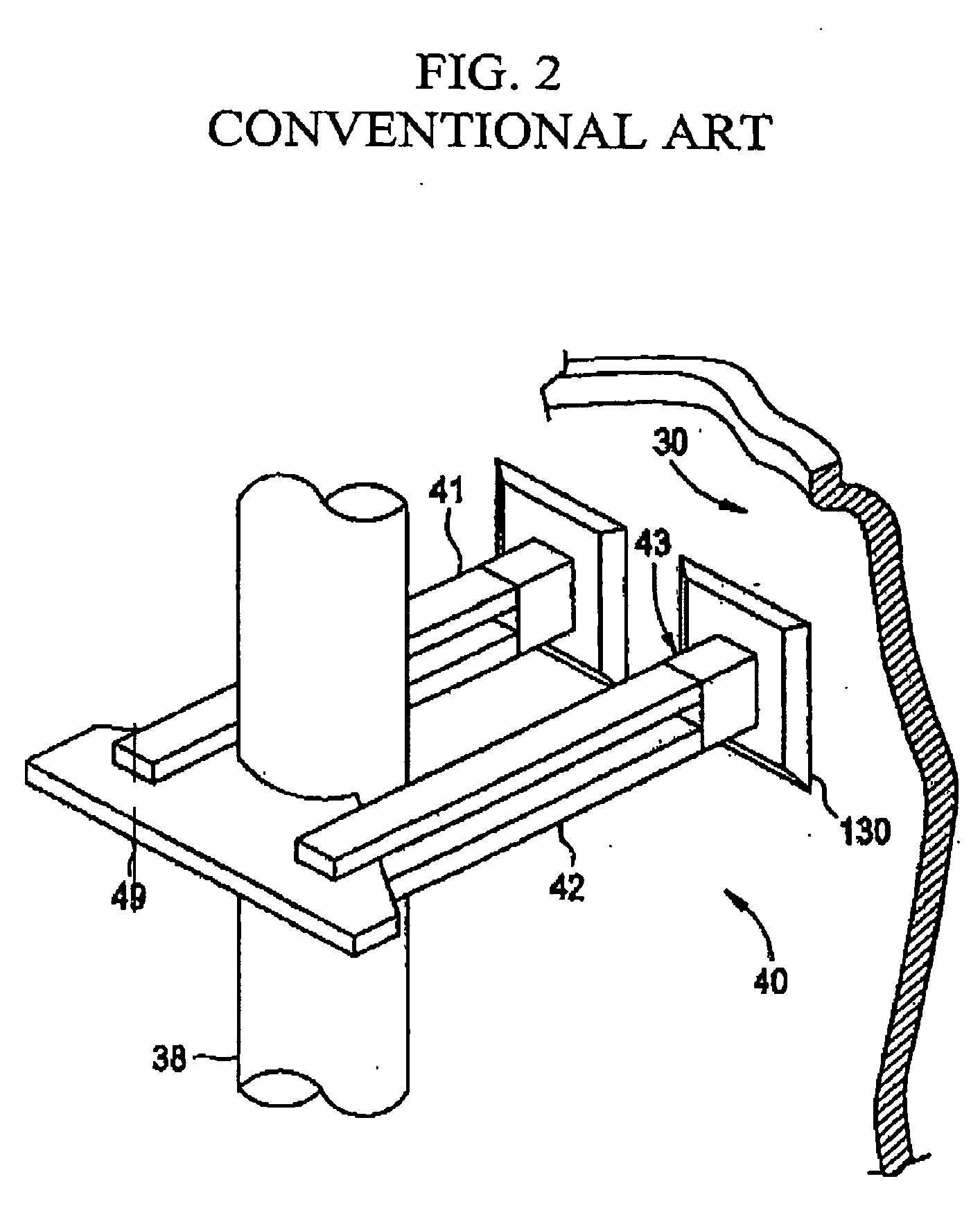

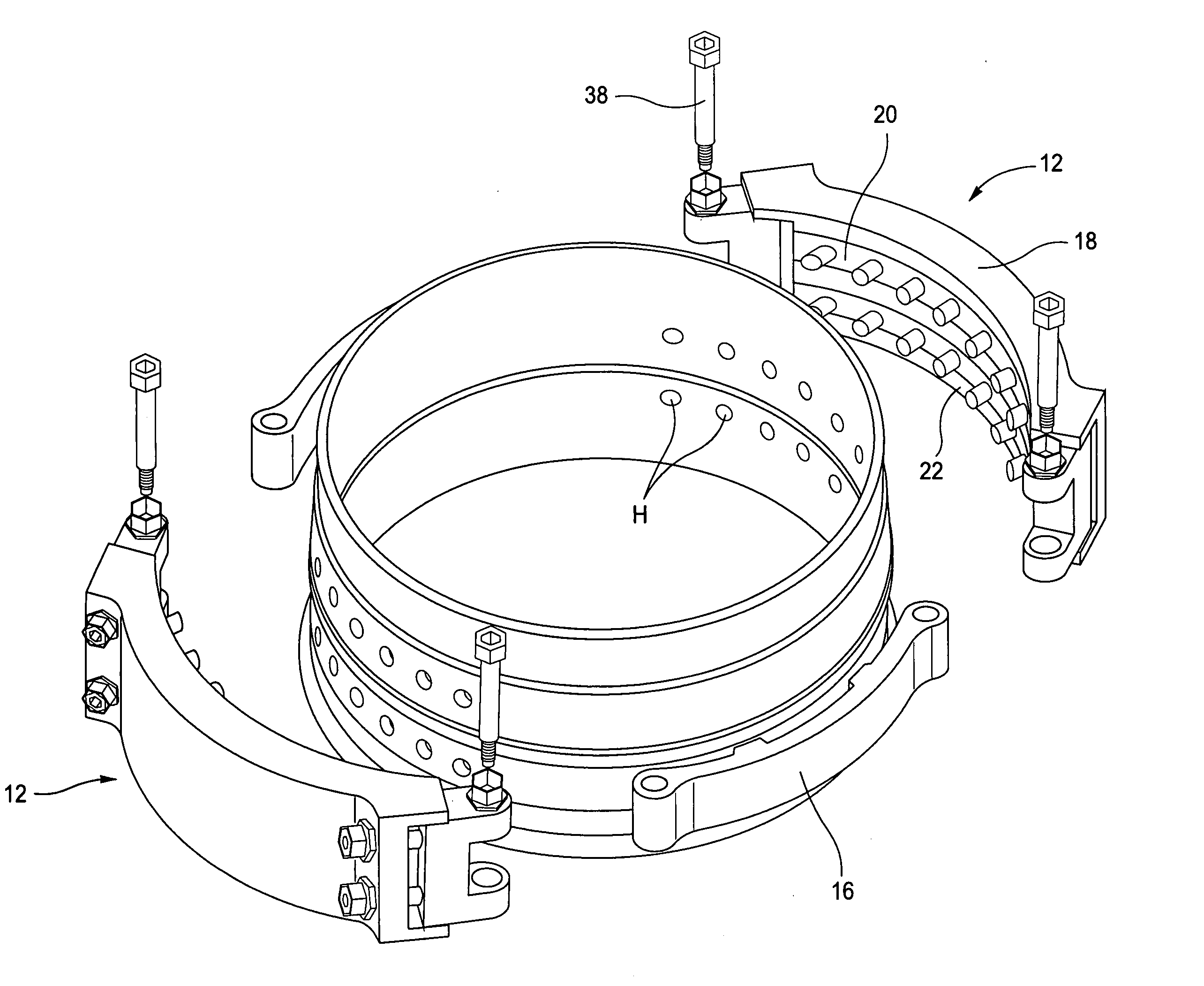

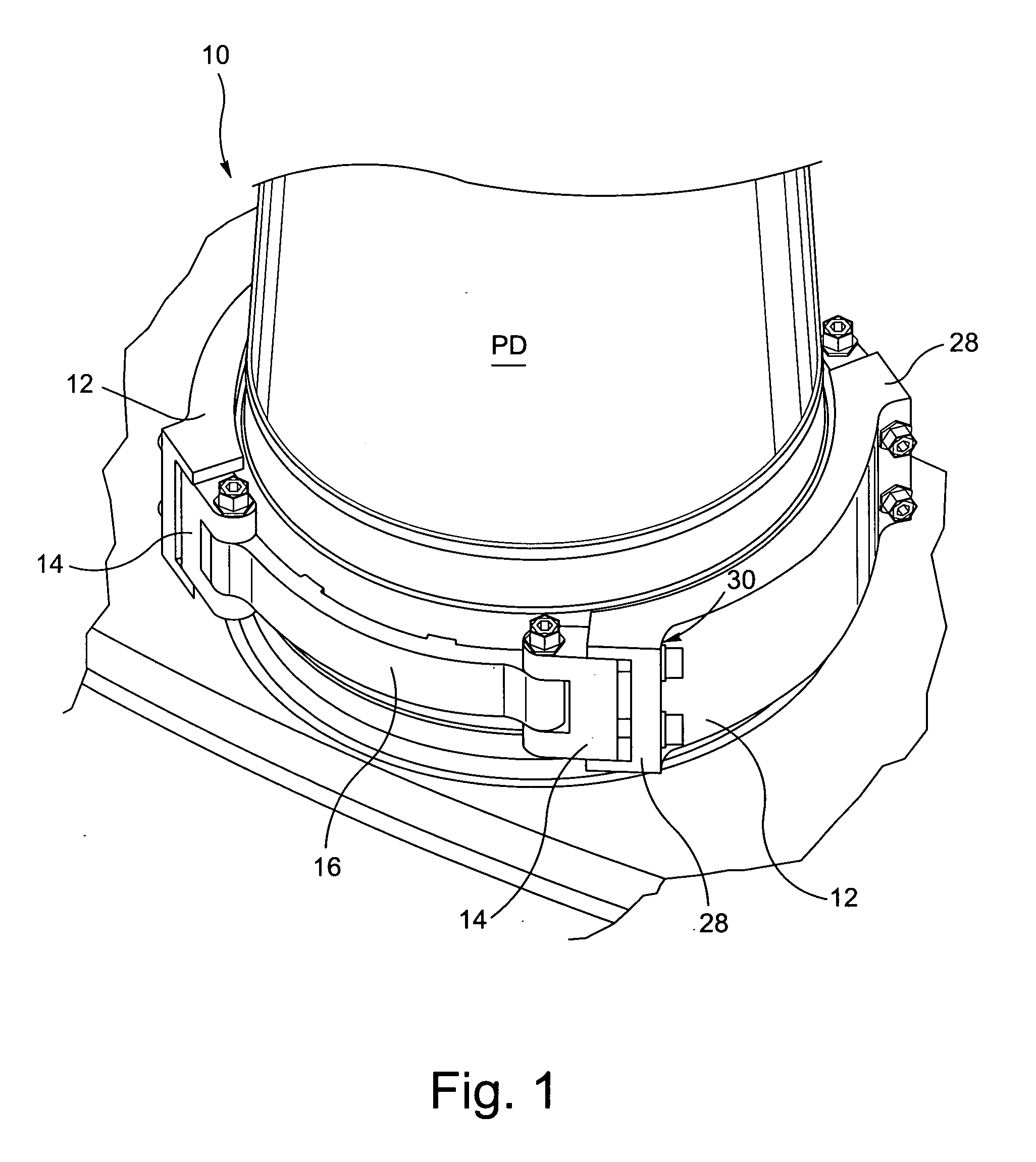

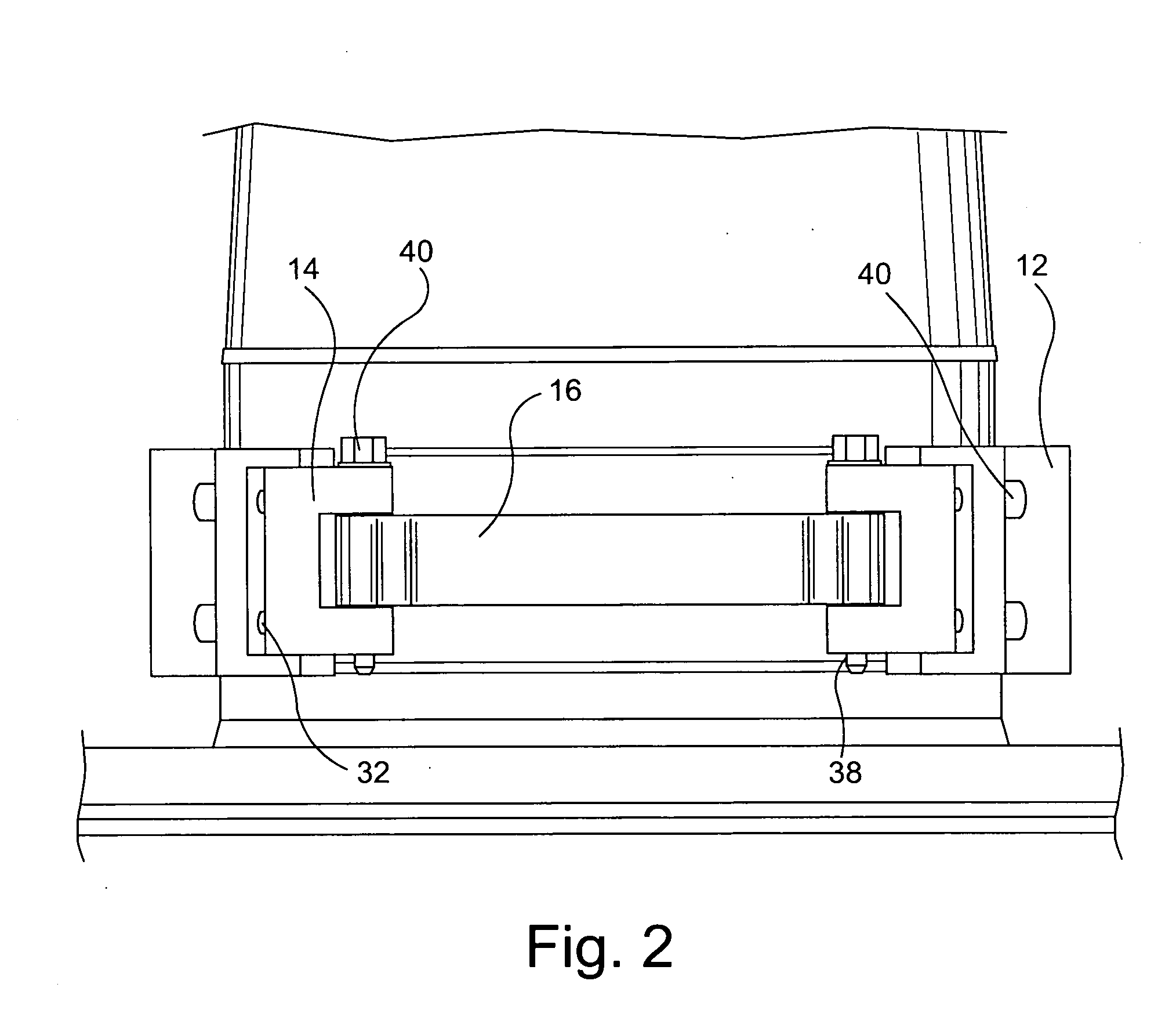

Method and apparatus for clamping a riser brace assembly in nuclear reactor

An apparatus and method are provided which are designed to structurally replace welds that attach a riser brace assembly to a jet pump riser pipe. The riser brace assembly may include an upper clamp assembly, a lower clamp assembly, and a plurality of mechanical fasteners to provide clamping forces to the upper clamp assembly and the lower clamp assembly. The upper clamp assembly and the lower clamp assembly sandwich a riser brace support, wherein the riser brace support is provided with at least one through-hole to accommodate the plurality of mechanical fasteners.

Owner:GENERAL ELECTRIC CO

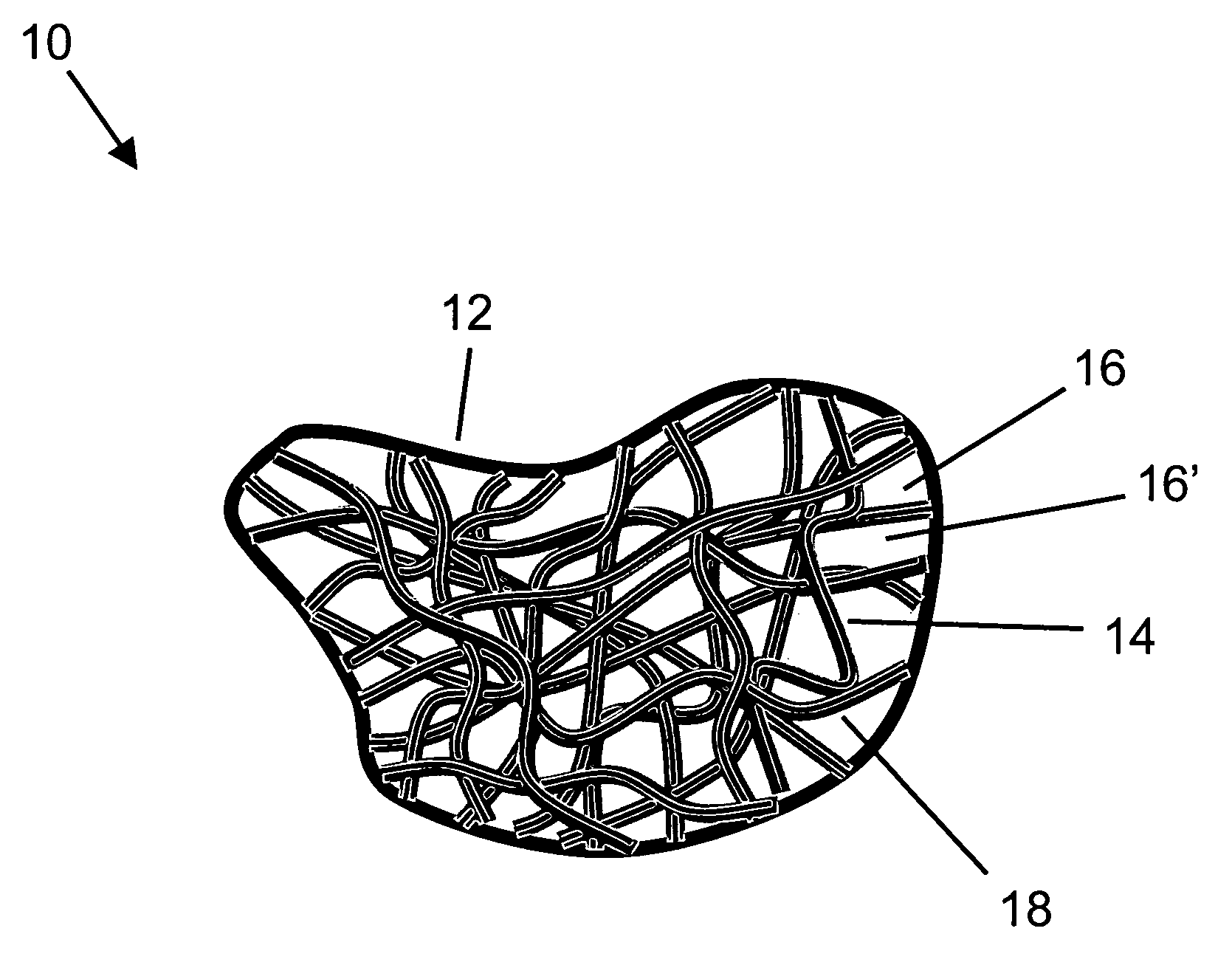

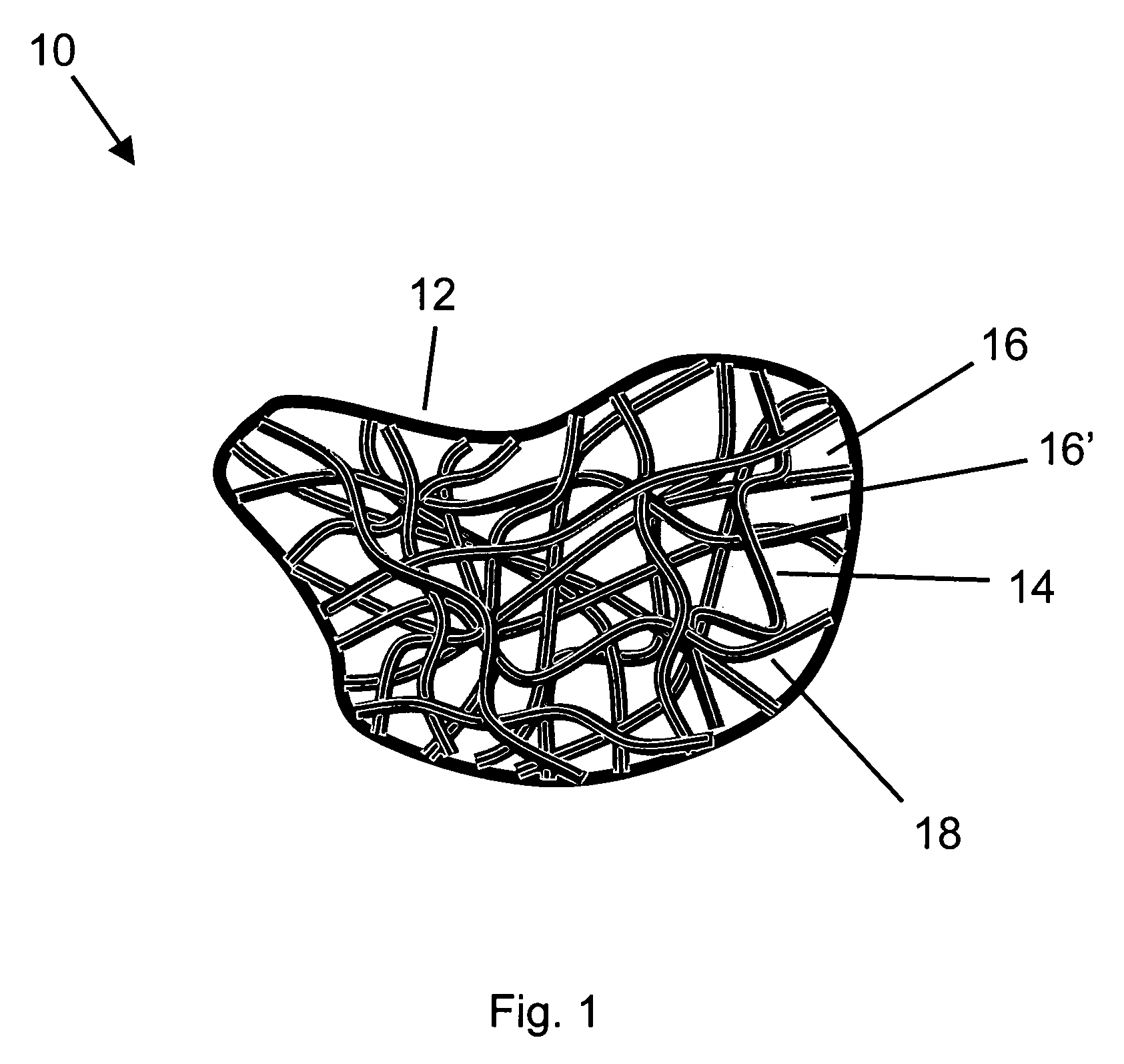

Methods for manufacturing porous nuclear fuel elements for high-temperature gas-cooled nuclear reactors

Methods for manufacturing porous nuclear fuel elements for use in advanced high temperature gas-cooled nuclear reactors (HTGR's). Advanced uranium bi-carbide, uranium tri-carbide and uranium carbonitride nuclear fuels can be used. These fuels have high melting temperatures, high thermal conductivity, and high resistance to erosion by hot hydrogen gas. Tri-carbide fuels, such as (U,Zr,Nb)C, can be fabricated using chemical vapor infiltration (CVI) to simultaneously deposit each of the three separate carbides, e.g., UC, ZrC, and NbC in a single CVI step. By using CVI, a thin coating of nuclear fuel may be deposited inside of a highly porous skeletal structure made, for example, of reticulated vitreous carbon foam.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Reactor tray vertical geometry with vitrified waste control

InactiveUS20050069075A1Reduce riskReduce the amount of wasteConversion outside reactor/acceleratorsNuclear energy generationVitrificationThermal energy

A nuclear-powered plant for systems of up to about 100 MWs with a confinement section where the reaction takes place in a core having a reactive thorium / uranium-233 composition, and where an external neutron source is used as a modulated neutron multiplier for the reactor core output. The core is housed in a containment structure that radiates thermal energy captured in a multiple-paths heat exchanger. The exchanger heat energy output is put to use in a conventional gas-to-water heat exchanger to produce commercial quality steam.

Owner:D B I CENTURY FUELS & AEROSPACE SERVICES

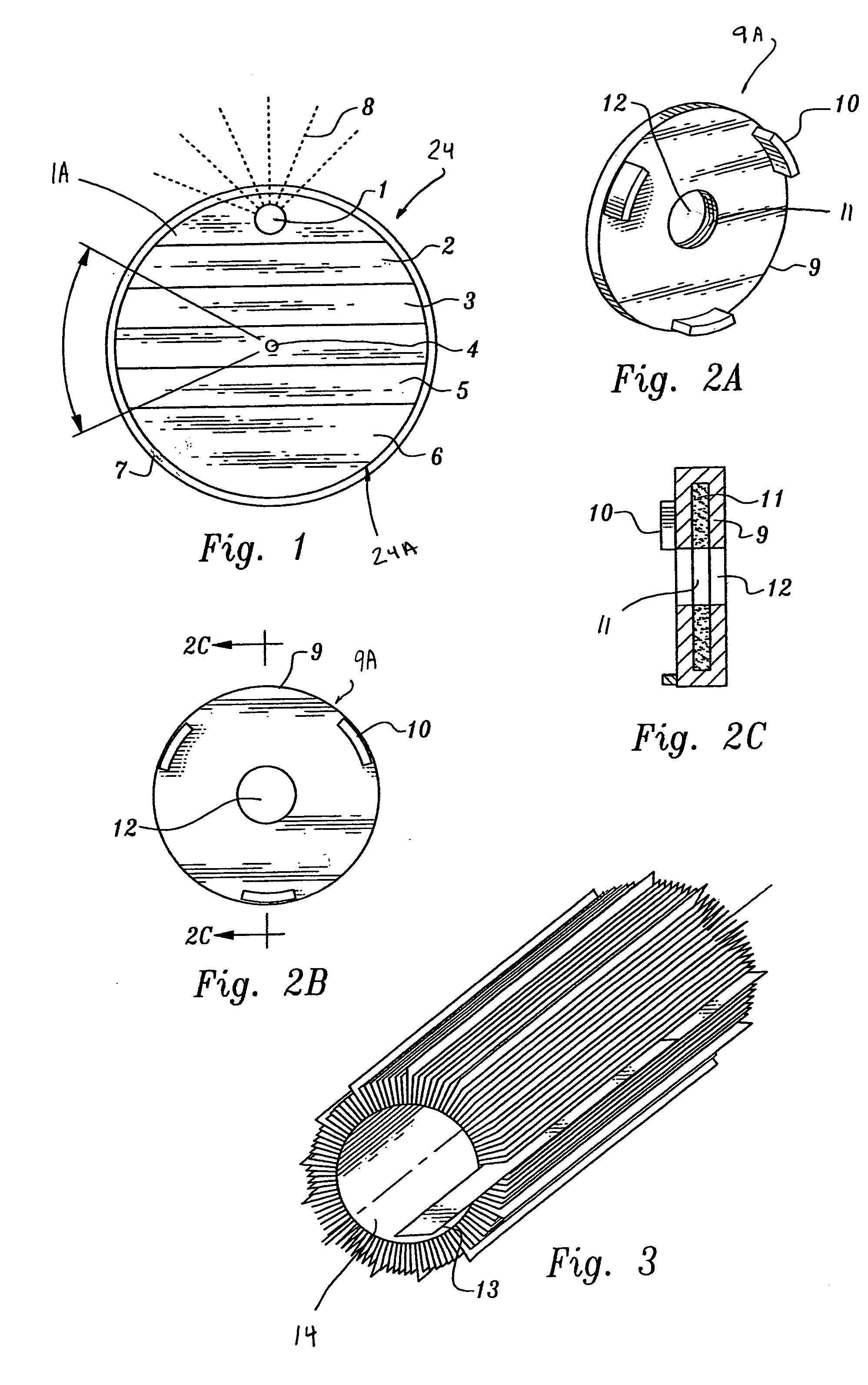

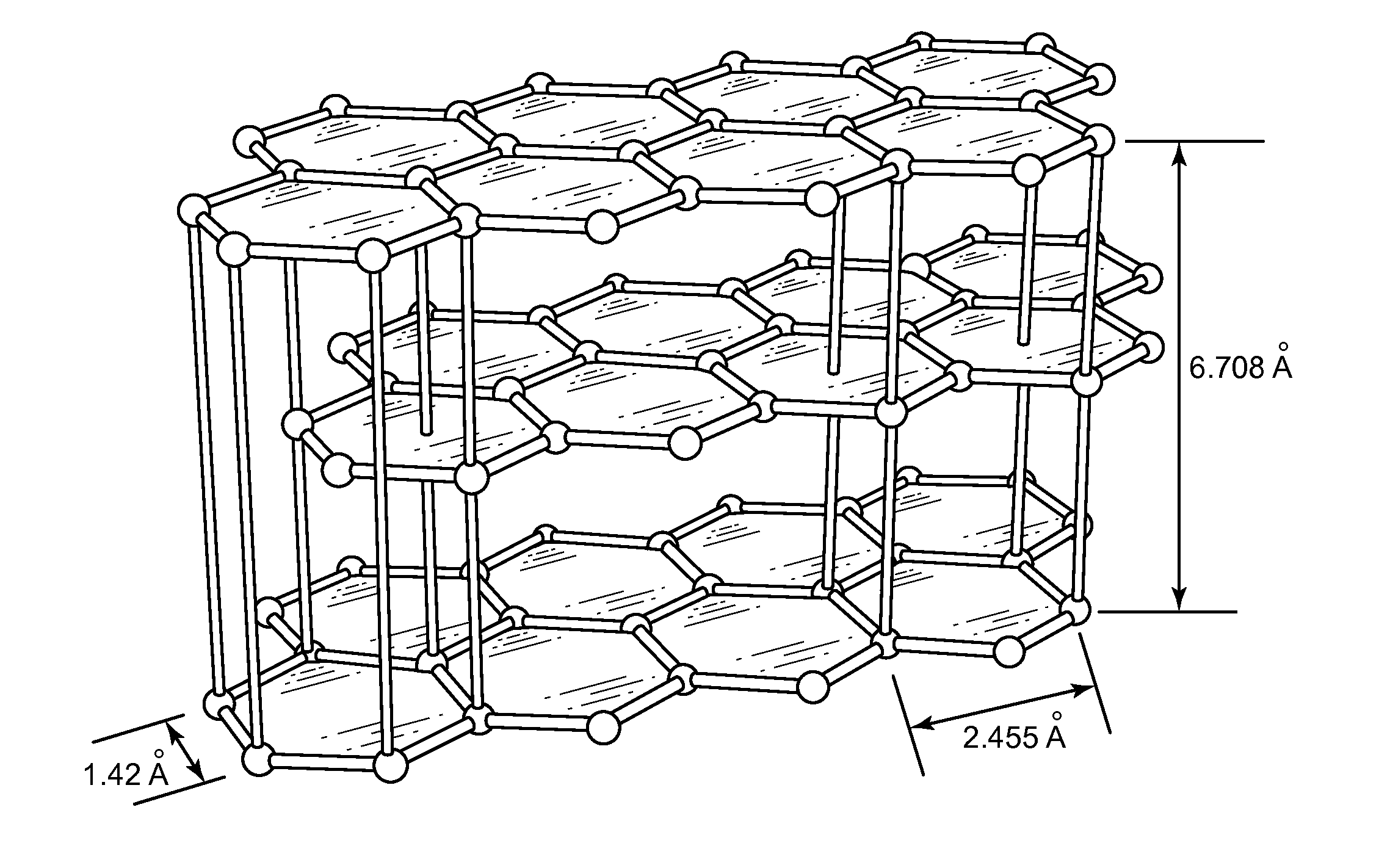

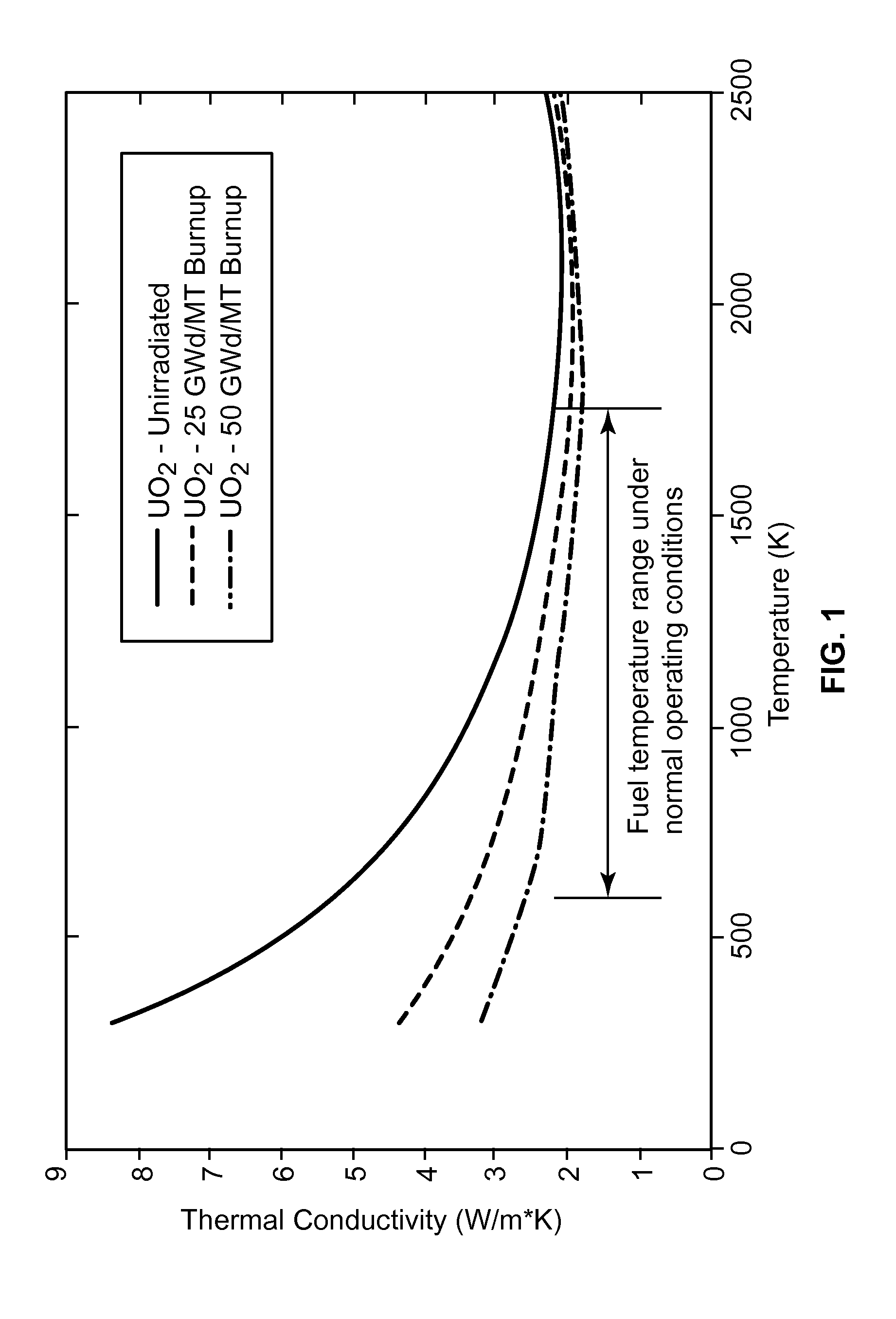

Composite nuclear fuel pellet

InactiveUS20120183116A1Improve thermal conductivityNuclear energy generationReactors manufactureMetallurgySolvent

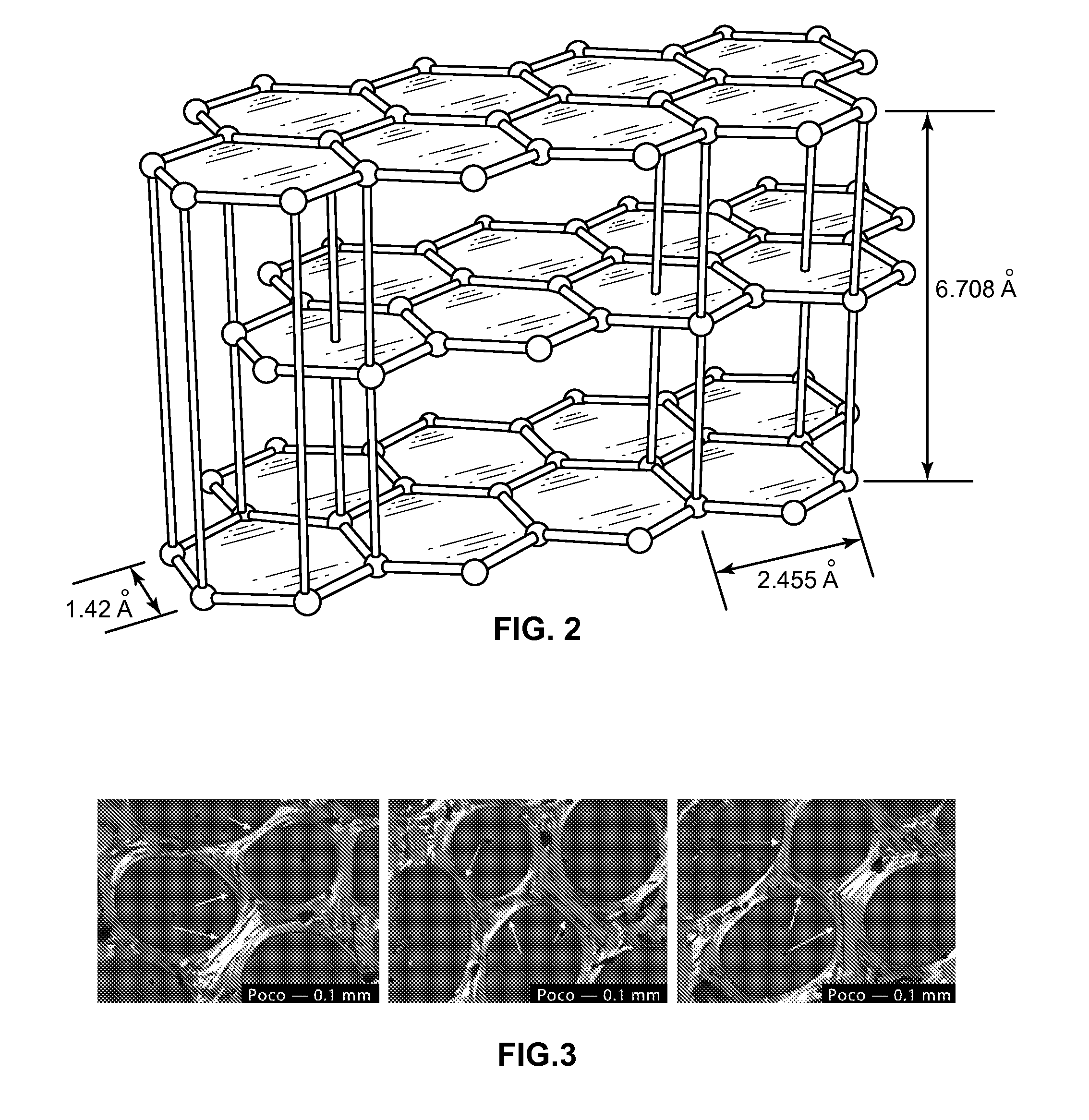

A composite nuclear fuel pellet comprises a composite body including a UO2 matrix and a plurality of high aspect ratio particies dispersed therein, where the high aspect ratio particies have a thermal conductivity higher than that of the UO2 matrix. A method of making a composite nuclear fuel pellet includes combining UO2 powder with a predetermined amount of high aspect ratio particles to form a combined powder, the high aspect ratio particles having a thermal conductivity higher than that of the UO2 powder; mixing the combined powder in a solvent to disperse the high aspect ratio particles in the UO2 powder; evaporating the solvent to form a dry mixture comprising the high aspect ratio particles dispersed in the UO2 powder; pressing the dry mixture to form a green body; and sintering the green body to form the composite fuel pellet.

Owner:UT BATTELLE LLC

Use of boron or enriched boron 10 in UO2

InactiveUS7139360B2Low parasitic cross-sectionAvoid problemsNuclear energy generationFuel element assembliesBoron containingCarbide

The present invention provides a nuclear fuel assembly, where a boron-containing compound is used as a burnable poison and is distributed in a majority of the rods in the assembly. The assembly comprises a plurality of fuel rods, each fuel rod containing a plurality of nuclear fuel pellets, wherein at least one fuel pellet in more than 50% of the fuel rods in the fuel assembly comprises a sintered admixture of a metal oxide, metal carbide or metal nitride and a boron-containing compound.

Owner:WESTINGHOUSE ELECTRIC CORP

Method and apparatus for clamping a riser brace assembly in nuclear reactor

An apparatus and method are provided which are designed to structurally replace welds that attach a riser brace assembly to a jet pump riser pipe. The riser brace assembly may include an upper clamp assembly, a lower clamp assembly, and a plurality of mechanical fasteners to provide clamping forces to the upper clamp assembly and the lower clamp assembly. The upper clamp assembly and the lower clamp assembly sandwich a riser brace support, wherein the riser brace support is provided with at least one through-hole to accommodate the plurality of mechanical fasteners.

Owner:GENERAL ELECTRIC CO

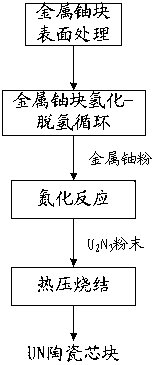

Preparation method of uranium nitride fuel powder and pellet

ActiveCN103466568AHigh purityHigh sintering activityNuclear energy generationNitrogen-metal/silicon/boron binary compoundsSurface cleaningDehydrogenation

The invention relates to a preparation method of uranium nitride fuel powder and a pellet, which comprises the following steps: (1) carrying out surface cleaning treatment on a pure metal uranium lump; (2) hydrogenating the pure metal uranium lump in hydrogen at 150-300 DEG C for 2-16 hours, dehydrogenating in a vacuum, and repeating the hydrogenation-dehydrogenation several times to obtain metal uranium powder; (3) nitridizing the metal uranium powder in nitrogen at 200-600 DEG C for 6-24 hours to obtain U2N3 powder; (4) denitrifying the U2N3 powder in a mold, keeping the system vacuum, pressurizing the mold to 30-60 MPa, sintering at 1450-1620 DEG C for 1-2 hours, and cooling to obtain the UN ceramic pellet. The method provided by the invention is simple in technique and easy to control; and the obtained intermediate product U2N3 powder has higher purity and higher sintering activity, and can be finally subjected to hot pressed sintering to obtain the UN fuel pellet of which the TD is up to 98.9%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

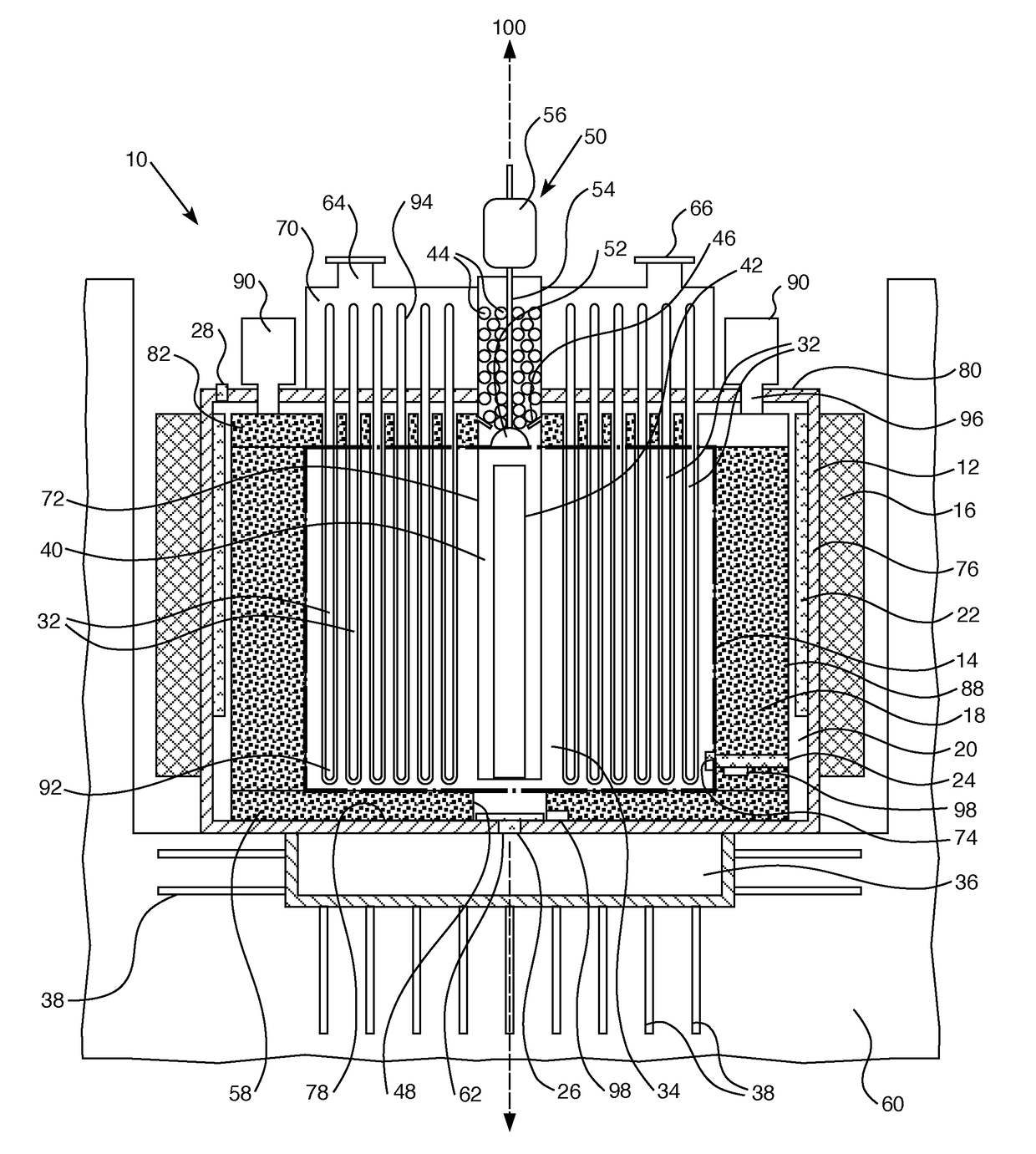

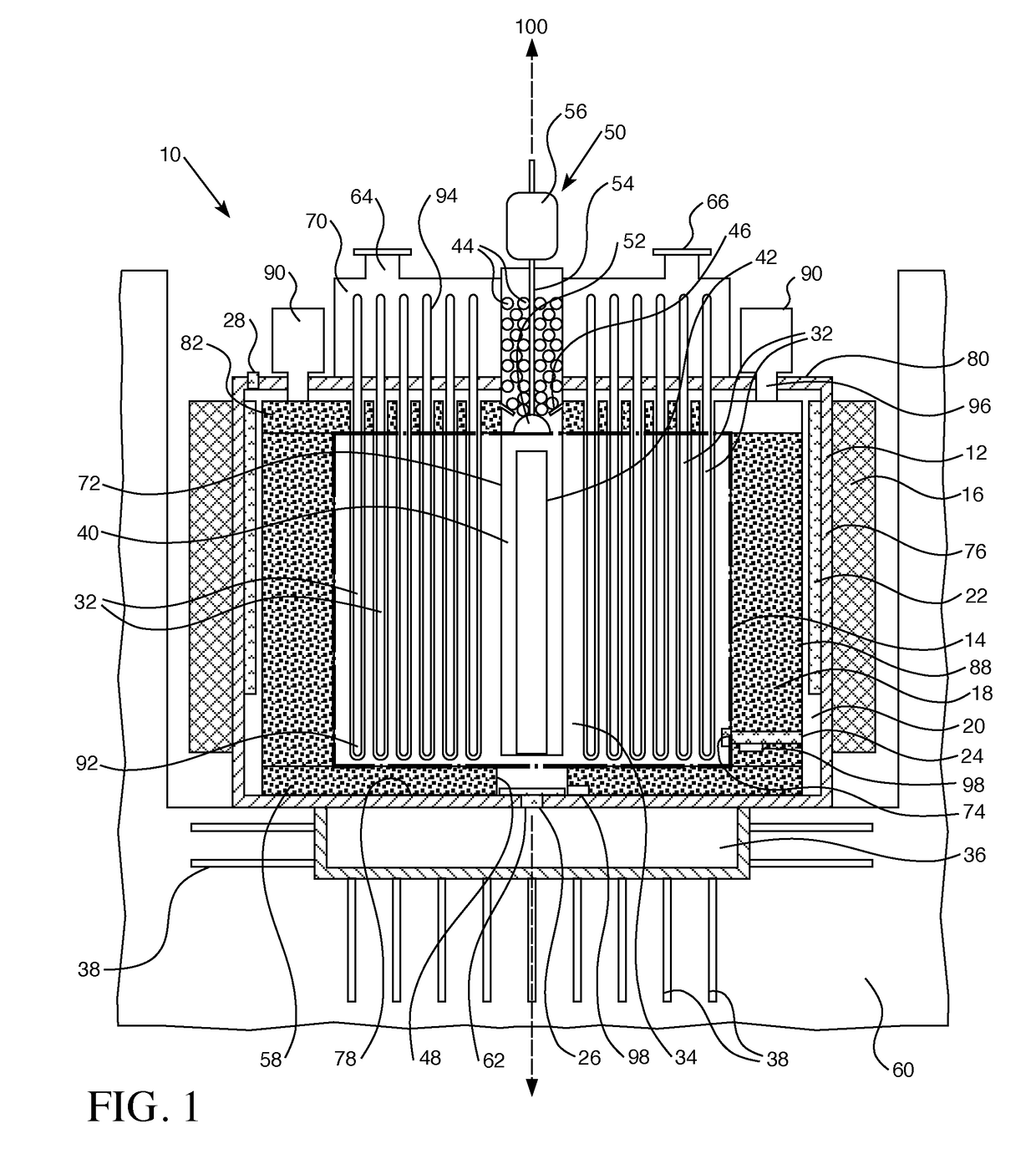

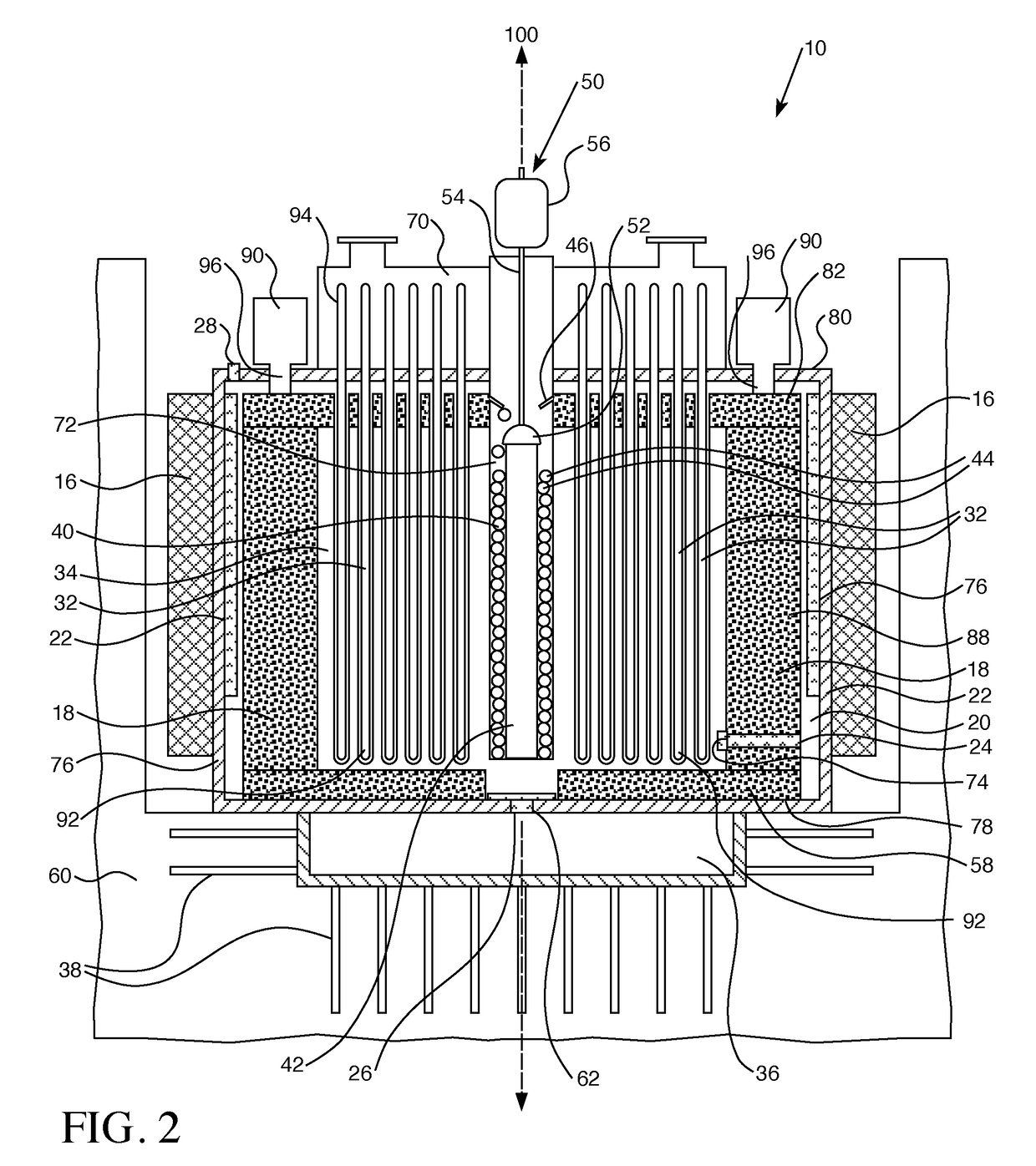

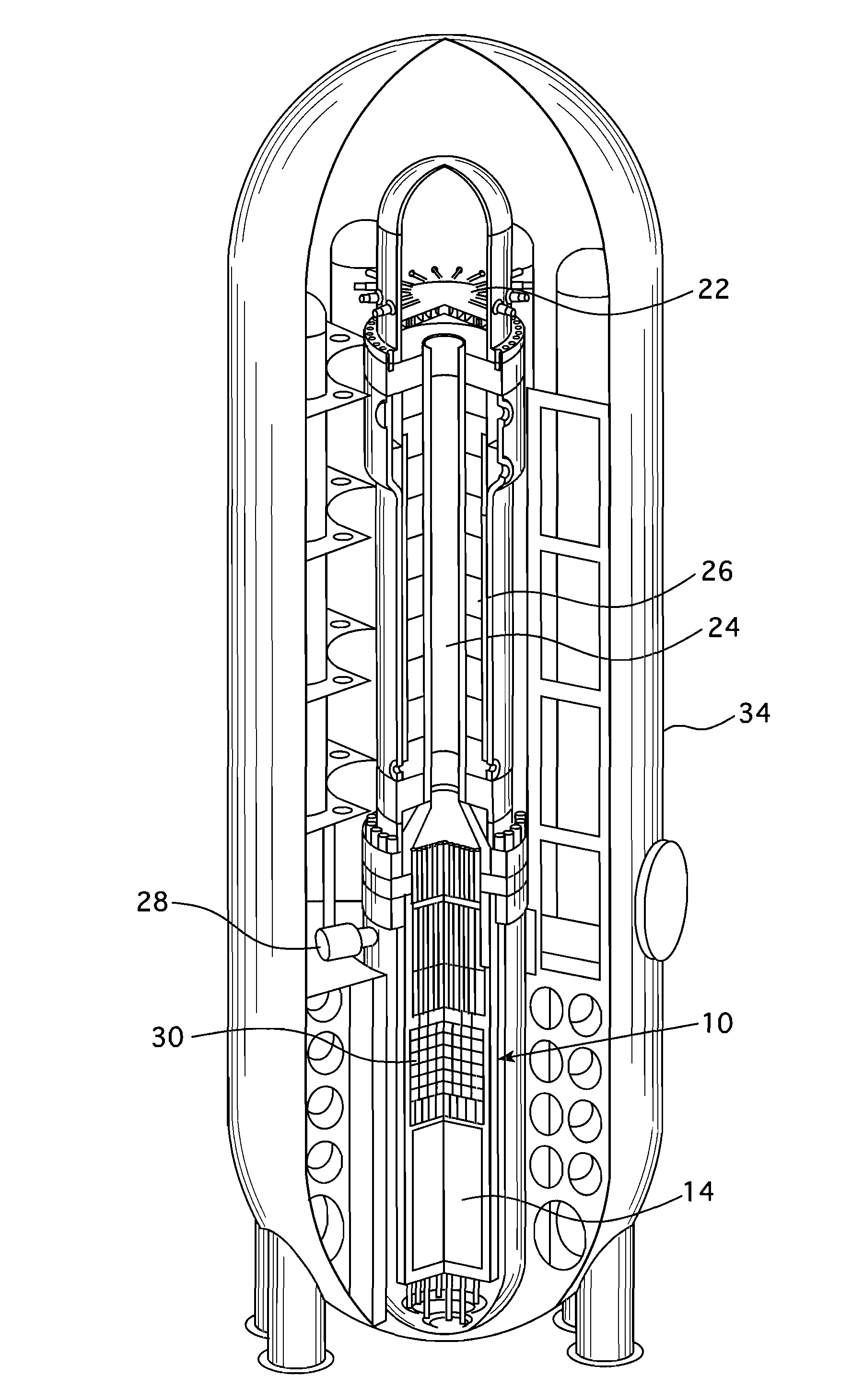

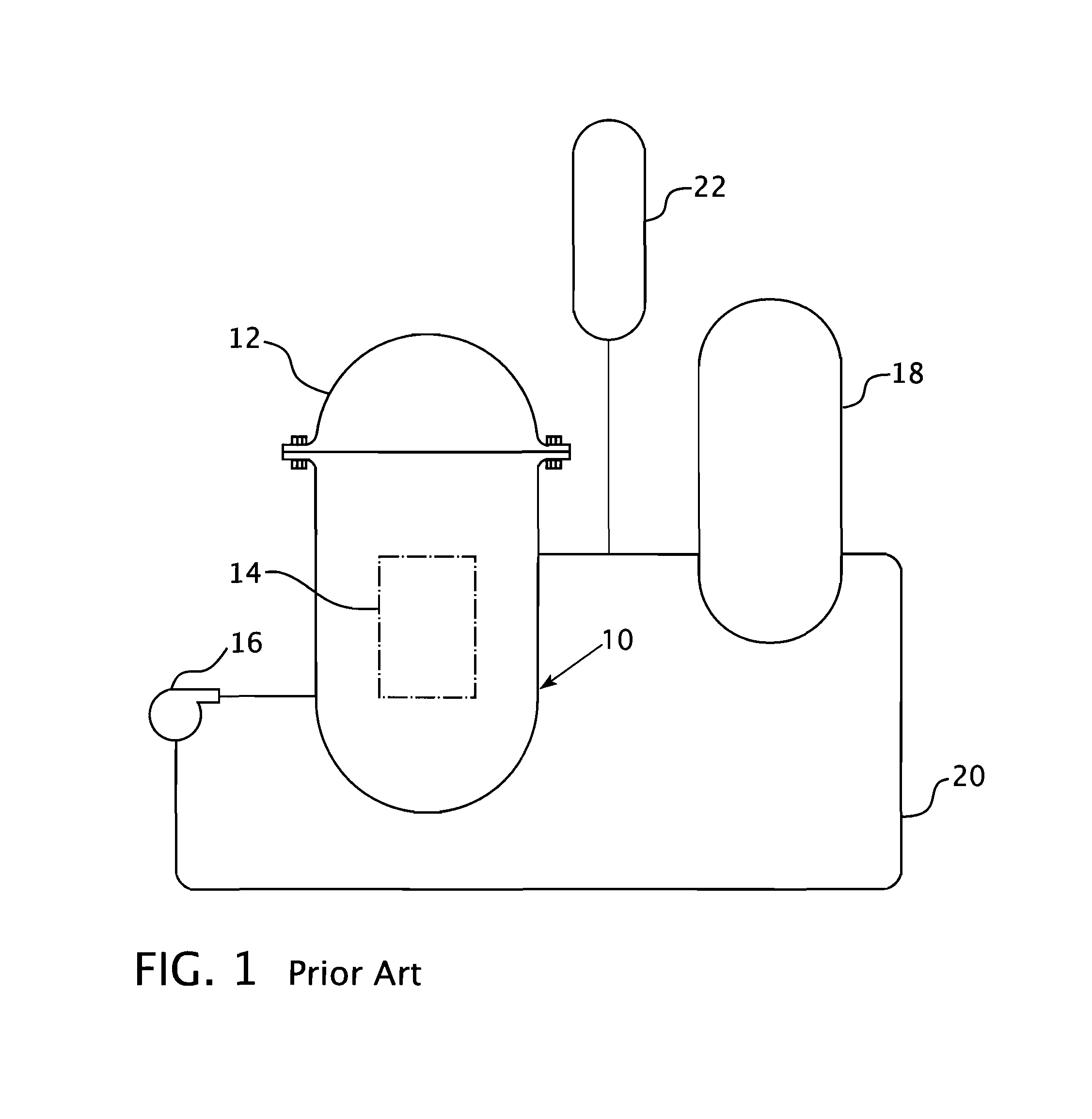

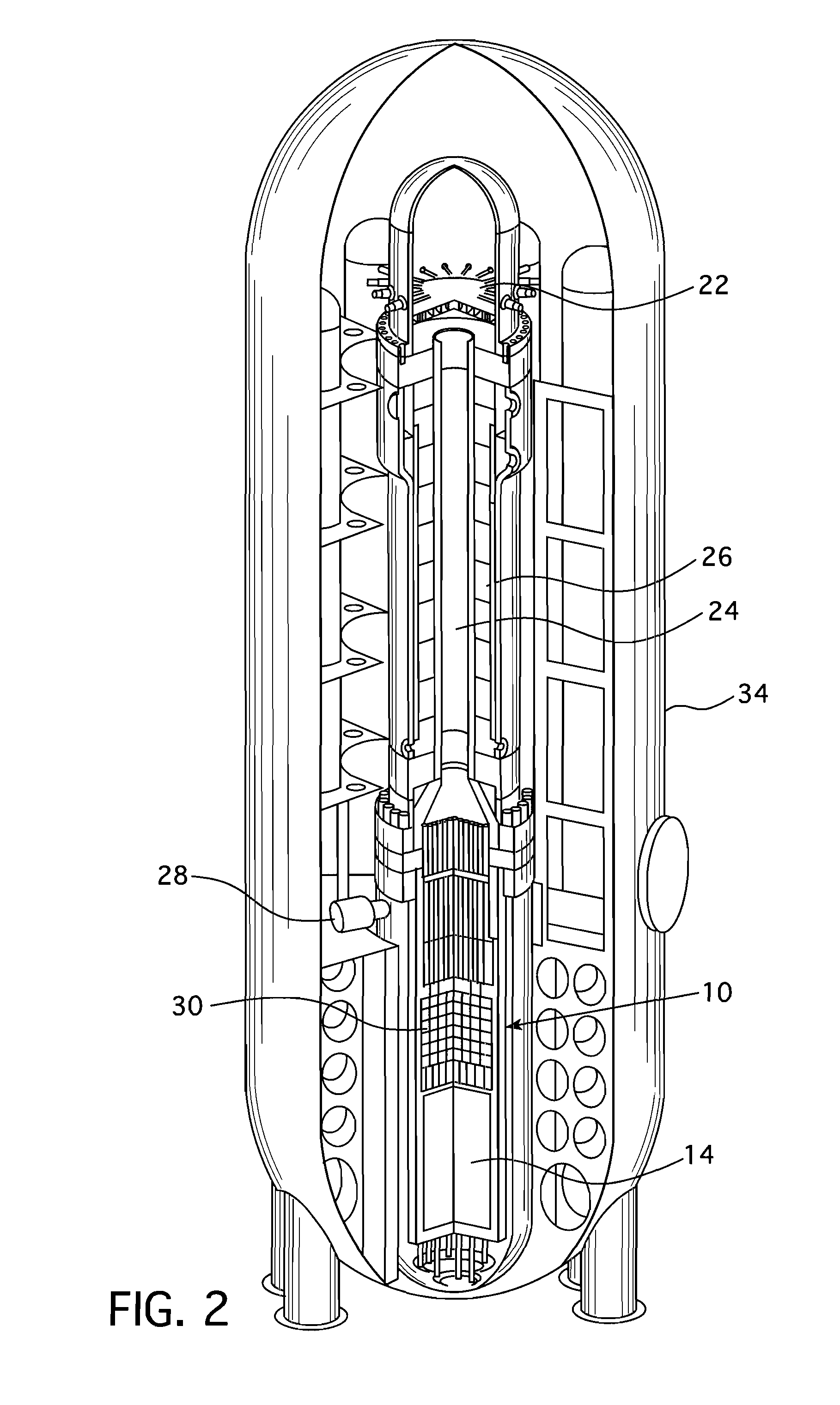

Pressurized water reactor compact steam generator

ActiveUS20130336442A1Facilitate natural recirculation of recirculatingBoiler drums/headersIntegral reactorsPressurized water reactorSteam drum

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

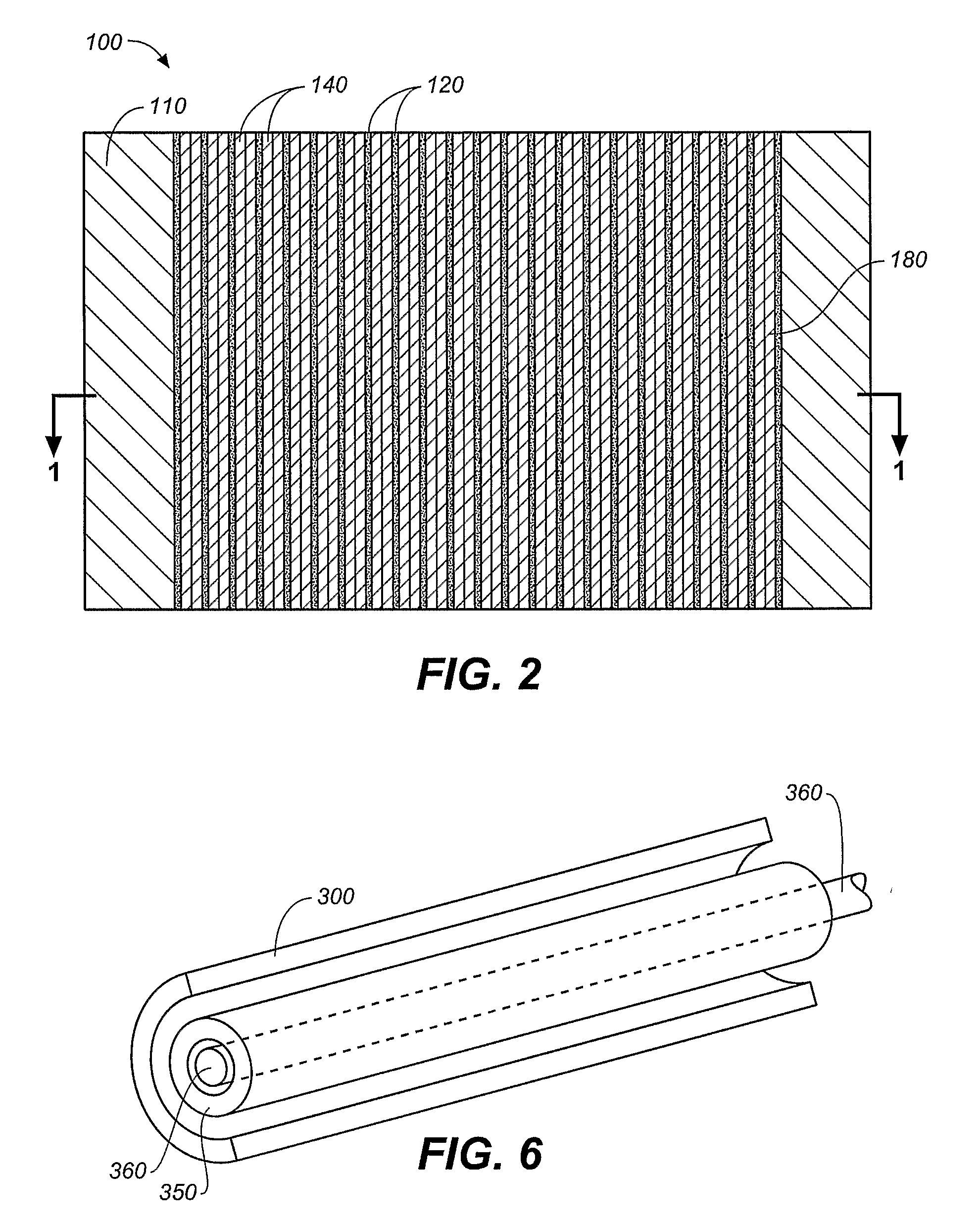

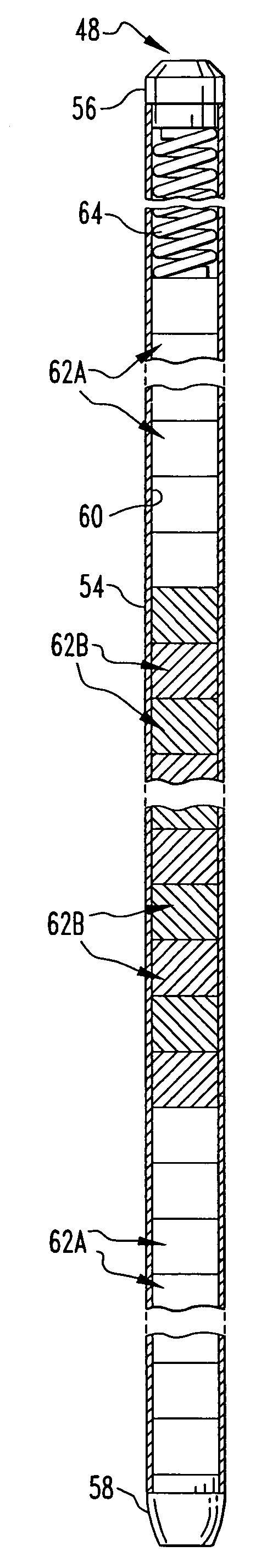

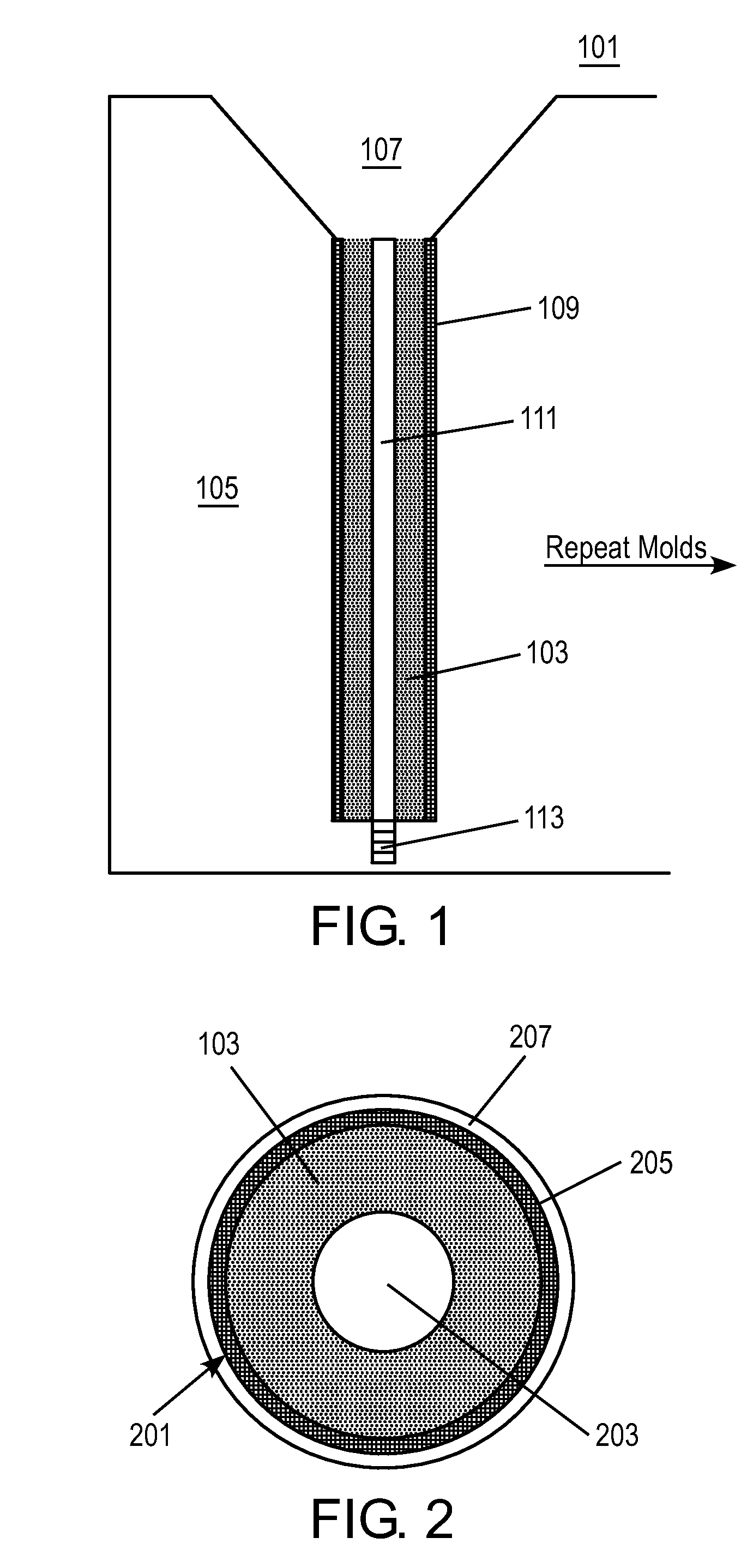

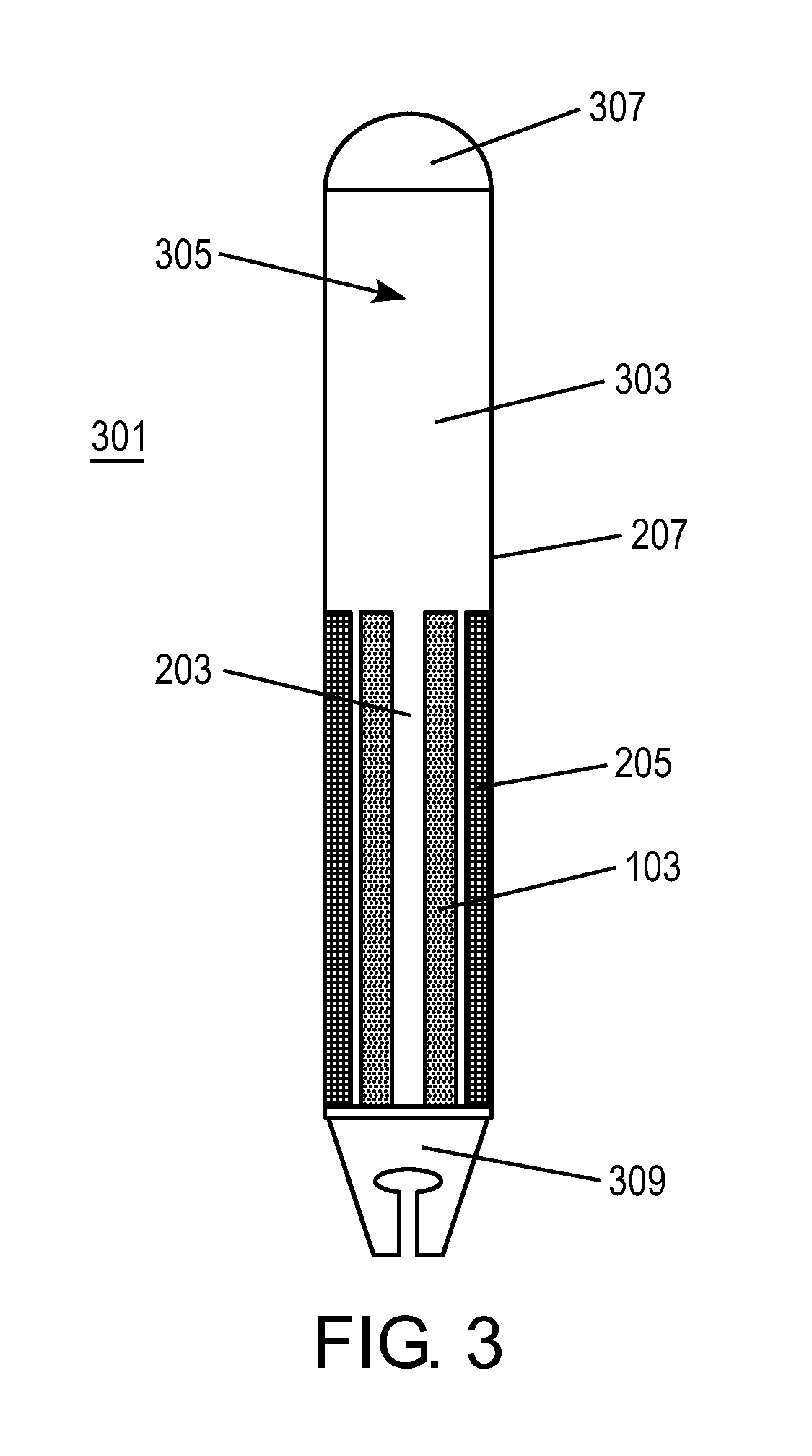

Sheathed, annular metal nuclear fuel

A sheathed, annular metal fuel system is described. A metal fuel pin system is described that includes an annular metal nuclear fuel alloy. A sheath may surround the metal nuclear fuel alloy, and a cladding may surround the sheath. A gas plenum may also be present. Mold arrangements and methods of fabrication of the sheathed, annular metal fuel are also described.

Owner:ADVANCED REACTOR CONCEPTS

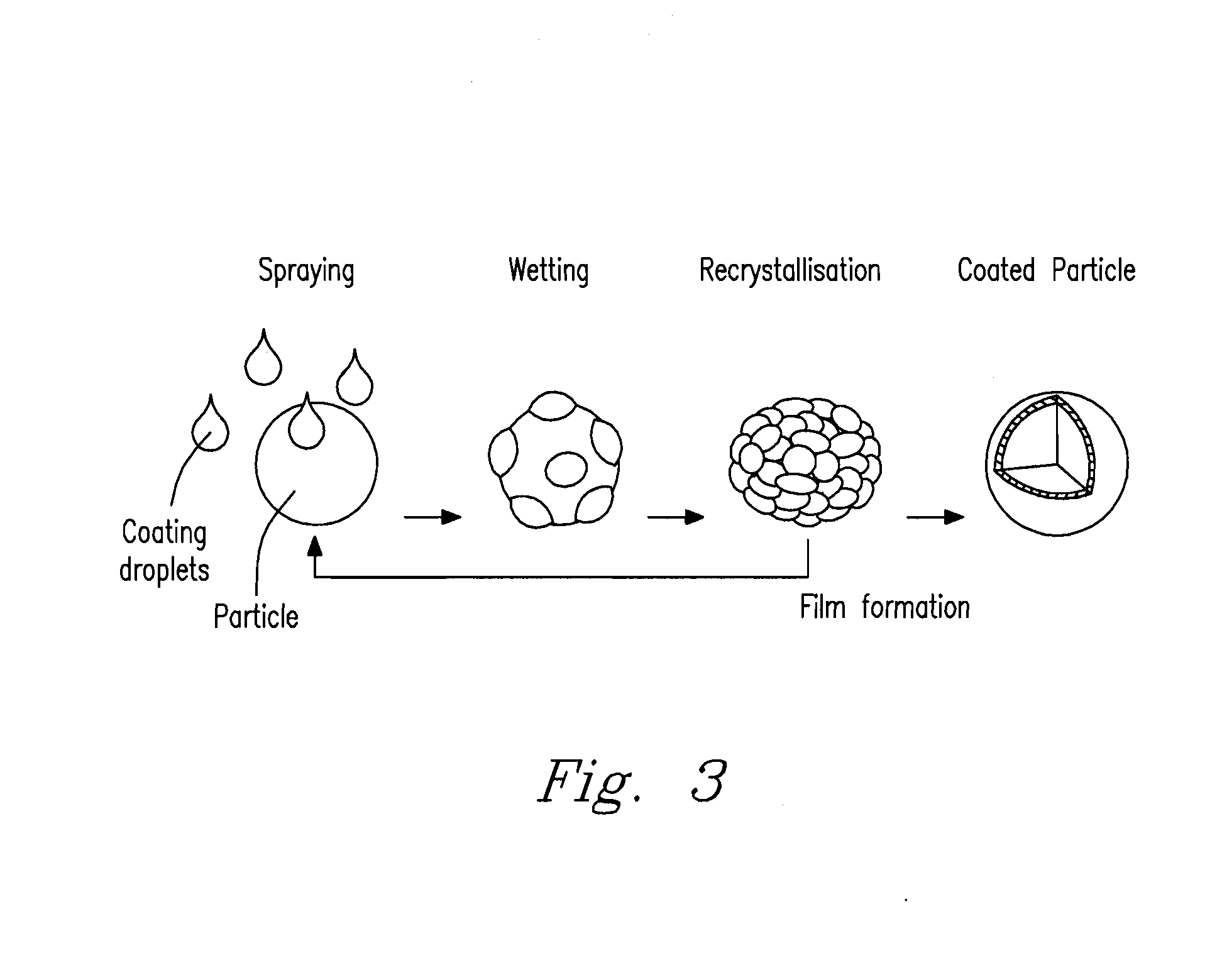

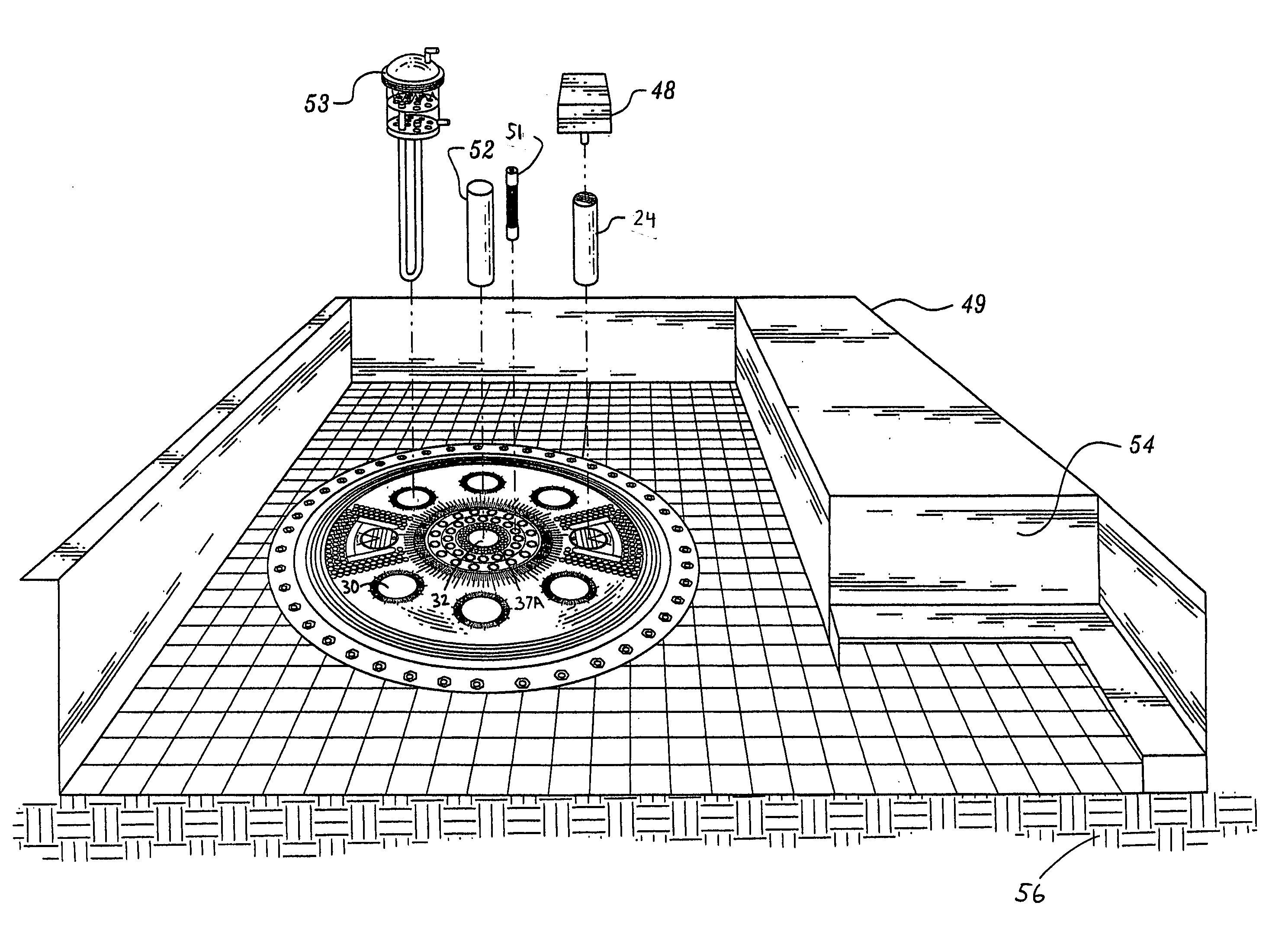

Methods and apparatuses for the development of microstructured nuclear fuels

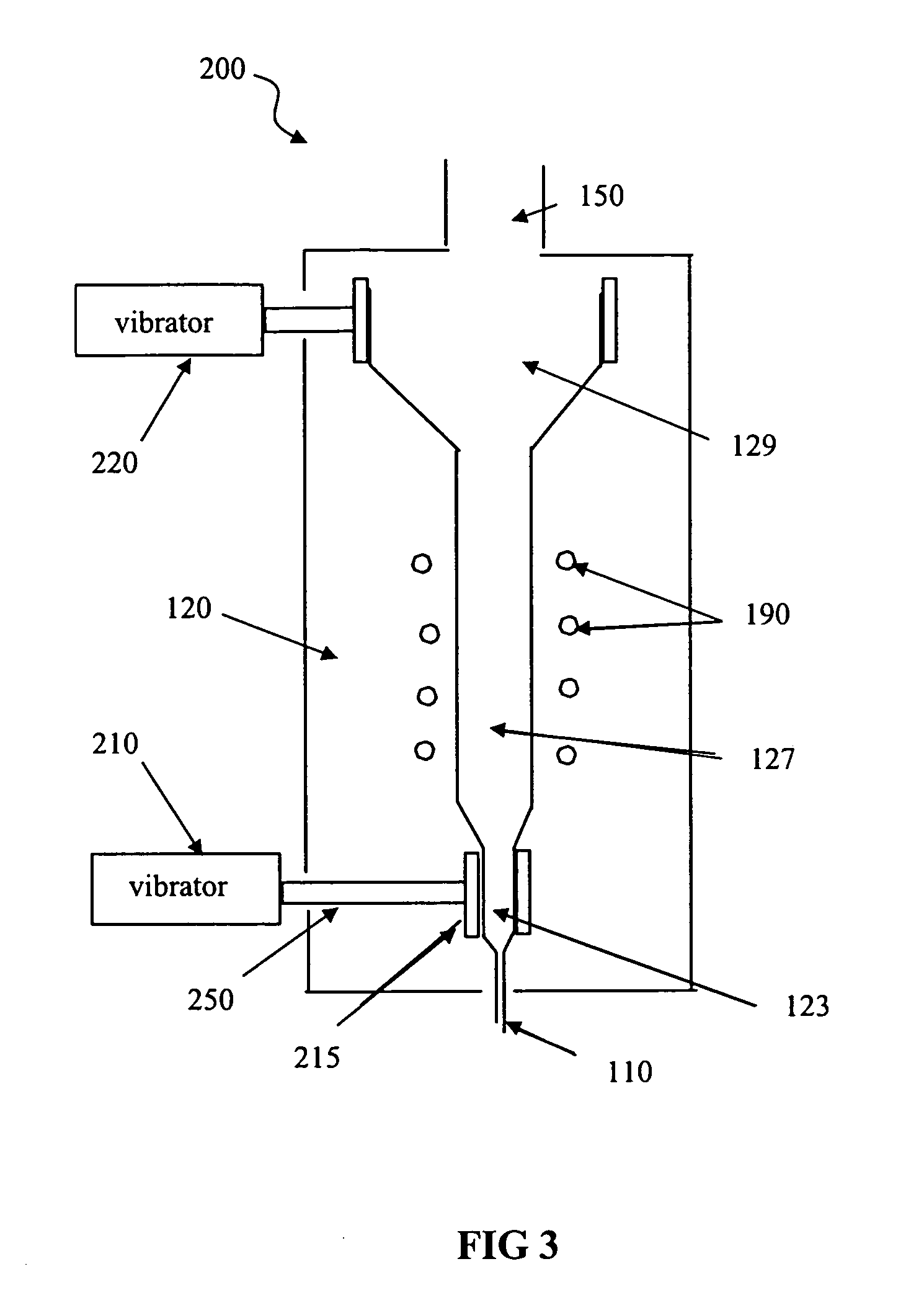

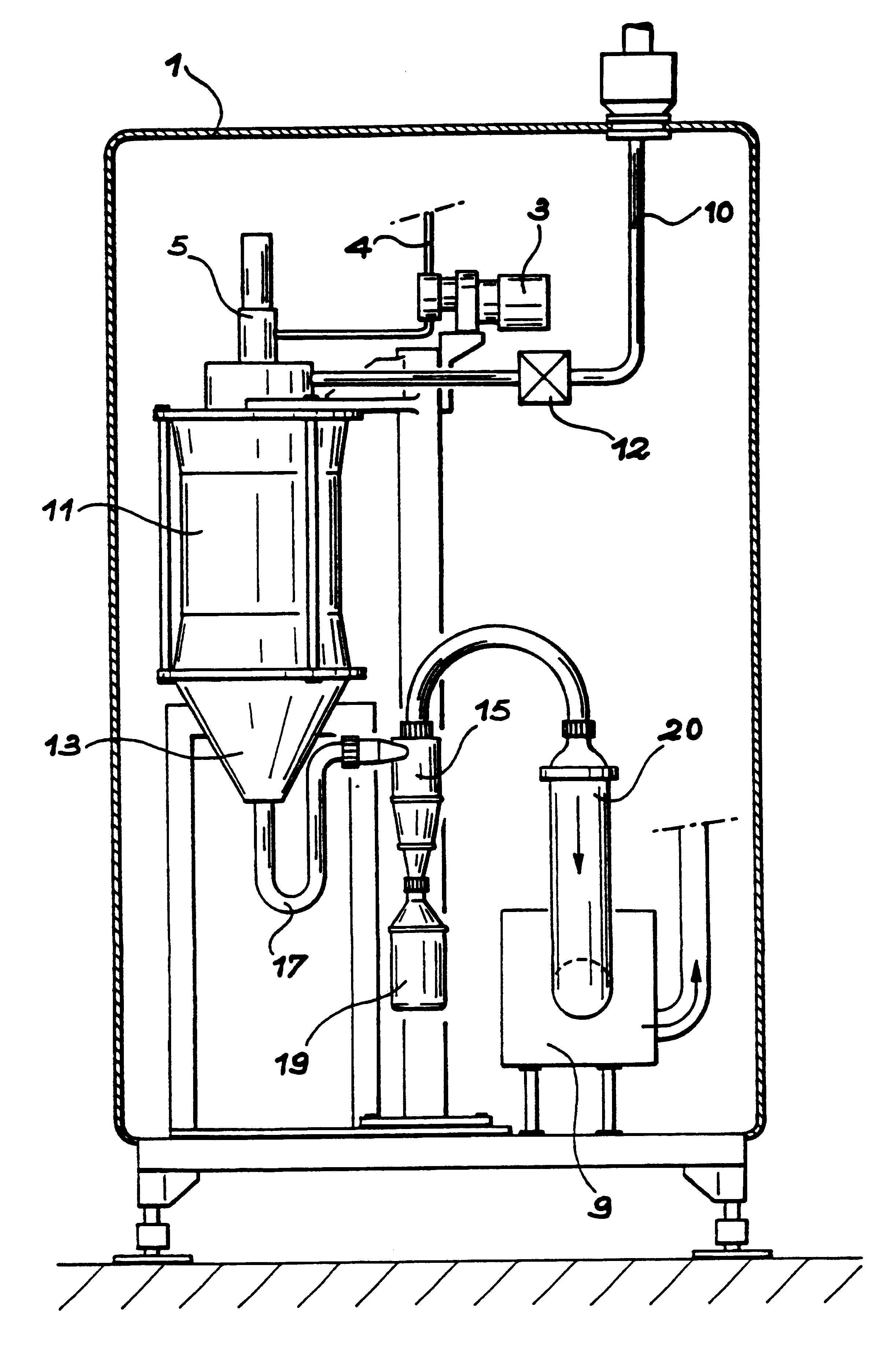

ActiveUS7521007B1Ensure uniform motionLow costFuel elementsNuclear energy generationChemical vapor depositionMaterials science

Microstructured nuclear fuel adapted for nuclear power system use includes fissile material structures of micrometer-scale dimension dispersed in a matrix material. In one method of production, fissile material particles are processed in a chemical vapor deposition (CVD) fluidized-bed reactor including a gas inlet for providing controlled gas flow into a particle coating chamber, a lower bed hot zone region to contain powder, and an upper bed region to enable powder expansion. At least one pneumatic or electric vibrator is operationally coupled to the particle coating chamber for causing vibration of the particle coater to promote uniform powder coating within the particle coater during fuel processing. An exhaust associated with the particle coating chamber and can provide a port for placement and removal of particles and powder. During use of the fuel in a nuclear power reactor, fission products escape from the fissile material structures and come to rest in the matrix material. After a period of use in a nuclear power reactor and subsequent cooling, separation of the fissile material from the matrix containing the embedded fission products will provide an efficient partitioning of the bulk of the fissile material from the fission products. The fissile material can be reused by incorporating it into new microstructured fuel. The fission products and matrix material can be incorporated into a waste form for disposal or processed to separate valuable components from the fission products mixture.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Preparation method of porous-fuel-core inert matrix dispersion fuel pellet

ActiveCN107123455AIncreased uranium abundanceImproved neutron economyNuclear energy generationReactors manufactureFuel reprocessingPower station

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

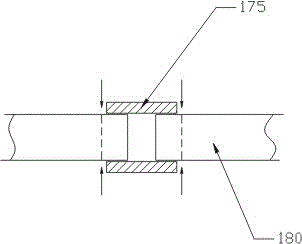

Method and apparatus for repairing a jet pump diffuser adapter to tailpipe weld

ActiveUS20080144761A1Evenly distributedNuclear energy generationNuclear engineering problemsNuclear reactorEngineering

A clamp assembly connects a diffuser adapter or lower ring to a diffuser tail pipe of a jet pump diffuser in a boiling water nuclear reactor. The clamp assembly includes at least two clamp segments shaped generally corresponding to an exterior circumference of the diffuser, a swivel link affixed at each end of each of the clamp segments, and at least two connecting bands pivotably secured to the swivel links between the ends of the clamp segments. The clamp segments each includes a locking assembly engageable with the diffuser adapter or lower ring and the diffuser tail pipe. The clamp assembly structurally replaces / repairs the weld joining the diffuser adapter or lower ring and the diffuser tail pipe.

Owner:GENERAL ELECTRIC CO

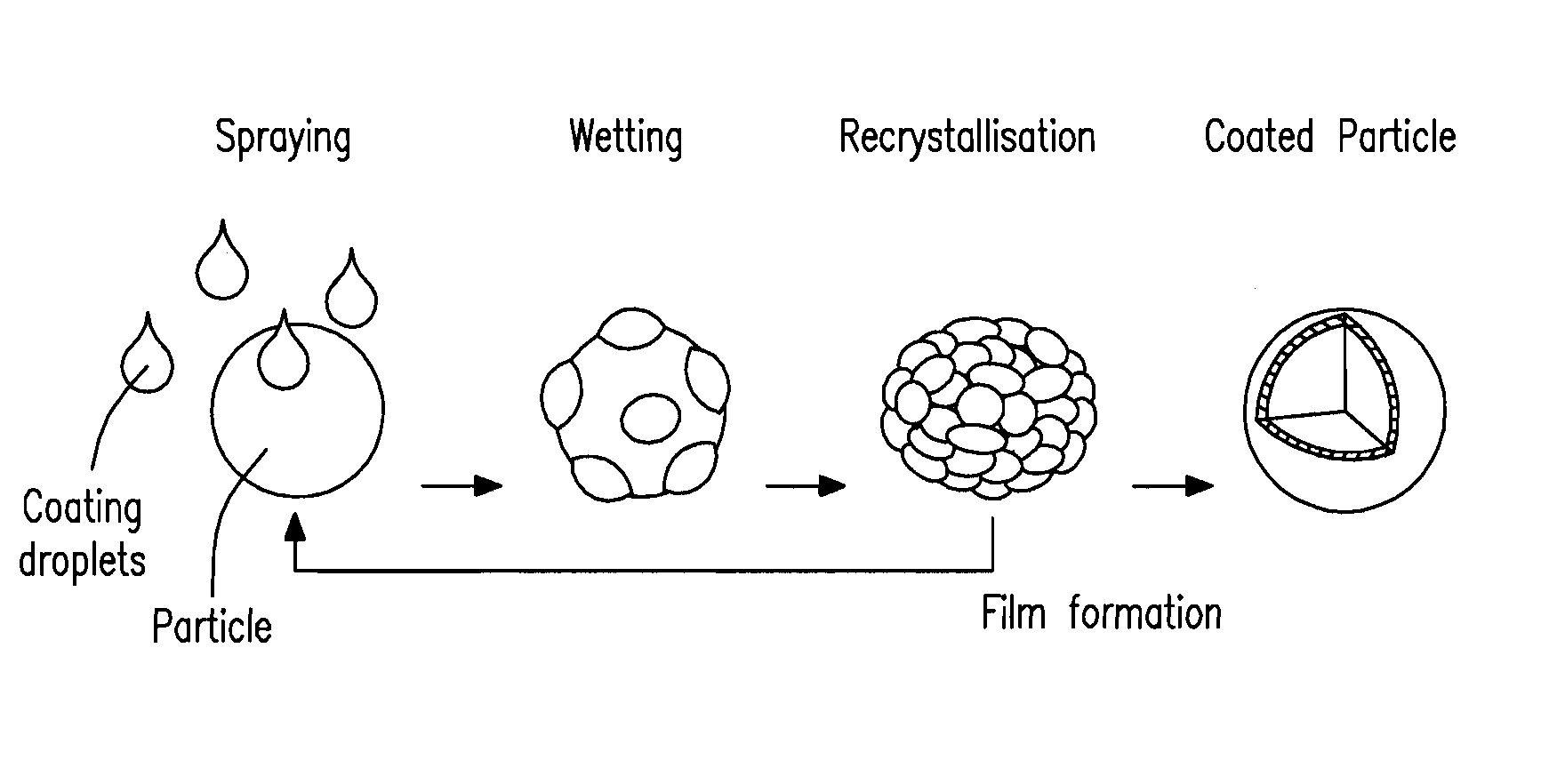

Method of manufacturing nuclear fuel elements and a container for implementing such a method

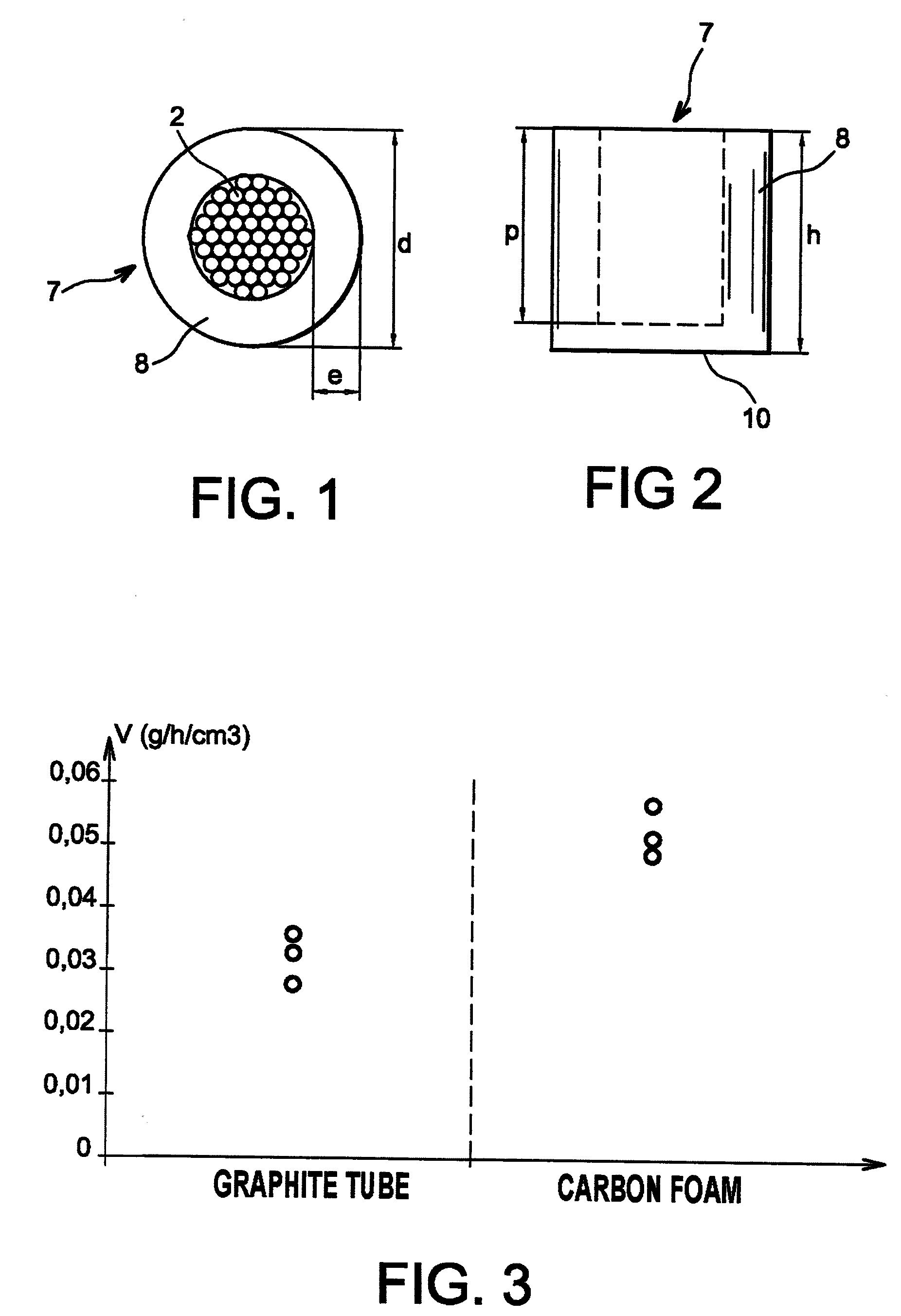

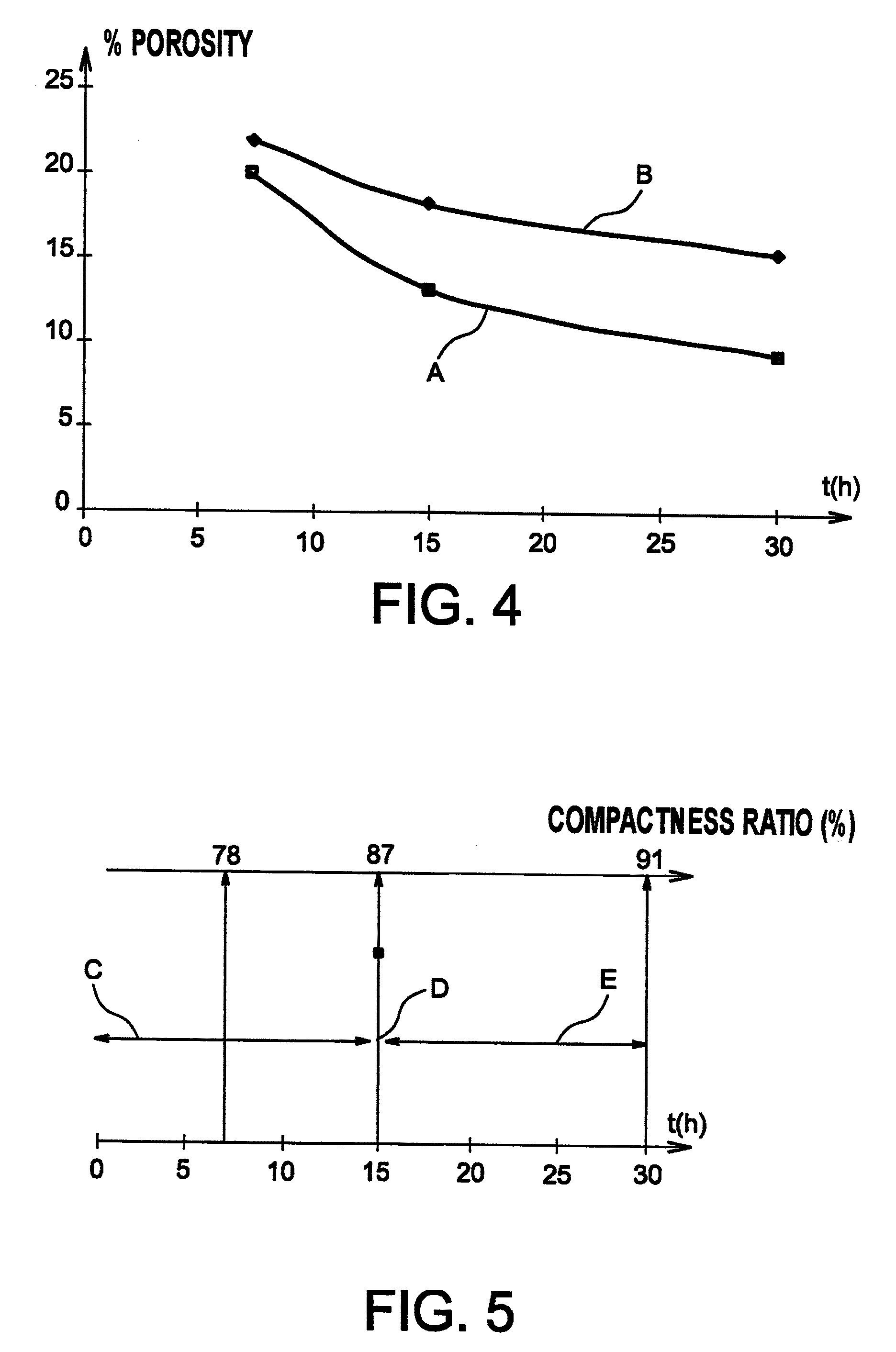

InactiveUS20100296621A1Good CVIAvoid damaging contentLiquid surface applicatorsFuel elementsNuclear fuel

A method of manufacturing nuclear fuel elements comprising the steps of placing nuclear fuel balls in the container made from ultra-porous material, applying a CVI to the container and removing the container. The container for manufacturing fuel elements comprising balls, and is produced from at least one ultra-porous material, for example carbon foam.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

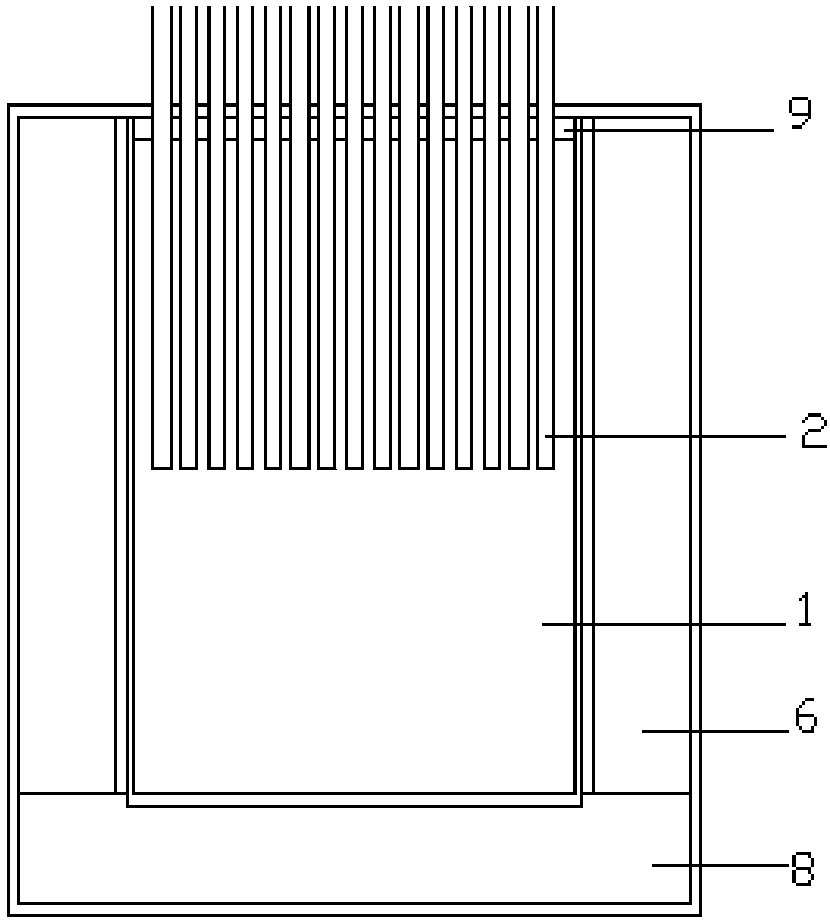

Integrated small molten salt reactor

ActiveCN107945887AImprove heat transfer effectLong-term efficient and stable transmissionFuel elementsNuclear energy generationNuclear engineeringNatural convection

The invention discloses an integrated small molten salt reactor. The reactor body of the integrated small molten salt reactor comprises a fuel salt, heat tubes, a core container, a side reflection layer, neutron absorbers, control drums, a shell and a lower reflection layer, wherein the heat tubes and the core container are integrally designed, the heat tubes are partly or fully inserted into thecore container, the core container is filled with the fuel salt, a cavity is formed between the core container and the liquid surface of the fuel salt, the outer wall of the core container is surrounded with the side reflection layer, the control drums are arranged in the side reflection layer, the neutron absorbers are arranged at one sides of the control drums, the lower reflection layer is arranged at the bottom of the core container, and the shell surrounds the external of the side reflection layer and the lower reflection layer. A heat tube technology is applied to the molten salt reactorin order to greatly simplify the structure of the above system, and natural circulation or natural convection is generated to realize the long-term efficient and stable transmission of heat and improve the safety and the reliability of the system.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Preparation by spray-drying of a flowable uranium dioxide powder obtained by dry process conversion of UF6

InactiveUS6656391B1Lower levelMaintain good propertiesNuclear energy generationUranium dioxideUranium hexafluorideViscosity

The invention relates to a process for preparing a castable powder of uranium dioxide UO2, for use in the manufacture of MOX fuel.This process comprises the following stages:1) to prepare an aqueous suspension of a powder of UO2 obtained by dry process from uranium hexafluoride, said suspension comprising 50 to 80% by weight of UO2 and at least one additive chosen among deflocculation agents, organic binders, hydrogen peroxide H2O2 and a powder of U3O8, in such a quantity that the viscosity of the suspension does not exceed 250 mPa.sec, and2) to atomise this suspension and dry it in a hot gas, at a temperature of 150 to 300° C., to obtain a castable powder of UO2 with an average particle size of 20 to 100 mum.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Nuclear fuel salts

InactiveUS20170301413A1Improve power densityImprove the level ofFuel elementsNuclear energy generationPresent methodChloride

This disclosure describes nuclear fuel salts usable in certain molten salt reactor designs and related systems and methods. Binary, ternary and quaternary chloride fuel salts of uranium, as well as other fissionable elements, are described. In addition, fuel salts of UClxFy are disclosed as well as bromide fuel salts. This disclosure also presents methods and systems for manufacturing such fuel salts, for creating salts that reduce corrosion of the reactor components and for creating fuel salts that are not suitable for weapons applications.

Owner:TERRAPOWER

A nucleus fuel with carborundum as inertial base and its making method

ActiveCN101188147AImprove thermal conductivityEasy to prepareNuclear energy generationReactors manufactureMass numberEngineering

The invention provides a nuclear fuel and a preparation method thereof, wherein, the nuclear fuel takes carborundum as an inert basal body. The carborundum inert basal body nuclear fuel equably disperses fuel globules of zirconia fuel to the carborundum basal body, and the mass number dispersed in the carborundum basal body is 5-35 percent. The nuclear fuel is a column-shaped or ring-shaped ceramic-ceramic complex fuel core block. The nuclear fuel has good thermal conduction performance and irradiation-resistant performance, and the chemical durability is high. The preparation method equably disperses fuel globules of zirconia fuel to the carborundum basal body, and then ceramic complex carborundum inert basal body nuclear fuel of the zirconia fuel globules equably dispersed in the carborundum basal body are formed through rapid agglomeration of electric sparks. The carborundum inert basal body nuclear fuel is the safe and environment-friendly nuclear fuel. The preparation method is simple and reliable.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

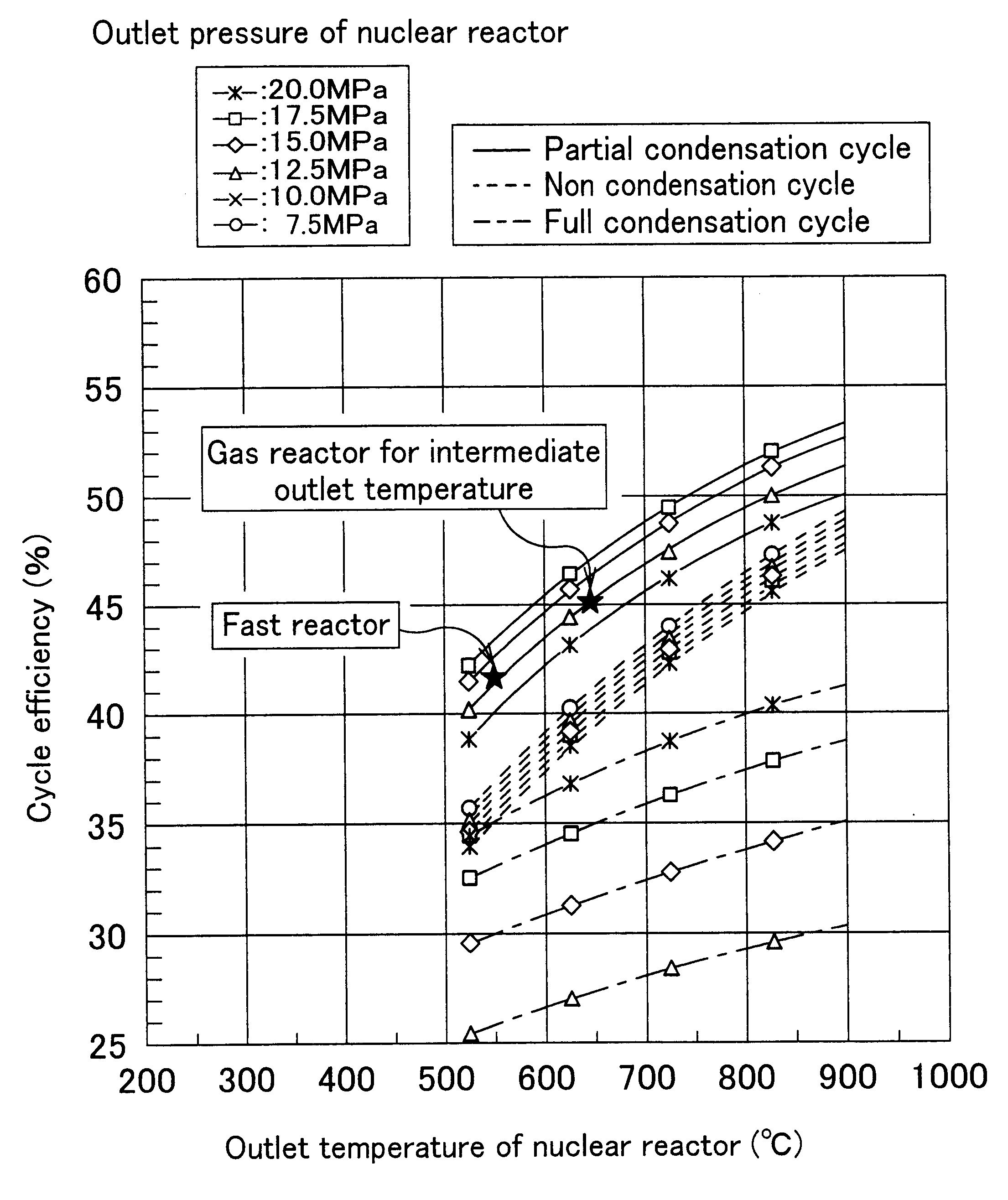

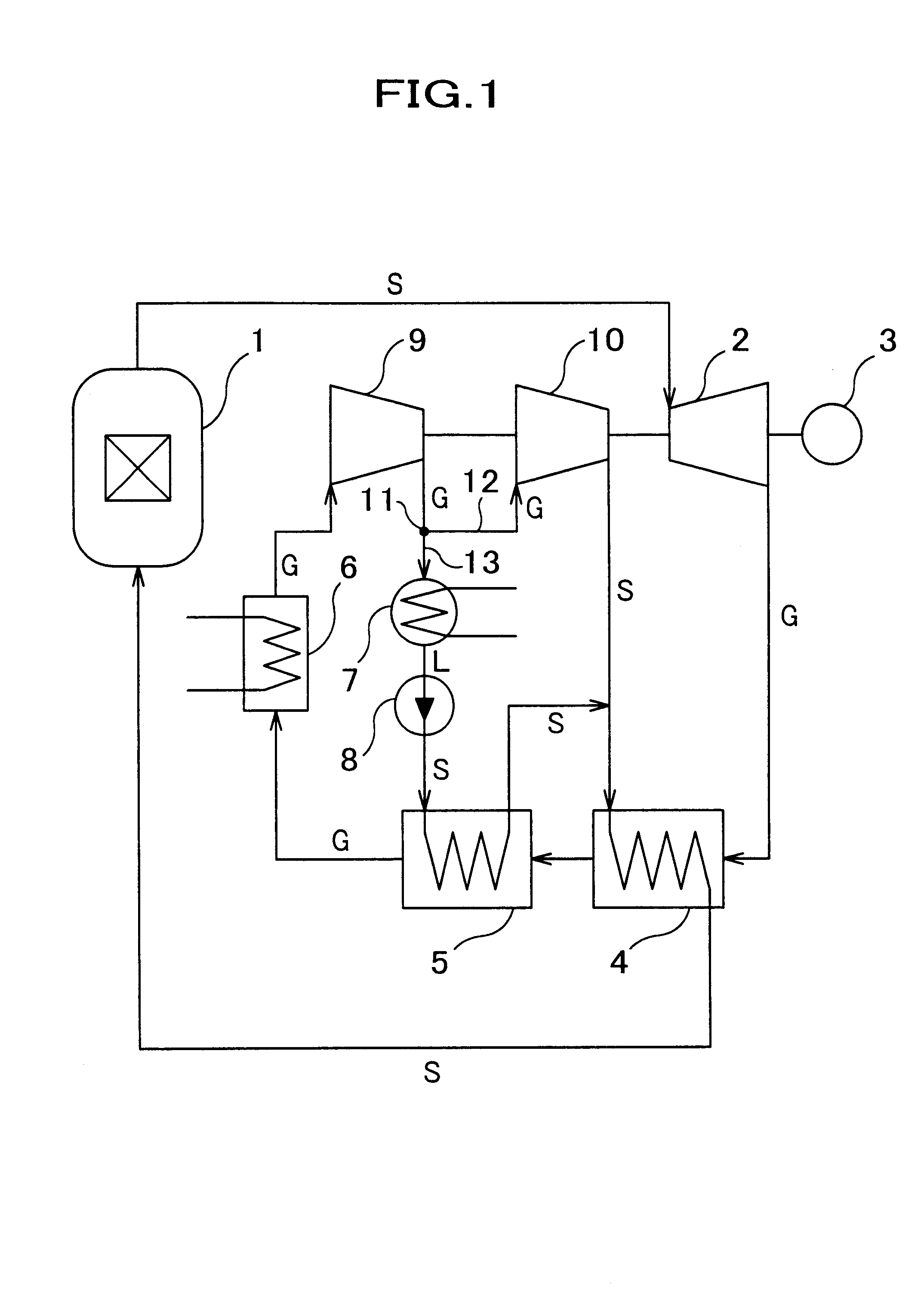

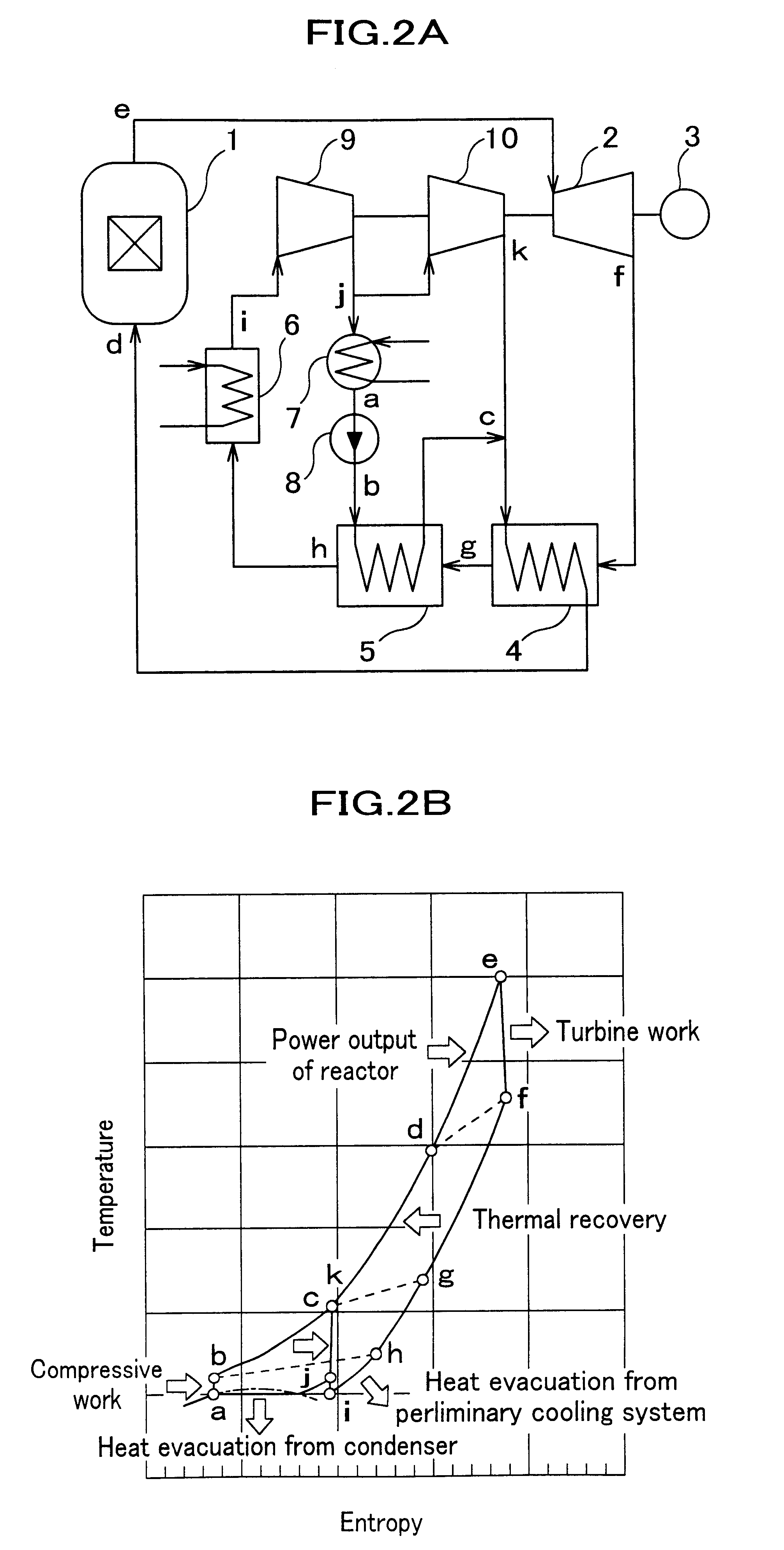

Nuclear reactor plant

InactiveUS6674830B2Nuclear energy generationWorking fluid for enginesNuclear reactor coreNuclear reactor

The subject of the present invention is to provide a nuclear reactor plant of which is a direct cycle nuclear reactor using a carbon dioxide as a coolant such that a heat evacuation for liquefying coolant is reduced while a compressive work is reduced by using a condensation capability of a carbon dioxide for enhancing a cycle efficiency.The nuclear reactor plant is comprised of a nuclear reactor 1, a turbine 2, and wherein, the coolant of supper critical state is heated by a heat of a nuclear reactor to directly drive a turbine, a gaseous coolant discharged from said turbine is chilled and compressed after said turbine is driven for keeping in a critical state, and then said coolant is circulated again into said nuclear reactor, and wherein, a carbon dioxide is used as said coolant, and a predetermined ratio of gaseous coolant discharged from said turbine is liquefied for being compressed in a liquid state while a rest of gaseous coolant is compressed in a gaseous state.

Owner:PRESIDENT OF TOKYIO INST OF TECH THE A JAPANESE NAT INST

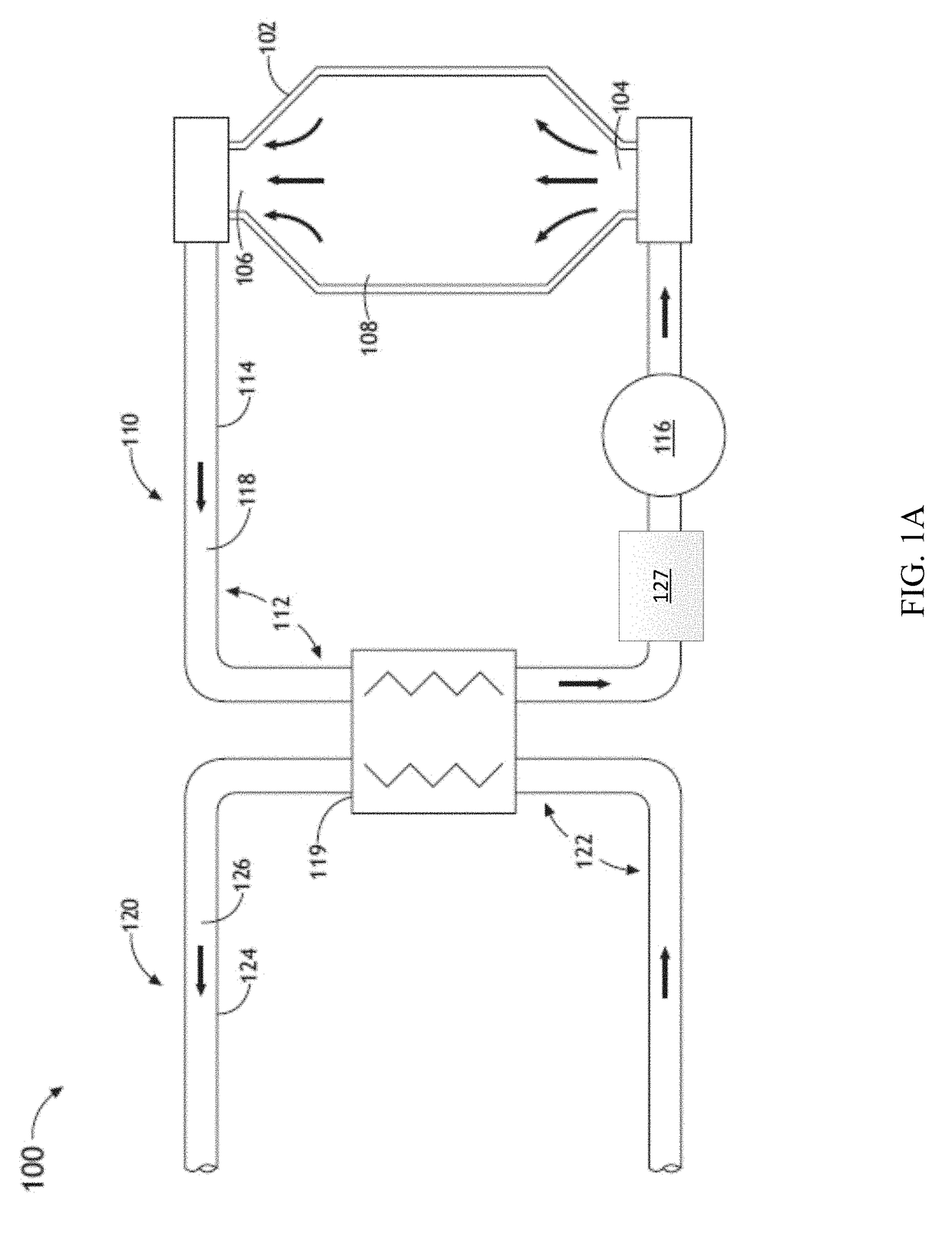

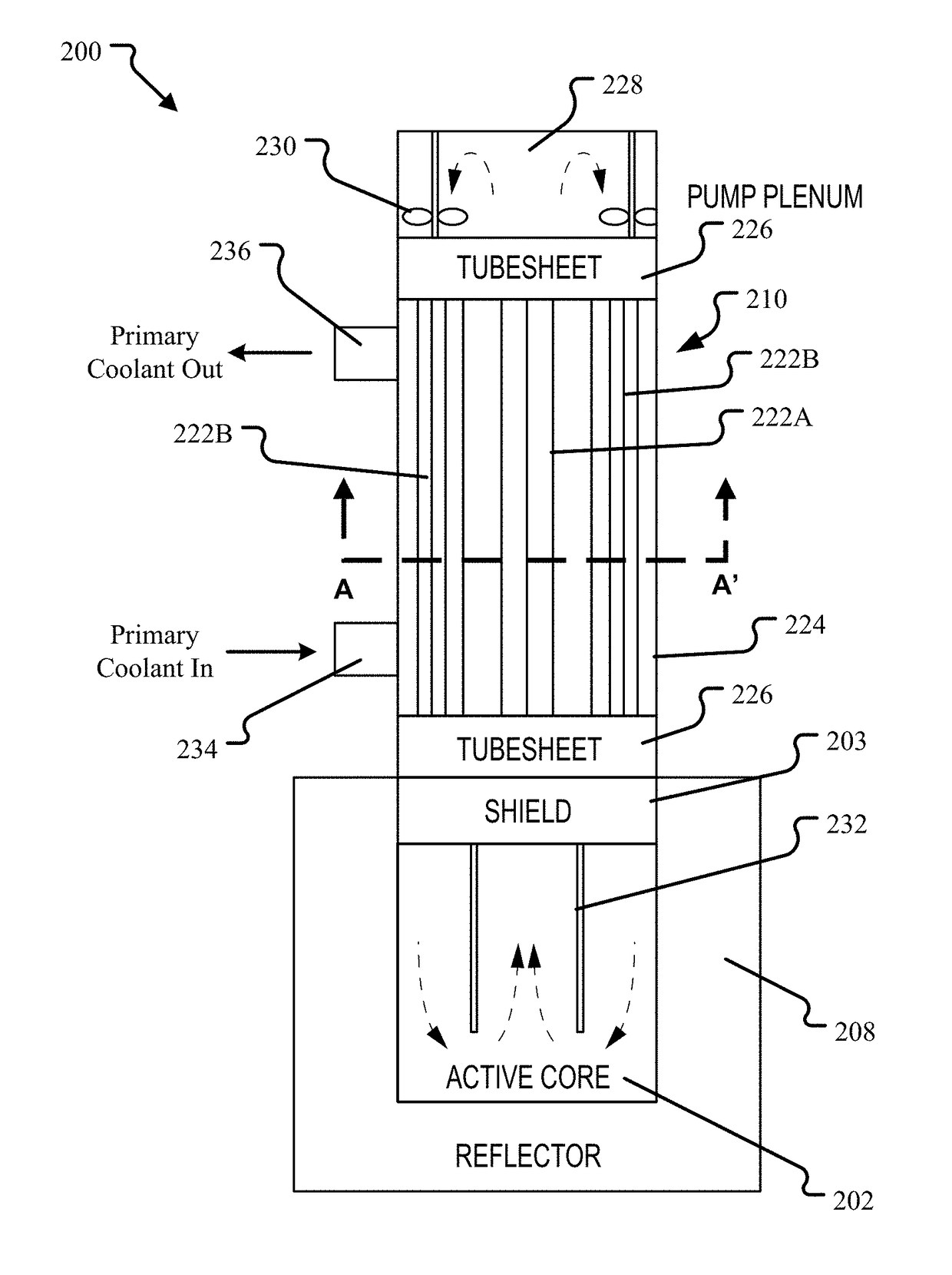

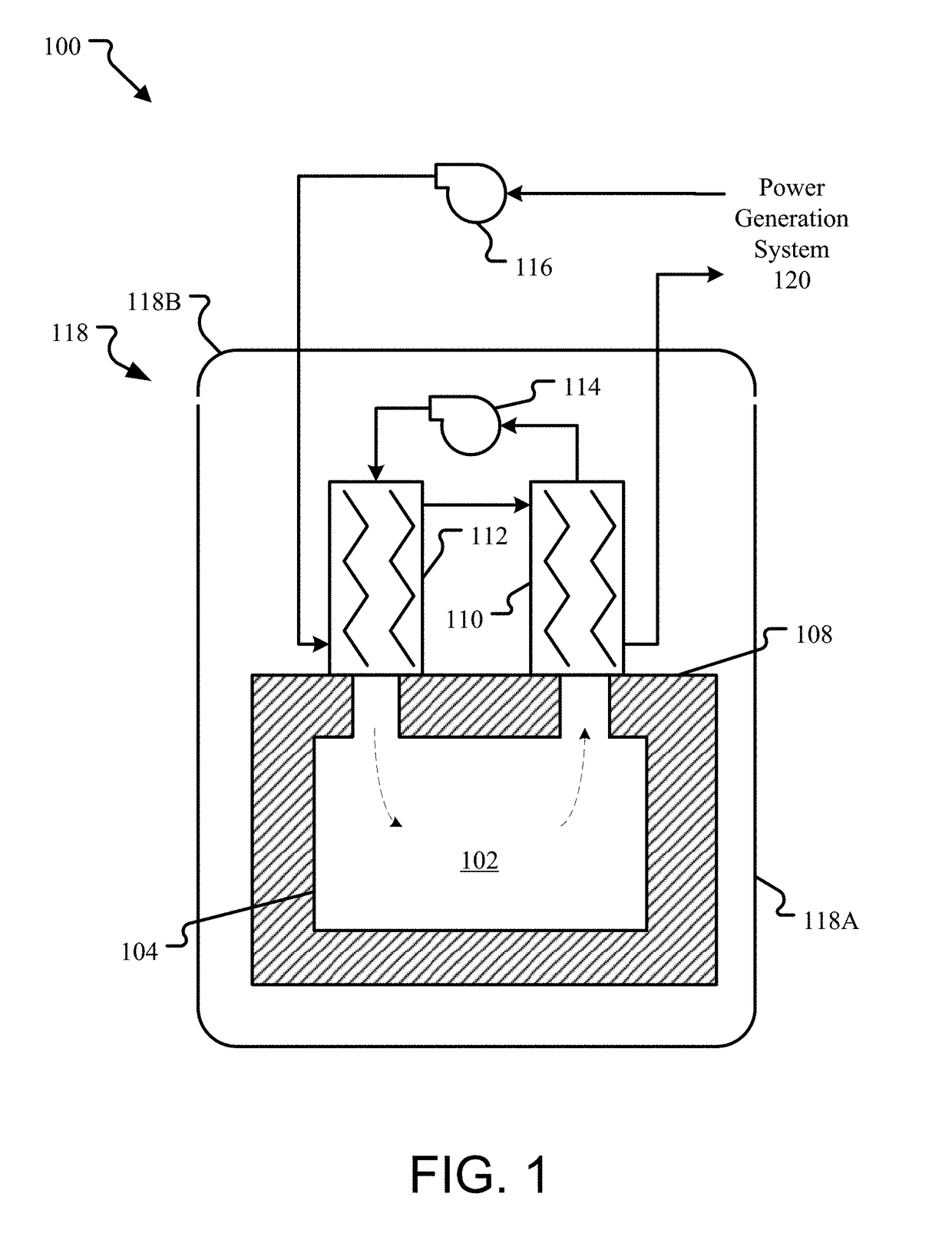

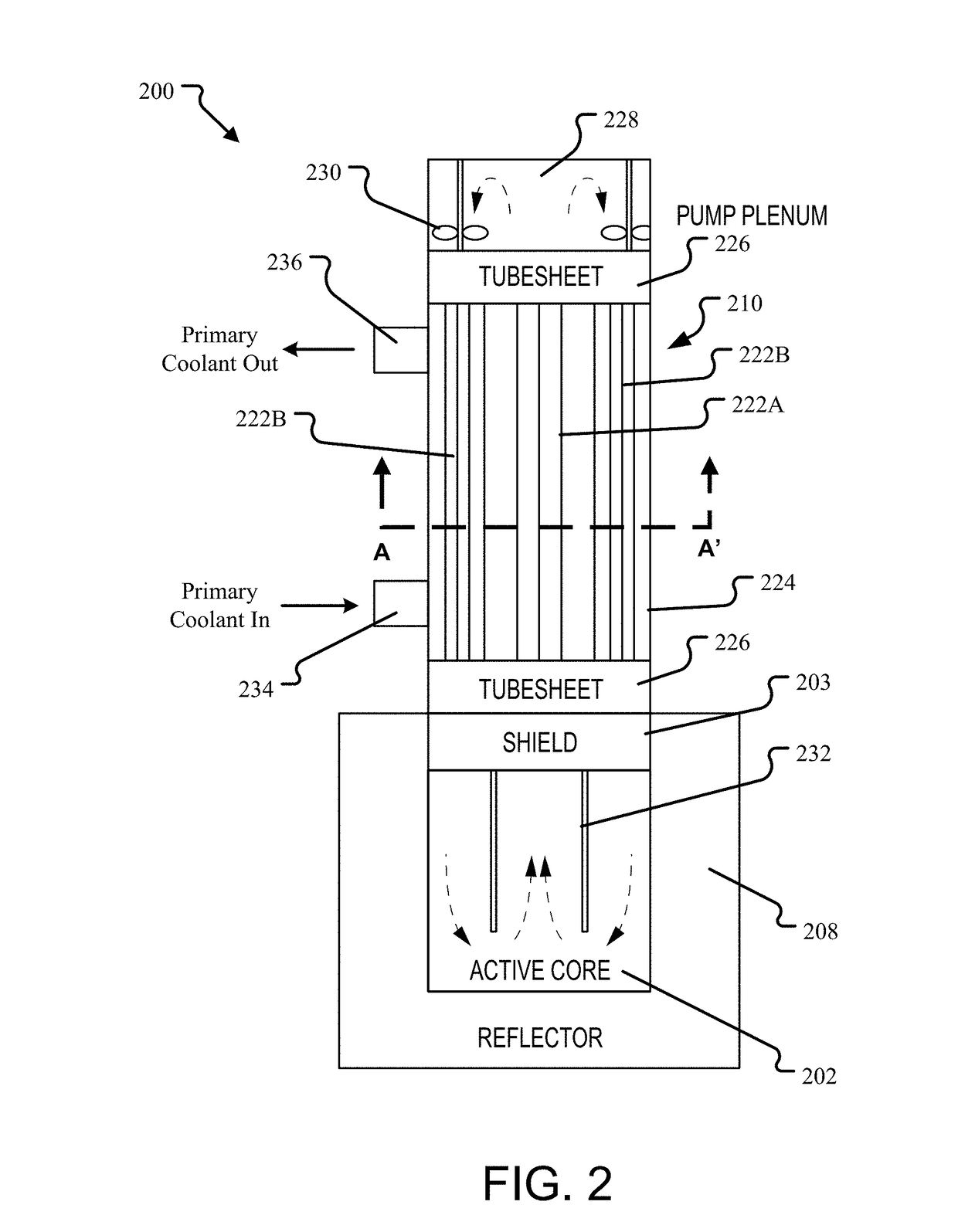

Vertically-segmented nuclear reactor

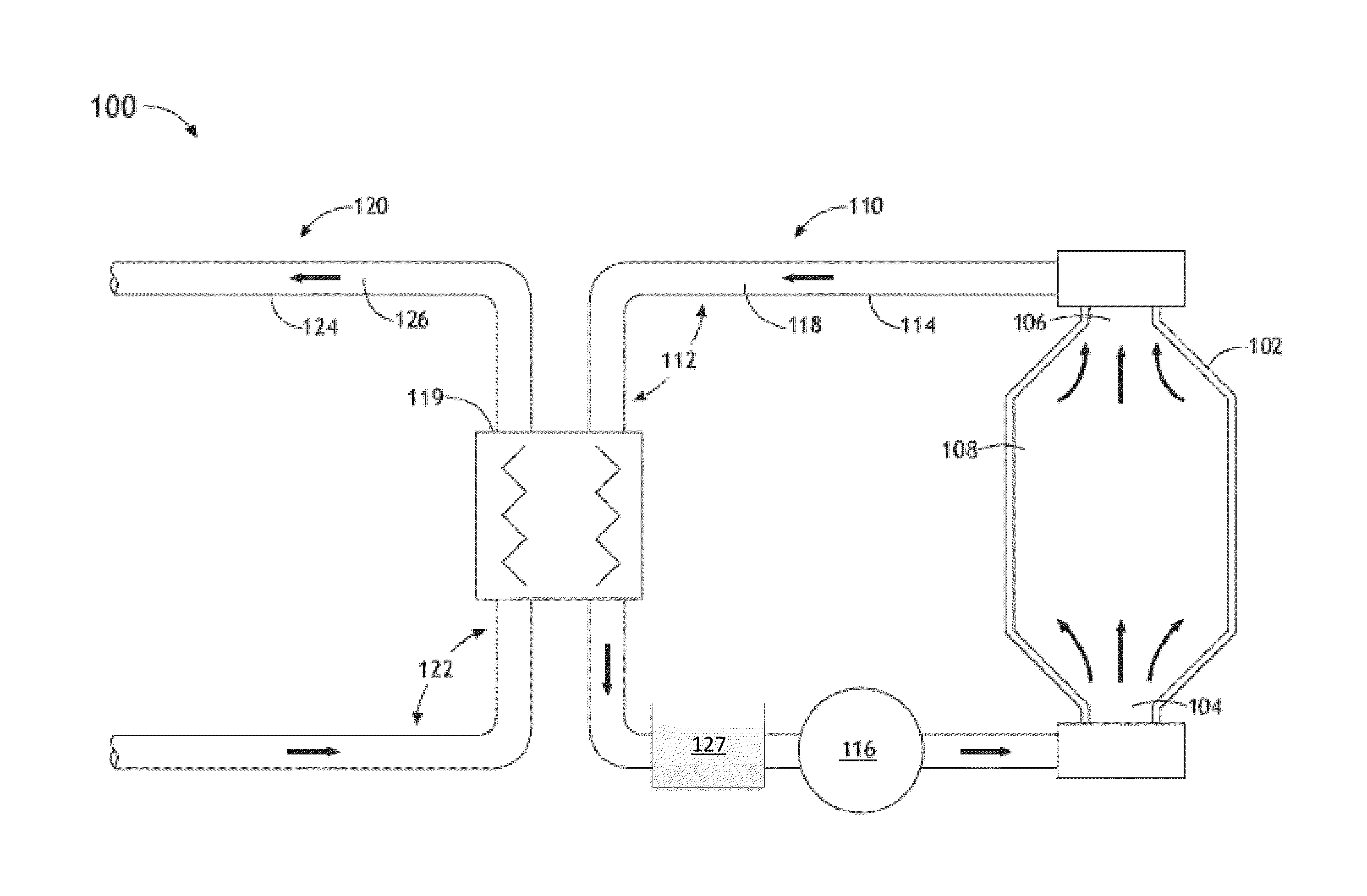

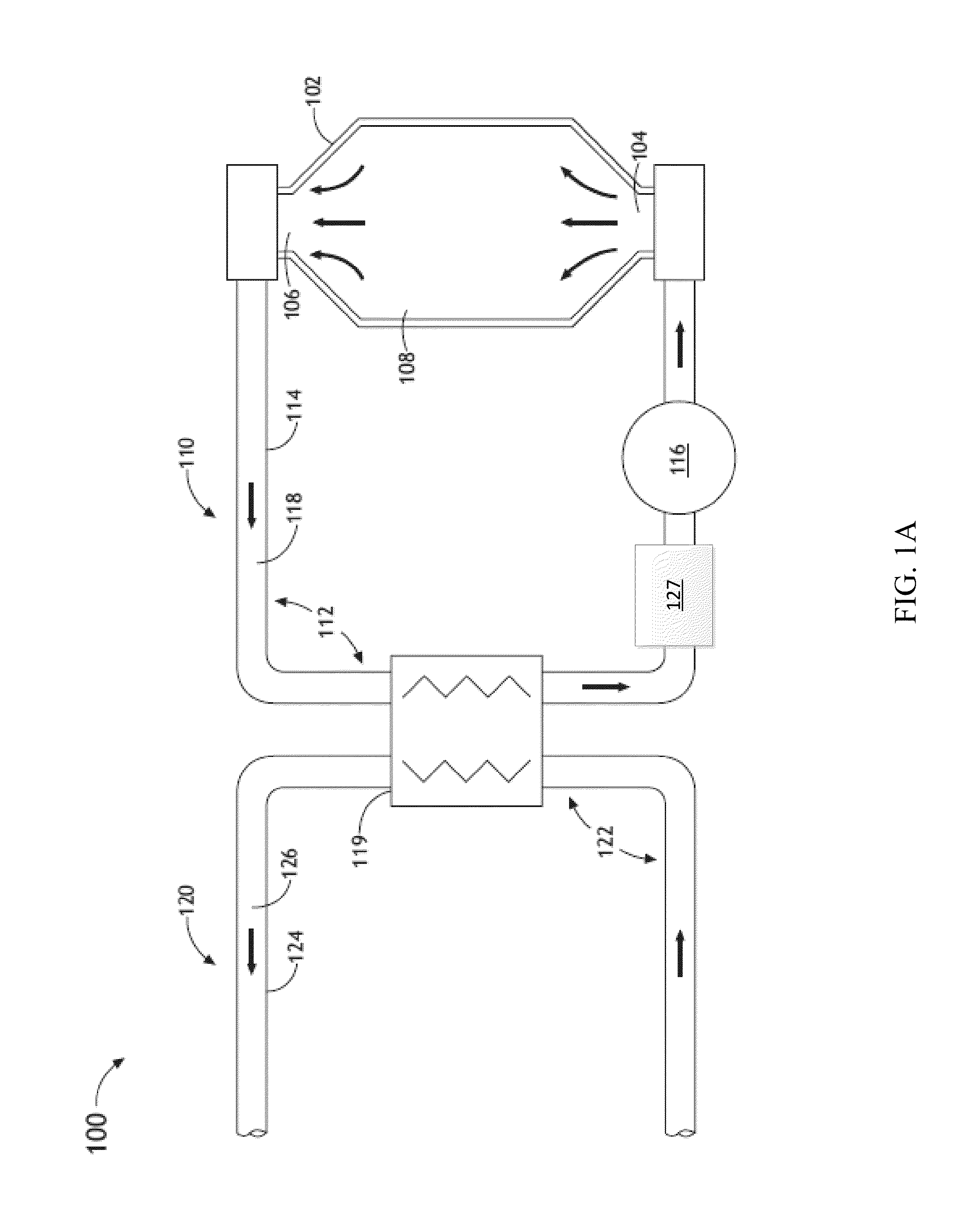

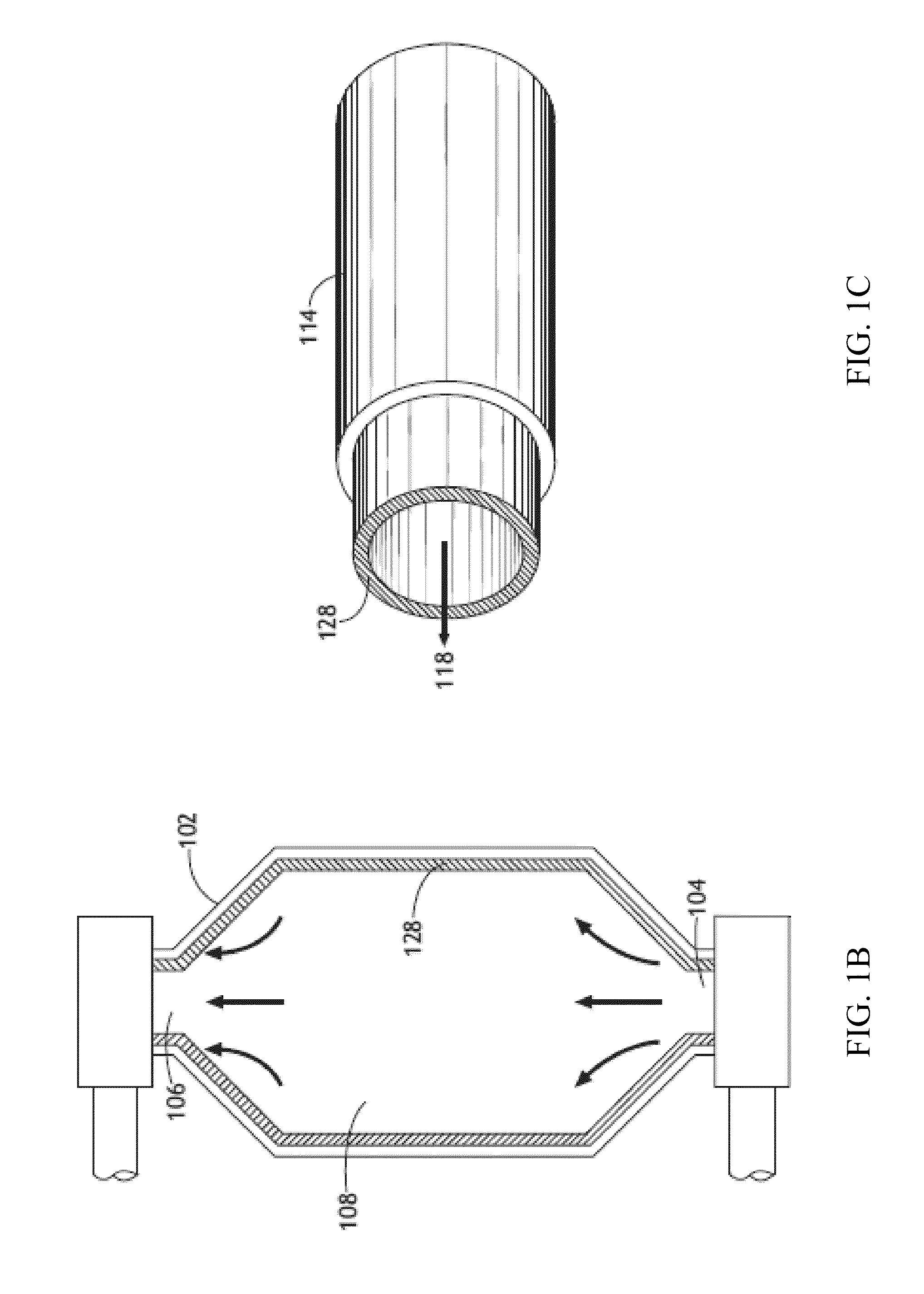

ActiveUS20180019025A1Improve power densitySave on fuel costsIntegral reactorsFuel elementsNuclear reactor coreNuclear reactor

This disclosure describes various configurations and components of a molten fuel fast or thermal nuclear reactor in which one or more primary heat exchangers are located above the reactor core of the nuclear reactor.

Owner:TERRAPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com