Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

604 results about "Void space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

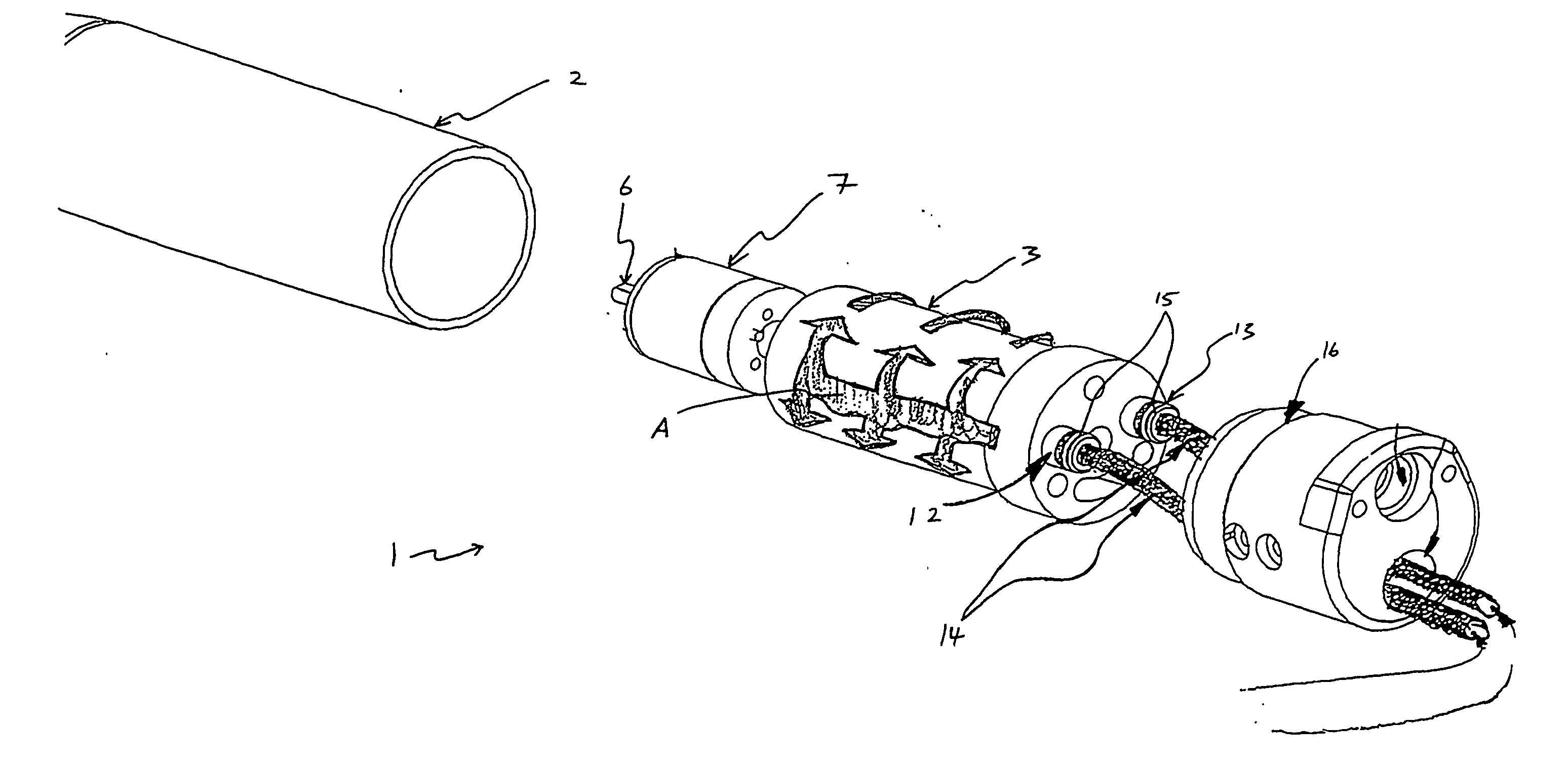

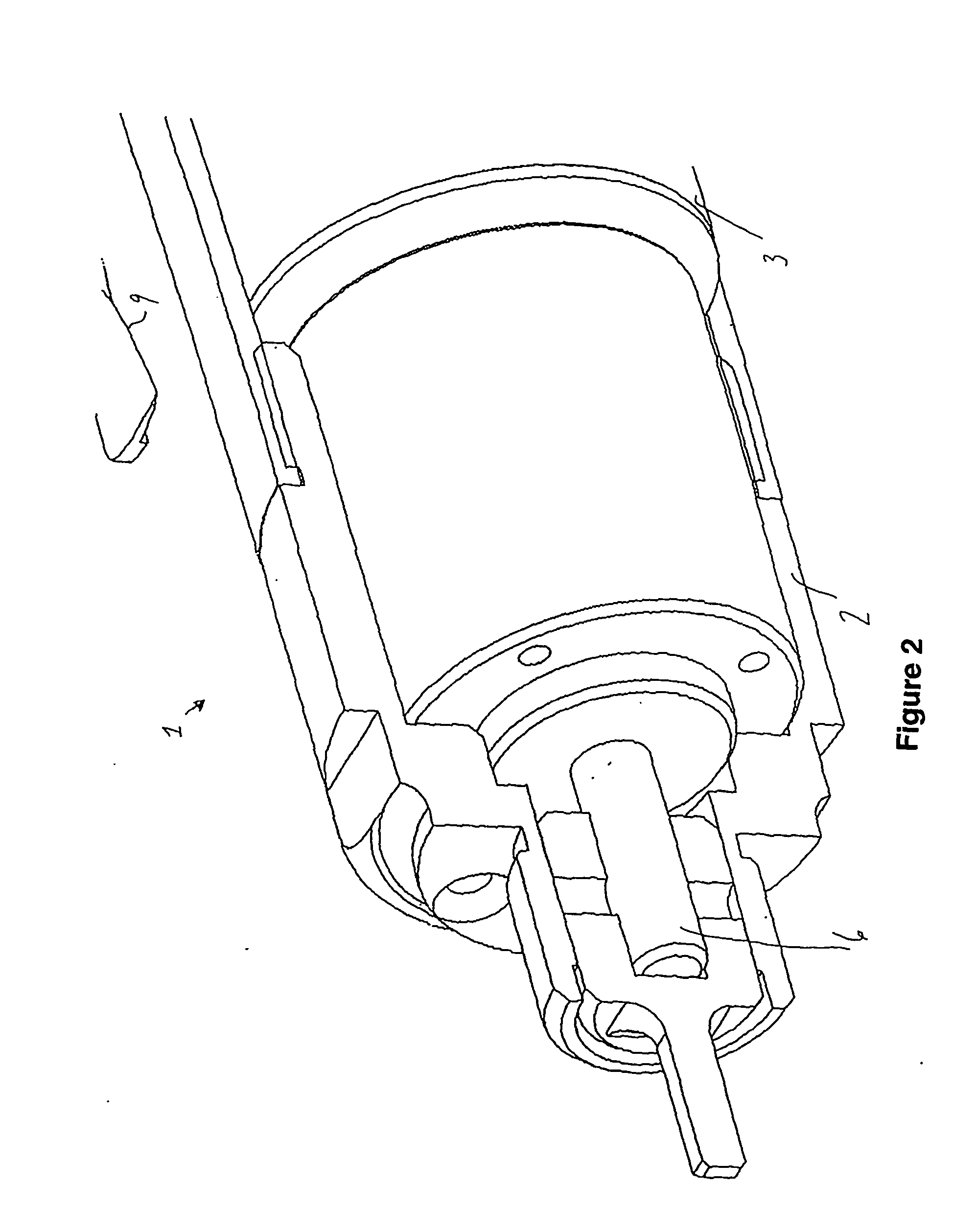

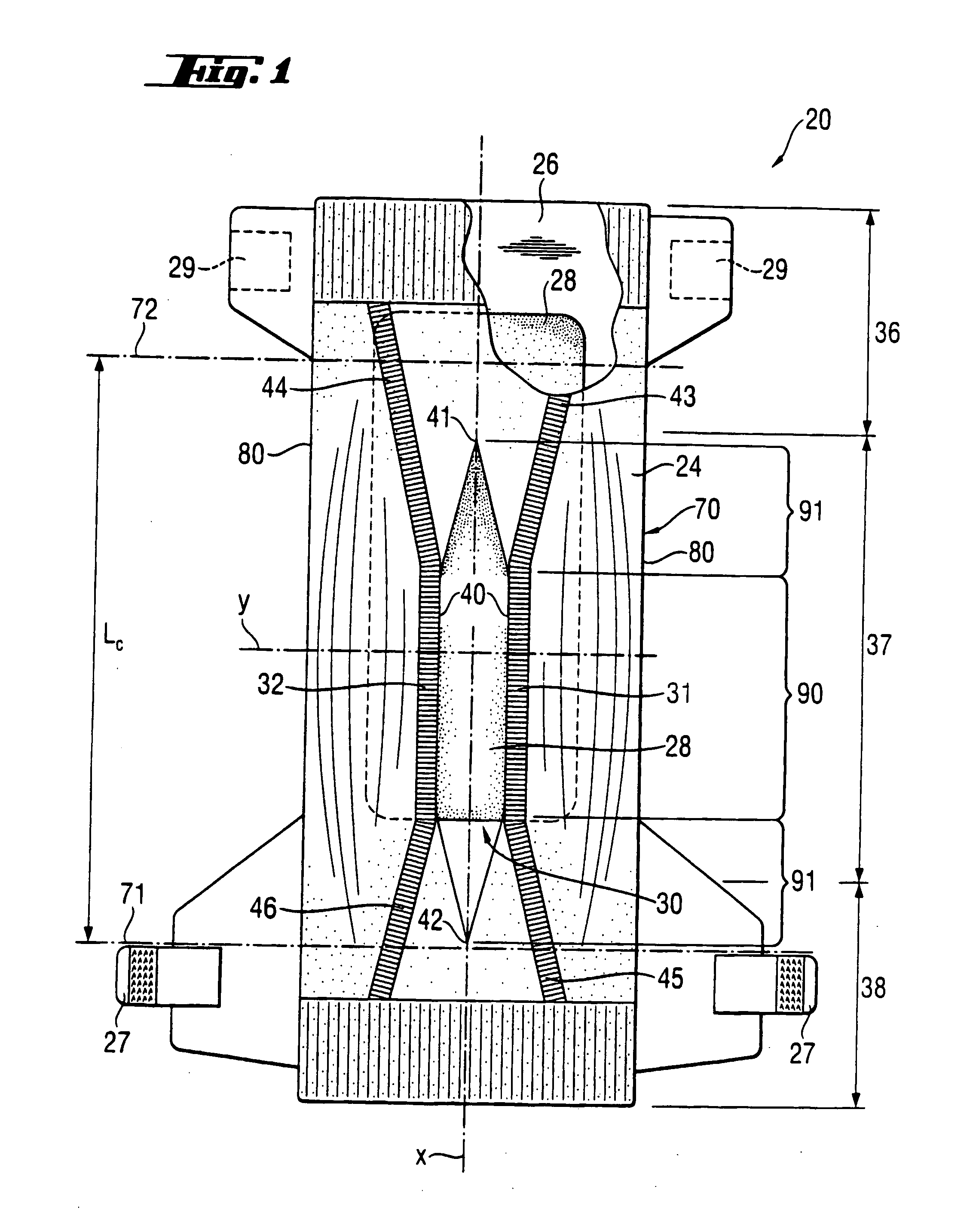

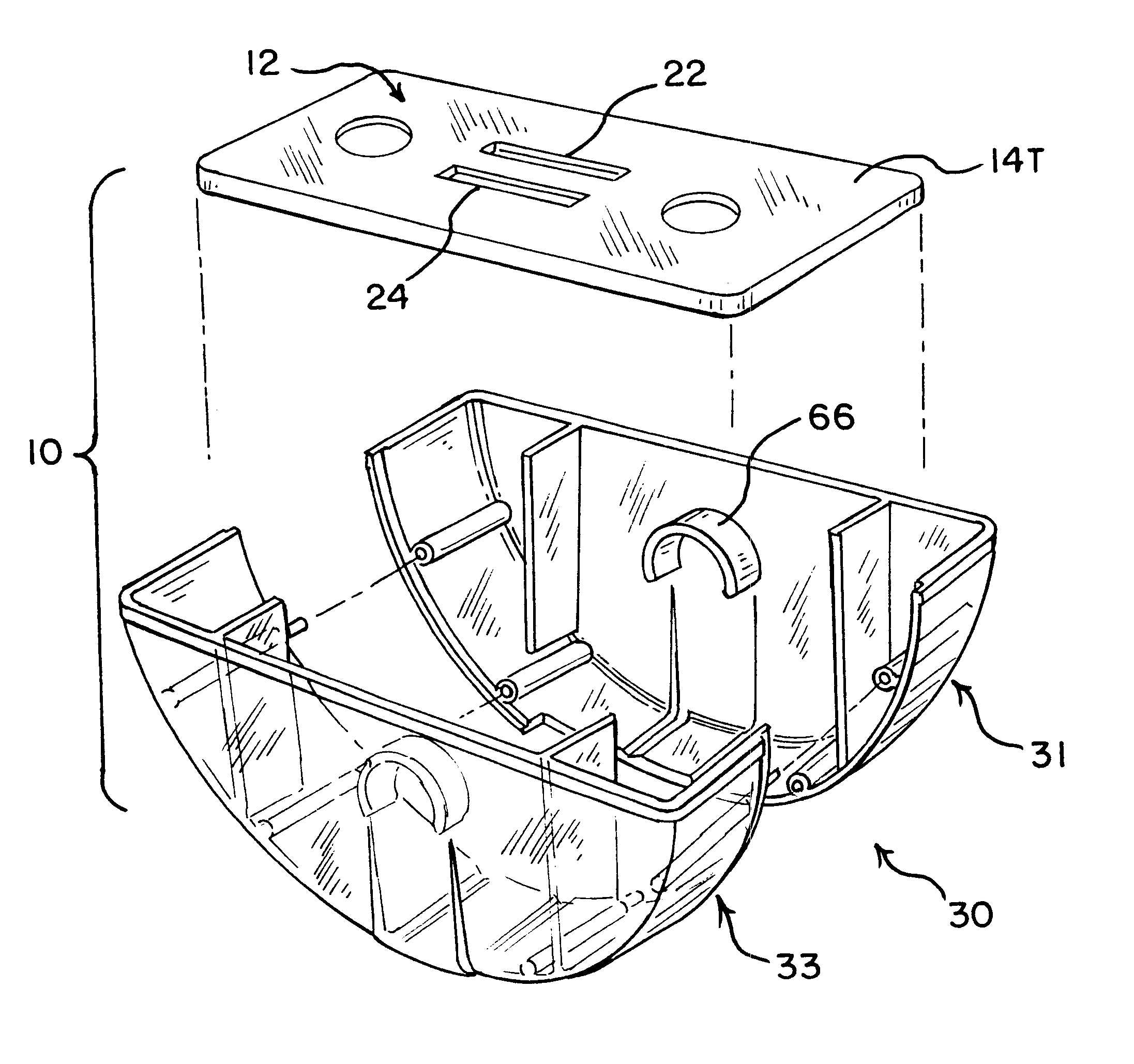

Powered Hand Tool

The invention relates to a hand tool for use with attachments. The hand tools of the invention may be used with attachments with various speed and torque requirements. Preferred hand tools comprise a body with a brushless DC motor and means. which control the energisation of the motor. In use the brushless DC motor of the preferred hand tool is electrically supplied to drive a power output means connected to said motor. Another preferred hand tool comprises a body with a motor contained therein, a void space between an internal surface of the body and at least a part of the motor, a fluid inlet port provided and a fluid outlet port provided in or on the body, and ducting means which provides a channel for fluid supplied via the fluid inlet port to and from the void space and then on to the fluid outlet port.

Owner:IBEX INDS

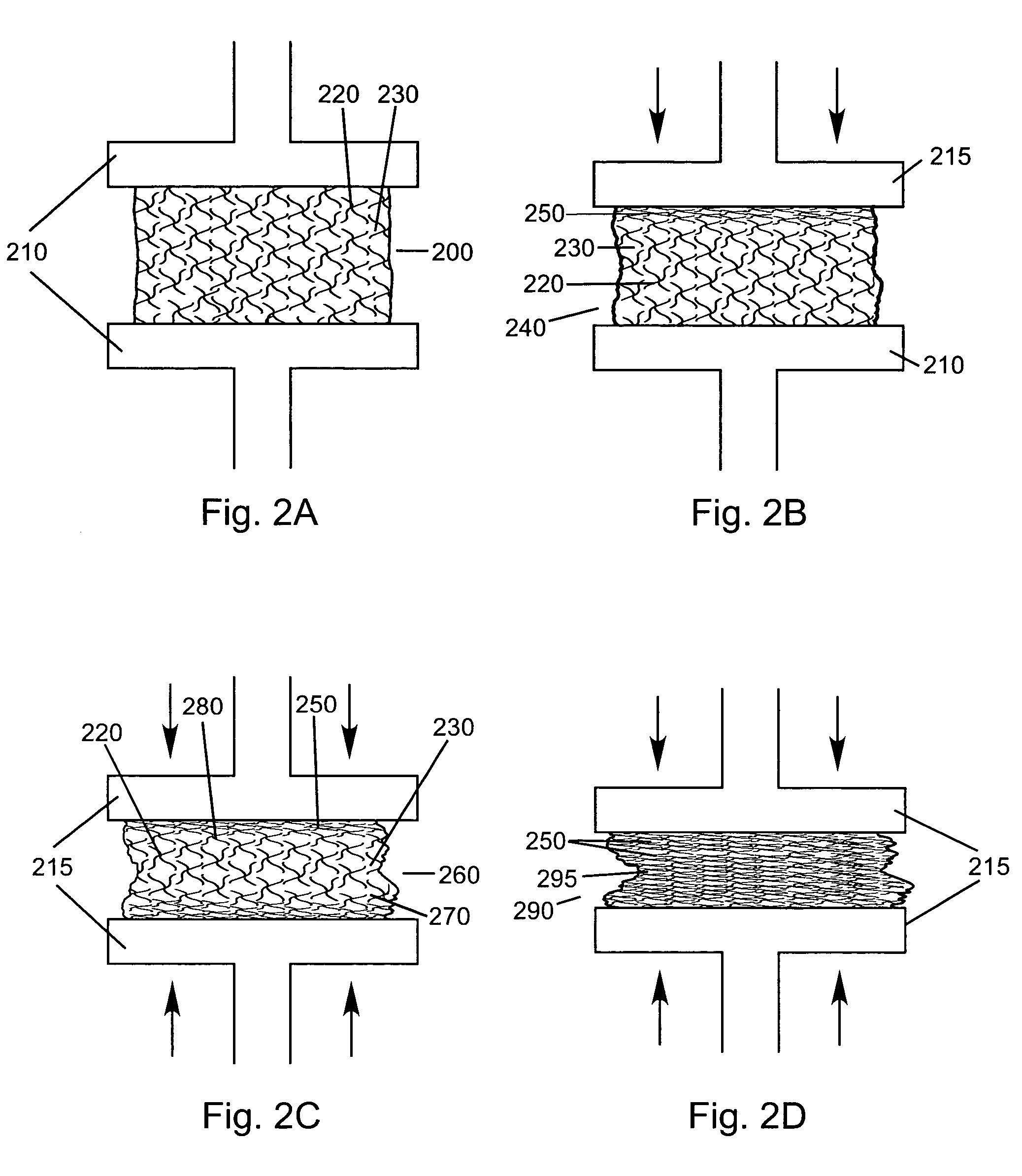

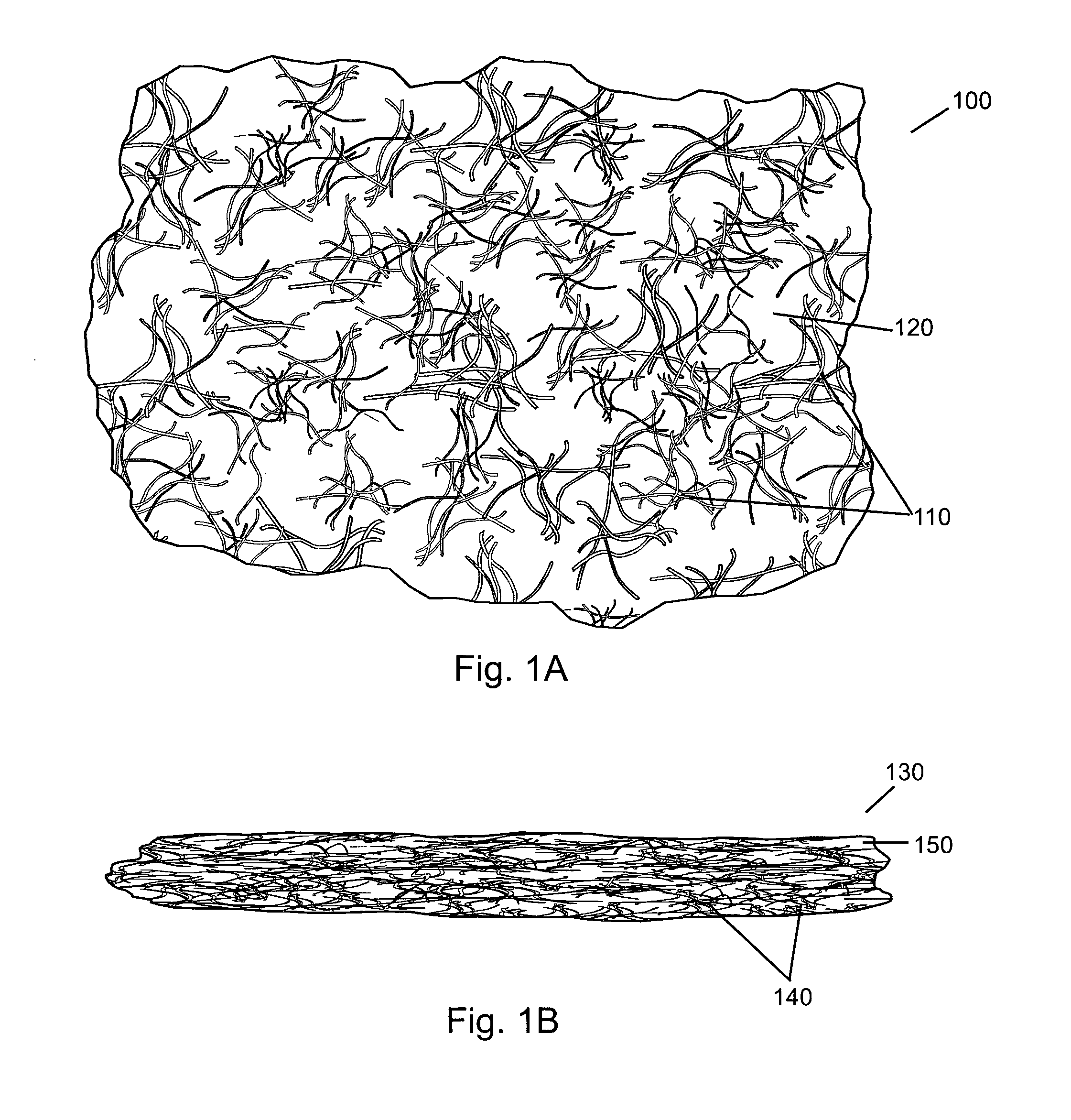

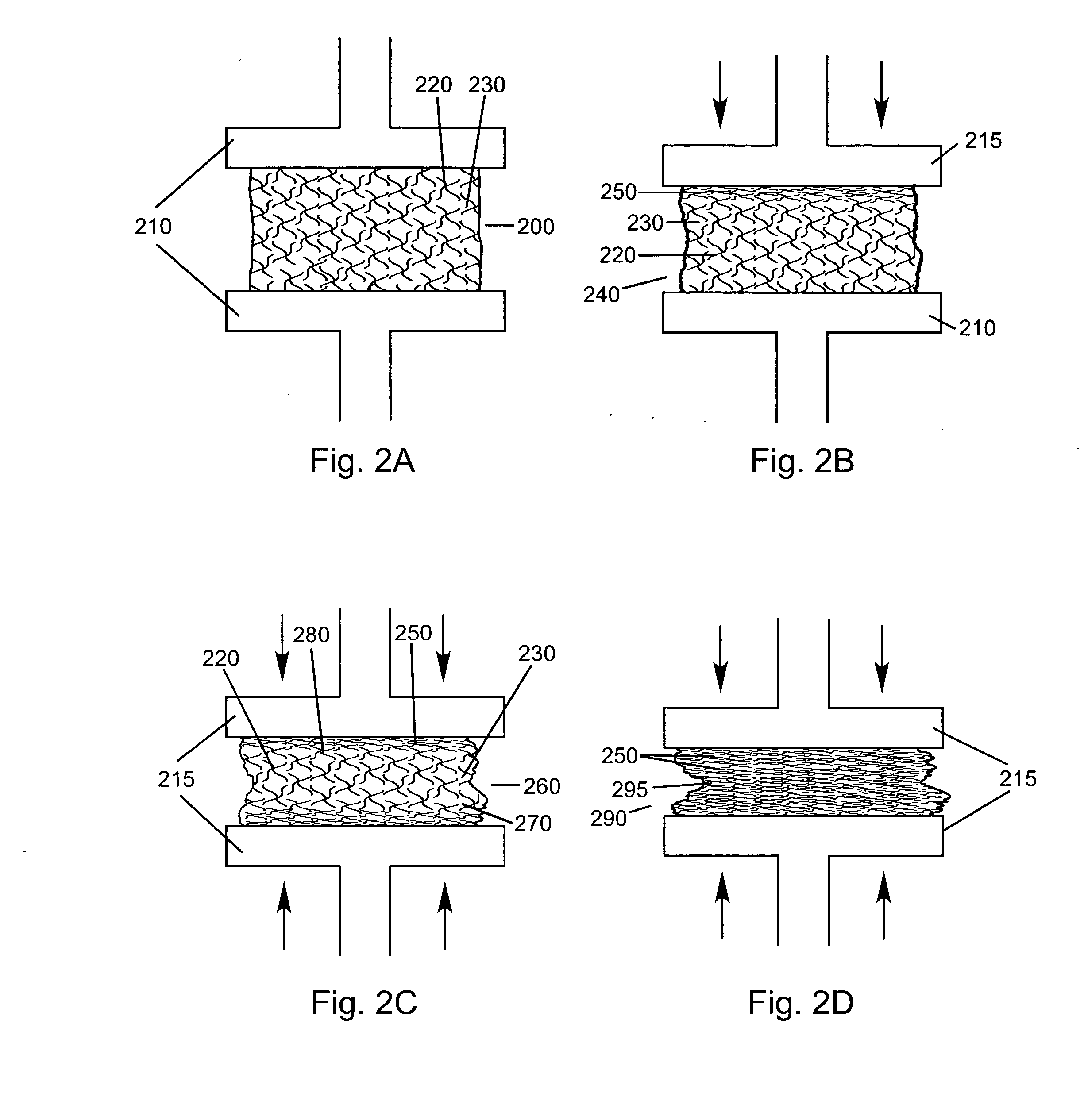

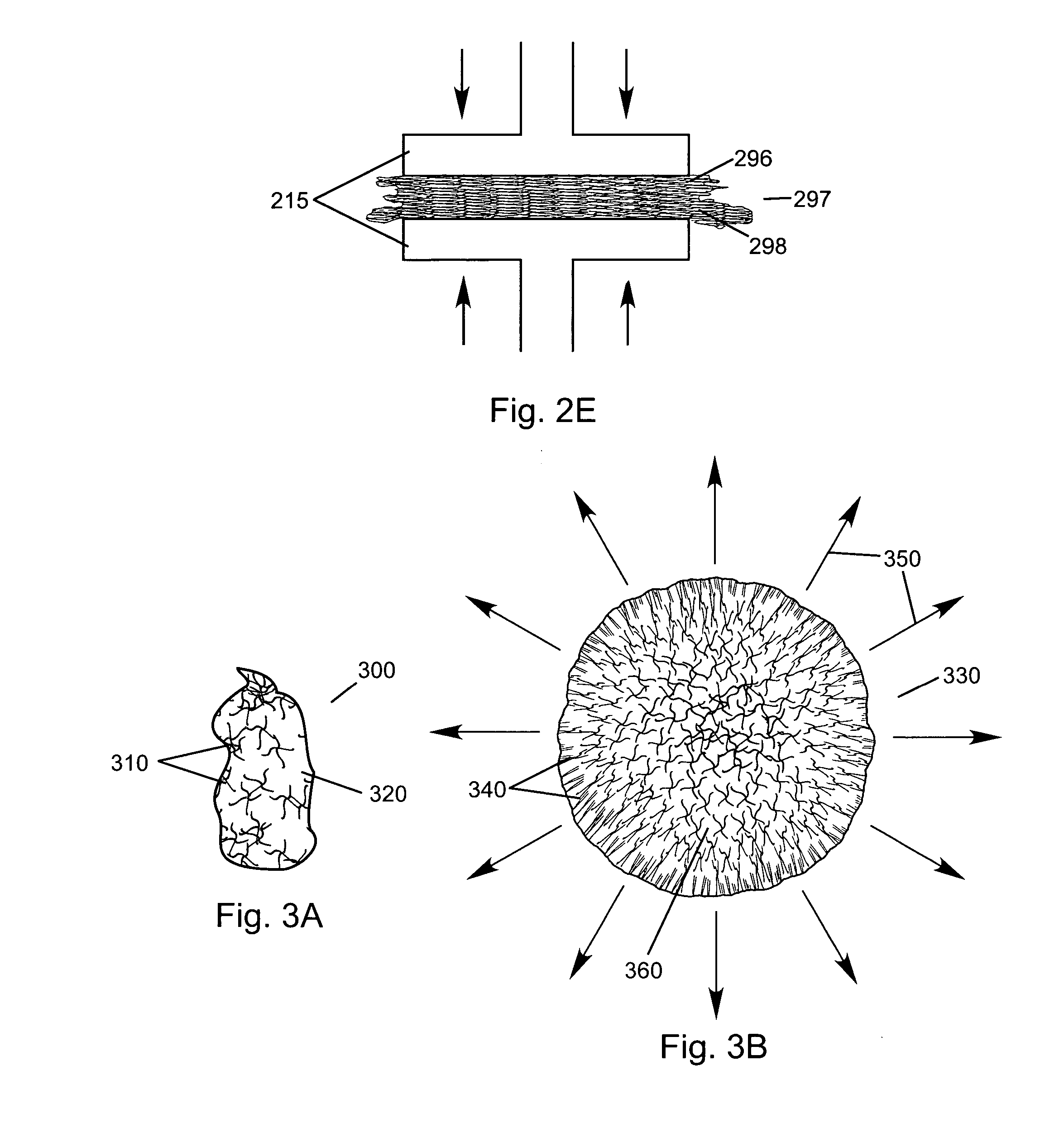

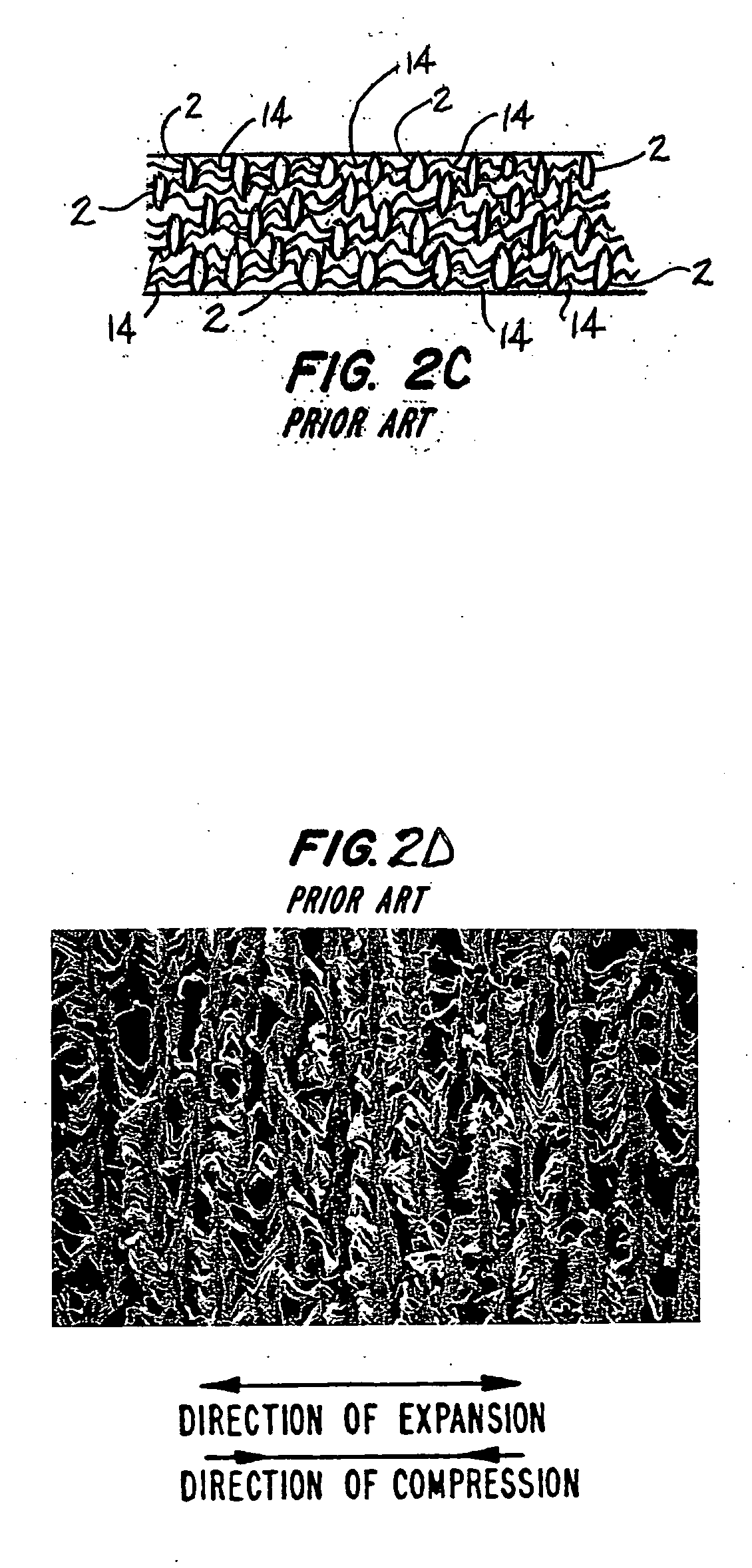

Compressed high density fibrous polymers suitable for implant

An embodiment of the present invention may be made by the following steps: providing a mixture comprising a plurality of fibers, a lubricant, and a suspension fluid, with the suspension fluid filling a void space between said fibers and subjecting said mixture to at least one compressive force. The compressive force causes the migration and alignment of said fibers; and may remove substantially all of the suspension fluid from said mixture. The mixture may further comprise a biologically active agent, or a reinforcing agent.

Owner:DSM IP ASSETS BV

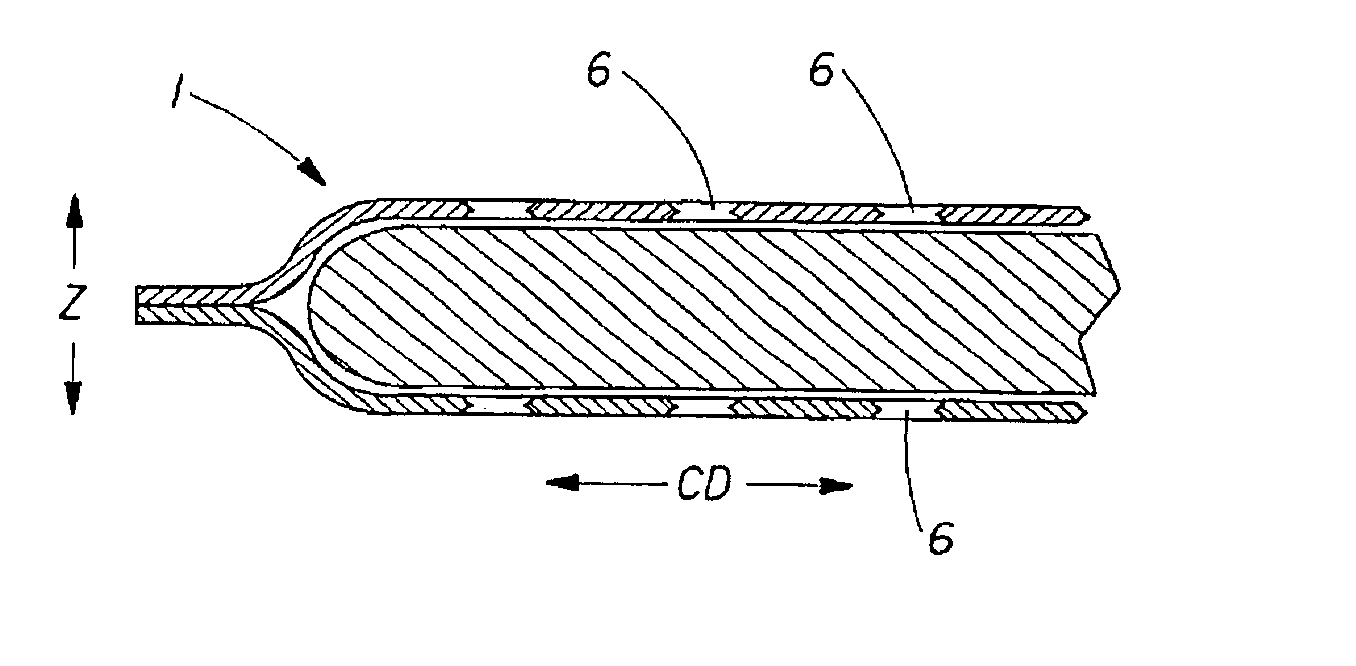

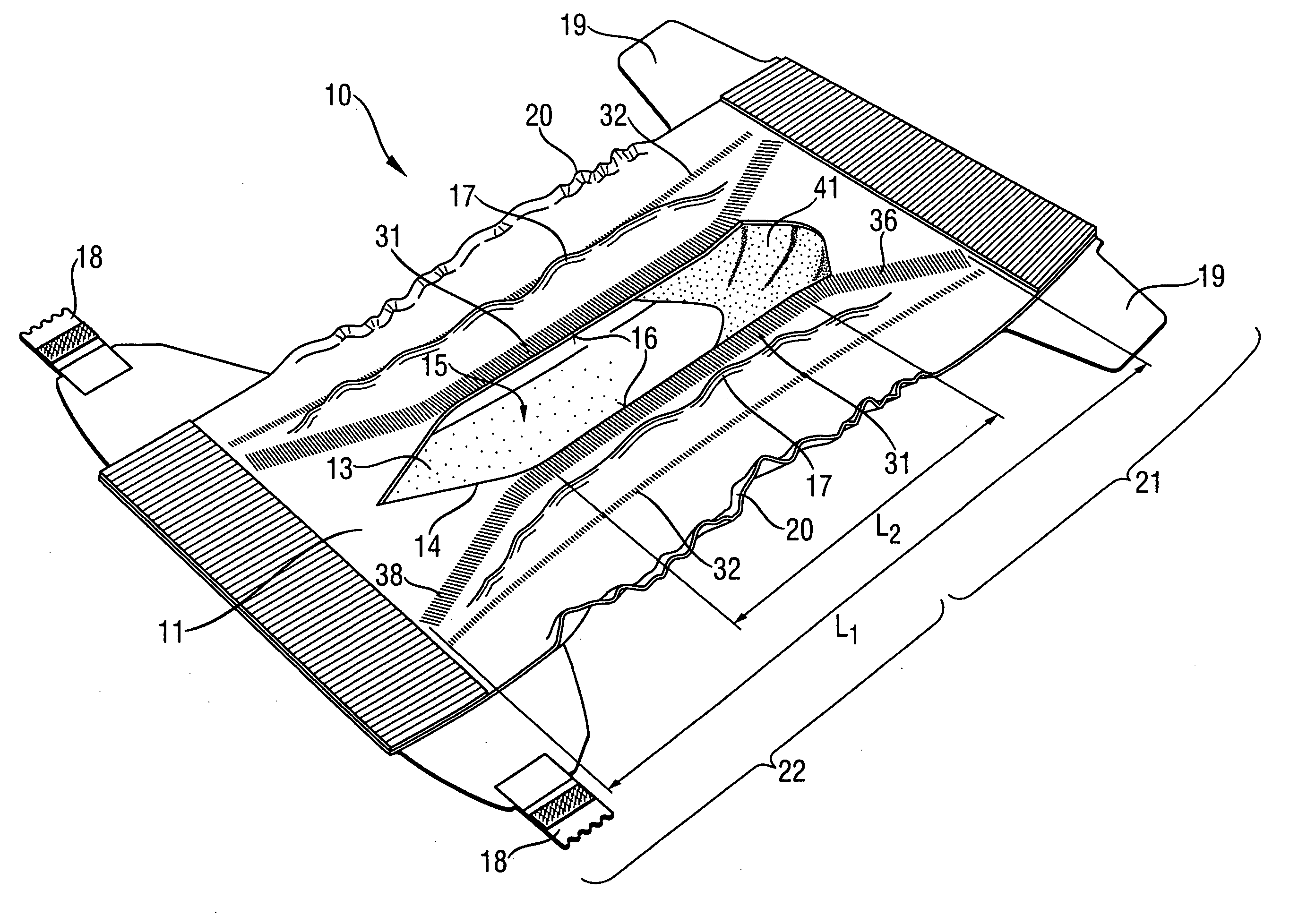

User-activatible substance delivery system

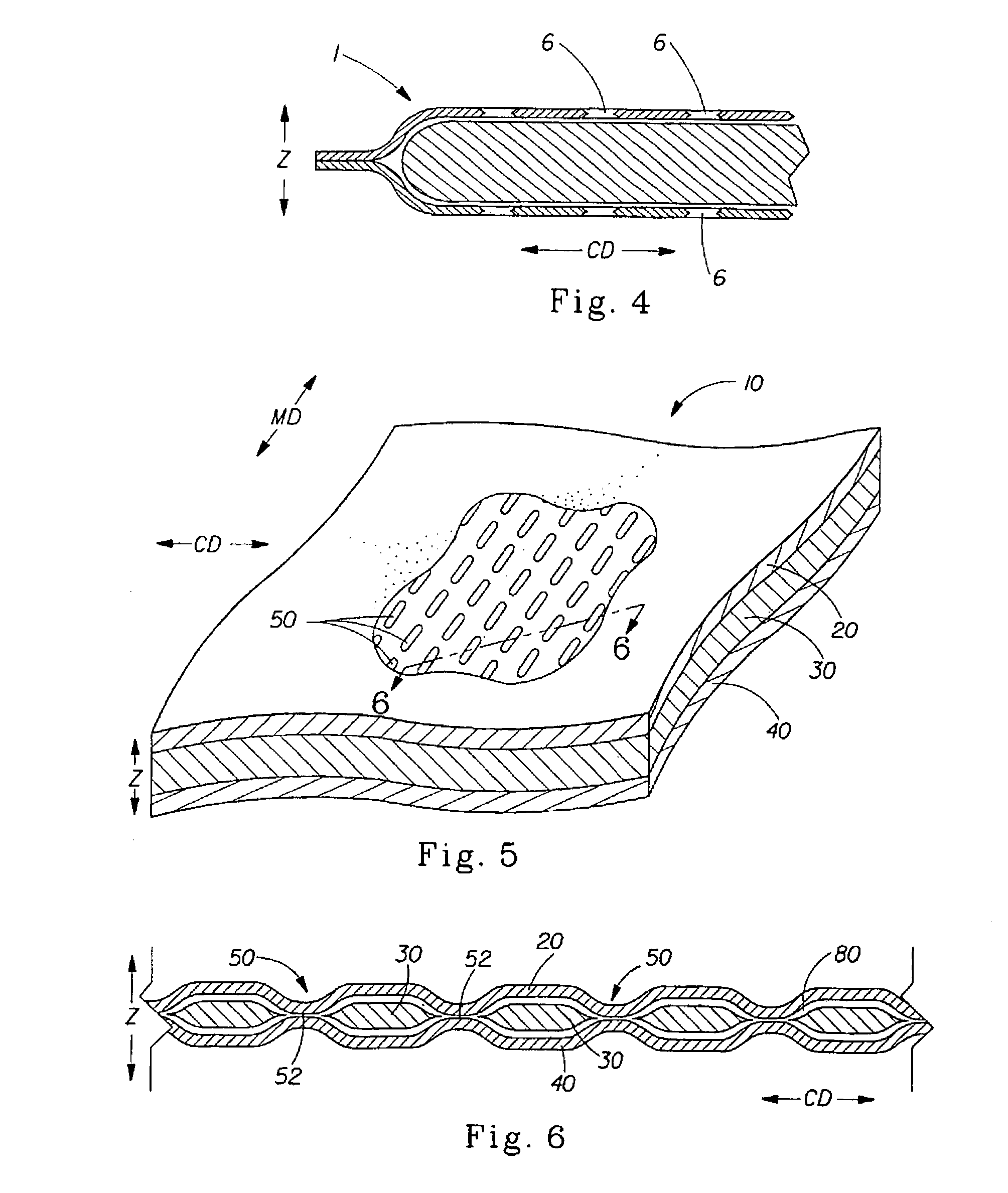

InactiveUS6863960B2Facilitate exposure and deliveryCosmetic preparationsToilet preparationsFiberTransverse axis

A user-activatible substance delivery system of the present invention comprises a first web and a second web, the first and second webs having a periphery and being enclosed about their respective peripheries and defining a void space therein. A substance for delivery upon user activation is disposed in the void space. At least one of the first or second webs has at least one bond site. The bond site(s) define(s) a melt weakened region such that upon application of a force having a vector component parallel to the transverse axis, the bond site(s) fracture(s) to form a corresponding aperture in the respective web. The apertures provide a fluid communication path to facilitate delivery of the substance from the void space.

Owner:THE PROCTER & GAMBLE COMPANY

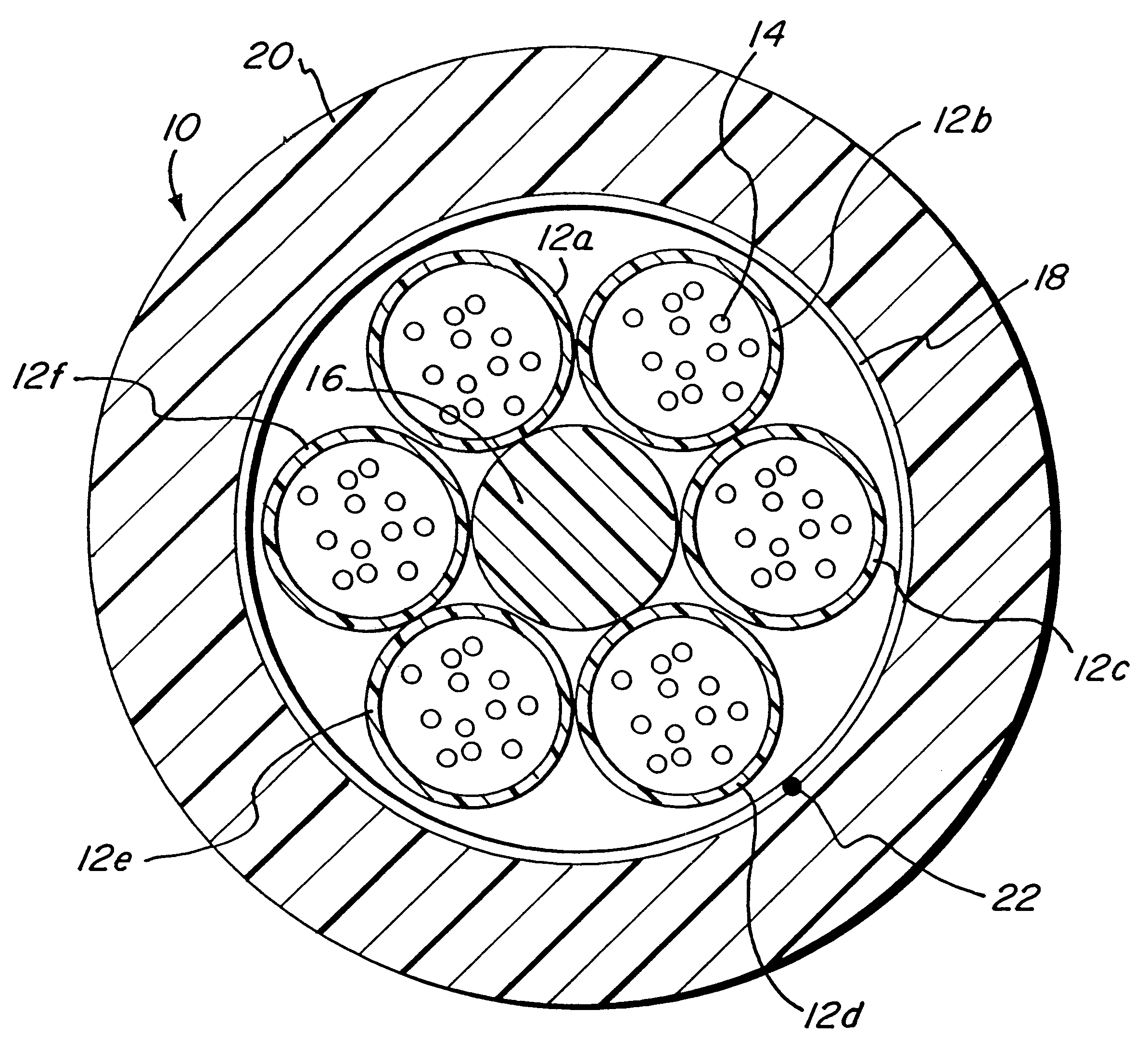

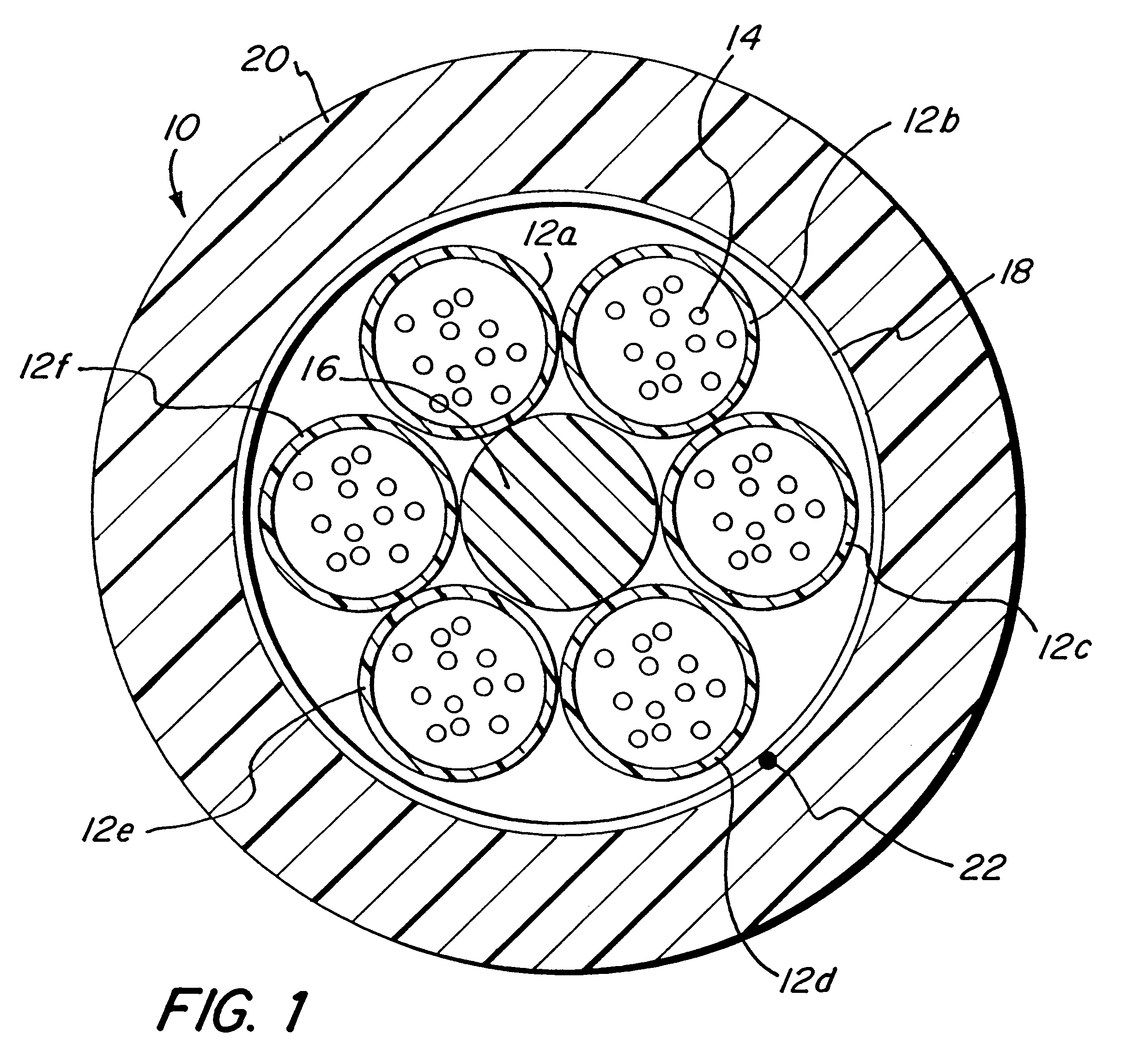

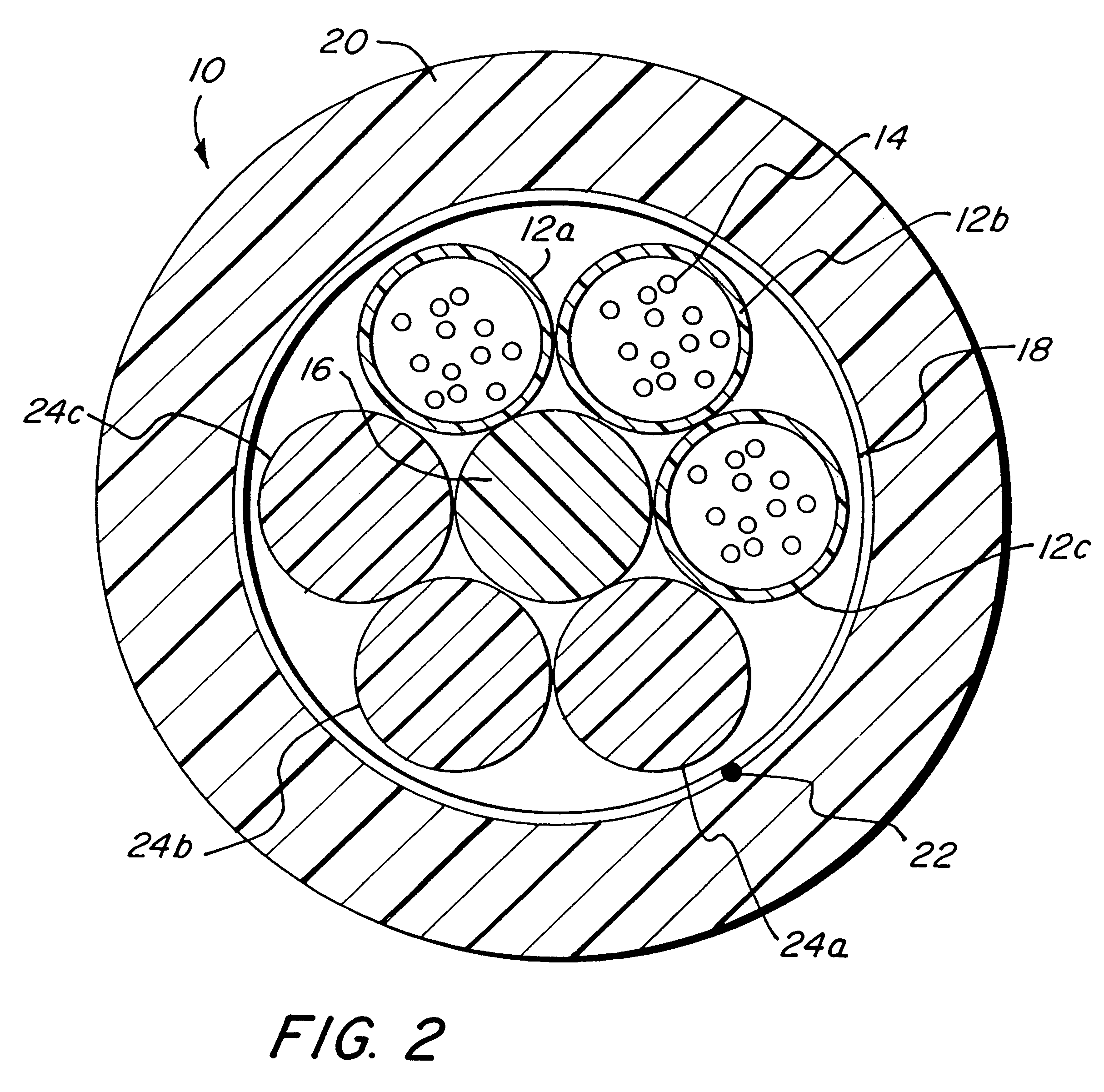

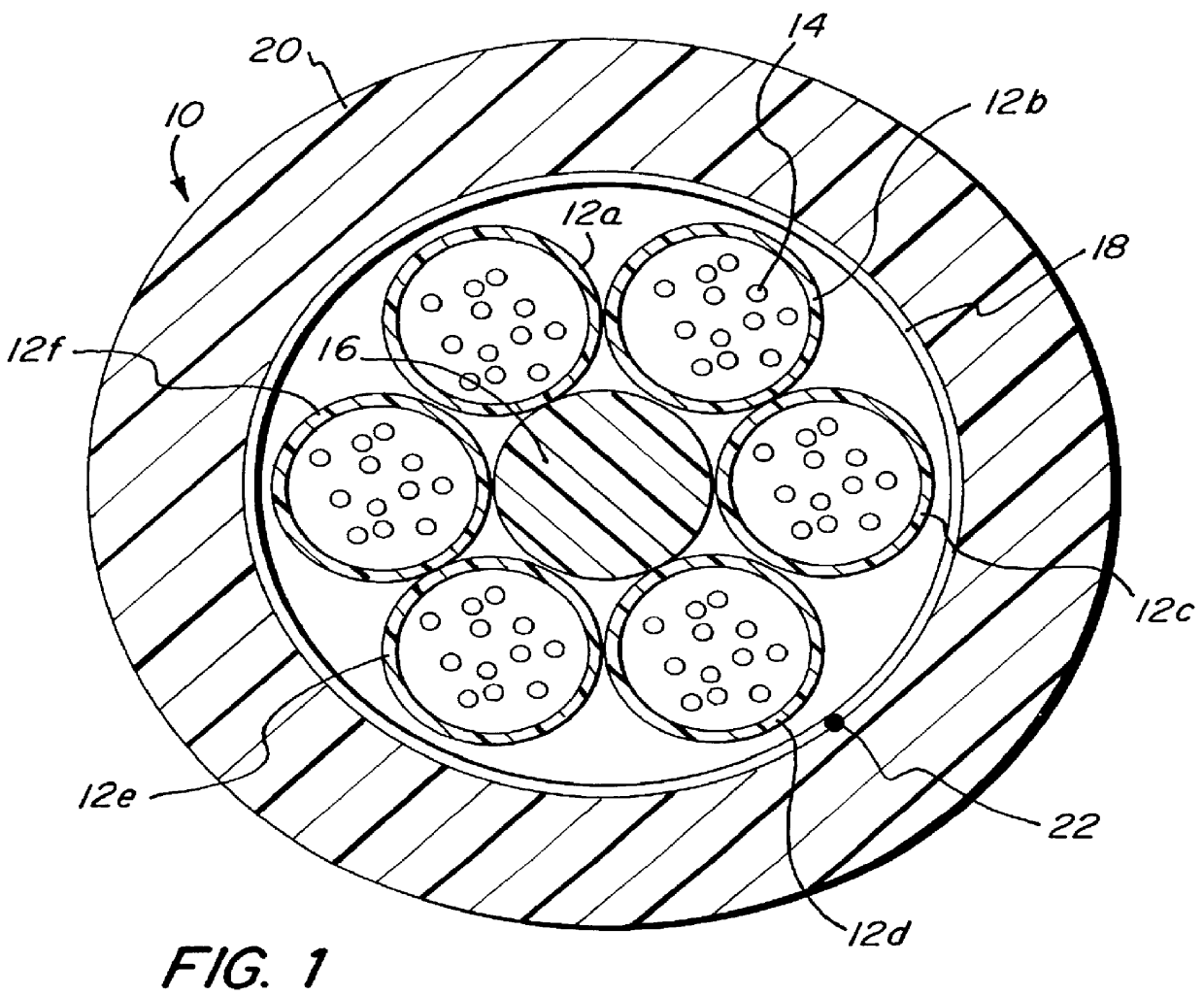

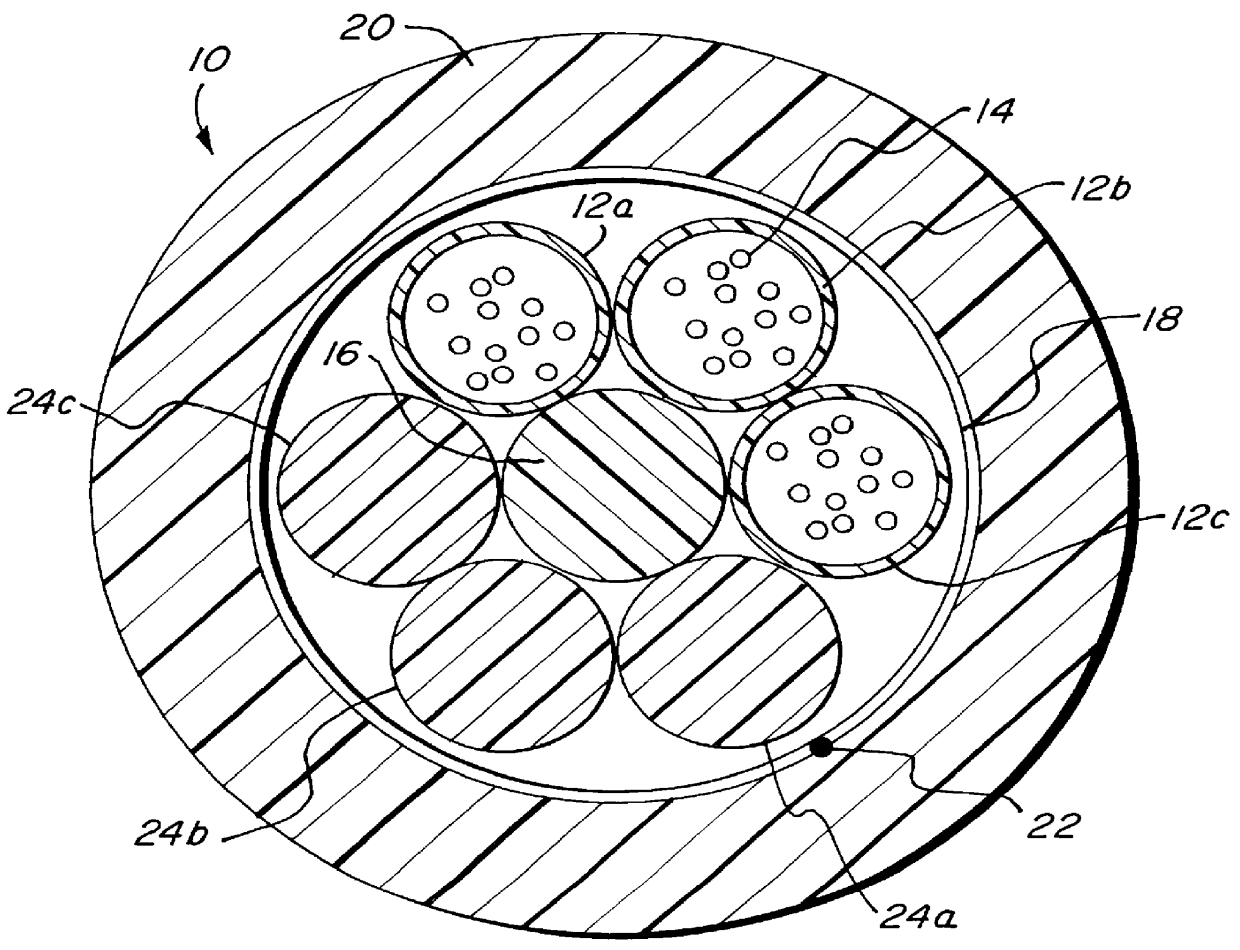

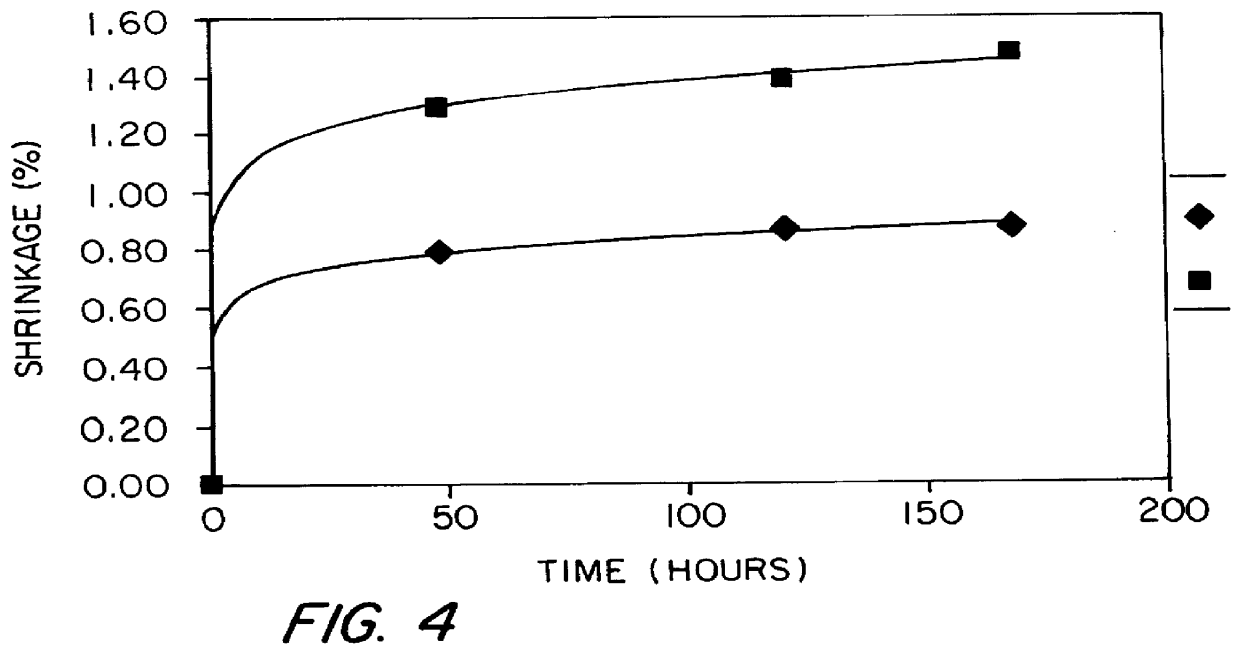

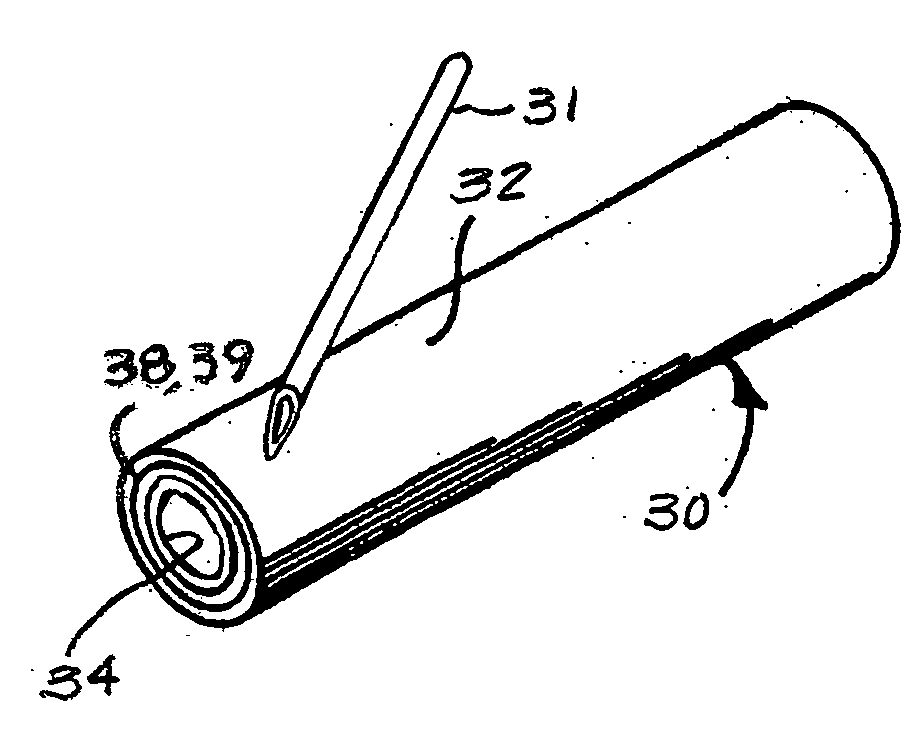

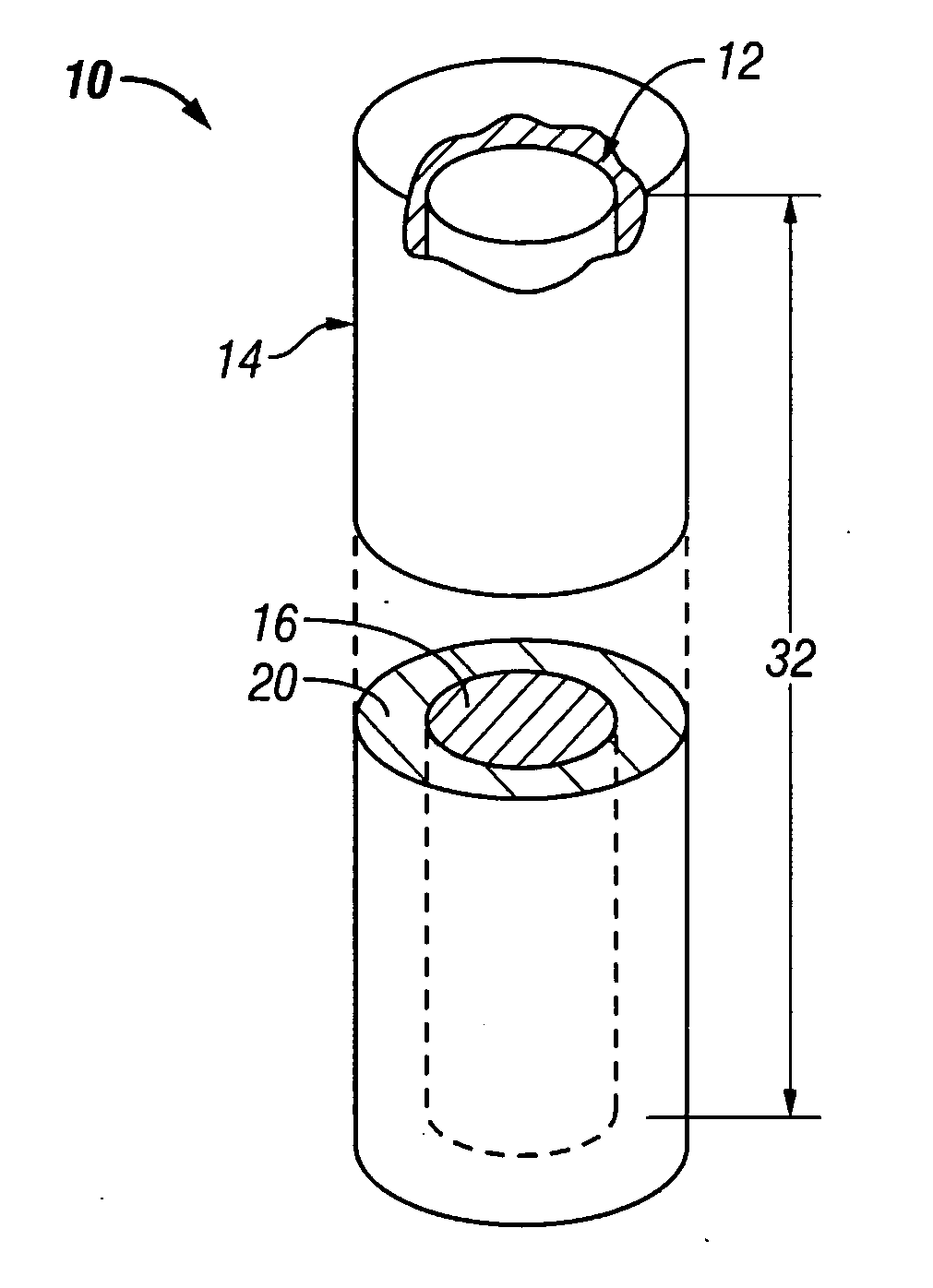

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

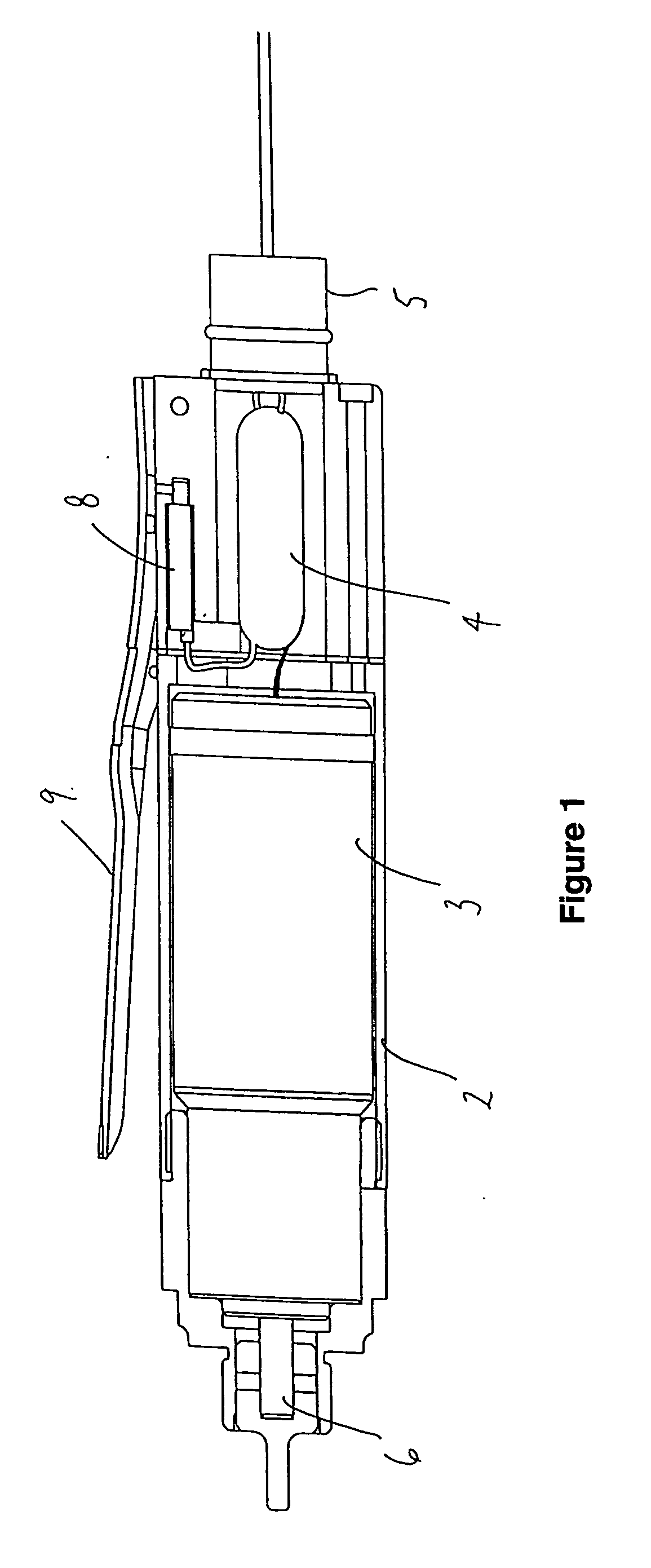

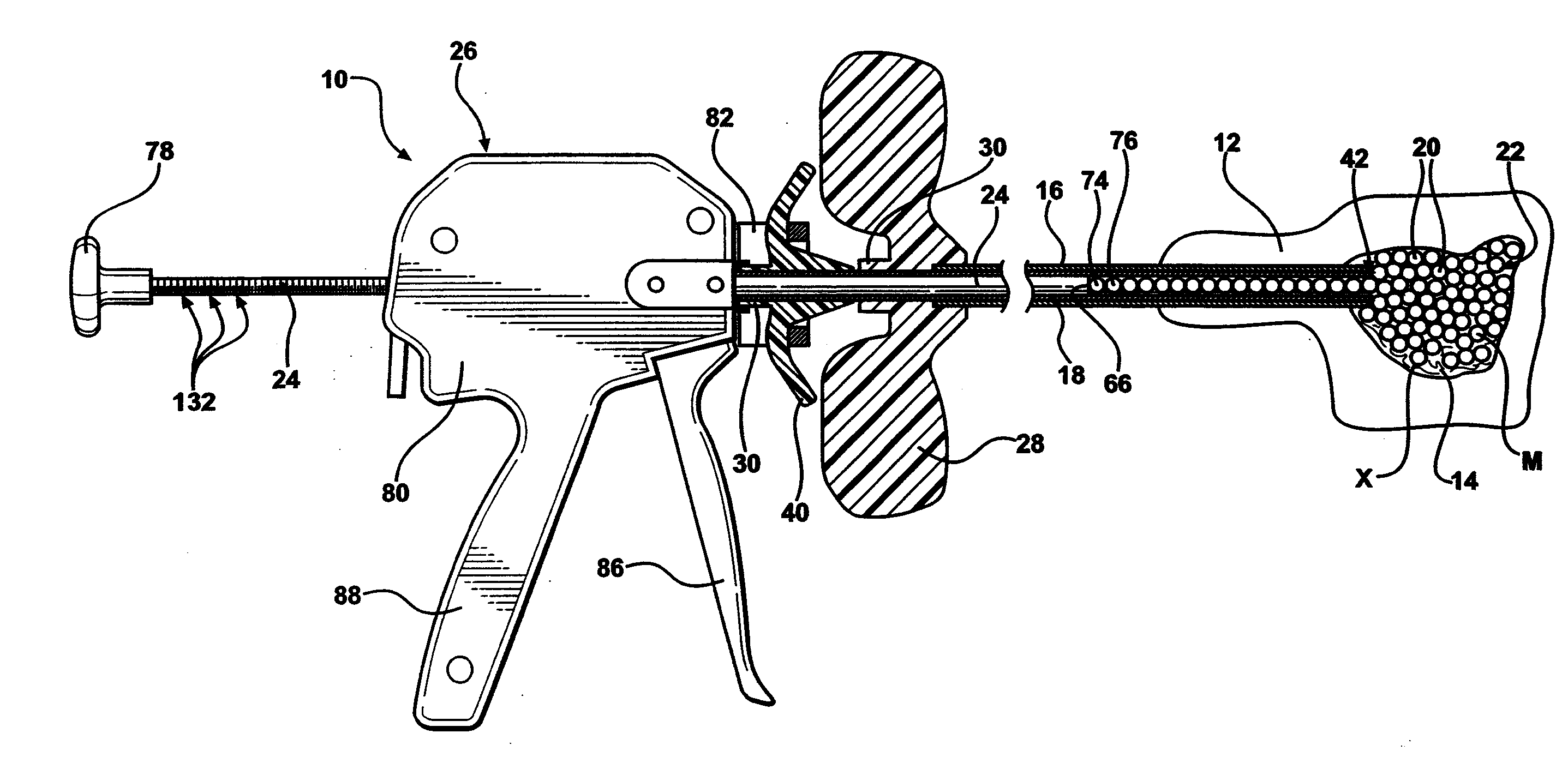

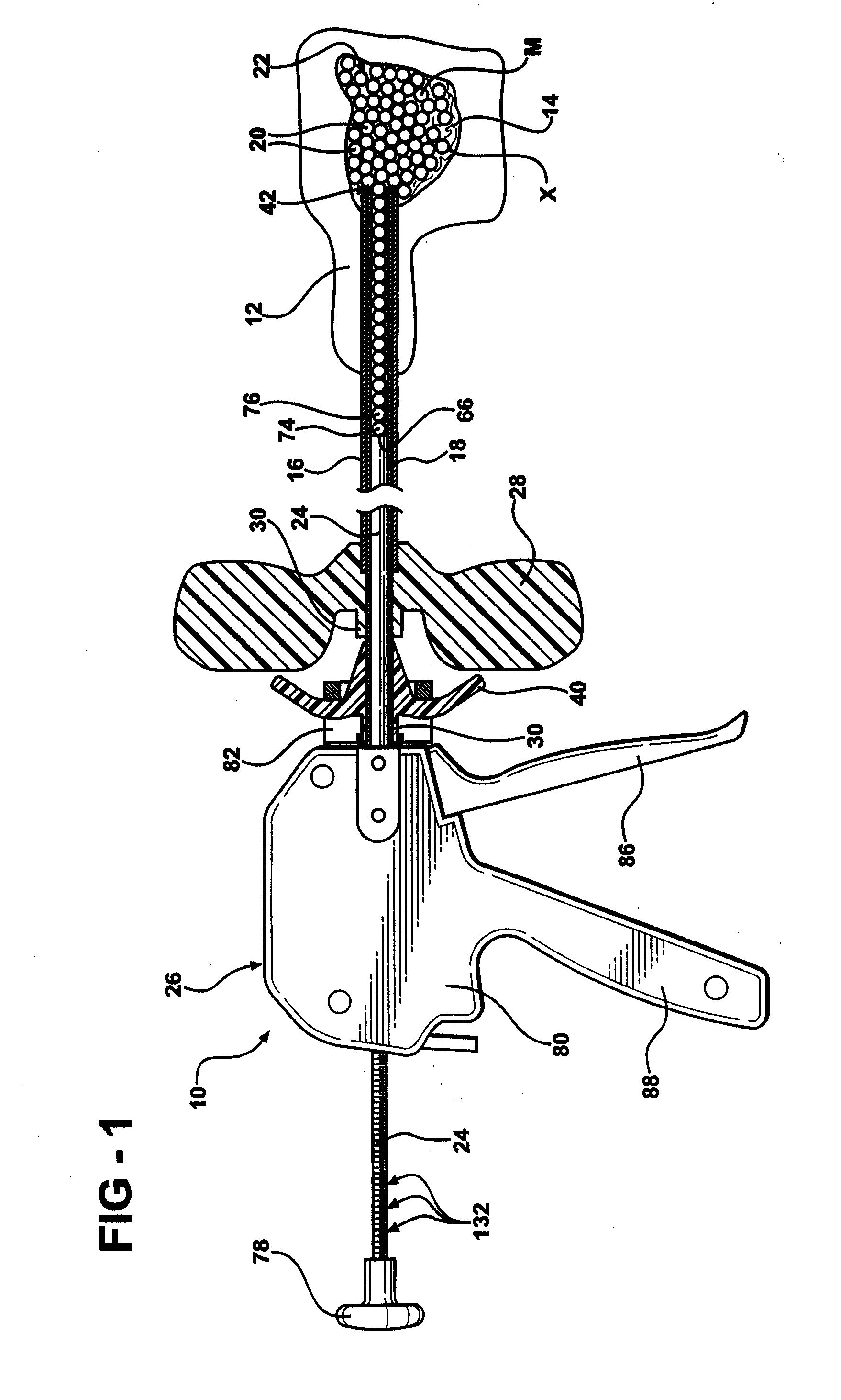

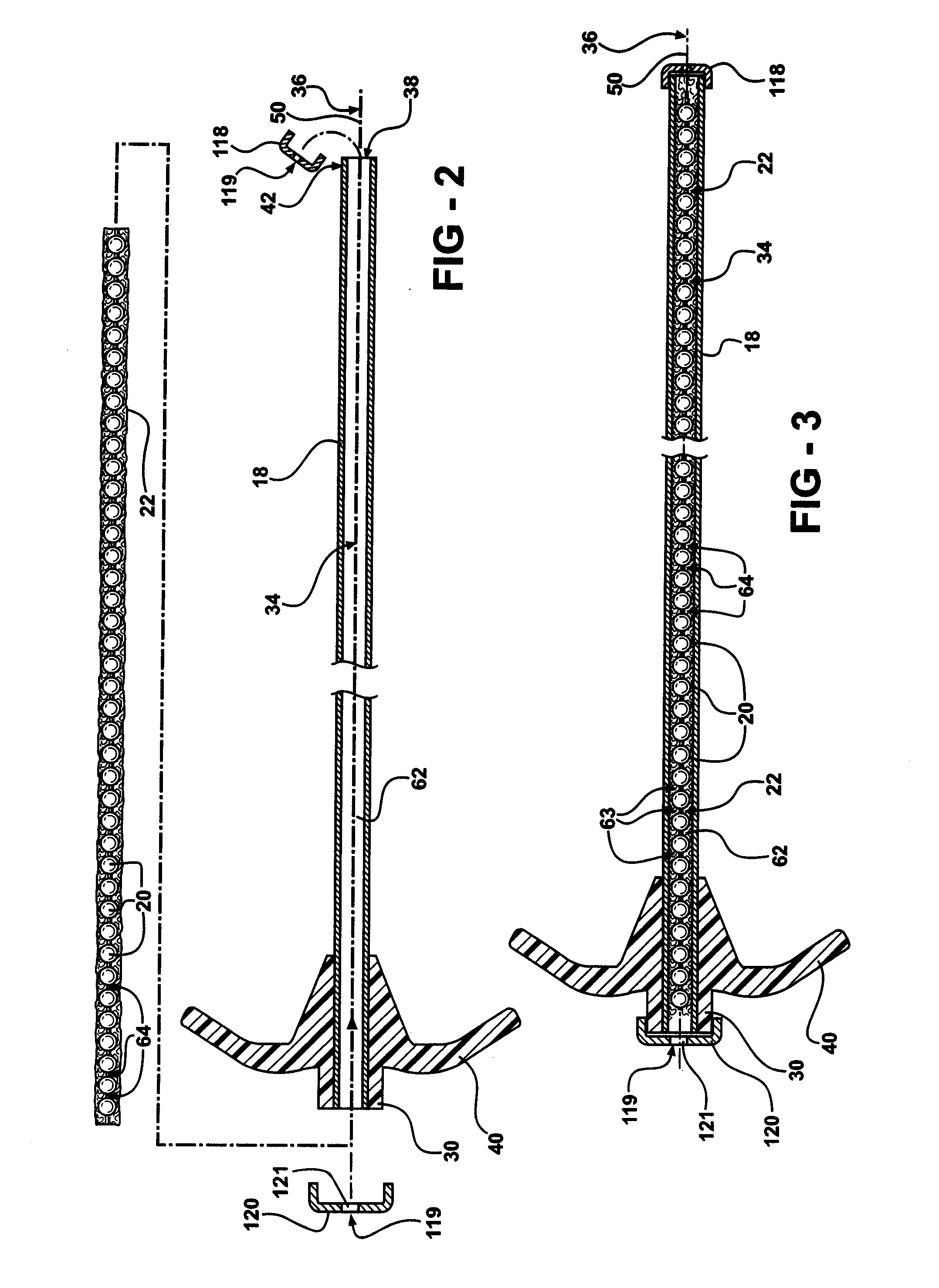

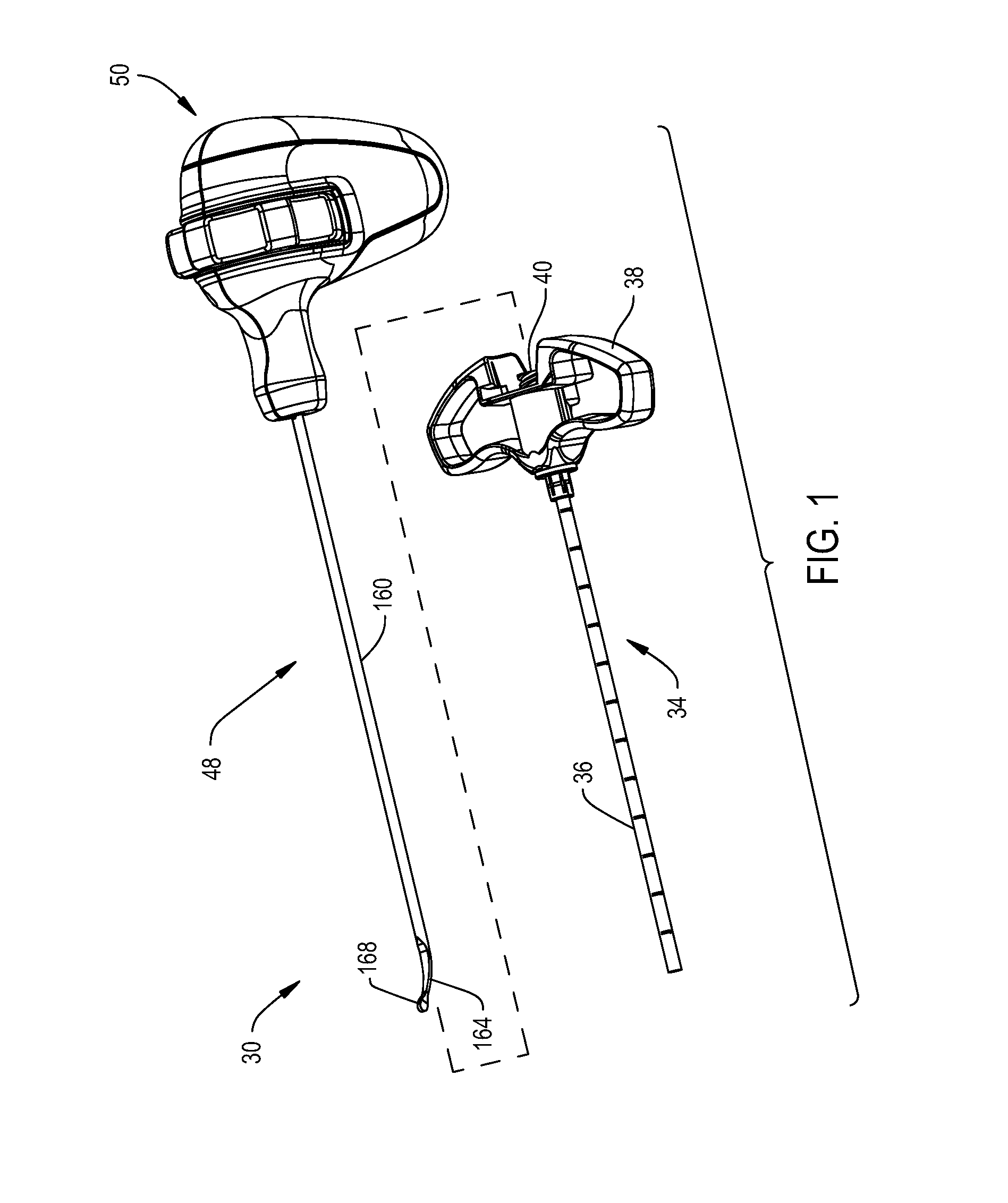

Low pressure delivery system and method for delivering a solid and liquid mixture into a target site for medical treatment

ActiveUS20070233146A1Improve stabilityAvoid relative motionInternal osteosythesisSurgical needlesDelivery systemBiomedical engineering

A system for forming an implant to stabilize an interior of a vertebral body is provided. The system includes a delivery cannula. A plurality of elements are disposed adjacent to one another in the delivery cannula with void spaces defined between the elements. A fluent material, capable of setting to a hardened condition, is disposed within at least a portion of the void space in the delivery cannula. A push rod is movably disposed within the delivery cannula to apply a force to move the elements through the delivery cannula and into the interior of the vertebral body. Upon application of the force, the elements simultaneously carry the fluent material through the delivery cannula and into vertebral body to delivery the fluent material at a low pressure. The fluent material sets to the hardened condition to secure the elements and form the implant.

Owner:STRYKER CORP

Polypropylene filler rods for optical fiber communications cables

InactiveUS6066397ACladded optical fibreFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

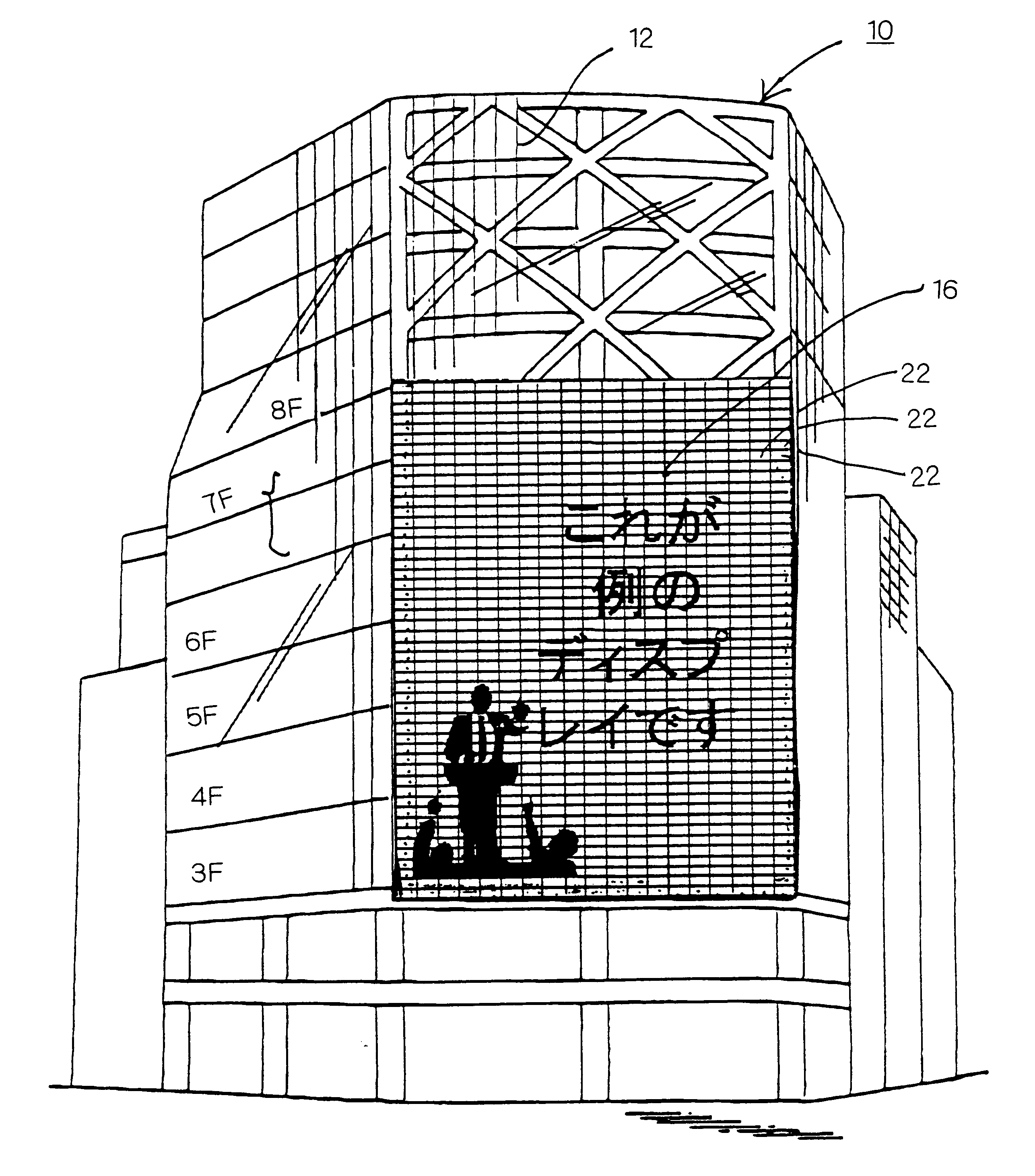

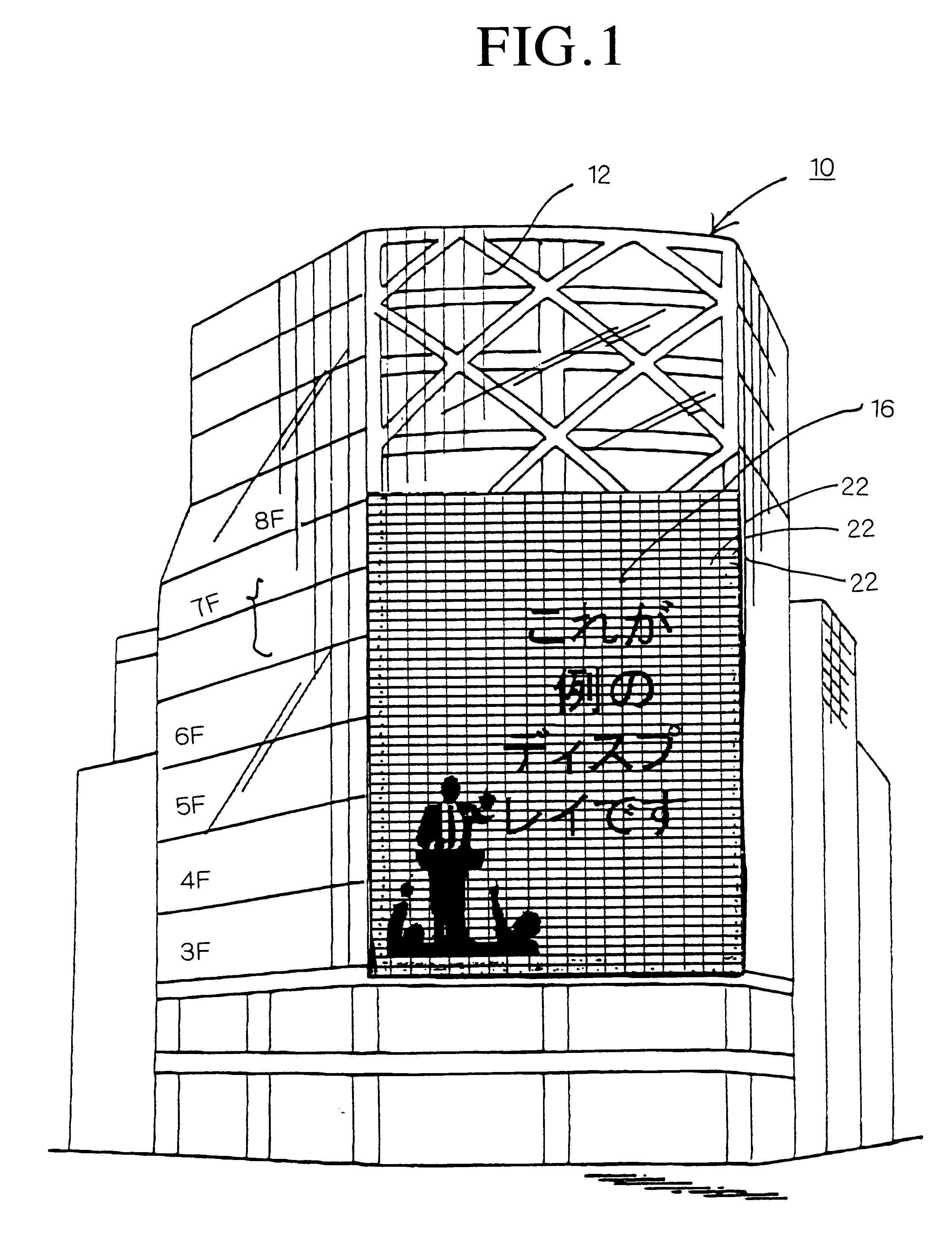

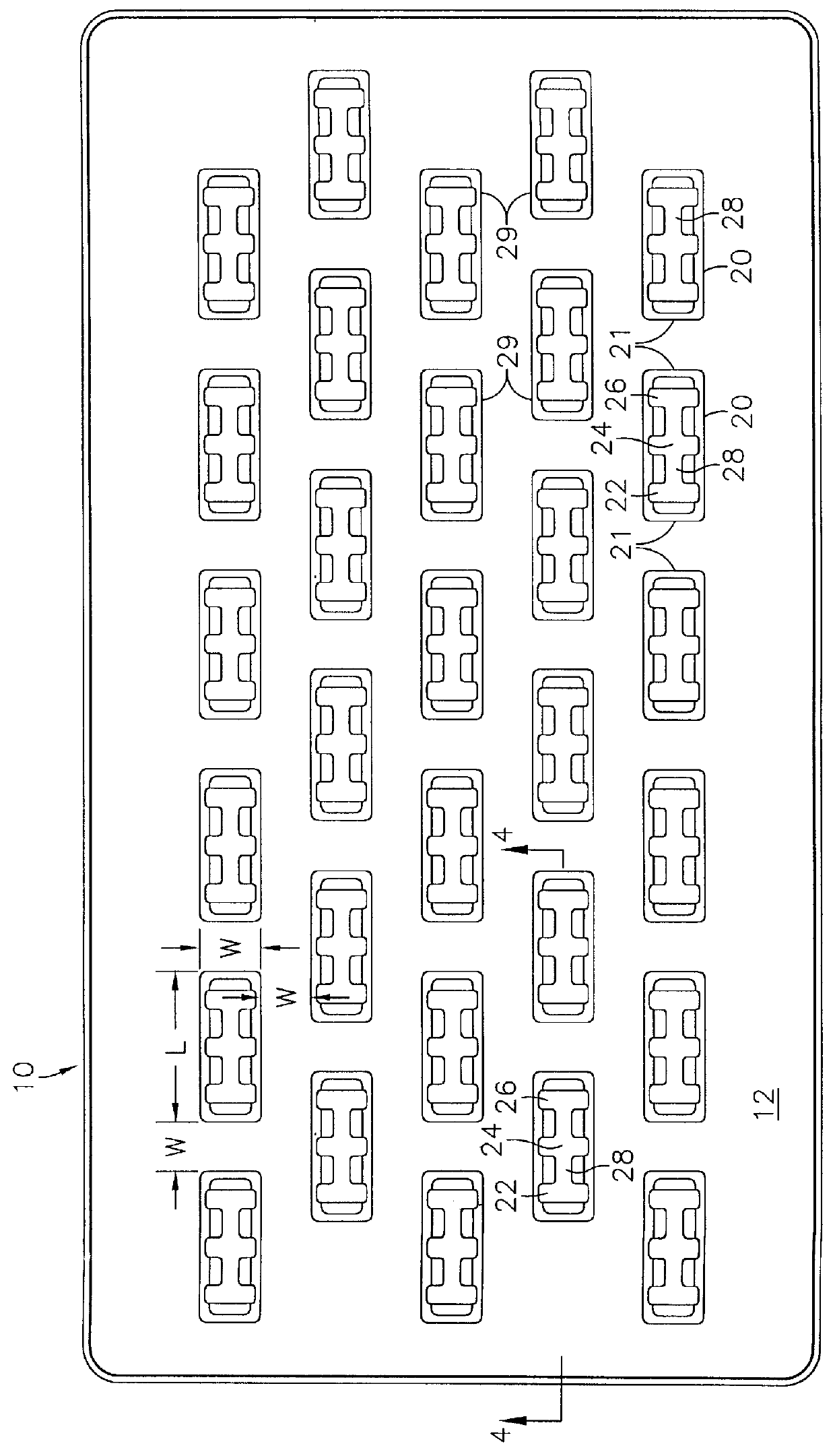

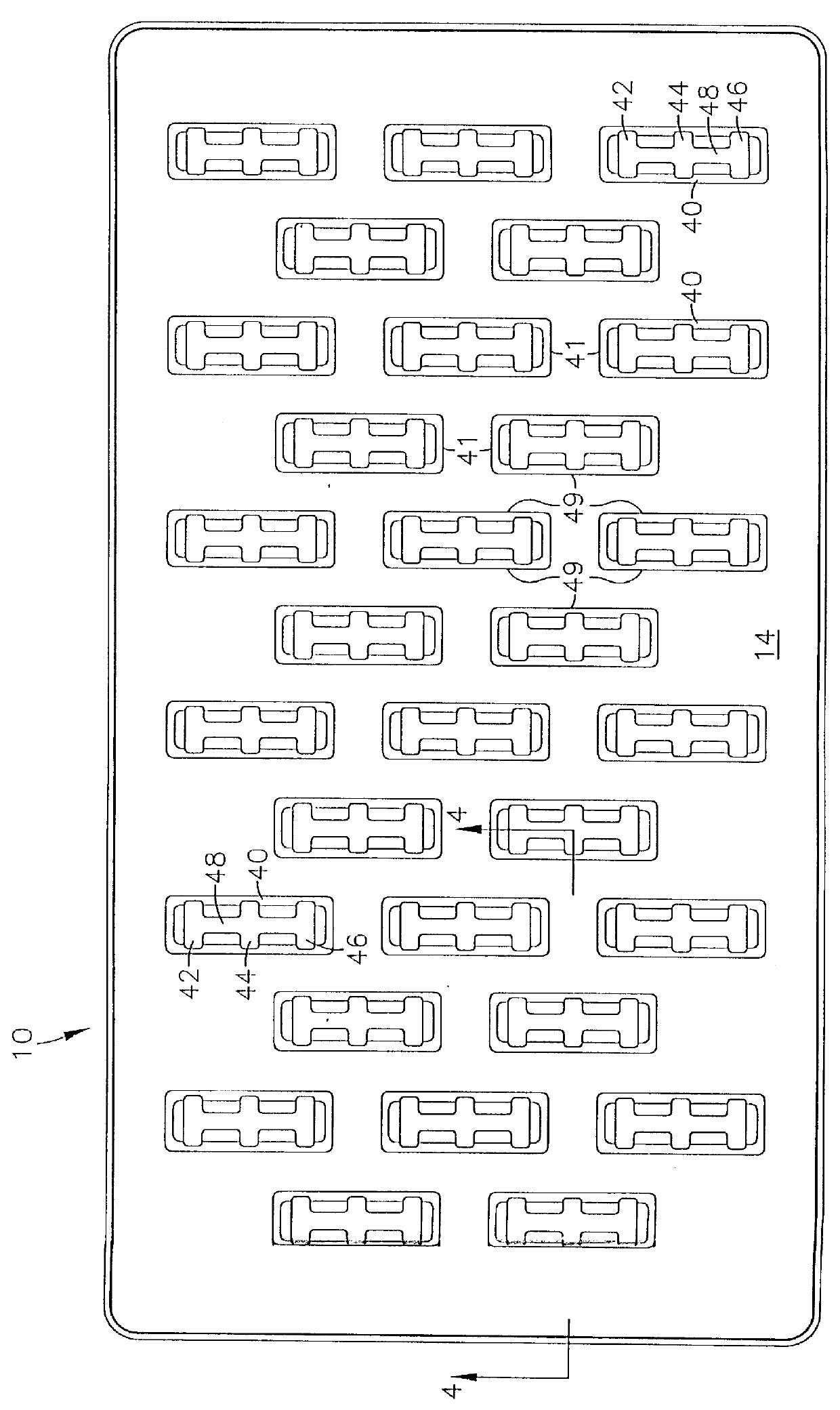

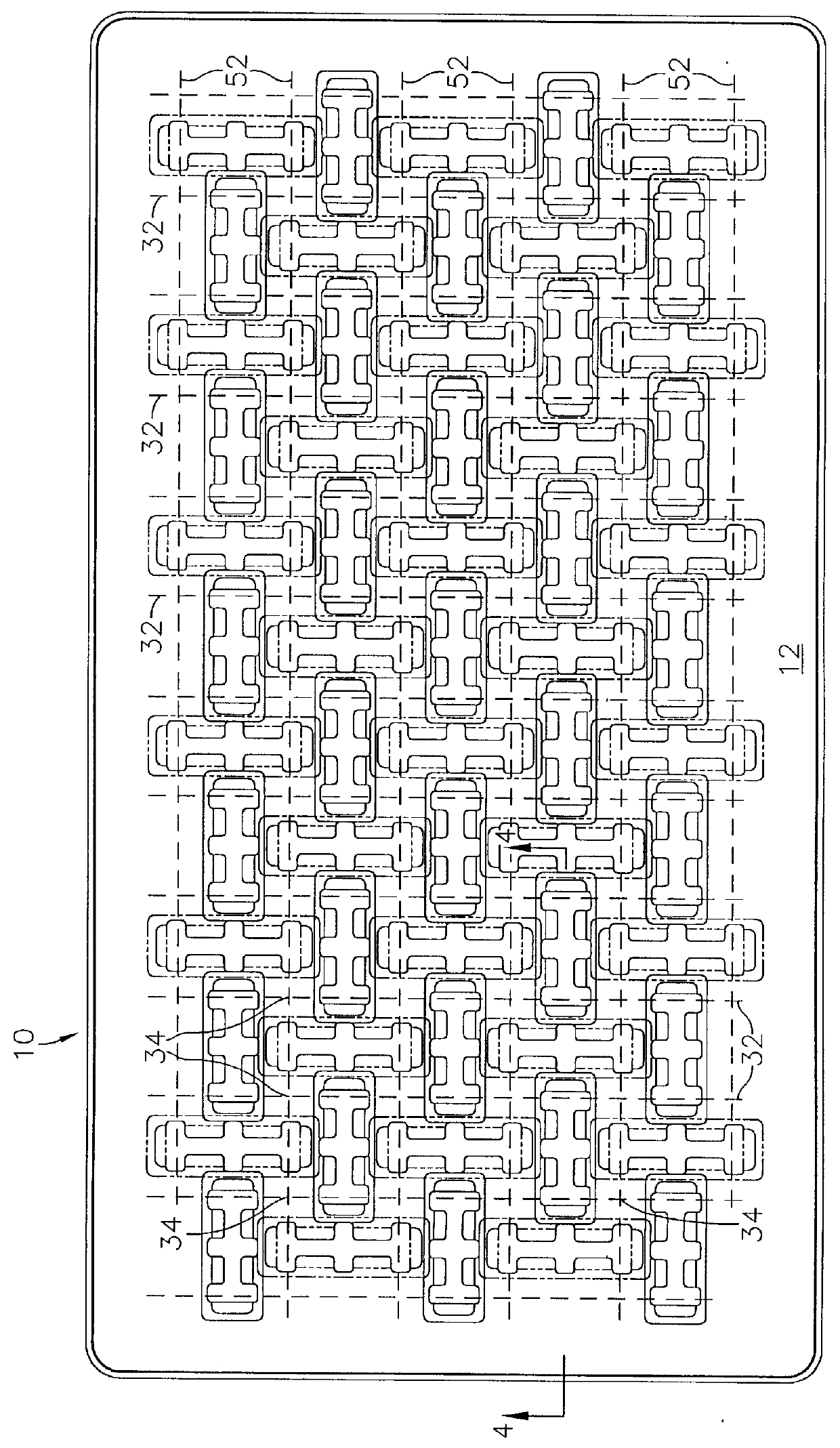

High-rise building with large scale display device inside transparent glass exterior

InactiveUS6237290B1Easy to carryImprove device performanceStampsPublic buildingsFloor slabWindow shutter

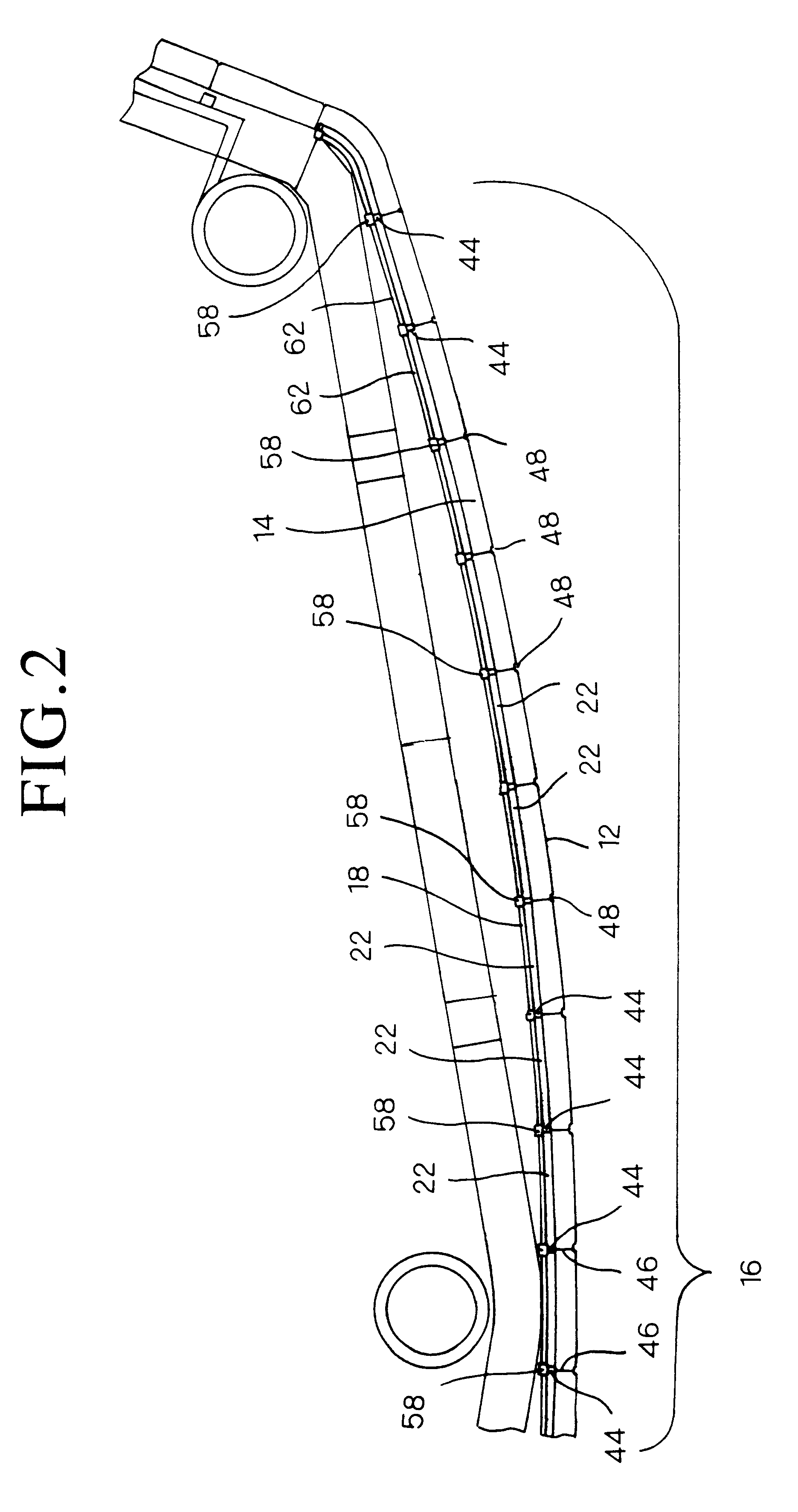

A high-rise building with a large scale dot-matrix display device is disclosed. The glass panels arranged in rows and columns form a curtain wall structured transparent outer wall 12 extending over an exterior of a building 10. Each panel is installed apart from end portions of floor slabs to form a void space therebetween. A plurality of louver structured modules 22 are arranged within the void space in rows and columns to form a large scale display area. Each module 22 has a louver-like structure formed of a plurality of posts 24 arranged in substantially parallel relationship and a plurality of parallel, uniformly spaced beams 26 connecting said adjacent posts 24. A plurality of LED combination lamps 28 are mounted on each beam 26 at uniform pitches as those between the adjacent beams 26. The LEDs are driven by drive circuits disposed in each beam 26. The vertical guide members 44 are fixed to the end portions of the floor slabs 20. The guide members 44 are arranged substantially in parallel relationship so that the modules 22 are supported between the adjacent guides 44 at the both lateral sides thereof. A plurality of vertical mullion members 48 fixed to the vertical guide members 44 as spaced apart from each of the vertical guides 44, so that the glass panels 12 are supported therebetween.

Owner:AVIX

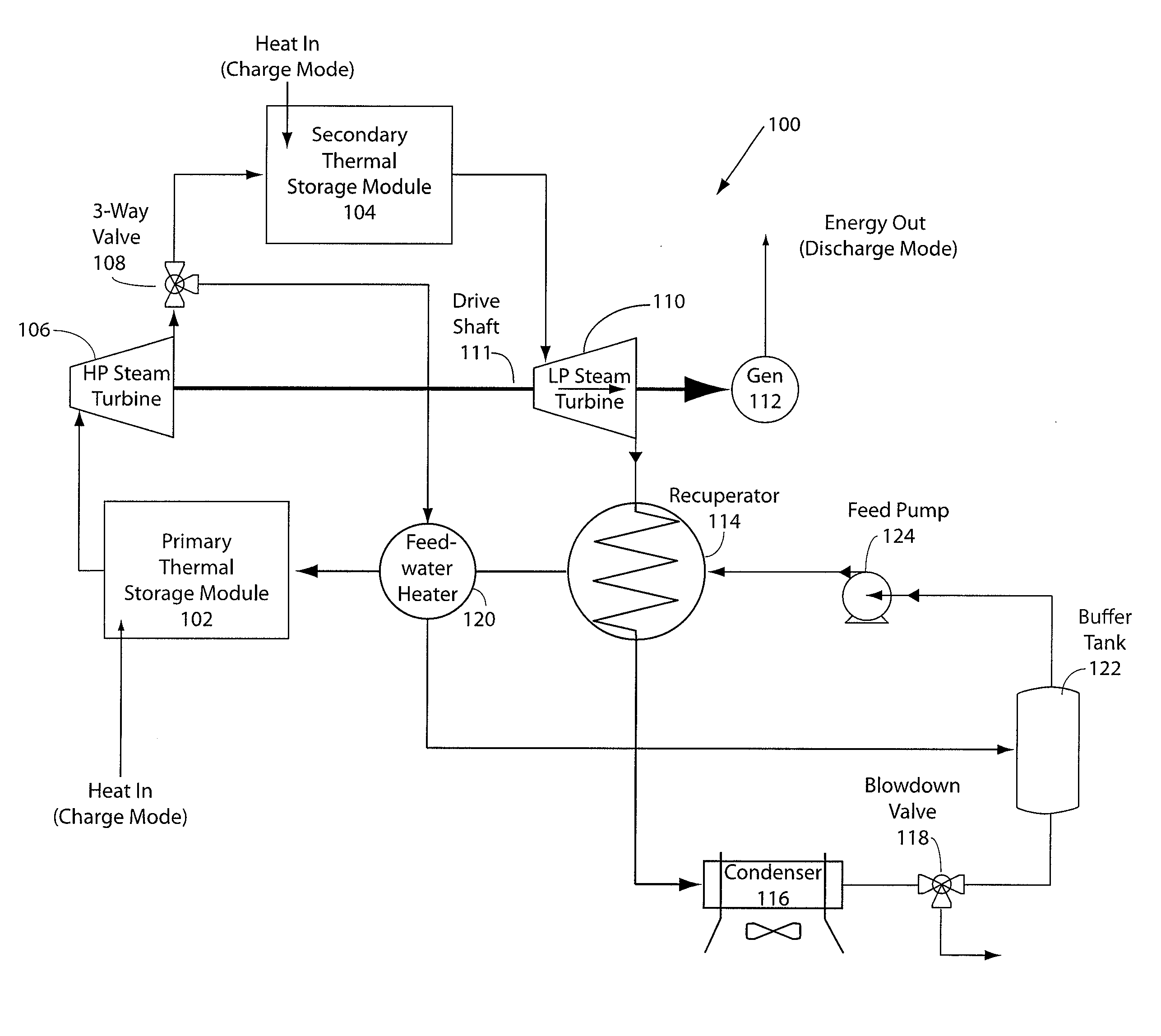

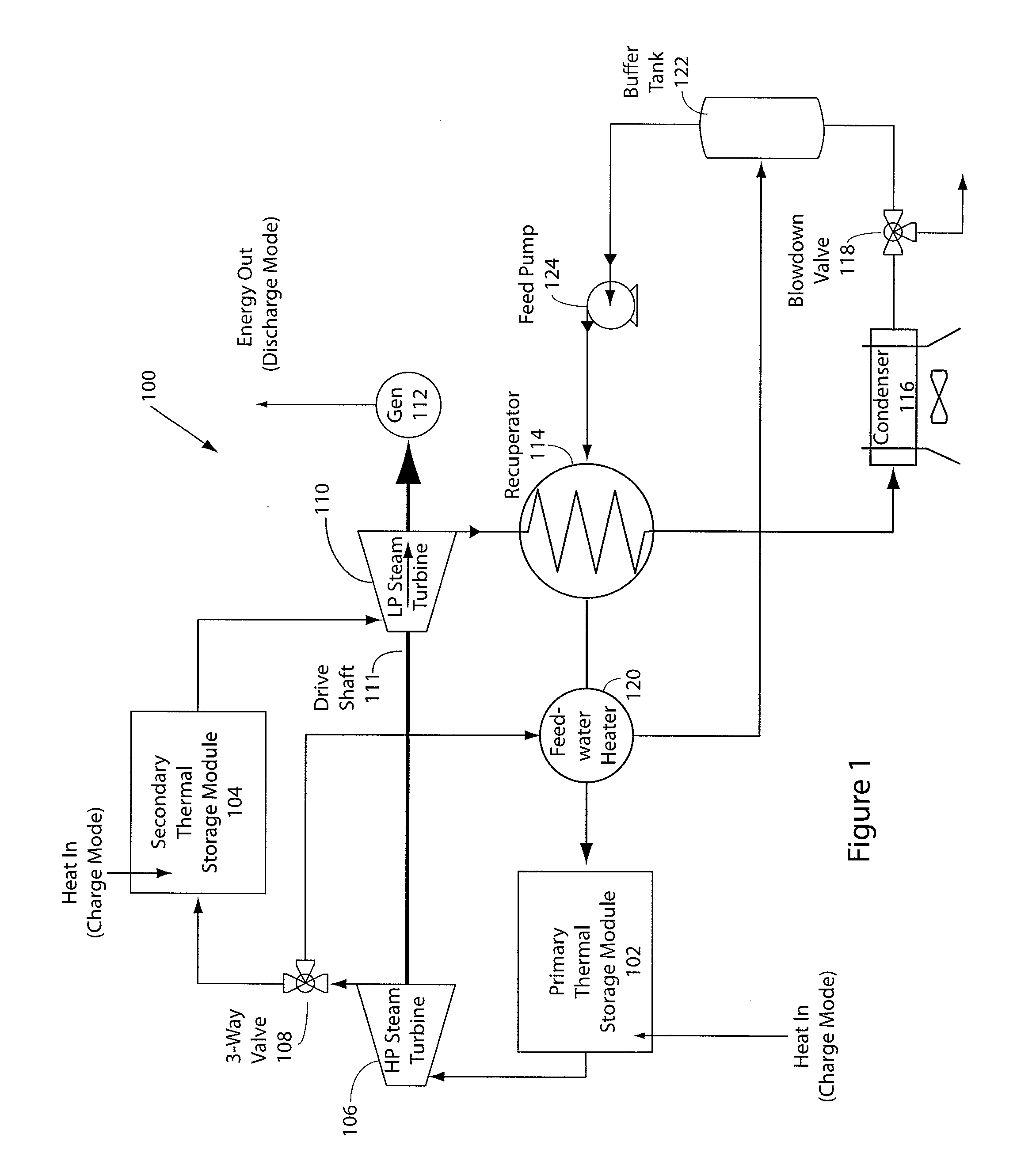

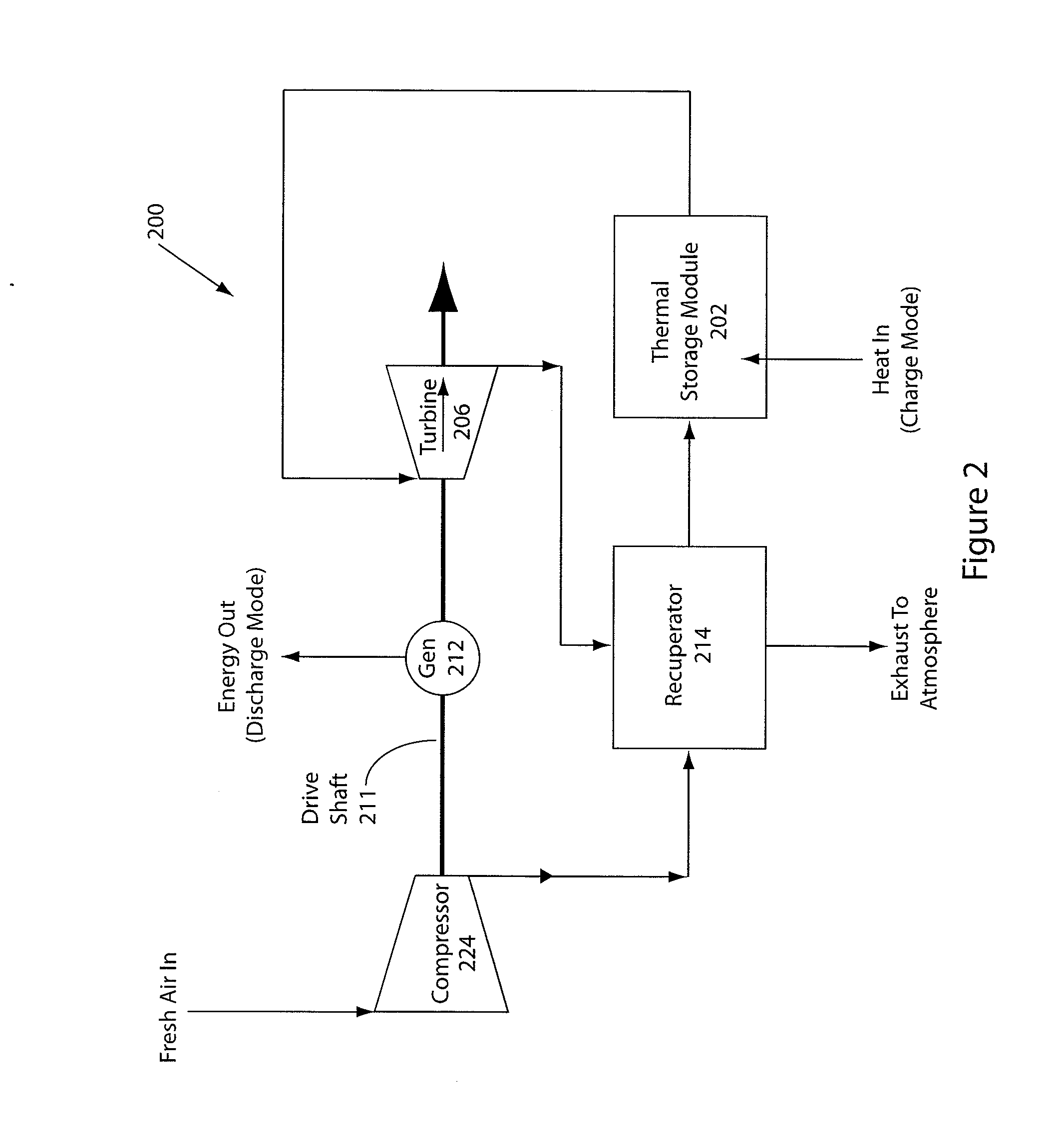

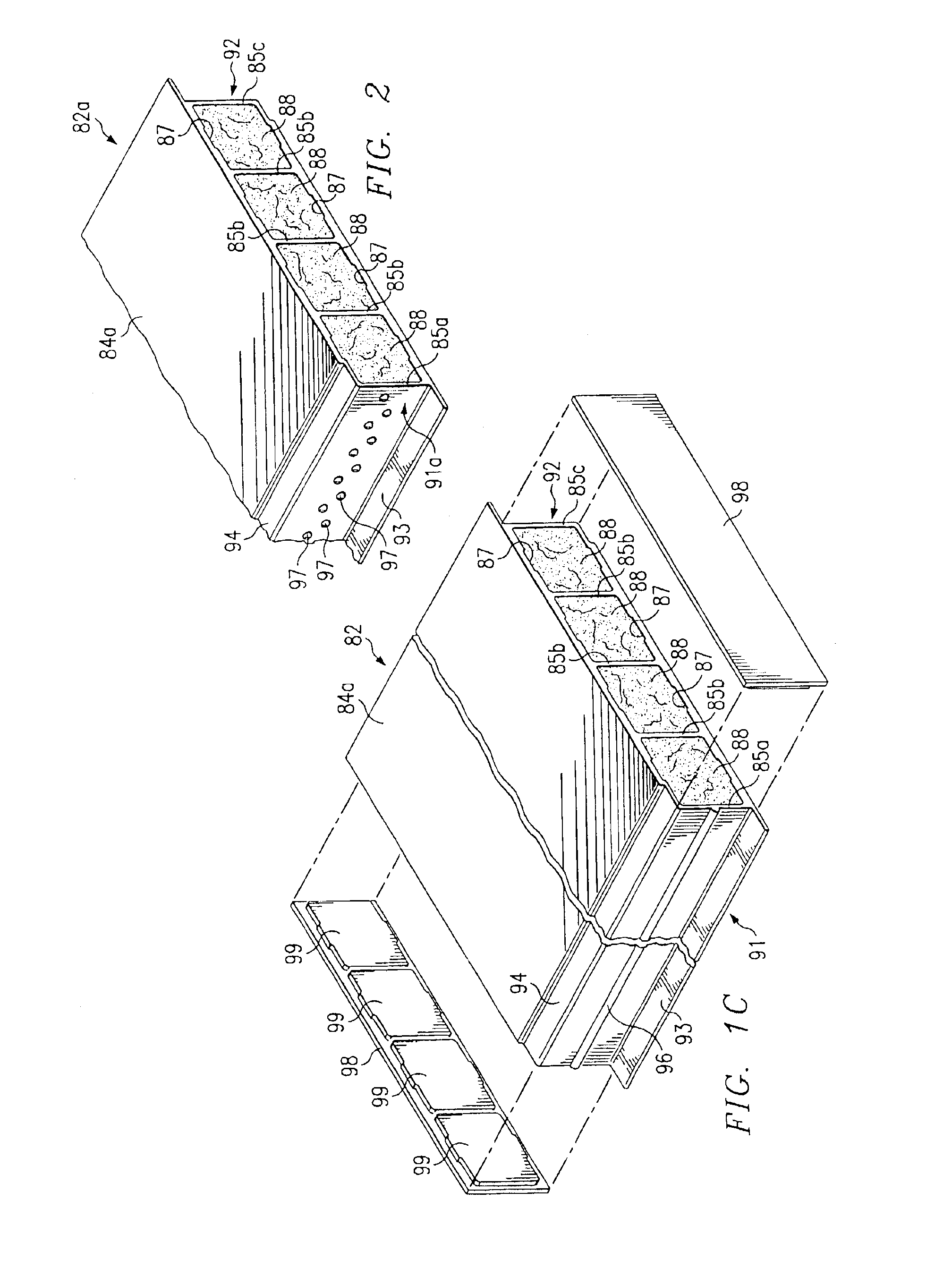

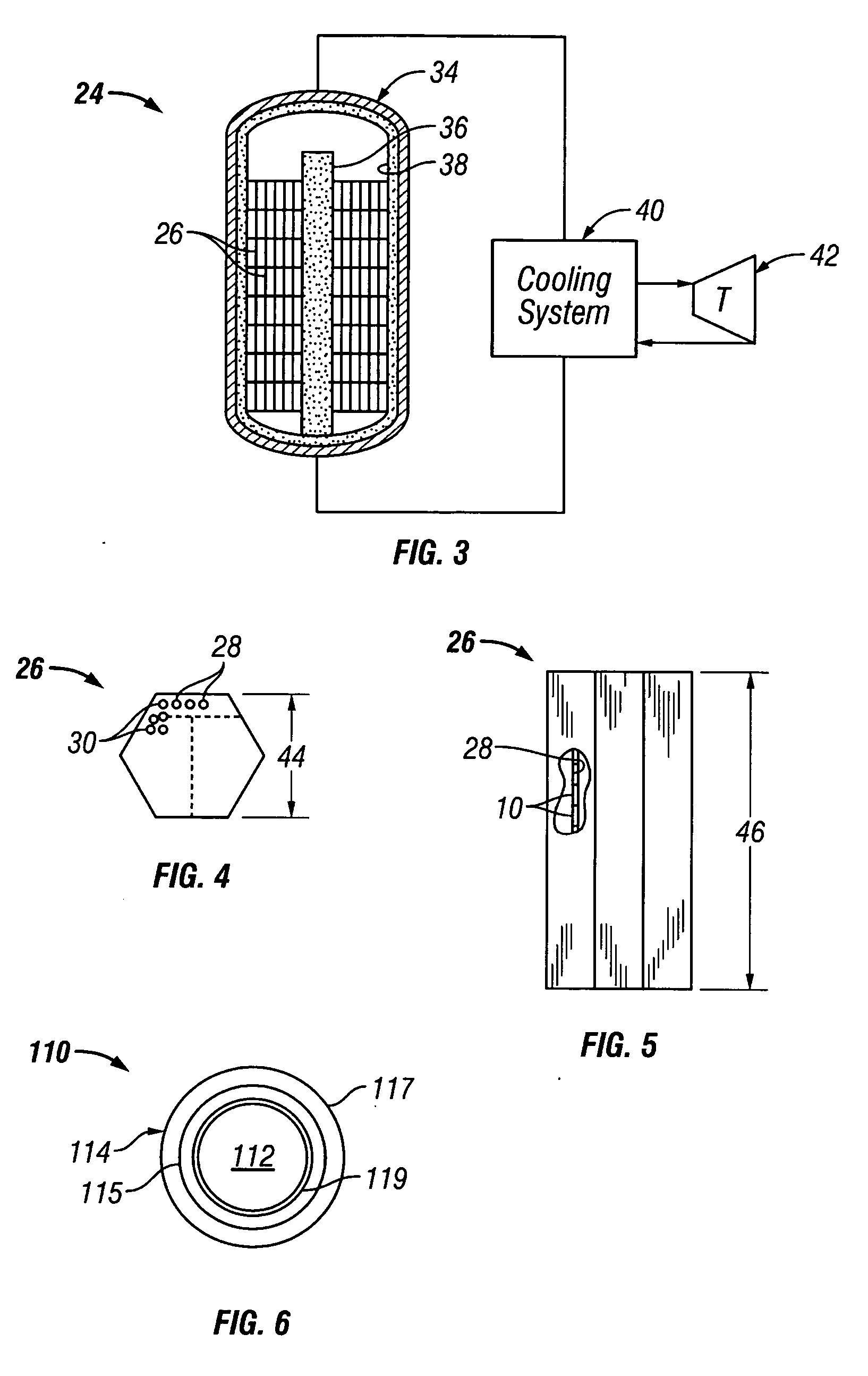

System and method for thermal energy storage and power generation

A thermal energy storage system is proposed in which the latent heat of fusion of common salts is used to store energy within a selectable temperature range, extending both above and below the melting / freezing temperature zone of the salt mixture. The salt mixture occupies interstitial void spaces in a solid endostructure. The solid material remains in the solid state throughout the thermal cycling of the energy storage system, and preferably has properties of thermal conduction and specific heat that enhance the behavior of the salt mixture alone, while being chemically compatible with all materials in the storage system. The storage system is capable of accepting and delivering heat at high rates, thereby allowing power generation using a suitable energy transfer media to power a turbine of an electric generator or a process heat need to provide a relatively local, dispatchable, rechargeable thermal storage system, combined with a suitably sized generator.

Owner:WOODWARD GOVERNOR CO

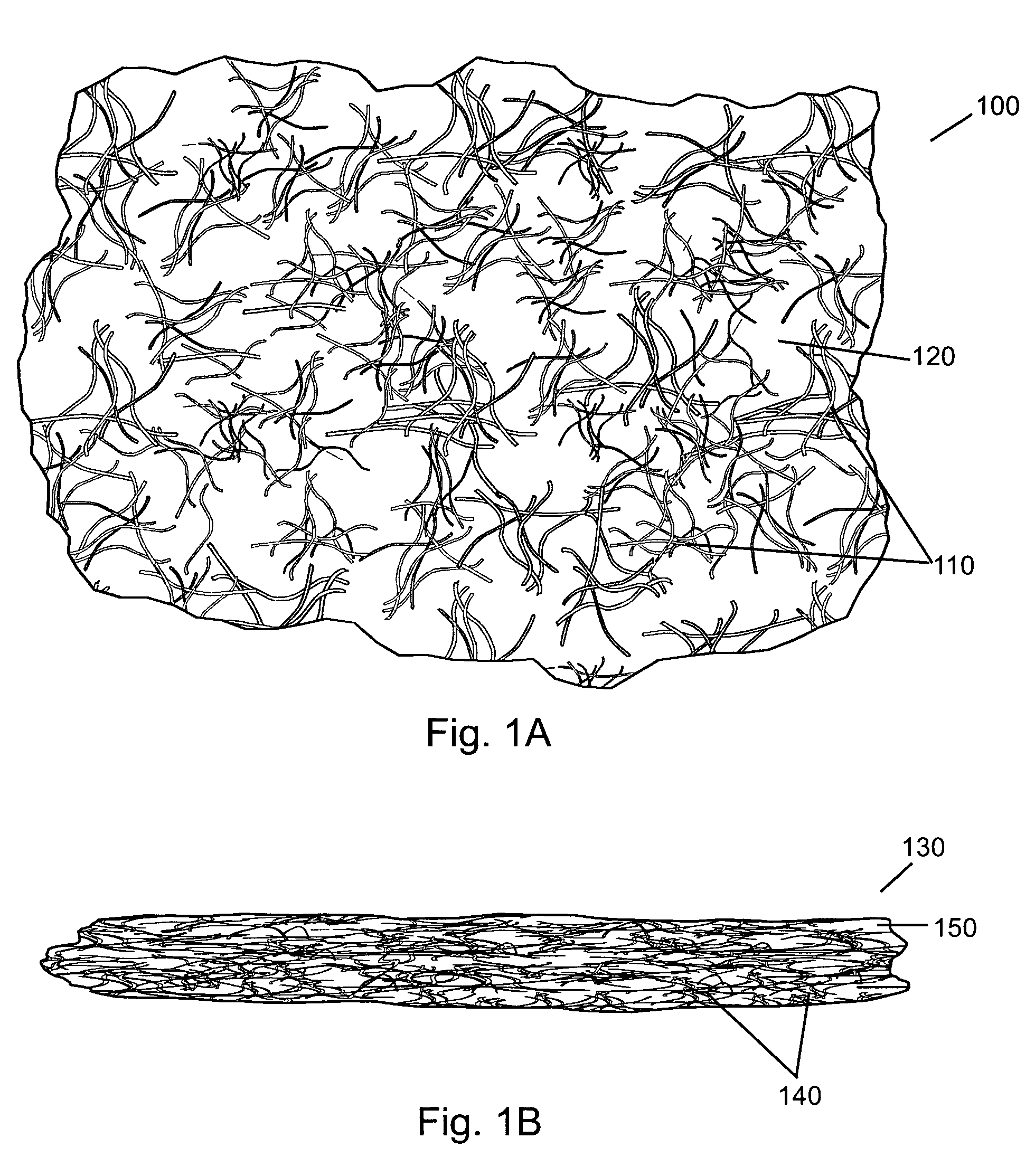

Compressed high density fibrous polymers suitable for implant

An embodiment of the present invention may be made by the following steps: providing a mixture comprising a plurality of fibers, a lubricant, and a suspension fluid, with the suspension fluid filling a void space between said fibers and subjecting said mixture to at least one compressive force. The compressive force causes the migration and alignment of said fibers; and may remove substantially all of the suspension fluid from said mixture. The mixture may further comprise a biologically active agent, or a reinforcing agent.

Owner:DSM IP ASSETS BV

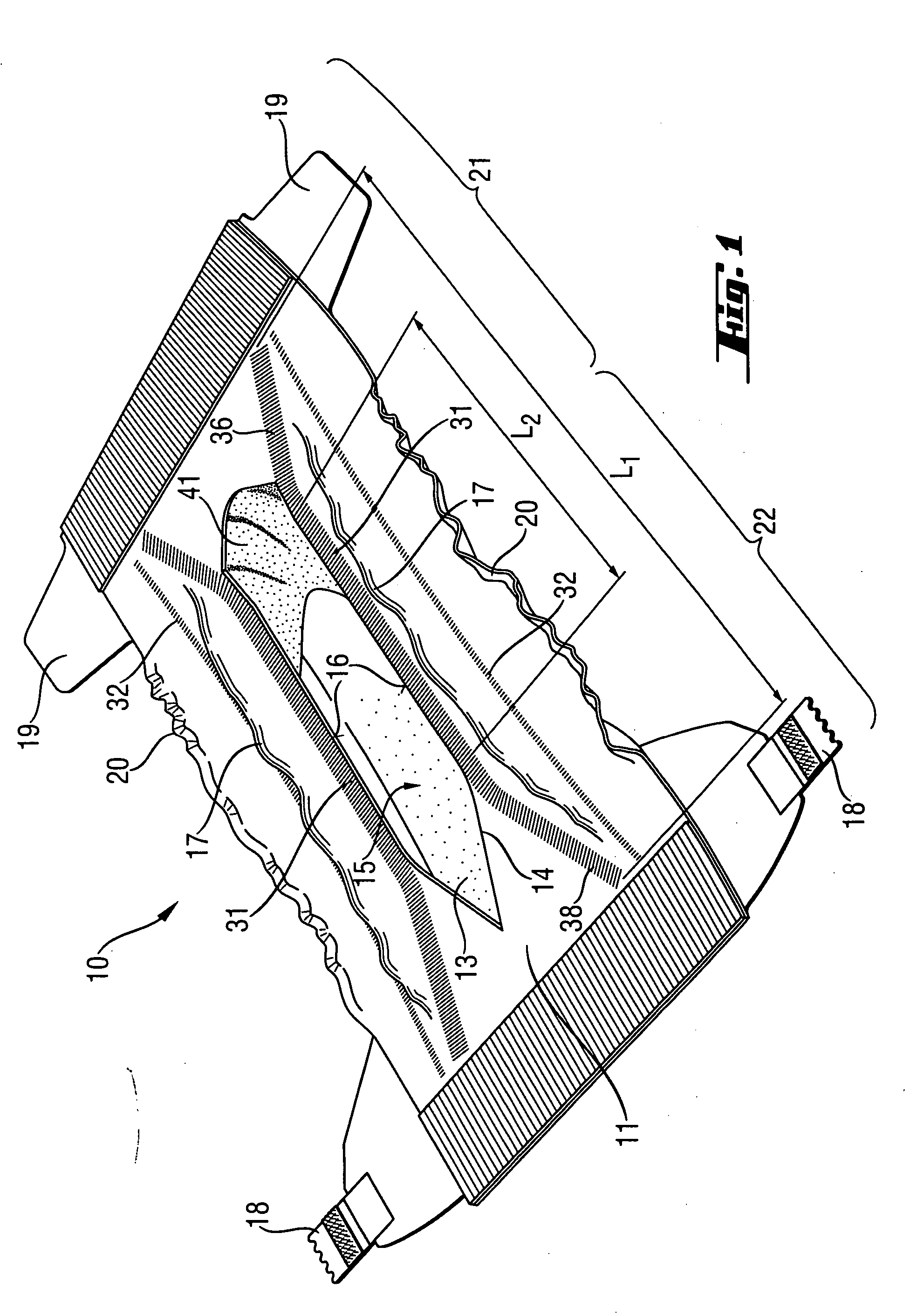

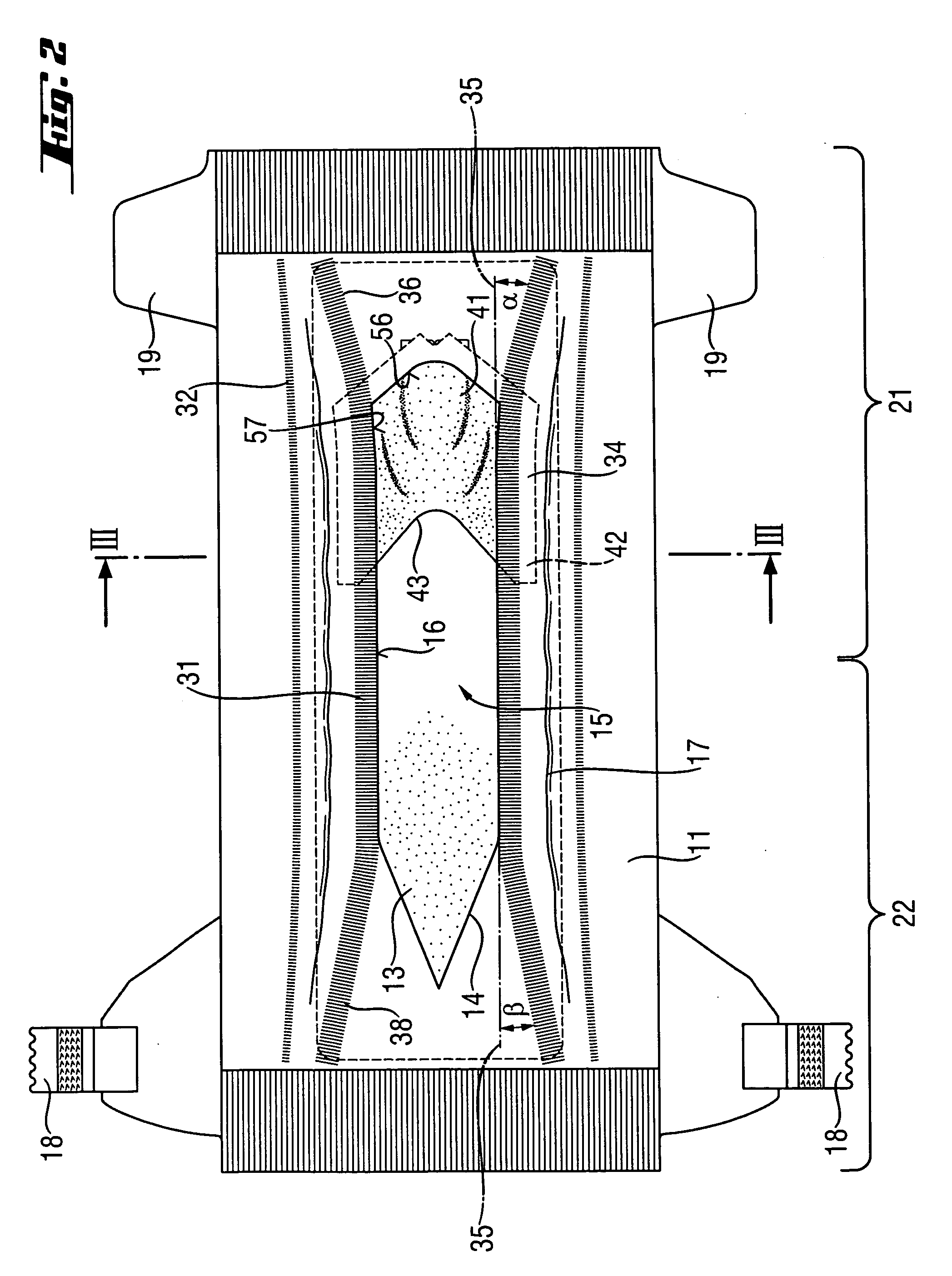

Absorbent article with urine-permeable coversheet

This invention is directed to an absorbent article, preferably a diaper or training pants, having a backsheet, an absorbent core and a topsheet, provided with at least one opening adapted to receive fecal material, comprising also a genital coversheet, which in use covers the genitals, and which is positioned in, under or above part of the opening, such that a void space can be created between the genital coversheet and the absorbent core and such that a void space is present between the topsheet and the absorbent core.

Owner:THE PROCTER & GAMBLE COMPANY

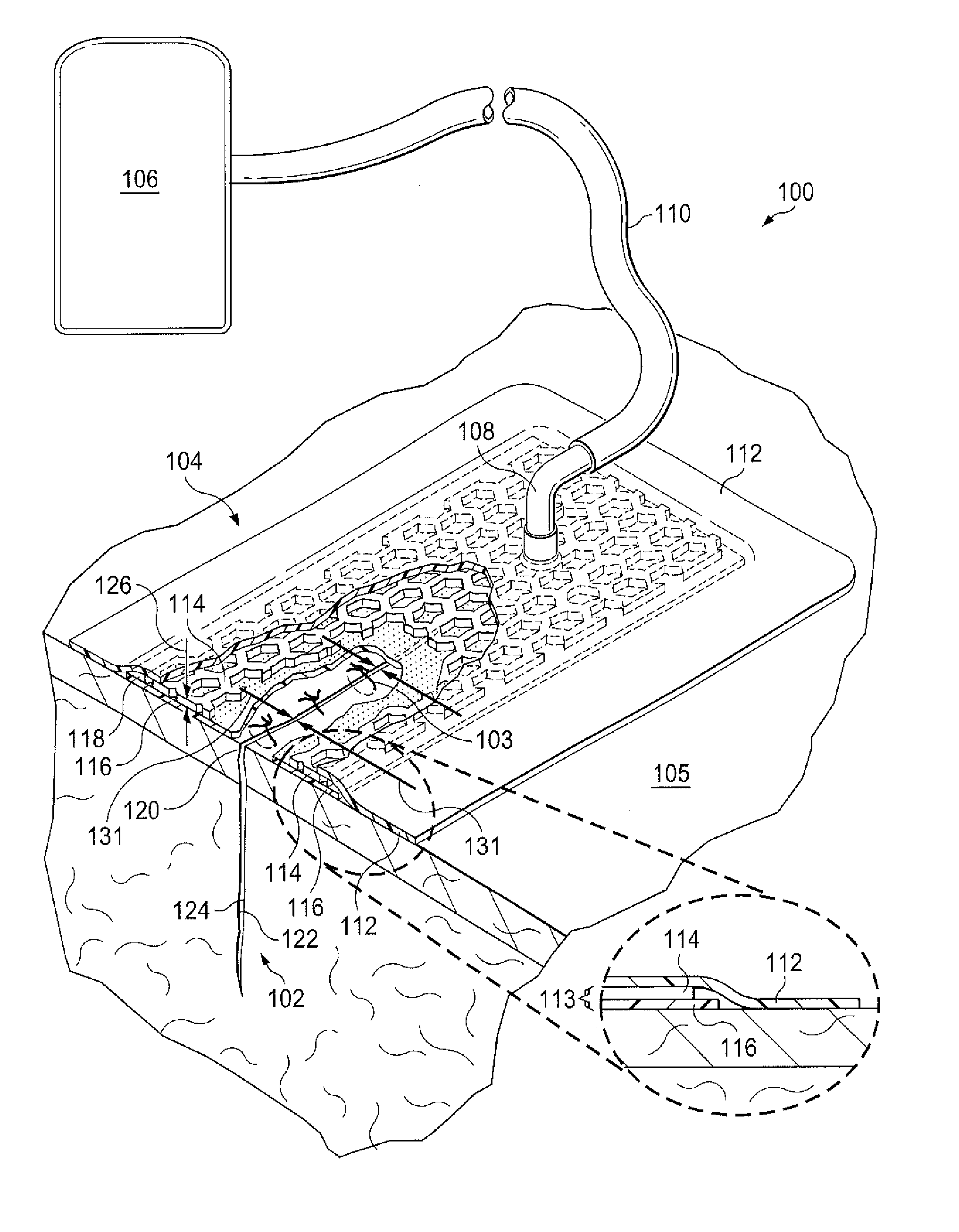

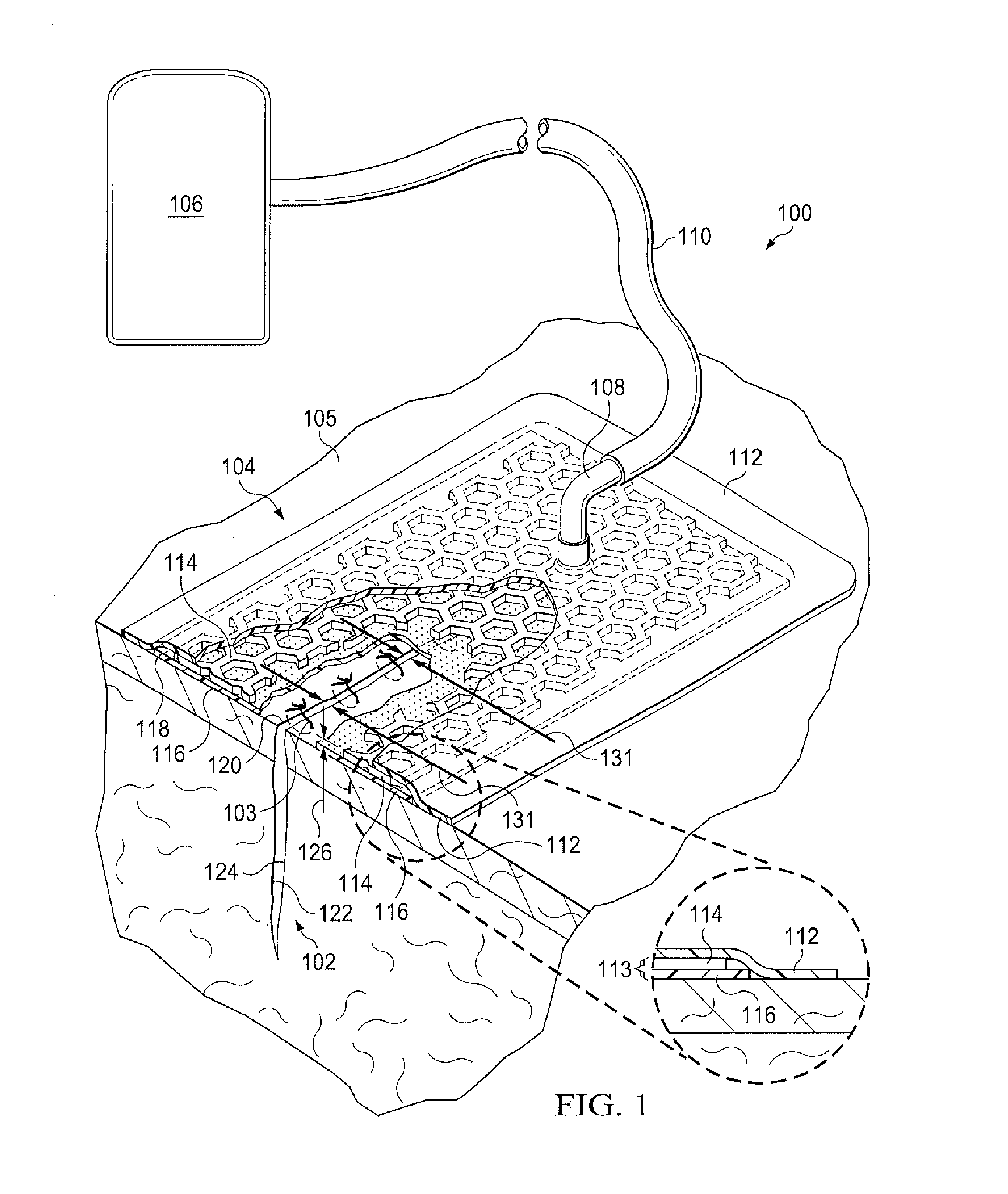

Dressing with contracting layer for linear tissue sites

Systems, apparatuses, and methods for closing an opening through a surface of a tissue site are described. The system includes a sealing member adapted to cover the opening to form a sealed space and a negative-pressure source adapted to be fluidly coupled to the sealed space to provide negative pressure to the sealed space. The system also includes a contracting layer adapted to be positioned adjacent the opening and formed from a material having a firmness factor and a plurality of holes extending through the contracting layer to form a void space. The holes have a perforation shape factor and a strut angle causing the plurality of holes to collapse in a direction substantially perpendicular to the opening. The contracting layer generates a closing force substantially parallel to the surface of the tissue site to close the opening in response to application of the negative pressure.

Owner:3M INNOVATIVE PROPERTIES CO

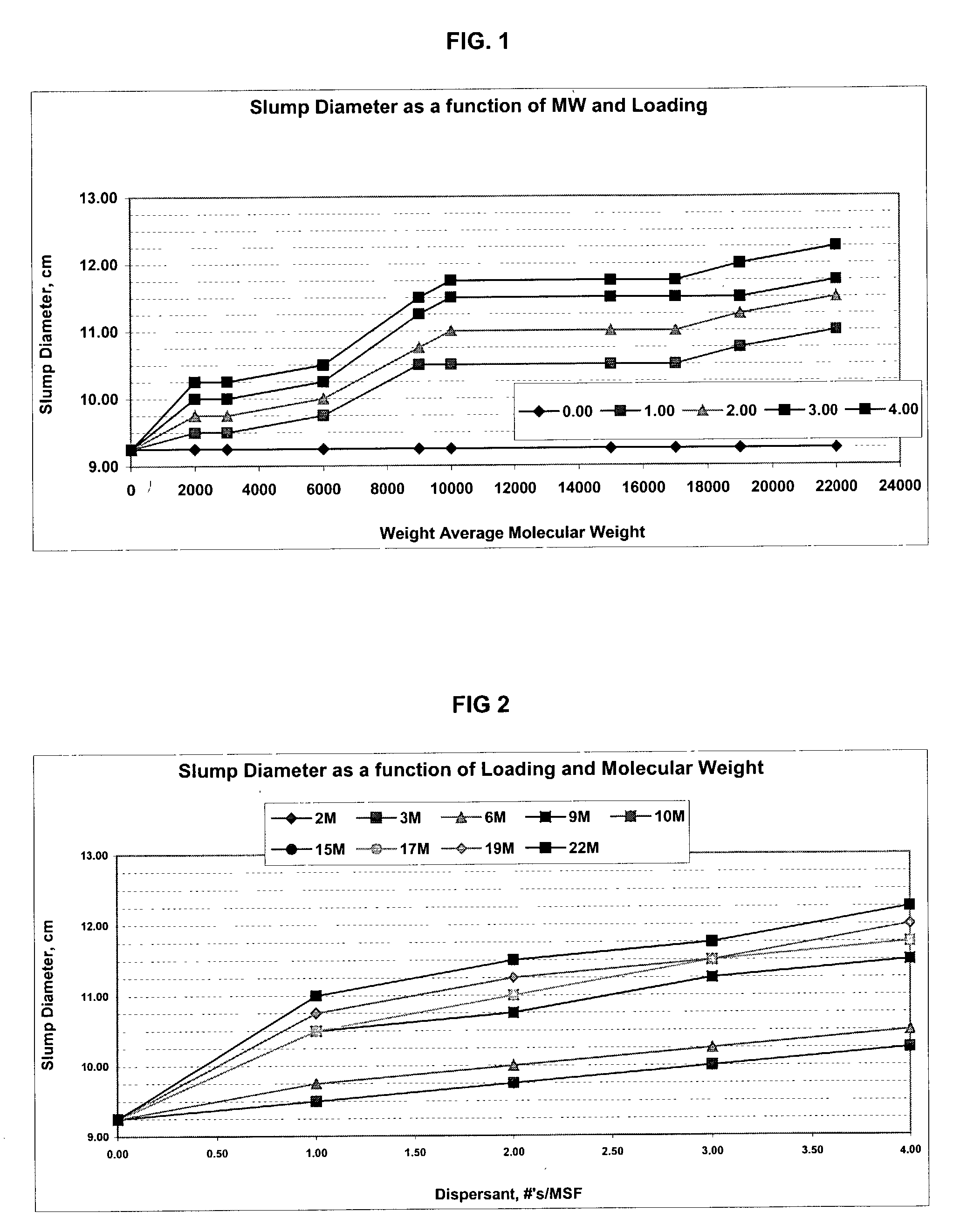

Dispersant and foaming agent combination

InactiveUS20040028956A1Low densityReduce weightConstruction materialOther chemical processesAlkaline earth metalAir entrainment

The present invention provides a dispersant and foaming agent combination that is useful in the production of gypsum wallboard and other aqueous cementitious products, a method of forming a gypsum wallboard and a gypsum wallboard. The dispersant in the combination according to the invention is a naphthalene sulfonate-aldehyde condensate alkali salt polymer having a weight average molecular weight of from about 17,000 to about 47,000. The alkali is preferably an alkali metal and / or an alkaline earth metal. The aldehyde is preferably formaldehyde. The foaming agent used in the combination according to the invention is a soap, preferably an alkali salt of an alkyl ether sulfate and / or an alkyl sulfate. The combination of a high molecular weight dispersant and a foaming agent produces a gypsum wallboard core effect that more efficiently entrains air (i.e., creates void space), thereby lowering overall board weight without detrimentally affecting strength. A gypsum wallboard formed using the dispersant and foaming agent combination according to the invention exhibits a higher nail pull value than gypsum wallboard formed using a conventional dispersant and a foaming agent at the same solids loading ratio.

Owner:GEO SPECIALTY CHEM

Articles with elasticated topsheets

InactiveUS20070191806A1Non-surgical orthopedic devicesSanitary towelsEngineeringMechanical engineering

Owner:PROCTER & GAMBLE CO

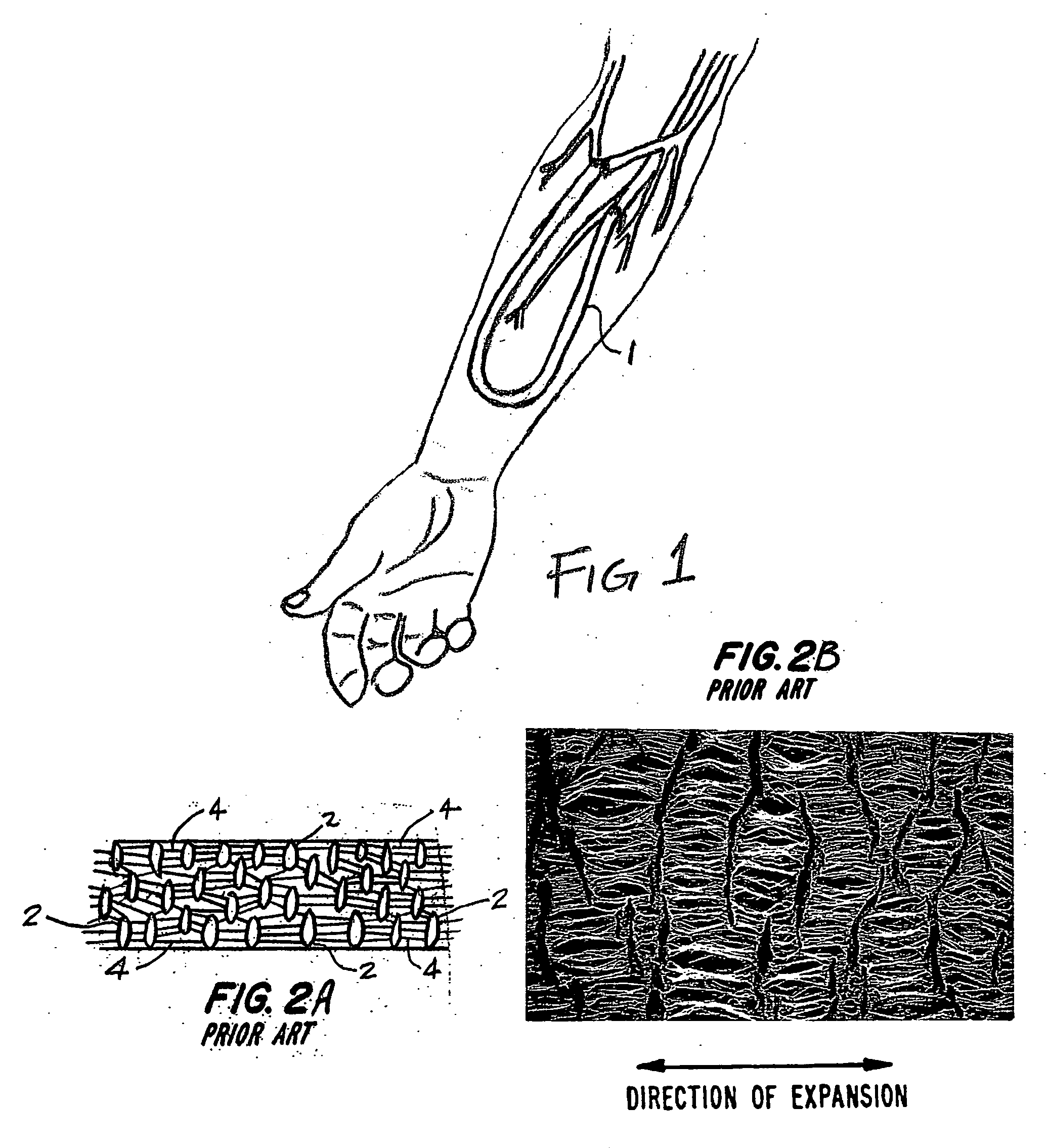

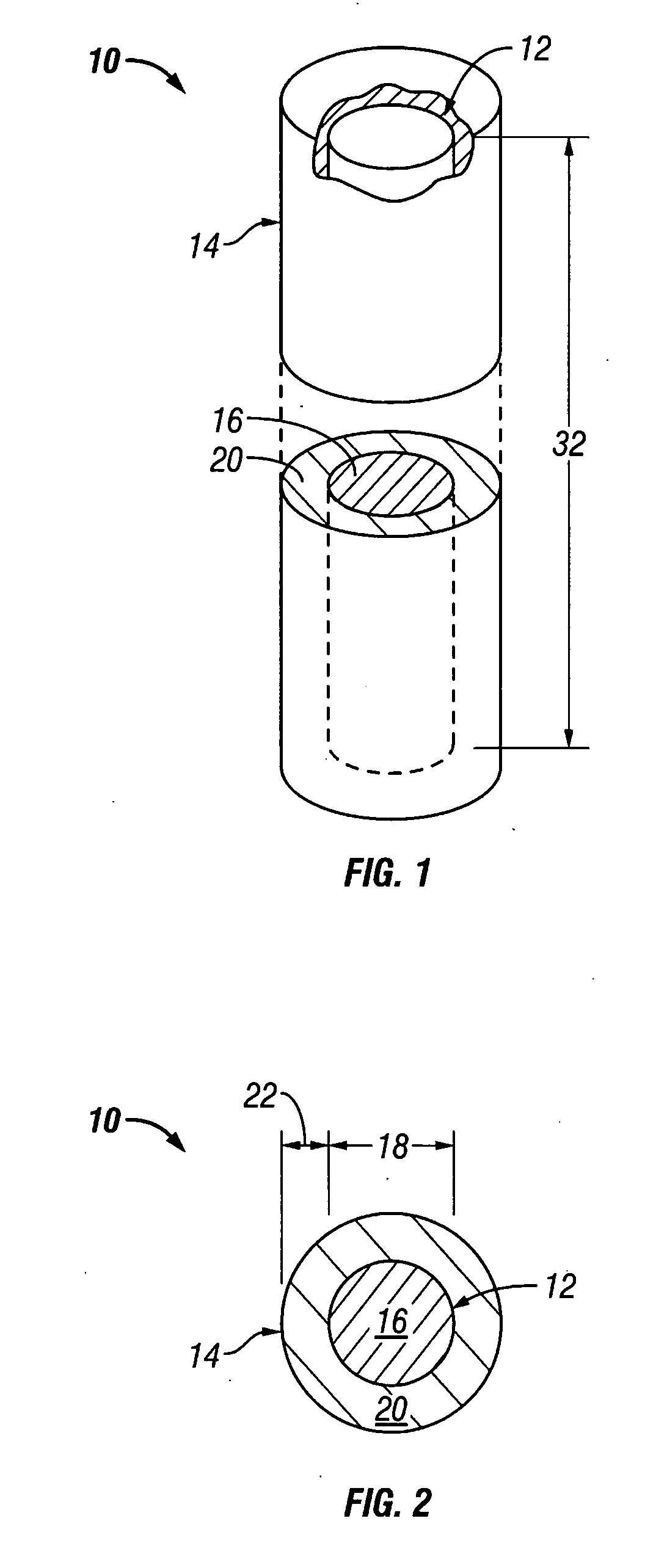

Implantable devices with reduced needle puncture site leakage

ActiveUS20060118236A1Reduce leakageGood biocompatibilitySynthetic resin layered productsLaminationElastomerFiber

A prosthetic implantable device that offers a reduction in fluid loss when the device is punctured, such as by a dialysis needle or suture needle, and the needle is subsequently removed. The device may be made to be thin and flexible, and with longitudinal stretch, in order that it also offers good handling and kink resistance to a surgeon. While the device is preferably of tubular form, flat sheets or other forms may also be made. The device includes inner and outer layers of a porous material having a microstructure of nodes interconnected by bent fibrils, and having void spaces between adjacent bent fibrils. The inner and outer layers are joined by an elastomeric adhesive that may interpenetrate the void spaces of the adjacent surfaces of the inner and outer layers, that is, the inner surface of the outer layer and the outer surface of the inner layer. Optionally, a middle layer of an elastomeric material may also be provided, joined to the inner and outer porous layers by the interpenetrating elastomeric adhesive. The device is preferably a vascular graft and more preferably a vascular graft for kidney dialysis.

Owner:WL GORE & ASSOC INC

Thermoformed twin-sheet panel

InactiveUS6018927AImprove cooling effectConstruction materialLayered productsFlexural strengthEngineering

A structural, load bearing panel is fabricated with twin-sheets of thermoformed polymer material to provide-substantially equal bending strength about each of substantially normal polar moment axes. Parallel rows of generally rectangular depressions in the top sheet surface are fused with a corresponding row pattern of depressions in the bottom sheet surface oriented substantially 90.degree. to the top sheet rows. End walls of top sheet depressions are fused with side walls of bottom sheet depressions. Conversely, end walls of bottom sheet depressions are fused with side walls of top sheet depressions. An orthogonal matrix of interconnected gas flow channels vent substantially all void spaces between the top and bottom sheets.

Owner:FORMALL

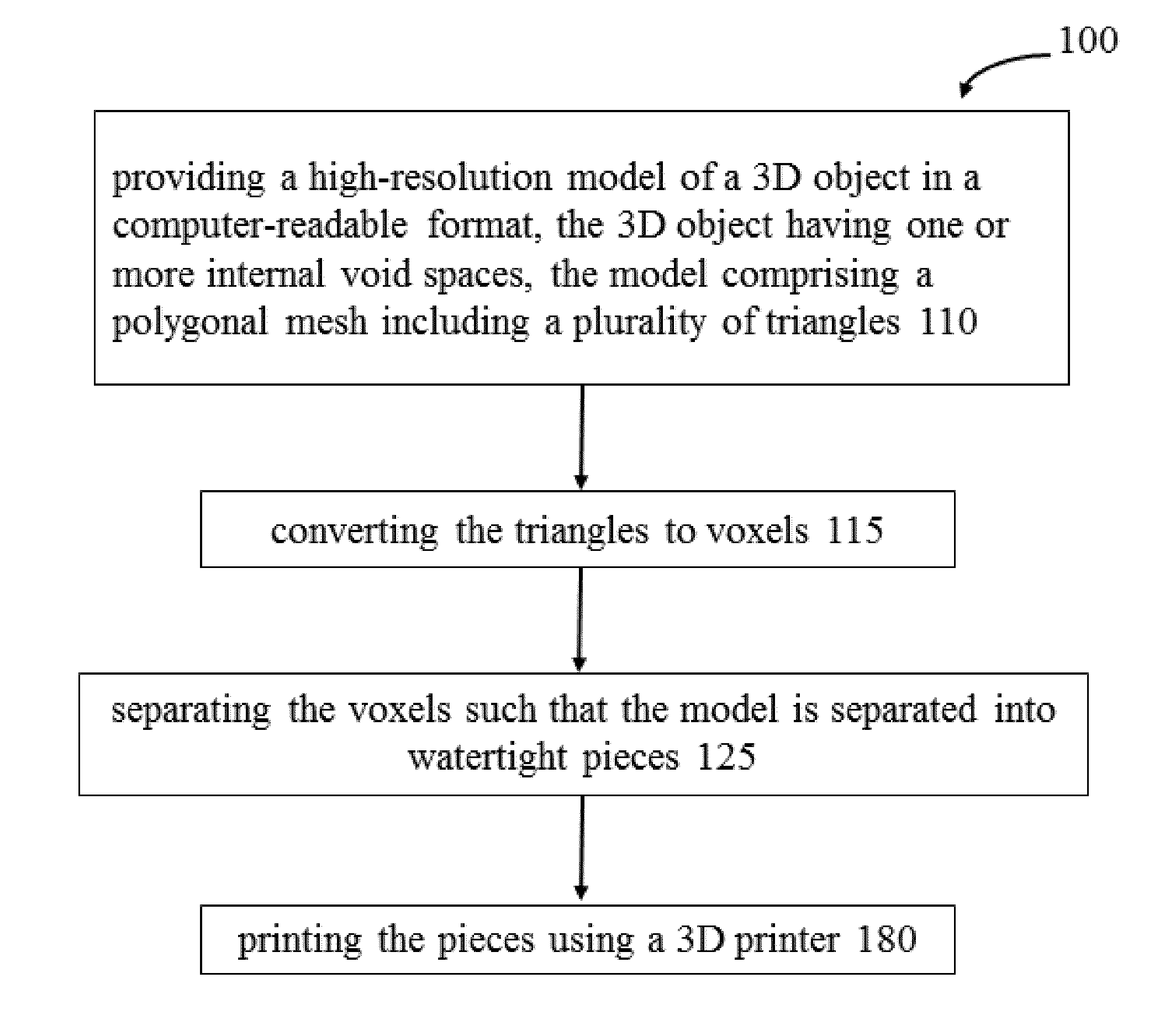

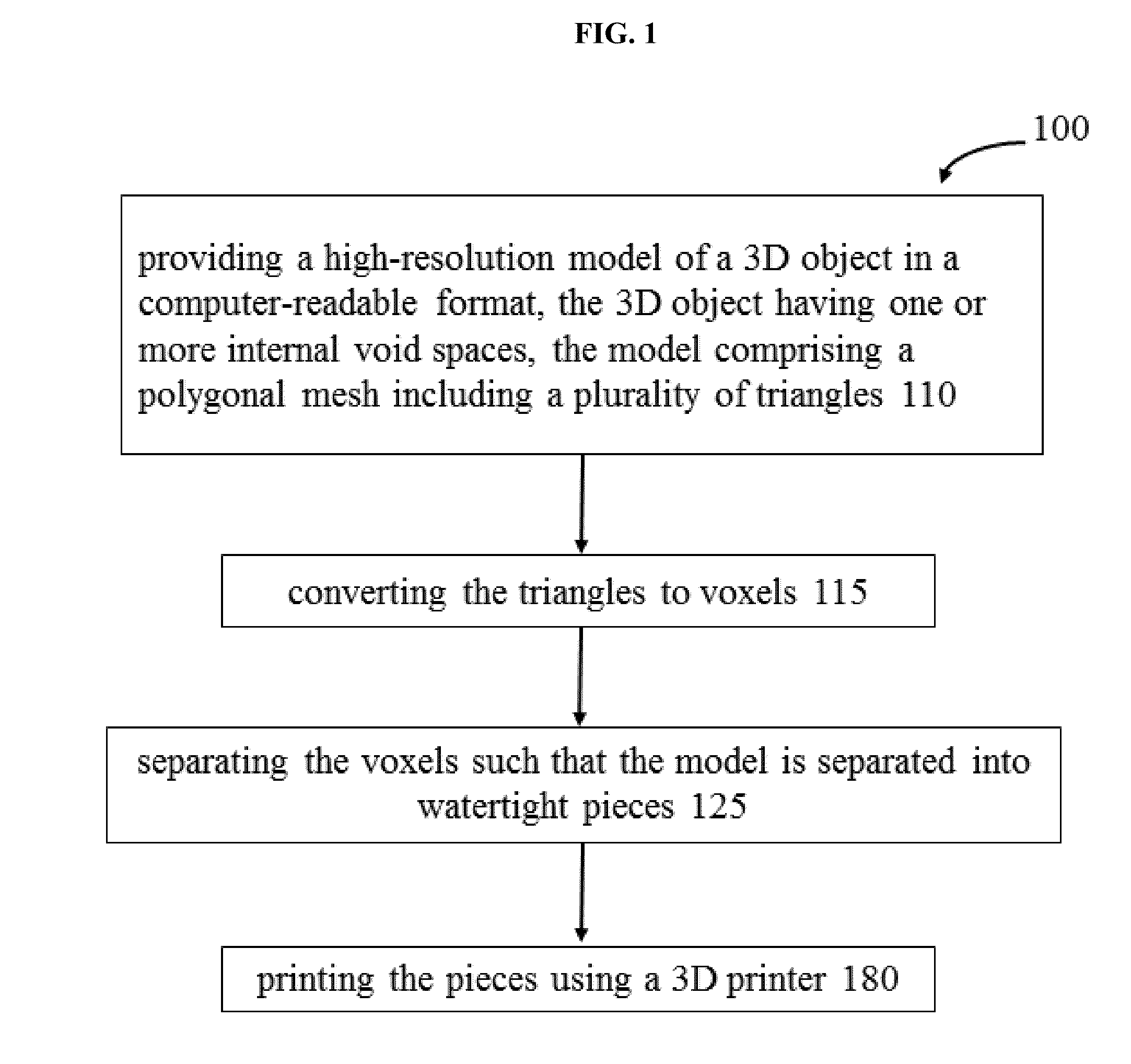

Method and system for rapid prototyping of complex structures

InactiveUS20140031967A1Facilitate user-directed placementHigh densityAdditive manufacturing apparatusManufacturing data aquisition/processingBone structureVoxel

A method is provided for rapid prototyping of complex structures, such as complex bone structures and internal neural and cardiovascular pathways. The method involves loading the triangles from a polygonal mesh computer model of a 3D object having one or more internal void spaces, converting the triangles to voxels, separating the voxels of the model into watertight pieces, and printing the pieces using a 3D printer such as a ZPrinter™. The method allows realistic internal void space representation through removal of excess powder from printing which would otherwise be trapped in the whole object and also allows the application of a resin to internal surfaces which may provide realistic internal object density useful for medical and other applications. Pegs and holes may also be added to and subtracted from the pieces to allow for assembly of the printed object. A system and computer program product is also provided.

Owner:6598057 MANITOBA

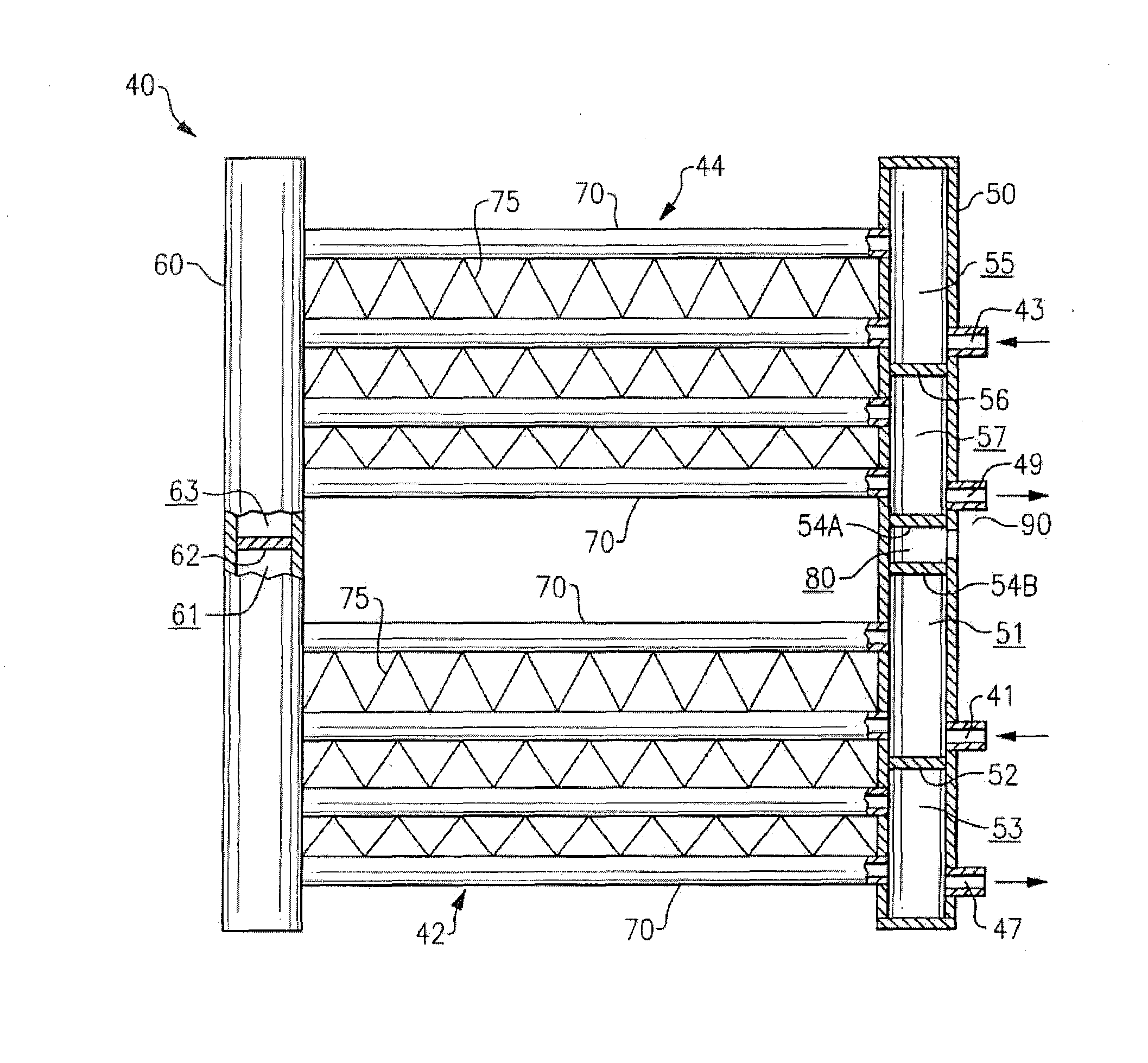

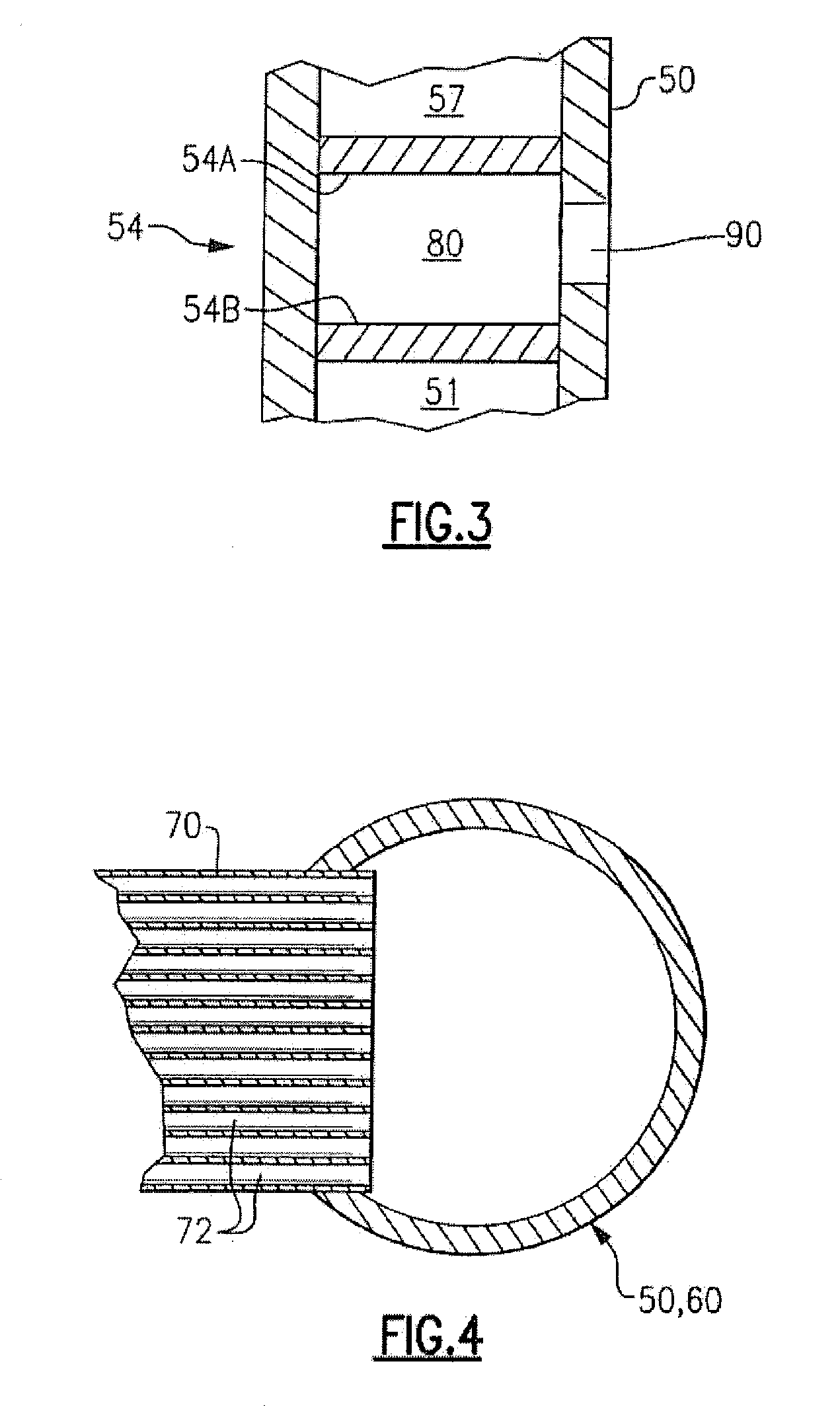

Multi-circuit heat exchanger

InactiveUS20120011867A1Preventing fluid cross-contaminationSafety devices for heat exchange apparatusCompression machines with non-reversible cycleEngineeringMechanical engineering

A baffle assembly is disposed within a manifold of a multi-circuit heat exchanger for dividing the interior volume of that manifold into a first chamber associated with one circuit and a second chamber associated with another circuit. The baffle assembly includes a pair of baffle members that extend generally transversely across the interior volume of the manifold are disposed in spaced apart relationship thereby forming a void space therebetween. The void space is in fluid communication with a region exterior of that manifold whereby any fluid leaking from either of the first or second chamber into the void space will be vented therefrom.

Owner:CARRIER CORP

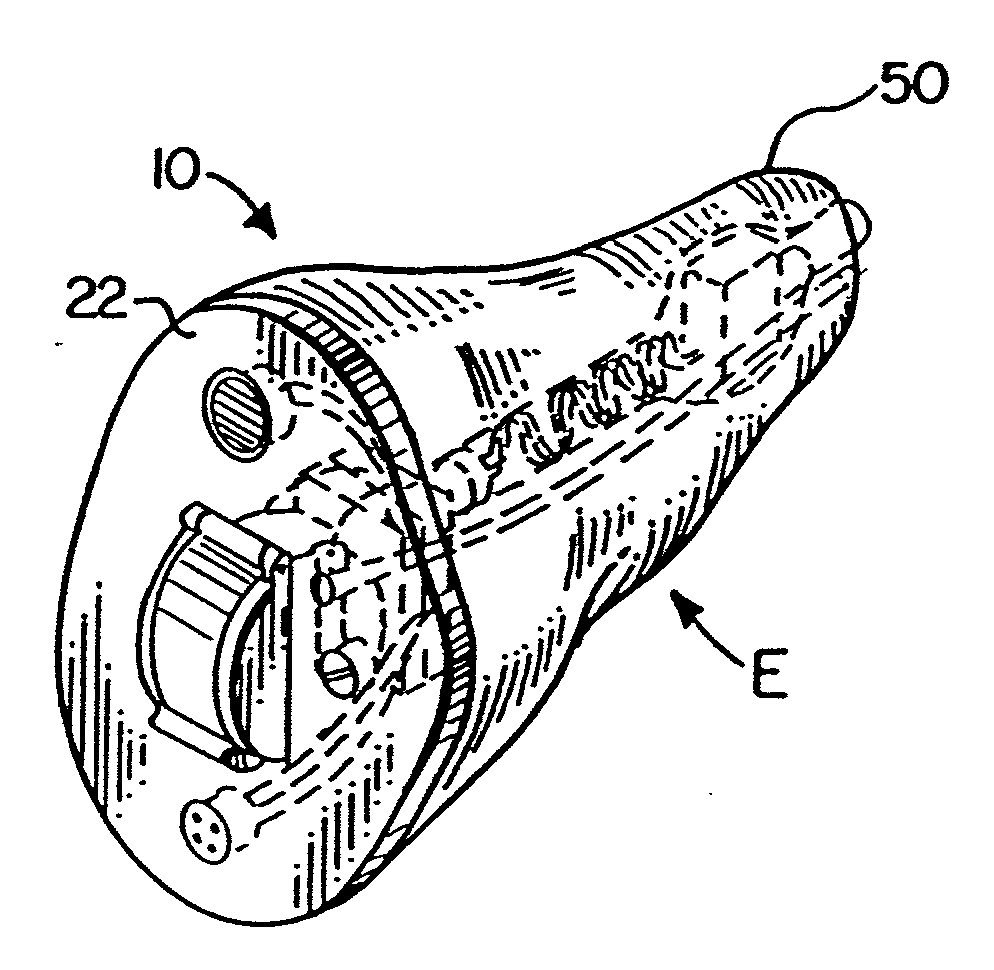

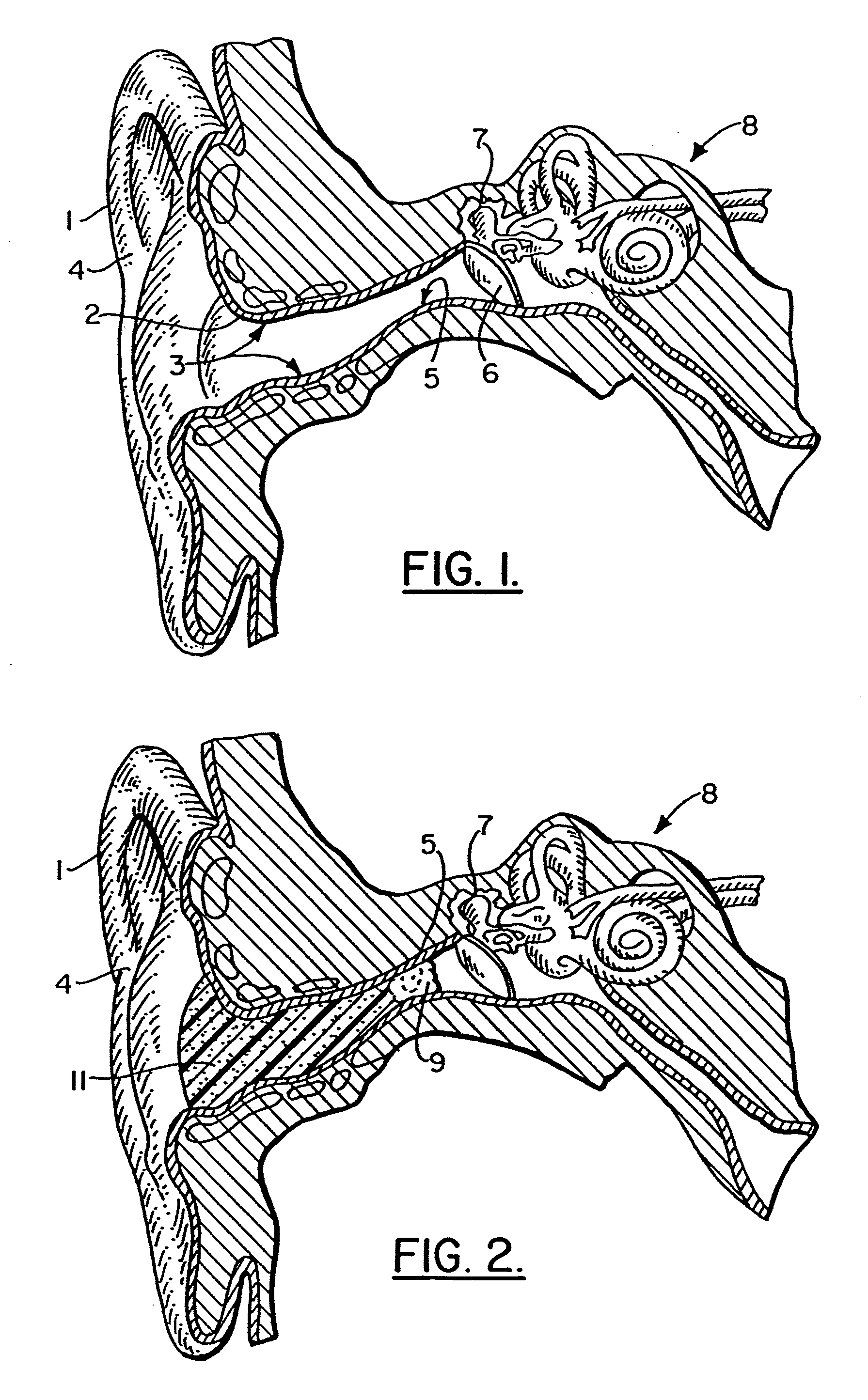

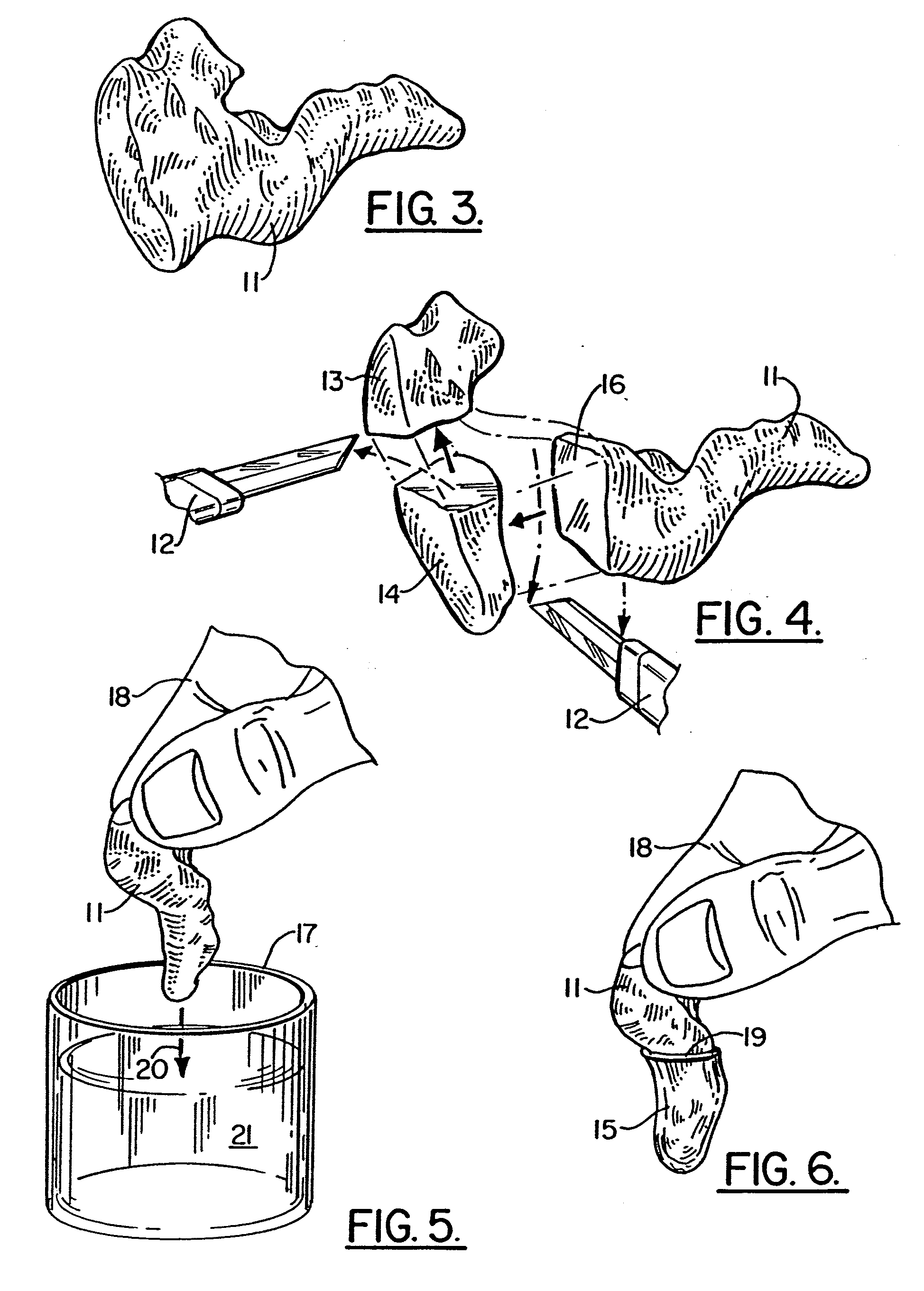

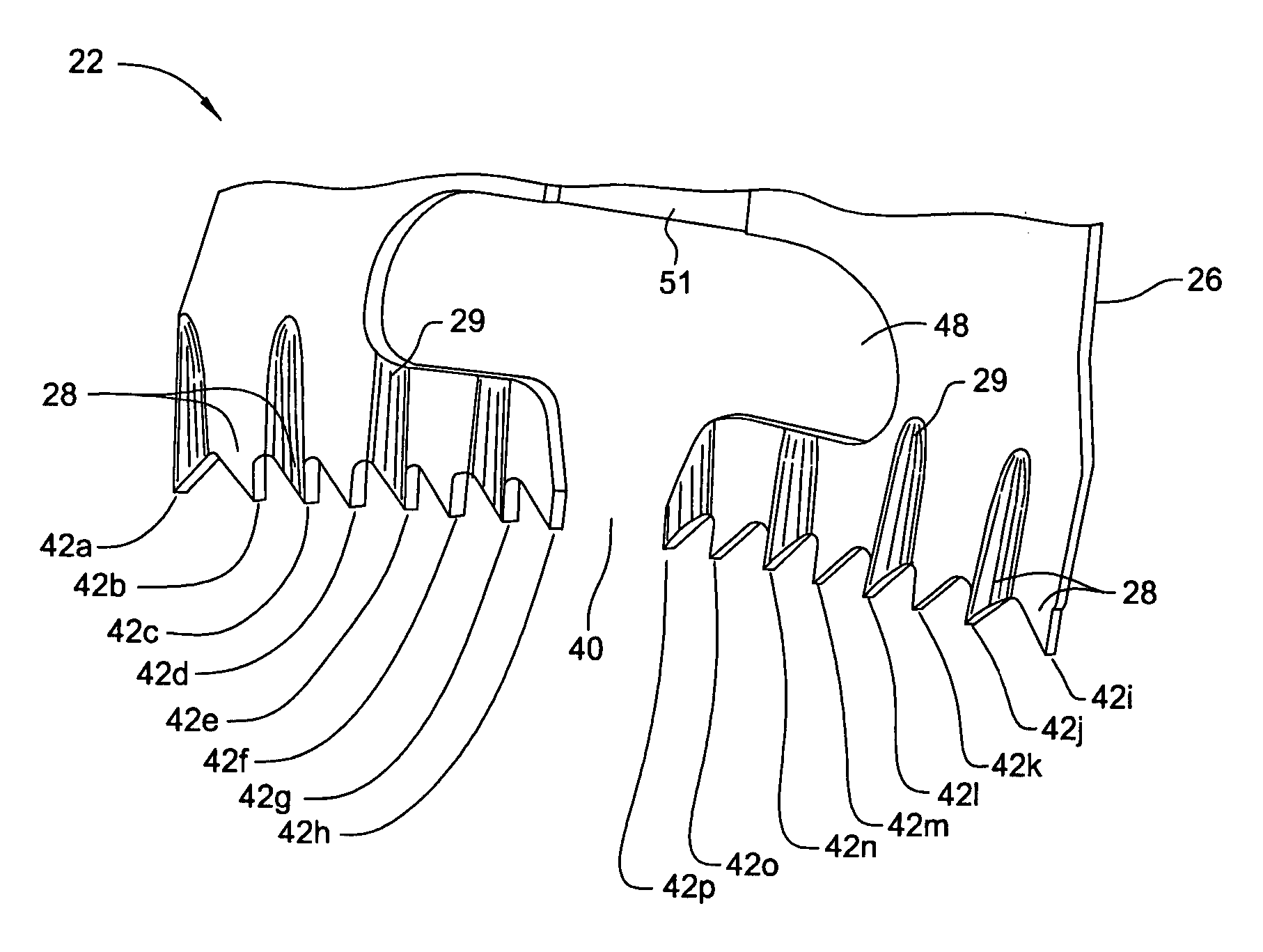

Method of manufacturing a soft hearing aid

A hearing aid instrument of the in-the-ear type (and preferably CIC) provides a plate member with electronic hearing aid components mounted thereto. The plate member is preferably of a harder material such as hard plastic. A soft polymeric body is bonded to the plate member and encapsulates preferably a plurality of the electronic hearing aid components. The body is soft and is shaped to conform to the ear canal of the user. The soft polymeric body and encapsulated electronic hearing aid components define a soft structure compliant to the ear canal during use and that is substantially solid and free of void spaces between at least some of the components and the ear canal. This combination of soft compliant structure and encapsulated electronic hearing aid components addresses problems of peripheral leakage, poor fit, pivotal displacement that occurs with jaw motion and internal cross talk of components housed in prior art hollow type hearing aids.

Owner:SOFTEAR TECH L L C

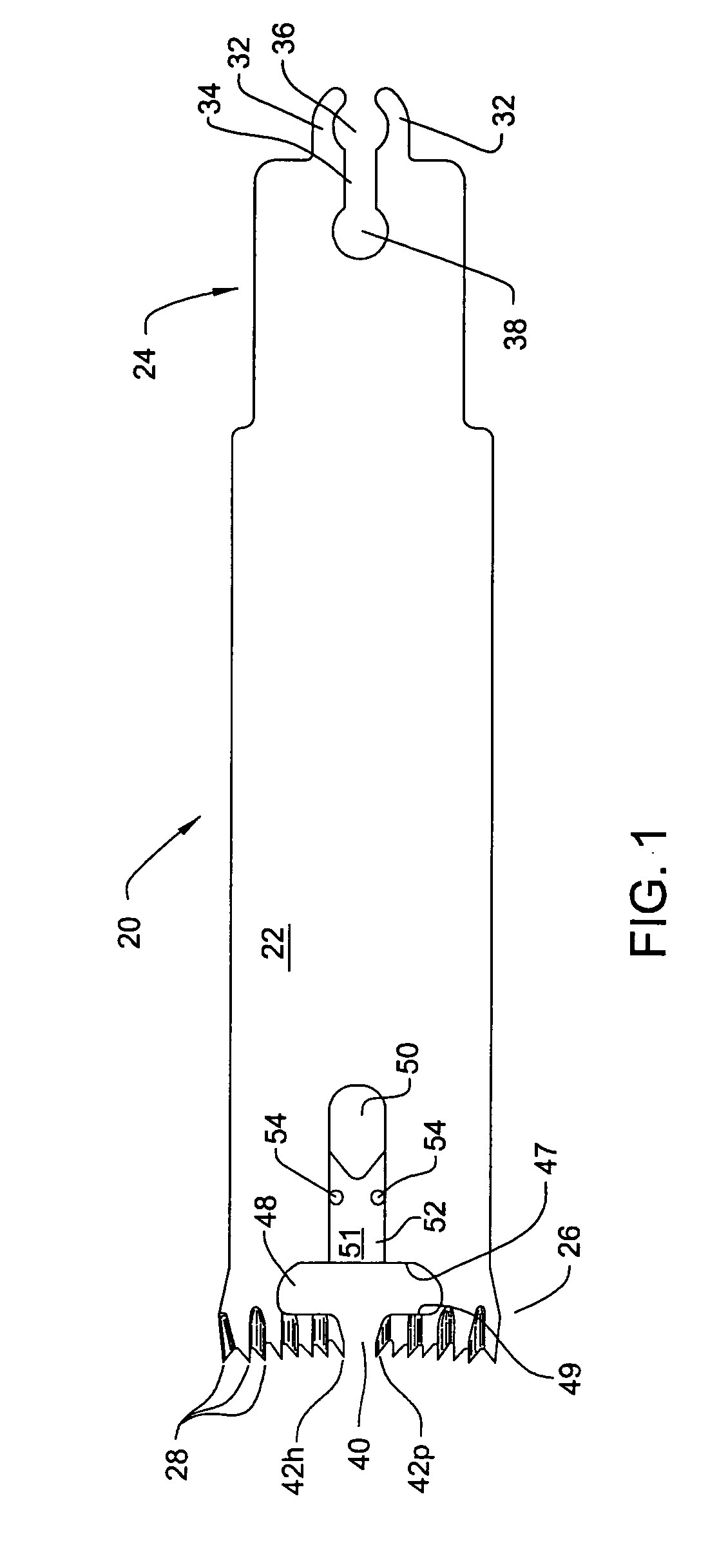

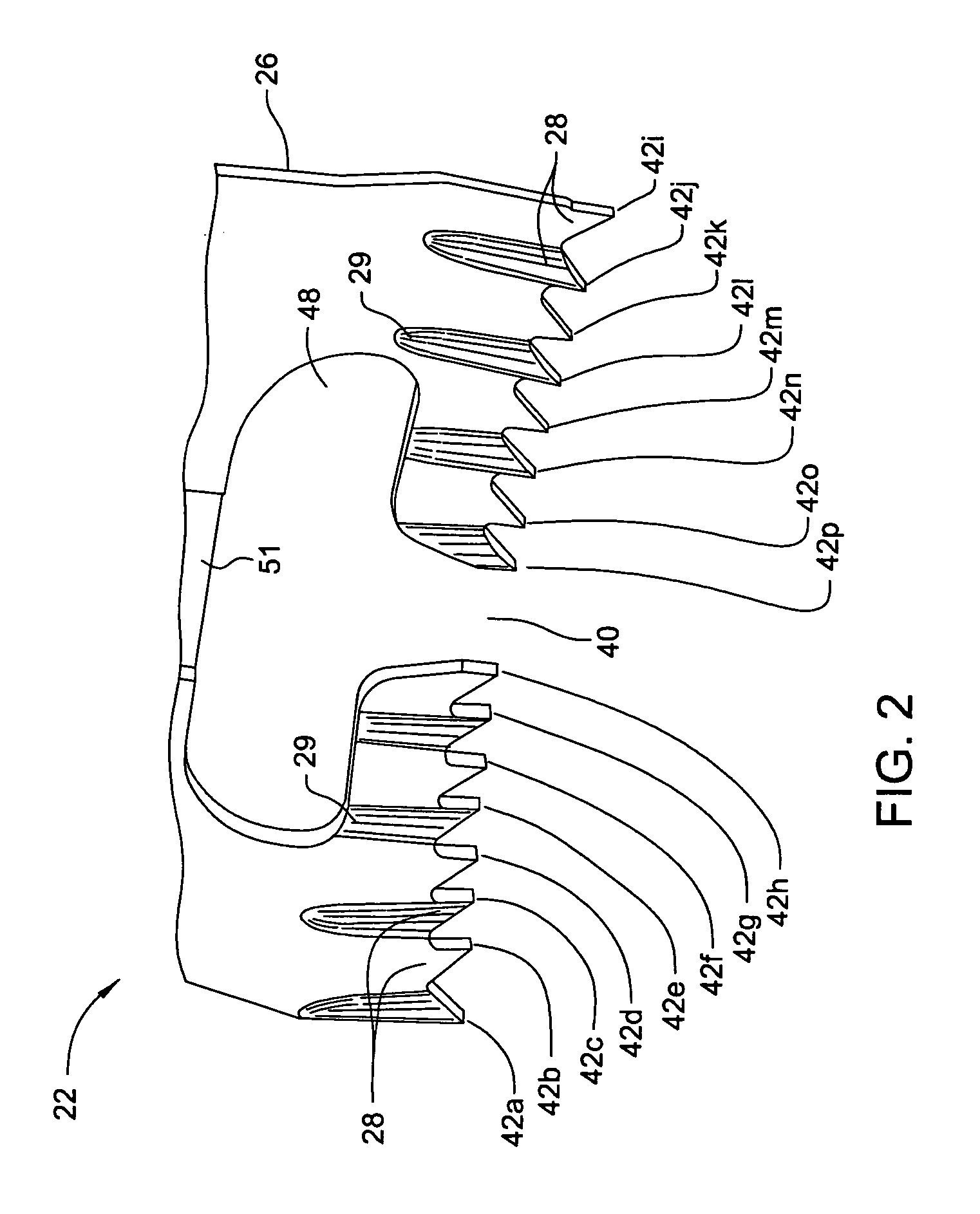

Surgical sagittal saw blade with angled teeth and chip catchment and reciprocating saw blade with broached teeth

A sagittal saw blade wherein the teeth are arranged so that relative to the teeth located closer to the outer sides of the blade, the inner located teeth are located closer to the proximal end of the blade. The blade is further formed to have an opening between at least two of the teeth that extends proximally rearward. The opening increases in width as the opening extends proximally along the length of the blade. The opening opens into a void space that functions as a chip catchment space.

Owner:STRYKER EURO OPERATIONS HLDG LLC

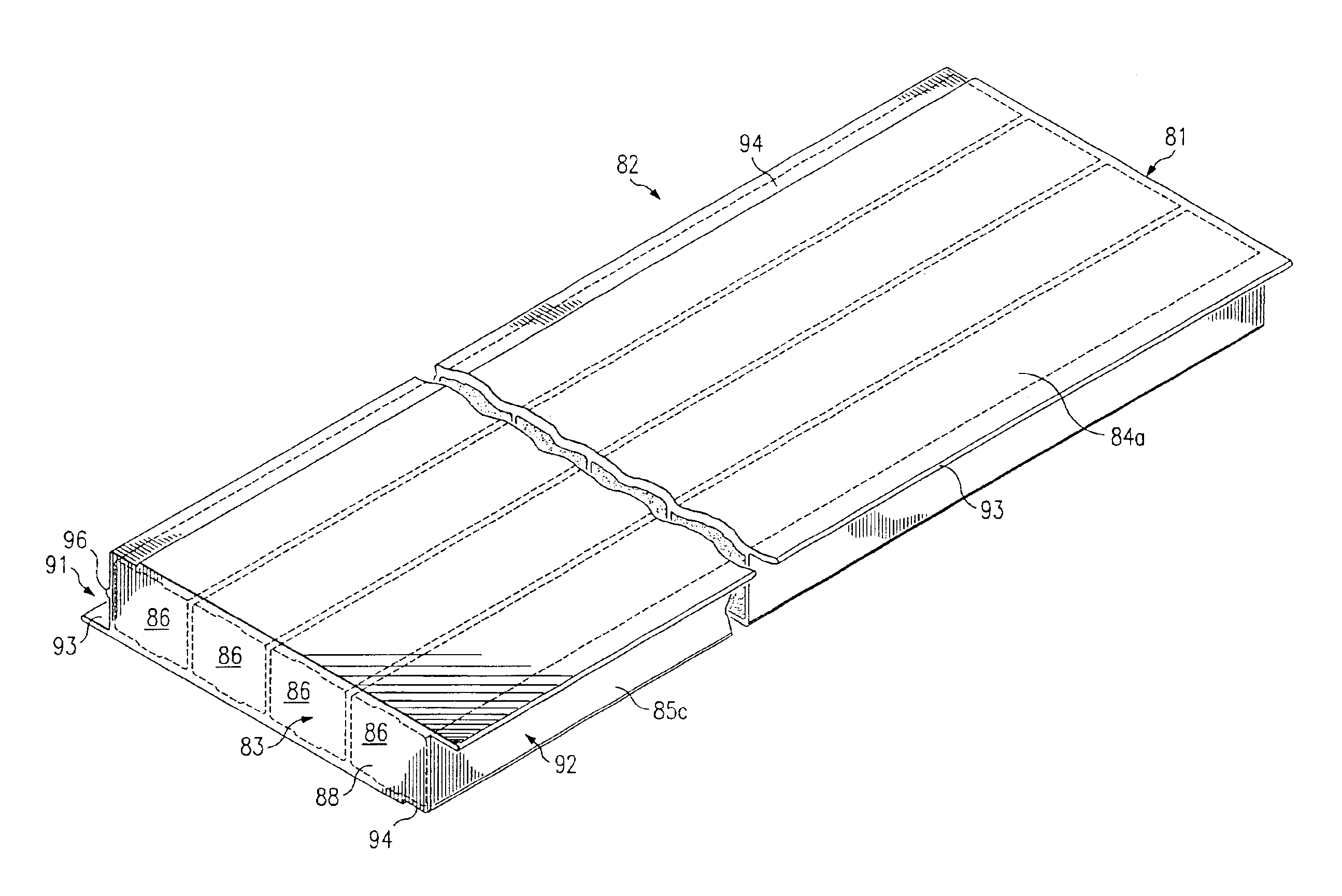

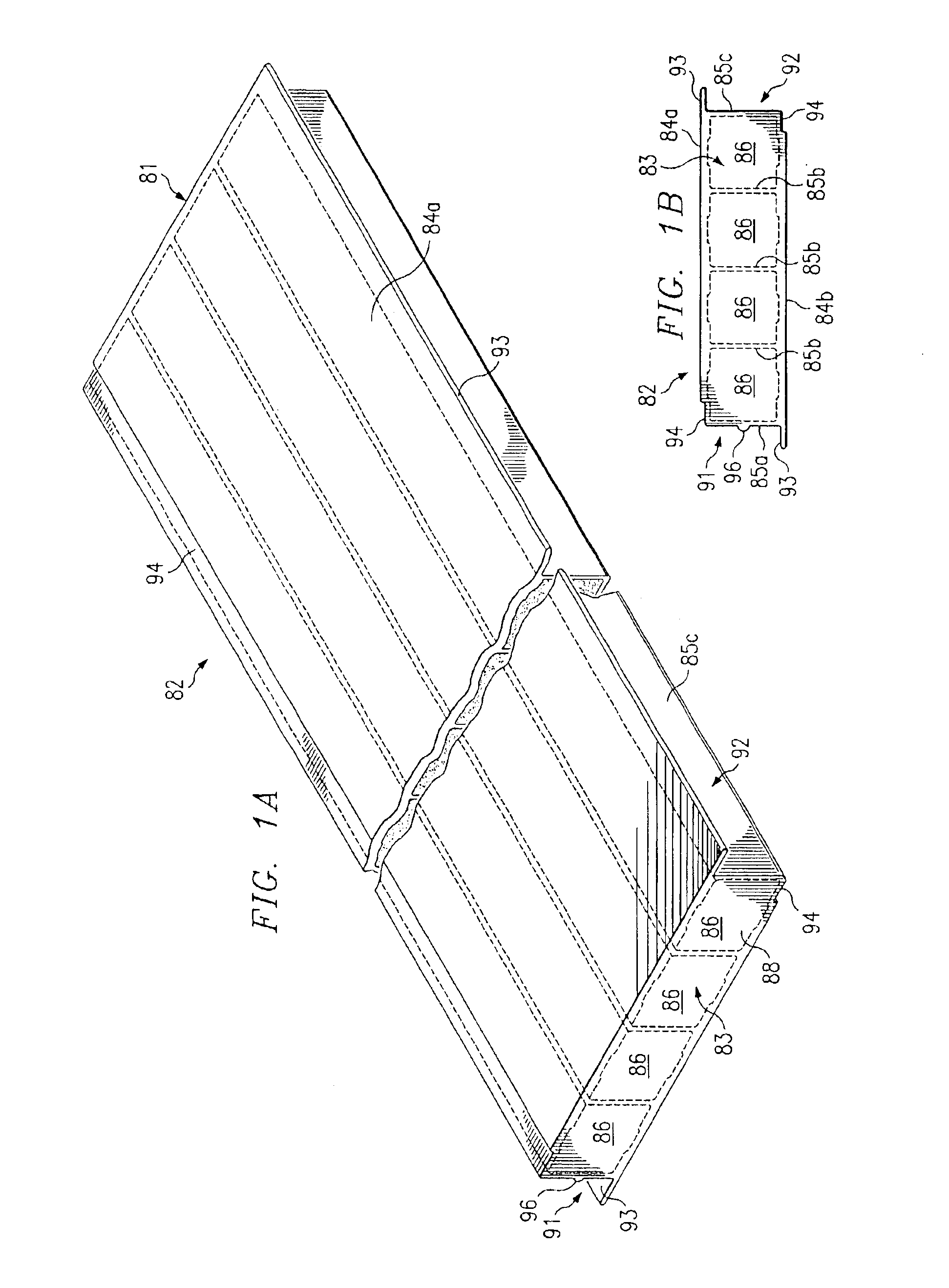

Pultruded panel

InactiveUS6871600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingAdhesiveEngineering

Pultruded panels having a first longitudinal edge profile and a second longitudinal edge profile may be used to form a floor assembly mounted on a railway car underframe. The pultruded panels may also be used to form walkways, bridges, piers and other structures. A bead may be placed on at least one of the longitudinal edge profiles to form a gap between an adjacent pultruded panel. An adhesive may be placed within the gap to couple or bond adjacent pultruded panels with each other. Void spaces may be formed within the pultruded panel and filled with foam to provide improved resistance to heat transfer through the respective panel. Respective coverings may be placed on opposite ends of each panel to block access to the associated void spaces.

Owner:TRINITY IND INC

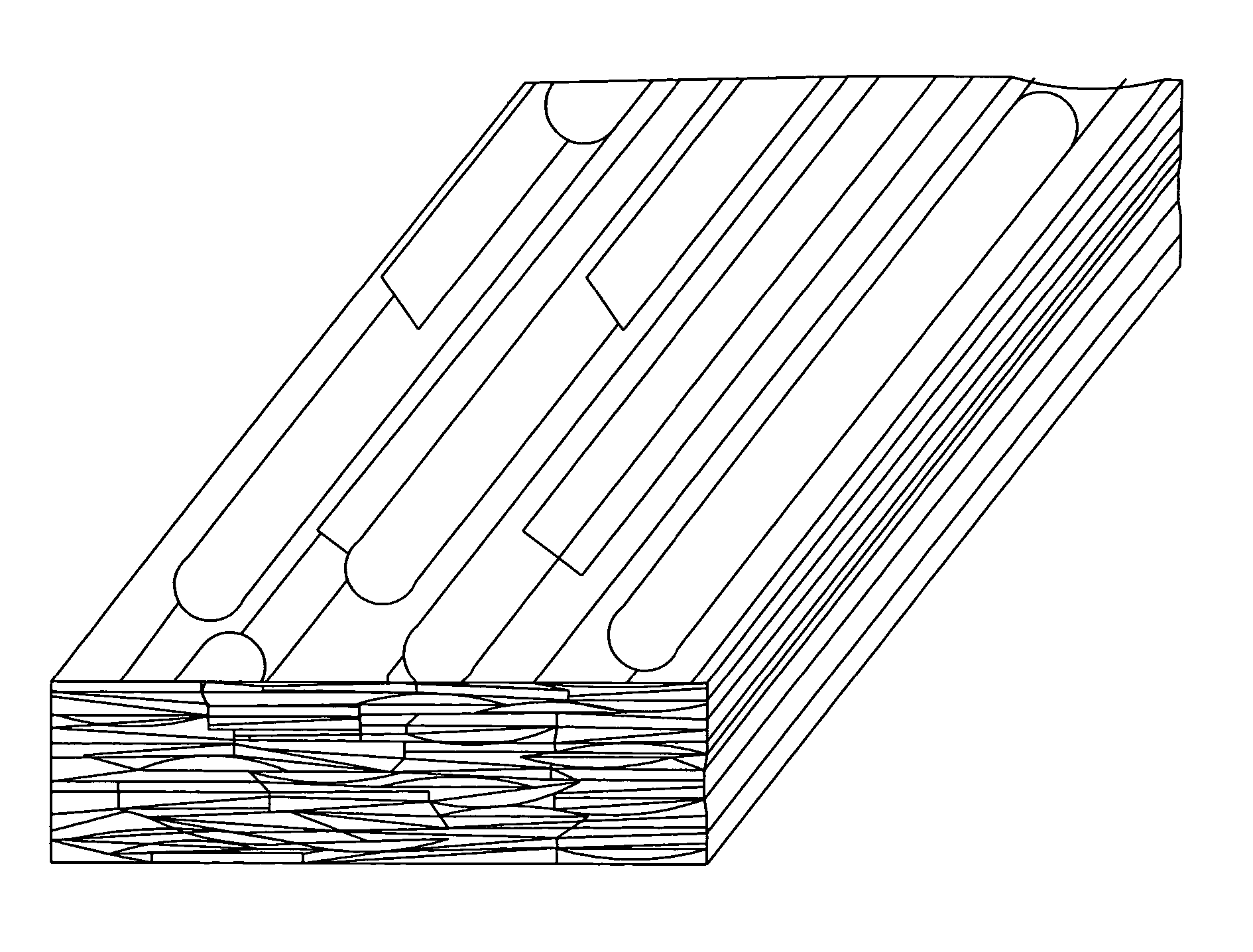

Bamboo chip treatment and products

InactiveUS20050161852A1Equally distributedVoid space is smallWood working apparatusAbsorbent padsEngineeringUltimate tensile strength

Thin elongated bamboo chips are produced and then are softened and dried. The softening of the chips reduces void spaces which uses less glue and produces stronger members. The chips are then joined together with glue under pressure to form a bamboo board. By varying the depth and length of the chip form, the member produced can form a board, chipboard, beams, or columns of any size. Additional boards may be produced and glued together to form a larger board, beam, or column. Several chipboard layers fabricated in large sheets and glued together will form ‘multi-ply bamboo’, a bamboo substitute for plywood. Once cured, the member is kiln dried and sealed for moisture. The resulting bamboo member's strength and geometrical form is stable and consistent enough to be used as a structural grade member for frames, homes, buildings, and furniture.

Owner:DECKER EMIL GUY +1

Process for producing a fibrous structure having increased surface area

InactiveUS7118647B2Non-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringFiber structure

Owner:THE PROCTER & GAMBLE COMPANY

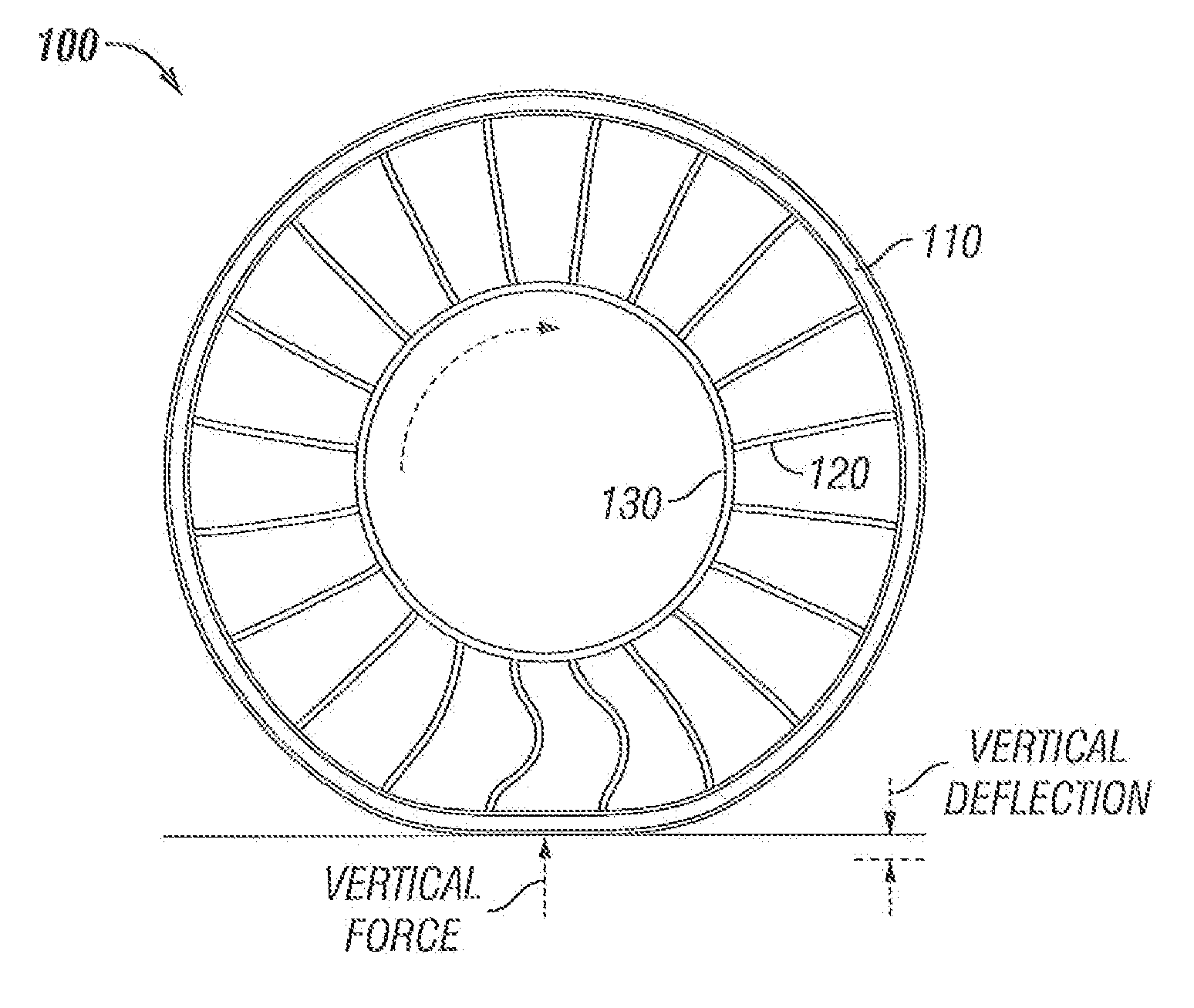

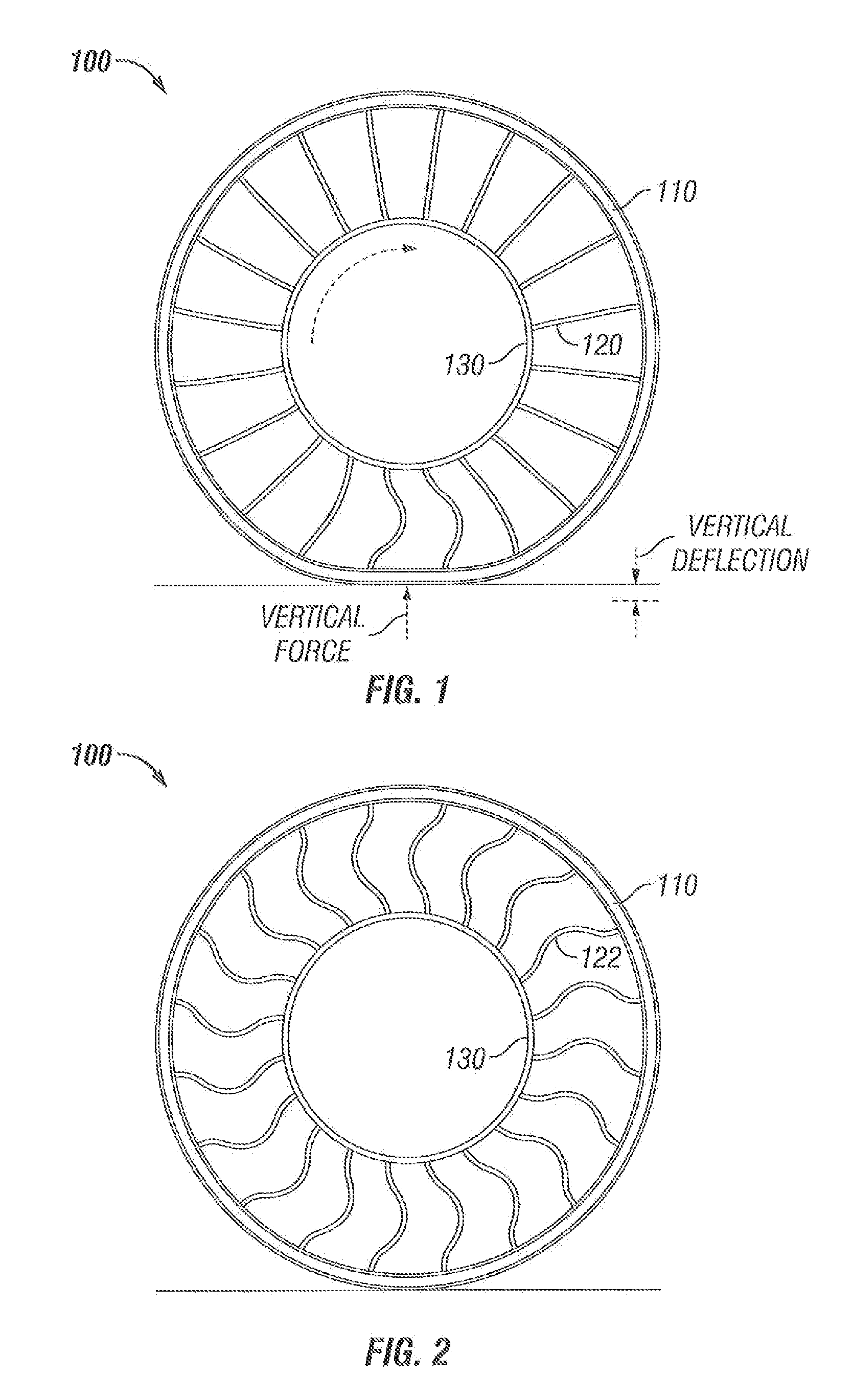

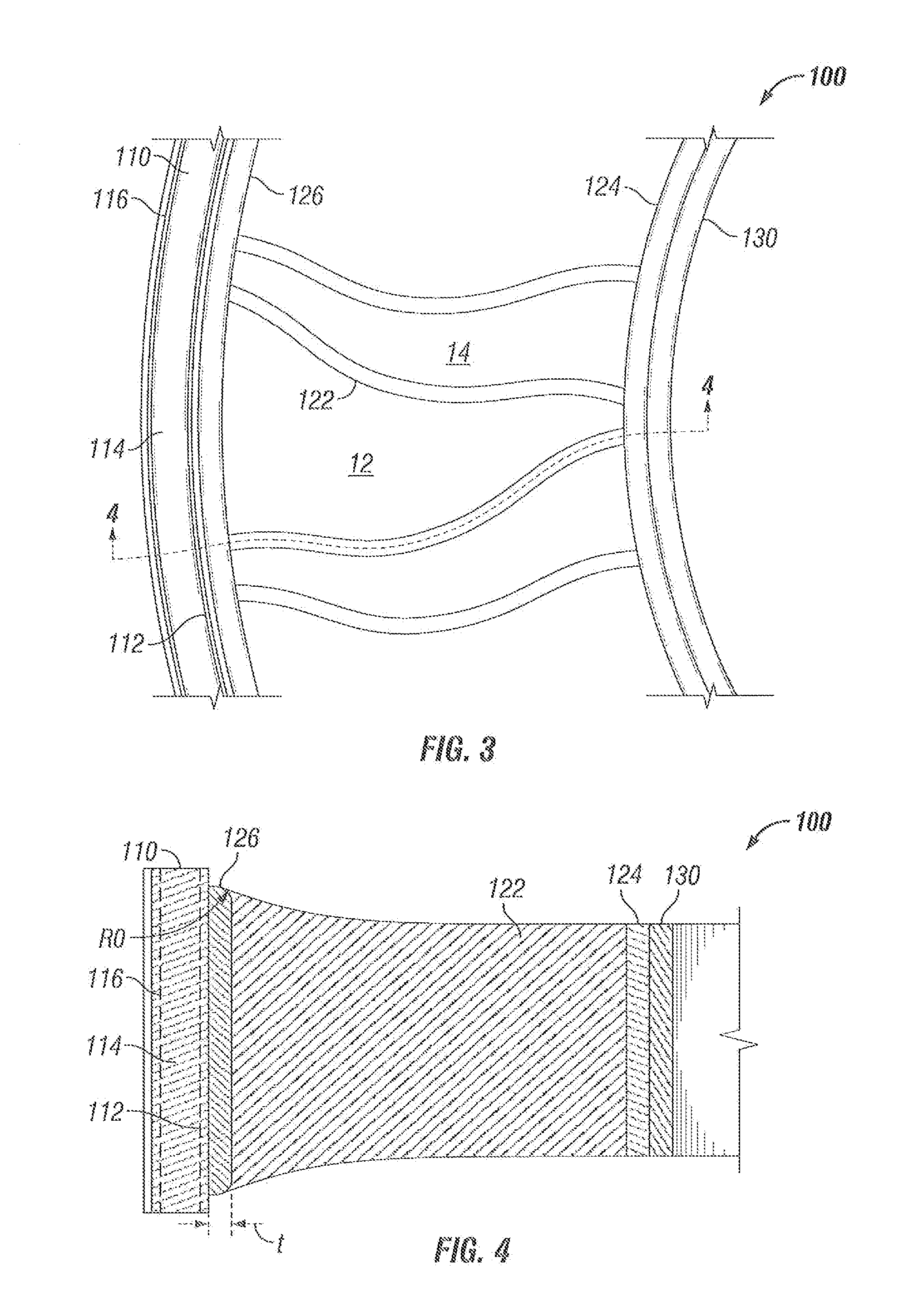

Molded article and venting assembly for a rotating mold

A molded article comprises an outer interface element, an inner interface element, and a plurality of web spokes positioned therebetween. The common surfaces of the inner and outer interface elements and a pair of adjacent web spokes form a void space. The surface of at least a portion of an interface element common to one of the voids has an edge radius with a variation from a maximum radius at a circumferential location corresponding to a mid point between a pair of adjacent web spokes to a minimum radius at a circumferential location corresponding to the intersection of the interface element with the web spoke.

Owner:MICHELIN RECH & TECH SA +1

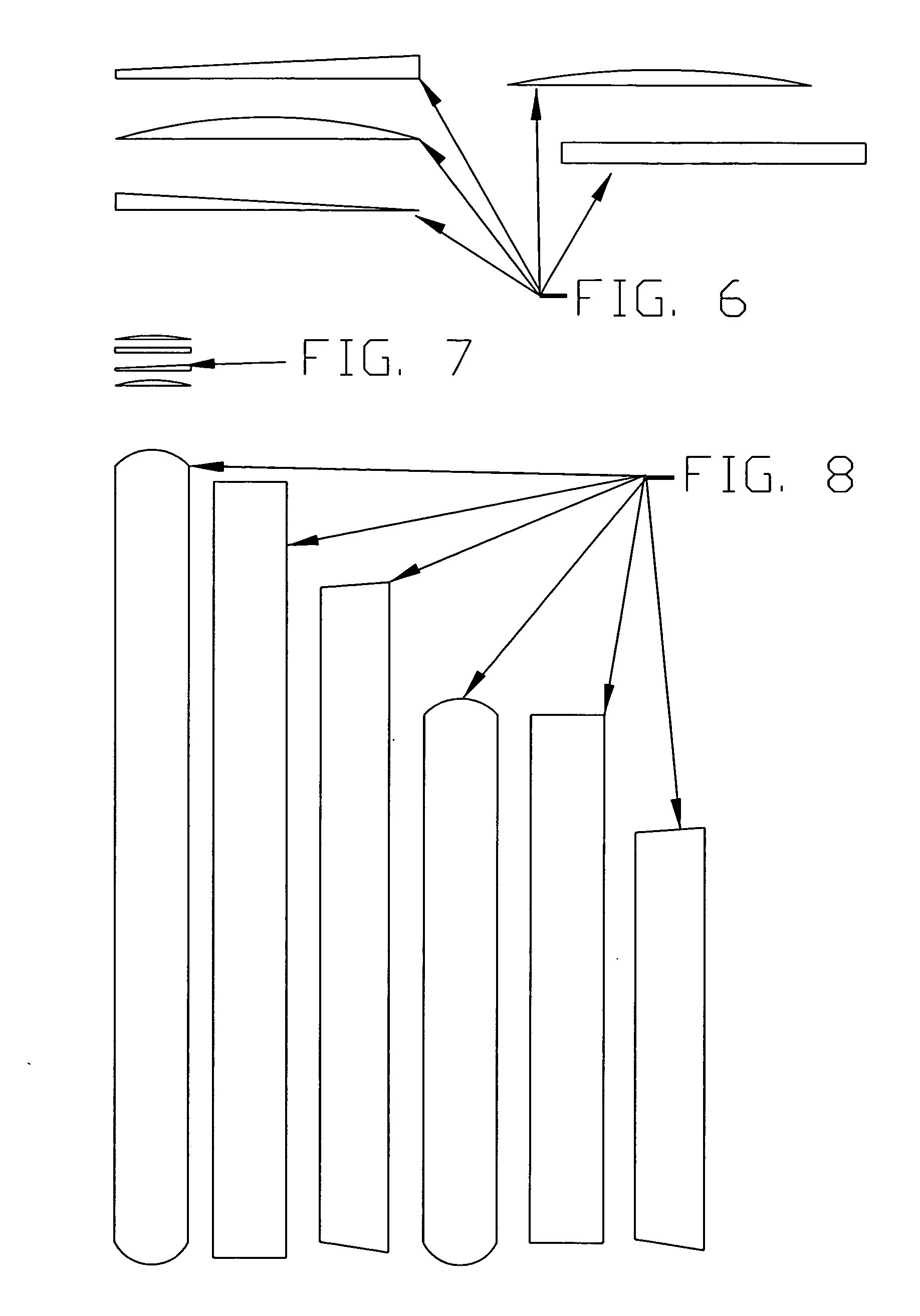

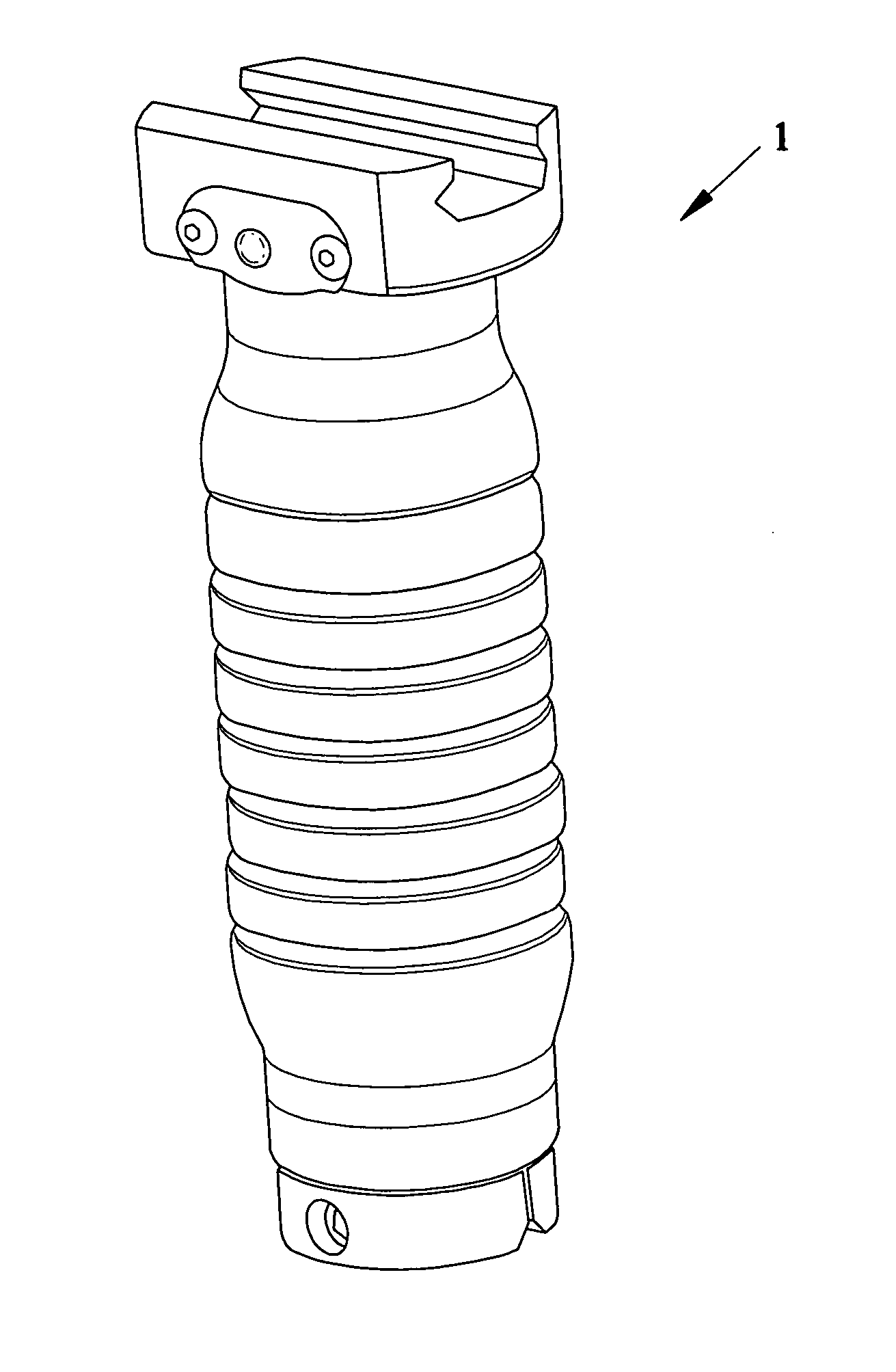

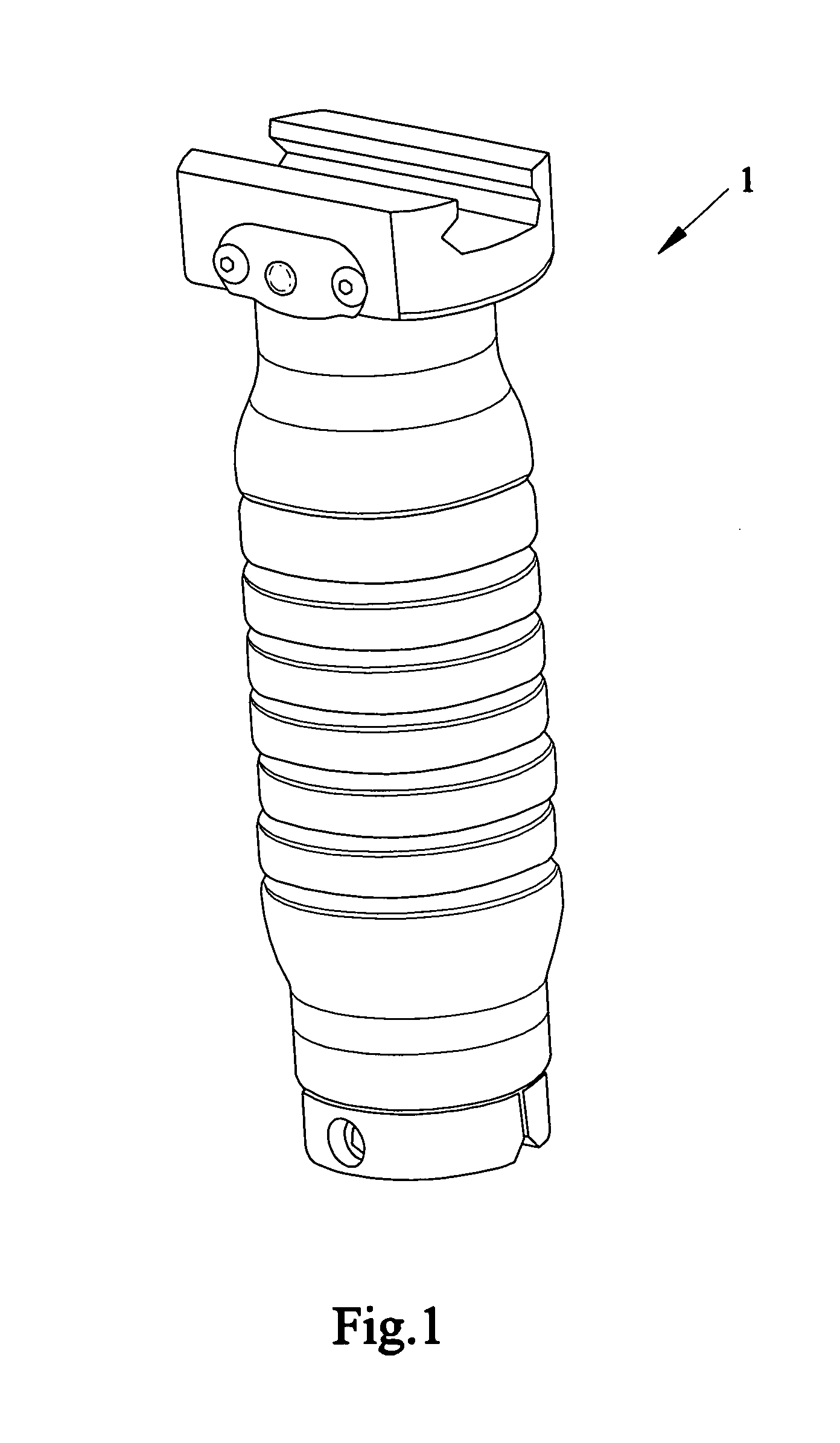

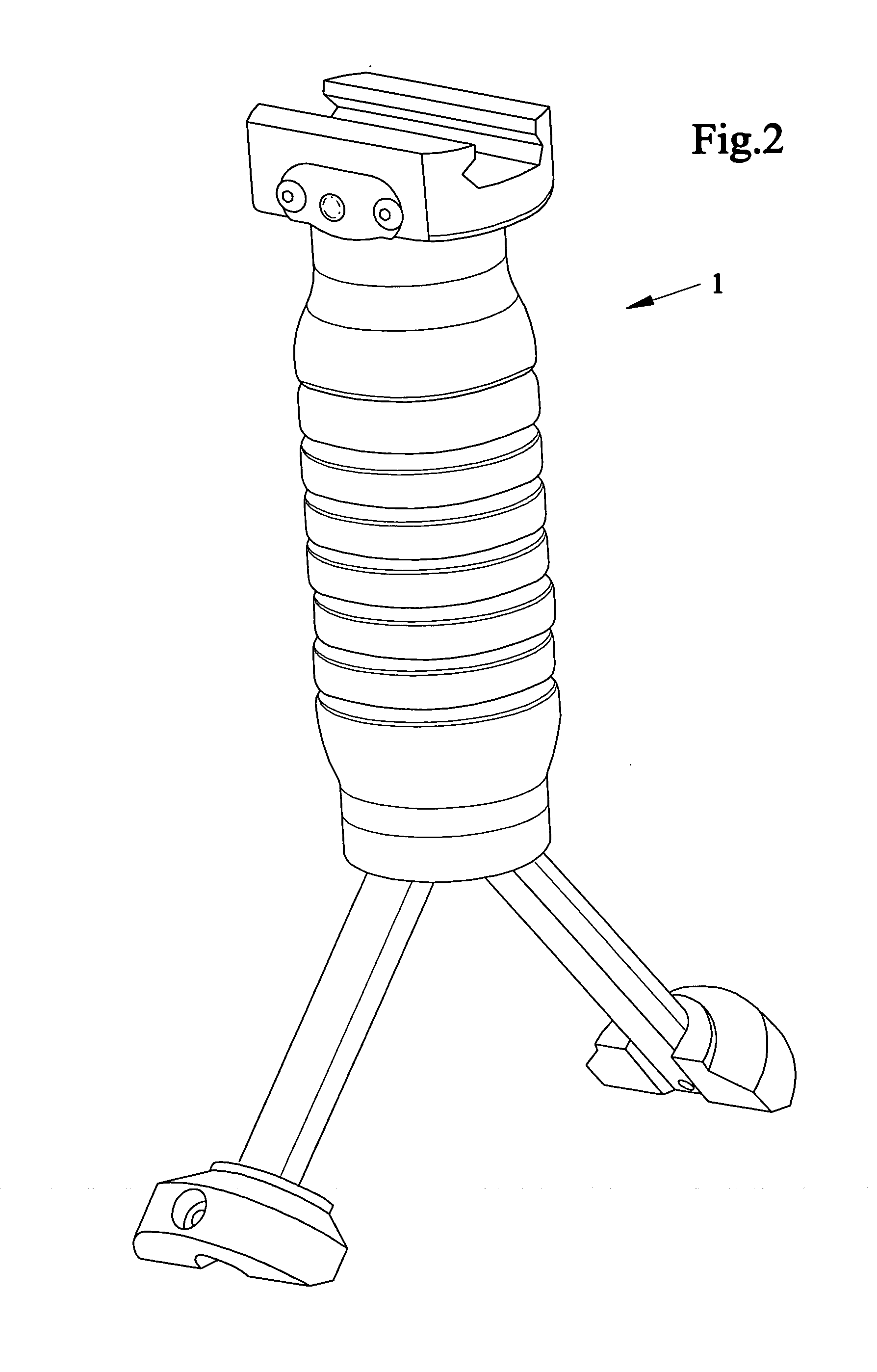

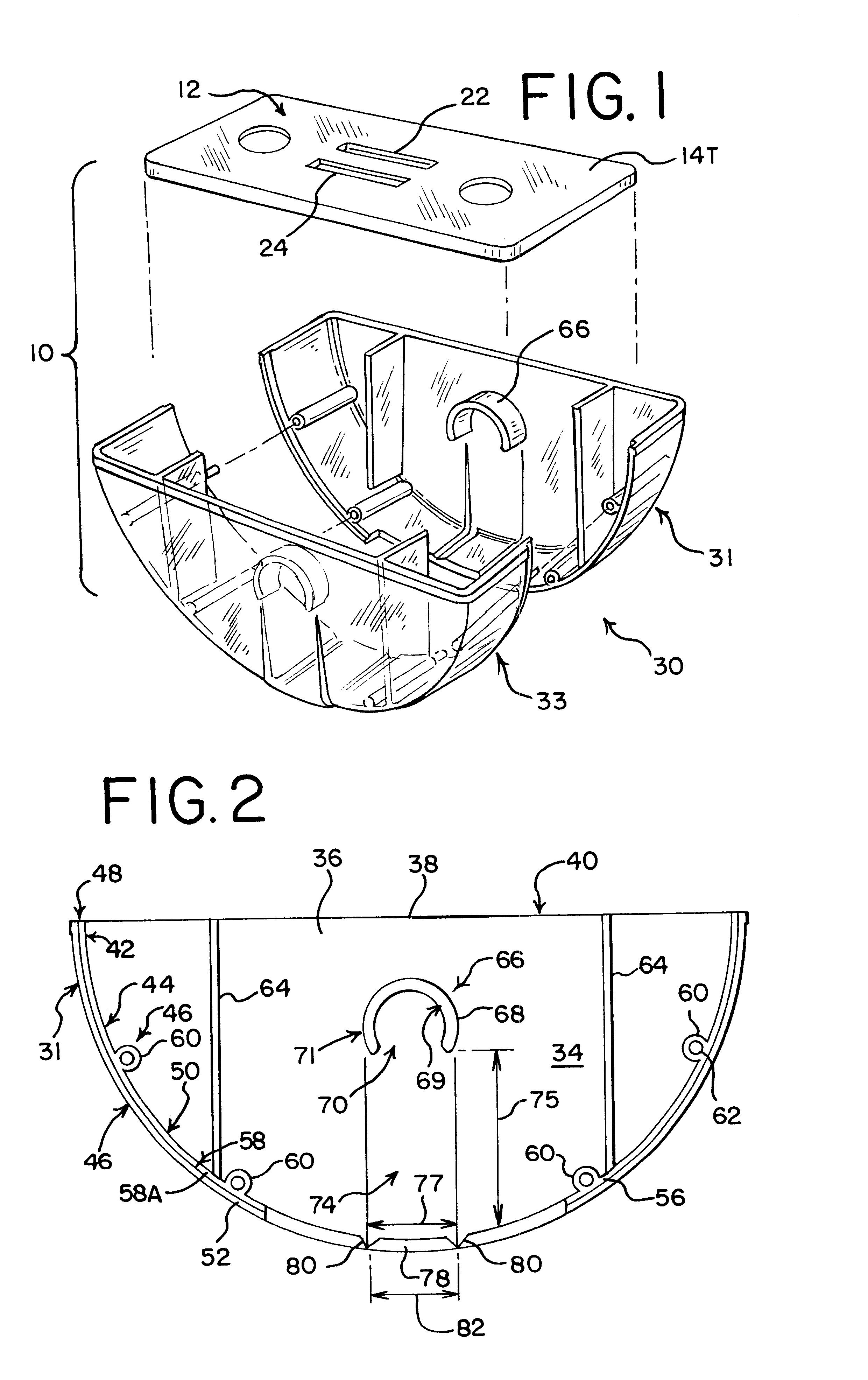

Vertical fore grip with bipod

ActiveUS20060277809A1Self containedSimple attachmentAmmunition loadingStands/trestlesTerrainLeg length

Devices, systems and methods of using an ergonomic fore grip / gun handle with a concealable and collapsible bipod. One version can have a tubular recess consisting of a first cylindrical cutout housing the bipod legs when concealed and a sliding piston that deploys the legs and a second cylindrical cutout housing a release mechanism and a void space for other accessories. The release mechanism has a compression spring positioned between the piston assembly and the bottom of the first cylindrical cutout and the compression spring. The legs are connected to the bottom of the piston assembly via a hinge and spring that when released from confinement within the fore grip, causes the legs to expand outward until fully deployed. Telescoping legs allow adjustment of leg length for use on uneven terrain. The grip portion has an outer surface with a flat surface on sides of the grip to provide a more stable grip, assist in orienting the mounted weapon and support pressure pads for lights.

Owner:GRIP POD SYST INT

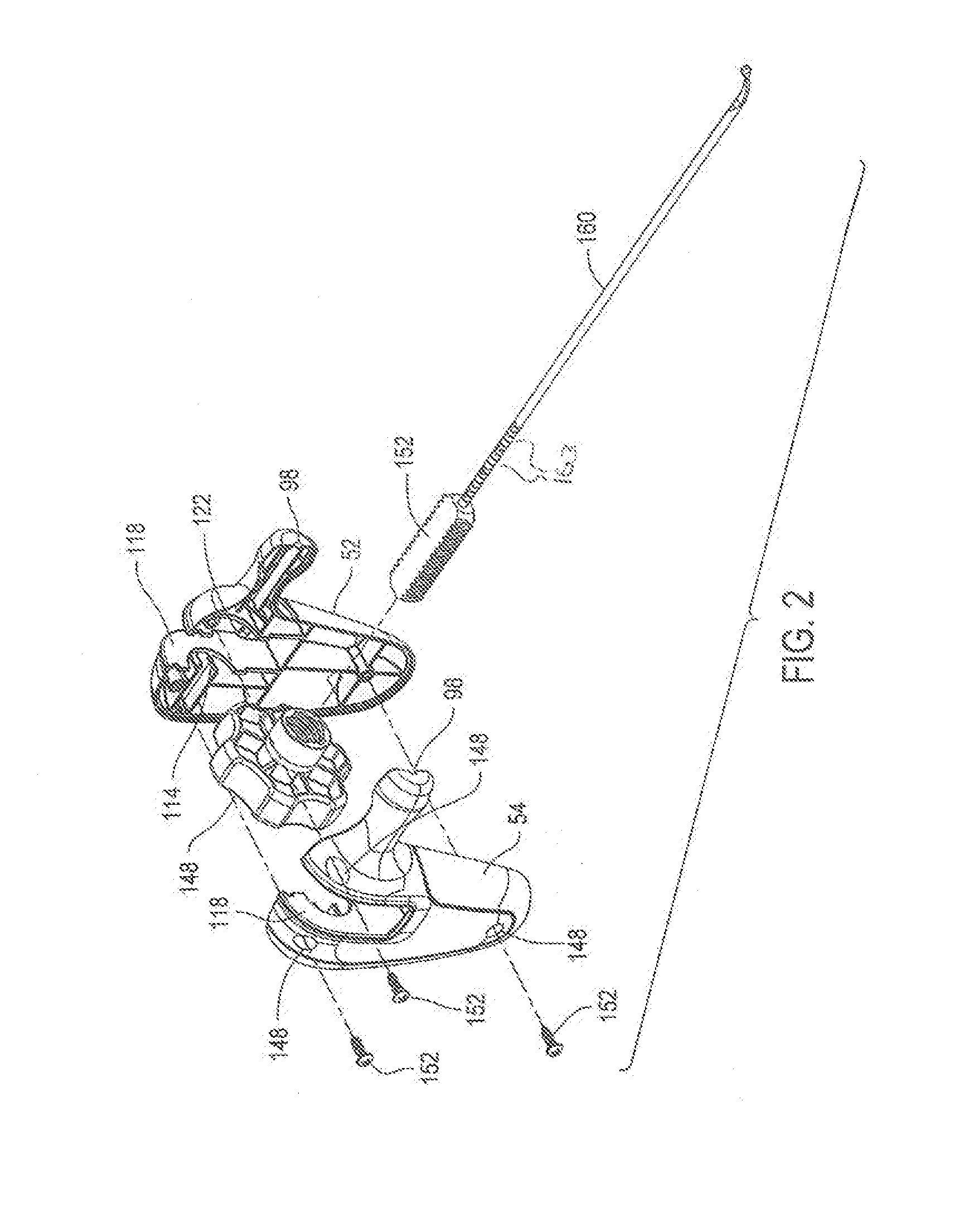

Device for creating a void space in a living tissue, the device including a handle with a control knob that can be set regardless of the orientation of the handle

A device for creating a void space in living tissue includes a handle from which a shaft extends. A tip is moveably attached to the distal end of the shaft. The angular position of the tip is controlled by the rotation of a knob mounted to the handle. The knob is mounted to the handle to project beyond opposed side surfaces of the handle and a surface that bridge between the side surfaces.

Owner:STRYKER CORP

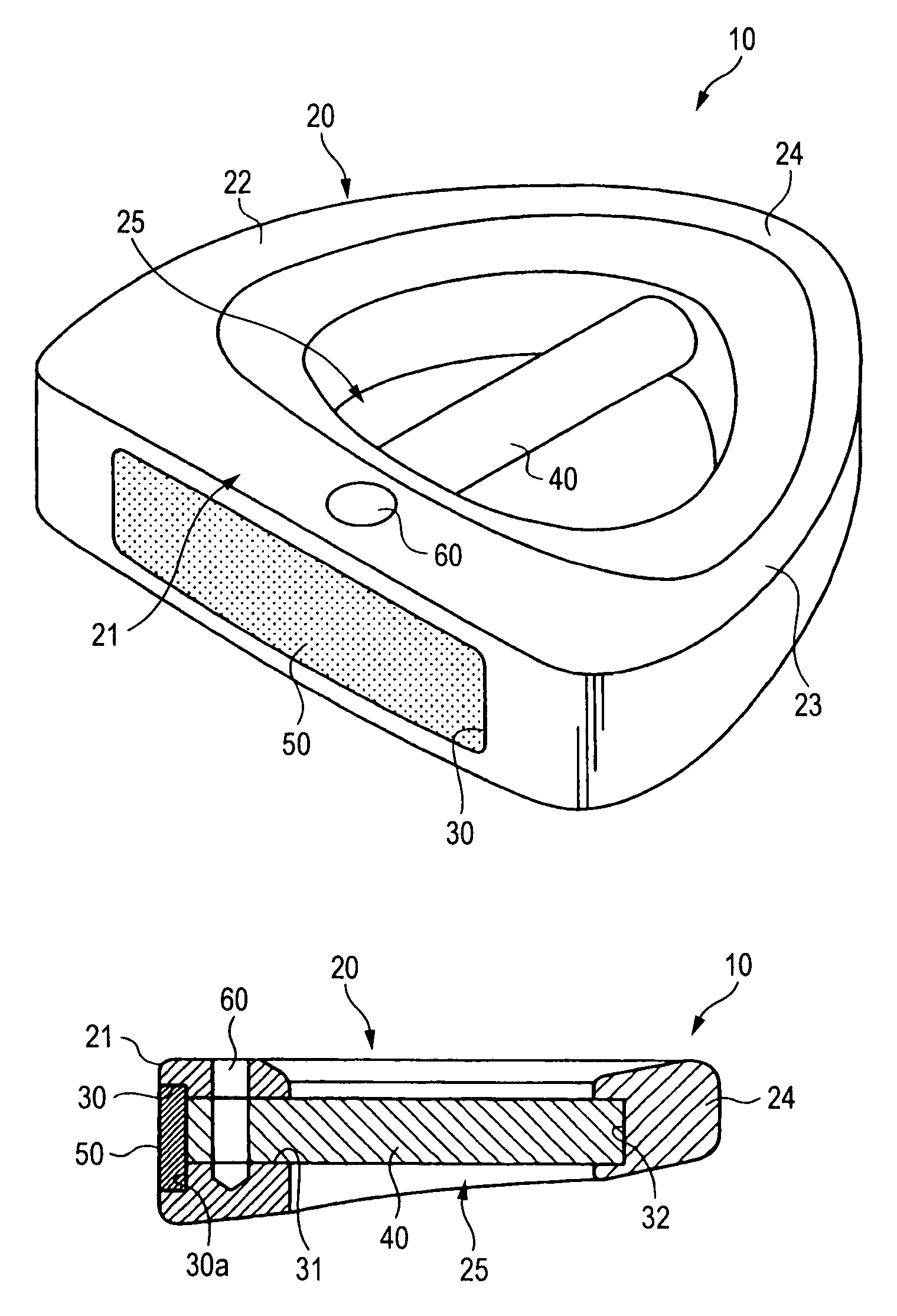

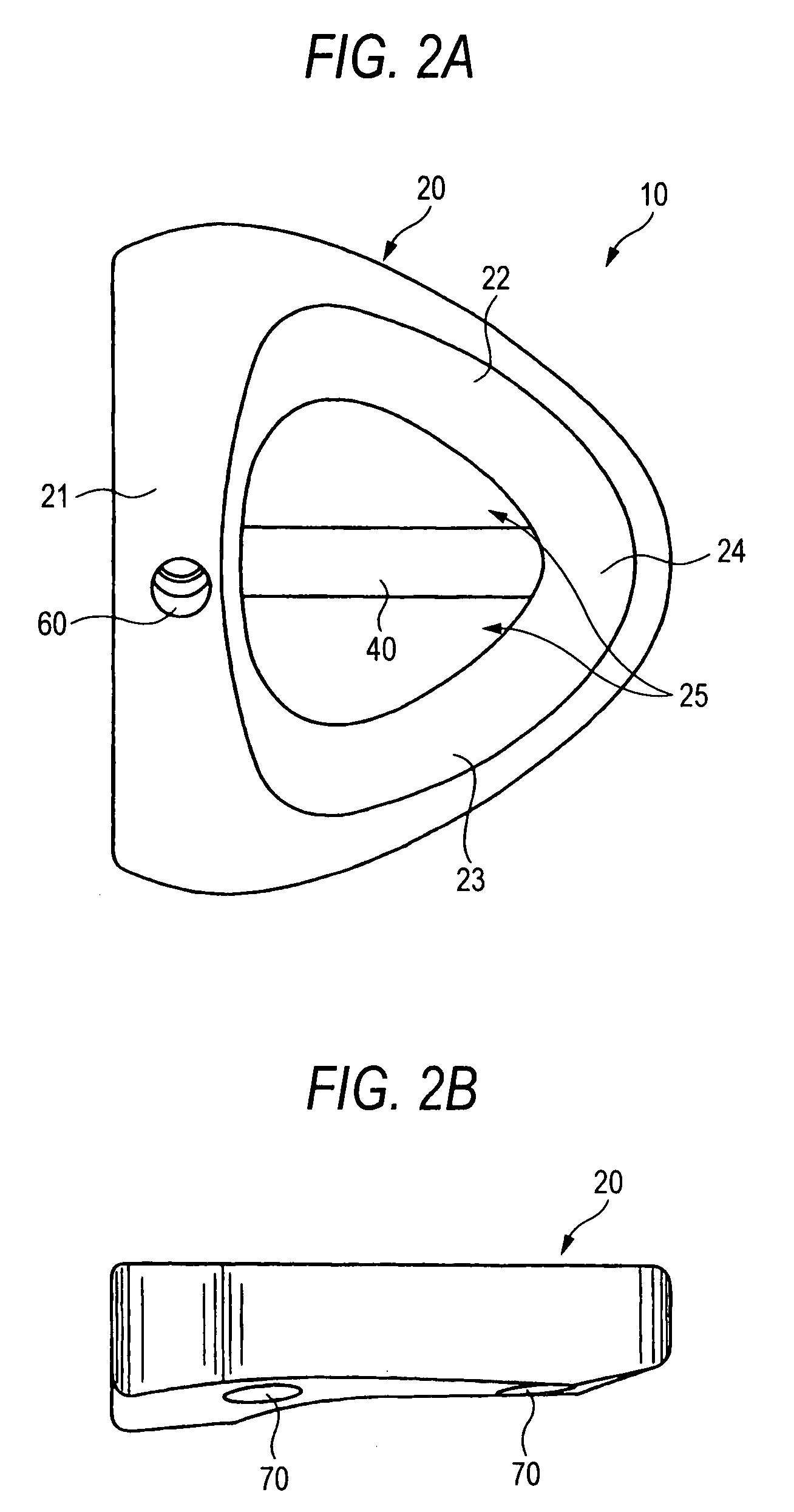

Putter head

InactiveUS7588499B2High dimensional accuracyEasy to manufactureGolf clubsRacket sportsAdhesiveEngineering

A putter head includes a head main body that defines a periphery of the putter head, and a bar that crosses a void space of the head main body in a forward-backward direction. The bar is inserted into insertion holes and fixed thereto by an adhesive. A face member is mounted on a recess. A shaft fixing hole is provided to pass through the bar from the top surface of a front portion of the head main body. A shaft is inserted into the shaft fixing hole and fixed thereto by an adhesive.

Owner:BRIDGESTONE SPORTS

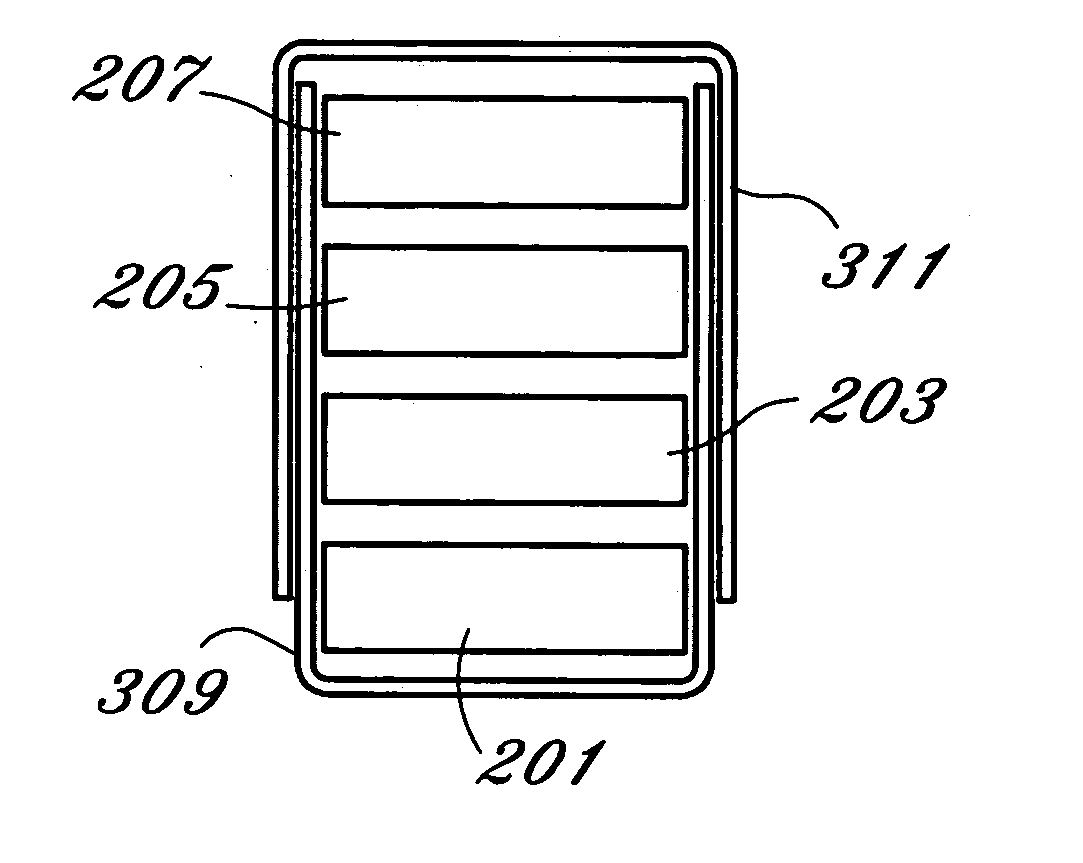

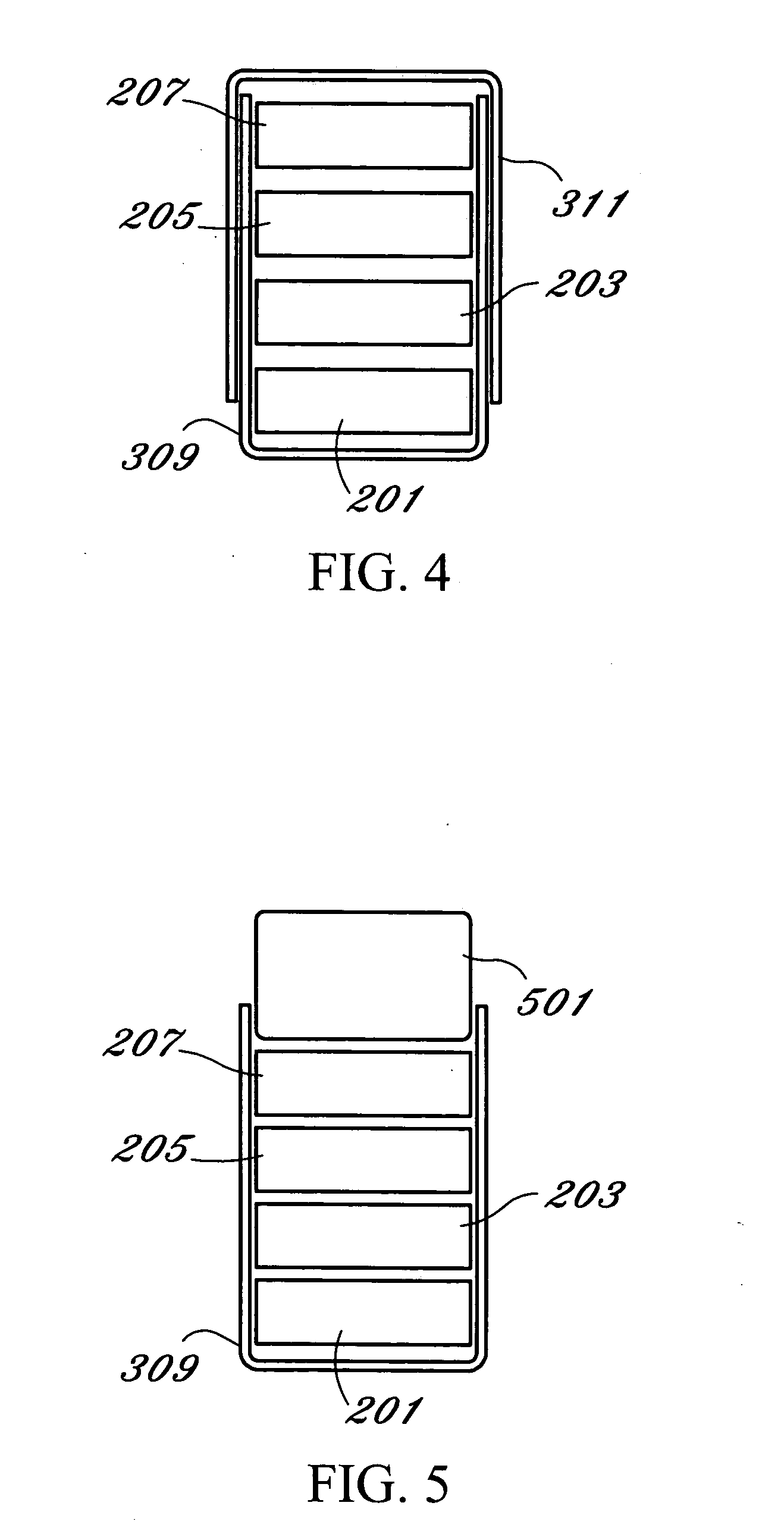

Medication delivery device

InactiveUS20050053649A1Minimize void spaceSpace minimizationOral administration devicePill deliveryBULK ACTIVE INGREDIENTActive ingredient

A medication delivery device by virtue of which multiple medications, each itself in a separate inner container (gel cap, coated pill or capsule), with the multiple separate containers themselves being contained within an outer container which is ingestible or insertable into a live body, and which outer container is made of a material which is biodegradable after ingestion or insertion into a live body, in which each separate inner container is of a particular standardized shape and size designed to fit closely together with each other, thereby resulting in minimum void space, minimum inert ingredients and maximum amount of active ingredients of medication containable within each inner container, and a standardized outer container shape, size and appearance. The outer container is typically a capsule type device, comprised of two components, with the length of the internal compartment of the said outer container capsule type or cylindrical shaped device being variable to accommodate a variety of volumes of internally contained multiple medications. The active ingredients in each of the inner containers is not in actual physical contact with the active ingredients of any of the other medication products also contained within the outer container. The several inner containers, and the outer container, of the medication delivery device may be variously constructed of material which is either opaque, translucent or transparent.

Owner:AMBO INNOVATIONS

Removable insert for creating a void space, as in precast concrete panels

A removable and reusable insert assembly for positioning and supporting a lifting system within a panel to be formed from cast concrete, the insert assembly having a left and right portion which are detachably removable from each other, and a lid that is secured over the insert. The lid protects an interior space of the insert assembly.

Owner:FROMELIUS LAWRENCE

High-density, solid solution nuclear fuel and fuel block utilizing same

A nuclear fuel element includes a core formed from a high density solid solution fissile material that is substantially free of carbon and void space. A cladding substantially surrounds the core.

Owner:MICRON TECH INC +1

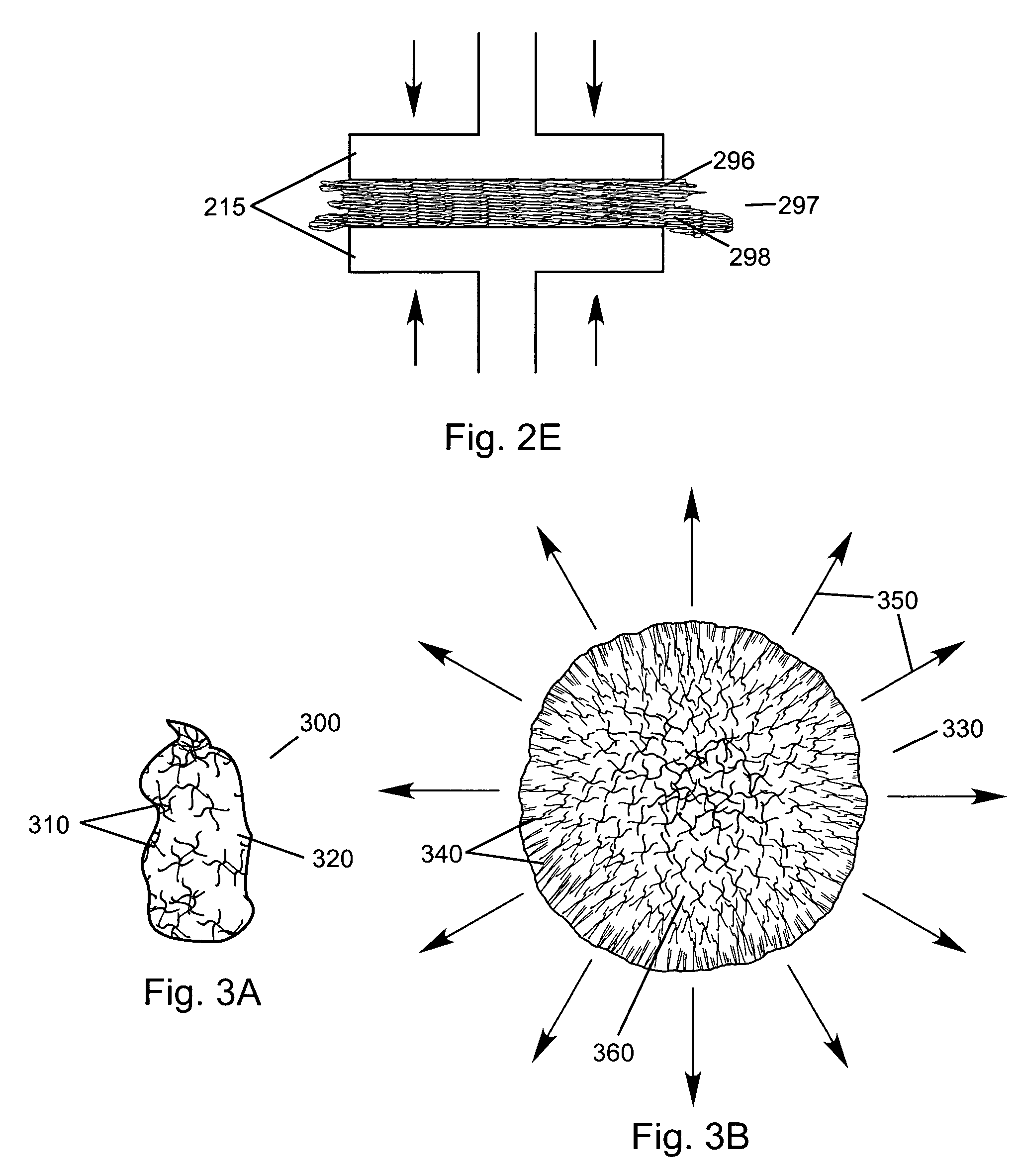

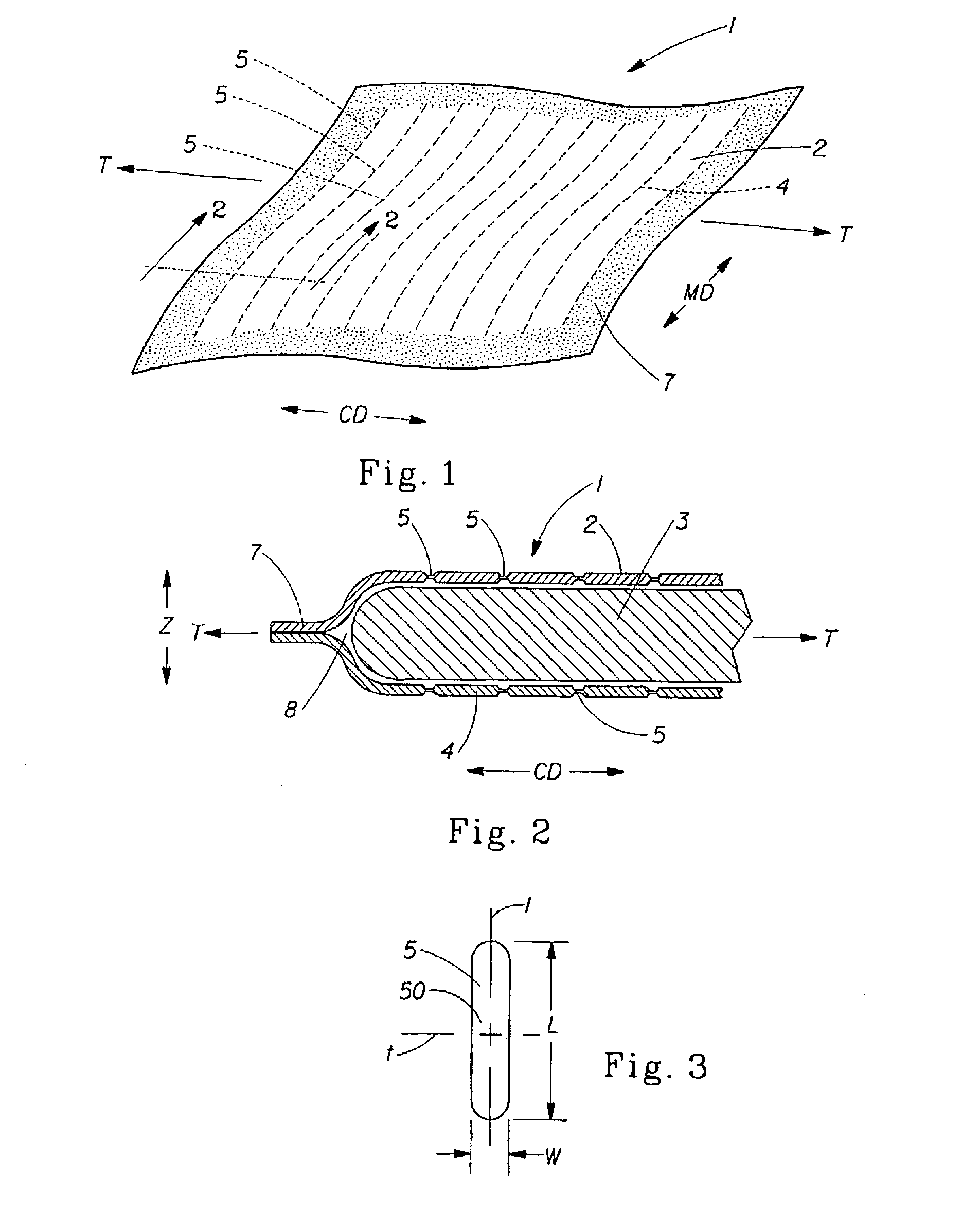

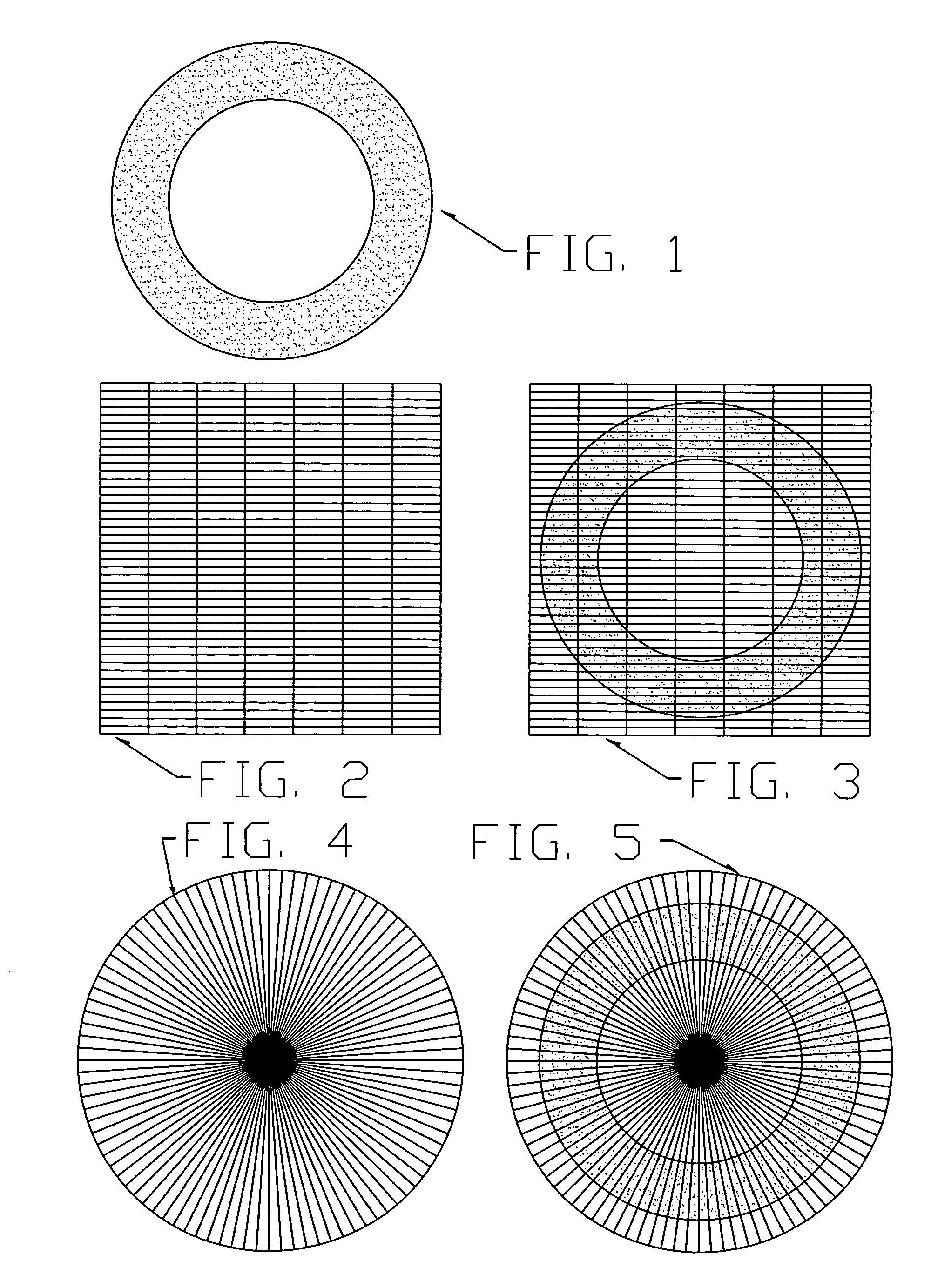

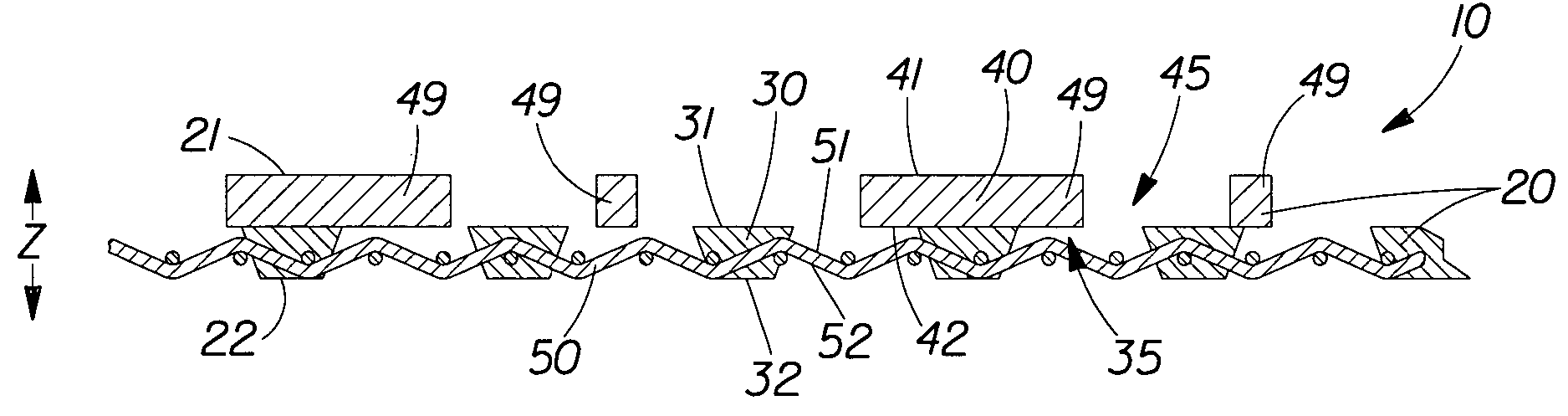

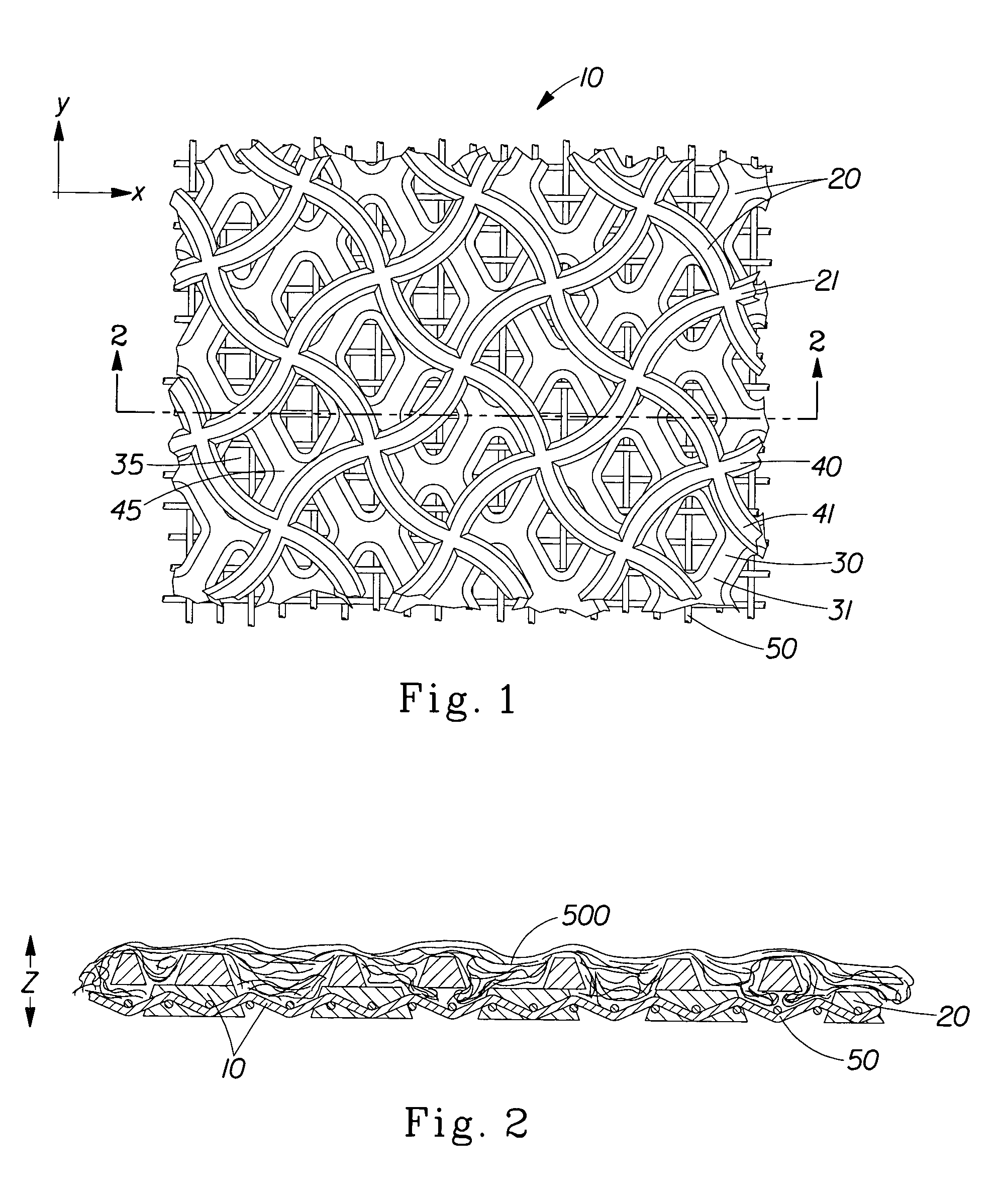

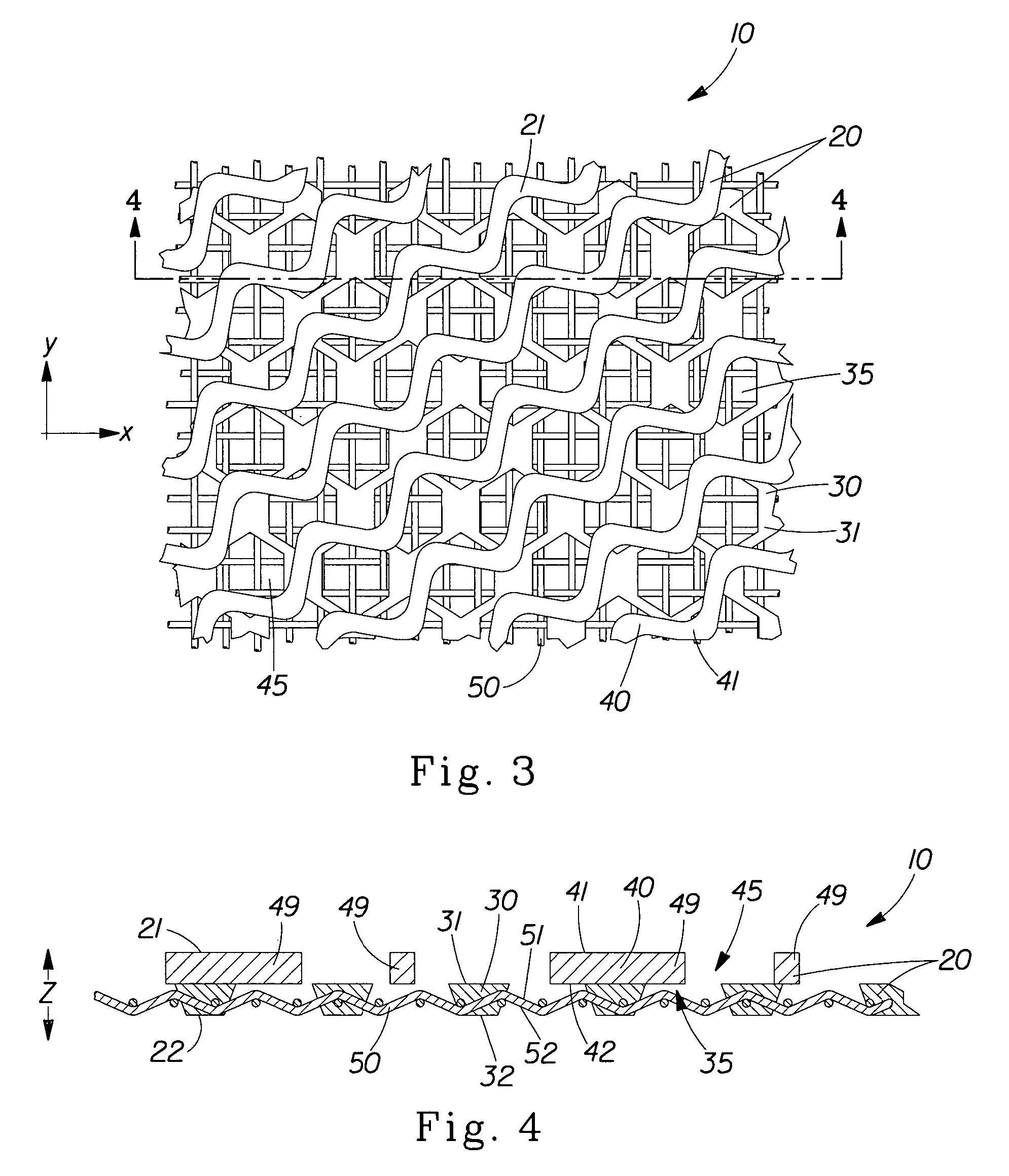

Infusible unidirectional fabric

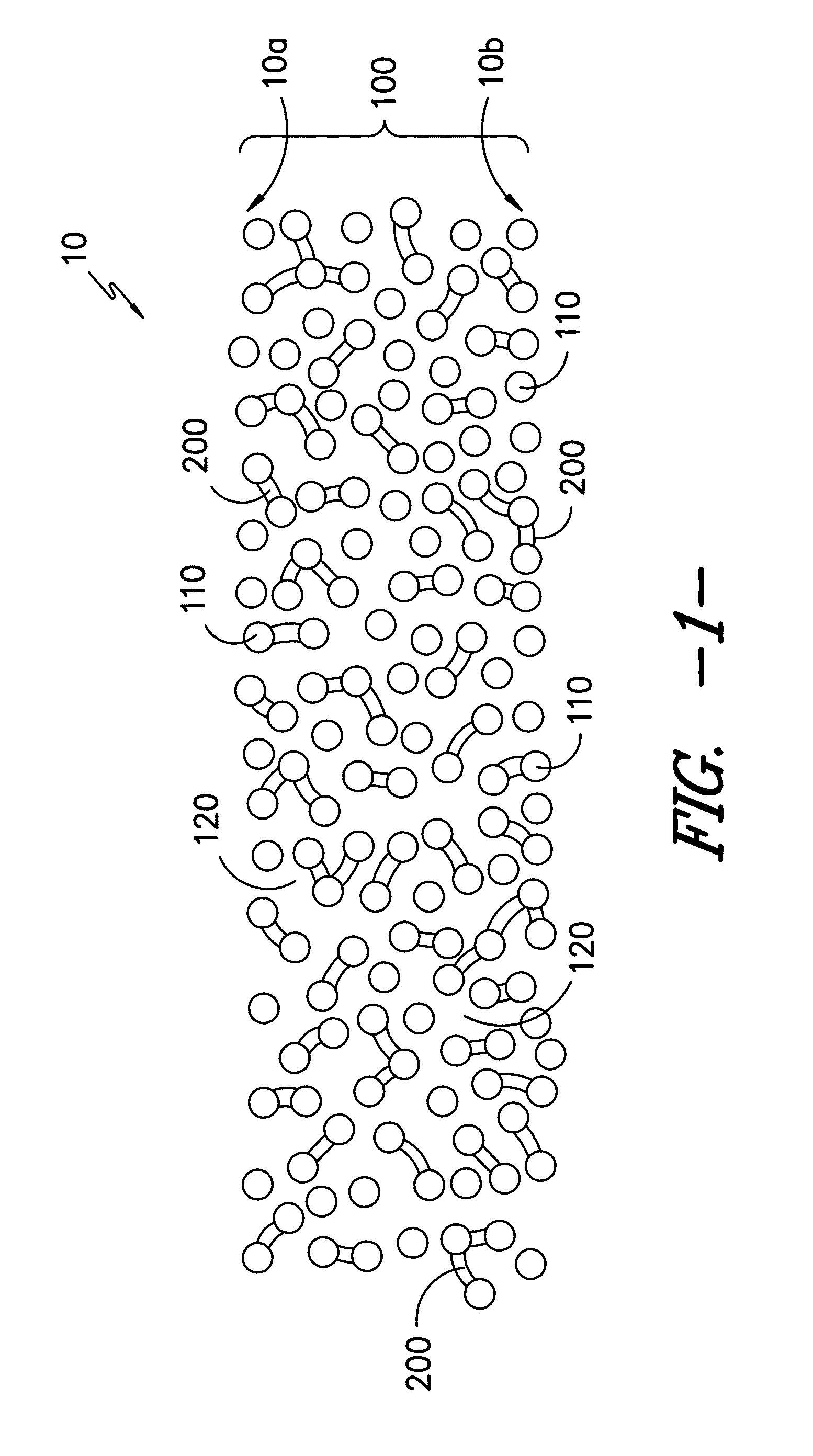

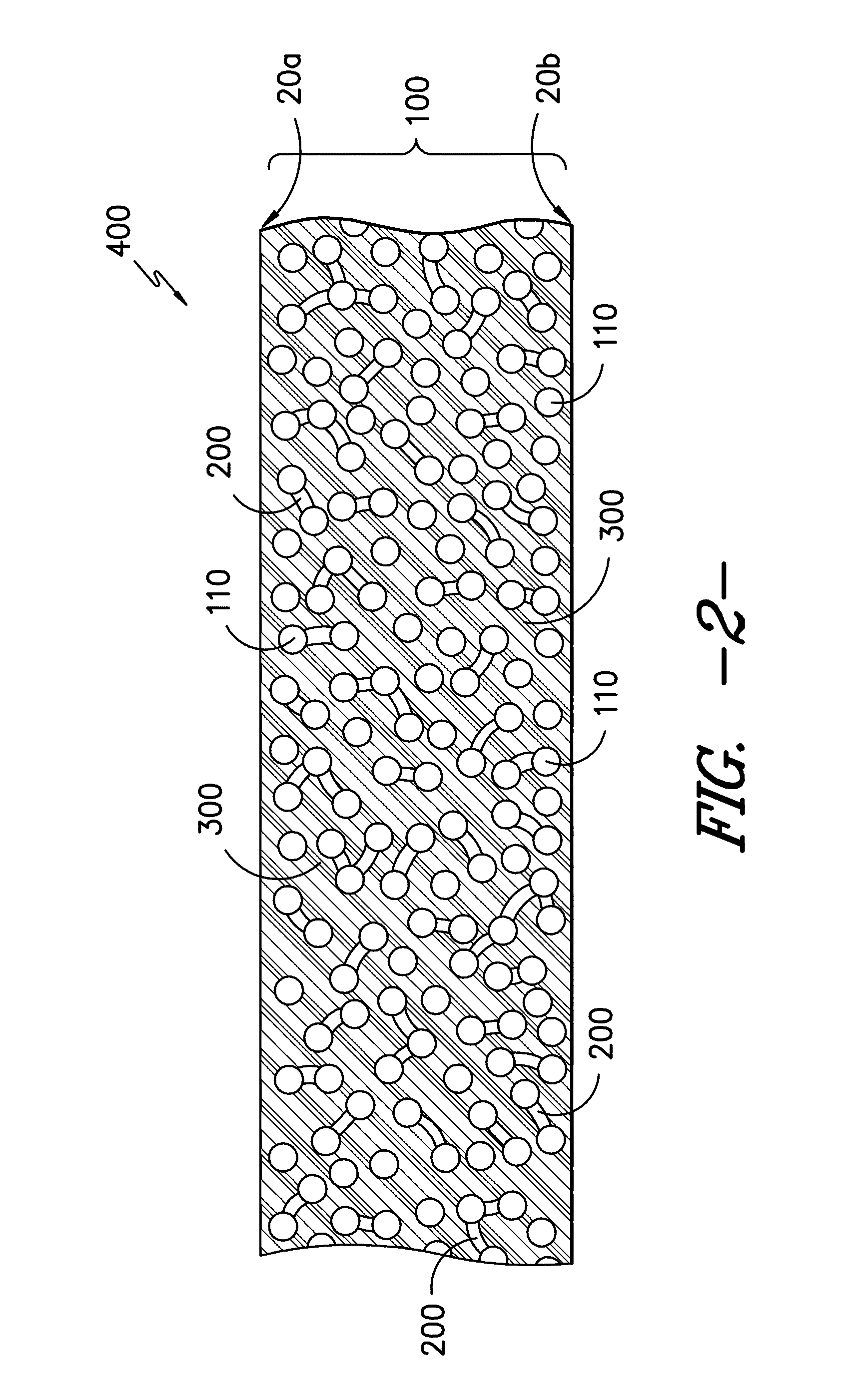

An infusible, unidirectional fabric containing a plurality of unidirectional fibers spaced uniformly in the unidirectional fabric, a plurality of bridges, and a plurality of void spaces between the unidirectional fibers. Each bridge is connected to at least 2 unidirectional fibers and at least 70% by number of fibers have at least one bridge connected thereto forming a bridged network of unidirectional fibers. The void spaces are interconnected and the fabric has a volume fraction of voids of between about 8 and 70%, a volume fraction of fibers of between about 35 and 85%, and at least 50% by number of the bridges have a bridge width minimum less than about 2 millimeters.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com