Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Agent Combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

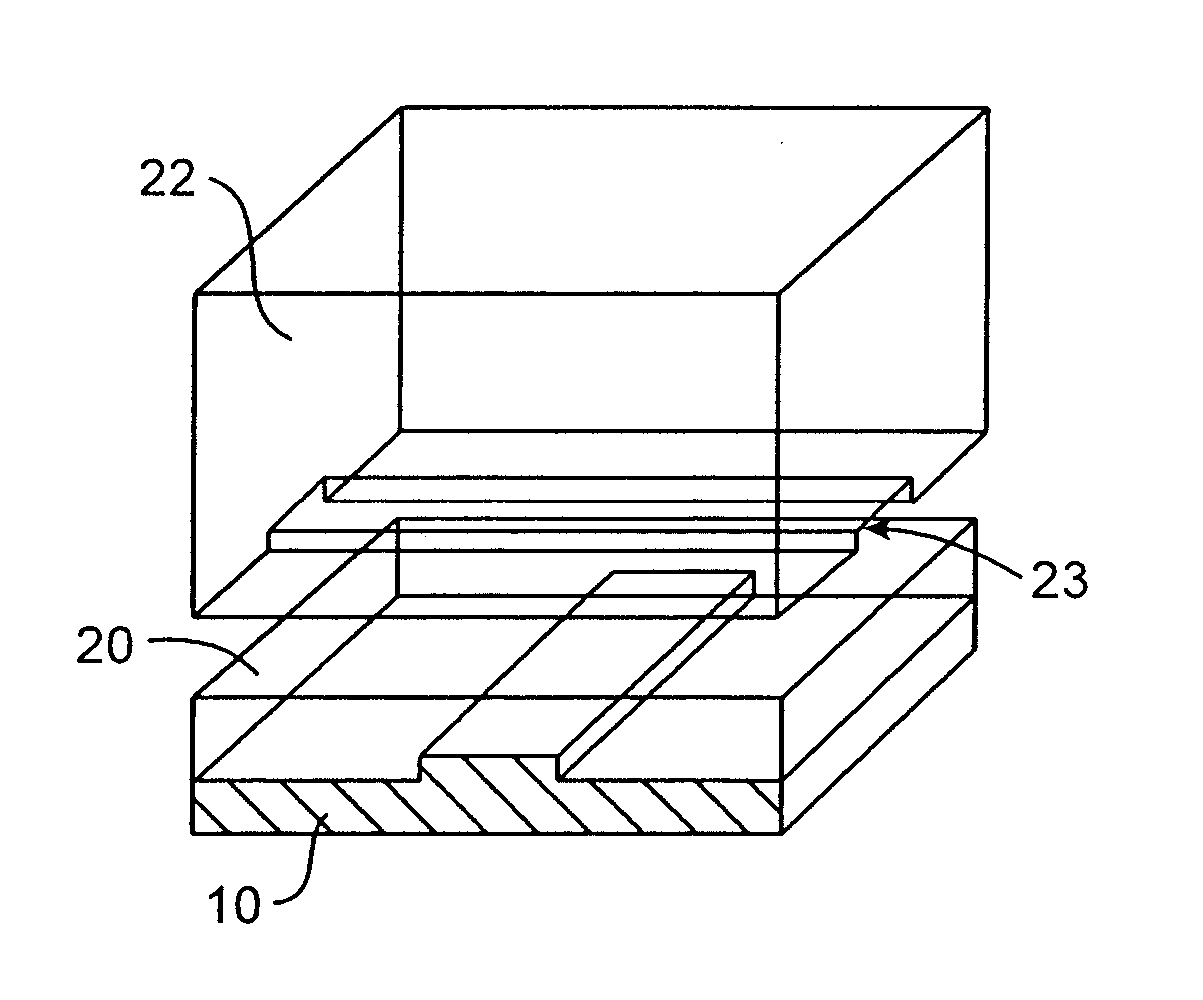

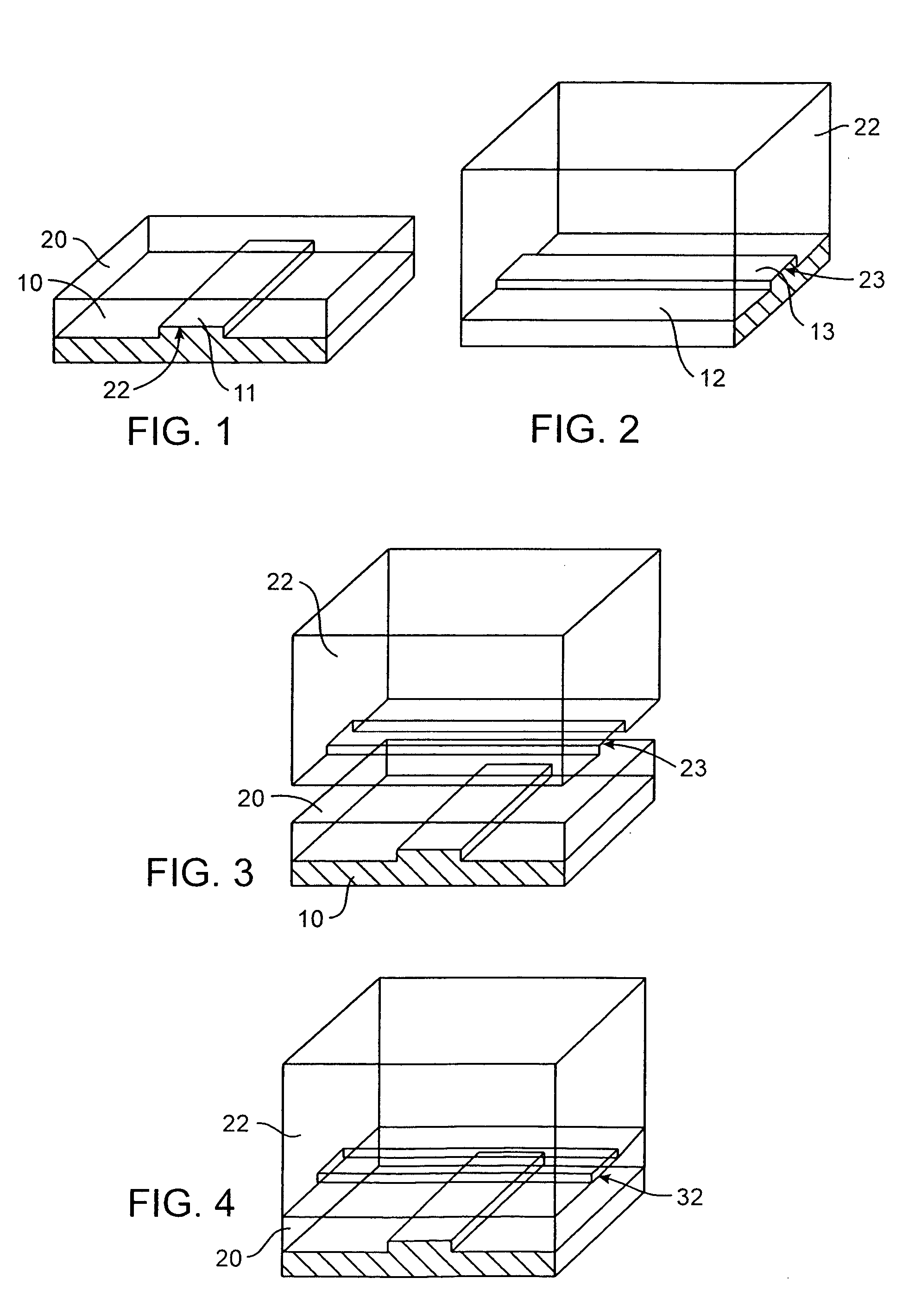

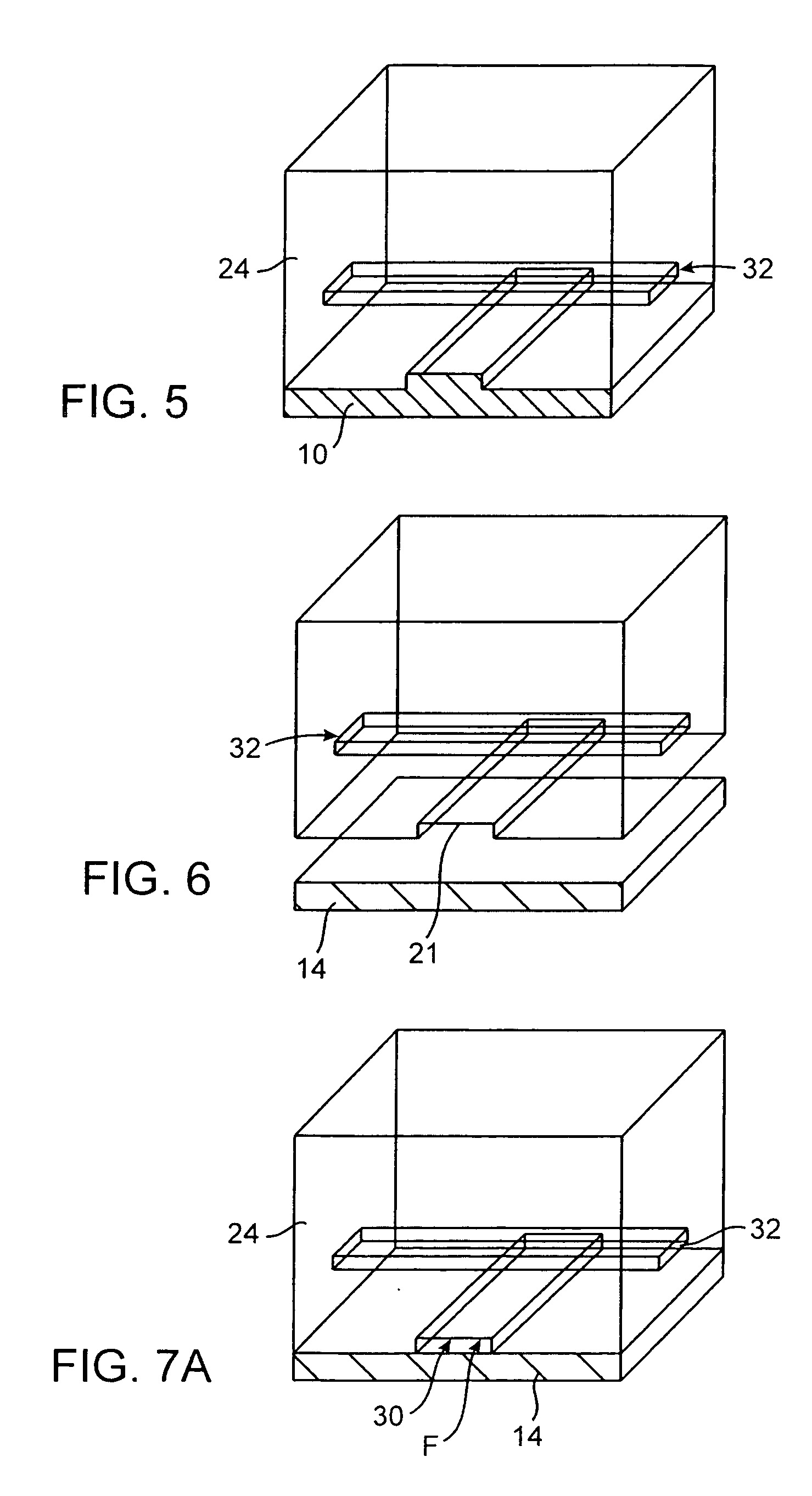

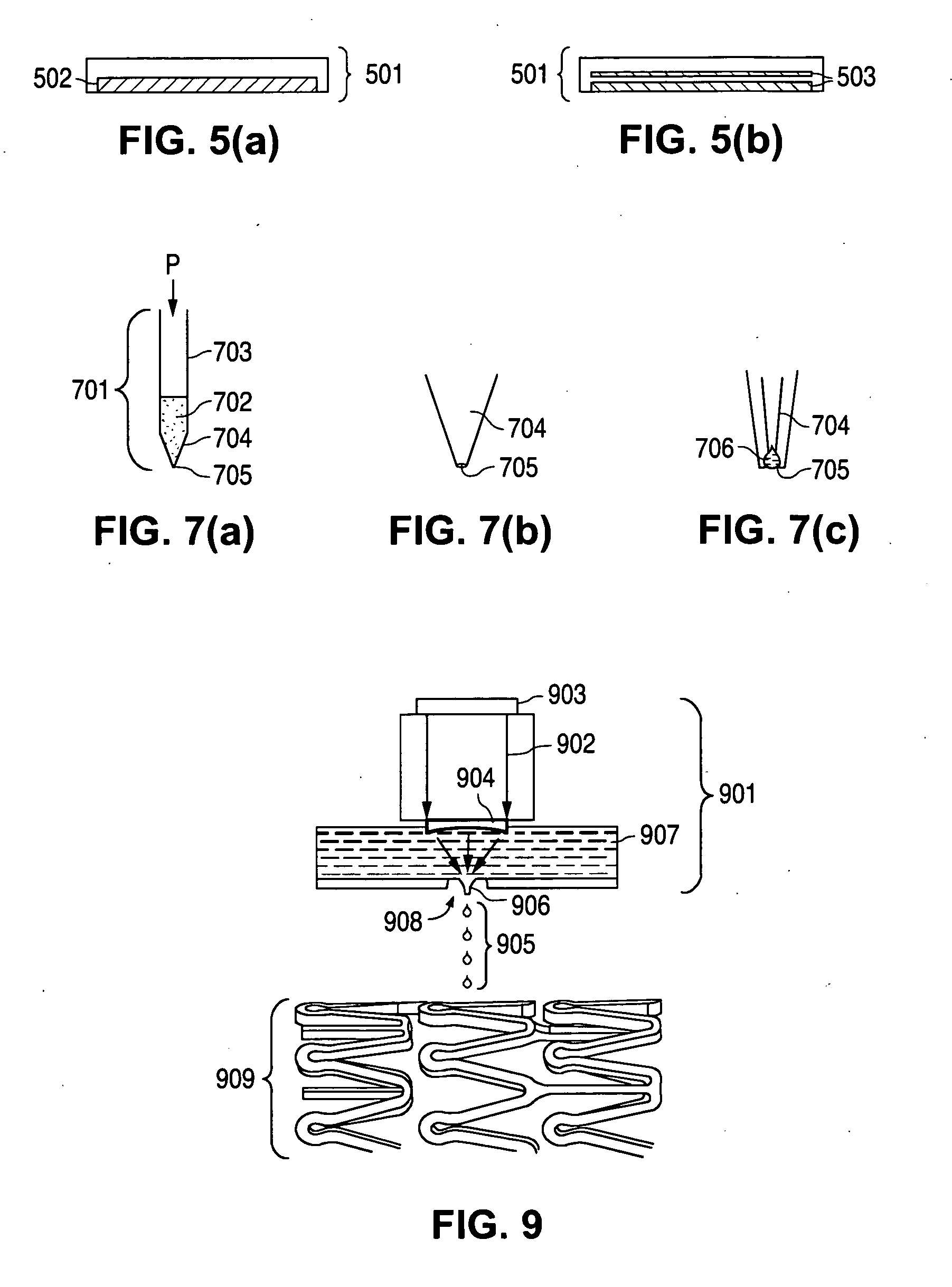

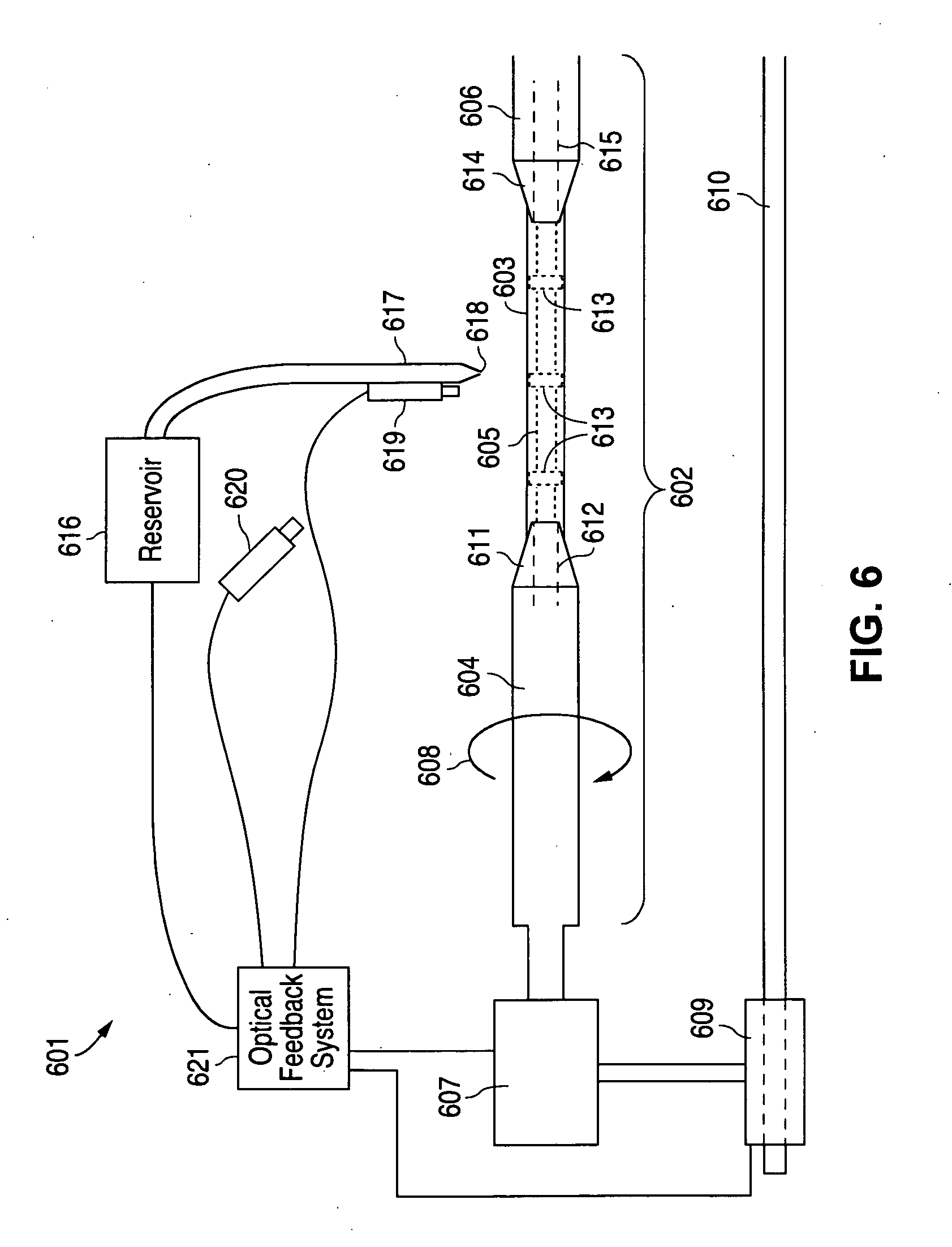

Microfluidic protein crystallography

InactiveUS20050205005A1High throughput screeningImprove throughputValve arrangementsPeptide librariesHigh-Throughput Screening MethodsAgent Combination

The use of microfluidic structures enables high throughput screening of protein crystallization. In one embodiment, an integrated combinatoric mixing chip allows for precise metering of reagents to rapidly create a large number of potential crystallization conditions, with possible crystal formations observed on chip. In an alternative embodiment, the microfluidic structures may be utilized to explore phase space conditions of a particular protein crystallizing agent combination, thereby identifying promising conditions and allowing for subsequent focused attempts to obtain crystal growth.

Owner:CALIFORNIA INST OF TECH

Chewing gum containing physiological cooling agents

A method for producing a chewing gum, as well as the chewing gum so produced, incorporates a physiological cooling agent, such as acyclic carboxamide, or combinations of physiological cooling agents. In another embodiment a combination of physiological cooling agents is made in a modified release structure. The modified release / cooling agents combination is preferably obtained by physically modifying the properties of the combination of cooling agents by coating and drying. When incorporated into gum, these particles are adapted to enhance the shelf stability of the flavor and / or produce a modified release when the gum is chewed. In another embodiment, the physiological cooling agent is present with menthol and menthone. In another embodiment, coated chewing gum has a coating that comprises a physiological cooling agent. The preferred inventive chewing gum provides a high flavor impact in which the harsh notes normally associated with such a high flavor impact have been reduced or eliminated. In addition, the preferred inventive gum provides a clean, high-quality, cooling chewing gum coating with xylitol or other polyols where xylitol has been reduced in concentration or eliminated.

Owner:WM WRIGLEY JR CO

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

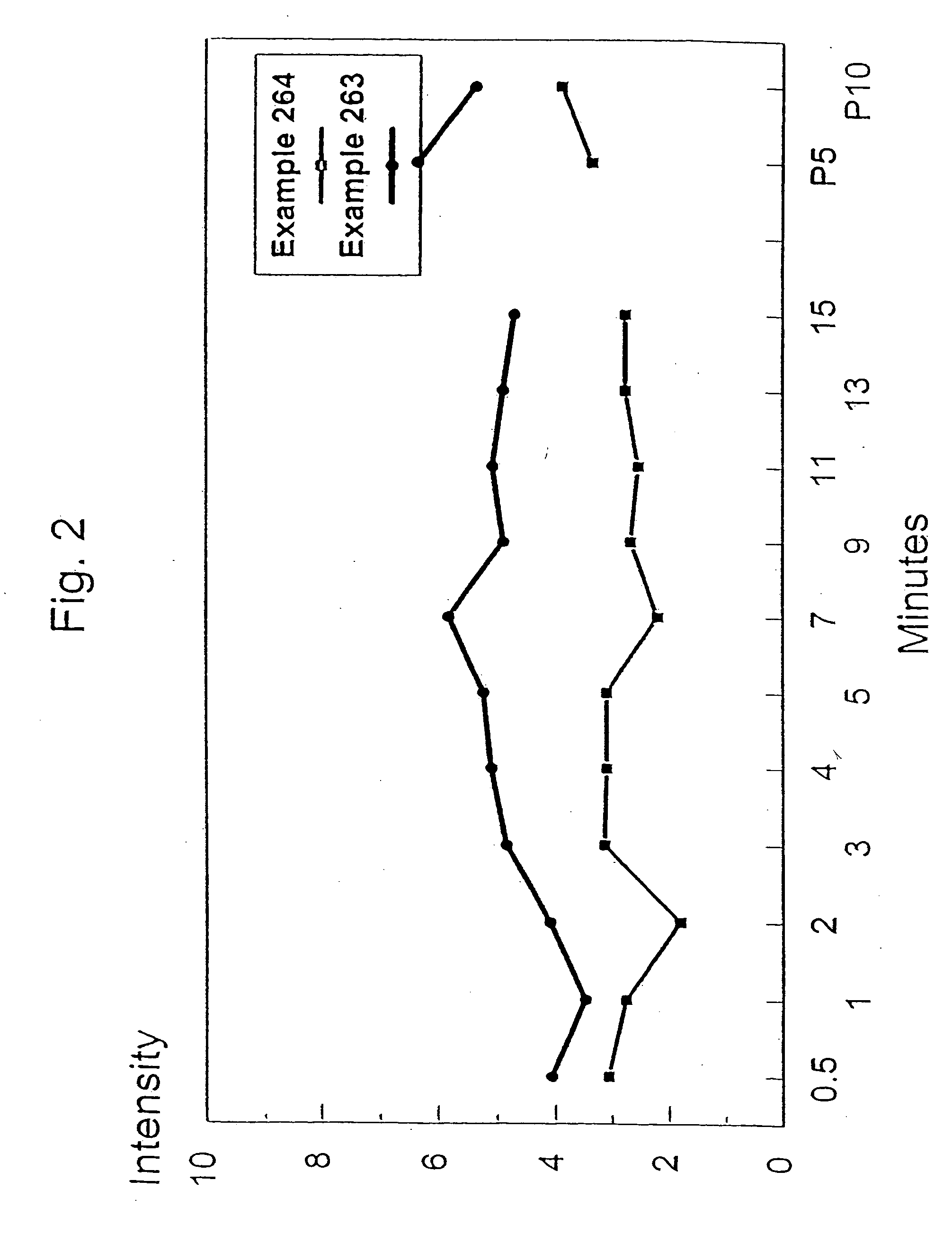

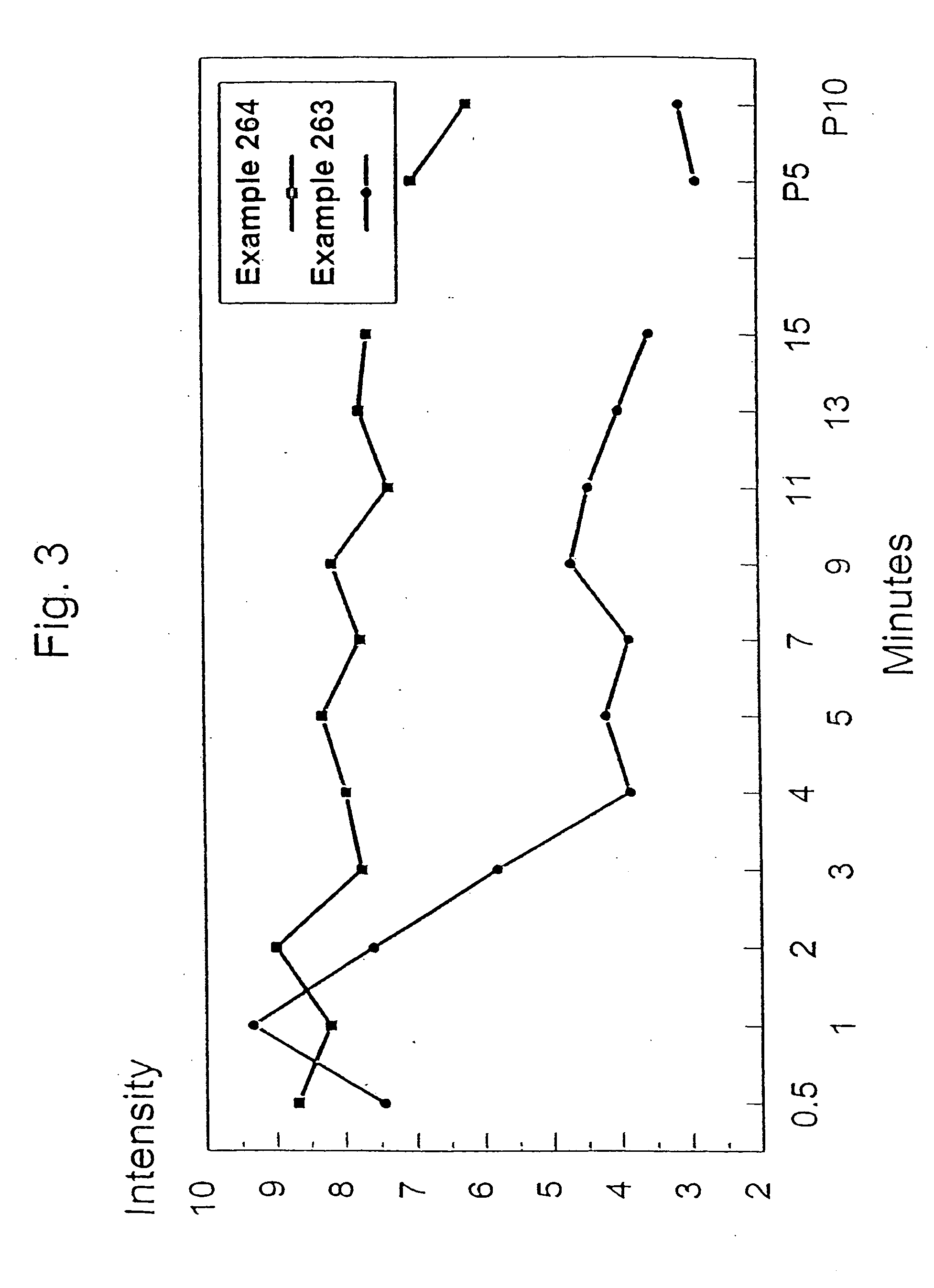

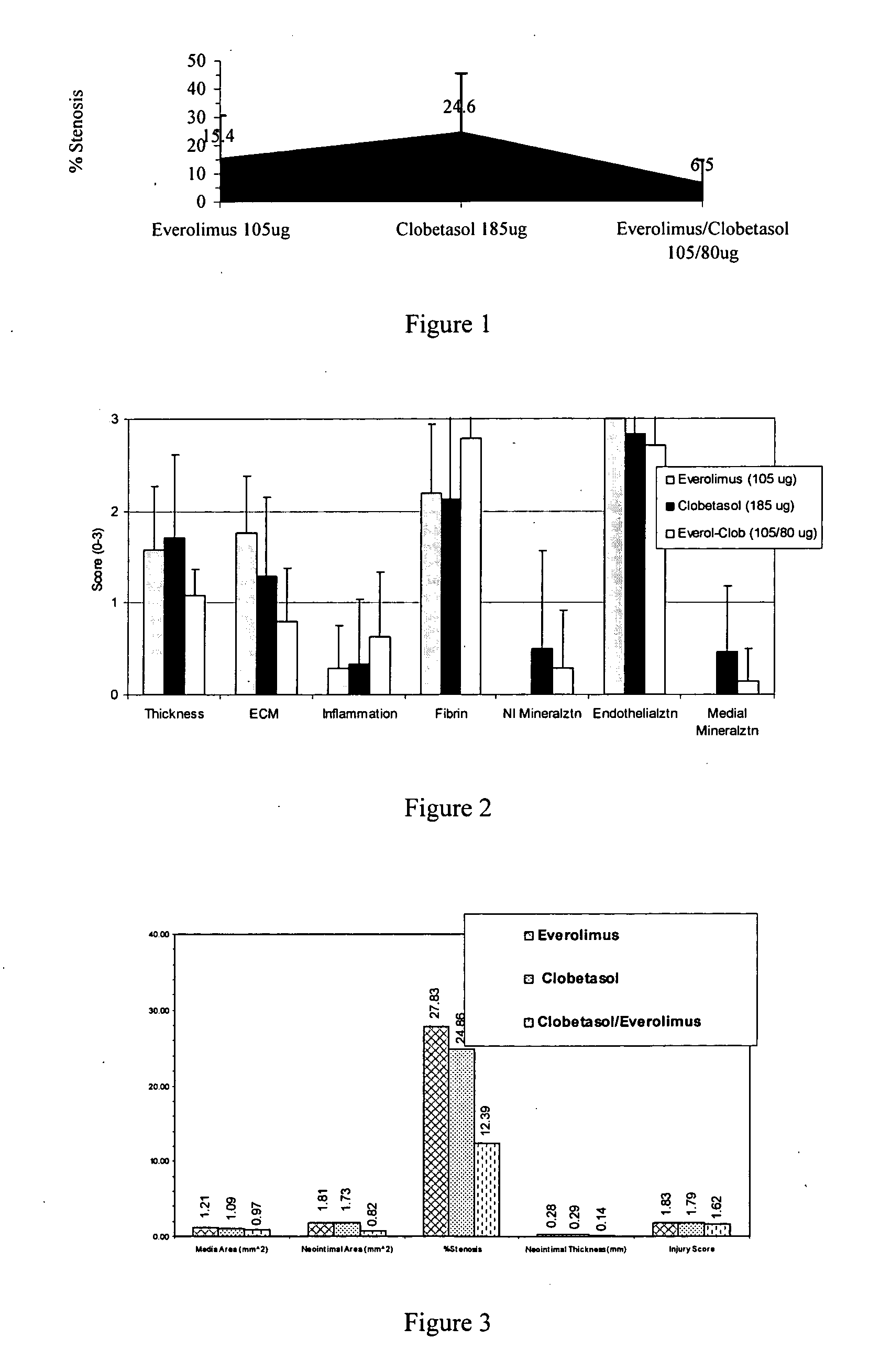

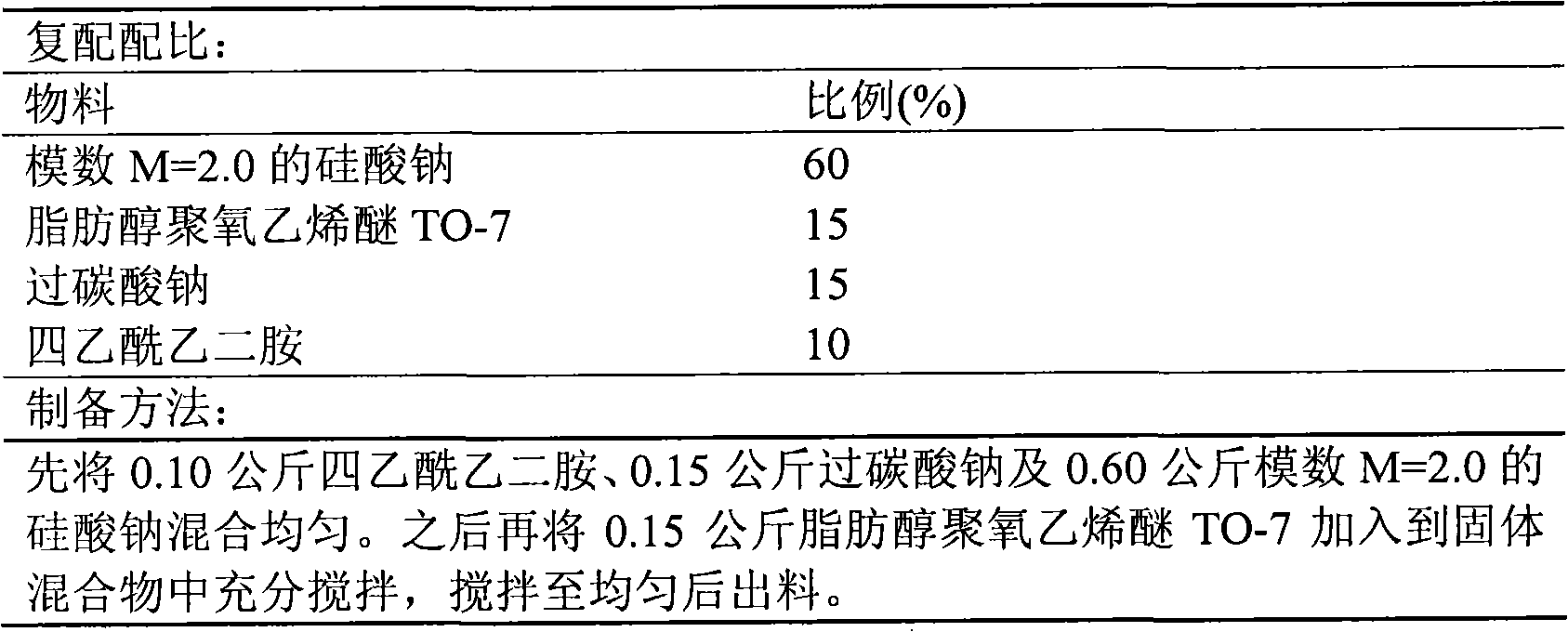

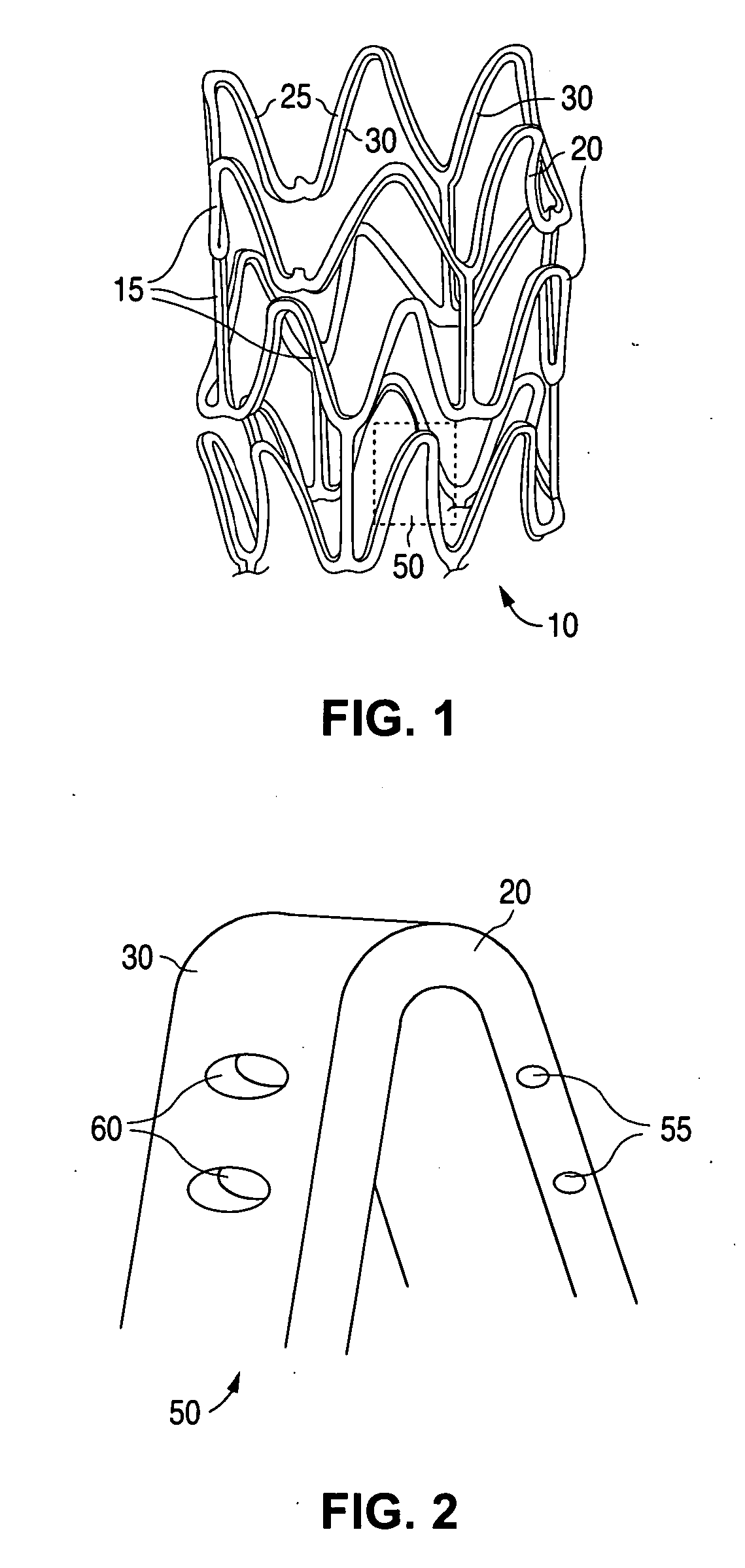

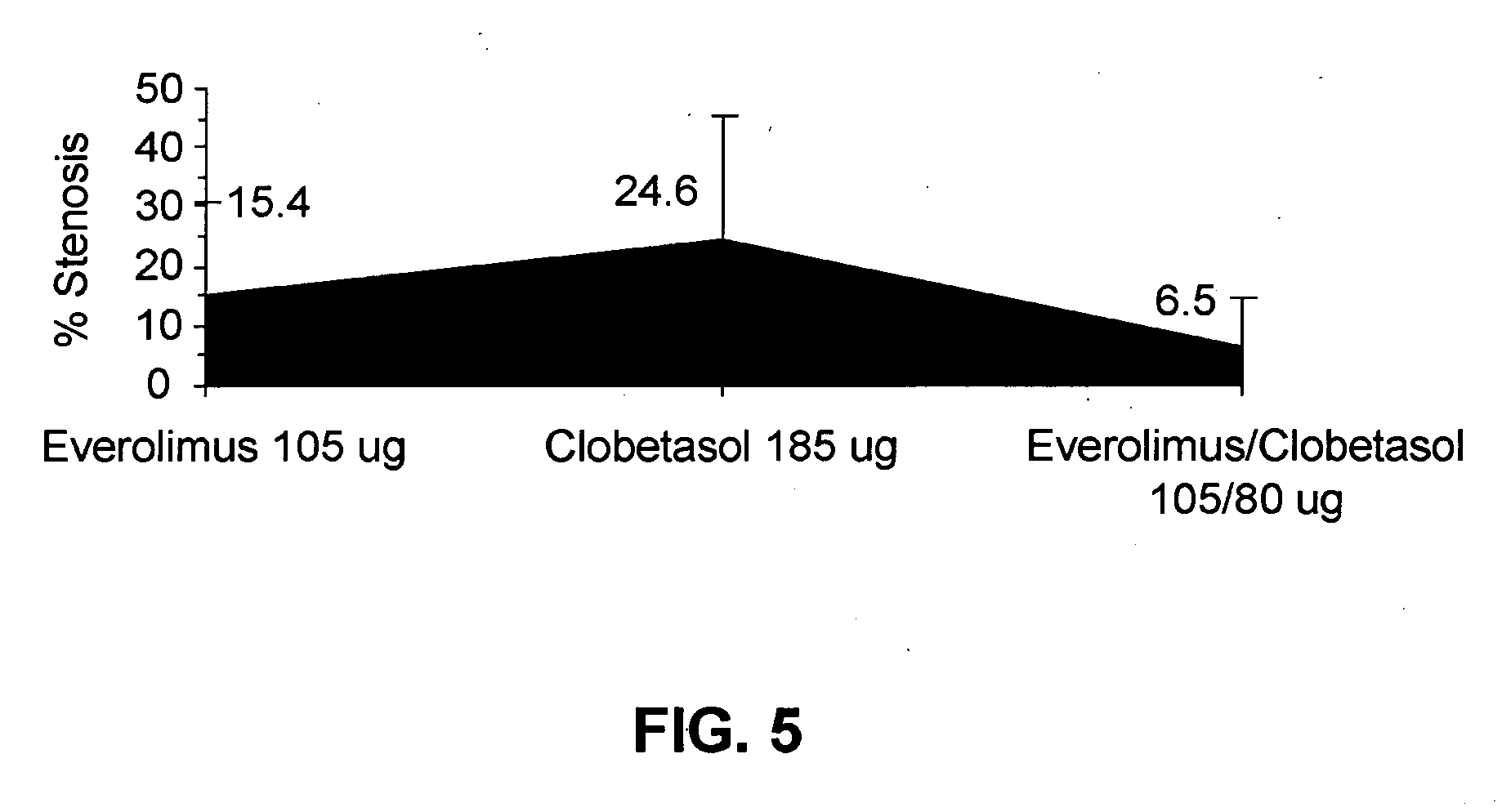

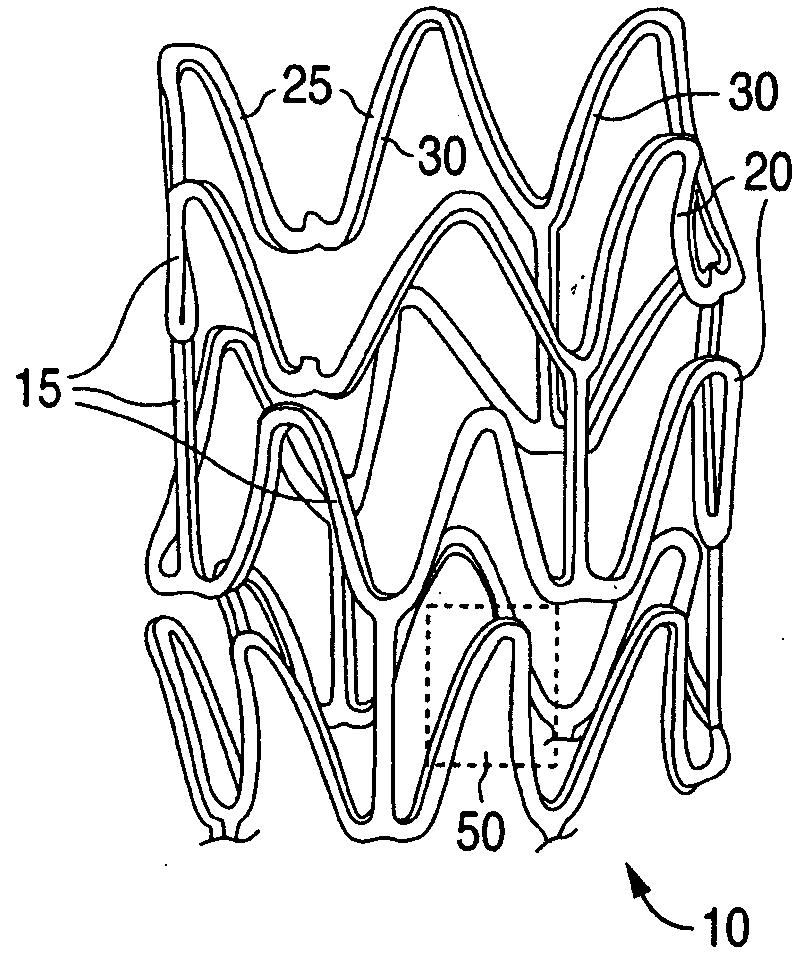

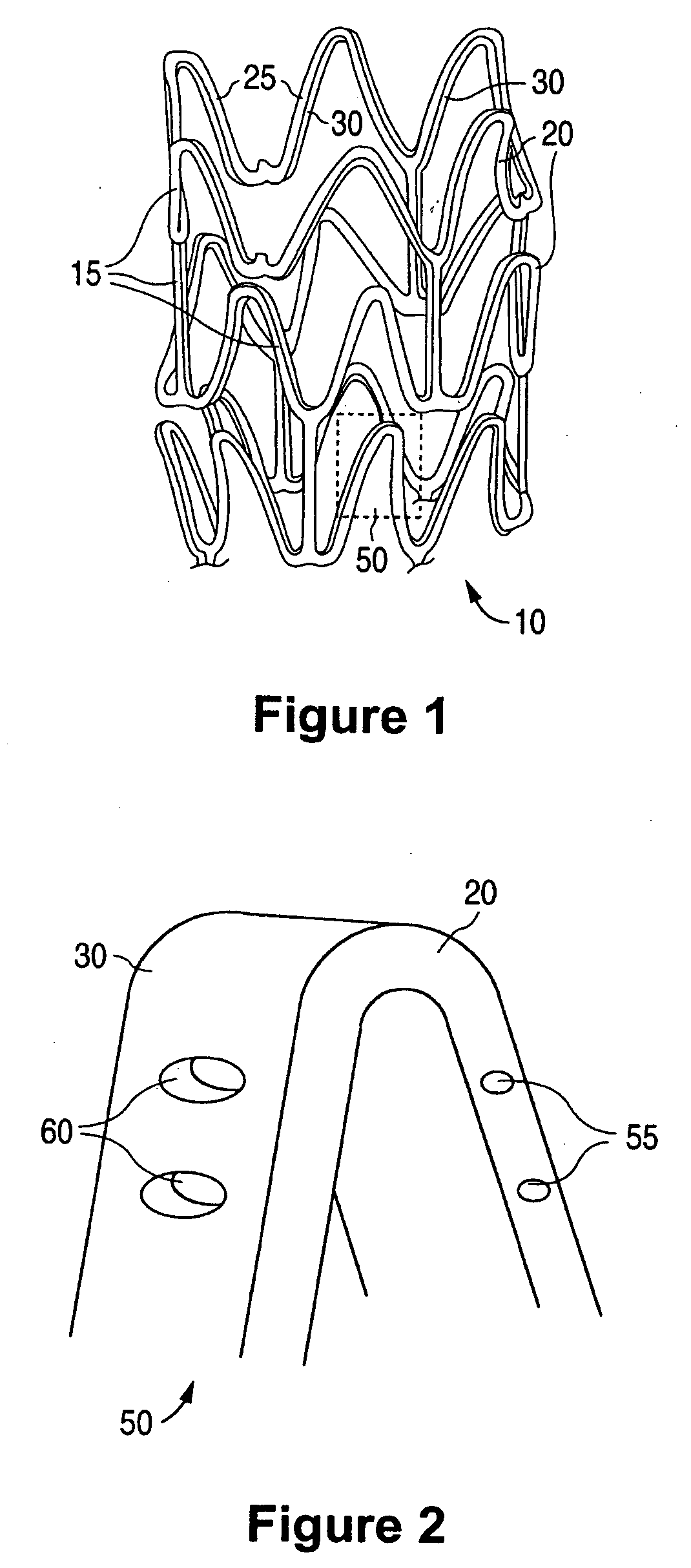

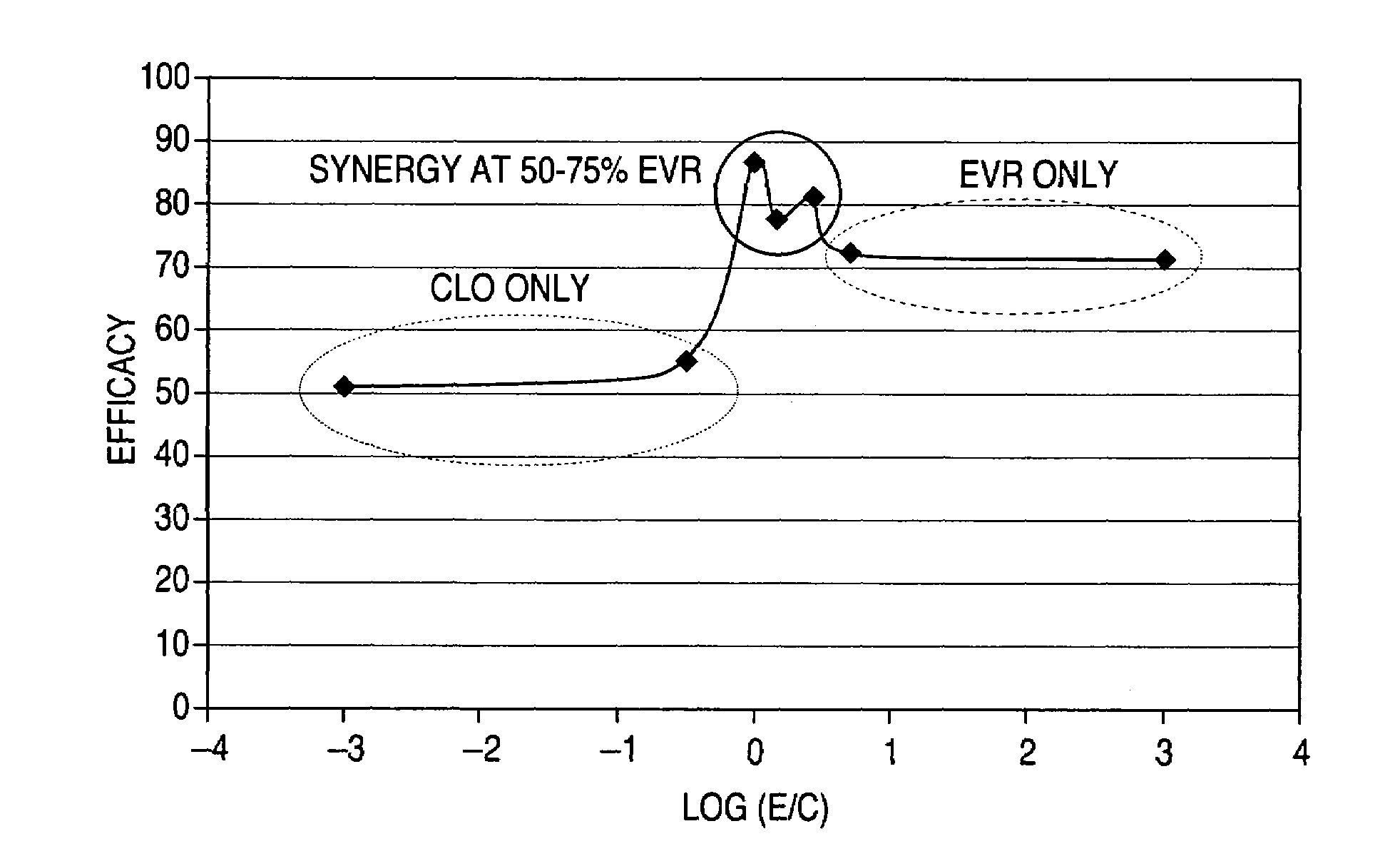

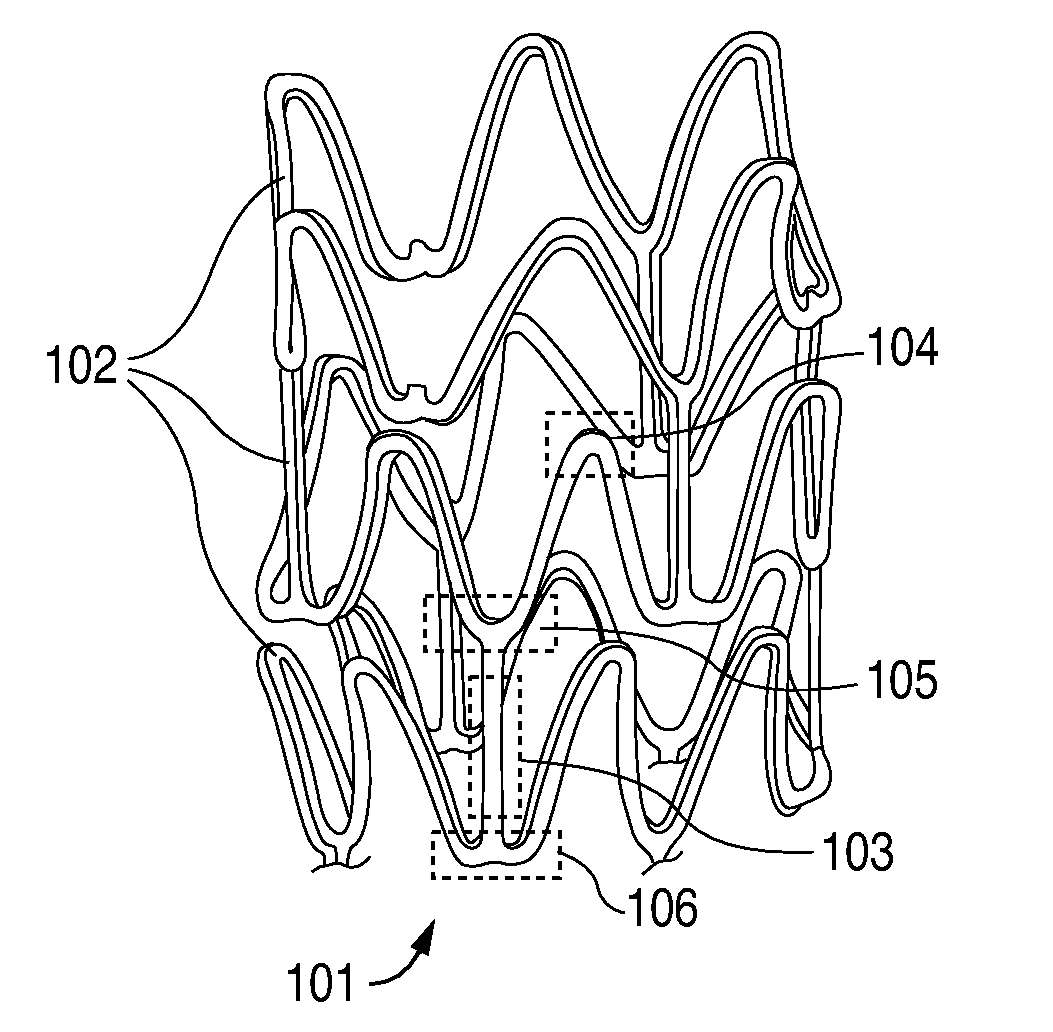

Anti-proliferative and anti-inflammatory agent combination for treatment of vascular disorders

Drug-delivery systems such as drug-delivery stents having an anti-proliferative agent such as everolimus and an anti-flammatory agent such as clobetasol are provided. Also disclosed are methods of treating a vascular impairment such as restenosis or vulnerable plaque.

Owner:ABBOTT CARDIOVASCULAR

Biosoluble coating comprising Anti-proliferative and Anti-inflammatory agent combination for treatment of vascular disorders

InactiveUS20090297578A1Less neointima thicknessPromote healingBiocideSurgeryEverolimusPercent Diameter Stenosis

Drug-delivery systems such as drug-delivery stents having an anti-proliferative agent such as everolimus and an anti-flammatory agent such as clobetasol are provided. Also disclosed are methods of treating a vascular impairment such as restenosis or vulnerable plaque.

Owner:ABBOTT CARDIOVASCULAR

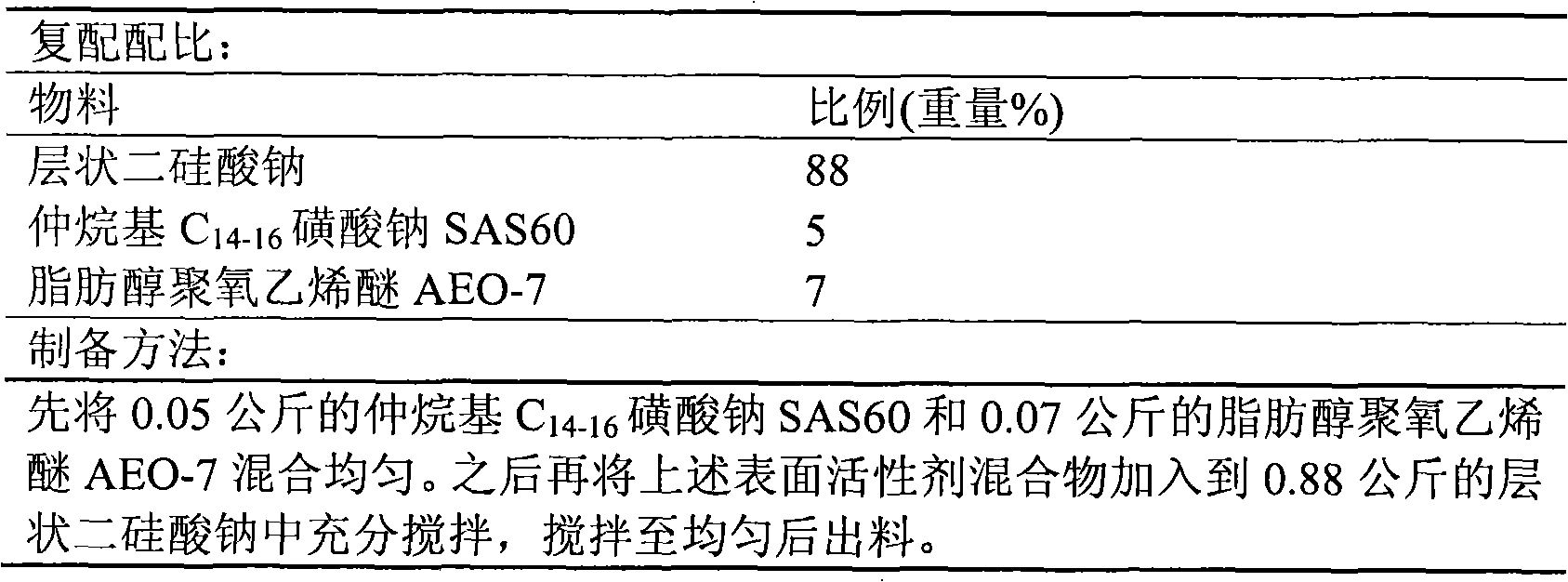

Scouring and bleaching agent combination and application thereof

InactiveCN101929064AReduce fiber damageAvoid Hole DefectsFibre treatmentBleaching apparatusWater savingAgent Combination

The invention discloses a scouring and bleaching agent combination used as an assistant for the pretreatment of cotton and blended fabrics and application thereof. Based on the total weight of the combination, the scouring and bleaching agent combination comprises the following components in percentage by weight: 40-95% of adsorptive abstergent, 5-20% of surfactant, 0-25% of water soluble alkali, 0-25% of scouring and bleaching synergist and 0-20% of chelate dispersant. When being used with oxydol, the scouring and bleaching agent can achieve a favorable effect of combining the refining procedure and the bleaching procedure. Compared with the traditional process, the treated fabric has better quality. The whole process achieves the advantages of continuous operation, low alkali discharge, water saving, energy saving, time saving and labor saving, thereby improving the production efficiency.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Anti-proliferative and anti-inflammatory agent combination for treatment of vascular disorders with an implantable medical device

Drug-delivery systems such as drug-delivery stents having an anti-proliferative agent such as everolimus and an anti-flammatory agent such as clobetasol are provided. Also disclosed are methods of treating a vascular impairment such as restenosis or vulnerable plaque

Owner:ABBOTT CARDIOVASCULAR

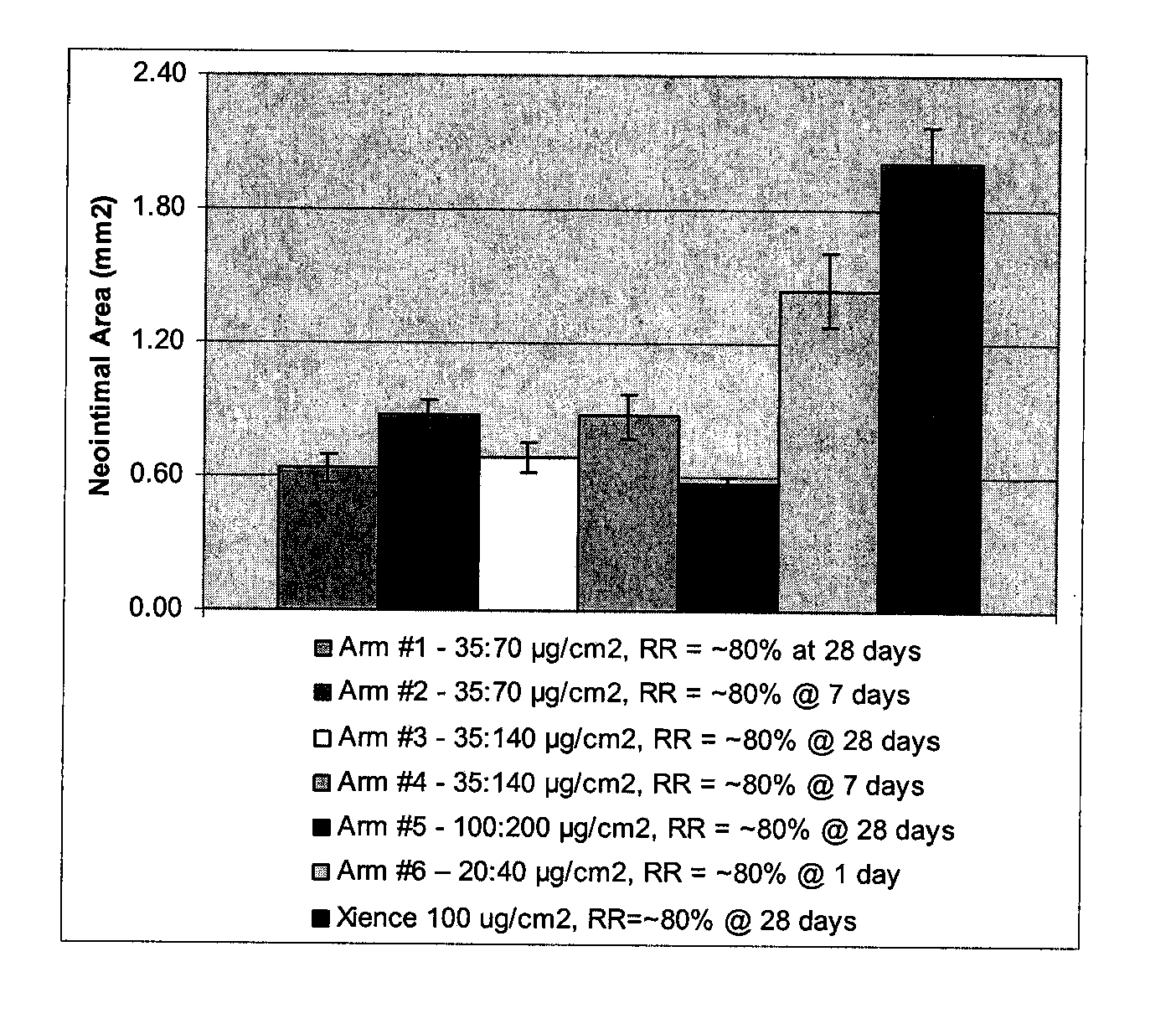

Anti-Proliferative and Anti-Inflammatory Agent Combination for Treatment of Vascular Disorders with an Implantable Medical Device

A drug-delivery system is provided including at least 100 μg of everolimus and clobetasol, such that the ratio of everolimus to clobetasol is at least 10:1 (w / w) or the amount of everolimus by weight is at least 10 times more than clobetasol. The system can be a stent. Also provided a method of treating restenosis or vulnerable plaque of a blood vessel, the method includes locally administering to a patient a first drug selected from a group consisting of rapamycin (sirolimus), Biolimus A9, deforolimus, AP23572, tacrolimus, temsirolimus, pimecrolimus, zotarolimus (ABT-578), 40-O-(2-hydroxy)ethylrapamycin (everolimus), 40-O-(3-hydroxy)propylrapamycin, 40-O-[2-(2-hydroxy)ethoxy]ethylrapamycin, 40-O-tetrazolylrapamycin and 40-epi-(N1-tetrazolyl)rapamycin, and locally administering to a patient a second drug consisting of clobetasol, wherein the minimum amount of the first drug that is locally administered is 100 μg, and wherein the ratio of the first drug to the second drug is, for example, 10:1 to 100:1 (w / w).

Owner:ABBOTT CARDIOVASCULAR

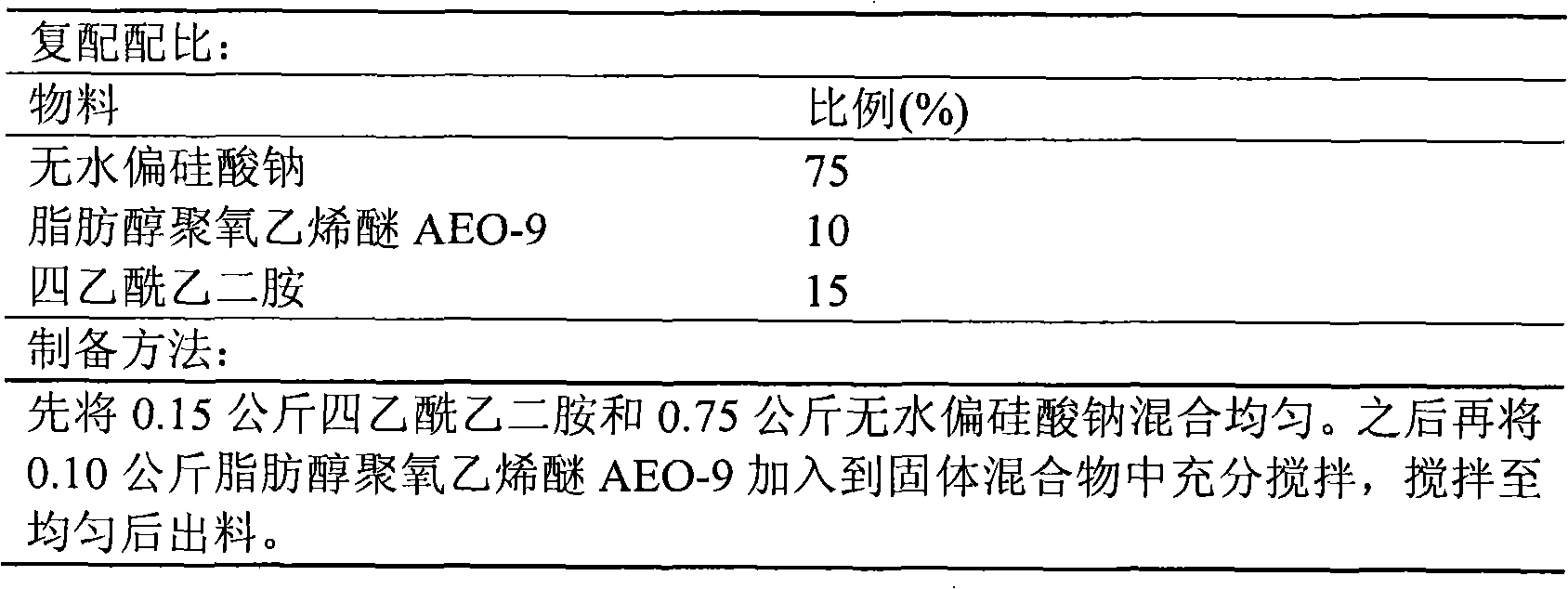

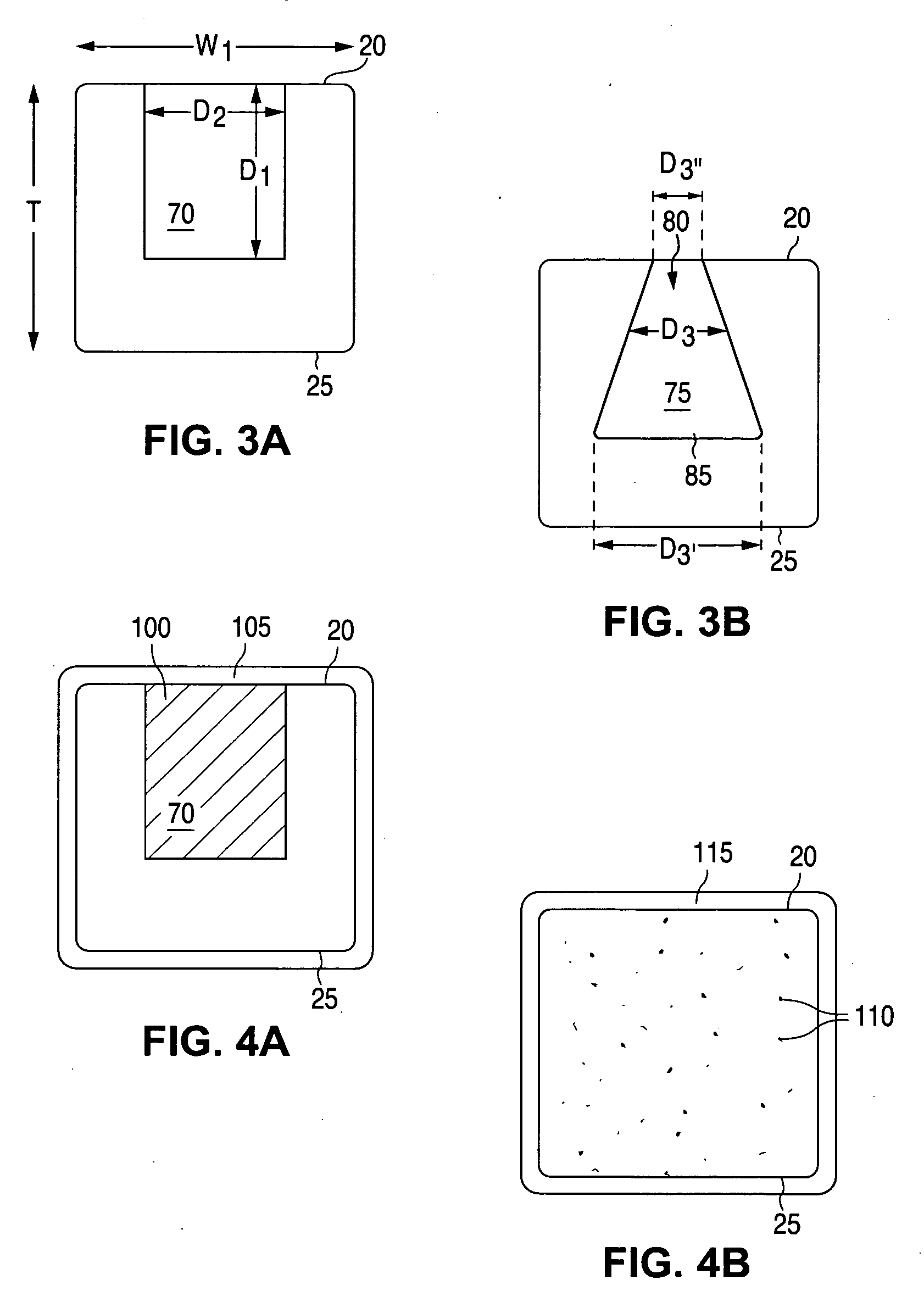

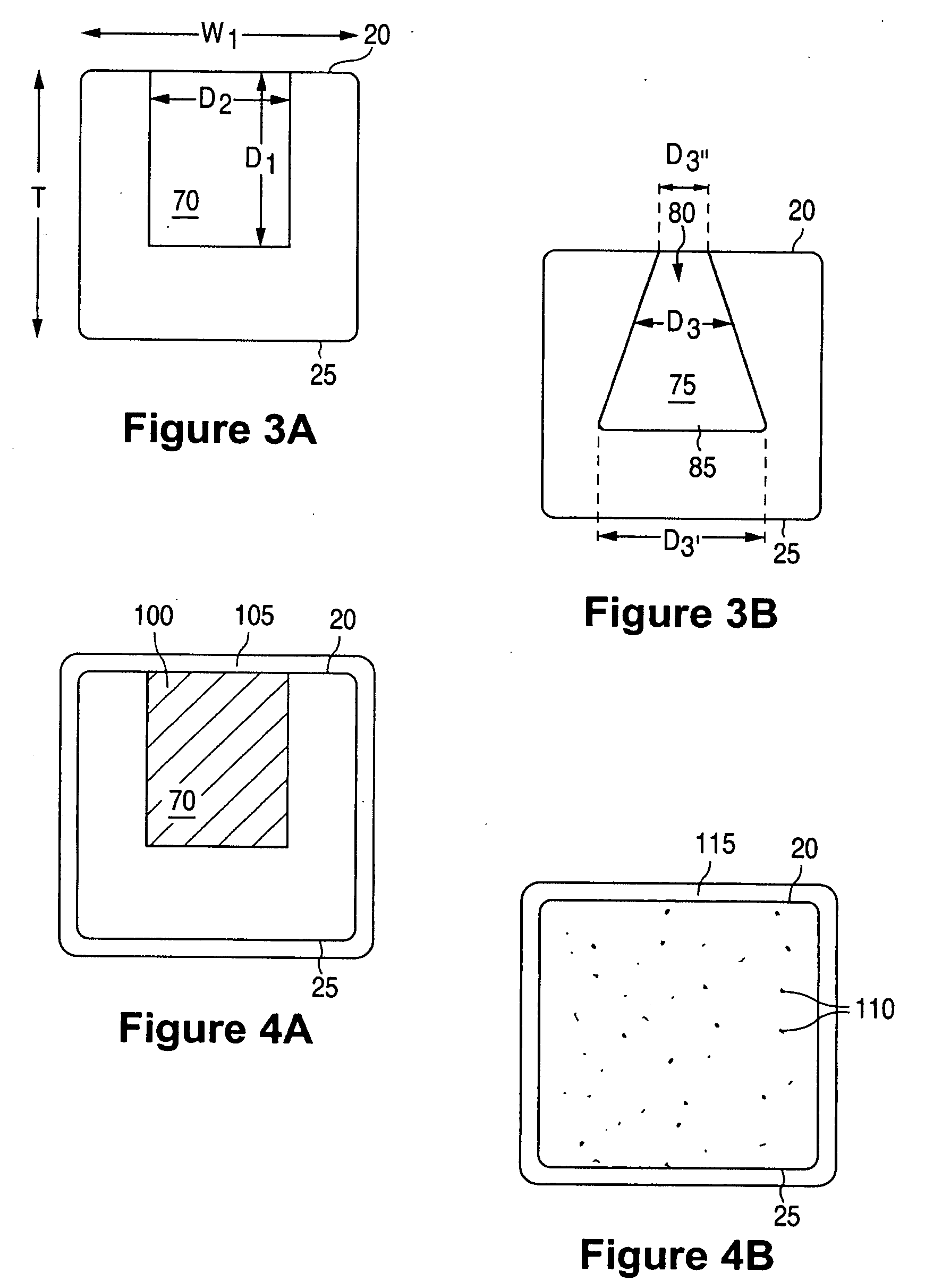

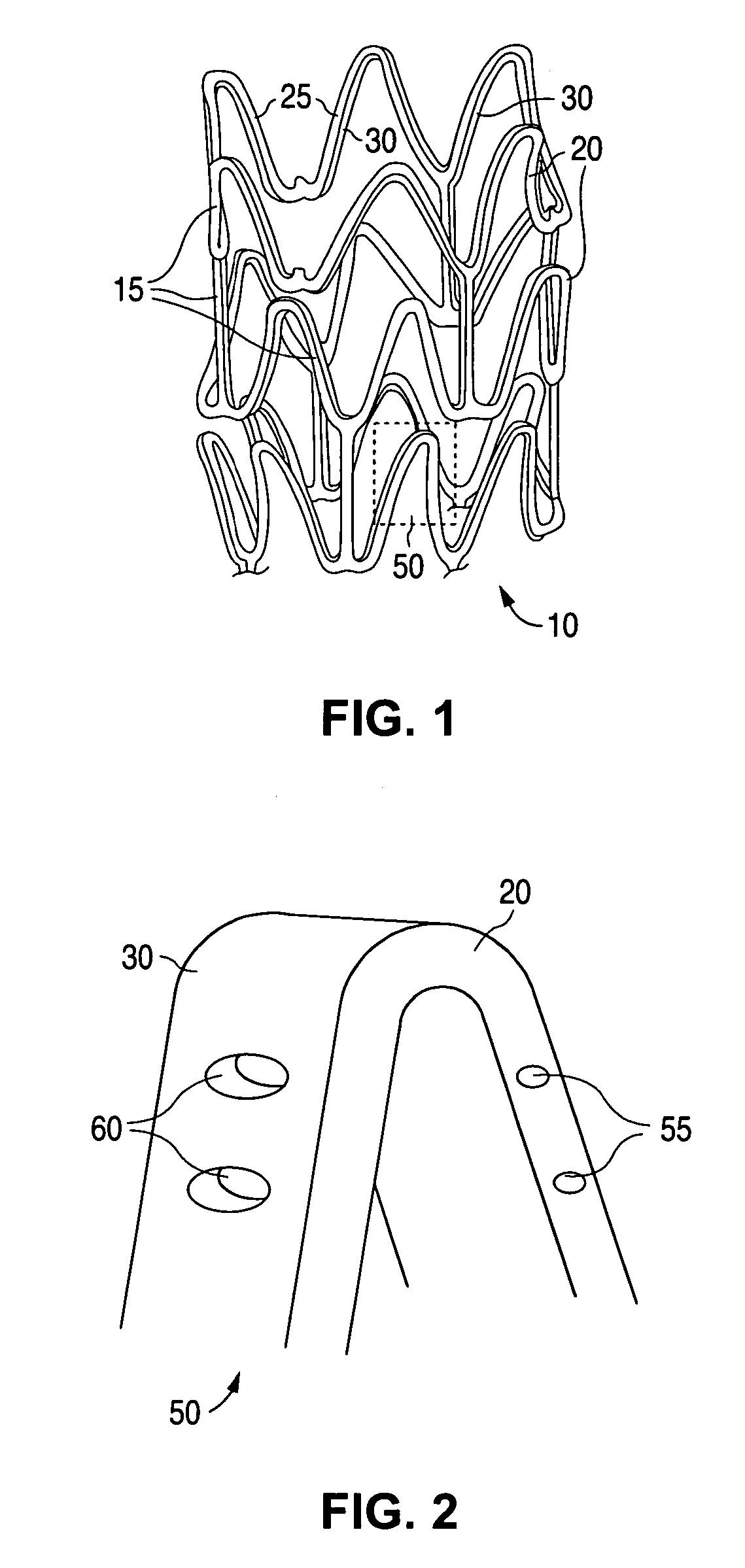

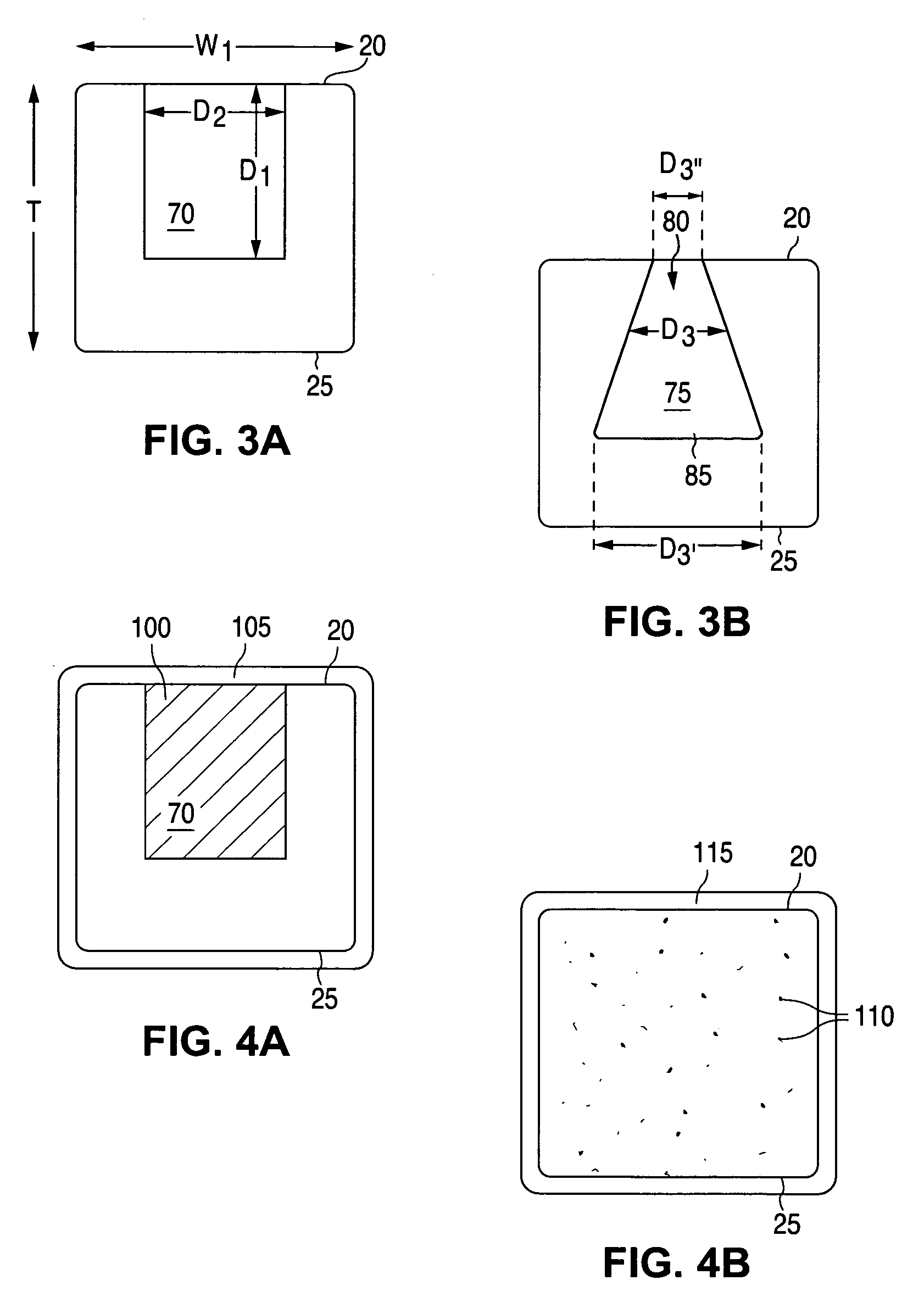

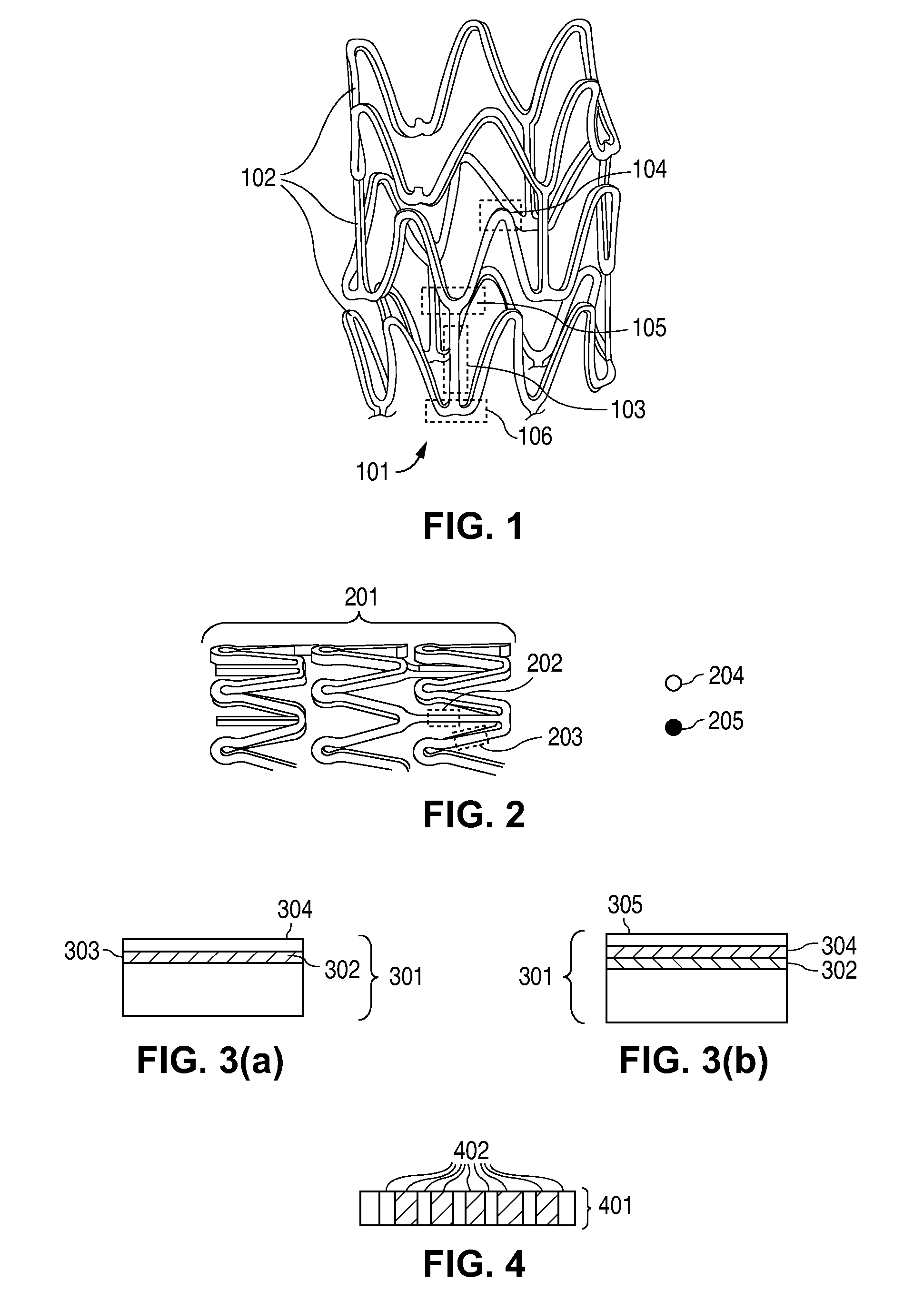

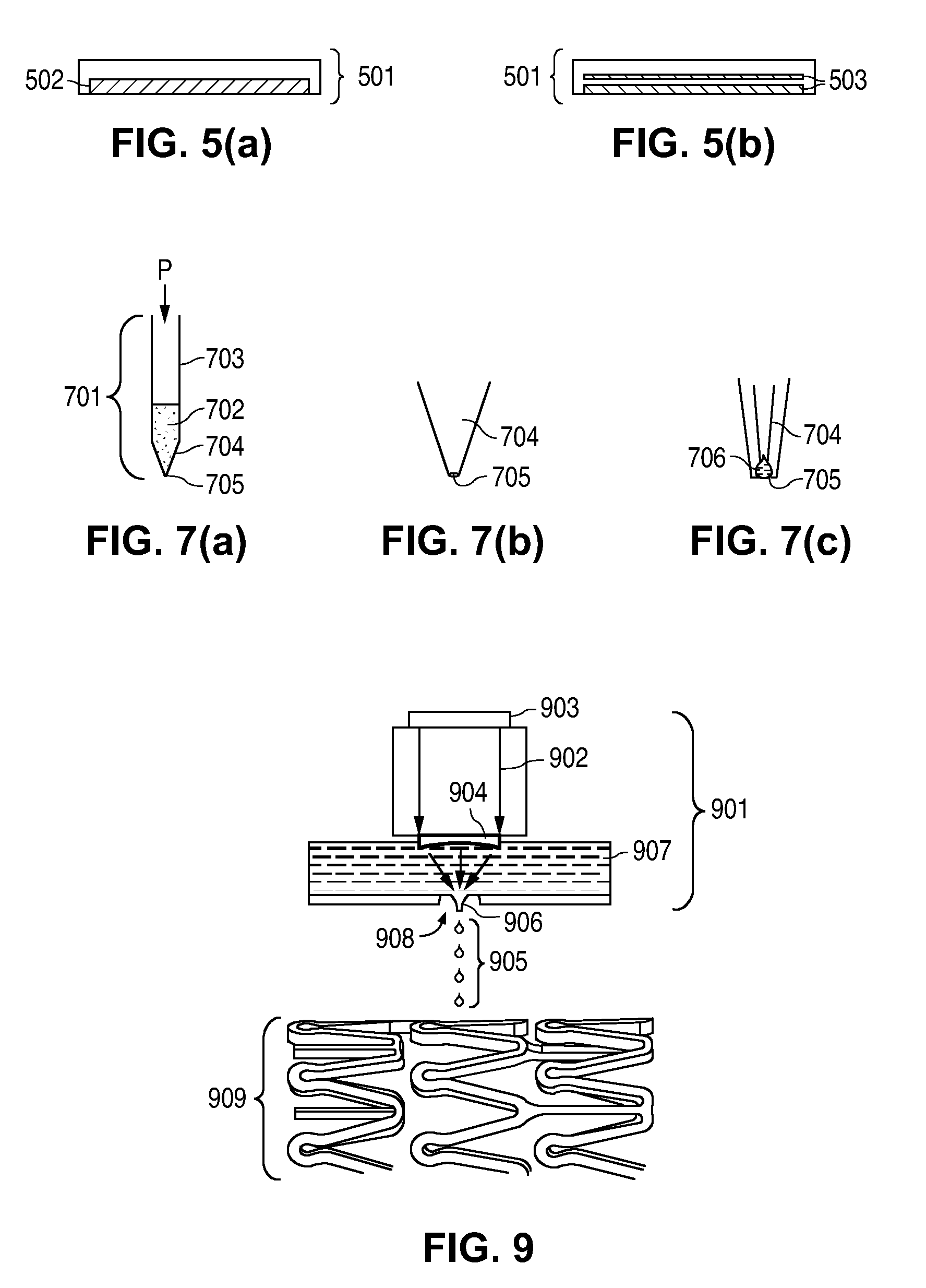

Compositions for medical devices containing agent combinations in controlled volumes

The present invention generally encompasses controlled-volume materials that may, for example, be in a medical device or applied on a medical device as a coating, as well as methods of applying these materials.

Owner:ABBOTT CARDIOVASCULAR

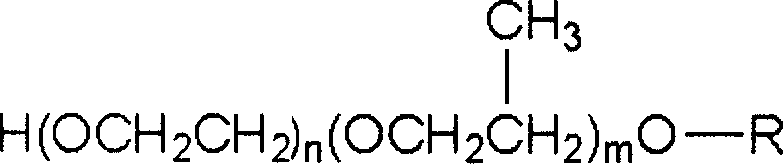

Defoaming agent composition and preparation method thereof

InactiveCN101053801APhysiologically inertHigh temperature resistantTransportation and packagingMixingAgent CombinationSecondary component

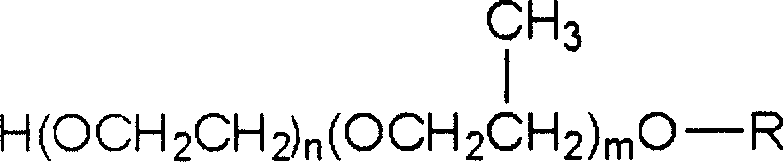

The invention discloses a polyether modified silicone defoaming agent combination, of which mass fraction is 40-75 of A, 10-55 of B, 0.5-2 of C and 1-5 of D, wherein A and B are the key component, C and D are the secondary component, A is polyether modified silicone defoaming agent, B is defoaming agent of other kinds, C is thickening agent, and D is emulsifying agent. The also discloses the preparation method of the defoaming agent combination. The defoaming agent combination of the invention has the character of polysiloxanes defoaming agent, of which the defoaming capability is high, and surface tension and volatility are low, and which is innocuity, nonpollution and physiologically inert. The defoaming agent combination also has the character of high temperature resistant and alkaliproof like polyethers defoaming agent, and has the advantage of long lasting defoaming agent, defoaming restrain, low incorporaticn and good adaptability. The performance and price ratio is high. It has a better effect when used in stretch thick dope.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Tire with rubber component containing silica and use of combination of blocked and unblocked alkoxyorganomercaptosilane coupling agents

InactiveUS20100190885A1High viscosityMinimize localized curingSpecial tyresElastomerAgent Combination

The invention relates to a tire having at least one component of a rubber composition comprised of at least one conjugated diene-based elastomer which contains silica reinforcement together with use of a combination of coupling agents for the silica. The coupling agent combination is comprised of blocked alkoxyorganomercaptosilane and unblocked alkoxyorganomercaptosilane coupling agents. Such tire component may be, for example, a tire tread.

Owner:HUA KUO CHIH +1

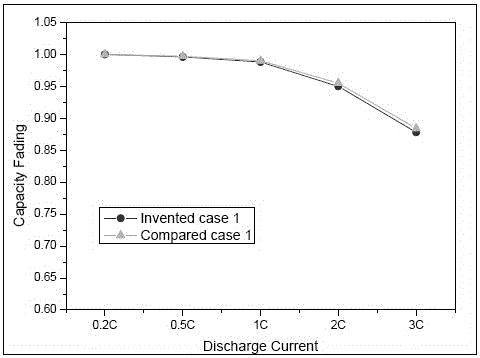

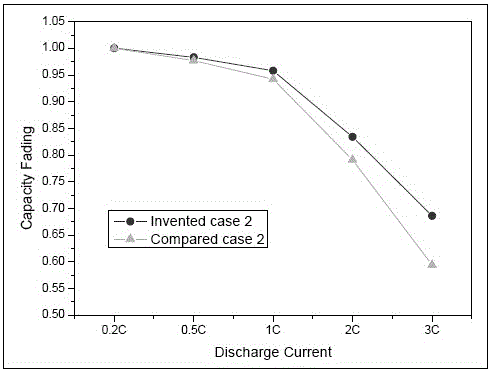

Conductive agent combined type lithium ion battery positive pole piece and manufacture method thereof

InactiveCN106207092AIncrease energy densityImprove Coulombic efficiencyCell electrodesSecondary cellsAgent CombinationSlurry

The invention discloses a conductive agent combined type lithium ion battery positive pole piece, which comprises a current collector and a positive pole film adhered to the current collector. The positive pole film comprises a positive pole active material, a conductive agent and a binding agent, wherein the conductive agent is a combination of CB and CNTs or CB and GNPs or CNTs and GNPs or CB, CNTs and GNPs. A manufacture method comprises the steps of (1) adding the binding agent into solvent and evenly stirring and mixing; (2) adding the conductive agent combination of two or three of CB, CNTs and GNPs into the solvent and evenly stirring and mixing; (3) adding the positive pole active material and evenly stirring and mixing to obtain positive pole slurry; (4) coating the positive pole slurry on the current collector and obtaining the lithium ion battery positive pole piece after roasting and rolling. The positive pole piece is high in energy density, low in expansion rate, high in coulombic efficiency and high in compaction.

Owner:APOWER ELECTRONICS CO LTD

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

Concentrated feed for laying hen in egg-laying peak period

InactiveCN102084939AHas the effect of disease prevention and health careImprove immunityFood processingAnimal feeding stuffYolkEggshell

The invention discloses a concentrated feed for laying hens in egg-laying peak period. The feed comprises a laying hen dietary feed with main components of soybean meal, cottonseed meal, rapeseed meal, corn germ cake, corn germ meal, enzyme hydrolyzed feather meal, stone powder, calcium hydrogen phosphate, medical stone, salt, and methionine; a health care agent combination pack and a premix are added into the laying hen dietary feed; the health care agent combination pack comprises ovary protecting elements, microecological preparations, enzyme preparations, diluents, and Chinese herbal medicine health care agents; and the premix comprises coated vitamins, mineral elements, methionine, and carriers. The feed can prolong the egg-laying peak period of laying hens, improve the body immunity of laying hens, improve the quality of the eggs, allow the eggshell to have a good texture and a pure color, allow the yolk to have a dark color, and allow the eliminated hens to be full-fledged and have good quality.

Owner:HENAN MUHE GROUP FEED

Novel pearly wood single plate coloring agent

InactiveCN101306546AImprove product added valueEvenly distributedReactive dyesWood treatment detailsAgent CombinationSingle plate

The invention discloses four novel preparative and operational versions of a staining agent of pearly single wood plate, and belongs to the wood modification field. The staining agent consists of a dye, a dyeing levelness and accelerating agent, a fixing agent and a penetrating agent. The wood imitation single plate can be levelly dyed at the temperature of 75 DEG C for 60 minutes to achieve the pearly effect. The agent combination has the advantages of reasonable design of preparation, good technical performance, uniform color, good pearly effect, small energy consumption, low cost, etc.

Owner:郭明辉 +1

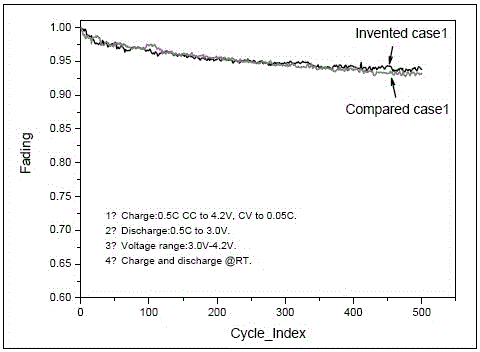

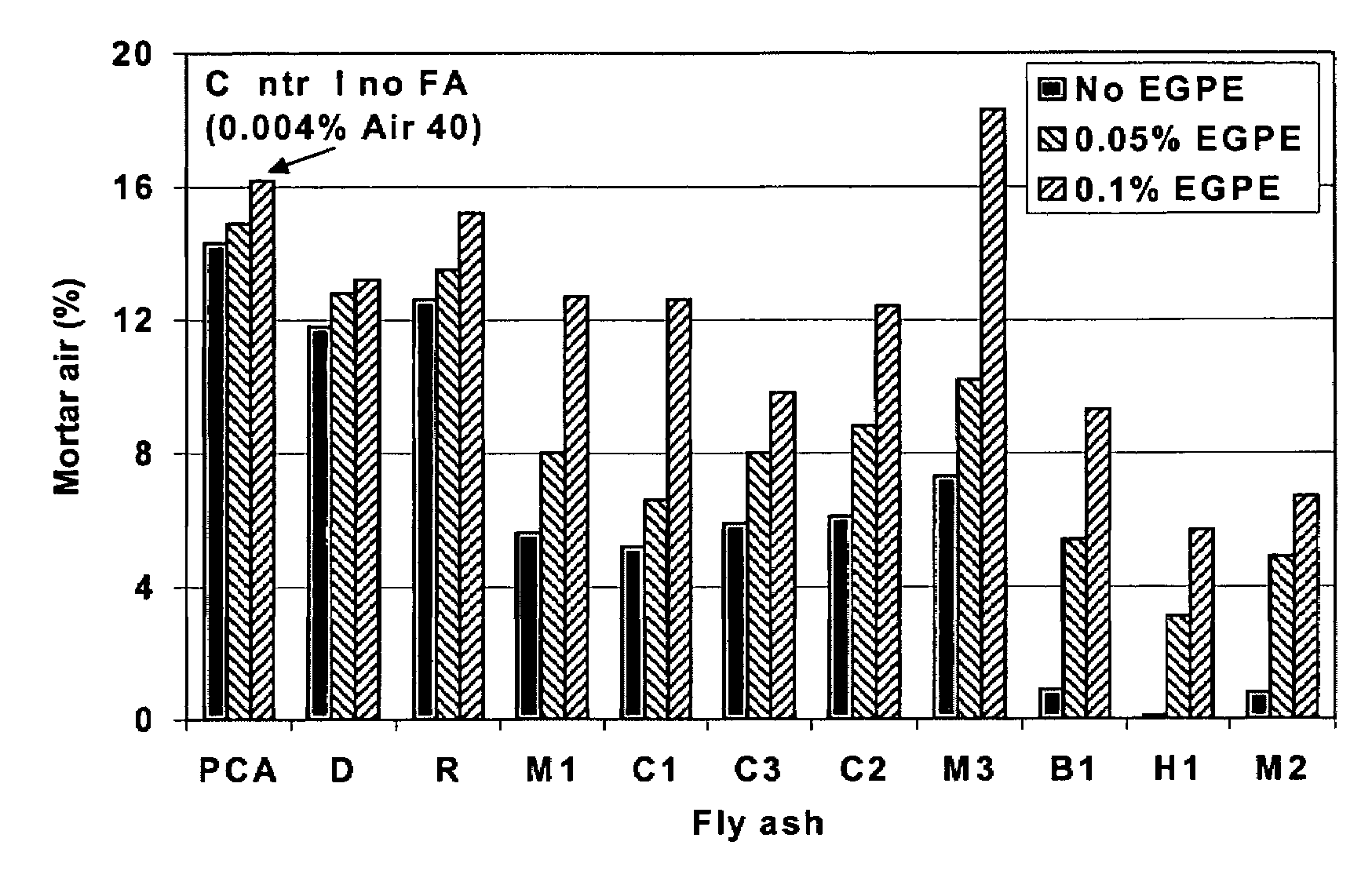

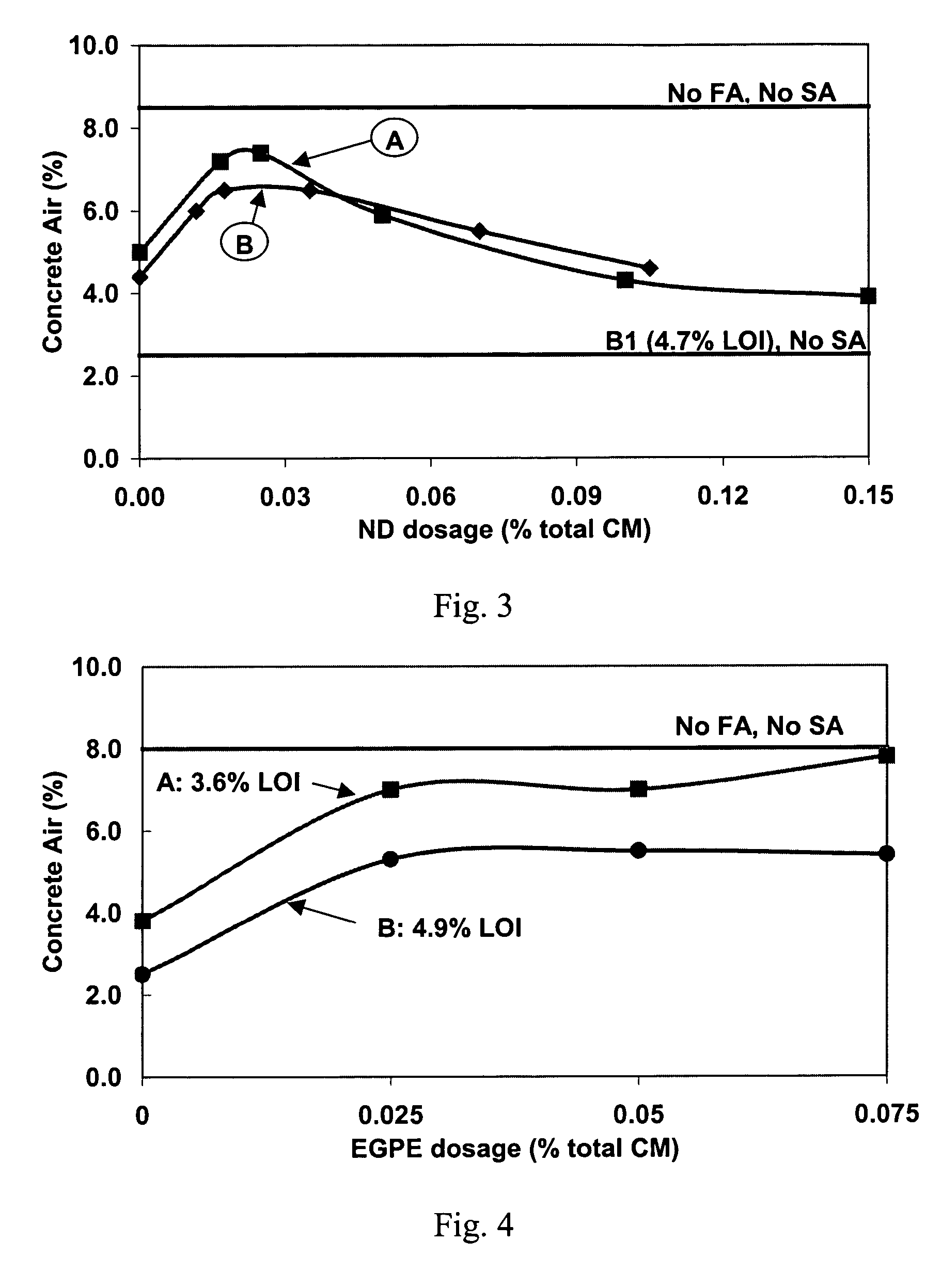

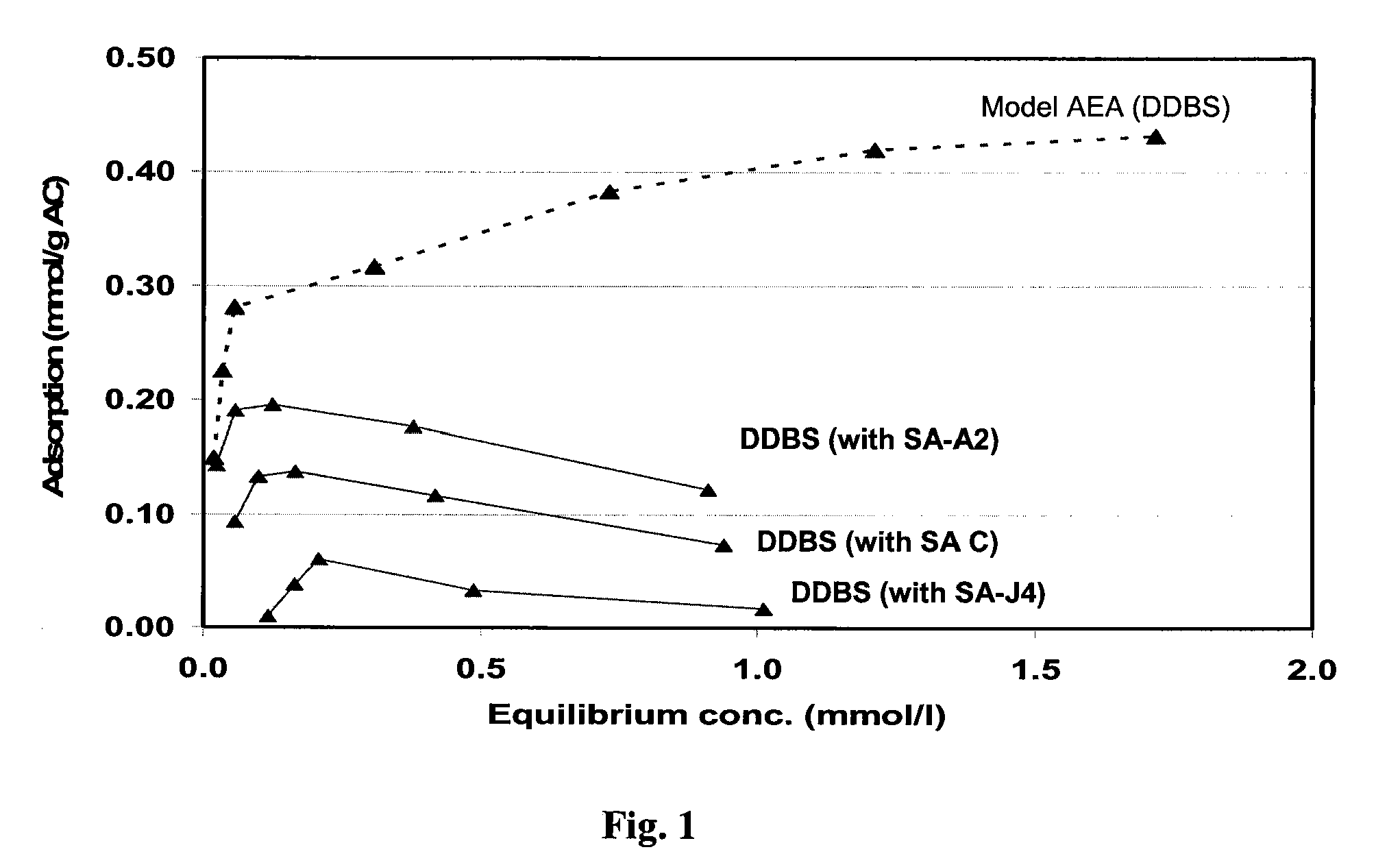

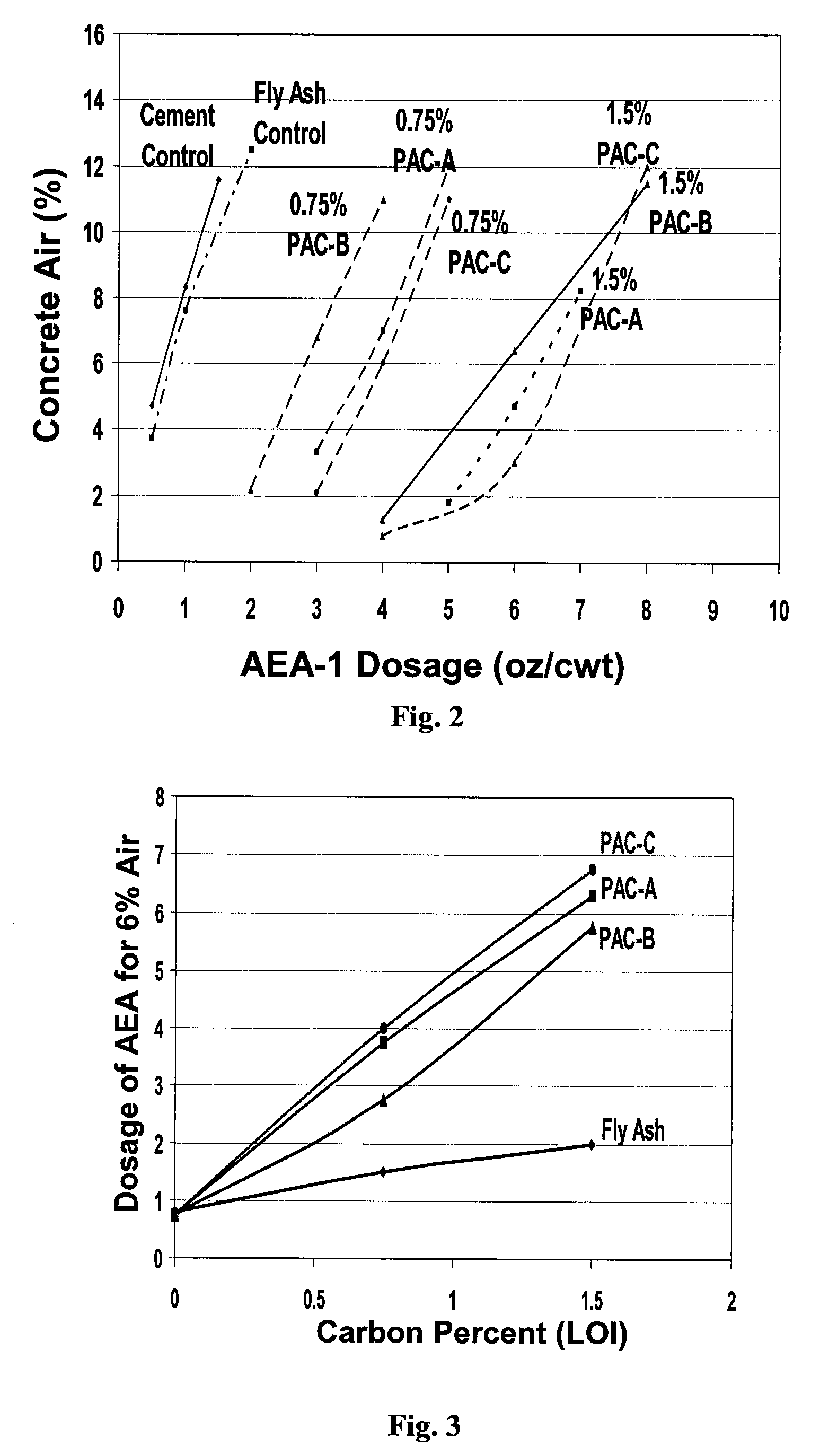

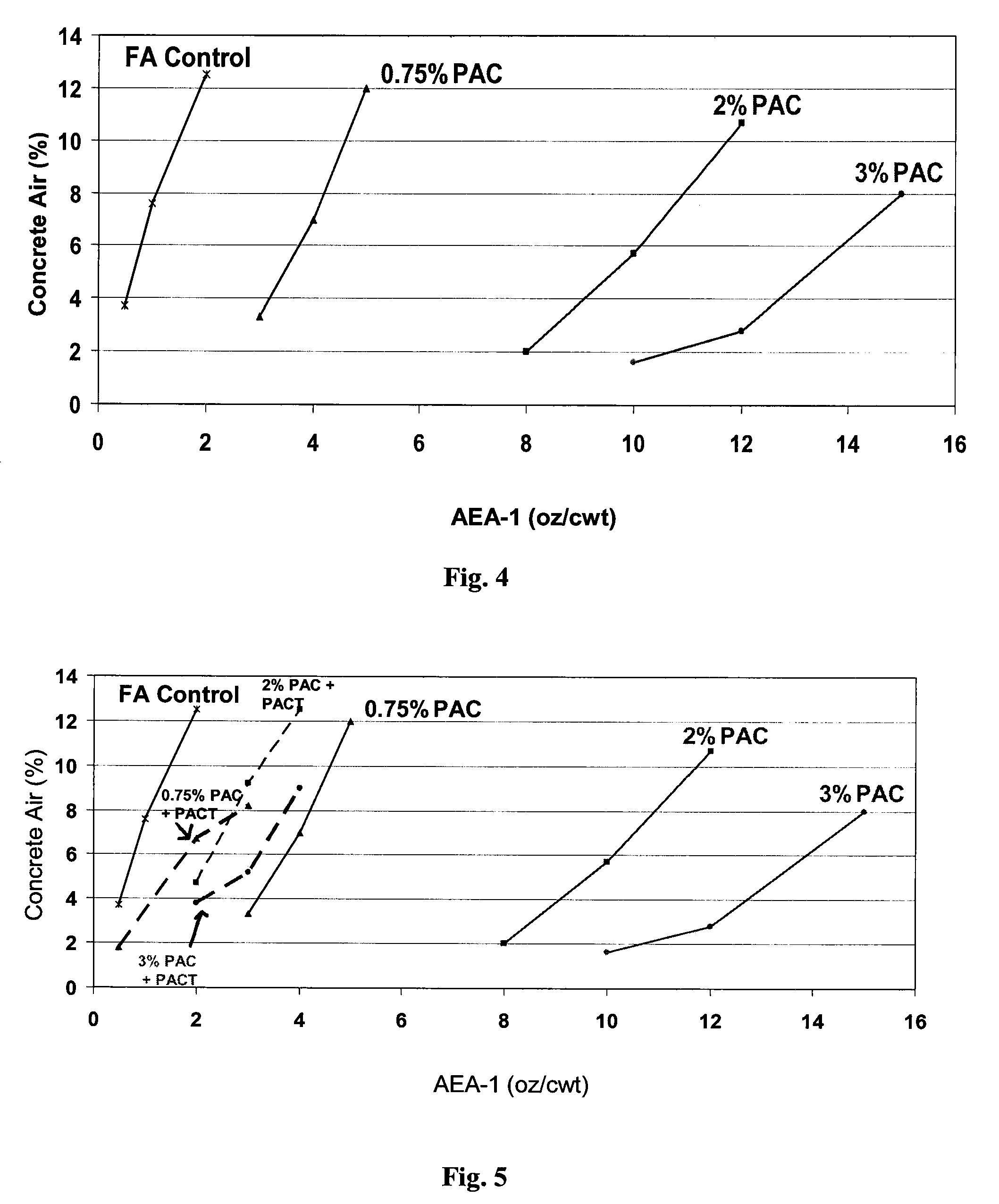

Sacrificial agents for fly ash concrete

ActiveUS7485184B2Facilitate spraying procedureBeneficial effect is somewhat lowSolid waste managementCoatingsChemical admixtureAgent Combination

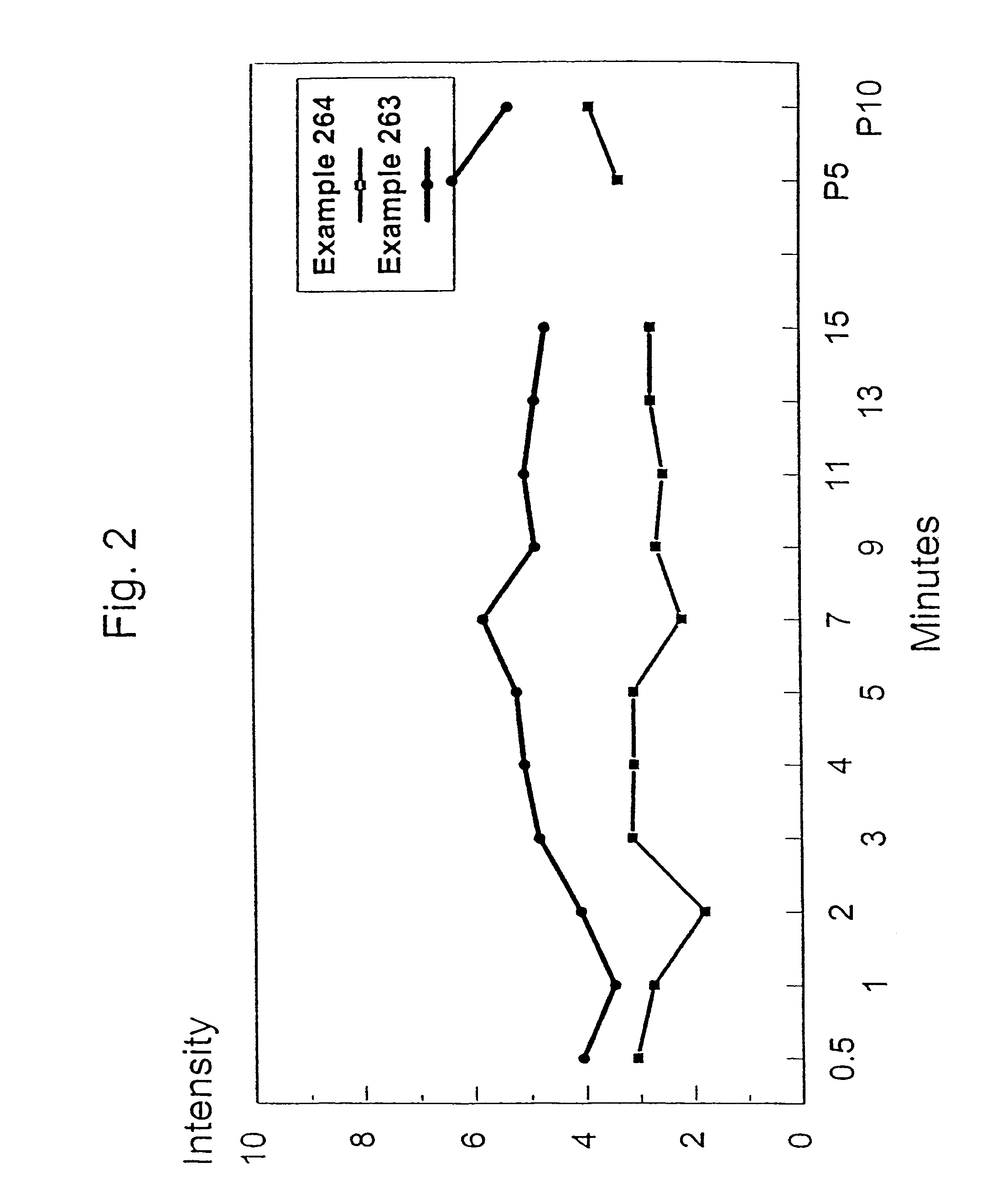

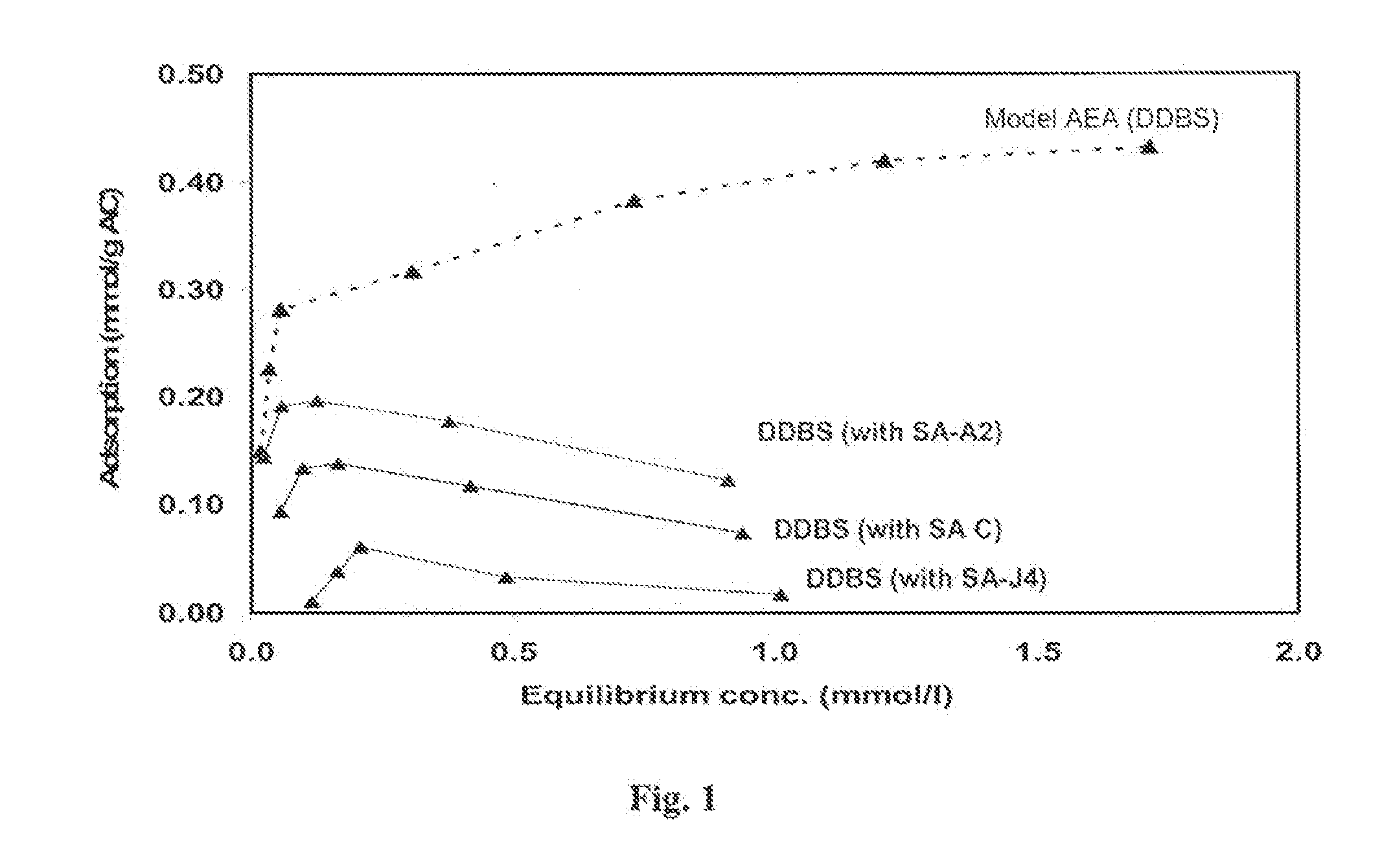

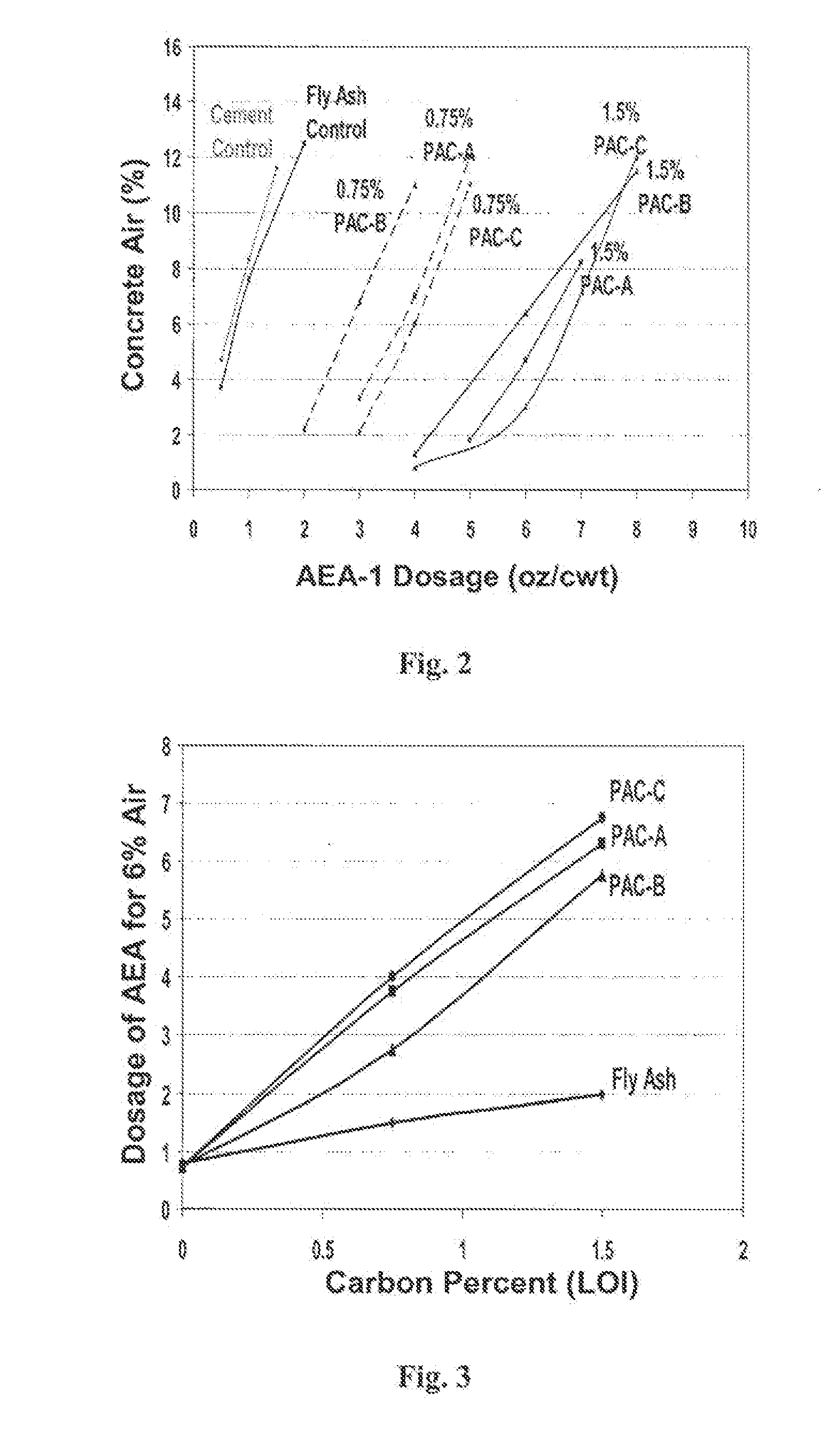

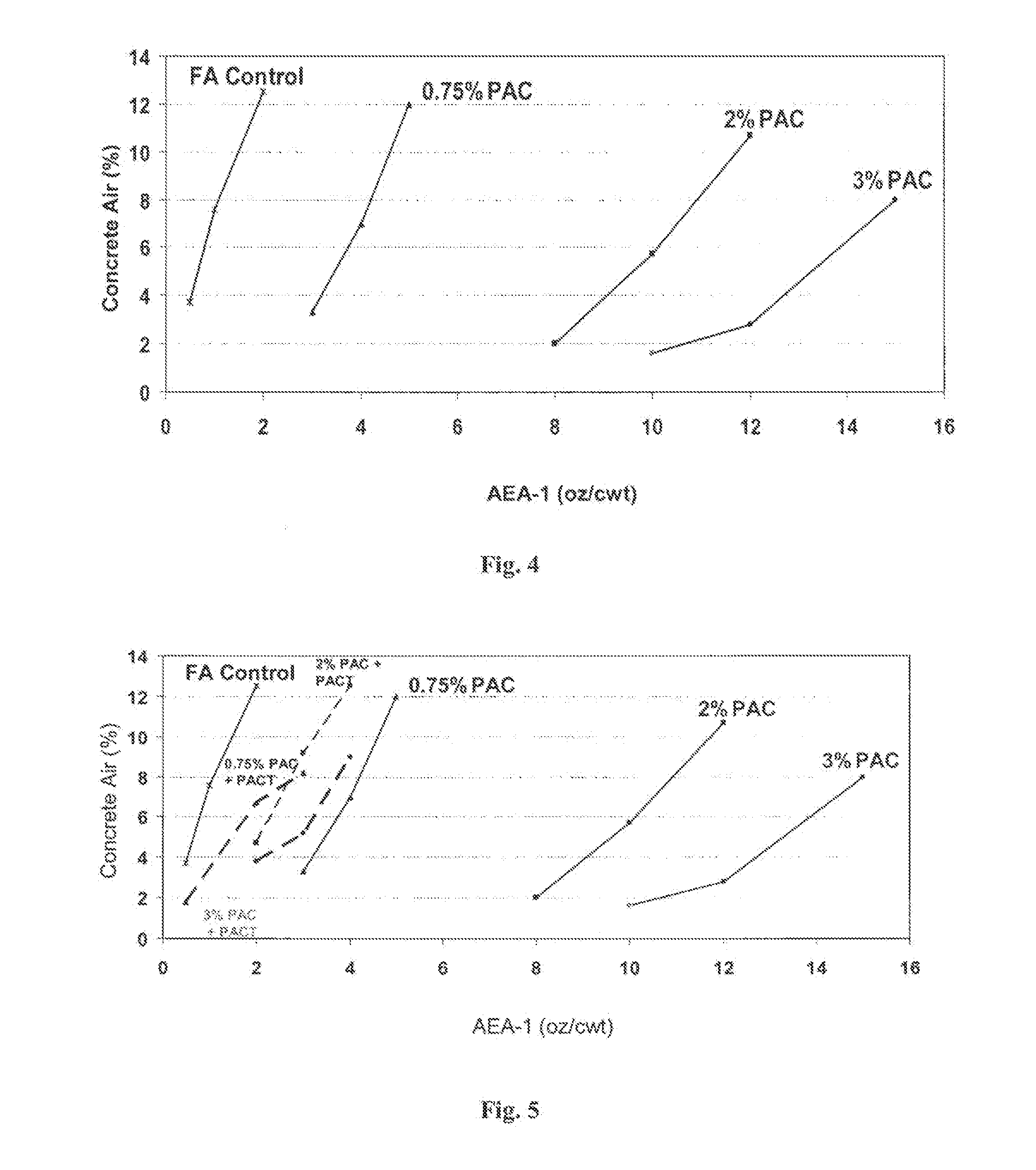

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one sacrificial agent is also included in the mixture. The sacrificial agent is a material or mixture of materials that is not required to act as an air entrainment agent but interacts preferentially with components of the fly ash that otherwise neutralize, repress or depress the activity of the air entrainment agent. The invention includes cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, and processes for selecting suitable sacrificial agents.

Owner:HANDY CHEM

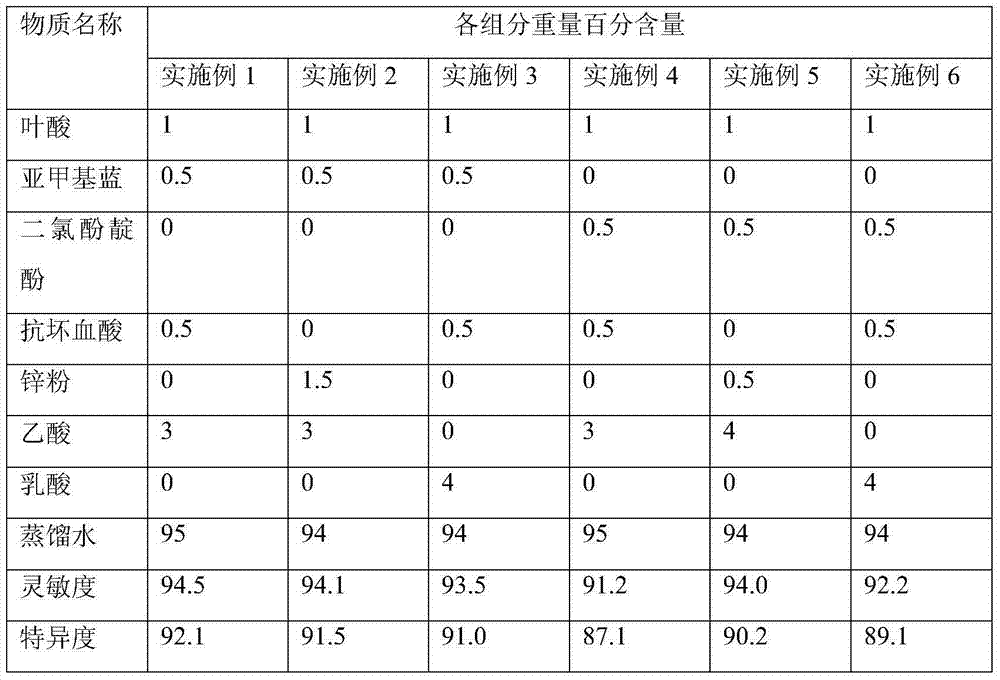

Long-life and low-foam emulsion for aluminium alloy cutting

InactiveCN106281616AImprove the lubrication effectHigh surface finishLubricant compositionMaterials science6111 aluminium alloy

The invention relates to a long-life and low-foam emulsion for aluminium alloy cutting, belonging to the technical field of metal processing media. The emulsion has the beneficial effects that the lubricating capacity of cutting fluid and the surface finish of workpieces are improved by adopting combination of extreme pressure lubricants and oily lubricants; the alkali retention capacity and pH stability of the cutting fluid are improved by adopting optimized alcohol amine combination and through cooperation of monoethanolamine, triethanolamine and special alcohol amines; the requirements of different aluminium alloys for aluminium corrosion inhibition are achieved by adopting compound aluminium corrosion inhibitor combination and combining the characteristics of phosphorus-containing aluminium corrosion inhibitors and silicon-containing aluminium corrosion inhibitors; the stability of the cutting fluid primary fluid and a diluent is enhanced and adverse effects on machine tool paint are avoided by adopting special coupling agent combination; control of foam in a high pressure fluid supply system and a high precision filtering system is achieved by adopting the foam inhibition properties of the systems and the defoaming properties of defoaming agents.

Owner:NANJING KERUN LUBRICANTS

Anti-proliferative and anti-inflammatory agent combination for treatment of vascular disorders

Drug-delivery systems such as drug-delivery stents having an anti-proliferative agent such as everolimus and an anti-flammatory agent such as clobetasol are provided. Also disclosed are methods of treating a vascular impairment such as restenosis or vulnerable plaque.

Owner:ABBOTT CARDIOVASCULAR

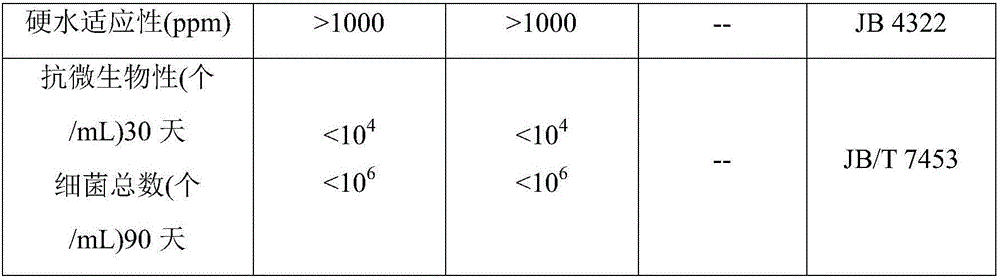

Staining agent combination for tumor tissue cell and preparation method thereof

ActiveCN103483872APrecise positioningAccurate detectionPreparing sample for investigationOrganic dyesAgent CombinationMedicine

The invention relates to a staining agent combination for tumor tissue cells, in particular to a staining agent combination for the tumor tissue cells. The combination comprises 0.01%-5% of a color developing agent, less than or equal to 6.5% of folic acid, 0.1%-10% of a leuco agent, less than or equal to 10% of a pH modifier and 3%-95% of water, wherein the color developing agent adopts methylene blue and / or dichlorophenolindophenol; the leuco agent adopts a reducing reagent; a targeted drug preparation adopts the folic acid; and the solution pH modifier and the water are adopted. The coloring agent for staining tumor cell can also be used for detecting the tumor cells. The invention also relates to a method of the staining agent combination used for detecting the tumor cells, a kit for detecting the tumor cells and a detection carrier.

Owner:QINGDAO AGRI UNIV

Chewing gum containing combinations of physiological cooling agents

InactiveUS20130156885A1High flavor impactReduce concentrationChewing gumFood ingredient as encapsulating agentFlavorAgent Combination

A method for producing a chewing gum and confections, as well as the chewing gum and confections so produced, incorporates combinations of physiological cooling agents. In another embodiment a combination of physiological cooling agents is made in a modified release structure. The modified release / cooling agents combination is preferably obtained by physically modifying the properties of the combination of cooling agents by coating and drying. When incorporated into gum and confections, these particles are adapted to enhance the shelf stability of the flavor and / or produce a modified release. In another embodiment, coated chewing gum has a coating that comprises combinations of physiological cooling agents. The preferred inventive chewing gum provides a high flavor impact in which the harsh notes normally associated with such a high flavor impact have been reduced or eliminated.

Owner:WM WRIGLEY JR CO

Chewing gum containing physiological cooling agents

A method for producing a chewing gum, as well as the chewing gum so produced, incorporates a physiological cooling agent, such as acyclic carboxamide, or combinations of physiological cooling agents.In another embodiment a combination of physiological cooling agents is made in a modified release structure. The modified release / cooling agents combination is preferably obtained by physically modifying the properties of the combination of cooling agents by coating and drying. When incorporated into gum, these particles are adapted to enhance the shelf stability of embodiment, the physiological cooling agent is present with menthol and menthone. In another embodiment, coated chewing gum has a coating that comprises a physiological cooling agent. The prefereed inventive chewing gum provides ahigh flavor impact in which the harsh notes normally associated with such a high flavor impact have been reduced or eliminated. In addition, the preferred inventive gum provides a clean, high-quality, cooling chewing gum coating with xylitol or other polyols where xylitol has been reduced in concentration or eliminated.

Owner:WM WRIGLEY JR CO

Anti-proliferative and anti-inflammatory agent combination for treatment of vascular disorders with an implantable medical device

Drug-delivery systems such as drug-delivery stents having an anti-proliferative agent such as everolimus and an anti-inflammatory agent such as clobetasol are provided. Also disclosed are methods of treating a vascular impairment such as restenosis or vulnerable plaque

Owner:ABBOTT CARDIOVASCULAR

Confections Containing a Blend of Physiological Cooling Agents

InactiveUS20070248717A1High flavor impactImprove cooling effectConfectioneryChewing gumAgent CombinationDiol

A method for producing a confection such as chewing gum, as well as the confection so produced, incorporates a blend of physiological cooling agents, including menthyl glutarate and one or more of L-isopulegol and p-menthane-3,8-diol. In another embodiment the blend of physiological cooling agents is made in a modified release structure. The modified release / cooling agents combination is preferably obtained by physically modifying the properties of the combination of cooling agents by coating and drying. When incorporated into gum, these particles are adapted to enhance the shelf stability of the flavor and / or produce a modified release when the gum is chewed. In another embodiment, the blend of physiological cooling agent is included in a confection coating.

Owner:WM WRIGLEY JR CO

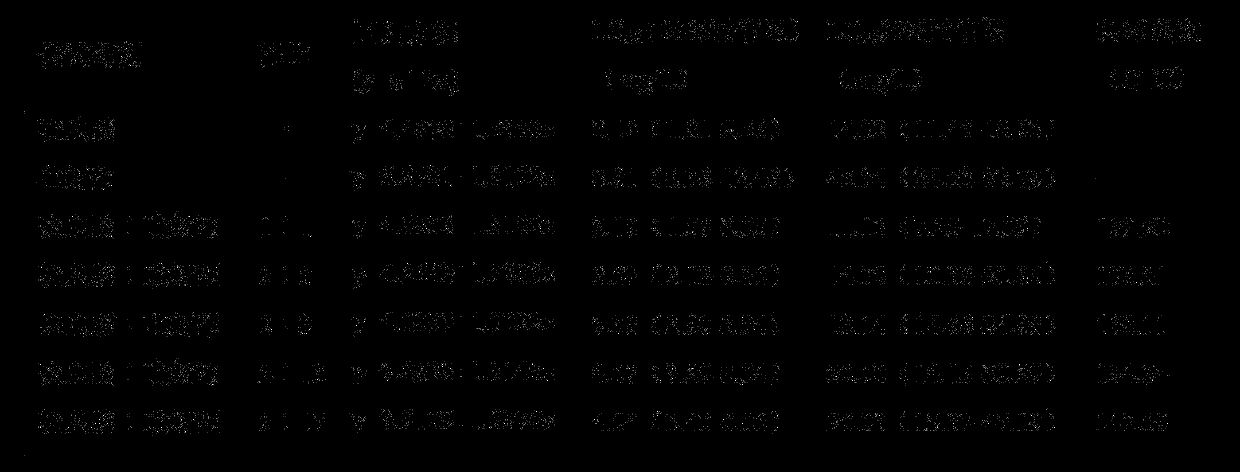

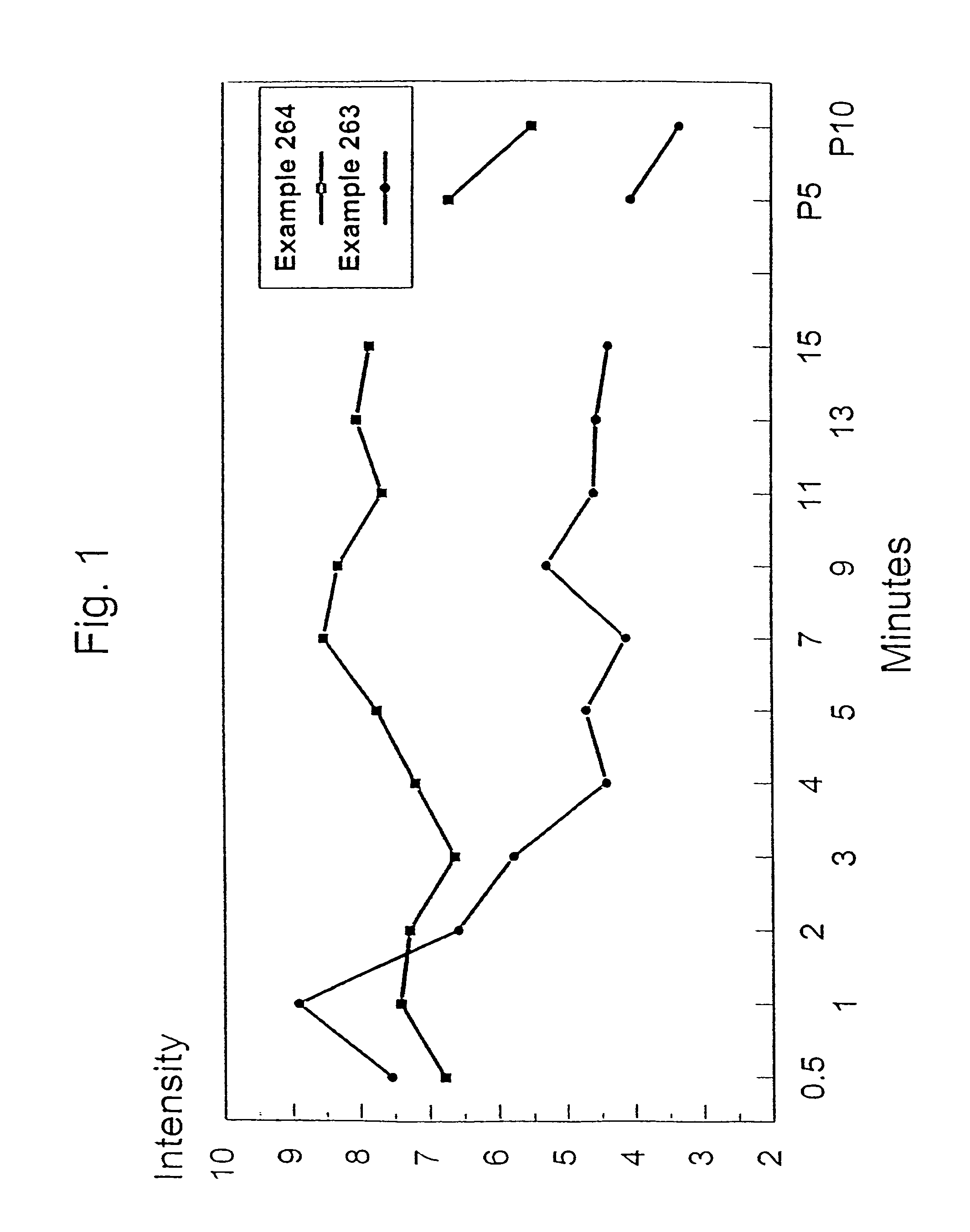

Amine Sacrificial Agents and Methods and Products Using Same

InactiveUS20100286312A1Promote formationFacilitate air entrainmentSolid waste managementCeramicwareChemical admixtureAgent Combination

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions is described. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one amine sacrificial agent is included in the mixture. The cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, are also described.

Owner:RUETGERS POLYMERS LTD

Pesticide for killing piercing-sucking type insects and preparation thereof

InactiveCN103385253AReduce pollutionLong durationBiocideAnimal repellantsWater dispersibleChlorfenapyr

The invention provides a pesticide for killing piercing-sucking type insects. The pesticide comprises dinotefuran with the mass percentage of 1%-80%, and a pesticide-acceptable addition agent combination, or comprises an effective component A and an effective component B with the mass ratio in a range from 80:1 to 1:80, and a pesticide-acceptable addition agent combination, wherein the effective component A is dinotefuran, and the effective component B is one of indoxacarb, chlorfenapyr and pymetrozine. The invention further provides a method for preparing the pesticide into soluble liquid, wettable powder, a water dispersible granule product and a suspension agent product. According to the pesticide disclosed by the invention, the dinotefuran is mainly applied to internal suction and penetration of insects, the lasting period is long and the generation of drug resistance can be retarded; the pesticide has an excellent effect for preventing and treating insects; meanwhile, the pollution to the environment is alleviated and an insecticidal spectrum can be expanded. The pesticide disclosed by the invention has excellent effects on prevention and treatment of various piercing-sucking type insects including thrips, plant hoppers, leafhoppers, aleyrodid, aphids, scale insects, tea lesser leafhoppers and the like.

Owner:陕西康禾立丰生物科技药业有限公司

Low-luster polishing agent combination and preparation method thereof

InactiveCN101037571AFully dispersedSolve the problem of levelingPolishing compositionsAgent CombinationFilm-forming agent

The invention discloses a low gloss polishing agent composition and preparation method thereof. Main character of the polishing agent composition is: at least containing one metal crosslinking or self-crosslinking polymer film forming agent, one dulling agent, and one dispersant. The polishing agent composition employs the dispersant to carry pre-dispersion operation of inorganic dulling agent, thereby effectively increasing decentrality of the dulling agent and benefiting leveling property of itself. The disclosed polishing agent composition coated on surface of ground and working bench can generate low gloss and unsmoothed effect and is adapted for special demand of surface.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Chewing gum containing physiological cooling agents and method of making

InactiveUS7078066B2Without unwanted harshness and flavor characteristicImprove impact performanceContainers for annular articlesChewing gumFlavorMenthone

Owner:WM WRIGLEY JR CO

Amine sacrificial agents and methods and products using same

InactiveUS20120085264A1Promote formationFacilitate air entrainmentSolid waste managementCeramicwareChemical admixtureAgent Combination

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions is described. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one amine sacrificial agent is included in the mixture. The cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, are also described.

Owner:RUETGERS POLYMERS LTD

Compositions for Medical Devices Containing Agent Combinations in Controlled Volumes

The present invention generally encompasses controlled-volume materials that may, for example, be in a medical device or applied on a medical device as a coating, as well as methods of applying these materials.

Owner:ABBOTT CARDIOVASCULAR

Positive photosensitive resist release agent compositions

InactiveCN101017333AImprove solubilityExcellent peelabilityPhotosensitive material processingSolubilityResist

This invention discloses one positive light anti-erosion agent peeling agent combination, which comprises the following parts: a, occupying organic amine for weight of 10 to 50; b, monoethylene glycol monoalkyl ether for weigth of 0 to 70 percent; c, non photon electrode solvent for weight of 20 to 90; d, based on the said three component total weight for 0.01 to 10 non-ion surface active agent. This invention relates to positive light anti-erosion peel agent combination to etch process with excellent solve property and peeling property of pattern film for light resistance.

Owner:DONGJIN SEMICHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com