Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1180results about How to "Improve product added value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

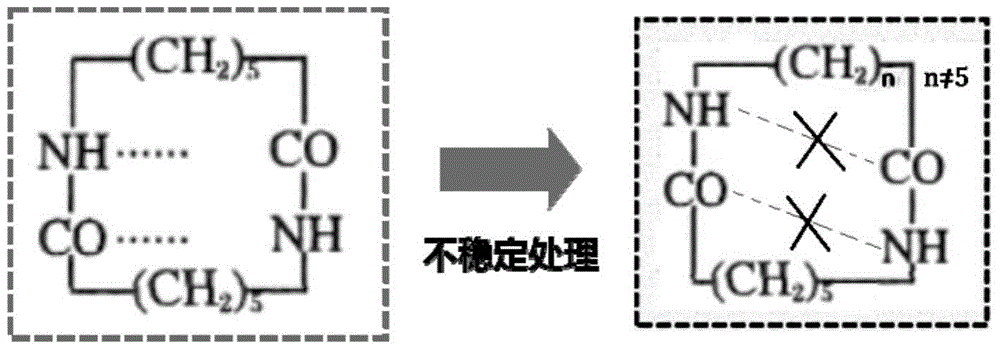

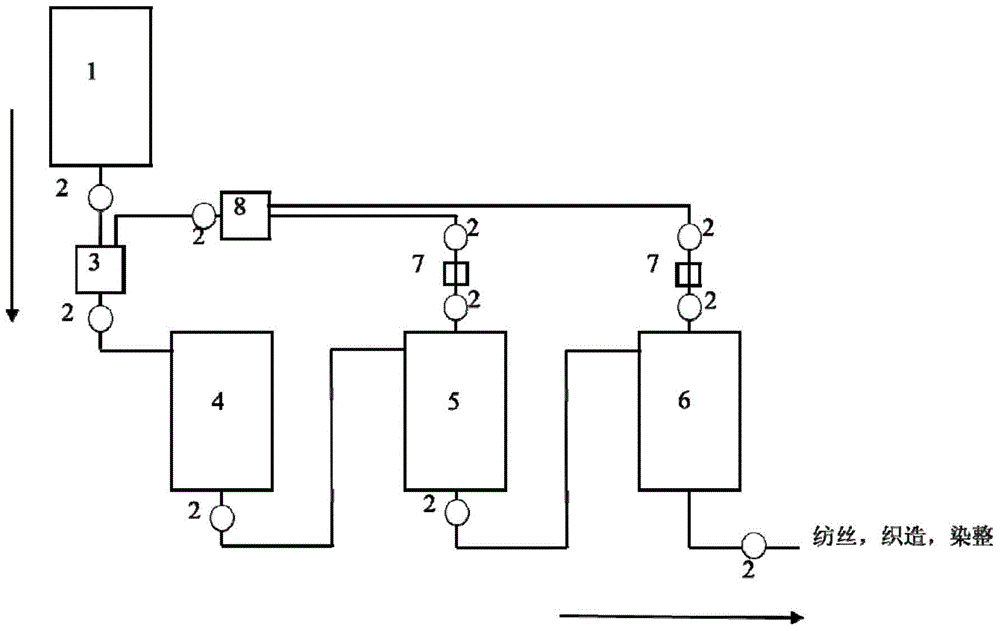

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

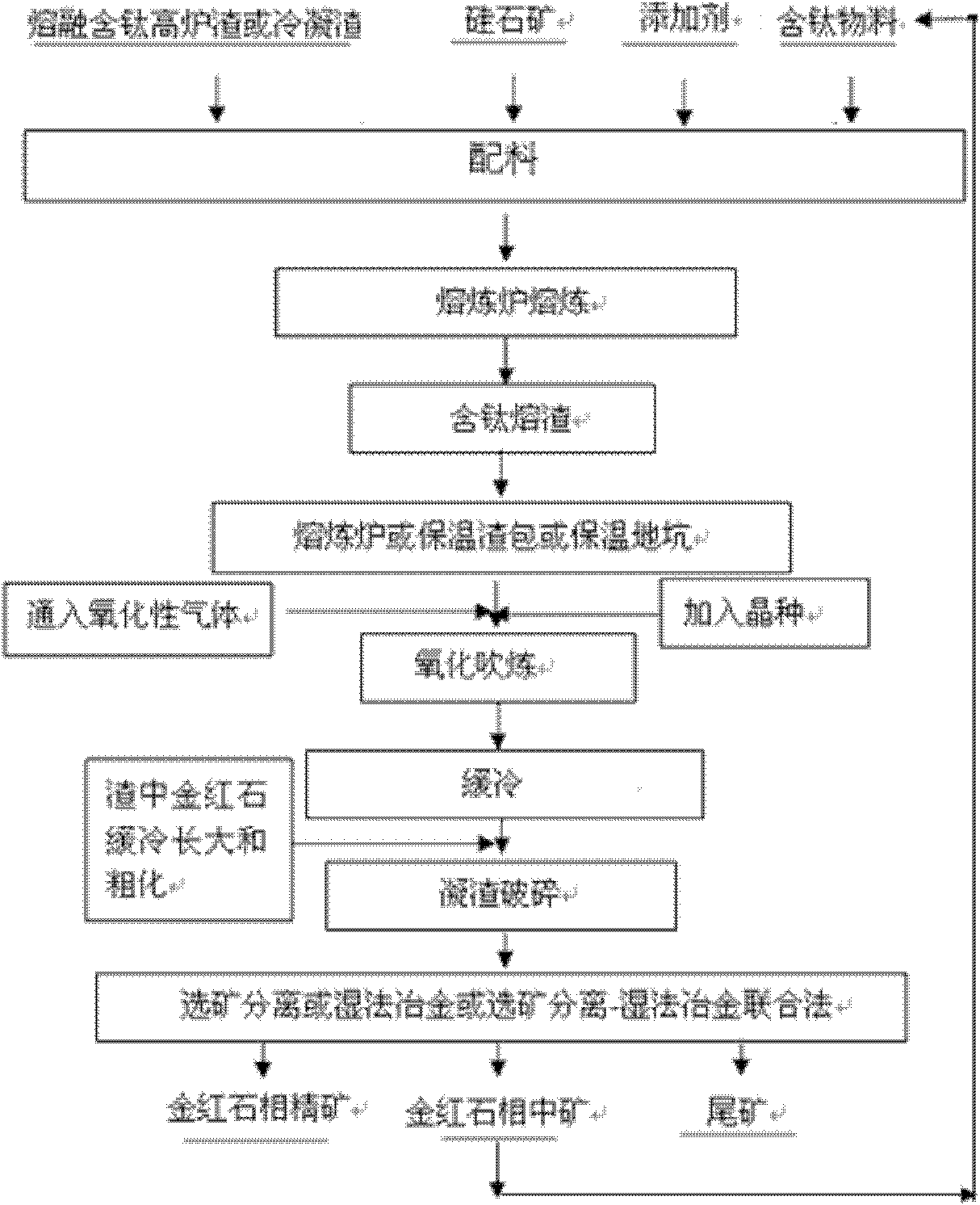

Method for producing artificial rutile from titanium-containing blast furnace slags

ActiveCN102154531ASimple compositionPromote coarseningRecycling and recovery technologiesProcess efficiency improvementTitaniumMolten slag

The invention provides a method for producing artificial rutile by taking the titanium-containing blast furnace slags as the raw material. The method has the advantages of short reaction time, high titanium recovery, low production cost, big treatment capacity and high product additional value and is environment-friendly. The method comprises the following steps: burdening: adding smelted or condensed titanium-containing blast furnace slags, a titanium-containing material, silica ores and an additive into a smelting furnace; smelting: smelting by the smelting furnace to keep the mixture underthe fusing state; oxidation: spraying and blowing an oxidizing gas into slags in the smelting furnace, or pouring the slags into a heat insulation slag tank or a heat insulation pit, spraying and blowing an oxidizing gas into slags in the heat insulation slag tank or the heat insulation pit to convert the titanium-containing substances in the slags into the rutile phase; cooling: keeping the temperature for the oxidized slags in the heat insulation slag tank or the heat insulation pit, and controlling the cooling rate to cool the slags to room temperature to cause the rutile phase to grow; and separation: and finally, breaking and levigating the oxidation modification condensed slags to separate the rutile phase to obtain the artificial rutile with high TiO2 grade.

Owner:喀左县钒钛资源综合开发利用工程技术研究中心 +1

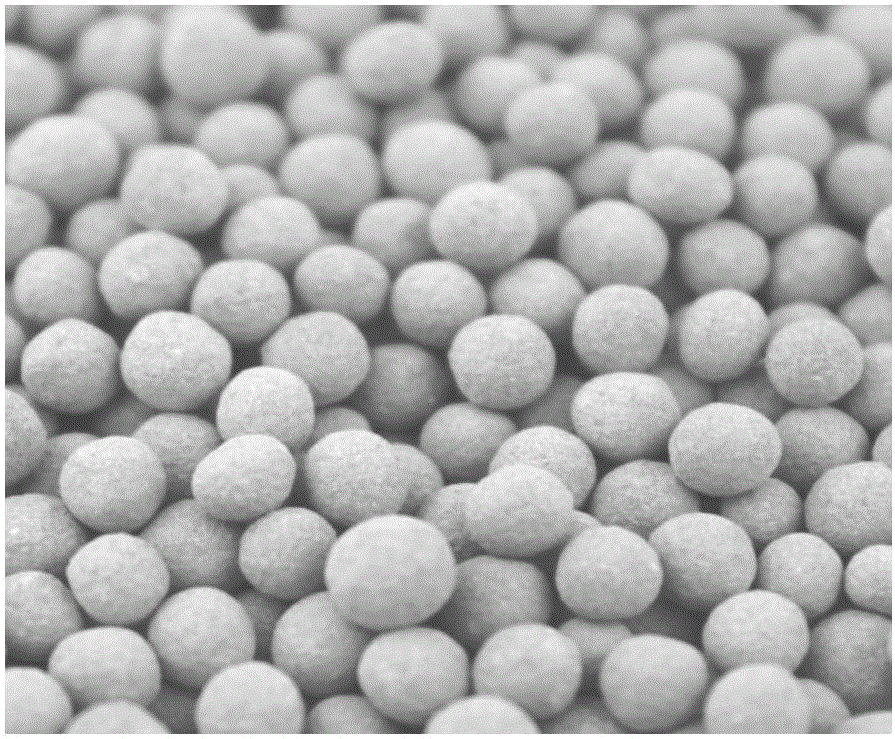

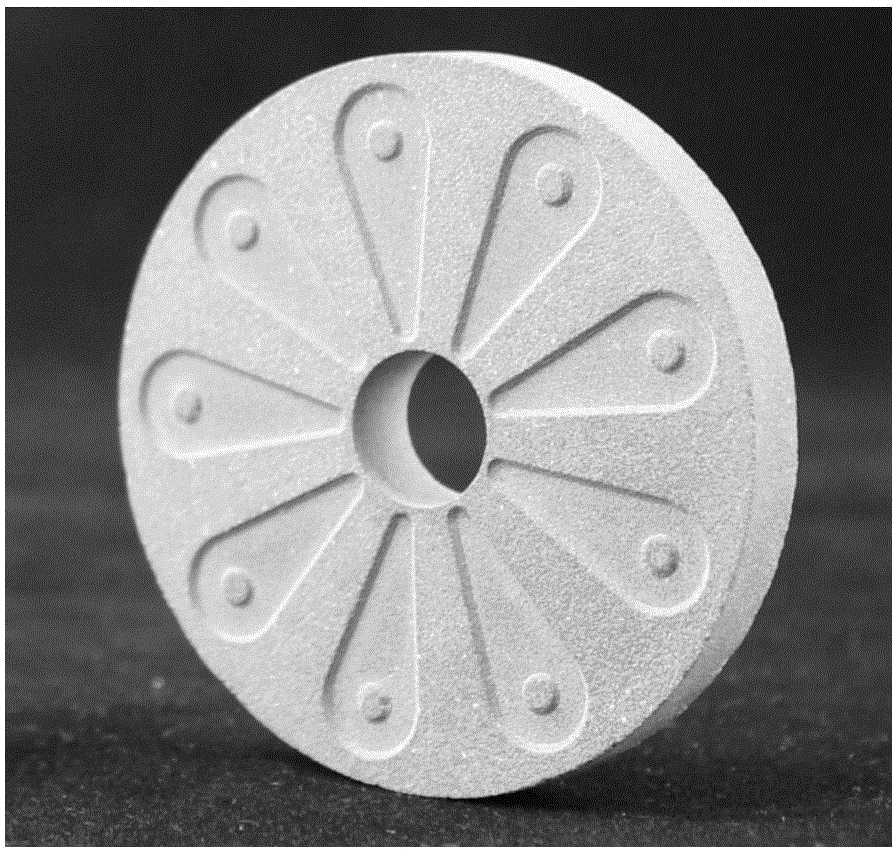

Ceramal material for manufacturing hydrogen-enriched water and preparing method and application thereof

The invention belongs to the technical field of new environment-friendly materials, and particularly relates to a ceramal material for manufacturing hydrogen-enriched water and the preparing method and application thereof. The ceramal material is prepared from, by weight, 30-85 parts of base material component, 20-60 parts of hydrogen-enriched component, 2-25 parts of anti-microbial component, and 3-30 parts of binder. The base material component is prepared from tourmaline, serpeggiante, silicon oxide, calcium oxide and zeolite. The hydrogen-enriched component is prepared from magnesium metal powder, magnesia powder and KDF alloy powder. The anti-microbial component is prepared from zinc oxide, titanium oxide and cerium oxide. The binder is prepared from one or more of high-purity distilled water, carboxypropyl cellulose and bentonite. The ceramal material can be used for manufacturing alkalescent water, negative-potential water and hydrogen-enriched water and also has an anti-microbial function and a water activating function. The invention further provides the preparing method and application of the ceramal material. The technology is simple and easy to realize. The ceramal material can be applied to products including water purifiers, water purifying kettles and cups.

Owner:山东木齐健康科技有限公司

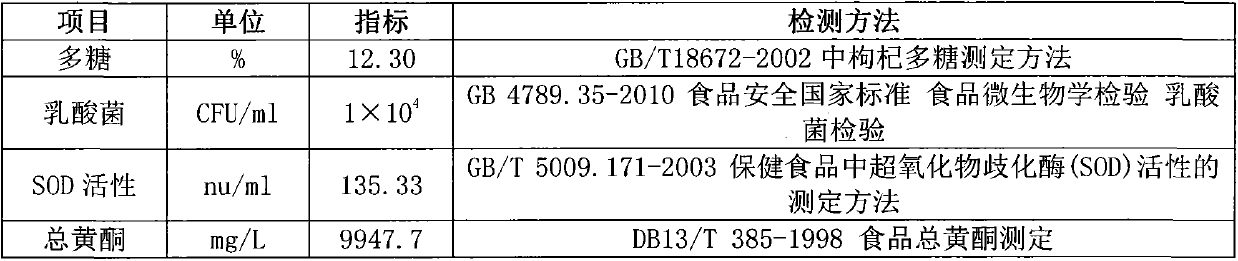

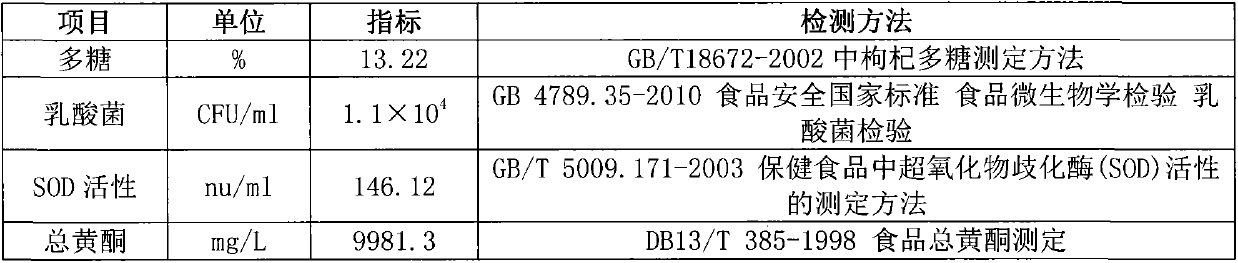

Chinese wolfberry ferment preparation method

InactiveCN104187602AHigh content of active substancesReduce wasteFood preparationLactic acid fermentationFermentation

The invention relates to a Chinese wolfberry ferment preparation method, aims to provide Chinese wolfberry ferment prepared by Chinese wolfberry treatment, enzymolysis, glucose reduction fermentation, lactic acid fermentation, ultrasonic low temperature concentration, blending, drying, crushing and other processes, , the method has the advantages of simple process, less addition agent and no residue, by the use of Chinese wolfberry defective products, the active substance content in the Chinese wolfberry ferment product can be promoted, the waste of resources can be reduced, the purposes of the comprehensive utilization of resources and improvement of the product added value can be achieved, and good economic and environmental benefits are obtained.

Owner:青海柴馥有机枸杞有限公司

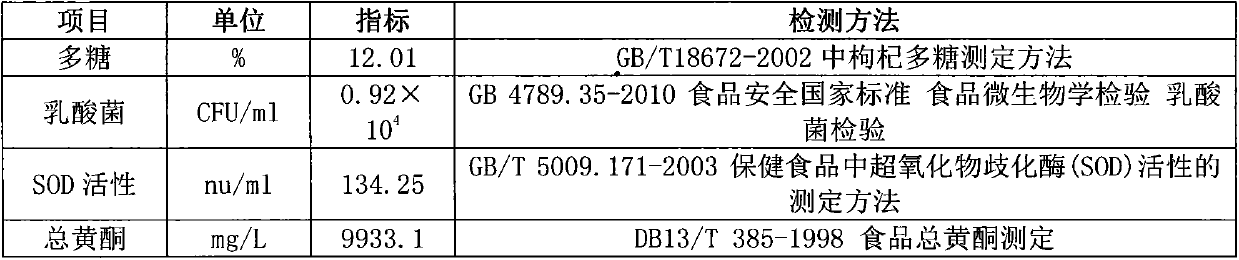

Integrated ammonia-process desulfurization method of various acidic gases in oil refining device

ActiveCN105126573ASimple processLess investmentDispersed particle separationSulfur preparation/purificationPtru catalystFlue gas

An integrated ammonia-process desulfurization method of various acidic gases in an oil refining device includes the following steps: (1) preparing heavy oil, light oil, acidic liquid and solvents through an atmospheric and vacuum distillation unit from crude oil, and feeding the heavy oil into a catalytic cracking device, the light oil into a hydrogenation device, and the acidic liquid and the solvents into a sulfur recovery combined device; (2) mixing a part of FCC oil, which is produced through the catalytic cracking device, with the light oil and feeding the mixed oil into the hydrogenation device to produce hydrogenated oil, the acidic liquid and solvents, wherein a part of the hydrogenated oil is fed into an adsorption device while the other part of the hydrogenated oil is stored and marketed as product oil; (3) feeding the acidic liquid and solvents and the acidic liquid and solvents prepared from the atmospheric and vacuum distillation unit into the sulfur recovery combined device to produce sulfur, and feeding the tail gas into an incineration unit for incineration to obtain incinerated flue gas; (4) feeding a part of the FCC oil which is produced in the catalytic cracking device into the adsorption device, performing adsorption desulfurization, and feeding an adsorption catalyst into a regenerative device to regenerate the adsorption catalyst in an oxidizing manner to obtain regenerated flue gas; and (5) feeding the FCC flue gas, the incinerated flue gas and the regenerated flue gas into an ammonia absorption device to perform absorption desulfurization and discharging cleaned flue gas after the flue gas meets standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

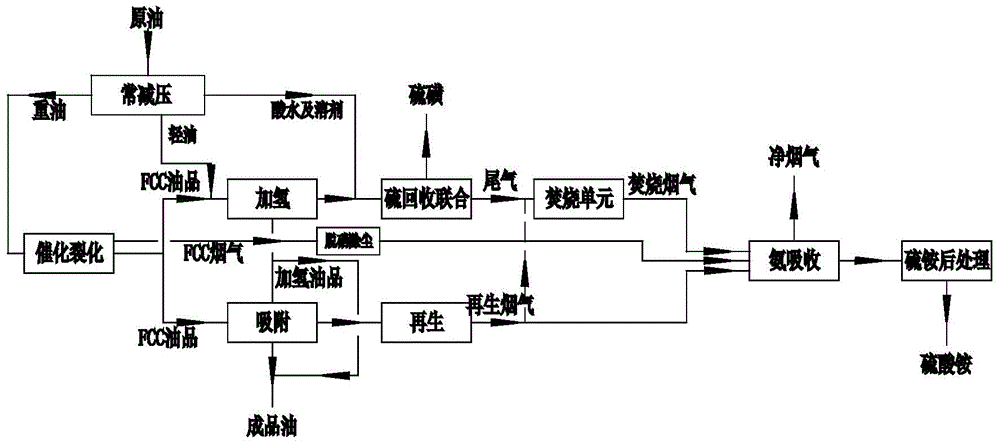

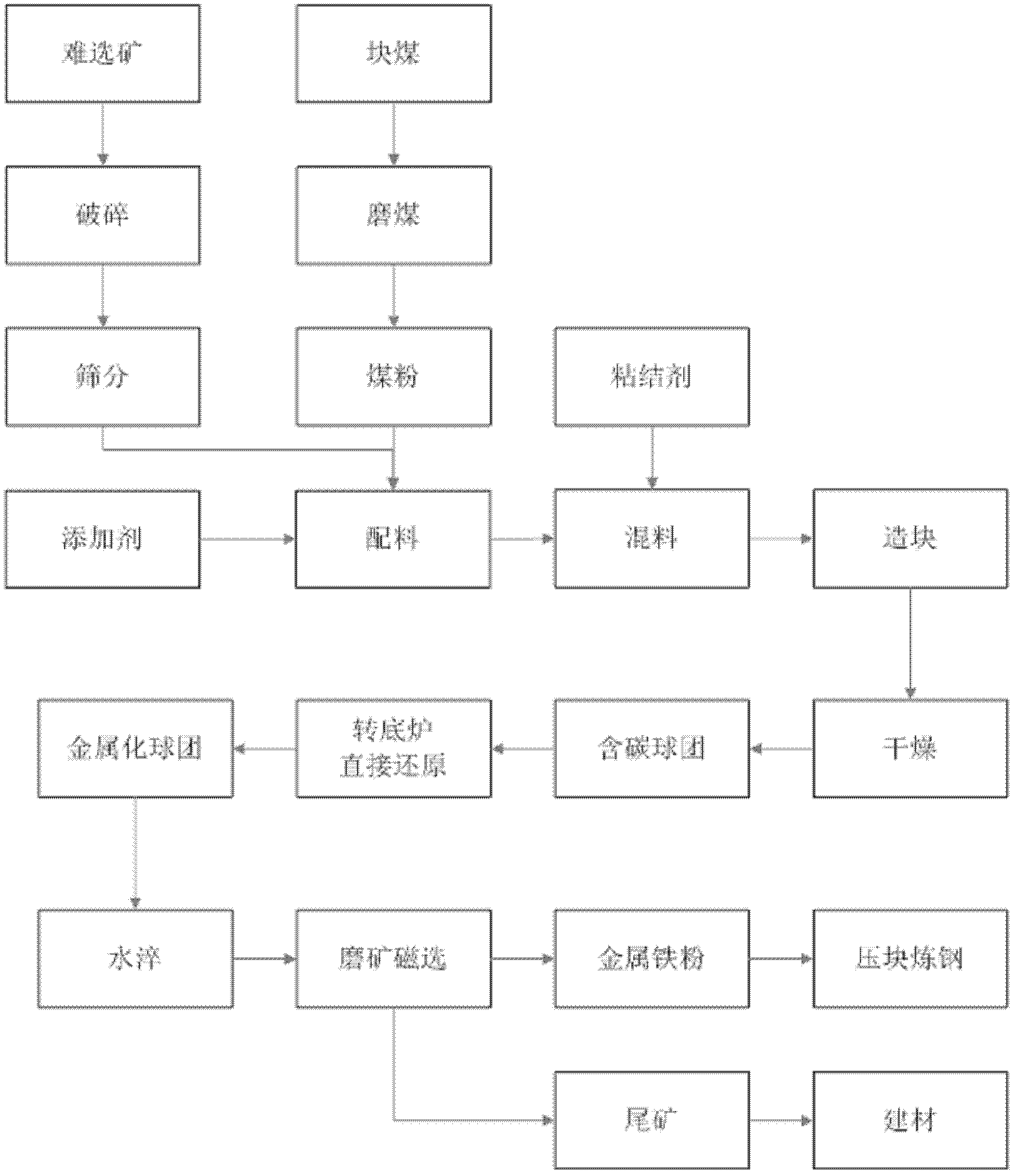

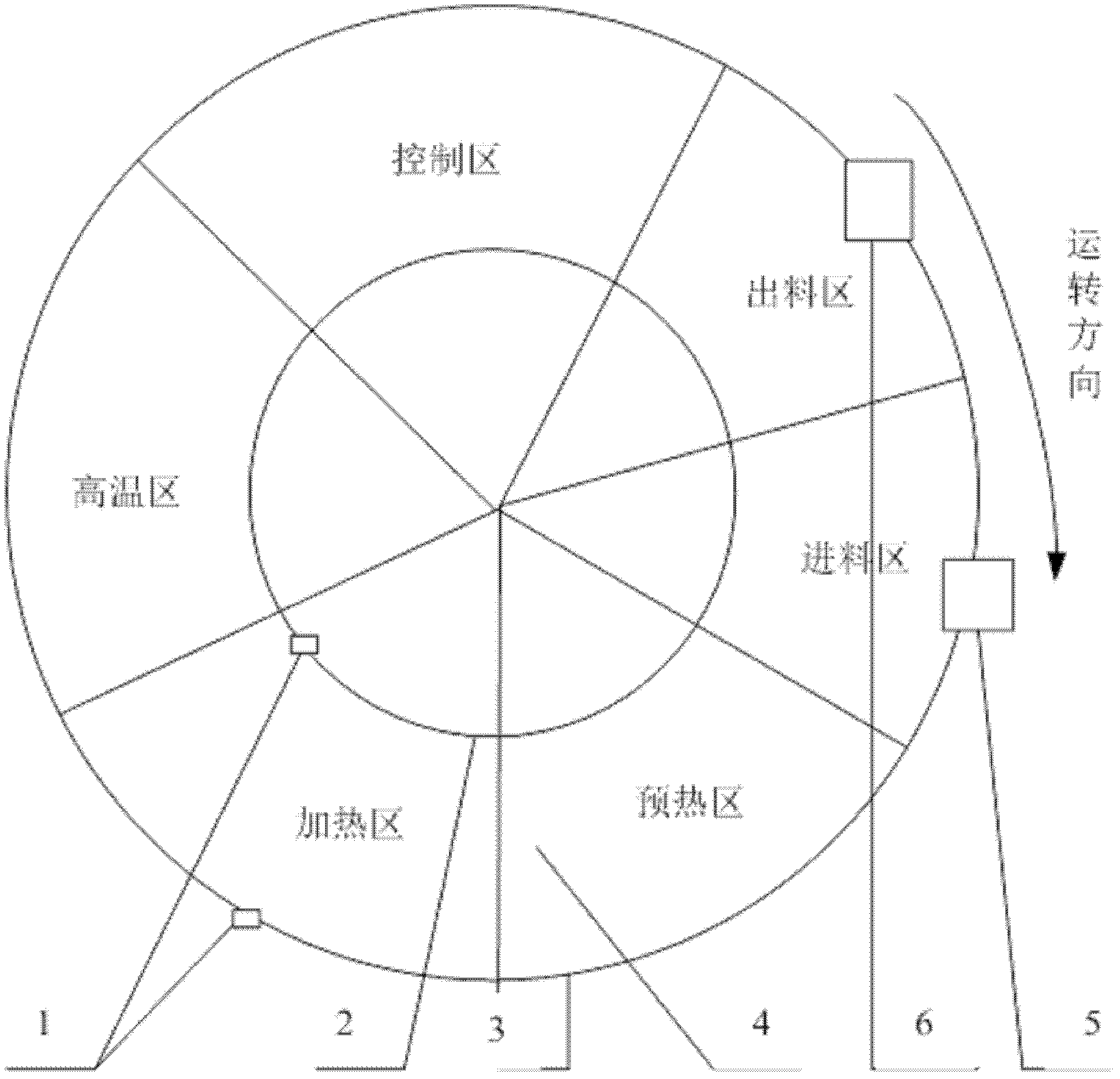

Device and method for treating refractory iron ore

InactiveCN102634621AImprove reduction efficiencyShort recovery timeProcess efficiency improvementCombustionControl area

Owner:SHENWU TECH GRP CO LTD

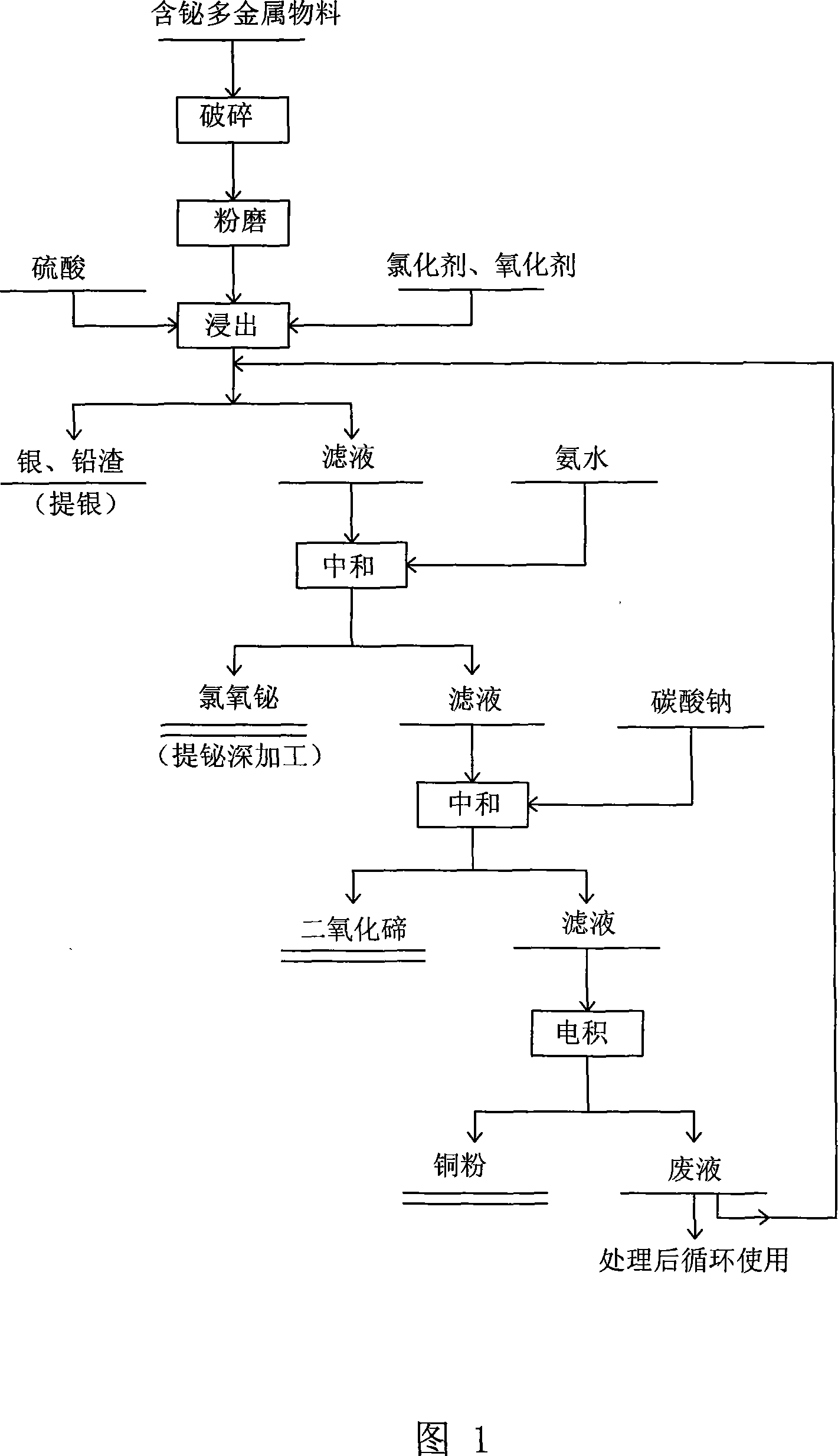

Comprehensive extraction of valent metal from bismuth-containing polymetallic material

InactiveCN101029353AHigh recovery rateImprove product added valuePhotography auxillary processesProcess efficiency improvementSesquioxideTe element

A method for extracting metal from bismuth-contained multi-metal material is carried out by leaching out copper and tellurium from bismuth-contained multi-metal by sulfuric acid, adding into chlorinating agent and oxidant to leach out metal bismuth, extracting silver from leaching-out slag with AgCl, PbSO4 and PbC12, adding ammonia water into leaching-out liquid, adjusting pH value to 1.5 to obtain bismuth oxychloride slag with 70% bismuth content, smelting into coarse bismuth by firing method or machining to obtain high-purity bismuth sesquioxide, adjusting pH value to 4.5 by Na2CO3, depositing tellurium to obtain tellurium dioxide and copper-contained solution, and electrically depositing to obtain copper powder with copper-contained content90%. It adopts wetting and firing metallurgical technology, has higher metal recovery rate and excellent leaching-out separation effect and effluent circulating utilization and no environmental pollution.

Owner:HUNAN JINWANG BISMUTH

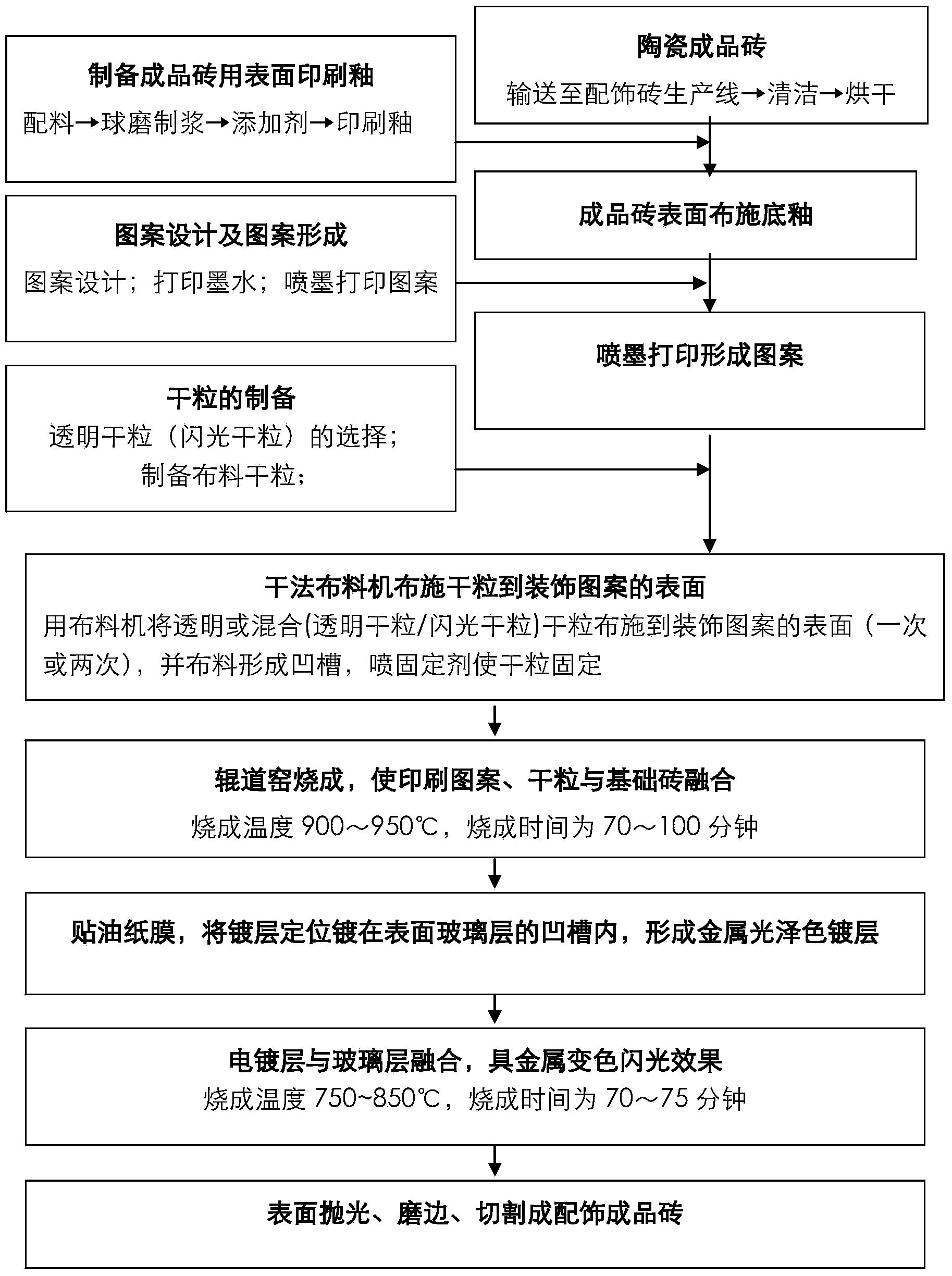

Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

The invention relates to a manufacturing process of a ceramic accessory tile and the ceramic accessory tile. The manufacturing process comprises the steps of: (1) printing a ground coat on the surface glass layer of sintered ceramic tile; (2) conducting ink-jet printing on the printing ground coat to form patterns; (3) applying transparent dry grains on the surface of the pattern layer for two times, and sintering; (4) electroplating metal color on a groove of the surface glass layer by adopting a lamination positioning electroplating method, and sintering; (5) polishing the surface of the sintered product; and (6) cutting the sintered accessory tile blank to prepare the accessory tile. The ceramic accessory tile comprises a base tile, ground coat applied on the surface of the base tile, the pattern layer attached on the ground coat, and the first dry grain layer and the second dry grain layer applied on the pattern layer. Irregular pits, grooves or concave curves, wherein the irregular pits, the grooves or the concave curves are hollowed towards the inside and are arranged on the layer surface of the second dry grain distribution layer. The accessory tile varieties include ground flowers, ground line, waist line and corner, and is used for supporting the ceramic wall and floor tiles.

Owner:JIANGXI HEMEI CERAMICS

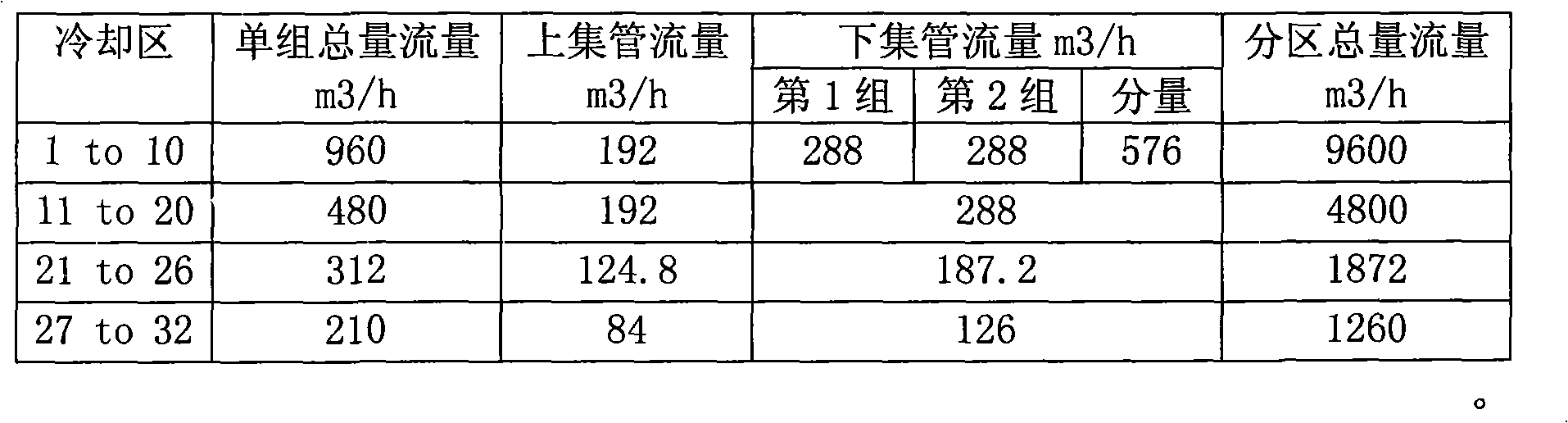

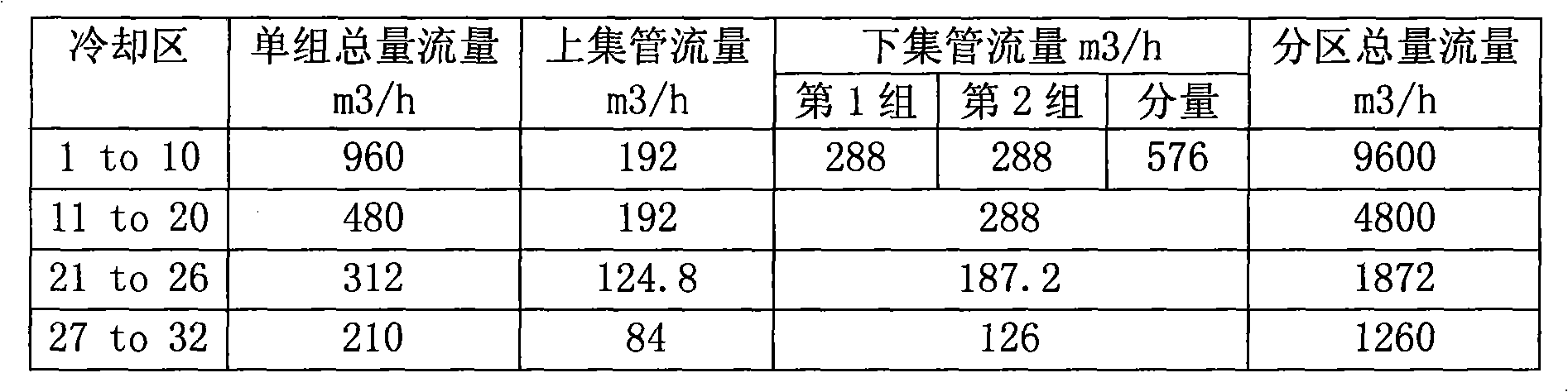

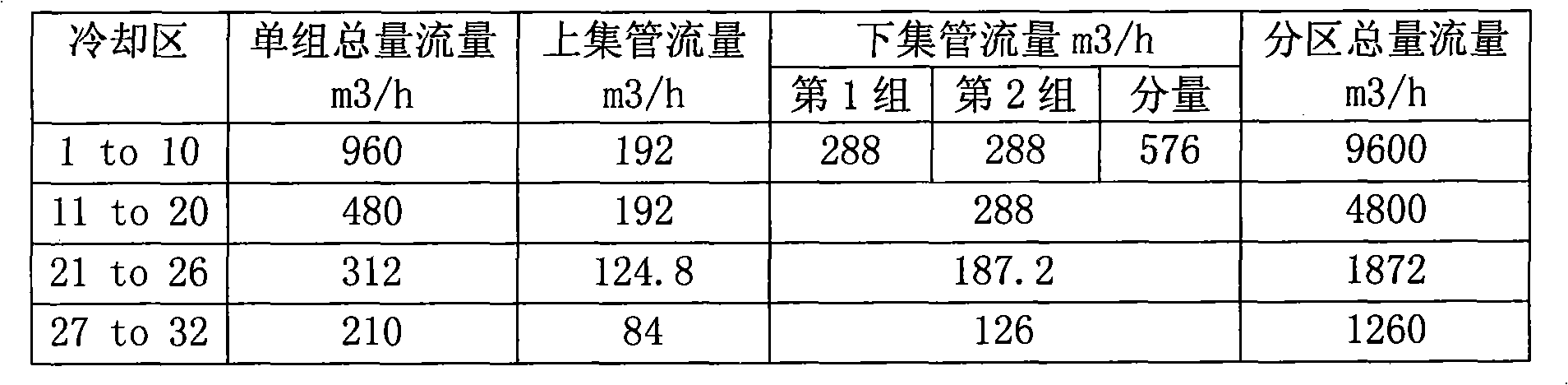

Process for producing high strength hardened and tempered steel by steekle mill on-line quenching

ActiveCN101353717AReduce consumptionLess investmentTemperature control deviceMetal rolling arrangementsWater resourcesHigh intensity

The invention relates to a production technology of high-strength quenched and tempered steel, in particular to a technology for the online quenching production of the high-strength quenched and tempered steel by using a steckel mill, comprising the following procedures of: (1) billet heating: temperature in a preheating section is less than or equal to 600 DEG C, and the temperature in a heating section is between 1220 DEG C and 1180 DEG C; (2) primary scale removal of high pressure water: the water pressure is more than or equal to 18Mpa; (3) controlled rolling: during the controlled rolling of a first stage, single path draft is more than or equal to 10 percent to 15 percent, and the total draft is more than or equal to 50 percent; during the controlled rolling of a second stage, steel rolling is carried out below recrystallization temperature, and the draft is controlled to be between 40 to 70 percent; (4) online quenching by using HACC; (5) offline tempering: the tempering temperature is between 550 to 670 DEG C, and the heat preservation time is 2 to 6min / mm. The technology for the online quenching and self-tempering production of the high-strength quenched and tempered steel by using the steckel mill can improve the production efficiency by dozens of times, lower the cost, not only reduce the reheating energy consumption, but also reduce the water resource consumption of offline quenching, and reduce investment on a quenching machine set.

Owner:NANJING IRON & STEEL CO LTD

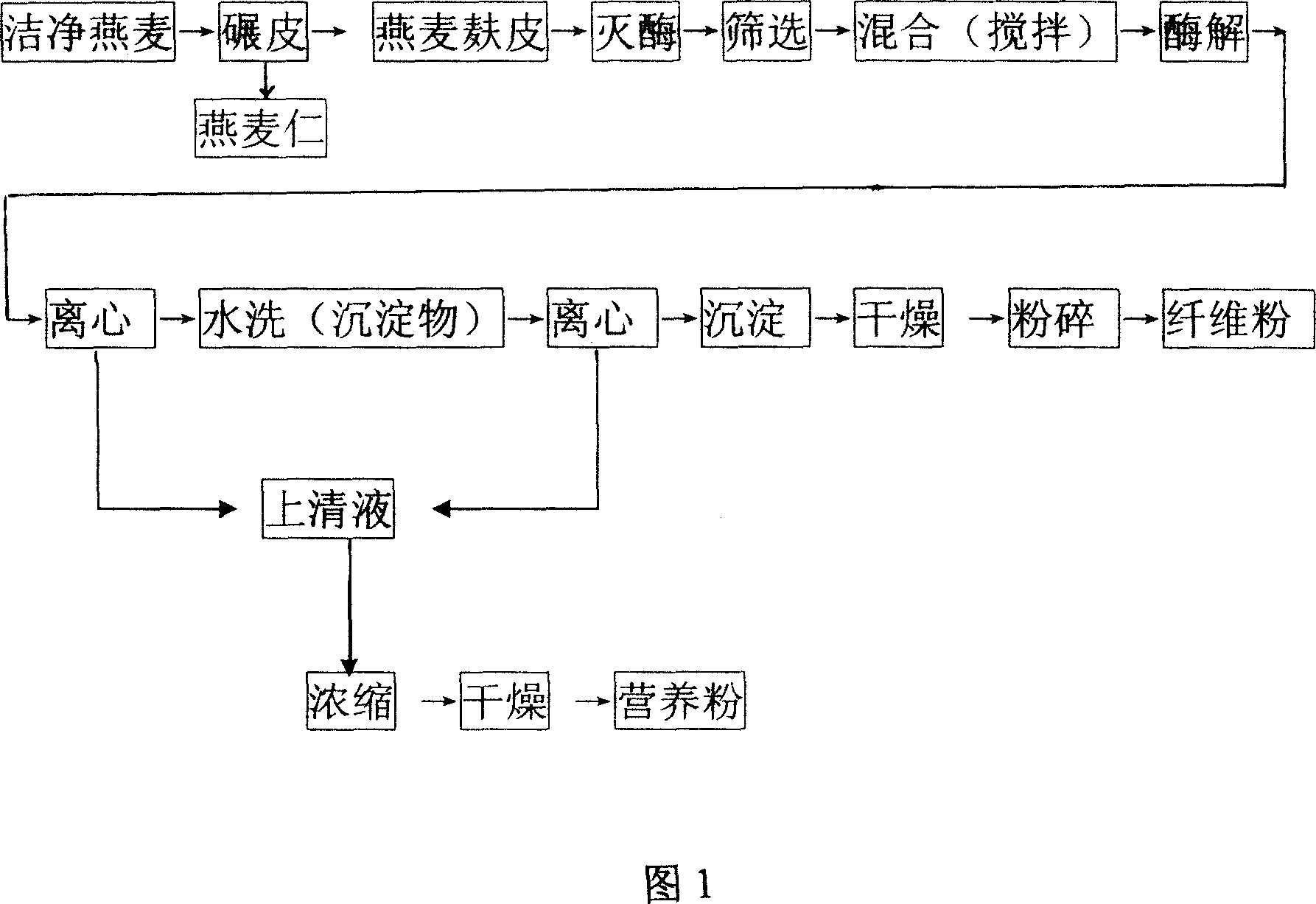

Technological process of producing oat diet fiber and nutritious powder with oat bran

The present invention relates to oat deeply processing technology, and is especially technological process of producing oat dietary fiber and nutritious powder with oat bran. The technological process includes microwave enzyme deactivation of oat bran, enzymolysis, centrifugal separation, drying the precipitate and superfine crushing to obtain oat dietary fiber powder, vacuum concentrating the separated supernatant and spray drying to obtain nutritious powder. The present invention extracts the nutritious matters from oat bran effectively, the product has high purity and the production process is environment friendly.

Owner:山西金绿禾燕麦研究所

Smelting process for producing low-carbon ultralow-phosphorus steel in converter

InactiveCN102634629ALess investmentAchieve productionManufacturing convertersSmelting processFerrosilicon

The invention discloses a smelting process for producing low-carbon ultralow-phosphorus steel in a converter. The smelting process comprises the following steps of: dephosphorizing molten iron desulfurized once by utilizing two times of slagging blowing process, namely, an early stage and a later, or three times of slagging blowing process, namely, an early stage, a middle stage and the later stage, or multiple times of slagging blowing process, wherein the content of phosphorus of the molten iron is 0.11-0.13%; utilizing silicon iron slag regulation, pouring the slag into a slag basin until the slag basin is full each time and controlling process temperature; pouring slag when oxygen blowing is carried out by 40-45%, wherein the target temperature of an early stage is 1,350-1,400 DEG C; and controlling the temperature between 1530 DEG C and 1550 DEG C when a sublance is used for blowing oxygen for 80%, and pouring the slag, so that the low-carbon ultralow-phosphorus steel with terminal phosphorus content being within 0.005% is obtained, wherein the terminal target temperature is 1560-1580 DEG C. The smelting process for producing the low-carbon ultralow-phosphorus steel in the converter, disclosed by the invention, can carry out multiple times of slagging on the molten iron desulfurized once in the converter and has the advantages of being small in molten iron physical heat loss, high in yield and efficiency, low in alloy consumption and cost, and energy-saving.

Owner:NANJING IRON & STEEL CO LTD

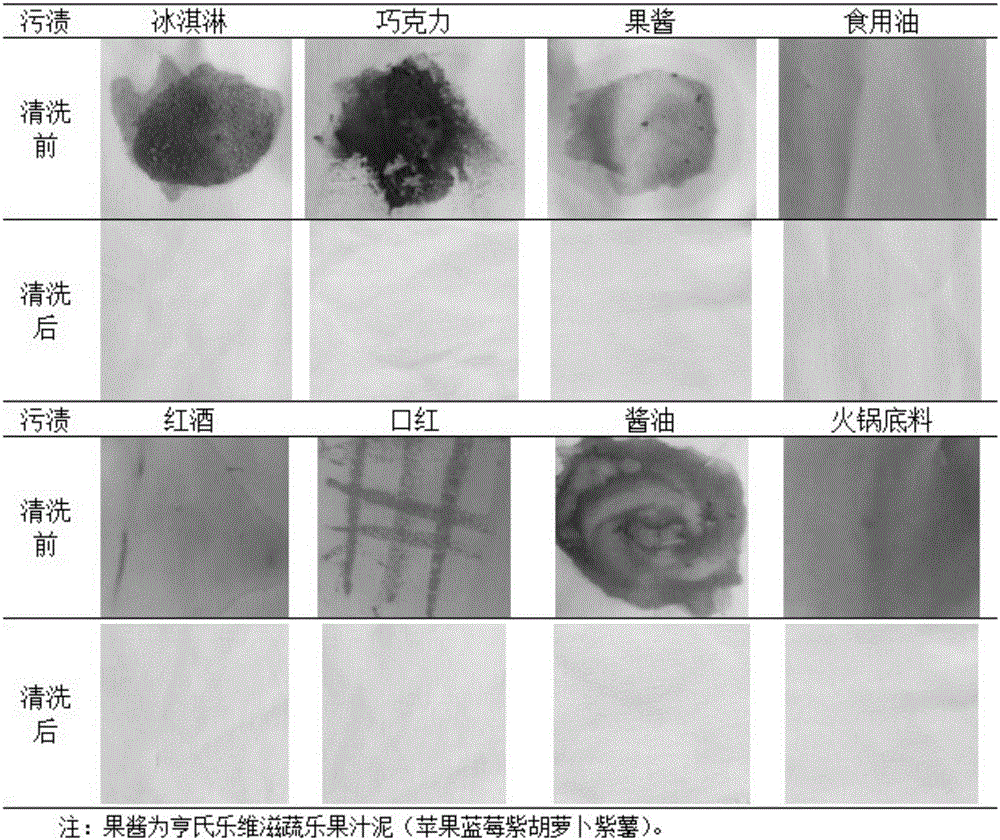

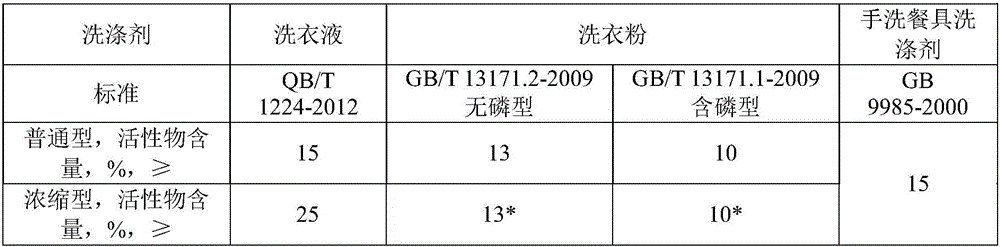

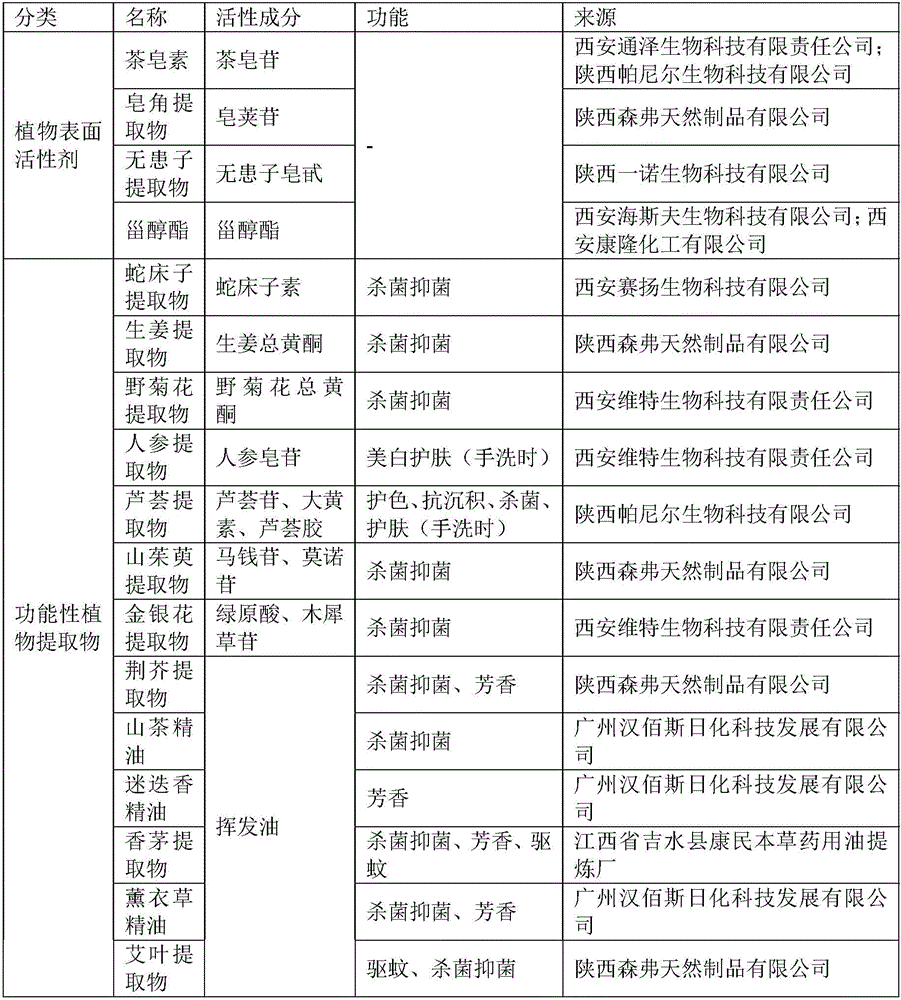

Biological detergent composition

InactiveCN106591013AImprove washing effectImprove product added valueNon-ionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsActive matterSurface-active agents

The invention relates to a biological detergent composition. The biological detergent composition is prepared from a biological surfactant, a plant surface active agent, a biological enzyme and at least one washing auxiliary material. In the biological detergent, the biological surfactant is compounded with the plant surface active agent, the biological enzyme and other adjuvant agents. The detergent is reasonable in formula, the total content of active matters is high, and through complex synergism, the washing effect can fully meet the needs of people.

Owner:DALIAN BITEOMICS INC

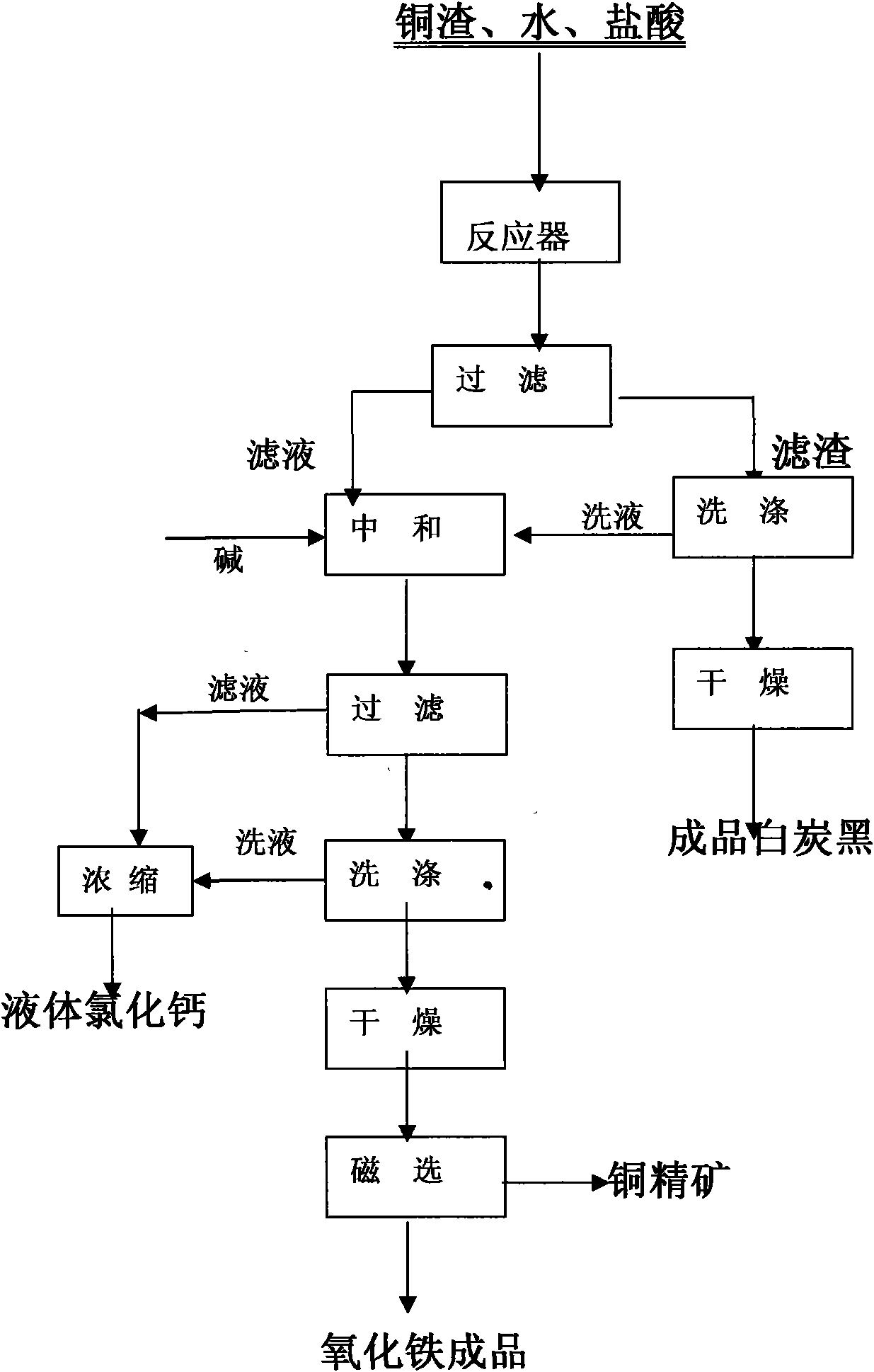

Method for comprehensively recovering Fe, Cu and Si from copper smelting slag

InactiveCN101555551AImprove resource utilizationImprove product added valueSilicaCalcium/strontium/barium chloridesSilicon dioxideMaterials science

The invention discloses a method for comprehensively recovering iron, copper and silicon dioxide from copper smelting slag. The method takes copper smelting slag as a raw material, and comprehensively recovers Fe, Cu and Si in copper slag by adopting wet chemistry metallurgical technology. A muriatic acid and an inorganic acid are mainly adopted for leaching the copper smelting slag, the leaching acid concentration, the solid to liquid ratio, the leaching temperature and the leaching time are selected according to the quality requirement of silicon dioxide products under certain conditions, and silicon dioxide is firstly separated through filtering and drying to prepare silica pigment; the leaching filtered liquid is counteracted, settled, filtered, dried and ground, and ferric oxide phase and copper-bearing phase are selectively separated by adopting a conventional mineral processing method.

Owner:KUNMING UNIV OF SCI & TECH

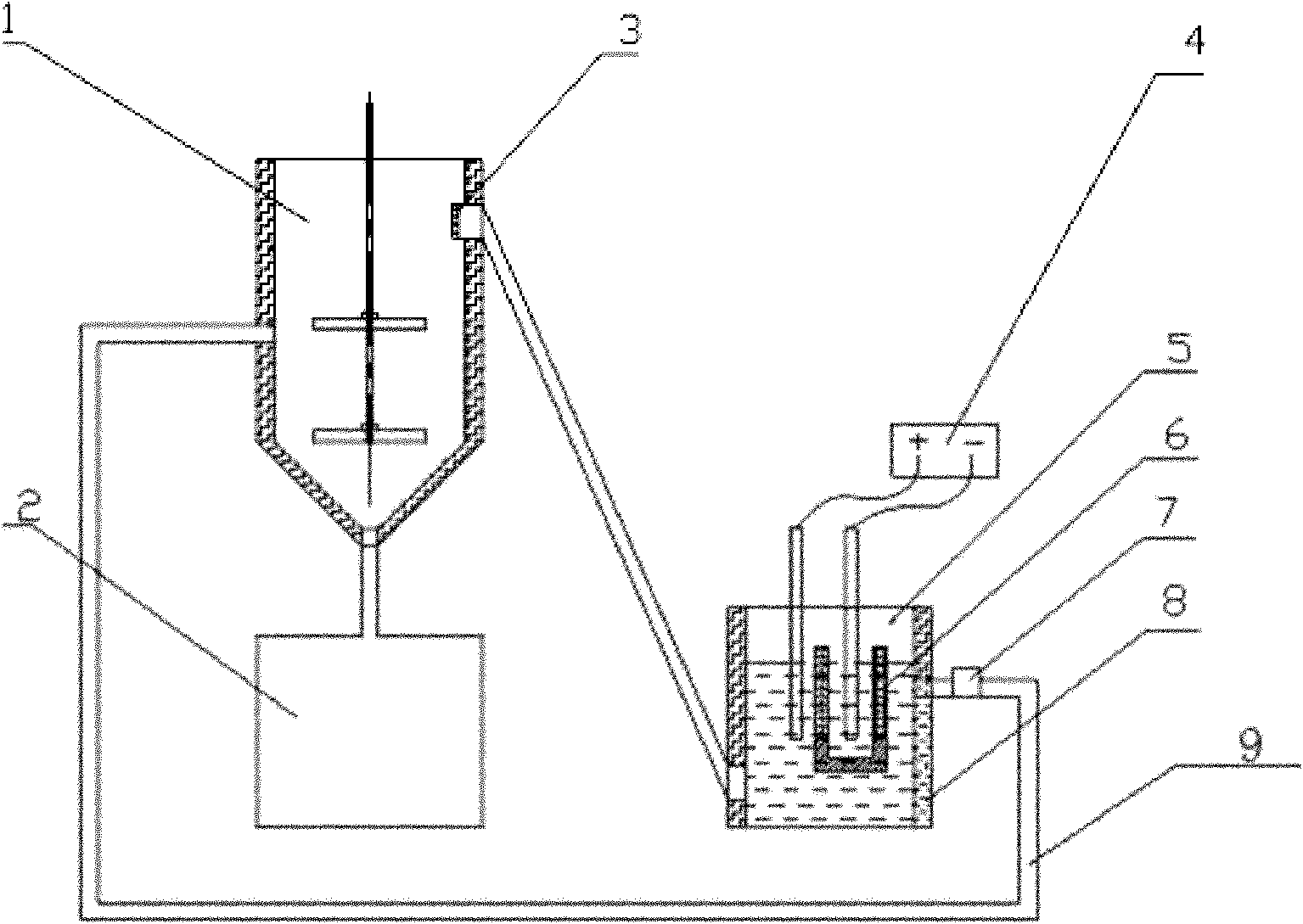

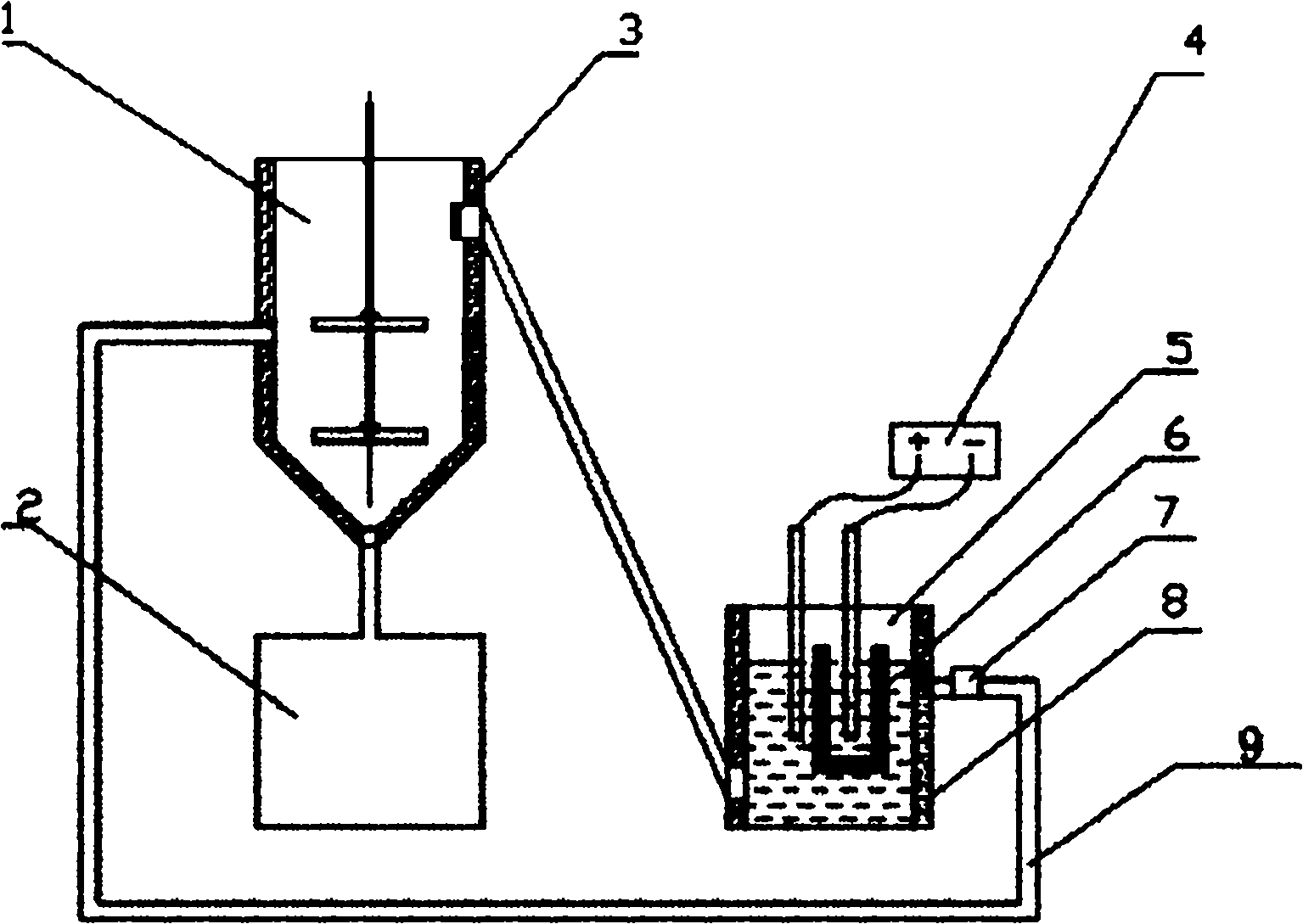

Method and device for recovering metallic lead from lead plaster of waste lead-acid storage battery

ActiveCN102031380AHigh concentrationConcentration unchangedPhotography auxillary processesProcess efficiency improvementLead dioxideSlag

The invention belongs to recovery treatment on lead plaster of a waste lead-acid storage battery. The method comprises the following steps of: mixing the lead plaster of the waste lead-acid storage battery with waste sulfuric acid in the waste lead-acid storage battery according to the design requirement and roasting; adding roasting sand in a stirring kettle; adding tap water to a water level line of the device and stirring the roasting sand; adding a proper amount of calcium acetate, acetic acid and nitric acid; starting a solution circulating system pump, leaching out the roasting sand and maintaining the concentration of lead acetate to be saturated; adding a proper amount of bone glue and beta-naphthol, electrolyzing immersion liquid, recovering the metallic lead at the cathode and recovering lead dioxide at the anode; press filtering residues to obtain lead-off slag and filtrate; and adding calcium carbonate in the filtrate and recycling. The device mainly comprises a leaching part, a press filtration part, a circulating part and an electrolysis part, and concretely includes eight key components of the stirring kettle, a press filter, an overflow port, an electrolysis direct current power supply, an electrolytic cell, a cathode titanium basket, a corrosion resistant pump and a heating element.

Owner:北京绿色引领环保科技研究院有限公司

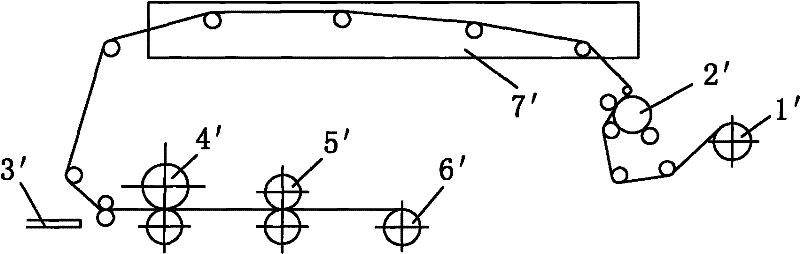

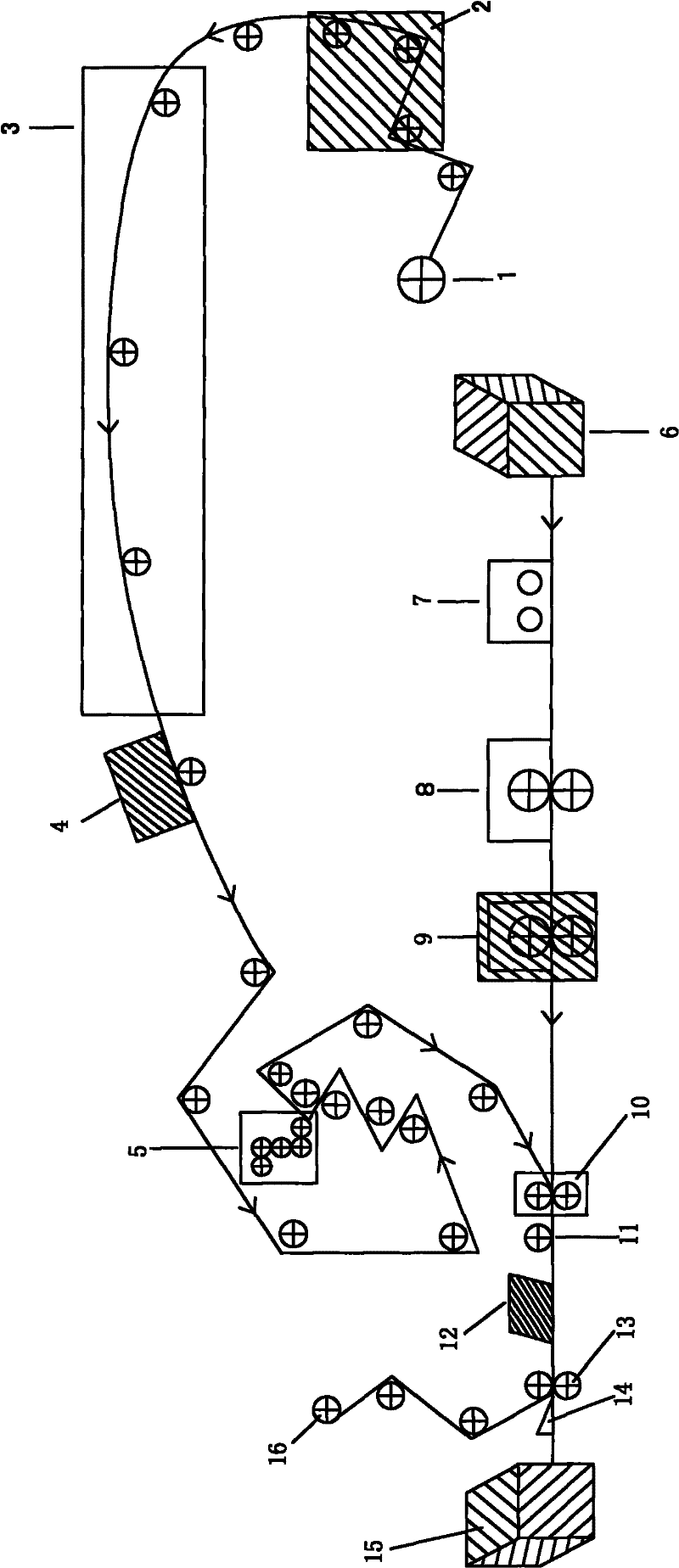

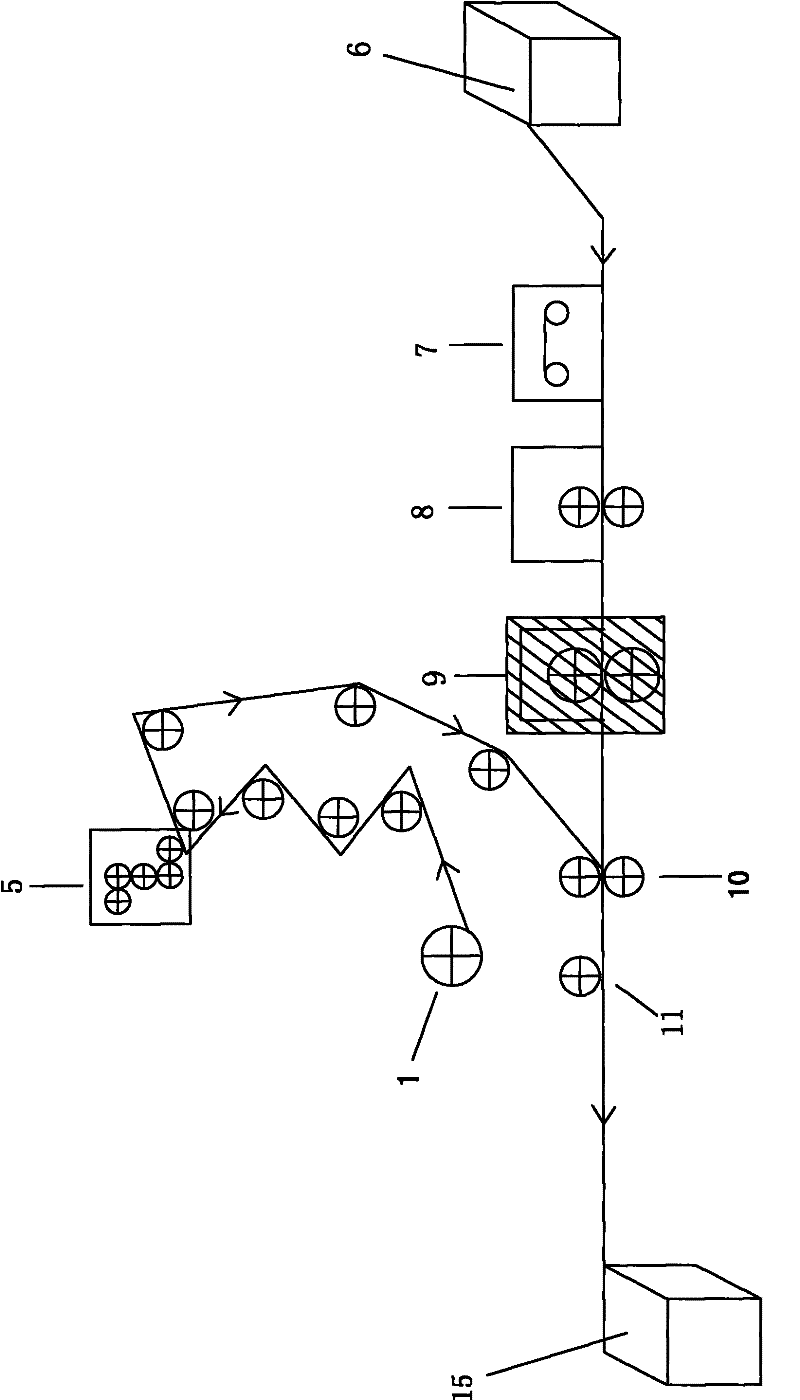

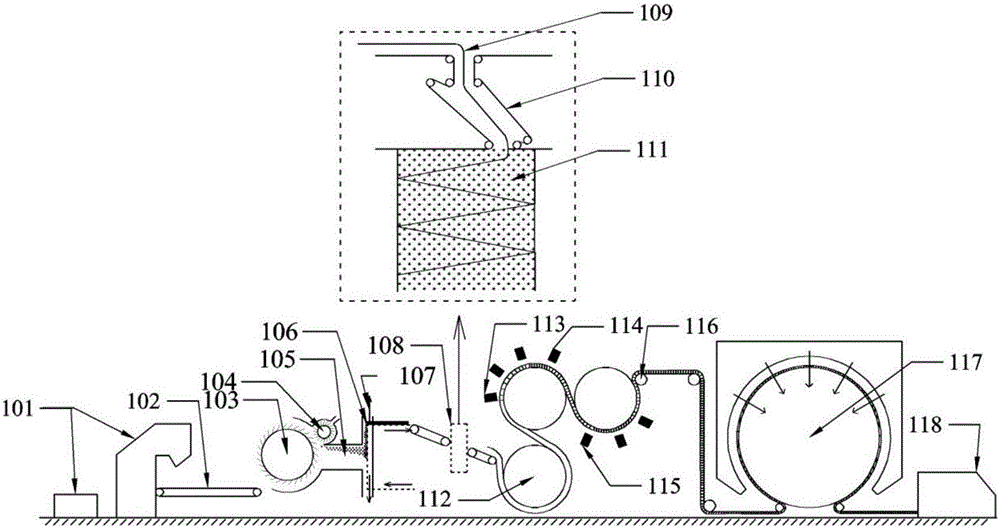

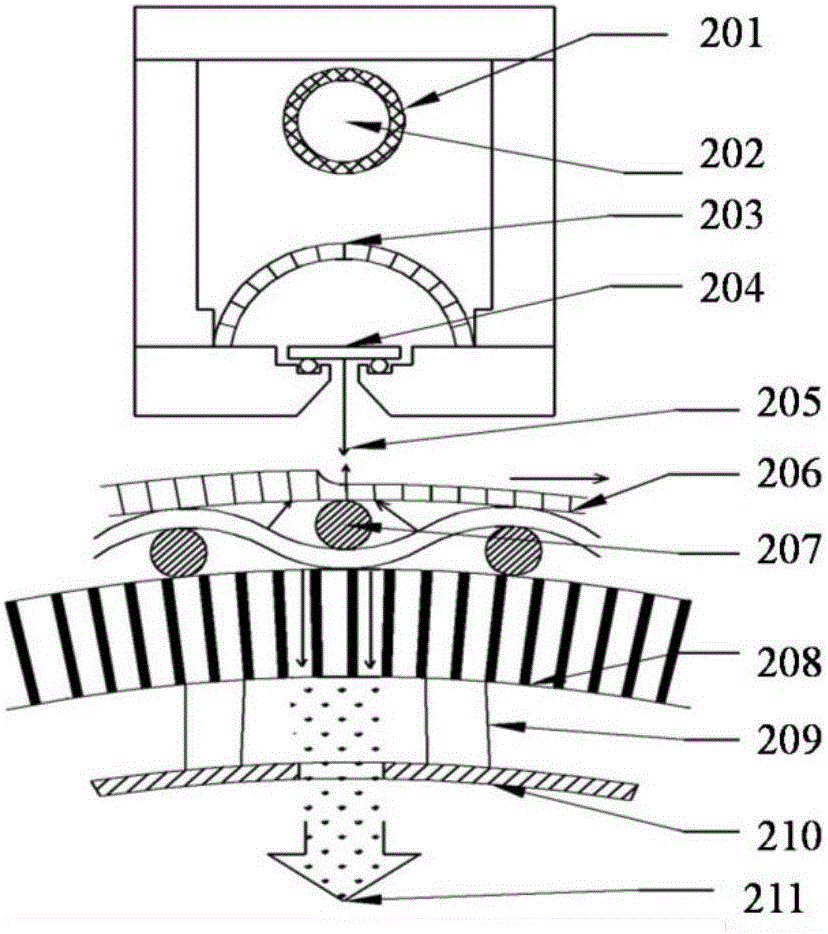

Control system and method for printing paper or coating film

InactiveCN102173193ASimplify operating proceduresImprove processing efficiencyRotary pressesPrinting press partsControl systemEngineering

The invention discloses a control system and a control method for printing paper or coating a film. The control system at least comprises a film unreeling device, a film gluing unit, a single-sheet unreeling device, a compounding unit, a film cutting device and a single-sheet delivery device. The control method at least comprises steps of feeding, gluing, compounding and reeling. The film coating, a film surface secondary pressing process, curing and cold foiling, and a laser transfer process are integrated, the operating procedures are simplified, the technological processing efficiency is improved, the additional value of a product is improved, a compound transfer process can be completed, the transferred film can be recycled, the cost is saved and the environment is protected.

Owner:东莞市博森印刷器材有限公司

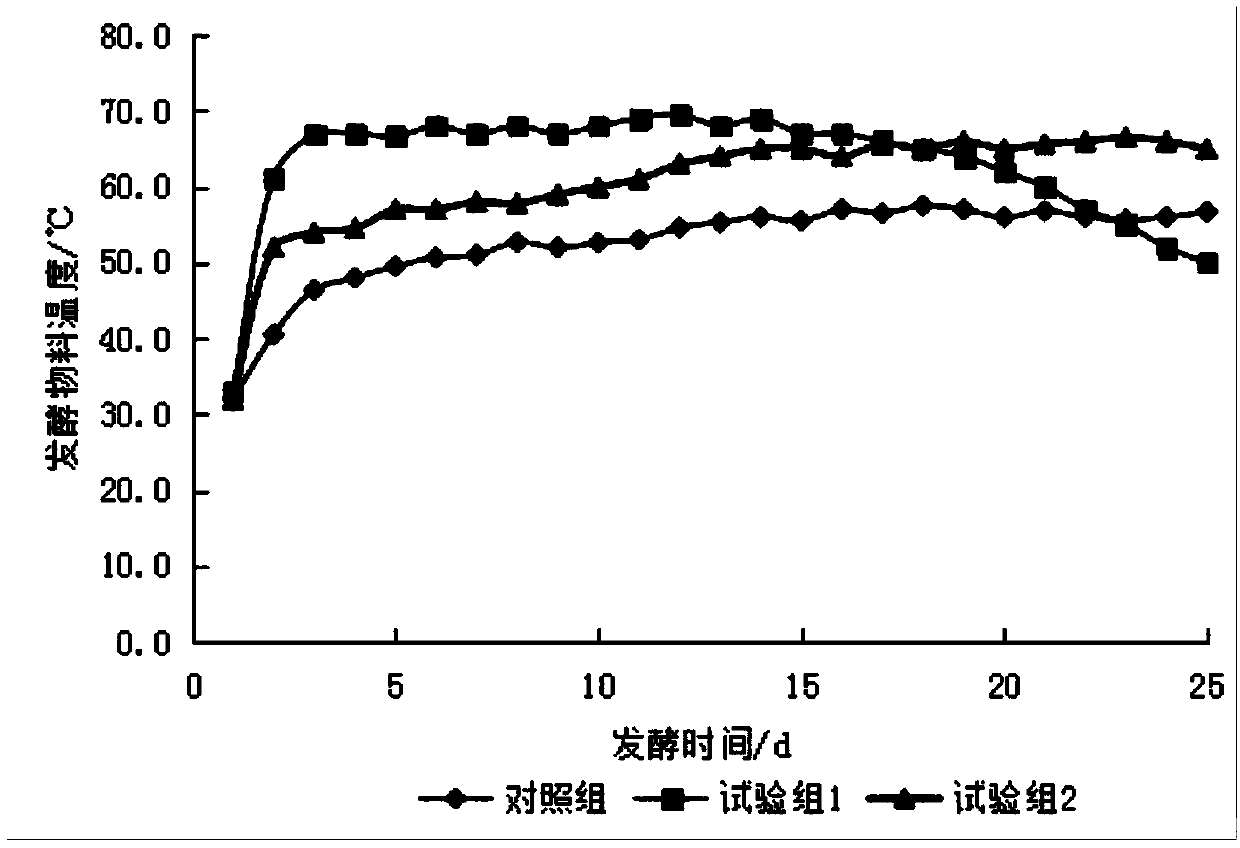

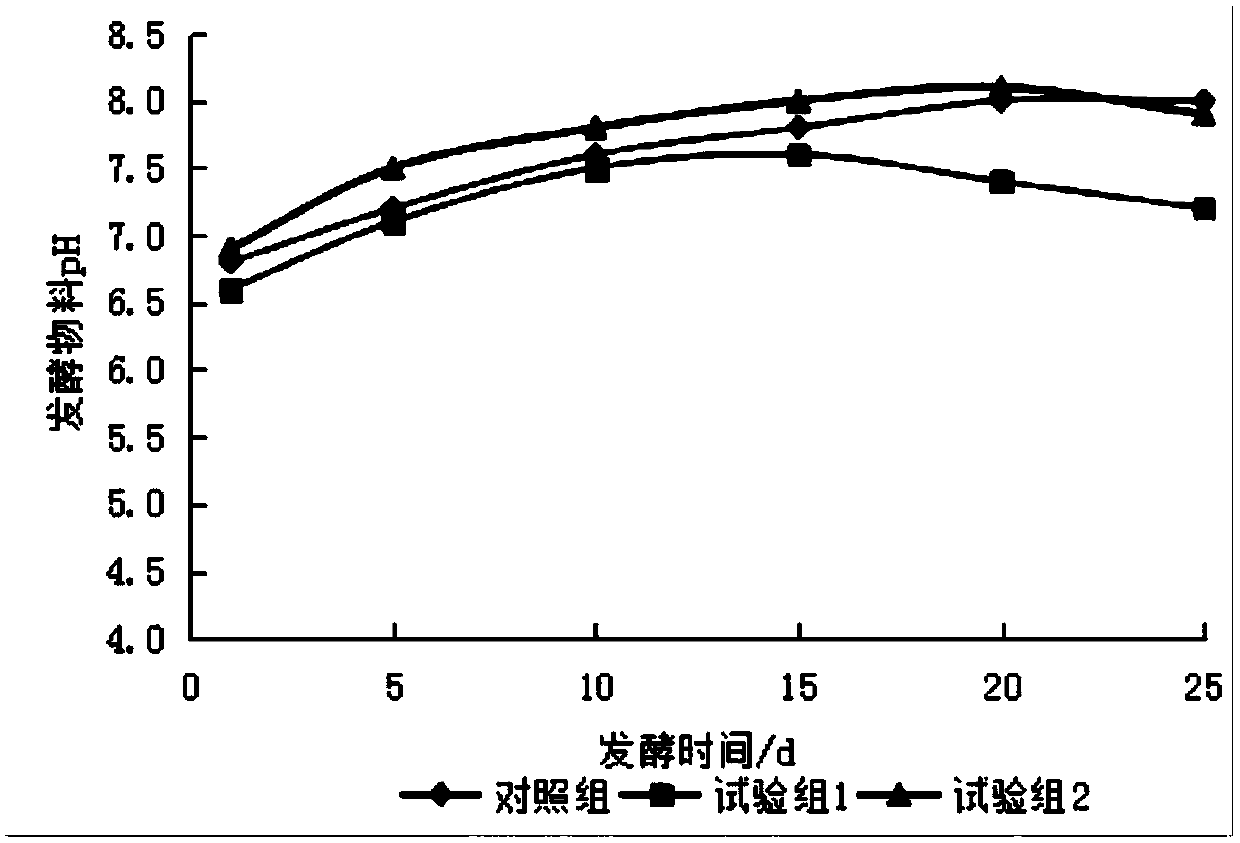

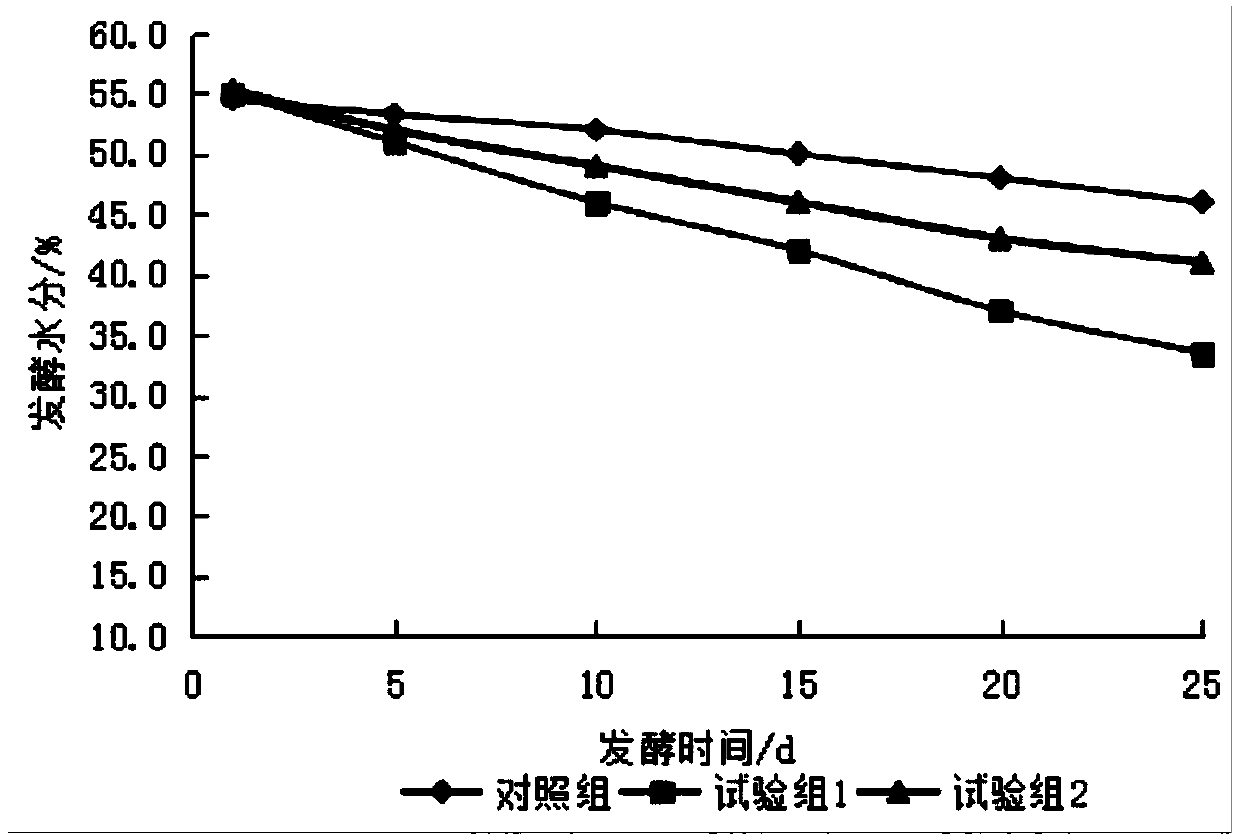

Livestock and poultry feces organic fertilizer fermentation compound functional package and preparation method and application thereof

InactiveCN109516845AKill pests and diseasesDegradation of antibiotic residuesBio-organic fraction processingExcrement fertilisersHydroxycitric acidHumic acid

The invention discloses a livestock and poultry feces organic fertilizer fermentation compound functional package, which comprises a compound functional package A and / or a compound functional packageB. The compound functional package A comprises a compound microbial agent, a compound enzyme preparation, humic acid, white spirit vinasse powder and zeolite powder; the compound functional package Bcomprises isomaltooligosaccharide, molasses meal, monopotassium phosphate, magnesium sulfate, ferrous bisglycinate, manganese bisglycinate, bamboo vinegar powder and citric acid. The package A and thepackage B are combined, the fermentation speed can be greatly increased, quick heating deodorization and thorough decomposition can also be achieved in the low-temperature season, diseases and insect pests and antibiotic residues can be effectively removed, the quality is stable, the quality guarantee period is long, and practicability is high. The invention further discloses a preparation method and application of the compound functional package, the compound functional package is used for livestock and poultry feces organic fertilizer fermentation, the harmless treatment efficiency is high, resource utilization is high, an obtained organic fertilizer product is high in functionality and comprehensive in nutrition, and has no toxicity, stink, harm and pollution, and the organic fertilizer use standard requirement is met.

Owner:湖南润丰达生态环境科技有限公司 +1

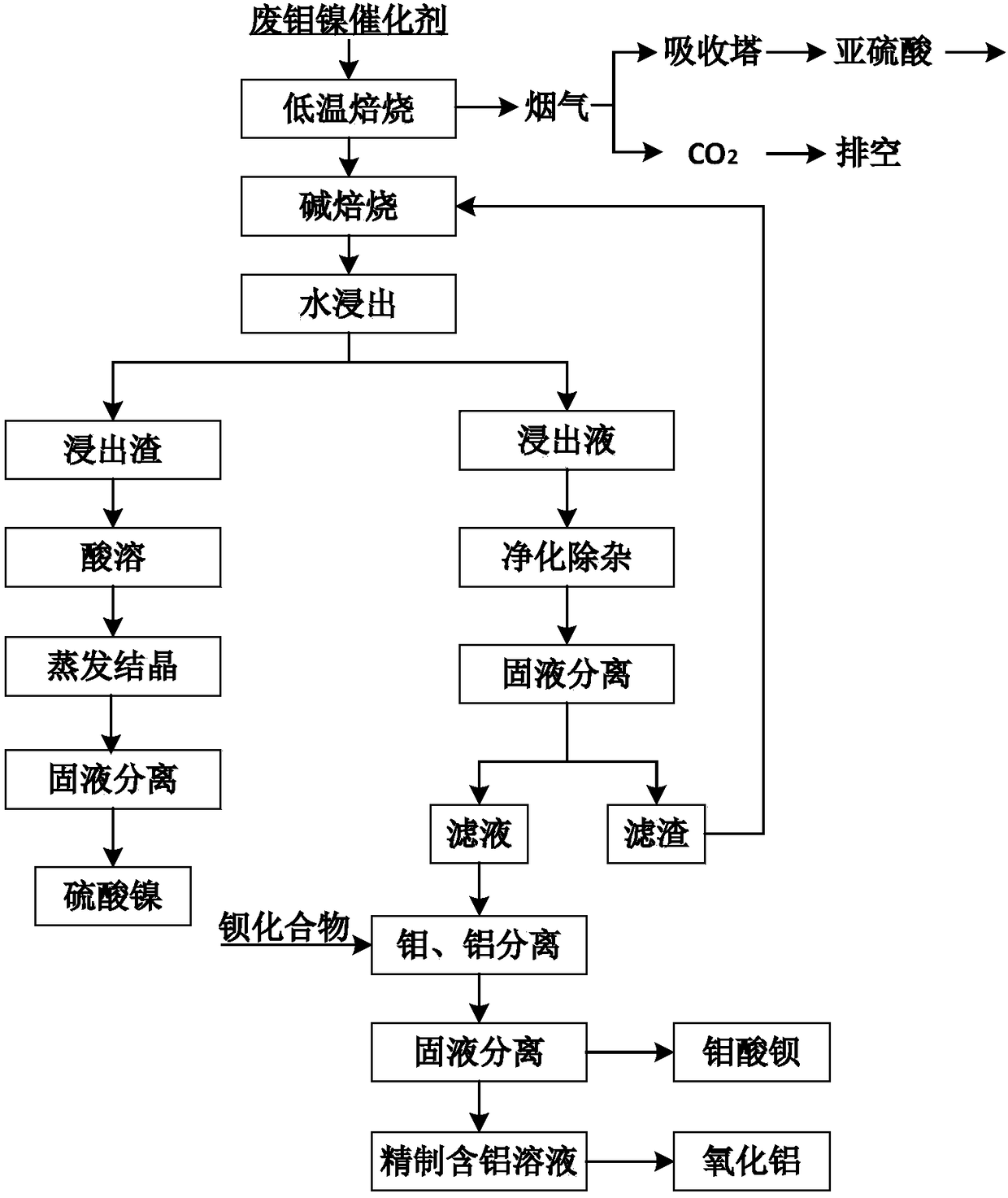

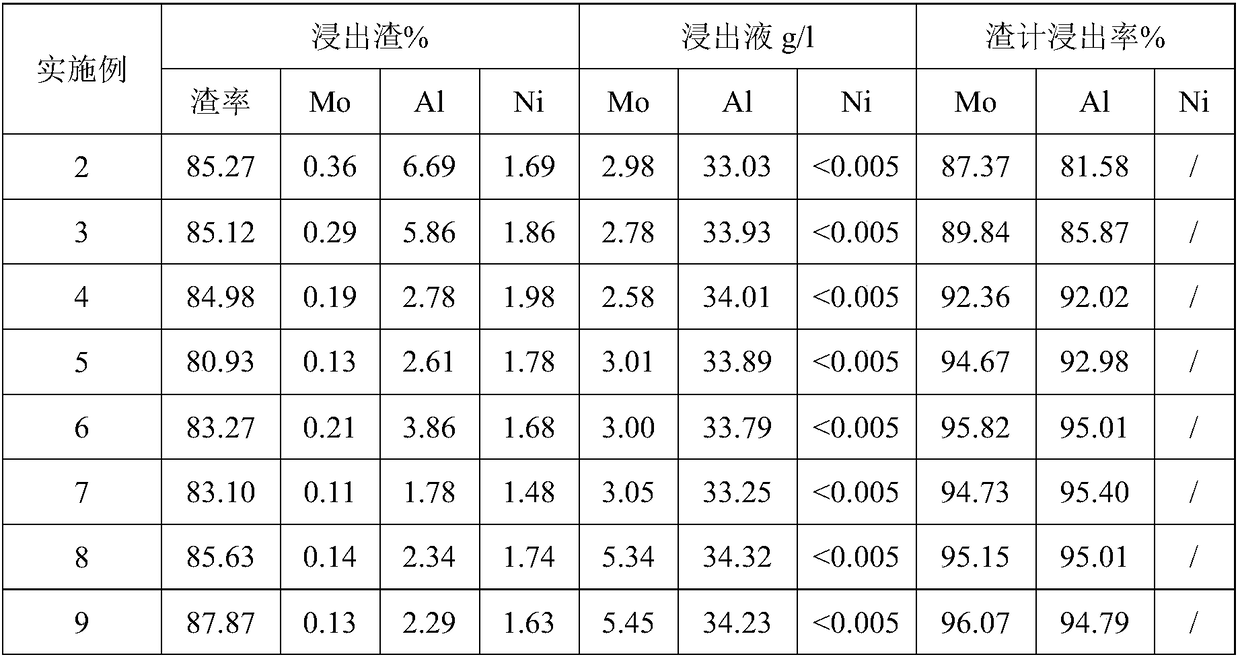

Method for recovering nickel and molybdenum from waste nickel-molybdenum catalyst

The invention discloses a method for recovering nickel and molybdenum from a waste nickel-molybdenum catalyst. The method comprises the concrete steps of firstly carrying out primary low-temperature roasting, then carrying out secondary high-temperature alkali roasting, and transforming molybdenum and aluminum components in the waste catalyst into water-soluble sodium molybdate and sodium metaaluminate; then carrying out water leaching and solid-liquid separation to obtain a nickel slag and an alkaline filter liquor containing molybdenum and aluminum; carrying out acid leaching, evaporative crystallization and solid-liquid separation on the nickel slag to obtain a nickel sulfate product; and adding a barium salt precipitant into the filter liquor to separate the aluminum and the molybdenum, obtaining a refined aluminum-containing solution, adopting a chemical precipitation method to obtain an aluminum hydroxide precipitate, and calcining to obtain an aluminum oxide product. According to the method for recovering the nickel and the molybdenum from the waste nickel-molybdenum catalyst provided by the invention, valuable metals in the catalyst is comprehensively recycled, three products such as nickel sulfate, barium molybdate and aluminum oxide are obtained, the valuable metal recovery rate is high, the product added value is high, and the method has a certain application value.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST +1

Waste Ni-Co-Mn lithium manganate positive electrode material recycling method

ActiveCN108539309APrevent oxidationHigh recovery rateCell electrodesWaste accumulators reclaimingAluminium hydroxideManganese

The invention discloses a waste Ni-Co-Mn lithium manganate positive electrode material recycling method. The waste Ni-Co-Mn lithium manganate positive electrode material recycling method comprises dismantling waste Ni-Co-Mn lithium manganate batteries, crushing positive electrode sheets, sieving and reducing crushed materials through hydrogen in a reducing furnace; washing reduced materials in hotpurified water to obtain washing solution and washed residues, inletting carbon dioxide into the washing solution to obtain lithium hydrogen carbonate solution and aluminum hydroxide precipitates, calcining the aluminum hydroxide precipitates to obtain ultrafine aluminum oxide, and pyrolyzing the lithium hydrogen carbonate solution to obtain battery-level lithium carbonate; adding the washed residues into hydrazine hydrate solution, then adding and stirring in sodium hydroxide for reaction, filtering the mixture to obtain a second filter liquor and second filtered residues, vacuum-drying thesecond filtered residues inside a vacuum drying oven, screening and magnetically-separating dried materials to obtain Ni-Co-Mn ternary alloy powder, or directly dissolving the dried materials in acidto obtain Ni-Co-Mn ternary mixed solution. The waste Ni-Co-Mn lithium manganate positive electrode material recycling method is low in cost, capable of achieving separation and recycling of all components, and high in recycling rate and value added of products.

Owner:中锂能新能源科技(烟台)有限公司

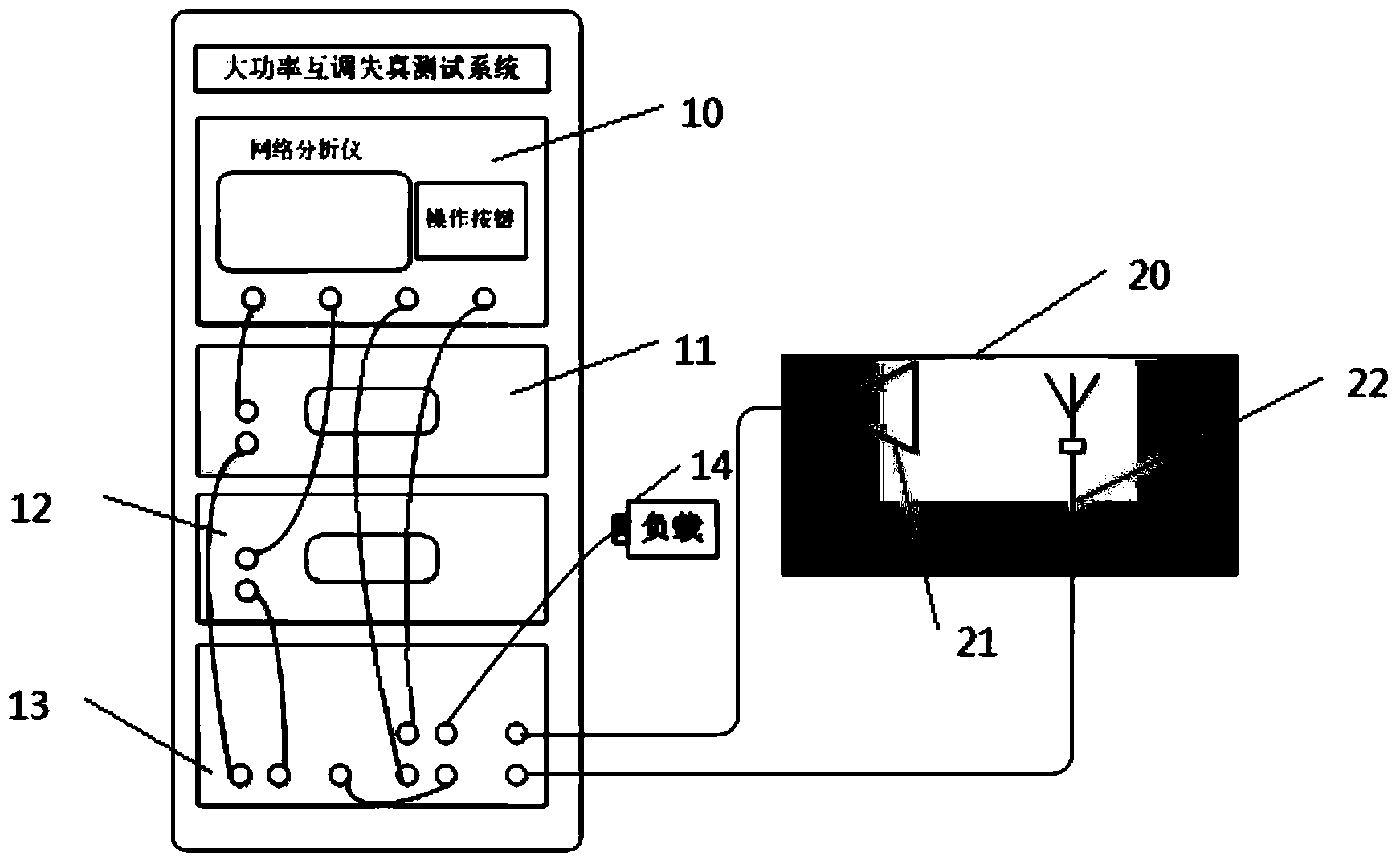

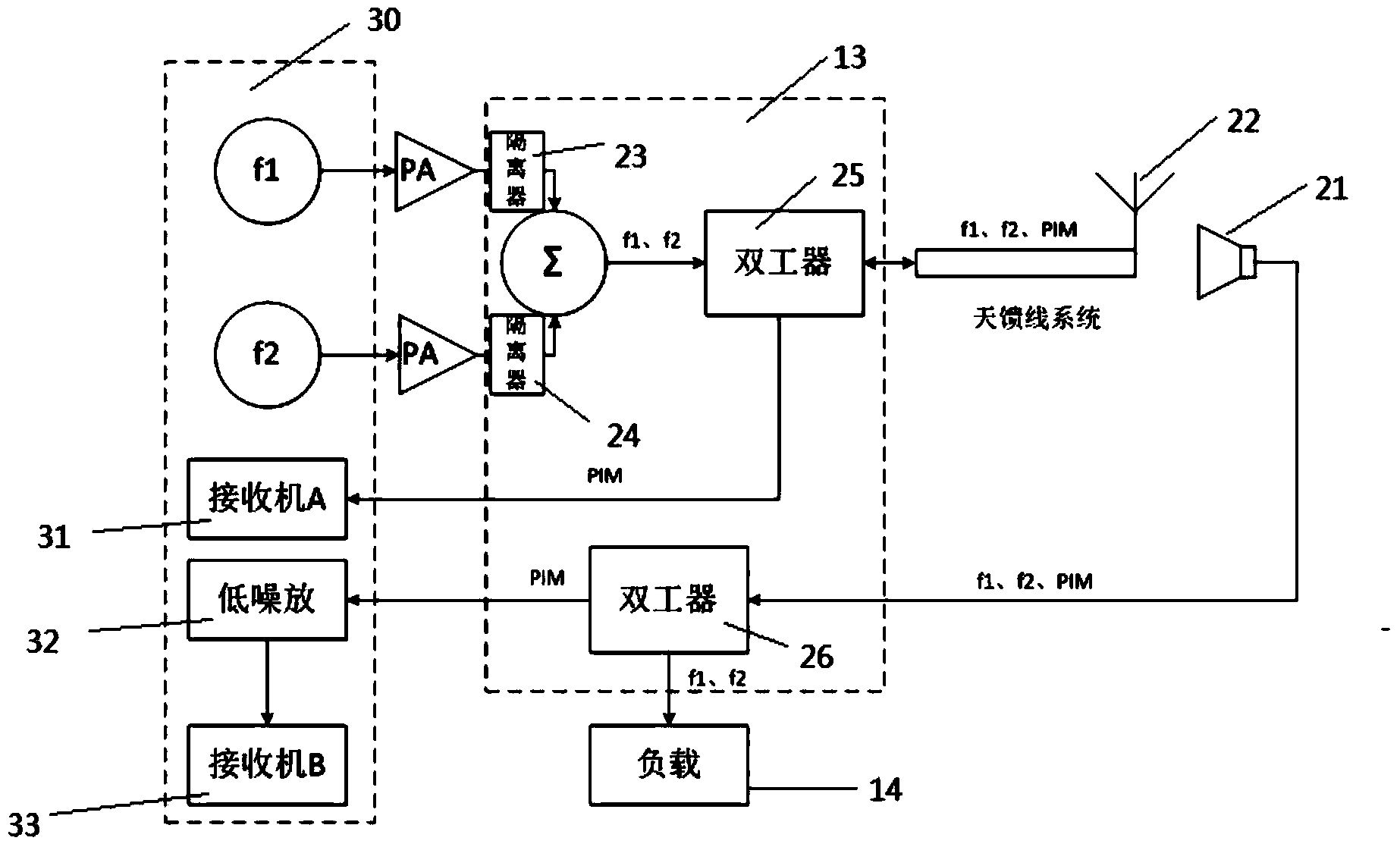

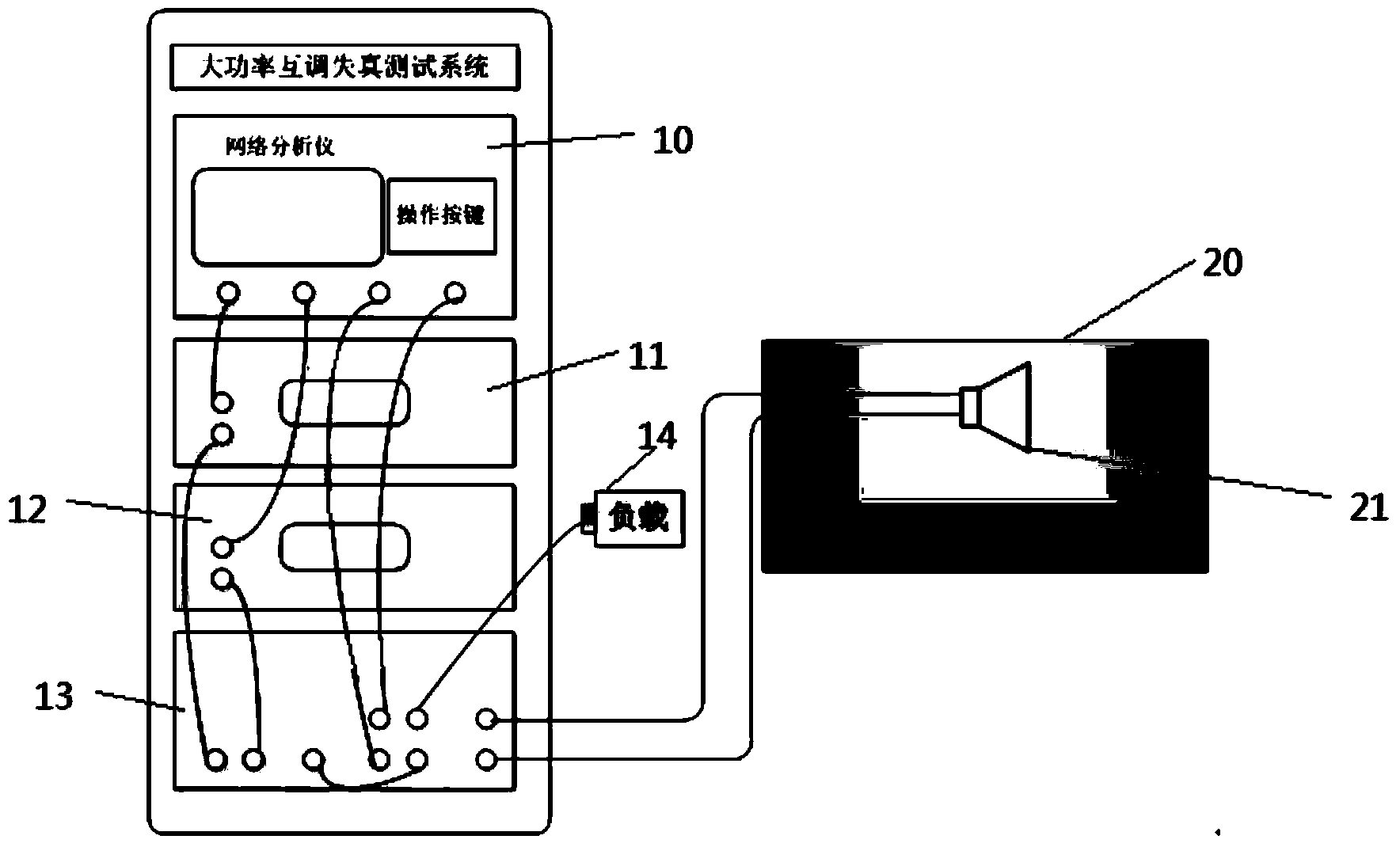

Intermodulation distortion testing method of high-power device

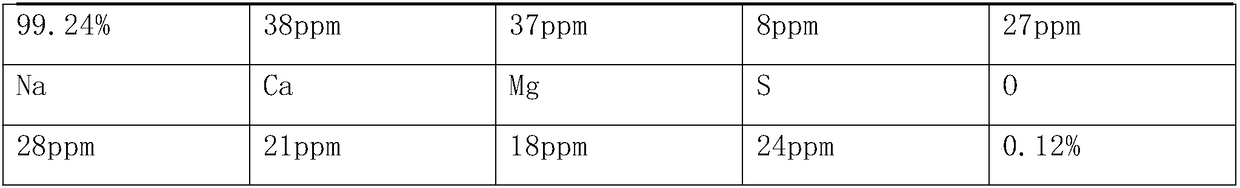

ActiveCN103684638AImprove product added valueLow costTransmitters monitoringReceivers monitoringAudio power amplifierMicrowave

The invention provides an intermodulation distortion testing method of a high-power device. The intermodulation distortion testing method of the high-power device comprises the steps that (1) a testing device, a first power amplifier, a second power amplifier and a network analyzer are connected with a tested part, (2) passive intermodulation or active intermodulation of the tested part is tested, (3) the network analyzer displays the intermodulation testing result, when passive intermodulation is carried out, a transmission PIM test result and an emission PIM test result are displayed at the same time, and when active intermodulation is carried out, the dual-tone signal power and the IM power of a tested amplifier are displayed at the same time. According to the scheme, a system formed by a device can be used for measuring the passive intermodulation characteristics of passive microwave device components, antennas and antenna feeder systems, and the active intermodulation characteristics of high-power amplifiers, and complete intermodulation distortion testing is provided for a communication system.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

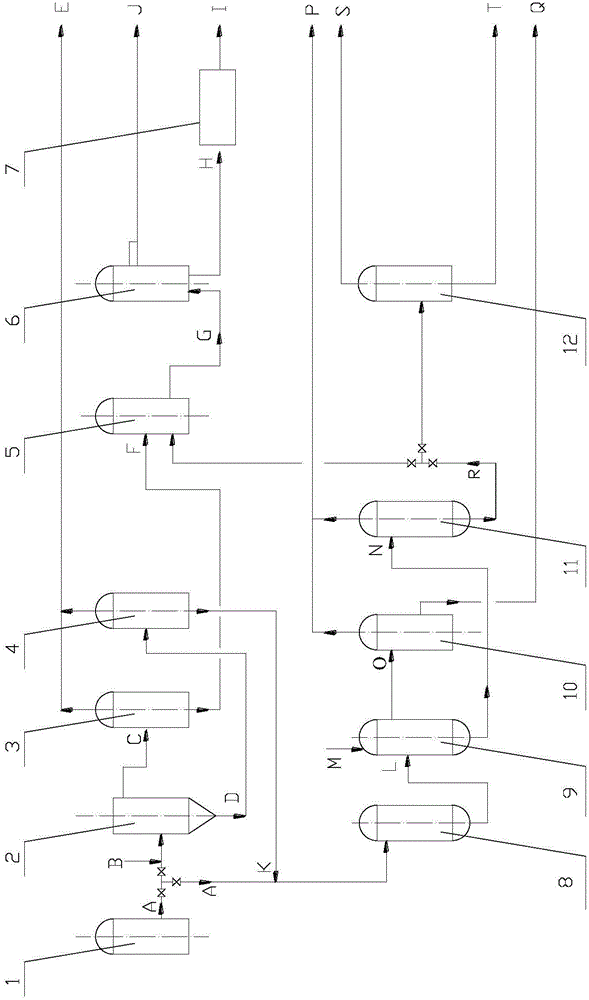

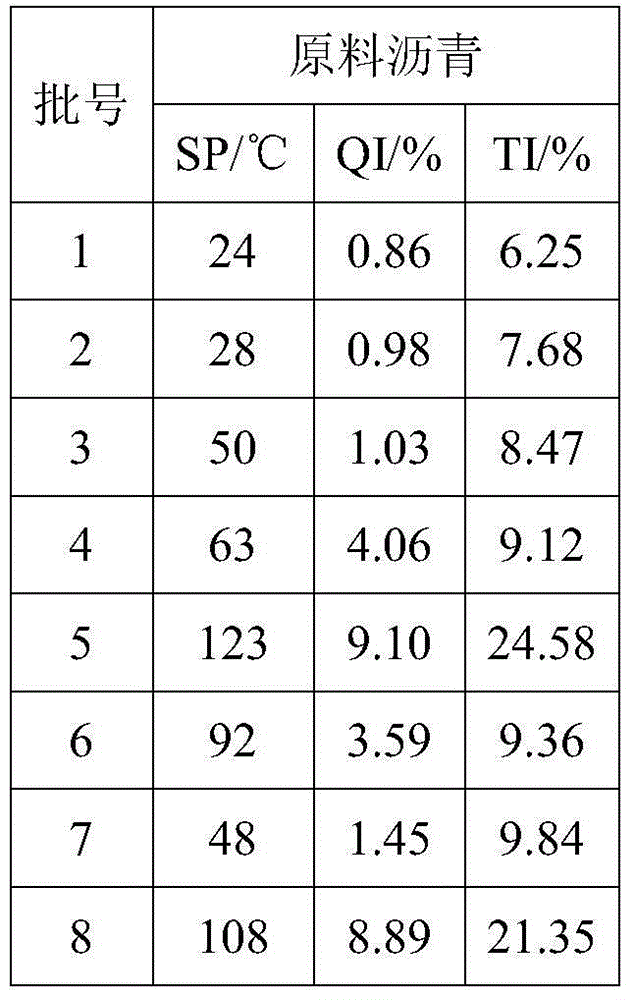

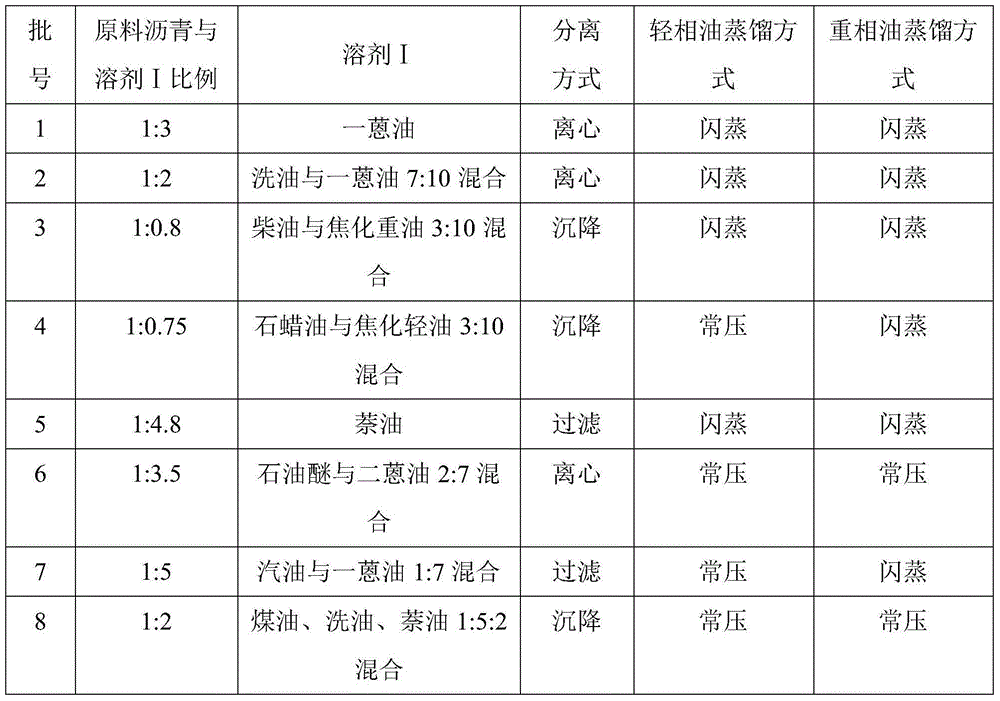

Co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt

ActiveCN104650938AHigh degree of processingLow costWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionMicrosphereEconomic benefits

The invention relates to a co-production technique of needle coke, mesocarbon microbeads and high-quality asphalt; heavy phase asphalt generated by raw material asphalt pre-treatment and raw material asphalt are mixed to produce mesocarbon microbeads, the byproduct asphalt of the production of misocarbon microbeads and the refined asphalt obtained by the raw material asphalt pre-treatment are mixed as a needle coke raw material; the technique comprises the steps of raw material asphalt pre-treatment, polymerization, polymerization product separating and drying, byproduct asphalt processing, coking and sintering. Compared with the prior art, the technique related by the invention has the following beneficial effects: (1) the coal tar asphalt processing degree is high, the cost is low, the varieties are diversified, the added value of the product is high, and the maximal economic benefit is realized; (2) the waste discharge is avoided during the whole production process, and the optimal environmental benefit is realized; (3) the process is flexible, the operation is simple, and the high-efficiency combination of needle coke, mesocarbon microbeads and high-quality asphalt is realized; and (4) the product index is flexible and adjustable, so as to adapt to market variations in time and improve the market risk resisting capability of an enterprise.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Process for preparing water transfer printing film

InactiveCN101695891AAvoid imprintingImprove product added valueDecorative surface effectsSputteringPolyvinyl alcohol

The invention relates to a process for preparing a water transfer printing film, which is mainly used for surface coating of workpieces. The process comprises the following steps: 1) preparing a polyvinyl alcohol film; 2) printing various patterns on the polyvinyl alcohol film, and adding a layer of bonding agent; 3) pressing logic grains on the polyvinyl alcohol film printed with the various patterns, or radiating laser film grains on the polyvinyl alcohol film in order to generate grains; 4) performing vacuum plating or sputtering on the polyvinyl alcohol film with the grains to generate metallic luster; 5) placing the polyvinyl alcohol film after the vacuum plating or sputtering on water surface, and letting a surface not printed with the pattern layer to contact the water surface; 6) spraying or coating a reducing agent on the printed surface, reducing the printed solid surface into a liquid surface, pressing a workpiece into the liquid surface from the top down, and transferring the patterns to the surface of a product through the water pressure; and 7) cleaning residues, drying, and spraying a finish paint to form a layer of transparent protective coating. The preparation process is simple and has low cost.

Owner:东莞市西迪艾史纳米科技有限公司

Ceramic ink with sinking effect and preparation method thereof

The invention discloses ceramic ink with a sinking effect and a preparation method thereof. The ceramic ink comprises sinking glaze and an organic composition; the organic composition comprises resin, a disperse agent, a defoamer and a solvent; the sinking glaze comprises V2O5, Bi2O3, Ba2CO3, ZnO, SiO2, Al2O3, K2O and Na2O. The ceramic ink with the sinking effect is low in viscosity, controllable, uniform in particle size distribution and excellent in quality stability and ink-jet printing performance, and can show concave-convex vivid texture and strong third dimension of a ceramic tile in a more sufficient and visual manner when being matched with pigment ink for ceramic ink-jet printing to further improve the decorative effect and the added value of the ceramic tile. According to the ceramic ink with the sinking effect, the preparation method is simple and efficient, the controllability is excellent, and the industrial mass production is applicable.

Owner:FOSHAN DOWSTONG TECH

Preparation method and use of aqueous polymer/isocyanate adhesive

InactiveCN101948669AHigh bonding strengthLow costMacromolecular adhesive additivesWater basedPolymer science

The invention relates to a preparation method and use of an aqueous polymer / isocyanate adhesive, which belong to the technical field of chemical adhesives. In the invention, recycled polyethylene terephthalate (PET), diethanol amine, caprolactam and aqueous solution of glacial acetic acid are used to prepare a PET water-based polymer; toluene diisocynate and castor oil are used to prepare an isocyanate-terminated polyurethane prepolymer; and when used, PET aqueous polymer emulsion and the isocyanate-terminated polyurethane prepolymer are mixed at room temperature to obtain the aqueous polymer / isocyanate adhesive. The aqueous polymer / isocyanate adhesive is used for adhering wood.

Owner:UNIV OF JINAN

Heat-conducting insulating composite material and preparation method thereof

ActiveCN103738022AHigh densityReduce weightSynthetic resin layered productsRough surfaceHeat conducting

The invention provides a heat-conducting insulating composite material and a preparation method of the heat-conducting insulating composite material. The composite material sequentially comprises a conduction layer and a heat dissipation layer according to the distance between the layers and a heat source from the near to the distant, wherein one side of the heat-conducting insulating composite material is a smooth surface, and the other side of the heat-conducting insulating composite material is a rough surface; the smooth surface is used for receiving a heat source, the thermal contact resistance can be greatly reduced through the smooth surface, and the heat energy can be well and rapidly absorbed; the rough surface is a heat dissipation surface and has a honeycomb porous structure, a far infrared radiation coefficient can be improved, convection is accelerated, and the heat dissipation capacity of the material is improved. The heat conductivity coefficient of the composite material can be 8-20W / m.k, the far infrared radiation coefficient can be over 0.9, the composite material has high heat-conducting performance, and the inherent good processability and insulating property are kept.

Owner:深圳市上欧新材料有限公司

Preparing technique of lactic acid bacteria zymolysis squash and its products

InactiveCN101161090ARealize comprehensive utilizationImprove product added valueConfectionerySweetmeatsLactic acid fermentationFlavor

The present invention discloses a preparing technics for lactobacillus ferment cushaw as well as its product. With cushaw as main material, to composite lactobacillus ferment agent through manpower inoculation, then to perment under the condition of non-oxygen, middle temperature and slow speed, after perment to prepare lactobacillus perment cushaw dried meat, cushaw catsup and cushaw drink three products. The perment product keeps the connatural nutrition components of cushaw, has the special nutrition and flavor of lactobacillus perment cushaw, sourness is gentleness, aroma is purity, without any essence, pigment and antiseptic, is a new type savageness cushaw perment product. The present invention provides a new technics for using cushaw, and adds a new variety for lactobacillus perment product and is convenient to produce with industrialization.

Owner:辽宁省农业科学院食品与加工研究所

Preparation method of spun-laced regenerated leather for automotive interior surface

ActiveCN105970657AImprove product added valueMany categoriesNon-woven fabricsWettingCost performance

The invention provides a preparation method of spun-laced regenerated leather for an automotive interior surface. The preparation method comprises the following specific steps: (1) loosening and mixing fibers; (2) forming a net; (3) spreading the net; (4) pre-wetting; (5) spun-lacing; (6) drying; (7) carrying out vacuum plastic-absorption and molding. The requirements on material molding properties and mechanical properties by the automotive interior surface and industrial standards are sufficiently considered at the beginning of designing, and raw material ratios and a production process are reasonably optimized, so that collaboration of design, preparation and molding machining of a composite material is realized. Compared with traditional automotive interior surfaces including polyvinyl chloride, polyurethane and the like, the prepared automotive interior surface has the advantages of greenness and environmental friendliness, no odor, excellent elasticity, moderate strength, comfortable hand feeling, high cost performance and the like and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

Marbled glass ceramics directly employing fusion blast furnace slag and preparation method of marbled glass ceramics

ActiveCN106587634AImprove mechanical propertiesImprove the decorative effectCharging furnaceGlass productionSlagPotassium carbonate

The invention discloses marbled glass ceramics directly employing fusion blast furnace slag and a preparation method of the marbled glass ceramics. The marbled glass ceramics comprises the following raw materials, by mass, 55-75 parts of blast furnace slag flux and 25-45 parts of auxiliary material flux; and auxiliary materials comprise the following components, by mass, 8.5-19.5 parts of quartz sand, 0.5-5.5 parts of limestone, 1-5 parts of sodium carbonate, 2-5 parts of potassium carbonate, 1-4 parts of zinc oxide, 1-4 parts of ammonium di-hydrogen phosphate, 1-2 parts of spodumene, 2.5-5 parts of sodium fluosilicate, 0.5-1.5 parts of sodium fluoroaluminate and 0.5-1 part of borax. The preparation method is characterized in that through controlling the mixed melting temperature and time of the blast furnace slag flux and the auxiliary material flux, a flux mixture is obtained; through forming, annealing and microcrystallization heat treatment, the marbled glass ceramics is obtained. The molten blast furnace slag and the auxiliary materials are mixed in a flux form and the flux mixture having certain micro-inhomogeneity is obtained accurately, then with the combination of subsequent forming and heat treatment technologies and the like, the marbled glass ceramics is obtained, so that the technology is easy to implement, and the influence of uncertainty on a product in a mixing process is reduced.

Owner:WUHAN UNIV OF TECH

Method for directly recovering and producing electrowinning cobalt from waste and old lithium ionic cell

InactiveCN101381817ALow priceHigh recovery ratePhotography auxillary processesProcess efficiency improvementLithiumOrganic solvent

The invention discloses a method for directly recovering and producing electro deposited cobalt from waste lithium ion cells. The method is mainly characterized in that: firstly, the waste lithium ion cells are disassembled and separated to obtain positive plates; secondly, the positive plates are immersed by an organic solvent N-methylformamide (NMP), and aluminum foils and anode materials of a current collector are separated; thirdly, the anode materials which contain lithium cobaltate are leached out by a hydrochloric acid and hydrogen peroxide system, and undissolved substances are filtered and separated; and fourthly, the electro deposited cobalt is obtained after electrodeposition of filtrate. By adoption of the method, the recovery rate of the cobalt in the waste lithium ion cells can be about 97.0 percent, and the purity of the electro deposited cobalt can be more than 99.8 percent.

Owner:GUANGDONG BRUNP RECYCLING TECH +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com