Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1316 results about "Material recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

"Recyclate" is a raw material that is sent to, and processed in a waste recycling plant or materials recovery facility which will be used to form new products.

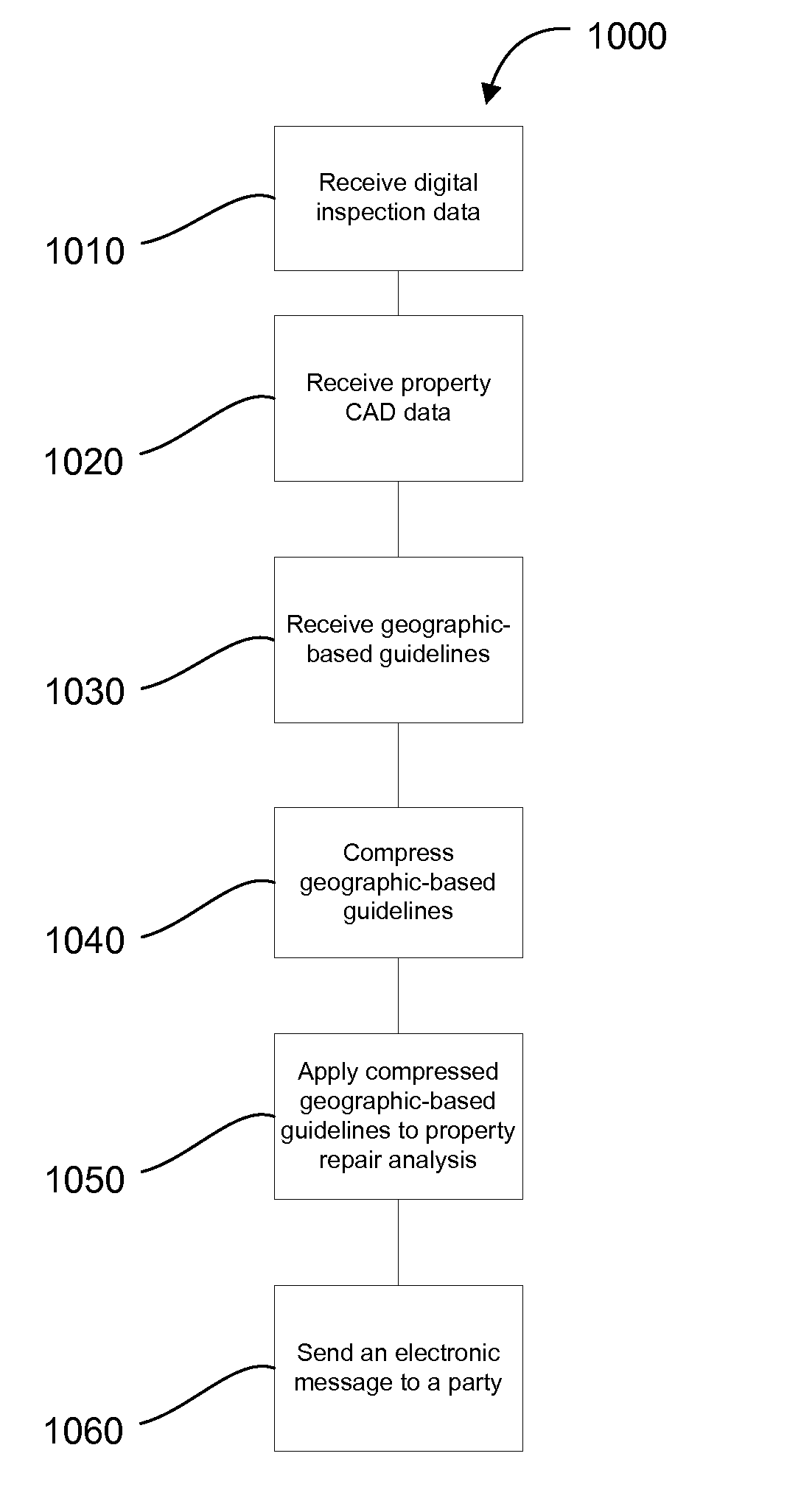

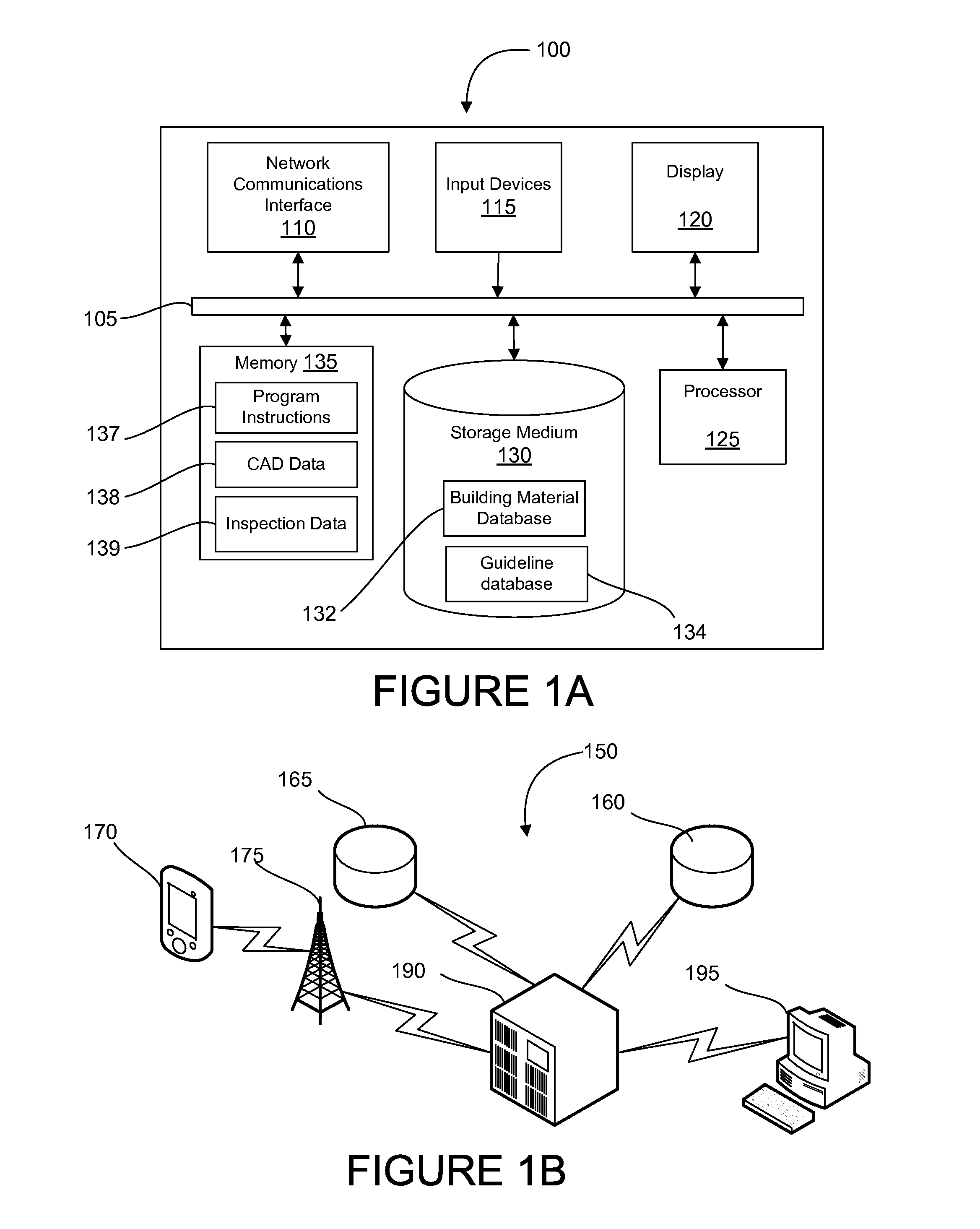

Method and system for property damage analysis

A system and method for intelligently combining CAD, inspection, and building guideline data for intelligently setting roof facet directionality, analyzing repair and replacement decisions and estimating material, material waste and recyclables, material recycling requirements, and repair or replacement costs for building facets is described. One embodiment includes receiving digital inspection data of a building facet of a property; receiving a first layer of geographic-based guideline data; receiving a second layer of geographic-based guideline data; reconciling a conflict between guideline data of the first and second layers of guideline data to reach a resulting guideline data item; determining a repair indicator for the building facet based at least in part on the resulting guideline data item and the digital inspection data; and sending an electronic message, wherein the electronic message includes at least a portion of the digital inspection data and the repair indicator.

Owner:ACCURENCE

Plastic reclamation process

A plastic article or plastic container reclamation process if provided in which plastic containers are divided into relatively large pieces, then washed, agitated and separated using an aqueous solvent to remove residual materials. The residual materials such as motor oil are reclaimed for reuse and the aqueous solvent is regenerated for reuse in the process. Residual materials such as dirt, labels and adhesives from the plastic containers is recovered for recycling or passed to waste for disposal or reuse.

Owner:DOONAN BILLIE ODELL

Systems and methods for sorting, collecting data pertaining to and certifying recyclables at a material recovery facility

Systems and methods for collecting data pertaining to glass, plastic and / or paper composition within an input stream that includes recyclable material. The data collected can pertain, for example, to the weight and / or volume of the glass, plastic and / or paper within the input stream. The data can be certified for use a third party.

Owner:THE CLOROX CO +1

Method for producing materials from recycled glass and cement compositions

InactiveUS20050045069A1High porosityEvenly distributedOther chemical processesSolid waste managementCementitious matrixAlkali–silica reaction

A method of producing material from recycled glass comprising: preparing a mixture of glass in a cementitious matrix, and an alkali-silica reaction suppressant; providing a mold of the material and coating said mold with a release agent; casting said mixture into said mold; curing said mold; and removing the material from said mold. The recycled glass and concrete compositions are: 25-79% by weight glass; 8-35% by weight cement and up to 22% by weight of an alkali-silica reaction suppressant.

Owner:ICESTONE

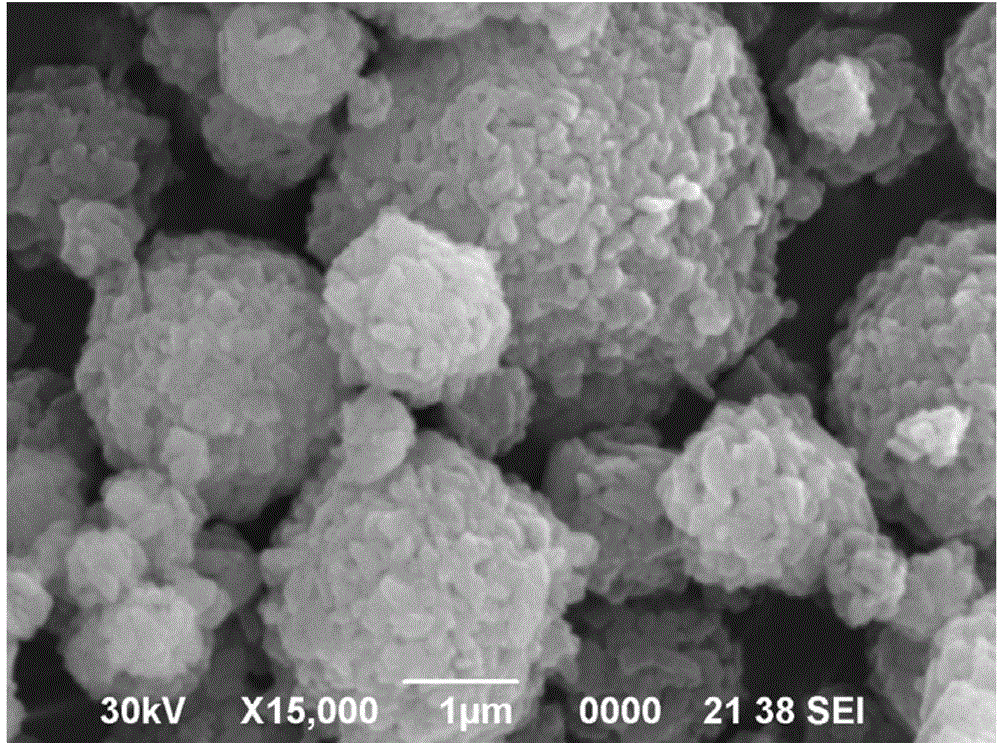

Preparation method of magnetic porous carbon/ ferric oxide nano composite material for oil-water separation

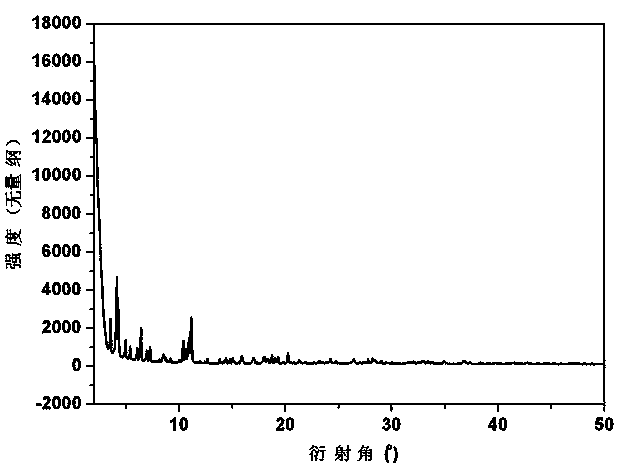

InactiveCN103908947ALarge specific surface areaMacroporous natureOther chemical processesAlkali metal oxides/hydroxidesPorous carbonMetal-organic framework

The invention discloses a preparation method of a magnetic porous carbon / ferric oxide nano composite material for oil-water separation, wherein the magnetic porous carbon / ferric oxide nano composite adsorption material for oil-water separation is porous carbon / Fe3O4 magnetic powder or porous carbon / gamma-Fe2O3 magnetic powder. The preparation method comprises the following steps: firstly, preparing a Fe-MIL-101 or Fe-MIL-100 metal-organic framework material of a porous structure by utilizing a hydrothermal method; then controlling the temperature to be 500-700 DEG C at the N2 / H2 atmosphere or the vacuum state, and forging for 2-8 hours, thereby obtaining the magnetic porous carbon / ferric oxide nano composite adsorption material for oil-water separation. The adsorption material can adsorb oil substances in water well; moreover, adsorption materials dispersed into a solution as well as the adsorbed oil materials can be recycled only by magnets; the preparation method is simple to operate, is low in production cost, is good safety performance, and is high in practicability.

Owner:SHANGHAI INST OF TECH

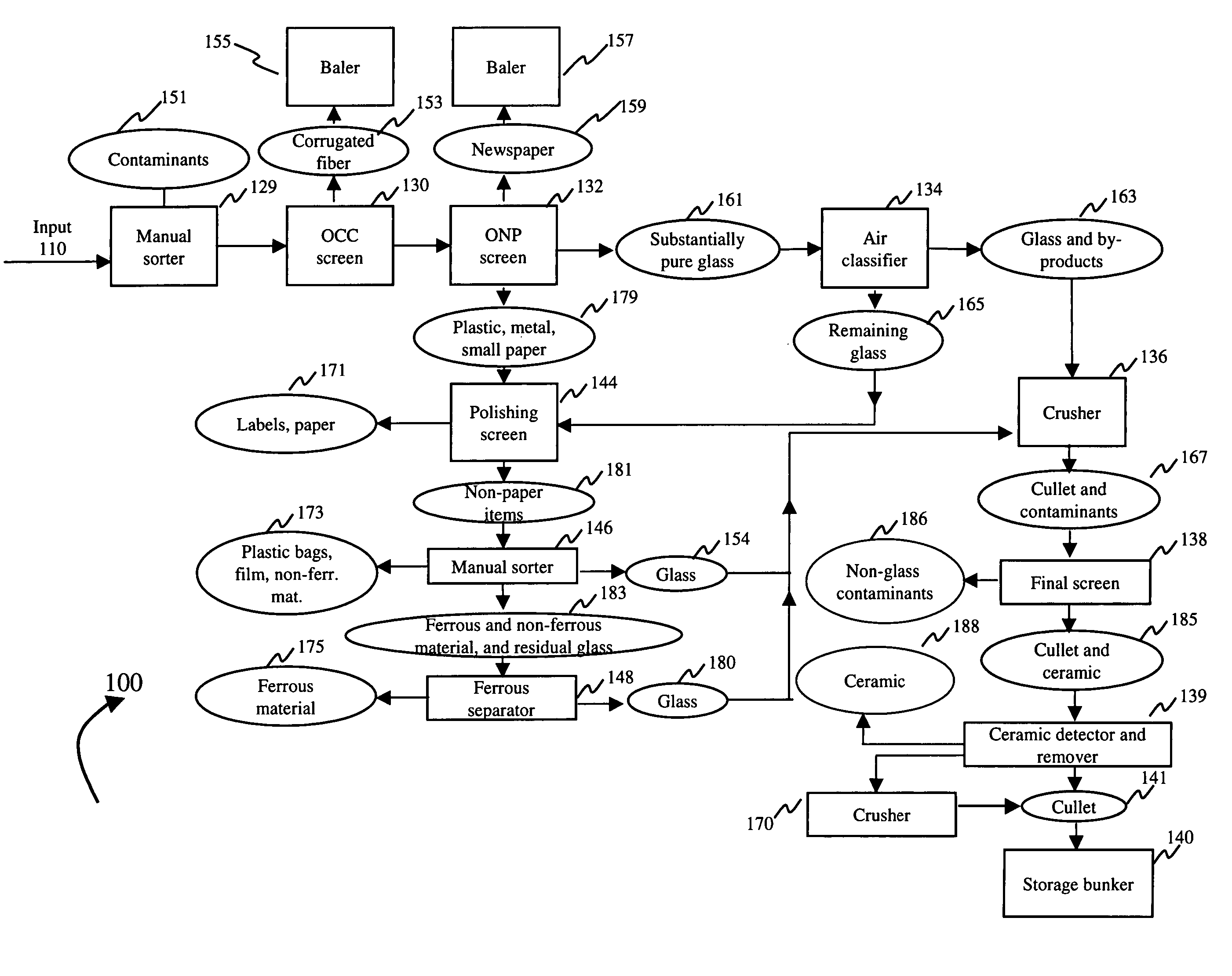

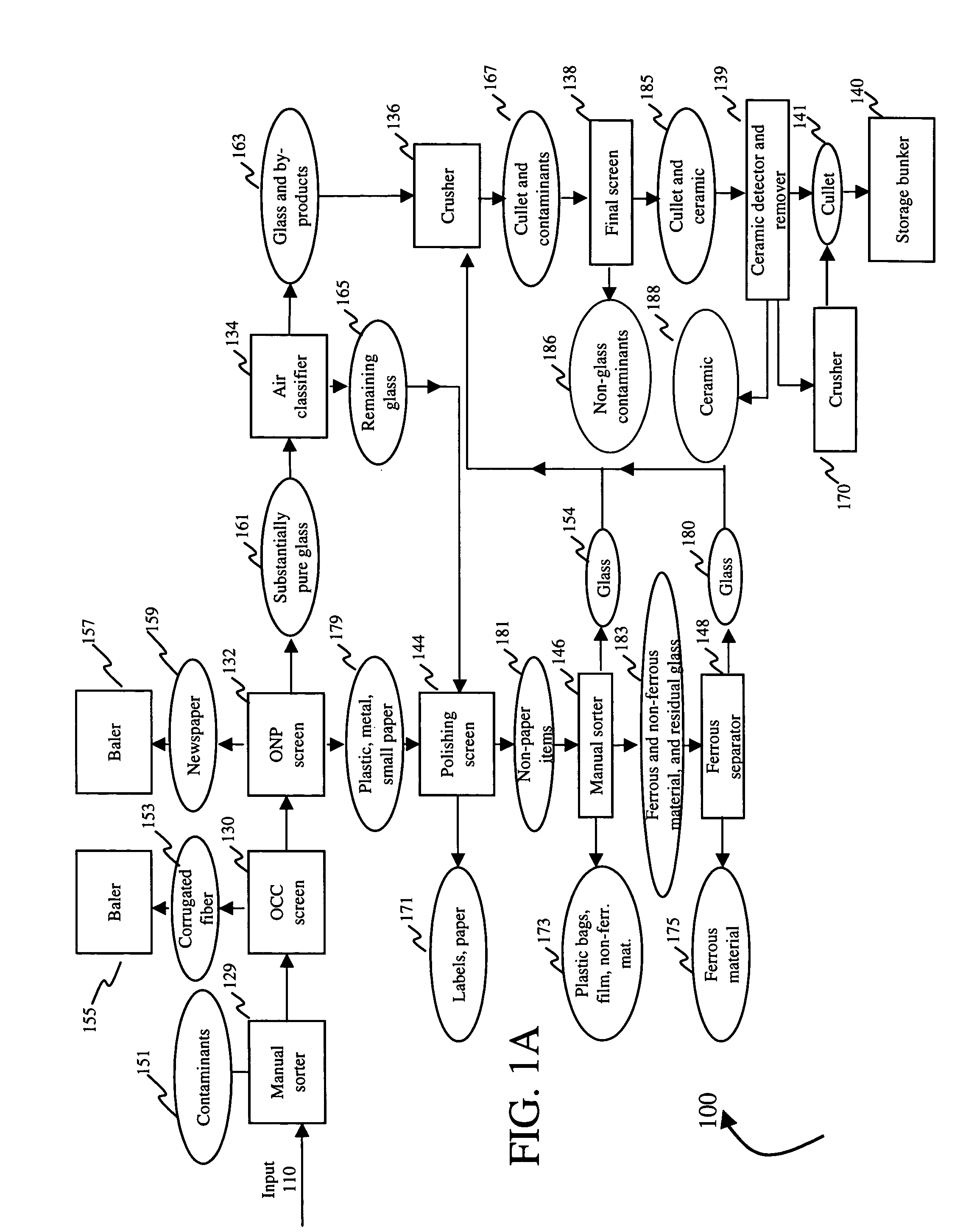

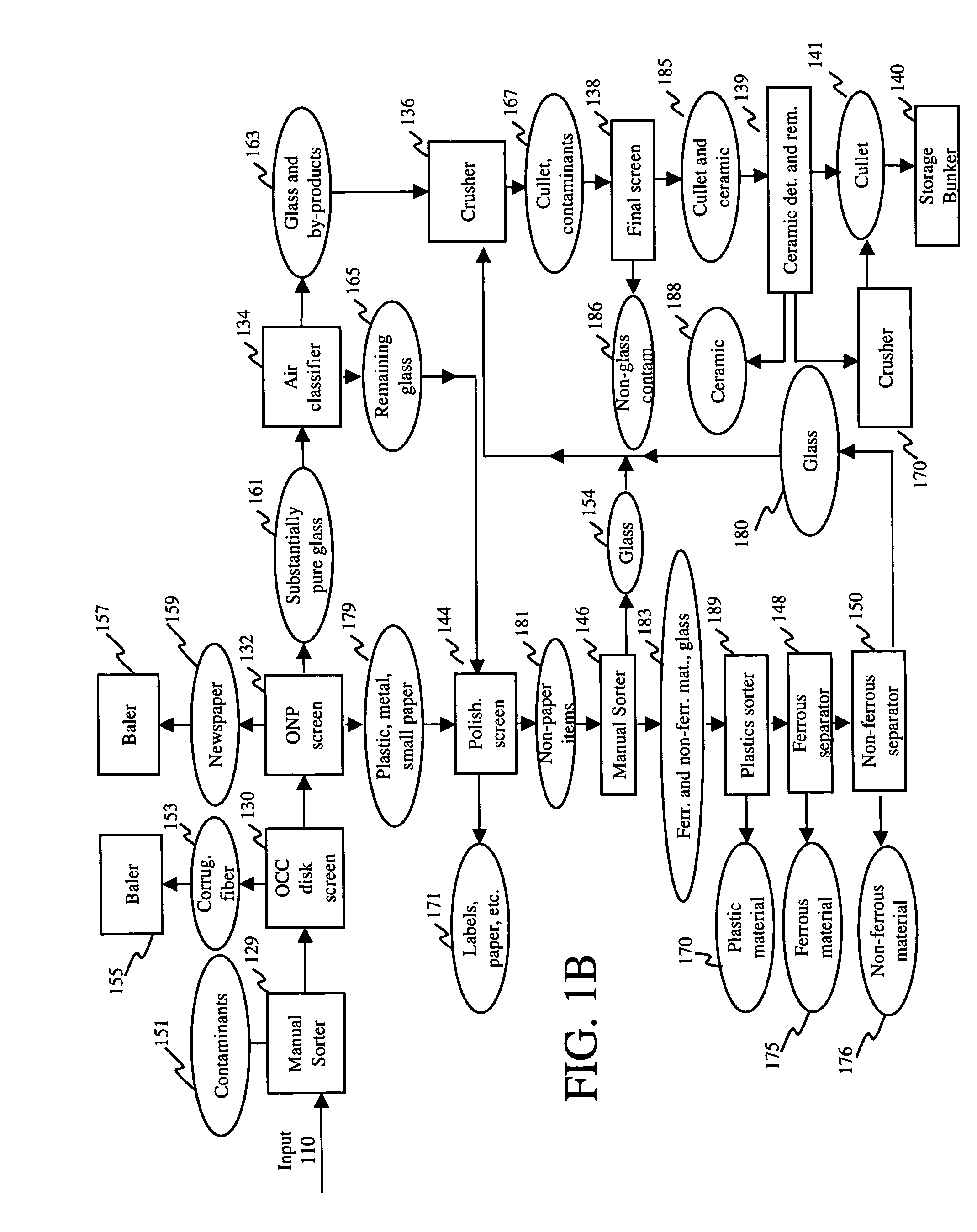

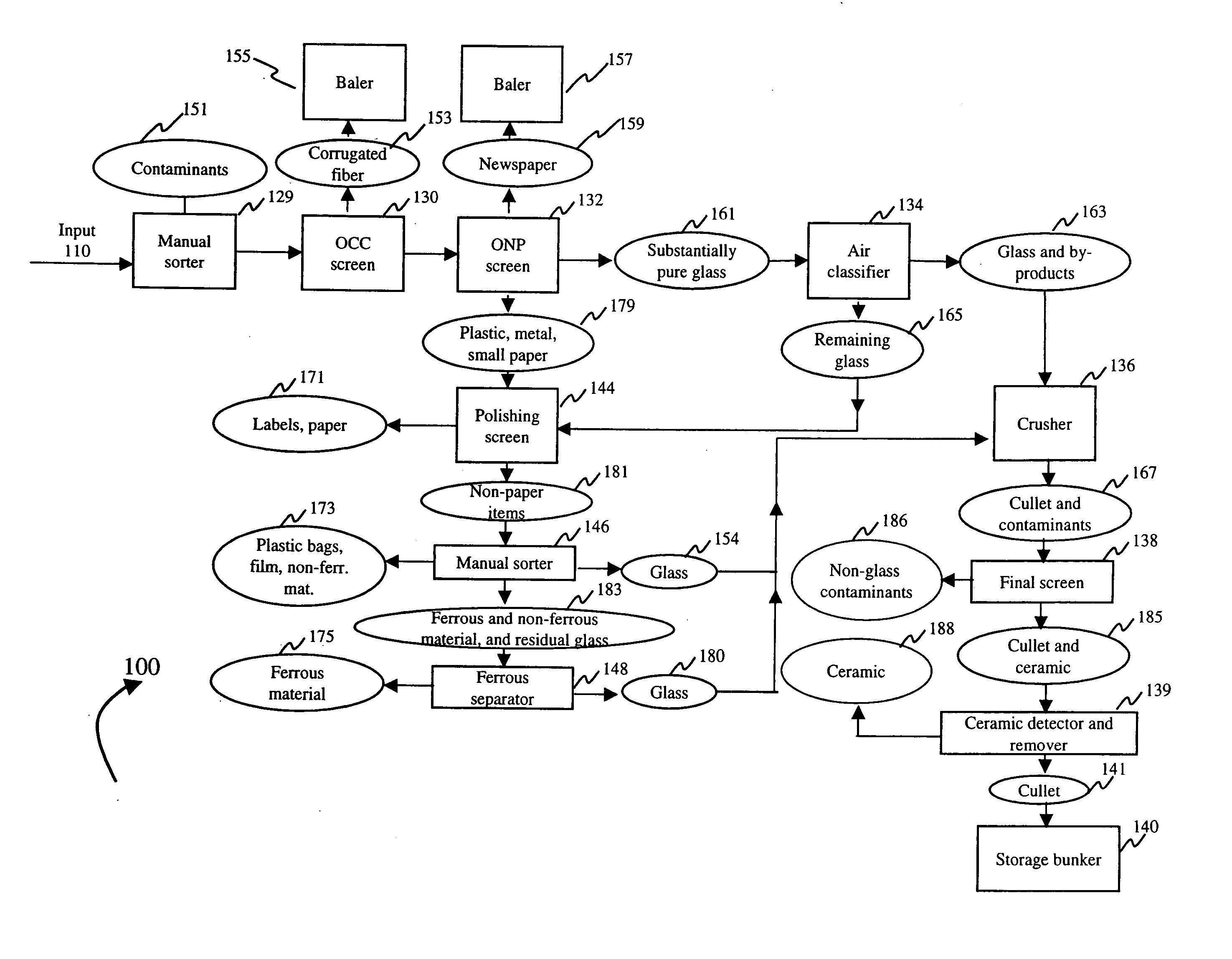

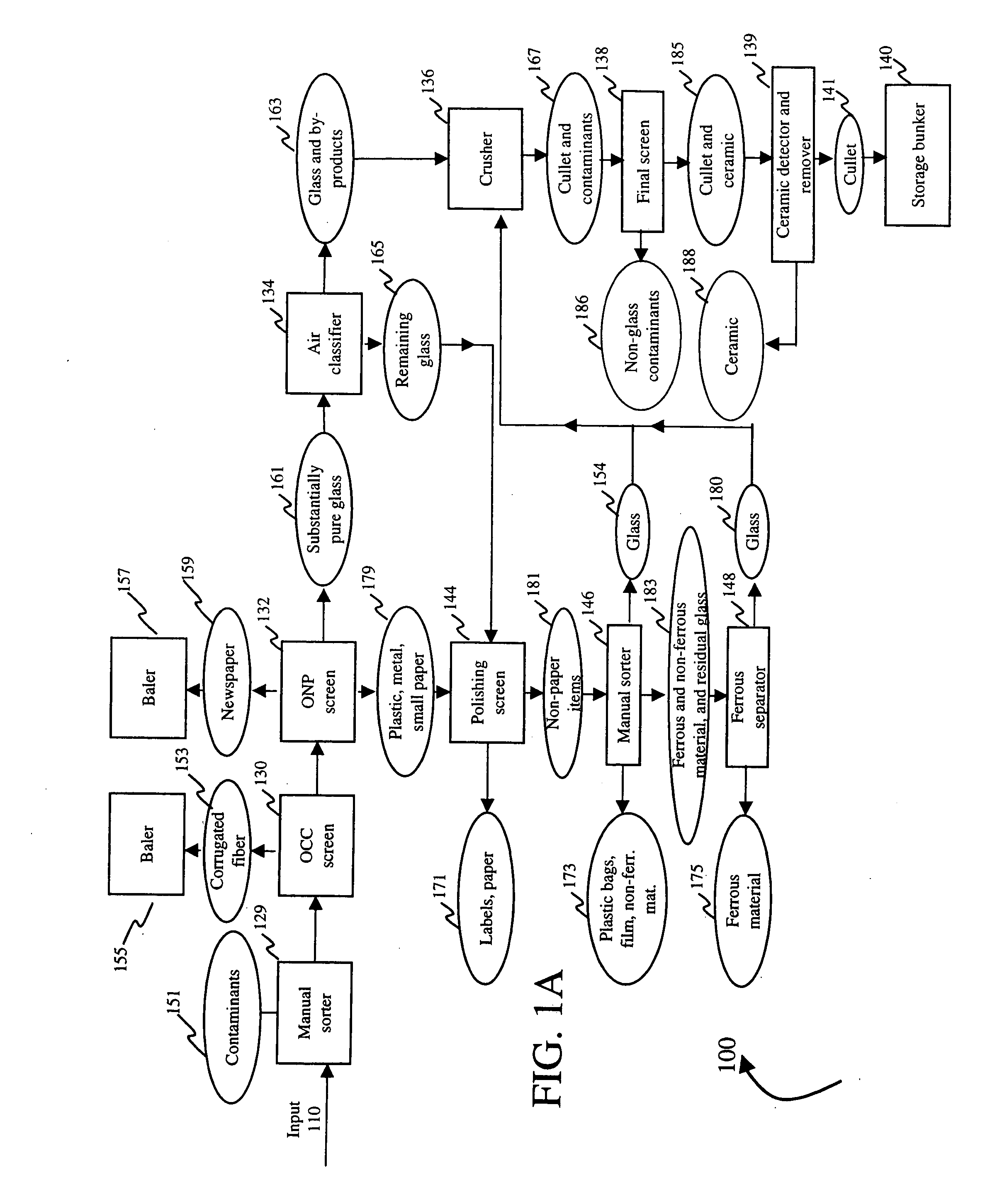

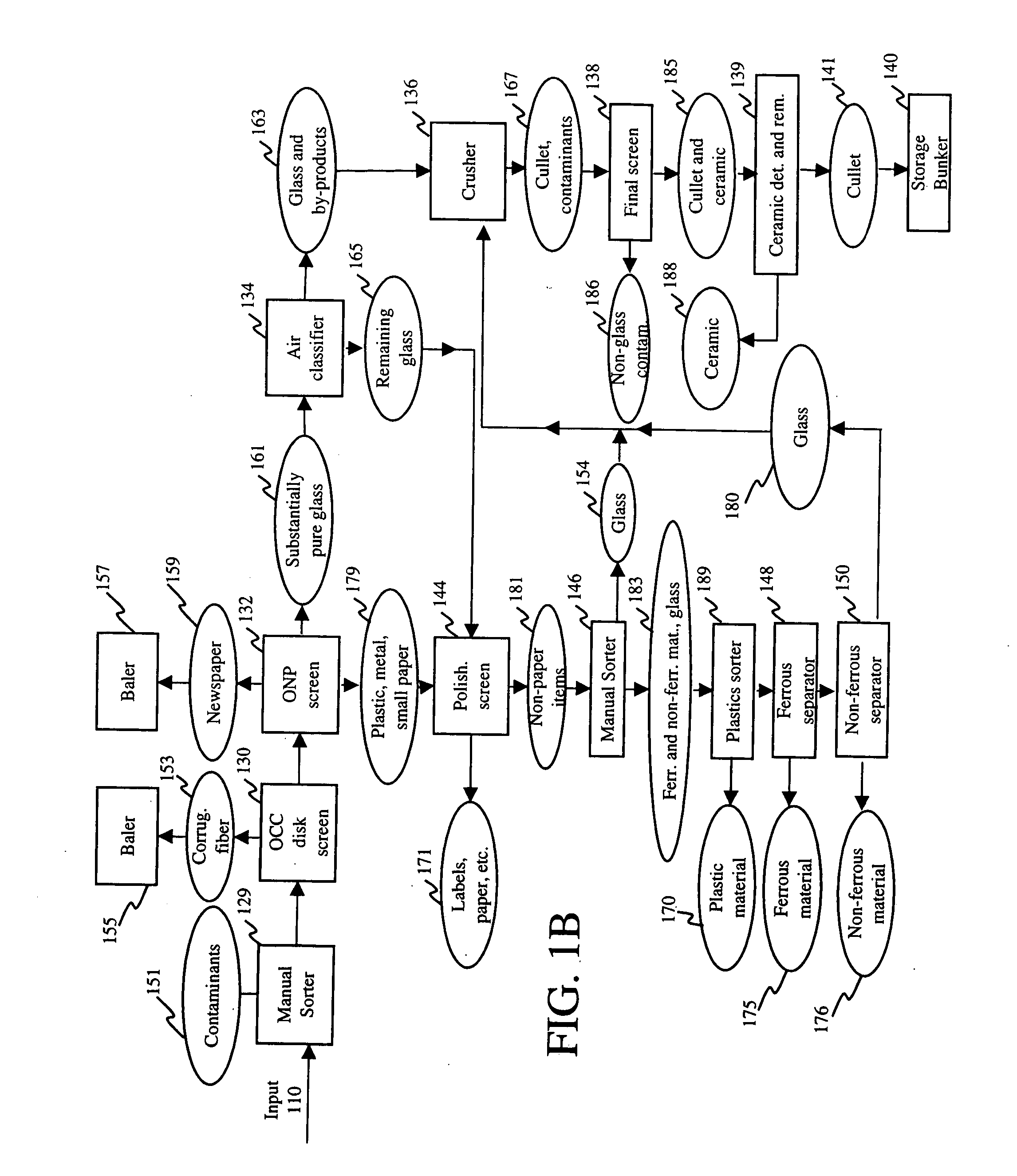

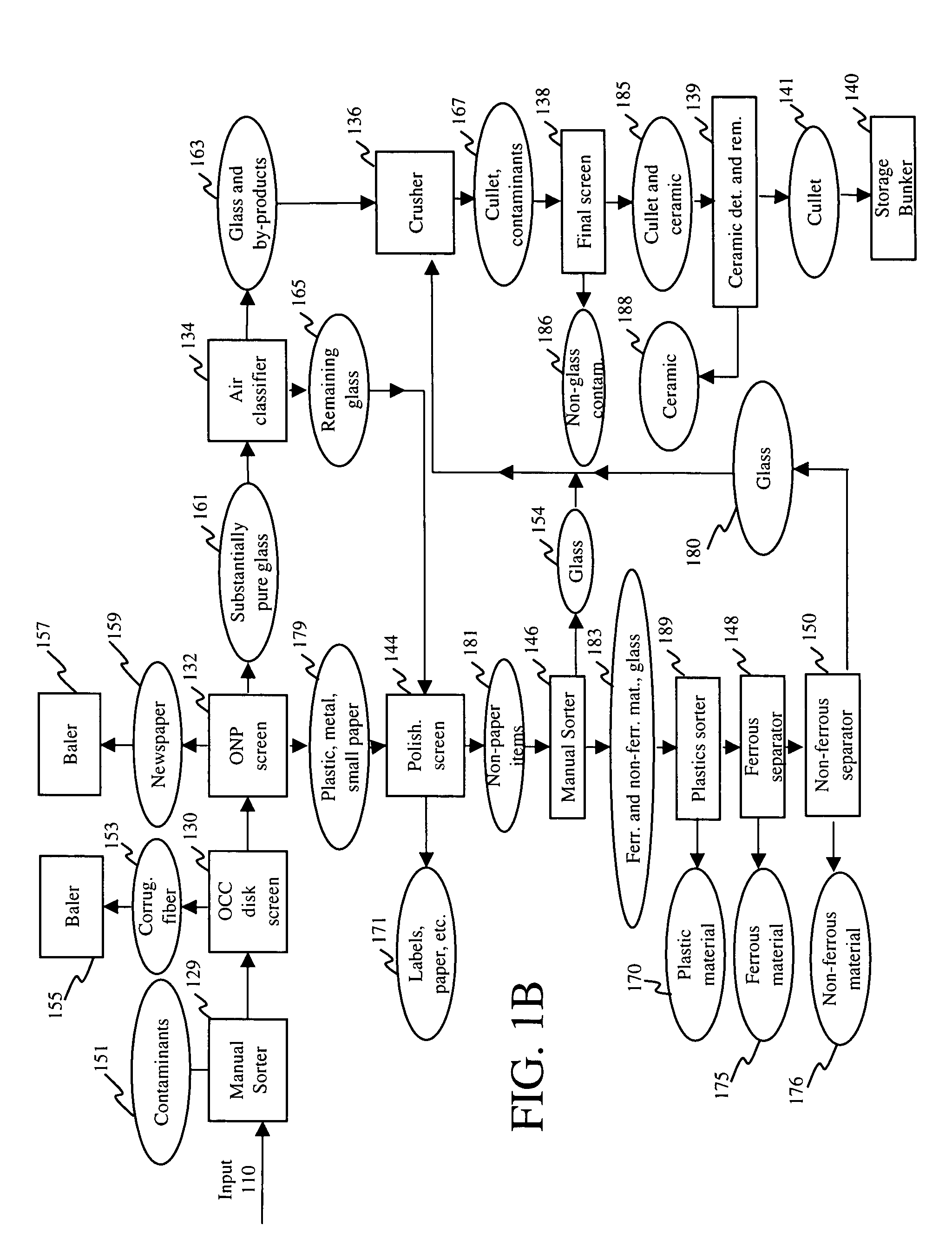

Systems and methods for sorting recyclables at a material recovery facility

InactiveUS20060254957A1Glass recyclingDigital data processing detailsProcess engineeringAir classifier

Owner:RE COMMUNITY HLDG II INC

Method and system for property damage analysis

Owner:ACCURENCE

Material recycling device based on Ad Hoc network

InactiveCN103226870AEasy to operateImprove reliabilityCo-operative working arrangementsReturnable containers actuationPaymentBarcode

The invention discloses a material recycling device based on an Ad Hoc network. After an IC card reading module indentifies personal information, a material identification sensor module is placed at a material throwing-in port, a recycling material bar code or two dimensional code is obtained through laser scanning, the materials to be thrown in are identified automatically, and material information is acquired; after identification succeeds, a machine module controls the material throwing-in port to open through a motor to allow the materials to be put in, and a storage box is used for storing the received materials / the materials put in; and a wireless data transmission module uploads material information to a central processor module, the central processor module controls a fund flow module to pay fund to a seller, and the material information and fund payment information are uploaded through the Ad Hoc network. According to the device, the material information is acquired through material identification, all information is uploaded to a community processing center through a wireless data transfer radio Ad Hoc network, and fund is paid to the seller according to a market price. The operation is simple, the reliability and the practicability are high, and popularization and application are facilitated.

Owner:ZHONGBEI UNIV

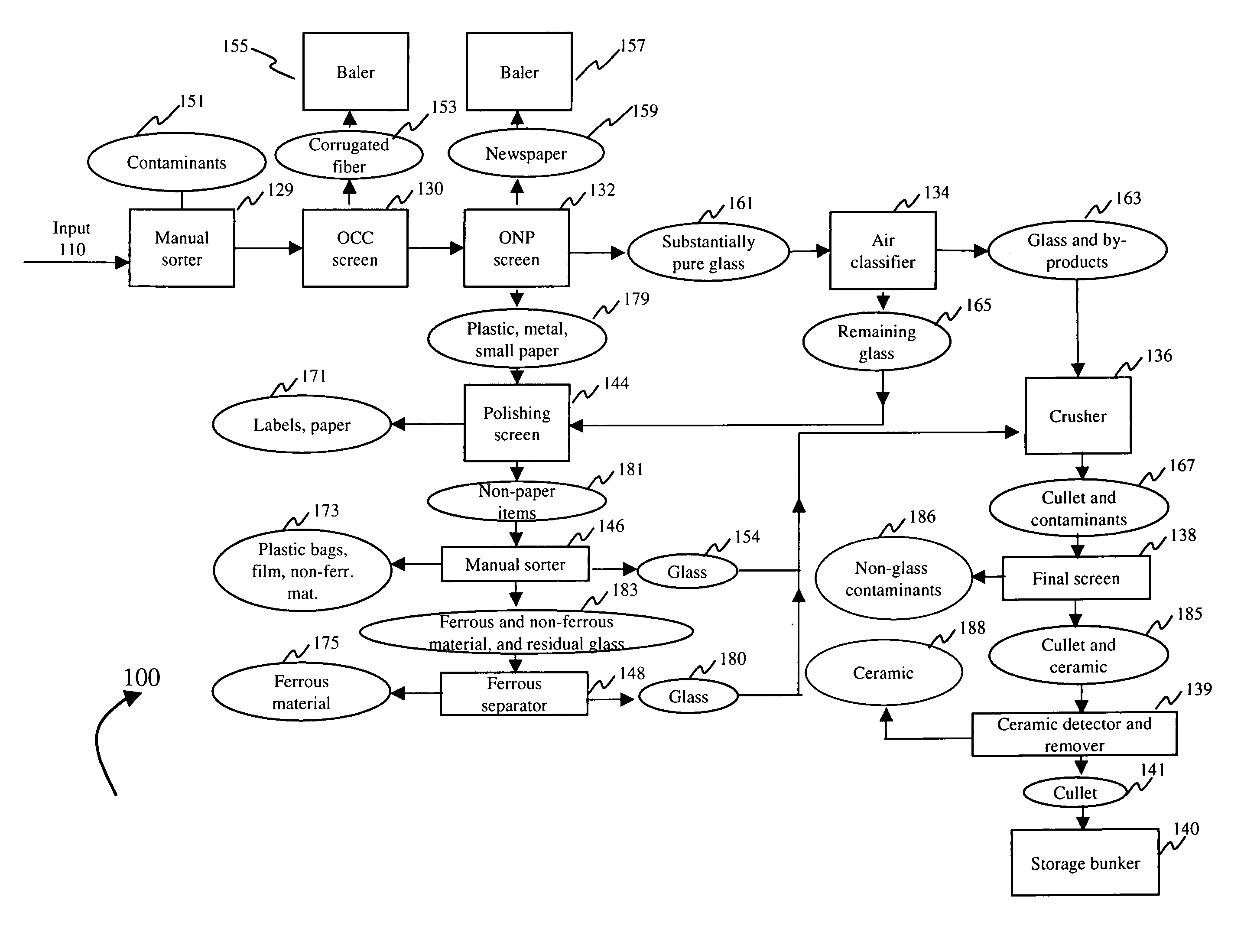

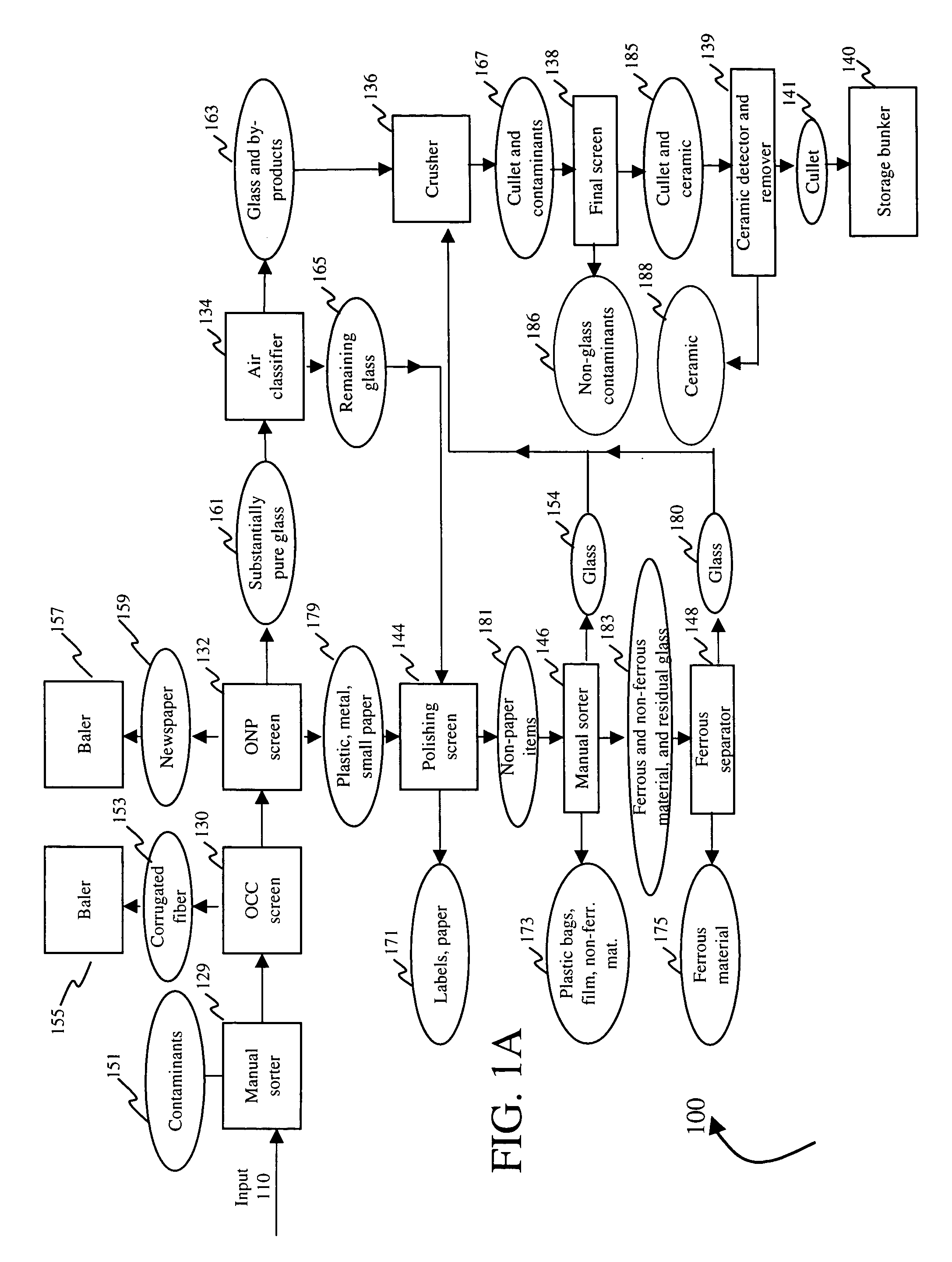

Systems and methods for sorting recyclables at a material recovery facility

Systems and methods for providing a quantity of cullet having at least two colors of glass from an input stream of recyclable material and non-recyclable material. In an embodiment, the system includes a sortation station, a screening apparatus, an air classifier, and a crushing apparatus to provide as output substantially pure cullet having at least two colors.

Owner:RE COMMUNITY HLDG II INC

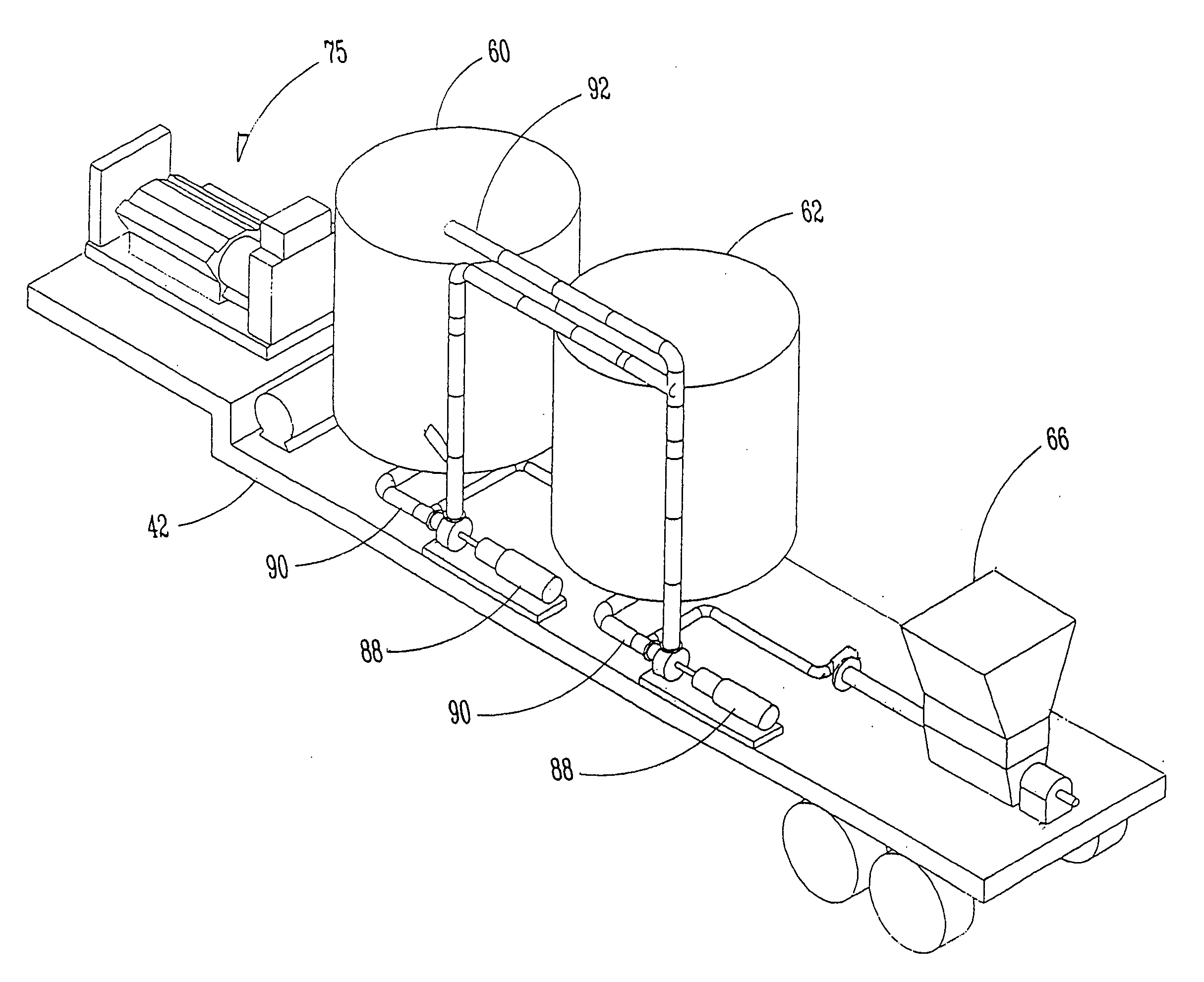

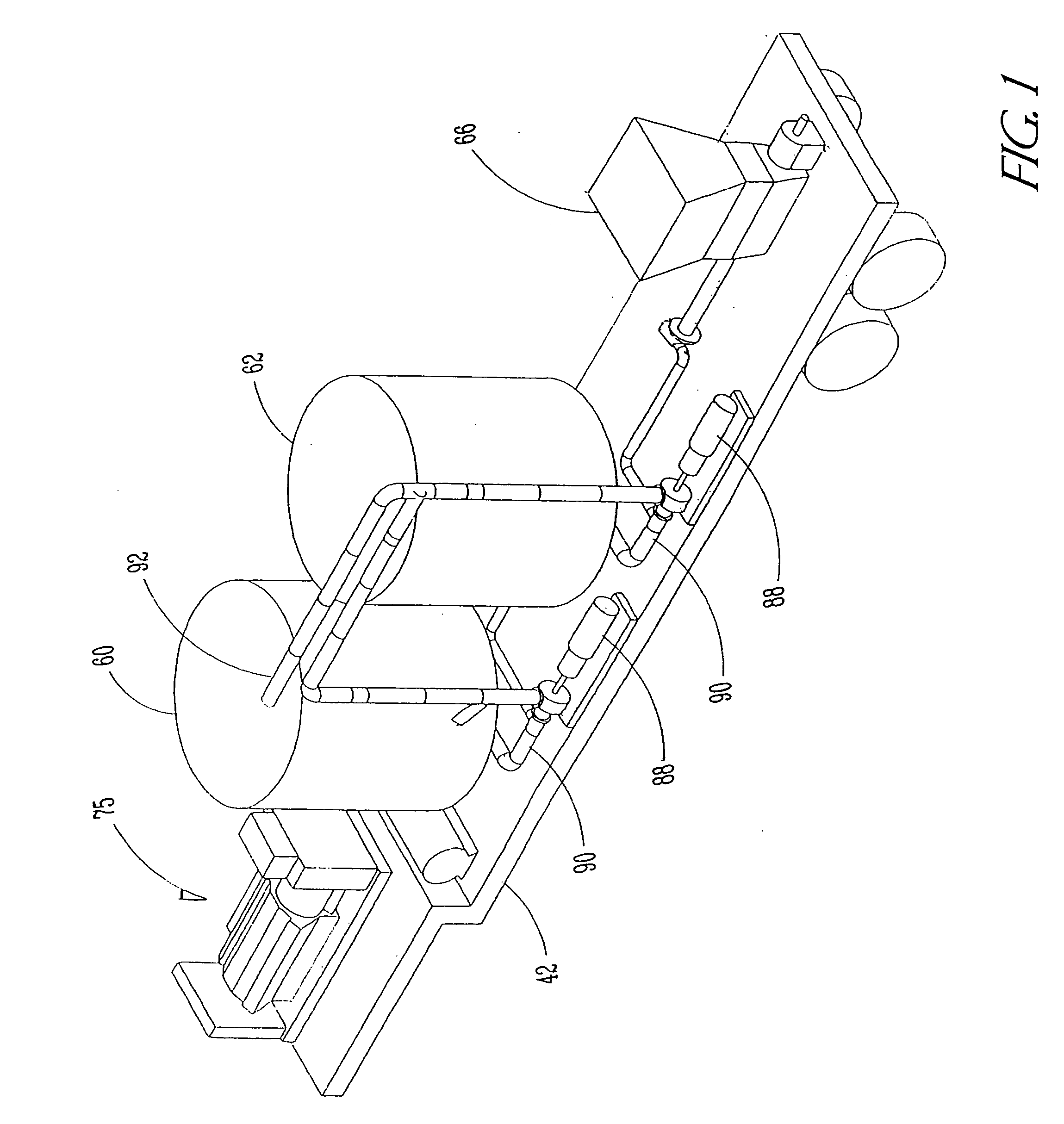

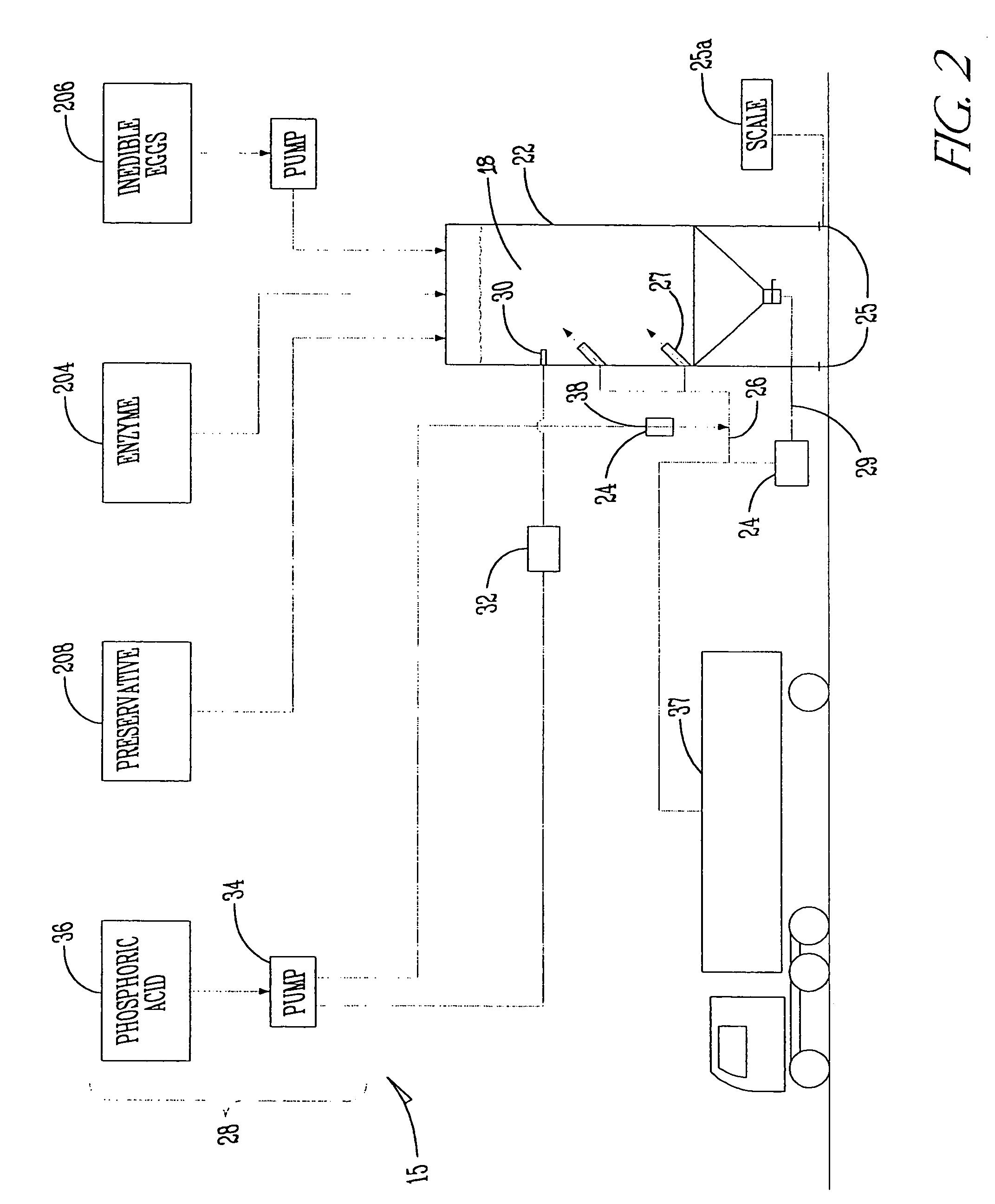

Apparatus for natural recycling of protein waste

ActiveUS20040265993A1Minimizing growth of bacteriaEfficient processBioreactor/fermenter combinationsSlaughtering animals fettering apparatusTruck-trailerProcessing plants

An apparatus and process for naturally recycling poultry carcasses for use as a nutritional supplement, the apparatus generally consists of four modules: an enzymatic digest medium mixing assembly that self adjusts for pH; a mobile grinding assembly mounted on a truck trailer; a digesting and emulsifying assembly which includes a heated tank and separator; and a drying system. Carcasses are loaded into the grinder, and the ground carcasses are pumped into a storage tank with the enzymatic digest medium to produce a protein soluble mixture. The particle size of this mixture is then further reduced, and transported to a centralized and stationary processing plant for digesting and emulsifying. The remaining emulsified proteins are then dried. The resulting pellet-like pieces are uniformly sized for packaging.

Owner:NATURALLY RECYCLED PROTEINS INC +1

Semi-automatic glass sandblasting machine

InactiveCN101653924AHigh degree of automationFlexible operationAbrasive machine appurtenancesAbrasive blasting machinesSand blastingSemi automatic

The invention relates to a semi-automatic glass sandblasting machine, which comprises a base, a frame, a sand storage tank, a semi-tight work cavity, a dust collection fan, a baffle, a clamp push plate, a work bench and the like. The work bench is connected with a rotary motor through a shaft and a belt hoop; the clamp push plate is connected with the baffle through a bracket and a threaded stud,and can move on the baffle back and forth and clamp a workpiece tightly; a lower filter screen, a scrap collection groove and the sand storage tank are arranged below the work cavity; an upper filterscreen, the dust collection fan, an aluminum pipeline and a dust collection tank are arranged above the work cavity; a spray gun platform and a first screw are embedded and connected in chutes on twoside walls in the work cavity; a third slide block on the spray gun platform is connected with a second screw and a spray gun; a screw end is connected with a motor; the sand storage tank is connectedwith the spray gun through a rubber conduit; and an air source is connected to the spray gun through a control valve to control sand-blasting processing. The glass sandblasting machine has the advantages of small volume, flexible operation, convenient assembly and motion, automatic or manual fixed-point sand blasting, dust collection, grinding material recycling and high manufacturing efficiency,and is suitable to be assembled and used by medium-sized and small enterprises.

Owner:SHANGHAI DIANJI UNIV

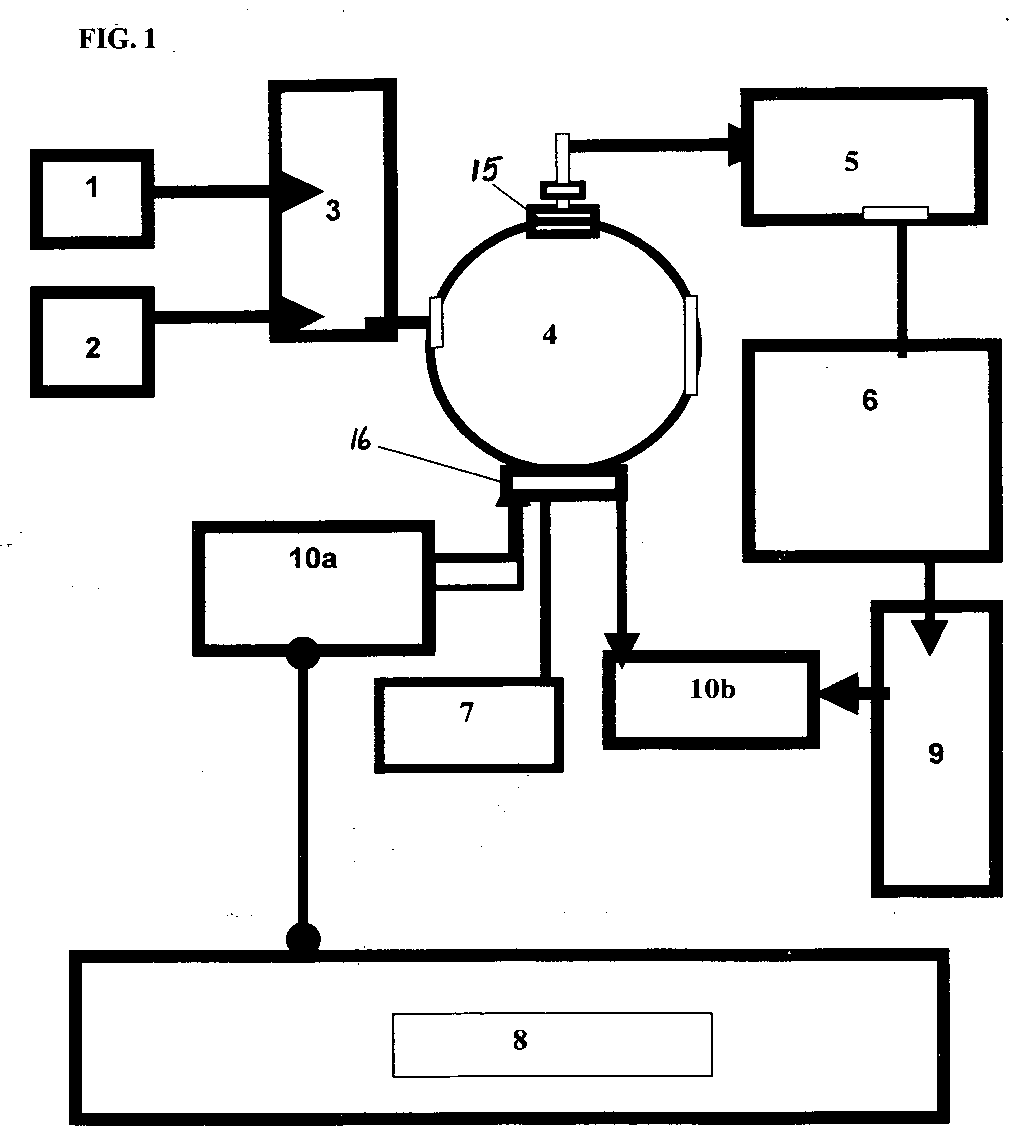

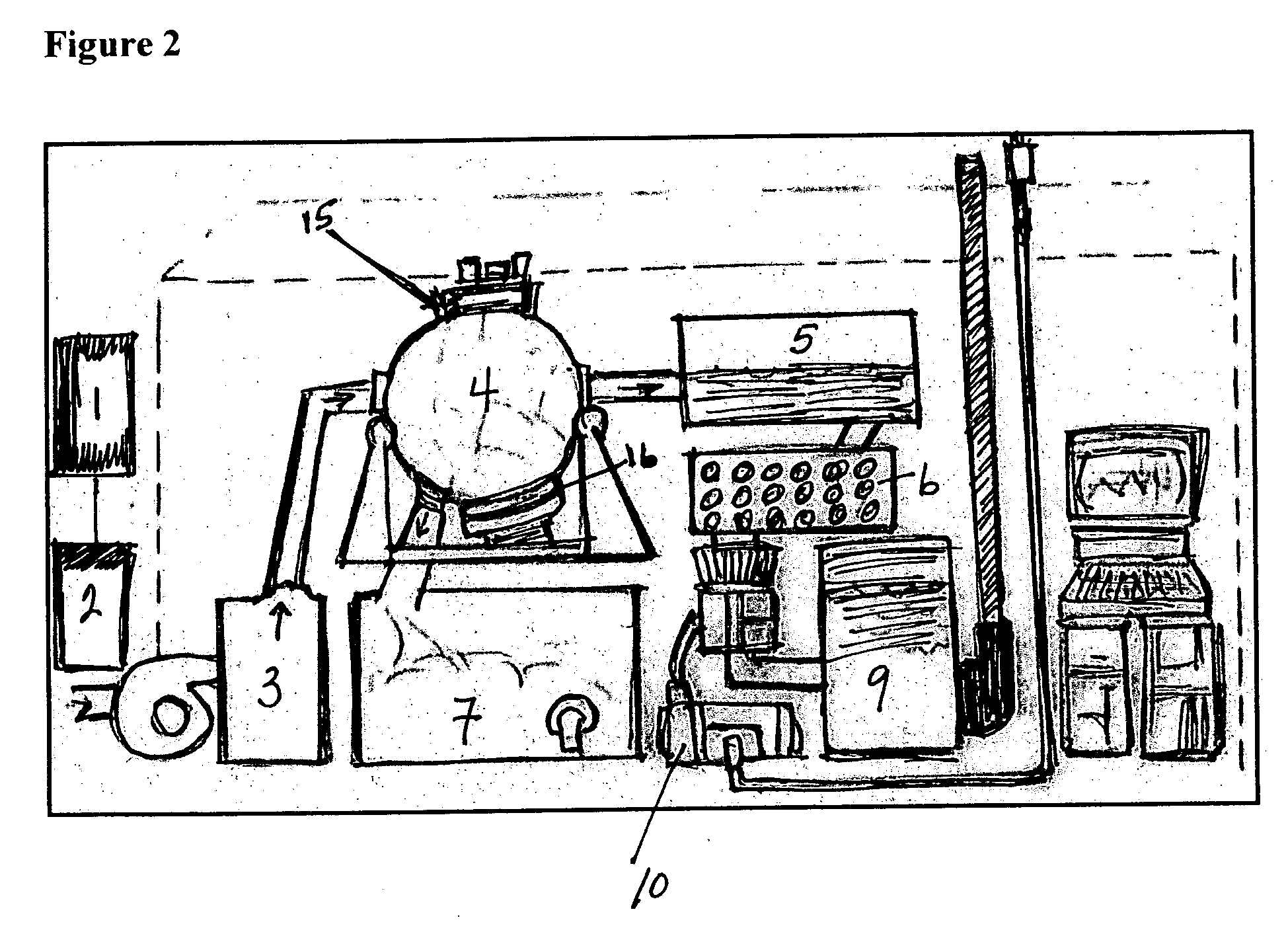

Hybrid magnetohydrodynamo (MHD) field sanitation generator for treating wastewater, sewages & sludge and recovering potable water

InactiveUS20050029174A1Sludge treatment by thermal conditioningWater/sewage treatment by irradiationSludgeFiltration

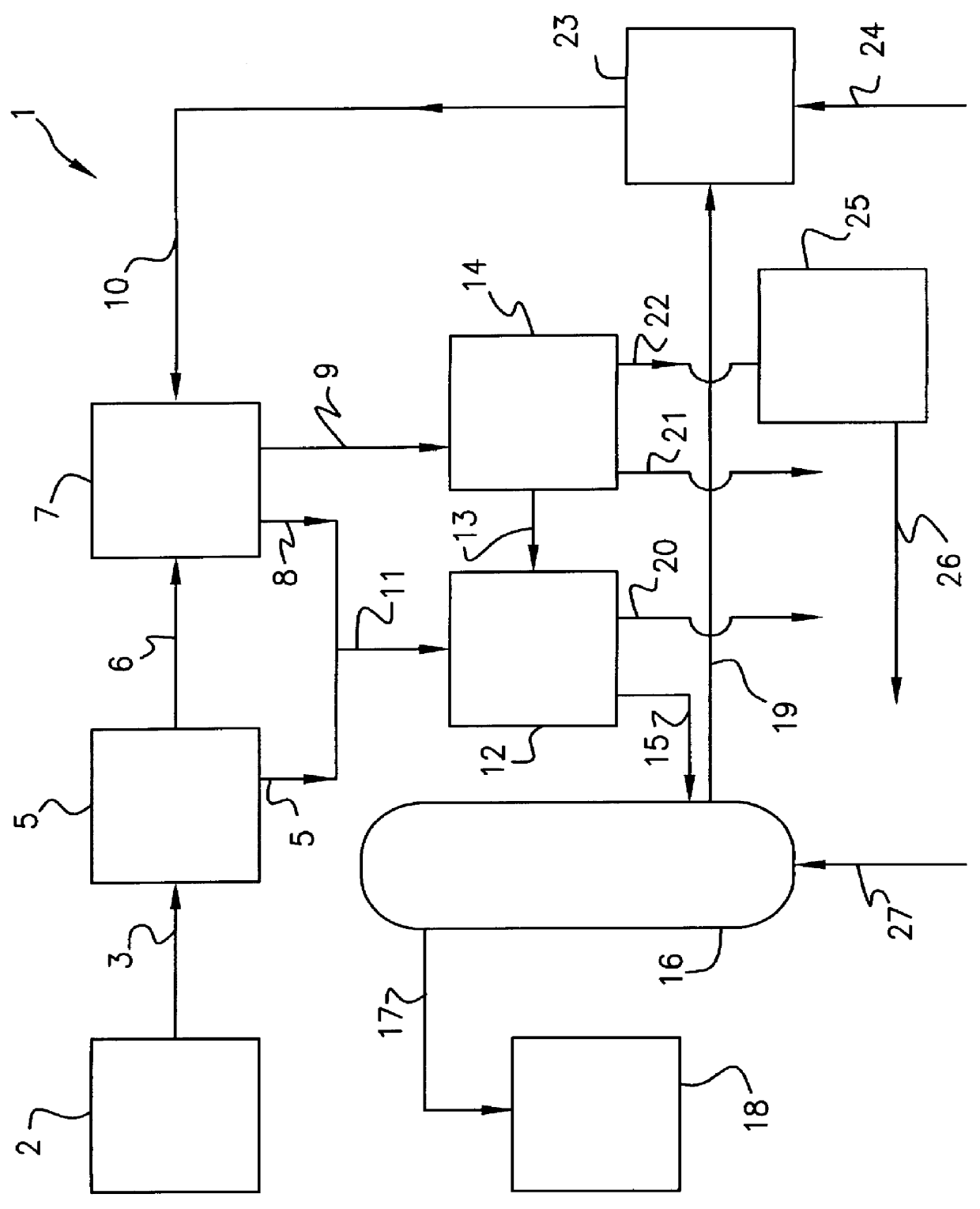

The Hybrid MHD-FSU (Field Sanitation Unit) innovation is a self-contained sewage treatment plant that fully converts sewage / wastewater into (1) solid organic material, (2) potable, pathogen-free drinking water, and (3) generates electricity. At a high level, the system consists of four main components: (1) Mixer, (2) MHD Reactor, (3) Filter, and (4) Turbine. The innovation presents a stand-alone compact configuration of typical wastewater treatment components (equalization & mixing, process treatment, filtration) that are combined with the customized MHD reactor to perform the waste treatment / water recovery processing. The Hybrid magnetohydrodynamo (MHD) Field Sanitation Unit has the ability (1) to recover an organic material (2) to recover a pathogen free, clean potable drinking water, and (3) to generate electricity using wastewater as the conductive medium. The invention also relates a core heating microwave source coupled to an outer rigid mantle boundary that compose an MHD electrode pair. The invention assemblies are generally configured of three components: (a) magnetron, waveguide & a launch assembly; (b) the perovskite ceramic components; and (c) the conductive wastewater sludge fluid but more specifically the MHD assemblies are described herein in detail. FIG. 1 illustrates a general process flow of the invention. The main components of the invention are composed of the following: (1) the clean water supply feed, (2) the influent raw wastewater (3) the mixer, (4) the MHD reactor chamber, (5) the storage tank for clean water, (6) the filtration system producing potable water, (7) the storage bin for solids & organic material (8) hydro-turbine (9) the potable drinking water storage, (10b) the battery storage system with power conditioning subsystem.

Owner:SPIRALCAT OF MARYLAND

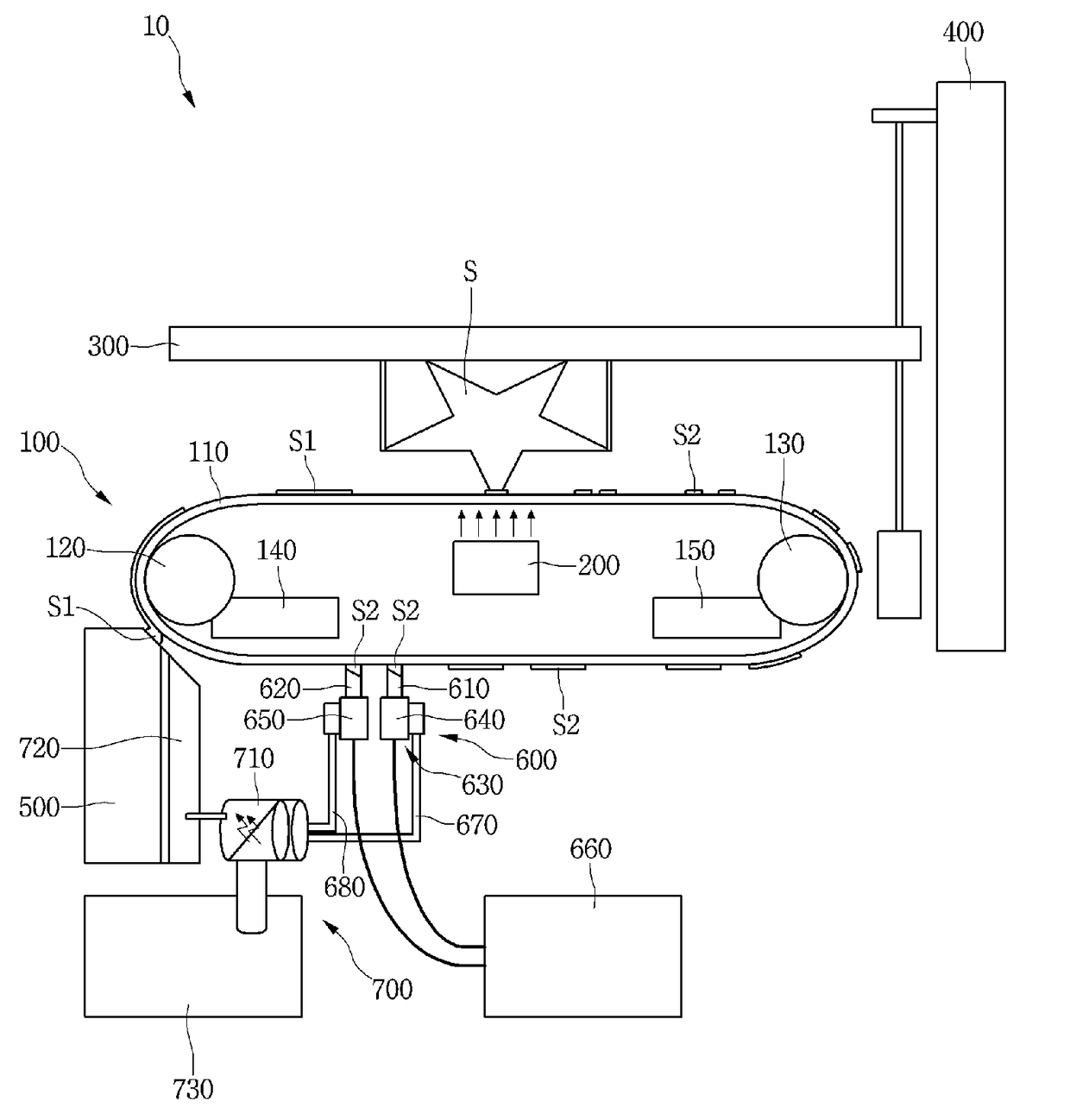

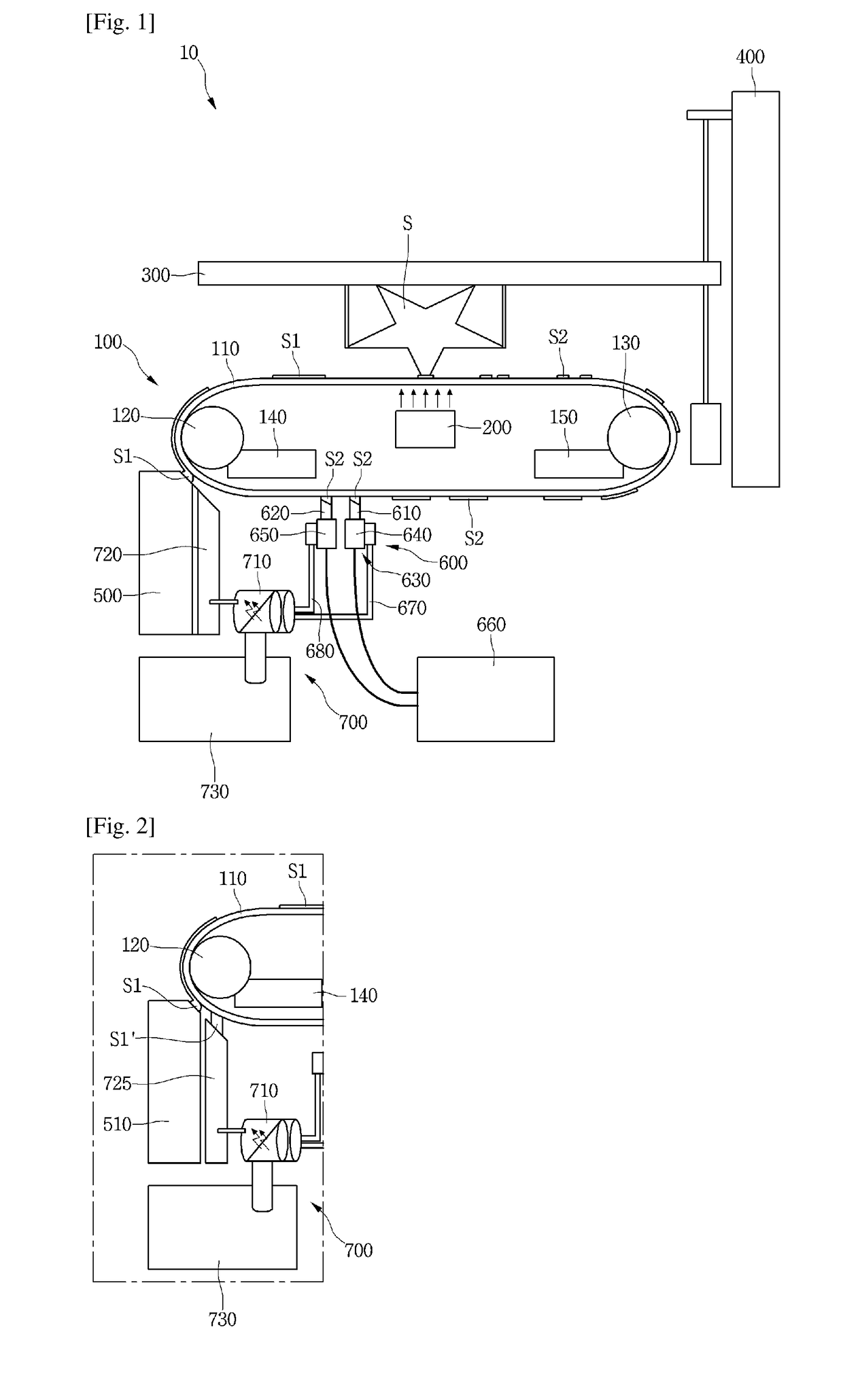

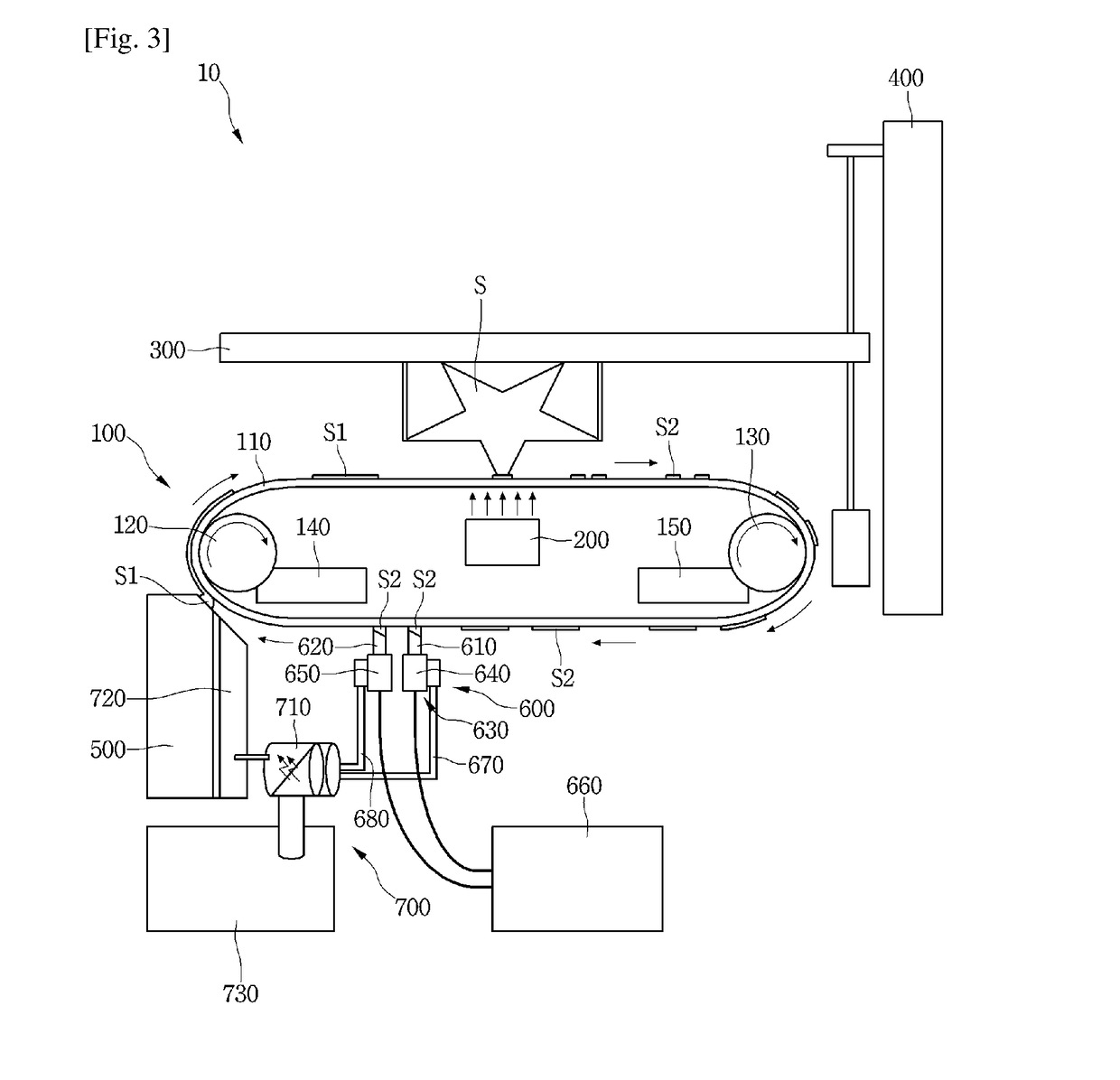

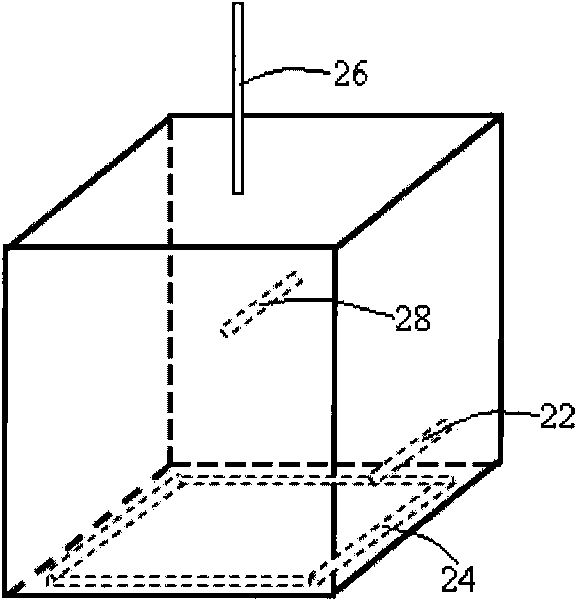

3D printing apparatus

InactiveUS20180043619A1Low costManufacturing platforms/substratesManufacturing driving meansEngineeringMaterial supply

A three-dimensional (3D) printing apparatus is provided. The 3D printing apparatus includes a modeling material circulating part for circulating a modeling material for modeling a 3D model, a light source unit disposed on one side of the modeling material circulating part to supply light toward the modeling material so that the modeling material is cured, a stage on which the modeling material cured through the light source unit is seated, the stage being disposed to face the modeling material circulating part, a stage driving part connected to the stage to provide a driving force for moving the stage, a modeling material supply part for supplying the modeling material to the modeling material circulating part, a modeling material collecting part for collecting the modeling material, which passes through the light source unit, of the modeling material circulating by the modeling material circulating part, and a modeling material recycling part connected to the modeling material collecting part to filter the collected modeling material to resupply the filtered modeling material to the modeling material circulating part.

Owner:LG ELECTRONICS INC

Method for recycling and preparing lithium iron manganese phosphate from positive electrode materials of waste lithium iron phosphate batteries

ActiveCN104609385ASolving Recycling ProblemsIncrease specific energySolid waste disposalWaste accumulators reclaimingPhosphoric acidLithium-ion battery

The invention discloses a method for recycling and preparing lithium iron manganese phosphate from positive electrode materials of waste lithium iron phosphate batteries. The method comprises the following steps: (1) discharging remnant electric quantities of the waste lithium iron phosphate batteries, disassembling the batteries, taking positive electrode sheets, washing, drying, roasting and separating lithium iron phosphate from aluminum foils; (2) by controlling the addition of acid, carrying out acid leaching on separated lithium iron phosphate, and filtering to separate insoluble iron phosphate and iron oxide to obtain a filtrate; (3) analyzing the filtrate, adjusting the molar ratio of the elements, namely, nLi to (nFe+Mn) to nP to 1: 1: 1 and adding a manganese source and a phosphorus source; and adjusting the pH to obtain a precipitate; drying the precipitate, adding a carbon source and mixing to obtain a pre-sintered material; and (4) carrying out solid sintering treatment on the pre-sintered material under non-oxidizing atmosphere to obtain the lithium iron manganese phosphate serving as the lithium ion battery positive electrode material. The method has the advantages of simplicity in process, environmental friendliness, good product properties and the like.

Owner:北京赛德美资源再利用研究院有限公司

Method for recycling silicon powder from silicon slice cut waste mortar

InactiveCN102173419AAchieve recyclingImprove applicabilitySiliconLubricant compositionPolyethylene glycolSilicon chip

The invention relates to a method for recycling silicon powder from silicon slice cut waste mortar. The invention comprises seven procedural steps of solid-liquid separation of silicon slice cut waste mortar, precision separation of silicon-contained liquid, liquid flotation, precision filtering, film separation, pickling and vacuum drying. The method in the invention is used to produce silicon powder with a purity of 99.5-99.9% and solve the problems existing in the existing silicon slice cut waste mortar recycling industry, such as difficult separation between solid and liquid, low purity of recycled products, poor recycling rate, incomplete recycling process and the like. In the invention, the polyethylene glycol and carborundum can be recycled and the recycling of polycrystalline silicon and monocrystalline silicon can be realized, which improves the material recycling ratio of the solar equipment industry and come up to the cleanness standards.

Owner:常州广正知识产权代理有限公司

Recycling process of positive electrode materials of waste batteries

ActiveCN109326843ASimple recycling processHarmless treatmentWaste accumulators reclaimingFlotationEngineeringBiological activation

The invention discloses a recycling process of positive electrode materials of waste batteries. The recycling process includes the steps of completely discharging the waste lithium batteries, subjecting the waste lithium batteries to primary crushing under inert gas protection, removing diaphragm paper through air classification after crushing, performing low-temperature pyrolysis, respectively removing iron materials and aluminum materials through sorting, performing re-pulverization to obtain electrode powder, determining a flotation reagent system according to the phase composition of the electrode powder, performing flotation in a flotation tank, and filtering and drying products at the bottom of the flotation tank to obtain the positive electrode materials; according to the Li / M ratioof the positive electrode materials, calculating the lithium source powder to be added, and mixing water-soluble dispersants and the lithium source powder with water to form a mixed solution; addingthe positive electrode materials to be repaired into the mixed solution, performing cooking activation at a high temperature and under high pressure, continuing to dry the product under normal pressure to obtain uniform mixture powder, and calcining the mixture powder under an aerobic condition to obtain the regenerated and repaired lithium ion battery positive electrode materials. The recycling process has the advantages of low repair cost, high activity after repair, and higher promotion and application value.

Owner:荆门动力电池再生技术有限公司

Movable formwork supporting truss and construction method thereof

ActiveCN104196235AHigh turnover utilizationSave manpower and material resourcesForms/shuttering/falseworksShoresMaterial resourcesEngineering

The invention relates to a movable formwork supporting truss and a construction method thereof. The movable supporting truss comprises a supporting rod assembly, a connecting buckle, adjustable supports and universal wheels. The supporting rod assembly is composed of stand rods, horizontal rods and inclined struts, and a truss structure is formed through the connecting buckle. The adjustable supports are placed at the upper ends and the lower ends of the stand rods and used for adjusting the supporting height, and when the adjustable supports on the lower portions of the stand rods are replaced by the universal wheels, the whole truss can move. The construction method comprises the steps of ground leveling, single rod piece assembling, overall truss assembling, overall truss removing, recycling and the like. Compared with the prior art, the movable formwork supporting truss and the construction method thereof have the advantages that the construction efficiency and the material recycling usage rate are increased by two or more times compared with a traditional construction method, labor and material resources are saved, the economical benefits are appreciable, the movable formwork supporting truss is especially suitable for a cross beam structure and the construction occasions with regular and orderly bay sizes and can also be used in a beamless slab construction, wherein the construction occasions include superstores, office buildings, underground garages and other frame structures with post-cast strips.

Owner:CHINA THIRD METALLURGICAL GRP

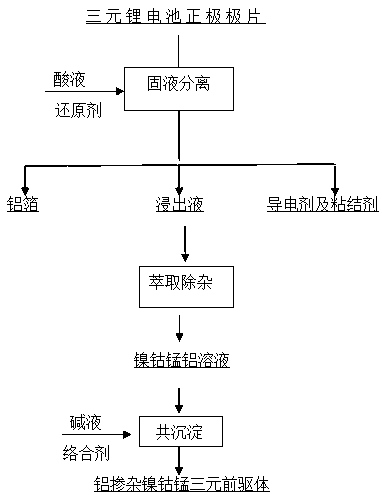

Method for preparing ternary anode material precursor from waste lithium battery anode pieces

ActiveCN108899604ASimple recycling processImprove structural stabilityCell electrodesWaste accumulators reclaimingAluminum IonManganese

The invention provides a method for preparing a ternary anode material precursor from waste lithium battery anode pieces. The method comprises the following steps: separating active substances from analuminum foil current collector in an anode material acid soaking procedure, directly recycling aluminum foil, regulating dissolved aluminum ions to a specific content in a later extraction and impurity removal step, and enabling the aluminum ions as a doping agent to join in nickel-cobalt-manganese coprecipitation reactions, thereby obtaining an aluminum doped nickel-cobalt-manganese ternary precursor. By adopting the method, an anode material recycling procedure can be effectively simplified, the cost can be reduced, various metallic elements in a waste ternary lithium battery anode can besufficiently utilized, a high-value aluminum doped nickel-cobalt-manganese ternary material precursor can be developed, and due to adoption of the aluminum doping agent, the electrochemical propertiesand the circulation stability of a ternary anode material can be improved.

Owner:郑州中科新兴产业技术研究院 +1

Novel laser 3D printer for printing ceramic materials and control method

ActiveCN107471399AIncrease profitAvoid wastingAdditive manufacturing apparatusAuxillary shaping apparatusComputer printingLaser scanning

The invention discloses a novel laser 3D printer for printing ceramic materials and a control method. The novel laser 3D printer comprises a printing bracket, an object carrying platform, a horizontal scraper system, a ceramic forming system, a recycling system and a laser scanning system, wherein the object carrying platform is arranged in the printing bracket, a front receiving port and a back receiving port are respectively formed in both ends of the object carrying platform, and a feed opening is formed behind the front receiving port; the horizontal scraper system is arranged on the object carrying platform and horizontally moves between the front receiving port and the back receiving port; the ceramic forming system comprises a printing platform, a forming cylinder barrel and a printing platform lifting mechanism; the recycling system comprises a material recycling box, a filtering system, a material storage box and a pumping system; and the laser scanning system is arranged above the printing bracket, a laser outlet of the laser scanning system is aligned with the central position of the printing platform, and the ceramic materials on the printing platform are irradiated by laser emitted by the laser scanning system during printing, so that the ceramic materials are solidified. According to the novel laser 3D printer, the utilization rate of the ceramic materials can be effectively increased, secondary pollution of the ceramic materials is avoided, and the rate of finished products is increased.

Owner:武汉因泰莱激光科技有限公司

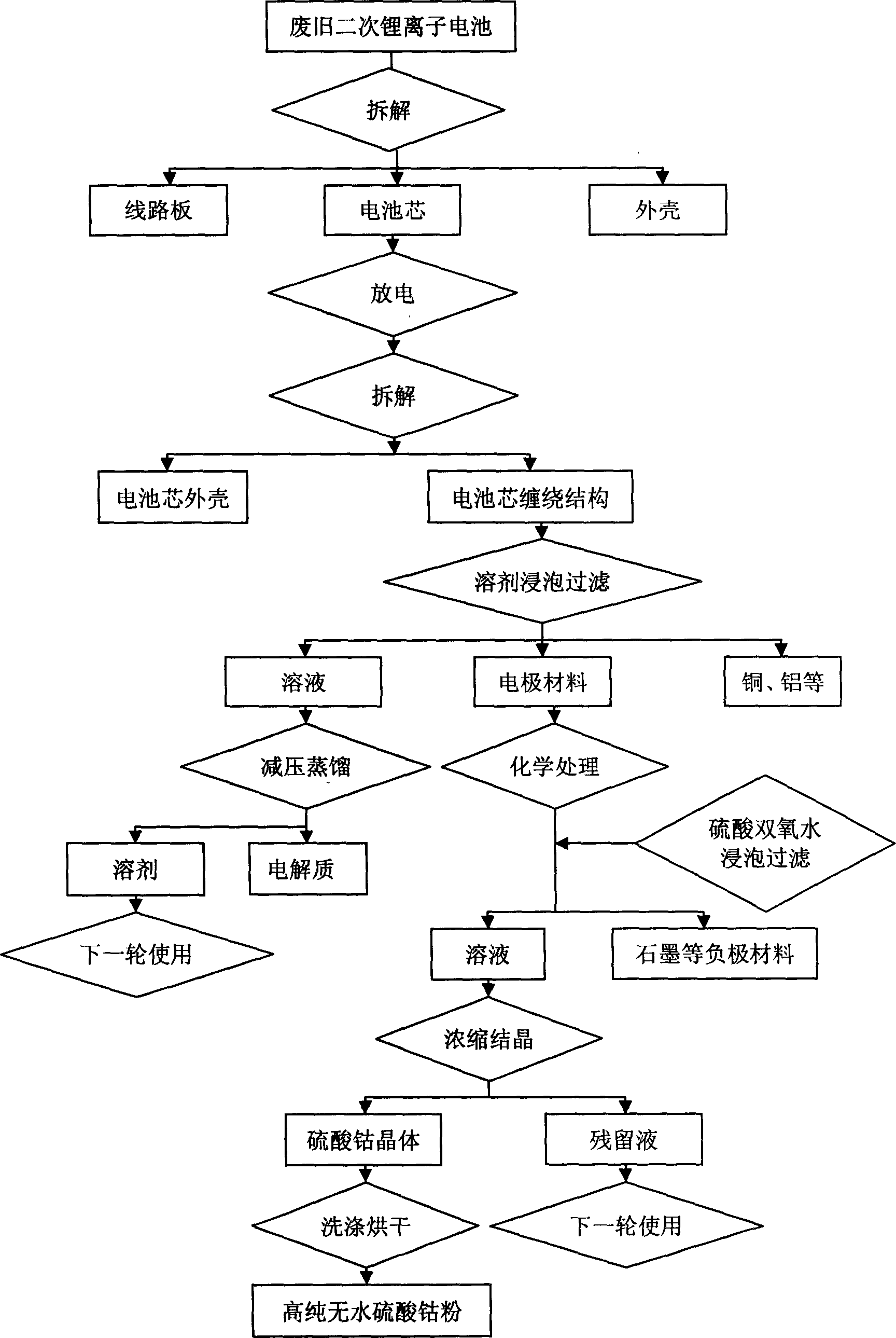

A method to reclaim and dispose waste secondary lithium ion battery

InactiveCN1964129AReduce cross contaminationReduce usageSolid waste disposalWaste accumulators reclaimingOrganic solventElectrical polarity

The related recovery and process method for waste secondary Li-ion cell comprises: separating cell shell, circuit board and cell core by mechanical means; discharging the core; then separating to obtain the shell and coiling material of cell core; putting the last one into some organic solvent to separate the cell polar material from collector foil, filtering to obtain the foil and active material for recovery by chemical way. With small investment, this invention is simple and safe and high yield.

Owner:BEIJING UNIV OF TECH

Alternative solvents for a method of reclaiming styrene and other products from polystyrene based materials

A method of pretreating polystyrene-containing materials to form a solution of polystyrene in a processing solvent from which the styrene in the polystyrene in the materials is reclaimed. The materials are mixed with an environmentally acceptable pretreating solvent having a lower boiling point than the processing solvent, typically at a location remote from the reclamation plant. The pretreating solvent is selected from the group consisting of d-limonene, l-limonene, dipentene, and blends thereof. Prior to actual processing to reclaim styrene, the pretreating solvent is substantially replaced with the processing solvent. The pretreating solvent may be recovered for reuse.

Owner:PONSFORD THOMAS E +1

Method for recycling and regenerating waste lithium ion battery electrode materials

InactiveCN105990617AEfficient recyclingCause secondary pollutionWaste accumulators reclaimingProcess efficiency improvementPole pieceLithium-ion battery

The invention discloses a method for recycling and regenerating waste lithium ion battery electrode materials, and belongs to the field of recycling and cyclic reuse of electrode materials. The method comprises the steps that waste lithium ion batteries are demounted, subjected to pole piece sorting, soaked with ammonium hydroxide, washed and dried; obtained positive pole pieces and negative pole pieces are subjected to high temperature treatment, a positive electrode powder material, a negative electrode powder material and a current collector are obtained through mechanical method separation; the obtained positive electrode powder material is subjected to lithium supplementing, calcination is carried out after sanding and spray drying, and a regenerated positive electrode material is obtained; the obtained negative electrode powder material is calcined after being subjected to sanding and spray drying, and a regenerated negative electrode material is obtained. According to the method, the positive electrode material and the negative electrode material are recycled, and the advantages of being low in energy consumption, simple in process, short in treatment period, good in regenerated material activity and free of three-waste pollution are achieved.

Owner:MICROVAST POWER SYST CO LTD

Method for preparing pyroceram by melting garbage incineration flying ash in arc furnace

The invention discloses a method for preparing pyroceram by melting garbage incineration flying ash in an arc furnace. The method comprises the following steps of: mixing pre-washed garbage incineration flying ash serving as a main raw material and one of nucleation agents TiO2 and Cr2O3; conveying the mixture to the arc furnace for high temperature melting treatment; directly pouring the flow-out liquid melted slag into a preheated molding die; and transferring the molded melted slag to a thermal treatment furnace for annealing and crystallization, and subsequently polishing to prepare the pyroceram. According to the method, the melted slag formed by melting the garbage incineration flying ash can be converted into recyclable available materials, additional economic benefits are supplied, and the melting treatment cost of the incineration flying ash is reduced effectively; furthermore, emission of acidic gas during melting of the flying ash can be reduced, erosion of chlorides in the flying ash to a fire resistant material of the melting furnace is eliminated, the physical sensible heat of the melted slag in the arc furnace is used effectively, and the energy consumption in the preparation process is reduced.

Owner:TIANJIN URBAN CONSTR COLLEGE

Method for producing materials from recycled glass and cement compositions

InactiveUS7700017B2High porosityEvenly distributedOther chemical processesSolid waste managementCementitious matrixSilicon dioxide

A method of producing material from recycled glass comprising: preparing a mixture of glass in a cementitious matrix, and an alkali-silica reaction suppressant; providing a mold of the material and coating said mold with a release agent; casting said mixture into said mold; curing said mold; and removing the material from said mold. The recycled glass and concrete compositions are: 25-79% by weight glass; 8-35% by weight cement and up to 22% by weight of an alkali-silica reaction suppressant.

Owner:ICESTONE

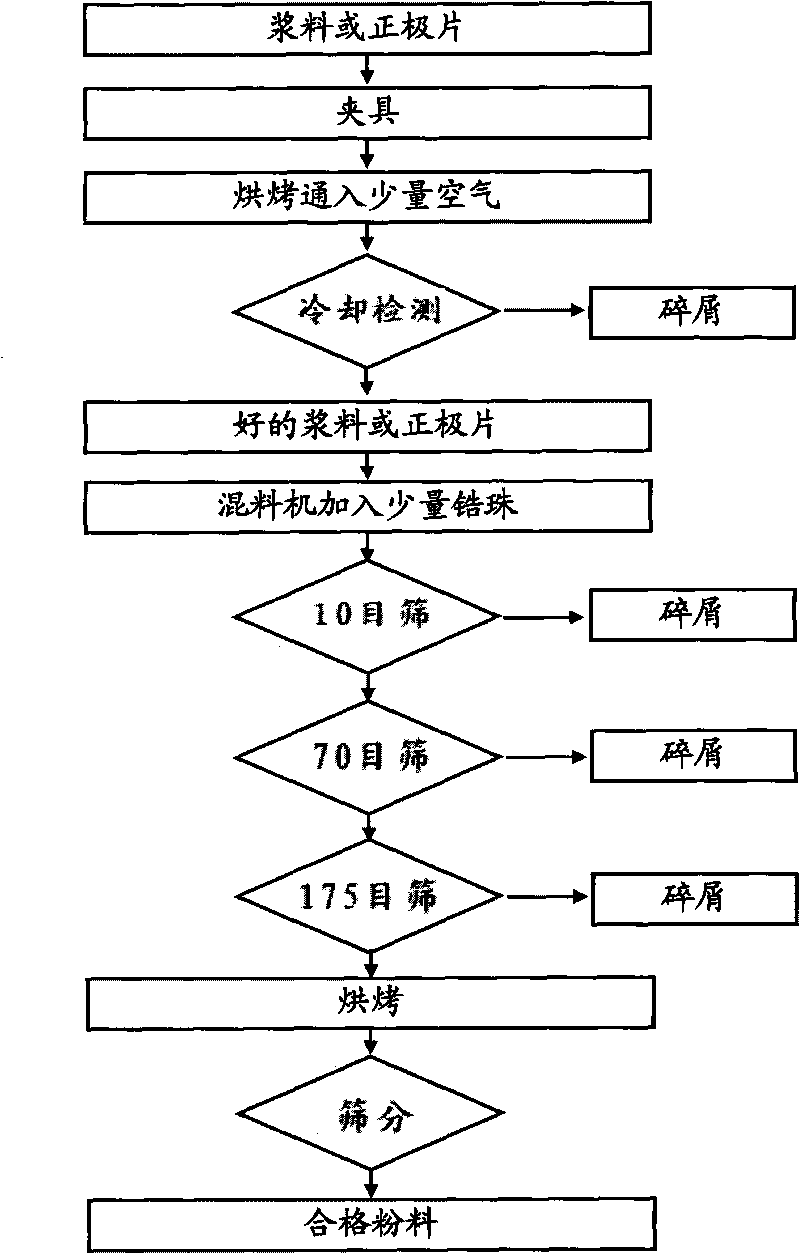

Method for recycling anode material of lithium ion battery

InactiveCN101707269ASimple processIncrease productivitySolid waste disposalWaste accumulators reclaimingMetallurgyAdhesive

The invention discloses a method for recycling anode material of lithium ion battery, which comprises the following steps: 1) putting crushed anode dry size or an anode plate to be recycled in a container, placing the container in a high temperature furnace for high temperature baking at 400-600 DEG C, afterwards taking out the processed powdery material or the anode plate and cooling for standby use; and 2) pulverizing the powdery material or the anode plate baked at high temperature in a pulverizer, de-powdering the pulverized anode plate, and finally sieving the powdery material to obtain qualified anode powdery material for recycling. The inventive method for recycling anode material of lithium ion battery carries out high temperature treatment on the anode material to cause the adhesive to decompose to lose adhesion function, but can not produce side effects on active substances and electrochemical properties thereof, the recycled active substances can be reused into production after simply sieving, and the invention has the advantages of simple technique, high production efficiency, obvious economic benefit, etc.

Owner:DONGGUAN AMPEREX TECH

Steel ball size detecting device

InactiveCN102607371AReduce labor intensitySolve visualMechanical diameter measurementsSteel ballUltimate tensile strength

The invention discloses a steel ball size detecting device, belonging to the detection field. The steel ball size detecting device comprises a worktable, a material storage bin, a screen mesh, a sliding chute, a material outlet, a material recycling channel and a material recycling box; the material storage bin is arranged on the worktable; the upper part of the material storage bin is provided with the screen mesh; the material storage bin is connected with the sliding chute; a long circular groove is arranged on the sliding chute; the width of the long circular groove is a little less than the diameter of a steel ball with a normal size; the sliding chute is connected with the material outlet; and the lower part of the sliding chute is connected with the material recycling channel and the material recycling box. According to the steel ball size detecting device disclosed by the invention, large-scale and continuous automatic detection is realized on the premise of reducing labor intensity of workers; and the steel ball size detecting device has the advantages of convenience for detection and high detection reliability, solves error assembly and error detection caused by visual fatigue or absent mindedness of detecting personnel, and effectively avoids the possibility that unqualified products enter into the next working procedure, therefore the brought potential risks for automobiles are eliminated.

Owner:耐世特凌云驱动系统(涿州)有限公司

Method for continuously producing low carbon alcohol by synthesis gas

ActiveCN101805242AImprove conversion rateHigh alcohol contentOrganic compound preparationPreparation by hydroxy group additionAlcoholFixed bed

The invention provides a method for continuously producing low carbon alcohol by synthesis gas, which is characterized by the unique technology of producing the low carbon alcohol by the synthesis gas and generating corresponding alcohol by the hydration of olefin and the ingenious combination thereof. In the invention, two fixed bed reactors are connected in series, i.e. a reactor for producing low carbon alcohol by the hydration of olefin is arranged behind a reactor for producing the low carbon alcohol by the synthesis gas, wherein deionized water enters the olefin hydration reactor by segments, and low-grade olefin passes through a catalyst bed layer from bottom to top. Reaction products enter a separation device, and unreacted synthesis gas, lower-grade olefin and deionized water arerespectively returned to the reactor for recycling. The invention controls unit energy consumption via a material recycling mode, and effectively increases the yield of the alcohol and the total conversion rate of the raw materials.

Owner:ENN XINNENG BEIJING TECH

Lithium battery positive electrode material recovery method

InactiveCN104577248AReduce recycling costsHigh purityWaste accumulators reclaimingProcess efficiency improvementRecovery methodAluminium hydroxide

The invention discloses a lithium battery positive electrode material recovery method. The method comprises the following steps: soaking in an alkaline solution, namely soaking a positive electrode plate of a waste lithium battery positive electrode material in a container filled with the alkaline solution; hydrolyzing, namely placing mixed liquid of an aluminum hydroxide solution obtained in former step and lithium cobalt oxide powder in pure water, hydrolyzing and then performing water screening and washing; carrying out hydrogen treatment, namely placing the lithium cobalt oxide powder treated through step a and b in an atmosphere furnace, then inflating the hydrogen in the furnace, heating at high temperature; hydrolyzing to remove lithium, namely placing the hydrogenated lithium cobalt oxide in the pure water to hydrolyze; carrying out solid-liquid separation, namely performing solid-liquid separation on the hydrogenated lithium cobalt oxide, and washing the separated solid for three times, drying, grinding to obtain cobalt oxide. The cobalt oxide as the positive electrode material is recovered by using the method of soaking in the alkaline solution, hydrolyzing, hydrogen treating, hydrolysis for lithium removal and solid-liquid separation; the recovery cost is low, the recovered cobalt oxide has few impurities, and is high in purity and good in effect.

Owner:CHANGSHA SHUNYANG METAL PROD

Method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid

ActiveCN111074074AWide range of sourcesShorten the timeWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryNanofluid

The invention discloses a method for recycling waste lithium ion battery anode materials based on deep-eutectic solvent nanofluid. The method mainly comprises the following several steps that (1) a dispersing agent and nano particles are sequentially added into a deep-eutectic solvent, and nanofluid with the deep-eutectic solvent as base fluid is prepared through stirring and ultrasonic treatment;(2) waste lithium ion batteries are disassembled after being completely discharged, and anode plates are obtained through separation; and (3) the anode plates are added into a prepared deep-eutecticsolvent nanofluid solution, stirring is carried out for 24-72 h under the temperature ranging from 25 DEG C to 220 DEG C, filtering is carried out, and the contents of valuable metal elements nickel,cobalt and lithium in the reacting solution are detected. The deep-eutectic solvent nanofluid is used for recycling the lithium ion battery anode materials, the process is simple, the recovery rate ofvaluable metal is high, and application and popularization are easy.

Owner:CHINA UNIV OF MINING & TECH

Energy-saving and environment-friendly rotary disc type automatic coating machine

ActiveCN105032671AImprove purification effectEasy to recycleLiquid surface applicatorsCoatingsEngineeringAssembly line

The invention discloses an energy-saving and environment-friendly rotary disc type automatic coating machine which comprises a machine frame, a rotary disc, a plurality of coating bins, a material conveying line, a taking mechanical hand, a discharging mechanical hand, a dust pumping device and a coating material recycling device. The rotary disc is rotationally installed on the machine frame and provided with a plurality of stations. Each station is provided with a workbench matched with a coated part. The workbenches are rotationally installed on the rotary disc. The coating bins are installed on the machine frame and located above the rotary disc. The lower portions of the coating bins are provided with openings. Coating devices are arranged in the coating bins. The material conveying line is used for conveying the coated part. The taking mechanical hand is used for transporting the coated part on the material conveying line to the rotary disc. The discharging mechanical hand is used for transporting the coated part machined on the rotary disc to the material conveying line. The dust pumping device is installed on the machine frame and used for pumping and discharging dust in the coating bins. The coating material recycling device is connected with the dust pumping device and used for recycling coating materials in air. By the adoption of the structure, the energy-saving and environment-friendly rotary disc type automatic coating machine can achieve assembly line type automatic coating, is small in occupied space, saves energy, and is environmentally friendly and high in working efficiency.

Owner:林群玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com