Method for recycling and regenerating waste lithium ion battery electrode materials

A technology for lithium ion batteries and electrode materials, which is applied in the field of recycling and regeneration of cathode materials and anode materials of lithium ion batteries, can solve the problem of high energy consumption, and achieve the effects of efficient recovery, high added value of products, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

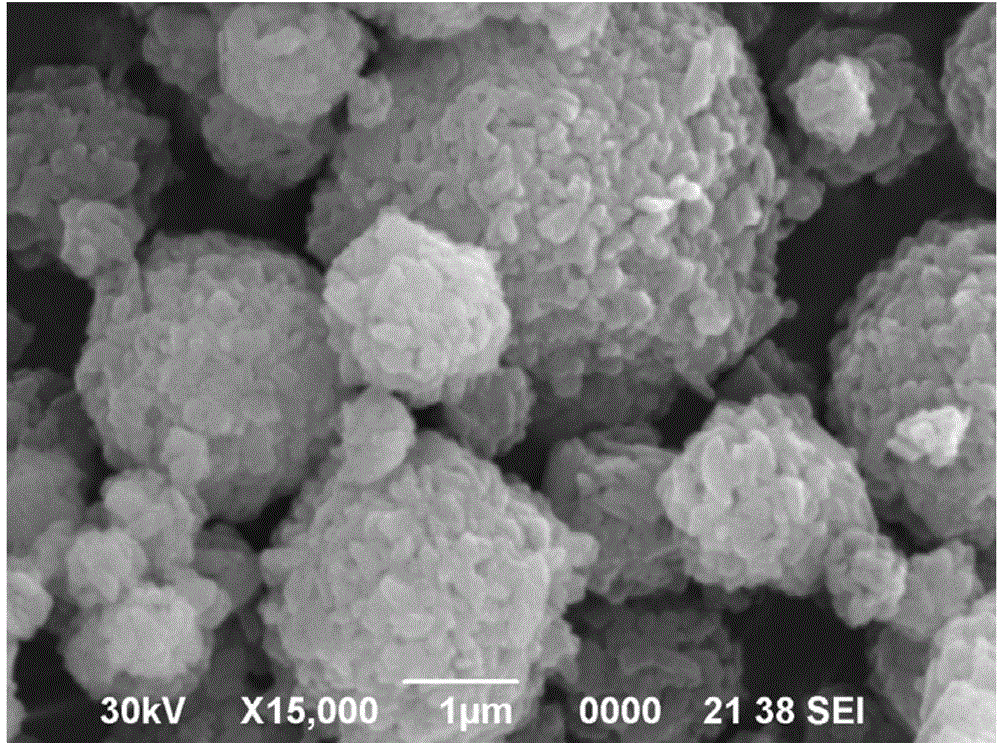

Image

Examples

Embodiment 1

[0033] After the waste soft-packed lithium titanate battery is tested and discharged, it is disassembled in the fume hood to select the positive electrode, negative electrode and separator, and the positive and negative electrodes are soaked in 8% ammonia water for 80 minutes, and then rinsed with clean water. Wash and dry at 120°C, put the obtained pole pieces into crucibles, and treat them in a muffle furnace at 400°C for 4 hours. Vibration can make the electrode material separate from the current collector metal foil, and obtain positive electrode powder materials and negative electrode powders containing conductive carbon. Body materials and collectors, recycling collectors.

Embodiment 2

[0035]After the waste soft-packed lithium titanate battery is tested and discharged, it is disassembled in a fume hood to select the positive electrode, negative electrode and separator, and the positive and negative electrodes are soaked in 1% ammonia water for 80 minutes, and then rinsed with clean water. Washing, drying at 120°C, putting the obtained pole pieces into crucibles respectively, and treating them at a high temperature of 500°C for 2.5 hours in a muffle furnace, vibration can make the electrode material separate from the metal foil of the current collector, and obtain the positive electrode powder material containing conductive carbon, the negative electrode Powder materials and collectors, recycling collectors.

Embodiment 3

[0037] After the waste soft-pack lithium titanate battery is tested and discharged, it is disassembled in a fume hood to select the positive electrode, negative electrode and separator, and the positive and negative electrodes are soaked in 28% ammonia water for 5 minutes, and then rinsed with clean water. Washing, drying at 120°C, putting the obtained pole pieces into crucibles respectively, and treating them at 600°C in a muffle furnace for 1.5 hours, vibration can make the electrode material separate from the current collector metal foil, and obtain positive electrode powder materials containing conductive carbon, negative electrode Powder materials and collectors, recycling collectors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com