Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1275results about "Sludge treatment by thermal conditioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

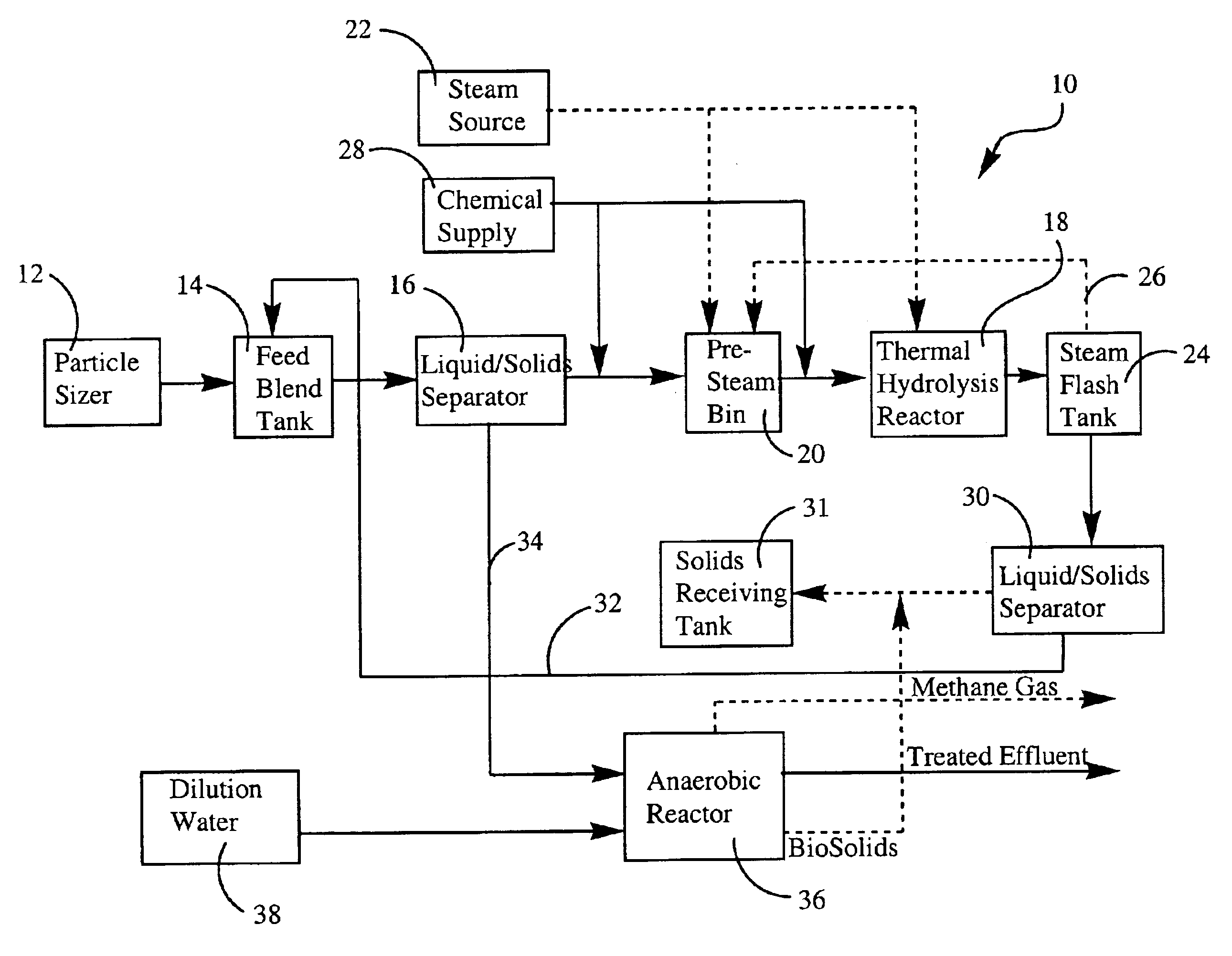

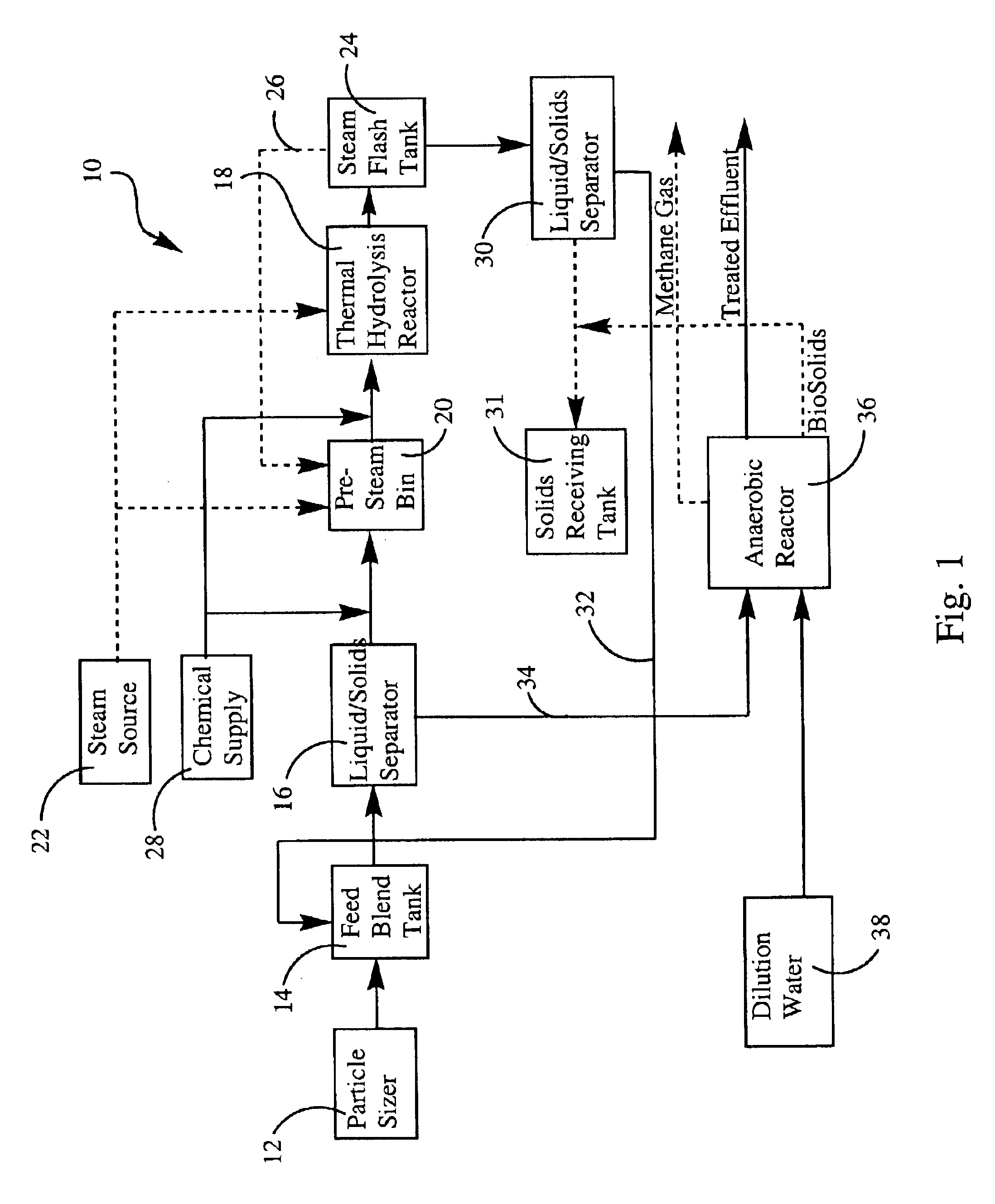

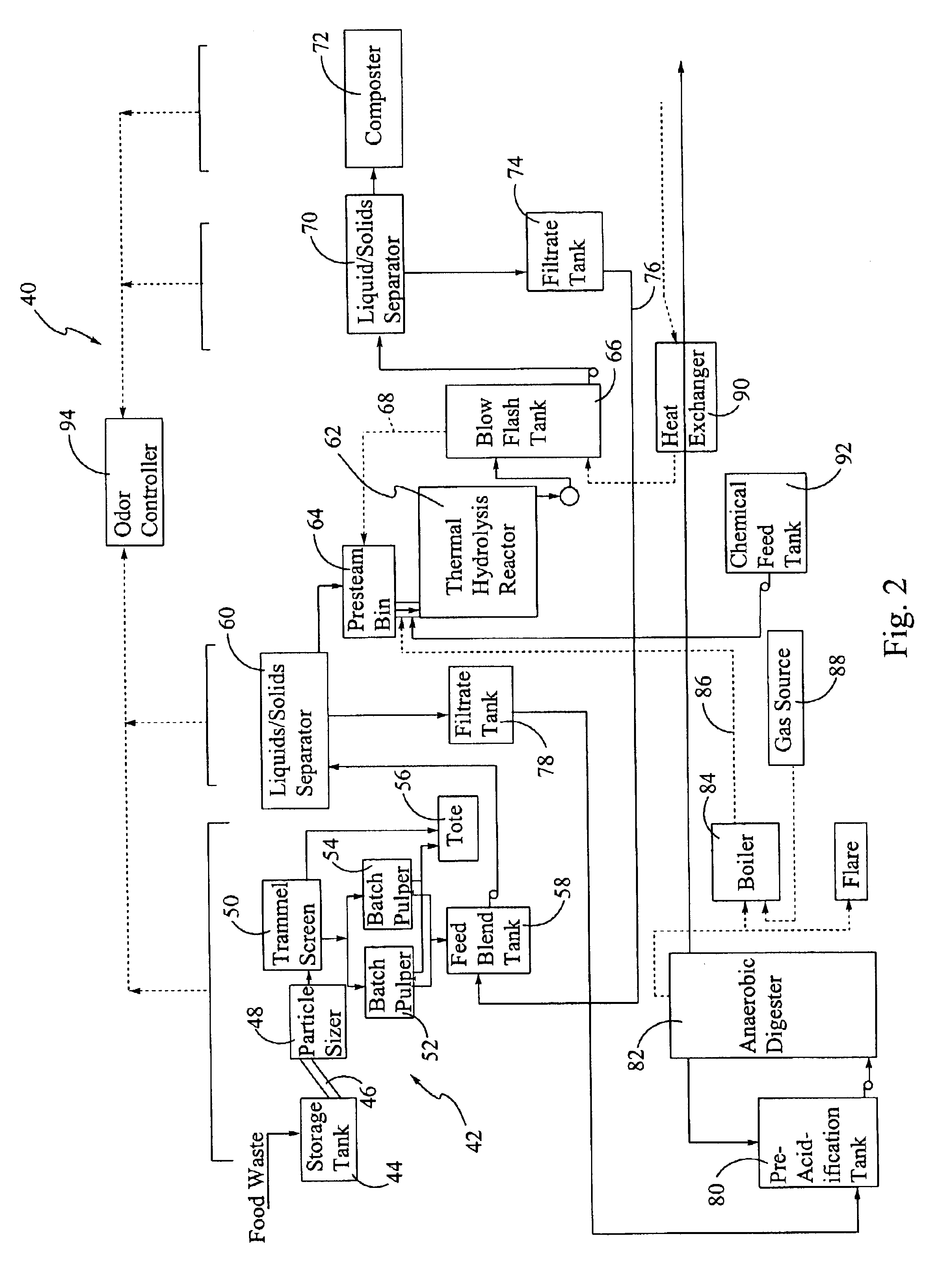

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

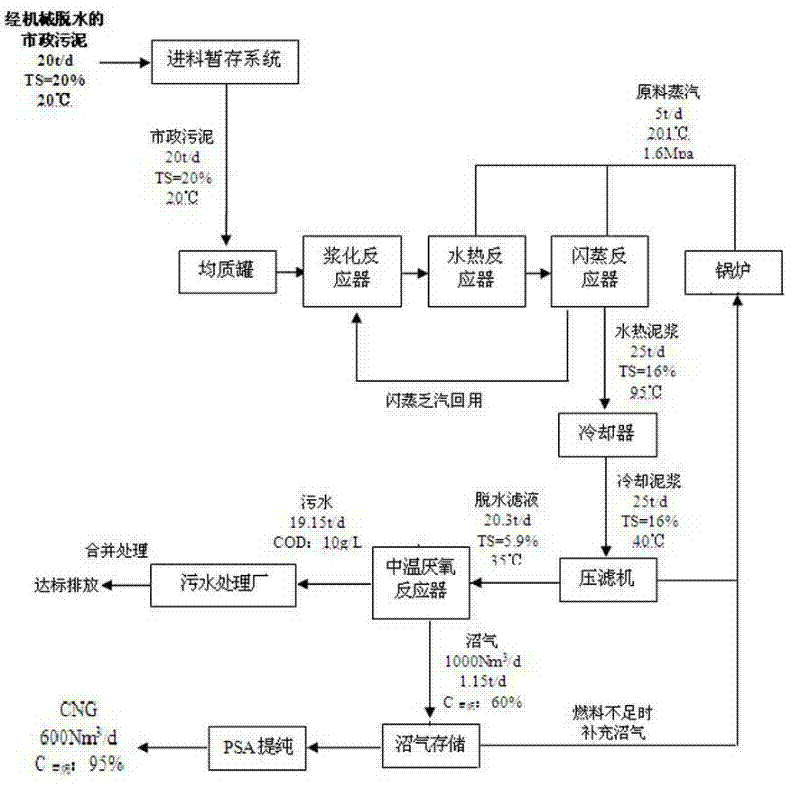

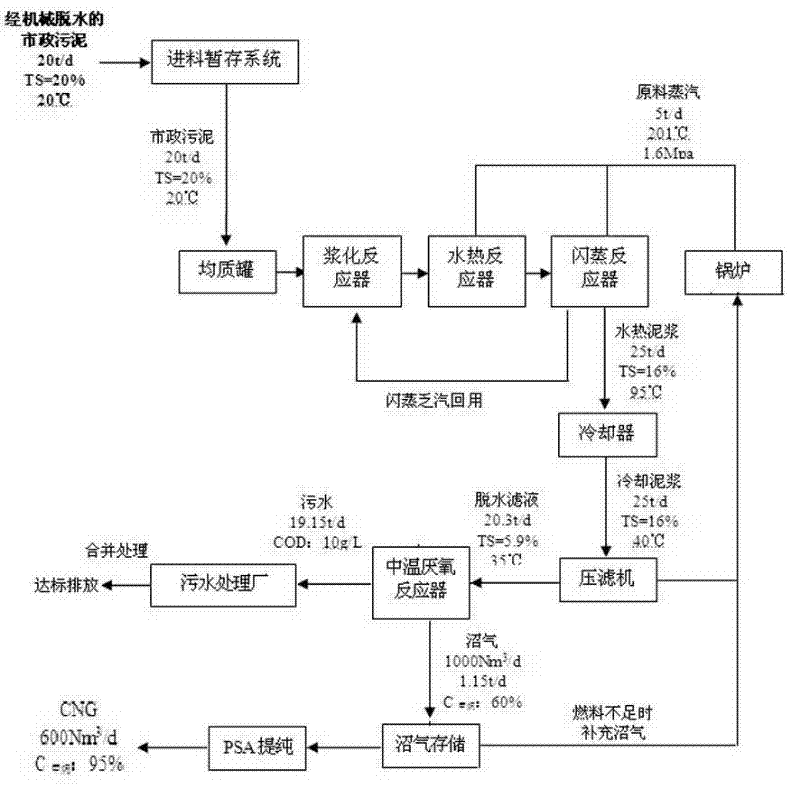

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

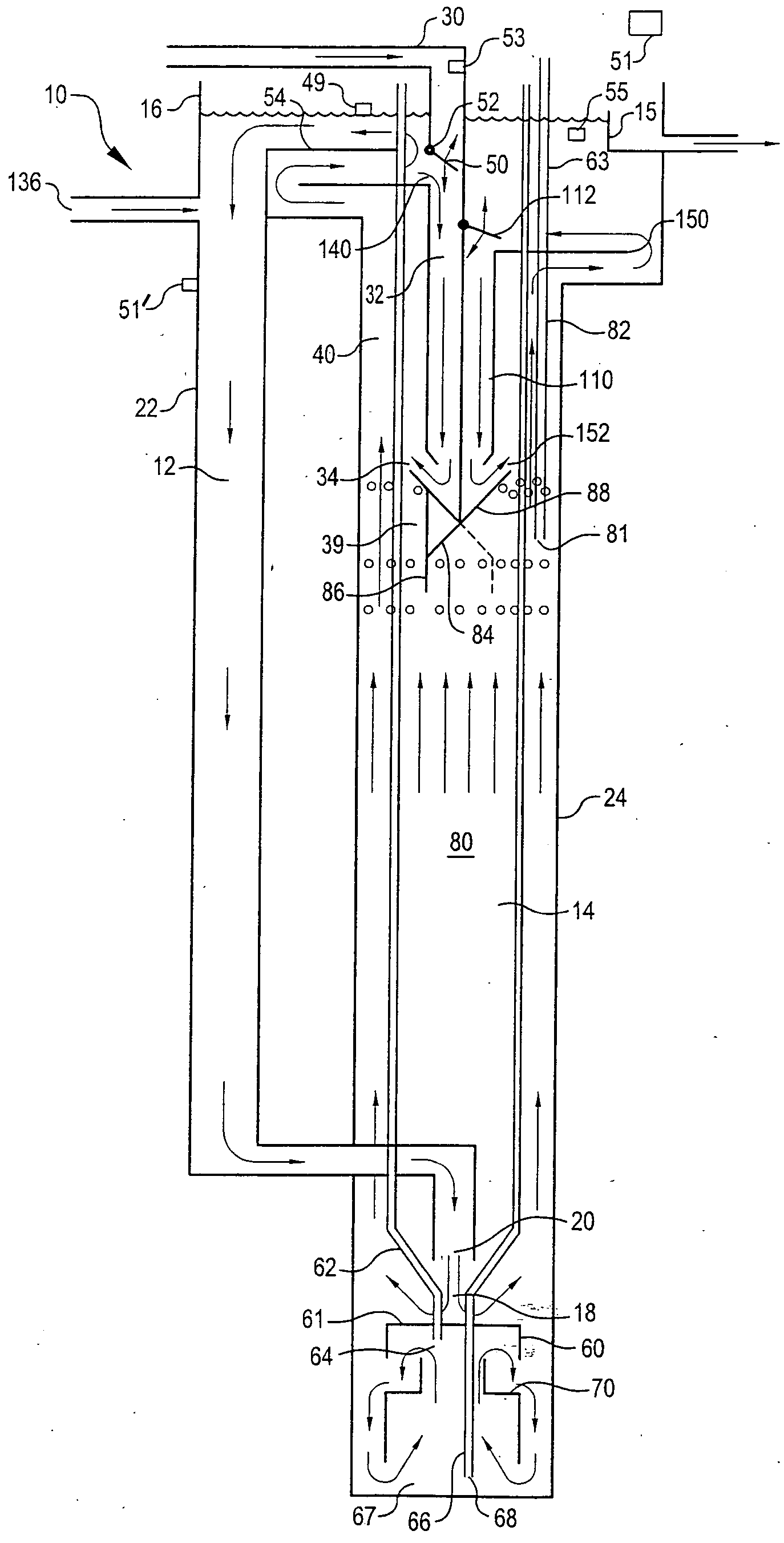

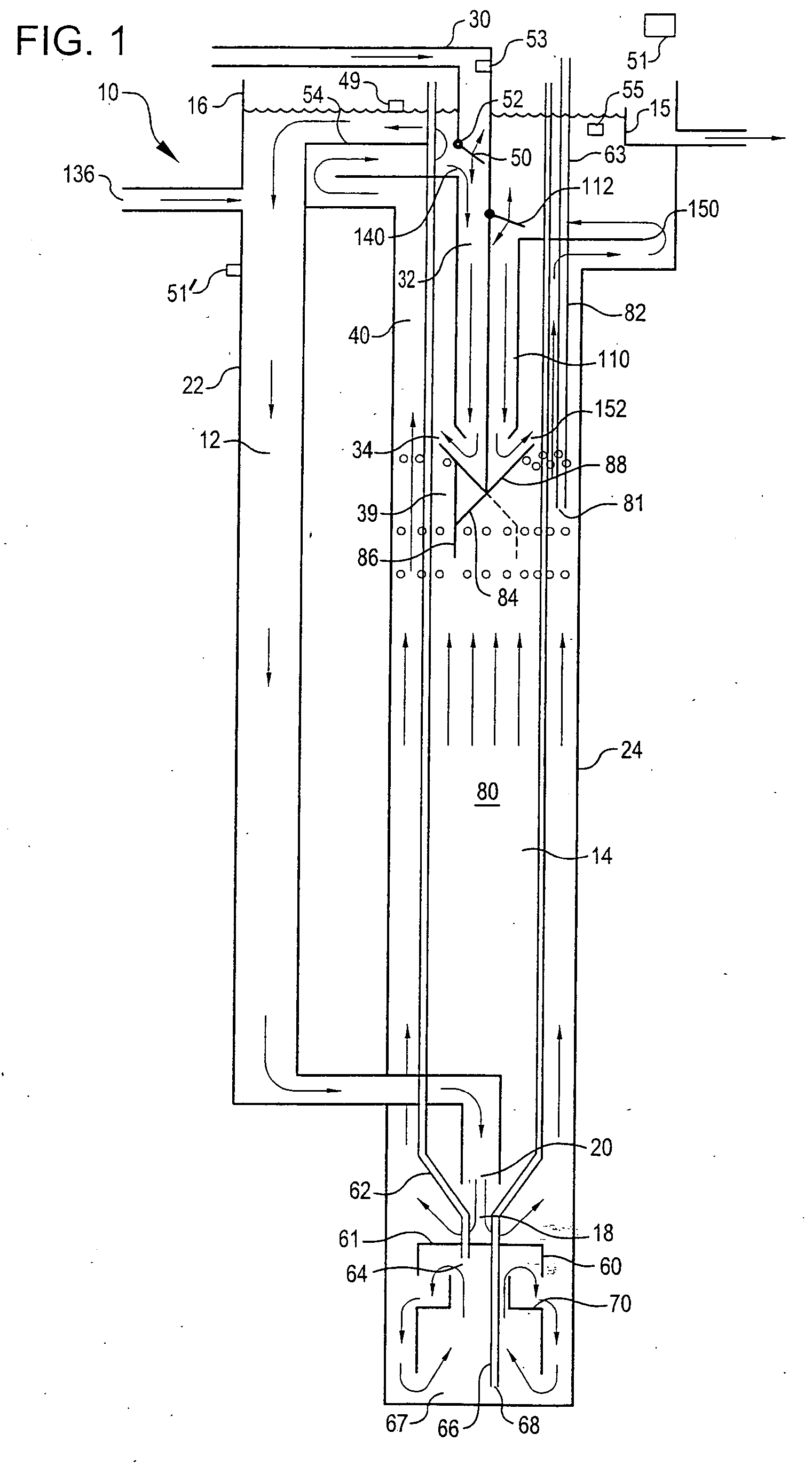

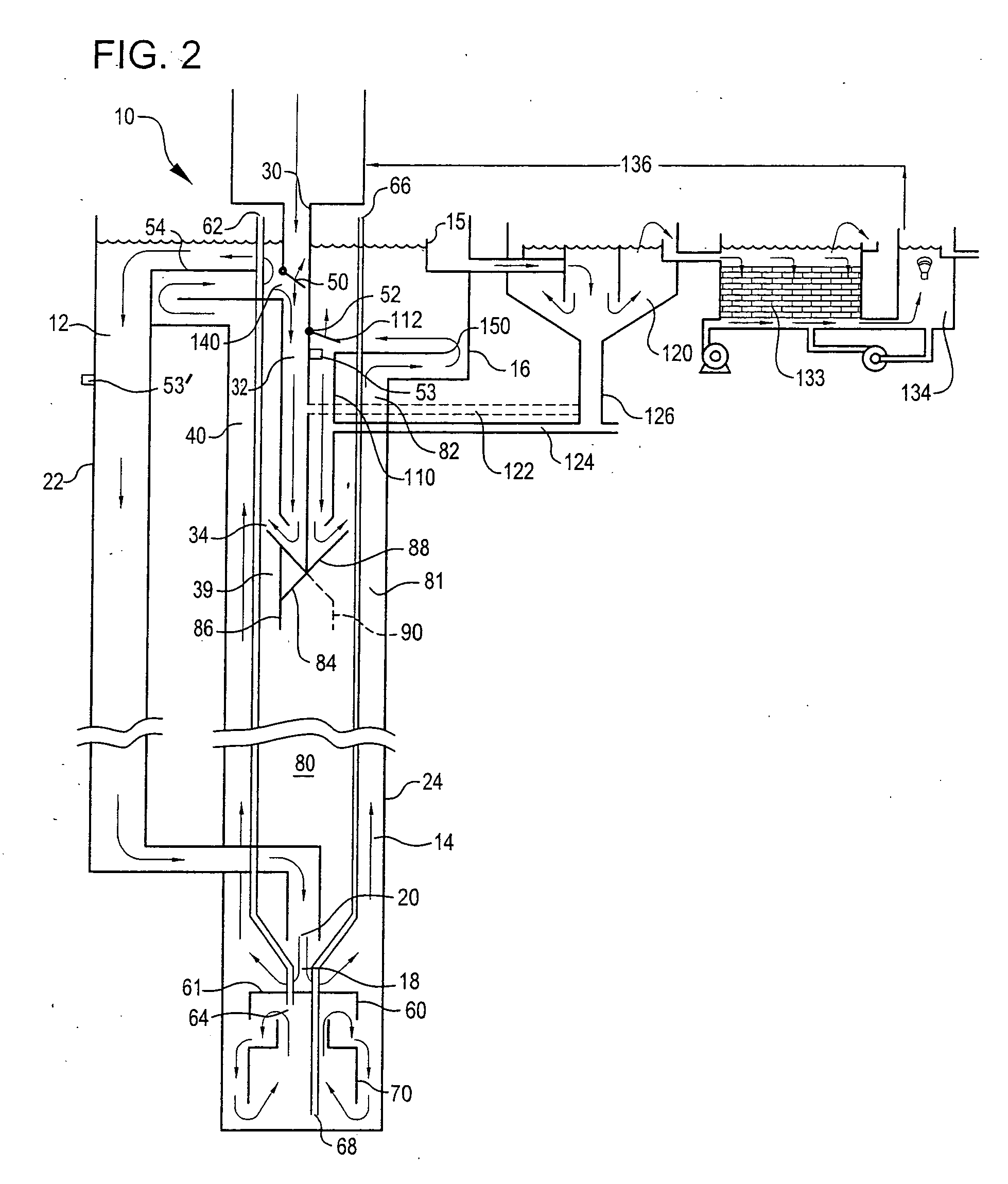

Methods and apparatus for biological treatment of waste waters

InactiveUS20050115880A1Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

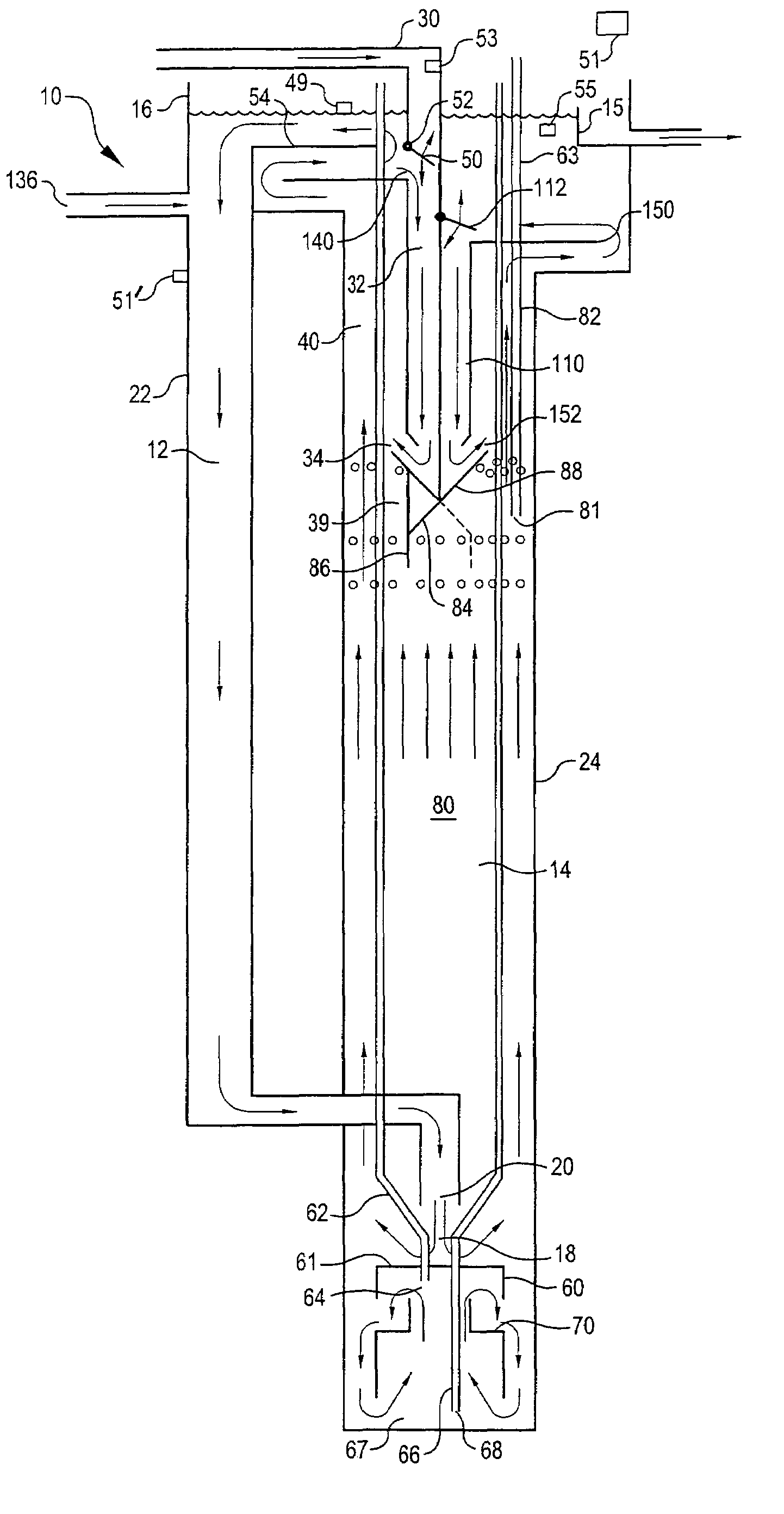

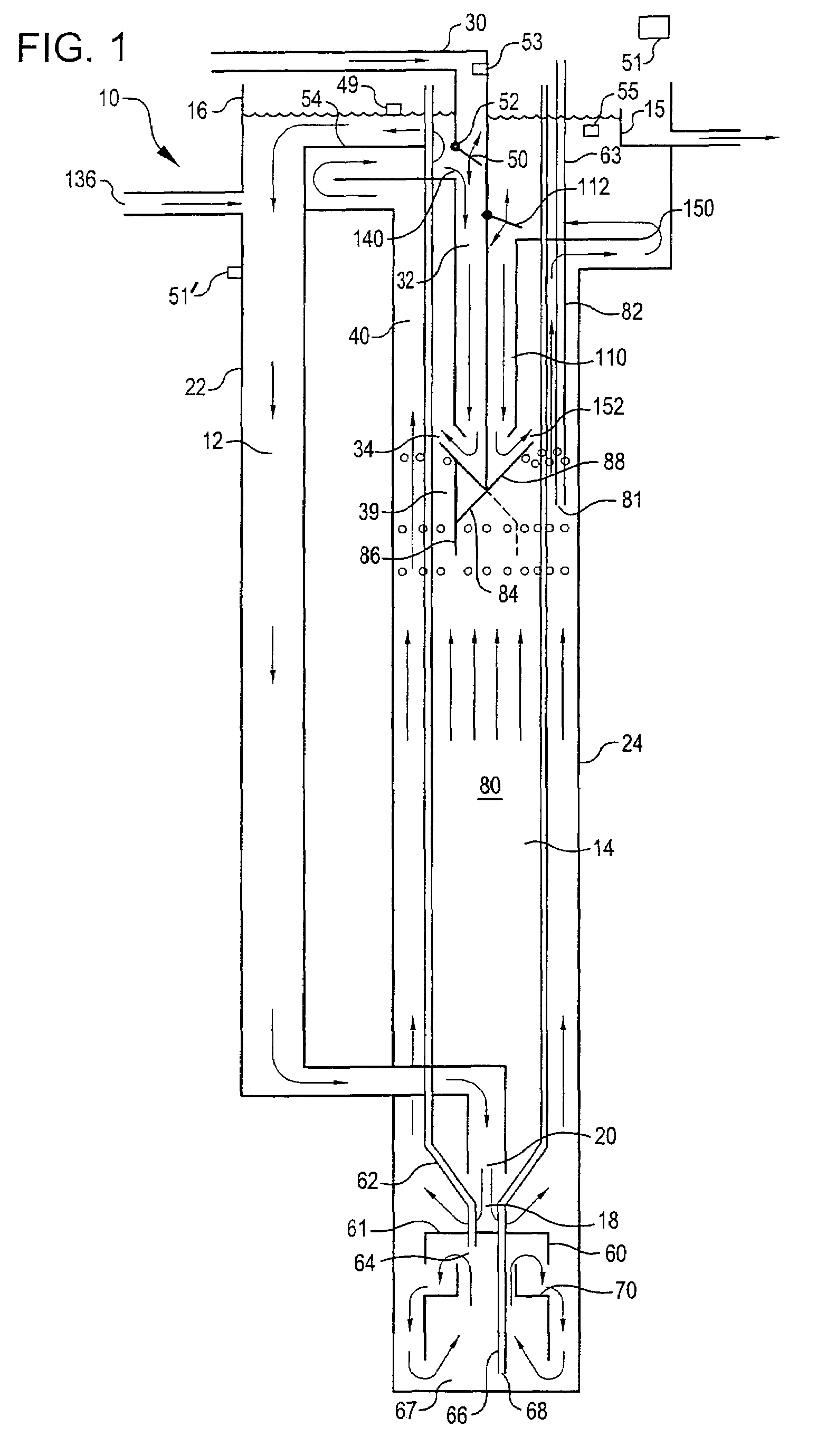

Apparatus for biological treatment of waste waters

InactiveUS7018530B2Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

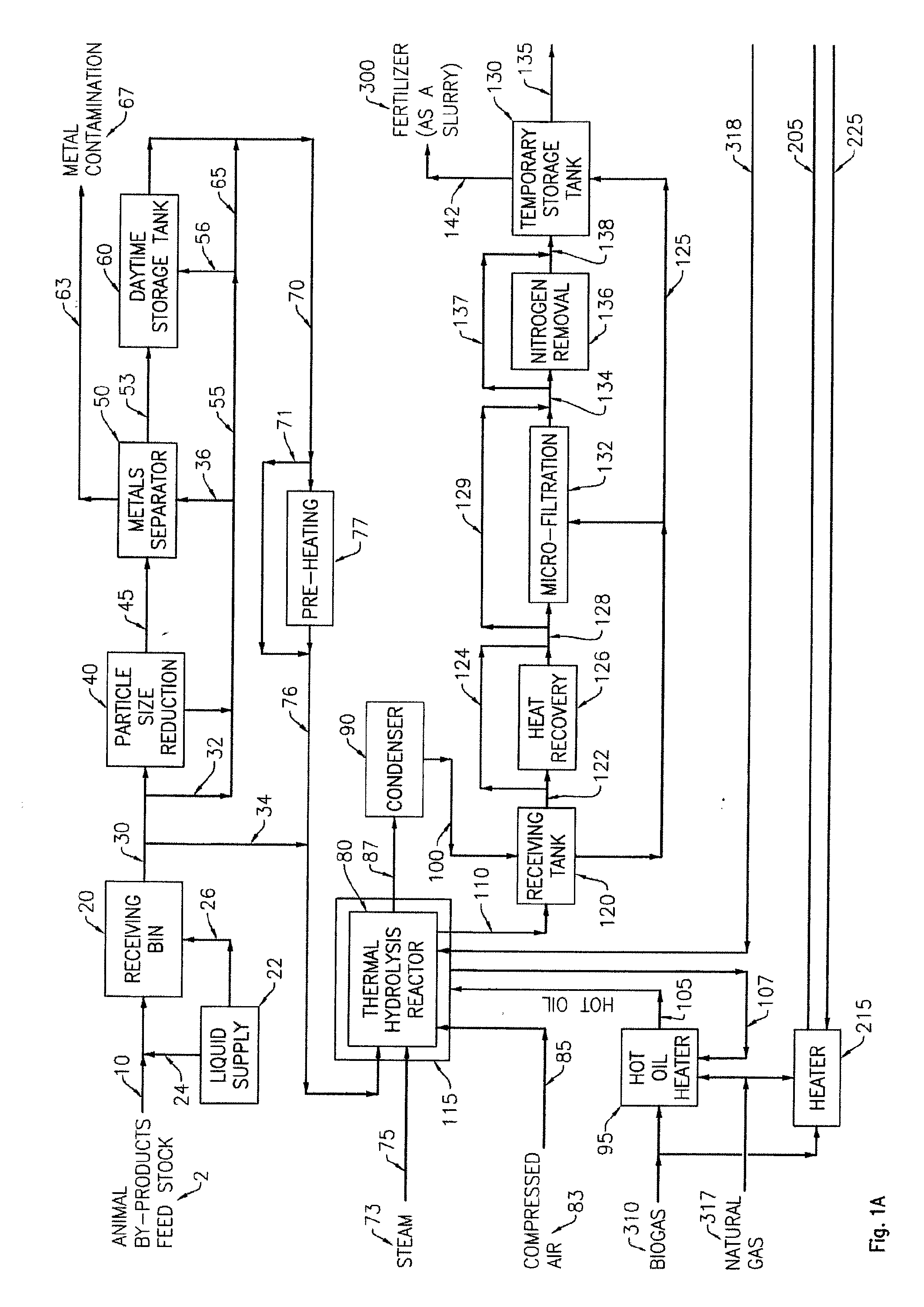

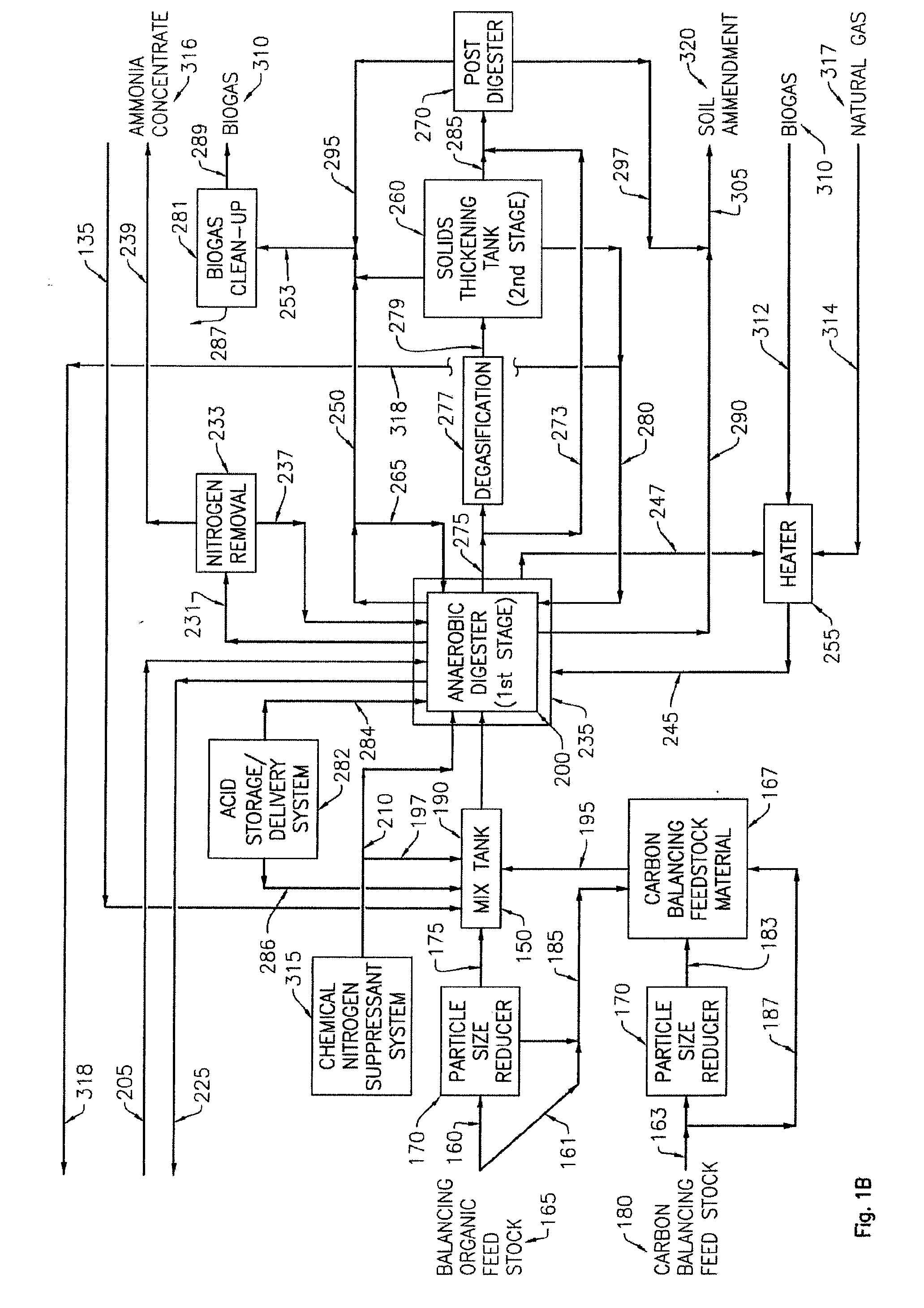

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

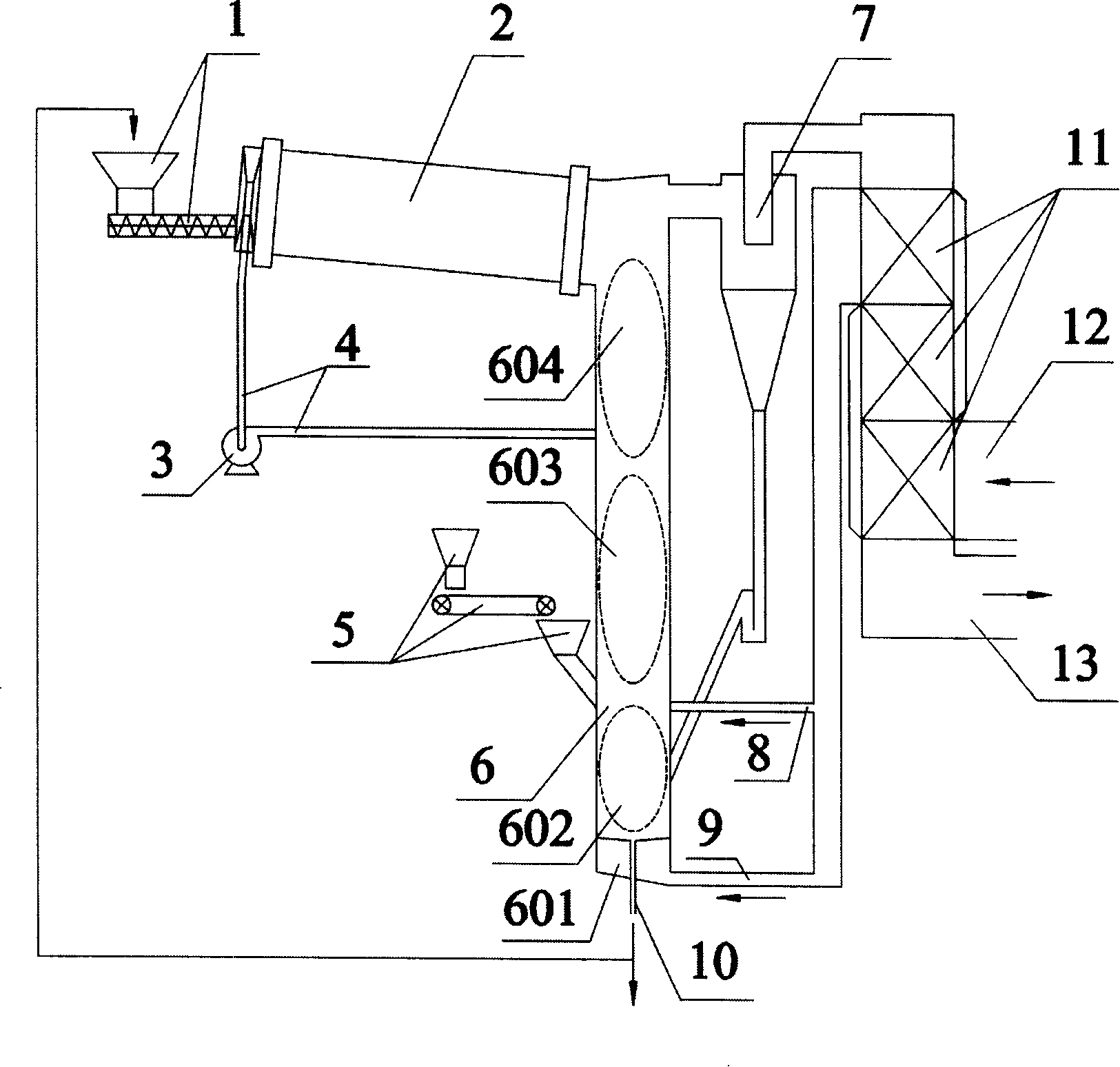

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

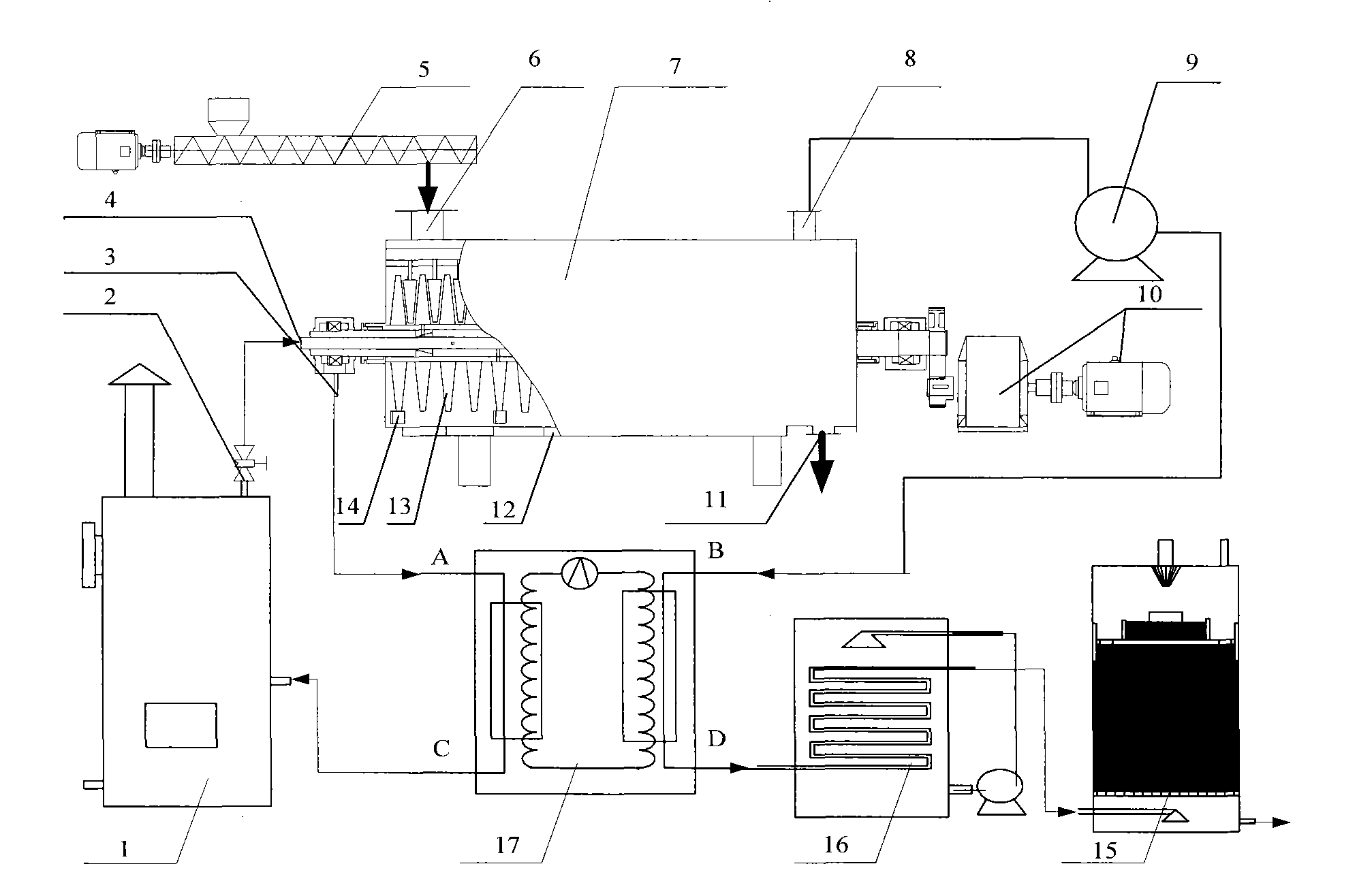

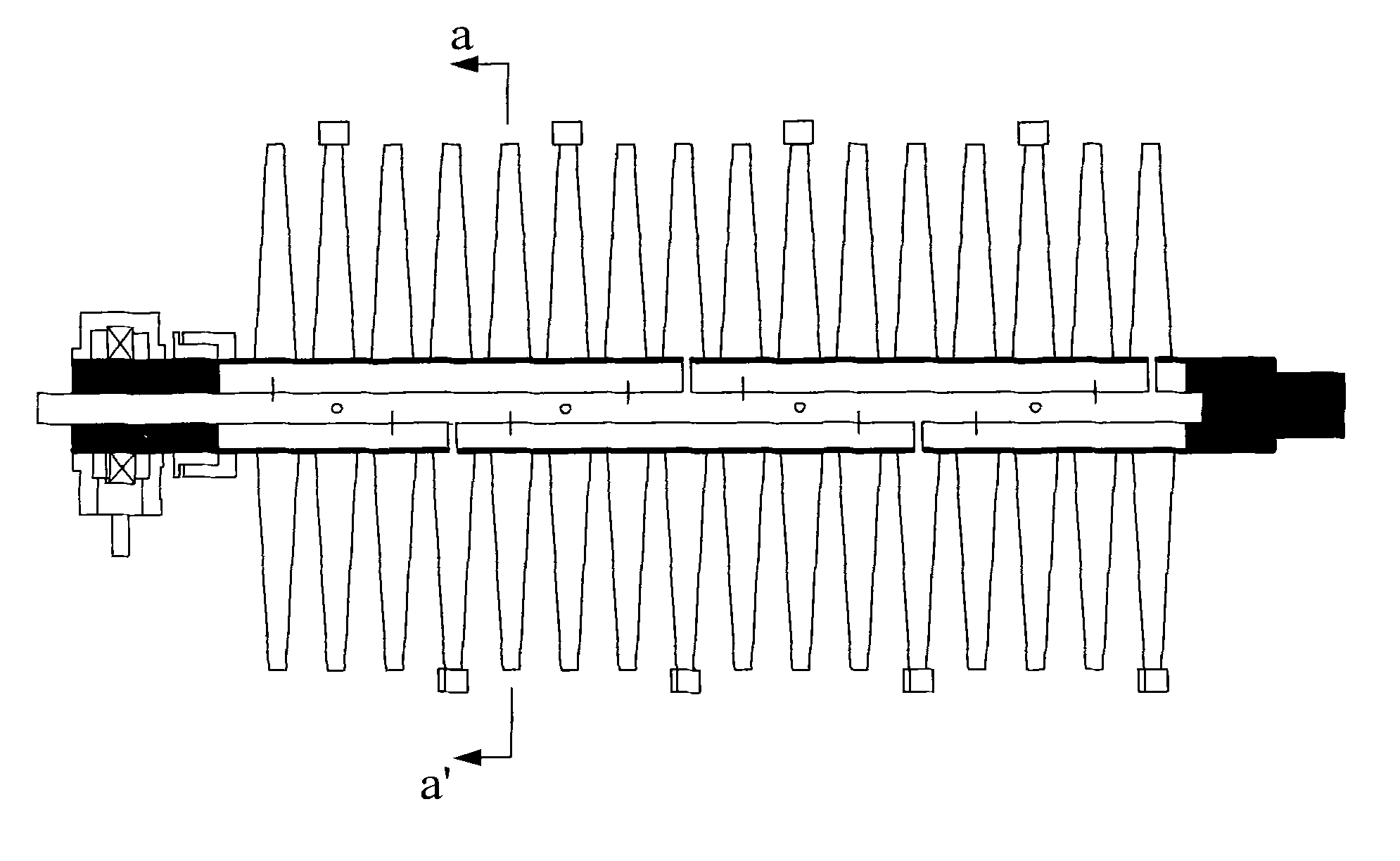

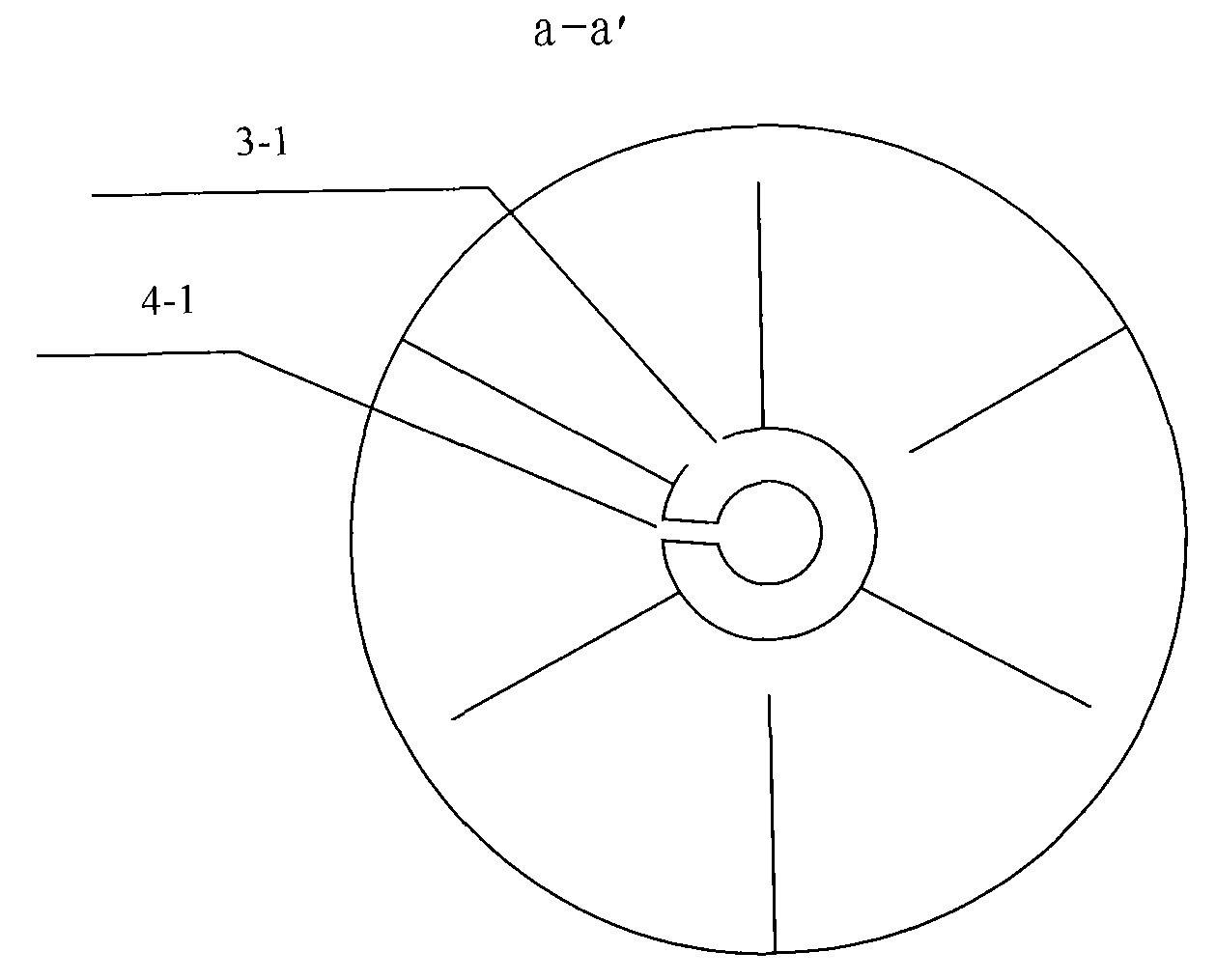

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

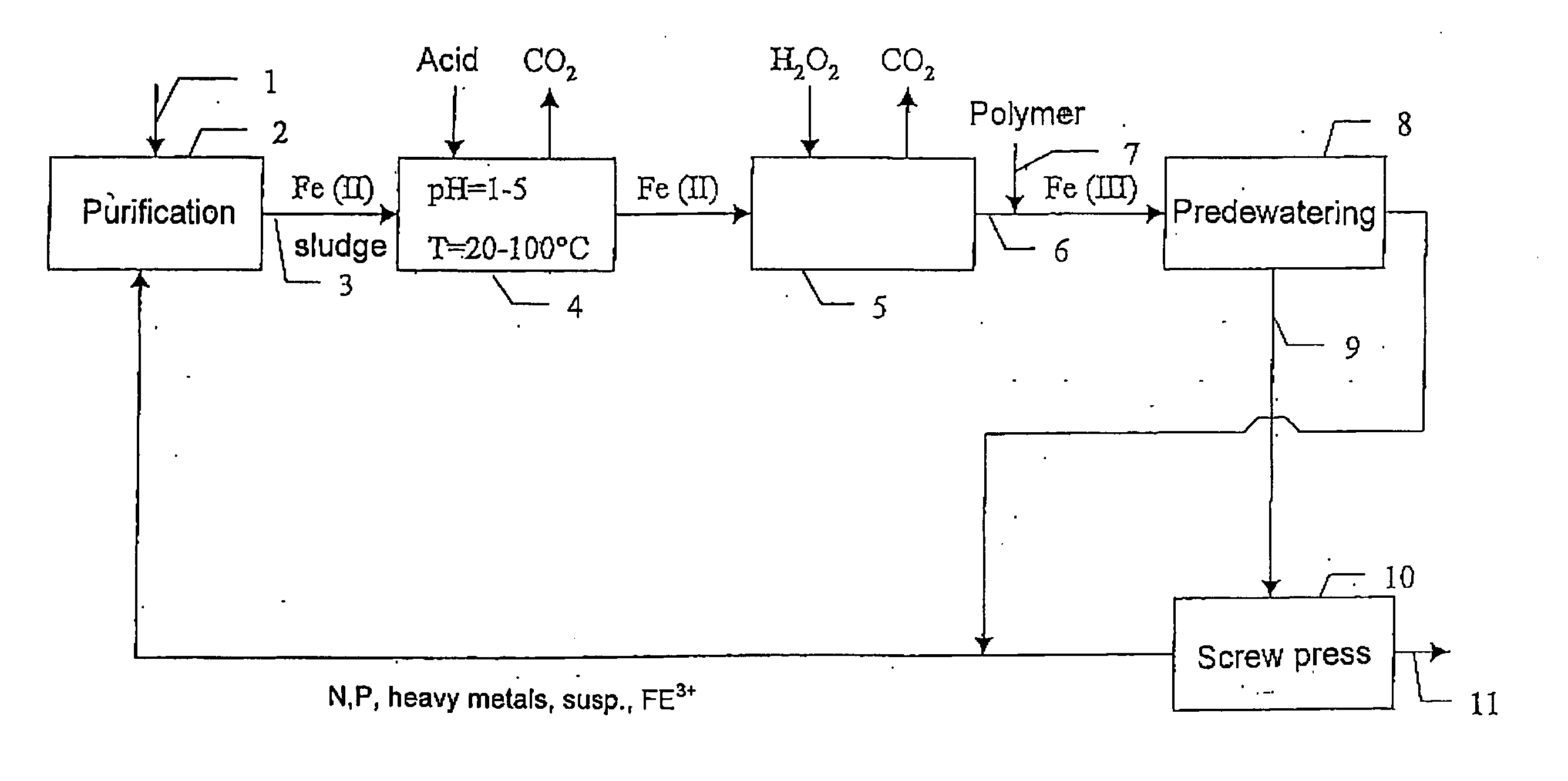

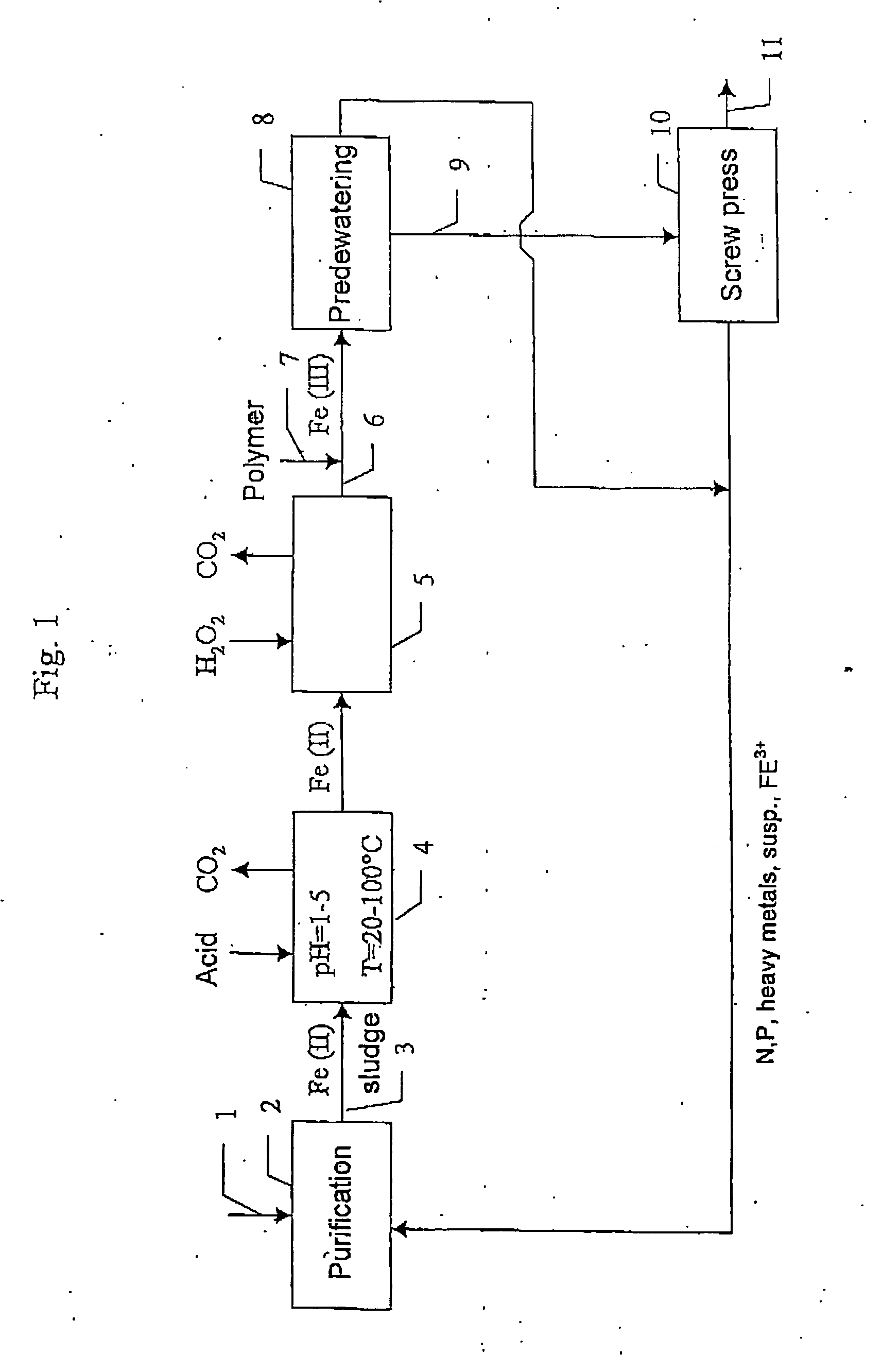

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

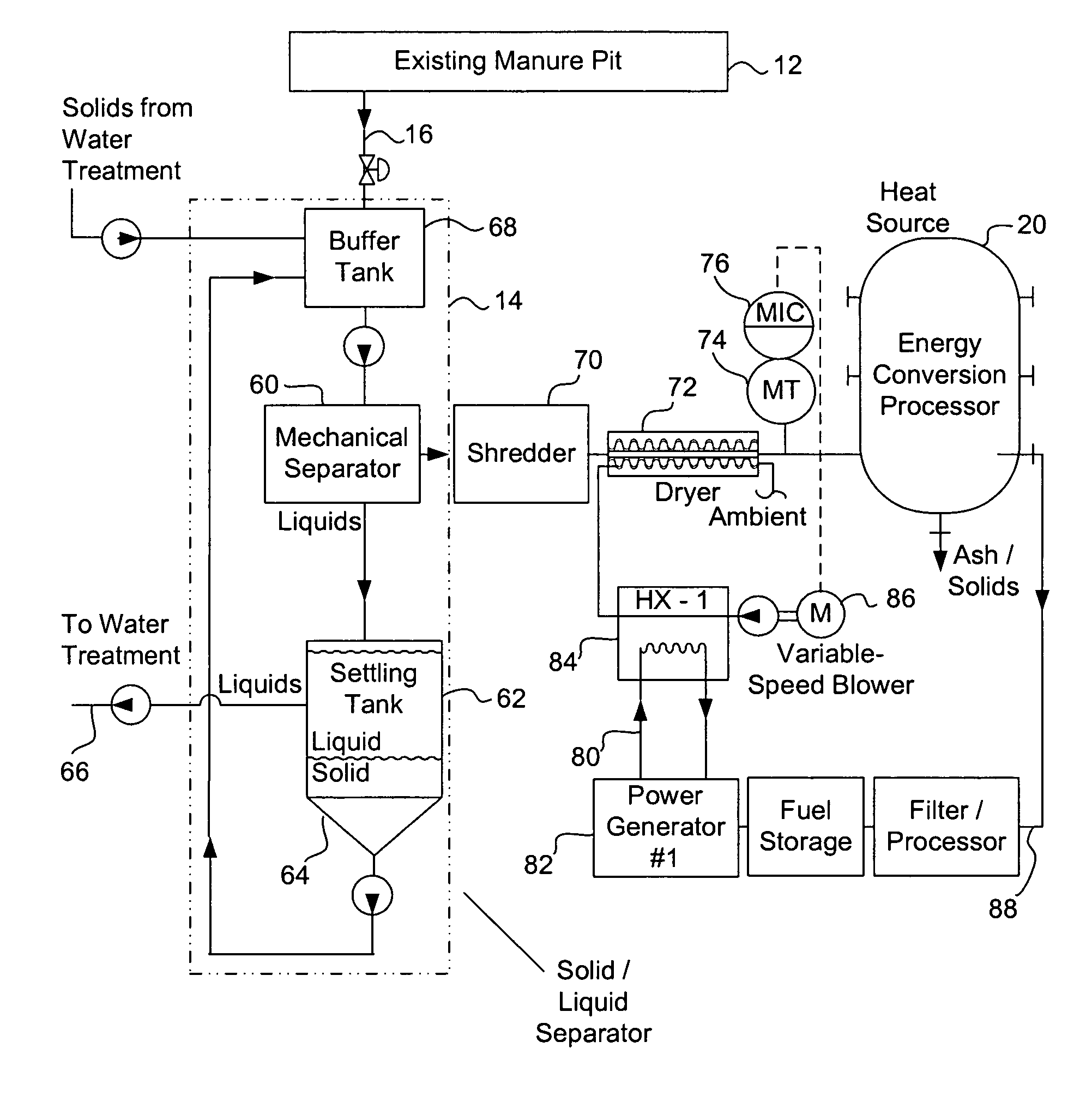

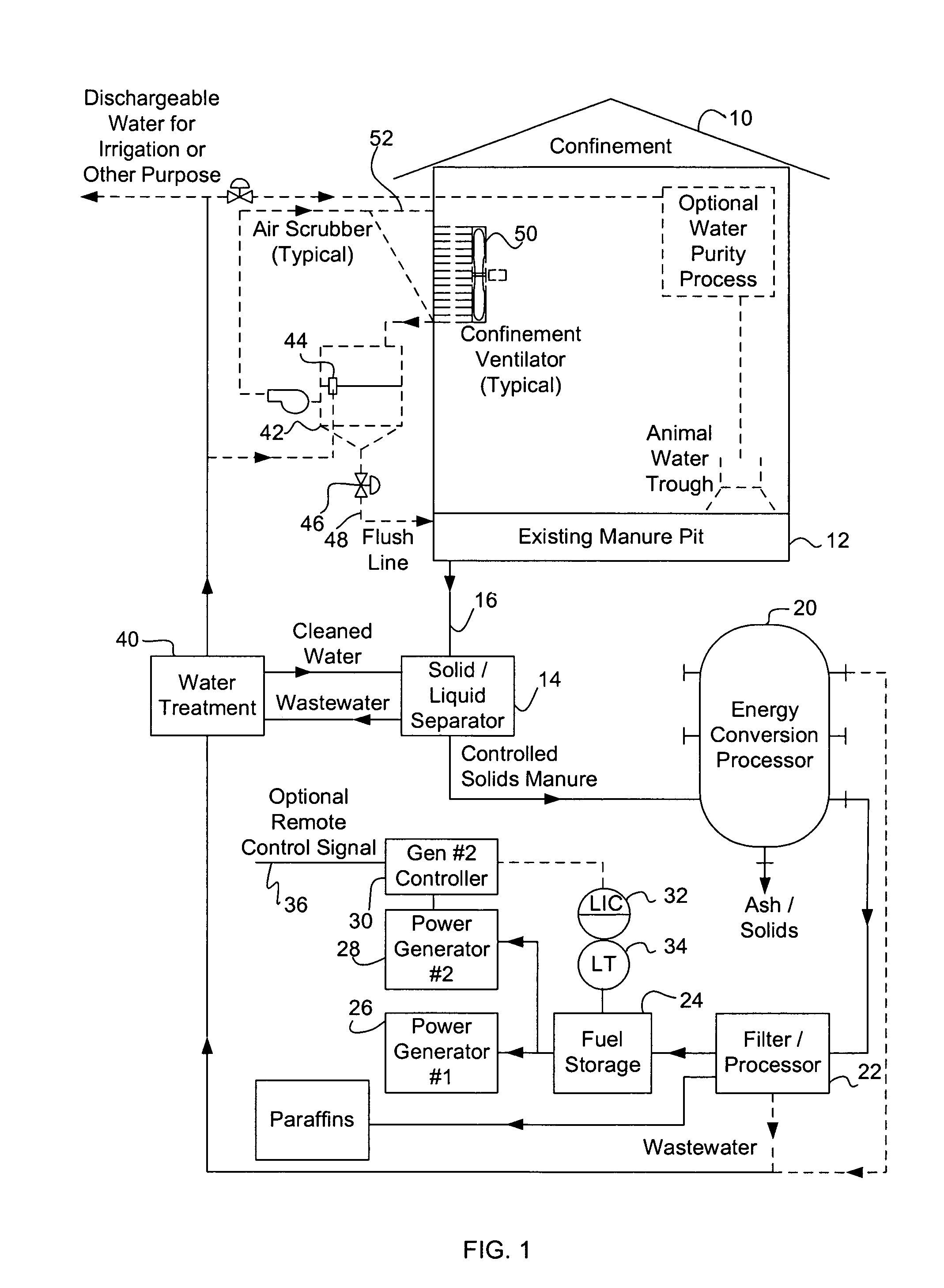

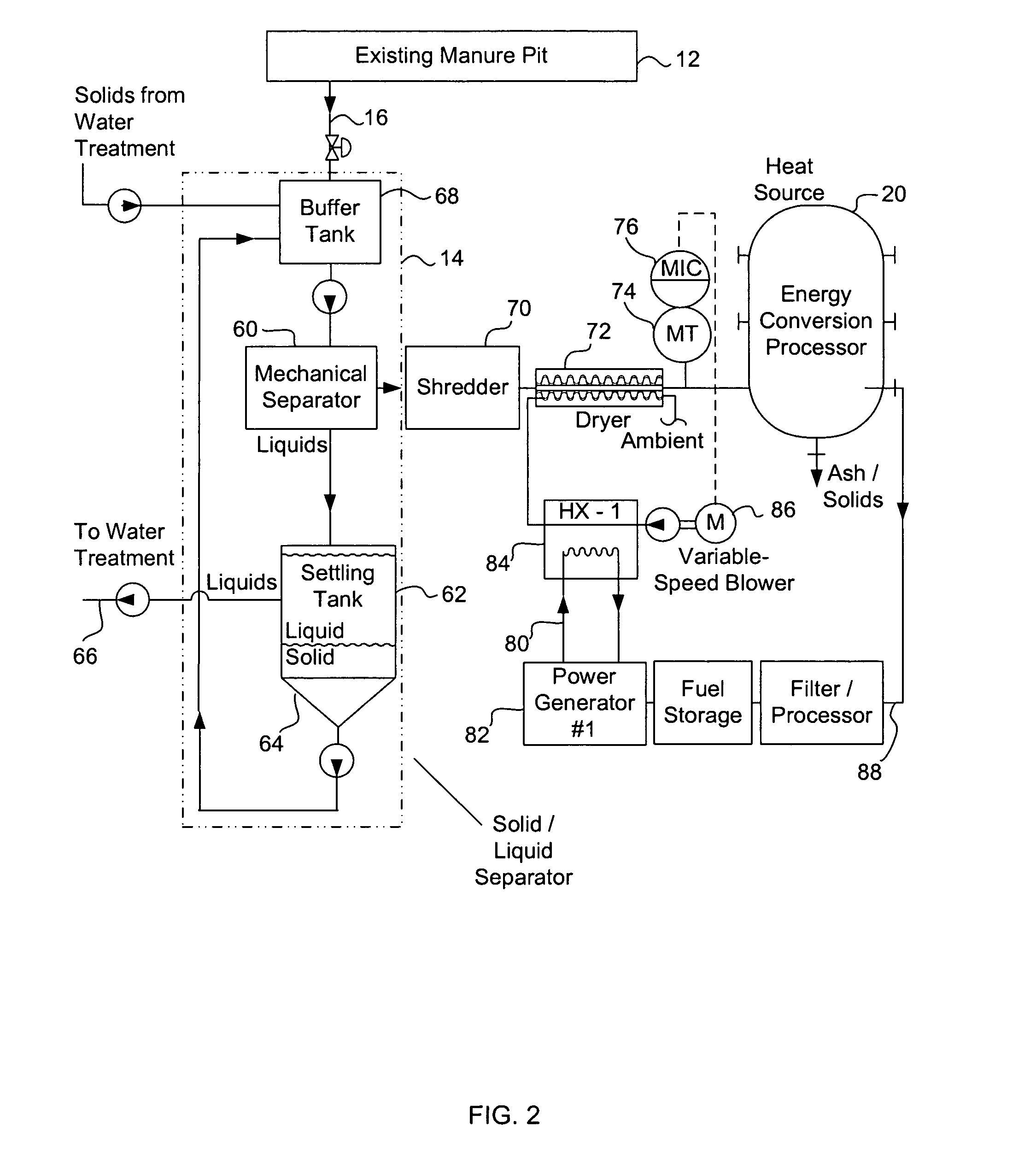

Methods and systems for converting waste into energy

A method for receiving animal waste from animal confinements or other concentrated animal waste sources and for converting the waste into a usable form is described. The waste contains both liquids and solids. The method includes separating the liquids and solids into separate waste streams, controlling an amount of moisture in the solids waste stream such that the amount of moisture in the solid waste stream is compatible with a selected energy conversion process, and feeding the moisture controlled solid waste into the energy conversion process.

Owner:SNAPSHOT ENERGY LLC

Sludge biological carbonizing technology based on hydrothermal reaction

ActiveCN102875005ALow running costImprove energy efficiencySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhysical chemistryCombustible gas

The invention discloses a sludge biological carbonizing technology based on hydrothermal reaction. The sludge biological carbonizing technology comprises the steps as follows: 1) dewatering the sludge, and transferring the sludge into a sludge pre-storage bin to be stored; 2) preheating the dewatered sludge; 3) transferring the preheated dewatered sludge into a hydrothermal reactor, thus obtaining hydrothermal lysis solution; 4) returning the hydrothermal lysis solution into a preheating system to preheat the dewatered sludge, and cooling the hydrothermal lysis solution so as to obtain a gaseous product; 5) transferring the cooled hydrothermal lysis solution into a filter press for filter pressing, thus obtaining a reacting filtrate and a solid product; 6) drying the solid product produced in previous step, and then transferring the solid product into a dry type carbonizing furnace to be carbonized, so as to obtain the solid biological carbon and other products, and transferring the other products into a gas-liquid separating device to be separated so as to obtain combustible gas and tar; and 7) transferring the gaseous product obtained in step 4) and the combustible gas and tar obtained in step 6) into a firebox to be burnt so as to generate heat; and supplying the generated heat to a hydrothermal reactor and the dry type carbonizing furnace. With the adoption of the sludge biological carbonizing technology disclosed by the invention, the product with high additional value can be obtained; and meanwhile, the energy can be saved.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

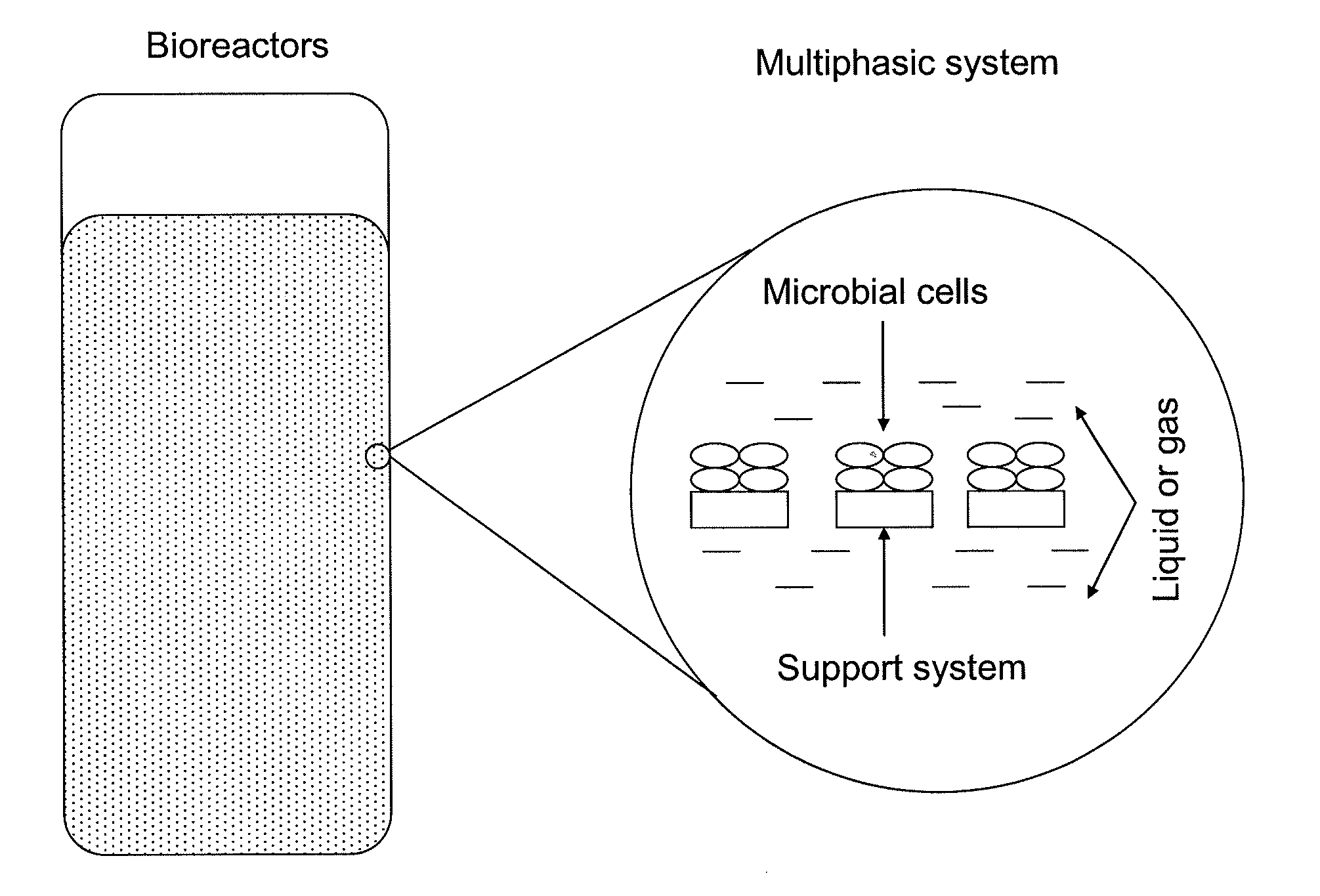

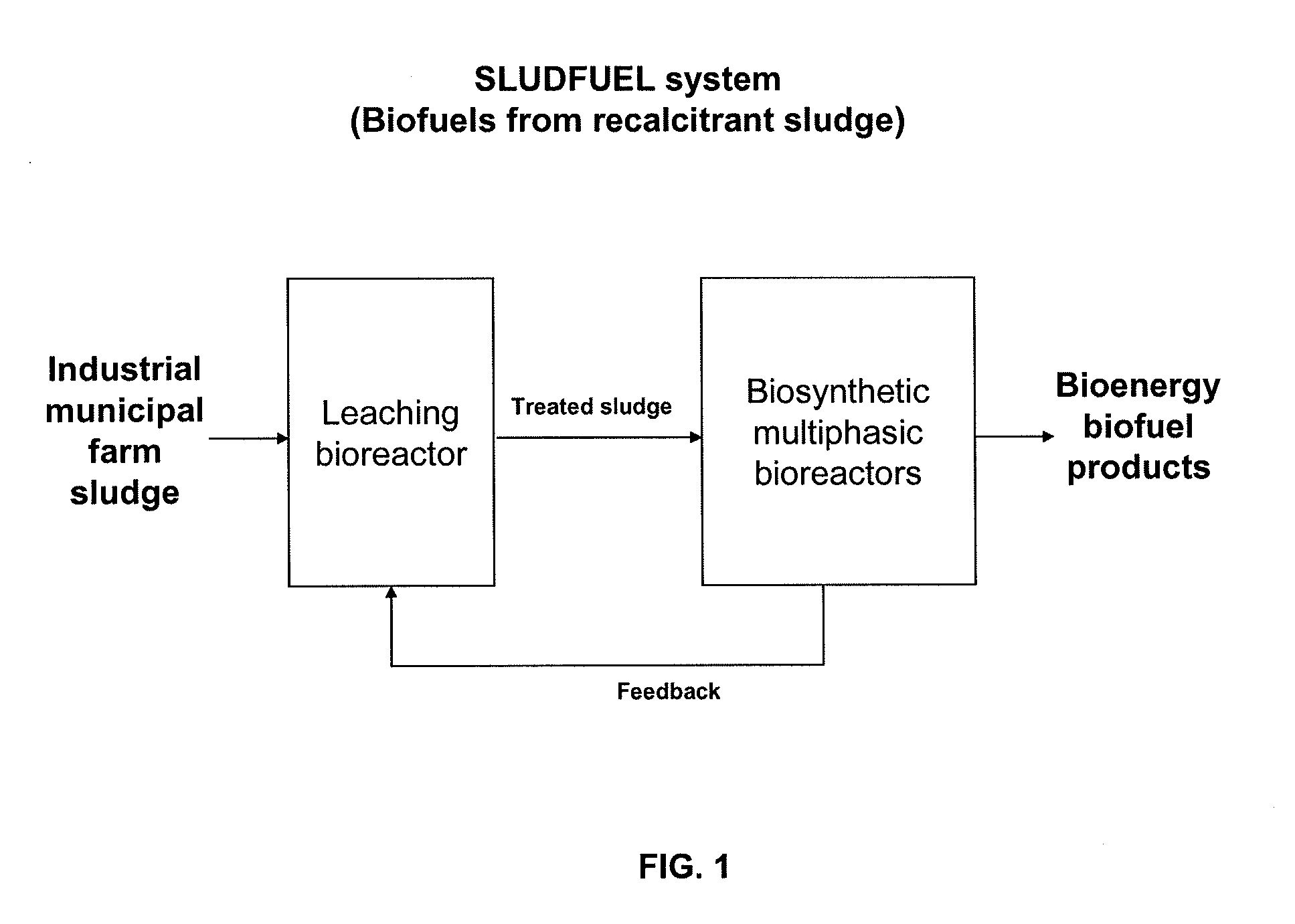

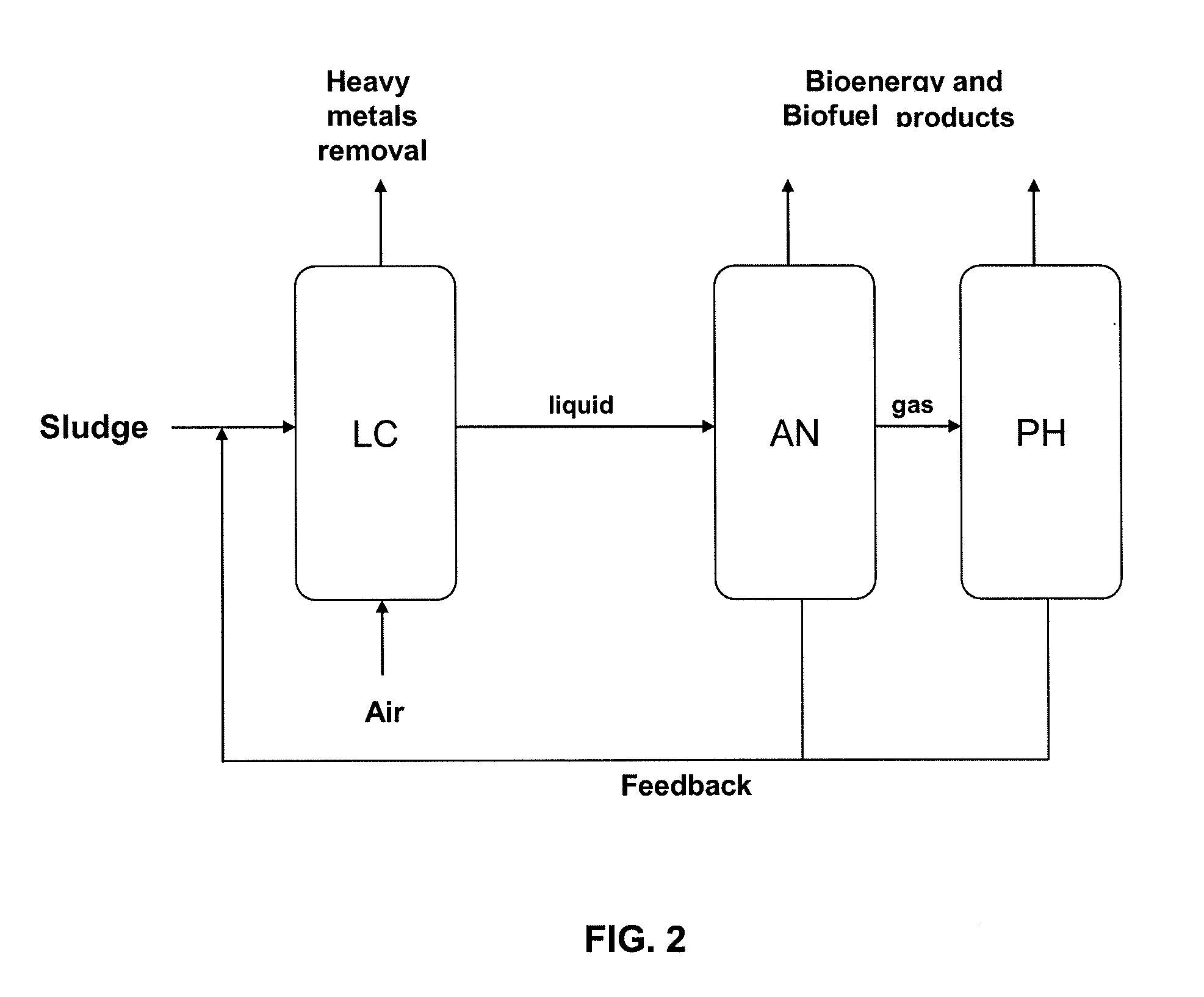

Methods and systems for production of biofuels and bioenergy products from sewage sludge, including recalcitrant sludge

InactiveUS20090325253A1Improper useReduce and eliminate pathogenBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationMicroorganism

The present invention provides methods and systems (SLUDFUEL system) for producing biofuel and bioenergy products using, as starting raw material, municipal, industrial, and / or farm sewage sludge, including recalcitrant sludge containing high concentrations of heavy metals, and produced after waste treatment. In accordance with the invention, municipal, industrial, and farm sewage sludge, including recalcitrant sludge, can serve as a carbon source to support the metabolism of synthetic microorganisms to produce biofuels and bioenergy products.

Owner:ASCON MIGUEL +1

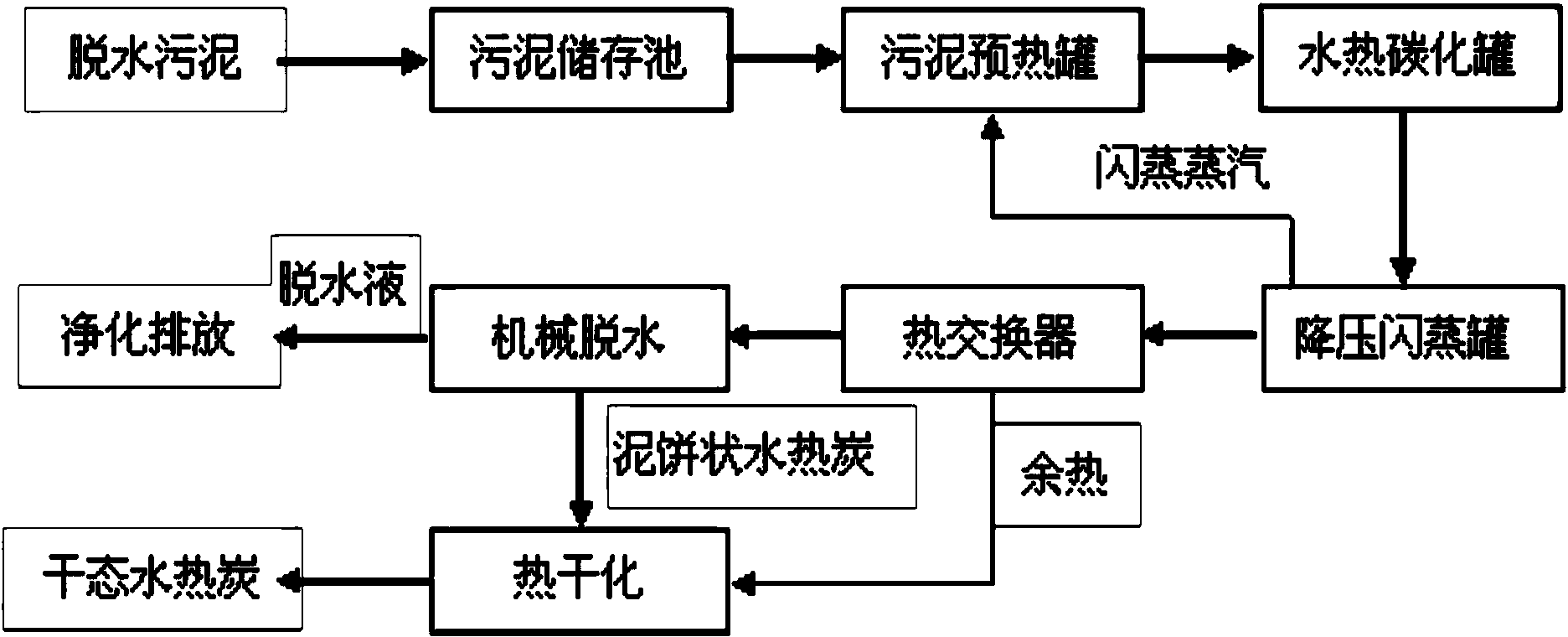

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

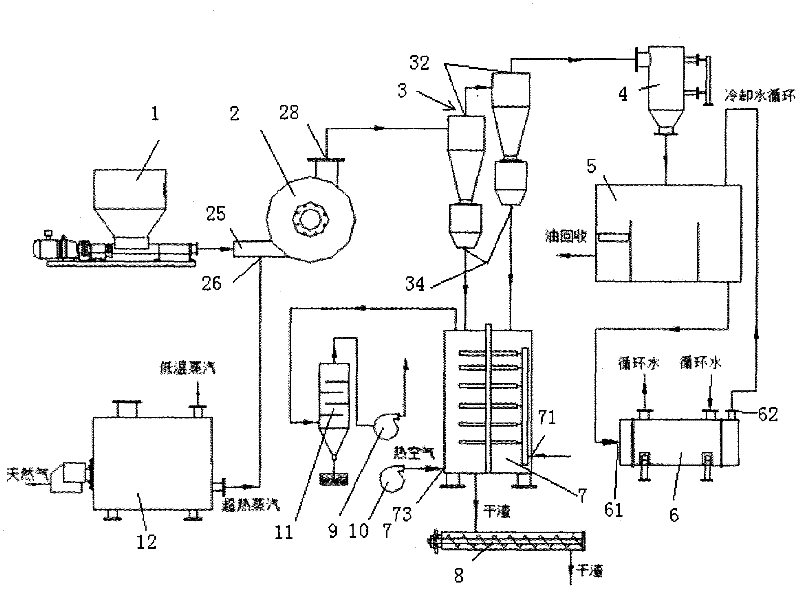

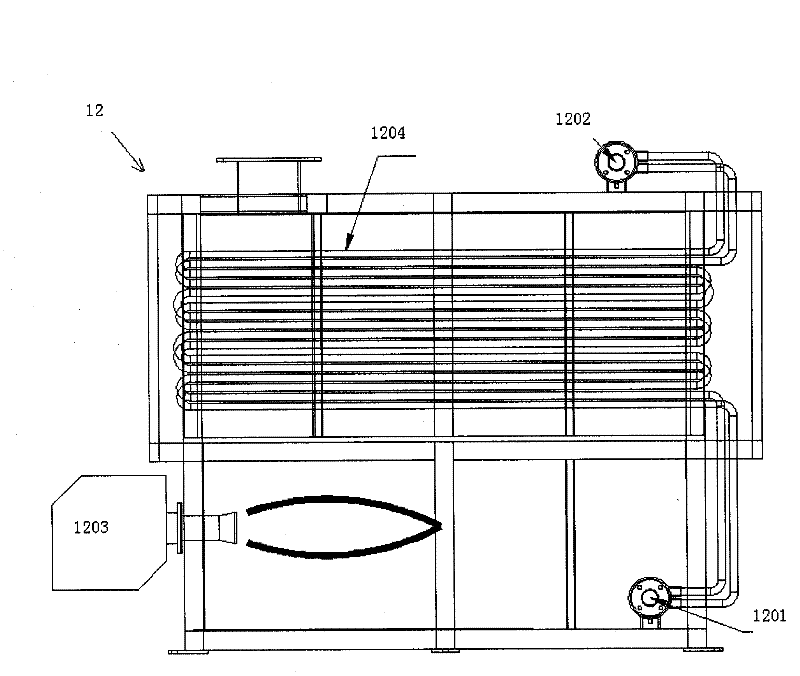

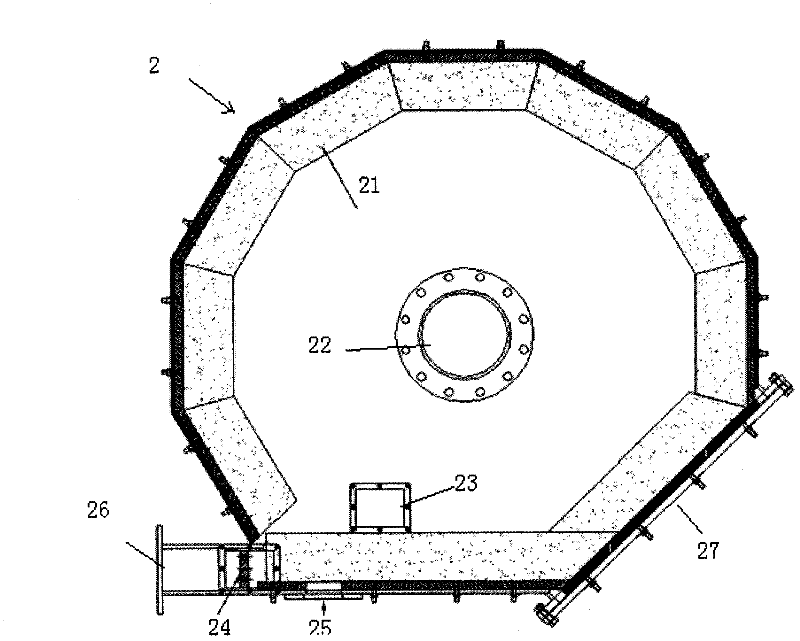

Treatment method and treatment apparatus of oily sludge

InactiveCN102503055AHigh recovery rateReduce moisture contentSludge treatment by thermal conditioningSludgeLiquid state

The invention provides a treatment method of oily sludge, which comprises the steps of: introducing overheated vapor into a high temperature treatment groove to roast the oily sludge so as to evaporate the liquid containing oil and water in the oily sludge to gas; separating the solid granules from the oily sludge and contained in the gas in a gas-solid separator, and conveying the solid granules to a drying machine to be dried and burnt so as to be discharged; condensing the gas separated from the gas-solid separator to liquid state oil and water, separating the liquid state oil and water in an oil-water separator to be respectively recycled, wherein the oily sludge is introduced into the high temperature treatment groove in a pumping manner, the overheated vapor is introduced into the high temperature treatment groove by supersonic jet flow and is vertically collided with the oily sludge. The invention further provides a treatment apparatus of oily sludge for executing the method; the treatment method and treatment apparatus provided by the invention have the advantages of guaranteeing high crude oil recovery, and small water content and oil content of finally generated dry residues.

Owner:河北海清大地环保科技有限公司

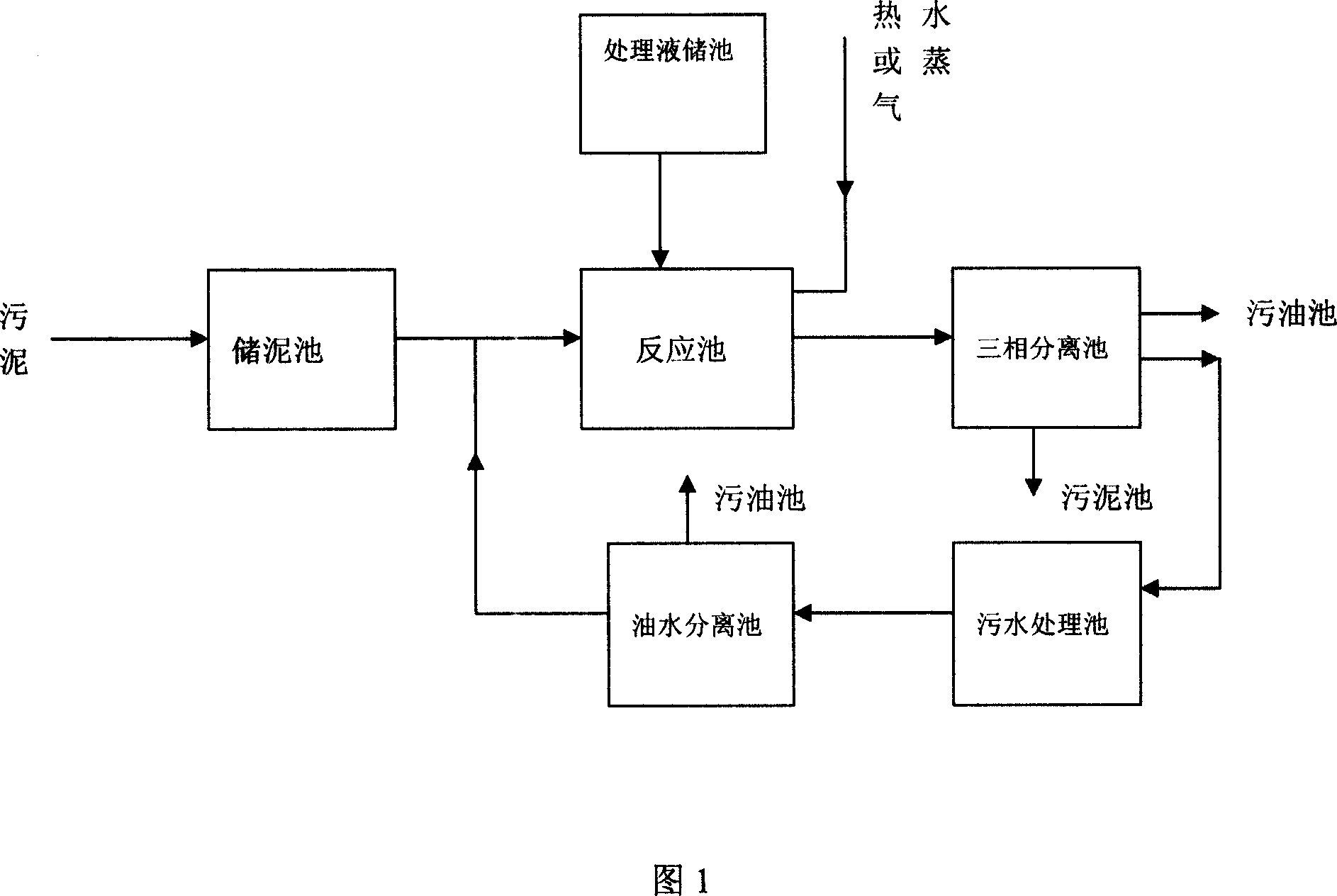

Process of treating oil-containing sludge

ActiveCN101088942ANo pollution in the processEfficient recyclingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningOil sludgeSewage

The present invention relates to oil-containing sludge treating process, which includes the following steps: pumping oil-containing sludge into sewage reacting tank and adding water while stirring; adding treating solution; heating and stirring to separate oil from sludge; adding coagulant while stirring to react for 2-30 min, adding polyacrylamide, stirring and solid-liquid separating into three layers; collecting oil, water and sludge separately; and collecting the sludge with oil content less than 1 wt% in the sludge collecting tank and further solidification or draining. The present invention has the advantages of recovering oil, reducing environmental pollution, low cost, etc.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

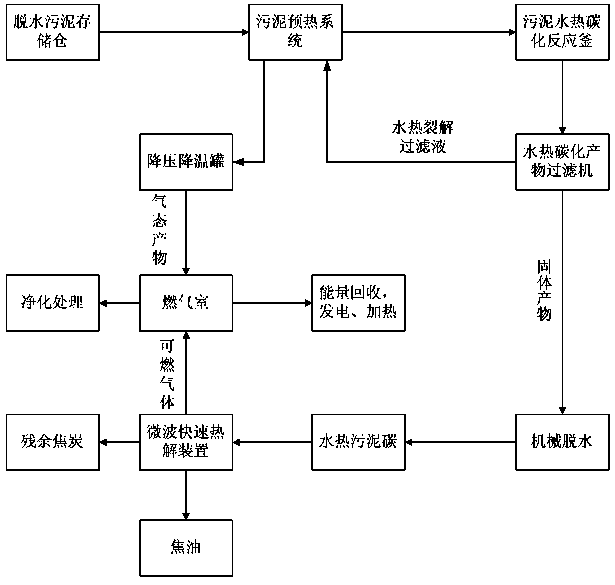

Comprehensive sludge treating method based on hydrothermal carbonization and fast microwave pyrolysis

InactiveCN104355519AImprove energy gradeOvercoming excessive moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMoistureResource utilization

The invention discloses a comprehensive sludge treating method based on hydrothermal carbonization and fast microwave pyrolysis. The method comprises two steps of hydrothermal carbonization and fast microwave pyrolysis of sludge. The hydrothermal carbonization is applied to pretreatment of the sludge at an earlier stage, and can be used for solving the difficulties of high moisture and low heating value of the sludge and improving the energy grade of the sludge from the sources; fast microwave pyrolysis is performed on the sludge carbon subjected to the hydrothermal carbonization, liquid fuel and combustible gas with better productivity can be obtained, and the residue solid cokes can be used as industrial raw materials, so that the energy source recycling with high efficiency and low pollution for the sludge is realized. The method has the advantages of high resource utilization degree, cleanness, environment protection, low operating cost and wide application prospect. Besides, the method is a method for fast treating the sludge.

Owner:SOUTH CHINA UNIV OF TECH

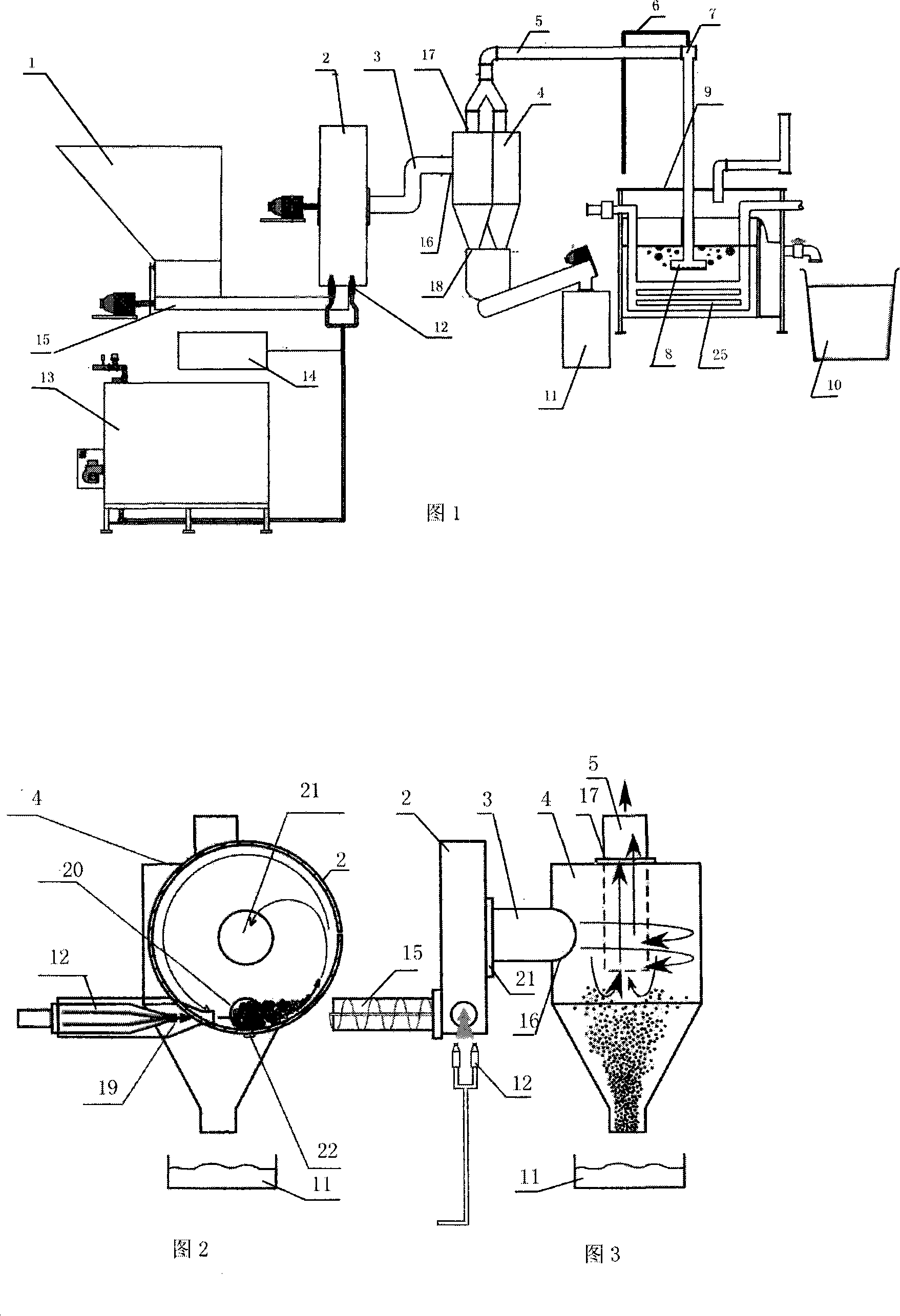

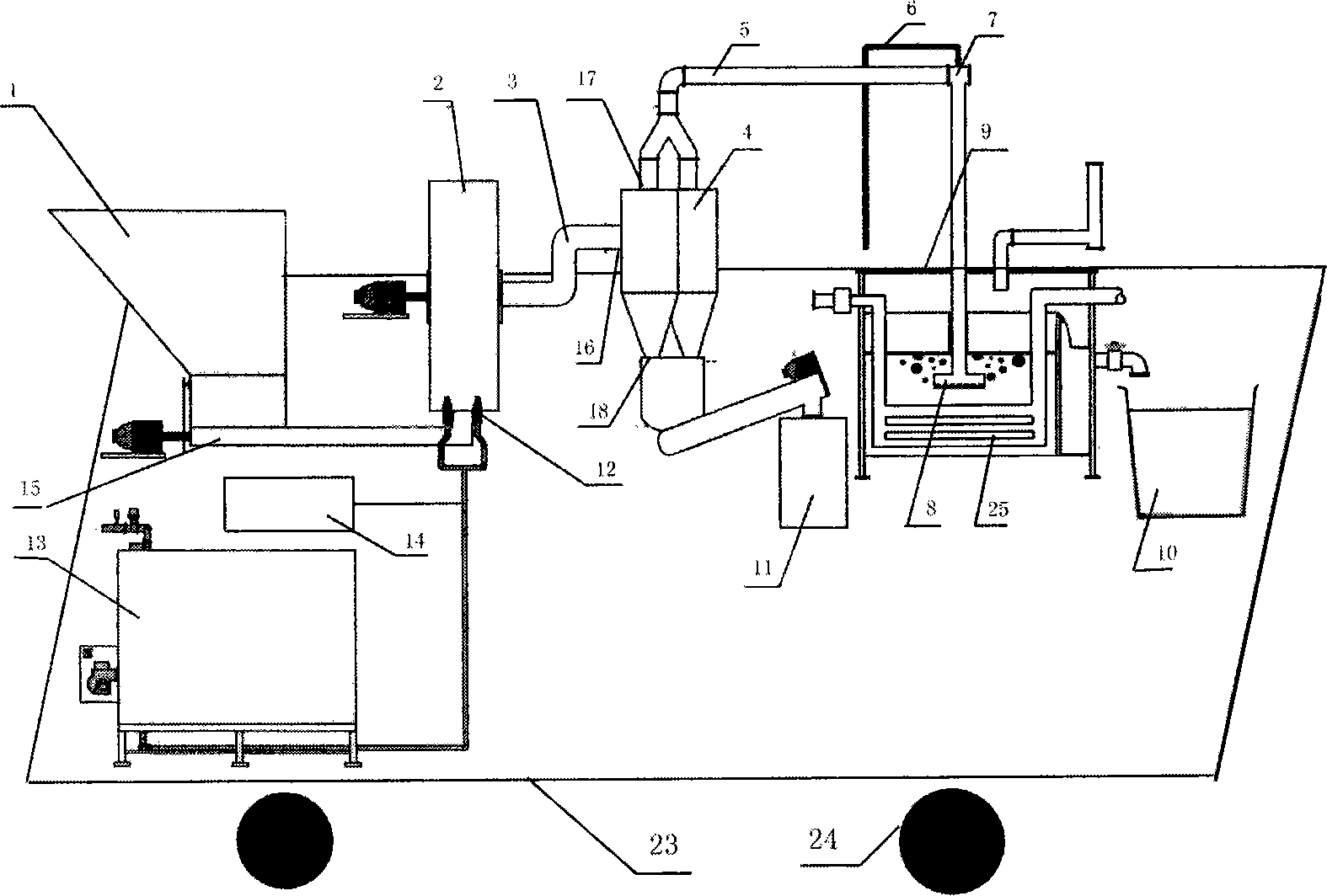

Dirty oil mud separating method and device

InactiveCN101239770ANo secondary pollutionEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWater vaporOil sludge

The present invention relates to a petroleum processing method and equipment, especially to an oil-bearing sludge separating method and equipment, provides a simple, economical, practical, environment-protecting and pollution-free oil-bearing sludge processing method and equipment, and the method comprises the following procedures: heating the water vapor to the superheated steam with temperature above 500 DEG C with a superheated steam boiler; injecting the superheated steam to the oil-bearing sludge with a speed of 2 mach, the oil-bearing sludge is crushed to small particles after instant colliding; separating the water component and the oil component which are evaporated and sublimed instantly with a cyclone separator; dropping the temperature and fluidifying through water spraying; and extracting the oil product up to standard by the separating of the oil-water separating pot, above 95% oil component in the oil-bearing sludge can be recovered and the oil content of the residue is lower than 5%, the petroleum processing method has the advantages of guaranteeing the quality of the recovered oil product, simple operation and maintenance, broad application that can be applied to varies types of oil-bearing sludge and oil-bearing sand, excellent economic benefit and low cost, the equipment is used for processing the oil-bearing sludge that is generated in the crude oil exploration and exploitation, crude oil transportation and the petroleum refinery wastewater treatment.

Owner:张贺新

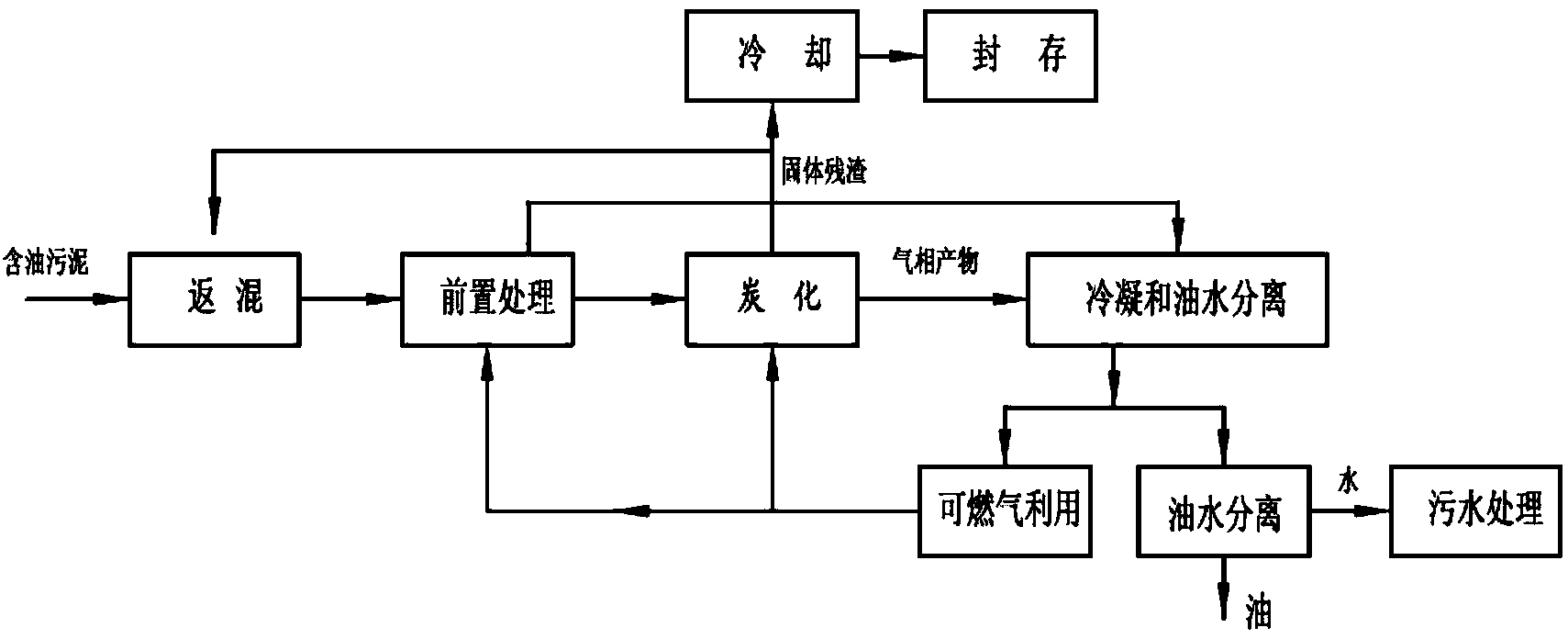

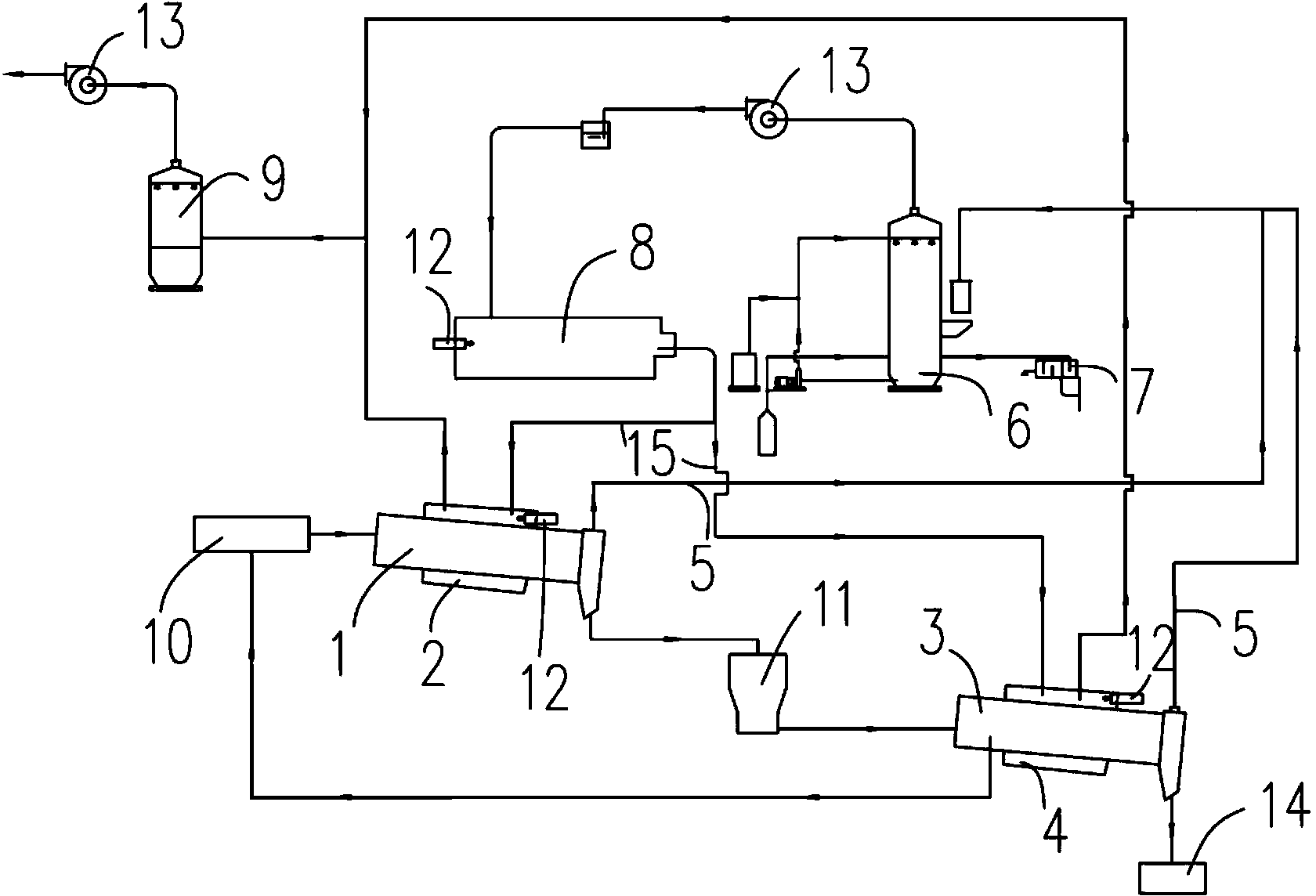

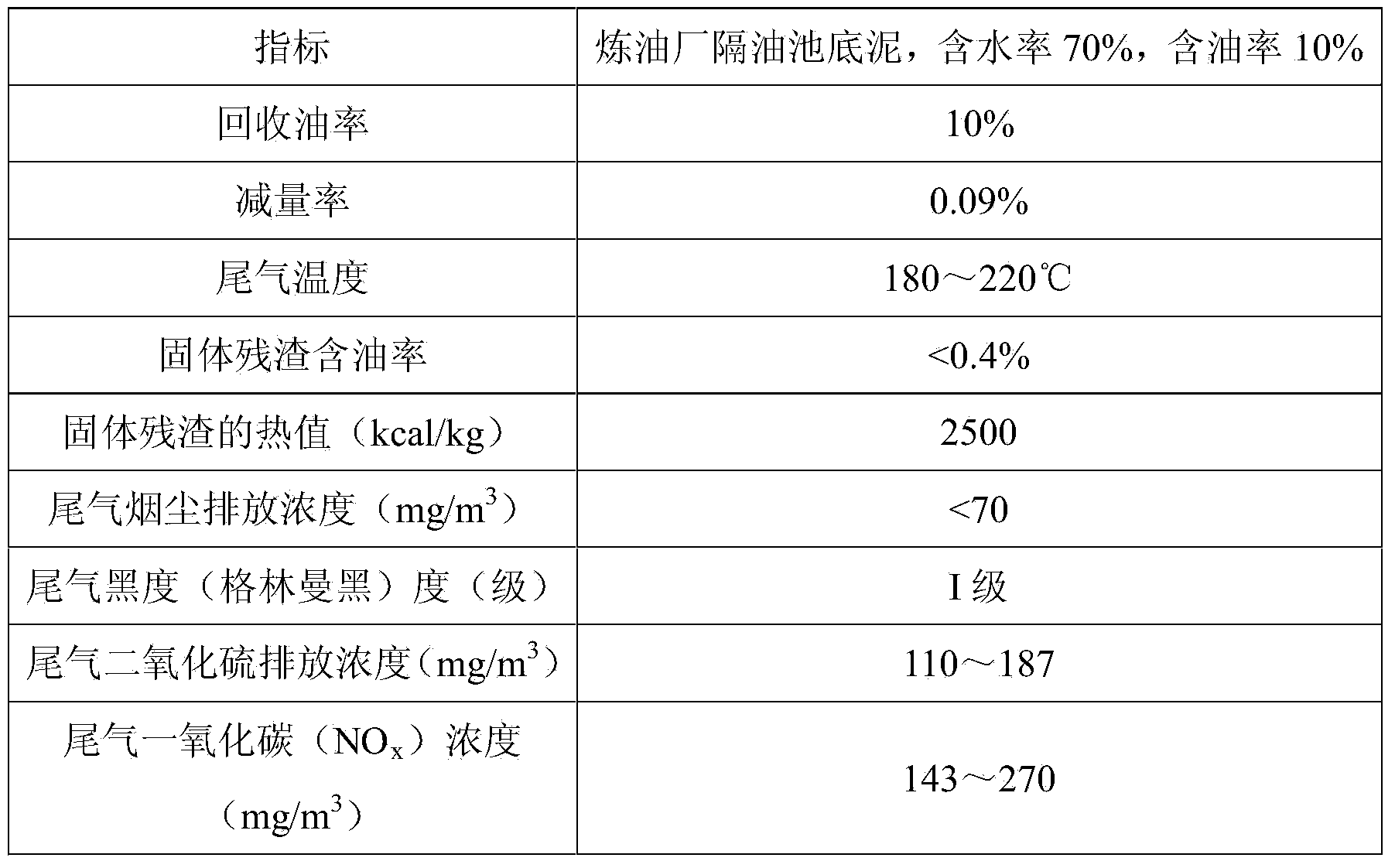

Method and device for refinery sludge carbonization treatment and carbon recovery

ActiveCN103449701AReduce the difficulty of process controlEfficient process operationSludge treatment by thermal conditioningCarbon preparation/purificationSludgeGas phase

The invention relates to a method and device for refinery sludge carbonization treatment and carbon recovery. The method comprises the following steps: pre-treatment: heating oil-containing sludge to 160-180 DEG C in an external heating manner while isolating air, and ensuring that the water content of the oil-containing sludge is controlled at 20% or below; carbonization: carbonizing the oil-containing sludge at 600-650 DEG C for 30-45 minutes, and recovering the solid residue generated by carbonization; condensation and oil-water separation: collecting gas-phase products generated by pre-treatment and carbonization, condensing in a water spray manner to obtain carbonization liquid and non-condensable gas, and performing oil-water separation on the carbonization liquid to obtain carbonization oil; utilization of combustible gas: performing combustion treatment on the non-condensable gas, enabling high temperature generated by combustion to provide heat energy for pre-treatment and carbonization, and performing purification treatment on the tail gas before discharging. The invention also provides a device for realizing the method. According to the invention, the advantages of high oil content recovery rate and stable and reliable process operation are achieved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

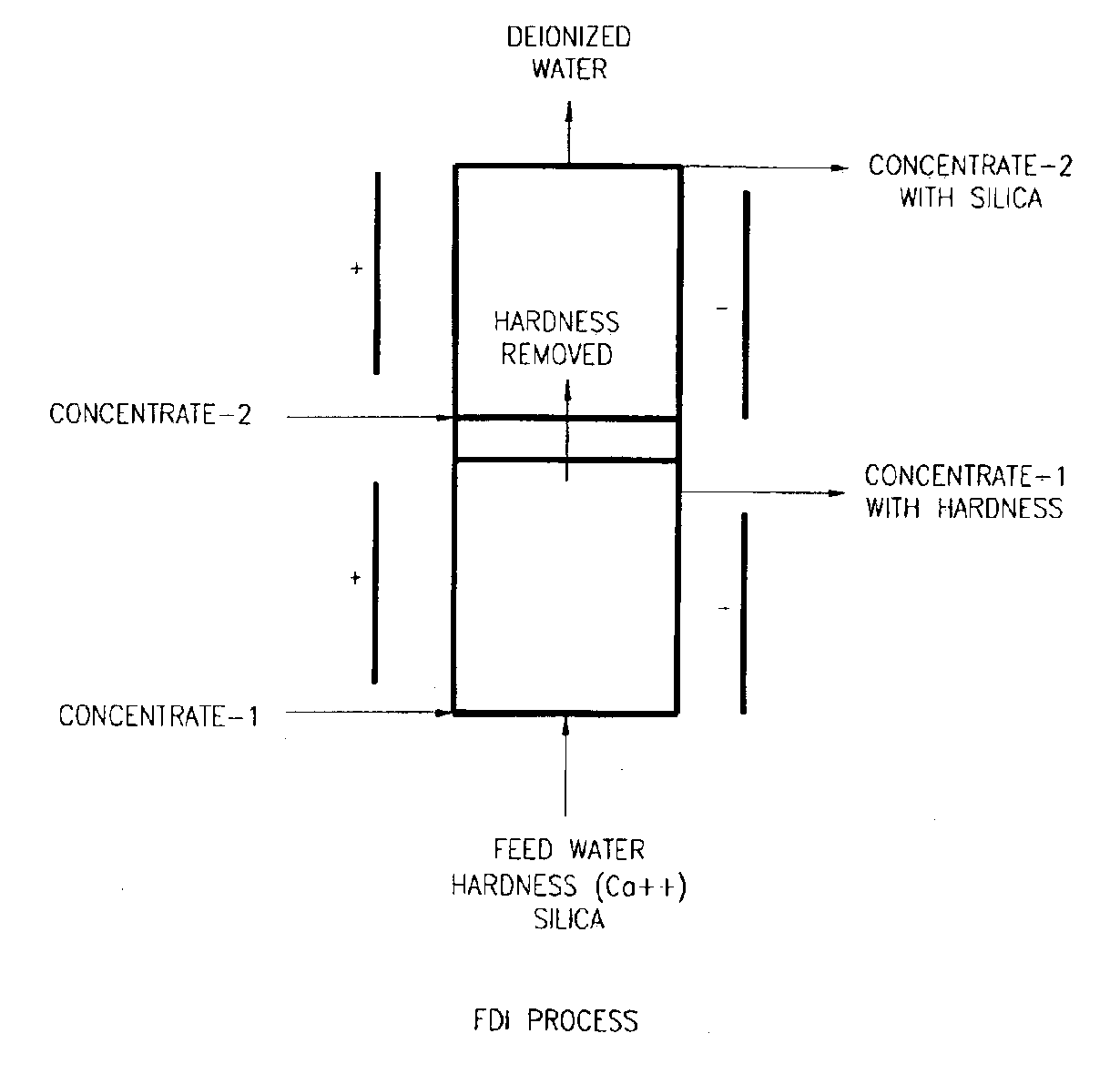

Fractional deionization process

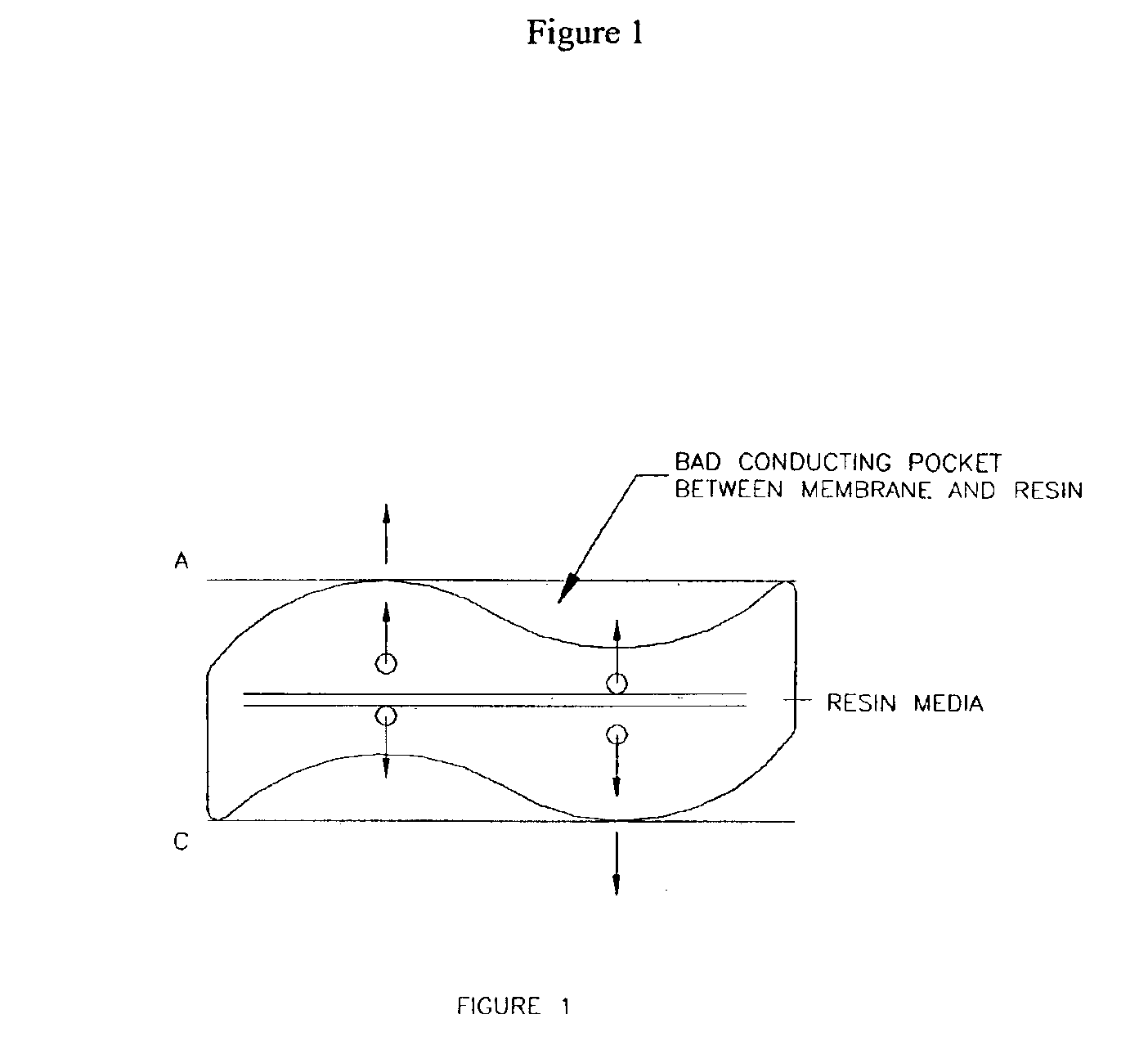

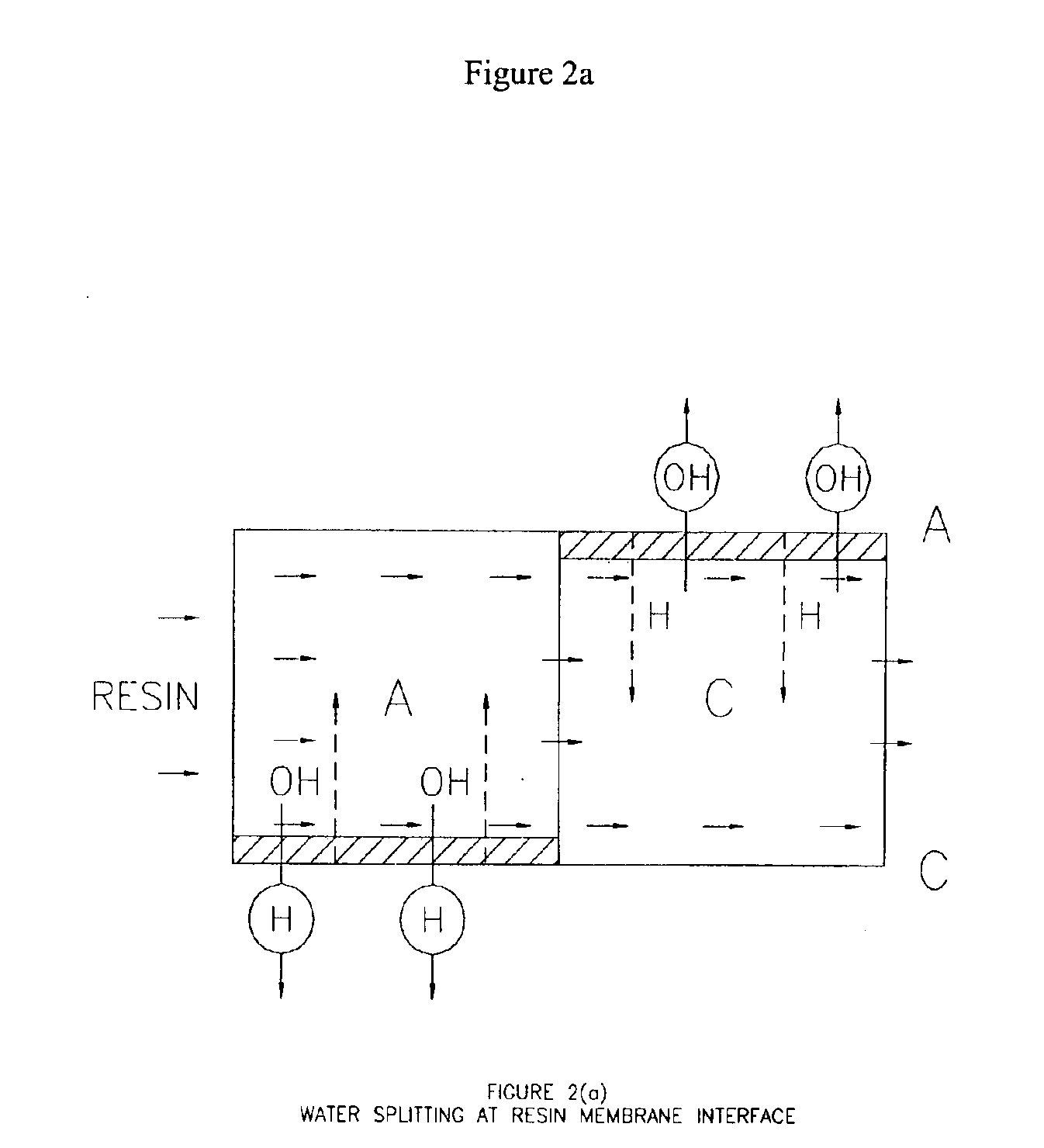

InactiveUS6896814B2Easy to disassembleEfficient removalElectrolysis componentsIon-exchanger regenerationElectricityIonic strength

A liquid treatment process is described for sequential removal of ionic species of progressively decreasing ionic strength without precipitation or “scaling.” An aspect of the invention includes dual electrodeionization operations. The first electrodeionization operation is performed at a voltage calculated to remove strongly ionized species such as calcium and magnesium from the feed water without scaling. The product of the first electrodeionization operation is then subjected to a second electrodeionization operation. The second electrodeionization operation is performed at a voltage greater than the first electrodeionization operation, and is designed to remove more weakly ionized species such as silica and carbon dioxide, preventing scaling. More than two successive electrodeionization operations may be performed if desired. Multiple electrodeionization operations may occur in a single electrodeionization stack or in multiple electrodeionization stacks.

Owner:AQUATECH INT LLC

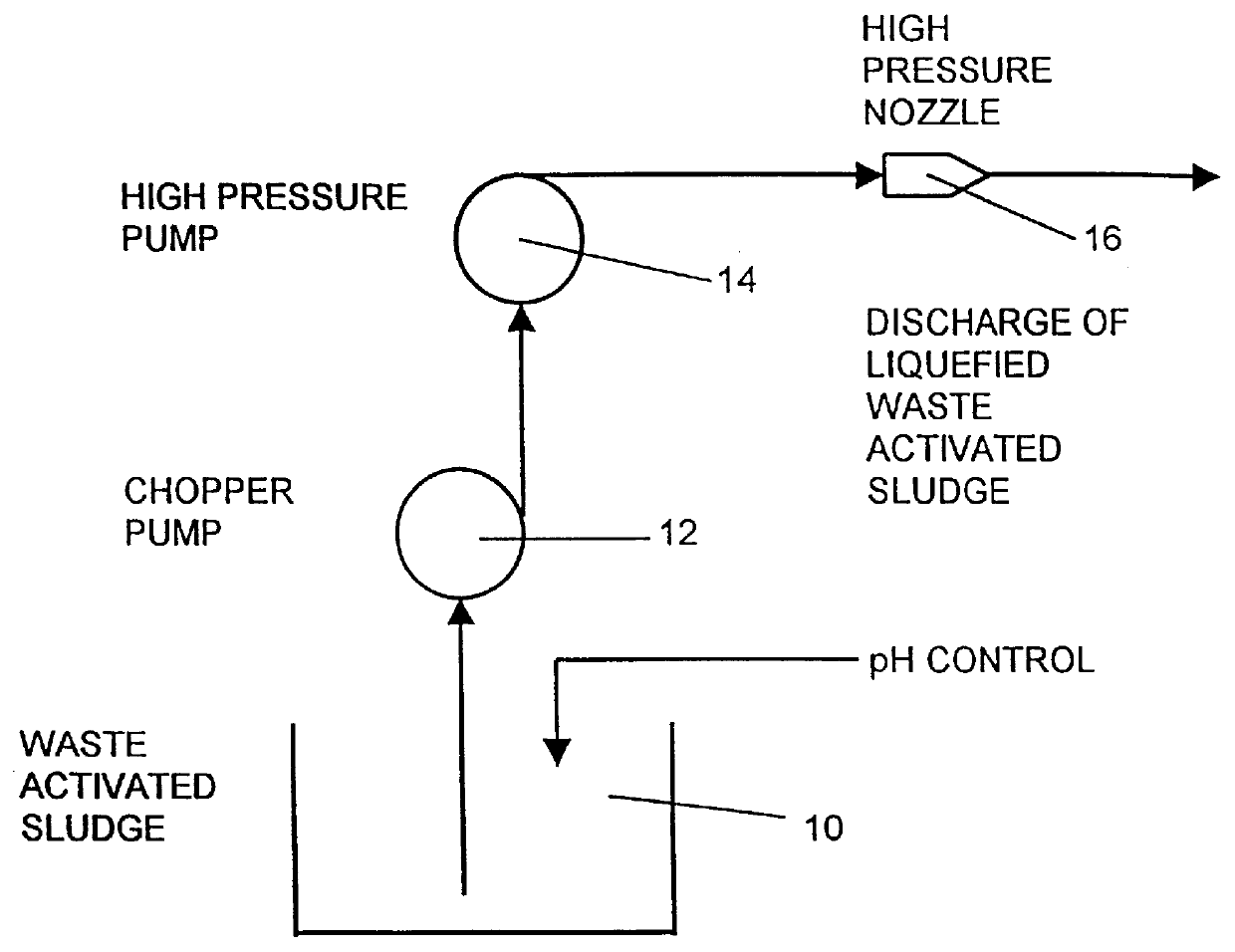

Method of liquefying microorganisms derived from biological wastewater treatment processes

InactiveUS6013183ASludge treatment by thermal conditioningSolid waste disposalActivated sludgeMicroorganism

A process for liquefying microorganisms present in biosolids, such as waste activated sludge, generated by municipal or industrial wastewater treatment plants is disclosed. The process includes the step of passing a slurry of the sludge at a high pressure through a nozzle having a restricted flow area to cause liquefication of the microorganisms as they are discharged from the nozzle. The pressure drop across the nozzle preferably exceeds 5,000 psi. At least part of the liquefied microorganisms may be recirculated to the treatment facility to feed nutrients to the wastewater treatment process. Optionally, the liquefied microorganisms may be anaerobically converted to methane and carbon dioxide. For optimum results, the sludge is subjected to pH adjustment and / or maceration prior to being pumped through the high pressure nozzle.

Owner:PARADIGM ENVIRONMENTAL TECH INC

Method for drying sludge by residual heat from boiler fume

ActiveCN1654378AEffective controlReduce the temperatureSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningBrickIndustrial waste water

The method of utilizing boiler fume afterheat in drying sludge is to dry sludge from sewage works at low temperature condition with boiler fume afterheat in a two-section or three-section process and to form hard sludge pellets one 1-6 mm size. The sludge pellets may be used as the auxiliary fuel for boiler and in baking light brick and cement product. The present invention has low cost and opens one way of utilizing waste in treating waste. The present invention results in high environment utility, economic utility and social utility.

Owner:ZHEJIANG UNIV

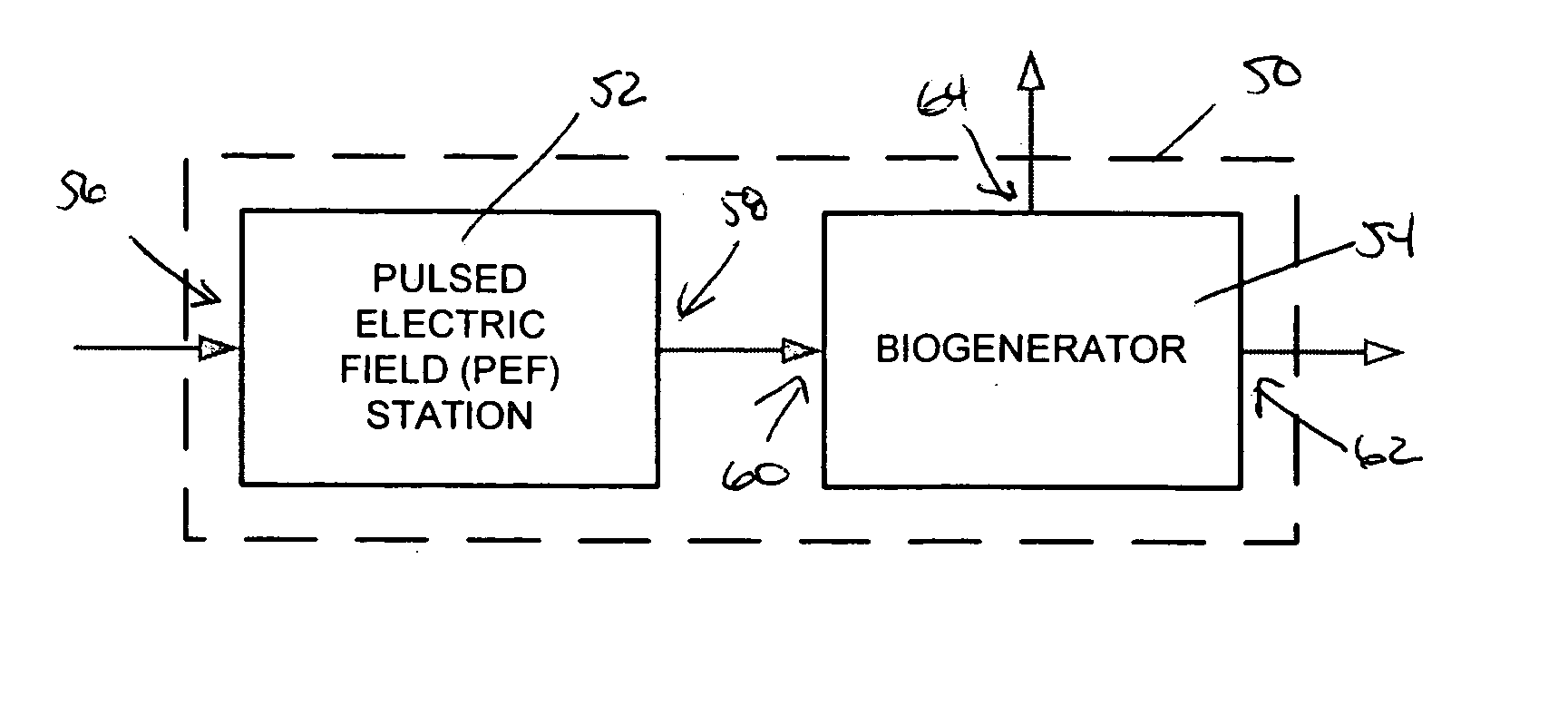

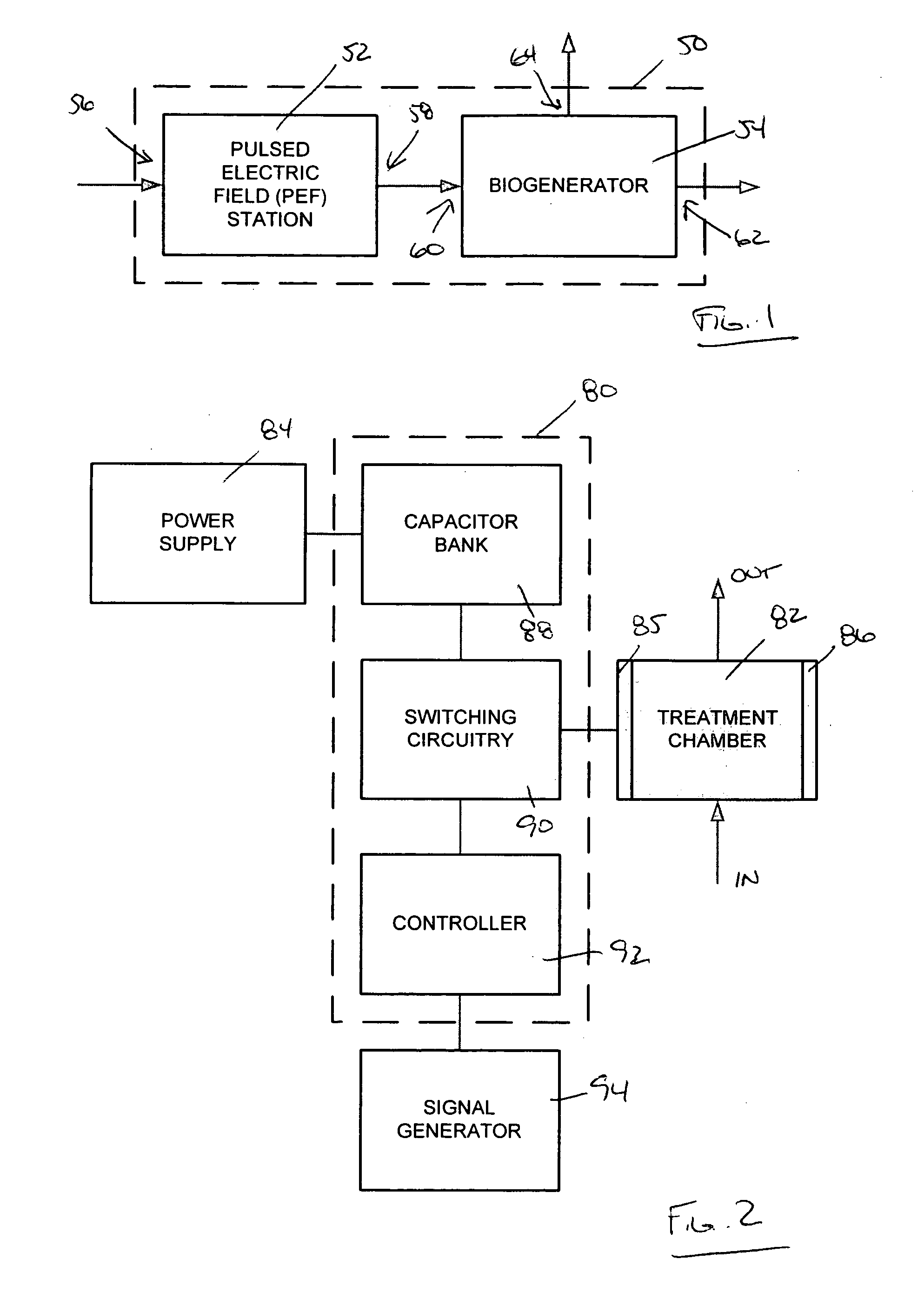

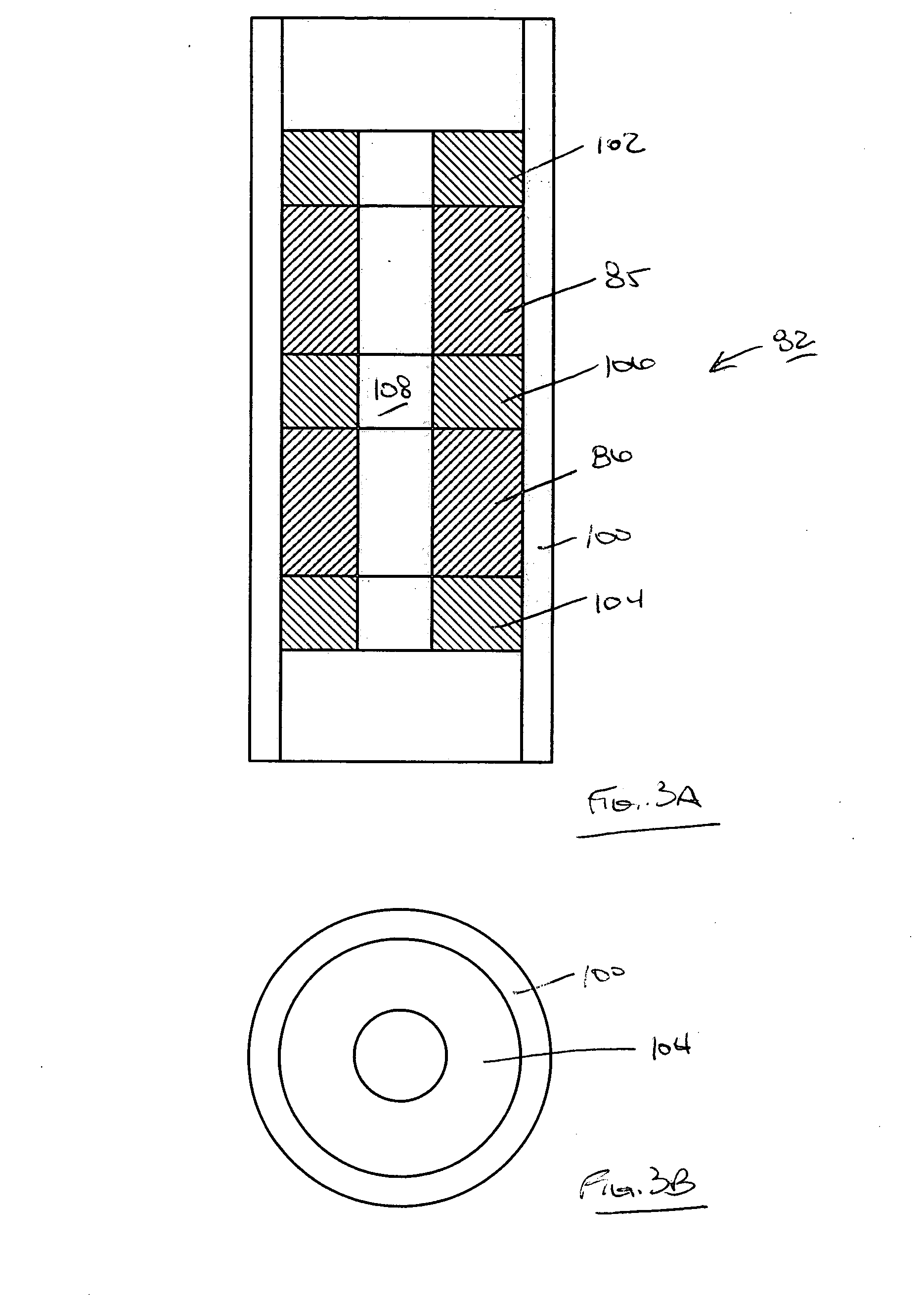

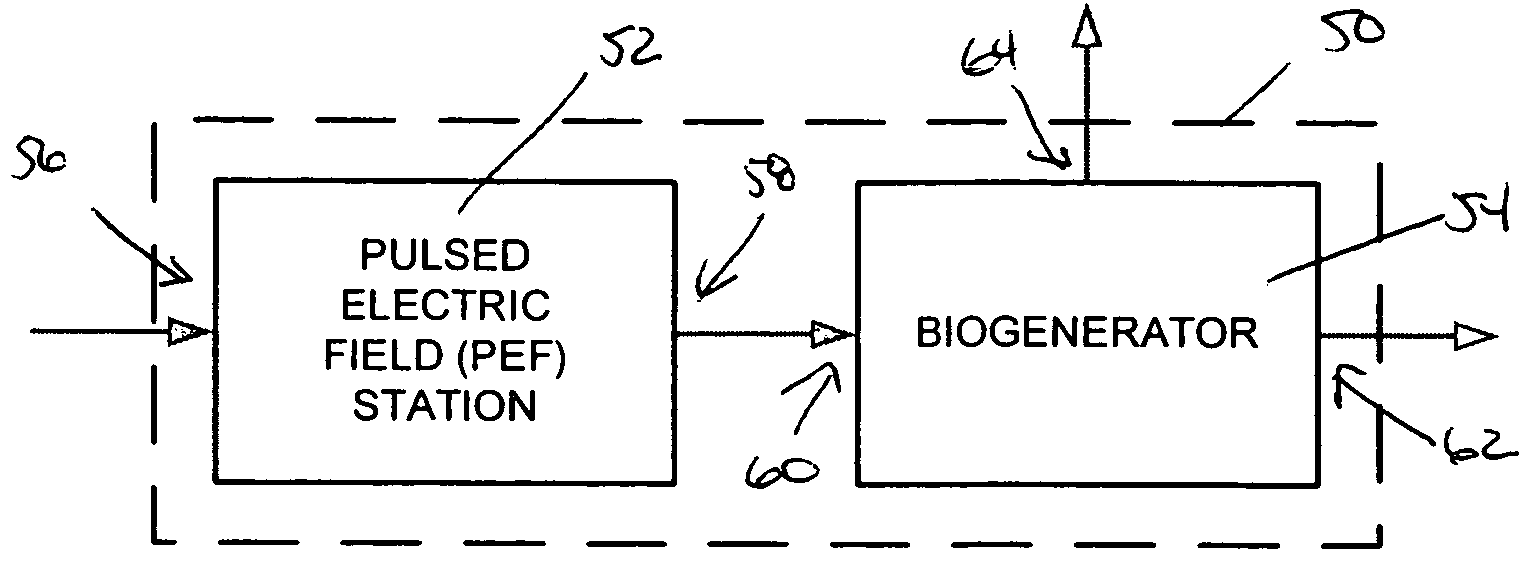

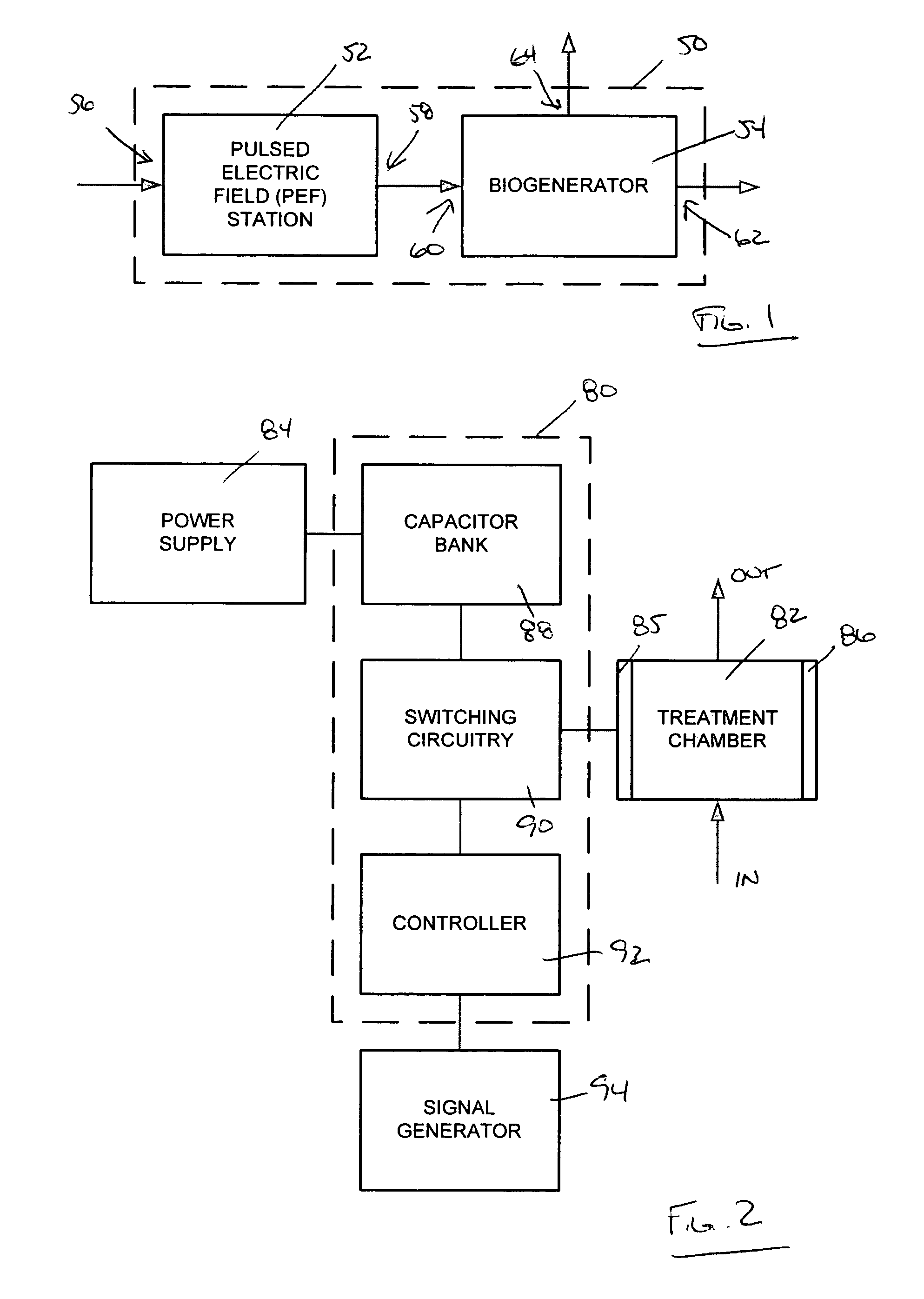

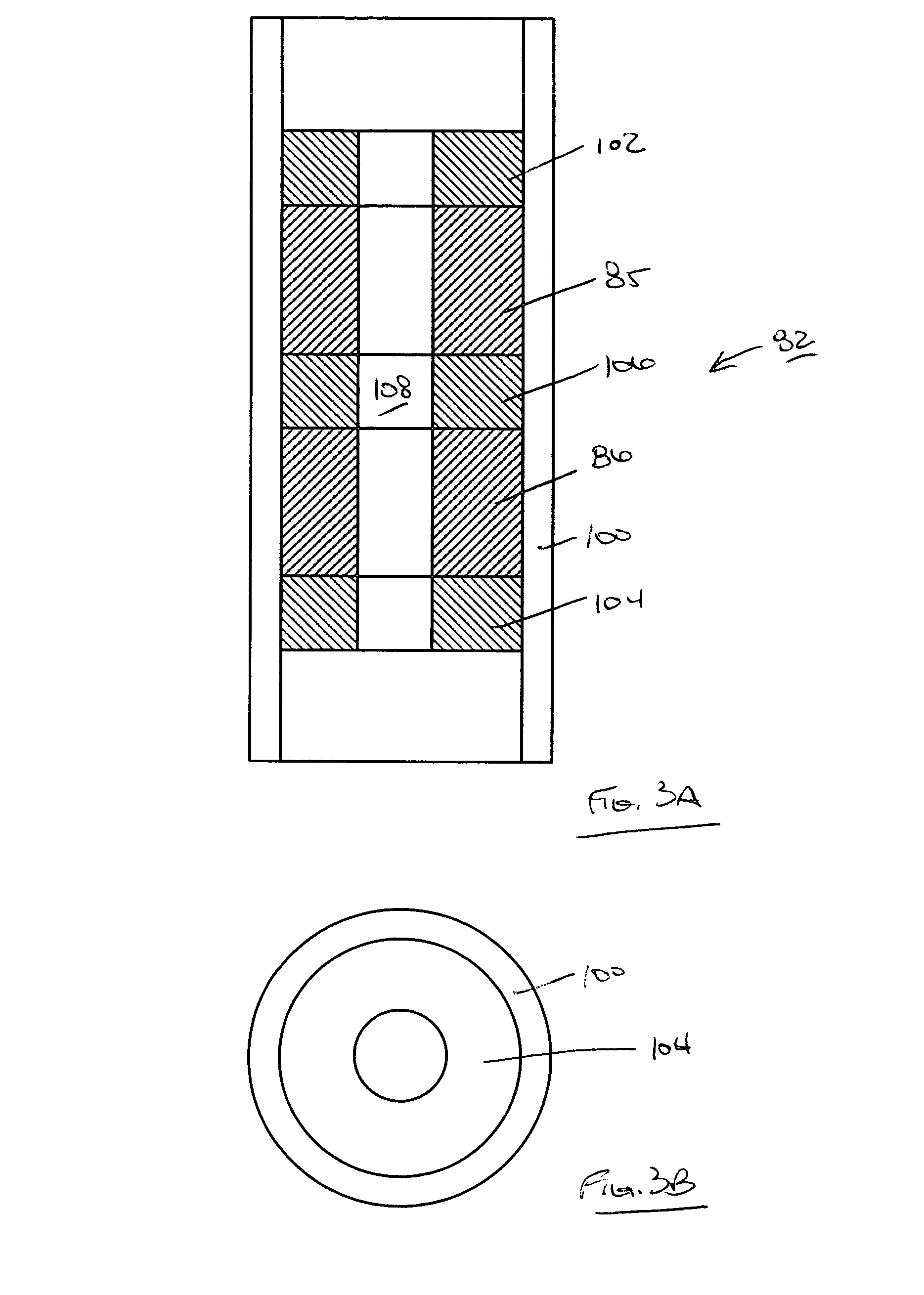

Method of and apparatus for converting biological materials into energy resources

InactiveUS20060118485A1Gas production bioreactorsTreatment involving filtrationEnvironmental engineeringBiological materials

A method of converting biological material into energy resources includes transmitting biological material to a pulsed electric field (PEF) station, and applying a PEF to the biological material within a treatment zone in the PEF station to generate treated biological material. The method also includes transmitting the treated biological material to a biogenerator, and processing the treated biological material in the biogenerator to produce an energy resource. A converter may carry out this process, and may include the PEF station and the biogenerator.

Owner:OPEN ACQUISITION LLC

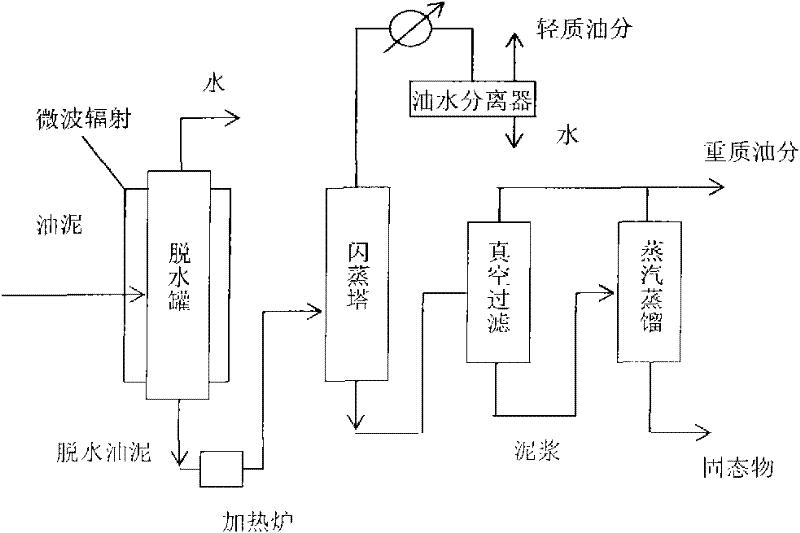

Method for treating oil sludge

ActiveCN102452776AImprove processing efficiencySmall scaleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFull recoveryOil sludge

The invention discloses a method for treating oil sludge. The method realizes oil sludge integrated treatment by utilization of microwave demulsification dehydration, heat treatment flash evaporation and steam distillation. Concretely, the method comprises the following steps of 1, carrying out a microwave pretreatment demulsification dehydration process on oil sludge to reduce water content of the oil sludge, 2, heating the oil sludge subjected to the microwave pretreatment demulsification dehydration process to a temperature of 100 to 300 DEG C in an oxygen-free environment, feeding the heated oil sludge into a separating column, carrying out a heat treatment flash evaporation process, through condensation, recovering a light oil component and water separated by the heat treatment flashevaporation, and taking out sludge comprising a heavy oil component and solids from the separating column, and 3, carrying out solid-liquid separation of the sludge in the bottom of the separating column, recovering the heavy oil component as a coking or catalytic cracking raw material, and carrying out a steam distillation process on the solids to further recover an oil component from the solids. The method can realize full recovery of various valuable components of oil sludge and has good industrial application economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

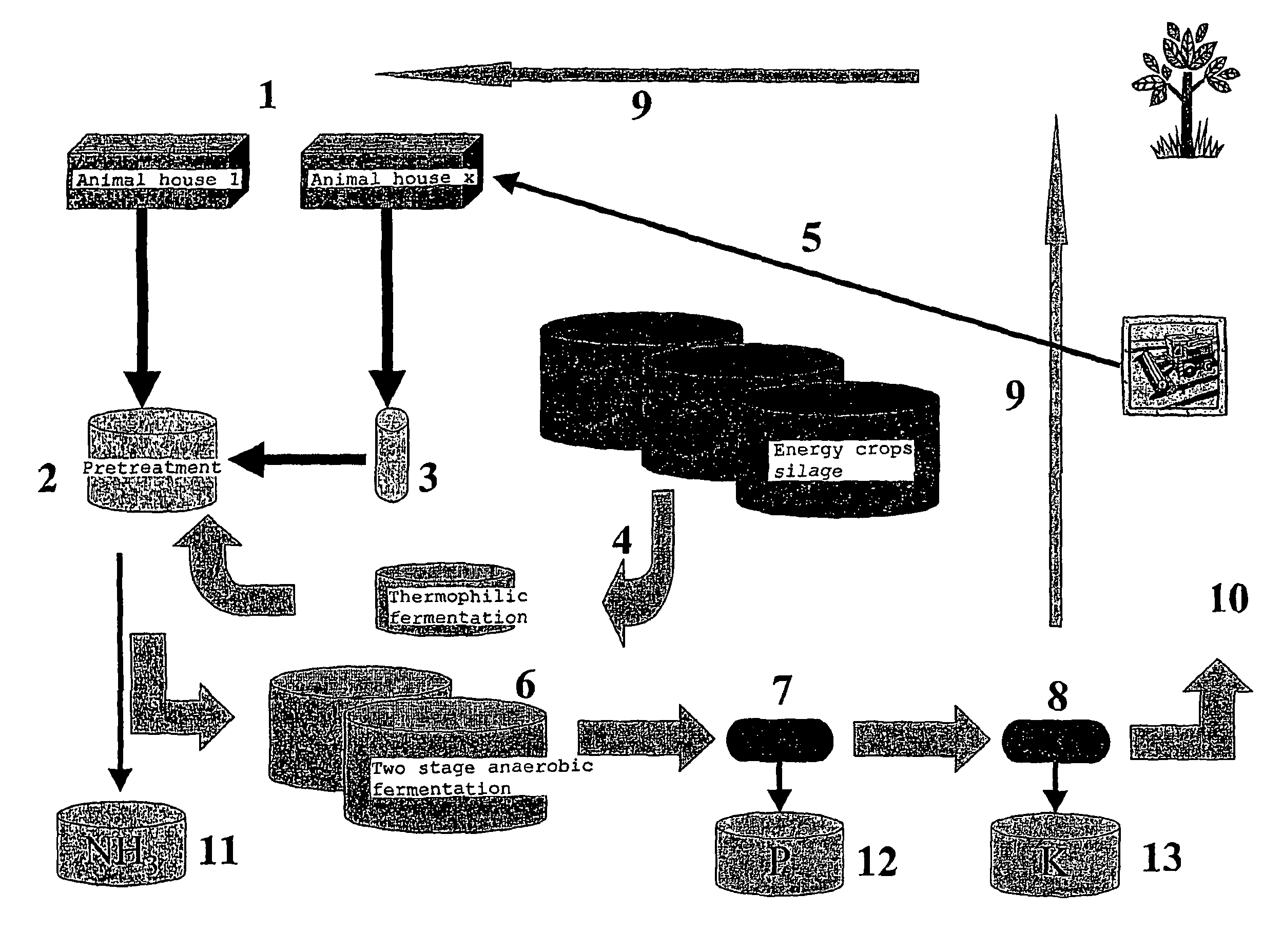

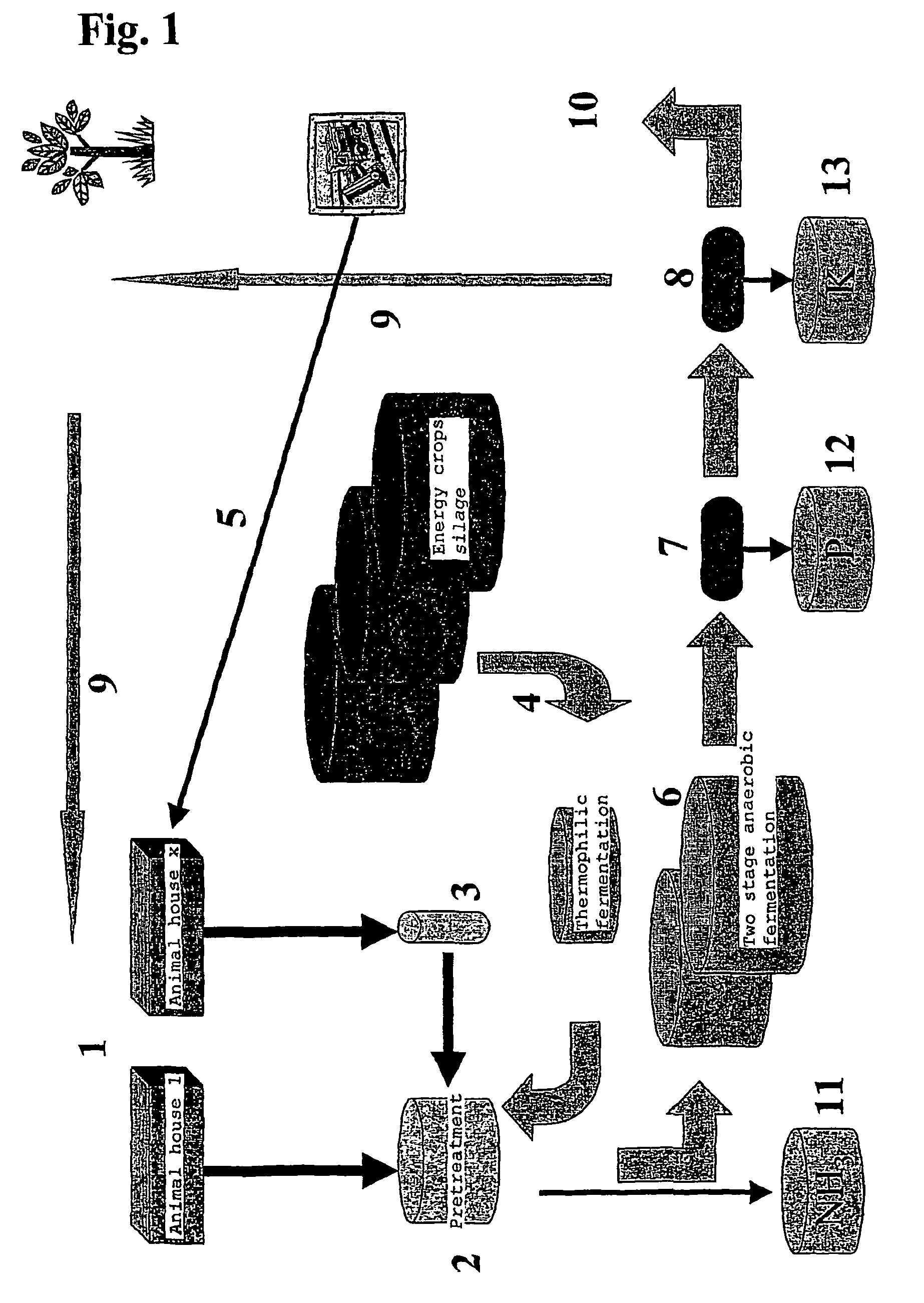

Concept for slurry separation and biogas production

InactiveUS7883884B2High yieldNot subsidisedBio-organic fraction processingAnimal corpse fertilisersEngineeringBiogas production

The present invention concerns an anaerobic digestion of animal manures, energy crops and similar organic substrates. The process is capable of refining nutrients comprised in the digested biomass to fertilizers of commercial quality. The invention also provides a method for oprocessing animal carcasses or fractions thereof including meat and bone meal etc., with the objective of providing an alternative means for processing the organic waste material of animal origin while at the same time facilitating the production of fertilizers. The risk of spreading BSE prions or any other prions to animals or humans is thus substantially reduced if not eliminated. The biogas and slurry separation system according to the present invention is preferably integrated with the operations of animal husbandries into a total concept in which the internal and external performances of animal husbandries are optimised. The internal performances concern quality aspects related to the management of the animal houses and include industrial hygiene, animal welfare, gaseous and dust emissions and food safety. The external performances concern mainly energy production and emissions to the environment of nutrients and greenhouse gases and the sale of high quality food product.

Owner:GFE PATENT AS

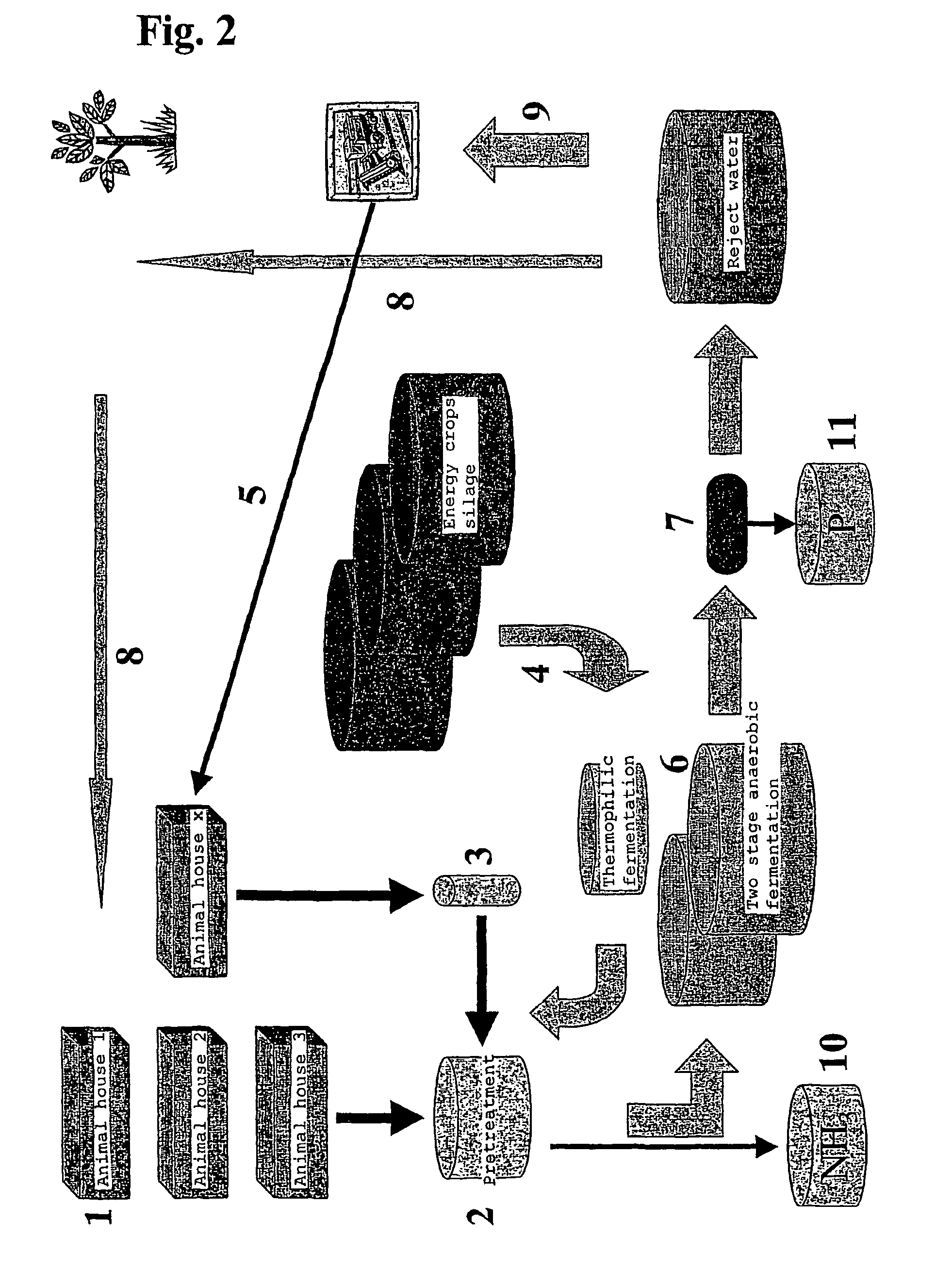

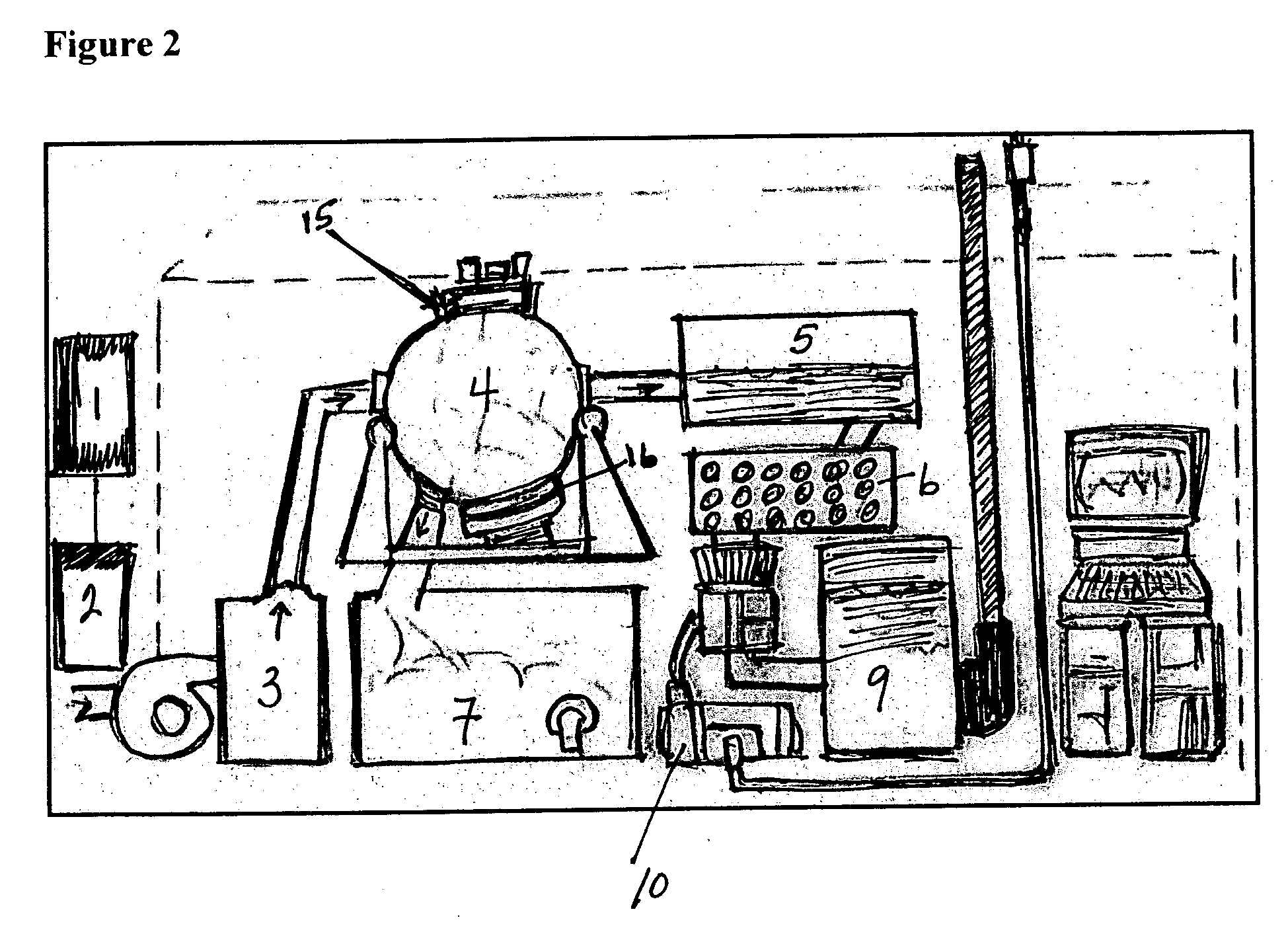

Hybrid magnetohydrodynamo (MHD) field sanitation generator for treating wastewater, sewages & sludge and recovering potable water

InactiveUS20050029174A1Sludge treatment by thermal conditioningWater/sewage treatment by irradiationSludgeFiltration

The Hybrid MHD-FSU (Field Sanitation Unit) innovation is a self-contained sewage treatment plant that fully converts sewage / wastewater into (1) solid organic material, (2) potable, pathogen-free drinking water, and (3) generates electricity. At a high level, the system consists of four main components: (1) Mixer, (2) MHD Reactor, (3) Filter, and (4) Turbine. The innovation presents a stand-alone compact configuration of typical wastewater treatment components (equalization & mixing, process treatment, filtration) that are combined with the customized MHD reactor to perform the waste treatment / water recovery processing. The Hybrid magnetohydrodynamo (MHD) Field Sanitation Unit has the ability (1) to recover an organic material (2) to recover a pathogen free, clean potable drinking water, and (3) to generate electricity using wastewater as the conductive medium. The invention also relates a core heating microwave source coupled to an outer rigid mantle boundary that compose an MHD electrode pair. The invention assemblies are generally configured of three components: (a) magnetron, waveguide & a launch assembly; (b) the perovskite ceramic components; and (c) the conductive wastewater sludge fluid but more specifically the MHD assemblies are described herein in detail. FIG. 1 illustrates a general process flow of the invention. The main components of the invention are composed of the following: (1) the clean water supply feed, (2) the influent raw wastewater (3) the mixer, (4) the MHD reactor chamber, (5) the storage tank for clean water, (6) the filtration system producing potable water, (7) the storage bin for solids & organic material (8) hydro-turbine (9) the potable drinking water storage, (10b) the battery storage system with power conditioning subsystem.

Owner:SPIRALCAT OF MARYLAND

Method of and apparatus for converting biological materials into energy resources

InactiveUS7507341B2Bioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringBiological materials

Owner:OPEN ACQUISITION LLC

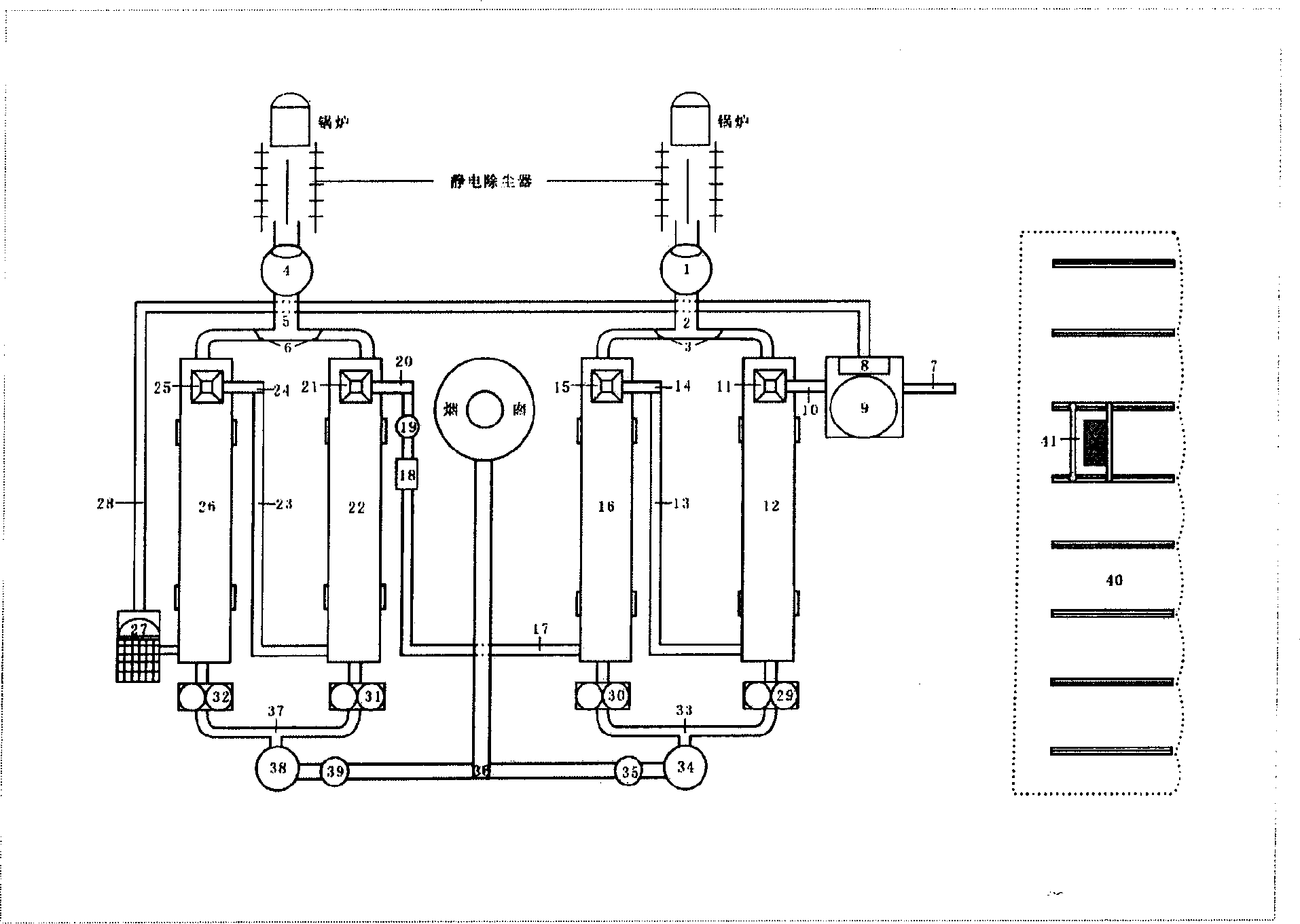

Tandem type anhydration system for sludge by using remaining heat of flue gas from steam power plant

InactiveCN1686879AWill not affect normal operationEffective controlSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFlue gasSludge

The present invention discloses a series-connected sludge anhydration system by utilizing waste heat of steam-power plant smoke. Said series-connected sludge anhydration system includes heat supply system, sludge pretreatment system, feeding system, sludge anhydration and granulation system and dust-removing and gas-removing system.

Owner:ZHEJIANG UNIV

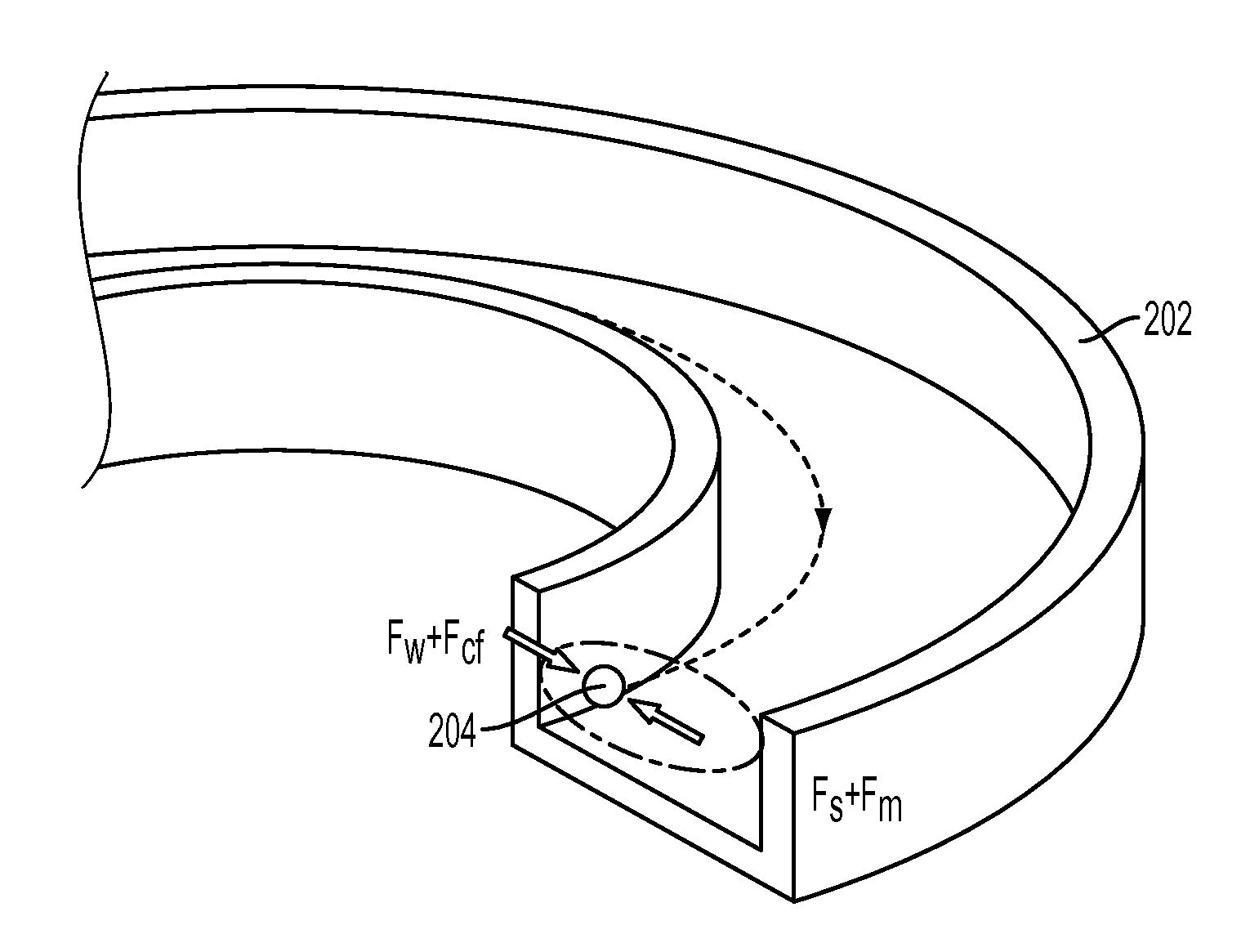

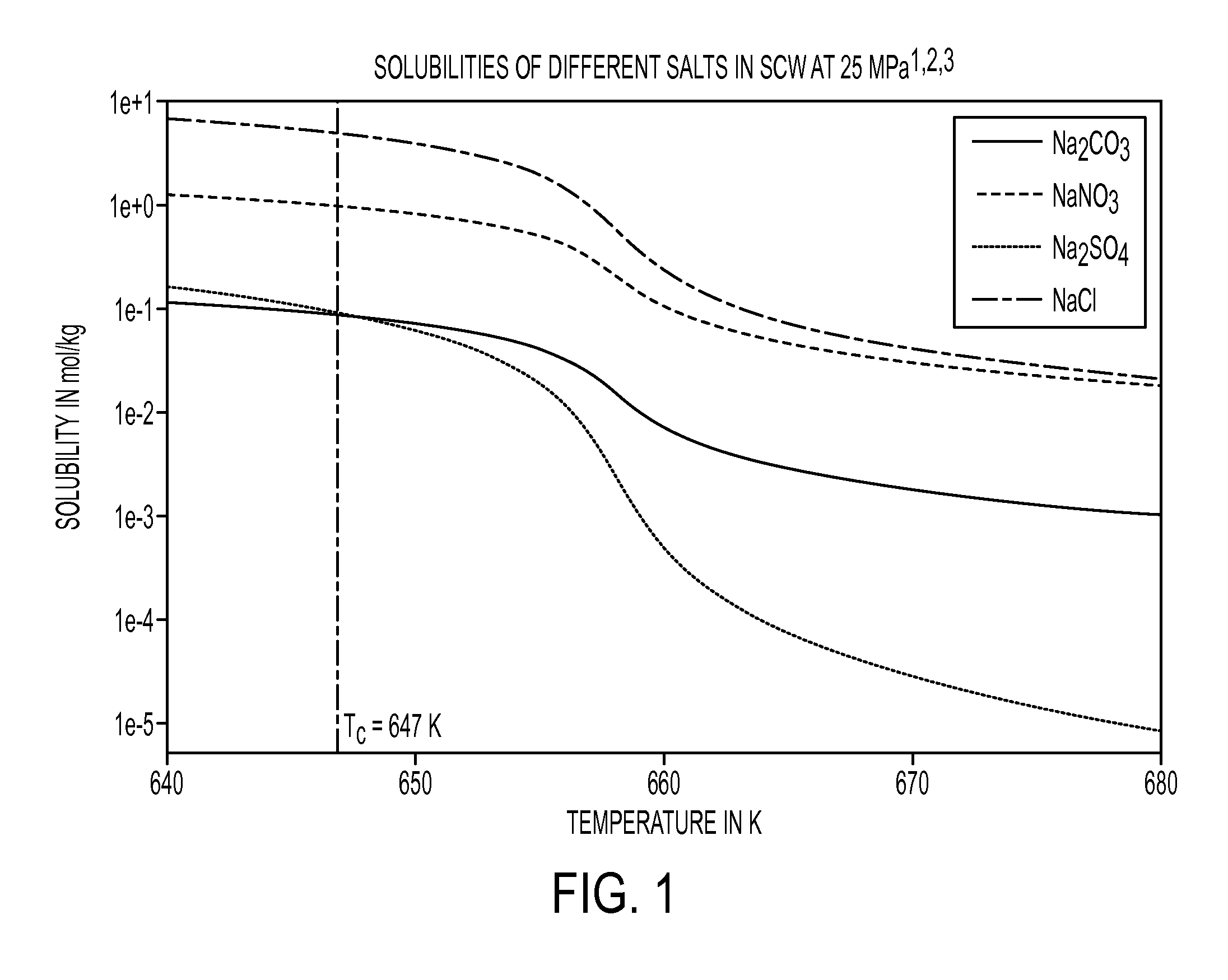

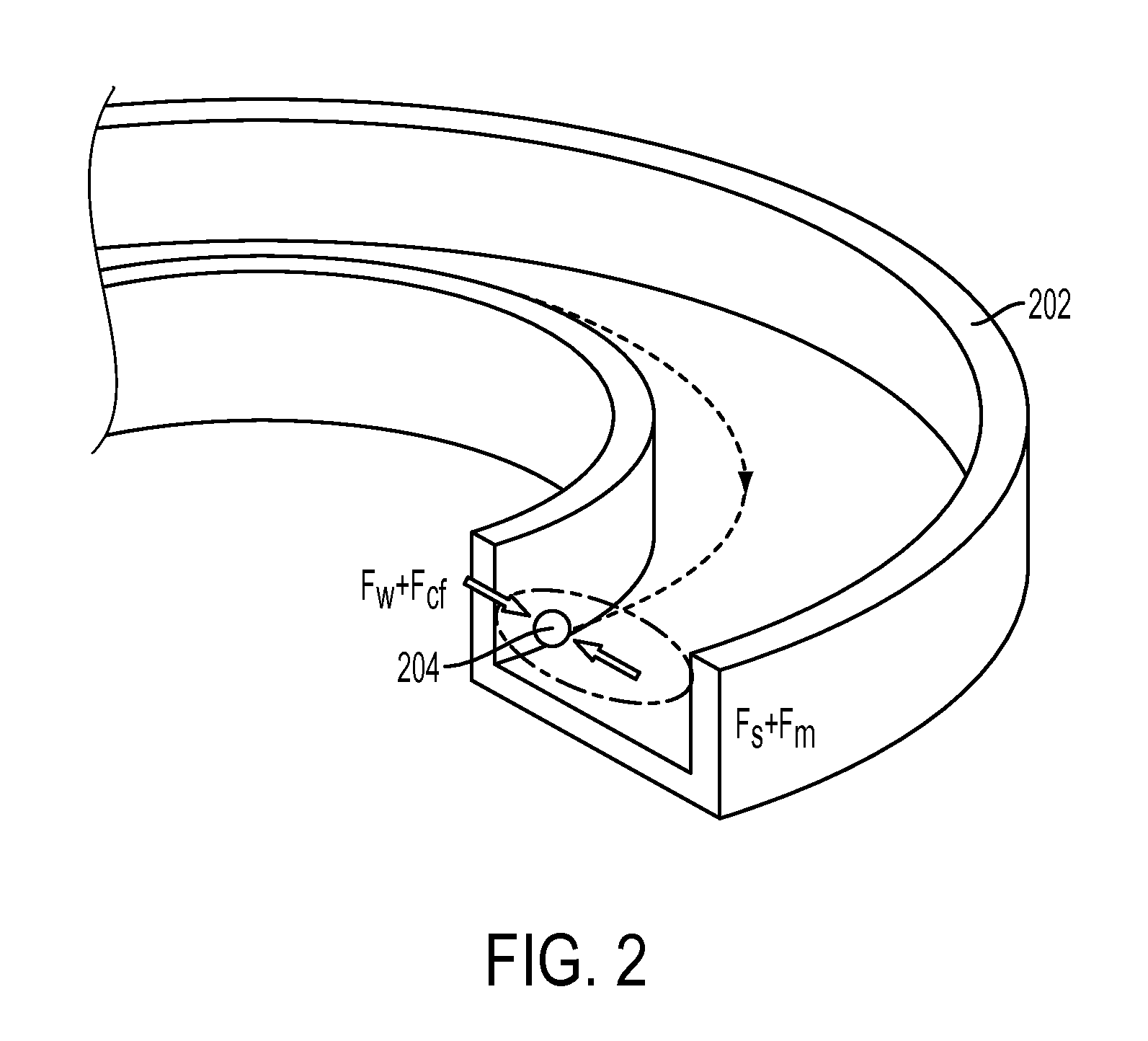

Desalination using supercritical water and spiral separation

InactiveUS20110108491A1Efficiency of desalination reducesLow efficiencySludge treatment by thermal conditioningGeneral water supply conservationSaline waterDesalination

The present application relates to systems and methods for the desalination of water. The systems and methods receive source water containing particles therein from a source of water such as, for example, the ocean. The source water may be pre-treated to remove suspensions and / or sub-micron organics in the source water. The source water is used to generate supercritical water having a pressure and temperature above a critical pressure and a critical temperature, respectively. The supercritical water is run through a spiral separator to generate effluent water and waste water containing aggregated particles therein. Energy may be recovered from the effluent water and used to generate additional supercritical water.

Owner:PALO ALTO RES CENT INC

Process for treating sewage to generate active mud and extract protein

InactiveCN1369445AReduce pollutionSimple processSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCellular DebrisSludge

A process for extracting protein from the active mud generated by treating sewage includes dewatering said mud, stirring at 15-90 deg.C for 5-60 min, regulating pH value to 7-12, stirring at constanttemp for 5-30 min, filter to obtain aqueous solution of protein, stirring until the pH value of 3-7, laying aside, depositing, removing supernatant, and drying. Its filtered dregs can be used as fuelor feed.

Owner:邵胜学

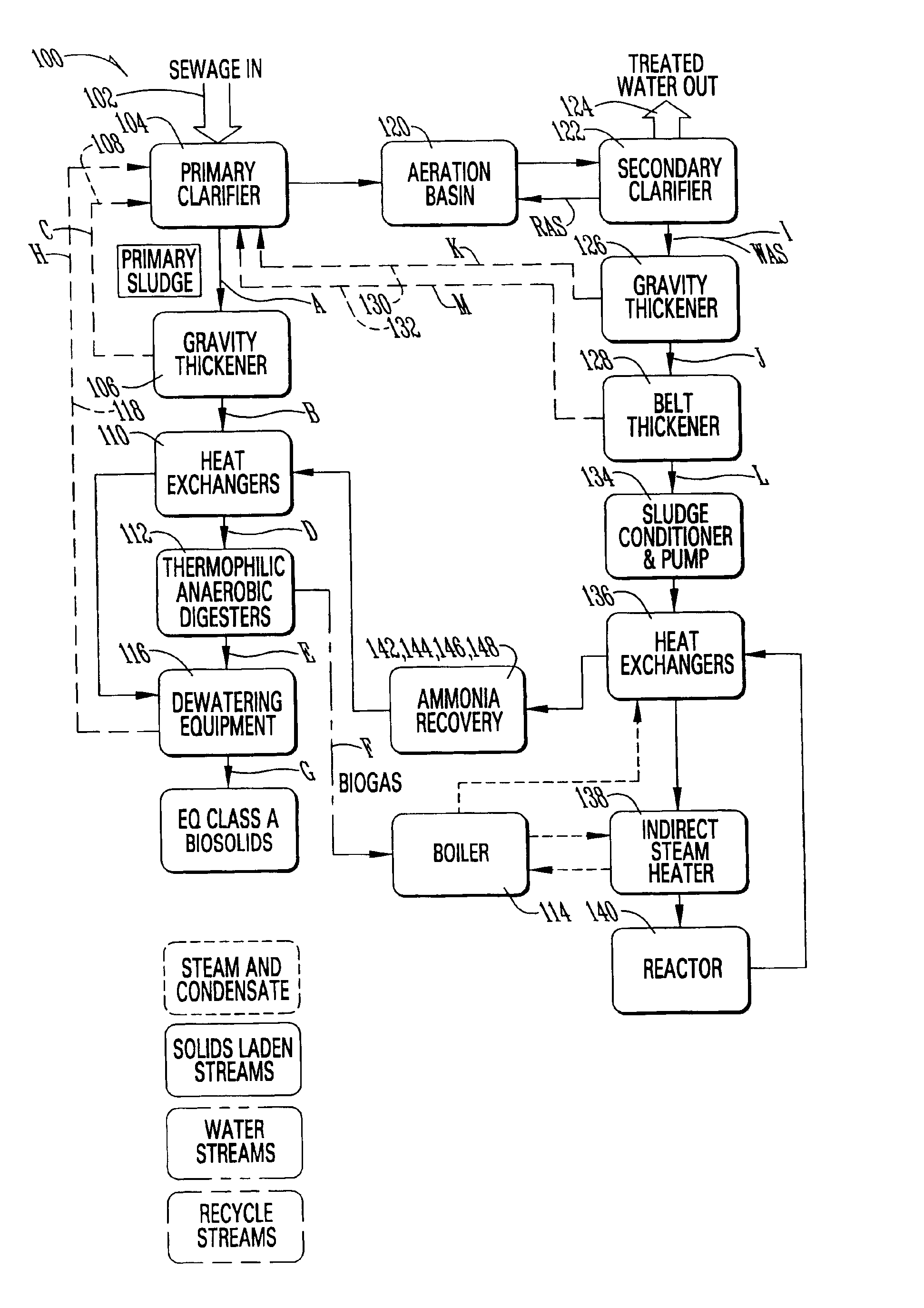

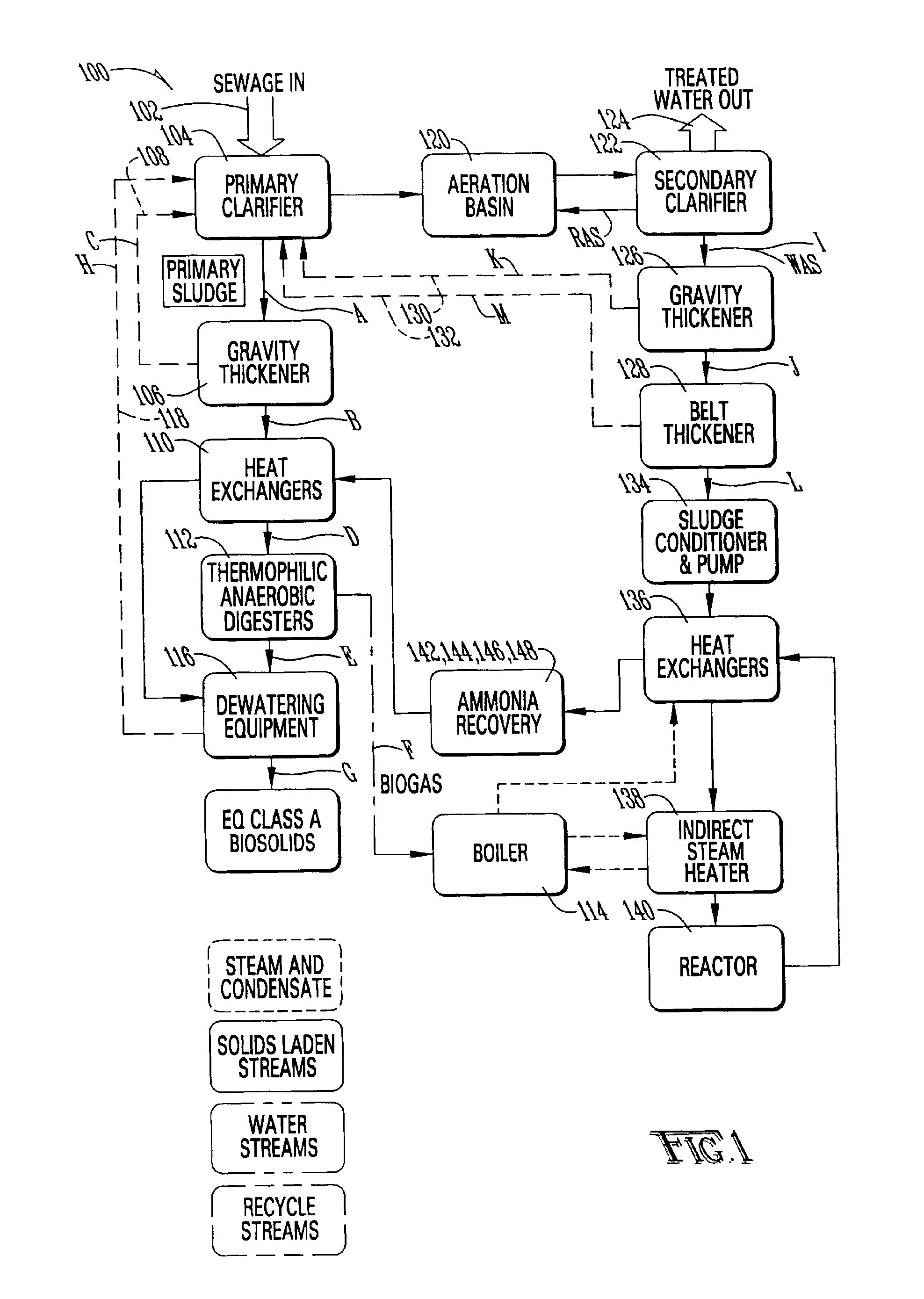

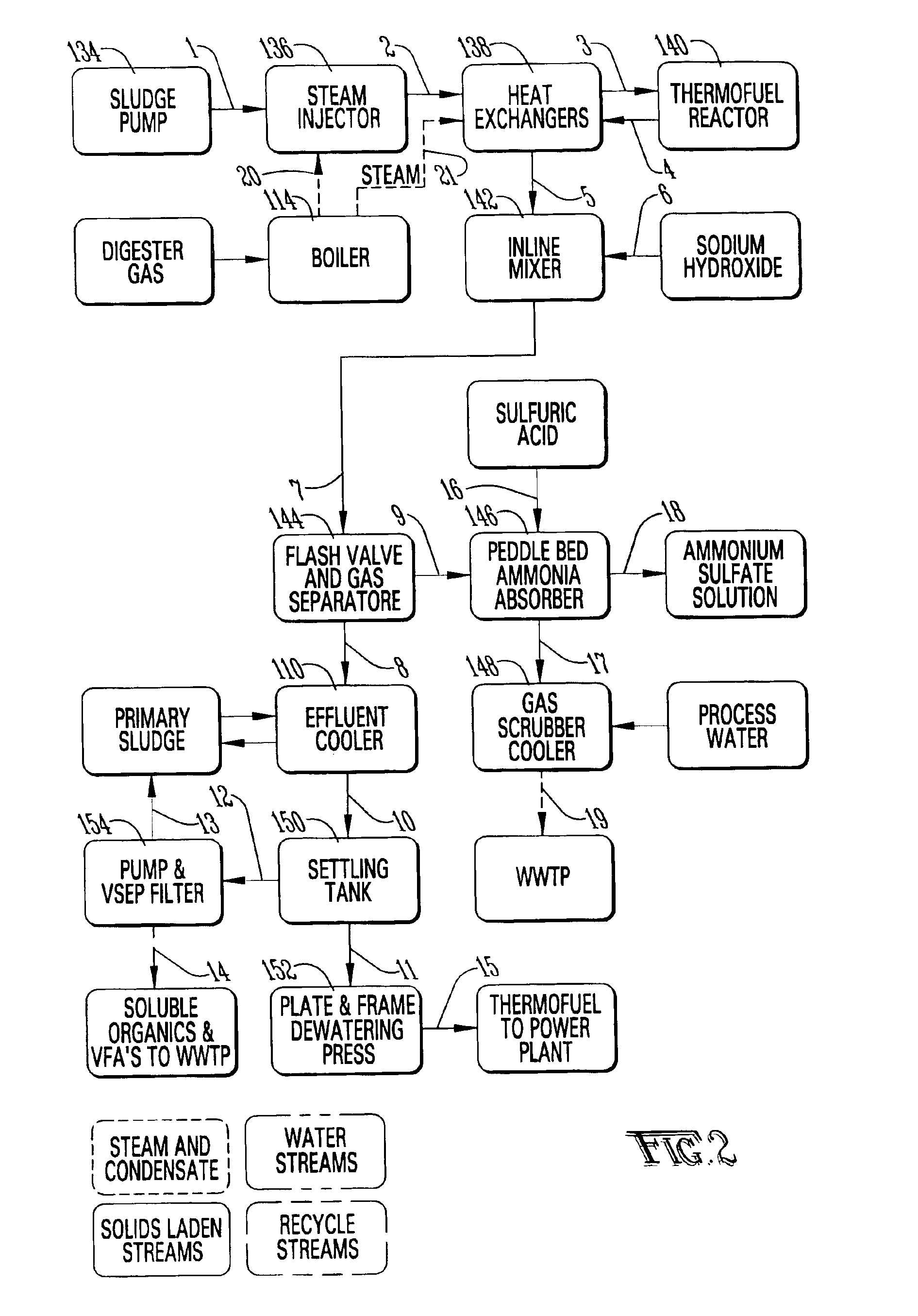

Sewage treatment system

InactiveUS6893566B2Lower cost of capitalReduce operating costsSludge treatment by thermal conditioningSolid waste disposalActivated sludgeWaste stream

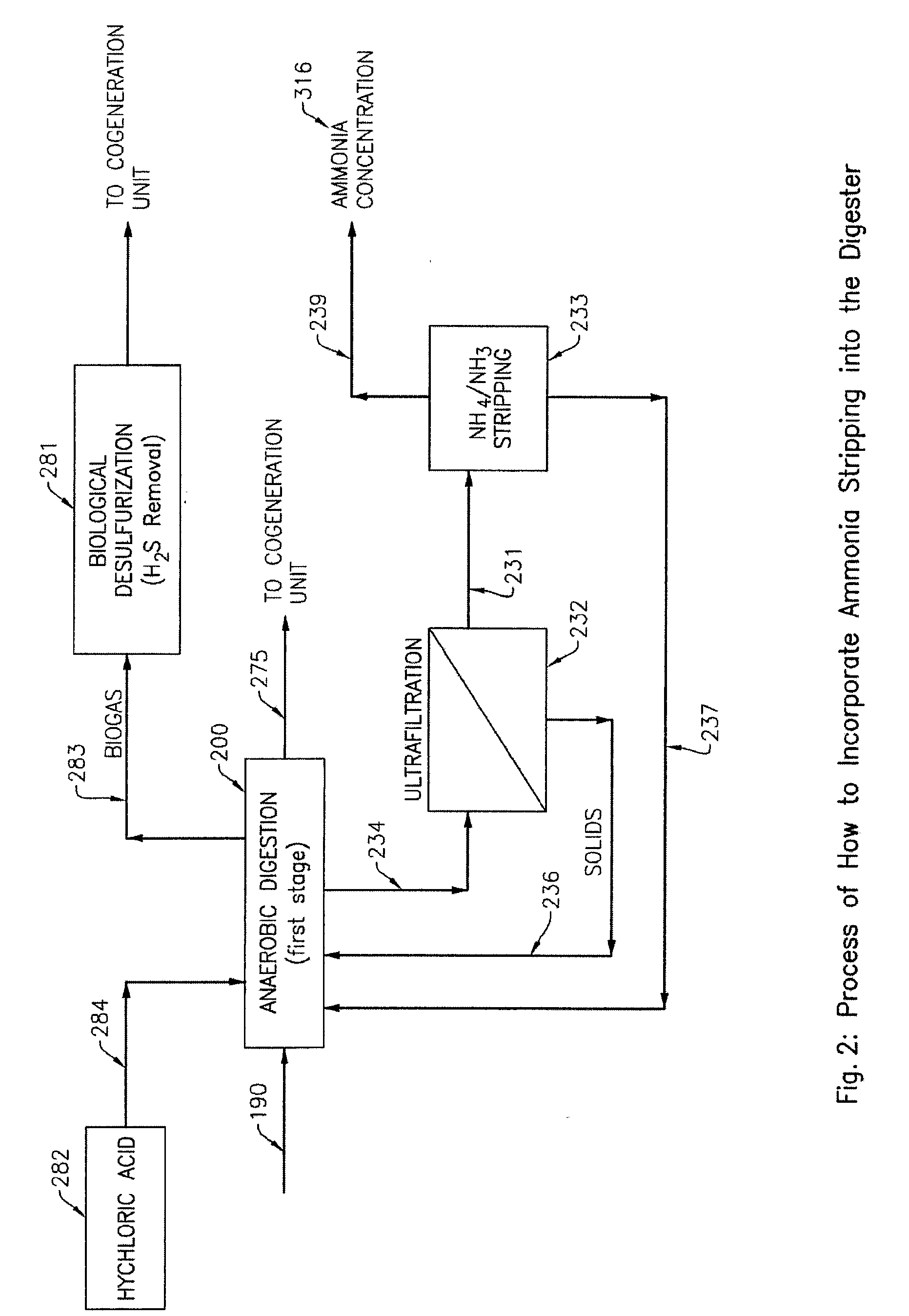

A sewage treatment system is disclosed in which a waste stream is separated into a primary sludge and water effluent, and the primary sludge is anaerobically digested and dewatered to produce a Class A biosolid. The water effluent is aerobically digested and separated to provide a waste activated sludge. The waste activated sludge is heated in a two-stage process with steam injection and indirect steam before it is passed to a hydrothermal process. The pH of the treated waste activated sludge is then increased, and the nitrogen is stripped and recovered as an ammonium salt. A low nitrogen stream with volatile fatty acids and soluble organics is then separated and fed to the aerobic digester. Biogas generated during anaerobic digestion provides energy for heating the waste activated sludge for the hydrothermal process, and reject heat from the hydrothermal process heats the primary sludge for thermophilic anaerobic digestion.

Owner:FASSBENDER ALEXANDER G

Sludge desiccation burning integral treatment method and device

InactiveCN101210678AAchieve burnoutSave burnoutSludge treatment by thermal conditioningDrying solid materials with heatAir preheaterFluidized bed

A method of integrated treatment of sludge drying and incineration is provided, which comprises the follow steps of: feeding sludge into a rotary-type sludge dryer, introducing a part of moderate-temperature fume inside a fluidized bed incinerator into the rotary-type sludge dryer to heat and evaporate the water in the sludge, feeding the obtained semi-dried sludge into the fluidized bed incinerator; introducing the other part of moderate-temperature fume into an air pre-heater, heating the fist-stage and second-stage air of the fluidized bed incinerator, transferring parts of ash and bed media exhausted from the fluidized bed incinerator to the rotary-type sludge dryer, and mixing with the sludge inside the rotary-type sludge dryer. A device for implementing the method comprises a storage feed device, the rotary-type sludge dryer and the fluidized bed incinerator. The invention realizes the integrated treatment of drying and incineration; omits the intermediate links between the drying and incineration links, such as sludge cooling, sludge storage, sludge transportation and heat medium drying; simplifies the system; reduces the occupied area; and reduces the investment and cost.

Owner:上海环保工程成套有限公司 +1

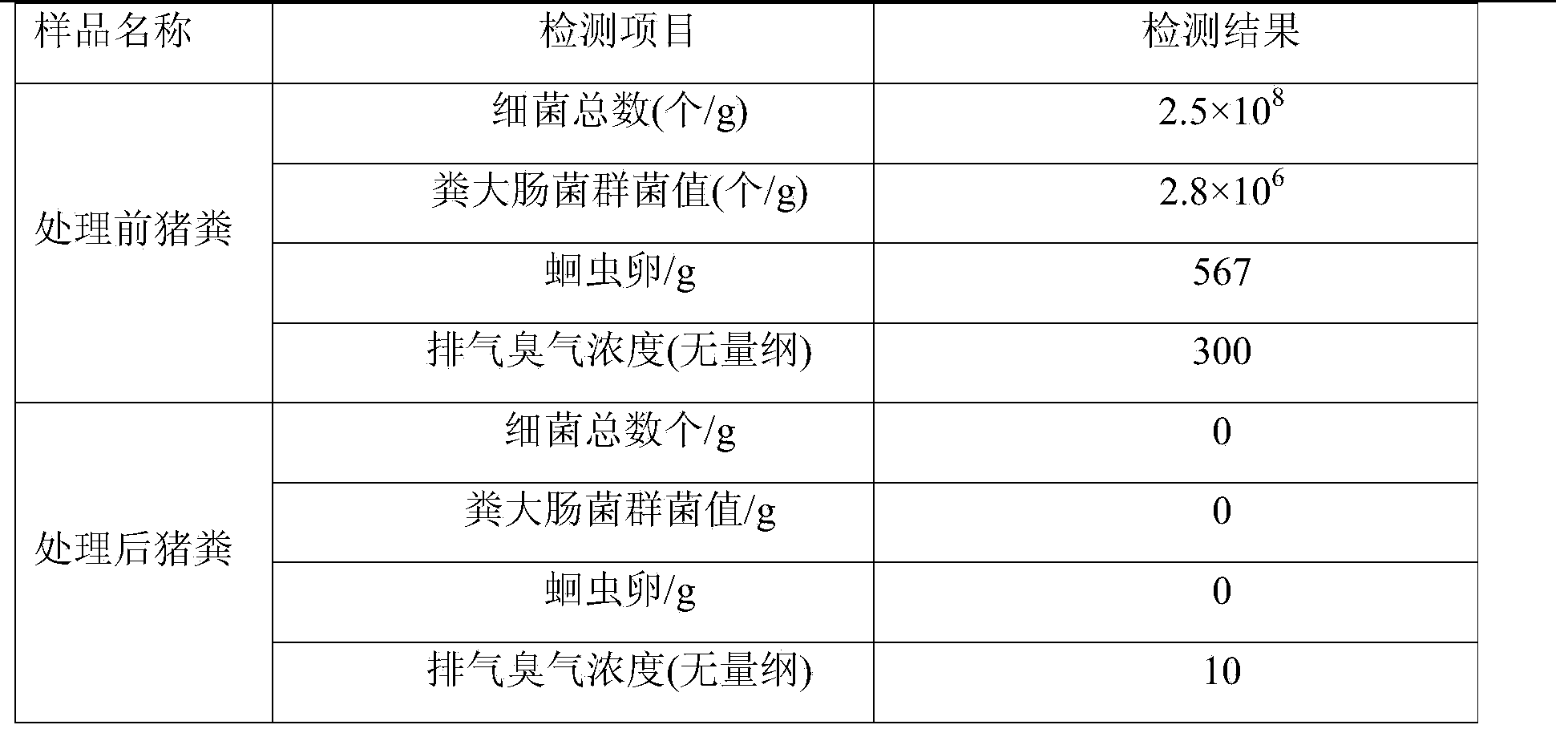

Sterilization, deodorization and deep-dehydration method for livestock excrements

ActiveCN103708689AWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMicrowaveFiltration

The invention relates to the field of treatment of livestock excrements, and in particular relates to a sterilization, deodorization and deep-dehydration method for livestock excrements. The method comprises the steps of acidification, namely adjusting the pH of the livestock excrements to be 3 to 6 by using acid; oxidization, namely adding an oxidizing agent into the acidified livestock excrements at the ratio that 0.5 to 1.2 moles of oxidizing agent is added into every kilogram of dry livestock excrements, and performing uniform stirring; microwave heating treatment, namely heating the oxidized livestock excrements to 95 to 120 DEG C by using microwaves, and continuing performing microwave treatment while stirring for 5 to 12 minutes at the temperature; pressure filtration dehydration, namely performing pressure filtration dehydration on the microwave-treated livestock excrements by using a pressure filter. The method is low in using cost, easy to operate and high in treatment speed, and the treated livestock excrements are high in solid recovery rate, low in heat value reduction and high in dehydration degree.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com