Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5147results about "Gas production bioreactors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

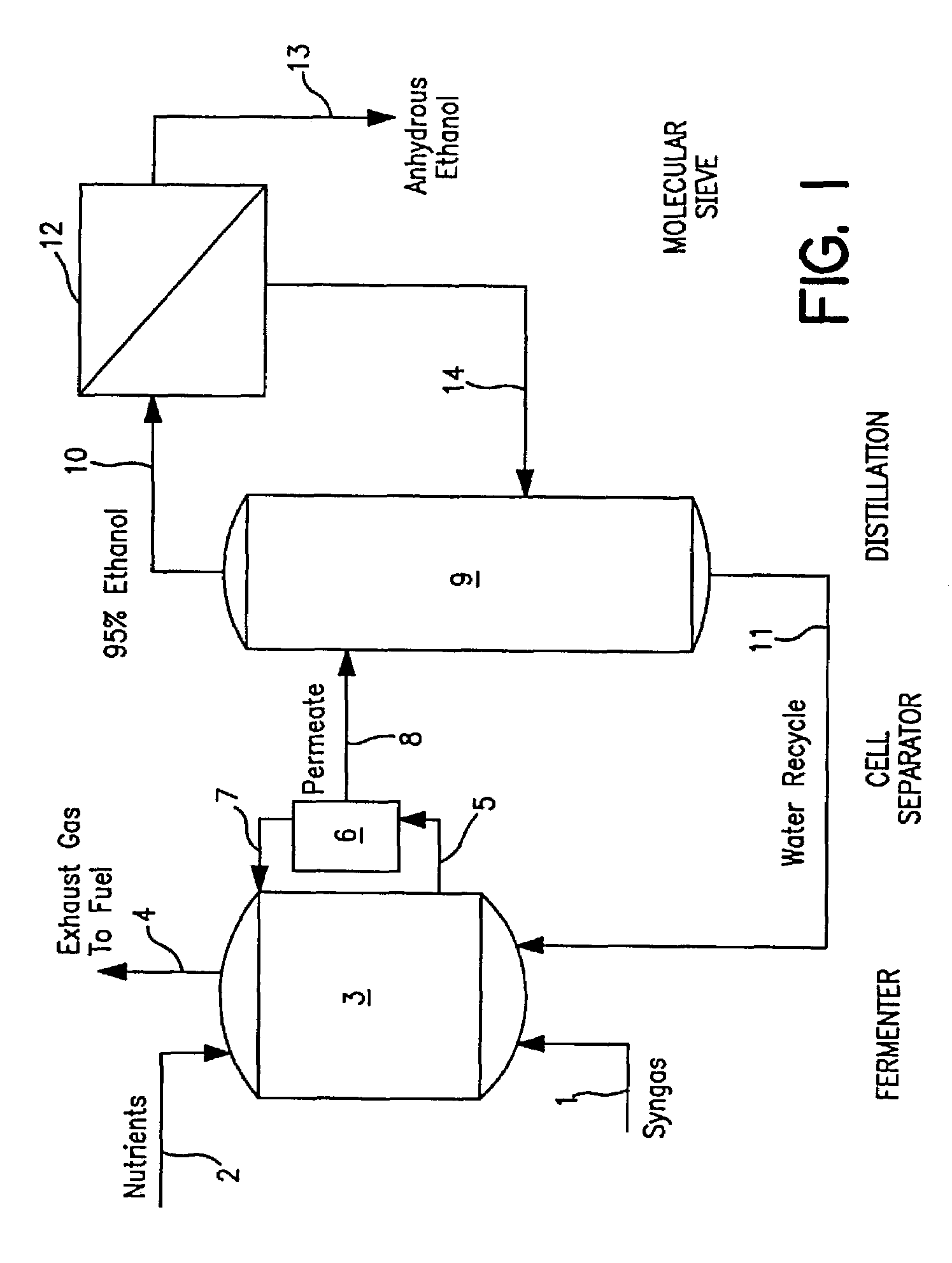

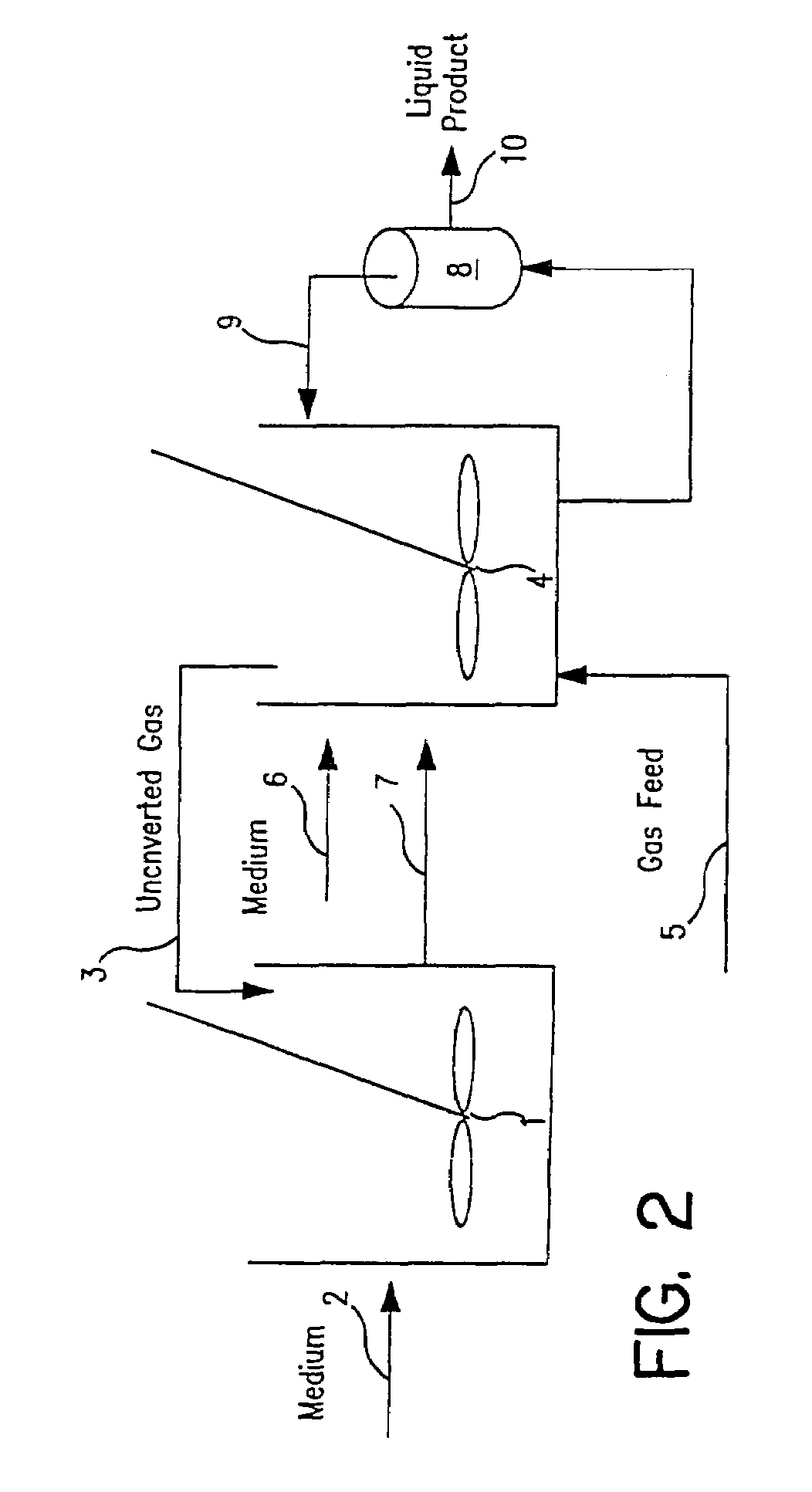

Methods for increasing the production of ethanol from microbial fermentation

InactiveUS7285402B2Good culture stabilityPermit growthBioreactor/fermenter combinationsSolid waste disposalBioreactorNutrient

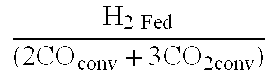

A stable continuous method for producing ethanol from the anaerobic bacterial fermentation of a gaseous substrate containing at least one reducing gas involves culturing a fermentation bioreactor anaerobic, acetogenic bacteria in a liquid nutrient medium; supplying the gaseous substrate to the bioreactor; and manipulating the bacteria in the bioreactor by reducing the redox potential, or increasing the NAD(P)H TO NAD(P) ratio, in the fermentation broth after the bacteria achieves a steady state and stable cell concentration in the bioreactor. The free acetic acid concentration in the bioreactor is maintained at less than 5 g / L free acid. This method allows ethanol to be produced in the fermentation broth in the bioreactor at a productivity greater than 10 g / L per day. Both ethanol and acetate are produced in a ratio of ethanol to acetate ranging from 1:1 to 20:1.

Owner:JUPENG BIO HK LTD

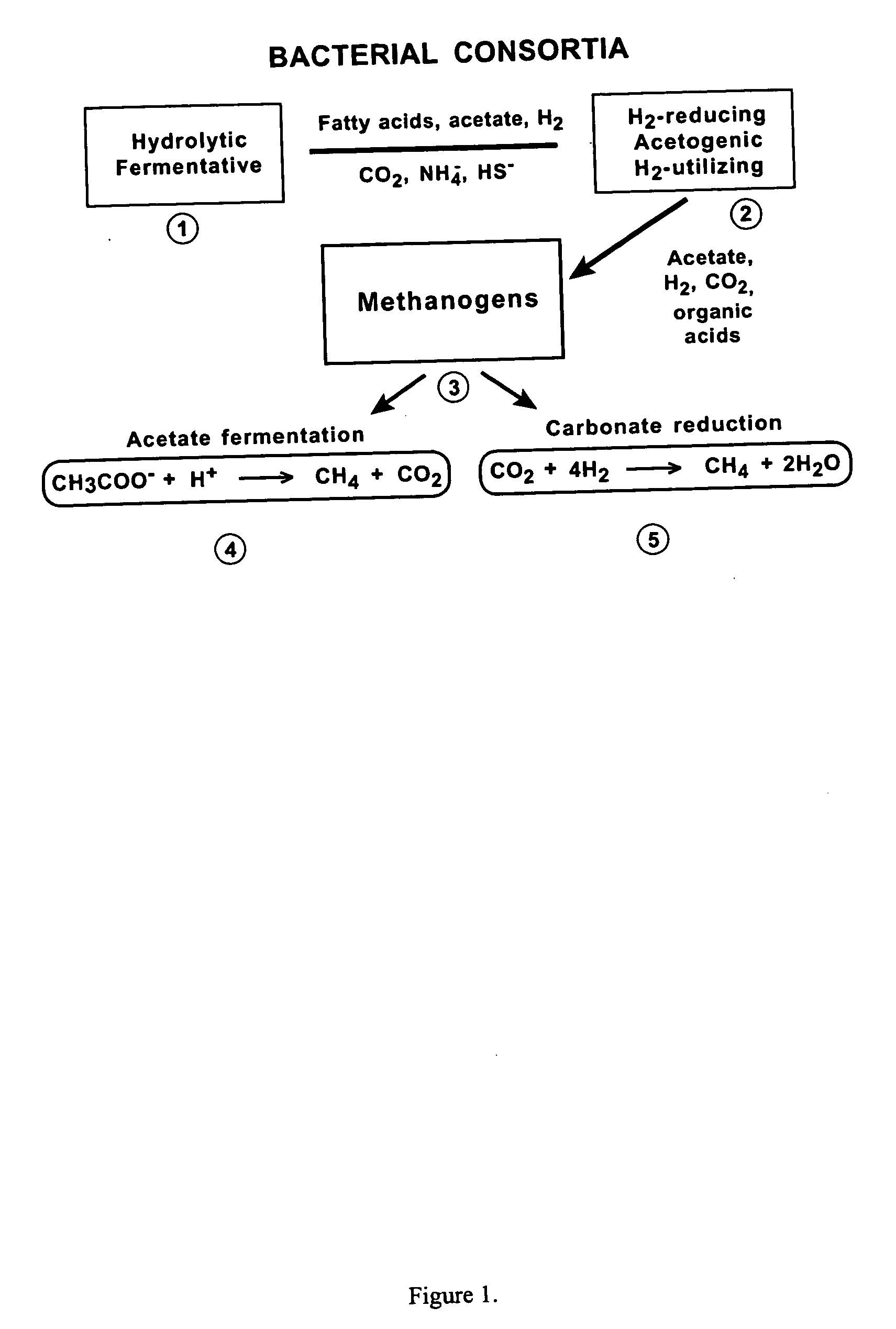

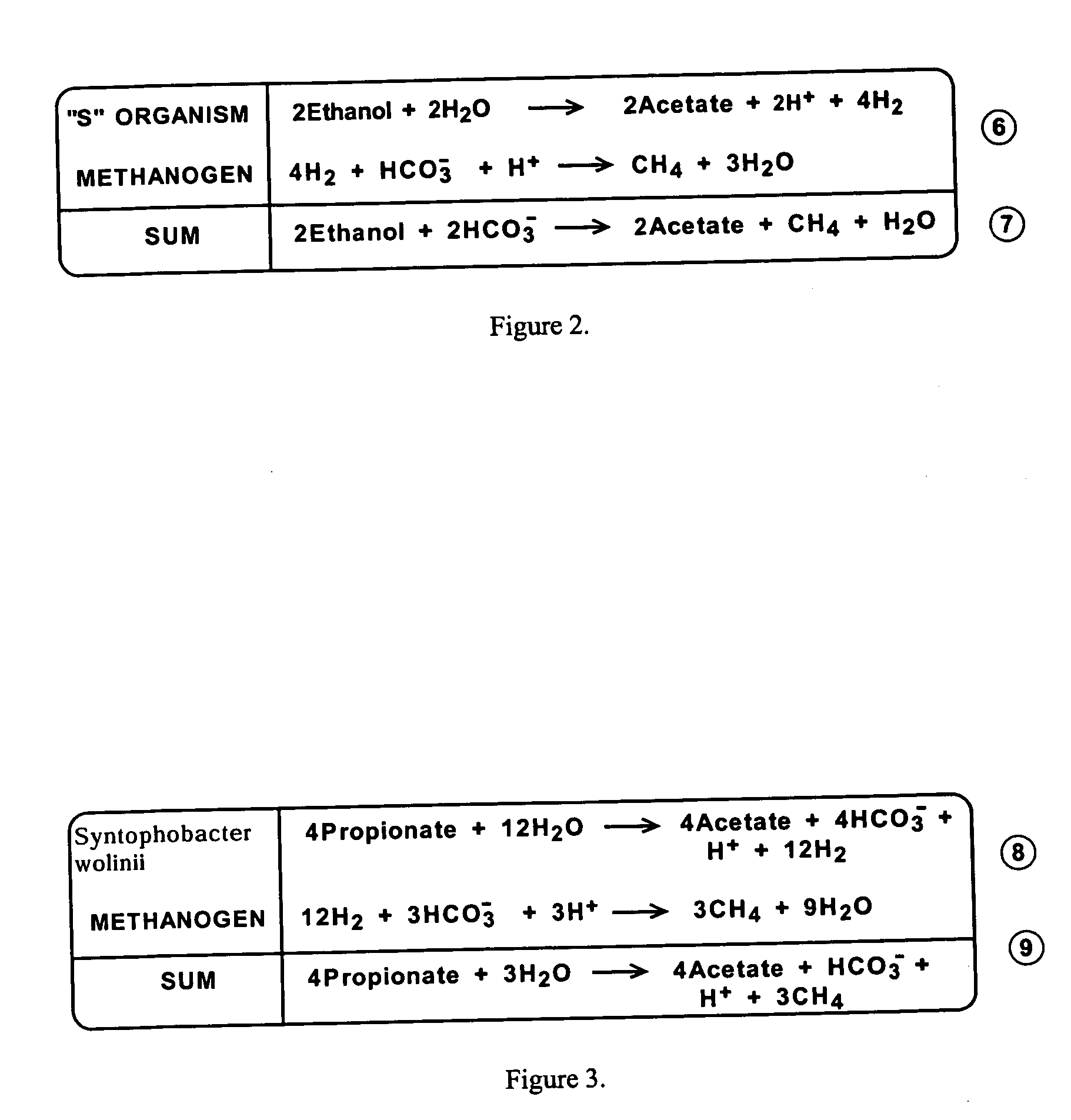

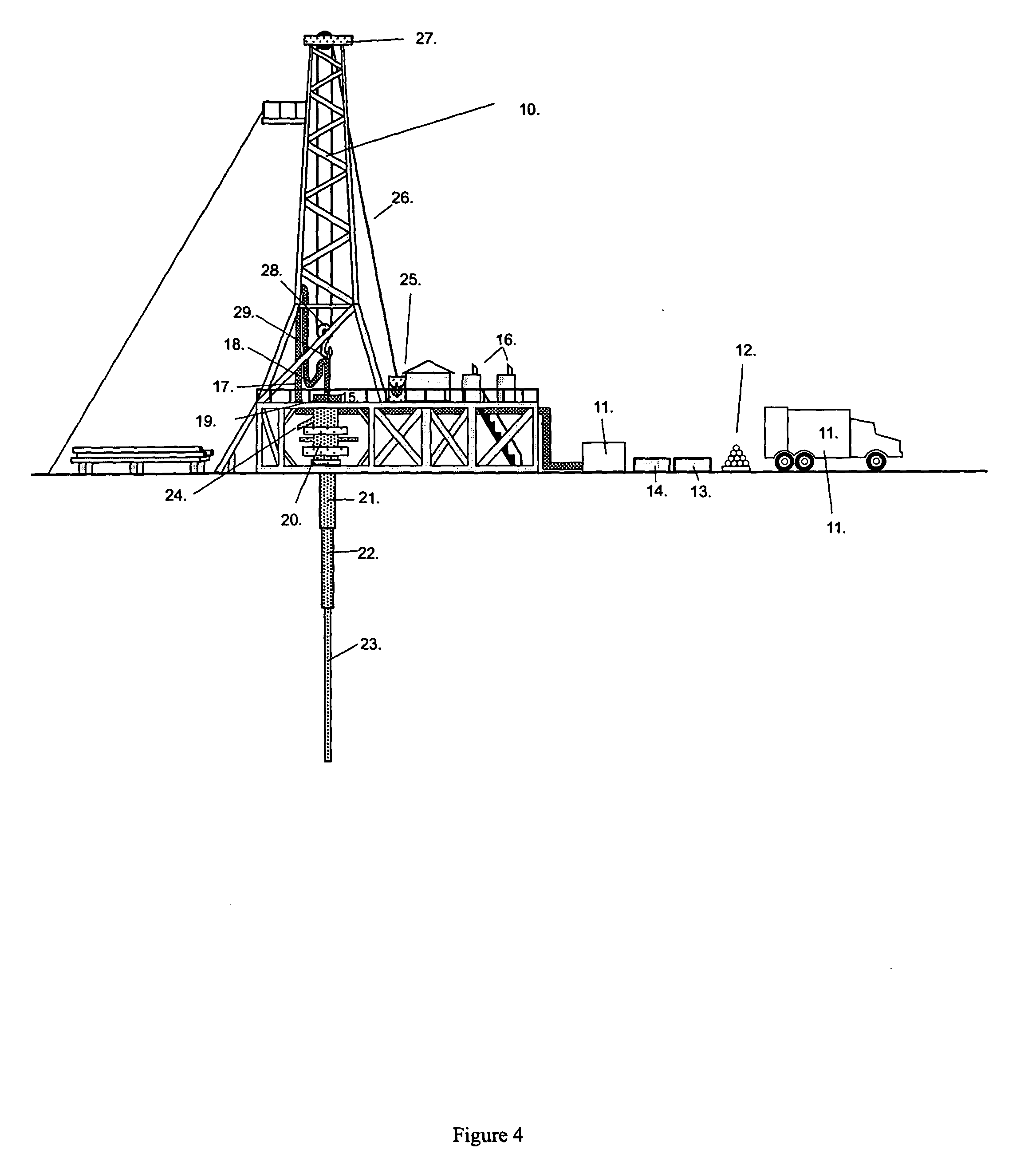

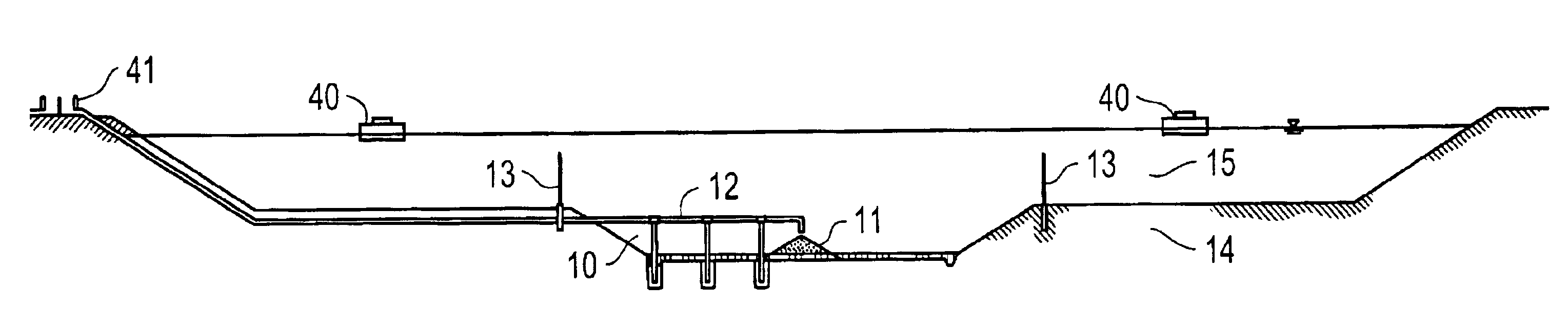

Method of generating and recovering gas from subsurface formations of coal, carbonaceous shale and organic-rich shales

InactiveUS20040033557A1Maximizes bacterial degradationStable and economically favorable and environmentally cleanMicrobiological testing/measurementGas production bioreactorsOrganic compoundCoal

A method of generating and recovering gas from naturally existing subsurface formations Of coal, carbonaceous shale or organic-rich shales comprising the steps Of: injecting into fracture of the subsurface formation, under substantially anaerobic conditions, a consortia of selected anaerobic, biological microorganisms for in situ conversion of organic compounds in said formation into methane and other compounds; and producing methane through at least one well extending from said subsurface formation to the surfaces.

Owner:SCOTT ANDREW R +1

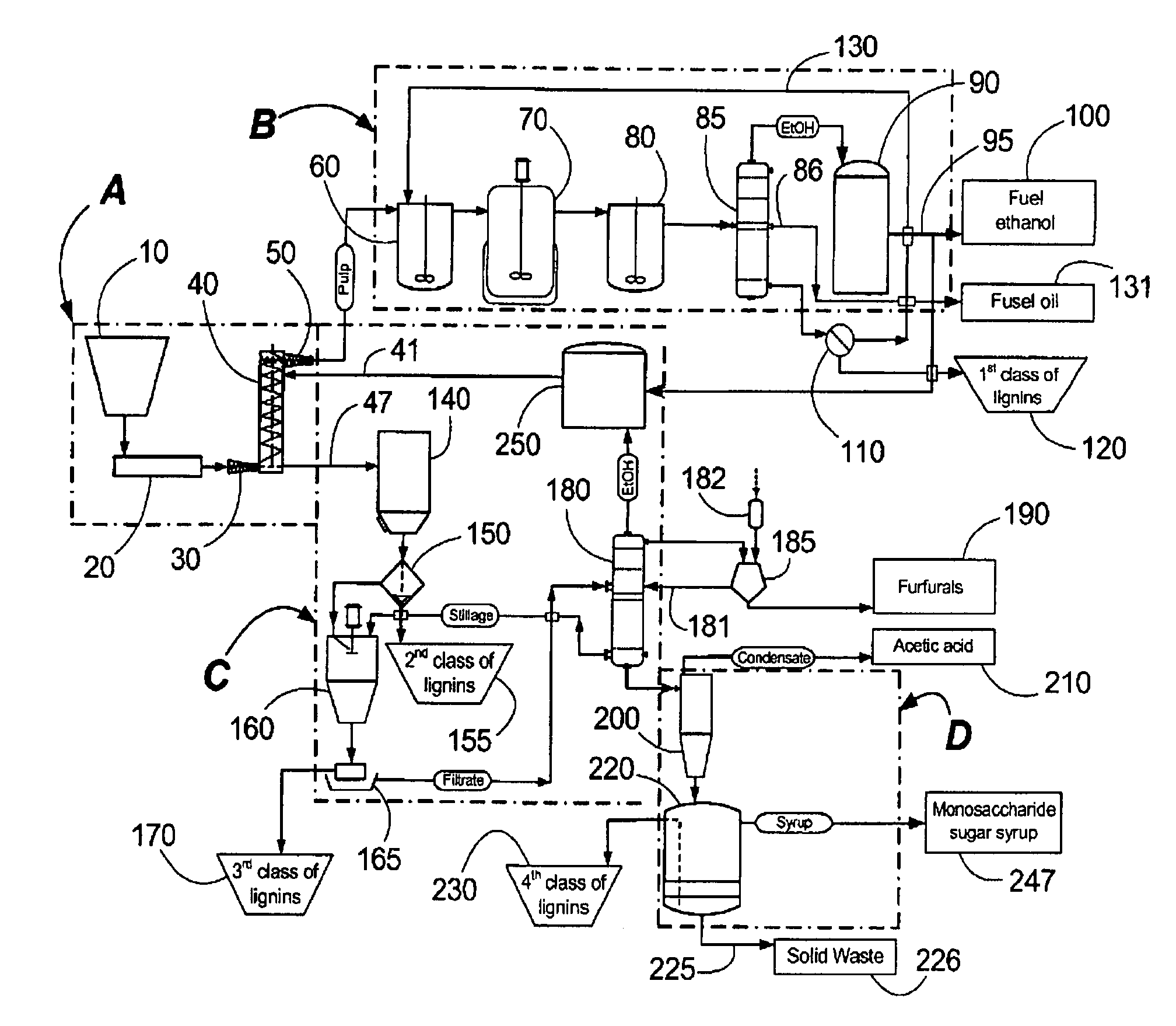

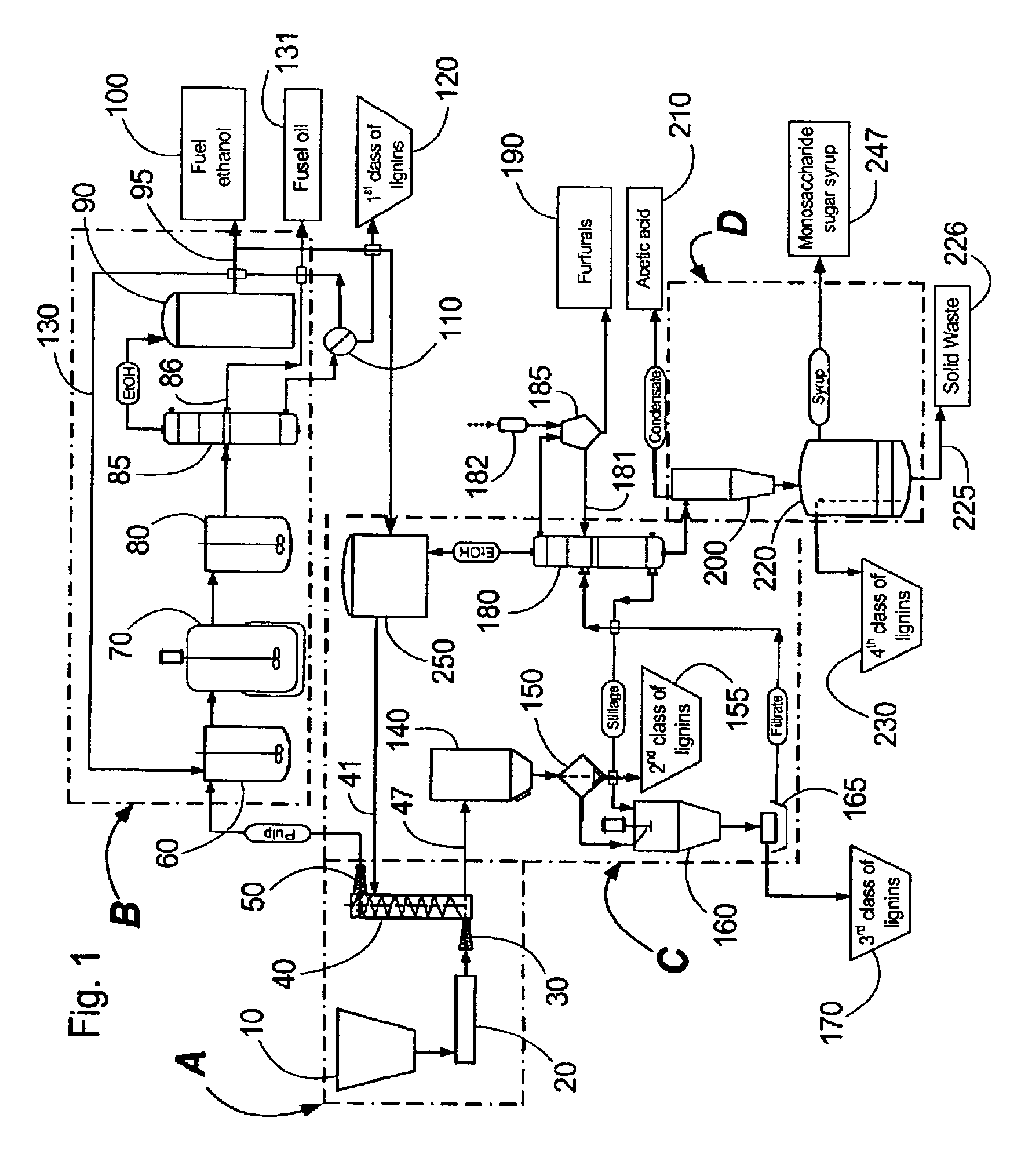

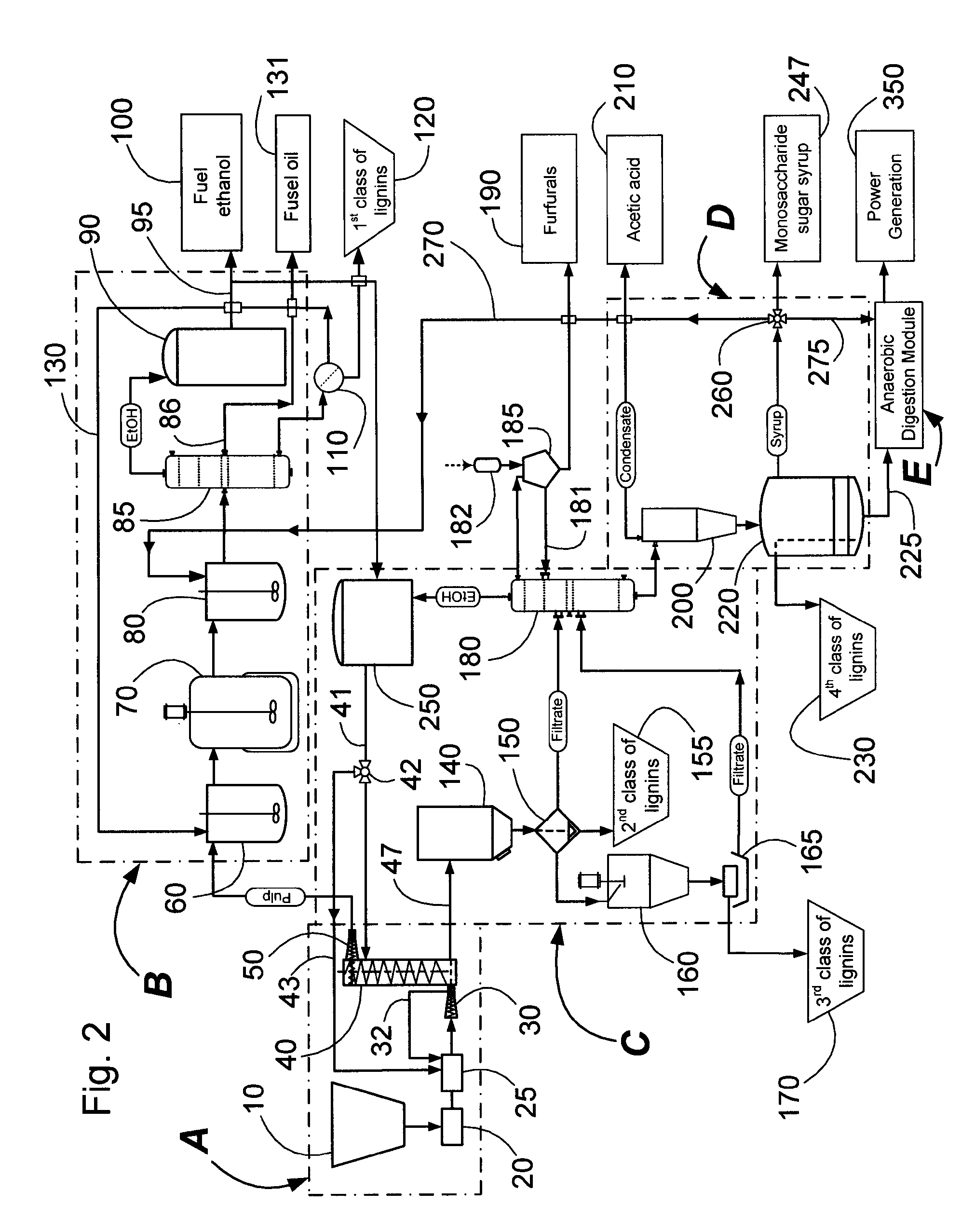

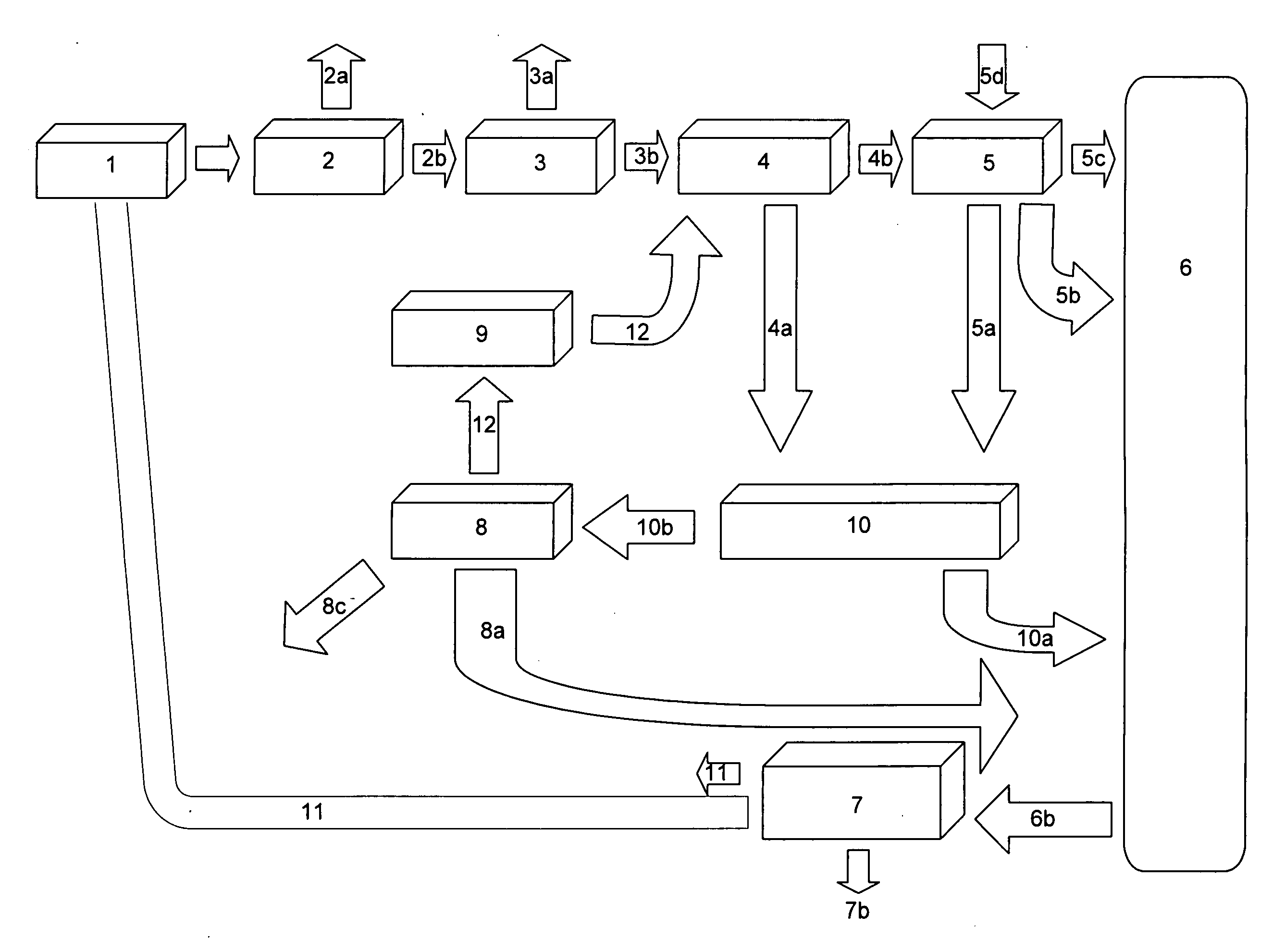

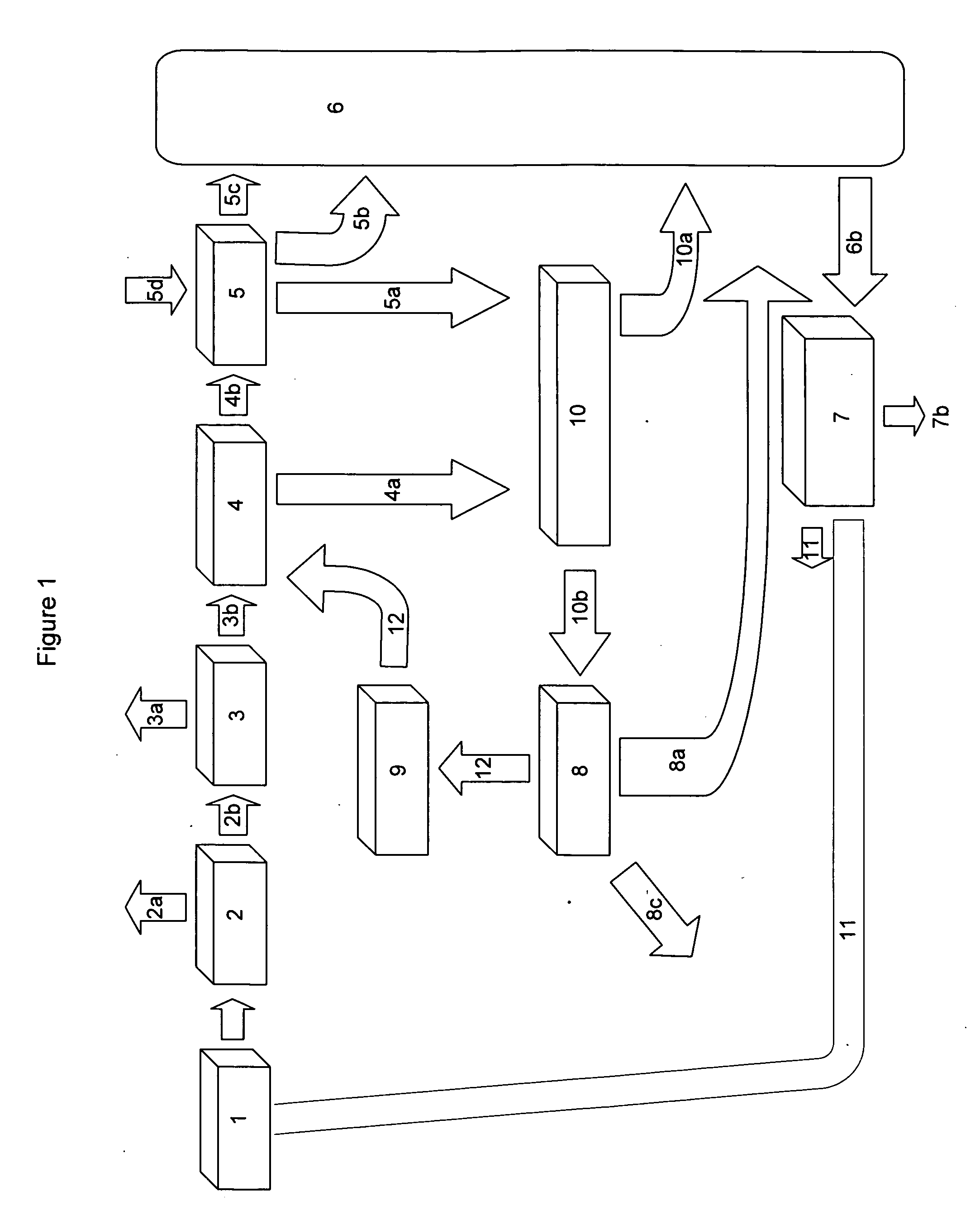

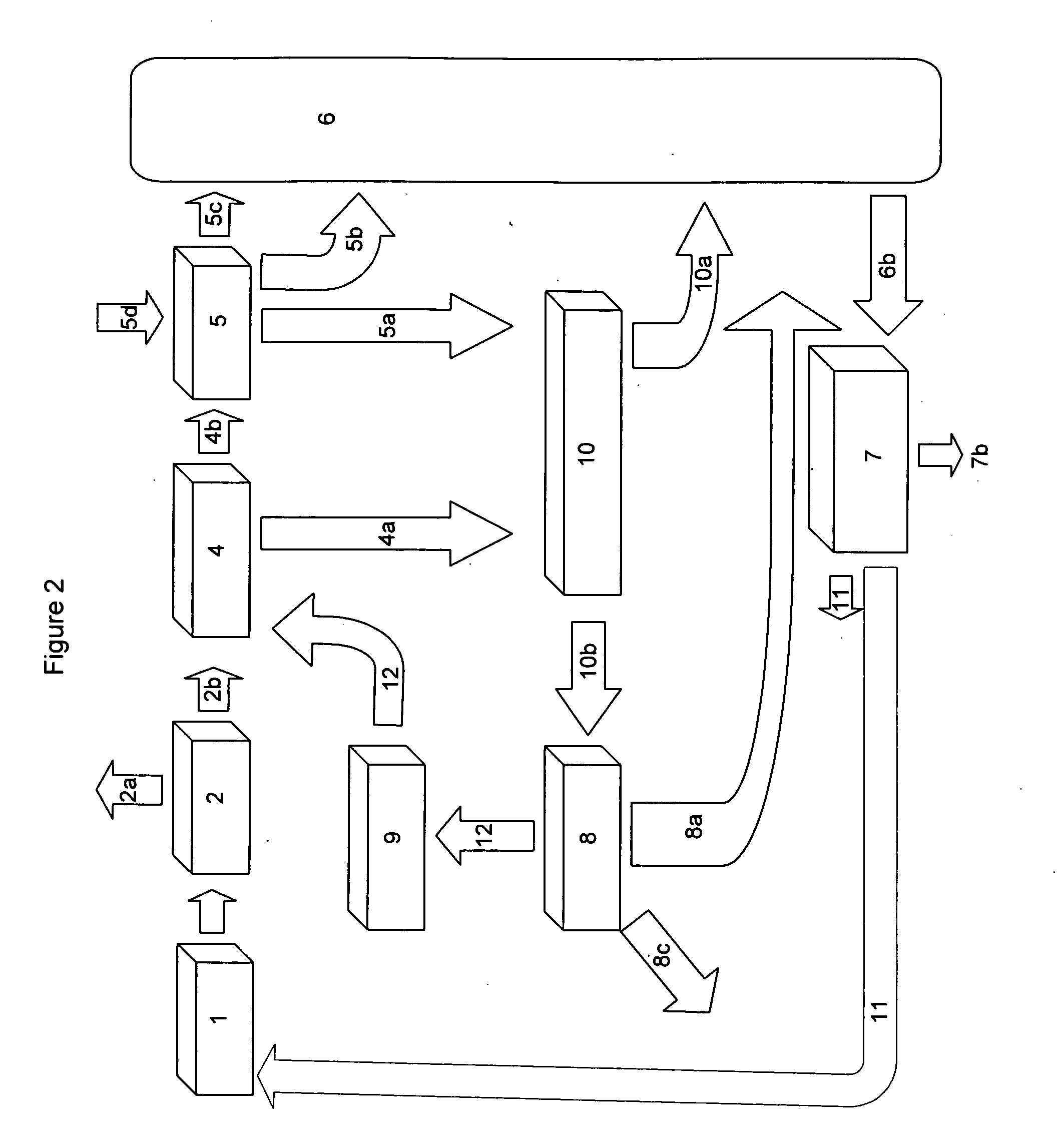

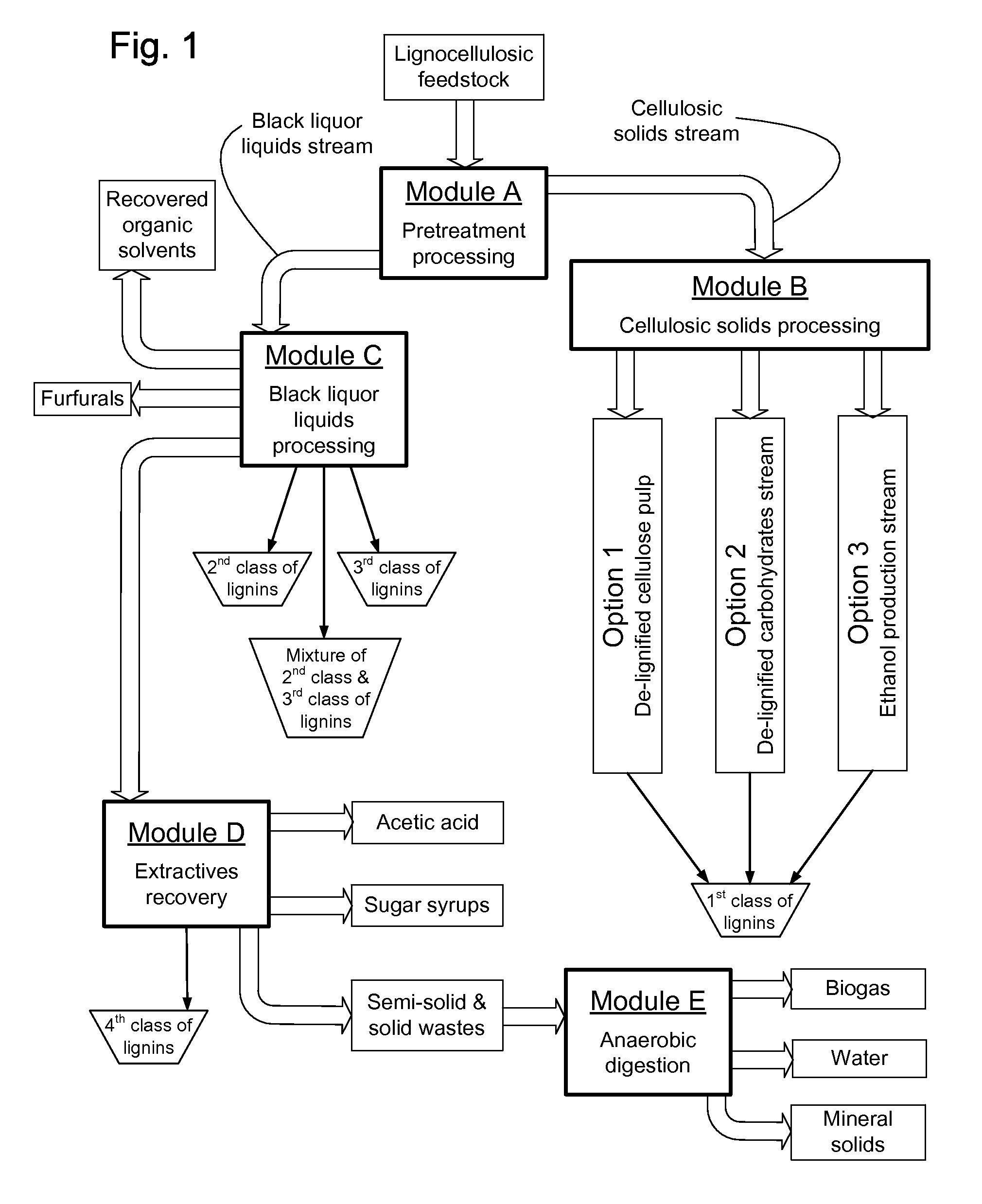

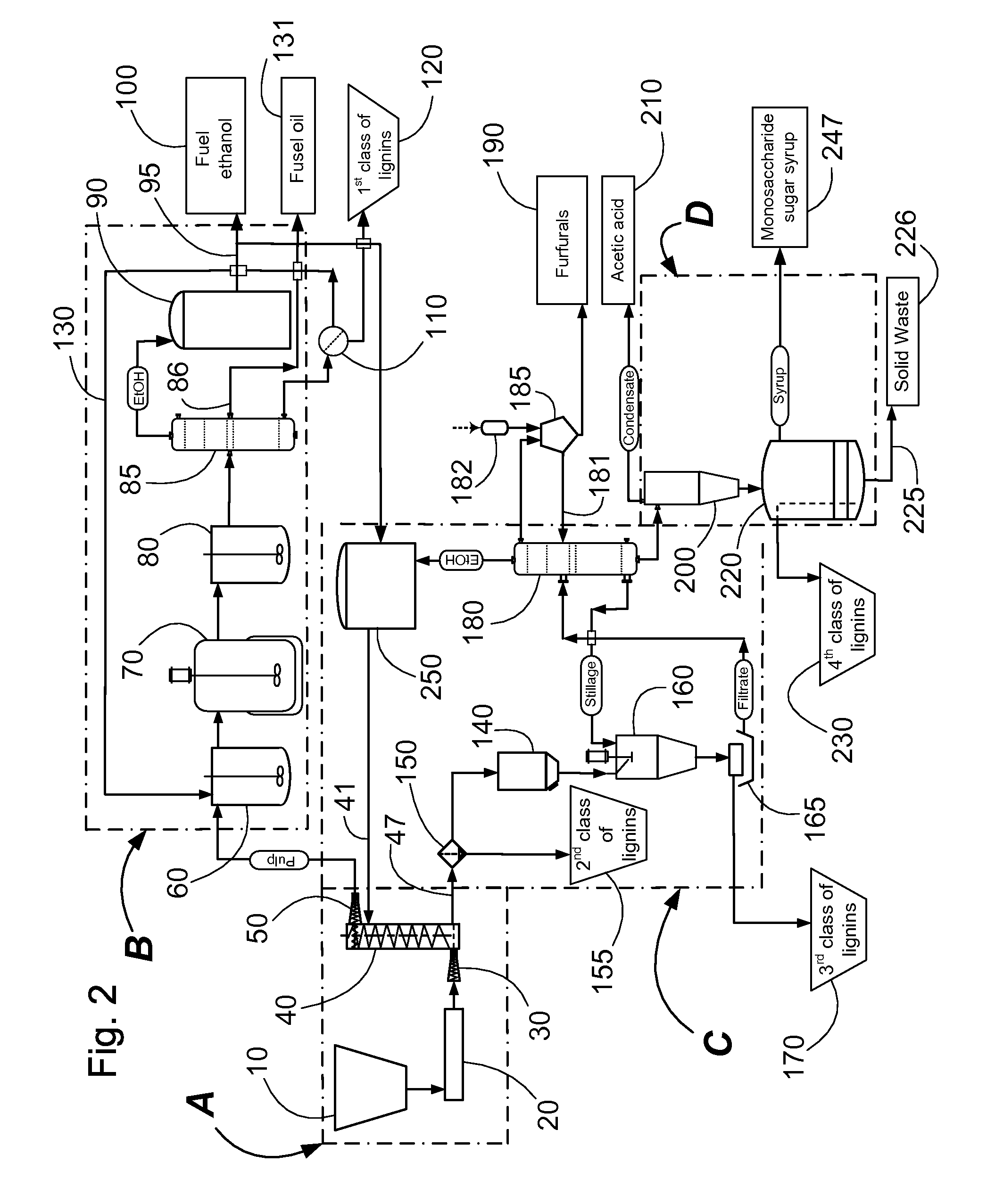

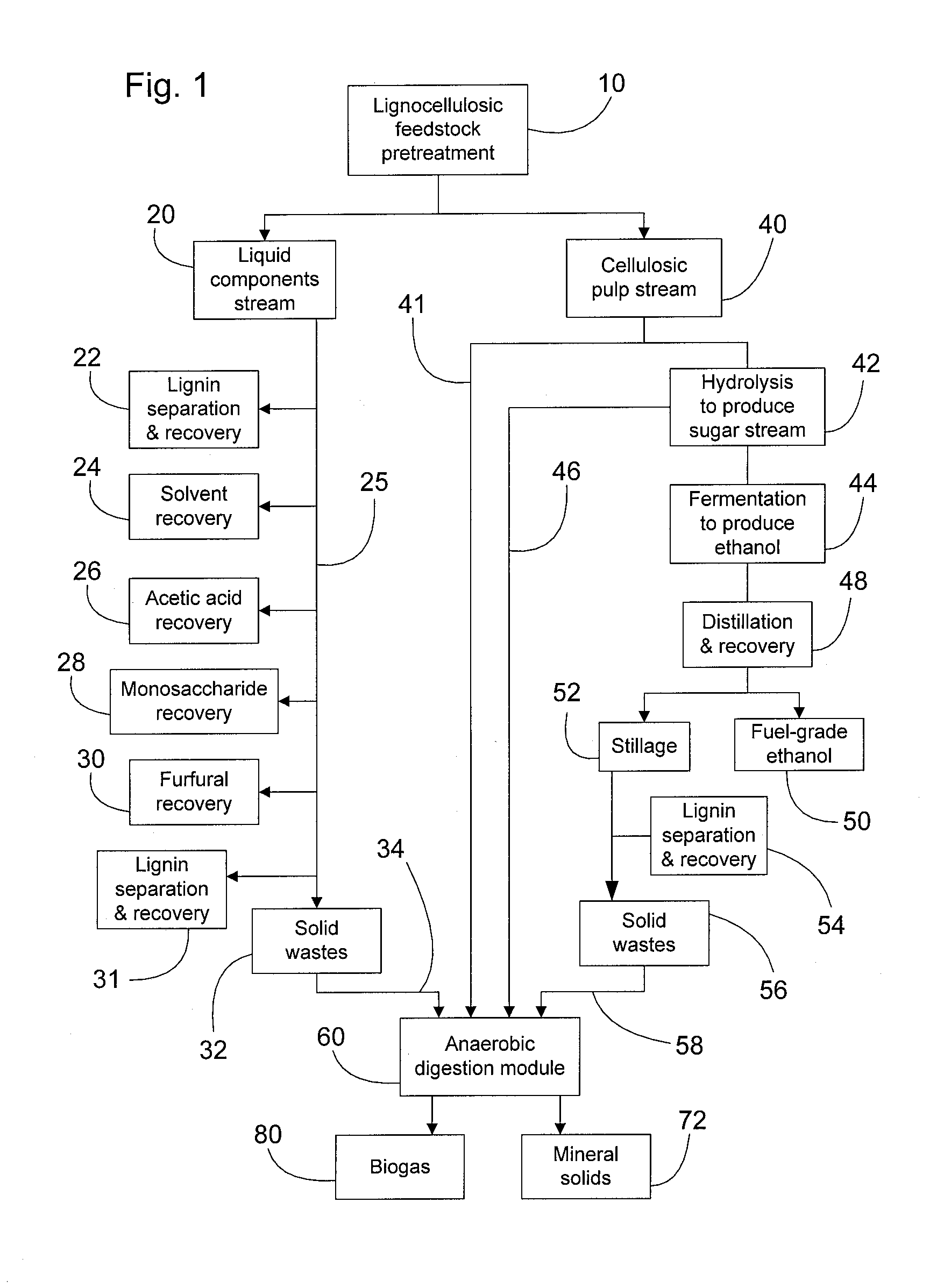

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

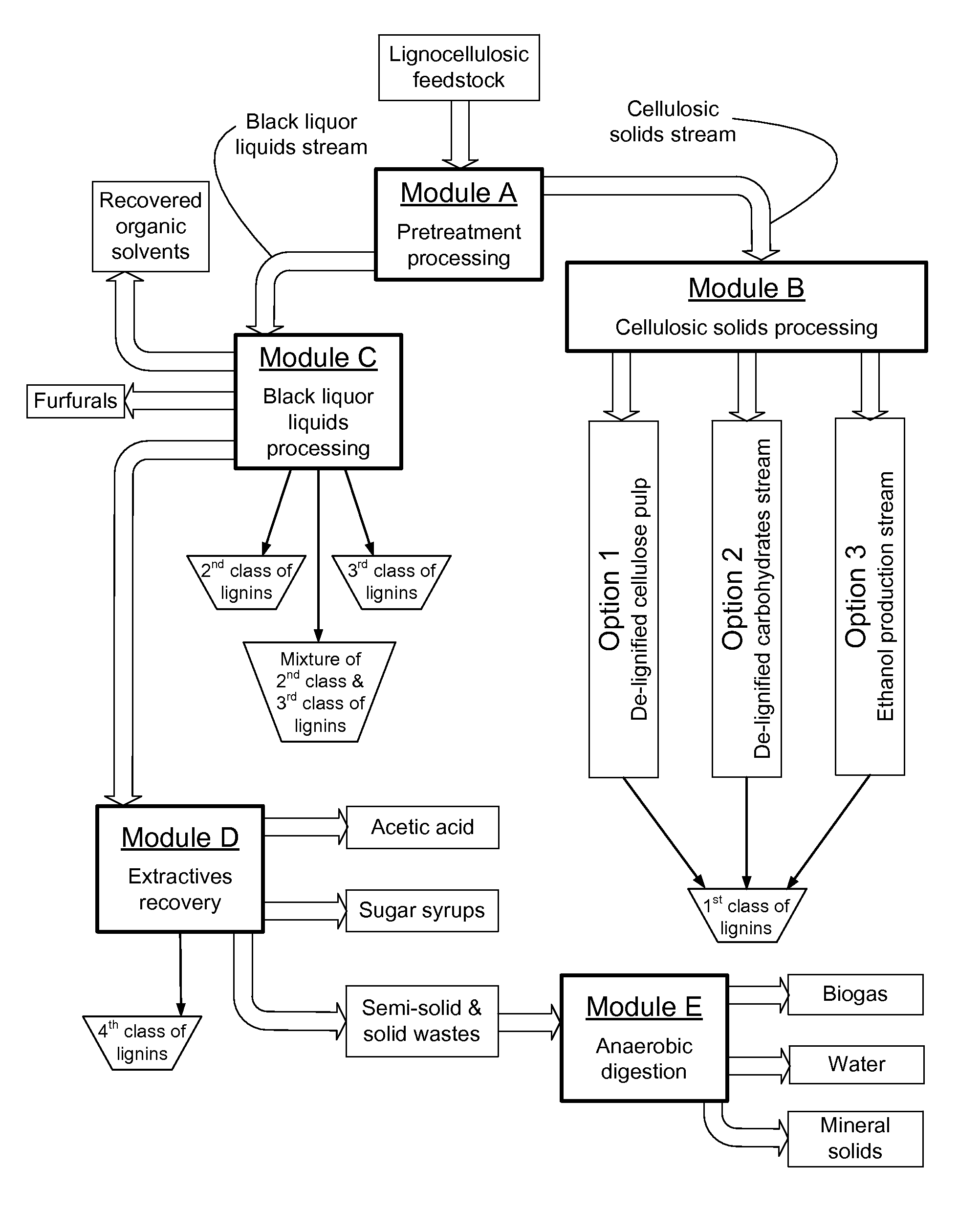

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

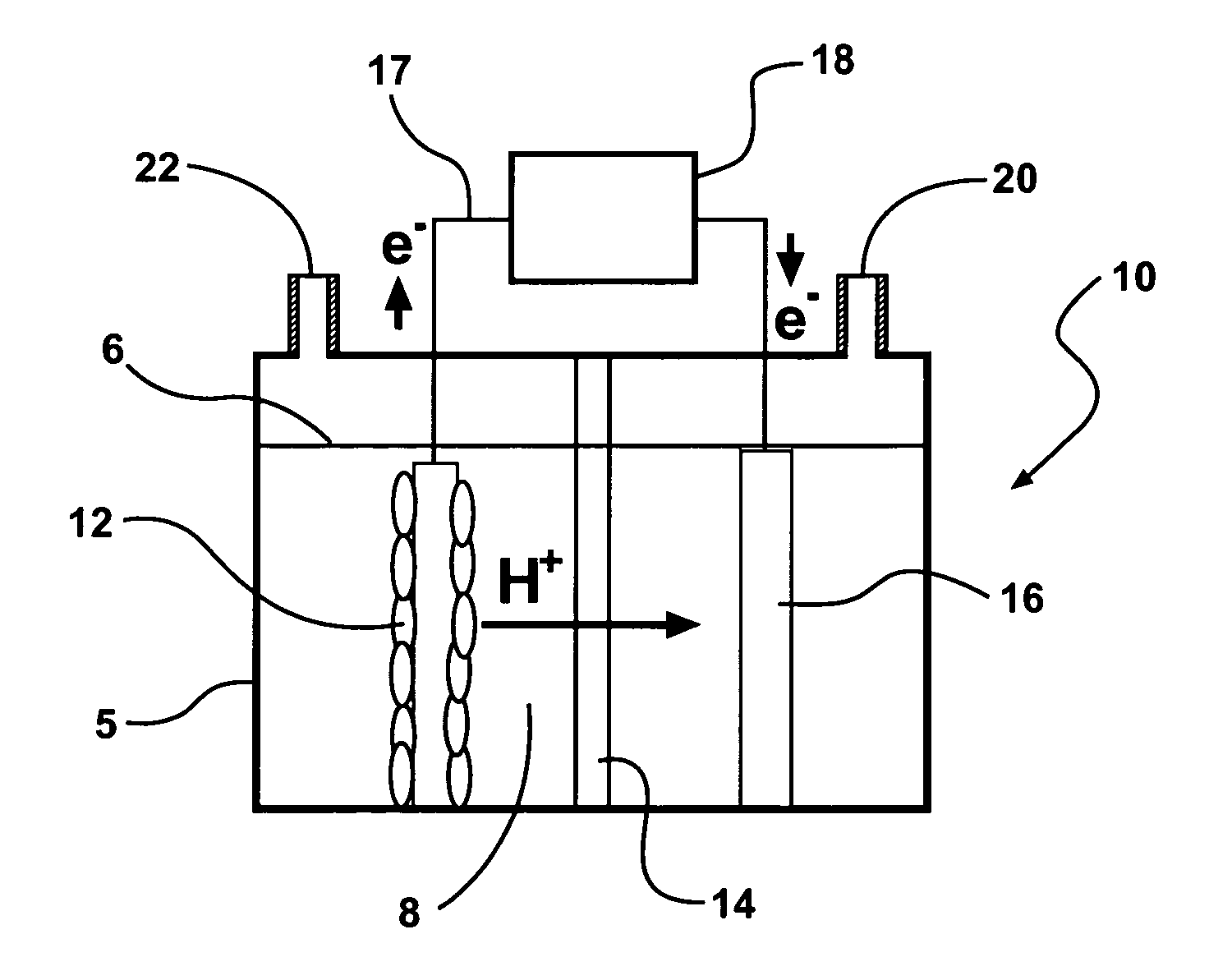

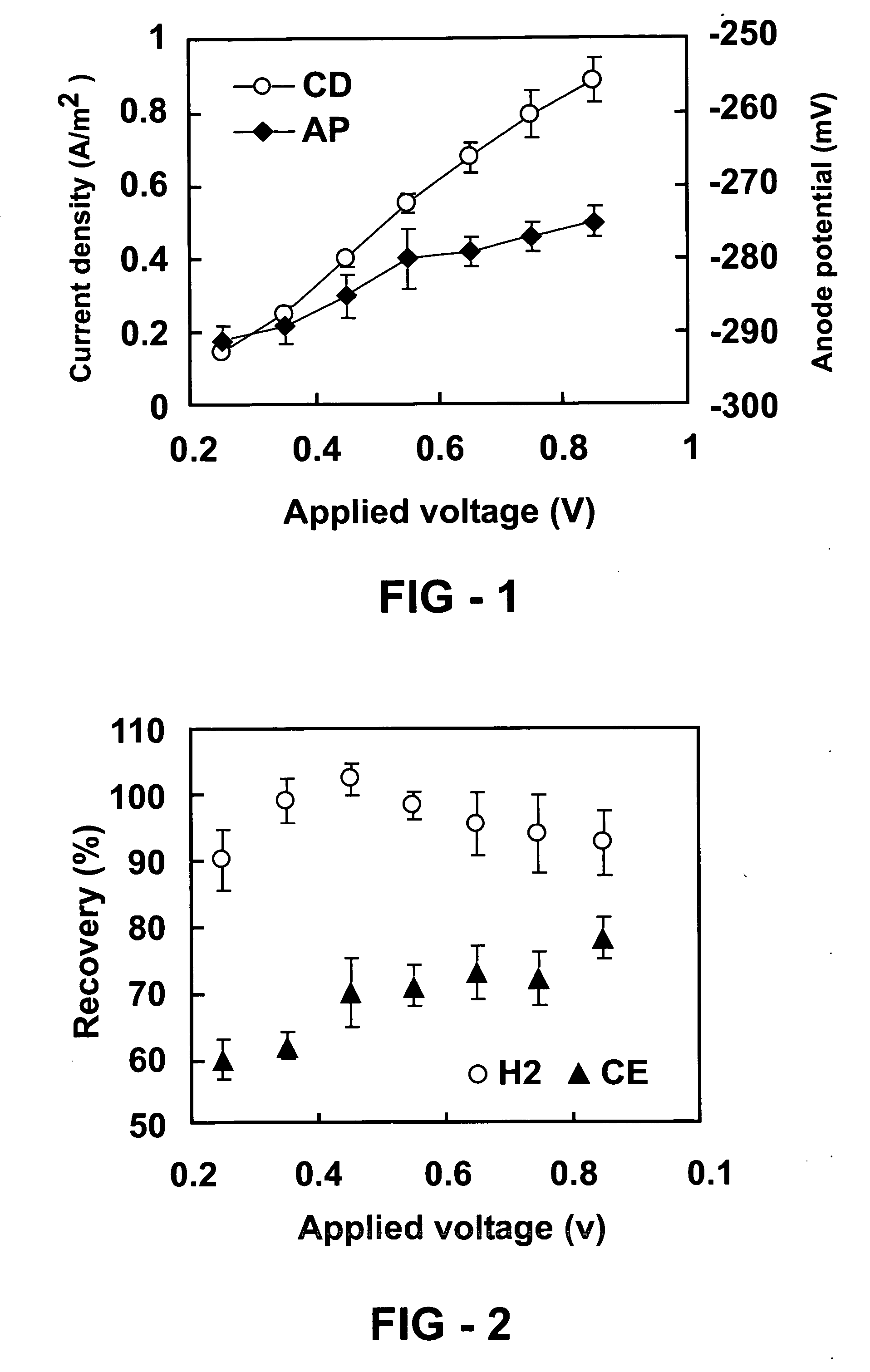

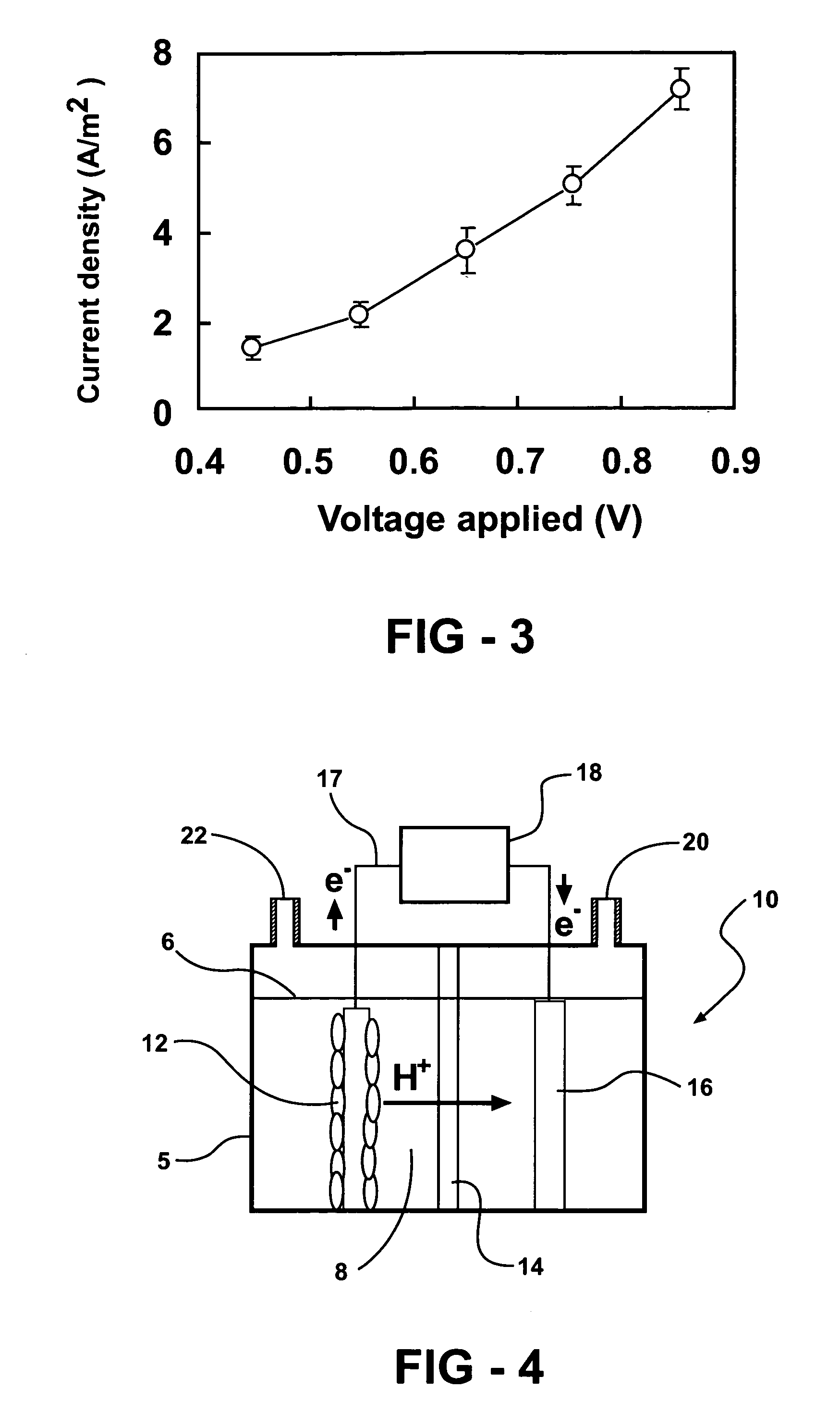

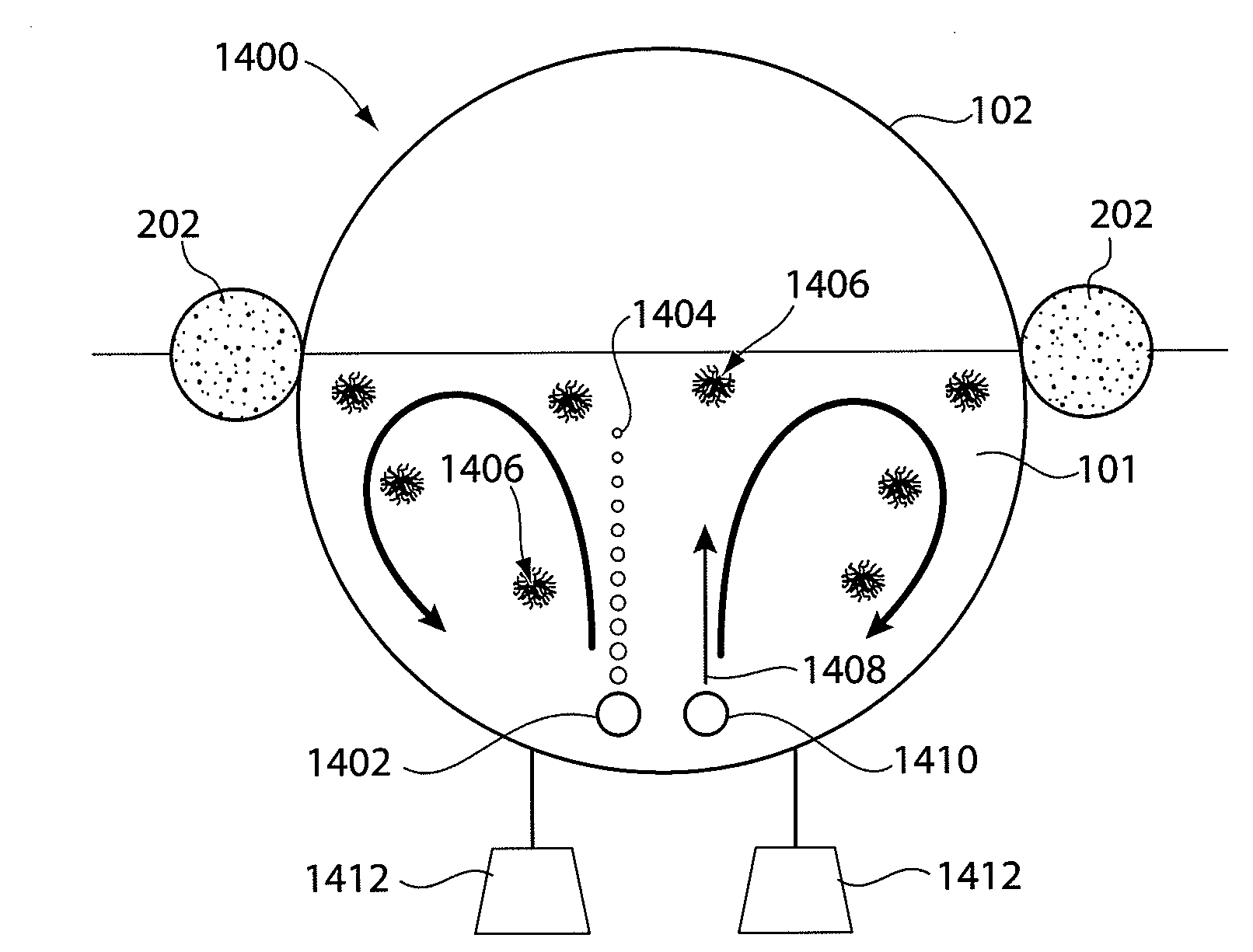

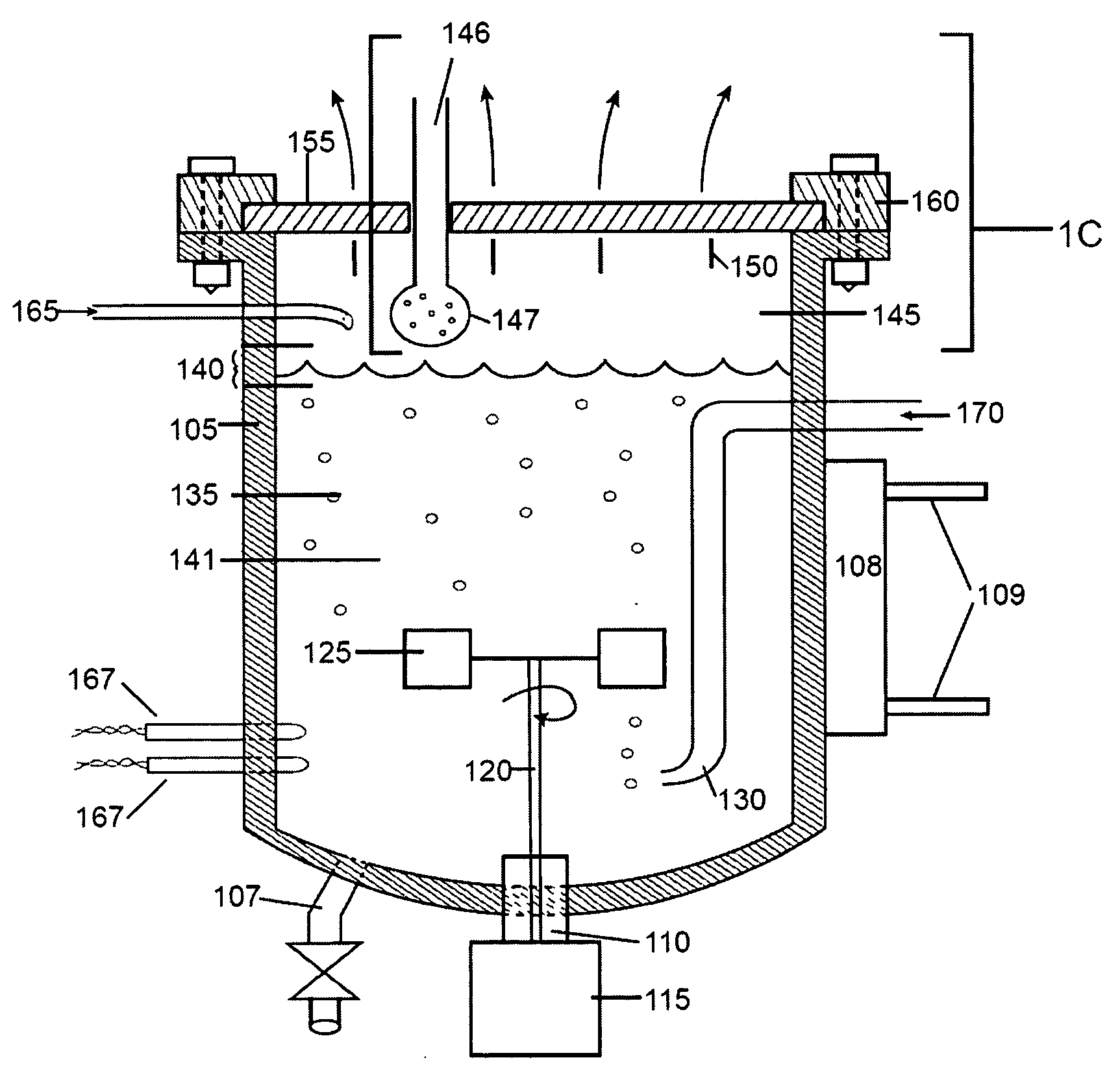

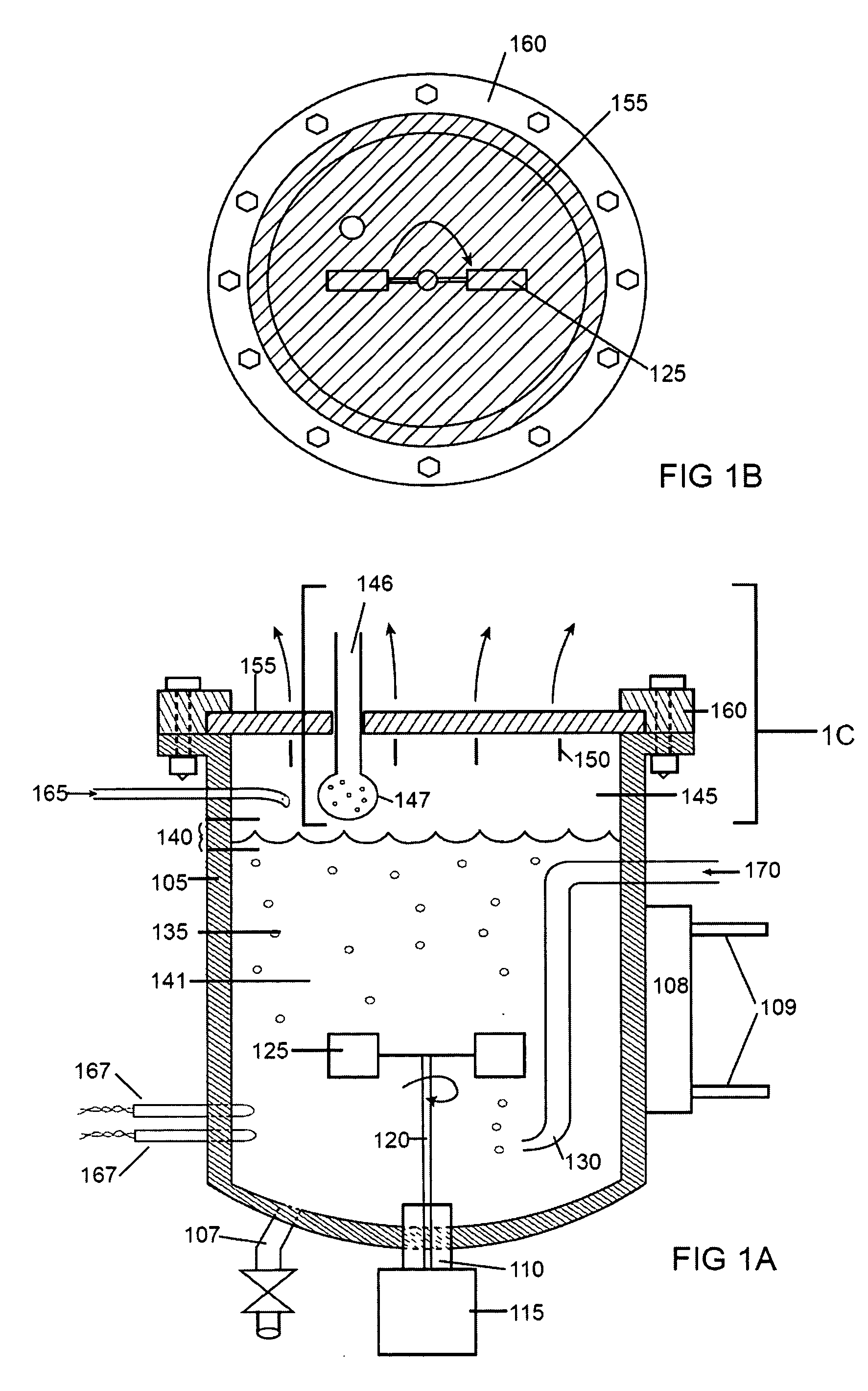

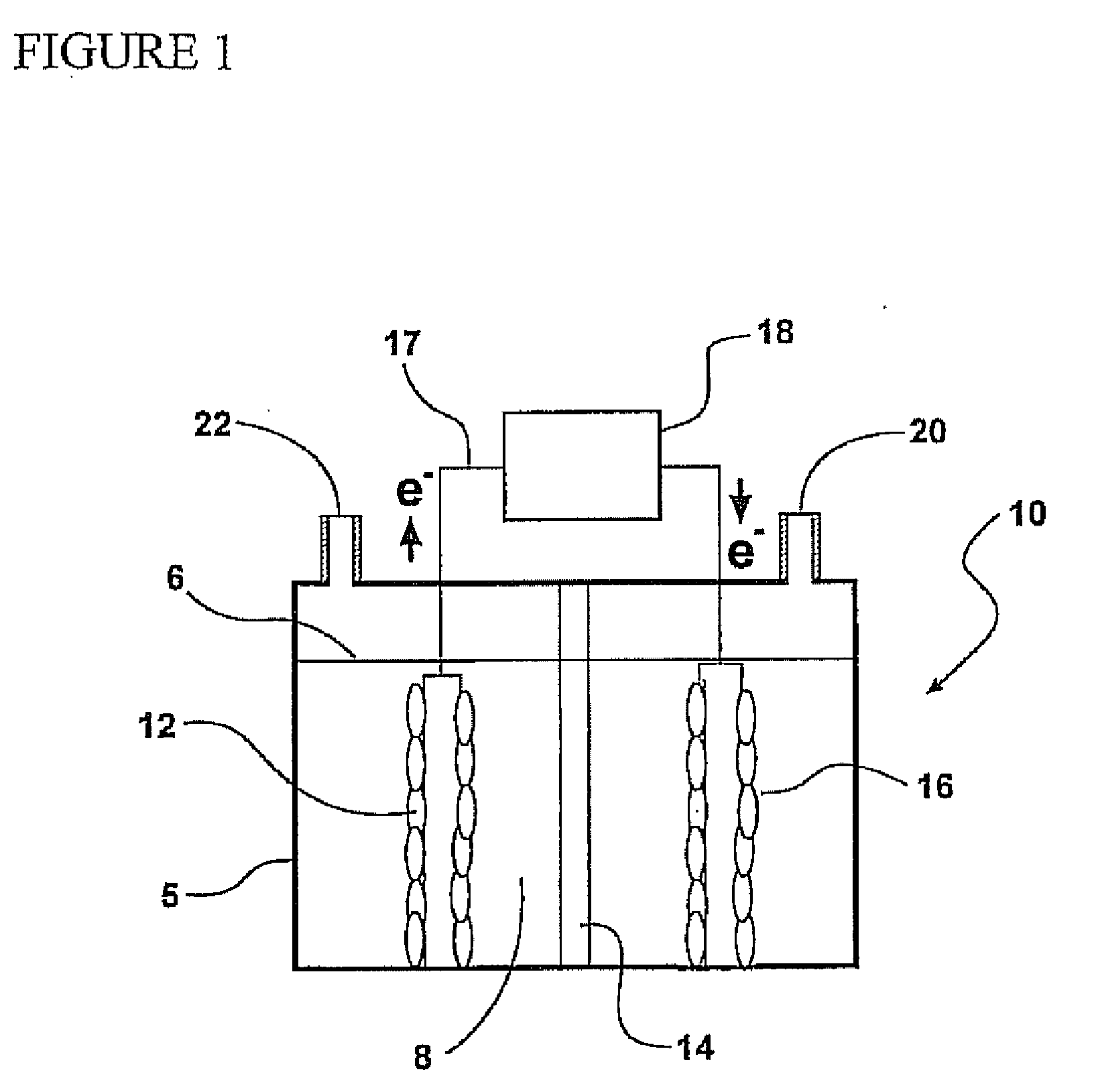

Bio-electrochemically assisted microbial reactor that generates hydrogen gas and methods of generating hydrogen gas

ActiveUS20060011491A1Provide supportGrowth inhibitionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityHydrogen

Systems and processes for producing hydrogen using bacteria are described. One detailed process for producing hydrogen uses a system for producing hydrogen as described herein, the system including a reactor. Anodophilic bacteria are disposed within the interior of the reactor and an organic material oxidizable by an oxidizing activity of the anodophilic bacteriais introduced and incubated under oxidizing reactions conditions such that electrons are produced and transferred to the anode. A power source is activated to increase a potential between the anode and the cathode, such that electrons and protons combine to produce hydrogen gas. One system for producing hydrogen includes a reaction chamber having a wall defining an interior of the reactor and an exterior of the reaction chamber. An anode is provided which is at least partially contained within the interior of the reaction chamber and a cathode is also provided which is at least partially contained within the interior of the reaction chamber. The cathode is spaced apart at a distance in the range between 0.1-100 centimeters, inclusive, from the anode. A conductive conduit for electrons is provided which is in electrical communication with the anode and the cathode and a power source for enhancing an electrical potential between the anode and cathode is included which is in electrical communication at least with the cathode. A first channel defining a passage from the exterior of the reaction chamber to the interior of the reaction chamber is also included.

Owner:PENN STATE RES FOUND +1

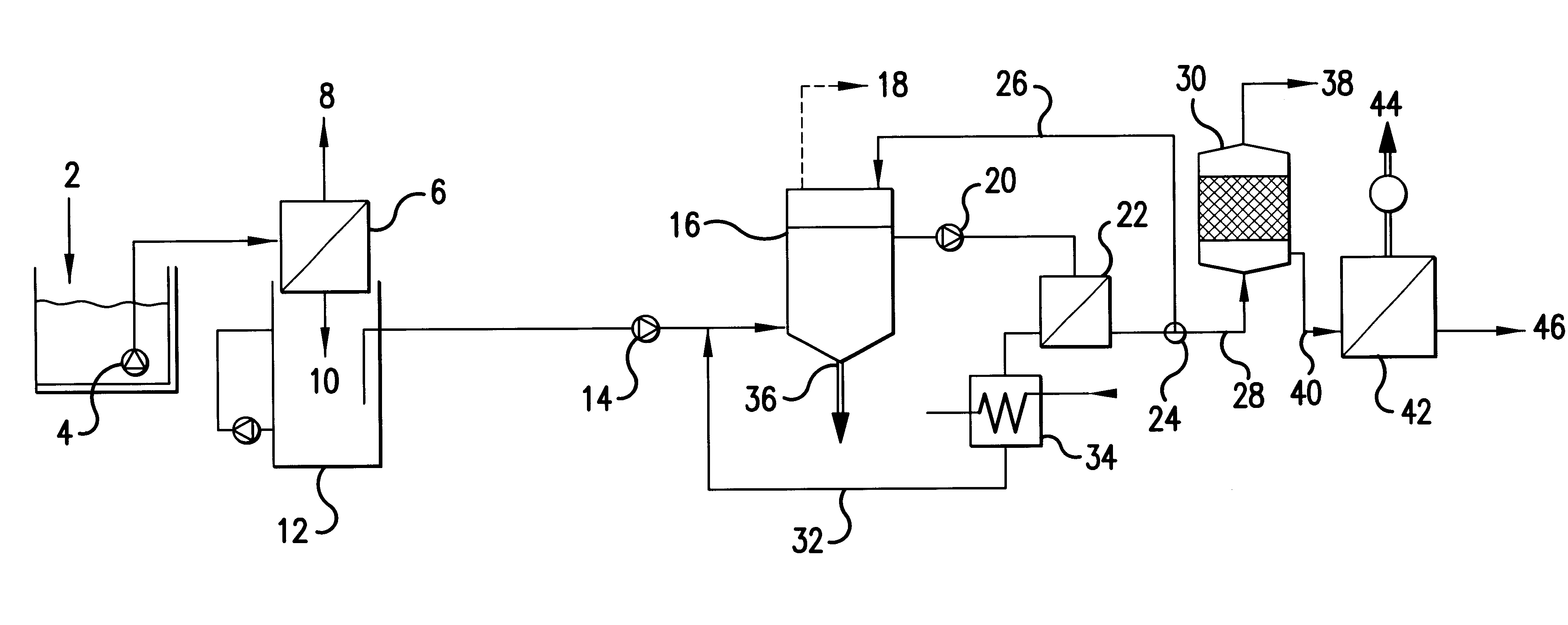

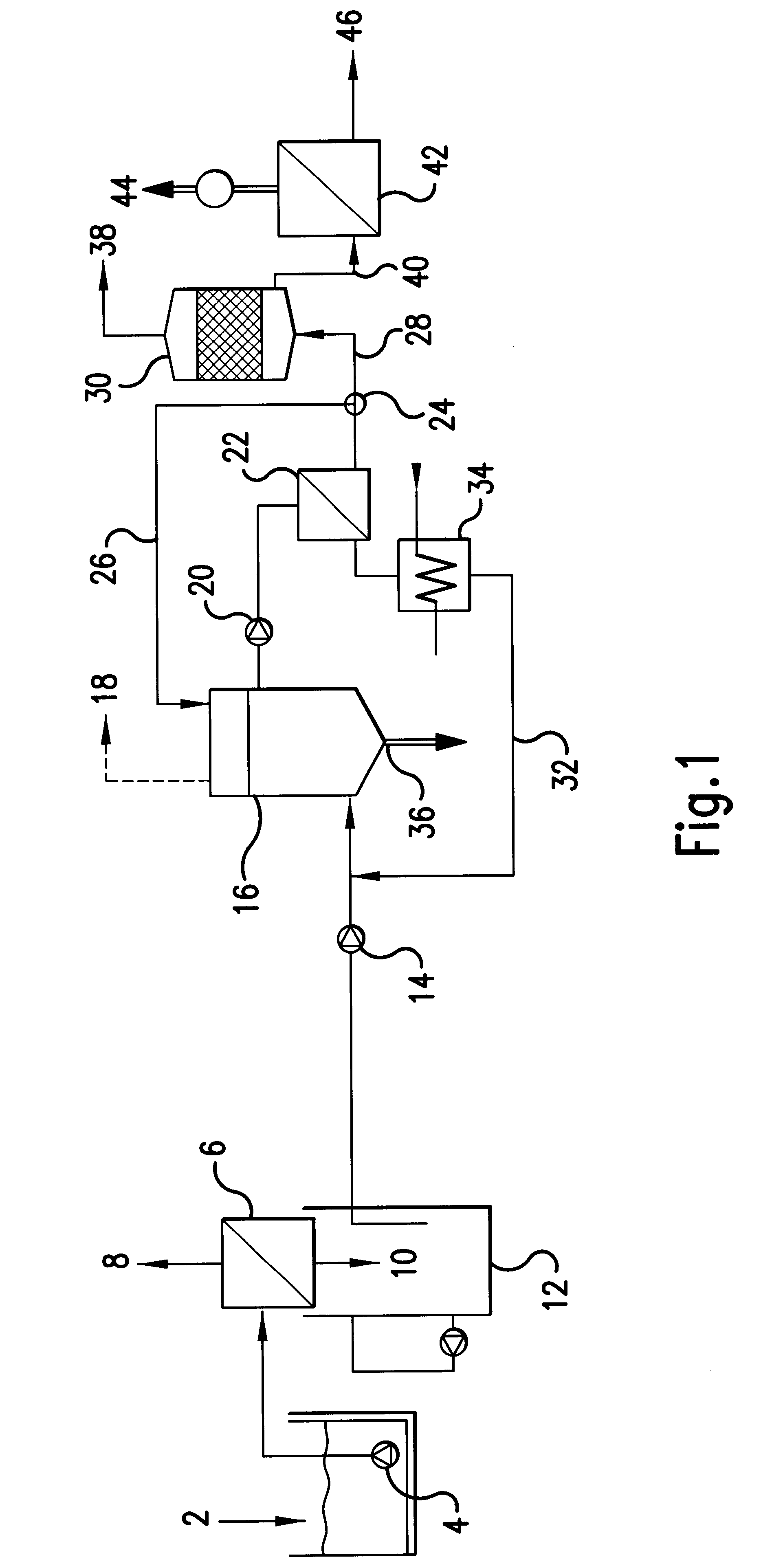

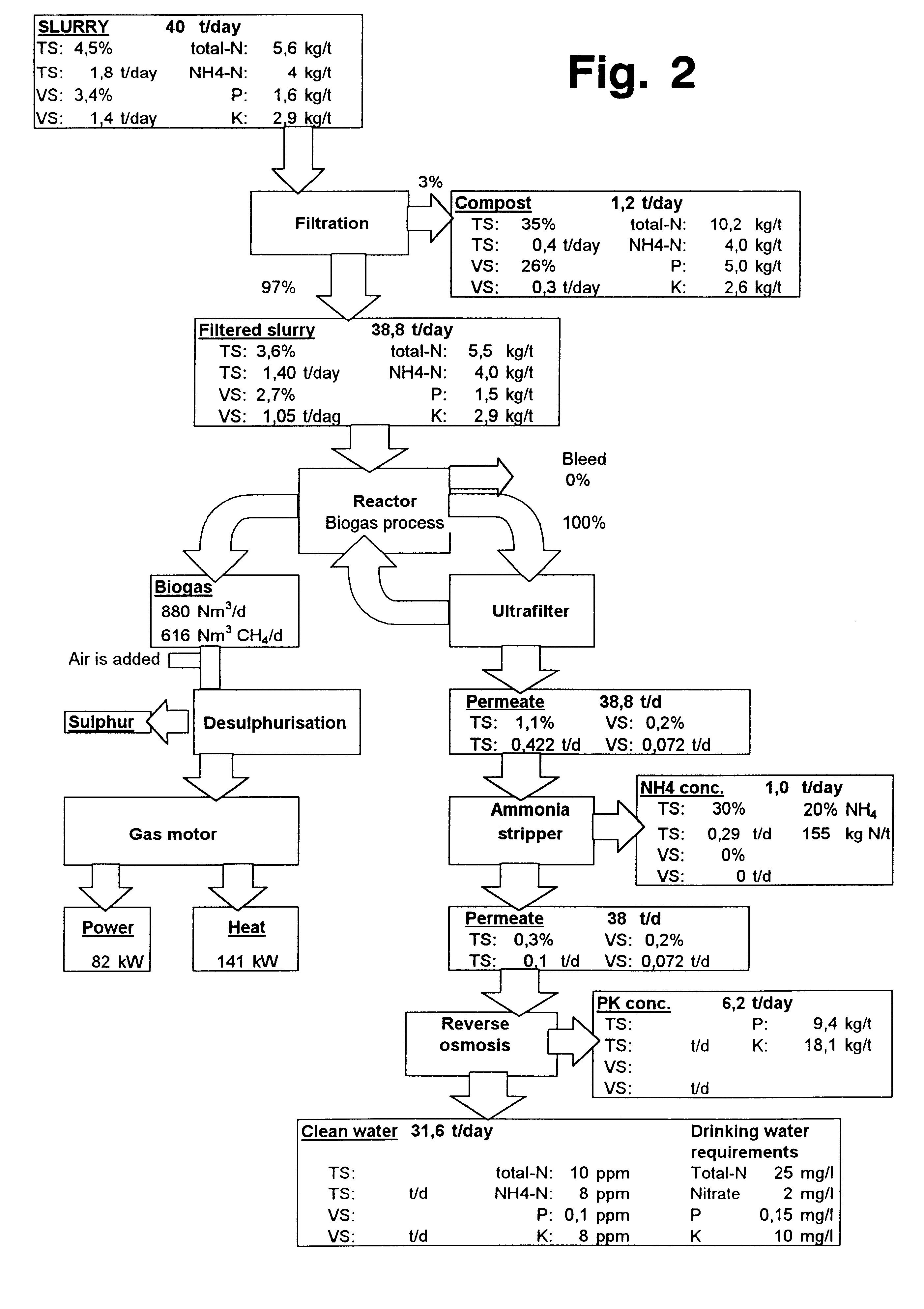

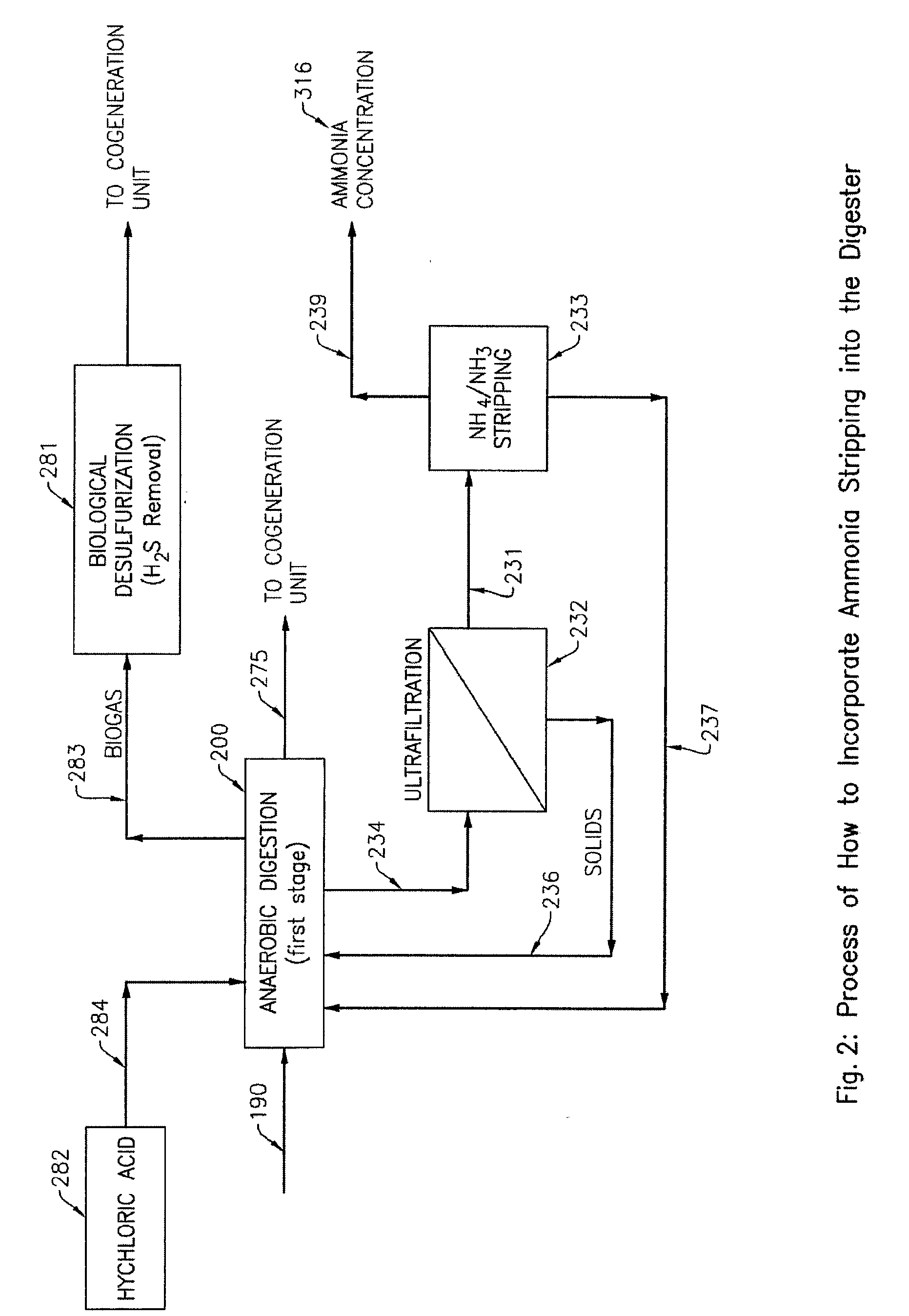

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

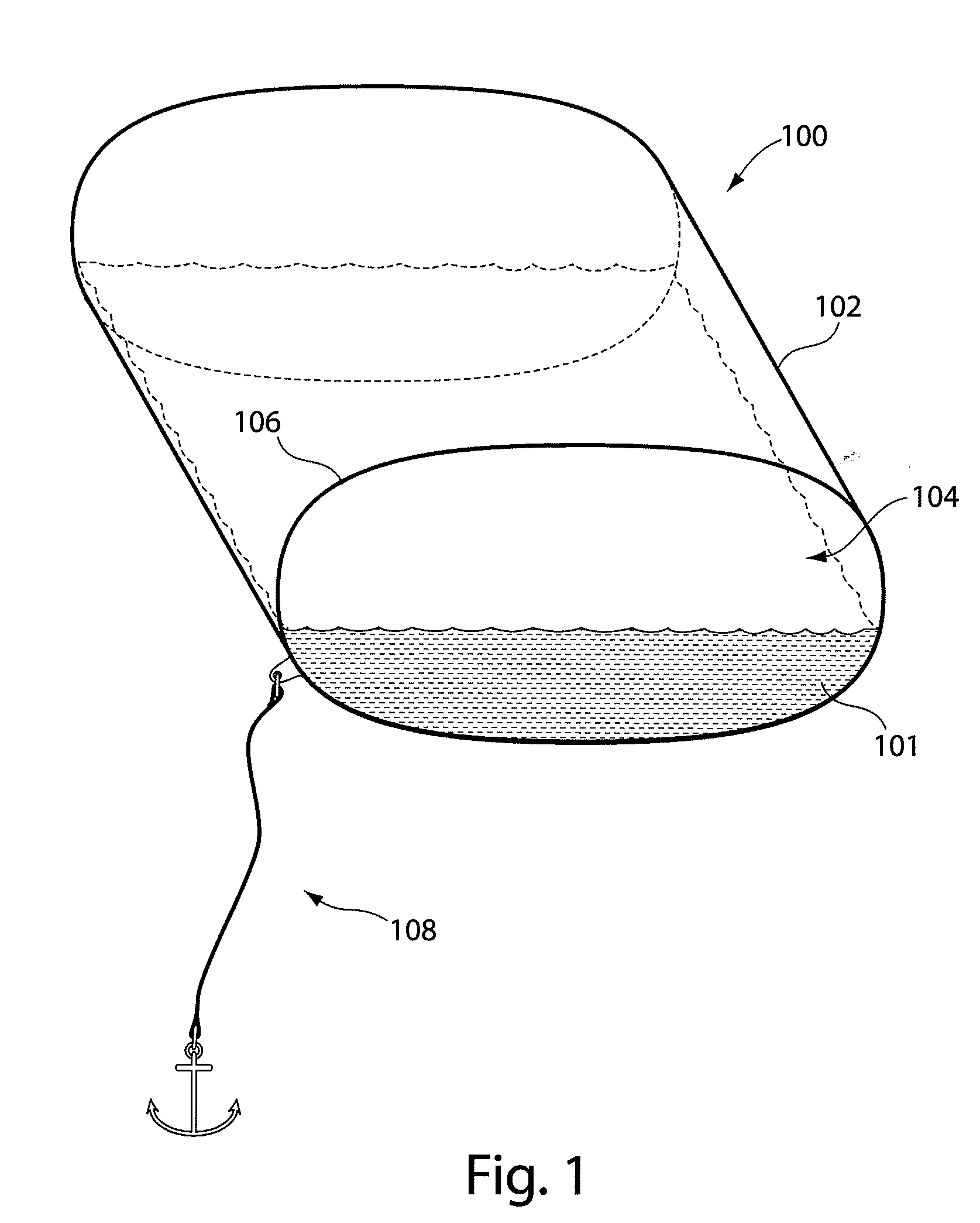

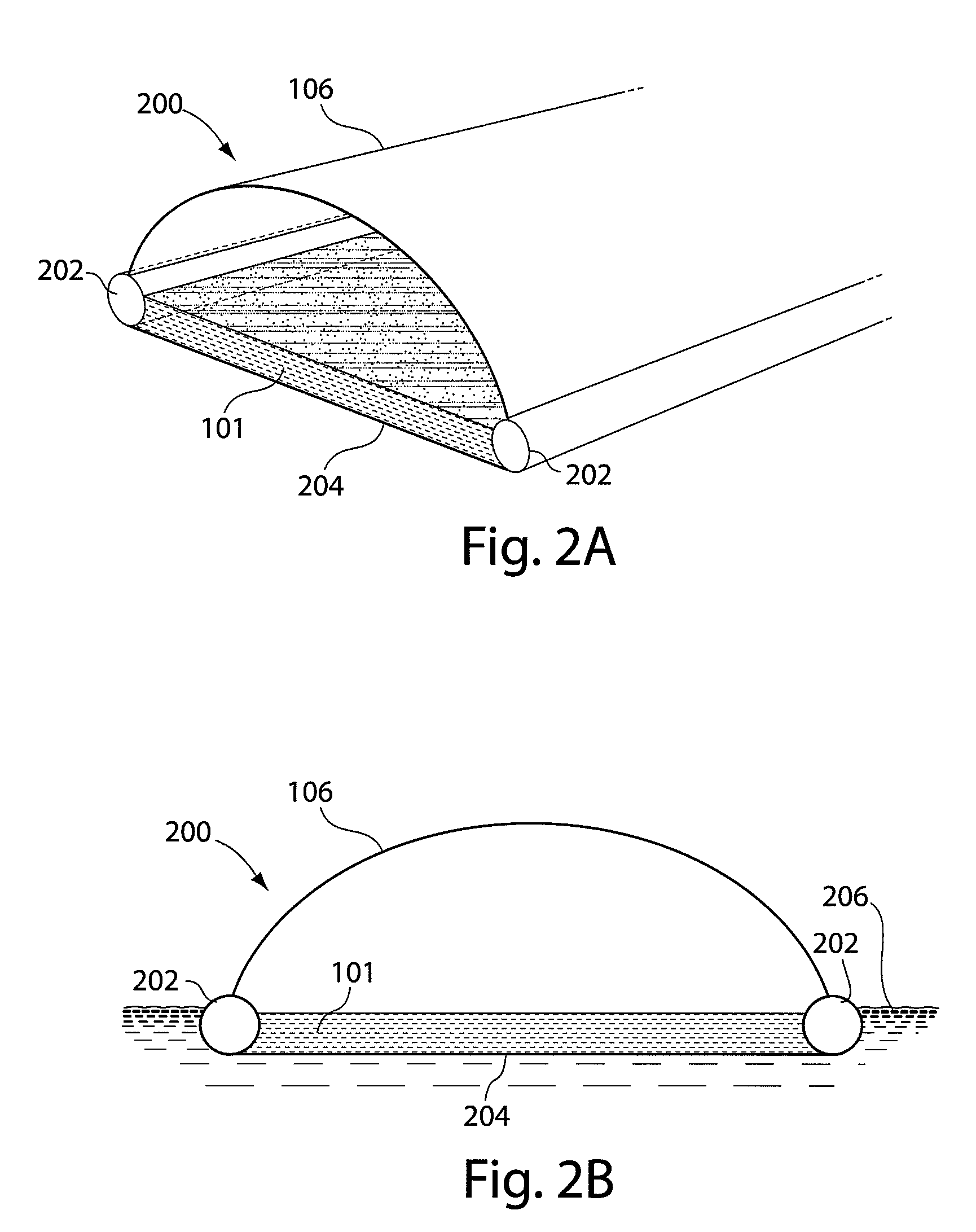

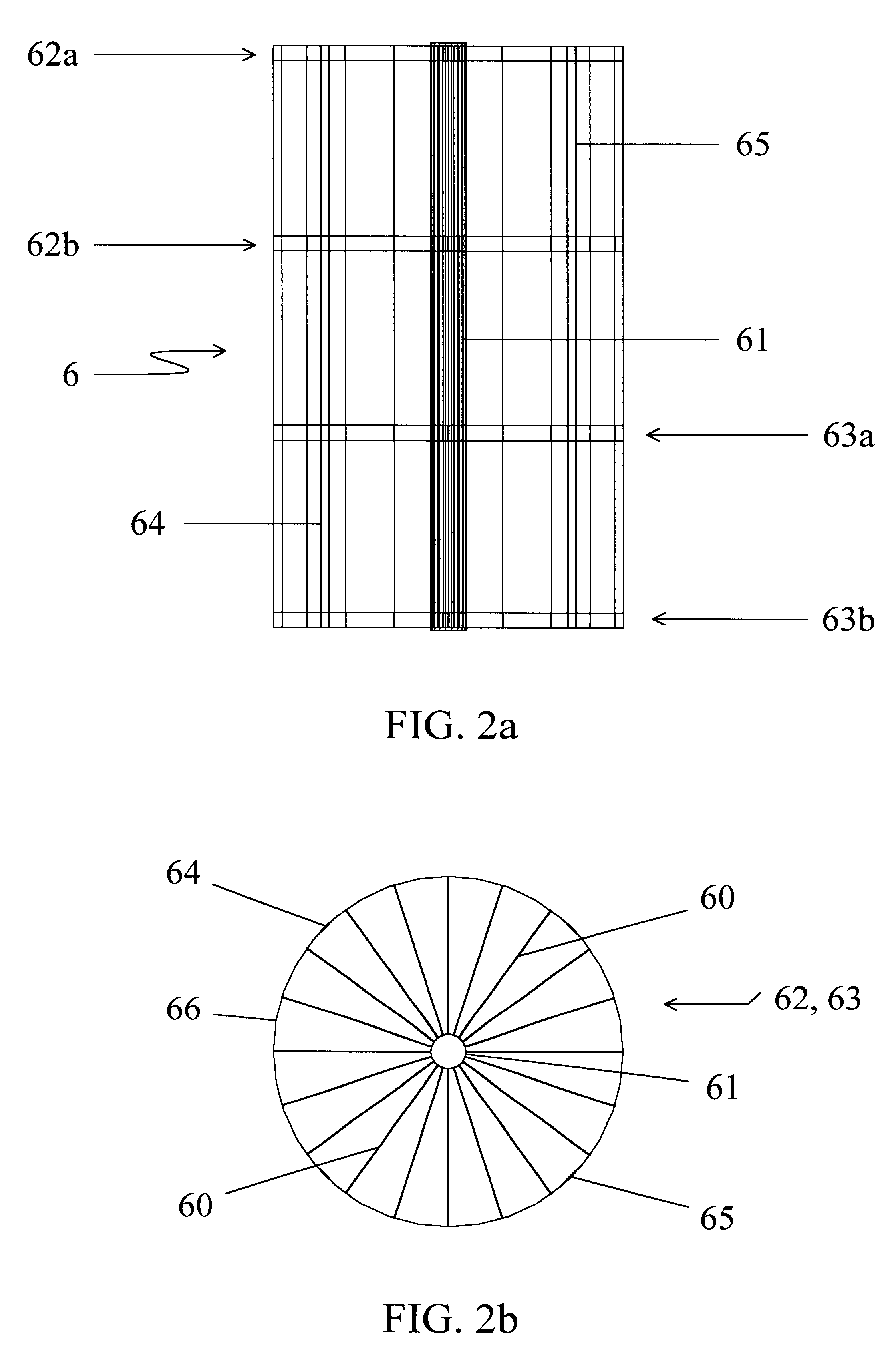

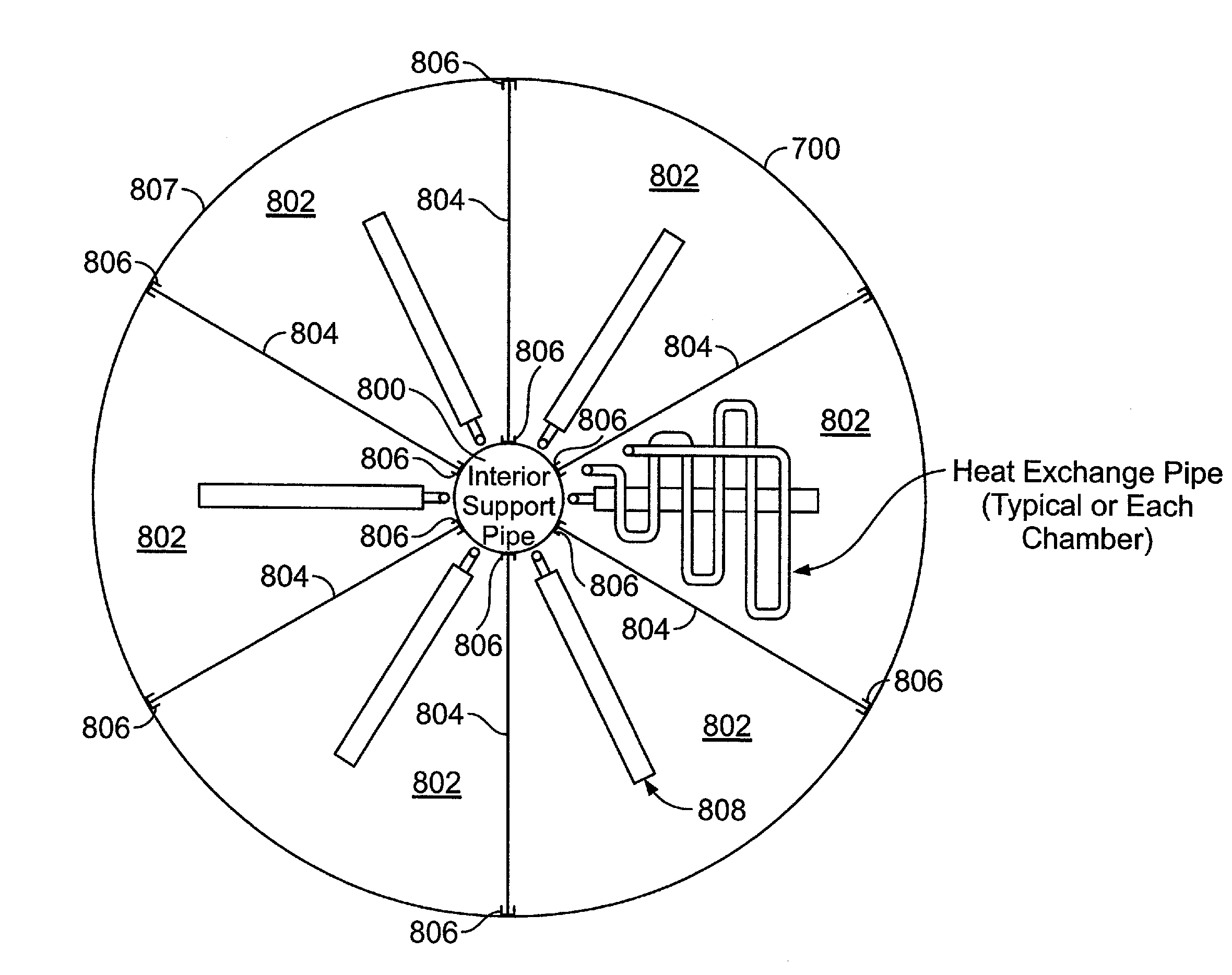

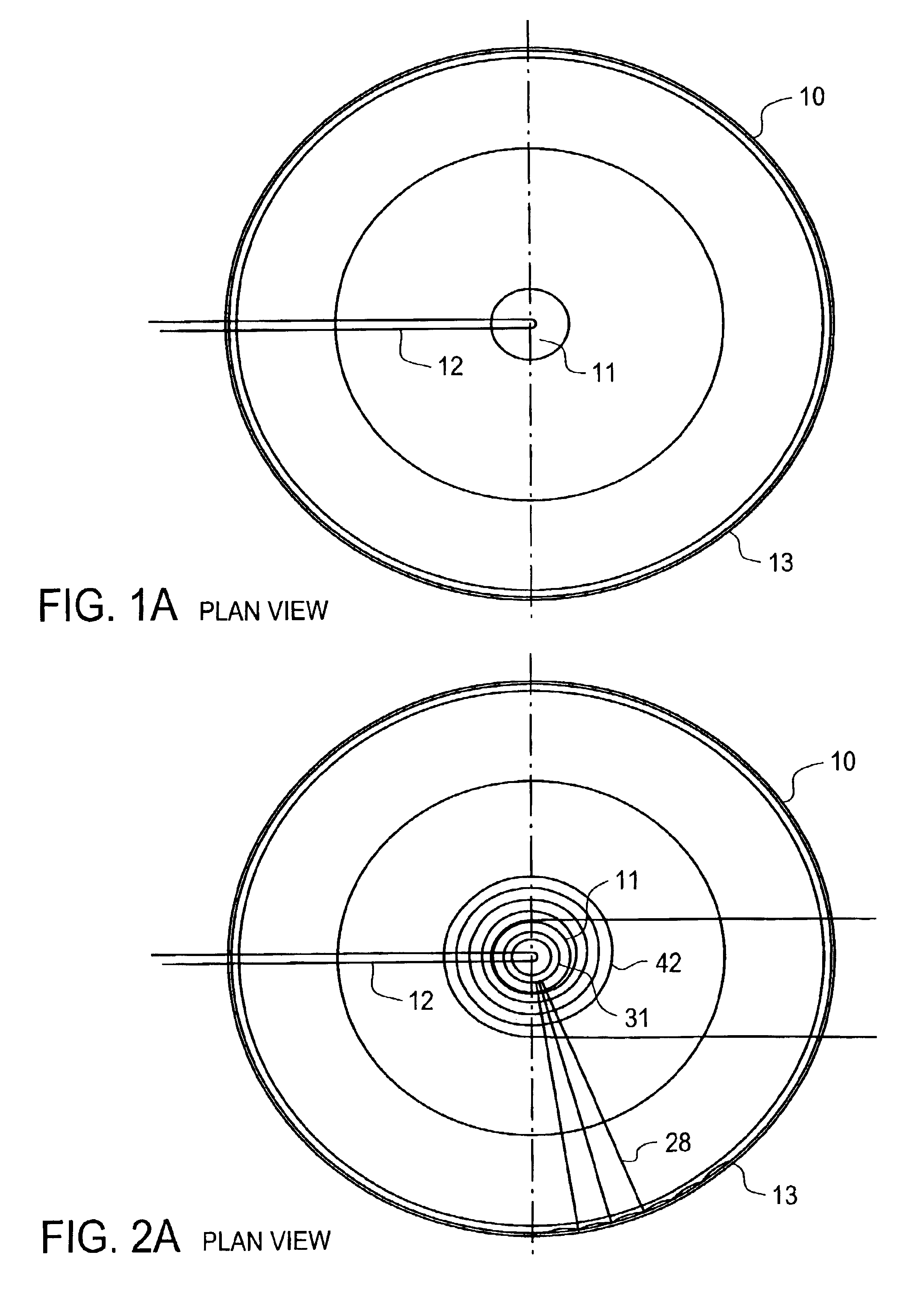

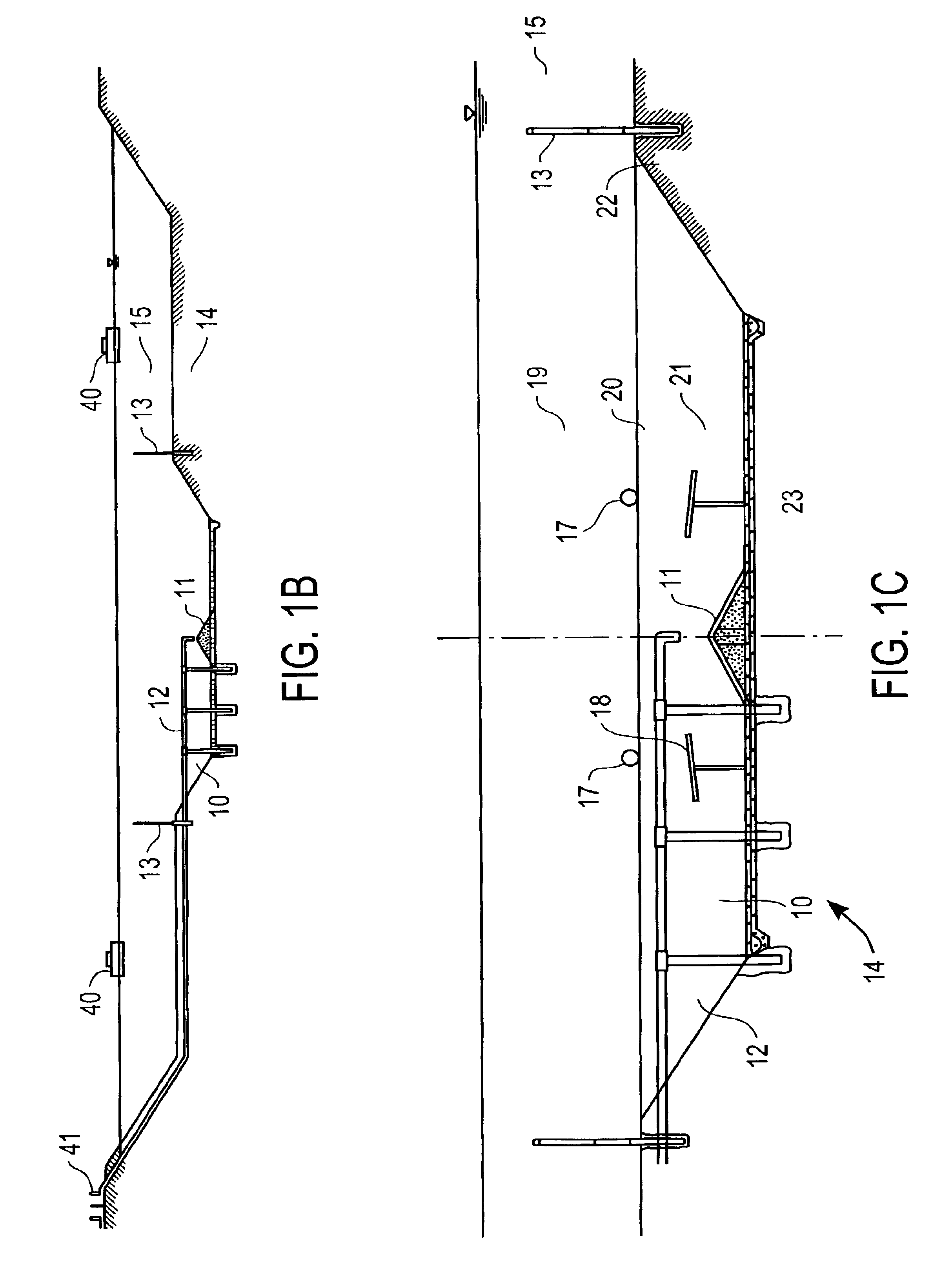

Photobioreactor systems positioned on bodies of water

InactiveUS20090130706A1Maintain depthConstant thicknessBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

Certain embodiments and aspects of the present invention relate to a photobioreactor including photobioreactor units through which a liquid medium stream and a gas stream flow. The photobioreactor units are floated on a body of water such as a pond or a lake. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, the photobioreactor units are formed of flexible, deformable material and are configured to provide a substantially constant thickness of liquid medium. In certain embodiments, a barrier between the photobioreactor unit and the body of water upon which the unit is floated facilitates thermal communication between the liquid medium and the body of water.

Owner:THE TRON GRP

Anaerobic digester system and method

InactiveUS6254775B1High densityIncrease alkalinityGas production bioreactorsTreatment with aerobic and anaerobic processesSlurryMethane gas

An anaerobic digester system has a vertically upright vessel, a matrix arranged in the vessel supporting a microorganism biomass thereon, an input for supplying an input slurry of liquid and suspended solids at an upper portion of the vessel above the matrix, a gas output at the top of the vessel for withdrawing gas generated by anaerobic digestion of solids, and an effluent output at the bottom of the vessel for withdrawing liquid and remaining solids. The vessel has a preferred liquid height to diameter ratio of 2 to 1, and is constructed of inert fiberglass-reinforced plastic coated with a translucent blue gel pigment layer for filtering light at wavelengths that promote biomass cultivation. The matrix is formed as an array of panels mounted to a spindle with wheels fixed at spaced intervals along its vertical height, and the panel are made of a polyethylene grass matting providing a high surface area to volume ratio of at least 20 to 1. Gas from the top of the vessel is recycled to the bottom to generate bubbles for mixing the feedstock. The related method of anaerobic digestion includes comminuting input wastes with a slurry grinder into a pumpable slurry 8-10 % by weight solids, and providing as the biomass hydrolytic bacteria, and fermentative bacteria including acetogenic and methanogenic bacteria to produce a methane gas product. Other products include an organic soil additive, bacterial solids plant food, and a filtrate used as plant tonic.

Owner:RENERGY

Novel bioreactor

InactiveUS20090130704A1Avoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsBiological bodyHydrogen

This invention provides bioreactors having a selectively permeable porous material with an open pore structure, useful for producing products including hydrogen gas, biomass, chemicals, and pharmaceuticals. The porous materials are utilized, for example, as one or more portions of or entire walls, covers, floors, filters, windows, or tubes of the bioreactors. This invention provides bioreactors comprising porous materials that are aerogels, xerogels, or sol-gel glasses, including silica aerogels. The selectively permeable porous materials are gas-permeable, and in addition optionally photopermeable, transparent, hydrophobic, and / or capable of functioning as sterile barriers. This invention provides methods for culturing cells and organisms employing the bioreactors of the invention. This invention further provides methods for producing gaseous products, including hydrogen, biomass, chemicals, and pharmaceuticals employing the bioreactors of the invention.

Owner:GYURE DALE C

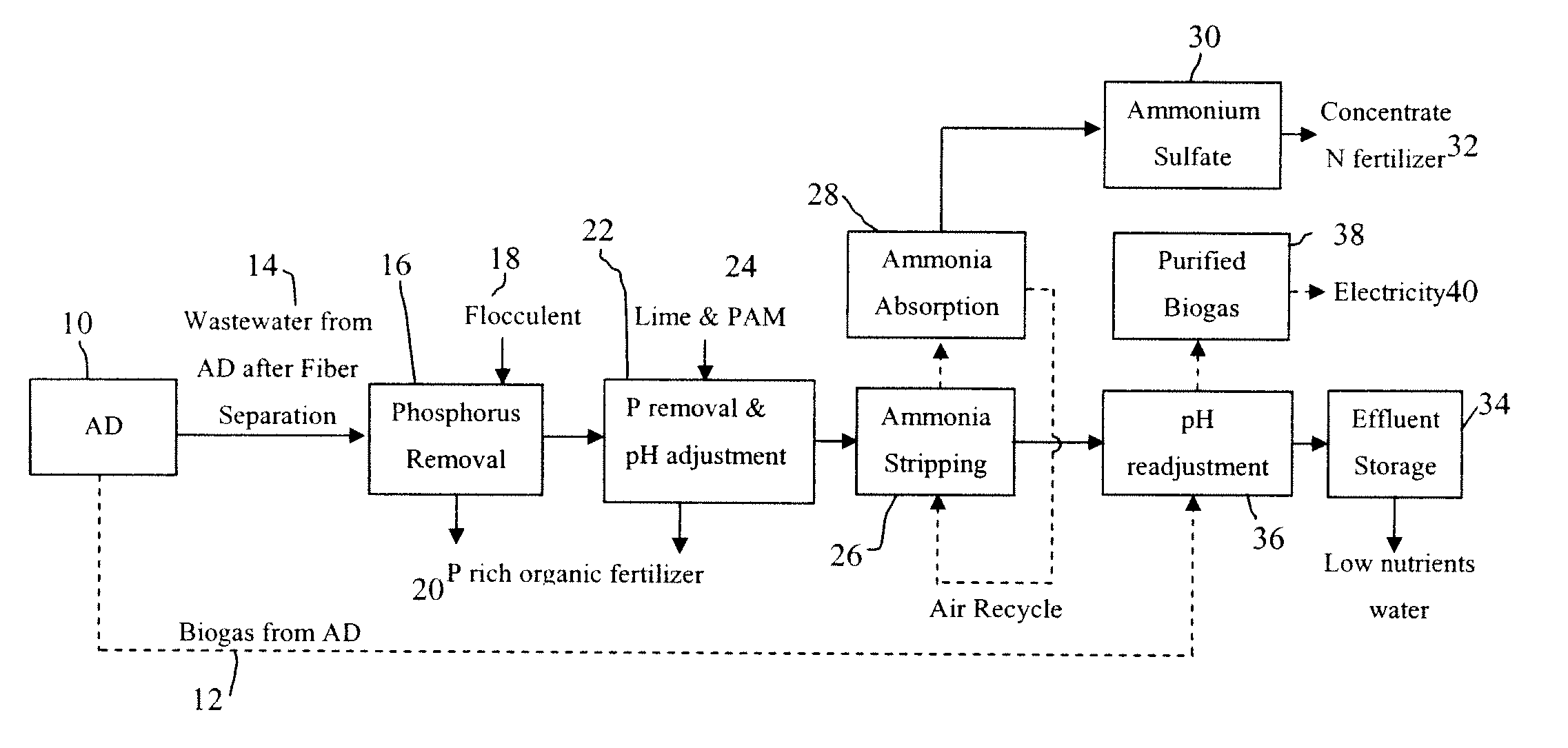

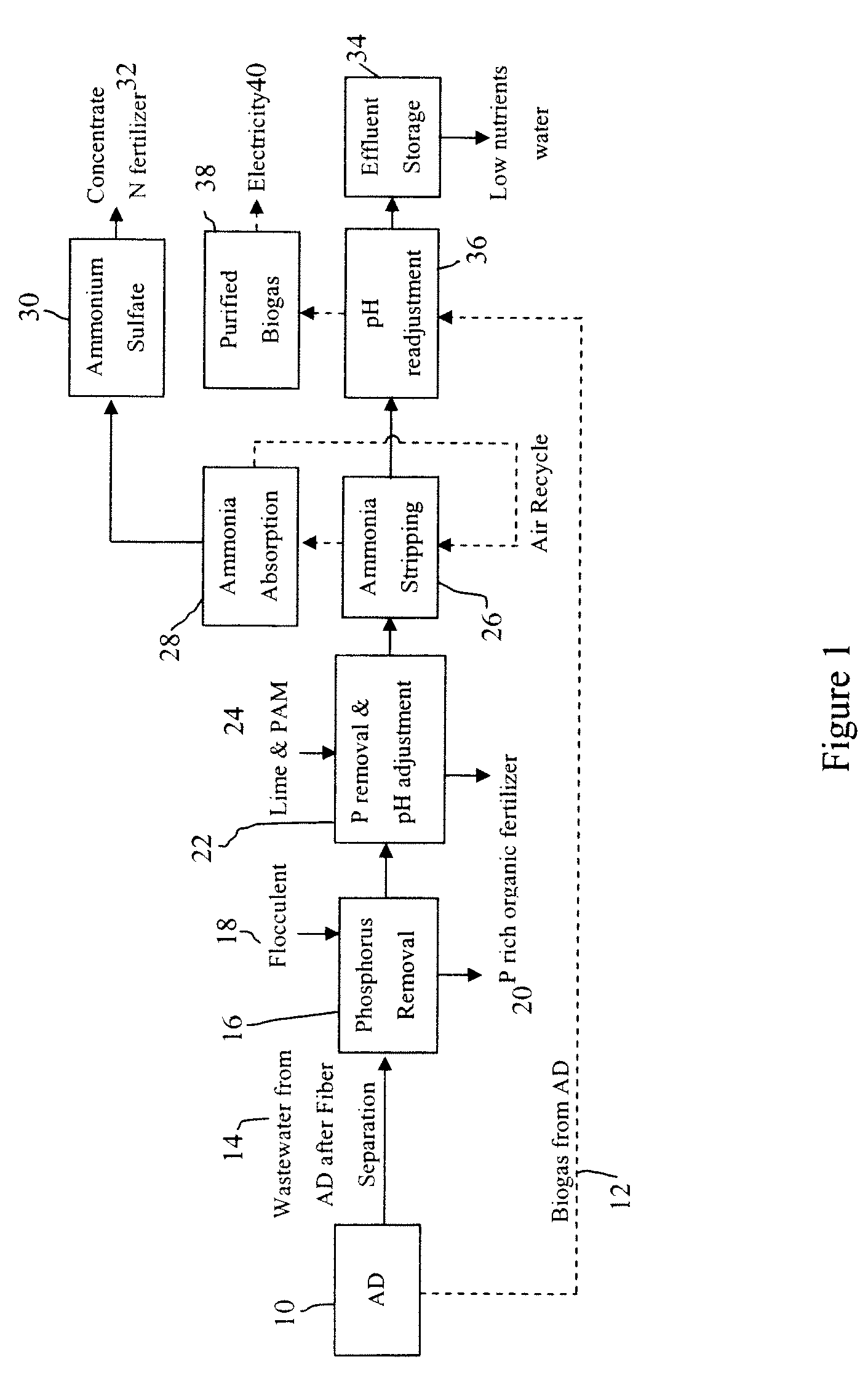

Combined nutrient recovery and biogas scrubbing system integrated in series with animal manure anaerobic digester

InactiveUS20090206028A1Inherent flexibilityIncrease flexibilityBio-organic fraction processingBiological substance pretreatmentsFecesNitrogen

An economical, integrated system works in series with anaerobic digestion of animal waste to recover nitrogen and phosphorous, while also scrubbing the produced biogas.

Owner:WASHINGTON STATE UNIV RES FOUND INC

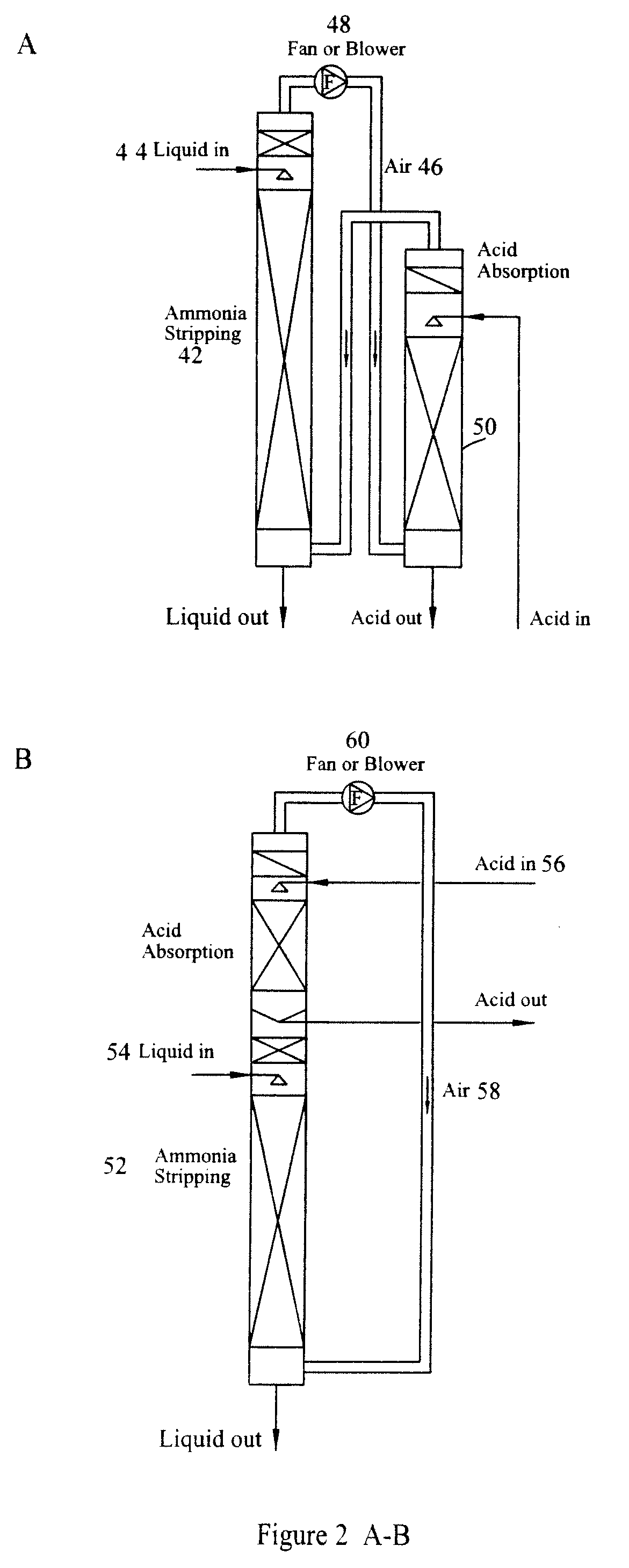

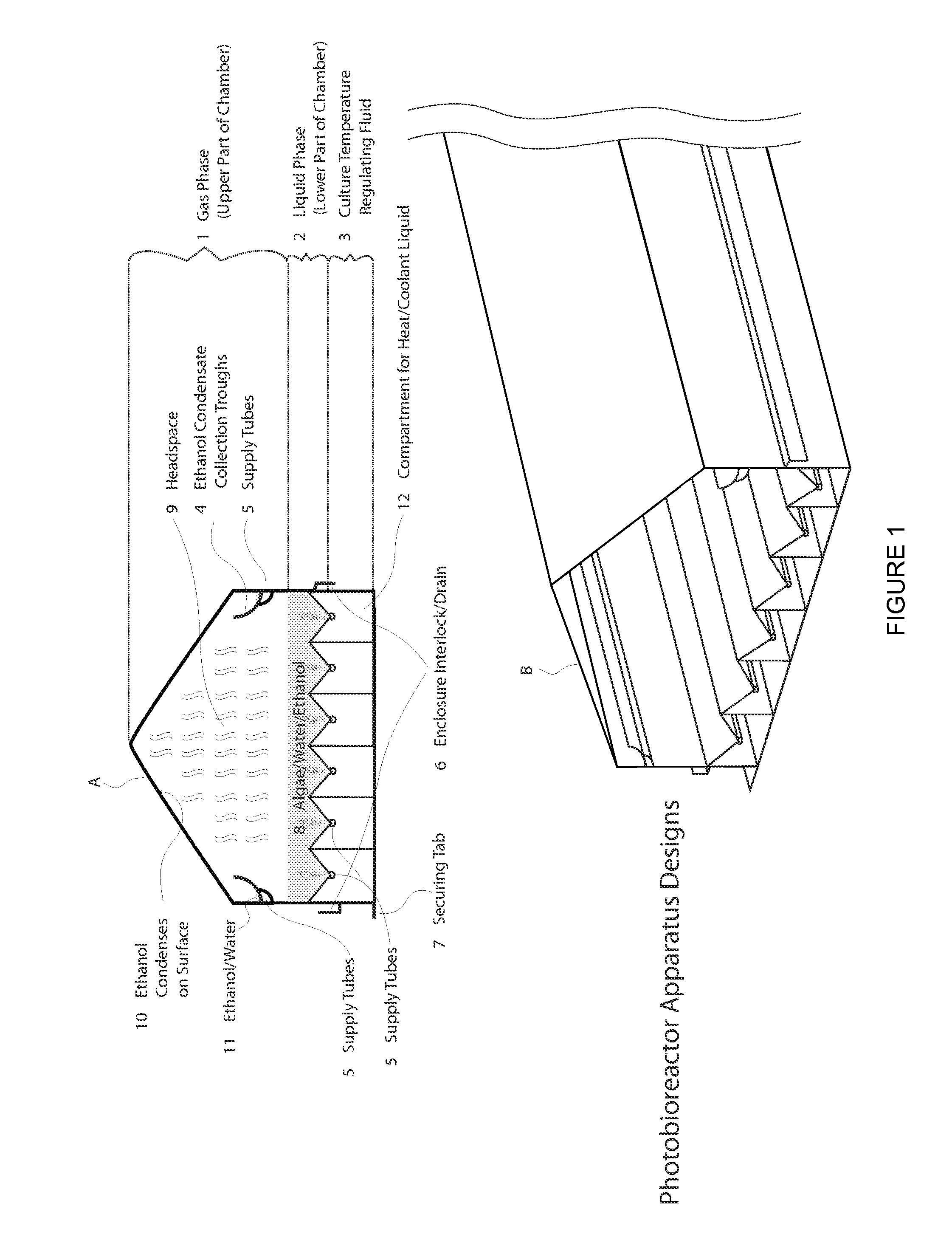

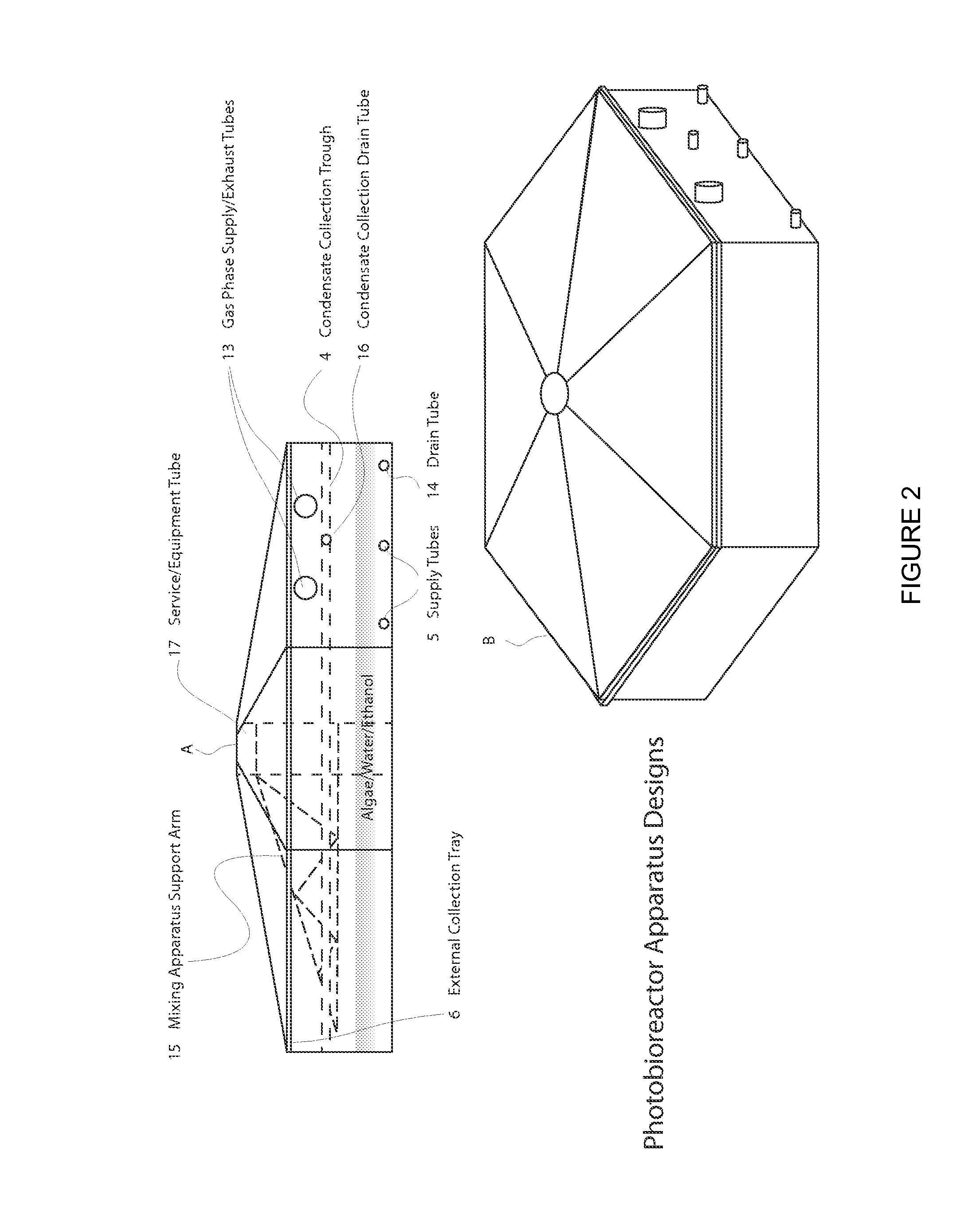

Closed photobioreactor system for continued daily in situ production, separation, collection, and removal of ethanol from genetically enhanced photosynthetic organisms

InactiveUS20080153080A1Bioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorOrganism

Owner:ALGENOL BIOFUELS SWITZERLAND

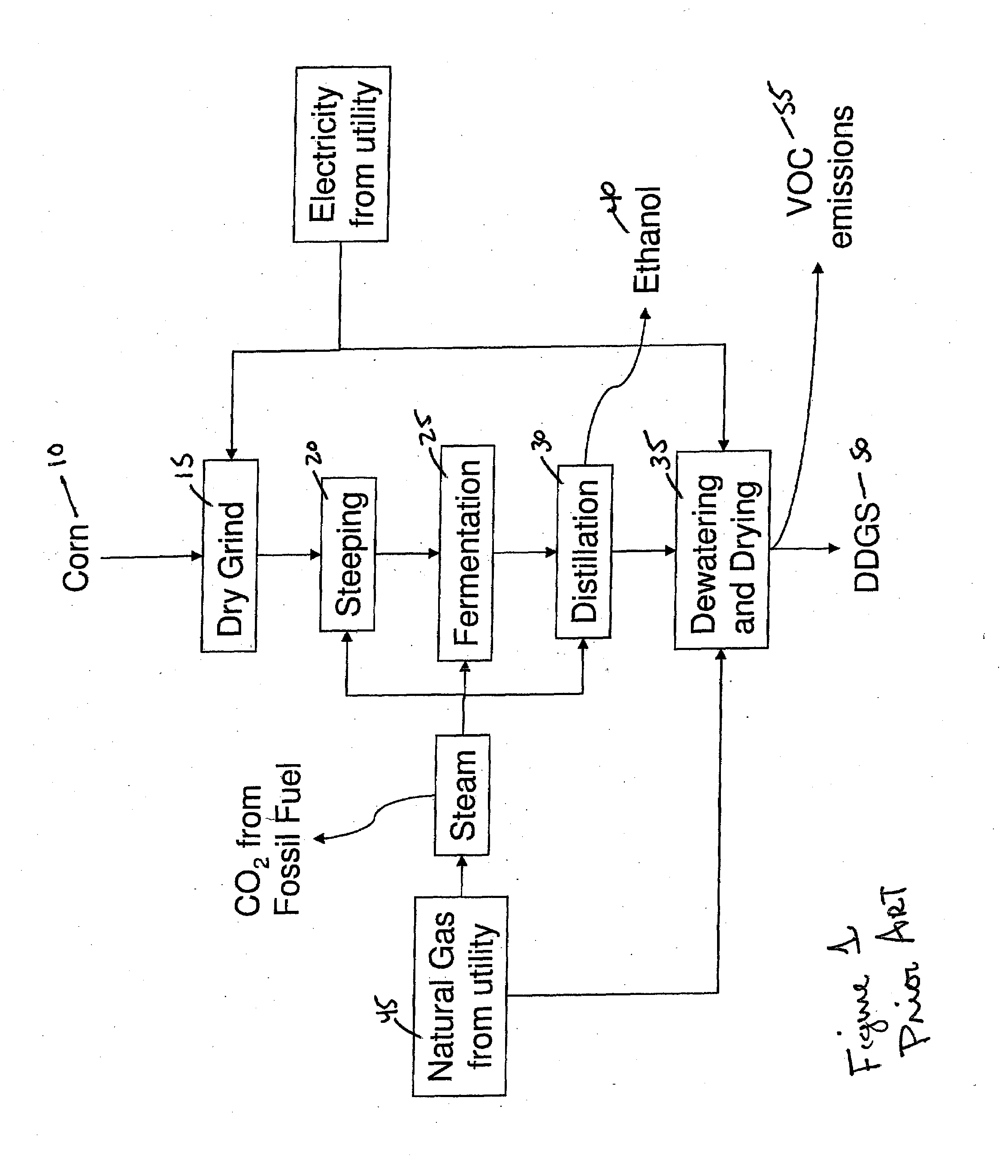

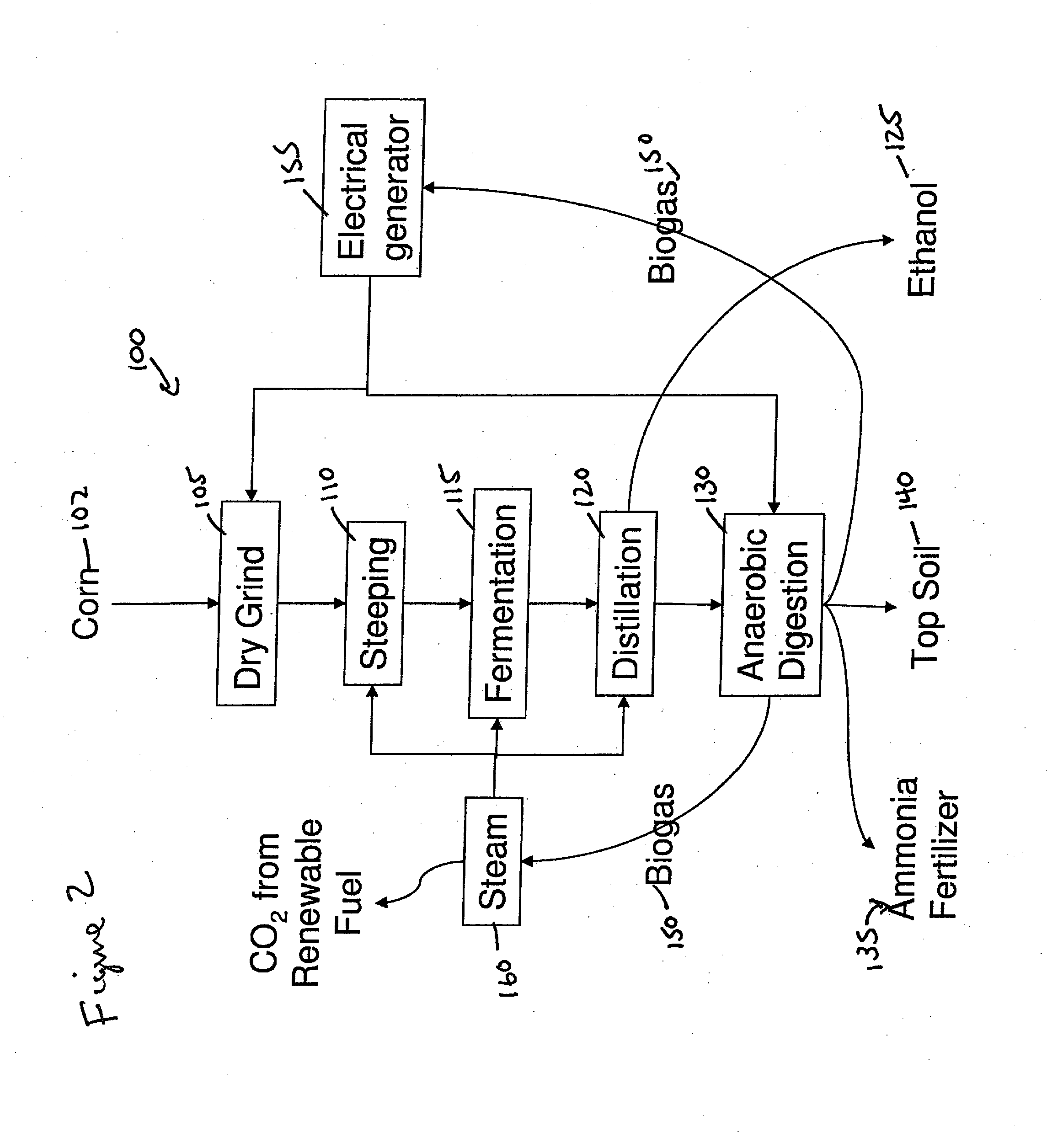

Process for producing ethanol and for energy recovery

InactiveUS20070141691A1Increasing net energy valueReducing the reliance of the ethanol industryBioreactor/fermenter combinationsBio-organic fraction processingElectricityDistillation

The present invention is directed to a process for the production of ethanol and energy. The process includes the steps of fermenting a corn mash in an aqueous medium to produce a beer. Next, the beer is distilled to produce ethanol and a whole stillage. The whole stillage is anaerobically digested to produce a biogas and a residue. The biogas is combusted to produce electricity and steam. The electricity and steam are used during the fermentation and distillation process. The residue may further be separated into a liquid fertilizer and top soil residue.

Owner:STANLEY CONSULTANTS

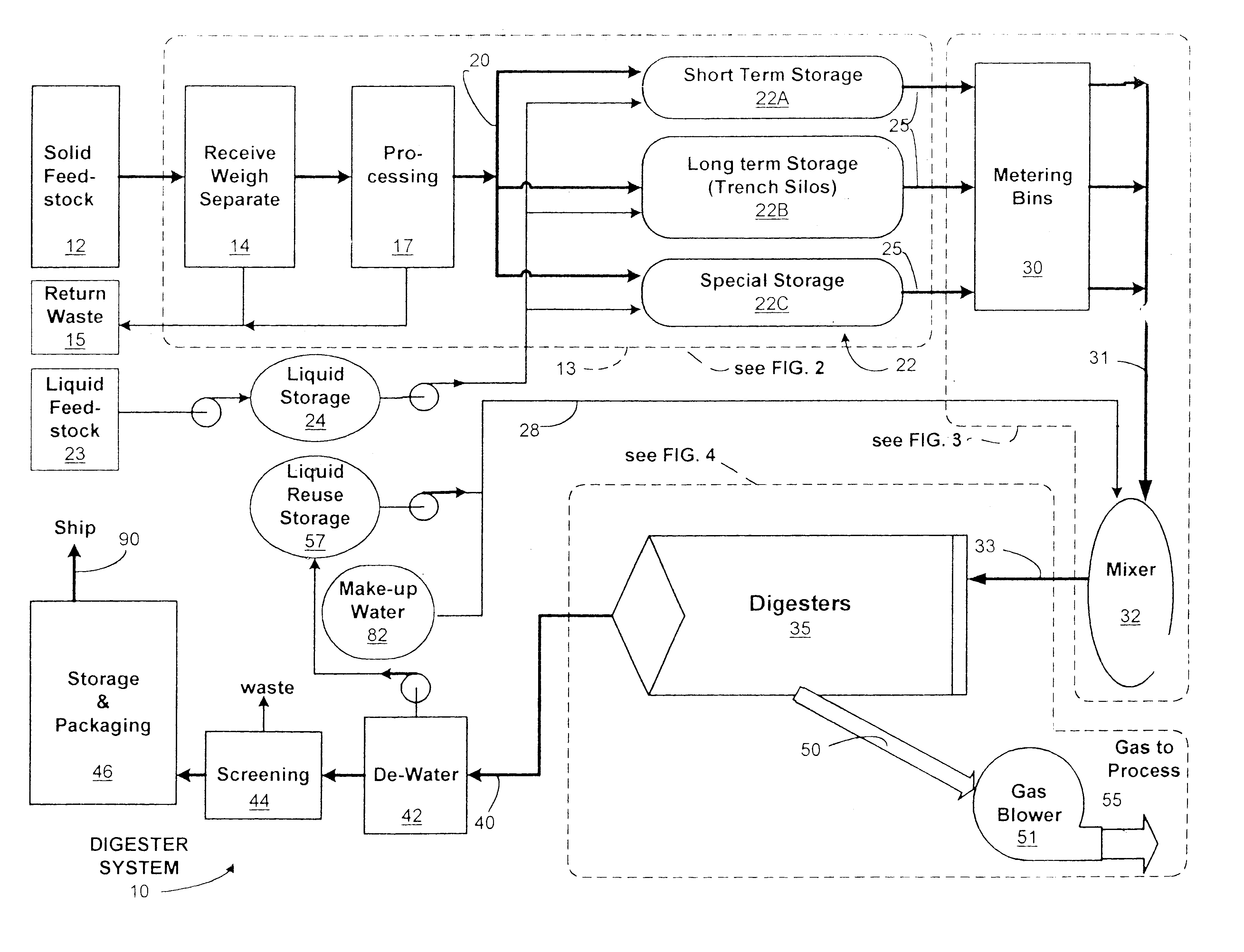

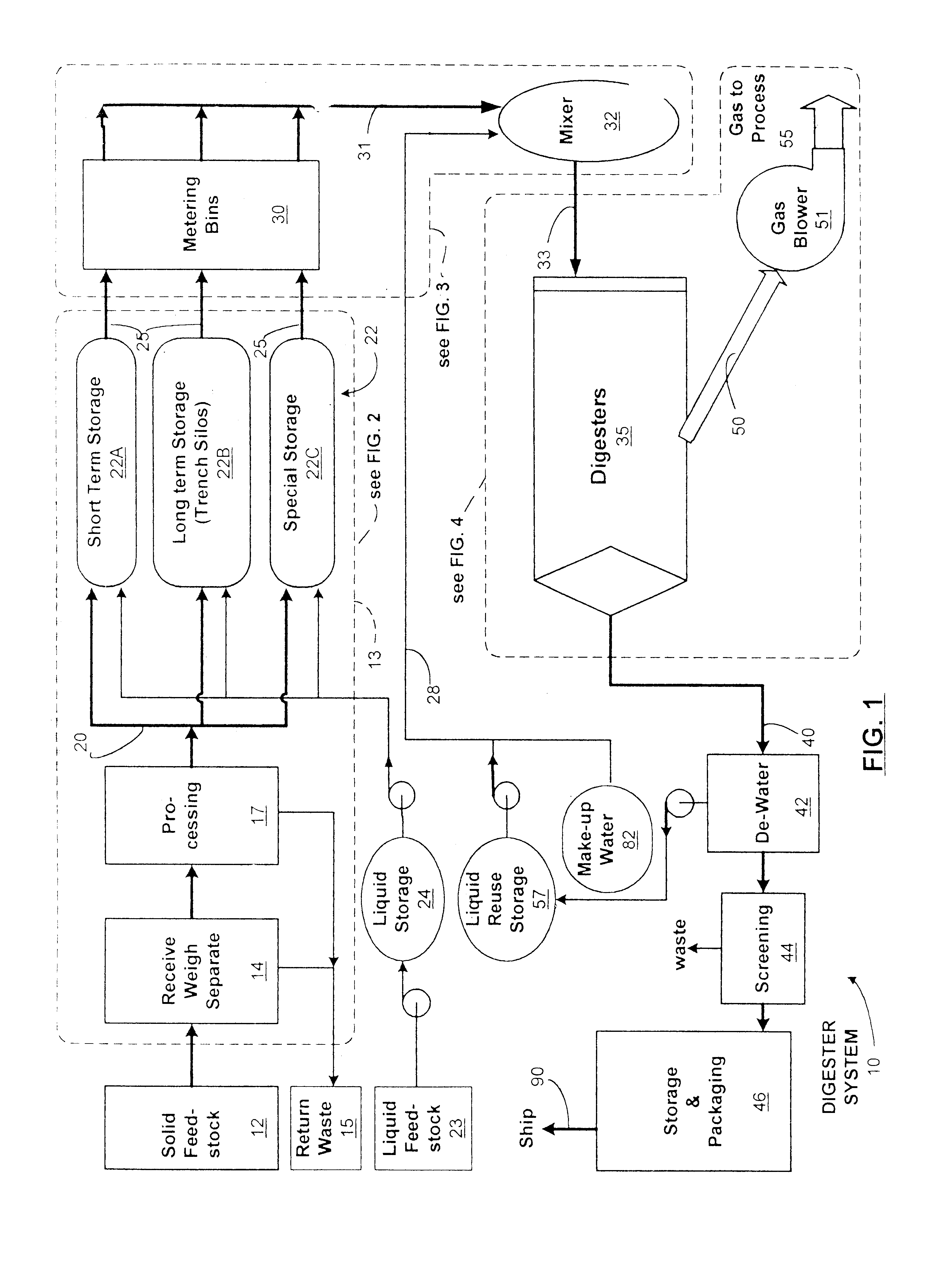

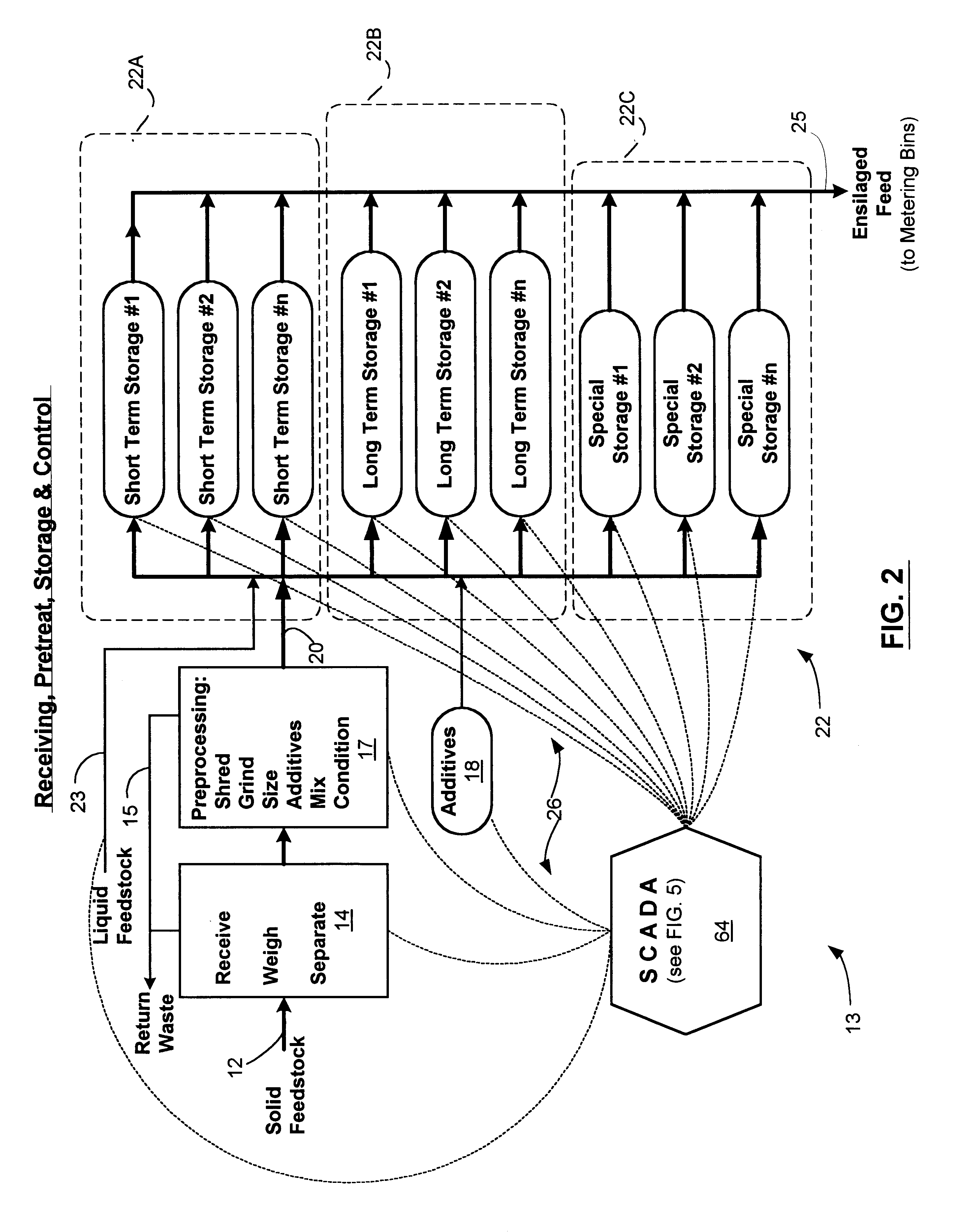

Anaerobic digester system

InactiveUS6296766B1Easy to monitorEasy to controlData processing applicationsBiological treatment regulationGrowth plantEnvironmental engineering

A method for an anaerobic digester system is provided that employs a cumulative data base to better monitor and control the anaerobic process, as compared with conventional anaerobic digester systems. The method includes the storing and ensiling of a feedstock, preferably a biomass, to form a digester feed material, which then processed by a digester. The process evolves a biogas and forms a digested material. The process is monitored, to collect a plurality of digester data from all stages of the process. These individual points or elements of the data are telemetered to a cumulative data base for storage and eventual retrieval and the cumulative data base is mined to compile predictive, feed forward controls and construct feedstock correlations between the metabolic activity within the digesters and an analysis of the feedstocks into the digesters. The method further includes the production of a high quality plant growth media from the digested mash, and recovery of the biogas generated within the digester. The biogas is collected with the aid of a biogas recovery system. The biogas is predominantly methane, and the anaerobic digester system is preferably operated to maximize the quantity and quality of methane generated.

Owner:TECHN INFORMATION

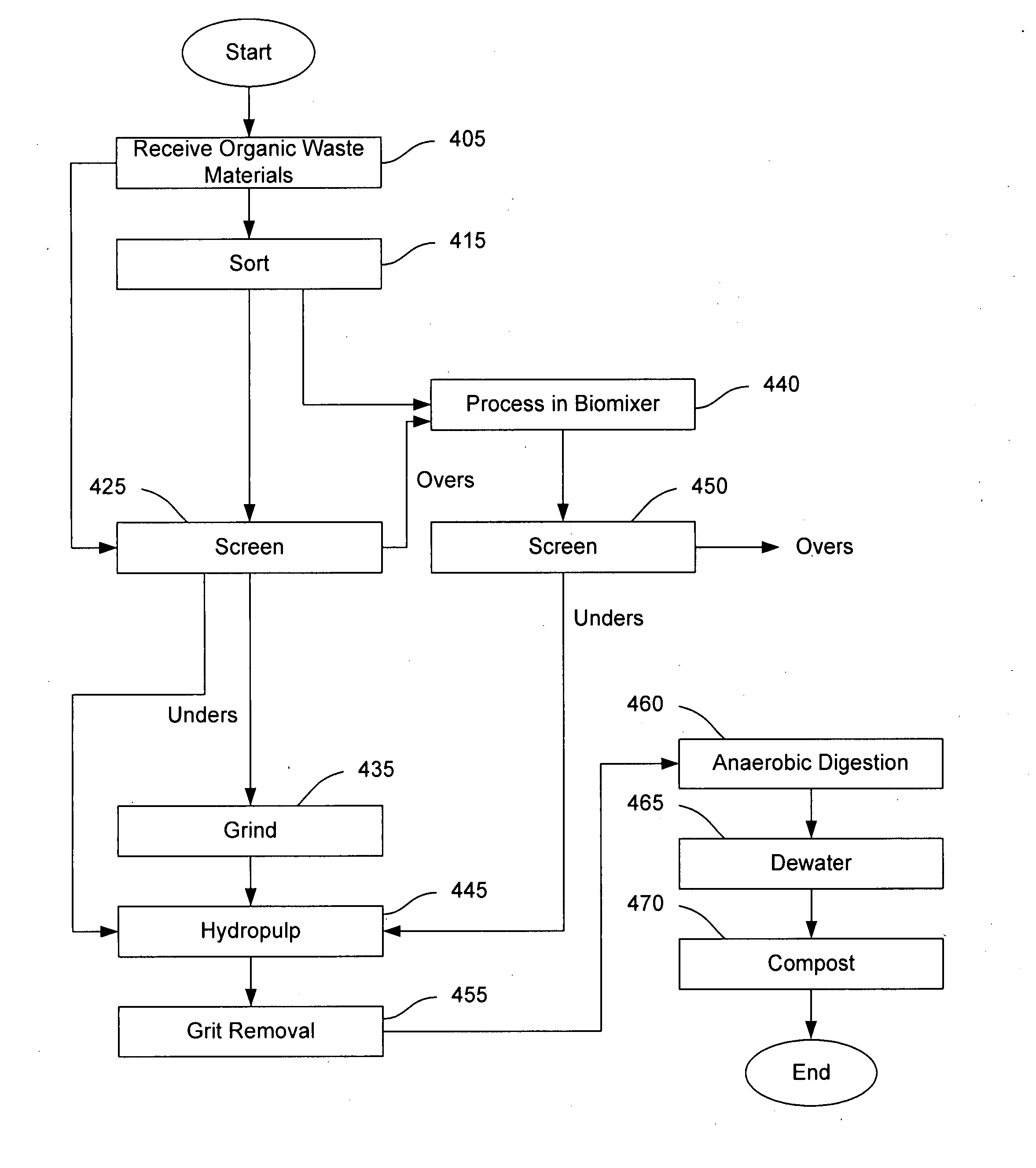

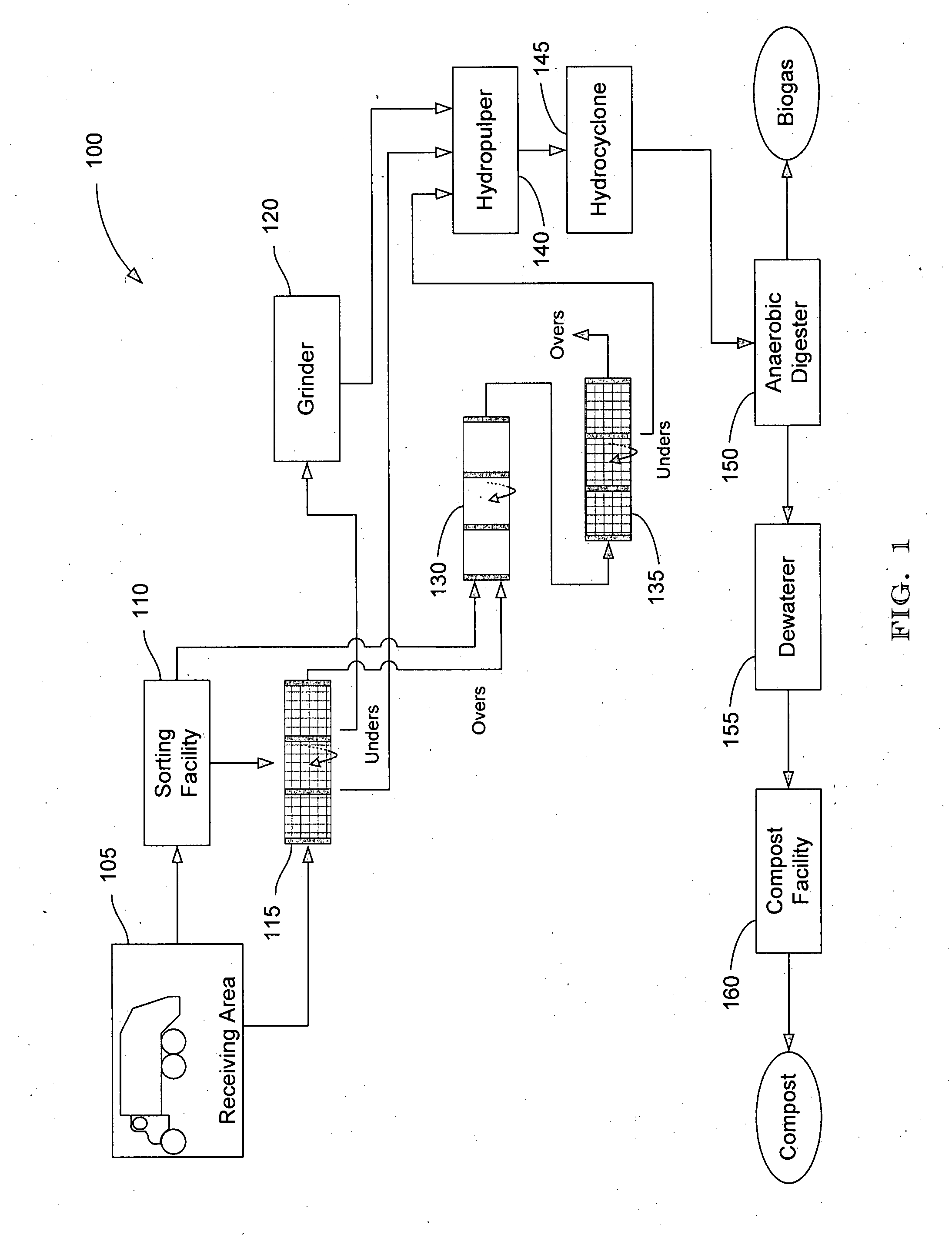

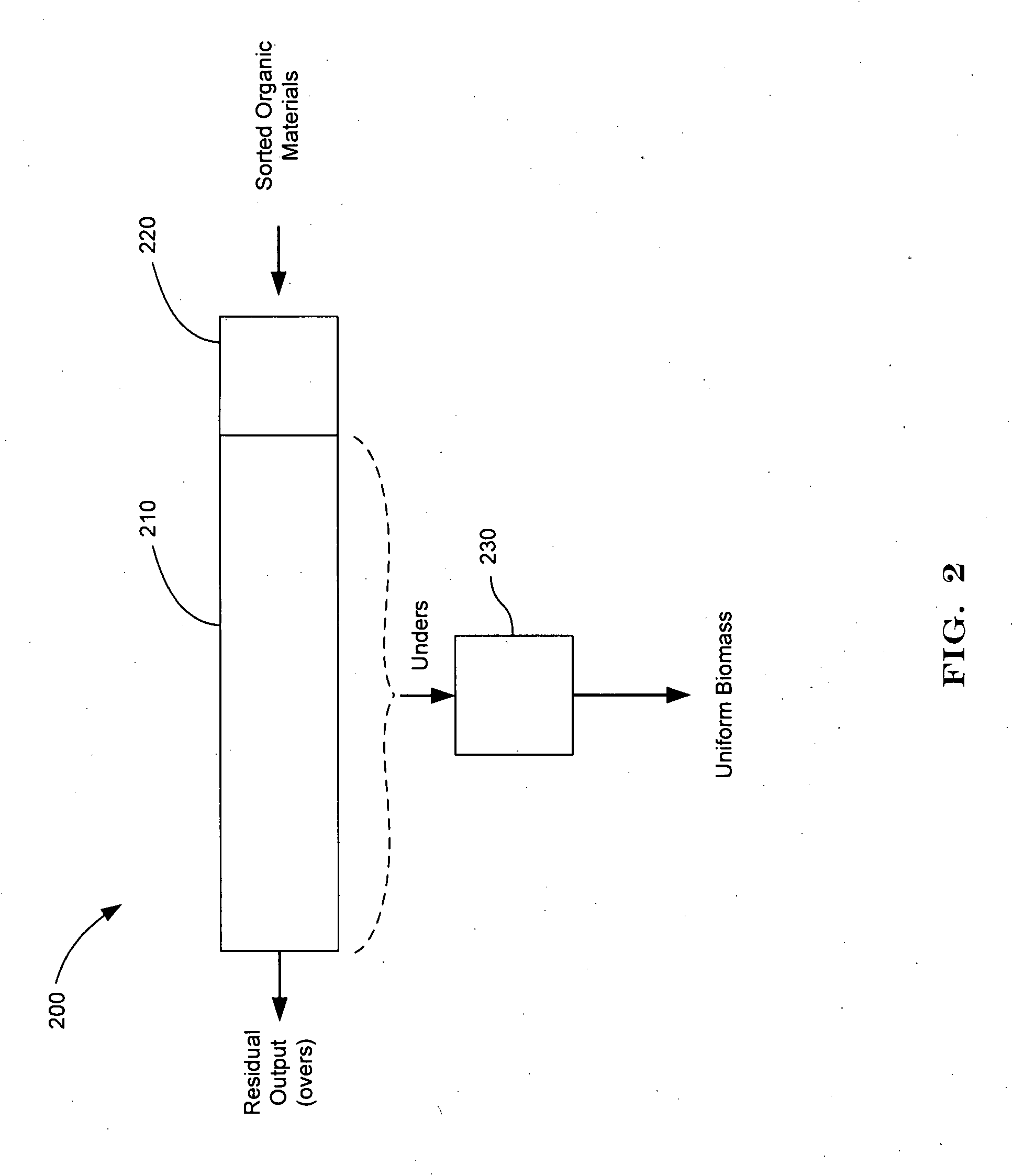

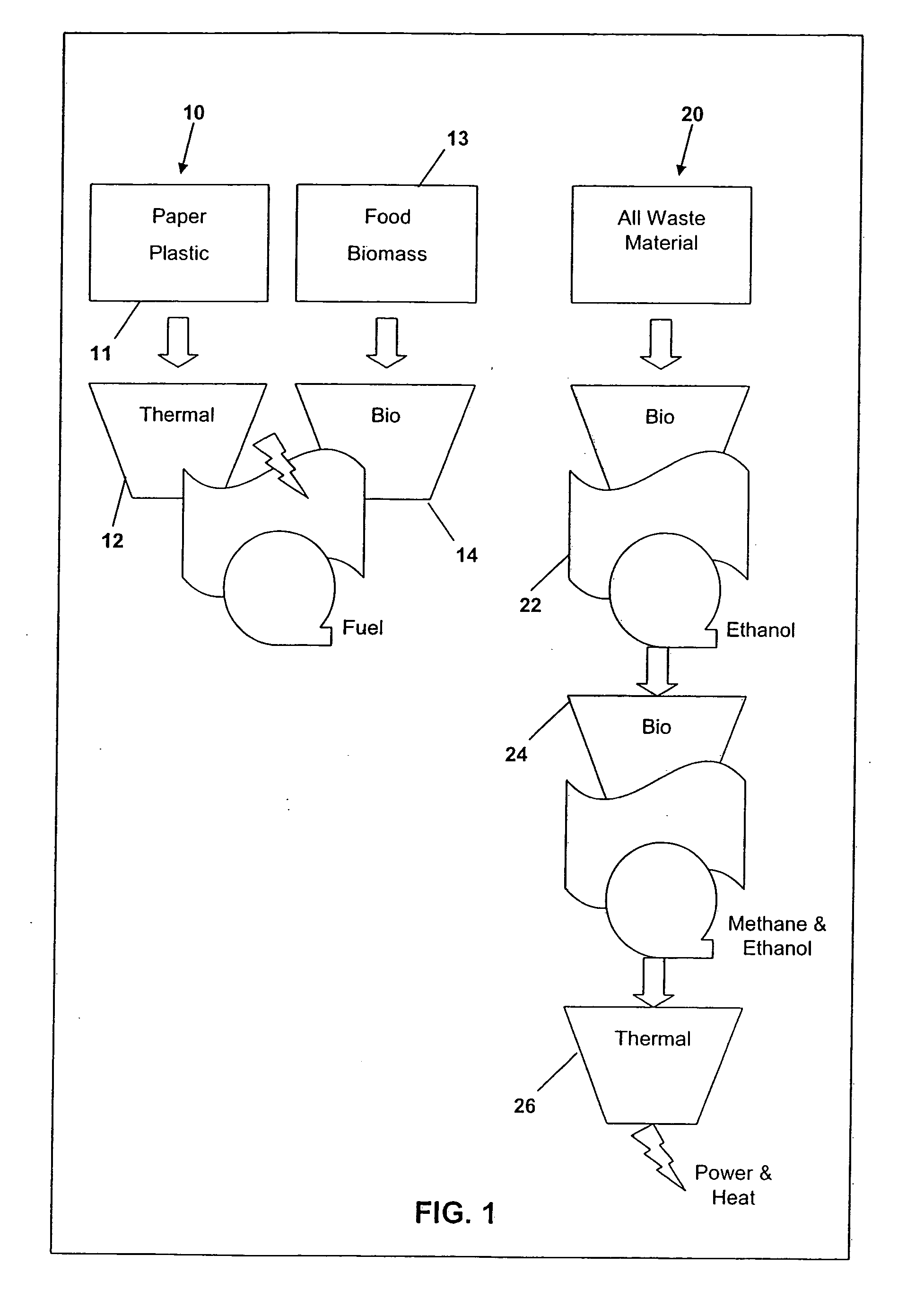

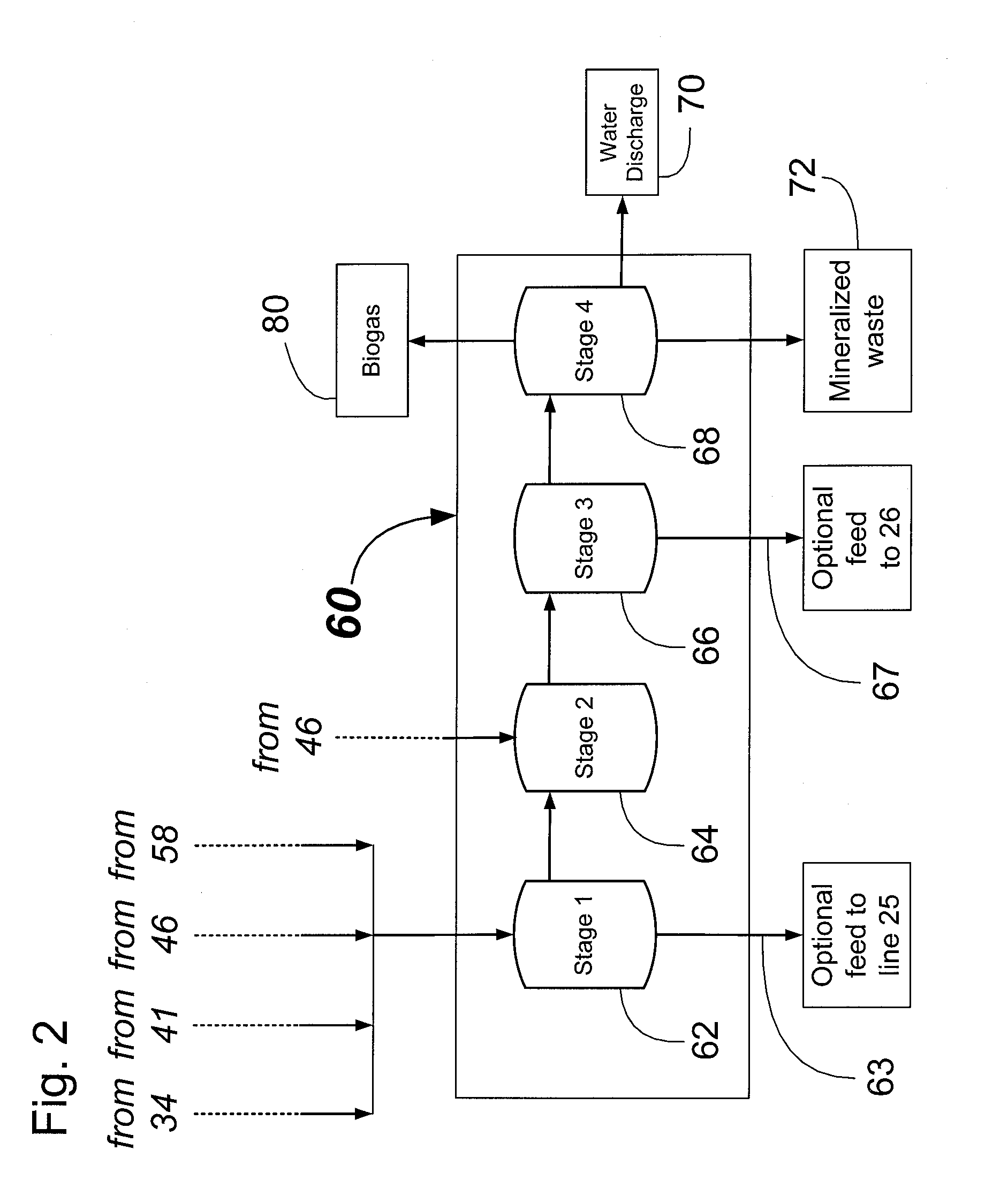

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

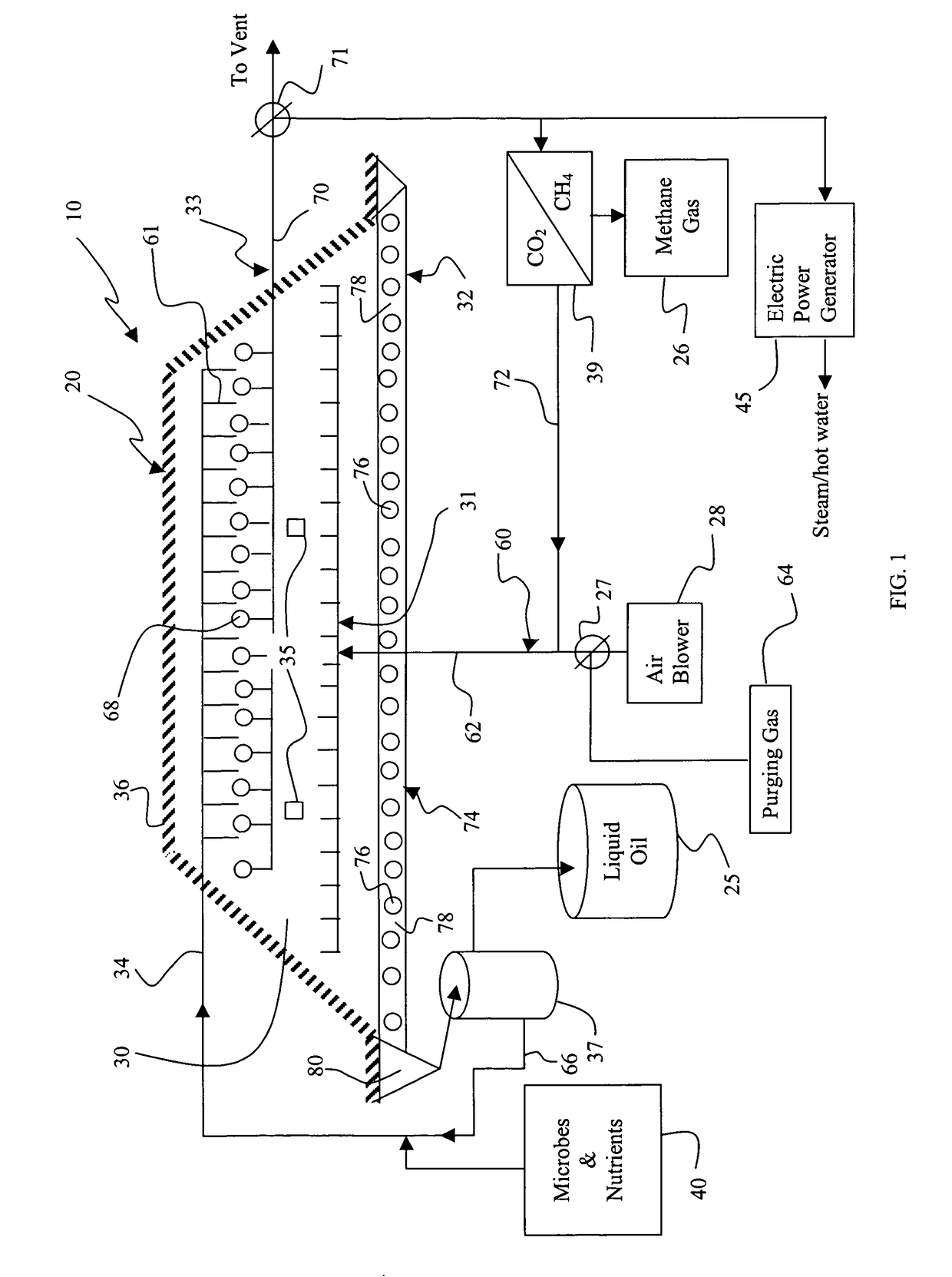

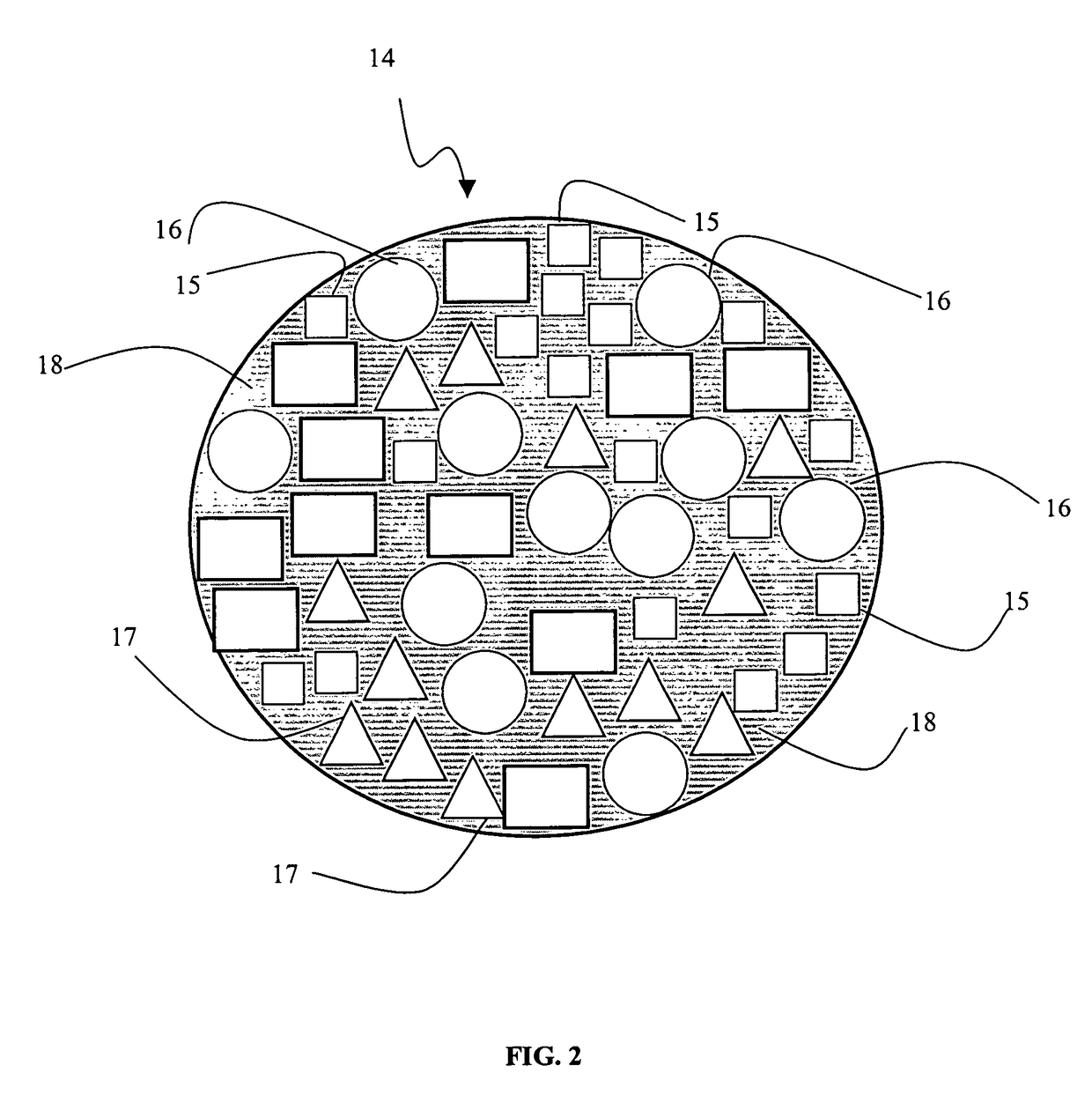

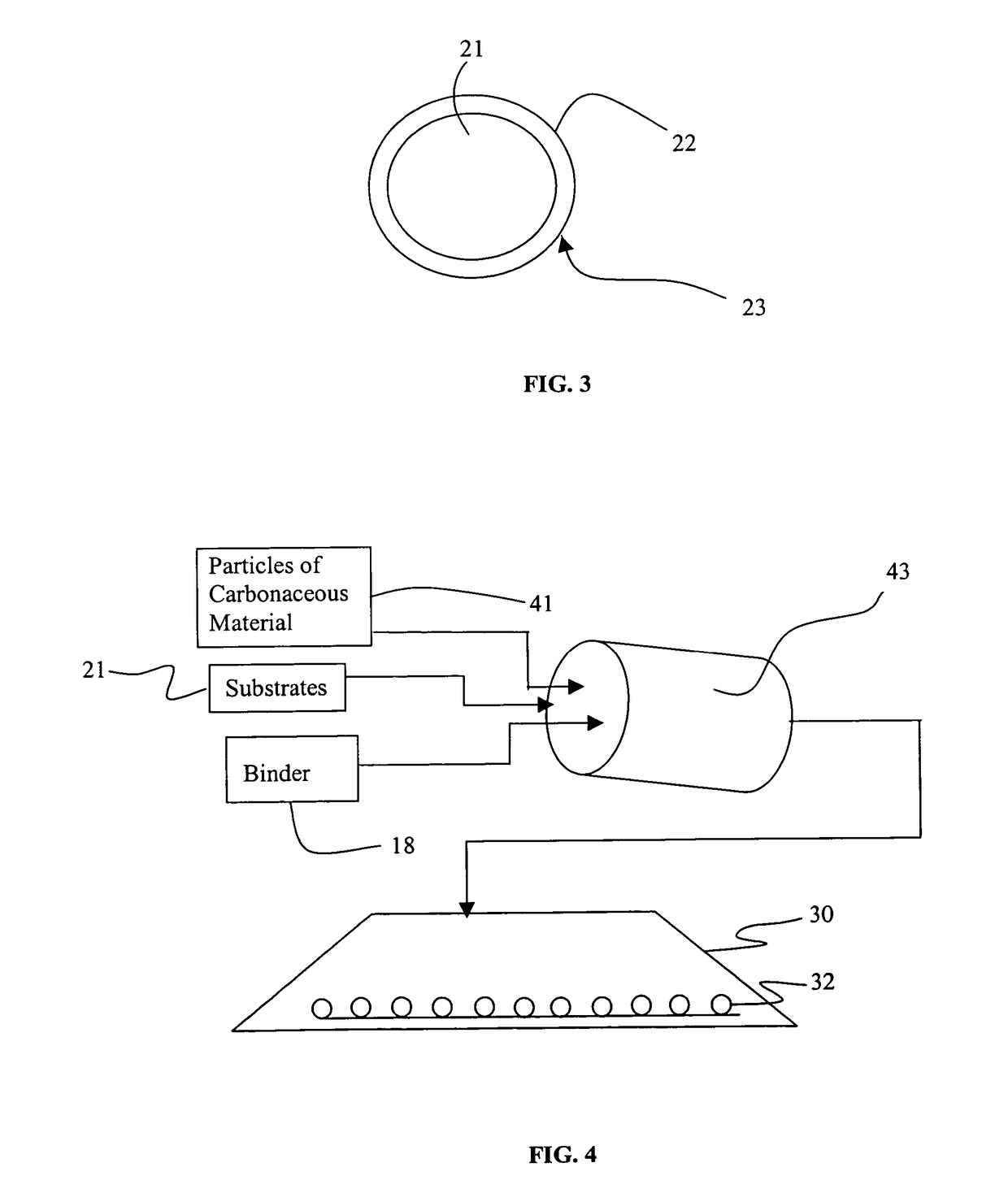

Method and bioreactor for producing synfuel from carbonaceous material

InactiveUS7906304B2Easily biodegradableImprove concentrationGas production bioreactorsWaste based fuelPetroleumBioreactor

A method of producing fuel from biodegradable carbonaceous material using a stacked particle bioreactor is provided. A stacked particle bioreactor is formed from particles including biodegradable carbonaceous material. The biodegradable carbonaceous material in the stacked particle bioreactor is aerobically and / or anaerobically bioconverted into one or more synfuels, which are collected from the reactor. The synfuels produced by the method may include synthetic petroleum, alcohol, and / or a gaseous fuel containing methane. Preferably the method includes an aerobic biotreatment phase followed by an anaerobic bioconversion phase. A stacked particle bioreactor for carrying out the anaerobic, and preferably aerobic, degradation is also described.

Owner:GEOSYNFUELS

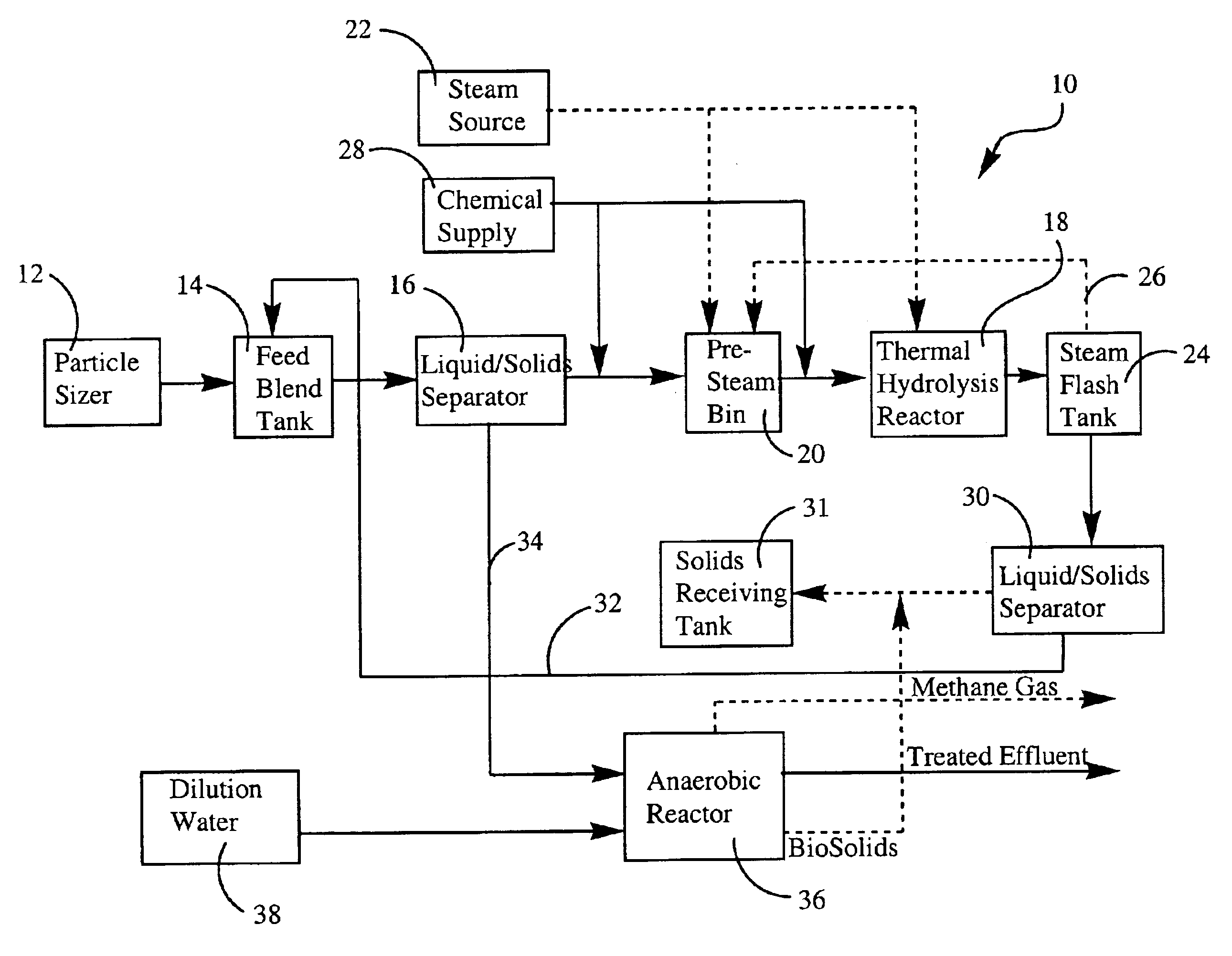

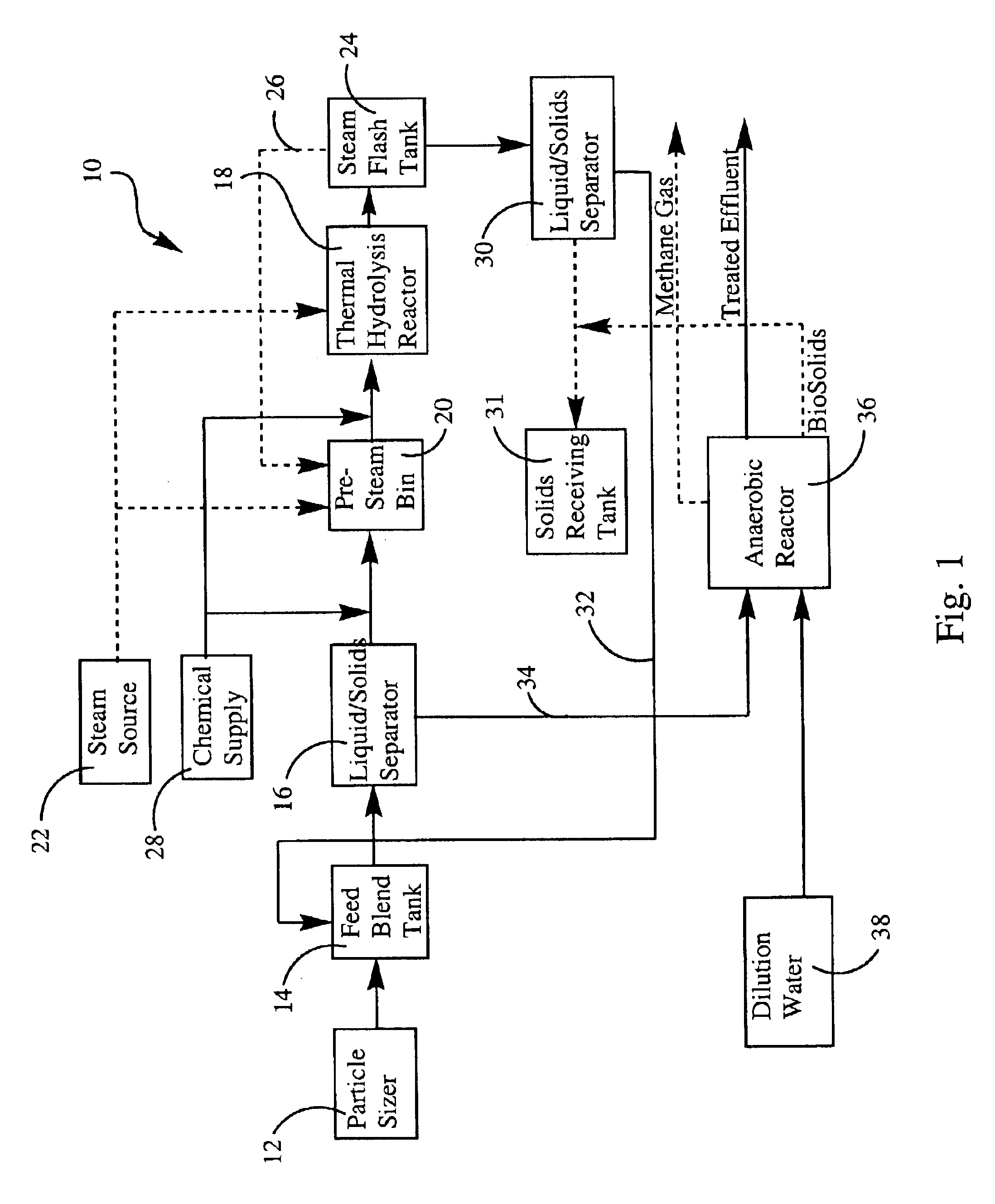

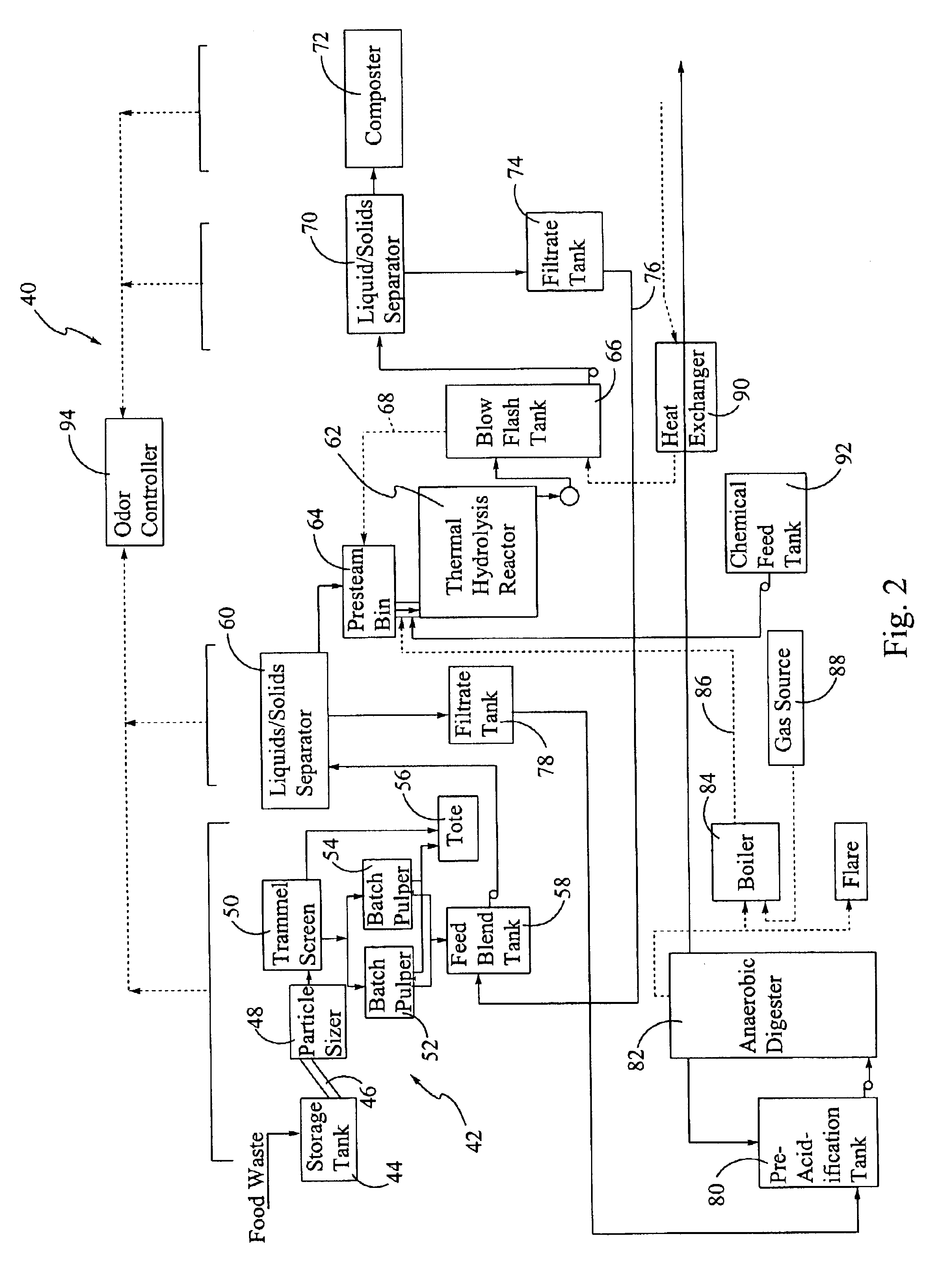

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

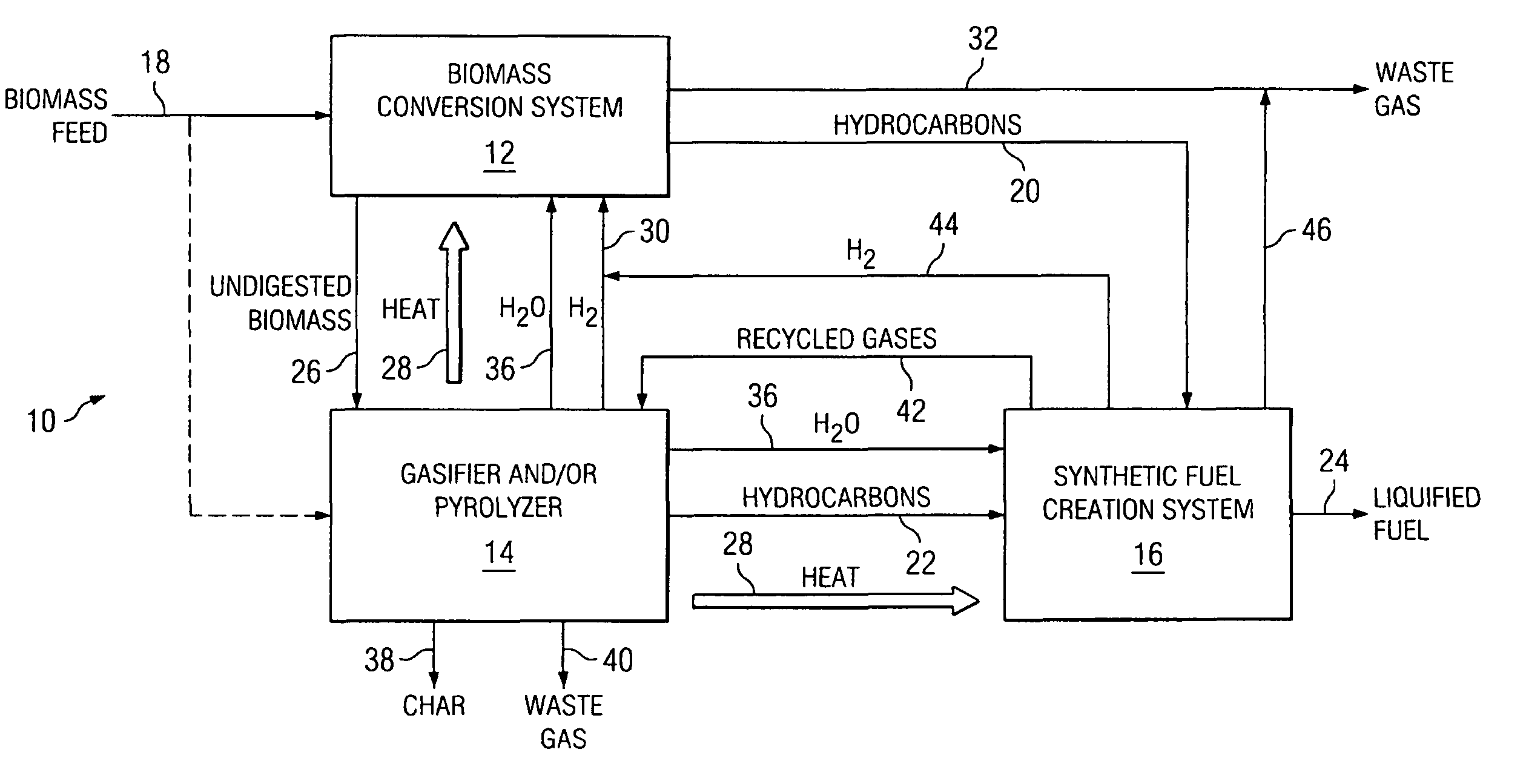

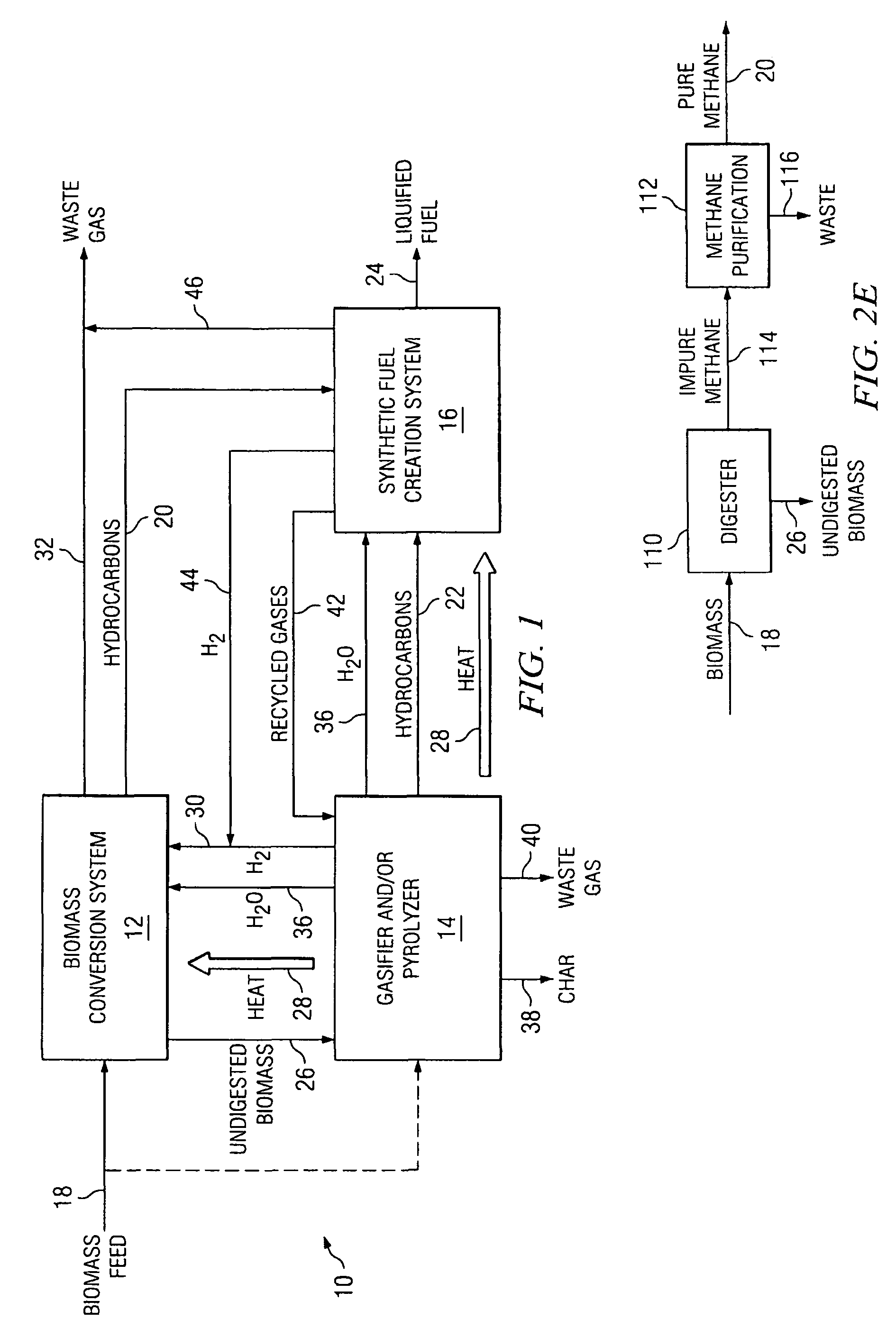

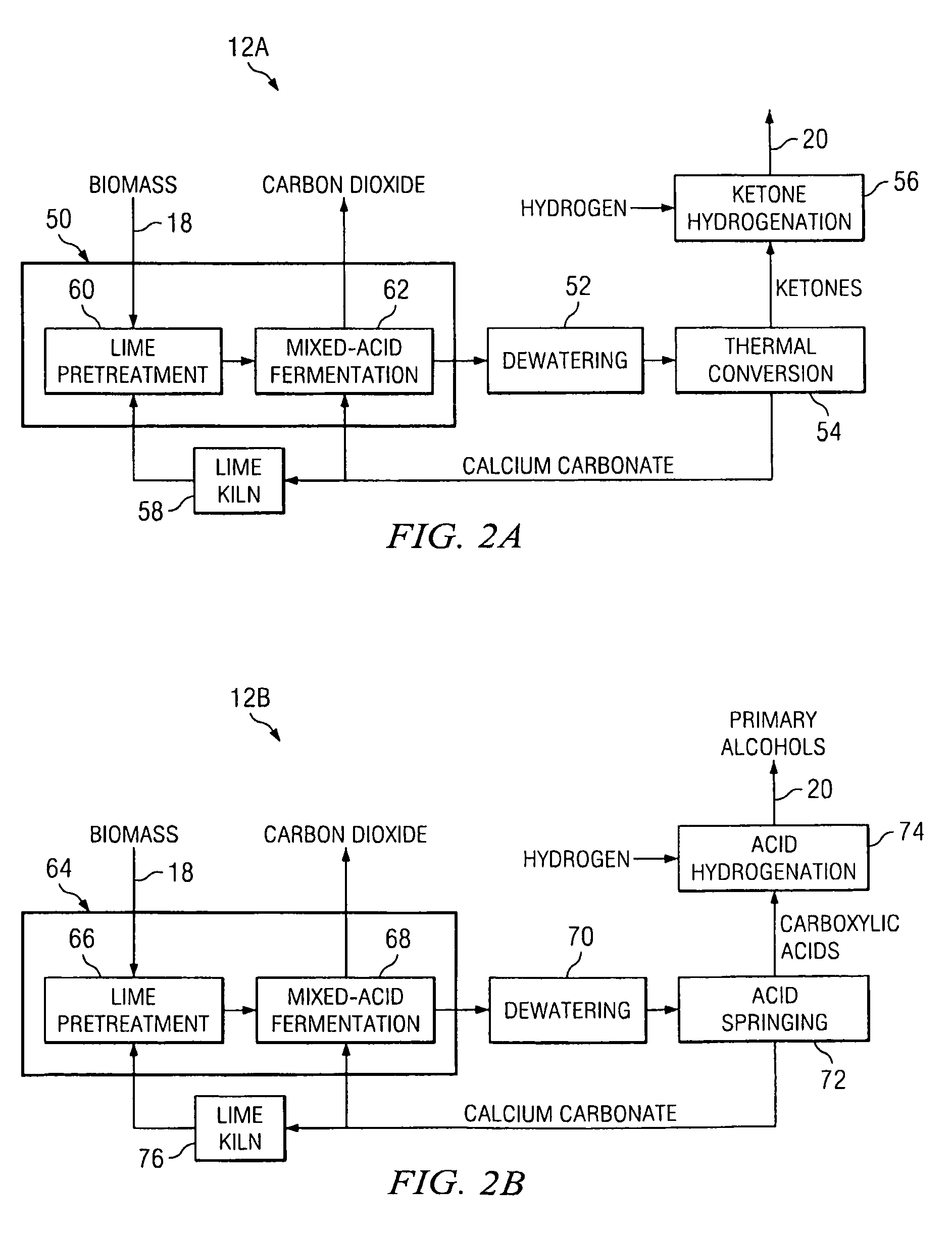

Integrated biofuel production system

InactiveUS8153850B2Improve efficiencyIncrease energy densityGas production bioreactorsWaste based fuelThermal energySystem integration

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

Methods and Systems for Biomass Recycling and Energy Production

InactiveUS20090227003A1Reduce the amount requiredPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeBiology

The present invention comprises methods and systems for treating biomass wastes to result in usable byproducts. Biomass is treated to remove debris, transferred to microbial digester units, such as anaerobic and aerobic digesters, and the resultant solids and liquids are provided to an algae production unit. Algae are harvested and beneficial byproducts are retained. Gases, heat and energy produced by energy conversion units are used in units of the system or provided to external sources. Water is cleaned and when separated from the algae and other solids in the algae harvesting unit may be provided to external sources, or may be used in other units of the system. The methods and systems disclosed herein provide for an efficient and substantially complete use of the components of the input biomass.

Owner:CORE INTPROP HLDG

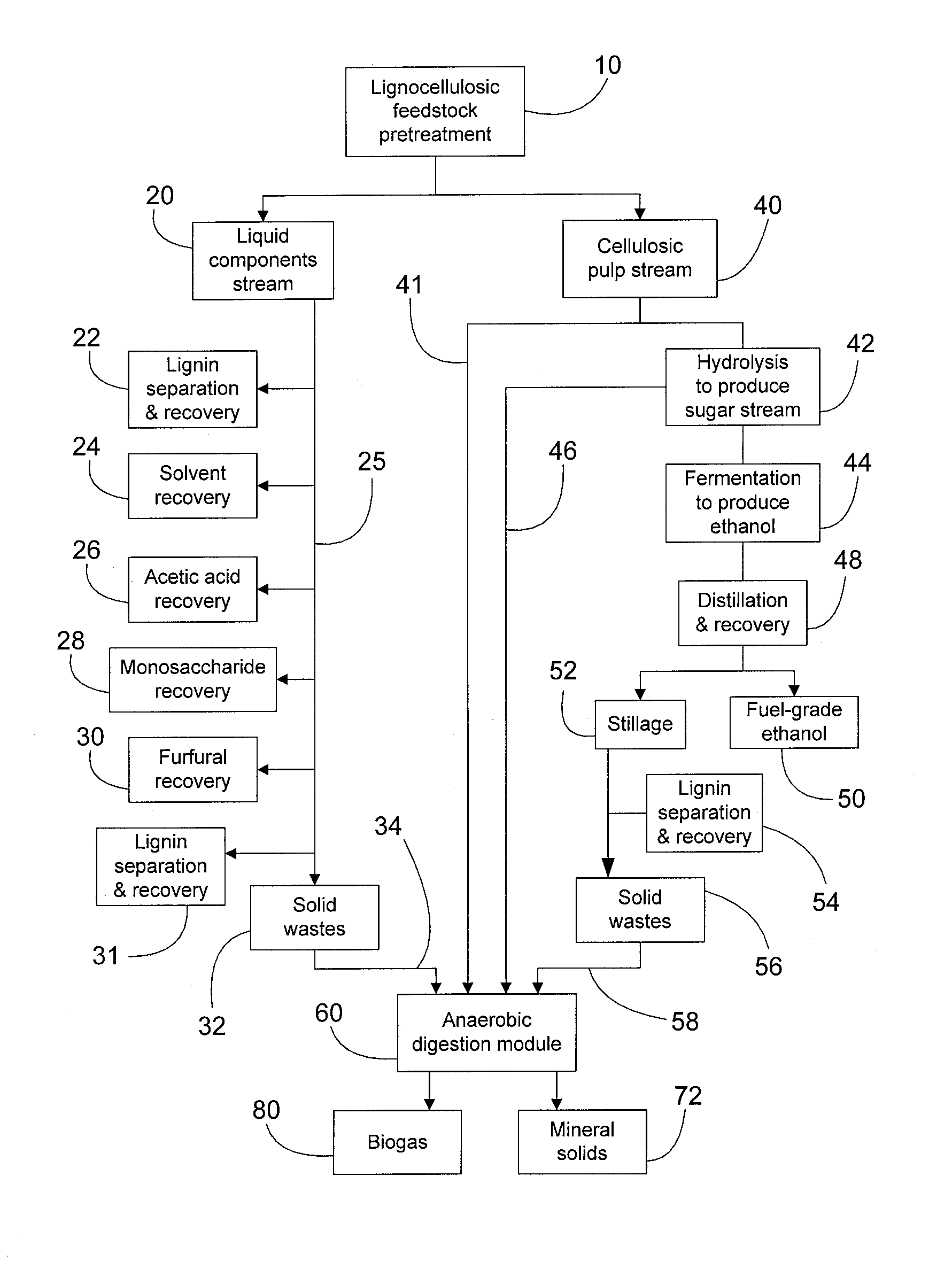

Continuous counter-current organosolv processing of lignocellulosic feedstocks

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into one or more of a de-lignified cellulose stream, a sugar stream, small-chain alcohol streams and four structurally distinct classes of lignin derivatives. The modular process comprises a first processing module configured for digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for recovering small-chain alcohols and optionally a first class of lignin derivatives from the cellulosic solids fraction, a third processing module configured for recovering from the liquid fraction at least one of a second class and a third class of lignin derivatives or mixtures thereof, and waste stream comprising a fourth class of lignin derivatives. The fourth processing module may optionally recover the fourth class of lignin derivatives.

Owner:SUZANO CANADA INC

Apparatus to establish and optimize sedimentation and methane fermentation in primary wastewater ponds

InactiveUS6923906B2Raise the pHIncreases the rate of die-away of pathogenic bacteriaLiquid degasificationMixing methodsSludgeIncrease ph

Owner:GREEN FRANKLIN BAILEY +2

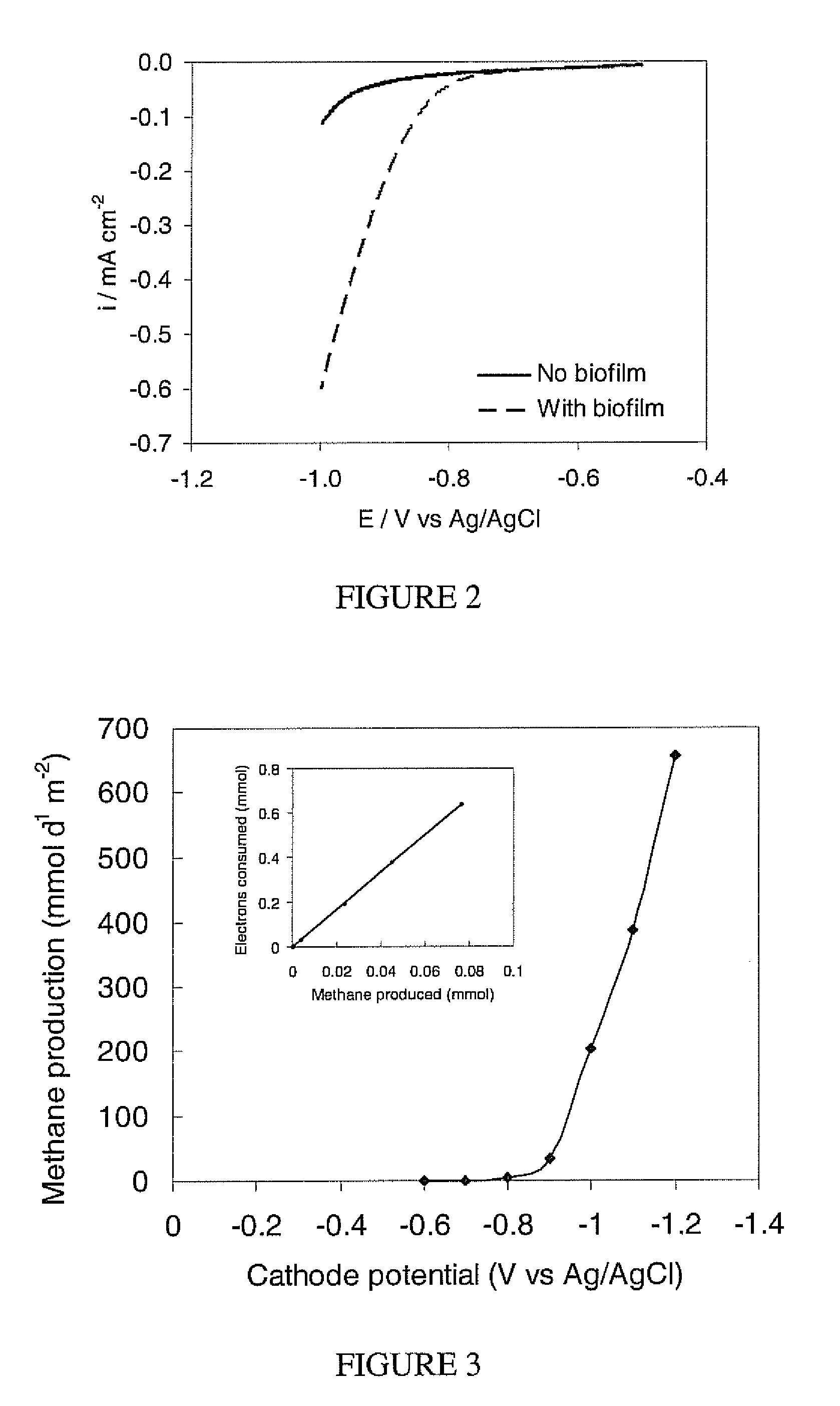

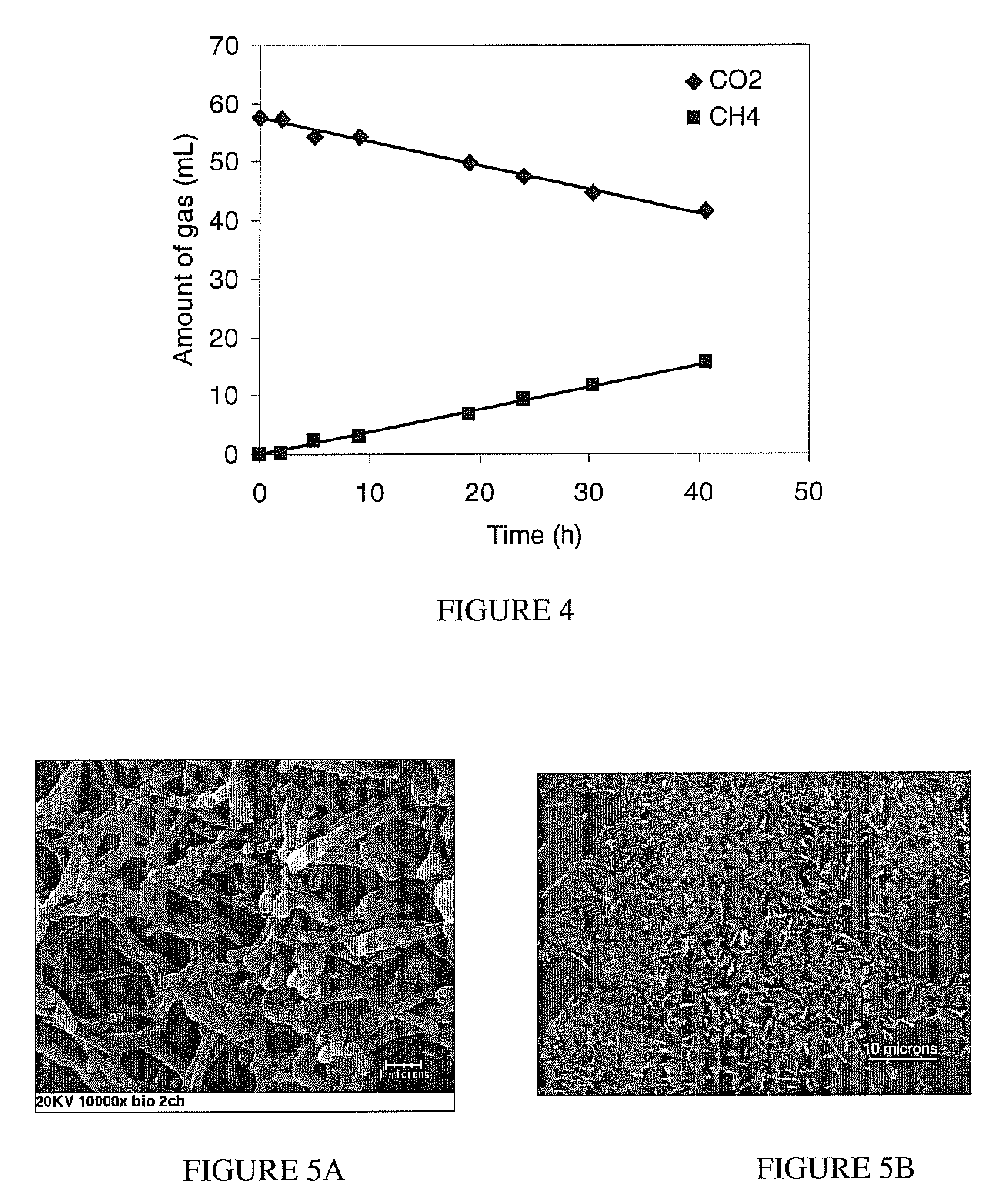

Electromethanogenic reactor and processes for methane production

ActiveUS20090317882A1Reduce deliveryImprove methane production efficiencyMicroorganismsGas production bioreactorsHydrogenCombustion

Increasing competition for fossil fuels, and the need to avoid release carbon dioxide from combustion of these fuels requires development of new and sustainable approaches for energy production and carbon capture. Biological processes for producing methane gas and capturing carbon from carbon dioxide are provided according to embodiments of the present invention which include providing an electromethanogenic reactor having an anode, a cathode and a plurality of methanogenic microorganisms disposed on the cathode. Electrons and carbon dioxide are provided to the plurality of methanogenic microorganisms disposed on the cathode. The methanogenic microorganisms reduce the carbon dioxide to produce methane gas, even in the absence of hydrogen and / or organic carbon sources.

Owner:PENN STATE RES FOUND

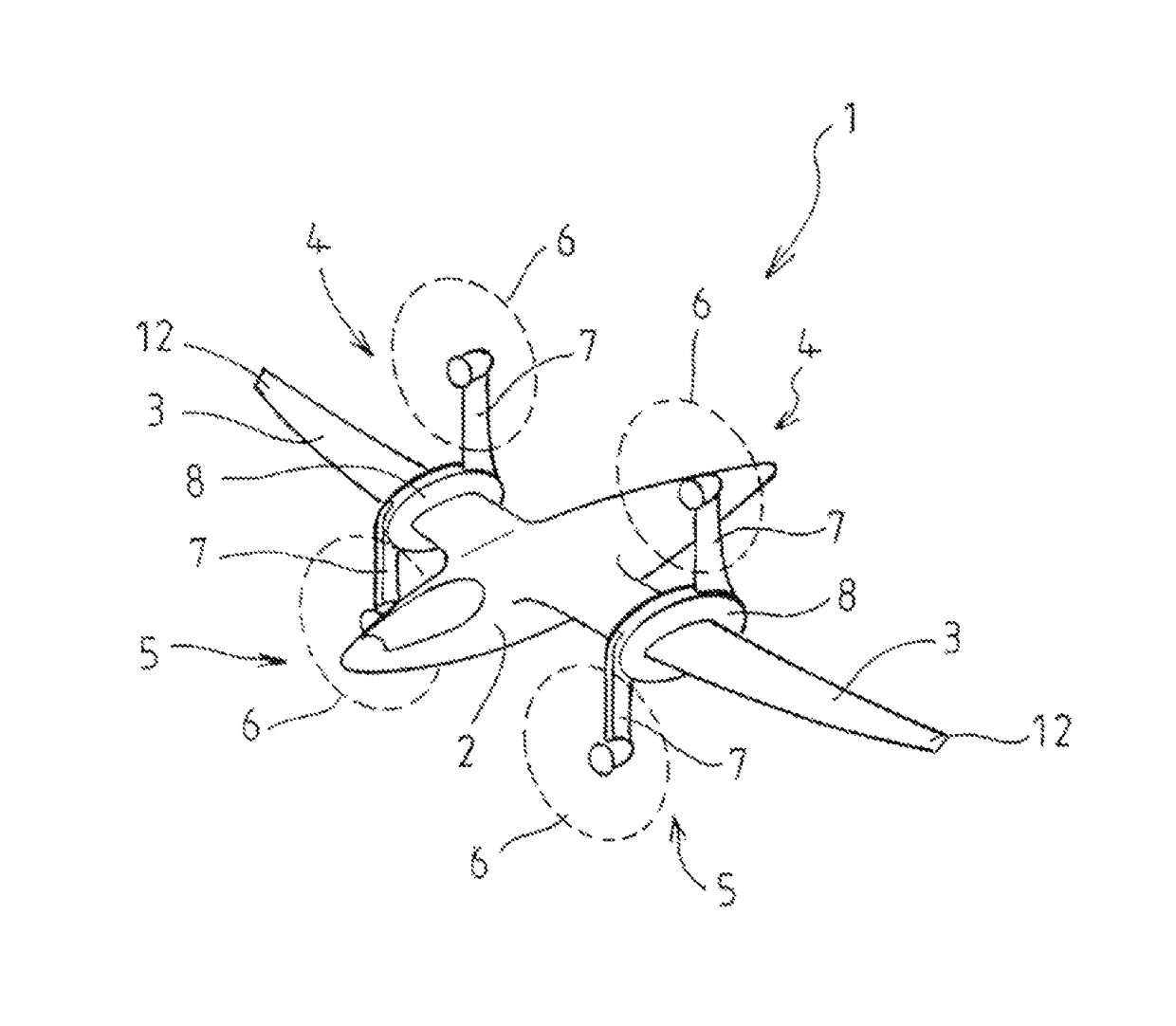

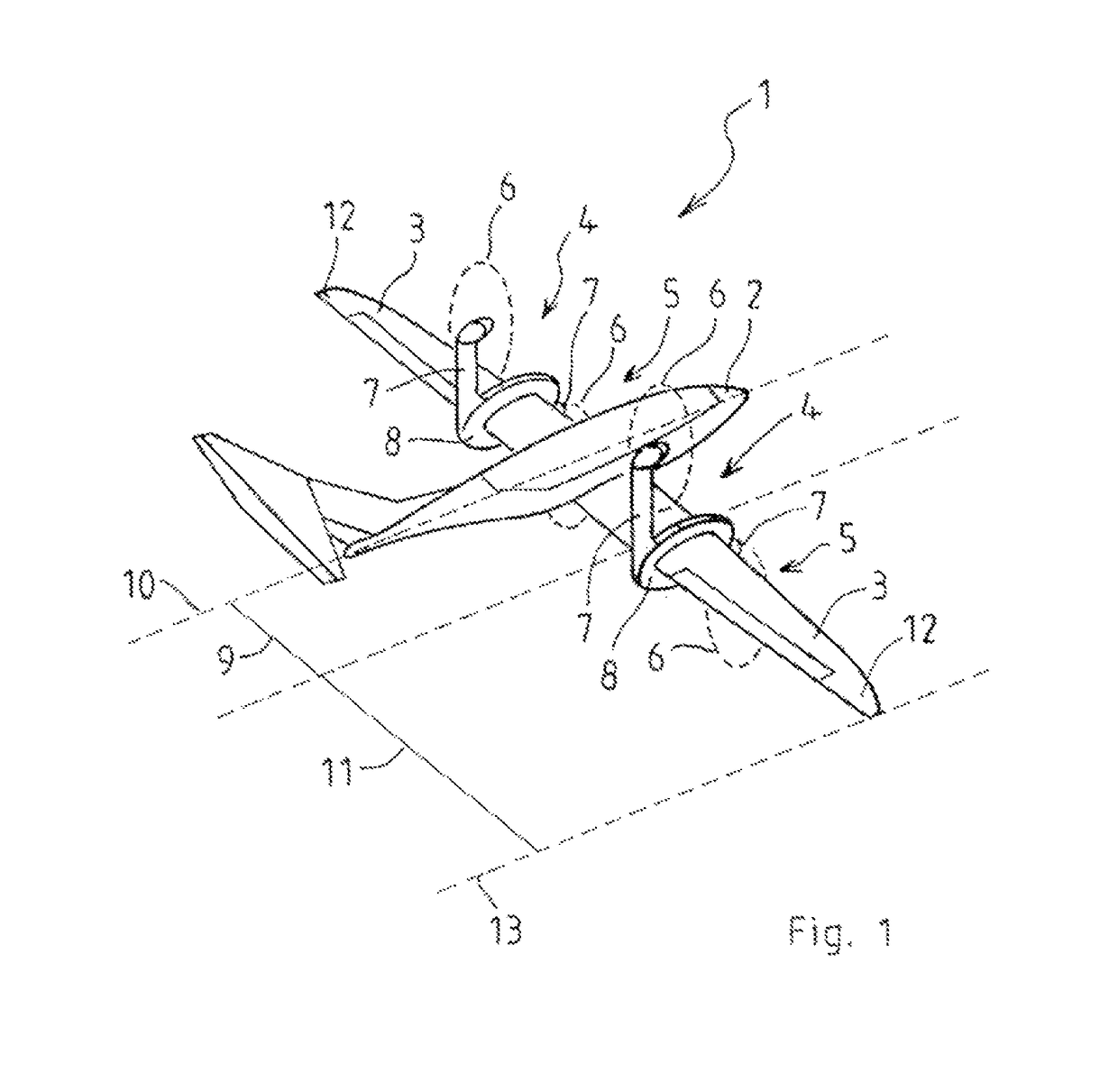

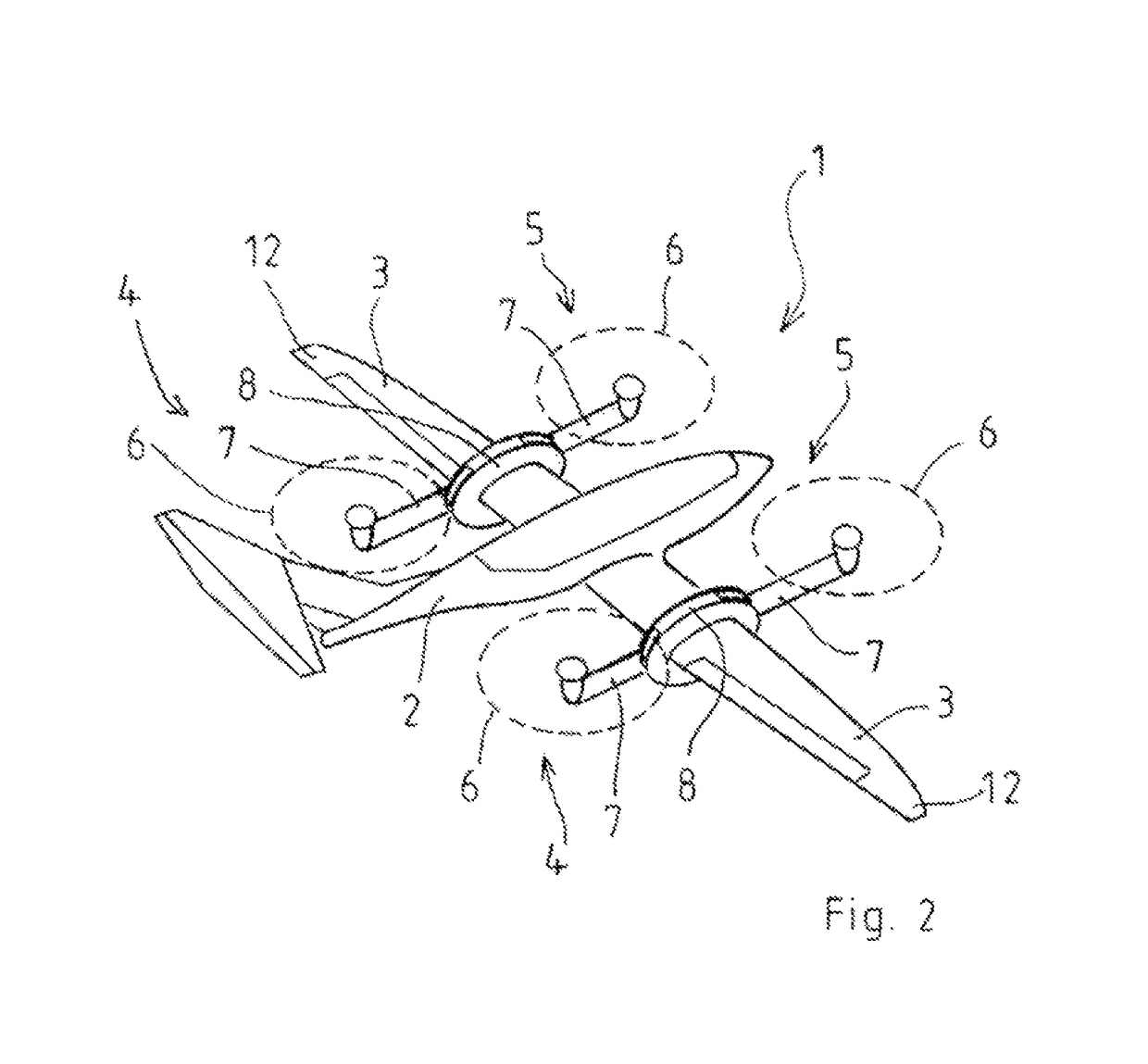

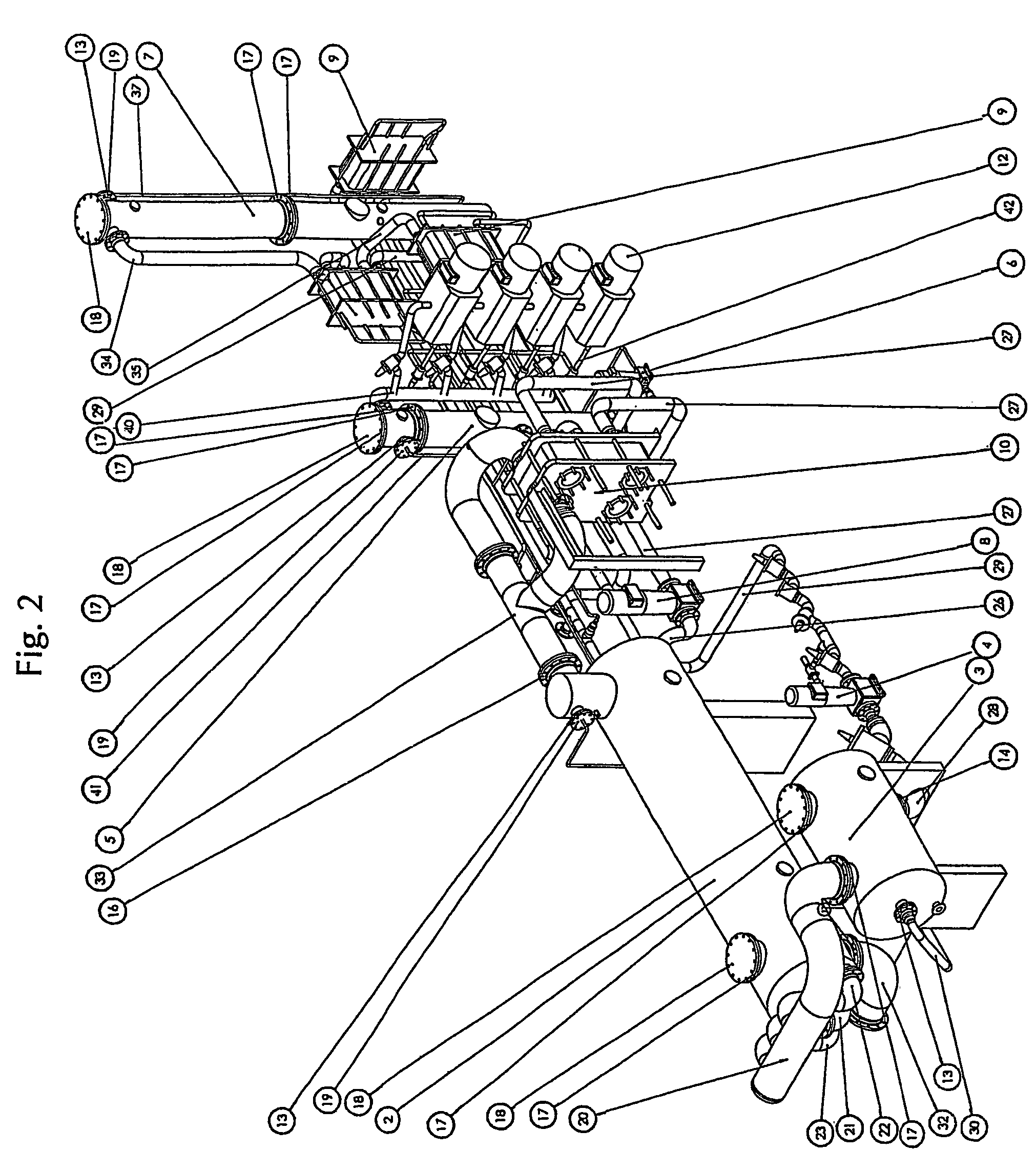

Vertical-takeoff aircraft

ActiveUS9643720B2Effective positioningImprove efficiencyPropellersPower plant constructionFlight vehicleAirplane

A vertical-takeoff aircraft with a wing. A first drive unit and a second drive unit are swivellably mounted on the wing. The first drive unit and the second drive unit are arranged on the wing at a distance from a wing-end of the wing. A first distance between the first drive unit and a longitudinal axis of the aircraft is approximately equal to a second distance between the second drive unit and the longitudinal axis of the aircraft. The first drive unit and the second drive unit are swivellable into a horizontal flying position and a vertical flying position. In the horizontal flying position the first drive unit is arranged above a wing surface and the second drive unit below the wing surface on the wing. In the vertical flying position the first drive unit and the second drive unit are arranged in an approximately horizontal plane. The first drive unit and the second drive unit each have a swivel arm, wherein the swivel arms are swivellably mounted on the wing.

Owner:WINGCOPTER GMBH

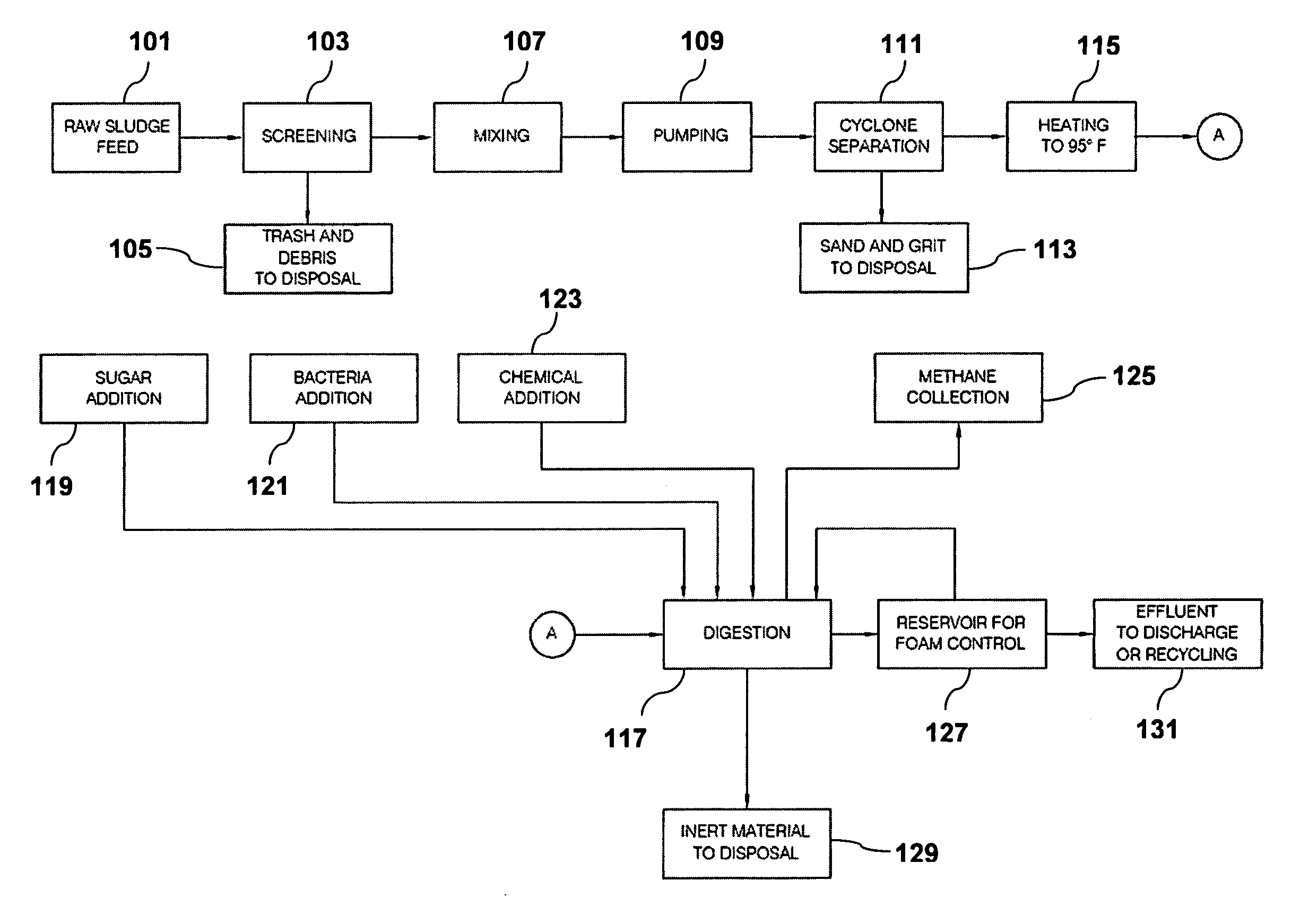

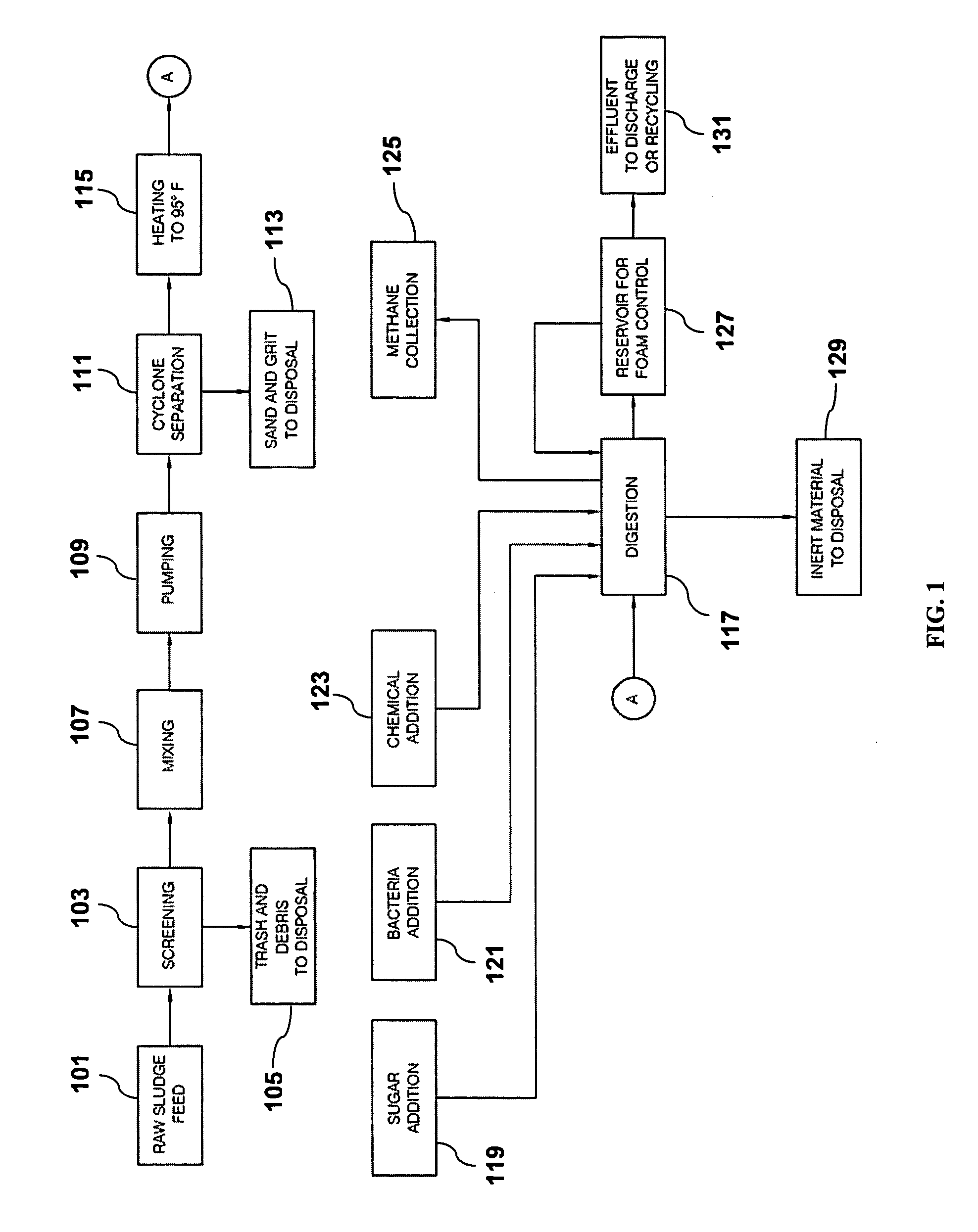

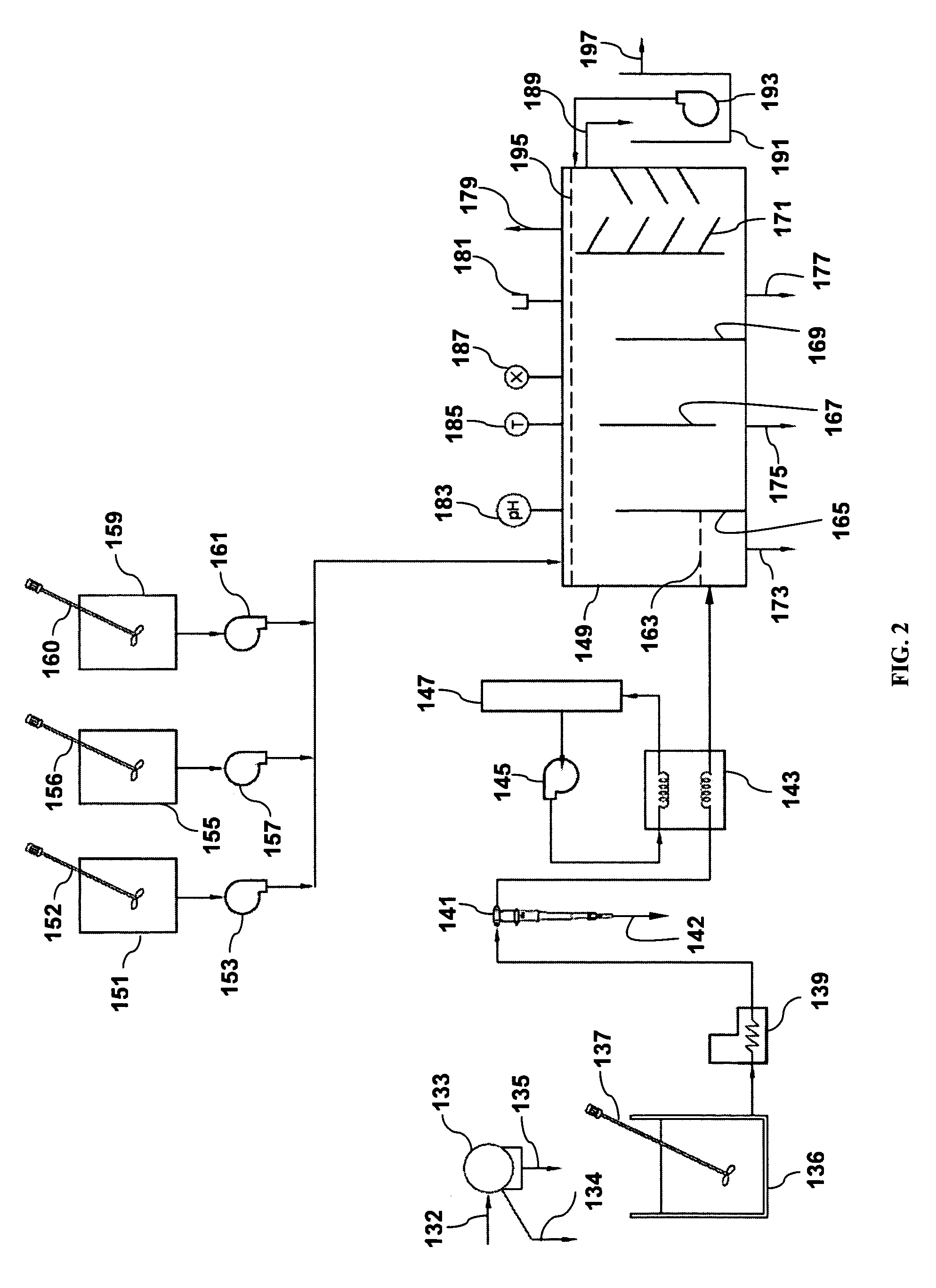

Digesters

Methods and devices are disclosed for converting predominantly organic waste materials, such as sludge, into useful byproducts.

Owner:TOLBERT & ASSOCS

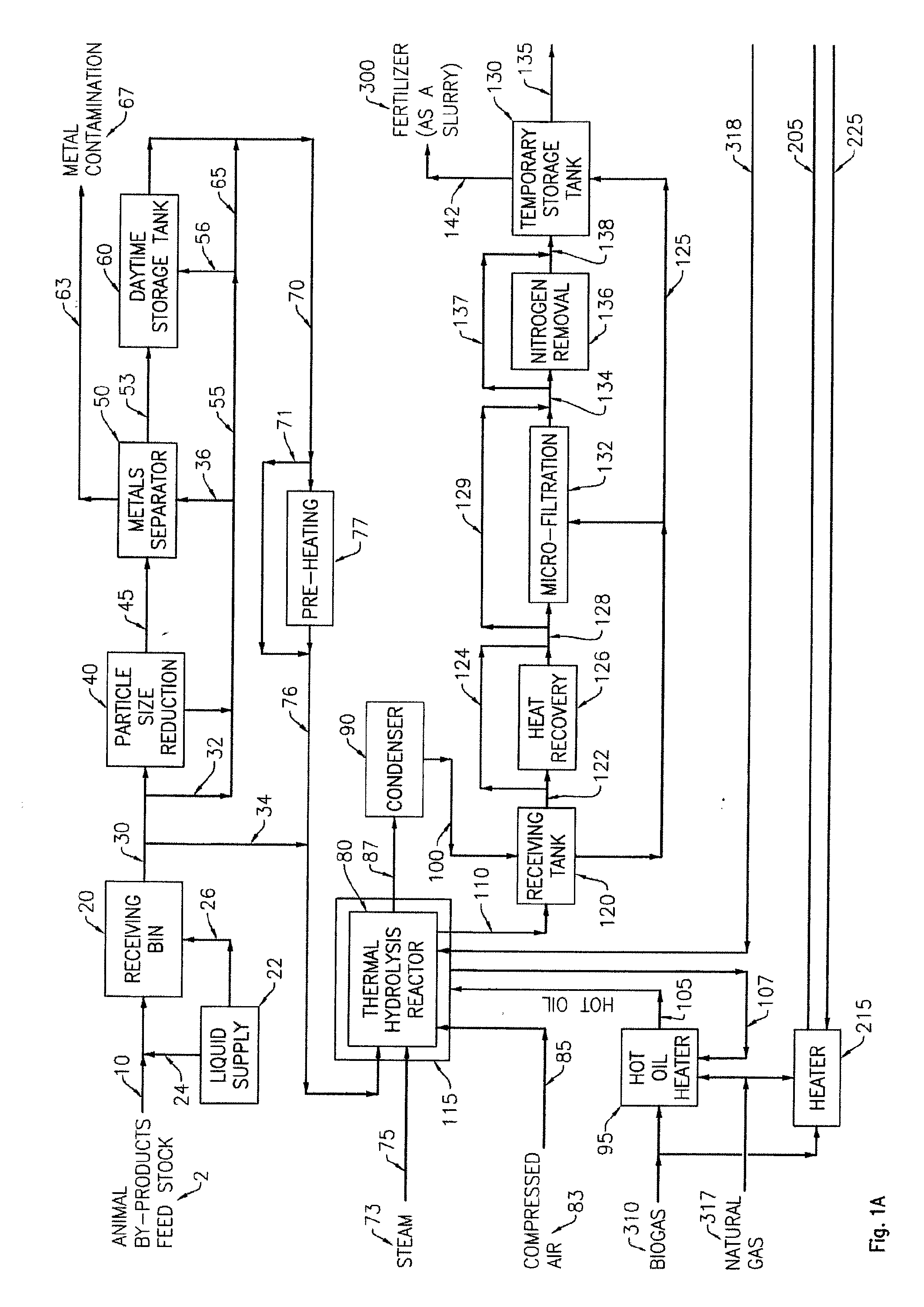

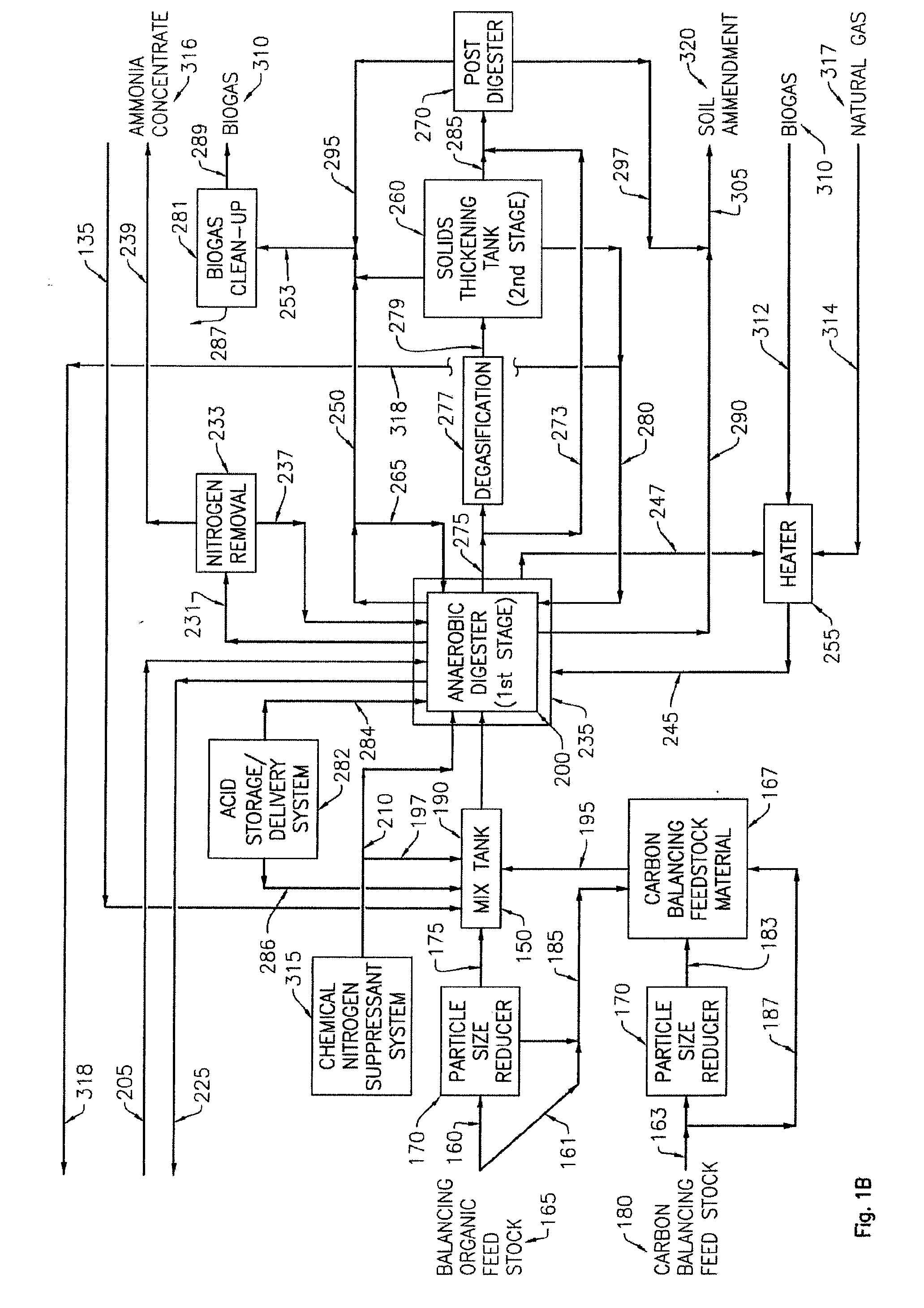

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

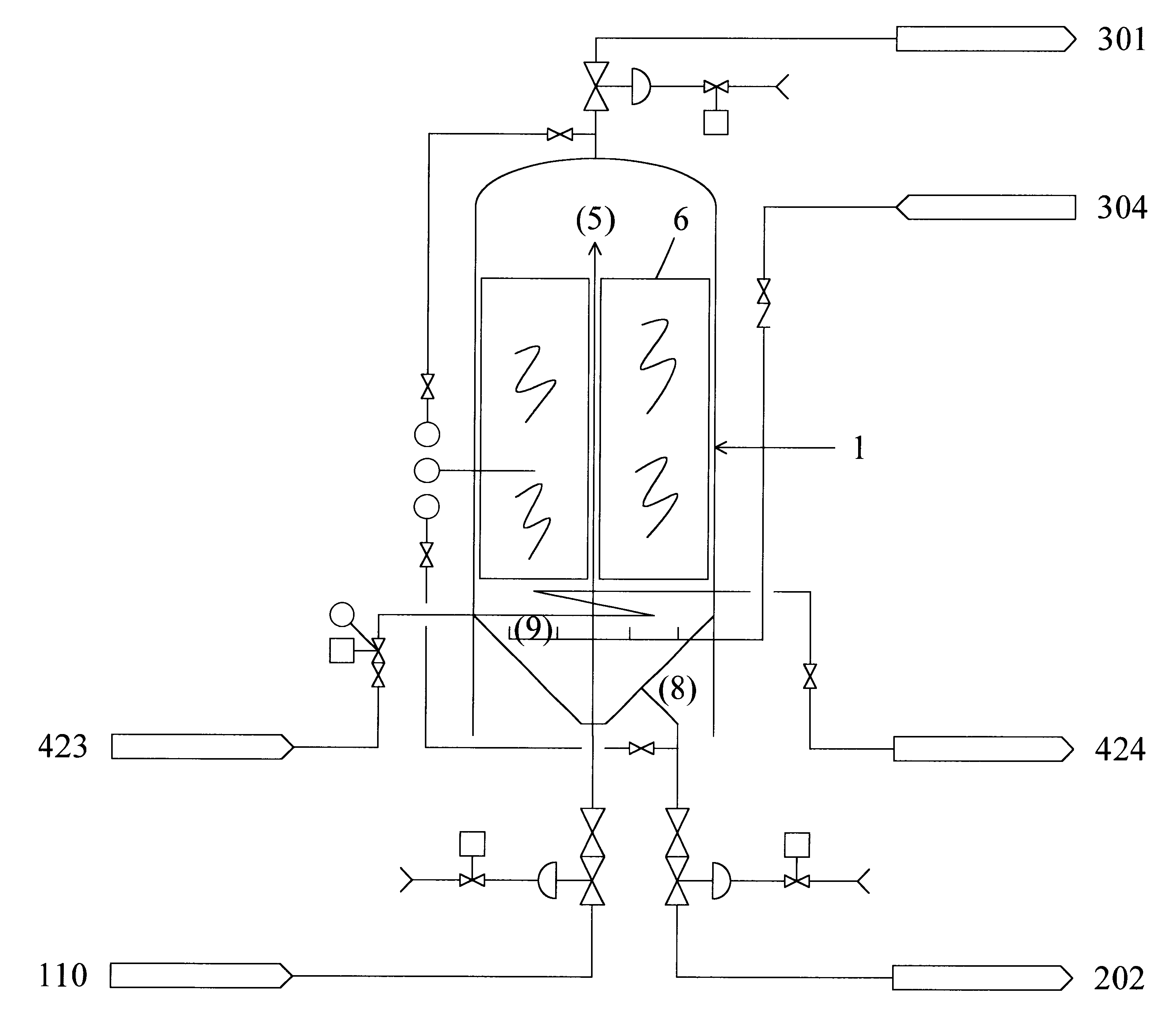

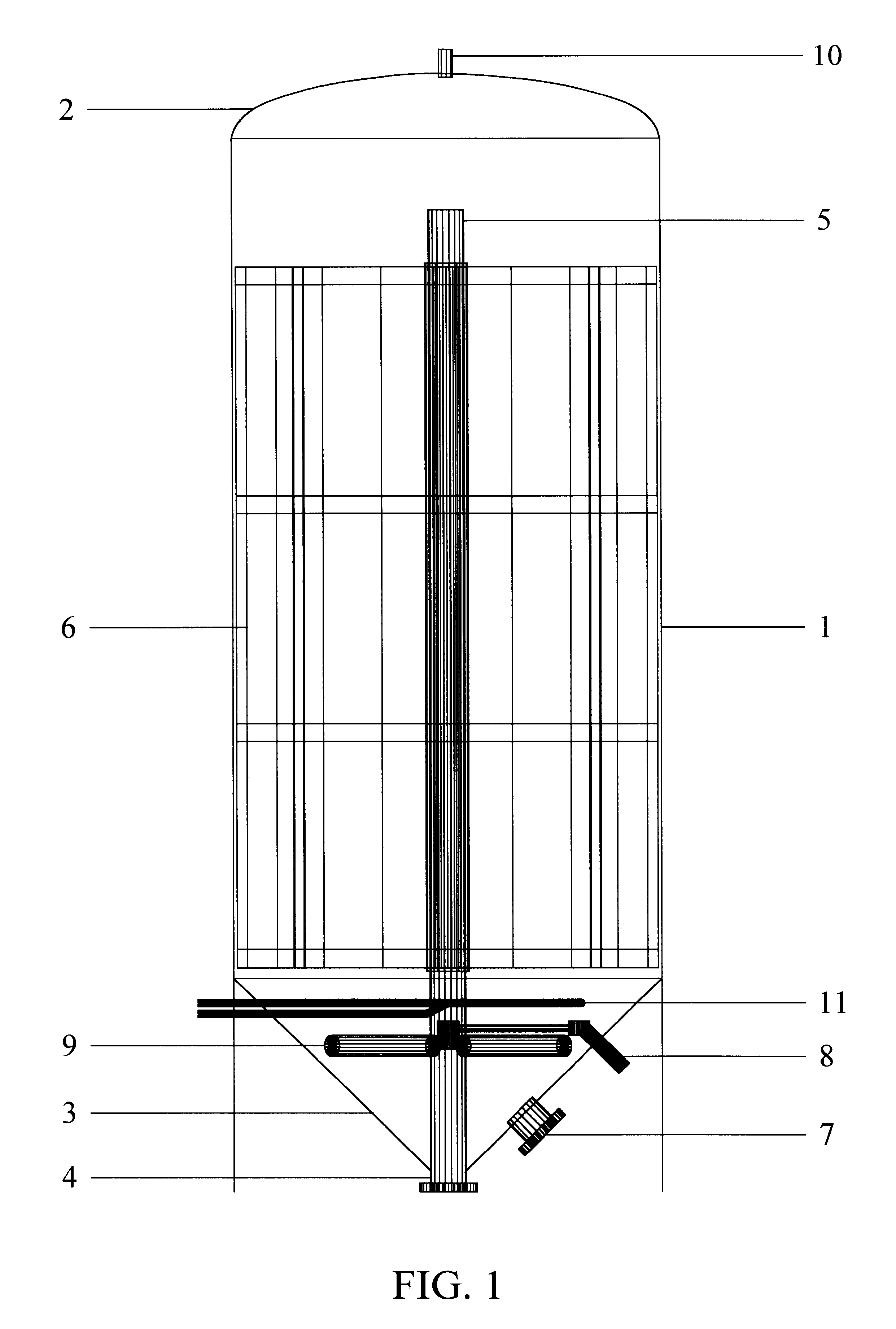

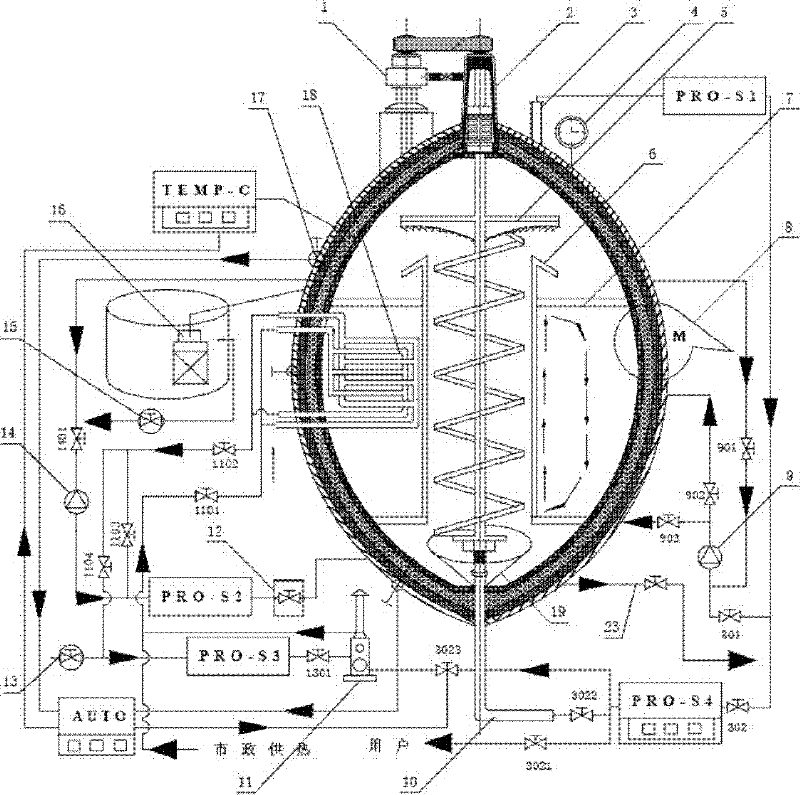

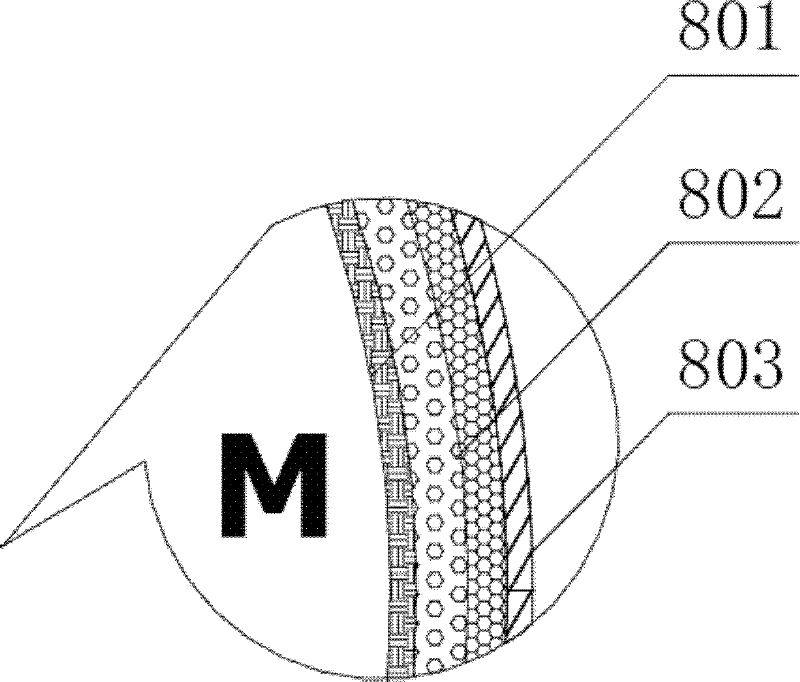

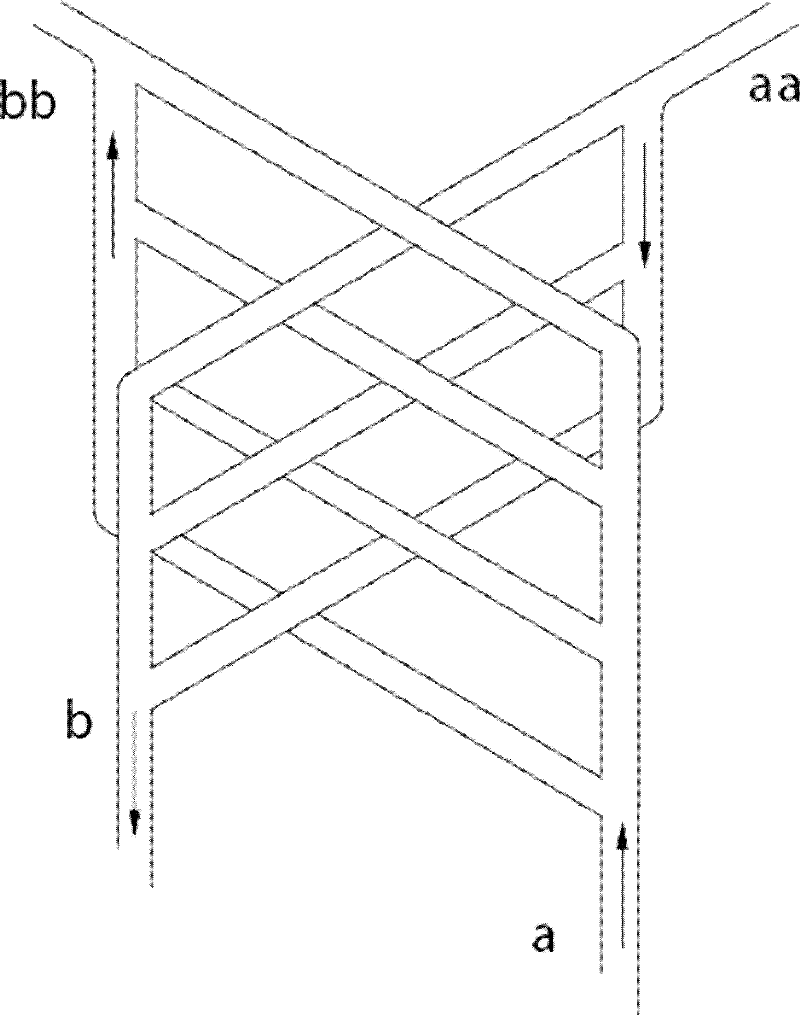

Multi-cycle stirring egg-shaped anaerobic fermentation system

ActiveCN102517199ASimple structureReasonable designBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringSlurry

The invention discloses a multi-cycle stirring egg-shaped anaerobic fermentation system. The system comprises a fermentation tank body and a driving device arranged on the fermentation tank body, wherein the fermentation tank body is egg-shaped, the center of the inner cavity of the fermentation tank body is provided with an inner barrel type spiral stirrer, the outside of the inner barrel type spiral stirrer is provided with a stirrer inner barrel, a temperature heating device is arranged between the wall of the fermentation tank body and the stirrer inner barrel, the bottom of the inside ofthe tank is provided with an umbrella-shaped gas flow distribution device; the upper part of the fermentation tank body is provided with a vent pipe and a pressure control device, the bottom of the fermentation tank body is provided with an umbrella-shaped gas flow distribution device gas inlet pipe and a mud-discharging and sand-discharging outlet; and the side wall of the fermentation tank bodyis communicated with a biogas circulation system, a biogas slurry circulation system, a gas-liquid circulation system, a heating system, a temperature control system and a biogas residue and biogas slurry storage pool respectively. The multi-cycle stirring egg-shaped anaerobic fermentation system adopts multi-cycle stirring to increase the stirring efficiency of the system; and the anaerobic fermentation environment is improved, the fluid is mixed evenly, the temperature difference slightly fluctuates, the energy consumption of the system is low, the fermentation rate is high and the system is suitable for popularization and application.

Owner:INNER MONGOLIA HUAMENG KECHUANG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

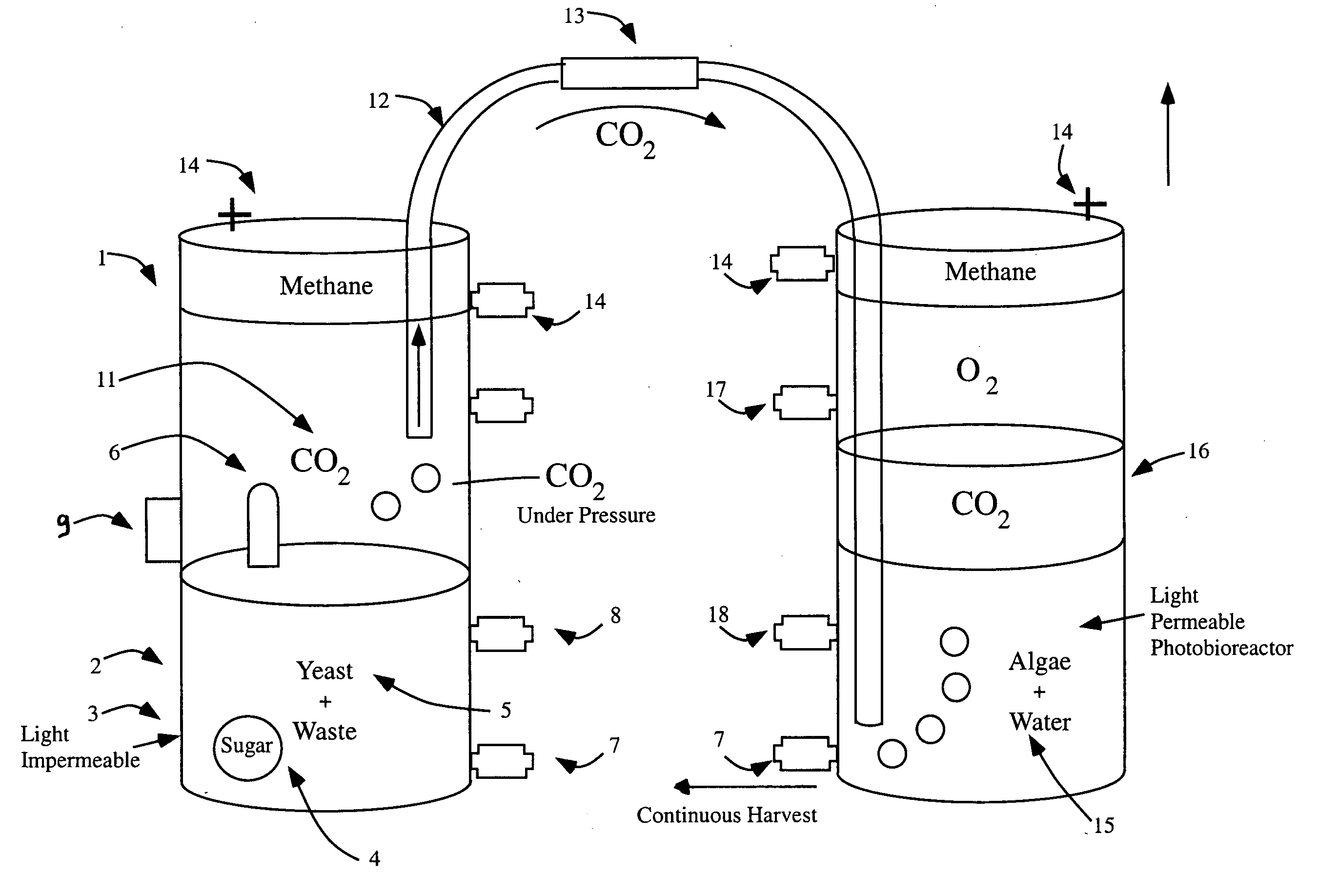

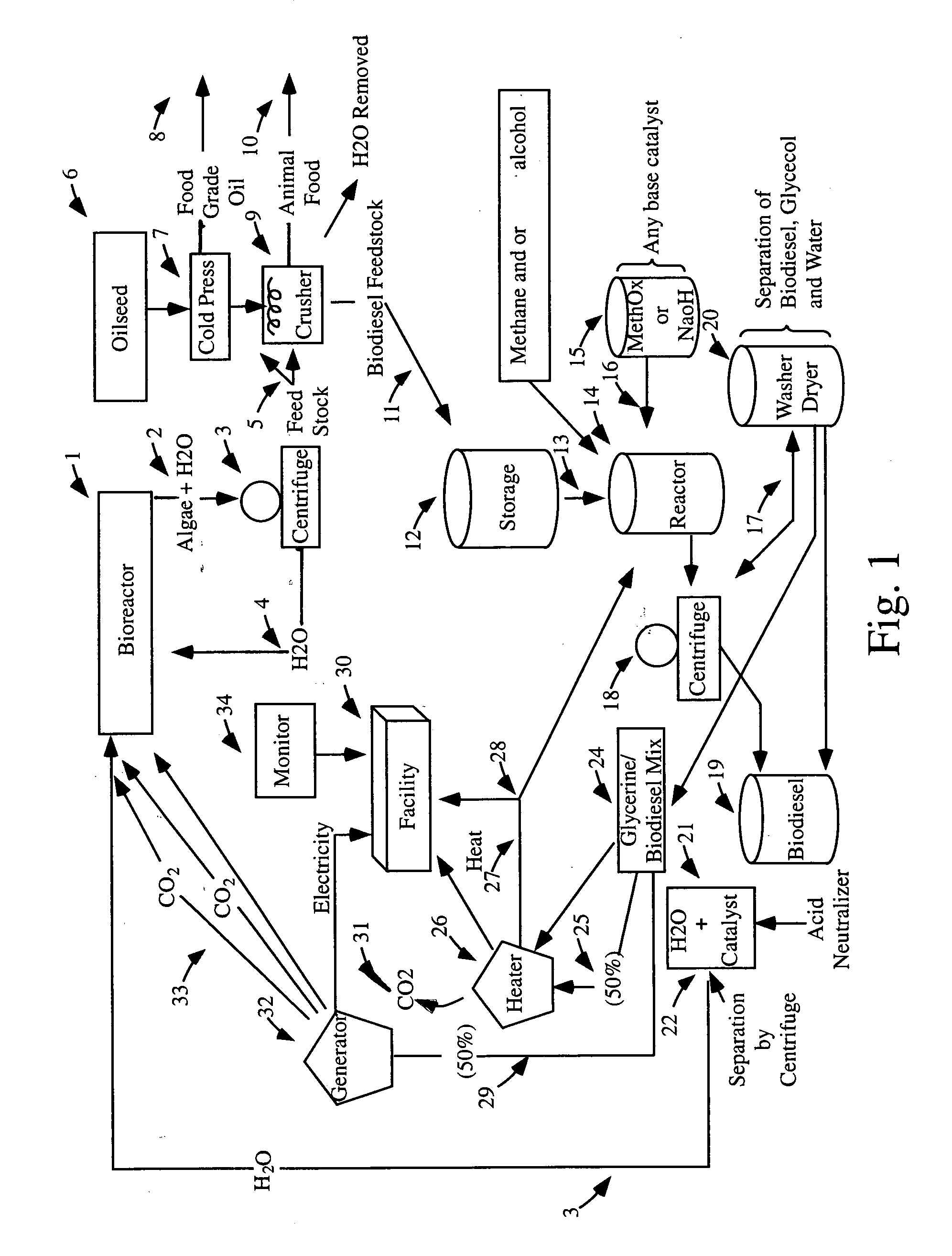

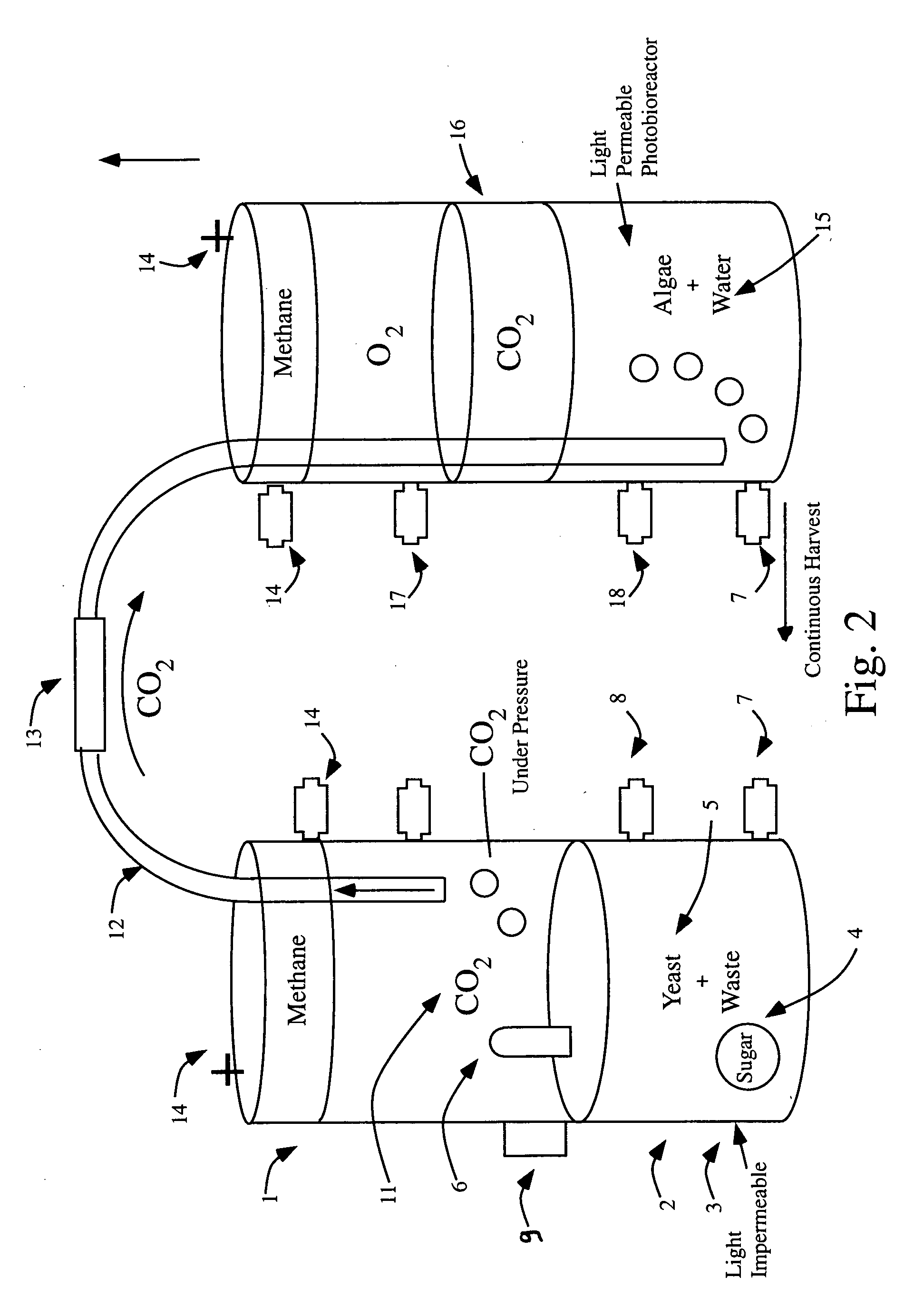

Systems and methods for production of biofuel

InactiveUS20100311157A1Reduce carbon footprintEasy to set upBioreactor/fermenter combinationsBiological substance pretreatmentsBrickCarbon credit

Self-sustaining, self-contained systems and methods for producing biofuels and for producing biofuel feedstock from algae. The system is carbon neutral or may be carbon positive, fixing more carbon than it releases to the atmosphere. In various embodiments, the system may be coupled to an existing carbon dioxide producing process to reduce or completely eliminate carbon dioxide output, making the existing system carbon neutral, and providing valuable and tradable carbon credits. The system may also comprise modular tiles comprising a biomass sandwiched between two panels and use a combination of microbes, nutrients, water, and sunlight to generate biological hydrocarbon compounds that can be used in almost any type of engine.

Owner:VAN ALSTYNE DAVID +1

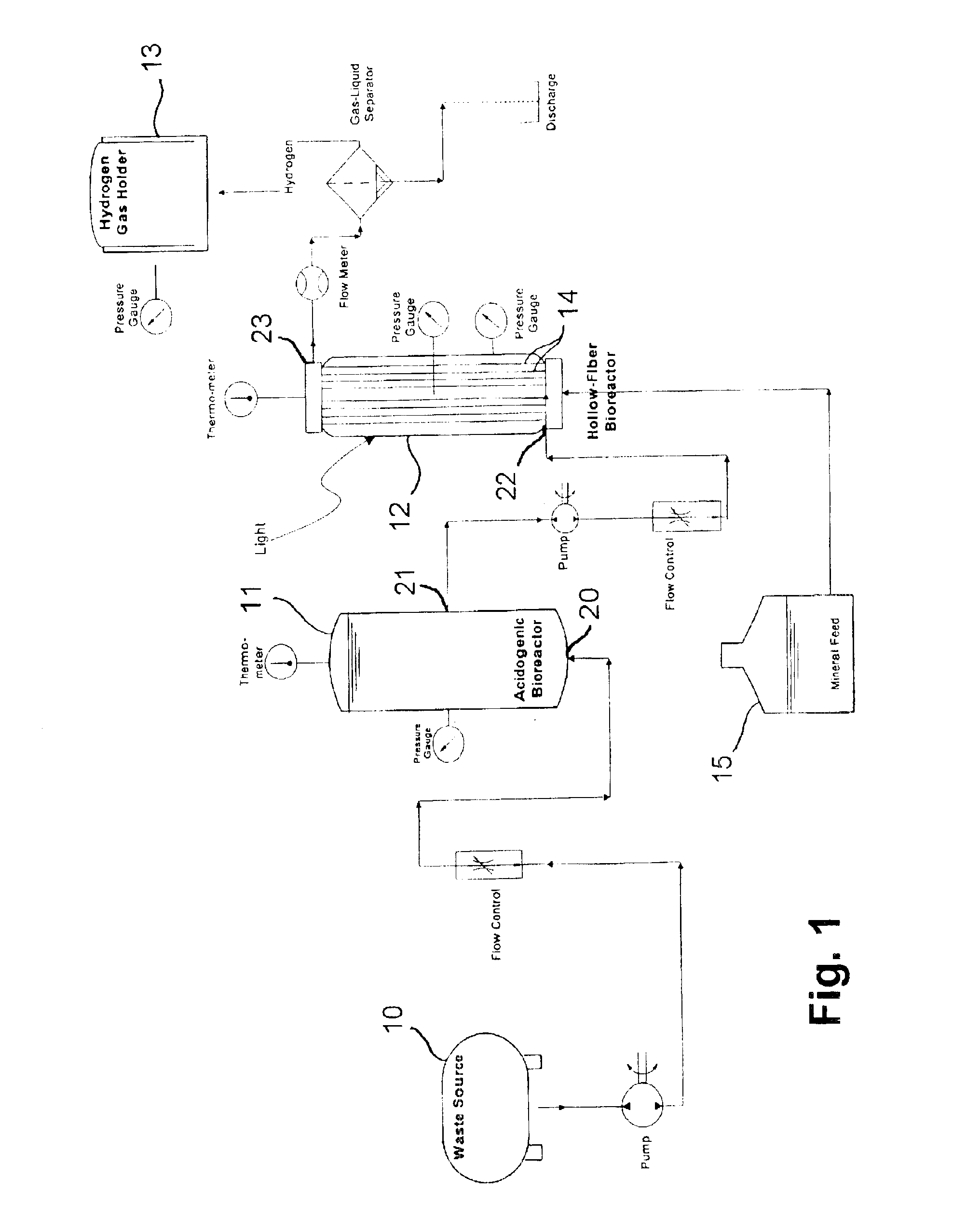

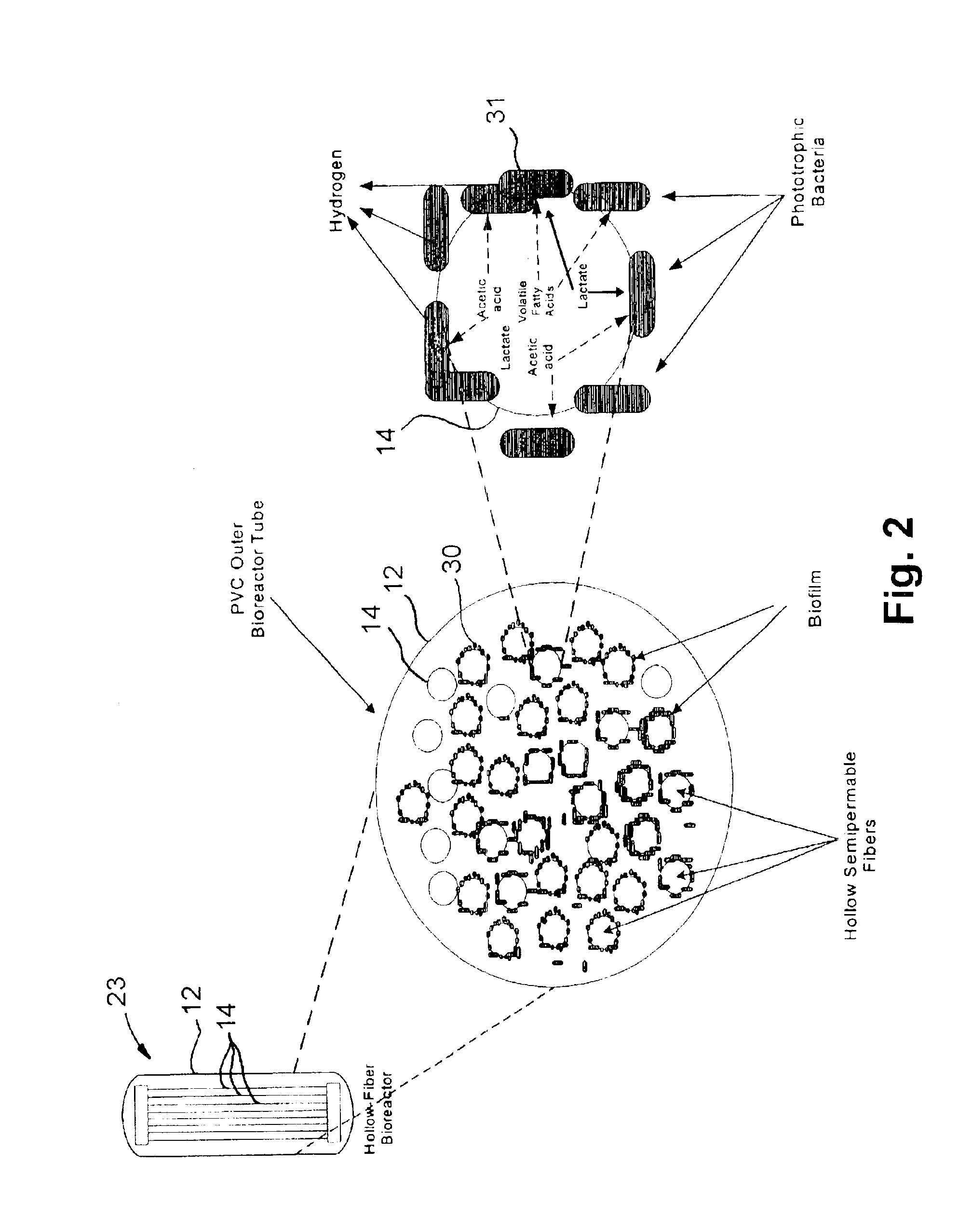

Method and apparatus for hydrogen production from organic wastes and manure

InactiveUS6887692B2Good characterBioreactor/fermenter combinationsBiological substance pretreatmentsFiberHollow fibre

Owner:GAS TECH INST

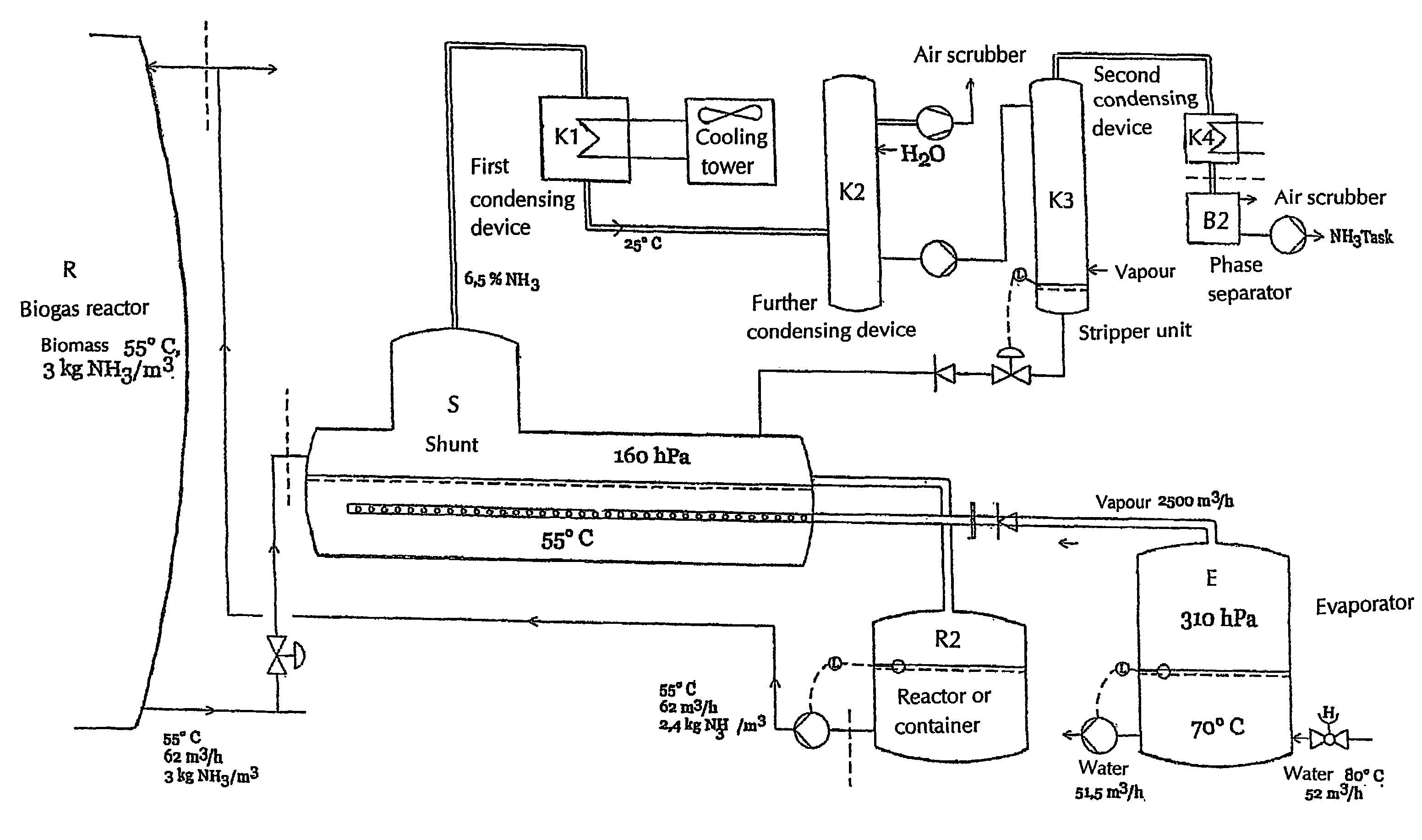

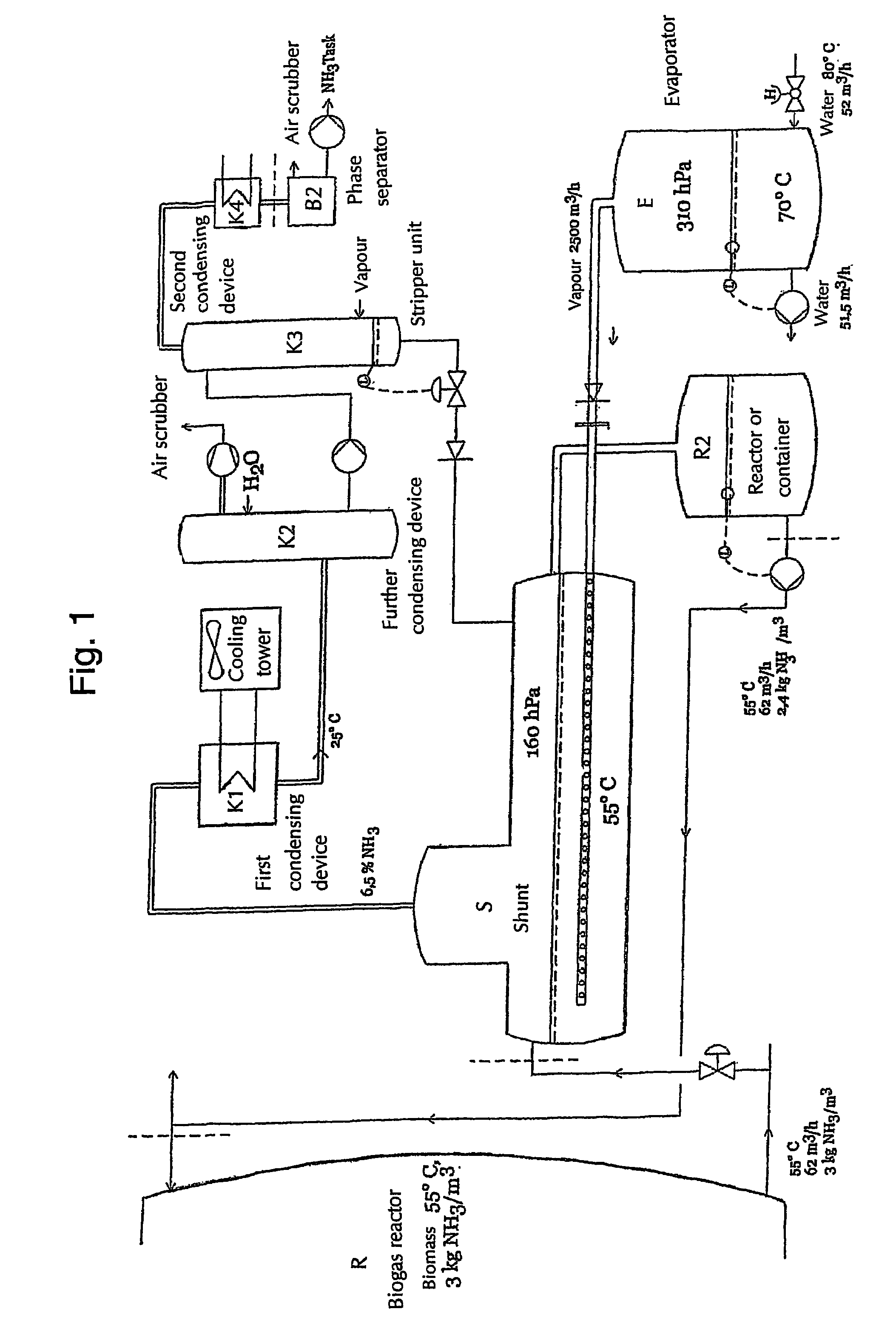

Method and device for stripping ammonia from liquids

InactiveUS7416644B2Simple and economic in operationLow-valuedBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumHigh pressure

Owner:GFE PATENT AS

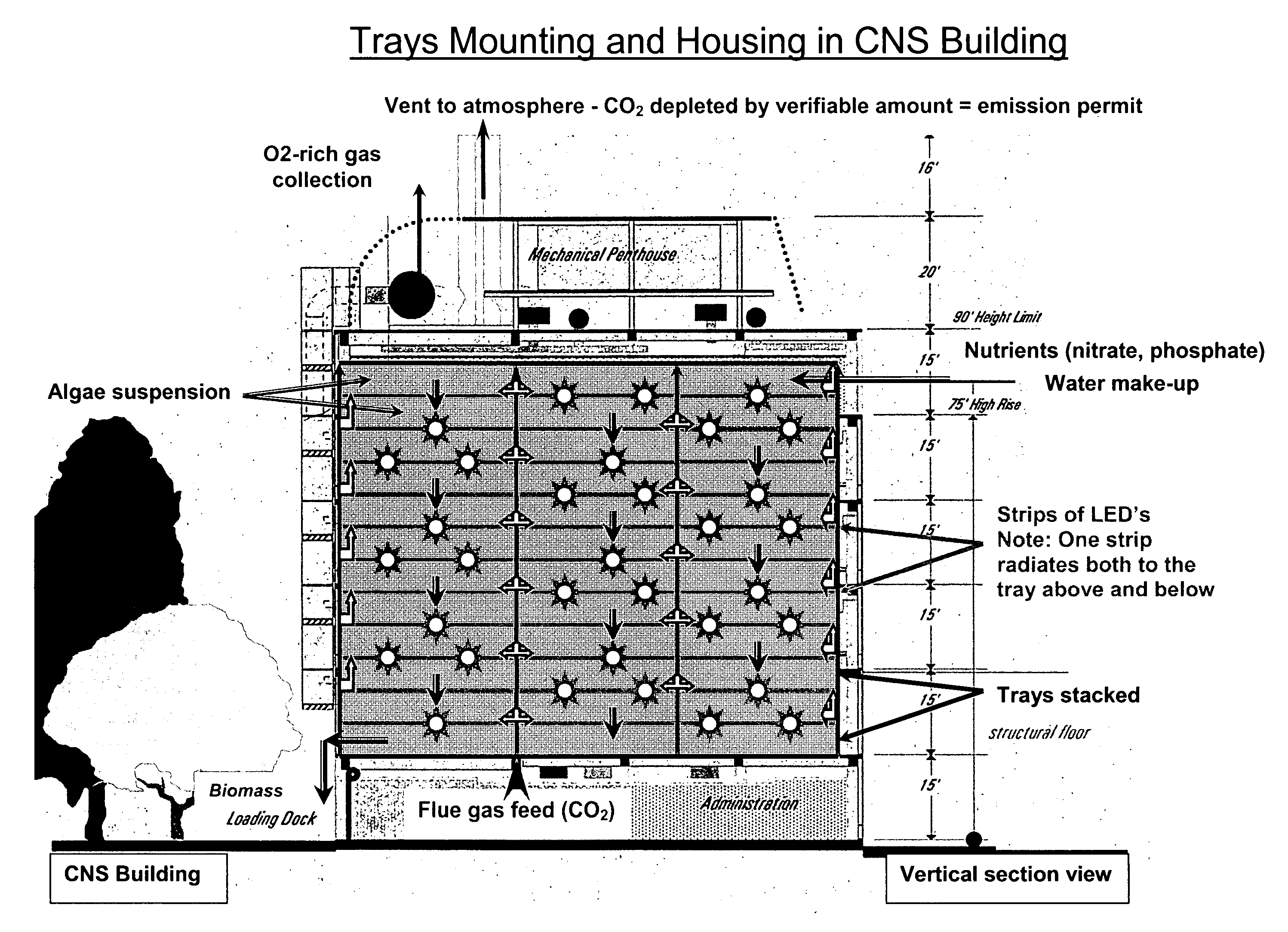

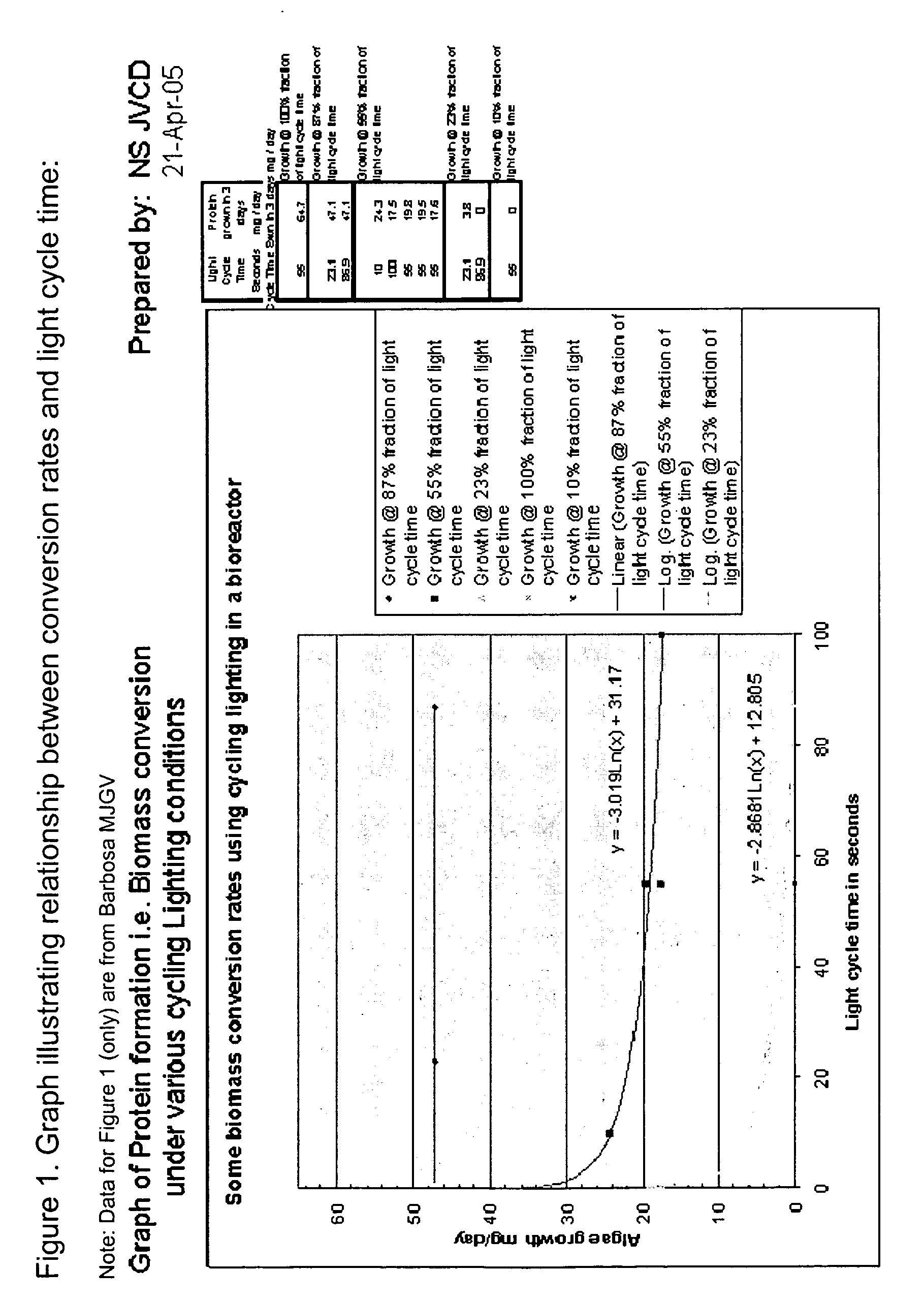

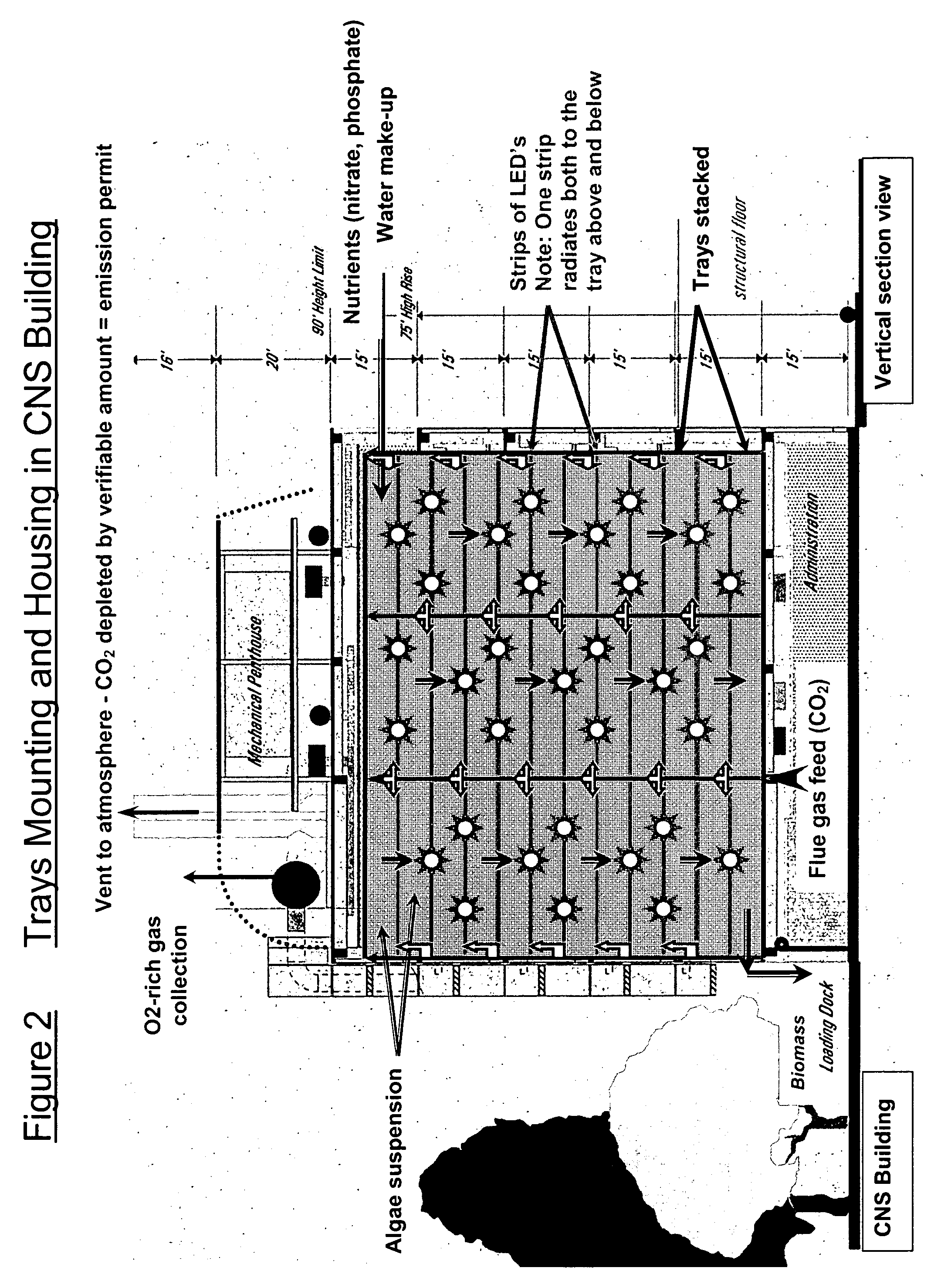

Carbon Neutralization System (CNS) for CO2 sequestering

InactiveUS20070092962A1Reduce energy costsSave energyBioreactor/fermenter combinationsBiological substance pretreatmentsWaste streamPhotobioreactor

A device and method for carbon dioxide sequestering involving the use of a photo-bioreactor with Light Emitting Diodes (LED's) for the cost-effective photo-fixation of carbon dioxide (CO2). This device and method is useful for removing undesirable carbon dioxide from waste streams.

Owner:SAUDI ARABIAN OIL CO

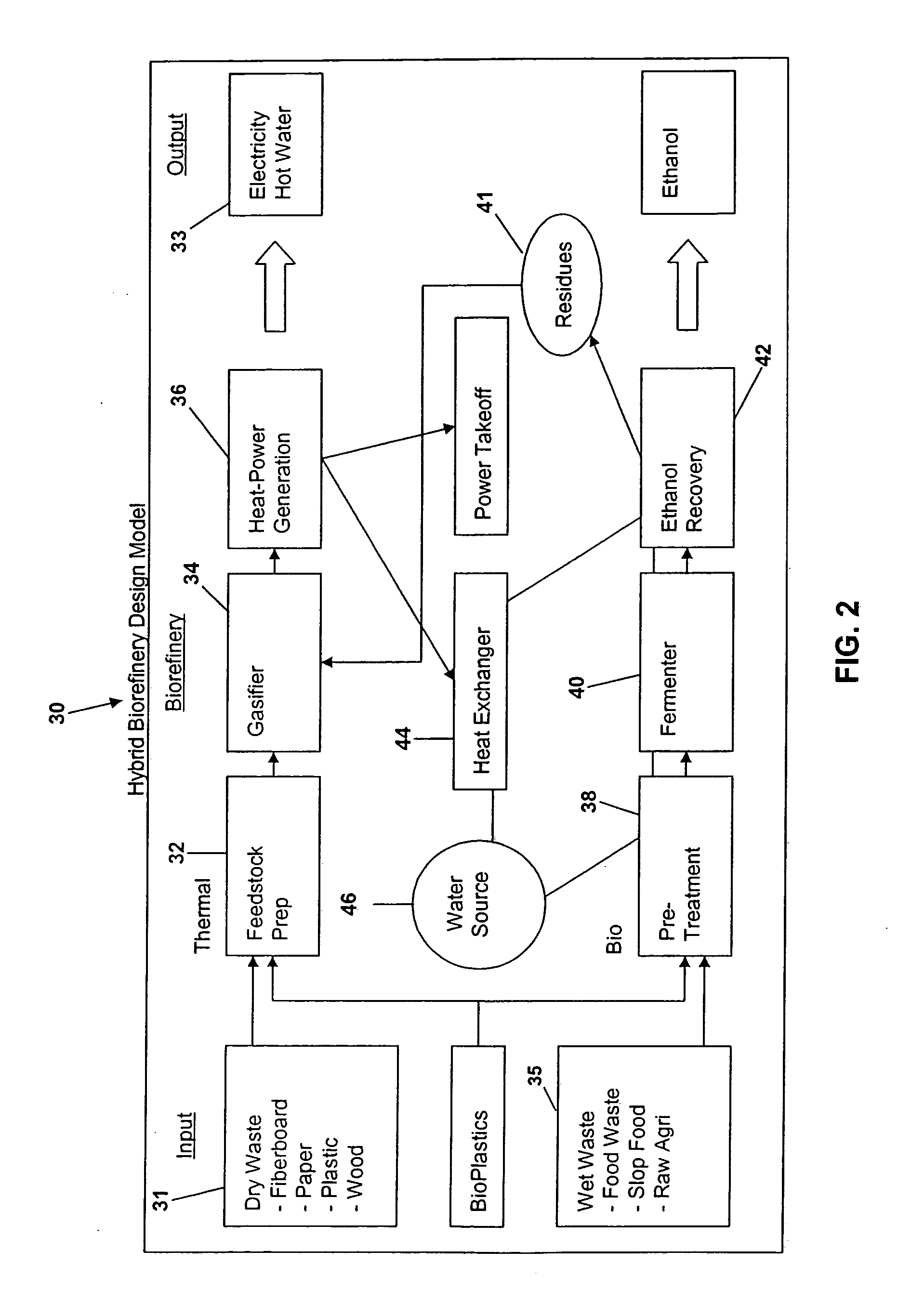

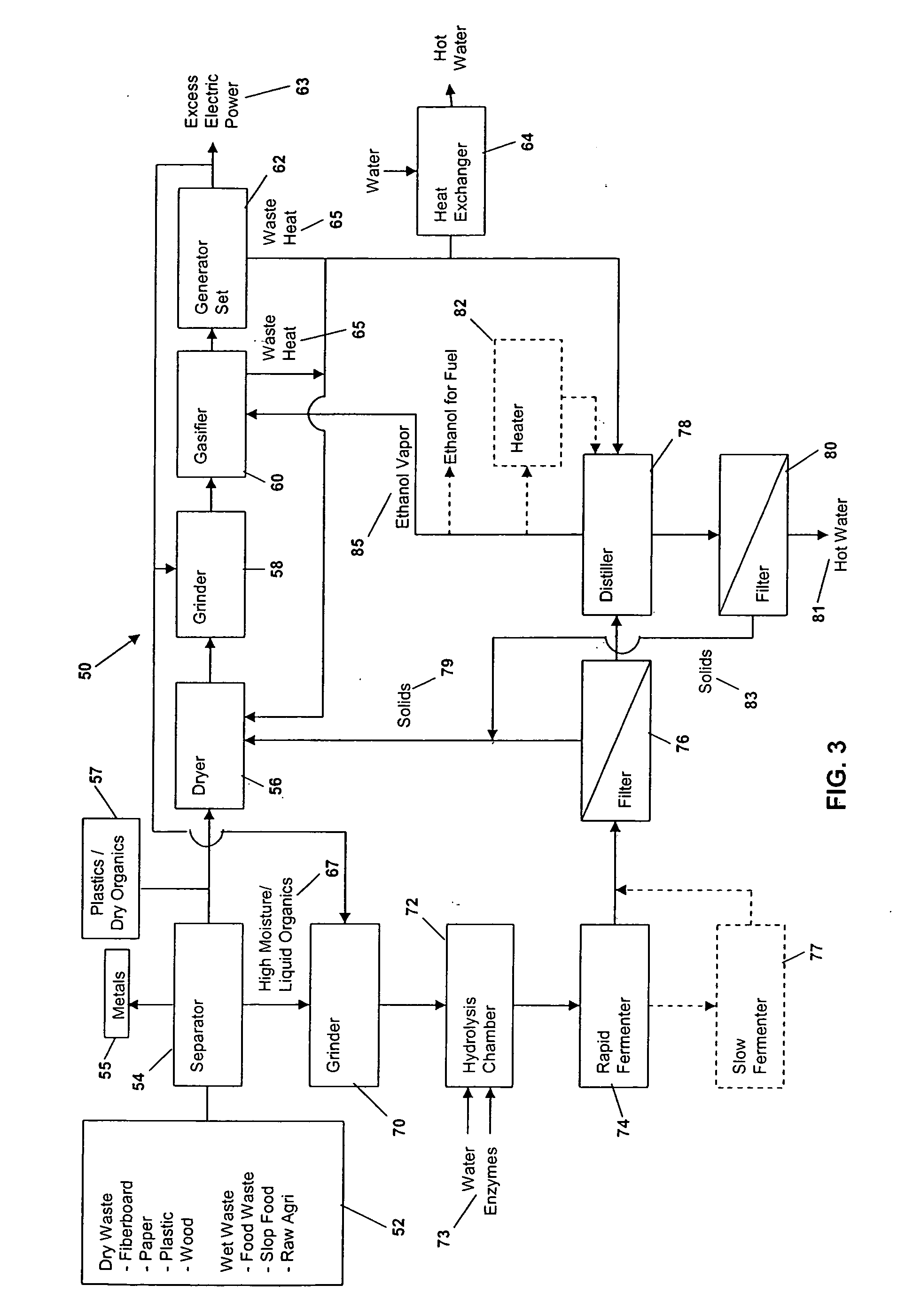

Integrated thermochemical and biocatalytic energy production system

InactiveUS20070117195A1Readily susceptibleEnergy costBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationWaste stream

A method and apparatus for treating organic wastes is provided. Organic wastes are separated into high and low moisture content organic waste streams. The low moisture content organic waste stream is subjected to a gasification process and generates a producer gas. The high moisture content organic waste is subjected to a fermentation process and produces a mixture of ethanol and water. Waste heat from the gasification process is subjected to a distillation column. Vapors recovered from the distillation column are mixed in a hydrous vapor form with the producer gas and produce fuel that can be used as an energy source.

Owner:PURDUE RES FOUND INC

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com