Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Maintain depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

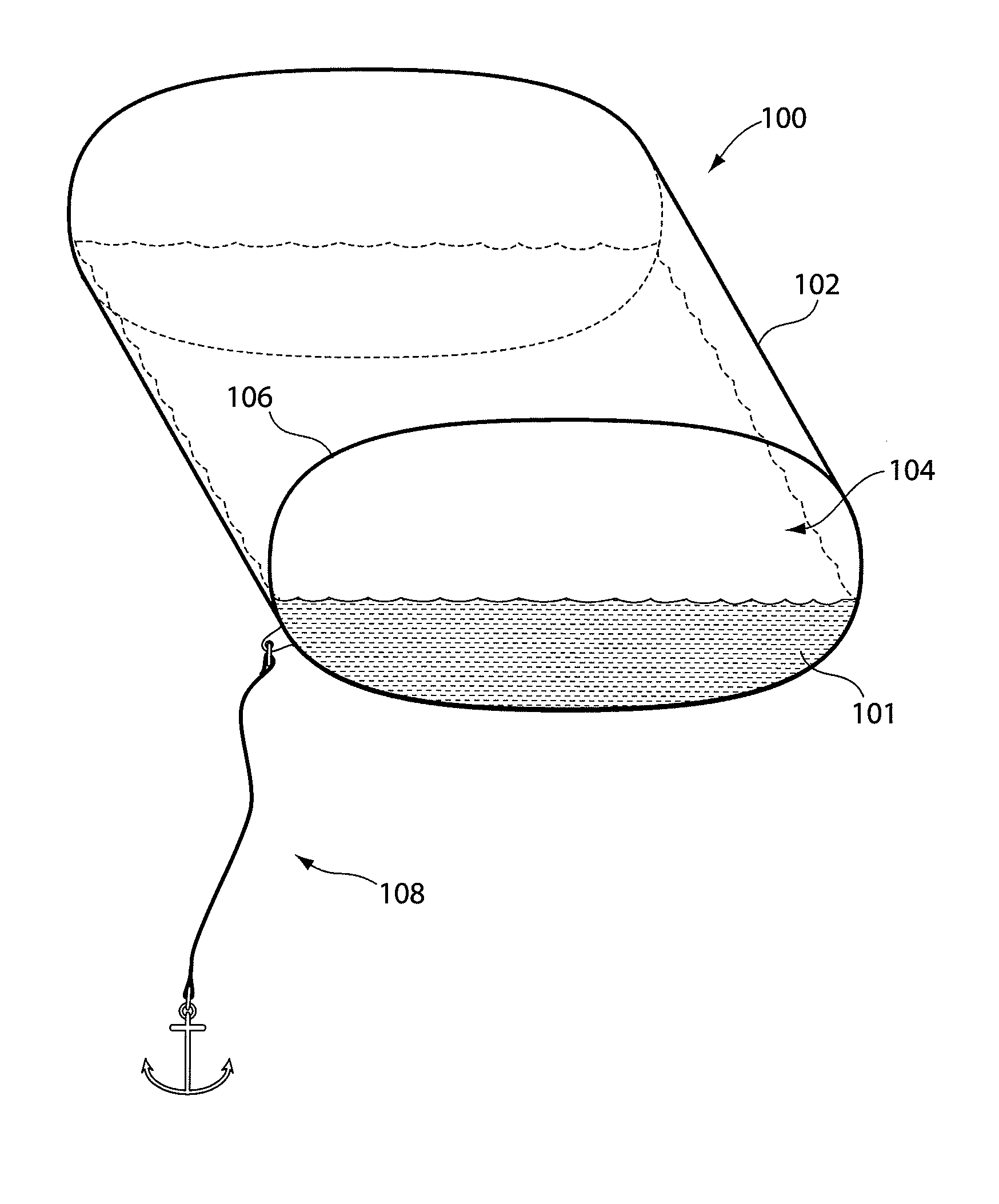

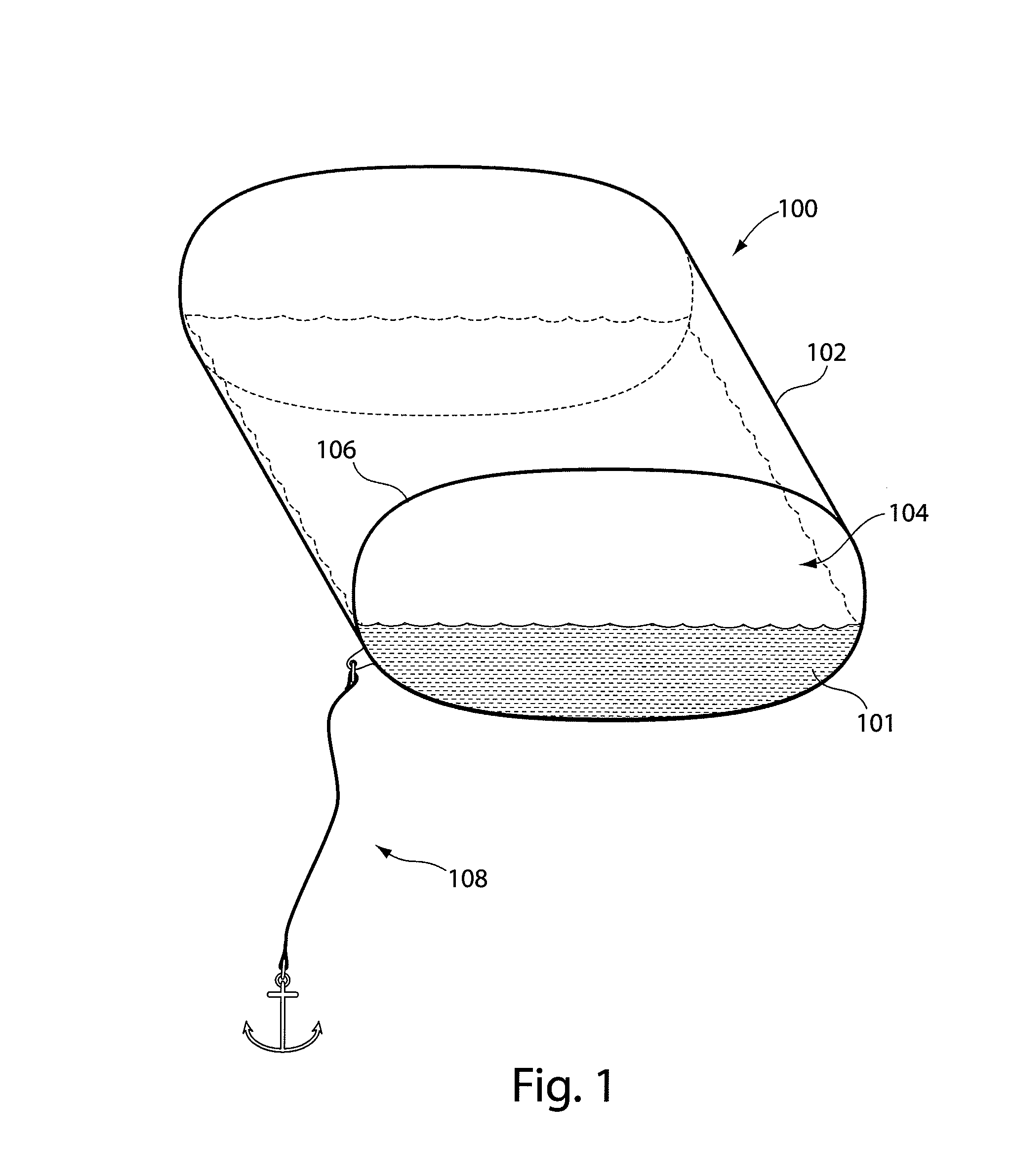

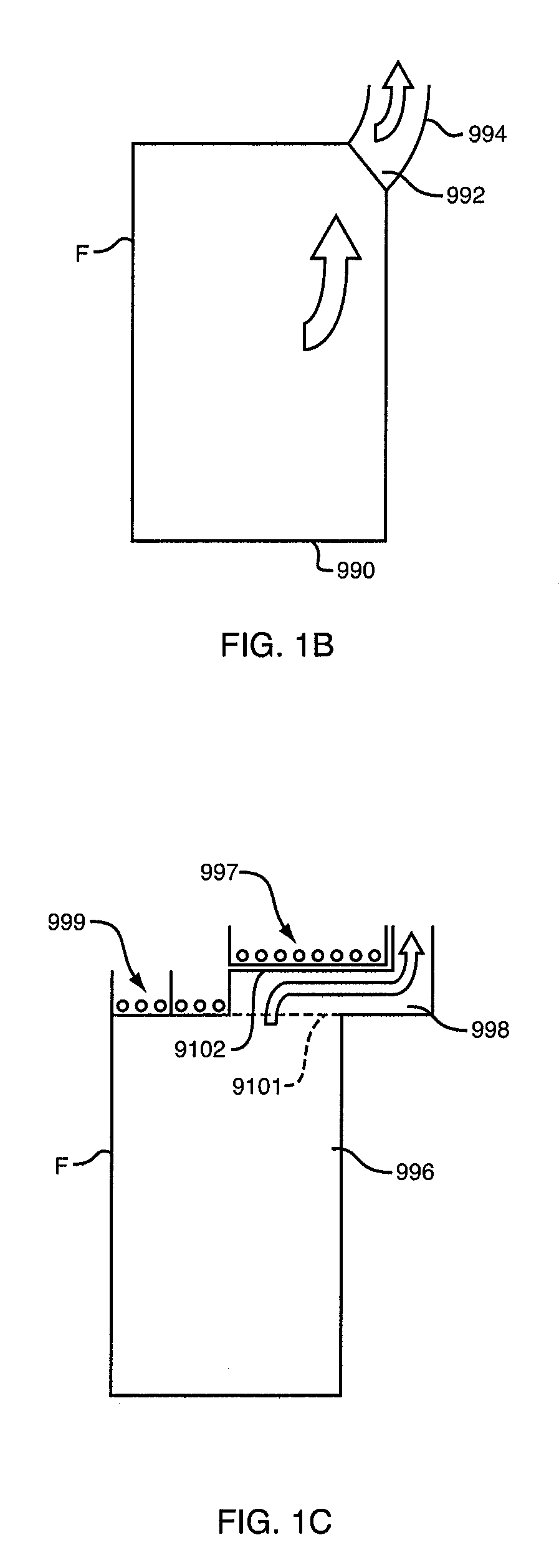

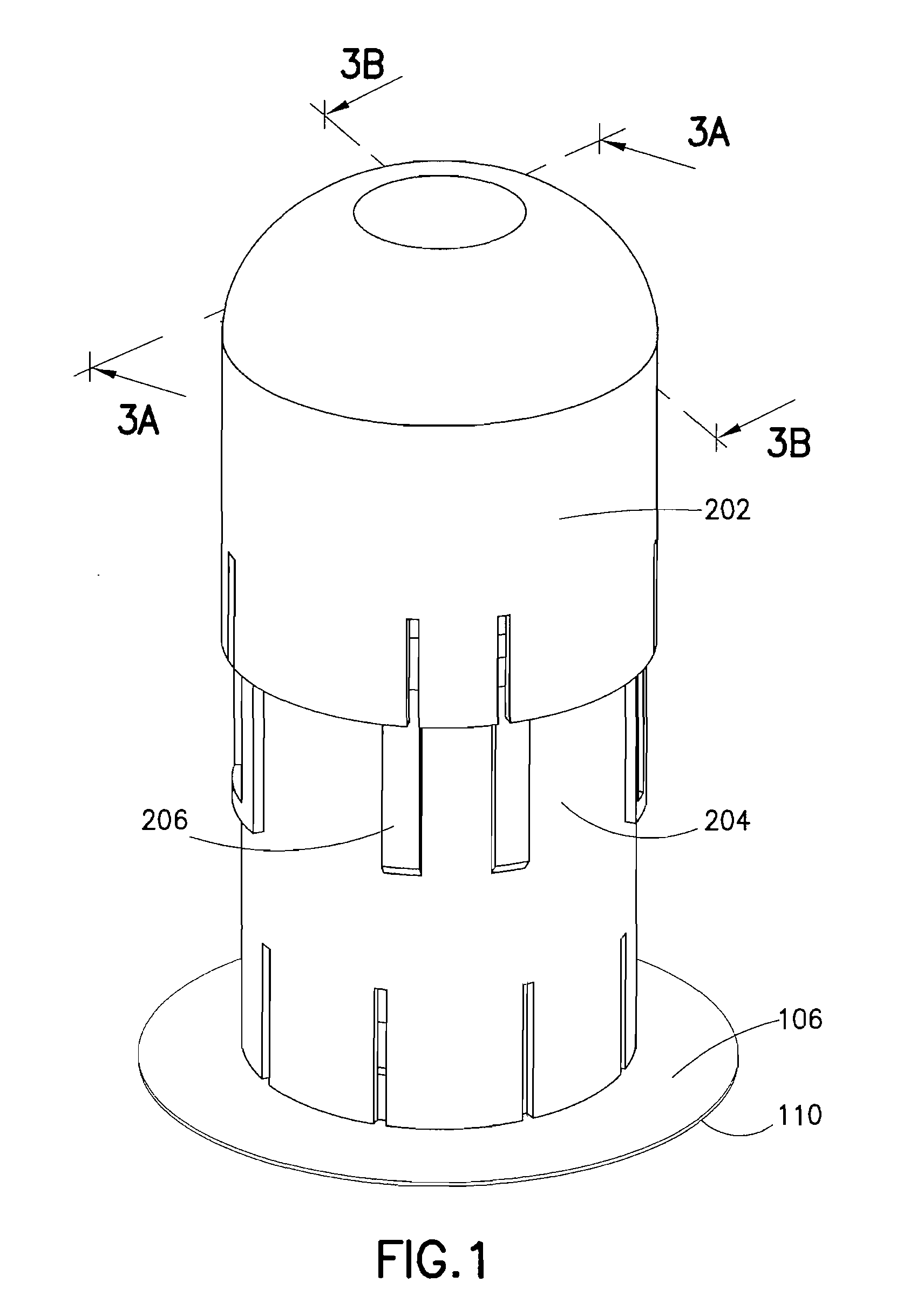

Photobioreactor systems positioned on bodies of water

InactiveUS20090130706A1Maintain depthConstant thicknessBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

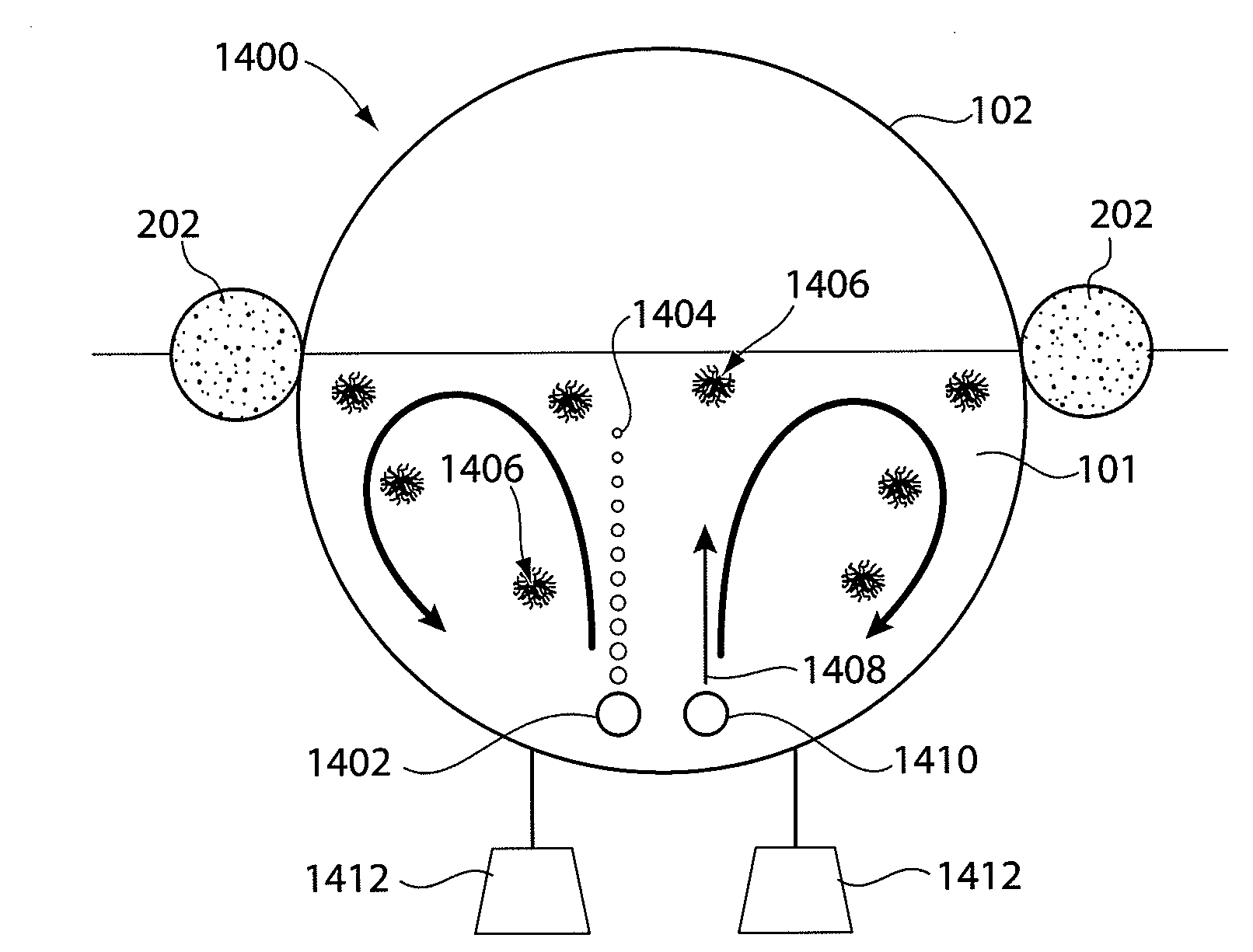

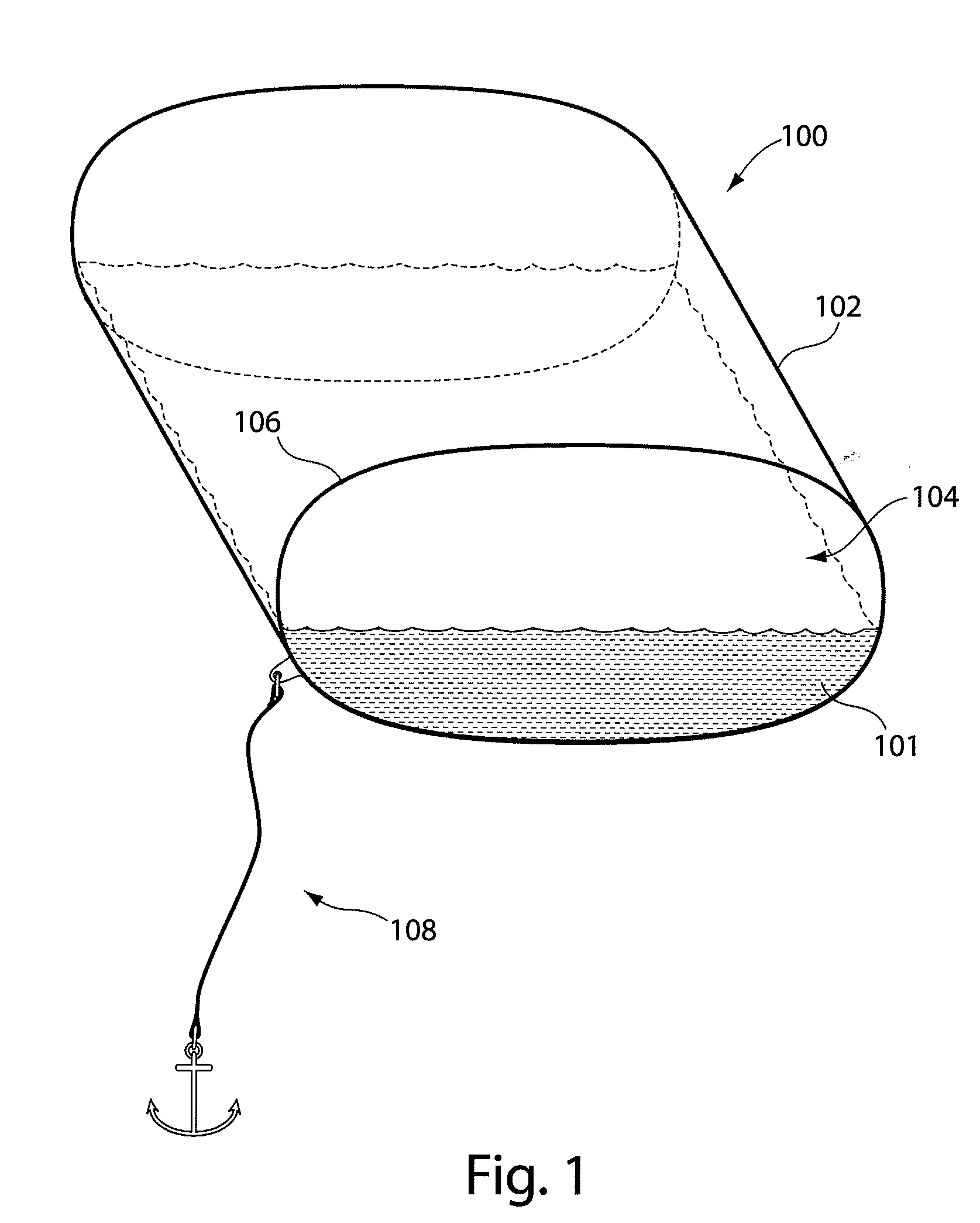

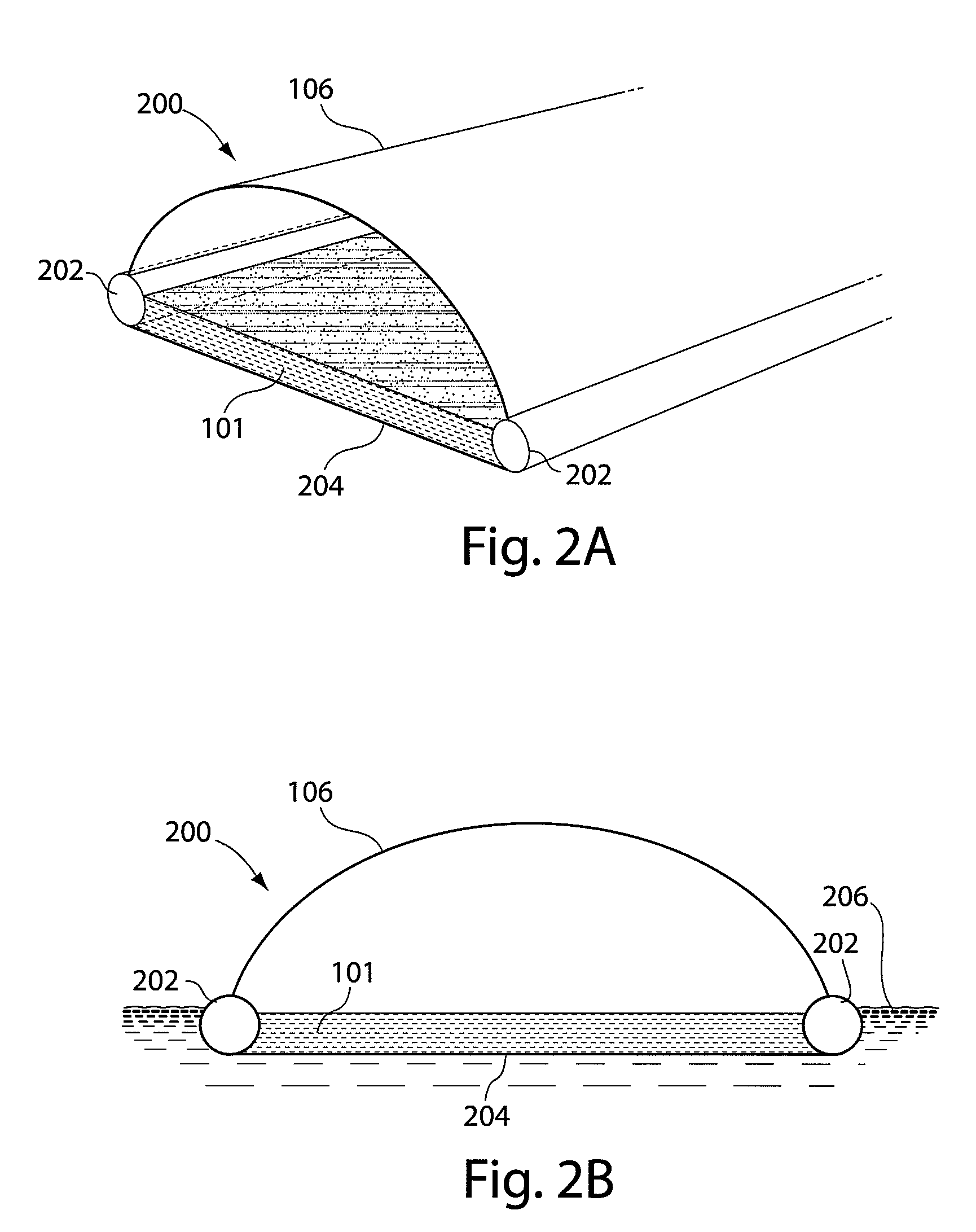

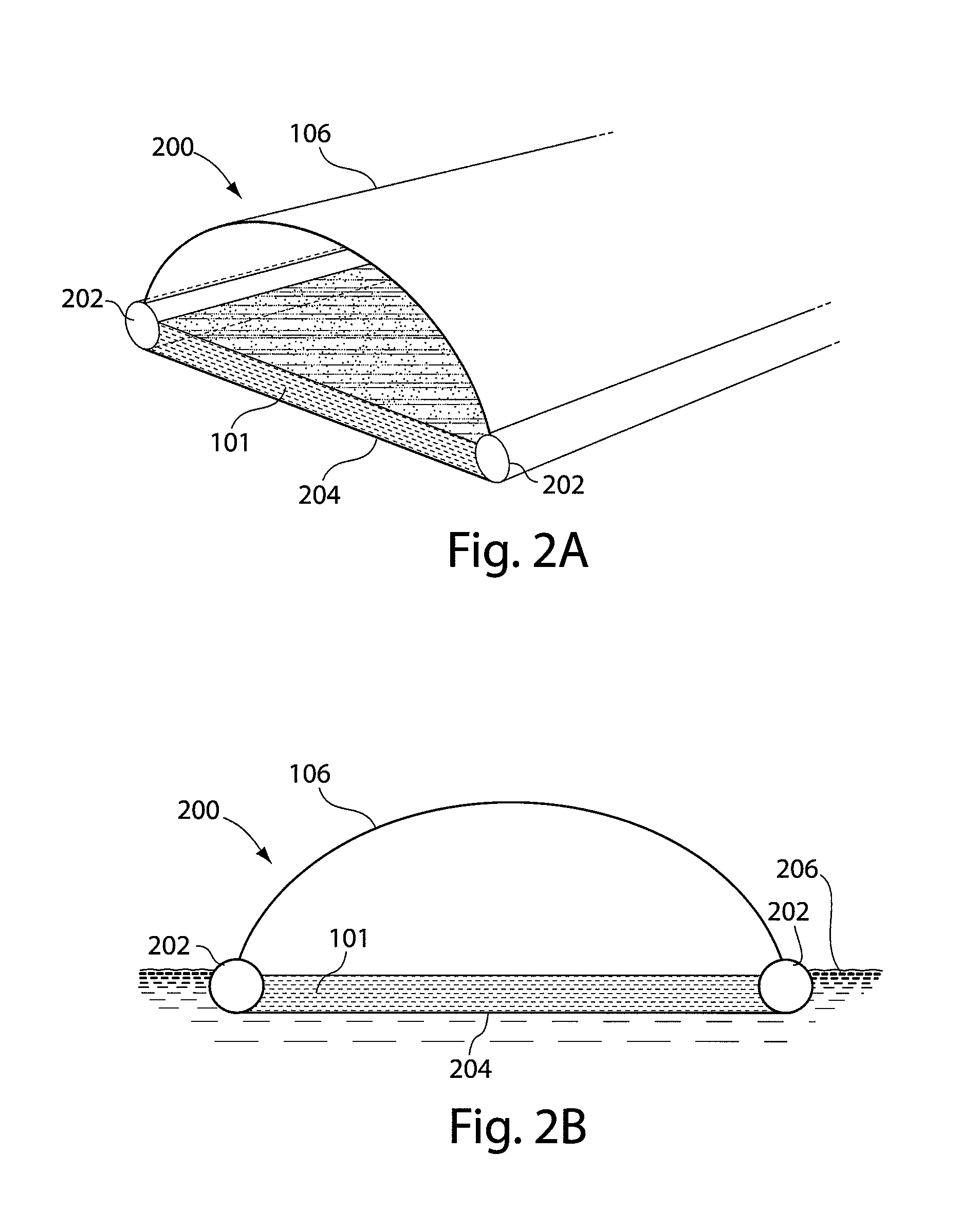

Certain embodiments and aspects of the present invention relate to a photobioreactor including photobioreactor units through which a liquid medium stream and a gas stream flow. The photobioreactor units are floated on a body of water such as a pond or a lake. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, the photobioreactor units are formed of flexible, deformable material and are configured to provide a substantially constant thickness of liquid medium. In certain embodiments, a barrier between the photobioreactor unit and the body of water upon which the unit is floated facilitates thermal communication between the liquid medium and the body of water.

Owner:THE TRON GRP

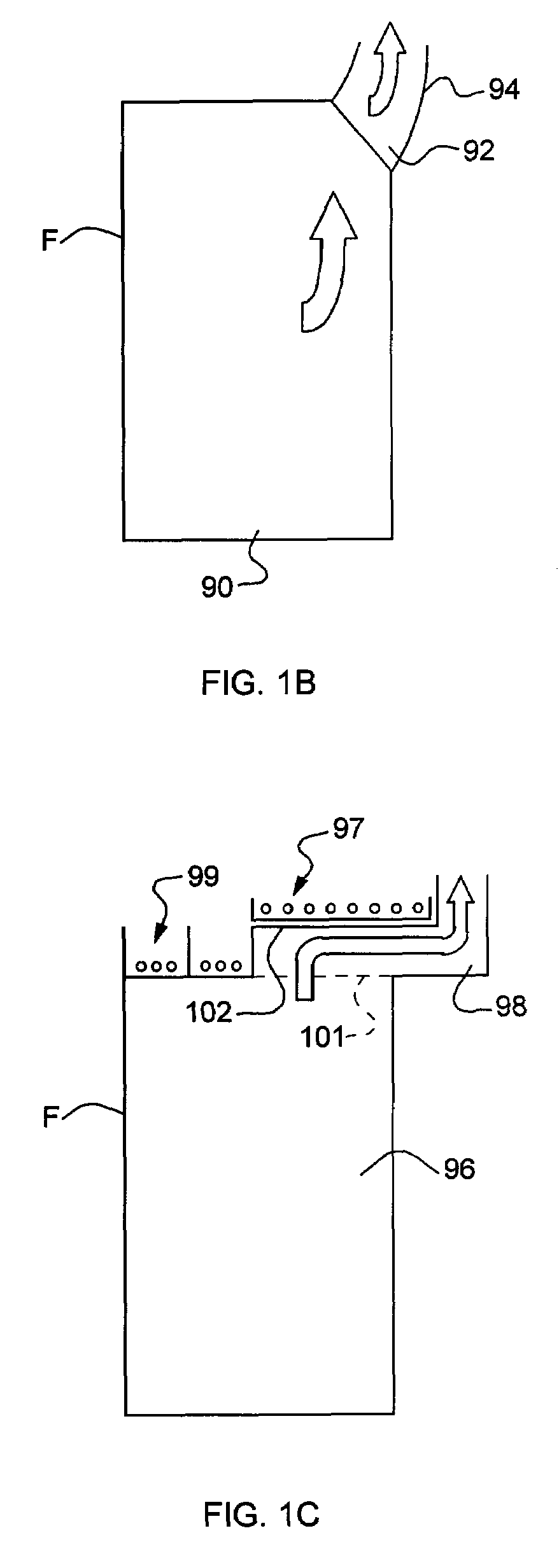

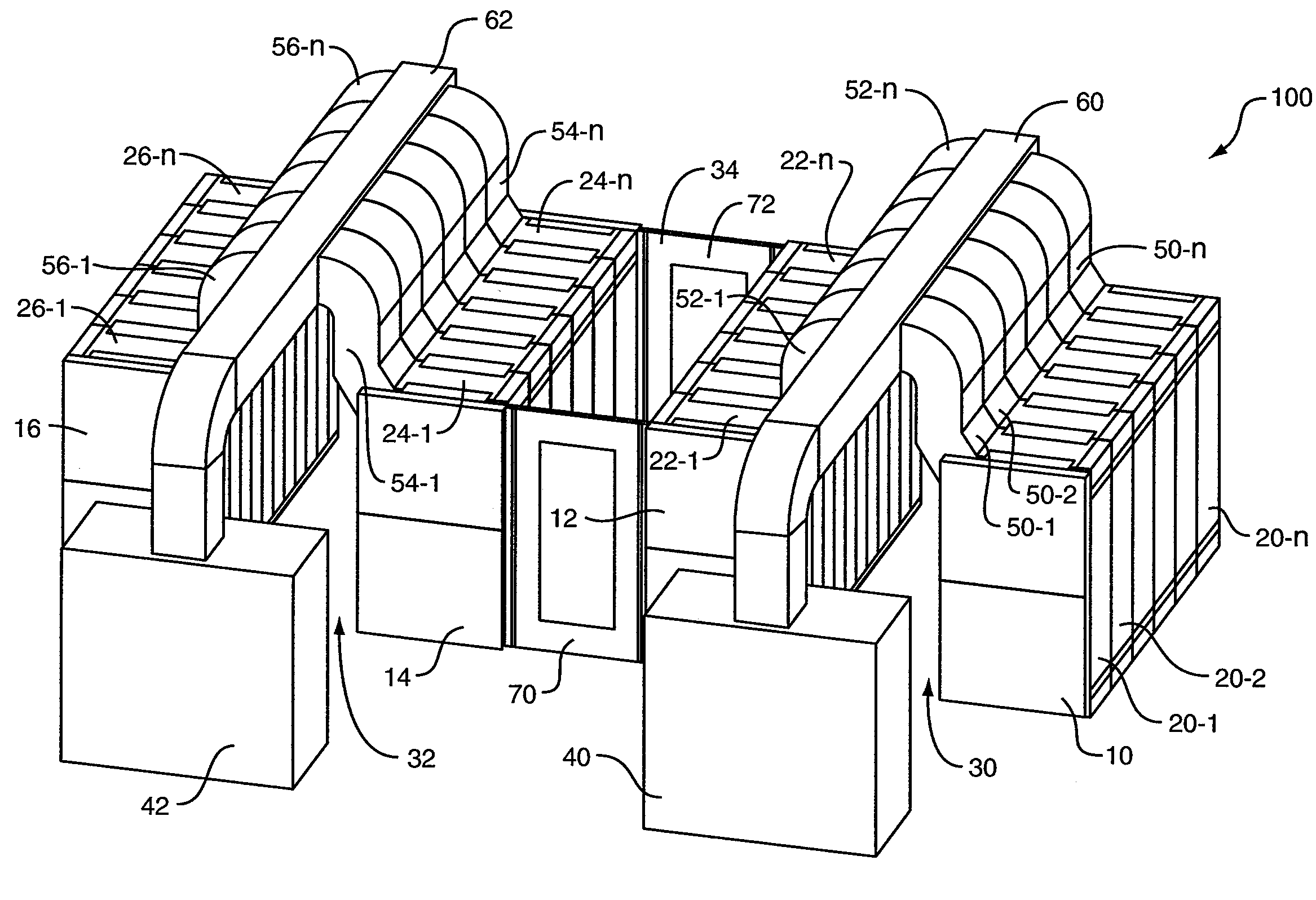

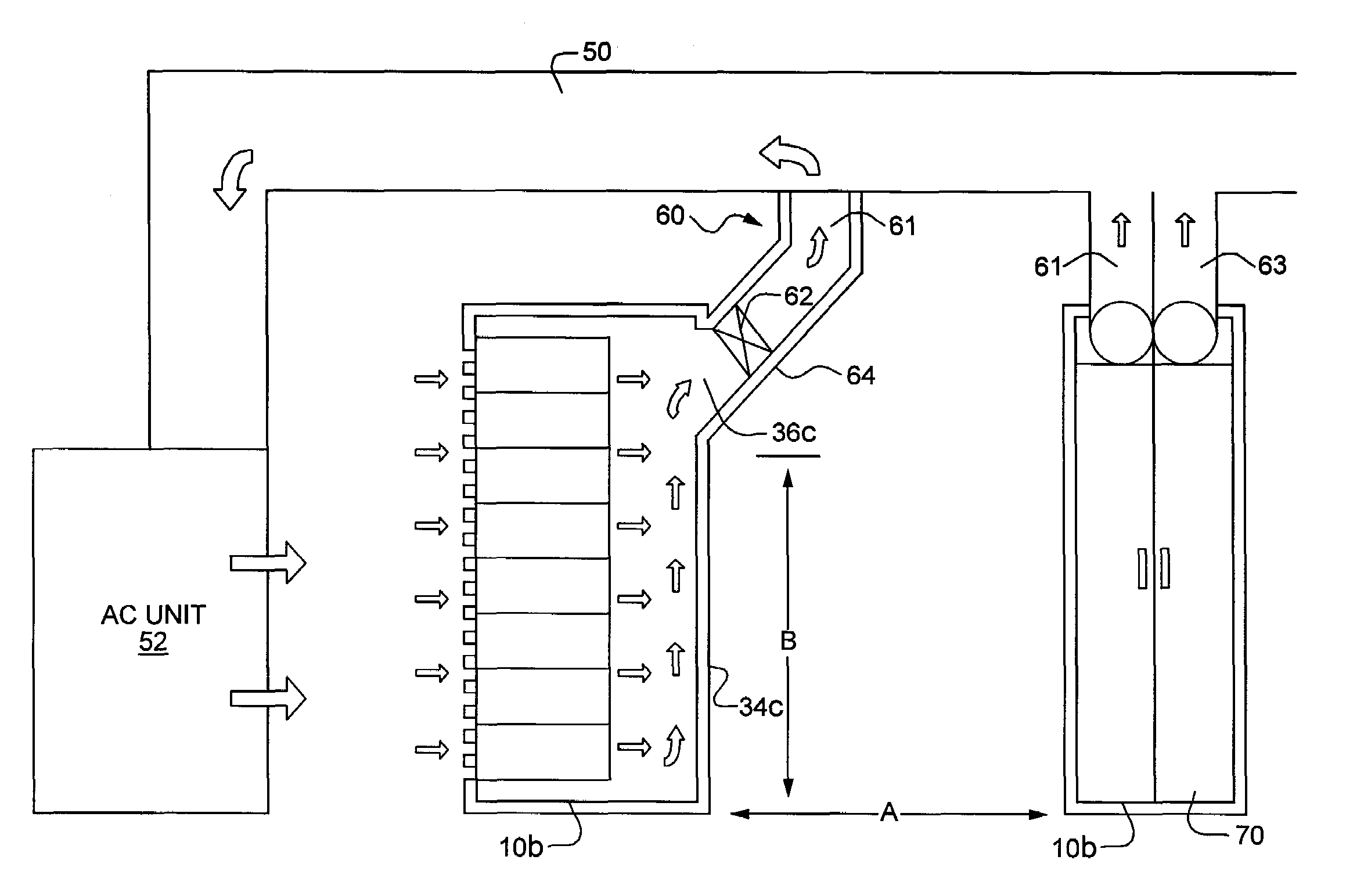

Systems and Methods for Closed Loop Heat Containment with Cold Aisle Isolation for Data Center Cooling

ActiveUS20100216388A1Maximize capacityMaintain depthCasings/cabinets/drawers detailsIndirect heat exchangersCold airData center

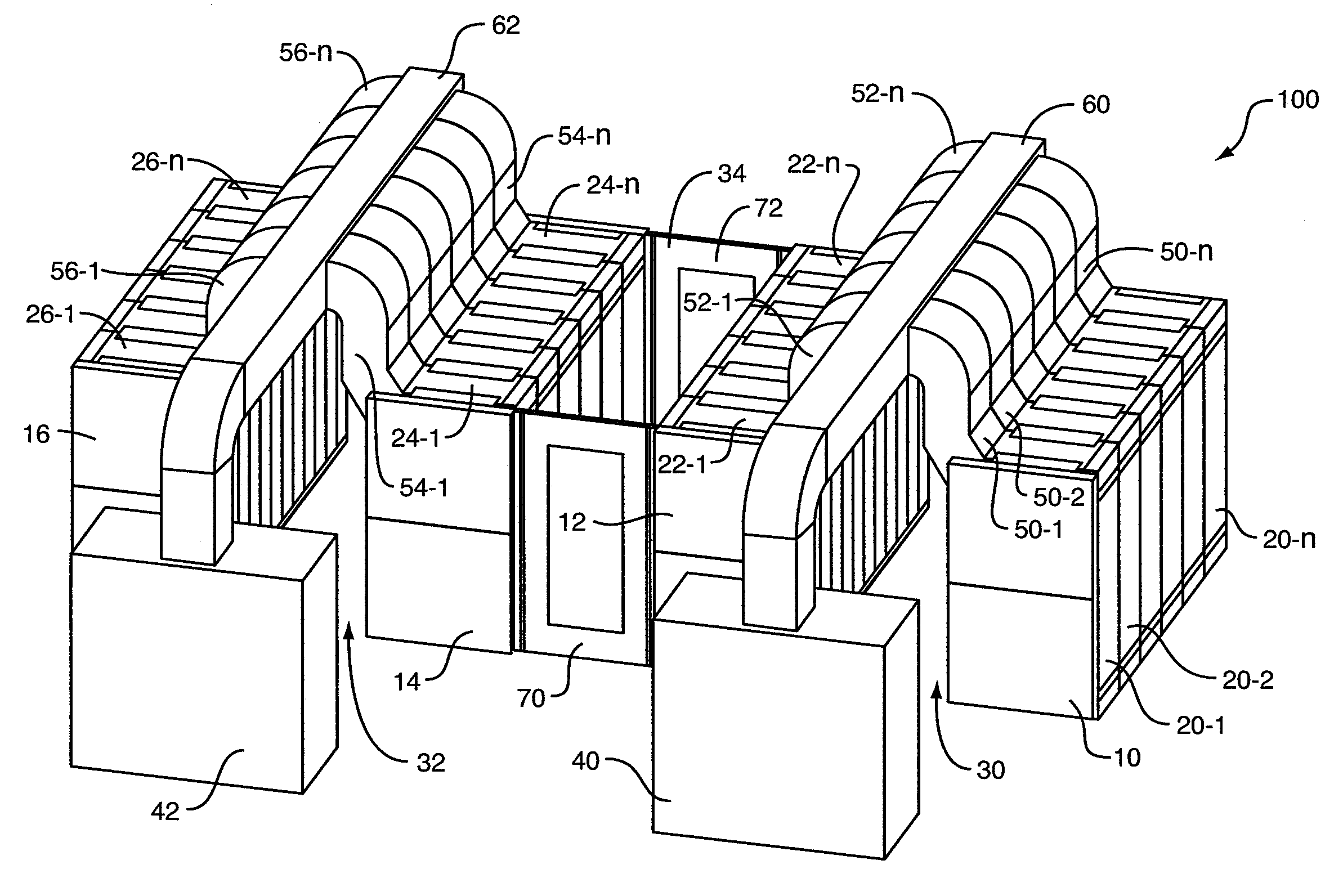

The invention combines systems and methods for heat containment and cold air isolation for managing airflow and temperature in data centers. The data center contains at least two rows of cabinets containing heat-generating equipment and arranged to form a cold aisle and a hot aisle. The data center system includes panels or doors at both ends of the cold aisle and an optional cover over the cold aisle to inhibit cooled air supplied by an air conditioning system from exiting the cold aisle and inhibit air warmed by the heat-generating components from entering the cold aisle,. A chimney coupled to the top, rear, or top and rear of the cabinets is configured to exhaust the warmed air into a region above the rows of cabinets. The chimneys may be ducted to a plenum or suspended ceiling or to the intake of the air conditioning system. Baffles and / or fans may be included in the chimneys, ducts, and / or plenums to control the air pressure. The invention may also include one or more data center air conditioning units, and each air conditioning unit may be configured to service one or more rows of cabinets. Alternatively, or in addition, cool air may be supplied by the building's air conditioning system.

Owner:EATON INTELLIGENT POWER LTD

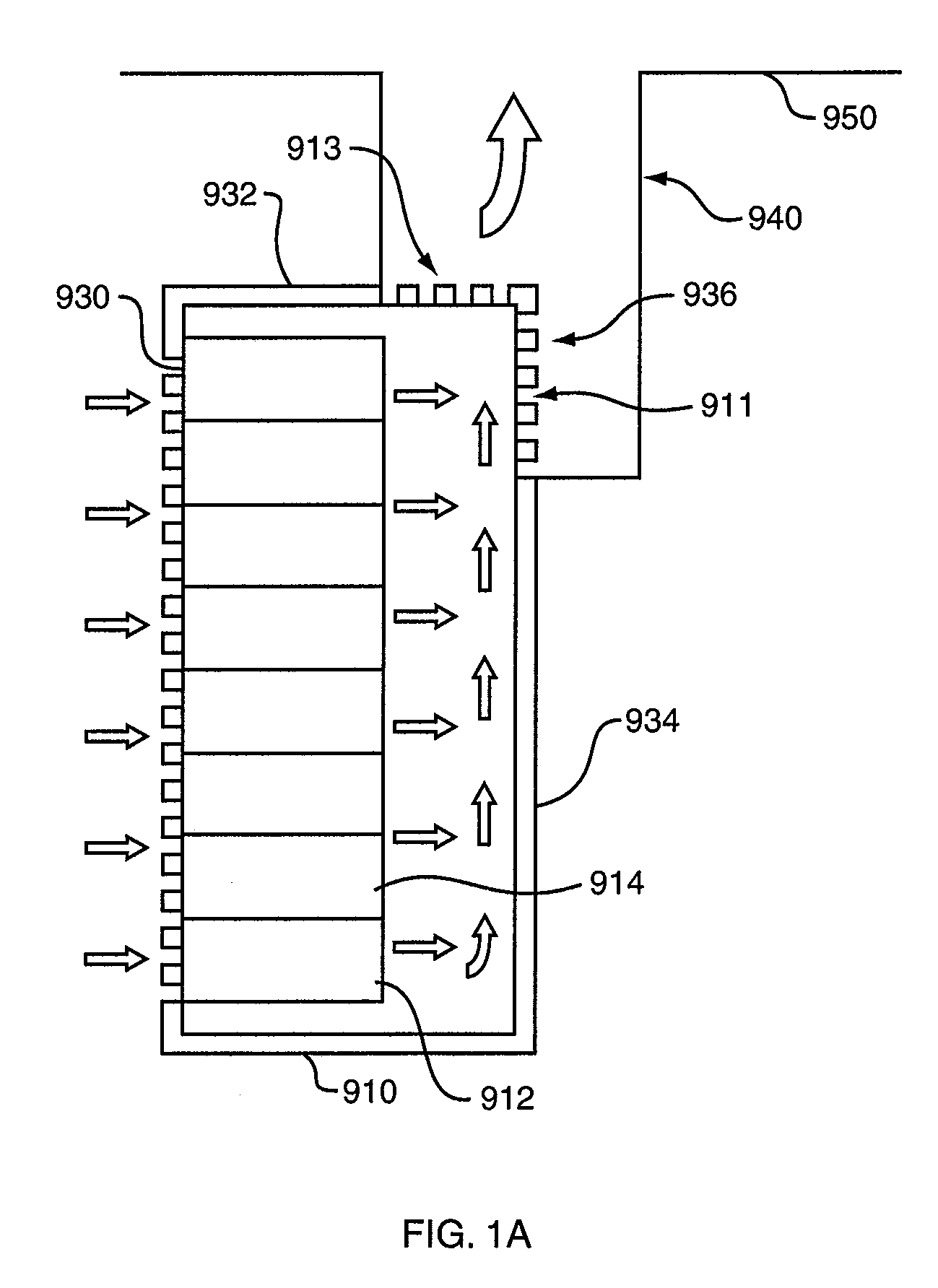

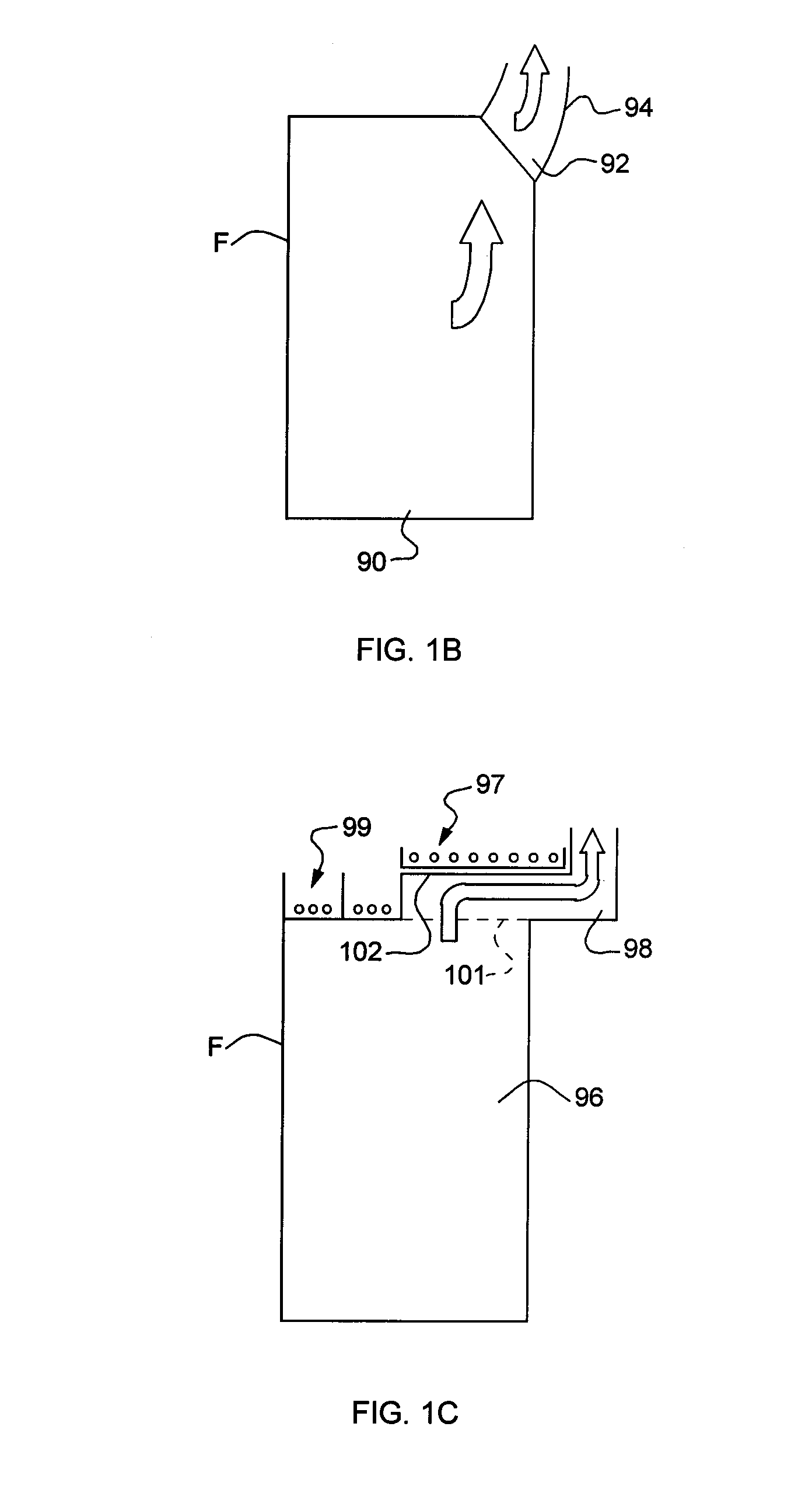

Assembly for extracting heat from a housing for electronic equipment

ActiveUS7604535B2Maximize capacityMaintain depthDomestic cooling apparatusLighting and heating apparatusElectronElectronic equipment

An assembly for extracting heat from a housing for electronic equipment, the housing having a front, a back, two sides and a top. The assembly is defined by a back for the housing that defines an open area proximate the top, and an air passageway in fluid communication with the open area in the back, to conduct heated air exiting the housing through the open area away from the housing.

Owner:EATON INTELLIGENT POWER LTD

Assembly for Extracting Heat from a Housing for Electronic Equipment

InactiveUS20090239460A1Maximize capacityMaintain depthElectrical apparatus contructional detailsElectrical apparatus casings/cabinets/drawersMechanical engineeringElectronic equipment

An assembly for extracting heat from a housing for electronic equipment with an interior that is adapted to hold heat-generating electronic equipment, the housing having an essentially solid top portion and an essentially solid back portion. The assembly includes a first opening in the top portion of the housing that leads to the housing interior, the first opening located at the back of the top portion, proximate the back portion of the housing, a second opening in the back portion of the housing that leads to the housing interior, the second opening located at the top of the back portion, proximate the top portion of the housing, wherein the first opening is contiguous with the second opening, and a chimney external to the housing and coupled to the housing such that the chimney encompasses and is in fluid communication with the first and second openings, the chimney defining an inlet for taking in air leaving the housing through the first and second openings and an outlet for conducting the air out of the chimney.

Owner:WRIGHT LINE

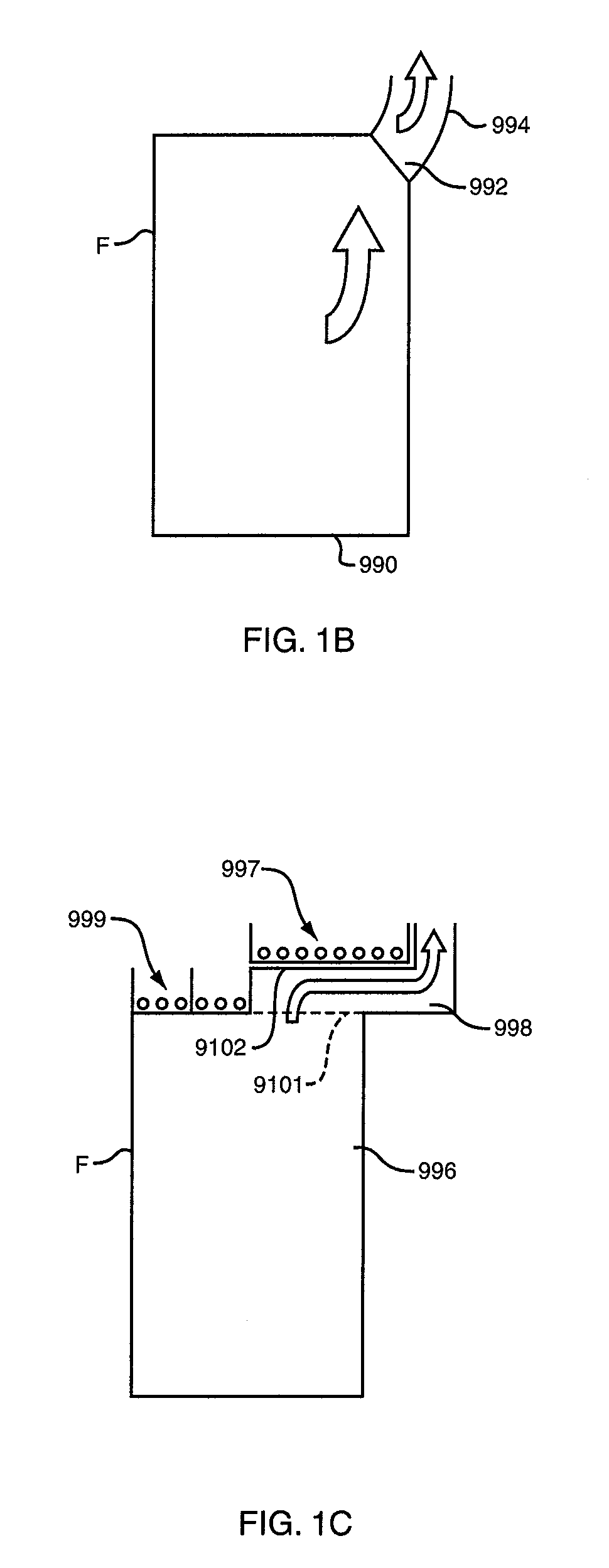

Assembly For Providing A Downflow Return Air Supply

InactiveUS20100248609A1Maximize capacityMaintain depthFluid heatersHot-air central heatingEngineeringAir conditioning

An assembly for supplying heated air to a housing with an interior that is adapted to hold air conditioning equipment. The housing has a top portion and a back portion, where the top portion defines a first opening that leads to the interior of the housing, and where the first opening is proximate the back of the top portion of the housing. The back portion of the housing defines a second opening that leads to the housing interior, where the second opening is proximate the top of the back portion. The assembly includes a flue external to the housing and adapted to be coupled to the housing such that the flue encompasses and is in fluid communication with the first and second openings, the flue defining an inlet for conducting heated air into the flue and an outlet for conducting heated air out of the flue and into the housing through the first and second openings. The air cooled by the air conditioning equipment in the housing is used to cool electronic equipment.

Owner:WRIGHT LINE

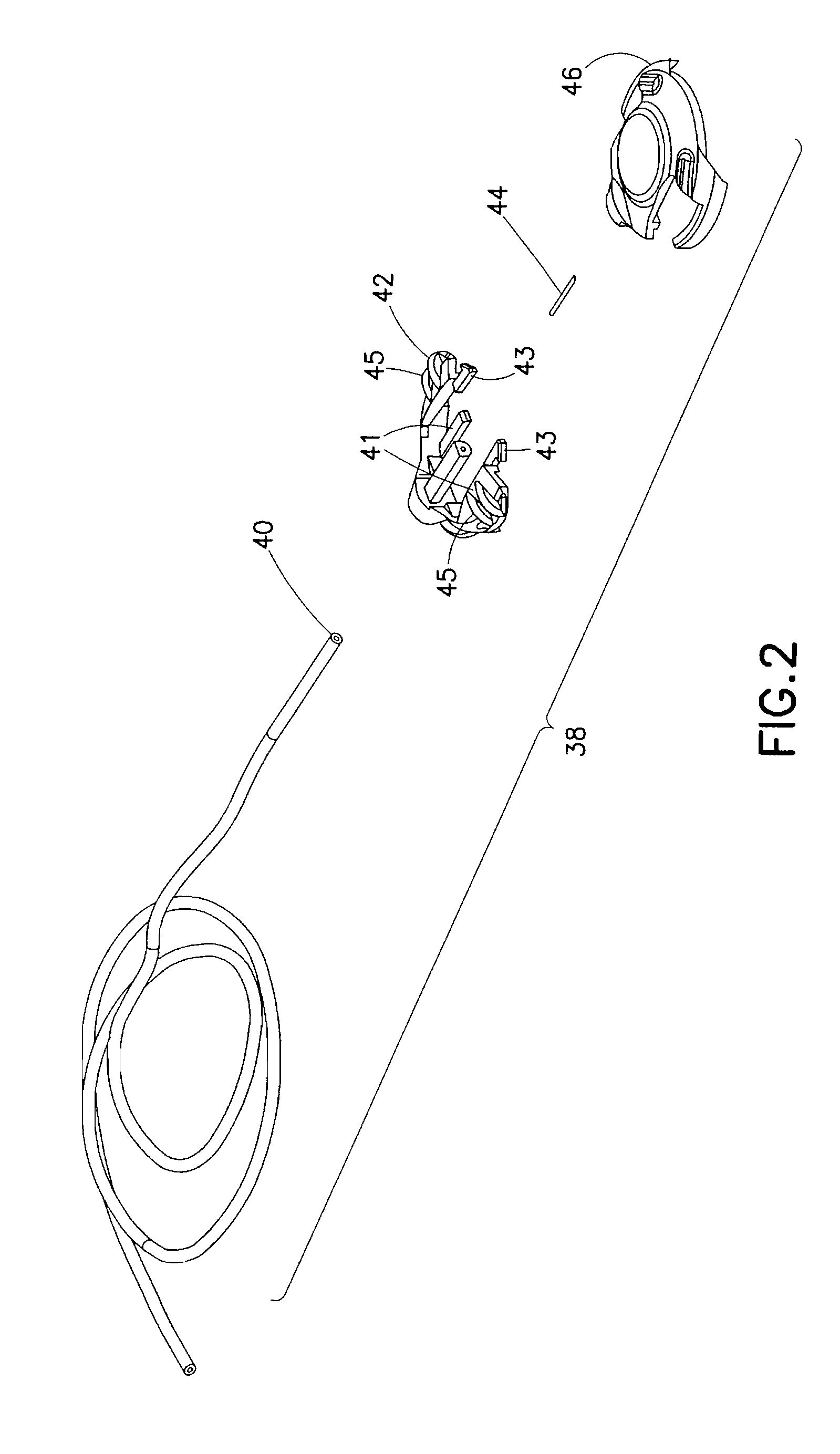

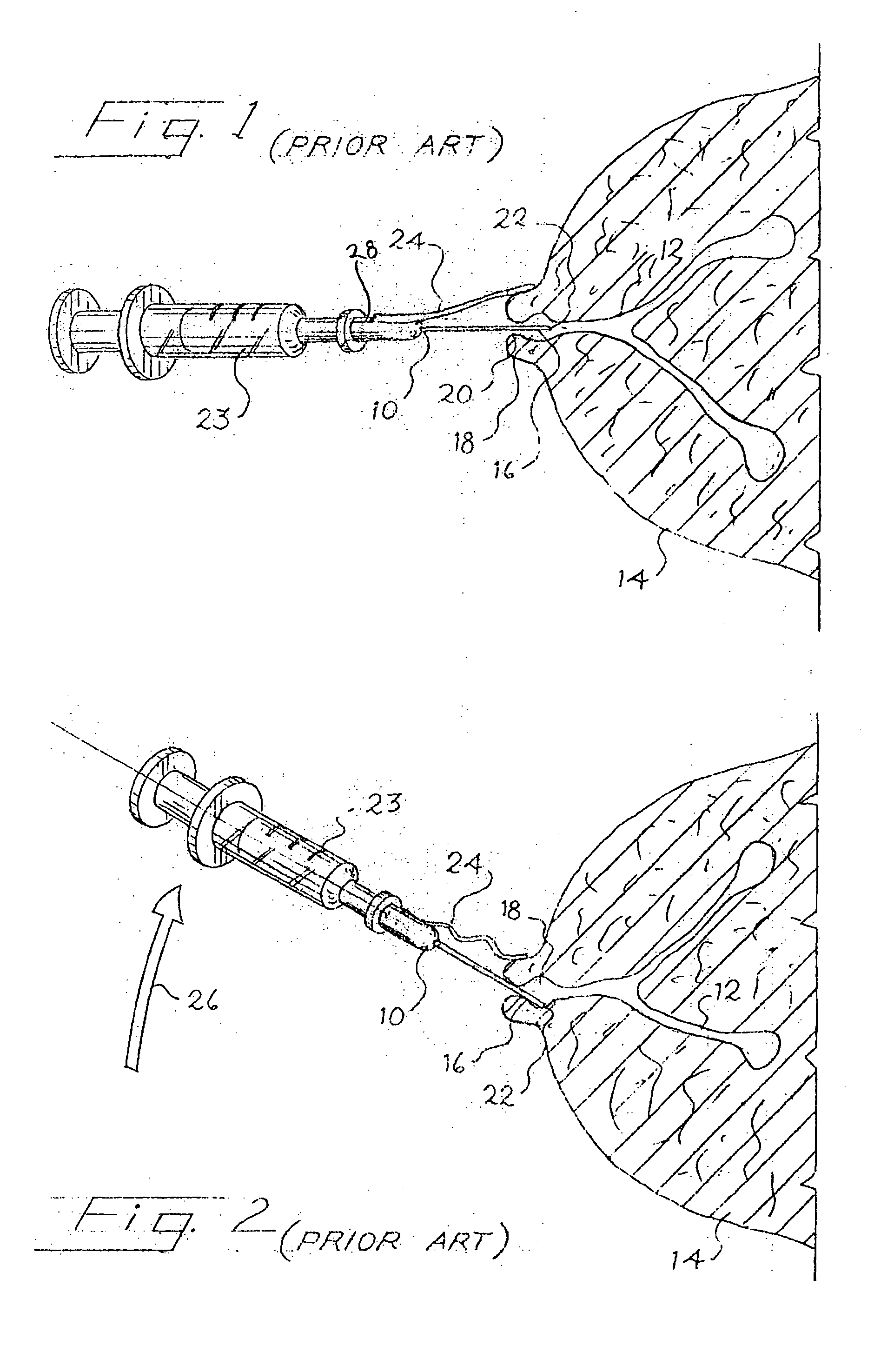

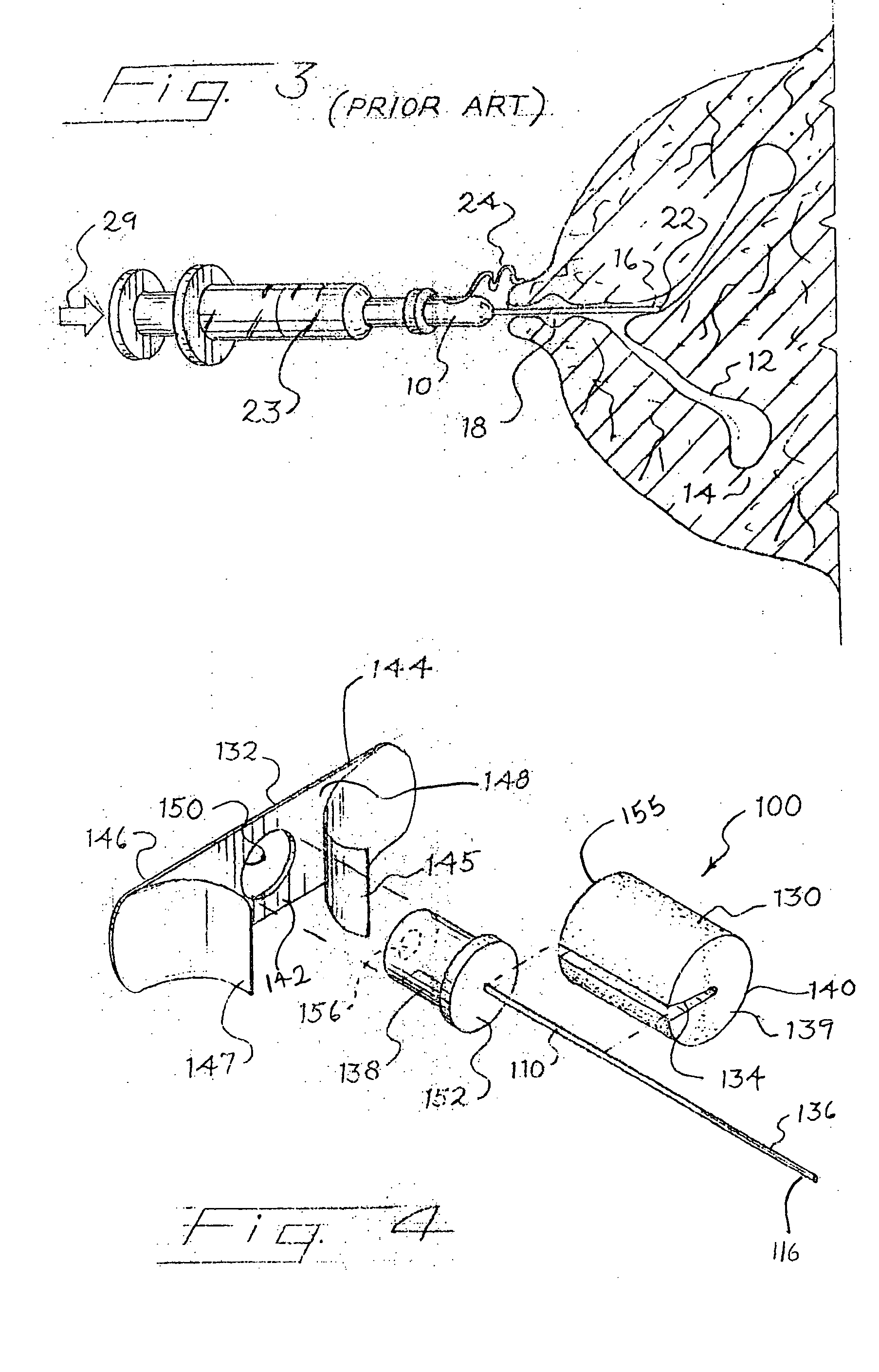

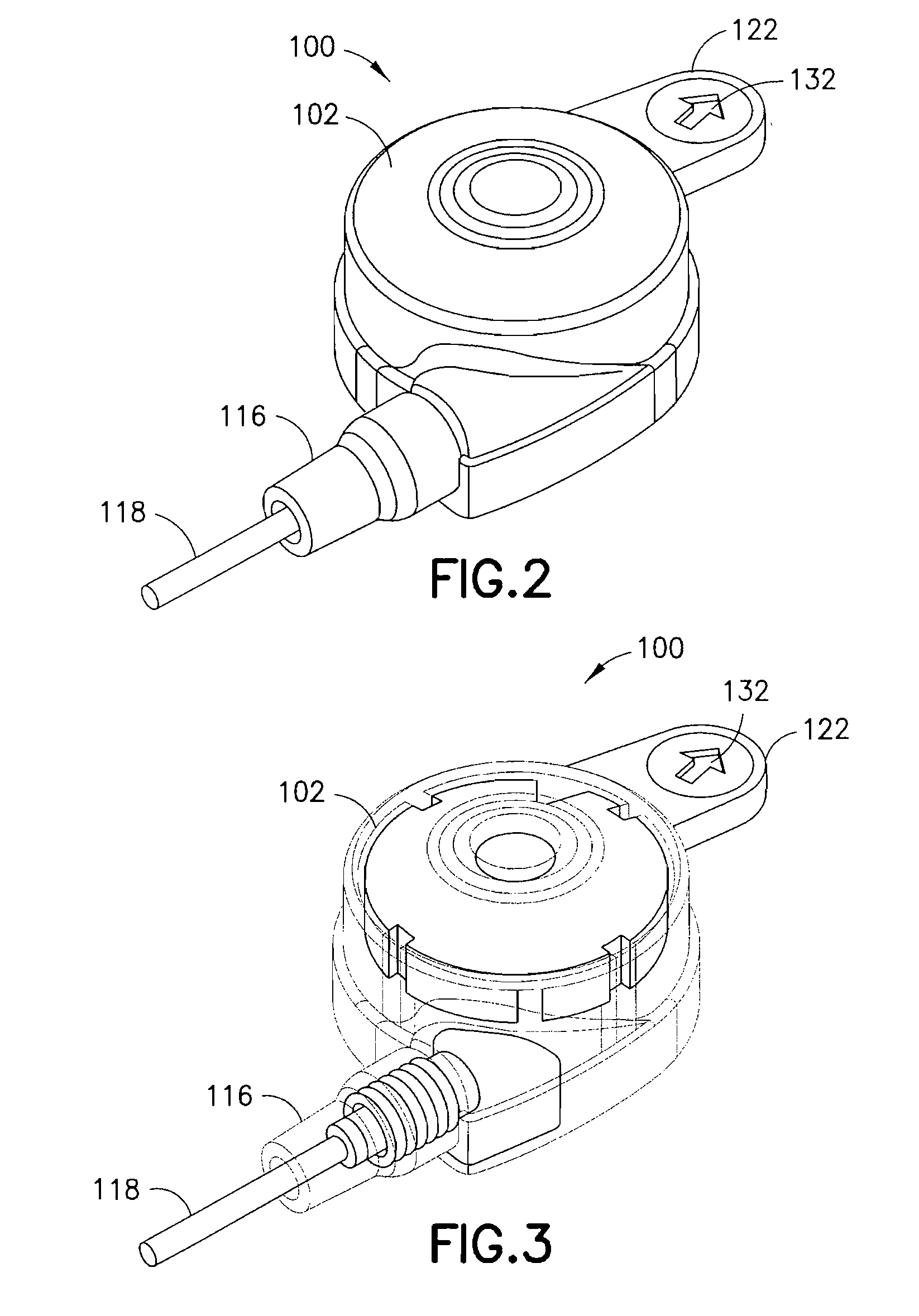

Insulin Pump Dermal Infusion Set Having Partially Integrated Mechanized Cannula Insertion With Disposable Activation Portion

An infusion set has a partially integrated ballistic inserter that can insert a needle at a controlled rate of speed to a depth to deliver content to the upper 3 mm of skin surface, and a skin-securing adhesive layer to secure the skin surface at the insertion site such that the inserter that can insert a needle with a reduced risk of tenting of the skin surface. A removable turnkey or pushable handle can be provided to release a driving spring of the ballistic inserter to insert a needle at a controlled rate of speed, of 3.3 ft / sec. (1.0 m / sec.) up to and including those greater than 10 ft / sec. (3.0 m / sec.), then release from the set for disposal. The infusion set can further include an extendable interface ring that retracts when the inserter is removed from the infusion set.

Owner:BECTON DICKINSON & CO

Assembly for extracting heat from a housing for electronic equipment

ActiveUS20070254583A1Maximize capacityMaintain depthDomestic cooling apparatusLighting and heating apparatusElectronic equipmentWaste management

An assembly for extracting heat from a housing for electronic equipment, the housing having a front, a back, two sides and a top. The assembly is defined by a back for the housing that defines an open area proximate the top, and an air passageway in fluid communication with the open area in the back, to conduct heated air exiting the housing through the open area away from the housing.

Owner:EATON INTELLIGENT POWER LIMITED

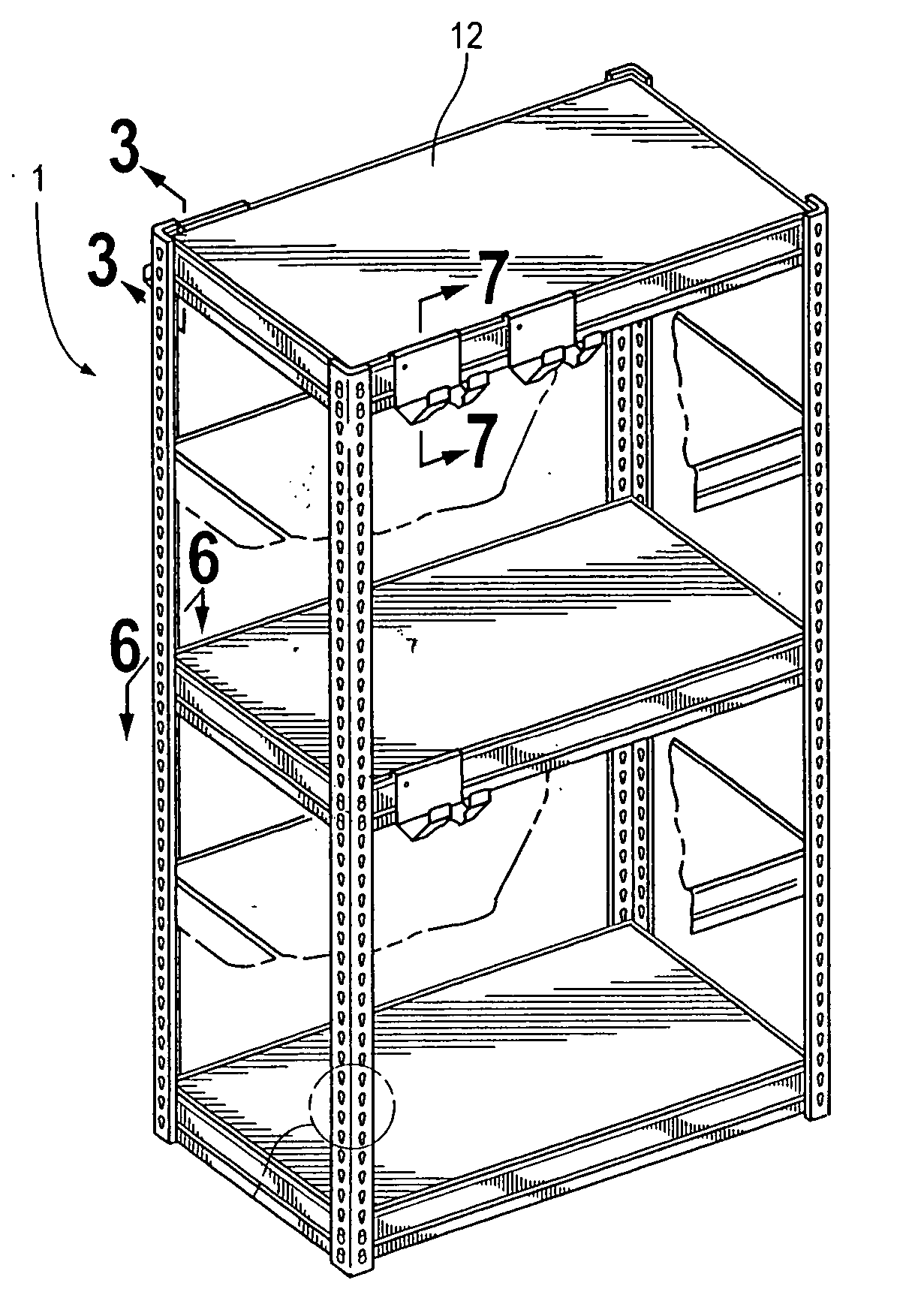

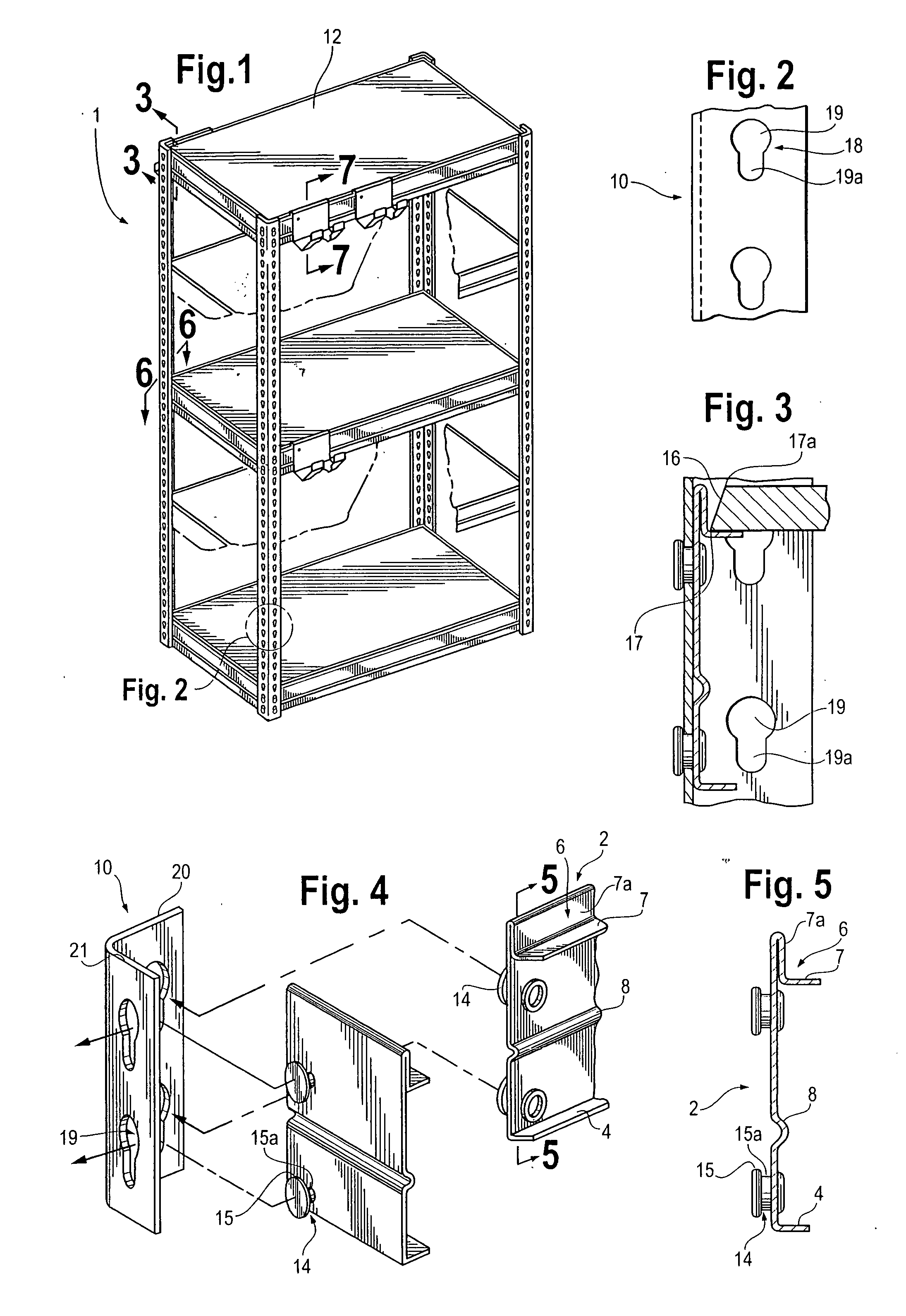

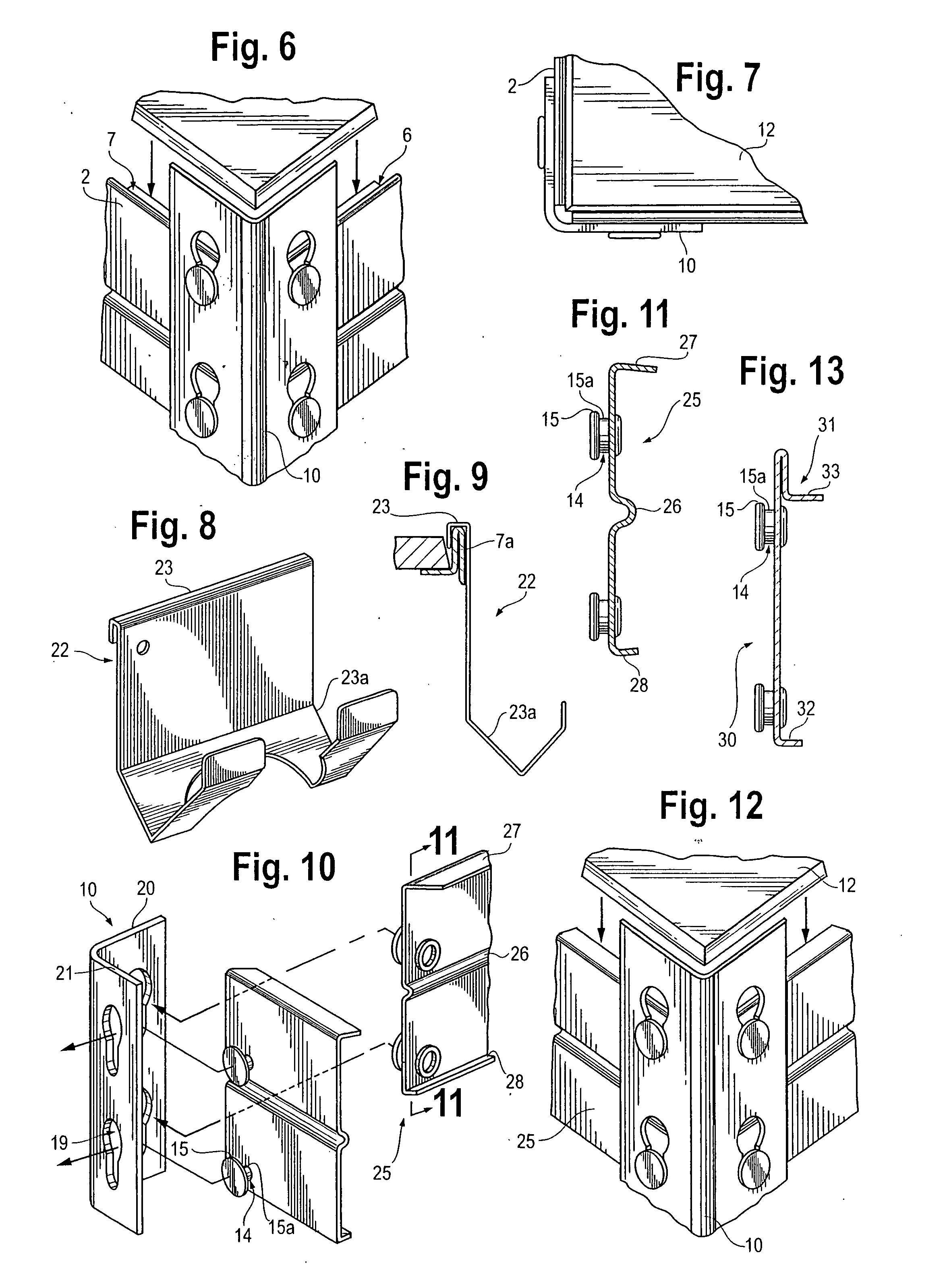

Cargo rack

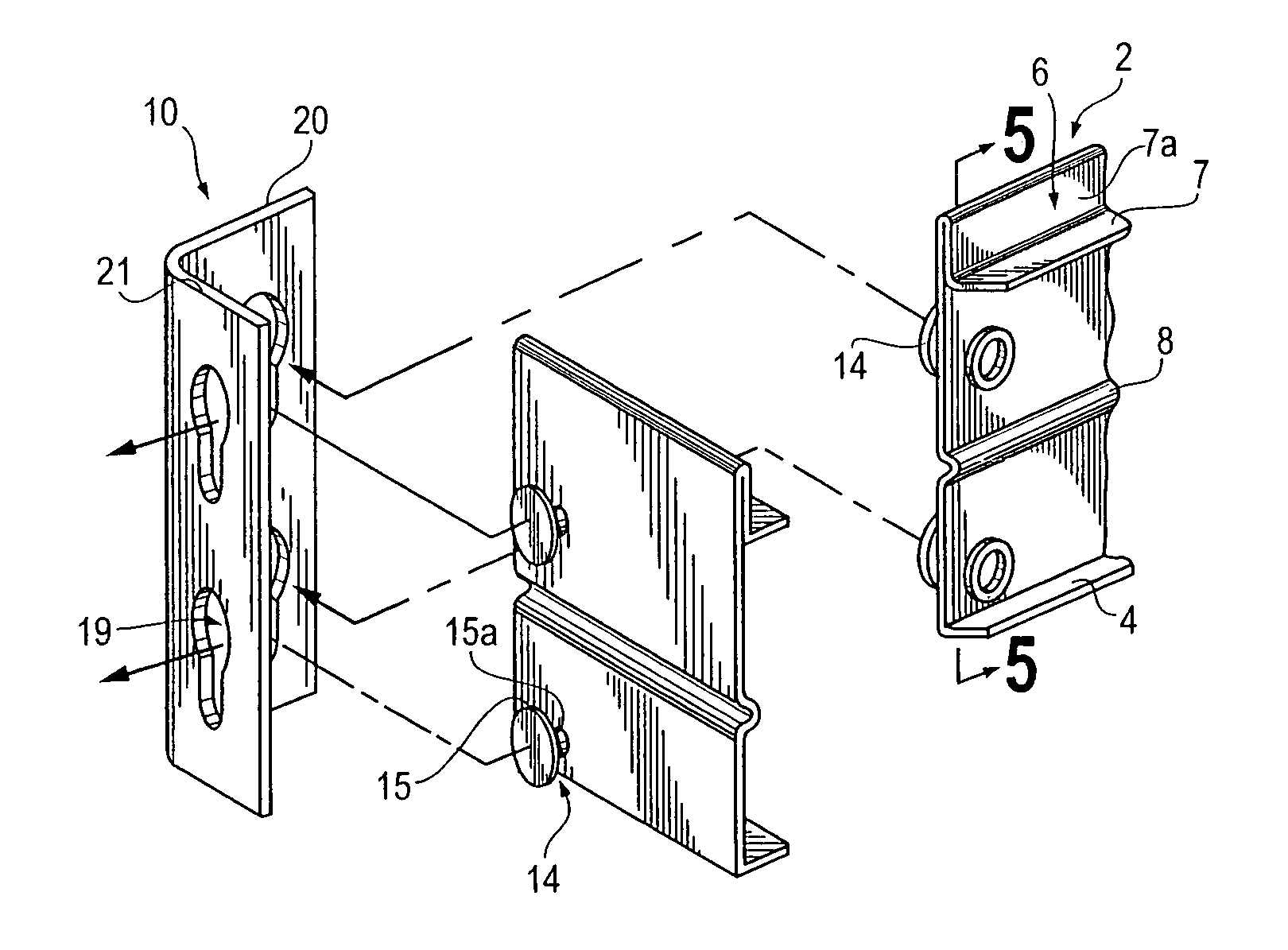

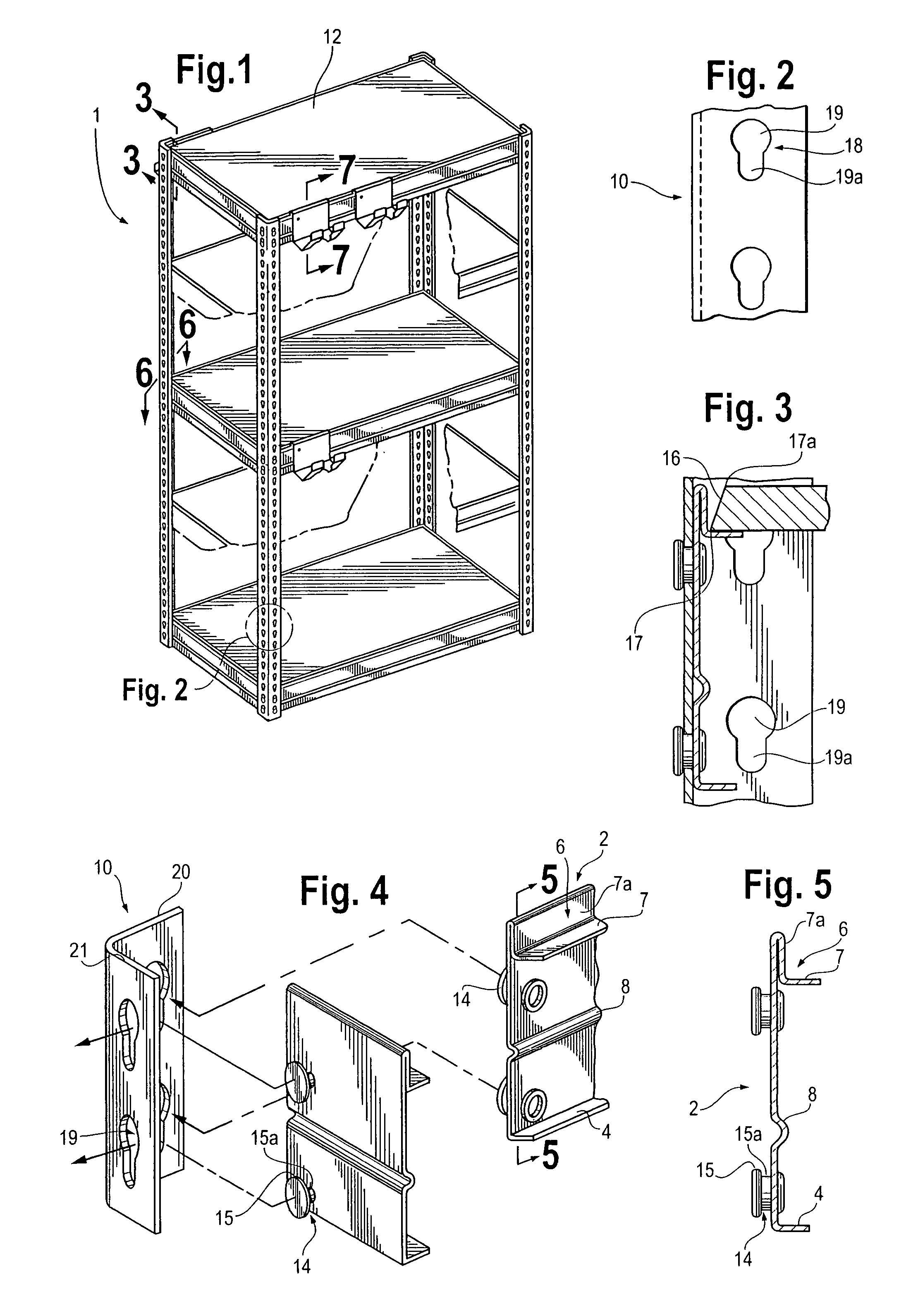

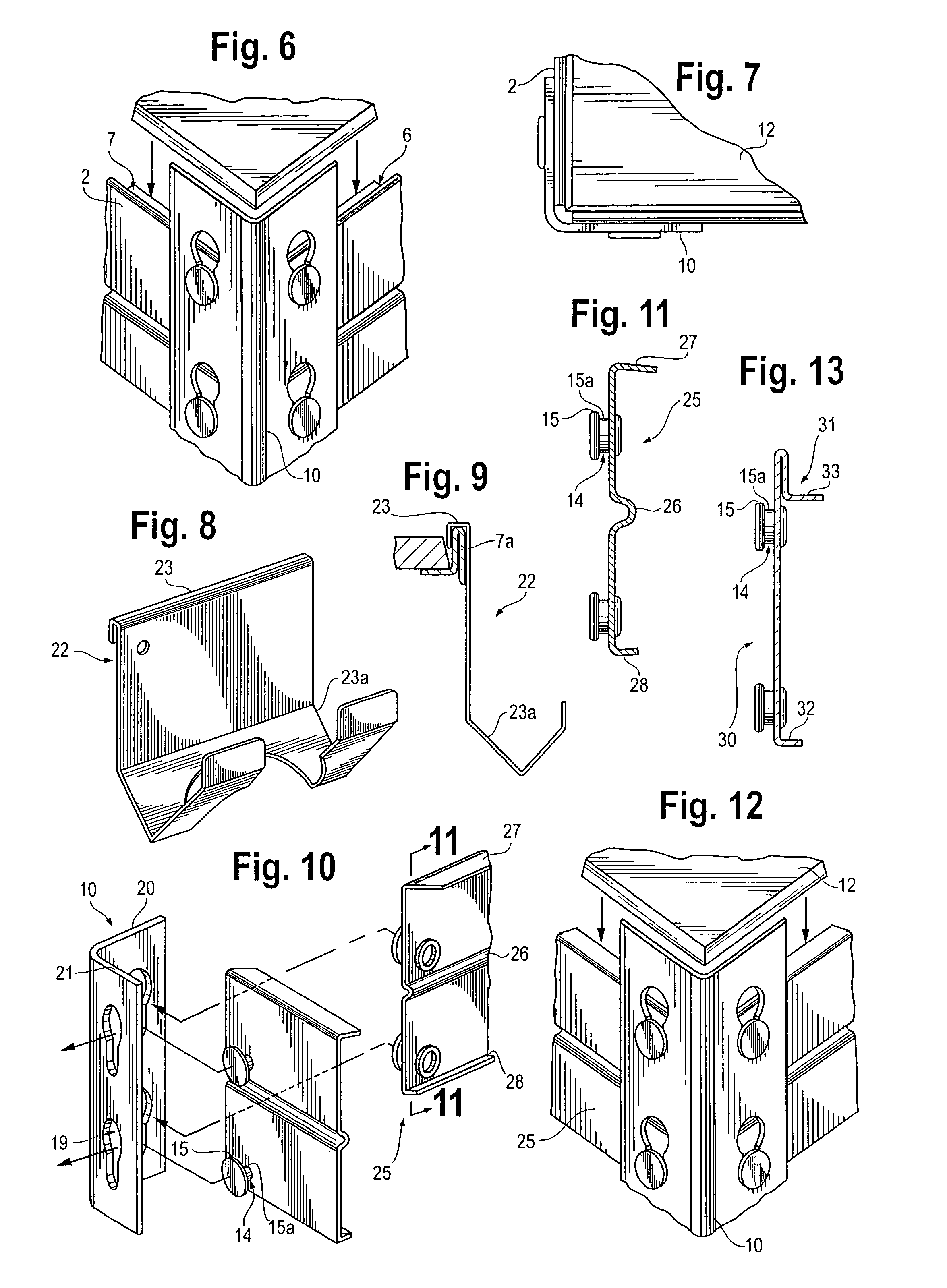

ActiveUS20050103733A1Minimizes cost per unitMaximizes strength to material weight ratioFurniture partsStands/trestlesEngineeringFlange

A cargo rack utilizing a structural beam in the form of three embodiments, two of the embodiments comprising a rib, one of which includes a recessed flange and a horizontal return flange, the other includes a standard angled flange and an angled return flange, the third embodiment includes a recessed flange and a horizontal return flange, structural beams used in a framework comprising a plurality of vertical posts containing key shaped apertures and a plurality of horizontal shelving members, structural beams contain nubs enabling structural beams to connect to vertical posts via key shaped apertures thereby enabling horizontal shelving members to be associated with structural beams and vertical posts, various attachments may be added to cargo rack when recessed structural beams are used via a slight clearance that is formed between the recessed edge and a slight taper on horizontal shelving member sides.

Owner:EDSAL MANUFACTURING COMPANY INC

Photobioreactor systems positioned on bodies of water

InactiveUS7980024B2Increase ratingsAvoid stagnationBioreactor/fermenter combinationsAlgae productsLiquid mediumStream flow

Owner:THE TRON GRP

Catheter retainer

InactiveUS20050113759A1Restrict movementMaintain positionCatheterInfusion needlesBreast DuctDuctal lavage

A catheter retainer includes a spacer and an anchor that coact to maintain a catheter in a predetermined position within a mammary duct during a ductal lavage procedure. The spacer and the anchor operate together to resist angular or axial displacement of the catheter. A catheter retainer kit is disclosed as well.

Owner:LACHOWICZ THEODORE COLLATERAL AGENT

Cargo rack

ActiveUS7128225B2Minimizes cost per unitEasy to assembleFurniture partsStands/trestlesFlangeVertical path

A cargo rack utilizing a structural beam in the form of three embodiments, two of the embodiments comprising a rib, one of which includes a recessed flange and a horizontal return flange, the other includes a standard angled flange and an angled return flange, the third embodiment includes a recessed flange and a horizontal return flange, structural beams used in a framework comprising a plurality of vertical posts containing key shaped apertures and a plurality of horizontal shelving members, structural beams contain nubs enabling structural beams to connect to vertical posts via key shaped apertures thereby enabling horizontal shelving members to be associated with structural beams and vertical posts, various attachments may be added to cargo rack when recessed structural beams are used via a slight clearance that is formed between the recessed edge and a slight taper on horizontal shelving member sides.

Owner:EDSAL MANUFACTURING COMPANY INC

Line laying apparatus

InactiveUS20070286681A1Reduce resistanceGain is not constantPipe laying and repairSoil-shifting machines/dredgersTerrainLeading edge

A mole-plough for forming a subterranean channel for laying a line includes a body incorporating a leading edge and nose for cutting the channel, a guide plate on the body located at the desired terrain surface level, an arcuate passage within the body for feeding each line to be laid, and a stabilizer disposed adjacent the exit of the passage and extending rearwardly of the body.

Owner:PARENT MICHEL

Method of forming shallow doped junctions having a variable profile gradation of dopants

Disclosed are methods for forming a shallow junction with a variable concentration profile gradation of dopants. The process of the present invention includes first providing and masking a surface on an in-process integrated circuit wafer on which the shallow junction is to be formed. Next, a low ion velocity and low energy ion bombardment plasma doping or PLAD operation is conducted to provide a highly doped inner portion of a shallow junction. In a further step, a higher ion velocity and energy conventional ion bombardment implantation doping operation is conducted using a medium power implanter to extend the shallow junction boundaries with a lightly doped outer portion. In various embodiments, the doping steps can be performed in reverse order. In addition, an anneal step can be performed after any doping operation.

Owner:ROUND ROCK RES LLC

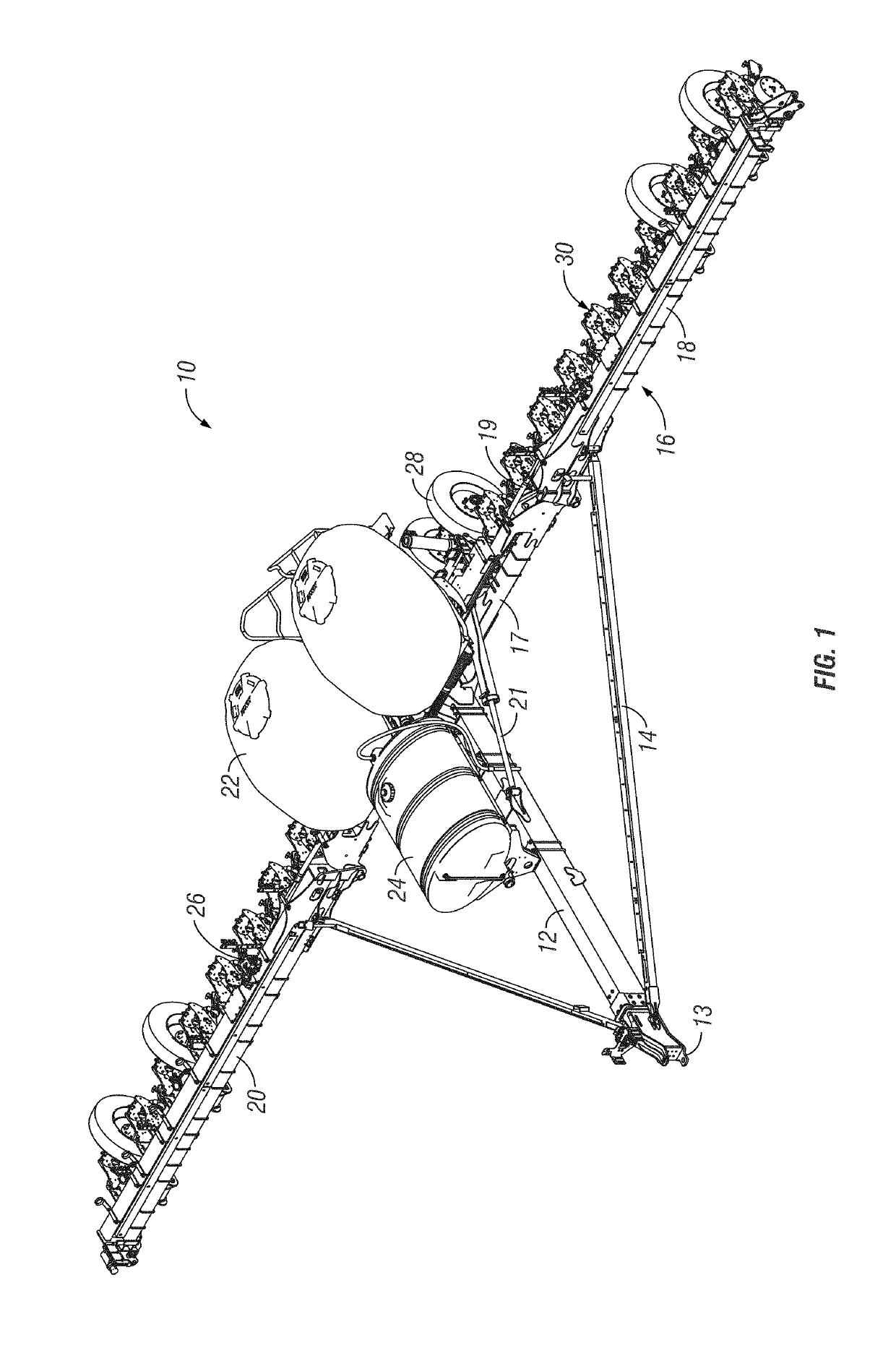

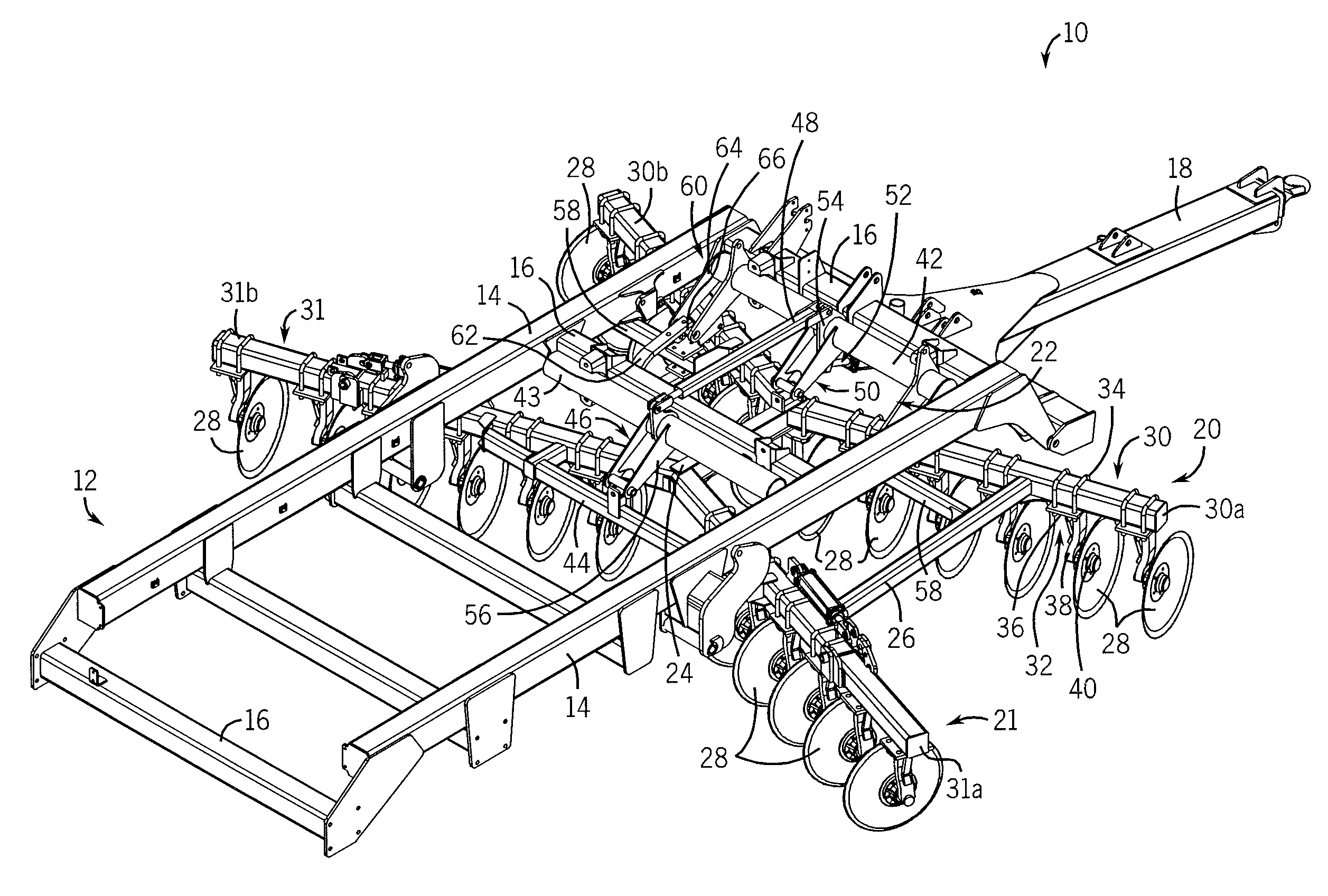

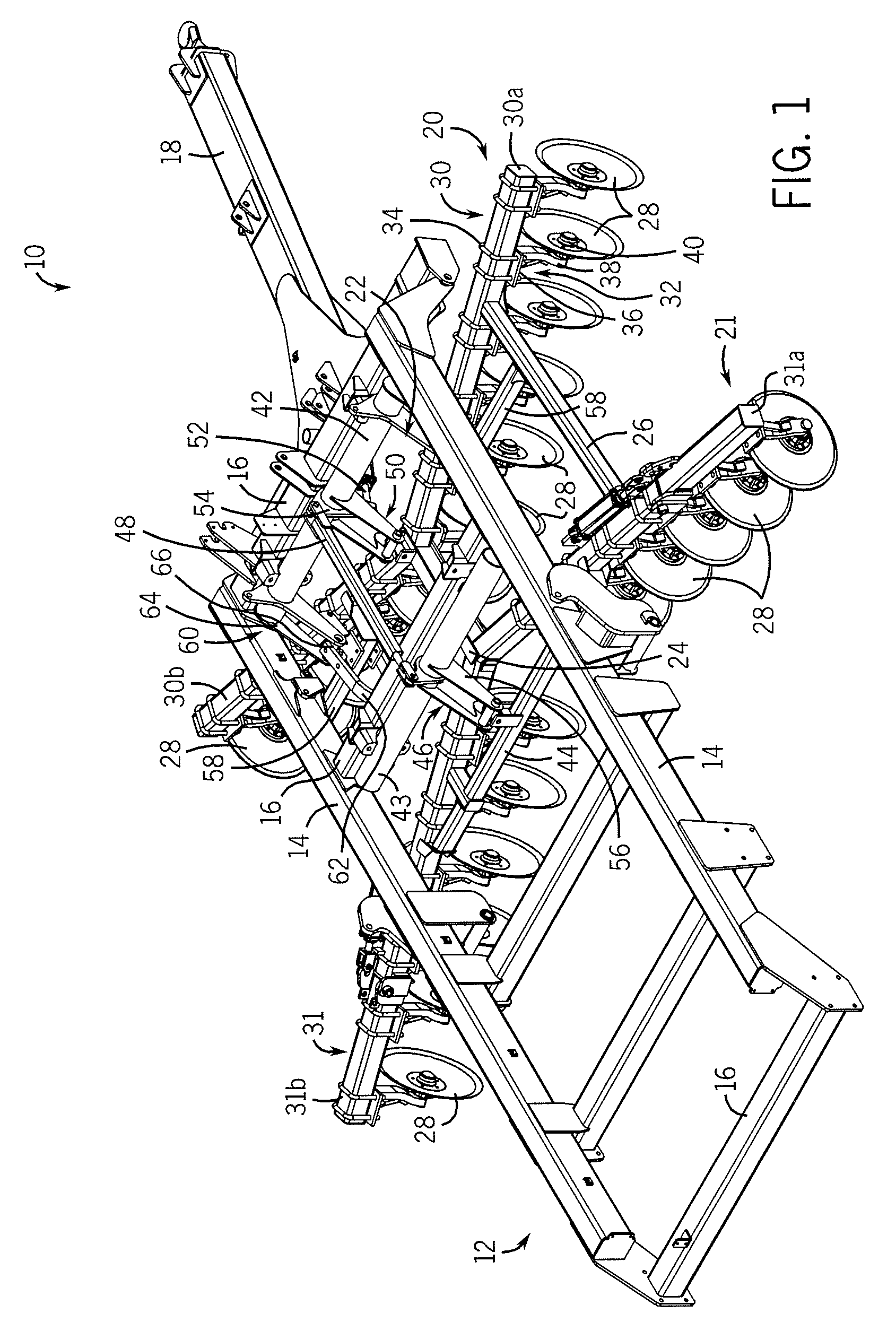

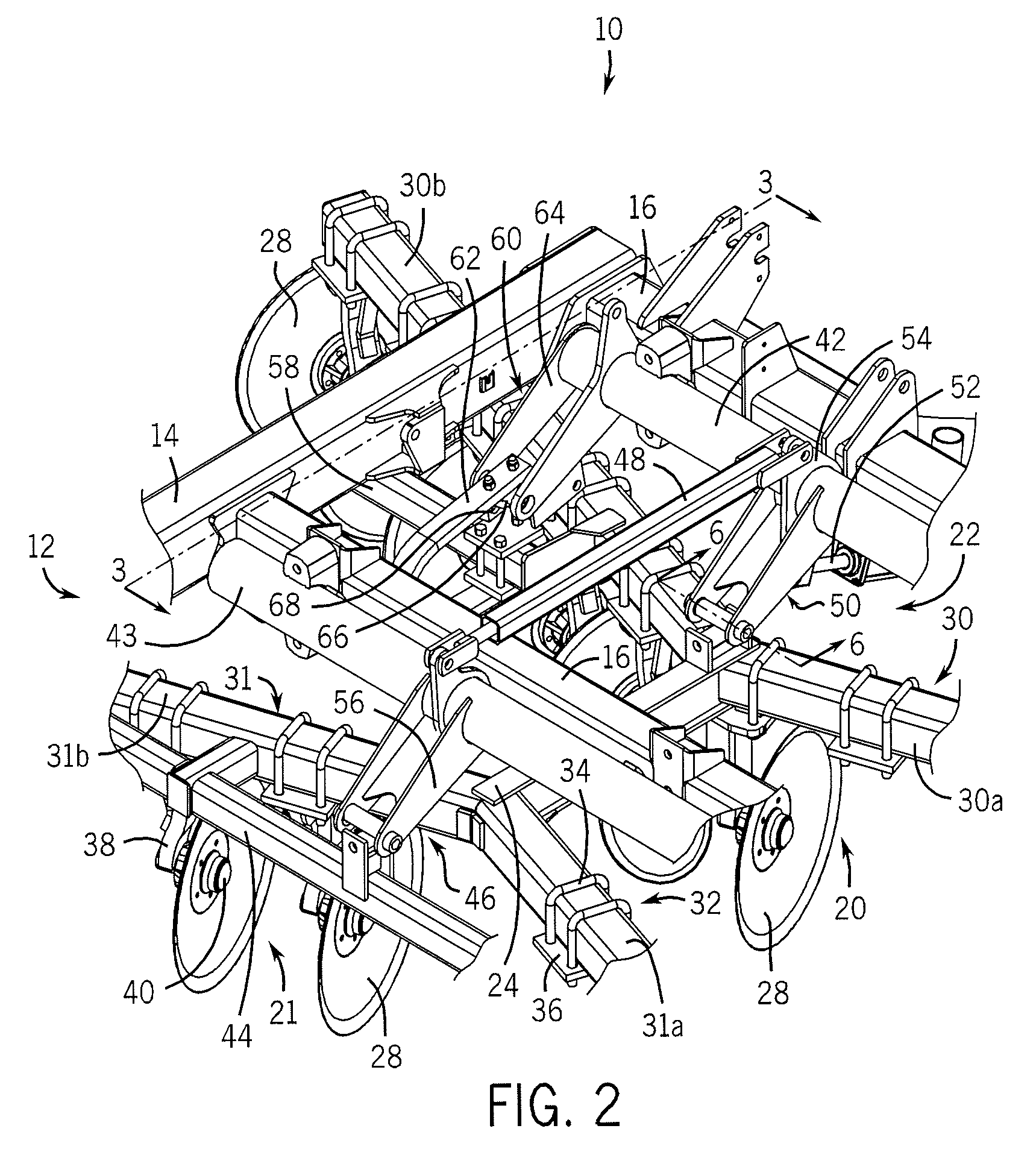

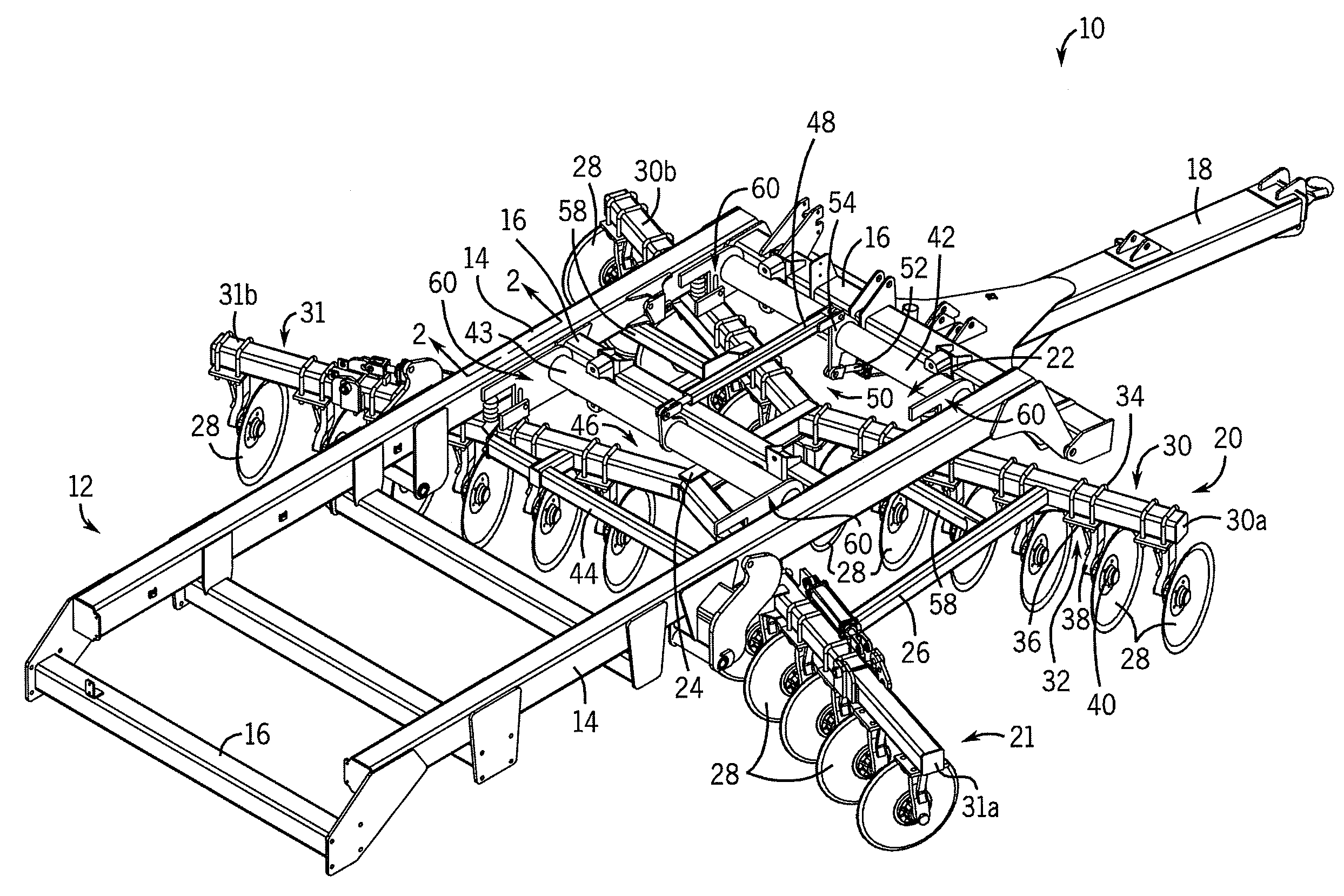

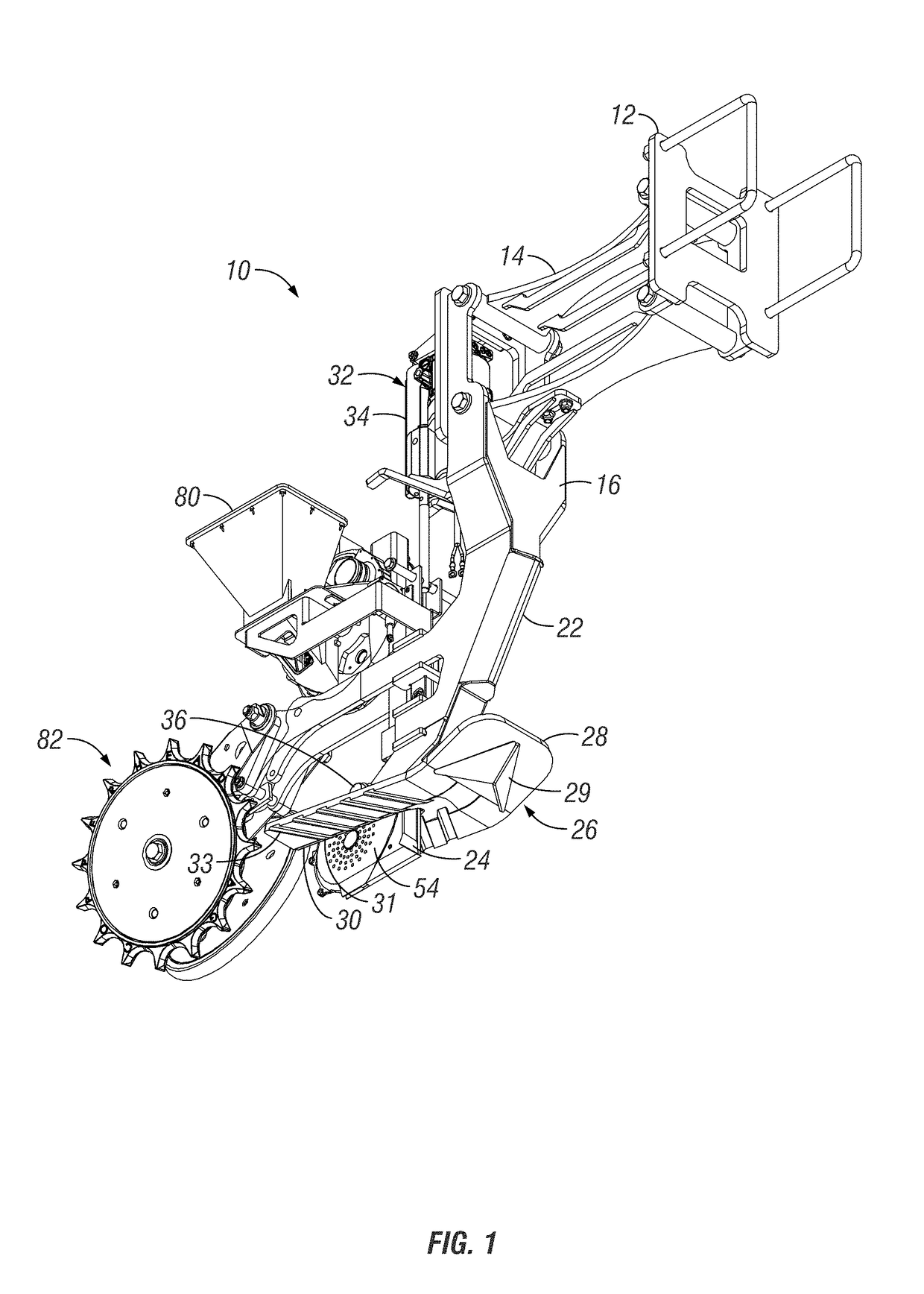

Systems, methods, and apparatus for controlling downforce of an agricultural implement

ActiveUS20190183036A1Maintain depthLittle strengthAgricultural machinesPlantingEngineeringUser defined

A downforce system adjusts the amount of downforce being applied to a row unit of an agricultural implement. The downforce system is controlled to increase or decrease the force on the row unit. A load is sensed at the row unit and compared to either or both of a user defined target and a lower threshold that can be based, at least in part, upon a percentage of a value. When the load is determined to be below the lower threshold, the user defined amount is increased at a rate of change until the load is above the threshold, at which point the increase is stopped, and reduced, if necessary.

Owner:KINZE MFG INC

Adjustable height needle infusion device

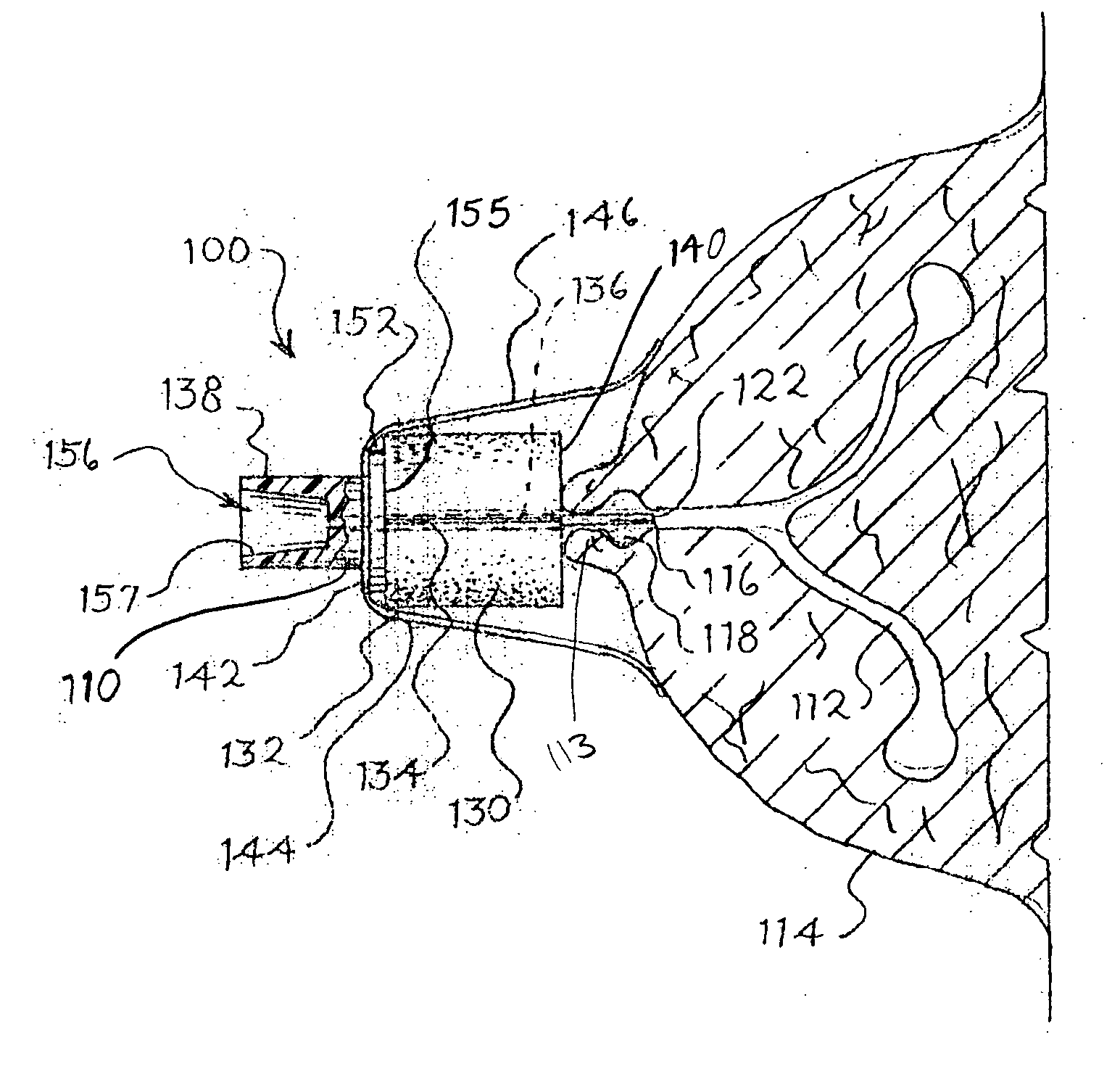

ActiveUS8795230B2Maintaining degree of comfortPromote absorptionInfusion syringesPressure infusionSkin surfaceInsertion depth

An infusion set has a retraction dial that can be removably assembled with the infusion set and access a threaded needle hub contained therein such that the dial can be used to advance or retract a needle hub and an inserted needle to a more precisely controlled insertion depth to deliver insulin or other medicament intradermally (i.e. to the upper 3 mm of skin surface). Position of the inserted needle can be maintained by providing a separated and isolated needle hub, main base and main hub of the infusion set that can isolate the inserted needle from external forces such that the needle can be maintained at a depth to deliver content to the upper 3 mm of skin surface during normal use.

Owner:BECTON DICKINSON & CO

Crop residue and soil conditioning agricultural implement

InactiveUS7743844B2Control impactReducing potentially-damaging impactAgricultural machinesSoil-working equipmentsTerrainCircular disc

A disc harrow composed of one or more disc gangs has a subframe coupled to the disc gangs to move the disc gangs in response to variations in farmland terrain to limit the impact of obstructions when encountered during the harrowing process. When the obstruction is cleared, the subframe automatically returns the disc gangs to their pre-obstruction position. In addition to reducing the potentially-damaging impact of obstructions, the subframe also maintains a more consistent reel depth during undulations or changes in the farmland terrain, such as during harrowing of slopes or unleveled fields such as valleys, near waterways, and along fence rows.

Owner:BLUE LEAF I P INC

Systems and methods for closed loop heat containment with cold aisle isolation for data center cooling

ActiveUS8764528B2Maximize capacityMaintain depthIndirect heat exchangersHeat transfer modificationCold airData center

The invention combines systems and methods for heat containment and cold air isolation for managing airflow and temperature in data centers. The data center contains at least two rows of cabinets containing heat-generating equipment and arranged to form a cold aisle and a hot aisle. The data center system includes panels or doors at both ends of the cold aisle and an optional cover over the cold aisle to inhibit cooled air supplied by an air conditioning system from exiting the cold aisle and inhibit air warmed by the heat-generating components from entering the cold aisle. A chimney coupled to the top, rear, or top and rear of the cabinets is configured to exhaust the warmed air into a region above the rows of cabinets. The chimneys may be ducted to a plenum or suspended ceiling or to the intake of the air conditioning system. Baffles and / or fans may be included in the chimneys, ducts, and / or plenums to control the air pressure. The invention may also include one or more data center air conditioning units, and each air conditioning unit may be configured to service one or more rows of cabinets. Alternatively, or in addition, cool air may be supplied by the building's air conditioning system.

Owner:EATON INTELLIGENT POWER LTD

Photobioreactor Systems Positioned on Bodies of Water

InactiveUS20110287544A1Increase ratingsAvoid stagnationAlgae productsBacteriaLiquid mediumStream flow

Certain embodiments and aspects of the present invention relate to a photobioreactor including photobioreactor units through which a liquid medium stream and a gas stream flow. The photobioreactor units are floated on a body of water such as a pond or a lake. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, the photobioreactor units are formed of flexible, deformable material and are configured to provide a substantially constant thickness of liquid medium. In certain embodiments, a barrier between the photobioreactor unit and the body of water upon which the unit is floated facilitates thermal communication between the liquid medium and the body of water.

Owner:IHI INC +1

Detachable developing apparatus and driving apparatus of the same

ActiveUS20050169670A1Minimize frictionReduce loadToothed gearingsElectrographic process apparatusDriven elementEngineering

A driving apparatus of a detachable developing apparatus, and the detachable developing apparatus using the driving apparatus. The driving apparatus includes: a coupling member including a coupling drive which is connected to a driving element and to which driving power is transferred from the driving element, a coupling gear to which driving power is transferred from the coupling drive, and a coupling disc positioned between the coupling drive and the coupling gear for flexibly connecting the coupling drive and the coupling gear; and a power transferring portion including a plurality of gears to transfer driving power from the coupling member to the developing element and the toner supply element. At least one of the plurality of gears is a reduction gear for reducing a load applied to the coupling member from the developing element and the toner supply element.

Owner:HEWLETT PACKARD DEV CO LP

Disc frame vibration dampening system

InactiveUS7578356B2Control impactReduce the amount requiredAgricultural machinesSoil-working equipmentsTerrainCircular disc

Owner:BLUE LEAF I P INC

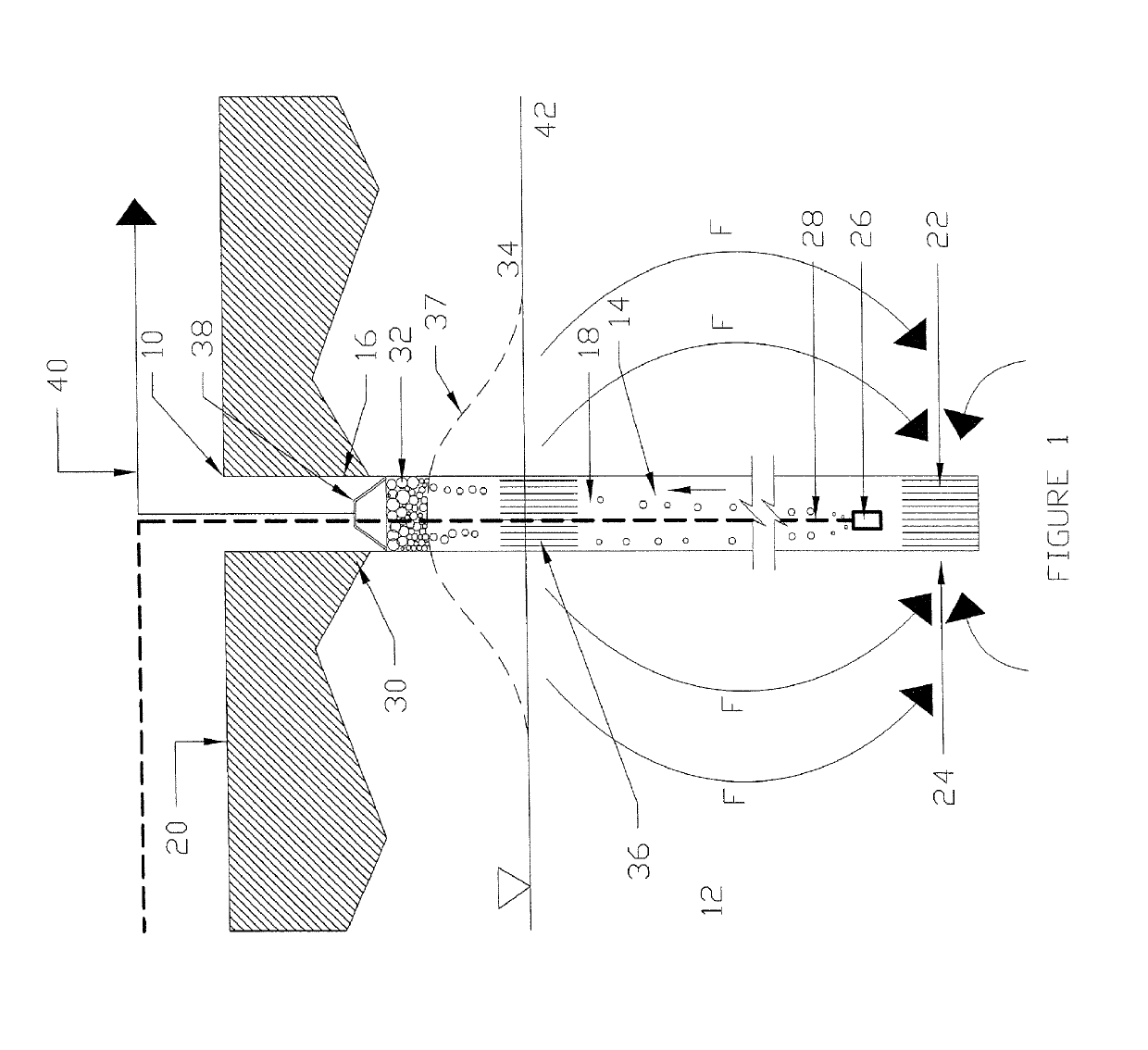

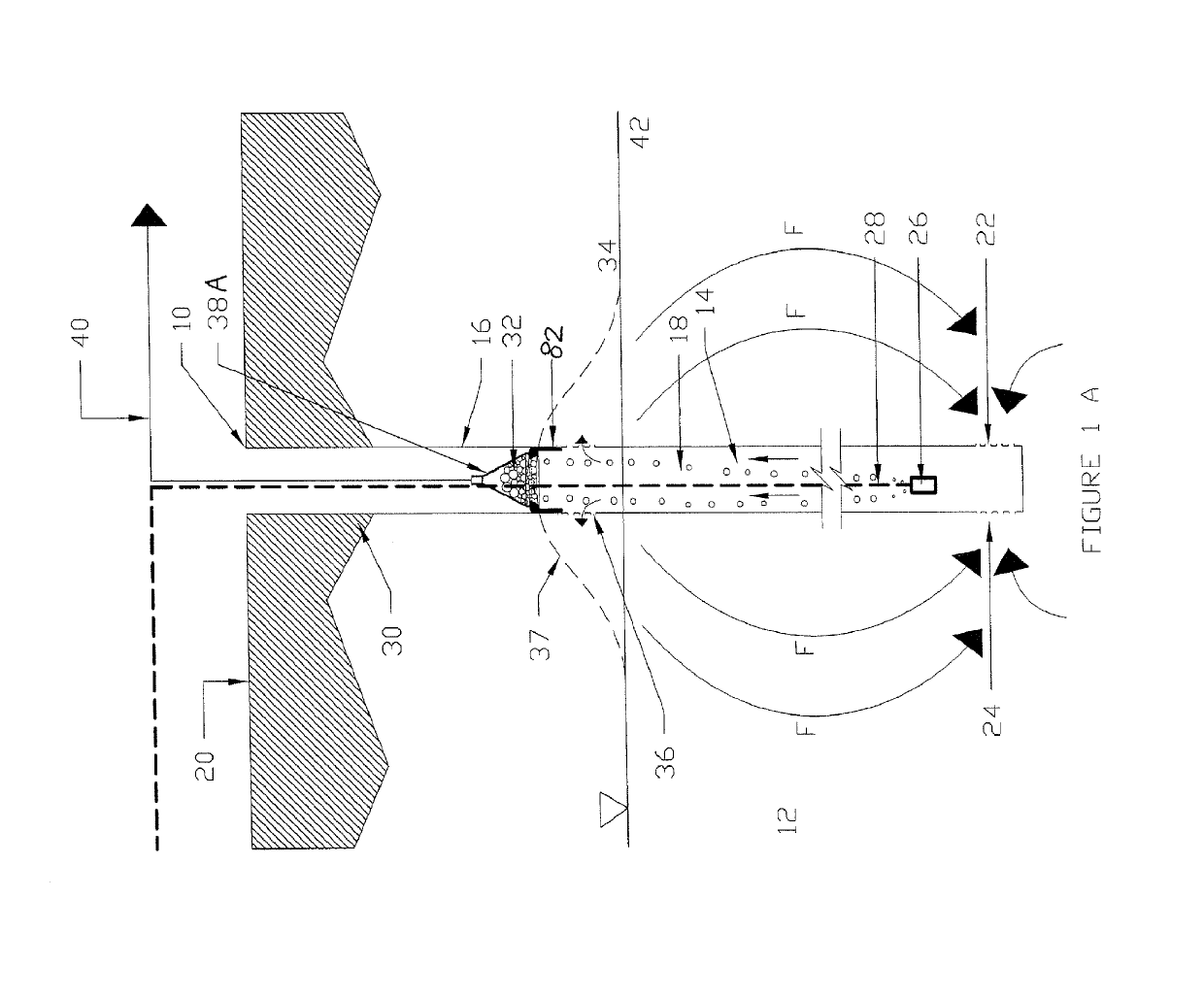

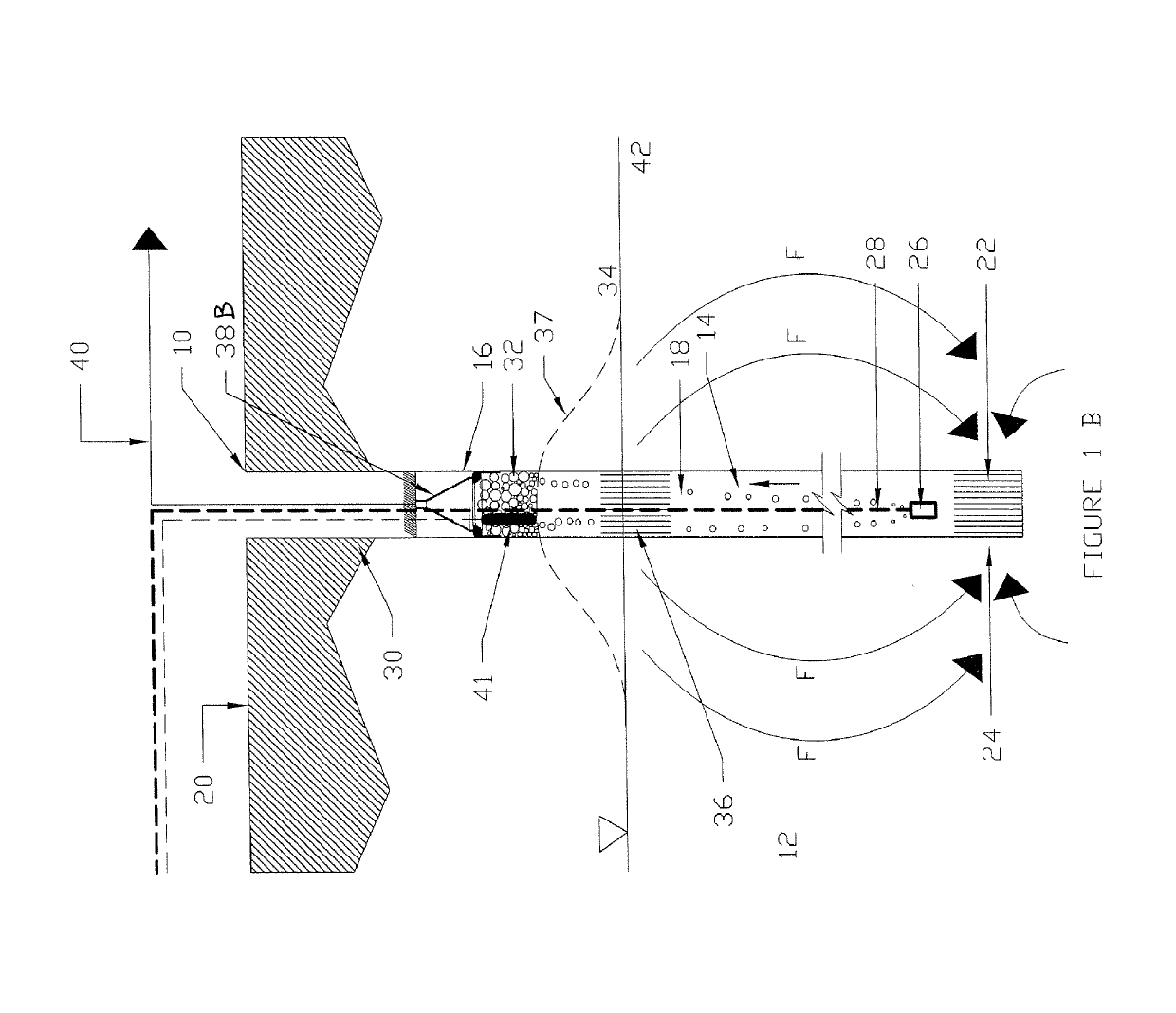

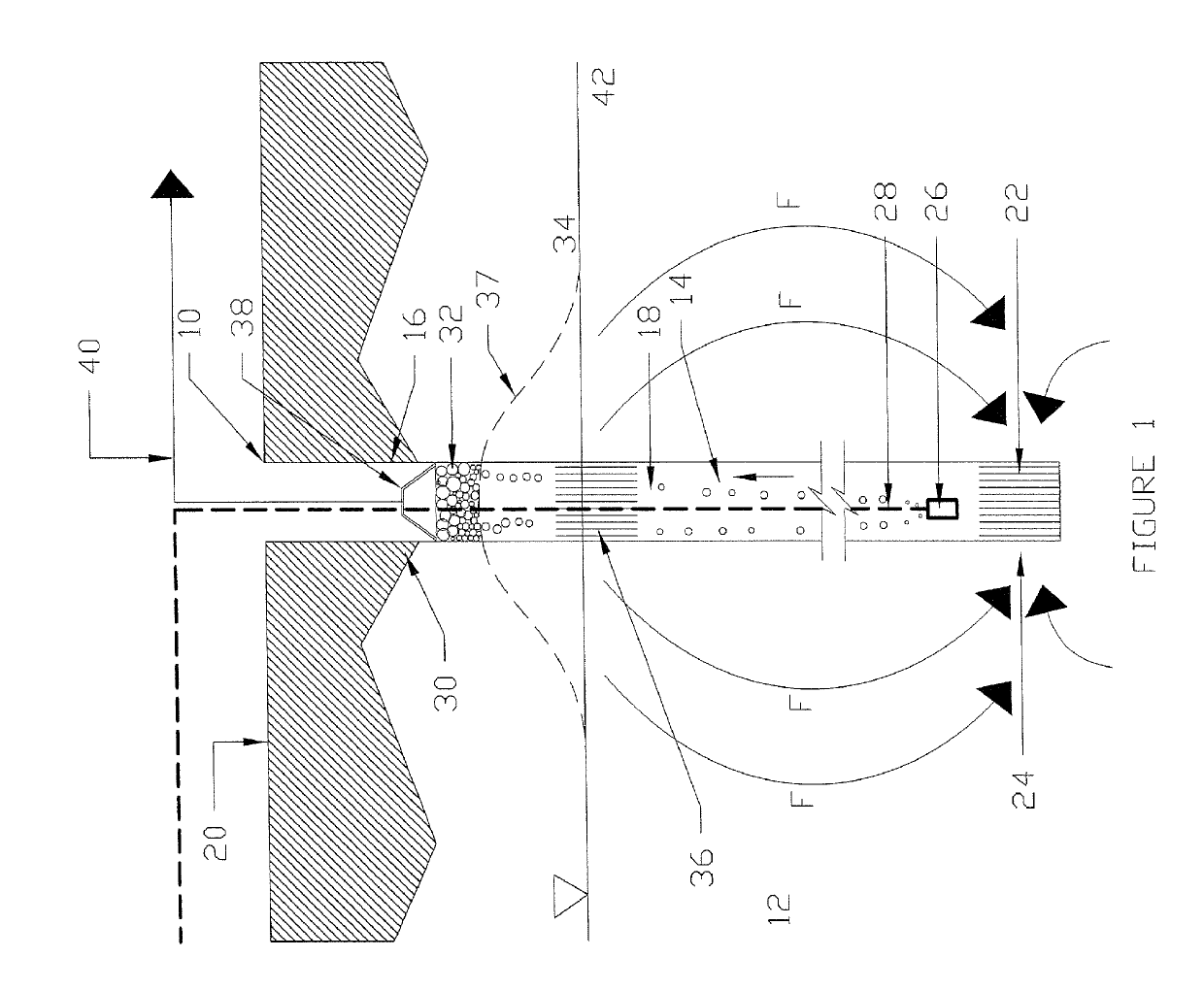

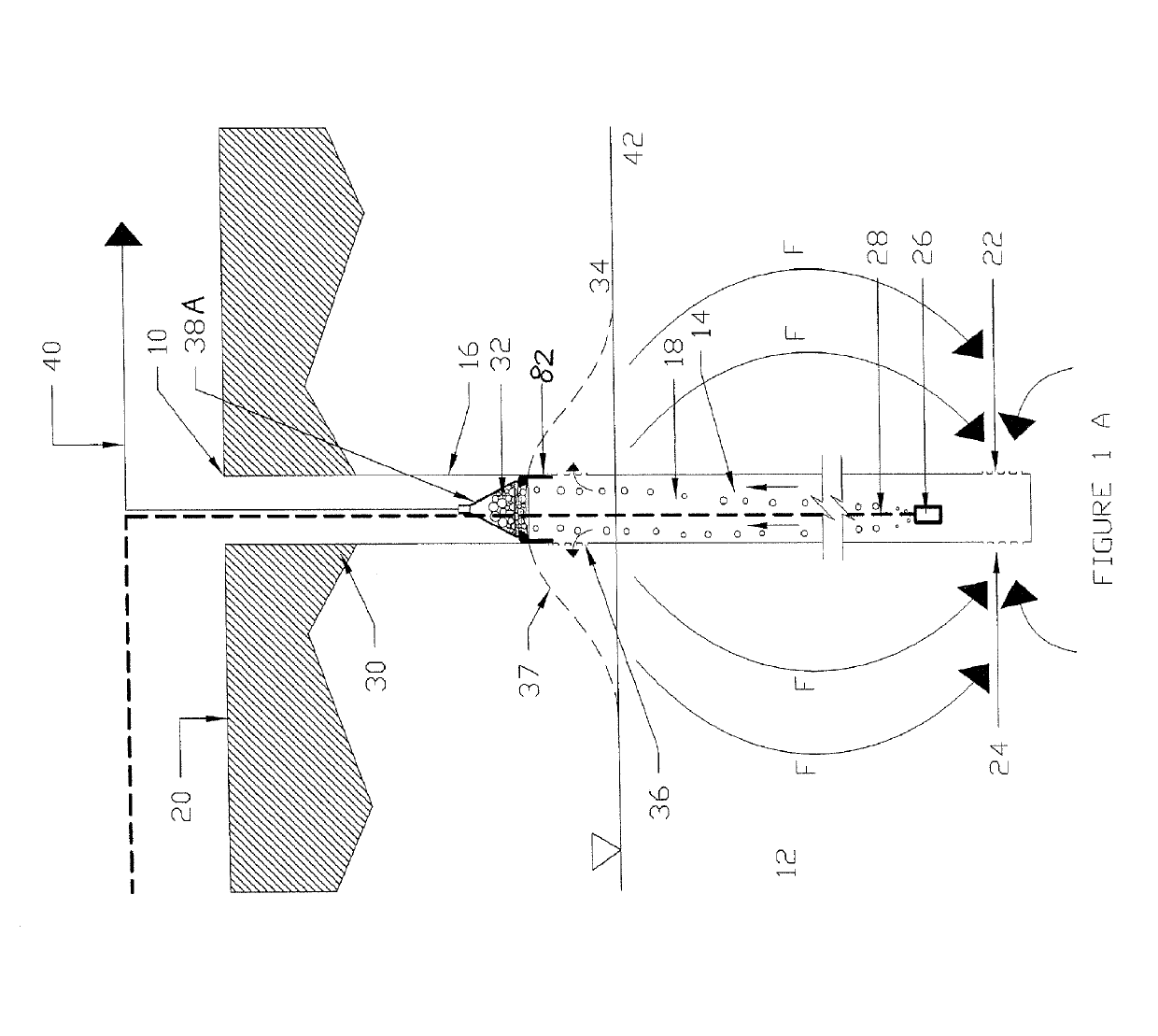

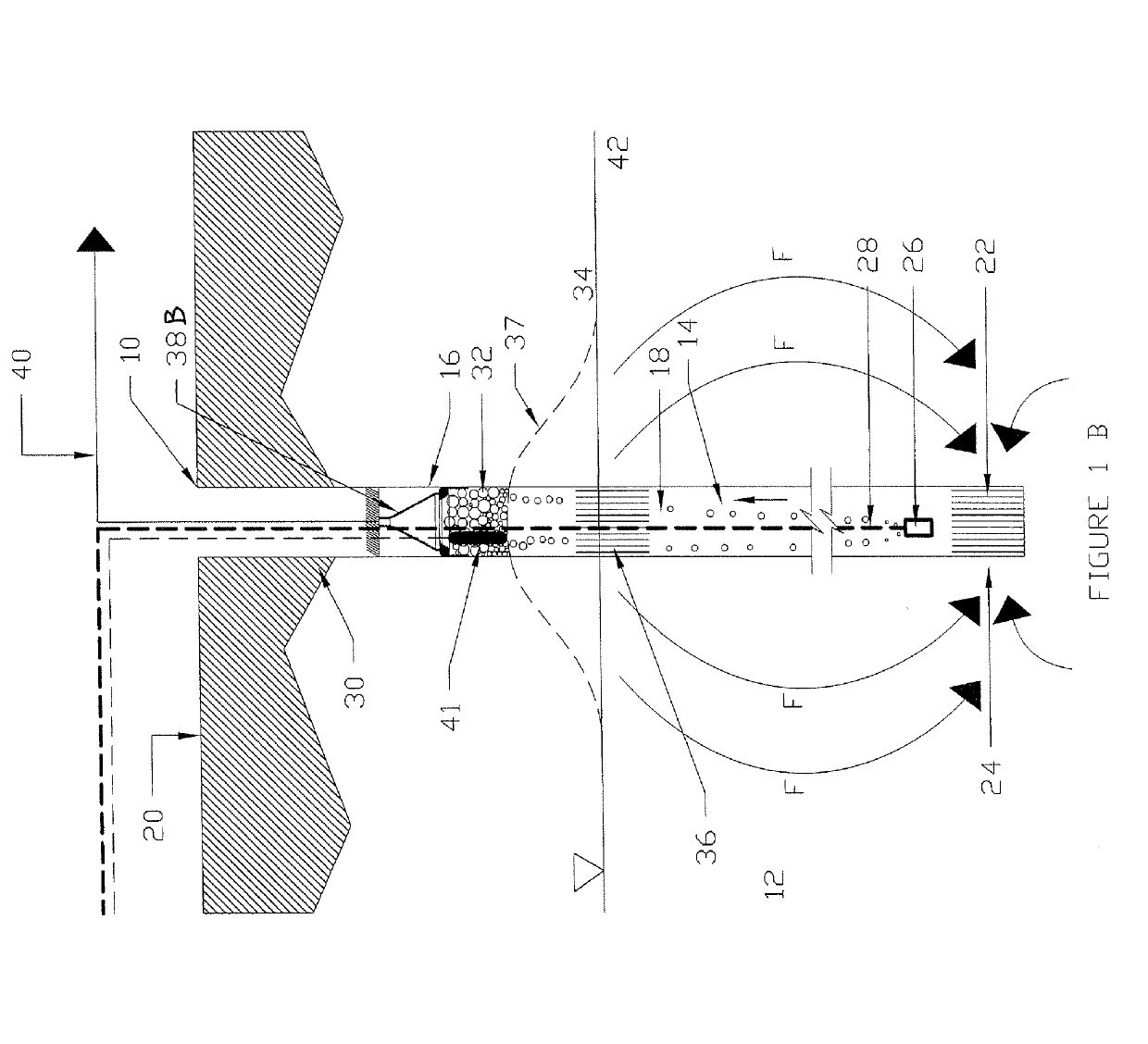

Method And Apparatus For Separation Of A Substance From Groundwater

PendingUS20190176101A1Adequate froth layer drainage characteristicEasy to changeWater treatment parameter controlMixing methodsEngineeringGroundwater

Apparatus is disclosed for separating an amount of a substance from groundwater, comprising an elongate chamber (18) having an inlet (22) which is arranged in use to admit groundwater into the chamber near a lower first end (24). There is also a gas sparger (26) located near the first end (24) which admits gas into the chamber for inducing groundwater to flow from the first end (24) of the chamber toward a second end upper end, and for producing a froth layer (32) which rises above an interface with the groundwater including a concentrated amount of the substance. A suction hood (38) can be moved downward from the top of the chamber (18) into a position to collapse the froth layer (32) and to cause it to be removed from the well body (14). The suction hood (38) (acting as a froth depth regulation device) controls the amount of groundwater in the froth layer (32), which influences the concentration of the contaminant substance achieved in the froth layer (32).

Owner:OPEC REMEDIATION TECH PTY LTD

Row unit with shank opener

A row unit for use with an agricultural implement is provided. The row unit includes a frame, a winged shank opener operatively connected to the frame, a depth-setting member operatively connected to the frame such that at least a portion of the winged shank extends below the depth-setting member to form a furrow and the depth-setting member at least partially controls the depth of said furrow, and a seed meter for planting seed in the depth formed by the winged shank opener. The depth setting member can be a ski, one or more gage wheels, or a combination of the same. A depth control mechanism can also be included to aid in controlling the depth of the furrow created.

Owner:KINZE MFG INC

Detachable developing apparatus and driving apparatus of the same

ActiveUS7283769B2Reduce frictionQuality improvementToothed gearingsElectrographic process apparatusCouplingEngineering

A driving apparatus of a detachable developing apparatus, and the detachable developing apparatus using the driving apparatus. The driving apparatus includes: a coupling member including a coupling drive which is connected to a driving element and to which driving power is transferred from the driving element, a coupling gear to which driving power is transferred from the coupling drive, and a coupling disc positioned between the coupling drive and the coupling gear for flexibly connecting the coupling drive and the coupling gear; and a power transferring portion including a plurality of gears to transfer driving power from the coupling member to the developing element and the toner supply element. At least one of the plurality of gears is a reduction gear for reducing a load applied to the coupling member from the developing element and the toner supply element.

Owner:HEWLETT PACKARD DEV CO LP

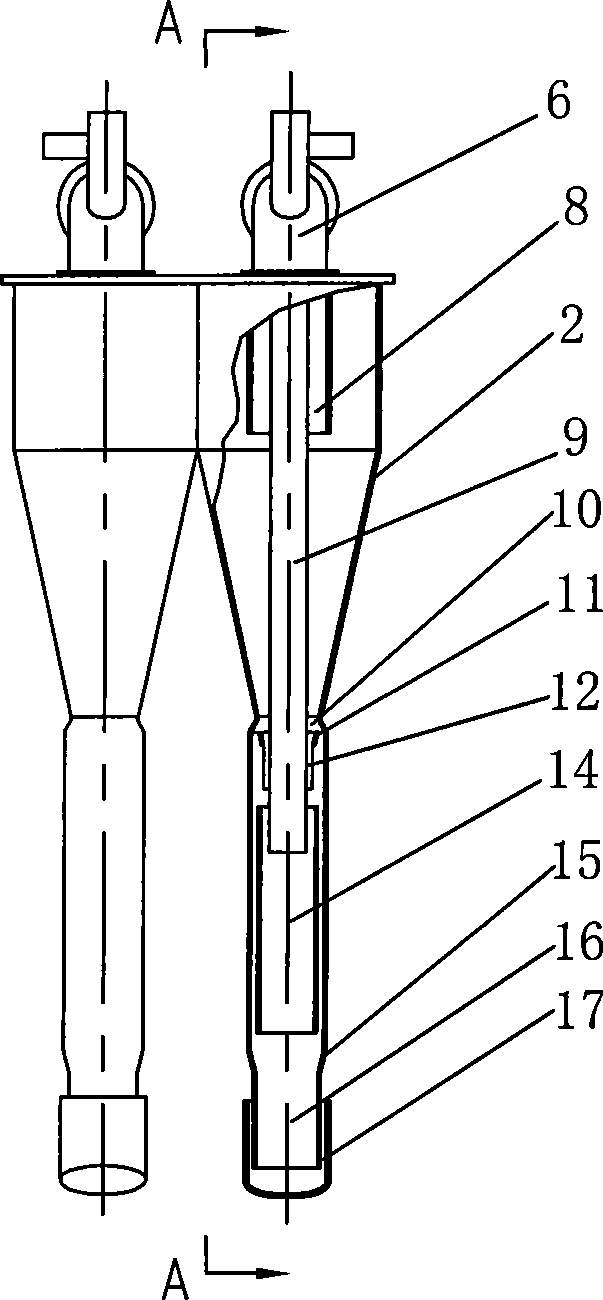

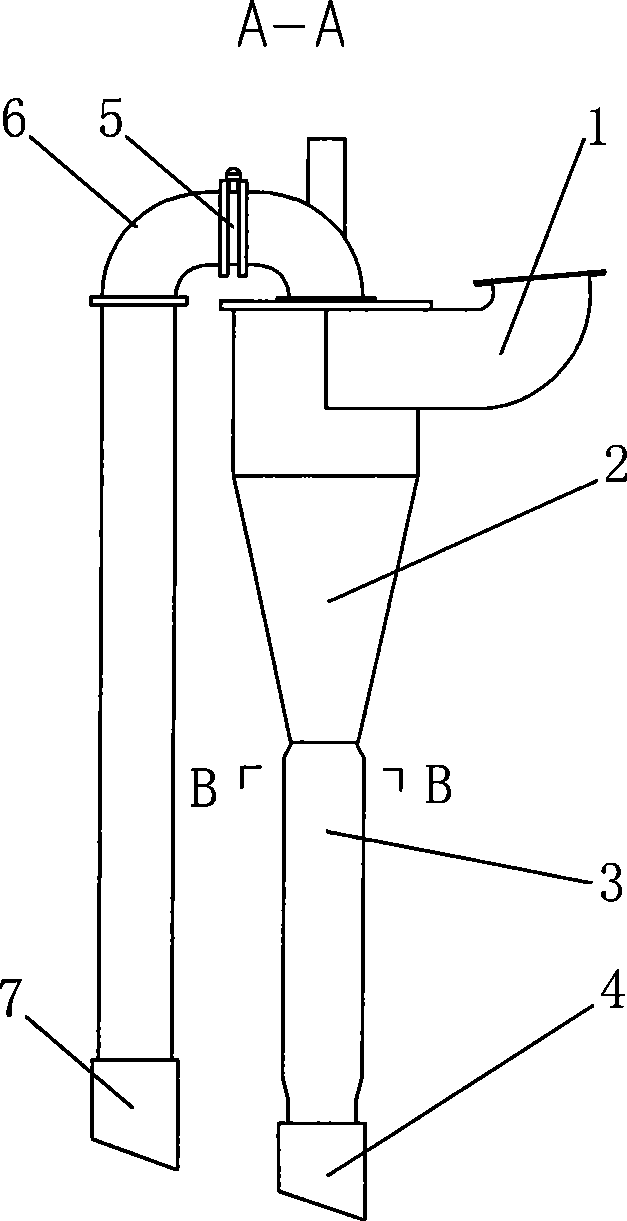

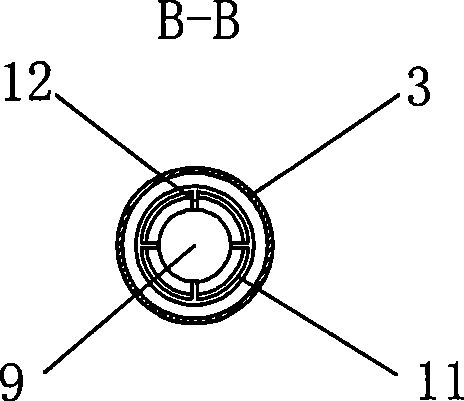

Pulverized coal burner

ActiveCN101446412AAchieve igniteEffective firePulverulent fuel combustion burnersCycloneCombustion chamber

A pulverized coal burner comprises at least one cyclone with a primary air powder tangential inlet line and a middle tapered shrinkage segment; an exhaust gas pipe having an exhaust gas adjusting air door and inserted on the top of the cyclone; a primary pulverized coal burning chamber and a secondary pulverized coal burning chamber arranged on the straight outlet segment of the cyclone; a micro-oil oil gun arranged on the top of the cyclone and inserted and penetrating the inlet of the exhaust gas pipe to the inlet of the primary pulverized coal burning chamber; a concentration ring and a rotation-eliminating blade arranged outside the throat at the interface of the shrinkage segment and the straight outlet segment of the cyclone; and a secondary air nozzle arranged at the outlet of the secondary pulverized coal burning chamber. The pulverized coal burner can achieve burn a great amount of pulverized coal by strengthened combustion and gradual amplification of trace oil by adopting the technical measures, such as ignition using micro-oil gasification oil gun, secondary pulverized coal burning, adjustable exhaust gas flow rate and pulverized coal concentration ratio, further pulverized coal concentration and rotation elimination, thereby achieving ignition of anthracite and lean coal, and achieving high oil saving rate. The coal burner is particularly suitable for W-shaped flame boiler.

Owner:EASTERN BOILER CONTROL CO LTD +1

Integrated Spring-Activated Ballistic Insertion For Drug Infusion Device

ActiveUS20120136310A1Small sizePrevent unwanted movementInfusion syringesSurgical needlesDrugs infusionHigh rate

An infusion set has an integrated ballistic inserter that can insert a needle at a controlled high rate of speed to a depth to deliver content to the upper 3 mm of skin surface, and a skin securing, adhesive layer to secure the skin surface at the insertion site such that the inserter that can insert a needle without a risk of tenting of the skin surface. A driving spring of the ballistic inserter is captured within the ballistic inserter, and can be released by user operation, to insert a needle at such a controlled rate of speed.

Owner:BECTON DICKINSON & CO

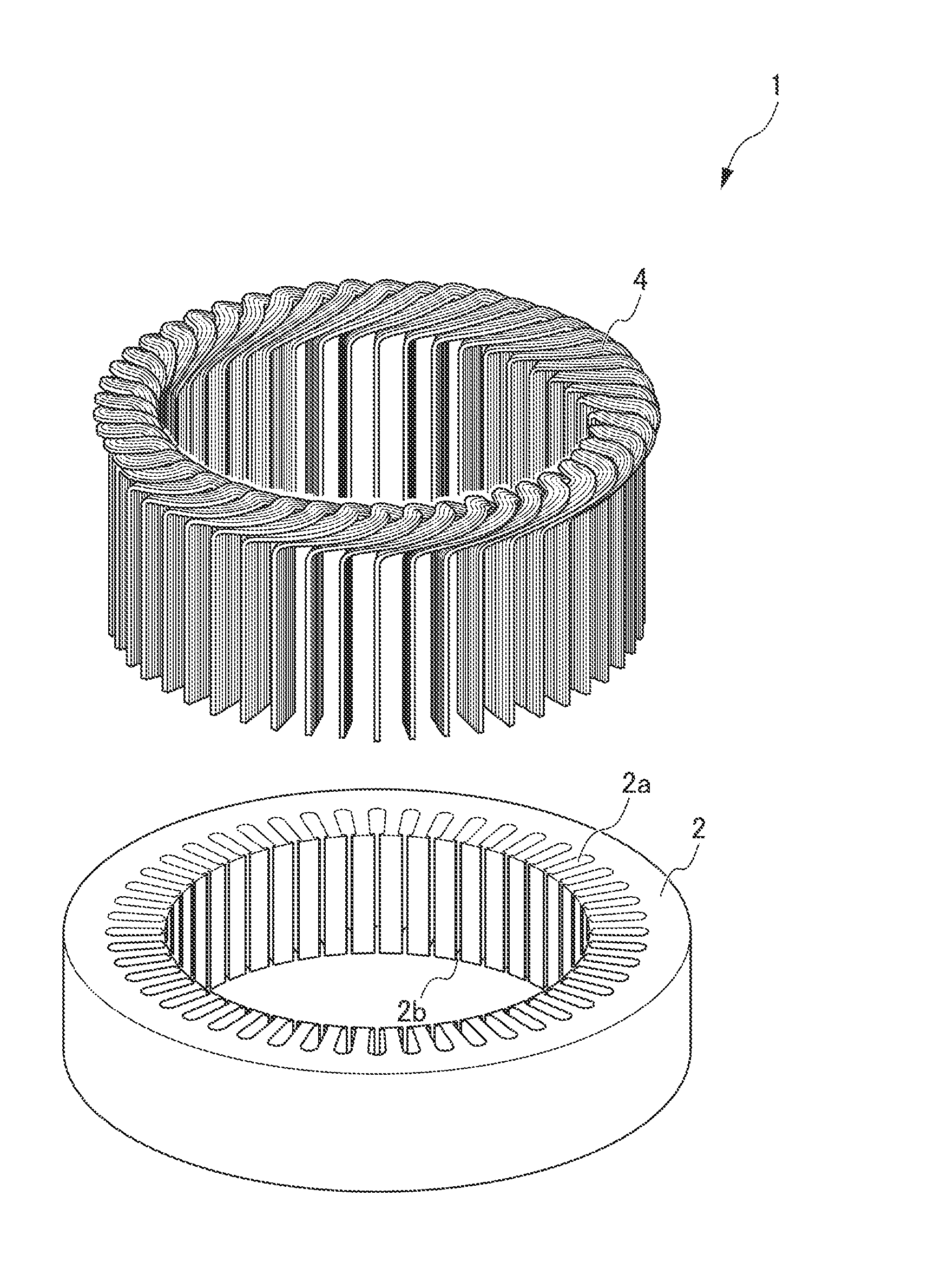

Production method of rotary electric machine

ActiveUS20140338183A1Improve joint strengthSmall surface areaManufacturing dynamo-electric machinesSoldered/welded connectionsElectrical conductorElectric machine

A production method of rotary electric machines is provided that can laser weld the leading end parts of a plurality of electrical conductors projecting from respective slots with high joint strength. A production method of rotary electric machines that produces a rotary electric machine by joining, by way of laser welding, leading end parts 41 of a plurality of electrical conductors 40 inserted in respective slots 2a provided in a stator core 2 and projecting from the respective slots 2a, includes the steps of matching and arranging the leading end parts 41 of two adjacent electrical conductors 40; and joining the leading end parts 41 of the two adjacent electrical conductors 40 by irradiating a laser onto the two adjacent electrical conductors 40 from a direction sloped at an angle θ relative to a joining face X of the leading end parts 41 of the two adjacent electrical conductors 40.

Owner:HONDA MOTOR CO LTD

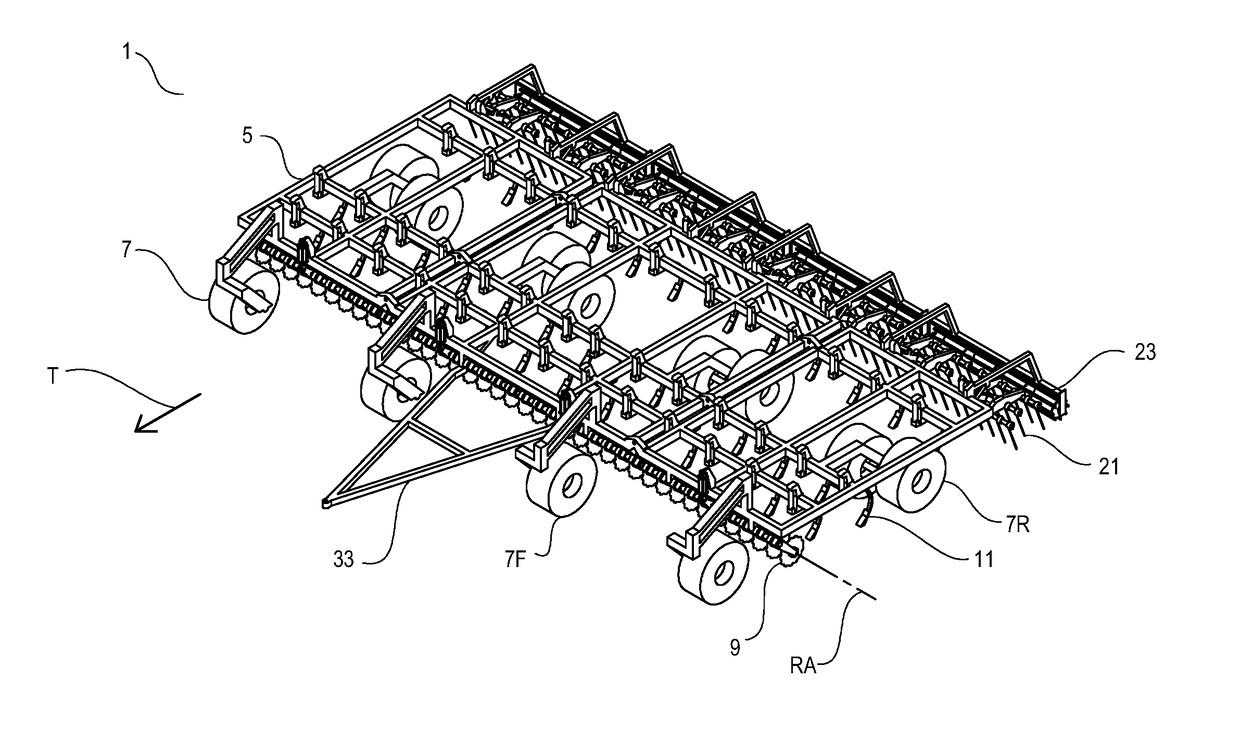

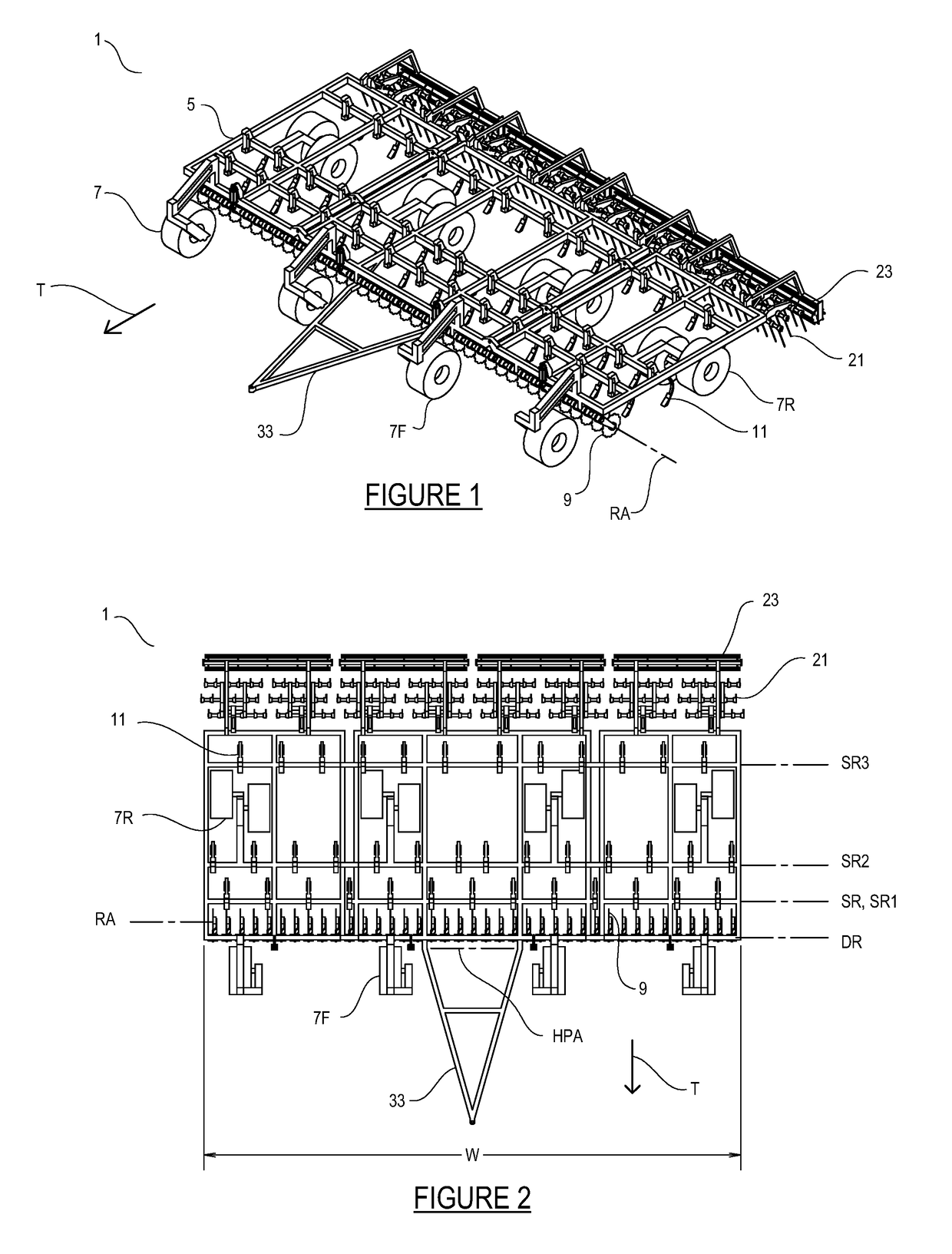

Method and apparatus for seed bed preparation

ActiveUS20180228072A1Increase computing speedHigh biasing forceSpadesAgricultural machinesHydraulic cylinderEngineering

An implement for preparing a seed bed has a front row of vertical discs, followed by three rows of shanks, followed by harrows and then rolling baskets. A hydraulic cylinder is mounted between each shank and the implement frame and exerts a constant selected trip bias force on the shanks that is adjustable up to 1300 pounds. The implement frame is configured such that a total weight on the wheels when the ground engaging tools are in the raised transport position is greater than about 850 pounds per foot of width of the implement frame. The implement is towed at speeds of at least seven miles per hour with the shanks penetrating the soil to a depth of three inches or more. Residue is cut and buried and the field surface left firm and smooth.

Owner:BOURGAULT INDS

Ballistic microneedle infusion device

ActiveUS8814831B2Maintaining degree of comfortPromote absorptionInfusion syringesMedical devicesSkin surfaceInfusion set

An infusion set has a disposable inserter that can insert a needle at a controlled rate of speed to a depth to deliver insulin or other medicament to the upper 3 mm of skin surface, and a skin securing, adhesive layer to secure the skin surface at the insertion site such that the inserter that can insert a needle without a risk of tenting of the skin surface. Position of the inserted needle can be maintained by providing a separated inner and outer hub of the infusion set that can isolate the inserted needle from external forces such that the needle can be maintained at a depth to deliver insulin or other medicament to the upper 3 mm of skin surface during normal use.

Owner:BECTON DICKINSON & CO

Side dam with insert

A composite side dam for a continuous twin roll caster includes a substrate made of a refractory material capable of withstanding casting temperature and having edge portions adapted to engage casting rolls and having a nip portion adjacent a nip between casting rolls and upper portions extending across the side dam to form a lateral restraint for a casting pool, an insert of at least 10 mm in thickness positioned in a pocket in the substrate and extending to engage the molten metal and extending from the upper portions of the substrate and positioned in the pocket to within 30 mm from the nip portion by insertion adjacent the upper portions of the substrate, and the insert adapted to fit into the pocket of the substrate to form a side dam formed of a refractory material having consumption rate less than 10 mm per hour. The material forming the insert may be between 40 and 60% SiAlON material and the remainder hBN material, or mullite material as described by FIG. 11, or between about 60 and 63 mole percent Al2O3 and the remainder SiO2, or fused silica, such as between 40 and 60% fused SiO2 and the remainder hBN material.

Owner:NUCOR CORP

Method And Apparatus For Separation Of A Substance From Groundwater

ActiveUS20190263679A1Extra layerEasy to changeTransportation and packagingContaminated soil reclamationEngineeringGroundwater

Apparatus is disclosed for separating an amount of a substance from groundwater, comprising an elongate chamber (18) having an inlet (22) which is arranged in use to admit groundwater into the chamber near a lower first end (24). There is also a gas sparger (26) located near the first end (24) which admits gas into the chamber for inducing groundwater to flow from the first end (24) of the chamber toward a second end upper end, and for producing a froth layer (32) which rises above an interface with the groundwater including a concentrated amount of the substance. A suction hood (38) can be moved downward from the top of the chamber (18) into a position to collapse the froth layer (32) and to cause it to be removed from the well body (14). The suction hood (38) (acting as a froth depth regulation device) controls the amount of groundwater in the froth layer (32), which influences the concentration of the contaminant substance achieved in the froth layer (32).

Owner:OPEC REMEDIATION TECH PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com