Pulverized coal burner

A pulverized coal burner and pulverized coal technology, applied in the direction of burners, burners burning powder fuel, combustion types, etc., can solve the problems of no application of micro-oil combustion technology, difficulties in ignition and stable combustion, and abnormal special structure of the burner, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

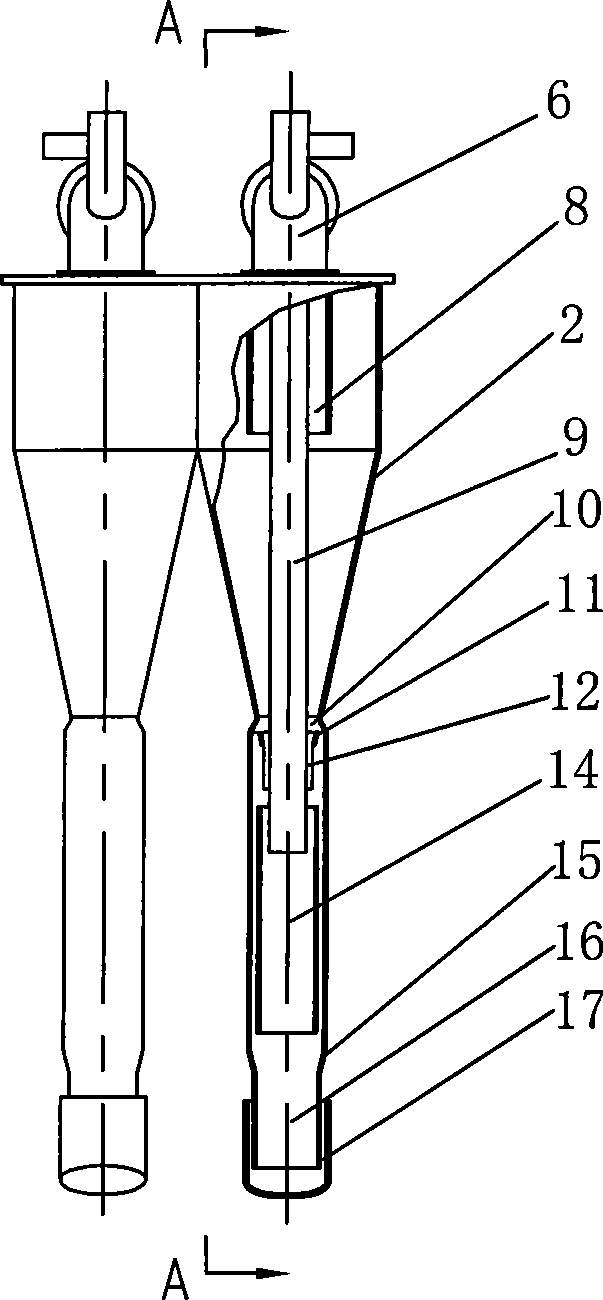

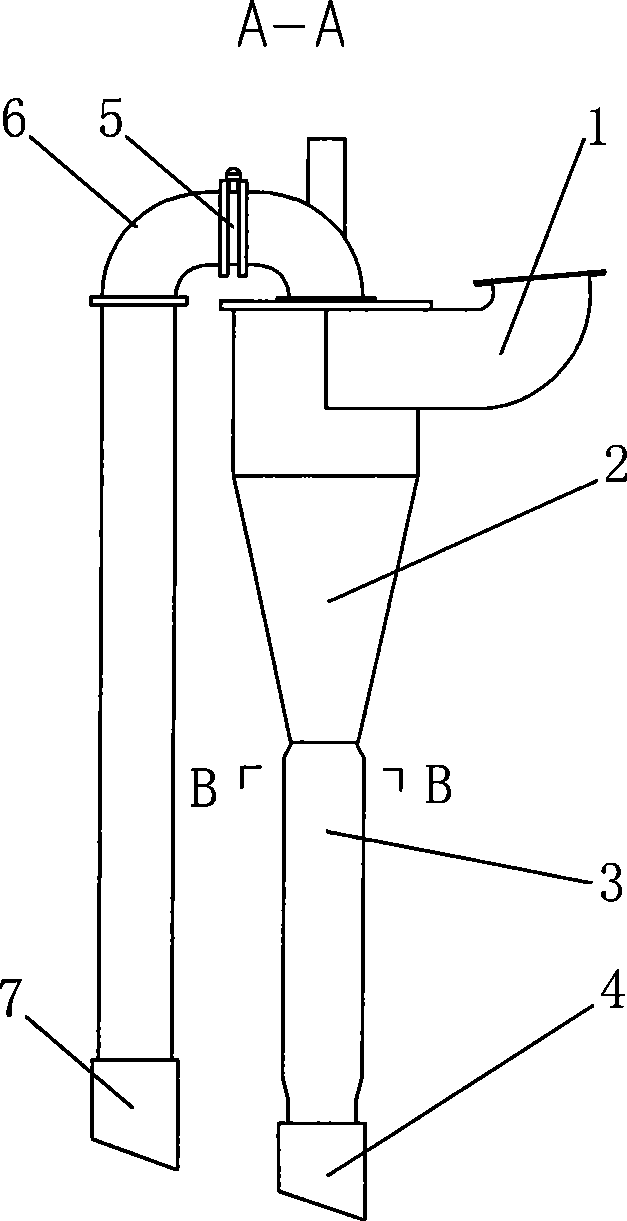

[0022] Example 1, such as figure 1 , 2 , Shown in 3, a kind of pulverized coal burner comprises two and has the cyclone tube 2 of primary air powder tangential inlet, and the cyclone tube is two parallel cylinders. The middle part of the cyclone 2 is a tapered constriction section; the exhaust gas pipeline 6 inserted from the top of the cyclone 2 and having the exhaust air regulating damper 5 is arranged in the primary pulverized coal combustion chamber 14 in the straight section 3 of the outlet of the cyclone 2 And secondary pulverized coal combustion chamber 16. It also includes a micro-oil gasification oil gun 9. The micro-oil gasification oil gun 9 is inserted from the top of the cyclone 2 and passes through the inlet 8 of the exhaust gas pipeline to the inlet of the first-stage pulverized coal combustion chamber 14. A more retracted throat 10 is provided at the junction of the constricted section of the cyclone 2 and the straight section 3 .

Embodiment 2

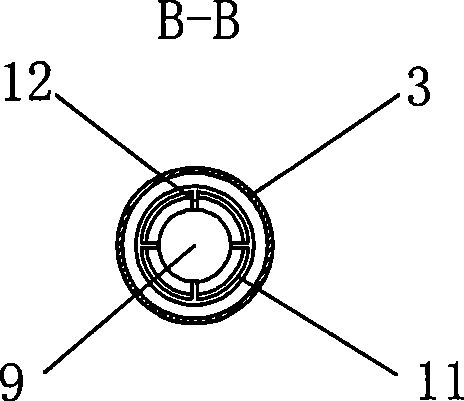

[0023] Embodiment 2, a pulverized coal burner, in order to further concentrate the pulverized coal concentrated at the throat, a concentration ring 11 is provided outside the throat 10 . All the other are with embodiment 1.

Embodiment 3

[0024] Embodiment 3, a pulverized coal burner, in order to eliminate the primary pulverized coal cyclone coming out of the cyclone and make the burner burn better, a derotation vane 12 is provided outside the throat 10 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com