Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Producer gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Producer gas is fuel gas that is manufactured from material such as coal, as opposed to natural gas. It can be produced from various fuels by partial combustion with air, usually modified by simultaneous injection of water or steam to maintain a constant temperature and obtain a higher heat content gas by enrichment of air gas with hydrogen. In this respect it is similar to other types of "manufactured" gas, such as coal gas, coke oven gas, water gas and carburetted water gas. Producer gas was used primarily as an industrial fuel for iron and steel manufacturing, such as firing coke ovens and blast furnaces, cement and ceramic kilns, or for mechanical power through gas engines. It was characteristically low in heating value but cheap to make, so that large amounts could be made and burned.

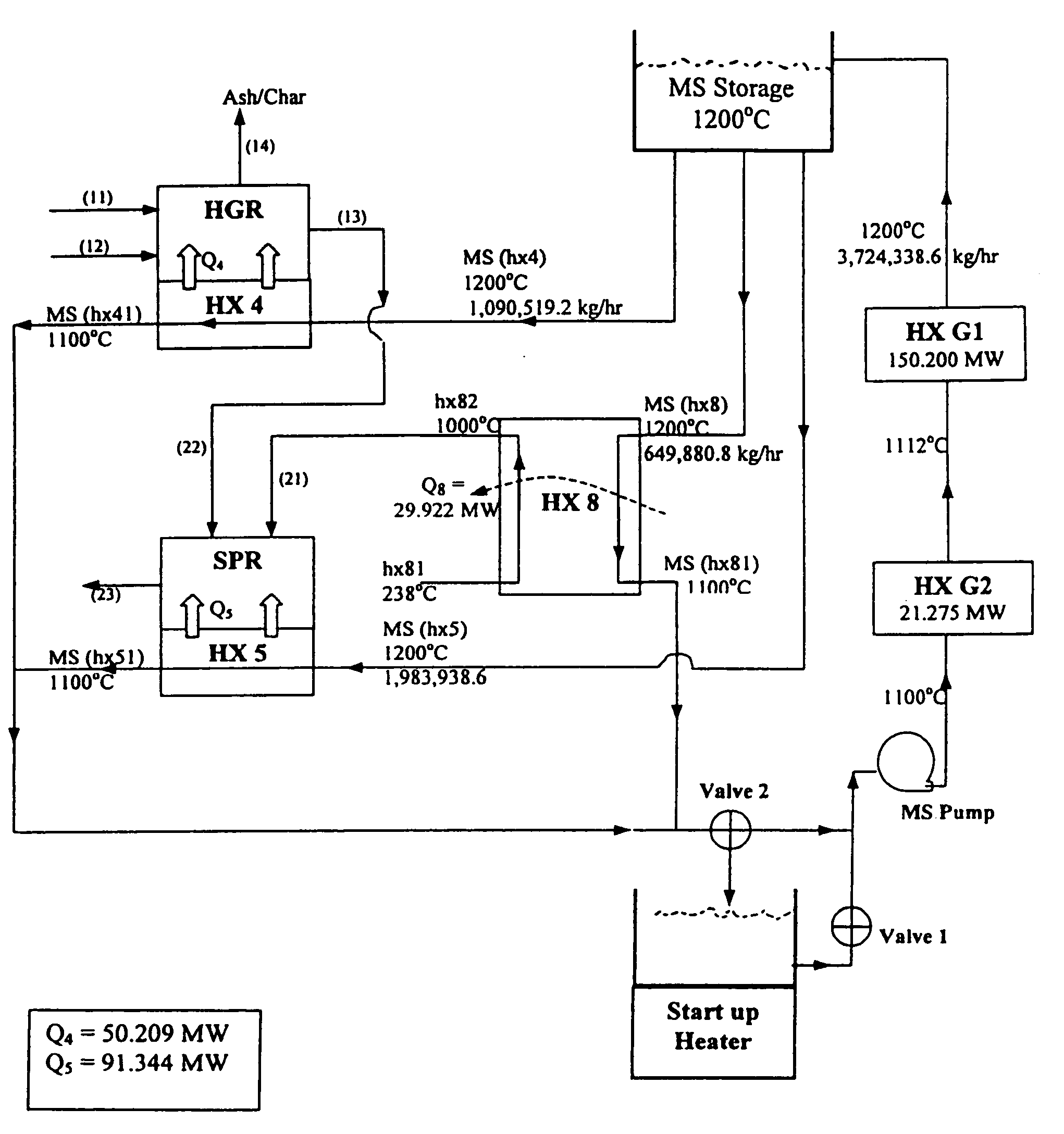

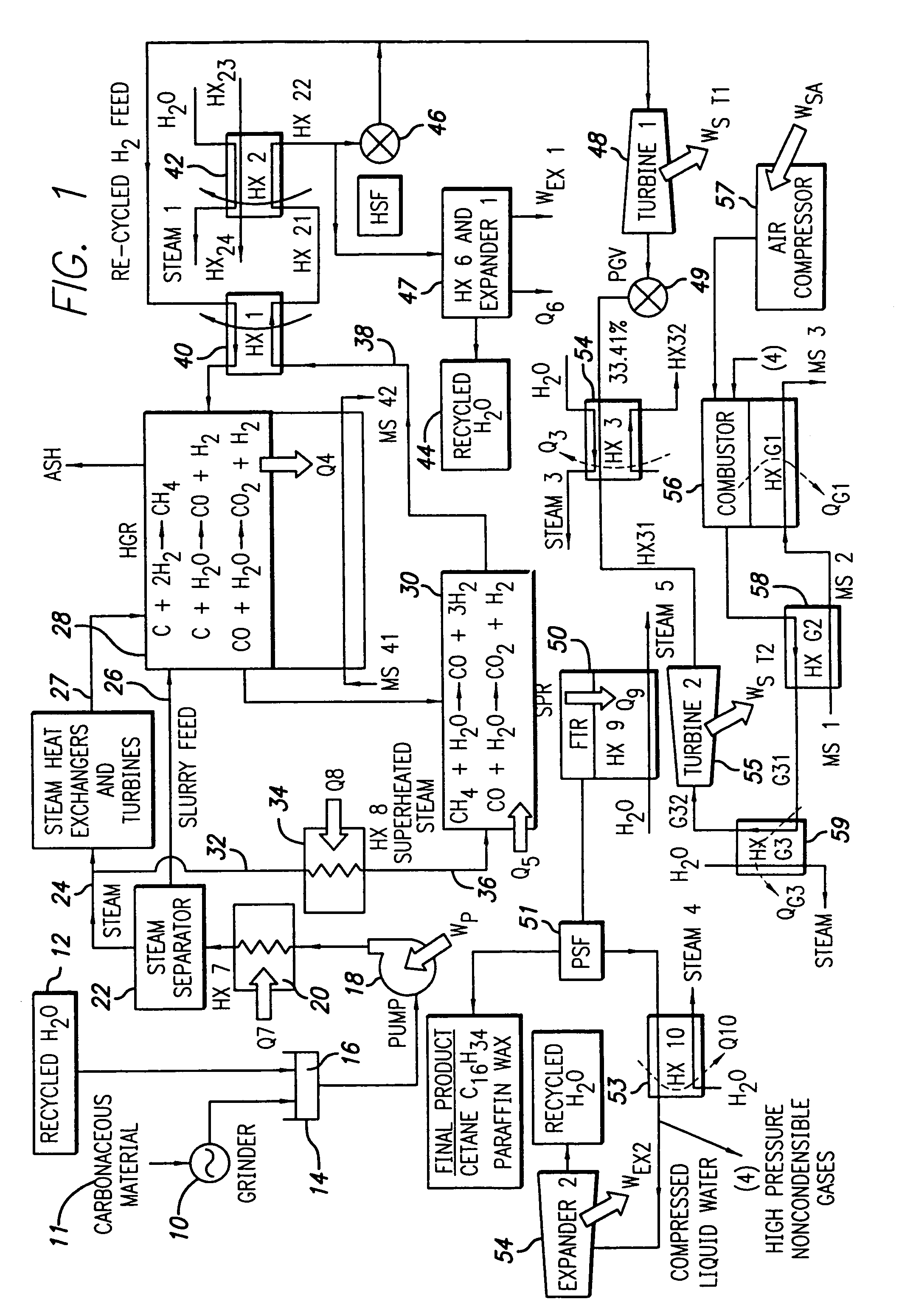

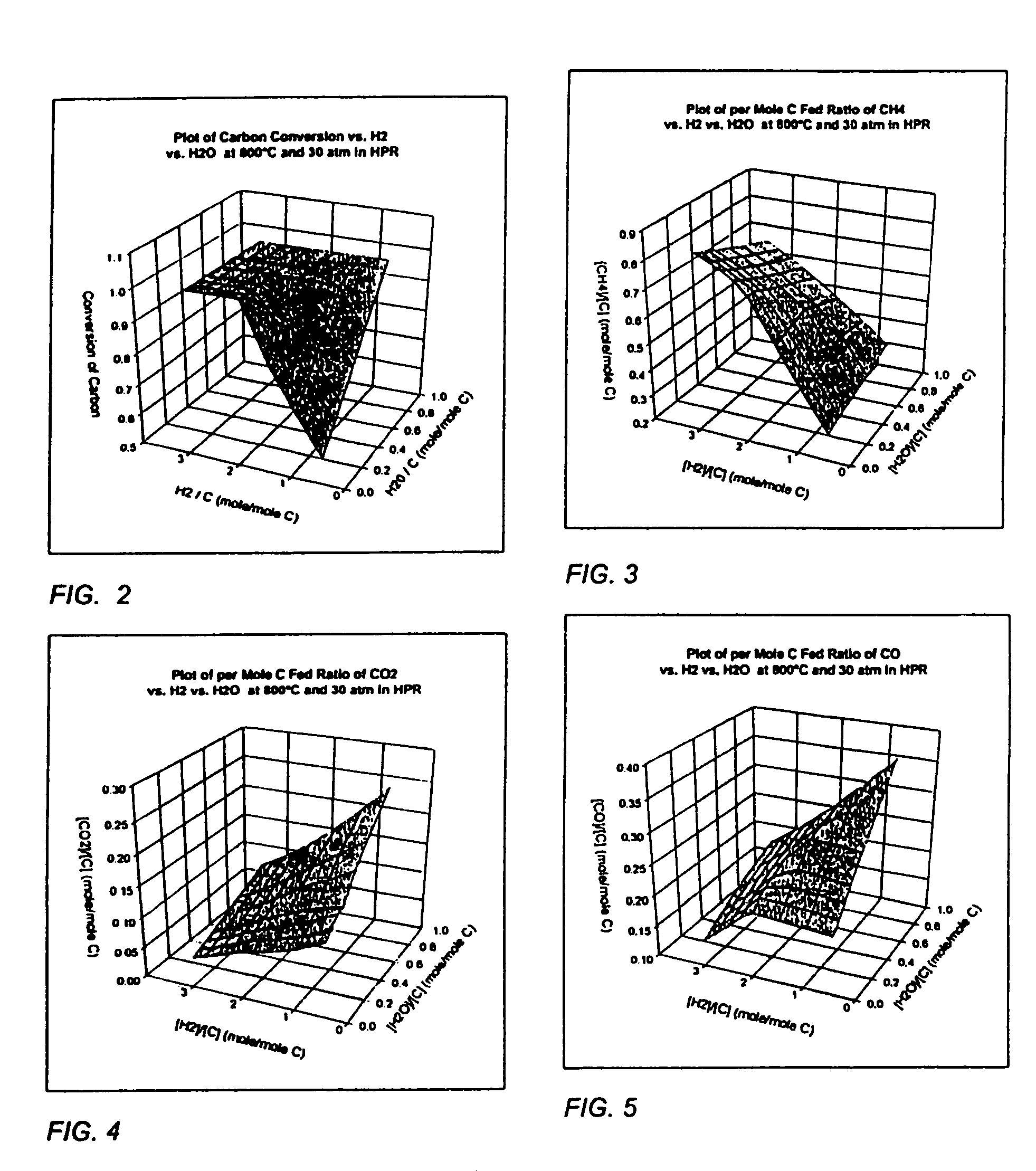

Production of synthetic transportation fuels from carbonaceous material using self-sustained hydro-gasification

InactiveUS7208530B2Easy to analyzeEnergy efficiencyWaste based fuelHydrogen productionElectricitySyngas

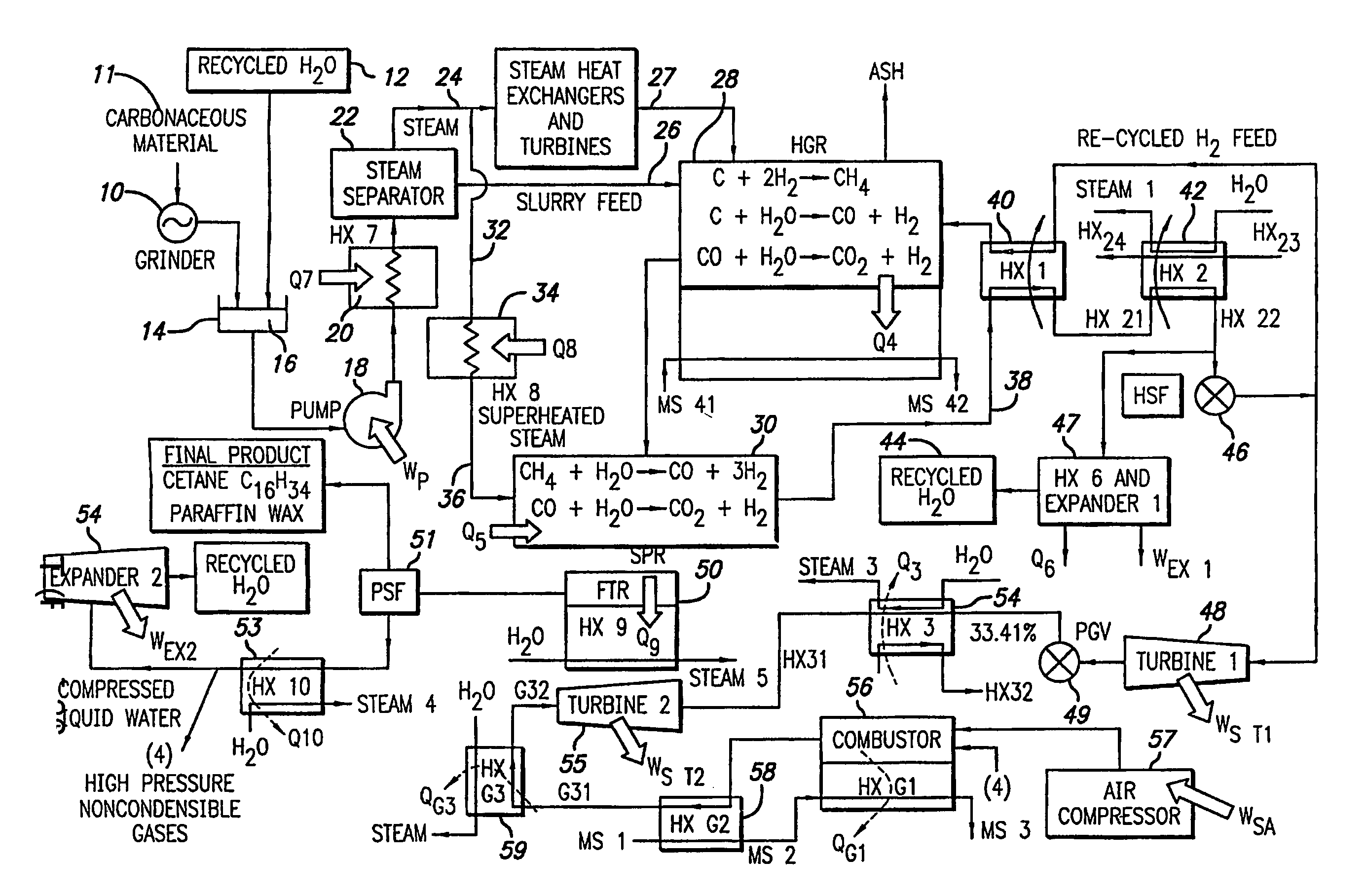

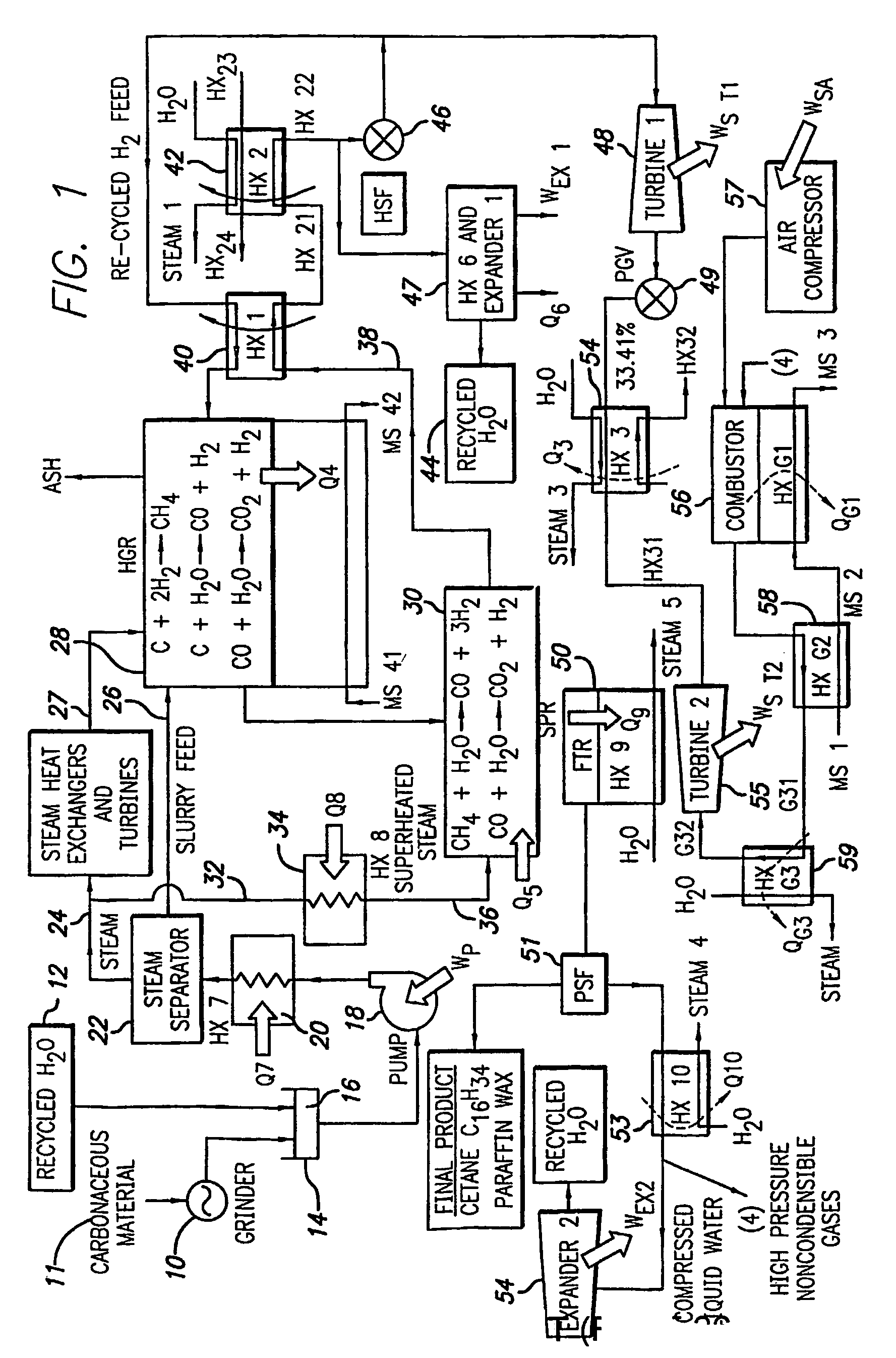

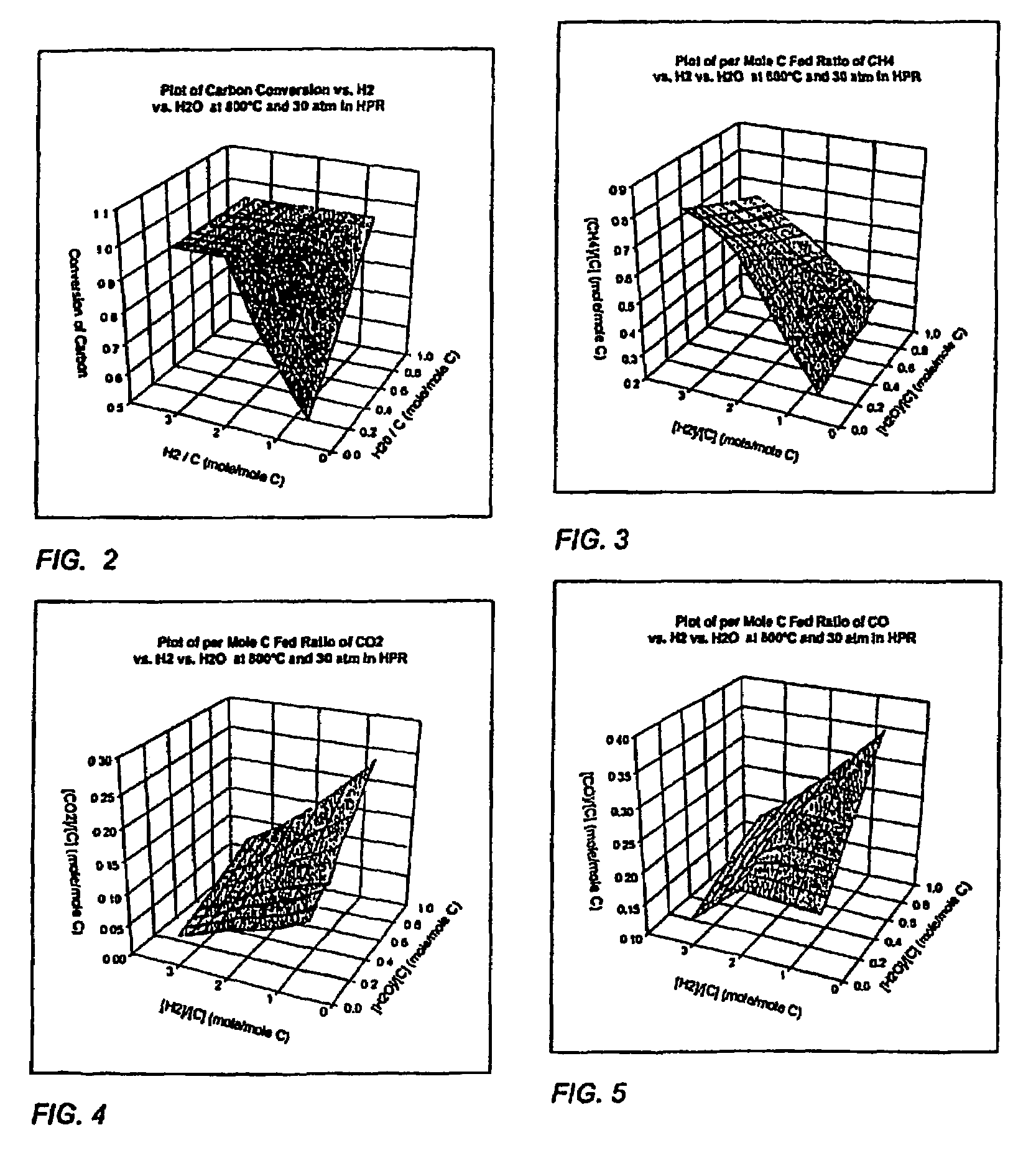

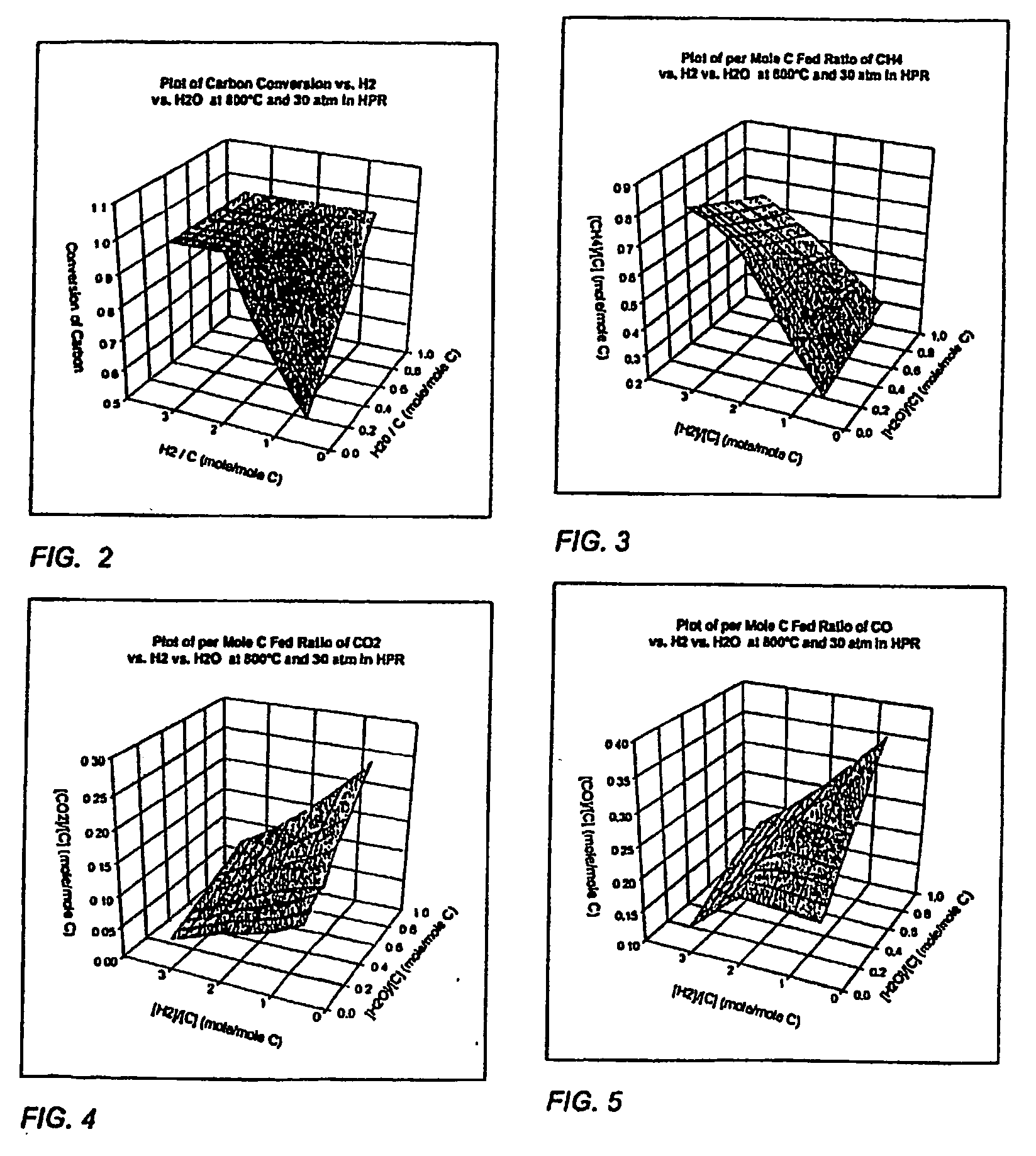

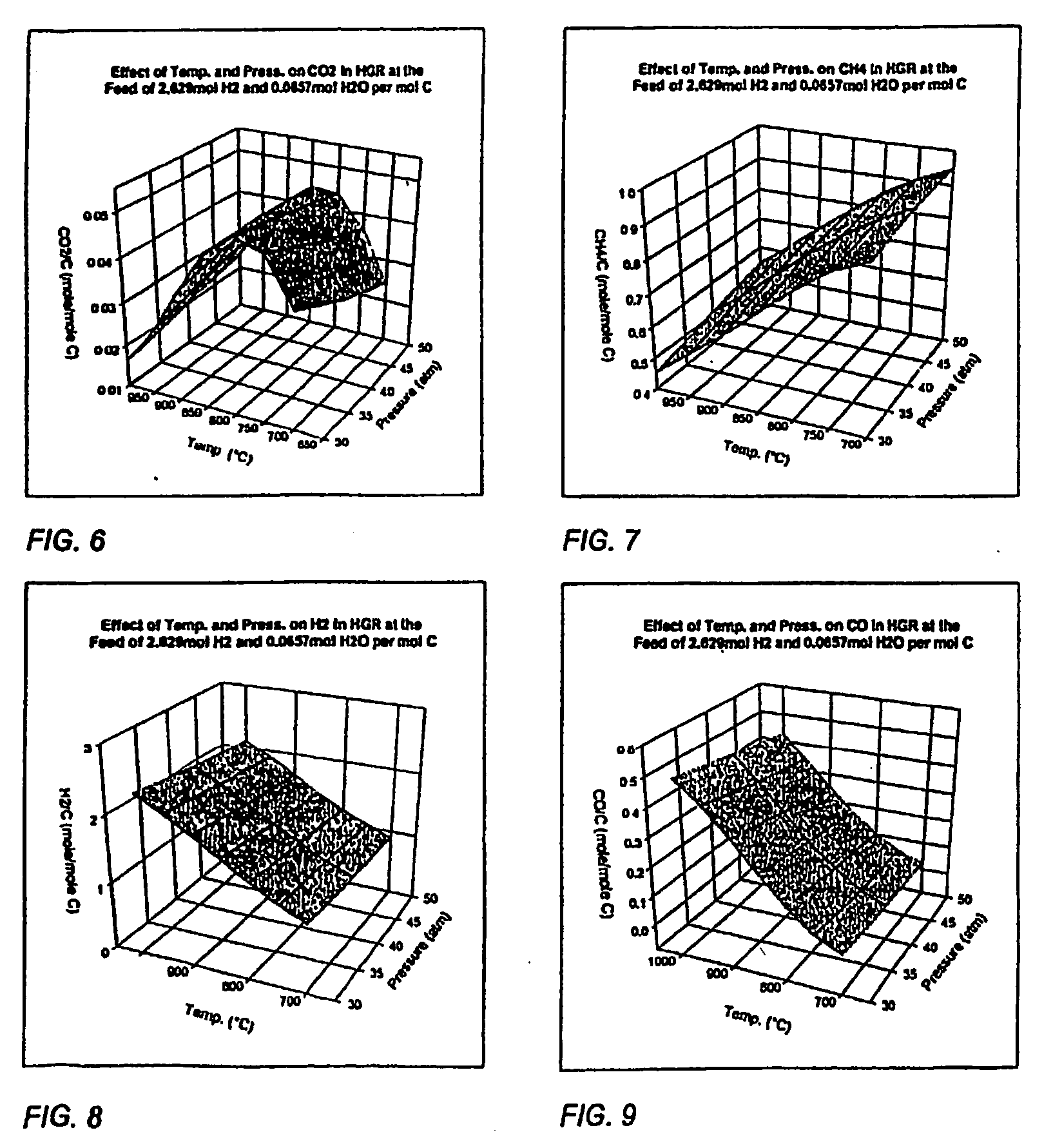

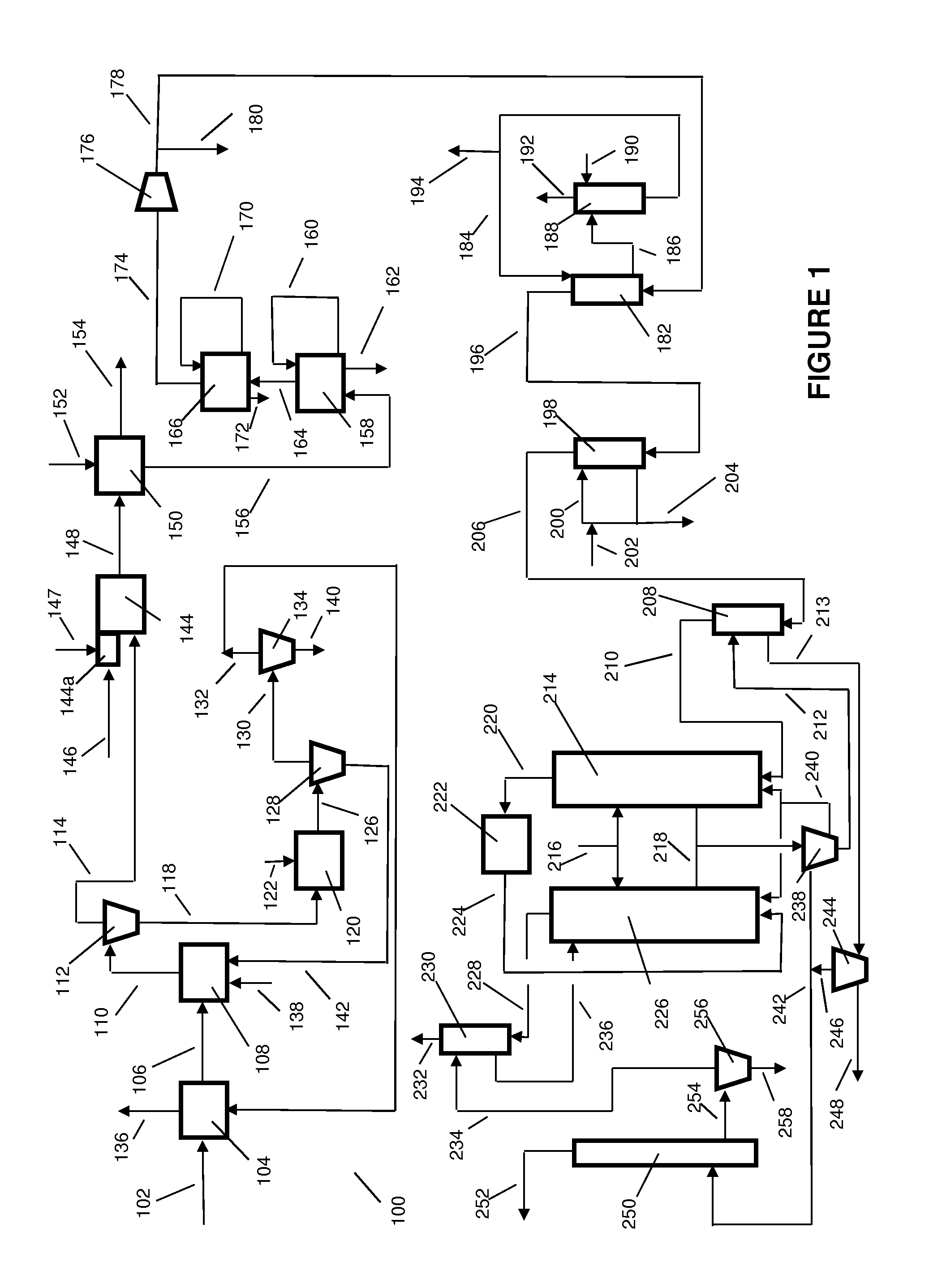

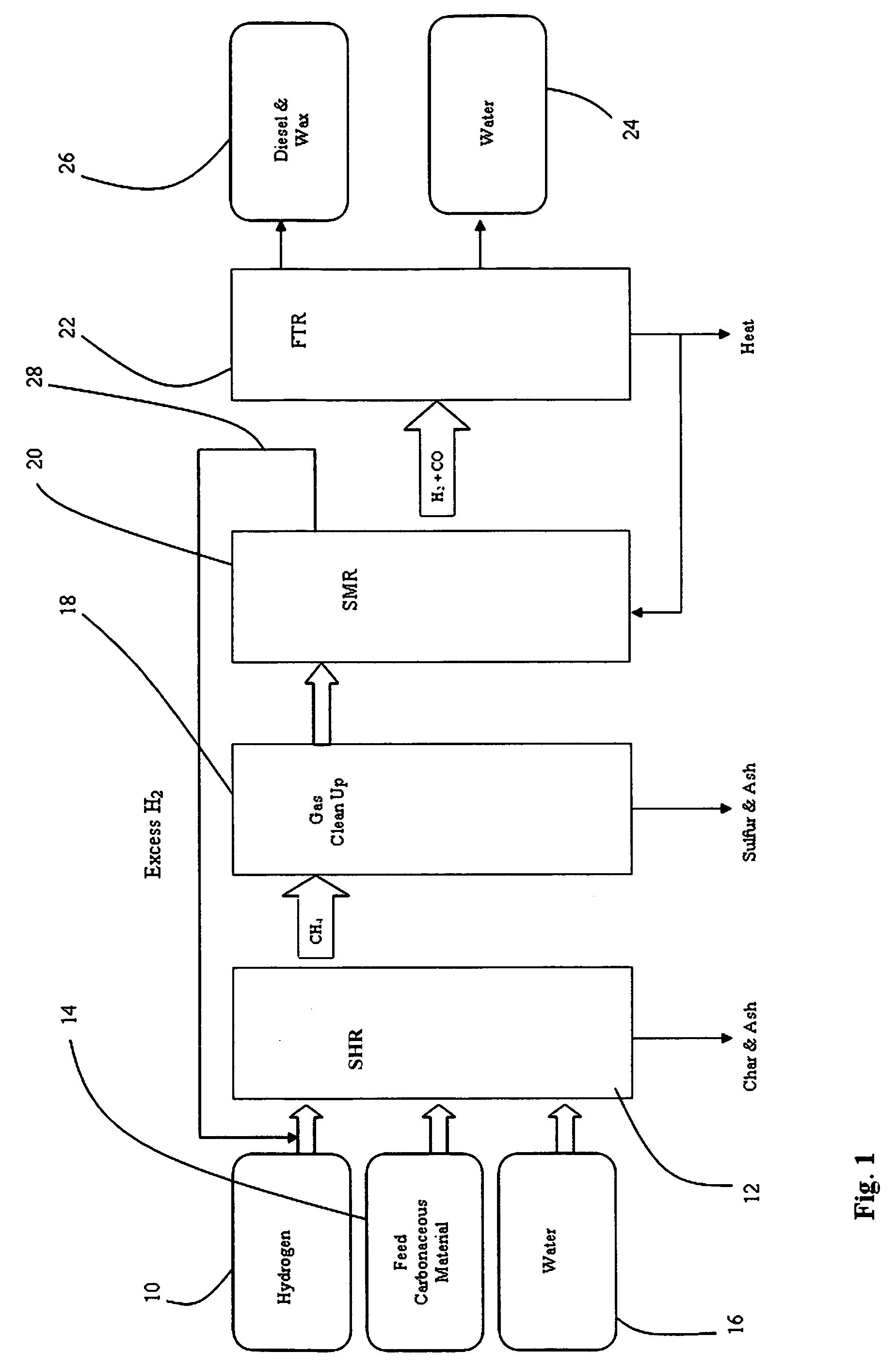

A process and apparatus for producing a synthesis gas for use as a gaseous fuel or as feed into a Fischer-Tropsch reactor to produce a liquid fuel in a substantially self-sustaining process. A slurry of particles of carbonaceous material in water, and hydrogen from an internal source, are fed into a hydro-gasification reactor under conditions whereby methane rich producer gases are generated and fed into a steam pyrolytic reformer under conditions whereby synthesis gas comprising hydrogen and carbon monoxide are generated. A portion of the hydrogen generated by the steam pyrolytic reformer is fed through a hydrogen purification filter into the hydro-gasification reactor, the hydrogen therefrom constituting the hydrogen from an internal source. The remaining synthesis gas generated by the steam pyrolytic reformer is either used as fuel for a gaseous fueled engine to produce electricity and / or process heat or is fed into a Fischer-Tropsch or similar reactor under conditions whereby a liquid fuel is produced.

Owner:RGT UNIV OF CALIFORNIA

Production of synthetic transporation fuels from carbonaceous material using self-sustained hydro-gasification

InactiveUS20050256212A1Reduce air emissionsImprove energy efficiencyWaste based fuelHydrogen productionSyngasProducer gas

A process and apparatus for producing a synthesis gas for use as a gaseous fuel or as feed into a Fischer-Tropsch reactor to produce a liquid fuel in a substantially self-sustaining process. A slurry of particles of carbonaceous material in water, and hydrogen from an internal source, are fed into a hydro-gasification reactor under conditions whereby methane rich producer gases are generated and fed into a steam pyrolytic reformer under conditions whereby synthesis gas comprising hydrogen and carbon monoxide are generated. A portion of the hydrogen generated by the steam pyrolytic reformer is fed through a hydrogen purification filter into the hydro-gasification reactor, the hydrogen therefrom constituting the hydrogen from an internal source. The remaining synthesis gas generated by the steam pyrolytic reformer is either used as fuel for a gaseous fueled engine to produce electricity and / or process heat or is fed into a Fischer-Tropsch reactor under conditions whereby a liquid fuel is produced. Molten salt loops are used to transfer heat from the hydro-gasification reactor, and Fischer-Tropsch reactor if liquid fuel is produced, to the steam generator and the steam pyrolytic reformer.

Owner:RGT UNIV OF CALIFORNIA

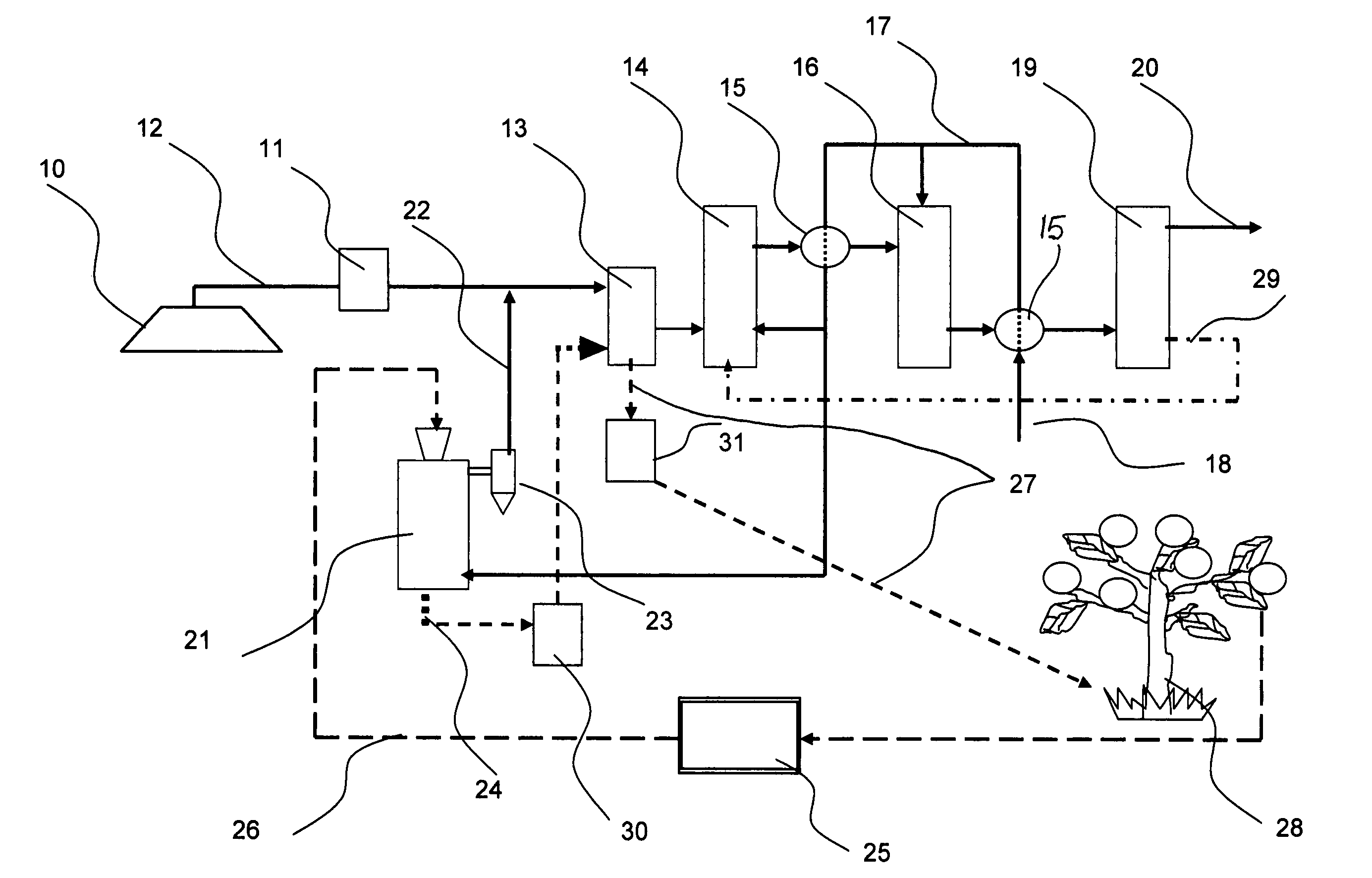

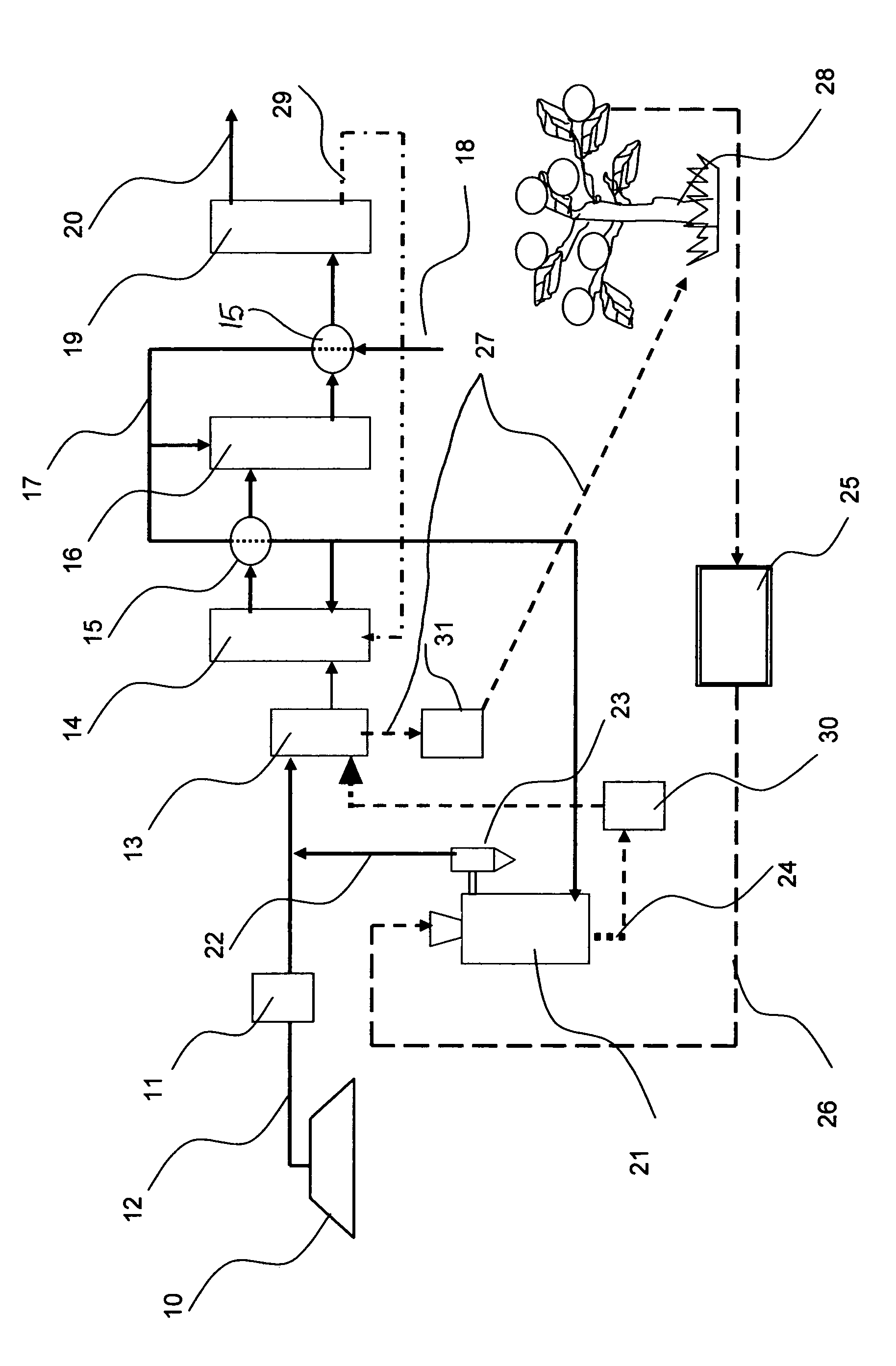

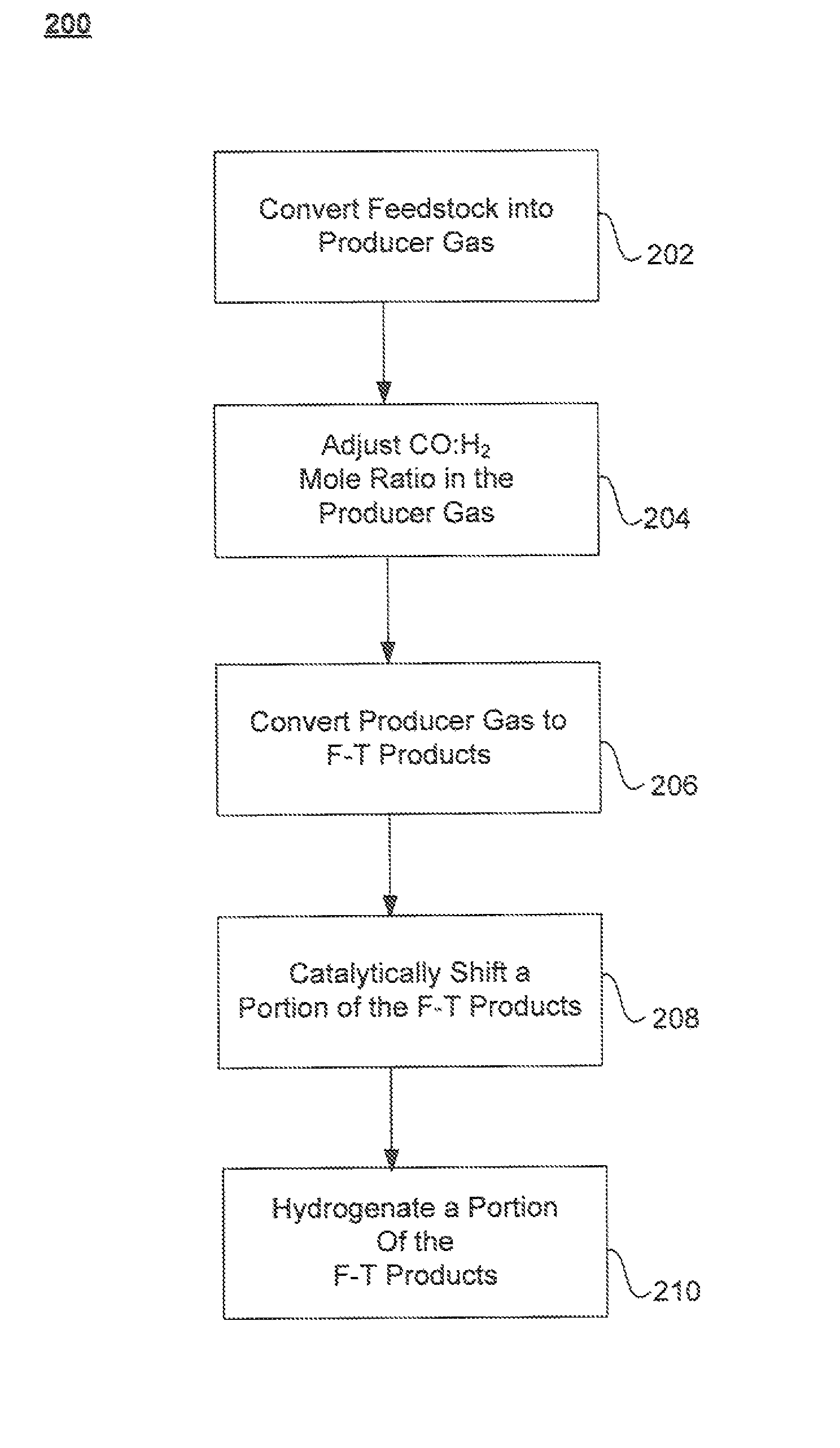

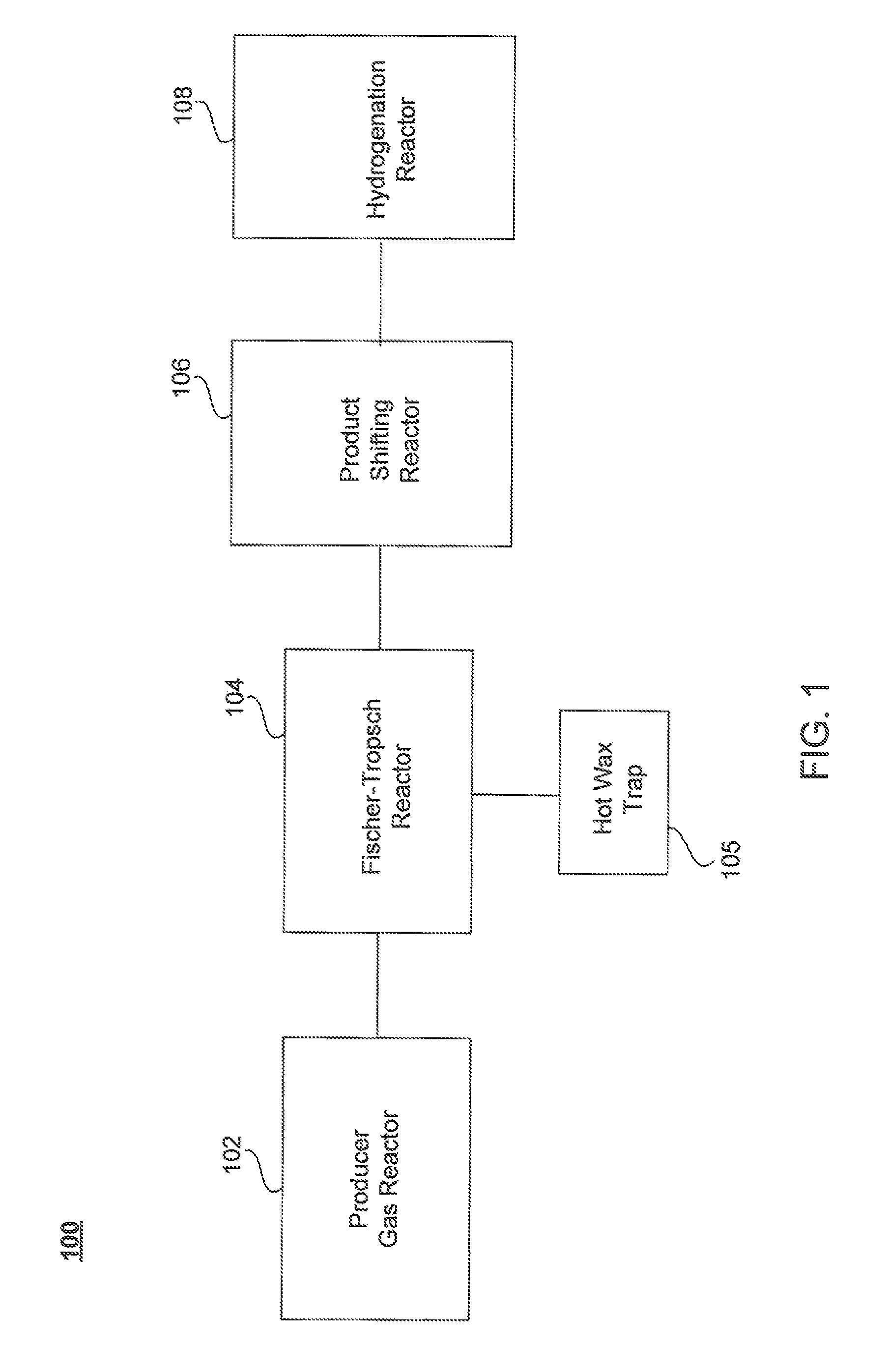

Conversion of biomass feedstocks into hydrocarbon liquid transportation fuels

InactiveUS20100036181A1Reducing and even eliminating transportationReducing and even eliminating and distribution costLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesProduct gasHydrocarbon

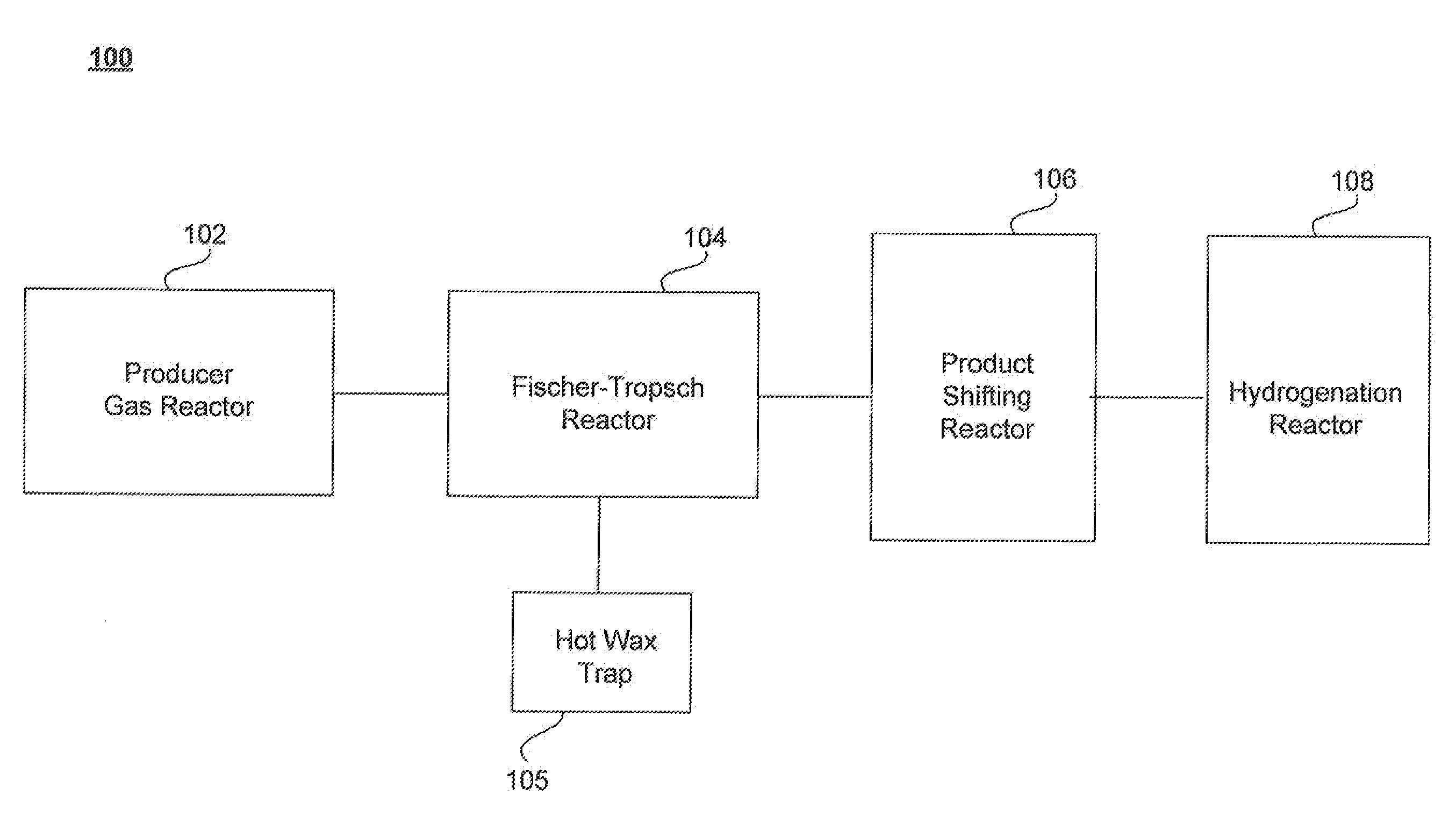

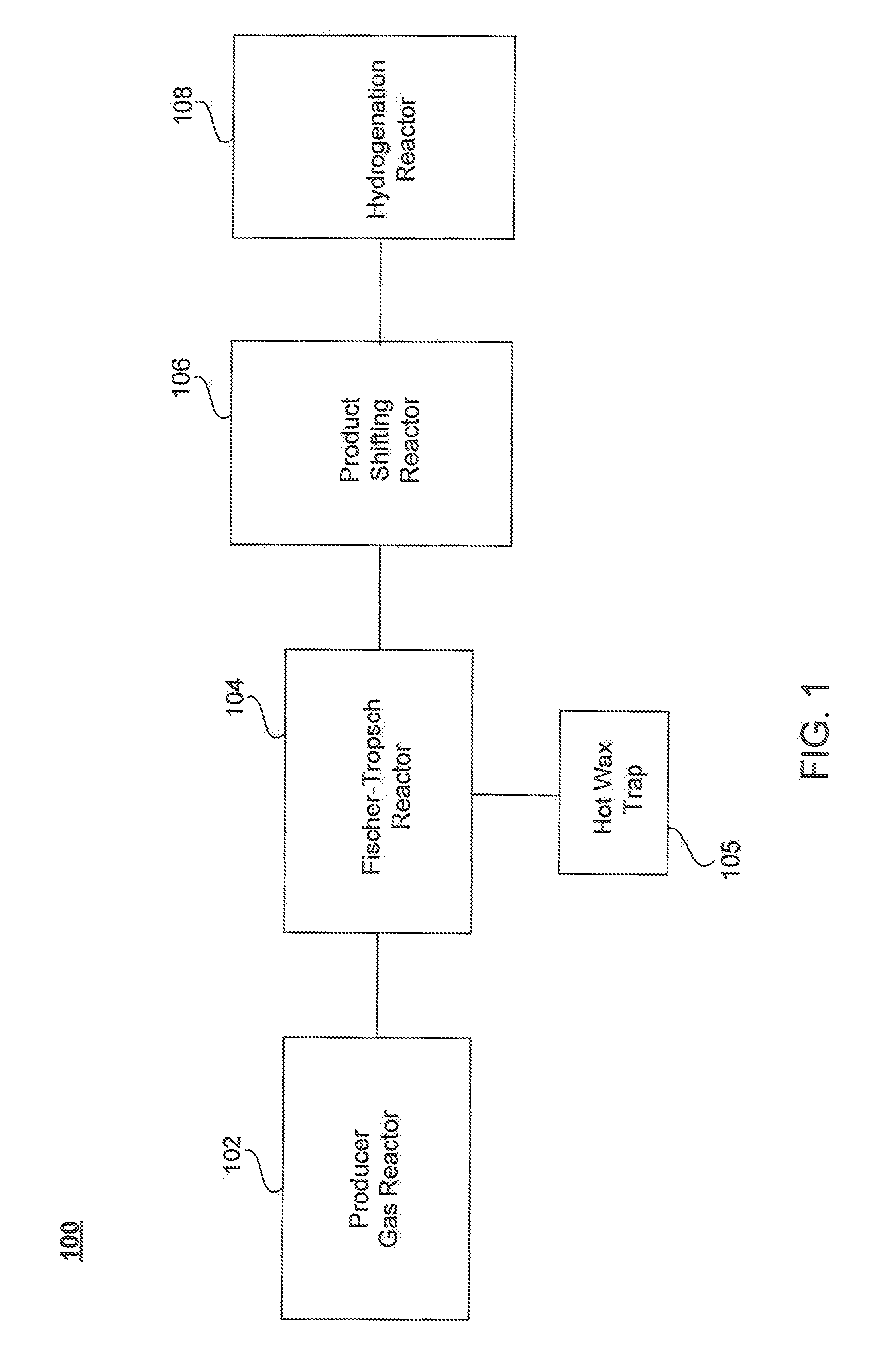

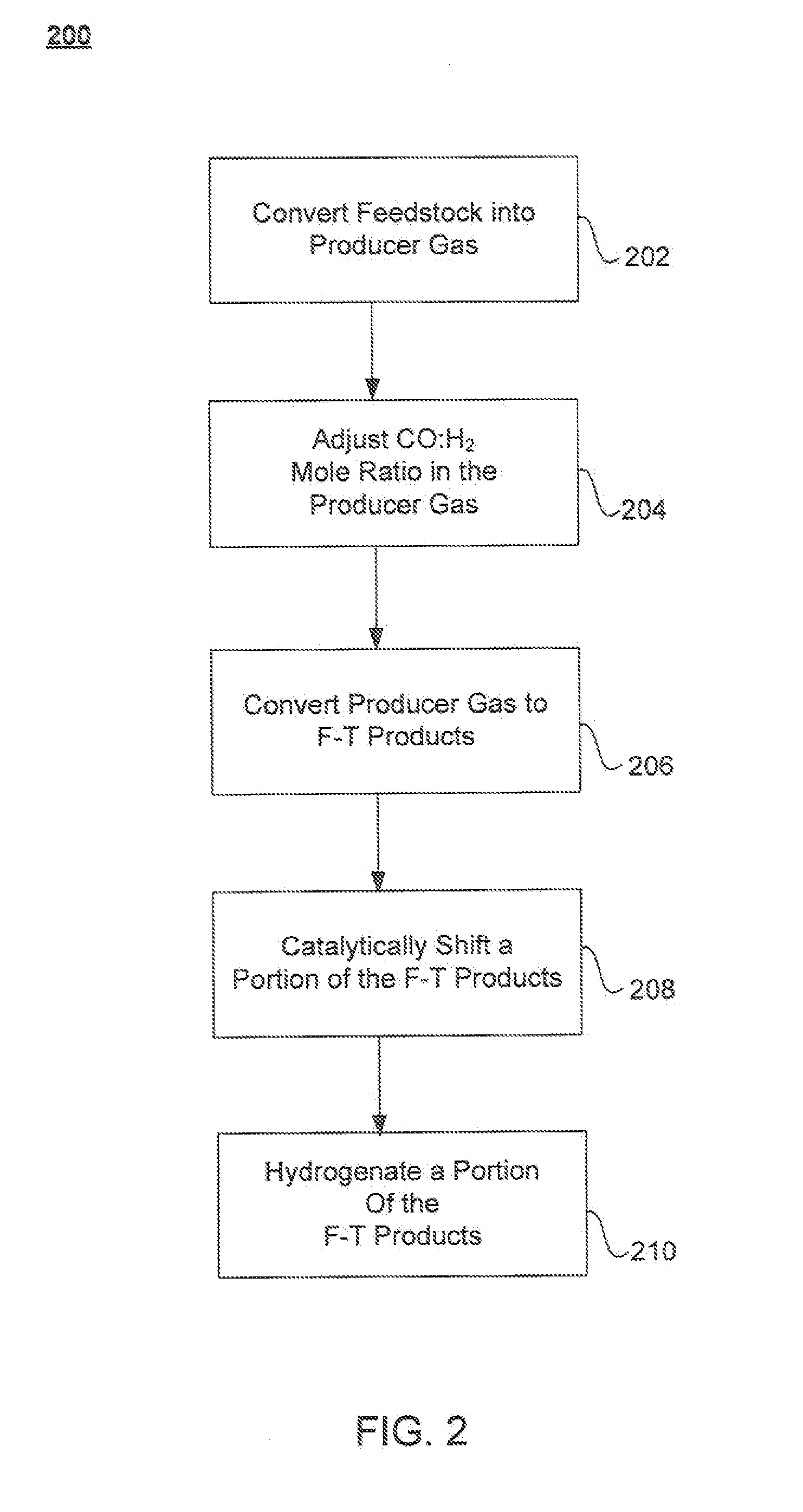

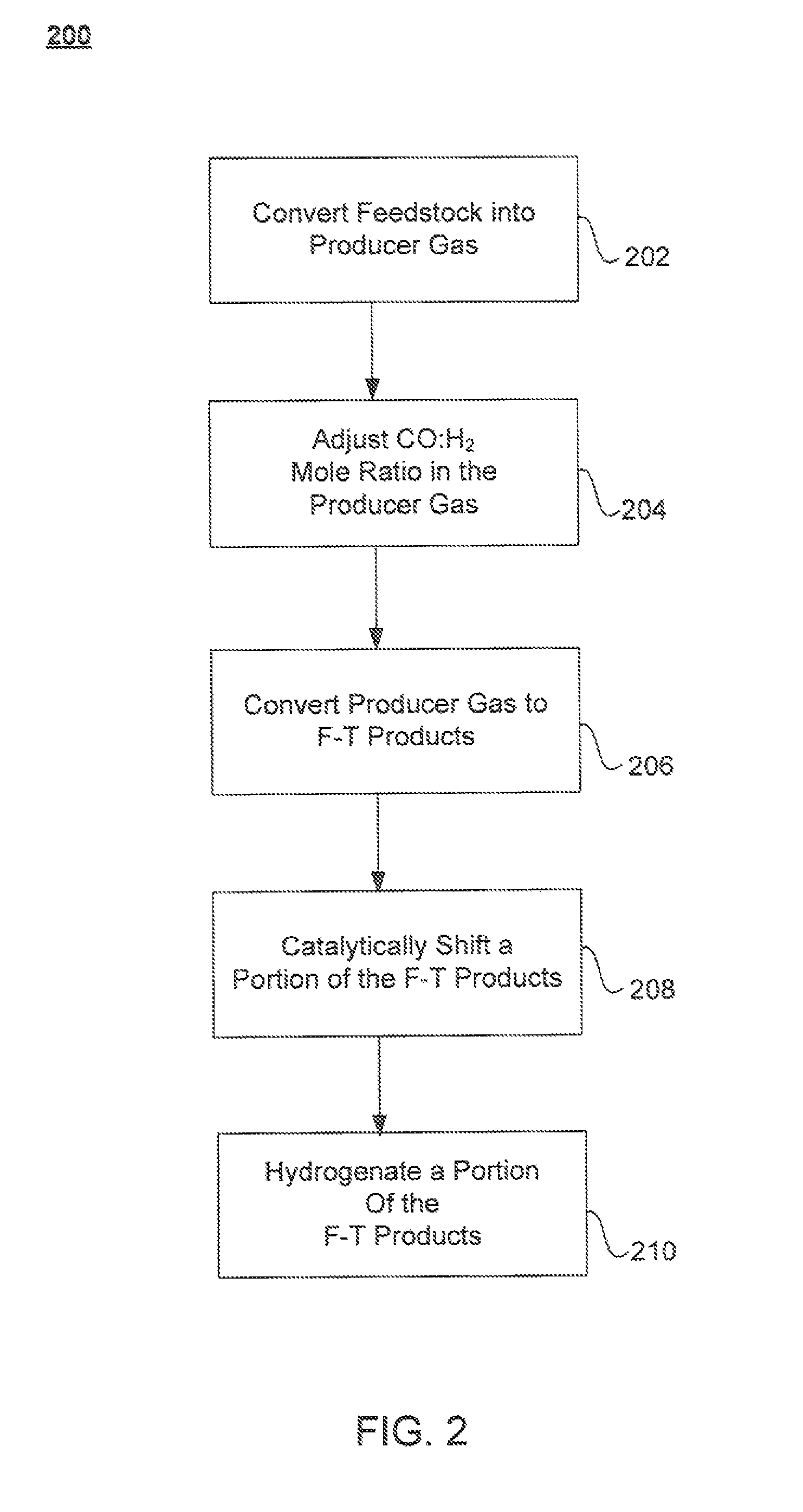

Methods for converting a carbon-containing feedstock into a fluid transportation fuel are described. The methods may include converting the carbon-containing feedstock into a producer gas comprising H2, CO, CO2, and N2, and reacting the producer gas with a substrate catalyst to produce a combination of Fischer-Tropsch (F-T) products, the F-T products including the fluid transportation fuel. A portion of the F-T products may be catalytically cracked to produce additional amounts of the fluid transportation fuel. A portion of the F-T products may also be hydrogenated to produce additional amounts of the fluid transportation fuel. Apparatuses are also described or converting a carbon-containing feedstock into a fluid transportation fuel. The apparatuses may include a producer gas reactor, a Fischer-Tropsch reactor, a cracking reactor, and a hydrogenation reactor.

Owner:COMMUNITY POWER CORP

Integrated thermochemical and biocatalytic energy production system

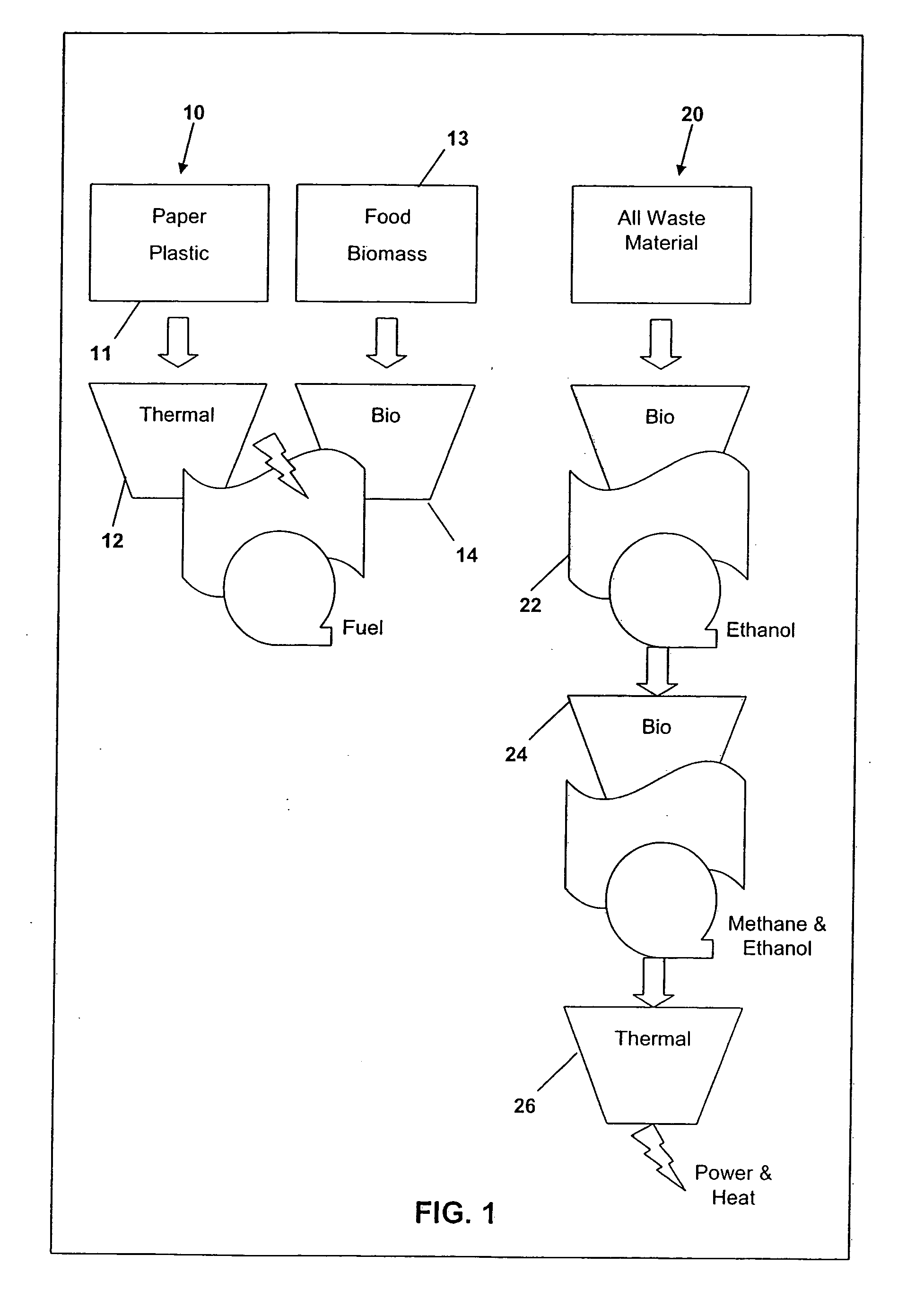

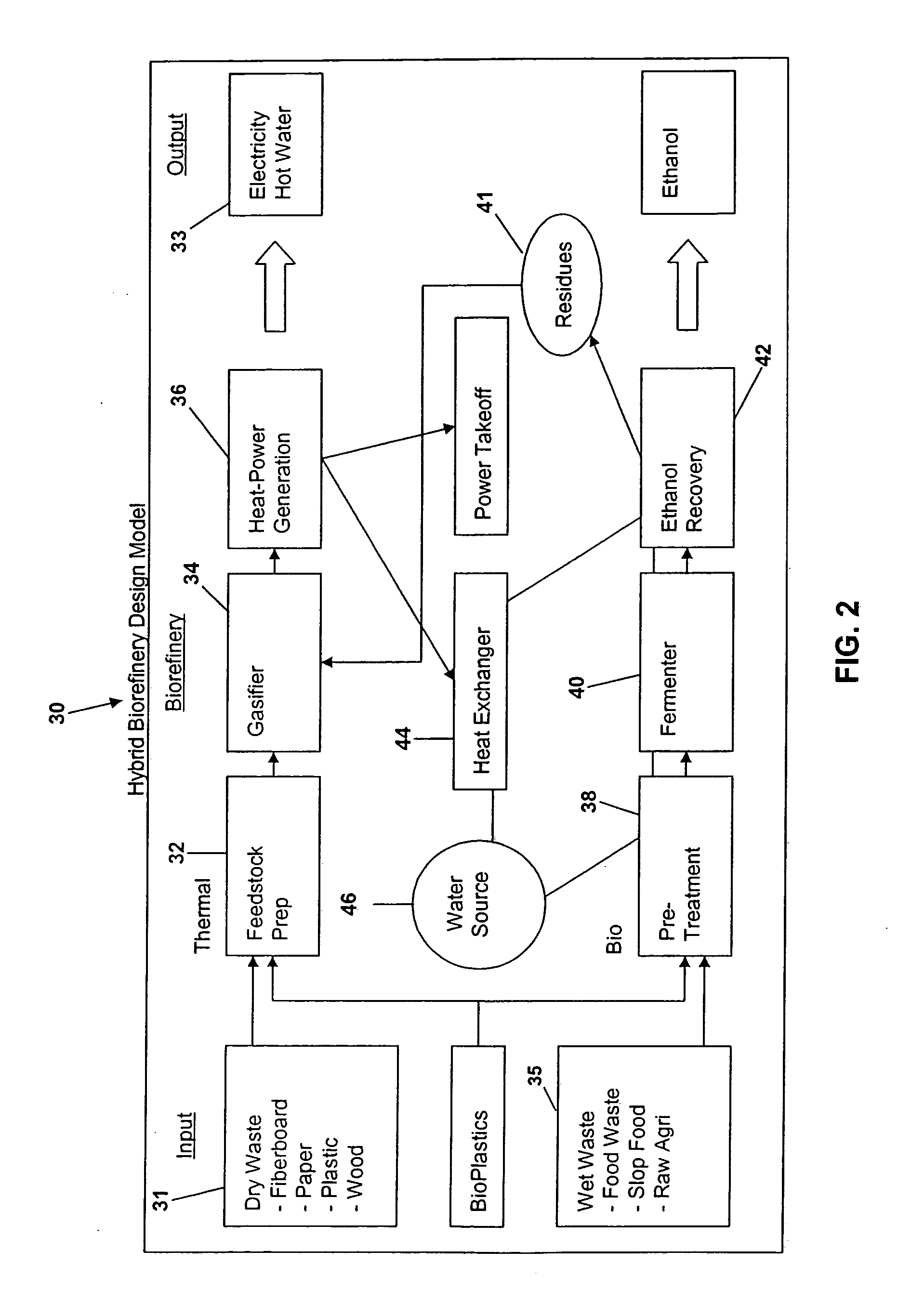

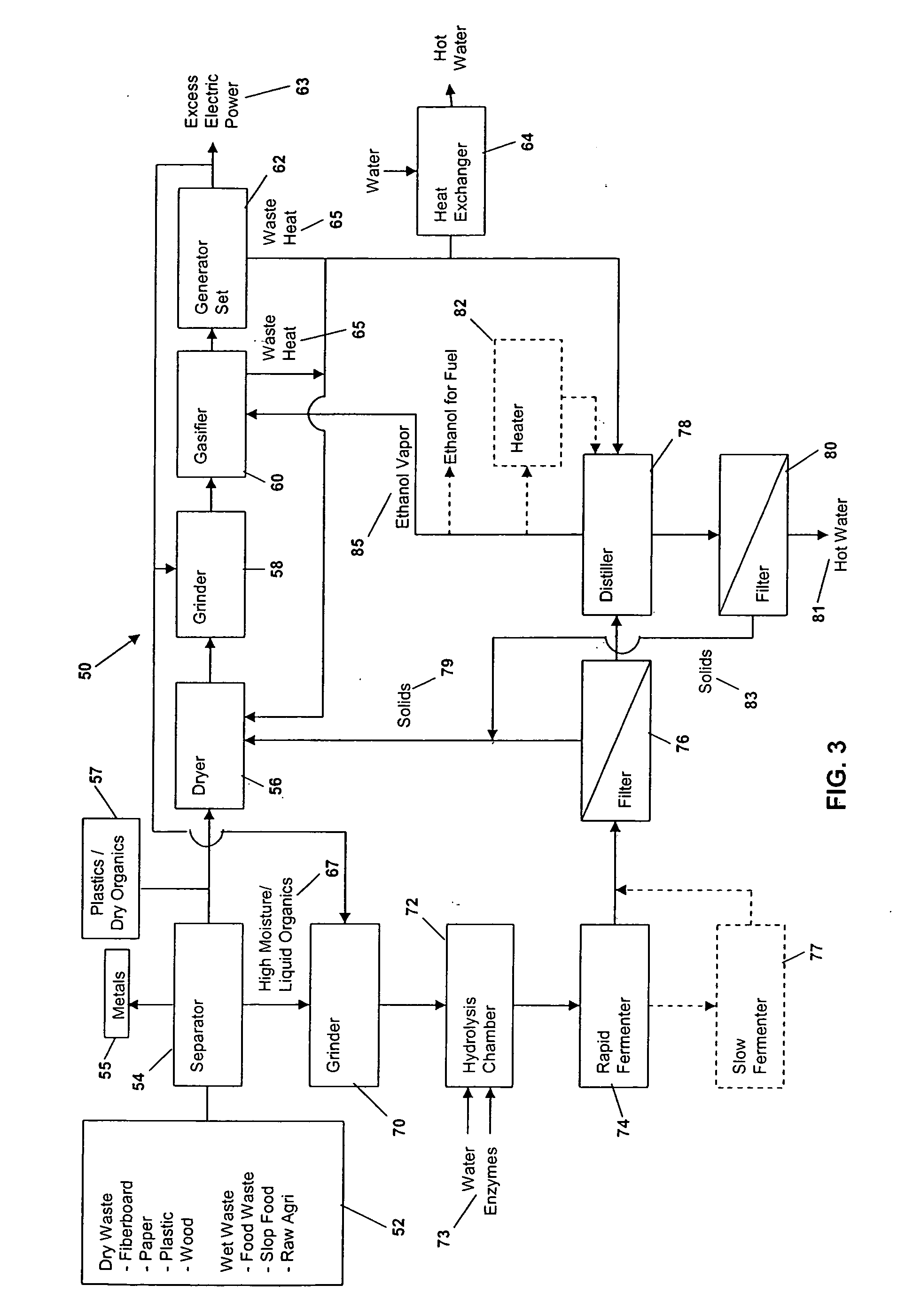

InactiveUS20070117195A1Readily susceptibleEnergy costBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationWaste stream

A method and apparatus for treating organic wastes is provided. Organic wastes are separated into high and low moisture content organic waste streams. The low moisture content organic waste stream is subjected to a gasification process and generates a producer gas. The high moisture content organic waste is subjected to a fermentation process and produces a mixture of ethanol and water. Waste heat from the gasification process is subjected to a distillation column. Vapors recovered from the distillation column are mixed in a hydrous vapor form with the producer gas and produce fuel that can be used as an energy source.

Owner:PURDUE RES FOUND INC

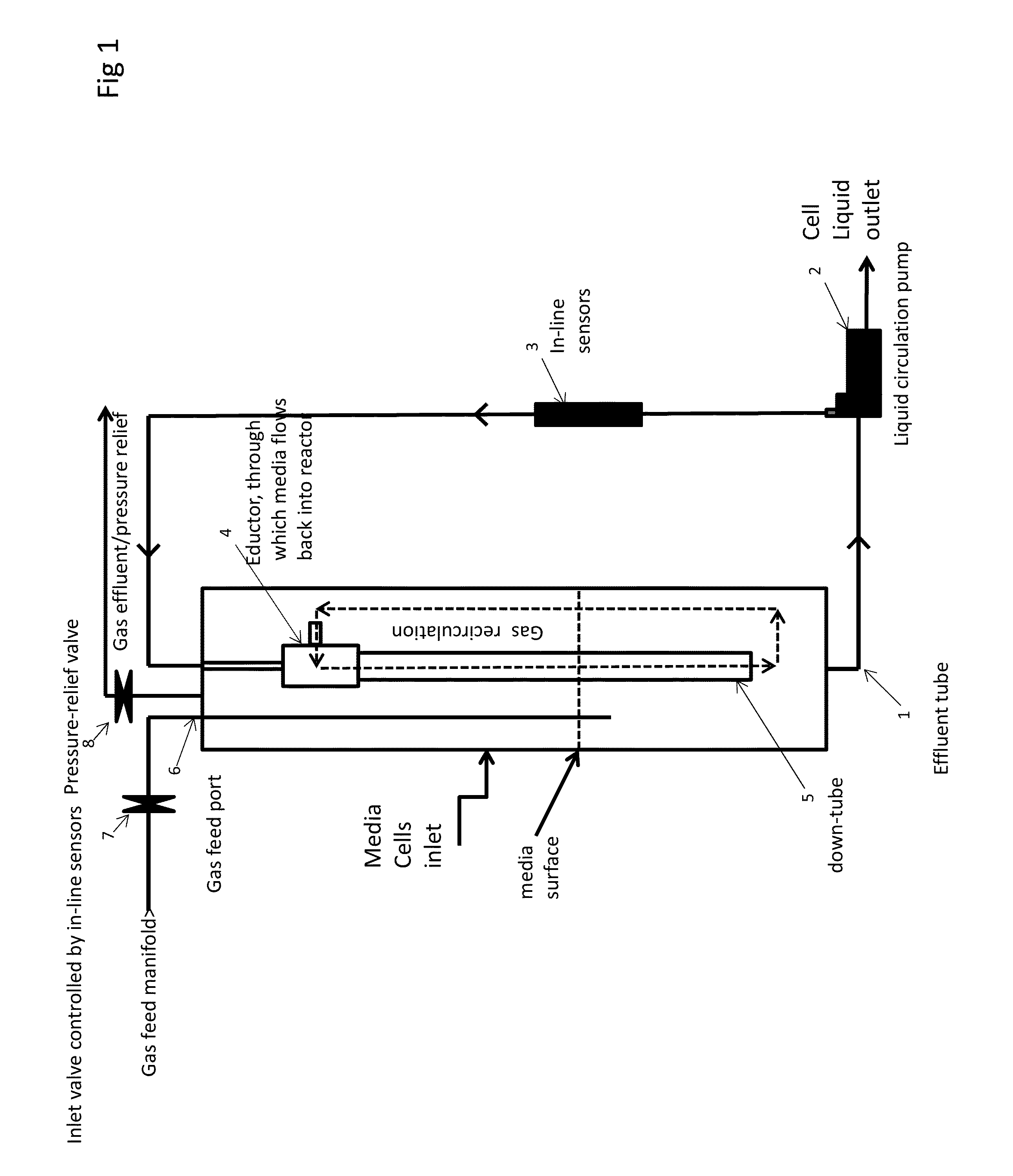

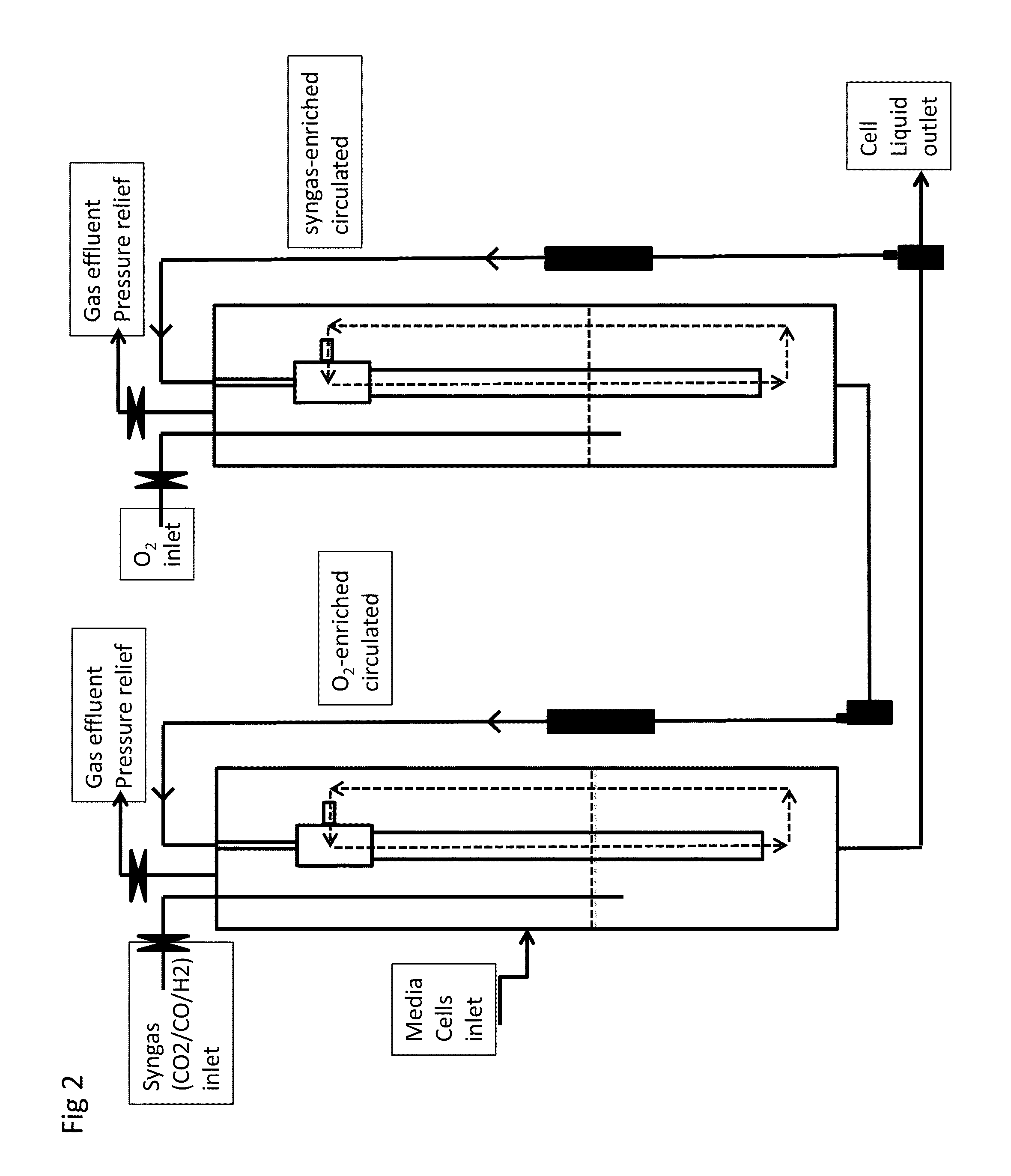

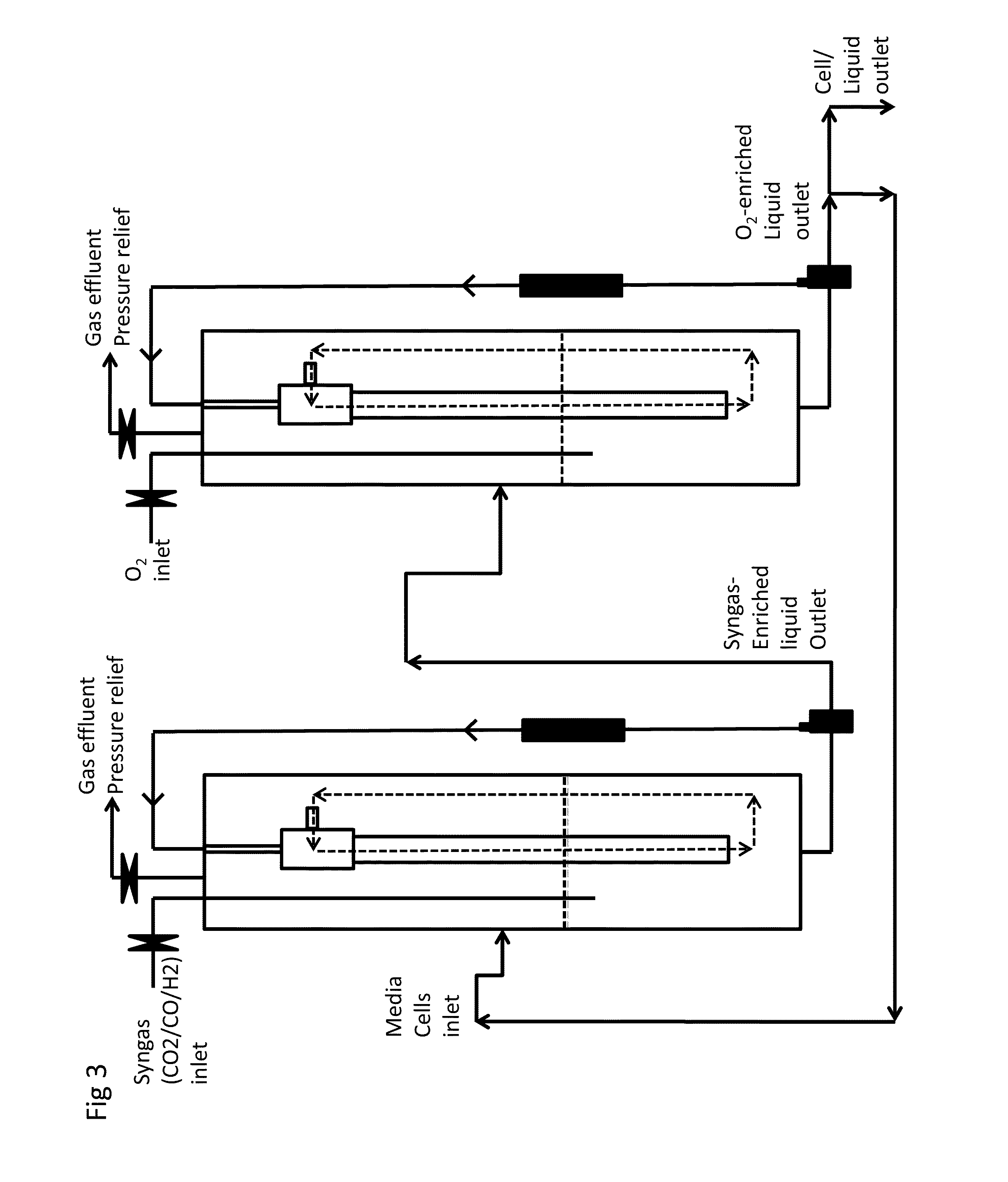

Method and apparatus for growing microbial cultures that require gaseous electron donors, electron acceptors, carbon sources, or other nutrients

ActiveUS20130189763A1Longer carbon chainIncrease energy densityBioreactor/fermenter combinationsBiological substance pretreatmentsLipid formationElectron donor

Compositions and methods and apparatus for growth and maintenance of microorganisms and / or bioprocesses using one or more gases as electron donors, electron acceptors, carbon sources, or other nutrients, and for a bioprocess that converts hydrogen and carbon dioxide, or syngas, or producer gas into lipid products, bio-based oils, or other biochemical products.

Owner:KIVERDI INC

Steam pyrolysis as a process to enhance the hydro-gasification of carbonaceous materials

InactiveUS7500997B2Easy to analyzeShort stayWaste based fuelLiquid hydrocarbon mixture productionSyngasElectricity

A process and apparatus for producing a synthesis gas for use as a gaseous fuel or as feed into a Fischer-Tropsch reactor to produce a liquid fuel in a substantially self-sustaining process. In one embodiment, a slurry of carbonaceous material in water, and hydrogen from an internal source, are fed into a hydro-gasification reactor to generate methane rich producer gases which are fed into a steam pyrolytic reformer to generate synthesis gas comprising hydrogen and carbon monoxide. A portion of the hydrogen is used as the internal hydrogen source. The remaining synthesis gas is either used as fuel to produce electricity and / or process heat or is fed into a Fischer-Tropsch reactor to produce liquid fuel. In another embodiment of the invention, carbonaceous material can be heated simultaneously in the presence of both hydrogen and steam to undergo steam pyrolysis and hydro-gasification in a single step.

Owner:RGT UNIV OF CALIFORNIA

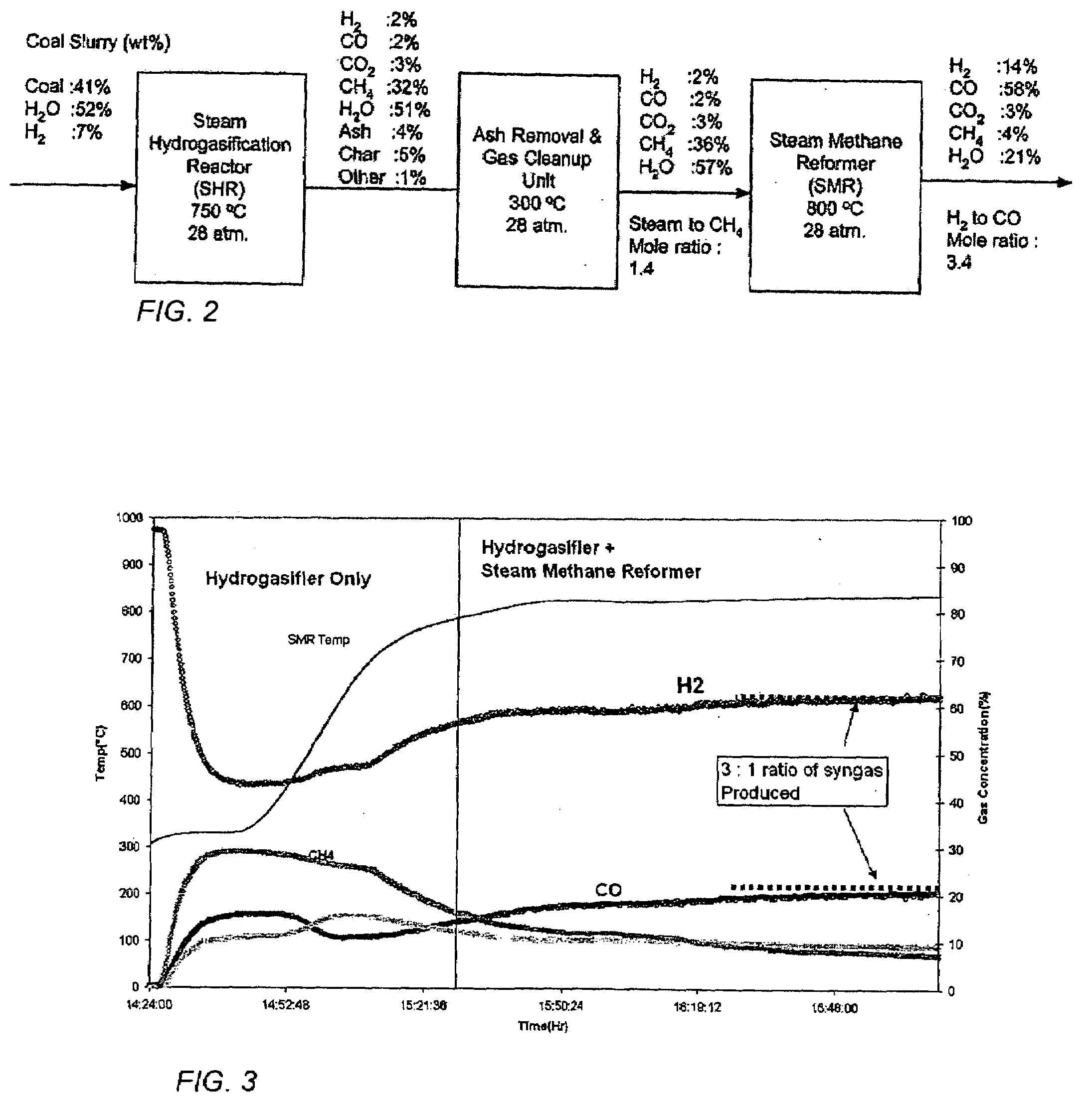

Operation of a steam methane reformer by direct feeding of steam rich producer gas from steam hydro-gasification

InactiveUS20080021122A1Improved and economical alternativeWaste based fuelLiquid hydrocarbon mixture productionProducer gasBoiling point

An improved, economical alternative method to supply steam and methane to a steam methane reformer (SMR) is accomplished by a combination of procedures, wherein product gas from a steam hydro-gasification reactor (SHR) is used as the feedstock for the SMR by removing impurities from the product stream from the SHR with a gas cleanup unit that operates substantially at process pressures and at a temperature above the boiling point of water at the process pressure, is located between the SHR and SMR.

Owner:RGT UNIV OF CALIFORNIA

Process for hydrogen production via integrated processing of landfill gas and biomass

InactiveUS7691182B1Simplify technological chainEfficient use ofCombination devicesMethane captureClosed loopHigh surface area

Hydrogen production is provided via integrated closed-loop processing of landfill gas (LFG) and solid biomass feedstocks such as various agricultural wastes with minimal environmental impact. LFG is purified of harmful contaminants over a bed of activated charcoal (AC) and is catalytically reformed to synthesis gas, which is further processed to pure hydrogen via CO-shift and pressure-swing adsorption stages. Biomass is gasified in the presence of steam with production of a producer gas and AC. The producer gas is mixed with LFG and is processed to hydrogen as described above. High-surface area AC produced in the gasifier is used for the purification of both LFG and producer gas. An integrated processing of LFG and biomass offers a number of advantages such as a high overall energy efficiency, feedstock flexibility, substantial reduction in greenhouse gas emissions and production of value-added product-biocarbon that can be used as a soil enhancer.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Thermochemical method for conversion of poultry litter

InactiveUS20090031616A1Bio-organic fraction processingExcrement fertilisersNuclear engineeringReactive gas

Methods for converting waste litter into a product slate by pyrolysis are described. Waste litter is entrained in a non-reactive gas and delivered to a fluid reactor bed maintained at a temperature sufficient to cause pyrolysis of the poultry litter. The reactor bed consists of a fluidizing medium, such as sand, which is fluidized by the non-reactive gas. Upon pyrolysis of the poultry litter, products such producer gas, biooil, and char are formed.

Owner:VIRGINIA TECH INTPROP INC

Microbial Conversion of CO2 and Other C1 Substrates to Vegan Nutrients, Fertilizers, Biostimulants, and Systems for Accelerated Soil Carbon Sequestration

ActiveUS20190390158A1Improve abilitiesImprove overall revenueBio-organic fraction processingElectrolysis componentsElectrolysisBiogenic Stimulators

Microorganisms and bioprocesses are provided that convert gaseous substrates, such as renewable H2 and waste CO2 producer gas, or syngas into high-protein biomass that may be used directly for human nutrition, or as a nutrient for plants, fungi, or other microorganisms, or as a source of soil carbon, nitrogen, and other mineral nutrients. Renewable H2 used in the processes described herein may be generated by electrolysis using solar or wind power. Producer gas used in the processes described herein may be derived from sources that include gasification of waste feedstock and / or biomass residue, waste gas from industrial processes, or natural gas, biogas, or landfill gas.

Owner:KIVERDI INC

Processes for the conversion of biomass to oxygenated organic compound, apparatus therefor and compositions produced thereby

ActiveUS20130137151A1Improve concentrationEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsPartial oxidationOrganic compound

Processes are disclosed for the conversion of biomass to oxygenated organic compound using a simplified syngas cleanup operation that is cost effective and protects the fermentation operation. The processes of this invention treat the crude syngas from the gasifier by non-catalytic partial oxidation. The partial oxidation reduces the hydrocarbon content of the syngas such as methane, ethylene and acetylene to provide advantageous gas feeds for anaerobic fermentations to produce oxygenated organic compounds such as ethanol, propanol and butanol. Additionally, the partial oxidation facilitates any additional cleanup of the syngas as may be required for the anaerobic fermentation. Producer gases and partial oxidation processes are also disclosed.

Owner:SYNATA BIO INC

Operation of a steam methane reformer by direct feeding of steam rich producer gas from steam hydro-gasification

InactiveUS20080021119A1Improved and economical alternativeWaste based fuelLiquid hydrocarbon mixture productionMethane reformerProduct gas

An improved, economical alternative method to supply steam and methane to a steam methane reformer (SMR) is accomplished by a combination of procedures, wherein product gas from a steam hydro-gasification reactor (SHR) is used as the feedstock for the SMR by removing impurities from the product stream from the SHR with a gas cleanup unit that operates substantially at process temperatures and pressures and is located between the SHR and SMR.

Owner:RGT UNIV OF CALIFORNIA

Method and Apparatus for Growing Microbial Cultures that Require Gaseous Electron Donors, Electron Acceptors, Carbon Sources, or Other Nutrients

ActiveUS20160102287A1Longer carbon chainIncrease energy densityBioreactor/fermenter combinationsBiological substance pretreatmentsLipid formationElectron donor

Compositions and methods and apparatus for growth and maintenance of microorganisms and / or bioprocesses using one or more gases as electron donors, electron acceptors, carbon sources, or other nutrients, and for a bioprocess that converts hydrogen and carbon dioxide, or syngas, or producer gas into lipid products, bio-based oils, or other biochemical products.

Owner:KIVERDI INC

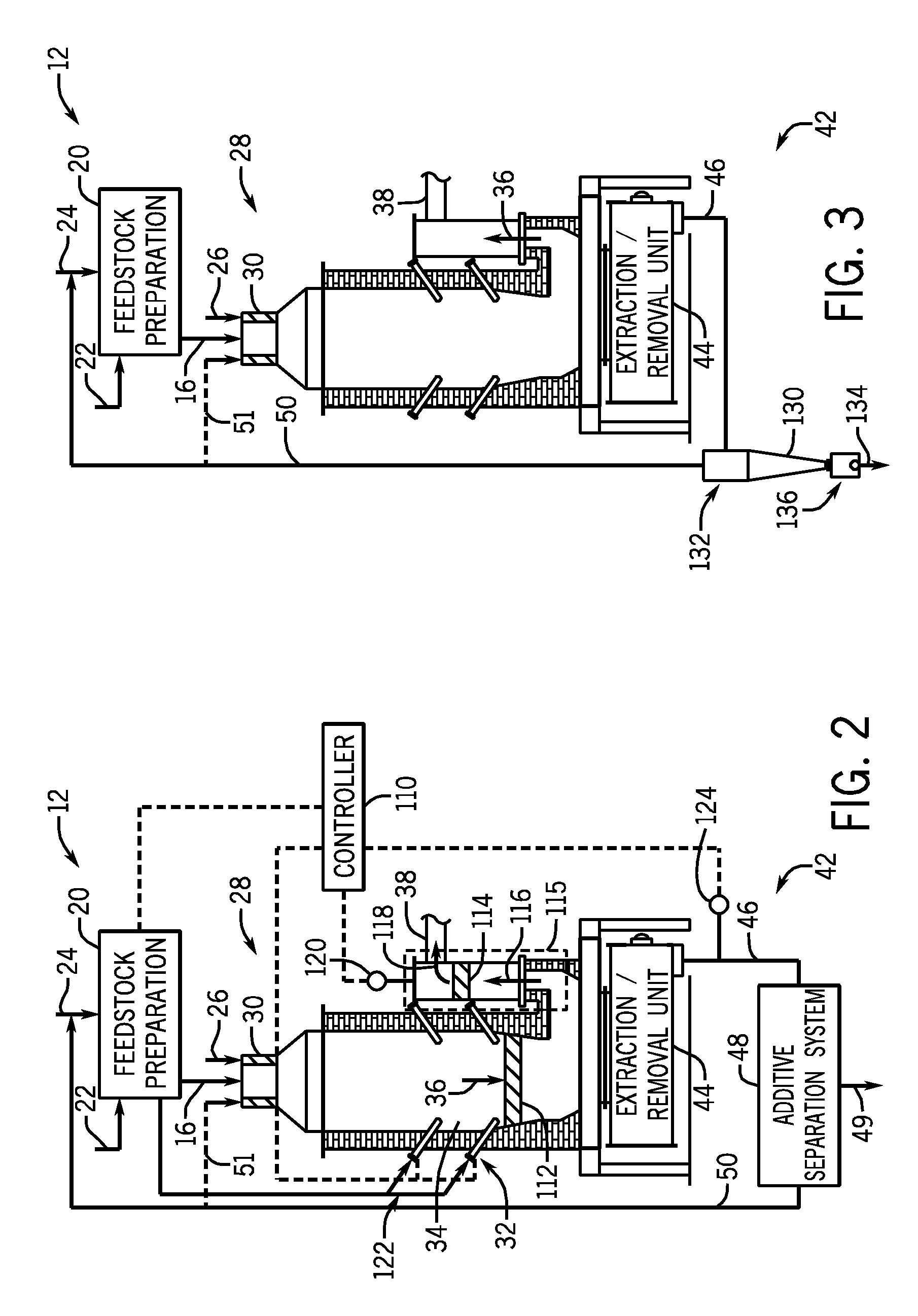

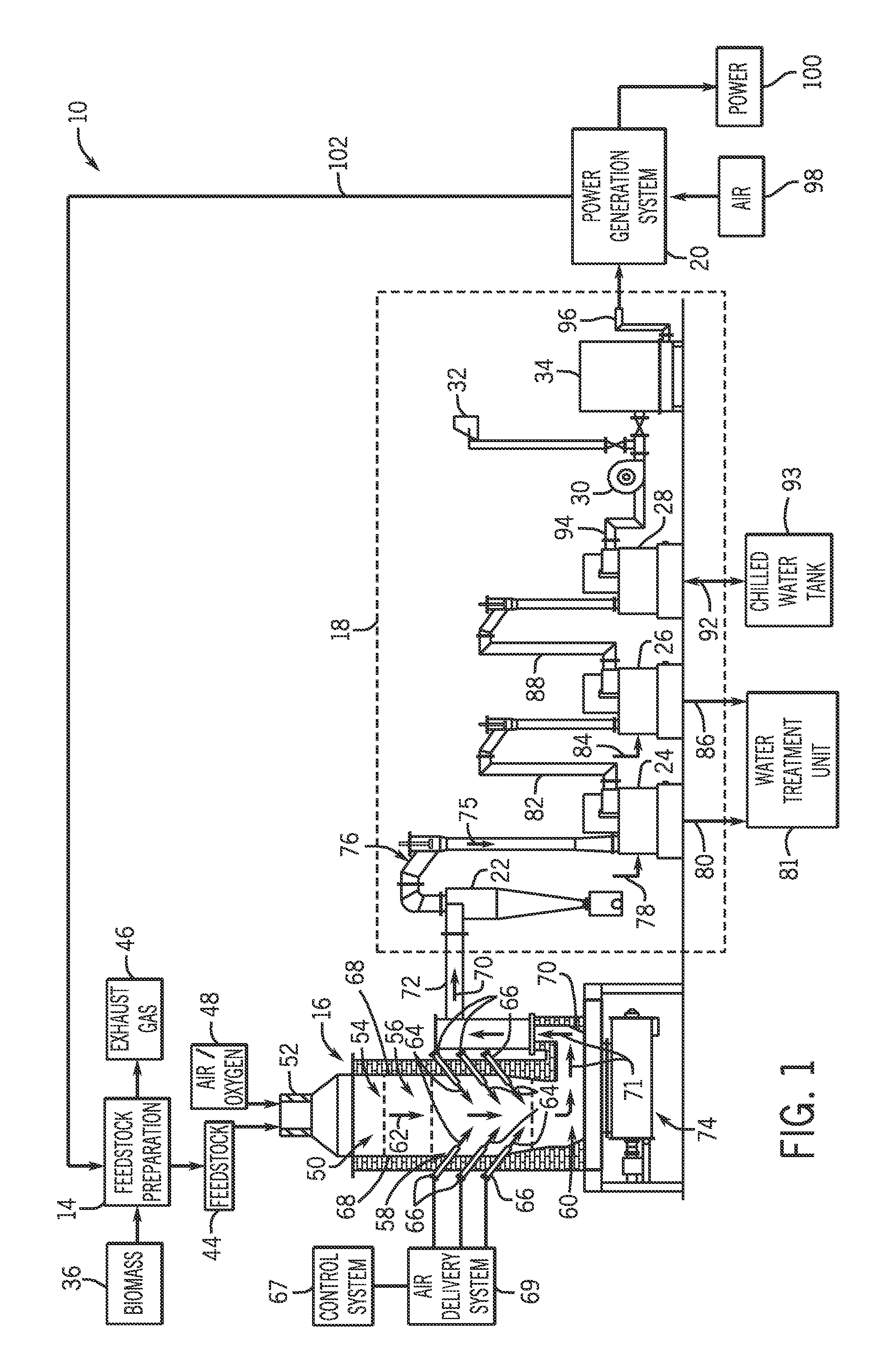

Additive systems for biomass gasification

The present embodiments provide additive systems for biomass gasification reactors. For example, in one embodiment, a biomass gasification system includes a feedstock preparation system configured to generate a biomass feedstock having a biomass fuel and a tar cracking additive. The system also includes a gasifier configured to receive the biomass feedstock and gasify the biomass fuel in the presence of the tar cracking additive to generate first and second mixtures. The first mixture has producer gas and the second mixture has the tar cracking additive and ash. The biomass gasification system further includes an additive recycle system configured to receive the second mixture and to separate at least a portion of the tar cracking additive from the ash to generate a recycled additive feed for the feedstock preparation system.

Owner:AIR PROD & CHEM INC

Tar removal for biomass gasification systems

The disclosed embodiments provide systems for the removal and use of tar from a biomass gasification system. For example, in one embodiment, a biomass gasification system includes a reactor configured to gasify a biomass fuel in the presence of air to generate a producer gas. The system also includes an absorber configured to receive a mixture of the producer gas and tar and to absorb the tar into an organic solvent to produce treated producer gas and a rich solvent mixture containing at least a portion of the tar. The system further includes a recycle line configured to direct the rich solvent mixture to a biomass gasifier.

Owner:AIR PROD & CHEM INC

Process and device for treating phenol-containing sewage of producer gas station

InactiveCN101708869AReduce consumptionZero emissionMultistage water/sewage treatmentWater/sewage treatment by heatingWater vaporSewage

The invention discloses a process and a device for treating phenol-containing sewage of a producer gas station. The process comprises the following steps of: treating phenol-containing sewage generated by a two-stage type gas producer through a phenol steam separator and then sending the treated sewage into a phenol water evaporator to flow in a shell pass of the phenol water evaporator; meanwhile, sending gas generated by the two-stage type gas producer into the phenol water evaporator to flow in a tube pass of the phenol water evaporator; and evaporating the phenol-containing sewage by utilizing the afterheat of the lower-stage gas and recycling generated phenol steam. The process and the device can control the energy waste and the pollution sources of the gas station from the resource and ensure that the gas station truly achieves the effects of high efficiency, energy saving and zero emission.

Owner:山东万丰煤化工设备制造有限公司

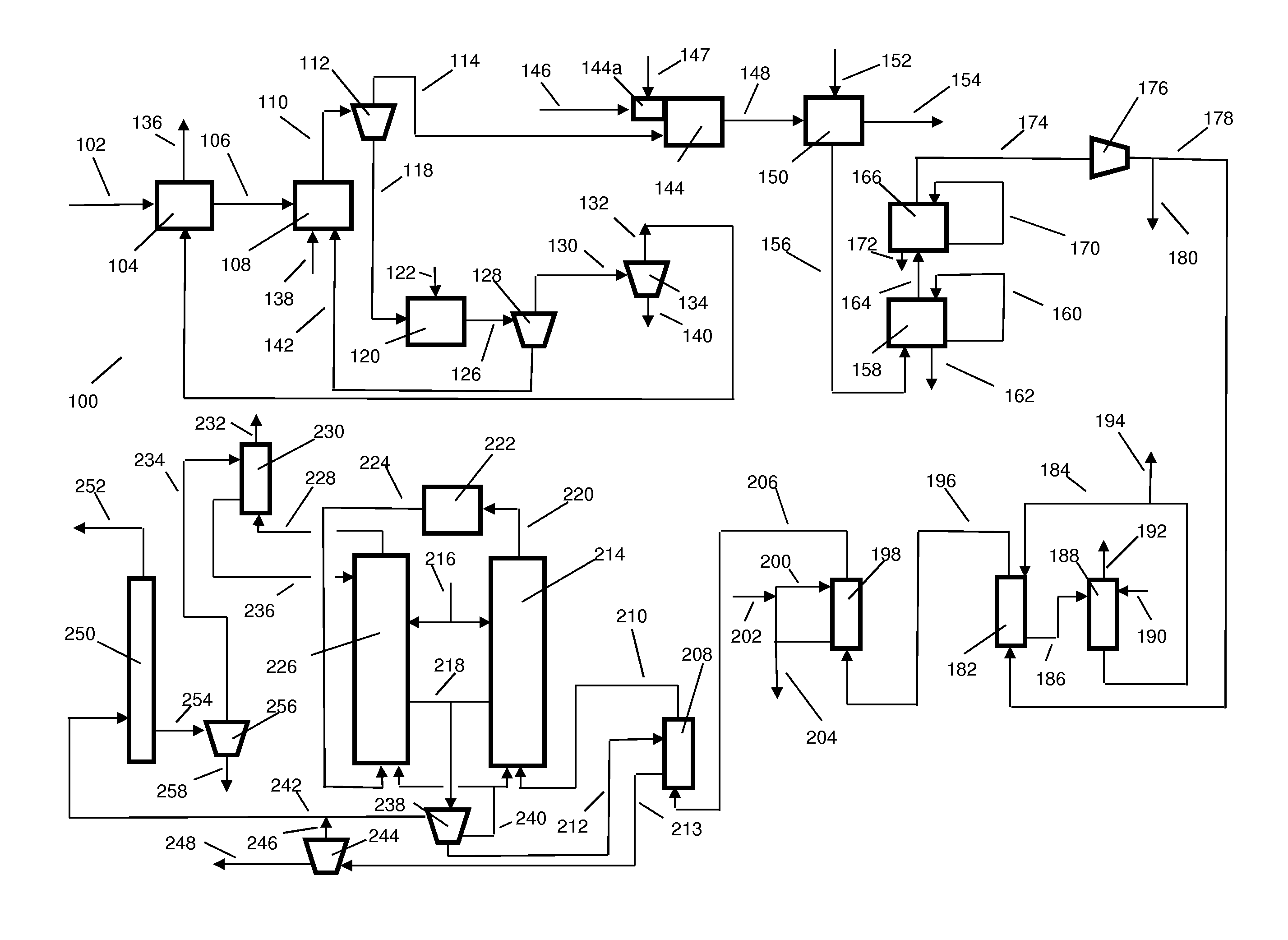

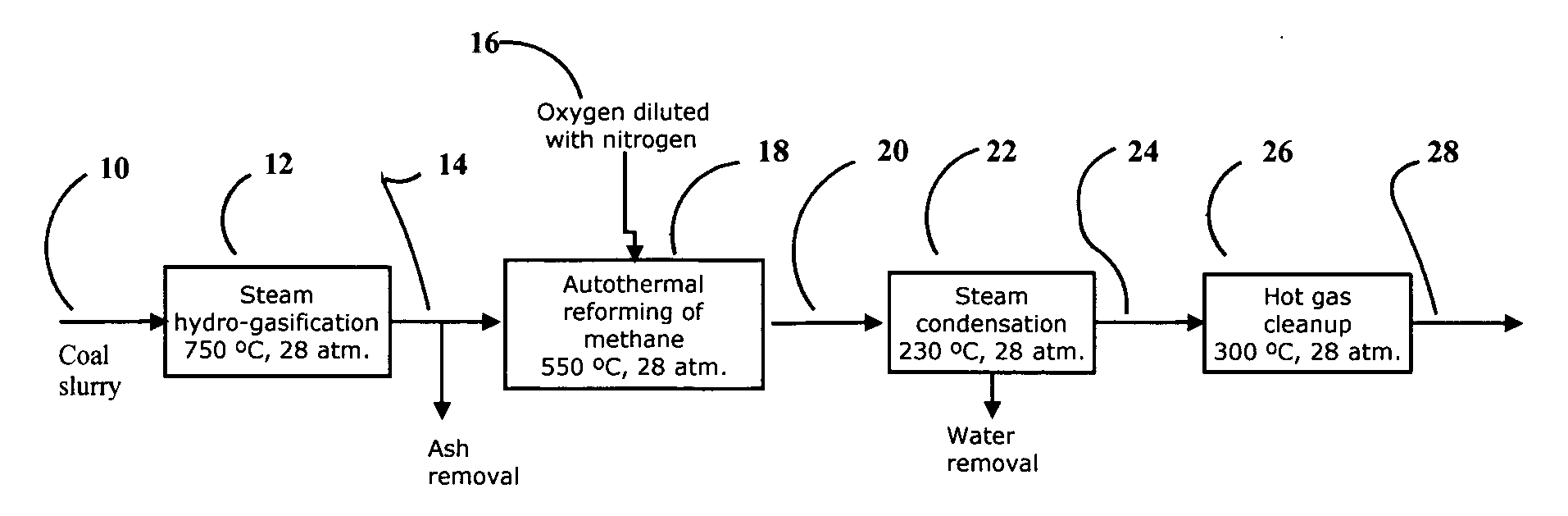

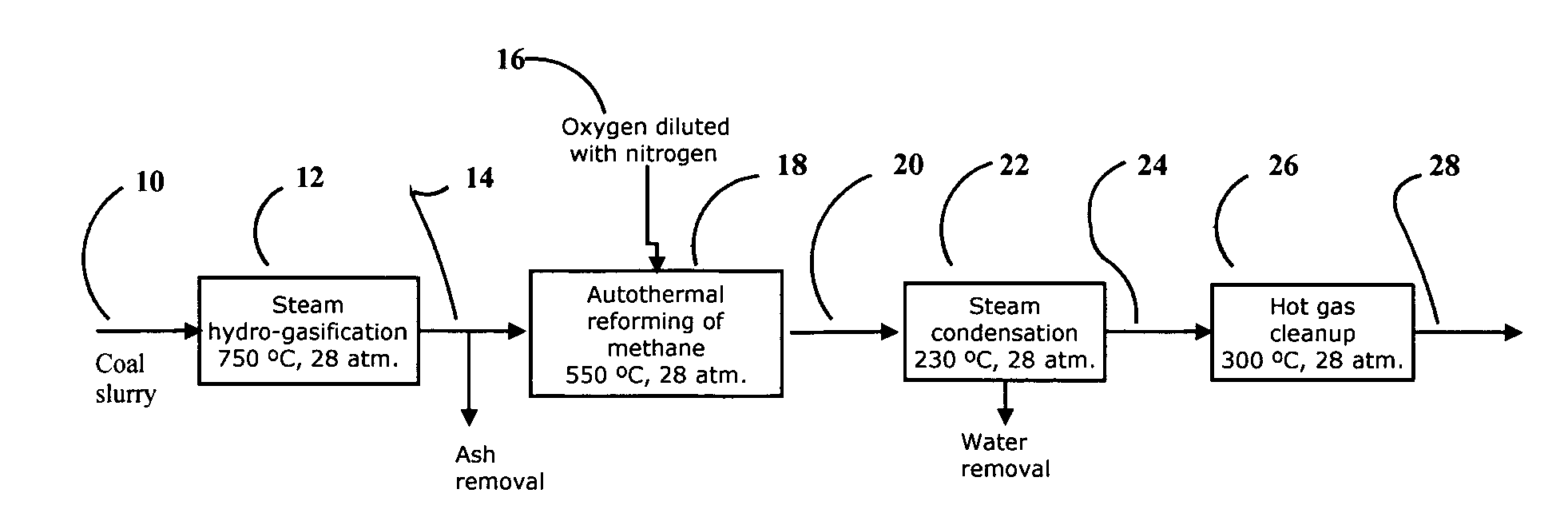

Process for enhancing the operability of hot gas cleanup for the production of synthesis gas from steam-hydrogasification producer gas

InactiveUS20080139675A1Improved and economical alternativeEasy to operateWaste based fuelLiquid hydrocarbon mixture productionHydrogenSulfur

A process for enhancing the operability of hot gas cleanup for the production of synthesis gas in which a stream of methane rich gas is autothermally reformed at a temperature and pressure sufficient to generate a stream of synthesis gas rich in hydrogen and carbon monoxide, the synthesis gas is subjected to condensation and removing the resultant water, and sulfur impurities are removed from the resultant synthesis gas stream.

Owner:RGT UNIV OF CALIFORNIA

Conversion of biomass feedstocks into hydrocarbon liquid transportation fuels

InactiveUS8624069B2Poor economicsLow and even costCoke ovensLiquid hydrocarbon mixture productionHydrocarbonBiomass

Owner:COMMUNITY POWER CORP

Method and apparatus for growing microbial cultures that require gaseous electron donors, electron acceptors, carbon sources, or other nutrients

ActiveUS9157058B2Longer carbon chainIncrease energy densityBioreactor/fermenter combinationsBiological substance pretreatmentsLipid formationElectron donor

Compositions and methods and apparatus for growth and maintenance of microorganisms and / or bioprocesses using one or more gases as electron donors, electron acceptors, carbon sources, or other nutrients, and for a bioprocess that converts hydrogen and carbon dioxide, or syngas, or producer gas into lipid products, bio-based oils, or other biochemical products.

Owner:KIVERDI INC

Heat recovery systems for biomass gasification systems

Biomass gasification systems including a reactor configured to gasify a dried biomass fuel in the presence of air to generate producer gas are provided. The biomass gasification systems also may include a heat exchanger adapted to transfer heat from the producer gas to a biomass feedstock to produce the dried biomass fuel and cooled producer gas.

Owner:AIR PROD & CHEM INC

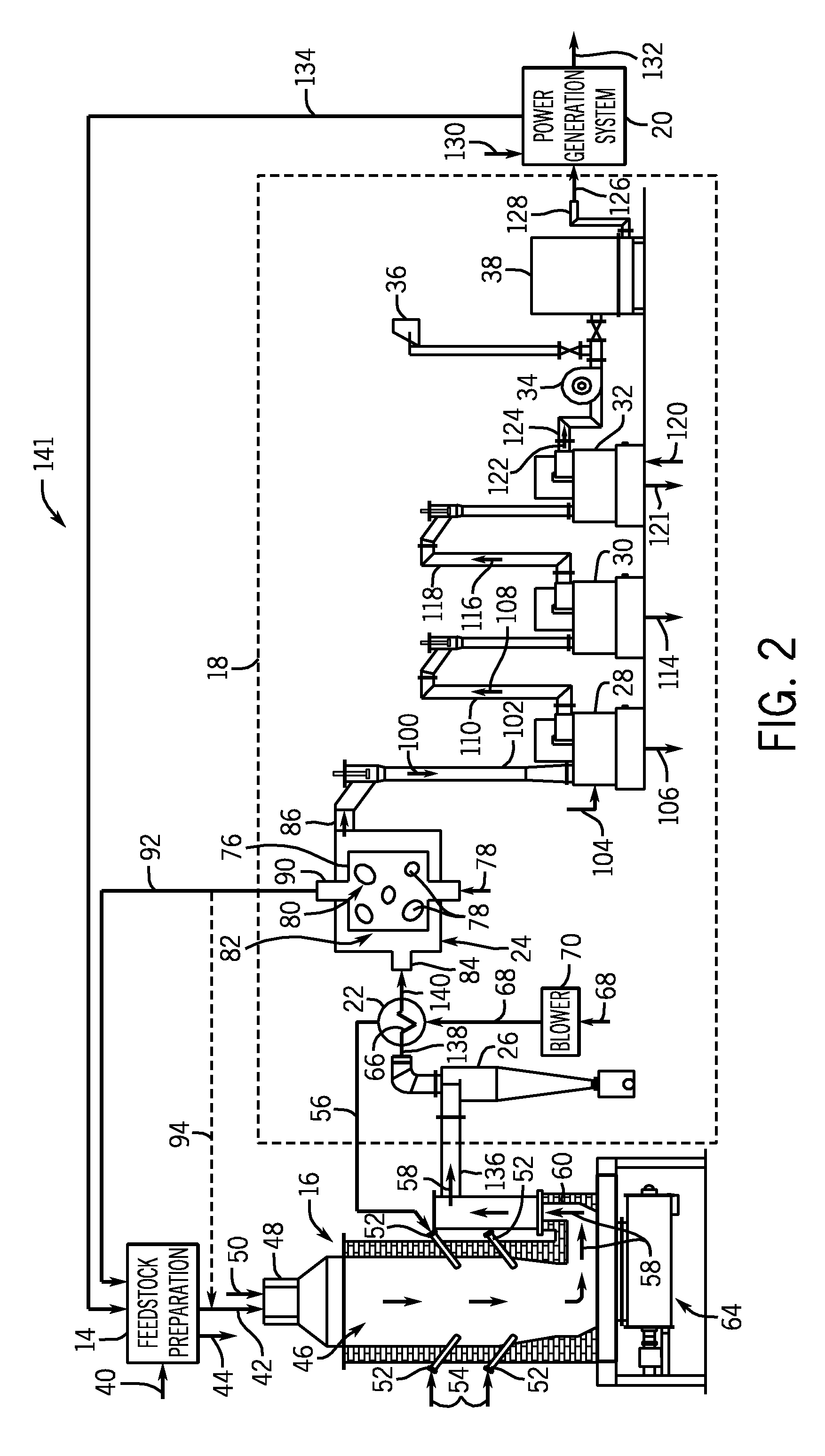

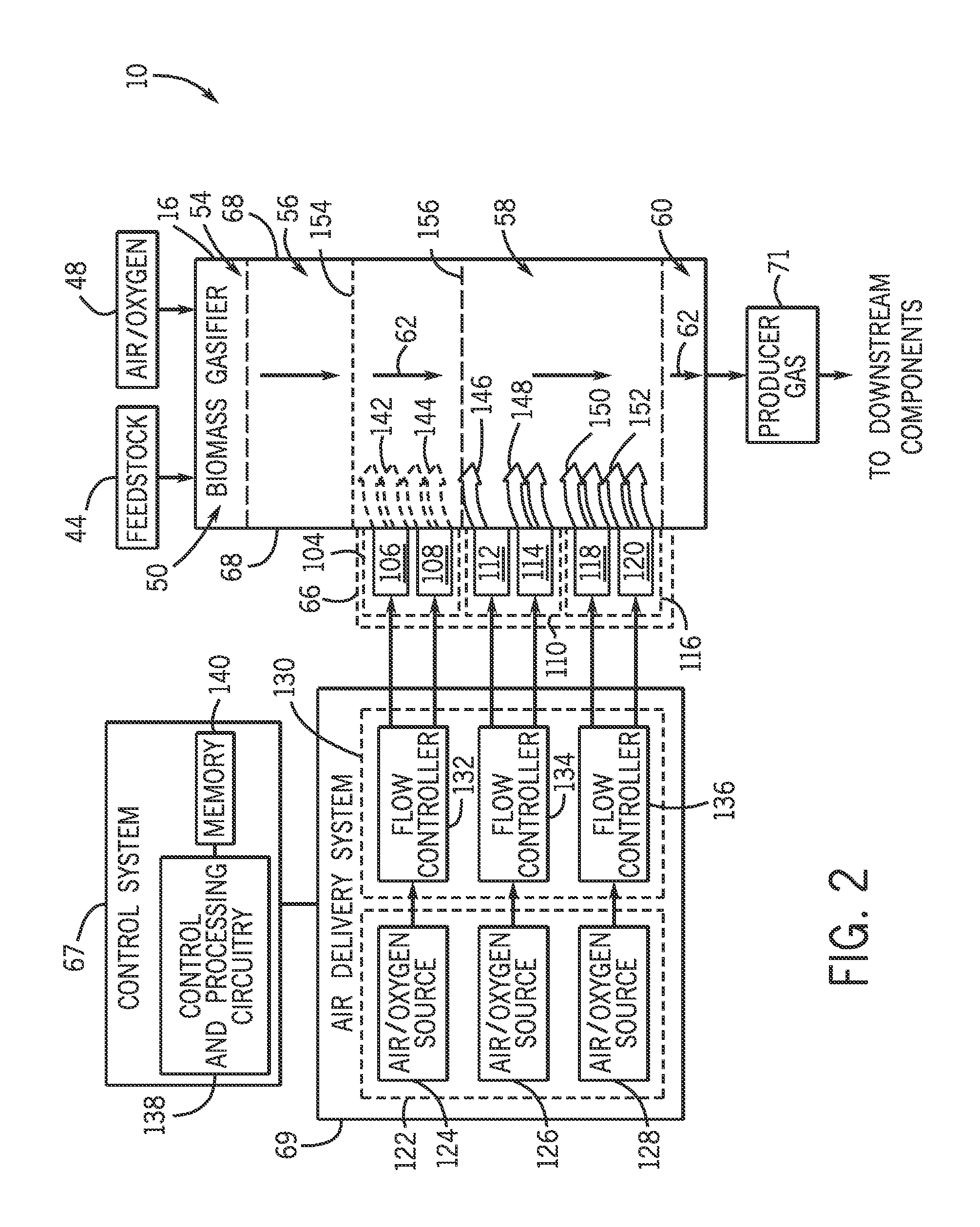

Biomass gasification systems having controllable fluid injectors

Biomass gasification systems including a reactor adapted to gasify a biomass feedstock to thermally convert the biomass feedstock into producer gas are provided. The reactor includes an enclosure disposed about a biomass gasification chamber. The enclosure includes an inlet, an outlet, and side walls disposed between the inlet and the outlet. The reactor also includes a plurality of fluid injectors disposed along a length of the side walls and adapted to inject fluid into the gasification chamber. The biomass gasification system also includes a control system communicatively coupled to the plurality of fluid injectors and adapted to independently control each fluid injector of the plurality of fluid injectors to independently control a flow of fluid through each fluid injector.

Owner:GENERAL ELECTRIC CO

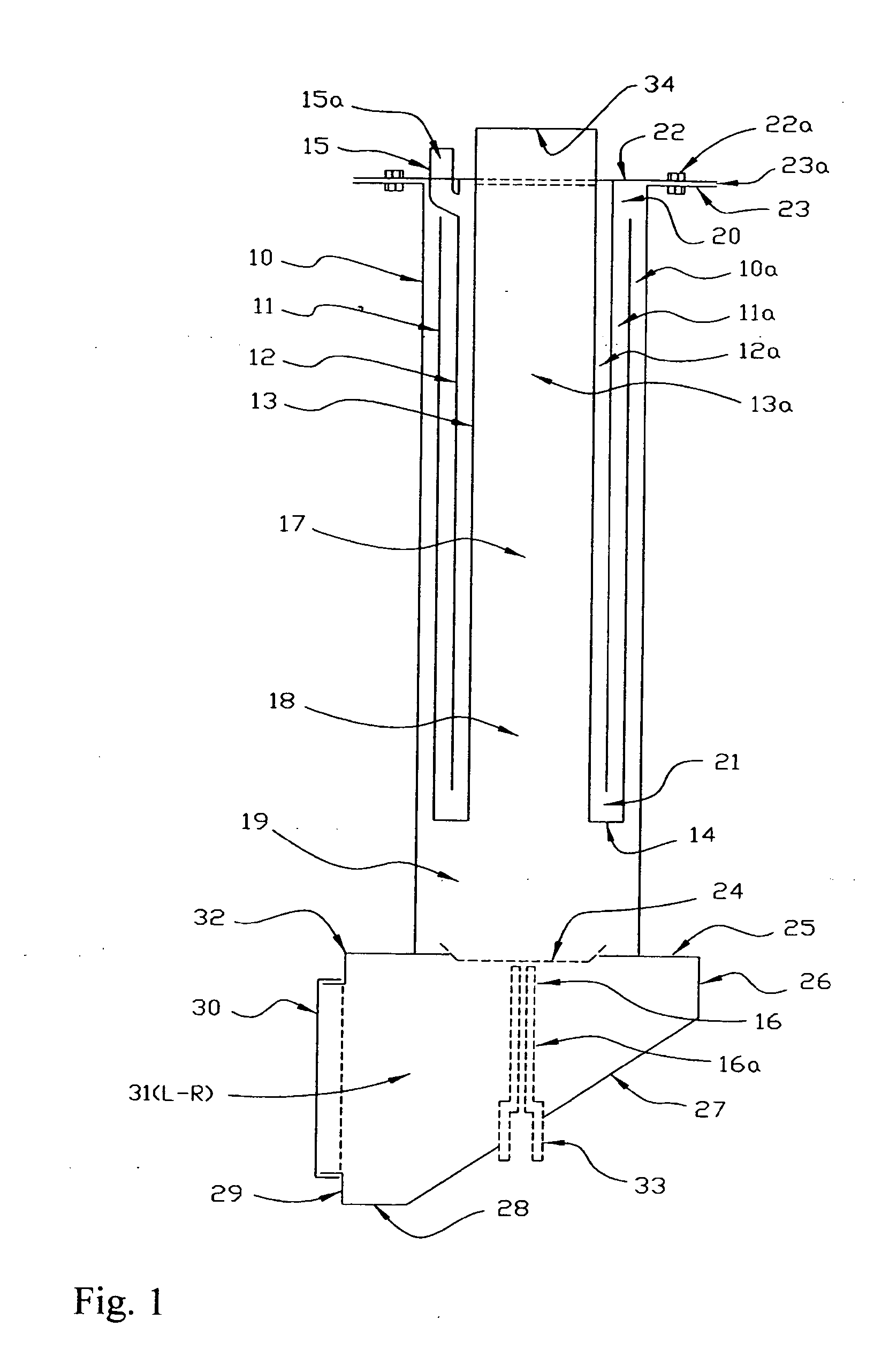

Multi pass gasifier

InactiveUS20070089367A1Reduce necessityIncrease temperatureProductsReagentsInternal combustion engineScrubber

Apparatus and method for high temperature, auto thermal gasification of solid material are disclosed. Resulting in a clean burning uniform gas usually referred to as Producer Gas. The apparatus is comprised of an outer chamber encircling a multi fold gas-path chamber that is suspended. The center of said chamber also serves as a continuous feed stock inlet. Combustion oxidizer is introduced to the lower portion of said chamber through a nozzle, just below a fire grate or screen, producing a high velocity oxidizer flow resulting in a high temperature localized heat zone. Flow is vertical through the combustion zone and into the descending feed stock, resulting in a counter-current flow. Gases and volatized tar and oil flow vertically in the space between the labyrinth and shell where said gas flow velocity is reduced considerably. Some tar and oil condensing takes place and said tar and oil flows downwardly to the heat zone to be further cracked. Said velocity reduction also inhibits particulate flow in said gas stream. Said gases enter the labyrinth as a reduced gas flow where further condensing of remaining tar and oil also takes place in the labyrinth where they will flow downwardly to the concentrated heat zone, resulting in a distilling, reducing, reacting environment. This process is repeated through the several labyrinth passes that produce the conditions and time necessary for complete cracking of the hydrocarbon compounds to a stable gas eliminating the need for tar removal equipment and or scrubbers. This utilizes more of the total B.T.U. available in the solid fuel. Evolved gases are eventually drawn off as a very uniform clean burning synthesis gas, filtered for particulates and fed directly to an internal combustion engine. Below the gasification chamber is an ash collection region, which allows for collection and removal of ash produced in the gasification process

Owner:GODDARD EDWARD PASCAL

Waste heat utilizing loop-closing system of industrial furnace with producer gas as fuel

InactiveCN1680767AImprove heating qualityReduce energy consumptionWaste heat treatmentLoop closingProcess engineering

The invention relates to a waste heat utilizing loop-closing system of industrial furnace with producer gas as fuel. The gas generator applies the saturated air mixed by the normal temperature air and steam as gasification agent. The produced gas by the method has a low heat value, a low temperature and a low pressure. The combustion-supporting air blown by industrial furnace is preheated that it is able to improve the heating quality of the further. The invention makes the high temperature gas in the industrial furnace flue exchange heat with two heat exchangers. The produced heat air is respectively infused to the industrial furnace for supporting combustion and to the gas generator as gasification agent. The hot steam or hot water produced by the industrial furnace cooling medium may being the gasification agent of the gas generator. The system can largely decreases the energy consumption of the industrial furnace and increases the gasification heat efficiency of the gas generator.

Owner:侯英武 +2

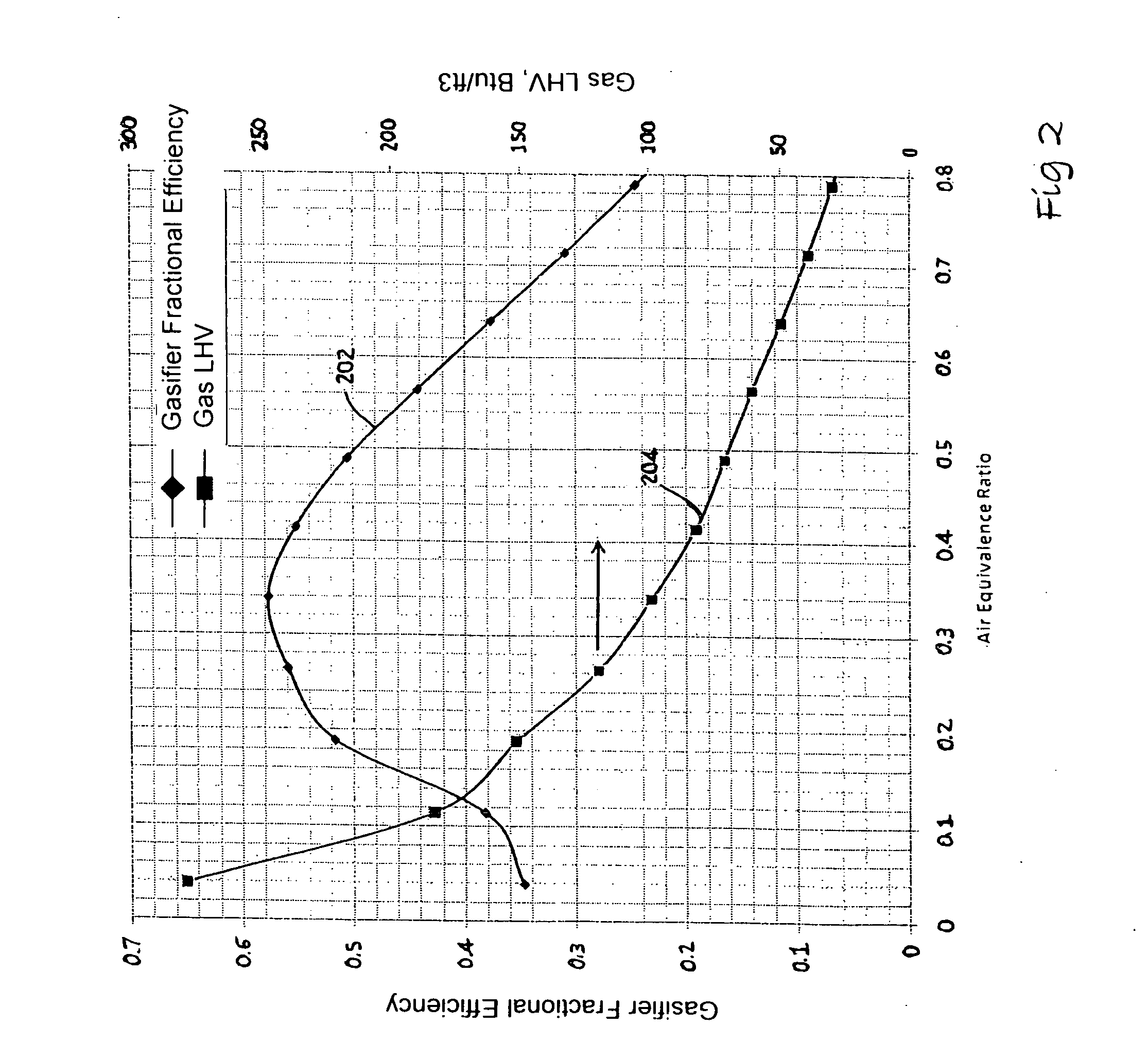

Method and apparatus for controlling gasifier efficiency

In a gasifier system, the gas thermal conductivity of the producer gas may beneficially be used as a control variable in controlling the combustion parameters of the gasifier process or gasifier system. For example, the control variable may be used to modulate the volume amount of air provided to a gasifier vessel or to modulate an oxidizer delivery rate.

Owner:NEATHERY JAMES K

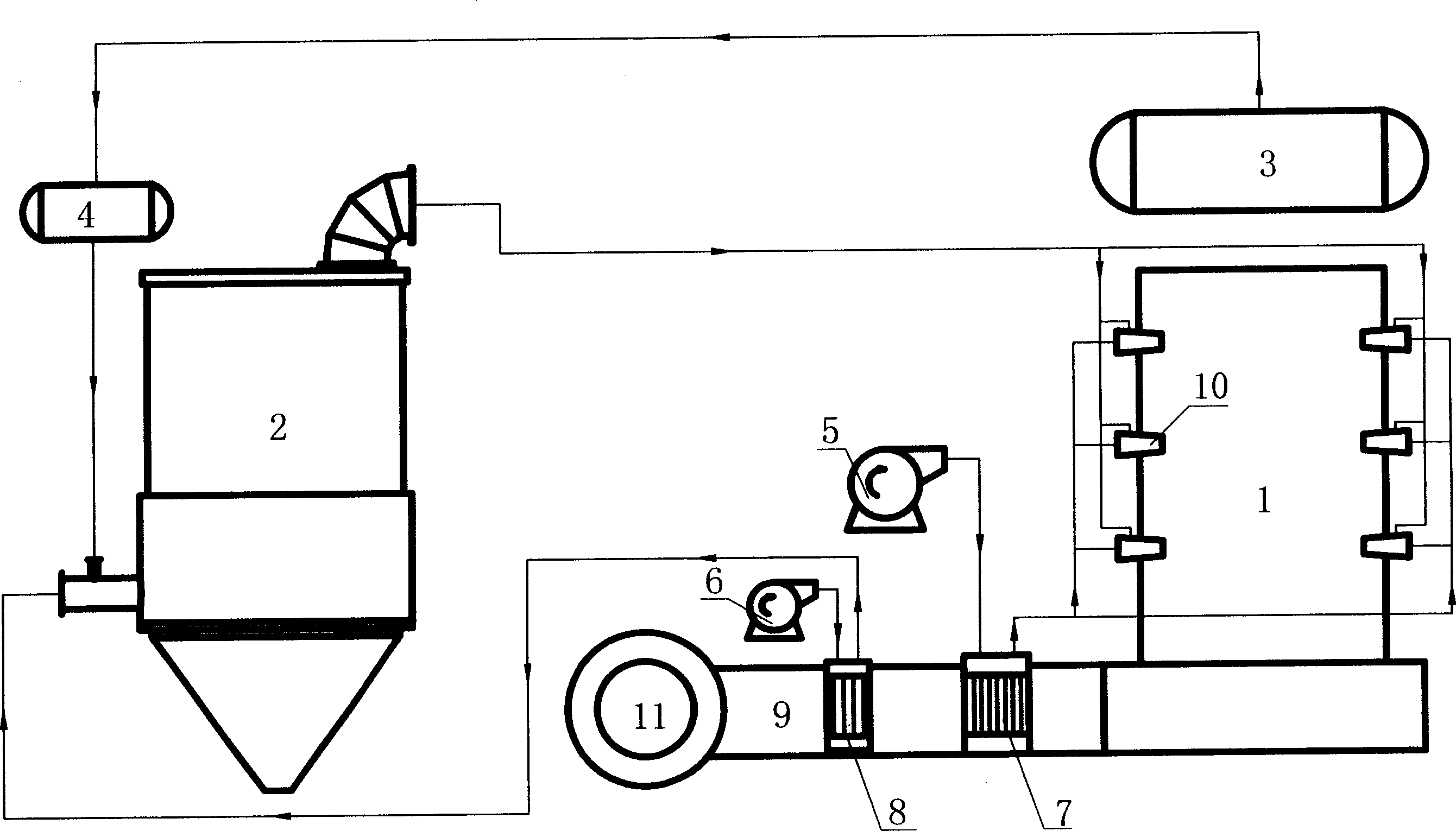

Straw gas heat source engine

InactiveCN102305416AEasy to useHigh technology contentLighting and heating apparatusStove/ranges for heating waterProcess engineeringElectric control

The invention discloses a straw gas heat source engine, which fundamentally solves the problems of low heating efficiency of circulating water and energy dissipation of the traditional straw gas producer. The straw gas heat source engine comprises a gas producer; and the technical key point is that the straw gas heat source engine also comprises a gas separator. The producer body of the gas producer is respectively provided with an upper producer chamber and a lower producer chamber; the producer wall and the producer bottom of the upper producer chamber are double layers of water pouring cavities; a feed hole is arranged on the top of the upper producer chamber; a material continuing hole is arranged on the producer shoulder of the upper producer chamber; a course gas outlet is arranged on the upper part of the producer wall of the upper producer chamber; and a blast pipe and a sealed producer door are arranged on the lower part of the upper producer chamber, wherein an electric control ignition bar is installed in the blast pipe; the lower producer chamber is formed by hermetically connecting the producer bottom of the upper producer chamber and a support skirt; and a gas stove communicated with an external gas port is arranged in the lower producer chamber. The gas separator comprises a primary clean room, an odorized secondary clean room arranged on the upper part of the primary clean room, an air box arranged on the lower part of the primary clean room and a gas separation room arranged on the top of the odorized secondary clean room. The straw gas heat source engine has the advantages of not only continuously burning produced gas for heat production but also rapidly heating the circulating water for sufficiently releasing the heat energy, and is suitable for production and life.

Owner:刘玉珂

Process for enhancing the operability of hot gas cleanup for the production of synthesis gas from steam-hydrogasification producer gas

InactiveUS8349288B2Easy to operateWaste based fuelLiquid hydrocarbon mixture productionHydrogenSulfur

A process for enhancing the operability of hot gas cleanup for the production of synthesis gas in which a stream of methane rich gas is autothermally reformed at a temperature and pressure sufficient to generate a stream of synthesis gas rich in hydrogen and carbon monoxide, the synthesis gas is subjected to condensation and removing the resultant water, and sulfur impurities are removed from the resultant synthesis gas stream.

Owner:RGT UNIV OF CALIFORNIA

Production of fuel

The present invention concerns the production and use of feedstock streams. Specifically, the present invention provides a process for the production of a commodity using two or more feedstock streams. Each feedstock stream is processed into a common intermediate and subsequently processed into a final product, such as electrical energy, a liquid fuel or a liquefied fuel, such as methanol, dimethyl ether, synthetic gasoline, diesel, kerosene, or jet fuel. The common intermediate may be synthetic gas (syngas), producer gas or pyrolysis gas.

Owner:FLECKNER KAREN

Salt-melting furnace for producer gas

The invention discloses a salt-melting furnace for producer gas. Mixed gas of CO and H2 produced by a water gas generator is adopted as a fuel; the fuel is burnt in a hearth of the salt-melting furnace to heat a salt-melting heating coil on the inner wall of the salt-melting furnace; and the heated molten salt flows out of the salt-melting furnace, then fully exchanges heat with heat equipment and releases energy to flow back to the salt-melting furnace for circular heating.

Owner:常州能源设备股份有限公司

Process and apparatus for reforming gaseous and liquid fuels

InactiveUS20090165368A1Good H selectivityHigh thermal efficiencyHydrogenSolid fuelsHydrogen concentrationProduct gas

A process for transitioning from gaseous fuel reformation to liquid fuel reformation has been invented. The process comprises a series of control steps wherein an autothermal reforming reactor's temperature can substantially be stable and satisfactory hydrogen concentration and selectivity can be achieved for producer gas during the transition process. The temperature is controlled by, for example, adjusting the air and water feed. Formulas and algorithms for writing control programs have also been developed.

Owner:TEXACO INC

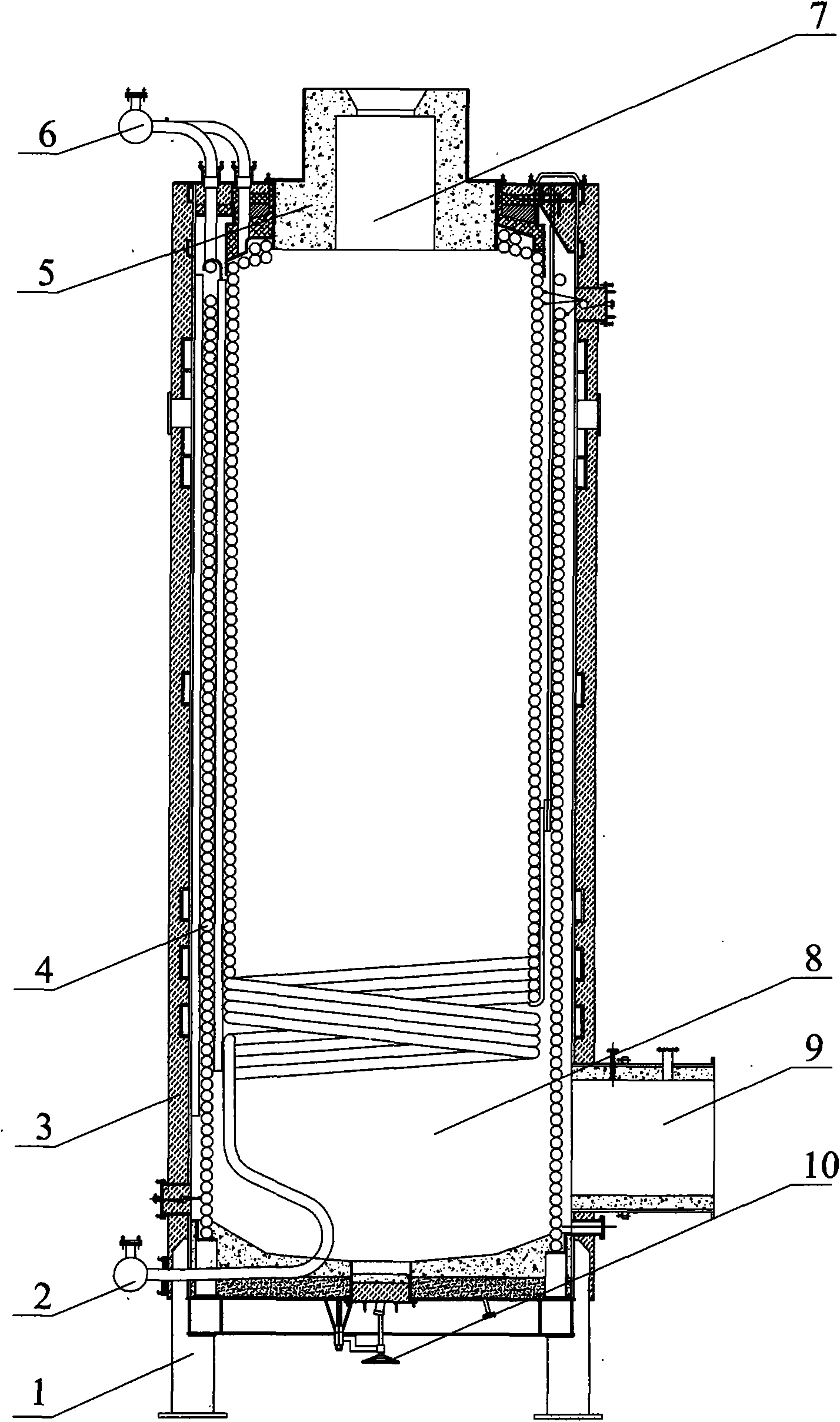

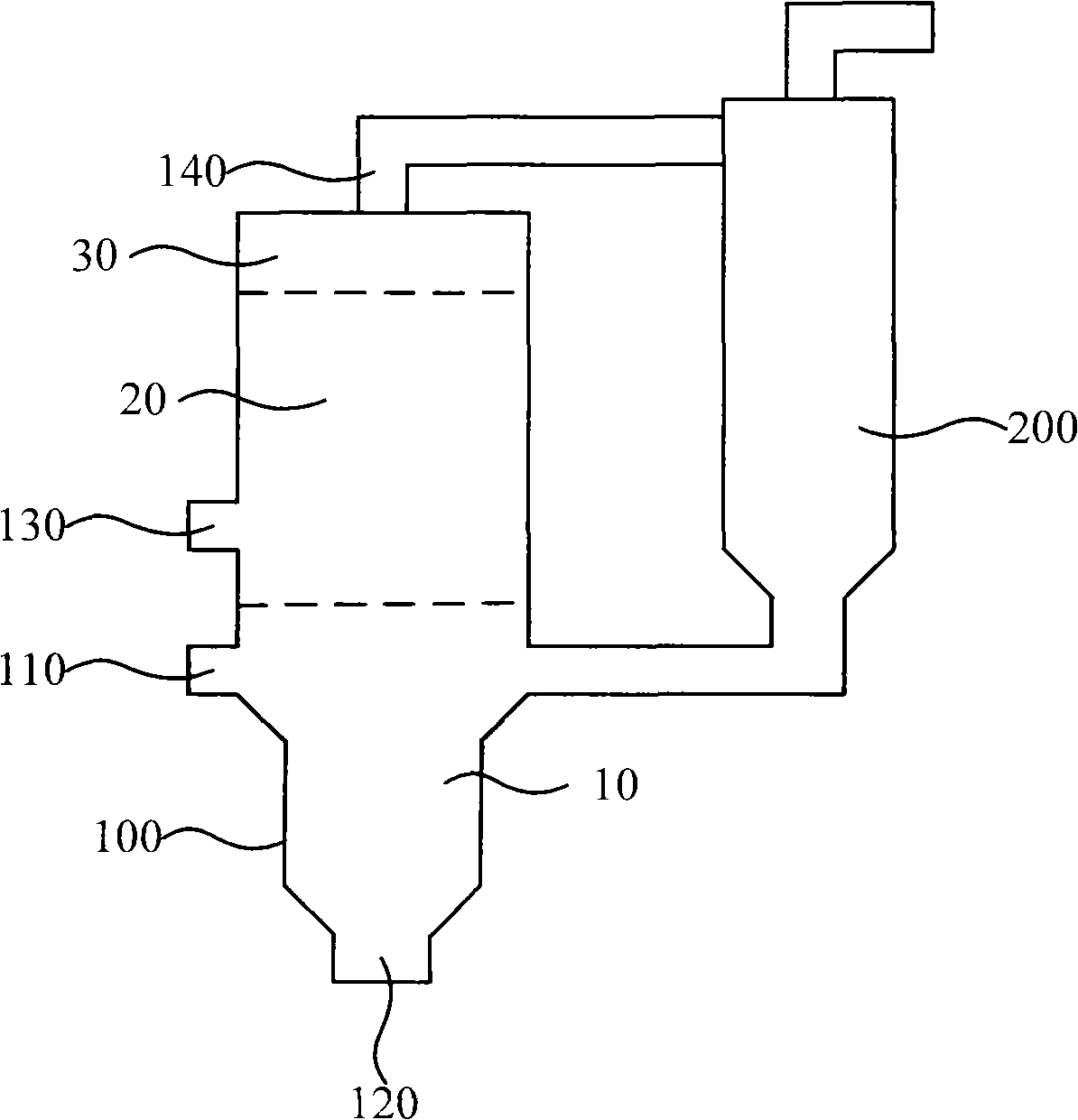

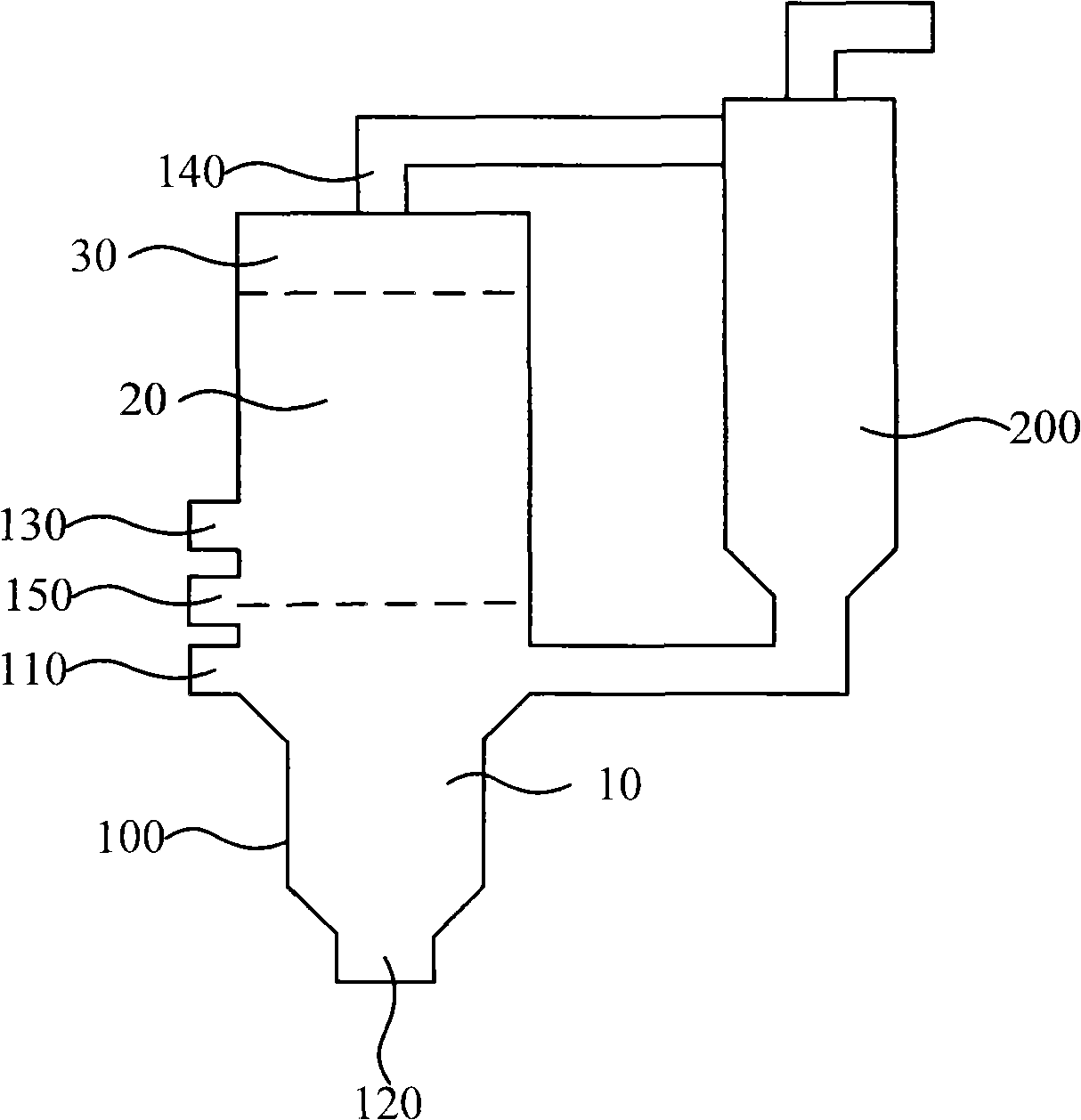

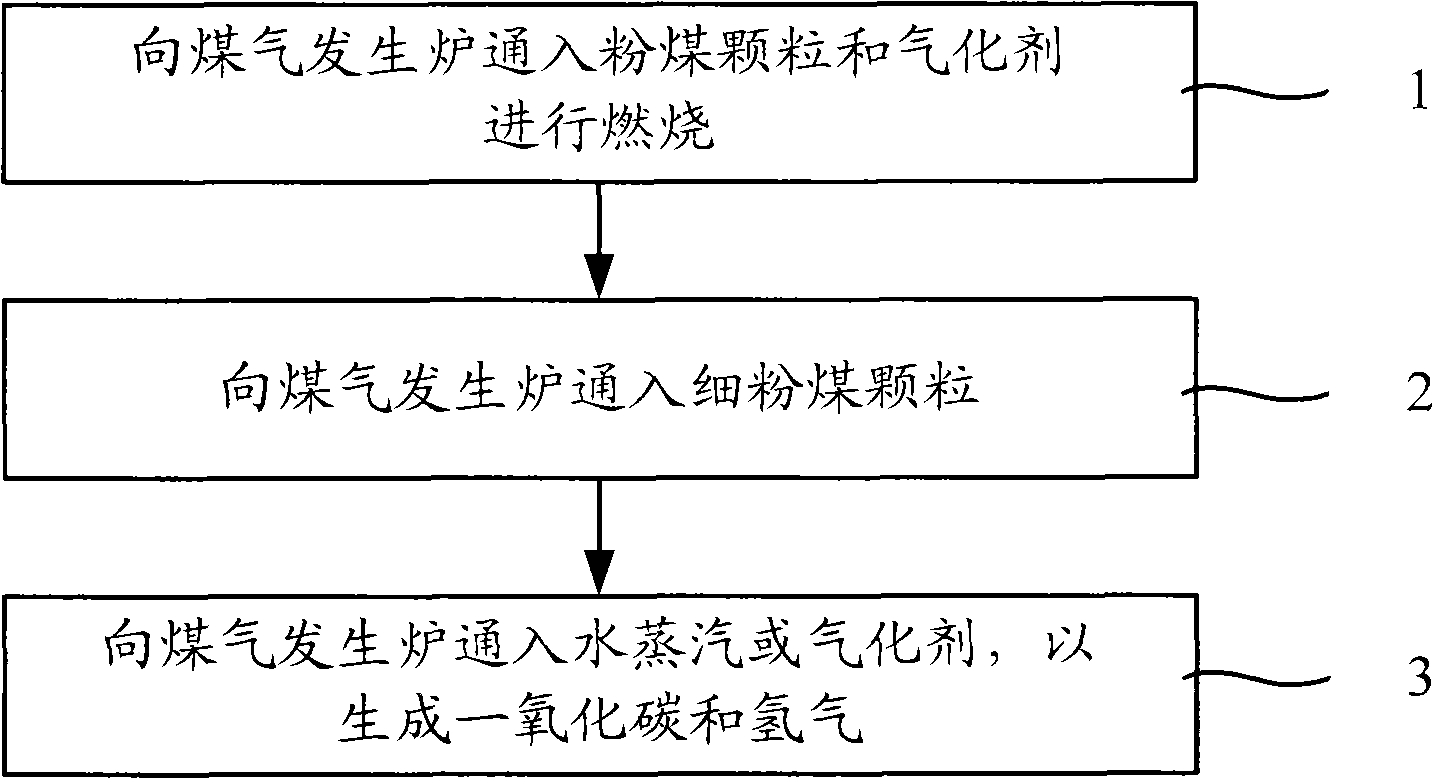

Gas producer and gas preparation method

ActiveCN101987975AImprove production efficiencyIncrease concentrationGranular/pulverulent flues gasificationHydrogenHearth

The invention relates to a gas producer and a gas preparation method. The gas producer comprises a hearth, a reducing zone and a gas guide zone which are sequentially arranged in a producer wall from top to bottom, wherein a pulverized coal inlet is formed on the wall face of the hearth; a second gas inlet is formed on the wall face of the reducing zone, and a fine pulverized coal inlet is also formed on the wall face of the reducing zone or a wall face at the intersection of the reducing zone and the hearth. The method comprises the following steps of: introducing pulverized coal particles and a gasification agent into the gas producer for burning; and introducing fine pulverized coal particles into the gas producer to ensure that the materials in the gas producer are reacted to form carbon monoxide and hydrogen gas. In the invention, the technical means of forming the fine pulverized coal inlet on the gas producer for leading the fine pulverized coal particles in a carbon monoxide preparing reaction through reduction is adopted, so that the concentration of materials in the reducing zone is improved; the reduction reaction efficiency in the reducing zone can be promoted; and then the preparation efficiency of gas can be improved.

Owner:KEDA MAS CLEAN ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com