Gas producer and gas preparation method

A gas generator and gas technology, which is applied in the direction of granular/powder fuel gasification, etc., can solve the problems of low reaction efficiency and low pressure of the gas generator, so as to improve the gas preparation efficiency, increase the carbon concentration, and improve the reduction. The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Example of gas generator

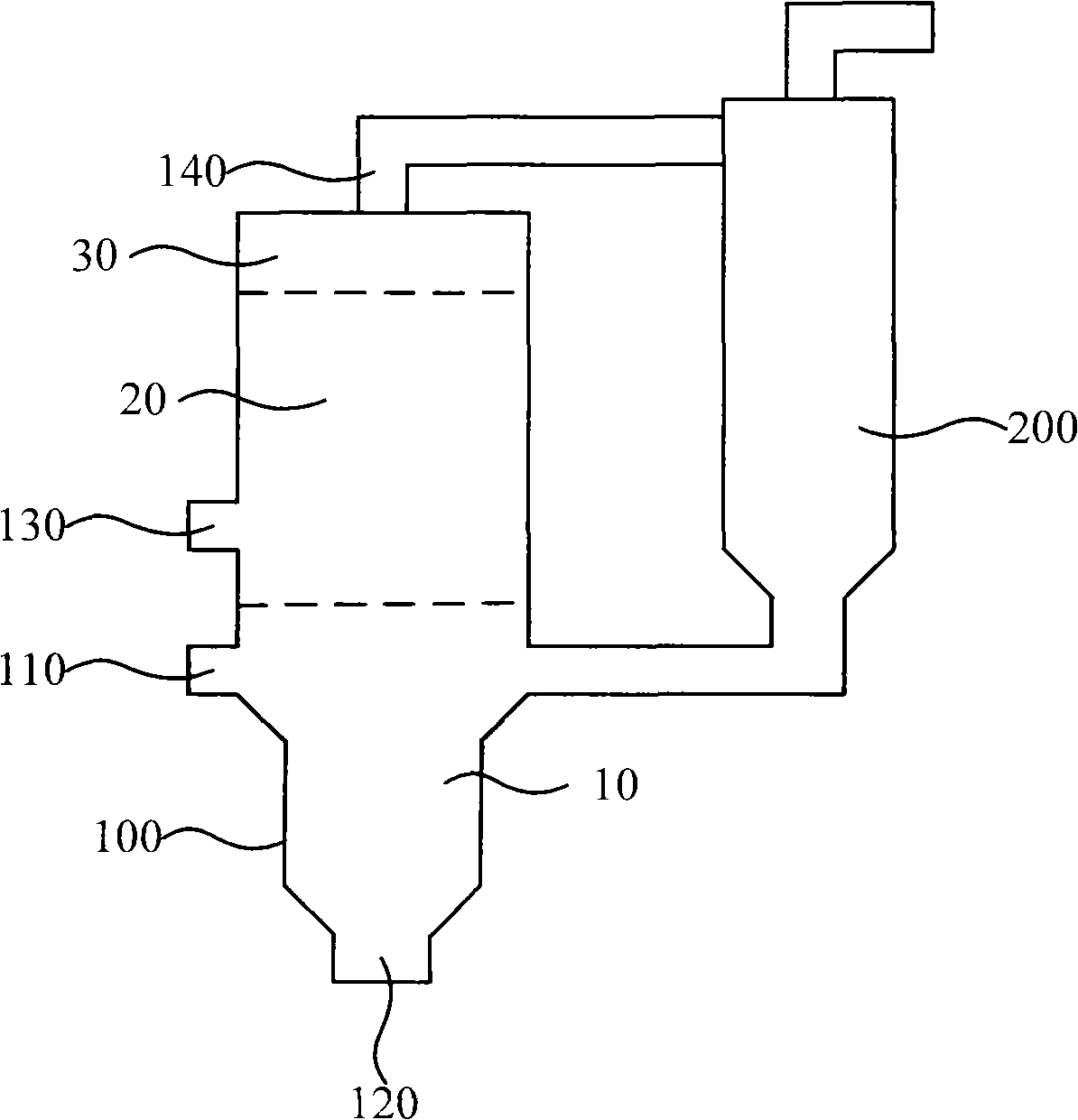

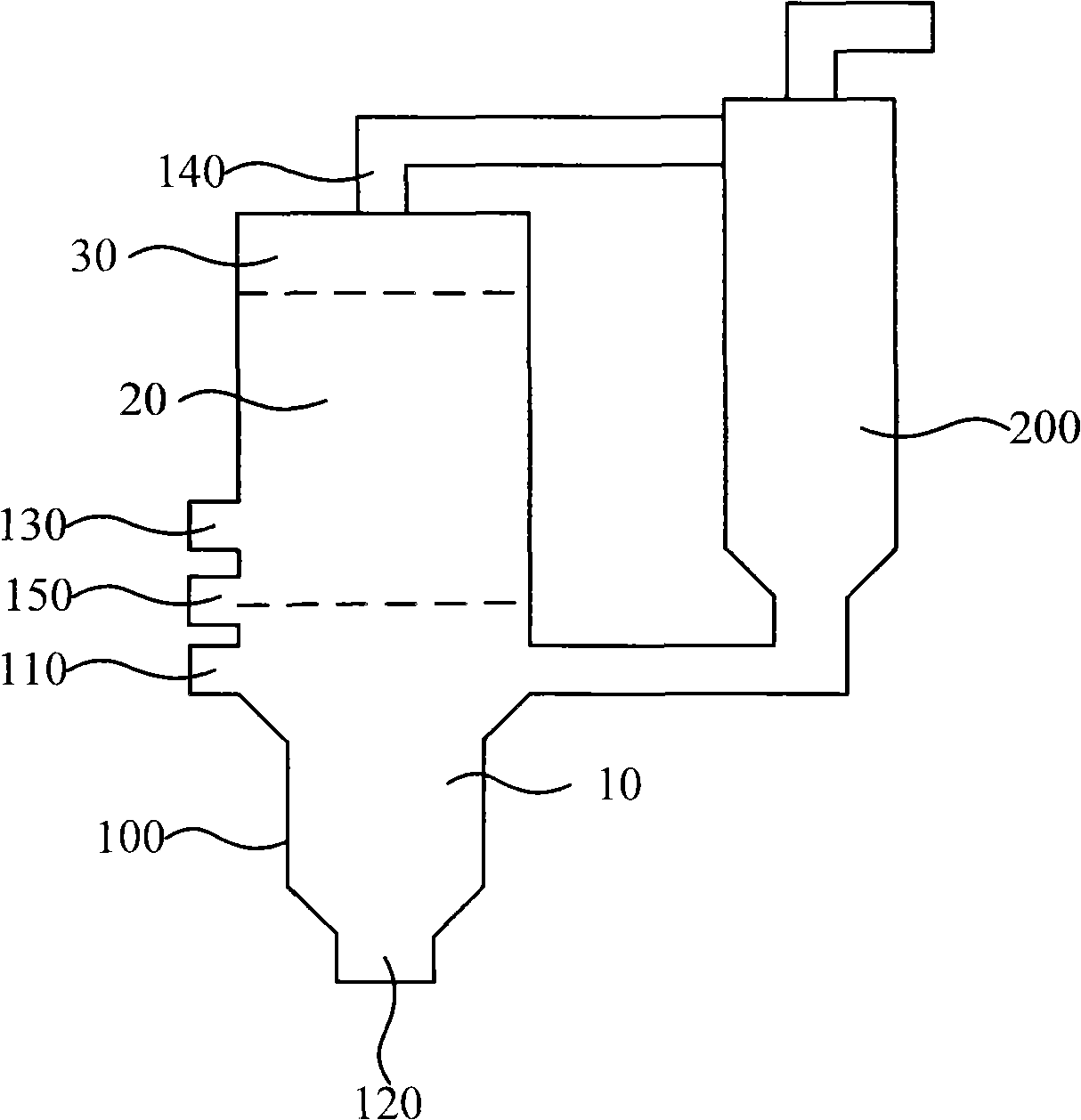

[0036] Such as figure 2 Shown is a schematic structural view of a specific embodiment of the gas generator of the present invention. The wall of the furnace body 100 of the gas generator includes a furnace 10 , a reduction zone 20 and a gas guiding zone 30 sequentially from bottom to top. The furnace 10 is connected to the first air inlet 120 arranged at the bottom of the furnace body 100 for introducing air, and also connected to the pulverized coal inlet 110 arranged at the middle and lower part of the furnace body 100 . The combustion reaction can be carried out in the furnace 10 after the pulverized coal particles and the gasification agent are introduced. The reduction zone 20 is located above the furnace 10, and the reduction zone 20 is connected to the second gas inlet 130 provided in the middle of the side wall of the furnace body 100 for introducing water vapor or gasification agent. The carbon dioxide produced after combustion, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com