Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1054results about "Stove/ranges for heating water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

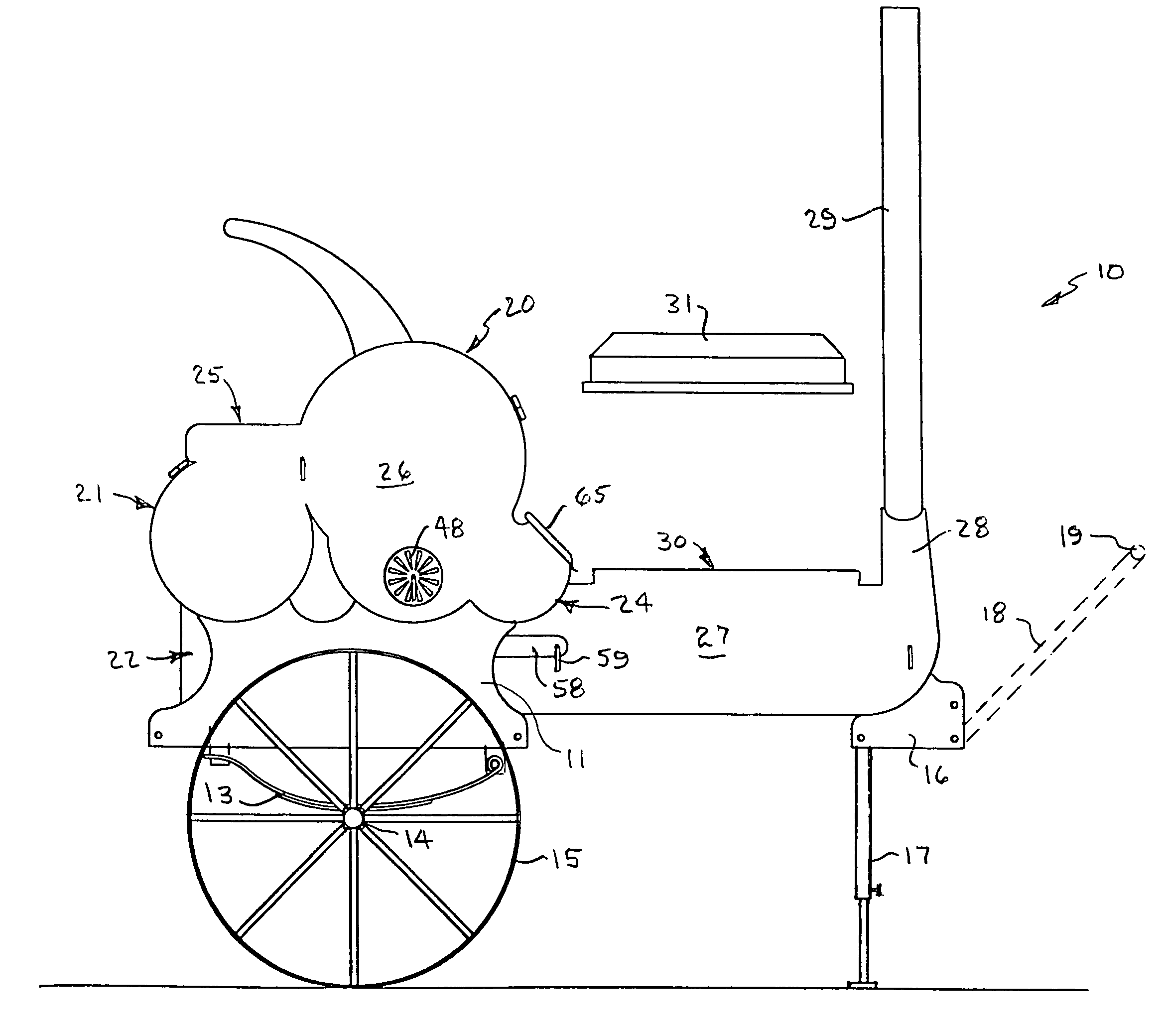

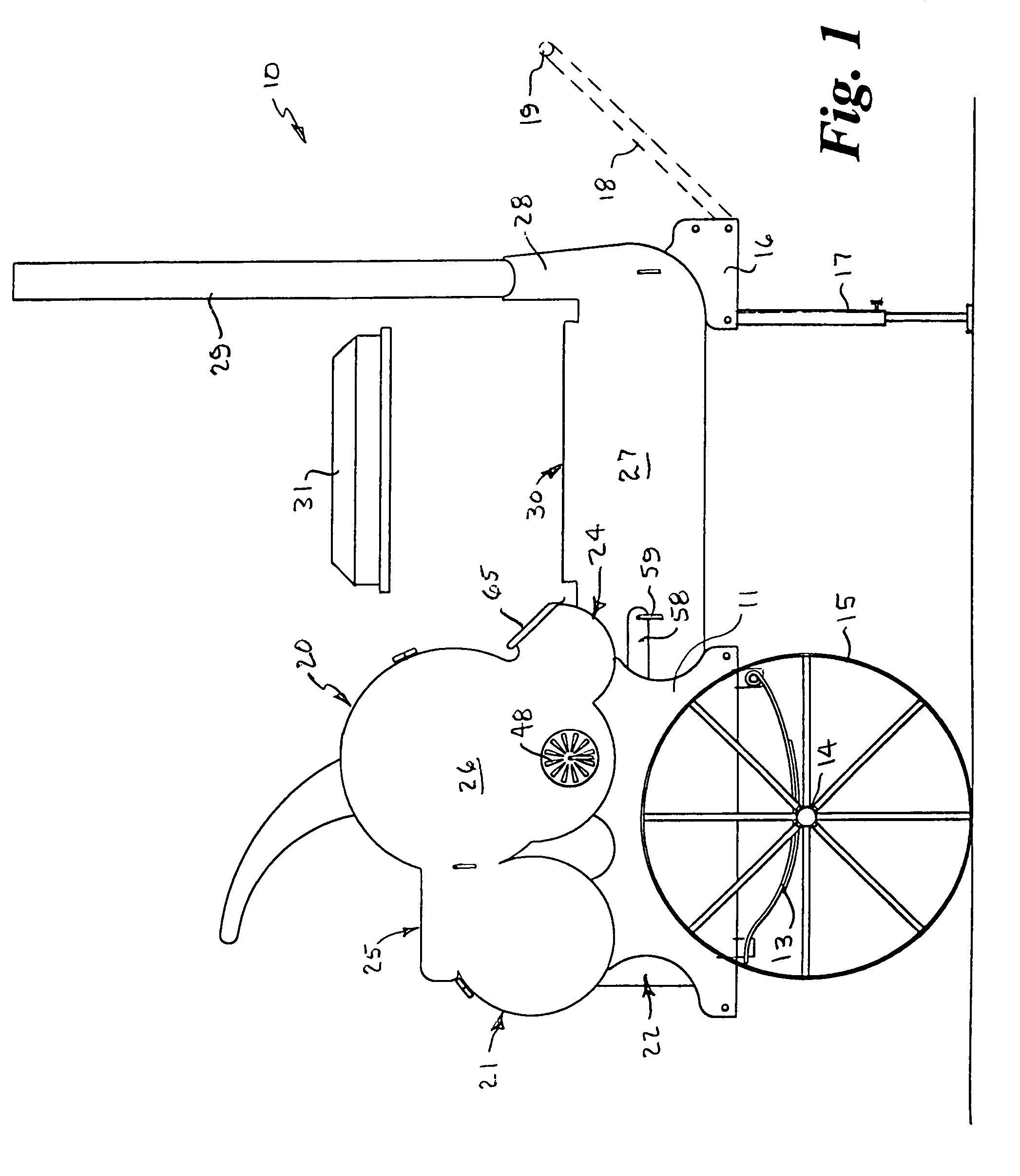

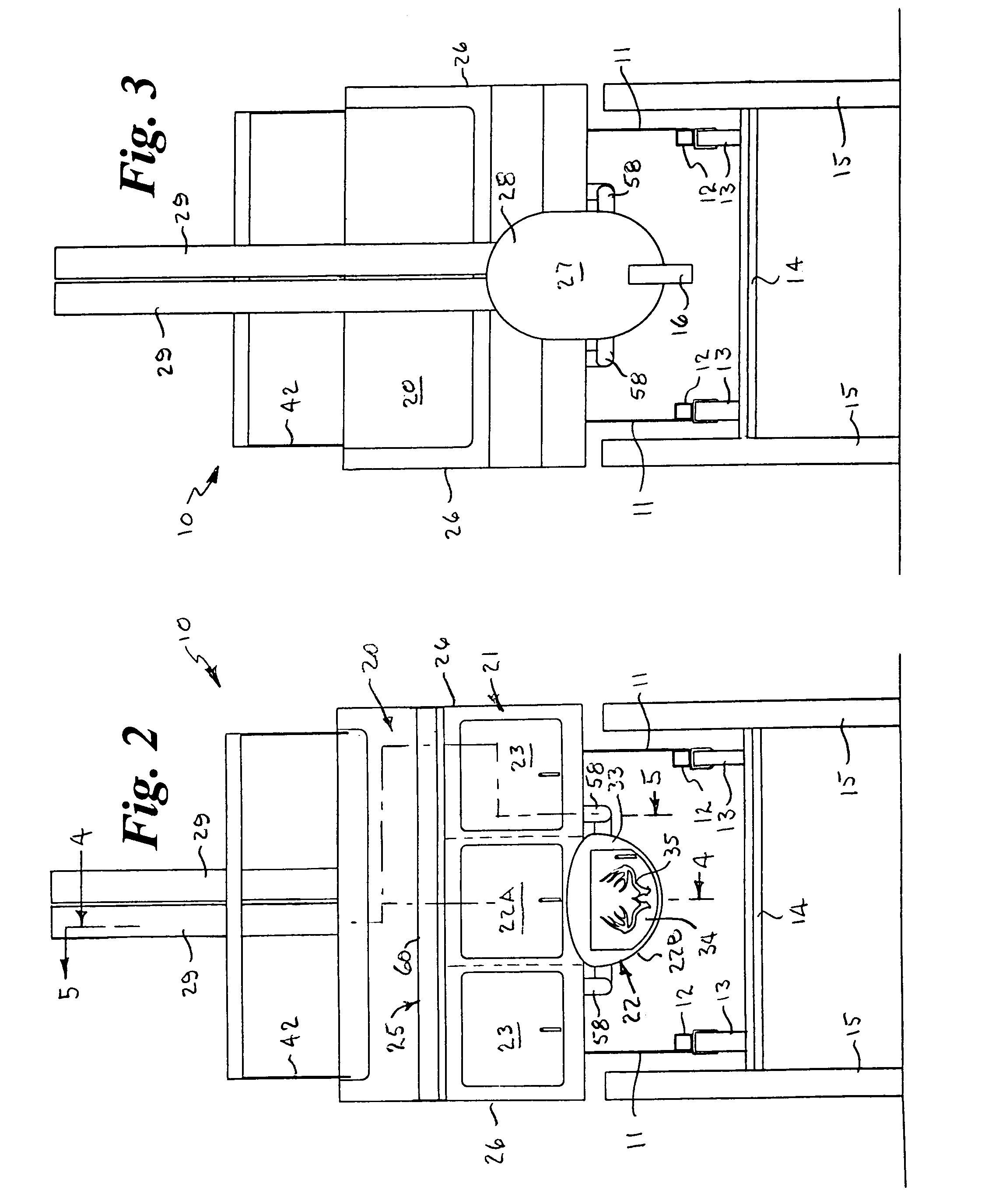

Outdoor multi-method cooker

InactiveUS7156087B1Lighting and heating apparatusStove/ranges for heating waterCombustionDifferential pressure

An outdoor multi-method cooker for preparing a wide variety of different foods at the same time using selective convection, radiant, or conduction cooking operations with or without smoke, or combinations thereof, using a single heat source. The cooker has a horizontal central longitudinal chamber with a firebox at one end and a pair of stacks at the opposed end, a main oven, a pair of lateral smokeless ovens, a warming compartment, and a griddle above the firebox, all disposed transversely on the longitudinal chamber in parallel spaced relation, and a steam table along the upper portion of the longitudinal chamber. The cooker operates on the principle of equalization of natural differential pressures caused by rising warmer air, similar to the draw created by the upper portion of a fireplace, for drafting hot gases or smoke laden hot gases from the combustion source and selectively routing it through passageways into and around the various components.

Owner:CHURCHILL III ALBERT B +1

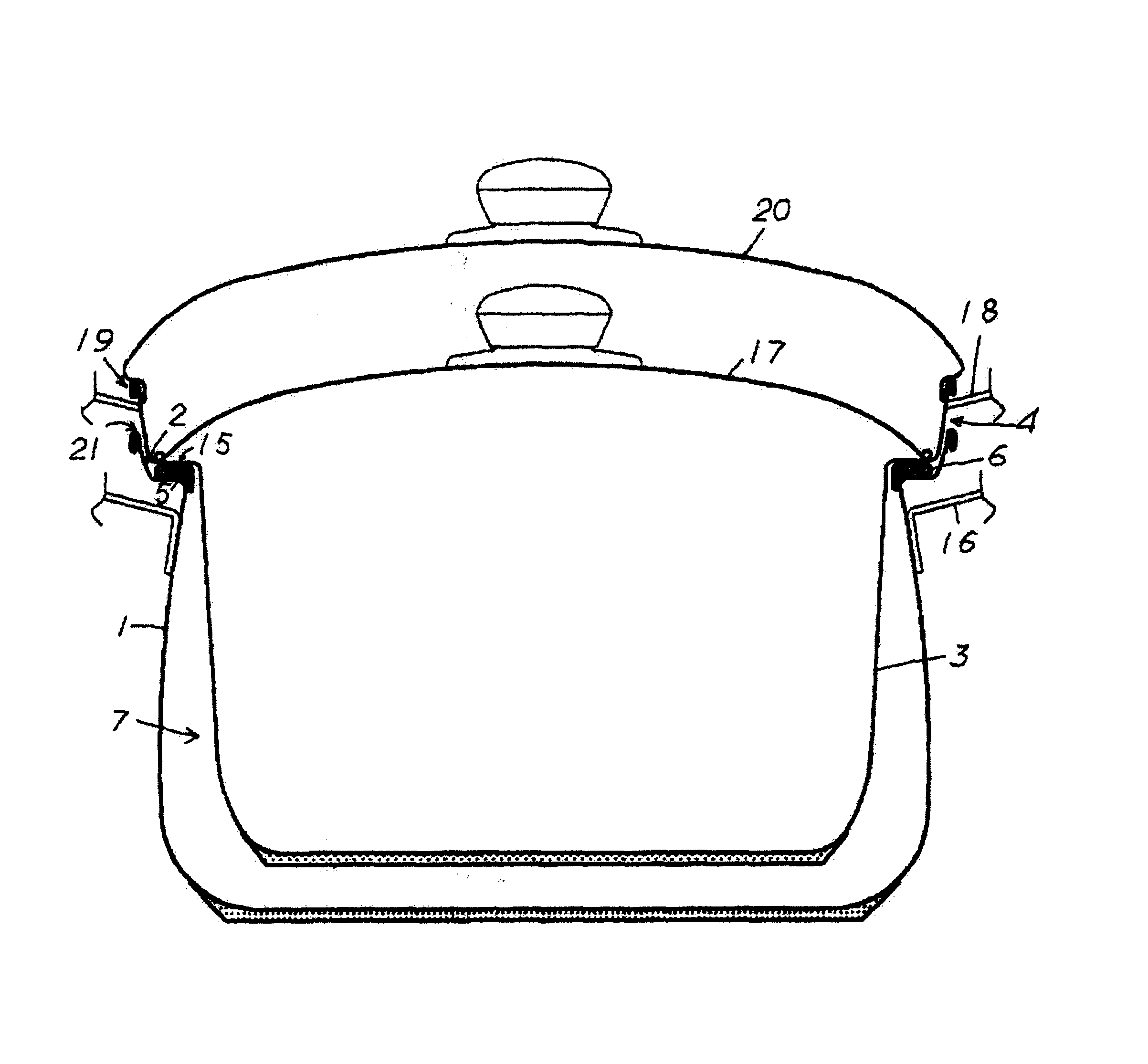

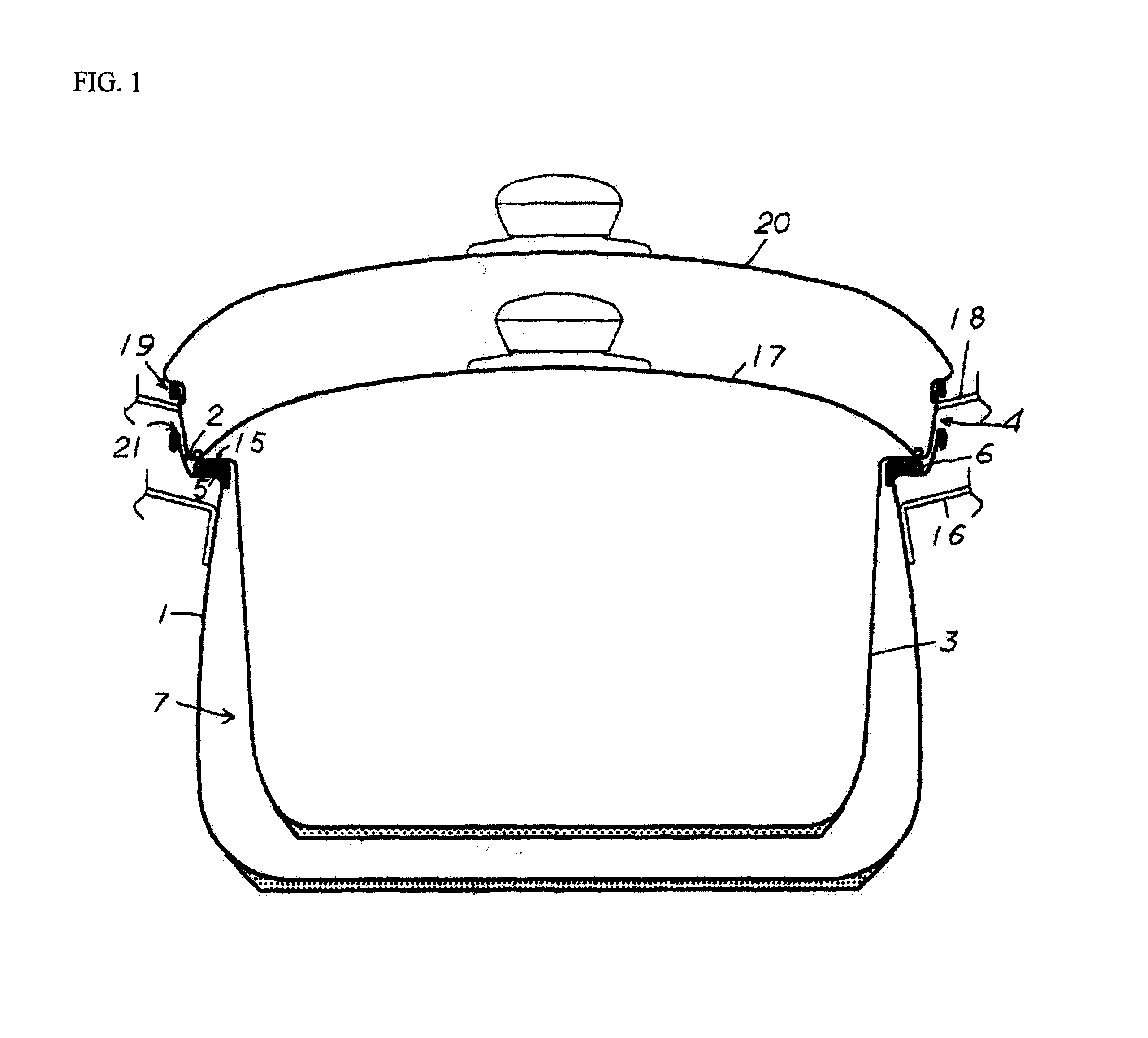

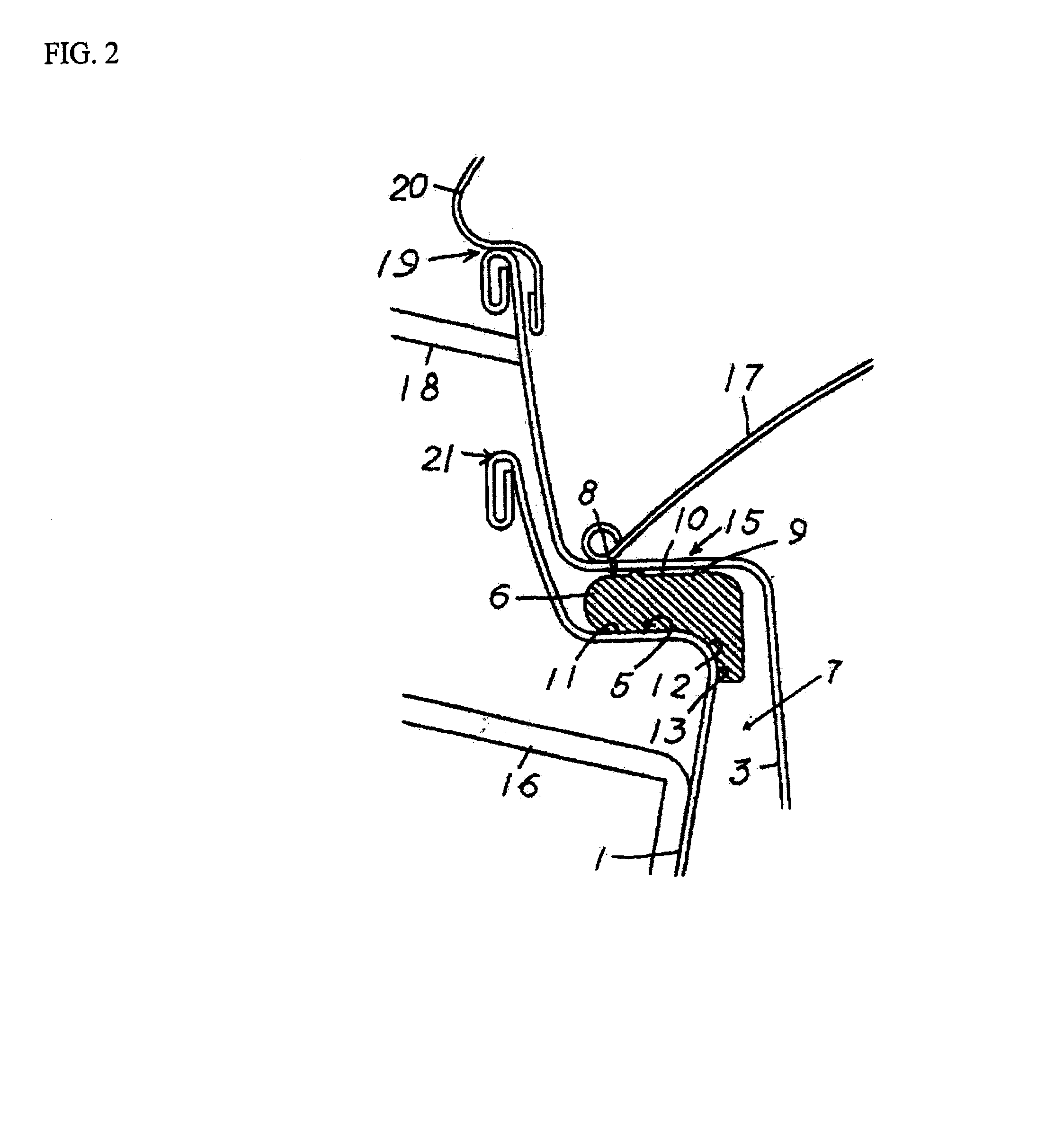

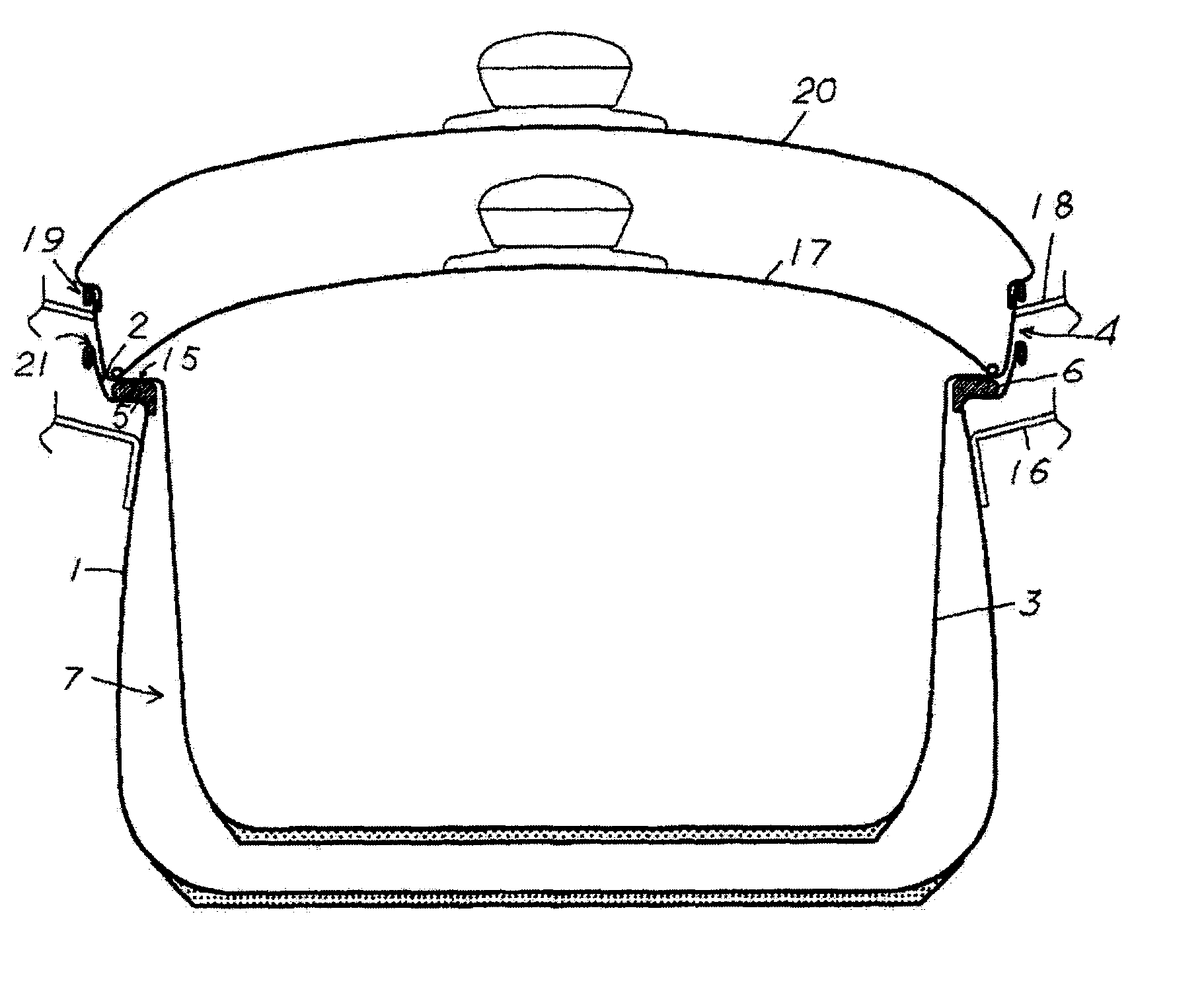

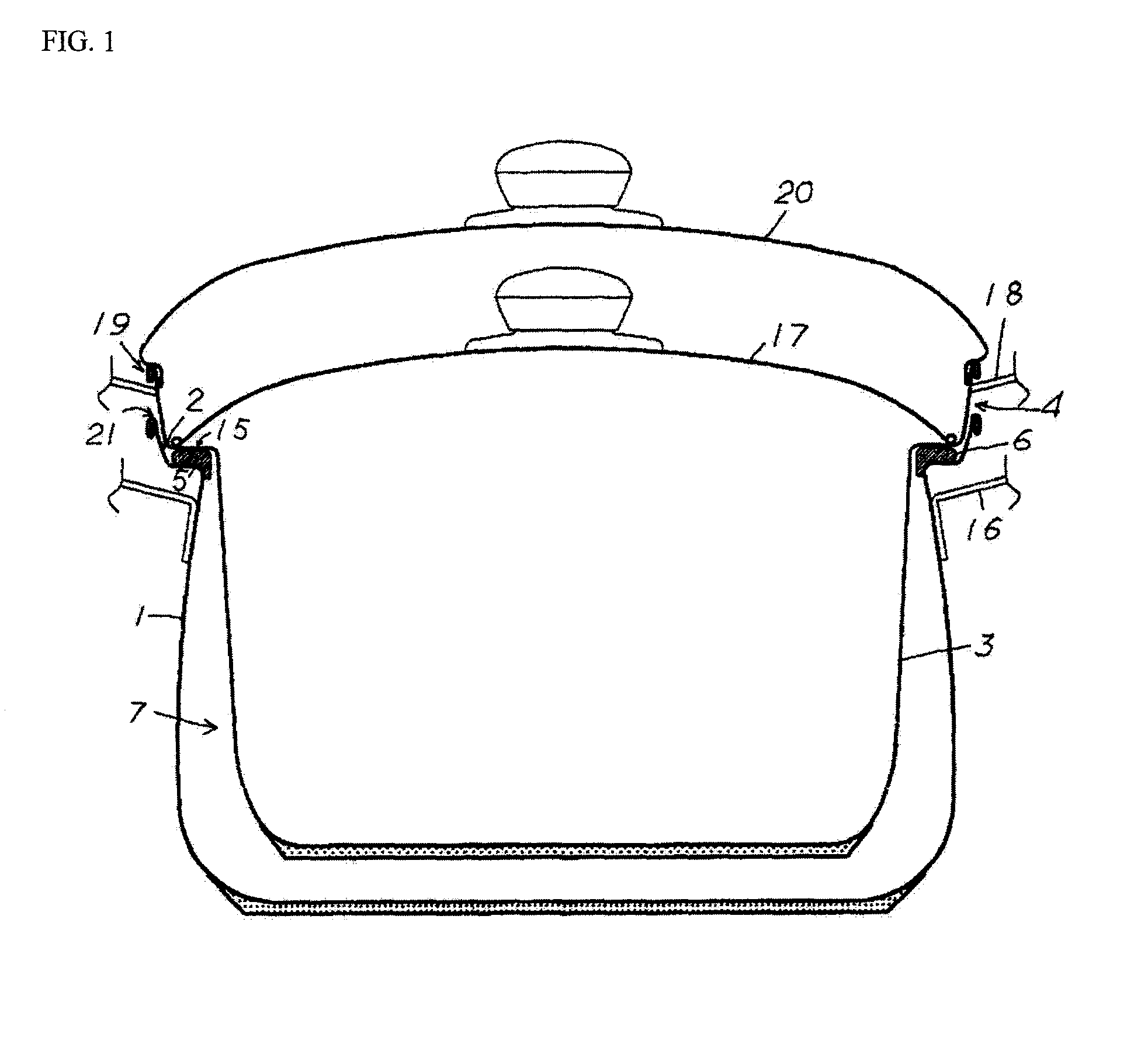

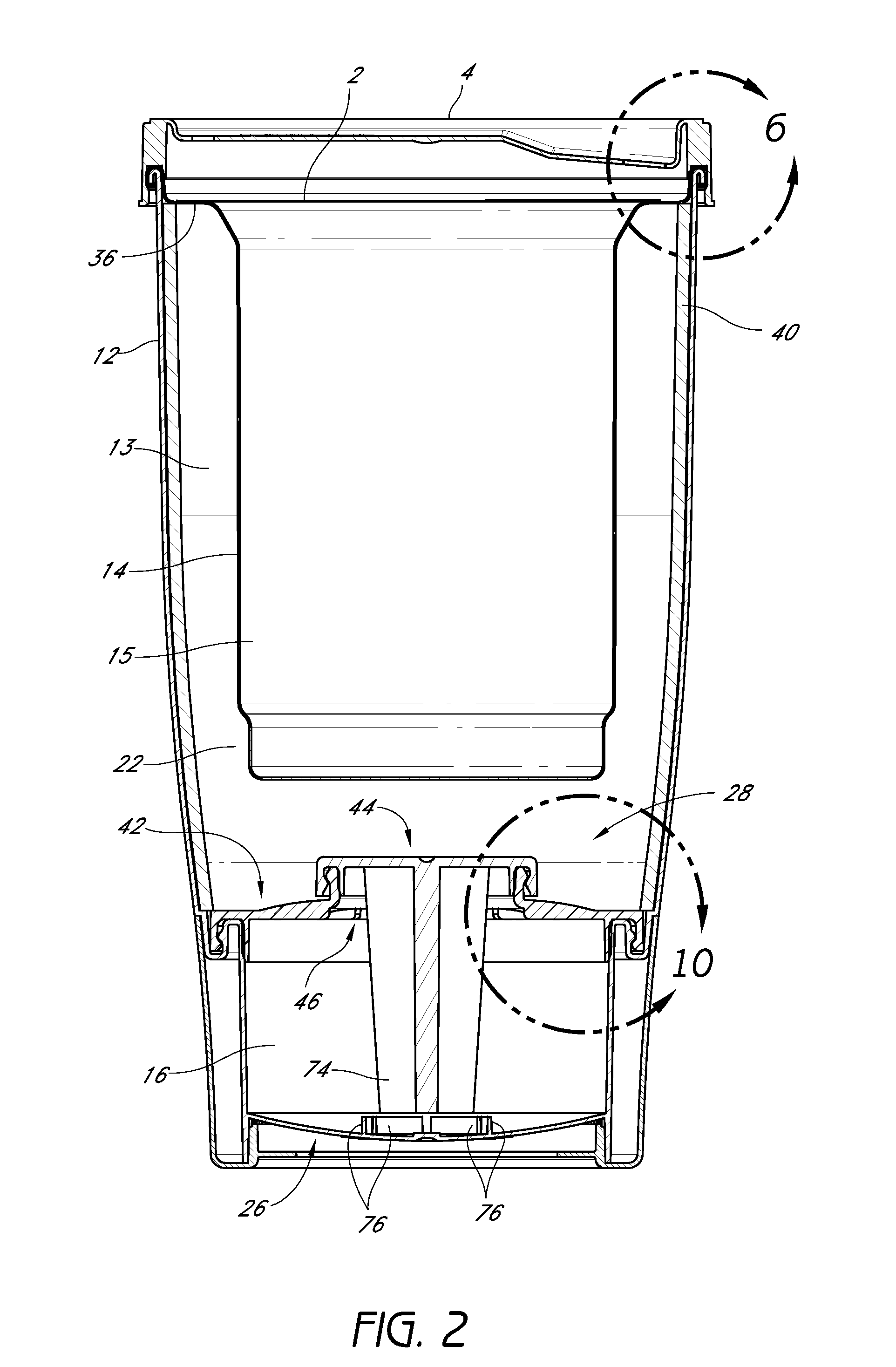

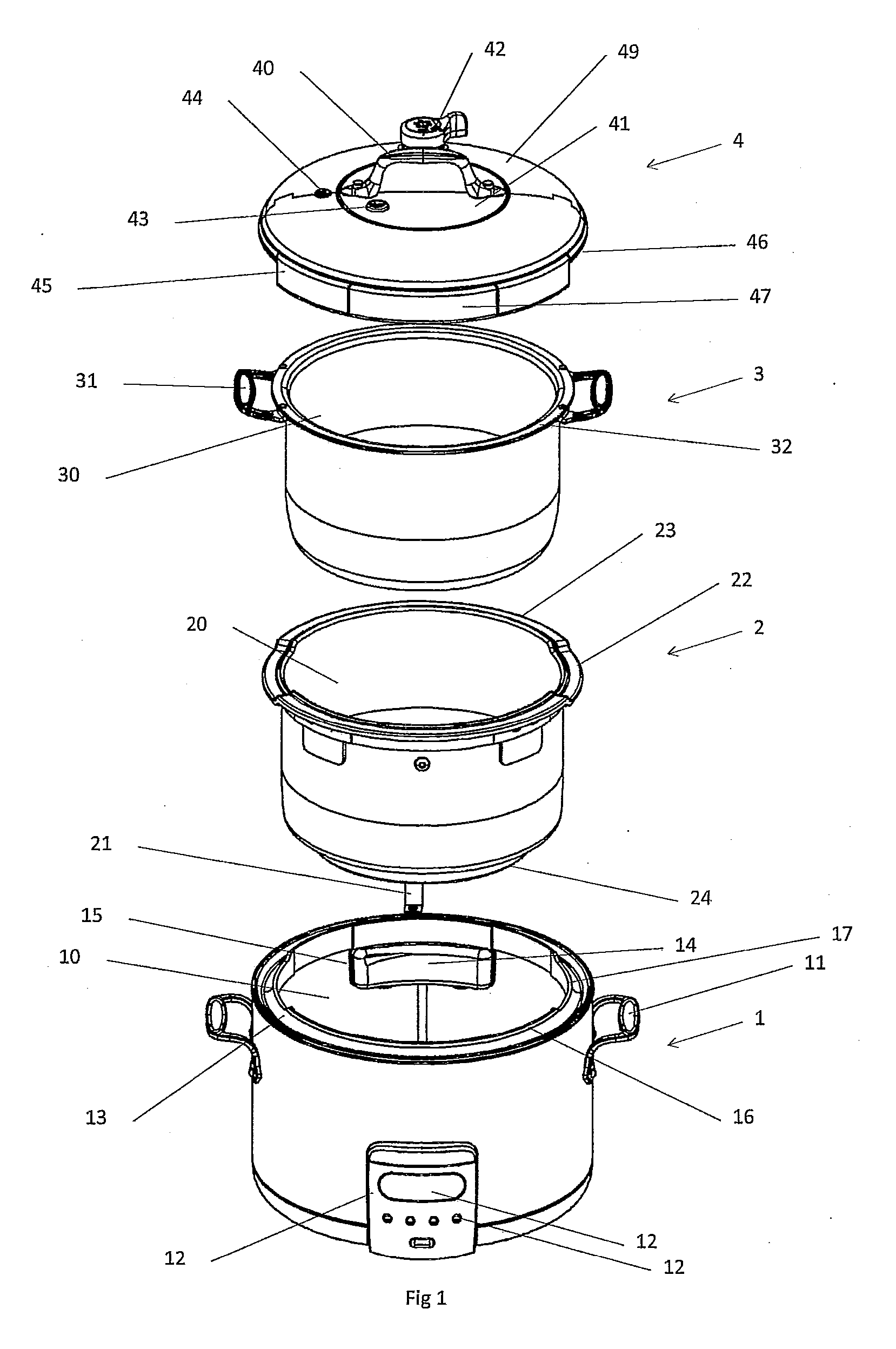

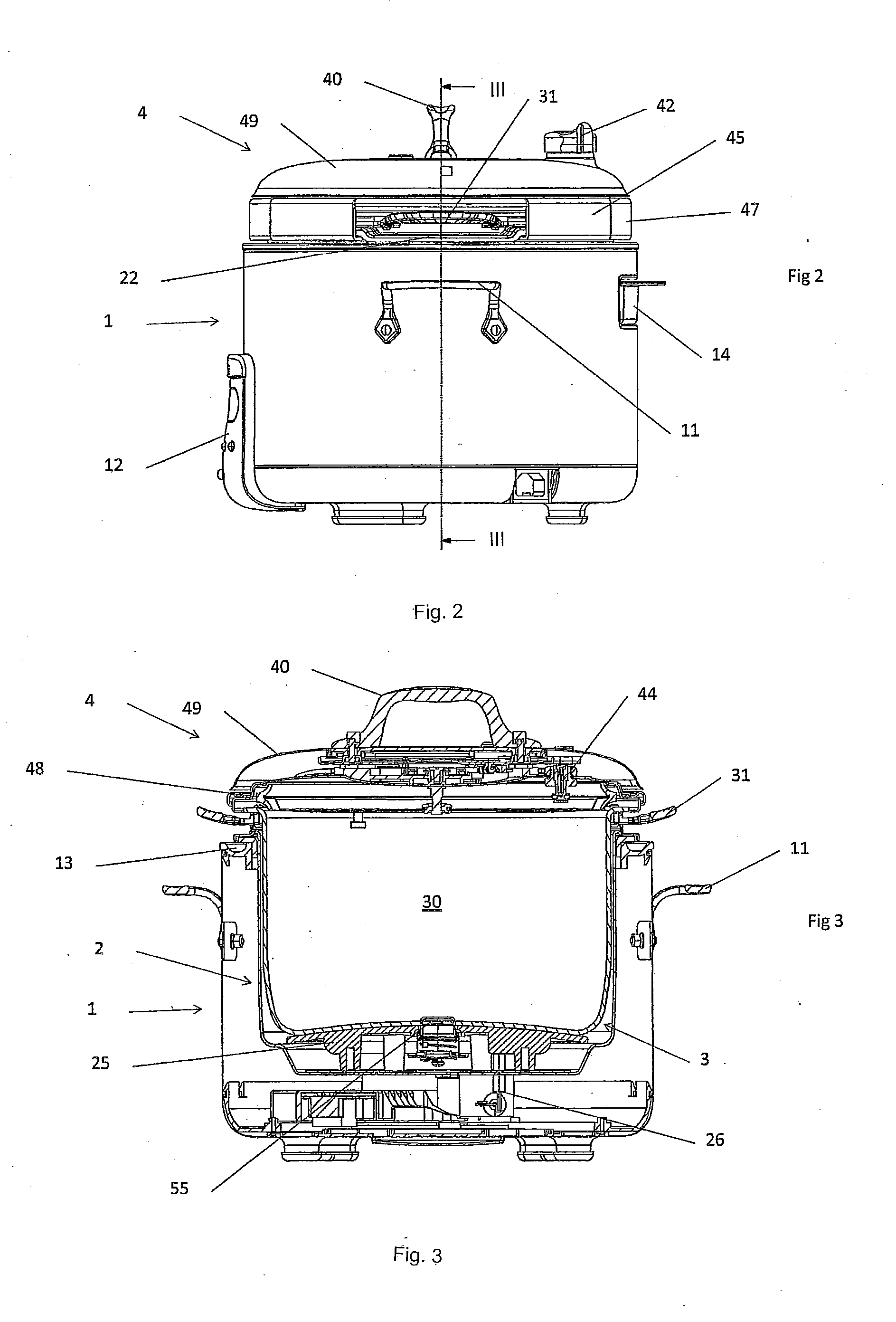

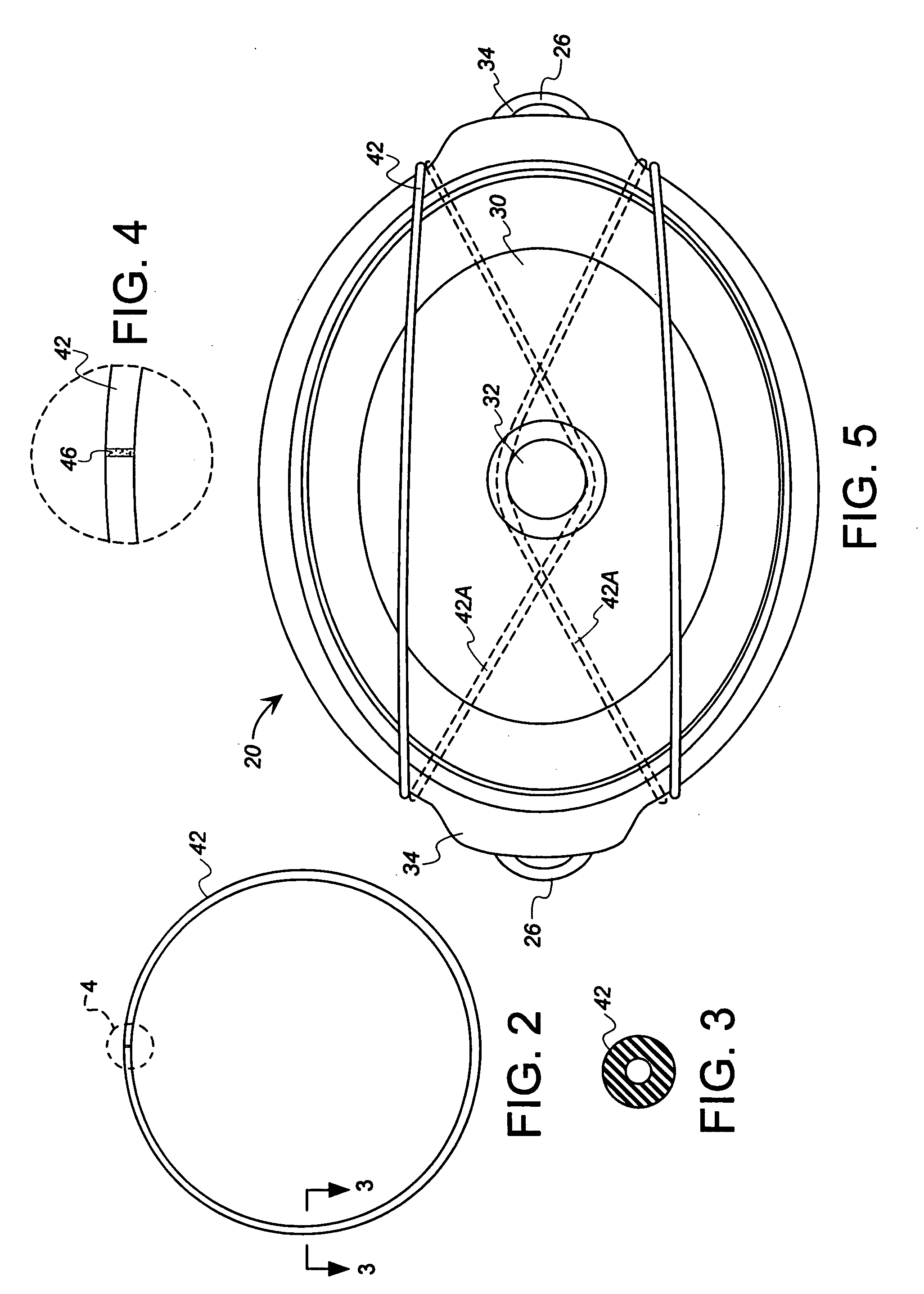

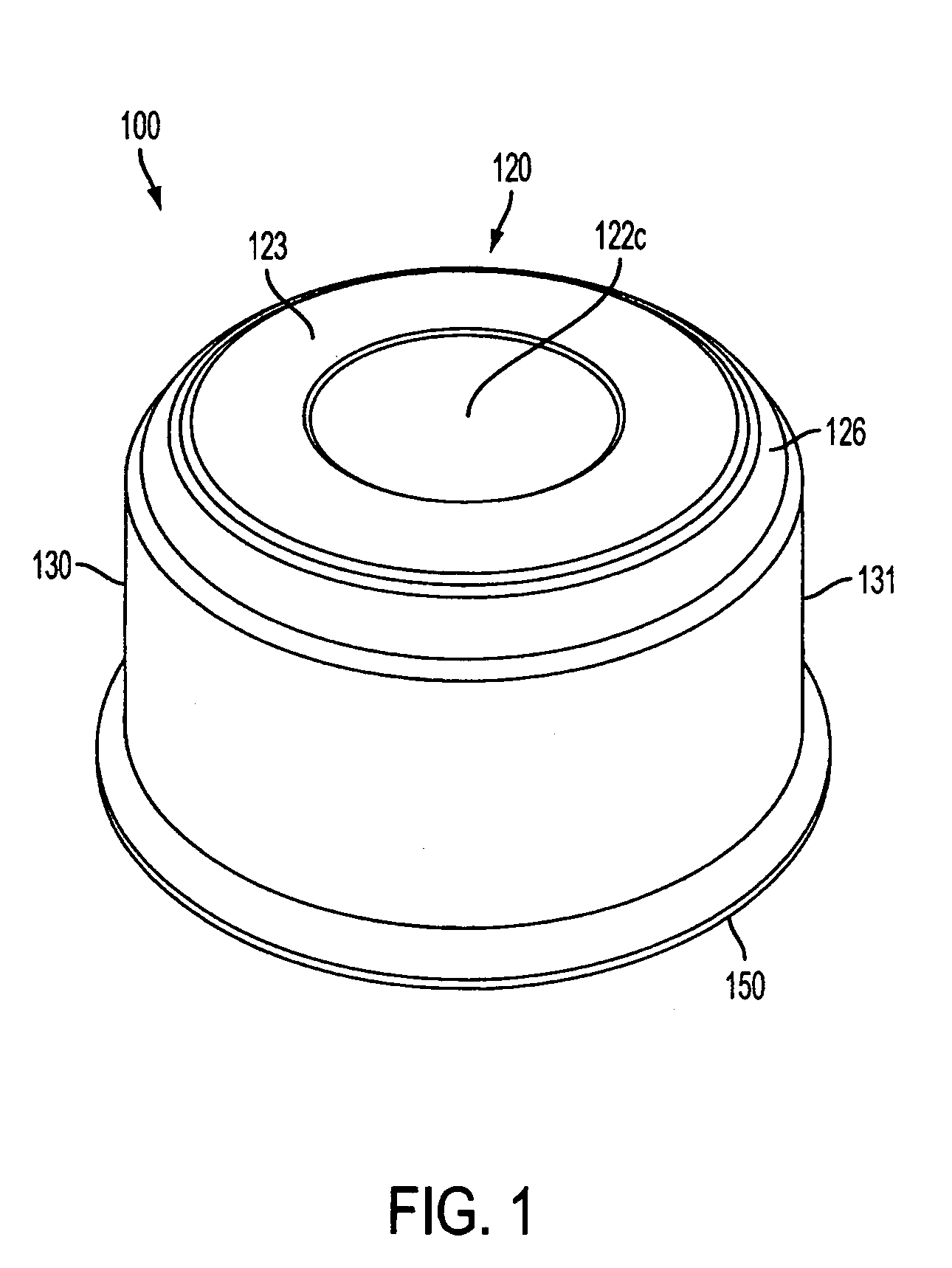

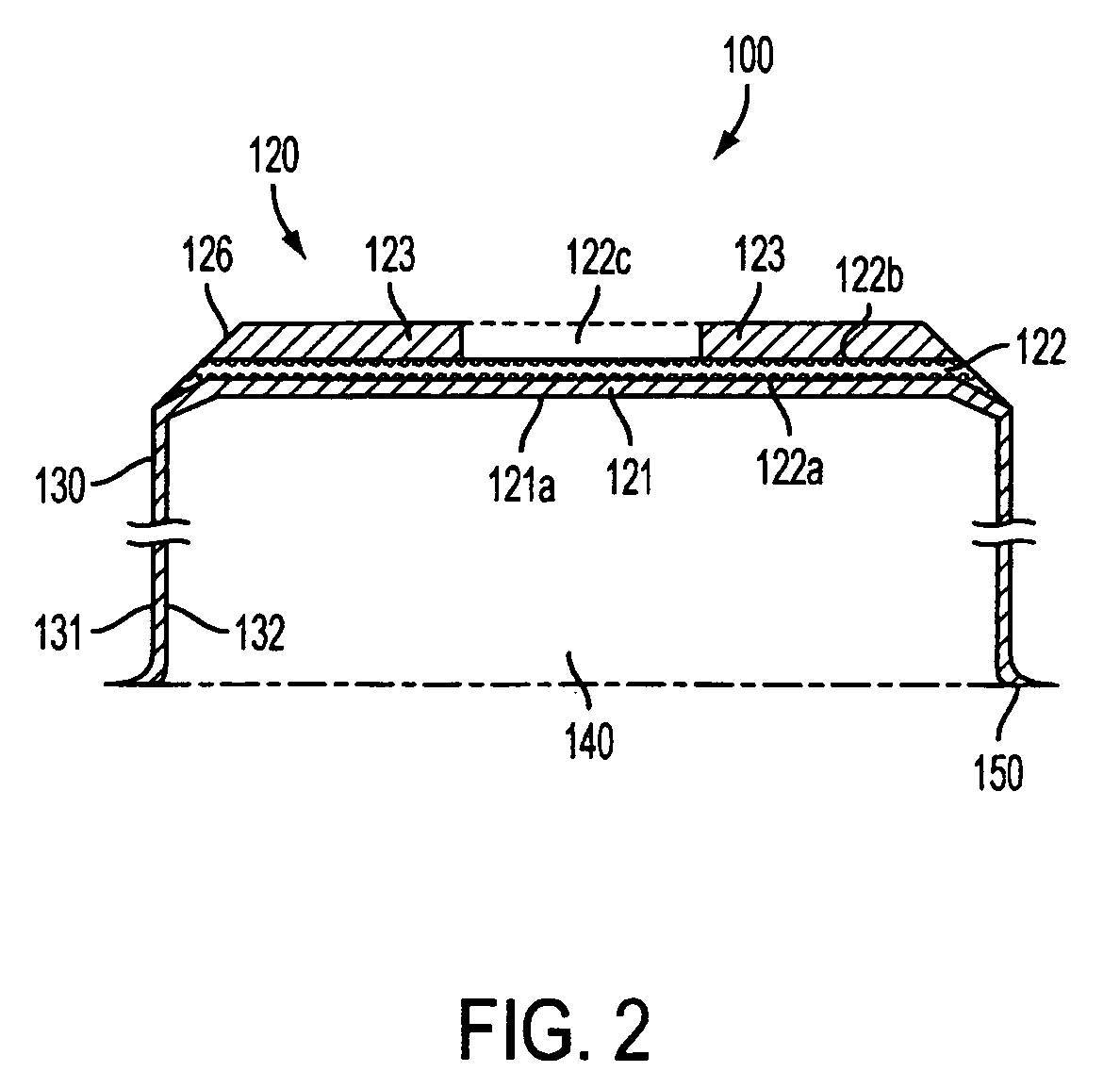

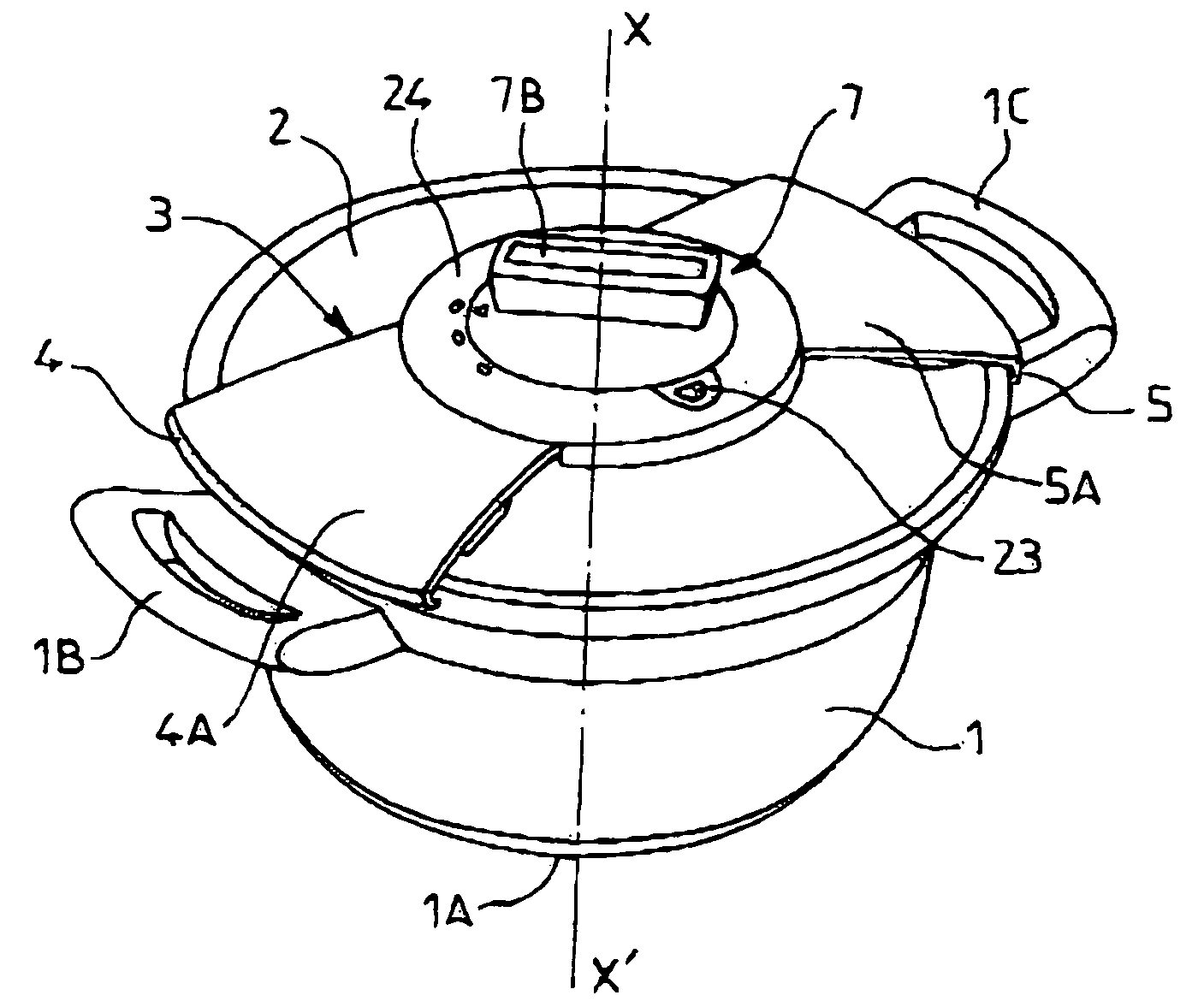

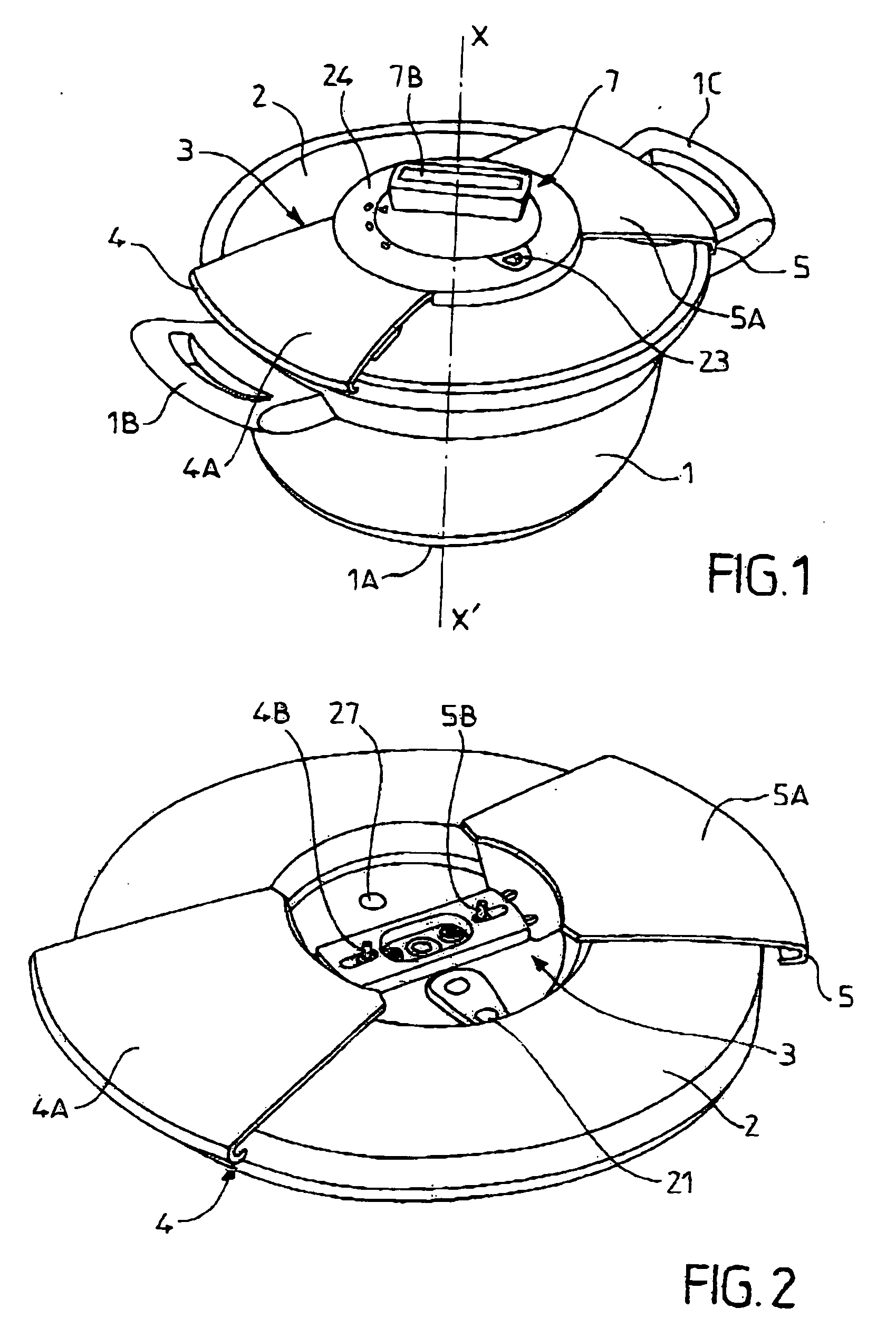

Thermally insulated pot

InactiveUS7086326B2Improve insulation effectImprove sealingWater heating stoves/rangesStove/ranges for heating waterThermal insulationEngineering

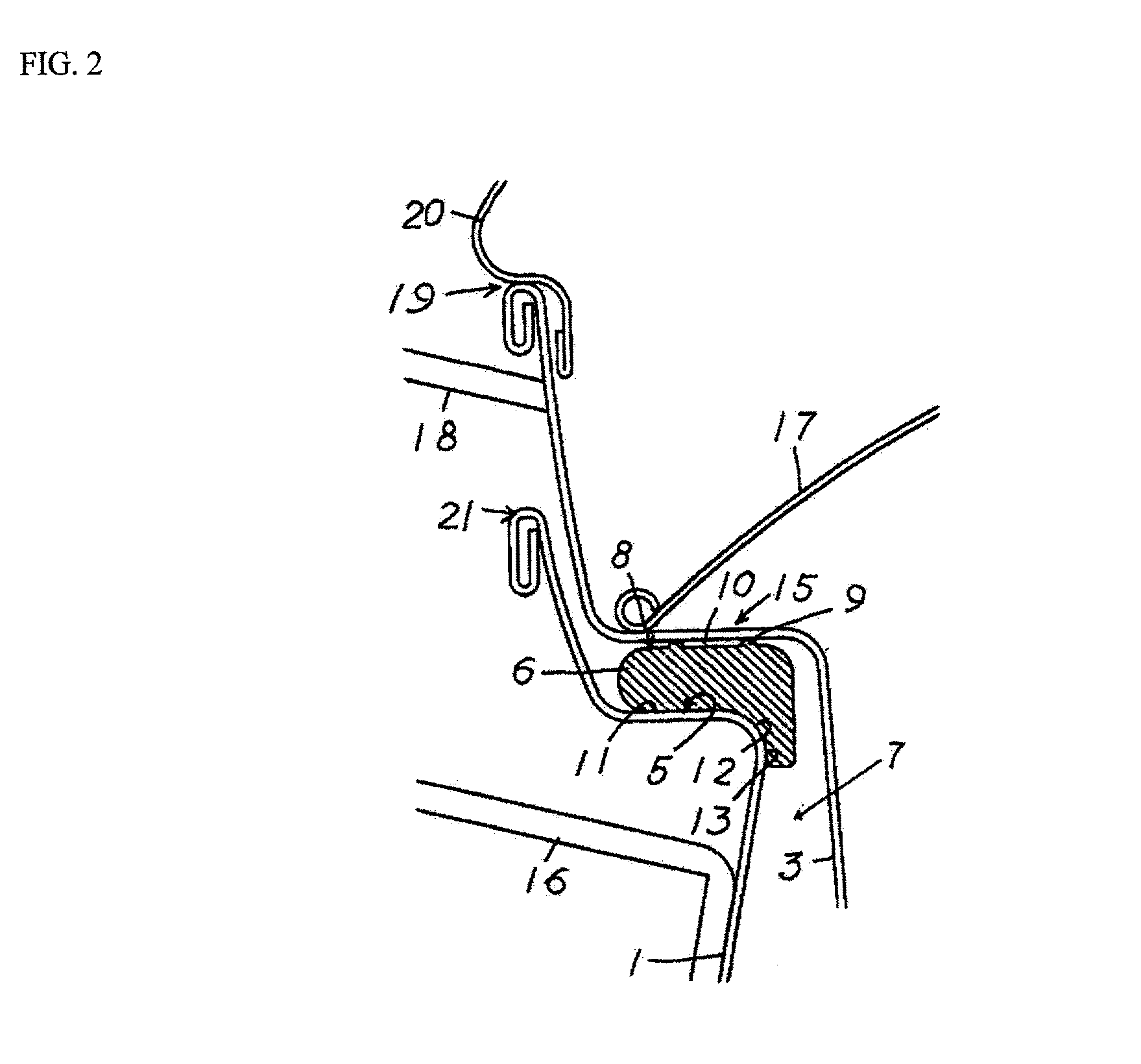

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

Thermally insulated pot

InactiveUS20020185012A1Multiple-unit cooking vesselsWater heating stoves/rangesThermal insulationEngineering

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

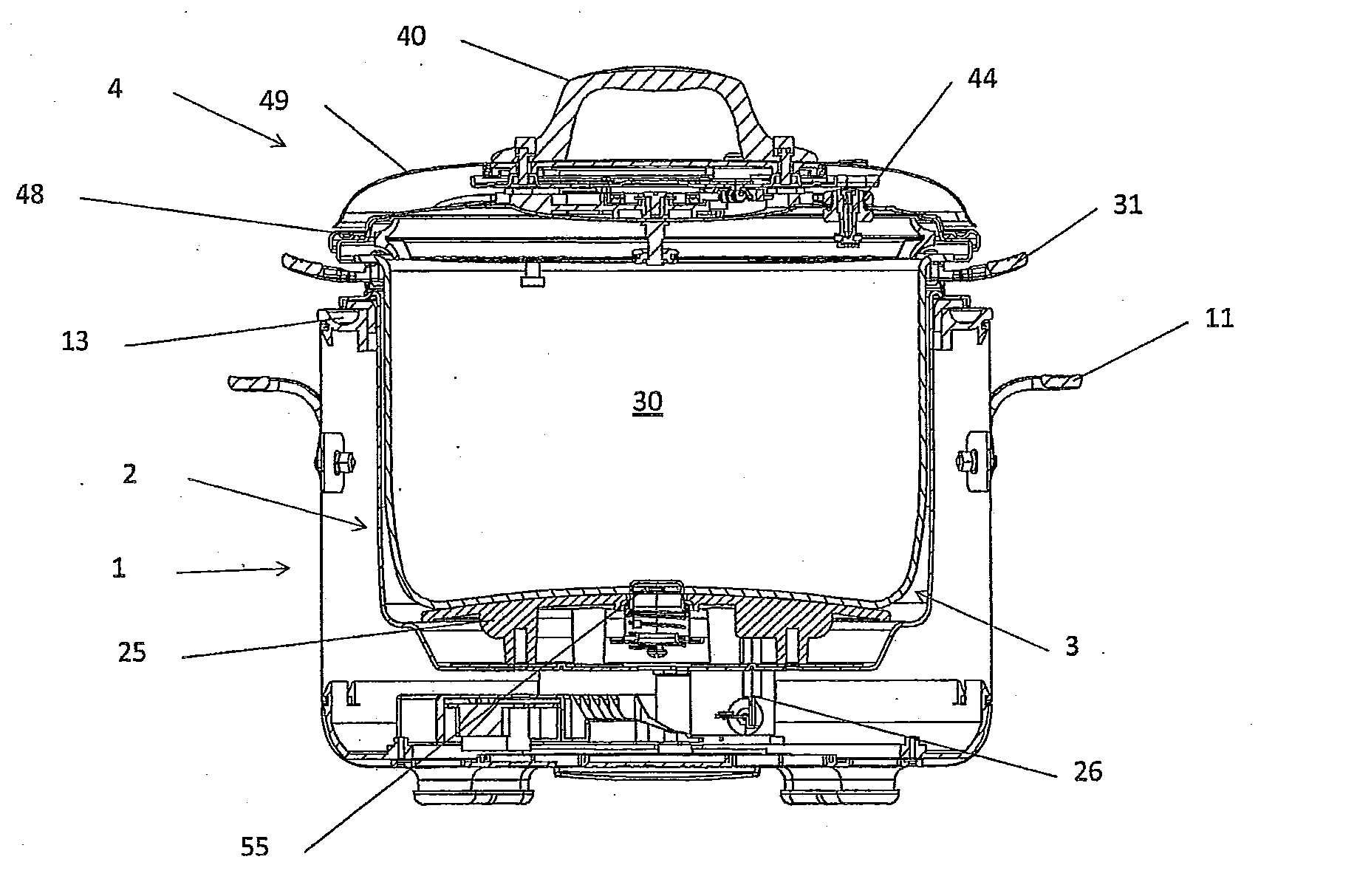

Electrical appliance for cooking food

InactiveUS8546731B2Easy and safe manipulationAvoid burnsRotary drum furnacesWater heating stoves/rangesEngineeringIngested food

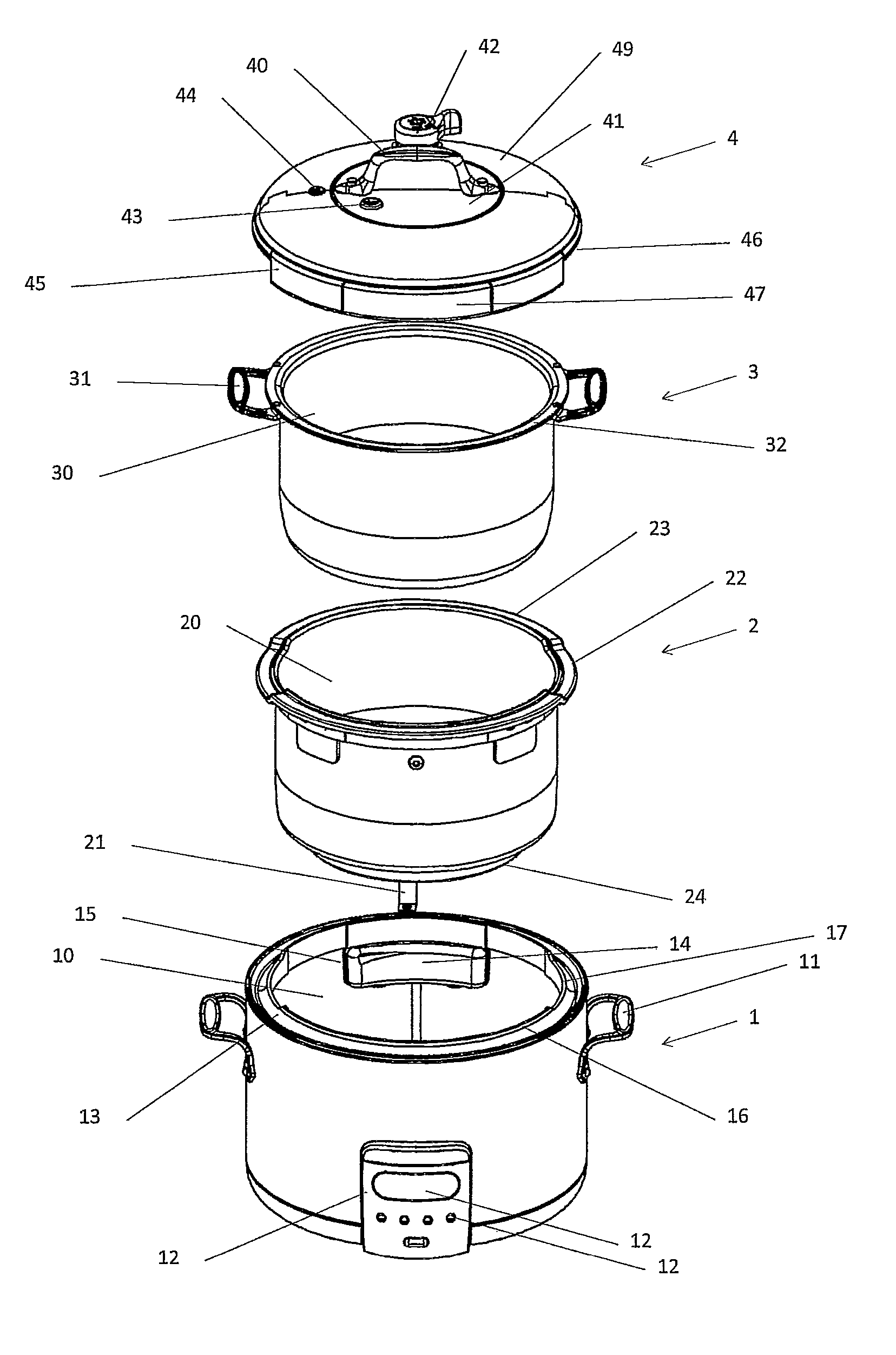

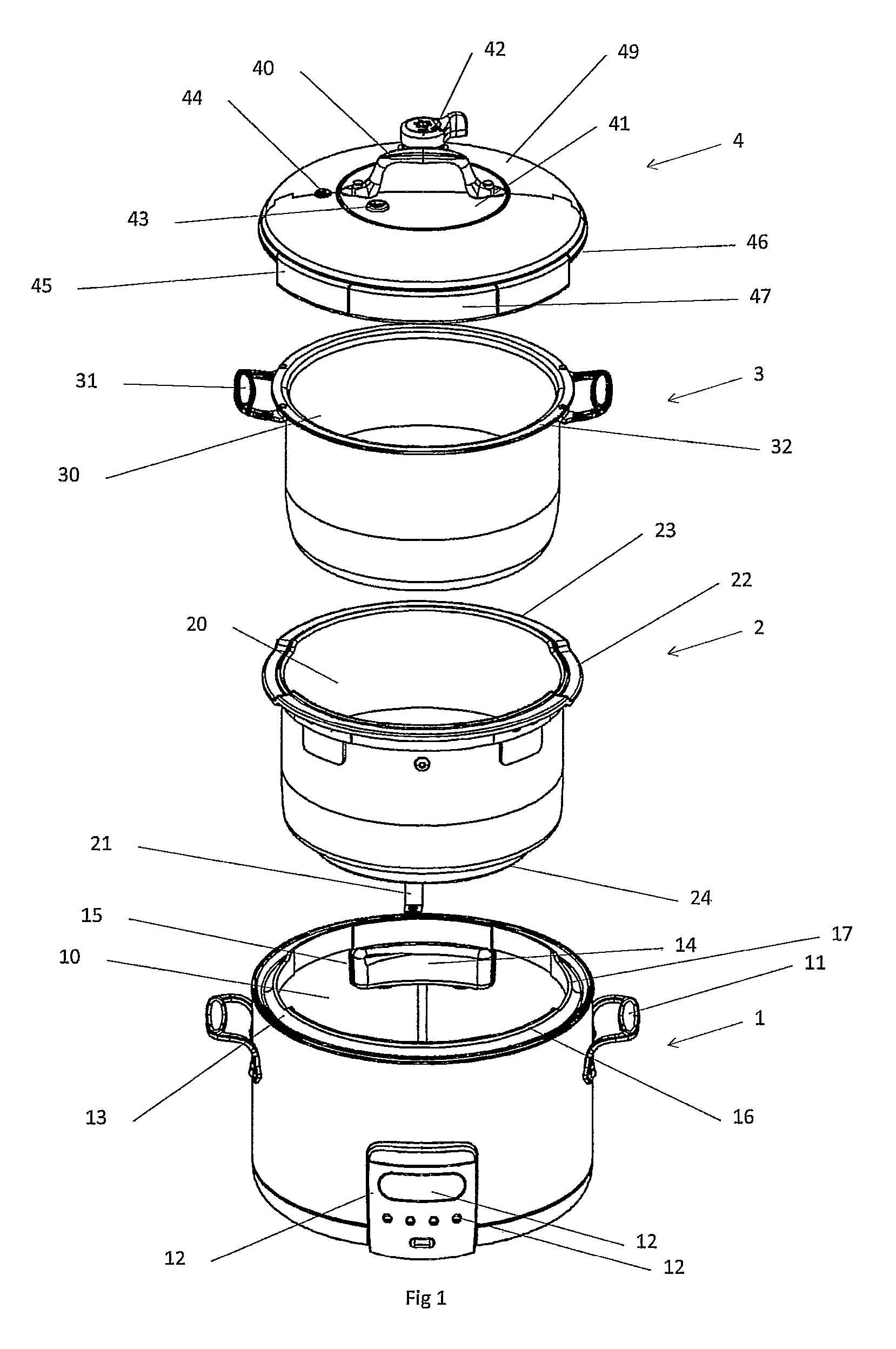

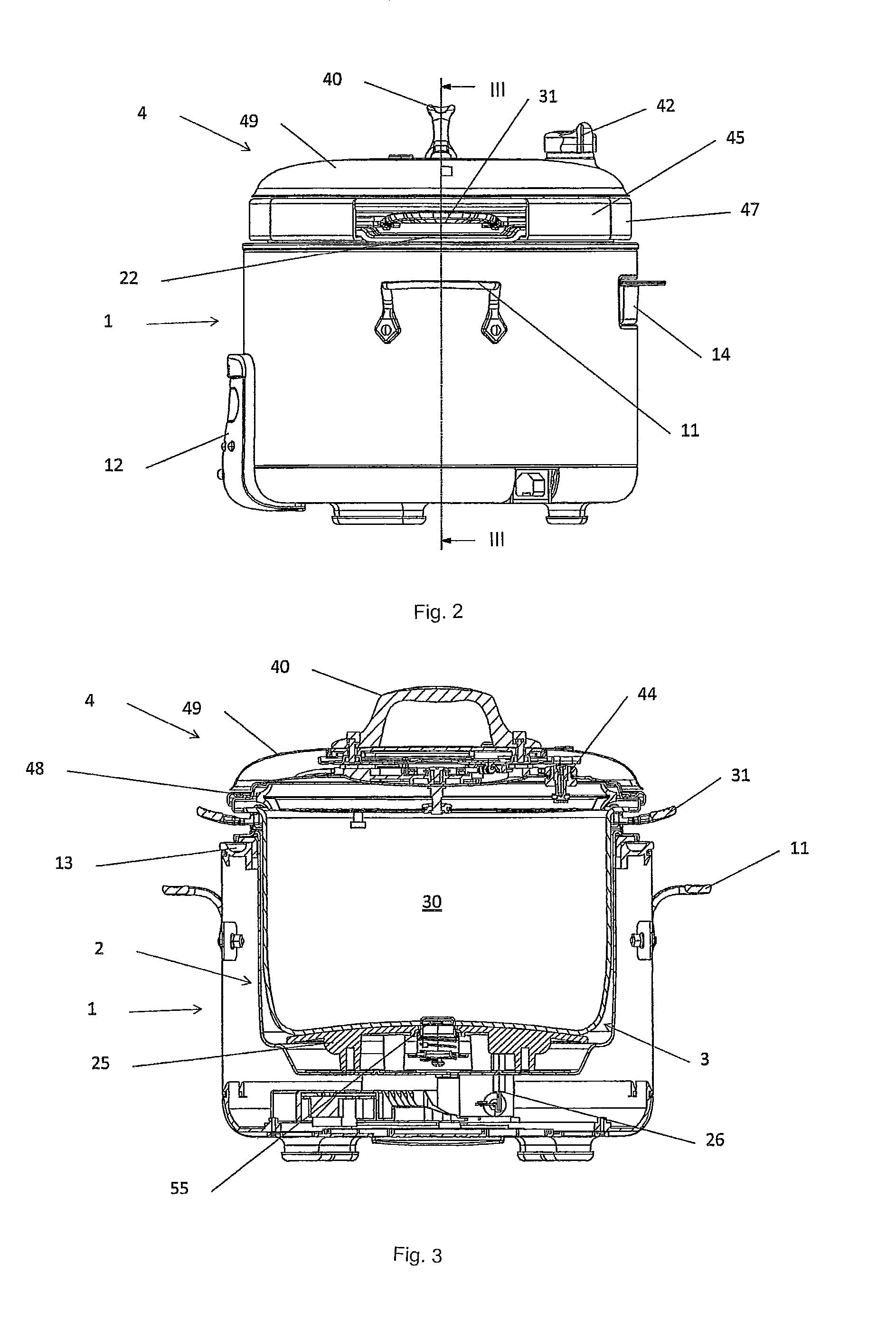

An electric appliance for pressure cooking food includes a casing (1) and a lid (4) forming the outer jacket of the appliance, an outer vessel (2) forming the inner chamber of the appliance, a heating element (25) placed in the bottom of the outer vessel (2), a removable inner vessel (3) forming the container (30) for cooking food, wherein the inner vessel (3) includes at least one handhold (31) extending past the periphery of the casing (1).

Owner:SEB SA

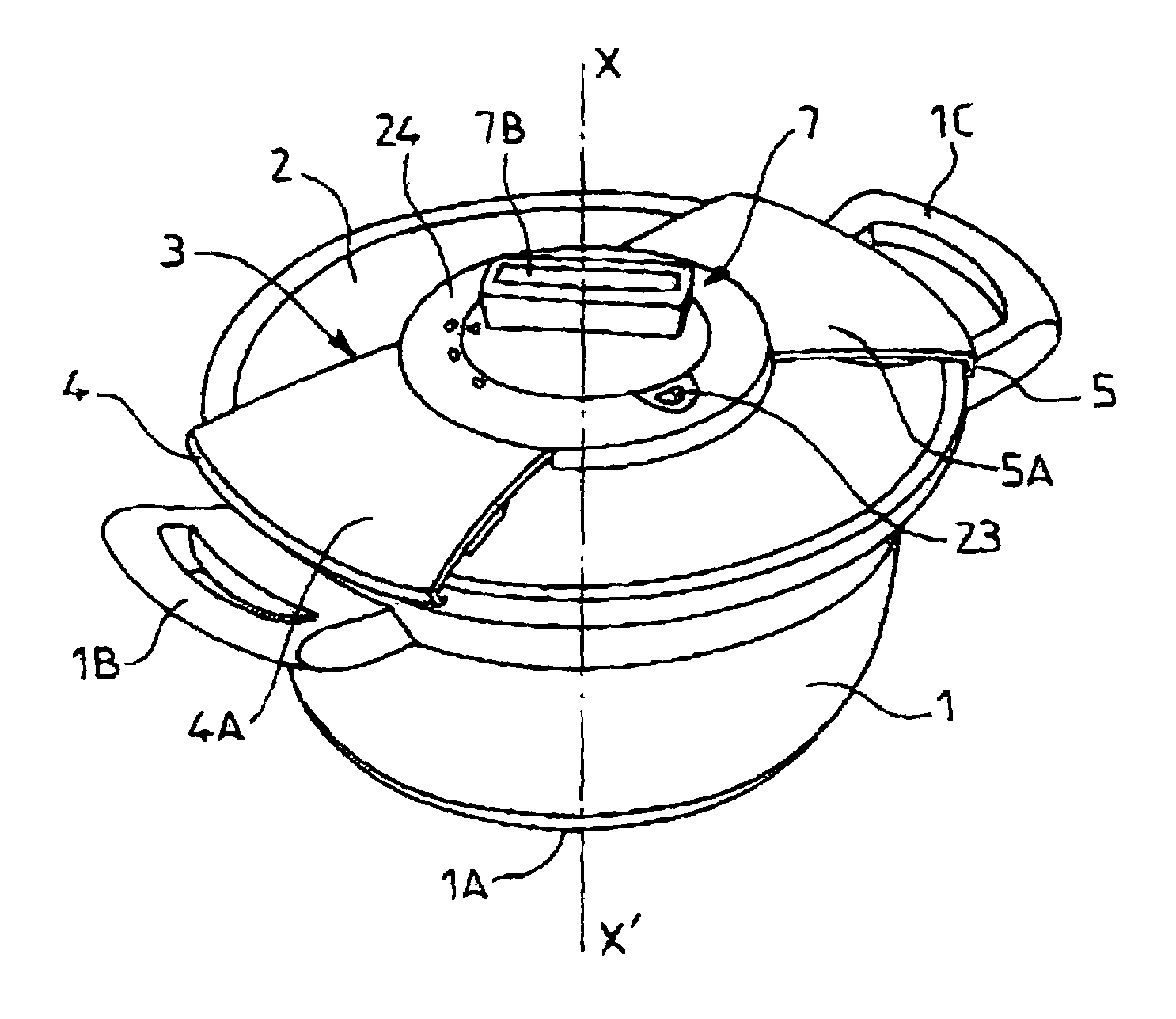

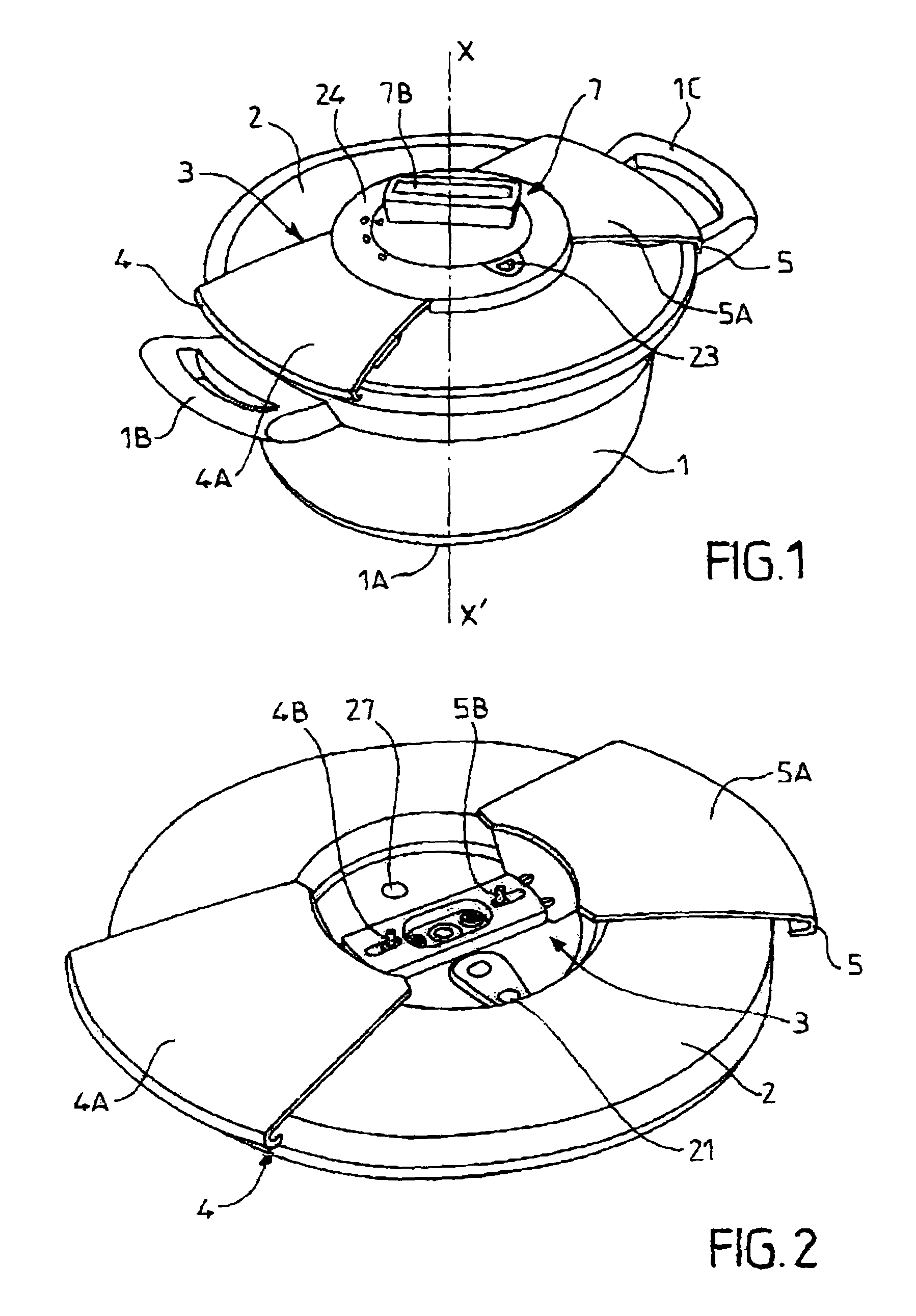

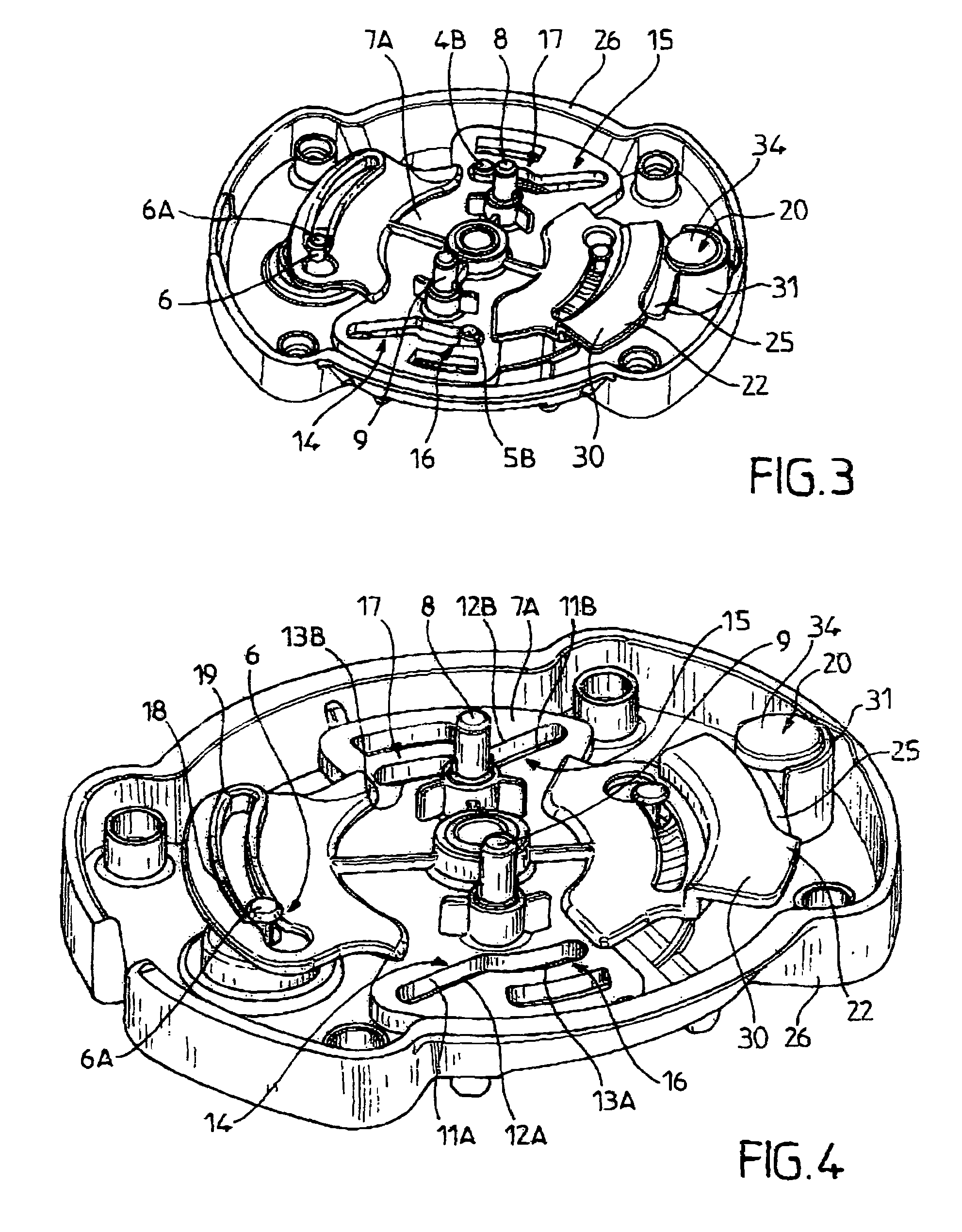

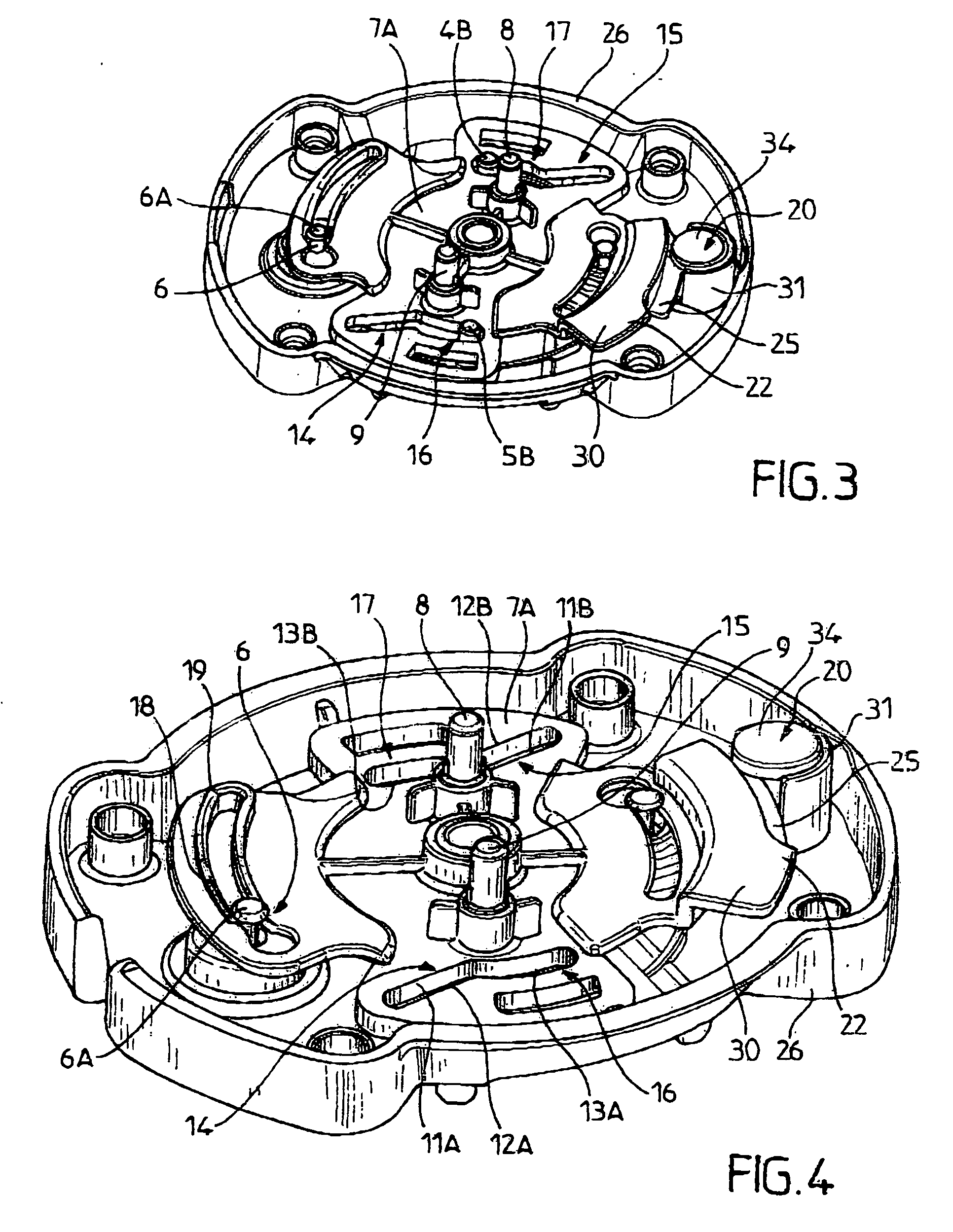

Pressure-cooking appliance including opening safety means

ActiveUS7523696B2Easy to useHigh speedWater heating stoves/rangesStove/ranges for heating waterHome applianceNeutral position

The invention relates to an appliance for cooking under pressure, the appliance comprising:a bowl and a lid; andopening safety means suitable for going between a neutral position, in which they allow the lid to be unlocked, and a blocking position, in which they prevent the lid from being unlocked, said safety means being designed to find themselves in the blocking position when the pressure prevailing inside the vessel is greater than or equal to a predetermined value or “rise pressure”, and / or when the temperature prevailing inside the vessel is greater than or equal to a predetermined value or “rise temperature”;said appliance being further comprising actuating means for actuating the safety means, which actuating means are arranged to make it possible to place the safety means in the blocking position. The invention is applicable to household appliances for cooking under pressure.

Owner:SEB SA

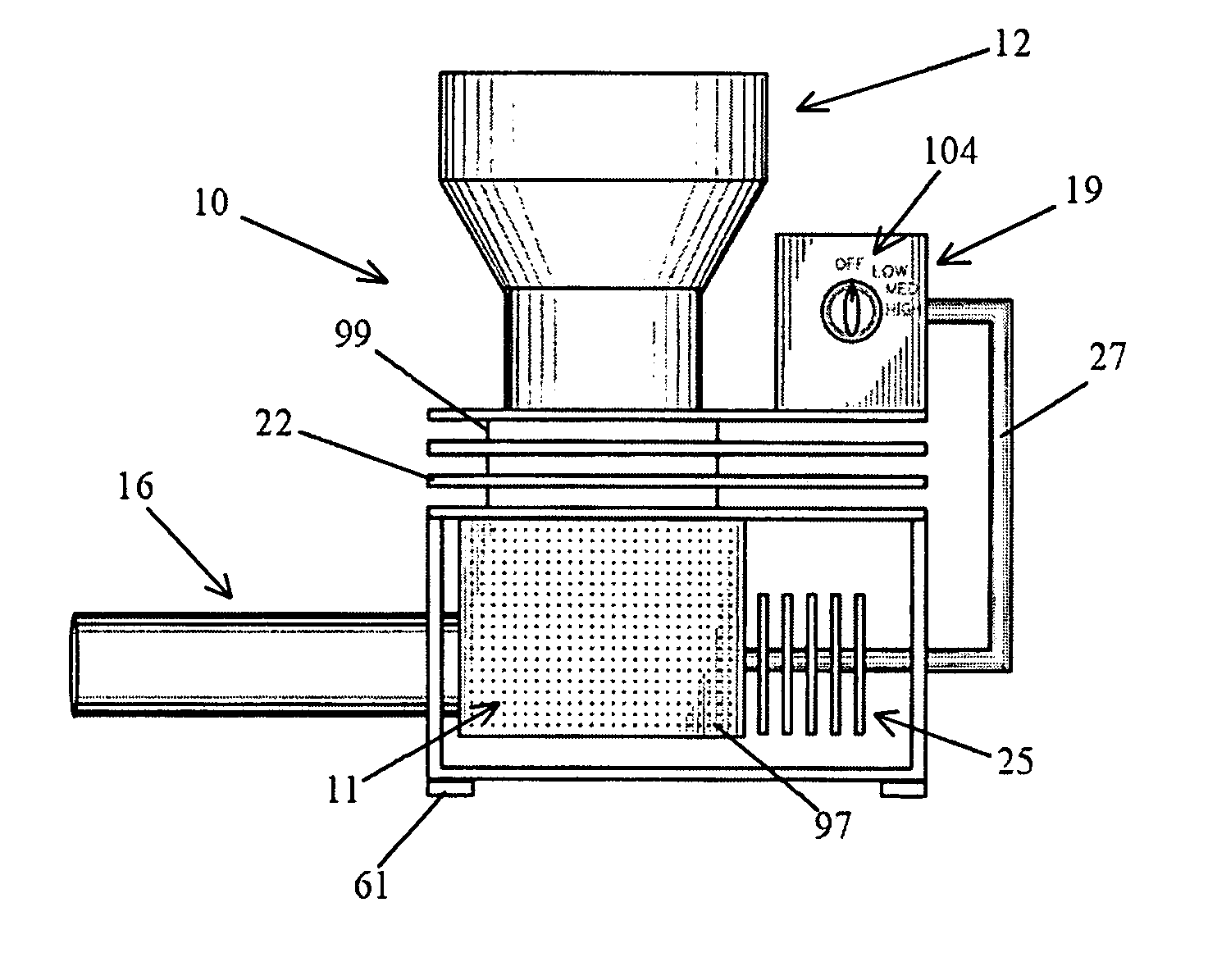

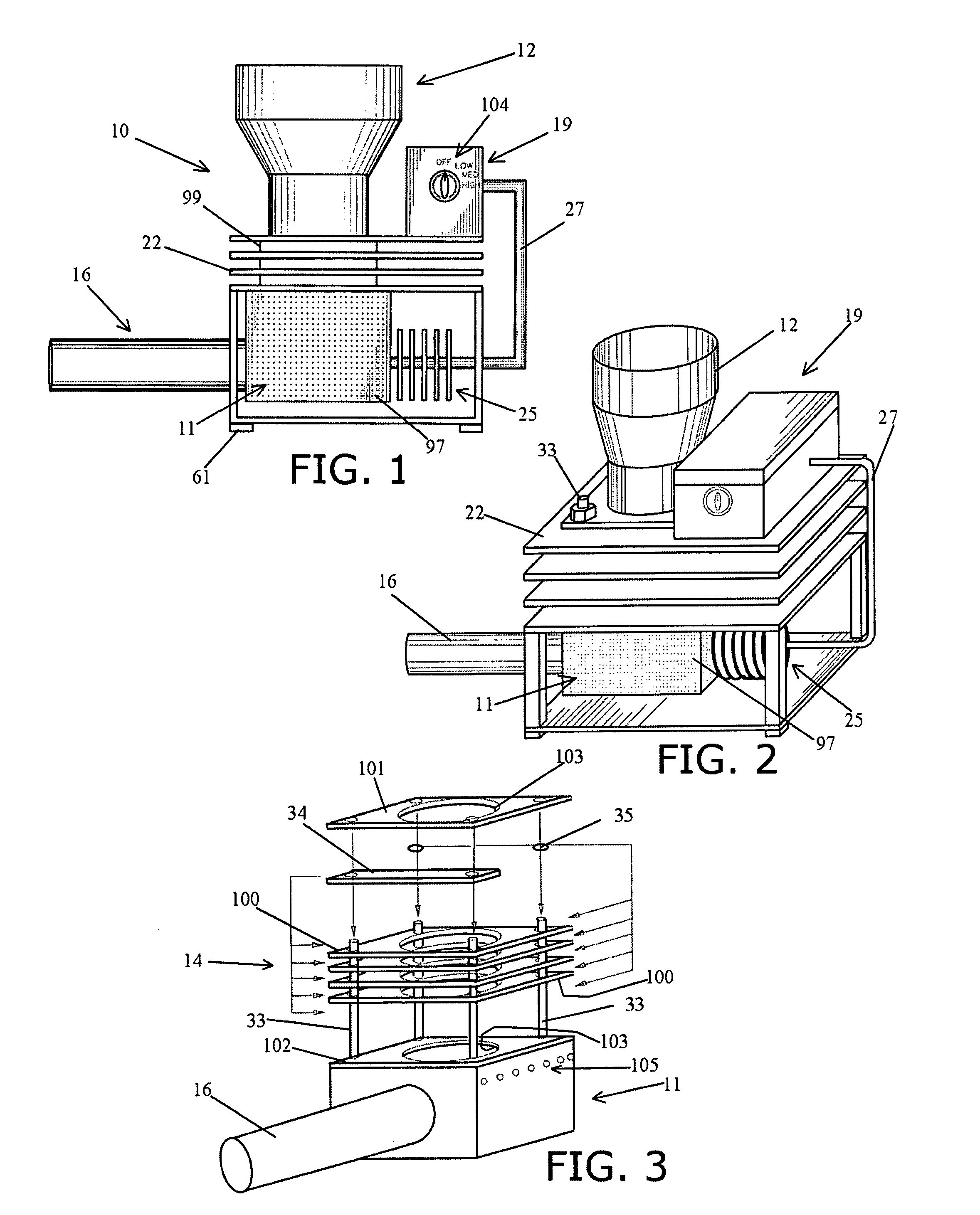

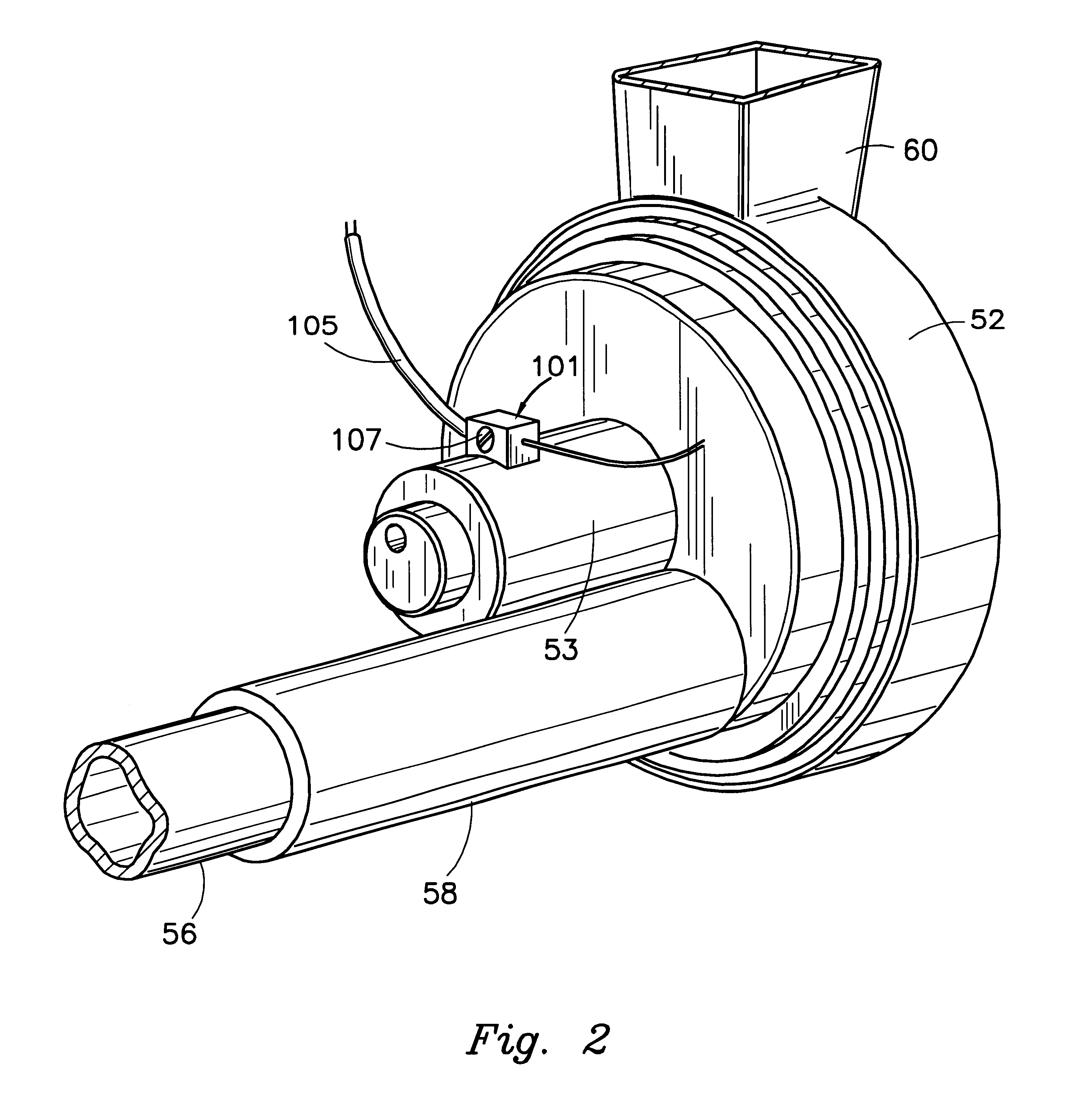

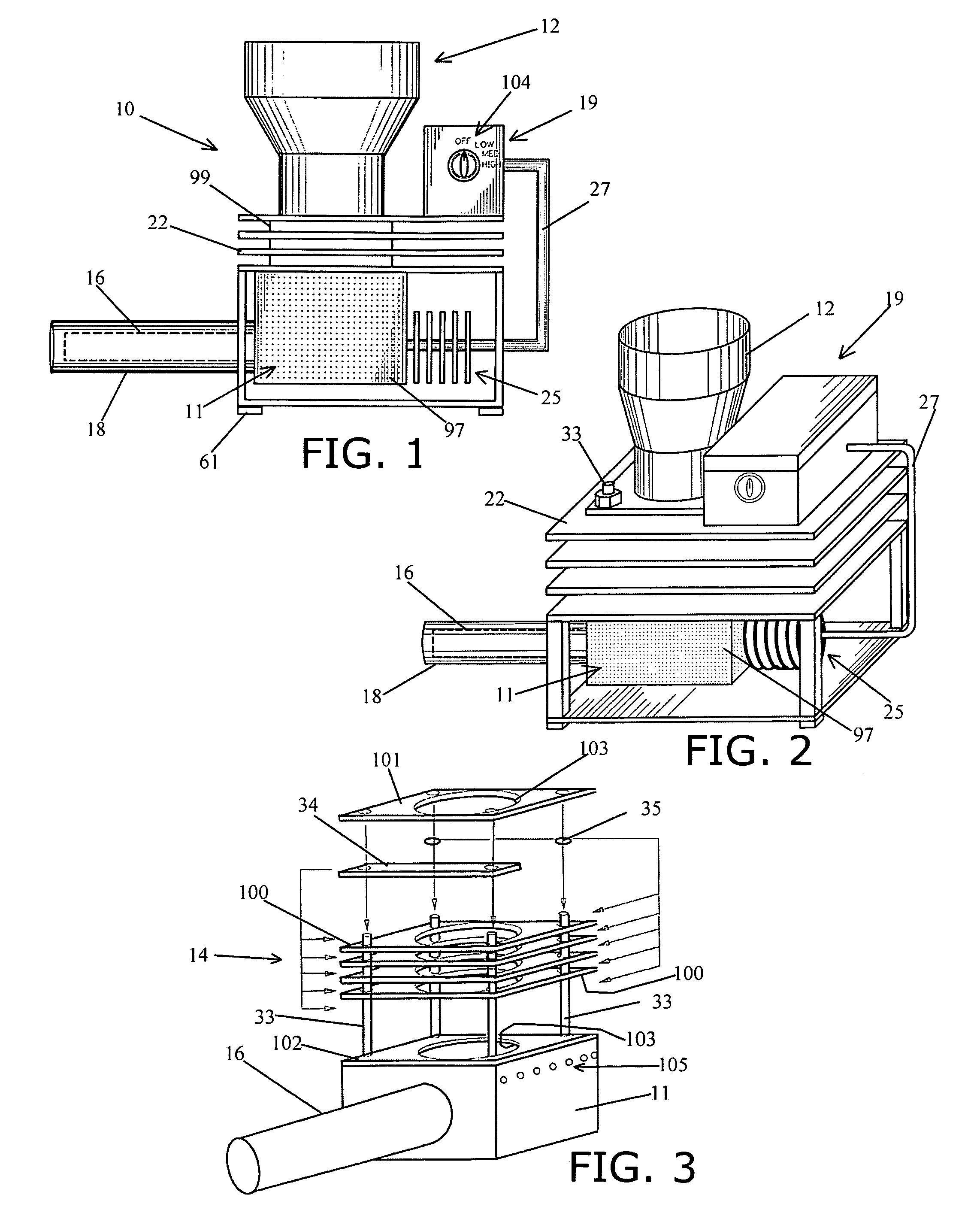

System for converting a kettle-type barbecue to employ fuel pellets

ActiveUS20100218754A1Easy to installQuickly and easily retrofitStoves/ranges with convection heatingLighting and heating apparatusMechanical engineeringEngineering

An apparatus and method used with a conventional barbecue, such as a kettle-type barbecue, which enables the barbecue to be fueled by fuel pellets burned in a fire box. The apparatus includes a support, a hopper and feeder structure for the fire box combined into a unitary construction selectively positionable as a unit on the barbecue body of the barbecue or removed therefrom. In embodiments illustrated, the fire box is positioned so as to direct heat to a desired location within the apparatus.

Owner:KUNTZ JOHN

System for converting a kettle-type barbecue to employ fuel pellets

ActiveUS8267078B2Easy to installQuickly and easily retrofitStoves/ranges with convection heatingLighting and heating apparatusEngineeringMechanical engineering

Owner:KUNTZ JOHN

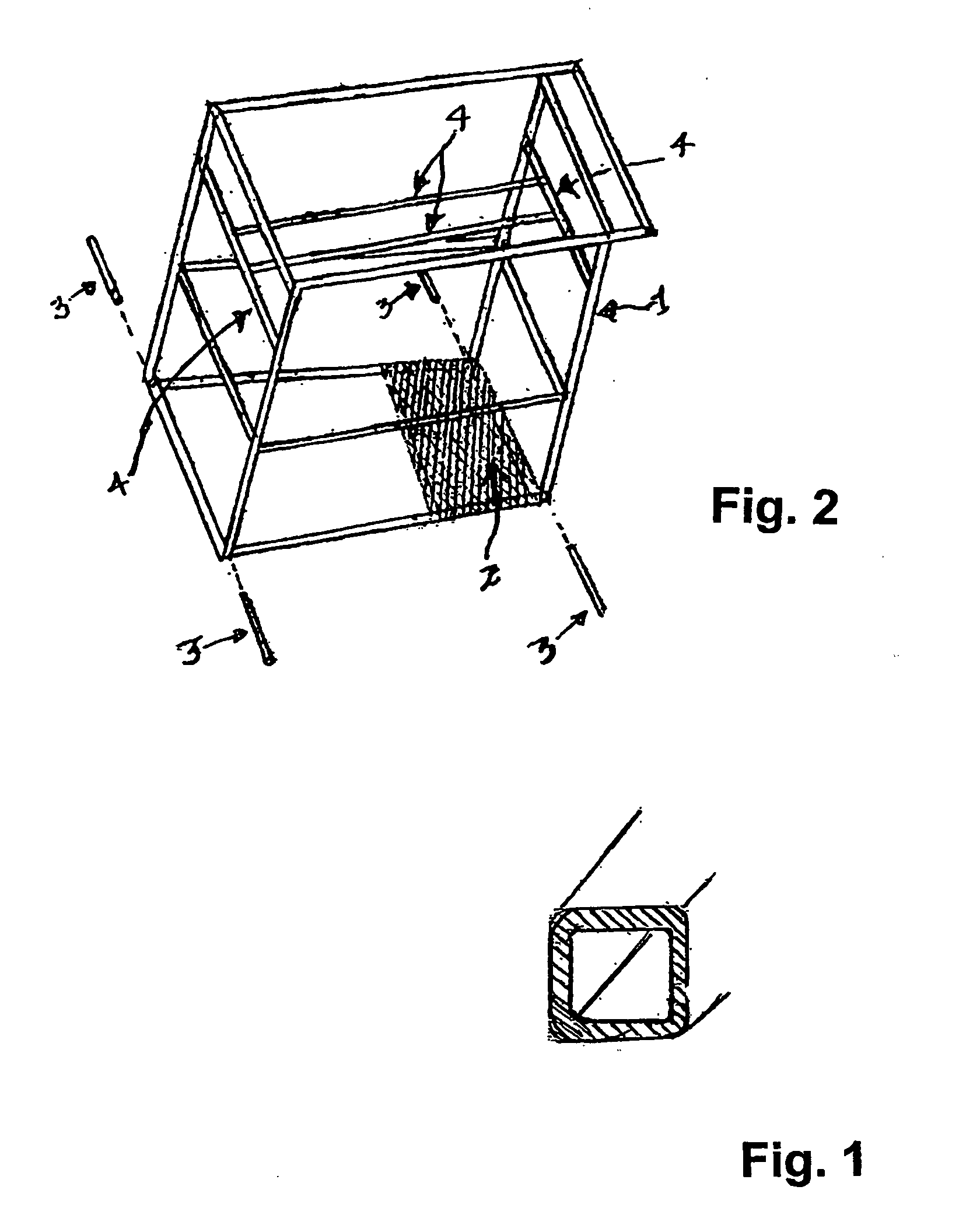

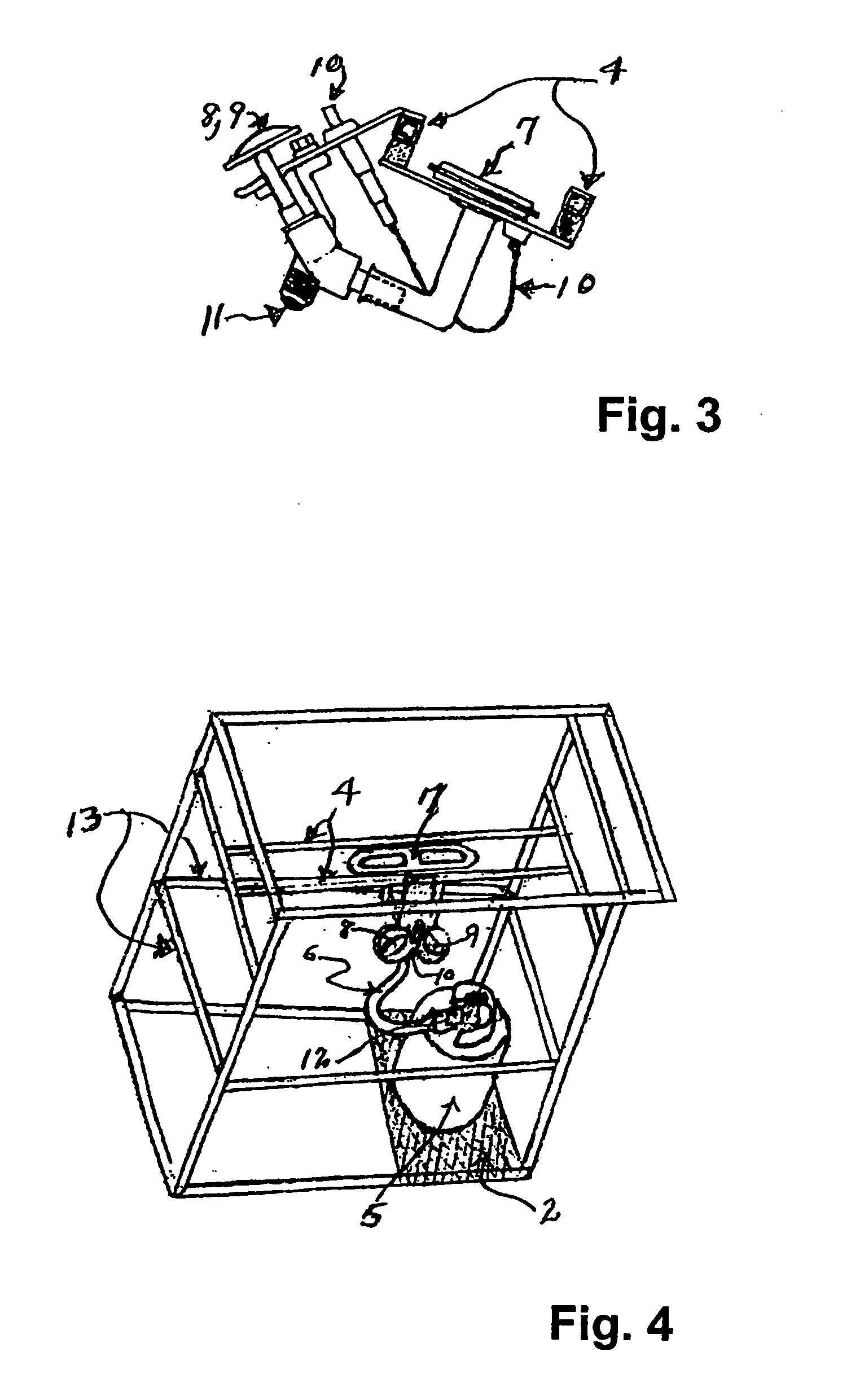

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

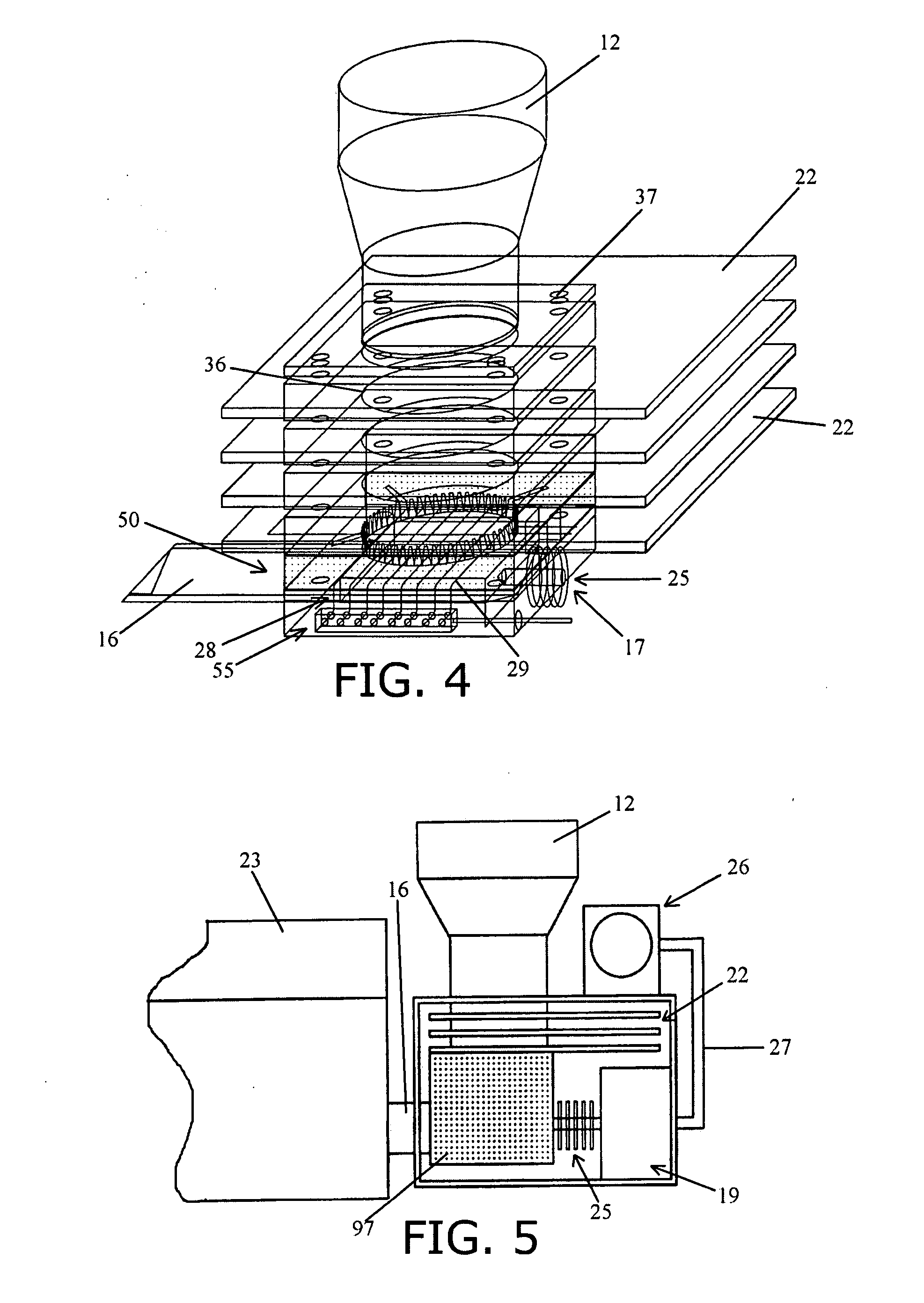

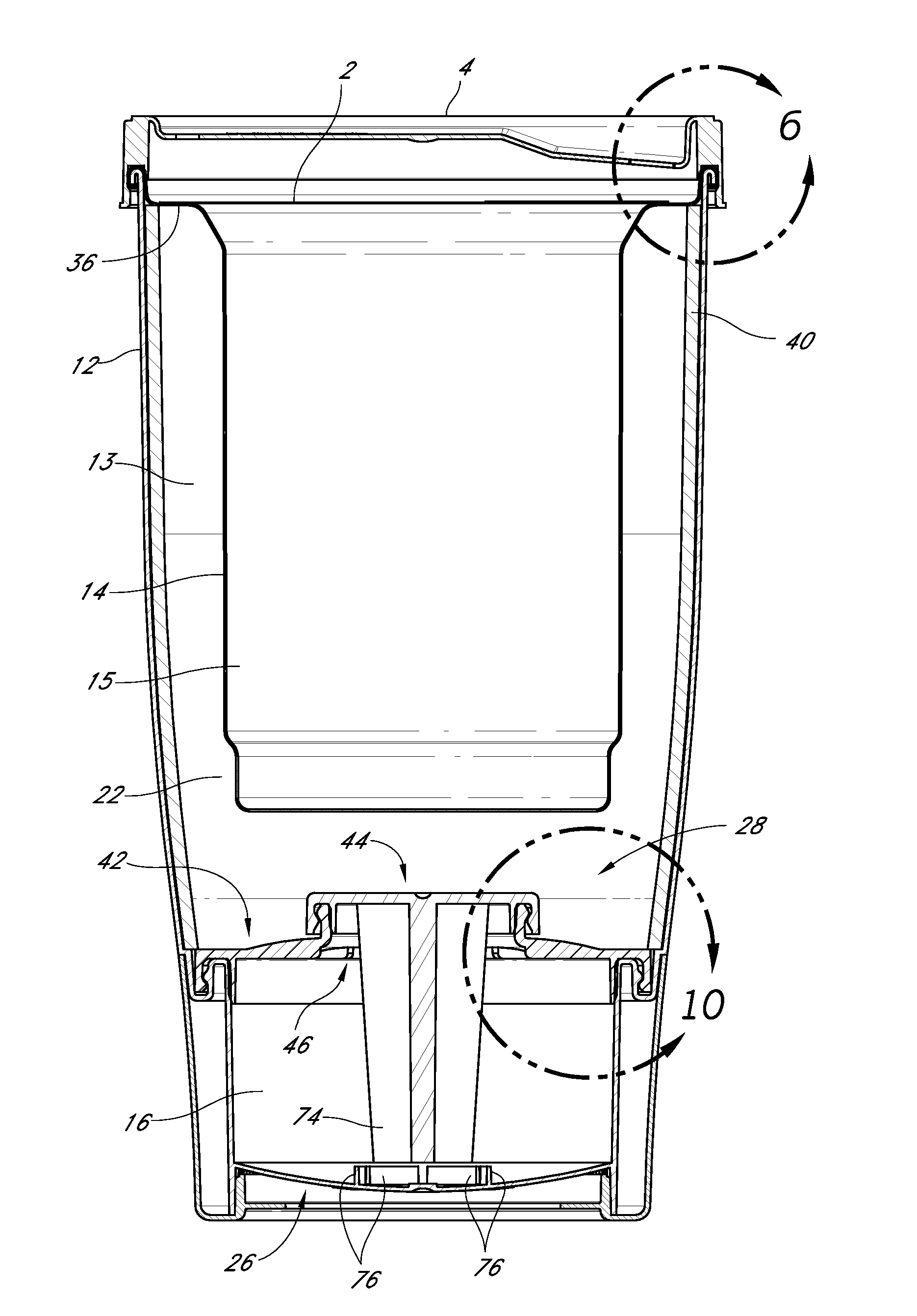

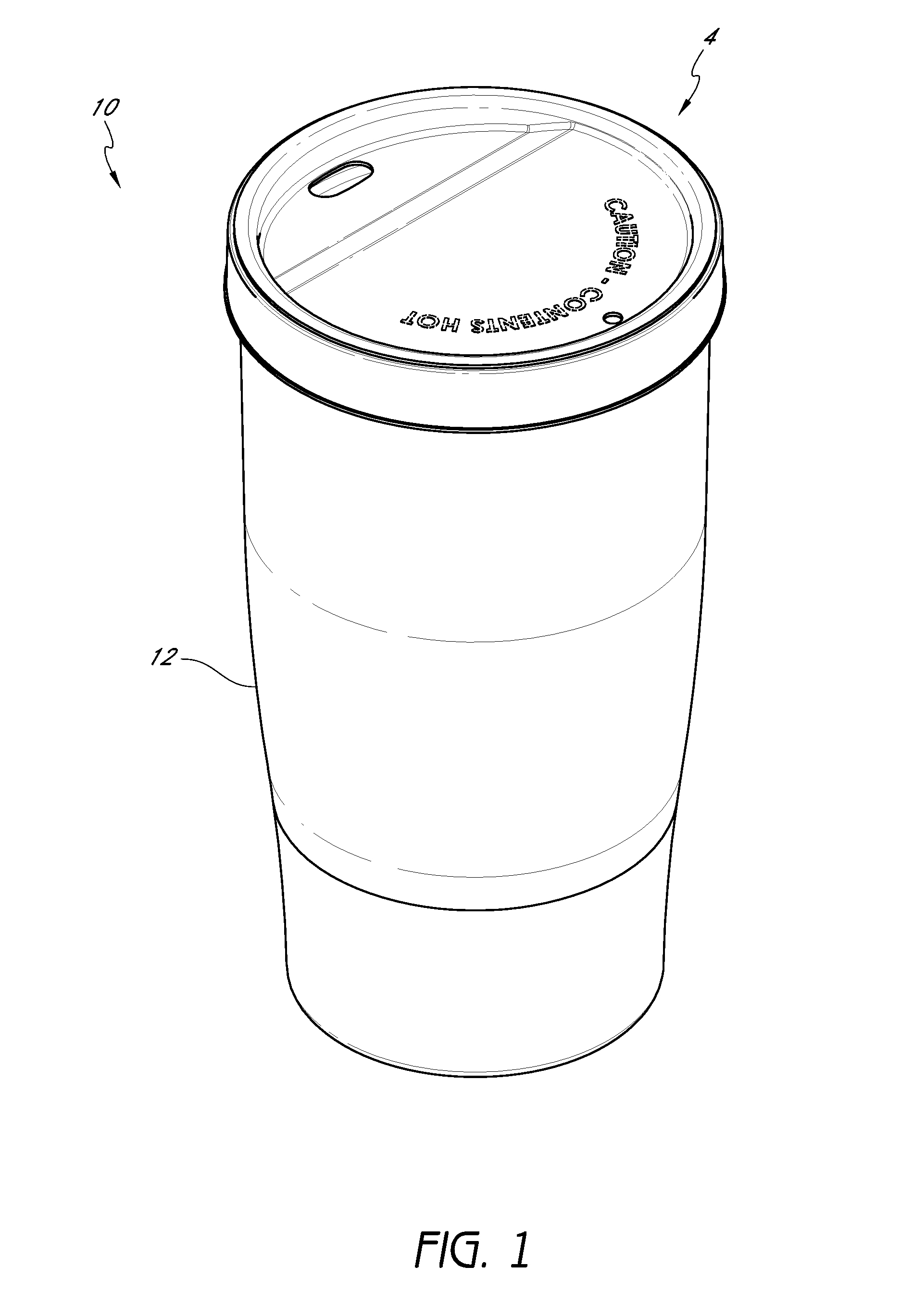

Self-heating systems and methods for rapidly heating a comestible substance

ActiveUS20090199843A1Easy to carryEasy to useExothermal chemical reaction heat productionDomestic cooling apparatusCompound (substance)Chloride

Self-heating systems for rapidly and effectively heating a comestible substance are disclosed. Self-heating systems generally include a reaction chamber and a heating chamber. The heating chamber contains a substance to be heated. The reaction chamber contains reactants that, when contacted, exothermically react. The containers and reactants can be configured to heat at least six fluid ounces of comestible substance in less than one minute. The solid chemical reactant mixture can comprise magnesium chloride, calcium chloride, and / or calcium oxide. Methods for heating at least six fluid ounces of comestible substance in less than one minute are also provided.

Owner:HEAT WAVE TECH

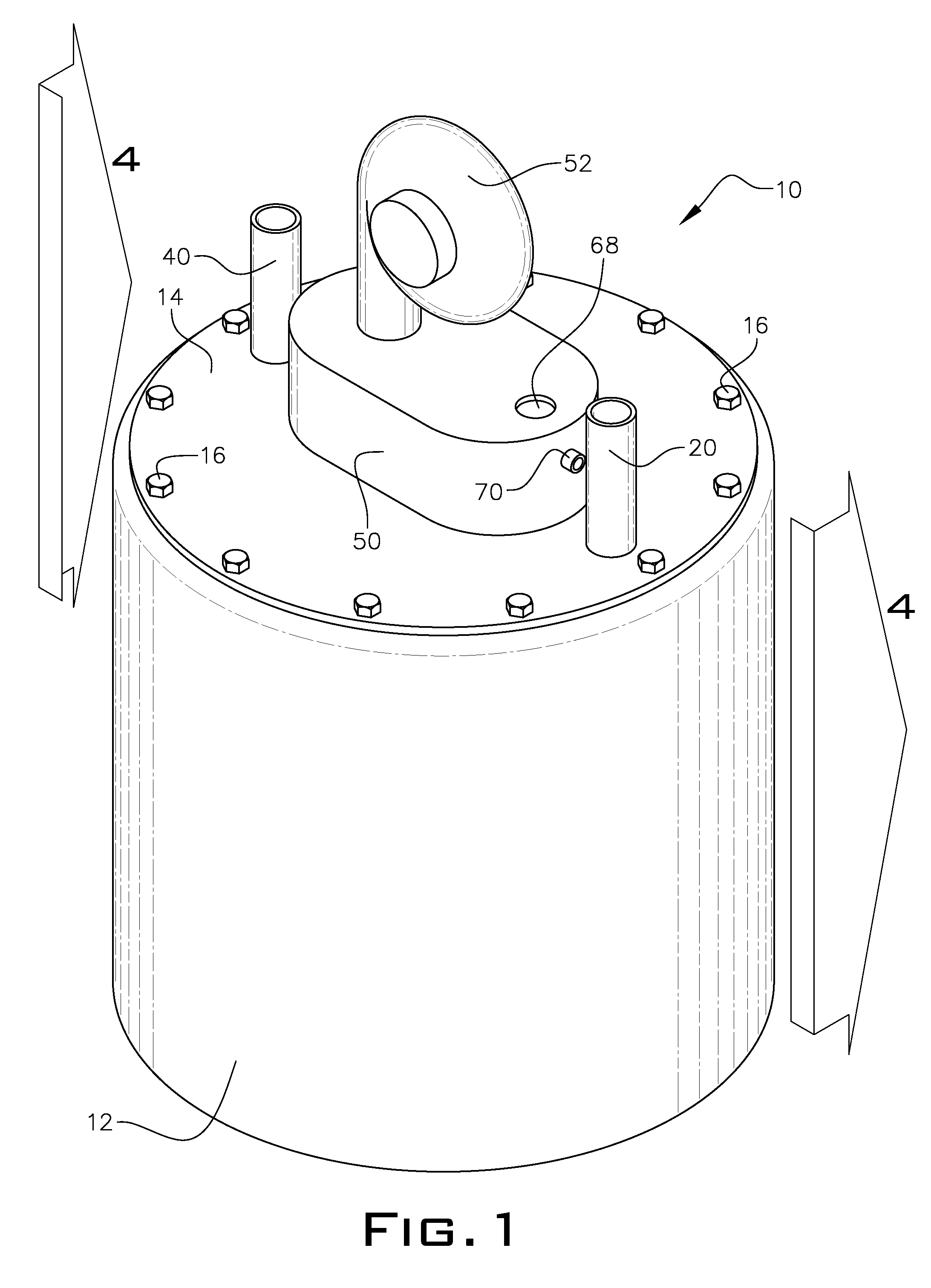

Water heater with reduced localized overheating

InactiveUSRE37240E1Reduce the effect of temperatureWater heating stoves/rangesBoiler cleaning apparatusWater cyclingEnvironmental engineering

A water and / or space heater is provided in which water is circulated to prevent the localized overheating or vaporization thereof.

Owner:FLEET CAPITAL CORPORATION

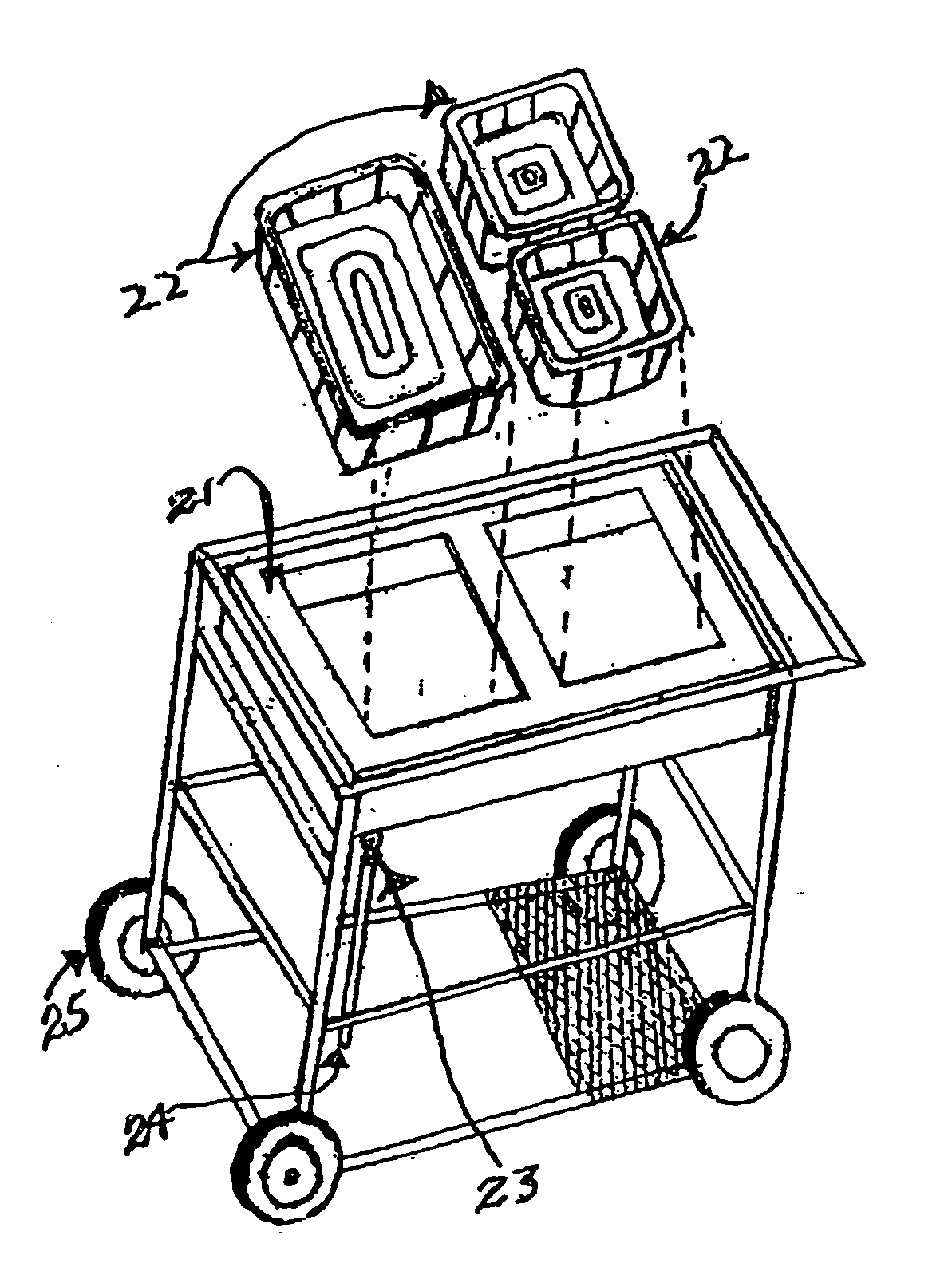

Portable steam table

InactiveUS20060288997A1Lighting and heating apparatusStove/ranges for heating waterLiquid propaneElectrical and Electronics engineering

A mobile portable steam table with a chafing dish system heated by liquid propane gas (LPG), to keep previously cooked meats and vegetables warm and moist through a water medium reservoir intimately involved directly beneath and holding the chafing dishes.

Owner:GRIFFIN EDWIN

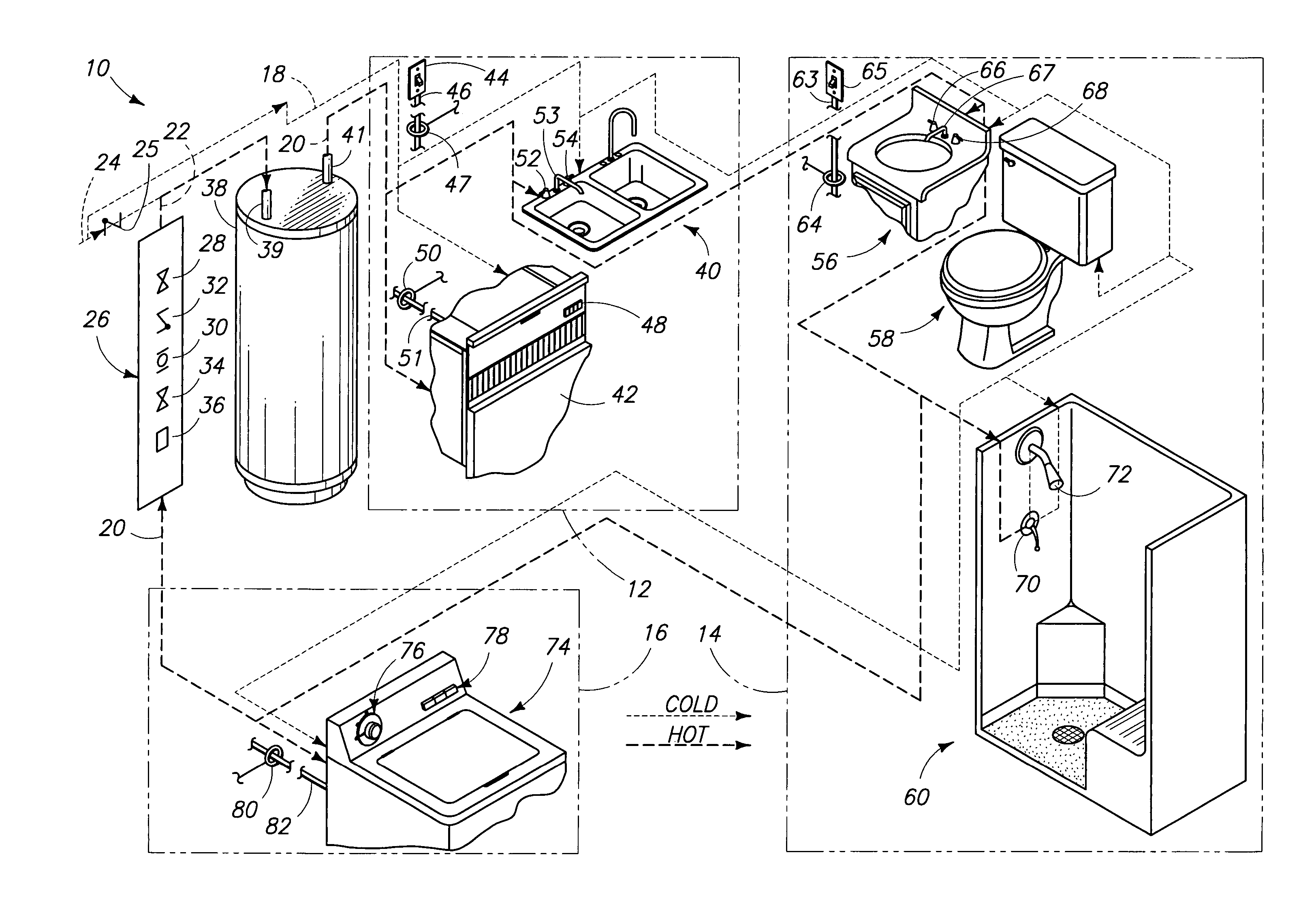

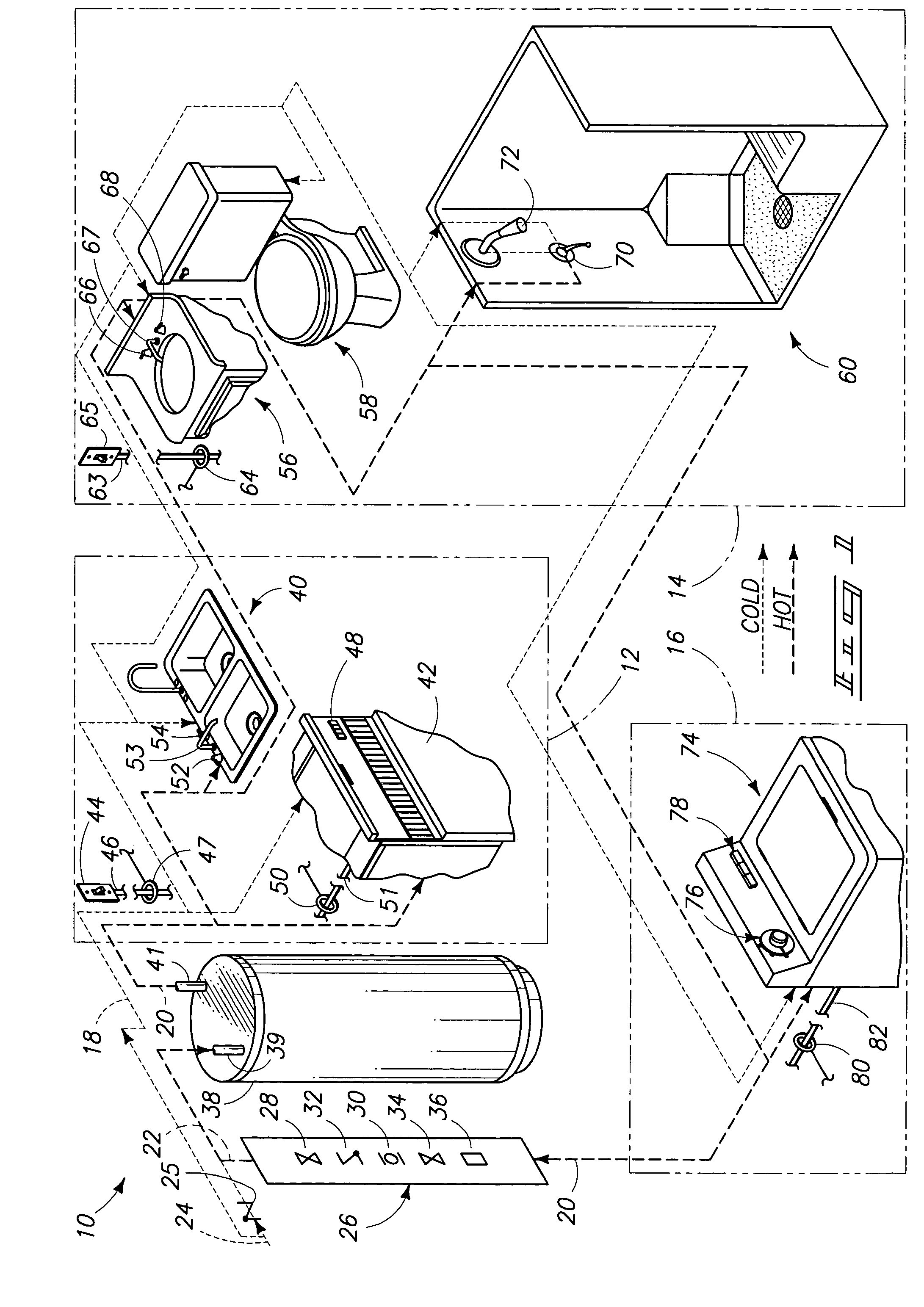

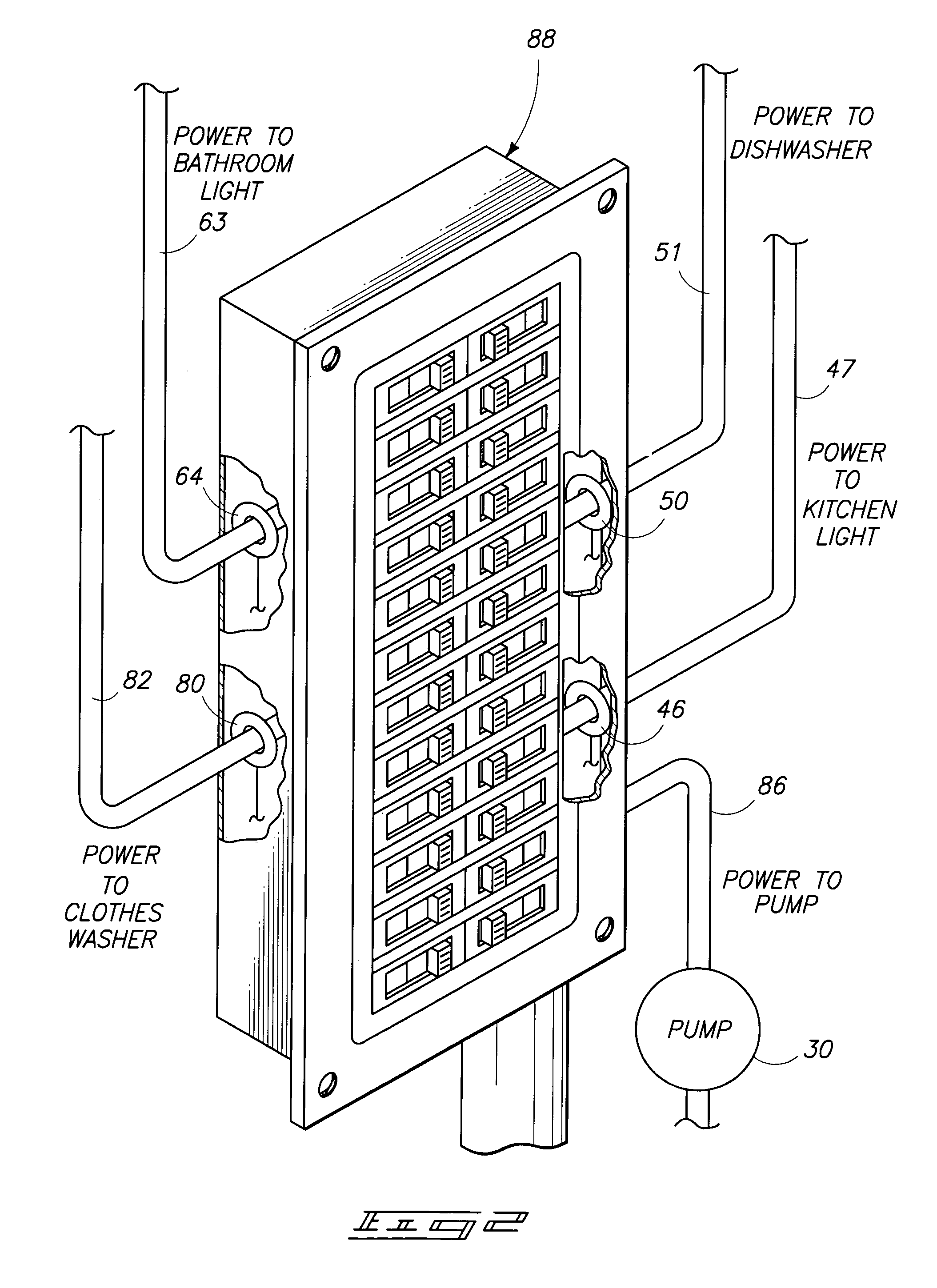

Hot water heater recirculation system and method

InactiveUS7036520B2Reduce complexityLow costWater heating stoves/rangesPipe heating/coolingEngineeringThermal water

A hot water recirculation system includes a source of hot water, a fixture, a fluid circuit, a fluid pump, and an electrical circuit sensor. The fixture is remote from the source of hot water and is configured to dispense hot water. The fluid circuit extends from the source to the fixture for delivering hot water to the fixture. The fluid circuit returns to the source for recirculating hot water in the fluid circuit back to the source for reheating. The fluid pump is configured for recirculating hot water through the fluid circuit. The electrical circuit sensor is configured to detect operation of an electrical circuit proximate the fixture and associated with a user operating the fixture. The electrical circuit sensor is further configured to initiate operation of the fluid pump responsive to detected operation of the electrical circuit to initiate hot water recirculation. A method is also provided.

Owner:PEARSON JR KENNETH W

Electrical Appliance for Cooking Food

InactiveUS20110147365A1Easy to operateEasy and safe manipulationRotary drum furnacesWater heating stoves/rangesEngineeringPressure cooking

An electric appliance for pressure cooking food includes a casing (1) and a lid (4) forming the outer jacket of the appliance, an outer vessel (2) forming the inner chamber of the appliance, a heating element (25) placed in the bottom of the outer vessel (2), a removable inner vessel (3) forming the container (30) for cooking food, wherein the inner vessel (3) includes at least one handhold (31) extending past the periphery of the casing (1).

Owner:SEB SA

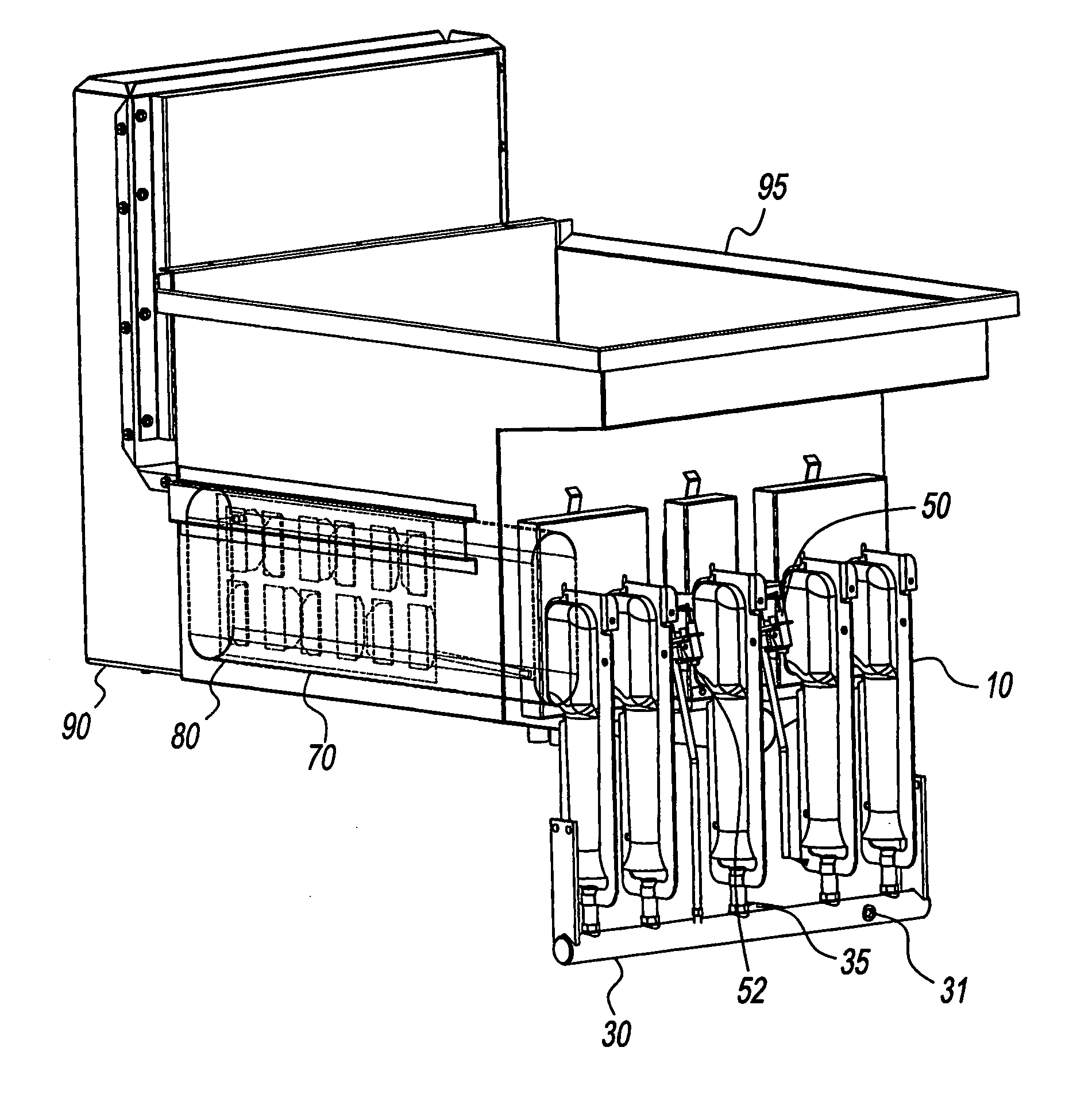

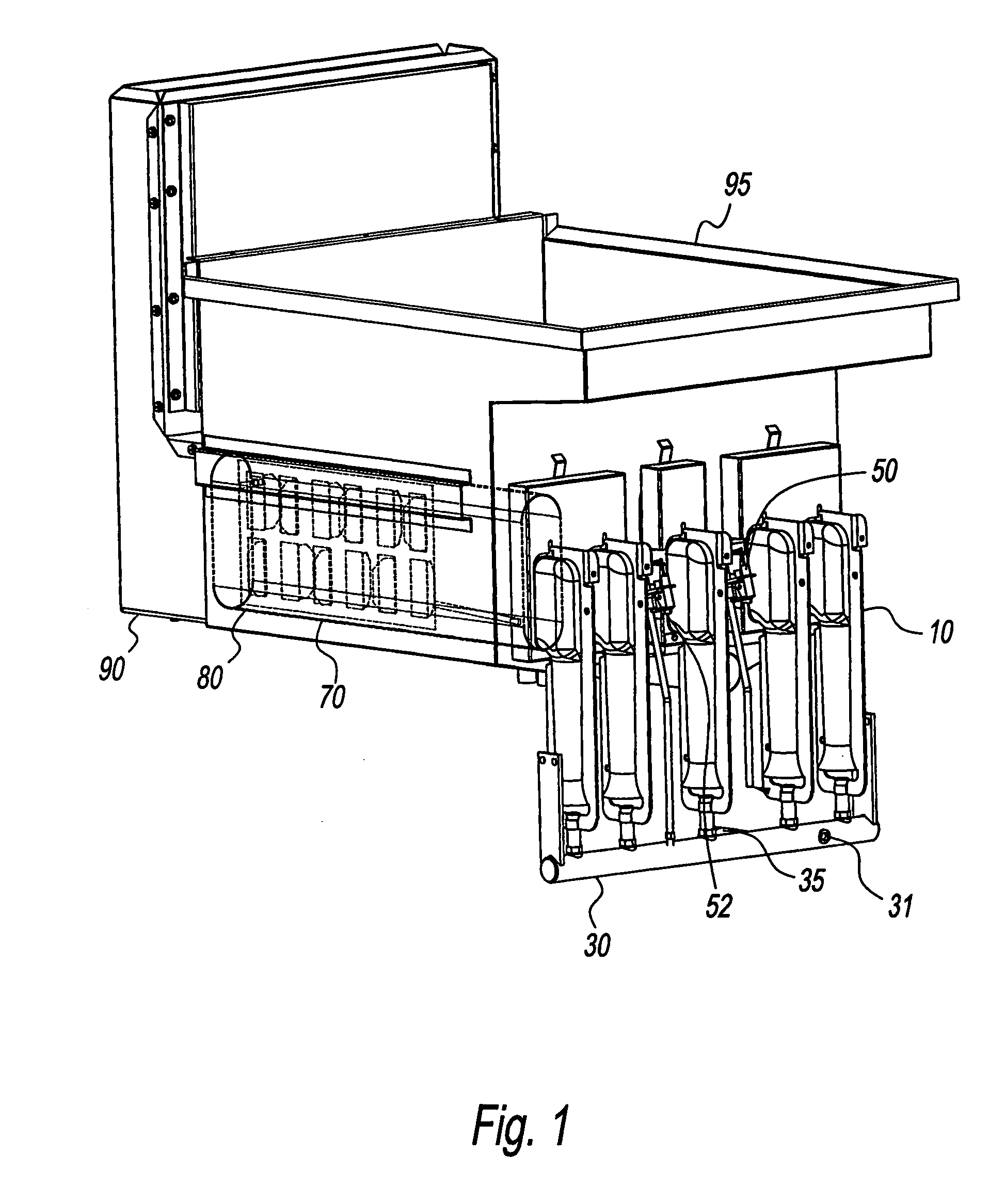

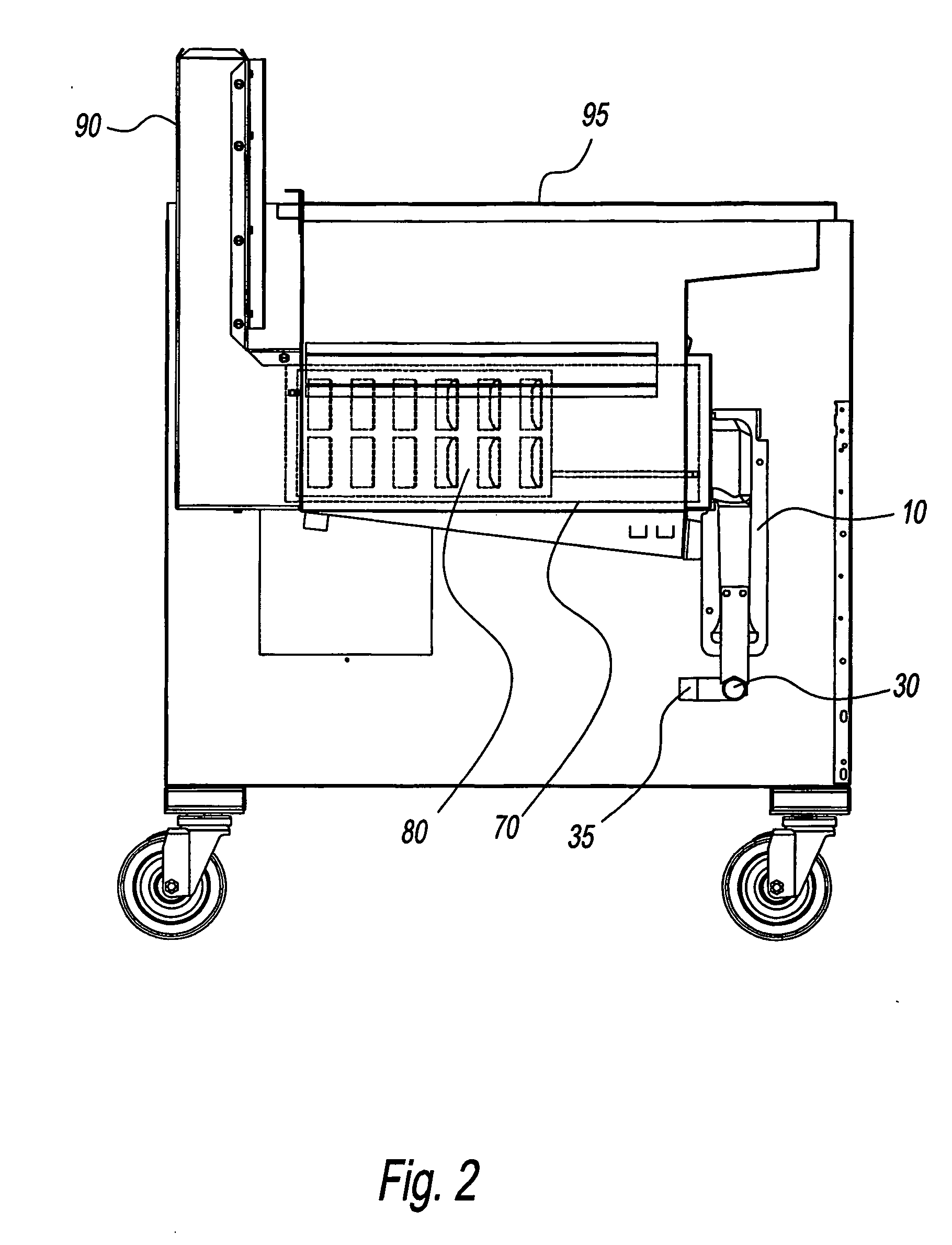

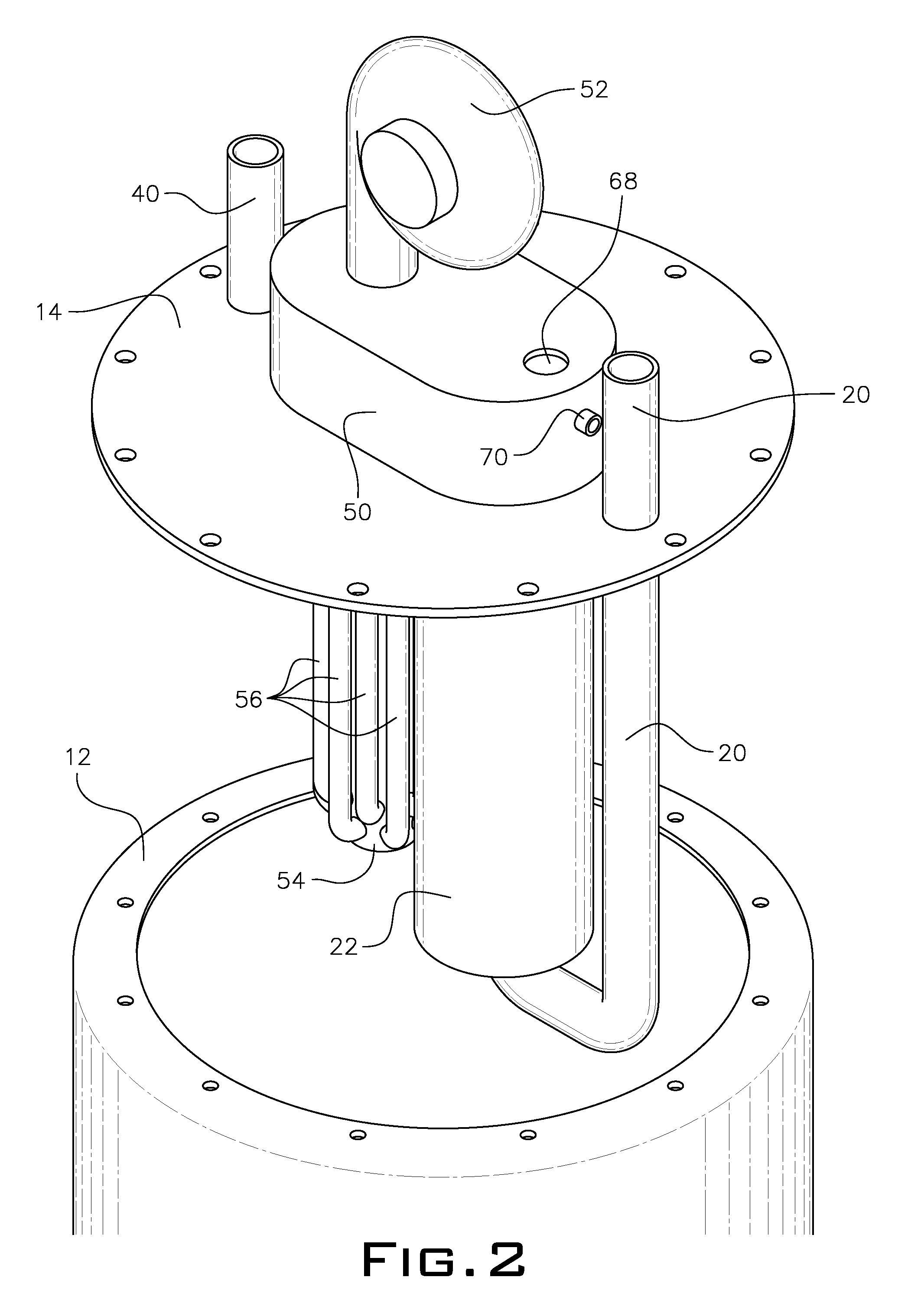

Deep fat tube fryer burner assembly

InactiveUS20070089732A1Increasing burner efficiencyAvoid large movementsBoiling over preventionWater heating stoves/rangesCombustorEngineering

The gas tube fryer comprises substantially 90° in-shot burners, burner mounting boxes, a one-piece burner mounting bracket, and a bracket housing, all of which are used in conjunction with heat exchanger tubes, heat transfer baffles, a frypot, and a flue in a fryer. The burner mounting boxes are keyed specifically to the face of the burner, preventing substantial movement of the burners and introduction of ambient air into the heat exchange tubes. Each burner is also keyed to the mounting bracket, also preventing substantial movement and providing easy installation and repair. The ninety-degree orientation of the burners facilitates mixing of the combustion gases, and the burner comprises a screen on its face that helps to ensure maximum burner efficiency.

Owner:THE FRYMASTER CORP LLC

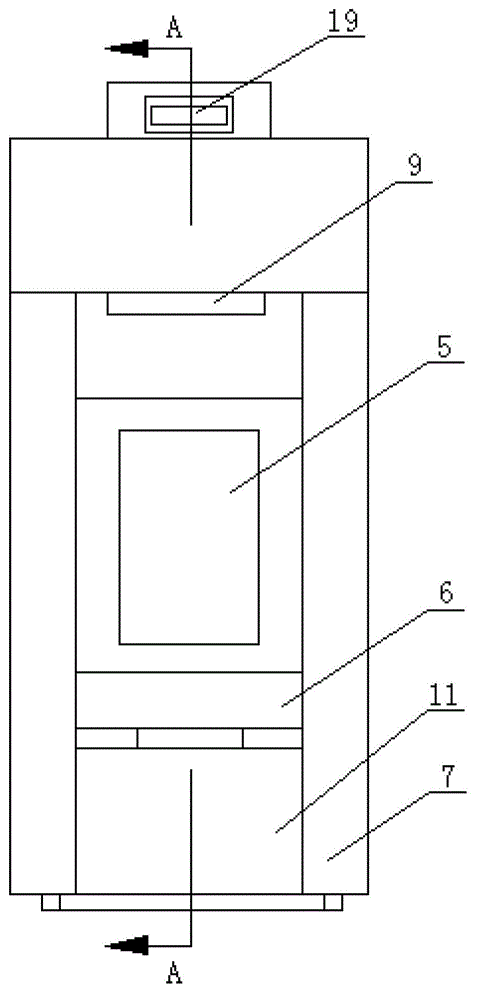

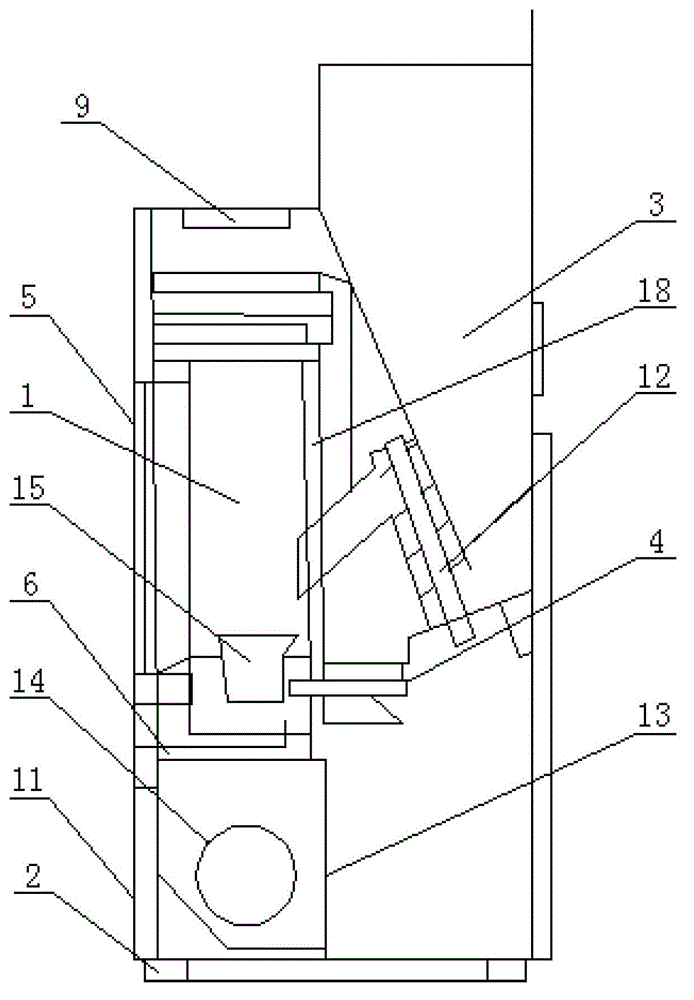

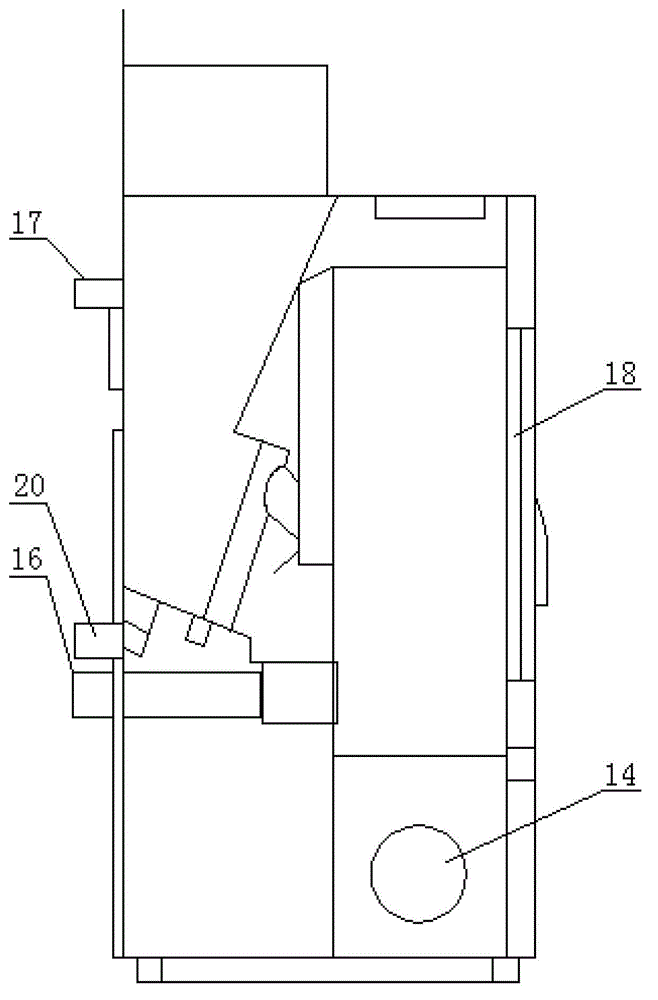

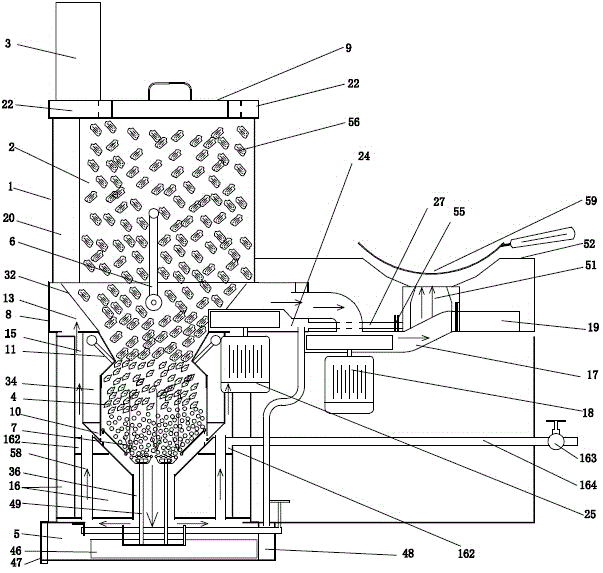

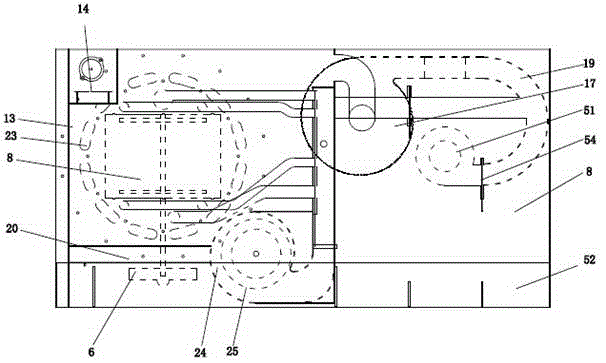

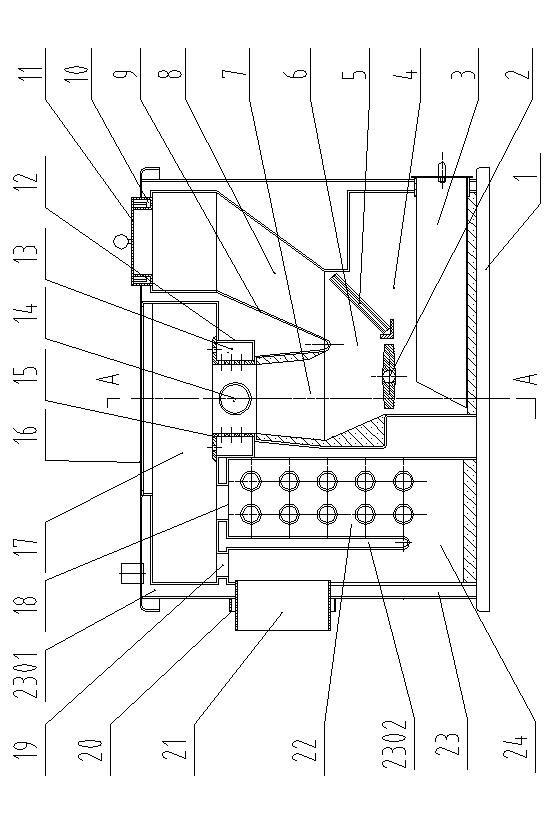

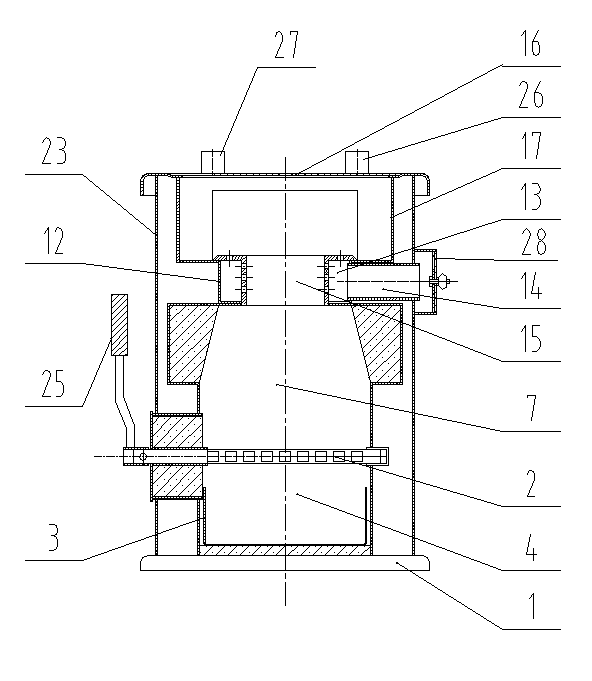

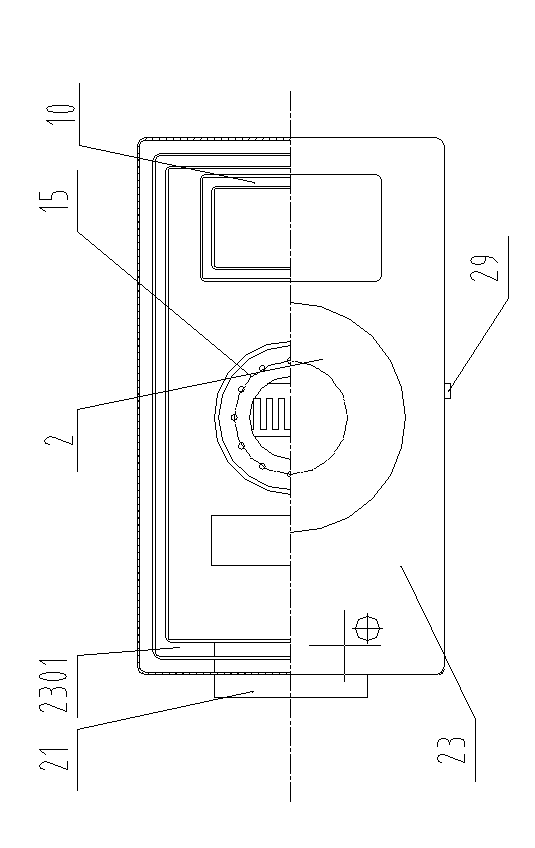

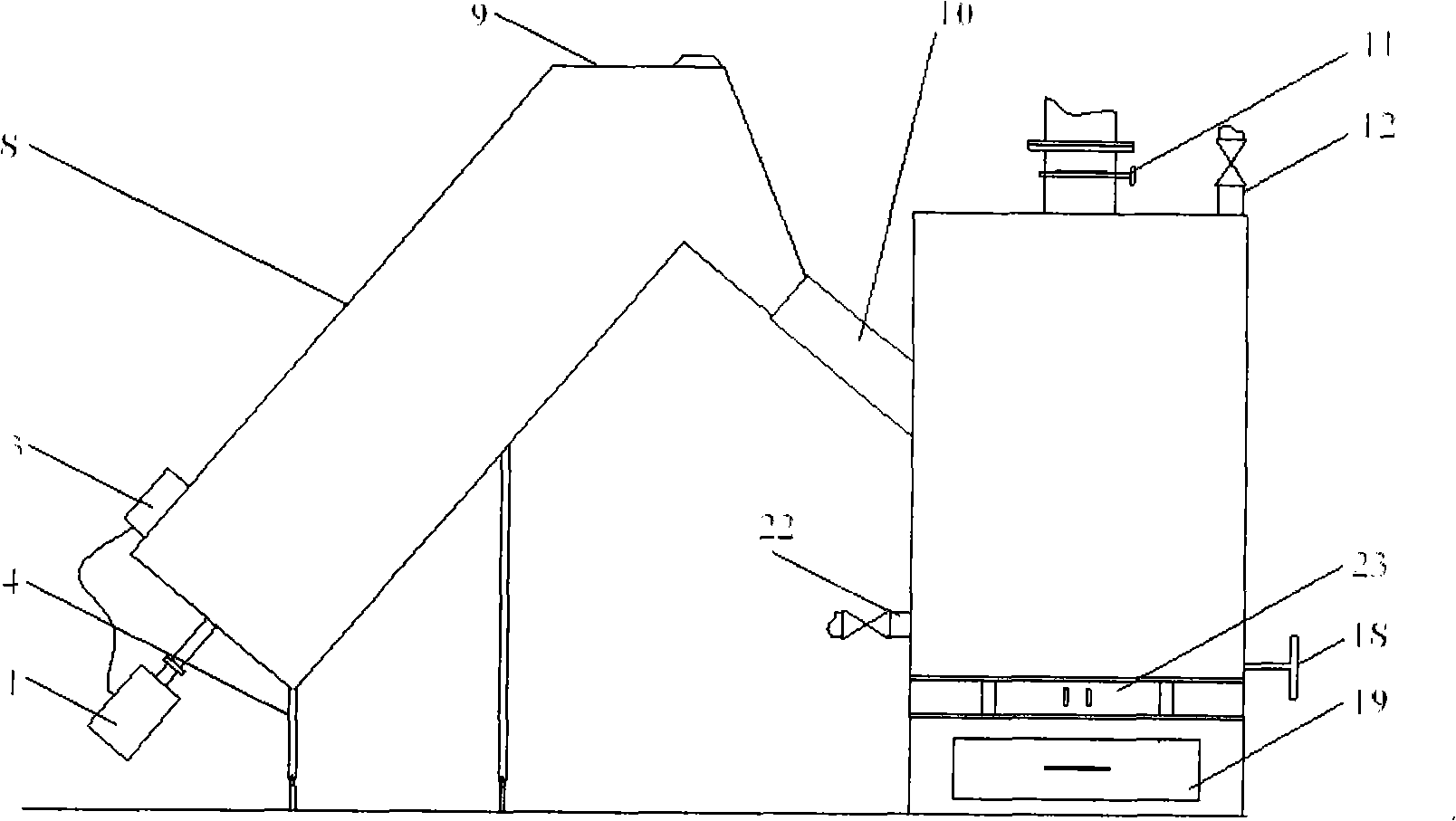

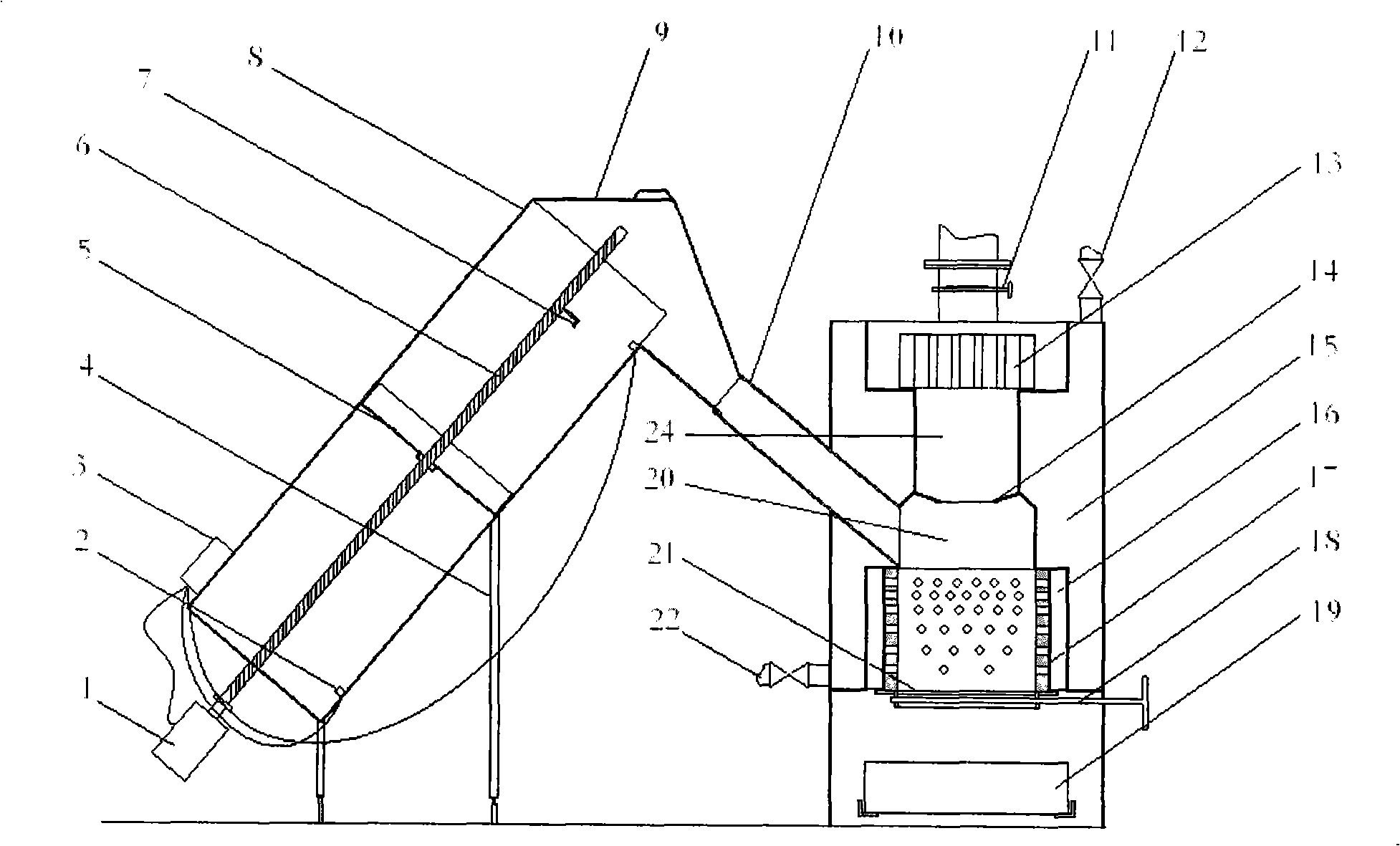

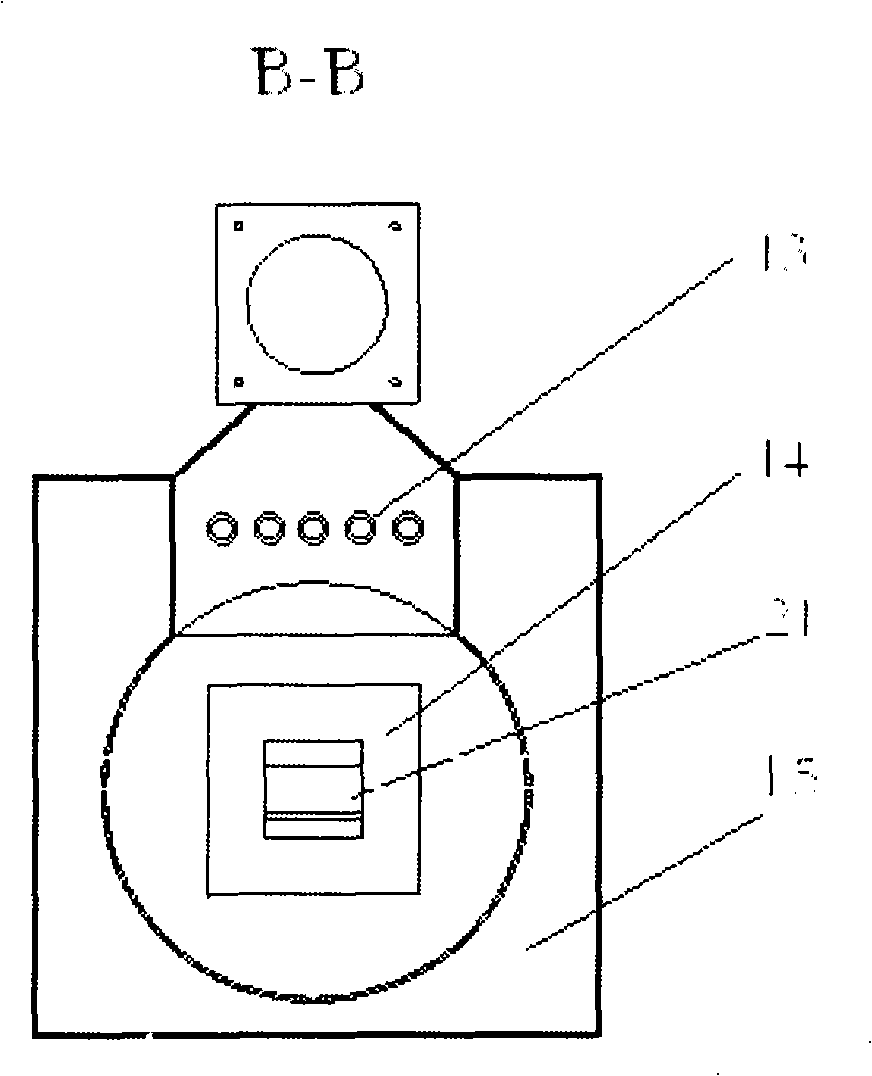

Automatic biofuel-combustion multipurpose furnace

InactiveCN102721169AFull and efficient combustionLow costStove/ranges for heating waterWater heatersAutomatic controlCombustion

An automatic biofuel-combustion multipurpose furnace comprises a furnace body, wherein the furnace body consists of a combustion furnace, a fuel bucket, a feeding device and an automatic control device, the fuel bucket is positioned above the combustion furnace which is obliquely provided with a feeding pipe and internally provided with a combustion pool, the lower port of the feeding pipe is positioned above the combustion pool, the feeding device is arranged between the upper port of the feeding pipe and the combustion bucket, the furnace body is provided with an automatic igniter, the front end of the automatic igniter is contacted with the combustion bucket, a water drum wall is arranged on the side wall of the combustion furnace, a water inlet and a water outlet corresponding to the water drum wall are arranged on the combustion furnace, a water boiling port is arranged at the upper end of the combustion furnace and provided with a water boiling tray, a slag collection box is arranged under the combustion furnace, the combustion furnace is provided with an air inlet under the automatic igniter, an air outlet is arranged at the lower part of the furnace body and provided with an exhaust fan. The automatic biofuel-combustion multipurpose furnace can save non-renewable resources by combusting biofuel, and has the advantages of environment friendliness and safety.

Owner:烟台市宜和环保设备有限公司

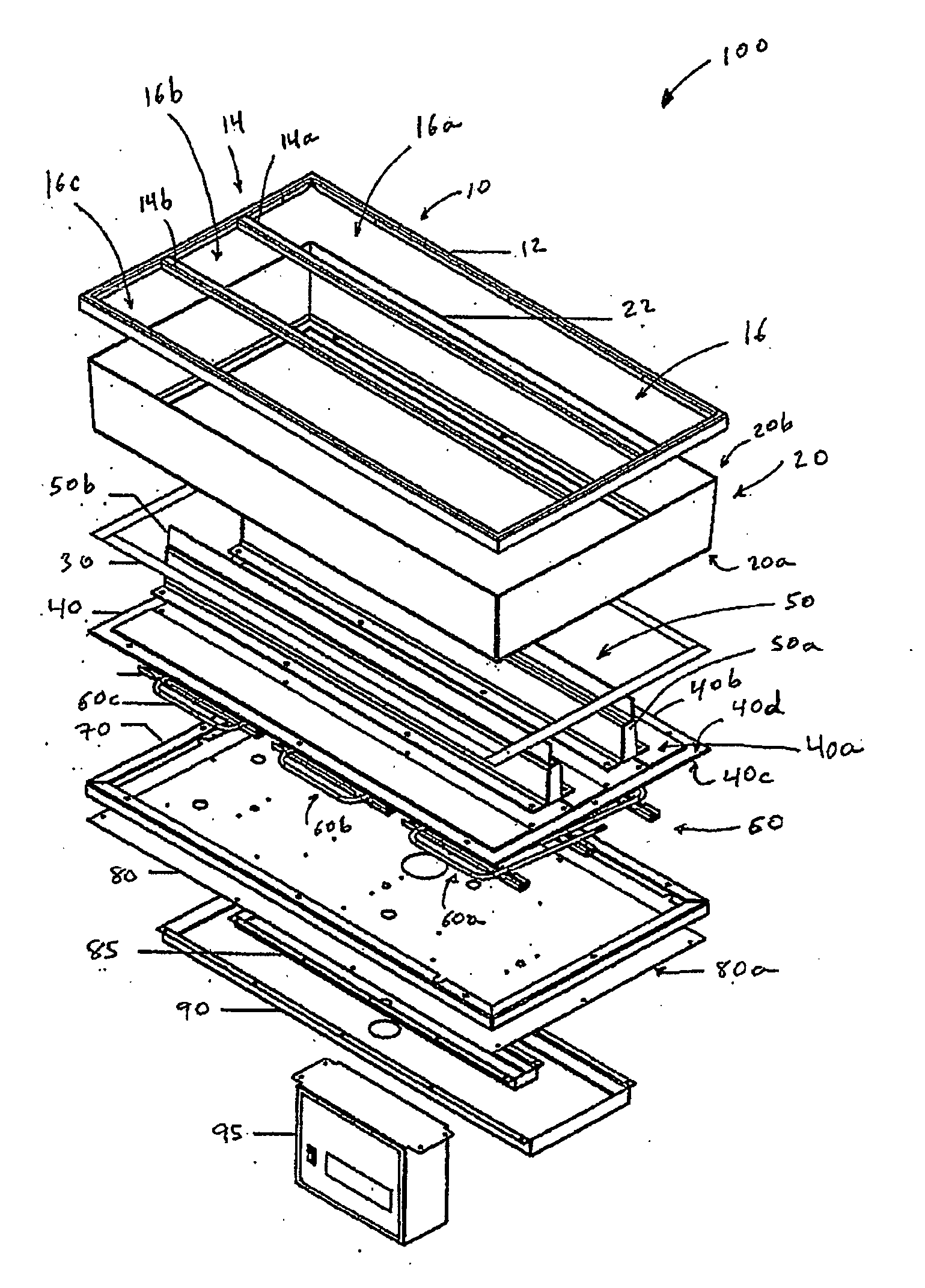

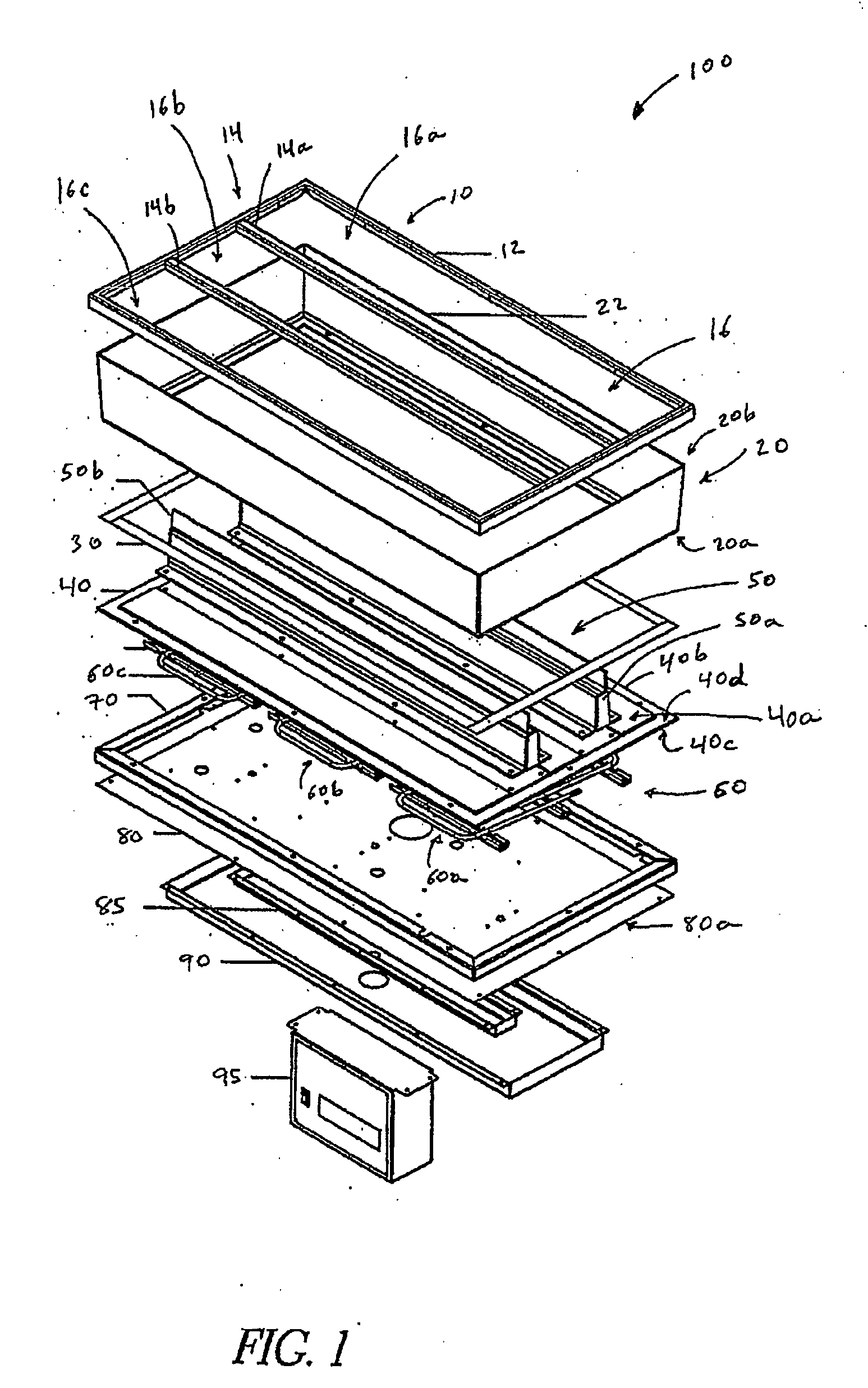

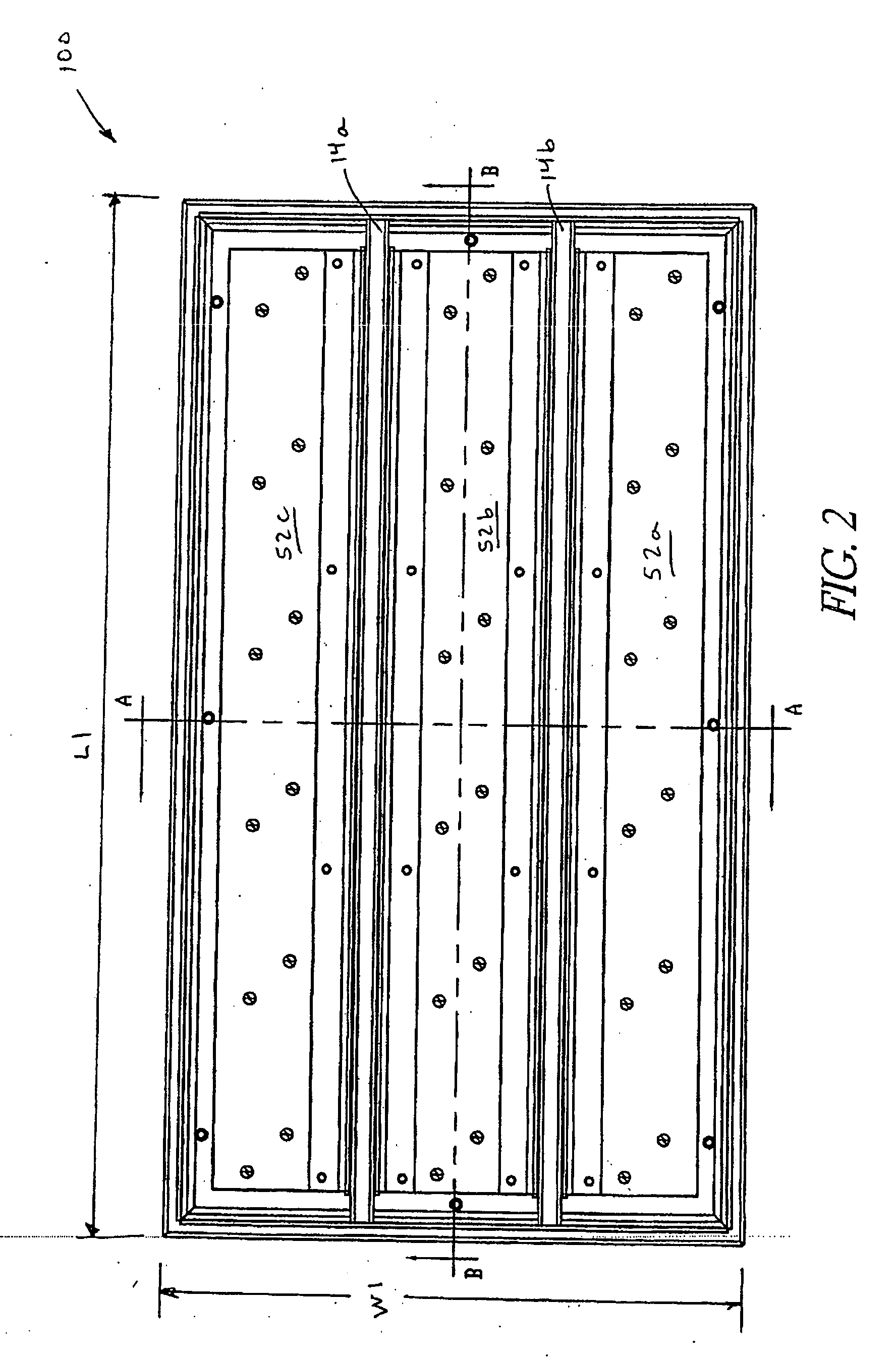

Drywell table

ActiveUS20070079822A1Minimize convectionMinimize radiationLighting and heating apparatusCooking fumes removalEngineeringConvection

A drywell table includes a top frame defining at least one opening configured to receive a serving pan therethrough and a heating plate disposed below the top frame. The drywell table also includes at least two heating fins extending between the heating plate and the top frame, and defining at least one row configured to receive the pan therein, wherein heat is transferred from the heating plate and heating fins to the serving pan via a sufficiently small air gap defined between the heating plate, heating fins and the serving pan, wherein the gap minimizes convection and radiation.

Owner:TACO BELL IP HOLDER LLC

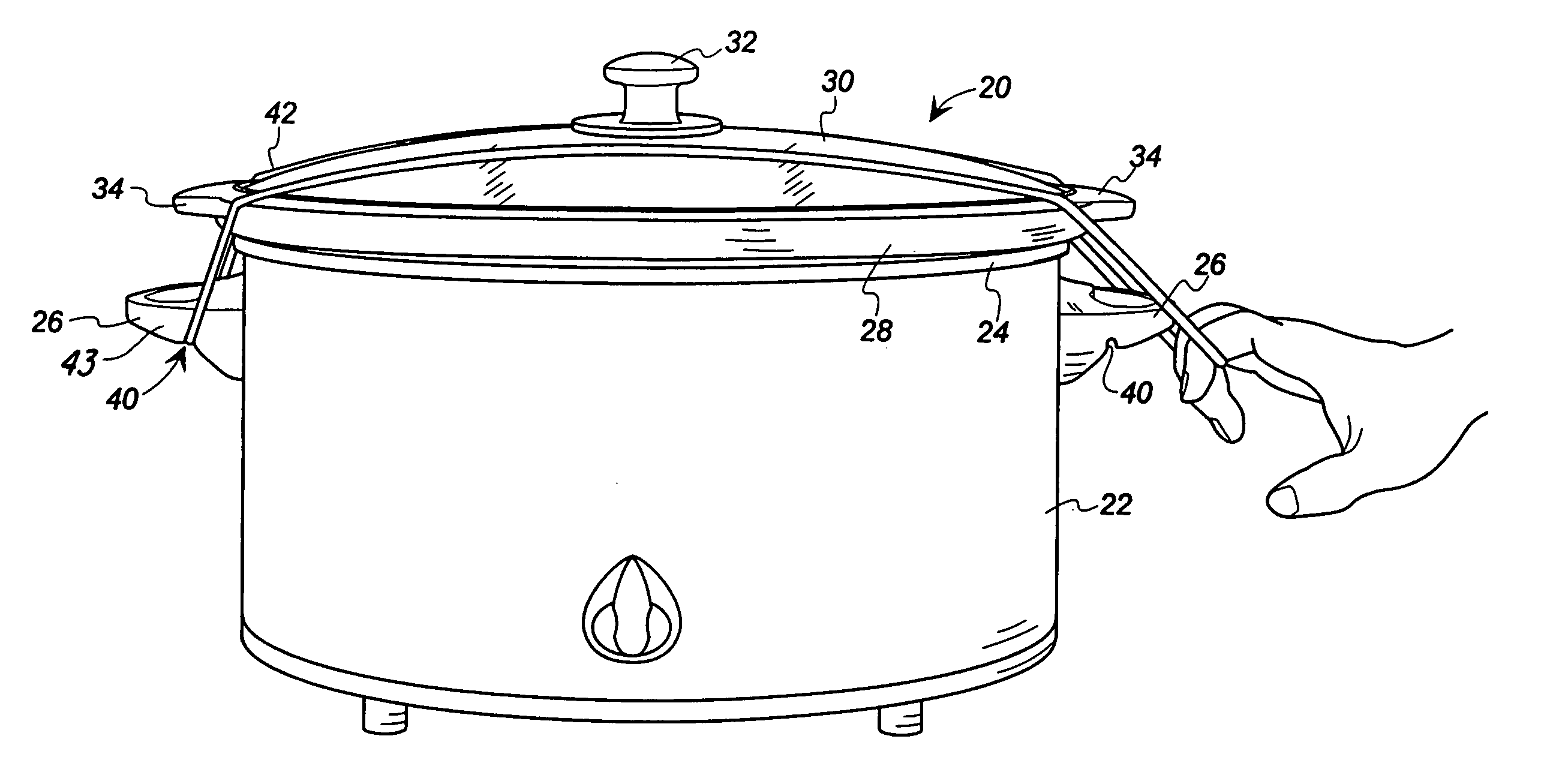

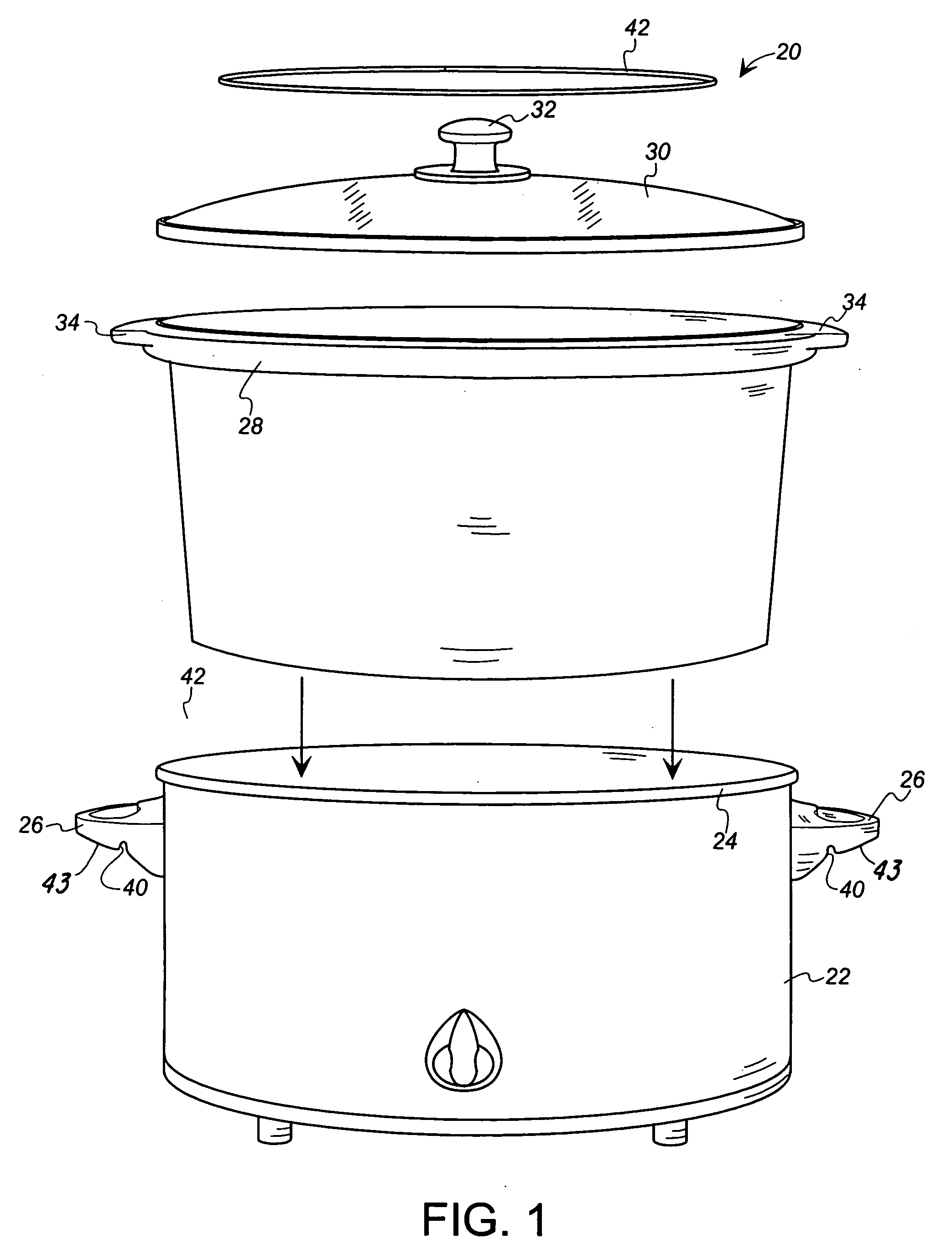

Slow cooker with lid clamp

InactiveUS7140506B1Inexpensive and reliable and easy to useWater heating stoves/rangesStove/ranges for heating waterEngineeringCooker

A slow cooker is provided with a clamp assembly for holding the parts of the cooker together when transporting the cooker from one location to another. The clamp assembly includes downwardly-opening grooved portions of housing handles and an elastomeric band having opposite end portions received within the grooved portions of housing handles.

Owner:HAMILTON BEACH BRANDS

Pellet burning heating assembly

Owner:GRILLSON

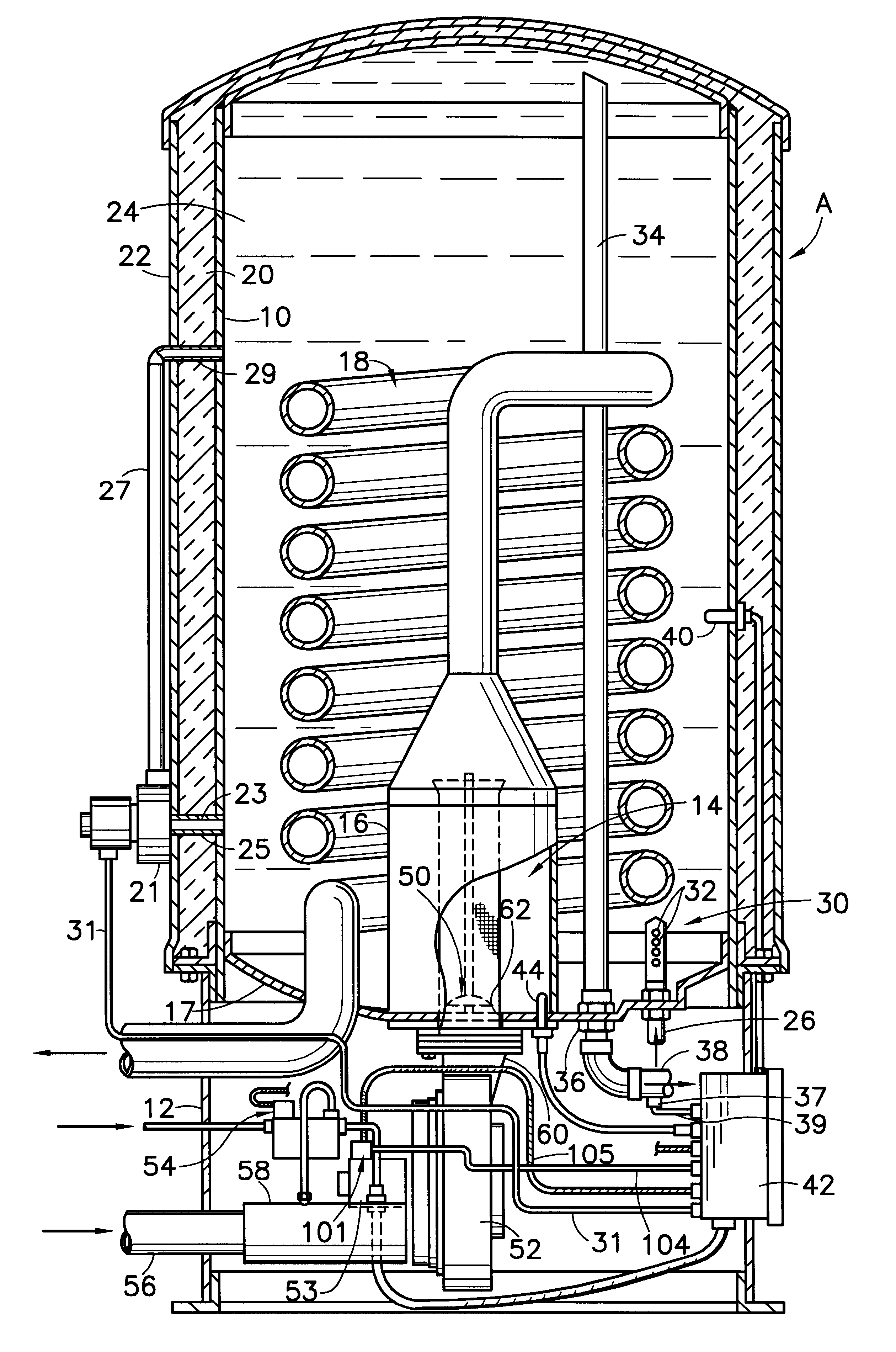

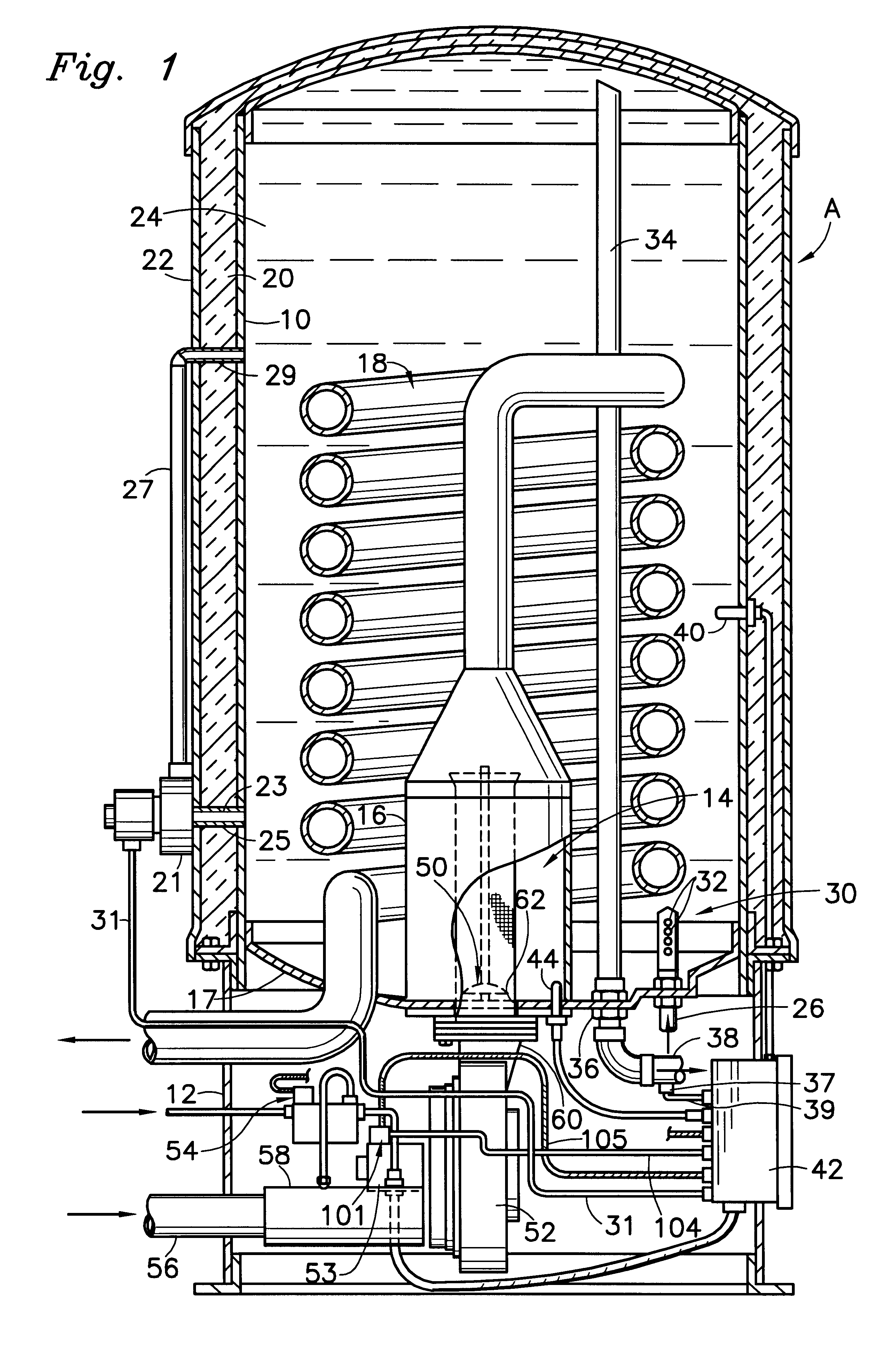

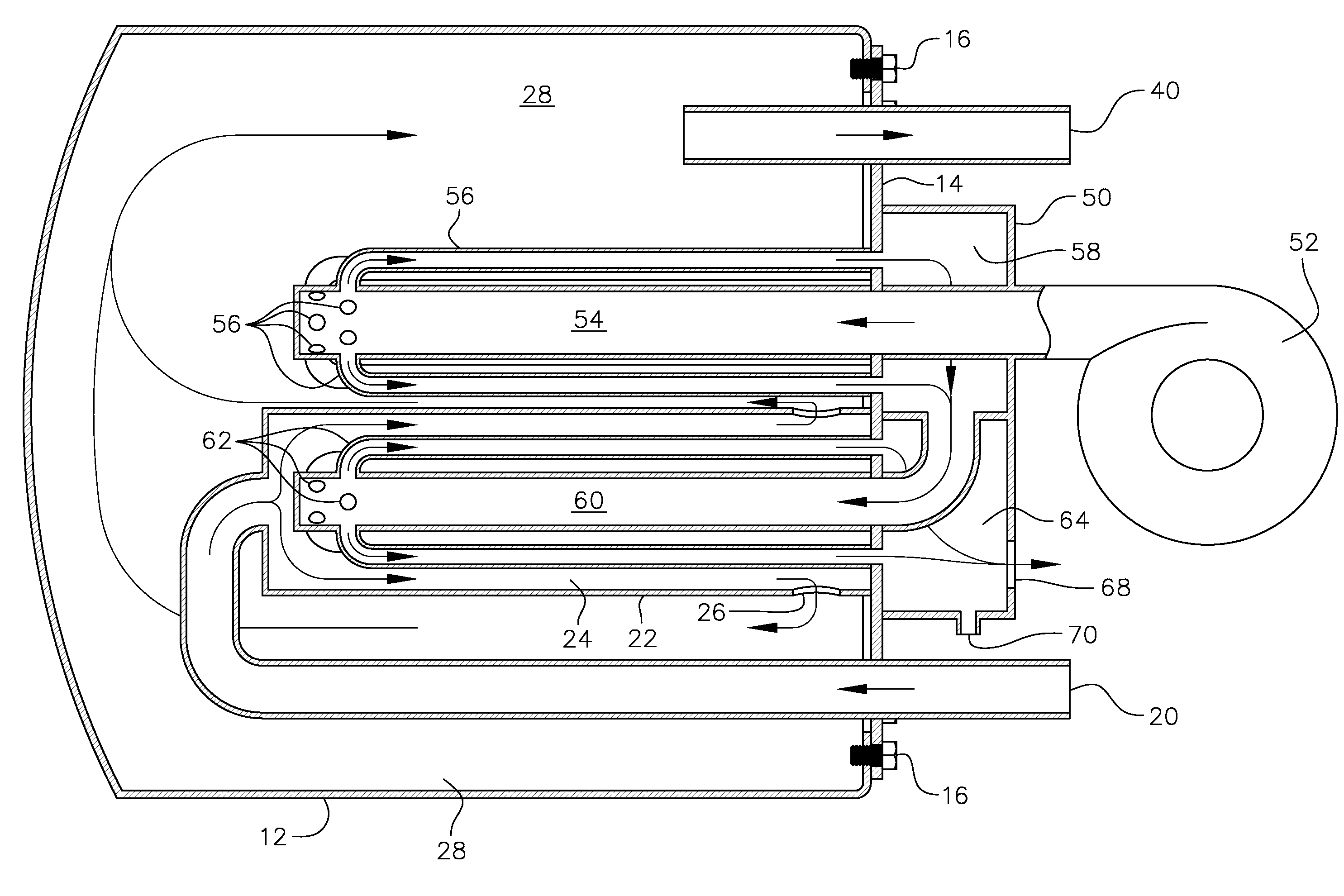

High efficiency water heater

An application for a method of heating water includes burning fuel to produce hot gases and heating a first mass of water with a first heat exchanger coupled to the hot gases. Heat remaining after the hot gases pass through the first heat exchanger is used by a second heat exchanger to heat a second mass of water. The first mass of water is partially isolated from the second mass of water and the first mass of water is contained substantially within the second mass of water. The second mass of water is colder than the first mass of water and, thereby, condenses more water vapor out of the hot gases.

Owner:WOOLLEN DONALD E JR

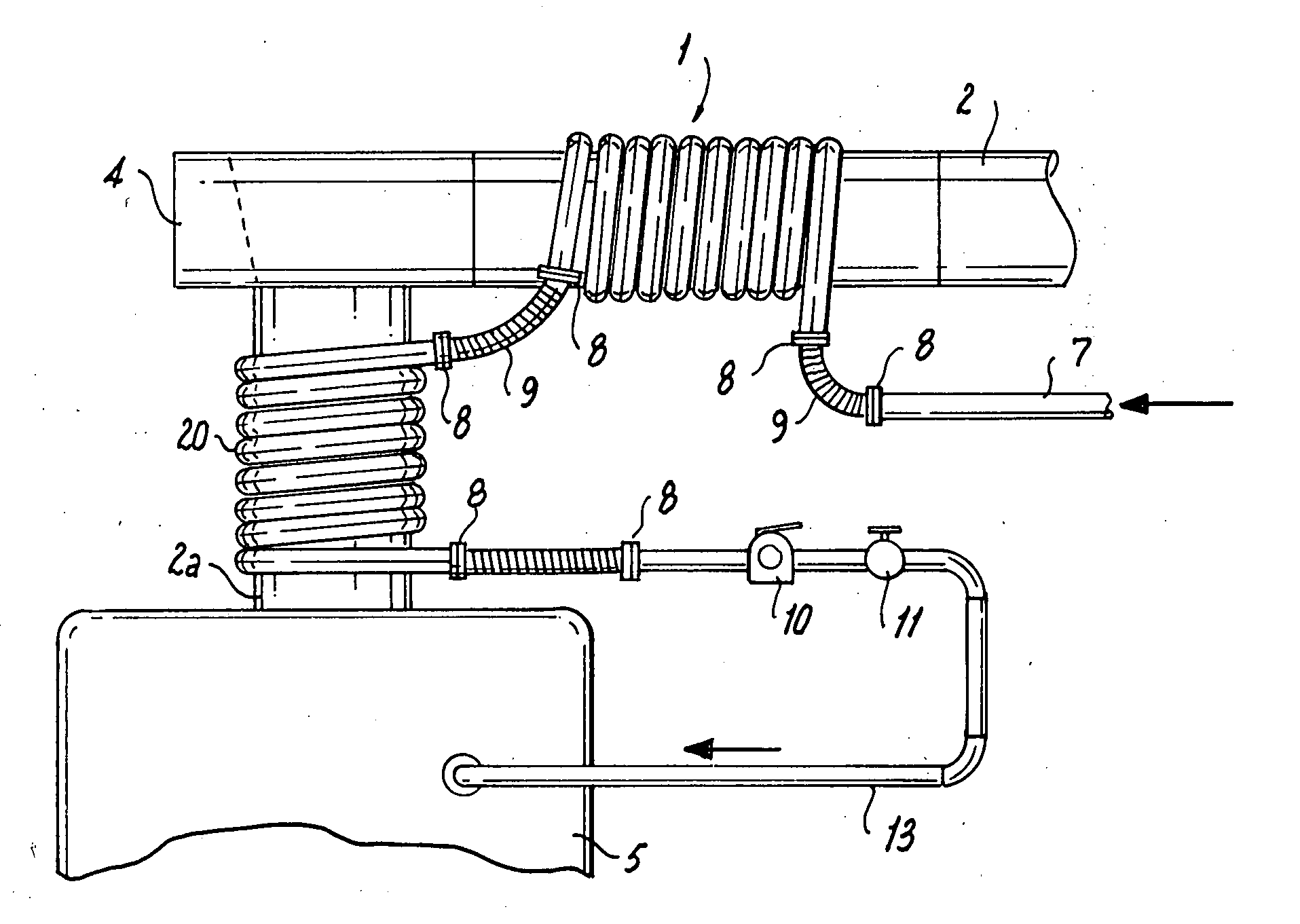

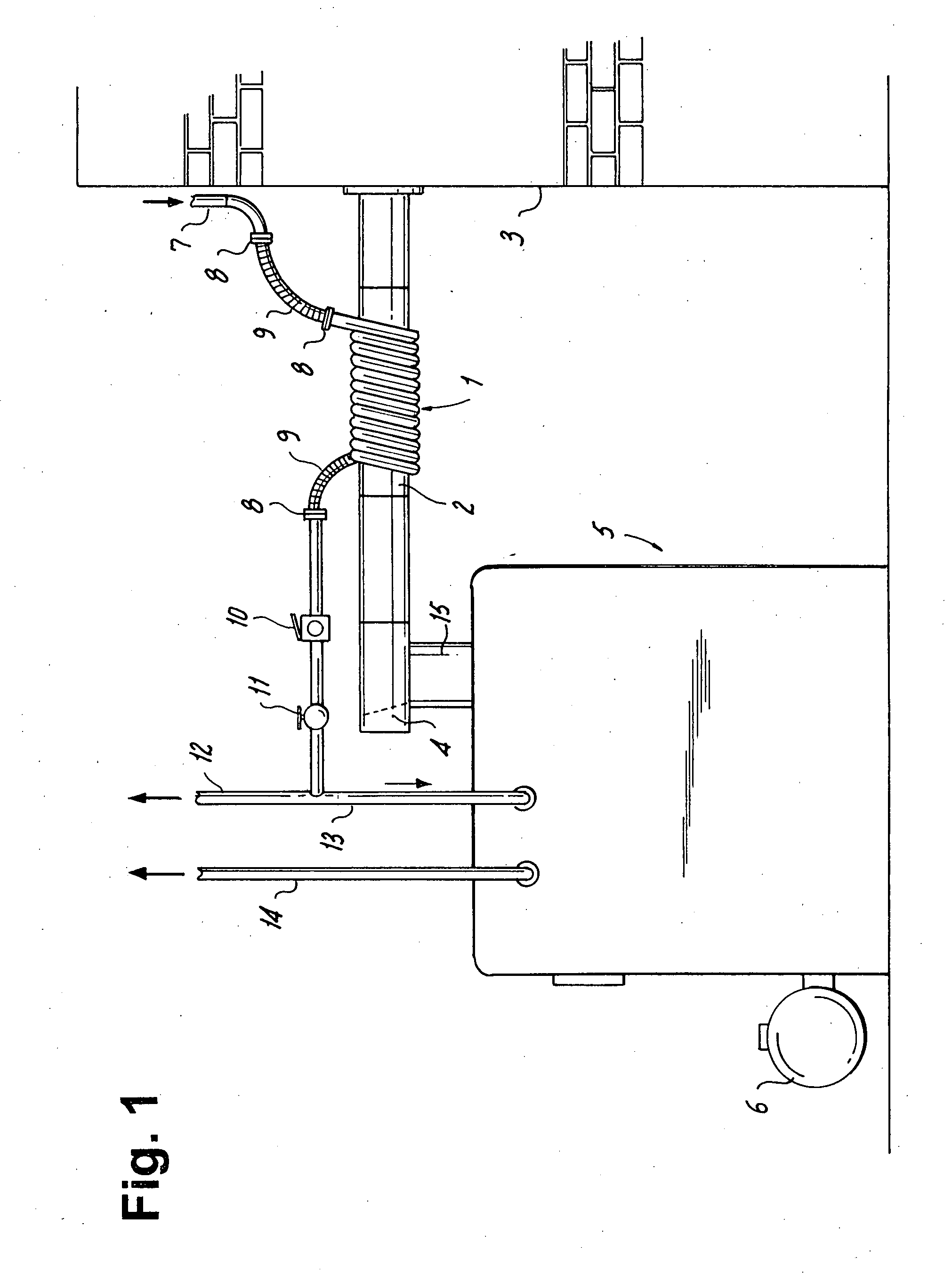

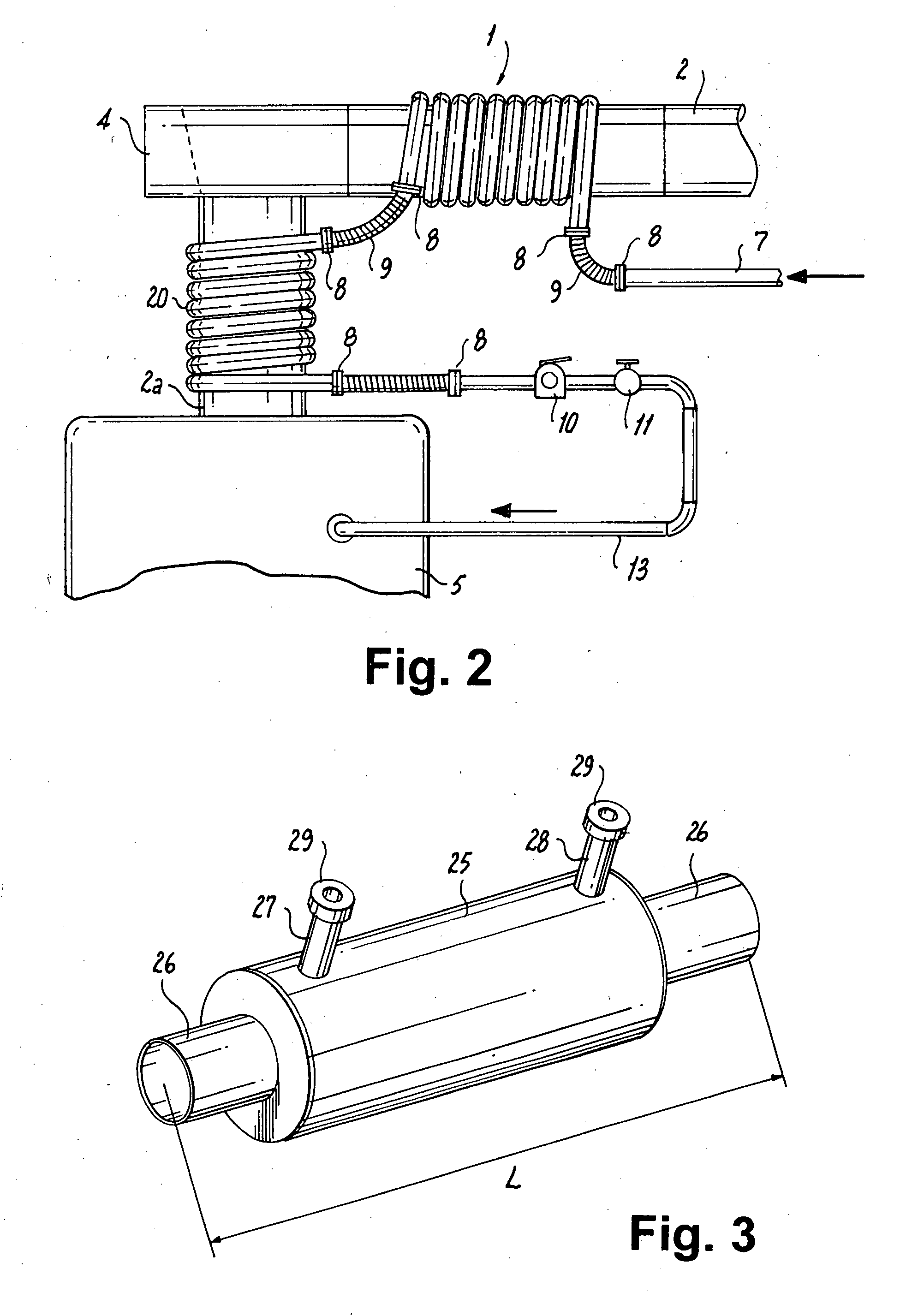

External flue heat exchangers

A heat exchanger is mounted external to a section of flue pipe or is an integral part of a section of flue pipe. The heat exchanger preheats a domestic hot water supply and boosts the return water temperature prior to reentry to the furnace coil. The heat exchanger reduces fuel use, pollution and wear of the furnace and burner. A typical heat exchanger installation includes an oil or gas burner located on a furnace or boiler having a flue pipe leading to a gaseous outlet, such as a masonry chimney. A short vertical flue section leads to a draft-regulating damper. The flue heat exchanger may be a coil of tubing wrapped around flue section, such that the tubing picks up heat from the heated flue gasses. Preheated water exits from the heat exchanger.

Owner:FERRARO JOSEPH C

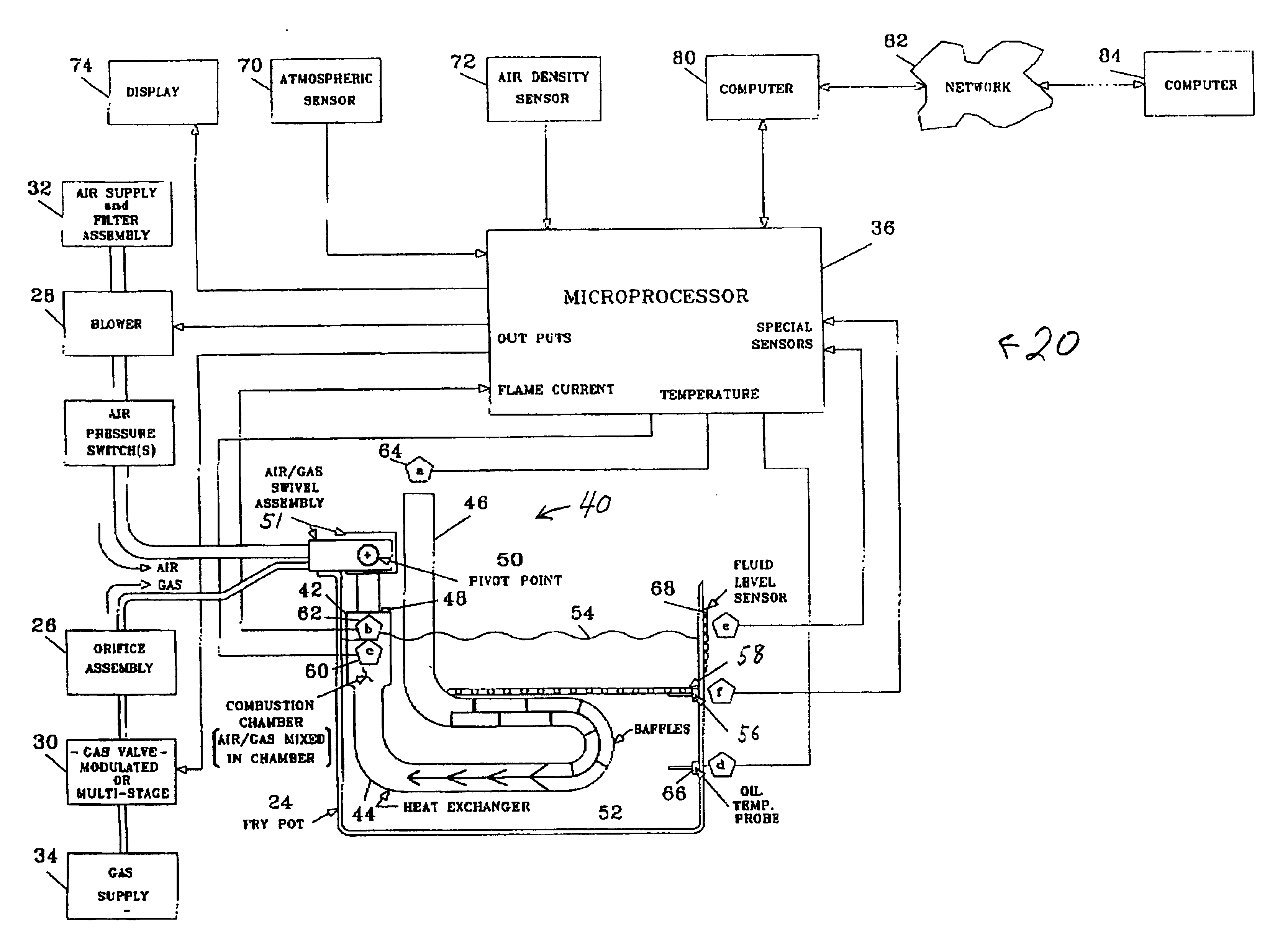

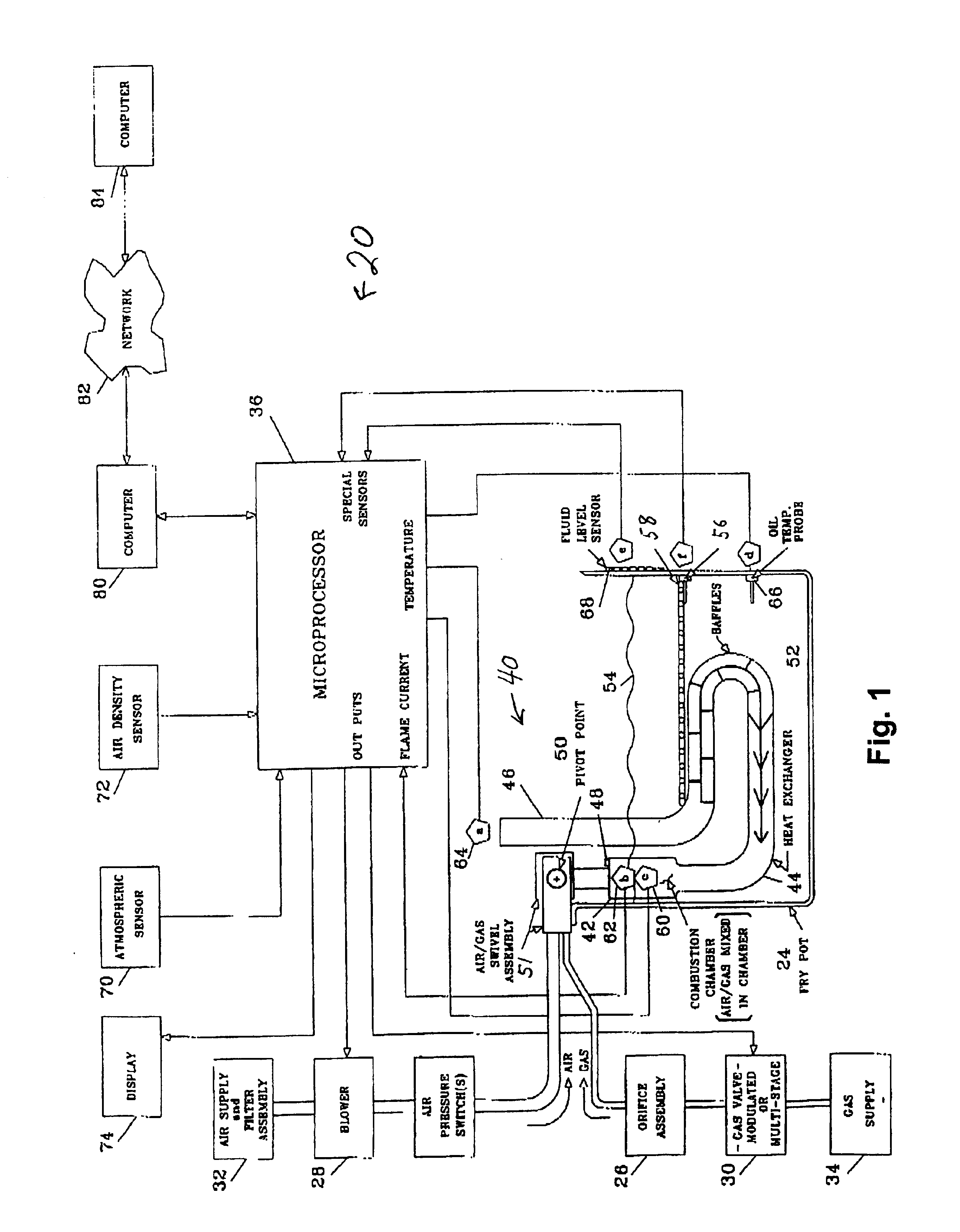

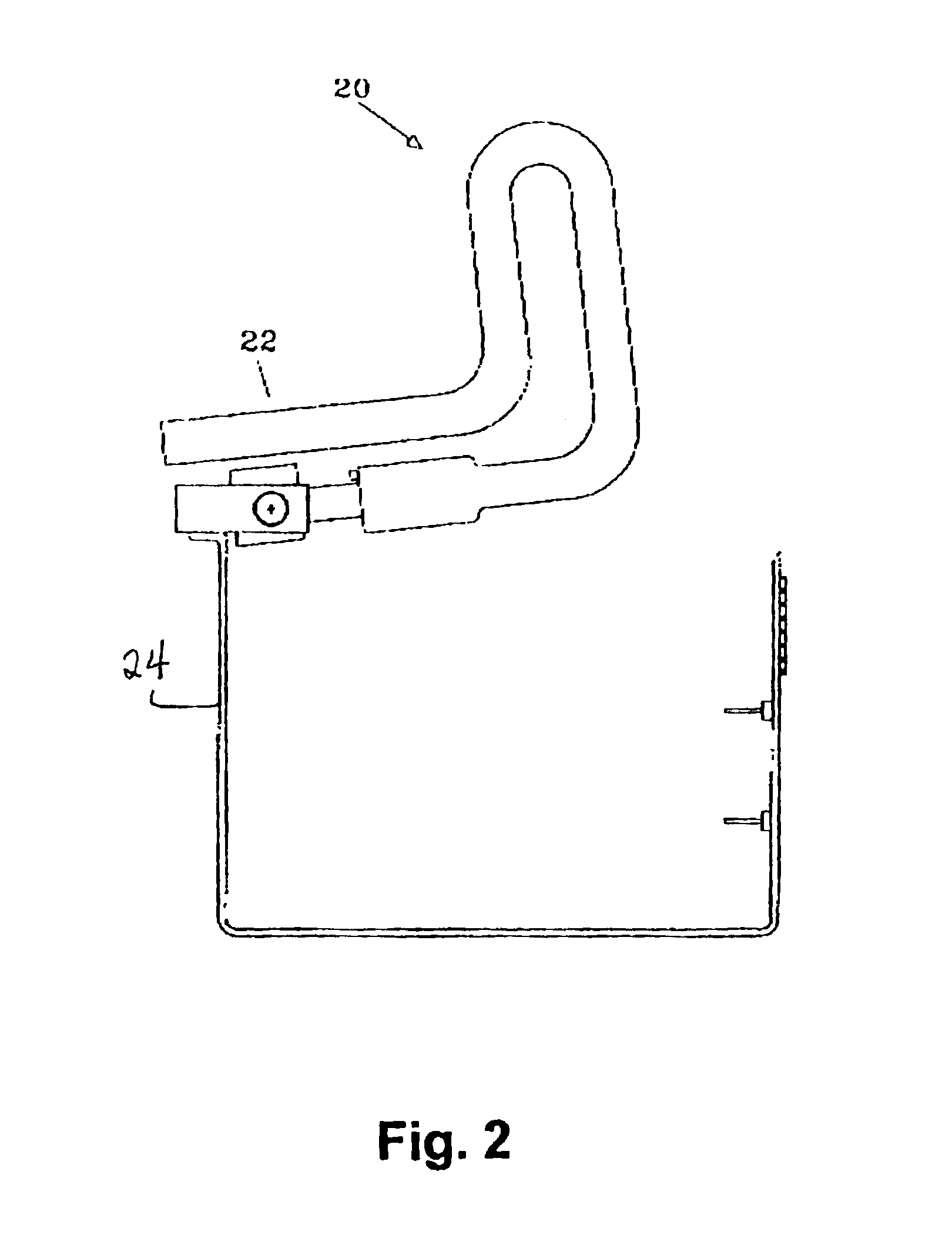

Frying apparatus with closed loop combustion control and method

InactiveUS6958166B2Improve efficiencyEasy to cleanStove/ranges for heating waterRoasters/grillsCombustion chamberCombustor

Frying apparatus for frying food, such as French fries, vegetables, bakery goods, meat fish, poultry and the like, in a heated fluid contained in a fry pot. The fluid is heated by a combustion burner that has a heat exchanger removably disposed in the heating fluid. When removed from the fluid, the heat exchanger and the fry pot can be easily cleaned. The air and / or gas is injected into the combustion chamber so as to provide an air gas ratio that supports clean combustion. A control monitors various temperatures and other parameters at various locations of the frying apparatus to control the efficiency of the frying apparatus to approximate a predetermined efficiency by altering the air / gas ratio.

Owner:FRYMASTER CORPTHE

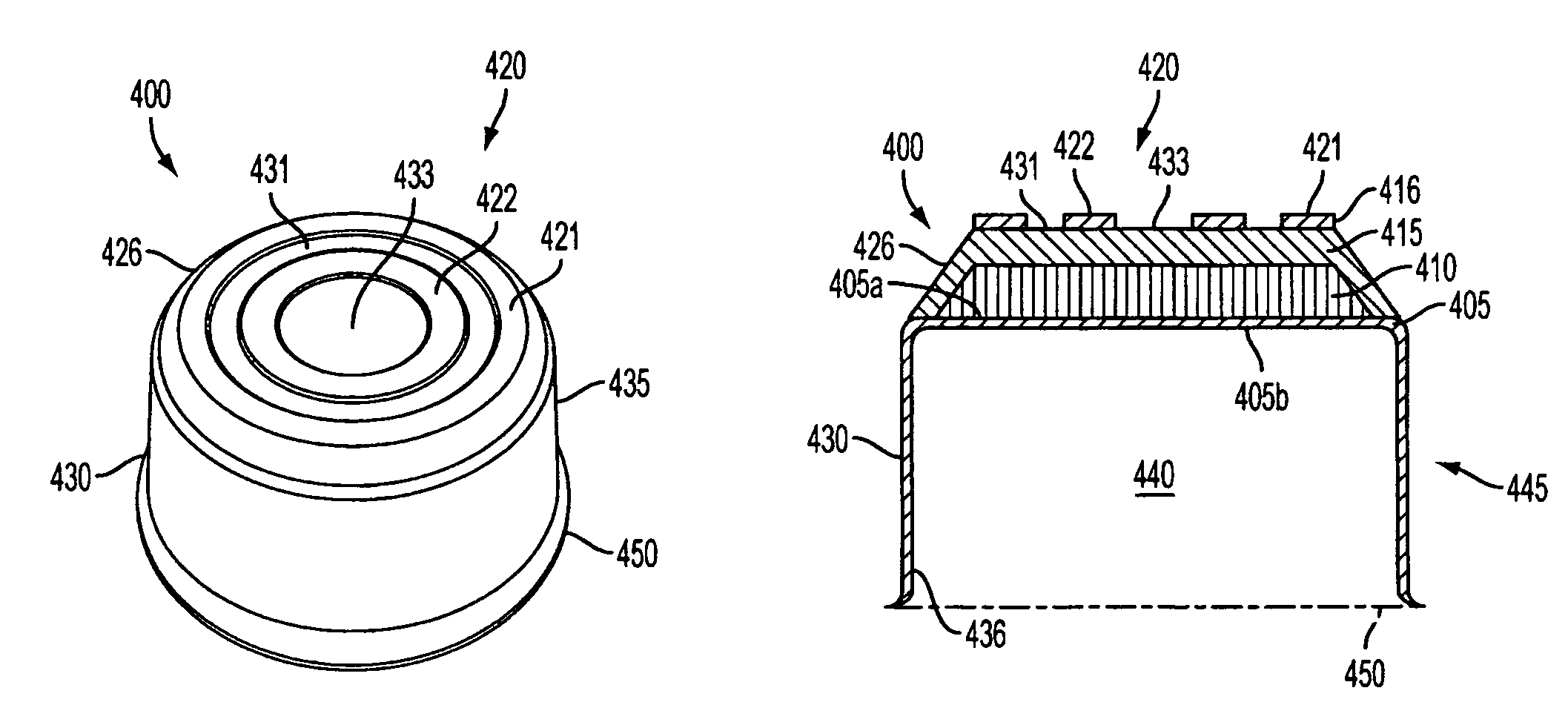

Cooking vessel with multiply ringed bottom surface

ActiveUS7150279B2Protected from abrasion during cookingWater heating stoves/rangesStorage heatersMarine engineeringConductive materials

Owner:MEYER INTPROP

Biomass gasification stove

ActiveCN104654364AEasy to removeReduce pollutionLighting and heating apparatusChemical industryStart timeThermal insulation

The invention discloses a biomass gasification stove. The biomass gasification stove is mainly characterized in that a smoke discharge chamber and a stock bin opening booster chamber are respectively formed in the upper part of a fuel bin, wherein a stock bin cover is arranged in the middle of the stock bin opening booster chamber; a flue gas channel is formed between a water tank and a furnace core; the gasification furnace core is communicated with the fuel bin and an ash collecting chamber, respectively; a funnel-shaped furnace grate with a ash shaking device and a movable fence gate is arranged between the gasification furnace core and the ash collecting chamber; a thermal insulation layer is arranged between the inner and outer walls of the gasification furnace core; the inner wall of a gasification reaction chamber in the gasification furnace core is an extension tube capable of freely stretching out and drawing back; an air spray nozzle is arranged on the side wall at the upper side of the gasification reaction chamber; an ignition device is arranged in the thermal insulation layer. The biomass gasification stove has the advantages that the structure is compact; the gasification reaction temperature is as high as 1200 DEG C; the heat-up starting time is short; the ignition is convenient and the gas production is efficient; hot water can be produced by heating the water tank, and tar which is mixed in a biomass fuel gas can be further removed to realize energy conservation and environment protection and prolong service lives of relevant appliances; the accumulated ashes or coked blocks are conveniently and quickly removed.

Owner:周勇

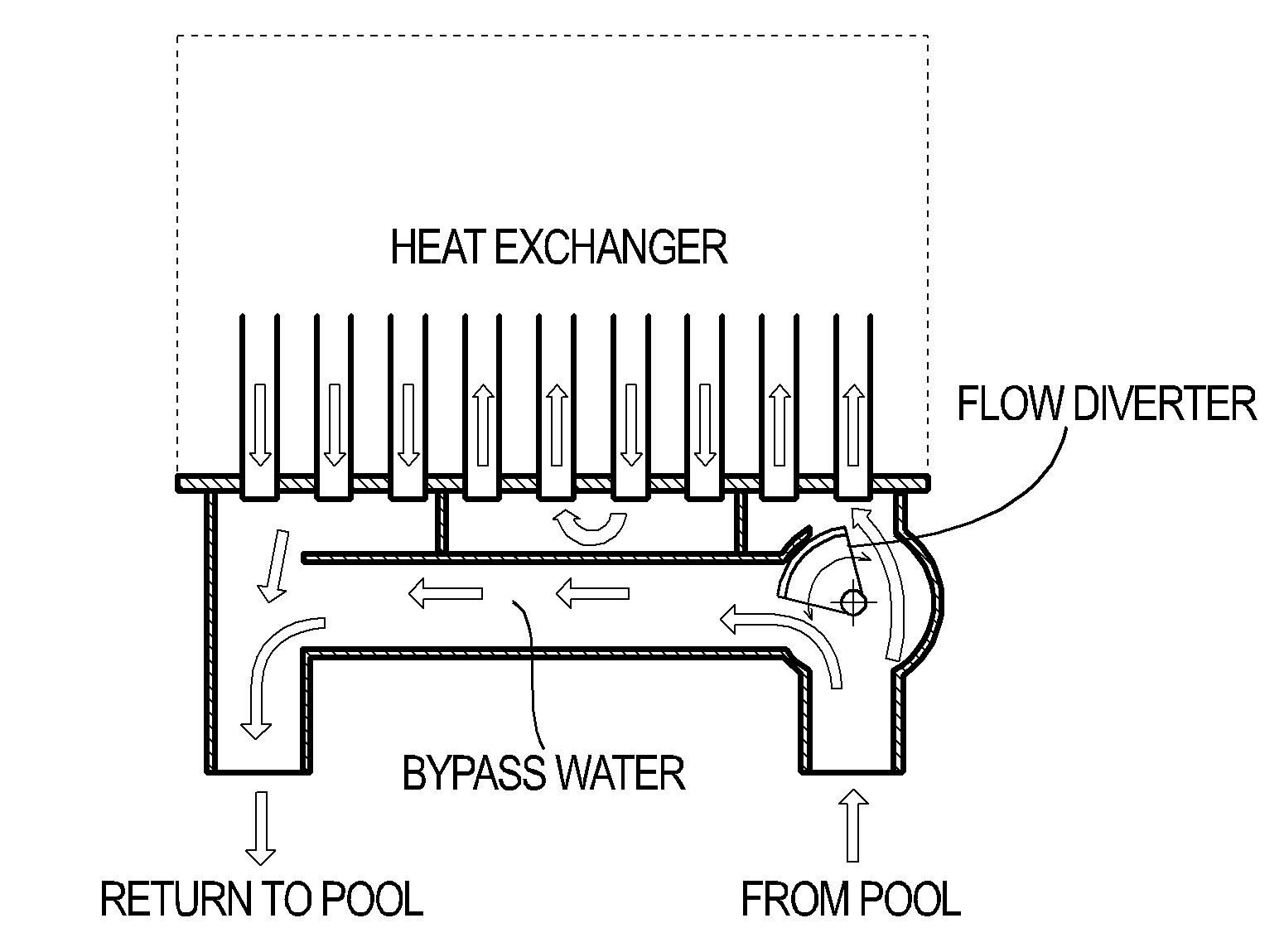

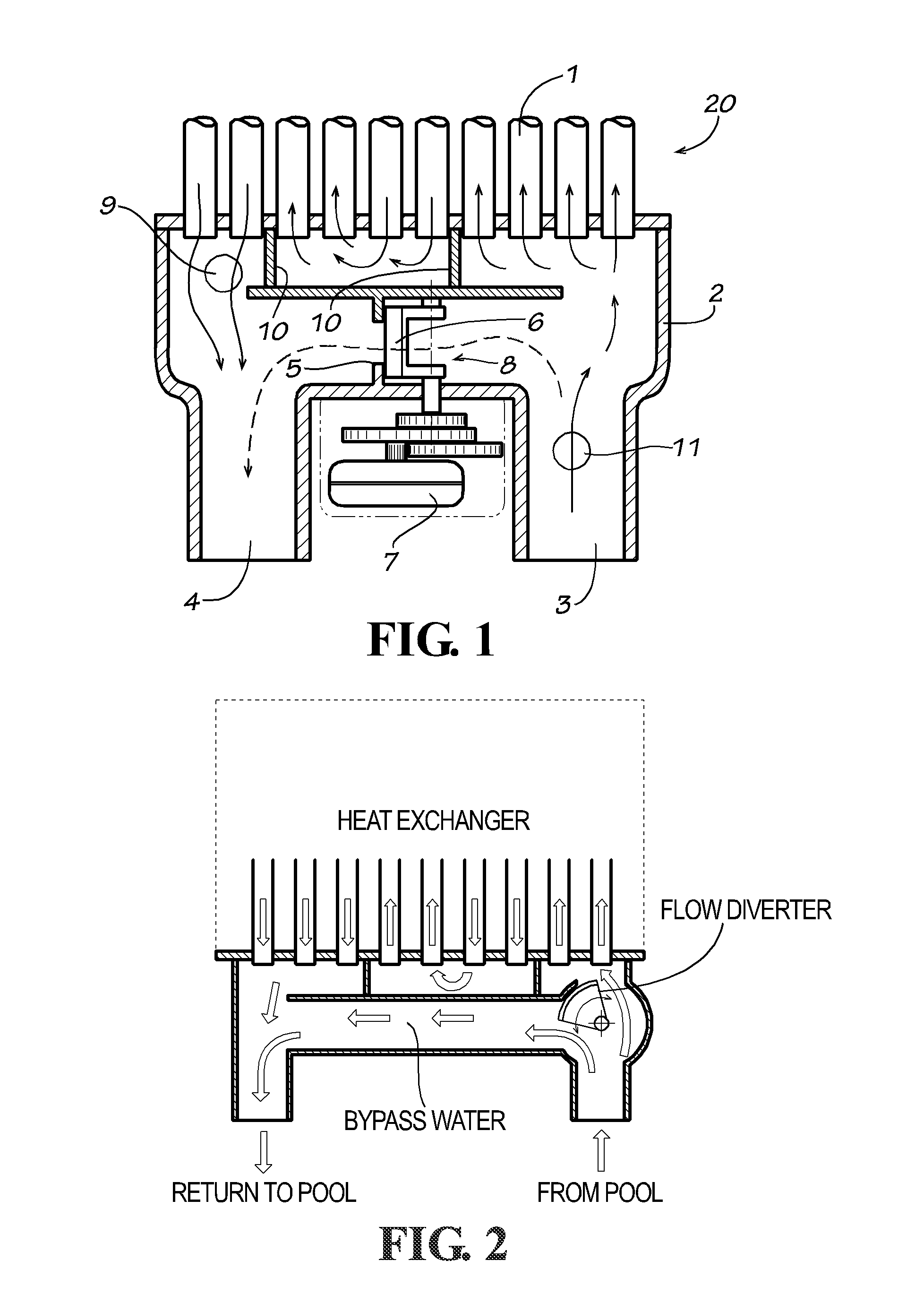

Flow control and improved heat rise control device for water heaters

ActiveUS20120042445A1Mechanical apparatusStove/ranges for heating waterStream flowProcess engineering

Disclosed are systems and devices for controlling the amount of water passing through a heat exchanger and the amount of water that by-passes the heater without passing through the heat exchanger. In some embodiments, the system includes a by-pass valve assembly having means for sensing a time-varying characteristic of fluid adjacent the inlet, means for sensing a time-varying characteristic of fluid adjacent the outlet, and a valve that alters the amount of fluid by-passing the fluid heater in response to differences in the time-varying characteristic of fluid adjacent the inlet and fluid adjacent the outlet.

Owner:ZODIAC POOL SYST LLC

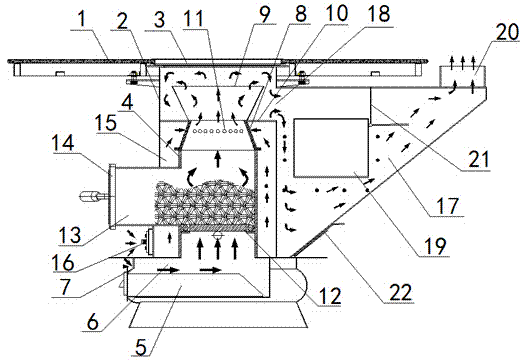

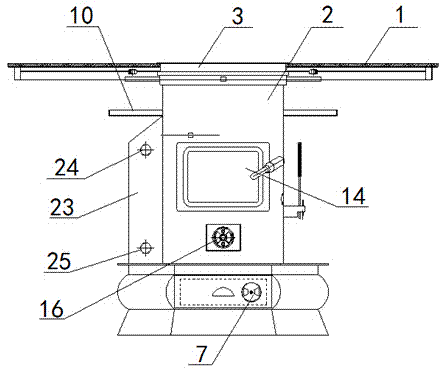

Downdraft biomass gasification combustion cooking and heating furnace

ActiveCN103742946ASolve high tar contentSolve the smellLighting and heating apparatusStove/ranges for heating waterCombustion chamberEnvironmental engineering

Provided is a downdraft biomass gasification combustion cooking and heating furnace. A furnace shell is arranged on a base, a feed port is formed in the upper surface of the furnace shell, a primary air chamber, a combustion chamber, a smoke channel, an ash discharge chamber and a cooking stove are arranged in the furnace shell, a lower stove ring is arranged between the primary air chamber and the combustion chamber, and a heat exchanger is arranged in the smoke channel. The downdraft biomass gasification combustion cooking and heating furnace is characterized in that an inclined gasification chamber communicated with an inlet of the primary air chamber is arranged on the upper portion inside the furnace shell, a V-shaped water channel is formed between the gasification chamber and the combustion chamber, a combined grate formed by an inclined fixed grate and a movable grate is arranged in the primary air chamber, an oxygen enrichment ring is arranged on the lower stove ring, a secondary air chamber is formed by a cavity between the lower stove ring and the oxygen enrichment ring, and an oxygen enrichment pipe is arranged on the lower stove ring. The downdraft biomass gasification combustion cooking and heating furnace has the advantages that the downdraft biomass gasification combustion cooking and heating furnace is low in PM2.5, sulfur dioxide and oxide emission index, free of tar, free of ash escape, smokeless, wide in fuel application range, high in thermal efficiency, long in hot standby time, free of reignition, low in fault rate and suitable for rural families.

Owner:JINZHOU SHENGTAI ENVIRONMENTAL PROTECTION EQUIP BOILER

Pressure-cooking appliance including opening safety means

ActiveUS20050132896A1Easy to useHigh speedWater heating stoves/rangesStove/ranges for heating waterEngineeringNeutral position

The invention relates to an appliance for cooking under pressure, the appliance comprising: a bowl and a lid; and opening safety means suitable for going between a neutral position, in which they allow the lid to be unlocked, and a blocking position, in which they prevent the lid from being unlocked, said safety means being designed to find themselves in the blocking position when the pressure prevailing inside the vessel is greater than or equal to a predetermined value or “rise pressure”, and / or when the temperature prevailing inside the vessel is greater than or equal to a predetermined value or “rise temperature”; said appliance being further comprising actuating means for actuating the safety means, which actuating means are arranged to make it possible to place the safety means in the blocking position The invention is applicable to household appliances for cooking under pressure.

Owner:SEB SA

Biomass cooking and heating stove

InactiveCN104501210AExtended discharge pathExtended stayLighting and heating apparatusStove/ranges for heating waterCooking & bakingCombustor

The invention provides a biomass cooking and heating stove. A burner in a conical structure is mounted at the top end of an inner container. A collector disc in an inverted cone structure is mounted at the top end of the burner. A baking tray is horizontally mounted at the joint of the burner and the collector disc. The burner, the collector disc and the baking tray are integrated. The braking tray seals the inner cross section of a stove body. The burner, the collector disc and the inner container are coaxial and are internally communicated with one another. The sidewall of the burner is provided with air holes. A gap between the inner container and the stove body serves as a secondary air passage. By secondary oxygen supply and complete utilization of waste heat, oxygen is supplied to primarily-burned gas in the inner container to allow the gas to secondarily burn in a semi-gasified manner, and burning efficiency is greatly improved. A special U-shaped flue system enables a flue gas discharge path to be longer and flue gas to stay longer in a flue, and waste heat is more sufficiently utilized; a flue adjusting plate allows a flue gas flow path and a flow direction to be adjusted during burning, and using is more facilitated.

Owner:湖北蓝焰生态能源有限公司

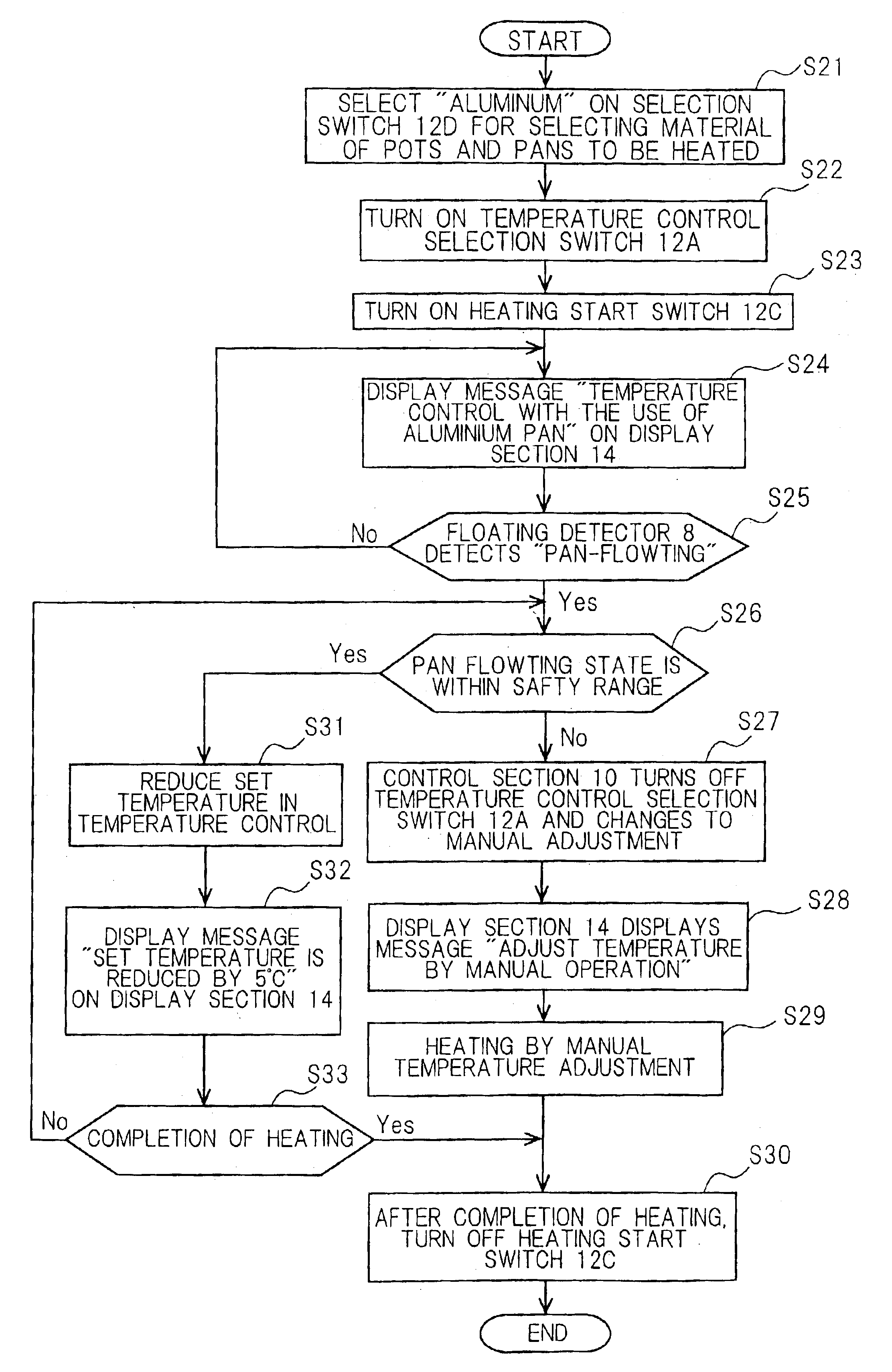

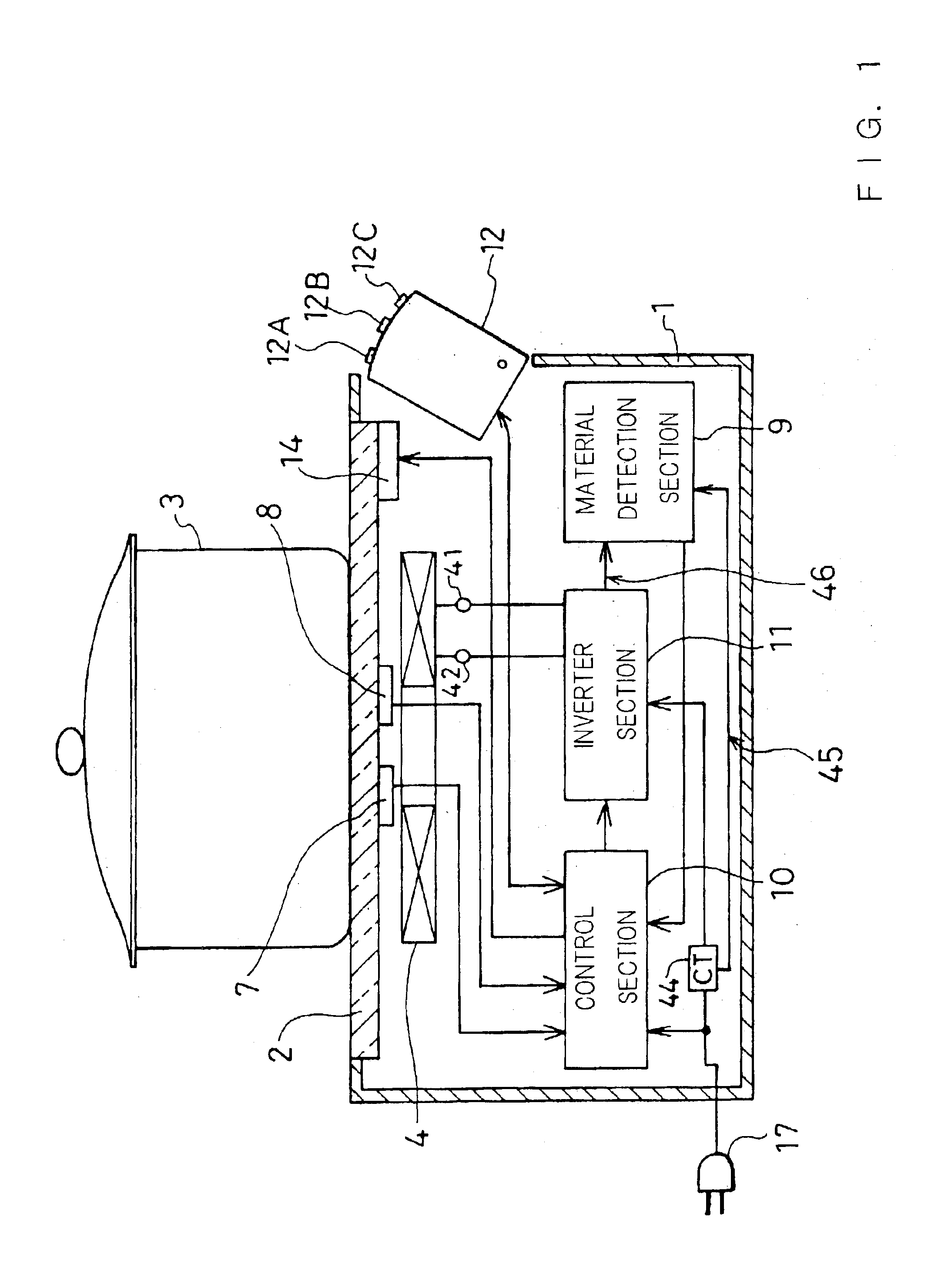

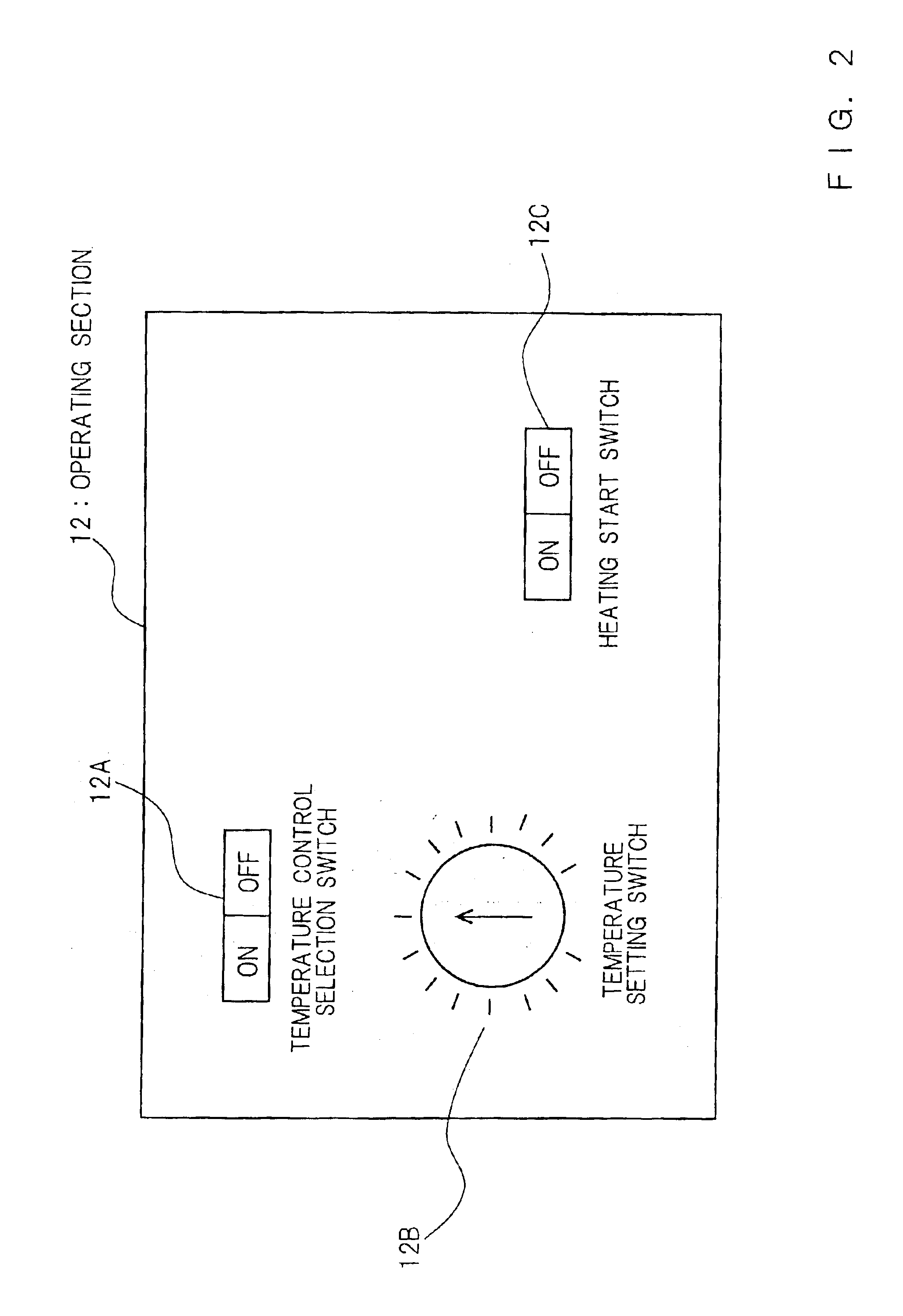

Induction heating apparatus

InactiveUS6894255B2Abnormal temperature rise can be preventedAbnormal temperature riseWater heating stoves/rangesCooking vesselsTemperature controlNon magnetic

When a pan made of a non-magnetic material, such as aluminum, is used for cooking while the temperature is being controlled, a notice is made to the user to the effect that the temperature control function has been stopped and that the temperature should be manually adjusted, when the material detection section detects that the pan is made of a non-magnetic material or a pan floating phenomenon has occurred, in order to prevent abnormal increase in the temperature of the pan due to incorrect temperature detection caused by the pan floating phenomenon, a set temperature is lowered.

Owner:PANASONIC CORP

Civil heating stove for automatically feeding with stalk briquette as fuel

ActiveCN101354146AIncrease flow rateFlow adjustmentStove/ranges for heating waterHome appliance efficiency improvementCombustion chamberEngineering

The invention relates to a civil heating stove feeding automatically and taking haulm briquettes as fuel, which comprises two parts, namely, a stove body and an automatic feeding device. The stove body essentially comprises a combustion chamber, a wind box, a rocking grate, a flue channel and a water jacket. The automatic feeding device essentially comprises a motor, a screw rod, a stock driving groove, a limit switch and a hopper and can realize 8 hours to 12 hours of timed and rationed automatic feeding. The civil heating stove is applicable to the clean combustion process of biomass fuels, has the advantages of high combustion efficiency, high thermal efficiency, low emission of contaminants, low generation of tar and labor conservation and the like, does not cause problems like indoor contamination resulted from condensation of the tar, and has simple structure, low cost and broad application prospect.

Owner:HEBEI UNIV OF TECH

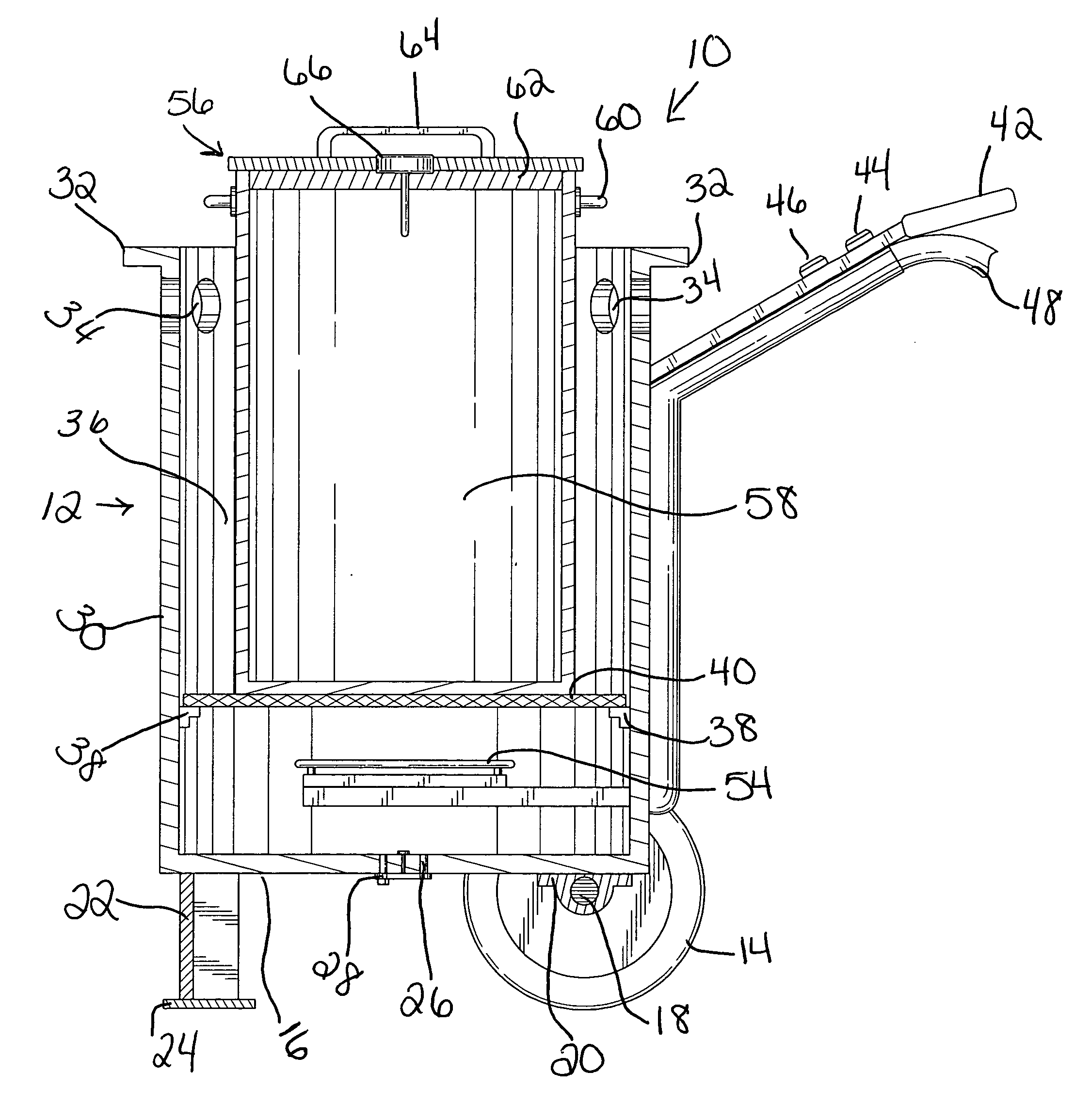

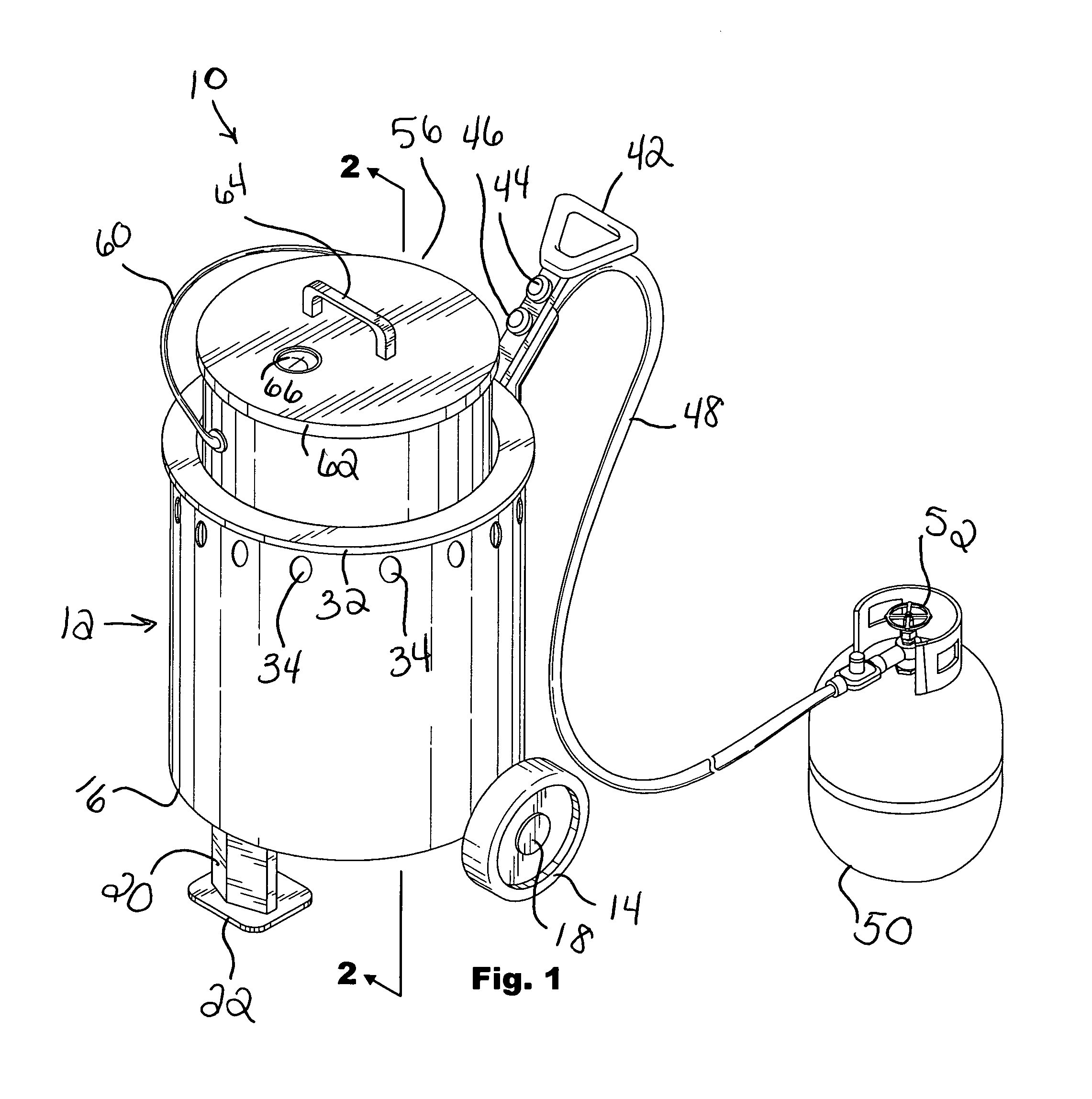

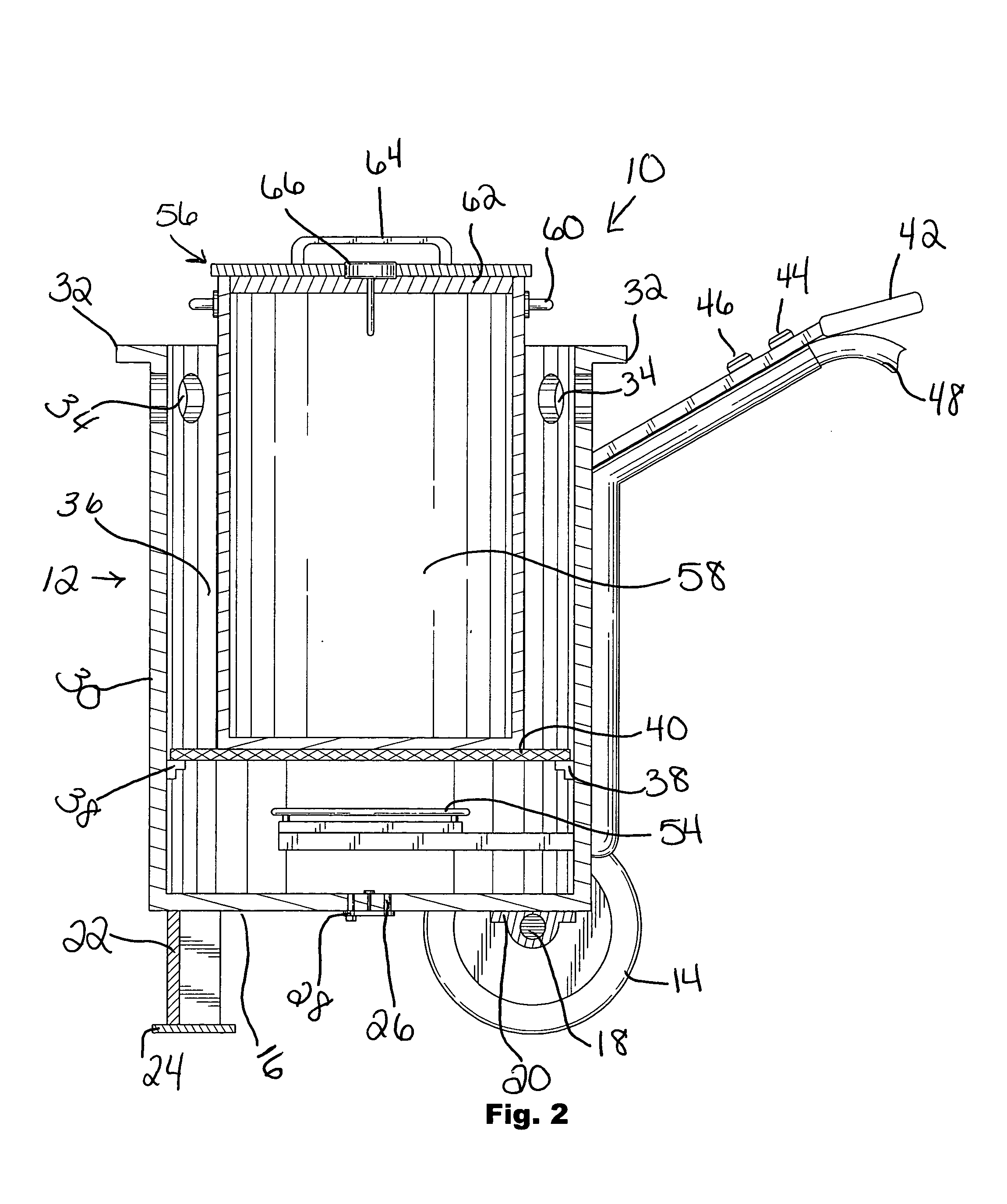

Portable tar heating and melting apparatus

InactiveUS6935331B2Fast recovery timeHigh cooking timeWater heating stoves/rangesCooking vesselsTarEngineering

A portable tar kettle includes a steel containment body mounted on wheels and having a handle projecting therefrom with the handle including an integral gas line that interconnects to an external propane tank and internally registers with a gas burner located within the containment body. Disposed within the containment body is a tar cooking vessel that holds the tar, and other material, to be heated and melted. The tar cooking vessel includes a lid with an integral temperature gauge. When the tar is appropriately heated and melted, the tar cooking vessel can be removed and carried to the roof of the structure, and this process can be repeated as many times as necessary to effect roof repair and maintenance.

Owner:FARMER RODNEY ANTHONY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com