Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

583 results about "Biomass gasifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A biomass gasifier is any process unit that heats and decomposes biomass into synthesis gas, a mixture of hydrogen, carbon monoxide, and carbon dioxide, in a restricted oxygen environment.

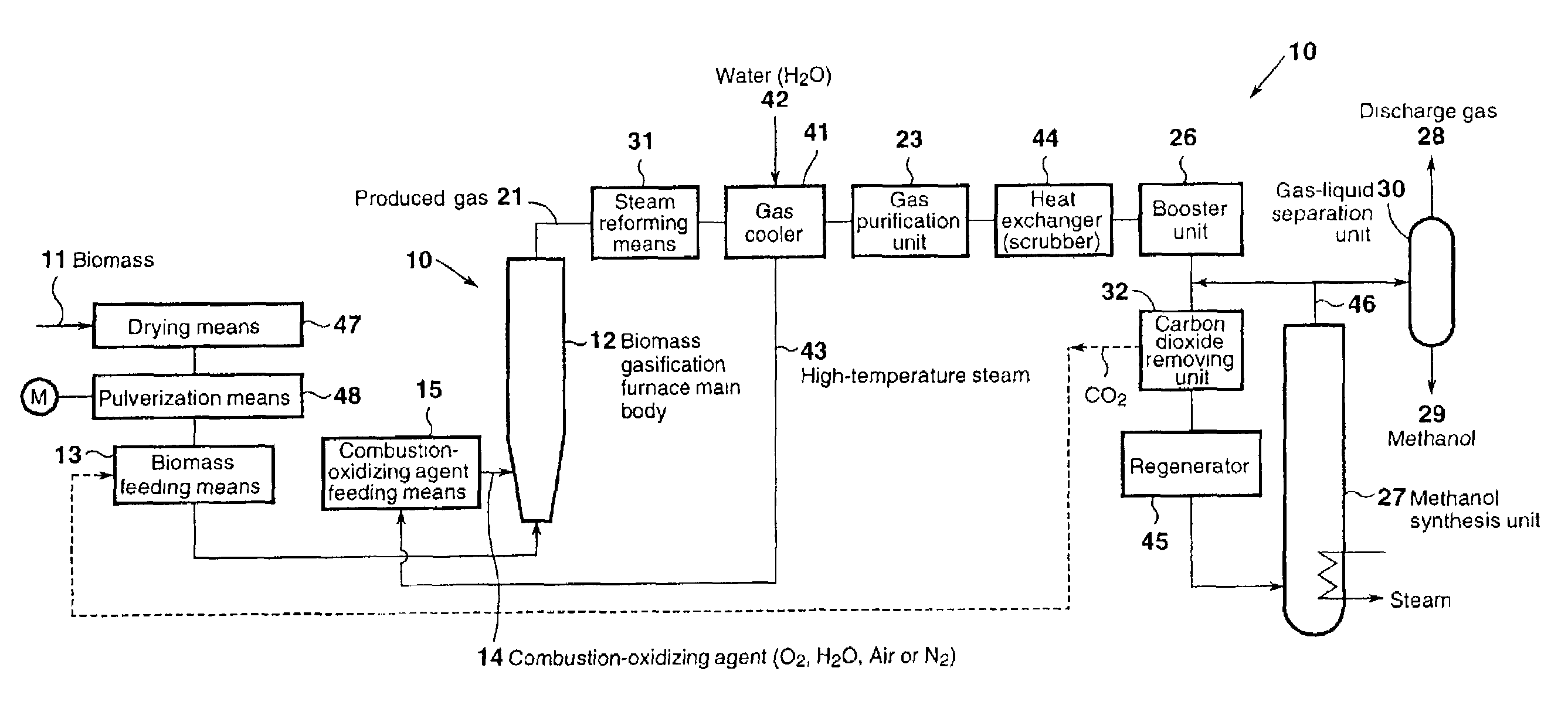

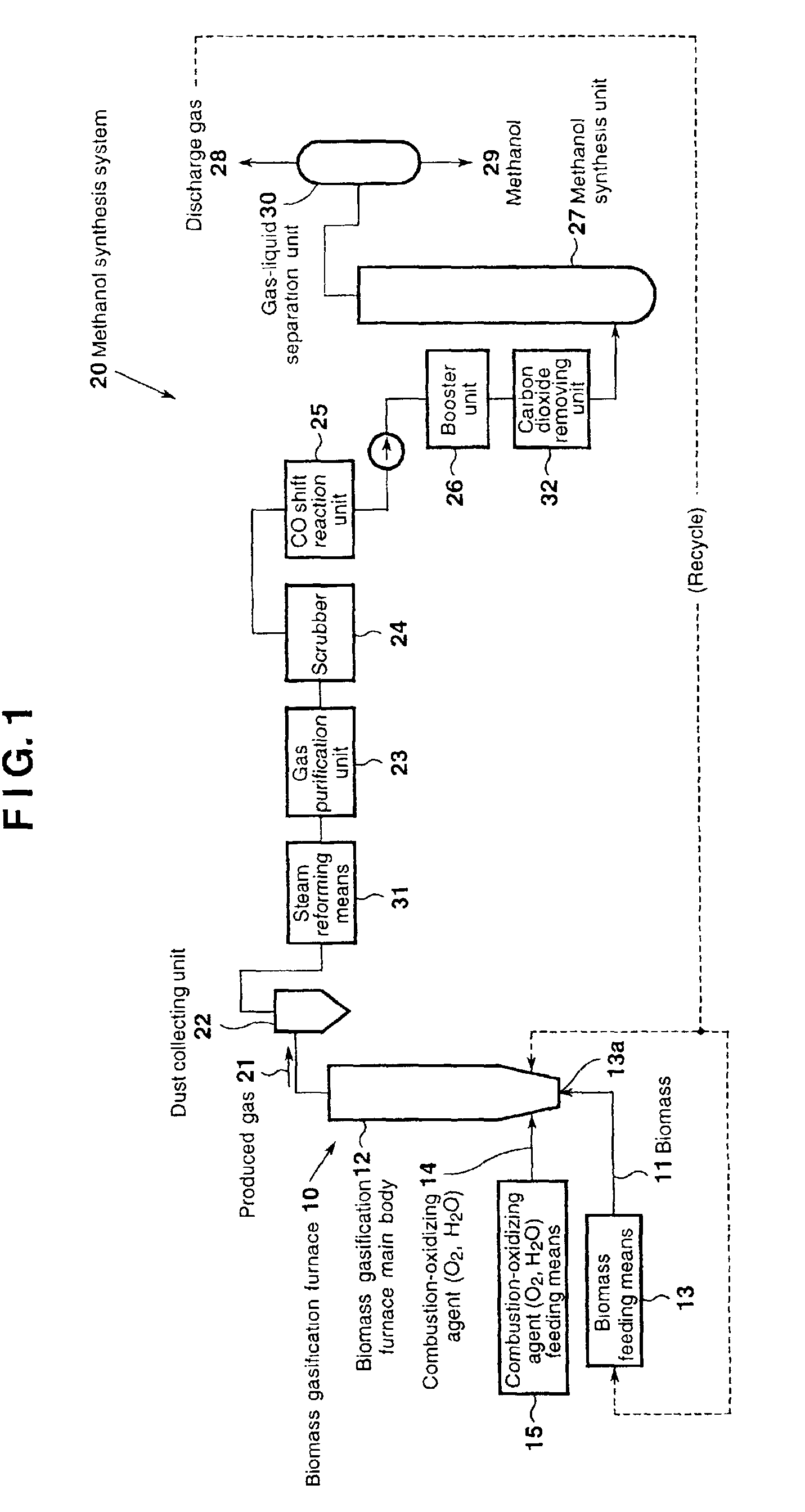

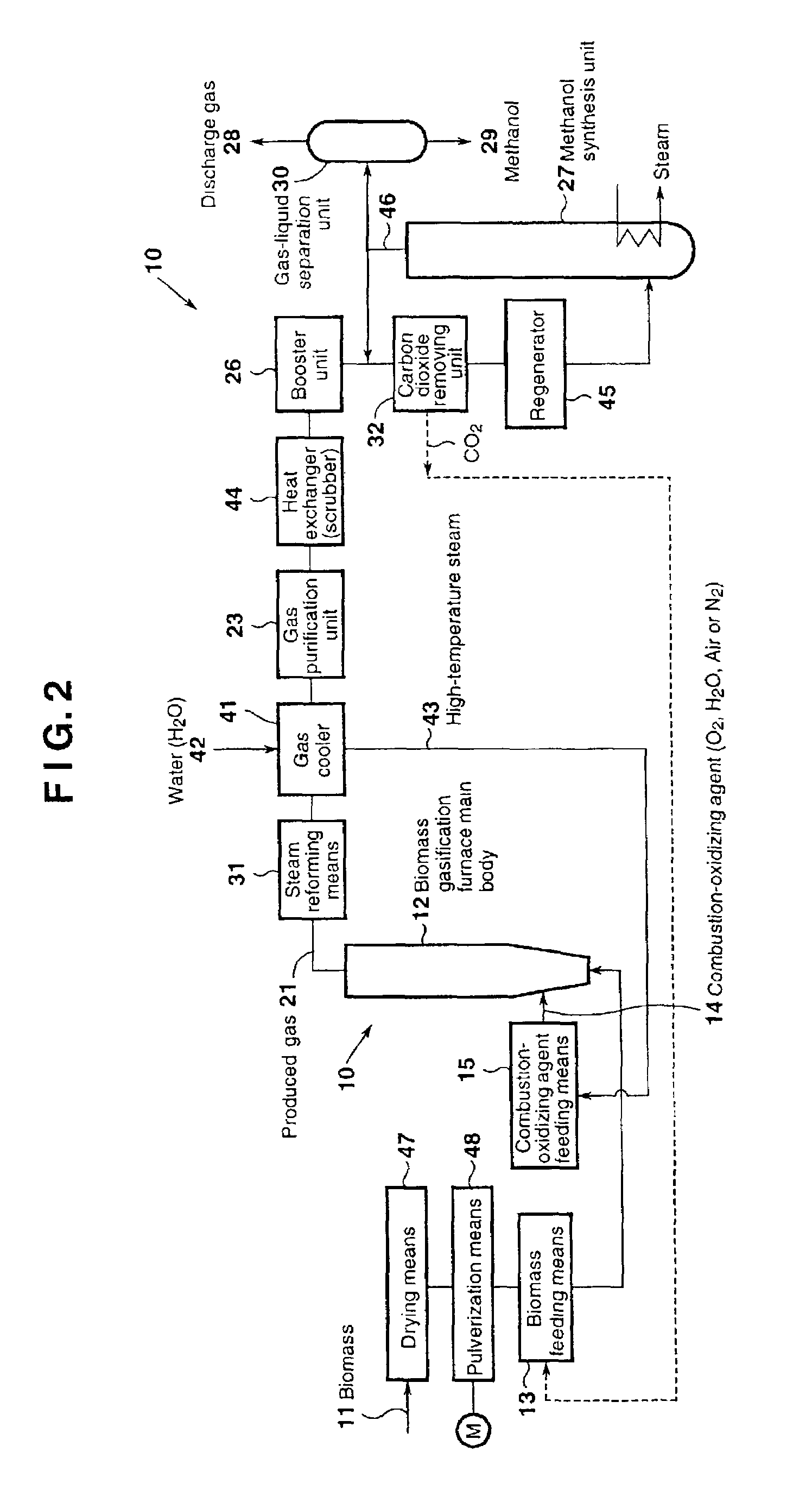

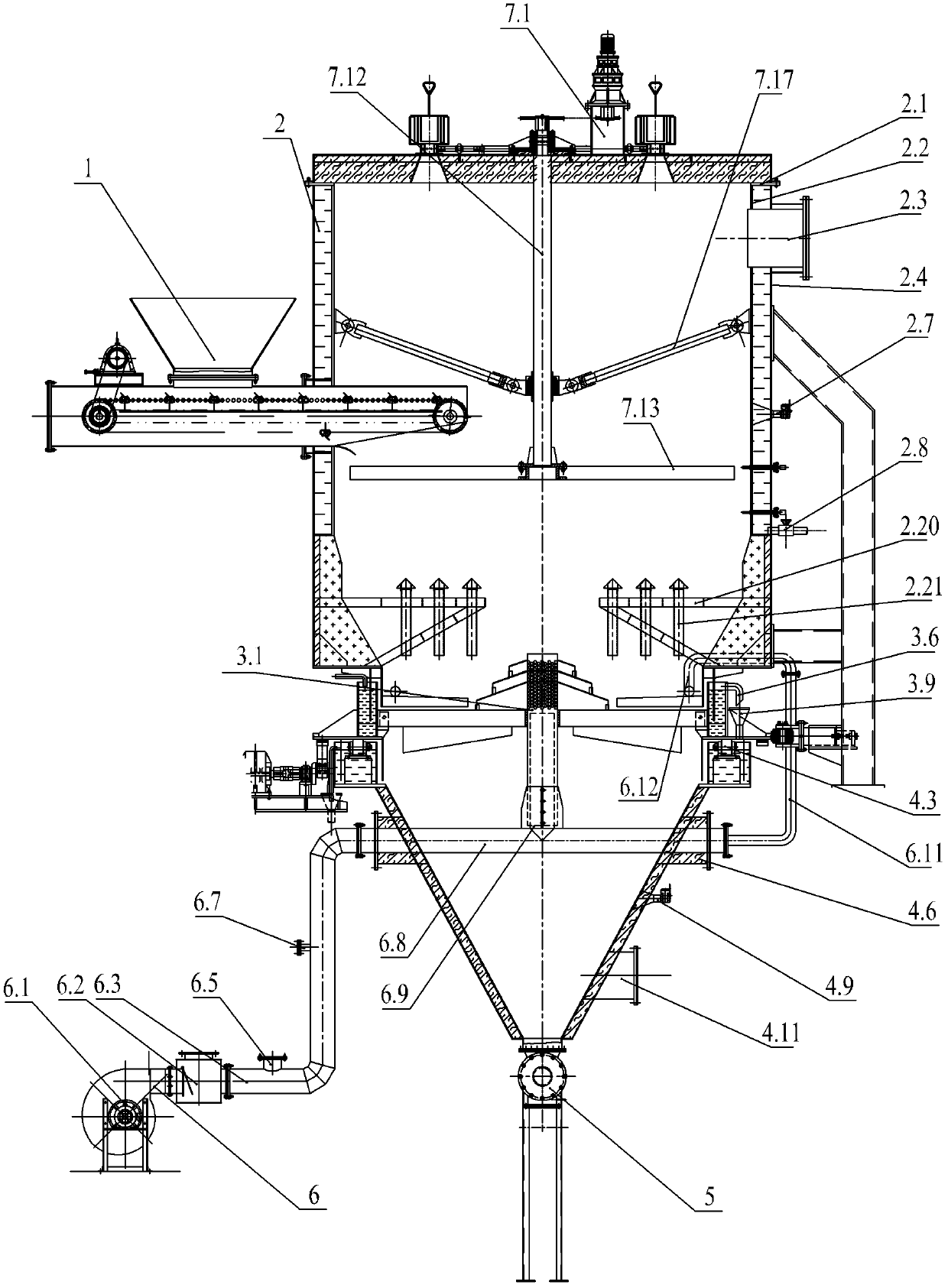

Biomass gasifycation furnace and system for methanol synthesis using gas produced by gasifying biomass

InactiveUS6991769B2Eliminate compression and entanglementCombustible gas catalytic treatmentBiofuelsCombustionProcess engineering

Methanol is synthesized from a gas produced through gasification of biomass serving as a raw material, making use of a biomass feeding means for feeding biomass into a furnace main body and, located above the biomass feeding means, combustion-oxidizing-agent-feeding means for feeding into the furnace main body a combustion-oxidizing agent containing oxygen or a mixture of oxygen and steam.

Owner:MITSUBISHI HEAVY IND LTD

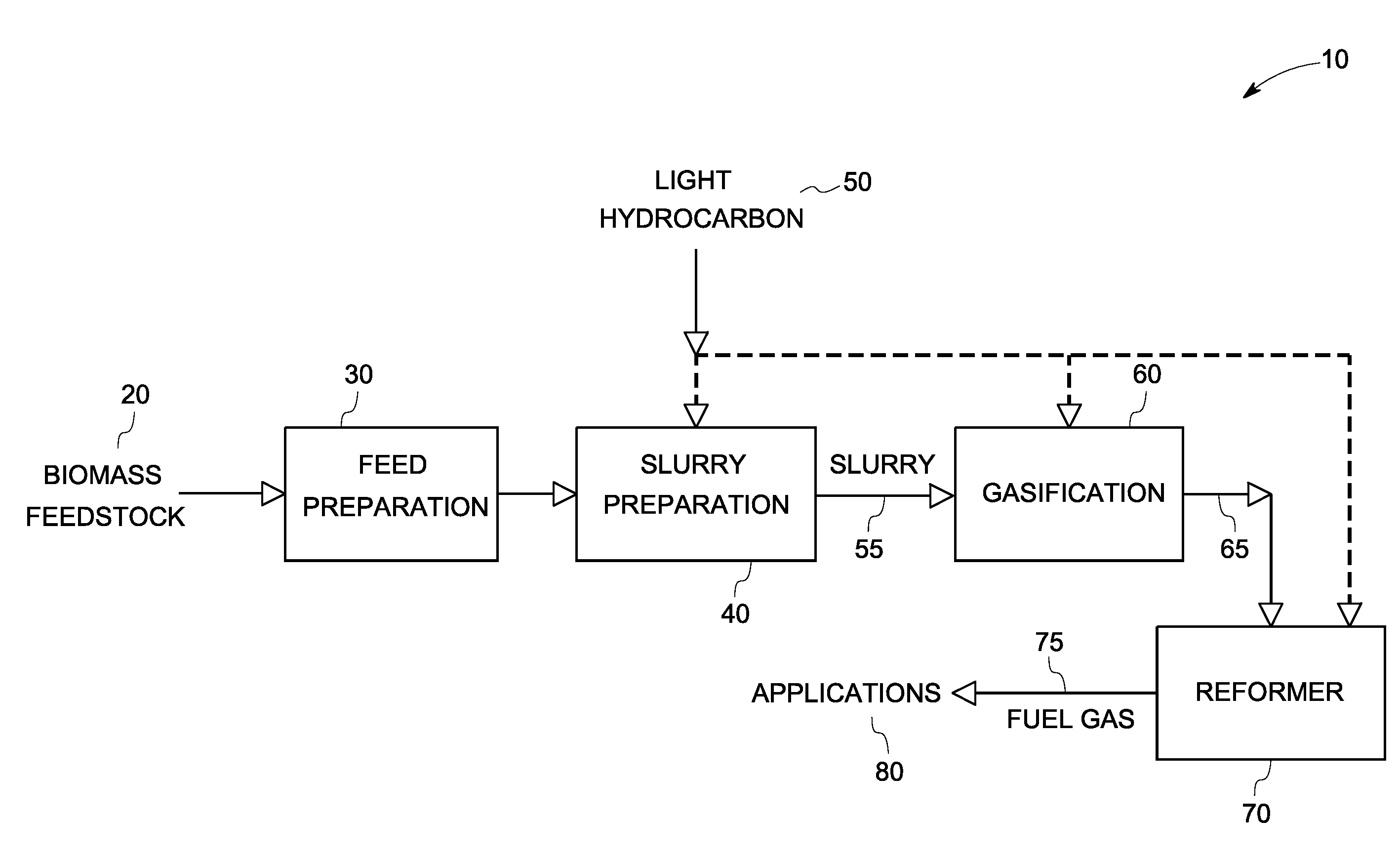

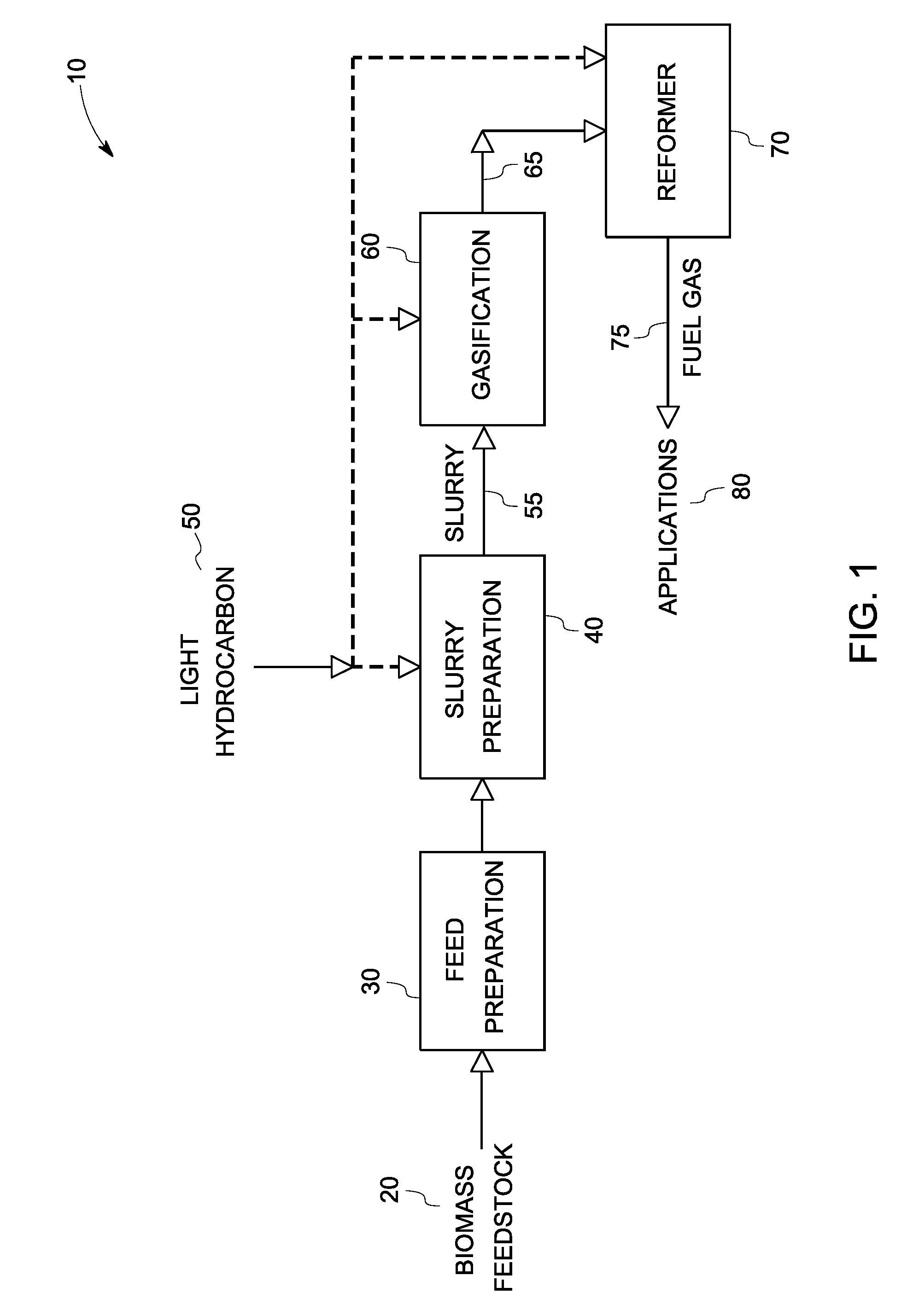

Method of biomass gasification

InactiveUS20090158663A1Efficient gasificationMinimizes problemProductsReagentsProcess engineeringProduct gas

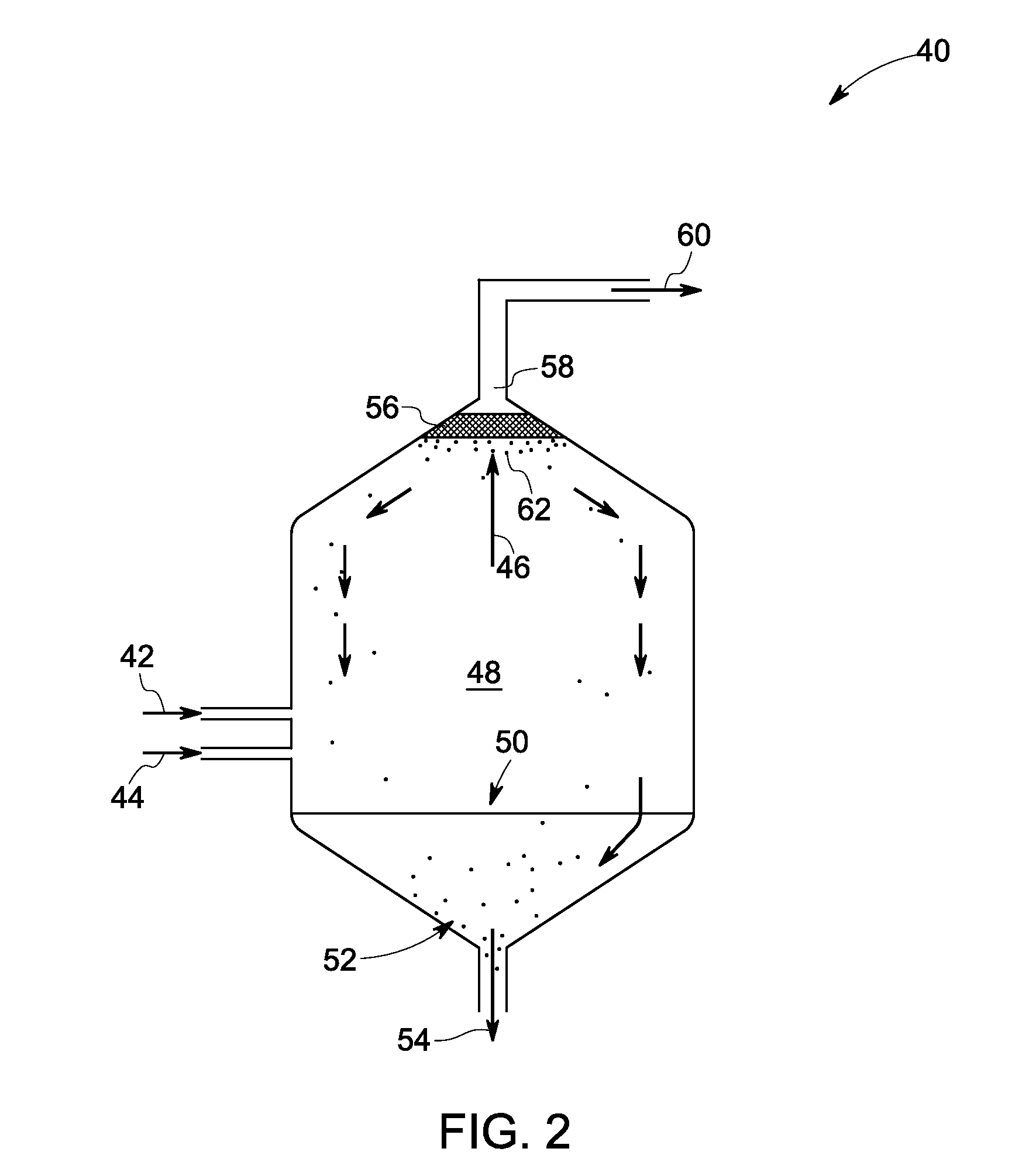

A method for the gasification of biomass, wherein the biomass feedstock is combined with a light hydrocarbon composition to form a slurry; followed by feeding the slurry to a gasifier to produce a fuel gas. In another embodiment, a method for the gasification of biomass is described. The method includes the steps of combining a biomass feedstock with water to form a slurry; feeding the slurry to a gasifier to produce a fuel gas; and injecting a light hydrocarbon into the gasifier, to generate gasification temperatures greater than about 900° C., by partial or complete combustion of the light hydrocarbon. In some other embodiments, the biomass gasifier product gas is coupled to a reformer, wherein a light hydrocarbon is injected to generate high temperatures.

Owner:GENERAL ELECTRIC CO

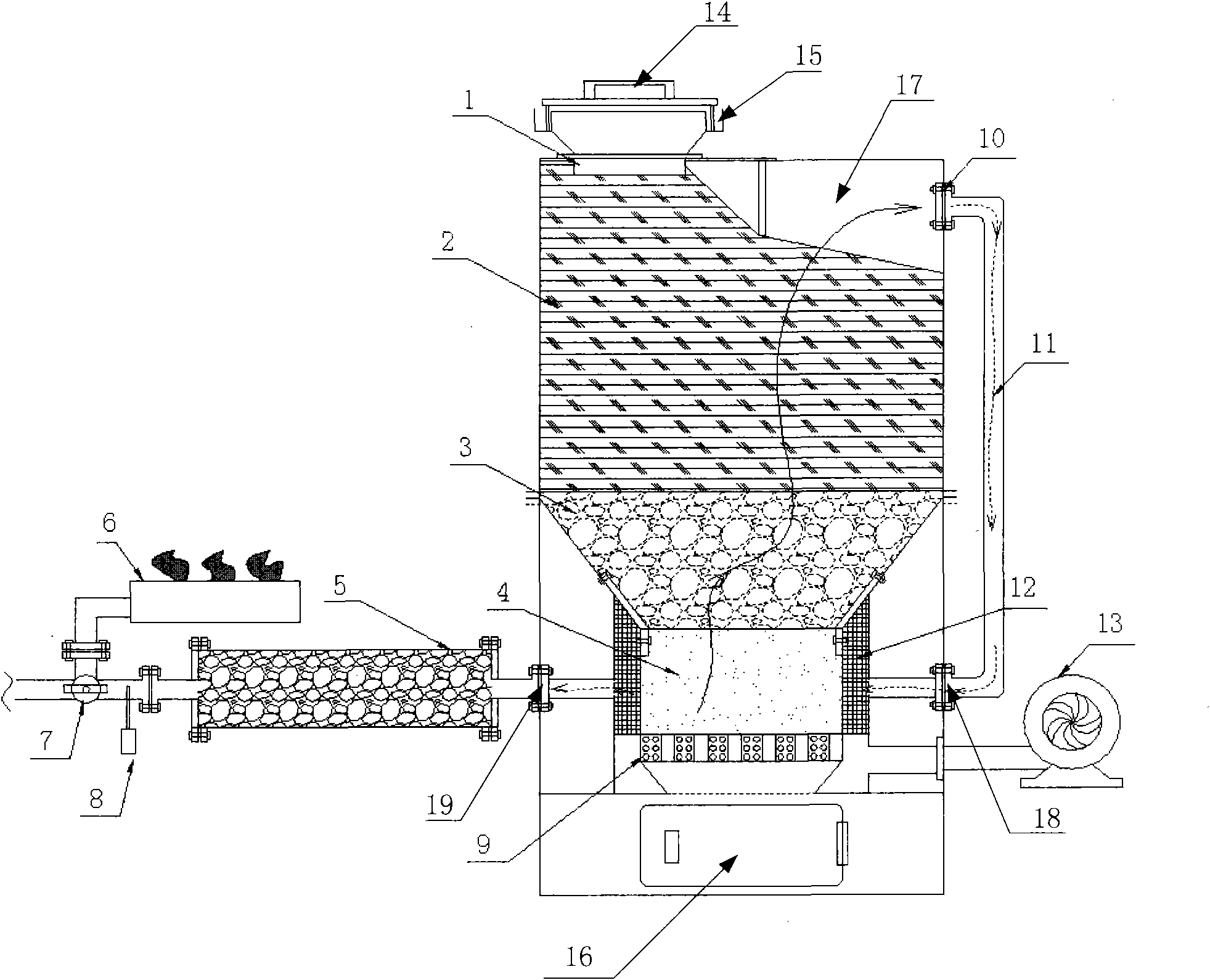

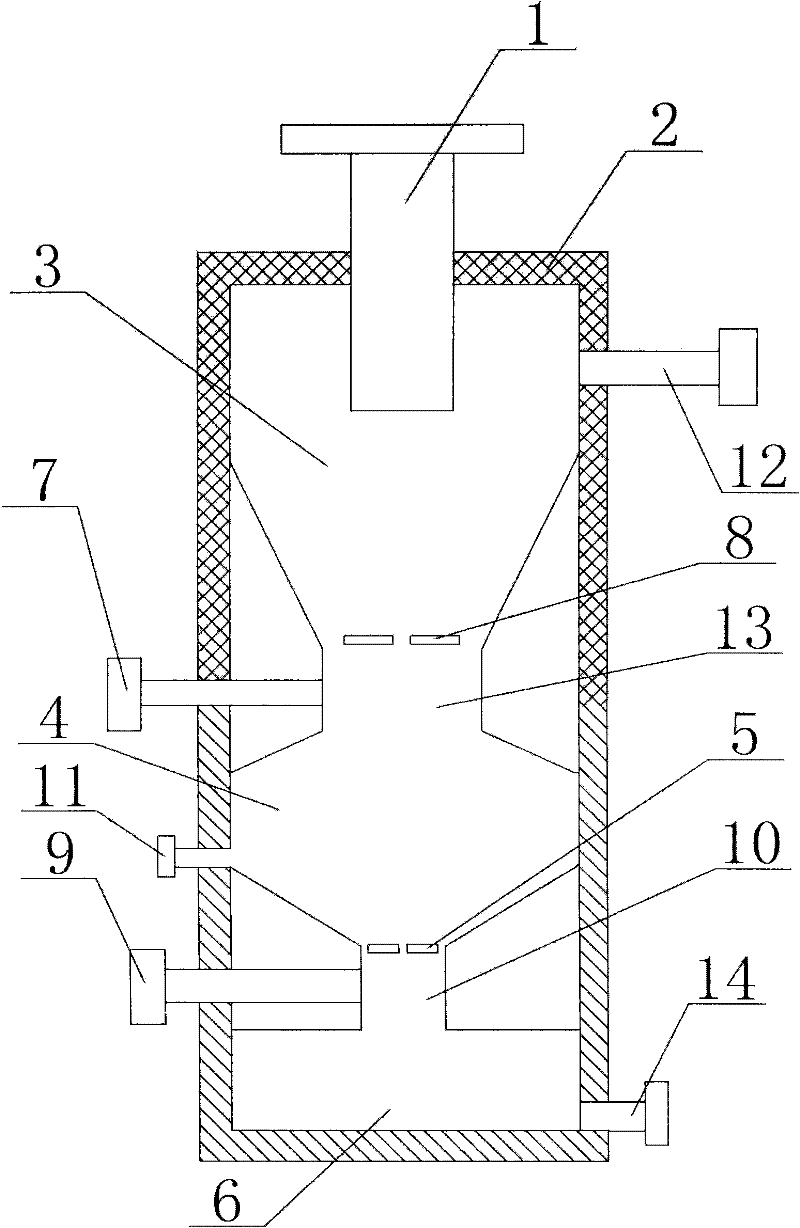

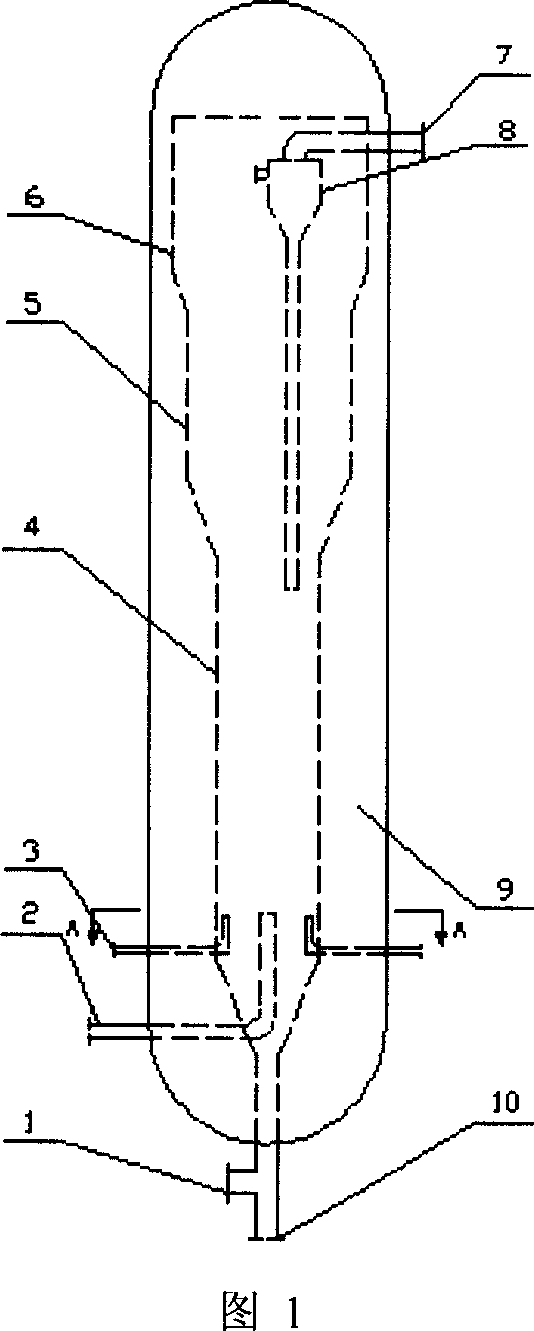

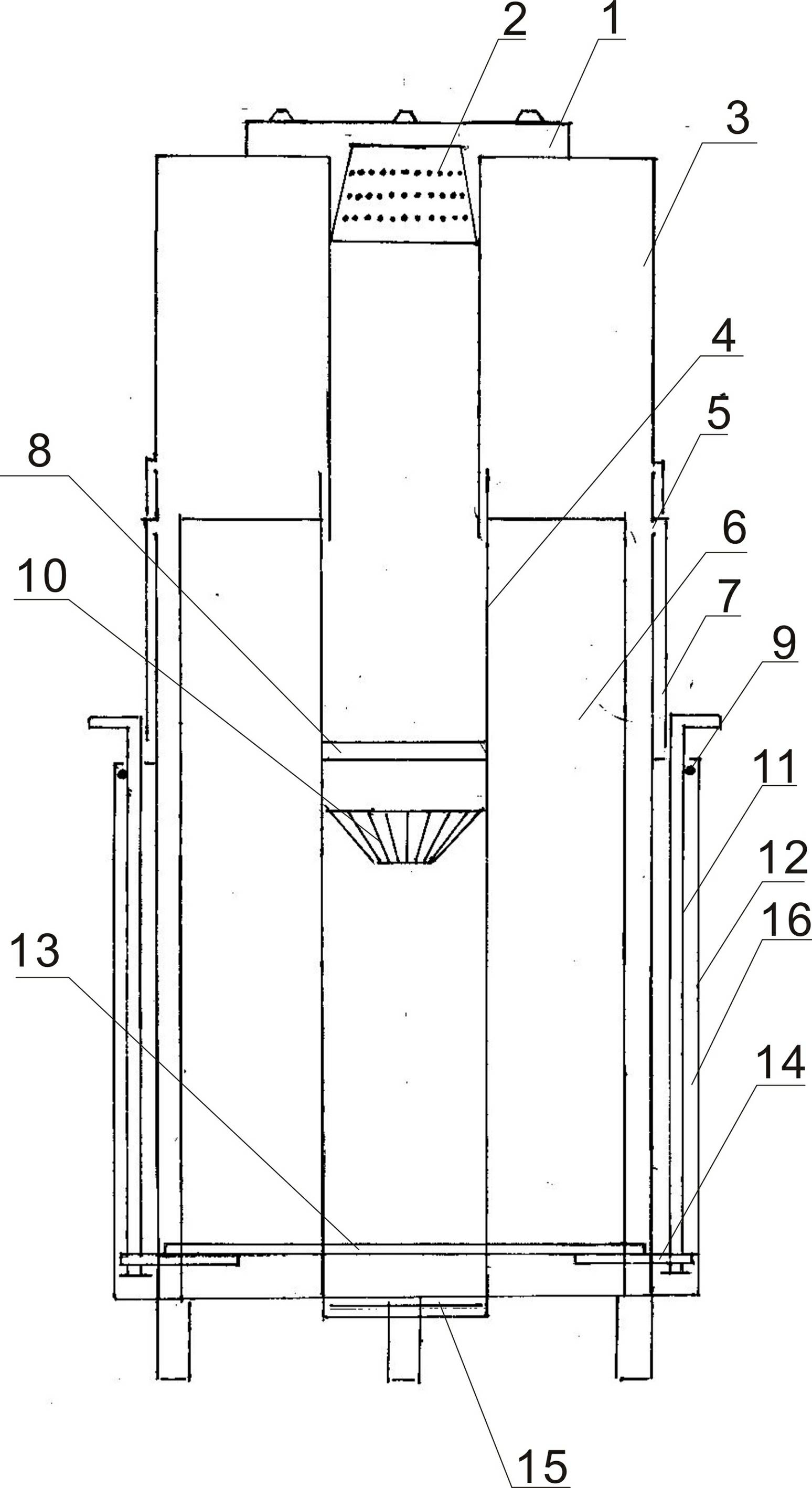

Biomass gasification method and biomass gasification furnace

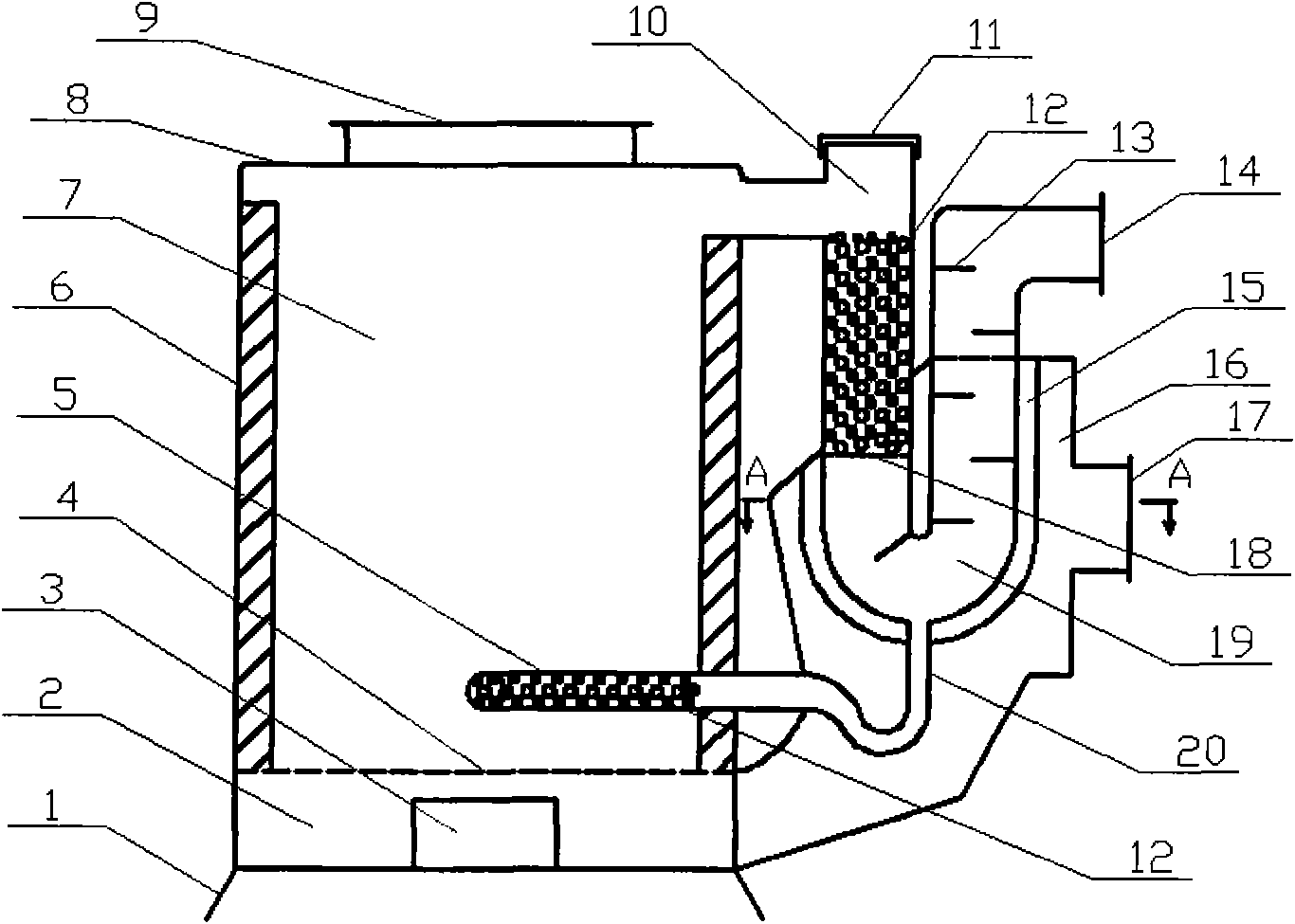

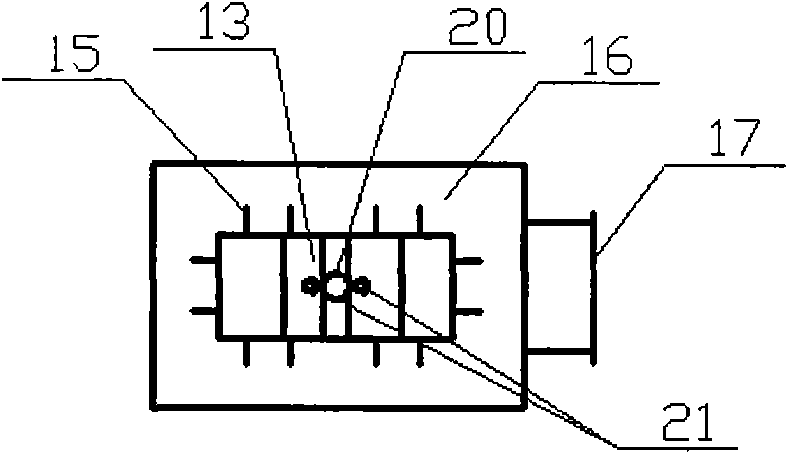

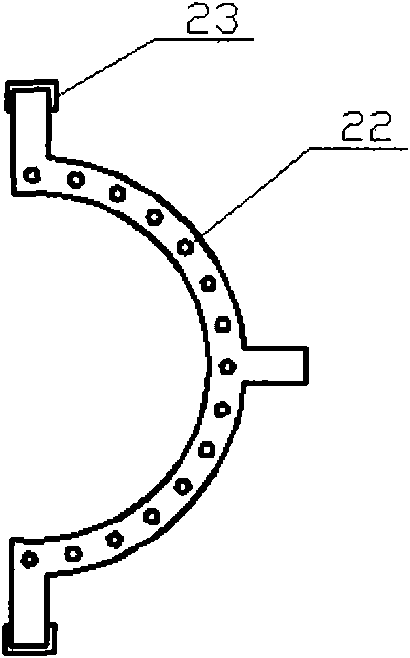

InactiveCN101781579AReduce the temperatureQuality improvementFixed-bed gasificationCombustion chamberTar

The invention provides a biomass gasification furnace which comprises a furnace body and a furnace cover. The furnace body consists of a feed port, a drying chamber, an oxidizing chamber, a combustion chamber, a combustion-supporting gas inlet, a secondary cracking chamber and an ash outlet. The drying chamber is communicated with the feed port and is arranged below the feed port, and a first gas outlet is arranged at the upper part of the drying chamber. The oxidizing chamber is communicated with the drying chamber and is arranged at the lower part of the drying chamber. The combustion chamber is communicated with the oxidizing chamber and is arranged at the lower part of the oxidizing chamber. The combustion-supporting gas inlet is arranged at the lower part of the furnace body and is communicated with the combustion chamber. The secondary cracking chamber is arranged at the outer side of the combustion chamber; the inner wall of the secondary cracking chamber serves as the outer wall of the combustion chamber; the secondary cracking chamber is provided with a gas inlet and a second gas outlet; and the gas inlet is connected with the first gas outlet through a circulating pipeline. The ash outlet is arranged at the bottom of the furnace body. Biomass has cracking reaction for two times in the biomass gasification furnace and the obtained combustible gas is low in tar content, so the quality of the combustible gas is improved.

Owner:王治刚

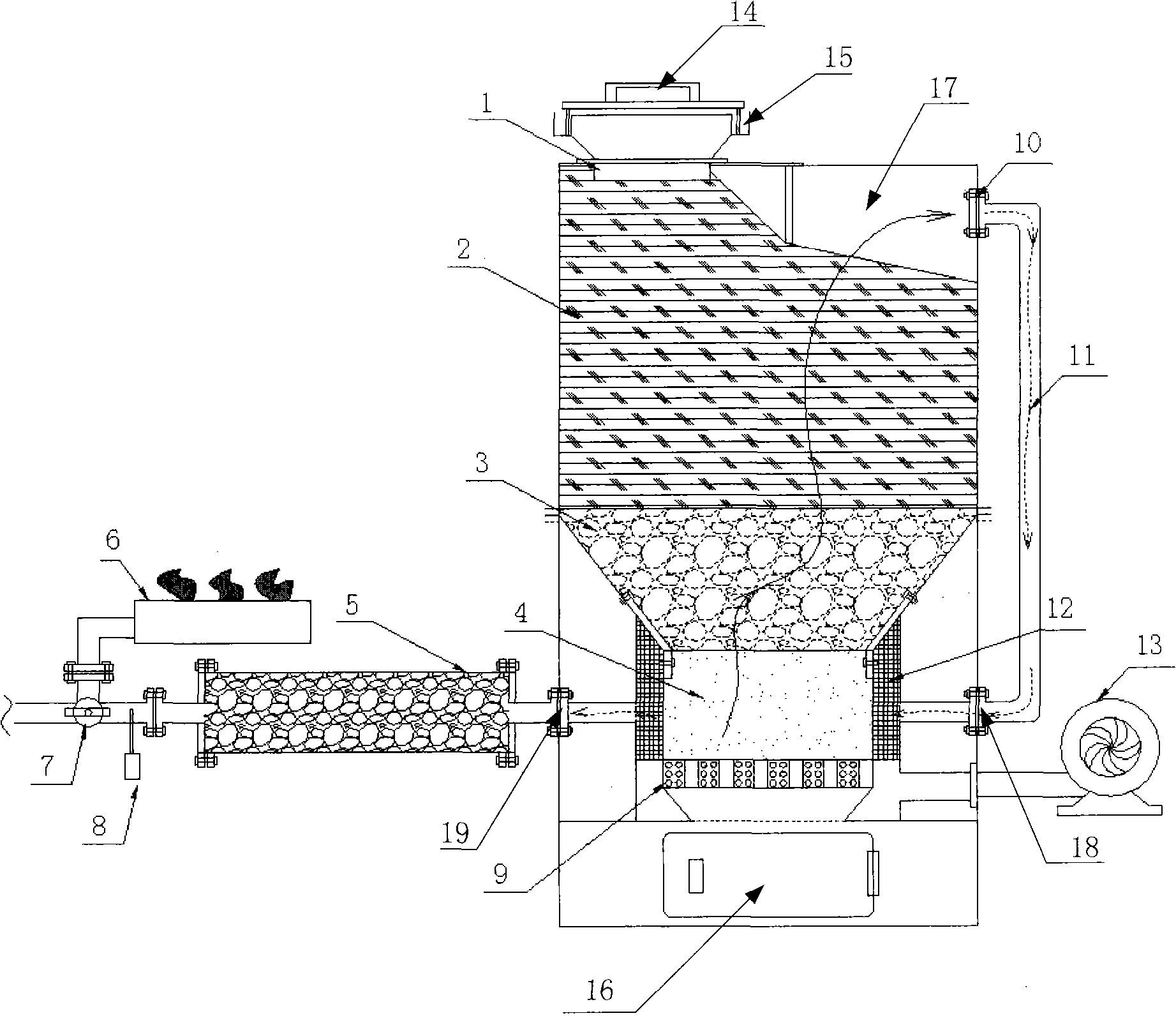

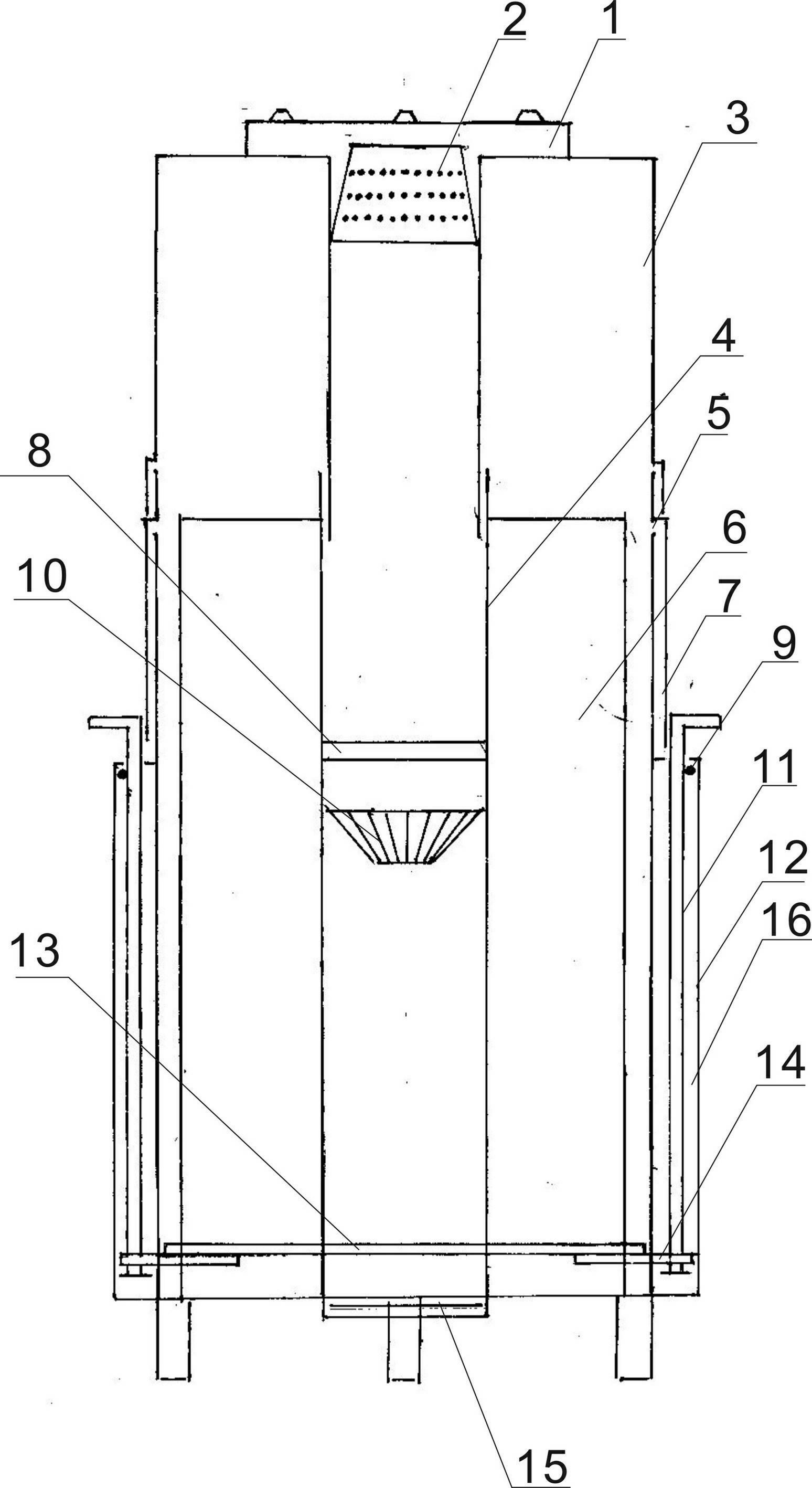

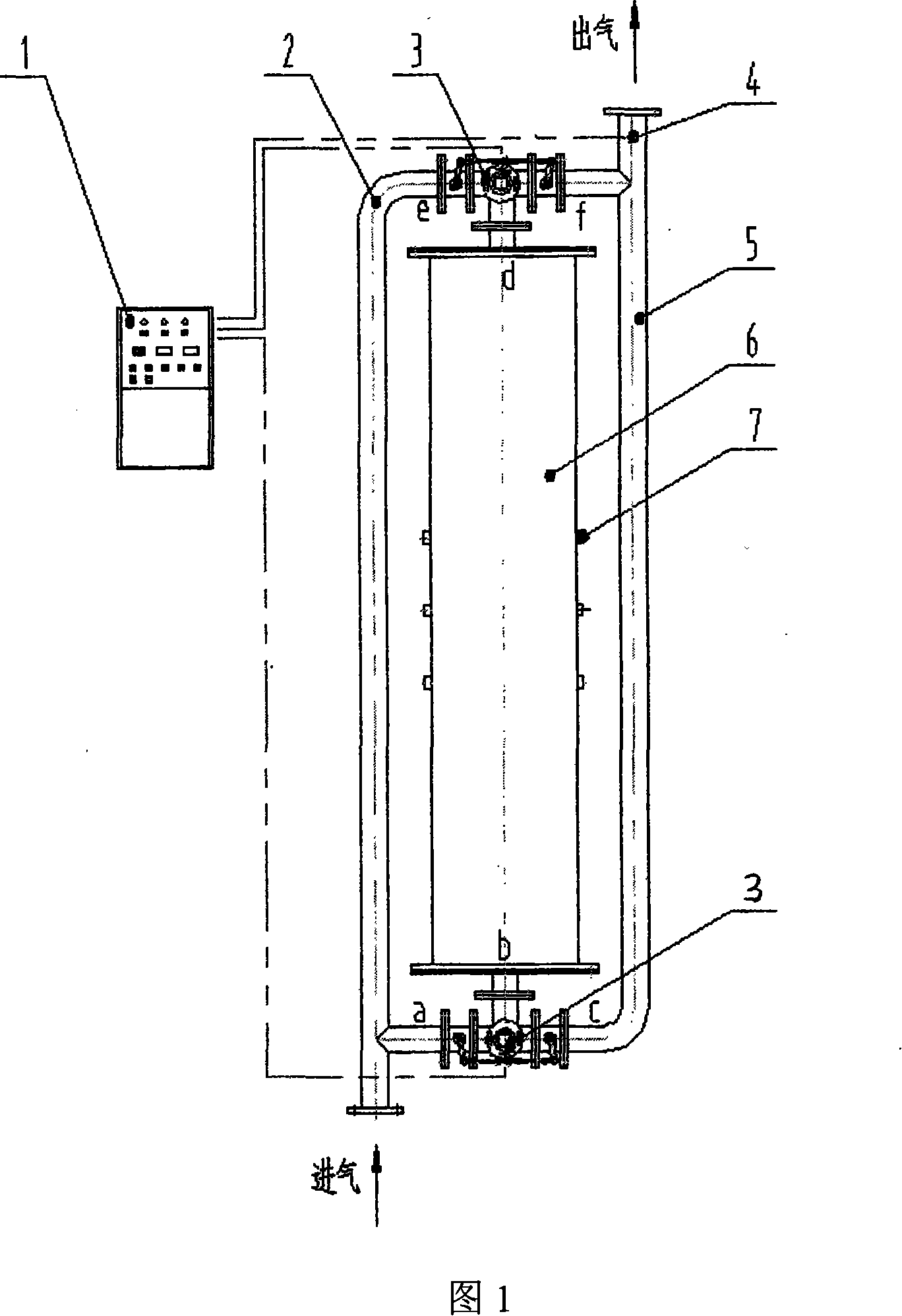

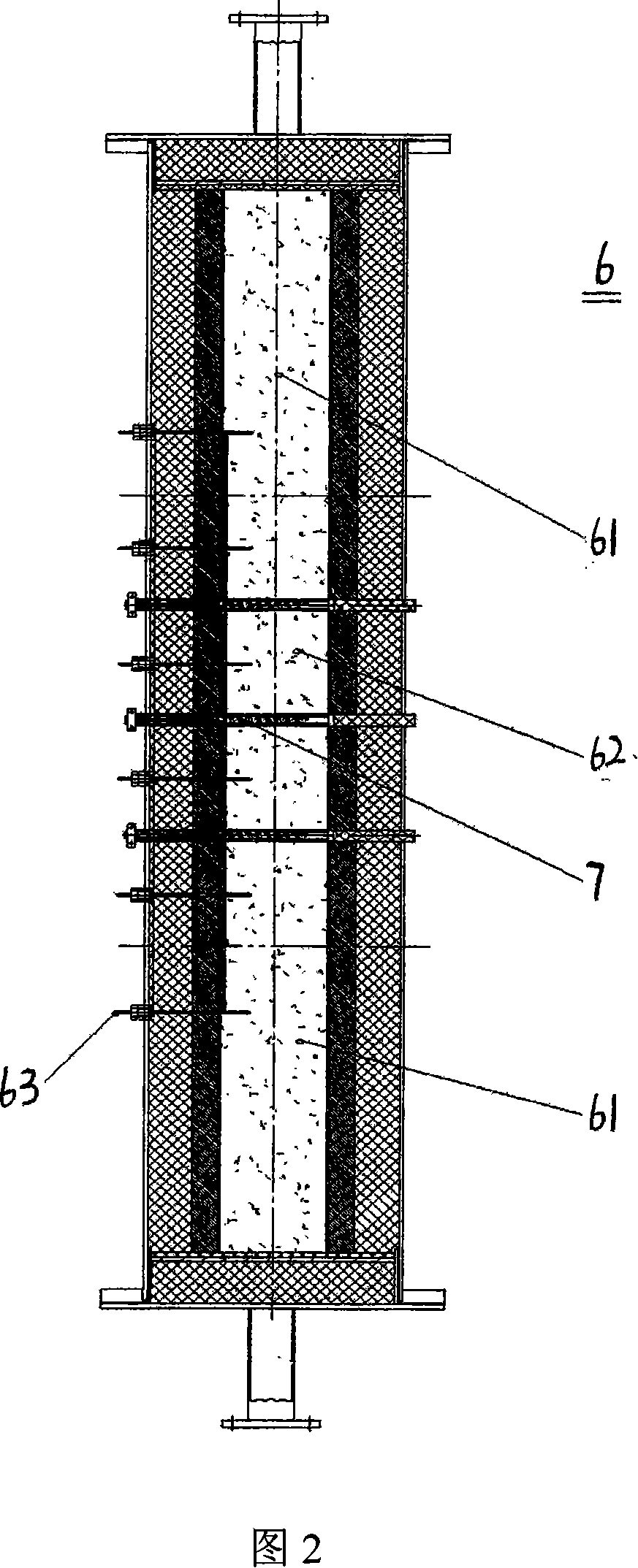

Three-section type biomass gasifying furnace

InactiveCN101144022AReduce tar contentSpecial form destructive distillationCombined combustion mitigationProduction rateCombustion

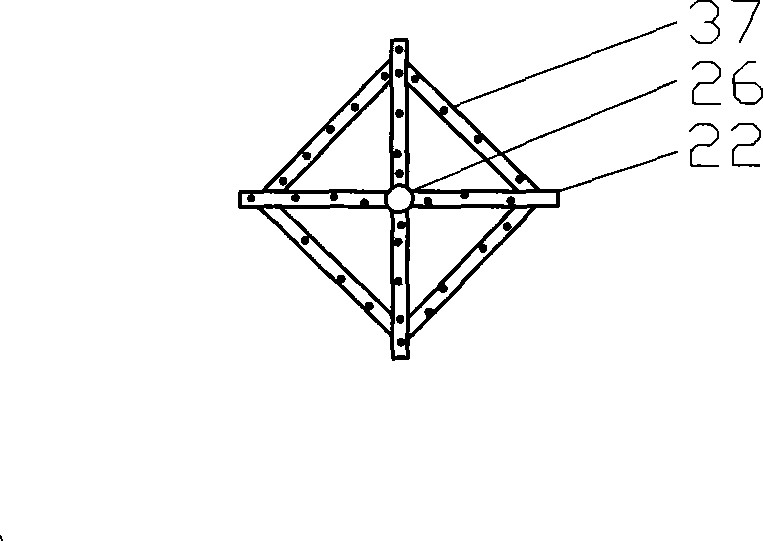

The invention relates to a three-portion biomass gasifier, in which the thermal cracking section is formed by jacketed type thermal cracking cylinder, the furnace body equipped with insulating layer is divided into a grate upper gasification section and a grate lower gasification section by a grate; the grate comprises a plurality of equilateral roof steels, an air inlet pipe is arranged along the circumference at the inlet of the furnace body with a laryngeal aperture deposited, a gasification gas outlet is located at the lower furnace wall of the grate and an air intake pipe is uniformly arranged at the bottom of the furnace body. The biomass is thermal cracked into thermal cracking air and biomass coke, and the thermal cracking air is transmitted to laryngeal aperture area to burn and the tar oil in the thermal cracking air is cracked under high temperature; the resulting air reacts with the biomass coke, and the incompletely reacted biomass coke is bowled off by the grate to continue the gasification reaction at the bottom of the furnace. The invention combine thermal cracking characteristic of biomass, combustion characteristic of air with gasification characteristic of biomass coke, to keep the stable combustion of the biomass thermal cracking products passing through, so as to reach high temperature state to crack most of tar oil, therefore to improve the gas production rate of the gasifier and decrease the level of the gas producing tar oil.

Owner:SHANGHAI JIAO TONG UNIV

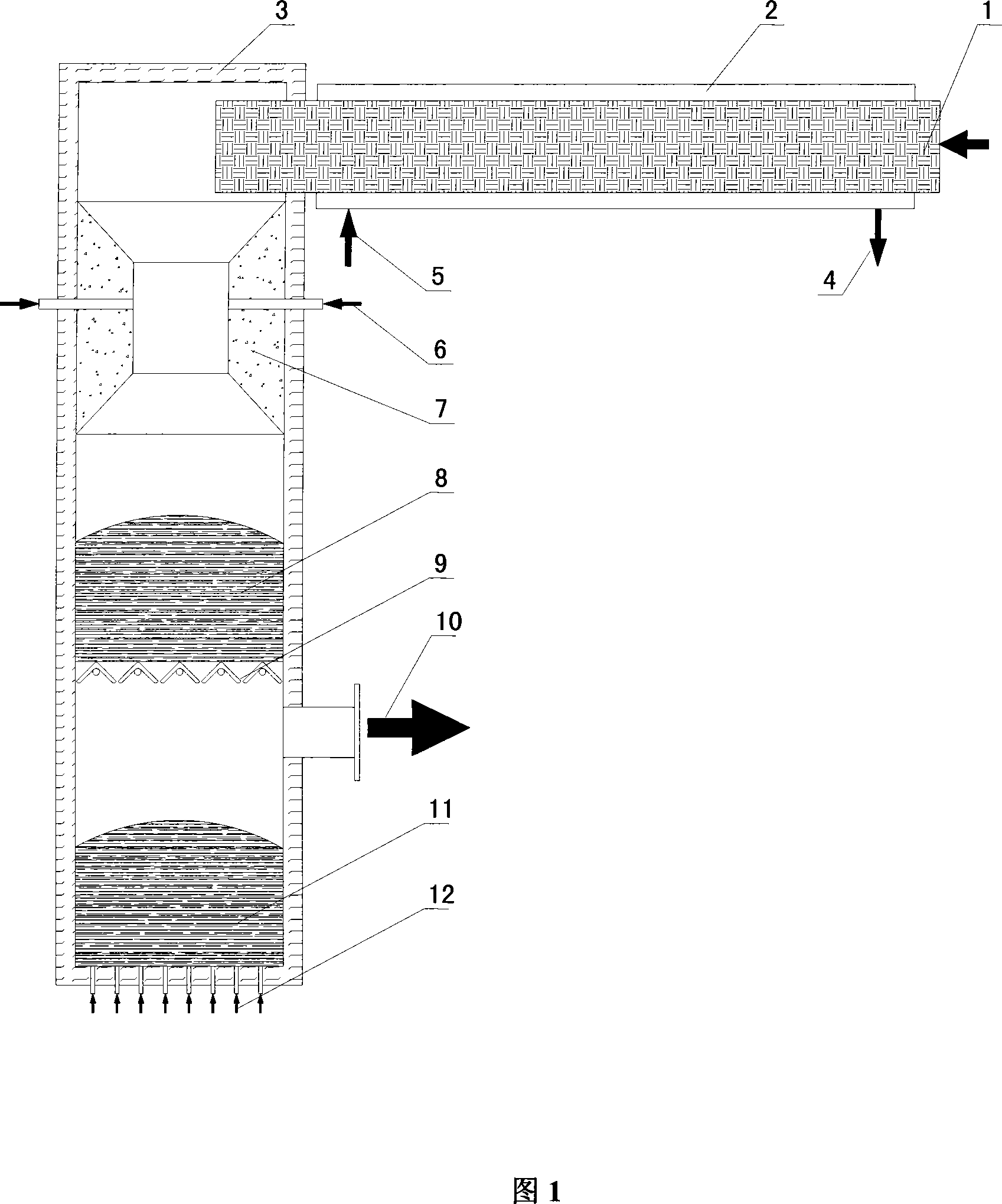

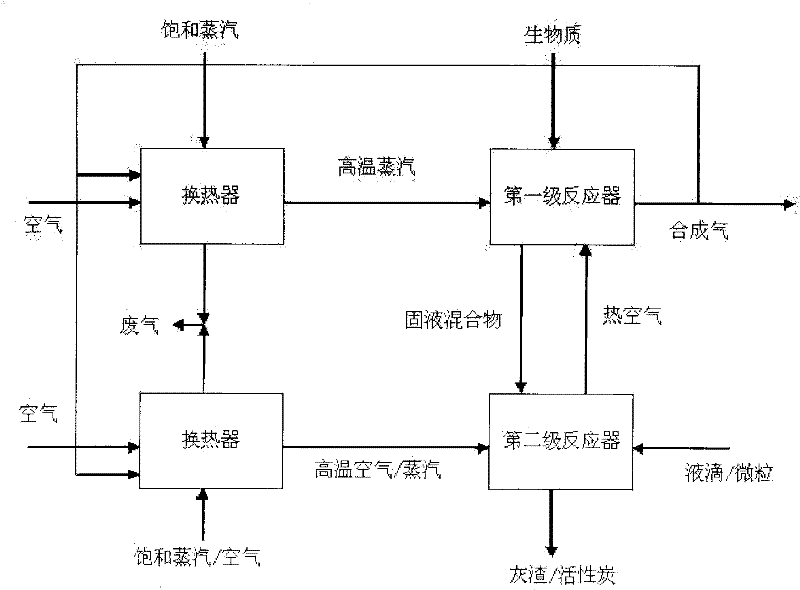

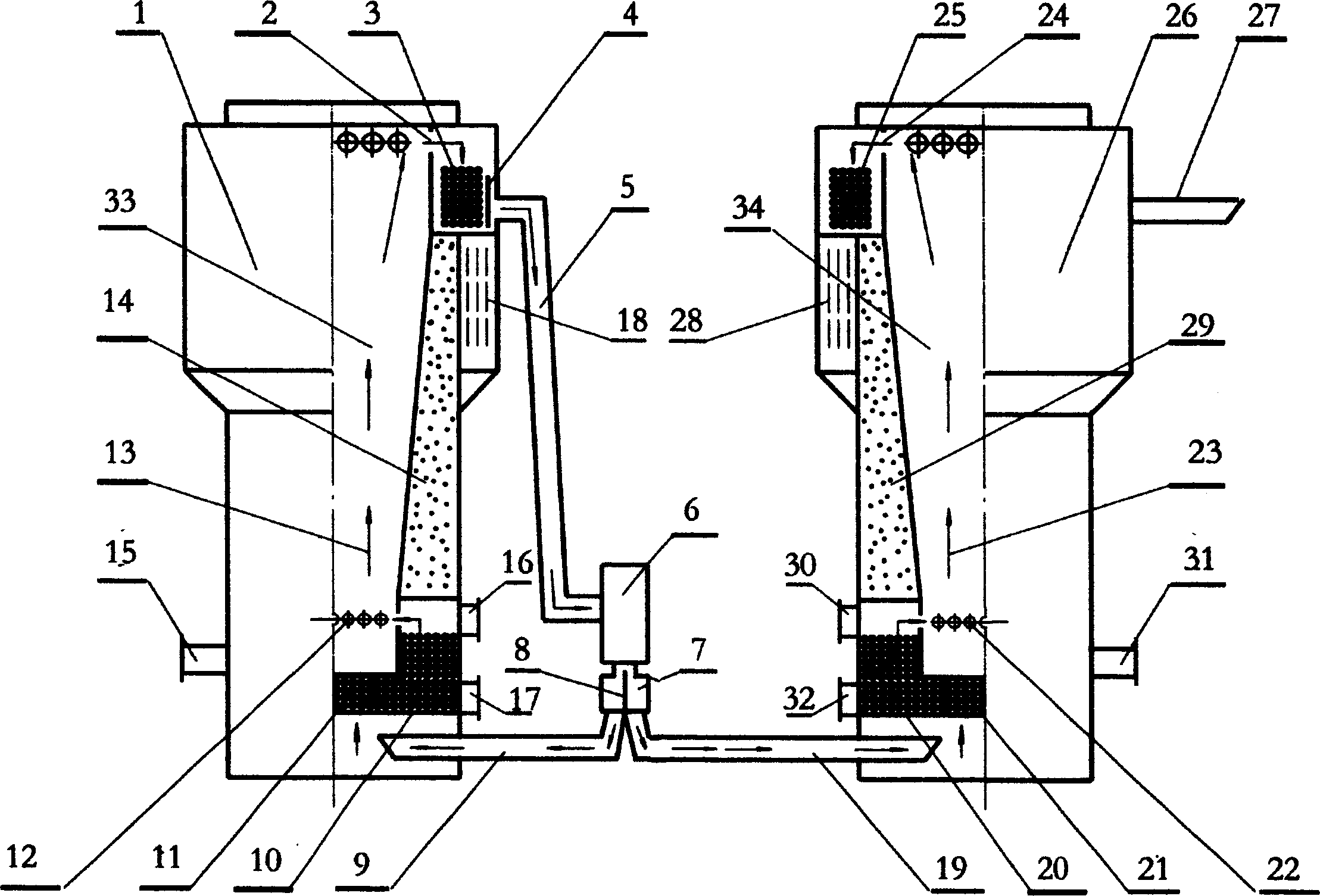

Two-stage high-temperature preheated steam biomass gasification furnace

The invention discloses a two-stage high-temperature preheated steam biomass gasification furnace. According to the invention, steam with a high temperature is used as a gasification agent. Fuel gas with high quality and high heat value is obtained through the gasification of the biomass. Meanwhile, active carbon, which is a byproduct, is produced. The gasification furnace is composed by a first reactor and a second reactor. The first reactor is a fixed bed gasification section, where volatile matters in feedings are removed. During the process, only high-temperature preheated pure steam provided by a high-temperature air generator is used. The second reactor is a spouted bed gasification section, where a high-temperature preheated mixture of air and steam is used for a complete cracking reaction and a tar breaking reaction. The biomass gasification furnace provided by the present invention has advantages of high gasification efficiency, high gasification speed, complete reaction, high utilance of raw materials, and is energy saving and environment protecting. The fuel gas produced by the gasification furnace has advantages of good quality and high heat value.

Owner:万贤法

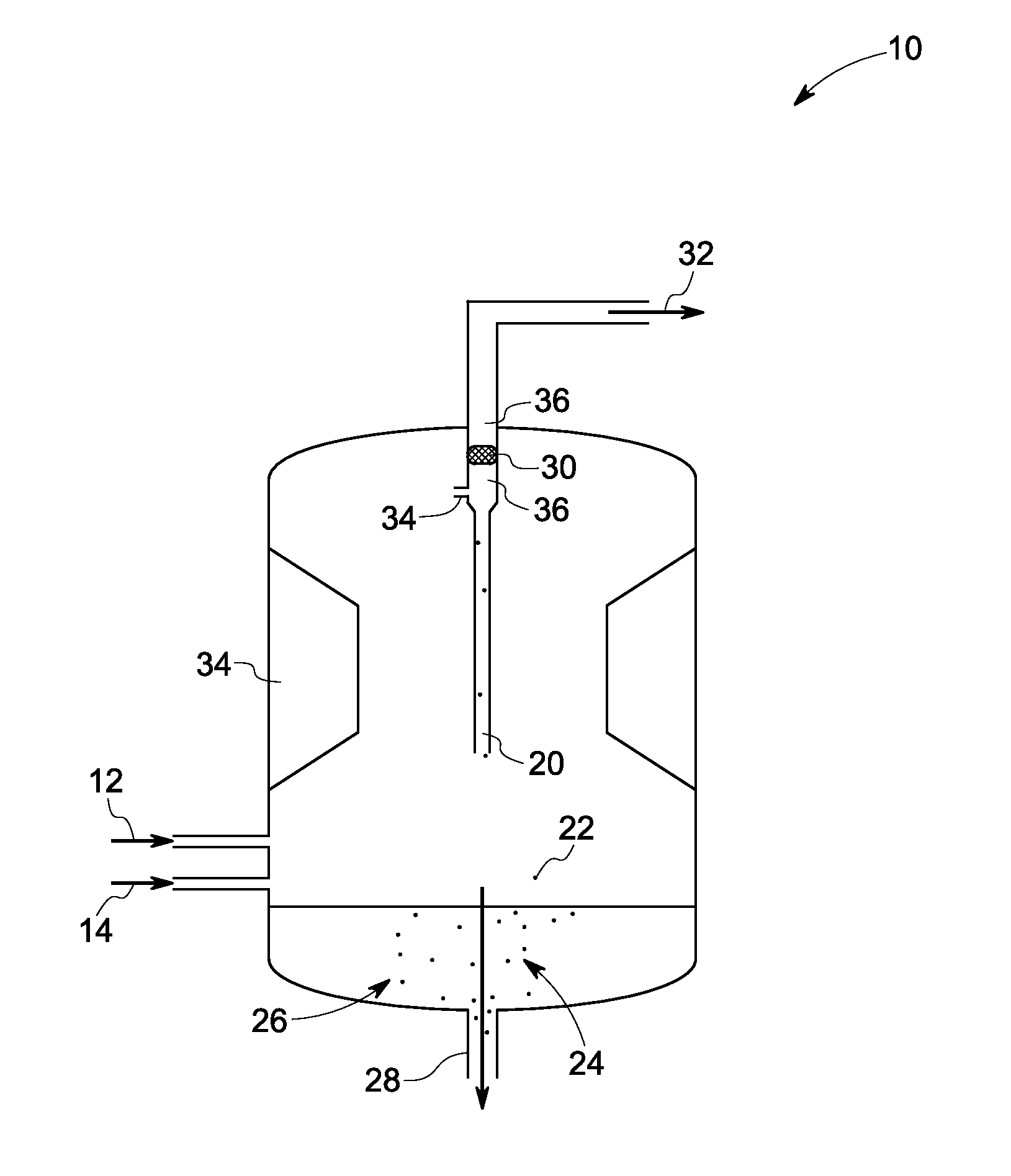

Biomass gasification reactor

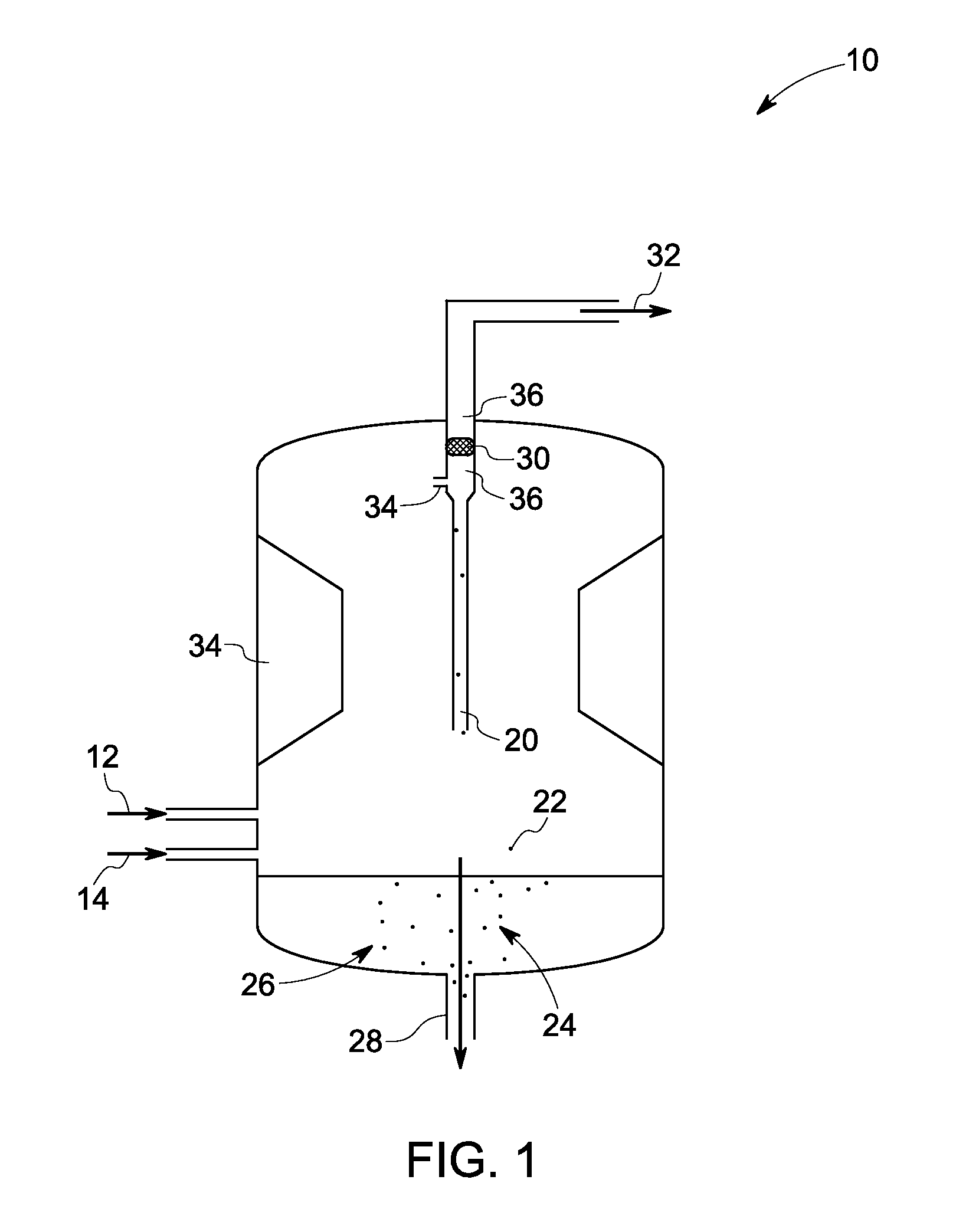

In one aspect, the present invention provides a biomass gasifier comprising a reactor. The reactor includes (i) an inlet for biomass, (ii) an inlet for an oxygen-containing gas, (iii) an inlet for steam, (iv) an outlet for reactor product gas, (v) an outlet for ash, (vi) a biogas exit conduit coupled to the outlet for the reactor product gas and (vii) an inlet for a secondary oxygen source. The biogas exit conduit includes a catalytic partial oxidation unit, the catalytic partial oxidation unit is substantially restricting the biogas exit conduit. A system and method for biomass gasification is also provided.

Owner:GENERAL ELECTRIC CO

Integrated composite gasification furnace

ActiveCN101825293ASolve the existing technical deficienciesSolve usabilityDomestic stoves or rangesLighting and heating apparatusTarBiomass gasifier

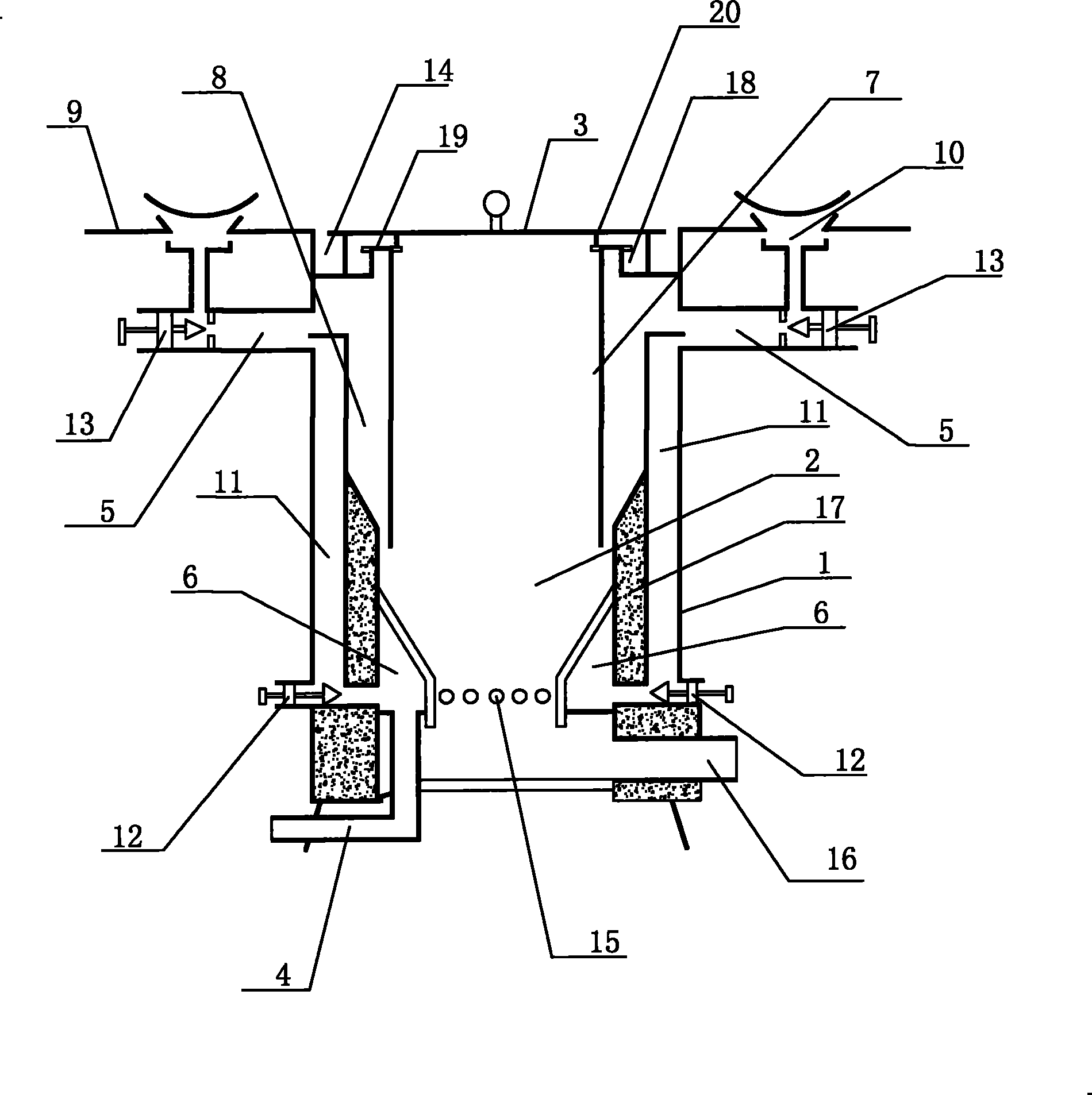

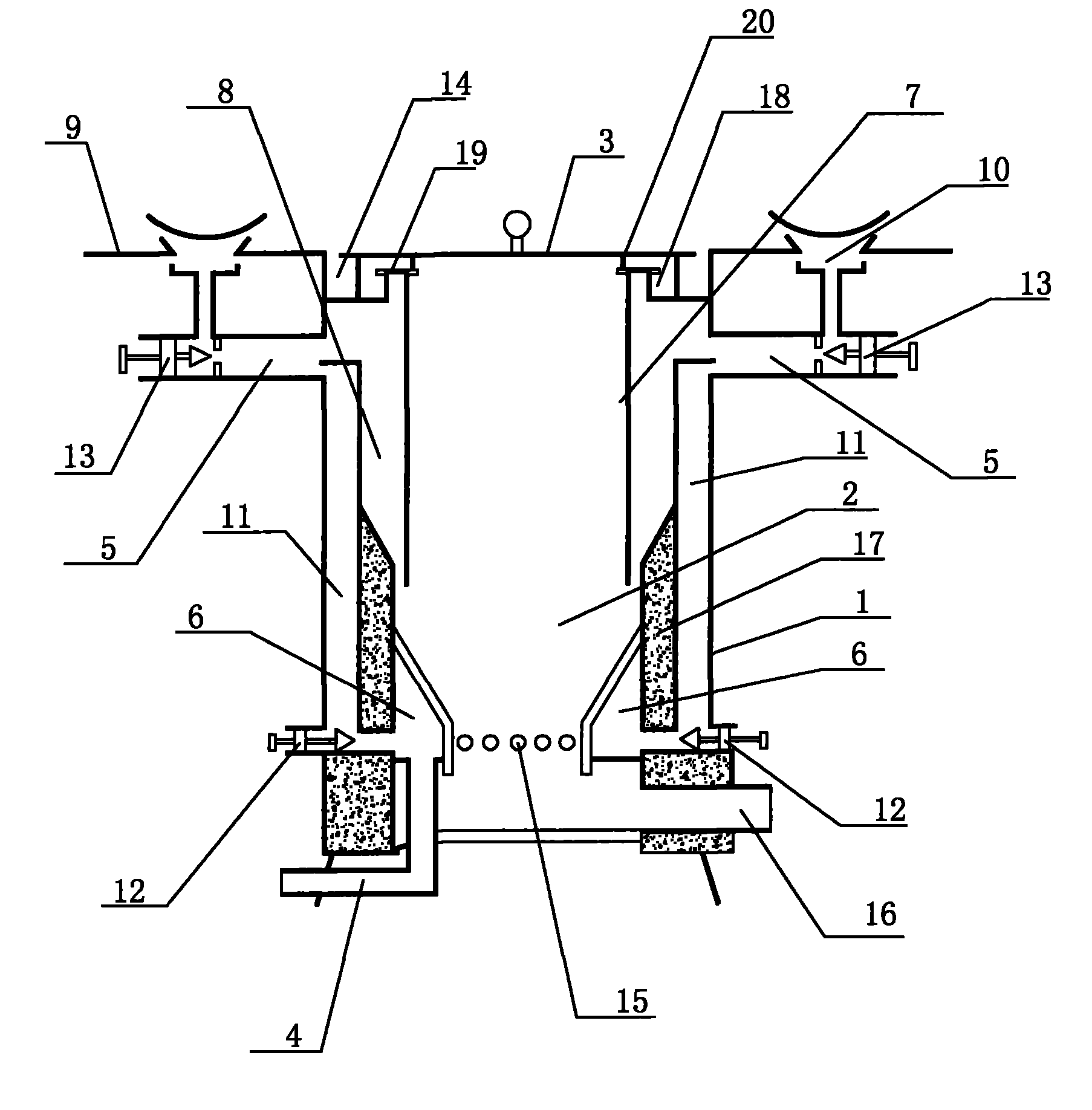

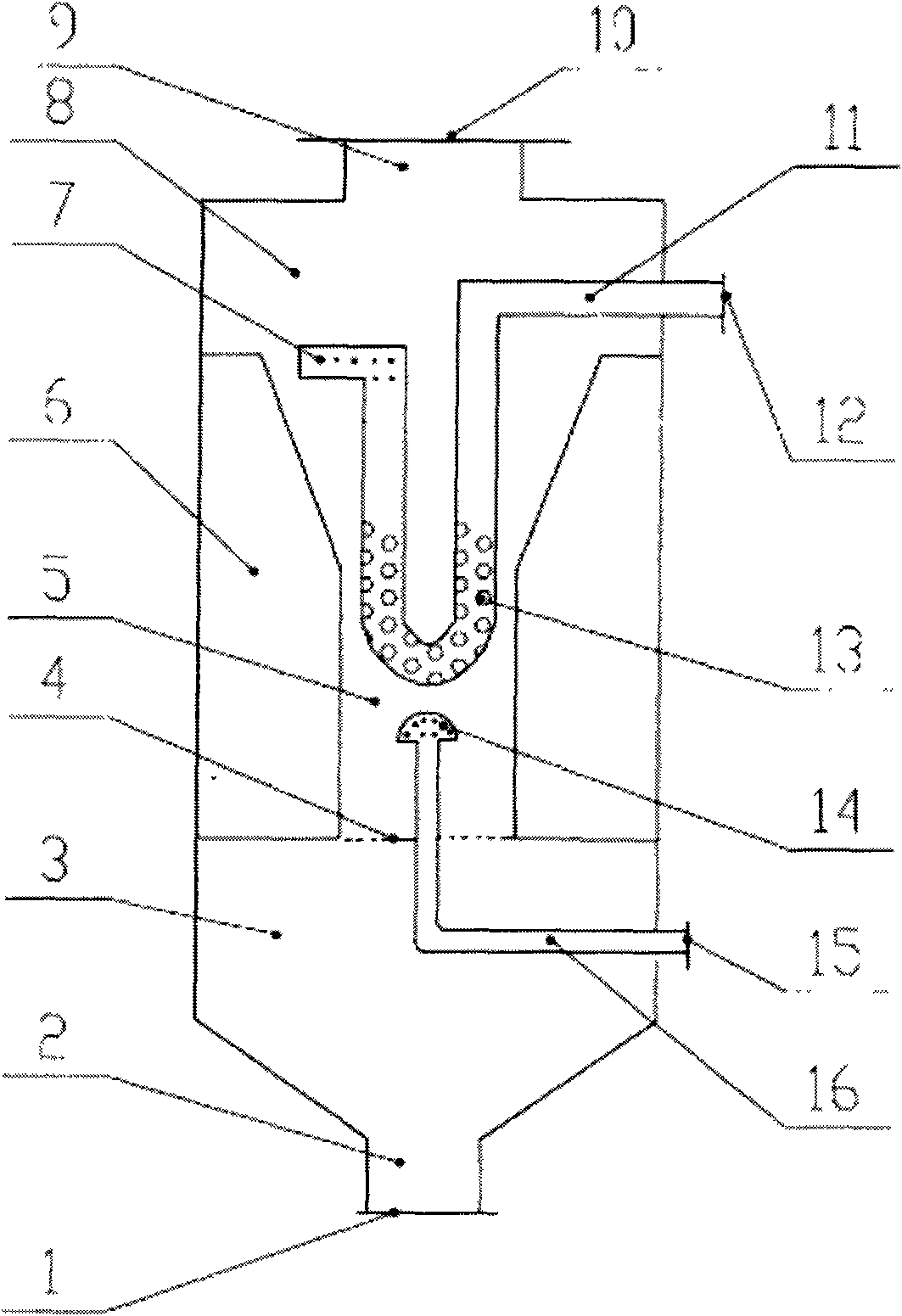

The invention discloses an integrated composite gasification furnace, which belongs to a biomass gasification furnace. The integrated composite gasification furnace comprises a furnace body (1), a hearth (2), a sealing cover (3), an air inlet pipe (4) and an air outlet pipe (5); the lower periphery of the hearth (2) is provided with an oxygen supply loop (6); the air inlet pipe (4) is communicated with the oxygen supply loop (6); the upper part of the hearth (2) is provided with a storage barrel (7); an air outlet chamber (8) is arranged between the storage barrel (7) and the inner wall of the hearth (2); the air outlet chamber (8) is communicated with the air outlet pipe (5); the top of the furnace body (1) is provided with a cooking bench (9); a gas stove (10) is arranged on the cookingbench (9); the gas stove (10) is communicated with the air outlet pipe (5); and the air outlet pipe (5) is connected with an oxygen distribution pipe (11) communicated with the atmosphere. The integrated composite gasification furnace has the characteristics of quick gas production, little fuel consumption in unit time, no tar or smoke discharge, low cost, simple structure, convenient use and thelike.

Owner:ZHANGJIAJIE SANMU ENERGY DEV

Purifying system for biomass gasifying oven

InactiveCN1667086ASimple structureLow production costSpecial form destructive distillationWater bathsCombustor

This invention discloses a biomass gasification furnace purification system. the main points of its technical proposal is that the system is consisted by catalysis ware, catalyst, labyrinth type gasometer, adsorption filter, adsorption filtering agent, waste tar and waste water collecting pit. Fuel gas current of biomass gasification furnace is transferred to labyrinth type gasometer through catalyst in the catalyst ware, then it istrasferred to adsorption filtering agent in the adsorption filter, the fuel gas current after three times purification is transferred to burner, and the whole purification course is finished. This invention is used to biomass gasification furnace purification system, its structure is simple, cost is low, and operation is simple. Water bath is not used in the system, the waste tar and water is few, and can be value things after proposed. The tar cracking ratio and gas current heating value is high, and the rate of gasification of the furnace can be improved. There is no environmental pollution.

Owner:许庆华

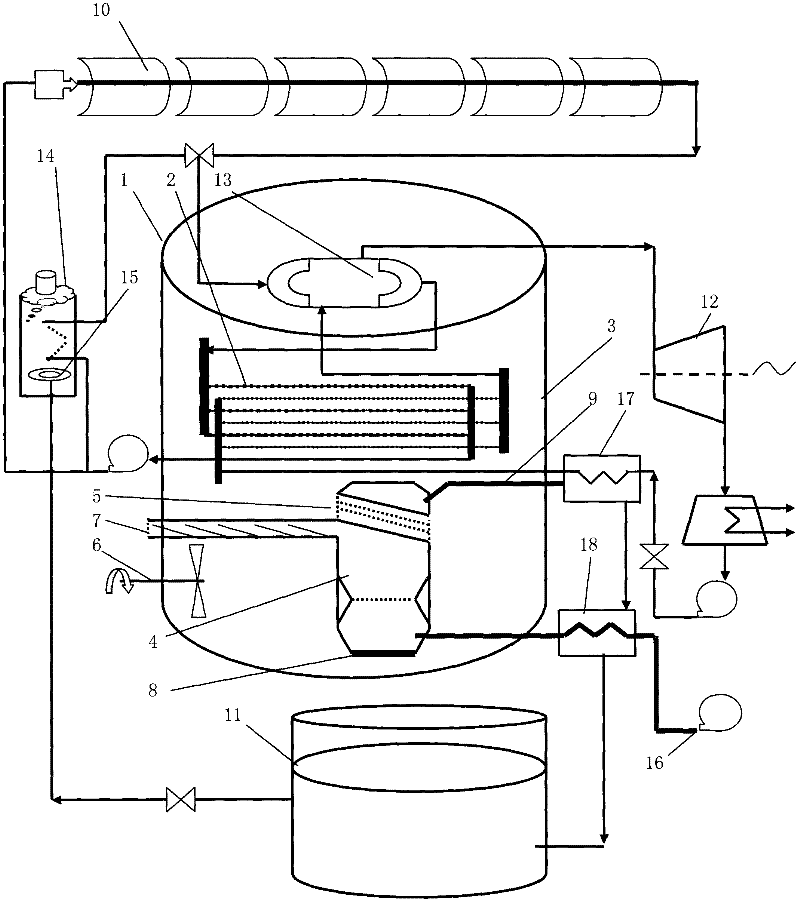

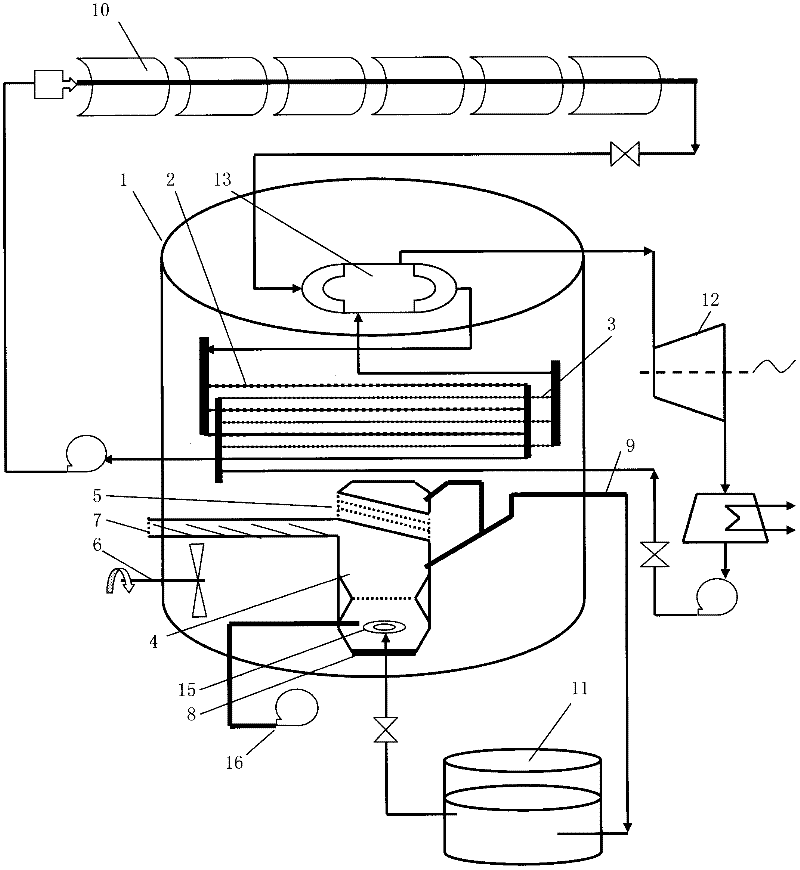

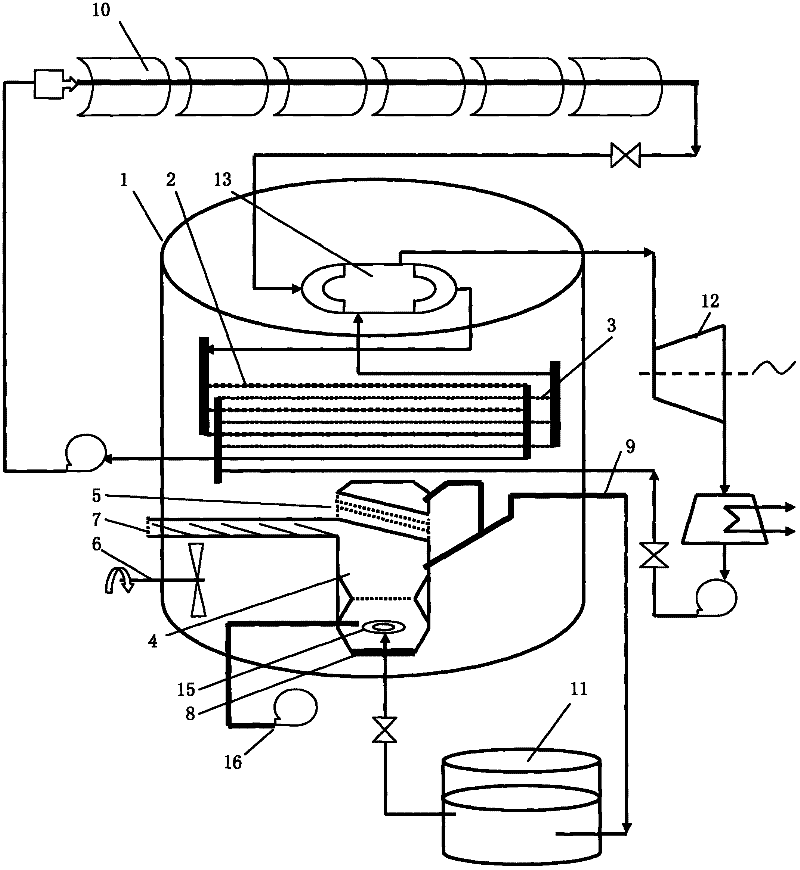

Heat generation device with complementary energy storage of solar energy and biomass gasification

InactiveCN102400871AImprove economyImprove practicalityFrom solar energyEnergy inputThermal energySolar light

The invention discloses a heat generation device with complementary energy storage of solar energy and biomass gasification. The thermal generation device consists of a solar light-gathering device, a heat storage and exchange tank, a fused-salt heat storage medium, a tube type or coil type heat exchanger and an evaporator, a temperature balance stirrer, a biomass gasifying furnace, a biomass material inlet, a waste residue discharging port, a biomass gas storage bag, a biomass gas boiler and a power generating unit. In order to overcome the technical defects that the solar heat generation and wind power are not controllable and continuous, the heat generation device realizes complementary and continuous heat generation with solar energy by utilizing the advantages of fused-salt heat storage and gas heat storage.

Owner:张建城

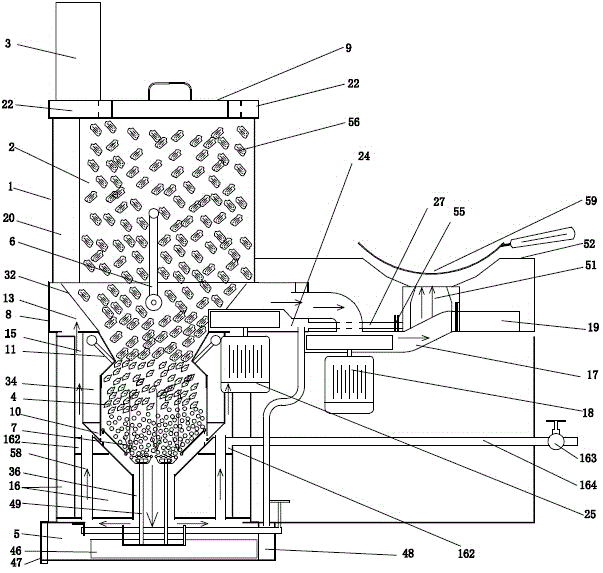

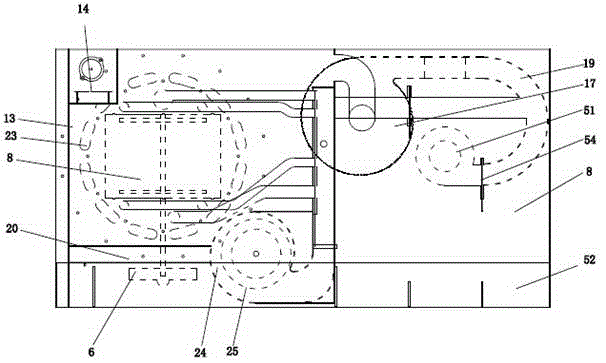

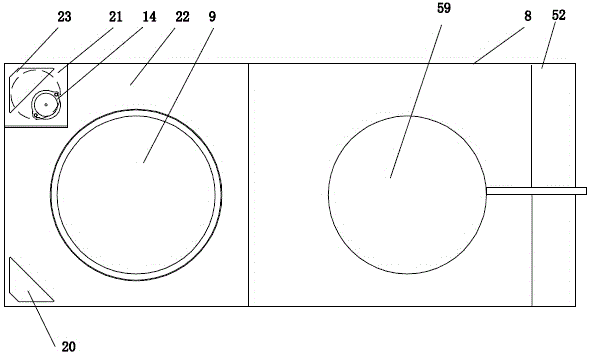

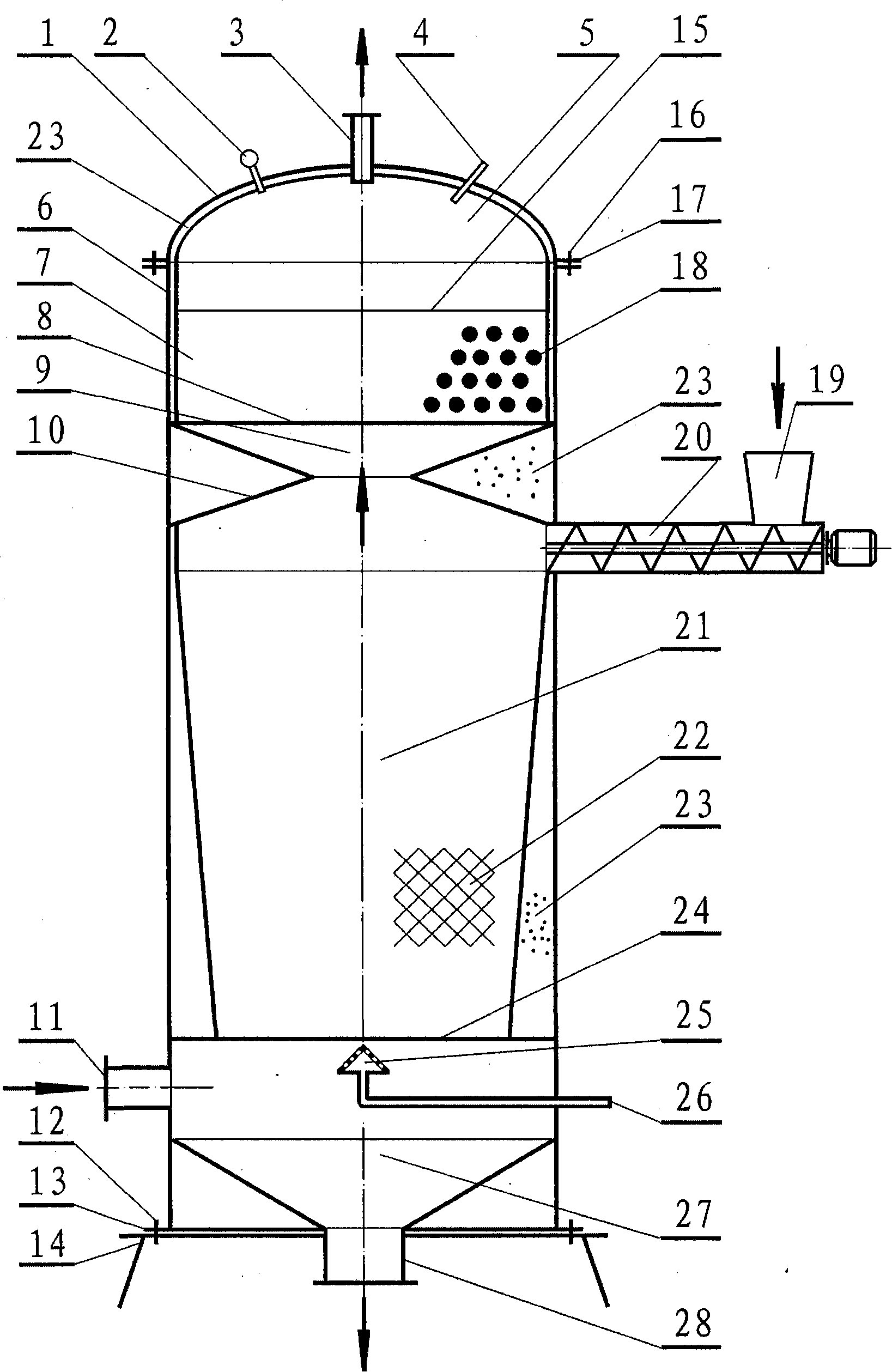

Biomass gasification furnace

InactiveCN101481630AIncrease contentAdjustable temperatureCombined combustion mitigationCombustible gas productionCombustionWater vapor

The invention relates to a biomass gasification furnace which comprises a furnace body, a feed inlet opened on the top of the furnace body, a filter embedded on the top of the furnace body, a fire observation hole and a lighting-up hole which are arranged on the side wall of the furnace body, a radiator connected with the filter, a purifier connected with the radiator, an exhaust pipe connected with the purifier, an ash hole communicated with the bottom of the furnace body, a mixer shaft arranged inside the furnace body, stirring teeth arranged on the mixer shaft, a mixer shaft motor arranged outside the furnace body, a feeding storage hopper that is connected at the front end of the feed inlet and can control the inlet and outlet materials, and a ash discharge hopper that is used for communicating the ash hole and the bottom of the furnace body and can control the inlet and outlet ash. The invention has the advantages that the biomass gasification furnace can continuously supply gas when the material is added and the ash is discharged, the gas dust in the furnace is not discharged outside, the position of a gasification layer in the furnace is unchangeable, water vapor can be used for combustion-supporting, etc.

Owner:蒋启富

Selective non-catalytic reduction method with added gasified biomass gas and used boiler

InactiveCN101433800AWidely distributedImprove the efficiency of denitrification reactionLighting and heating apparatusDispersed particle separationFlue gasProcess engineering

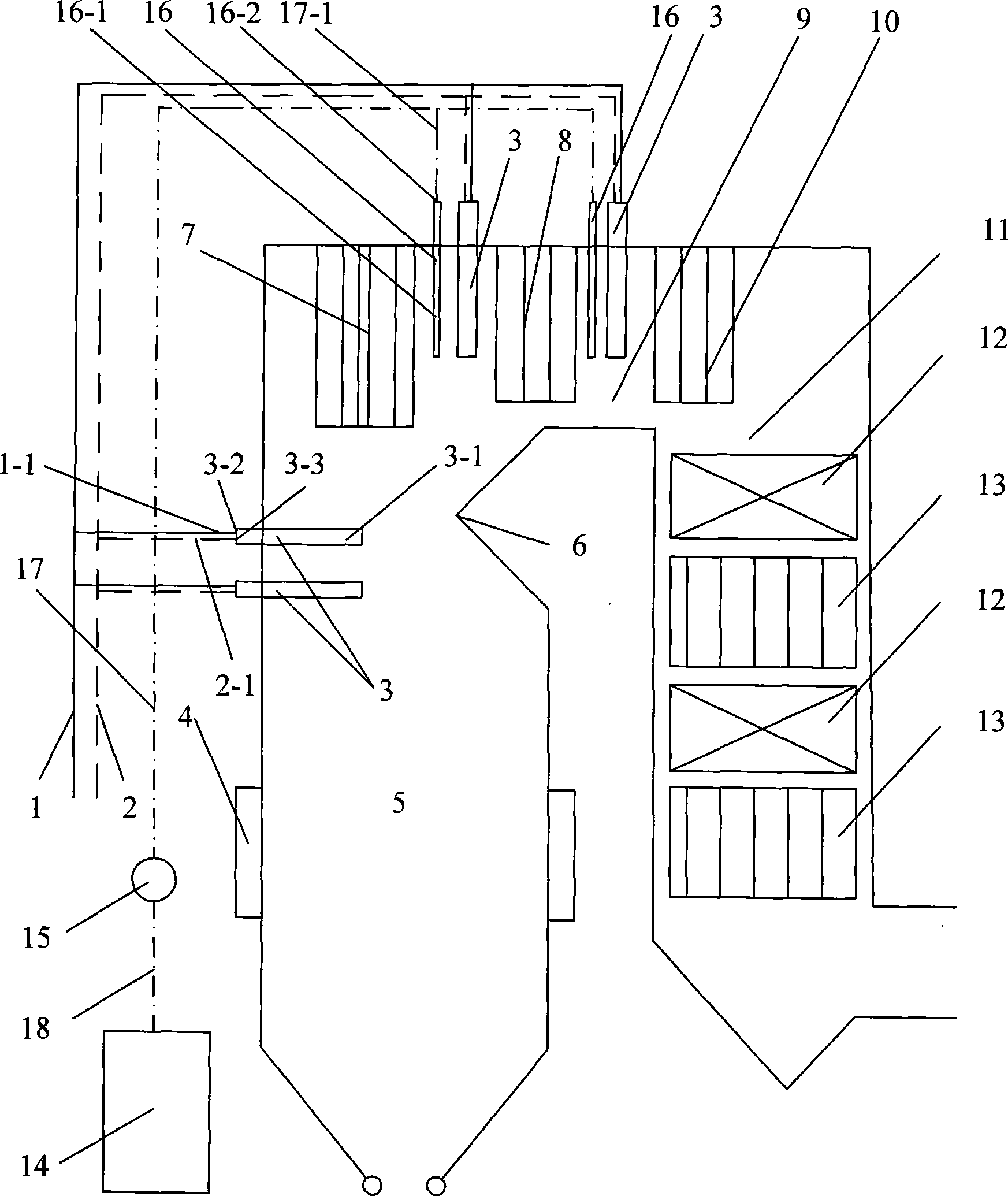

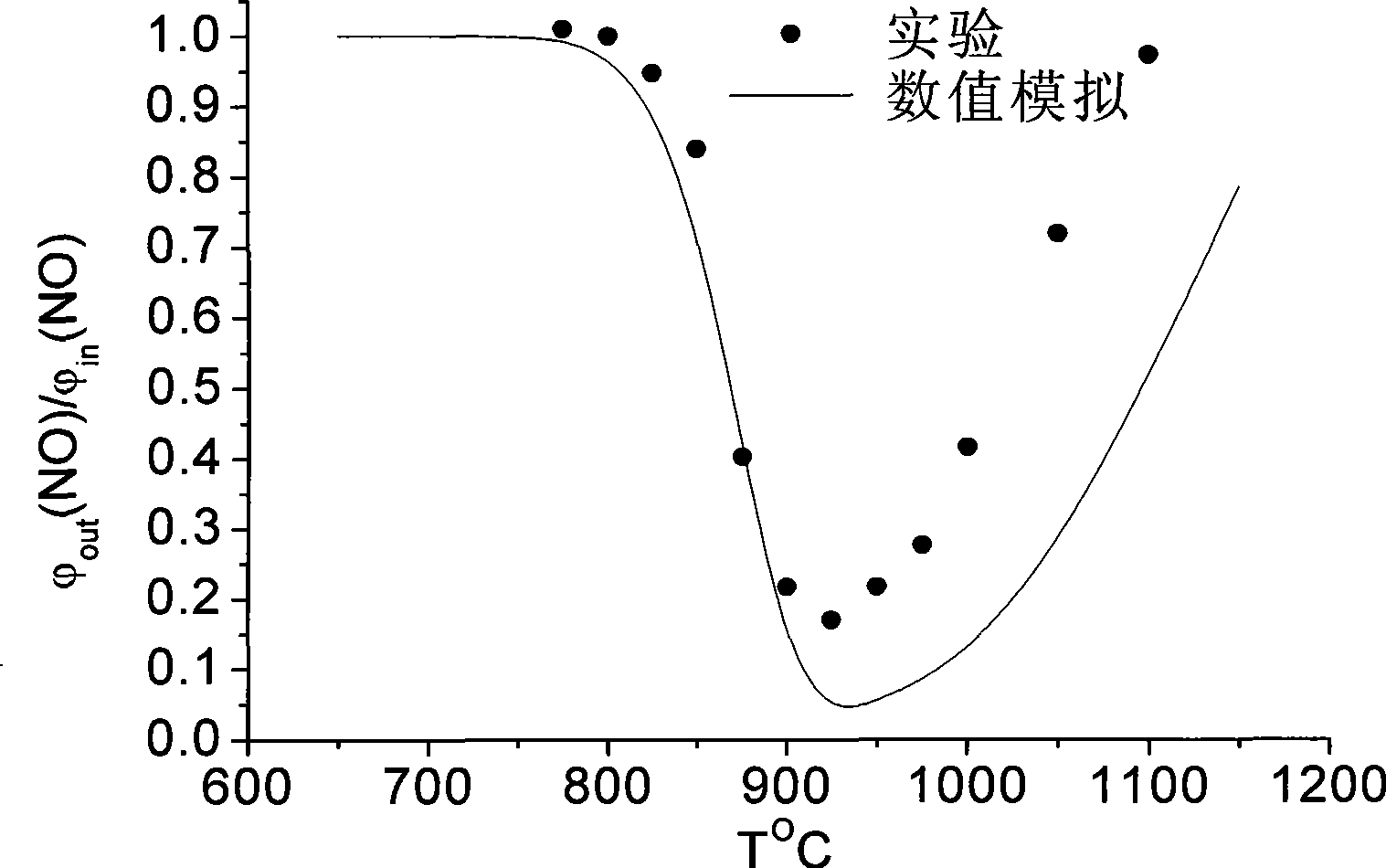

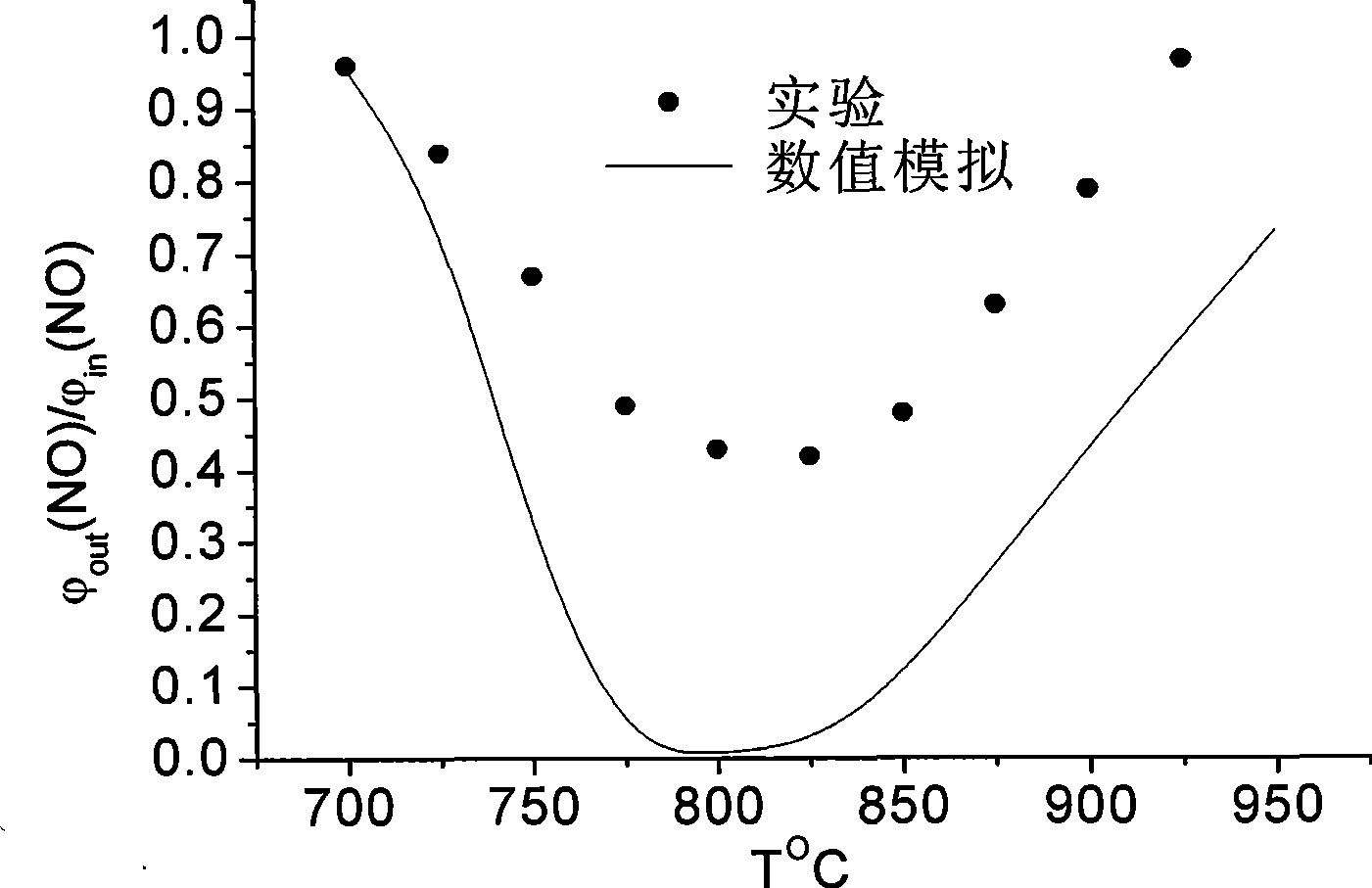

The invention relates to a selective non-catalytic reduction method with the addition of biomass gasified gas and a boiler used by the same, which relate to the selective non-catalytic reduction method and the boiler used by the same. The invention solves the problems that the prior selective non-catalytic reduction method has narrow temperature window, low denitration efficiency at a low temperature region and single effective component in synthesis gas of a reaction additive. A plurality of spraying ends of a plurality of gas additive spraying devices of the boiler pass through the lateral wall of a horizontal flue and are arranged in the horizontal flue. The selective non-catalytic reduction method pressurizes the biomass gasified gas generated by a biomass gasifier, sprays the pressurized gas into a furnace chamber and a horizontal flue in a region with a temperature of between 800 and 950 DGE C through a biomass gasified gas spaying device, wherein the mol ratio of the total spraying amount of the biomass gasified gas to NOx in the flue gas before the biomass gasified gas is sprayed is between 0.3 and 1.2. The selective non-catalytic reduction method makes use of biomass resources to improve the denitration efficiency and enlarges the temperature window. The boiler system of the invention is simple and has high reliability.

Owner:HARBIN INST OF TECH

Multi-jet composite fluidized bed coal and biomass gasifier

InactiveCN1974733ARealize gasificationGood fluidization effectCombined combustion mitigationGranular/pulverulent flues gasificationFluidized bedWater vapor

The multi-jet composite fluidized bed coal and biomass gasifier consists of a fluidized bed, a synthesized gas outlet, a water vapor inlet and jet pipes. The fluidized bed consists of three parts, including the lower conic bed body, the middle expanding section and the upper expanding section, and has one cyclonic separator inside the upper expanding section. The synthesized gas outlet is in the top of the cyclonic separator. The jet pipes in the lower bed body include radial auxiliary material feeding jet pipes in two layers and main material feeding jet pipes in the center of bed body. The bed body has cinder outlet in the conic bottom and water vapor inlet beside the cinder outlet and the fluidized bed has outside heat insulating layer. The present invention has the advantages of simple structure, low cost and easy operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

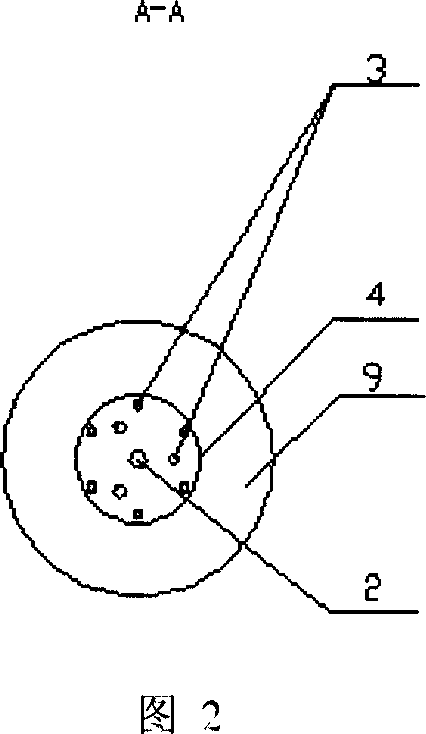

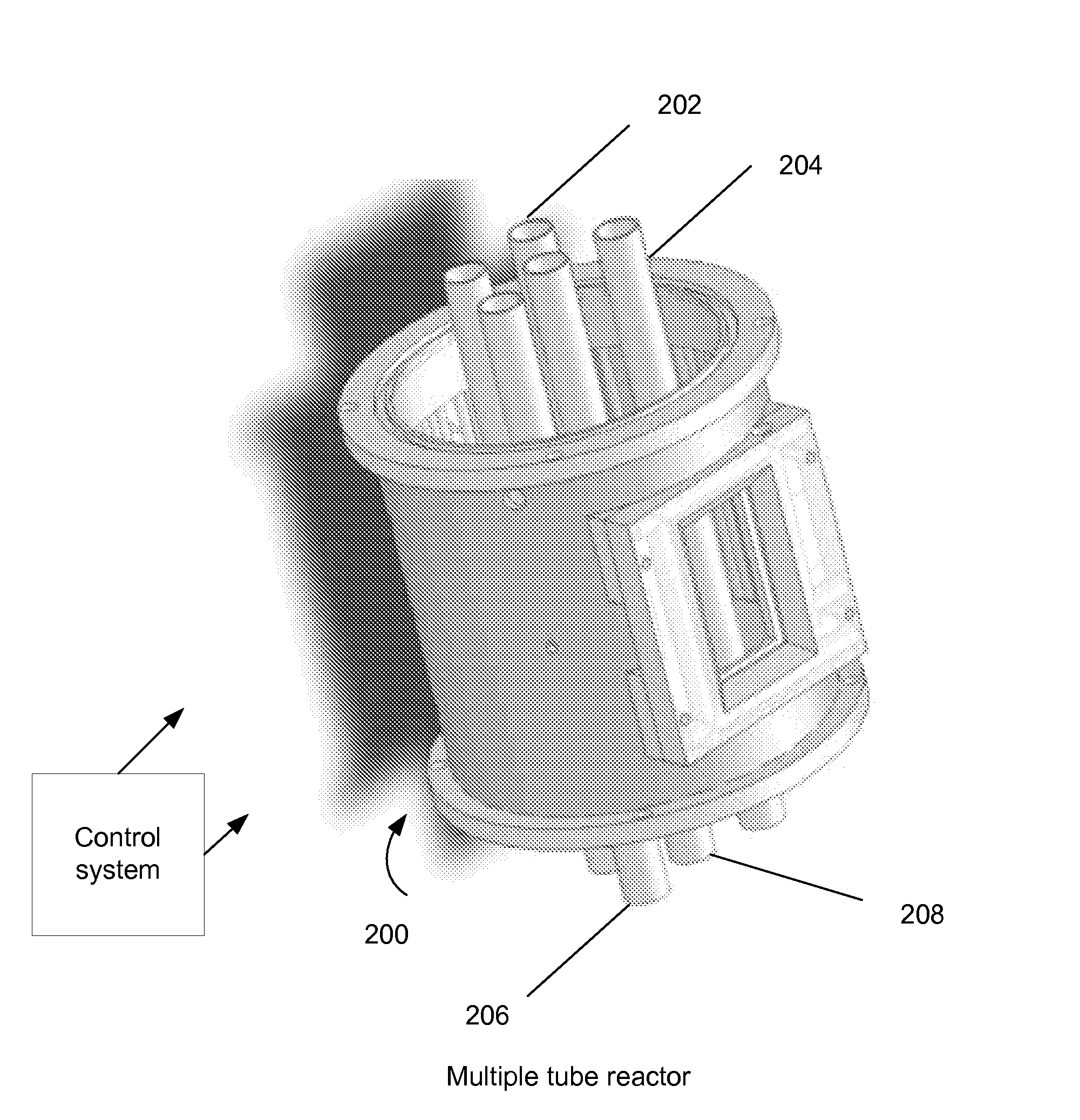

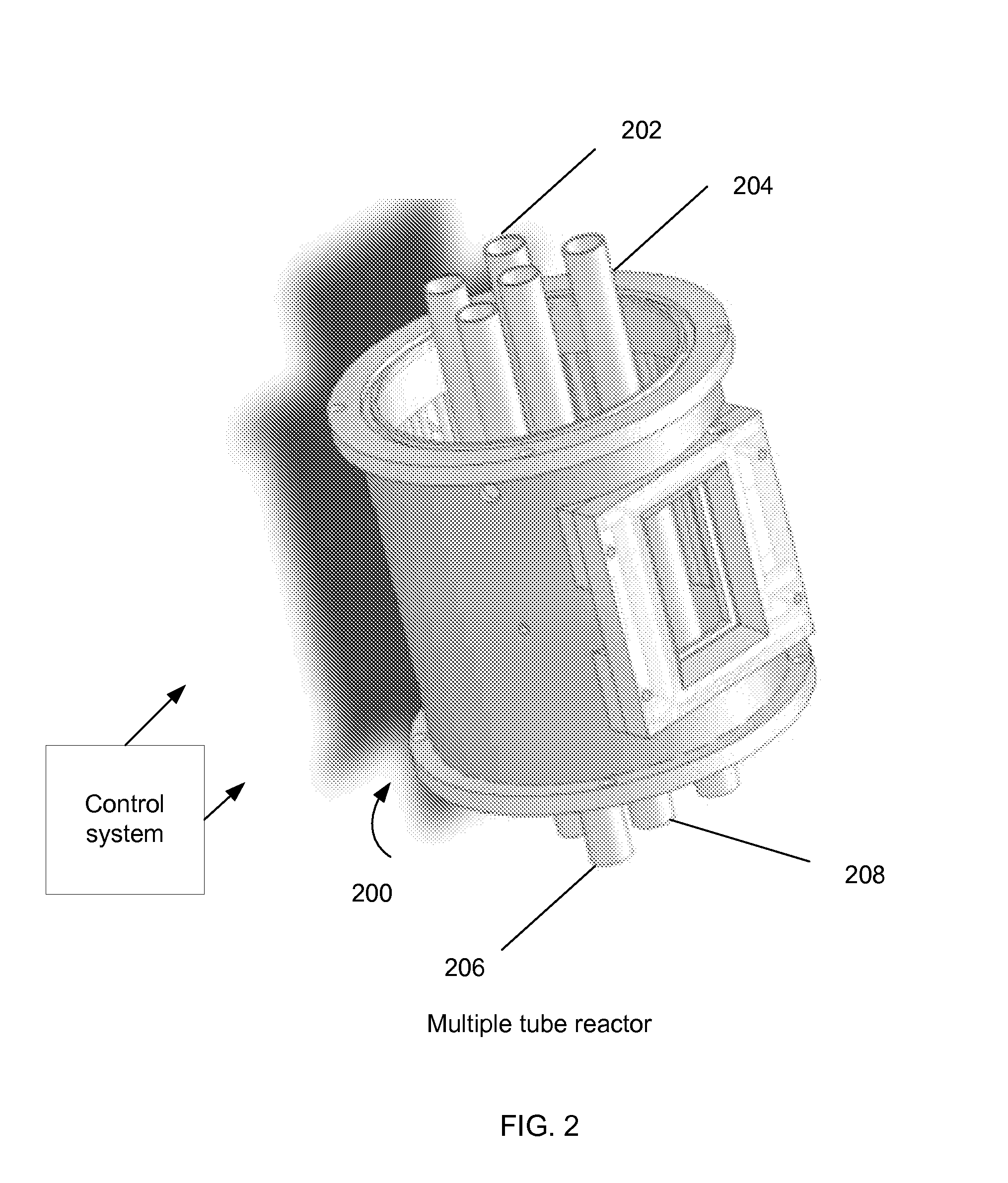

Systems and methods for biomass gasifier reactor and receiver configuration

InactiveUS20100247387A1Complete gasificationProcess control/regulationSolar heating energyHydrogenHeliostat

A method, apparatus, and system for solar-driven chemical plant may include a solar thermal receiver to absorb concentrated solar energy from an array of heliostats. Additionally, some embodiments may include a solar driven chemical reactor that has multiple reactor tubes. The concentrated solar energy drives the endothermic gasification reaction of the particles of biomass flowing through the reactor tubes. Some embodiments may also include an on-site fuel synthesis reactor that is geographically located on the same site as the chemical reactor and integrated to receive the hydrogen and carbon monoxide products from the gasification reaction.

Owner:SUNDROP IP HLDG LLC

Biomass gasification catalyst and its production method

InactiveCN1686606AIncrease gas calorific valueHigh cracking rateOther chemical processesGas purification with selectively adsorptive solidsTarBiomass gasifier

A catalyst used in biomass gasifier or gas furnace for cracking tar and removing uncracked tar and alkali metal is prepared from attapulgite-type clay, high-A alumina, iron oxide, magnesium oxide, calcium oxide and anthracite through proportionally mixing, stirring, grinding, granulating and baking.

Owner:许庆华

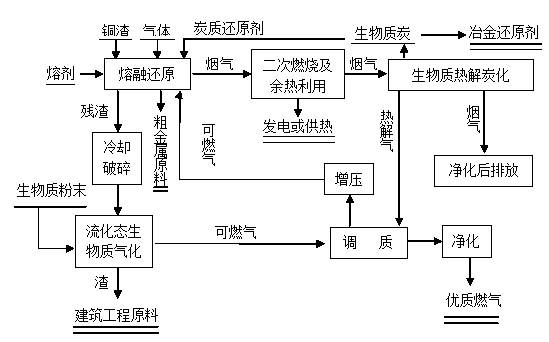

Low-carbon comprehensive utilization method of copper slag after smelting reduction

ActiveCN103537480AEfficient recyclingPromote resource utilizationSolid waste disposalCarbonizationBiomass gasifier

The invention relates to a low-carbon comprehensive utilization method of copper slag after smelting reduction, belonging to the technical field of resources and environment. After a smelting reduction process of copper slag, crude metal raw materials and residues are obtained, and in the smelting reduction process, high-temperature flue gas can be also generated. A residue utilization method comprises the steps of cooling and solidifying the residues by water, mechanically grinding and crushing, adding the crushed residues and biomass powder to a fluidized-state biomass gasifier, and carrying out a gasification reaction under a condition of spraying a gasifying agent, wherein in the gasification reaction process, flammable gases and residues can be generated, and the residues are used as raw materials in constructional engineering. A high-temperature flue gas utilization method comprises the steps of carrying out secondary combustion on the high-temperature flue gas, cooling by waste heat utilization, and then introducing into a biomass pyrolysis and carbonization process as an external heat source, wherein pyrolysis gas, flue gas and biomass charcoal are obtained in the biomass pyrolysis and carbonization process, and the flue gas is discharged after being purified. According to the low-carbon comprehensive utilization method, the technical method of preparing flammable gas and biomass charcoal by pyrolyzing and gasifying biomass by means of waste heat of copper slag and coupling with a smelting reduction process of copper slag is a novel low-carbon metallurgical technology.

Owner:KUNMING UNIV OF SCI & TECH

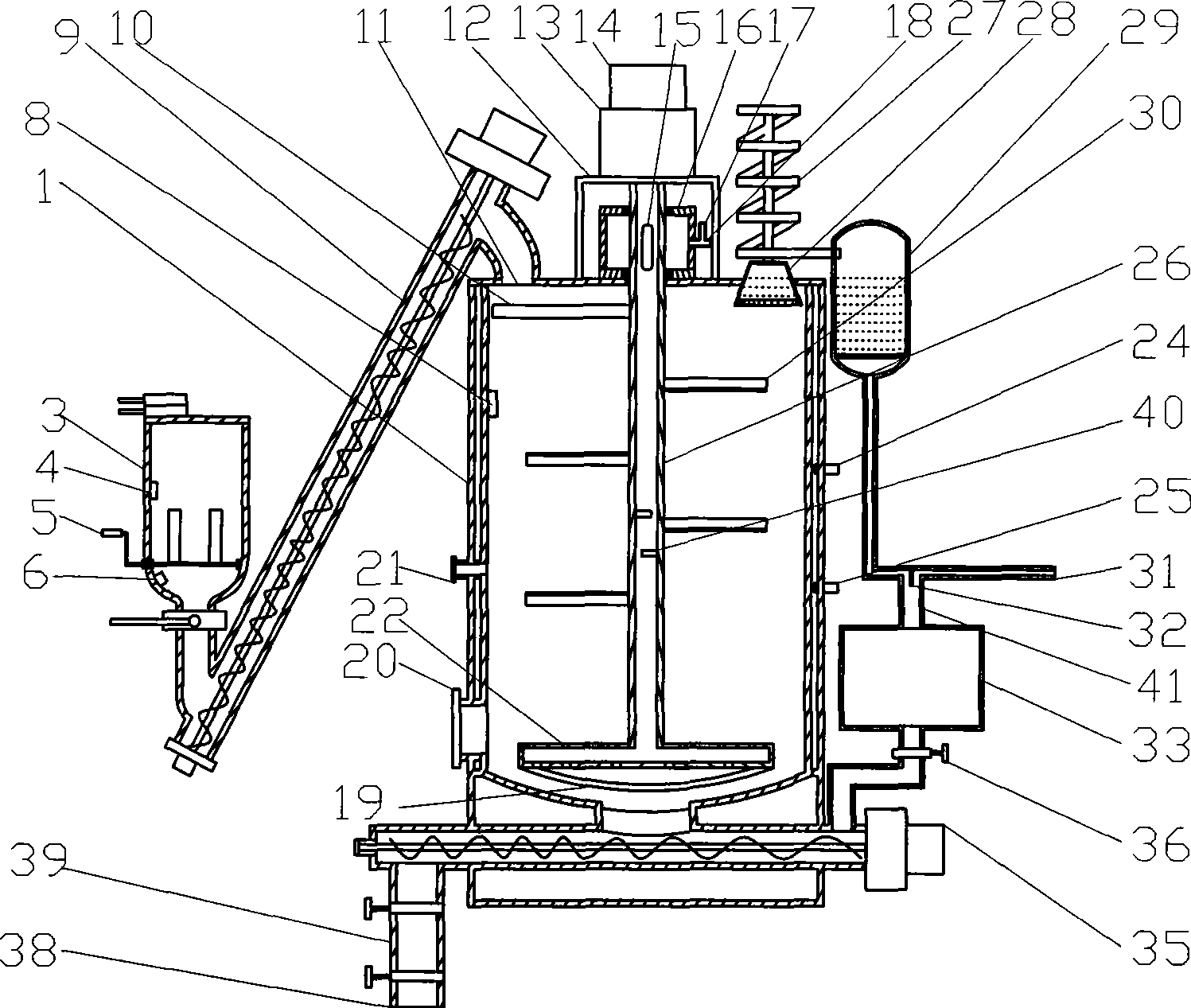

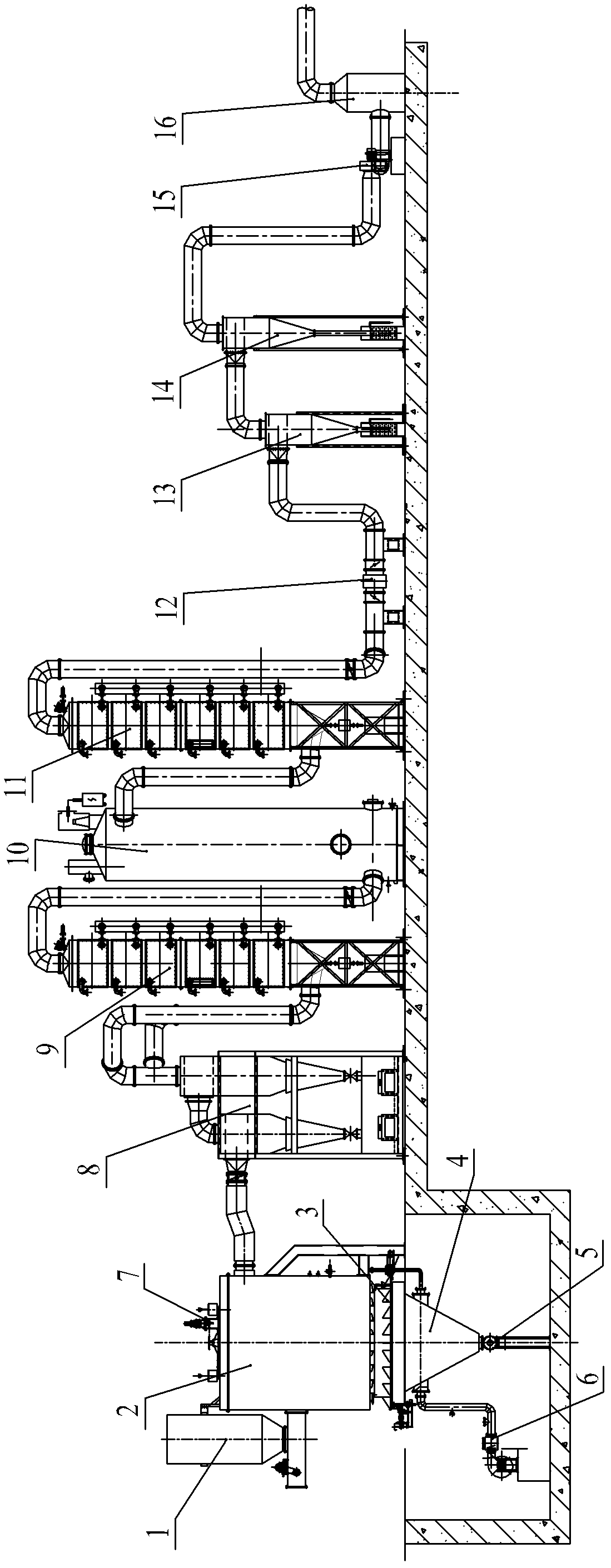

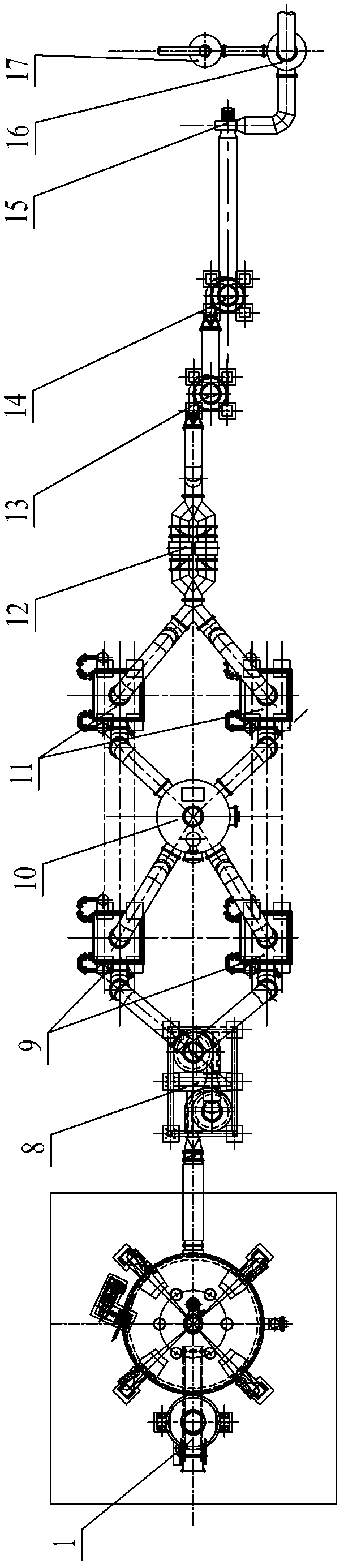

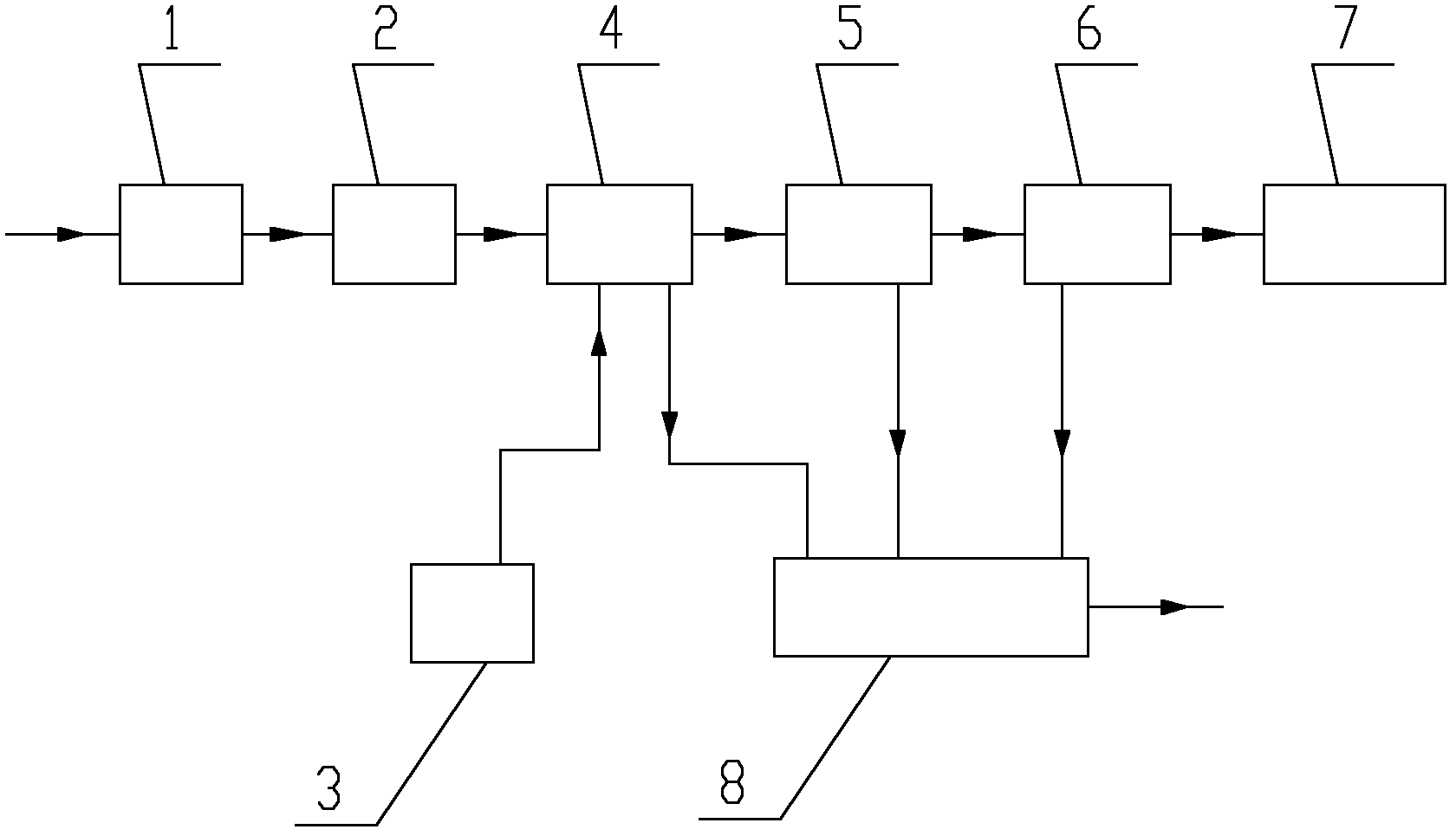

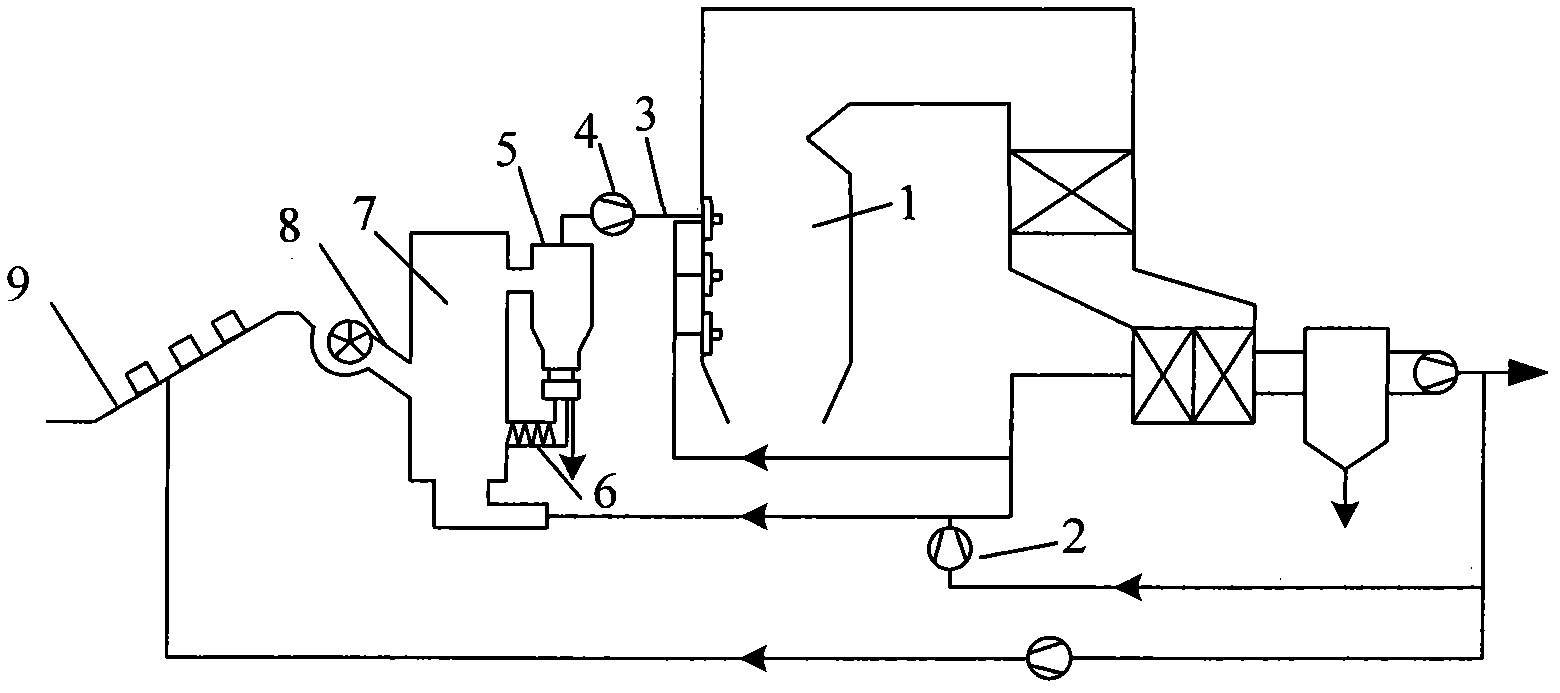

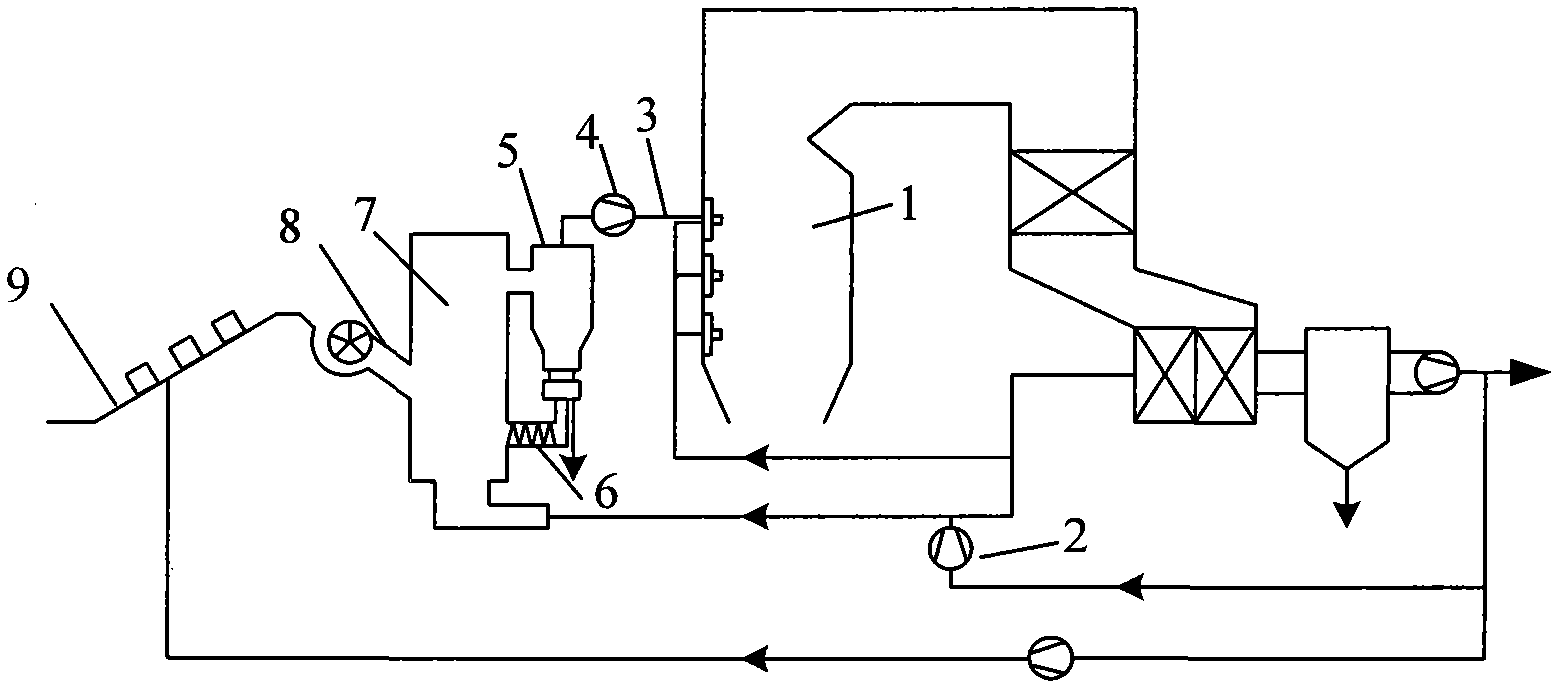

Biomass gas generation system

ActiveCN102703121AProduce secondary pollutionIngenious and reasonable structureProductsReagentsIntercoolerBiomass gasifier

The invention relates to a biomass gas generation system. The system comprises a feed device, a biomass gasification furnace, a post-treatment system and a gas transmission and storage pipeline system which are connected in a sequence of gas generation and treatment, wherein the biomass gasification furnace is provided with a fuel inlet and a gas outlet, the fuel inlet is connected with the feed device, and the gas outlet is communicated with the post-treatment system through a connecting pipe fitting; and the post-treatment system comprises a cyclone dust collector, a primary pipe-type intercooler, an electrical tar precipitator, a secondary pipe-type intercooler, a filter and purification device, a primary water-steam separator and a secondary water-steam separator. The biomass gas generation system has a smart and reasonable structure, cannot cause secondary pollution to the surrounding environment while biomass energy is reasonably utilized; and prepared gas can be applied to civil use instead of the conventional stove or liquefied gas, and can be applied to the industrial field, such as directly being used as industrial gas or being used for supplying power generation for power generation equipment.

Owner:无锡湖光工业炉有限公司

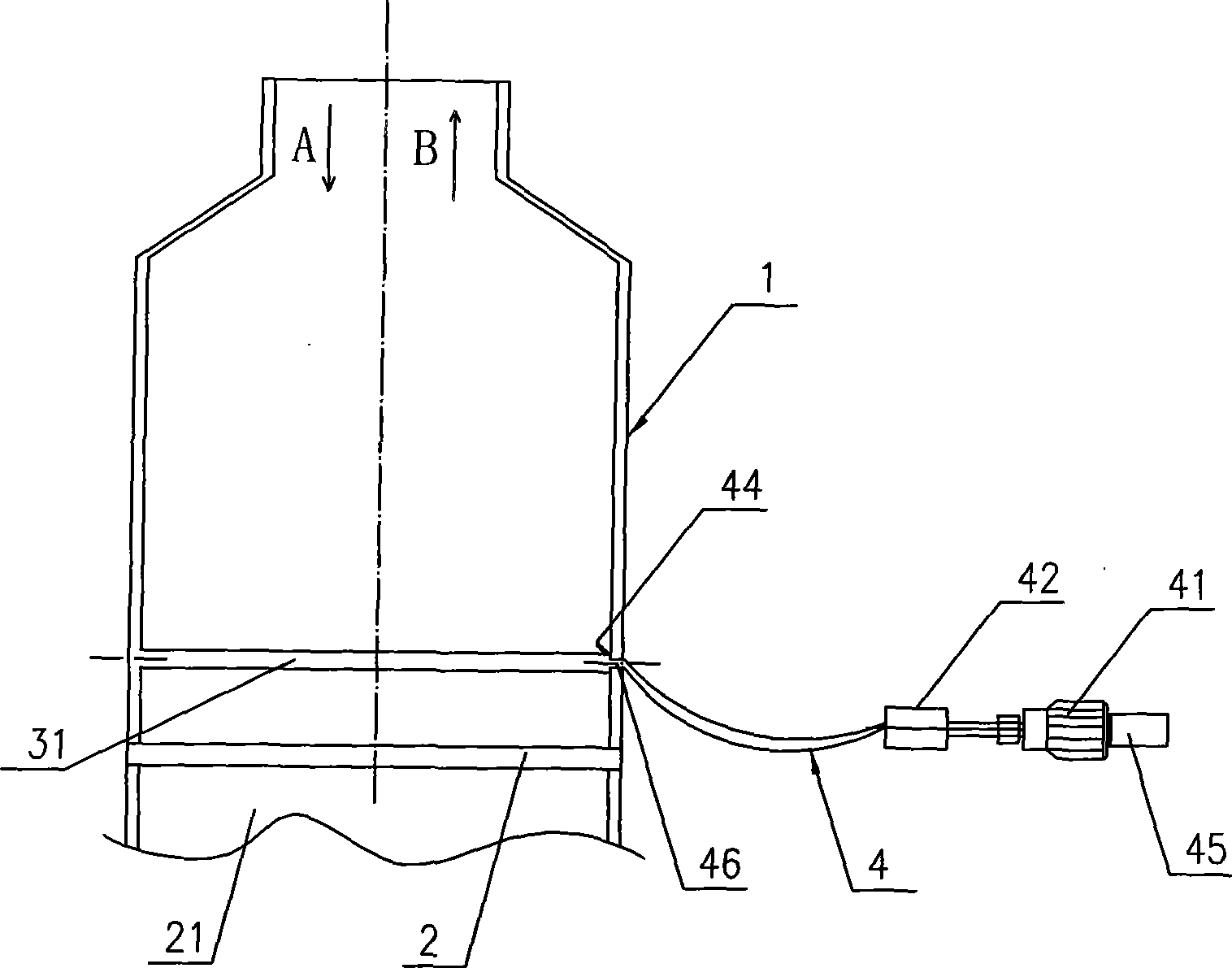

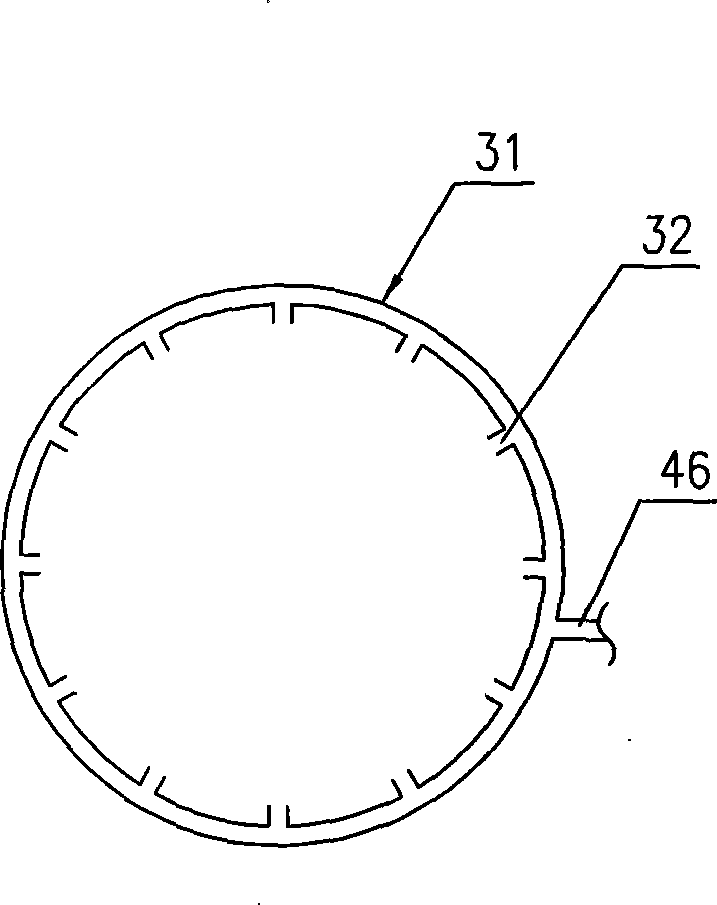

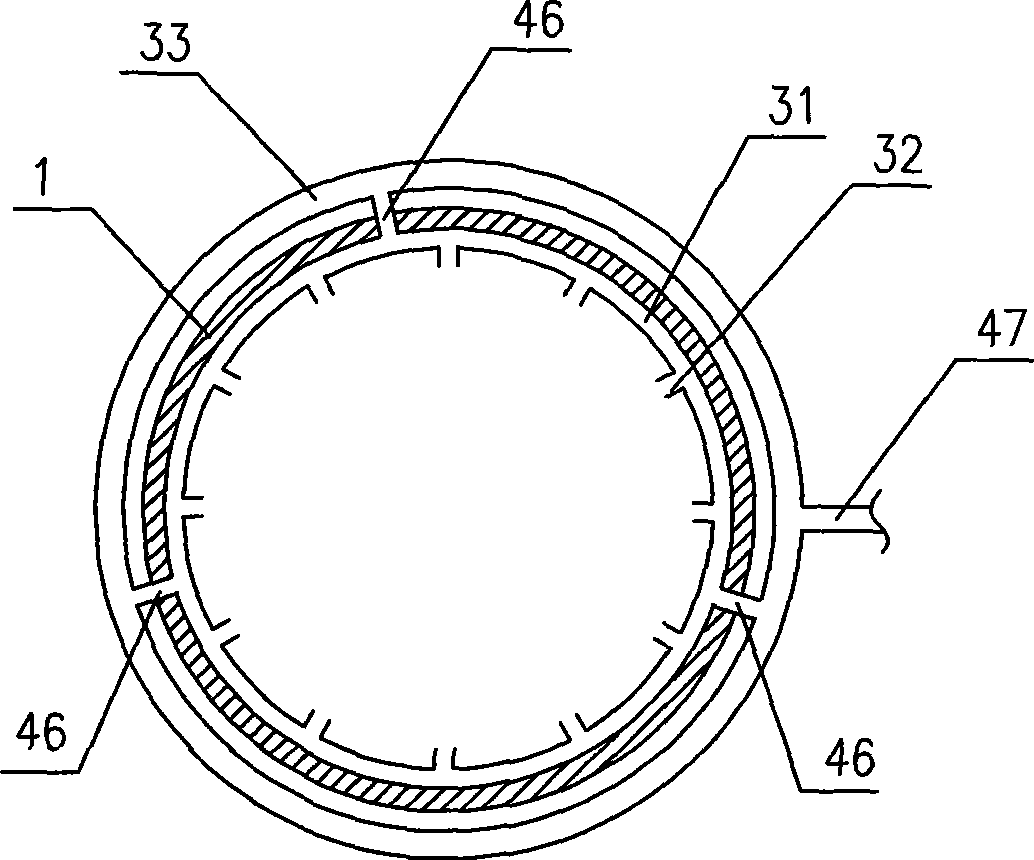

Down-draught type biomass gasifier for secondarily cracking tar

ActiveCN101812327AGuaranteed uptimeImprove energy efficiencyCombustible gas productionTarEngineering

The invention relates to a down-draught type biomass gasifier for secondarily cracking tar and aims at the problems that tar in the down-draught type biomass gasifier has high content and blocks a pipeline after being combined with water, ash, carbon and the like so as to influence the stable running of the gasifier. The lower end of an inner gasifier tube is arranged in an ash bin; a movable gassifier gate is arranged below the inside of a reduction chamber; a fuel gas secondary cracking chamber is arranged between a flame-retardant coating and the inner gasifier tube; a fuel gas secondary cracking chamber inlet is arranged between the outer wall at the lower end of the inner gasifier tube and the inner wall of the flame-retardant coating; one end of an air inlet pipe passes through the side wall of an outer gasifier tube which is arranged above a hearth necking, a heat-insulating layer, a flame-retardant coating and a fuel gas secondary cracking chamber and the side wall of the inner gasifier tube as well as is communicated with a hearth; the other end of the air inlet pipe is in threaded connection with a plug; the side wall of the plug is provided with a plurality of air inlet holes; and an air exhaust pipe passes through the side wall of the outer gasifier tube, the heat-insulating layer and the flame-retardant coating and is communicated with the fuel gas secondary cracking chamber. The invention can realize that tar in the fuel gas is secondarily cracked in a high-temperature area, greatly reduce the content of the tar in combustible gas and meet the requirement of rural residents on gas application.

Owner:湖南哈工机器人研究院有限公司

High temperature normal pressure biomass gasification island process

The invention provides a high temperature normal pressure biomass gasification island process. The process comprises the procedures of pretreatment and storage of biomass, gasification by using a biomass gasification furnace, cooling of gasified crude gasification gas, rinsing, dedusting and storage of fresh gasification gas, wherein in gasification by using the biomass gasification furnace, an external heat source is used to supply heat, reaction temperature in the gasification furnace is controlled to be 1300 to 1750 DEG C, liquid state slag removal is adopted by the gasification furnace, cooling of gasified crude gasification gas is realized through recovery of sensible heat by a quenching tower and a two-stage heat boiler, cooled crude gasification gas is subjected to rinsing and electric precipitation, fresh gasification gas is stored in a gas storage cabinet, and whole gasification island equipment operates under a negative pressure or a positive pressure of 0 to 50 KPa. According to the process, the external heat source is utilized for gasification, which enables the quality of crude gasification gas to be improved; a normal pressure fixed bed is employed for gasification, which enables the equipment of gasification furnace body to have the advantages of simpleness, small investment and easy operation; feeding, deslagging and purifying systems are simple; a wide variety of raw materials are applicable, gasification of various biomass, MSW, raw coal, sludge and the like can be realized, and blended gasification of a plurality of fuels can be realized; systems and equipment are mature, and a high localization degree is obtained.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Cracking type biomass gasifier in tar furnace

InactiveCN101560409AReduce tar contentReduce gas productionCombined combustion mitigationBulk chemical productionCombustion chamberThermal insulation

The invention pertains to the technical field of biomass energy utilization and particularly relates to a device which adopts biomass for preparing gas and comprises a lower furnace door, an ash discharging mouth, an ash bin, a grate, a combustion chamber, a thermal insulation bin, a gas inlet, a storage bin, a feed inlet, a furnace cover, a gas pipe, a gas outlet, a porous medium, an air secondary inlet, an air primary inlet and an air pipe; the cracking type biomass gasifier is characterized in that: a gas primary outlet, the porous medium, the gas pipe and the gas outlet form a gas transmission pipeline which is arranged in the storage bin; the gas transmission pipeline is a U-shaped pipe or a spiral coil; and the porous medium is thermal storage ceramic material or tar catalyst material such as dolomite, olivine, clay ore, charcoal, alkali metal compound, nickel base, etc. When going through a combustion area through the gas pipe, the gas is not mixed and burned with the air in the combustion area, therefore, the difficult technical problem that the air and the gas in the existing down-draft biomass gasifier are easy to be burnt out; and the gas can be heated in the combustion area through the gas pipe, and the tar contained in the gas is further converted through the thermal storage, filtering and catalysis of the porous medium, thus reducing the tar content of the biomass gas, and simultaneously improving the conversion rate and the thermal value of gas.

Owner:安徽喜阳阳新能源科技有限公司

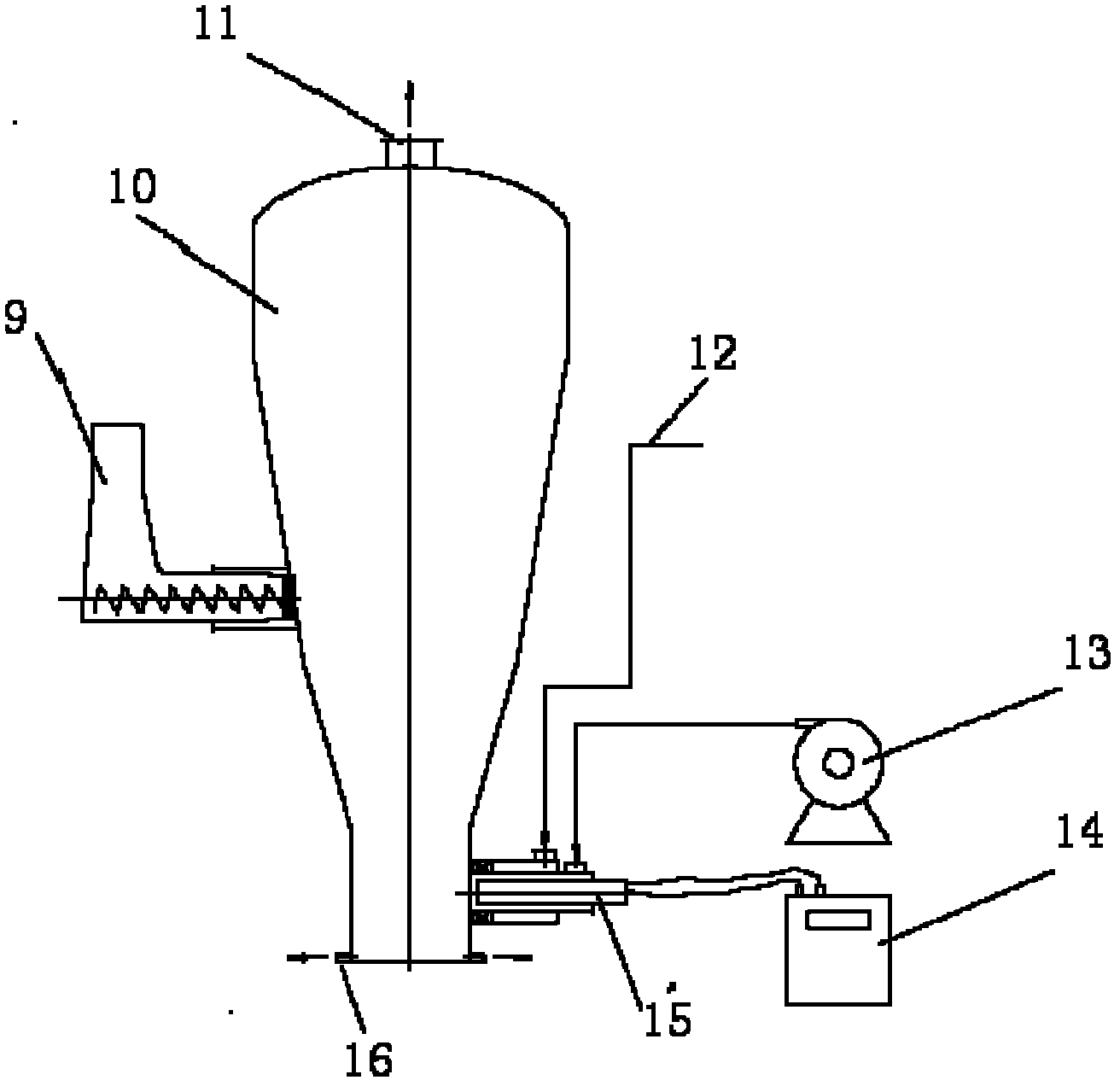

Biomass pyrolysis liquefying systems

InactiveCN1490380ALow costTake advantage ofLiquid hydrocarbon mixture productionHeat carrierResidual biomass

A biomass cracking and liquefying system is disclosed. The Z-shaped reaction pipe has a top end connected respectively with the feeder of biomass and the heat carrier outlet of the heat carrier heater, and a bottom end connected to the separator whose top end is connected to cooling unit and whose bottom end has residual biomass outlet and heat carrier outlet. The input of gas mixer is connected respectively to the gas outlet of biomass gasifier and the thermocomposed gas outlet of cooling unit, and its output is connected to gas burner communicated to the heater of heat carrier. It features that the combustible gas generated in gasifying and liquefying biomass is used as the energy source for thermodecomposing and liquefying, so having low cost.

Owner:SHANDONG UNIV OF TECH

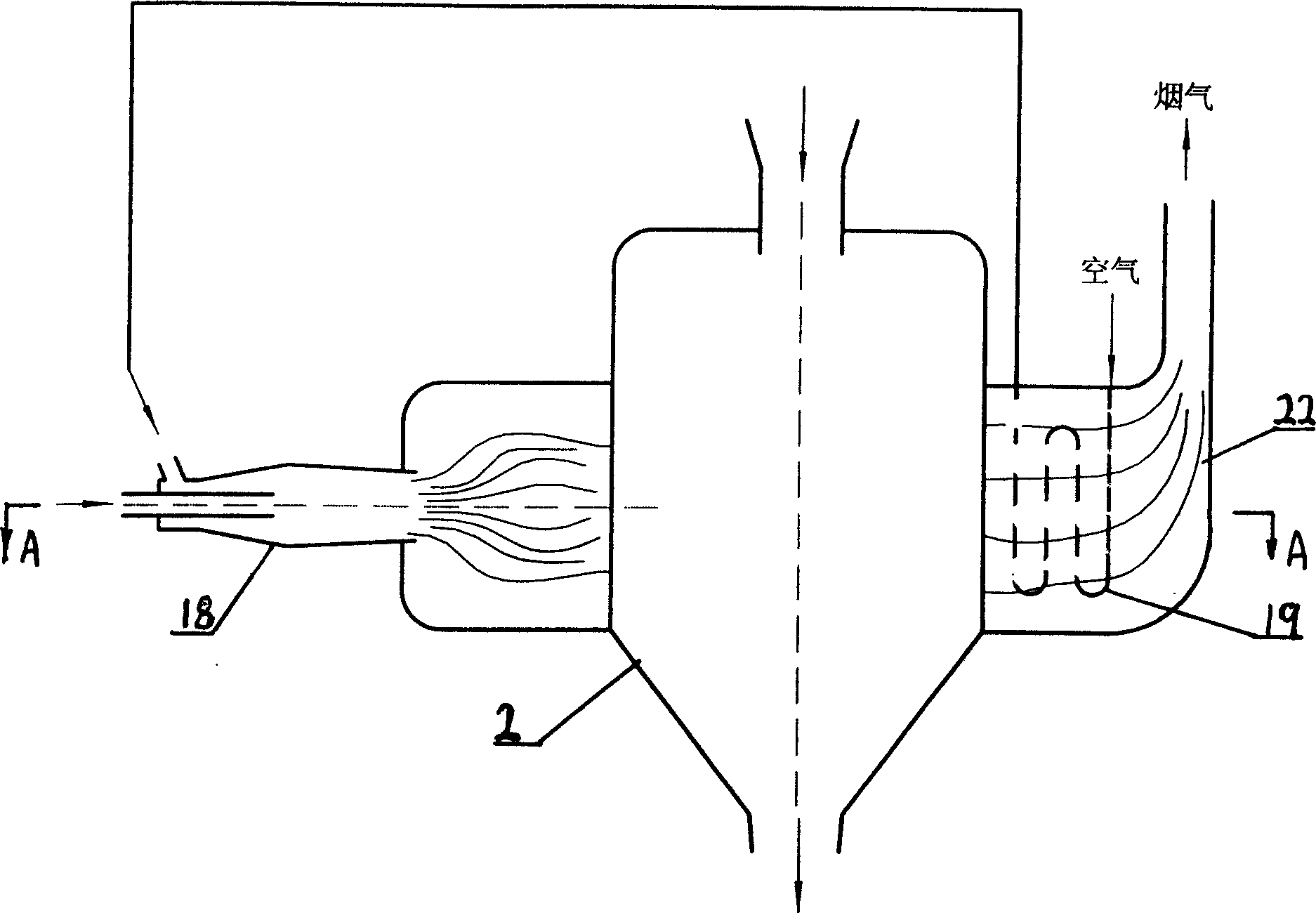

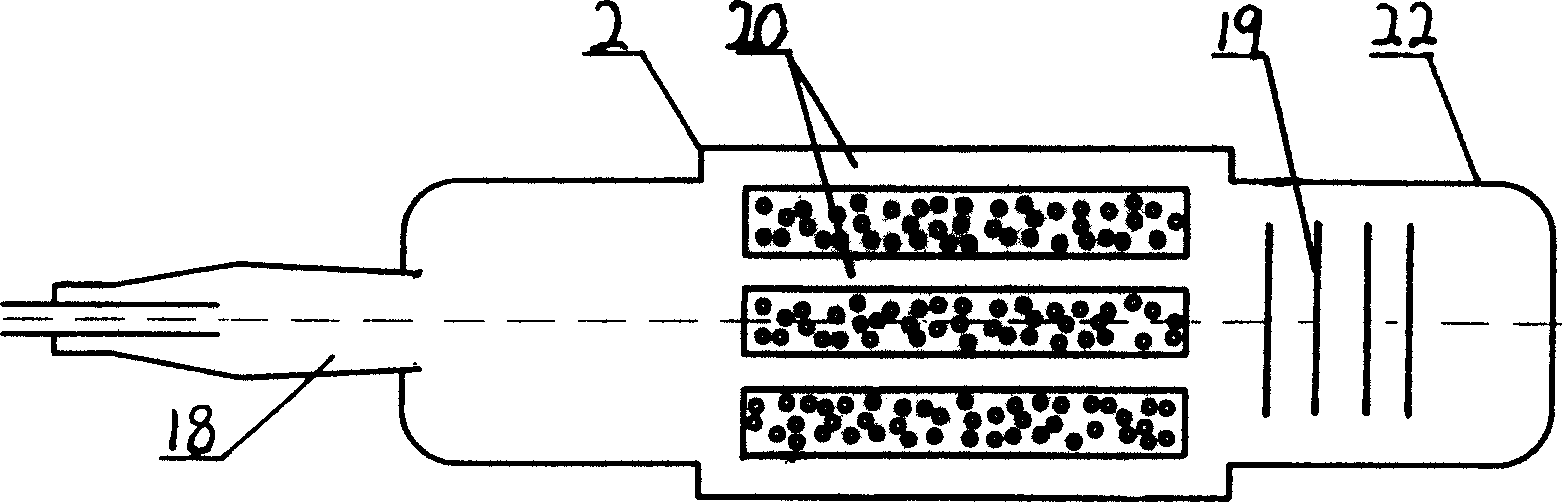

Method and device for detarring small-sized biomass gasifier

InactiveCN101613625AAchieve separationImprove efficiencyEnergy inputCombined combustion mitigationTarWater flow

The invention discloses a method and a device for detarring a small-sized biomass gasifier. The device comprises a furnace body, an air preheating chamber, an external furnace catalyzing chamber, a purifying chamber, a separating chamber, a tar recycling pipe, an internal furnace cracking pipe and the like. The method comprises the following steps that: coarse fuel gas flows into the catalyzing chamber arranged outside the furnace from a furnace outlet; partial tar is catalytically cracked, and then enters the purifying chamber and the separating chamber; the separating chamber is internally provided with a baffling plate, and the outer wall is provided with longitudinal fins; the fuel gas exchanges heat with air in the air preheating chamber when flowing; and the tar continuously condensing and water flow into the recycling pipe provided with a U-shaped liquid sealing section along the wall of the purifying chamber, and then circularly flow into a semi-arc catalytic cracking pipe positioned in a high-temperature oxidation zone of the gasifier. The preheated air can obviously increase the temperature of the internal furnace oxidation zone, which is greatly favorable for fully carrying out tar catalytic cracking reaction in the pipe, and the tar flows into a furnace hearth through exhaust holes on the pipe wall. The method and the device can realize the secondary catalytic cracking and separation recycling of the tar, obviously improve the gasifier efficiency and the fuel gas calorific value, and have the advantages of small system flow resistance and easy implementation.

Owner:YANGZHOU POLYTECHNIC INST

Combined biomass vaporization furnace and thermal cracking device thereof

InactiveCN1664066ALow production costEasy to useRetortsSpecial form destructive distillationTarVaporization

The invention discloses a compound biological gasification stove and thermal cracking device, the main point of which is: it is comprised with two biological gasification stove, four U-shaped catalytic reactor, catalyst, one aerator and air regulator. The gas produced in the gasification stove 1 is introduced to the catalyst 3, taking part in the first thermal cracking; through the modification by the aerator a part of gas flow is introduced into the gasification stove 1 and mixed with catalyst 11,taking part in the second thermal cracking and the new produced gas flow is introduced to the catalyst 3 and for the third thermal cracking; another part of gas flow is introduced into gasification stove 26 and mixed with catalyst 21 for the fourth thermal cracking, and is introduced into upper catalyst 25 for the fifth thermal cracking; and therefore, the oil tar is cracked thoroughly. The invention is characterized by the low production cost, convenient usage, and the improvement in oil tar cracking efficiency, gasifying efficiency and gas thermal value on the original base.

Owner:许庆华

Multi-directional air distribution fixed bed biomass gasification stoves

InactiveCN101475814AIncrease reaction strengthIncrease powerSpecial form destructive distillationFixed bedTar

The invention discloses a multi-ventilation fixed bed biomass gasification furnace, which comprises a furnace body and a fire gate, wherein the fire gate is arranged in the middle part of the furnace body; the furnace body is provided with a forced air intake system which comprises an air feed mechanism, a ventilation device and a connecting pipe; the ventilation device is a ventilation pipeline which is positioned above the fire gate in the furnace body and is used for inletting air from a plurality of directions; and the air feed mechanism is positioned outside the furnace body and is connected with the ventilation pipeline through the connecting pipe which penetrates through the furnace wall so as to provide a forced air supply for the inside of the furnace. The multi-ventilation fixed bed biomass gasification furnace adopts a forced air feed mode that the air feed mechanism is combined with the ventilation device to feed air; and compared with the prior normal pressure air feed mode, the multi-ventilation fixed bed biomass gasification furnace improves the power of the gasification furnace, reduces the tar content in fuel gas, greatly reduces the tar content in waste water, and is advantageous for environmental protection; besides, the multi-ventilation fixed bed biomass gasification furnace does not have specific requirements on the dimension, the dryness, the feeding mode and the like of biomass raw materials, thereby widening the application range of the biomass raw materials.

Owner:广州市宇联机电有限公司

Novel biomass gasification furnace

InactiveCN102486314AFierce firepowerDomestic stoves or rangesLighting and heating apparatusHeat conductingEngineering

The invention relates to a novel biomass gasification furnace, which comprises a furnace head, a furnace cover, a furnace wall, a furnace core and a raw material lifting device. The center of the furnace wall is provided with the furnace core, the periphery of the furnace core is provided with a plurality of heat-conducting plates with the same spacing, the middle part of the furnace core is provided with a ring-shaped gas outlet, a furnace bridge is arranged in the furnace core and under the gas outlet, the bottom of the furnace core is provided with a damper, a material tray is arranged in a material storage chamber, is provided with gaps corresponding to the heat-conducting plates and can move up and down in the material storage chamber, the two sides of the material tray are symmetrically provided with tray connecting rods, the tray connecting rods penetrate through the furnace wall and are connected with a tray lifting rod, the part of the tray lifting rod contacted with the furnace wall is provided with a vertical gap so that the tray lifting rod can move up and down, a sleeve is jacketed outside the tray lifting rod and is connected with the furnace wall, the lower end of the sleeve is closed, and the upper end of the sleeve is provided with a lifting rod clamping spring. By adopting the structure, the novel biomass gasification furnace is particularly suitable for firewood gasification and combustion, the fire is strong, and no smoke, dust or odor can be produced. Moreover, charcoals are produced after gasification and combustion of raw materials and can be reused, and thus the novel biomass gasification furnace is efficient and energy-saving.

Owner:许国贵

Biomass gasification stove

ActiveCN104654364AEasy to removeReduce pollutionLighting and heating apparatusChemical industryStart timeThermal insulation

The invention discloses a biomass gasification stove. The biomass gasification stove is mainly characterized in that a smoke discharge chamber and a stock bin opening booster chamber are respectively formed in the upper part of a fuel bin, wherein a stock bin cover is arranged in the middle of the stock bin opening booster chamber; a flue gas channel is formed between a water tank and a furnace core; the gasification furnace core is communicated with the fuel bin and an ash collecting chamber, respectively; a funnel-shaped furnace grate with a ash shaking device and a movable fence gate is arranged between the gasification furnace core and the ash collecting chamber; a thermal insulation layer is arranged between the inner and outer walls of the gasification furnace core; the inner wall of a gasification reaction chamber in the gasification furnace core is an extension tube capable of freely stretching out and drawing back; an air spray nozzle is arranged on the side wall at the upper side of the gasification reaction chamber; an ignition device is arranged in the thermal insulation layer. The biomass gasification stove has the advantages that the structure is compact; the gasification reaction temperature is as high as 1200 DEG C; the heat-up starting time is short; the ignition is convenient and the gas production is efficient; hot water can be produced by heating the water tank, and tar which is mixed in a biomass fuel gas can be further removed to realize energy conservation and environment protection and prolong service lives of relevant appliances; the accumulated ashes or coked blocks are conveniently and quickly removed.

Owner:周勇

Integration biomass gasification stove catalytic splitting process and device thereof

InactiveCN101338204ANo pollution in the processPromote sustainable developmentSpecial form destructive distillationThermal energyTar

The invention discloses an integrated biomass gasified furnace catalytic cracking method and a device thereof. The technical proposal is characterized in that in the integrated biomass gasified furnace catalytic cracking method, biomass fuel enters a combustion room from a feeding port through a spiral input device to be combusted; a large amount of combustible gas after the combustion rises to an X-type fuel gas buffer room and then enters a tar catalysis cracking chamber; the combustible gas enters a gas purifying chamber after the complete catalysis cracking and the purification filtering and is discharged from an outlet pipe to be used by users. The integrated biomass industrial gasifier consists of a gasifier body, the gas purifying chamber, the tar catalysis cracking chamber, catalyst for the biomass gasifier, the fuel gas buffer room, the spiral input device, the combustion room, a conical recoiling device, an ash storing chamber and a base. The integrated biomass gasifier catalyst cracking method and the device thereof are used for providing heat energy for various industrial and mining enterprises and biomass power plants.

Owner:辽宁东戴河新区乡电电力有限公司

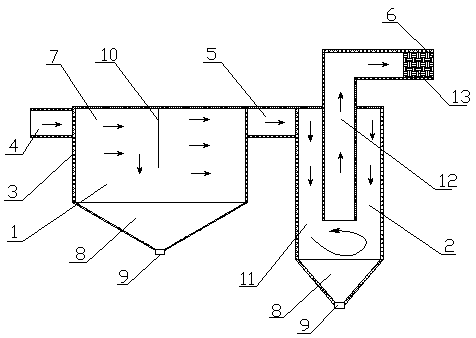

Multi-stage dust remover

InactiveCN102698552AEfficient dust removalImprove dust removal efficiencyCombination devicesGas dust removalBiomass gasifierCyclonic spray scrubber

The invention discloses a multi-stage dust remover comprising a gravity dust remover, a cyclone dust remover, a filter bag and a casing, and further comprising an air inlet, a connector, and an air outlet, wherein the gravity dust remover comprises a settling chamber below which a dust collecting chamber is arranged; and a dust outlet is formed at the bottom of the dust collecting chamber; and the cyclone dust remover comprises a cyclone dust removing chamber, inside which a discharge pipe is arranged, a dust collecting chamber is arranged below the cyclone dust removing chamber, and a dust outlet is formed at the bottom of the dust collecting chamber. Due to the adoption of the way, the multi-stage dust remover is suitable for a biomass gasifier, can effectively remove the dust of the cracked biomass gas, and has high dust removing efficiency.

Owner:郭丰亮

Method for generating power by gasifying integrated straws in supercritical coal-fired generator set

InactiveCN102010757AEasy to storeSmall footprintInternal combustion piston enginesEnergy inputBiomass gasifierBubbling fluidized bed

The invention discloses a method for generating power by gasifying integrated straws in a supercritical coal-fired generator set. The method comprises the following steps of: packing and forming biomass straws serving as a gasification raw material of a gasifier of a bubbling fluidized bed, wherein primary wind-heat air surplus in a power station and tail gas fume of a boiler are used as gasifying agents. A biomass gasifier is effectively integrated by simply modifying the conventional supercritical unit to make biomass gasified, combusted and generate power, so that the defect that the biomass is directly blended and combusted is effectively overcome, the influence of biomass ash on fly ash is avoided, and the problem that the conventional auger feeding equipment is easy to damage is solved; therefore, biomass energy can be efficiently utilized and pollutant emission of coal-fired power stations is further reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

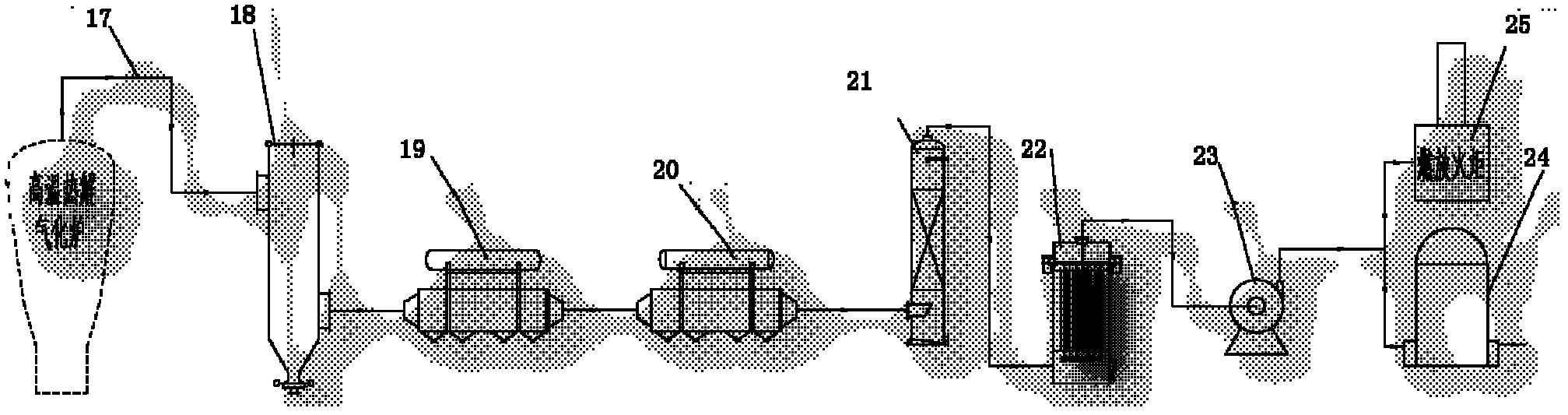

Method and apparatus for pyrolysis of biomass gas tar oil

InactiveCN101130698AGood removal effectHigh calorific valueThermal non-catalytic crackingTar working-up by thermal treatmentElectricityCombustible gas

The invention discloses a high temperature cracking method of biomass gas tar and device, which comprises the following steps: (A) gasifying biomass in gasification stove; (B) washing; filtering; (C) cracking under high temperature; leading the 250-350 deg. c biomass gas form the step (A) and (B) into private high temperature cracking oven; proceeding the cracking reaction with temperature at 800-1200 deg. c; generating marsh gas with low carbon, ethane and ethene combustible gas; purifying; entering into user net; setting the device as controller, air inlet pipe, change-over valve, flame couple, discharge pipe, cracking furnace and heater; setting the cracking furnace as triple-fired structure; setting the middle as high temperature heating segment; arranging the two sides as low temperature storing segment; assembling the change-over valve at the two ends of the cracking furnace; connecting the one end of the valve to the air inlet pipe; connecting the other end to the discharge pipe; assembling the flame couple on the discharge pipe and the change-over valve; electric-connecting to the controller.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

Tar removal for biomass gasification systems

The disclosed embodiments provide systems for the removal and use of tar from a biomass gasification system. For example, in one embodiment, a biomass gasification system includes a reactor configured to gasify a biomass fuel in the presence of air to generate a producer gas. The system also includes an absorber configured to receive a mixture of the producer gas and tar and to absorb the tar into an organic solvent to produce treated producer gas and a rich solvent mixture containing at least a portion of the tar. The system further includes a recycle line configured to direct the rich solvent mixture to a biomass gasifier.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com