Method and apparatus for pyrolysis of biomass gas tar oil

A high-temperature pyrolysis and biomass gas technology, which is used in tar processing, cracking, petroleum industry and other directions by heat treatment method, can solve the problems that the gas purification effect is difficult to meet the actual use requirements, cannot be reused, and contains many impurities, and achieves the removal effect. Good, avoid secondary pollution, improve the effect of cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

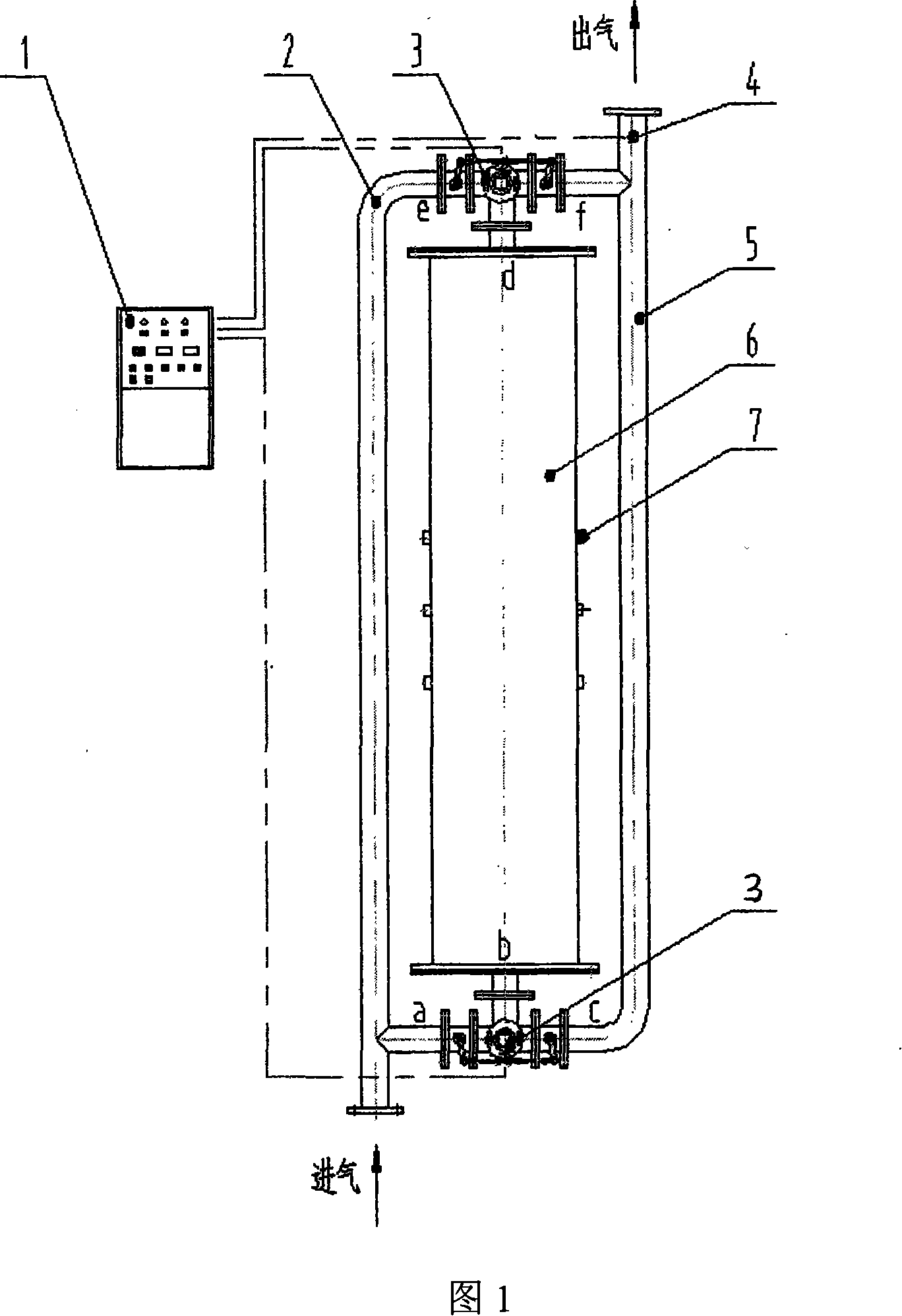

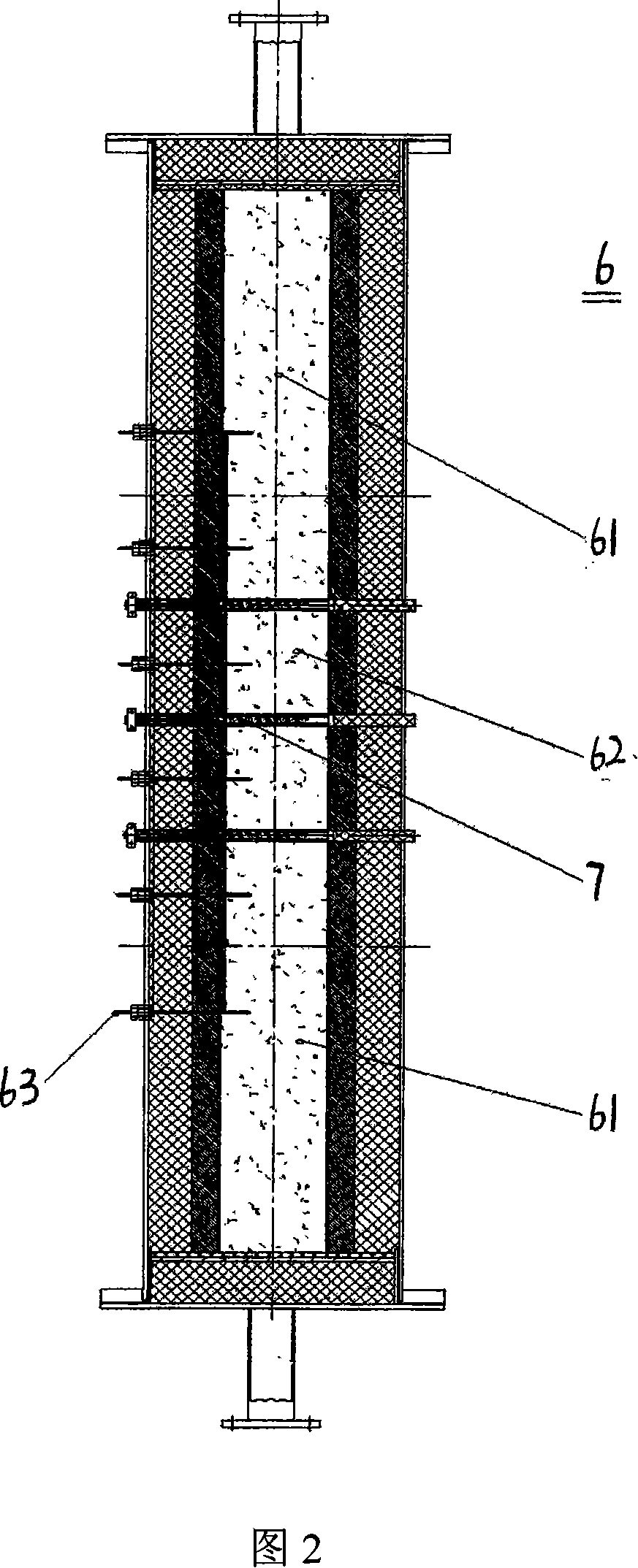

[0014] A high-temperature pyrolysis method for biomass gas tar, which mainly includes the steps of (A) gasification in a biomass gasifier; (B) washing and filtering, and (C) a high-temperature cracking step. (C) The high-temperature cracking step is performed in a dedicated In the high-temperature cracking device, the biomass gas discharged from steps (A) and (B) at a temperature of 250°C to 350°C enters a dedicated high-temperature cracking furnace 6, and undergoes a cracking reaction at a high temperature of 800°C to 1200°C. Generate low-carbon methane, ethane and ethylene combustible gases; the purified gas enters the user network for use.

[0015] During high temperature cracking in step (C), countercurrent catalytic cracking is carried out under the control of the electronically controlled high temperature reversing valve 3 in the device.

[0016] A biomass gas tar pyrolysis device, referring to Fig. 1-Fig. 2, includes a controller, an air intake pipe, a reversing valve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com