Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about "Tar working-up by thermal treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of soluble mesophase pitch

InactiveCN102942945AImprove solubilityFacilitate subsequent processingWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

The invention belongs to the technical field of a preparation method of spinning raw materials of high-performance pitch-based carbon fibers, and particularly relates to a preparation method of soluble mesophase pitch, which mainly solves the problems of the existing mesophase pitch preparation method that the process is complicated, requirements on the equipment are high, the cost is high, the industrialization process is difficult and the like. The invention adopts the technical scheme that the preparation method of the soluble mesophase pitch comprises the following steps of (1) thermally treating raw material pitch or ethylene bottom oil with a low softening point in an inert atmosphere, then distilling the material in a short distance or flashing the material, removing light ends, and collecting heavy fraction, i.e. heavy end pitch; (2) preparing the heavy enbd pitch into mesophase pitch; and (3) cooling the mesophase pitch to 320DEG C to 400DEG C, removing internal light ends, and collecting the heavy fraction, i.e. the mesophase pitch. The preparation method has the advantages of simplicity in process, moderate in reaction condition, low equipment requirement, low cost and adaptability to industrialized production.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

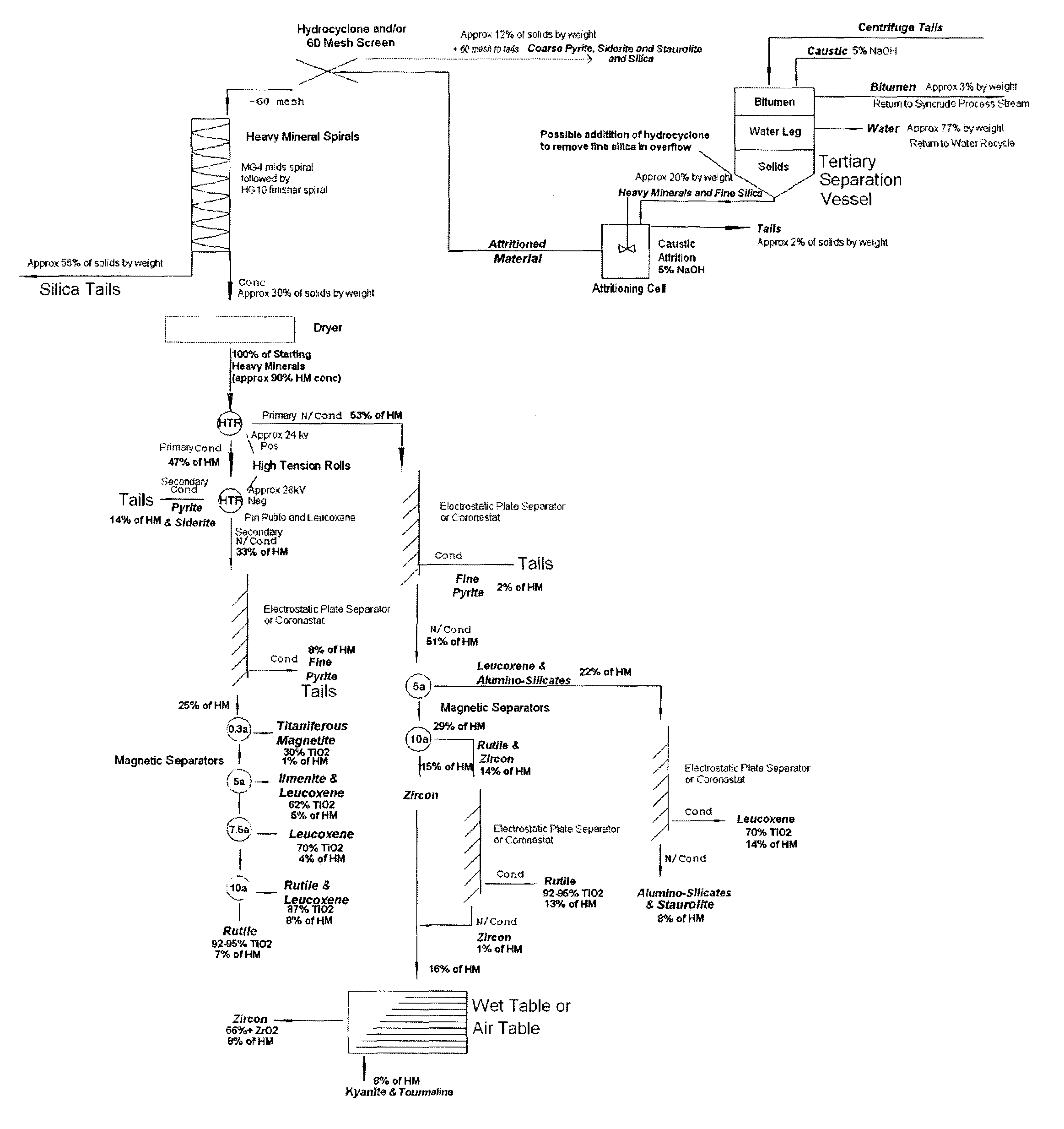

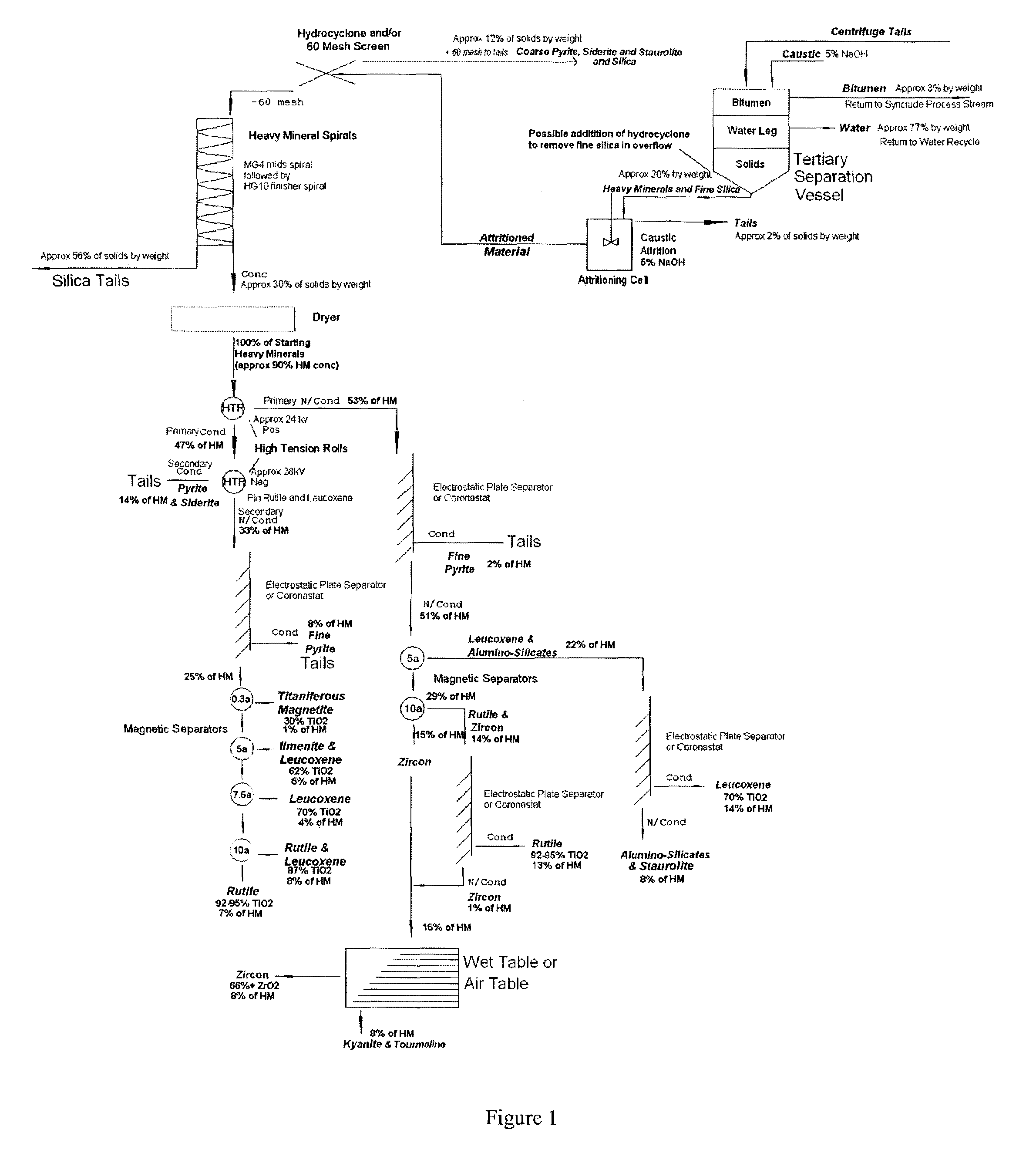

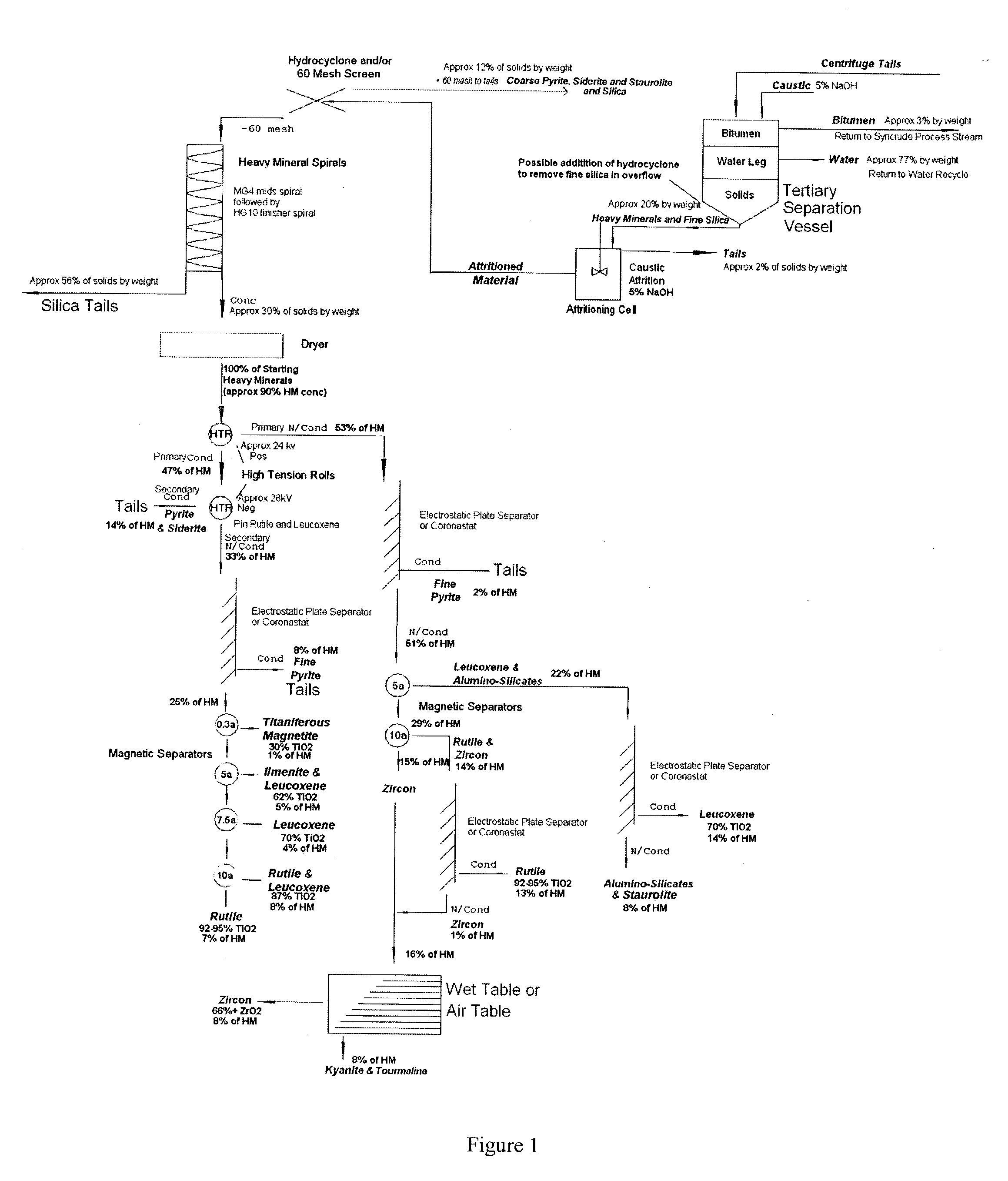

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

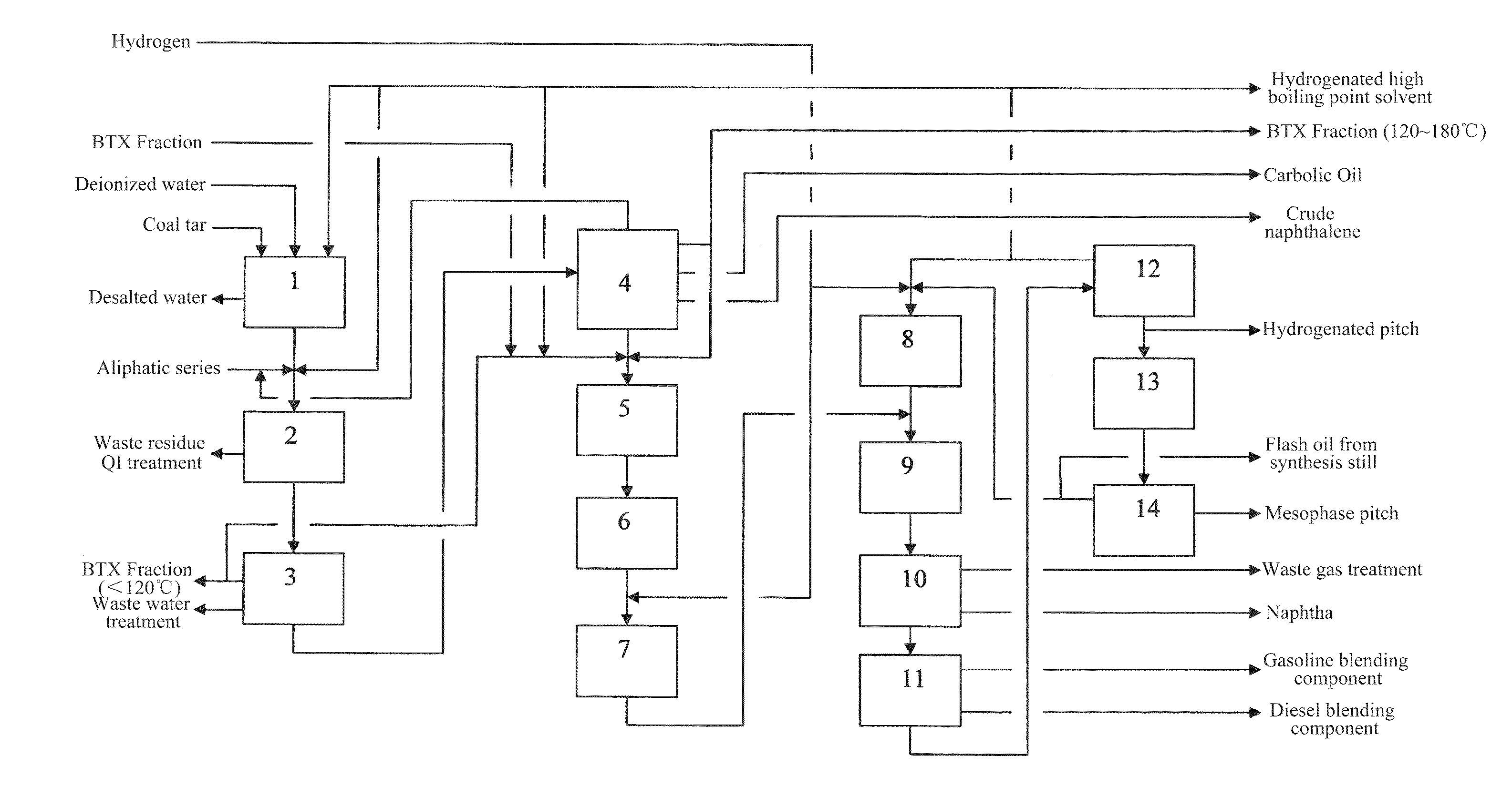

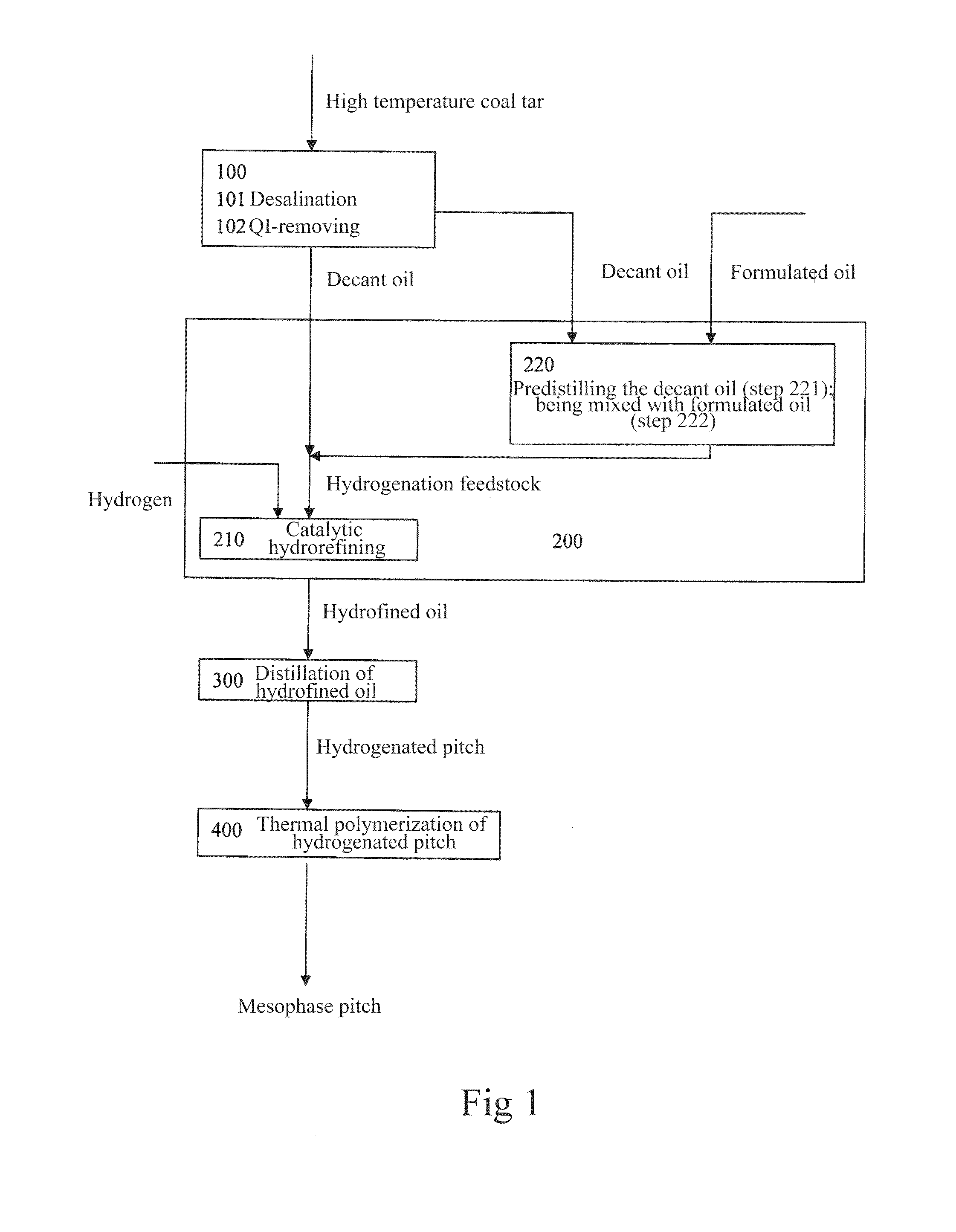

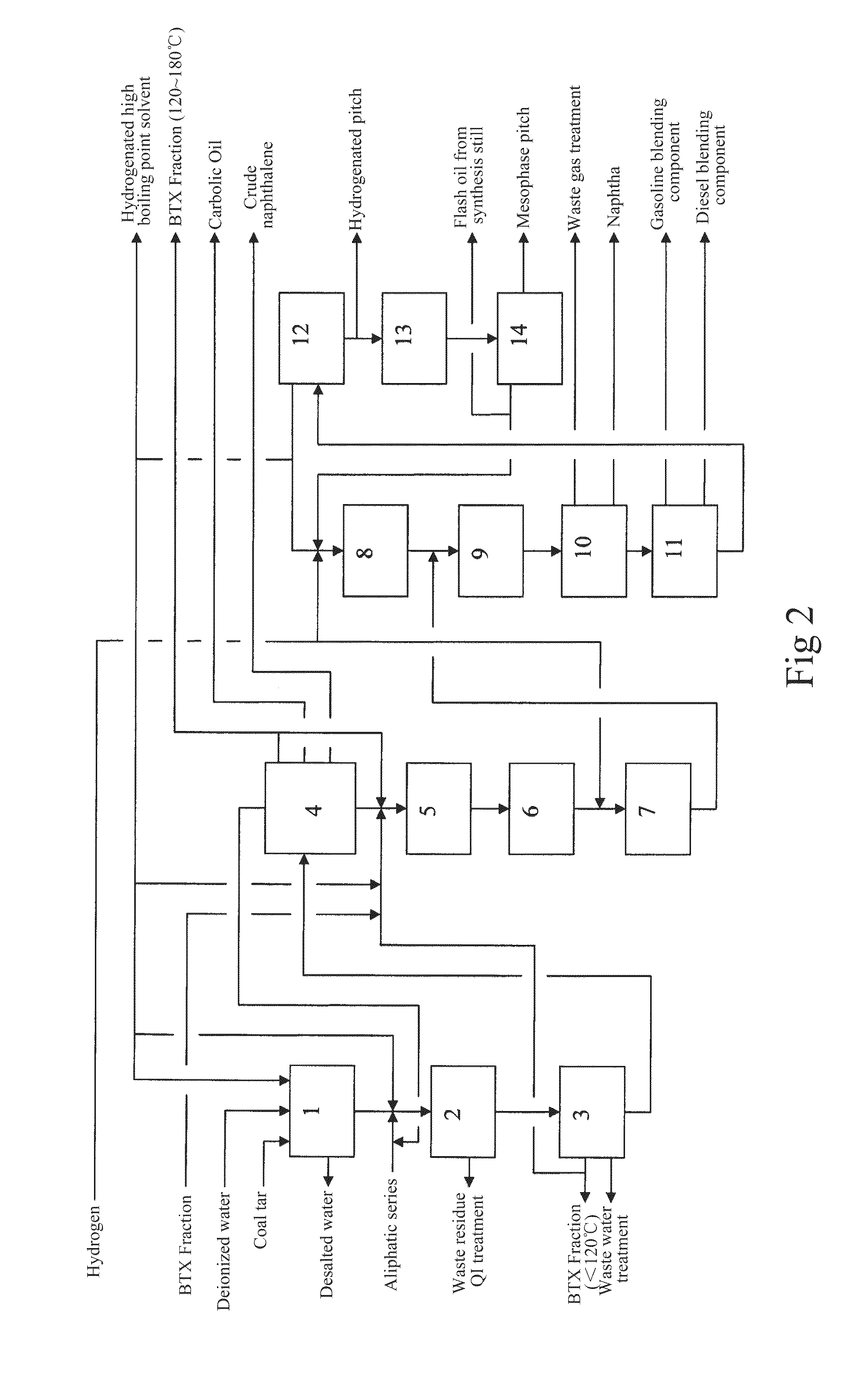

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

Processes for producing coke, artificial graphite and carbon material for negative electrode of non-aqueous solvent type secondary battery and pitch composition used therefor

InactiveUS7008526B2Improve productivityHigh degree of graphitizationCell electrodesDirect heating destructive distillationHigh densityGraphite

When a pitch composition prepared by mixing 100 parts by weight of mesophase pitch with 10 to 1,000 parts by weight of coal tar pitch, is heat-treated at a temperature of 500° C. or higher, it is possible to produce a high-density coke at a high yield while avoiding the foaming of the mesophase pitch. In addition, when the coke is graphitized at a temperature of 2,000° C. or higher, it is possible to obtain an artificial graphite having a high graphitization degree. Further, when the coke is first pulverized and then graphitized at a temperature of 2,000° C. or higher, it is possible to obtain a high-crystallinity graphite powder which can be suitably used as a carbon material for a negative electrode of non-aqueous solvent type secondary battery having a high discharge capacity and a high charge-discharge efficiency.

Owner:MITSUBISHI GAS CHEM CO INC

Noah's pitch process

A process for producing pitch from pitch precursors, such as wood tar, coal tar or petroleum fractions is disclosed. Direct contact heat exchange of the pitch precursor with molten metal, preferably maintained as a metal continuous bath, heats the pitch precursor to a temperature sufficient to induce thermal polymerization reactions and produce a pitch product.

Owner:DTX TECH

Recovery of heavy minerals from a tar sand

A process for recovering heavy minerals (e.g., titanium minerals such as TiO2) from a feedstock comprising tar sands or a tar sands-derived solids fraction. The feedstock comprises bitumen and heavy minerals. The process comprises the steps of: (i) contacting the solids fraction with water at a temperature of at least about 100° F. to cause production a bituminous phase and a heavy minerals phase; and (ii) separating the heavy minerals phase from the bituminous phase. Optionally, these steps may be preceded by one or more steps used to produce a tar-sands derived solids fraction from a tar sands feedstock.

Owner:TITANIUM CORP

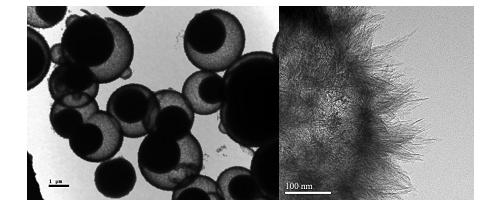

Method for preparing hollow spherical nickel-based catalyst for catalytic pyrolysis of oil tar

InactiveCN102179247AGood dispersionImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsTar working-up by thermal treatmentCatalytic pyrolysisPolymer science

The invention relates to a method for preparing a hollow spherical nickel-based catalyst for catalytic pyrolysis of oil tar and belongs to the technical field of catalyst preparation processes. In the invention, a core-shell or hollow spherical gamma-Al2O3 carrier with a specific surface area up to 285 to 443m<2> / g is prepared by a hydrothermal process, and a NiO active component is loaded by a residue leaching method. The catalyst comprises 5 to 15 weight percent of NiO and the balance of gamma-Al2O3. The catalyst prepared by the method is used for catalyzing the oil tar cracking reaction using methylbenzene as a model, and has high reaction activity, high-temperature stability and carbon deposit resistance.

Owner:SHANGHAI UNIV

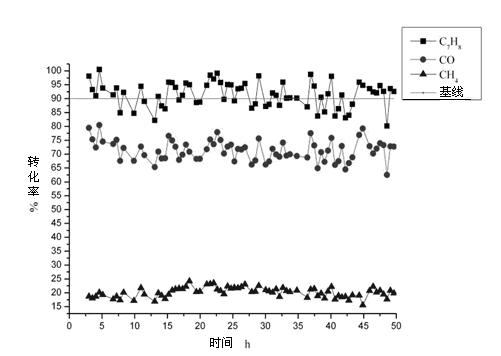

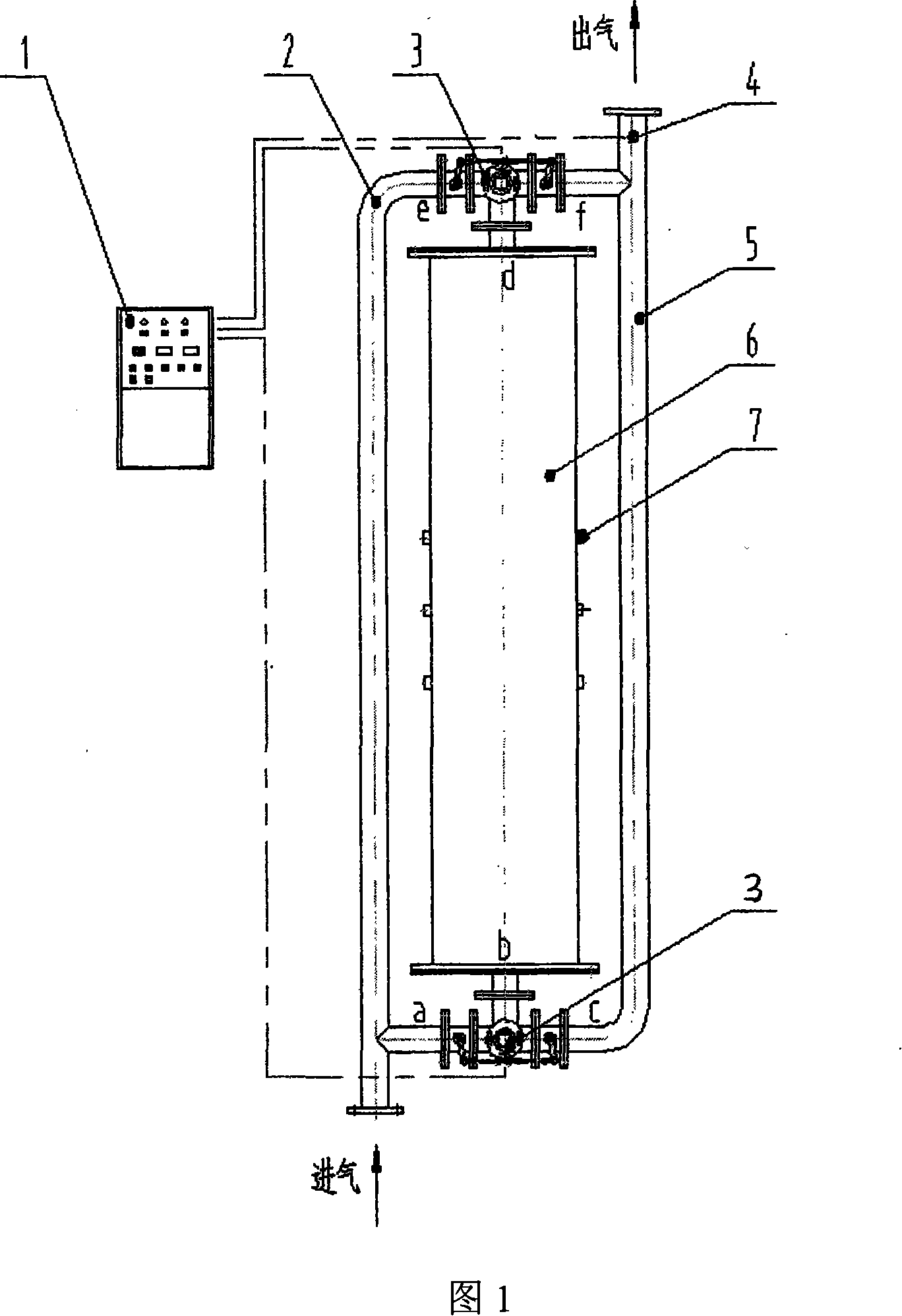

Method and apparatus for pyrolysis of biomass gas tar oil

InactiveCN101130698AGood removal effectHigh calorific valueThermal non-catalytic crackingTar working-up by thermal treatmentElectricityCombustible gas

The invention discloses a high temperature cracking method of biomass gas tar and device, which comprises the following steps: (A) gasifying biomass in gasification stove; (B) washing; filtering; (C) cracking under high temperature; leading the 250-350 deg. c biomass gas form the step (A) and (B) into private high temperature cracking oven; proceeding the cracking reaction with temperature at 800-1200 deg. c; generating marsh gas with low carbon, ethane and ethene combustible gas; purifying; entering into user net; setting the device as controller, air inlet pipe, change-over valve, flame couple, discharge pipe, cracking furnace and heater; setting the cracking furnace as triple-fired structure; setting the middle as high temperature heating segment; arranging the two sides as low temperature storing segment; assembling the change-over valve at the two ends of the cracking furnace; connecting the one end of the valve to the air inlet pipe; connecting the other end to the discharge pipe; assembling the flame couple on the discharge pipe and the change-over valve; electric-connecting to the controller.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

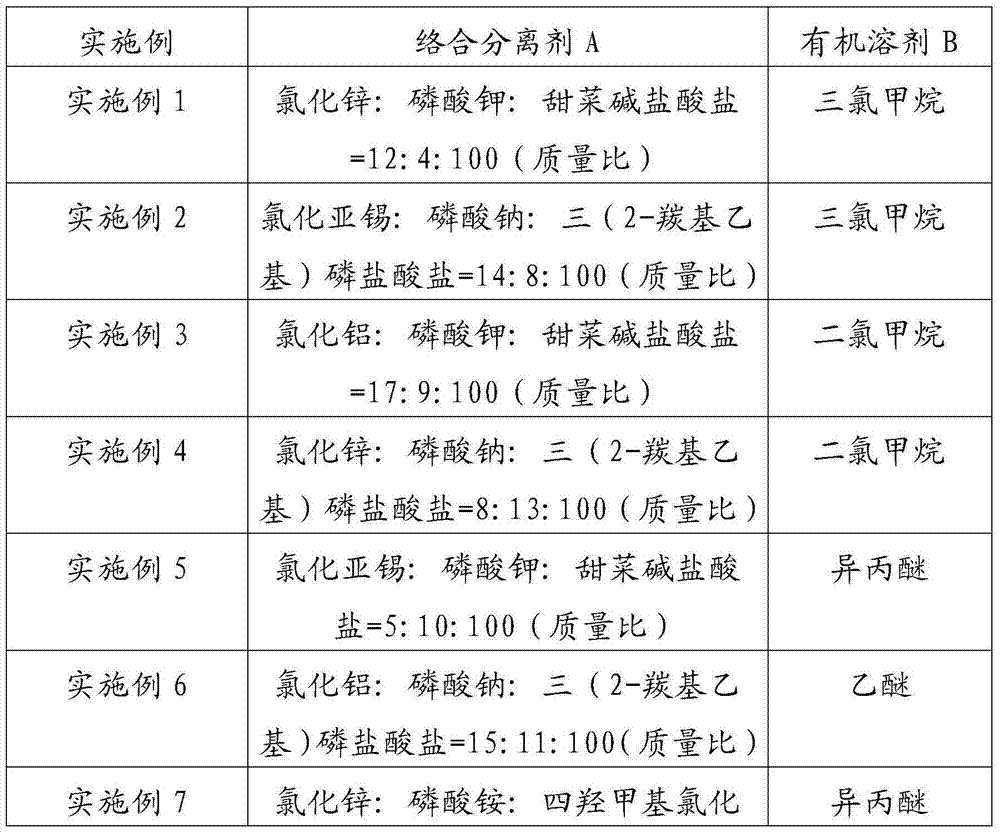

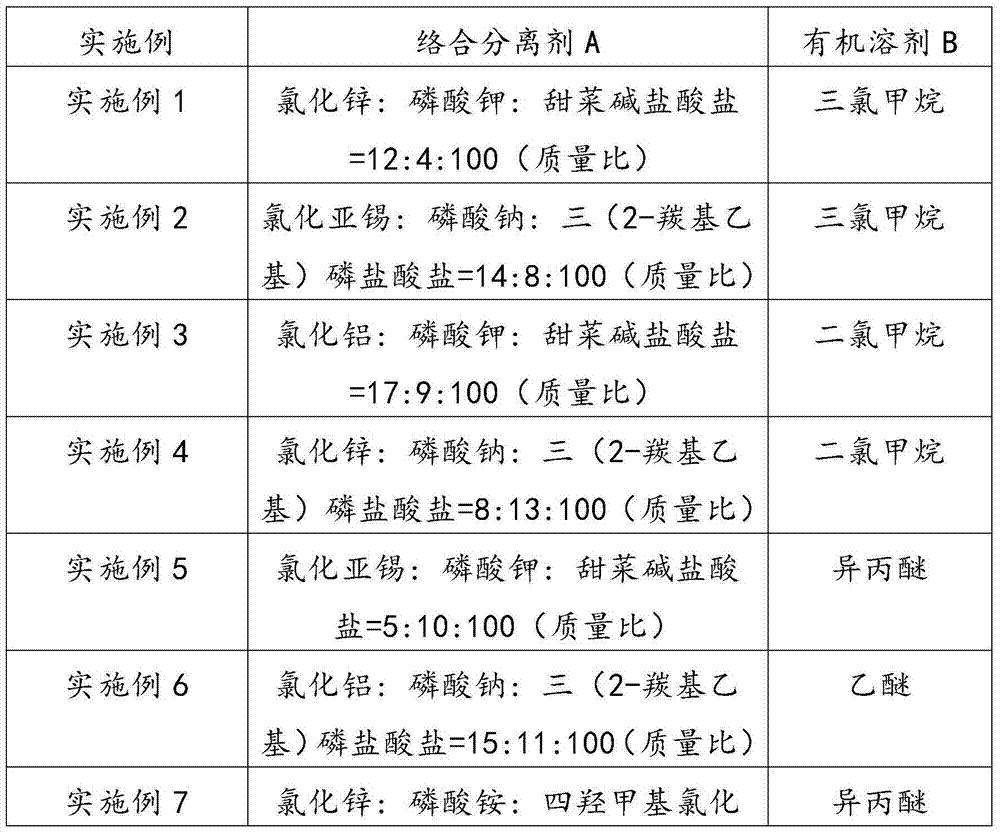

Separation method for phenol compounds and nitrogen-containing compounds in coal tar

ActiveCN103937522AAchieve recyclingEasy to separateTar working-up by chemical refiningTar working-up by solvent extractionNitrogenEvaporation

The present invention discloses a separation method for phenol compounds and nitrogen-containing compounds in coal tar, wherein the problem that the coal tar is generally subjected to phenol compound separation is solved. The technical scheme comprises: adding a complexation separation agent to coal tar to carry out a complexation reaction, and then adopting an evaporation and back extraction manner to rapidly separate the nitrogen-containing compounds, the phenol compounds, the renewable separation agent and the solvent. The separation method has characteristics of simple process, environmental protection, no phenol-containing wastewater production, achievement of rapid and synchronous removal of phenol compounds and nitrogen-containing compounds, and good removal effect.

Owner:WUHUAN ENG

Aluminum industry solid waste recovery/petroleum coke high-temperature desulphurization device and using method thereof

InactiveCN105603216AEfficient use ofEasy to recycleProcess efficiency improvementTar working-up by thermal treatmentPetroleum cokePetroleum

The invention discloses an aluminum industry solid waste recovery / petroleum coke high-temperature desulphurization device and a using method thereof, and belongs to the technical field of metallurgy environmental protection. The device comprises a furnace body, a low-melting-point matter crystallizer at the rear end of the furnace body, and a liquid low-melting-point matter collector below the low-melting-point matter crystallizer. A main material chamber in the furnace body is used for containing aluminum electrolysis cell waste cathode carbon broken blocks or petroleum coke used as a resistance heating body. A sleeve is arranged at the rear end of the furnace body to be communicated with the low-melting-point matter crystallizer. The bottom of the low-melting-point matter crystallizer is communicated with a liquid collector through a valve. The using method mainly comprises the steps that the resistance heating body is placed into the main material chamber, vacuumizing is carried out, cooling water is introduced, the resistance heating body is powered on and heated, vacuumizing and heating are stopped after vacuum high-temperature separation, argon is introduced, and materials coagulated by the low-melting-point matter crystallizer are heated to be molten to enter the liquid low-melting-point matter collector. According to the device and the method, operation is easy, energy is saved, and pollution is reduced.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

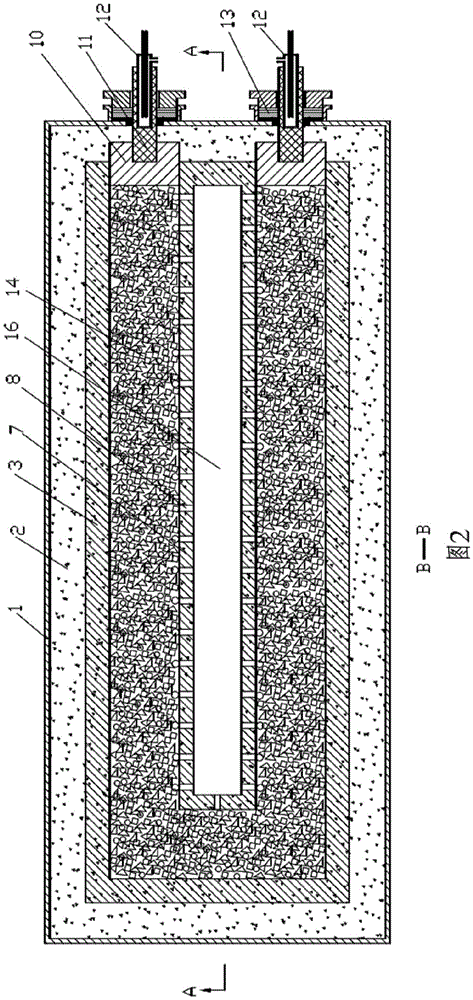

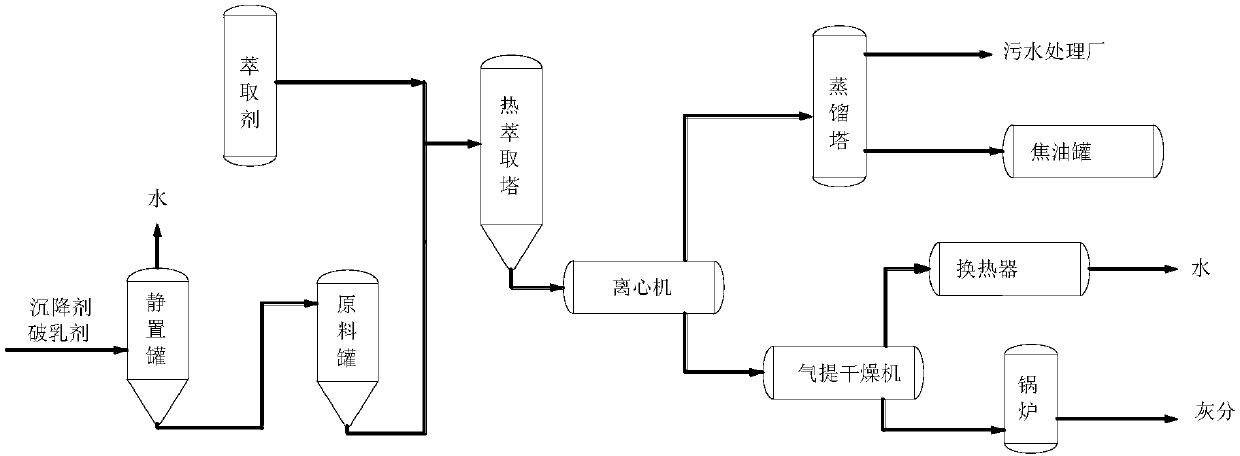

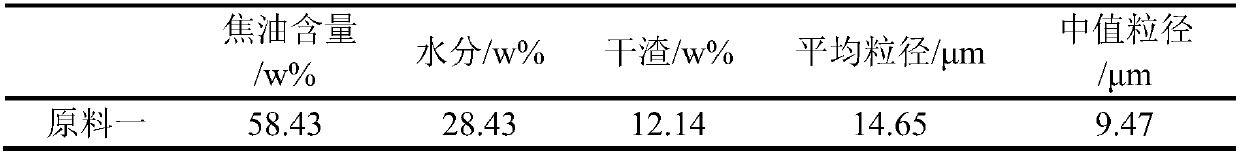

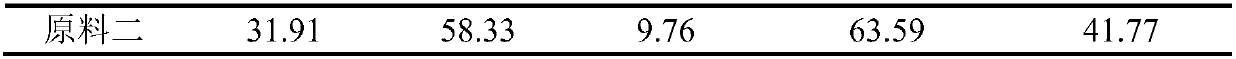

Resourceful treatment process of tar residue

ActiveCN107557044AAchieve three-phase separationEasy to separateTar working-up by water removalTar working-up by distillationSolventWater content

The invention provides a resourceful treatment process of tar residue. The resourceful treatment process is characterized in that demulsification dehydration, solvent extraction and centrifugal separation are taken as the core, distillate oil, obtained at the temperature of 200-230 DEG C, of coal tar is used as a main extracting agent, a small amount of crude benzene and industrial naphthalene areadded so as to form a composite extracting agent, and the proportion of all the components used in the process is as follows: 90-95wt / % of the distillate oil, obtained at the temperature of 200-230 DEG C, of the coal tar, 4.1-9.7wt / % of the crude benzene and 0.3-0.9wt / % of the industrial naphthalene; a technology of combining heat extraction and centrifugation is adopted under the conditions thatthe temperature of the demulsification dehydration is 35-55 DEG C, extraction temperature is 55-60DEG C, the pressure is 101.325kPa, the pump circulating flow rate is 15-20m<3> / h, the extraction timeis 3-4h, the centrifuge rotating speed is 2500-3000r / min, and the like, so that the recovery rate of tar in the tar residue reaches up to 95% or above. The resourceful treatment process is verified to be capable of well adapting to the raw material tar residue with water content of 20-60% in the aspect of raw material adaptability; the extracting agent used in the process does not need to be recovered after oil-water-residue separation is finished, can be directly used as an oil product component in the oil so as to be stored and utilized, and does not need to be recycled, so that the separation link is simplified, waste is avoided, and energy is saved; the resourceful treatment process effectively solves the problems of the tar residue in the aspects of energy utilization and environment-friendly treatment.

Owner:NORTHWEST UNIV(CN)

Method of recycling impregnated sludge carbon to catalytically gasify and recycling sludge carbon for secondary conversion of tar

InactiveCN106348561AHigh catalytic activityOvercome the disadvantage of easy inactivationSludge treatment by pyrolysisByproduct vaporizationSludgeTar

The invention discloses a method of recycling impregnated sludge carbon to catalytically gasify and recycling sludge carbon for secondary conversion of tar. The method includes: pyrolyzing sludge, and performing impregnation pretreatment to obtain the impregnated sludge carbon; pyrolyzing to obtain impregnated pyrolytic carbon; adding a cracking reactor using the impregnated pyrolytic carbon as a catalyst to the lower reach of a sludge pyrolysis reaction system to perform high-temperature cracking on tar generated by primary sludge pyrolysis; converting the tar into gaseous compounds having low molecular weight and other products. The method recycles sludge pyrolysis carbon as the catalyst; through secondary pyrolysis conversion of the tar, tar content can be lowered obviously, gas yield and quality can be improved, and the method has the advantages of high efficiency and low cost. After the impregnated pyrolytic carbon as the catalyst is inactivated, the impregnated pyrolytic carbon can restore its activity through steam gasification reaction. The recycling process can be operated for more than 5 times cyclically.

Owner:BEIJING UNIV OF CHEM TECH

Coal tar desalination process

ActiveCN104910944AGood desalination effectEasy to operateTar working-up by thermal treatmentDecompositionWater content

The invention belongs to the field of coal chemical processes, and in particular relates to a coal tar desalination process which comprises the following steps: filling desalted water into coal tar, heating to 85-95 DEG C, performing first-stage dehydration by using a horizontal screw centrifuge to remove solid phase of which the particle size is greater than 50mu m, dehydrating until the water content is less than 2%, performing second-stage dehydration by using a flottweg separator so as to remove solid phase of which the particle size is within 5-50mu m, dehydrating until the water content is 0.5% or below, and performing hydrotreating on the treated coal tar. The coal tar desalination process provided by the invention is good in desalination effect, and stable to operate, the desalination rate is greater than 99.5%, the temperature is lower than that of electric desalination, the process is easy to operate, salt decomposition can be avoided, the problem that an oil-water interface cannot be completely separated in a conventional electric desalination process can be avoided, and the problem that an electric desalination tank has sedimentation and scaling can be also avoided.

Owner:SHANDONG BAOTA NEW ENERGY CO LTD

Bio-asphalt, bio-asphalt composition and method for preparing them

ActiveUS20160194580A1Low production costLow costOrganic oxidationIn situ pavingsBituminous materialsAromatic hydrocarbon

The disclosure provides bio-asphalt, bio-asphalt compositions and a method for preparing them. It belongs to the technical field of asphalt material. The method of the disclosure uses bio-oil as the raw material, adopts a combination of extraction process and oxidation process to prepare bio-asphalt, and modifies the product obtained from bio-oil by extraction process or bio-asphalt with ordinary petroleum asphalt and / or aromatic hydrocarbon oil and a macromolecular material to obtain a bio-asphalt composition.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

Method for improving creosote content in biomass molding fuel tar

InactiveCN104312604AThe total relative content increasedHigh synthesis reaction efficiencyCarbon compoundsBiofuelsAir atmosphereCreosote

The invention discloses a method for improving creosote content in biomass molding fuel tar and is suitable for a production technology for preparing molding charcoal through the pyrolysis of a rodlike fuel briquetted by the raw materials of pine chips, fir chips and hard mixed wood chips under the condition of an oxygen containing environment. The biomass molding fuel is pyrolyzed under an alkaline air atmosphere (VNH3: V air = (1-3): 100), and ammonia gas is produced in a mode of heating ammonia water. The constituents of the tar pyrolyzed by the biomass molding fuel can be obviously changed by the pyrolysis method. The total creosote relative content can be improved from less than 80wt% to 85-92wt%, the substitution ratio of the tar byproduct in the reaction of substituting part of phenol and synthesizing a phenolic resin adhesive is increased from 25% to 30-50%, the pollution of the tar byproduct to the environment in the production process of the biomass molding fuel can be reduced, and the preparing cost of the phenolic resin adhesive is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

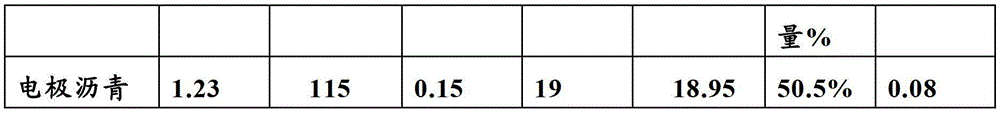

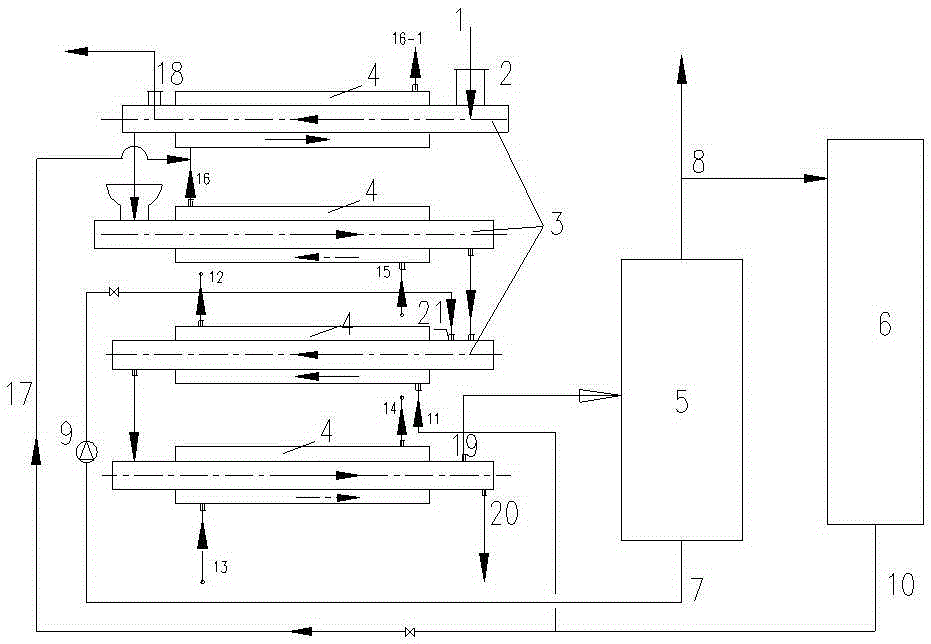

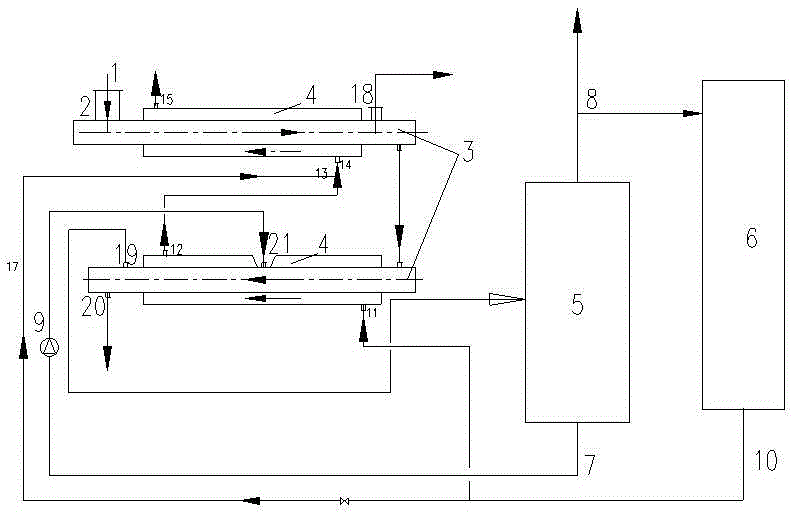

Tar treatment method and treatment device

InactiveCN106811223AEasy to transportAchieve separationPipeline systemsTar working-up by thermal treatmentTarPetrochemical

The invention relates to the technical field of petrochemical industry and aims to provide a tar treatment method and a tar treatment device. The tar treatment method comprises the following steps: 1, treating a tar-containing DMF cycling solvent through heating and pressure-reducing treatment and separating out tar; 2, heating ethylene disk oil; 3, mixing separated tar and the ethylene disk oil. The tar treatment device comprises a first container, a second container and a conveying system; heating devices and discharge pipes are arranged on the first container and the second container; the conveying system is connected with the second container. The tar treatment method and the tar treatment device have the beneficial effects that the tar is separated out through proper temperature and vacuum degree; the tar is diluted and dissolved by the ethylene disk oil, conveying of the tar is facilitated and the tar can be conveyed to the required procedure in a long distance; the whole process is sealed, a worker does not need to be in direct contact with the art, and the treatment process is safe and environmentally-friendly.

Owner:福建省环境工程有限公司

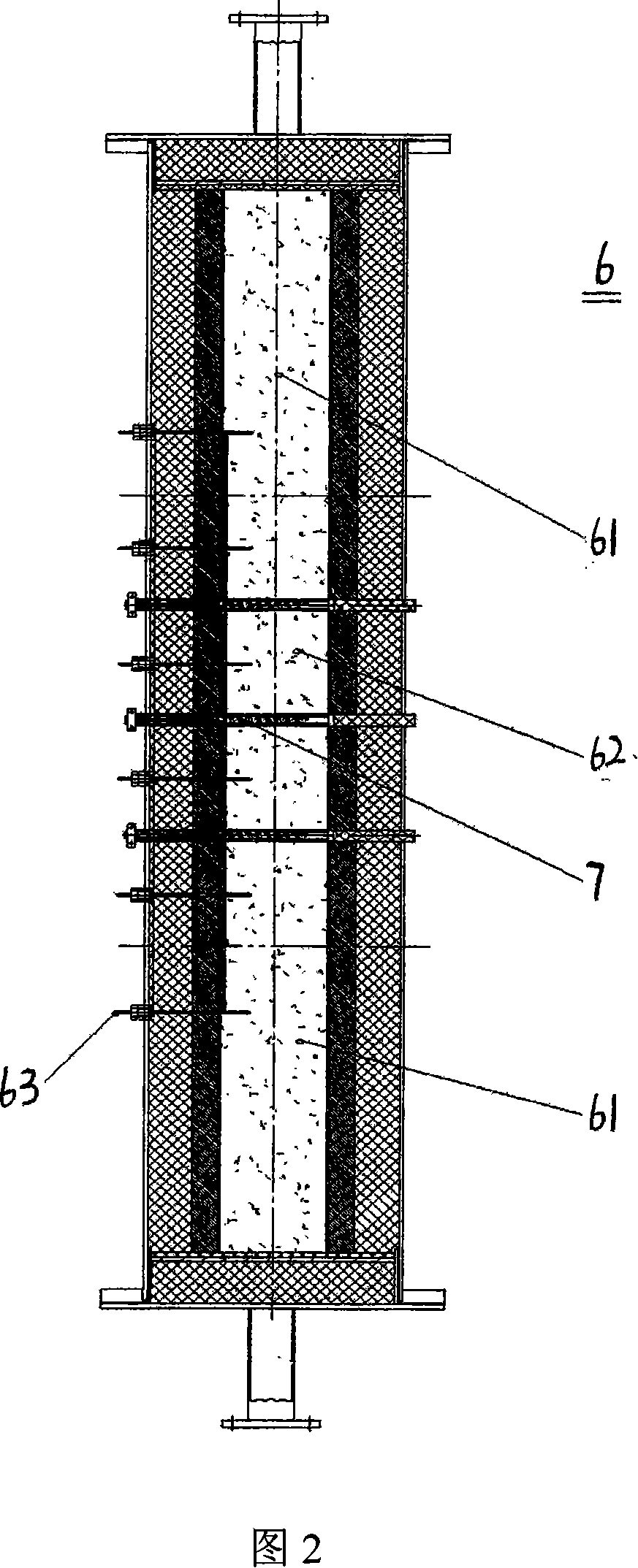

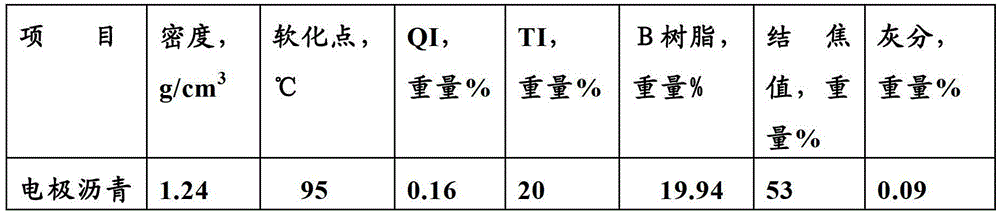

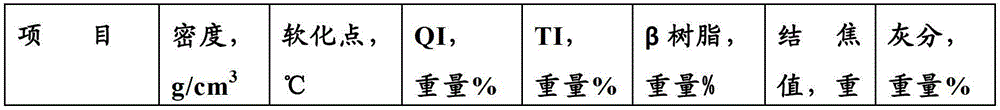

Electrode pitch and preparation method thereof

ActiveCN104031669ALow softening pointLow QI contentTar working-up by solvent extractionTar working-up by thermal treatmentOrganic solventAtmosphere

The invention provides a method for preparing an electrode pitch by using direct coal liquefaction residues as a raw material. The method comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent to obtain extracted pitch; and 2, processing the extracted pitch in inert atmosphere at 350-420DEG C to obtain the electrode pitch. The softening point of the electrode pitch is 90-120DEG C, the QI content of the electrode pitch is lower than 0.2%, and the coking value of the electrode pitch is greater than 50%. The invention provides the cheap electrode pitch prepared by using the cheap direct coal liquefaction residues as a raw material, and the preparation method thereof.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

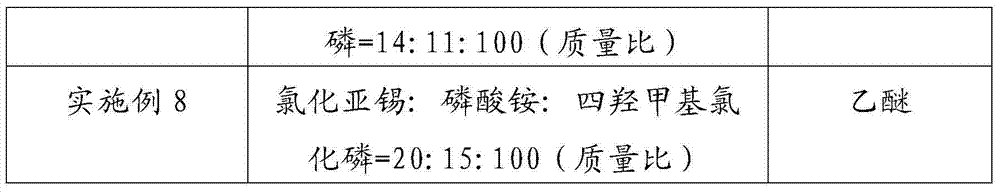

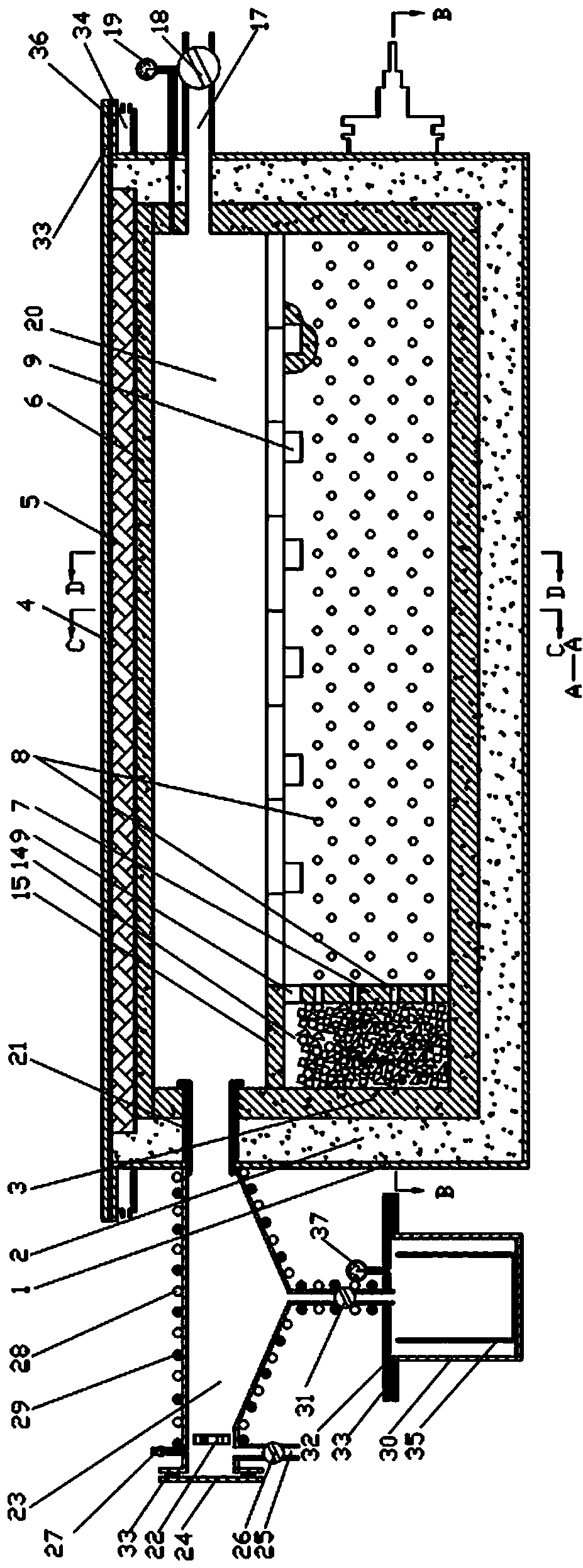

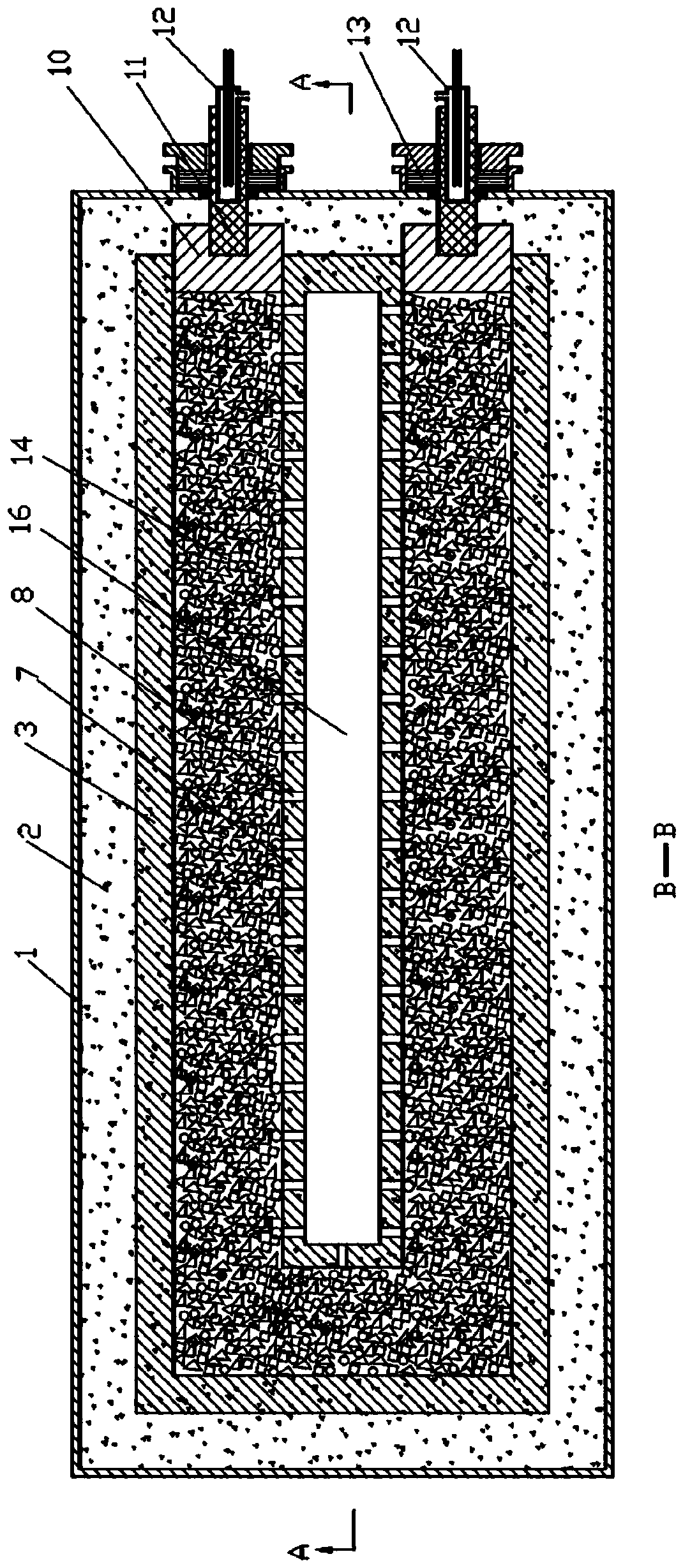

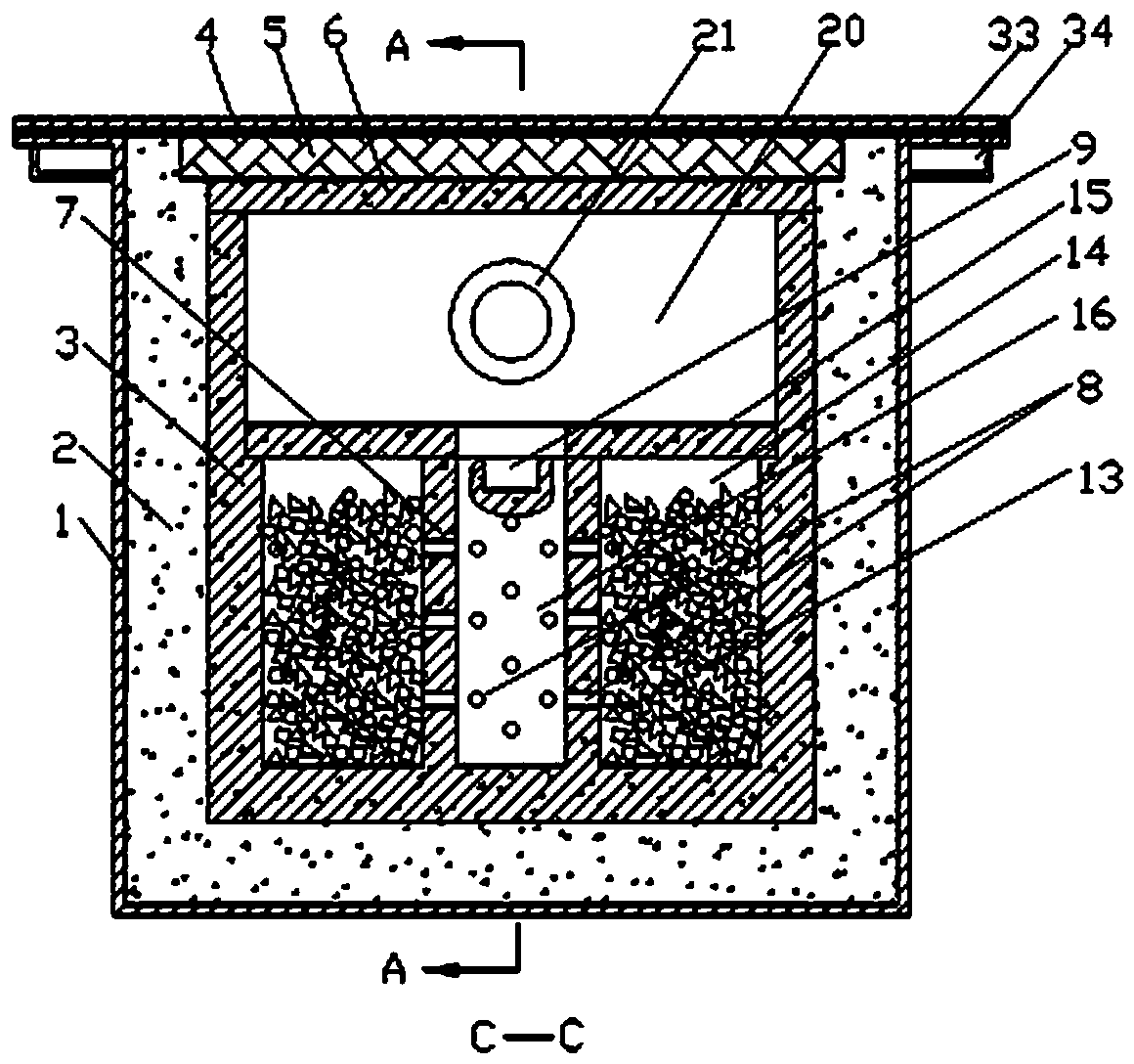

Charing and gasification composite furnace

ActiveCN106256877AEasy to controlEasy to shareGasifier feeding meansGasification catalystsSludgeFlue gas

The invention relates to a charing and gasification composite furnace, which can realize charing and gasification of to-be-processed materials such as garbage, sludge, sawdust, ground bark, rice husk, rice straw, peanut shell, peanut vine, coconut shell, palm shell, hemp xyloid stem, cotton stalk and straw, and two products of combustible gas and charcoal with calorific value of greater than 10-12 MJ / Nm<3> can be obtained. The charing and gasification composite furnace comprises a multistage pyrolysis channel, a flue gas channel, an oil and gas separator and a combustion gas combustion furnace. The multistage pyrolysis channel comprises a feed inlet of a to-be-processed material, a discharge port, an oil returning port, a volatile matter guiding outlet, a charcoal discharge port, and can form a segmentation sleeve with the flue gas channel; the discharge port is positioned at the pyrolysis channel with the feed inlet, the oil returning port is positioned at a middle and rear part of the pyrolysis channel; the volatile matter guiding outlet and an inlet of the oil and gas separator are connected; an oil chamber at the upper part of the oil and gas separator is connected with the oil returning port on the multistage charing pipe through an oil pump; and a gas chamber at the upper part of the oil and gas separator is simultaneously connected with a contact tube and a combustion gas combustion furnace. A connection pipe is arranged on a flue gas channel on outside of the pyrolysis channel with the oil returning port, and is connected with the combustion gas combustion furnace, and the flue gas departs from the channel, then passes through the high and low temperature material channels.

Owner:TONGJI UNIV

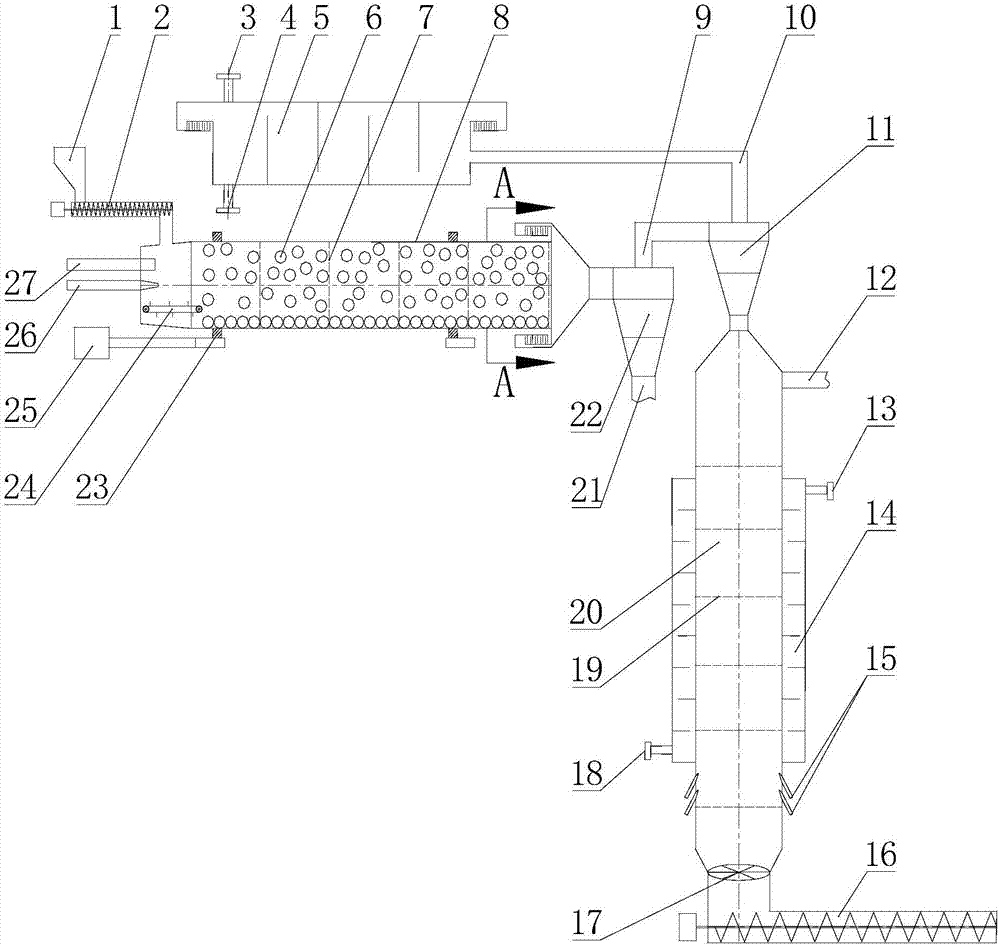

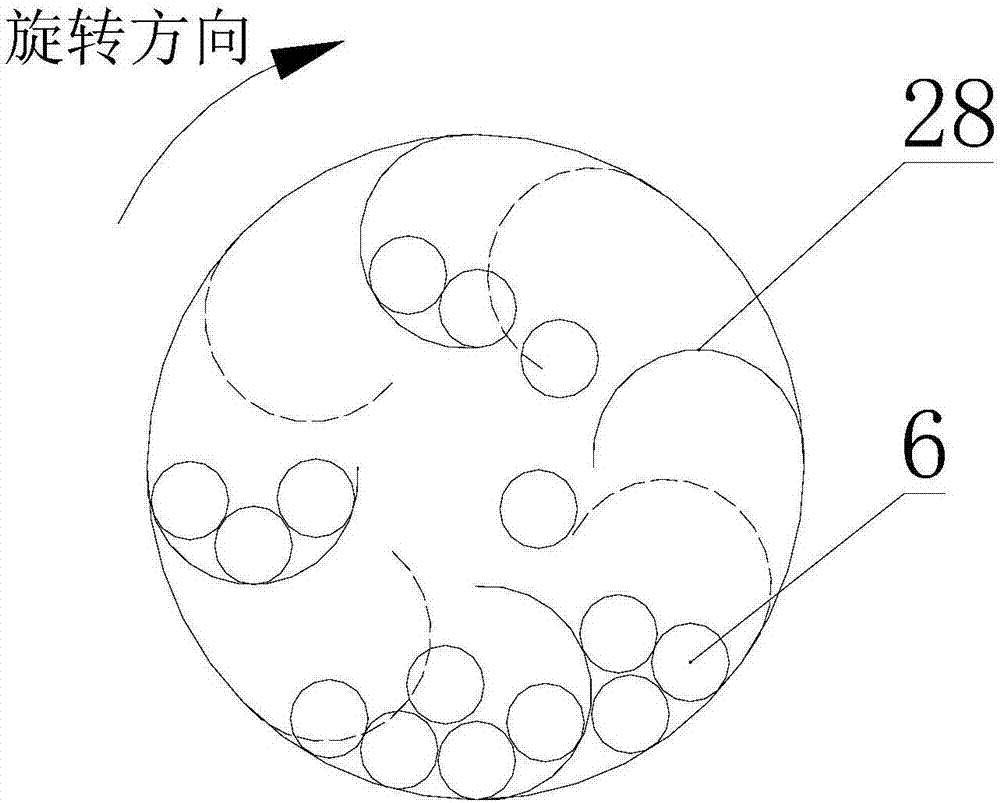

Device for co-producing phenol-enriching liquid and iron-doped carbon electrode material

ActiveCN106995711AAchieve conversionCrushed fullyHybrid capacitor electrodesCarbon preparation/purificationLiquid productBiological activation

The invention discloses a device for co-producing a phenol-enriching liquid and iron-doped carbon electrode material. The device comprises a wood tar catalytic thermal decomposition rotary reactor and an iron-doped carbon activation furnace, wherein the wood tar catalytic thermal decomposition rotary reactor comprises a feeding packing auger, a wood tar spraying nozzle, crushing iron balls, a screen mesh, a rough and fine grain separator and a gas-solid separator; an iron ore catalyst is sufficiently crushed and sieved and is in sufficient contact with wood tar, so that the wood tar is subjected to sufficient catalytic thermal decomposition reaction to generate high-quality phenol-enriching liquid and iron-doped carbon product; the iron-doped carbon activation furnace comprises an activated gas spraying nozzle, rotary fan blades and a high-temperature flue gas flue; high-temperature activated gas forms intensive disturbance under the action of the rotary fan blades and the high-temperature activated gas and iron-doped carbon, which moves downward layer by layer, are subjected to deep activation reaction to prepare a super-capacitor iron-doped carbon electrode material. According to the device disclosed by the invention, two grades of wood tar catalytic thermal decomposition and iron-doped carbon activation reaction are utilized and high-quality phenol-enriching liquid products and super-capacitor iron-doped carbon electrode materials can be prepared; efficient and high-value utilization of the wood tar can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

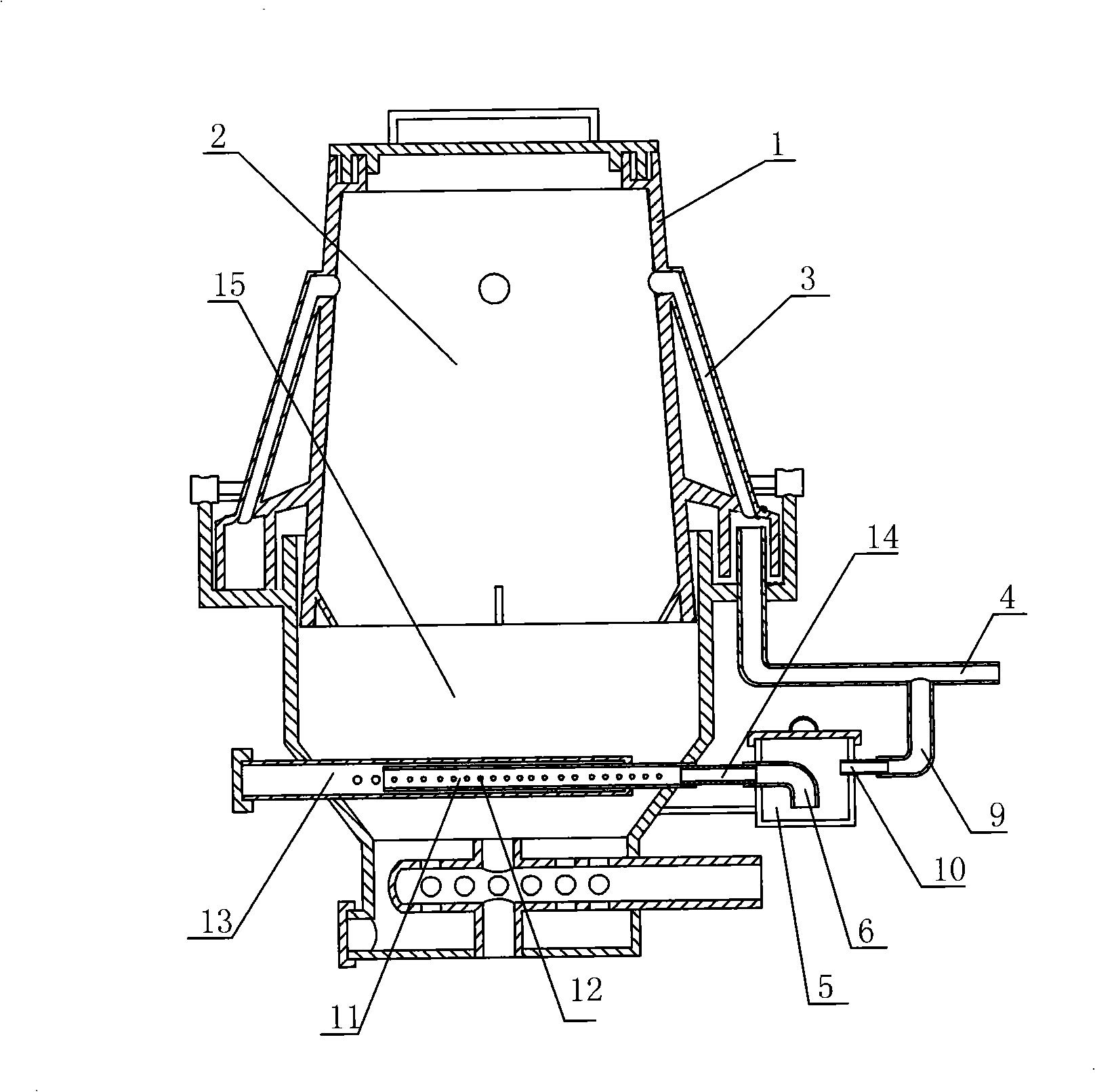

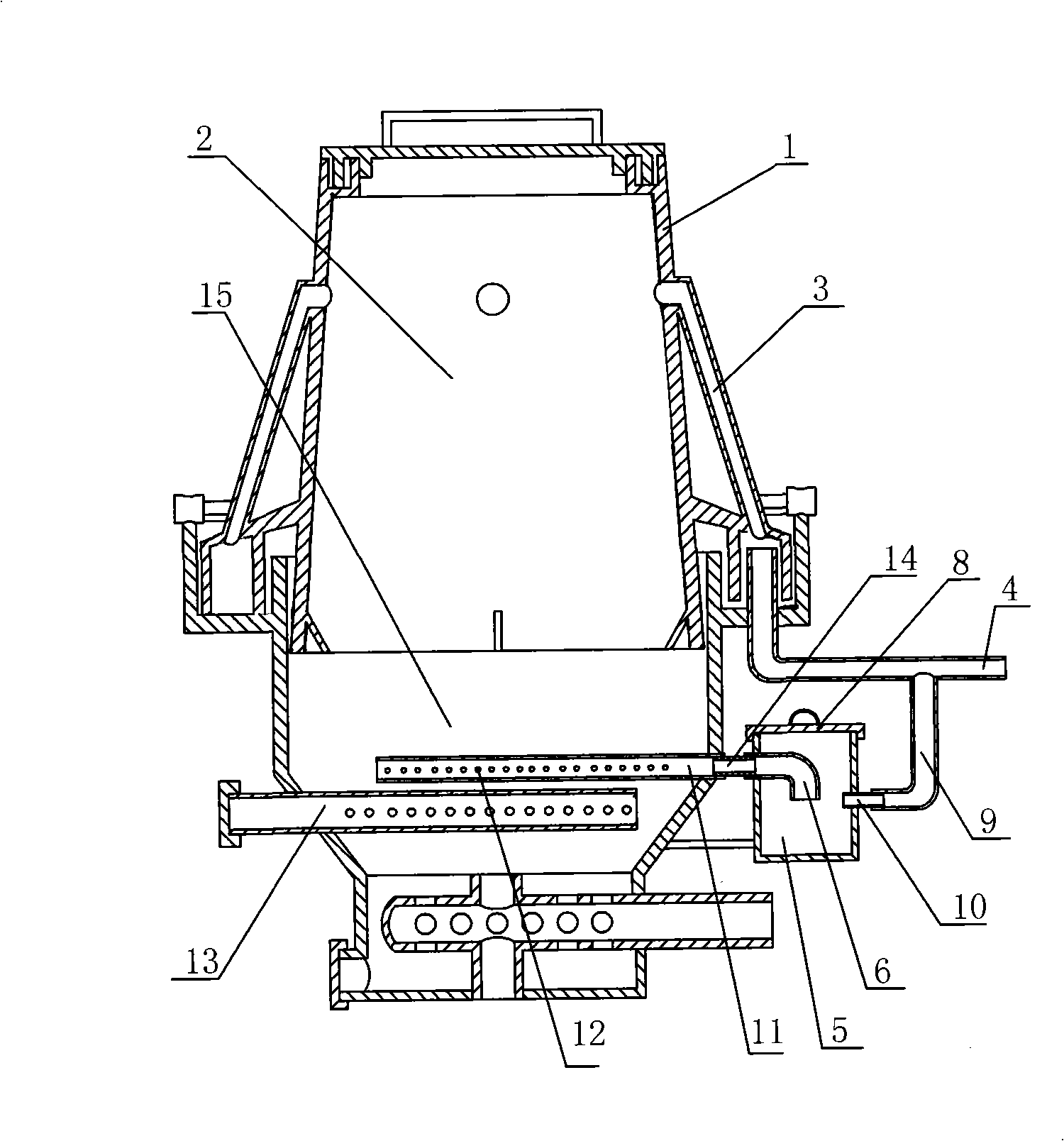

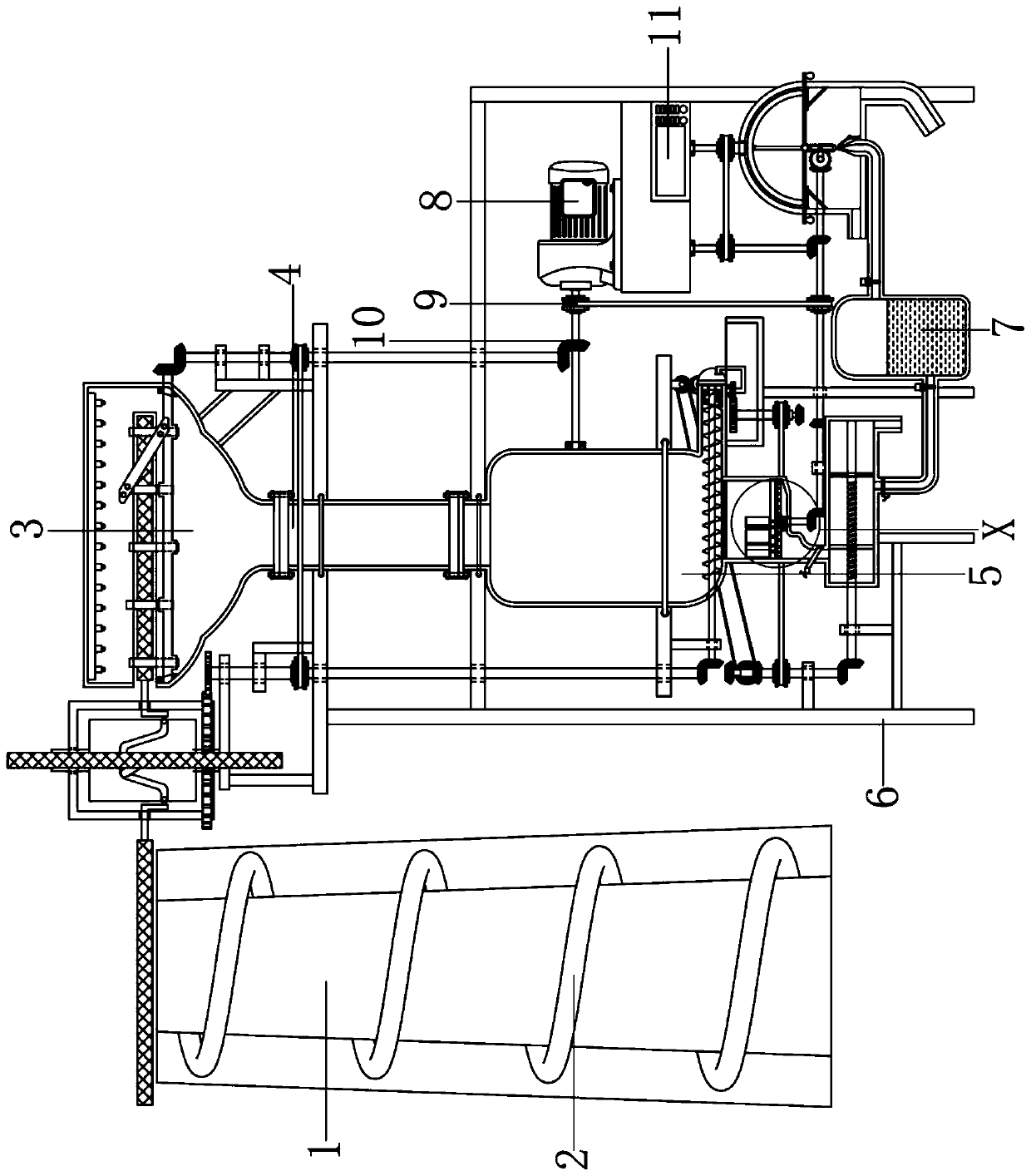

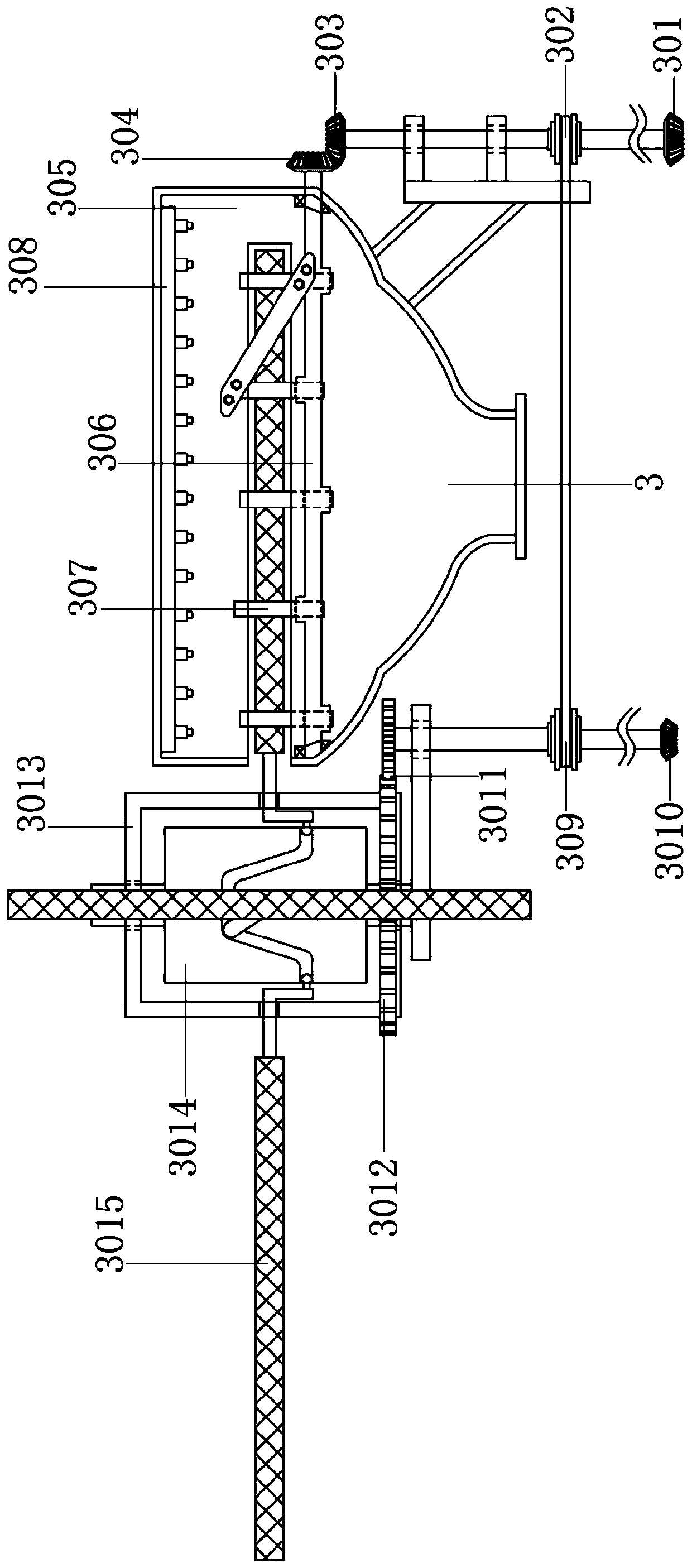

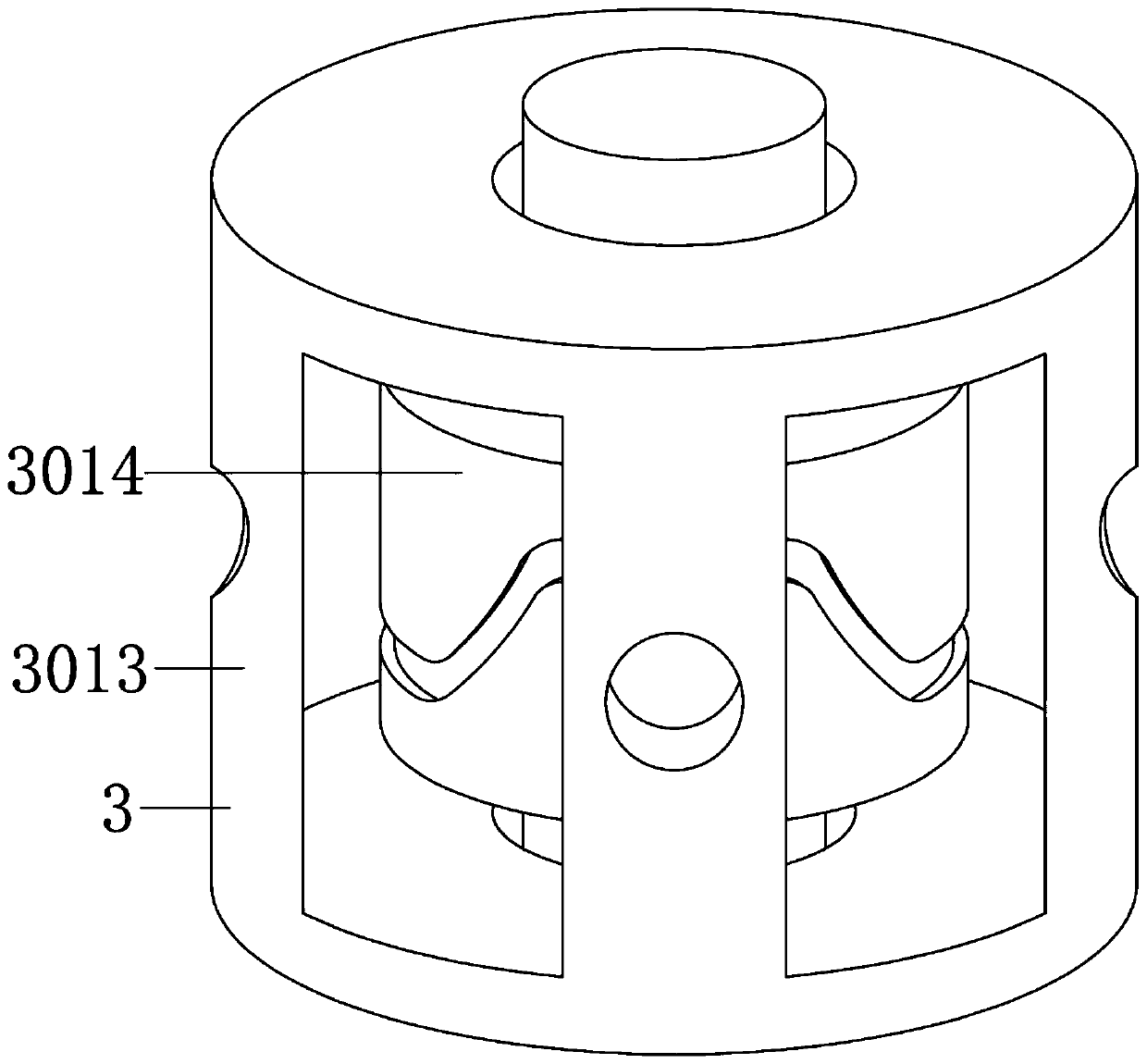

Tar cracking device of biomass gasifier

InactiveCN101284996AFully lysedQuality improvementSpecial form destructive distillationTar working-up by thermal treatmentCombustible gasTar

The invention relates to a tar cracking device for biomass gasifiers. The lower part outside a furnace hearth (2) is provided with a reflow device (5); a V-shaped pipe (6) is arranged in the reflow device (5); one end of the V-shaped pipe (6) stretches into the hollow lower part of the reflow device (5); the other end of the V-shaped pipe (6) is connected with a cracking reaction pipe (11) and stretches into a furnace hearth high temperature area (15); the reflow device (5) is communicated with a gas transmission pipe (4) through a reflow pipe (9); a reaction hole (12) is arranged on the cracking reaction pipe; the reflow device (5) is arranged lower than the gas transmission pipe (4). The tar cracking device has tar and water reflow to enter the furnace hearth, utilizes the high temperature produced in the working process of a gasifier to transform tar and water into combustible gas, realizes tar cracking without additional heat source, cracks tar fully, produces no matter such as black charcoal, cannot cause secondary pollution, and can improve the quality of produced gas. In addition, the tar cracking device is simple in structure and very convenient to operate.

Owner:ZHANGJIAJIE SANMU ENERGY DEV

Separation method for phenol compounds and nitrogen-containing compounds in coal tar

ActiveCN103937522BEasy to separateImprove qualityTar working-up by chemical refiningTar working-up by solvent extractionNitrogenEvaporation

The present invention discloses a separation method for phenol compounds and nitrogen-containing compounds in coal tar, wherein the problem that the coal tar is generally subjected to phenol compound separation is solved. The technical scheme comprises: adding a complexation separation agent to coal tar to carry out a complexation reaction, and then adopting an evaporation and back extraction manner to rapidly separate the nitrogen-containing compounds, the phenol compounds, the renewable separation agent and the solvent. The separation method has characteristics of simple process, environmental protection, no phenol-containing wastewater production, achievement of rapid and synchronous removal of phenol compounds and nitrogen-containing compounds, and good removal effect.

Owner:WUHUAN ENG

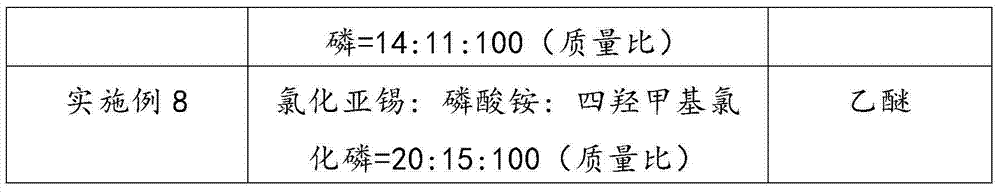

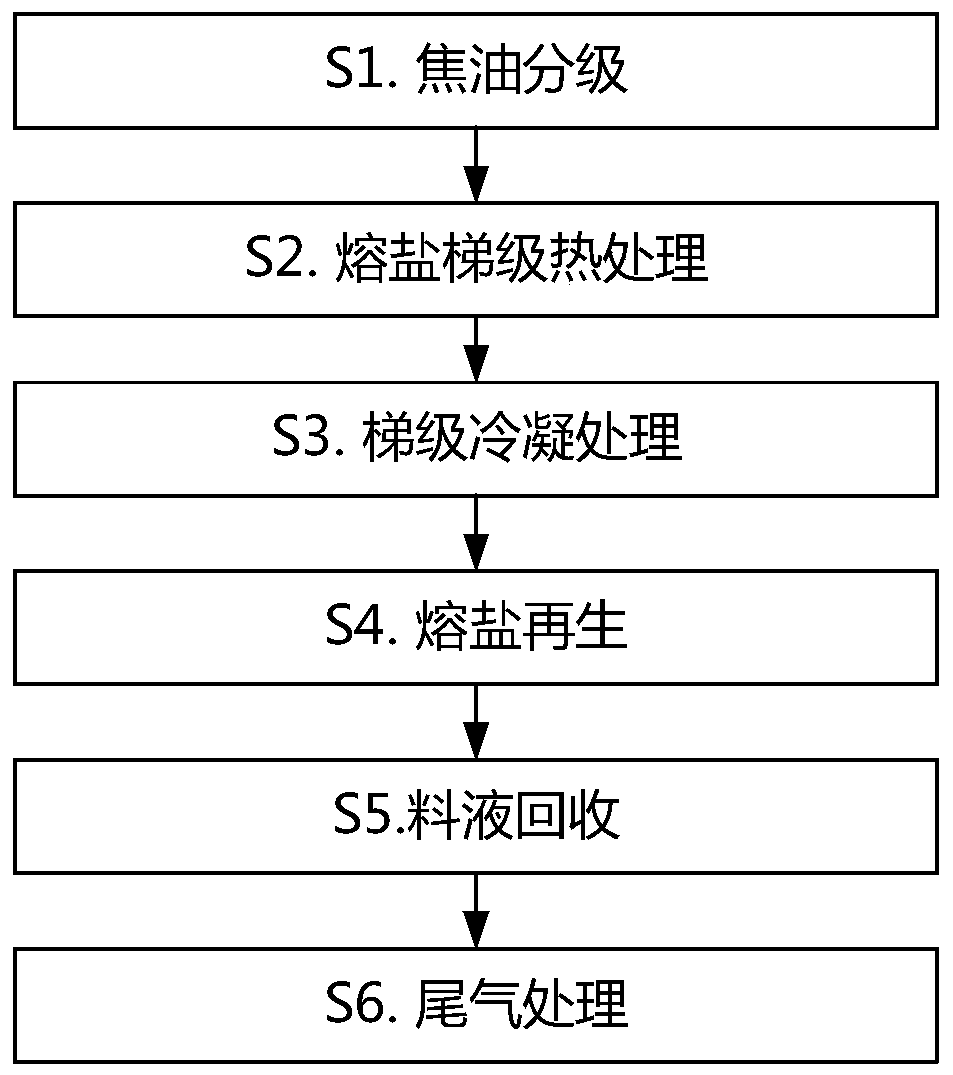

Solid waste pyrolysis liquid-phase product fused salt cascade treatment impurity removal and quality improvement device

ActiveCN111518583ARealize classification conversionReduce energy consumptionTar working-up by thermal treatmentFluid phaseLiquid storage tank

The embodiment of the invention provides a solid waste pyrolysis liquid phase product fused salt cascade treatment impurity removal and quality improvement device. The device comprises a tar grading unit, a fused salt cascade heat treatment unit, a cascade condensation treatment unit, a fused salt regeneration unit, a feed liquid recovery unit and a tail gas treatment unit. When the device works,a solid waste pyrolysis liquid-phase product is subjected to settling and grading treatment and then fed into a second-stage molten salt reactor for cascade heat treatment, generated slag is further regenerated and then returns to the molten salt reactor, a reaction product enters a two-stage condenser to realize gas-liquid separation, a second-stage liquid-phase product is used as a working medium to enter a cooling circulation system to cool a first-stage condenser, separated liquid after circulation enters a liquid storage tank, and generated gas is further subjected to tail gas treatment and reutilization. The device provided by the invention solves the problems of low utilization rate of the solid waste pyrolysis liquid phase product, possible secondary pollution and the like, and realizes the technical goals of comprehensive treatment and resource utilization of the solid waste pyrolysis liquid phase product.

Owner:HUAZHONG UNIV OF SCI & TECH

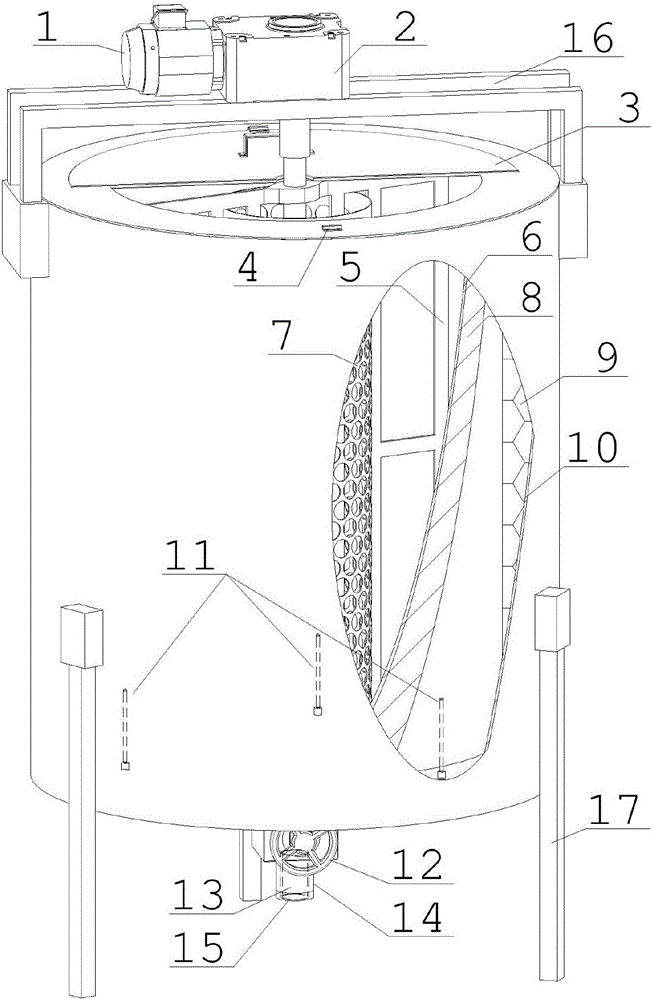

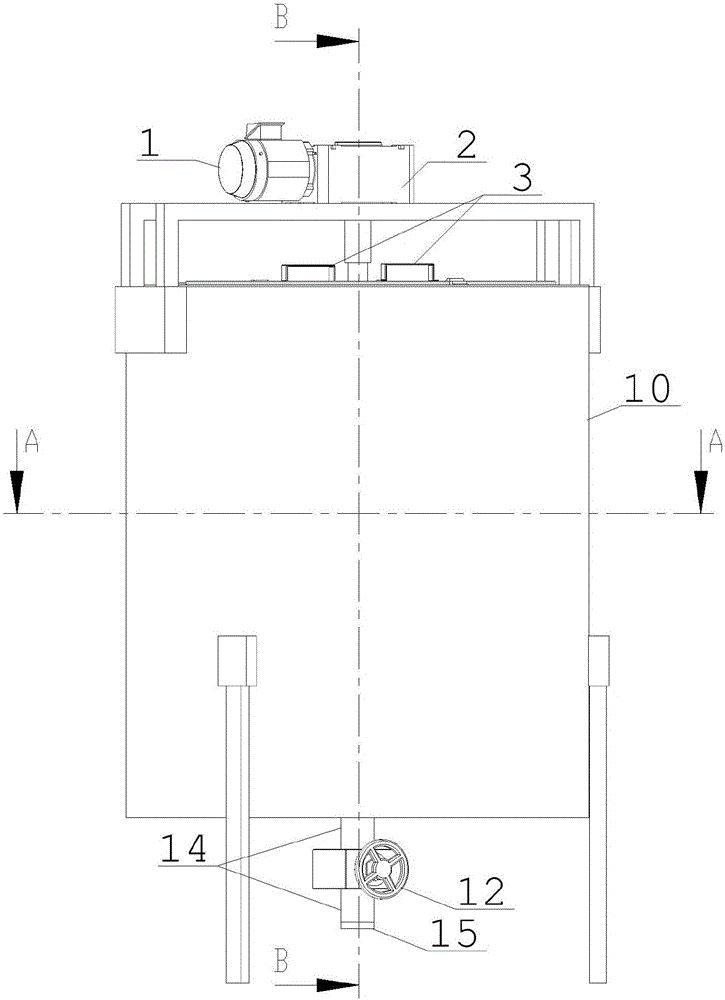

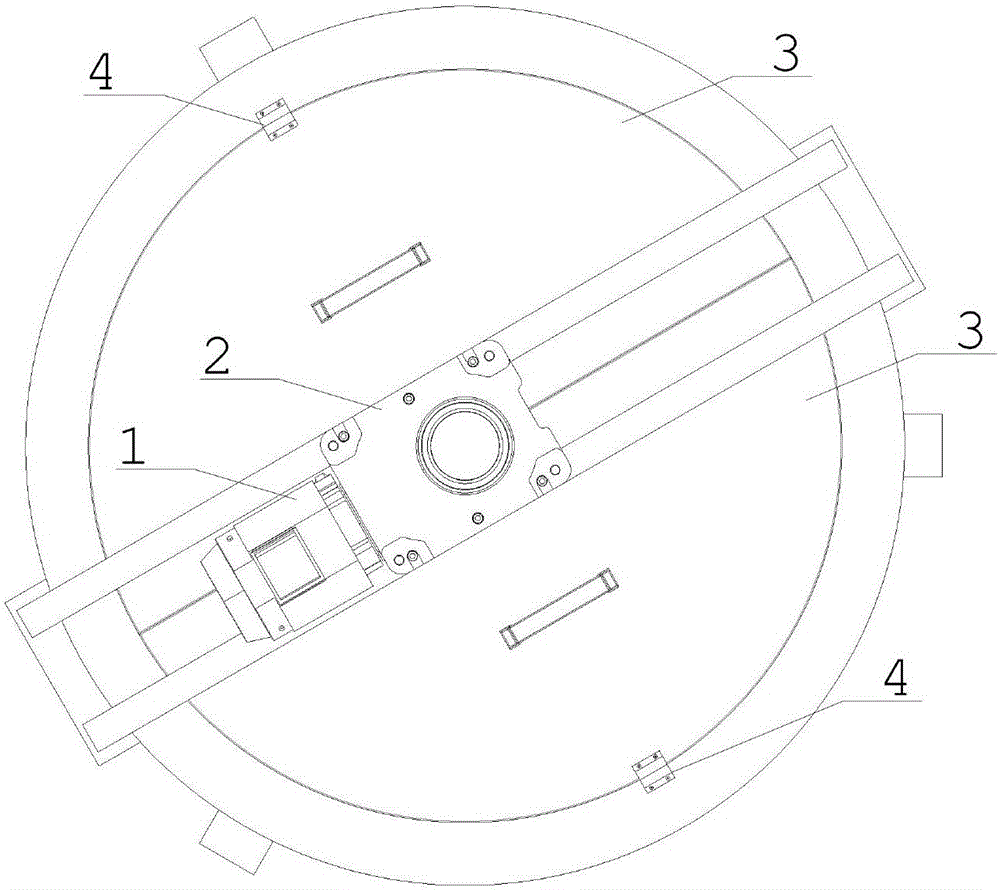

Device for preparing polishing glue

PendingCN106475002AUniform stress distributionRealize automated productionRotary stirring mixersTransportation and packagingStress distributionInsulation layer

The invention discloses a device for preparing polishing glue, belonging to the technical field of optical machining. The device comprises a barrel body, a barrel inner layer, a heat insulation layer between the barrel body and the barrel inner layer, and a barrel cover at the upper part of the device, wherein an upper bracket is arranged at the upper part of the barrel body; a motor, a speed reducer and stirring blades are arranged on the upper bracket; supporting legs are arranged at the lower part of the barrel body; a discharge pipe and a discharge valve are arranged at the bottom of the barrel body; an annular filter net is arranged among the stirring blades in the barrel body; and an annular ceramic heater is arranged between the barrel inner wall and the heat insulation layer. The stress distribution in the polishing glue obtained by pouring forming is uniform, so as to beneficial for controlling the surface shape of a processed element, and shortening the convergence time of the surface shape; however, filter nets arranged in the barrel and at an outlet can filter out impurity particles in a raw material, thereby reducing the content of large-grained impurities on the surface of the formed polishing glue, and reducing the probability of generating defects by an optical element. Finally, automatic production of the polishing glue is achieved, the preparation flow is simplified, and the forming quality of the polishing glue is improved.

Owner:成都精密光学工程研究中心

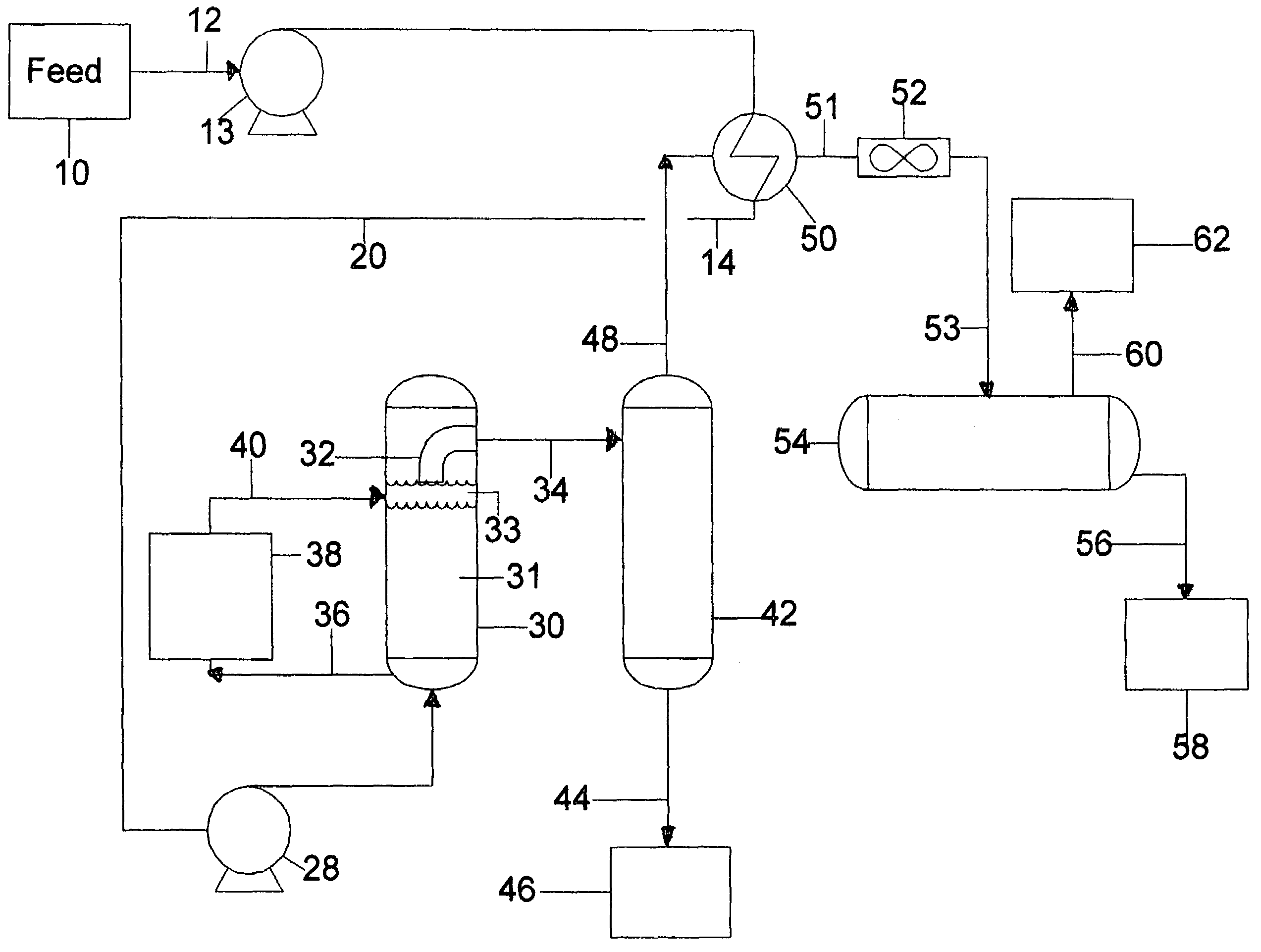

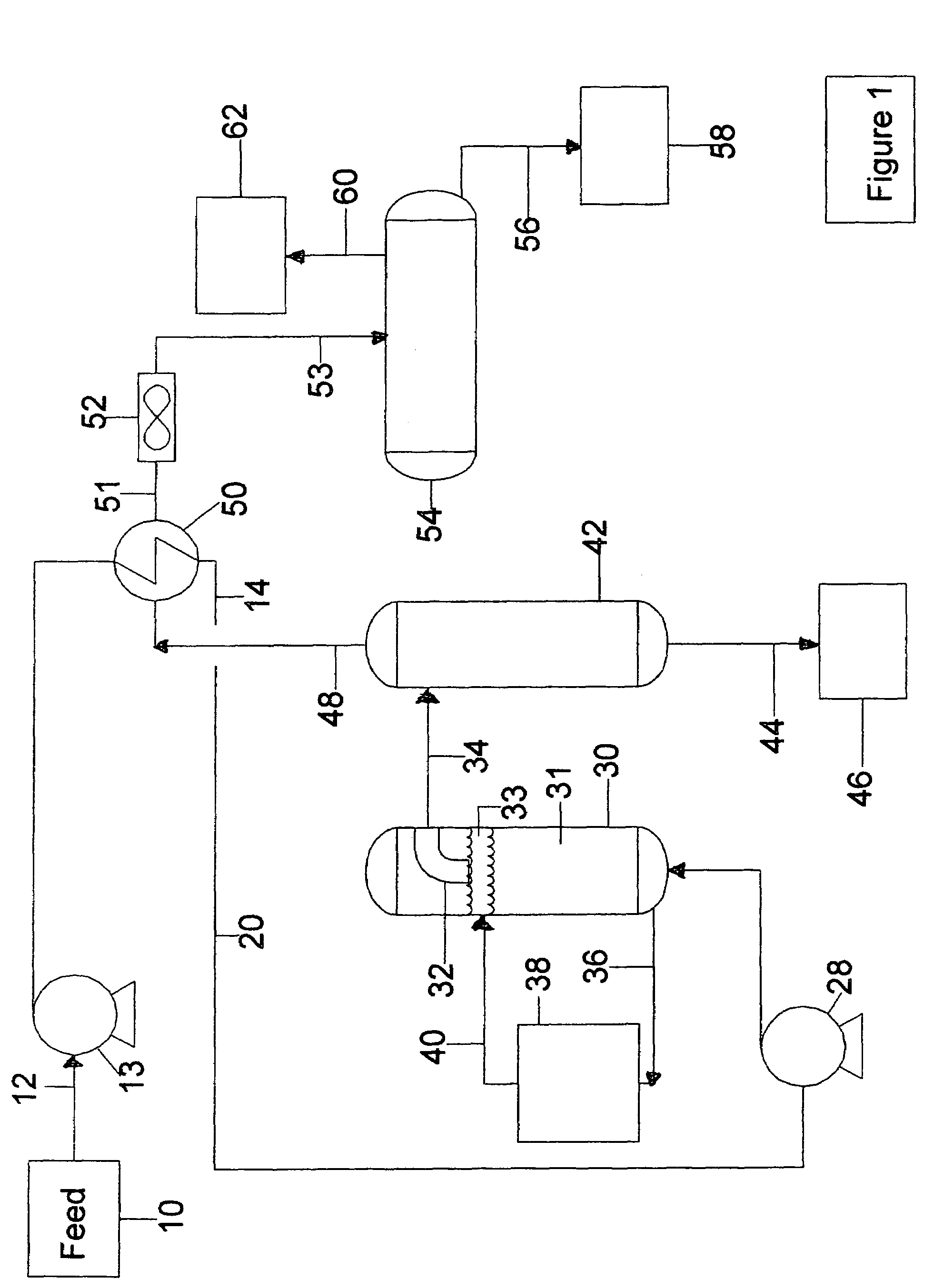

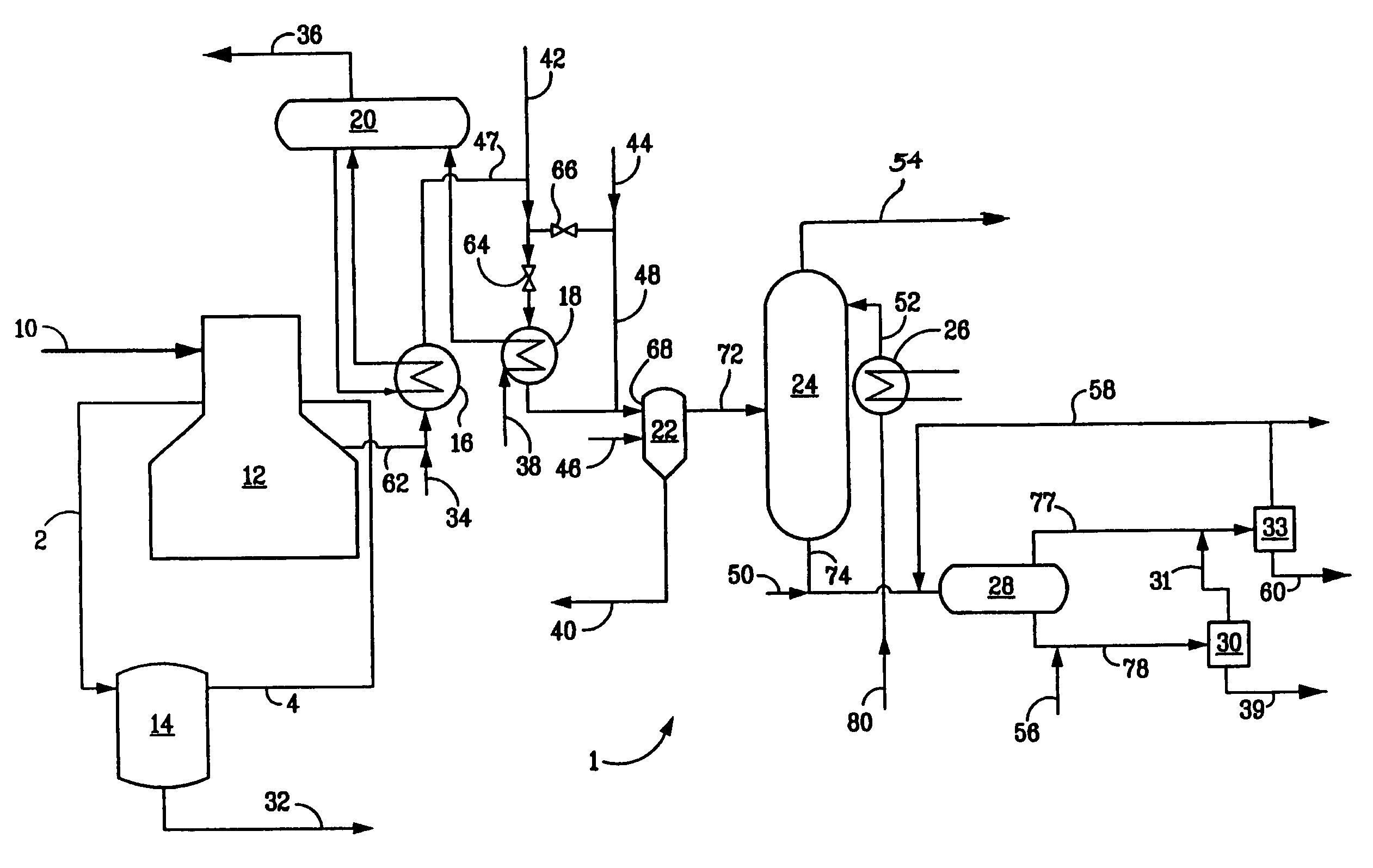

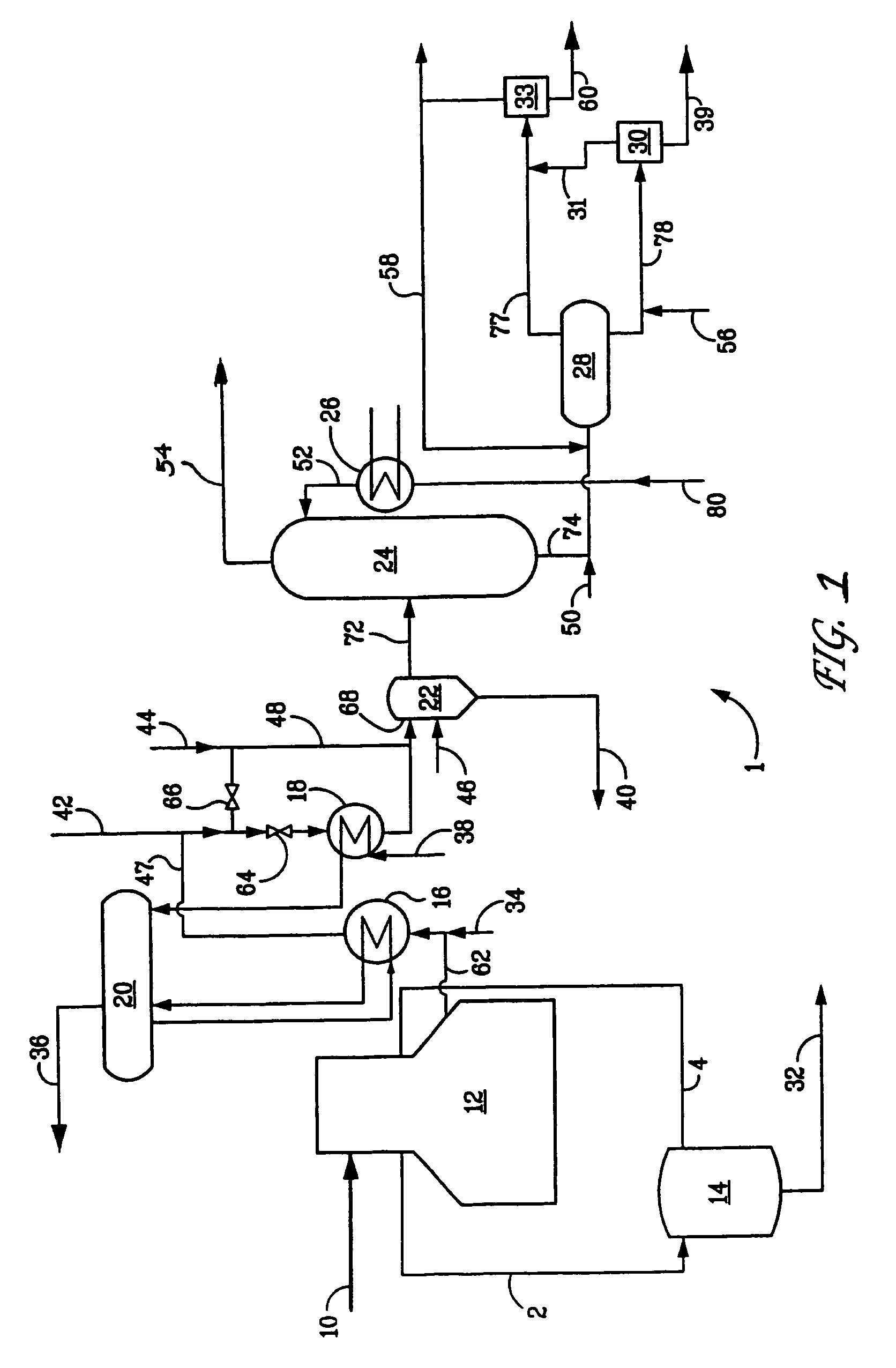

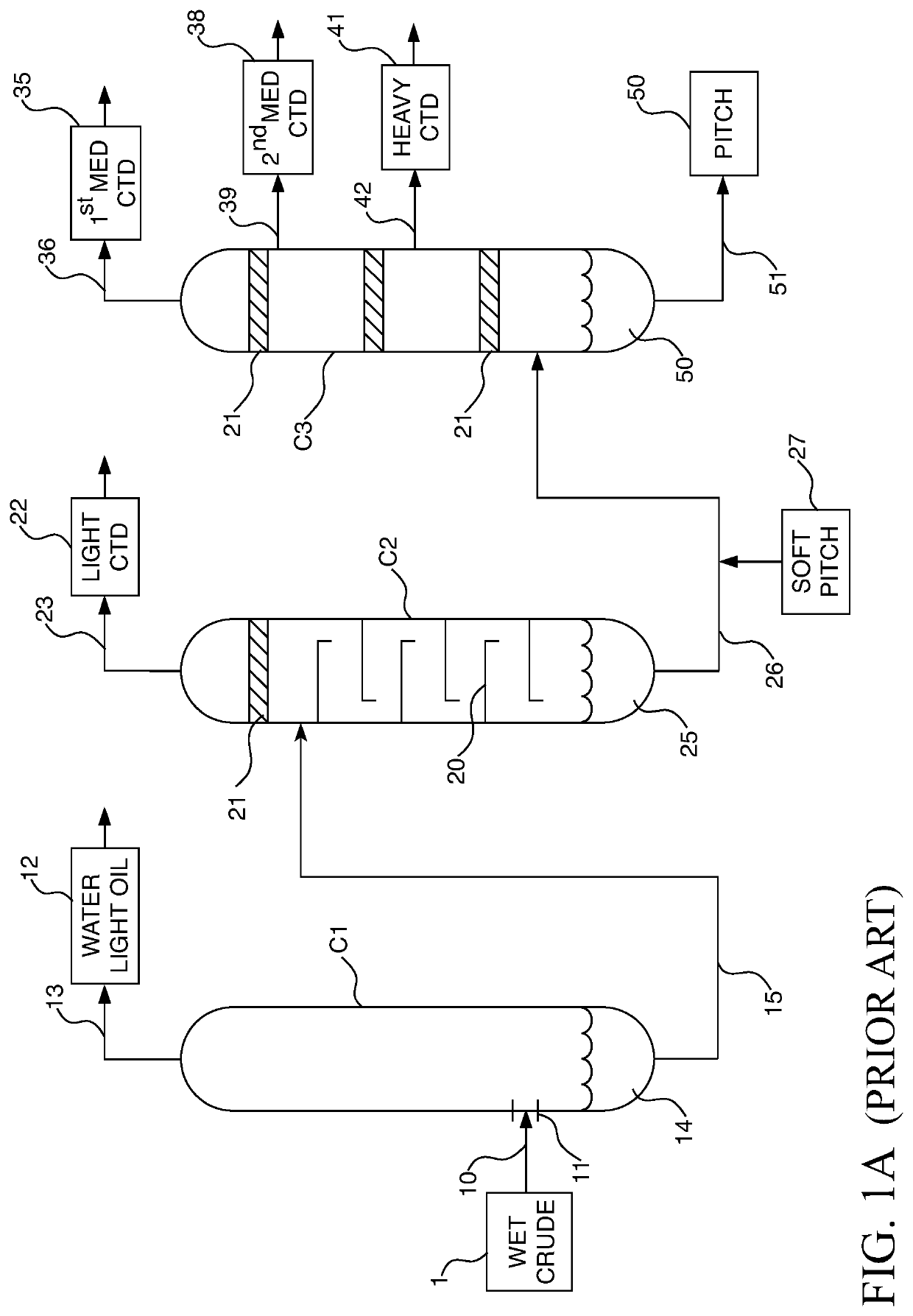

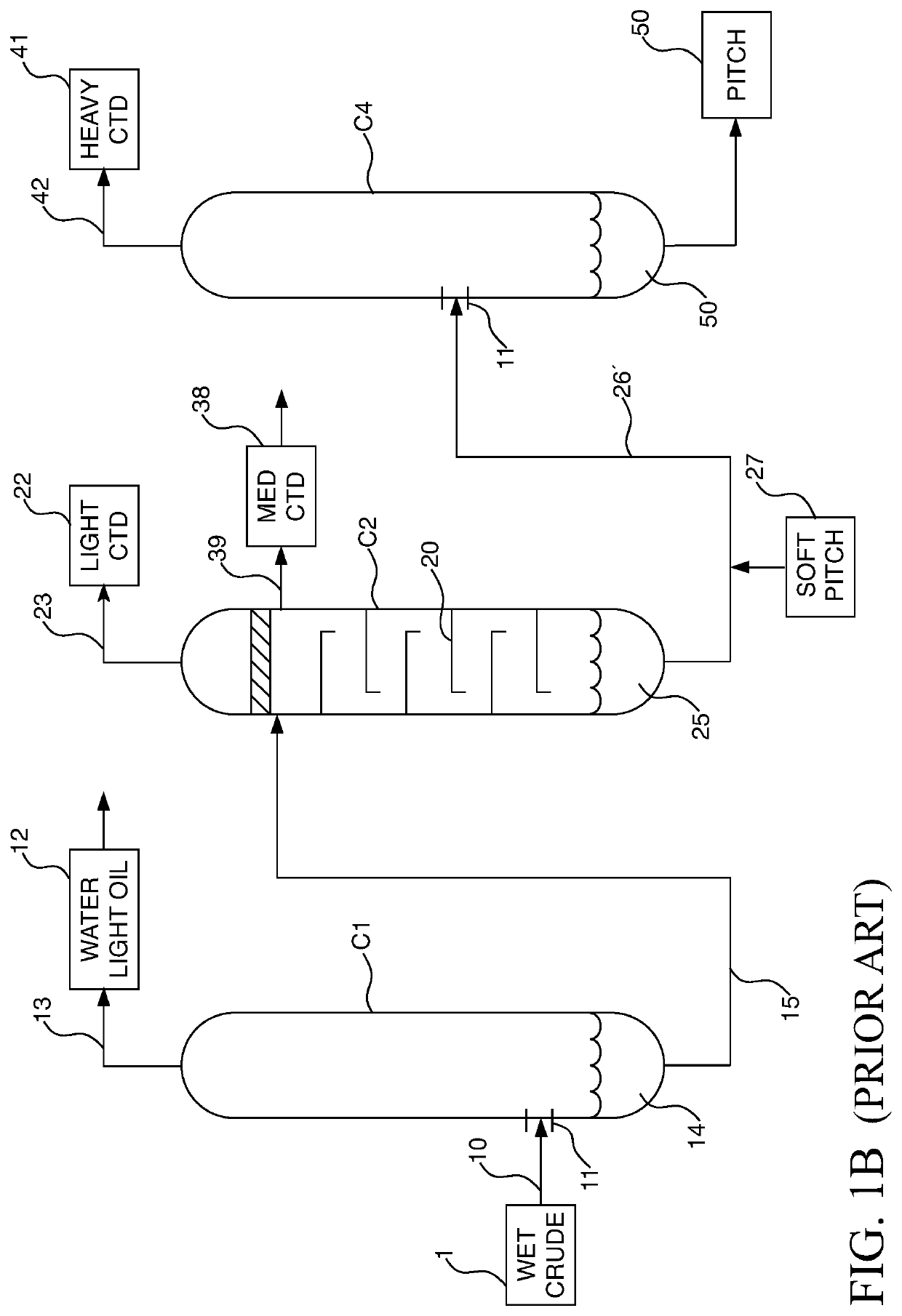

Controlling tar by quenching cracked effluent from a liquid fed gas cracker

ActiveUS7582201B2Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansProcess systemsTar

In a system for thermal cracking gaseous feedstocks, the system including a gas cracker for producing an effluent comprising olefins, at least one transfer line exchanger for the recovery of process energy from the effluent and a water quench tower system, a process for extending the range of system feedstocks to include liquid feedstocks that yield tar is provided. The process includes the steps of injecting a first quench fluid downstream of a primary transfer line exchanger to quench the process effluent comprising olefins, separating in a first separation vessel a cracked product and a first byproduct stream comprising tar from the quenched effluent, directing the separated cracked product to a water quench tower system and quenching the separated cracked product with a second quench fluid to produce a cracked gas effluent for recovery and a second byproduct stream comprising tar. An apparatus for carrying out such process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

Waste gas cracking device

InactiveCN111265966AReduce the effectIncrease profitPigmenting treatmentDispersed particle separationExhaust gas emissionsCoke

The invention relates to waste gas treatment, in particular to a waste gas cracking device. The technical problem to be solved by the invention is to provide the waste gas cracking device. The waste gas cracking device comprises a discharge chimney, a cooling pipe, a tar adhesion ammonia washing mechanism, a tar residue compression mechanism, a digestion cracking mechanism, a stepping motor and acontrol display; wherein an inner interlayer of the exhaust chimney is connected with the cooling pipe in a sleeving manner; a tar adhesion ammonia washing mechanism is arranged at the top of the right end of the discharge chimney; the middle part of the bottom end of the tar adhesion ammonia washing mechanism is in bolted connection with the extension pipe; and the bottom plate of the tar adhesion ammonia washing mechanism is connected with a bottom frame. The device achieves the effects that the coke sulfur waste gas is recycled again, after the waste gas is treated, carbon-containing organic matter in the waste gas is extracted through biological thermal cracking, then the organic matter is converted into carbon black through ignition, the carbon black is hung and collected and used forplastic manufacturing, the utilization rate of crude oil is increased, and meanwhile the effect of waste gas emission on air is reduced.

Owner:苏合梅

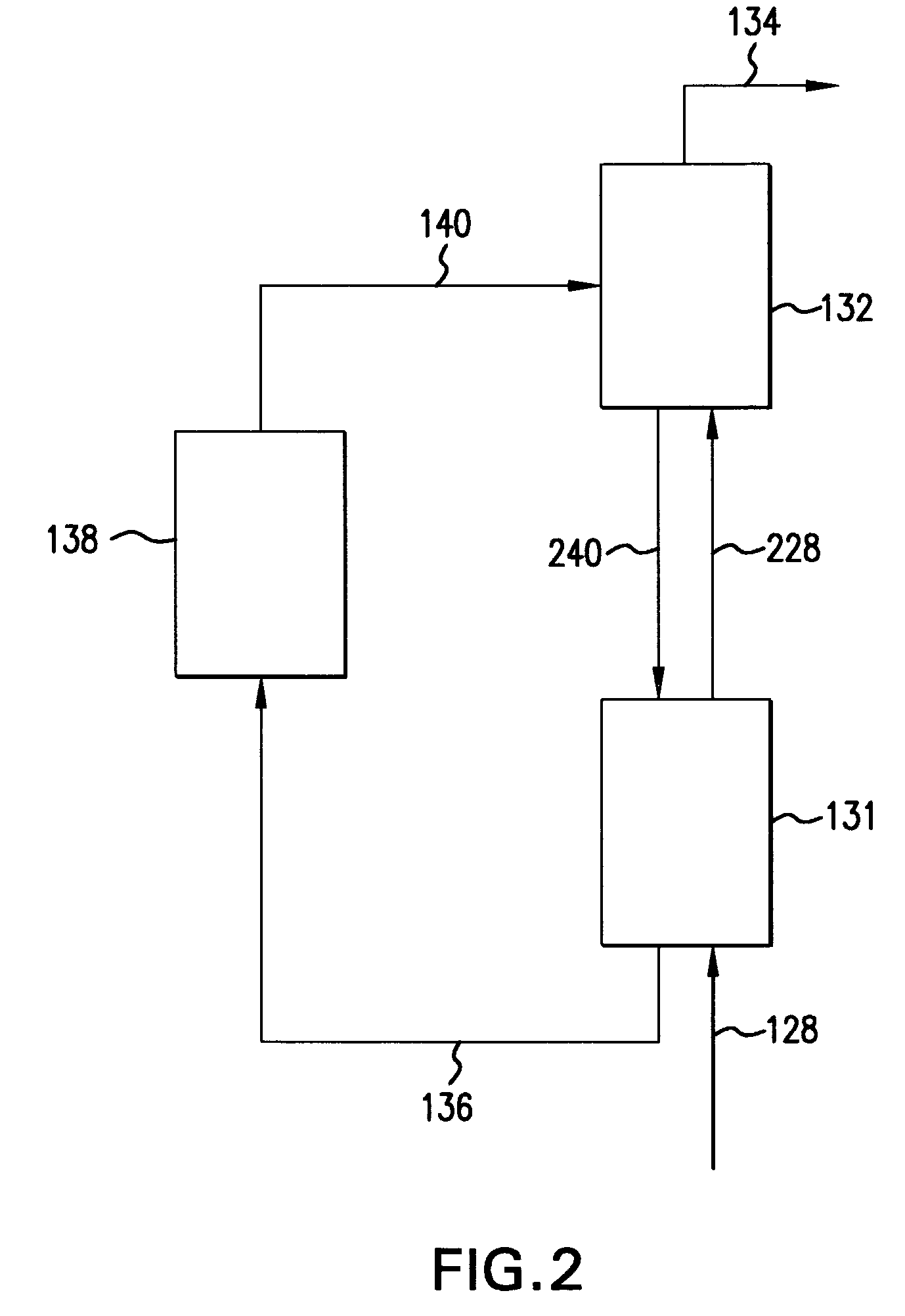

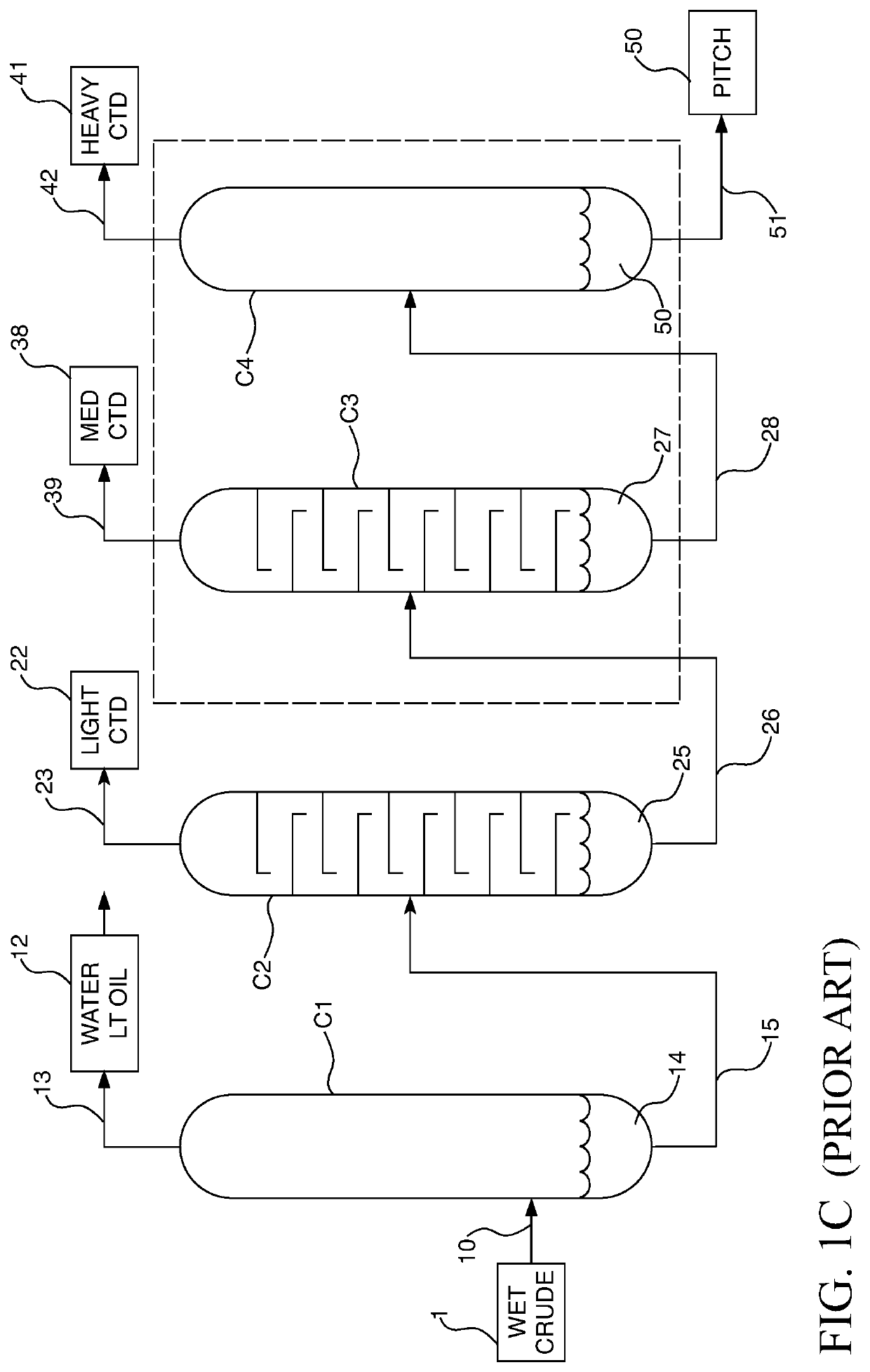

Heat Treatment Process and System for Increased Pitch Yields

ActiveUS20210024830A1Improve efficiencyIncrease productionWorking-up pitch/asphalt/bitumen by distillationTar working-up by distillationThermodynamicsPetroleum oil

Pitch production systems utilizing coal tar or decant oil for coal. or petroleum based pitch are disclosed. Total pitch production yields are increased by heat treating distillate fractions from the pitch production process. A heat treatment system and process are disclosed in embodiments. The heaviest distillates having the highest molecular weights are subjected to heat treatment, though other embodiments contemplate heat treating a variety of combined distillate fractions. The heat treatment systems require heat soaking the distillate(s) at elevated temperatures of 459-535° C. at a near-constant temperature with near-uniform flow. A fraction of the heat-treated distillate may be reintroduced to the pitch production system as part of a continuous process.

Owner:KOPPERS DELAWARE INC

Preparation method of soluble mesophase pitch

InactiveCN102942945BLow softening pointLow viscosityWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

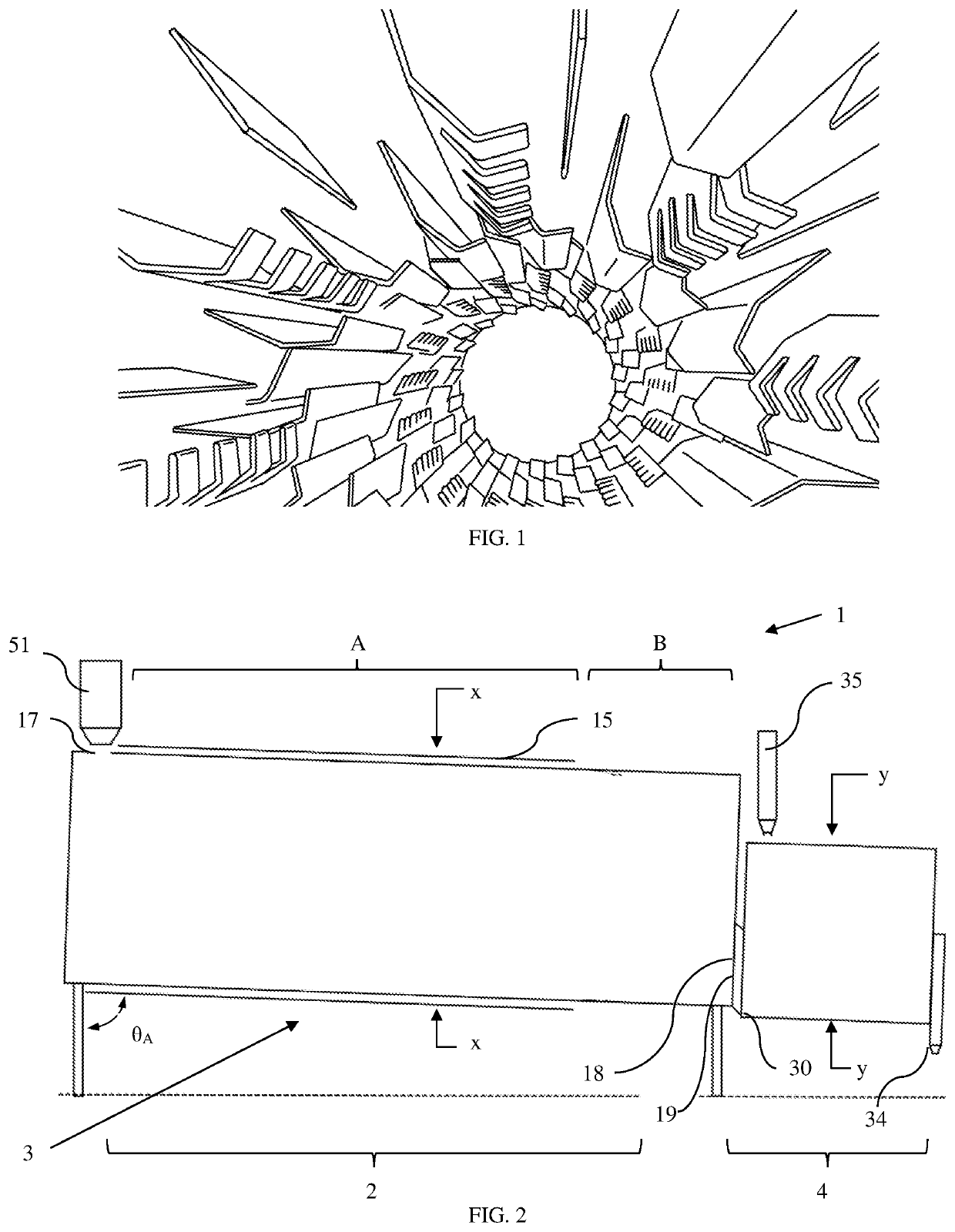

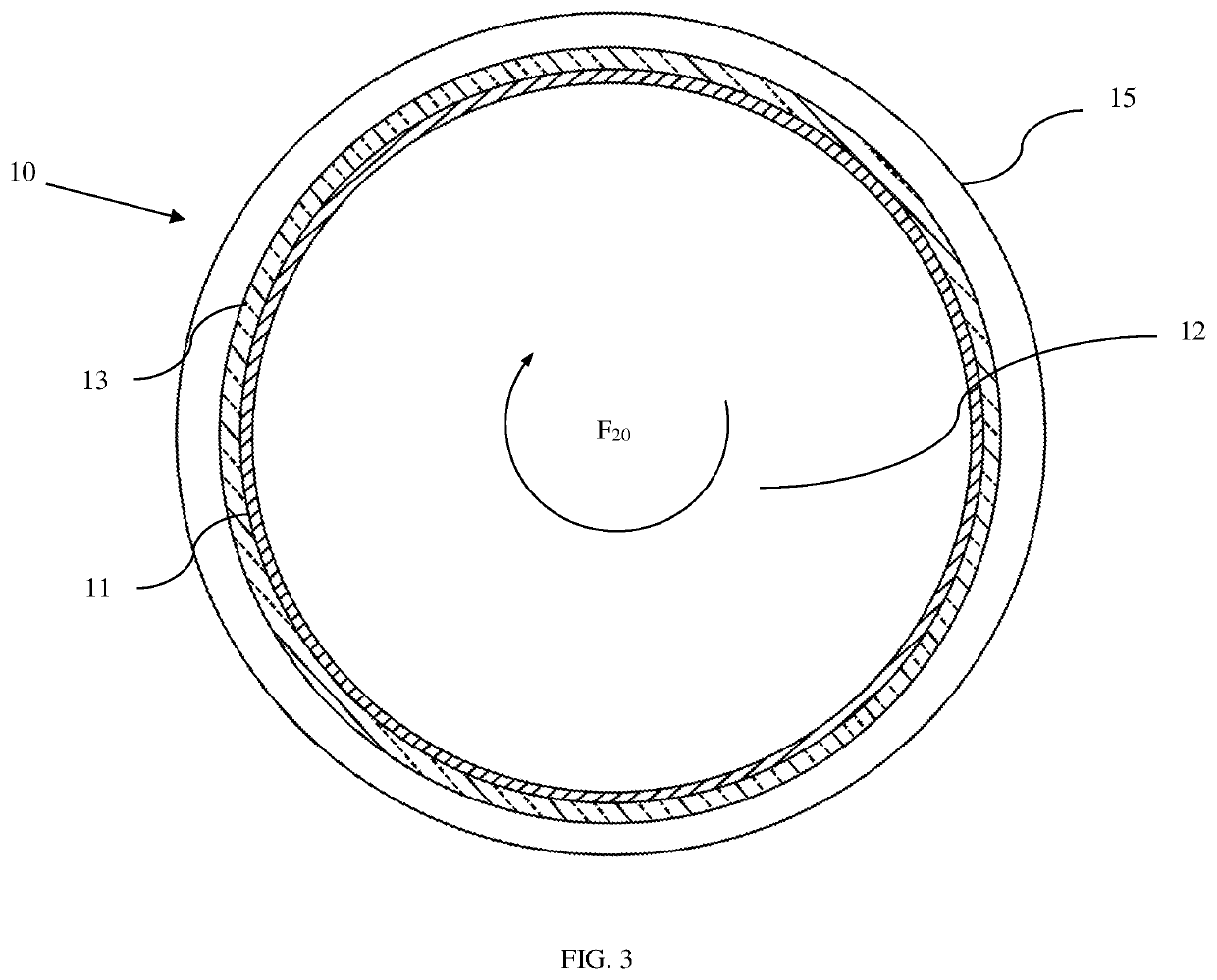

Rotational Mixing and Induction Heating System and Method for Recycling Asphalt Using the Same

ActiveUS20200248410A1Easy to transportEasy to changeRotating receptacle mixersIn situ pavingsThermodynamicsEngineering

An asphalt processing system is formed from a heating drum and an induction heating system. Flights move asphalt through the heating drum, which concurrently heat the asphalt along with the heating drum wall. A mixing drum can be connected to the heating drum, and include paddles or flights to move the asphalt, while concurrently mixing the material to ensure consistent temperatures through the asphalt cement. The asphalt is heating using one or more induction heating systems to quickly heat the asphalt to between 275° F. and 750° F., followed by moving the asphalt to between 275° F. and 350° F. The system can include a convection system that heats recirculated air through the heating drum. A water condenser can be employed to remove moisture during air recirculation, and reduce asphalt moisture content. The asphalt cement is optionally modified by addition of one or more rejuvenation oils. This system is particularly useful for recycled asphalt pavement, but can be used for all asphalt products.

Owner:CRUPI FRANCESCO

Rotational mixing and induction heating system and method for recycling asphalt using the same

ActiveUS10889940B2Easy to transportEasy to changeRotating receptacle mixersIn situ pavingsThermodynamicsEngineering

An asphalt processing system is formed from a heating drum and an induction heating system. Flights move asphalt through the heating drum, which concurrently heat the asphalt along with the heating drum wall. A mixing drum can be connected to the heating drum, and include paddles or flights to move the asphalt, while concurrently mixing the material to ensure consistent temperatures through the asphalt cement. The asphalt is heating using one or more induction heating systems to quickly heat the asphalt to between 275° F. and 750° F., followed by moving the asphalt to between 275° F. and 350° F. The system can include a convection system that heats recirculated air through the heating drum. A water condenser can be employed to remove moisture during air recirculation, and reduce asphalt moisture content. The asphalt cement is optionally modified by addition of one or more rejuvenation oils. This system is particularly useful for recycled asphalt pavement, but can be used for all asphalt products.

Owner:CRUPI FRANCESCO

Aluminum industry solid waste recovery/petroleum coke high temperature desulfurization device and its use method

InactiveCN105603216BEfficient use ofEasy to recycleProcess efficiency improvementTar working-up by thermal treatmentAluminum industryPetroleum coke

The invention discloses an aluminum industry solid waste recovery / petroleum coke high-temperature desulphurization device and a using method thereof, and belongs to the technical field of metallurgy environmental protection. The device comprises a furnace body, a low-melting-point matter crystallizer at the rear end of the furnace body, and a liquid low-melting-point matter collector below the low-melting-point matter crystallizer. A main material chamber in the furnace body is used for containing aluminum electrolysis cell waste cathode carbon broken blocks or petroleum coke used as a resistance heating body. A sleeve is arranged at the rear end of the furnace body to be communicated with the low-melting-point matter crystallizer. The bottom of the low-melting-point matter crystallizer is communicated with a liquid collector through a valve. The using method mainly comprises the steps that the resistance heating body is placed into the main material chamber, vacuumizing is carried out, cooling water is introduced, the resistance heating body is powered on and heated, vacuumizing and heating are stopped after vacuum high-temperature separation, argon is introduced, and materials coagulated by the low-melting-point matter crystallizer are heated to be molten to enter the liquid low-melting-point matter collector. According to the device and the method, operation is easy, energy is saved, and pollution is reduced.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

Popular searches

Fibre chemical features Sulfur-trioxide/sulfuric-acid Hydrocarbon oils refining Treatment with hydrotreatment processes Bio-feedstock Refining by centrifugal force Working-up pitch/asphalt/bitumen by thermal means Indirect and direct heating destructive distillation Indirect heating destructive distillation Additives

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com