Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about "Refining by centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

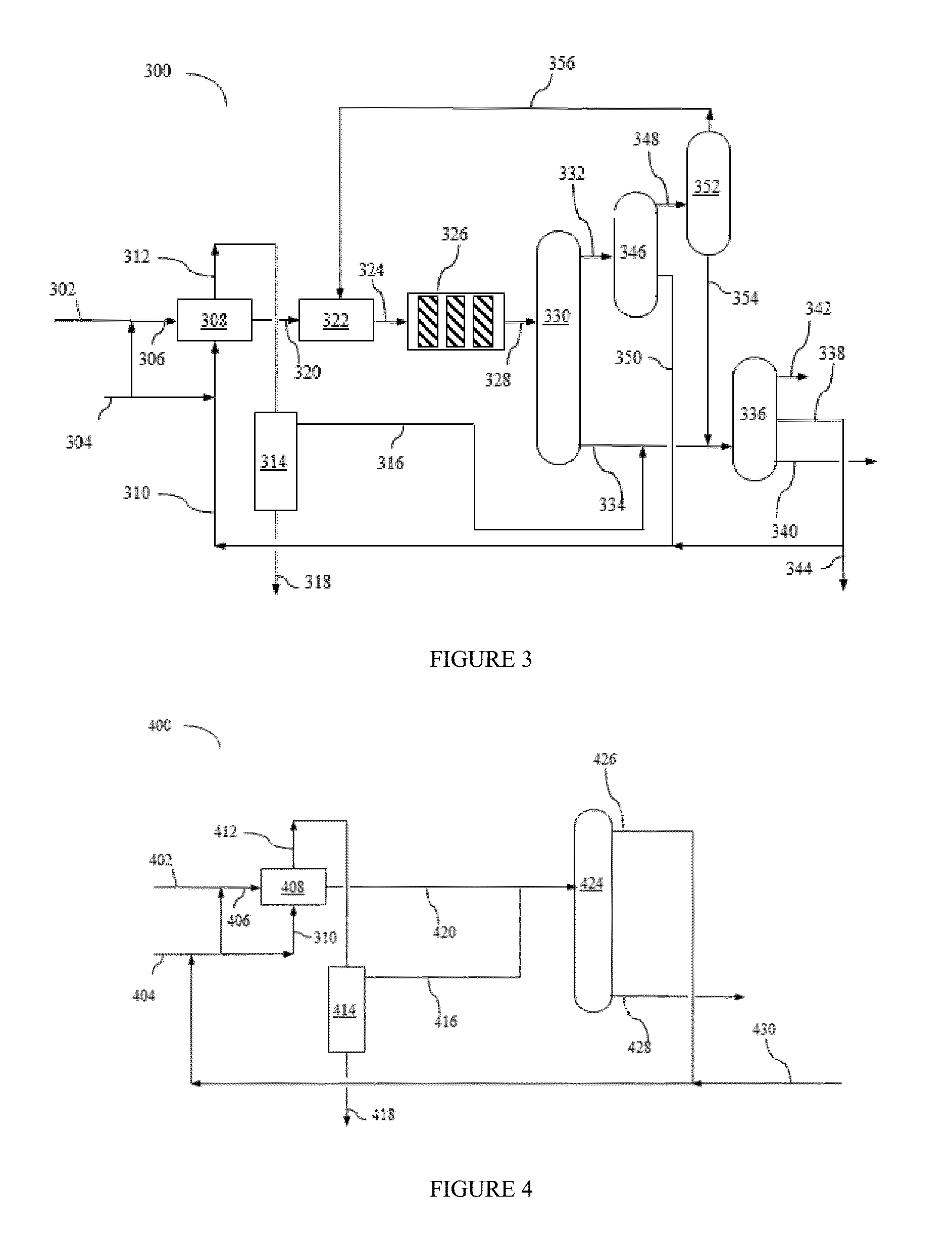

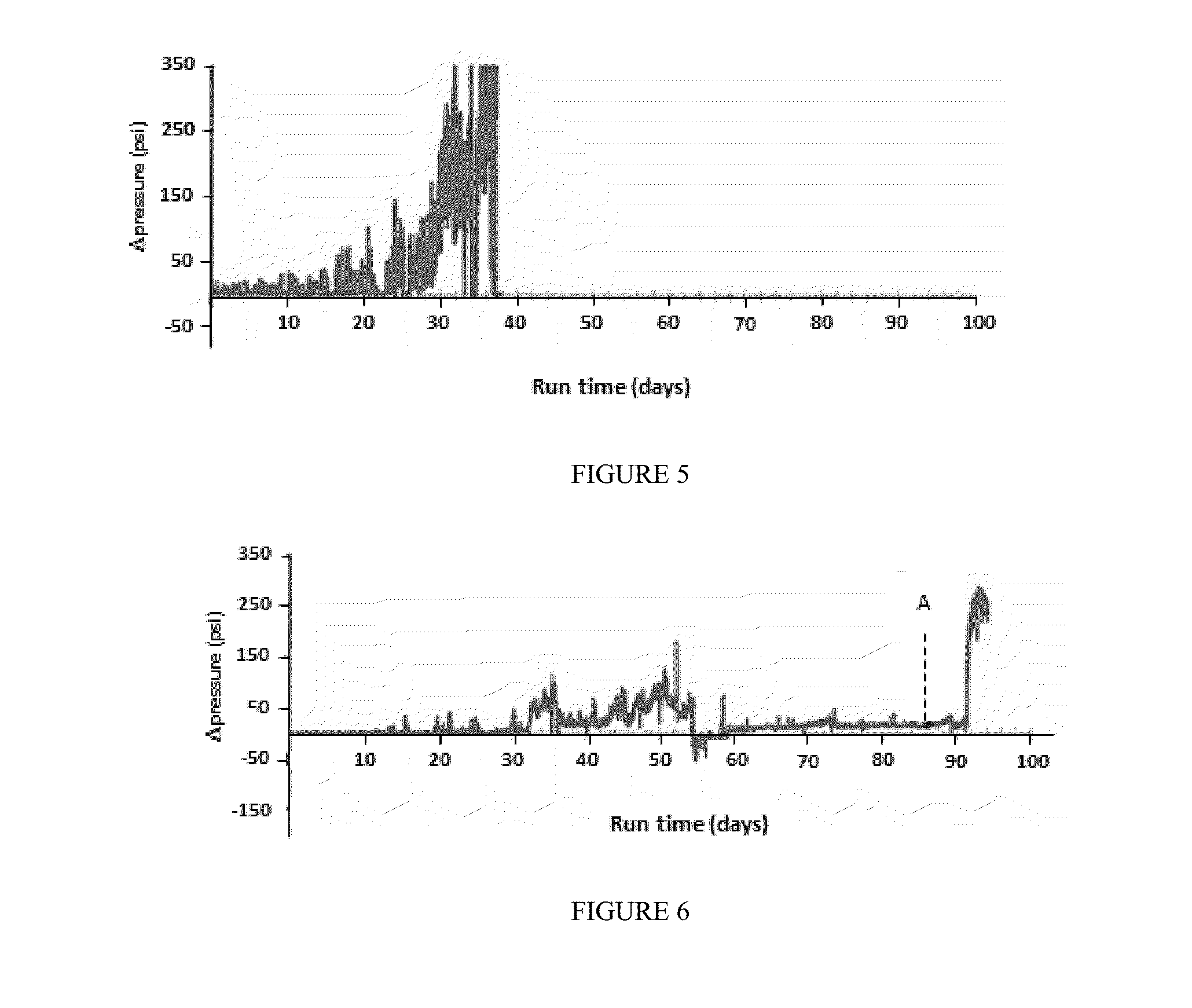

Refinery desalter improvement

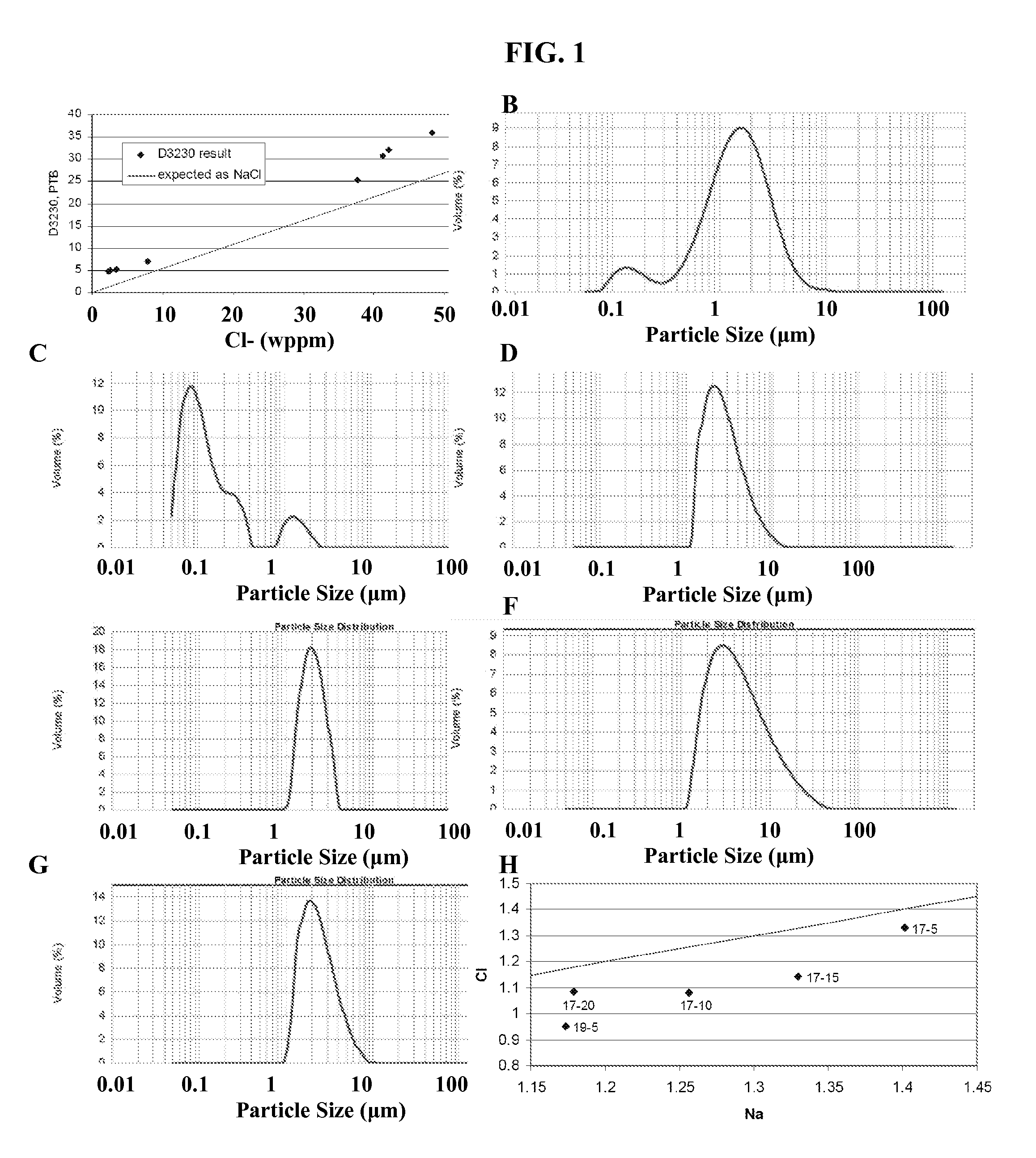

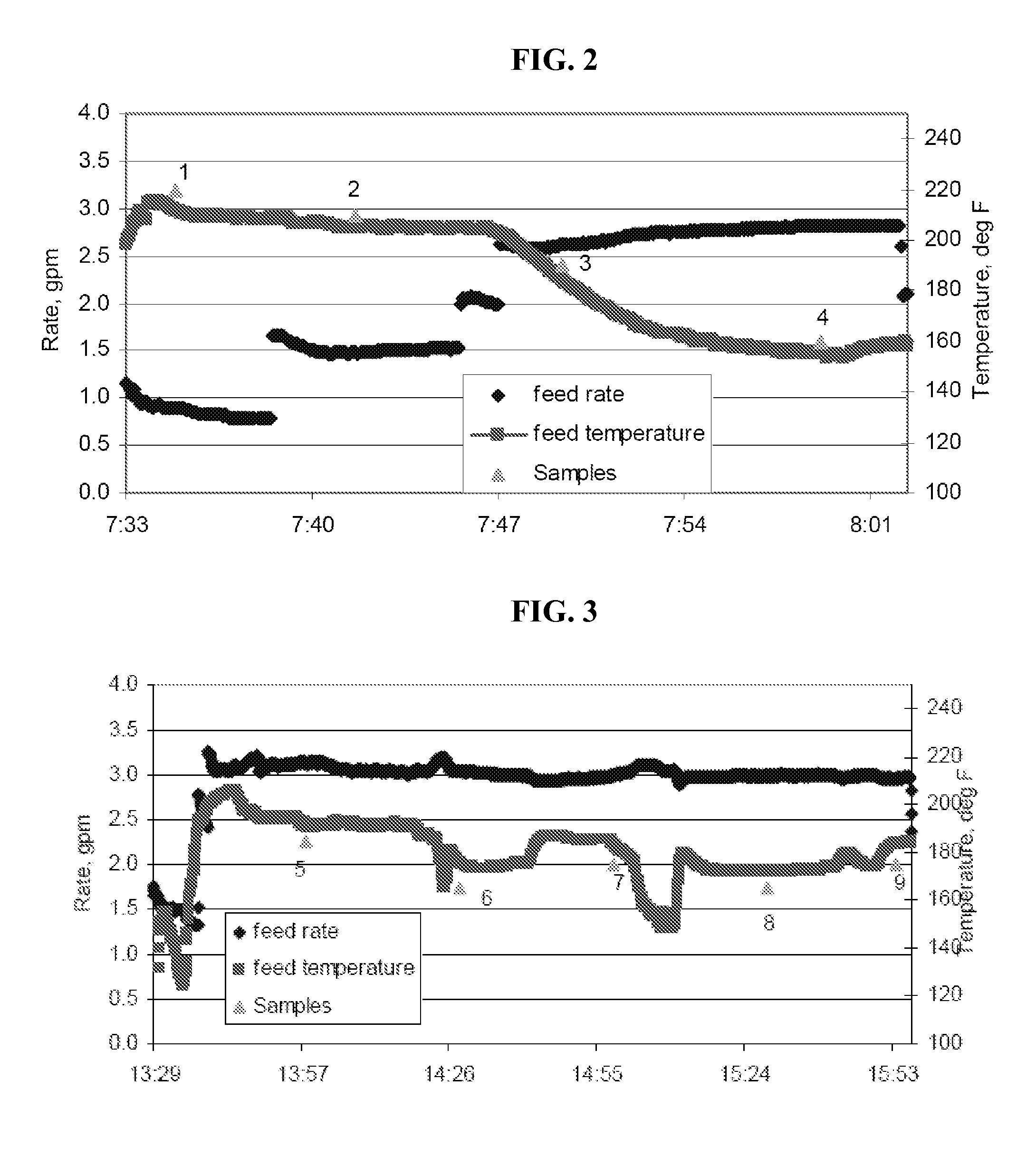

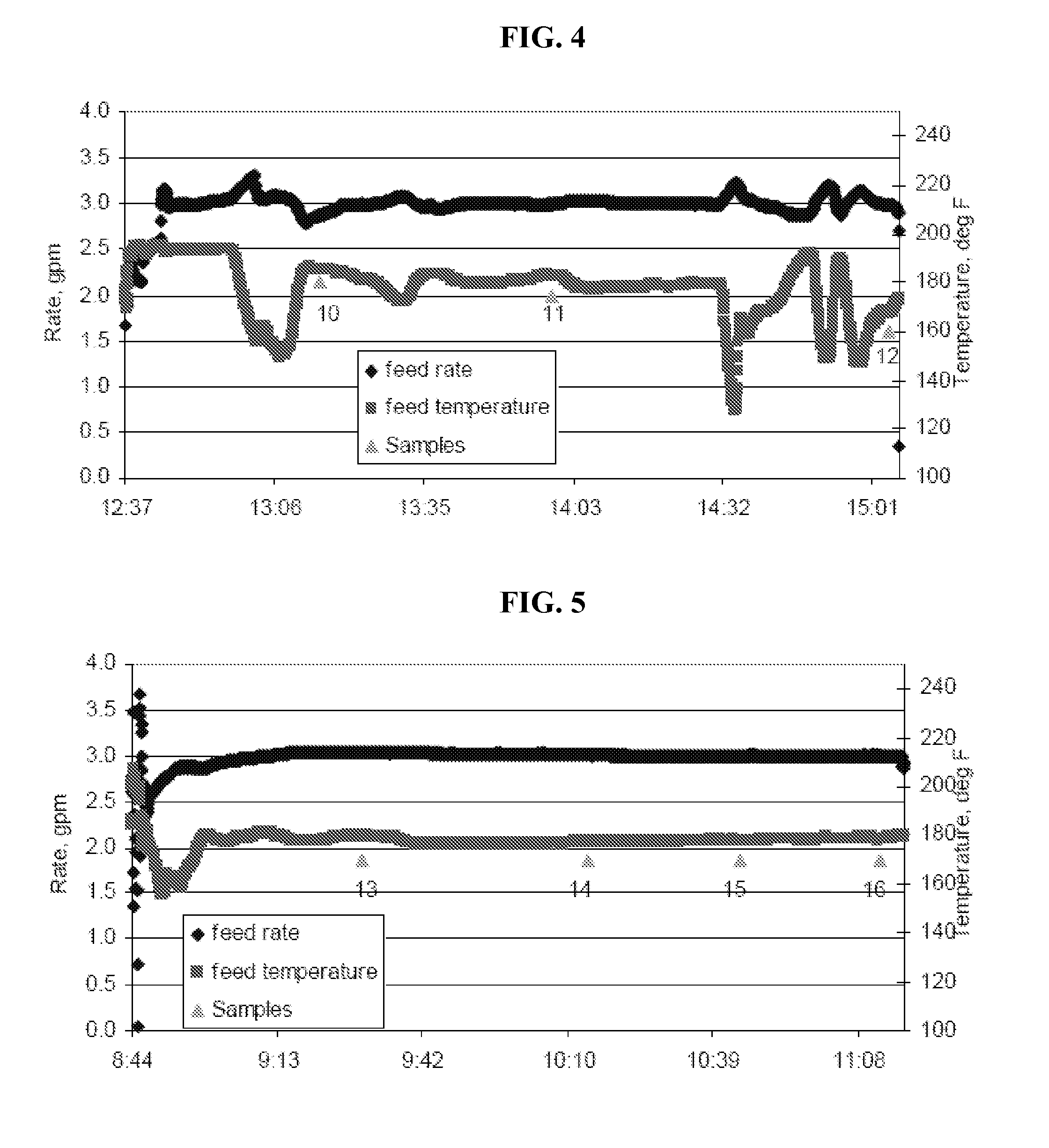

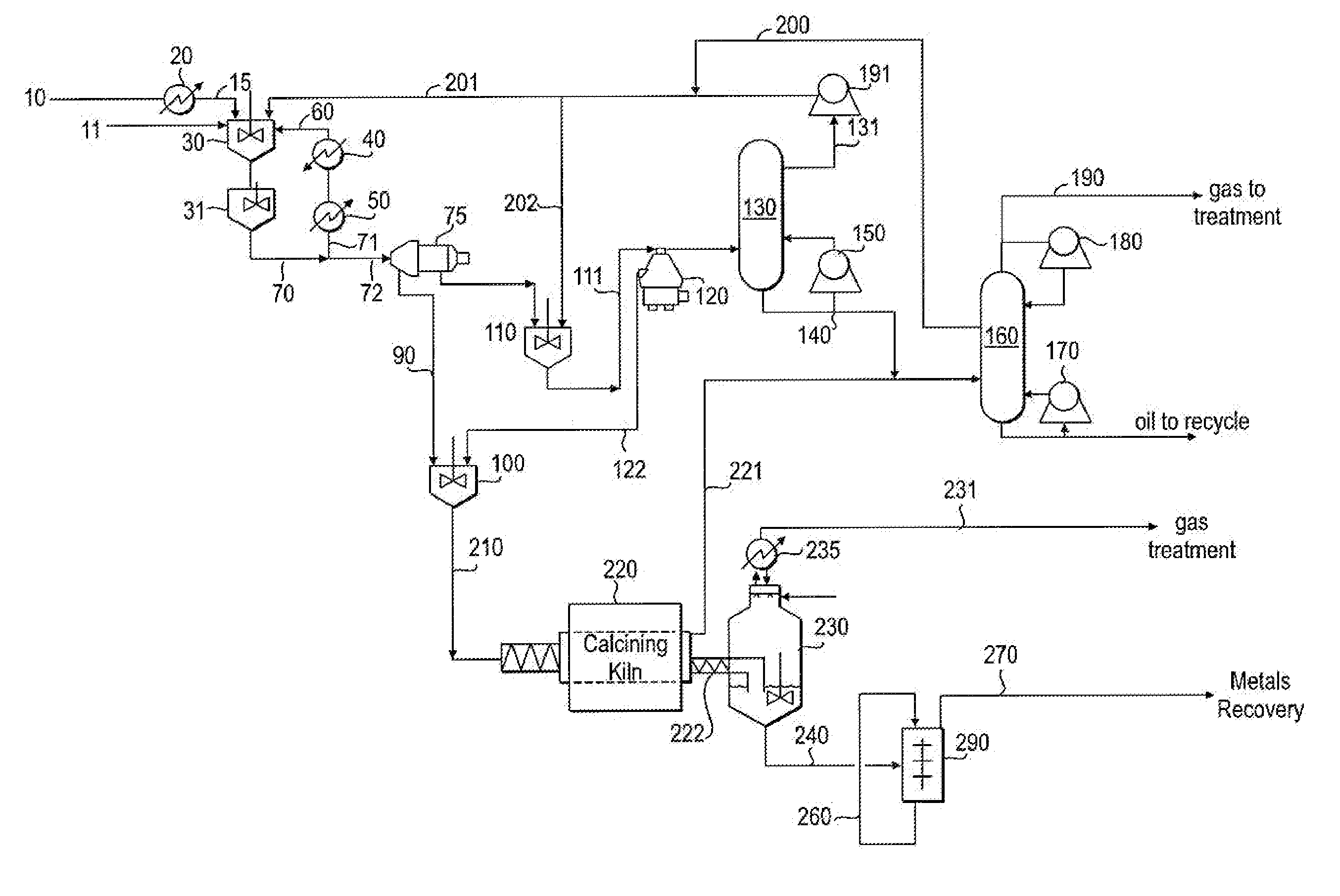

ActiveUS20120024758A1Increase capacityEasy to separateDewatering/demulsification with mechanical meansRefining by water treatmentDesalinationDesalter

The invention relates to improved methods of desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

Process for recovering ultrafine solids from a hydrocarbon liquid

ActiveUS20080156700A1Good curative effectSemi-permeable membranesCatalytic naphtha reformingFlocculationParticulates

A method for separating and recovering ultrafine particulate solid material from a suspension or slurry of the solid material and a hydrocarbon liquid by precipitation or flocculation of a heavy fraction of the hydrocarbon liquid with an effective amount of a precipitation or flocculation agent such that the precipitated heavy fraction encapsulates the particulate solid material. The method further comprises coking the precipitated heavy fraction and grinding the coked product to an ultrafine size.

Owner:CHEVROU USA INC

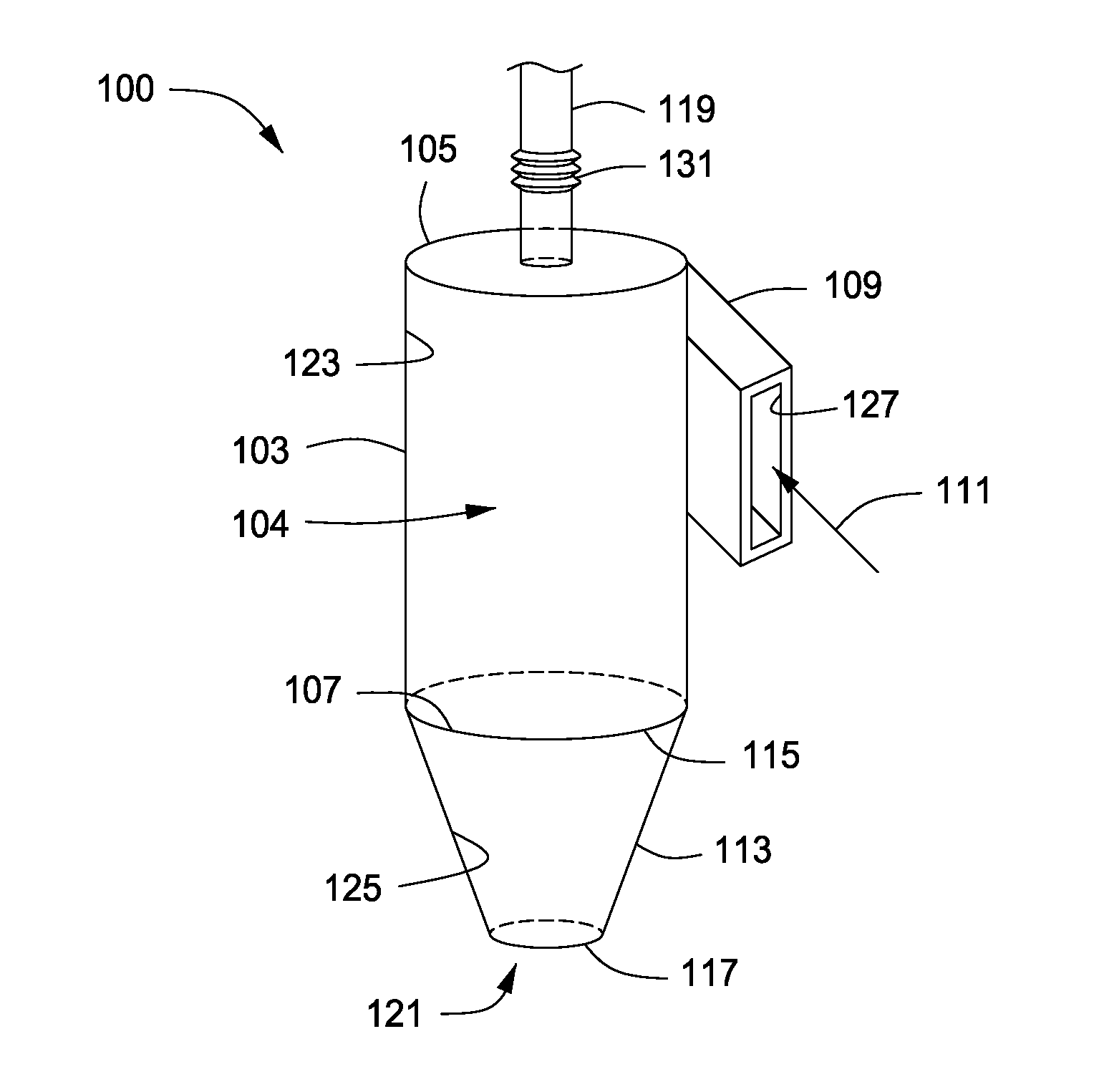

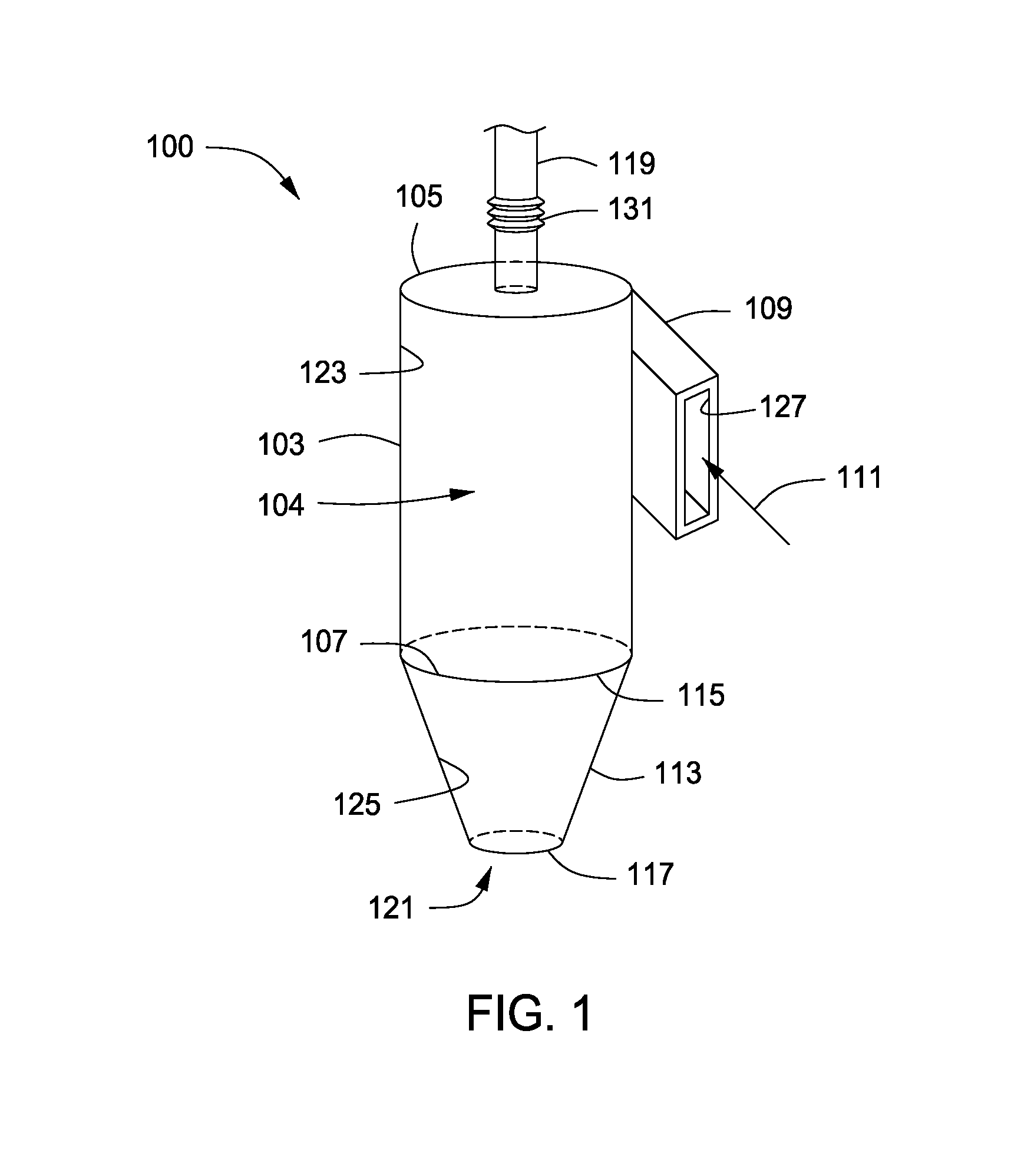

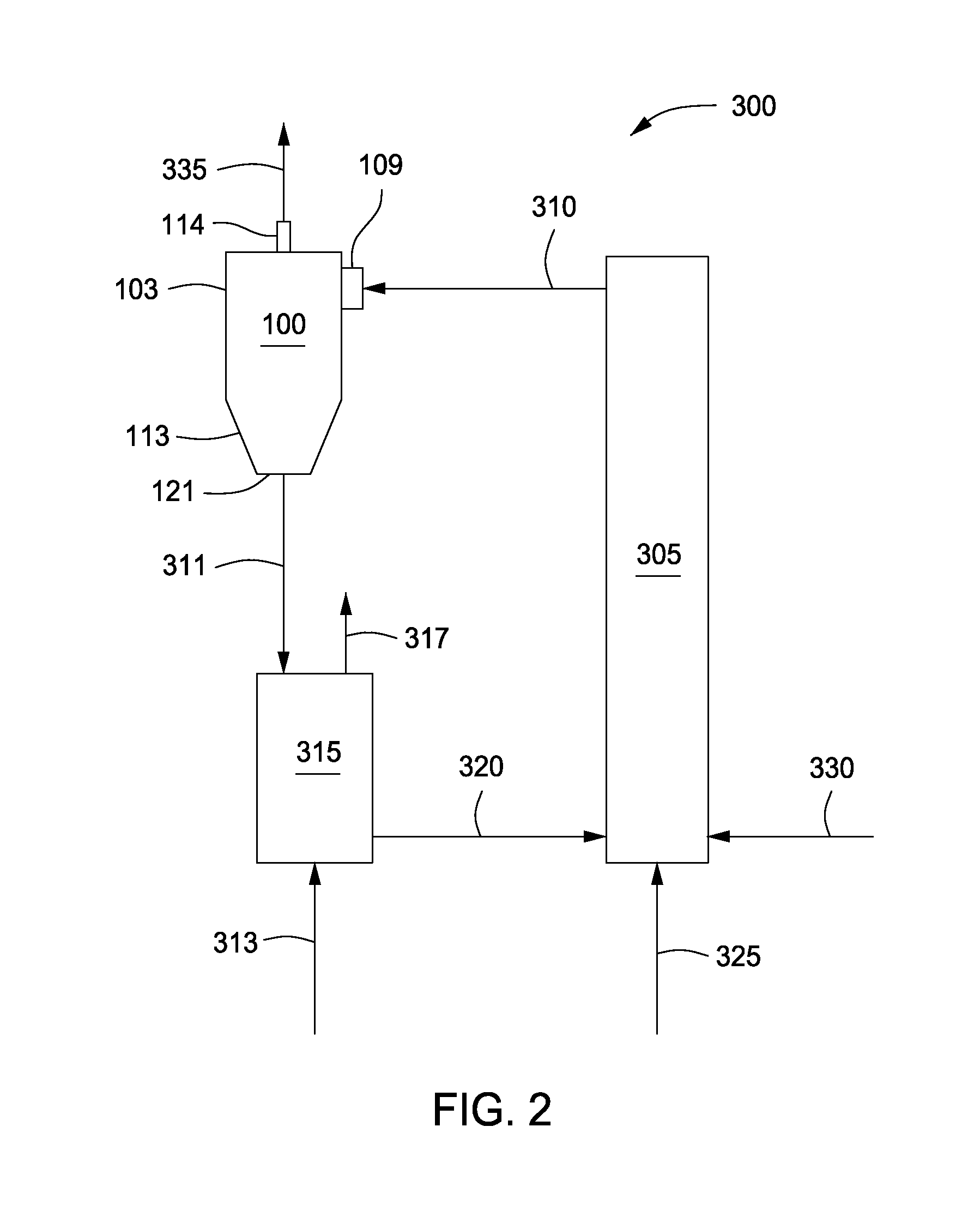

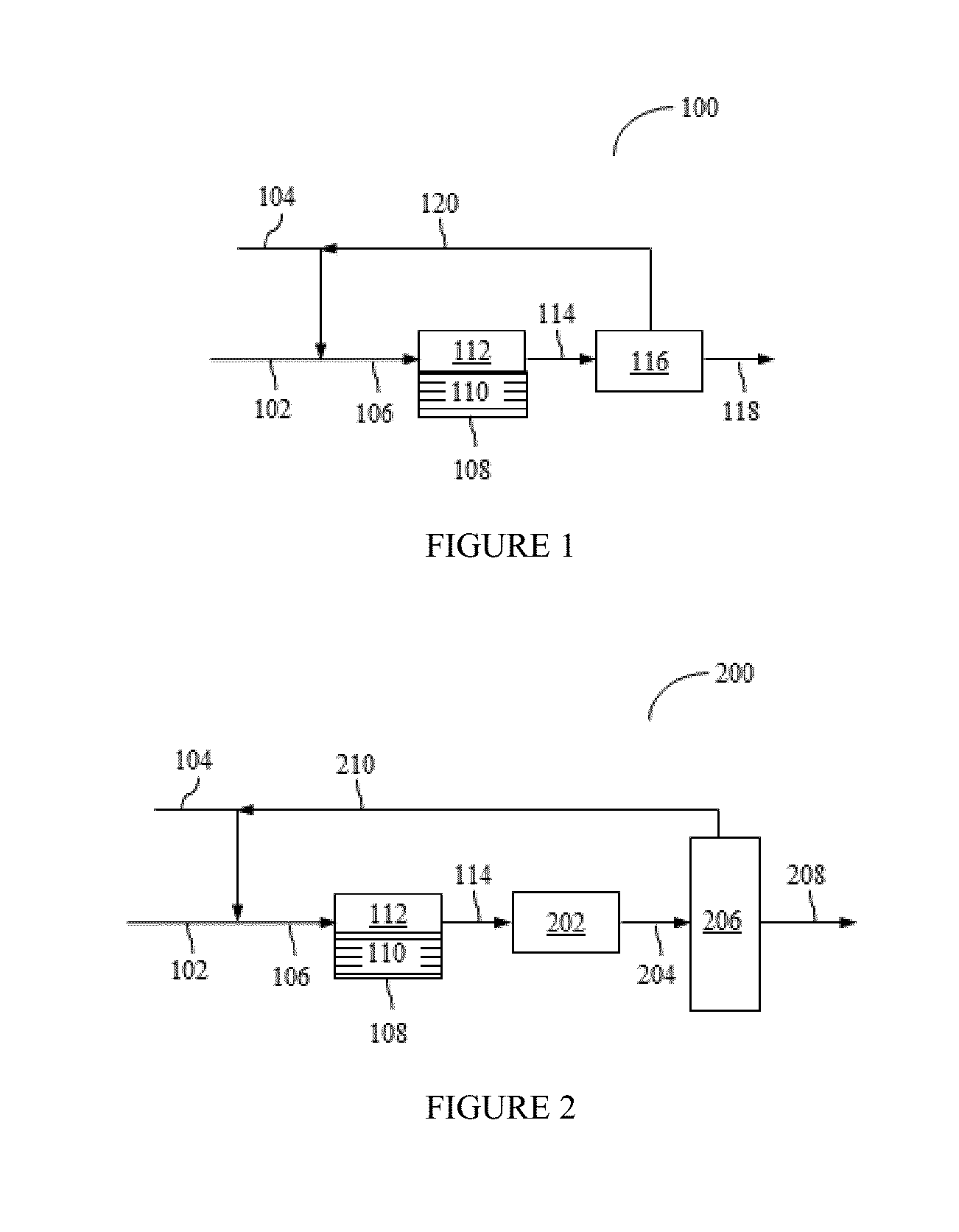

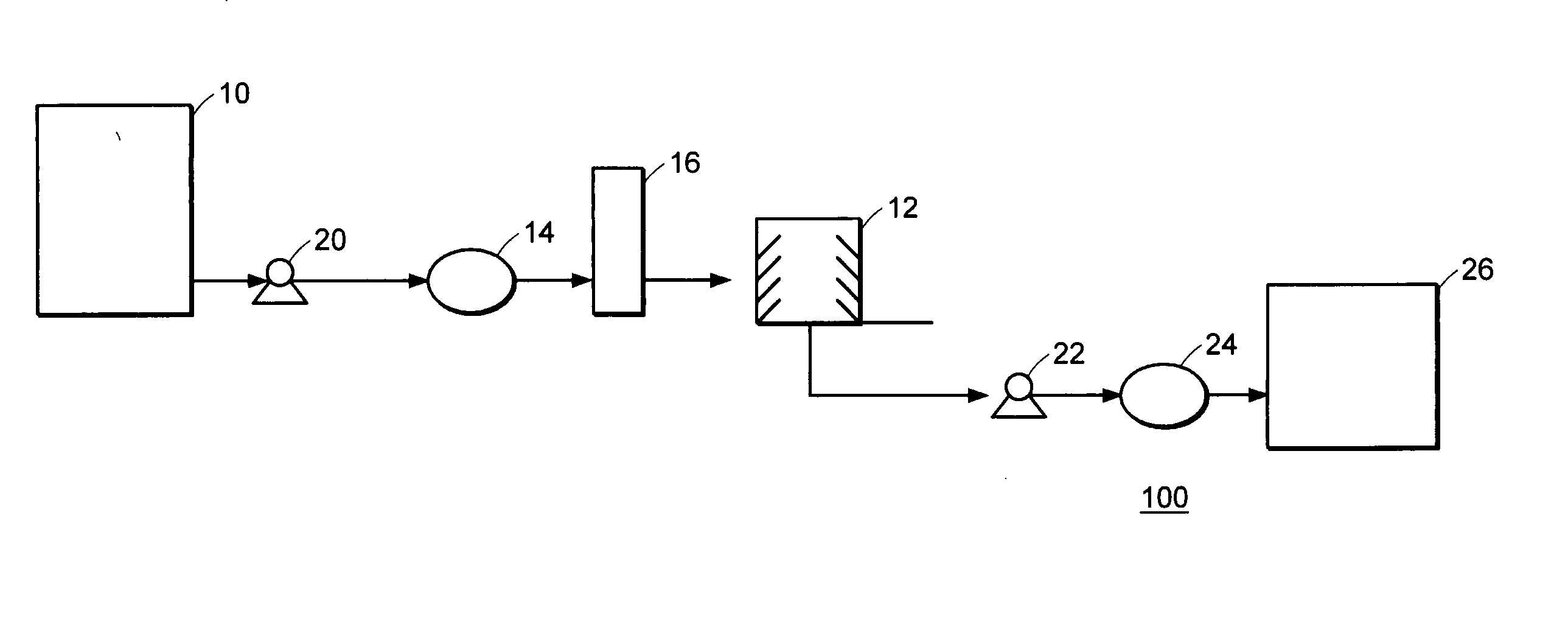

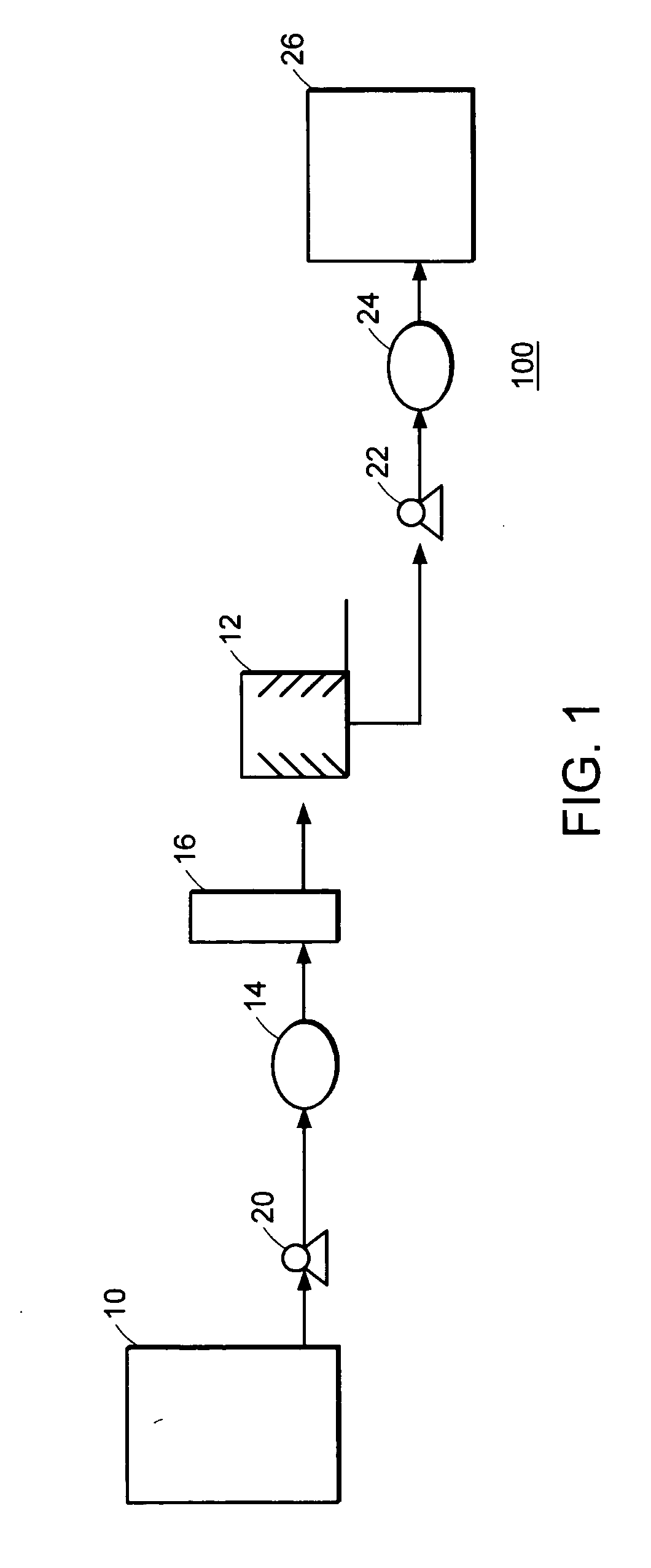

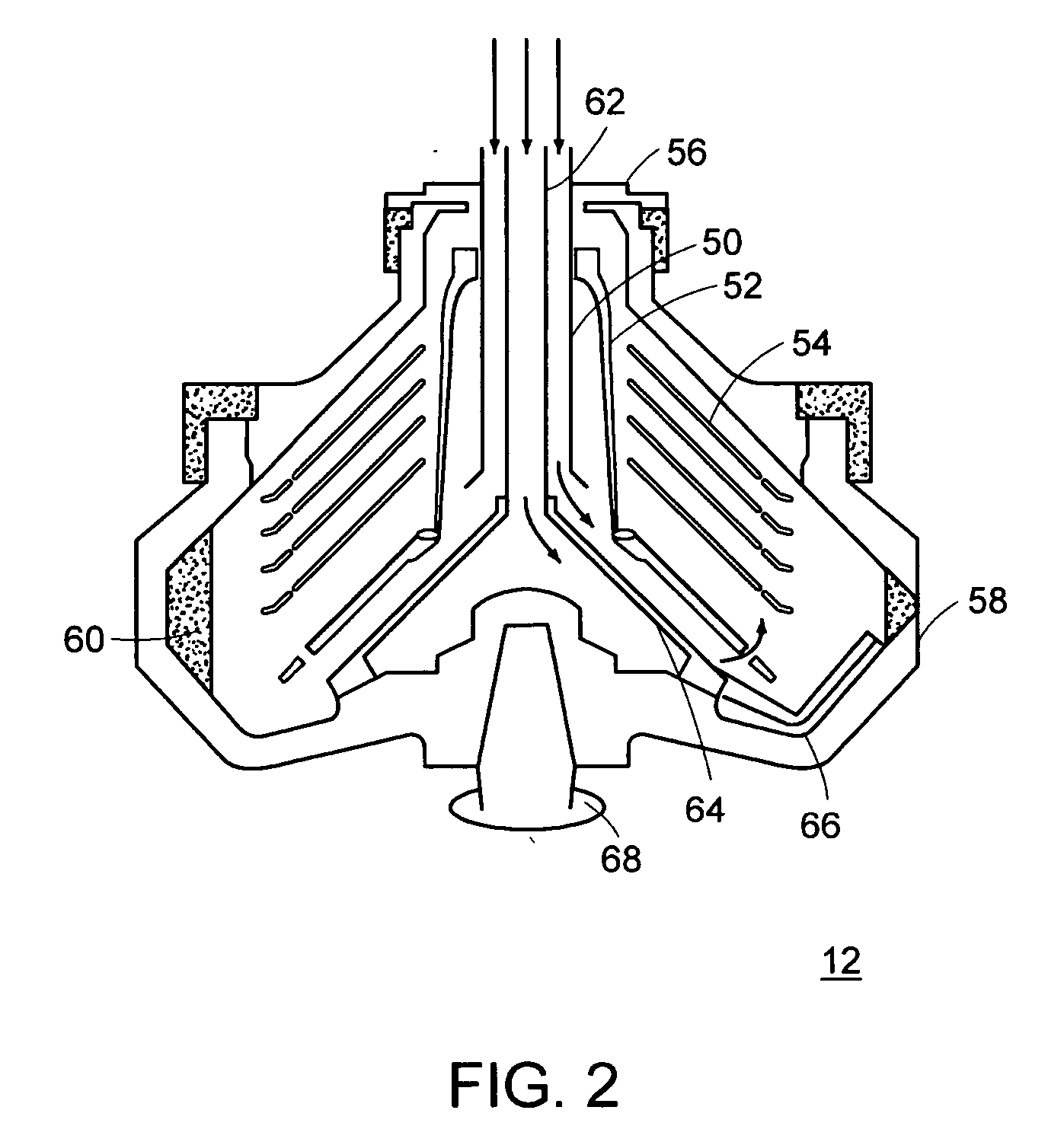

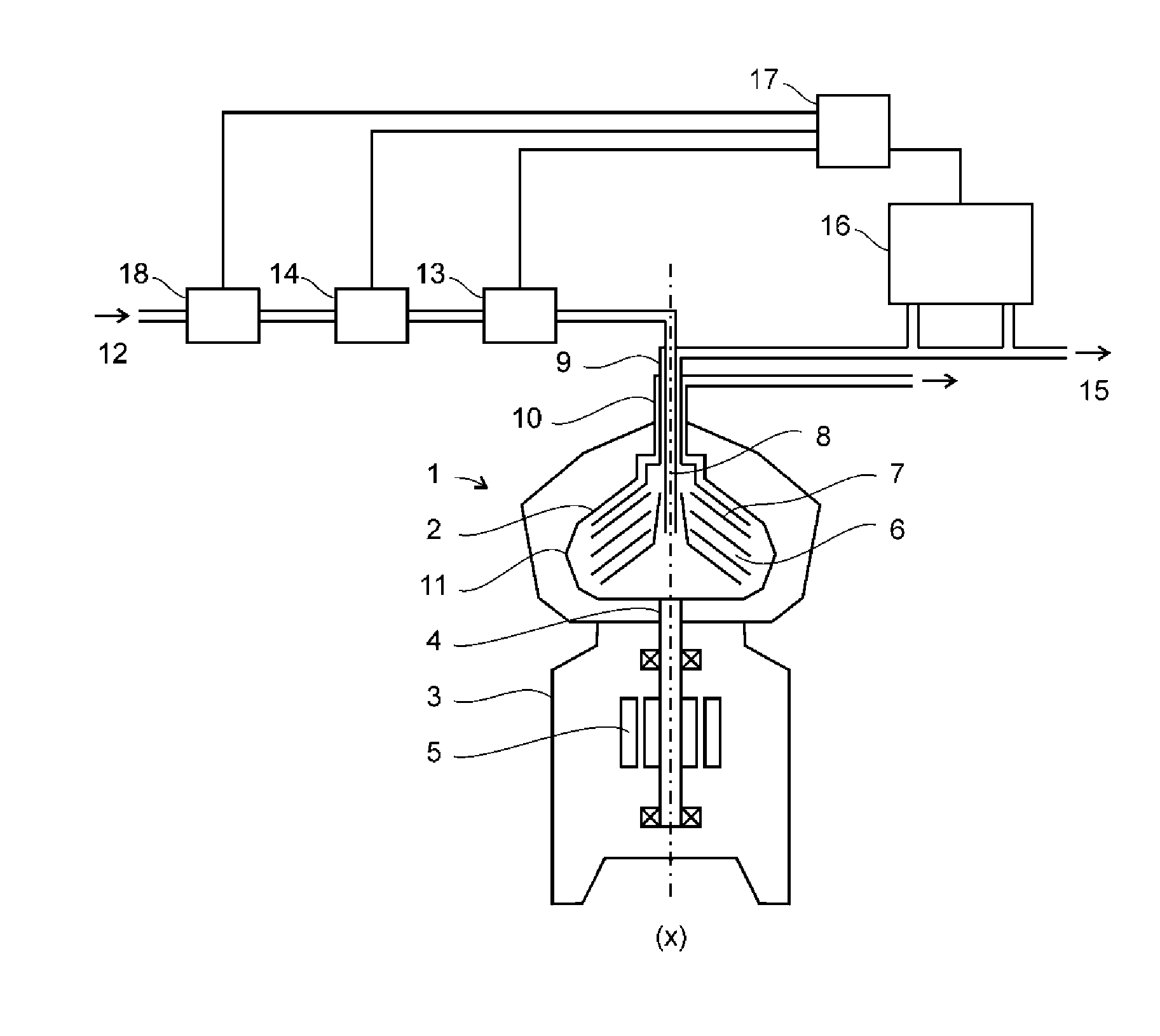

Systems and methods for processing fluids

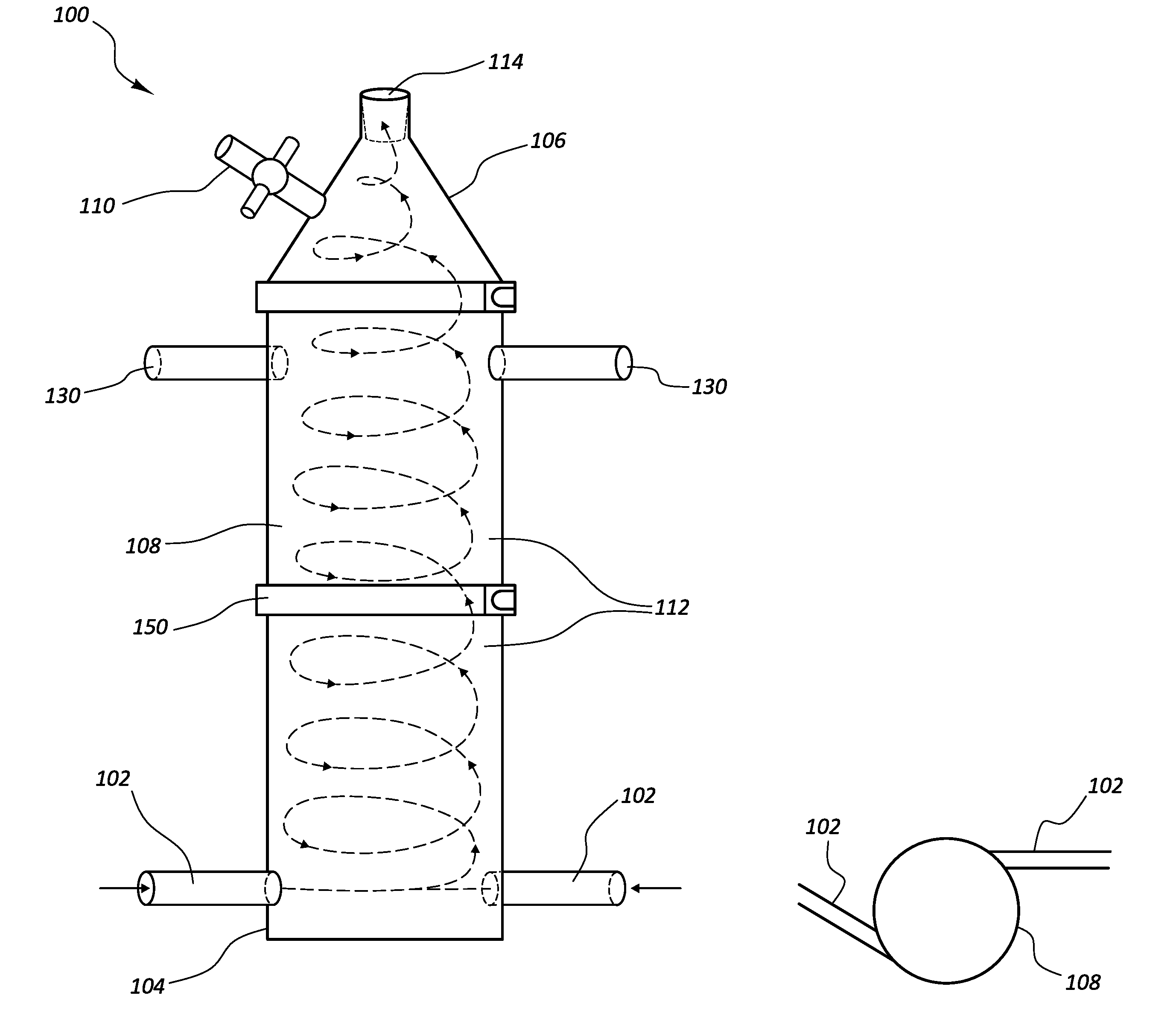

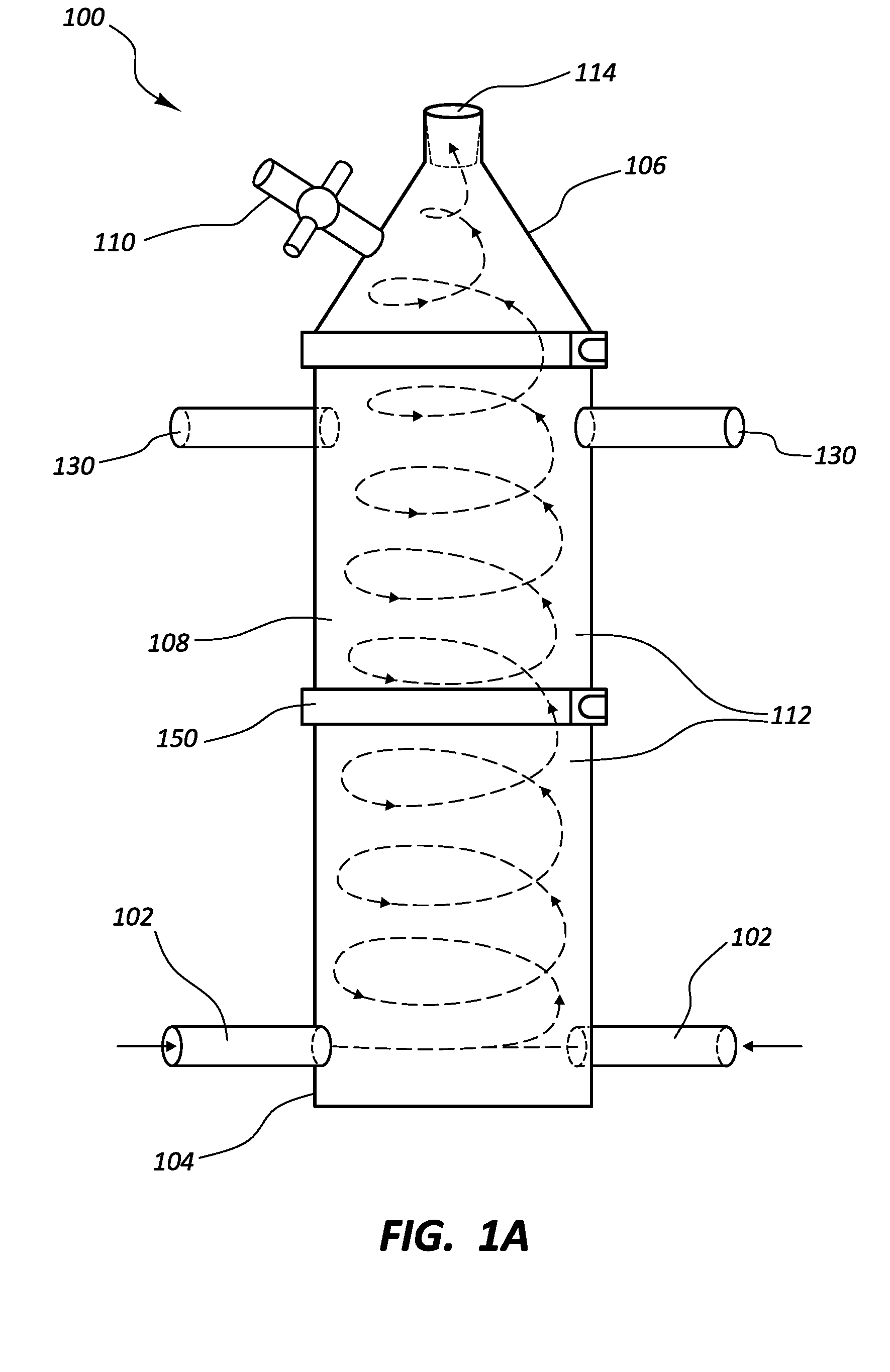

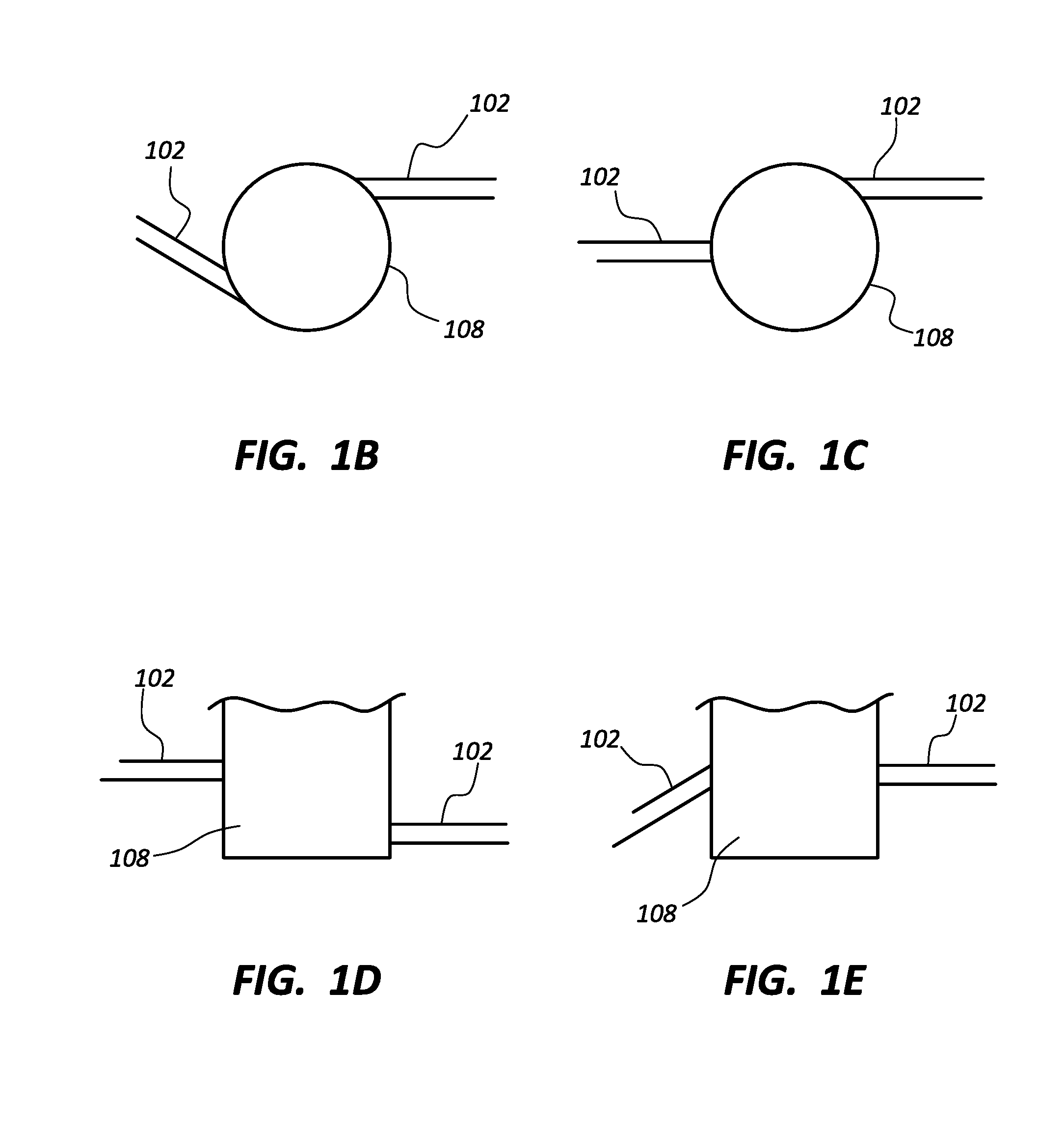

InactiveUS20160346758A1Promote generationReducing and eliminating cavitation-induced erosionShaking/oscillating/vibrating mixersSludge treatmentChemical effectsNuclear engineering

A vortex reactor includes a reactor body having first and second ends, with one or more inlet ports coupled to the first end. The reactor is configured to form one or more vortices in a fluid passed into the reactor. The inlet port(s) may be positioned to advance a reactor fluid into the reactor body at an angle tangential to an inner surface of the reactor body, forming a vortex that advances toward the second end along the inner surface of the reactor body. A vortex induction mechanism can be disposed within the reactor to induce or augment a vortex within the reactor. The reactor includes an ultrasound-imparting device configured to generate cavitation bubbles in the reactor fluid. The fluid flow within the reactor concentrates the cavitation bubbles within the vortex, thereby providing beneficial physical and / or chemical effects, while protecting the reactor walls and other reactor components from cavitational erosion.

Owner:CETAMAX VENTURES

Methods and apparatus for separating particulates from a particulate-fluid mixture

Methods and apparatus for separating particulates from a fluid are provided. The apparatus can include a separation section having at least one wall, a first end, a second end, and an inner metal surface exposed to an internal volume of the separation section. The apparatus can also include a fluid discharge outlet in fluid communication with the internal volume at the first end. The apparatus can also include a particulate discharge outlet in fluid communication with the internal volume at the second end. The apparatus can also include an inlet in fluid communication with the internal volume. The inlet can be disposed intermediate the first end and the second end.

Owner:KELLOGG BROWN & ROOT LLC

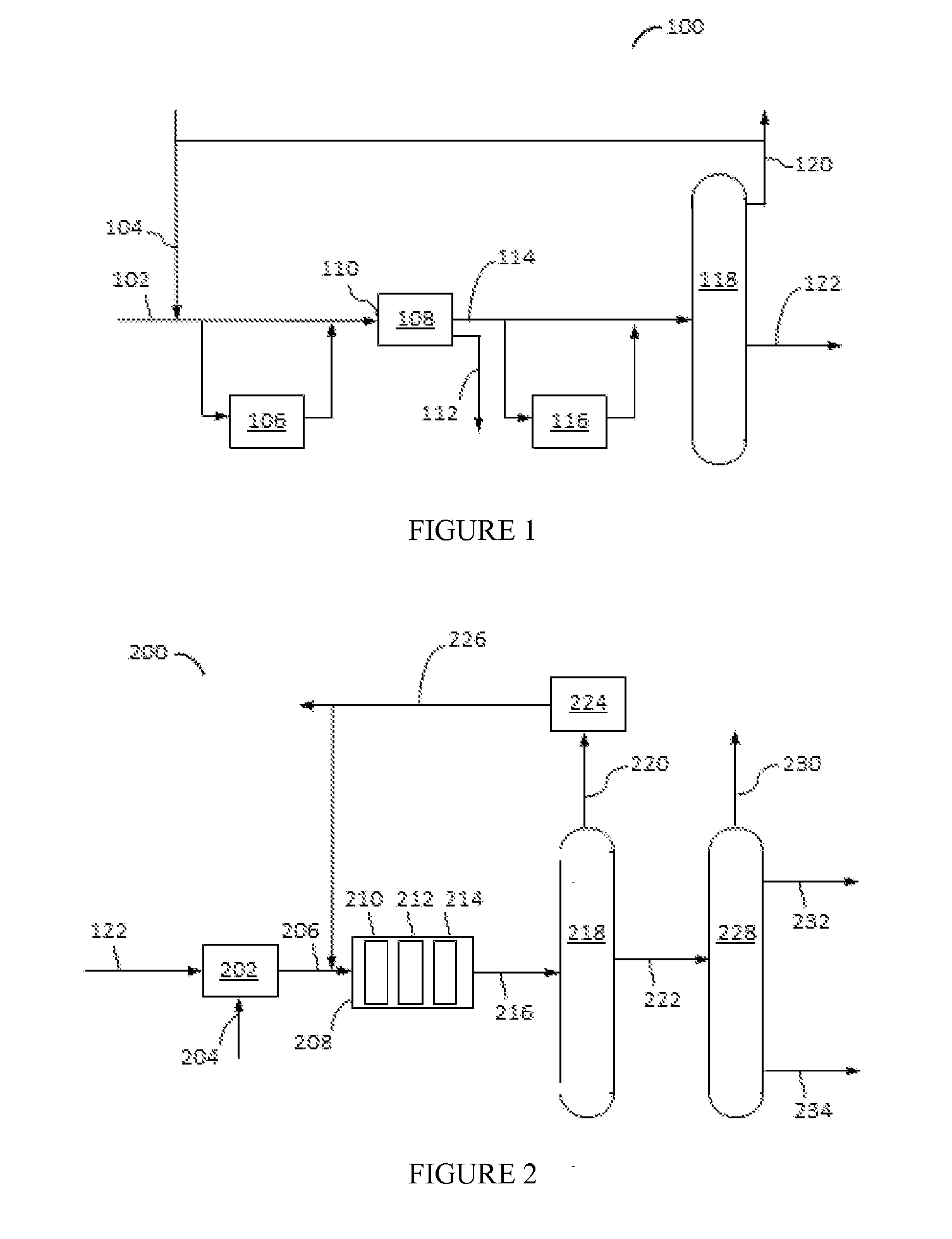

Method and Apparatus for Improving A Hydrocarbon Feed

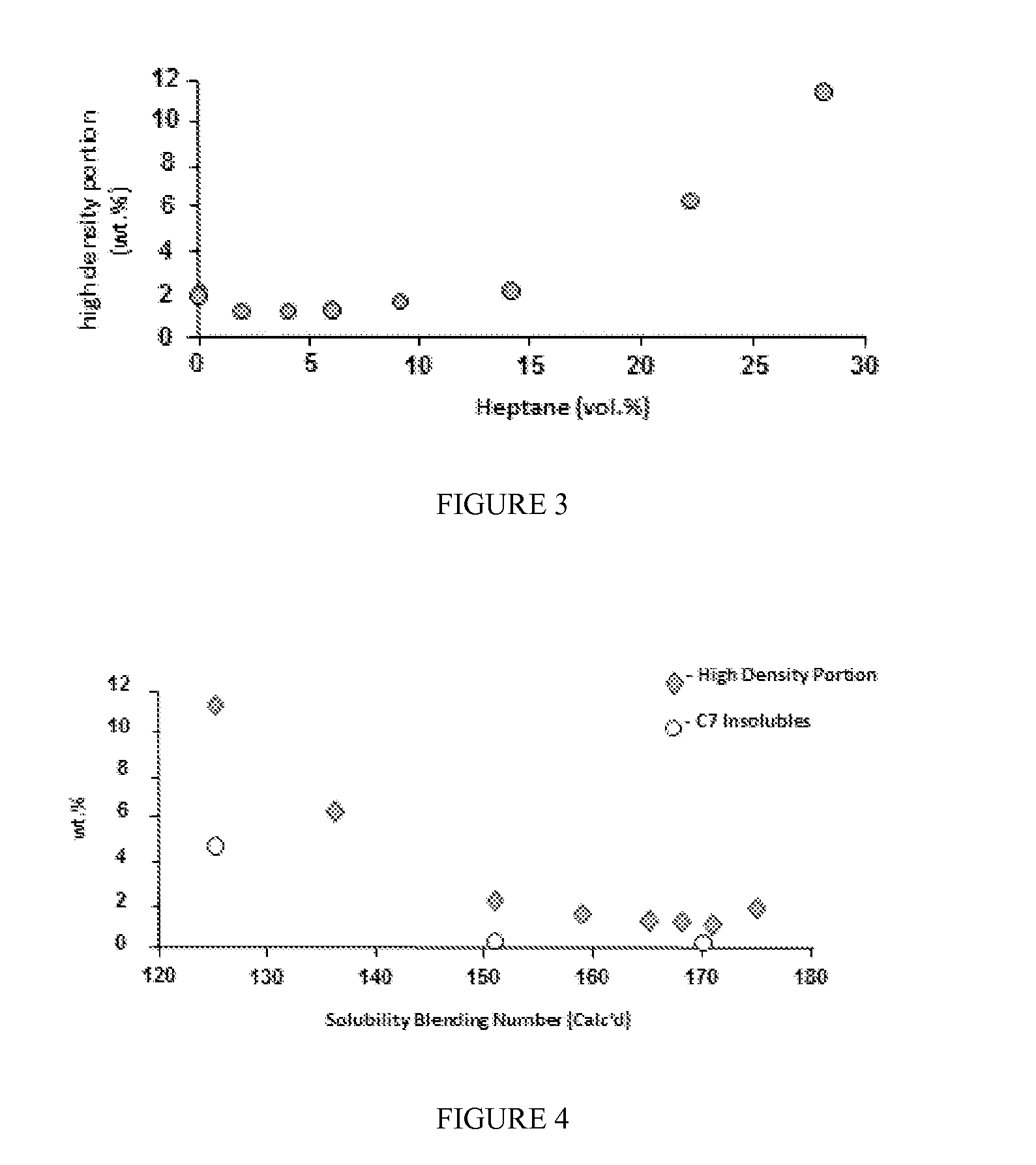

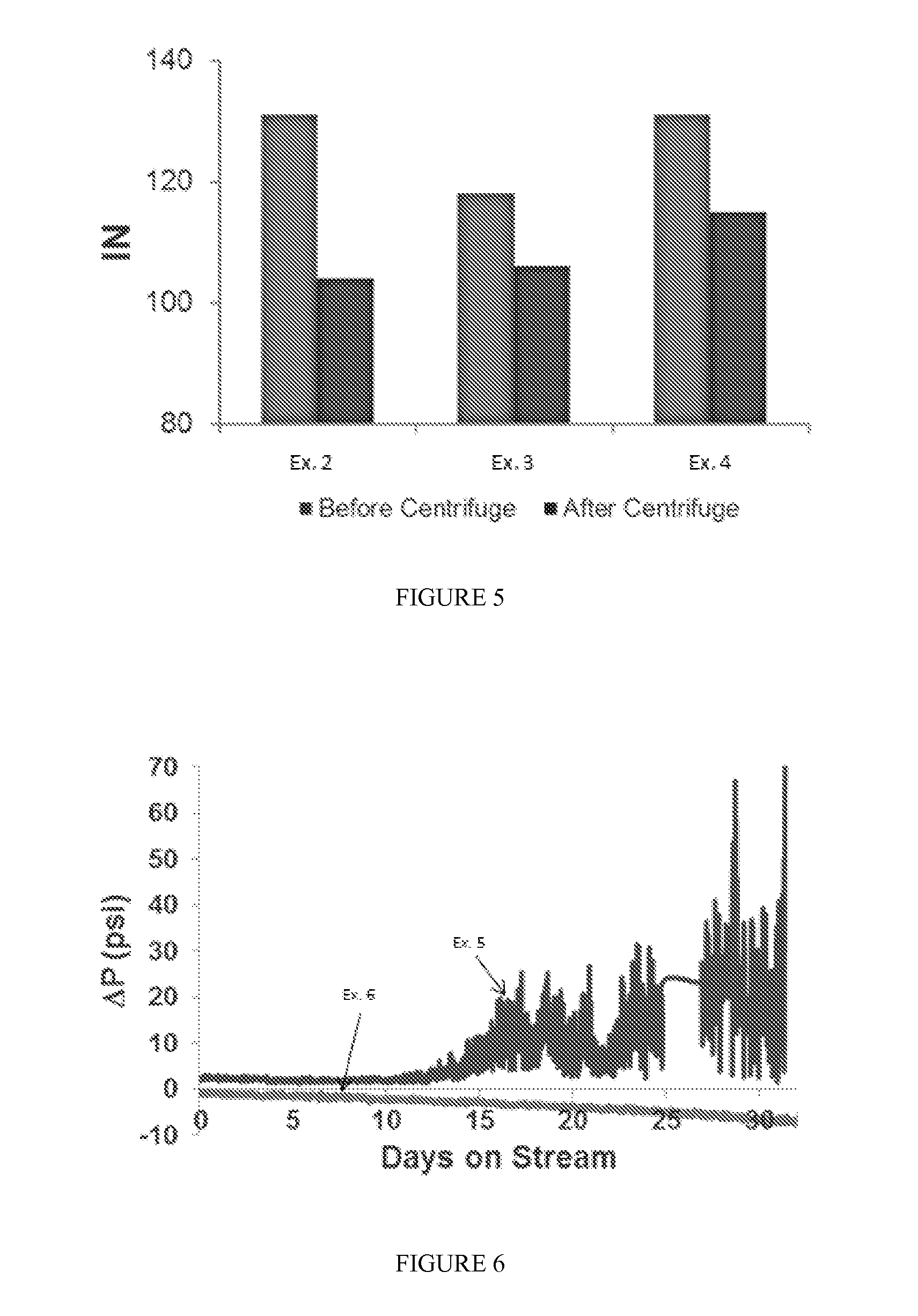

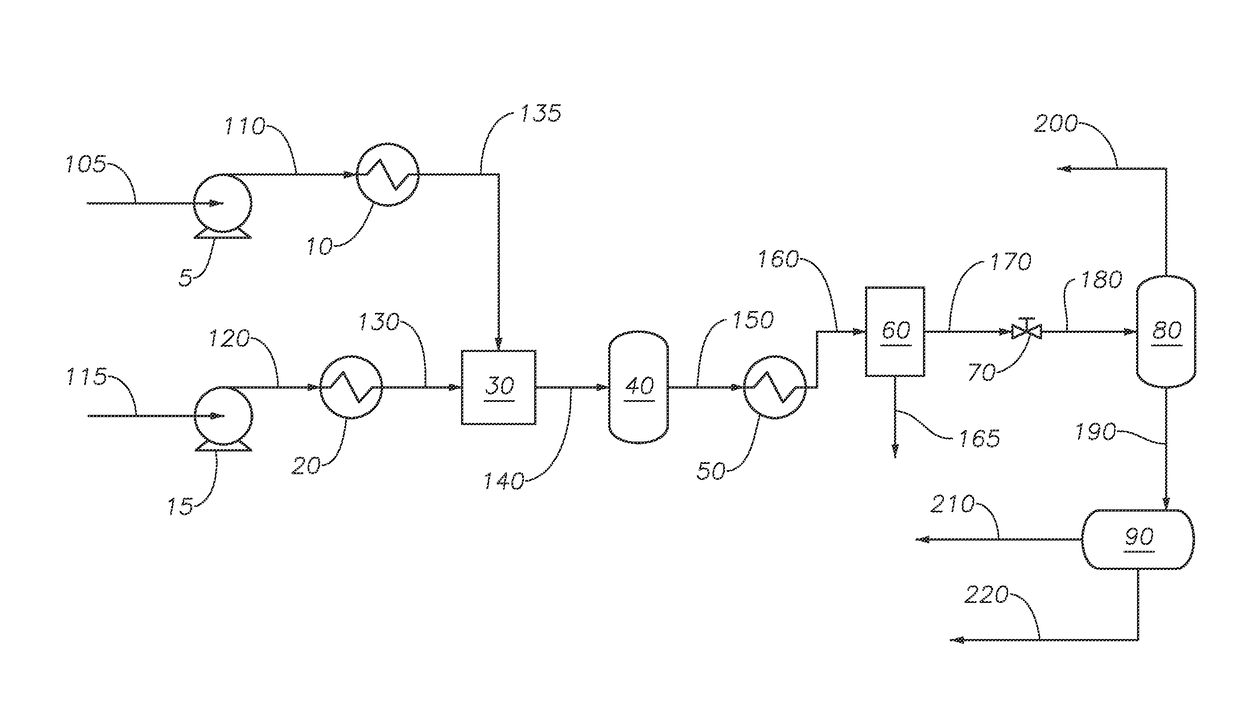

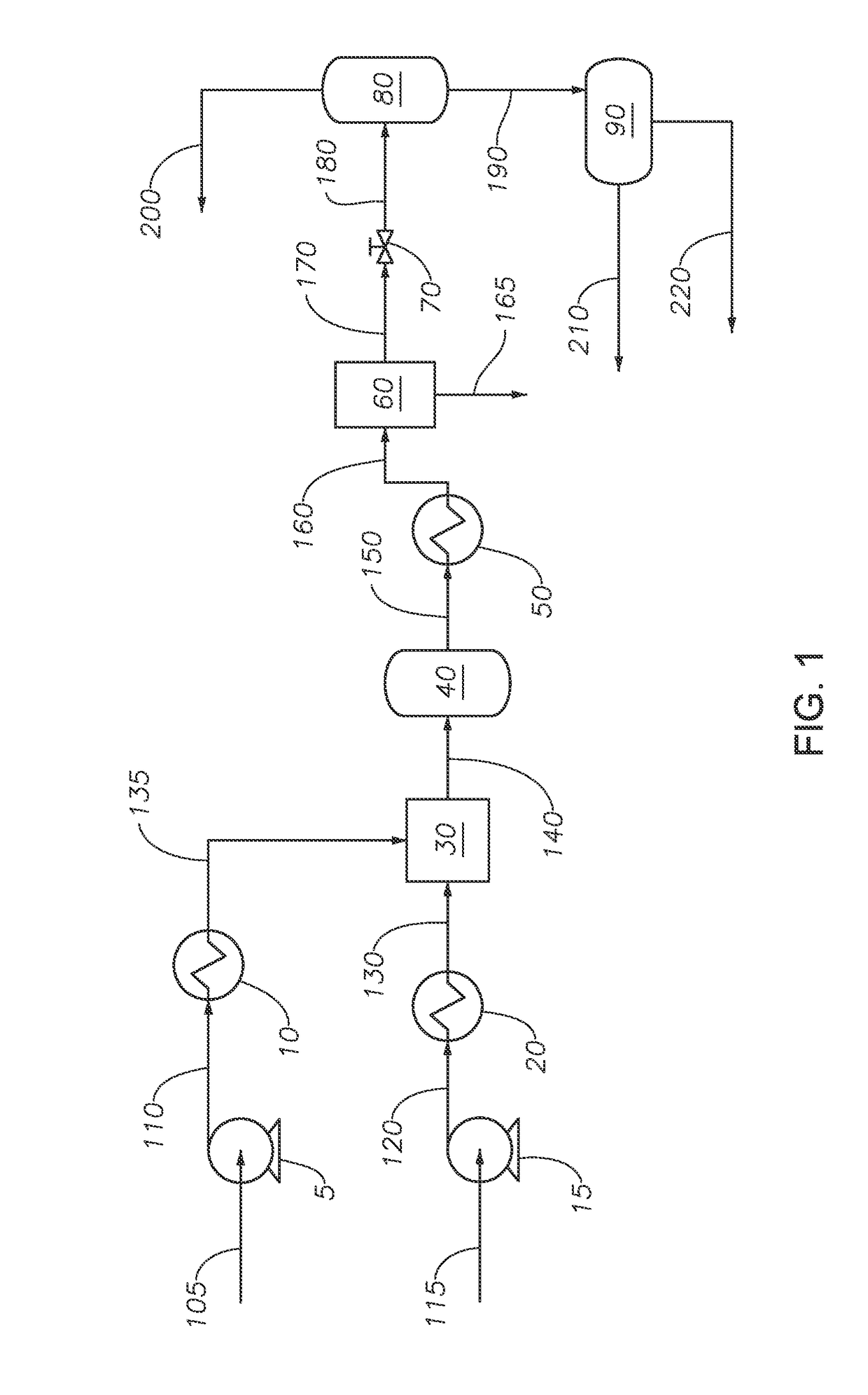

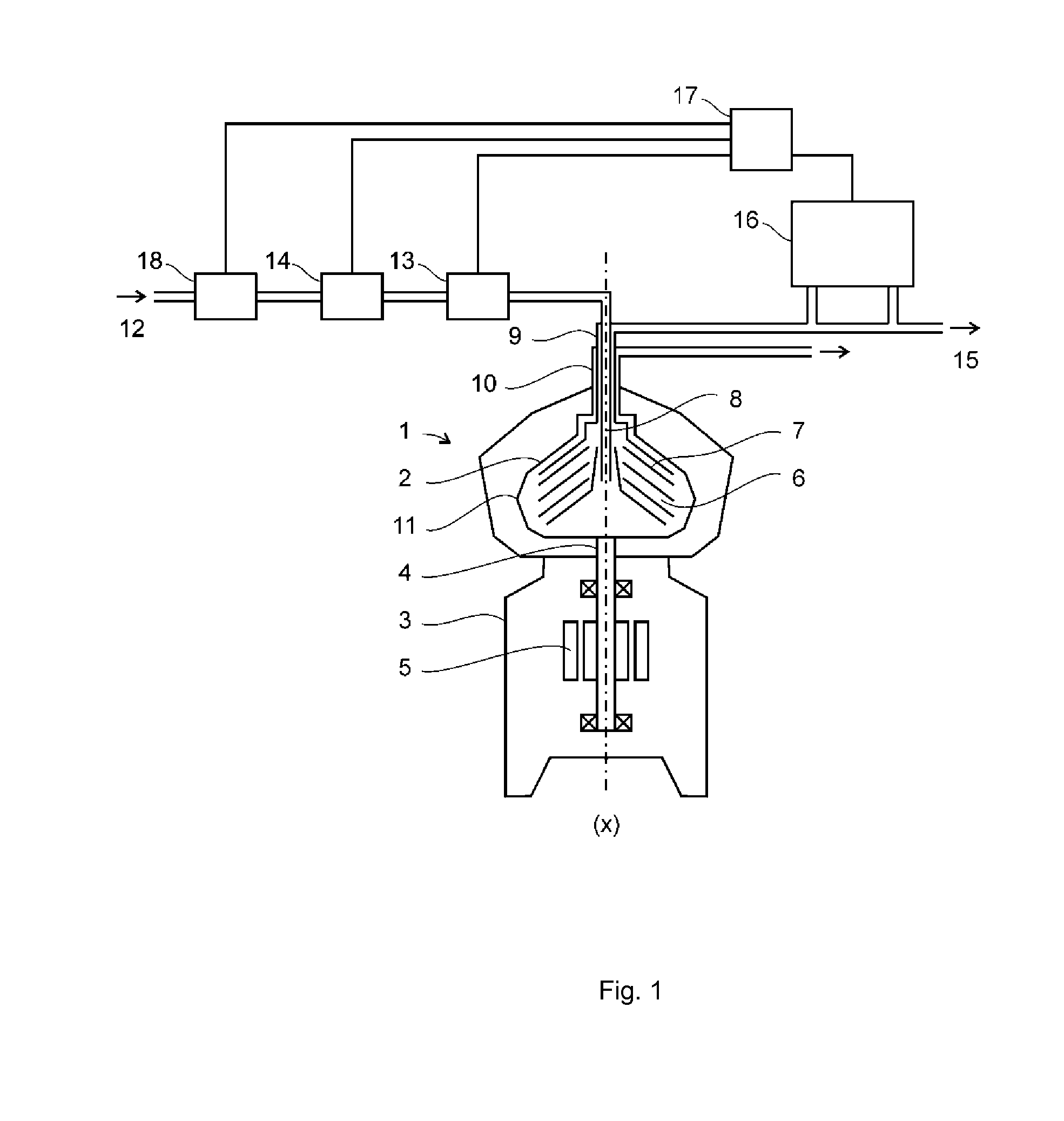

ActiveUS20150361354A1Improve compatibilityImprove scalabilityTreatment with plural serial stages onlyRotary centrifugesHigh densityVolumetric Mass Density

Methods for upgrading a hydrocarbon feed are disclosed. The methods include a hydrocarbon feed having an insolubility number, Ifeed, with at least a first fluid to form a fluid-feed mixture; and inducing a centrifugal force to the fluid-feed mixture sufficient to form at least a higher density portion and a lower density portion, said lower density portion having an insolubility number, ILD, wherein ILD / Ifeed≦0.95. Methods and apparatus for hydroprocessing the treated feed and blending with a fuel oil blend-stock are also described.

Owner:EXXONMOBIL CHEM PAT INC

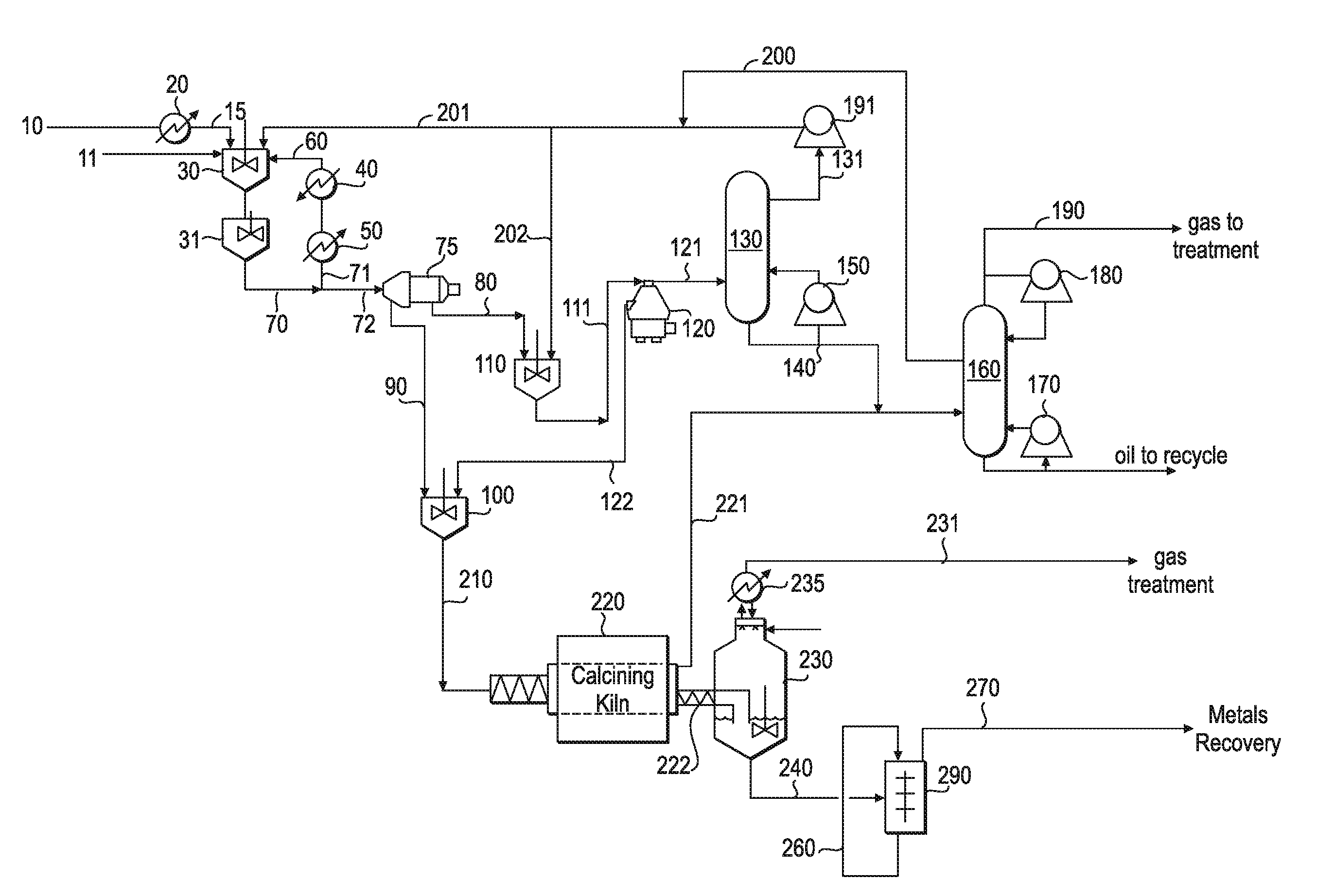

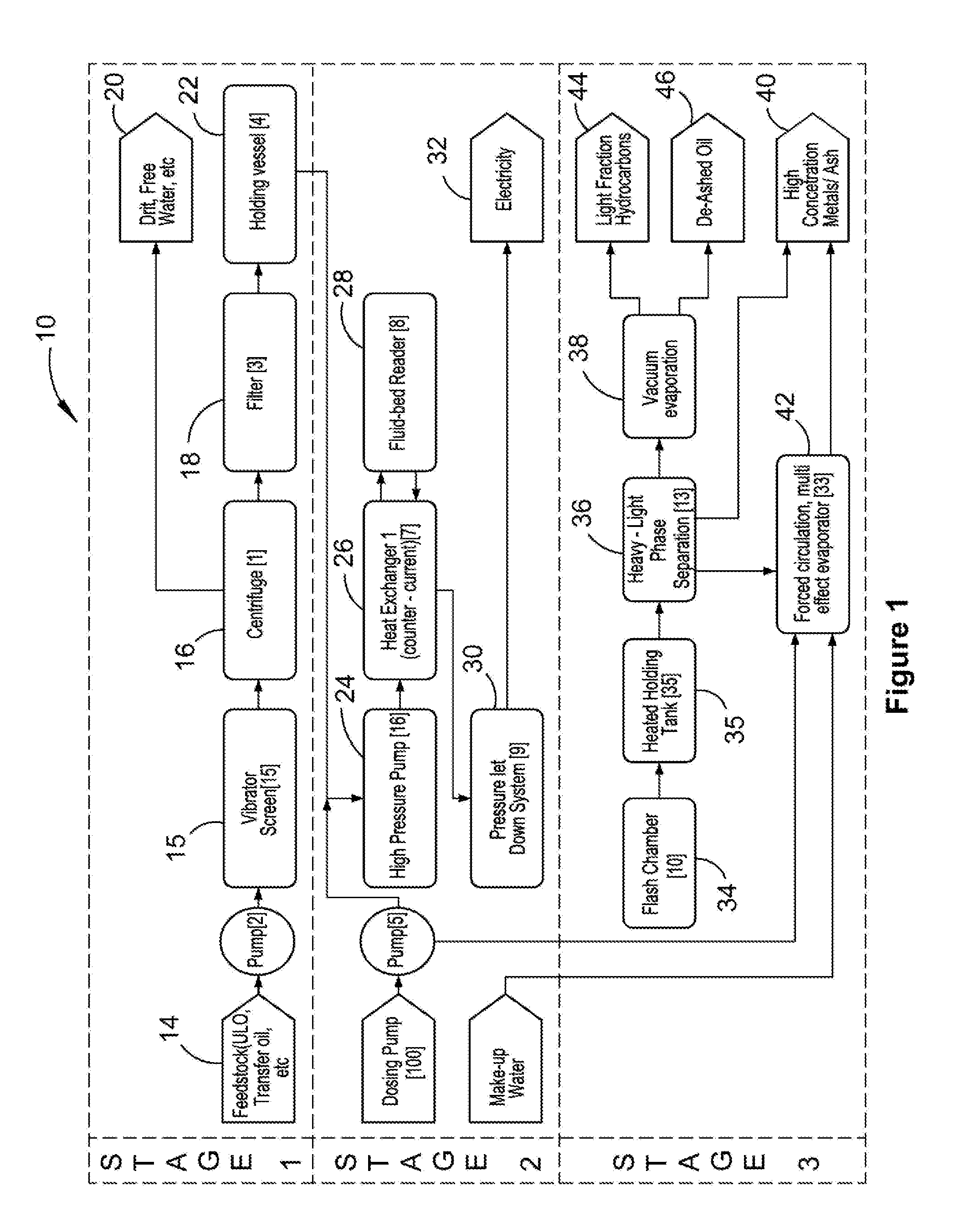

Method to remove metals from petroleum

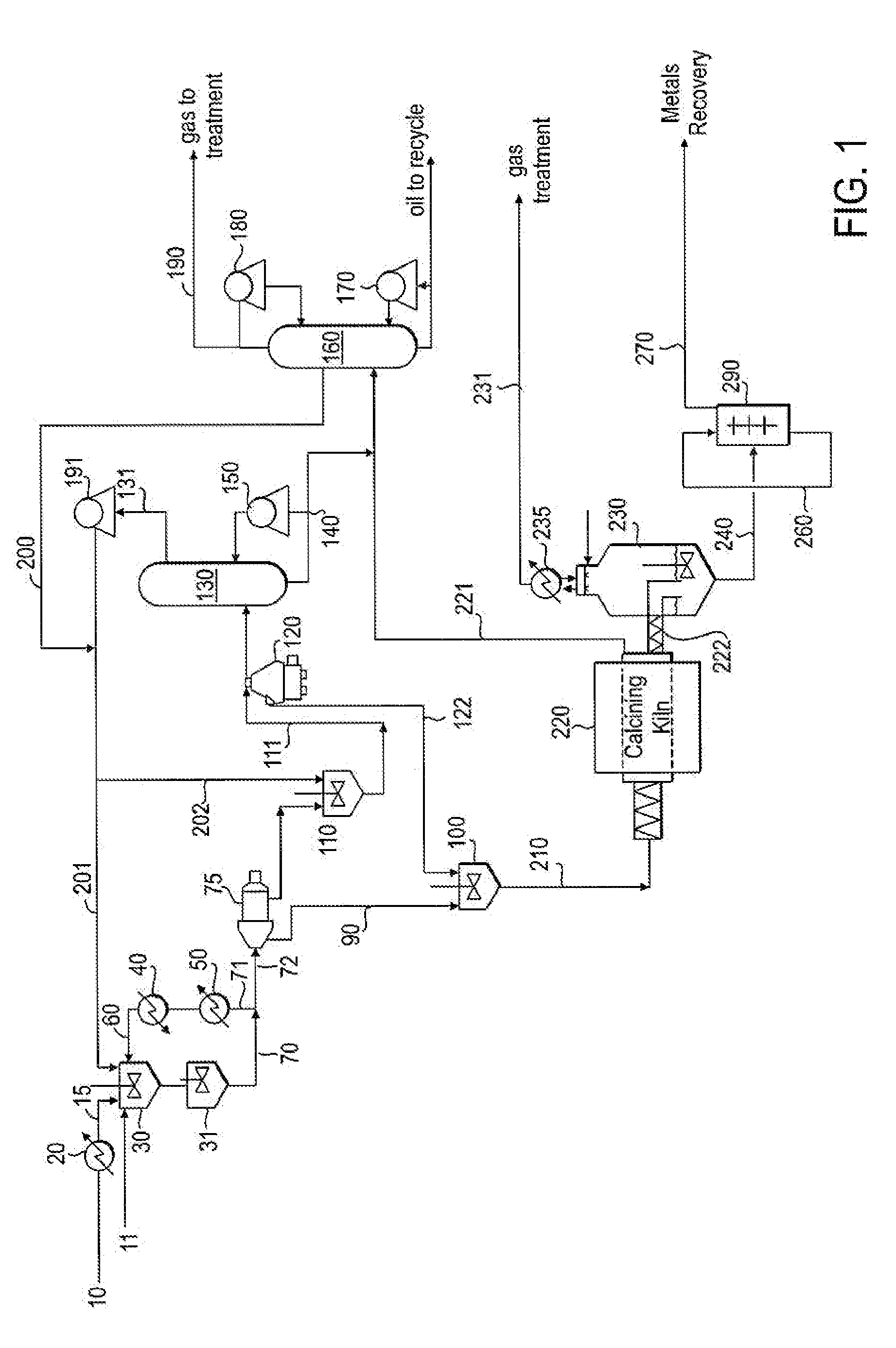

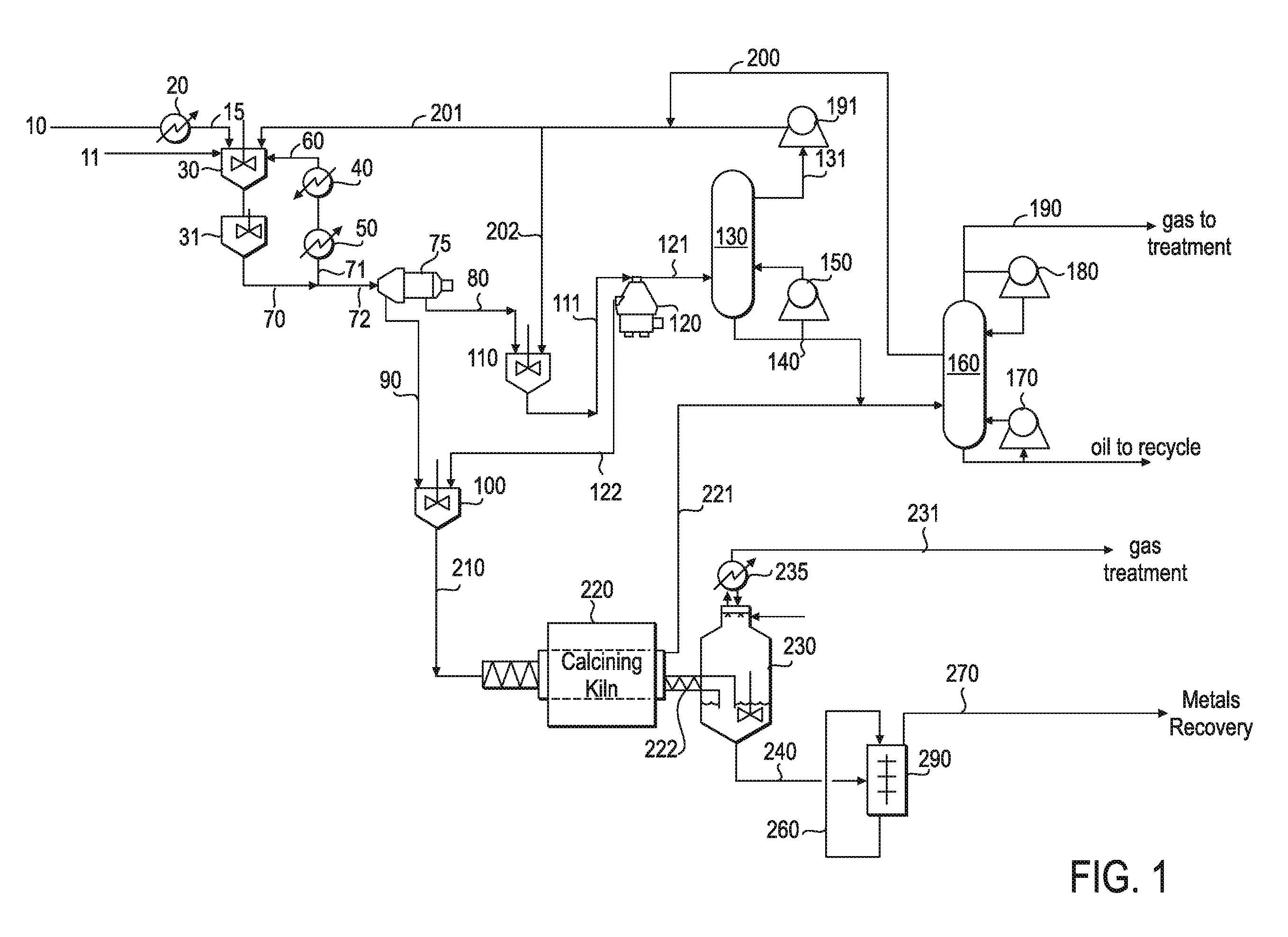

ActiveUS20170107433A1Low sulfurThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productGas phase

A method to remove a metals impurity from a petroleum feedstock for use in a power generating process is provided. The method comprising the steps of mixing a heated feedstock with a heated water stream in a mixing device to produce a mixed stream; introducing the mixed stream to a supercritical water reactor in the absence of externally provided hydrogen and externally provided oxidizing agent to produce a reactor effluent comprising a refined petroleum portion; cooling the reactor effluent to produce a cooled stream; feeding the cooled stream to a rejecter configured to separate a sludge fraction to produce a de-sludged stream; reducing the pressure of the de-sludged stream to produce a depressurized product; separating the depressurized product to produce a gas phase product and a liquid product; separating the liquid product to produce a petroleum product, having a reduced asphaltene content, reduced concentration of metals impurity, and reduced sulfur.

Owner:SAUDI ARABIAN OIL CO

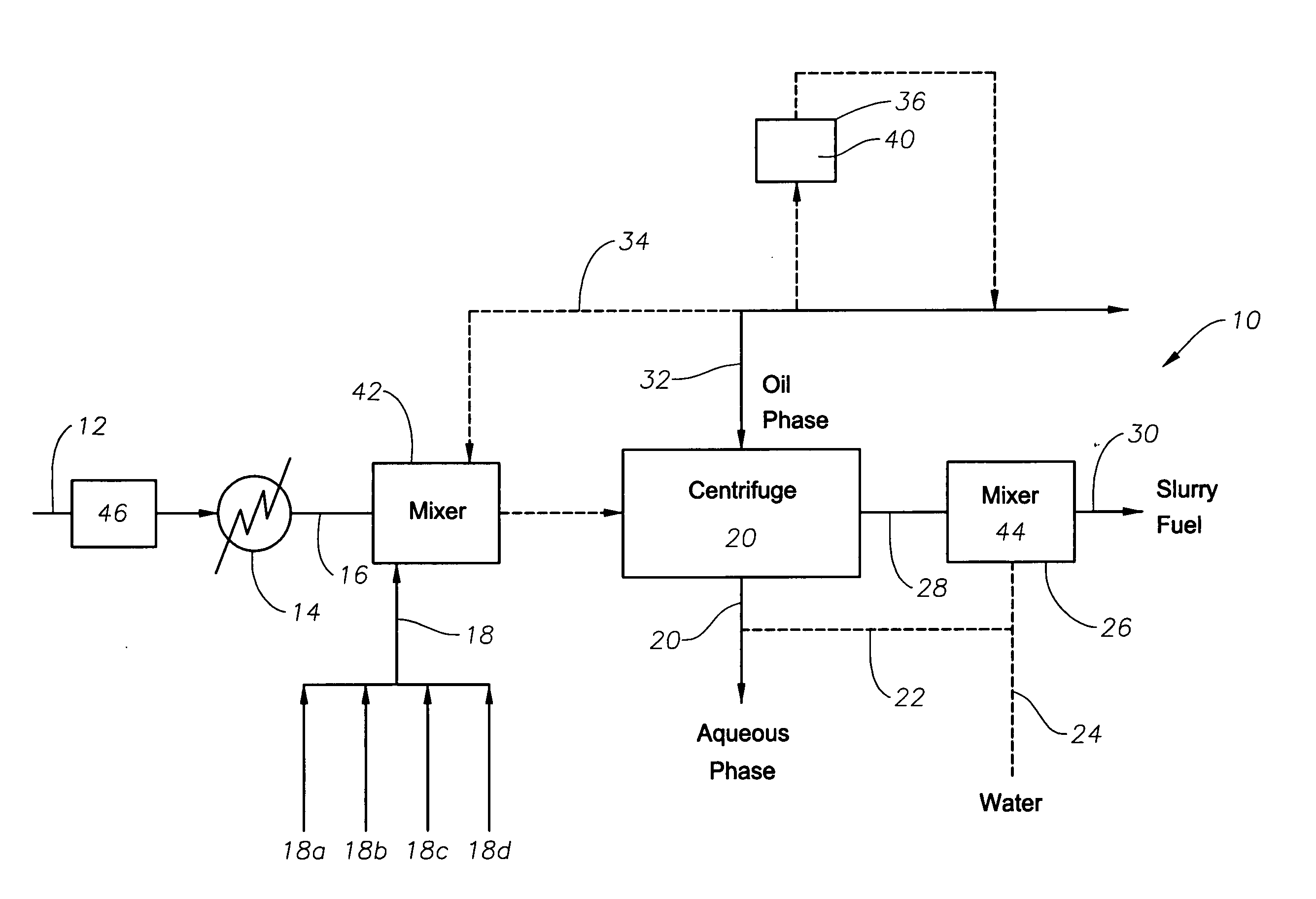

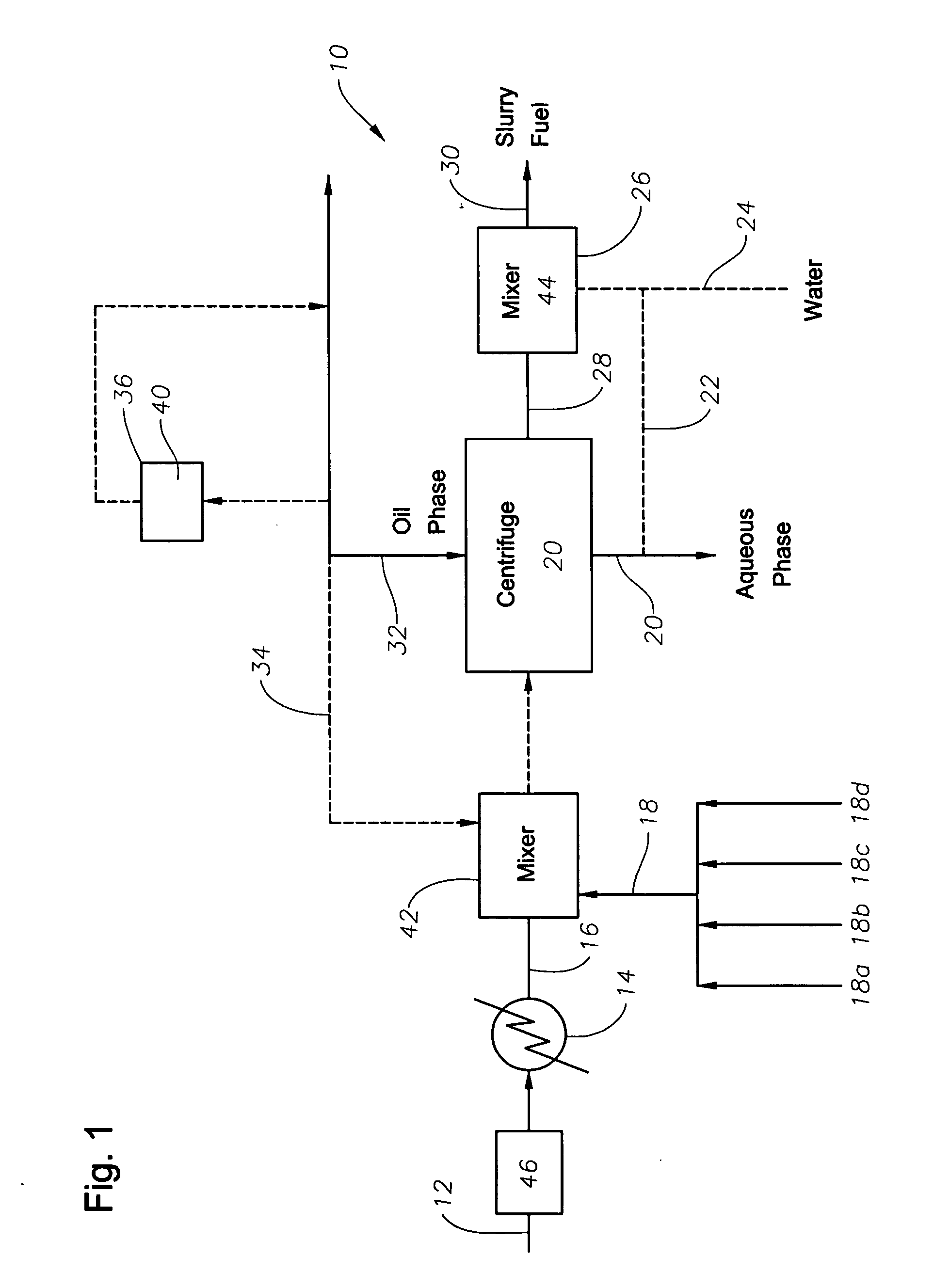

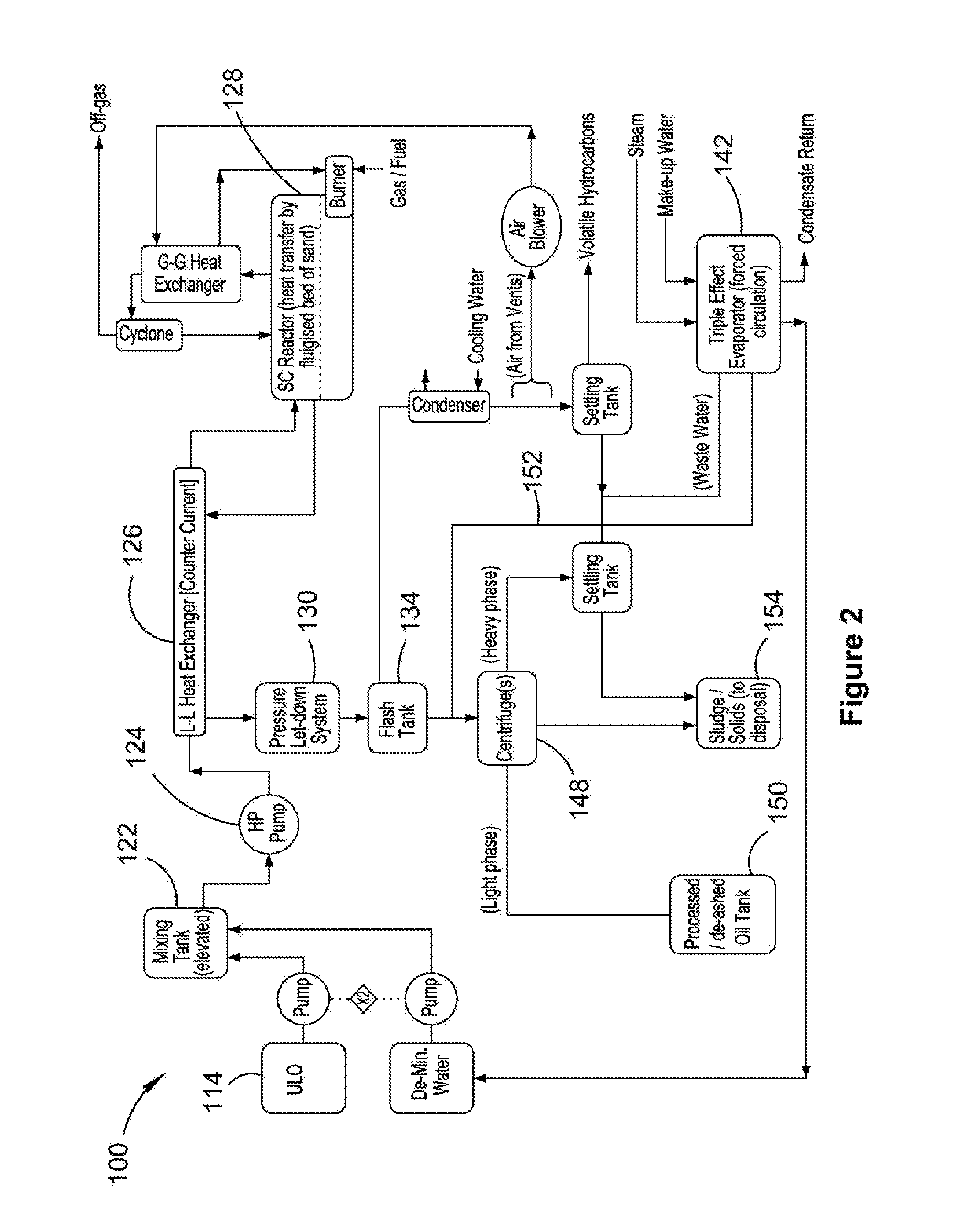

Method for utilizing hydrocarbon waste materials as fuel and feedstock

ActiveUS20060070912A1Low costDewatering/demulsification with mechanical meansRefining by heating/coolingFiberCarbon fibers

The fuel properties of petroleum hydrocarbon waste having an API gravity varying from about 5 to 30 are improved by heating the hydrocarbon to a temperature of about 35° C. to 90° C. and mixing the heated hydrocarbon stream with a suitable solvent to reduce the viscosity of the hydrocarbon, which is then separated by a centrifuge to obtain an aqueous phase stream, an oil phase stream, and a separated solids stream. The oil phase stream has a viscosity range of about 250 centipoise (cP) to about 1000 cP. The oil phase stream is utilized in a refinery, while a slurry fuel is prepared with the separated solids stream and aqueous phase stream as a feedstock for road asphalt, a fuel for a combustor, or a fuel for a gasification process. The oil phase stream is used for fuels and feedstock for making carbon fiber.

Owner:SAUDI ARABIAN OIL CO

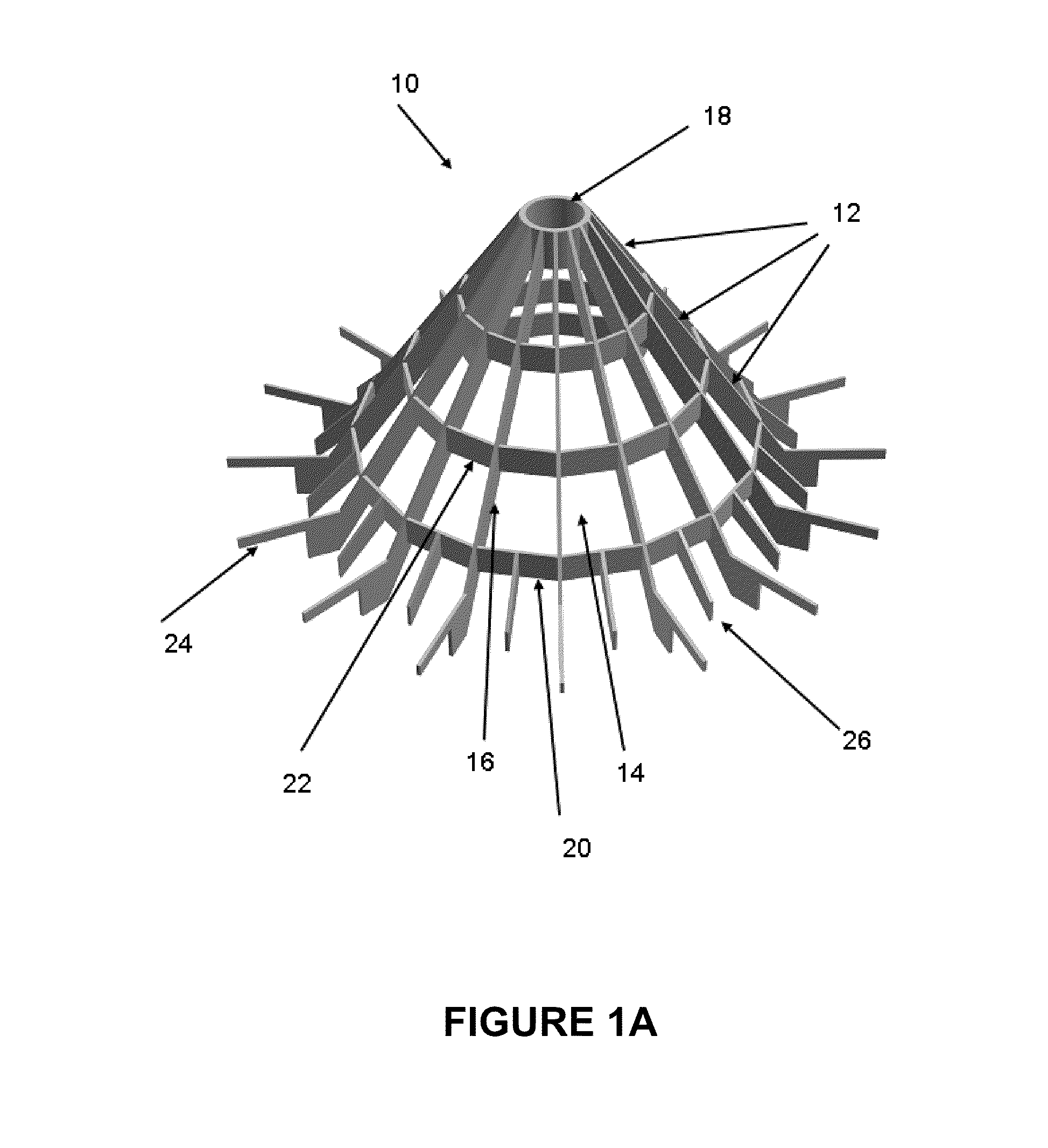

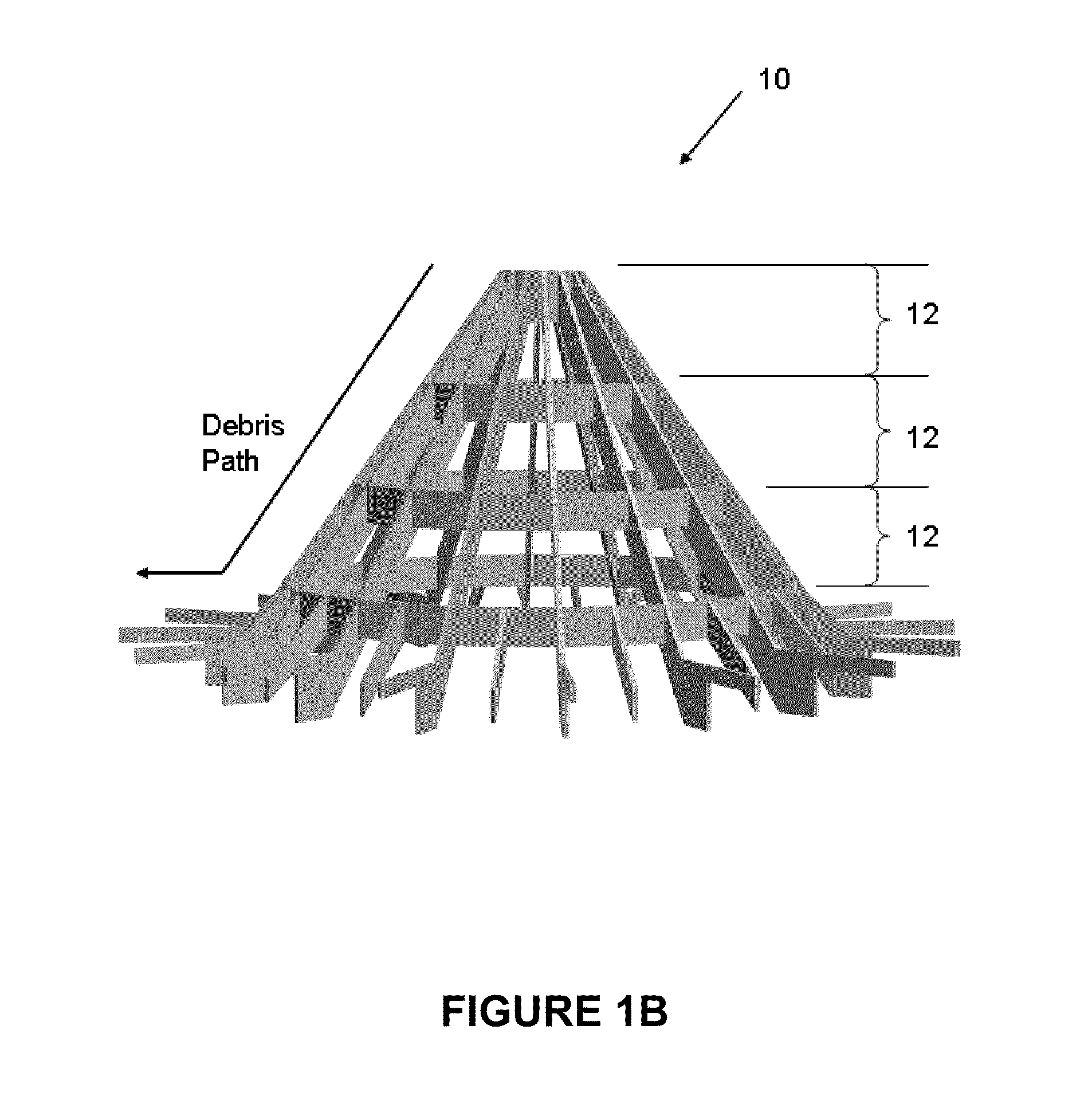

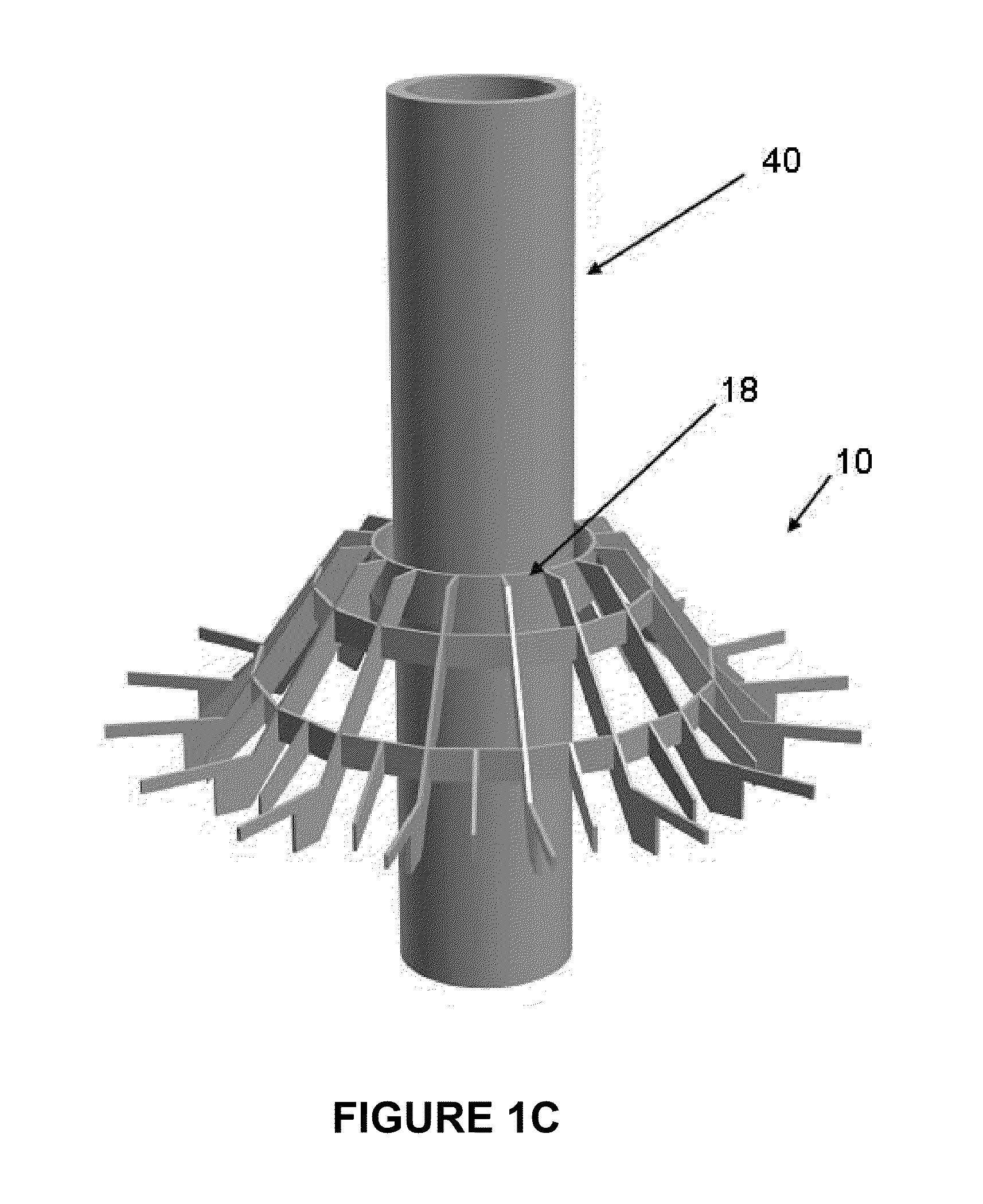

Debris Separation Device and Method of Use

InactiveUS20110240526A1Efficient screeningCatalytic crackingRefining by dialysisVertical planeEngineering

A device for use in separating debris from a flowing stream which comprises a substantially hollow, substantially conical shaped structure comprising a top end member and a plurality of adjacently positioned side members angularly extending from a top end member to a substantially circular bottom end. The top end member has a smaller diameter than the circular bottom end. The adjacently positioned side members are configured to provide multiple tiers in a vertical plane in the conically shaped structure. The multiple tiers comprise a plurality of apertures in a horizontal plane in the conically shaped structure. The plurality of apertures are configured for separating large debris particles, generally formed from coke and spent catalyst, from a flowing fluidized catalytic cracking stream, and directing the captured debris toward the circular bottom end of the device. A method of separating debris from a flowing stream is also provided. In particular, the device and method are useful for separating coke deposits in a fluidized catalytic cracking (FCC) process.

Owner:EXXON RES & ENG CO

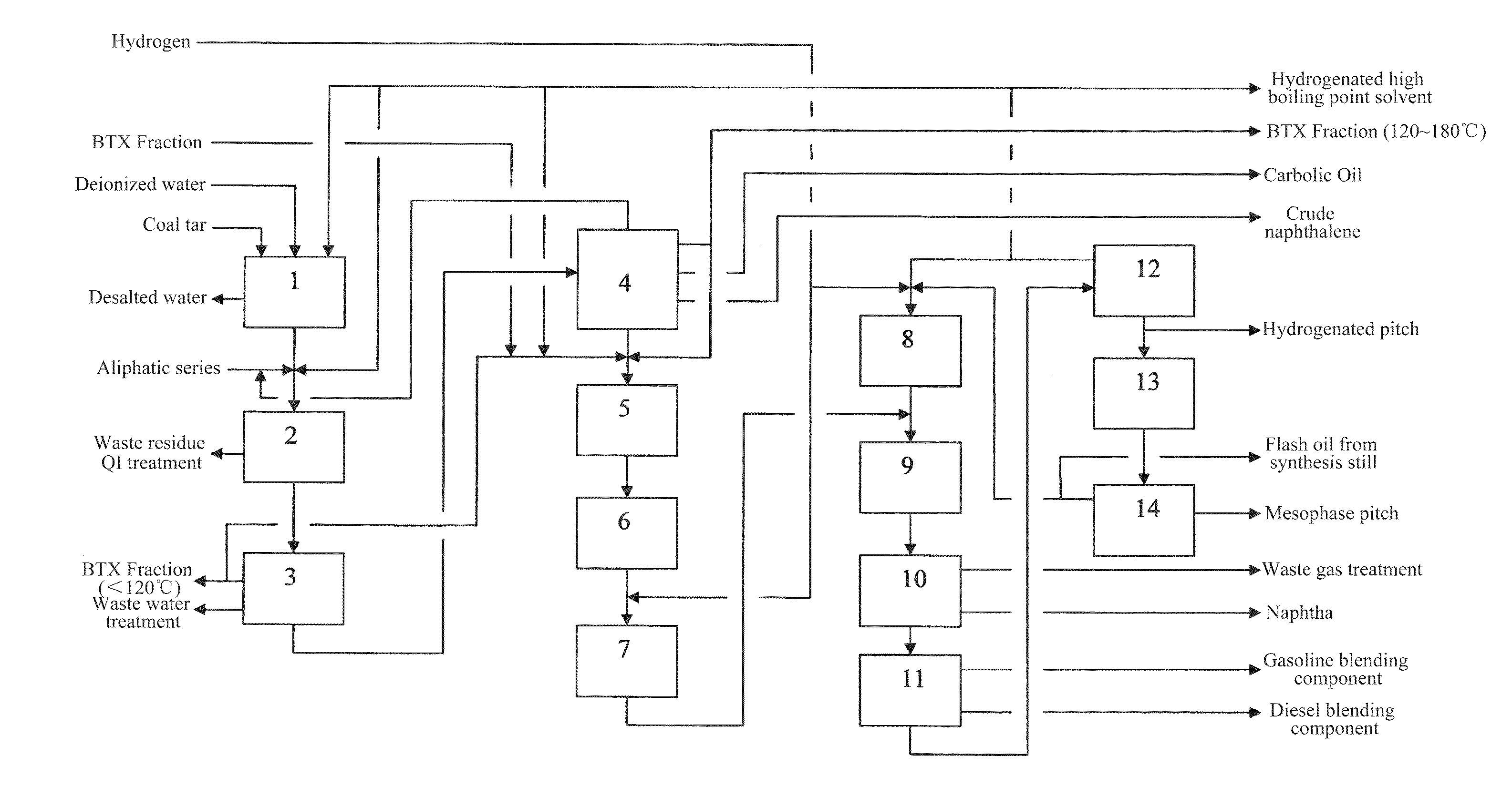

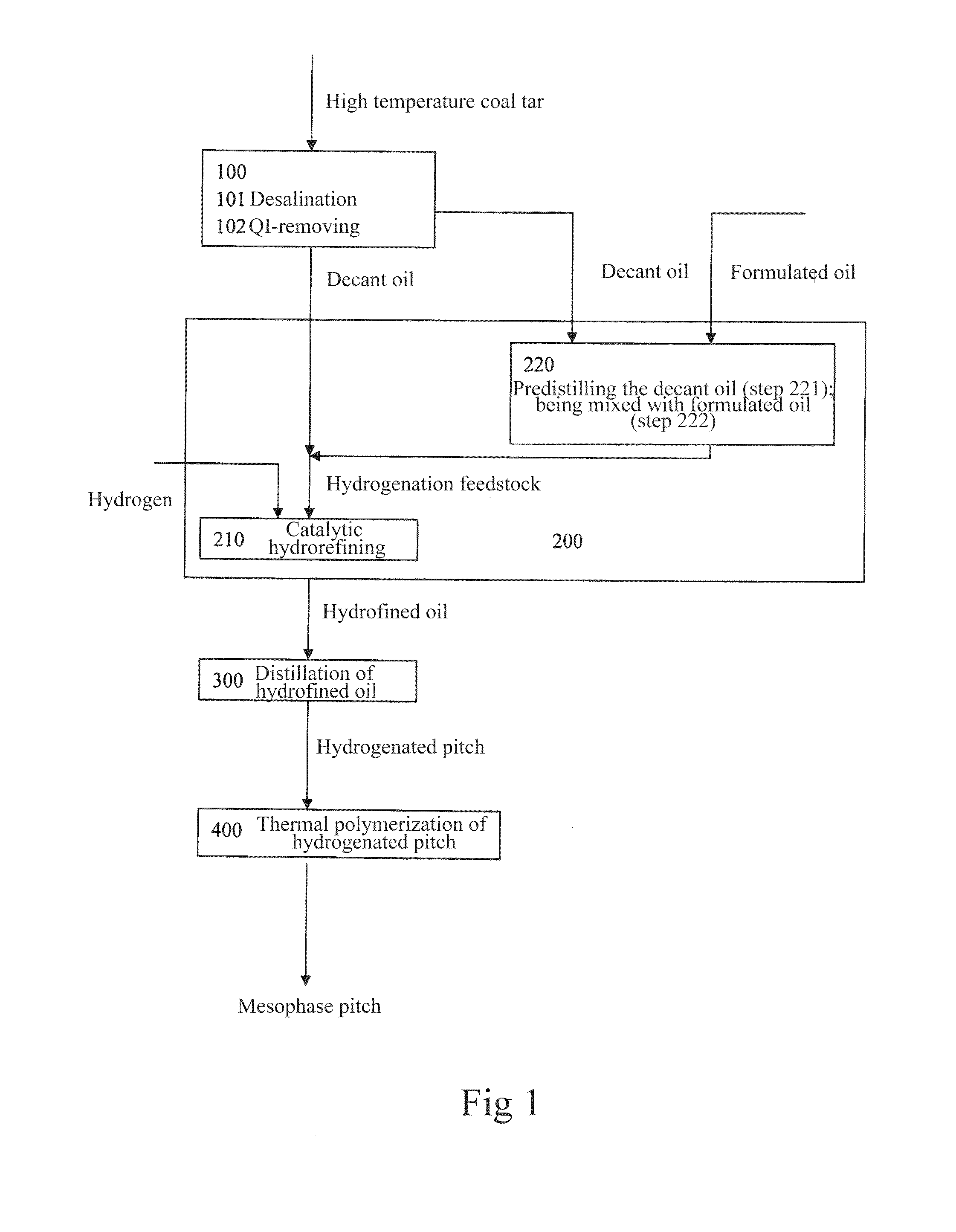

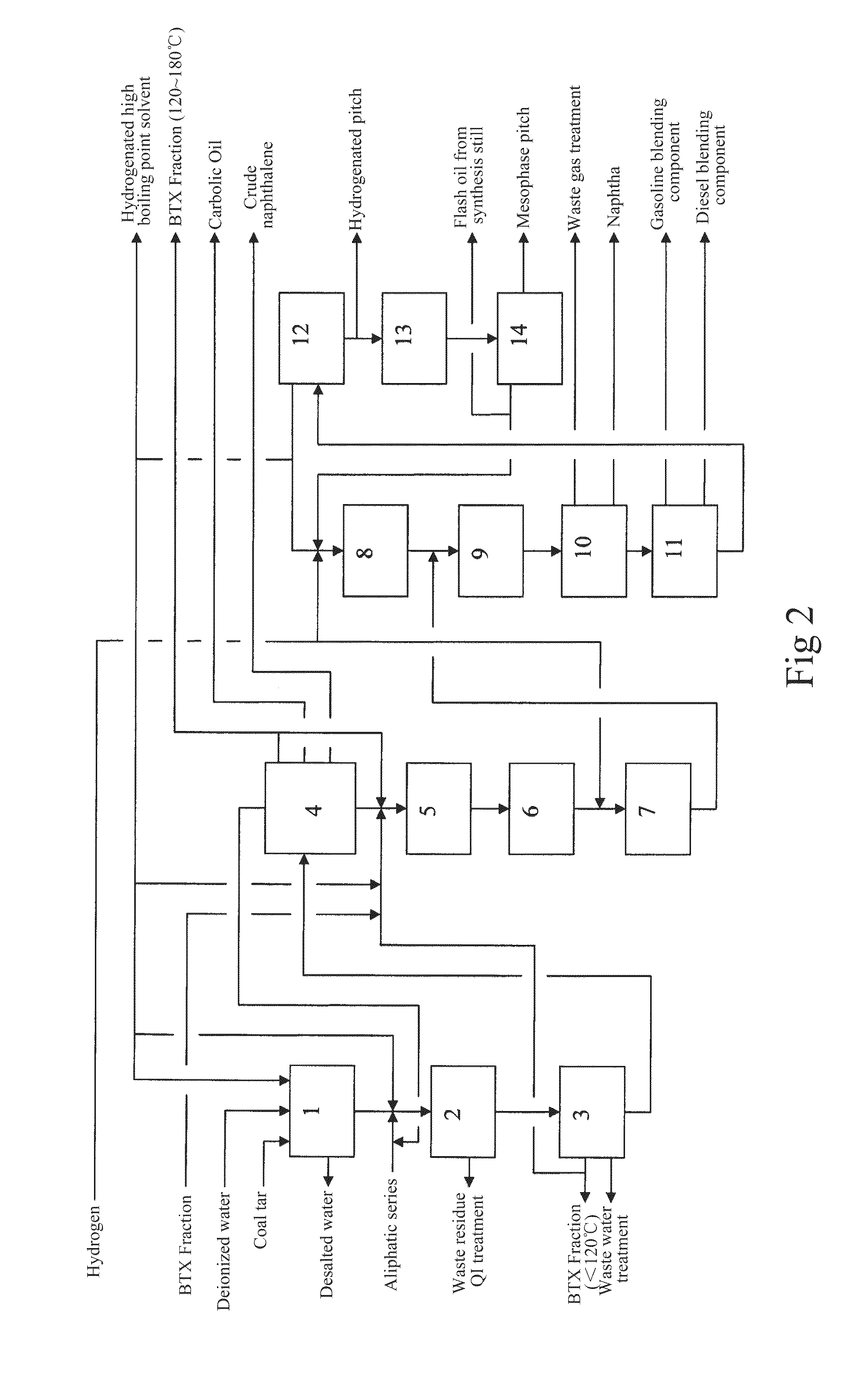

Process for Producing Mesophase Pitch by Hydrogenation of High-temperature Coal Tar

ActiveUS20150076031A1Increase H/C ratioHigh content of mesophase pitchWorking-up pitch/asphalt/bitumen by distillationLiquid hydrocarbon mixtures productionBoiling pointCoal tar

A process for producing mesophase pitch from high-temperature coal tar comprises: removing salts and quinoline insoluble fraction from a high-temperature coal tar to obtain a decant oil; using the decant oil as a hydrogenation feedstock, or pre-distilling the decant oil to obtain a residue with a boiling point higher than 230 and formulating the residue into a hydrogenation feedstock; catalytic hydrorefining the hydrogenation feedstock to obtain a hydrofined oil; distilling the hydrofined oil to obtain hydrogenated pitch; and subjecting the hydrogenated pitch to the thermal polymerization to obtain the mesophase pitch. The process has features such as an easily controllable degree of hydrogenation, complete removal of impurities, good raw material flowability, not tending to form the carbon deposition and the coking during the process, and not tending to jam the reactor. The product has a high content of mesophase pitch, a low softening point and a low impurity content.

Owner:ECO CARBON MATERIALS HLDG (SHENZHEN) CO LTD +1

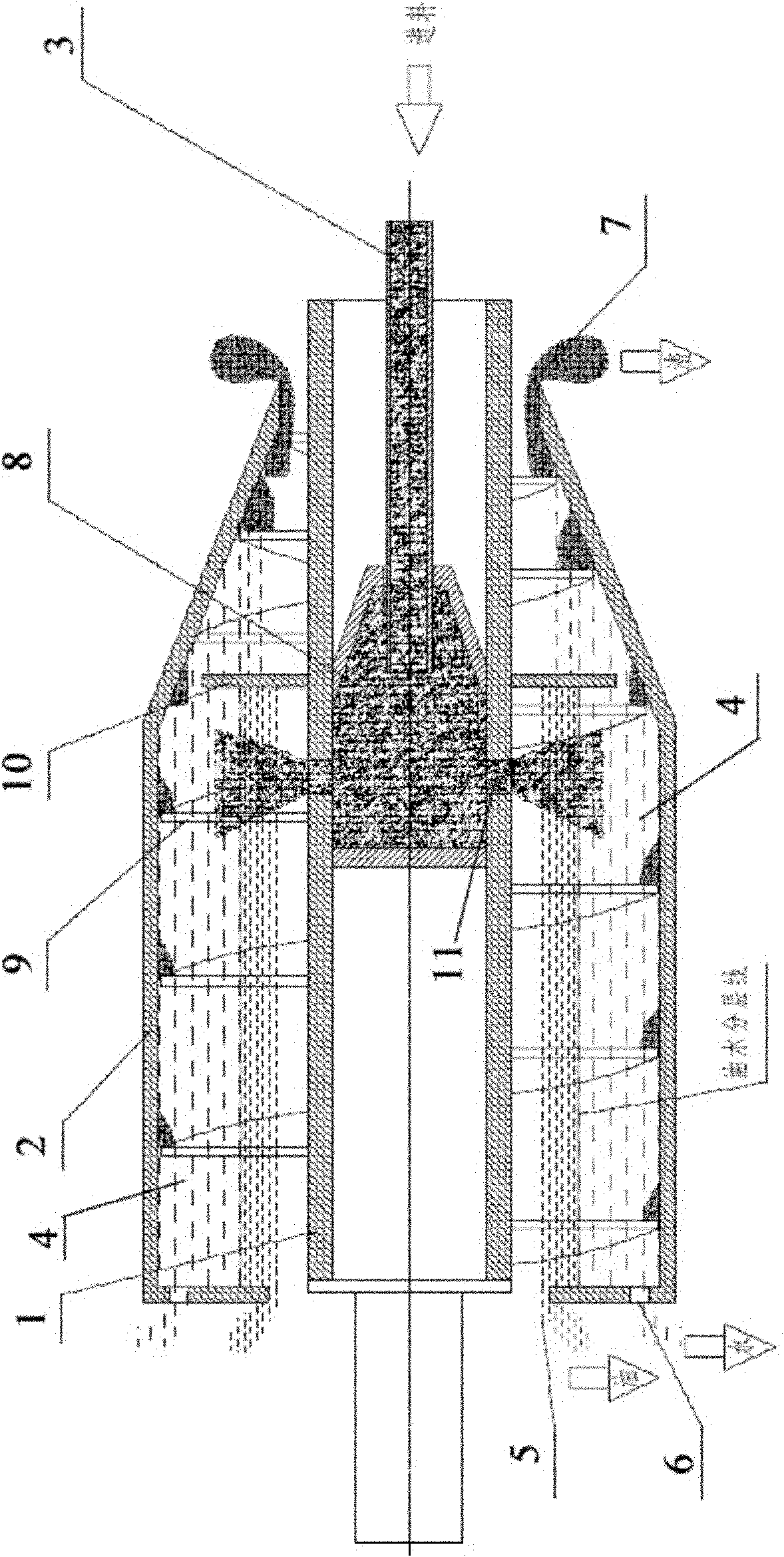

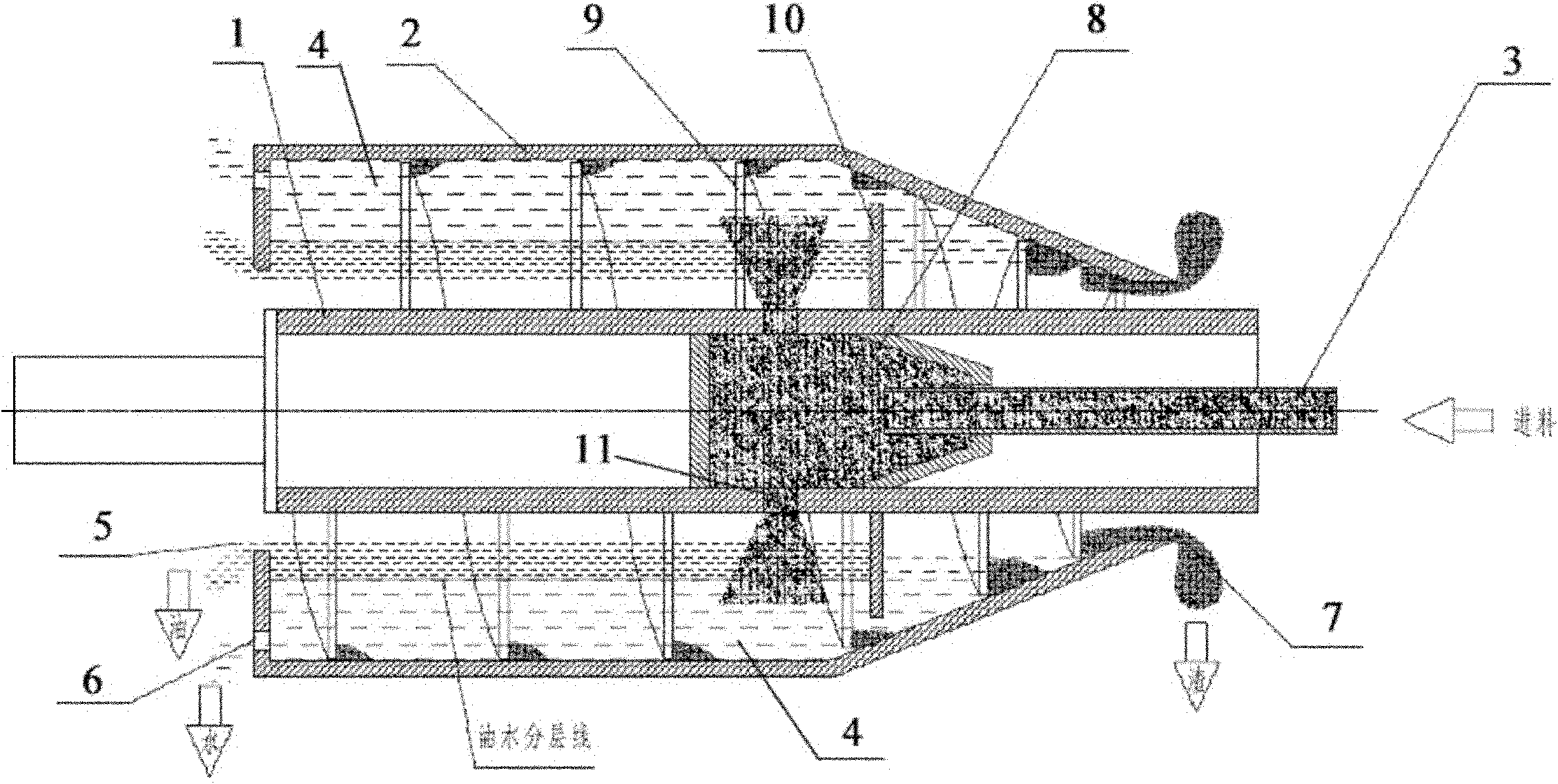

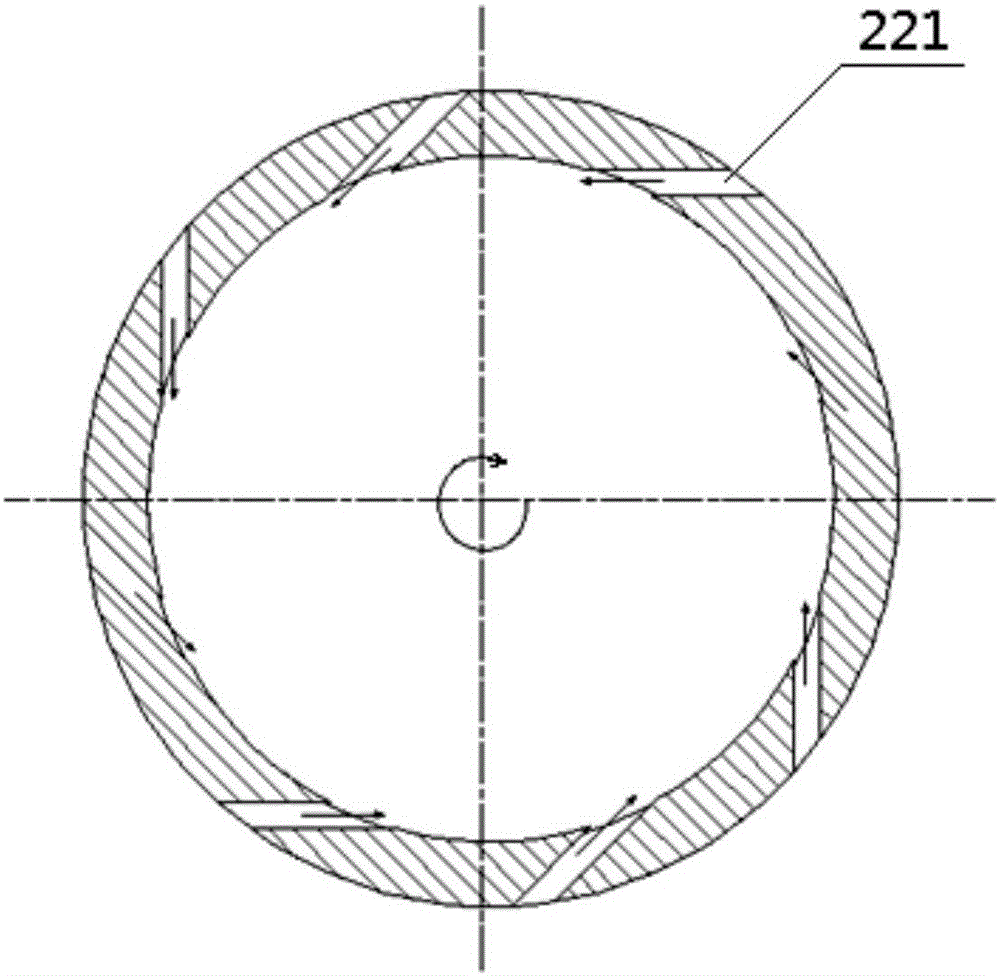

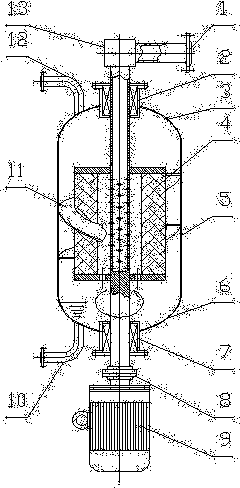

Method for treating ageing oil of viscous oil

ActiveCN102041038AExact decomposition surfaceDecomposition is achieved accuratelyDewatering/demulsification with chemical meansRotary centrifugesPhenolPetroleum engineering

The invention relates to a method for treating ageing oil of viscous oil, which provides a demulsifier for ageing oil of viscous oil, comprising the following raw materials in weight percent: 0.5-1% phenol, 1.5-2% styrene, 0.5-1% ethyleneamine, 0.5-1% formaldehyde, 0.5-1% catalyst, 40-50% ethylene oxide and 40-50% epoxypropane. The invention further provides a three-phase decanter centrifuger, comprising a differential mechanism, a spiral propeller, a rotary drum, a housing, an engine base, a motor and a feed pipe. The invention further provides a method for treating ageing oil of viscous oil, comprising the following steps of: using the demulsifier to perform demulsification treatment to the ageing oil of the viscous oil, then inputting the ageing oil of the viscous oil after the demulsification treatment in the three-phase decanter centrifuger to centrifuging and separating so as to respectively obtain fatlute, sewage and the oil. The ageing oil, especially the ageing oil of the viscous oil, is treated by adopting the demulsifier to combine with the centrifuging method; the demulsification and dehydration problem of the ageing oil of viscous oil in the oil field is solved, and the requirement of the field production can be satisfied.

Owner:PETROCHINA CO LTD +1

Hydrocarbon Upgrading

ActiveUS20150361359A1Hydrocarbon by isomerisationHydrocarbon purification/separationParticulatesRaffinate

Aspects of the invention provide a process for upgrading a hydrocarbon feed. The process includes providing a hydrocarbon feed and a utility fluid. Then selectively extracting from the feed at least a portion of particulates to produce a raffinate and an extract. Third hydroprocessing at least a portion of the raffinate.

Owner:EXXONMOBIL CHEM PAT INC

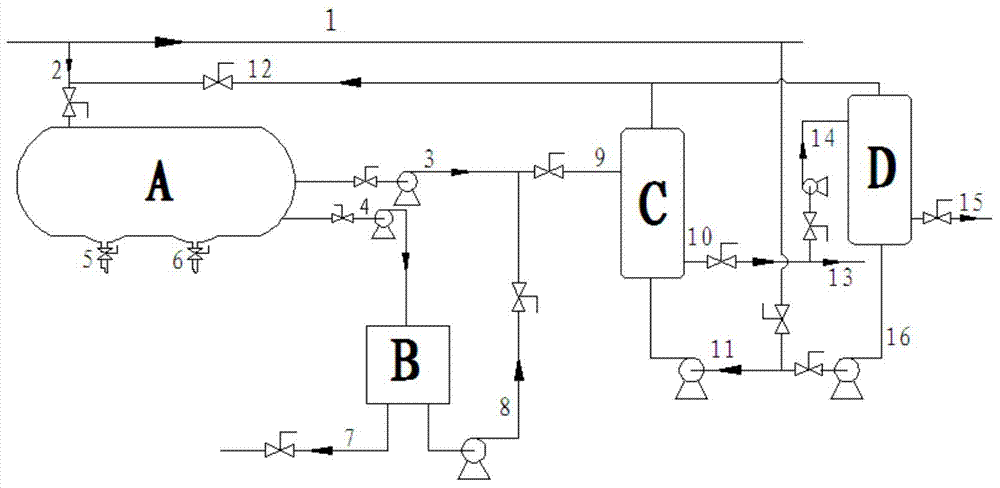

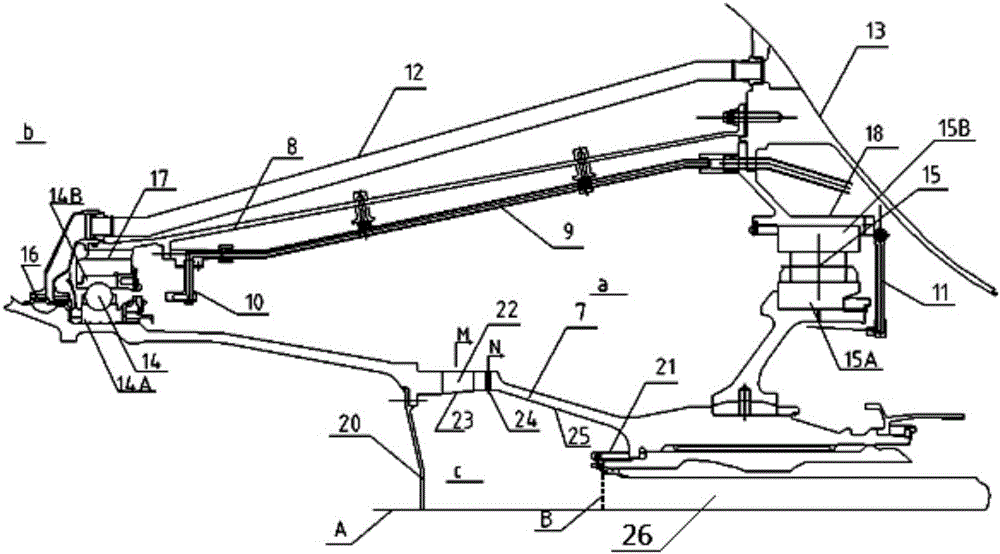

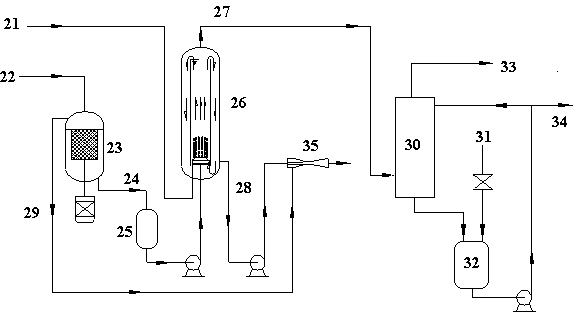

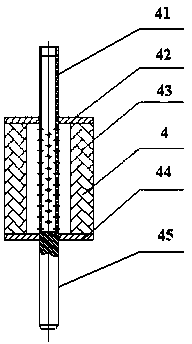

Purifying equipment and purifying method for purifying catalytic cracking slurry oil

ActiveCN103484148AImprove electrostatic separation efficiencyImprove separation stabilityRefining by centrifugal forceSolid phasesEnergy consumption

The invention provides purifying equipment and a purifying method for purifying catalytic cracking slurry oil. According to the purifying method, the catalytic cracking slurry oil enters a settling tank from a pipeline (2), overflowing slurry oil is conveyed into a primary static separator from a pipeline (3), and a bottom flow is pumped into a centrifugal machine from a pipeline (4); a solid phase at the bottom of the settling tank is discharged from a discharge pipe at the bottom of the tank and sent into a lift pipe after centrifuged, and a liquid phase is pumped into the primary static separator from a pipeline (8) after centrifuged; a slurry oil product finishing static purification is sent into a product tank from a pipeline (10); and after fillers of the primary static separator is saturated through absorption, to-be-purified catalytic cracking slurry oil is introduced from a pipeline (11) and back back-washed from the bottom of the primary static separator, a backwash liquid returns to the settling tank from the top of the separator through a pipeline (12), and the purified slurry oil product is discharged into a product tank from a pipeline (15). The provided method is high in purification efficiency, stable in operation, long in production period, low in energy consumption and high in recycling rate of oil slurry, and effectively overcomes defects of a single separation method.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

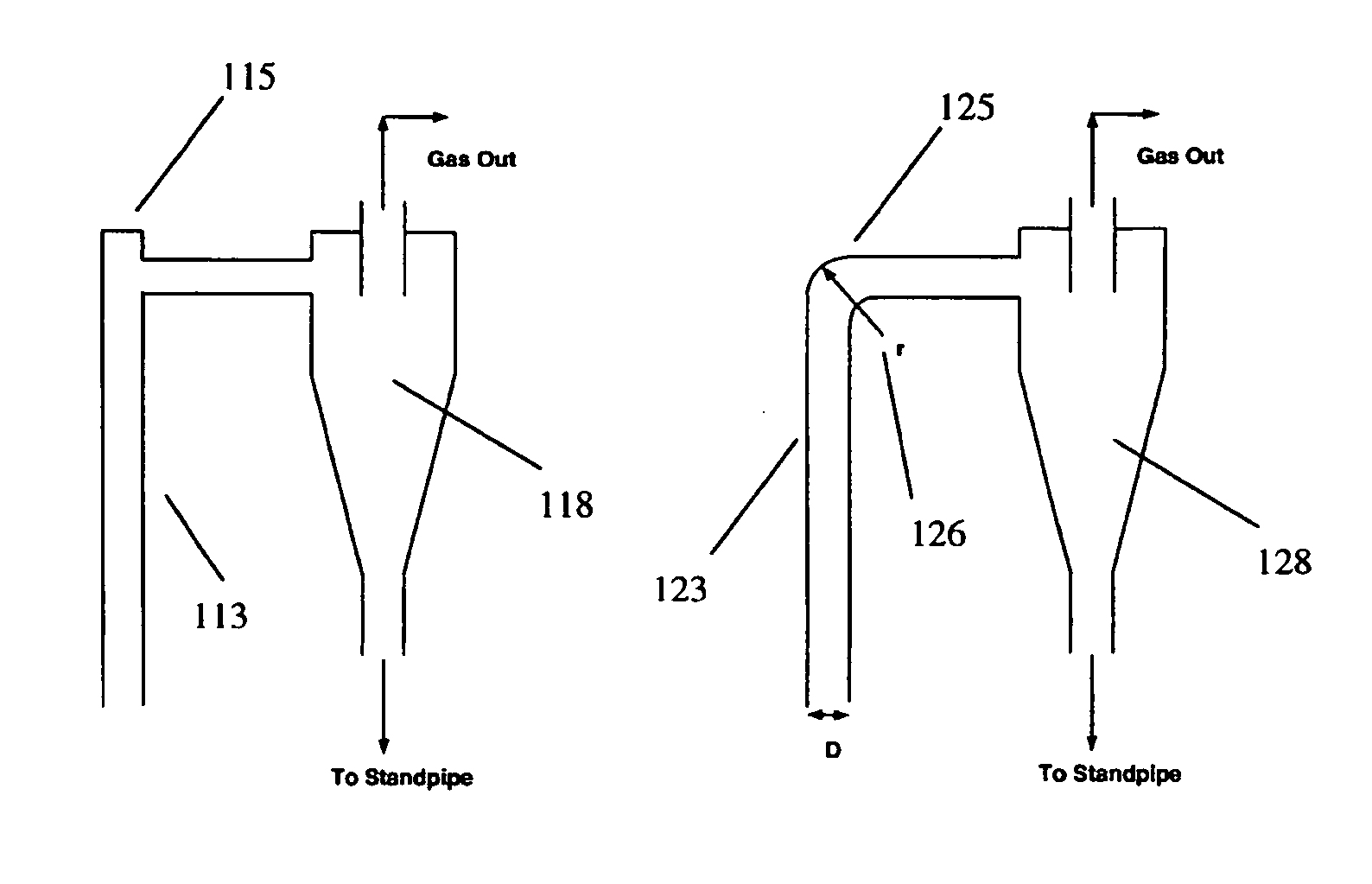

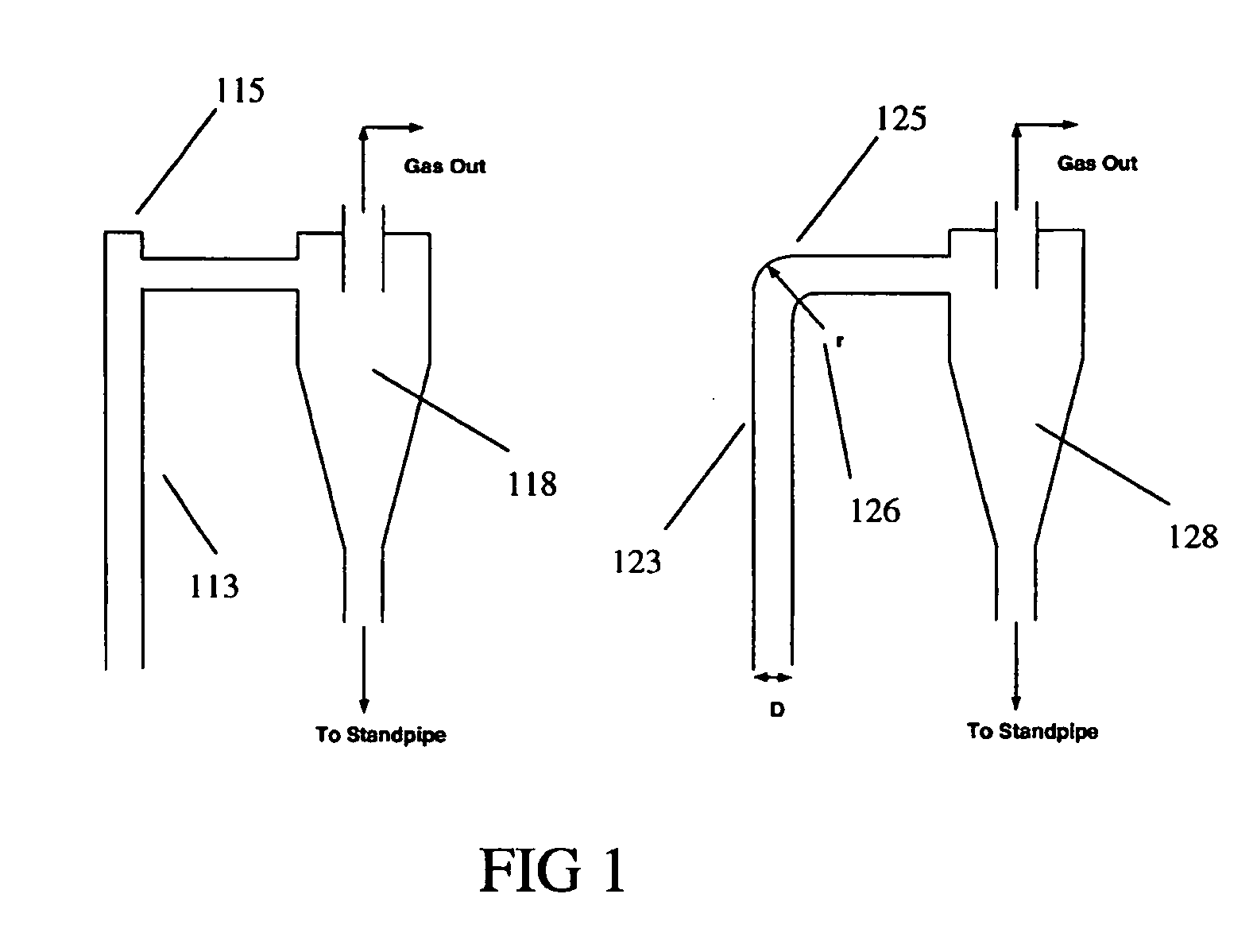

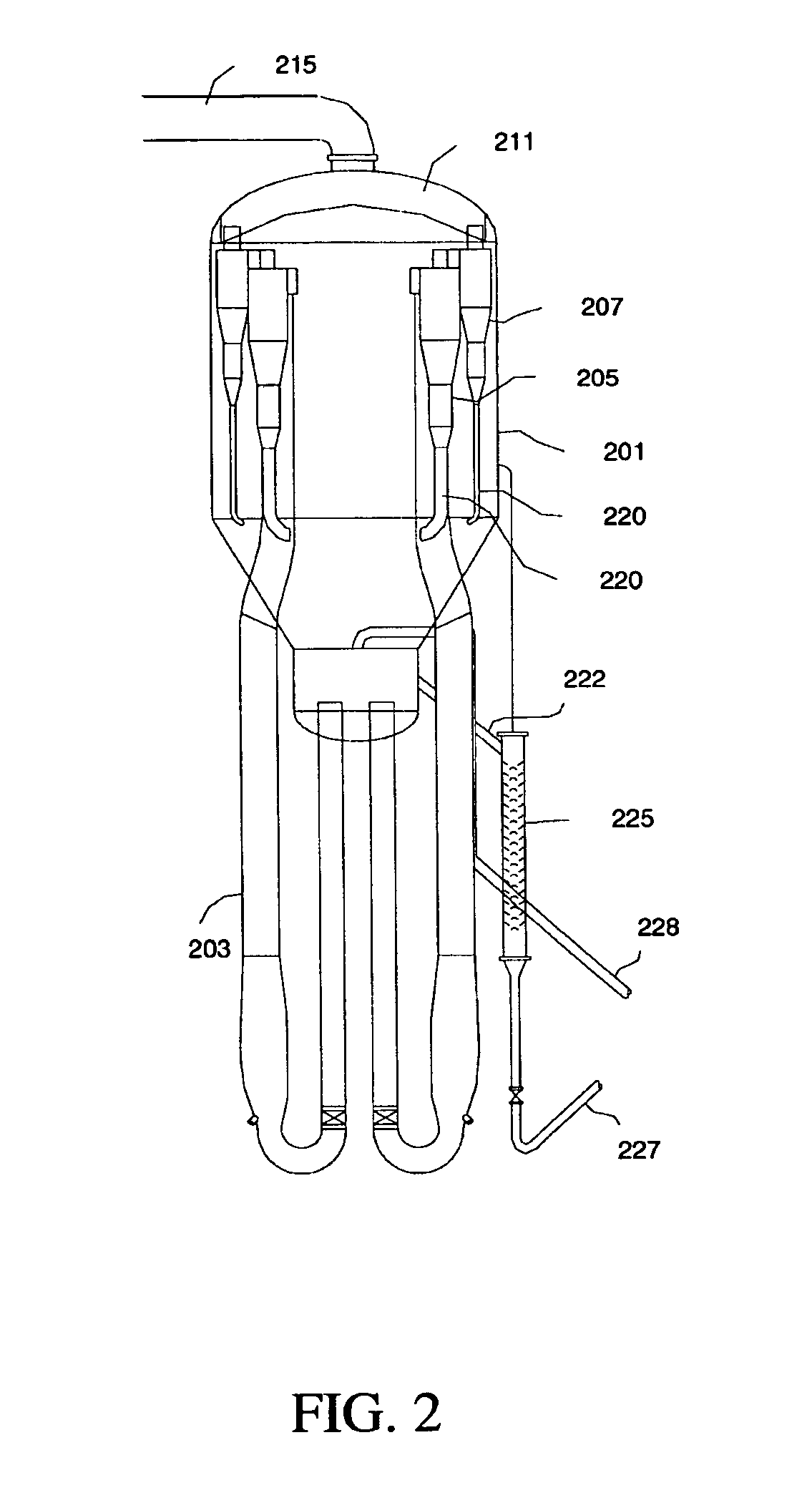

Riser termination devices for reduced catalyst attrition and losses

InactiveUS20070049782A1Reducing or minimizing the solid attrition and/or loss of solidsCatalytic crackingMolecular sieve catalystEngineeringReaction system

A gas-solids reaction system with termination devices to connect a riser with one or more separation devices. The termination devices have a radius of curvature that is at least 1.0 times as great as the diameter of the conduit forming the termination device. The termination devices can be openly or closely coupled to the separation devices.

Owner:EXXONMOBIL CHEM PAT INC

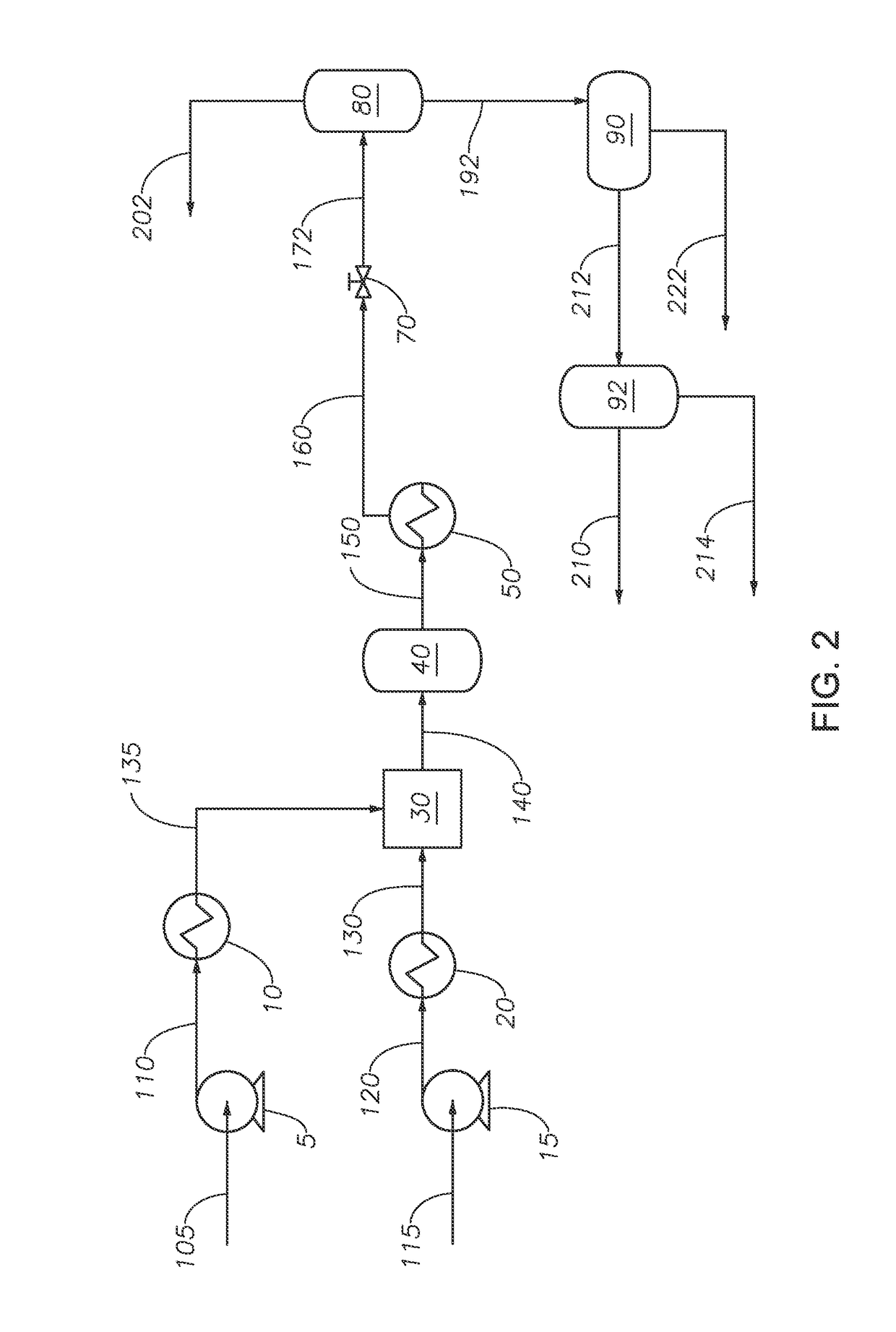

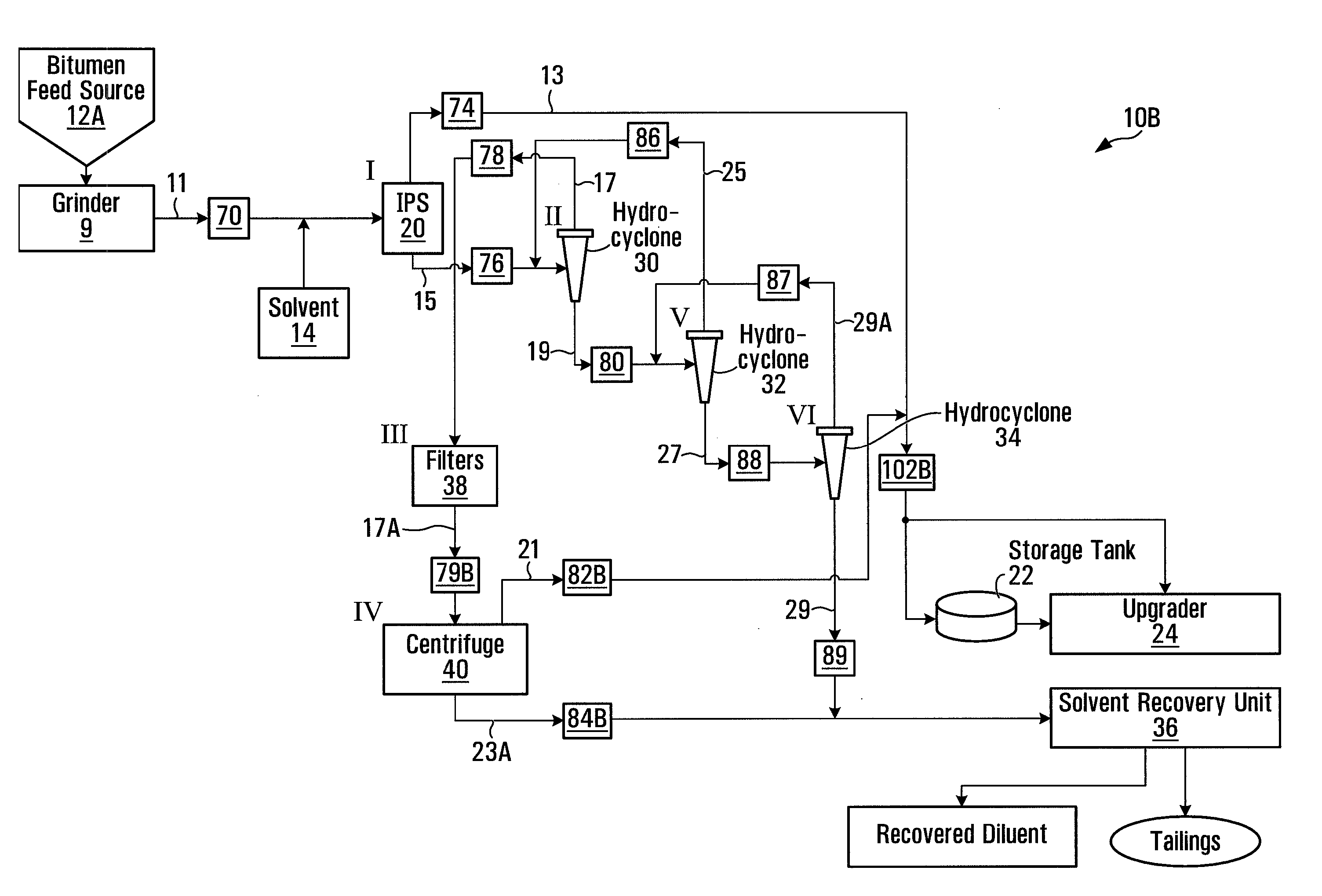

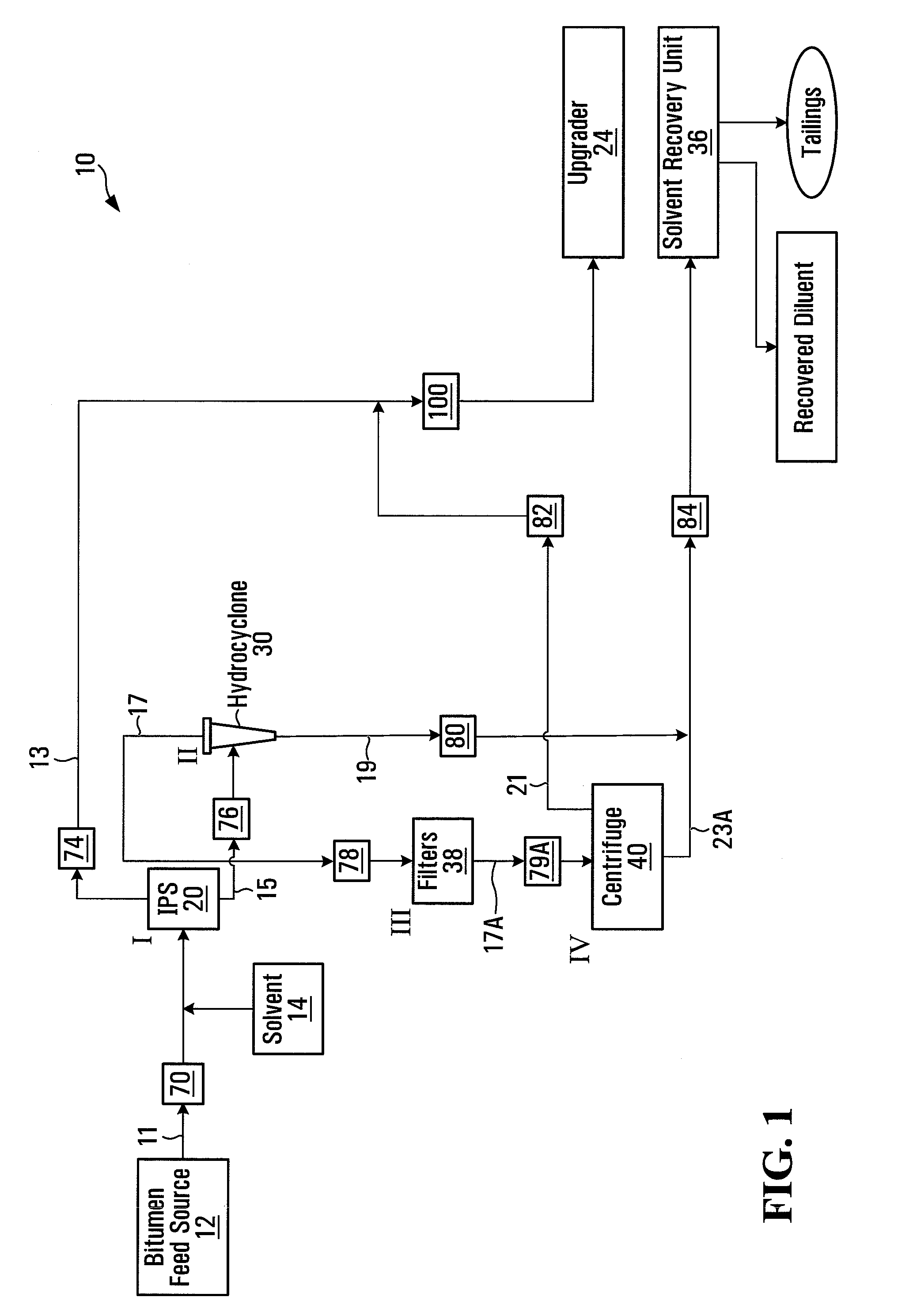

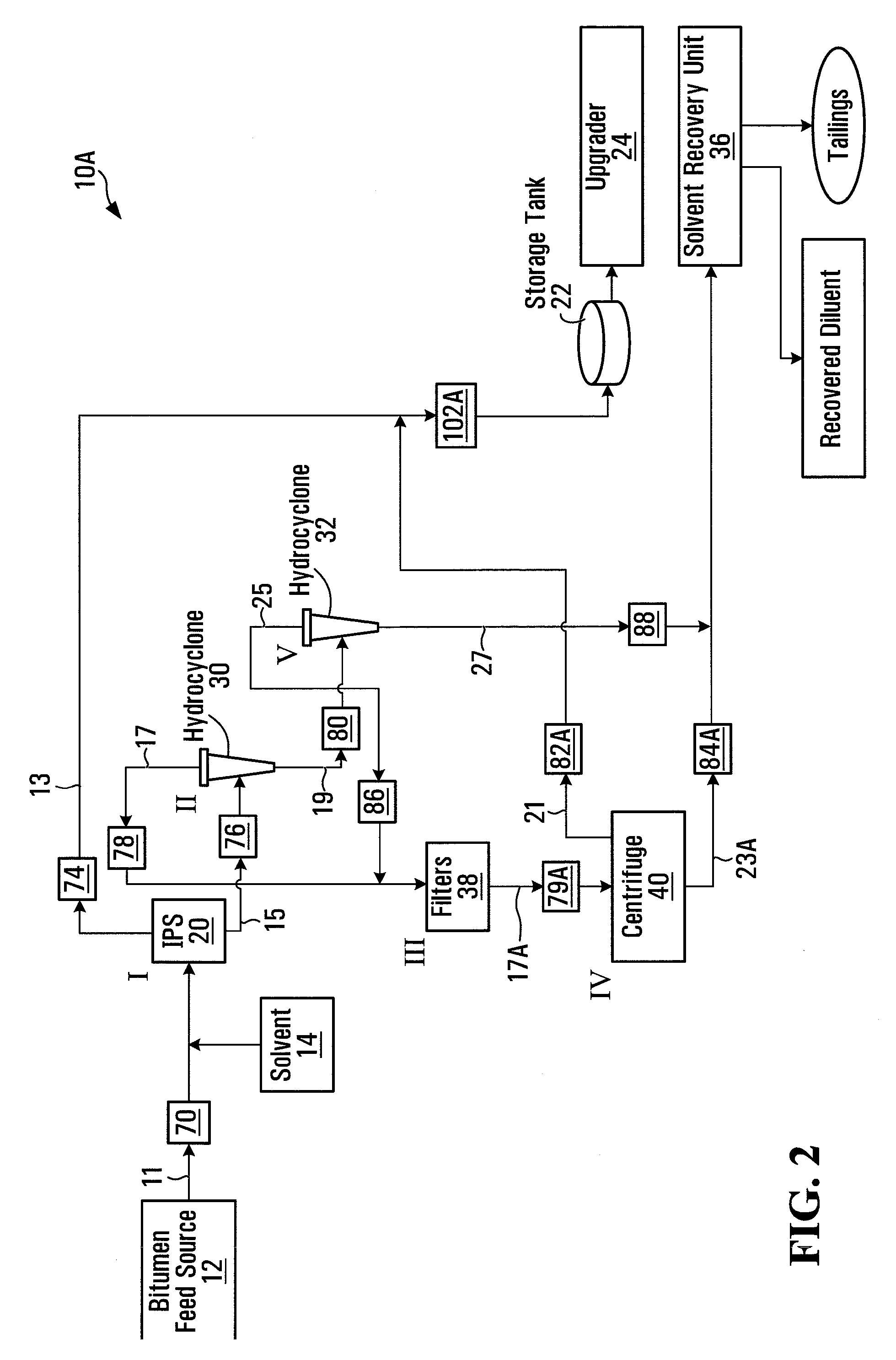

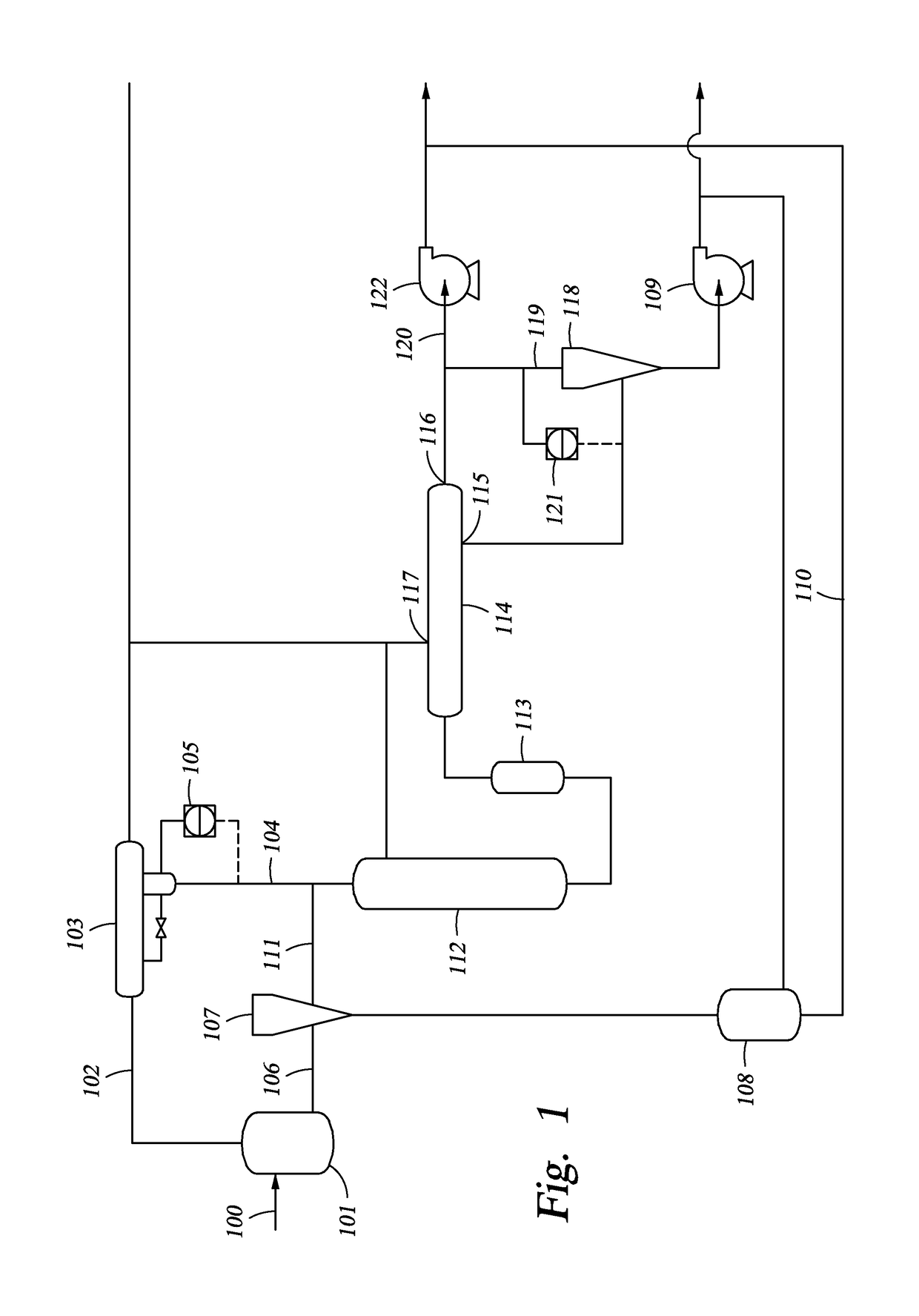

System and process for concentrating hydrocarbons in a bitumen feed

A system and process for concentrating hydrocarbons in a bitumen feed comprising bitumen, water and solids. The system comprises an inclined plate separator, a hydrocarbon cyclone and a centrifuge. The inclined plate separator separates the bitumen feed into a first overflow stream and a first underflow stream, the first overflow stream having a first bitumen concentration greater than that of the first underflow stream. The hydrocarbon cyclone separates the first underflow stream into a second overflow stream and a second underflow stream. The centrifuge separates the second overflow stream into a third overflow stream and a third underflow stream, the third overflow stream having a third bitumen concentration that is greater than that of the third underflow stream.

Owner:SUNCOR ENERGY INC

Purification of impure oil by centrifugation

InactiveUS20060000787A1Reduce wearLow costWater/sewage treatment by centrifugal separationLiquid organic insulatorsCentrifugationEngineering

The present invention relates to methods, apparatus and systems of purifying an impure oil by subjecting the impure oil to a disk stack centrifuge at a rate greater than about 80 gallons per minute, to obtain a purified oil. In particular, the purified oil can have an impurity content of less than about 0.3% by weight, or greater than about 2 fold less than the impurity content of the impure oil. In one embodiment, the present invention utilizes a particular type of dick stack centrifuge referred to as a “disk type nozzle centrifuge”.

Owner:ALLSTATE POWER VAC

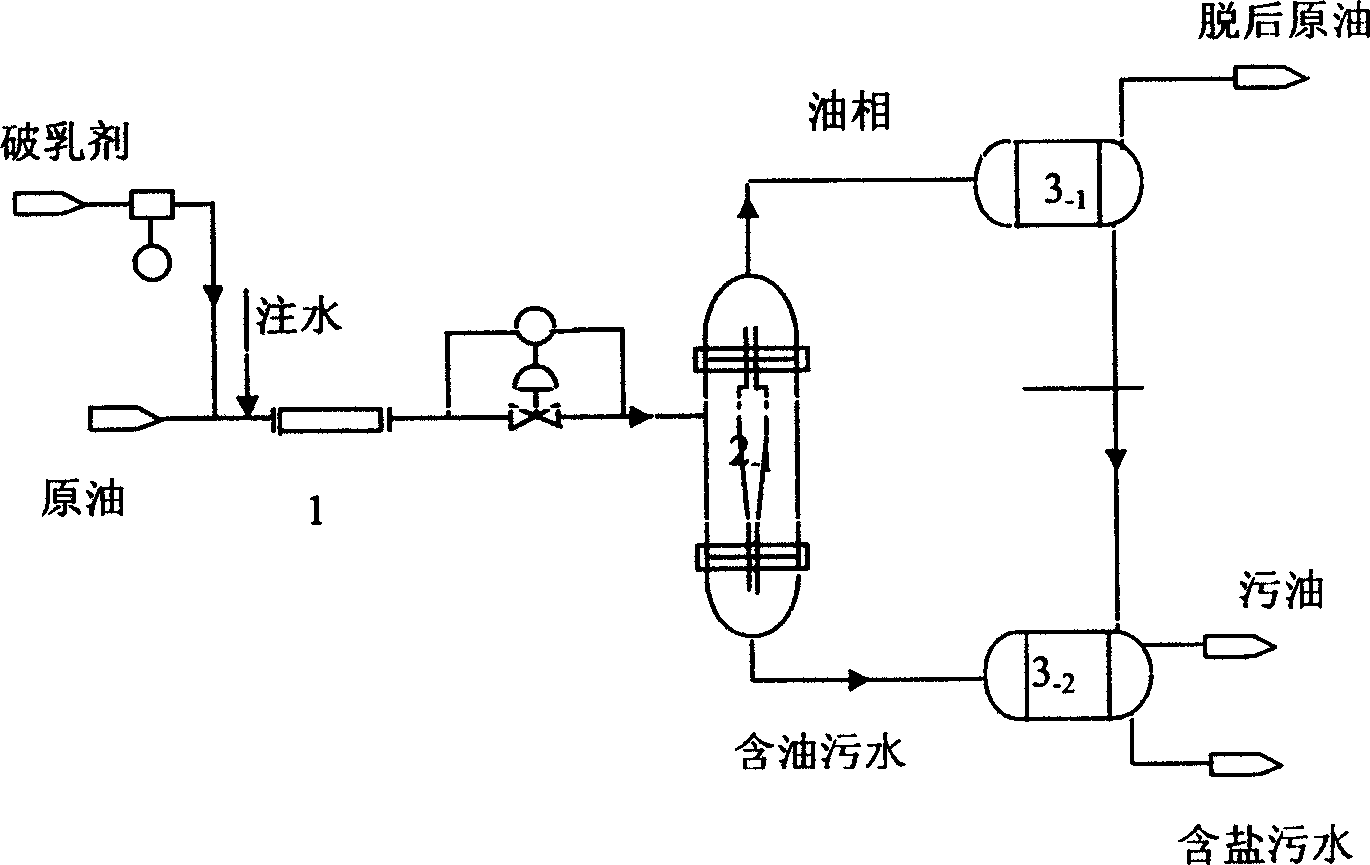

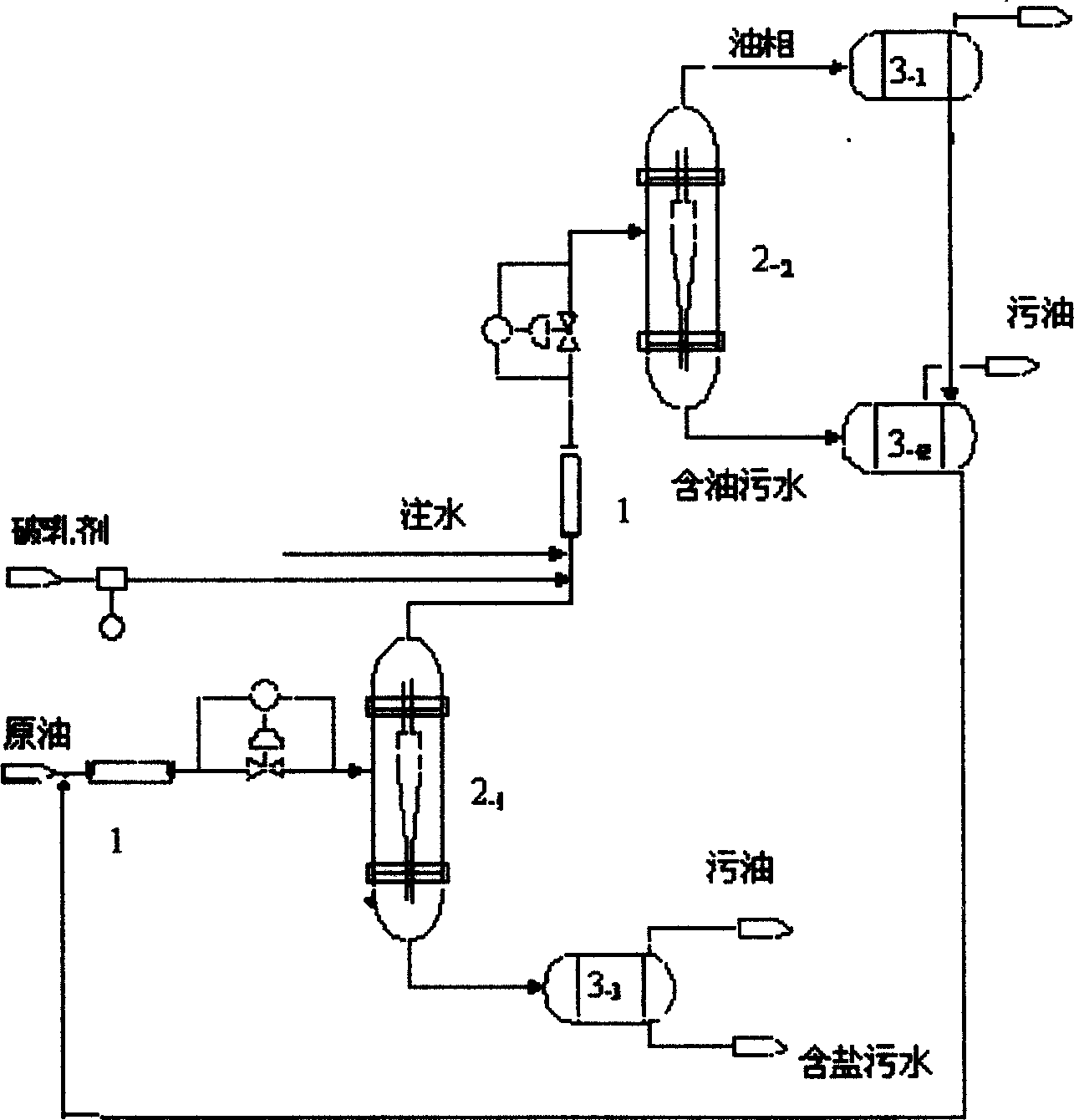

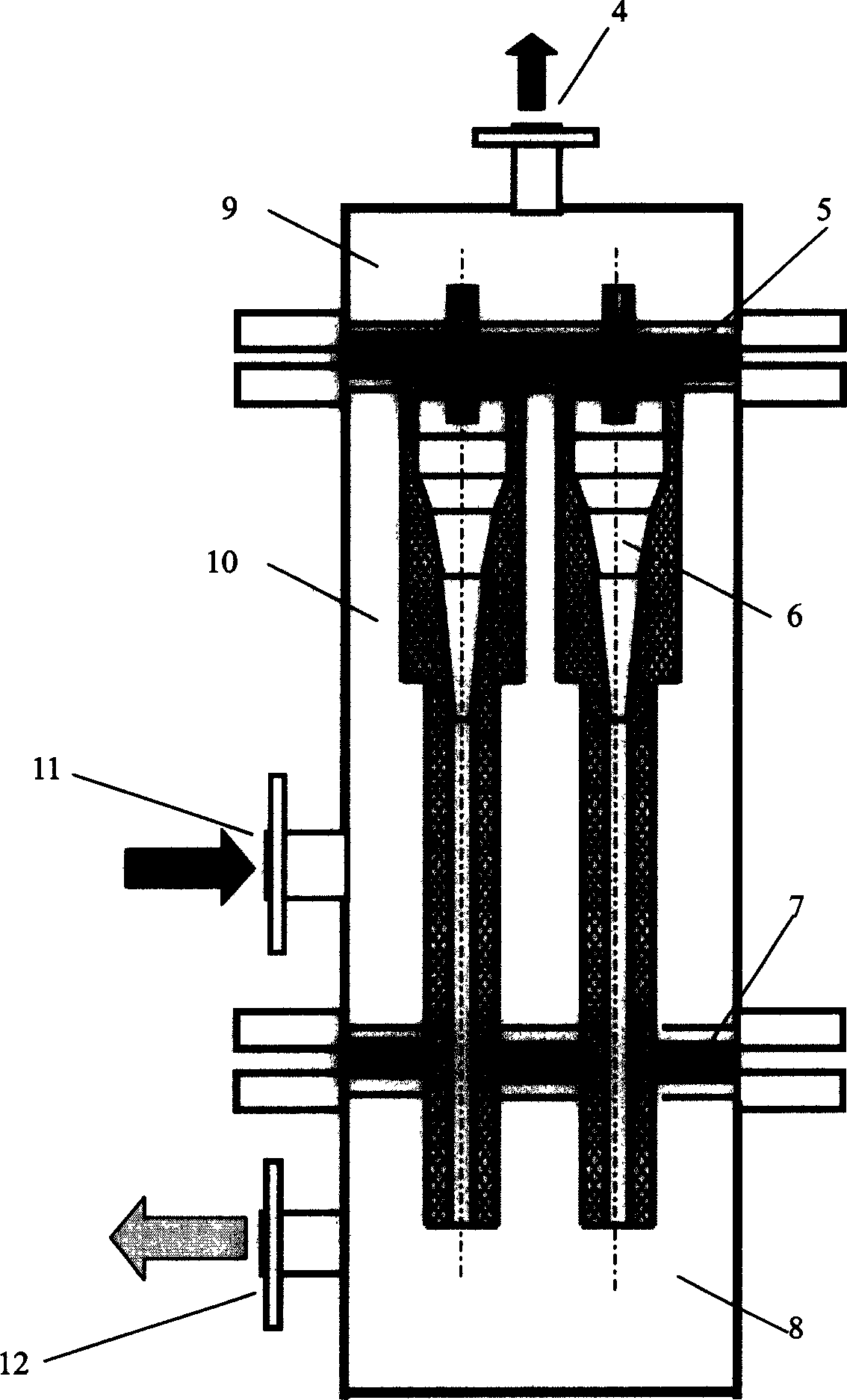

Crude oil desalting method and device using rotational flow breakaway technology

InactiveCN1570033AOvercome energy consumptionOvercoming centrifugationSingle direction vortexRefining by centrifugal forceCycloneSeparation technology

The invention disclose a crude oil desalting method and device using rotational flow breakaway technology, wherein the method consists of, isolating the primary oil with charged water and demulsifying agent into oil phase and oil-contaminated water at 100-300 deg. C, isolating the oil phase through sedimentation by precipitation tank, entering downstream unit, charging the dirty oil into dirty oil tank, and discharging the salt-containing sewage water. One stage, two stage or multiple stage cyclone desalting unit can be utilized based on the requirement.

Owner:EAST CHINA UNIV OF SCI & TECH

Process for recovering ultrafine solids from a hydrocarbon liquid

ActiveUS7674369B2Good curative effectSemi-permeable membranesCatalytic naphtha reformingFlocculationParticulates

A method for separating and recovering ultrafine particulate solid material from a suspension or slurry of the solid material and a hydrocarbon liquid by precipitation or flocculation of a heavy fraction of the hydrocarbon liquid with an effective amount of a precipitation or flocculation agent such that the precipitated heavy fraction encapsulates the particulate solid material. The method further comprises coking the precipitated heavy fraction and grinding the coked product to an ultrafine size.

Owner:CHEVROU USA INC

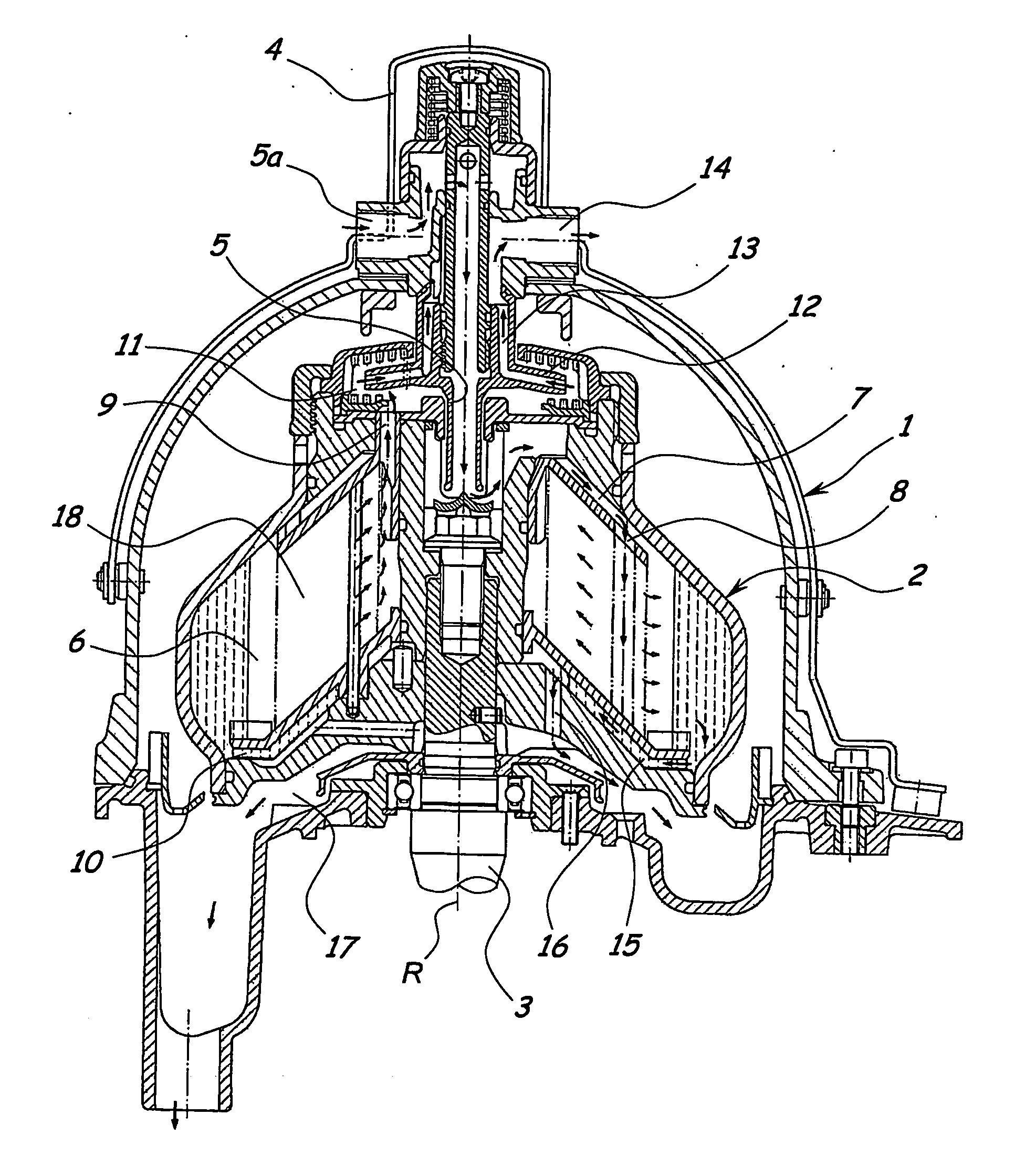

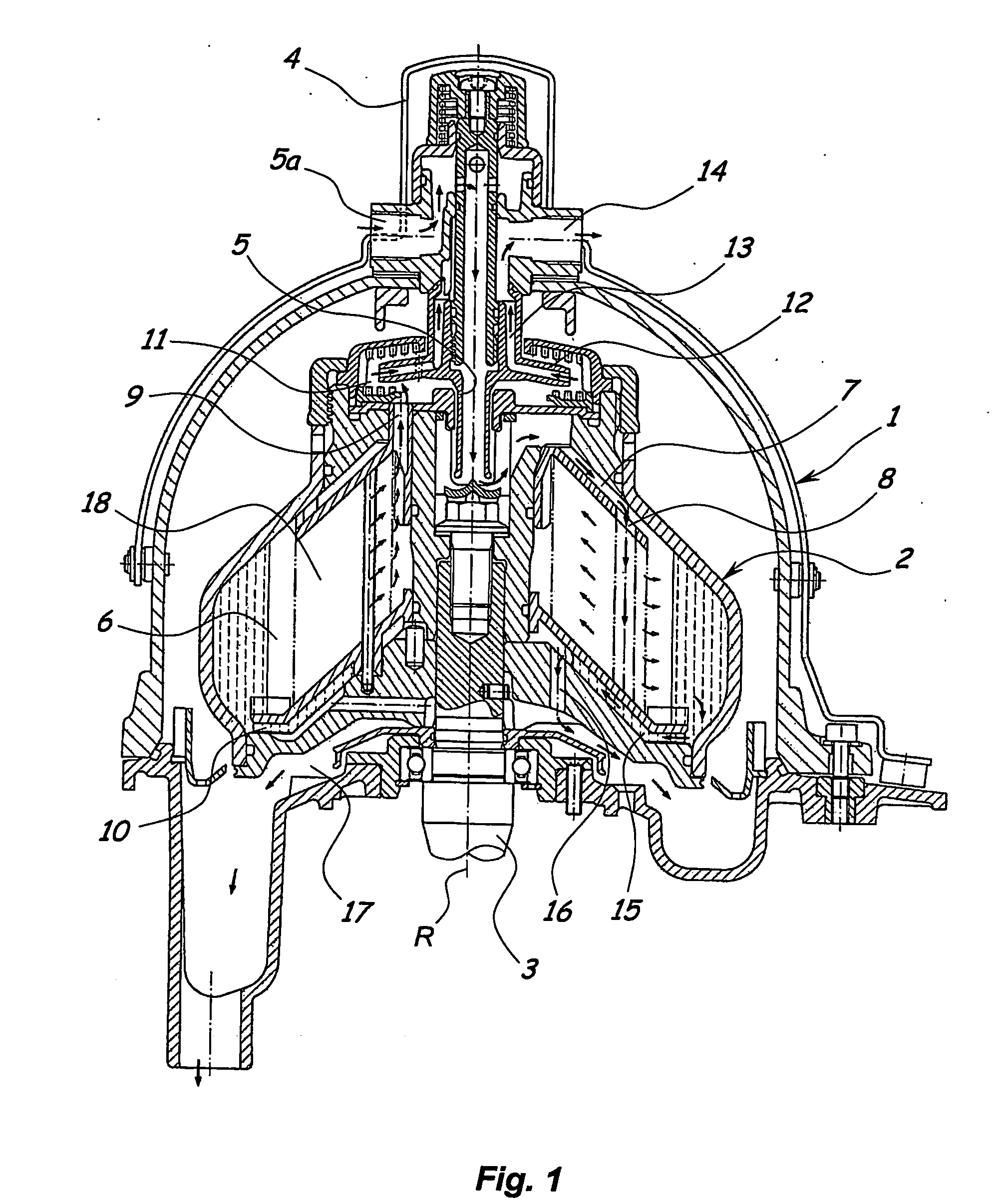

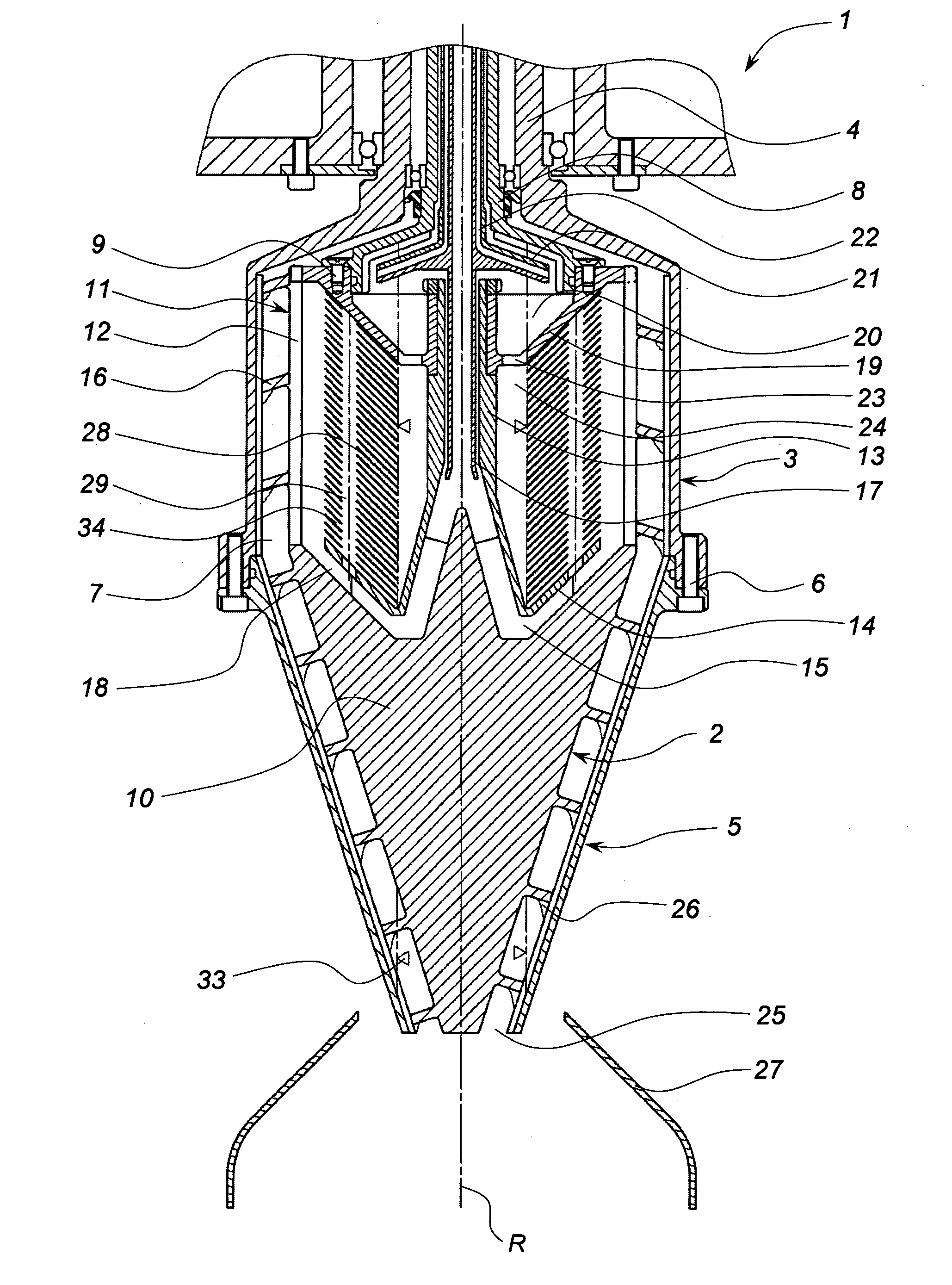

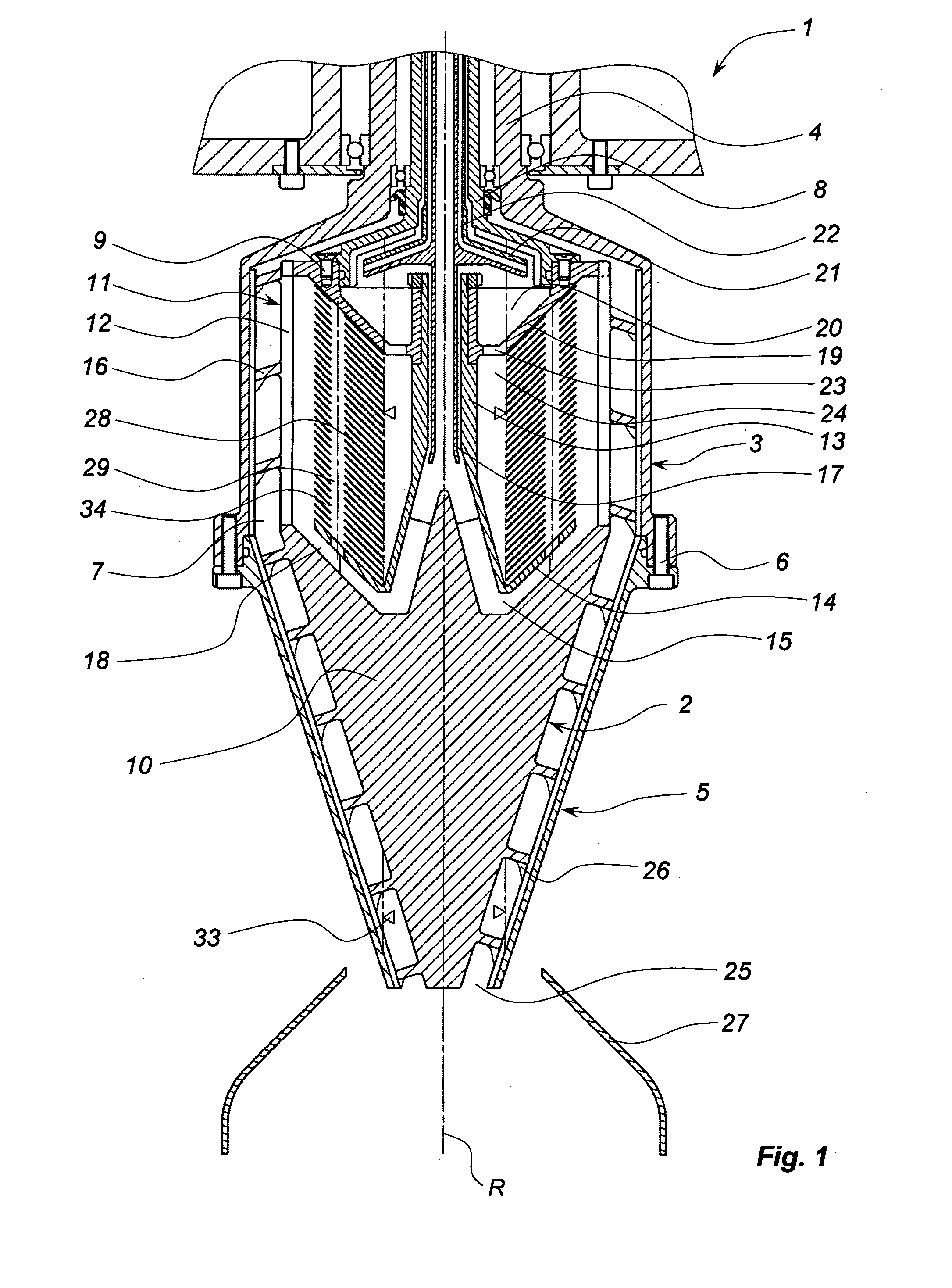

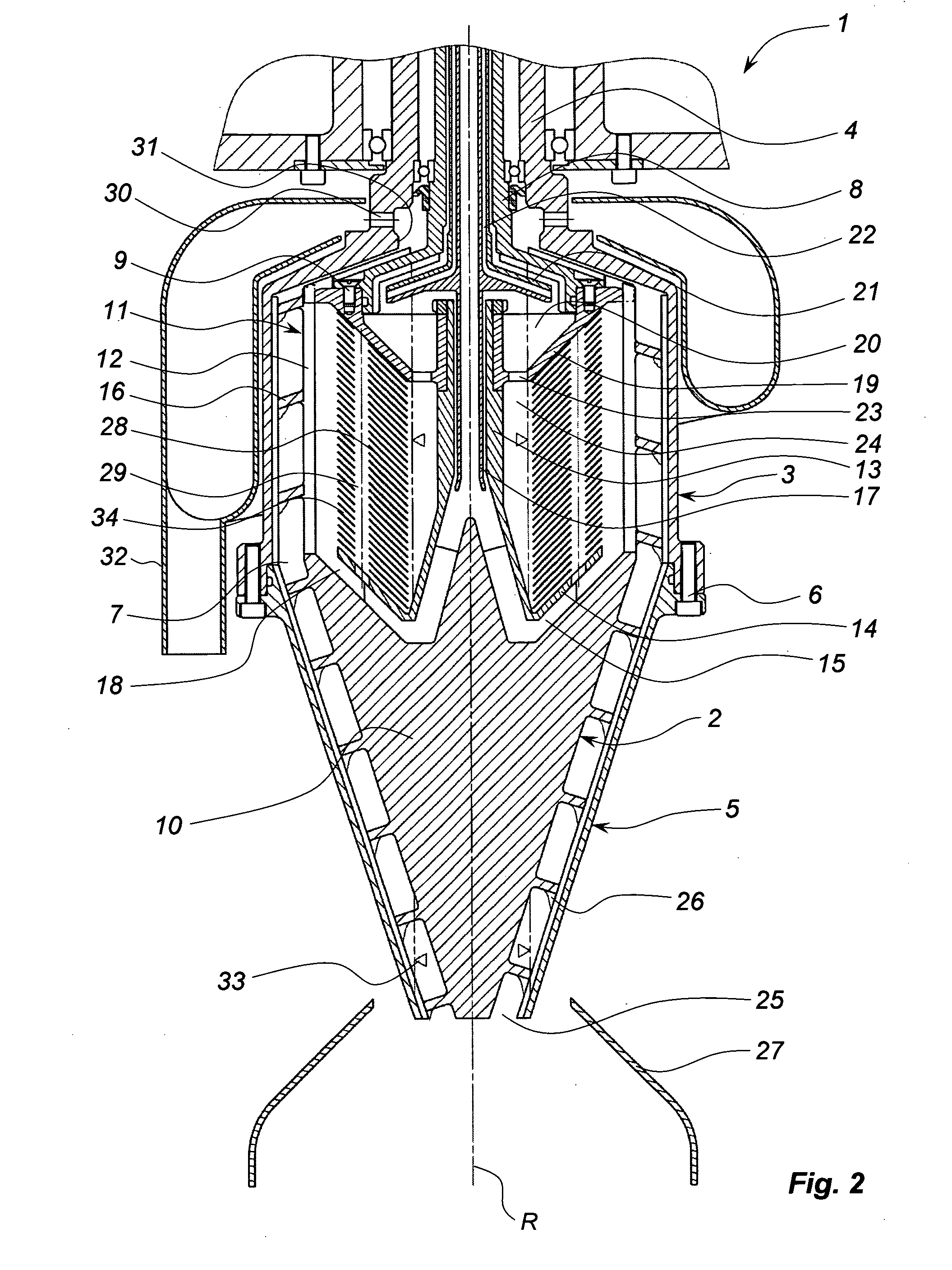

Method of purifying contaminated oil from particles suspended in the oil in a centrifugal separator

ActiveUS20060217254A1Easy to separateDispersed particle separationRotary centrifugesEngineeringOil supply

In a centrifugal separator the liquid separation aid attracts / binds contaminating particles in oil supplied to a separation chamber. Purified oil is discharged through a central light phase outlet of the separation chamber, the liquid separation aid and separated particles are discharged through a heavy phase outlet. Purification is carried through using a starting liquid, supplied to the separation chamber to form a layer that creates a liquid seal in the centrifugal rotor, covering said heavy phase outlet. Contaminated oil and liquid separation aid are supplied to the separation chamber. While purified oil leaves the separation chamber through the light phase outlet, at starting liquid and liquid separation aid together with particles are discharged through the heavy phase outlet.

Owner:ALFA LAVAL CORP AB

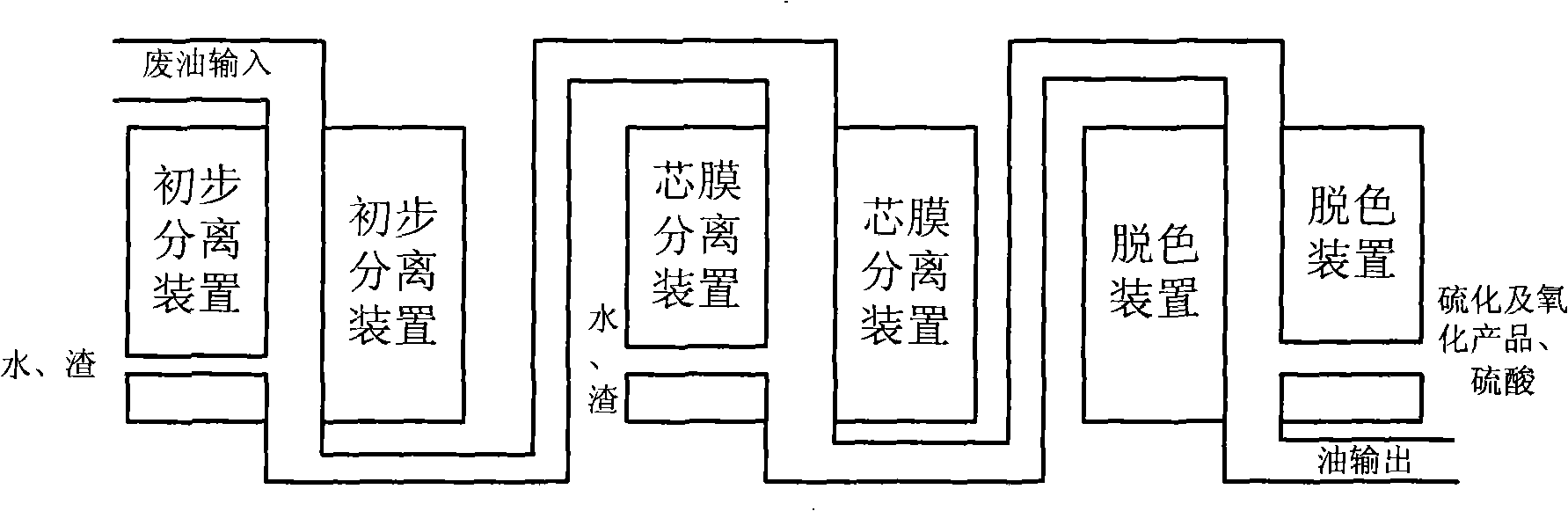

Waste oil treatment system and method

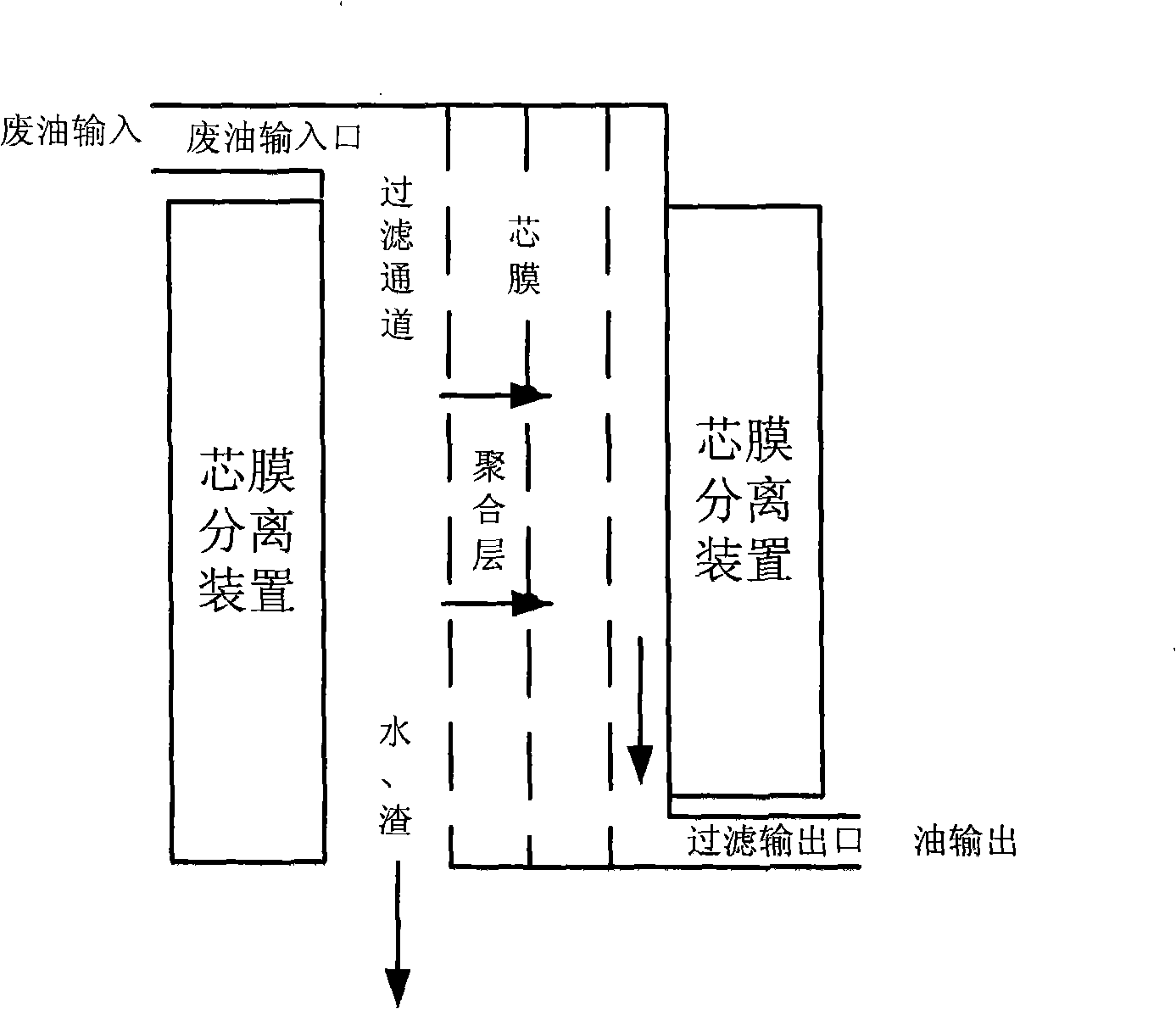

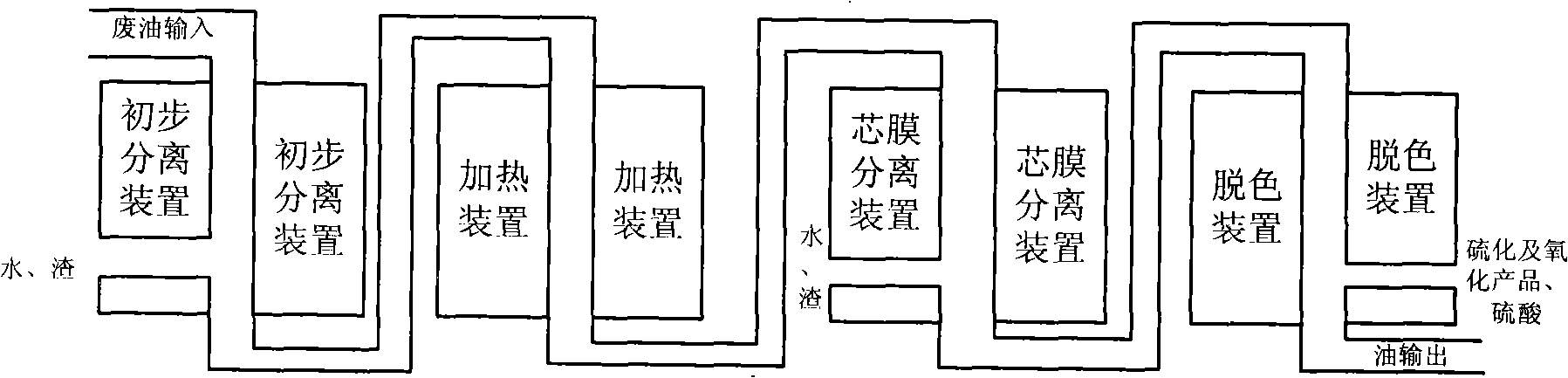

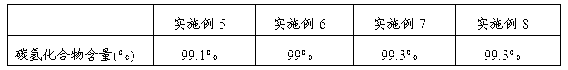

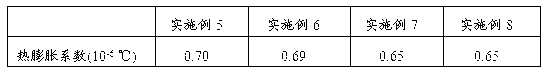

InactiveCN101550355AAchieve separationSolve technical problemsTreatment with plural serial refining stagesRefining by filtrationSlagWaste oil

The invention discloses a waste oil treatment system and method. The waste oil treatment system includes: an initial gross separation device for performing oil, water and slag initial gross separation to the waste oil; a decolorizing device for decolorizing the waste oil; and a core membrane separation device connected between the initial gross separation device and the decolorizing device, wherein, the core membrane separation device includes a core membrane for filtering the waste oil, and the core membrane includes a polymerization layer passing oil molecule while excluding water molecule and solid molecule. The invention can rapidly, reliably, and environmentally-friendly process the waste oil to obtain high-quality oil products.

Owner:SHENZHEN SENKEYAN TECH

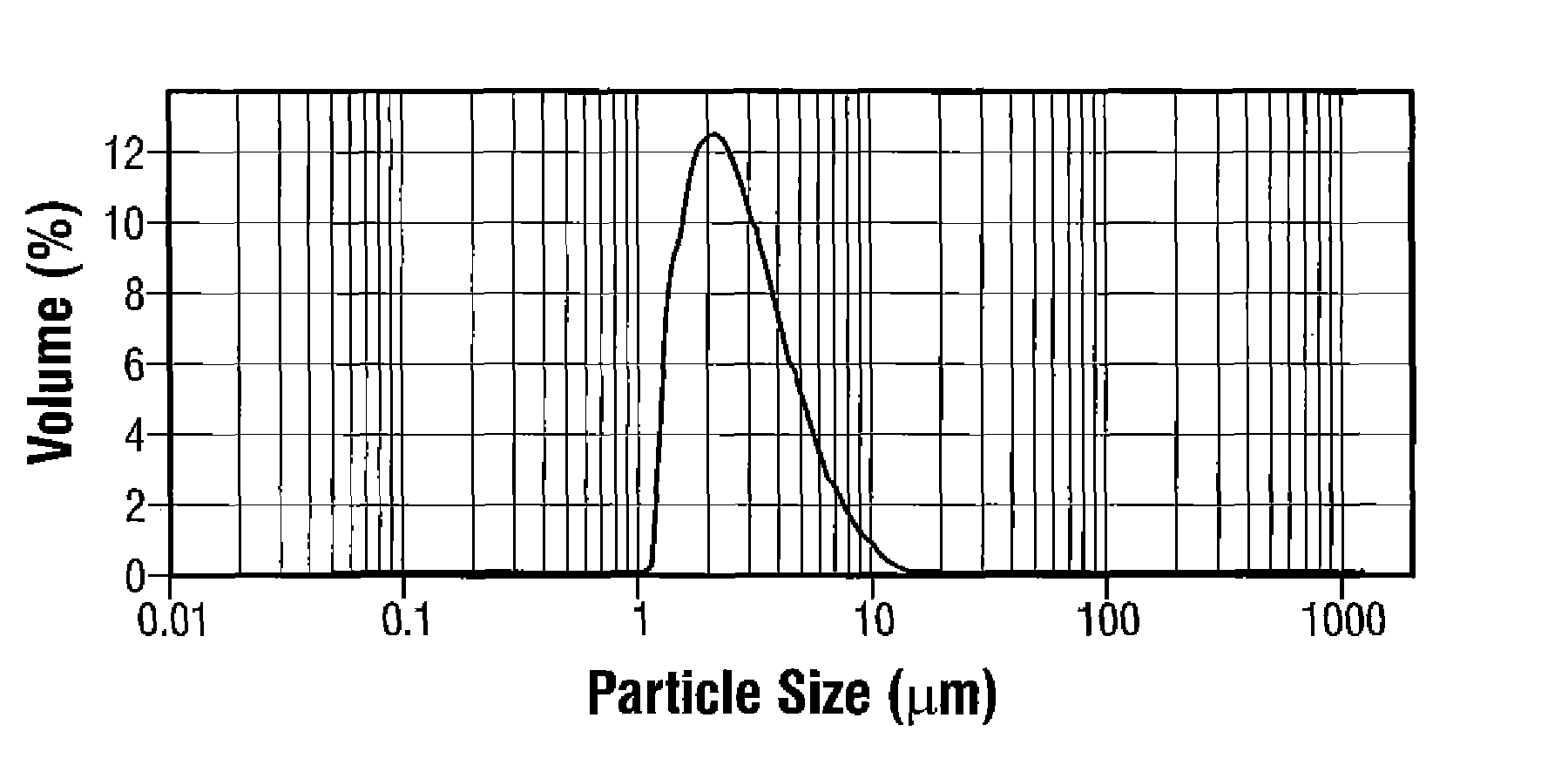

Process for purifying coal tar through centrifugation method and preparing needle coke by using coal tar

ActiveCN102839006AImprove removal efficiencyImprove adsorption capacityWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCentrifugationCoke

The present invention provides a process for purifying coal tar through a centrifugation method. The process is characterized in that a viscosity of the centrifugated and separated coal tar is 30-100 mpa.s. According to the present invention, the viscosity of the coal tar is set to 30-100 mpa.s, and the viscosity is further preferably 50-100 mpa.s so as to effectively improve removing efficiency of QI particles in the coal tar.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method and device for cleaning of a fluid in a centrifugal separator

ActiveUS20100144508A1Easy to separateDispersed particle separationRotary centrifugesHigh densityEngineering

A method for purifying a fluid from contaminating particles in a centrifugal separator by means of a separation aid which is of higher density than the fluid and which binds said particles, the centrifugal separator having a rotor body that rotates about an axis of rotation. The fluid to be purified is led via an inlet into a separation chamber delimited by the rotor body. Separated particles are discharged via a first outlet and clarified fluid cleared is discharged via a second outlet. The fluid being mixed with an amount of separation aid, supplied to the separation chamber. The pollutant particles are bound to the separation aid, which is forced out by the rotation of the rotor body to the periphery thereof. A small flow of separation aid and particles bound thereto are discharged from the separation chamber via the first outlet, and a flow of purified fluid is discharged from the separation chamber via the second outlet.

Owner:ALFA LAVAL CORP AB

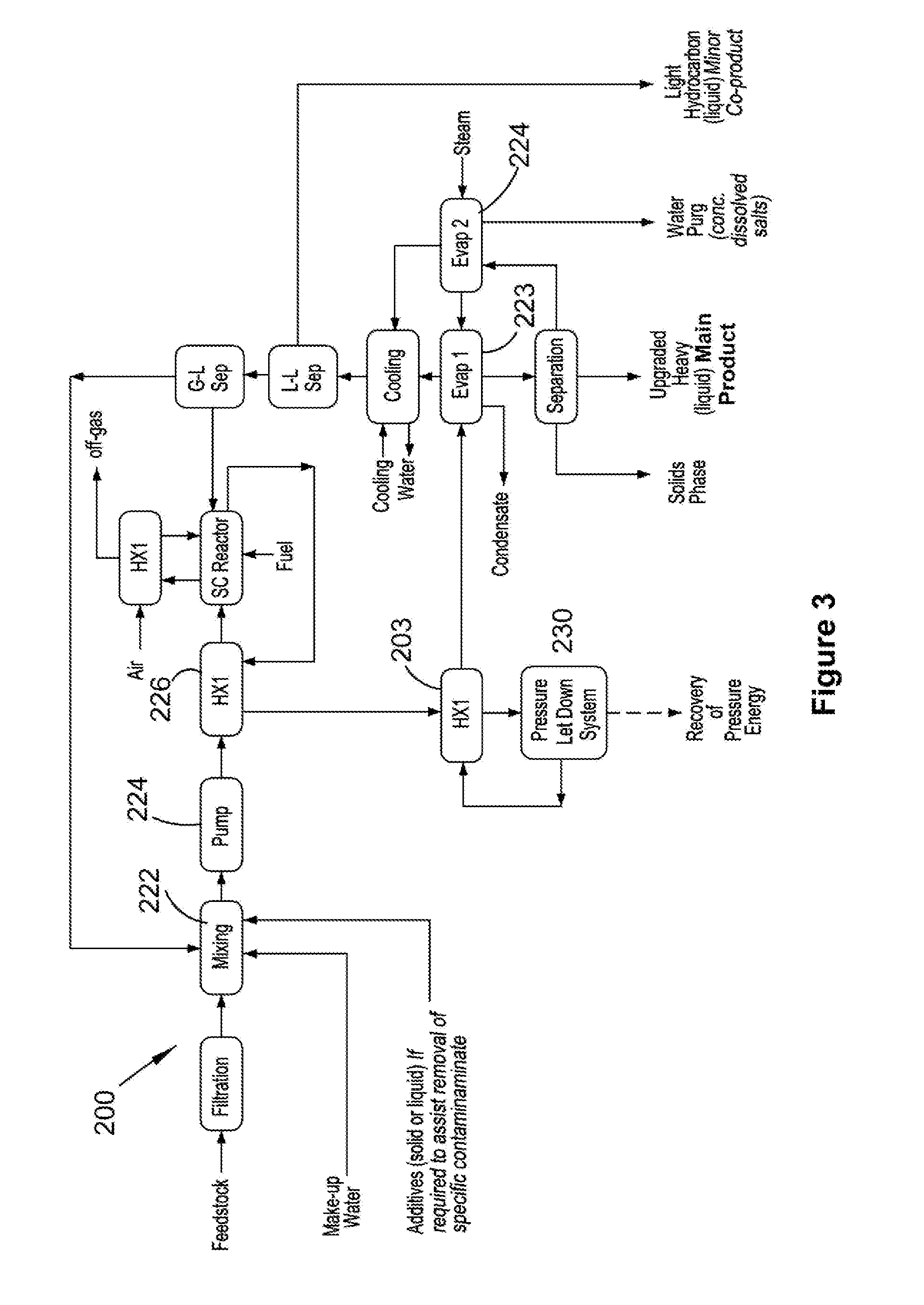

Method and apparatus for upgrading a hydrocarbon

InactiveUS20160010003A1Improve distillation yieldReduce metal contentRefining by heating/coolingRefining by water treatmentContinuous flowPetroleum

A method and apparatus is described for removing at least some contaminants from a hydrocarbon feedstock, such as a petroleum. The method includes treating the contaminated feedstock during flow through a supercritical reactor with supercritical water to facilitate the removal of at least some of the contaminants. The flow through the supercritical reactor is a continuous flow.

Owner:IND PROCESS TECH

Crude oil desulfurization

ActiveUS20120111769A1Low costReduce usageRefining with non-metalsTransportation and packagingInorganic saltsChemistry

A method of removing sulfur from sour oil by subjecting sour oil having a first sulfur content to high shear in the presence of at least one desulfurizing agent to produce a high shear treated stream, wherein the at least one desulfurizing agent is selected from the group consisting of bases and inorganic salts, and separating both a sulfur-rich product and a sweetened oil product from the high shear-treated stream, wherein the sulfur-rich product comprises elemental sulfur and wherein the sweetened oil product has a second sulfur content that is less than the first sulfur content. A system for reducing the sulfur content of sour oil via at least one high shear device comprising at least one rotor and at least one complementarily-shaped stator, and at least one separation device configured to separate a sulfur-rich product and sweetened oil from the high shear-treated stream.

Owner:HRD CORP +1

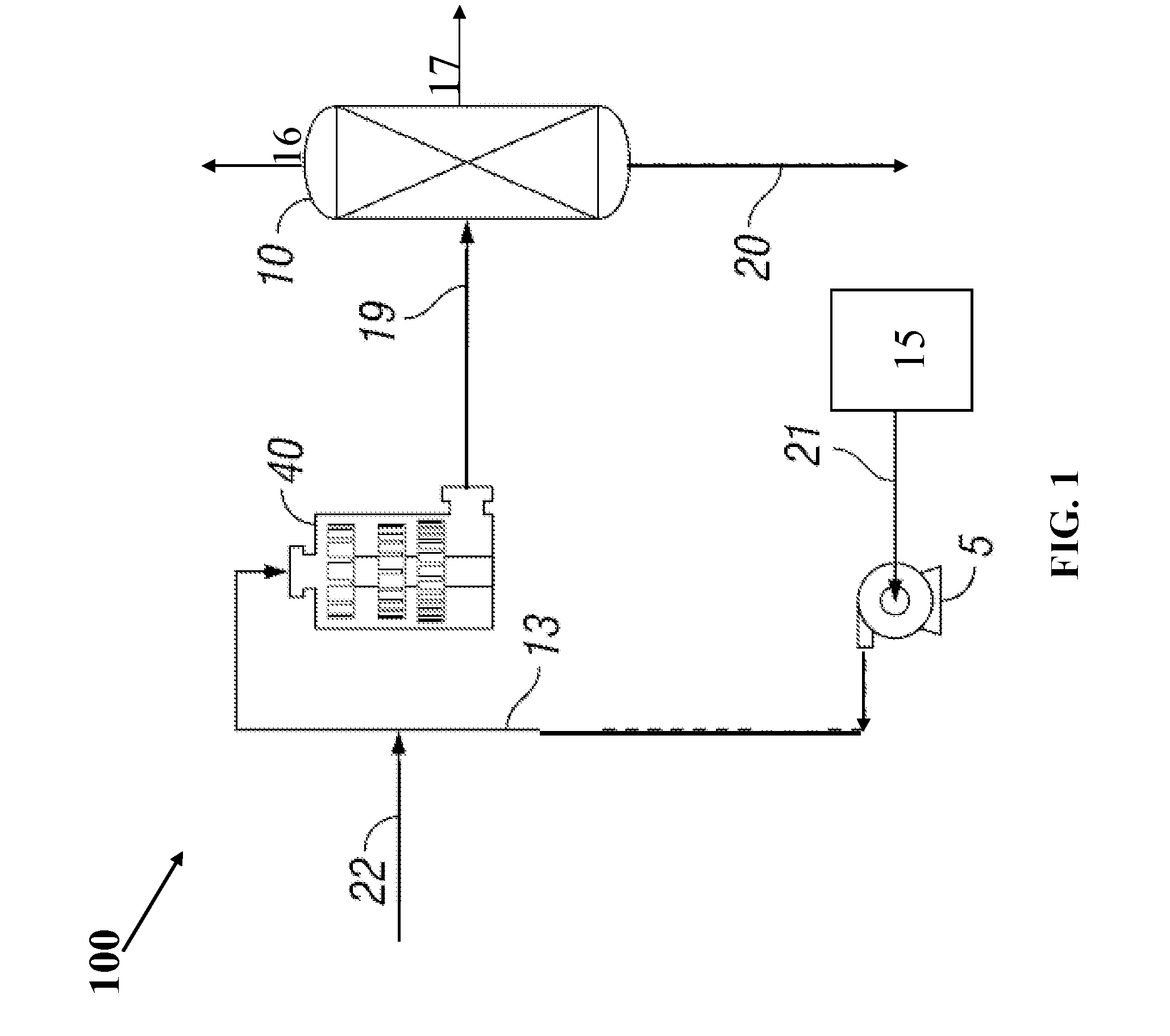

System and method to treat a multiphase stream

ActiveUS9764252B2Easy to separateLiquid separation by electricityElectrostatic separationStream flowEngineering

A system and method for enhancing separation of a denser phase liquid from a lighter phase liquid within a multiphase stream. In one example, a cyclonic coalescer has a tubular housing and a plurality of coaxial flow chambers extending in the axial direction of the housing. A swirling element is associated with each of the plurality of coaxial flow chambers. The swirling elements are constructed and arranged to impart a tangential velocity of the stream flowing through the associated flow chamber.

Owner:EXXONMOBIL UPSTREAM RES CO

Bio-oil having reduced mineral content, and process for making

InactiveUS20120137571A1Reduce the amount requiredLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionMetalBiomass

Owner:MARD INC

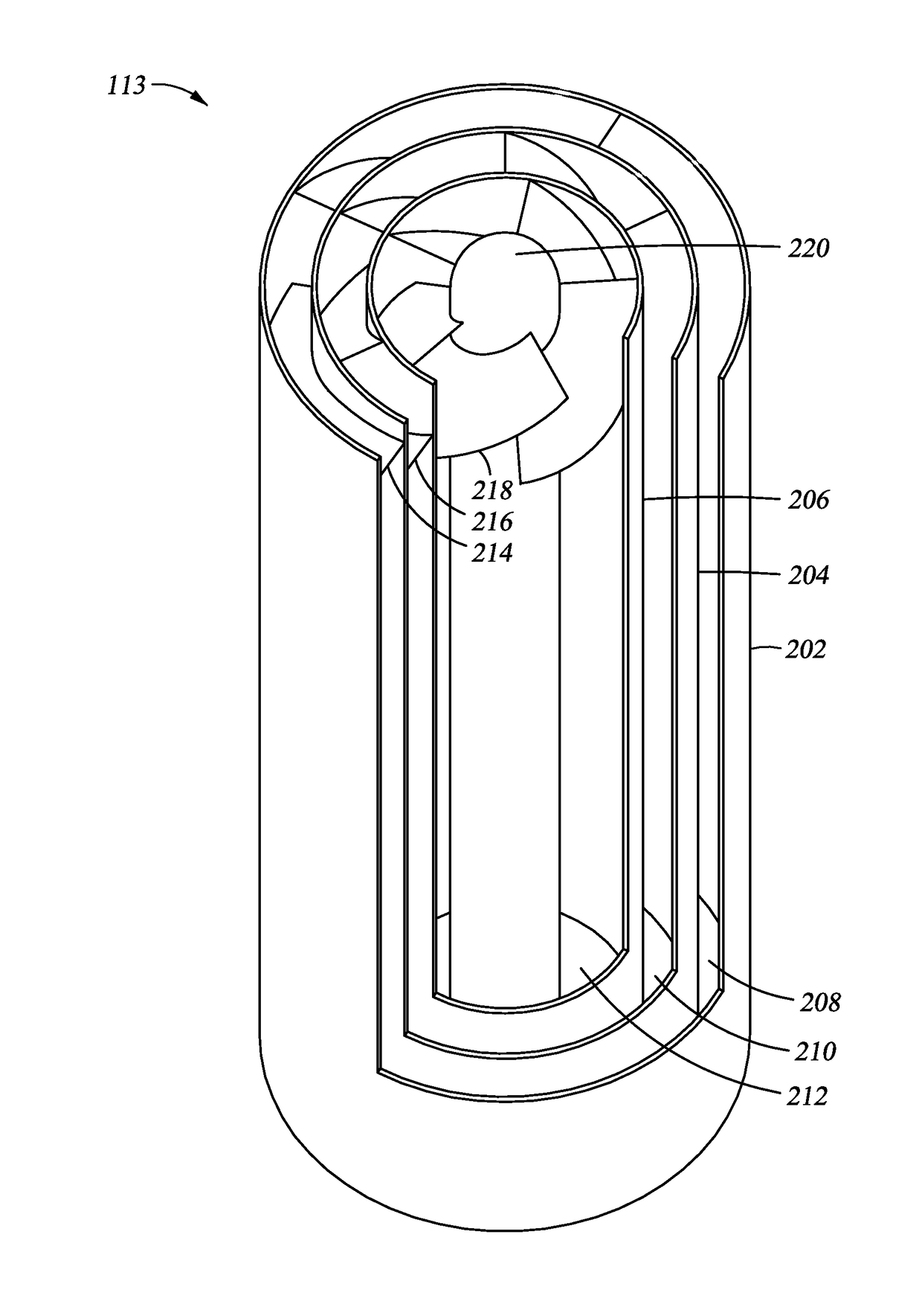

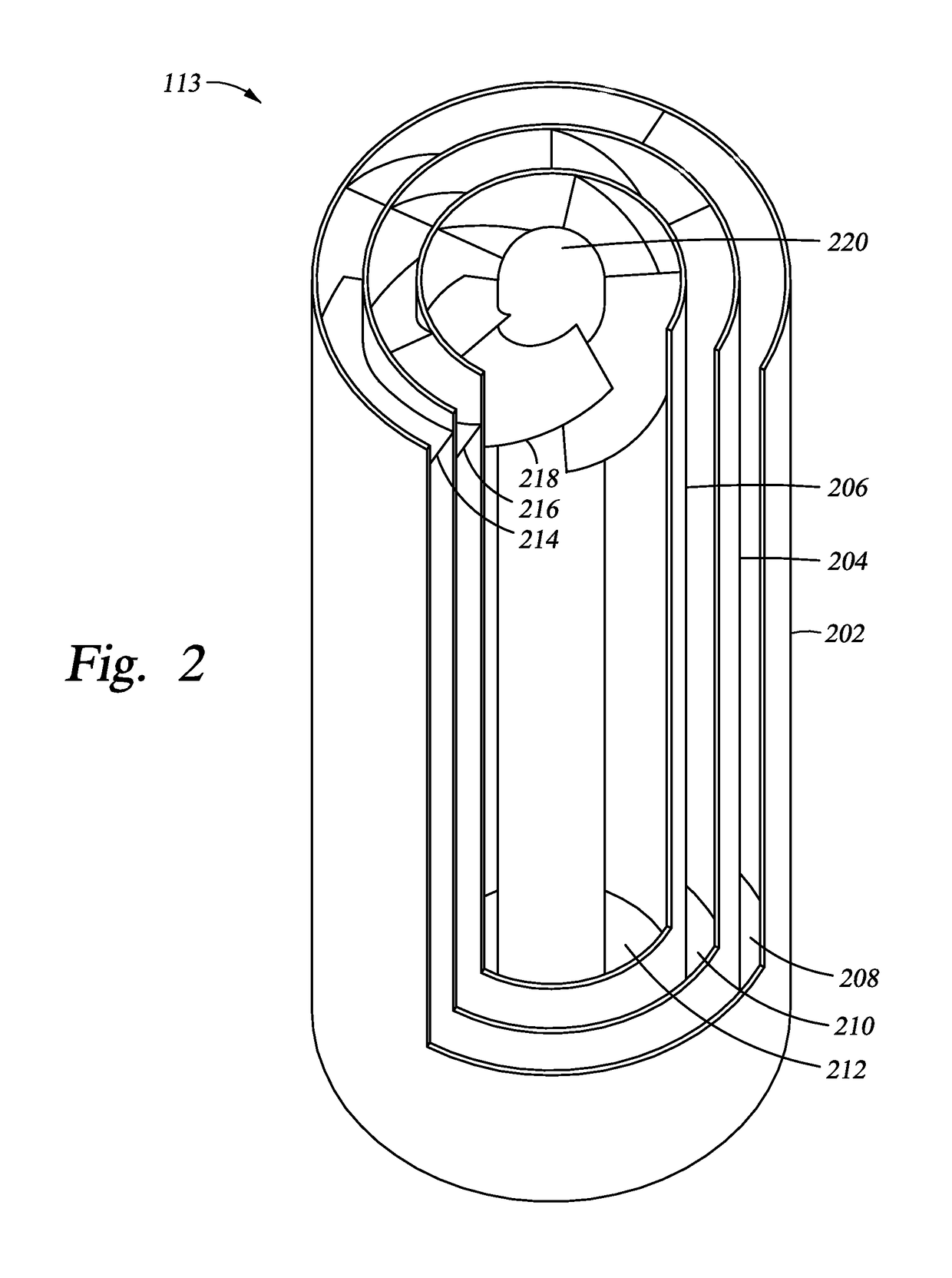

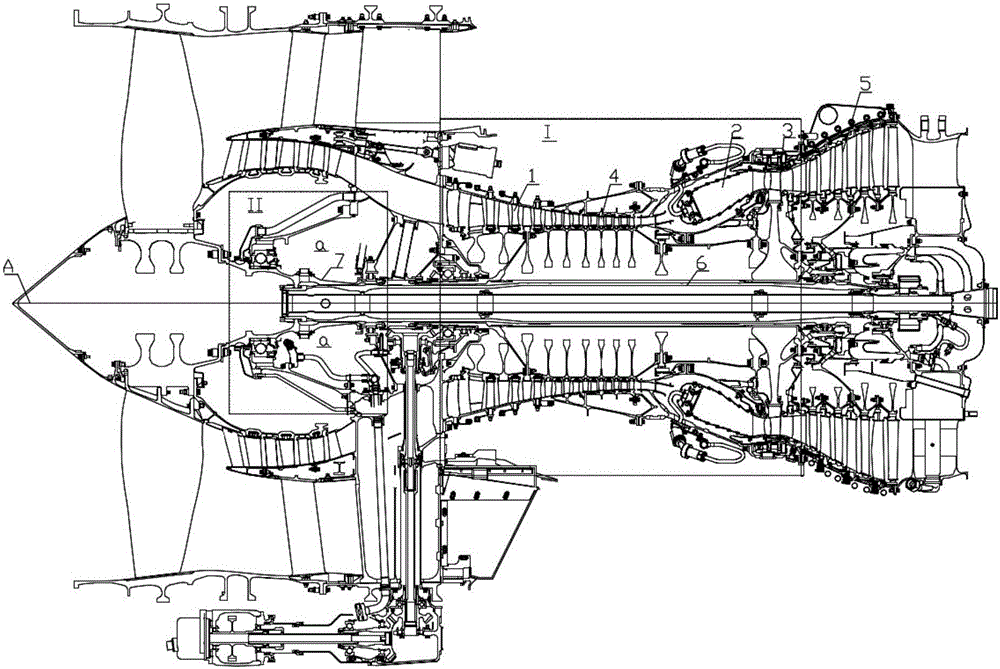

Oil-gas separation device and gas turbine engine

ActiveCN107435590AEasy to separateImprove separation efficiencyFlash degasificationRefining by centrifugal forceEngineeringTurbine

The invention relates to an oil-gas separation device and a gas turbine engine. The oil-gas separation device comprises a cavity structure provided with a separation cavity. The wall face of the separation cavity is provided with an inlet, a first outlet and a second outlet. The inlet comprises multiple tangential channels. The multiple tangential channels enable oil-gas mixture to enter the separation cavity in the tangential direction. The first outlet is arranged in the radial direction of the separation cavity, the second outlet is arranged in the axial direction of the separation cavity, the separation cavity is rotated to achieve oil-gas separation for the oil-gas mixture, oil obtained after separation flows out through the first outlet, and gas obtained through separation flows out through the second outlet. In the embodiment of the oil-gas separation device and the gas turbine engine, the oil-gas mixture entering the separation cavity has the large tangential speed and small or almost zero radial speed and axial speed, standing time of vortical motion of the oil-gas mixture in the separation cavity can be longer, and the oil-gas separation efficiency can be better improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Refinery desalter improvement

ActiveUS8747658B2Increase capacityEasy to separateDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansDesalterImproved method

The improved methods relate to desalting hydrocarbon feeds using a separator with a stacked disk centrifuge to separate an emulsified oil and water rag layer. This method is effective for desalting heavy, high ionic, and non-traditional crude oils.

Owner:PHILLIPS 66 CO

System and Method for Auto Distilling Liquids at Strictly Defined Conditions Regardless of Composition

ActiveUS20180036648A1Good reproducibilityMinimizes human errorSamplingDistillation regulation/controlTemperature controlAtmospheric air

A system and method for distillation of a liquid sample at atmospheric pressure for the improved prediction of the heating necessary before the initial boiling point (IBP) of the sample is detected regardless of sample composition to ensure the IBP is observed within certain time constraints. A plurality of infrared (IR) sensors provides real-time temperature control in addition to a conventional measurement of vapor temperature. One IR-sensor monitors the liquid sample temperature in the distillation flask to obtain a corrected IBP time independent of the sample properties. Another IR-sensor monitors the temperature of the rising vapor column as the vapor rises up the neck of the distillation flask. Alternatively, an IR matrix may monitor the temperature of the rising vapor column. The system and method expand the scope of samples analyzed with improved signal, reproducibility, and test accuracy and still remain within the prescribed limits of a selected standard.

Owner:INSTR SCI DE LABORTOIRE ISL

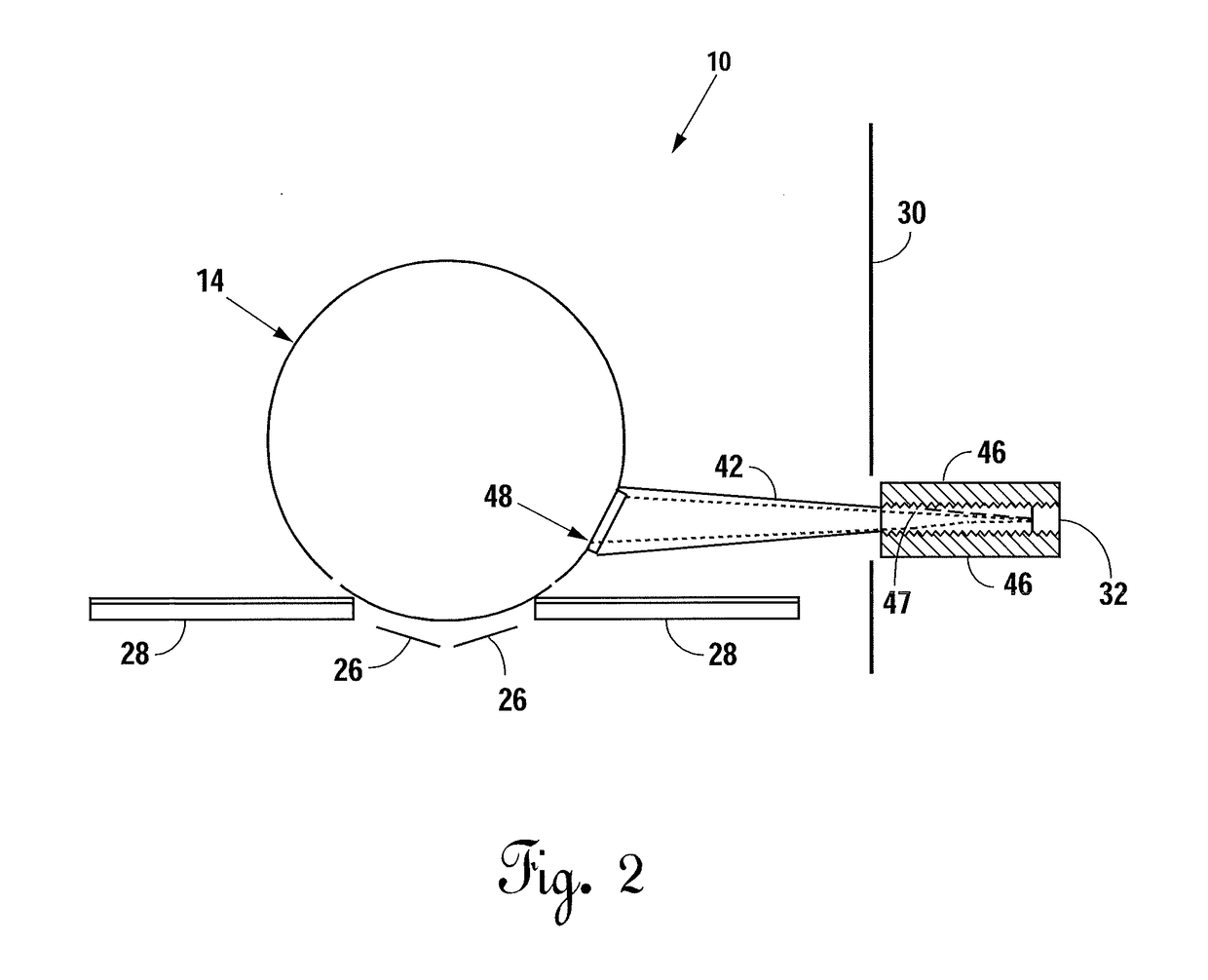

Method and system for separating catalyst fines from an oil stream

InactiveUS20150191660A1Quantity minimizationReduce risk of damageHydrocarbon purification/separationLiquid carbonaceous fuelsChemistryCentrifugal separator

The present invention relates to a method for separating catalyst fines from an oil stream comprising the steps of; separating catalyst fines from an inlet oil stream in a centrifugal separator to generate a stream of purified oil; obtaining an NMR response signal from an NMR apparatus related to the amount of catalyst fines in the purified oil stream and / or the inlet oil stream and initiating the addition of or increasing the amount of separation aid to the inlet oil stream when the NMR response signal indicates an increased amount of catalyst fines in the purified oil stream and / or the inlet oil stream, such as to increase the performance of separating catalyst fines from the oil stream.

Owner:ALFA LAVAL CORP AB

Treating method for waste gas containing sulfur and hydrocarbons

ActiveCN104587814AEffective prolapseIncrease concentrationDispersed particle separationRefining by centrifugal forceForeign matterKerosene

The invention discloses a treating method for waste gas containing sulfur and hydrocarbons. The method comprises the following steps that: crude diesel or crude kerosene enters a rotating packed bed for devolatilization pretreatment; a material discharged from the liquid phase outlet of the rotating packed bed enters absorption equipment as an absorbent and contacts and reacts with waste gas containing sulfur and hydrocarbons, and hydrocarbons in the waste gas are recovered; waste gas discharged from the absorption equipment enters an alkali liquor absorption device for removal of sulfur-containing compounds in the waste gas, and a rich absorption solvent discharged from the absorption equipment directly enters a hydrogenation device; and waste gas discharged from the alkali liquor absorption device meets national standard and is discharged. The treating method for the waste gas containing sulfur and hydrocarbons provided by the invention adopts the rotating packed bed for pretreatment of the crude diesel or crude kerosene so as to remove foreign matters like hydrogen sulfide and volatile components in the crude diesel or crude kerosene, thereby preventing the waste gas from producing secondary pollution; and the method has the advantages of simple process, economical performance and reasonability and is applicable to absorption treating process for the waste gas containing sulfur and hydrocarbons.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Popular searches

Separation devices Settling tanks heating/cooling Liquid separation Tar working-up by chemical refining Hydrocarbon dewatering Centrifugal force sediment separation Treatment with hydrotreatment processes Water/sewage treatment by flocculation/precipitation Refining by solvent de-asphalting Moving filtering element filters

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com