Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2466 results about "Waste oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste oil is defined as any petroleum-based or synthetic oil that, through contamination, has become unsuitable for its original purpose due to the presence of impurities or loss of original properties.

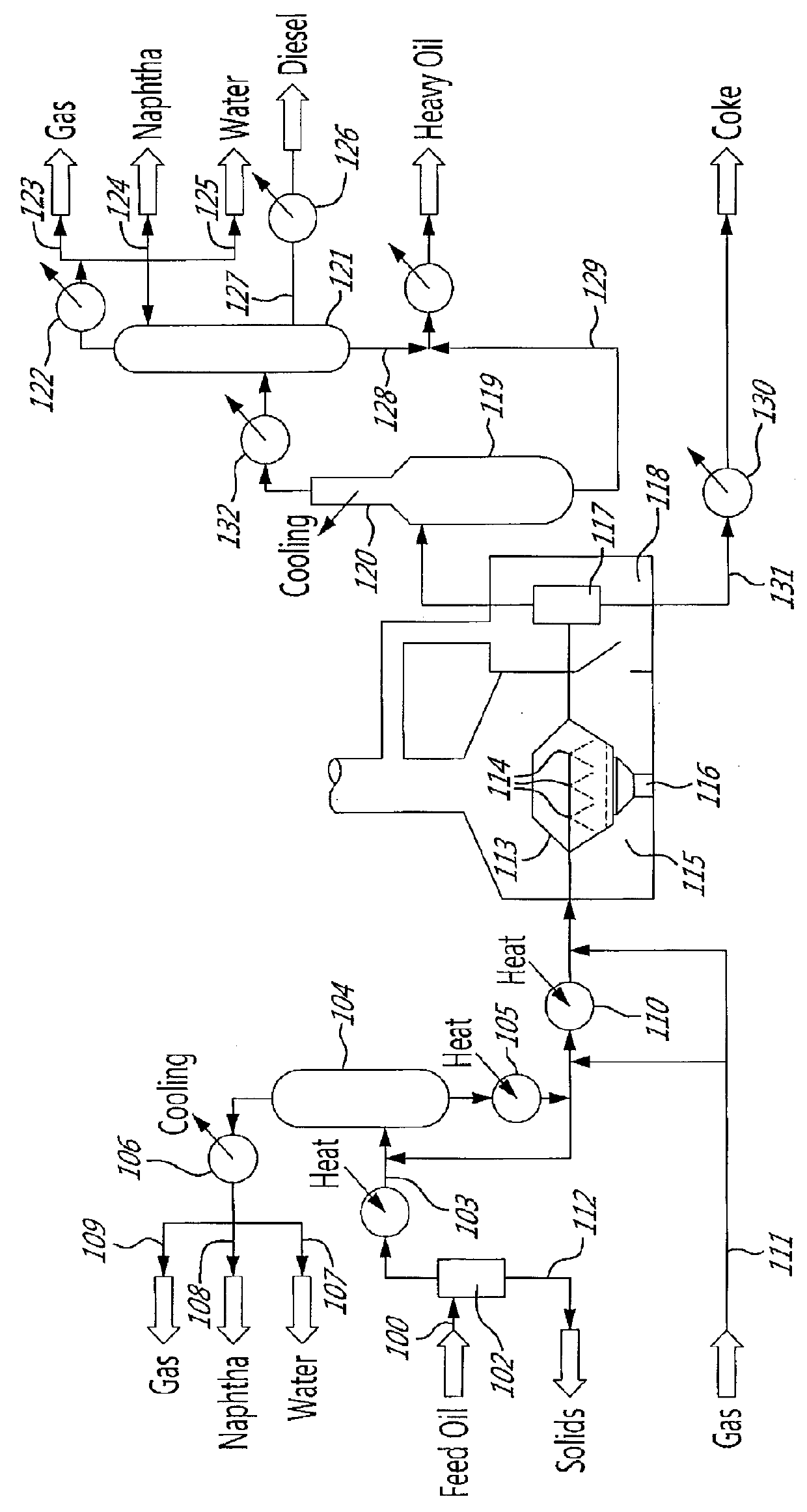

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

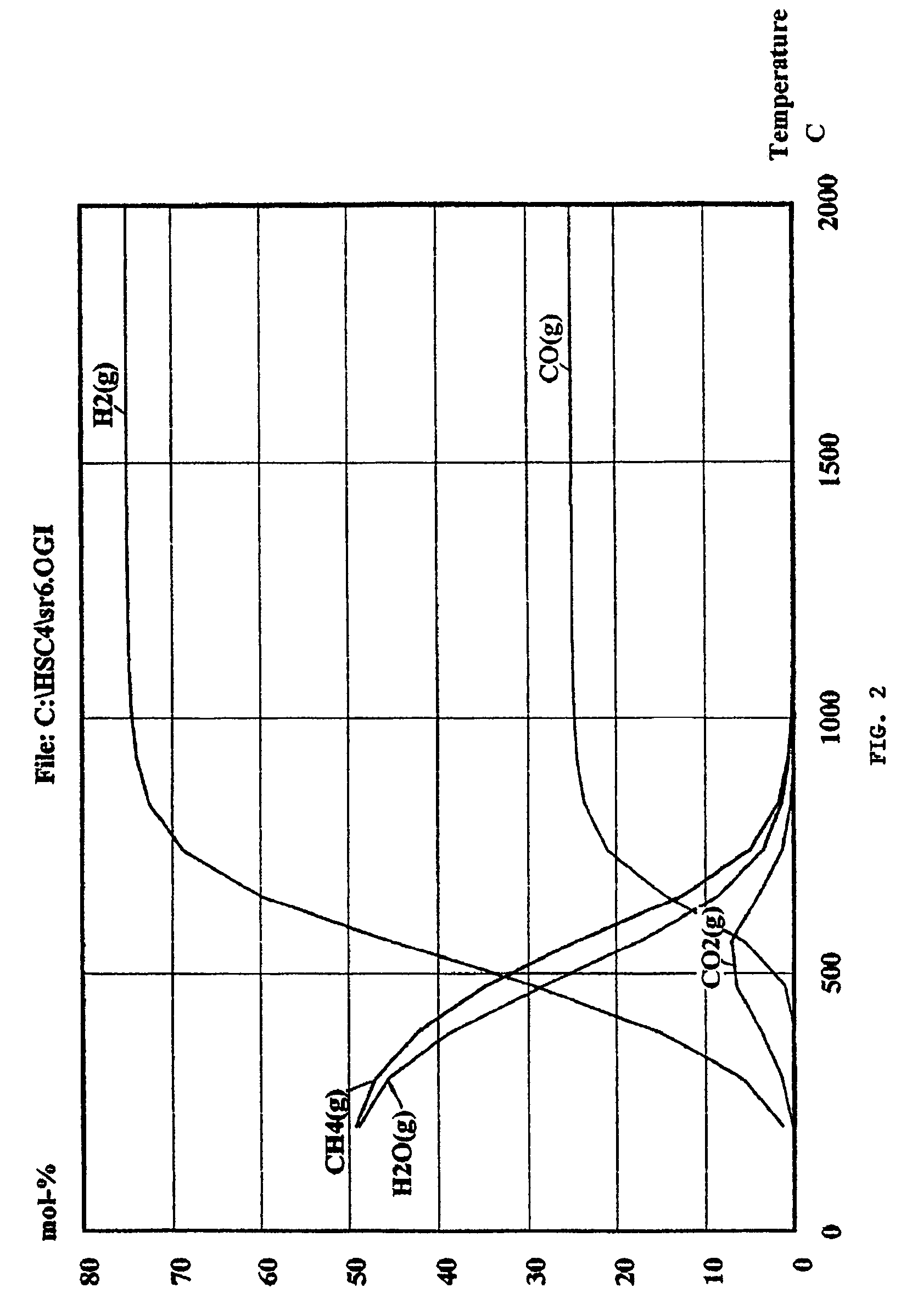

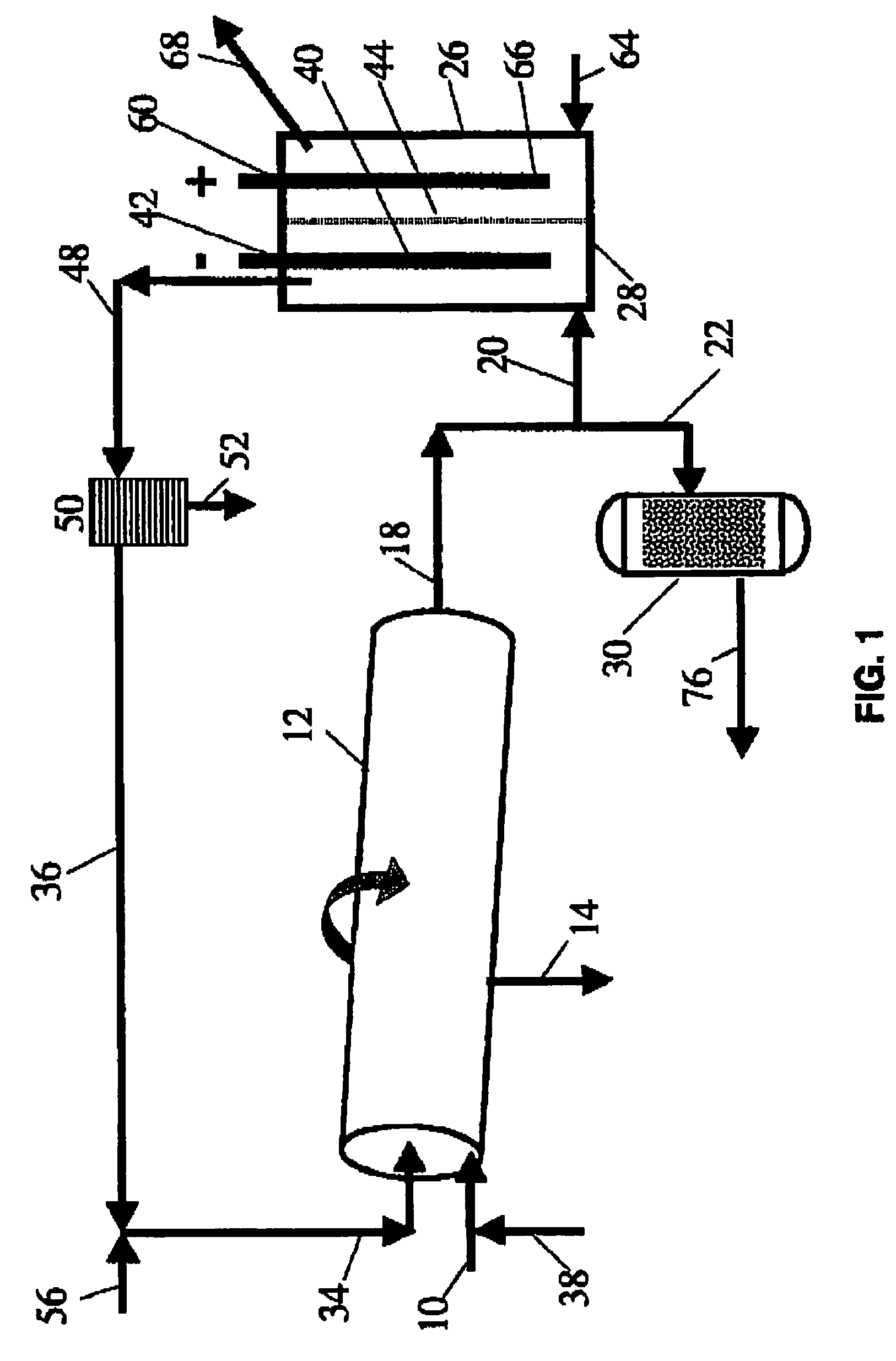

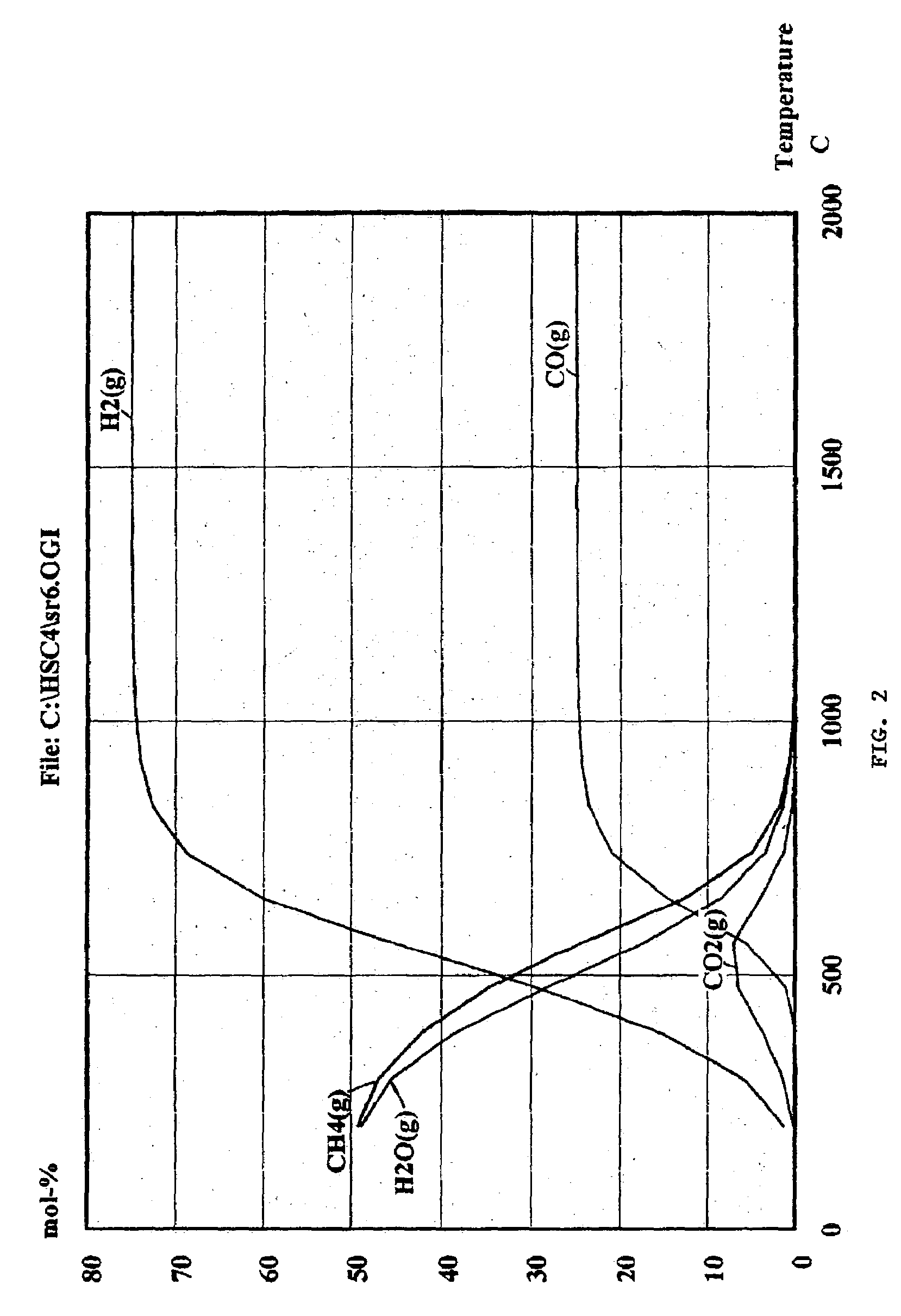

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

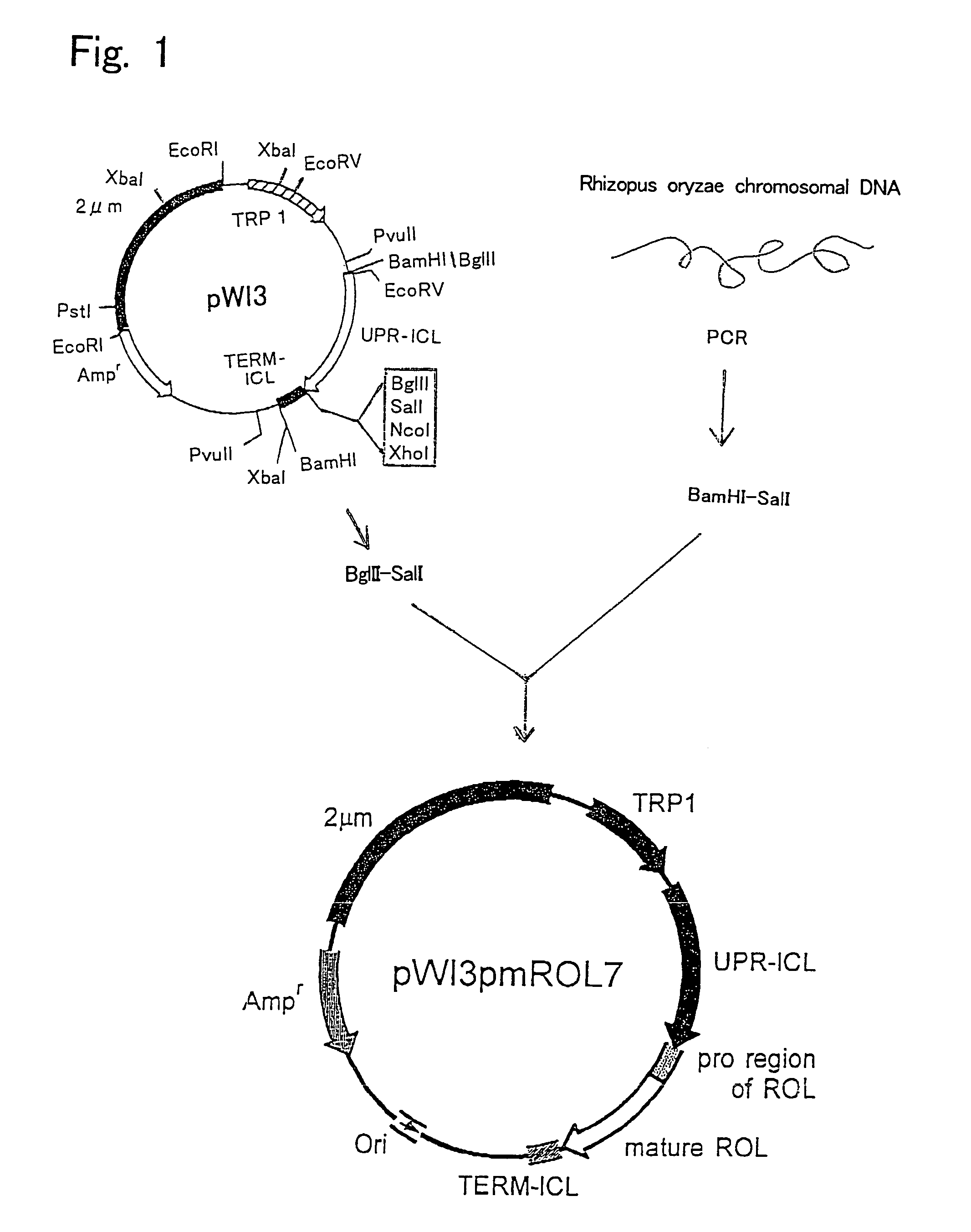

Process for producing fatty acid lower alcohol ester

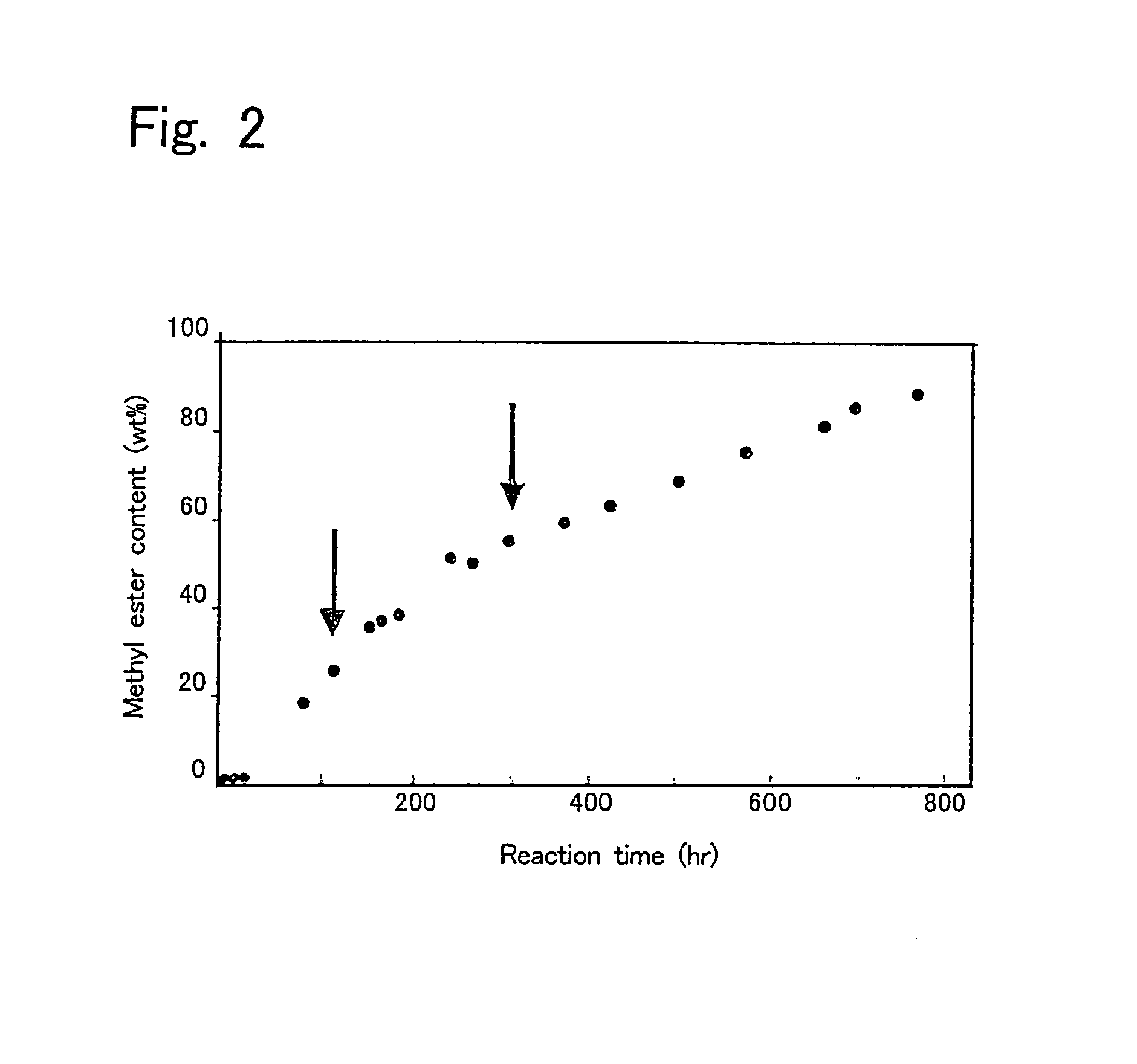

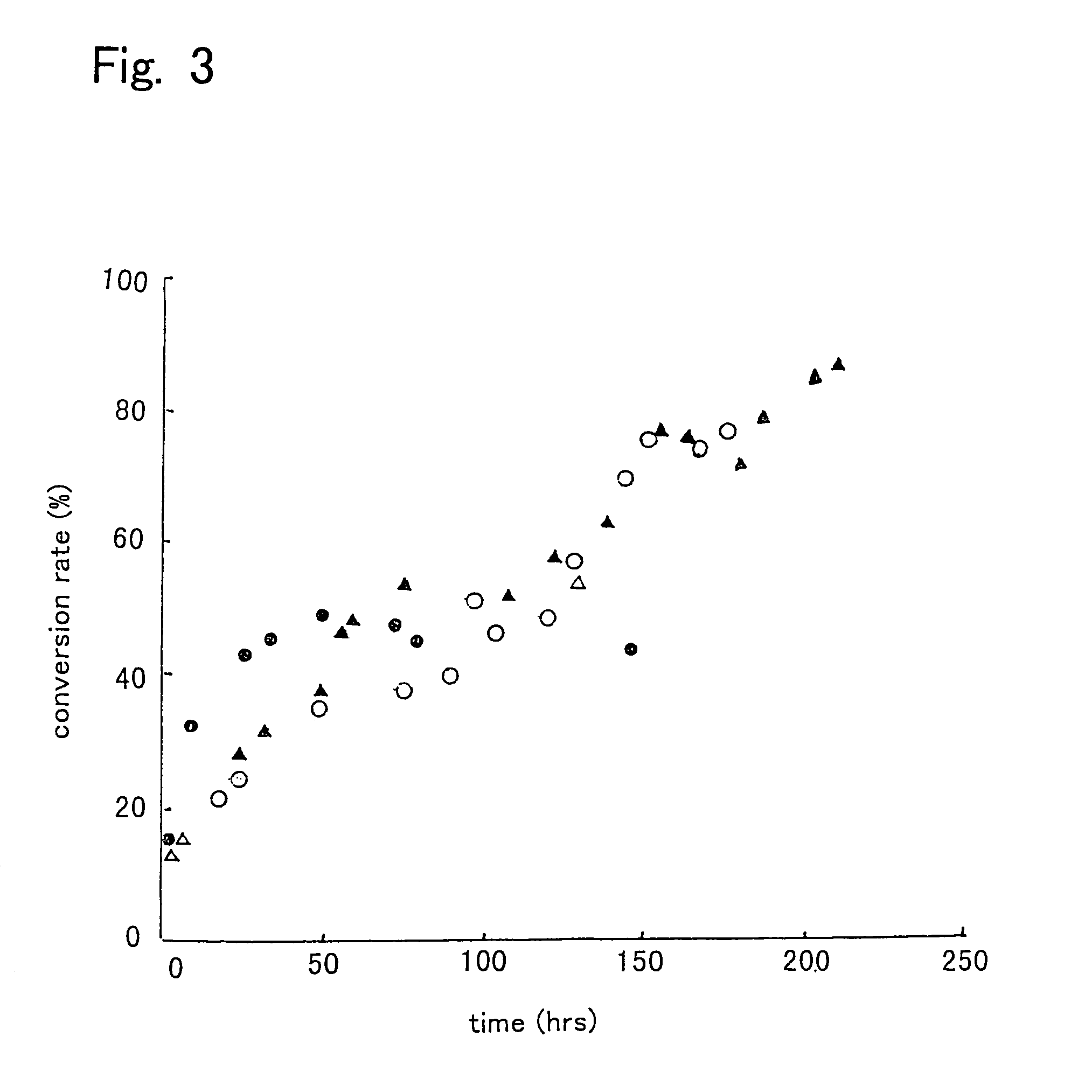

InactiveUS6982155B1Efficient productionImprove permeabilityFatty acid chemical modificationOrganic compound preparationOil and greaseMicroorganism

The present invention provides a method for producing a fatty acid ester inexpensively and efficiently by reacting a lipase or an intact mircroorganism containing a lipase, an oil and fat, and a linear lower alcohol in a system containing little or no solvent in the presence of water. The intact microorganism has not been treated with a solvent or the like, and is used as such, so that a fatty acid ester can be prepared in a simple manner. An oil and fat, a natural oil and fat such as a vegetable oil and fat, an animal oil and fat, as well as a waste oil thereof can be used. According to the method of the present invention, a reaction proceeds even in the presence of water, so that waste oils containing a large amount of water can be used as a raw material. Therefore, the waste oil to be dumped into the environment can be recycled, and a biodiesel fuel, which hardly pollutes the environment, can be provided at the same time.

Owner:KANSAI CHEM ENG CO LTD

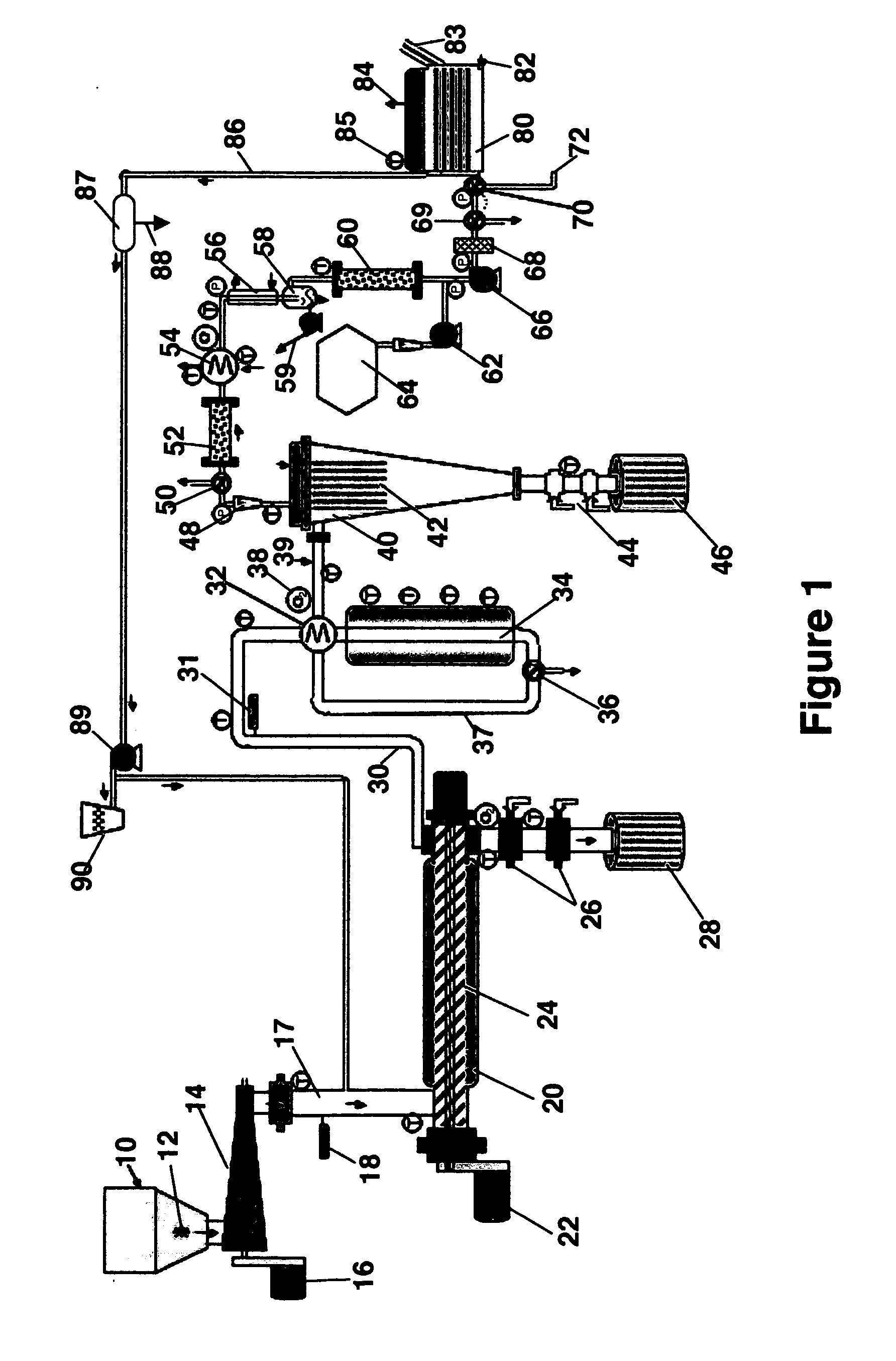

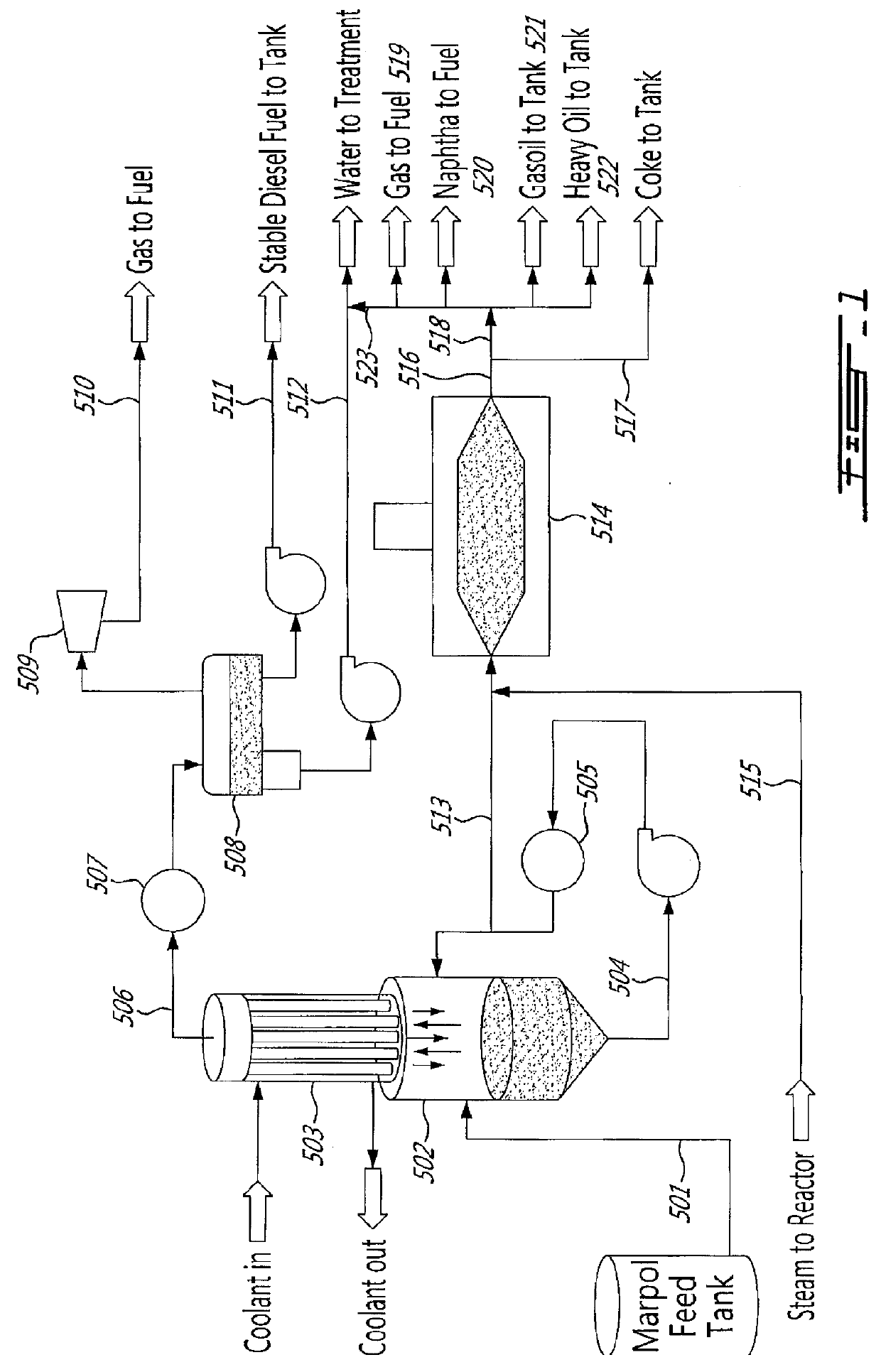

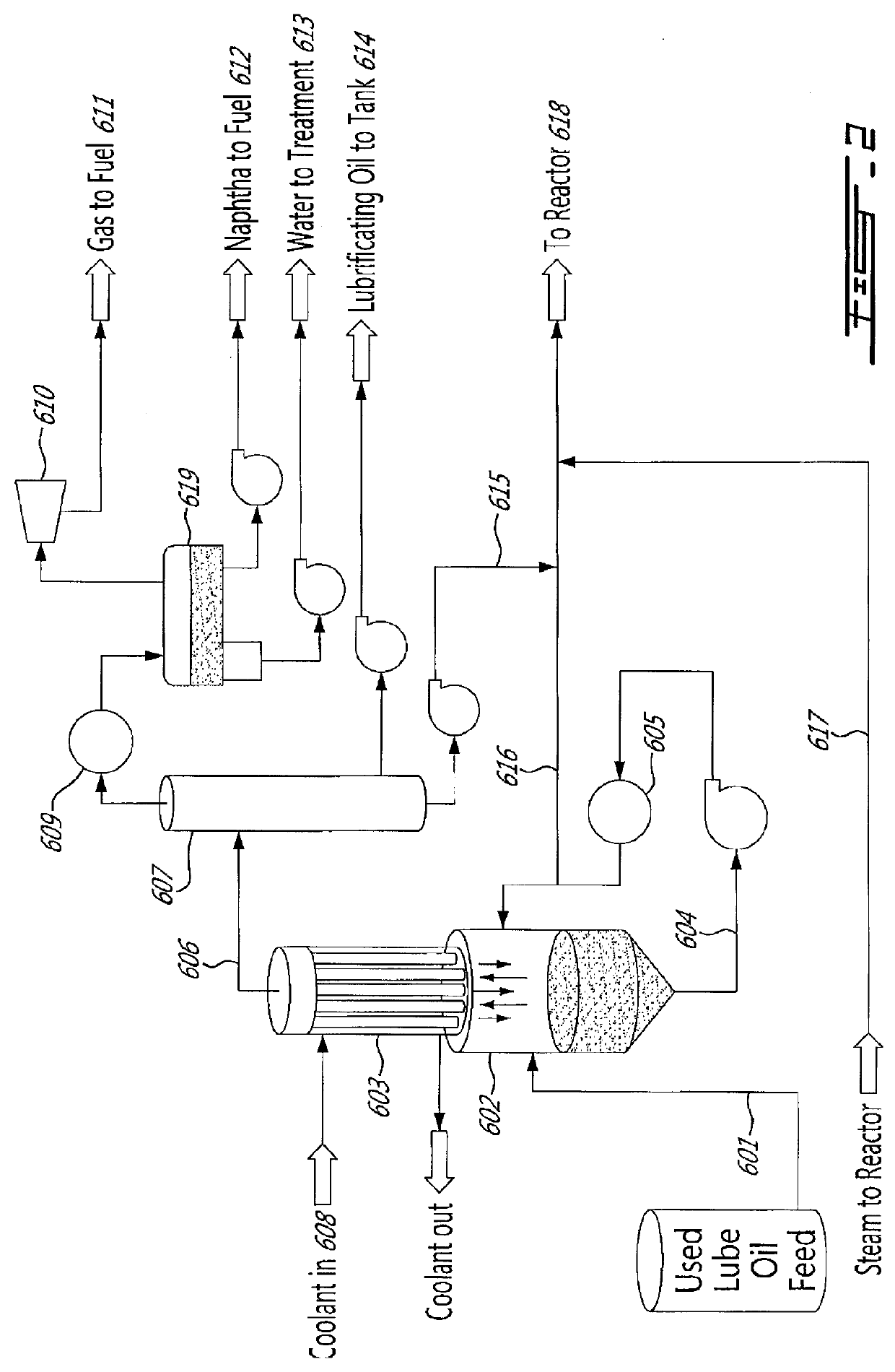

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

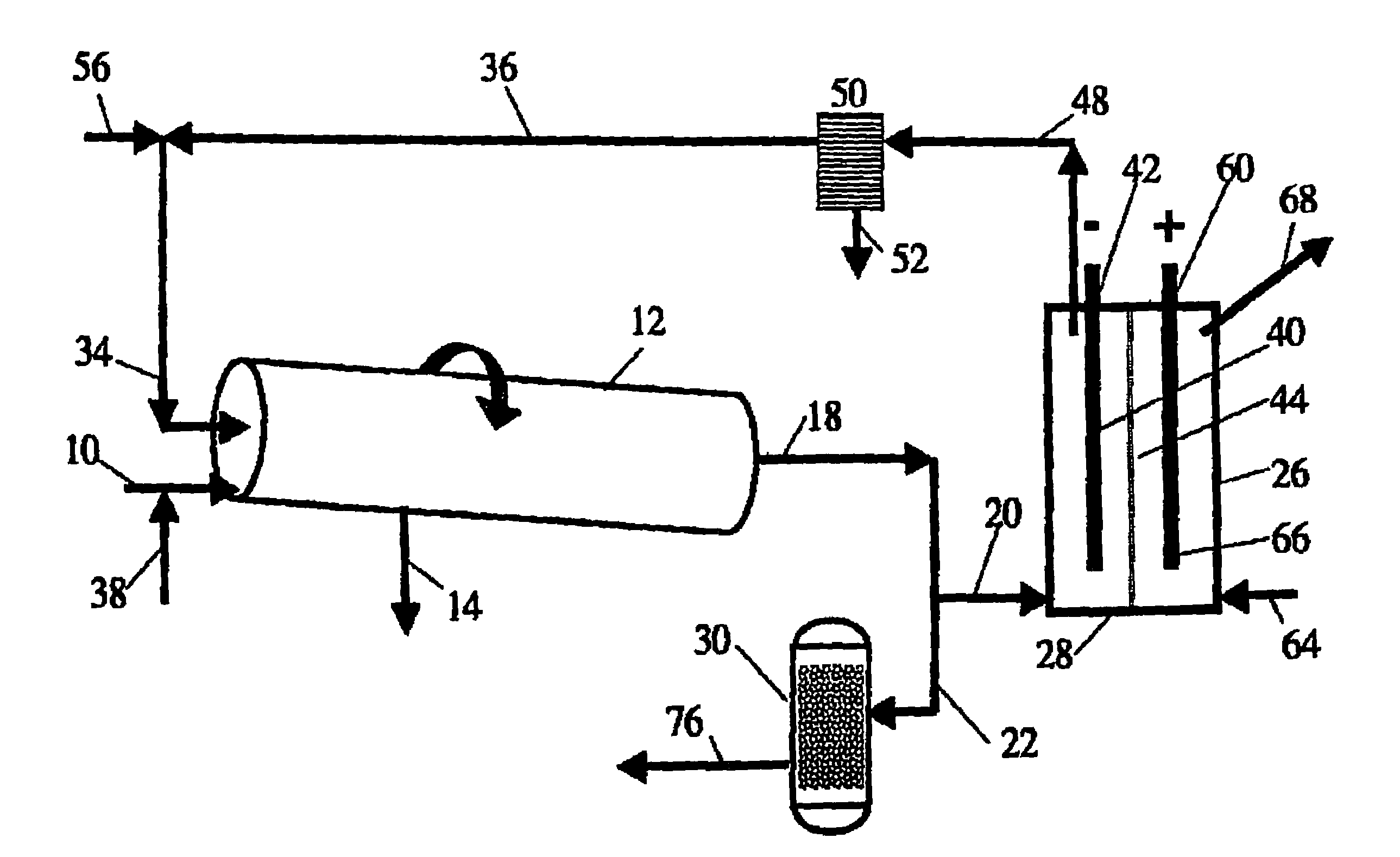

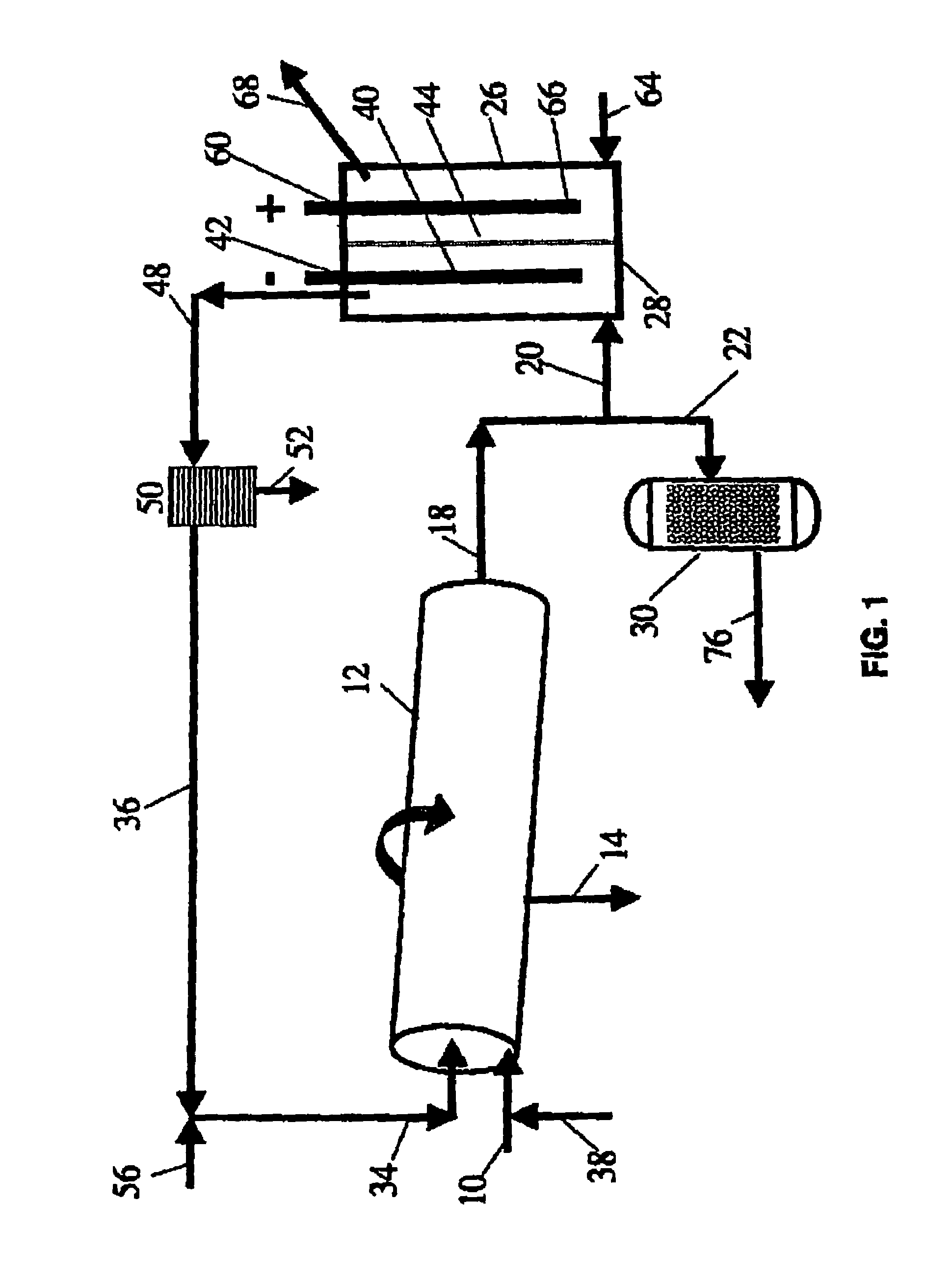

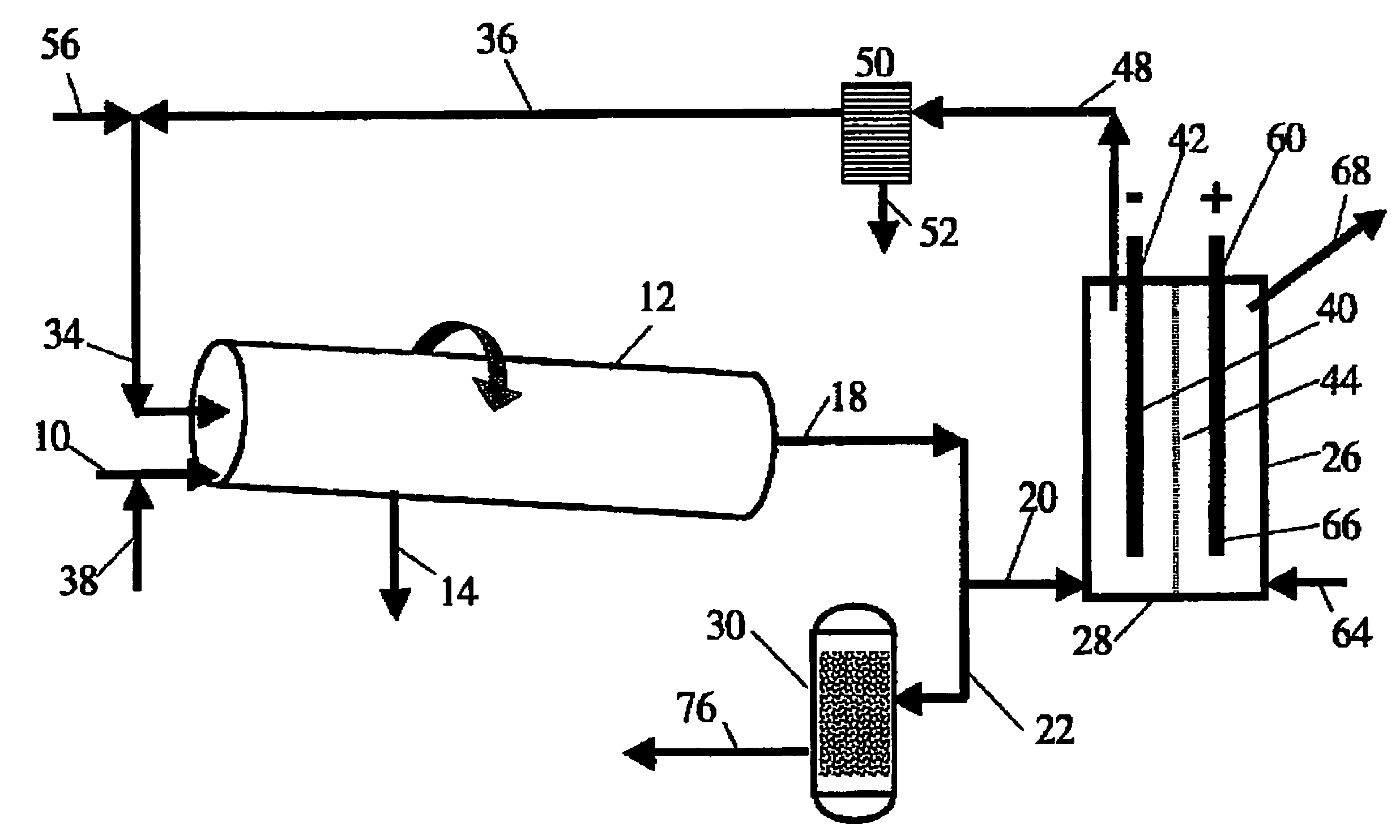

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

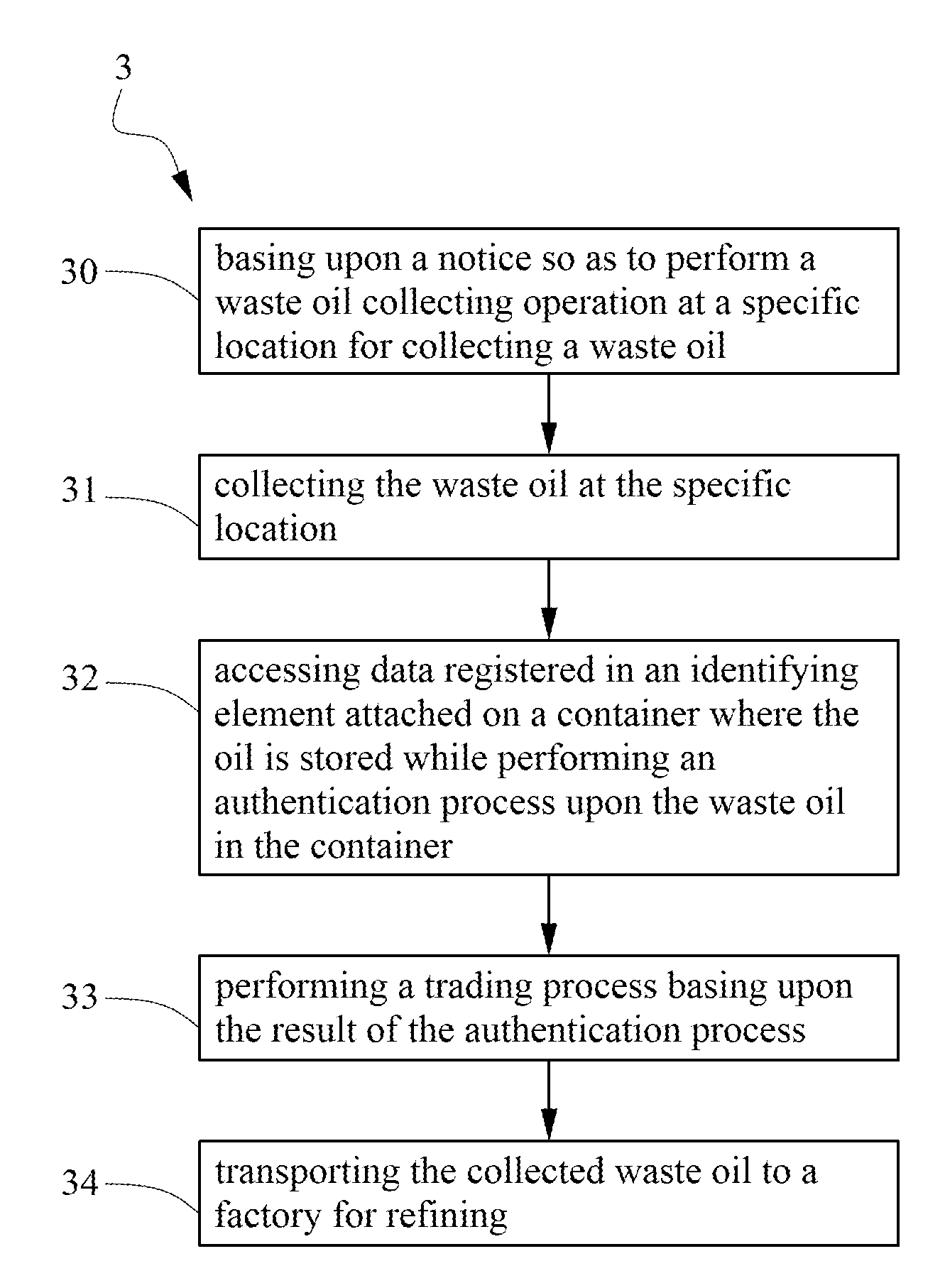

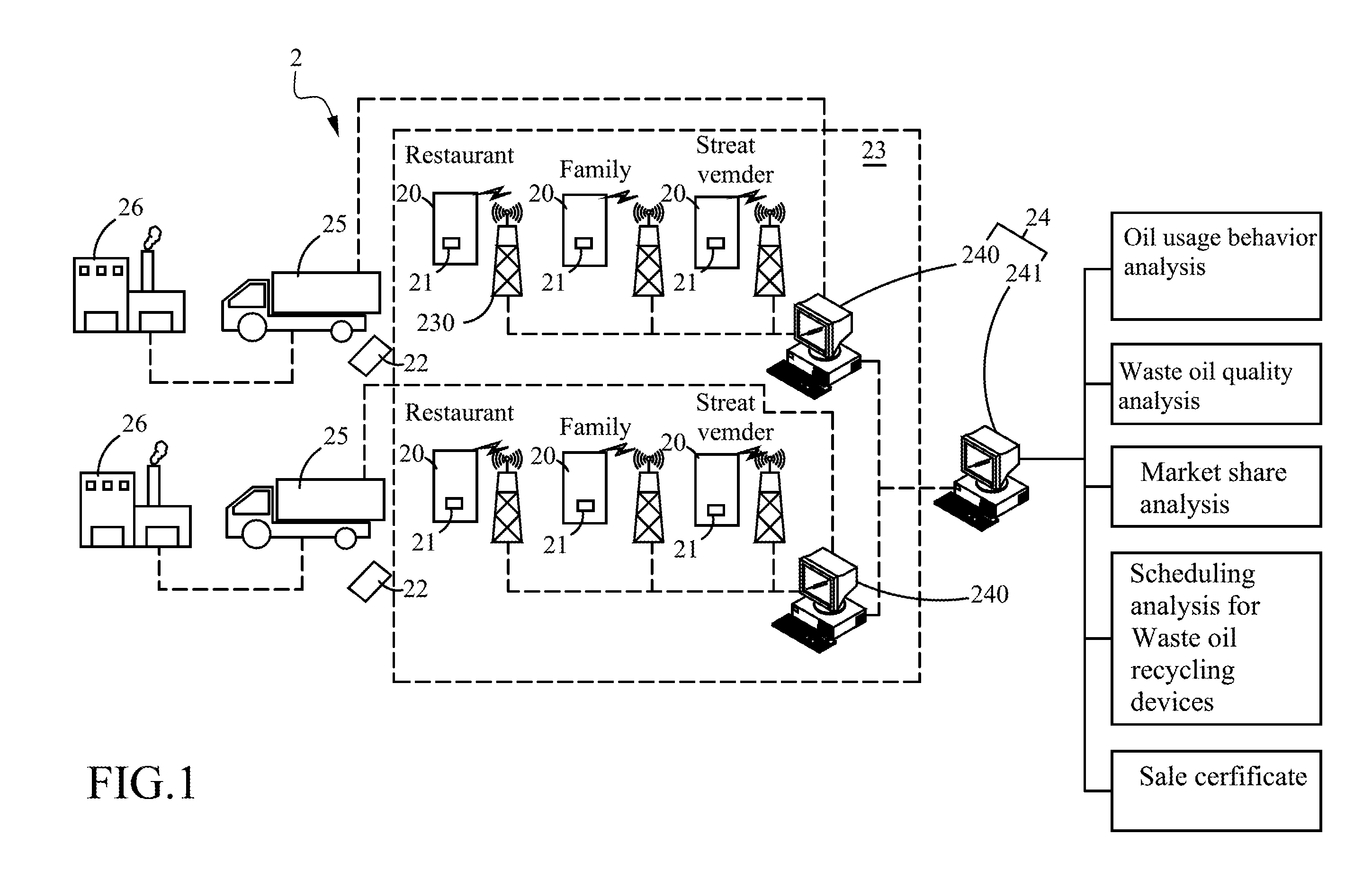

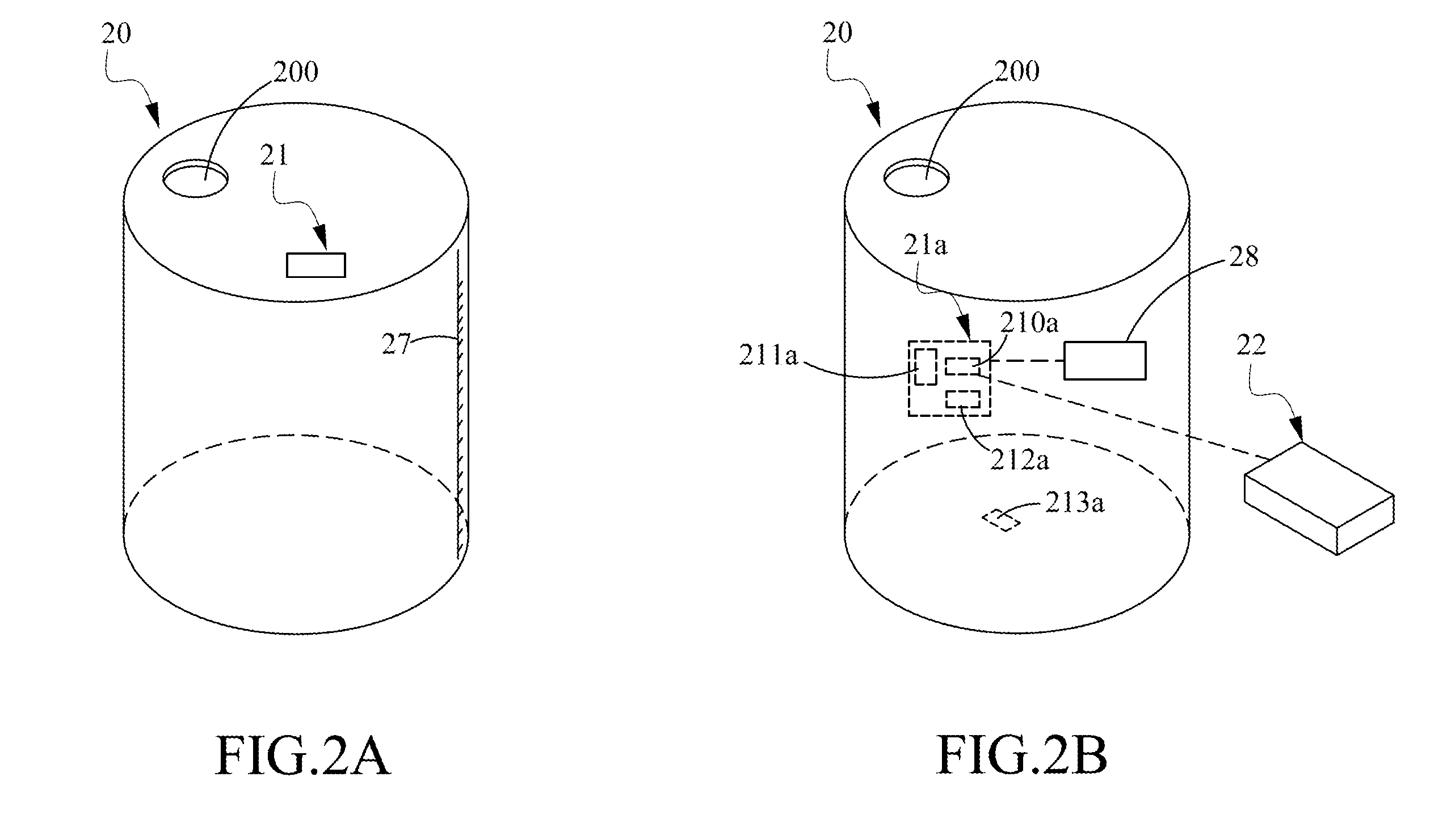

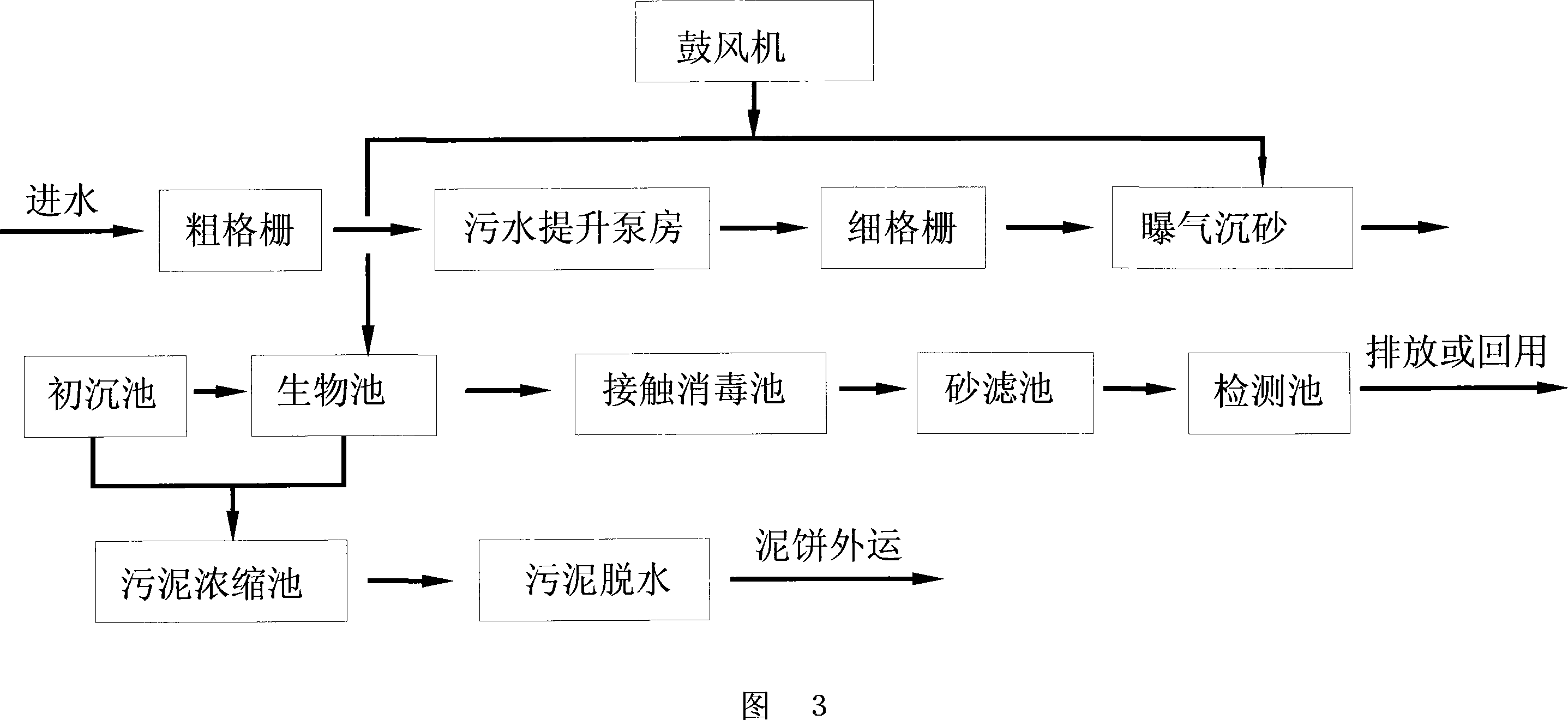

System and method for managing waste oil

InactiveUS20100312601A1Promote productionMaximizing costElectric signal transmission systemsDigital data processing detailsEngineeringWaste oil

The present invention provides a system for managing waste oil, which comprises at least one container wherein each container has an identifying element disposed thereon for recording information with respect to the waste oil provider, container, and quality of the waste oil. By means of the system, the present invention further provides a method for managing and trading the waste oil, which refers to a business method for implementing transaction such as sale of waste oil or exchange between waste oil and daily necessaries according to the information of the identifying element whereby the business center can control the logistics, cash flow and information flow easily and efficiently so that the waste oil provider can have service of transaction easily.

Owner:GITEN ENERGY MFG

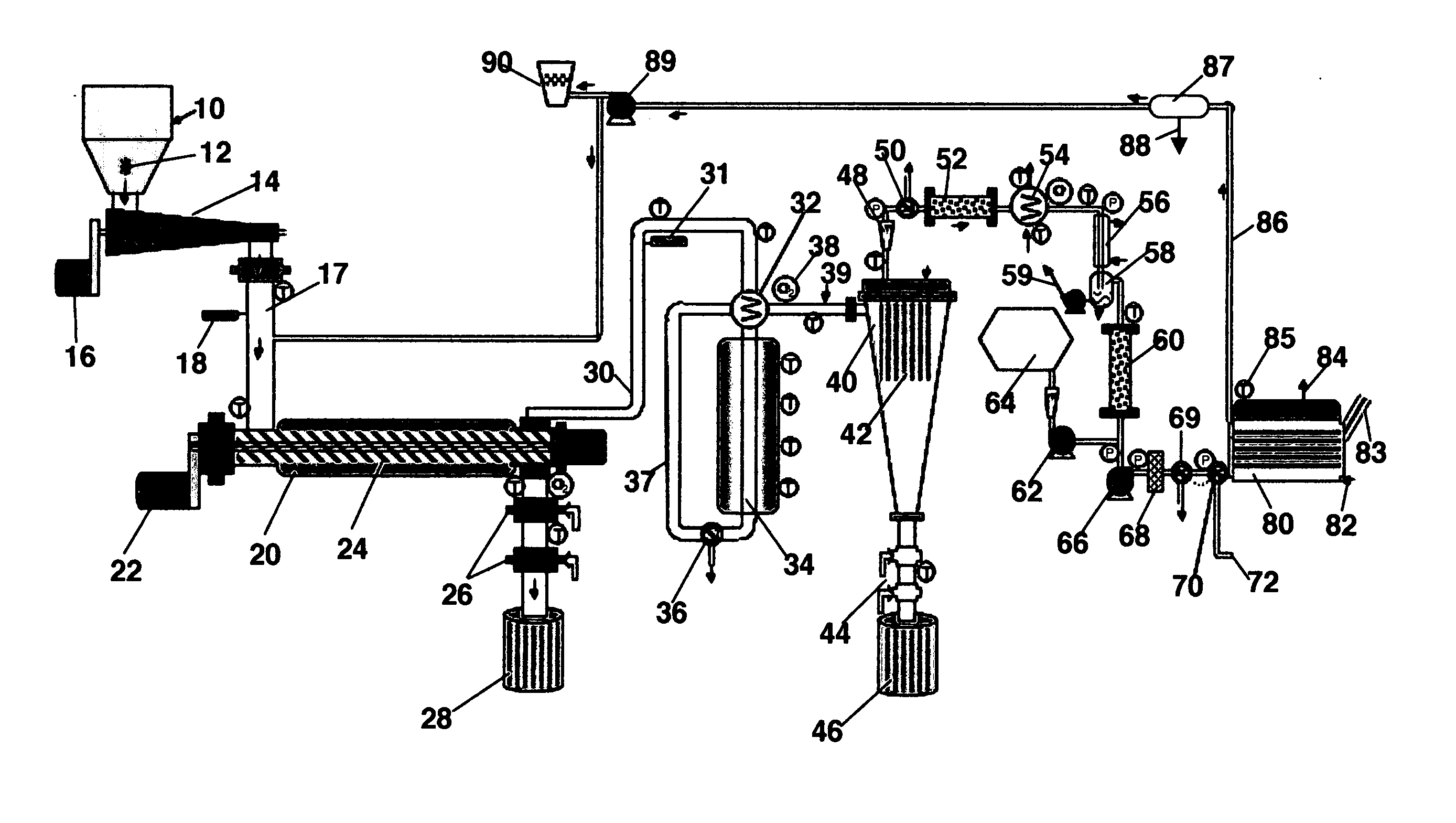

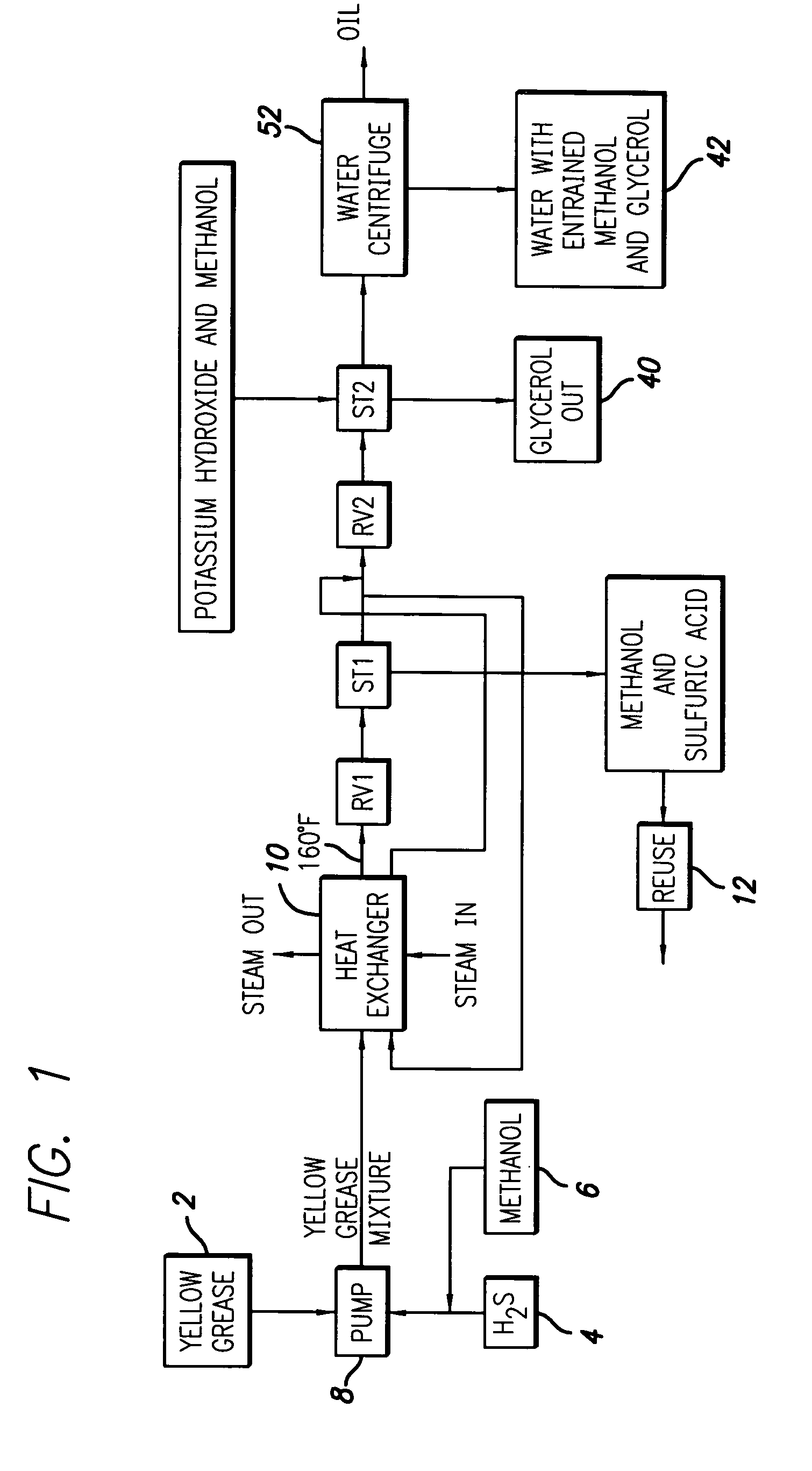

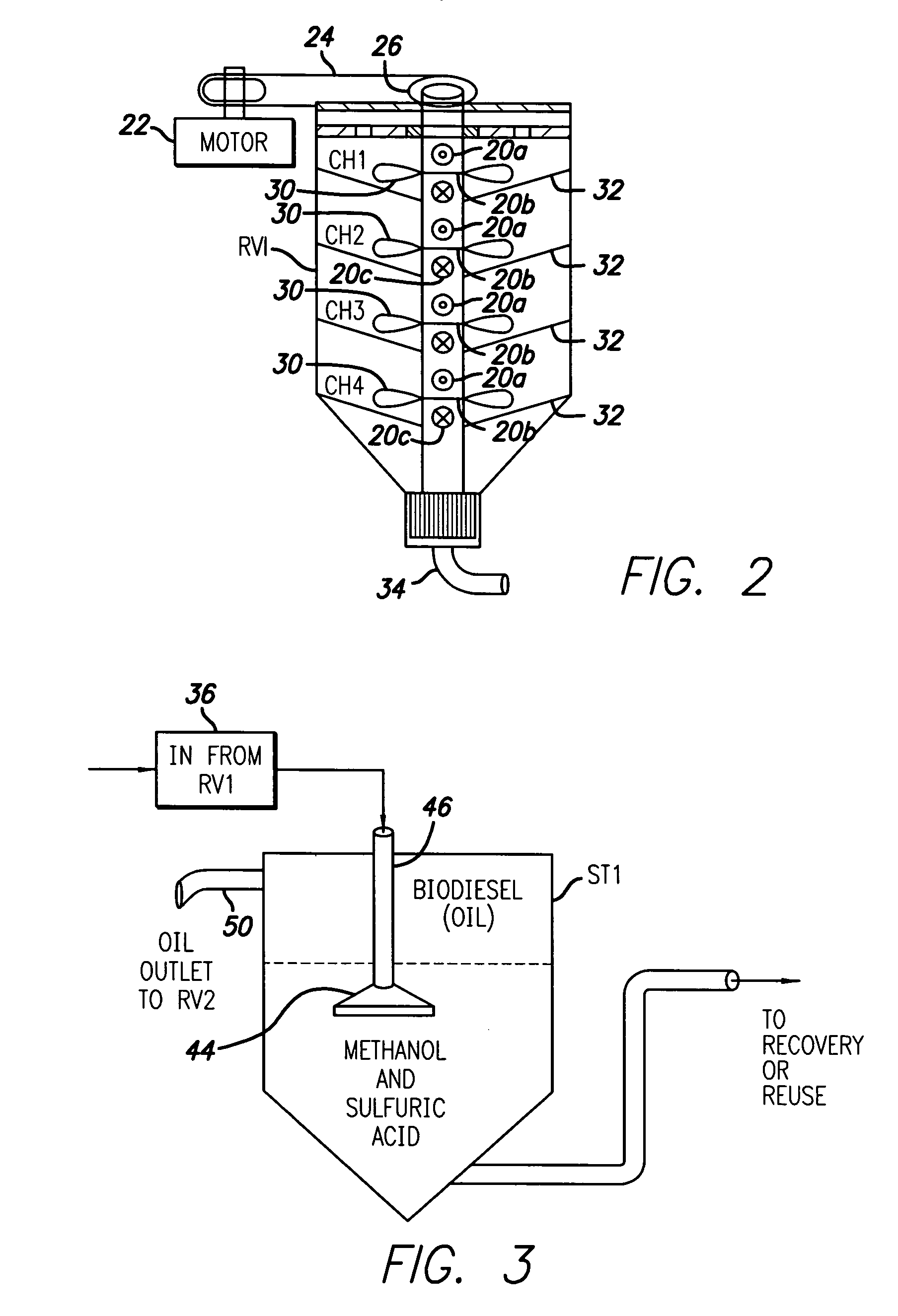

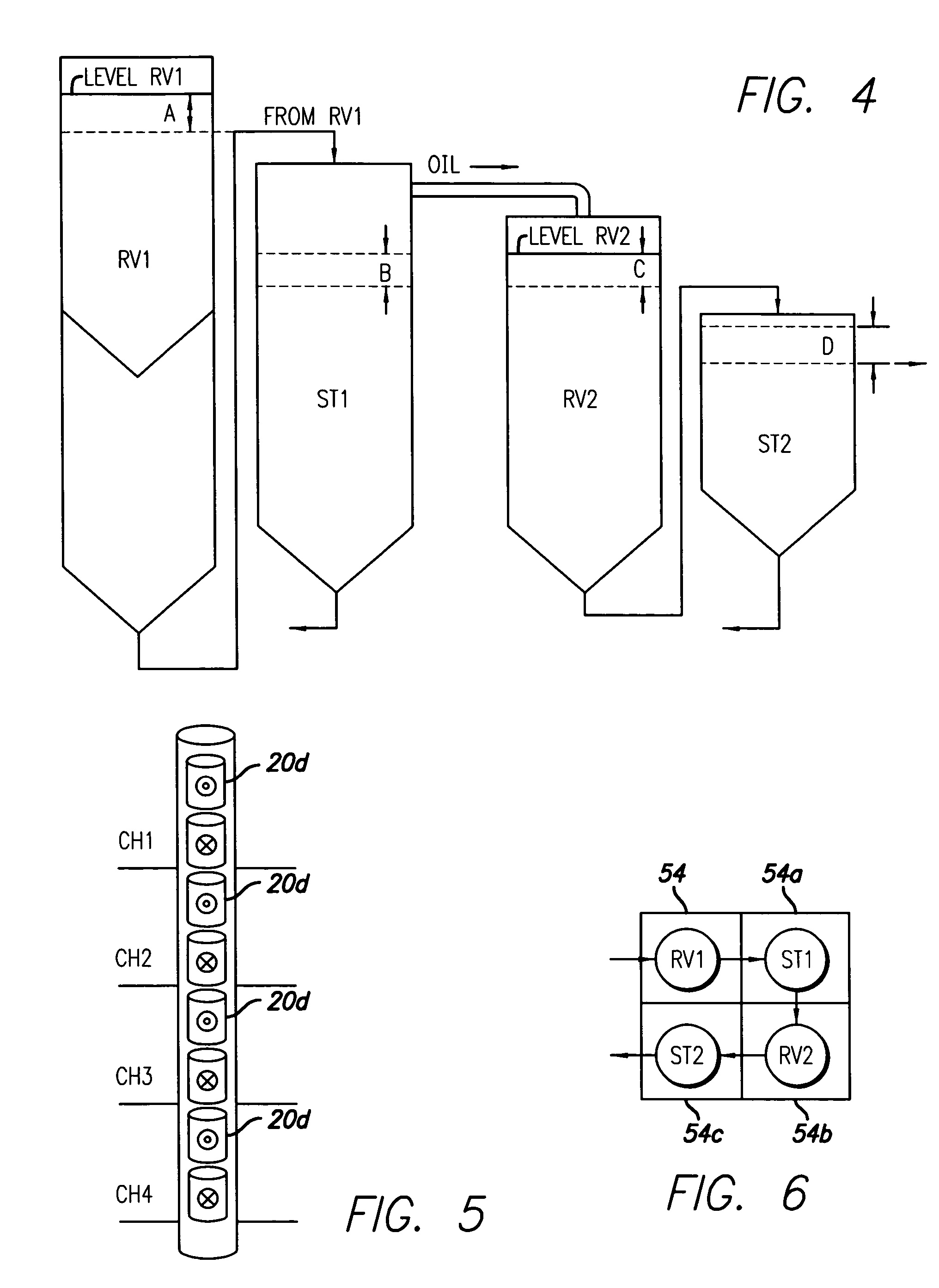

Continuous flow method and apparatus for making biodiesel fuel

InactiveUS20050081435A1Small footprintAvoid small quantitiesTransportation and packagingRotary stirring mixersOil and greaseVegetable oil

In an economical and efficient process and apparatus for producing biofuel from waste oil, such as vegetable oils and animal fats, waste oil is esterified with alcohols to produce alcohol esters and the by-products of the transesterification reaction are recovered. Static pressure may be used as well as continuous flow-through reaction vessels and separation tanks without the need for additional pumps. There may also be specialized reaction tanks that have vertical rotating feed tubes having separators and inlet and outlet openings. The method and device achieves efficient production of biofuel while employing reaction and mixing tanks having a limited size, which in turn permits a smaller plant layout or “footprint”. For example, the largest tank may be in a size of about 36 / 100,000 times the desired plant output in gallons per year. The benefits of the process and apparatus include minimal space for a plant; minimal on-site feedstock needed therefore minimal on-site storage is needed; minimal capital costs to build a plant e.g., reduction by about fifty to sixty five percent (50 to 65%); reduction in construction time from typically over one year to under three months in many plants; minimal energy usage, e.g., reduction by about sixty percent (60%); minimal labor costs due to the automatic continuous flow; minimal pumps needed thereby reducing pump operation and maintenance costs; environmentally friendlier and safer plant design; and due to smaller plant footprint, lower capital cost and minimal construction time enables site selection much nearer to the raw material supplies, thereby minimizing or even eliminating transportation costs for yellow grease or vegetable oil.

Owner:BIO CLEAN FUELS

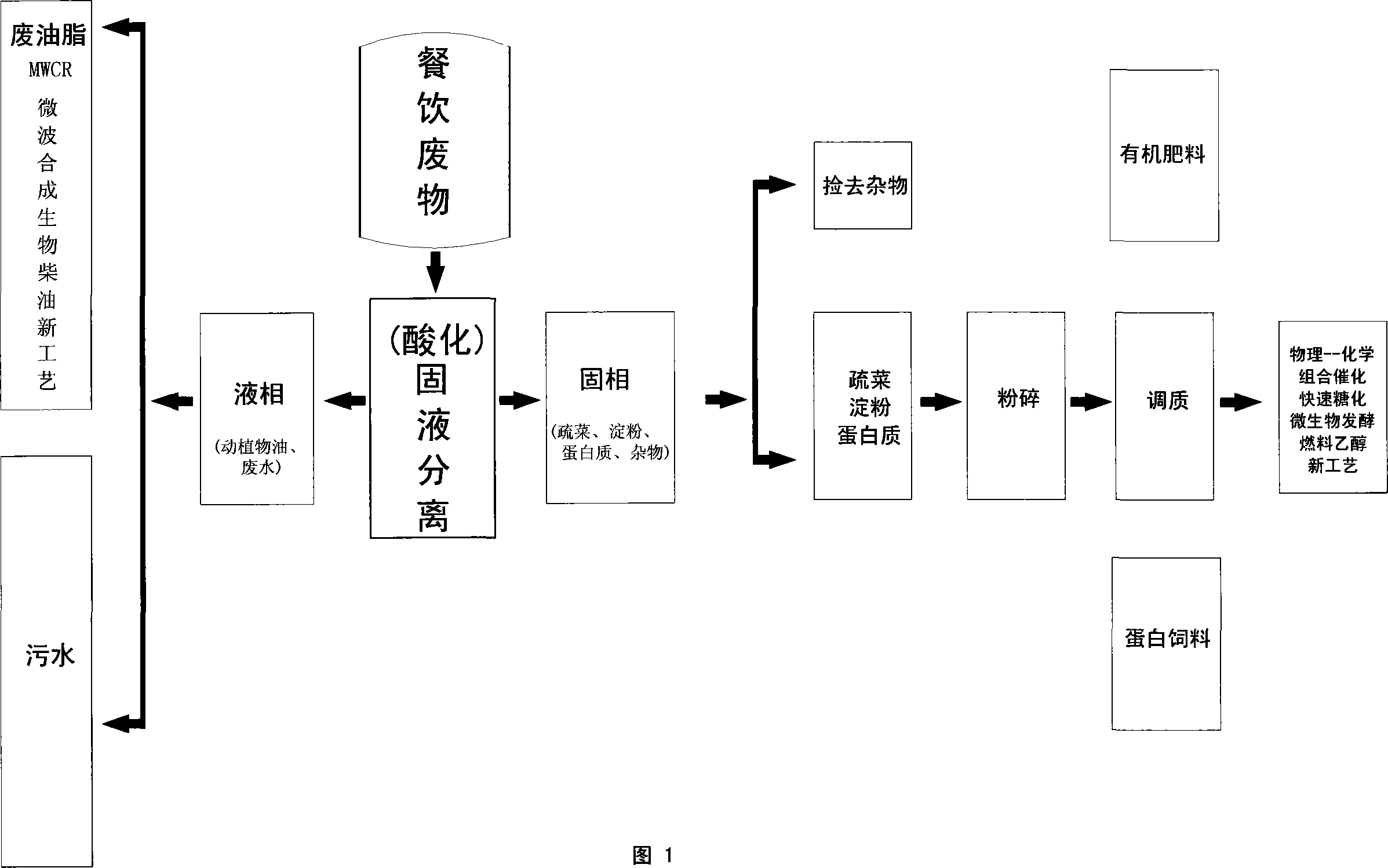

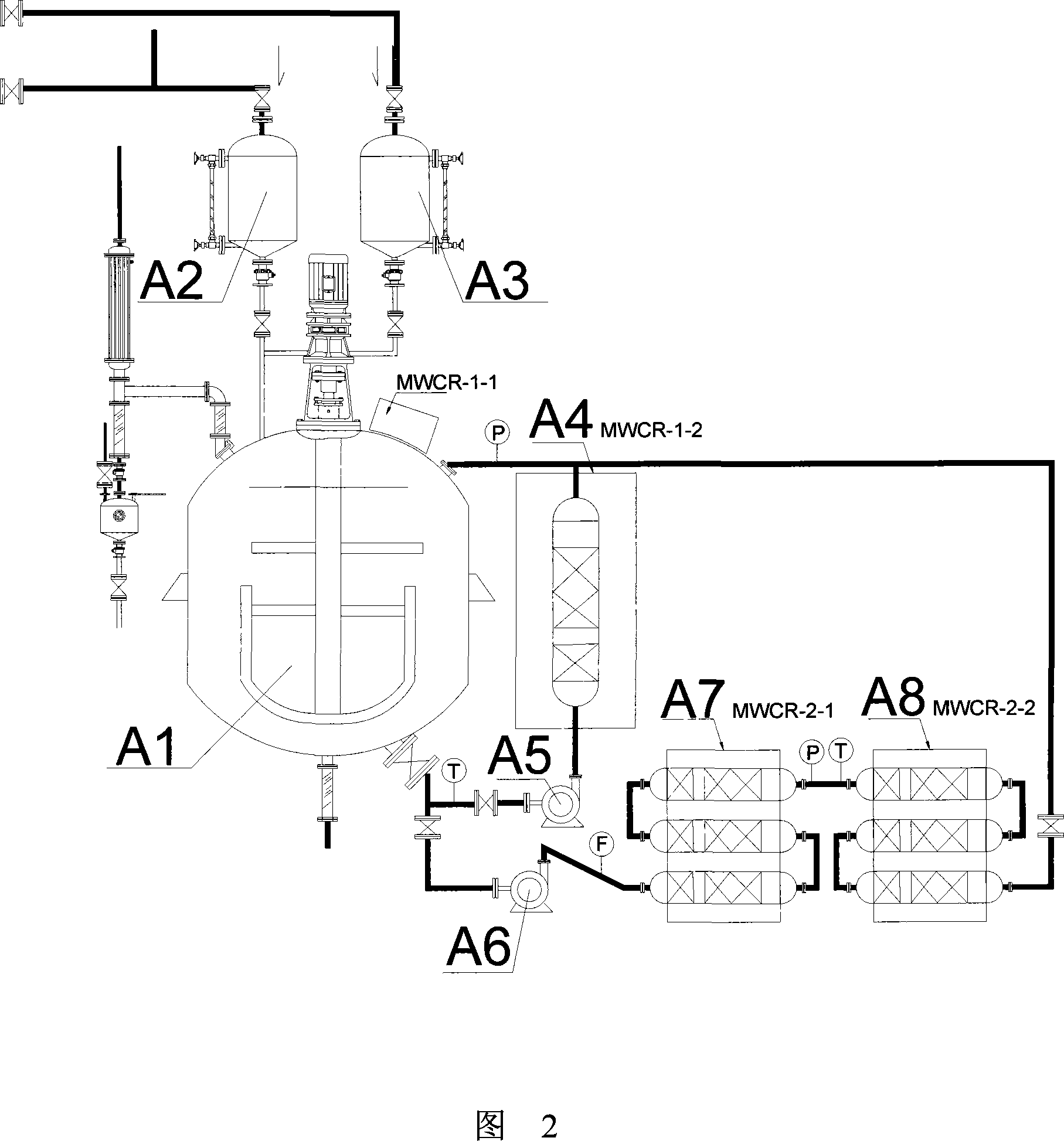

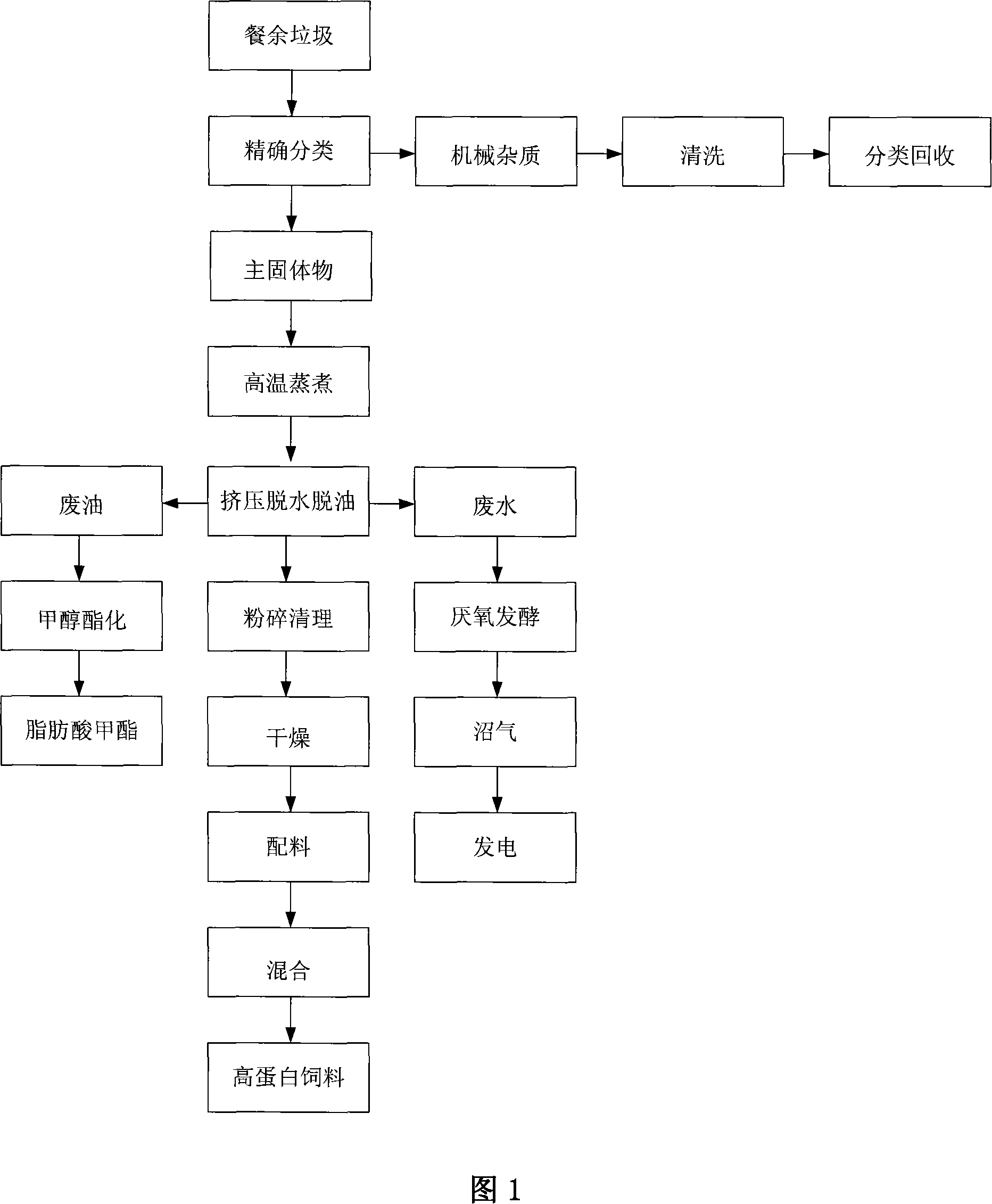

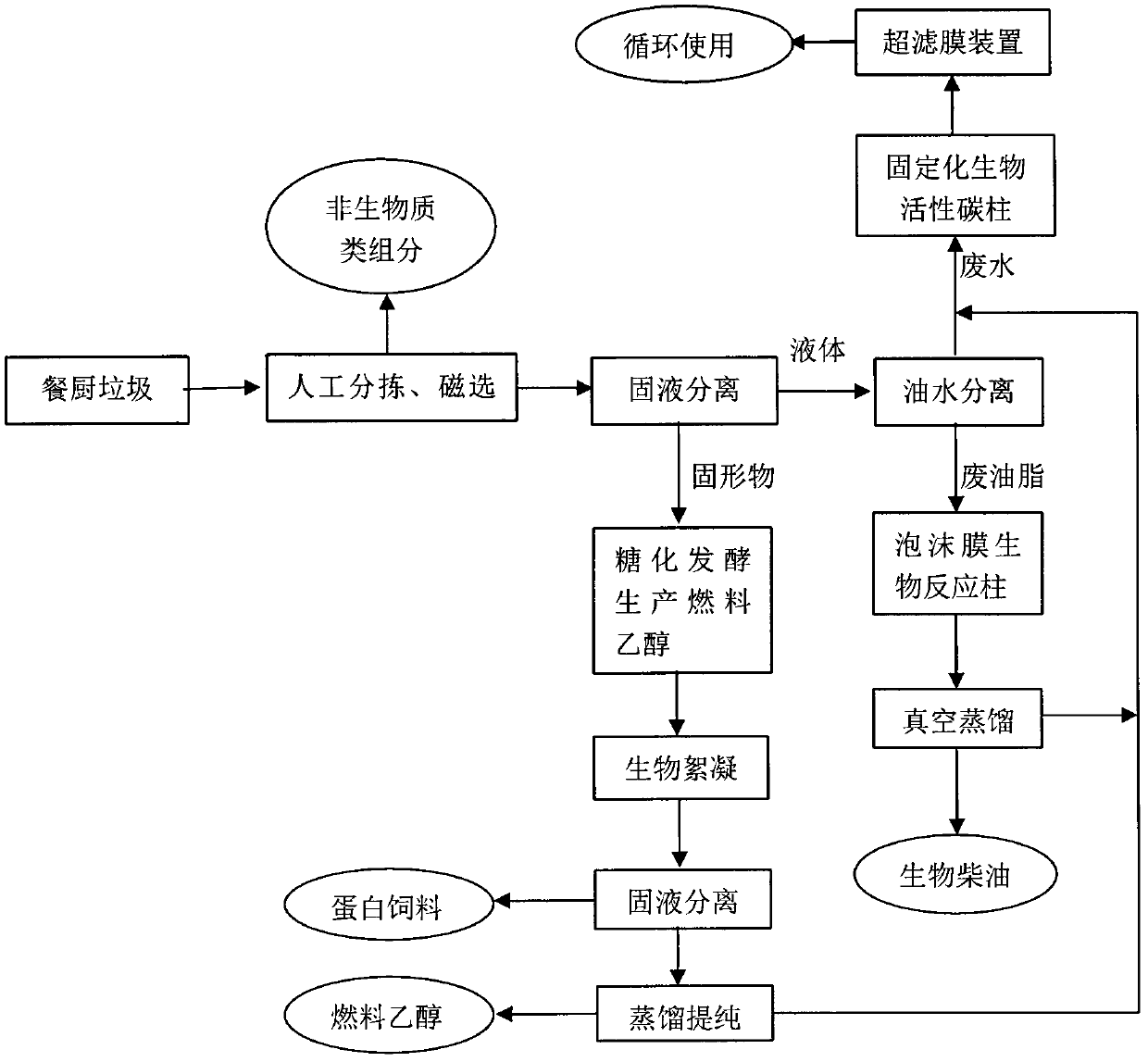

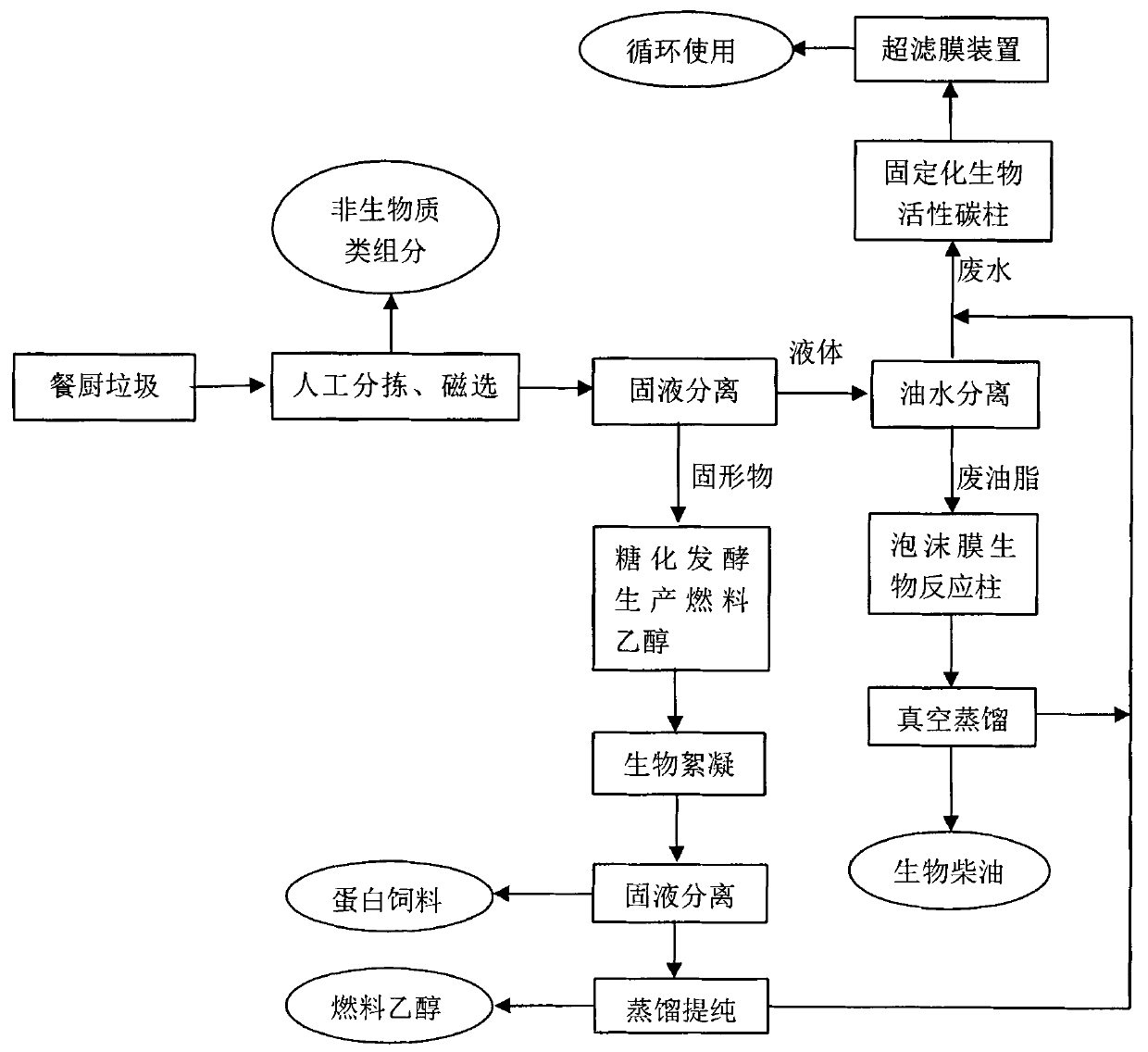

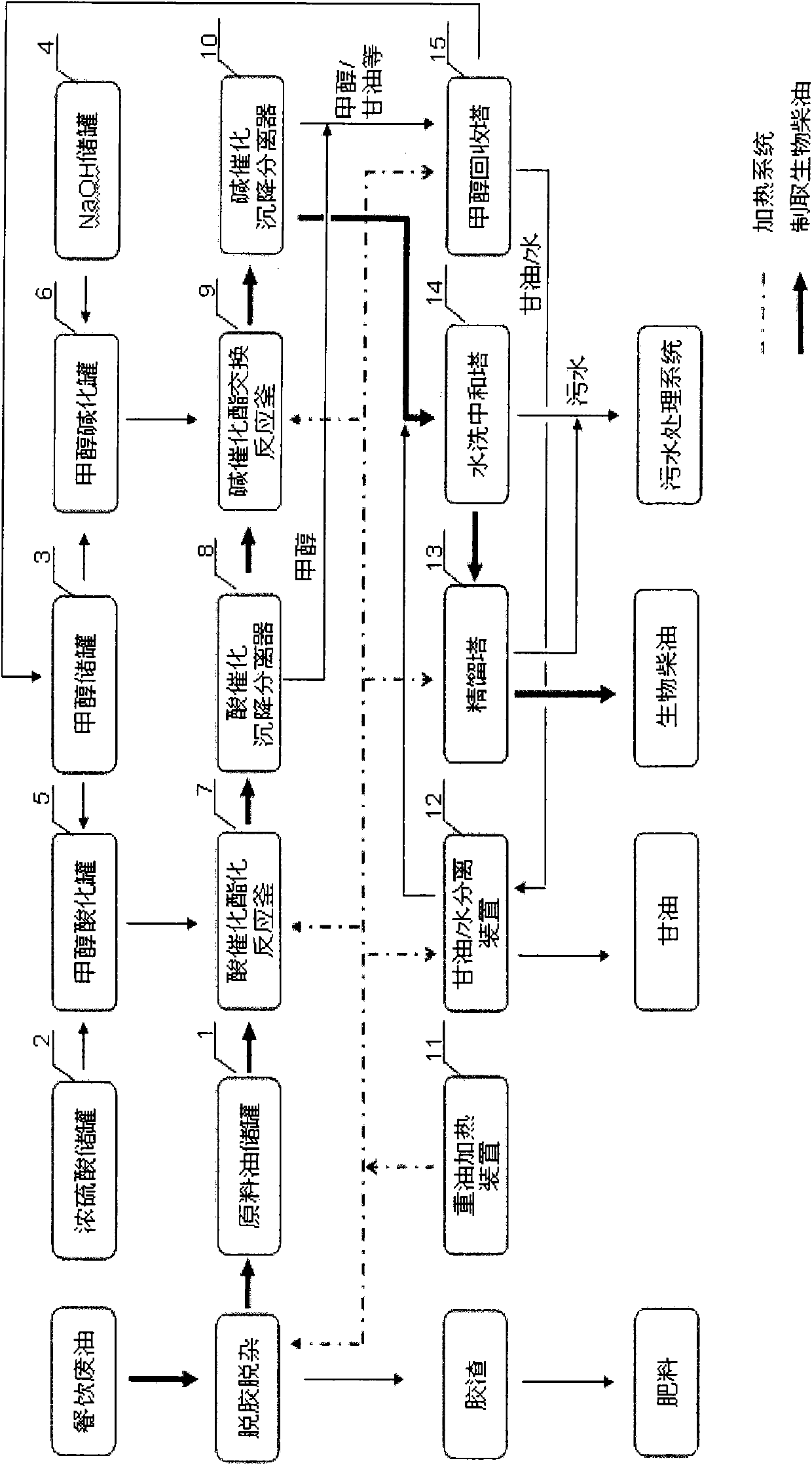

Resource using method for food and drink garbage

InactiveCN101058097AImprove conversion rateImprove efficiencyFood processingSolid waste disposalEngineeringWaste oil

The invention relates to a catering garbage reutilization method. It separates the liquid and the solid garbage and acidify them, then separate oil and water to get waste oil grease and sewage, using the waste grease synthesizing into biological diesel, processing the sewage to the required standard, crushing and grinding the solid, which are mixed with water to generate alcohol, batching, sterilizing, fermenting and drying the animal fodder. In this way, it can realize harmless processing of food waste, with zero discharge and enclosed green production.

Owner:中船重工(西安)东仪环保科技有限公司

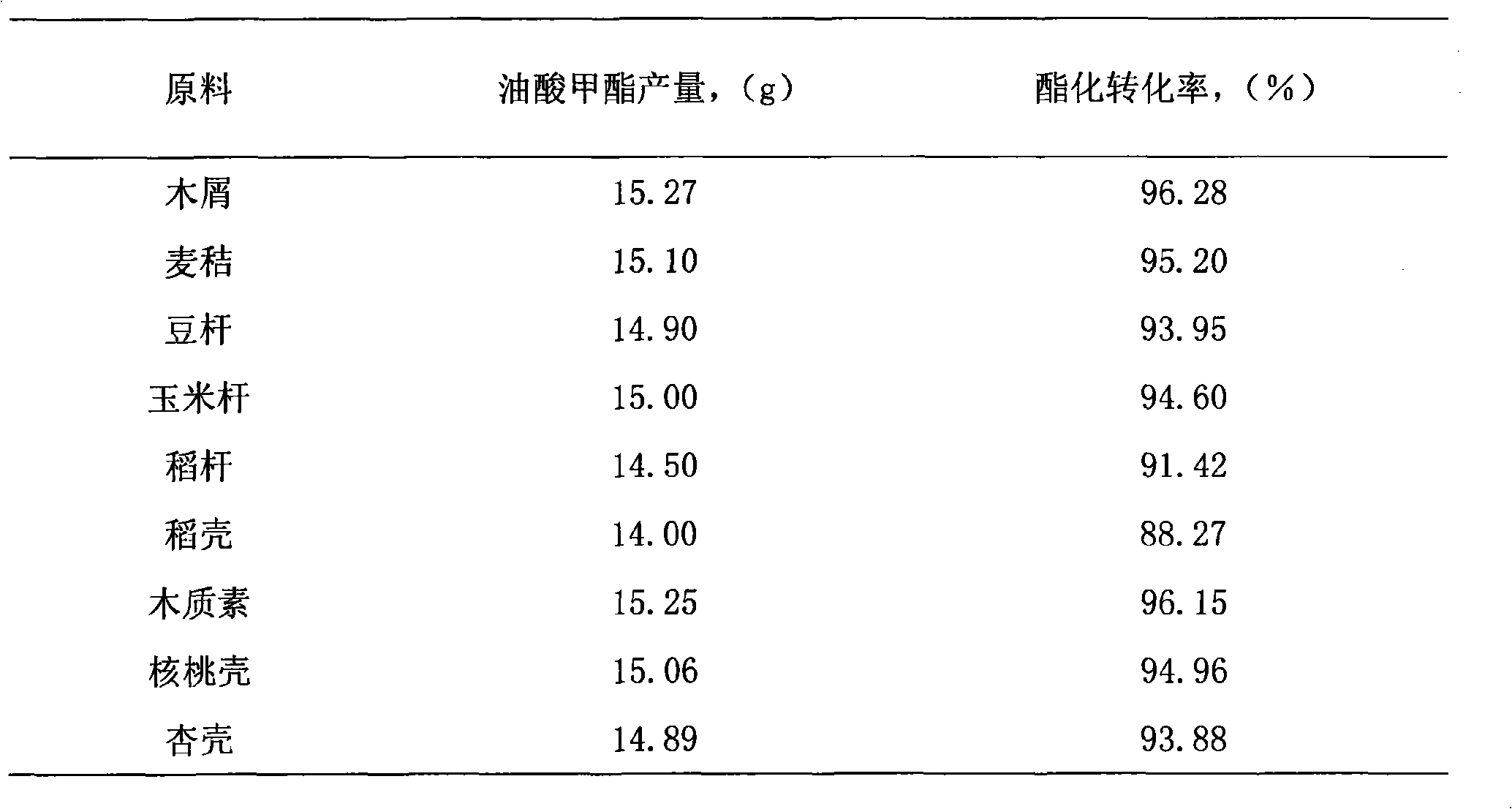

Method for preparing biocarbon solid acid catalyst and biodiesel

InactiveCN101298566AReduce manufacturing costAbundant and renewable resourcesPhysical/chemical process catalystsPreparation by ester-hydroxy reactionBiodieselSolid acid

The invention pertains to the new material technical field, and relates to a method for preparing a carbonaceous solid acid catalyst and biodiesel by taking pure natural biological substances as raw materials. The method is characterized by: taking the pure natural and renewable biological substances as the raw materials; adopting the technical route and method of low-temperature carbonization firstly, oxidation secondly and sulfonation then according to the constituent and structural characteristics to prepare the bio-carbonaceous solid acid catalyst; and adopting a continuous rectification-water separating esterification reaction technology to produce the biodiesel by carrying out the catalytic esterification reaction of a free fatty acid or waste oil and short chain alcohol. The raw materials adopted by the invention are rich in resources, low in price, pure natural and renewable, which pertains to waste utilization; the preparation technology is simple with moderate and controllable reaction conditions; the catalyst has the advantages of high activity, good stability, easy recycling and no corrosion to equipment, which is an really environment-friendly catalyst, thus being applicable to the large scale industrial production of the biodiesel. The method can also be applied to a plurality of organic reactions such as alkylation, hydrolysis and hydration, etc.

Owner:DALIAN UNIV OF TECH

Method for comprehensive processing garbage of food and recycling to use

ActiveCN101130194AAccurate classificationRealize resource processingFood processingSolid waste disposalWaste oilFatty acid methyl ester

The invention discloses a synthetic processing recycling reusing method of residual dining rubbish, which comprises the following steps: cutting to remove package bag, waste table cloth and plastic bag; vibrating and sieving to pick chopstick; using magnet to attract bottle cap; washing the separated materials mechanically; collecting splitly; boiling main solid material under 130-150 deg. c for 30-60 min; squeezing the boiled material to separate solid from liquid; proceeding oil-water separation for the squeezed water and oil through centrifuging; doing anaerobic ferment for the waste water to produce methane; esterifying waste oil and carbinol to prepare fatty acid methyl ester. The invention eliminates secondary pollution during environmental protection and disposal, which is a reasonable, industrial, scaling, non-harmful, resourcing disposing pattern for the dining rubbish with good applying prospect.

Owner:鲁控环保(苏州)有限公司

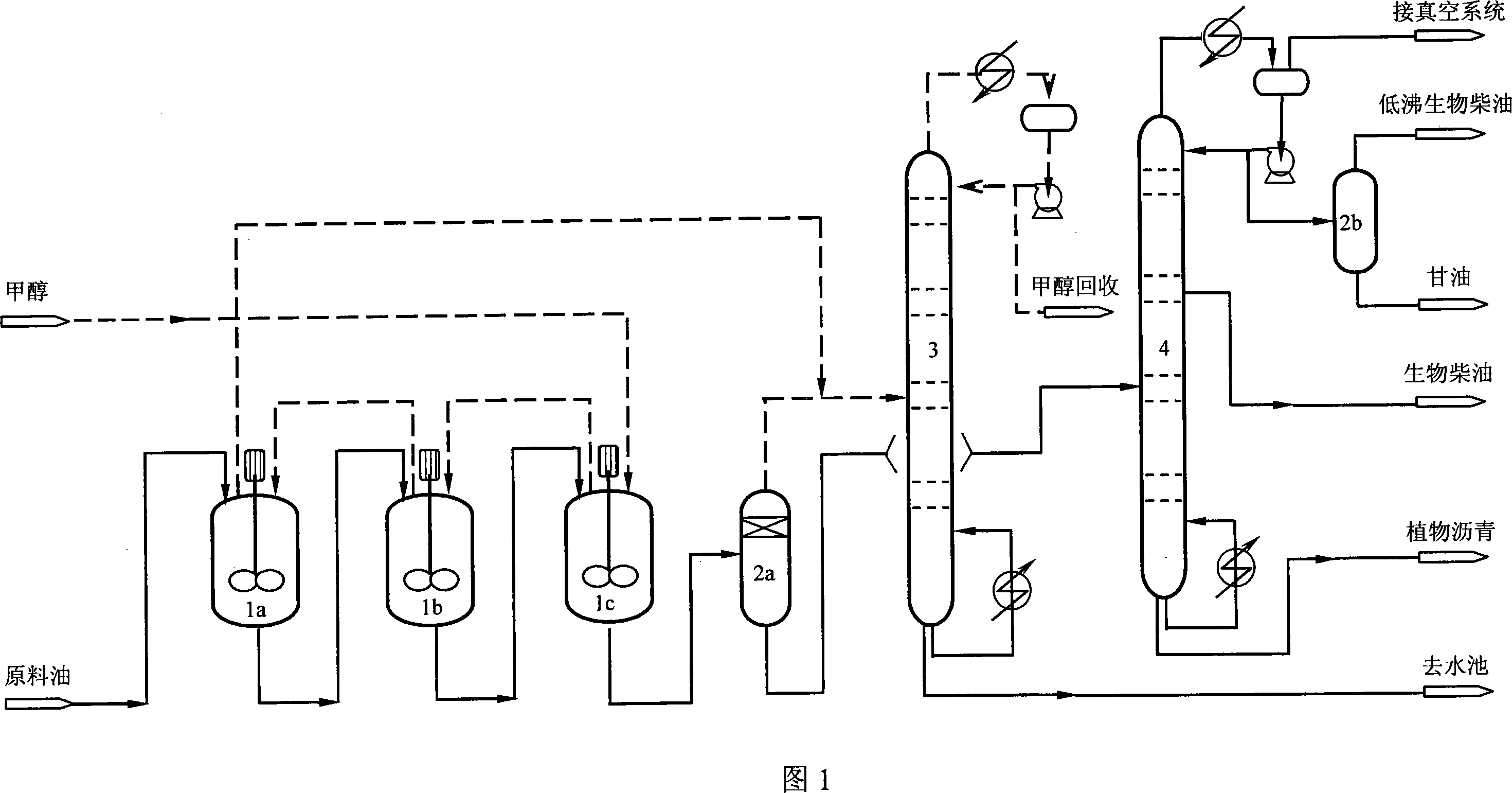

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

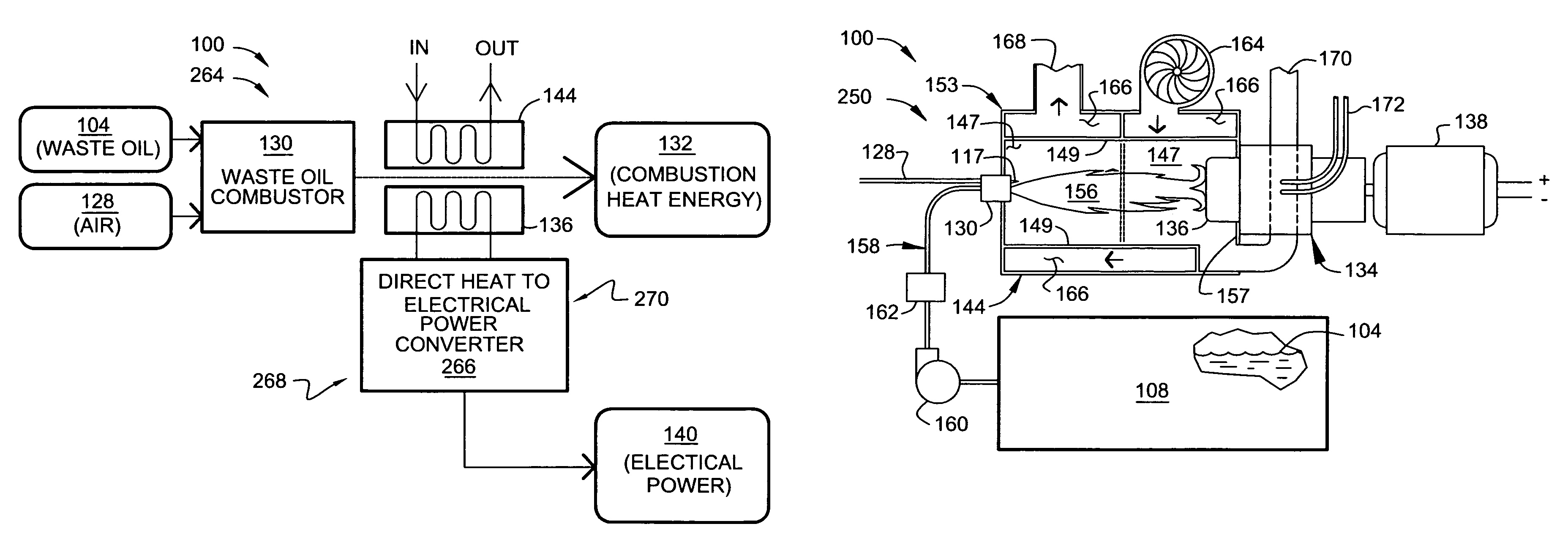

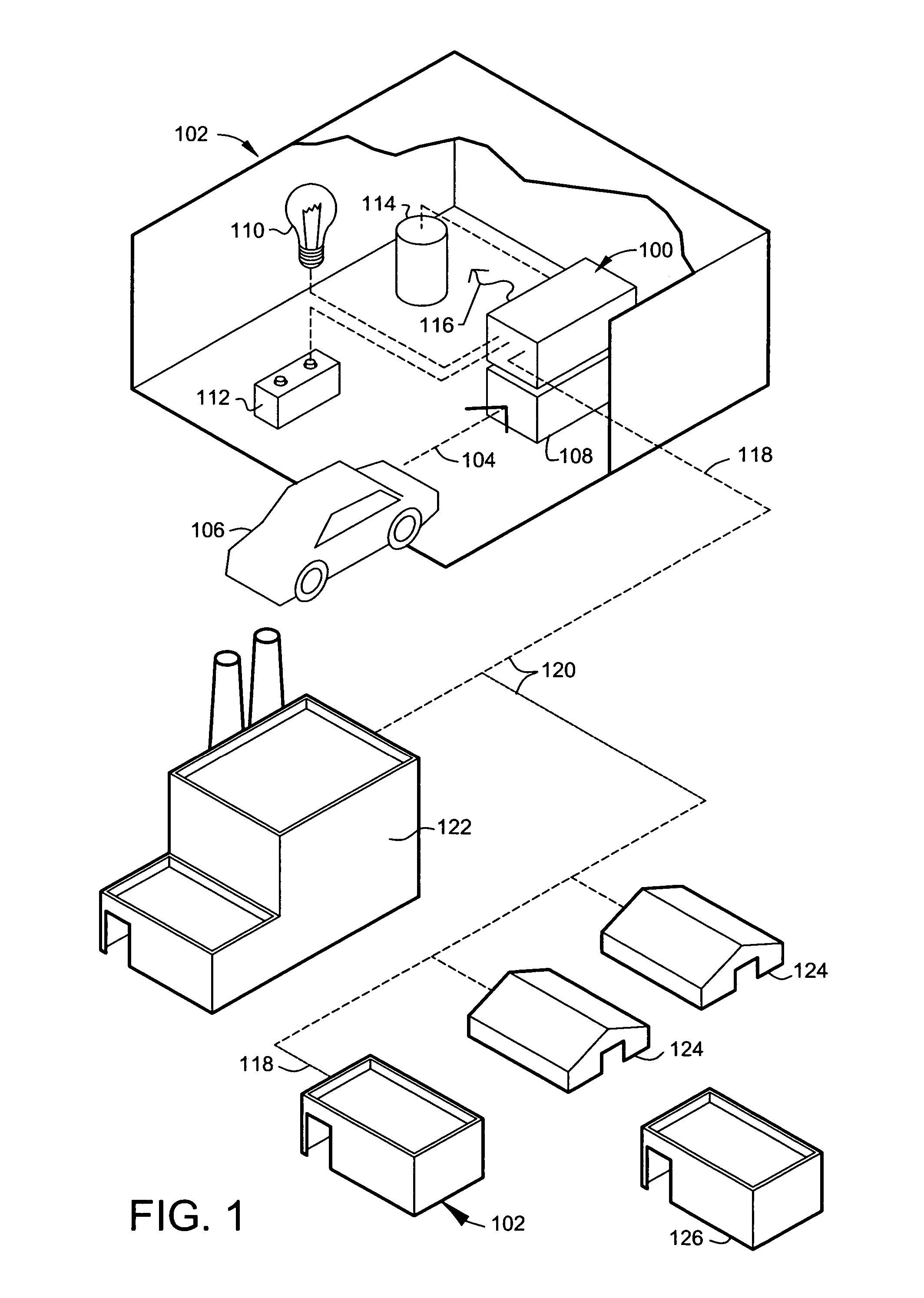

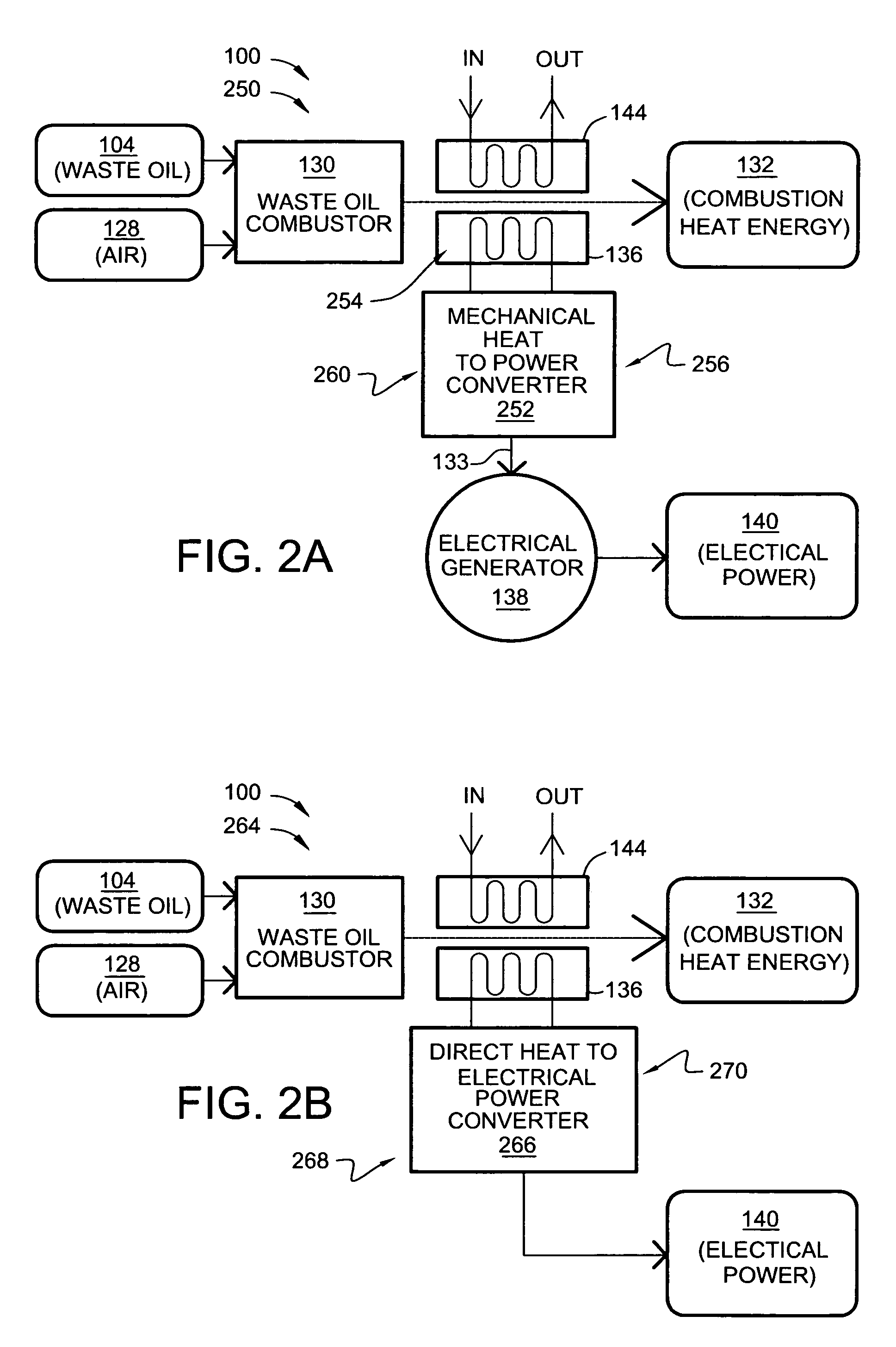

Waste oil electrical generation systems

Owner:BASSETT TERRY E

Full-biomass resource utilization method for kitchen waste

InactiveCN102553886AShorten fermentation timeOvercome the defects of single enzymatic hydrolysisFatty oils/acids recovery from wasteFatty acid esterificationOil and greaseResource utilization

The invention relates to a full-biomass resource utilization method for kitchen waste. The method comprises the following steps: sorting kitchen waste and then performing solid-liquid separation, performing oil-water separation on the liquid phase, grinding the solid phase and then producing fuel ethanol by complex enzyme preparation and multi-step hydrolysis, producing protein feeds from the solid residues and yeast after production purification, and performing transesterification on the separated waste oil to produce bio-diesel oil. The invention has the advantages that different components in the kitchen waste are transformed with high efficiency respectively by utilizing the process integration technology to produce fuel ethanol, bio-diesel oil, protein feeds and other products with high value added, so that the cost of kitchen waste treatment is reduced, and the economic benefits are improved; the operation process is mild, the energy consumption is reduced, and the process flow is environment-friendly; and the kitchen waste is turned into treasure, and the comprehensive waste reduction, resource and energy utilization can be achieved.

Owner:天津新生环境发展有限公司 +2

Method for producing epoxy plasticizer dirty oil and vegetable and animal waste oil

A method for producing epoxy plasticizer from refused animal and vegetable oil is carried out by adding refused oil 97-99.8wt% and porous carrier solid acid 0.2-3wt% into reactor, inducing into gas-phase methanol at 95-130degree, agitating for 1-4hrs, esterification reacting, separating out solid acid, adding liquid 70-80wt%, methanol 15-25wt% and solid alkali catalyst 1-5wt% into reactor, agitating at 50-65degree and normal pressure for 0.5-2hrs, separating out to obtain aliphatic acid methoxy-carbonyl, adding hydrogen peroxide 25-5wt%, methane acid 2.5-10wt% and sodium tripolyphosphate 0-1wt% into aliphatic acid methoxy-carbonyl 55-70wt%, agitating for 8-10hrs at 60+-5degree, reacting, separating out acid water, neutralizing, washing and dewatering to obtain the final product. It's simple, cheap and has less consumption.

Owner:江苏悦达卡特新能源有限公司

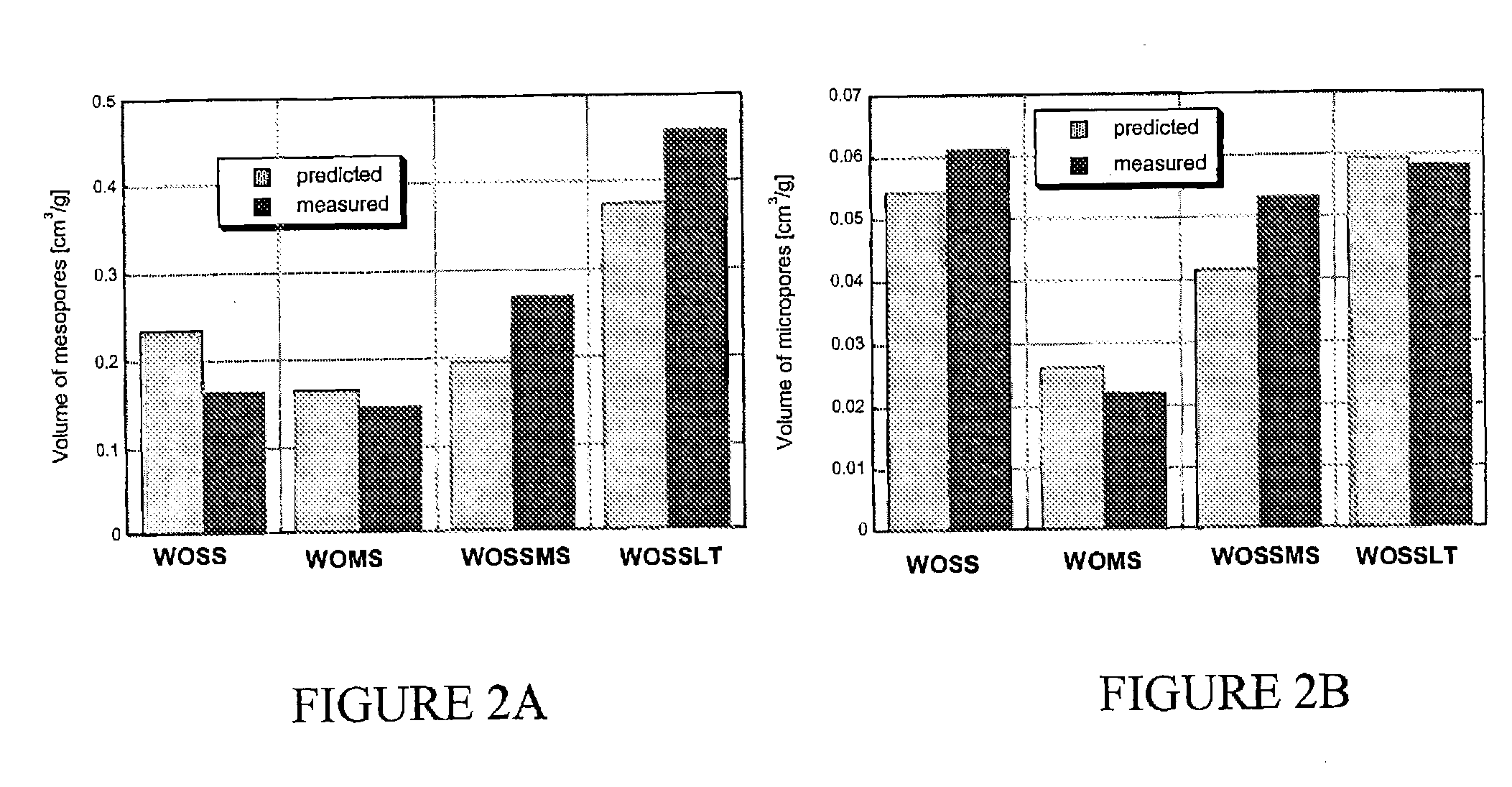

Catalytic adsorbents obtained from municipal sludges, industrial sludges, compost and tobacco waste and process for their production

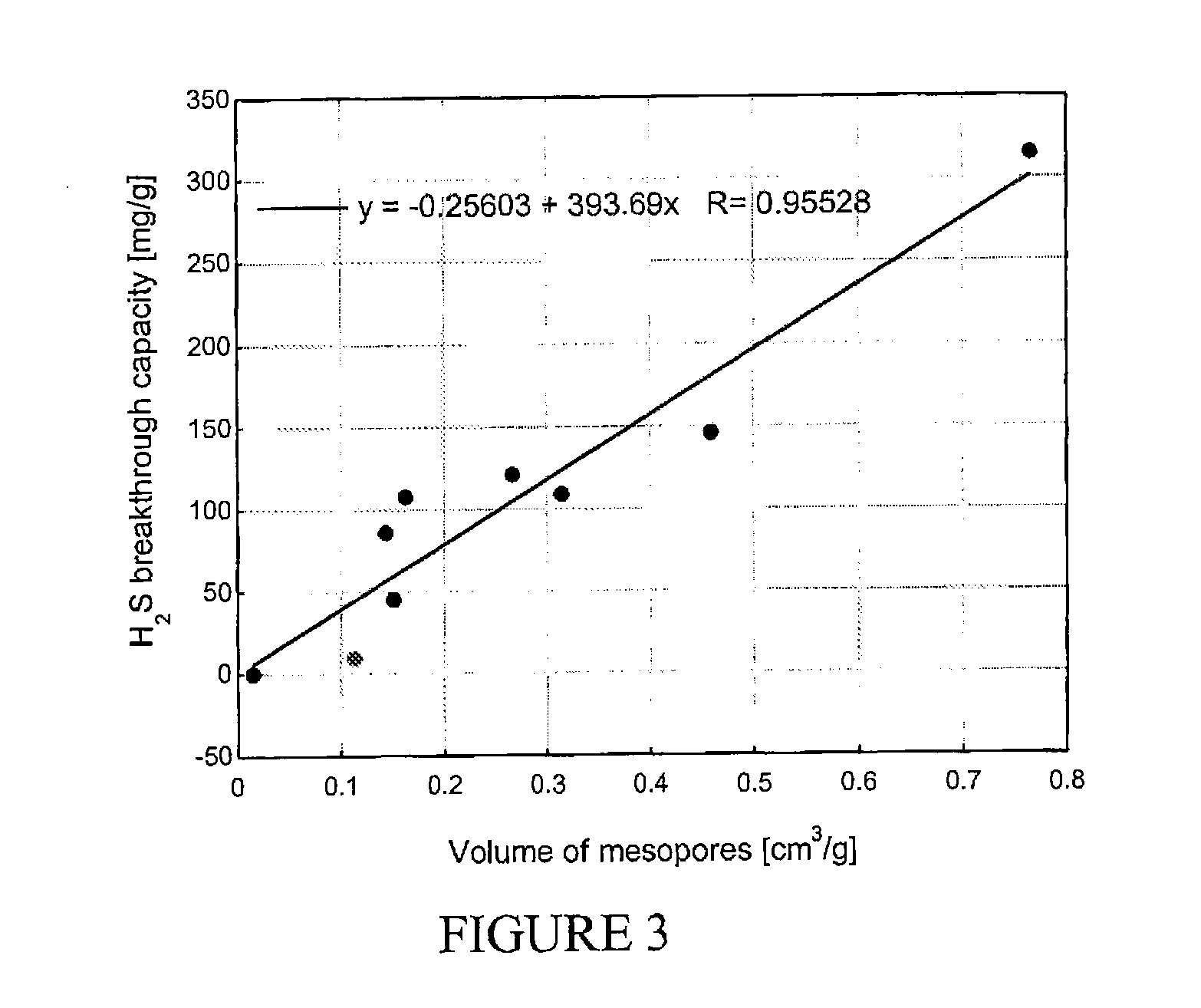

InactiveUS20070113736A1Large capacityQuick removalGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsSorbentSludge compost

Industrial waste derived adsorbents were obtained by pyrolysis of sewage sludge, metal sludge, waste oil sludge and tobacco waste in some combination. The materials were used as media to remove hydrogen sulfide at room temperature in the presence of moisture. The initial and exhausted adsorbents after the breakthrough tests were characterized using sorption of nitrogen, thermal analysis, XRD, ICP, and surface pH measurements. Mixing tobacco and sludges result in a strong synergy enhancing the catalytic properties of adsorbents. During pyrolysis new mineral phases are formed as a result of solid state reaction between the components of the sludges. High temperature of pyrolysis is beneficial for the adsorbents due to the enhanced activation of carbonaceous phase and chemical stabilization of inorganic phase. Samples obtained at low temperature are sensitive to water, which deactivates their catalytic centers.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

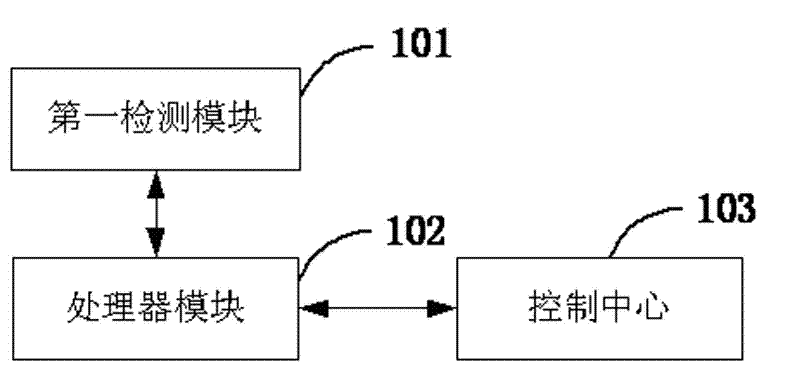

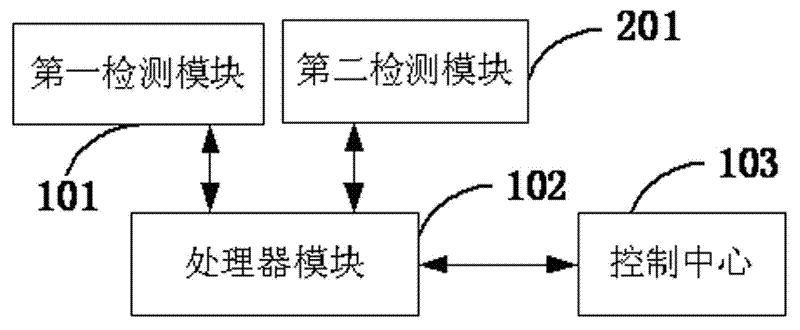

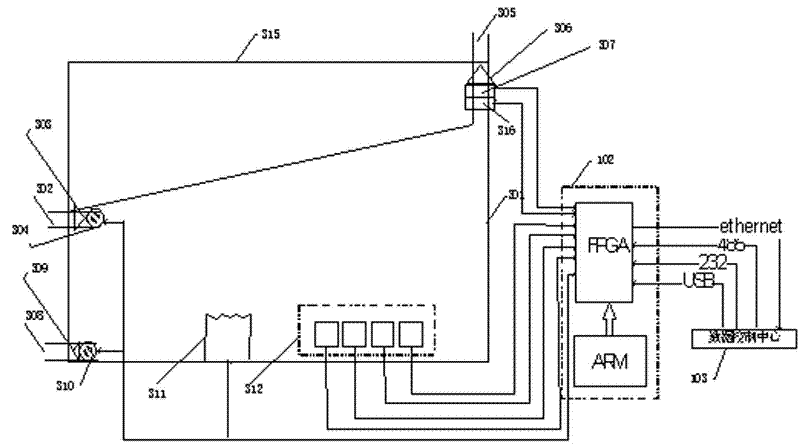

System and method for monitoring liquid oil quality

The invention relates to a system and a method for monitoring liquid oil quality, which makes scientific and effective judgment on the quality of the liquid oil by simultaneously monitoring multiple physical and chemical parameters of the liquid oil. For instance, when being used for monitoring the qulaity of the lubricating oil of a motor, the system can provide scientific and reasonable advice about when to replace the lubricating oil according to multiple quality standards of the lubricating oil as well as monitoring parameters, thereby being capable of prolonging the service lifetime of a motor, reducing the fuel consumption, and and reducing pollution. Moreover, the system avoids unnecessary replacement, prolongs the service lifetime of the lubricating oil, reduces the quantity of waste oil, and accordingly reduces the pollution thus incurred. The system is also significant in monitoring the quality of transmission oil, transmission liquid oil, and hydraulic oil. Therefore, the system and method for monitoring the liquid oil quality are of significance.

Owner:BEIJING ANSAIBO TECH

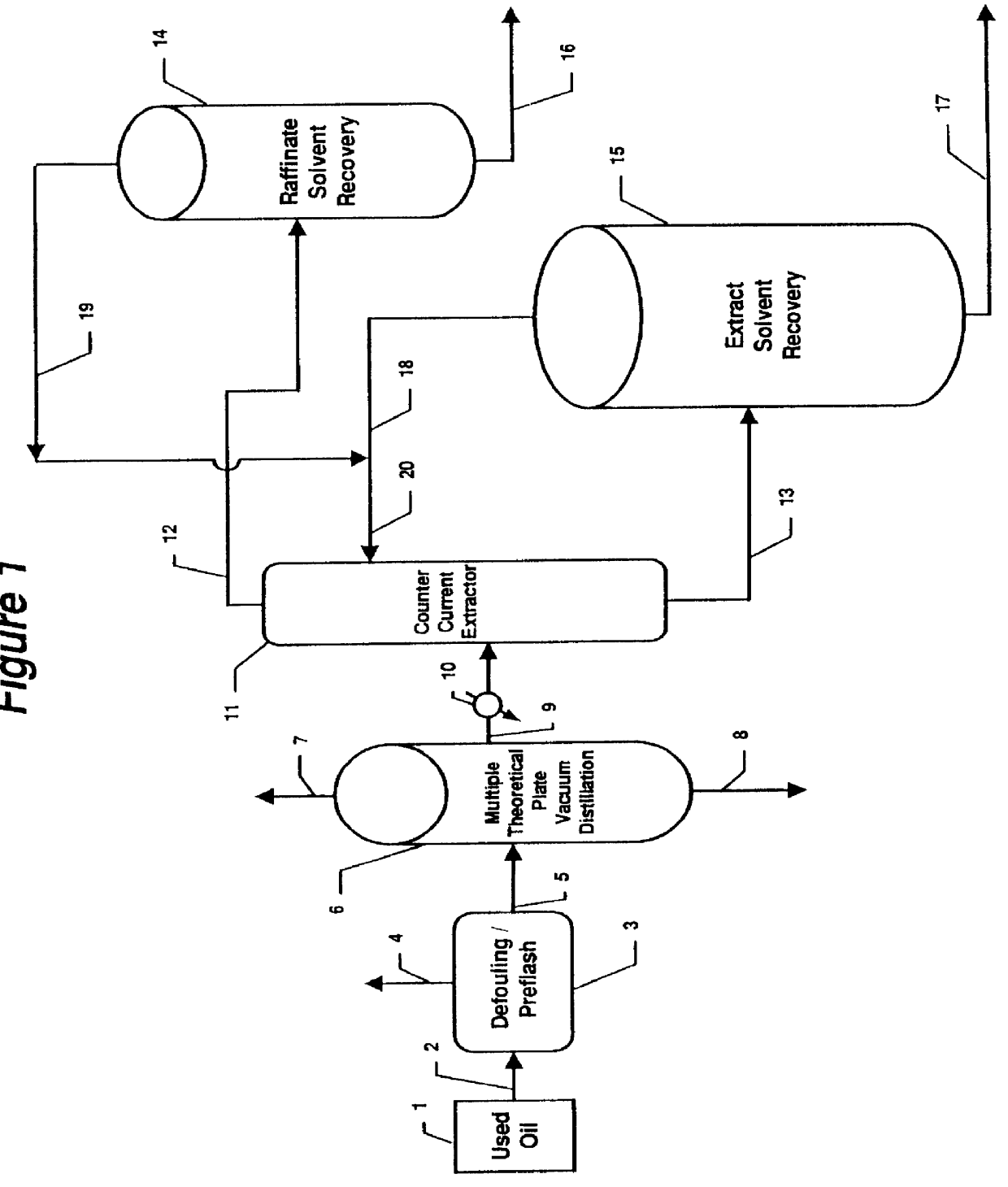

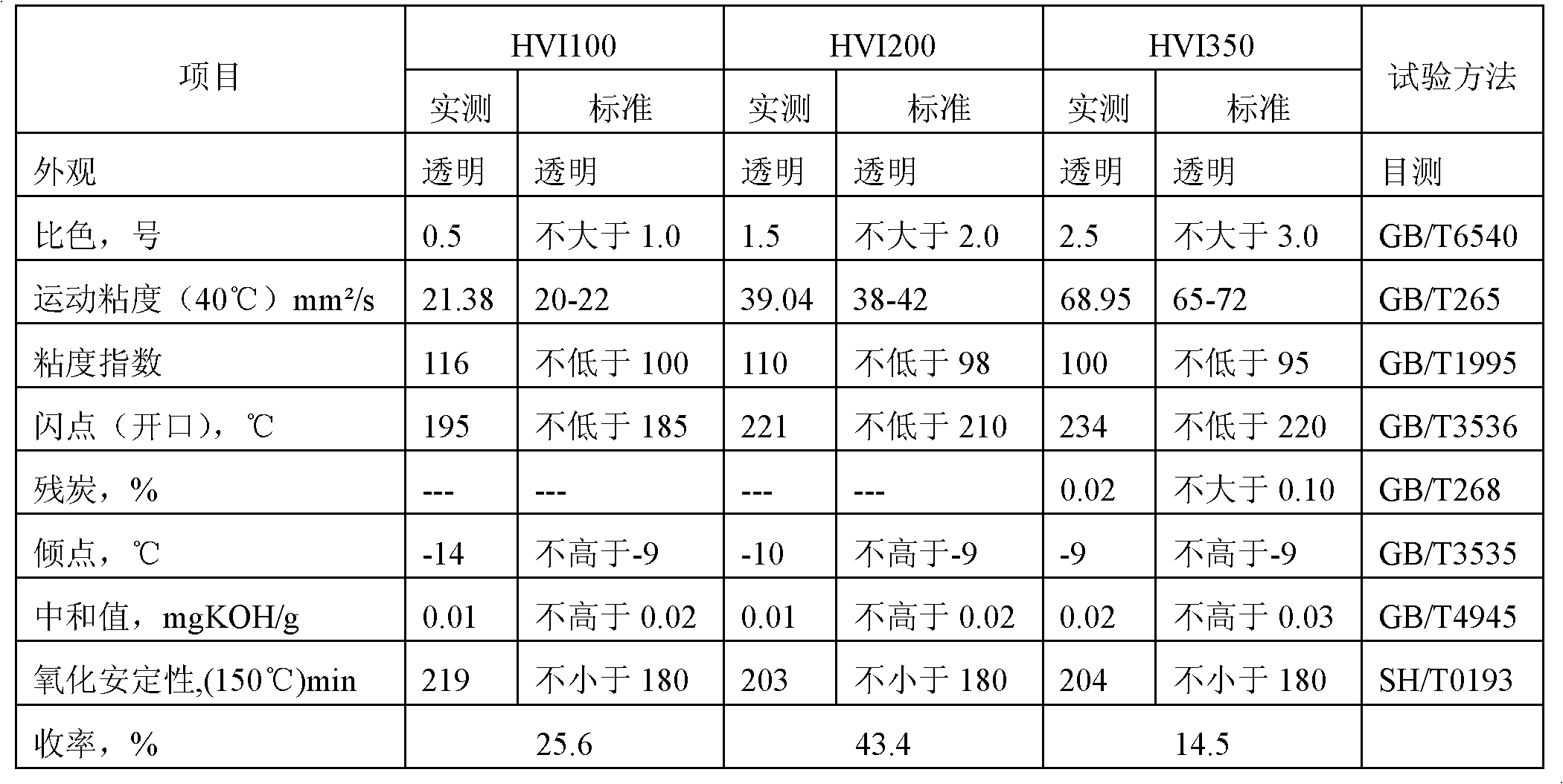

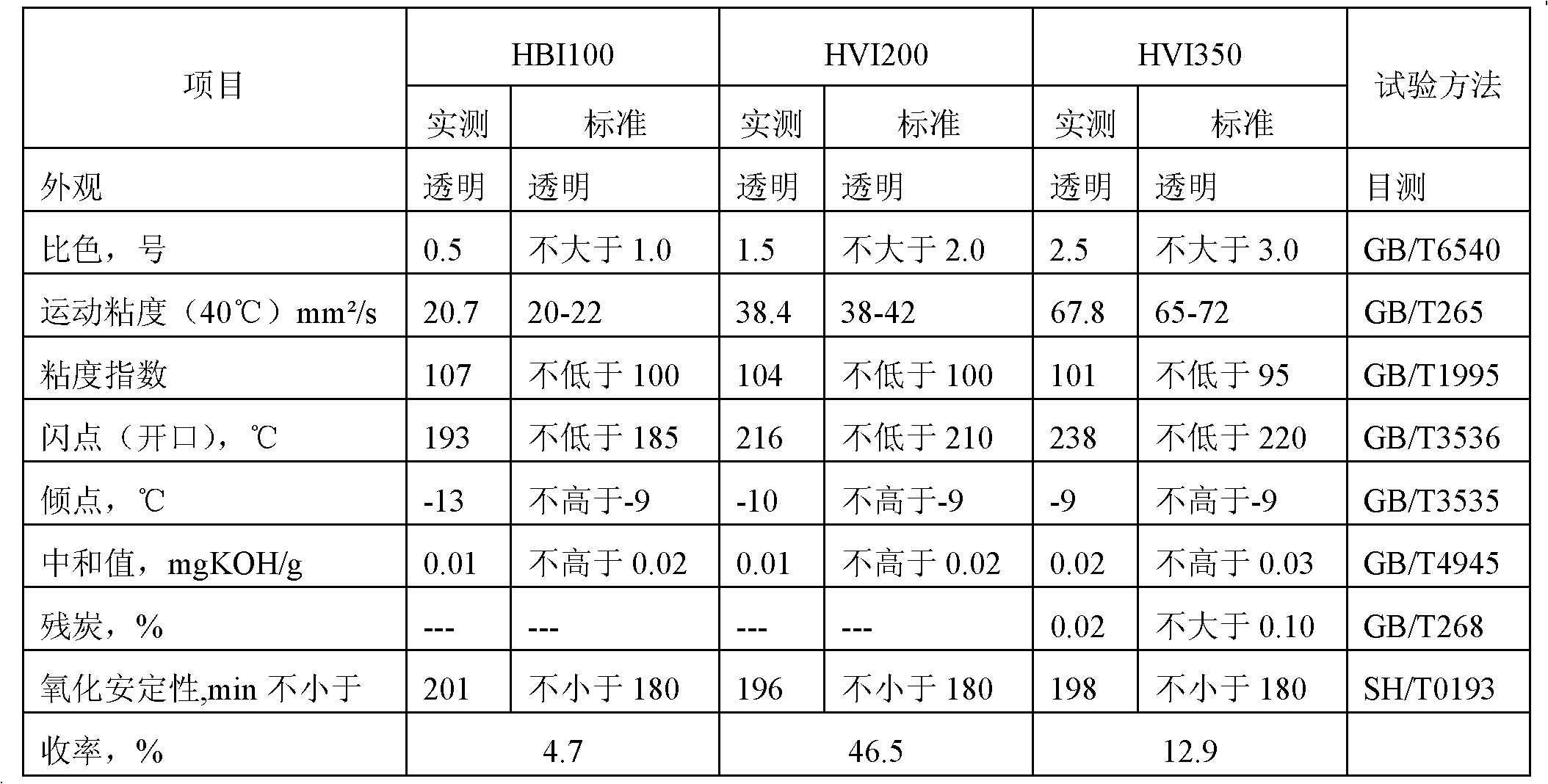

Method of rerefining waste oil by distillation and extraction

InactiveUS6117309AHigh yieldLower the volumeRefining with acid-containing liquidsLubricant compositionTheoretical plateDistillation

Owner:SARP

Regeneration method of waste lubricating oil

InactiveCN102504933ASimple methodFlexible operationTreatment with hydrotreatment processesLubricant compositionWaste oilPre treatment

The invention provides a regeneration method of waste lubricating oil which at least comprises the steps of waste oil pretreatment, short path distillation and hydrofining. Compared with the prior art, the invention has the advantages that the technology is simple, the operation is flexible, no pollution is caused, all the quality indexes of produced lube base oil meet the standard requirements of universal base oil of lubricating oil, and the produced lube base oil can be used for preparing various lubricating oil products. Therefore, the regeneration method of the waste lubricating oil has a wider application range and is more environment-friendly.

Owner:北京耀锋技术开发中心

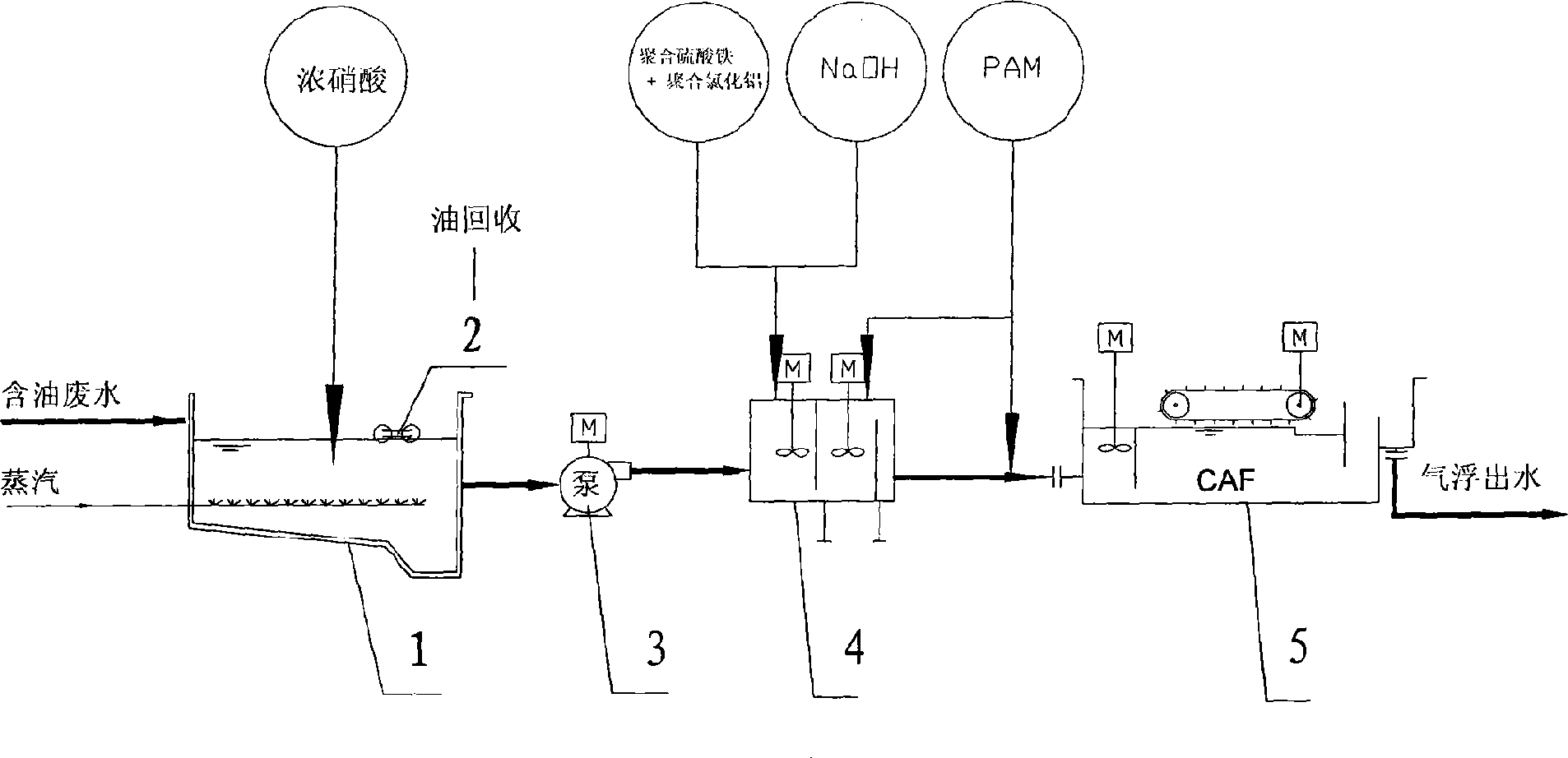

Pretreatment process for oily watewater of cold rolling mill

InactiveCN101475272AHigh recovery rateReduce concentrationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFlocculationHigh energy

The invention relates to a process for pre-treating wastewater containing oil of a cold rolling mill, which solves the problems of poor demulsification effect, high investment, high energy consumption, low recovery rate of waste oil, mass waste residue generation and substandard treated effluent existing in the prior process for pre-treating wastewater containing oil of the cold rolling mill. Recycling of waste oil can be realized through acidification demulsification, oil reclaiming treatment, re-demulsification treatment, flocculation treatment and air floatation separation by steam introduction and the acidification demulsification, so that reclamation rate of the waste oil is improved, energy consumption and investment are reduced, the amount of the waste residue is small, and each index of the pretreated wastewater can be reduced to meet the requirement of secondary treatment so as to greatly reduce the load of the secondary treatment.

Owner:WUHAN IRON & STEEL (GROUP) CORP

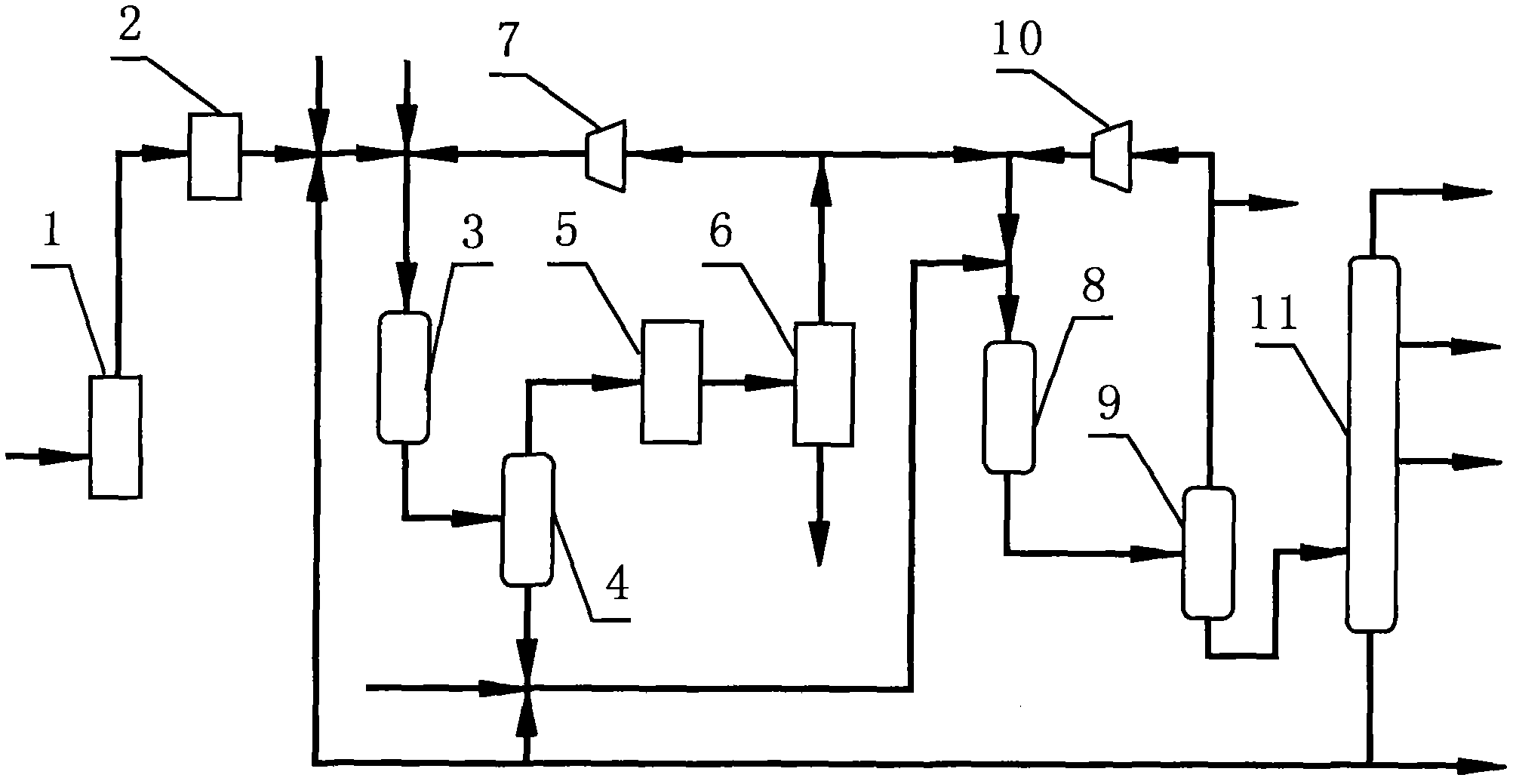

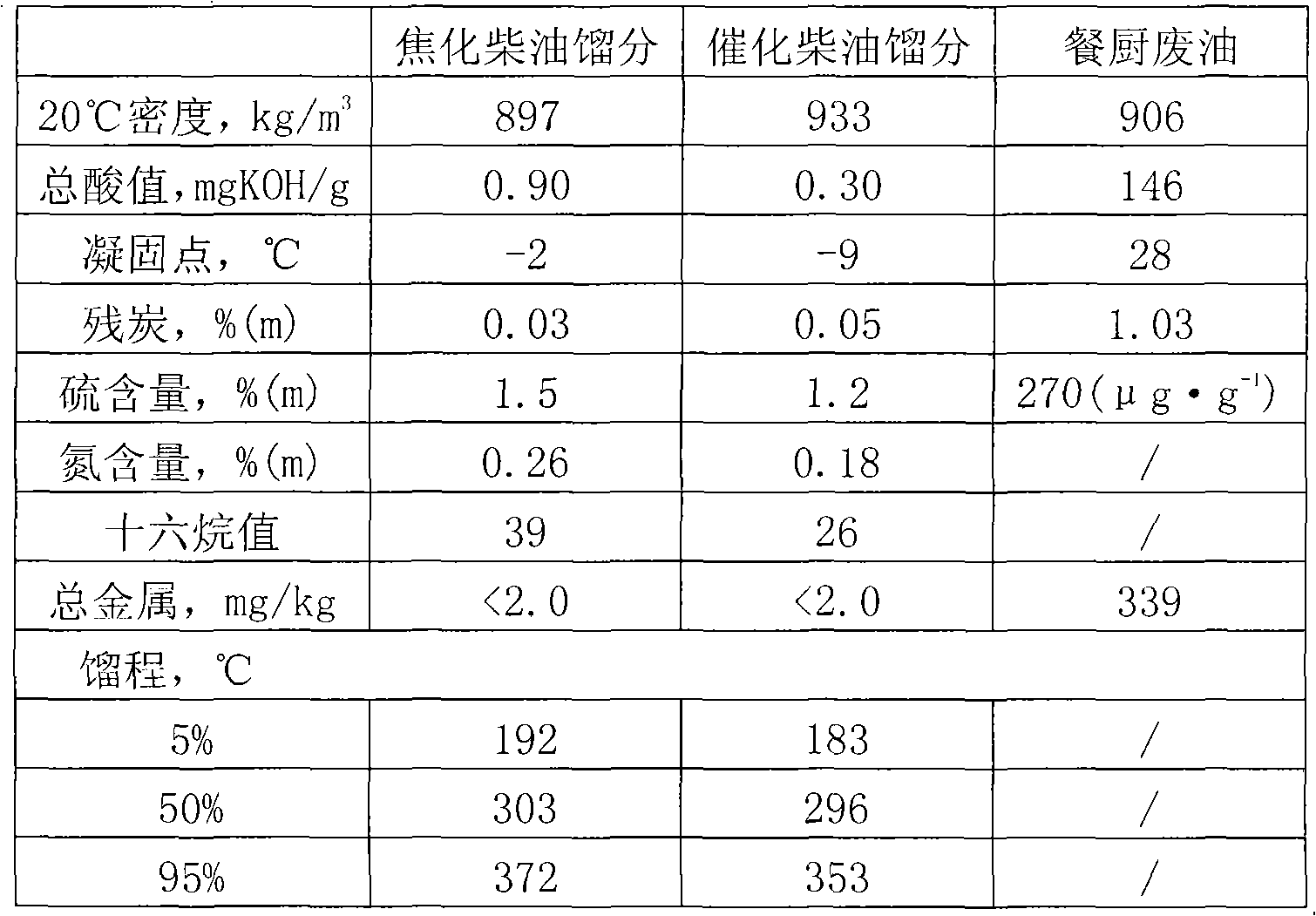

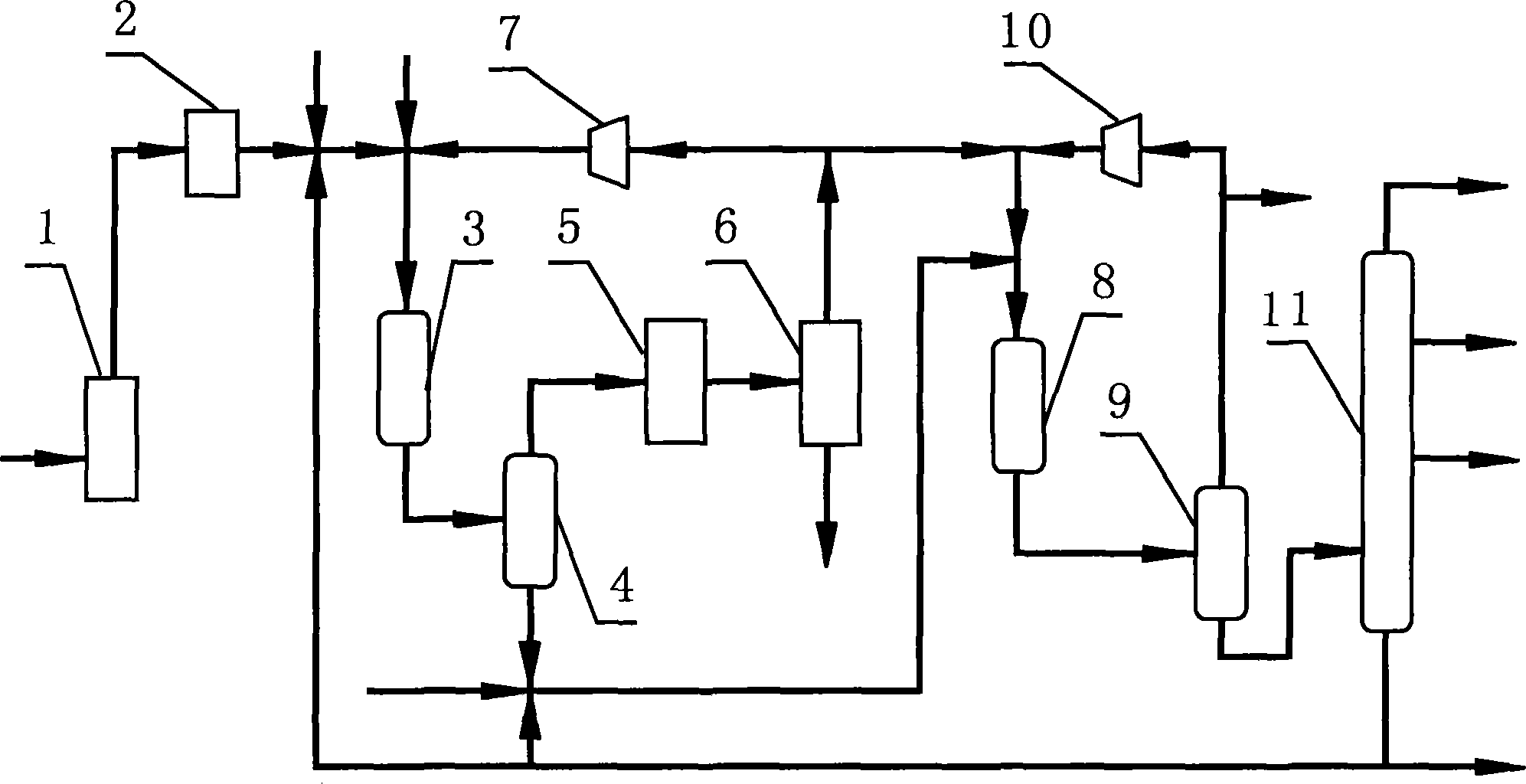

Method for preparing biodiesel by mixing waste edible oil with mineral diesel oil and hydrogenization

ActiveCN102504866AHigh activityConcentration effective controlBiofuelsEfficient propulsion technologiesOil and greaseVegetable oil

The invention relates to a method for preparing biodiesel by mixing waste edible oil with mineral diesel oil and hydrogenization. The method comprises the steps as follows: pretreatment of waste edible oil, a first stage of hydrogenization process, a second stage of hydrogenization process, and a product fractionation process. The method adopts the waste edible oil and the mineral diesel oil as raw materials for preparing high-quality biodiesel and biological aviation kerosene components which have low polycyclic aromatic hydrocarbon contents, high cetane values, low sulfur contents and low nitrogen contents, effectively solves the problems of blockage of a catalyst bed caused by the settlement of metal and gelatine in the animal and vegetable hydrogenization process, influence on the activity of catalyst from H2O, CO2 and CO produced in reaction, sulfur supplement of a hydrogenization system, and influence on the service life of the catalyst caused by centralized release of reaction heat, can realize the continuous hydrogenization and industrial production of materials containing animal and vegetable oils, and has practical significance.

Owner:海南环宇新能源有限公司

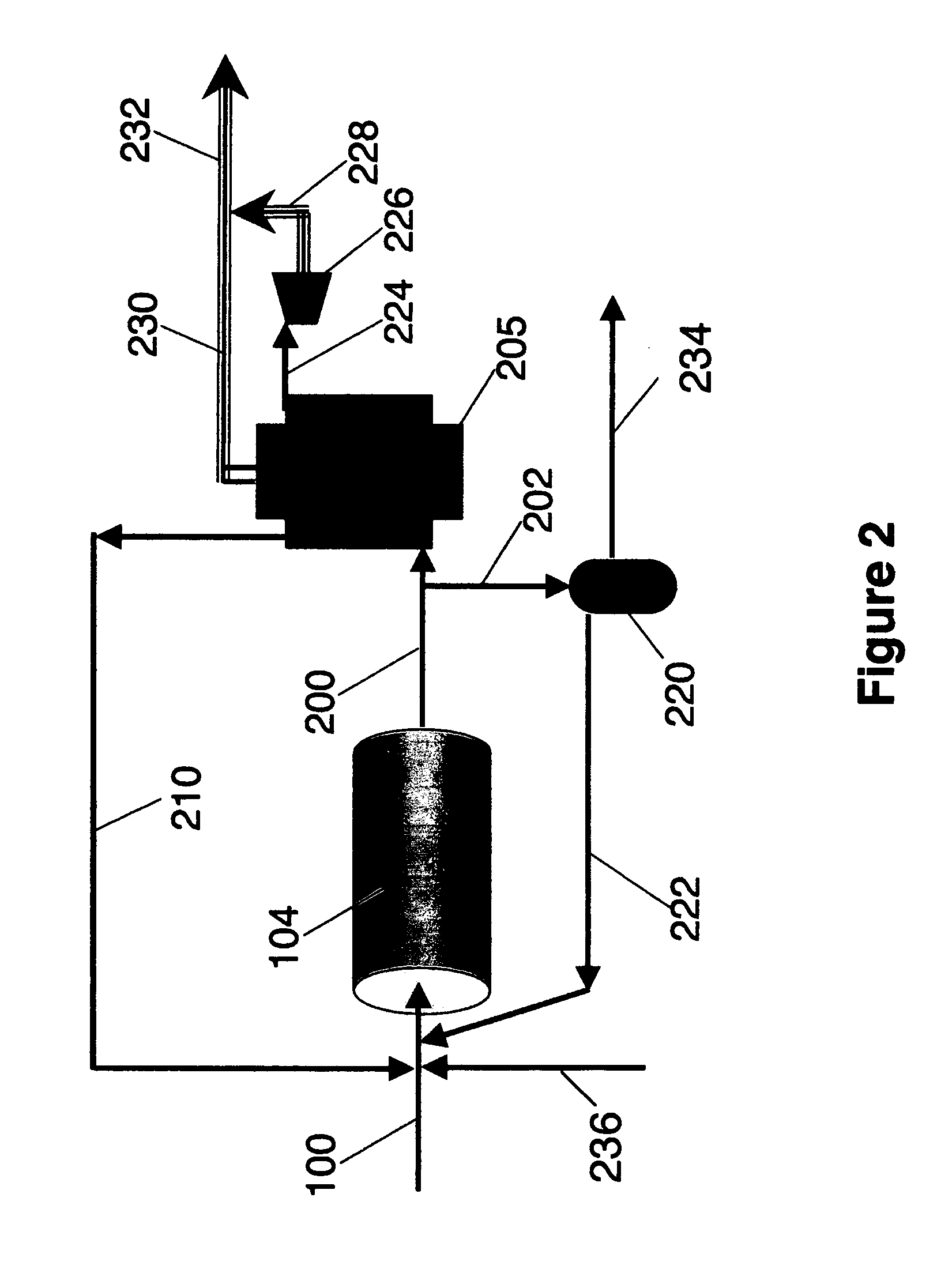

Hybrid thermal process to separate and transform contaminated or uncontaminated hydrocarbon materials into useful products, uses of the process, manufacturing of the corresponding system and plant

ActiveUS20160053184A1Increase volumeReduce contentThermal non-catalytic crackingChemical/physical/physico-chemical reactor detailsChemical compoundWaste oil

Process for reclaiming useful products from a waste oil, comprising a thermal separation step performed in a vessel at conditions, of temperature and pressure, allowing to substantially avoid cracking of the waste oil and to assure the separation of said heated waste oil into a first heavy oil fraction and into a second light oil fraction having, in comparison with the waste oil, a low content in solids and / or in other contaminants that are different from water and from inert gas. The process is further characterized in that while, during the thermal separation treatment, the waste oil is heated to a temperature about the boiling temperature of the heavy oil fraction, and below the cracking temperature of the waste oil, and at a pressure that is preferably below the atmospheric pressure, the heavy oil fraction of the vapours existing the vessel, in contact with a cooler surface, condenses and falls back into the vessel, while the second fraction, in a gaseous state, is eventually submitted to at least one further separation treatment. When water is present in the waste oil, said water is used to improve the amount of recovered light oils; and / or when no water is present in the waste oil, water or at least one inert gas or at least one component that may become an inert gas by heating may be added to the waste oil or to the thermal separation unit. Uses of the process for environmental applications and for treating used oils and to prepare oil products. Systems for reclaiming useful products from waste oils comprising at least one rotating kiln and at least one self-refluxing condenser and / or at least one dephlegmator.

Owner:ENVIROLLEA

Oil-water separator

ActiveCN103663851ASolve environmental problemsReduce processing linksFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSlagSludge

The invention discloses an oil-water separator comprising a water inlet, a water outlet, a container, a movable filter residue bucket, a fixed filter net, an oil storage area, a vortex shallow filter, a sludge bucket, an electronic integration controller, an oil suction port, a slag suction port and a biological filter disc, wherein the fixed filter net finely filters the wastewater; an oil drop of which the diameter is 10-100 microns is separated and ascended to the oil storage area in the vortex shallow filter; the sludge bucket concentrates the waste residue; the waste residue descends to the bottom of the sludge bucket to be gathered under the effect of gravity after participating on the sludge bucket; the oil suction port is used for absorbing oil; the slag suction port is used for absorbing the slag; the biological filter disc is used for discharging the residual sewage. By adopting the oil-water separator, the environment-friendly problem of emission of restaurant waste water is solved, so that the discharged water achieves the corresponding national emission standards, the congestion problems of drainage pipelines caused by waste oil wall built-up are solved, separated excessive oil impurities are solved, and the processing link of restaurant waste oil in specified use is reduced.

Owner:CLEAR SUZHOU ENVIRONMENTAL TECH CO LTD

Method for preparing biodiesel by utilizing food waste recycling oil

ActiveCN101906355AReduce manufacturing costImprove pollutionFatty acid esterificationBiofuelsBiodieselGlycerol

The invention relates to a method for preparing biodiesel by utilizing food waste low-cost high-efficiency recycling oil, which is realized by four steps of dining waste oil degumming and impurity removing treatment, acid catalytic esterification reaction, base catalytic transesterification reaction and biodiesel refining. The final product is colourless biodiesel, and all performance indexes can reach the European and American biodiesel quality standard. The invention has the advantages of low production cost, high conversion rate and less pollutant discharge and overcomes the defect of preparation by a single method. When the biodiesel is produced, by-products comprise glycerol and methanol.

Owner:北京昊业怡生科技有限公司

Method and apparatus for burning oils of varying viscosity

InactiveUS6132203AEfficient combustionPrevents possibility of fire and explosionLiquid fuel feeder/distributionSpraying apparatusHeating oilCombustor

Disclosed is an oil burning system that is capable of burning oils of varying viscosities, including high viscosity waste oils and low viscosity heating oils. Suitable as a new installation or a retrofit modification, the present invention incorporates the use of a variable rate, high-pressure oil delivery system, along with an oil pre-heater, in conjunction with a modified high-pressure atomizing nozzle. Installed in a sliding drawer burner arrangement that allows for quick and easy access, the oil burning system also includes a means by which particulate matter and carbonization build-ups are removed from the burner nozzle automatically, thereby eliminating the need for frequent cleaning.

Owner:MASIN RADEK

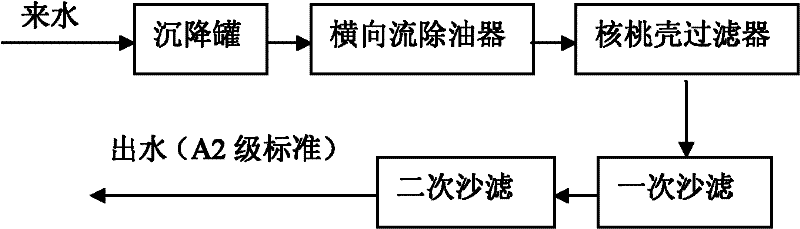

Membrane treatment process for oilfield reinjection water

ActiveCN102225812ATake full advantage of the characteristicsGive full play to the filtration precisionFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisConcentration ratioUltrafiltration

The invention relates to a membrane treatment process for oilfield reinjection water, which comprises the specific steps of: firstly introducing oil-containing wastewater into a settling tank for naturally settling to remove part of large suspended solid granules and waste oil; directly introducing the settled water into a ceramic membrane ultrafiltration device for internal circulating filtration, directly using the liquid penetrating through the membrane for reinjection, introducing the circulating liquid containing large amounts of suspended solid granules and waste oil which do not penetrate through the membrane into the settling tank for continuing settlement, mixing with inflow water and introducing into the ceramic membrane ultrafiltration device for filtration again; automatically discharging pollutants when the wastewater in a circulation tank reaches a certain concentration ratio; and automatically adjusting the membrane surface flow rate of an online detection device according to the inflow water quality conditions, so as to achieve the purpose of energy conservation. The membrane treatment process provided by the invention has the advantages of simple process, low investment cost, high filtering precision, no need for the introduction of any reagents during the treatment process, no secondary pollution, etc.

Owner:JIANGSU JIUWU HITECH

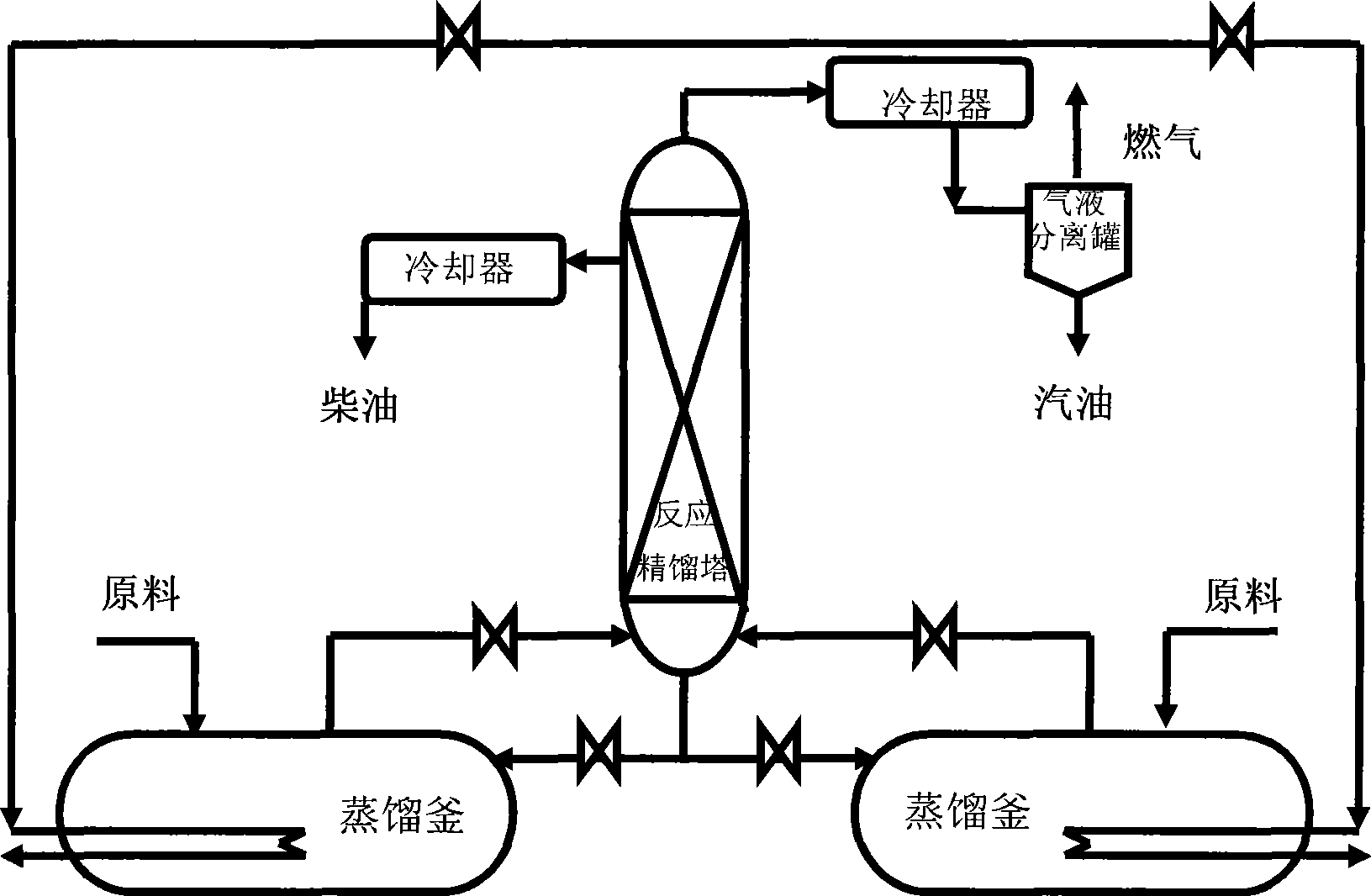

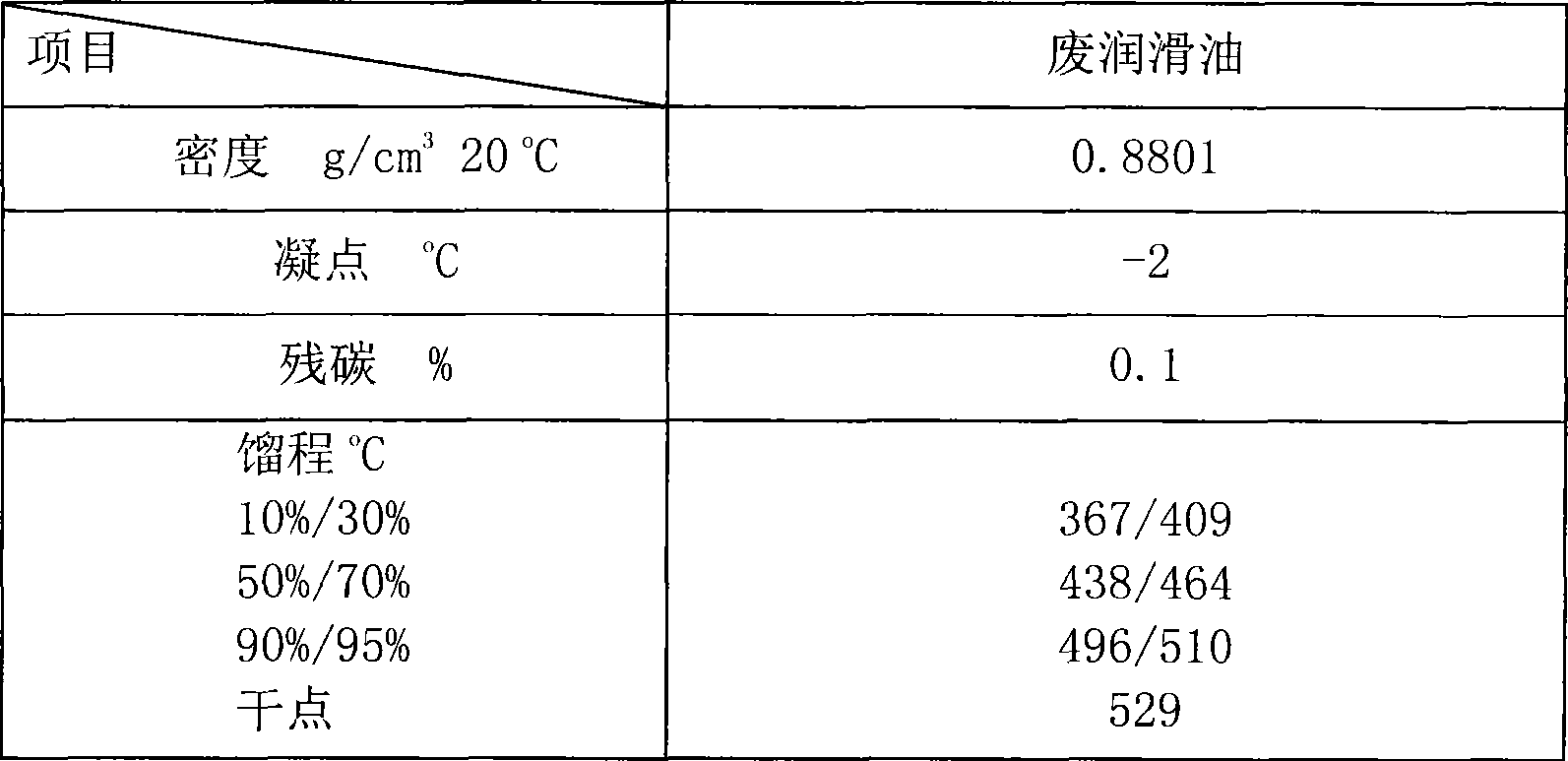

Method for producing petrol and diesel oil by recycling waste lubricant oil

ActiveCN101475870ASimple processLow costHydrocarbon distillationLubricant compositionDistilled oilGas phase

The invention relates to a method for producing gasoline and diesel fuel through resource utilization of waste lubricant oil, which belongs to the technical field of environmental protection and energy resources. The method comprises: integrally performing the vapor phase catalytic cracking process on molecular sieve / alumina catalyst of the waste lubricant oil and the fractionation and separation process of reaction products in a reaction fractionator; injecting crude waste oil into a distillation kettle, and adopting waste residue and fuel gas generated during conversion of the waste lubricant oil for heating, wherein the temperature of the distillation kettle is controlled to be between 250 and 500 DEG C; making distilled oil gas enter the reaction fractionator which is filled with the molecular sieve / alumina catalyst for reaction and rectification when the distillation kettle is heated to 250 DEG C, wherein the ratio of the catalyst to oil is controlled to be between 1 and 20; and cutting the oil into the gasoline and the diesel fuel according to the distilled temperature, wherein fuel gas generated by reaction and residual cinder can be used for heating the distillation kettle, and generated fuel gas can be used for heating the distillation kettle. The method has the advantages of wide range of raw materials, normal-pressure reaction and separation, simple technological flow, high conversion and selectivity of products, long service life of the catalyst, comprehensive utilization of the fuel gas and the cinder, no secondary pollution, large operating flexibility of a production apparatus, and small investment.

Owner:DALIAN UNIV OF TECH

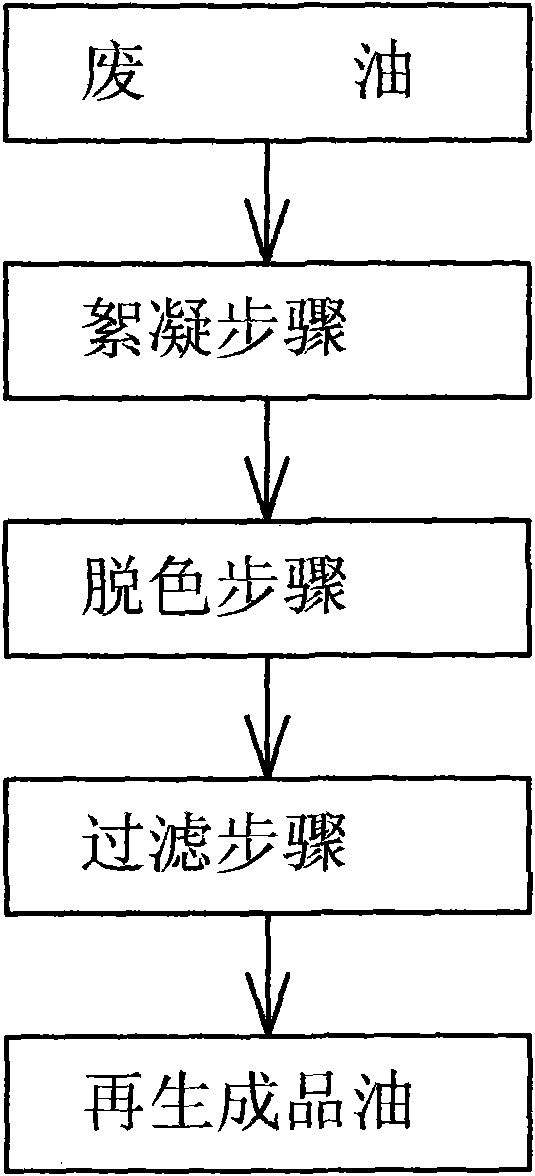

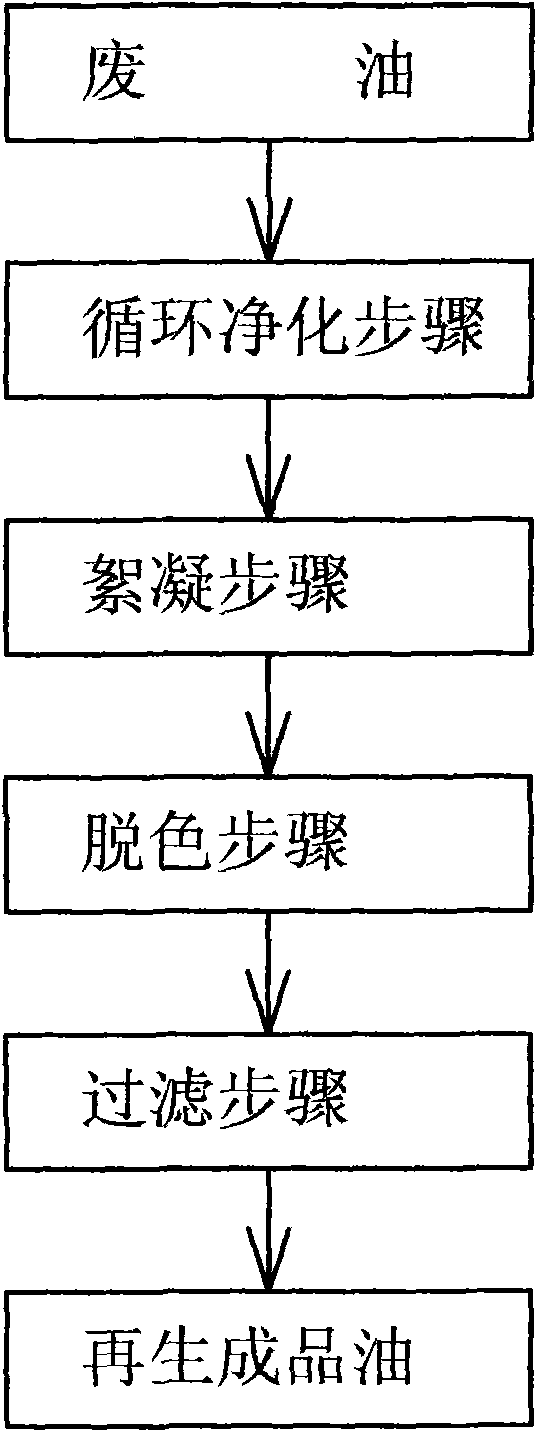

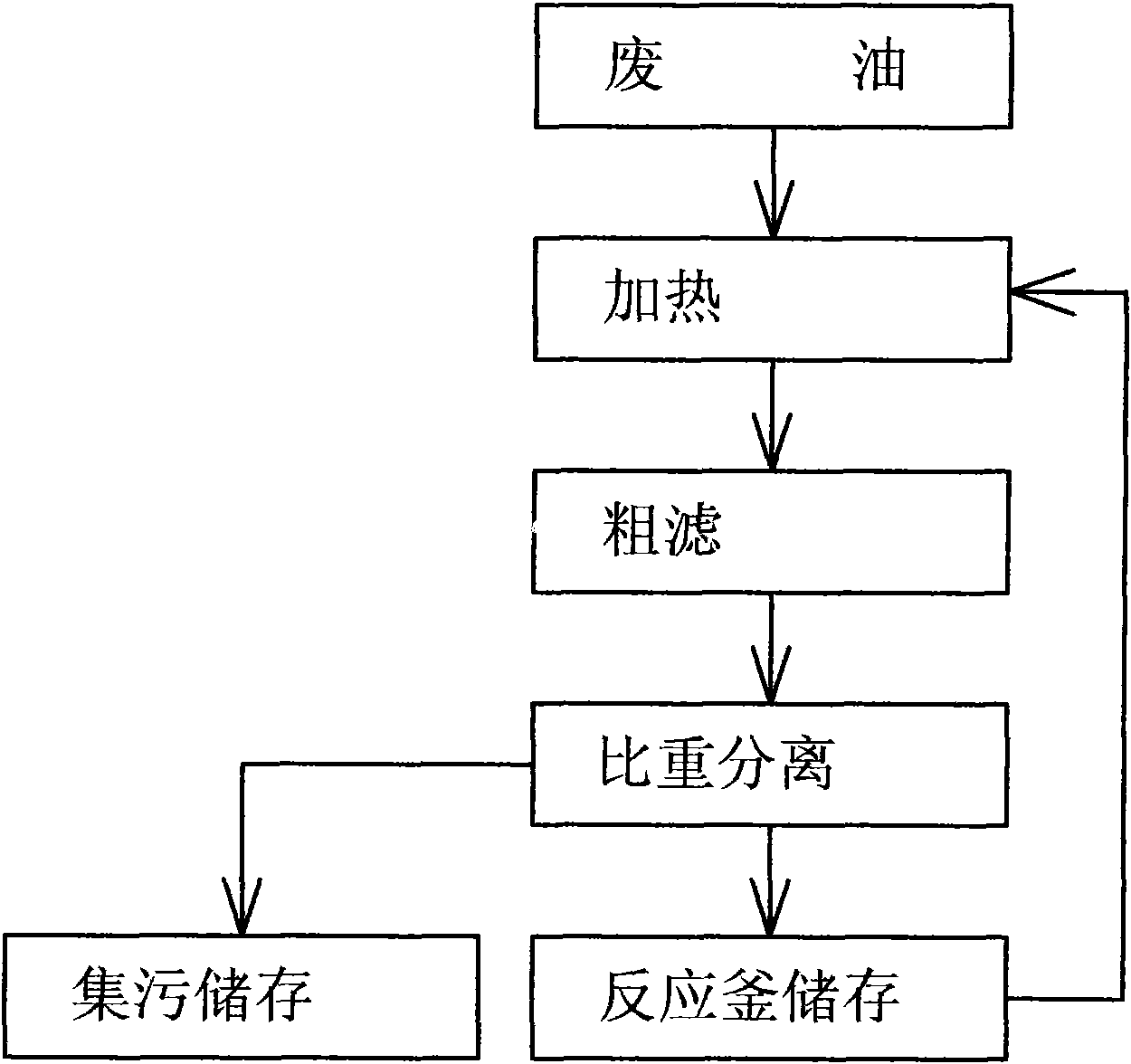

Acid and alkali free quick regeneration method for waste oil

InactiveCN101597541AShorten the timeLow costTreatment with plural serial refining stagesLubricant compositionFlocculationAlkali free

The invention discloses an acid and alkali free quick regeneration method for waste oil, which comprises the steps of: flocculation, namely adding the waste oil into a reaction kettle, adding activated clay which accounts for 0.5 to 2 percent of the weight of the oil and cationic-type polyacrylamide which accounts for 0.1 to 1 percent of the weight of the oil into the oil, stirring the mixture for 10 to 30 minutes, standing and precipitating the mixture for 60 to 180 minutes, and removing oxidation residue and a precipitate from the bottom of the reaction kettle; decolorization, namely addingthe activated clay which accounts for 3 to 12 percent of the weight of the oil into the flocculated oil in the reaction kettle, and stirring the mixture for 10 to 30 minutes; and filtration, namely pumping the decolorized oil into a filter for filtration to obtain regenerated product oil. The acid and alkali free quick regeneration method for the waste oil has the advantages that: 1, acid and alkali do not need to be added when the waste oil is regenerated; 2, the regeneration of the waste oil has short time and only needs 1 to 6 hours; 3, the regeneration of the waste oil has low cost, and one ton of the regenerated product oil only needs 180 to 250 yuan; 4, the regenerated oil has good quality; and 5, the regeneration of the waste oil has good working environment and low power consumption, and has promotion value.

Owner:豆远奎

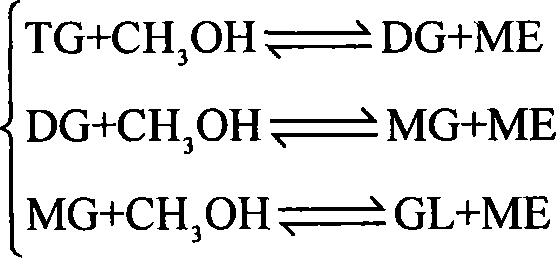

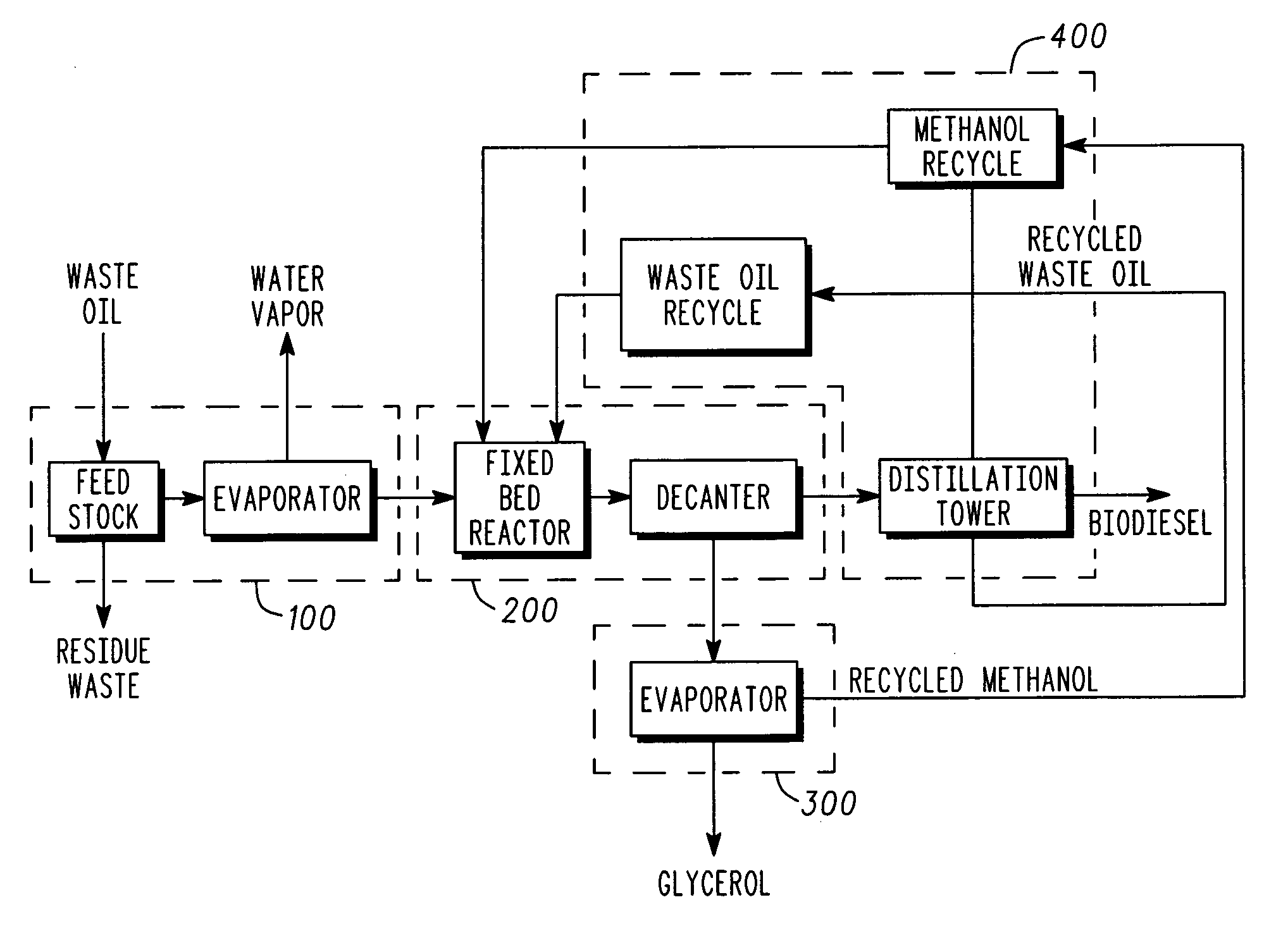

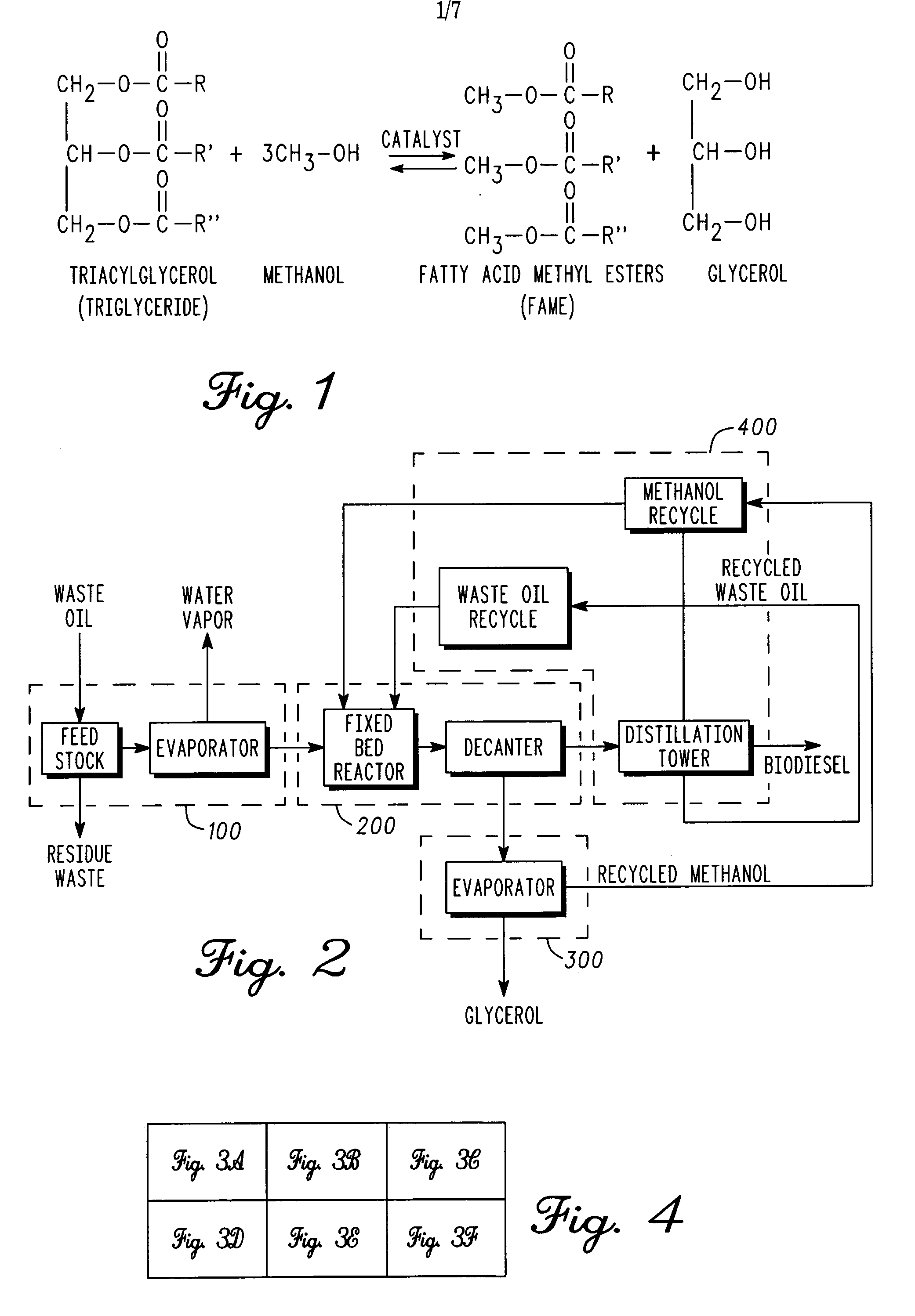

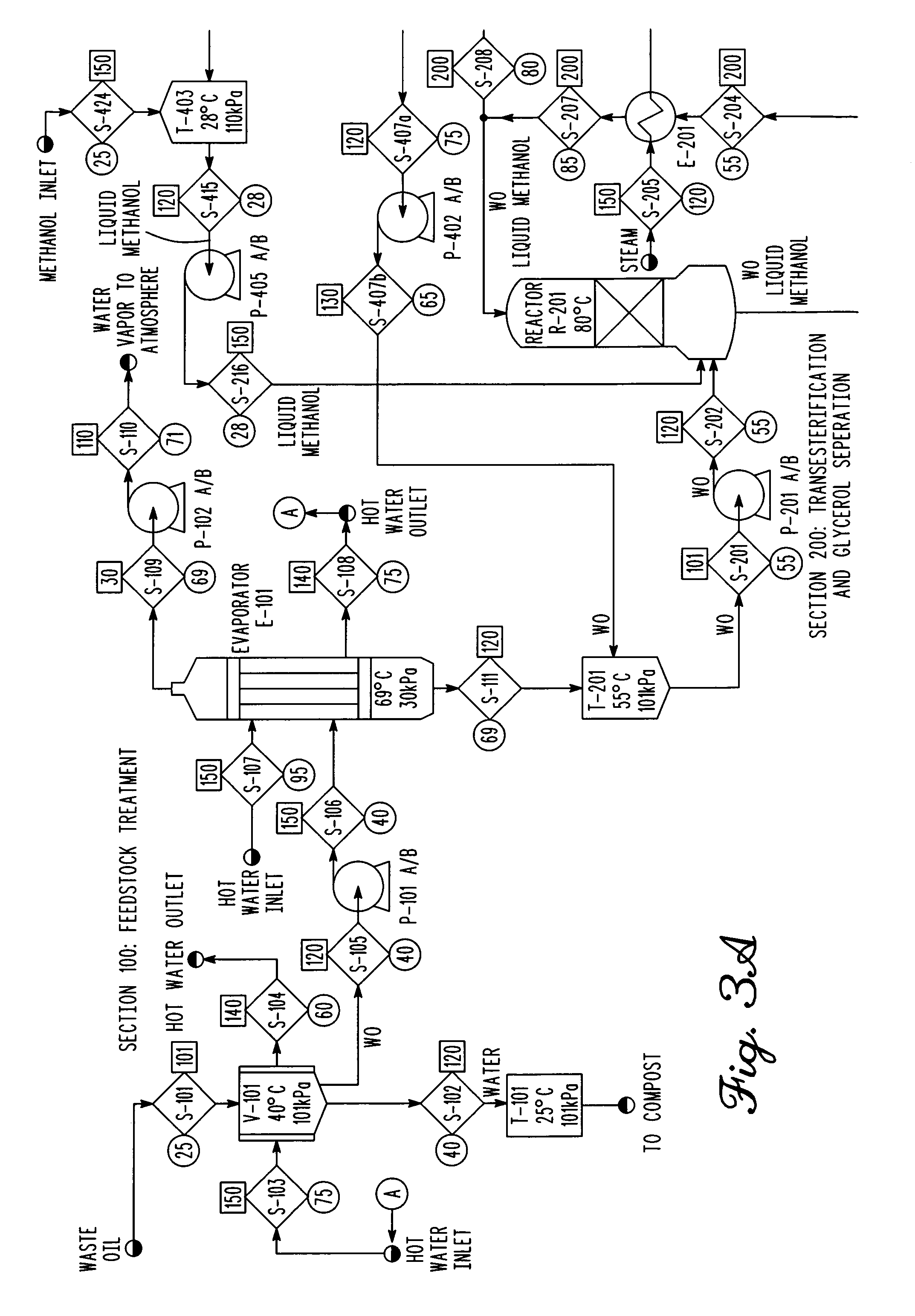

System and process of biodiesel production

ActiveUS20100166620A1Optimizing overall efficiency of processMinimal negative impactFatty acid esterificationBiofuelsTransesterificationGlycerol

A system and process for continuous production of fatty acid methyl esters (FAME) from the fatty acid triglycerides of waste oil via transesterification in the presence of a reusable sugar-based catalyst. The system and process incorporates re-cycling and re-use of waste bi-product streams to result in a near-zero emissions, with a 97% product yield mix consisting of almost pure biodiesel and a very small percentage of impurities including glycerol.

Owner:GURSKI STEPHANIE MARIE +3

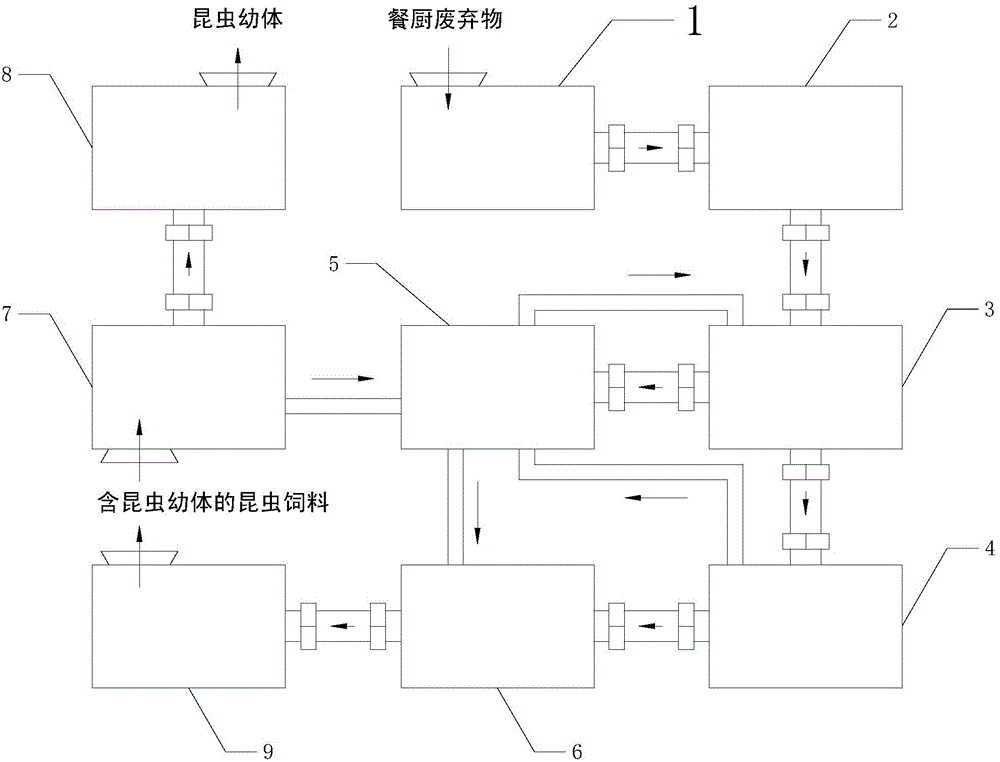

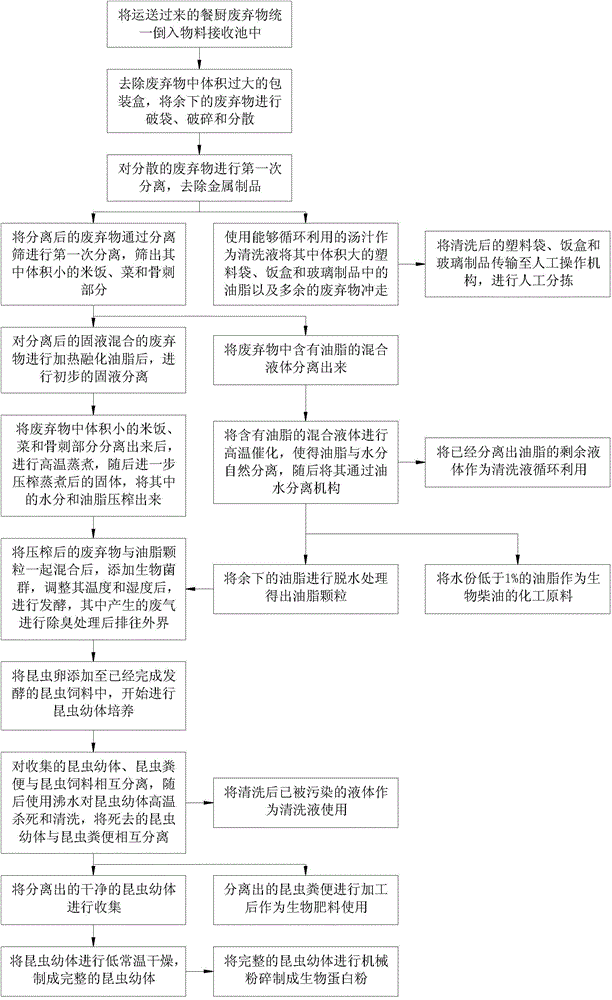

Insect treatment system of kitchen waste and method thereof

ActiveCN104384177AImprove efficiencyReasonable structureSolid waste disposalAnimal husbandryLiquid wasteWaste oil

The invention relates to a kitchen waste biological treatment system, and discloses an insect treatment system of kitchen waste. The insect treatment system of kitchen waste comprises a material receiving tank, a pretreatment device, a separation device, a stewing and squeezing device, a waste oil treatment device, a preservative device, an insect cleaning device and an insect drying device for processing collected insect larva further. The insect treatment system of kitchen waste, which is provided by the invention, is reasonable in structure, and the separated waste liquid part acts as a cleaning liquid for cleaning waste, so that not only can the waste liquid after fat separation be effectively applied to the operation process of the system, but also the waste liquid can be recycled, and the use efficiency of waste is improved greatly; meanwhile, multiple air blowing-air inducing mechanisms are adopted for cleaning the insect larva, so that an insect feed can be completely separated away from the insect larva, and thus the quality of the prepared insect larva can be improved, and moreover, insect excrement can be extracted individually to act as a biological fertilizer, and the actual use effect of the treatment system is improved.

Owner:JIAXING SUYUAN BIOTECH

Method for treatment of waste emulsion

InactiveCN101792239AEasy to separateSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentElectrolysisWaste oil

The invention discloses a method for the treatment of waste emulsion, more particularly a method for the treatment of waste emulsion generated in the machining processes such as cutting, grinding and the like. The method comprises the following steps: separation of stored emulsion breakers, mechanical air flotation, ion-carbon electrolysis, coagulating sedimentation, oil separation with inclined plate, microorganism purification, sedimentation, sand filtering, etc.; the method has the advantages of simple technology and standard-reaching wastewater, and devices for the implementation of the method have small floor area, little investment, low running cost, low energy consumption, maximal recycling of waste oil resource and prominent operability and is widely suitable for machining and the treatment of waste emulsion in other industries. The waste oil recycled according to the method is completely capable of being used for the production of patented product, the protective grease, thus idealized application of resources is achieved.

Owner:成都蜀光石油化学有限公司

Method for detecting waste oil in qualified edible oil

InactiveCN101387612AImprove applicabilityEasy to operatePreparing sample for investigationMaterial resistanceWaste oilOrganic matter

The invention relates to a method for checking the waste oil of qualified edible oil, which utilizes food residue of catering trades as raw material and utilizes the processes of degumming, alkali refining, dewatering, decolorizing and deodorizing and the like to obtain refined waste oil. Since the waste oil is generated by adding the flavorings as salt and gourmet into cooked qualified edible oil, and the organic matter in cooking will decompose and generate ionize matters to improve the conductivity, the conductivity of water phase can be measured after the extraction of deionized water, the test result can be compared to judge if the qualified edible oil is doped with waste oil. The method has high practicality and simple operation.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com