Membrane treatment process for oilfield reinjection water

A technology for oil field re-injection and treatment process, applied in the field of oil-field re-injection water treatment, can solve the problems of complex composition of oil field produced water, failure to reach the water injection precision of ultra-low permeability oil layers, complex treatment process, etc., and achieve one-time investment reduction and simplification The effect of re-injection process and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

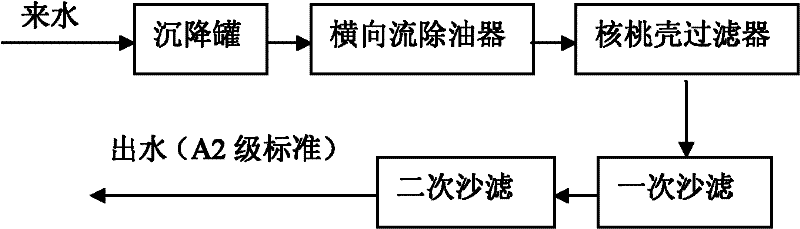

[0031] Such as Figure 6 Shown, a kind of oilfield reinjection water membrane treatment process comprises the following steps:

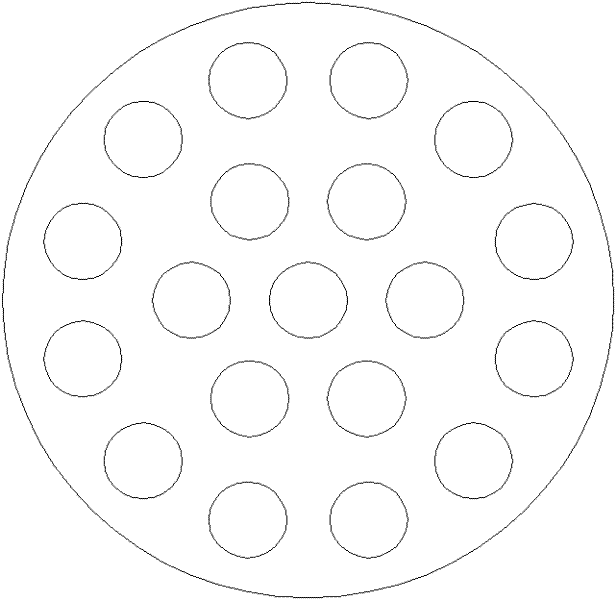

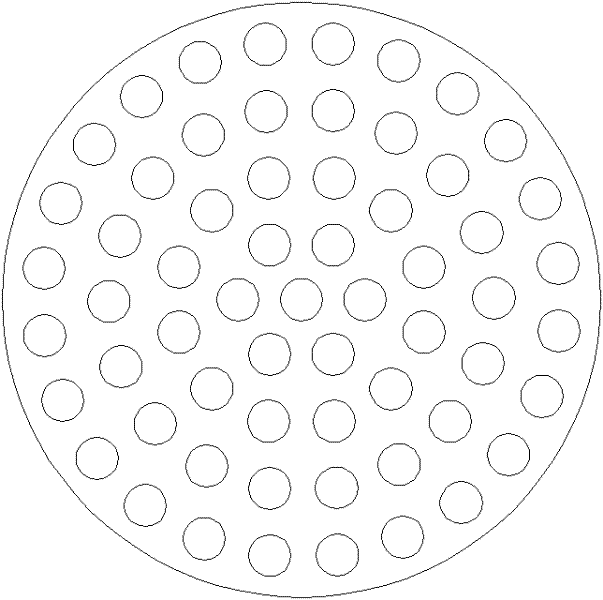

[0032] (1) After the oily sewage is naturally settled to remove most of the suspended solids and oil, it is input into the circulation tank, and then enters the ceramic membrane equipment through the feed pump and the circulation pump in turn. On-line detection equipment is installed at the water inlet of the ceramic membrane ultrafiltration equipment to realize on-line monitoring of the incoming water quality, and automatically adjust the frequency of the circulating pump according to the change of the incoming water quality to change the flow rate of the membrane surface. In this embodiment, the incoming water oil content is 15.3mg / l, and the ceramic membrane in the ceramic membrane equipment is a high-flux ceramic membrane (such as figure 2 As shown), the ceramic membrane adopts symmetric or asymmetrical film formation with an average pore diame...

Embodiment 2

[0035] Such as Figure 6 Shown, a kind of oilfield reinjection water membrane treatment process comprises the following steps:

[0036] (1) After the oily sewage is naturally settled to remove most of the suspended solids and oil, it is input into the circulation tank and then enters the ceramic membrane equipment through the feed pump and the circulation pump in turn. On-line detection equipment is installed at the water inlet of the ceramic membrane ultrafiltration equipment to realize on-line monitoring of the incoming water quality, and automatically adjust the frequency of the circulating pump according to the change of the incoming water quality to change the flow rate of the membrane surface. In this embodiment, the incoming water oil content is 53.1mg / l, and the ceramic membrane in the ceramic membrane equipment is a high-flux ceramic membrane (such as figure 2 As shown), the ceramic membrane adopts symmetrical or asymmetrical film formation with an average pore size...

Embodiment 3

[0039] Such as Figure 6 Shown, a kind of oilfield reinjection water membrane treatment process comprises the following steps:

[0040] (1) After the oily sewage is naturally settled to remove most of the suspended solids and oil, it is input into the circulation tank, and then enters the ceramic membrane equipment through the feed pump and the circulation pump in turn. On-line detection equipment is installed at the water inlet of the ceramic membrane ultrafiltration equipment to realize on-line monitoring of the incoming water quality, and automatically adjust the frequency of the circulating pump according to the change of the incoming water quality to change the flow rate of the membrane surface. In this embodiment, the incoming water oil content is 81.4mg / l, and the ceramic membrane in the ceramic membrane equipment is a high-flux ceramic membrane (such as figure 2 As shown), the ceramic membrane adopts symmetric or asymmetrical film formation with an average pore diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com