Method for determining maximum reactive capacity of MMC type direct-current ice melting device

A technology of DC ice melting and maximum reactive power, applied in reactive power compensation, reactive power adjustment/elimination/compensation, overhead installation, etc., can solve the problems that cannot be calculated, have many parameters, and do not reasonably and effectively satisfy the coupling of internal and external parameters relationship and other issues to achieve the effect of improving equipment availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

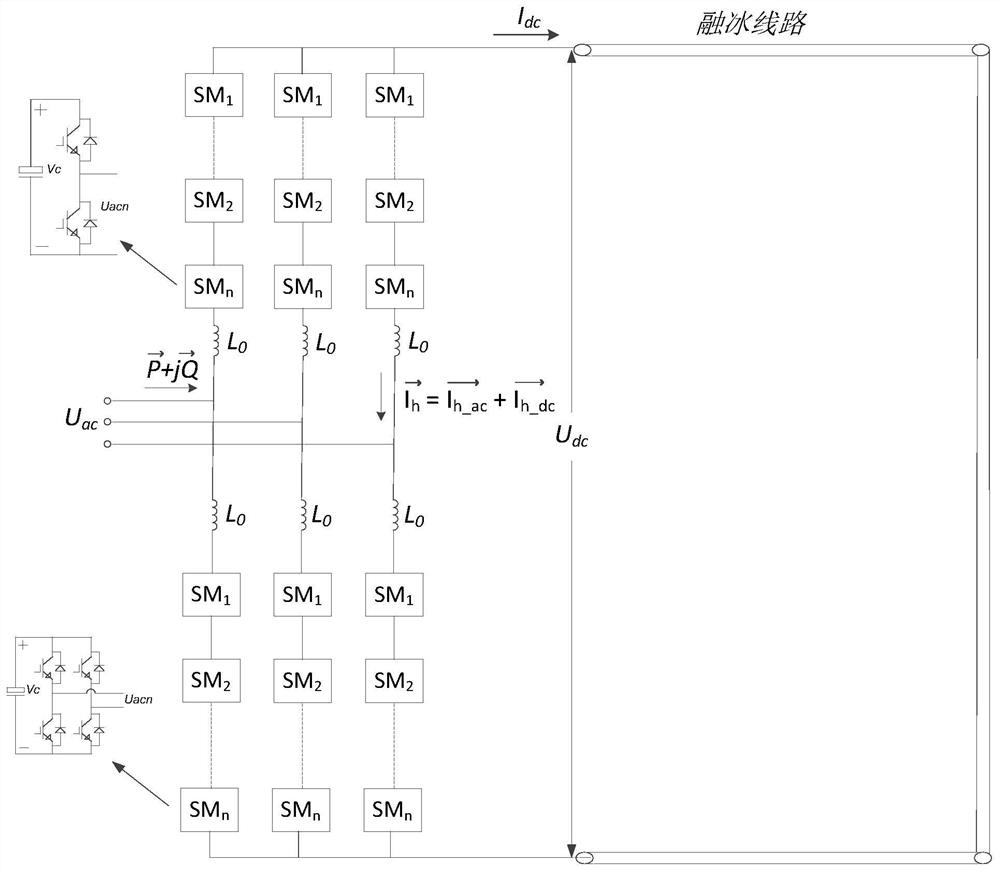

[0034] A method for determining the maximum reactive capacity of an MMC type DC deicing device, used to determine the active capacity and maximum reactive capacity of an MMC type DC deicing device according to engineering requirements, determine the PQ circle for device operation, and set the required The DC resistance value of the ice-melting line is R, and the DC ice-melting current of the line is I dc , the DC ice-melting voltage is U dc , the AC system line voltage is U ac , the steps to determine the capacity of the MMC DC ice-melting device are as follows:

[0035] S1: According to the DC resistance value R and the 1-1, 1-2 wiring mode of the deicing wiring, calculate the equivalent deicing resistance R eq , according to the line DC ice melting current I dc , calculate the required active capacity as The required DC ice-melting voltage is U dc = I dc *R eq ;

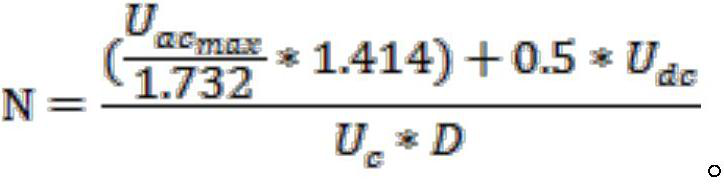

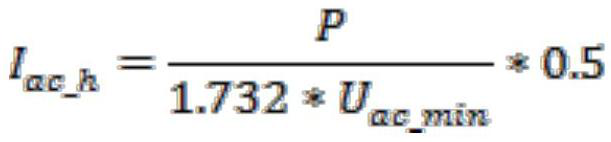

[0036] S2: according to the AC side line voltage U of the ice melting device ac and its fluctuation ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com