Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Surface ph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ocean's surface has an average pH of around 8.1, which is slightly basic. Although the pH changes appear small, pH is on a log scale meaning that a change of one unit represents an order of magnitude change in the acidity of the seawater.

Methods and articles having a high antiviral and antibacterial efficacy

InactiveUS20080145390A1Enhance persistent antiviral controlCut surfaceHalogenated hydrocarbon active ingredientsHeavy metal active ingredientsSurface phAntibacterial efficacy

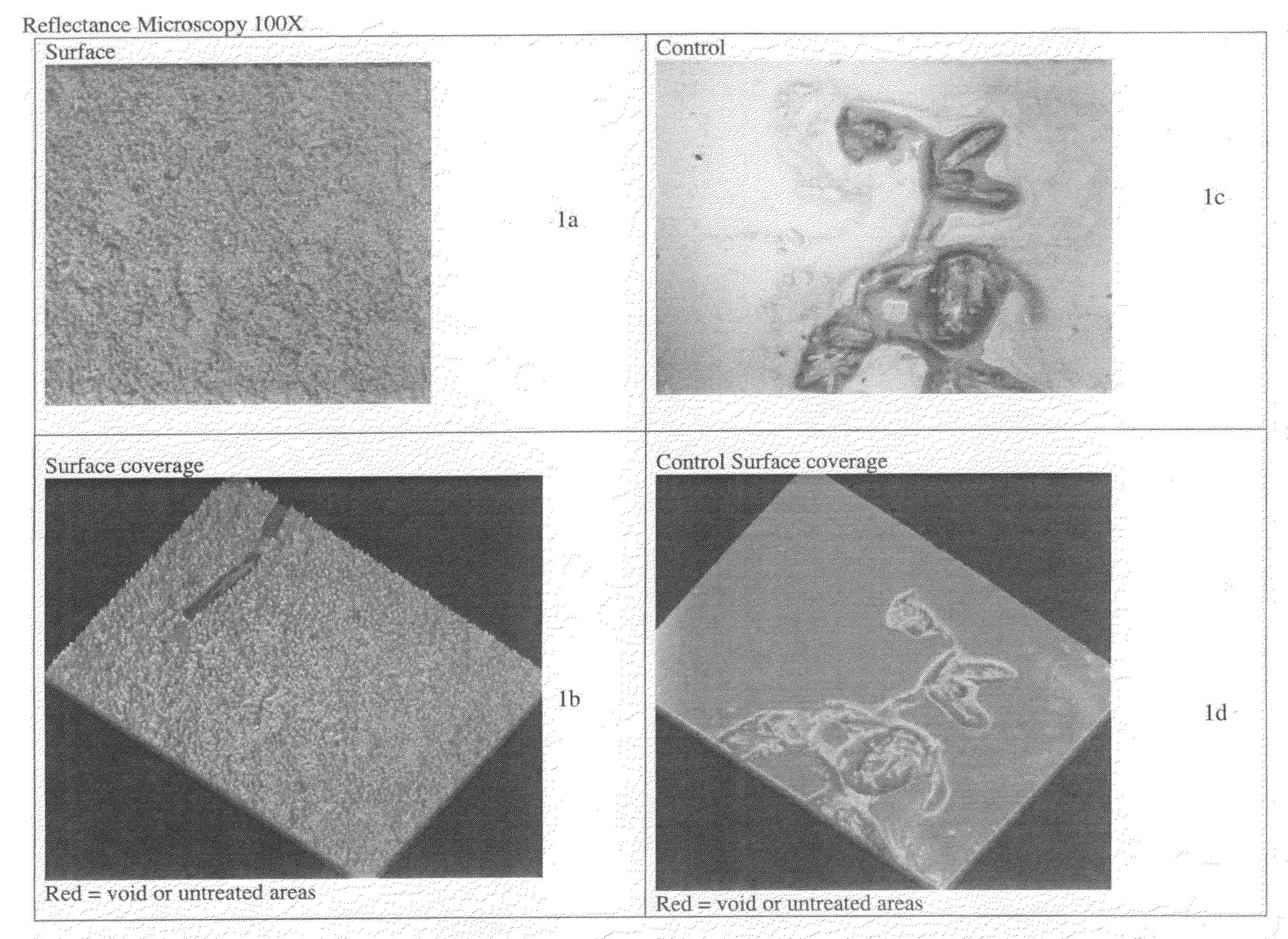

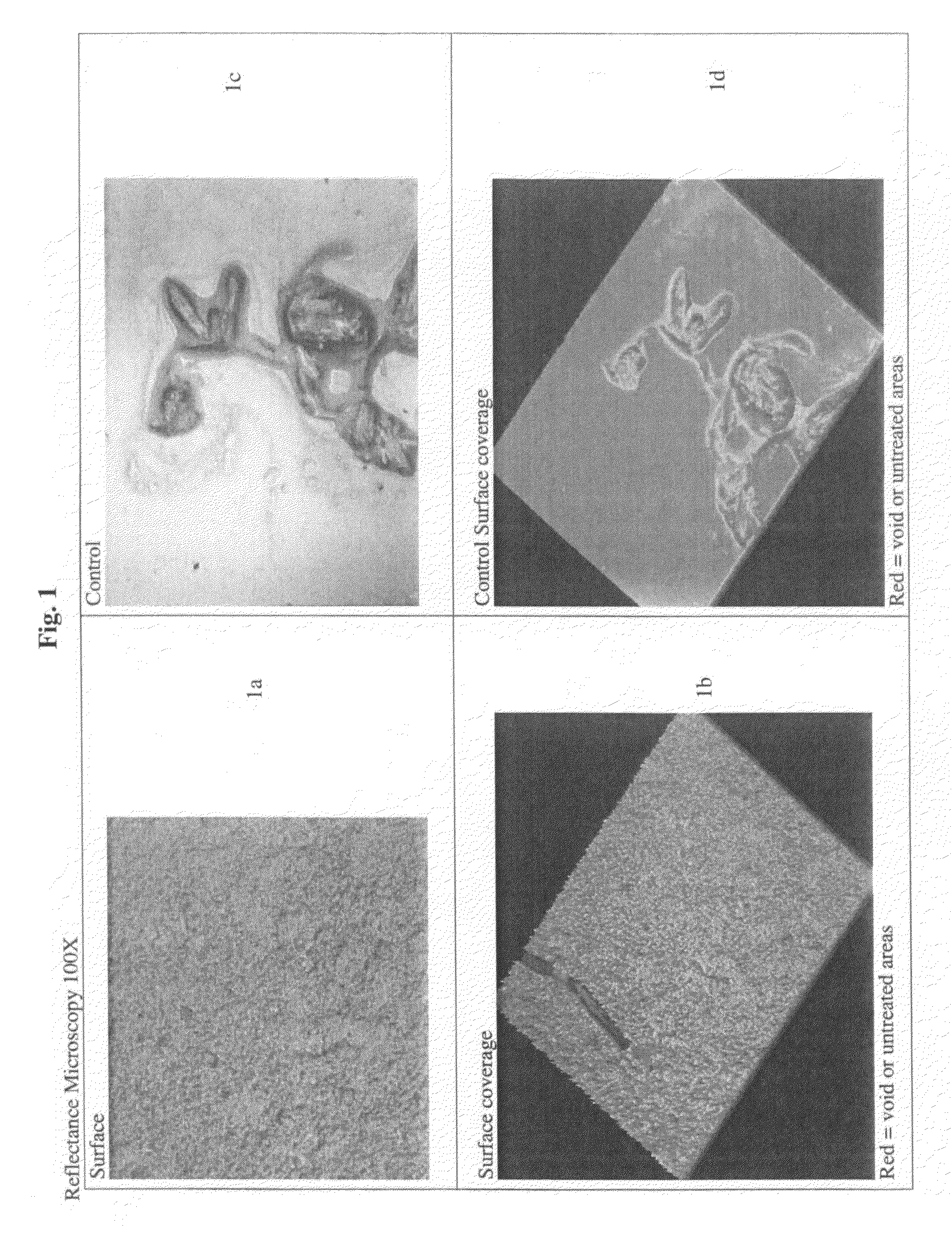

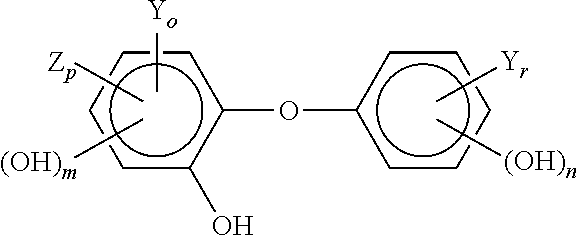

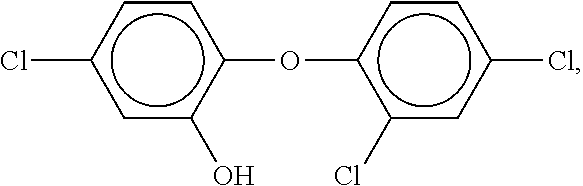

Method and article for providing a rapid, broad spectrum bacterial control, and a rapid and persistent antiviral control on an inanimate surface is disclosed. In the method, a compound or composition capable of lowering surface pH to less than about 4 is applied to the surface, and preferably is allowed to remain on the surface, and the nonvolatile components of the composition can form a barrier film or layer on a treated surface.

Owner:DIAL CORPORATION

Catalytic adsorbents obtained from municipal sludges, industrial sludges, compost and tobacco waste and process for their production

InactiveUS20070113736A1Large capacityQuick removalGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsSorbentSludge compost

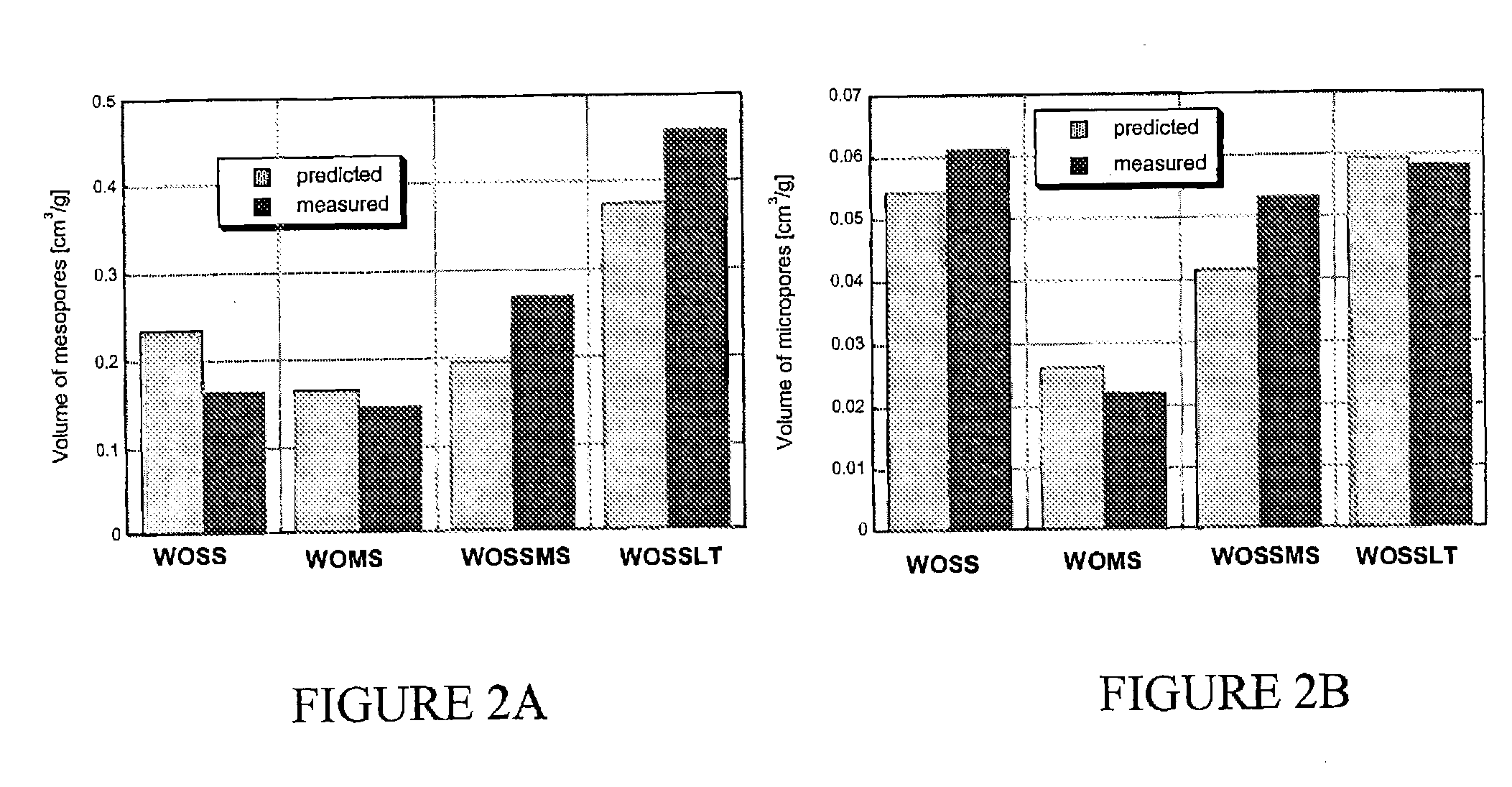

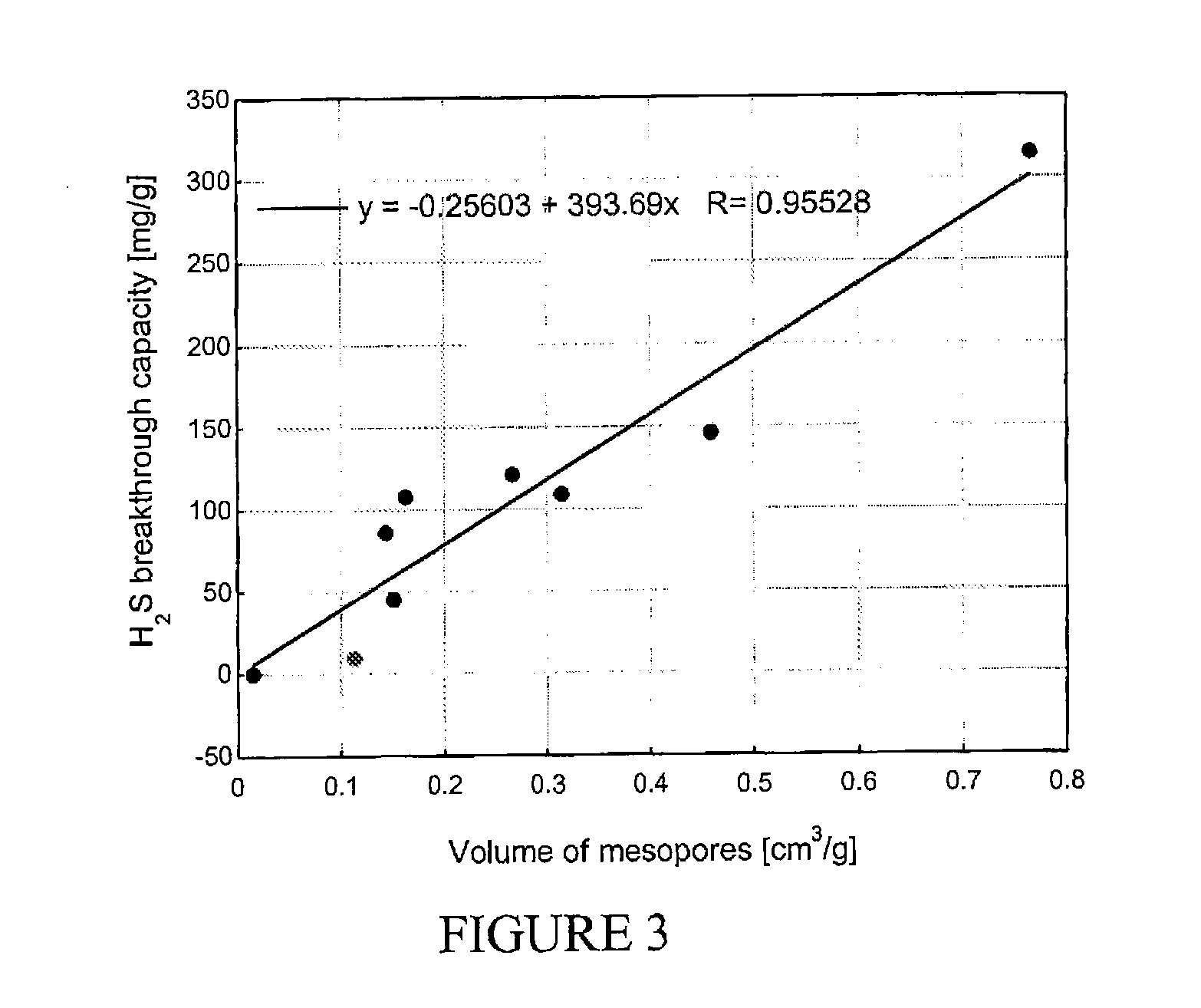

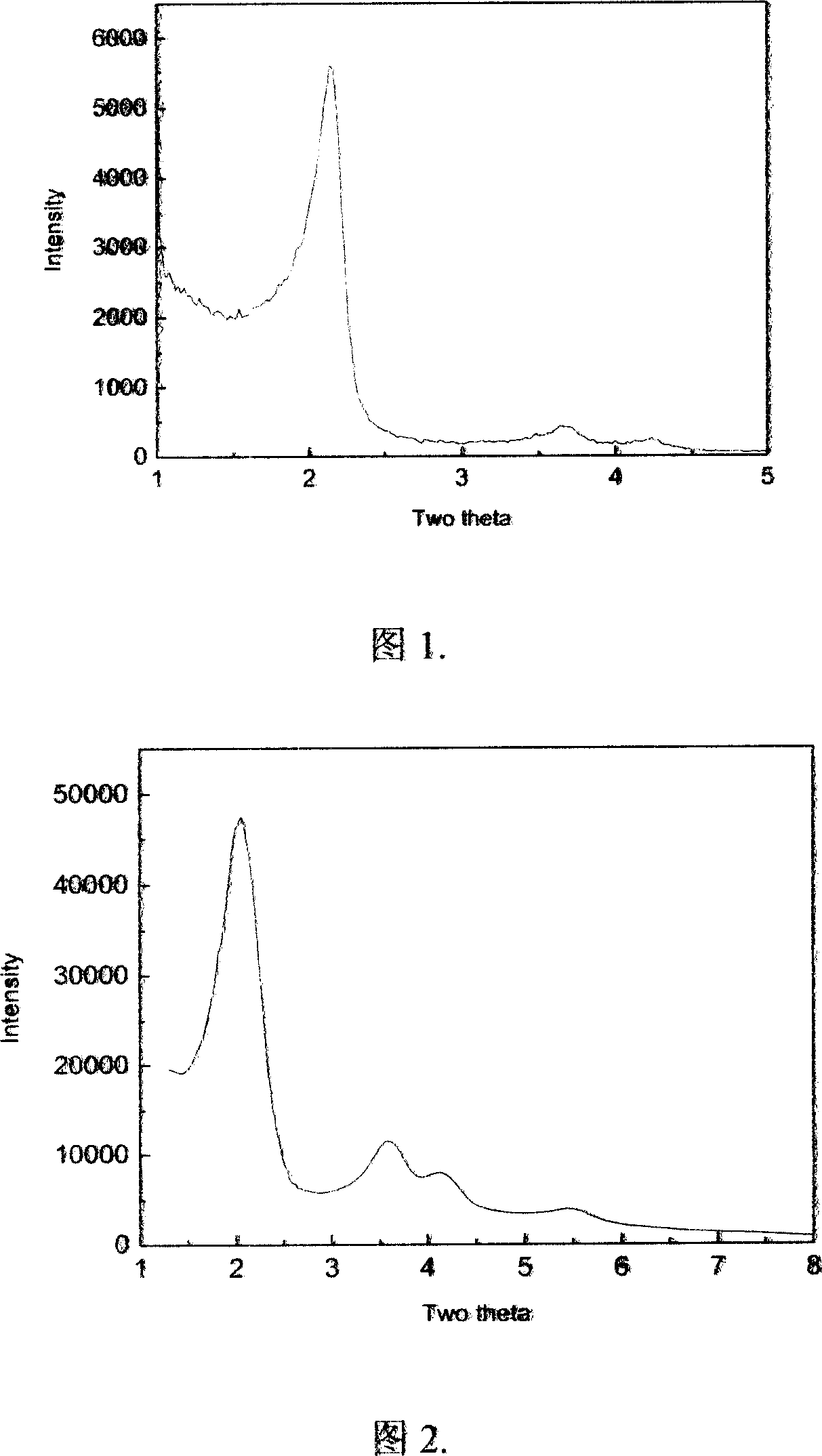

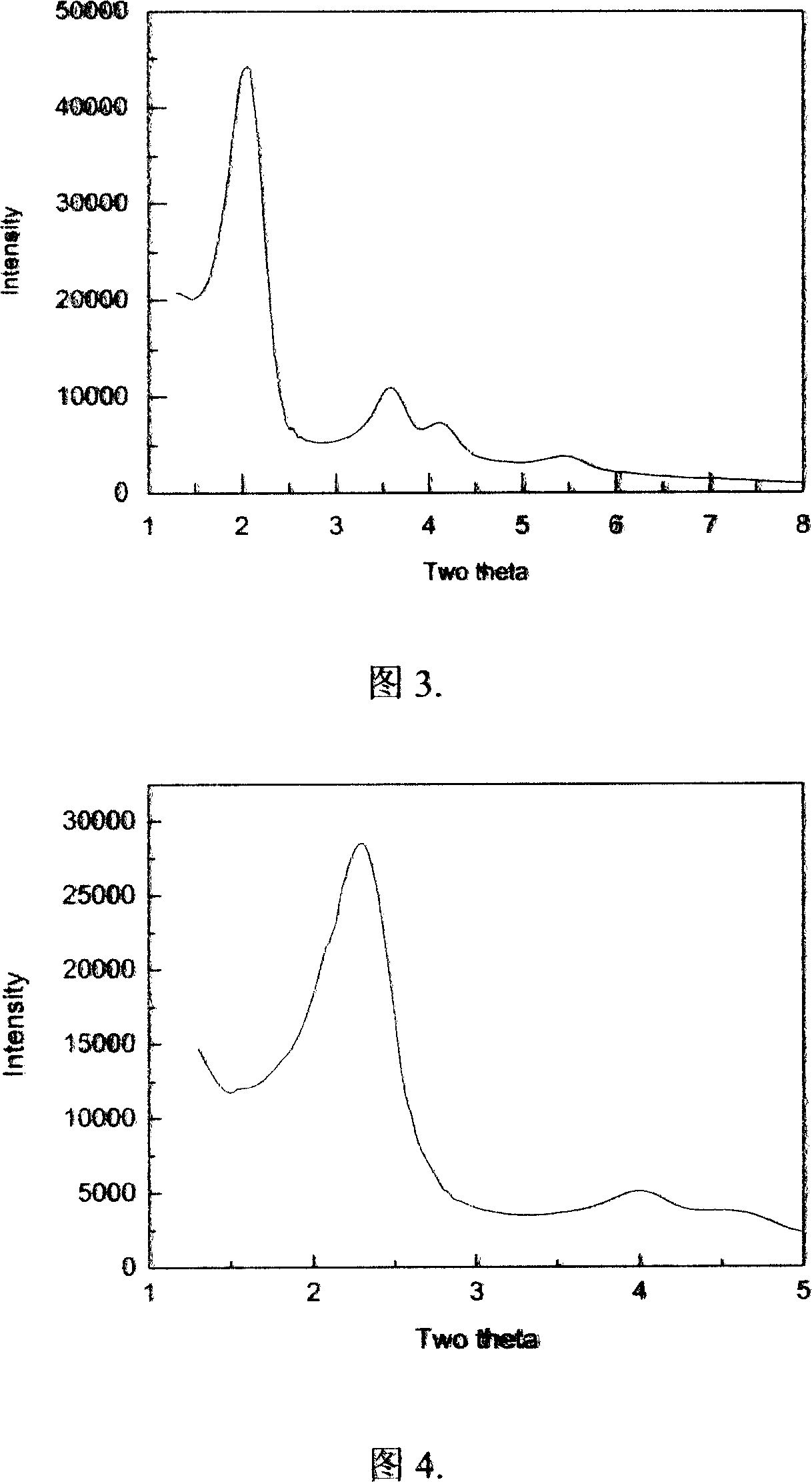

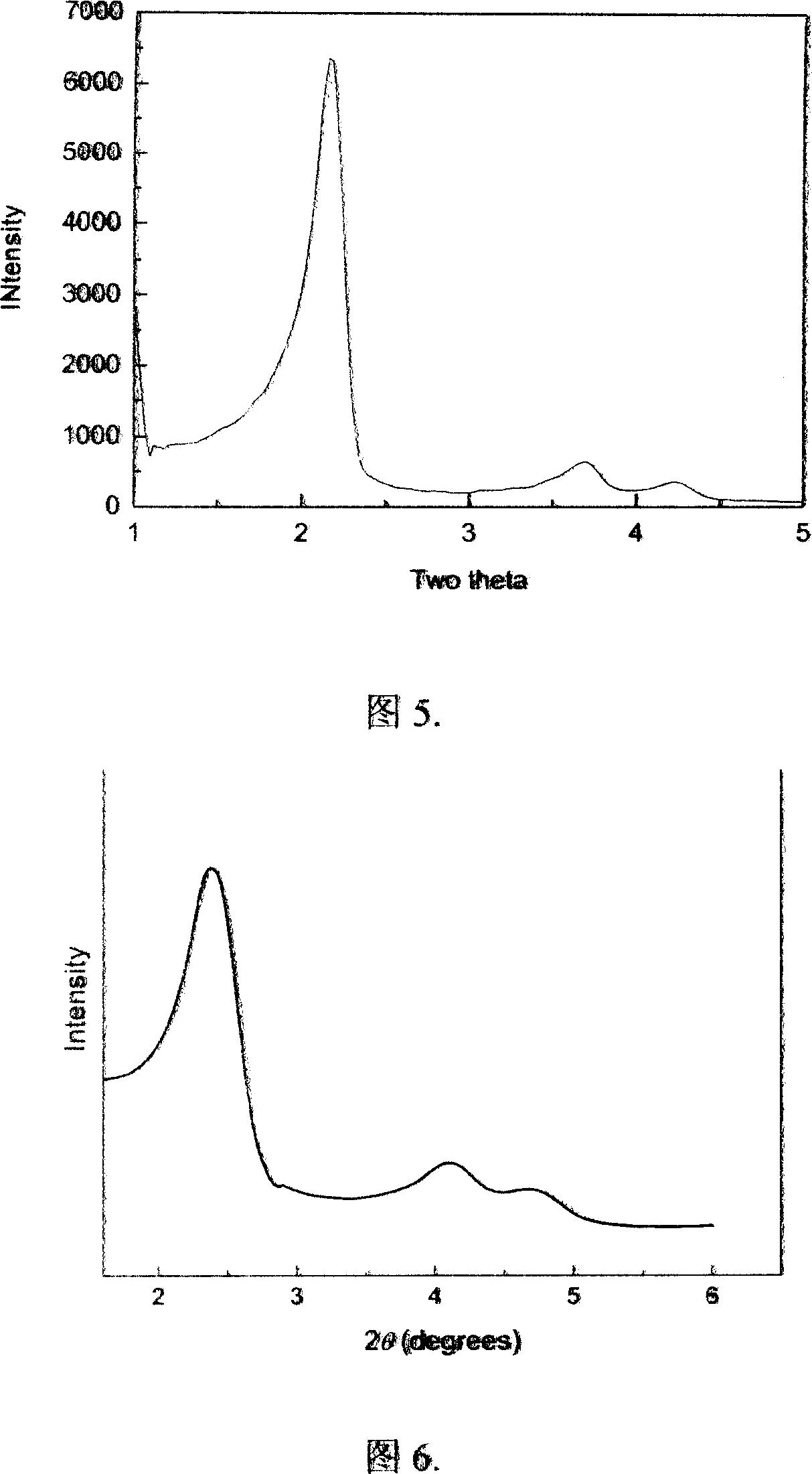

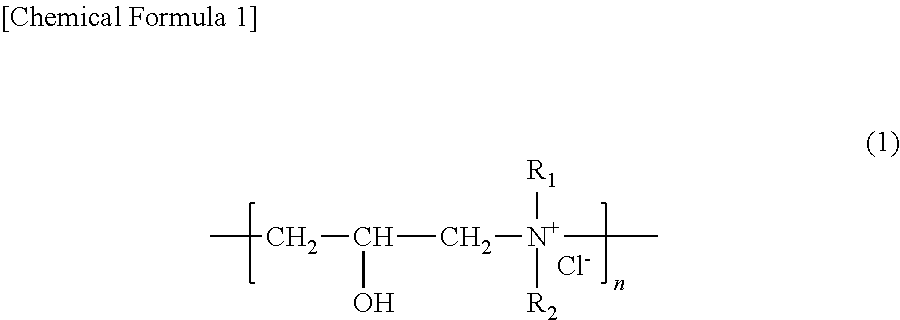

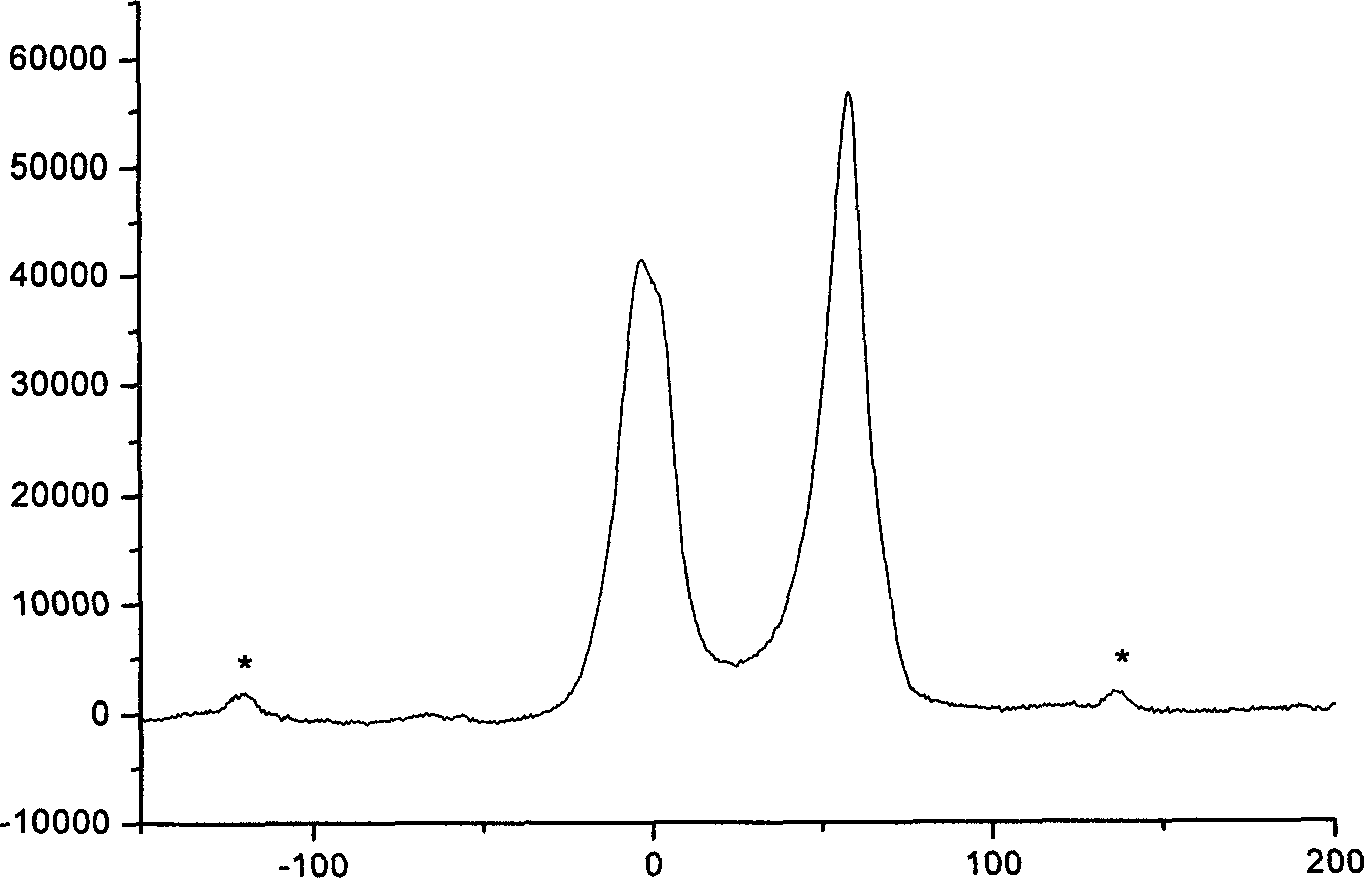

Industrial waste derived adsorbents were obtained by pyrolysis of sewage sludge, metal sludge, waste oil sludge and tobacco waste in some combination. The materials were used as media to remove hydrogen sulfide at room temperature in the presence of moisture. The initial and exhausted adsorbents after the breakthrough tests were characterized using sorption of nitrogen, thermal analysis, XRD, ICP, and surface pH measurements. Mixing tobacco and sludges result in a strong synergy enhancing the catalytic properties of adsorbents. During pyrolysis new mineral phases are formed as a result of solid state reaction between the components of the sludges. High temperature of pyrolysis is beneficial for the adsorbents due to the enhanced activation of carbonaceous phase and chemical stabilization of inorganic phase. Samples obtained at low temperature are sensitive to water, which deactivates their catalytic centers.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Process for treating industrial and municipal waste water highly loaded with ammonium

InactiveUS6881339B1Separation devicesTreatment with aerobic and anaerobic processesIndustrial waste waterDenitrifying bacteria

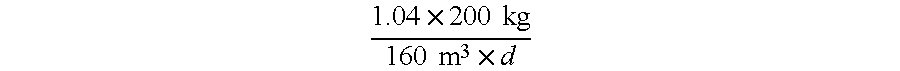

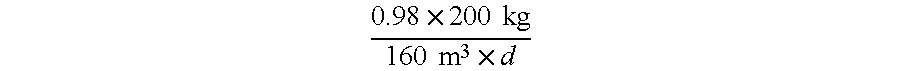

There is a disclosed or process for treating industrial waste water highly loaded with ammonium, by treating the waste water with nitrifying microogransims (nitric bacteria) in the presence of a suspended carrier substance with a specific surface area of >20 m2 / g and optionally a denitrification with denitrifying microorganisms (denitrifying bacteria). According to a modification of the process, a finely-divided carbon-containing material with a surface-pH value of around 6 to 9 is used instead of the silicate carrier substance.

Owner:SUD CHEM AG

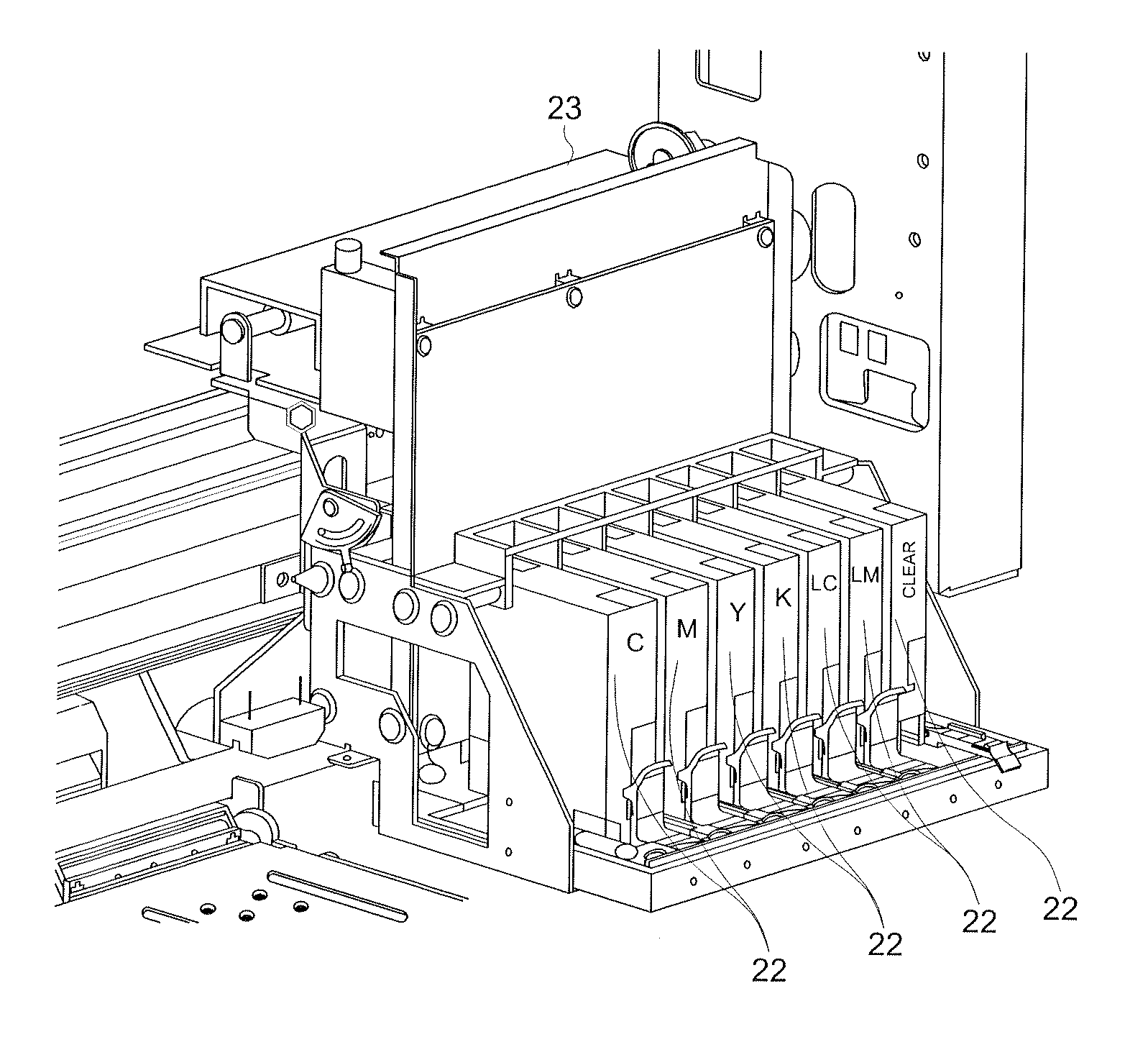

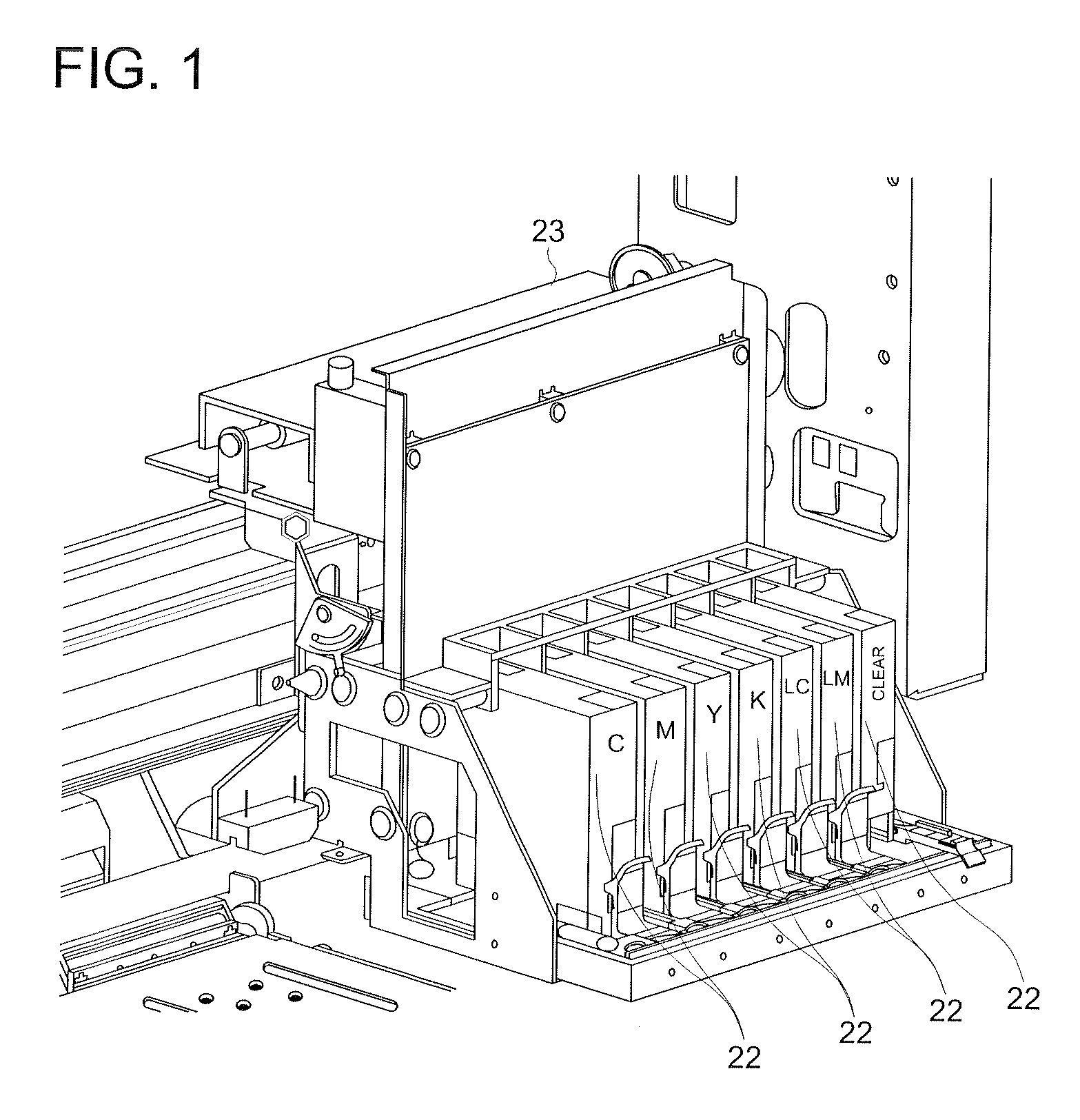

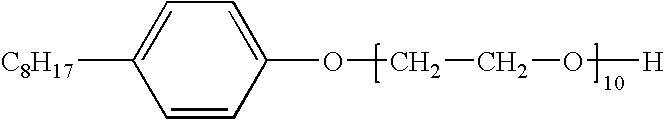

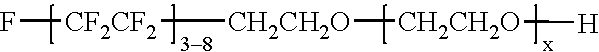

Ink-jet image forming method

InactiveUS20070052785A1Good weather resistanceHigh glossLiquid surface applicatorsMeasurement apparatus componentsWater dispersiblePolymer chemistry

A method of forming an ink-jet image comprising the steps of: i. ejecting ink compositions from an ink-jet head onto a recording medium; and ii. forming an image, wherein a) the recording medium is a porous type medium having a porous ink absorbing layer on a non-water absorptive support, b) the ink-jet head has a plurality of nozzles which eject more than two ink compositions respectively, and one ink composition is a clear ink, and one ink composition is a color ink, c) the clear ink contains water dispersible microscopic resin particles having an average diameter of 10-200 nm of more than 1 weight %, and d) pH of the ink compositions is 6.5-11.0, and an absolute value of a difference, between an ink composition pH and film surface pH of the recording medium, is less than 4.0.

Owner:KONICA MINOLTA PHOTO IMAGING

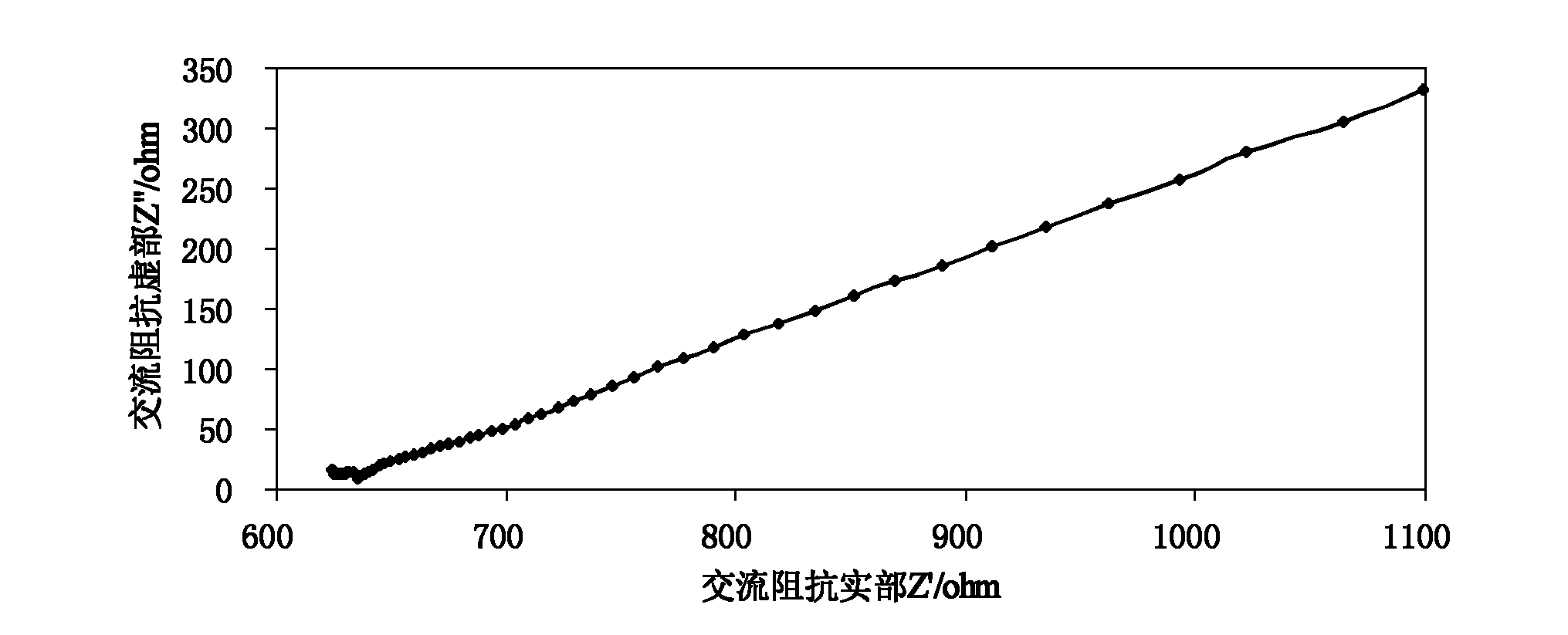

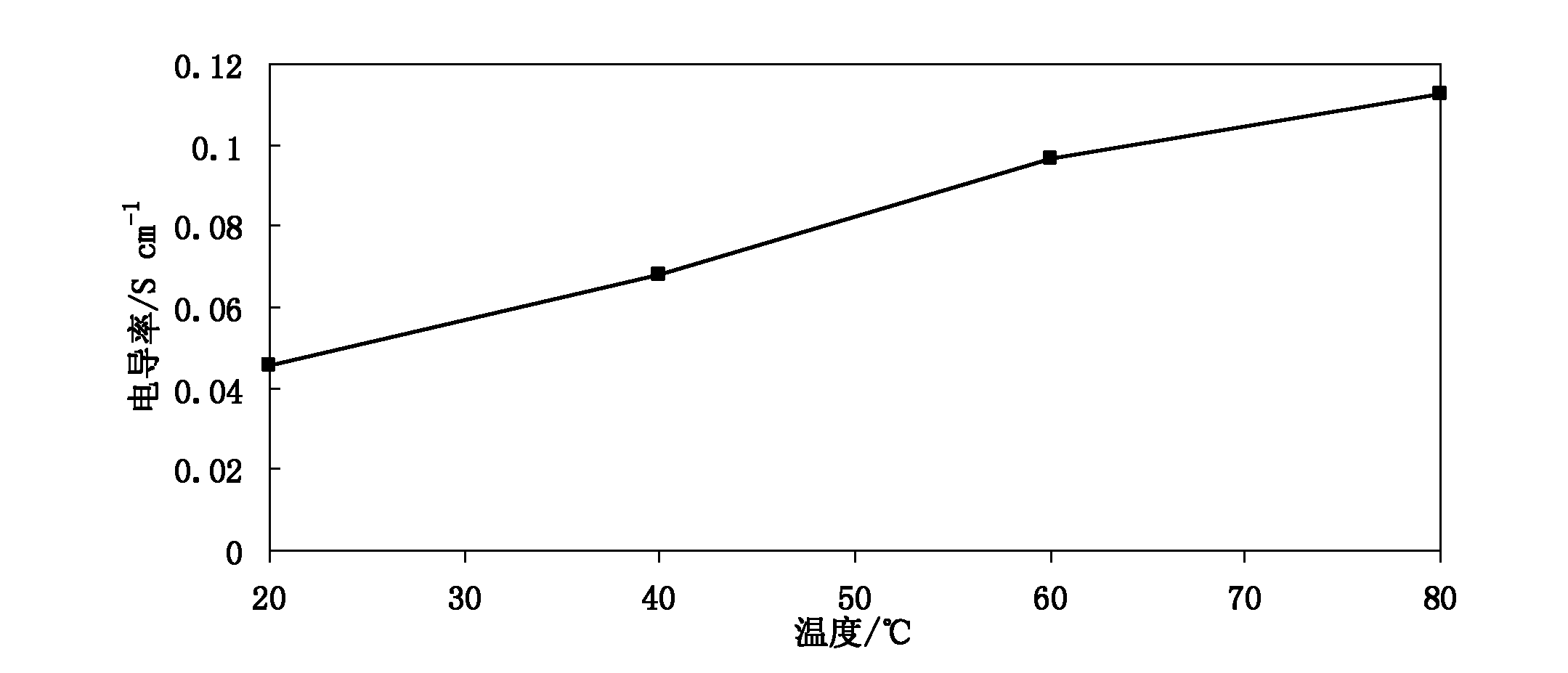

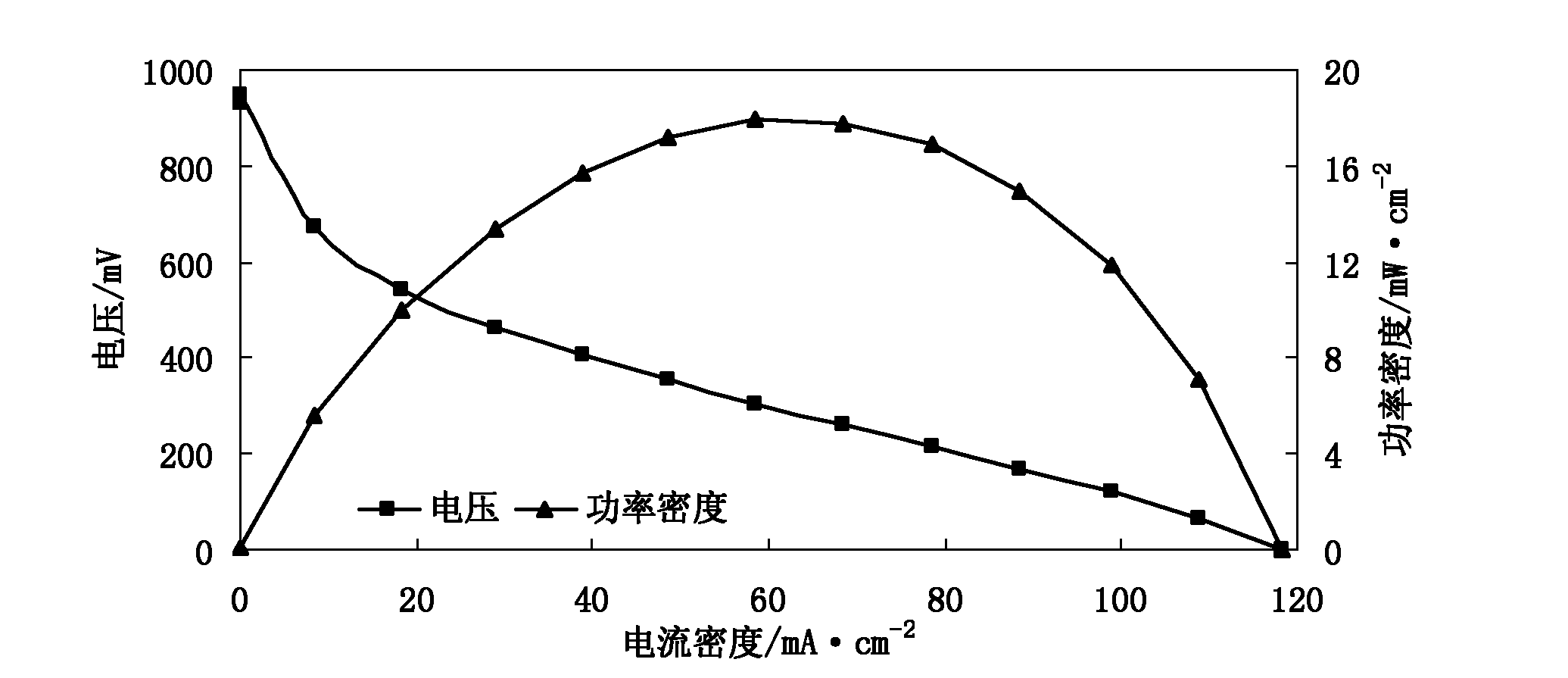

Method for preparing proton exchange membranes from modified bacterial cellulose membranes and application thereof

ActiveCN102321265AReduce pollutionSimple manufacturing processCell component detailsFuel cell detailsWater bathsOrganic acid

The invention relates to a method for preparing proton exchange membranes from modified bacterial cellulose membranes and an application thereof. The method comprises the following steps that: (1) the bacterial cellulose membranes are taken to be flushed, residual culture medium impurities are removed, then, the bacterial cellulose membranes are placed in alkaline solution for water bath treatment for 0.5 to 2h until the bacterial cellulose membranes become white and semitransparent, the bacterial cellulose membranes are then flushed and is boiled for 0.5 to 2h, and the bacterial cellulose membranes are taken out to be flushed until the pH value of the bacterial cellulose membranes is neutral; and (2) the bacterial cellulose membranes with the neutral surface pH value are soaked in superfluous inorganic acid or organic acid, and the proton exchange membranes are obtained through drying. The prepared modified bacterial cellulose proton exchange membranes are used for being assembled into fuel cells. The preparation process is simple, the cost is low, the environment pollution is little, and the cellulose membranes have higher proton conductivity and better thermal stability.

Owner:DONGHUA UNIV

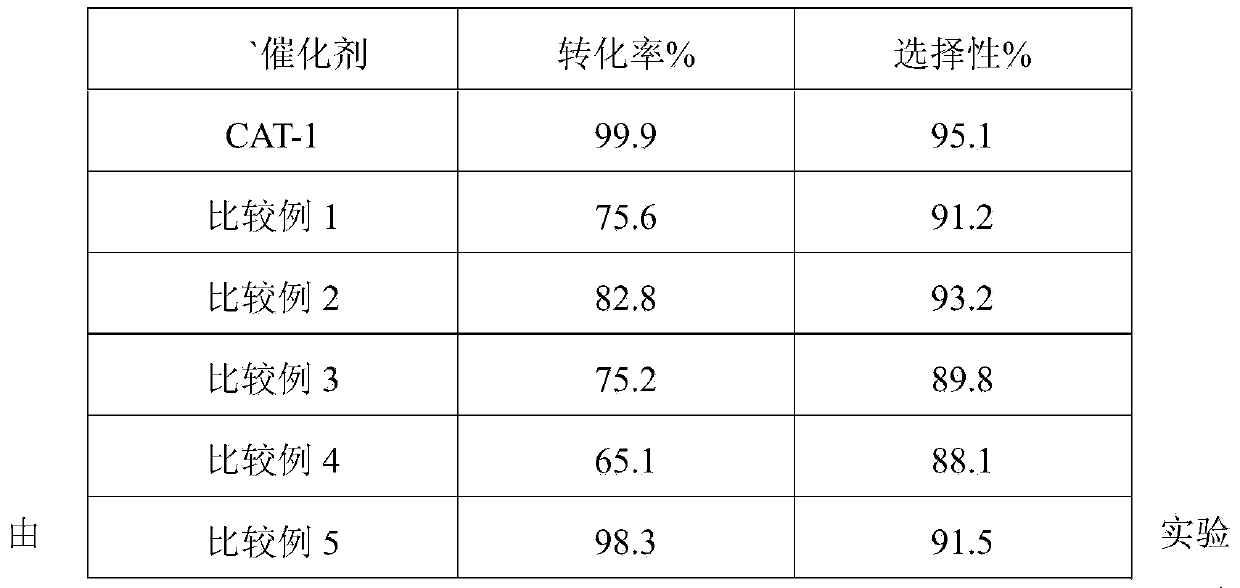

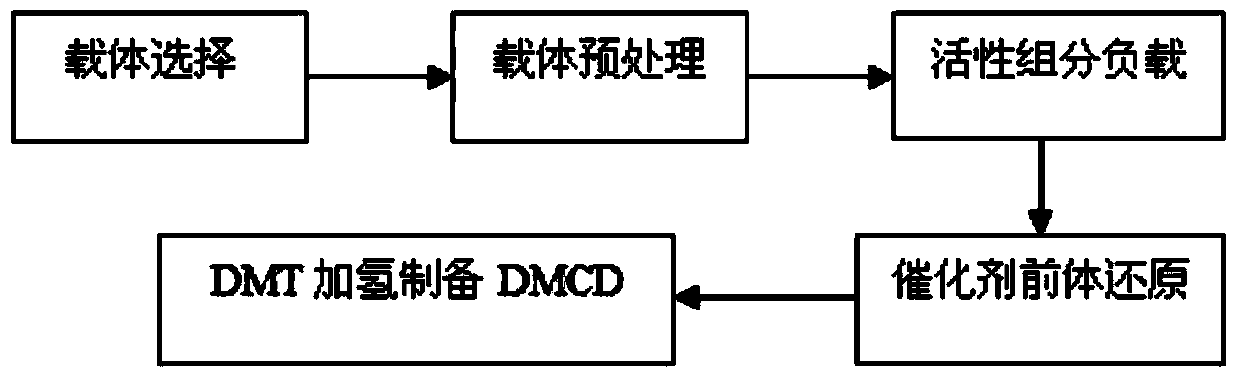

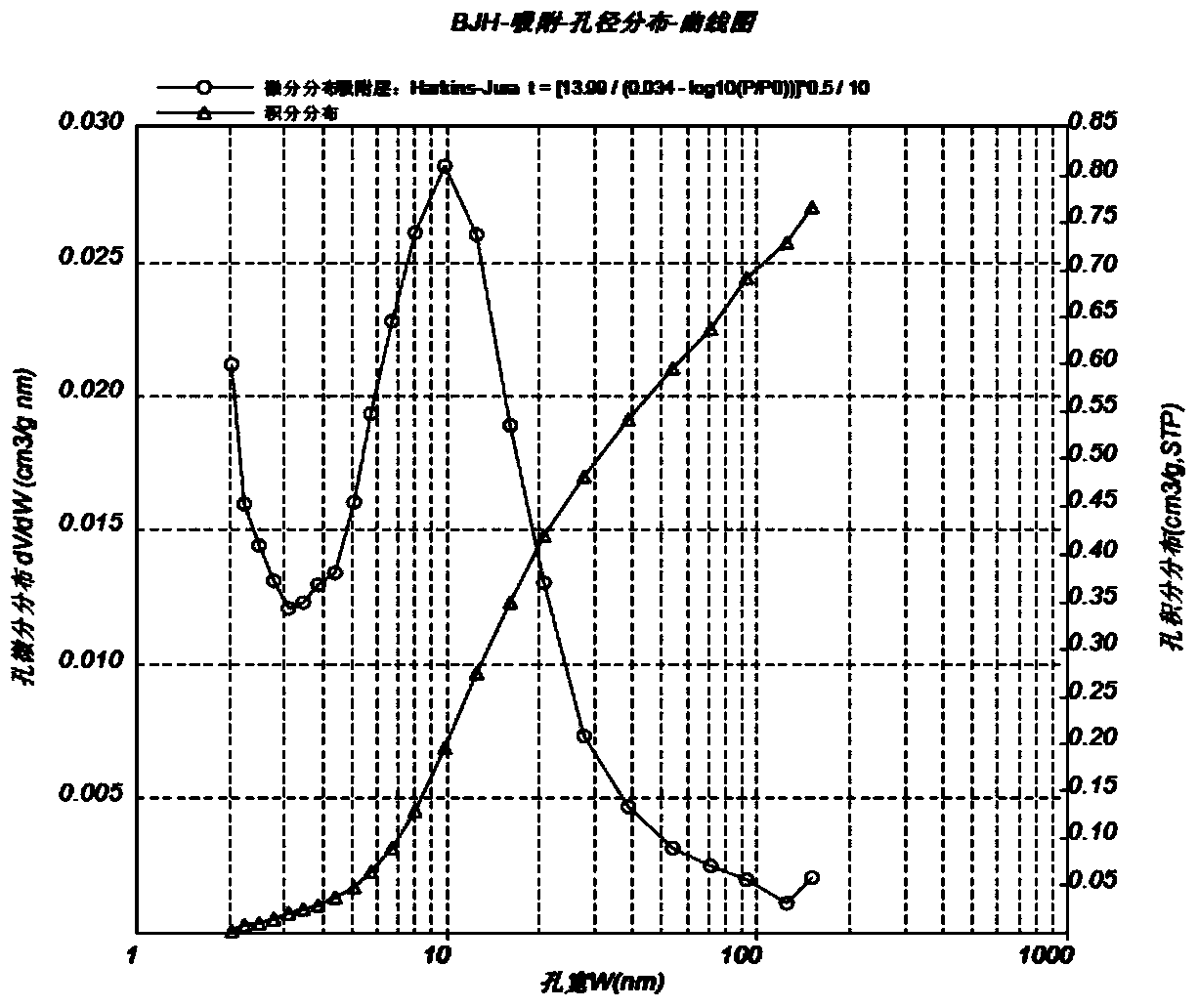

Ruthenium/aluminum oxide catalyst, as well as preparing method and application thereof

InactiveCN103691432AEfficient removalGood dispersionOrganic compound preparationCarboxylic acid esters preparationDistillationSmall hole

The invention discloses a ruthenium / aluminum oxide catalyst, as well as a preparing method and application thereof. The carrier of the catalyst is Al2O3, and Ru is used as an active ingredient of the catalyst, wherein the loading capacity of the Ru is 3.0% to 8.0%, and the grain diameter of the Ru is 1nm to 5nm. The catalyst has a specific surface area of 100-500m<2> / g, a pore volume of 0.8-1.2ml / g and a pore diameter of 2-50nm. Macro-porous aluminum oxide is used as a carrier precursor, water in micro-pores is effectively removed through baking pre-processing, the surface potential of hydrogen distribution and the pore diameter distribution are changed, and the dispersion degree of the ruthenium is improved. The prepared catalyst is used for the hydrogenation of dimethyl terephthalate (DMT) to prepare dimethyl cyclohexanedicarboxylates (DMCD). The activity of the catalyst is not reduced after being used in a 5000ml autoclave for 20 times. The conversion rate of the DMT is 99.3% to 100%, and the selectivity of the DMCD is 95.5% to 96.4%. Through simple distillation and purification, the purity of the DMCD is bigger than 99.5%. The preparing method has the advantages of mild technical conditions, simple equipment, no emission of three wastes, investment saving, low energy consumption and easy realization of industrialization.

Owner:JIANGSU GOLD BRIDGE SALT & CHEM GRP +1

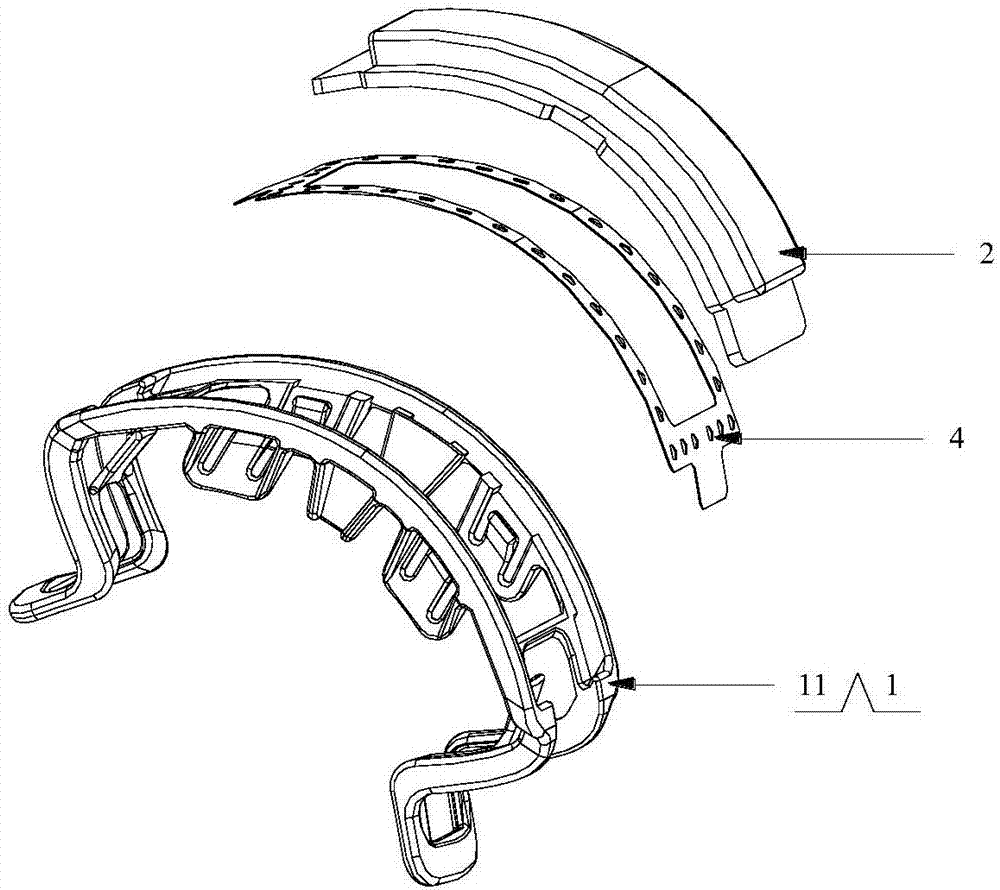

Convex array probe clamping sleeve assembly and convex array probe assembly

ActiveCN107411775AGood for drop protectionImprove experienceUltrasonic/sonic/infrasonic diagnosticsSurgical furnitureCouplingUltrasonic attenuation

The invention discloses a convex array probe clamping sleeve assembly and a convex array probe assembly. The clamping sleeve assembly includes a clamping sleeve and a solid medical ultrasonic coupling patch; the clamping sleeve is used for clamping the solid medical ultrasonic coupling patch so as to allow an external convex probe to contact a surface of the solid medical ultrasonic coupling patch; the other surface of the solid medical ultrasonic coupling patch faces outward and is used for detection. The solid medical ultrasonic coupling patch can be clamped on the convex array probe; the solid medical ultrasonic coupling patch is used in ultrasonic operation, an output ultrasonic image is clear in a far-field end, an intermediate-field end, and a near-field end; when the solid medical ultrasonic coupling patch is used, the conventional liquid coupling agent can be avoided, and the user experience is improved. The ultrasonic coupling patch is solid and flexible, and is flat and glossy in surface; a moisture retaining liquid adheres to a surface of a solid gel tablet, the surface pH is neutral, and probe sound lens corrosion or rupture can be avoided; the clamping sleeve can protect the probe from falling.

Owner:SHENZHEN MINHAO TECH CO LTD

Ink-jet printing receiving sheet comprising gelatin and a metal salt

InactiveUS6841205B1Improve post printed drop sweatingExcellent glossinessDuplicating/marking methodsCoatingsGelatin productSurface ph

The present invention refers to an ink jet receiving sheet having a surface pH value lower than 5.0 and comprising a support and at least a receiving layer containing a binder selected from the group consisting of gelatin and gelatin derivatives and at least a salt of a metal selected from the IIA and IIB groups of the periodic table of elements or complexes which comprise said metal salts.The ink jet receiving sheet of the invention provides minimum post printed drop sweating after stressed ageing in the resulting image, still maintaining a good glossiness.

Owner:SPA FERRANIA

Method and apparatus for measuring calcium oxalate scaling

InactiveCN1443307AWide range of usesInhibit growthAnalysing fluids using sonic/ultrasonic/infrasonic wavesTesting water hardnessHydrogenQuartz crystal microbalance

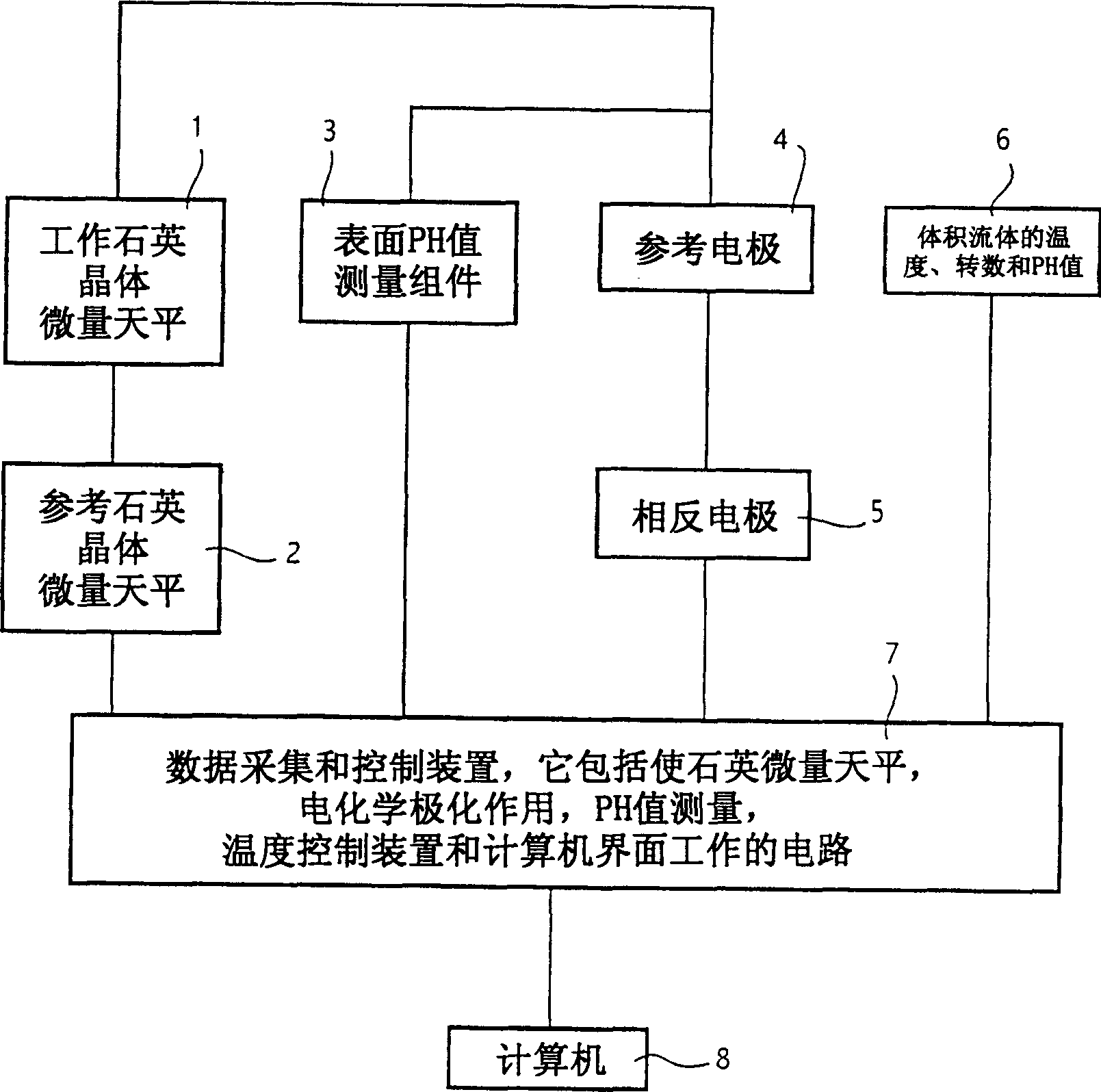

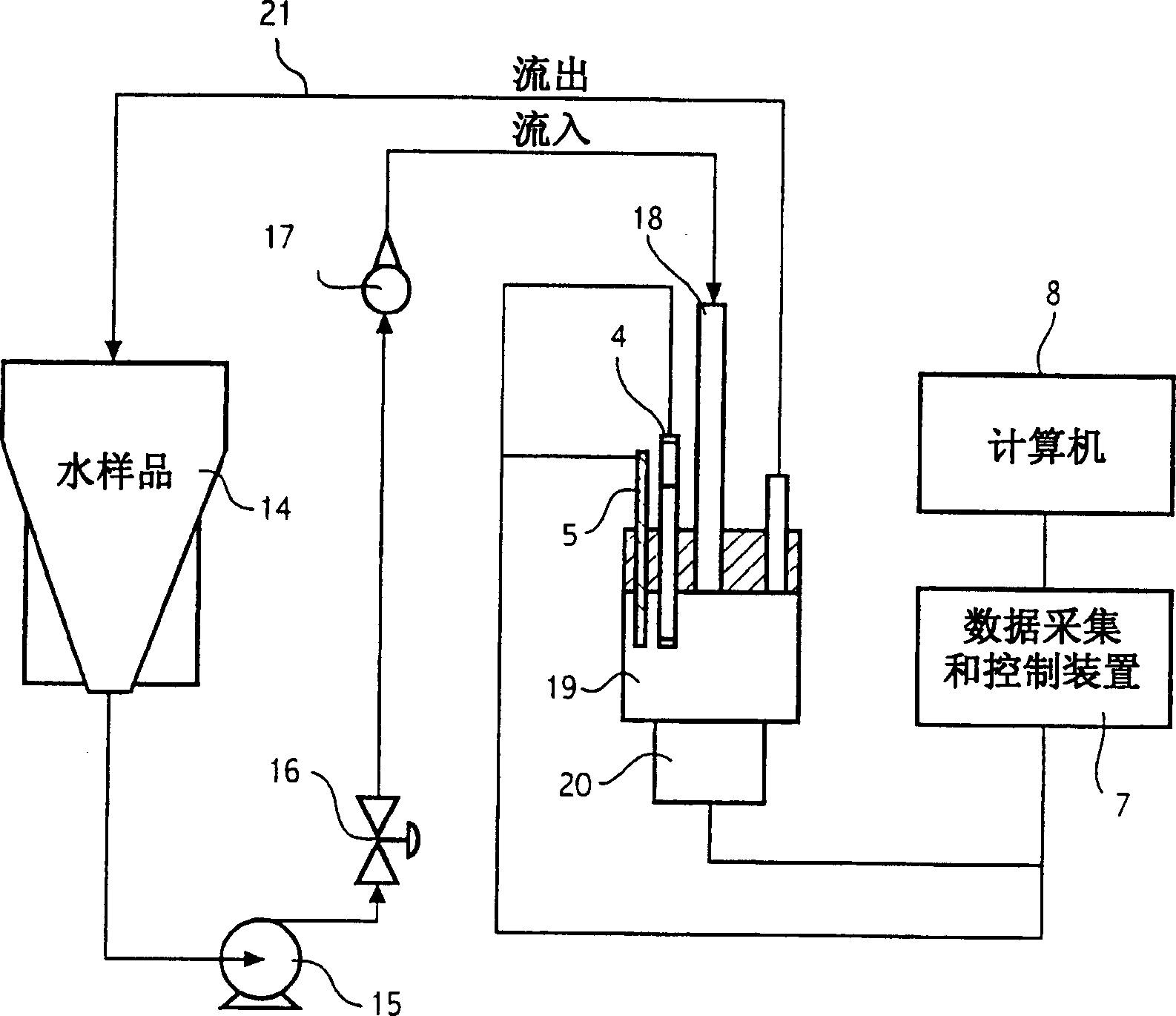

The invention relates to an apparatus for measuring the calcium oxalate scale forming propensity of a continuously flowing solution having a pH of from 2 to 3 which comprises a quartz crystal microbalance having a top side comprising a working electrode for exposure to the solution and a bottom side isolated from the solution, wherein the working electrode is coated with or made of a conductive material on which the intensive evolution of hydrogen gas proceeds at potentials more negative than necessary to achieve a pH of 3.5-9 proximate to the microbalance.

Owner:NALCO CHEM CO

Cleaning method applicable to components with surface adhesion substance being Ceramic

ActiveCN109277357AQuick removalAvoid damageCleaning using toolsCleaning using liquidsHydrofluoric acidFree cooling

The invention discloses a cleaning method applicable to components with surface adhesion substance being Ceramic. The method comprises the following steps of 1, conducting chemical cleaning, wherein soaking treatment is conducted on a workpiece through an ammonium hydroxide and hydrogen peroxide solution, wherein the adopted ammonium hydroxide and hydrogen peroxide solution is prepared from H2O2,H2O and NH4OH according to the volume ratio of (2.5-3.5): (3.5-4.5): (0.5-1.5); 2, rinsing the workpiece through pure water; 3, conducting a neutralization reaction through nitric-fluoric acid, wherein the adopted nitric-fluoric acid is prepared from nitric acid and hydrofluoric acid, and the volume ratio of HNO3 to HF to H2O is (17-23): (0.5-1.5): (17-23); 4, conducting wiping; 5, soaking the workpiece in DIWater for 10 minutes or above at the normal temperature; 6, conducting a workpiece surface PH test; 7,conducting ultrasonic oscillation cleaning; 8, conducting a workpiece surface PH test;9, conducting CDA blowing; 10, conducting ultrasonic oscillation cleaning; 11, conducting heating and drying; and 12, conducting natural cooling.

Owner:深圳仕上电子科技股份有限公司

Method for preparing modified MCM-41/aluminium oxide composite carrier

ActiveCN101069854ARegulate surface pHImprove structural stabilityMolecular sieve catalystsAlumina compositeStructural stability

The present invention relates to a preparation method of modified MCM-41 / aluminium oxide composite carrier material, belonging to the field of composite new material technology. Said invention uses F- modified aluminium oxide as aluminium source, uses water-glass as silicon source, uses hexadecyl trimethyl ammonium bromide as template agent and adopts a hydrothermal synthesis process to prepare the invented MCM-41 / aluminium oxide composite material. Said MCM-41 / aluminium oxide composite material can be used as carrier of hydrogenation catalyst for diesel oil hydrogenation desulfurisation, hydrogenation denitrification, aromatic hydrocarbon hydrogenation saturation and heavy distillate hydrotreating process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Water-dispersible paper

ActiveUS8877678B2Good water dispersibilityQuick water dispersion propertyStampsSpecial ornamental structuresCelluloseWater dispersible

An object of the present invention is to provide a water dispersion paper having quick water dispersion property and high strength (printability) and whose paper surface pH is 6 to 8 (neutral range), and also to provide a water dispersion coated paper designed to ensure quick water dispersion property and prevent discoloration over time.A water dispersion paper made of wood pulp and / or non-wood pulp, wherein said water dispersion paper is characterized in that purified pulp containing α-cellulose by 88 percent by weight or more accounts for 15 to 95 percent by weight of all pulp, as well as a water dispersion coated paper having a water-soluble coating layer on said water dispersion paper.

Owner:NIPPON PAPER PAPYLIA

Compositions Having a High Antiviral and Antibacterial Efficacy

Antimicrobial compositions having a rapid antiviral and antibacterial effectiveness, and a persistent antiviral effectiveness, are disclosed. The anti-microbial compositions contain (a) an antimicrobial agent, (b) a disinfecting alcohol, and (c) (i) an organic acid, (ii) an inorganic salt comprising a cation having a valence of 2, 3, or 4 and a counterion capable of lowering a surface pH to about 5 or less, (iii) an aluminum, zirconium, or aluminum-zirconium complex, or (iv) mixtures thereof, wherein the composition has a pH of about 5 or less.

Owner:DIAL CORPORATION

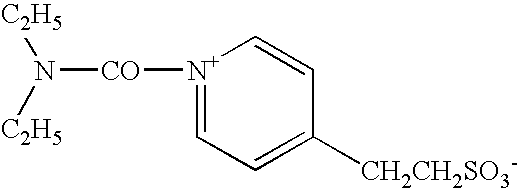

Method for making a lithographic printer plate precursor

InactiveUS20100129755A1Improved roll-up performanceImprove performanceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusWater solublePrinting press

A method for making a lithographic printing plate precursor is disclosed comprising the steps of a. providing a lithographic printing plate precursor including a support having a hydrophilic surface or which is provided with a hydrophilic layer, a photopolymerizable coating comprising a photopolymerizable composition, and an overcoat layer comprising a water soluble low molecular weight acid, wherein said overcoat layer has a surface pH-value ranging between 1 to 6; b. image-wise exposing the precursor; c. optionally heating the exposed precursor; d. processing the obtained precursor by applying a gum solution and optionally brushing the precursor, and / or by mounting the precursor on a plate cylinder of a lithographic printing press and rotating the plate cylinder while feeding dampening liquid and / or ink to the coating. The printing plate obtained after imaging and processing in an off-press configuration with a gum solution or in an on-press configuration with fountain solution and ink shows an improved roll-up performance in the start-up of a printing process on a printing press.

Owner:AGFA NV

A method for making a lithographic printing plate precursor

A method for making a lithographic printing plate precursor is disclosed comprising the steps of a. providing a lithographic printing plate precursor including a support having a hydrophilic surface or which is provided with a hydrophilic layer, a photopolymerizable coating comprising a photopolymerizable composition, and an overcoat layer comprising a water soluble low molecular weight acid, wherein said overcoat layer has a surface pH-value ranging between 1 to 6; b. image -wise exposing the precursor; c. optionally heating the exposed precursor; d. processing the obtained precursor by applying a gum solution and optionally brushing the precursor, and / or by mounting the precursor on a plate cylinder of a lithographic printing press and rotating the plate cylinder while feeding dampeningliquid and / or ink to the coating. The printing plate obtained after imaging and processing in an off- press configuration with a gum solution or in an on-press configuration with fountain solution andink shows an improved roll- up performance in the start-up of a printing process on a printing press.

Owner:AGFA NV

Ammonium ion sieve, its preparation method and application

InactiveCN1824386ASimple manufacturing methodImprove automationWater/sewage treatment by ion-exchangeCrystalline aluminosilicate zeolitesDistilled waterMuffle furnace

The present invention relates to an ammonium ionic sieve, its preparation method and application. Said ammonium ionic sieve is made up by using kaoline modified by modifying agent and distilled water. Its preparation method includes the following steps: a). pulverizing kaoline raw material, grinding and sieving; b). heating the sieved sample in muffle furnace to obtain activated kaoline; c). uniformly mixing the activated kaoline, modifying agent and water and stirring them; d). heating mixture, drying, cooling and soaking the obtained product in distilled water, washing until the sample surface pH value is less than 10; and e). drying the obtained product in drying oven so as to obtain the invented ammonium ionic sieve.

Owner:TIANJIN UNIV

Catalyst for preparing isobutene through isobutane dehydrogenation and preparation method thereof

InactiveCN105435773AImprove pore structureImprove surface propertiesCatalyst carriersHydrocarbonsAlkaline earth metalDehydrogenation

The invention belongs to the technical field of chemical catalysts and relates to a catalyst for preparing isobutene through isobutane dehydrogenation and a preparation method thereof. 0.5-10.0% by mass of silicon oxide is added into an alumina carrier, then the alumina carrier is loaded with vanadium oxide with a vanadium content of 3.0-11.0% by mass and then 0.1-5.0% by mass of an alkali metal or an alkaline earth metal as a cocatalyst is added into the alumina carrier. Silicon oxide is introduced into the alumina carrier so that an alumina carrier pore structure and surface properties are improved and vanadium oxide active site distribution is changed. Through use of an alkali metal and an alkaline earth metal, catalyst surface pH and electron properties are improved, a conversion rate and selectivity of isobutane dehydrogenation preparation of isobutene are improved and a catalyst service life is prolonged.

Owner:FUDAN UNIV

Silicon-carbon separation method for polysilicon carbon head materials

InactiveCN101691222BAchieve separationControllable separation efficiencySilicon compoundsGraphiteMaterials science

Owner:隋聚勇

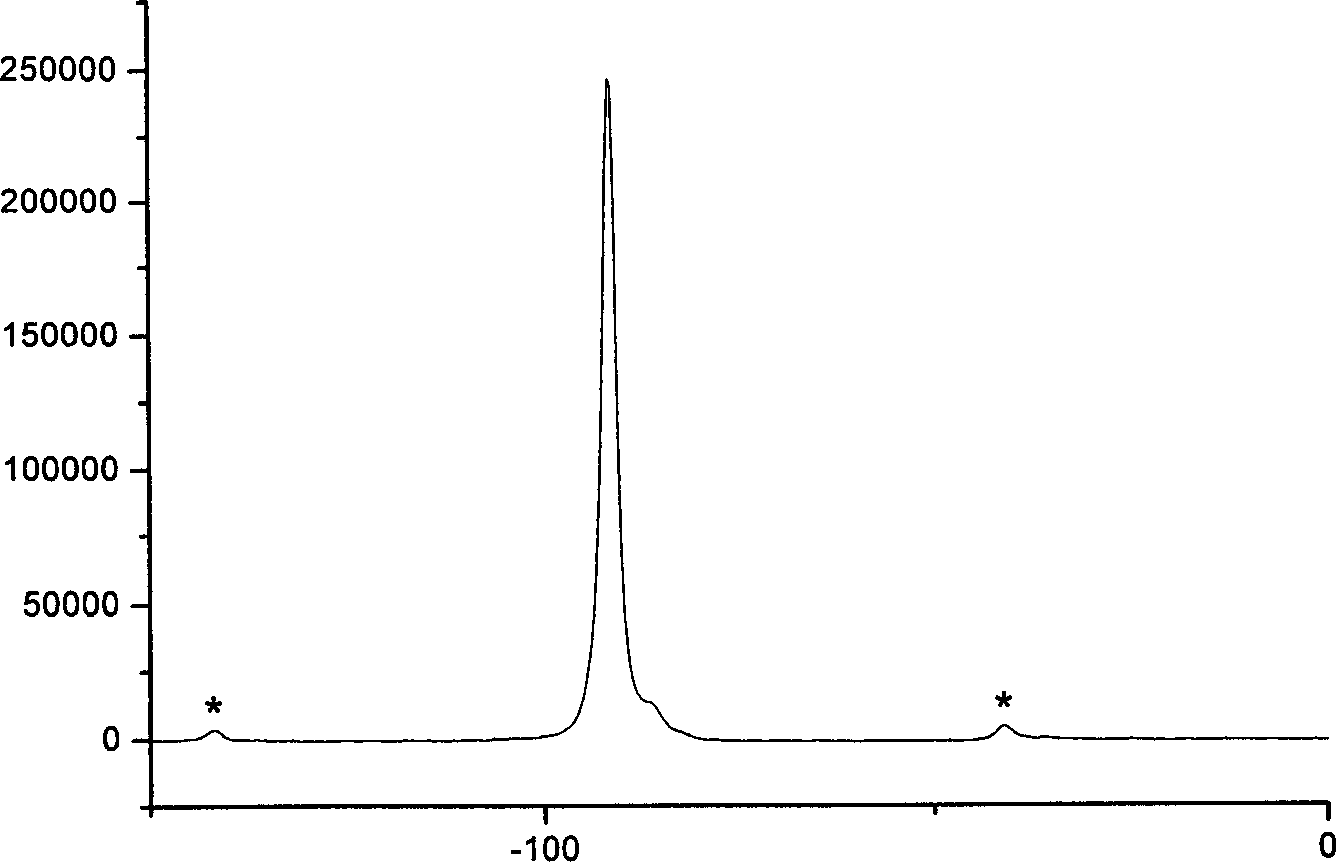

Preprocessing method for glass fiber cloth

ActiveCN103290672AImprove temperature resistanceGood chemical stabilityCatalyst carriersFibre treatmentGlass fiberPretreatment method

The invention discloses a preprocessing method for glass fiber cloth. The preprocessing method is characterized by comprising the following process steps: (1) processing on the glass fiber cloth for 30-60 minutes at 400 to 550 DEG C; (2) soaking the glass fiber cloth for 1-5 minutes by utilizing 0.1M HCl solution; (3) processing the glass fiber cloth by utilizing 2.5-4M HCl+HNO3 mixed solution with the temperature of 92-100 DEG C for 120-240 minutes; (4) washing the glass fiber cloth until the surface pH is higher than 6; and (5) drying the glass fiber cloth for 5-30 minutes at 105 to 120 DEG C. The glass fiber cloth processed by utilizing the method disclosed by the invention has the silicon dioxide content higher than 93% (percentage by weight) and the characteristics of porous structure and high specific surface area, surface activity, temperature tolerance and acid-base resistance. The preprocessing method has the advantages of simple processing process, high production efficiency, low cost, stable product quality and the like and is suitable for large-scale production of photocatalytic carrier materials.

Owner:CHINA JILIANG UNIV

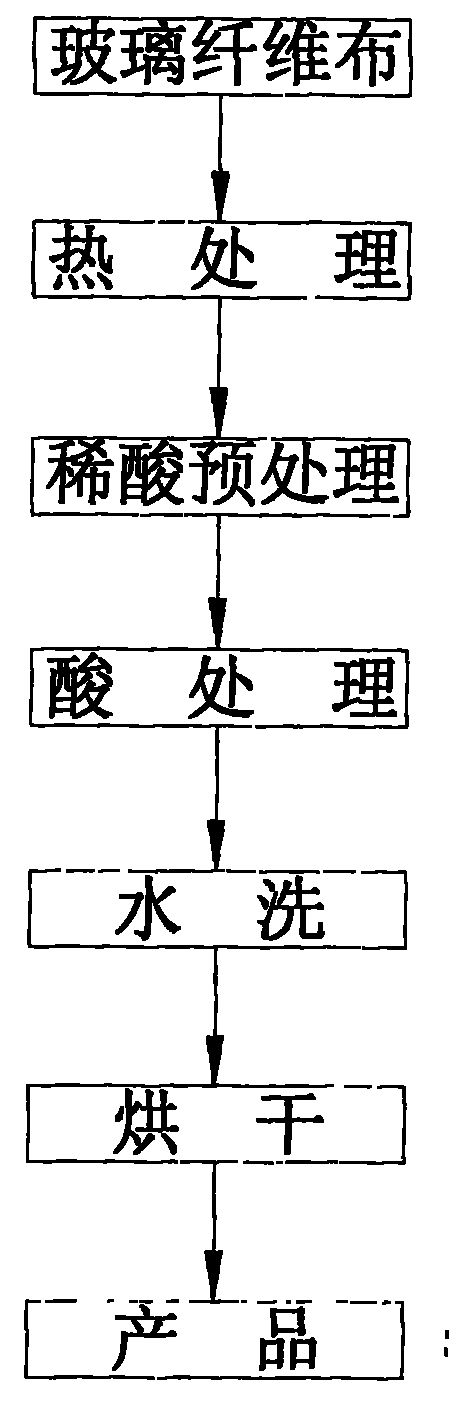

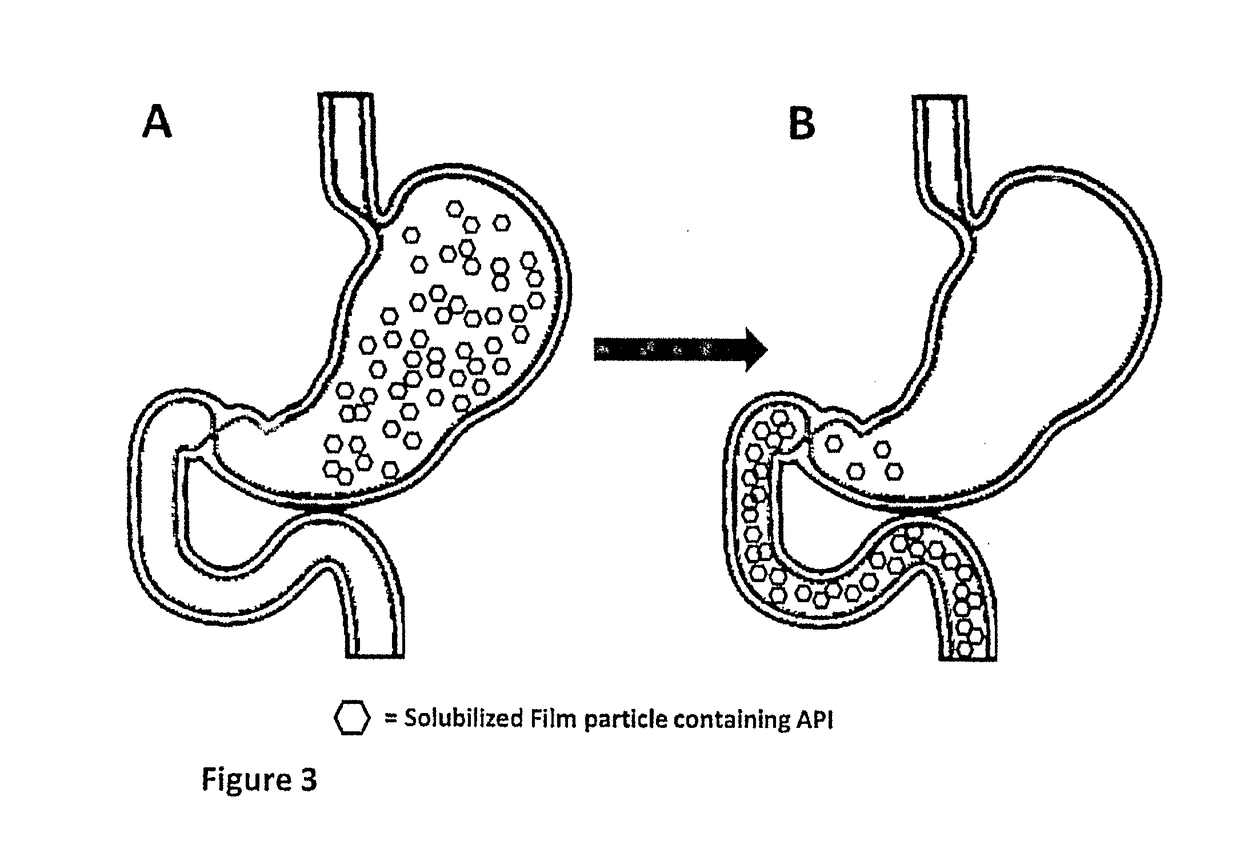

Method of treatment and device for the improved bioavailability of leukotriene receptor antagonists

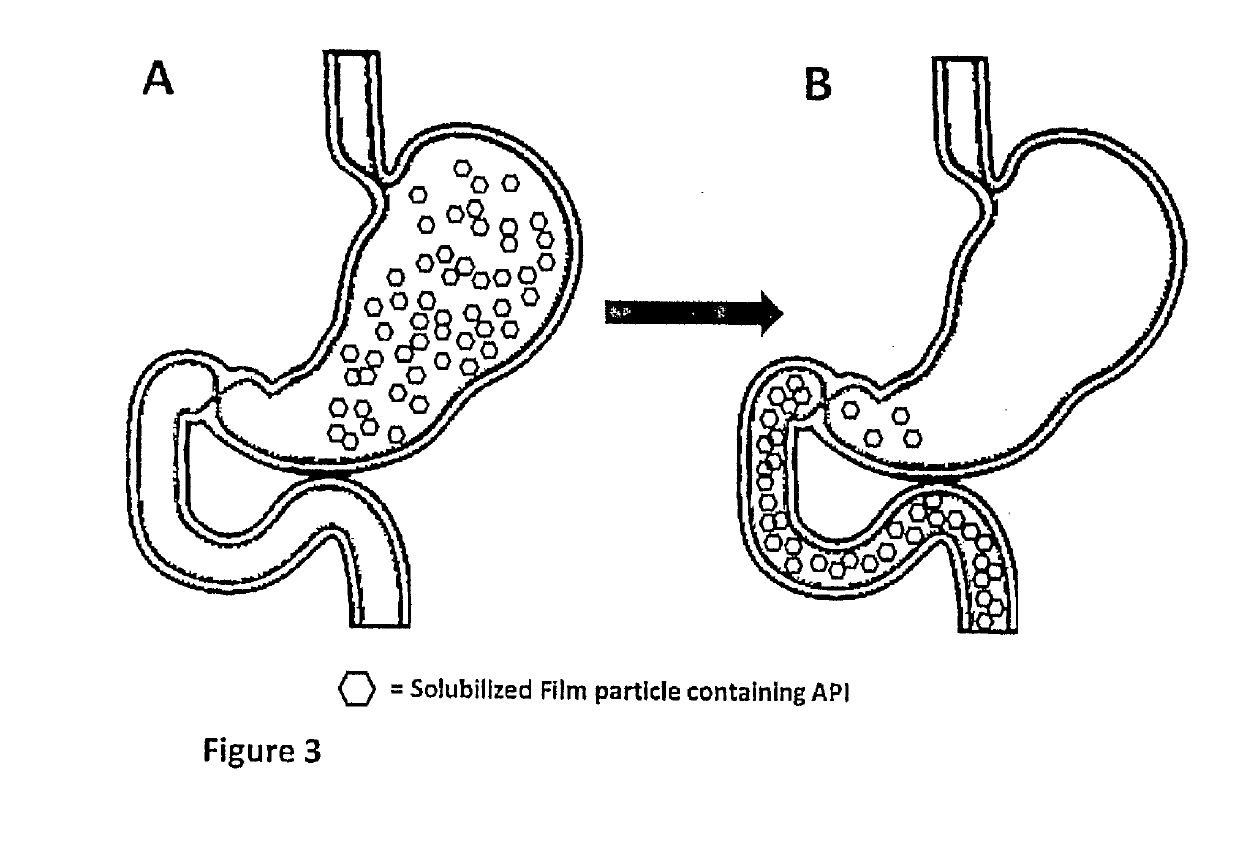

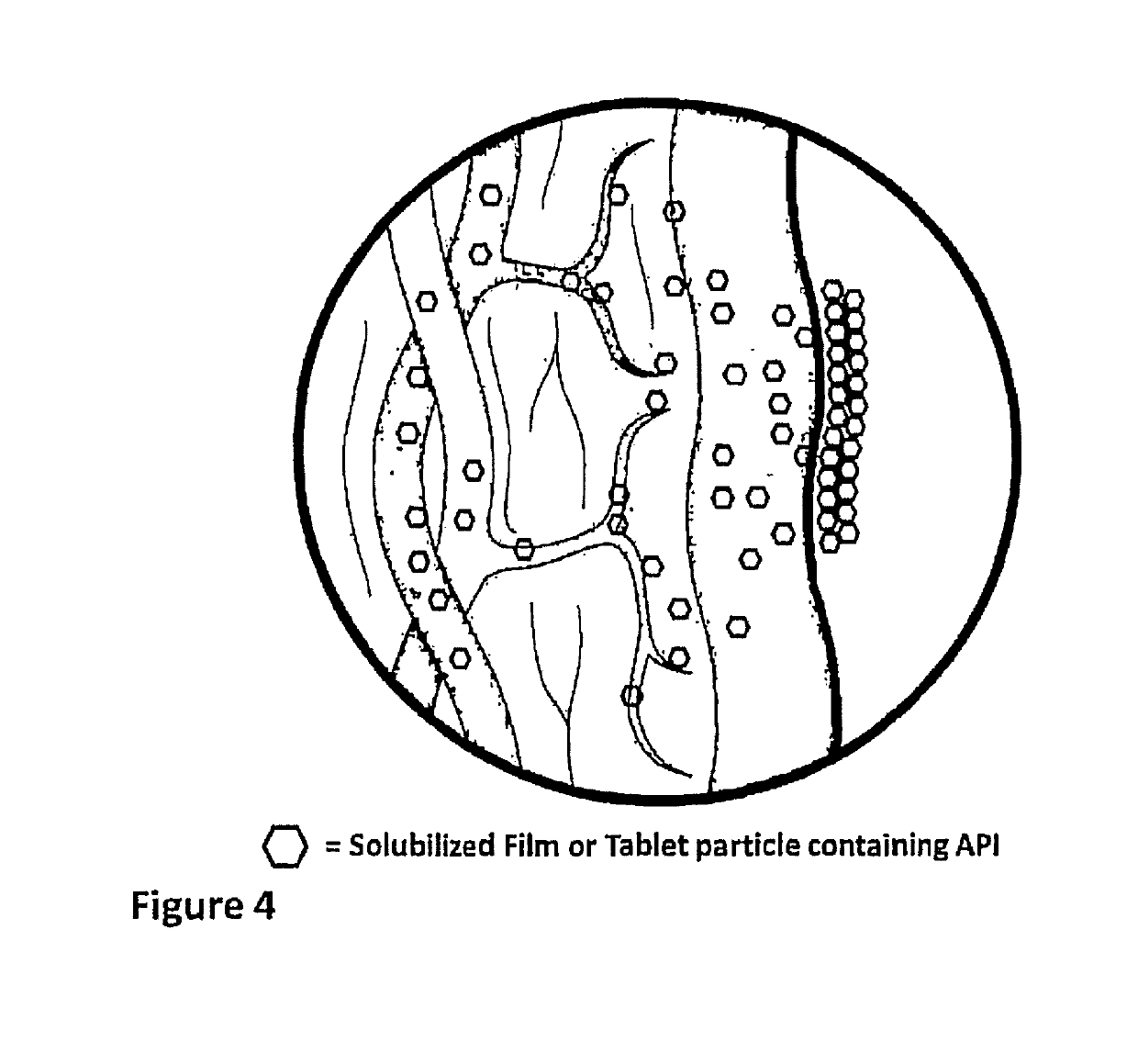

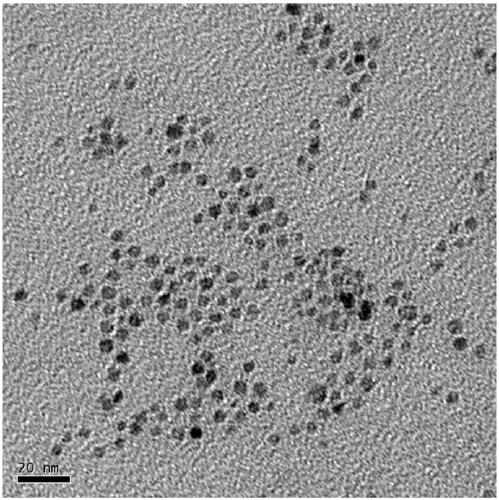

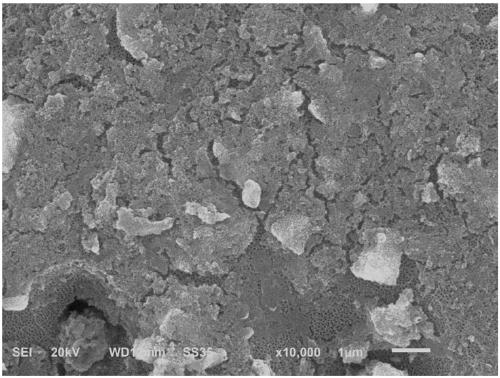

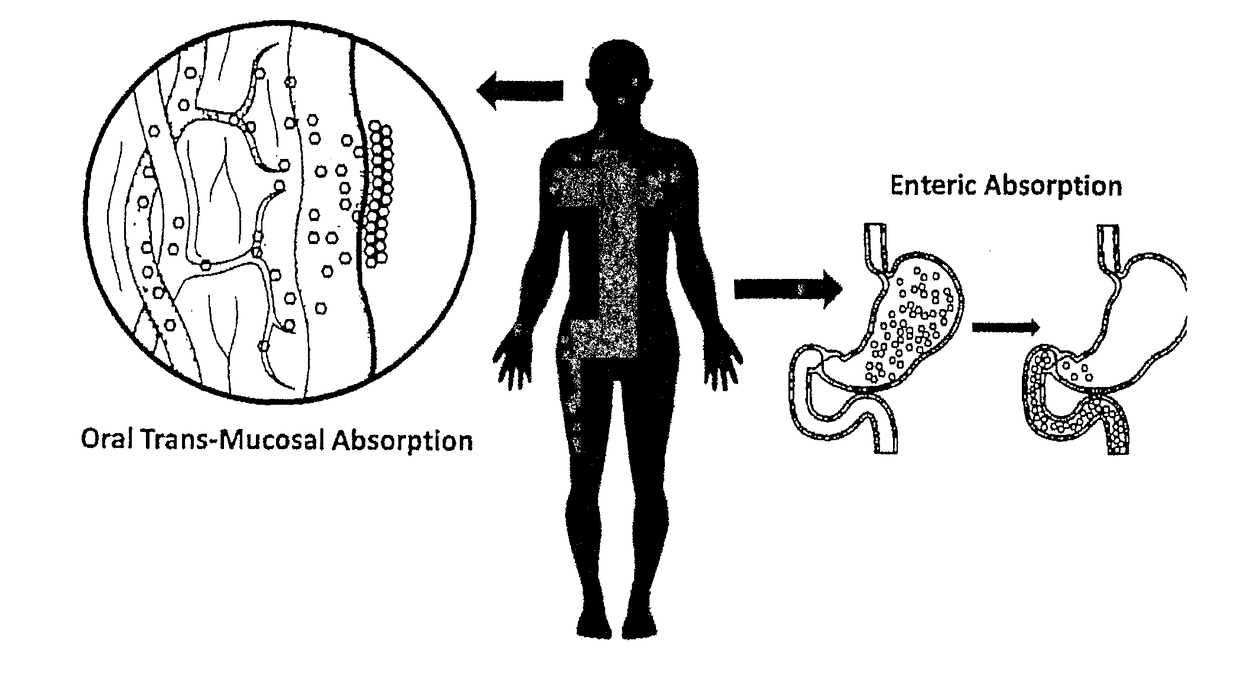

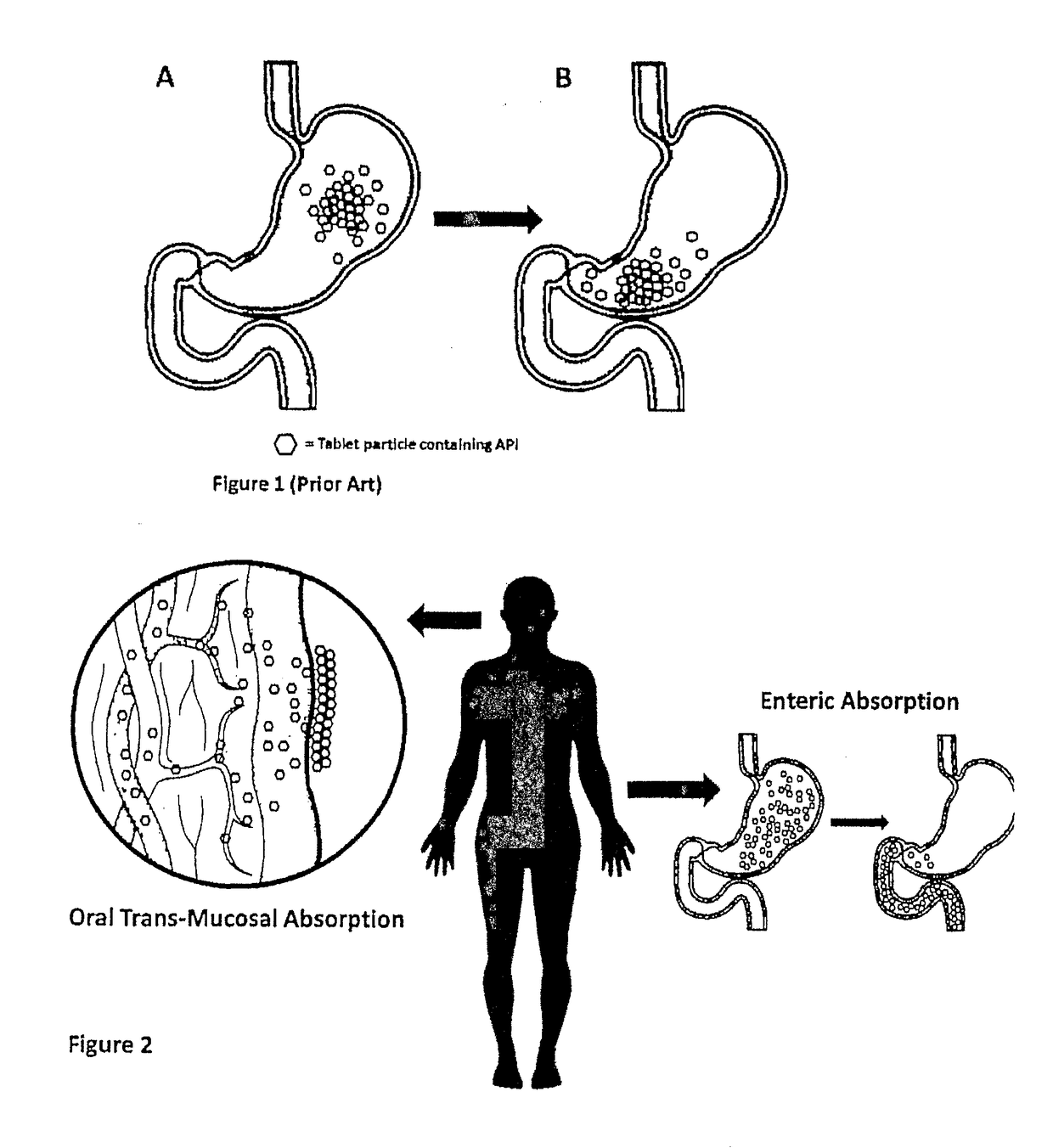

InactiveUS20190133925A1Improve bioavailabilityInorganic non-active ingredientsPharmaceutical delivery mechanismDiseaseFilm Dosage Form

Disclosed is a method of administration and device for the improved bioavailability of leukotriene receptor antagonists. This method and device involve an alkaline surface pH oral film dosage form designed to deliver leukotriene receptor antagonists, such as Montelukast, to the stomach in an amorphous precipitate suspended in aqueous medium. Also disclosed is a device and method for treating a disease, such as a neurodegenerative disease or condition associated with neuroinflammation induced by a leukotriene. The device is a film unit dosage form having an alkaline surface pH film layer and a safe and effective amount of Montelukast. The device is configured and formulated to predominantly achieve enteral delivery of the Montelukast. The method includes enterally delivering to a human or an animal in need of treatment, a safe and effective amount of Montelukast capable of crossing the blood-brain barrier.

Owner:INTELGENX CORP

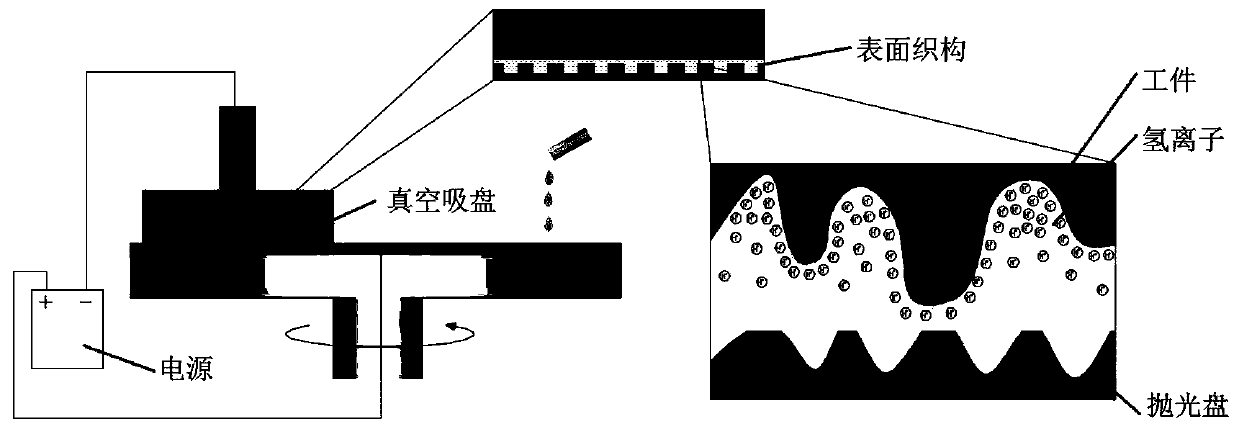

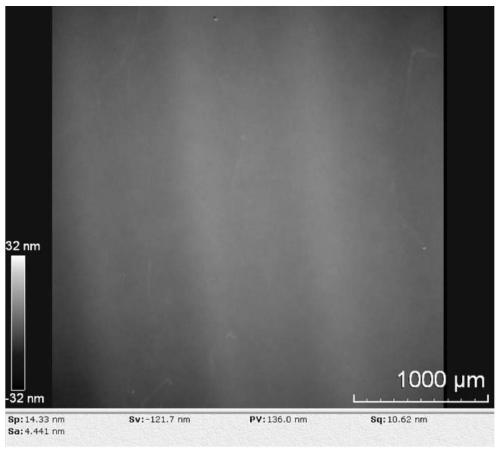

Germanium plane mirror chemical polishing method by using electric field effect to improve acidity and basicity of processing area

ActiveCN110328607AEnhanced chemical corrosivenessImprove polishing efficiencyLapping machinesAqueous dispersionsPlane mirrorOxygen ions

The invention discloses a germanium plane mirror chemical polishing method by using an electric field effect to improve acidity and basicity of a processing area. The germanium plane mirror chemical polishing method comprises the following steps of manufacturing a high dielectric constant vacuum sucker and a high dielectric constant polishing disc; coating high-temperature silver pastes on the nonworking end surfaces of the polishing disc and a base disc, connecting electrodes, and carrying out insulating treatment; and vacuumizing a germanium plane mirror on the porous ceramic base disc, andpolishing with a chemical polishing solution. The polishing principle of the method is that the high dielectric constant ceramic polishing disc is used, after the polishing disc and the vacuum adsorption ceramic base disc are connected with electrodes, a strong electric field is generated in a polishing area, and hydrogen ions or hydrogen oxygen ions move to the workpiece surface, so that the surface acidity and alkalinity of a workpiece are improved, the corrosiveness of the polishing solution to the workpiece surface is improved, and under the shear action of hydraulic pressure fluid, the surface of the workpiece is subjected to chemical non-contact polishing. According to the germanium plane mirror chemical polishing method by using the electric field effect to improve acidity and basicity of the processing area, the pH value of the workpiece surface can be controlled by the electric field, and through chemical non-contact polishing, the quality of the workpiece surface is improved, and the surface wear is avoided.

Owner:嘉兴知酷客信息科技有限公司

Pretreatment method of electric vehicle paint spraying

InactiveCN105772369ATightly boundMethod system is reasonablePretreated surfacesCoatingsPretreatment methodSurface cleaning

The invention discloses a pretreatment method of electric vehicle paint spraying. The pretreatment method comprises the following specific steps of: (1) surface cleaning, to be specific, washing a shell needing to be subjected to paint spraying by using clear water, then soaking the shell in a defatted powder water solution, and washing by using the clear water; (2) rust removal by neutralization, to be specific, putting the shell cleaned in the step (1) in a special acid solution, carrying out ultrasound treatment, washing by using clear water, and ensuring that the pH value of the surface of the shell is in a certain range; (3) phosphorization, to be specific, putting the shell treated in the step (2) in a phosphatizing agent solution, heating and soaking, heating again and slowly turning over the shell; and (4) drying and cleaning, to be specific, putting the shell treated in the step (3) in a drying machine, and taking out the shell after drying the shell, and uniformly purging the surface of the shell by using clean air after naturally cooling. The pretreatment method has the beneficial effects that a system is reasonable; the treatment method is careful and strict; parameter setting meets treatment requirements; and the treated shell can cause paint and the shell to be combined more tightly in a paint spraying process and flaws such as unevenness to be less likely to occur.

Owner:HUAIYUAN JINHAO ELECTRONICS TECH CO LTD

Image recording method

InactiveUS20050212885A1High resolutionEasy feedingMeasurement apparatus componentsDuplicating/marking methodsOrganic solventInorganic particle

An image recording method is disclosed. To form an image, an ink is caused to adhere on a recording medium which is provided with at least one ink-receiving layer on a base material. The ink is an inkjet recording ink, which is composed of a high-molecular dispersant, a water-insoluble colorant, a water-soluble organic solvent and water. The high-molecular dispersant contains at least one hydrophobic block and at least one hydrophilic block. The ink-receiving layer contains fine inorganic particles and a water-soluble resin and / or water-dispersible resin, and a surface pH of the ink-receiving layer is controlled within a range of from 3.0 to 6.5.

Owner:COPYER

Coated paper for printing by industrial ink jet printing machine

ActiveUS9370957B2High densityIncrease speedDuplicating/marking methodsCoatingsColloidal silicaGas phase

A coated paper having a base paper and at least two coating layers, a first coating layer and a second coating layer, provided on at least one surface of the base paper. The first coating layer is provided on the base paper and contains an organic pigment, a cationic compound, a binder, and a dogtooth-shaped precipitated calcium carbonate having a minor axis of 0.1-0.5 μm and a major axis of 0.5-2.5 μm. The second coating layer is provided on the first coating layer and contains at least an inorganic ultrafine particle that is selected from hydrated alumina, gas phase process silica, pulverized wet-process silica, and colloidal silica, and that has a mean particle size of 330 nm or less. The paper has a surface pH of from 5.0 to 7.5, and the coated surface coated with the second coating layer has a 75-degree gloss value of 45% or more.

Owner:MITSUBISHI PAPER MILLS LTD

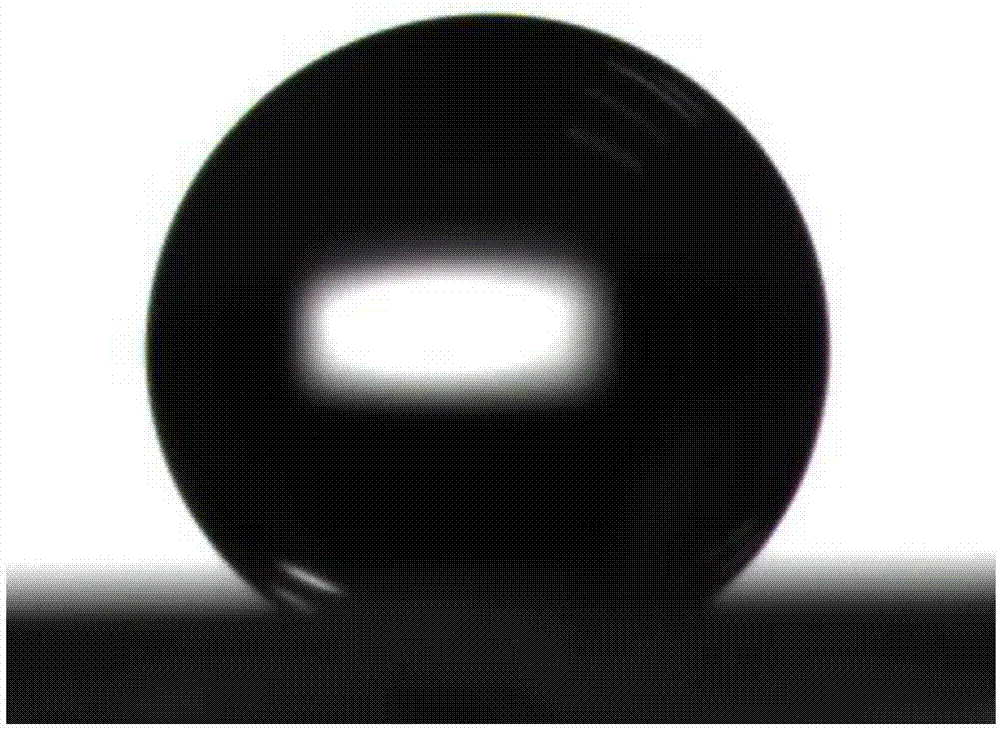

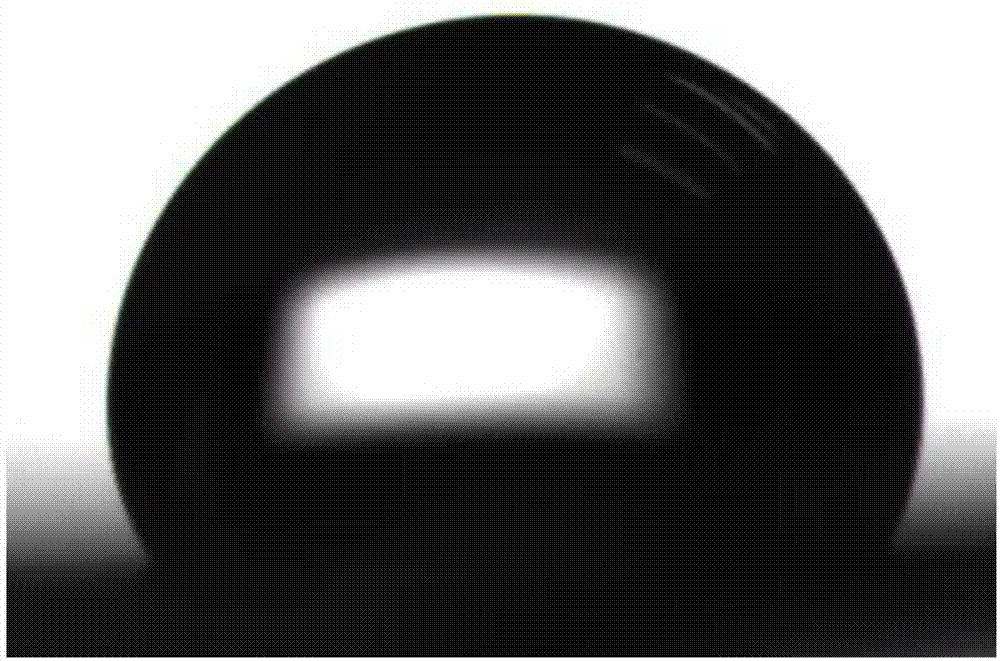

Method for utilizing PDPAEMA modified shape memory polymers to regulate and control surface permeability

The invention discloses a method for utilizing PDPAEMA modified shape memory polymers to regulate and control surface permeability, and relates to the method for regulating and controlling the surfacepermeability of materials. The method comprises the main steps of 1, etching silicon wafers by means of photolithography; 2, shaping the silicon wafers by utilizing PDMS; 3, shaping a shape memory epoxy resin micro-array by utilizing a PDMS template; 4, grafting poly2-(diisopropylaminoethyl methacrylate) (PDPAEMA) on the surface of the epoxy resin micro-array; 5, regulating and controlling the surface permeability by utilizing a sample obtained in the step 4. The method has the advantages that surface microstructure regulation and control is combined with surface pH response molecules for thefirst time, through the synergistic effect of physical regulation and control and chemical regulation and control, the controllable permeability conversion on the same surface is achieved from a super-hydrophilic mode to a super-hydrophobic mode, the obtained intelligent surface can be used for surface cell, oil-water separation and the like of intelligent devices, and the method is a novel preparation technology of response surfaces.

Owner:HARBIN INST OF TECH

Coated paper for printing by industrial ink jet printing machine

ActiveUS20150298478A1High densityIncrease speedDuplicating/marking methodsCoatingsWater basedColloidal silica

A coated paper for printing by industrial inkjet printing machines that is also suitable for offset printing, that has superior ink absorption properties in printing by an industrial inkjet printing machines, exhibits superior color densities and water resistance of images when printed by an industrial inkjet printing machine that uses water-based dye inks, superior reduction or elimination of uneven printing when printed by an industrial inkjet printing machine that uses water-based pigment inks, and desirable gloss. The present invention provides a coated paper for printing by an industrial inkjet printing machine comprising a base paper and at least two coating layers, a first coating layer and a second coating layer, provided on at least one surface of the base paper. The first coating layer is provided on the base paper and contains an organic pigment, a cationic compound, a binder, and a dogtooth-shaped precipitated calcium carbonate having a minor axis of 0.1-0.5 μm and a major axis of 0.5-2.5 μm. The second coating layer is provided on the first coating layer and contains at least an inorganic ultrafine particle that is selected from hydrated alumina, gas phase process silica, pulverized wet-process silica, and colloidal silica, and that has a mean particle size of 330 nm or less. The paper has a surface pH of from 5.0 to 7.5, wherein the surface pH is determined in accordance with Japan Technical Association of the Pulp and Paper Industry (JAPAN TAPPI) No. 49-2: 2000 by dropping an indicator solution for determining a pH on a surface of the second coating layer, spreading the solution into a thin layer over the surface to color the solution, and comparing the hue that the indicator solution shows with the hues in the pH standard color change table, and the coated surface coated with the second coating layer has a 75-degree gloss value as defined by JIS Z8741 of 45% or more.

Owner:MITSUBISHI PAPER MILLS LTD

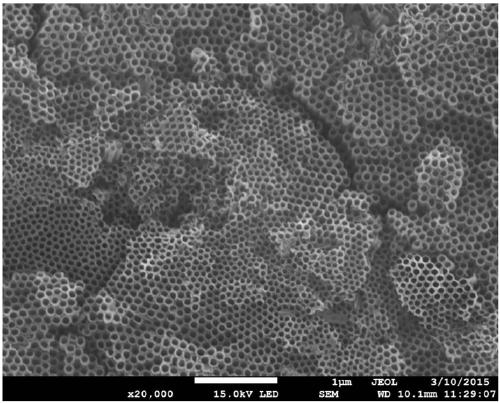

Drug-loaded structure of titanium metal surface pH controlled-release drug and preparation method of drug-loaded structure

InactiveCN109157674AAchieve antibacterial effectImprove antibacterial propertiesSurgerySurface reaction electrolytic coatingTitanium metalTithonia longiradiata

The invention discloses a drug-loaded structure of a titanium metal surface pH controlled-release drug and a preparation method of the drug-loaded structure. The structure comprises a titanium dioxidenanotube grown on the surface of titanium metal and a composite coating encapsulated on the surface of the titanium dioxide nanotube and containing folic acid and zinc oxide quantum dots; the preparation method comprises the following steps: after treating the titanium metal, allowing titanium dioxide nanotube to grow on the surface of the titanium metal by anodic oxidation, then loading a drug into the tube, and encapsulating the titanium dioxide nanotube with the prepared composite containing the folic acid and the zinc oxide quantum dots. According to the invention, the folic acid and a zinc oxide quantum dot coating in the drug-loading structure disclosed by the invention can control drug release in response to the pH, the slow release of zinc oxide in an acidic environment enhances an antibacterial cycle, the addition of the folic acid can promote cell proliferation and differentiation and facilitate the healing of a bacterial infection area, and both the folic acid and zinc oxide can be degraded in a human body, therefore, the drug-loading structure is harmless to a human body. The preparation method disclosed by the invention is simple, easy to operate and less in resourceconsumption, and has no influence on the environment.

Owner:HUBEI UNIV

Dressing process for bringing smooth hand feeling, elasticity and natural style to cotton textiles

This invention involves one kind of reorganization craft which can spin the purified cotton fabric feel crisply to slide, soft has the elasticity and has the natural style, its characteristic lies in after reorganizes in the craft to use the highly concentrated alkali silk to increase the fabric's gloss,then increases the laundering working procedure to the fabric surface pH value near neutrality, prevented the fabric body bone stiff and increases the soft slippery feeling; When stereotypia baiting; Reduces the soft medicinal preparation the amount, after drying carries on roll chasing the working procedure with under 80 DEG C + / -5 DEG C temperatures and 38 - 48 tons pressures, finally uses 40 ~ 60 meters / minute vehicle speeds to carry on shrinks in advance; Reorganizes after this craft, the purified cotton to spin the fabric feel crisply to slide, soft has the elasticity and has the natural style, the economic efficiency greatly increases.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Method of treatment and device for the improved bioavailability of leukotriene receptor antagonists

InactiveUS20180250240A1Improve bioavailabilityPharmaceutical non-active ingredientsSheet deliveryDiseaseBioavailability

Disclosed is a method of administration and device for the improved bioavailability of leukotriene receptor antagonists. This method and device involve an alkaline surface pH oral film dosage form designed to deliver leukotriene receptor antagonists, such as Montelukast, to the stomach in an amorphous precipitate suspended in aqueous medium. Also disclosed is a device and method for treating a disease, such as a neurodegenerative disease or condition associated with neuroinflammation induced by a leukotriene. The device is a film unit dosage form having an alkaline surface pH film layer and a safe and effective amount of Montelukast. The device is configured and formulated to predominantly achieve enteral delivery of the Montelukast. The method includes enterally delivering to a human or an animal in need of treatment, a safe and effective amount of Montelukast capable of crossing the blood-brain barrier.

Owner:INTELGENX CORP

Photothermographic material

InactiveUS20020055068A1X-ray/infra-red processesPhotothermographic systemsOrganic acidHeat sensitive

In a photothermographic material having an image-forming layer and a protective layer on a support, (A) a nucleating agent having a particular structure is added to at least one of the layers formed on the image-forming layer side of the support and NH4+ content in all the layers formed on the image-forming layer side is controlled to be 0.06 mmol / m2 or less, or (B) a nucleating agent and an organic acid compound having a particular structure are added to at least one of the layers formed on the image-forming layer side so that film surface pH is substantially unchanged. This photothermographic material is characterized by low fog, high Dmax, little increase of fog during storage and little temperature and humidity dependency upon heat development.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com