Ruthenium/aluminum oxide catalyst, as well as preparing method and application thereof

A catalyst and alumina technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve uneconomical production, increase operating costs, high-pressure reaction device costs, etc. problems, to achieve the effect of no three wastes discharge, long service life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

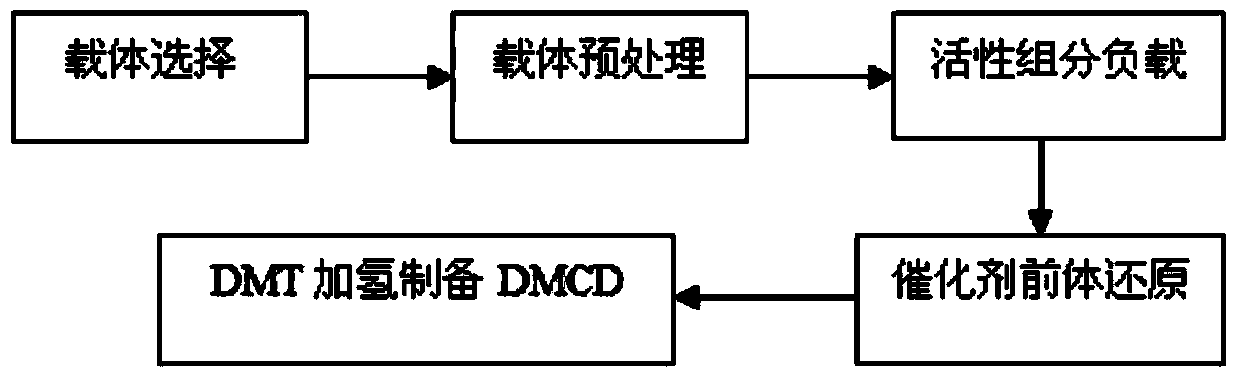

Method used

Image

Examples

Embodiment 1

[0043] (1) Macroporous water-thin pseudobauxite (Na 2 O≤0.1%, Fe 2 O 3 ≤0.02%) Calcination at 550℃ for 8h, heating rate 10℃ / min, to obtain γ-Al 2 O 3 Carrier, spare

[0044] (2) Prepare ruthenium solution based on 5% ruthenium loading, with a concentration of 1.0mol / L;

[0045] (3) Slowly add the solution prepared in (2) dropwise to alumina, immerse in vacuum for 6 hours, and let stand for 1 hour;

[0046] (4) Use 10% NaOH aqueous solution to adjust the pH value of the solution at 80°C to 11-12, precipitate for 3 hours, and let stand for 1 hour;

[0047] (5) Reduce the above solution with 37wt% formaldehyde, the amount used is 130% of the theoretical amount, and then stand for 2h after reduction for 2h;

[0048] (6) Filtration, washing, no Cl detected by silver nitrate solution - ; Keep it wet for later use.

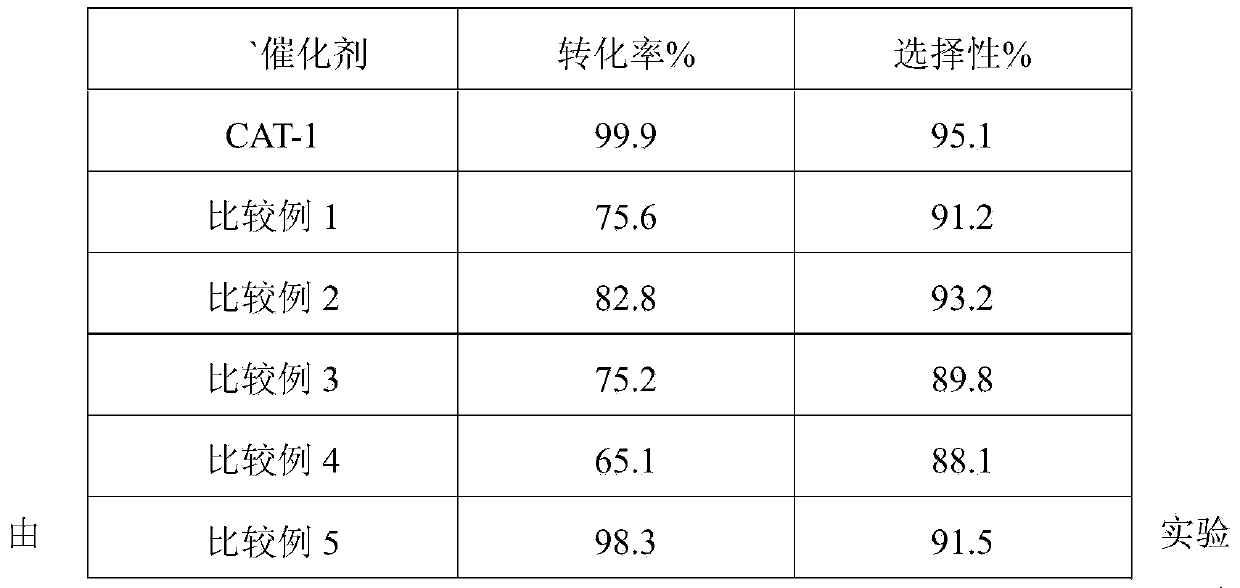

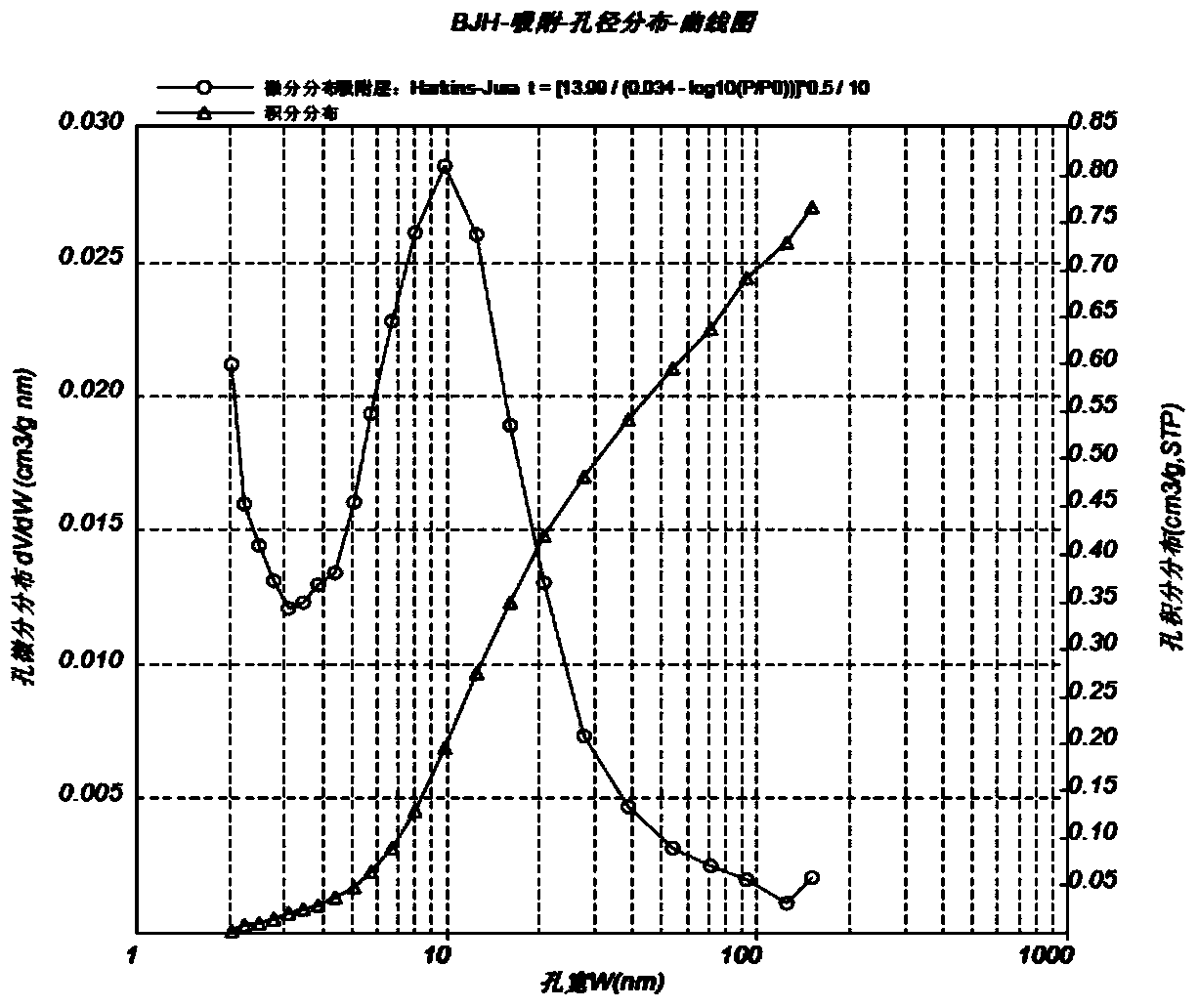

[0049] The catalyst number is CAT-1. The pore size distribution of the catalyst is shown in figure 2 , The catalyst is used for DMT hydrogenation to prepare DMCD product distribu...

Embodiment 2

[0051] Change the ruthenium loading in step (2) in Example 1 to 3%, and the other steps are the same as in Example 1. The catalyst number is CAT-2.

Embodiment 3

[0053] Change the ruthenium loading in step (2) in Example 1 to 6%, and the other steps are the same as in Example 1. The catalyst number is CAT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com