Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

787results about How to "Improve catalytic selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

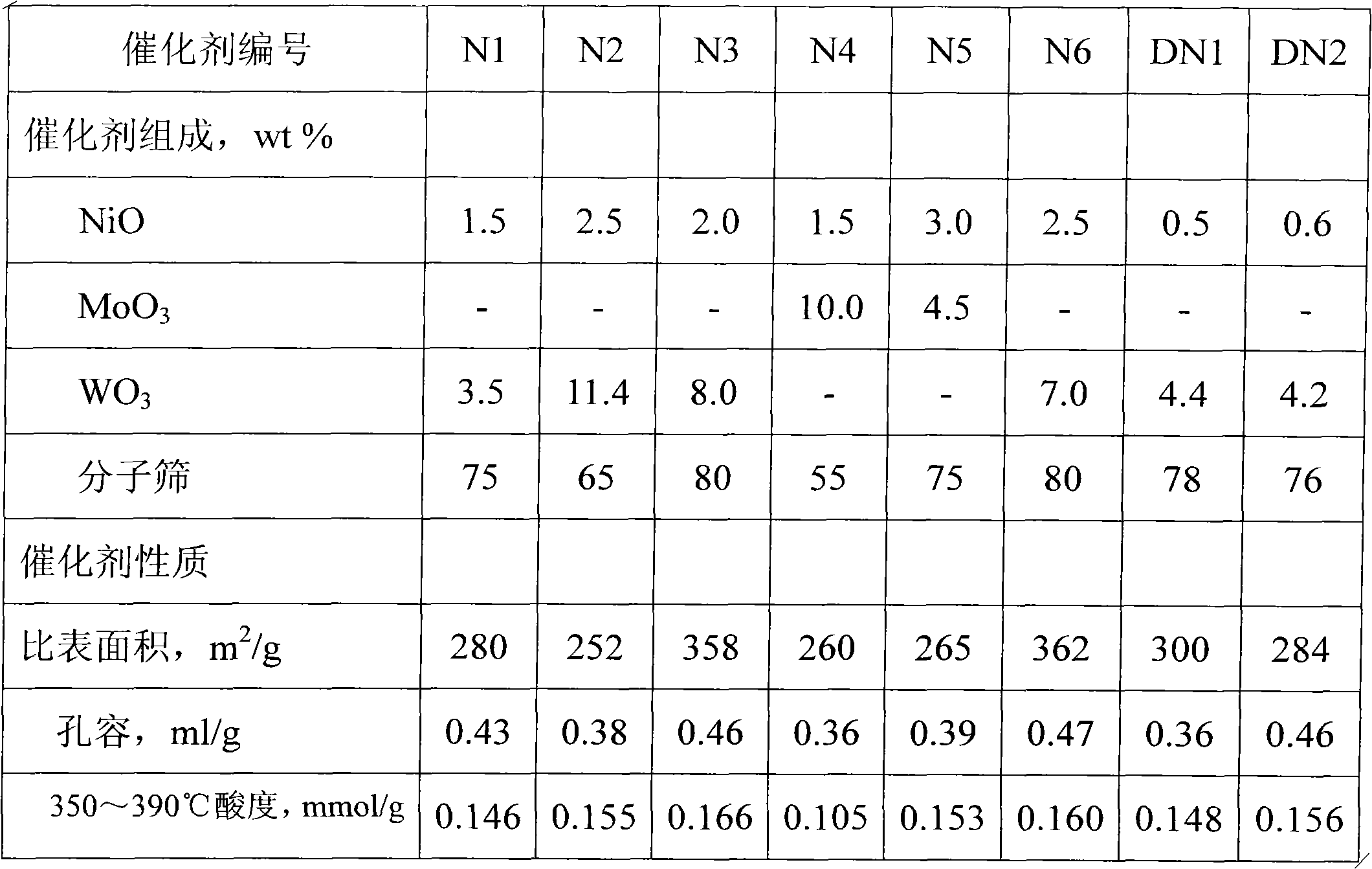

Diesel oil hydrogenation pour point depressing method

ActiveCN102051232ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveWax

The invention discloses a diesel oil hydrogenation pour point depressing method. A series flow of hydrofining and hydrogenation pour point depressing is adopted in the method, wherein a hydrogenation pour point depressing catalyst is modified by metal auxiliary agent and silicon, effectively regulates the acidity and orifice shape of the inner surface and the outer surface of a shape-selective cracking molecular sieve, is favorable for dispersing wax molecules in a diesel oil raw material into pore canals of the molecular sieve to perform shape-selective cracking reaction, and has high catalytic activity and selectivity of a target product; and because the acidity of the outer surface of the molecular sieve is weak, side reactions such as secondary cracking and the like are reduced, the pour point depressing effect of the diesel oil is good, and the fraction yield of the diesel oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

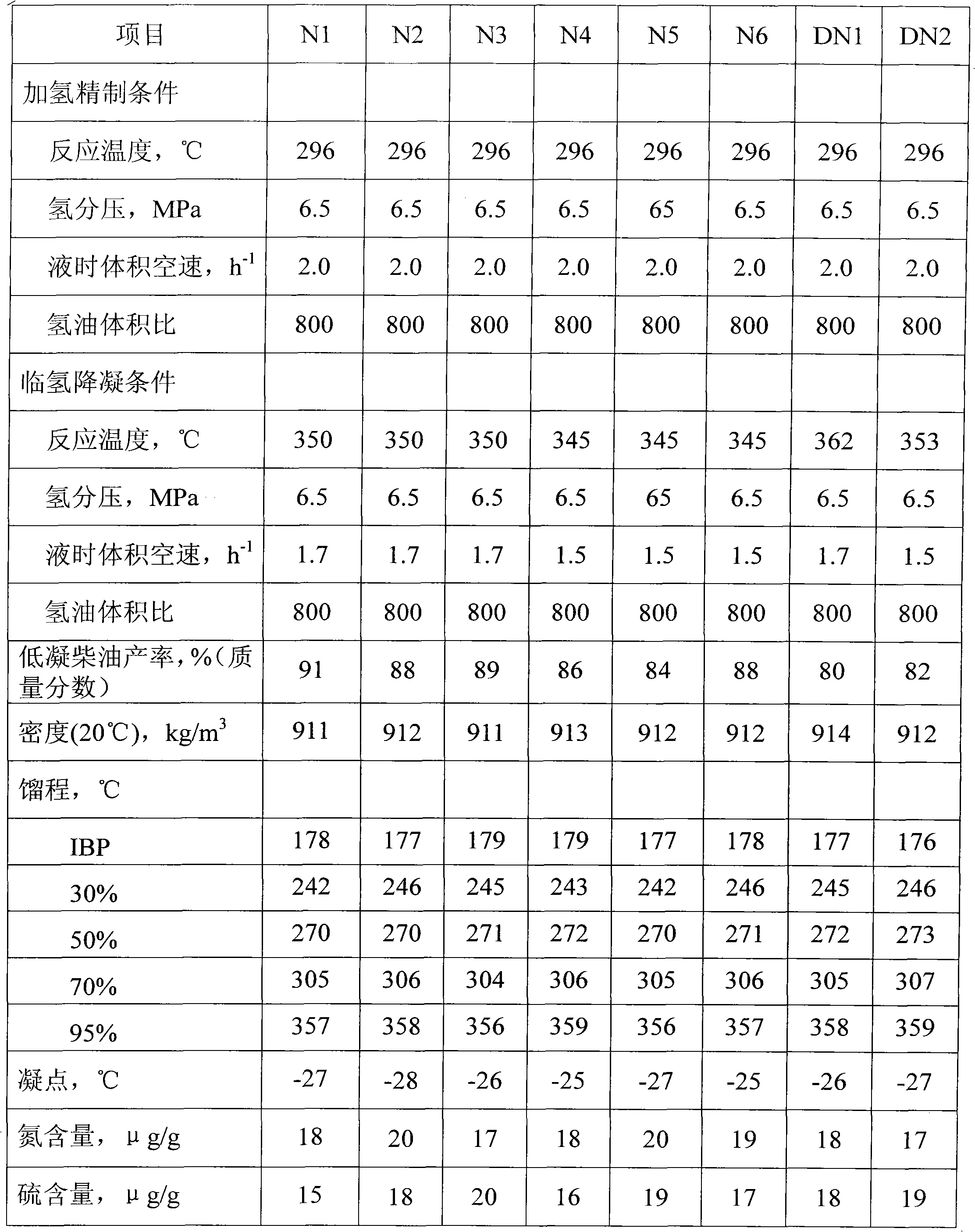

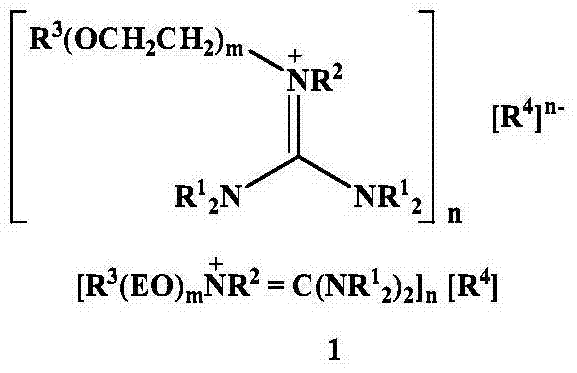

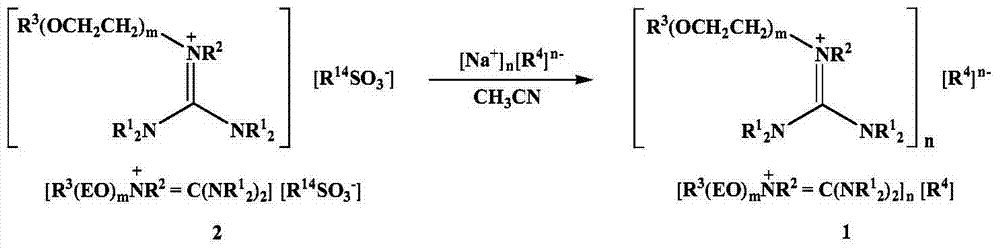

Preparation method of first-class phosphorus functionalized ionic liquid and application of ionic liquid in hydroformylation

ActiveCN103483381AEasy to synthesizeThe synthetic method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeOrganic reaction

The invention relates to synthesis of first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid, and an application of the first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid in a homogeneous catalytic reaction. The functionalized ionic liquid of such class can be easily prepared by an ion exchange reaction between the polyether alkyl guanidinium ionic liquid and sulfonic acid type water soluble phosphine ligand. The designed phosphorus functionalized ionic liquid can be applied to organic reactions, including hydroformylation, hydroesterification, hydrocarboxylation and catalytic hydrogenation under the catalyzing of a transition metal; the dosage of the ionic liquid used in the catalytic reaction can be decreased; the activity of the catalytic reaction can be improved; a catalyst can be separated and cycled simply and conveniently.

Owner:QINGDAO UNIV OF SCI & TECH

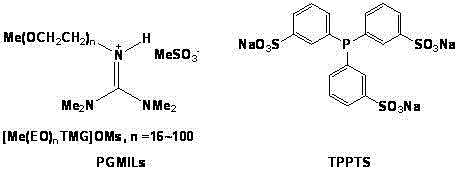

Olefin two-phase hydroformylation method

ActiveCN102617308AEffective fixed loadSeparation and easy handlingOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionTPPTSPolymer science

The invention relates to an olefin two-phase hydroformylation method, which consists of three parts: polyether guanidine mesylate ionic liquid (PGMILs) with room temperature solidifiable characteristics, complex catalysts (Rh-TPPTS) formed by RhCl3.3H2O or dicarbonylacetylacetonato rhodium and triphenylphosphine sodium trithionate (TPPTS), and reactants of C6-C14 straight chain 1-olefin, wherein the Rh-TPPTS is dissolved in the PGMILs to form a lower layer catalyst phase, the C6-C14 straight chain 1-olefin or product aldehyde forms an upper layer organic phase, the selectivity of high-carbon aldehyde is 85 to 99 percent, the mol ratio of normal aldehyde to isomerism aldehyde is 2.0 to 2.4, the PGMILs phase containing Rh-TPPTS can be cyclically used for 35 times, the activity and the selectivity are unchanged, the accumulated conversion number (TON) reaches higher than 30000, rhodium flowing to the product phase is 0.04 percent to 0.07 percent, and ultra-long-period catalysis activity and selectivity can be realized.

Owner:山东聚强绿洲生物科技有限公司

Preparation of amines

InactiveUS6140539ASimplifies work-upIncreased space-time yieldOrganic compound preparationOrganic chemistry methodsHydrogenMetal

In a process for preparing amines, in which at least one compound containing at least one nitro group is reacted with hydrogen in the presence of a supported catalyst comprising, as catalytically active metal, nickel, if desired together with at least one metal of transition group I, V, VI and / or VIII, the reduced and stabilized supported catalyst comprises nickel crystallites having a bimodal nickel crystallite size distribution having maxima at 30-80 Angstr+E,uml o+EE m and 81-150 Angstr+E,uml o+EE m on a support comprising ZrO2, ZrO2-HfO2 and / or SiO2-ZrO2 and / or SiO2-ZrO2-HfO2 and in the reduced and passivated state has a nickel content of 60-80 percent by mass, an SiO2 content of 0-20 percent by mass, a ZrO2 content of 0-40 percent by mass, an HfO2 content of 0-4 percent by mass and after further reduction for one hour at 100 DEG C. has a degree of reduction of at least 70%.

Owner:BASF AG

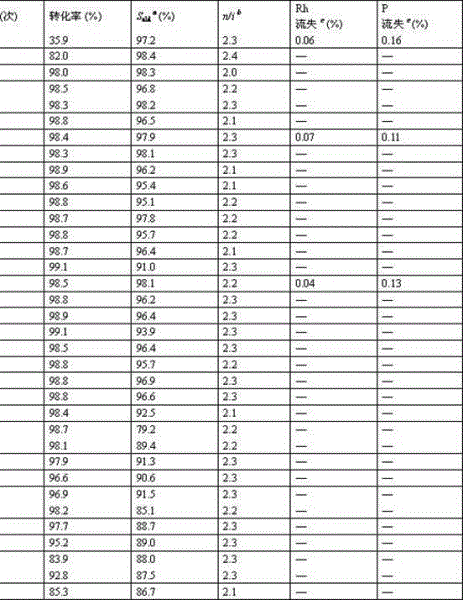

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

Method for ion liquid abstraction-catalytic oxidation desulfurization

InactiveCN101220293AMild reaction conditionsGood catalytic activity and selectivityRefining with oxygen compoundsIonTungsten

The invention relates to a method which uses ionic liquids extraction coupling tungsten, molybdenum and other polyoxometallate to catalyst oxidation so as to reduce the content of sulfur in the oil. The invention dissolves the catalyst into the ionic liquid and the volume ratio of the ionic liquid and the oil is 1:3 to 1:5, and the quantity range of the catalyst and the sulfur compounds is 1:100 to 4:100. The concentration of the aqueous hydrogen peroxide is 5 percent to 40 percent, and the content range with the sulfur compounds in the oil is 1:2 to 1:10. When the temperature is between 30 and 70 DEG C and the reaction time is 0.5 to 3 hours, coupling catalyst oxidation is extracted to reduce the content of sulfur in the oil to be less than 10 ppm. Compared with the traditional method, the method has the advantages that the sulfur has high removal efficient, and the reaction system is very simple, and the reaction condition is very soft and no pressure equipment is needed; the separation is very convenient and the ionic liquid can be recycled.

Owner:CRPC INNOVATION ENERGY

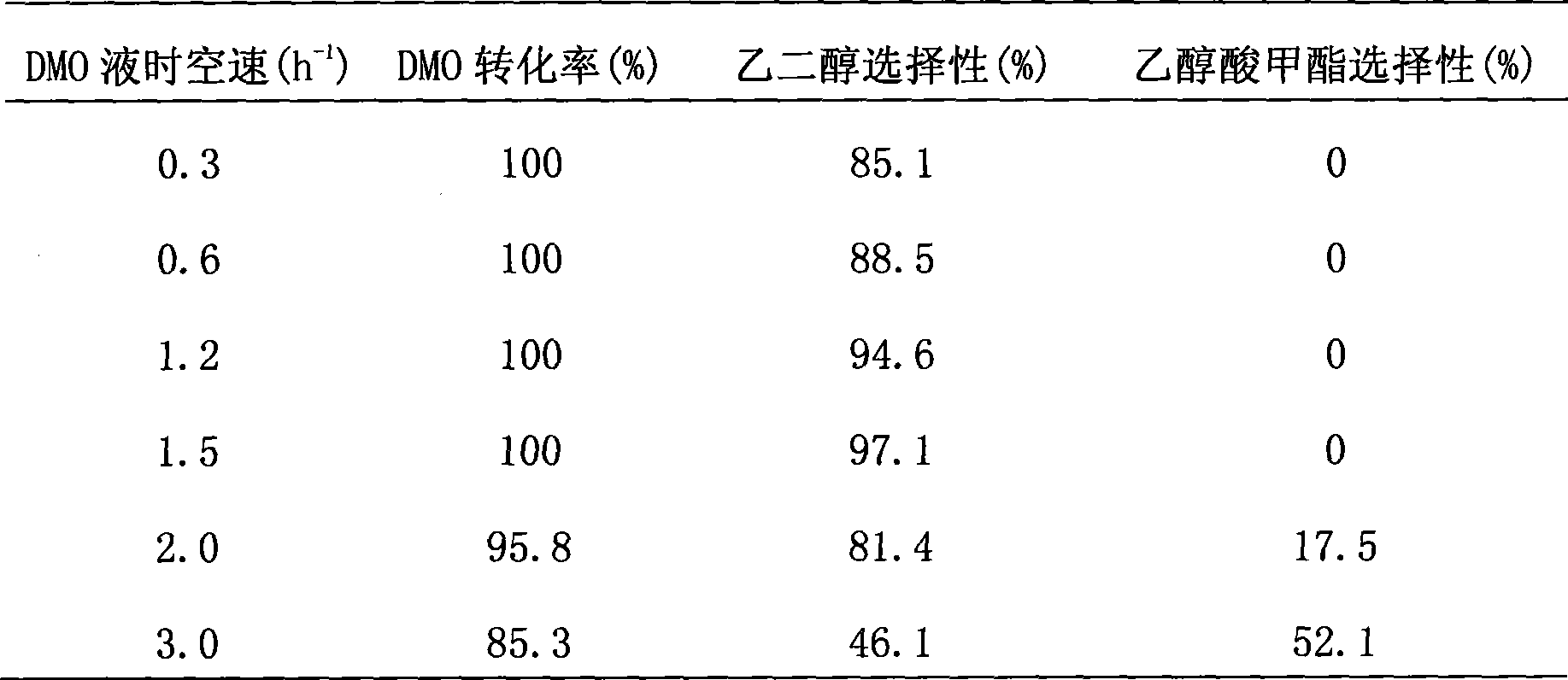

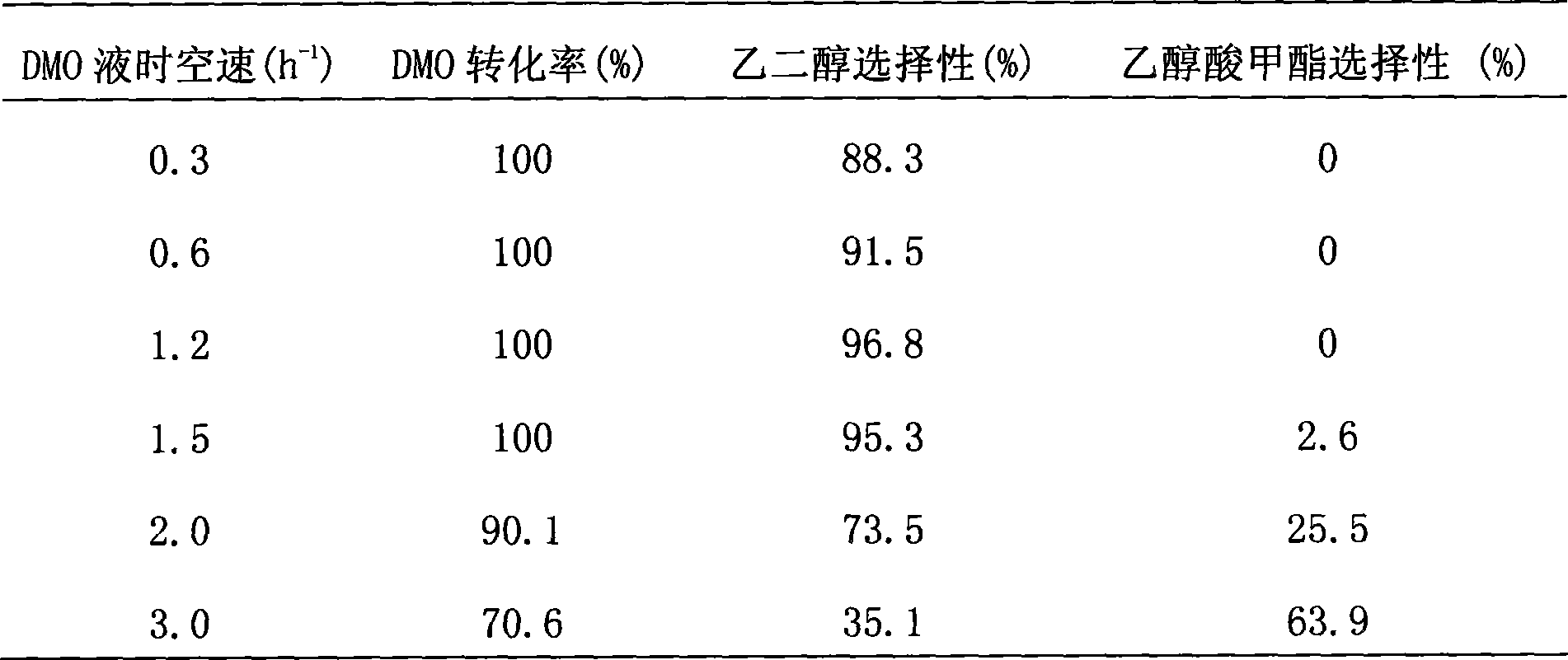

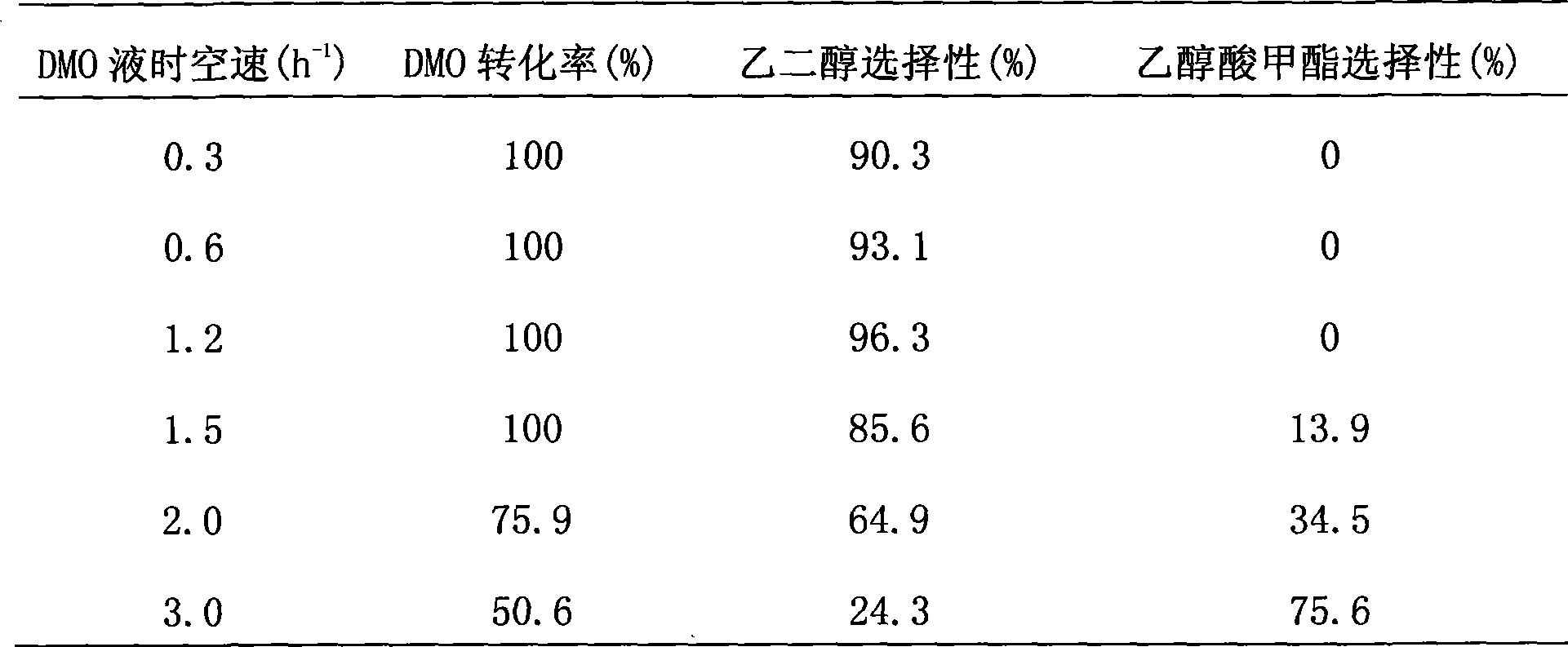

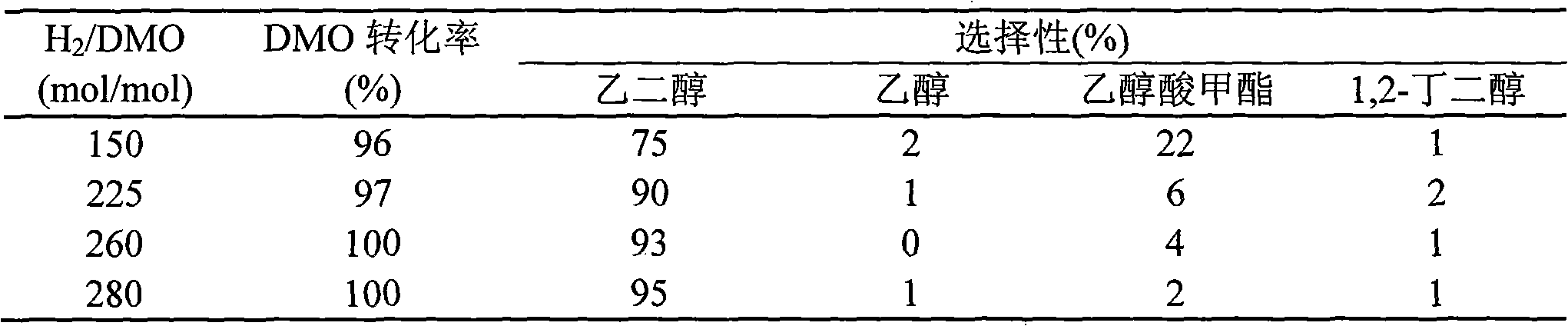

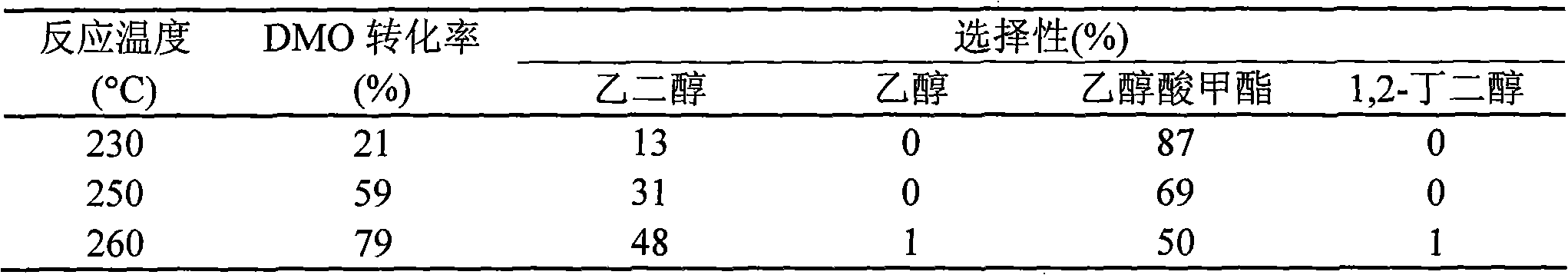

Method for preparing catalyst used in method for preparing ethanediol by dimethyl oxalate hydrogenation

InactiveCN101411990AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationCopper nitrateMesoporous silica

The invention relates to the field of chemical technology, in particular to a method for preparing a catalyst for hydrogenating dimethyl oxalate to prepare glycol. The method comprises the following steps: step one, copper nitrate is used to prepare a cuprammonium complex compound; step two, the cuprammonium complex compound is added with a mesoporous silica molecular sieve, is dripped with distilled water, and is filtered, washed, dried and roasted to prepare a catalyst precursor; and step three, the catalyst precursor is reduced in a hydrogen-nitrogen mixed atmosphere to prepare the catalyst. In the catalyst, according to mass percentage, the content of copper is between 5 and 40 percent; and the content of the mesoporous silica molecular sieve is between 60 and 95 percent. The method has the advantages that a silicon copper catalyst prepared through the new method has high catalytic activity and glycol selectivity in the reaction of hydrogenating the dimethyl oxalate to prepare the glycol, has long service life, smooth reaction performance and easy control.

Owner:FUDAN UNIV

Process for the start-up of an epoxidation process, a process for the production of ethylene oxide, a 1,2-diol, a 1,2-diol ether, a 1,2-carbonate, or an alkanolamine

InactiveUS20090281339A1Improve catalytic selectivityHigh selectivityProductsOrganic compound preparationOrganic chloride compoundOxygen

A process is provided for the start-up of an ethylene epoxidation process comprising: (a) contacting a catalyst bed comprising a high selectivity epoxidation catalyst with a feed comprising ethylene, oxygen and an organic chloride for a period of time until an increase of at least 1×10−5 mole-% of vinyl chloride (calculated as the moles of vinyl chloride relative to the total gas mixture), preferably 2×10−5 mole-% of vinyl chloride is detected in a reactor outlet gas or a recycle gas loop; and (b) subsequently adjusting the quantity of organic chloride in the feed to a value sufficient to produce ethylene oxide at a substantially optimum selectivity.

Owner:SHELL OIL CO

Benzene hydrogenation catalyst as well as preparation method and application thereof

ActiveCN102600888AExcellent benzene hydrogenation catalytic performanceHigh catalytic activityMolecular sieve catalystsHydrocarbon by hydrogenationBenzeneAdjuvant

The invention relates to a benzene hydrogenation catalyst as well as a preparation method and application of the benzene hydrogenation catalyst. The catalyst consists of an active component Ru and adjuvants, wherein the active component Ru is loaded on the catalyst by a carrier; the adjuvants are one or two of La, Ce, Fe, Zn, Cu and B, and the carrier is a mesoporous molecular sieve MCM-41 modified by one or two of ZrO2, ZnO and CuO. The invention also provides a method for preparing cyclohexene and cyclohexane by benzene hydrogenation catalyzed by the catalyst. The catalyst provided by the invention can be prepared by a dipping sedimentation method or a chemical reduction method and has a higher catalytic activity and cyclohexene selectivity.

Owner:XIANGTAN UNIV

Catalytic cracking method for sugar and sugar alcohol

InactiveCN101613253AReduce tensionLow costOrganic compound preparationHydroxy compound preparationAlcohol sugarsPropanediol

The invention relates to a method for preparing low-carbon alcohol through the catalytic cracking of sugar and sugar alcohol, which comprises the steps: under the action of an Ni-based catalyst, taking polycarbon sugar such as glucose, fruit sugar, xylose, sorbierite, mannite and xylitol, and water solution of various carbon sugar and sugar alcohol as raw materials, and cracking the raw materials into low-carbon alcohol of C3 or below C3 (particularly glycol and 1,2-propanediol) in a high selectivity mode through hydrogenation and dehydration processes. The conversion rate of the raw materials reaches over 95 percent. The yield of the glycol and the 1,2-propanediol in the low-carbon alcohol reaches over 50 percent. The method has the advantages of high efficiency, mild conditions, and high selectivity of the low-carbon alcohol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

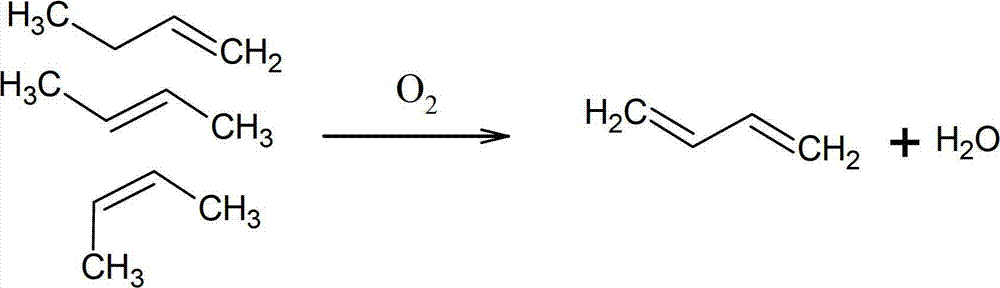

Catalyst and method used for preparing 1,3-butadiene by oxidative dehydrogenation of n-butene

ActiveCN102824914AHigh catalytic activityImprove catalytic selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMagnesium saltDehydrogenation

The invention discloses a catalyst and a method used for preparing 1,3-butadiene by oxidative dehydrogenation of n-butene. The catalyst is a cobalt and magnesium modified zinc ferrite catalyst which is obtained by proportioning a ferric salt, a zinc salt, a cobalt salt, a magnesium salt and a deionized water in a mole ratio, regulating pH value with ammonia water, concentrating, filtering, drying, roasting, cooling, grinding and screening. The method for preparing 1,3-butadiene by utilizing the catalyst comprises the following steps of: with C4 fraction produced by MTO (methanol to olefin) as a raw material, carrying out catalytic oxidative dehydrogenation reaction on a reaction mixture which is formed by the C4 fraction, air and vapour under the action of the cobalt and magnesium modified zinc ferrite catalyst so as to efficiently prepare1,3-butadiene, wherein the main ingredient of the C4 fraction is n-butene. The method disclosed by the invention has the advantage that the C4 fraction is not required to be refined to remove impurities such as oxygenated chemicals, thus the method disclosed by the invention is a simple and efficient method for preparing a high-additional-value product by utilizing C4 resource of the MTO.

Owner:SHAANXI COAL & CHEM TECH INST

Catalyst for Catalytic Cracking Fluidized Bed

InactiveUS20090288990A1Good effectHigh yieldCatalytic crackingMolecular sieve catalystsNaphthaFluidized bed

The present invention relates to a catalyst for catalytic cracking fluidized-bed, and the technical problems to be primarily solved by the present invention are high reaction temperature, low cryogenic activity of catalysts and worse selectivity during the preparation of ethylene-propylene by catalytically cracking naphtha. The present invention uses the composition having the chemical formula (on the basis of the atom ratio): AaBbPcOx, so as to magnificently solve said problems. The present invention therefore can be industrially used to produce ethylene and propylene by catalytically cracking naphtha.

Owner:CHINA PETROCHEMICAL CORP +1

Method for synthesizing methyl propionate by ethylene

ActiveCN103319337AGood choiceReduce consumptionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionPtru catalystPropanoic acid

The invention discloses a method for synthesizing methyl propionate by ethylene. The methyl propionate is prepared from the materials: ethylene, methanol, carbon monoxide and water under existence of a catalyst in a carbonyl combination manner; and the adopted catalyst is a composite catalyst system taking palladium acetate as a main catalyst, and metal ions such as cobalt, nickel or ruthenium and the like as a promoter. The method disclosed by the invention has good catalytic activity and selectivity at a low temperature and low pressure; the composite catalyst system has the advantages of low consumption, good selectivity, long service life and the like; carbonyl synthesis of the methyl propionate from the ethylene can be efficiently catalyzed; the reaction result is based on the ethylene; the yield of the methyl propionate is greater than 95%; and the entire method has good commercial value.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

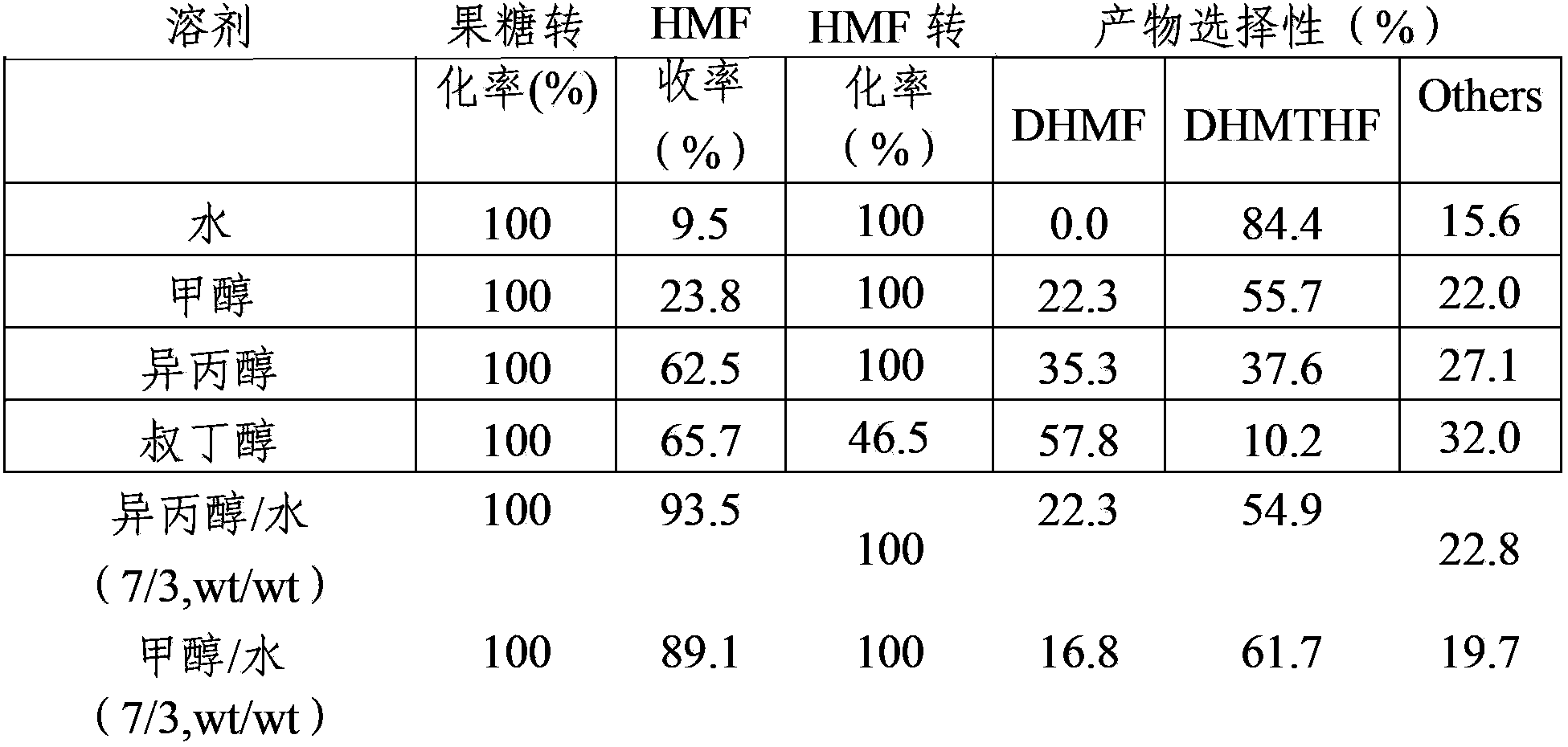

2, 5-dihydroxy methyl furan or 2, 5-dihydroxy methyl tetrahydrofuran synthesis method

InactiveCN103804329AWide variety of sourcesHigh catalytic activity and selectivityOrganic chemistryFructoseHexose

The invention relates to a method which uses a sugar catalyst to directly synthesize 2, 5-dihydroxy methyl furan or 2, 5-dihydroxy methyl tetrahydrofuran. The method comprises the steps that fructose and other hexose is used as a raw material, and is dehydrated in the presence of a solid acid catalyst to generate 5-hydroxymethyl furfural; the solid acid is separated; a hydrogenation catalyst is added; and reaction with hydrogen inlet is carried out under normal temperature and pressure to generate the 2, 5-dihydroxy methyl furan or 2, 5-dihydroxy methyl tetrahydrofuran. The method has the advantages of mild reaction condition, cheap and easily obtained raw material, easy reaction process operation, and high yield of 2, 5-dihydroxy methyl furan or 2, 5-dihydroxy methyl tetrahydrofuran.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

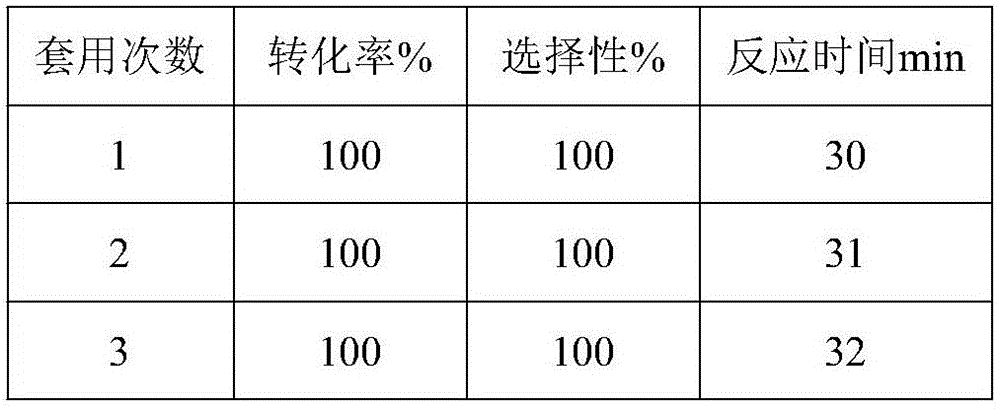

Porous carbon-loaded composite material catalyst as well as preparation method and application thereof

ActiveCN106732549AImprove transfer abilityModulation distribution characteristicsOrganic compound preparationAmino compound preparationIridiumPorous carbon

The invention discloses a porous carbon-loaded composite material catalyst as well as a preparation method and application thereof. The catalyst consists of a carrier, an active component and a carbon quantum dot, wherein the active component and the carbon quantum dot are loaded on the carrier; the size of the carbon quantum dot is not more than 10 nm; the carrier is porous activated carbon; the active component is one of or a combination of several of platinum, palladium, iridium, ruthenium and rhodium; based on the mass of the carrier, the loading quantity of various metals in the active component is shown as follows: the platinum is 0-10.0 percent by weight, the palladium is 0-10.0 percent by weight, the iridium is 0-10.0 percent by weight, the ruthenium is 0-10.0 percent by weight, and the rhodium is 0-5.0 percent by weight; the loading quantity of the platinum, the rhodium and the palladium is not 0; the total loading quantity of the active component is more than 0.5 percent by weight and is not more than 20 percent by weight; based on the mass of the carrier, the loading quantity of the carbon quantum dot is not more than 15.0 percent by weight. The invention further provides application of the porous carbon-loaded composite material catalyst to the reaction of synthesis of chloroaniline by selective catalytic hydrogenation of chloro-nitrobenzene. The catalyst has the characteristics of being high in conversion rate, high in catalytic activity and high in stability.

Owner:ZHEJIANG UNIV OF TECH

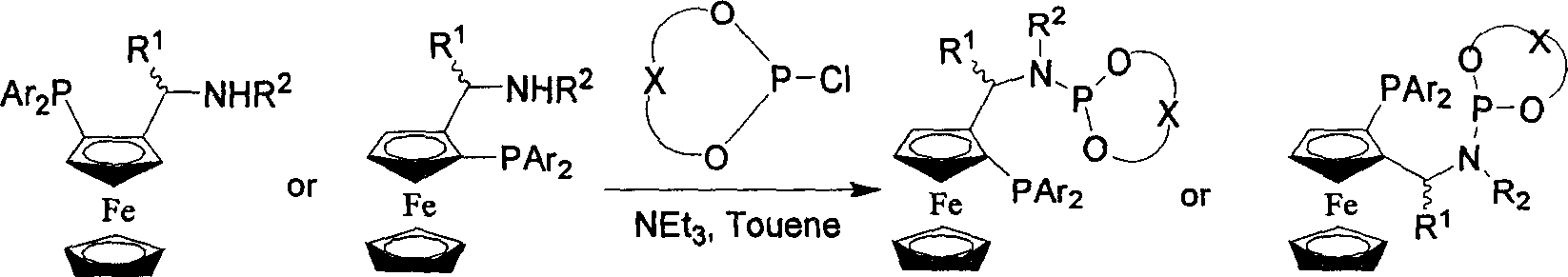

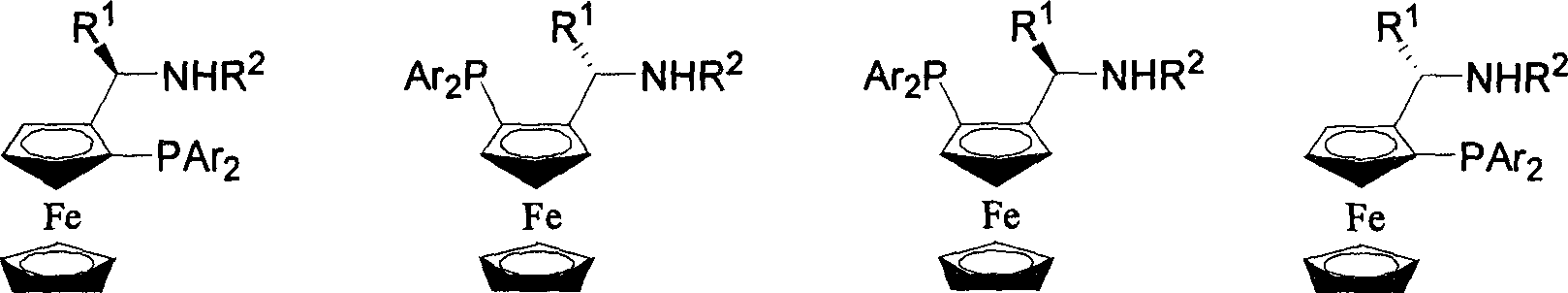

Catalyst using phosphine-phosphoramidite ester as ligand, its preparation method and application

InactiveCN1768944AThe synthetic route is simpleHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsIridiumPt element

The invention relates to a catalyst which uses the phosphor-phosphamide as ligand, which is the phosphor-phosphamide ligand metallic complex of chiral ferrocenyl bone, wherein, the metal is rhodium, ruthenium, iridium, platinum or palladium; and the mol rate between the ligand and the metal precursor is 1.1:1-2.2:1. The ligand is compounded from chiral ferrocenyl to intermediate compound via several reaction steps, to be processed condensation with phosphite ester chloridate to attain the phosphor-phosphamide ligand with different chiral centers. Said ligand has new structure, stable property, simple compounding method, and wider application to the catalyst, which has higher catalysis activity (TON reaches 10000) and higher spatial selectivity (ee reaches more than 99%) in catalyzing asymmetry hydrogenization of itaconic acid, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

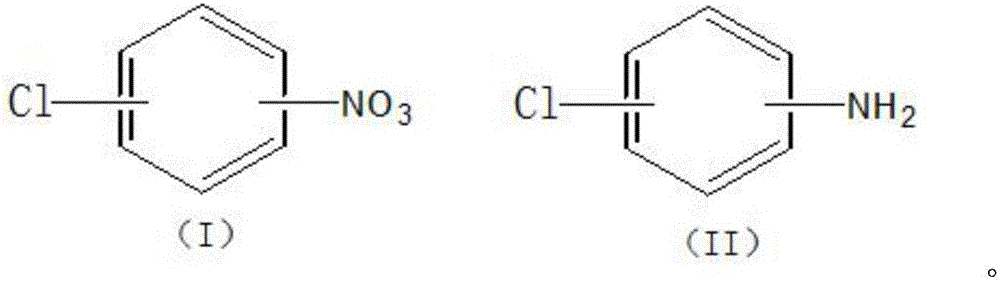

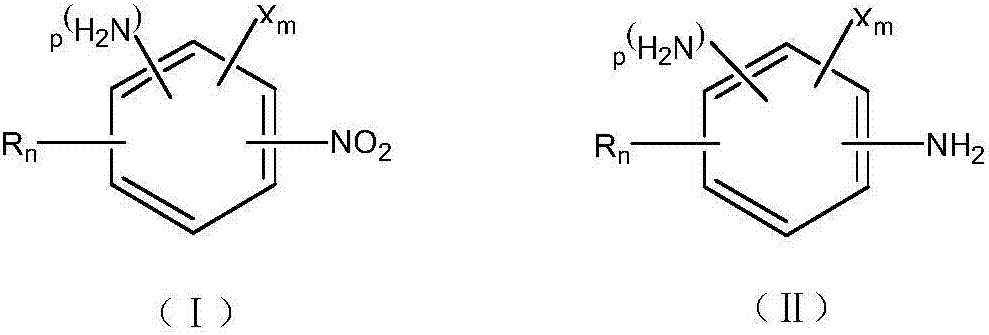

Nitrogen-doped activated carbon supported noble metal catalyst and application thereof

ActiveCN107413331AEnhanced electron transfer capabilityRedistribution of electronsOrganic compound preparationAmino compound preparationActivated carbonIridium

The invention discloses a nitrogen-doped activated carbon supported noble metal catalyst and an application thereof. The catalyst is composed of a carrier and an active component; the carrier is nitrogen-doped activated carbon; the active component is one of palladium, platinum, rhodium, ruthenium and iridium; and the load of the active component is not higher than 15wt% based on the mass of the carrier. The invention provides the application of the nitrogen-doped activated carbon supported noble metal catalyst to reaction for preparing an alkyl-containing halogenated aromatic aminocompound shown as a formula (II) by carrying out catalytic hydrogenation reduction on an alkyl-containing halogenated aromatic nitrocompound shown as a formula (I) to show that the nitrogen-doped activated carbon supported noble metal catalyst has the characteristics of high hydrogenation reaction rate, high catalytic activity, high selectivity and high stability.

Owner:ZHEJIANG UNIV OF TECH

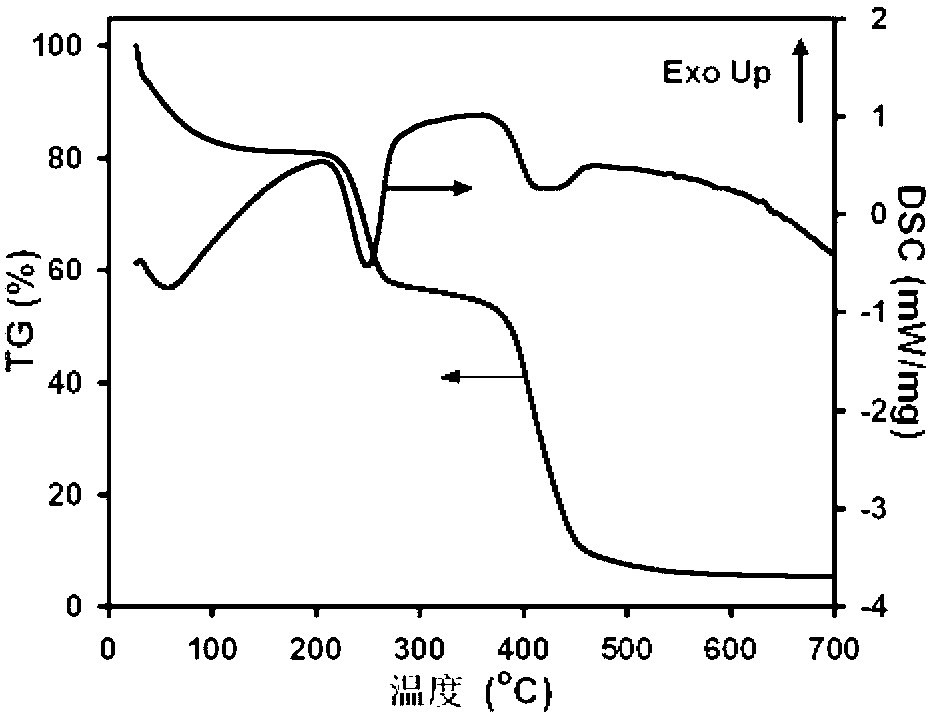

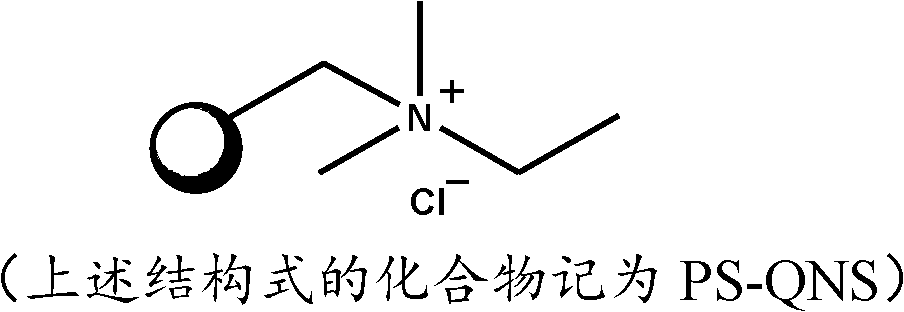

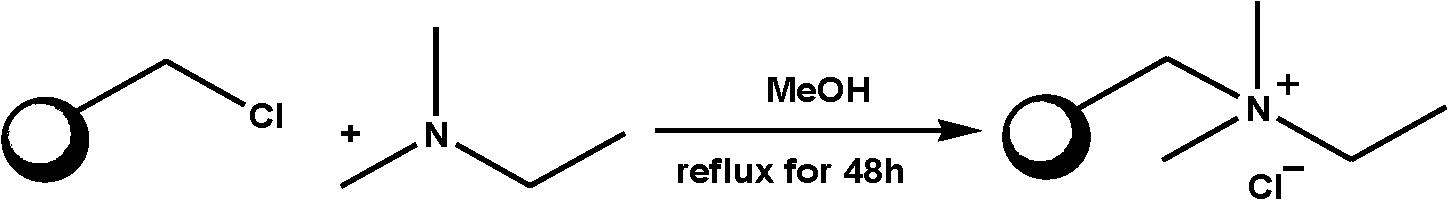

Polymer supported quaternary ammonium salt ion catalyst as well as preparation method and application thereof

InactiveCN102698799ALow costEasy to prepareOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCarbamatePolystyrene

The invention relates to a polymer supported quaternary ammonium salt ion catalyst as well as a preparation method and an application thereof. The preparation method is characterized in that chloromethylated polystyrene is taken as a carrier and reacts with N, N-dimethylethylamine to obtain polymer supported quaternary ammonium salt ion liquid catalyst; and under the condition that the catalyst dosage is 0.04-0.4 g, the initial pressure of carbon dioxide is 0.5-5.0 MPa, the reaction temperature is 110-180 DEG C, and the reaction time is 1-10 h, cyclic carbamate is prepared with high selectivity through cycloaddition reaction of carbon dioxide and epoxide. The catalyst has higher catalytic activity to the cycloaddition reaction of carbon dioxide and epoxide without adding any organic solvent or catalyst promoter, and the reaction condition is mild, and the obtained cyclic carbamate has a high yield and selectivity. The solid catalyst has the advantages of low price of raw material, simplie preparation method, good hydrothermal stability, convenience in recovery, and reusability.

Owner:HUNAN UNIV

Method and Catalyst for the Transalkylation/Dealkylation of Organic Compounds

InactiveUS20080021253A1Improve catalytic selectivityMaximize productionHydrocarbon by isomerisationMolecular sieve catalystsCatalytic methodCrystal structure

The invention relates to a catalytic method for the transalkylation / dealkylation of organic compounds, consisting in bringing a supply comprising organic compounds into contact with a catalyst containing a first zeolitic component that is selected from among: a) one or more zeolites having crystalline structure ITQ-13; b) one or more zeolites having crystalline structure ITQ-13, which are modified either by means of selectivation or with the incorporation of one or more metals, or both; and c) a mixture of a) and b). The invention also relates to a catalyst comprising one or more modified zeolites having crystalline structure ITQ-13.

Owner:CORMA CANOS AVELINO +3

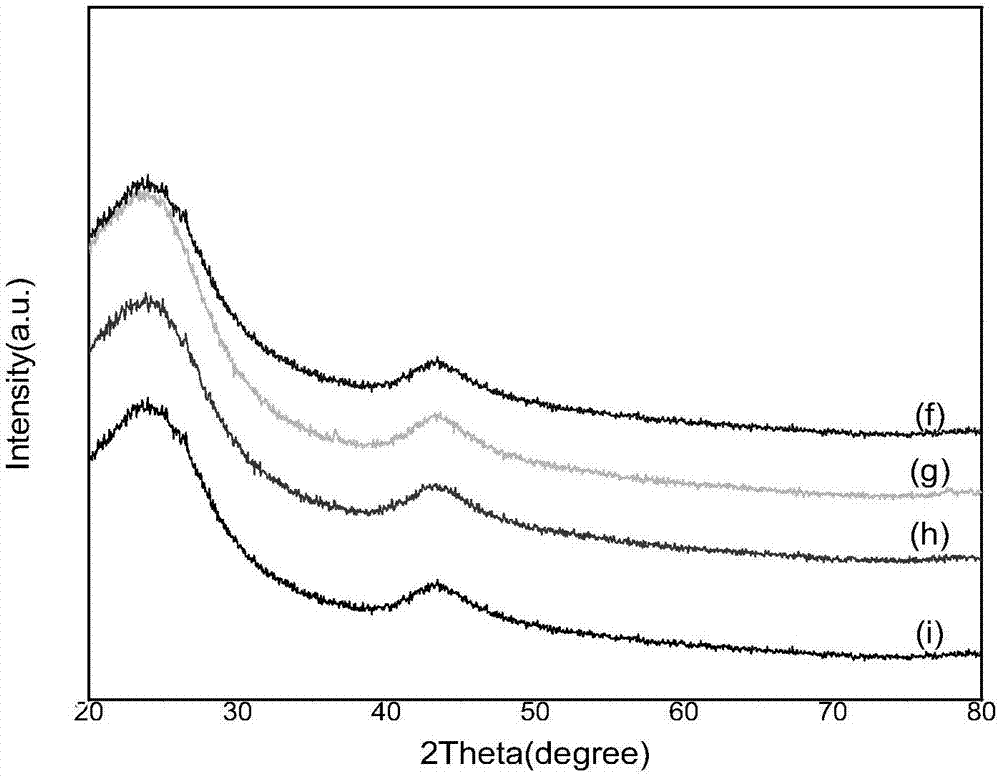

Preparation method of nickel based metal load type catalyst

ActiveCN101455964AHigh catalytic activityImprove catalytic selectivityMetal/metal-oxides/metal-hydroxide catalystsActivation methodHydrogen atmosphere

The invention discloses a method for preparing nickel-base metal supported catalyst. The preparation method comprises the steps of reducing a nickel-base layered hydrotalcite precursor for 1 to 12 hours by use of hydrogen in hydrogen atmosphere at a temperature between 200 and 800 DEG C and directly generating the nickel-base metal supported catalyst. The composition of the nickel-base layered hydrotalcite precursor is Ni1-y-xMxAly(OH)2(CO3)y / 2+x(z-2) / 2.nH2O, wherein x is between 0 and 0.5; y is between 0.1 and 0.33; z is a valence of M; and the M is Fe, Co, Cu, Sn, Mg, Zn, La or Ce. As a direct H2 reduction-activation method leaves out the step of intermediate roasting, the method has the advantages of simplifying a catalyst- activating process and reducing energy consumption, and is an optimal option for preparing a metal supported catalyst by reducing and activating a catalyst precursor which contains a transitional metal catalyst prepared by a precipitation method.

Owner:ZHEJIANG UNIV OF TECH

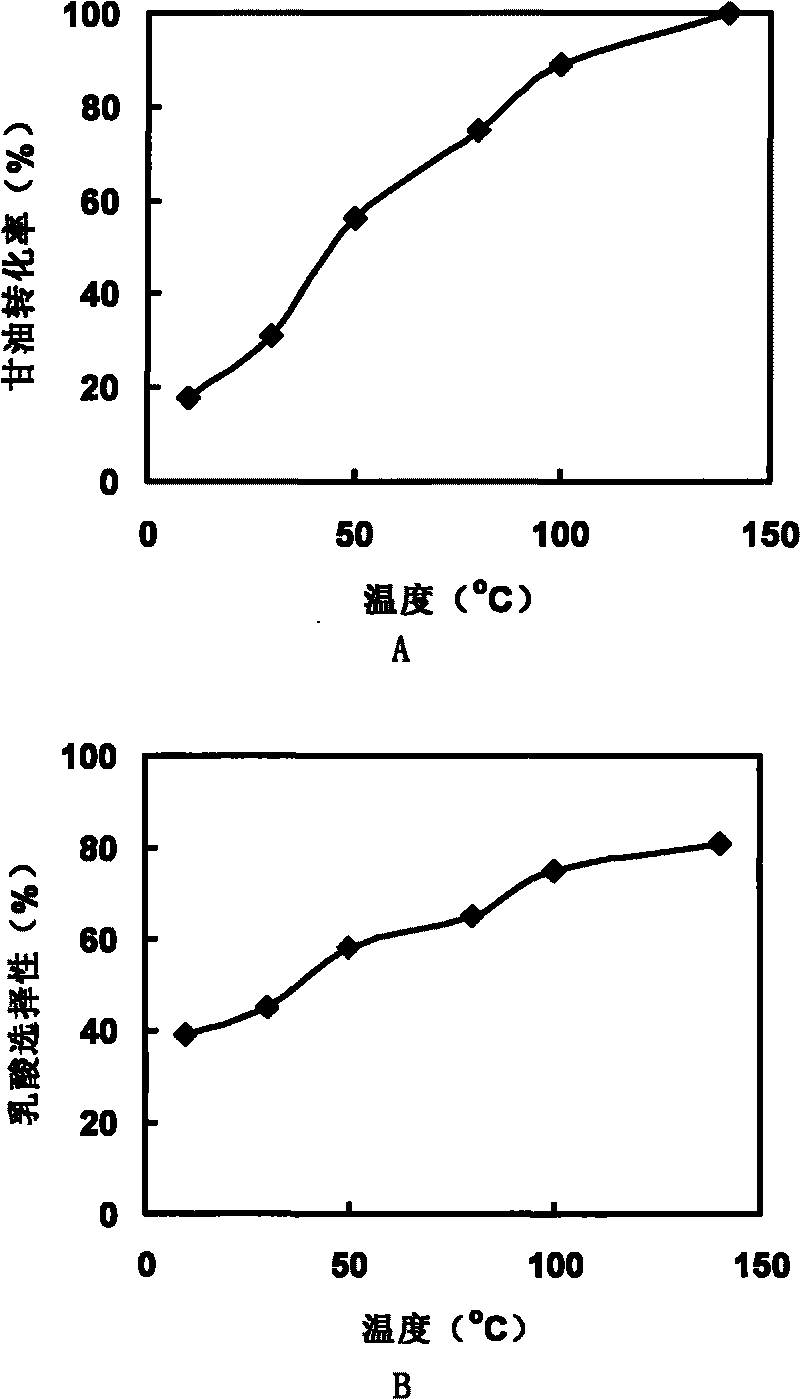

Method for producing lactic acid by using glycerin and special catalyst for production of lactic acid by using glycerin

ActiveCN101695657AImprove performanceImprove reaction efficiencyOrganic compound preparationCatalyst activation/preparationGlycerolBULK ACTIVE INGREDIENT

The invention provides a method for producing lactic acid by using glycerin and a special catalyst for the production of the lactic acid by using the glycerin. The catalyst provided by the invention is obtained by loading 0.1 to 30 mass parts of an active ingredient onto 100 mass part of carrier, wherein active ingredient is (1) Pt or (2) a composite of Pt and other noble metals. The catalyst can be used in the production of the lactic acid by using the glycerin. In the presence of the catalyst of the invention, the glycerin can be converted into the lactic acid effectively under a mild reaction condition. The catalyst of the invention has the advantages of high activity and selectively, easy preparation, low price, easy industrialization, long service life, loss prevention and good application prospective.

Owner:PEKING UNIV

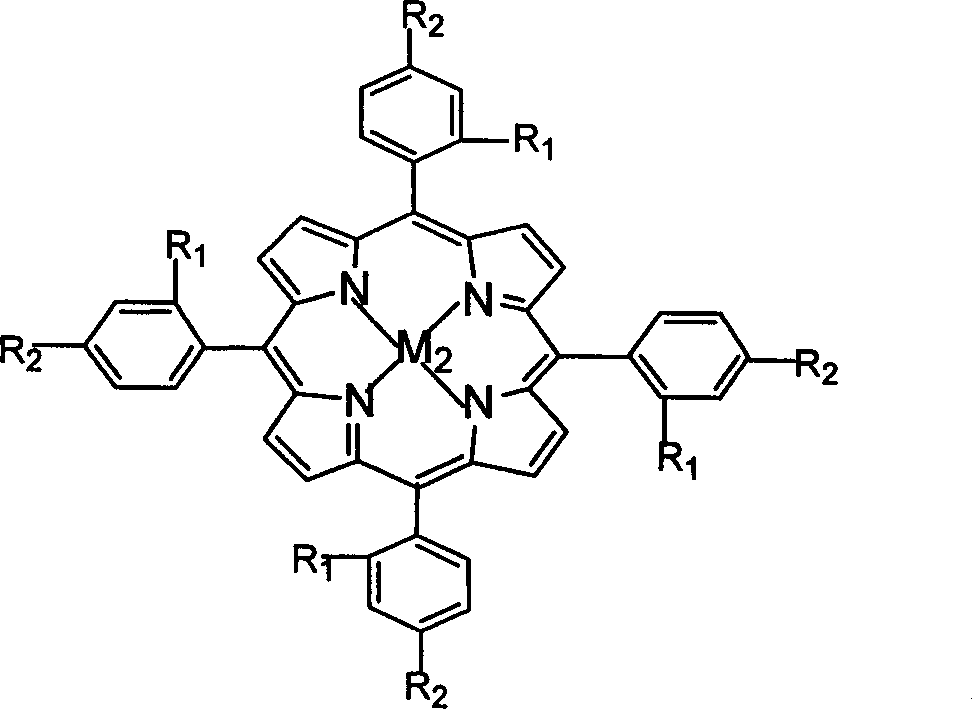

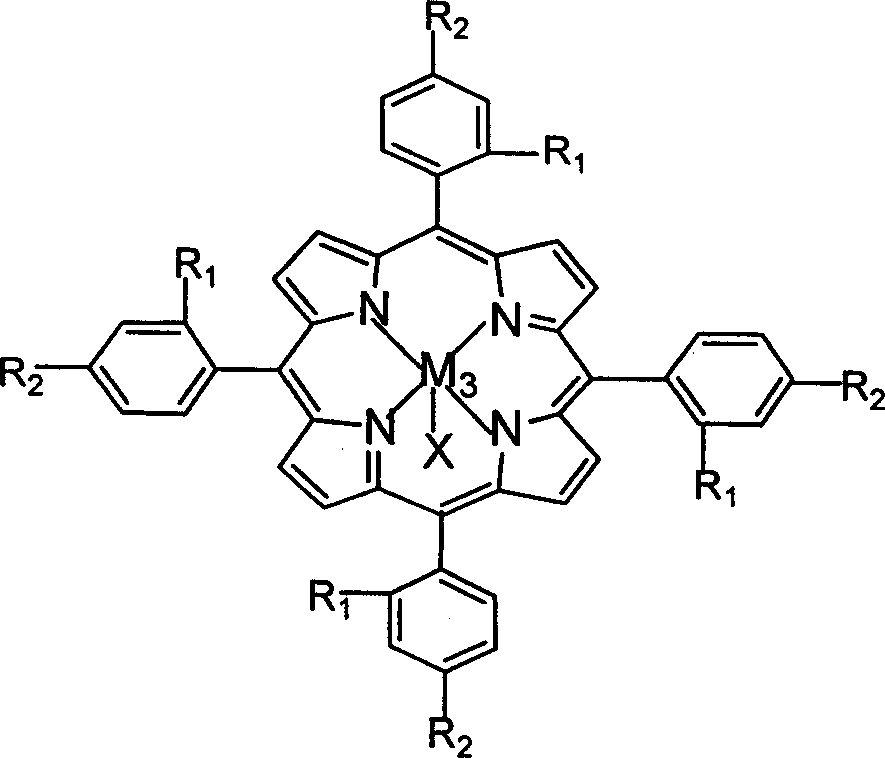

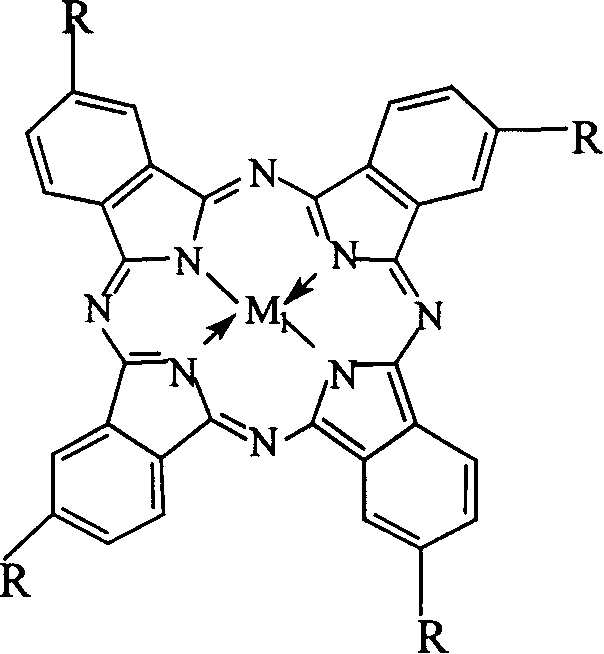

Method of preparing adipinic acid using bionic catalytic oxggen to oxidize cyclohexane

InactiveCN1556088AHigh catalytic activity and selectivityOxidation depth is easy to controlOrganic compound preparationCarboxylic compound preparationSolventCyclohexane

A bionic process for preparing hexanedioic acid by catalytic oxidation of cyclohexane features that under existance of catalyst which may be metallic phthalocyanine, single-nucleus metallic porphyrin, or mu-oxy-dual-nucleus metallic porphyrin, the hexane and O2 take part in oxidizing reaction at 110-160 deg.C for 4-32 hr.

Owner:BEIJING UNIV OF TECH

Process for preparing beta zeolite containing phosphorus

ActiveCN1616351AImprove catalytic selectivityMolecular-sieve and base-exchange phosphatesALUMINUM PHOSPHATESilica gel

During the preparation process of phosphorus containing beta-zeolite, work water solution compounded with aluminum source, alkali source and tetraethyl ammonium cationic solution is mixed with silica gel of granularity 20-300 mesh as silicon source to moisten the surface of the silica gel grain; the mixture is maintained at 80-140 deg.c for 20-80 hr to obtain crystal seed colloid; aluminum phosphate in the amount of 5-30 wt% of the crystal seed colloid is thrown into the crystal seed colloid, and through homogeneous mixing, crystallization at 140-170 deg.c for 50-100 hr, separation of solid matter, washing to Na2O content less than 0.1 wt% and drying, phosphorus containing beta-zeolite is prepared. The beta-zeolite product may contain phosphorus up to 5 wt% and has relatively high catalytic selectivity when being used in alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

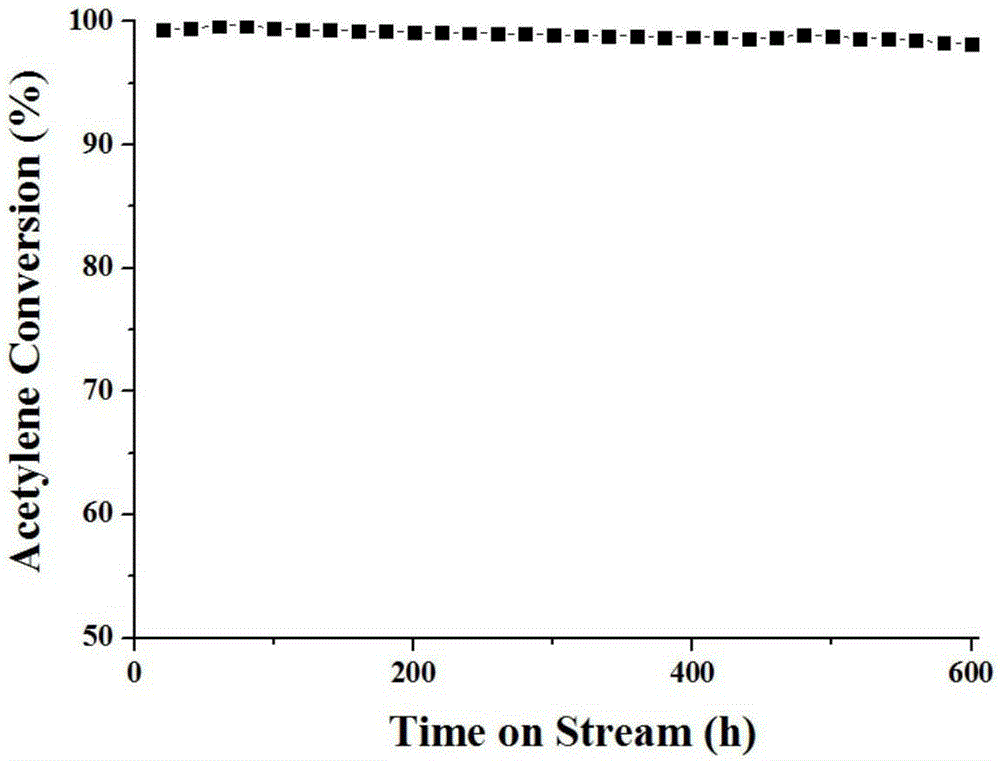

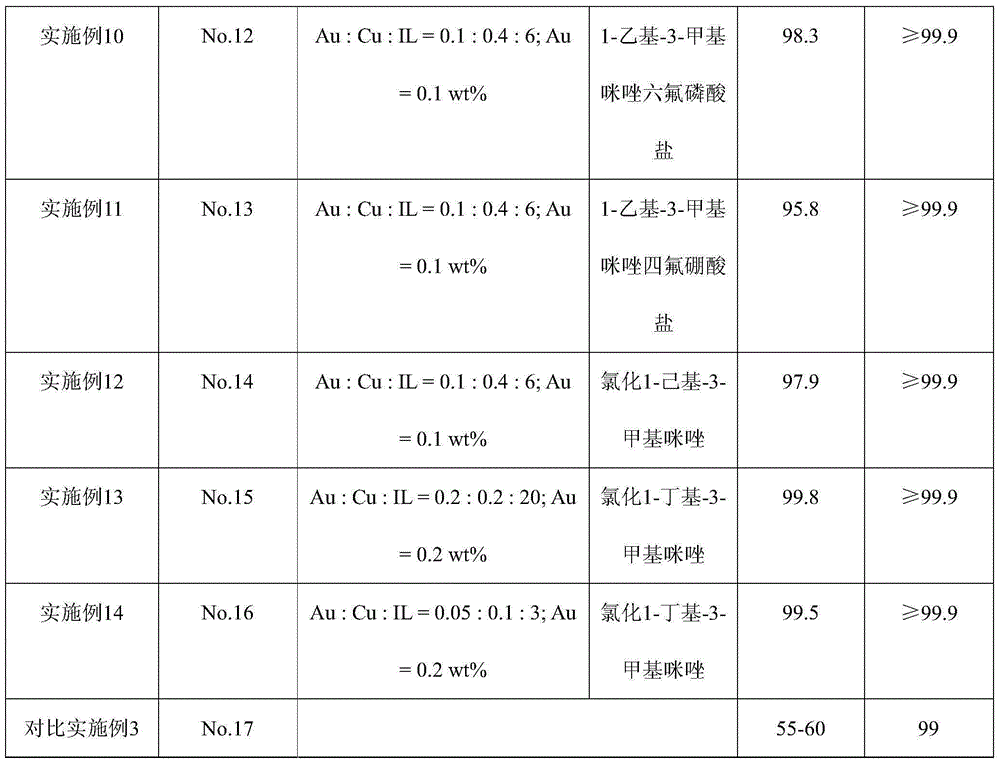

Porous solid material supported ionic liquid-gold catalyst, as well as preparation and application thereof

ActiveCN105148989AGood chemical stabilityImprove thermal stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsIonic liquidHigh selectivity

The invention provides a porous solid material supported ionic liquid-gold catalyst, as well as preparation and application thereof. The catalyst comprises a porous solid material carrier and a complex which is prepared from an ionic liquid and a metal ionic compound and is loaded on the carrier surface, wherein the metal ionic compound is a gold compound or a combination of a gold compound and a third metal chloride; the gold compound is selected from one of gold chloride, chloroauric acid, ethylenediamine gold chloride, chloro(triphenylphosphite)gold and chloro(triethylphosphine)gold; the third metal is selected from one of Cu, In, Bi, Ba, Sr, Fe, Mn, Zn, Co, Cs, K, Ca, Sn and Ni; and the ionic liquid is an imidazole ionic liquid. The porous solid material supported ionic liquid-gold catalyst has good chemical and thermal stability and high heat transmission efficiency in the reacting atmosphere for synthesizing vinyl chloride by ethyne hydrochlorination, and has the characteristics of high catalytic activity, high selectivity, good stability, low cost and the like.

Owner:ZHEJIANG UNIV OF TECH

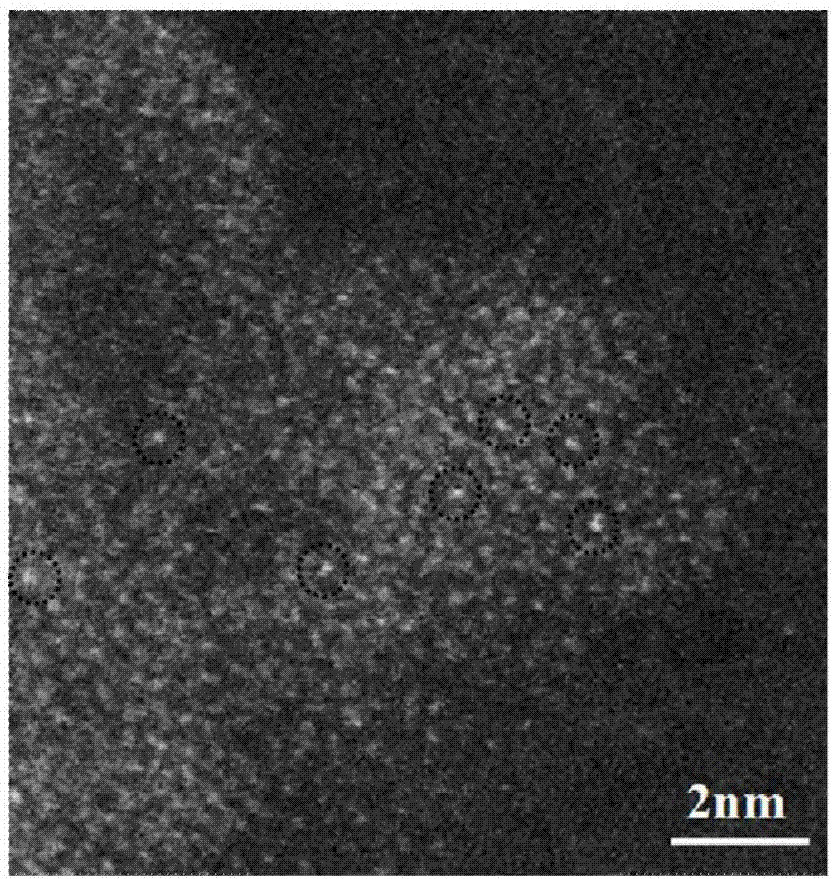

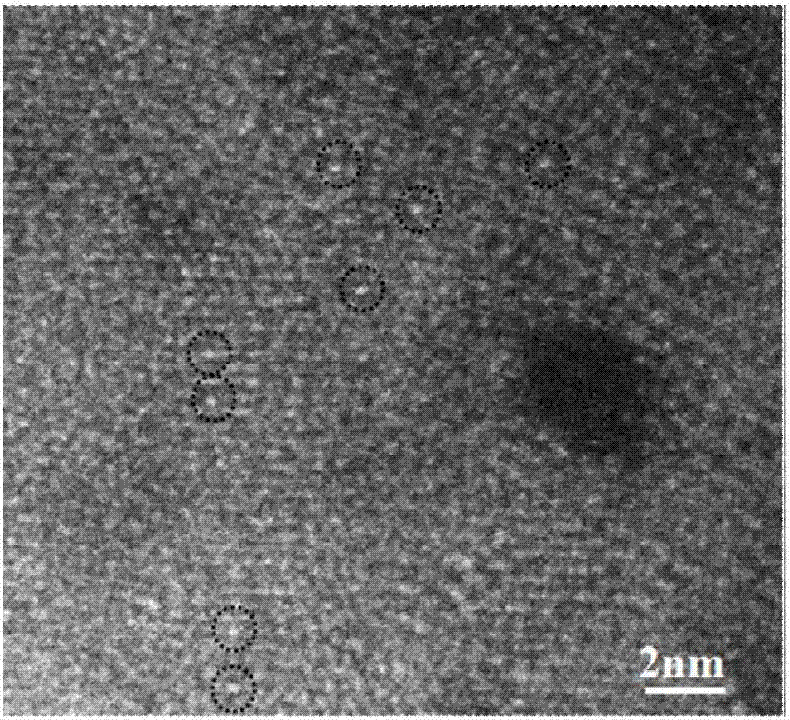

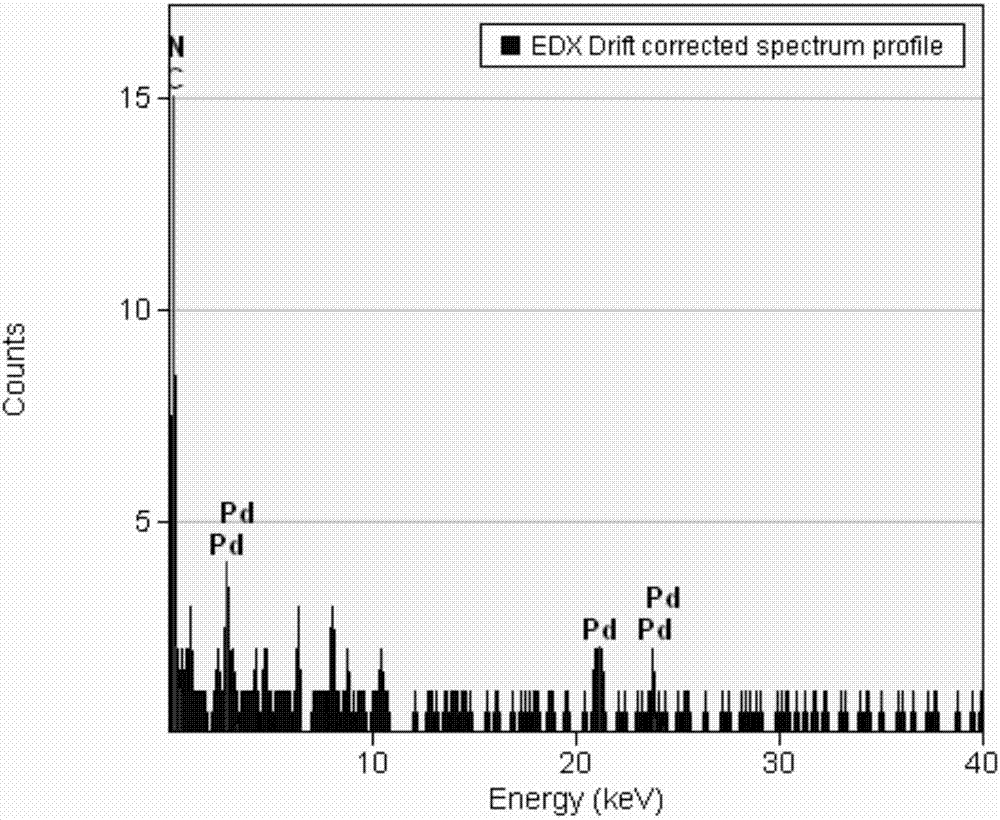

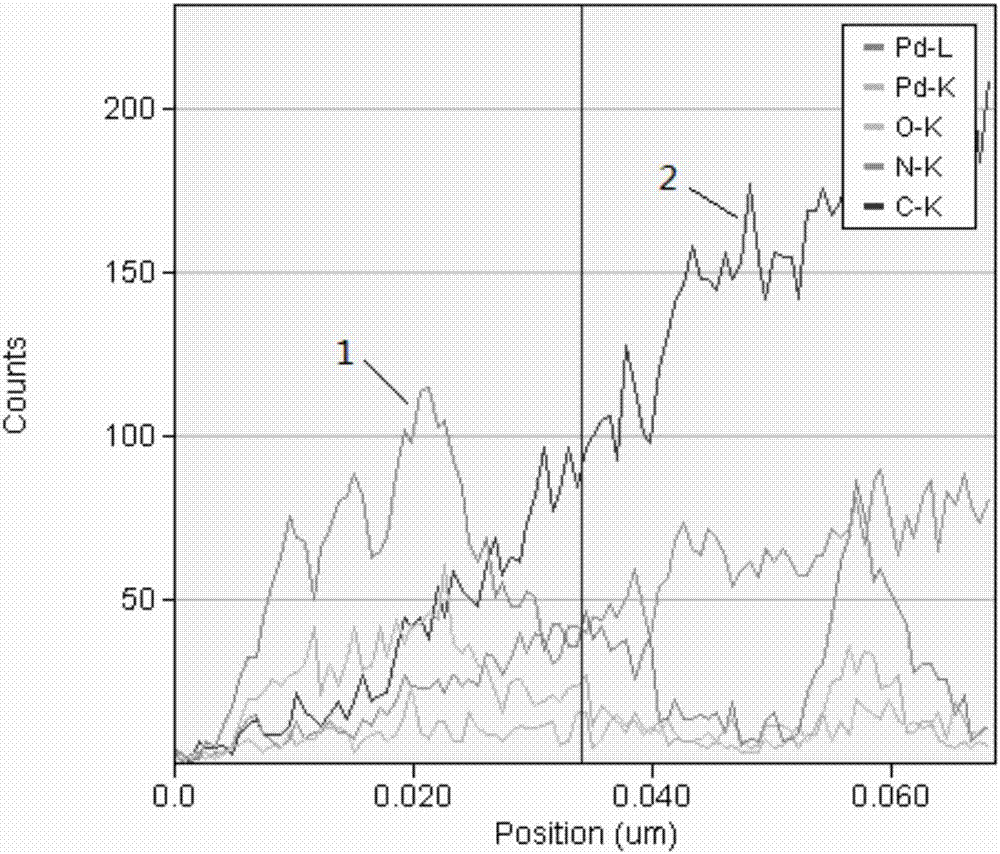

Preparation method and catalytic application of monatomic dispersion palladium-based catalyst

ActiveCN107008290AHigh catalytic activityImprove catalytic selectivityHydrocarbon by hydrogenationCatalystsReduction treatmentPalladium catalyst

The invention discloses a preparation method and catalytic application of a monatomic dispersion palladium-based catalyst. The preparation method of the monatomic dispersion palladium-based catalyst is a photo-deposition method, and uses zinc-containing hydrotalcite as a carrier to prepare the monomeric dispersion palladium-based catalyst. Namely, an alcohol solution and an H2PdCl4 solution are added to a hydrotalcite carrier-dissolved aqueous solution; electrons are transferred from a valence band to a conduction band in a hydrotalcite semiconductor under irradiation of ultraviolet light; alcohol molecules in the solution are subjected to oxidation reaction to generate hydroxyl radicals in holes. Study on photo-deposition process shows that a monatomic palladium catalyst can be prepared by controlling the amount of added H2PdCl4 solution and illumination time. The preparation method provided by the invention performs reduction treatment on catalyst samples at different temperatures, monatomic palladium is not aggregated at the moment; the monatomic dispersion palladium-based catalyst has excellent catalytic activity and selectivity for hydrogenation reaction of phenylacetylene.

Owner:BEIJING UNIV OF CHEM TECH

Method of preparing adipinic acid using bionic catalytic oxggen to oxidize cyclohexane

InactiveCN1231449CReduce dosageHigh catalytic activityOrganic compound preparationCarboxylic compound preparationRecyclable catalystEnzyme structure

Owner:BEIJING UNIV OF TECH

Copper and silicon catalyst for preparing ethanediol by hydrogenating dimethyl oxalate and preparation method thereof

ActiveCN101648134AHigh catalytic activityImprove catalytic selectivityOrganic compound preparationHydroxy compound preparationAlcoholAmmonium hydroxide

The invention discloses a copper and silicon catalyst for preparing ethanediol by hydrogenating dimethyl oxalate and a preparation method thereof. The copper and silicon catalyst is prepared by a one-pot method under conditions of taking ester orthosilicate as a silicon source and taking alcohol as a cosolvent and is concretely prepared in such a way that the ester orthosilicate is hydrolyzed andaged in a water-alcohol mixing solution of a copper ammonia complex, and then moisture, alcohol and ammonia are evaporated to enable copper components inside a copper ammonia solution to be uniformlysubsided, and finally washing, drying, roasting and reducing are carried out. The copper and silicon catalyst comprises copper and silicon dioxide, wherein the mol ratio of the copper to the silicon dioxide is 0.05-0.4 to 1. The copper and silicon catalyst shows very high reaction activity and selectivity in the reaction for preparing the ethanediol by hydrogenating the dimethyl oxalate and withina wider temperature range, is easy to operate and beneficial to industrial application.

Owner:ZHEJIANG UNIV

Catalyst as well as preparation method and application of catalyst

ActiveCN107413330AThe synthesis method is simpleLow costMaterial nanotechnologyCatalyst carriersNitro compoundIridium

The invention discloses a catalyst as well as a preparation method and application of the catalyst. The catalyst is composed of a carrier and a composite carbon-metal quantum dot supported on the carrier; the particle size of the catalyst ranges from 100nm to 1000nm; the carrier is a mesoporous carbon microsphere; the composite carbon-metal quantum dot is not larger than 15nm and contains 10-90% of metal; the metal in the composite carbon-metal quantum dot is one or a combination of several of platinum, palladium, iridium, ruthenium and rhodium; the loads of platinum, palladium, iridium, ruthenium and rhodium are respectively 0-10.0%, 0-10.0%, 0-10.0%, 0-10.0% and 0-5.0% based on the mass of the carrier, and the loads of palladium, platinum and rhodium are not equal to zero; and the total load of the metal is 1.0-11.5%. The invention provides the application of the catalyst to reaction for synthesizing a chlorinated aromatic amine compound shown as a formula (II) by carrying out selective catalytic hydrogenation on a chlorinated aromatic nitrocompound shown as a formula (I), and the catalyst has the characteristics of high hydrogenation reaction rate, high conversion rate, high catalytic activity and high stability.

Owner:ZHEJIANG UNIV OF TECH

CdS/metallic organic frame composite photocatalysis material as well as preparation method and application thereof

InactiveCN109331883AImprove photoelectric stabilityLarge specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsCarbon monoxideNanoparticleThermal methods

The invention discloses a CdS / metallic organic frame composite photocatalysis material as well as a preparation method and application thereof. The composite photocatalysis material is prepared by modifying a metallic organic frame on the surfaces of CdS nanoparticles. The preparation method of the composite photocatalysis material comprises the following steps: firstly, synthesizing the CdS nanoparticles by using a solvent thermal method, and modifying the metallic organic frame on the surfaces of the CdS nanoparticles by using an in-situ heterogeneous deposition method, thereby obtaining theCdS / metallic organic frame composite photocatalysis material. Compared with conventional CdS, the CdS / metallic organic frame composite photocatalysis material has improved photoelectric stability, and conversion efficiency, circulation stability and catalysis selectivity of photocatalytic reduction of carbon dioxide.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com