Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

349results about How to "Increased space-time yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of amines

InactiveUS6140539ASimplifies work-upIncreased space-time yieldOrganic compound preparationOrganic chemistry methodsHydrogenMetal

In a process for preparing amines, in which at least one compound containing at least one nitro group is reacted with hydrogen in the presence of a supported catalyst comprising, as catalytically active metal, nickel, if desired together with at least one metal of transition group I, V, VI and / or VIII, the reduced and stabilized supported catalyst comprises nickel crystallites having a bimodal nickel crystallite size distribution having maxima at 30-80 Angstr+E,uml o+EE m and 81-150 Angstr+E,uml o+EE m on a support comprising ZrO2, ZrO2-HfO2 and / or SiO2-ZrO2 and / or SiO2-ZrO2-HfO2 and in the reduced and passivated state has a nickel content of 60-80 percent by mass, an SiO2 content of 0-20 percent by mass, a ZrO2 content of 0-40 percent by mass, an HfO2 content of 0-4 percent by mass and after further reduction for one hour at 100 DEG C. has a degree of reduction of at least 70%.

Owner:BASF AG

Process for regenerating a catalyst

InactiveUS20080214384A1Reduced activityIncreased space-time yieldInorganic chemistryMolecular sieve catalystsAcroleinGlycerol

Owner:EVONIK DEGUSSA GMBH

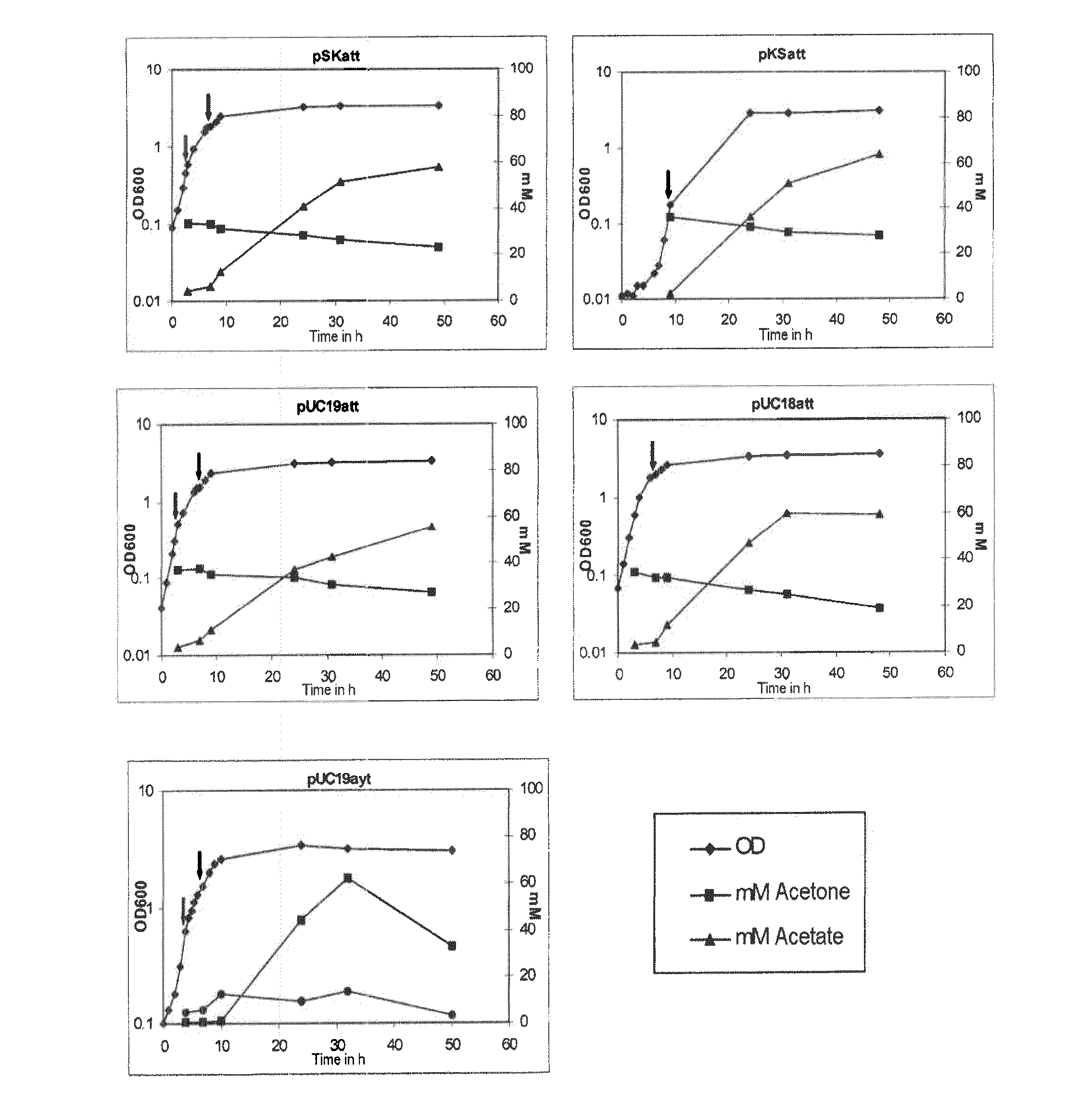

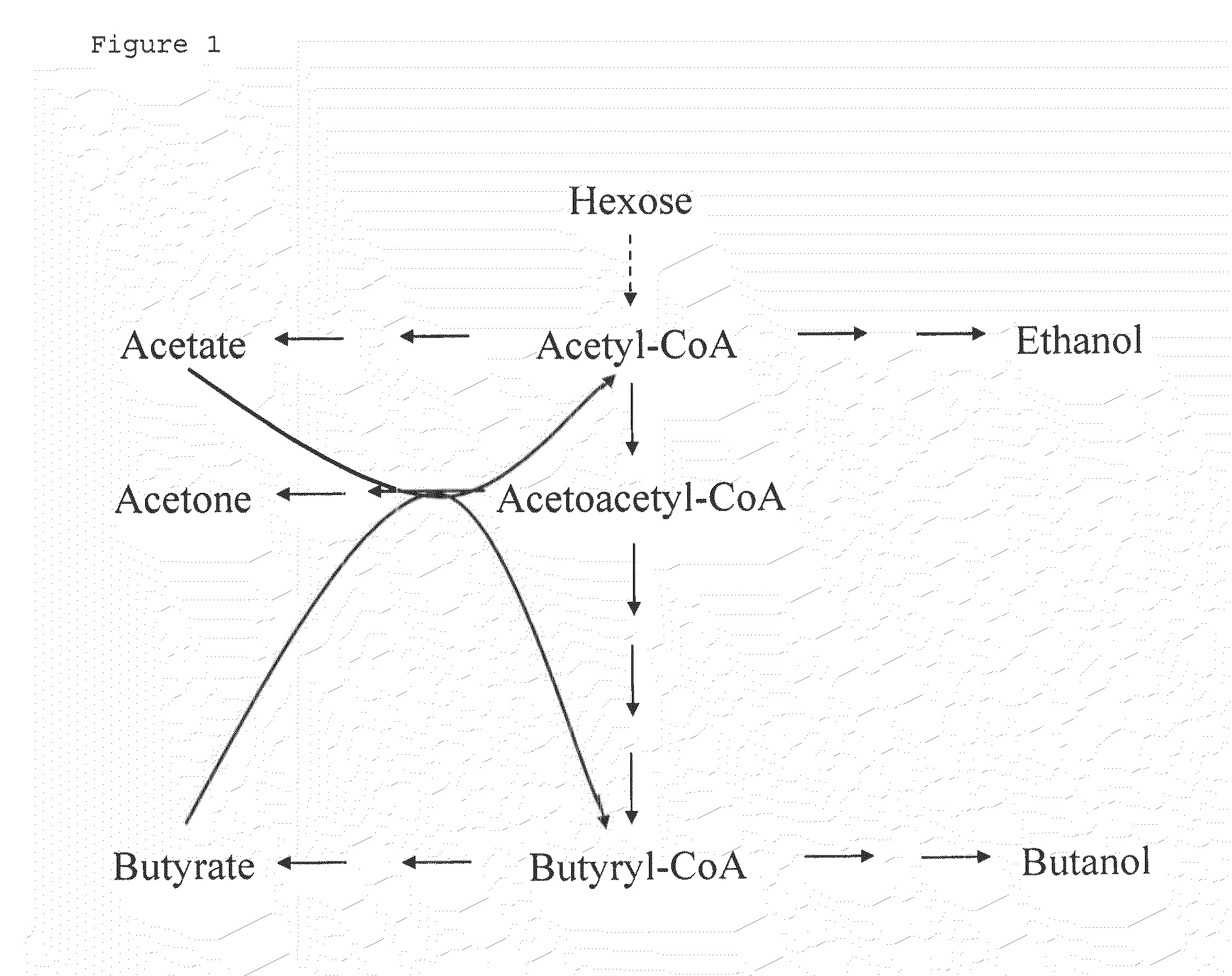

Fermentative production of acetone from renewable resources by means of novel metabolic pathway

ActiveUS20100261237A1YieldHigh yieldSugar derivativesHydrolasesAcyl Coenzyme A SynthetasesAcyl-CoA synthetase

The invention describes a process for preparing acetone starting from acetyl-coenzyme A comprising process steps A. enzymatic conversion of acetyl-CoA into acetoacetyl-CoA B. enzymatic conversion of acetoacetyl-CoA into acetoacetate and CoA and C. decarboxylation of acetoacetate to acetone and CO2, which is characterized in that the coenzyme A is not transferred in process step B to an acceptor molecule. In addition, process step B is surprisingly catalysed by enzymes of the classes of acyl-CoA thioesterase, acyl-CoA synthetase or acyl-CoA thiokinase.A completely novel metabolic pathway is concerned, because the enzymatic hydrolysis of acetoacetyl-CoA without simultaneous transfer of CoA to a receptor molecule has never previously been described for any microbial enzyme.

Owner:EVONIK OPERATIONS GMBH

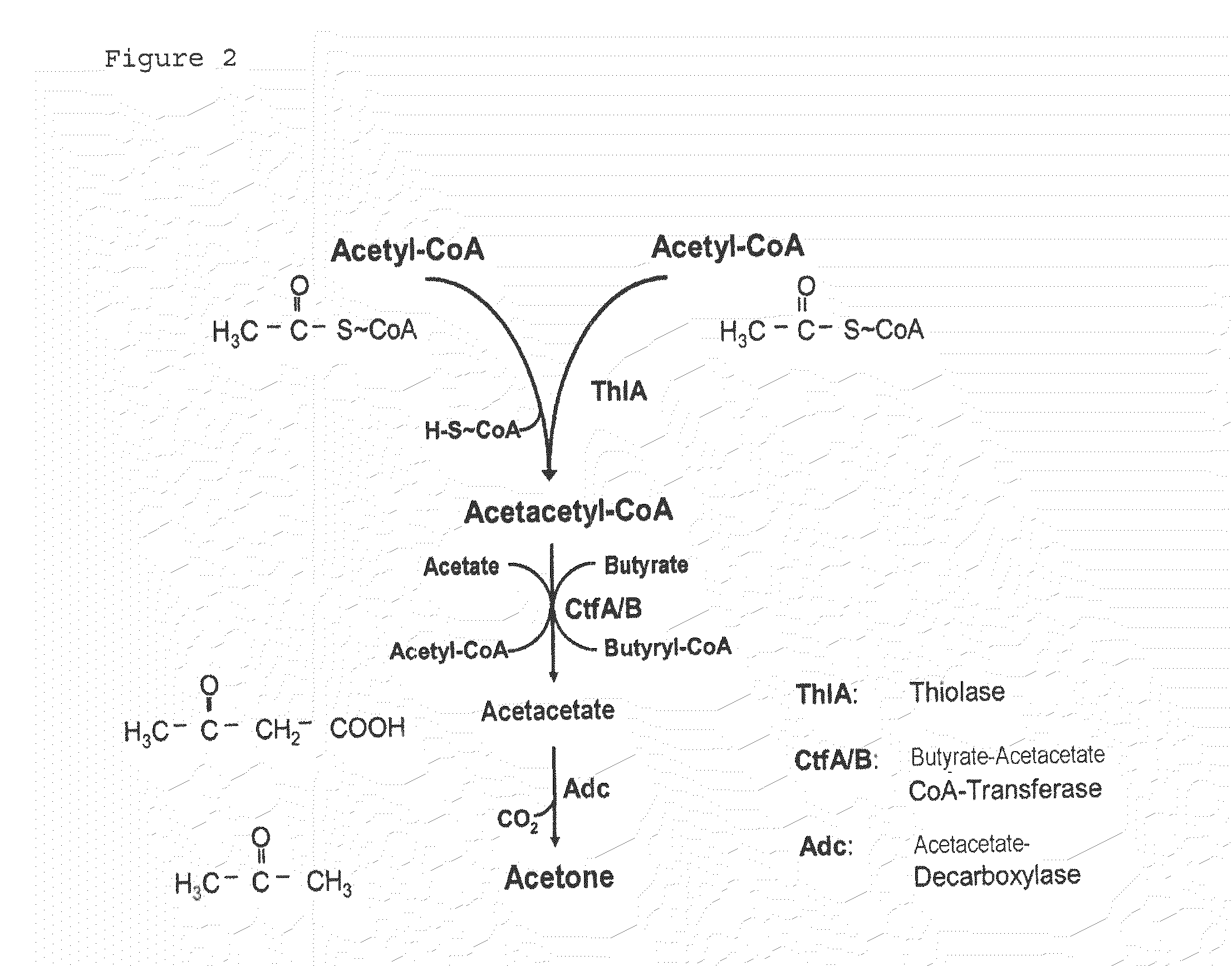

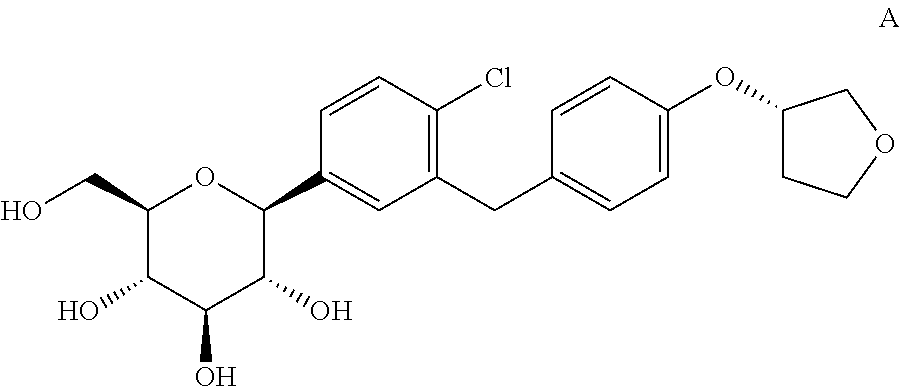

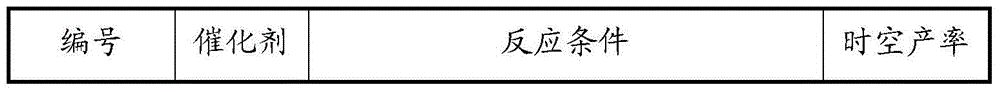

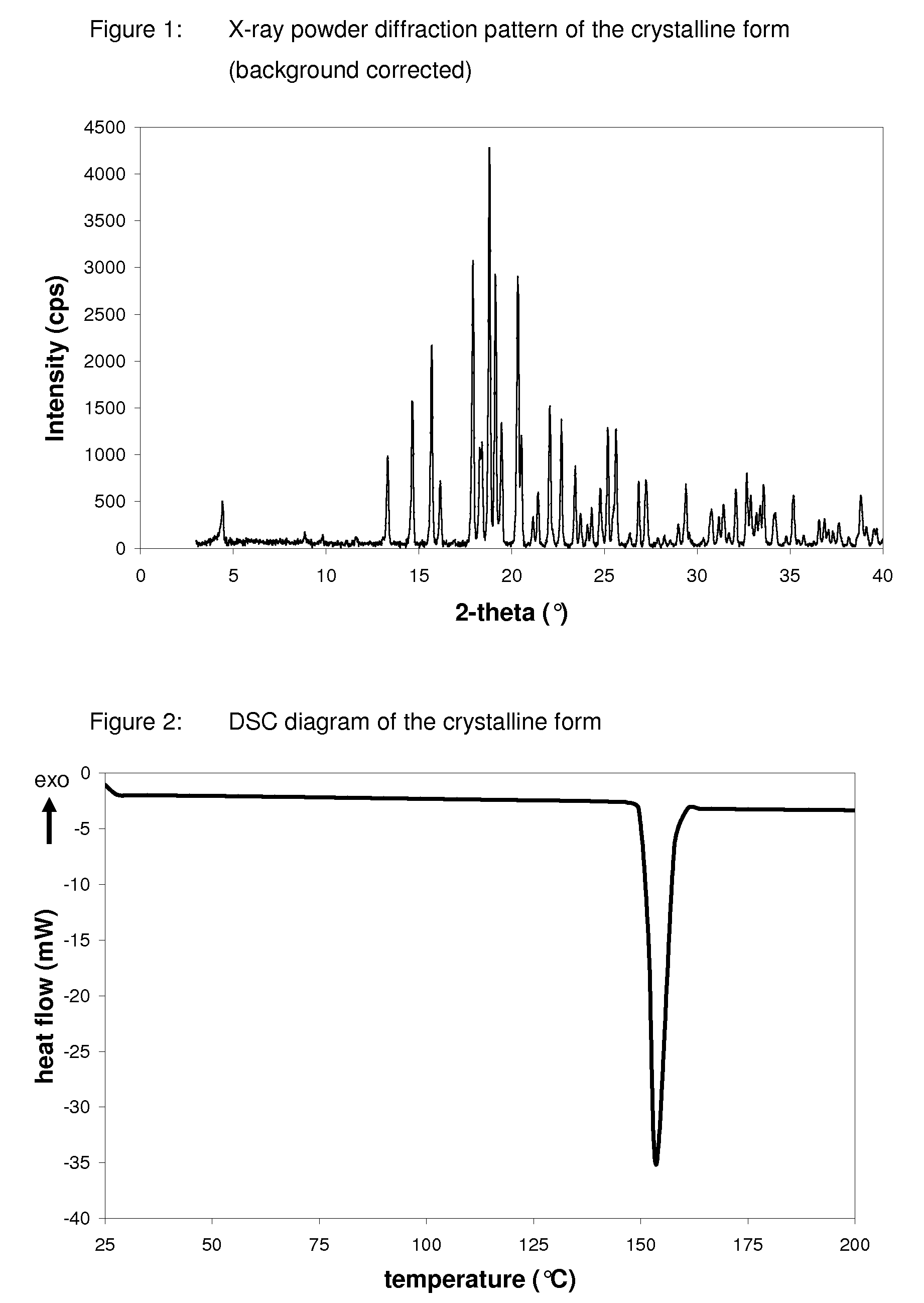

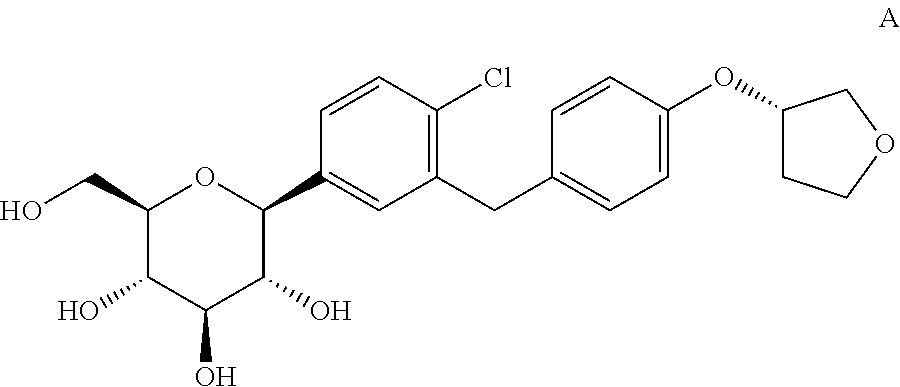

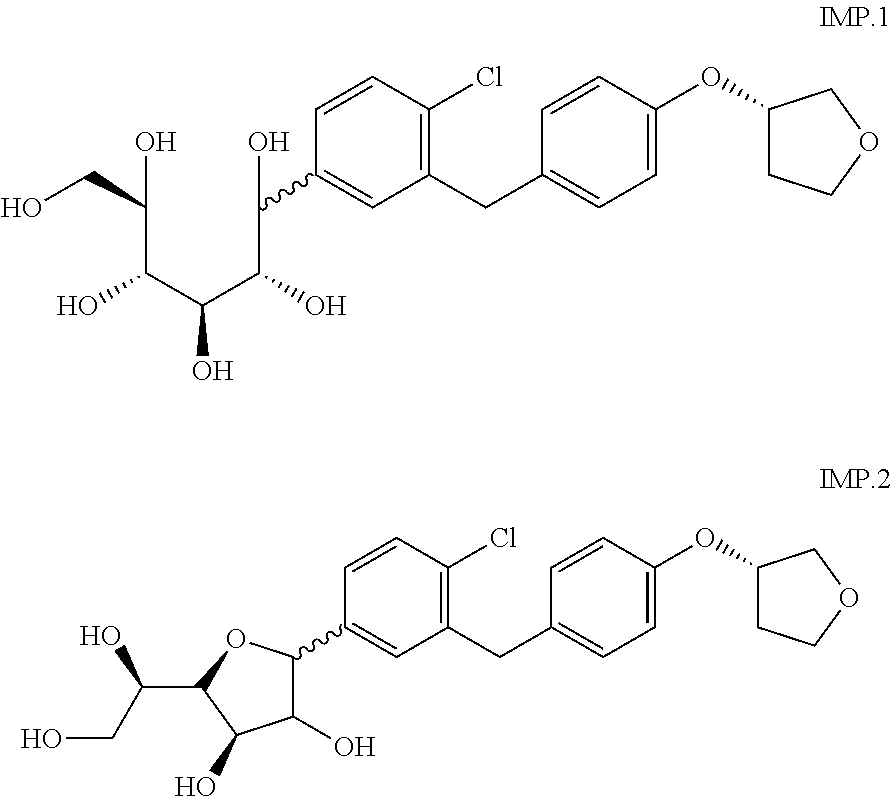

Method for the preparation of a crystalline form

ActiveUS20110237526A1High purityHigh yieldBiocideSaccharide with heterocyclic radicalsBenzeneCrystallography

The invention relates to a method for the preparation for a crystalline form of 1-chloro-4-(β-D-glucopyranos-1-yl)-2-[4-((S)-tetrahydrofuran-3-yloxy)-benzyl]-benzene. In addition the invention relates to a crystalline form obtainable by this method, to a pharmaceutical composition and to the use thereof for preparing medicaments.

Owner:BOEHRINGER INGELHEIM INT GMBH

Methanol synthesizing catalyst and its prepn

InactiveCN1810357AEasy to makeEasy to industrializeOrganic compound preparationHydroxy compound preparationSyngasNitrate

The methanol synthesizing catalyst has the molar ratio of Cu to Zn to Al to Li equal to 6:3:1:0.5, and is prepared through coprecipitation process. The preparation process includes the following steps: 1. dropping mixed solution of nitrate of Cu, Zn, Al and Li in certain molar ratio and Na2CO3 solution into small amount of deionized water while stirring and maintaining the solution pH in 7-8; and 2. ageing for 2 hr after finishing dropping, suction filtering, washing and stoving to obtain the catalyst precursor, and stoving and roasting to obtain the catalyst product. The preparation process is simple and easy to use in industrial production, and the catalyst has activity higher than traditional Cu-Zn-Al catalyst and wide application range for traditional synthetic gas and synthetic gas with relatively high CO and CO2 content.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

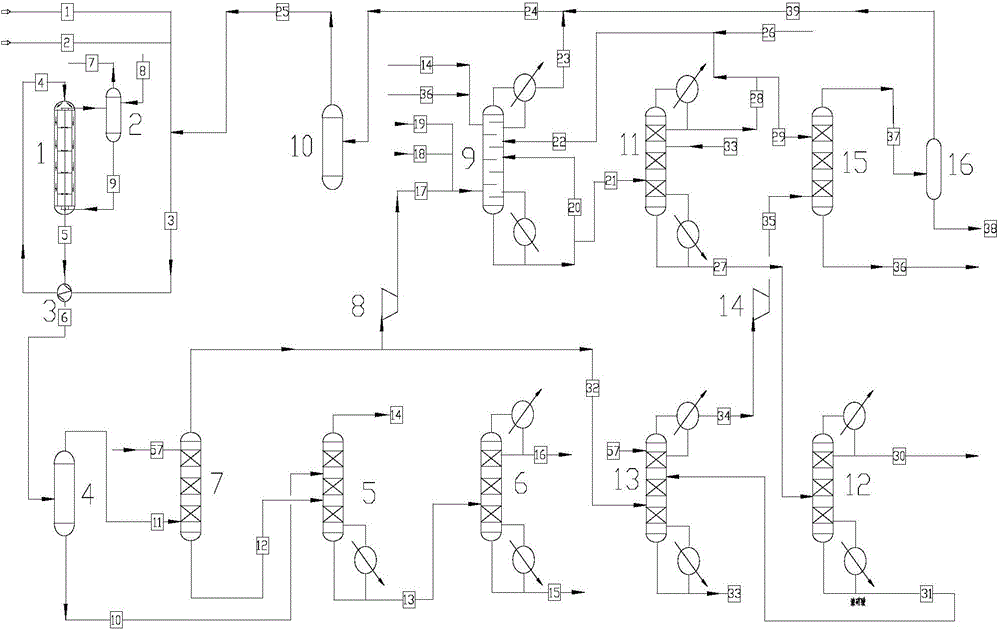

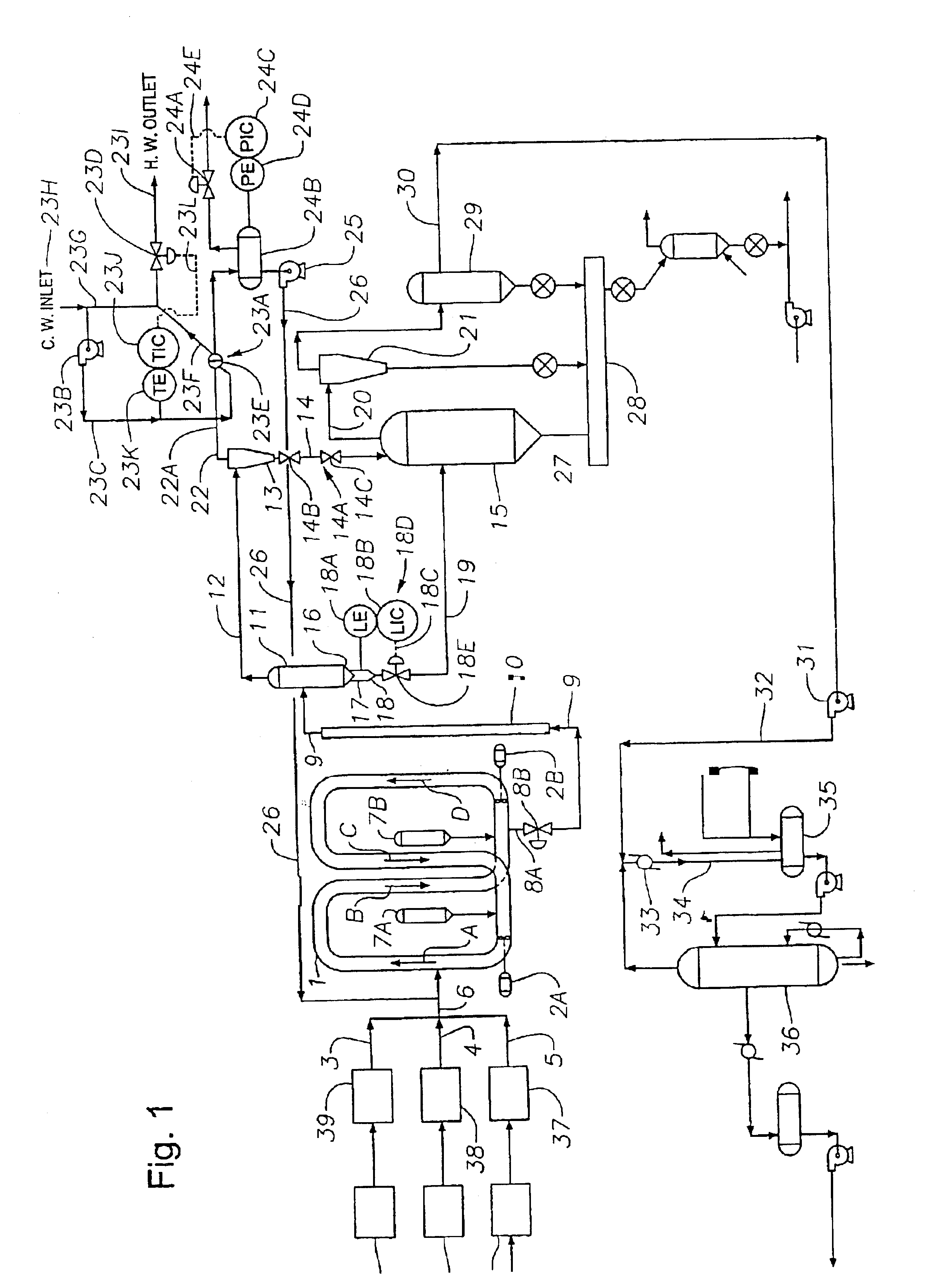

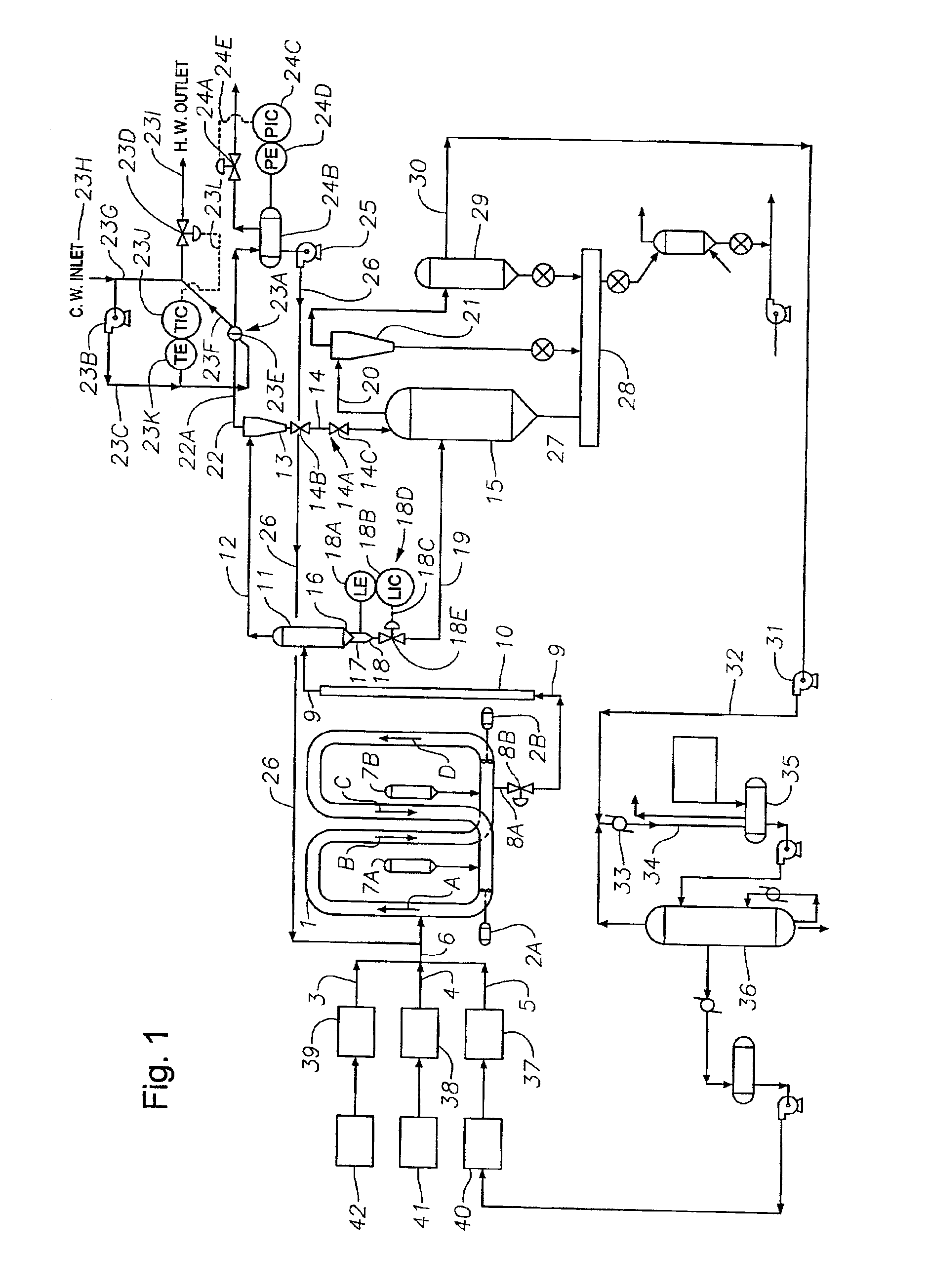

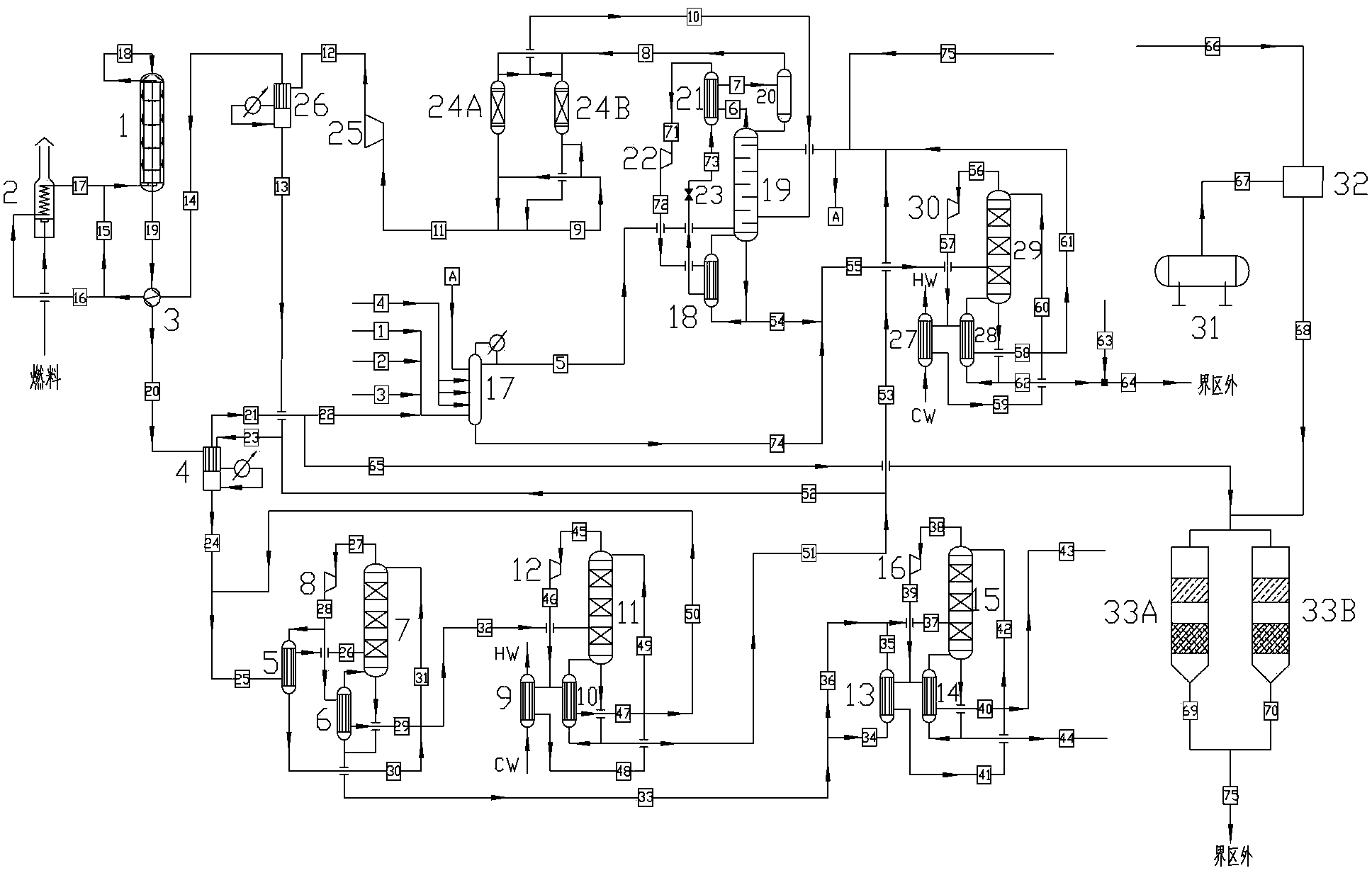

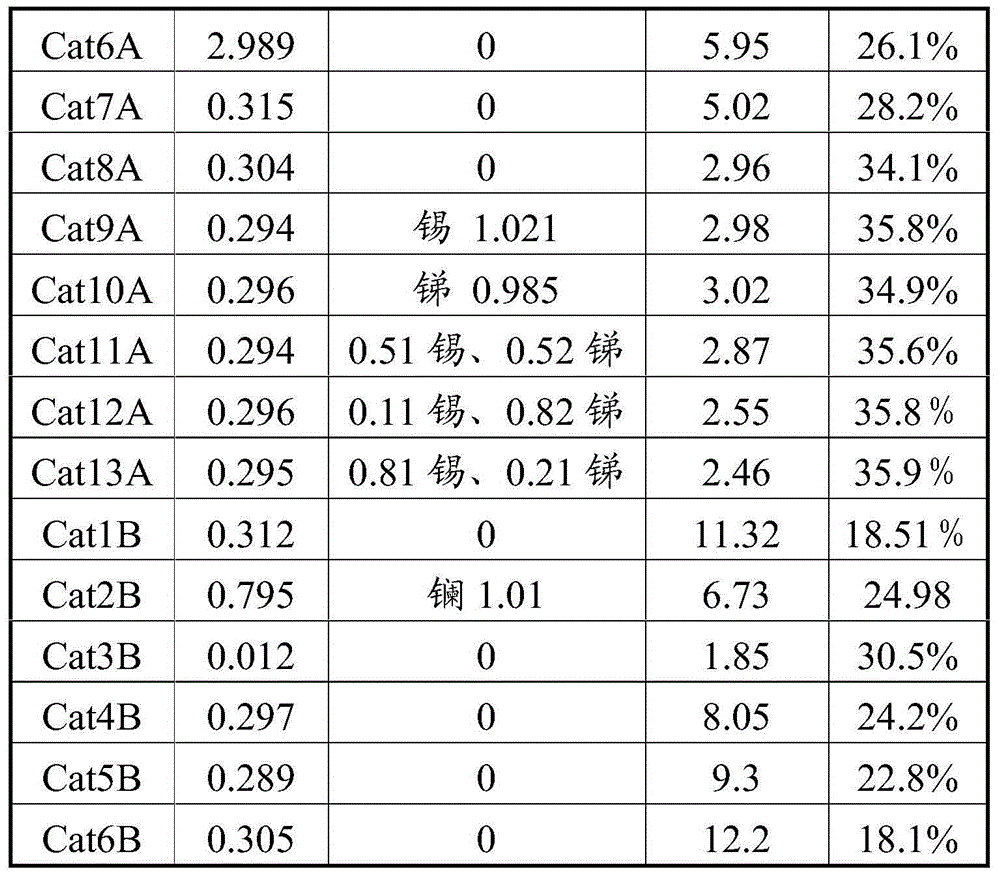

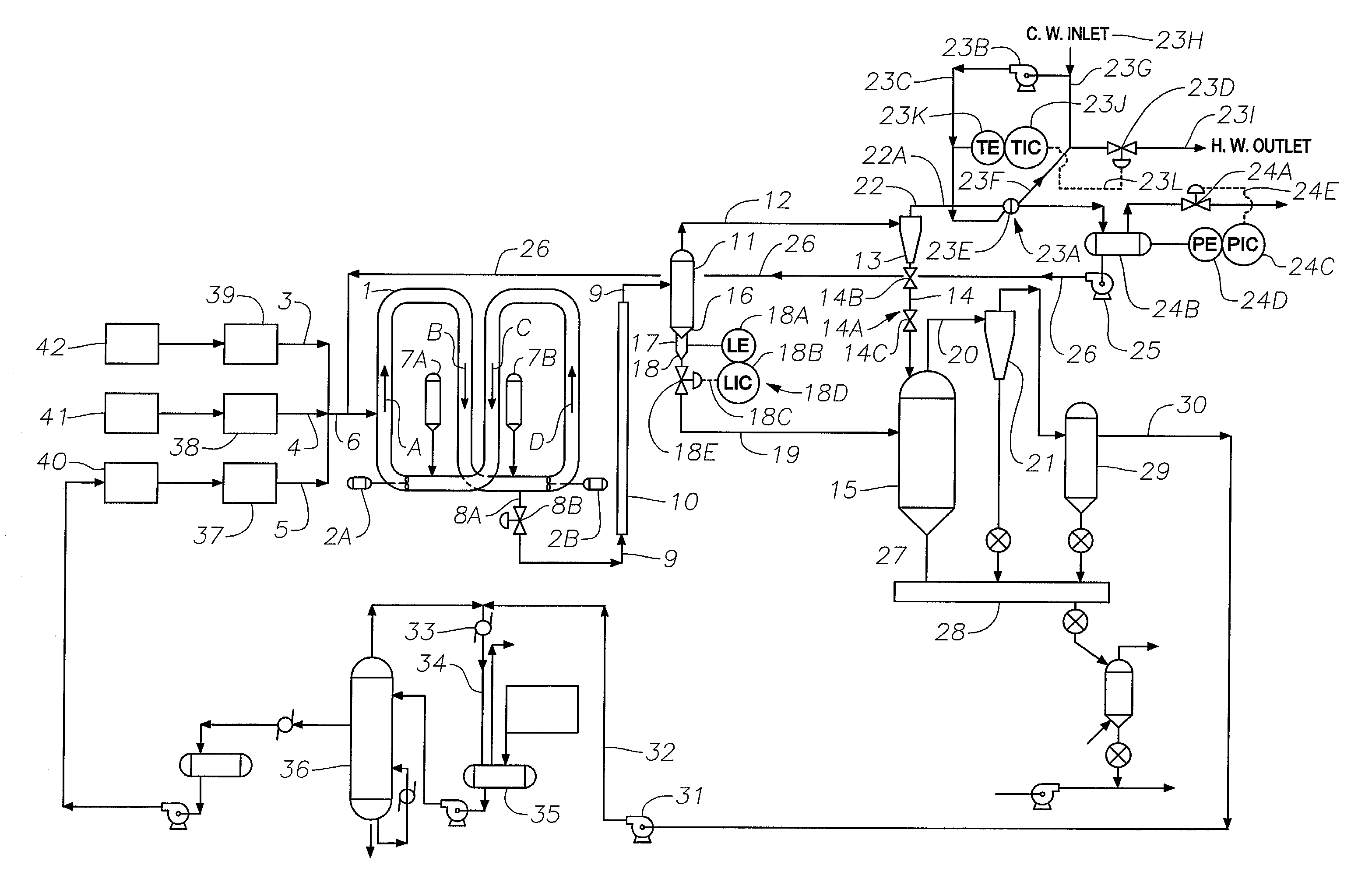

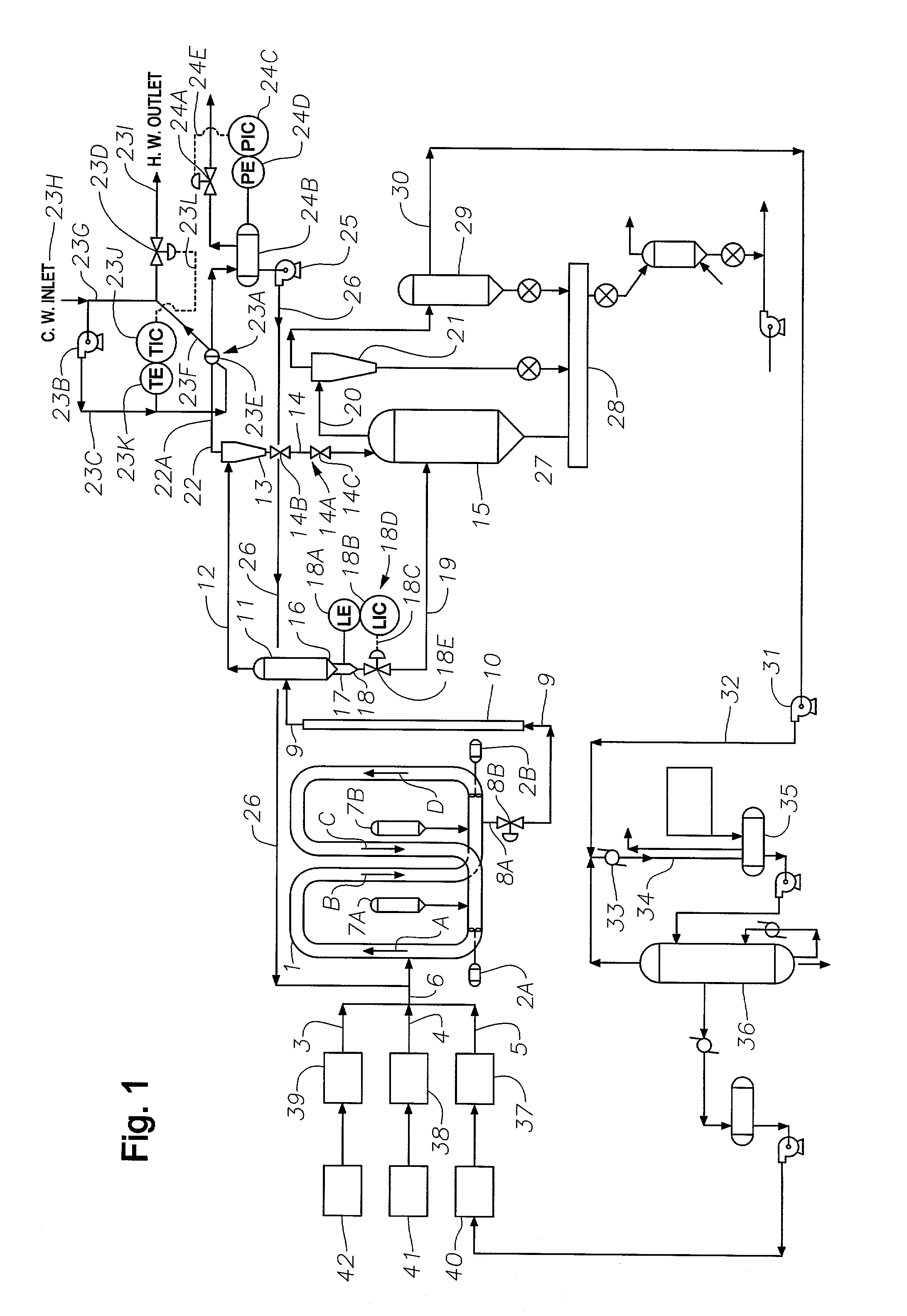

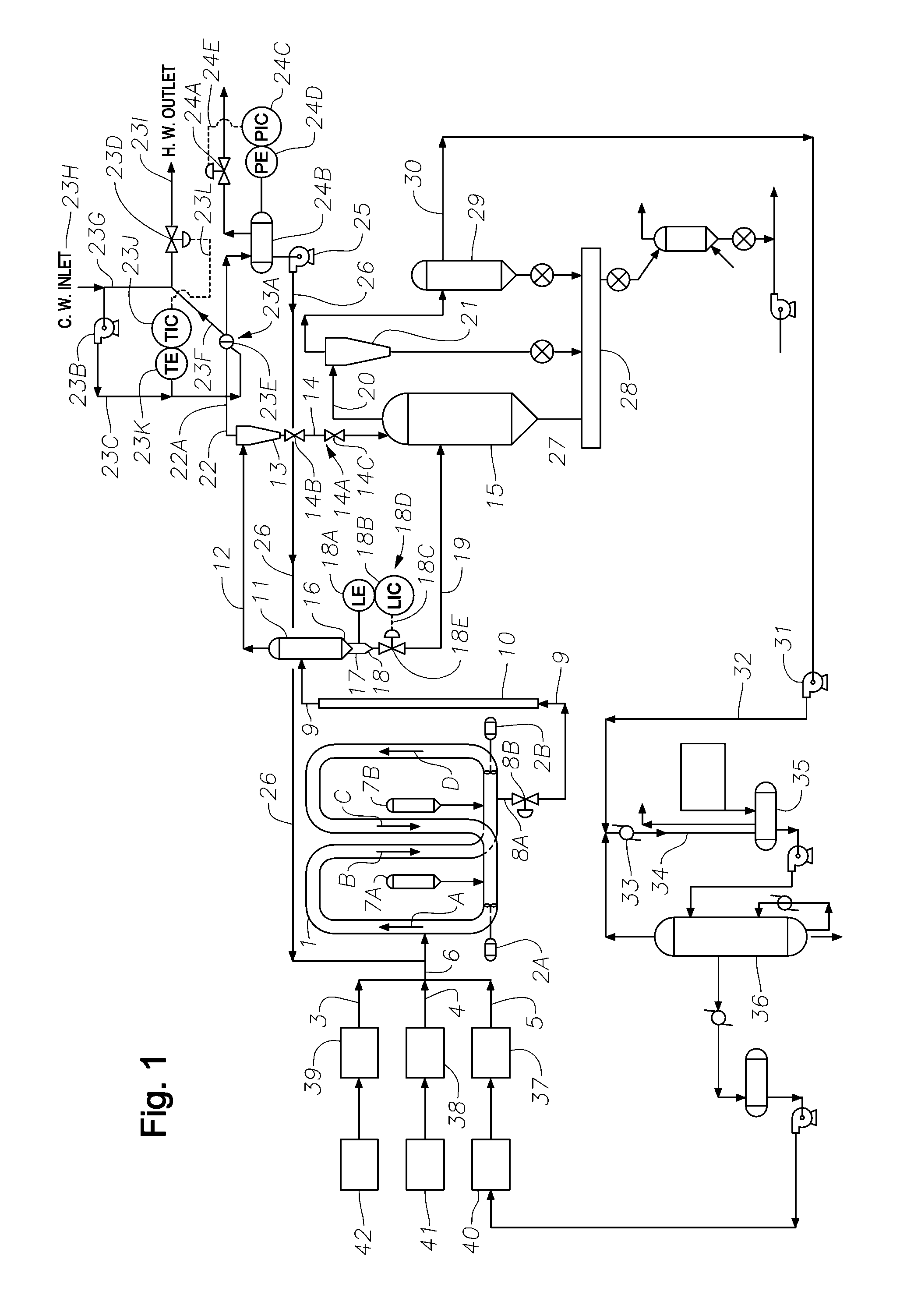

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

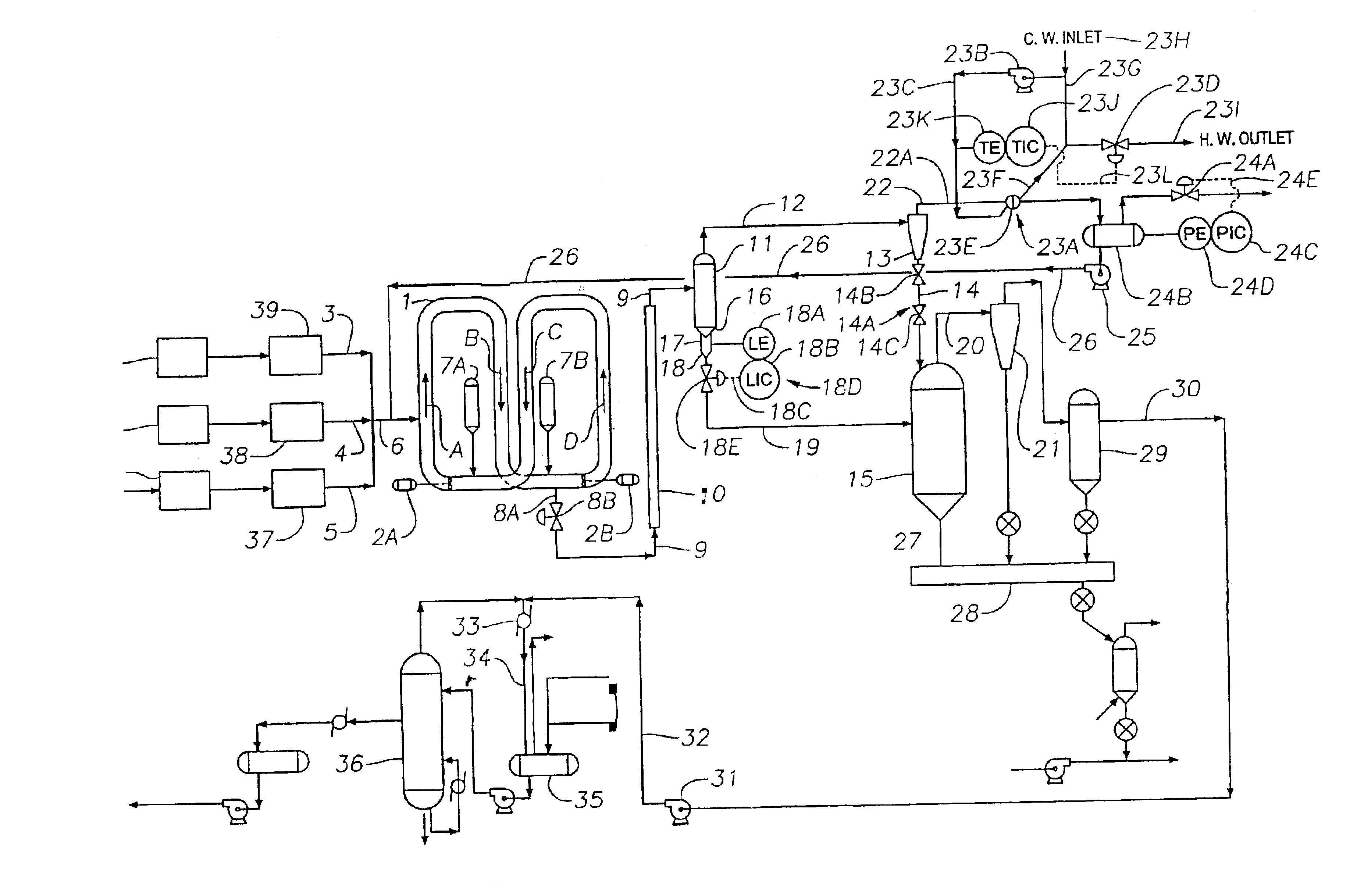

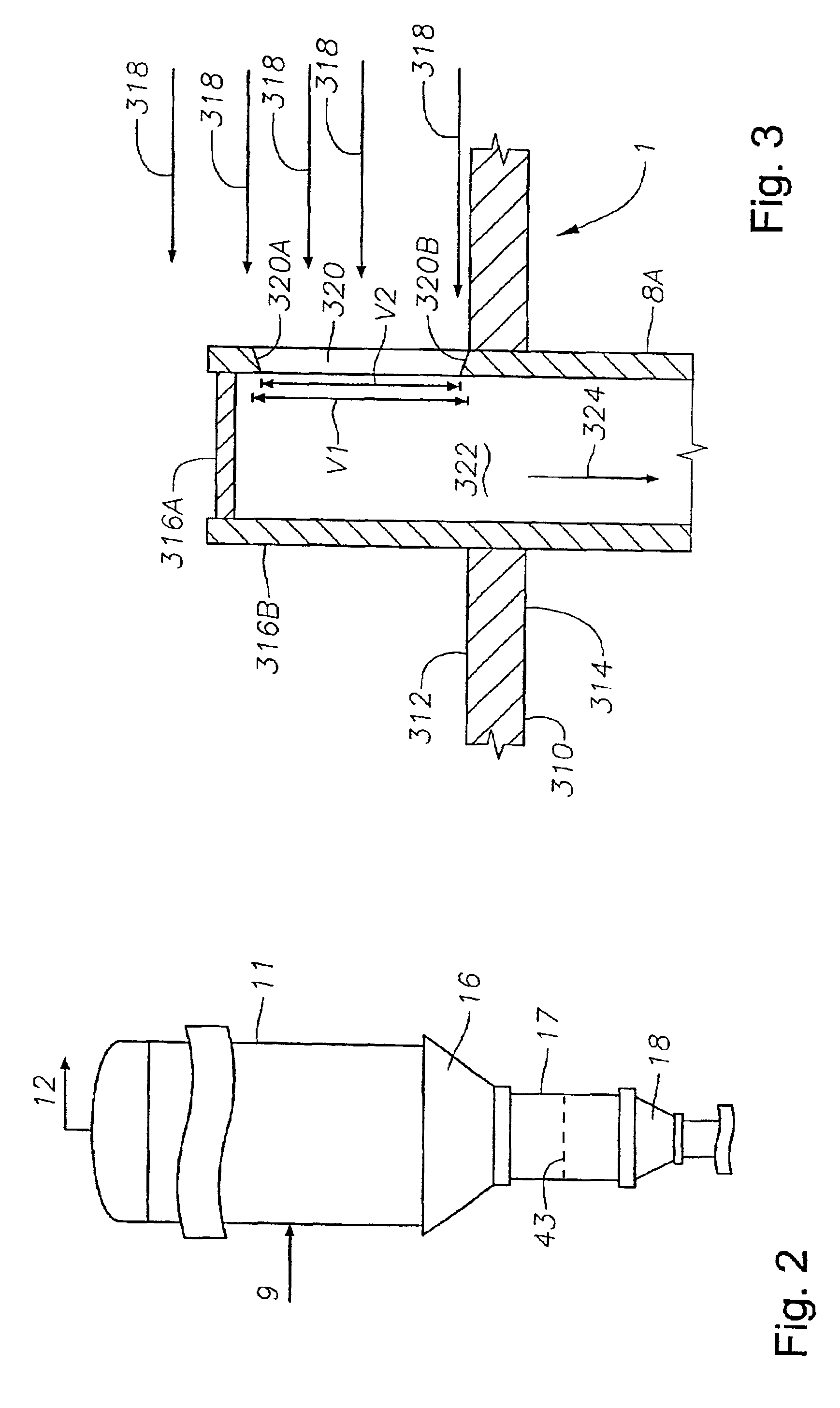

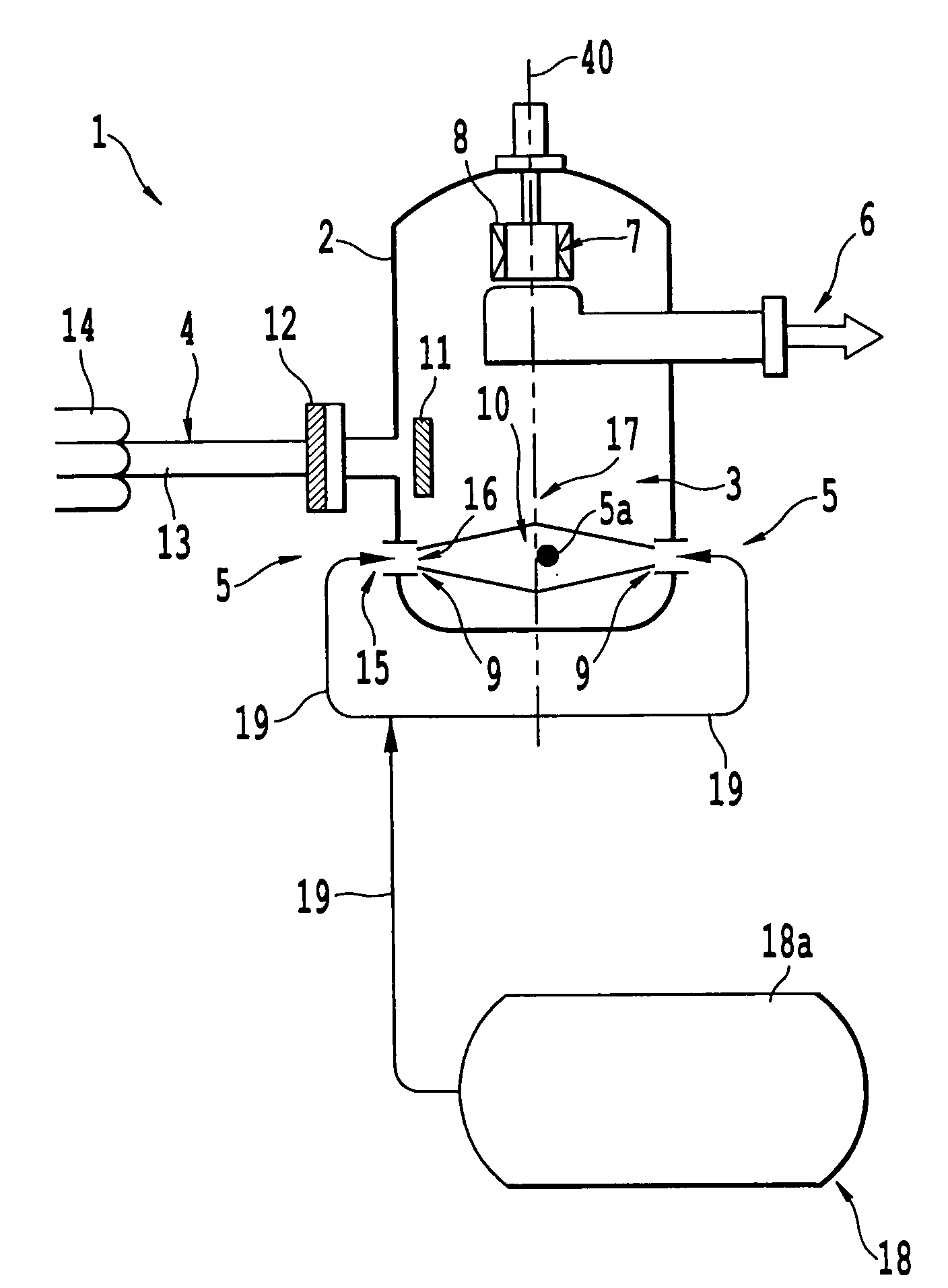

Process for the continuous preparation of isocyanates

ActiveUS20070299279A1High chemical yieldIncreased space-time yieldOrganic compound preparationIsocyanic acid derivatives purification/separationProcess engineeringPhosgene

Isocyanates are produced by reacting an organic amine with phosgene in process which includes at least three stages. The first stage is carried out in a dynamic mixer. The second stage is carried out in at least one reactor. The third stage is carried out in at least one material separating apparatus. The pressure in the reactor of the second stage must be greater than or equal to the pressure in the dynamic mixer. The pressure in the third stage material separating apparatus must be lower than the pressure in the second stage reactor.

Owner:COVESTRO DEUTSCHLAND AG

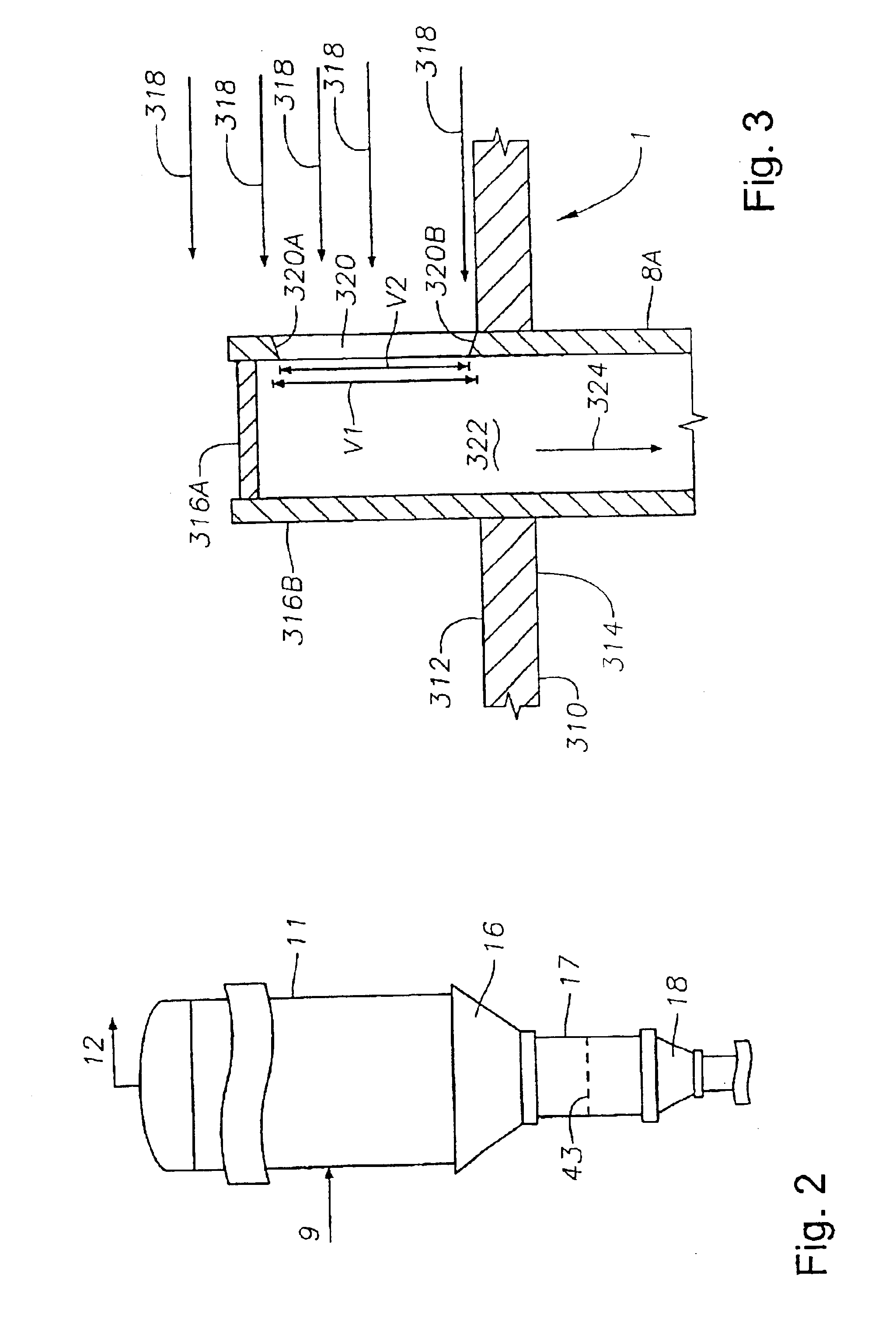

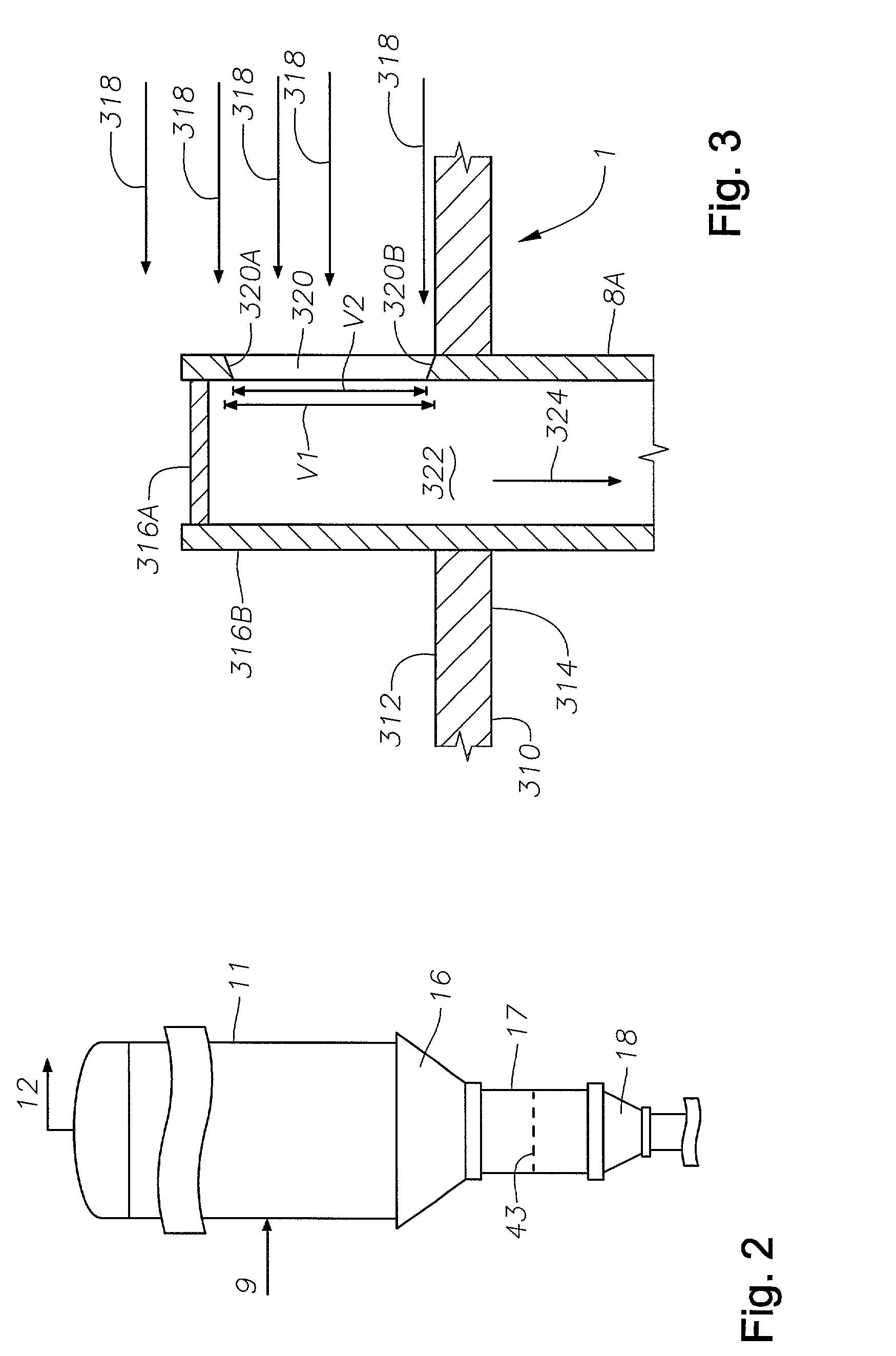

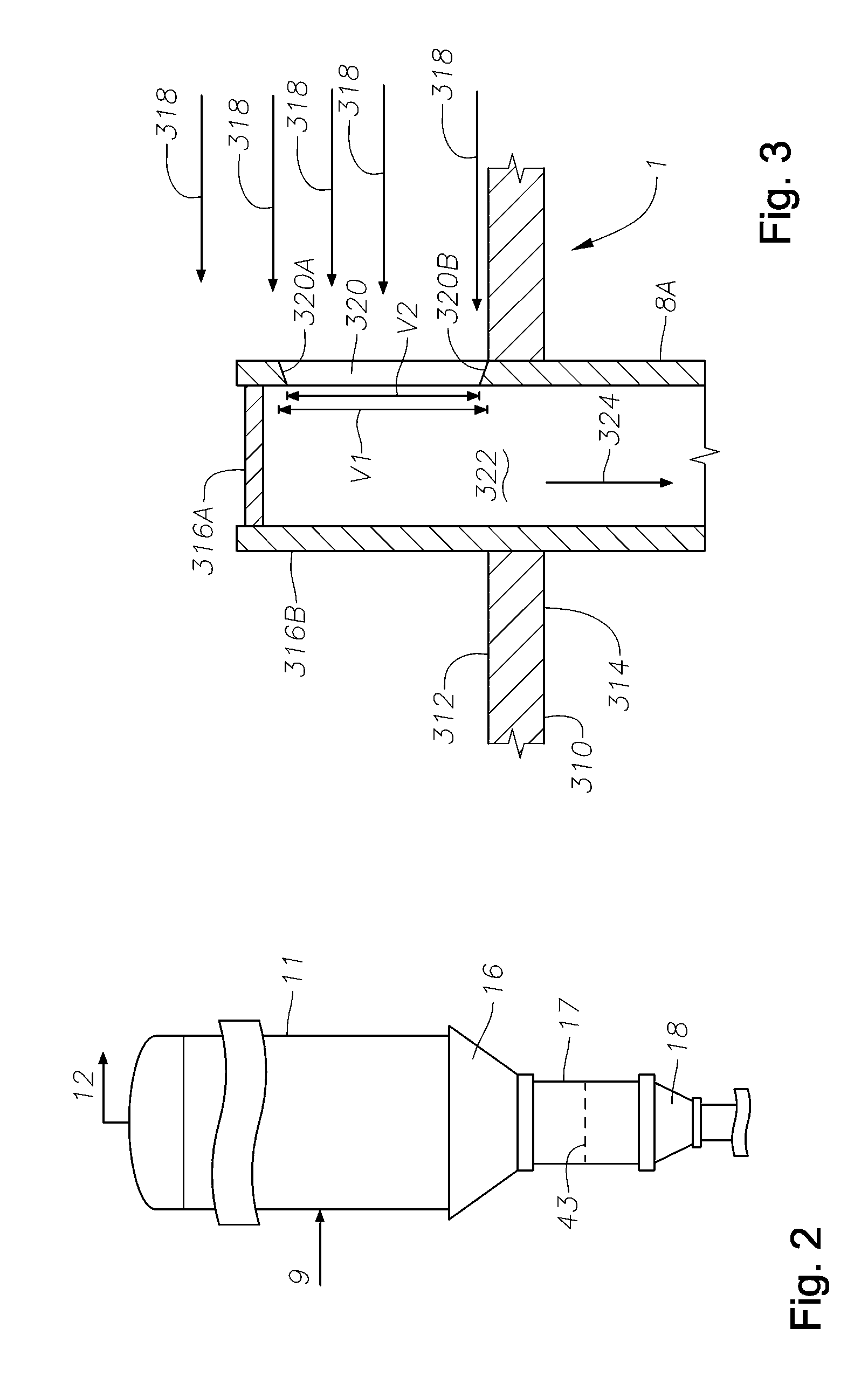

Continuous slurry polymerization volatile removal

InactiveUS6858682B2Increase ethylene concentrationReduce energy consumptionChemical/physical/physico-chemical stationary reactorsFlash distillationDiluentMonomer

A process / apparatus is disclosed for continuously separating a liquid medium comprising diluent and unreacted monomers from a polymerization effluent comprising diluent, unreacted monomers and polymer solids, comprising a continuous discharge of the polymerization effluent from a slurry reactor through a discharge valve and transfer conduit into a first intermediate pressure flash tank with a conical bottom defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the slurry / polymer solids and an exit seal chamber of such diameter (d) and length (l) as to maintain a desired volume of concentrated polymer solids / slurry in the exit seal chamber such as to form a pressure seal while continuously discharging a plug flow of concentrated polymer solids / slurry bottom product of said first flash tank from the exit seal chamber through a seal chamber exit reducer with inclined sides defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the polymer solids which remain after removal of about 50 to 100% of the inert diluent therefrom to a second flash tank at a lower pressure.

Owner:EXXONMOBIL CHEM PAT INC

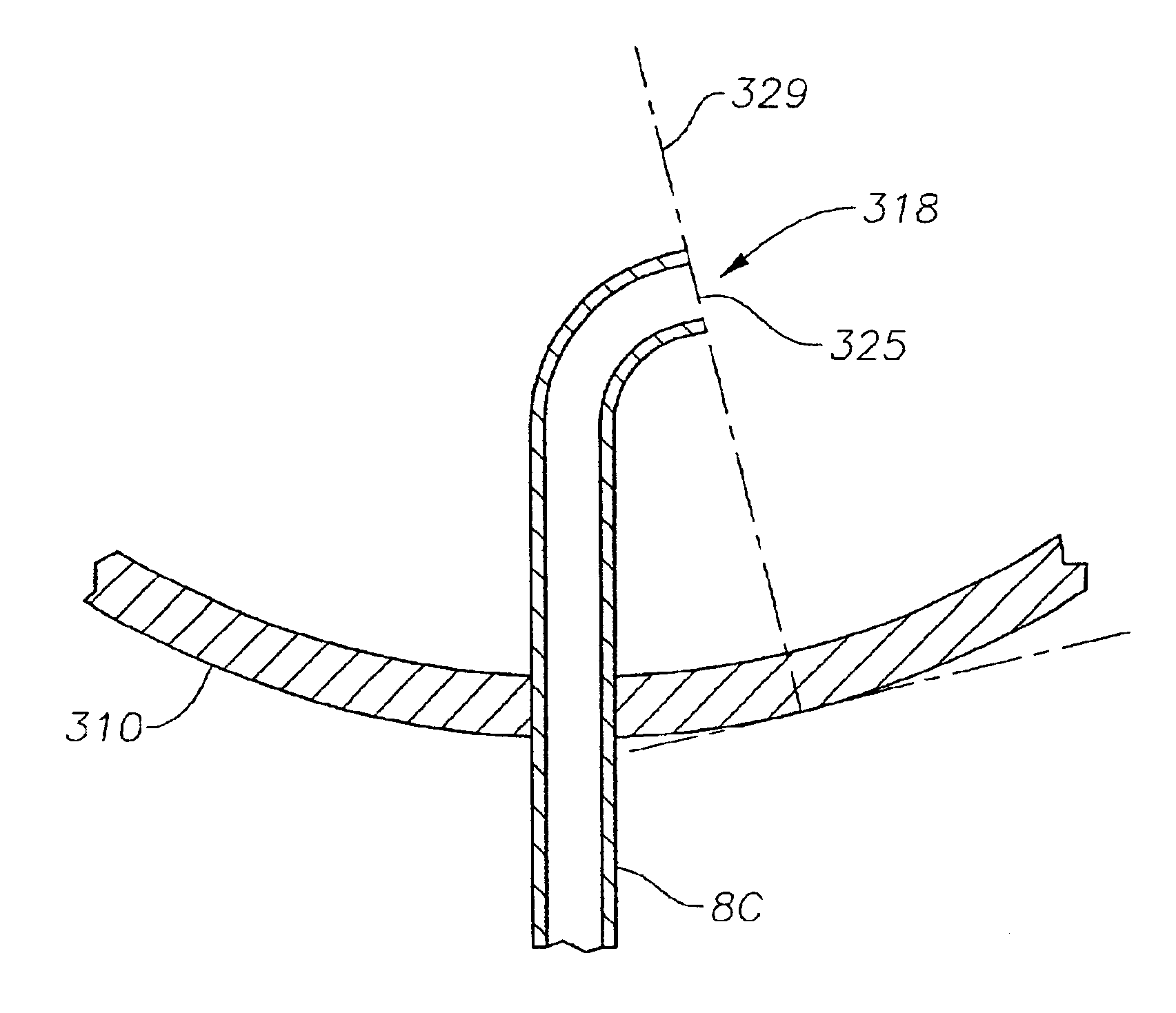

Continuous slurry polymerization volatile removal

InactiveUS6926868B2Increase contentSmall sizeChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesLiquid mediumSlurry reactor

A process / apparatus is disclosed for continuously separating a liquid medium comprising diluent and unreacted monomers from a polymerization effluent of a slurry loop reactor containing a flow of slurry therein, comprising a discharge conduit extending a distance into the loop reactor; the conduit having a longitudinal axis and an opening inside the loop reactor; at least a portion of the conduit being curved along its longitudinal axis inside the loop reactor; and the opening substantially facing the flow of the slurry, wherein the discharge conduit is located within a lower leg of the loop reactor such that a continuous discharge of the polymerization effluent from a slurry reactor through a discharge valve and transfer conduit into a first intermediate pressure flash tank wherein volatile inert diluent and unreacted monomers are removed and the polymer solids which remain after removal of about 50 to 100% of the inert diluent therefrom to a second flash tank at a lower pressure.

Owner:EXXONMOBIL CHEM PAT INC

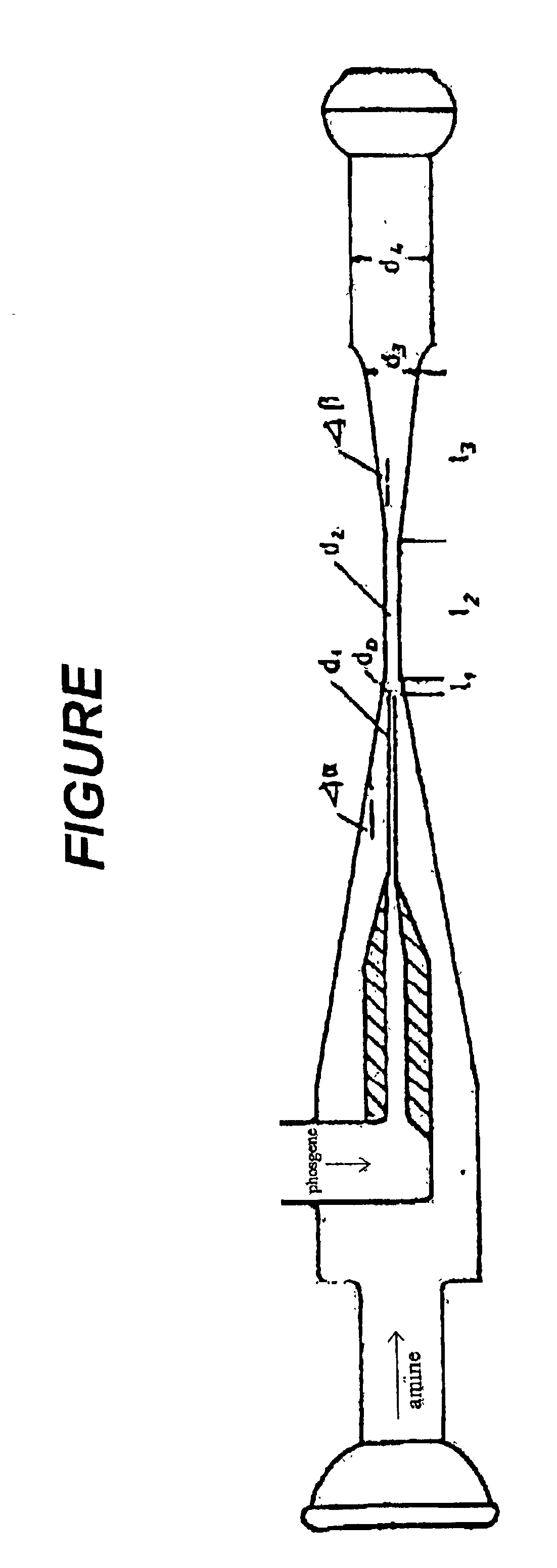

Process for the preparation of isocyanates in the gas phase

ActiveUS20080146834A1Increase the number ofShorten the timeOrganic compound preparationIsocyanic acid derivatives purification/separationGas phaseContact time

An isocyanate is produced by reacting a primary amine with phosgene in the gas phase above the boiling point of the amine over an average contact time of 0.05 to 15 seconds under adiabatic conditions.

Owner:COVESTRO DEUTSCHLAND AG

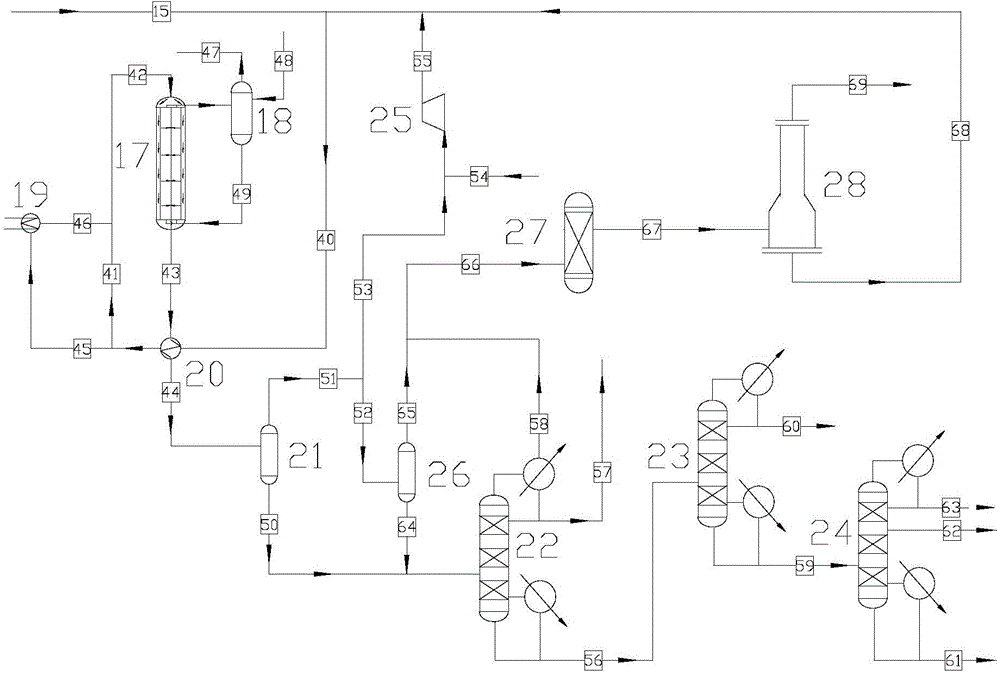

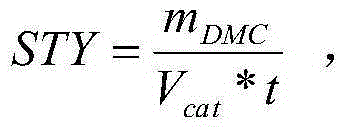

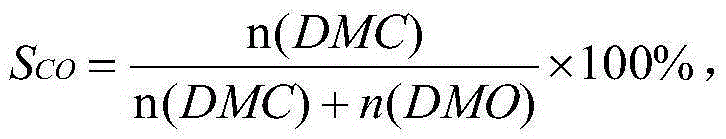

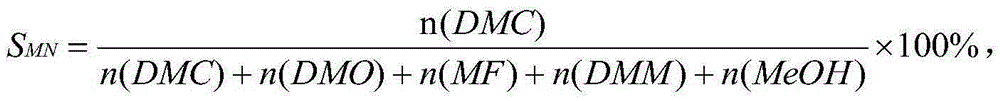

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

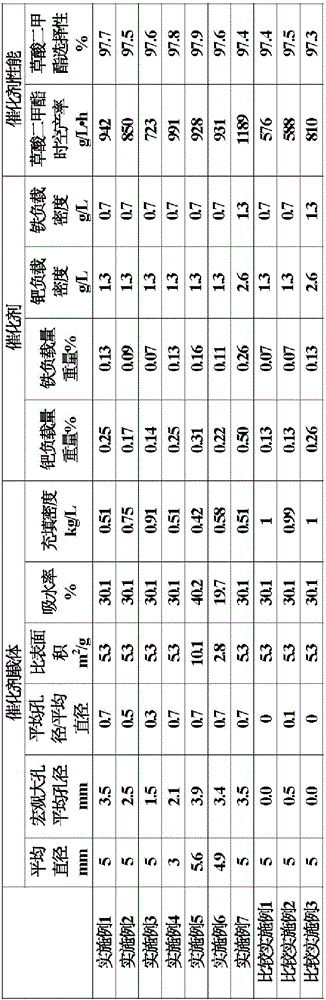

Catalyst carrier and catalyst comprising the same

ActiveCN106457227AEasy to fillEvenly stackedCatalyst carriersCatalyst activation/preparationOxalateGas phase

The invention relates to a catalyst carrier used in a process of coupling and synthesizing dialkyl oxalates through gas phase catalysis of carbon monoxide, the catalyst carrier comprises micro pores and one or more macro pores which can pass through the catalyst carrier, wherein the ratio of the average pore size of the macro pores and the average diameter of the catalyst carrier is more than 0.2. The invention also relates to the catalyst carrier and a catalyst which comprises activated components and an optional additive and is loaded on the catalyst carrier. The catalyst can effectively perform gas phase catalysis on carbon monoxide to couple and generate the dialkyl oxalates, the heat dissipation is improved, the pressure drop is reduced, the usage amount of precious metal such as palladium is reduced, the usage cost of the catalyst and the production cost of the dialkyl oxalates are reduced, so that the industrial mass production of the dialkyl oxalates can be contributed to realize.

Owner:HIGHCHEM

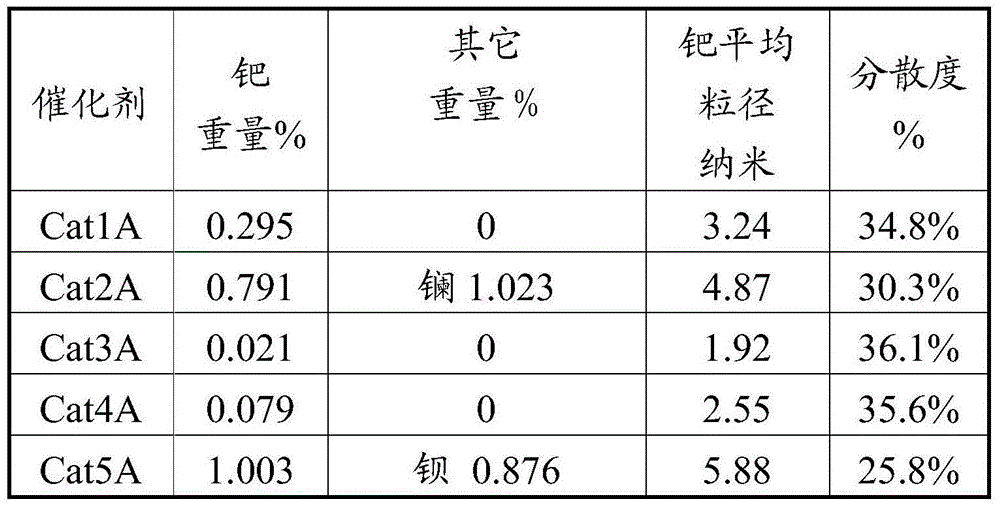

Carbon monoxide gas phase coupling oxalate synthesis catalyst and preparation method and application thereof

ActiveCN105363436AIncreased space-time yieldGood dispersionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveActive component

The invention relates to a carbon monoxide gas phase coupling oxalate synthesis catalyst and a preparation method and application thereof. The problem that the oxalate synthesis caviation yield is low due to the fact that an existing catalyst is low in active component Pd dispersity and microcrystal content is mainly solved. The catalyst prepared from, by weight, 0.02-3 parts of an active component Pd and 97-100 parts of at least one carrier of alpha-aluminum oxide or a molecular sieve or silicon oxide is prepared through the method comprising the steps of impregnation, vacuum freeze drying and calcination, wherein the dispersity of the active component Pd is larger than 26%. The problems are well solved, and the carbon monoxide gas phase coupling oxalate synthesis catalyst can be used for industrial production of carbon monoxide gas phase coupling oxalate synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for synthetizing compound of dicarbon containing oxygen by CO hydrogenation

InactiveCN1724151AIncreased space-time yieldHigh activityOrganic compound preparationHydroxy compound preparationPtru catalystPhysical chemistry

A catalyst Rh-Mn-Ti-M1-M2 / SiO2, where M1 is alkali metal (Li or Na) and M2 is chosen from Ru, Fe and Ir features that the wt ratio of Rh is 0.1-3%, Mn / Rh is 0.5-12, Ti / Rh is 0.001-3, M1 / Rh is 0.01-1 and M2 / Rh is 0.1-1. Its advantage is high catalytic activity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for the preparation of a crystalline form

ActiveUS8802842B2High purityHigh yieldBiocideSaccharide with carbocyclic radicalsCrystallographyBenzene

Owner:BOEHRINGER INGELHEIM INT GMBH

Amorphous submicron particles

ActiveUS20080173739A1Increased space-time yieldProcess is directionalNatural mineral layered productsThin material handlingProcess engineeringAmorphous solid

A process for milling amorphous solids using a milling apparatus can result in particles having a median particle diameter d50 of <1.5 μm. The process includes: operating a mill in a milling phase with an operating medium selected from the group consisting of gas, vapor, steam, a gas containing steam and mixtures thereof, and heating a milling chamber in a heat-up phase before the actual operation with the operating medium in such a way that a temperature in the milling chamber, the mill exit or both, is higher than a dew point of the operating medium.

Owner:EVONIK OPERATIONS GMBH

Process for preparing (cyclo)aliphatic isocyanates

InactiveUS6838578B2Increased space-time yieldEqual and good quality of productIsocyanic acid derivatives preparationOrganic compound preparationPolymer scienceGas phase

The present invention relates to a process for preparing (cyclo)aliphatic diisocyanates and triisocyanates corresponding to the formulaR—(NCO)n (I),whereinR represents a (cyclo)aliphatic hydrocarbon group having up to 15 carbon atoms, provided that there are at least two carbon atoms between two nitrogens,n represents the number 2 or 3,bya) separately heating phosgene and a diamine or triamine corresponding to the formulaR—(NH2)n (II), to a temperature of 200° C. to 600° C., wherein the amine may optionally be diluted with an inert gas or with the vapors of an inert solvent,b) optionally passing the reactants over torque-producing baffles andc) continuously reacting phosgene and the amine in the gas phase in a reaction chamber without moving parts and with constrictions of the walls in the region of the reaction zone.

Owner:COVESTRO DEUTSCHLAND AG

7beta-hydroxysterol dehydrogenase mutant and application of 7beta-hydroxysterol dehydrogenase mutant in ursodeoxycholic acid synthesis

ActiveCN107099516AEasy to separate and extractOvercoming the problem of inactivation processingOxidoreductasesGenetic engineeringChenodeoxycholic acidSubstrate concentration

The invention discloses a 7beta-hydroxysterol dehydrogenase mutant with increased activity and stability which is obtained through molecular evolution, recombinant expression plasmid containing the 7beta-hydroxysterol dehydrogenase mutant gene and a recombinant expression transformant and a preparation method of a recombinant mutant enzyme preparation, and the invention also provides an application of the recombinant mutant enzyme preparation in ursodeoxycholic acid synthesis. The 7beta-hydroxysterol dehydrogenase has excellent activity and heat stability, can efficiently catalyze asymmetric reduction of 7-carbonyl lithocholic acid to prepare the ursodeoxycholic acid; the 7beta-hydroxysterol dehydrogenase is subjected to immobilization and then is subjected to couple by an enzyme method with the immobilized 7beta-hydroxysterol dehydrogenase, epimerization of a substrate chenodeoxycholic acid with low cost can be directly catalyzed, ursodeoxycholic acid can be prepared through continuous conversion, and the operation is simple. Compared with the prior art reported currently, ursodeoxycholic acid prepared by hydroxysterol dehydrogenase through catalysis has the advantages of high substrate concentration, short reaction time, complete reaction, and high product purity, and has strong industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Catalyst for synthesizing dimethyl carbonate through indirect vapor phase method and preparation method of catalyst

ActiveCN105363485AGood dispersionIncreased space-time yieldMolecular sieve catalystsPreparation from organic carbonatesGas phaseMethyl carbonate

The invention discloses a catalyst for synthesizing dimethyl carbonate through an indirect vapor phase method and a preparation method of the catalyst. The main active component of the catalyst is palladium, the assistant active component of the catalyst is Co or Cu or Ni or La or Ce or K, and the carrier of the catalyst is a NaX type molecular sieve or a NaY type molecular sieve or a Beta molecular sieve or an MCM-41 molecular sieve or a ZSM-35 molecular sieve. The main active component in the catalyst accounts for 0.1-3% of the total mass of the catalyst, and the assistant active component in the catalyst accounts for 0.1-10% of the total mass of the catalyst. The preparation method of the catalyst is characterized in that the catalyst is prepared through an ion exchange ammonia distillation method. According to the method, the active components and positive ions on the carrier can be exchanged, so that the chloride-free catalyst is obtained. When applied to the reaction of preparing dimethyl carbonate through CO and methyl nitrite vapor phase synthesis, the catalyst can eliminate the problems of equipment corrosion and inactivation caused by a chlorine-containing catalyst and is good in stability and high in yield.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for modifying titanium silicon zeolite by aqueous solution containing ammonia

InactiveCN1413768AImprove effective utilizationIncreased space-time yieldMolecular sieve catalystsGas phaseOxide composite

A process for modifying the TiSi zeolite used as catalyst features that the said TiSi zeolite is modified by making the ammonia contained aqueous solution in liquid or gas phase contact with it or the oxide copmosition containing TiSi zeolite at 80-600 deg.C for 0.5-1200 hr. When the modified catalyst is used to prepare epoxy propane by epoxidizing propene, the output rate can be greatly increased.

Owner:DALIAN QIYUAN TECH CO LTD

Continuous slurry polymerization process and apparatus

InactiveUS7268194B2Eliminate cloggingImprove securityChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesProcess engineeringSlurry

A process of converting a loop reactor into multiple loop reactors comprising starting with a loop reactor comprising at least 8 vertical legs, at least two non-vertical conversion runs, each non-vertical run connected in fluid flow communication with two vertical legs; at least two feed inlets; and at least two continuous discharge conduits; disconnecting at least one connection of each conversion run; and reconnecting each conversion run in fluid flow communication with a different vertical leg in such a manner to form multiple loop reactors each having at least one feed inlet and at least one continuous discharge conduit.

Owner:EXXONMOBIL CHEM PAT INC

Process for the hydrogenation of oxo aldehydes having high ester contents

InactiveUS7524997B2Low costHigh product yieldCatalyst protectionPreparation by oxo-reaction and reductionCobaltAldehyde formation

Owner:EVONIK DEGUSSA GMBH

Continuous Slurry Polymerization Process and Apparatus

InactiveUS20070274873A1Increase contentSmall sizeChemical/physical/physico-chemical stationary reactorsFlash distillationPolymer scienceSlurry reactor

A process / apparatus is disclosed for continuously separating a liquid medium comprising diluent and unreacted monomers from a polymerization effluent comprising diluent, unreacted monomers and polymer solids, comprising a continuous discharge of the polymerization effluent from a slurry reactor through a discharge valve and transfer conduit into a first intermediate pressure flash tank with a conical bottom defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the slurry / polymer solids and an exit seal chamber of such diameter (d) and length (l) as to maintain a desired volume of concentrated polymer solids / slurry in the exit seal chamber such as to form a pressure seal while continuously discharging a plug flow of concentrated polymer solids / slurry bottom product of the first flash tank from the exit seal chamber through a seal chamber exit reducer with inclined sides defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the polymer solids which remain after removal of about 50 to 100% of the inert diluent therefrom to a second flash tank at a lower pressure.

Owner:EXXONMOBIL CHEM PAT INC

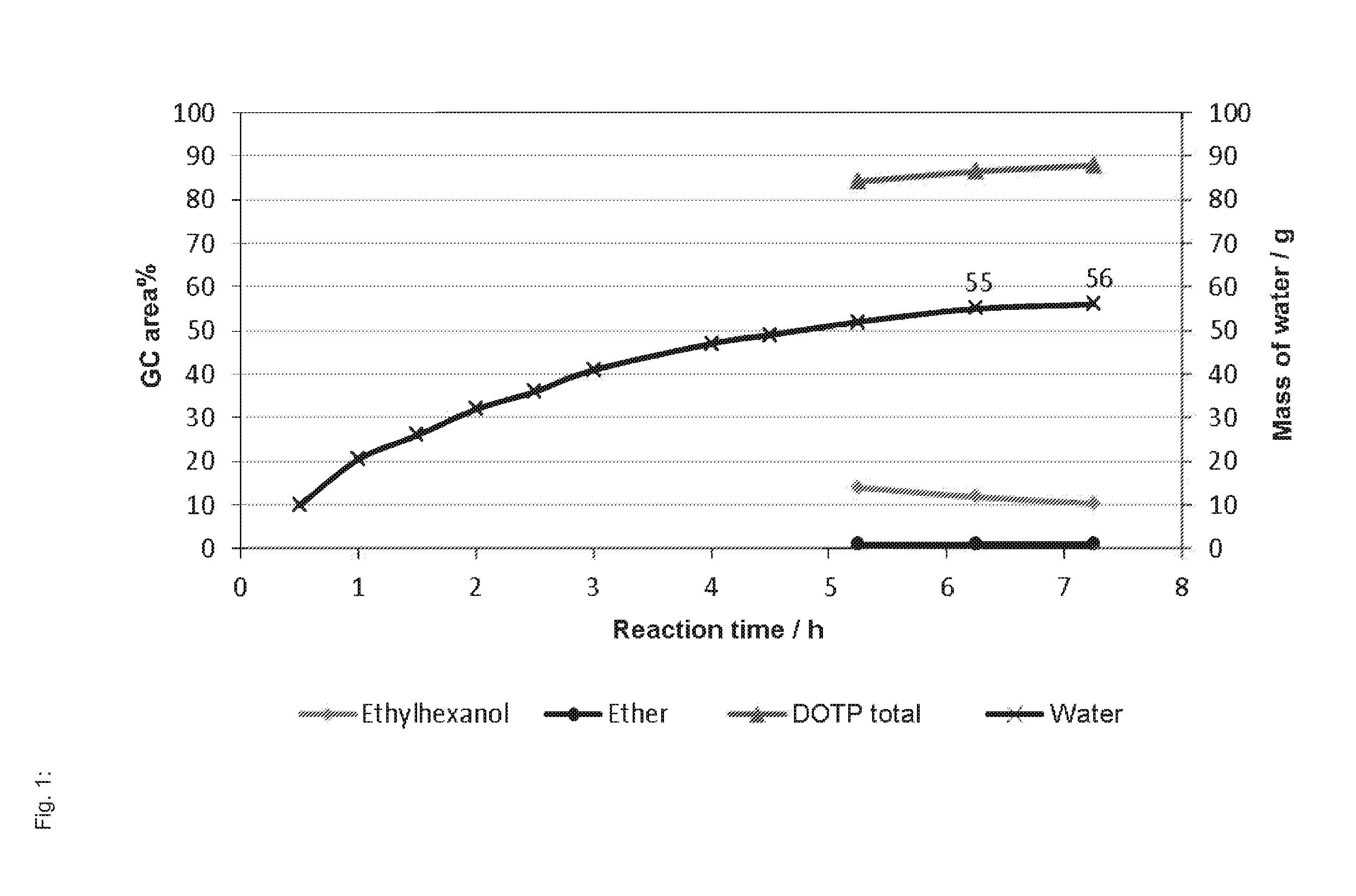

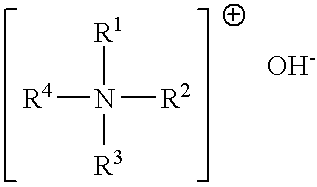

Method for producing carboxylic acid esters and the use thereof as plasticizers

ActiveUS20160264509A1Short reaction timeIncreased space-time yieldOrganic compound preparationCarboxylic acid esters separation/purificationElastomerAlcohol

The present invention relates to a process for the production of carboxylic esters by reaction of carboxylic acids and / or carboxylic anhydrides with at least one alcohol selected from alkanols having at least 5 carbon atoms, cycloalkanols, and alkoxy-alkanols, in the presence of an acidic esterification catalyst. The invention further relates to the use of the resultant carboxylic esters as plasticizers or in a plasticizer composition for thermoplastic polymers and elastomers.

Owner:BASF AG

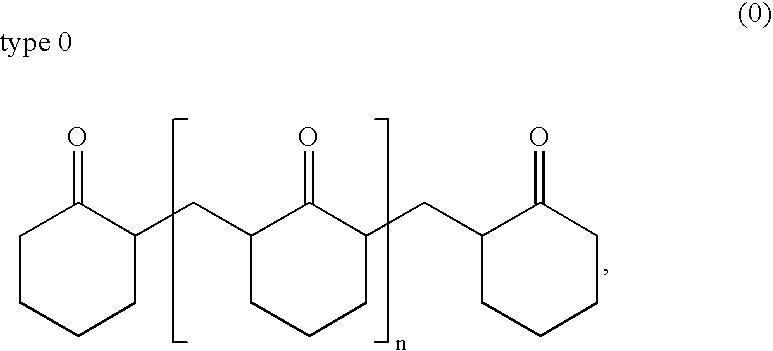

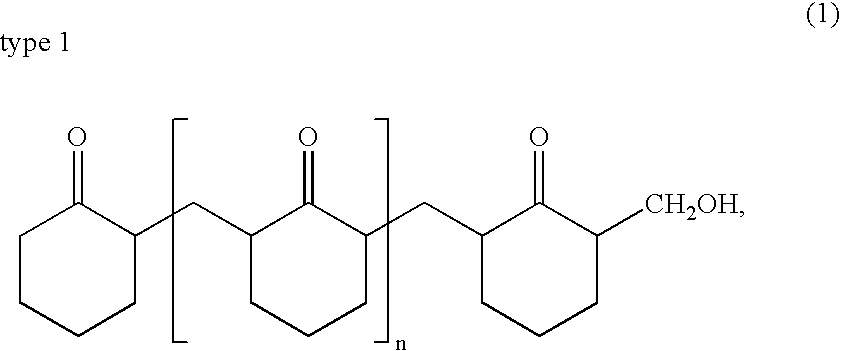

Preparation of ketone-formaldehyde resins

InactiveUS7183372B2Reduce the amount requiredIncreased space-time yieldSynthetic resin layered productsNatural resin processCyclohexanoneKetone

A process for preparing ketone-formaldehyde resins, especially acetophenone- and cyclohexanone-formaldehyde resins, having a low water content and high thermal stability and yellowing resistance, and a process for their production and their use.

Owner:DEGUSSA AG

Preparation process of composite copper powder catalyst

ActiveCN102941102AReduce lossesPrecise control of ingredientsMetal/metal-oxides/metal-hydroxide catalystsElectrolysisZinc alloys

The invention provides a preparation process of a composite copper powder catalyst, comprising the steps of cutting an electroplating copper plate into a copper block and machining into copper scales; grinding the copper scales into sheet-shaped copper powder; obtaining sheet pure copper powder through a magnetic selection and air flow grading technology; smelting and atomizing a copper-tin-zinc alloy to prepare needed copper-tin-zinc alloy powder; drying and screening, and grinding to obtain scale-shaped copper-tin-zinc alloy powder; magnetically selecting and screening to obtain the needed copper-tin-zinc alloy powder; and mixing the sheet pure copper powder with the copper-tin-zinc alloy powder according to a ratio to obtain the needed composite copper powder catalyst. According to the preparation process of the composite copper powder catalyst, elements which are harmful to an environment are not introduced in a whole process, the quality stability of a product is good, concave-convex defects of the surface of powder grains are more and the specific surface is large; the catalysis property of the composite copper powder catalyst is obviously better than that of common composite copper powder so that the effect of an organic silicon monomer synthesized metal catalyzing system is improved, the time-space yield of an organic silicon monomer synthesized fluidized bed is increased, a synthesis reaction period is prolonged, the selectivity is improved, the cost is reduced and good economic benefits are created.

Owner:湖南省天心博力科技有限公司

Promoting cobalt-copper base catalyst for preparation of low carbon mixed alcohol-carbon nano tube from synthetic gas and preparing method thereof

InactiveCN1669649AIncrease conversion rate per passHigh selectivityOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention relates to a method for preparing a catalyst, which is used in making low-carbon mixed alcohol carbon nanometer tube promoting Co-Cu group. The catalyst comprises Co, Cu and carbon nanometer tube, wherein the mass percent is: Co:40-75wt%,Cu:15-50wt%,CNTs:5-25wt%, the CNTs is a multi-wall carbon nanometer tube. The catalyst is prepared through coprecipitation, which has high activity and stability, and the C2+ alcohol has high selective, besides, both the conversion rate of CO and space time productivity of the low-carbon mixed alcohol are higher than the present catalyst.

Owner:XIAMEN UNIV

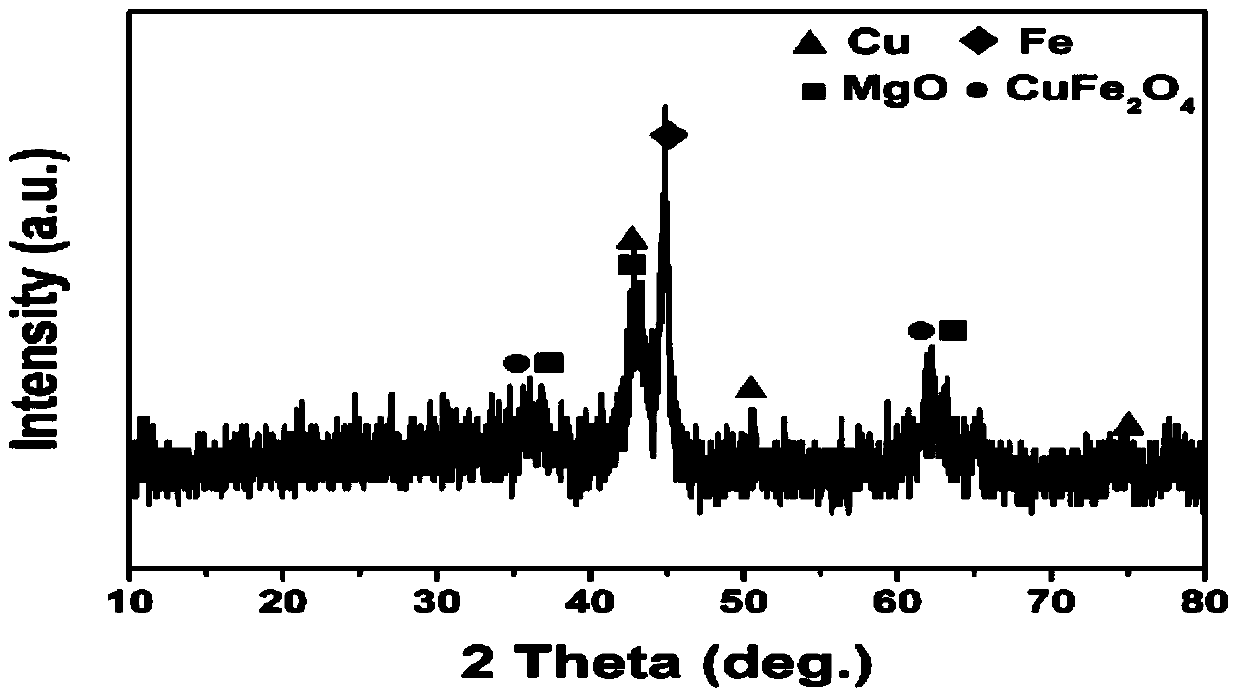

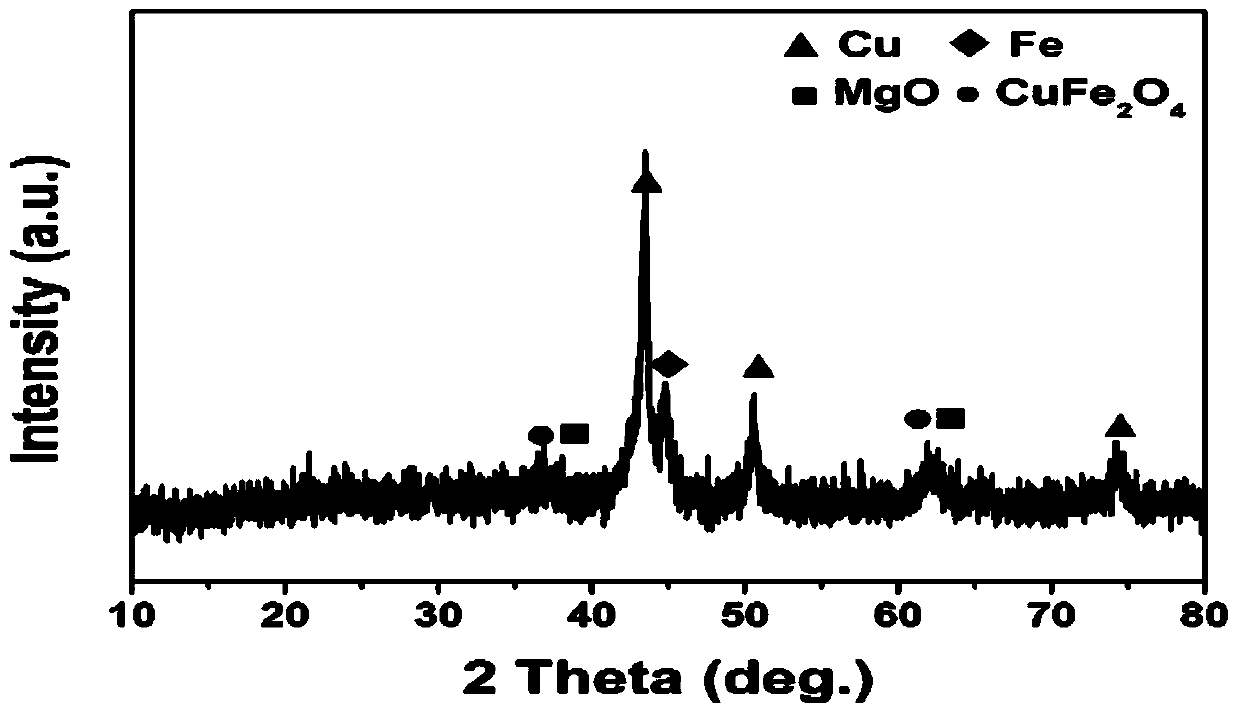

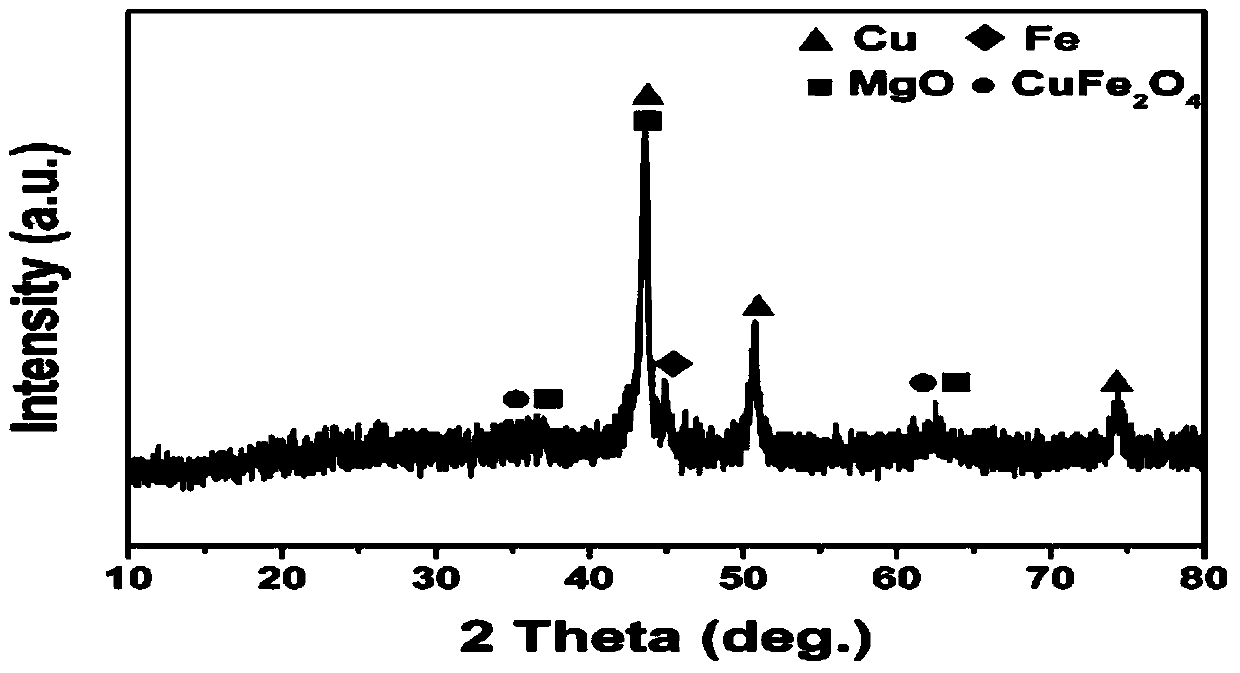

Copper-iron based catalyst and application thereof in preparing low mixed alcohols by catalyzing synthesis gas

InactiveCN103464159ATo achieve co-precipitation reactionGuaranteed uniformityOrganic compound preparationHydroxy compound preparationPtru catalystAlcohol

The invention discloses a copper-iron based catalyst in the technical field of catalyst preparation and application thereof in preparing low mixed alcohols by catalyzing synthesis gas. According to the invention, a copper-magnesium-iron hydrotalcite precursor is prepared by a nucleation-crystallization isolating method, and then the copper-magnesium-iron hydrotalcite precursor is roasted and then subjected to reduction treatment to obtain the copper-iron based catalyst of highly dispersed nanoparticles. The catalyst has the characteristics that the catalytic active ingredients are highly dispersed, the catalytic active ingredients have strong interaction with one another, and are high in stability, and as a result, the activity and selectivity of the catalyst are improved. After the copper-iron based catalyst is applied to preparing low mixed alcohols from the synthesis gas, the CO conversion rate is high, and the selectivity and space time yield of the low mixed alcohols are also improved; besides, the conversion rate of CO for synthesizing low mixed alcohols through CO hydrogenation is 56.89% and the selectivity of alcohols is 49.07%.

Owner:BEIJING UNIV OF CHEM TECH

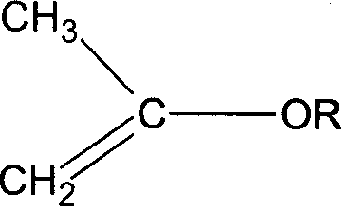

New technique for synthesizing 2-alkoxyl propylene

InactiveCN1660742AReduce consumptionHigh conversion rate of cracking reactionOrganic chemistryOrganic compound preparationCracking reactionPropane

Owner:ZHEJIANG UNIV +1

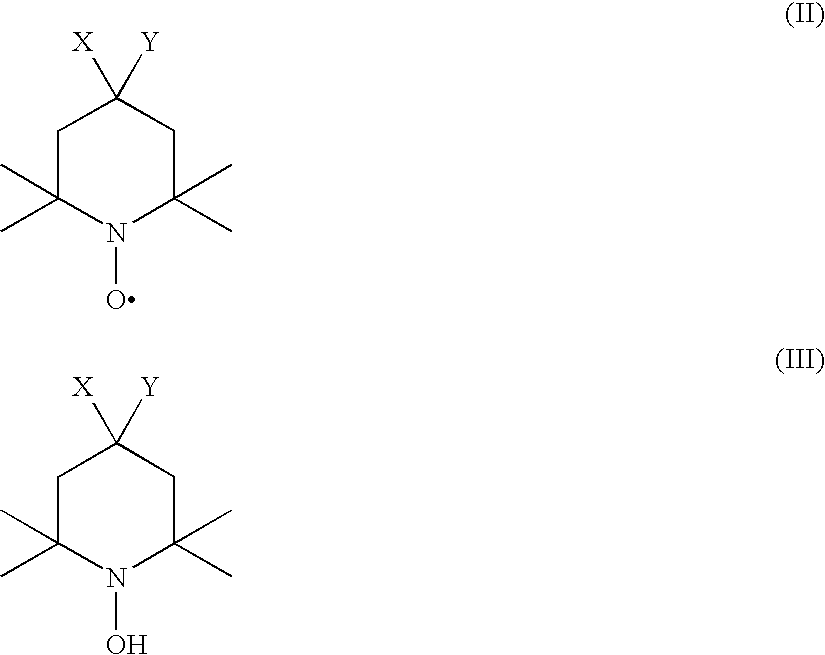

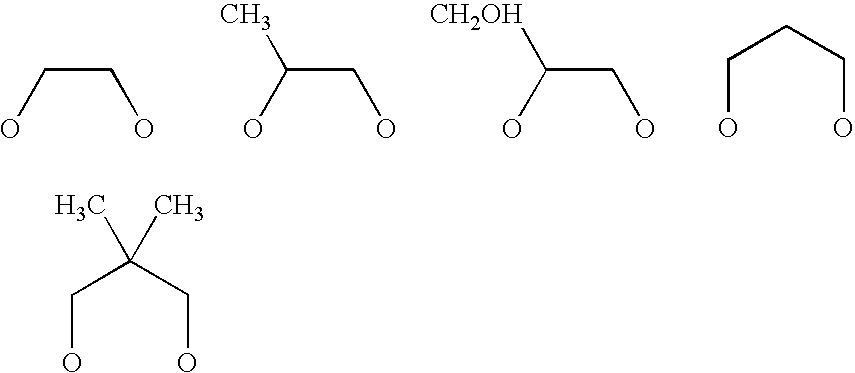

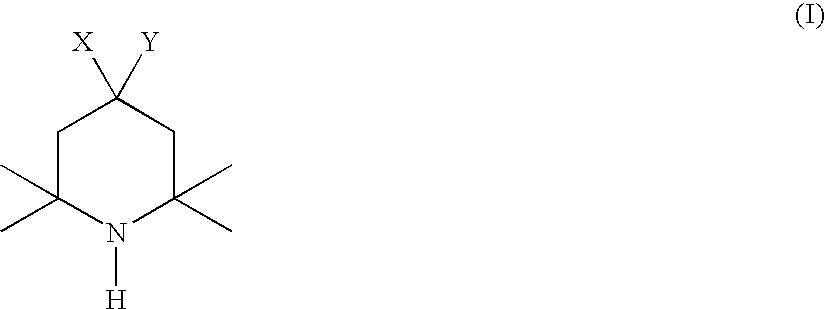

Process for preparing 4-substituted 2,2,6,6-tetramethylpiperidin-N-oxy and 2,2,6,6-tetramethylpiperidin-N-hydroxy compounds

A process for preparing 4-substituted 2,2,6,6-tetramethylpiperidin-N-oxy compounds (II) or mixtures of (II) and 4-substituted 2,2,6,6-tetramethylpiperidin-N-hydroxy compounds (III) where X+Y can be O or can represent a cyclic ketal with the radicals or can represent an open-chain ketal in which X═O—R and Y═O—R′, where R and R′ can be identical or different and can each be CH3, CH2—CH3, CH2—CH2—CH3, CH(CH3)—CH3, CH2—CH2—CH2—CH3 and CH2—CH(CH3)—CH3, by oxidizing corresponding 4-substituted 2,2,6,6-tetramethylpiperidines (I) with hydrogen peroxide in the presence of alkali metal hydrogencarbonate and / or ammonium hydrogencarbonate and in the presence or absence of a solvent, in which the reaction is carried out with the addition of Brönsted acids which have an acid strength greater than that of the hydrogencarbonate.

Owner:DEGUSSA AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com