Catalyst carrier and catalyst comprising the same

A catalyst carrier and catalyst technology, which is applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems that cannot be fully satisfied, precious metals are not easy to recycle, and the use cost is high, so as to reduce pressure drop and achieve large Large-scale industrial production and the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation method of catalyst carrier

[0040] Taking a spherical catalyst carrier with a macroscopic macropore with a circular cross section as an example, its preparation method roughly includes the following steps: kneading the raw material powder, extruding it into a hollow cylinder with a ratio of inner and outer diameters > 0.2, pelletizing, and rounding , dried, and calcined to obtain a catalyst carrier with microscopic pores and a macroscopic macropore passing through the catalyst carrier in a straight line. In the kneading process, dilute nitric acid or acetic acid may be used. The above steps are conventional in the field of catalysts and are well known to those skilled in the art. Pelletizing and rounding can be performed, for example, by means of a pelletizer with roller knives. Drying is, for example, preferably carried out at a temperature of 90-150°C, especially 100-130°C. The calcination temperature of the catalyst support varies between 1150°C and 1...

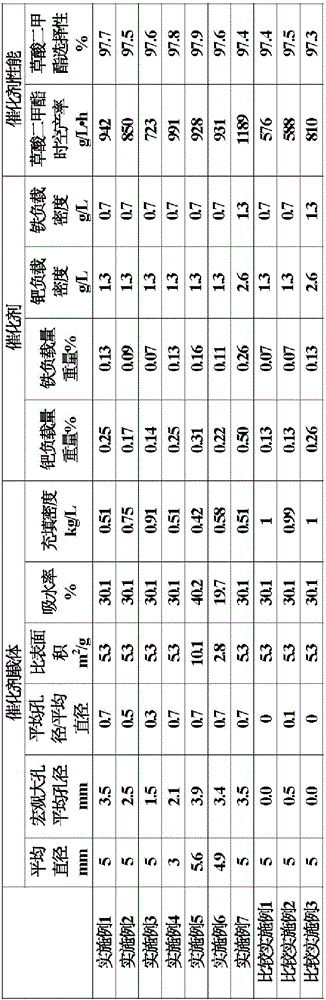

Embodiment 1

[0062] Preparation of catalyst support

[0063] The purity is 99.99%, the specific surface area is 310m 2 The pseudo-boehmite / g is wetted with 1% by weight of nitric acid aqueous solution, kneaded, and extruded into a hollow cylinder with an inner diameter and an outer diameter of 4.6 mm and 6.5 mm; The hollow cylinder is pelletized and rounded to make a sphere with macroscopic macropores penetrating both ends of the carrier; the hollow sphere is dried overnight at 120°C and roasted at 1250°C for 8 hours to obtain the catalyst carrier of the present invention, which has microscopic Fine holes and a hollow spherical α-alumina carrier with circular macroscopic macropores passing through both ends of the carrier in a straight line and with the diameter of the sphere as the central axis, wherein the average diameter of the carrier is 5 mm, and the average diameter of the macroscopic macropores is is 3.5 mm, the average pore diameter / average diameter ratio is 0.7, and the specific...

Embodiment 2

[0069] Preparation of catalyst support

[0070] Repeat Example 1, but extrude into a hollow cylinder with an inner diameter and an outer diameter of 3.3 mm and 6.5 mm, respectively, to obtain a hollow spherical α-alumina carrier with an average pore diameter / average diameter ratio of 0.5, wherein the average diameter is 5 mm , with an average pore diameter of 2.5mm and a specific surface area of 5.3m 2 / g, the water absorption rate is 30.1% by weight, and the packing density is 0.75kg / L.

[0071] Catalyst preparation

[0072] The catalyst carrier of the present invention of 50g embodiment 2 was impregnated in equal volume for 2 hours by using mixed impregnating solution, wherein mixed impregnating solution was passed through by 0.14g palladium chloride, 0.21g ferric chloride hexahydrate, 14.6g water and 0.08g 61% hydrochloric acid Prepared by heating and dissolving, other steps are the same as in Example 1, thereby obtaining a hollow spherical α-alumina catalyst, wherein t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com