Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Oakum treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

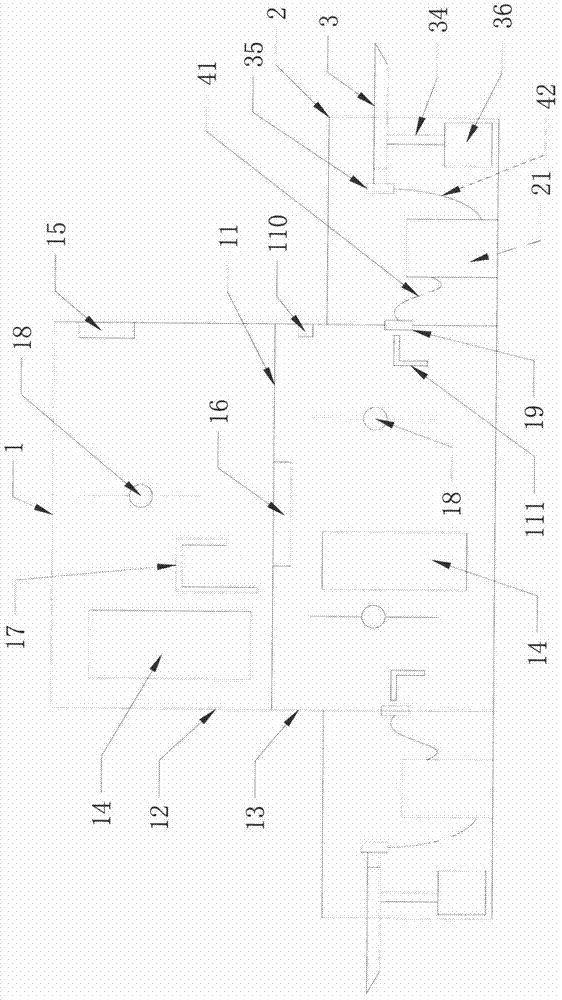

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

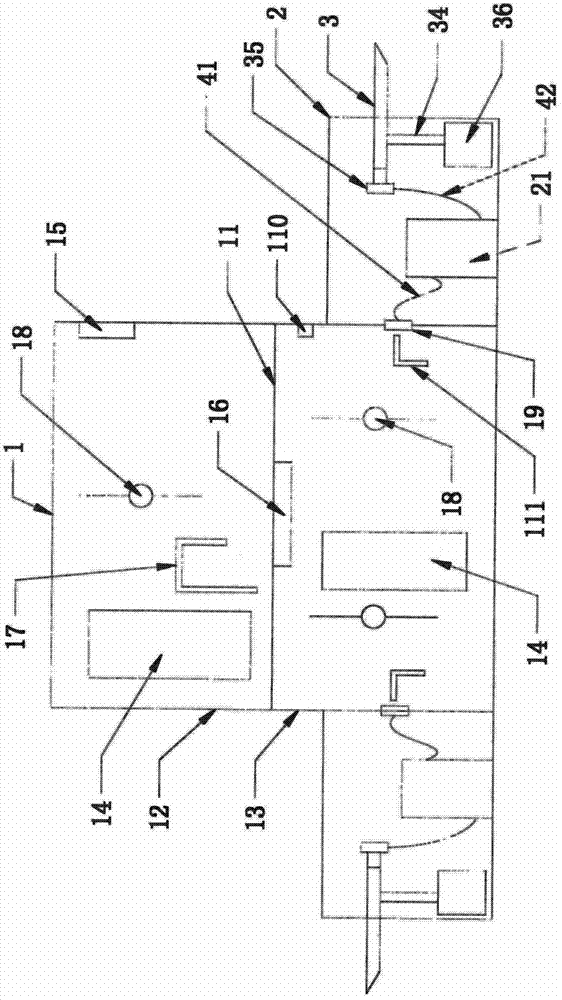

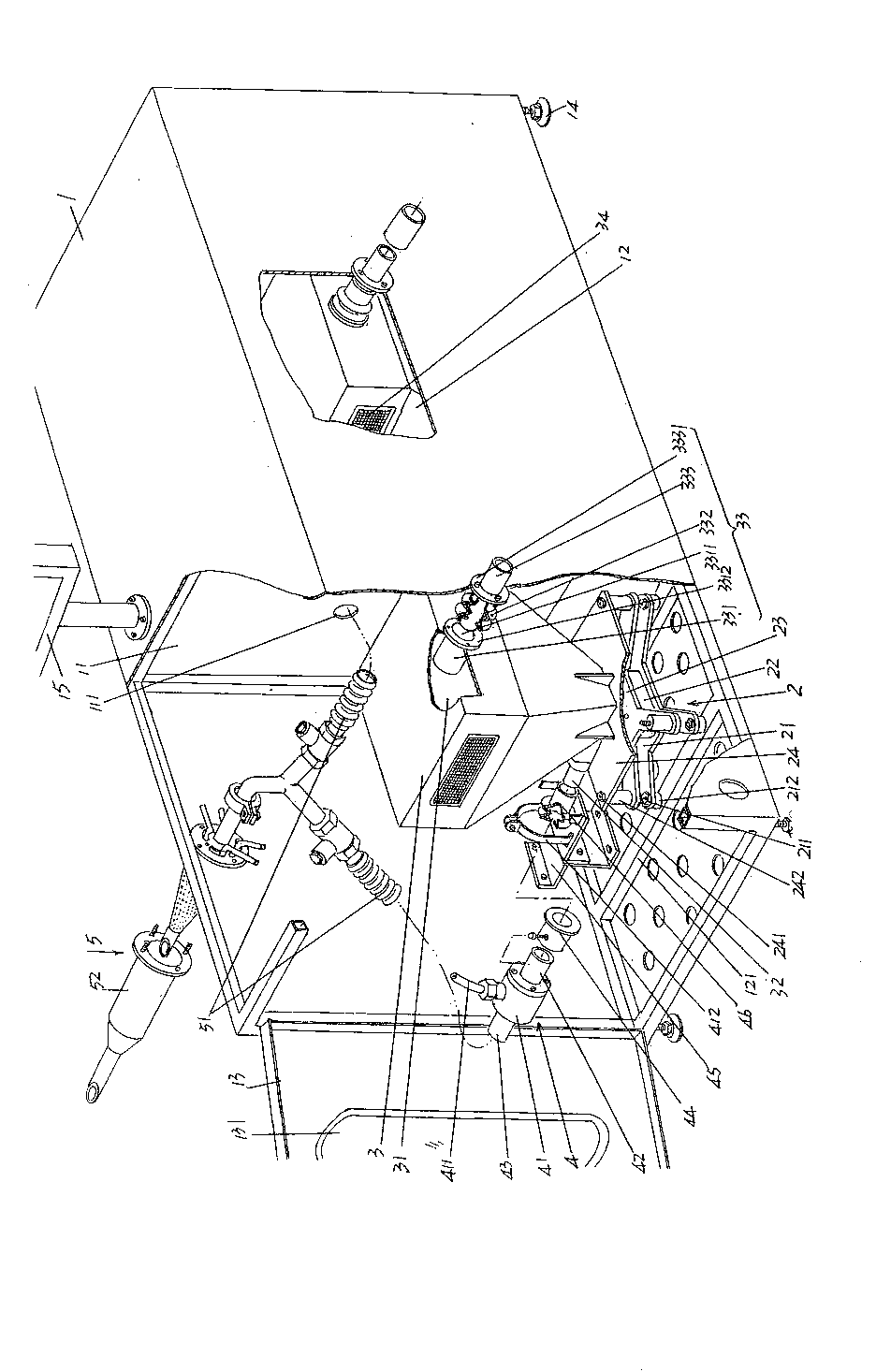

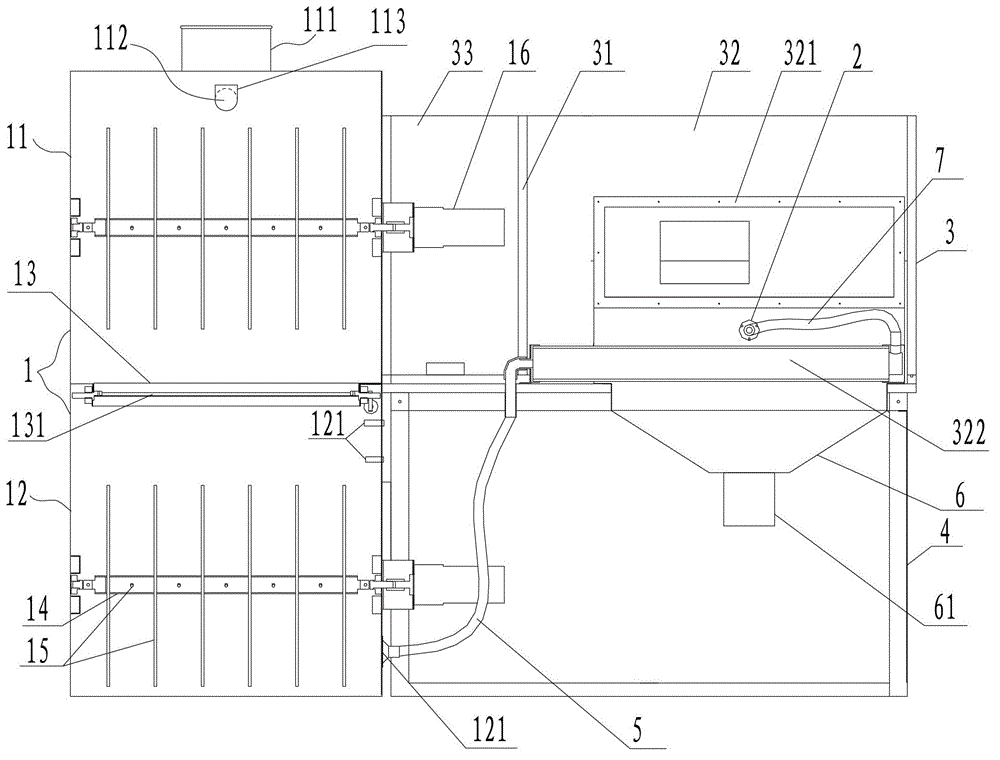

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

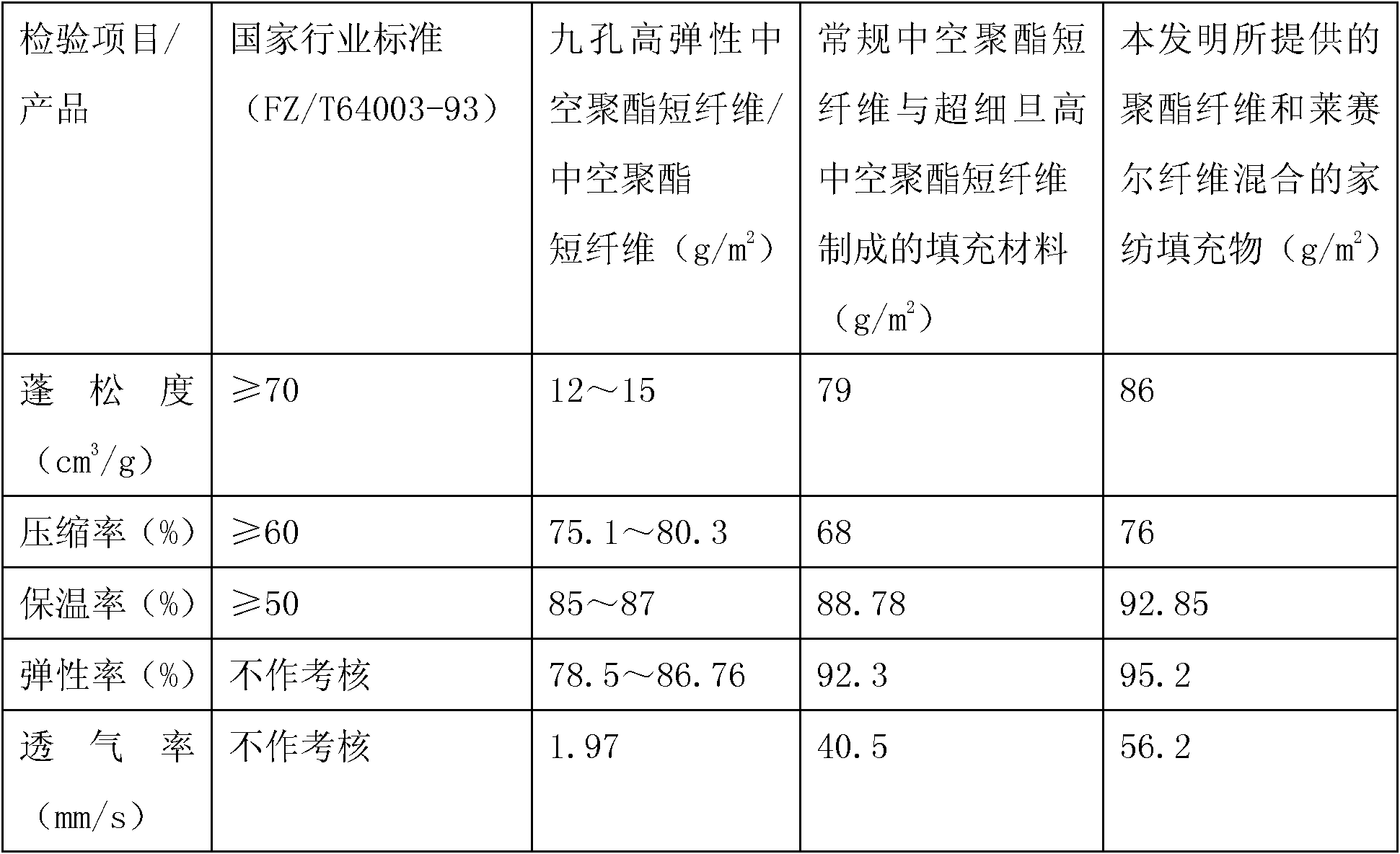

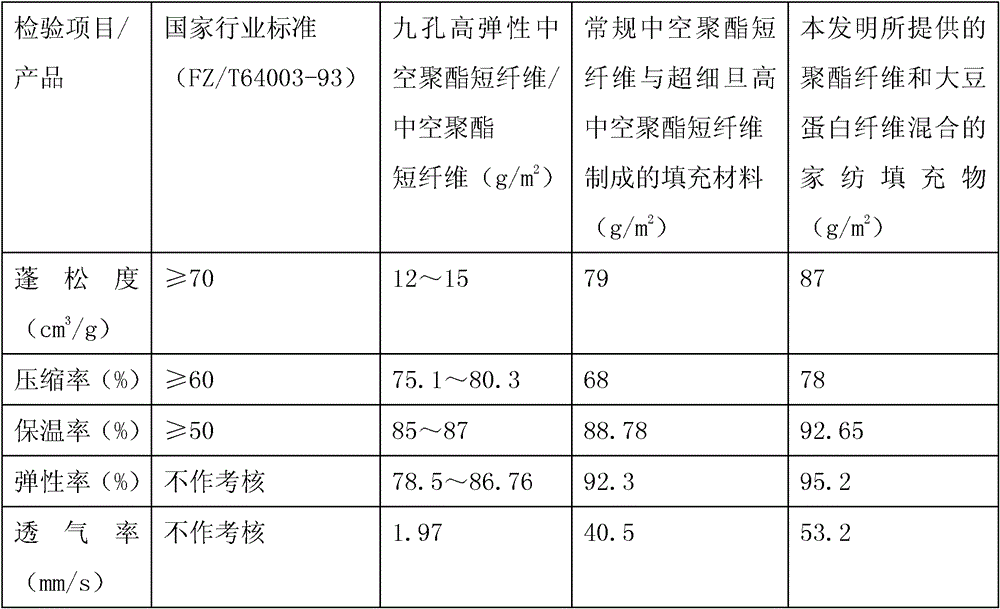

Polyester fiber filling materials and filling process therefor

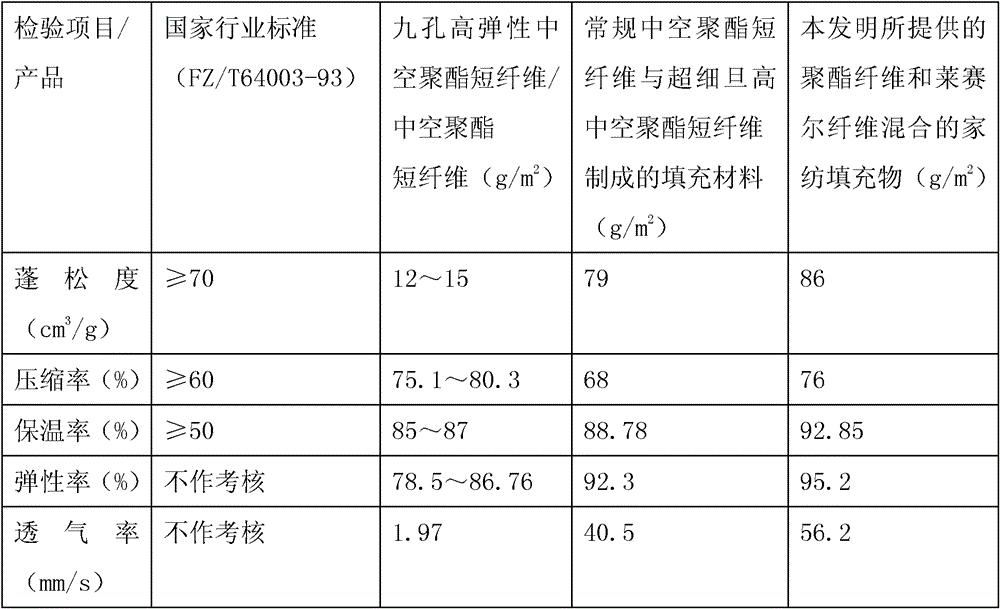

InactiveCN1966789AWell mixedEvenly filledOakum treatmentHollow filament manufacturePolyesterLife quality

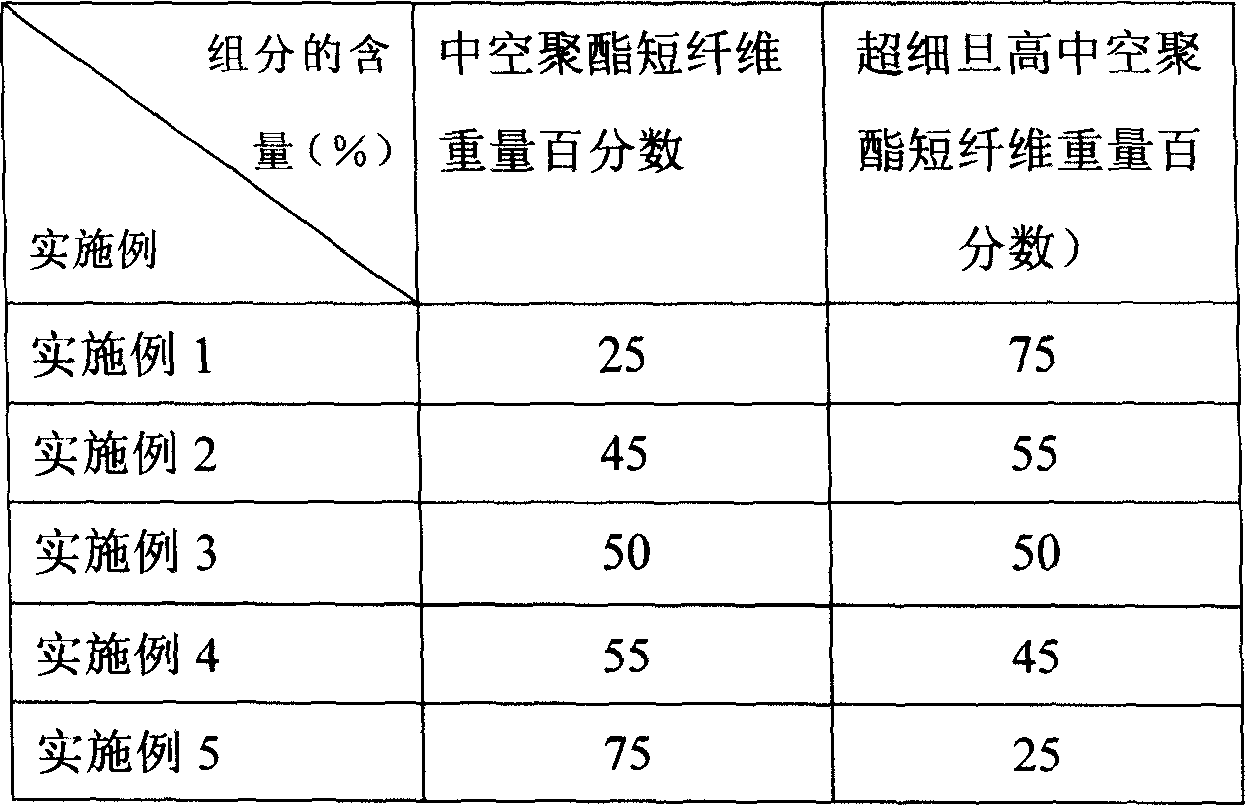

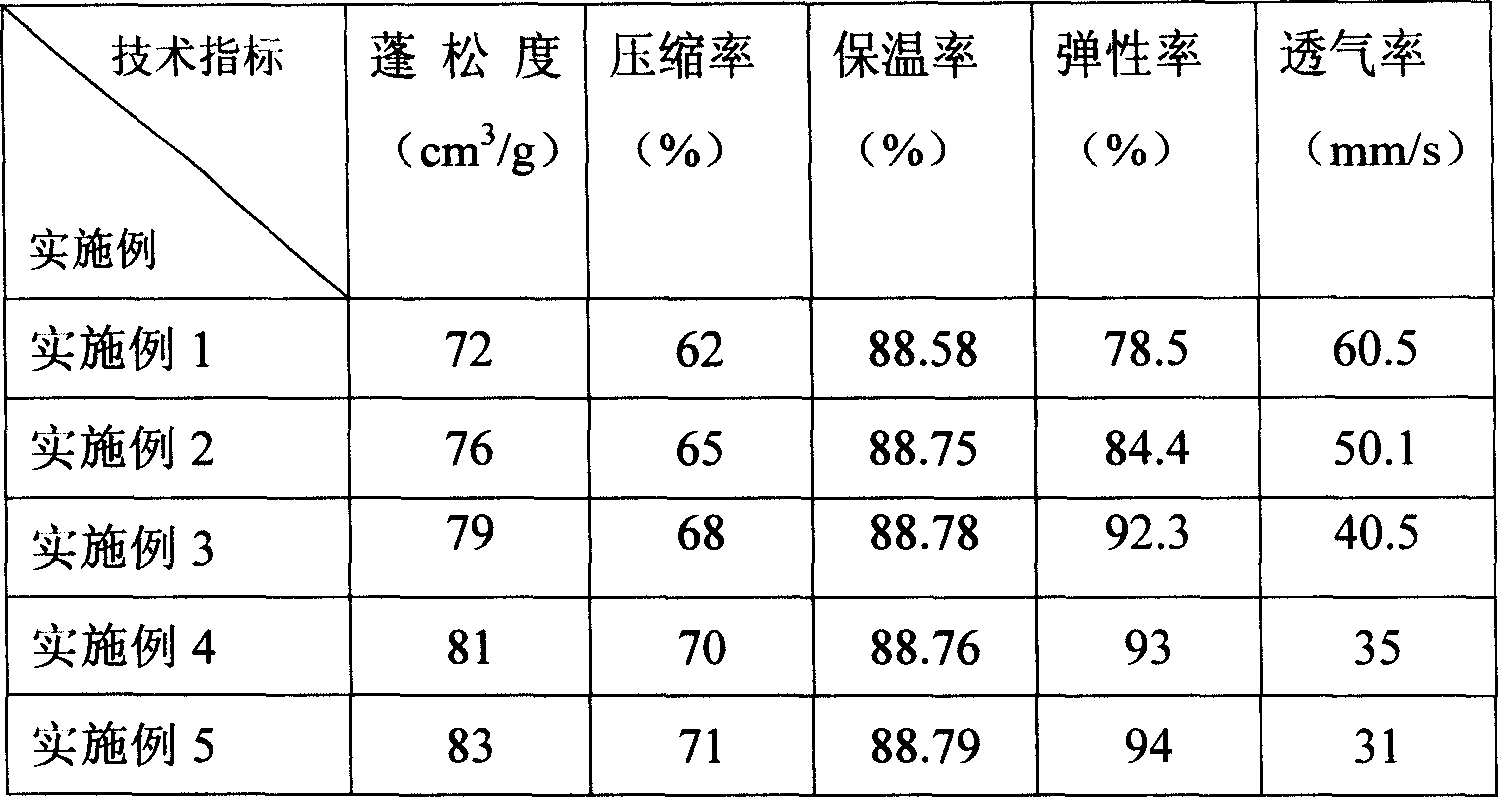

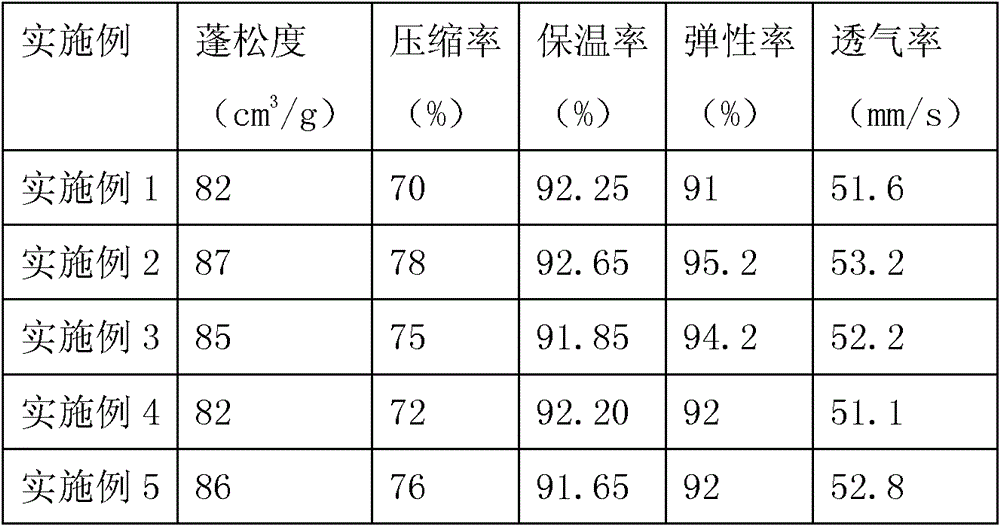

The polyester fiber filler is the combination of the regular hollow cut staple polyester fiber and a superfine super high hollow cut staple polyester fiber. Their weight ratings are hollow cut staple polyester fiber 25%-75%, superfine super high hollow cut staple polyester fiber, with their optimum weight rating of 50%: 50%. It also provides a production process for filling the above said materials through the process of opening picking, mixing, and carding and final air blowing suede. The filled product with this process looks even and trim, it is light, fluffy, sustainable elastic ability, fine heat protection, soft in touching, and provides people with refined living quality.

Owner:上海龙头家纺有限公司

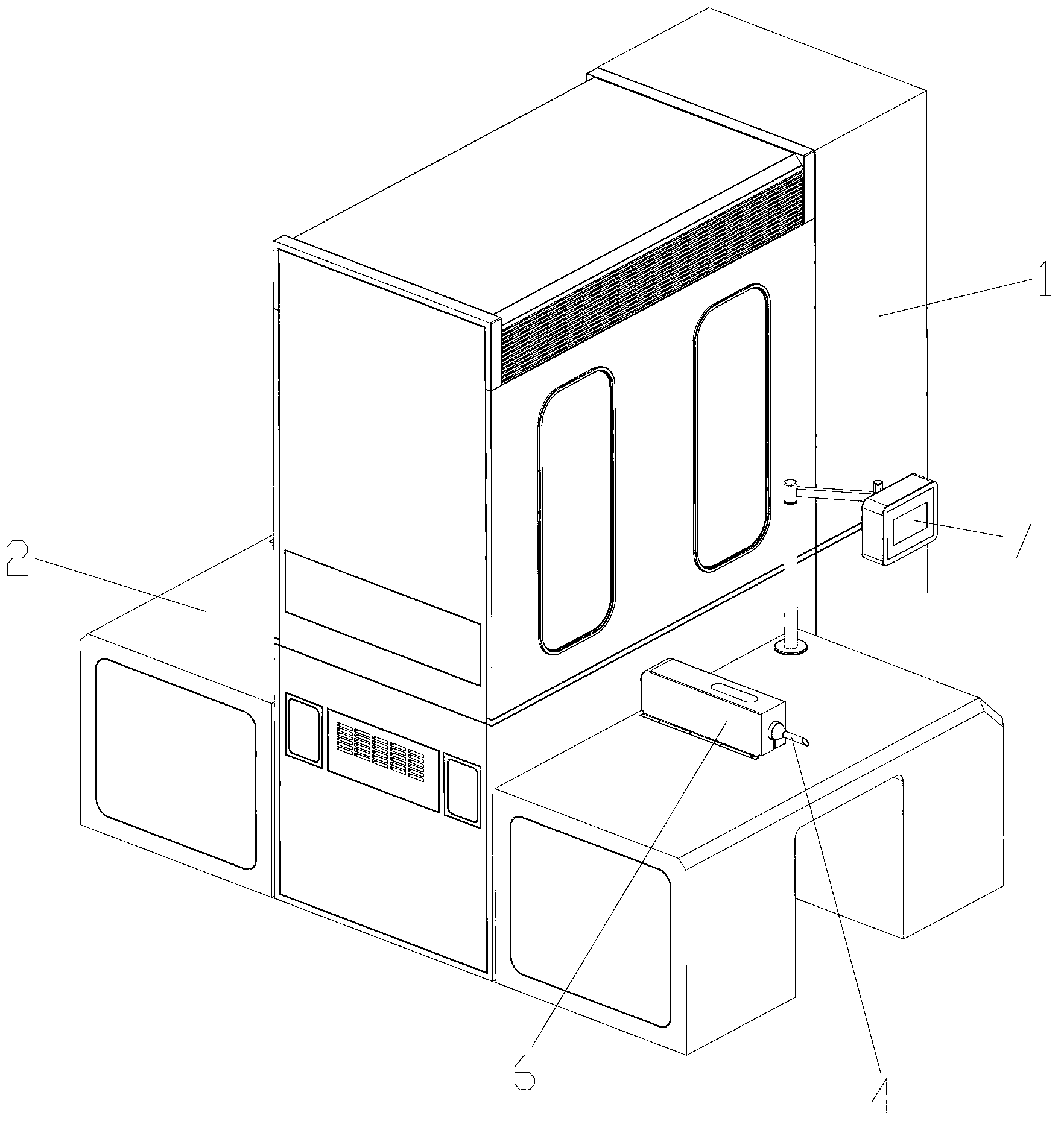

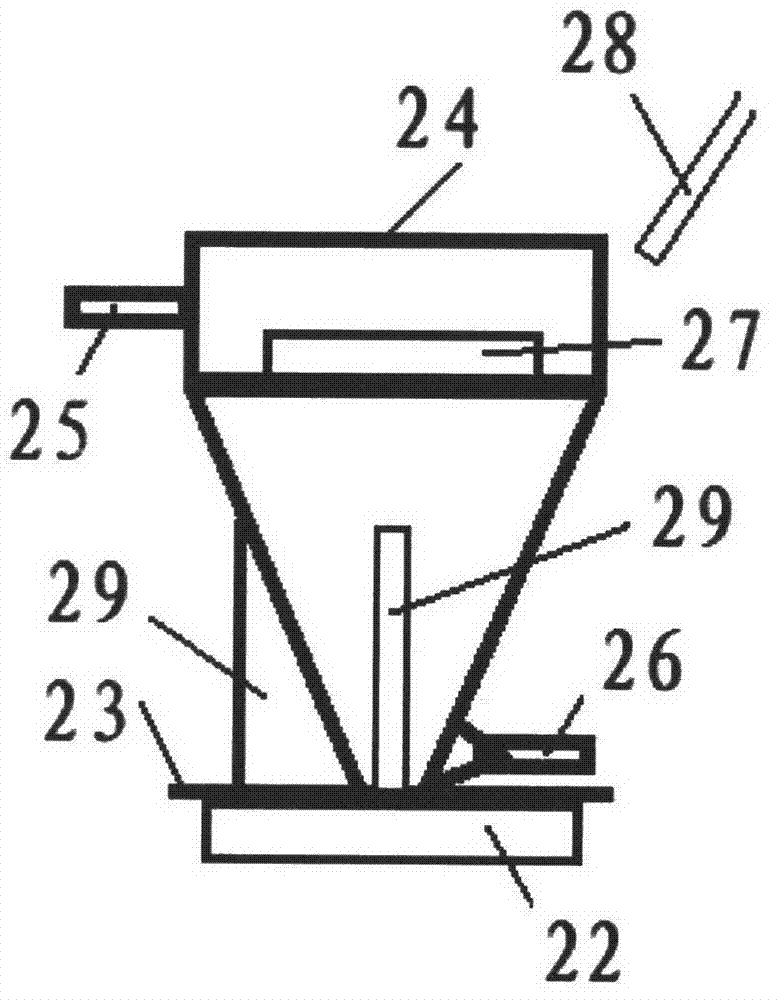

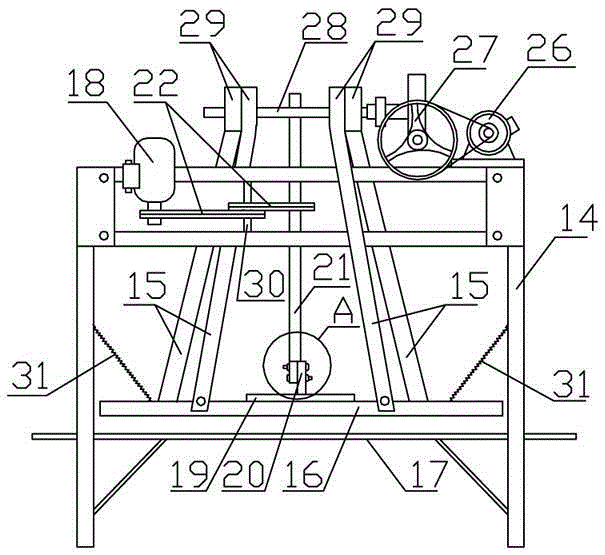

Metering system of automatic down filling machine

InactiveCN103397411AImprove reliabilityImprove stabilityOakum treatmentWeighing apparatus for materials with special property/formGramDisplay device

The invention discloses a metering system of an automatic down filling machine. The metering system comprises at least two weighing sensors, a transmitter, a controller and a terminal display. The weighing sensors are respectively in communication connection with the transmitter, the transmitter, the controller and the terminal display are sequentially in communication connection with one another, and weighing metering hoppers are further placed at the upper ends of the weighing sensors. Owing to the mode, the metering system of the automatic down filling machine has the advantages that the weighing sensors can simultaneously weigh down feather at various positions before the down feather is filled, the metering system has a simultaneous weighing function, is good in reliability and stability and low in error rate and is applied to quantitatively filling products such as down jackets, down sleeping bags, down cushion, down mattresses and down quilts, the requirement on filling different gram weights of down feather at different positions of the same product can be met, and the production efficiency is improved.

Owner:CHANGSHU SHIBO MACHINERY

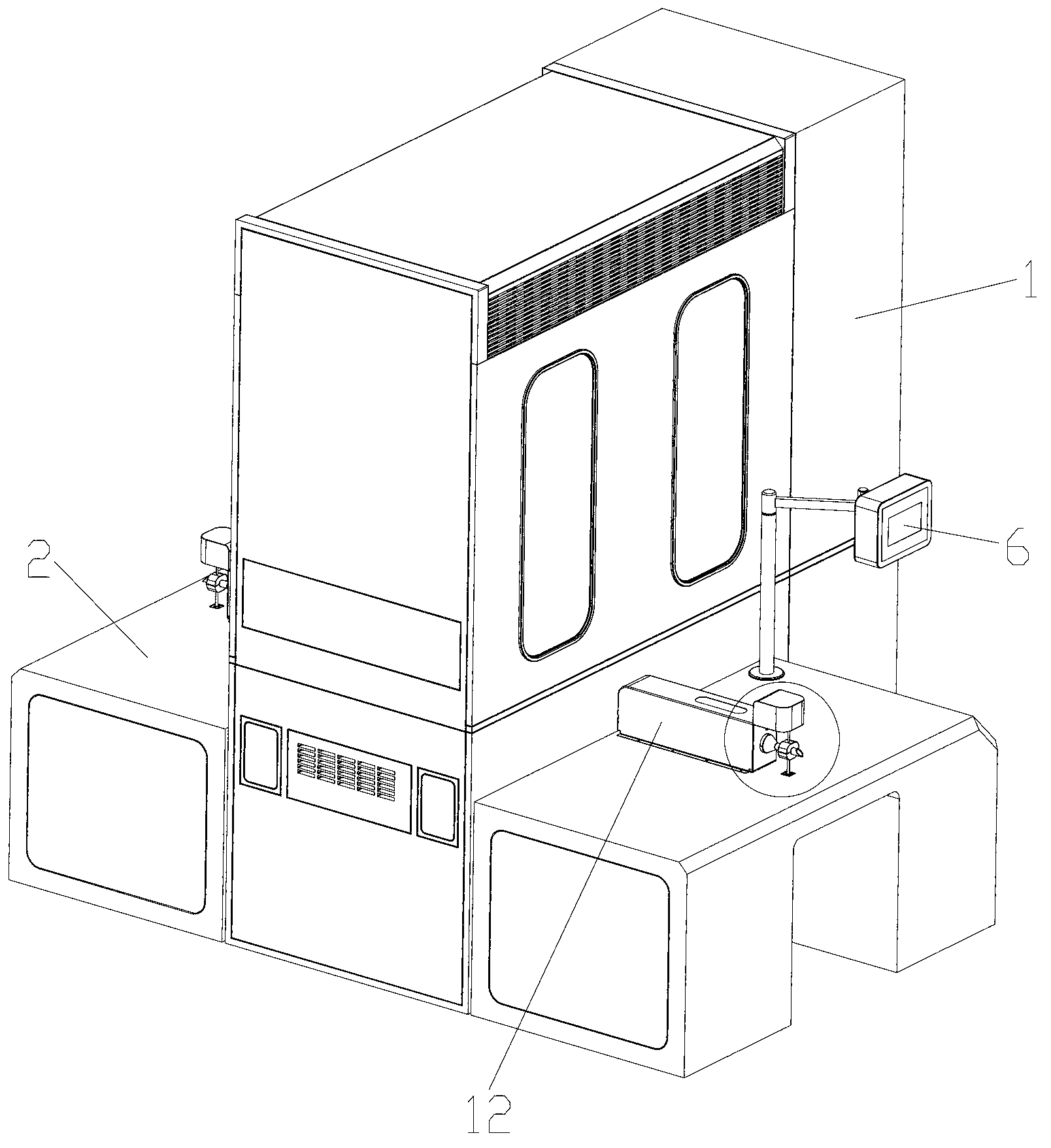

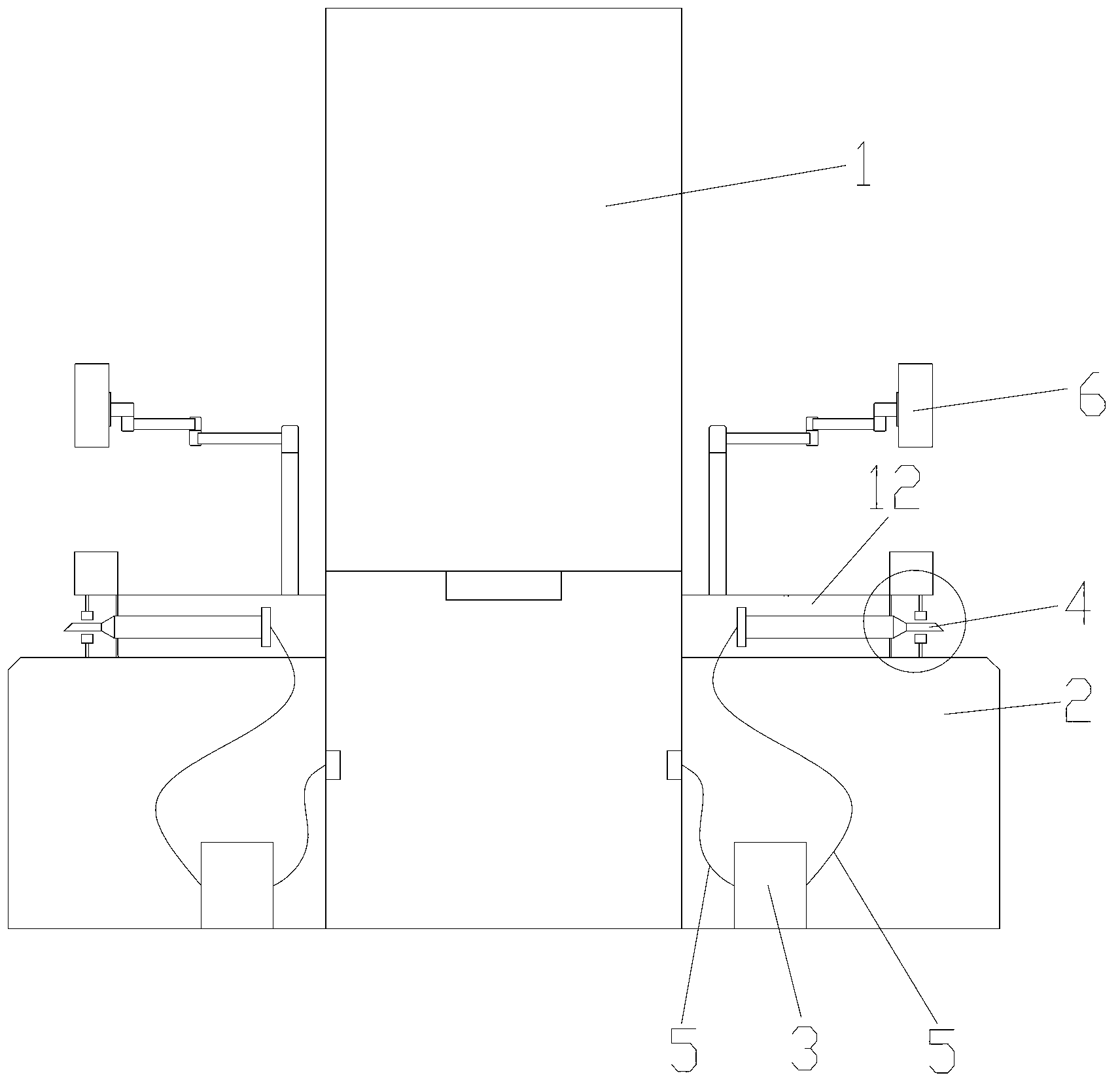

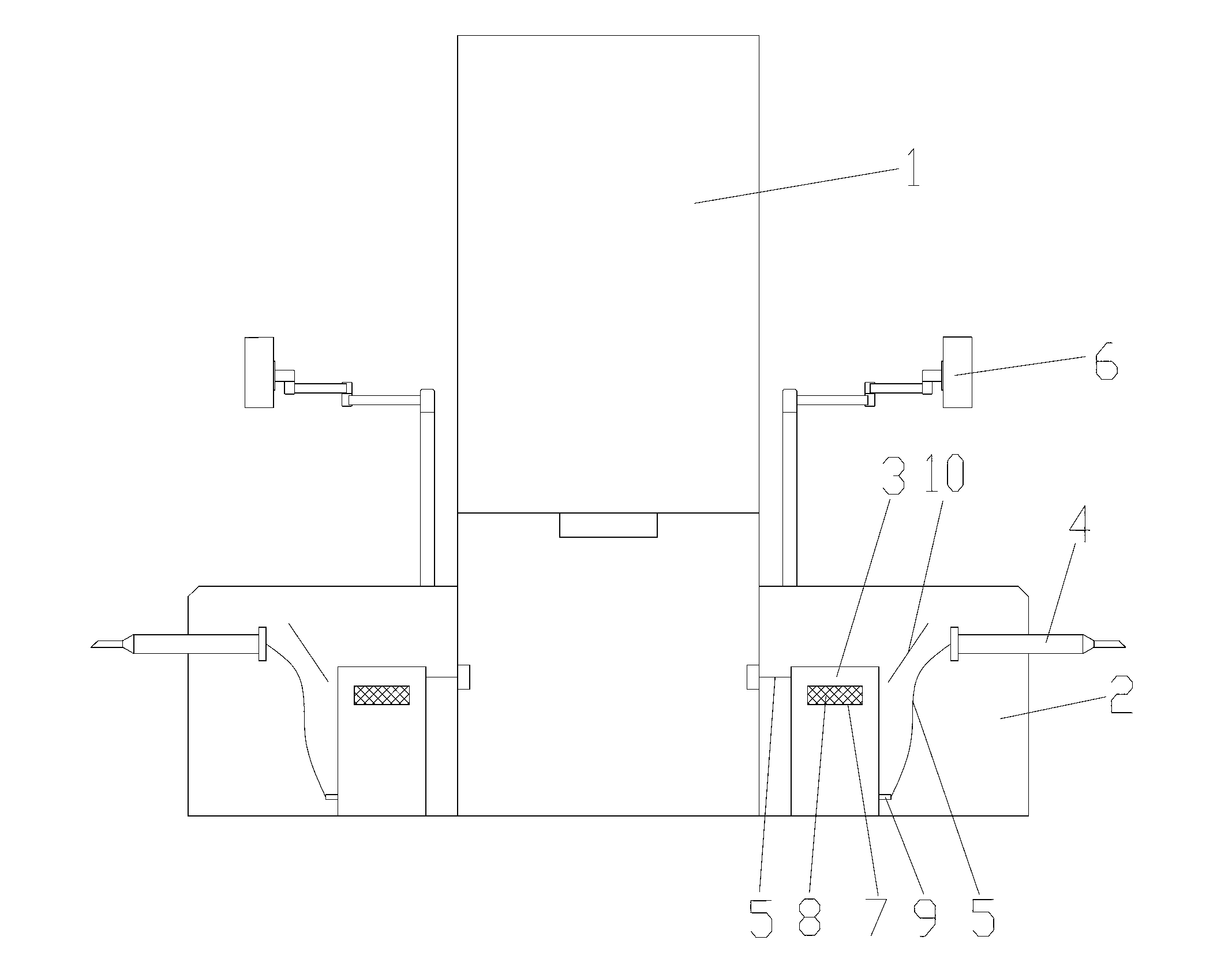

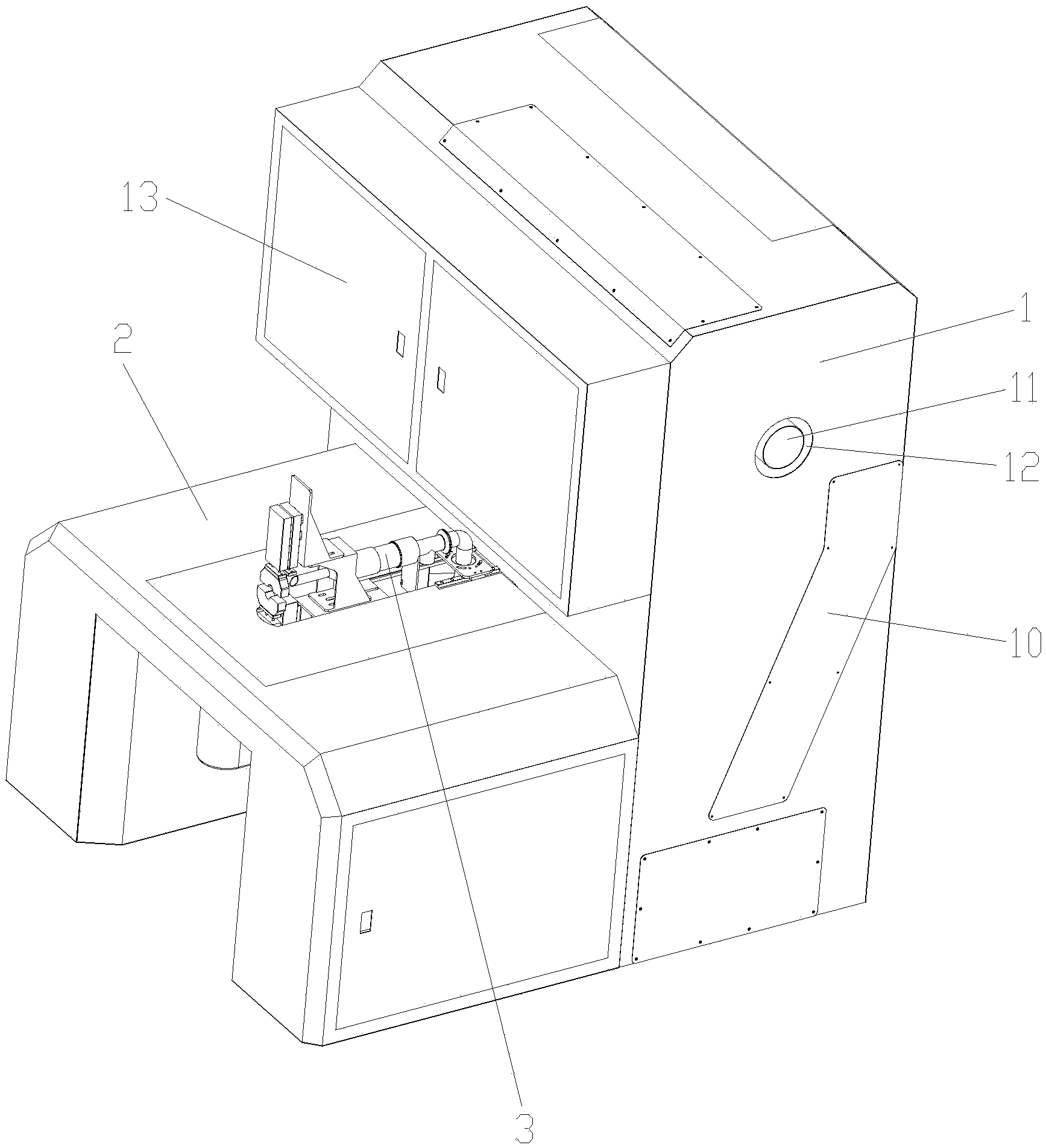

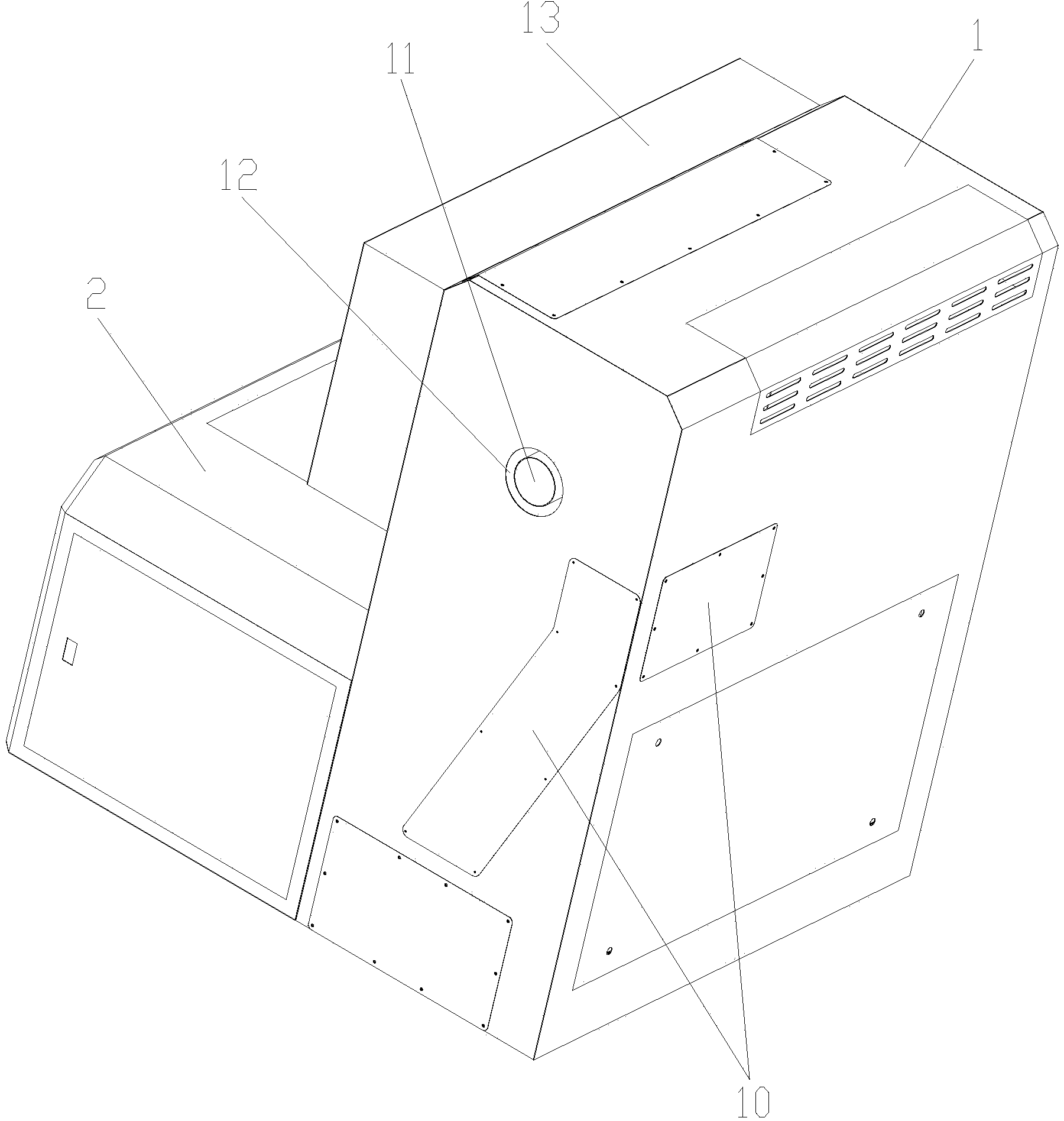

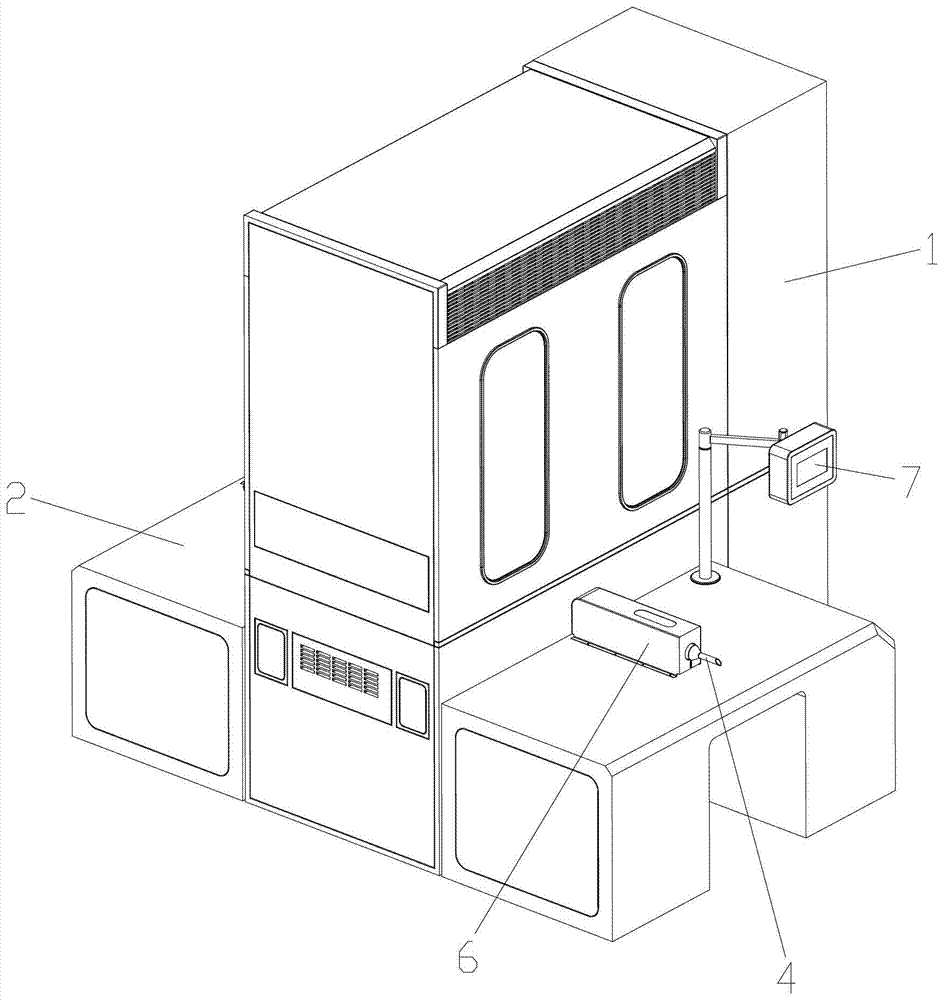

Automatic down feather filling machine

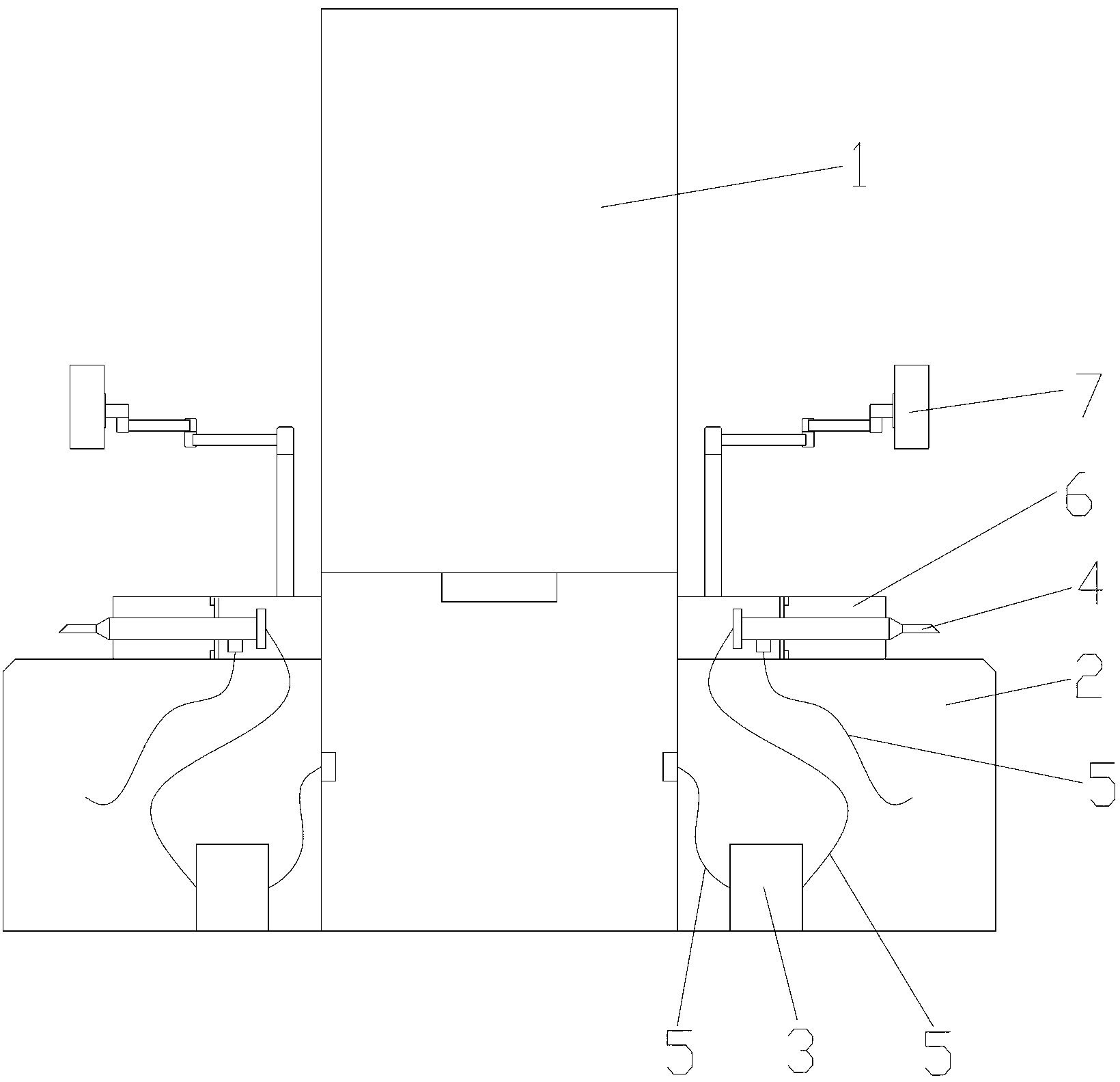

InactiveCN103225138AReduce labor intensityPrevent spillageOakum treatmentWorking environmentUltimate tensile strength

The invention discloses an automatic down feather filling machine which comprises a down feather storage box, weighing cabinets, weighing boxes, down feather filling pipes, a control mechanism and a transmission mechanisms, wherein the weighing cabinets are arranged on two sides of the down feather storage box; the weighing boxes are arranged in the weighing cabinets; the down feather filling pipes are arranged on the weighing cabinets and connected with the transmission mechanisms; the transmission mechanisms are controlled by the control mechanism; the control mechanism controls the transmission mechanisms to deliver down feathers in the down feather storage box to the weighing boxes and discharge the down feathers in the weighing boxes from the down feather filling pipes; and locking devices are arranged at the front ends of the down feather filling pipes and controlled by the control mechanism. By the aid of the automatic down feather filling machine, the labor intensity of an operator is reduced, down feathers are prevented from spilling in a down feather filling process, and expensive down feathers are prevented from being wasted at the same time, and the working environment is improved.

Owner:SUZHOU TRANSPARENT TECH CO LTD

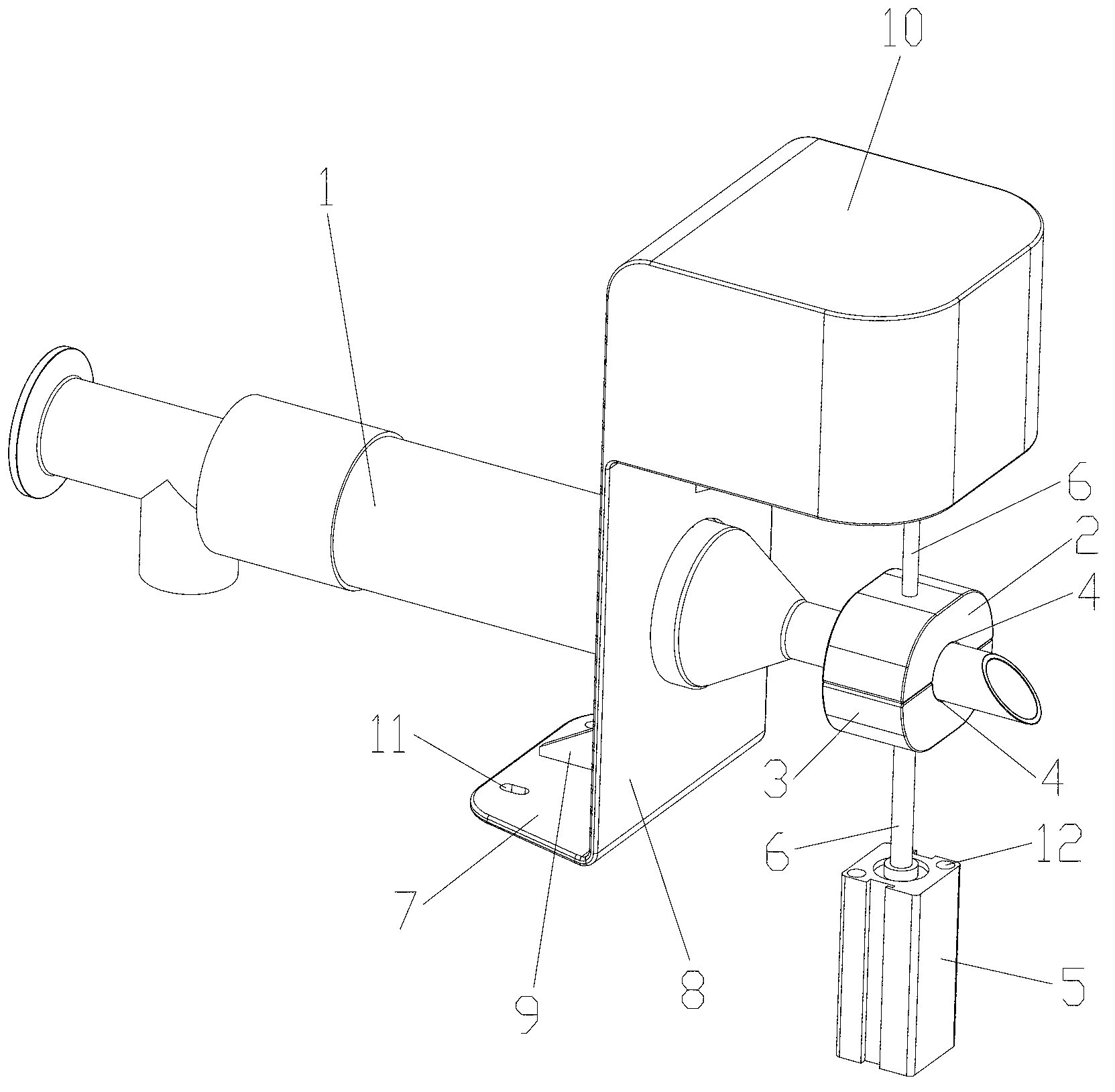

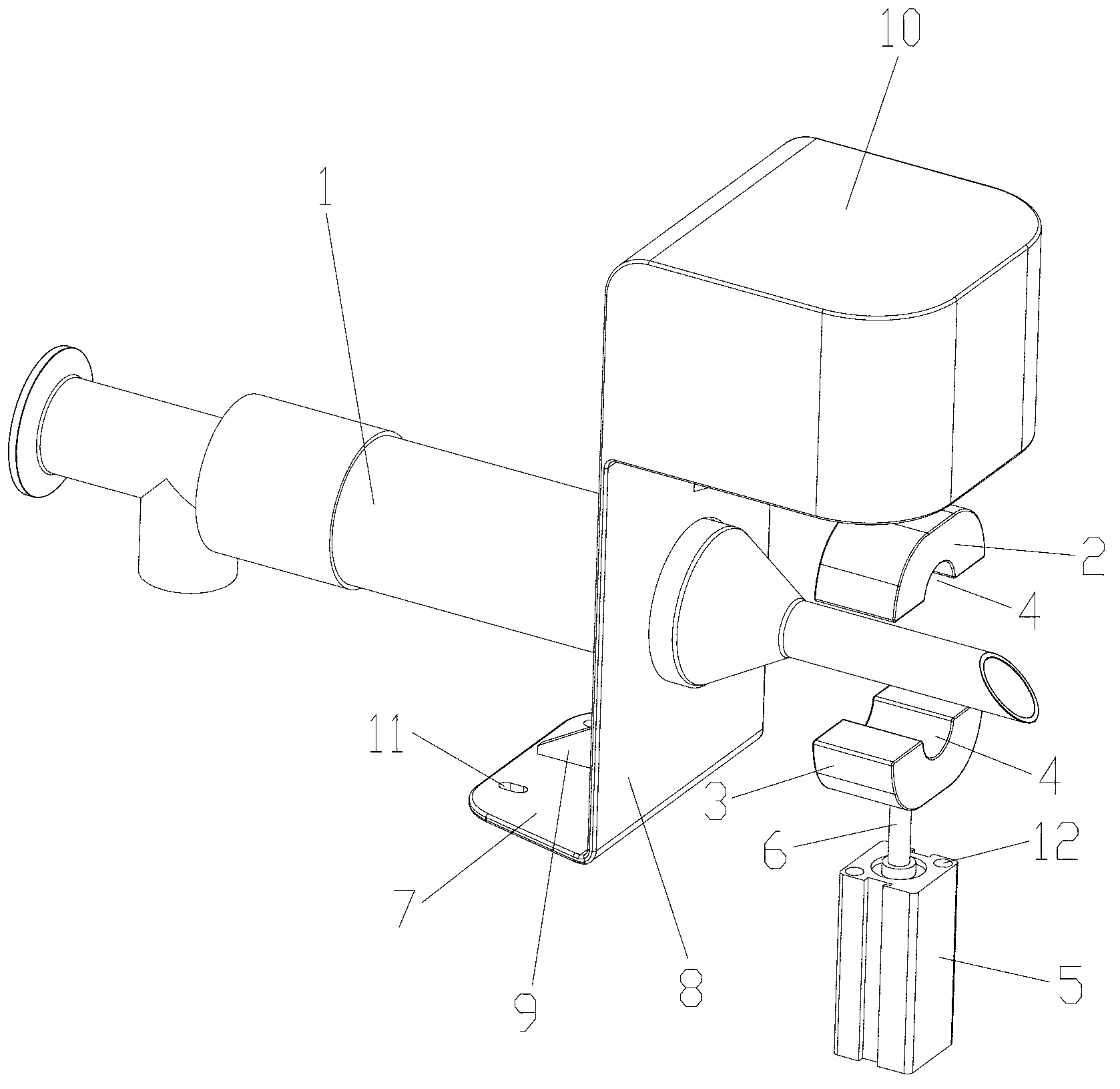

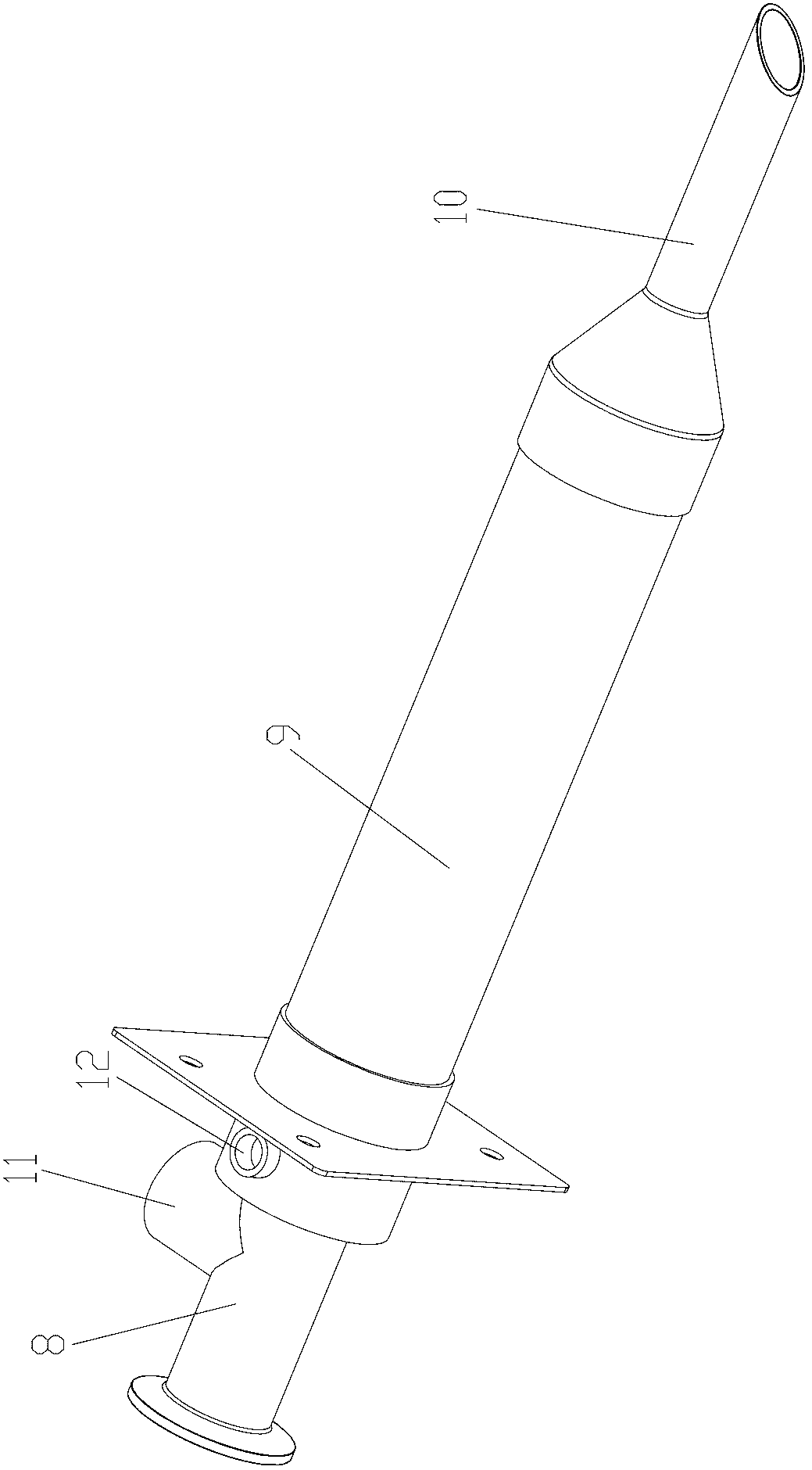

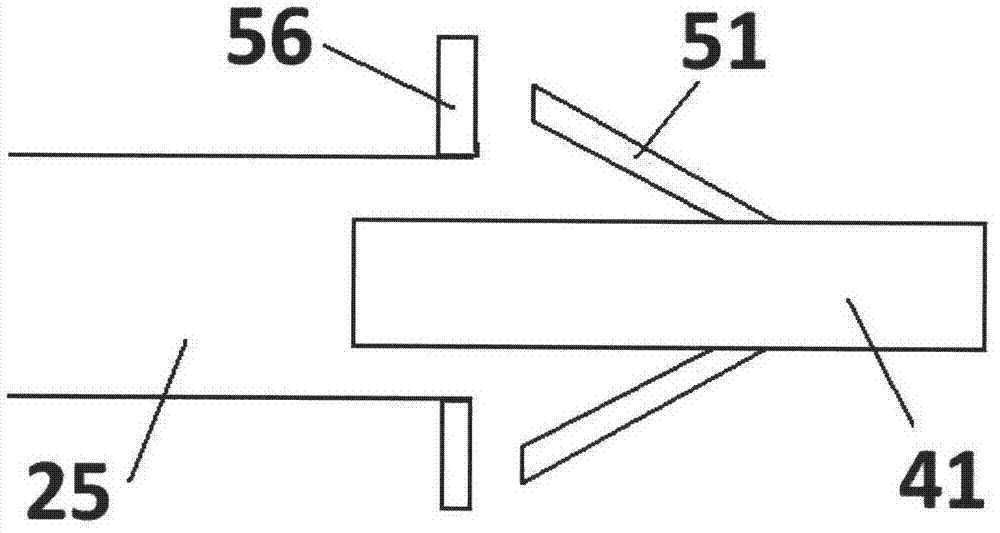

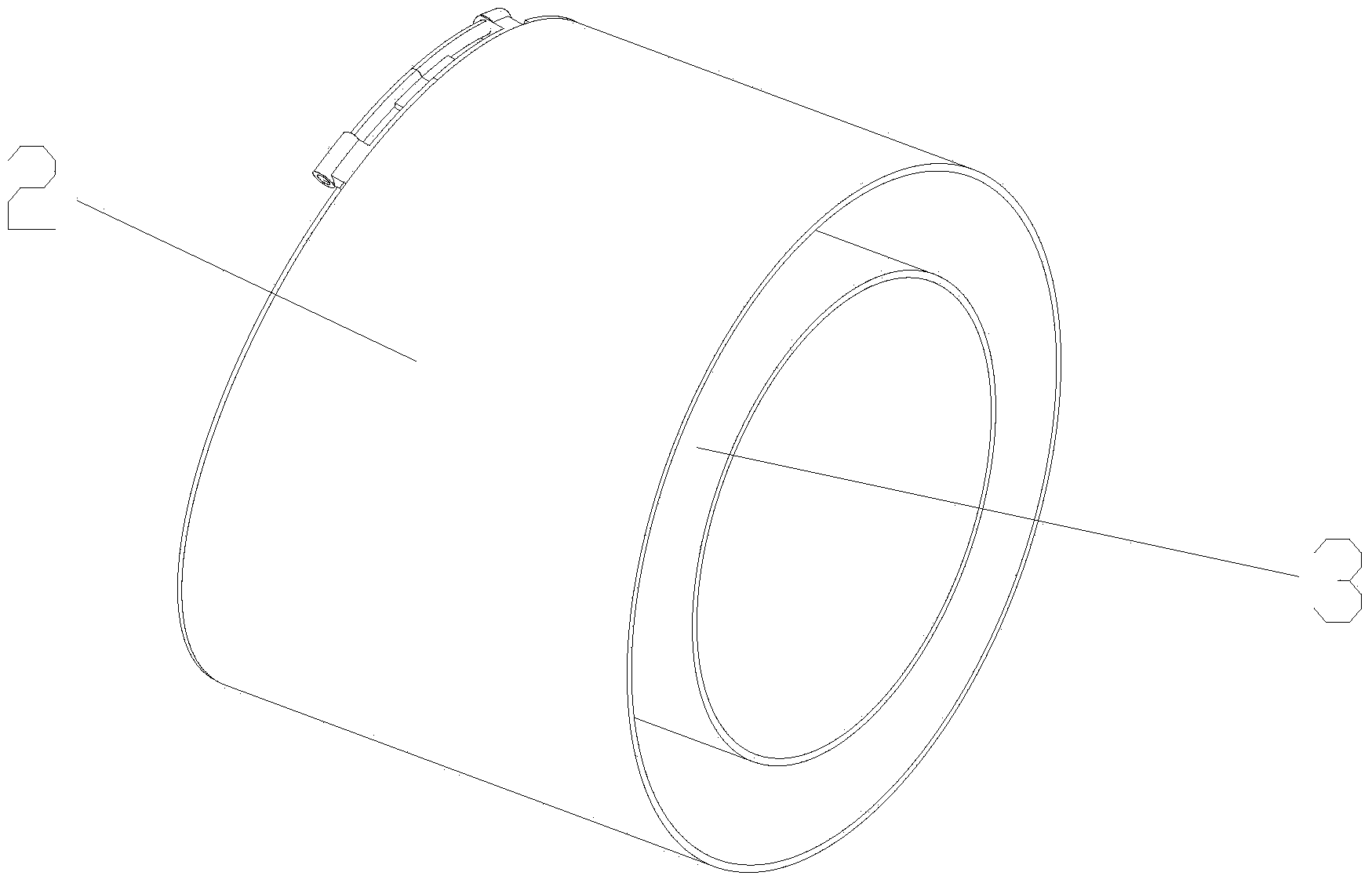

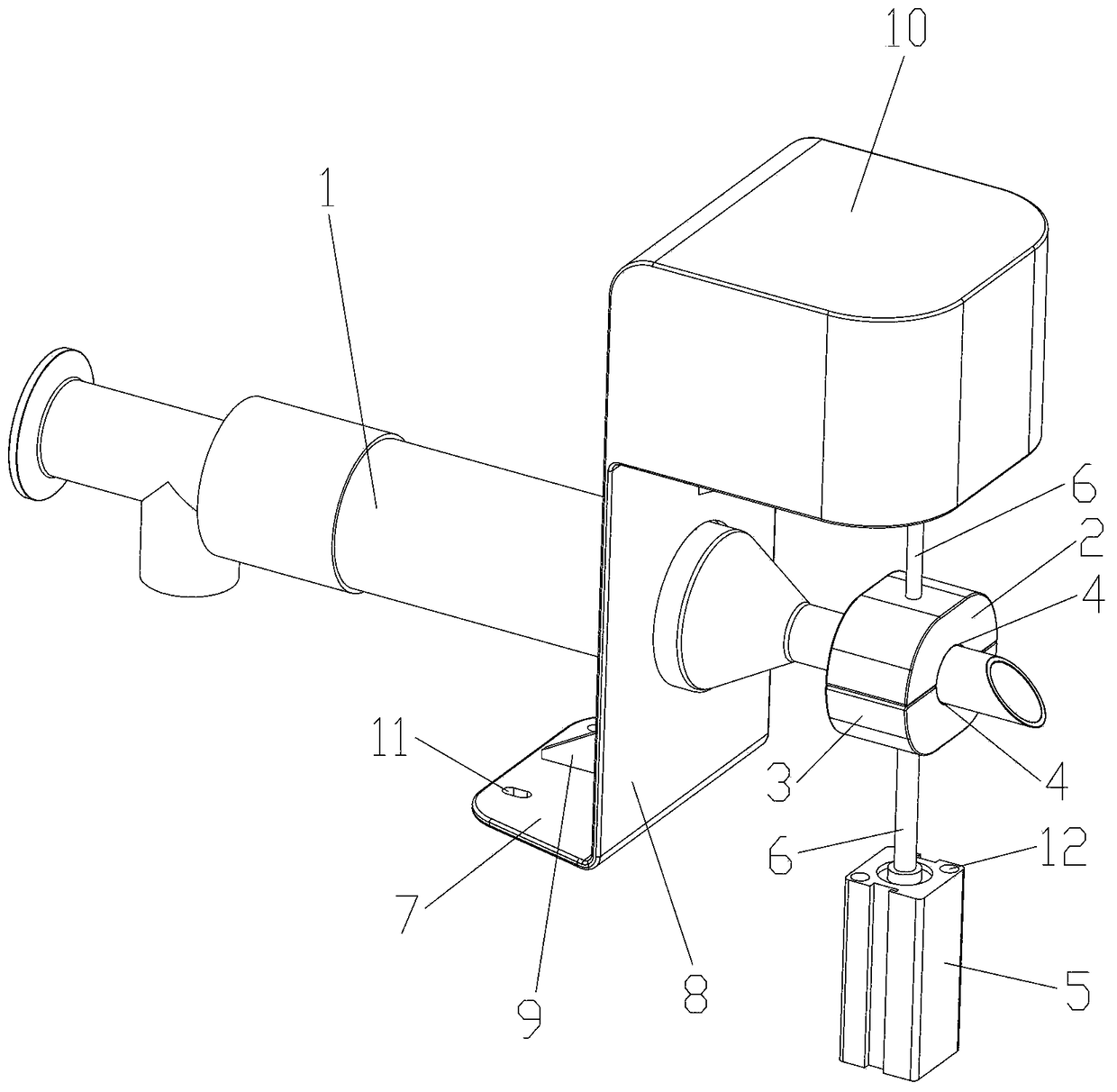

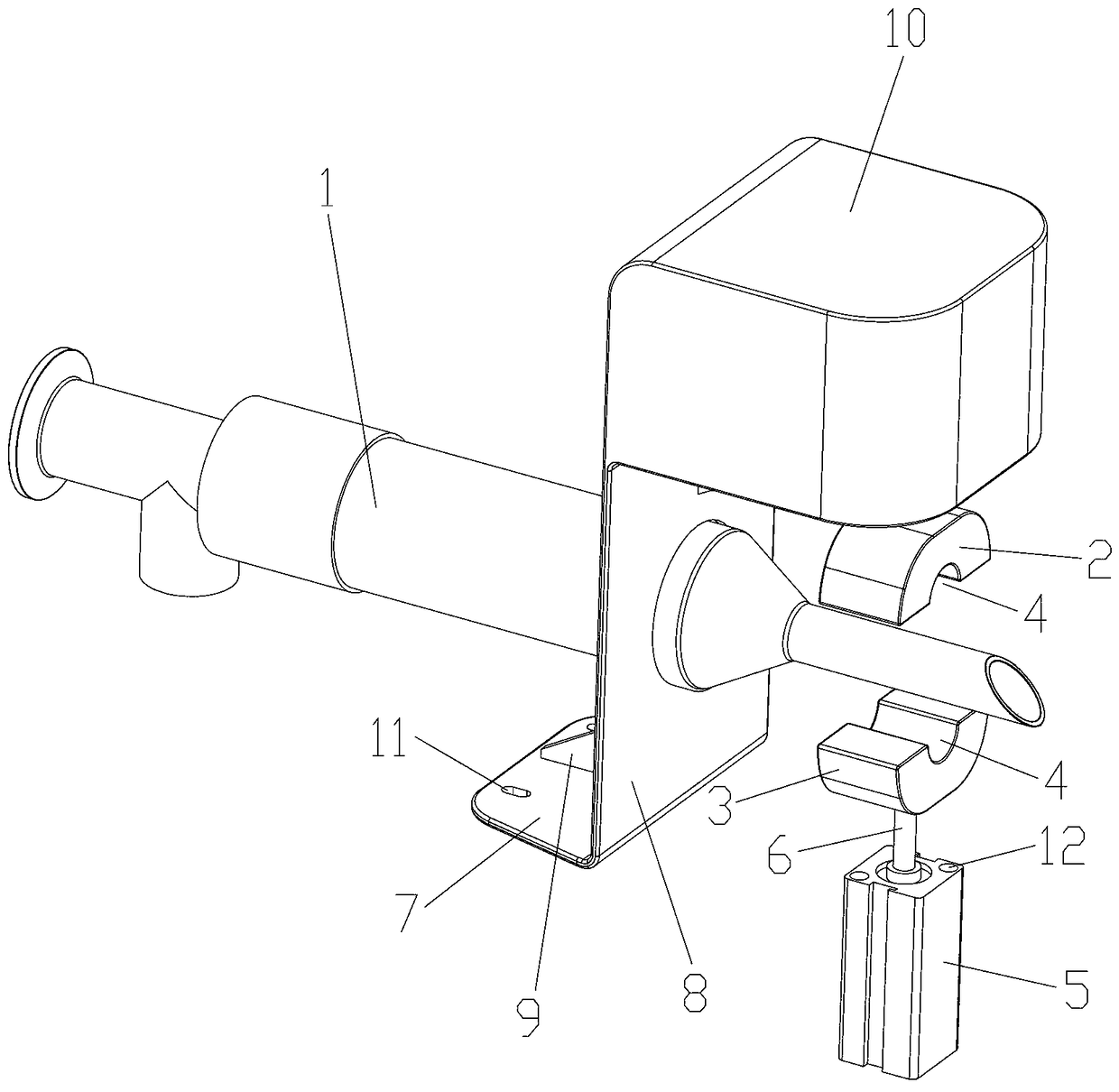

Down filling pipe

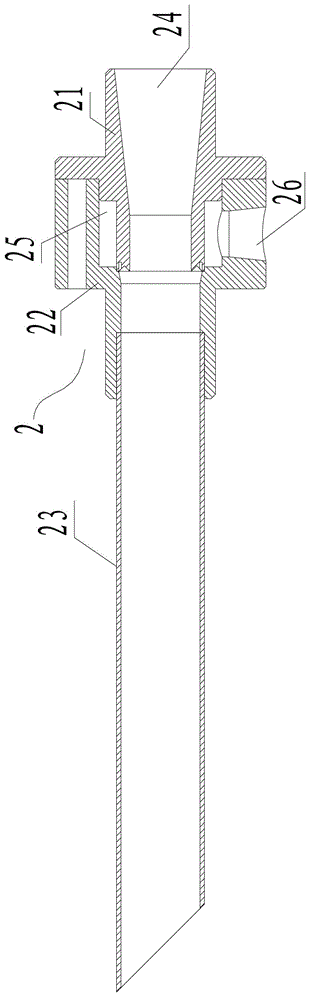

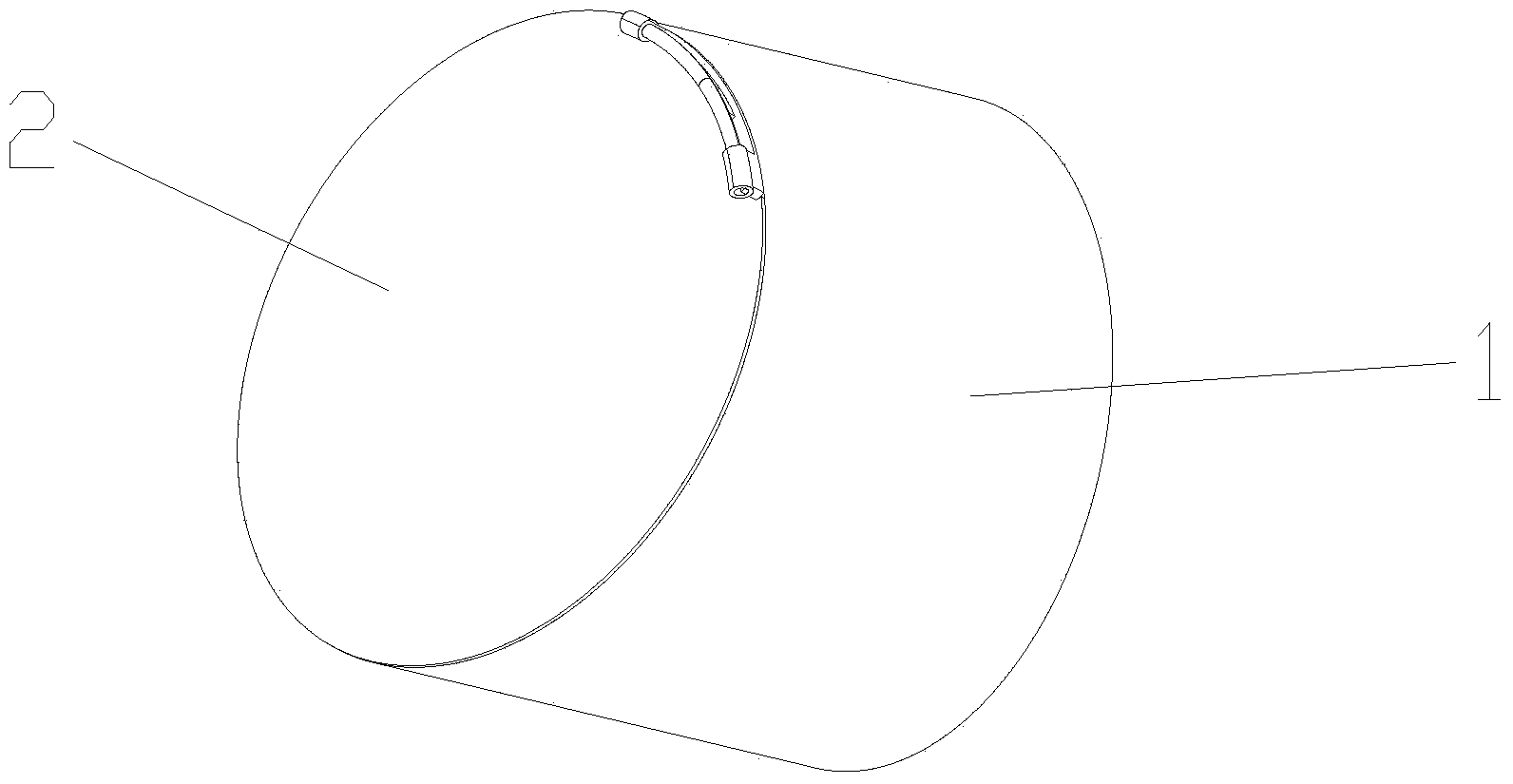

The invention discloses a down filling pipe which comprises a down filling pipe body, wherein a lock clamp device is arranged at the front end of the down filling pipe body. According to the down filling pipe, since the lock clamp device is arranged at the front end of the down filling pipe body, an operator is only required to insert the front end of the down filling pipe body into a liner chamber to be filled with down products and then controls the lock clamp device during down filling, the lock clamp device can clamp cloth with the front end of the down filling pipe body tightly, the labor intensity of the operator is reduced, the down leakage is avoided, the working environment is improved, and the waste of expensive down is avoided.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Down filling machine

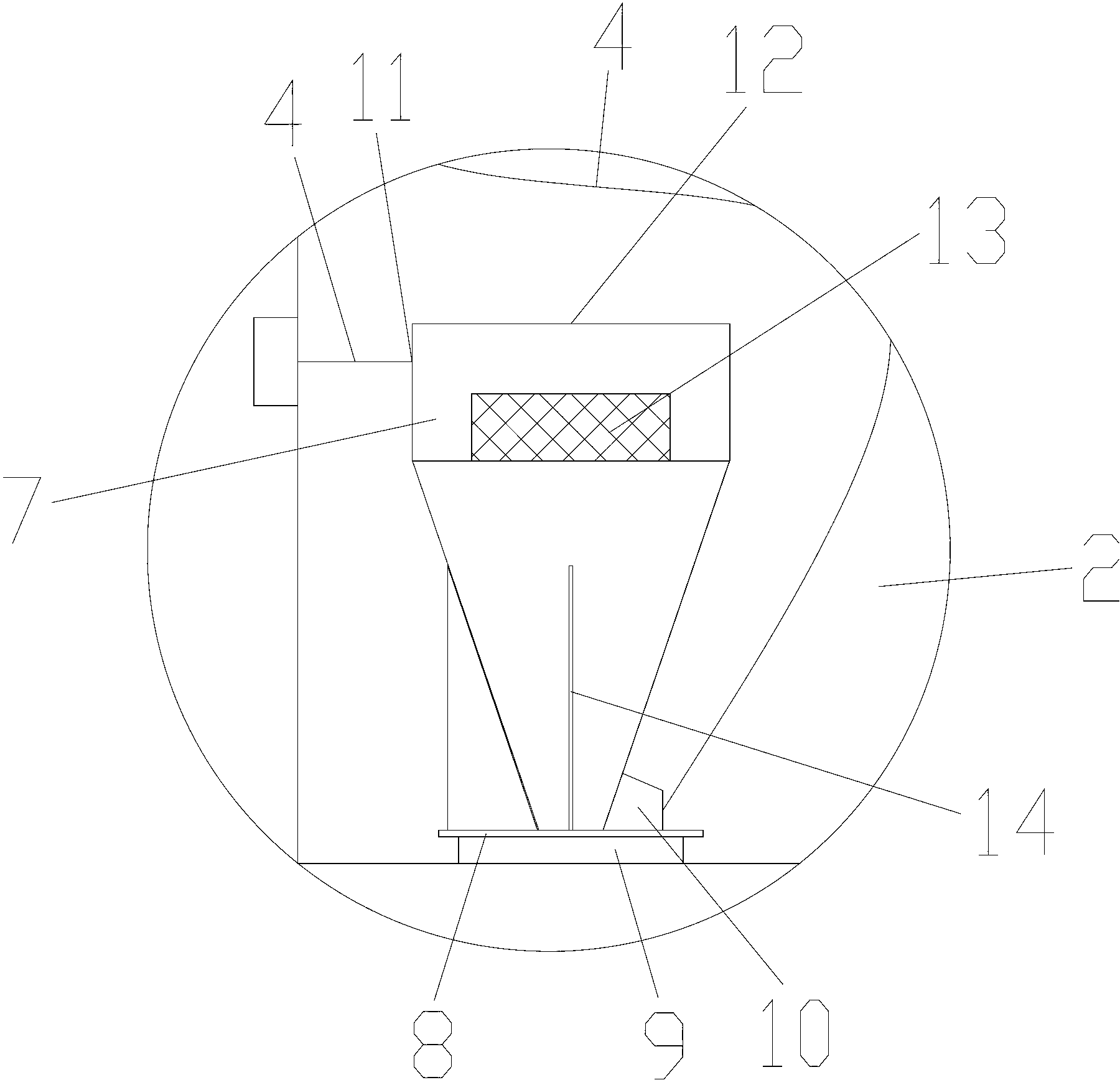

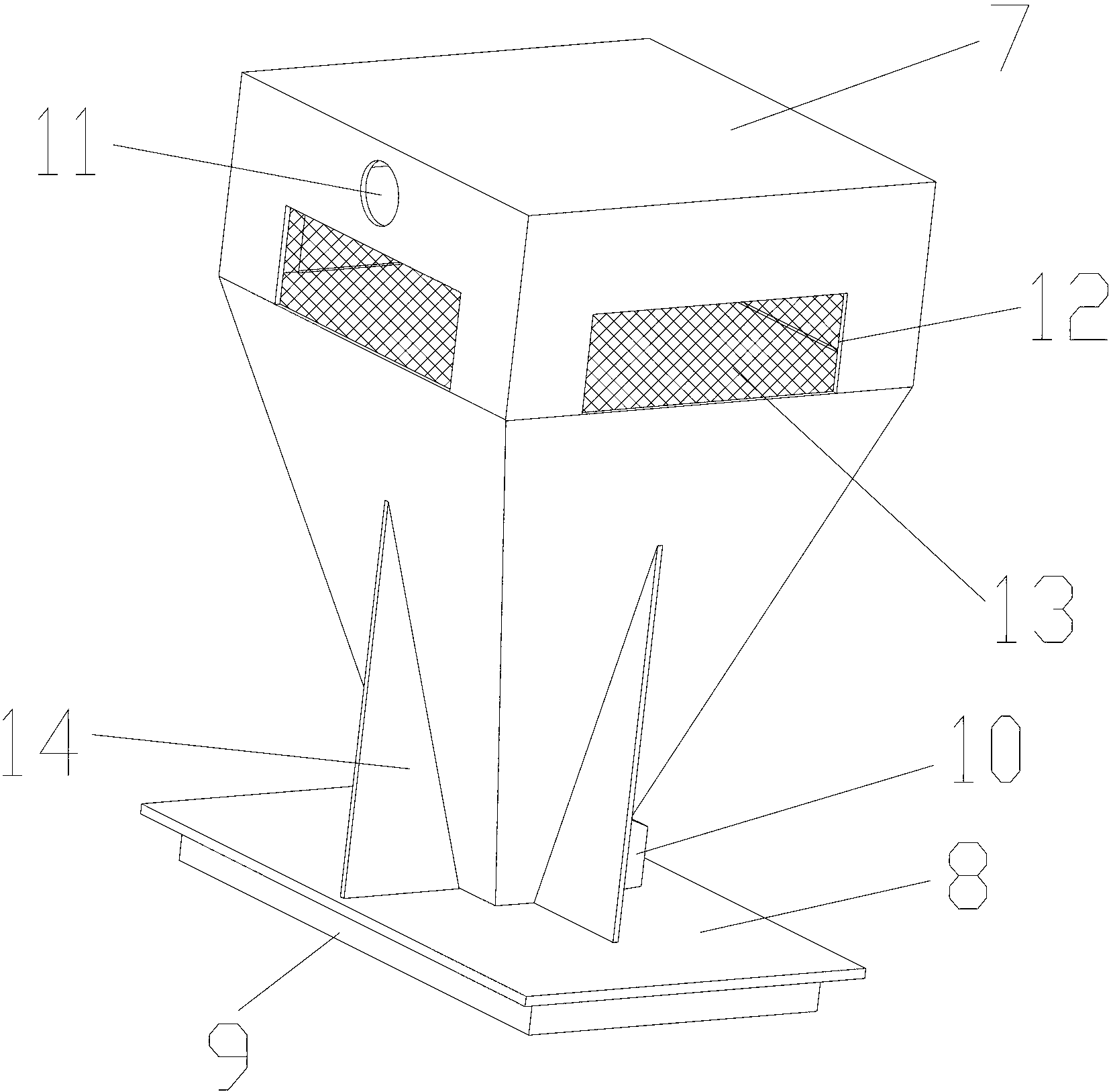

InactiveCN103233300AGuaranteed accuracyLarge displacementOakum treatmentEngineeringMechanical engineering

The invention discloses a down filling machine which comprises a down storage box, weighing cabinets, weighing boxes, down filling pipes, a control mechanism and a transmission mechanism; the weighing cabinets are arranged on two sides of the down storage box; the weighing boxes are arranged in the weighing cabinets; the down filling pipes are arranged on the weighing cabinets and connected with the transmission mechanism; the transmission mechanism is controlled by the control mechanism; the control mechanism controls the transmission mechanism to transmit down feather from the down storage box to the weighing boxes, and the down feather in the weighing boxes is discharged through the down filling pipes; ventilating windows are formed at the upper parts of the weighing boxes, and filter screens are arranged on the ventilating windows; and balance mechanisms used for allowing the weighing boxes to keep balance are arranged in the weighing cabinets. According to down filling machine provided by the invention, slight displacement of the weighing boxes are avoided, so that the weighing accuracy of the weighing boxes in the next weighing are ensured and the filling accuracy of the down filling machine are further ensured.

Owner:苏州琼派瑞特科技股份有限公司

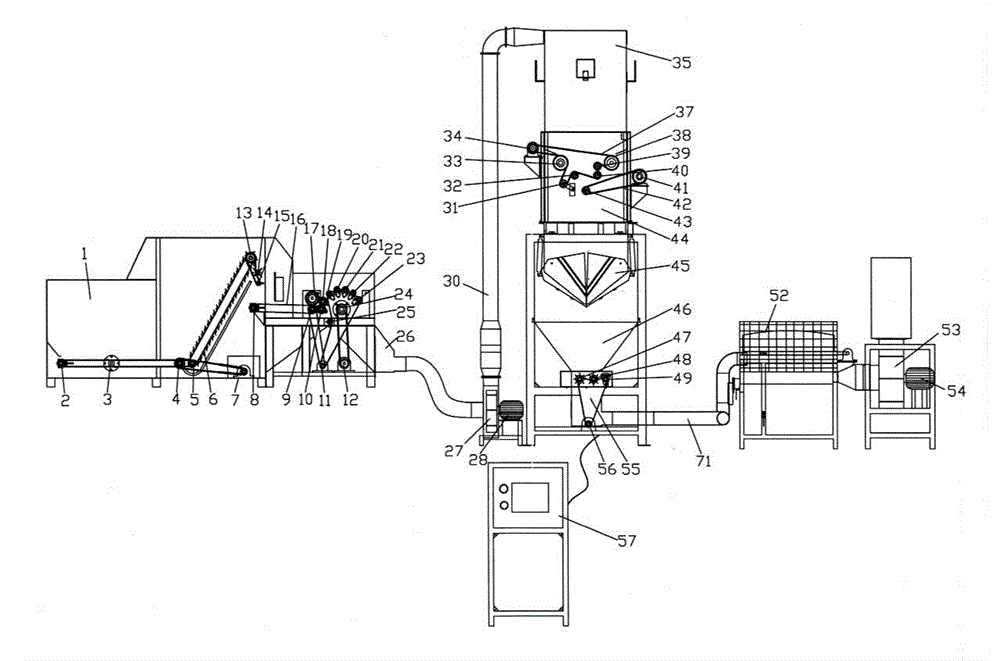

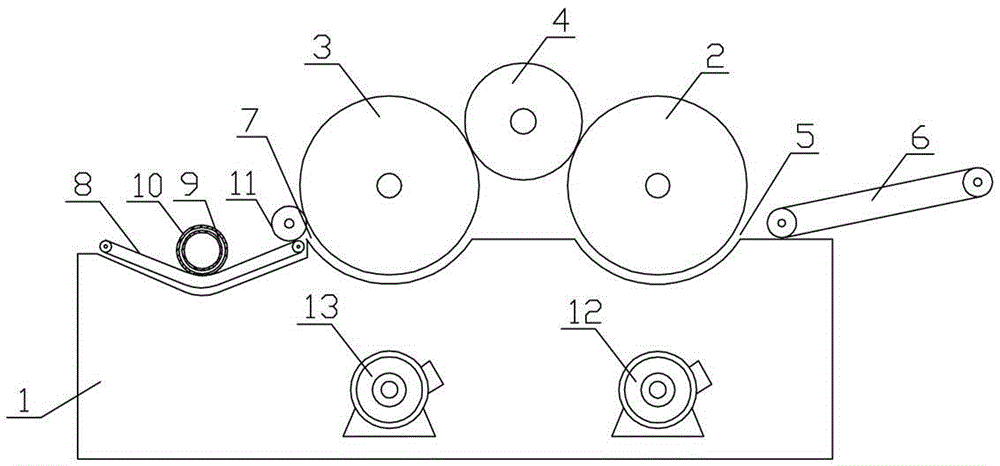

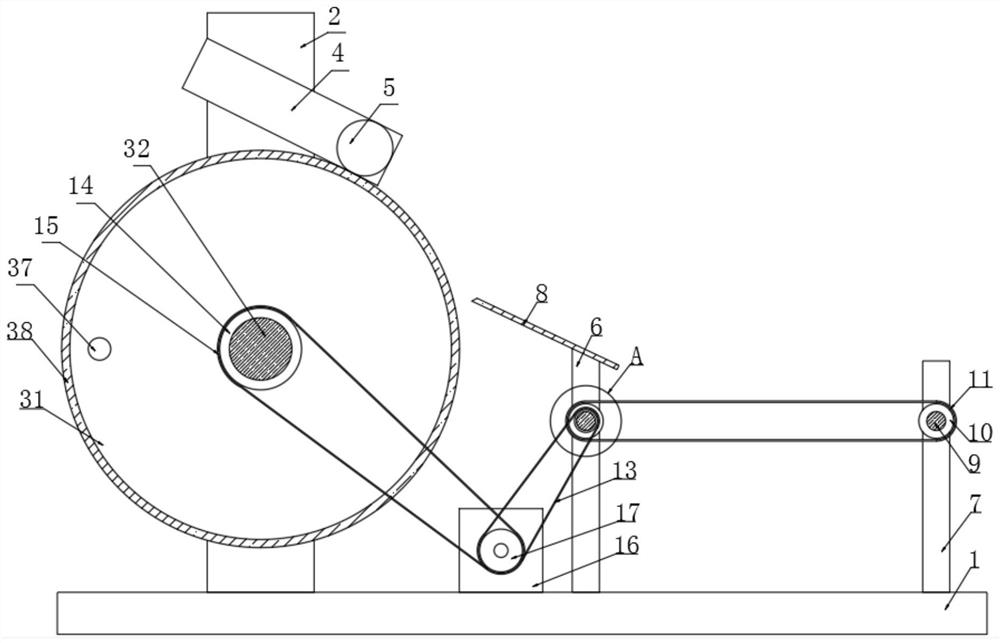

Pillow inner filling machine

InactiveCN102976259AVersatileReasonable designUpholstery manufactureOakum treatmentEngineeringAutomation

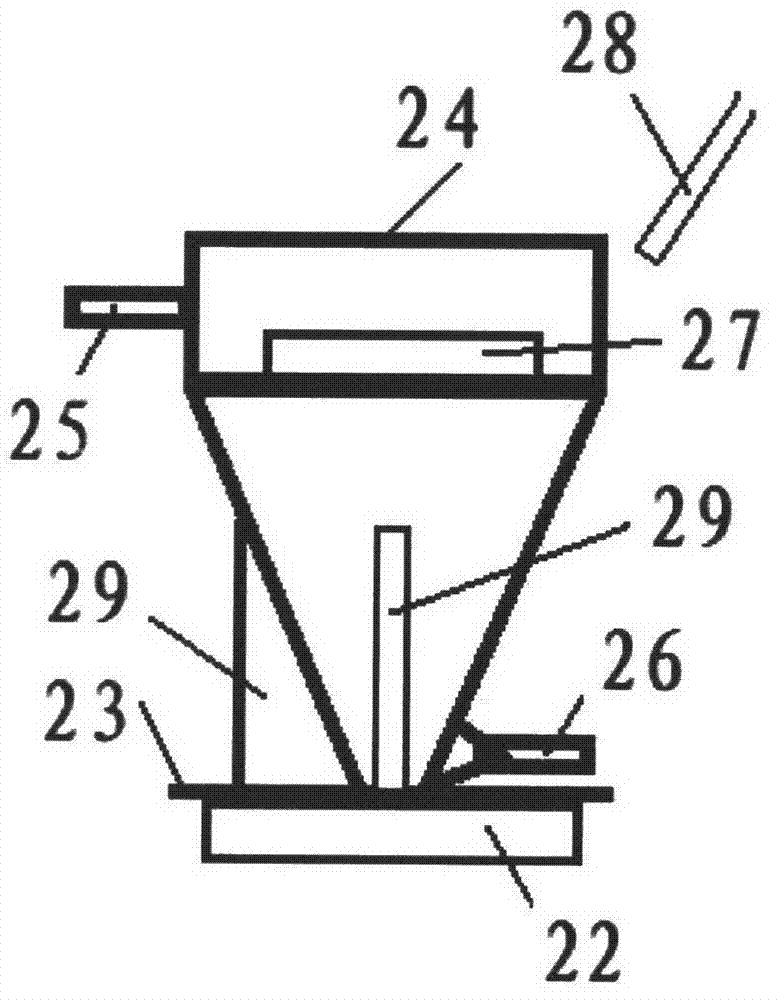

The invention discloses a pillow inner filling machine, which is characterized in that the middle lower part of a cotton conveying device is provided with a cotton conveying motor; the left side of the cotton conveying motor is provided with a cotton conveying roll shaft; the left side of the cotton conveying roll shaft is provided with a riding wheel roll shaft; the left side of the riding wheel roll shaft is provided with a cotton inlet roll shaft; the right side of the cotton conveying roll shaft is provided with a delivered cotton conveying roll shaft; the cotton conveying roll shaft is provided with a cotton conveying roll; a cotton inlet roll shaft is provided with a cotton inlet roll; the cotton inlet roll and the cotton conveying roll are provided with an inlet cotton conveying belt; the delivered cotton conveying roll shaft and a delivered cotton transmission roll shaft are provided with a delivered cotton conveying belt; the right side of the delivered cotton conveying belt is provided with a carding machine; the bottom ends of carding roll shafts are respectively provided with discharge rolling teeth; the lower ends of the discharge rolling teeth are provided with a discharge hopper; the right side of the discharge hopper is provided with a discharge hole; the bottom end of the discharge hole is provided with a blanking barrel; the lower side of the discharge hopper is provided with a weighing hopper; the lower end of the weighing hopper is provided with a funnel; the bottom end of the funnel is provided with a discharge hopper; the right side of the discharge hopper is provided with a discharge pipeline; and the right side of the discharge pipeline is provided with a filling machine. The pillow inner filling machine disclosed by the invention is complete in function, high degree of automation and good in using effect.

Owner:深圳市迈普斯科技有限公司

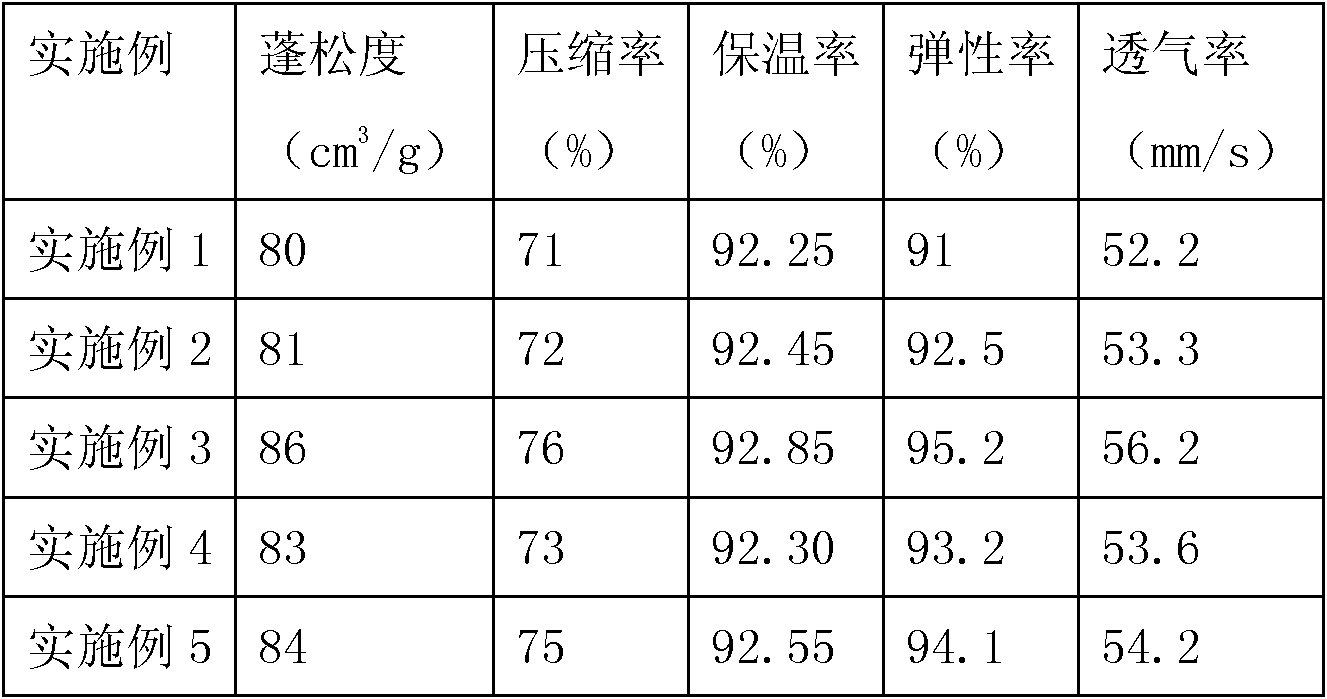

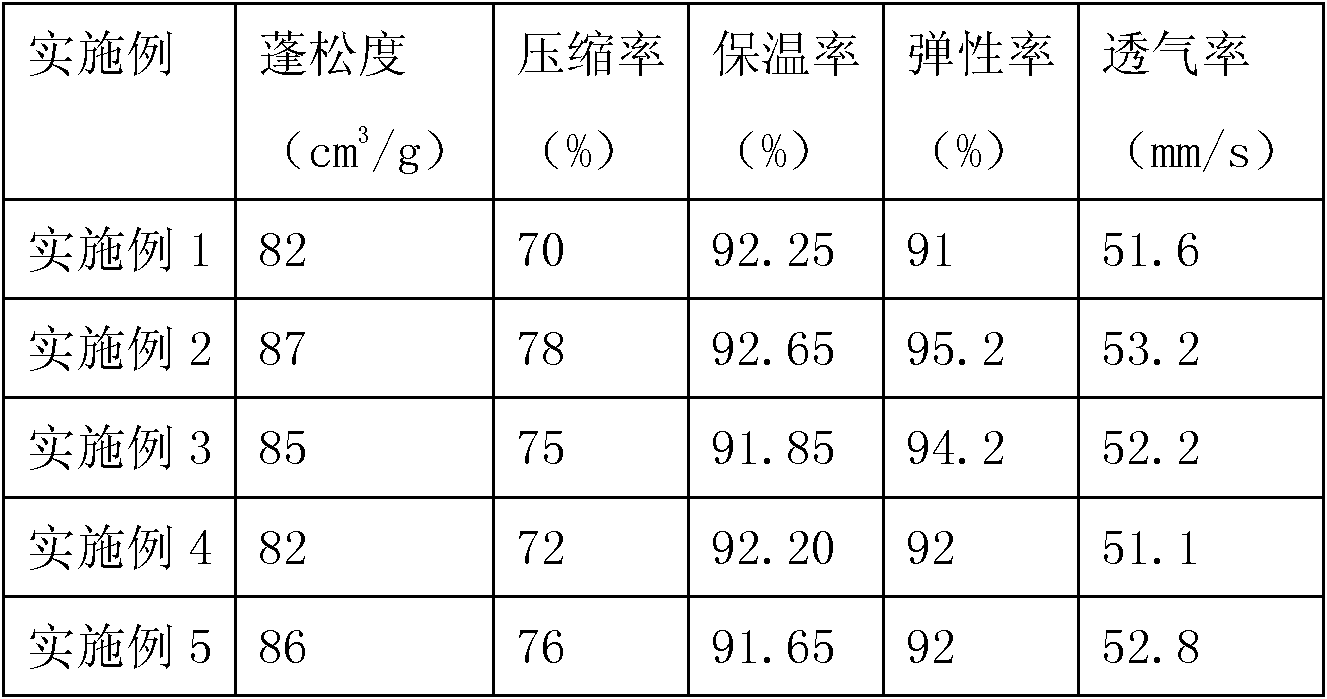

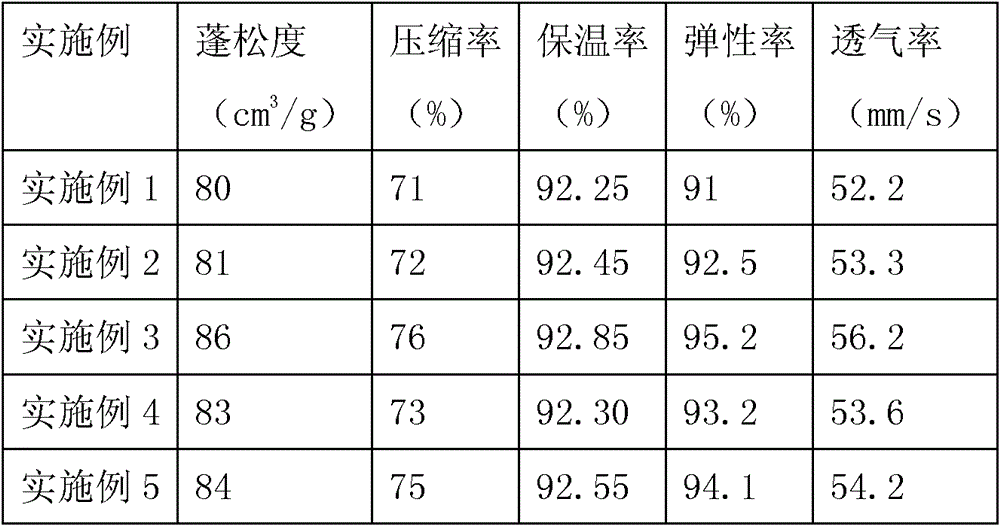

Home textile filler mixing with polyester fibers and lyocell fibers and preparation method thereof

The invention discloses home textile filler mixing with polyester fibers and lyocell fibers. The home textile filler is characterized in that the home textile filler is formed by mixing with common hollow polyester short fibers and lyocell fibers, wherein the fiber number of the used hollow polyester short fibers is 6.67DTEX, the hollow degree is 10 percent, and the length is 38mm; the fiber number of the used lyocell fibers is 1.5-3.0DTEX, the length is 50-80 mm, and curl fibers are used for the lyocell fibers; and the weight percentage of the hollow polyester short fibers and the lyocell fibers is that the hollow polyester short fibers take up by 25-75 percent, and the lyocell fibers take up by 25-75 percent. The invention further provides a preparation method for the home textile filler mixing with the polyester fibers and the lyocell fibers. Various stuffing products prepared by the home textile filler mixing with polyester fibers and lyocell fibers have the advantages that the appearance is uniform and smooth, lightness, a high fluffy degree, continuous elastic restoration, excellent heat preservation, and soft feel, thus people feel comfortable, and the quality of sleep and life can be improved.

Owner:SOUTH BEDDING TECH

Down filling machine filling down precisely

ActiveCN103225141AAvoid wastingExtended service lifeOakum treatmentEngineeringMechanical engineering

The invention discloses a down filling machine filling down precisely. Weighing cabinets are arranged on the two sides of a down storage box; weighing boxes are arranged in the weighing cabinets; down filling pipes are arranged on the weighing cabinets and connected with conveying mechanisms; the conveying mechanisms are controlled by a control mechanism; the control mechanism controls the conveying mechanisms to convey the down in the down storage boxes into the weighing boxes and then discharge the down in the weighing boxes from the down filling pipes; each down filling pipe comprises a down inlet pipe, a connecting pipe and a down outlet pipe which are sequentially connected into a down filling pipe body; an air return pipe and a blowing pipe are arranged on each down inlet pipe; the down inlet pipes, the air return pipes and the blowing pipes are connected with the conveying mechanisms; the air return pipes and the blowing pipes are communicated with the down inlet pipes; each down filling pipe body is internally provided with a down conveying pipe; a gap is reserved between the front end of each down conveying pipe and the tail end of each down outlet pipe; an air return filter screen pipe is fixed between each down conveying pipe and each down filling pipe body; and each air return pipe is communicated with each air return filter screen pipe. The down filling machine filling the down precisely is high in down filling precision and good in down filling effect.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Down filling machine

ActiveCN102808245BEasy inputHigh outputUpholstery manufactureOakum treatmentEngineeringMechanical engineering

Owner:CHANGSHU BEALEAD AUTO MACHINERY

Filling material with PET and PTT composite filament as raw materials and manufacturing method thereof

InactiveCN104532416AGood flexibilityFluffy goodOakum treatmentNon-woven fabricsFiberFilling materials

The invention discloses a filling material with PET and PTT composite filament as raw materials and a manufacturing method. The down jacket and the cold protective clothing adopting the filling material are low in cost, good in heat insulation performance and free of odor. At the moment, the PET and PTT composite filament fiber are curly and have elasticity, and the stable filling material with good quality is obtained. The filling material includes the PET and PTT composite filament fiber and mixed fiber components which are mixed, then opened or pelletized to make the filling material. The content of the PET and PTT composite filament fiber is larger than 0 and smaller than 100%. The content of the mixed fiber components is larger than or equal to 0 and smaller than 100%. The manufacturing method of the filling material is further disclosed and includes the following steps of (1) mixing, (2) cotton feeding; (3) opening and (4) pelletizing.

Owner:福建省海兴凯晟科技有限公司

Home textile filler mixing with polyester fibers and soybean protein fibers and preparation method thereof

The invention discloses home textile filler mixing with polyester fibers and soybean protein fibers. The home textile filler is characterized in that the home textile filler is formed by mixing with common hollow polyester short fibers and soybean protein fibers, wherein the fiber number of the used hollow polyester short fibers is 6.67DTEX, the hollow degree is 10 percent, and the length is 38mm; the fiber number of the used soybean protein fibers is 1.5-3.0DTEX, the length is 38mm, and curl fibers are used for the soybean protein fibers; and the weight percentage of the hollow polyester short fibers and the soybean protein fibers is that the hollow polyester short fibers take up by 25-75 percent, and the soybean protein fibers take up by 25-75 percent. The invention further provides a preparation method for the home textile filler mixing with the polyester fibers and the soybean protein fibers. Various stuffing products prepared by the home textile filler mixing with polyester fibers and soybean protein fibers have the advantages that the appearance is uniform and smooth, lightness, a high fluffy degree, continuous elastic restoration, excellent heat preservation, and soft feel, thus people feel comfortable, and the quality of sleep and life can be improved.

Owner:SOUTH BEDDING TECH

Textile internally provided with ultra-thin cotton quilt and preparation method

ActiveCN105386235AReduce manufacturing costLow priceOakum treatmentNon-woven fabricsEngineeringMechanical engineering

The invention relates to the field of cotton product production, and particularly discloses a textile internally provided with ultra-thin cotton quilt and a preparation method of the textile. The textile comprises upper fabric and lower fabric, the ultra-thin cotton quilt is filled into the portion between the upper fabric and the lower fabric, the content of ginned cotton in the ultra-thin cotton quilt is 100 percent, the length of the ultra-thin cotton quilt ranges from 3 m to 6 m, the thickness ranges from 0.7 cm to 2.6 cm, and the unit area weight ranges from 0.15 kg / m<2> to 0.45 kg / m<2>. The preparation method of the textile comprises the steps of dehydration, cotton ginning, opening and scutching, impurity removing, carding, coiling, cotton kneading and shaping and fabric sewing, wherein in the cotton kneading and shaping process, the distance between a connecting shaft on a kneading plate of a cotton kneading machine and the central axis of a rotational motion shaft needs to be maintained to range from 10 mm to 15 mm. According to the textile internally provided with the ultra-thin cotton quilt and the preparation method of the textile, the processing technology is simple, the production efficiency is high, the prepared textile is thin in thickness, light in unit area weight, and the preparation method can be suitable for warmth-keeping products such as winter clothes and blankets.

Owner:湖北威平服装棉胎有限公司

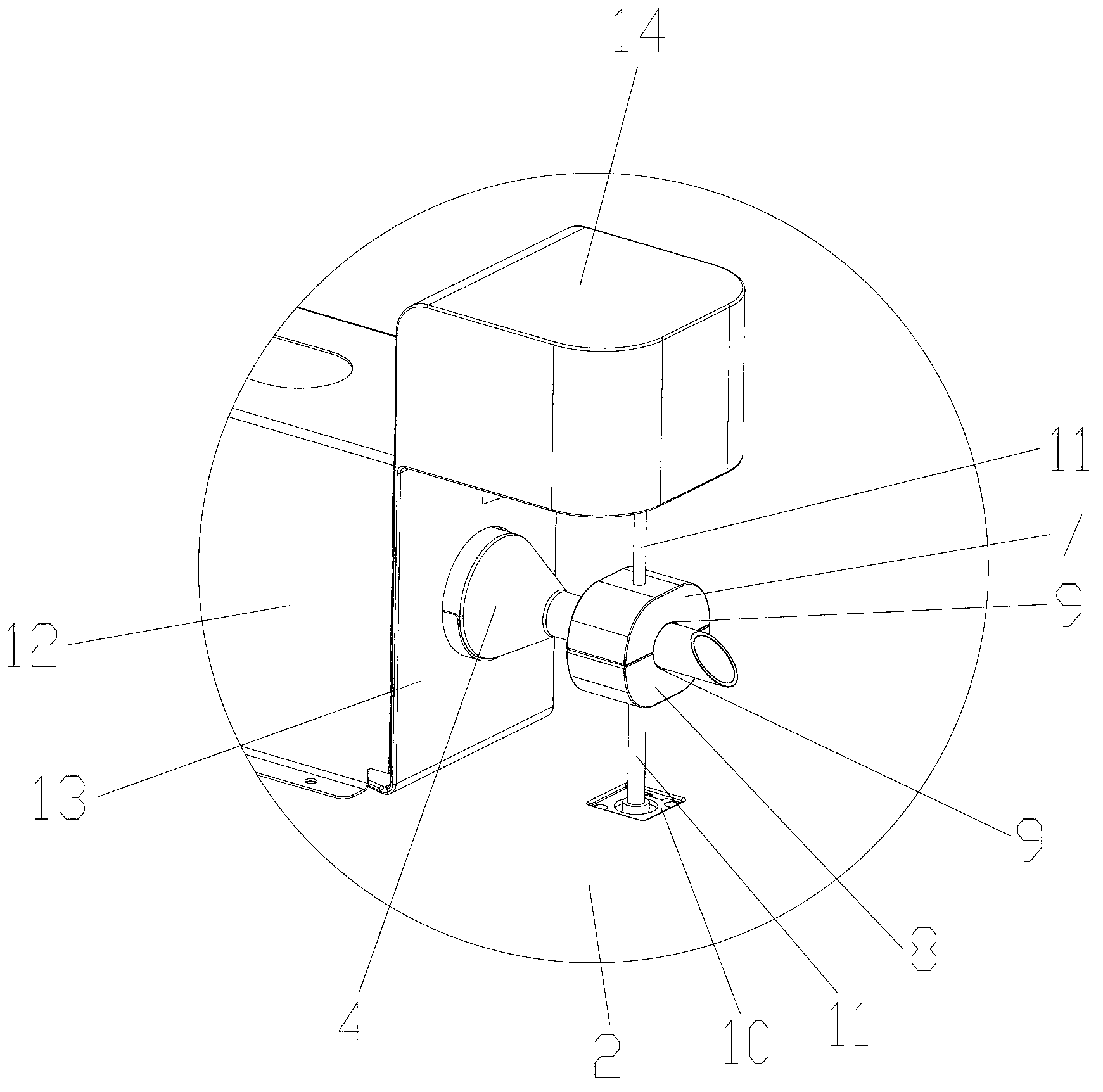

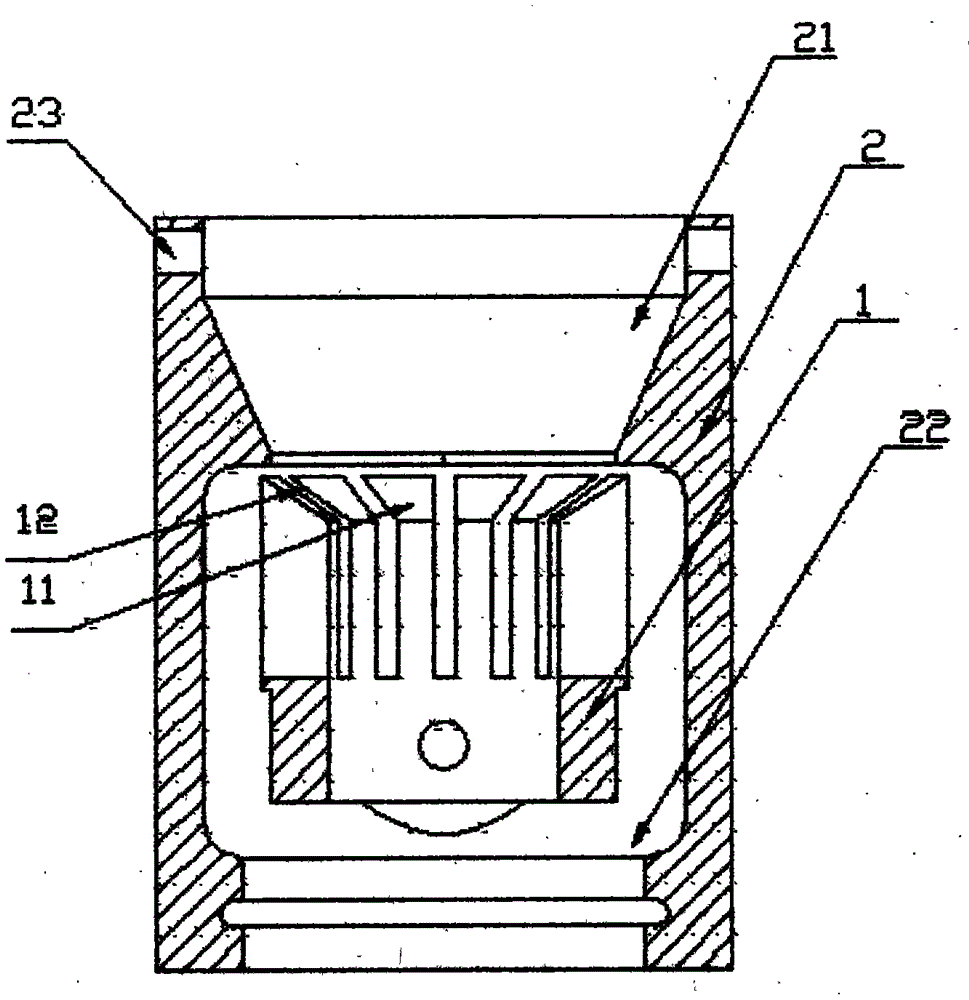

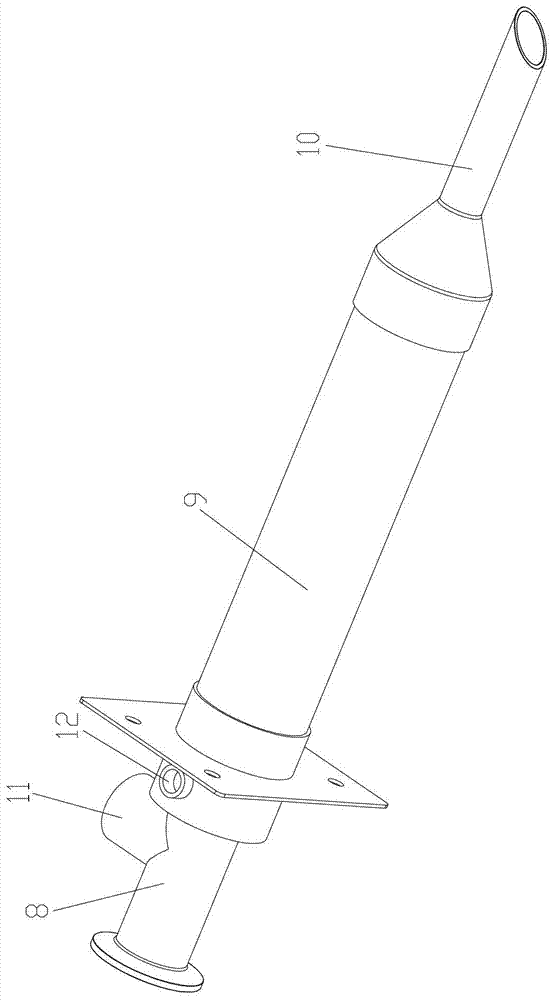

Down filling head

InactiveCN103484984ADoes not cause bulging problemsGuaranteed weightUpholstery manufactureOakum treatmentBody positionsOuter Cannula

The invention discloses a down filling head which comprises a down outputting pipe, an air return pipe and an outer sleeve. The outer sleeve comprises a sleeve cavity and a down filling nozzle connected with one end of the sleeve cavity, the other end of the sleeve cavity is sealed by a flange, the air return pipe is sleeved outside the down outputting pipe, the other end of the air return pipe is sealed with the other end of the down outputting pipe, one ends of the down outputting pipe and the air return pipe are arranged in the sleeve cavity while the other ends of the same extend out of the sleeve cavity, an air return hole is formed in an air return pipe body positioned outside of the sleeve cavity, an outer air return pipe is sleeved outside the down filling nozzle, and an outer air return space is formed between the down filling nozzle and the outer air return pipe; at a down outlet of the down filling nozzle, an interval between one end of the outer air return pipe and the down filling nozzle is smaller than that allowing down to pass, and an air outlet is arranged between the other end of the outer air return pipe and the down filling nozzle. When the down filling head is utilized for down filling, the down cannot fly around, so that environment is unaffected, and weight of the down entering a garment piece is guaranteed; and more importantly, smoothness of air return is guaranteed, so that plumping of the garment piece is avoided.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

Pillow filling machine

InactiveCN102976259BVersatileReasonable designUpholstery manufactureOakum treatmentPulp and paper industryAutomation

The invention discloses a pillow inner filling machine, which is characterized in that the middle lower part of a cotton conveying device is provided with a cotton conveying motor; the left side of the cotton conveying motor is provided with a cotton conveying roll shaft; the left side of the cotton conveying roll shaft is provided with a riding wheel roll shaft; the left side of the riding wheel roll shaft is provided with a cotton inlet roll shaft; the right side of the cotton conveying roll shaft is provided with a delivered cotton conveying roll shaft; the cotton conveying roll shaft is provided with a cotton conveying roll; a cotton inlet roll shaft is provided with a cotton inlet roll; the cotton inlet roll and the cotton conveying roll are provided with an inlet cotton conveying belt; the delivered cotton conveying roll shaft and a delivered cotton transmission roll shaft are provided with a delivered cotton conveying belt; the right side of the delivered cotton conveying belt is provided with a carding machine; the bottom ends of carding roll shafts are respectively provided with discharge rolling teeth; the lower ends of the discharge rolling teeth are provided with a discharge hopper; the right side of the discharge hopper is provided with a discharge hole; the bottom end of the discharge hole is provided with a blanking barrel; the lower side of the discharge hopper is provided with a weighing hopper; the lower end of the weighing hopper is provided with a funnel; the bottom end of the funnel is provided with a discharge hopper; the right side of the discharge hopper is provided with a discharge pipeline; and the right side of the discharge pipeline is provided with a filling machine. The pillow inner filling machine disclosed by the invention is complete in function, high degree of automation and good in using effect.

Owner:深圳市迈普斯科技有限公司

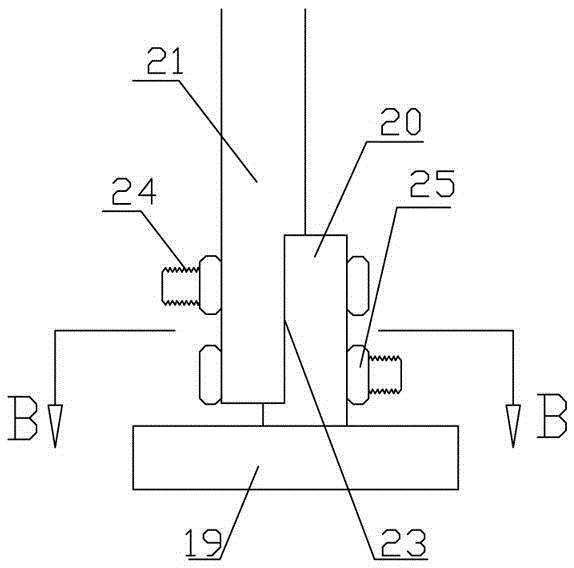

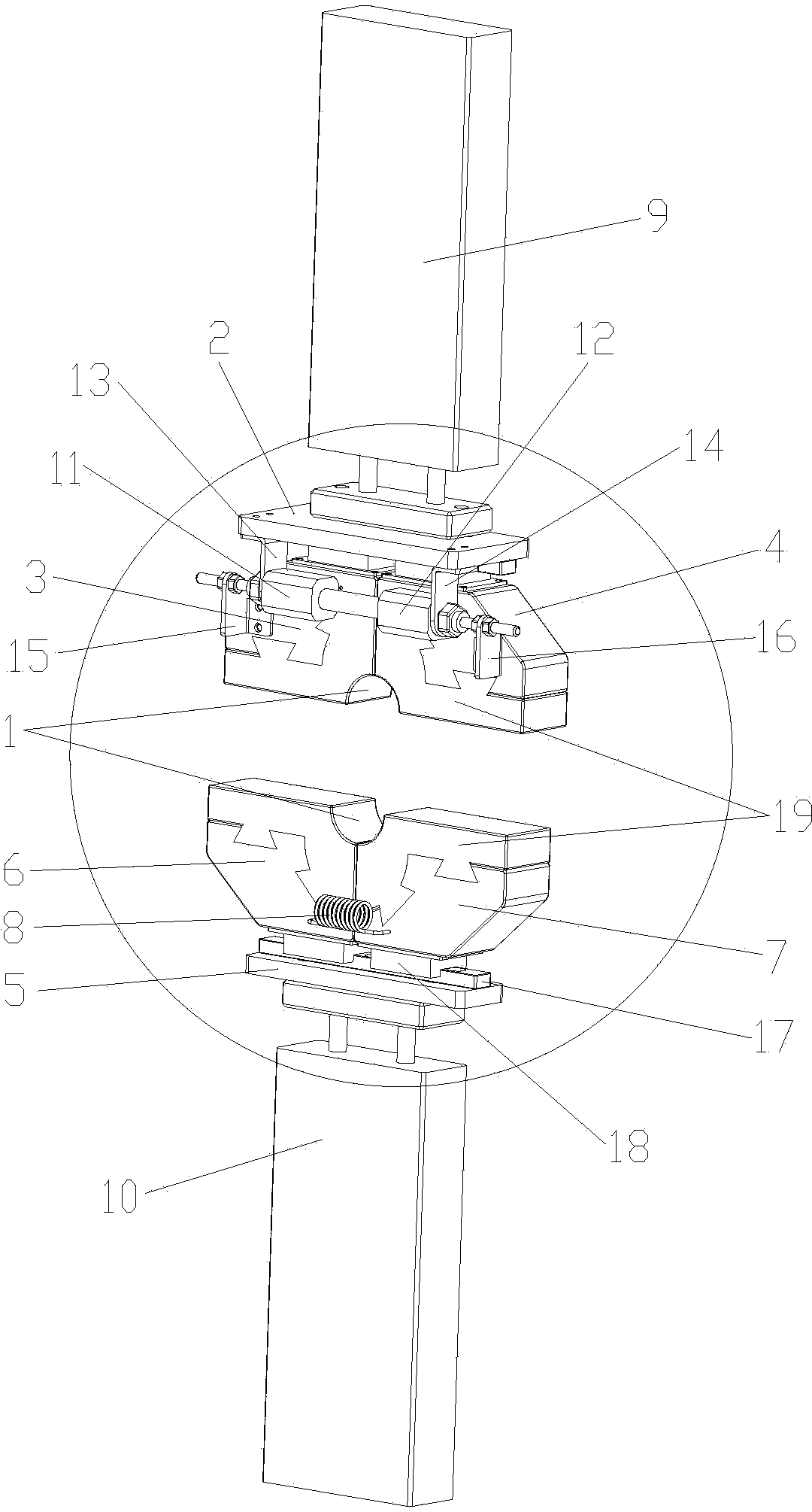

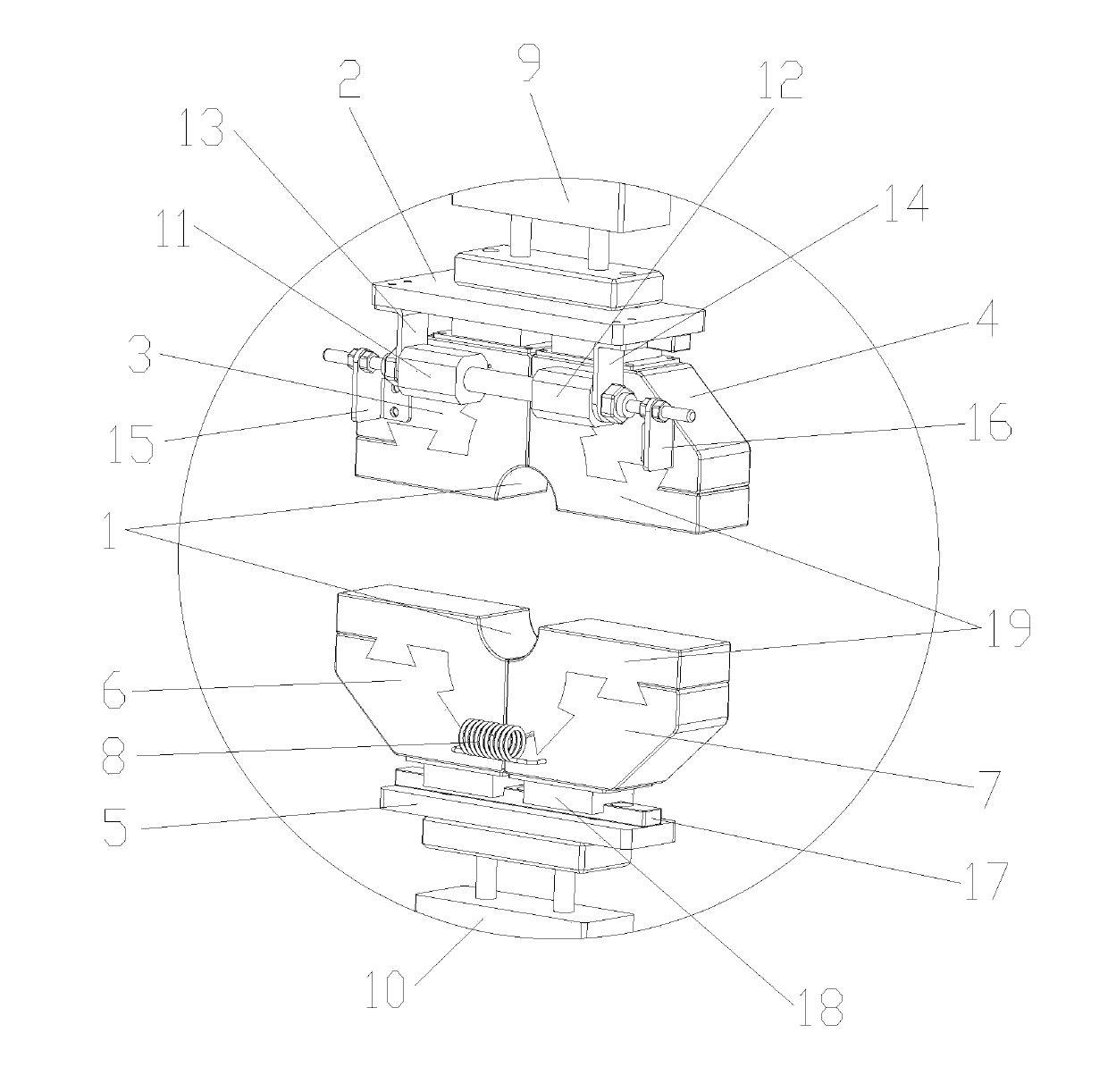

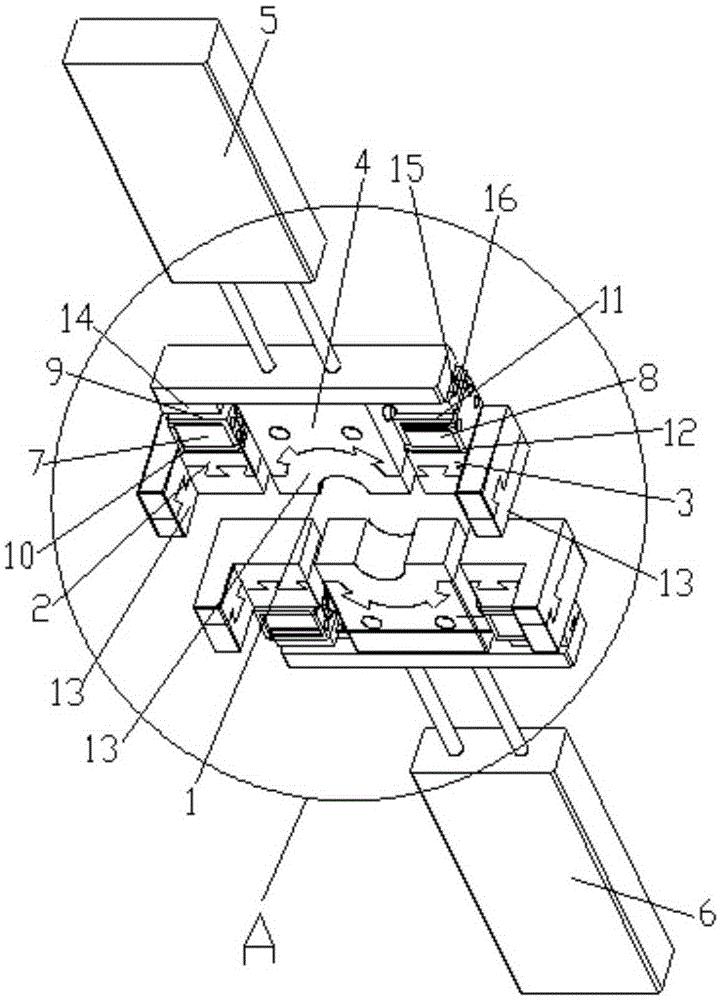

Locking clamping device

ActiveCN103437001AMeet the use requirementsPlay the role of flatteningOakum treatmentEngineeringMechanical engineering

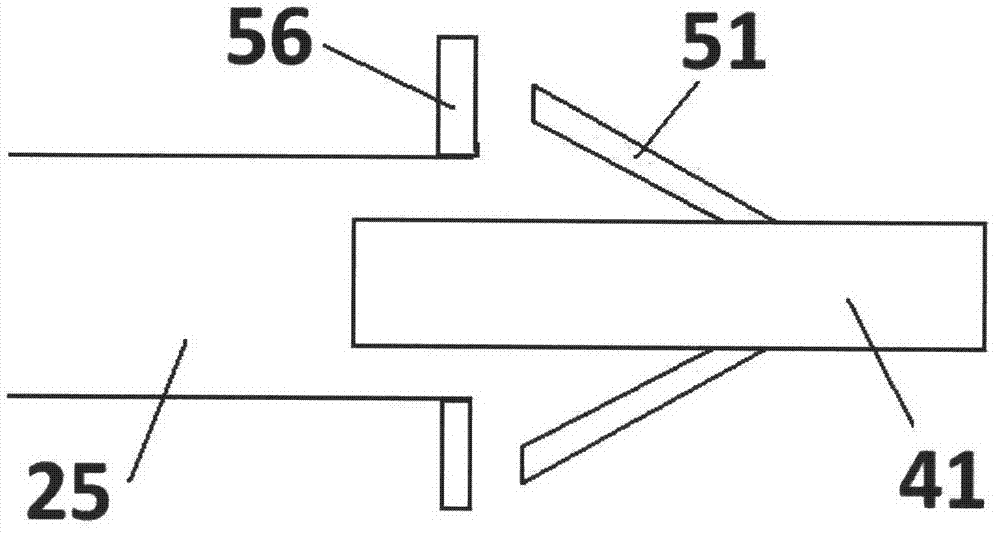

The invention discloses a locking clamping device which comprises an upper clamping device, a lower clamping device, a first driving device and a second driving device, wherein the first driving device and the second driving device control the upper clamping device and the lower clamping device to move up and down respectively. Semicircle grooves matched with the front end of a down feather filling pipe are formed in the upper surface of the upper clamping device and the upper surface of the lower clamping device. The upper clamping device comprises a first fixing block, a first clamping block, a second clamping block, a third driving device and a fourth driving device. The lower clamping device comprises a second fixing block, a third clamping block, a fourth clamping block and an elastic part. According to the locking clamping device, after a cutting piece to be filled with down feather is clamped, the cutting piece to be filled with the down feather can be pulled to be flat, at the moment, when a cutting piece after filling is completed is sealed, an opening to be sealed of the cutting piece is not prone to wrinkling, the sealing quality is improved, and therefore the locking clamping device can meet the use requirements of a down feather filling machine with the sealing function after down feather filling is completed.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Automatic down filling machine filling down precisely

The invention discloses an automatic down filling machine filling down precisely. The automatic down filling machine comprises a down storage box, weighing cabinets, weighing boxes, down filling pipes, a control mechanism and conveying mechanisms, wherein the weighing cabinets are arranged on the two sides of the down storage box; the weighing boxes are arranged in the weighing cabinets; the down filling pipes are arranged on the weighing cabinets and connected with the conveying mechanisms; the conveying mechanisms are controlled by the control mechanism; each weighing box comprises a closed weighing box body, a bottom plate, a weighing sensor and an air outlet connecting pipe; each weighing sensor is fixed below each bottom plate; each weighing box body is fixed on the bottom plate; each weighing box body is perpendicular to each bottom plate; an air inlet pipe orifice is formed at the upper part of each weighing box body; each air outlet connecting pipe is arranged at the lower part of each weighing box body; each air inlet pipe orifice and each air outlet connecting pipe are connected with each conveying mechanism; ventilated windows are formed at the peripheries of cuboids at the upper parts of the box bodies; and filter screens are arranged on the ventilated windows. The automatic down filling machine filling the down precisely is high in down filling precision and good in down filling effect.

Owner:SUZHOU TRANSPARENT TECH CO LTD

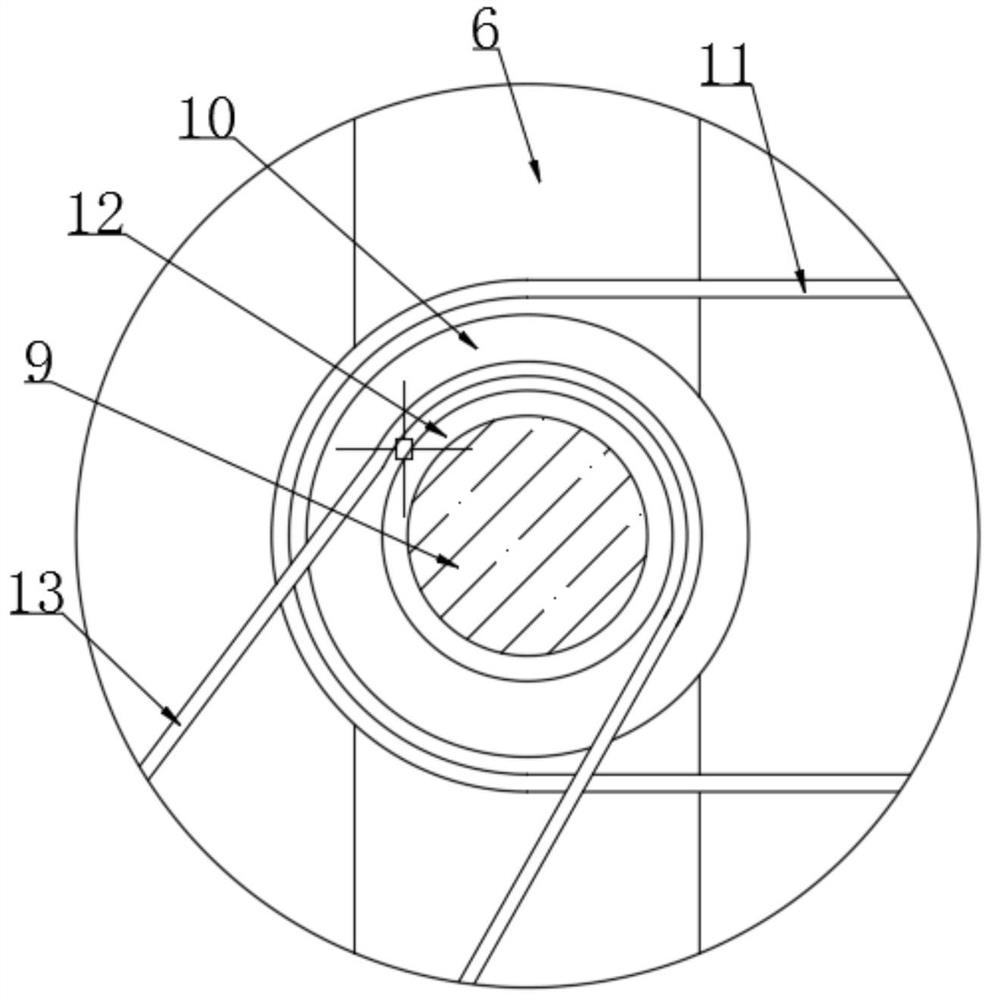

Roller cotton collecting machine for refined cotton

PendingCN112626654ASolve problems that easily affect salesAvoid affecting salesOakum treatmentFiberAgricultural engineering

The invention discloses a roller cotton collecting machine for refined cotton, and relates to the technical field of textile processing. The roller cotton collecting machine comprises a supporting plate, a left supporting column and a right supporting column, the bottoms of the left supporting column and the right supporting column are fixedly connected with the top of the supporting plate, and the outer surfaces of the left supporting column and the right supporting column are symmetrically arranged. A cotton collecting mechanism is arranged between the sides, close to each other, of the outer surfaces of the left supporting column and the right supporting column, the cotton collecting mechanism comprises a cotton collecting barrel, a left rotating column and a right rotating column, and one end of the left rotating column and one end of the right rotating column are rotationally connected with the outer surfaces of the supporting columns. According to the roller cotton collecting machine for the refined cotton, through the combination of the structures such as the cotton collecting barrel, a cotton suction net, a draught fan, the rotating columns and an exhaust pipe, negative pressure is generated in a vacuum cavity, the cotton collecting barrel can adsorb cotton fibers through the cotton suction net and adsorption holes, and the situation that selling is affected due to the fact that the refined cotton is polluted in the processing process is avoided; and through the combination of the structures, the problem that selling is easily influenced when the refined cotton is processed by a traditional cotton collector is solved.

Owner:孙建平

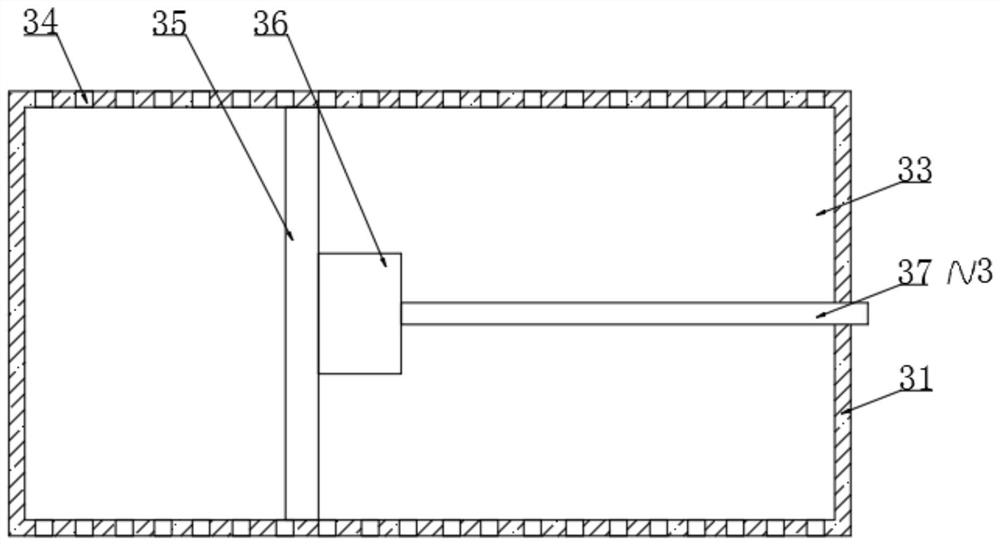

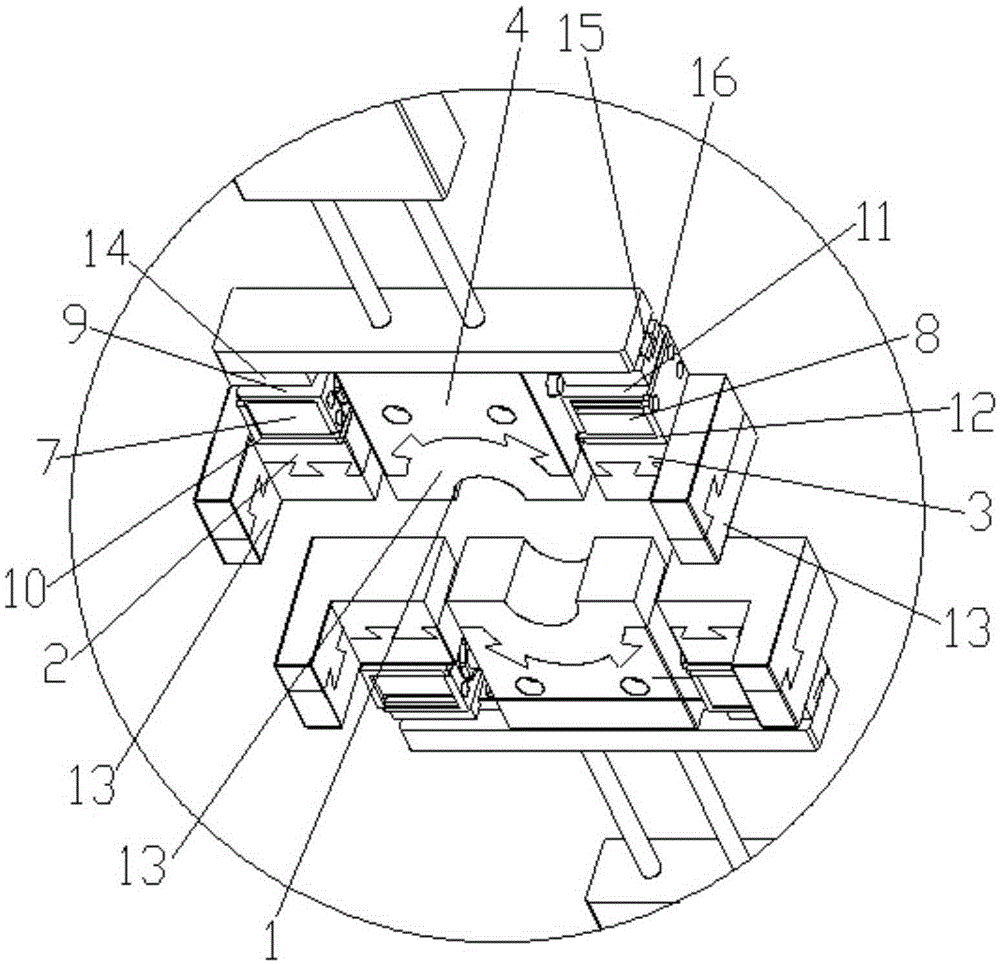

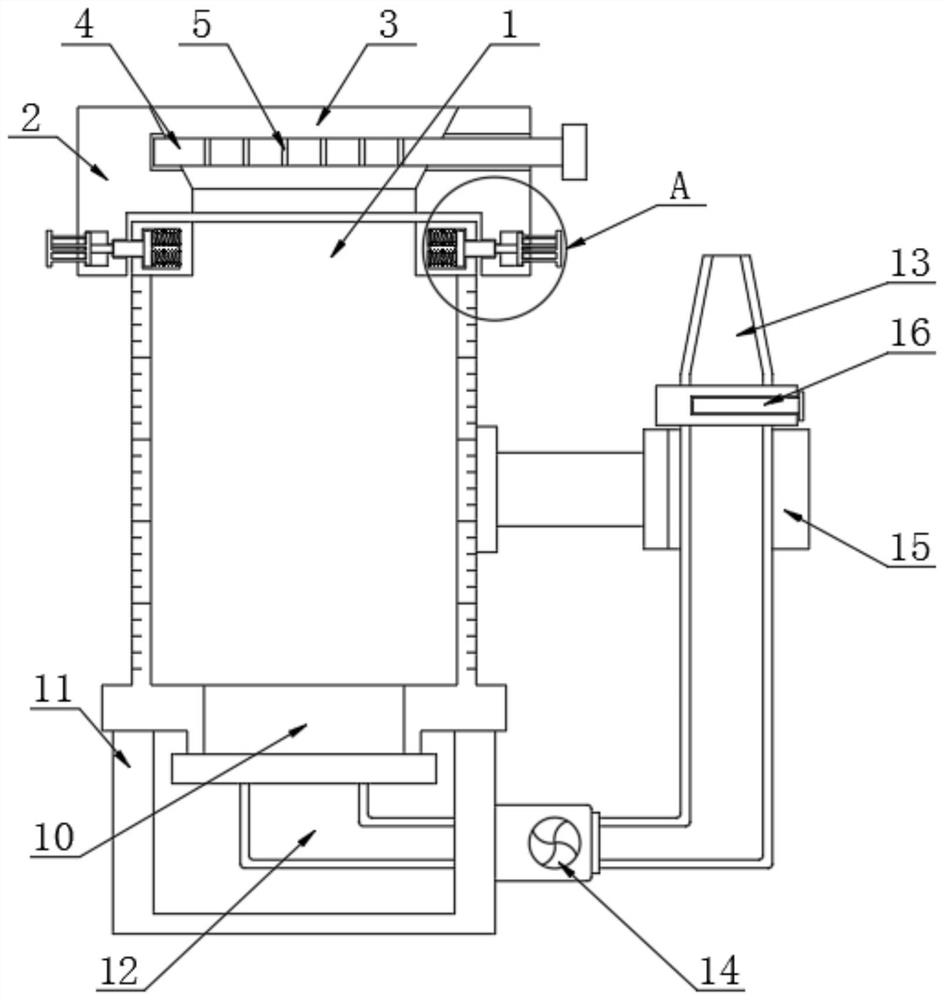

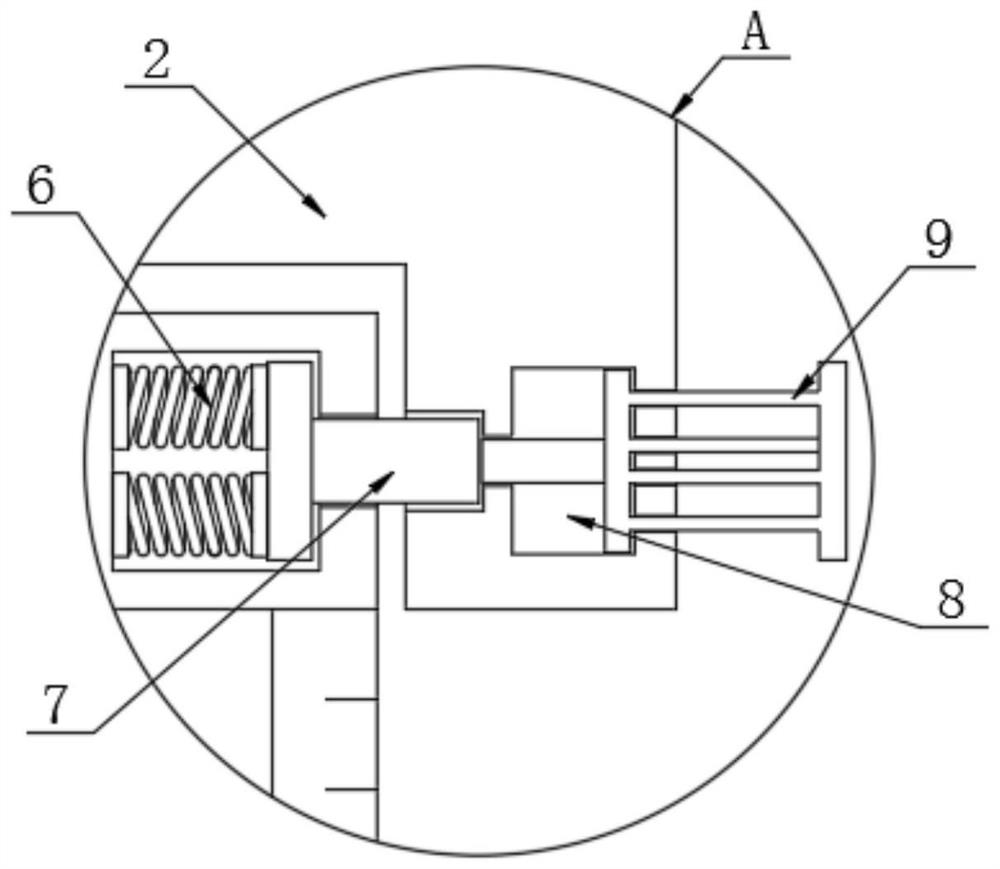

Weighing metering mechanism of automatically quantitative down filling machine

InactiveCN103103638AFirmly connectedEasy to manufactureOakum treatmentWeighing apparatus for materials with special property/formEngineeringLoad cell

The invention discloses a weighing metering mechanism of an automatically quantitative down filling machine, and belongs to the technical field of stowage equipment for down and feather filled products. The weighing metering mechanism of the automatically quantitative down filling machine comprises a metering box body. The metering box body is internally provided with a box body cavity separation board. A weighing device and a weighing hopper are placed inside the box body cavity, and the weighing hopper is arranged on the weighing device. The weighing metering mechanism of the automatically quantitative down filling machine is characterized in that the weighing device comprises a weighing sensor base, a weighing sensor, a weighing frame and a weighing hopper fixing plate. The weighing sensor base is fixed on the bottom of the box body cavity of the metering box, the weighing sensor is placed on the weighing sensor base, the weighing frame is fixed on the weighing sensor, the weighing hopper fixing plate is fixed on the weighing frame, and the weighing hopper is fixed on the weighing hopper fixing plate. A weighing hopper down output pipe is connected with the lower side portion of the weighing hopper in an extending mode, a down lead-in device is placed on the upper side portion of the weighing hopper in a matched mode, and the weighing hopper down output pipe is connected with a down output mechanism of the automatically quantitative down filling machine. The weighing metering mechanism of the automatically quantitative down filling machine has the advantages of being capable of ideally being matched with the automatically quantitative down filling machine and guaranteeing the precise effects of metering, and being simple in structure and convenient to manufacture and install.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

A kind of home textile filler mixed with polyester fiber and lyocell fiber and preparation method thereof

InactiveCN103031664BUniform appearanceSmooth appearanceOakum treatmentNon-woven fabricsPolyesterPolymer science

The invention discloses home textile filler mixing with polyester fibers and lyocell fibers. The home textile filler is characterized in that the home textile filler is formed by mixing with common hollow polyester short fibers and lyocell fibers, wherein the fiber number of the used hollow polyester short fibers is 6.67DTEX, the hollow degree is 10 percent, and the length is 38mm; the fiber number of the used lyocell fibers is 1.5-3.0DTEX, the length is 50-80 mm, and curl fibers are used for the lyocell fibers; and the weight percentage of the hollow polyester short fibers and the lyocell fibers is that the hollow polyester short fibers take up by 25-75 percent, and the lyocell fibers take up by 25-75 percent. The invention further provides a preparation method for the home textile filler mixing with the polyester fibers and the lyocell fibers. Various stuffing products prepared by the home textile filler mixing with polyester fibers and lyocell fibers have the advantages that the appearance is uniform and smooth, lightness, a high fluffy degree, continuous elastic restoration, excellent heat preservation, and soft feel, thus people feel comfortable, and the quality of sleep and life can be improved.

Owner:SOUTH BEDDING TECH

Novel full-automatic down filling machine

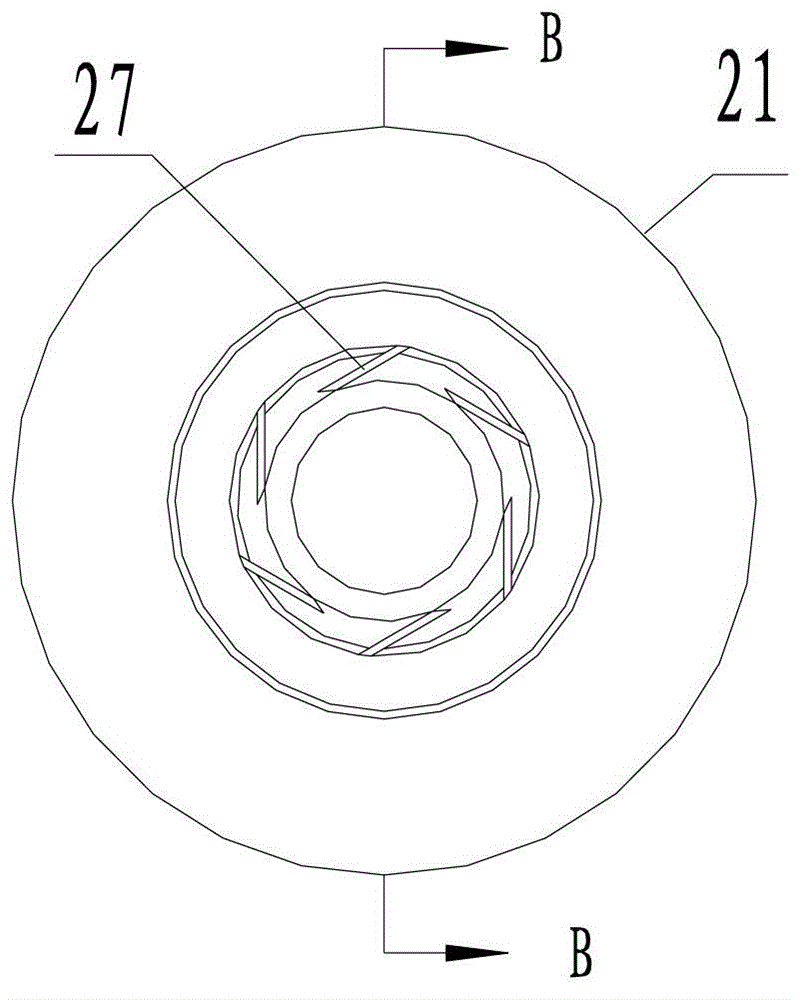

The invention discloses a novel full-automatic down filling machine. The down filling machine comprises a fan, a down storage box, a weighing device and a down filling pipe, wherein the down filling pipe comprises an inner pipe, an outer pipe and a long pipe, a through down incoming hole is formed in the middle of the inner pipe, two steps are arranged at the front end of the inner pipe, a step is arranged at the rear end inside the outer pipe, the step at the rear end inside the outer pipe is in lap joint with the first step at the front end of the inner pipe in a sealing mode, an annular cavity is formed by the step at the rear end inside the outer pipe and the second step at the front end of the inner pipe, a gas inlet which is communicated with the annular cavity is arranged on one side of the outer pipe, a plurality of gas outgoing grooves which are communicated with the annular cavity are uniformly formed in the front end of the inner pipe and are formed in an inclined mode in the clockwise or anticlockwise direction, and the long pipe is connected with the front end of the outer pipe in a sealing mode. Compared with the prior art, the down filling machine has the advantages of being simple in structure, convenient to operate, high in working efficiency, low in energy consumption, low in labor intensity, uniform in down filling and high in down filling quality.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

Down feather feeding pipe

The invention discloses a down feather feeding pipe. The down feather feeding pipe comprises a pipe body, a baffle and a torsion spring, wherein the baffle is arranged at the tail end of the pipe body and hinged to the pipe body, the torsion spring is arranged in the hinging position of the pipe body and the baffle, and an inner sleeved pipe is further arranged inside the pipe body. In the down feather conveying process of the down feather feeding pipe, the air flow for conveying down feather overcomes the torsion of the torsion spring, jacks the baffle open and conveys the down feather. After the down feather is conveyed, the baffle is closed due to the torsion of the torsion spring. The down feather feeding pipe can only convey the down feather in a signal direction, and can well prevent the down feather from flowing backwards.

Owner:SUZHOU TRANSPARENT TECH CO LTD

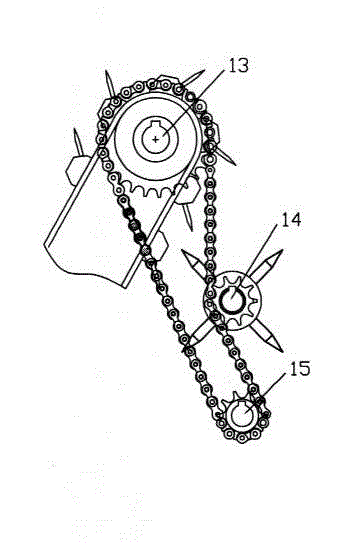

Small down filling machine

The invention discloses a small down filling machine. The small down filling machine comprises a down storage box, a weighing cabinet, a down filling pipe, a stirring roller, a driving motor and a synchronous belt, wherein the weighing cabinet is arranged on one side of the down storage box, the down filling pipe is arranged on the weighing cabinet and the stirring roller is arranged inside the down storage box. The down storage box is provided with first space and second space. One end of the stirring roller penetrates through the body wall of the down storage box and is arranged inside the first space. The driving motor is arranged inside the second space, and an output shaft of the driving motor penetrates through the body wall of the down storage box and is arranged inside the second space and connected with one end of the stirring roller through the synchronous belt. The small down filling machine is small in occupied workshop space. On the condition that the workshop space is increasingly limited at present, the small down filling machine is high in use efficiency and can be applied and popularized well.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Home textile filler mixed with polyester fiber and soybean protein fiber and preparation method thereof

The invention discloses home textile filler mixing with polyester fibers and soybean protein fibers. The home textile filler is characterized in that the home textile filler is formed by mixing with common hollow polyester short fibers and soybean protein fibers, wherein the fiber number of the used hollow polyester short fibers is 6.67DTEX, the hollow degree is 10 percent, and the length is 38mm; the fiber number of the used soybean protein fibers is 1.5-3.0DTEX, the length is 38mm, and curl fibers are used for the soybean protein fibers; and the weight percentage of the hollow polyester short fibers and the soybean protein fibers is that the hollow polyester short fibers take up by 25-75 percent, and the soybean protein fibers take up by 25-75 percent. The invention further provides a preparation method for the home textile filler mixing with the polyester fibers and the soybean protein fibers. Various stuffing products prepared by the home textile filler mixing with polyester fibers and soybean protein fibers have the advantages that the appearance is uniform and smooth, lightness, a high fluffy degree, continuous elastic restoration, excellent heat preservation, and soft feel, thus people feel comfortable, and the quality of sleep and life can be improved.

Owner:SOUTH BEDDING TECH

Antibacterial and deodorant down feather composite wadding and preparation method thereof

InactiveCN105133096AImprove toughnessHigh resilienceOakum treatmentArtificial filaments from viscosePeppermintsPliability

The invention discloses an antibacterial and deodorant down feather composite wadding characterized by comprising the following raw material by weight parts: 10-20 parts of eider, 100-150 parts of viscose fiber stock solution, 0.05-0.1 parts of eucalyptus oil, 0.02-0.04 parts of peppermint oil, 0.02-0.04 parts of honeysuckle flower oil, 1-2 parts of nanometer powdered steatile, 0.1-0.2 parts of sodium lauroyl sarcosine, and 1-2 parts of glycerin. The antibacterial and deodorant down feather composite wadding is excellent in heat retention, intensity, flexibility and weatherability, proper in compressibility and ventilating moisture permeability, has antibacterial and deodorant effects, and is good in processing performance and usage performance.

Owner:ANHUI SWAN TECH IND GRP

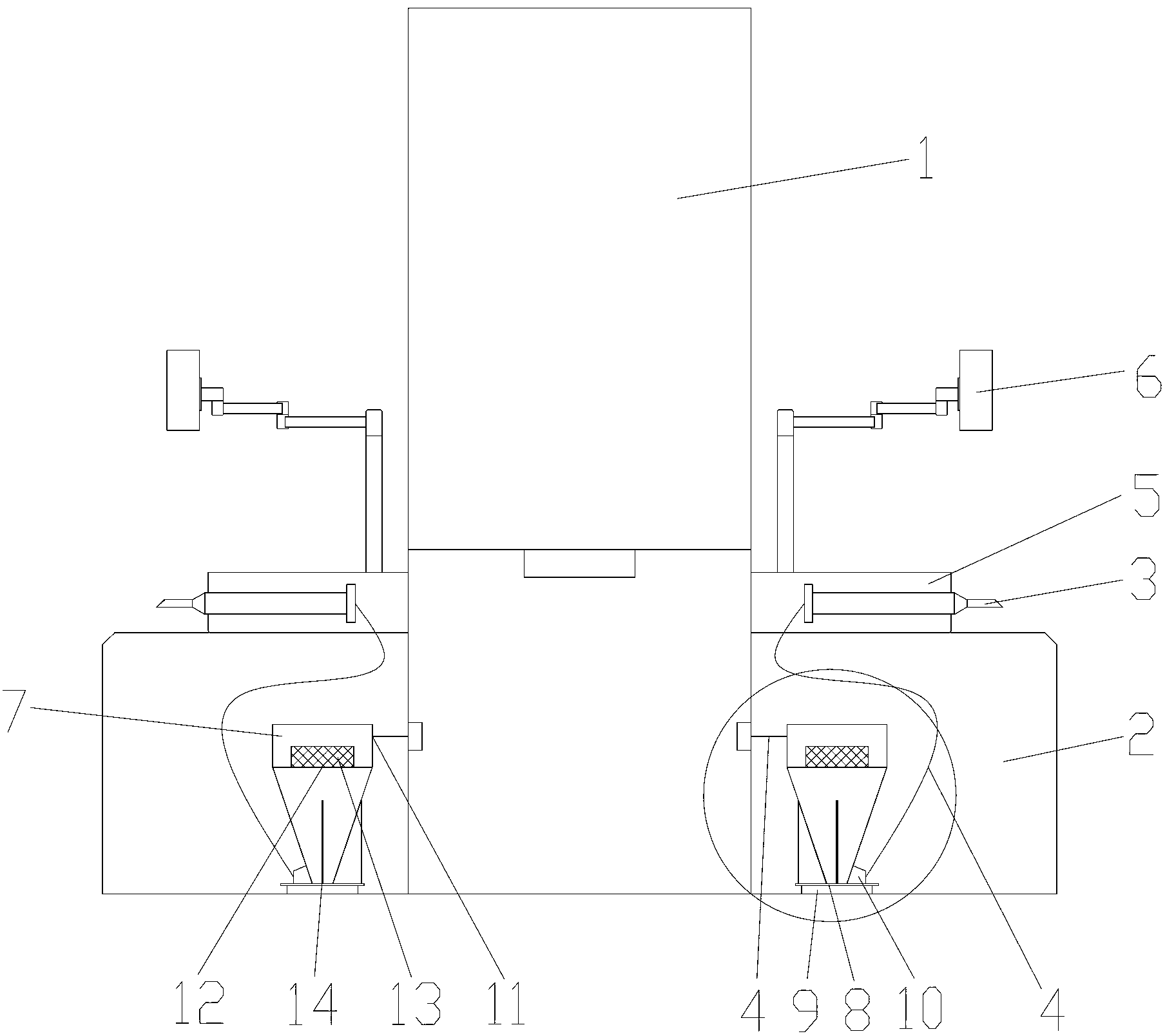

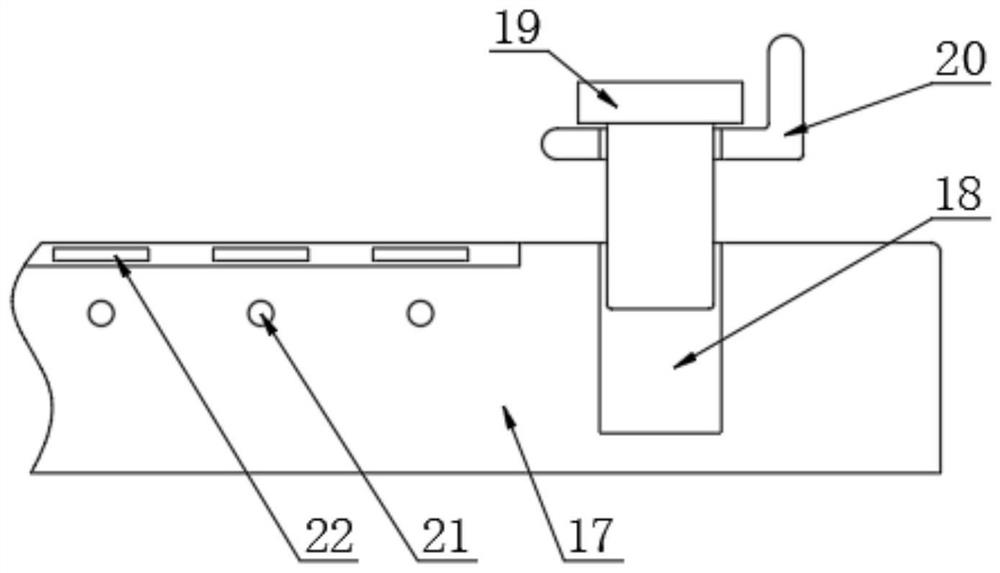

A cutting device for sealing, separating and closing

ActiveCN103668580BQuality improvementMeet the use requirementsOakum treatmentWrinkle skinEngineering

The invention discloses a cut piece seal splitting and integrating clamping device which comprises an upper pressing device, a lower pressing device, a first driving device and a second driving device. The first driving device and the second driving device respectively control the upper pressing device and the lower pressing device to move up and down. The lower surface of the upper pressing device is provided with a semicircular groove matching with the front end of a down filling pipe. The upper pressing device comprises a first compressing block, a second compressing block, a clamping block, a third driving device and a fourth driving device. The first compressing block and the second compressing block which are capable of moving leftward and rightward through the third driving device and the fourth driving device respectively are arranged under the first driving device. The clamping block is arranged between the first compressing block and the second compressing block and fixed on the first driving block. The lower pressing device and the upper pressing device are identical in structure and mutually symmetrical. By the application of the cut piece seal splitting and integrating clamping device, a seal of a cutting piece to be sealed which is smooth and high in quality wrinkles less easily, and operating requirements of a down filling machine with a sealing function after down filling is completed are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Dispersed fiber gathering and distributing device

Owner:KUSN MUFENG TEXTILE

a velvet tube

Owner:SUZHOU TRANSPARENT TECH CO LTD

An automatic duvet filling machine

ActiveCN108862183BImprove ventilationEasy to put inUpholstery manufactureOakum treatmentHand partsPhysics

The invention discloses an automatic duvet filling machine, which comprises a housing and a placement plate, a cover plate is provided on the top of the housing, a leak is provided on the surface of the cover, and a partition is provided inside the leak. A hole is provided on the surface of the partition, a spring is provided on the inner wall of the top of the housing, a limit frame is provided on one side of the spring, a cavity is provided on the inner wall of both sides of the cover plate, and a press frame is provided on the inner wall of the cavity , the bottom of the housing is provided with an outlet, the outside of the outlet is provided with a bracket, the bottom of the outlet is provided with a connecting pipe, and one end of the connecting pipe is provided with a spout. In the present invention, a cover plate is provided, and the limit frame is pressed by the hand, and the limit frame produces a squeezing effect on the spring, so that the limit frame enters the interior of the housing, and the cover plate is conveniently placed on the top of the housing, and the limit frame is used to The frame and the cover plate are buckled, and then the press frame is pushed out, and the hole is used to increase the ventilation effect inside the shell, so that the fluff inside the shell can be discharged through the connecting pipe.

Owner:YUEXI YUHONG TEXTILE ARTS & CRAFTS PROD CO LTD

A Down Filling Machine with Accurate Down Filling

The invention discloses a down filling machine with accurate down filling. The weighing cabinet is arranged on both sides of the down storage box; the weighing box is arranged in the weighing cabinet; connected; the transmission mechanism is controlled by the control mechanism; the control mechanism controls the transmission mechanism to transport the down in the down storage box to the weighing box, and then discharge the down in the weighing box from the down filling tube; the down filling tube includes the down tube, the connecting tube and the outlet tube. down tube; the down tube, the connecting tube and the down tube are connected successively to form a down tube body; the down tube is provided with a return pipe and an air blowing tube; the down tube, the return tube and the blowing tube are connected to the transmission mechanism; The trachea and the air blowing pipe communicate with the down pipe; the down filling tube body is provided with a down tube; there is a gap between the front end of the down tube and the tail end of the down tube; the down tube and the down tube body are fixed with a Return air filter pipe; the return air pipe communicates with the return air filter pipe; the down filling machine with precise down filling of the present invention has high down filling precision and good down filling effect.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com