Small down filling machine

A down filling machine, a small technology, applied in textiles and paper making, fiber treatment, flocking treatment and other directions, can solve the problems of large space occupied by the down storage box, lack of application and promotion, and poor utilization rate of the down filling machine. , to achieve the effect of high utilization rate, reduced space occupied, good application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described below in conjunction with accompanying drawing.

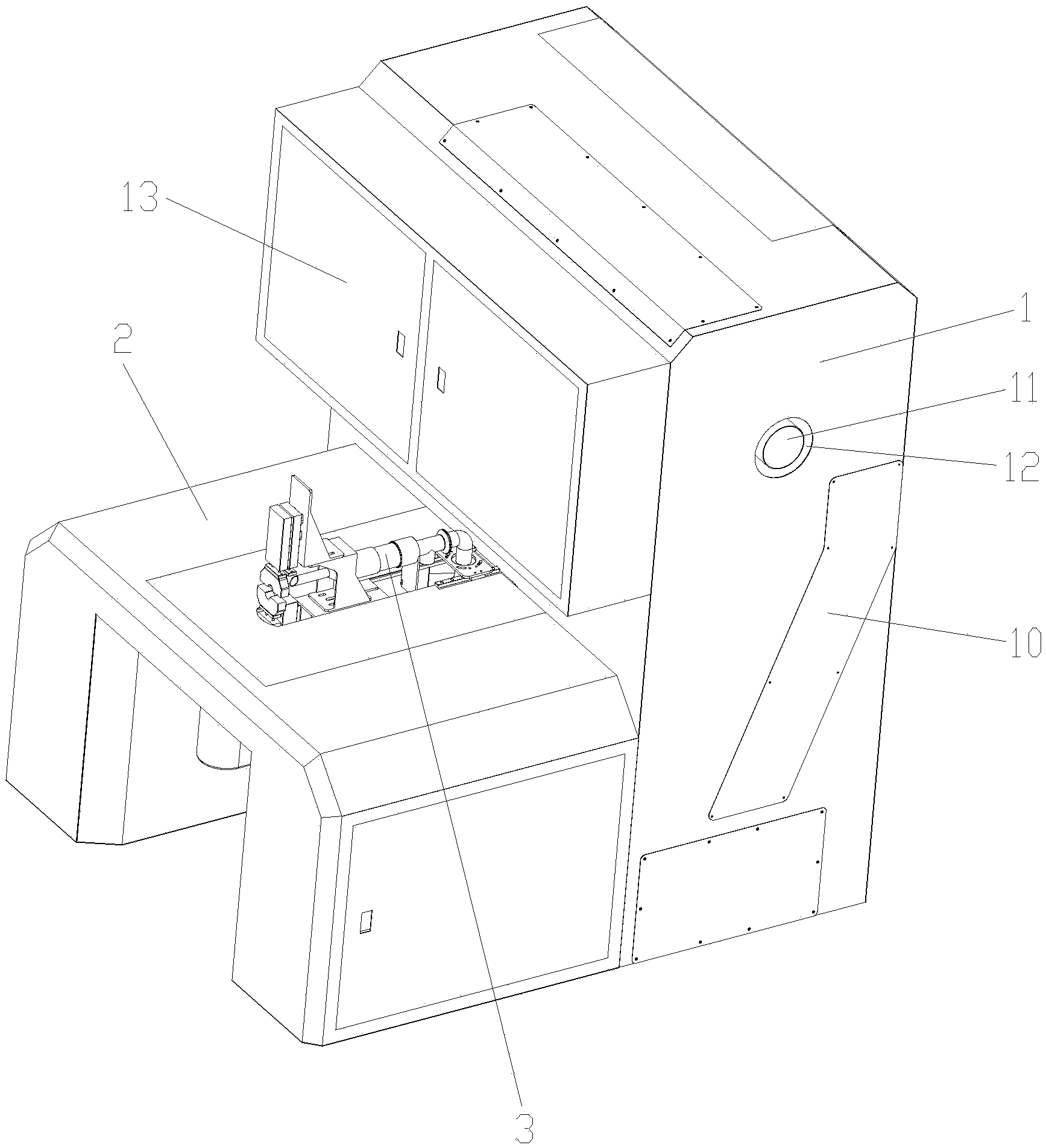

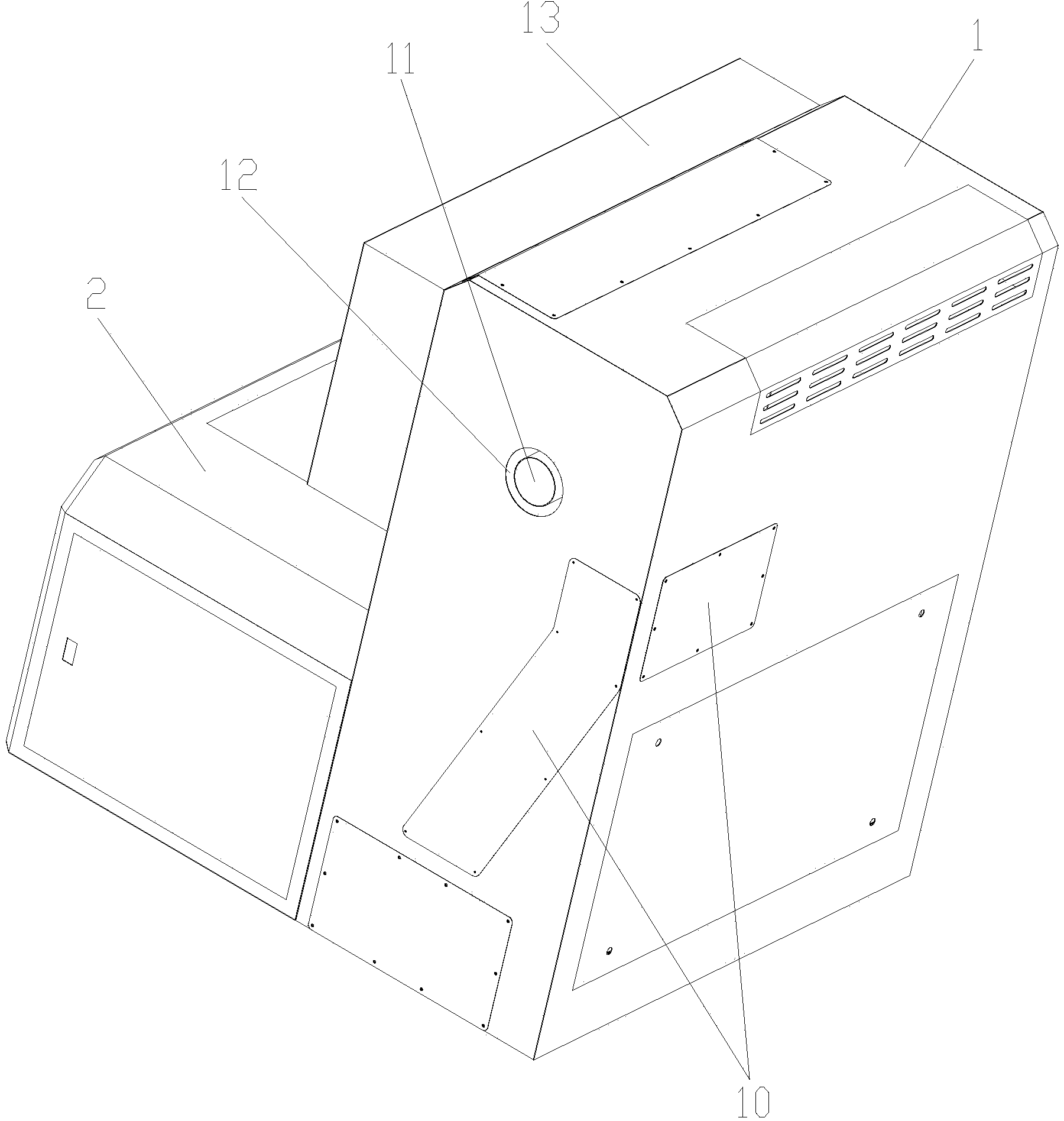

[0020] as attached Figure 1-4 The shown small down filling machine of the present invention includes a down storage box 1, a weighing cabinet 2, a down filling pipe 3, a stirring roller 4, a driving motor 5 and a timing belt 6; the weighing cabinet 2 is set On one side of the cashmere storage box 1; the down filling pipe 3 is arranged on the weighing cabinet 2; the stirring roller 4 is arranged in the cashmere storage box 1; the first space 7 and the cashmere storage box 1 are provided The second space 8; one end of the stirring roller 4 passes through the cashmere storage box 1 body wall and is placed in the first space 7; the second space 8 is provided with a driving motor 5; the output shaft 9 of the driving motor 5 Pass through the wall of the velvet storage box 1 and place it in the second space 6; the output 9 of the drive motor 5 is connected to one end of the stirring roller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com