Textile internally provided with ultra-thin cotton quilt and preparation method

A technology for textiles and cotton batts, applied in the field of textiles with built-in ultra-thin cotton batts and its preparation, can solve the problems of lack of flexibility, uneven filling, low production efficiency, etc., and achieve increased economic benefits, good heat preservation effects, and improved production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A textile with a built-in ultra-thin batt, which has two layers of fabric, the middle of the fabric is filled with batt, the cotton batt contains 100% lint, the batt is 6m long, 0.7cm thick, and weighs 0.15kg per unit area / m 2 .

[0034] A method for preparing a textile with a built-in ultra-thin batt in this embodiment, the steps include:

[0035] The first step: dehydration, ginning

[0036] Dry the fine-staple cotton until the water content is below 12%, and then pass through the conventional ginning process to produce lint;

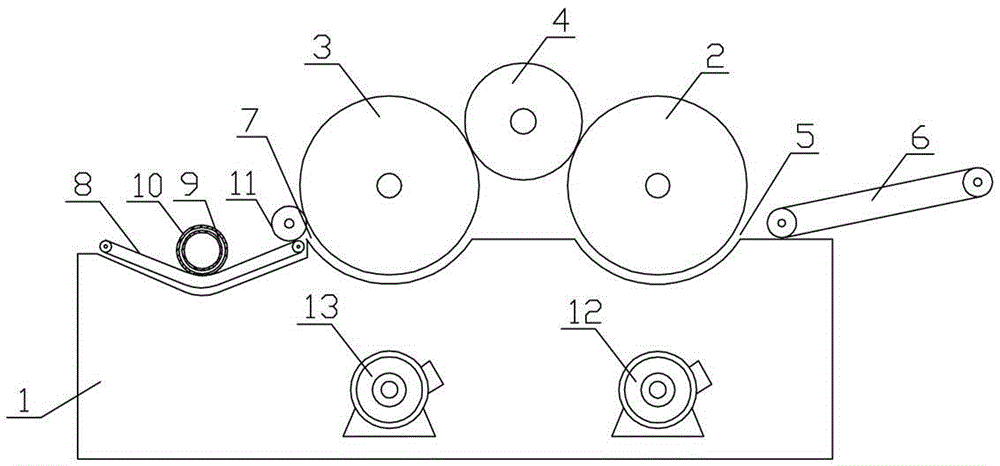

[0037] The second step: opening, removing impurities, combing, rolling

[0038] The lint cotton obtained in the first step is opened, removed, and combed according to the conventional cotton batt production process by a popping machine, and is made into a primary blank roll through the coiling tube 10;

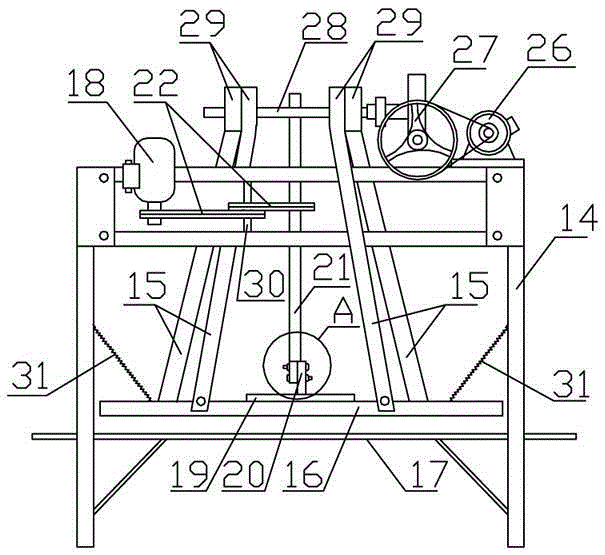

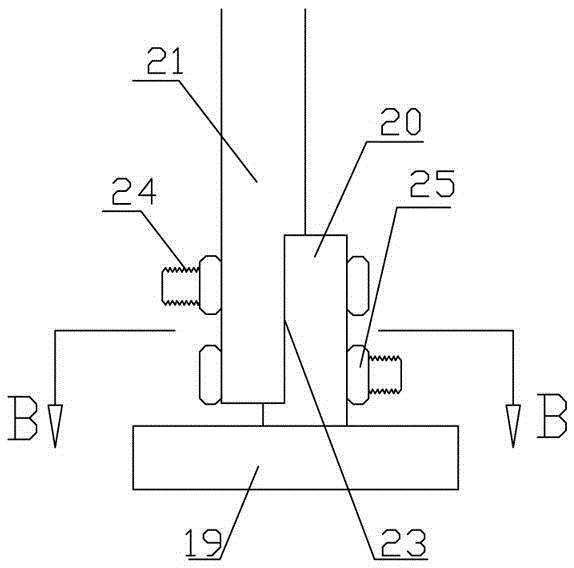

[0039] The third step: Knead the cotton and shape it

[0040] Spread out the primary billet obtained in step 2 to form a layer with a le...

Embodiment 2

[0050] A textile with a built-in ultra-thin batt, which has two layers of fabric, the middle of the fabric is filled with an ultra-thin batt, the lint content of the ultra-thin batt is 100%, the length of the batt is 4.5m, the thickness is 1.5cm, and the unit area is The weight is 0.3kg / m 2 .

[0051] A method for preparing a textile with a built-in ultra-thin batt in this embodiment, the steps include:

[0052] The first step: dehydration, ginning

[0053] Step is identical with embodiment 1;

[0054] The second step: opening, removing impurities, combing, rolling

[0055] Step is identical with embodiment 1;

[0056] The third step: Knead the cotton and shape it

[0057] Spread out the primary billet obtained in step 2, and superimpose two layers to form a length of 4.5m and a weight per unit area of 0.3kg / m 2 The primary cotton tire is used, and then the primary cotton tire is rubbed on both sides by a kneading machine, and the process is as follows:

[0058] First...

Embodiment 3

[0065] A textile with a built-in ultra-thin batt, which has two layers of fabric, the middle of the fabric is filled with an ultra-thin batt, the content of lint in the ultra-thin batt is 100%, the length of the batt is 3m, the thickness is 2.6cm, and the unit area is The weight is 0.45kg / m 2 .

[0066] A method for preparing a textile with a built-in ultra-thin batt in this embodiment, the steps include:

[0067] The first step: dehydration, ginning

[0068] Step is identical with embodiment 1;

[0069] The second step: opening, removing impurities, combing, rolling

[0070] Step is identical with embodiment 1;

[0071] The third step: Knead the cotton and shape it

[0072] Spread out the primary billet obtained in step 2, and superimpose 3 layers to form a length of 3m and a weight per unit area of 0.45kg / m 2 The primary cotton tire is used, and then the primary cotton tire is rubbed on both sides by a kneading machine, and the process is as follows:

[0073] Firstl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com